Mitsubishi Electric Mr. Slim PU-5TJSA1, Mr. SlimPU-5TJSA2, Mr. Slim PU-6TJSA2, Mr. SlimPU-6TJSA1 Service Manual

Page 1

Outdoor unit

SPLIT-TYPE, AIR CONDITIONERS

TECHNICAL & SERVICE MANUAL

Outdoor unit

[Model names]

[Service Ref.]

2003

No.OC199

REVISED EDITION-A

PU-5TJSA

PU-6TJSA

PU-5TJSA

PU-6TJSA

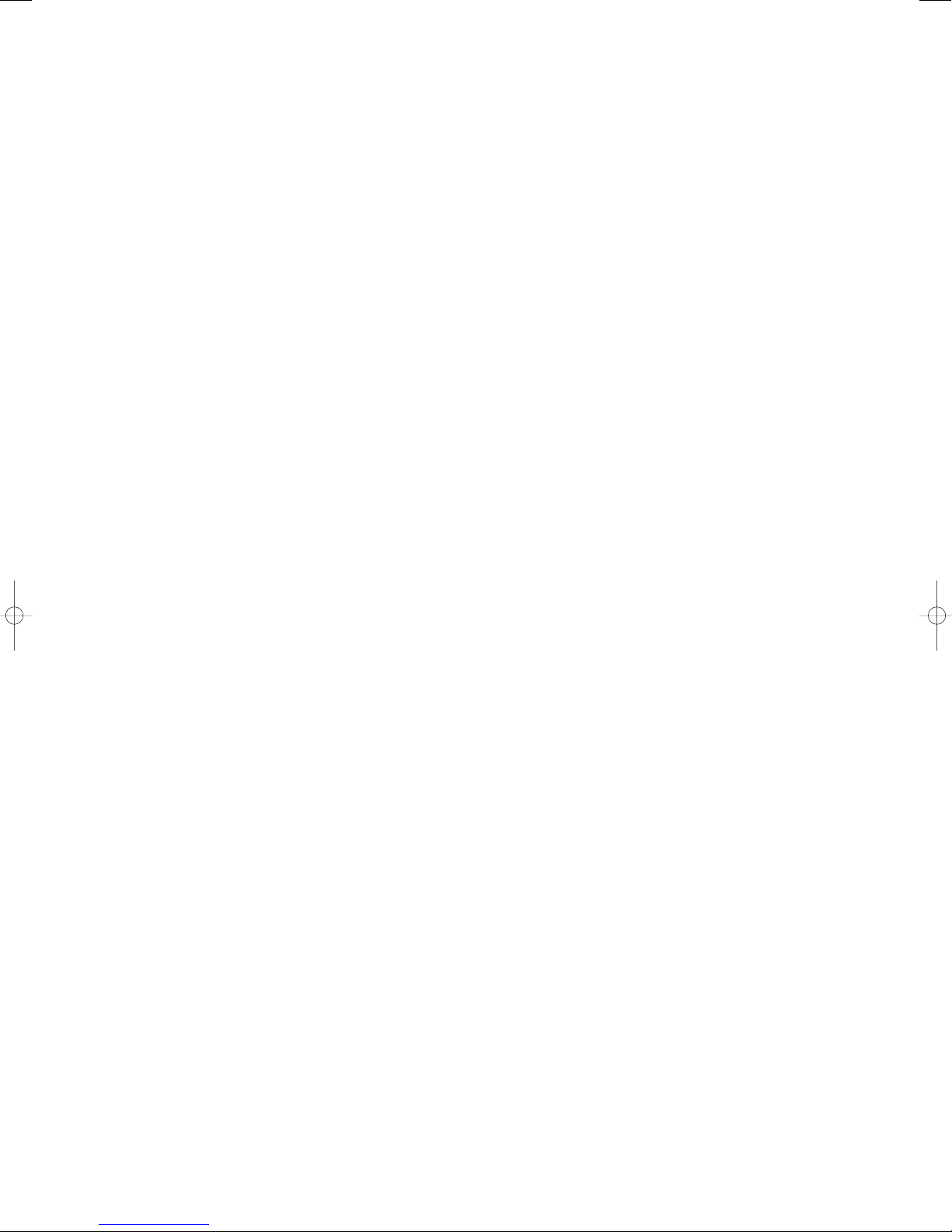

CONTENTS

1

PU-5TJSA

1

PU-6TJSA

Revision:

• This service manual describes only the

change points.

