Page 1

Page 2

SAFETY PRECAUTIONS

(Please read these instructions before using this equipment.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to handle the product correctly.

These precautions apply only to this product.

In this manual, the safety instructions are ranked as "DANGER" and "CAUTION".

Indicates that incorrect handling may cause hazardous

Depending on circumstances, procedures indicated by

results.

In any case, it is important to follow the directions for usage.

Please save this manual to make it accessible when required and always forward it to the end user.

DANGER

CAUTION

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury or

physical damage.

CAUTION may also be linked to serious

A - 1

Page 3

For Safe Operations

1. Prevention of electric shocks

DANGER

Never open the front case or terminal covers of the servo amplifier while the power is ON or the

unit is running, as this may lead to electric shocks.

Never run the unit with the front case or terminal cover of the servo amplifier removed. The high

voltage terminal and charged sections will be exposed and may lead to electric shocks.

Never open the front case or terminal cover of the servo amplifier at times other than wiring work

or periodic inspections even if the power is OFF. The insides of the position board and servo

amplifier are charged and may lead to electric shocks.

Completely turn off the externally supplied power used in the system before mounting or

removing the position board, performing wiring work, or inspections. Failing to do so may lead to

electric shocks.

When performing wiring work or inspections, turn the power OFF, wait at least ten minutes, and

then check the voltage with a tester, etc. Failing to do so may lead to electric shocks.

Be sure to ground the controller incorporating the position board, servo amplifier and servo

motor. (Ground resistance : 100

The wiring work and inspections must be done by a qualified technician.

Wire the units after installing the position board, servo amplifier and servo motor. Failing to do so

may lead to electric shocks or damage.

Never operate the switches with wet hands, as this may lead to electric shocks.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this

may lead to electric shocks.

Do not touch the position board, servo amplifier or servo motor terminal blocks while the power is

ON, as this may lead to electric shocks.

Do not touch the built-in power supply, built-in grounding or signal wires of the position board

and servo amplifier, as this may lead to electric shocks.

2. For fire prevention

or less) Do not ground commonly with other devices.

CAUTION

Install the position board, servo amplifier, servo motor and regenerative resistor on incombustible.

Installing them directly or close to combustibles will lead to fire.

If a fault occurs in the position board or servo amplifier, shut the power OFF at the servo

amplifier’s power source. If a large current continues to flow, fire may occur.

When using a regenerative resistor, shut the power OFF with an error signal. The regenerative

resistor may abnormally overheat due to a fault in the regenerative transistor, etc., and may lead

to fire.

Always take heat measures such as flame proofing for the inside of the control panel where the

servo amplifier or regenerative resistor is installed and for the wires used. Failing to do so may

lead to fire.

Do not damage, apply excessive stress, place heavy things on or sandwich the cables, as this

may lead to fire.

A - 2

Page 4

3. For injury prevention

CAUTION

Do not apply a voltage other than that specified in this manual and the instruction manual of the

product you are using on any terminal.

Doing so may lead to destruction or damage.

Do not mistake the terminal connections, as this may lead to destruction or damage.

Do not mistake the polarity ( + / - ), as this may lead to destruction or damage.

Do not touch the heat radiating fins of position board or servo amplifier, regenerative resistor and

servo motor, etc., while the power is ON and for a short time after the power is turned OFF. In this

timing, these parts become very hot and may lead to burns.

Always turn the power OFF before touching the servo motor shaft or coupled machines, as these

parts may lead to injuries.

Do not go near the machine during test operations or during operations such as teaching.

Doing so may lead to injuries.

4. Various precautions

Strictly observe the following precautions.

Mistaken handling of the unit may lead to faults, injuries or electric shocks.

(1) System structure

CAUTION

Always install a leakage breaker on the controller incorporating the position board and servo

amplifier power source.

If installation of an electromagnetic contactor for power shut off during an error, etc., is specified in

the instruction manual for the servo amplifier, etc., always install the electromagnetic contactor.

Install the emergency stop circuit externally so that the operation can be stopped immediately and

the power shut off.

Use the position board, servo amplifier, servo motor and regenerative resistor with the correct

combinations listed in the instruction manual. Other combinations may lead to fire or faults.

If safety standards (ex., robot safety rules, etc.,) apply to the system using the position board,

servo amplifier and servo motor, make sure that the safety standards are satisfied.

Construct a safety circuit externally of the position board or servo amplifier if the abnormal

operation of the position board or servo amplifier differ from the safety directive operation in the

system.

In systems where coasting of the servo motor will be a problem during the forced stop, emergency

stop, servo OFF or power supply OFF, use dynamic brakes.

