Page 1

SPLIT-TYPE, AIR CONDITIONERS

ADVANCE AND EVER ADVANCING

TECHNICAL & SERVICE MANUAL

<indoor unit> Service ref.

Models

PED-2EJA1.UK

PED-2.5EJA

1

.UK

The Slim Line.

From Mitsubishi Electric

TM

1. FEATURES ················································· 1

2. PART NAMES AND FUNCTIONS ·············· 2

3. SPECIFICATIONS ······································ 4

4. DATA ··························································· 5

5. REFRIGERANT SYSTEM DIAGRAM ······· 8

6. OUTLINES AND DIMENSIONS ················· 9

7. WIRING DIAGRAM ···································· 10

8. DISASSEMBLY INSTRUCTIONS ············· 11

9. PARTS LIST ·············································· 14

10

. MICROPROCESSOR CONTROL·············· 19

11

. TROUBLE SHOOTING ······························25

12

. OPTIONAL PARTS ···································· 27

CONTENTS

INDOOR UNIT

REMOTE CONTROLLER

This manual does not cover the

following outdoor units. When

servicing them, please refer to

the service manual No.OC149B

and this manual as a set.

PU-2VJA2.UK

PU-2.5VJA

2.UK

2000

Page 2

Page 3

1

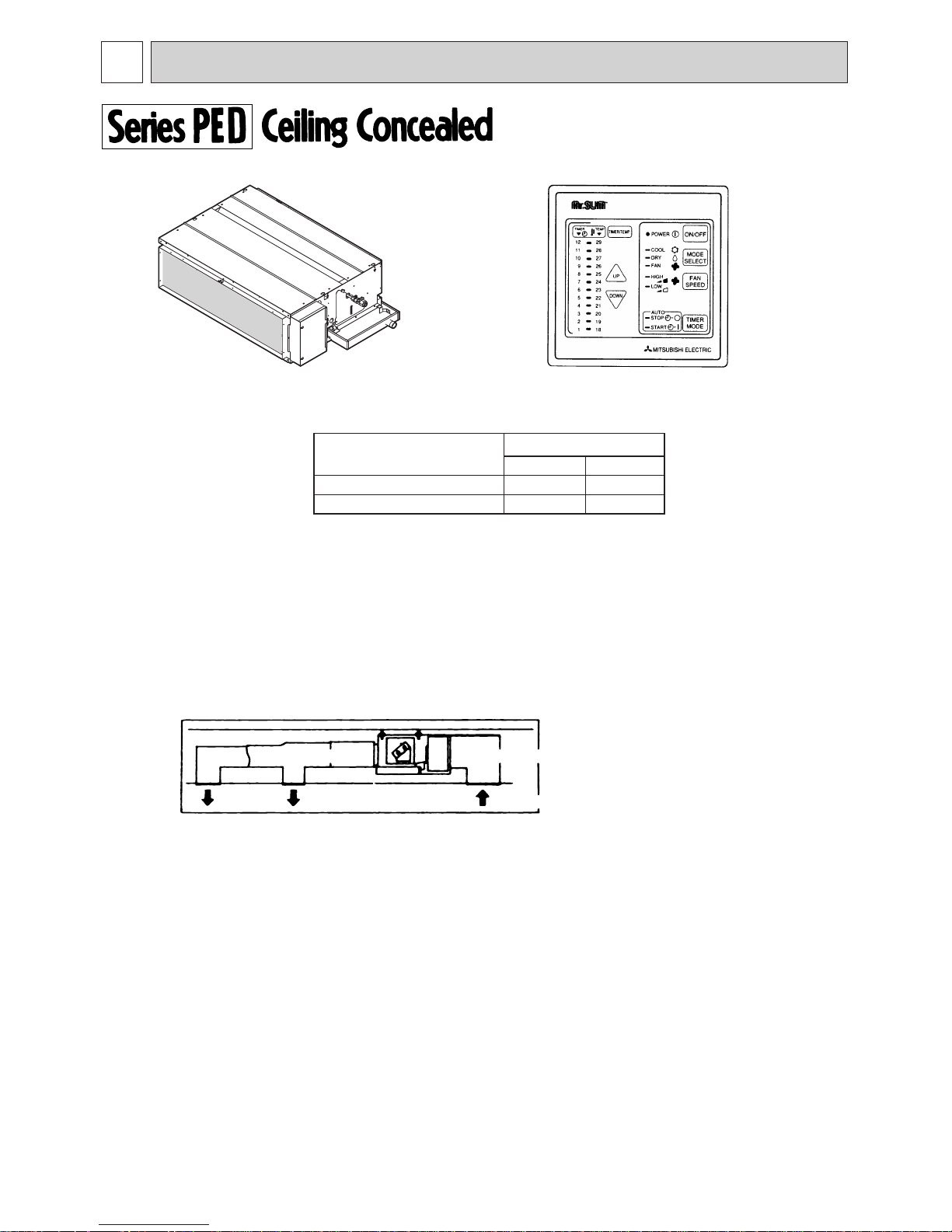

1. TOTALLY INVISIBLE INDOOR UNIT BEHIND THE CEILING

The totally hidden indoor unit that lies above the ceiling surface enables you to utilize full floor space while allowing for

flexible interior design.This new feature is recommended for stores and offices where the user's own imagination is

allowed to be incorporated.

2. MOST SUITABLE FOR SIMULTANEOUS TWO ROOM AIR CONDITIONING

Using air ducts for cooling airflow that matches the structure and purpose of the room, enables you to provide two air

outlets for simultaneous cooling of two rooms.

3. HIGH EXTERNAL STATIC PRESSURE

The exceptional external static pressure of 70Pa allows long ducts to be used more extensively to achieve convenient

location of indoor units. (The factory setting is 30Pa.)

4. DRAIN WATER LIFT-UP MECHANISM (OPTION KIT)

This allows more versatility when selecting drain piping layouts.

FEATURES

1

lndoor unit

Remote controller

Models

W Btu/h

Cooling capacity (240V)

PED-2EJA1.UK

PED-2.5EJA

1

.UK

5,500

6,500

18,800

22,200

air outlet air outlet

Air outlet duct

Air intake duct

air intake

Page 4

2

5. ADVANCED MICROPROCESSOR CONTROL

(1) Ultra - thin 12mm(1/2" )remote controller.

(2) Attractive LED display .

Every operation condition is indicated on the LED display.

(3) Simultaneous display of set temperature and room temperature.

(4) Convenient 12 - hour ON-OFF timer.

This convenient timer allows the unit to be switched on and off automatically,at the time you set.Once the

timer is set,the remaining time is shown on the LED display..

(5) Self - diagnostic function indicates problems instantly on remote controller.

(6) The useful memory feature can store instructions.

The previous set value is memorized so that constant temperature control can be obtained.For example,if a

power failure occurs, this feature will conveniently memorize the previous temperature and reset accordingly.