• Please refer to OC127 REVISED EDITION-A

as to excluding this manual.

• PU-5TJSA2 and PU-6TJSA2 are added to

REVISED EDITION-A .

• Please void OC199.

1. TECHNICAL CHANGE····································3

2.

COMBINATION OF INDOOR AND OUTDOOR UNITS

3. SPECIFICATIONS···········································4

4. OUTLINES AND DIMENSIONS······················5

5. WIRING DIAGRAM ·········································6

6. REFRIGERANT SYSTEM DIAGRAM ·············7

7. PARTS LIST····················································8

2

2

···3

Page 2

Page 3

1 TECHNICAL CHANGE

Service Manual No.

Service Ref.

OC138

(REVISED EDITION-A)

PL- • GJSB1

PC- • GJSA1

Outdoor unit

Indoor unit

PU-5TJSA

1

PU-5TJSA2

PU-6TJSA1

PU-6TJSA2

OC143

(REVISED EDITION-A)

PS- • GJS1

OC134

(REVISED EDITION-A)

PL- • GJSC

OC162

(REVISED EDITION-A)

PE- • EJSA2.TH

PE- • EJHSA

1

OC155

(REVISED EDITION-B)

OC171

PL- • AKSC

PL- • AKSD

OC227

PC- • GJSD OC215

(OC199)

PU-5TJSA PU-5TJSA1

PU-6TJSA PU-6TJSA1

(CHANGE POINTS)

1. LP switch is added.

Refer to 5.WIRING DIAGRAM, 6.REFRIGERANT SYSTEM DIAGRAM and 7.PARTS LIST for details.

2. Combination of indoor and outdoor units are added.

Refer to 2.COMBINATION OF INDOOR AND OUTDOOR UNITS.

3. The location of GROUND TERMINAL is changed.

Refer to 4.OUTLINES AND DIMENSIONS.

(OC199 REVISED EDITION-A)

PU-5TJSA1 PU-5TJSA2

PU-6TJSA1 PU-6TJSA2

(CHANGE POINTS)

1. COMPRESSOR CONTACTOR has been changed to the one equipped THERMAL RELAY.

Refer to 5.WIRING DIAGRAM and 7.PARTS LIST for details.