Make sure that the system considers the coasting amount even when using dynamic brakes.

In systems where perpendicular shaft dropping may be a problem during the forced stop,

emergency stop, servo OFF or power supply OFF, use both dynamic brakes and electromagnetic

brakes.

A - 3

Page 5

CAUTION

The dynamic brakes must be used only on errors that cause the forced stop, emergency stop, or

servo OFF. These brakes must not be used for normal braking.

The brakes (electromagnetic brakes) assembled into the servo motor are for holding applications,

and must not be used for normal braking.

The system must have a mechanical allowance so that the machine itself can stop even if the

stroke limits switch is passed through at the max. speed.

Use wires and cables that have a wire diameter, heat resistance and bending resistance

compatible with the system.

Use wires and cables within the length of the range described in the instruction manual.

The ratings and characteristics of the parts (other than position board, servo amplifier and servo

motor) used in a system must be compatible with the position board, servo amplifier and servo

motor.

Install a cover on the shaft so that the rotary parts of the servo motor are not touched during

operation.

There may be some cases where holding by the electromagnetic brakes is not possible due to the

life or mechanical structure (when the ball screw and servomotor are connected with a timing belt,

etc.). Install a stopping device to ensure safety on the machine side.

(2) Parameter settings and programming

CAUTION

Set the parameter values to those that are compatible with the position board, servo amplifier,

servo motor and regenerative resistor model and the system application. The protective functions

may not function if the settings are incorrect.

The regenerative resistor model and capacity parameters must be set to values that conform to

the operation mode and servo amplifier. The protective functions may not function if the settings

are incorrect.

Set the mechanical brake output and dynamic brake output validity parameters to values that are

compatible with the system application. The protective functions may not function if the settings

are incorrect.

Set the stroke limit input validity parameter to a value that is compatible with the system

application. The protective functions may not function if the setting is incorrect.

Set the servo motor encoder type (increment, absolute position type, etc.) parameter to a value

that is compatible with the system application. The protective functions may not function if the

setting is incorrect.

Set the servo motor capacity and type (standard, low-inertia, flat, etc.) parameter to values that

are compatible with the system application. The protective functions may not function if the

settings are incorrect.

Set the servo amplifier capacity and type parameters to values that are compatible with the

system application. The protective functions may not function if the settings are incorrect.

Use the program commands for the program with the conditions specified in the instruction

manual.

A - 4

Page 6

(3) Transportation and installation

CAUTION

Transport the product with the correct method according to the mass.

Use the servo motor suspension bolts only for the transportation of the servo motor. Do not

transport the servo motor with machine installed on it.

Do not stack products past the limit.

When transporting, installing, and removing the position board, never touch the print board

inner part and electronic components. Hold the front panel or edge of the print board.

When transporting the position board or servo amplifier, never hold the connected wires or

cables.

When transporting the servo motor, never hold the cables, shaft or detector.

When transporting the position board or servo amplifier, never hold the front case as it may fall

off.

When transporting, installing or removing the position board or servo amplifier, never hold the

edges.

Install the unit according to the instruction manual in a place where the mass can be withstood.

Do not get on or place heavy objects on the product.

Always observe the installation direction.

Mount the position board to a connector or slot that is compatible with standards, and keep the

designated clearance between the position board and other boards.

Keep the designated clearance between the position board or servo amplifier and control panel

inner surface or the position board and servo amplifier, position board or servo amplifier and

other devices.

Do not install or operate position board, servo amplifiers or servo motors that are damaged or

that have missing parts.

Do not block the intake/outtake ports of the servo amplifier and servo motor with cooling fan.

Do not allow conductive matter such as screw or cutting chips or combustible matter such as oil

enter the position board, servo amplifier or servo motor.

The position board, servo amplifier and servo motor are precision machines, so do not drop or

apply strong impacts on them.

Securely fix the position board, servo amplifier and servo motor to the machine according to the

instruction manual. If the fixing is insufficient, these may come off during operation.

A - 5

Page 7

CAUTION

Always install the servo motor with reduction gears in the designated direction. Failing to do so

may lead to oil leaks.