(7) There is a polar 12 core - conductor cable between the remote controller and indoor board.The cable can be

extended up to 50m.(option)

PART NAMES AND FUNCTIONS

2

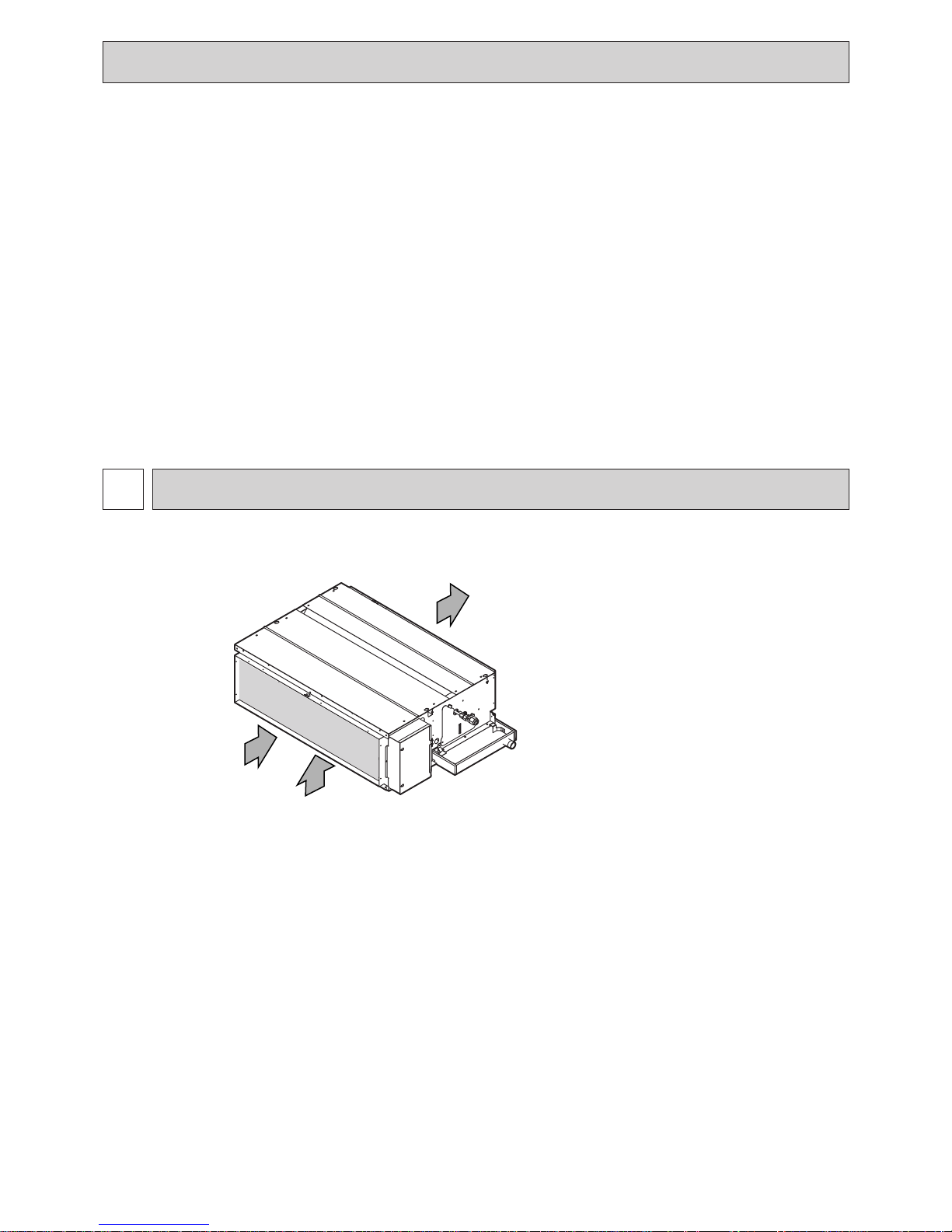

● Indoor Unit

Air intake

(sucks the air from inside the room into the unit)

Air outlet

or

Page 5

3

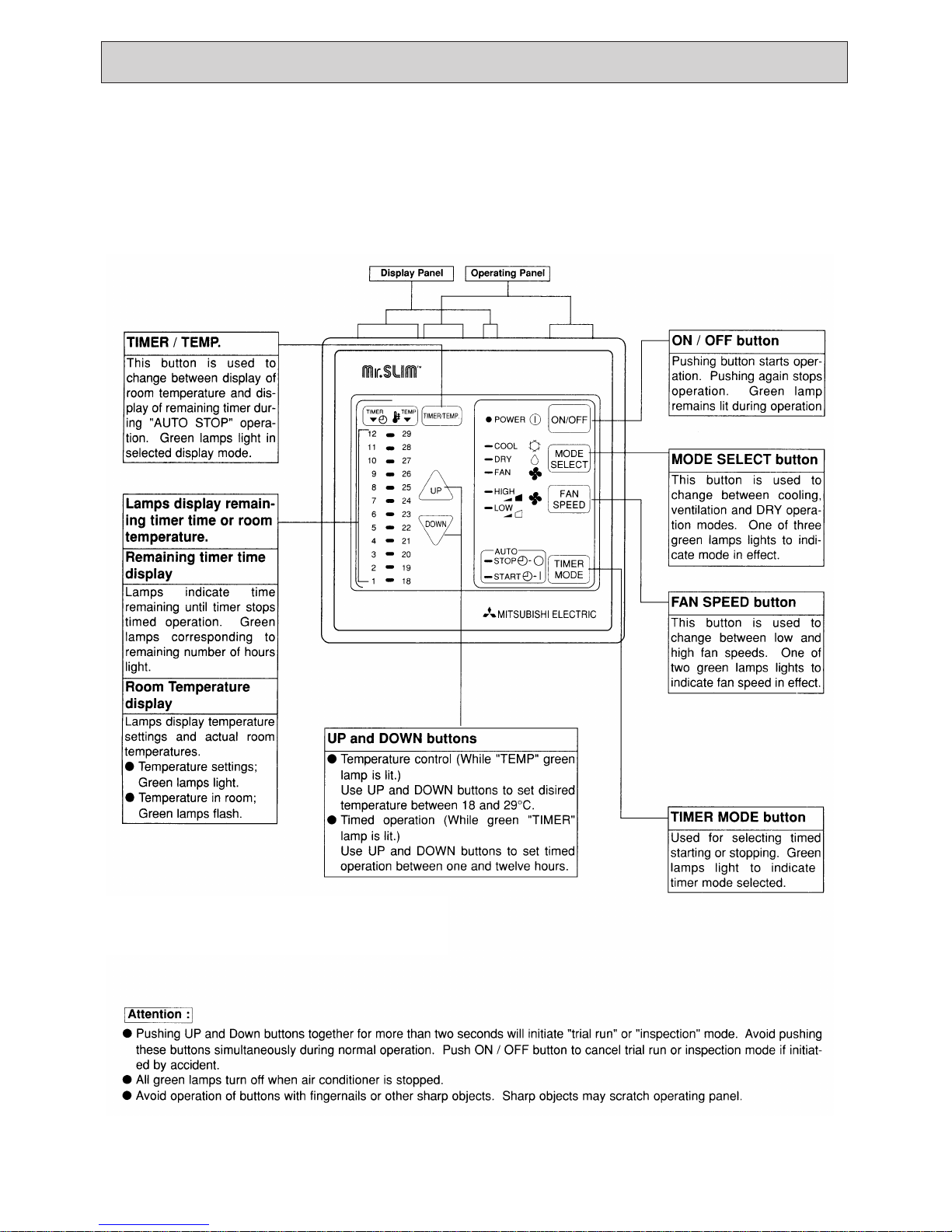

● Remote controller

● Operation buttons

● Settings remain in effect until changed. Air conditioner can

be operated by simply pushing ON/OFF button once settings

have been made.

(Example display readings are for explanations only

;actual display readings will differ.)