2

COMBINATION OF INDOOR AND OUTDOOR UNITS

3

Page 4

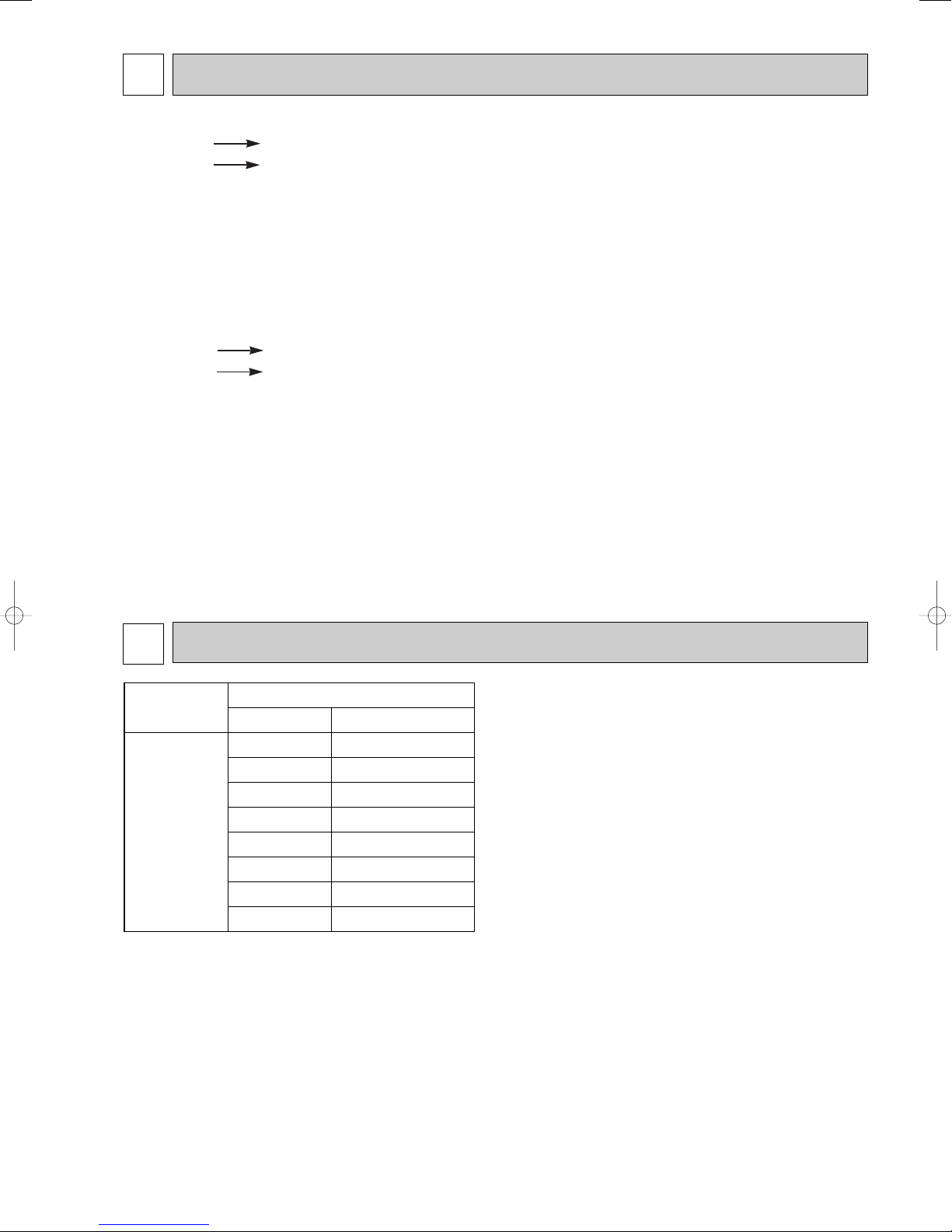

3 SPECIFICATIONS

Service Ref.

Power supply (phase, cycle, voltage)

External finish

Refrigerant control

Compressor

Heat exchanger

Defrost method

Noise level

Dimensions

Weight

Refrigerant

Pipe size O.D.

Connection method

Between the indoor & outdoor unit

Input

Running current

Starting current

Model

Motor output

Starter type

Protection devices

Crankcase heater

Fan(drive) o No.

Fan motor output

Airflow

Charge

Oil (Model)

W

D

H

Liquid

Gas

Indoor side

Outdoor side

Height difference

Piping length

OUTDOOR UNIT

REFRIGERANT

PIPING

kW

A

A

kW

kW

k/

min(CFM)

dB

mm(in)

mm(in)

mm(in)

kg(lbs)

kg(lbs)

L

mm(in)

mm(in)

Notes1. Rating Conditions

(JIS B8616) Indoor : D.B. 27°C (80°F), W.B. 19°C (66°F)

Outdoor : D.B. 35°C (95°F), W.B. 24°C (75°F)

PU-5TJSA

1

PU-5TJSA2

5.63

16.83

135

ZR61KC-TF5

3.5

55

114(282)

5.1(11.2)

2.130 (SONTEX 200LT)

PU-6TJSA

1

PU-6TJSA2

6.15

18.70

140

ZR68KC-TF5

4.0

56

117(313)

5.7(12.6)

1.774 (SONTEX 200LT)

3, 60Hz, 220V

Munsell 5Y 7/1

Capillary tube

Hermetic

Line start

Thermal switch, HP switch, LP switch, Inner thermostat

—

Plate fin coil

Propeller (direct) o2

0.10+0.10

100(3530)

—

970(38-3/16)

345+24(13-9/16+1)

1258(49-1/2)

R-22

[9.52 (3/8)

[19.05(3/4)

Flared

Flared

Max.50m

Max.50m

4

Page 5

4 OUTLINES AND DIMENSIONS

150 10

1000For 10 units or less

300

Outdoor Unit-Necessary surrounding clearance

(Concentrated installation)

Outdoor Unit-Necessary surrounding clearance

The upper side must be open.