Page 6

4

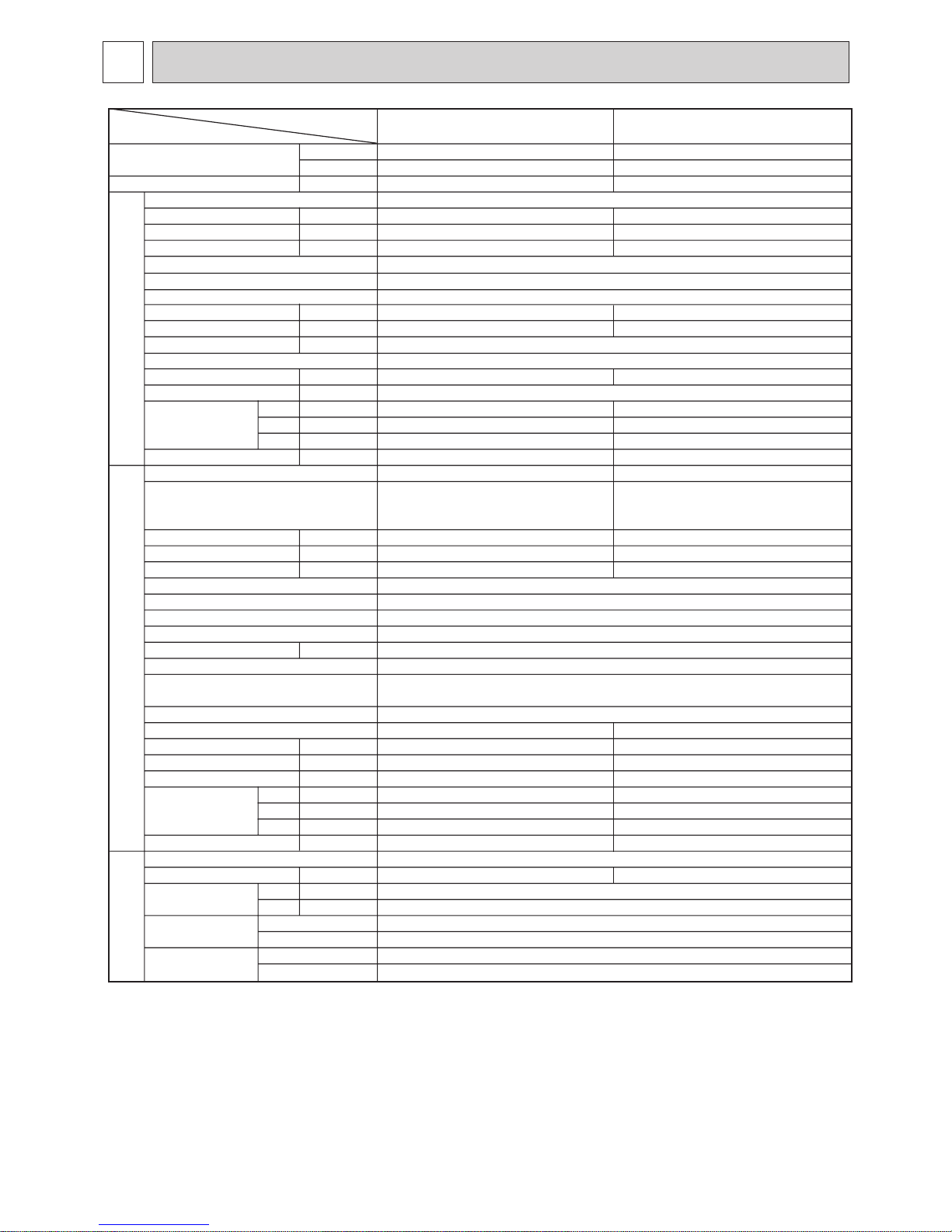

3

SPECIFICATION

Model

PED-2.5EJA

1

.UKPED-2EJA1.UK

Item

Cooling capacity

4 Btu/h 22,200

W 6,500

Total input 4 kW 2.69

Power supply

~/N, 50Hz, 220-240V

Input kW 0.17

Running current A 0.72

Starting current A 1.6

External finish

Galvanized sheets

Heat exchanger

Plate fin coil

Plate fin coil

Fan (drive) ~No.

Centrifugal (direct)x2

Fan motor output 1 kW 0.116

Airflow (Low-High) CMM,(CFM)

17-21 (600-740)

External static pressure 2 Pa(mmAq)

30(3)/70(7) at Hi-notch

Operation control & Thermostat

Remote control&Built-in

Noise level (Low-High)

3, 5 dB (A) 37-41

Cond. drain conn. O.D.

mm, (in)

32(1-1/4)

W mm, (in) 1175(46-1/8)

Dimensions

D mm, (in) 700(27-9/16)

H mm, (in) 295(11-5/8)

Weight

kg, (lbs) 42(93)

Model name

Power supply

Input kW

Running current A

Starting current A

2.52

10.7

52

External finish

Munsell 5Y 7/1

Refrigerant control

Capillary tube

Compressor

Hermetic

Model

Motor output kW

Starter type

Line Start

Protection devices Inner thermostat,HP switch,LP switch

Heat exchanger

Fan (drive) ~No.

Fan motor output kW 0.085

Airflow CMM,( CFM) 50(1765)

Noise level dB (A) 52

W mm, (in) 870(34-1/4)

Dimensions D mm, (in)

H mm, (in) 850(33-7/16)

Weight kg, (lbs) 71(157)

Refrigerant

R-22

Charge kg, (lbs) 2.4(5.29)

Pipe size O.D. Liquid mm, (in)

9.52(3/8)

Gas mm, (in)

(m)

(m)

Connection method Indoor side

Flared

Outdoor side

Flared

Between the indoor Height difference

& outdoor unit Piping length

18,800

5,500

2.63

0.15

0.63

1.1

0.076

13.5- 17(476-600)

36-40

935(36-13/16)

700(27-9/16)

295(11-5/8)

33(73)

PU-2VJA.UK PU-2.5VJA.UK

~/N

50Hz

220-240V

2.48

10.8

52

~/N

50Hz

220-240V

NHJ41VMDT

1.9

Propeller(direct)X1

Propeller(direct)X1

0.065

45(1588)

49

870(34-1/4)

295+24(11-5/8 add 1) 295+24(11-5/8 add 1)

650(25-5/8)

60(132)

1.78(3.92)

15.88(5/8)

30

30

1. External static pressure at 70Pa. 4.Rating condition <JIS B 8615>

2. Ex-works at 30Pa. INDOOR : 27 ˚CDB, 19 ˚CWB

3. External static pressure at 30Pa. OUTDOOR : 35 ˚CDB

5.Noise level : Sound pressure level

INDOOR UNIT

OUTDOOR

UNIT

REFRIGERANT

PIPING

✻

✻

✻

✻✻

✻

✻

✻

✻

✻

✻

Page 7

5

4

DA T A

Service Ref.

Indoor

intake air

WB˚C

20 25 30 35 40 45

CA P.C. CA P.C. CA P.C. CA P.C. CA P.C. CA P.C.

1. PERFORMANCE DATA

1) COOLING CAPACITY

Note C A: Capacity(W)

P.C.: Power consumption(kW)

Service Ref.

Refrigerant piping length(one way)

5m 10m 15m 20m 25m 30m

2) COOLING CAPACITY CORRECTION FACTORS

16

18

20

22

PED-

2.5EJA1.UK

5,599

5,957

6,320

6,688

6,617

7,039

7,468

7,904

2.13

2.17

2.21

2.25

2.18

2.22

2.26

2.30

5,445

5,803

6,171

6,562

6,435

6,858

7,355

7,754

2.22

2.27

2.30

2.35

2.27

2.32

2.36

2.40

5,225

5,566

5,929

6,309

6,175

6,578

7,007

7,456

2.38

2.44

2.49

2.54

2.43

2.49

2.54

2.60

4,989

5,324

5,676

6,050

5,896

6,292

6,708

7,150

2.54

2.61

2.66

2.72

2.60

2.66

2.72

2.79

4,741

5,071

5,418

5,786

5,603

5,993

6,403

6,838

2.70

2.77

2.84

2.92

2.76

2.83

2.90

2.98

4,488

4,813

5,154

5,511

5,304

5,688

6,091

6,513

2.15

2.30

2.47

2.63

2.20

2.36

2.52

2.70

16

18

20

22

PED2EJA1.UK

PED- 2.5EJA1.UK

1.00 0.983 0.972 0.961

0.951 0.940

PED- 2EJA1.UK

1.00 0.985 0.975 0.964

0.954 0.944

Outdoor intake air DB˚C

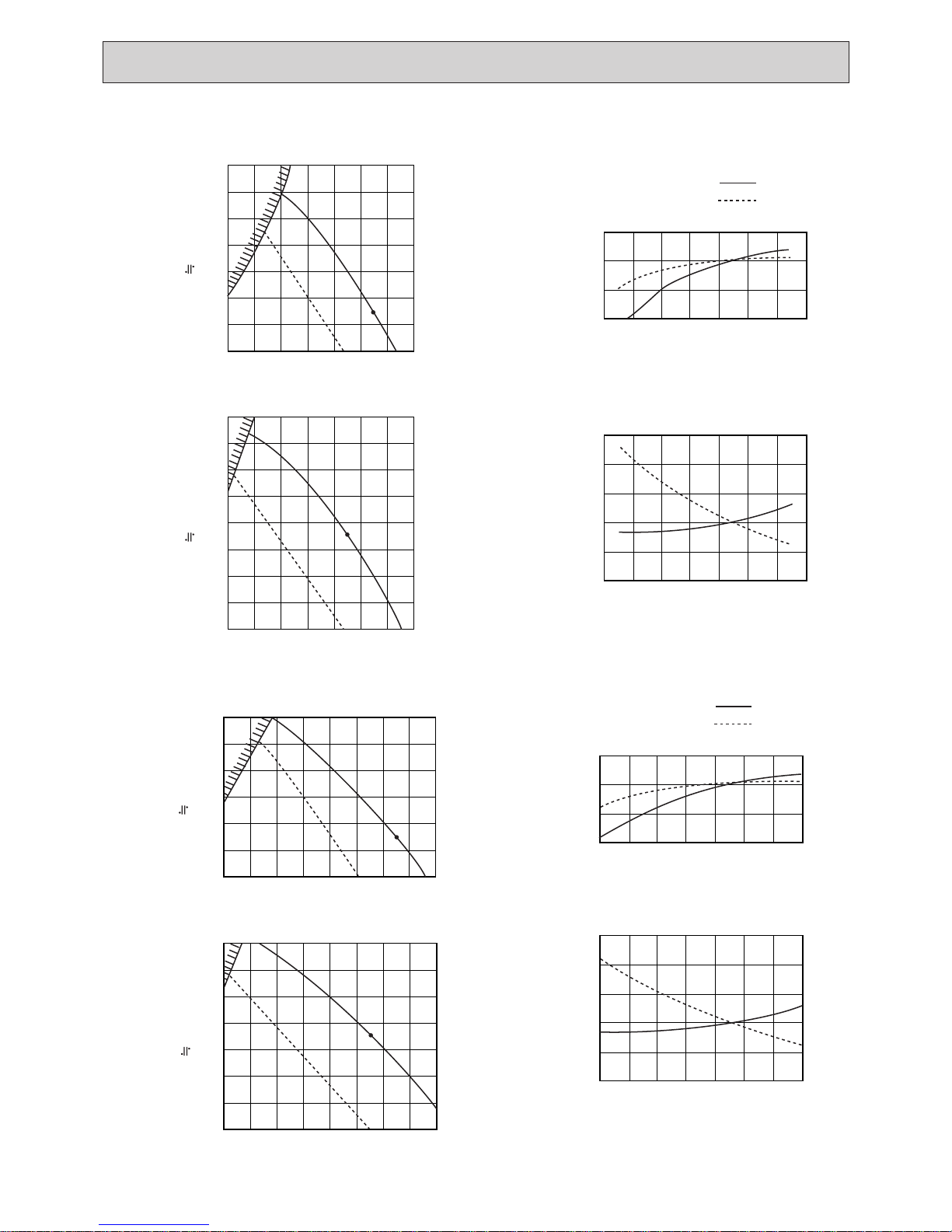

2. PERFORMANCE CURVE (CAPACITY RATIO & TOTAL INPUT RATIO)

PED-2EJA

1.UK

PED-2.5EJA

1.UK

Cooling

1.4

1.2

1

0.8

0.6

1.4

1.2

1

0.8

0.6

0.4

22

20

18

16

22

20

18

16

INDOOR WB

(˚C)

INDOOR WB

(˚C)

CAPACITY(RATIO)

TOTAL INPUT(RATIO)

OUTDOOR DB

(˚C)

-5 5 15 25 35 46

Page 8

6

Fan Performance <30Pa>

External static pressure (Pa)

(1Pa 0.1mmAg)

Air Flow (CMM)

6 8 10 12 14 16 18 20

8 101214161820 22

20

40

60

80

100

120

140

0.8

0.9

1.0

1.1

Corrected Air Flow

Capacity

input

Cooling

Air flow (CMM)

Correction factor

Fan Performance <70Pa>

External static pressure (Pa)

(1Pa 0.1mmAg)

Air Flow (CMM)

8 10121416182022

8 101214161820 22

20

40

60

80

100

120

140

160

0.8

0.9

1.0

1.1

1.2

1.3

Heating

Air flow (CMM)

Correction factor

3. FAN PERFORMANCE AND CORRECTED AIR FLOW

PED-2EJA1.UK

Fan Performance <30Pa>

External static pressure (Pa)

(1Pa 0.1mmAg)

Air Flow (CMM)

8 1012141618202224

12 14 16 18 20 22 24 26

20

40

60

80

100

120

0.8

0.9

1.0

1.1

Corrected Air Flow

Capacity

input

Cooling

Air flow (CMM)

Correction factor

Fan Performance <70Pa>

External static pressure (Pa)

(1Pa 0.1mmAg)

Air Flow (CMM)

10 12 14 16 18 20 22 24 26

12 14 16 18 20 22 24 26

20

40

60

80

100

120

140

0.8

0.9

1.0

1.1

1.2

1.3

Heating

Air flow (CMM)