Handle

for moving

138

95

Rear piping hole

23

33

Rear fresh

air intake

Side air intake

7 24(1)345(13-9/16)

Outlet guide

installation hole

352

Air intake

Air intake

Air outlet

970(38-3/16)

185

(7-9/32)

185

(7-9/32)

600(23-5/8)

380(14-31/32)

412(16-1/4)

1715

39.5 27.5

Terminal block for

indoor and outdoor

unit connection

Terminal block for power line

with ground terminal

300

10

10

10

Note:Allow adequate

upper clearance

150

500

500

Service space

Handle for moving

52461

585

83 524

345

382

403

959

1258(49-1/2)

90 60524

Service panel

Handle

for moving

Refrigerant-pipe flared

connection [19.05 3/4F

Refrigerant-pipe flared

connection [9.52 3/8F

Knock out hole

for front piping

(refrigerant,drainage

and wiring)

Knock out hole

for right piping

(refrigerant,

drainage and wiring)

R20

R20

60

120

4553

25 max.

Knock out holes for

power line 2-[27

Standard bolt length

65

Front right piping holes-

detail figures

80

17

52

57

12

R6

104

39

Bottom

piping hole

2-U-shaped

notched

holes

Drain hole

Drain hole

2-12o23 Oval holes

(standard bolt M10)

Front opening

PU-5TJSA1 PU-6TJSA1

PU-5TJSA2 PU-6TJSA2

Unit : mm (inch)

5

Page 6

5 WIRING DIAGRAM

CIRCUIT

BREAKER

WHT

T2/4

49C

49C

49C

GRY

47

T1/2

GRN/YLW

3~ (3PHASE)

220V 60Hz

POWER SUPPLY

L1

L2

L3

BLK

WHT

RED

(5A)

F3

WHT

RED

A1

A2

GRY

1413

63L

52C

GRY

RED

WHT

GRY

RED

BLK

YLW

47

RTS

RED

WHT

BLK

L3/5

L2/3

L1/1

52C

C

52

T3/6

BLU

T3

T2

T1

BLK

WHT

RED

MF4

WHT

ORN

RED

BLU

WHT

YLW

BRN

BLU

MC

MF3

49F3

49F4

C4

C3

WHT

ORN

RED

BLU BLU

RED

ORN

WHT

3

1

2

4

3

1

2

4

CP

X17

X6

X14

52C

P2P3P3

52C

P1BA

WHT

RED

TB3

X6

2

1

*

*

1

2

X17X14

CP

C3, 4

F3

MC

MF3, 4

TB1

TB3

26C

49C

49F3,4

52C

63H

63L

COMPRESSOR PROTECTOR

FAN MOTOR CAPACITOR

FUSE (5A)

COMPRESSOR

FAN MOTOR

TERMINAL BLOCK (POWER SUPPLY)

TERMINAL BLOCK (CONNECTING WIRES INDOOR/OUTDOOR)

THERMAL SWITCH

INTERNAL THERMOST AT (MC)

INTERNAL THERMOSTAT (MF3, 4)

COMPRESSOR CONTACTOR

HIGH PRESSURE SWITCH

LOW PRESSURE SWITCH

NOTES: 1.THE DOTTED LINES SHOW FIELD WIRING.

2. TO INDOOR UNIT TERMINAL BLOCK.

BLK

A

C

63H

26C

47 PHASE PROTECTOR

TB1

PHASE PROTECTOR47

TERMINAL BLOCK

(CONNECTING WIRES INDOOR/OUTDOOR)

CP

TERMINAL BLOCK(POWER SUPPLY)

COMPRESSOR

FAN MOTOR

FUSE(5A)

FAN MOTOR CAPACITOR

COMPRESSOR PROTECTOR

THERMAL RELAY51C

LOW PRESSURE SWITCH63L

INTERNAL THERMOSTAT FOR MC49C

2.* TO INDOOR UNIT TERMINAL BLOCK.