Correction factor

PED-2.5EJA1.UK

Page 9

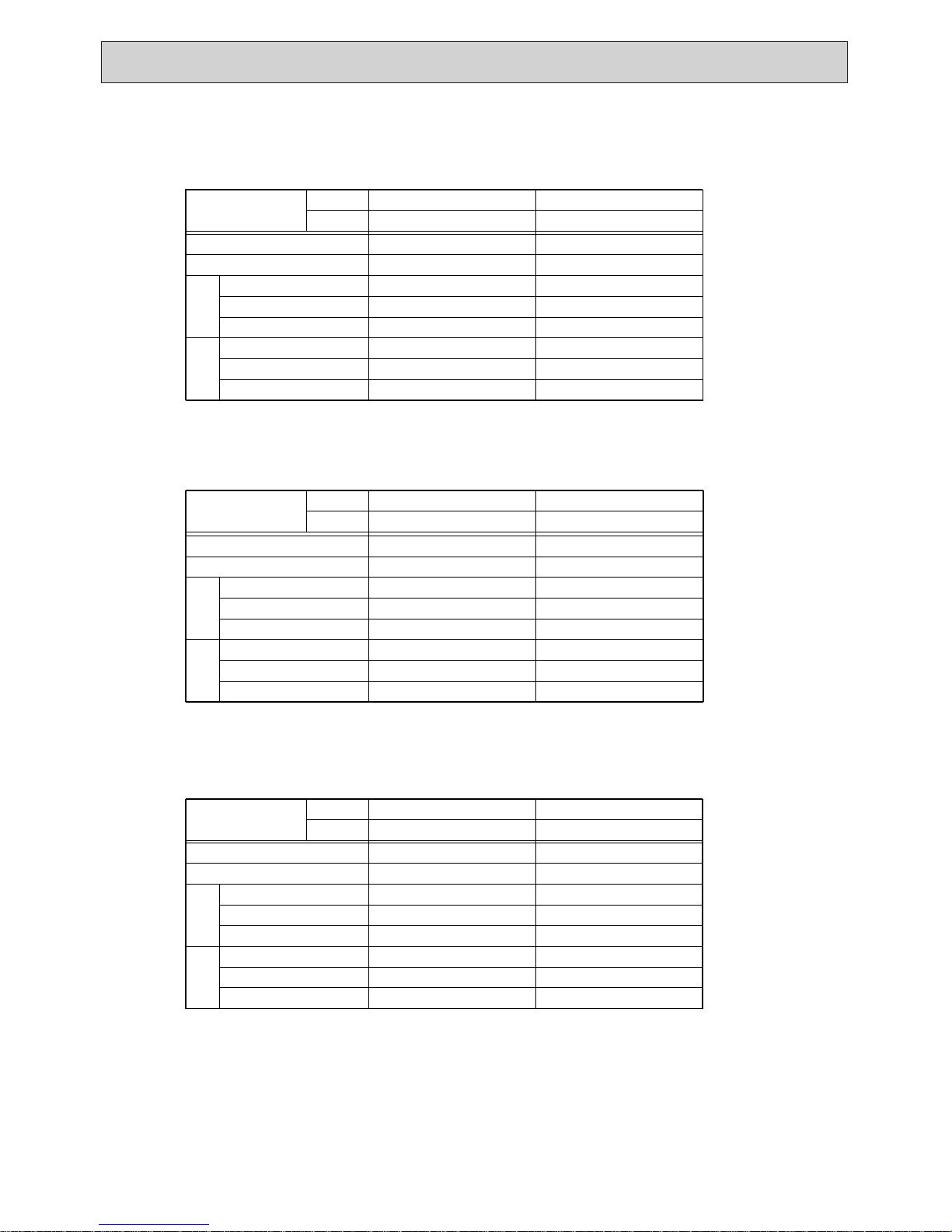

7

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

Indoor ······220V 50Hz 1phase

Outdoor ···220V 50Hz 1phase

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

Indoor ······230V 50Hz 1phase

Outdoor···230V 50Hz 1phase

Models

Indoor

Outdoor

Capacity(W)

Total input(kW)

Input(kW)

Current(A)

Starting current(A)

Input(kW)

Current(A)

Starting current(A)

IndoorOutdoor

Indoor·······240V 50Hz 1phase

Outdoor···240V 50Hz 1phase

PED-2.5EJA1.UKPED-2EJA1.UK

PU-2.5VJAPU-2VJA

PED-2.5EJA

1

.UKPED-2EJA1.UK

PU-2.5VJAPU-2VJA

PED-2.5EJA

1

.UKPED-2EJA1.UK

PU-2.5VJAPU-2VJA

5,400

2.57

0.13

0.60

1.05

2.44

11.3

48

6,300

2.61

0.15

0.69

1.53

2.46

11.4

48

5,450

2.60

0.14

0.61

1.07

2.46

11.0

50

6,400

2.65

0.16

0.70

1.56

2.49

11.0

50

5,500

2.63

0.15

0.63

1.10

2.48

10.8

52

6,500

2.69

0.17

0.72

1.60

2.52

10.7

52

4. ELECTRICAL DATA

Page 10

8

PED-2EJA1.UK

PED-2.5EJA

1.UK

Strainer

Refrigerant pipe

(option)

9.52mm(3/8)

(With heat insulator)

Flexible tube

Flared

connection

Thermistor

RT2

Distributor

Refrigerant pipe

(option)

15.88mm(5/8)

(With heat insulator)

Indoor unit

5. STANDARD OPERATION DATA (COOLING)

Models

TotalElectrical circuitRefrigerant circuit

Indoor side

Outdoor

side

SHF

BF

Capacity

Input

Indoor unit model

Phase Hz

Volts

Amperes

Outdoor unit-model

Phase,Hz

Volts

Amperes

W

kW

Discharge pressure

Suction pressure

Discharge temperature

Condensing temperature

Suction temperature

Ref.Pipe length

Intake air temperature

Intake air temperature

Diischarge air temperature

MPa

MPa

˚C

˚C

˚C

m

DB˚C

WB˚C

DB˚C

DB˚C

WB˚C

PED-2EJA1.UK

5,500

2.63

PED-2EJA

1, 50

240

0.63

PU-2VJA

1, 50

240

10.8

1.98

0.46

77.3

52.5

15.3

5

27.0

19.0

14.8

35.0

24.0

0.74

0.32

PED-2.5EJA

1

.UK

6,500

2.69

PED-2.5EJA

1, 50

240

0.72

PU-2.5VJA

1, 50

240

10.7

2.00

0.51

78.6

53.1

8.5

5

27.0

19.0

16.0

35.0

24.0

0.71

0.27

REFRIGERANT SYSTEM DIAGRAM

5

Page 11

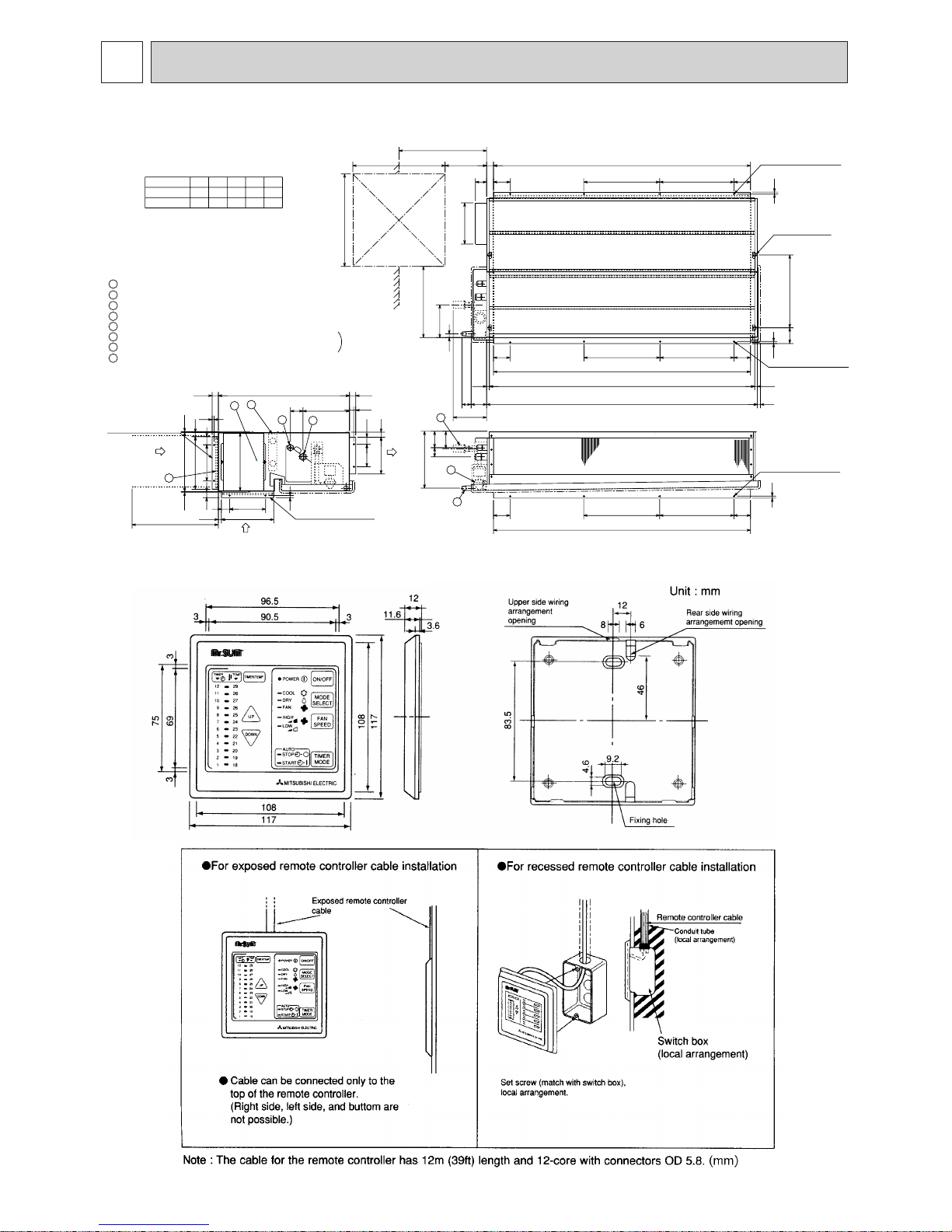

9

10

10

30

15

256

17640

A

81 C B 81

29

22761

81

A

E 1313

163

282

85

45 80

277

21

30 640 30

24

35

10

179

109

10

3.53.5

256

288

40176

Set

10-ø3 (1.6, 2HP)

12-ø3 (2.5HP)

10-ø3 (1.6, 2HP)

12-ø3 (2.5HP)

450

450

A

C B 81

10

C

30D

In case of bottom inlet

In case of rear inlet

10-ø3 (1.6, 2HP)

12-ø3 (2.5HP)

(14✕22)

Lifting bolt hole

8

8

Air inlet

35556

10

81B

365~465

159

18

44 75

7

6

7

5

6

5

4

3

2

1

Refrigerant piping flare connection (liquid ø9.52 copper tube):HP

Refrigerant piping flare connection (gas ø15.88 copper tube):LP

Drain R1(External thread)

Electrical parts box

Electric Heater···Only PEHD-EKHA Type

Drain Pump (Option)

Drain Pipe (Option)···Use VP25(O.D.ø32 PVC TUBE)

Filter

Keep duct-work length 850mm or more.

Be sure to apply the air filter (field supply) near the air inlet grille.

Service space:500 or more

197

81

50~150

55

Access door

Air outlet

Air inlet

4

3

1

2

PED-2

PED-2.5

Model

1012

772 305

280 290

830

1070

804

1044

-

ABCDE

6

OUTLINES & DIMENSIONS

1. INDOOR UNIT

PED-2EJA

1.UK

PED-2.5EJA1.UK

2. REMOTE CONTROLLER

Page 12

10

7

WIRING DIAGRAM

3

1

312

3124321

3

2

1

321

1

3

1

3

7

*

*

Drain sensor

Drain pump

Drain sensor connector

Drain pump connector

DS

DP

CN50

CNP

*

fig: *1

220V

230V

220 RED

230 ORANGE

240 YELLOW

NOTES

1.Since the indoor transfomer(T) is connected with 240V power. if 220,230V

power is used, Change the wiring connection shown at fig: 1

When power supply is

(indoor/outdoor connecting line)

Terminal block

NAME NAME NAME

SYMBOL EXPLANATION(*·····Option parts)

LD3<R.B>

F1, 2<I.B>

CNR120<R.B>

CN51<I.B>

Connector (remote controller)

Capacitor (fan motor) C

SYMBOL

LD5<R.B>

Auxiliary relay (fan motor)

X5,X6(I.B)

Thermistor (pipe temperature sensor

0˚C/15kΩ, 25˚C/5.4kΩ)

Terminal block (power)

TB1

SYMBOL

SYMBOL

LD4<R.B>

CN120<I.B>

I.B

TB2

ZNR<I.B>

T

RT1

RT2

Indoor controller board

Fuse <6.3A>

Varistor

Transformer

Thermistor (room temperature sensor

0˚C/15kΩ, 25˚C/5.4kΩ)

LD7<R.B>

LD8<R.B>

LD1<R.B>

Run indicator LED

Connector (centrally control)

Connector (remote controller)

Cooling indicator LED

Fan mode indicator LED

Fan high indicator LED

Indicator mode temperature LED

Indicator mode timer LED

LD12<R.B>

LD11<R.B>

LD10<R.B>

LD9<R.B>

Dry indicator LED

Fan low indicator LED

Off timer indicator LED

On timer indicator LED

LD13-24<R.B>

Temperature/Timer remaining

time indicator LED

MF

Indoor Fan motor

Function switch

SW1(I.B)

SW2(I.B)

Unit switch

SW3(I.B)

Emergency operation switch

SW1(R.B)

ON/OFF switch

SW2(R.B)

Operation mode switch

SW3(R.B)

Fan hige/low switch

SW5(R.B)

Indicator switch

SW6(R.B)

Temperature and timer setting up switch

SW7(R.B)

Temperature and timer setting down switch

SW8(R.B)

Timer continuous ON/OFF switch

R.B Remote controller board

GRN/YLW

BRN

BRN

BLU

BLK

BLK

GRY

GRY

YLW

GRN/YLW

BLU

RED

ORN

YLW

GRN/YLW

BLU

BLK

RED

WHT

WHT

ORN

YLW

WHT

RED

AC10.6V

AC14.5V

BRN

RED

TRANSMISSION WIRES

12VDC 12CORE CONNECTOR

TO OUTDOOR UNIT

CONNECTING WIRES

12VDC(non-polar)

CN31

HEA TER

CN51

MUL TIPLE

BLU

2

1

4

3

2

1

DS

4

3

1

OFF

ON

SW5

SW8

SW3

SW2

ON

OFF

SW1

R.B

SW3

I.B

CN50

DRAIN

CN21

PIPE

CN20

INTAKE

1

1

2

2

2

5

RT2

RT1

SW2

SW1

3

1

CND

POWER

OFF

ON

LD8 LD7

LD13

LD14

LD15

LD16

LD17

LD18

LD19

LD20

LD21

LD22

LD23

LD24

LD1

LD3

LD9

LD4

LD5

LD10

LD11

LD12

SW6

SW7

1

MODELS:PED-2,2.5EJA

WIRING DIAGRAM

NOTES

1. Since the outdoor side electric wiring may change be sure

to check the outdoor unit electric wiring for servicing.

2. Symbols used in circuit diagram above are, :Terminal block,

:connector.

3. Emergency operation

If a trouble occurs with either the remote controller or

the indoor microcomputer and no other trouble exists,emer gency operation for cooling can be performed by changing

the setting of dip switch (SW3<I.B>) on the indoor controller

board (emergency dry operation is not possible).

<Check items>

(1) Make sure that no other trouble exists with the outdoor unit.

Trouble with the outdoor unit prevents emergency operation.

(If any trouble exists with the outdoor unit,the trouble

location will be displayed on the remote controller and

the trouble position will be shown on the outdoor contro ller board LED.See electric circuit diagram of the outdoor

unit for details.)

(2) Make sure that there is no trouble with the indoor fan.

Emergency operation will be a continuous run with the power

ON/OFF(ON/OFFwith the remote controller is not possible).

<Emergency operation procedure>

(1) Set the dip switch(SW3<I.B>)on the indoor controller board

to 1 - 2 on and 3 off for cooling.

(2) Turn on the outdoor unit side circuit breaker.

(3) During emergency operation indoor fan runs at High speed.

(4) Thermostat will not function.Cold air blows out for defro sting during heating thus do not operate de frosting for

a long time.