NOTES: 1.THE DOTTED LINES SHOW FIELD WIRING.

HIGH PRESSURE SWITCH

COMPRESSOR CONTACTOR

INTERNAL THERMOSTAT FOR MF3,4

THERMAL SWITCH

63H

52C

49F3,4

26C

TB3

TB1

MF3,4

MC

F3

C3,4

96

95

TB1

51C

51C

T2/4

T1/2

T3/6

63H

BLK

CIRCUIT

BREAKER

WHT

49C

49C

49C

GRY

26C

GRN/YLW

3~ (3PHASE)

220V 60Hz

POWER SUPPLY

L1

L2

L3

BLK

WHT

RED

(5A)

F3

WHT

RED

A1

A2

GRY

A

C

1413

63L

47

52C

GRY

RED

WHT

GRY

RED

BLK

YLW

47

RTS

RED

WHT

BLK

L3/5

L2/3

L1/1

52C

C

52

BLU

T3

T2

T1

BLK

WHT

RED

MF4

49F4

WHT

ORN

RED

BLU

WHT

ORN

RED

BLU

MC

MF3

49F3

C4

C3

WHT

ORN

RED

BLU BLU

RED

ORN

WHT

3

1

2

4

3

1

2

4

CP

X17

X6

X14

52C

P2P3P3

52C

P1BA

WHT

RED

TB3

X6

2

1

*

*

1

2

X17X14

PU-5TJSA1 PU-6TJSA1

PU-5TJSA2 PU-6TJSA2

6

Page 7

6 REFRIGERANT SYSTEM DIAGRAM

Outdoor heat

exchanger

Ball

valve

Ball valve

(with service port)

High pressure

switch

Compressor

Accumulator

DPR

Capillary tube

PU-5TJSA

1

(O.D. 4.0 oI.D. 2.4 o400)

PU-5TJSA

2

PU-6TJSA1

(O.D. 4.0 oI.D. 2.4 o200)

PU-6TJSA

2

Capillary tube

PU-5TJSA

1 PU-5TJSA2

(O.D. 4.0 oI.D. 2.4 o840)o2pcs

PU-6TJSA

1 PU-6TJSA2

(O.D. 4.0 oI.D. 2.4 o740)o2pcs

[9.52

(3/8)

[19.05

(3/4)