(5) Emergency cooling should be limited to 10 hours maximum(the

indoor unit heat exchanger may freeze).

X6 X5

ZNR

F2

T

CN4T

TRANS

CNT

TRANS

FAN1

F1

:OPTION PARTS

pressure 70Pa

External static

pressure 30Pa

External static

WHITE

RED

2

4

2

3

53

6

1

DP

PE

BREAKER

TO DUCT

TB2

CN30

OUTDOOR

CN120

TO RC

TB1

N

L

POWER SUPPLY

~(1phase)

220-240VAC 50Hz

C

5

4

6

1

MF

CNR120

Page 13

11

8

DISASSEMBLY INSTRUCTIONS

Figure1.

Disconnect the fan motor connecter

(and the booster heater connector)

Drain pan

catches (Hidden)

Drain pan

catches (Hidden)

Filter

Bottom plate

Drain pan

Heat exchanger

Bottom plate

assembly

1

2

A

11

. Removing the fan motor

1. Removing the 9 screws that fix the bottom plate A, and

remove it.

2. Removing the drain pan as follows:

(1) Remove the screw that fixes the drain pan.

(2) Slide the drain pan in the direction 1, Figure1 and

unhook the drain pan catch near the drain pipe.

(3) Slide the drain pan in the direction 2, Figure1 and

unhook the 2 catches on the other side of the drain

pipe.

3. Remove the 8 screws that fix the bottom plate assembly,

and remove it.

4. Disconnect the fan motor connector from the controller

box.

5. Remove the fan plate as follow:

Figure2.

(1)Remove the 4 screws1

(2)Slide down the fan plate to remove.

6. Remove the sirocco fan setting screw and the

motor fixture setting screw to remove the motor

fixture.

Remove the other motor fixture as well, and then

remove the fan motor.

1

1

Fan base

Page 14

12

Figure3.

Fan base

Sirocco fan

Sirocco fan

Housing assembly

Housing

assembly

Piece

Piece

Leg

Bush

Bush

Motor

Page 15

13

Pump cover

assembly

Drain socket

Drain pan cover

Drain pump

assembly

Drain hose

Rubber plug

Drain pan

1

2

2. Removing the drain water lift-up pump

1. Remove the drain pan.(Refer 1- 2.)

2. Disconnect the drain pump connector and drain sensor connector from the

controller box.

3. Remove the two screws of the pump cover assembly.

4. Remove the drain hose from drain socket.

5. Remove the three screws of the drain pump assembly.

6. Remove the earth screw and four nuts of the drain pump assembly.

7. Remove the drain pump from drain pump assembly.

Figure4.

Page 16

14

9

PARTS LIST

PED-2EJA1.UK

PED-2.5EJA1.UK

EXTERNAL PARTS

9, 10

1.2

7, 8

3, 4

5, 6

No.

1

2

3

4

5

6

7

8

9

10

11

Part No. Part Name Drawing No.

Qt’y/set

Spec.

1

1

PED-

2.5EJA

1

PED-

2EJA

1

W638918G02Bottom plate 2 ass’y

W638940G02Bottom plate 2 ass’y

W638917Z03Bottom plate 1

W638939Z03Bottom plate 1

W268511G03H.EX.General ass’y

W268511G02H.EX.General ass’y

W638920G01Drain pan ass’y

W638942G01Drain pan ass’y

W638181G02

Filter

W638181G01

Filter

S70 091 669

S70 081 669

S70 011 669

S70 031 669

S70 021 480

S70 020 480

S70 021 529

S70 011 529

S70 031 500

S70 021 500

1

1

1

1

1

1

1

1

Page 17

15

PED-2EJA1.UK

PED-2.5EJA1.UK

BLOWER PARTS

5, 6

7, 8

1

1

4

4

9, 10

11

7, 8

5, 6

2, 3

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Part No. Part Name Drawing No.

Qt'y/set

W353715H01 22

22

2

2

1

1

1

11

1

W122296G01

W638949G03

W241060H03

P714774X01

<MF>

<MF>

Attachment

W638905G02Fan base ass'y

W638932G02Fan base ass'y

Sirocco fan

2

W122297G01Sirocco fan

Housing ass'y

2

W638949G04Housing ass'y

Motor

Motor support

P714316X02Motor

W818836H01Bush

S07 652 131

S70 061 677

S70 051 677

S70 A88 114

S70 A89 114

S70 989 110

S70 985 110

S70 Y56 221

S70 652 130

S70 Y58 220

S70 922 105

PED-

2.5EJA

1

PED2EJA

1

Page 18

16

PED-2EJA1.UK

PED-2.5EJA1.UK

CONTROL BOX PARTS

6

5

3

4

7

2

1

7

No.

1

2

3

4

5

6

7

8

9

10

Part No. Part Name Drawing No.

P436109X01

P436110X01

BG00L760G22

BG65T178H03

BG71V161H04

BG71V162H08

P419114X01

Qt’y/set

Spec.

<TB2>

<TB1>

<I.B.>

<T>

<RT1>

<RT2>

PED-

2.5EJA

1

PED2EJA

1

11

11

11

11

11

11

22

Terminalbed

Terminalbed

Controller

Transformer

Thermistor S

Thermistor H

Ferrite core

S70 918 717

S70 979 717

S70 010 310

S70 11K 799

S70 010 202

S70 020 202

S70 010 292

Page 19

17

PED-2EJA1.UK

PED-2.5EJA1.UK

ELECTRICAL PARTS

No.

1

2

3

4

5

Part No. Part Name Drawing No.

BC00C006G34

BG00K507G02

BG78R190G10

Qt’y/set

Spec.

J controller

10m

0.5m

11

11

11

PED-

2.5EJA

1

PED2EJA

1

Remote controller

Remote controller cable

Cable ( for board )

S70 010 713

S70 A00 305

S70 010 304

1

3

2

Page 20

18

PED-2EJA1.UK

PED-2.5EJA1.UK

DRAIN WATER LIFT-UP PUMP PARTS (OPTIONAL PARTS)

3

4

1.2

5

No.

1

2

3

4

5

Part No. Part Name Drawing No.

BG56J144G13

DB26F111H03

BB00P145G17

DE00H343G21

P312040X01

Qt’y/set

Spec.

PED-

2.5EJA

1

PED2EJA

1

11

44

11

11

11

Drain pump-94

Cushion

Drain socket ass’y

Drain sensor ass’y

Rubber plug

S70 11K 355

S70 010 533

S70 K01 523

S70 W28 266

S70 E69 558

Page 21

19

10

MICROPROCESSOR CONTROL

Page 22

20

l

Page 23

21

l

Page 24

22

l

l

after

Page 25

23

Page 26

24

Page 27

25

11

TROUBLE SHOOTING

Page 28

26

Page 29

27

12

OPTIONAL PARTS

1. REFRIGERANT PIPES

28˚C

26˚C

8:00

Normai

operation

8:00

Normai

operation

23:00

Setback

operation

3. TIMER

When using a program timer, a program timer adapter (PAC-825AD)is also needed.

3-1 Program timer specifications

3-2 Feature of program timer

(1) Daily timer function

Daily timer can be set in 30 minute units for up to 24 hours.

Each unit can be set for unit ON, unit OFF, or setback operation.

(2) Setback operation(PAC-SK65PT)

Set back operation is useful for reducing running costs.

e.g.AT a hotel with a 24-hour system

8:00~23:00 Cooling operation with set temperature at 26 ˚C

23:00~8:00 Setback operation with 2 degrees of setback

As shown in the chart on the right, the set temperature rises 2

degrees automatically during the setback operation.When the setback operation ends, normal operation will begin.