Check plug

Charge

plug

: flow of refrigerant

Strainer

Low pressure

switch

Strainer

PU-5TJSA1 PU-6TJSA1

PU-5TJSA2 PU-6TJSA2

7

Page 8

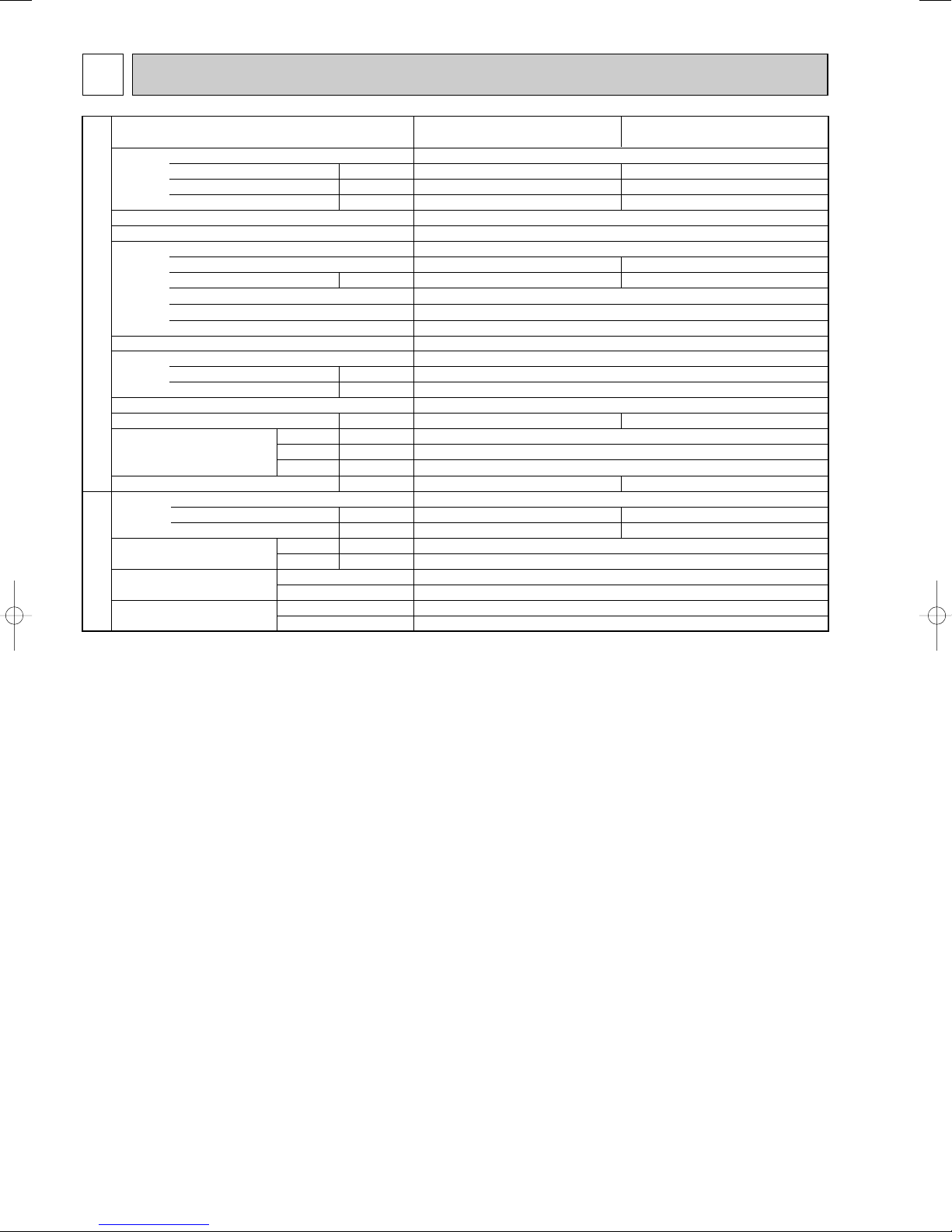

7 PARTS LIST

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

1

1

1

1

1

1

1

1

1

13

1

1

2

3

1

1

1

1

1

1

1

1

1

13

1

Part No. Part Name

SpecificationNo.

Wiring

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

Remarks

(Drawing No.)

(BC79G510H02)

(DG79R130H01)

(Z004M203H10)

(5o10)

TJSA

TJSA

1

TJSA2

TJSA

TJSA1

TJSA2

PU-5 PU-6

R01 A14 668

R01 A00 675

R01 A00 655

R01 AK6 686

R01 A14 658

—

R01 A14 682

R01 A14 661

—

T7W E03 698

R01 A14 641

T7W E00 130

—

R01 A14 662

FRONT PANEL

FAN GUARD

HANDLE

BASE

PANEL COVER

LABEL(BRAND)

REAR PANEL

SERVICE PANEL

LABEL (MITSUBISHI)

REAR GUARD

TOP PANEL

MOTOR SUPPORT

F. ST SCREW

LEFT SIDE PANEL

Q,ty/set

STRUCTURAL PARTS

PU-5TJSA PU-6TJSA

PU-5TJSA1 PU-6TJSA1

PU-5TJSA2 PU-6TJSA2

1

14

13

12

11

10

8

9

7

2

6

3

5

34

8

Page 9

FUNCTIONAL PARTS

Part No. Part Name Specification

No.

Q,ty/set

TJSA

TJSA

1 TJSA2

Wining

Diagram

Symbol

Recom-

mended

Q,ty

Price

Unit

Amount

PU-5

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

MF3,4

63H

MC

26C

63L

52C

52C

C3,4

47

TB1

CP

TB3

F3

FAN MOTOR

HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

COMPRESSOR

BALL VALVE

BALL VALVE

STRAINER

THERMAL SWITCH

CHARGE PLUG

DISCHARGE PRESSURE REGULATOR

CAPILLARY TUBE

CHARGE PLUG

CAPILLARY TUBE

LOW PRESSURE SWITCH

ACCUMULATOR

ACCUMULATOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

PHASE PROTECTOR

TERMINAL BLOCK

COMPRESSOR PROTECTOR

TERMINAL BLOCK

FUSE HOLDER

FUSE

PA6N100-UE

M8

CUT 3.3MPa

ZR61KC-TF5

3/8"

3/4"

{4.0o{2.4o400A

{4.0o{2.4o840A

CUT -0.03MPa

S-N25EX

MSO-N25KF

4+ 440V

4P (L1,L2,L3,;)

220V

2P (1,2)

250V 5A

T7W A04 763

T7W A00 408

R01 A00 115

R01 30L 097

T7W A04 208

T97 512 500

R01 943 410

R01 670 411

R01 42L 450

T7W A01 201

R01 02L 413

T7W A00 401

T7W A20 425

R01 943 413

T7W A15 425

R01 25T 209

R01 A14 440

T7W E01 440

T7W A15 708

T7W E07 708

R01 E01 255

R01 748 290

T7W 513 716

T7W 967 282

T7W 515 716

T7W 510 241

T7W 510 239

PU-5TJSA

PU-5TJSA1

PU-5TJSA2

24 23 21 19 17

25

1

22

20

18

2

16

3

1

15

2

3

4

5

9

6

7

14

13

12

11

10

9

8

Page 10

FUNCTIONAL PARTS

Part No. Part Name Specification

No.

Q,ty/set

TJSA

TJSA

1 TJSA2

Wining

Diagram

Symbol

Recommended

Q,ty

Price

Unit

Amount

PU-6

Remarks

(Drawing No.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

MF3,4

63H

MC

26C

63L

52C

52C

C3,4

47

TB1

CP

TB3

F3

FAN MOTOR

HEAT EXCHANGER

PROPELLER FAN

NUT

HIGH PRESSURE SWITCH

COMPRESSOR

BALL VALVE

BALL VALVE

STRAINER

THERMAL SWITCH

CHARGE PLUG

DISCHARGE PRESSURE REGULATOR

CAPILLARY TUBE

CHARGE PLUG

CAPILLARY TUBE

LOW PRESSURE SWITCH

ACCUMULATOR

ACCUMULATOR

COMPRESSOR CONTACTOR

COMPRESSOR CONTACTOR

FAN MOTOR CAPACITOR

PHASE PROTECTOR

TERMINAL BLOCK

COMPRESSOR PROTECTOR

TERMINAL BLOCK

FUSE HOLDER

FUSE

PA6N100-UE

M8

CUT 3.3MPa

ZR68KC-TF5

3/8"

3/4"

{4.0o{2.4o200A

{4.0o{2.4o740A

CUT -0.03MPa

S-N25EX

MSO-N25KF

4+ 440V

4P (L1,L2,L3,;)

220V

2P (1,2)

250V 5A

T7W A04 763

T7W A01 408

R01 A00 115

R01 30L 097

T7W A04 208

T97 521 501

R01 943 410

R01 670 411

R01 42L 450

T7W A01 201

R01 02L 413

T7W A00 401

T7W A17 425

R01 943 413

T7W A16 425

R01 25T 209

R01 A14 440

T7W E01 440

T7W A15 708

T7W E07 708

R01 E01 255

R01 748 290

T7W 513 716

T7W 967 282

T7W 515 716

T7W 510 241

T7W 510 239

PU-6TJSA

PU-6TJSA1

PU-6TJSA2

24 23 21 19 17

25

1

22

20

18

2

16

3

1

15

2

3

4

5

10

6

7

8

14

13

12

11

10

9

Page 11

Page 12

HEAD OFFICE : MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU TOKYO 100-8310, JAPAN

CCopyright 1999 MITSUBISHI ELECTRIC ENGINEERING CO.,LTD.

Distributed in Nov. 2002. No. OC199 REVISED EDITION-A517

Reprinted in Oct. 2002. No. OC199 5

Reprinted in Apr. 2002. No. OC199 50

Reprinted in Feb. 2002. No. OC199 5

Issued in Jul. 1999. No. OC199 570

Made in Japan.

New publication, effective Nov.2002

Specifications subject to change without notice.

Loading...

Loading...