(3) Weekly timer function

Daily timer function can apply to each day of the week.

Part No. PAC-05FFS-E PAC-07FFS-E PAC-10FFS-E PAC-15FFS-E

5m 7m 10m 15mPipe length

Pipe size OD

Connection method

Liquid:/ø9.52 Gas:/ø15.88

Indoor unit:Flared Outdoor unit:Flared

Note 1.How to connect refrigerant pipes.

Factory supplied optional piping contains refrigerant at above atmospheric pressure. As long as the

connection takes no more than 5 minutes, no air will enter, and there will be no need for air purging.

Remove the blind caps and make the connections within 5 minutes. After the connections for the indoor and

outdoor units are made, open the stop valve on the outdoor unit to allow refrigerant gas to flow.

If piping length exceeds 5m, an additional charge of refrigerant is needed.

Note 2.The following main parts are contained in the optional refrigerant piping kit.

Heat insulating cover, vinyl tapes, nipples, sleeve and flange(for wall hole), connecting cables.

Part No.

Model Name

PAC-SK65PT(with set back function)

Program timer

Part name

Part No.

Program timer

PAC-SK65PT

Exterior dimensions(mm)

120X120X15 (mm)

Installation Wall mount

Type of clock Quartz

Clock accuracy

±

50second/month

Display-Time Liquid crystal display

Liquid crystal display

Liquid crystal display

Program cycle

-Timer

-Week

24 hours

Timer setting unit 30 minutes

No. of set points 48/day

Power rating

5V DC

Set back function

Provided

2. REMOTE CONTROLLER EXTENSION CABLE

When installing the remote controller at a distance from the air conditioner, use the designated extension cable with

connector.

Part No. PAC-905EC PAC-906EC PAC-918EC PAC-919EC

12m 20m 30m 50mLength

Page 30

28

3-3 HOW to connect program timer

(1) Install the program timer next to the remote controller the same way as the remote controller is installed.

(2) Connect the program timer and the remote controller with a 6-wire cable as shown in the figure below.

NOTE:While the program timer is connected to the remote controller,

the 24 hour ON/OFF timer on the remote controller will not

operate.

3-4 Names and functions

<PAC-SK65PTA>

Page 31

29

117

117

12

113

113

56.5

23.5 11

8

"ENGAGED" indicator

When this indicator is lit, transmisson is in

progress and all swiches are inoperative.

switch

This change-over switch governs the operation of the accessory remote controller.

"DUAL"

Instructions from both the accessory

remote controller and the centralized

remote controller are valid. (Priority

given to the last instruction received.)

"CENTRAL"

ON / OFF switching by the accessory

remote controller is invalidate. Operation is

controlled by the centralized remote controller only.

Inital setting is "DUAL"

LCD Matrix display

This display indicates the operational status of all connected units either by steady

lighting or by flashing.

switch

Operation ON / OFF switch.

buttons

These buttons are used to designate the

attached unit (s). (They designate the unit

to be centrally controlled.)

•When group "00" is designated ; collective ON/OFF instruction is sent to all

units.

•When group "01" - "16" is designated;

ON/OFF instruction is sent only to

the designated units.

switch

This change-over switch is for the program timer.

(It selects the timer operation on the

program timer.)

Use "BYPASS" when a program timer is

not connected.

"ACTIVE"

The switch turns ON/OFF commands

given from the program timer

automatically.

"BYPASS"

ON/OFF Operation is controlled by the

centralized remote controller only. Initial

setting is "BYPASS".

Independent "DUAL / CENTRAL" and "ACTIVE / BYPASS" setting of all the groups is prossible. When the power supply to

the centralized remote controller is cut due to power failure, all settings will return to the original "DUAL" and "BYPASS".

DUAL/CENTRAL

POWER ON/OFF

BACK AHEAD

ACTIVE/BYPASS

4. CENTRALIZED REMOTE CONTROLLER

Allows individual or combined control of up to 16 units.

4-1 Dimensions

Part No. PAC-805RC

4-2 Functions

Unit:mm

Page 32

30

4-3 Connection method

(1) Connection in the power supply cord.

1. Connect the power supply cord to the power supply terminal-block and fix in-place with a tie-wrap. Connect a single

phase 200V AC(220, 230, 240V)to AN .

As E is the GND terminal,be sure to ground the earth wire.

2. Connect the transmission line to the transmission terminal-block and fix it in-place with a tie-wrap. Use a ø1.6

(AWG14)or above two-wire cable for the transmission line.

CAUTION:Ne

ver connect the power supply cord to the transmission terminal-block.

TERMINAL-BLOCK

FOR TRANSMISSION

TERMINAL-BLOCK

OF POWER SUPPLY

Fuse(5A)

TRANSFORMER

Tie-wrap

Tie-wrap

Transmission

POWER

SUPPLY

Wiring has to be changed when

a 200,230 or 240V power is used.

TO adaptor's

terminal-block

TO adaptor's

terminal-block

Non-polar

two-wire cable

Power supply board box

Centralized

remote controller

Power supply

board

Dip swirch

SW17

(2) Connection method of centralized remote controller and power supply board.

1. Connect the centralized remote controller and power supply board with a non-polar, two-wire cable.

2.Wiring diagram

3. Be sure to set the maximum address number with the dipswitch

SW17 on the centralized remote controller.

Page 33

31

5. PROGRAM TIMER ADAPTER

This adapter is needed when a program timer(PAC-815PT)or a centralised remote controller(PAC-805RC)is used.

Part No. PAC-825AD

5-1 Parts included

1 ADAPTER ···································x1 2 3-core cable ·································· x1 2 3-core cable ·································· x1

2 4-core cable ·································· x1 2 5-core cable ·································· x1

Length:2m(6' 7")

Length:2m(6' 7")

Length:2m(6' 7" )

Length:2m(6' 7")

5-2 Connection method

Connection and wiring methods differ with the type of the indoor unit used. Confir m the type before carrying out

the work.

(1) Connections in the adapter box

1. Connect the power supply cord to the terminal-block and fix in-place with a tie-wrap.

Connect a single phase 200V AC(220, 230, 240V) to LN.

As

; is the GND ter minal, be sure to ground the ear th wire.

2. Connect the transmission line to the transmission terminal-block and fix it in-place with a tie-wrap, when a centralized remote controller is being used.

CAUTION:Never connect the power supply cord to the transmission terminal-block.

Page 34

32

Part No. PAC-559AD

7. REMOTE INDICATION ADAPTER

This adapter is used for remote indication(operation/check.)

1

5

Power

supply

BRN

RED

ORN

YRW

GRN

BRN

RED

ORN

YRW

GRN

5

2

5

±

JST

XHP3

<Wiring>

CN51

connector(5P)

Optional multiple

display adaptor

The maximum distance between

indoor board and relay is 10m.

Wiring at the actual

place

X1

X2

RL

GL

Electrical insulation is needed.

BROWN

RED

ORANGE

YELLOW

GREEN

X1

X2

6. TIMER ADAPTER

This adapter is needed for system control and for operation via external contacts.

Part No. PAC-SA89TA-E

1

2

3

ORN

BRN

RED

8. DRAIN WATER LIFT-UP MECHANISM

This allows more versatility when selecting drain piping layouts.

Part No. PAC-SK001DM-F

PED-2EJA

1

.UK, PED-2.5EJA1.UK

Applied model

Page 35

Page 36

HEAD OFFICE MITSUBISHI DENKI BLDG. MARUNOUCHI TOKYO100 TELEX J24532 CABLE MELCO TOKYO

MEE00K028

Issued in Nov. 2000

Printed in Japan

New publication, effective Nov. 2000

Specifications subject to change without notice.

TM

Loading...

Loading...