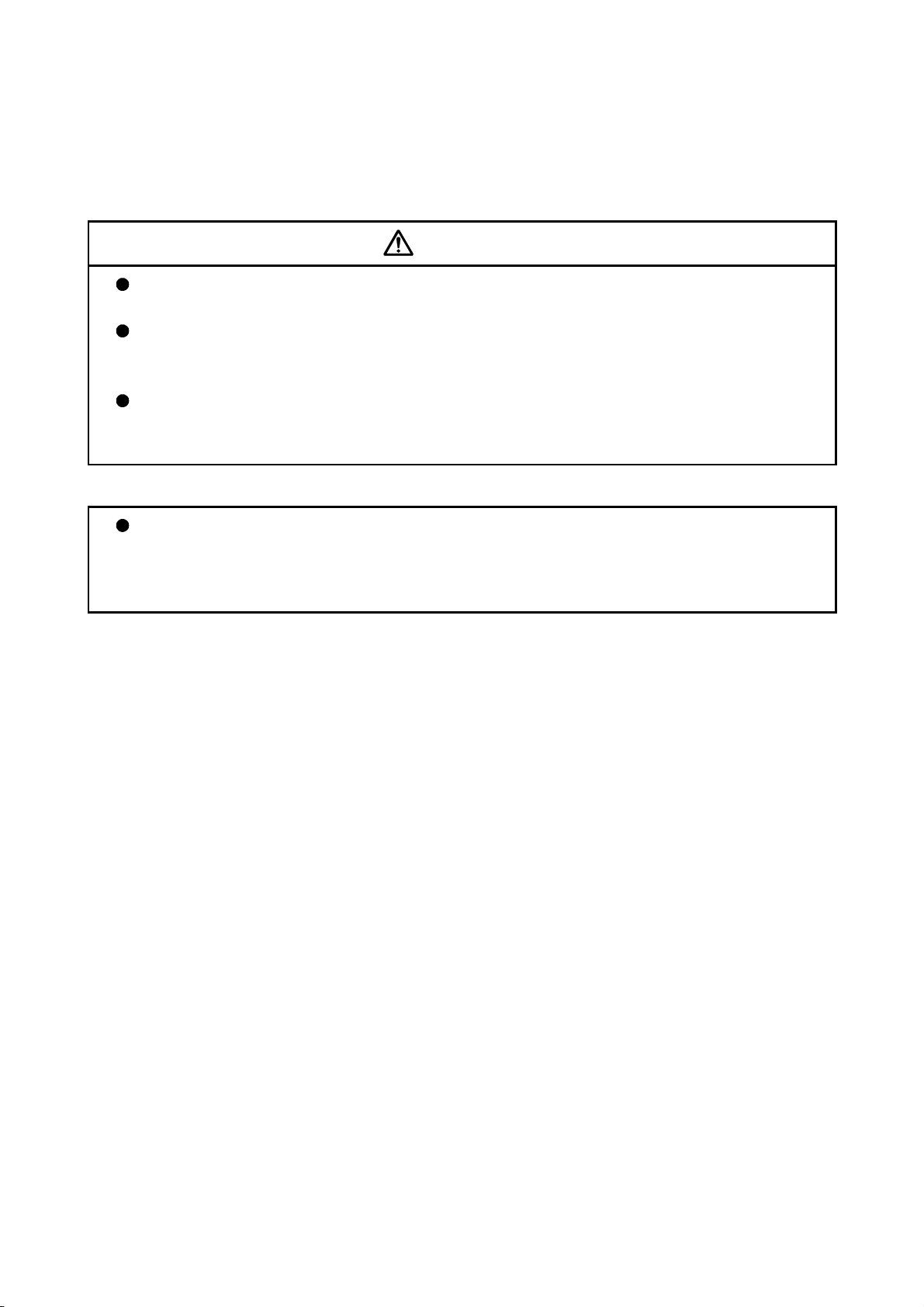

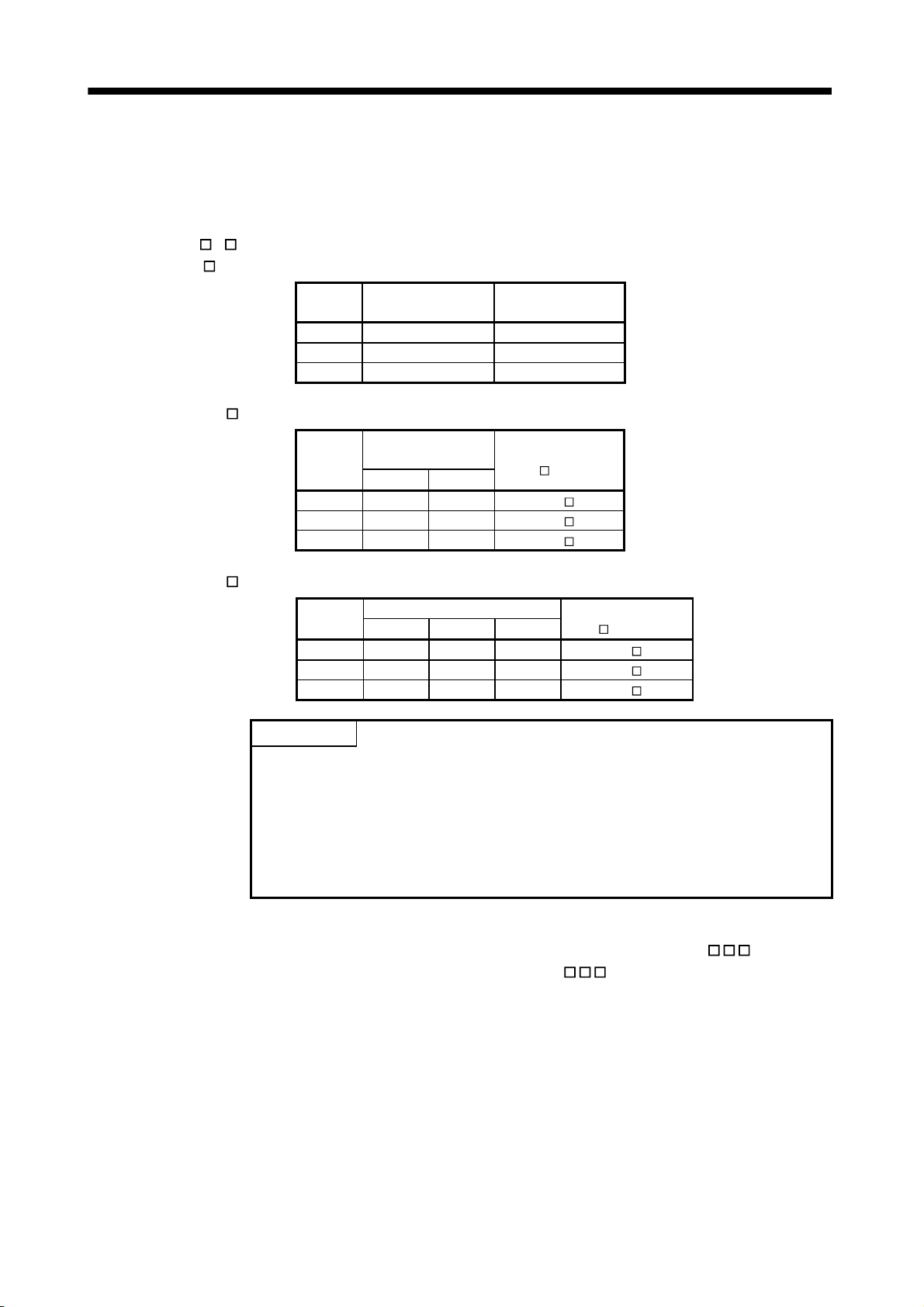

Store and use the unit in the following environmental conditions.

Environment

Position board/Servo amplifier Servomotor

Ambient

temperature

Ambient humidity According to each instruction manual.

Storage

temperature

Atmosphere

Altitude 1000m (3280.84ft.) or less above sea level

Vibration According to each instruction manual

According to each instruction manual.

According to each instruction manual.

Indoors (where not subject to direct sunlight).

No corrosive gases, flammable gases, oil mist or dust must exist

Conditions

0°C to +40°C (With no freezing)

(32°F to +104°F)

80% RH or less

(With no dew condensation)

-20°C to +65°C

(-4°F to +149°F)

When coupling with the synchronous encoder or servo motor shaft end, do not apply impact such

as by hitting with a hammer. Doing so may lead to detector damage.

Do not apply a load larger than the tolerable load onto the synchronous encoder and servo motor

shaft. Doing so may lead to shaft breakage.

When not using for a long time, disconnect the power line from the servo amplifier.

Place the position board and servo amplifier in static electricity preventing vinyl bags and store.

When storing for a long time, please contact with our sales representative.

Also, execute a trial operation.

When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine

are used for disinfecting and protecting wooden packaging from insects, they cause malfunction

when entering our products.

Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat method).

Additionally, disinfect and protect wood from insects before packing products.

A - 6

Page 8

(4) Wiring

CAUTION

Correctly and securely wire the wires. Reconfirm the connections for mistakes and the terminal

screws for tightness after wiring. Failing to do so may lead to run away of the servo motor.

After wiring, install the protective covers such as the terminal covers to the original positions.

Do not install a phase advancing capacitor, surge absorber or radio noise filter (option FR-BIF)

on the output side of the servo amplifier.

Correctly connect the output side (terminal U, V, W) and ground. Incorrect connections will lead

the servo motor to operate abnormally.

Do not connect a commercial power supply to the servo motor, as this may lead to trouble.

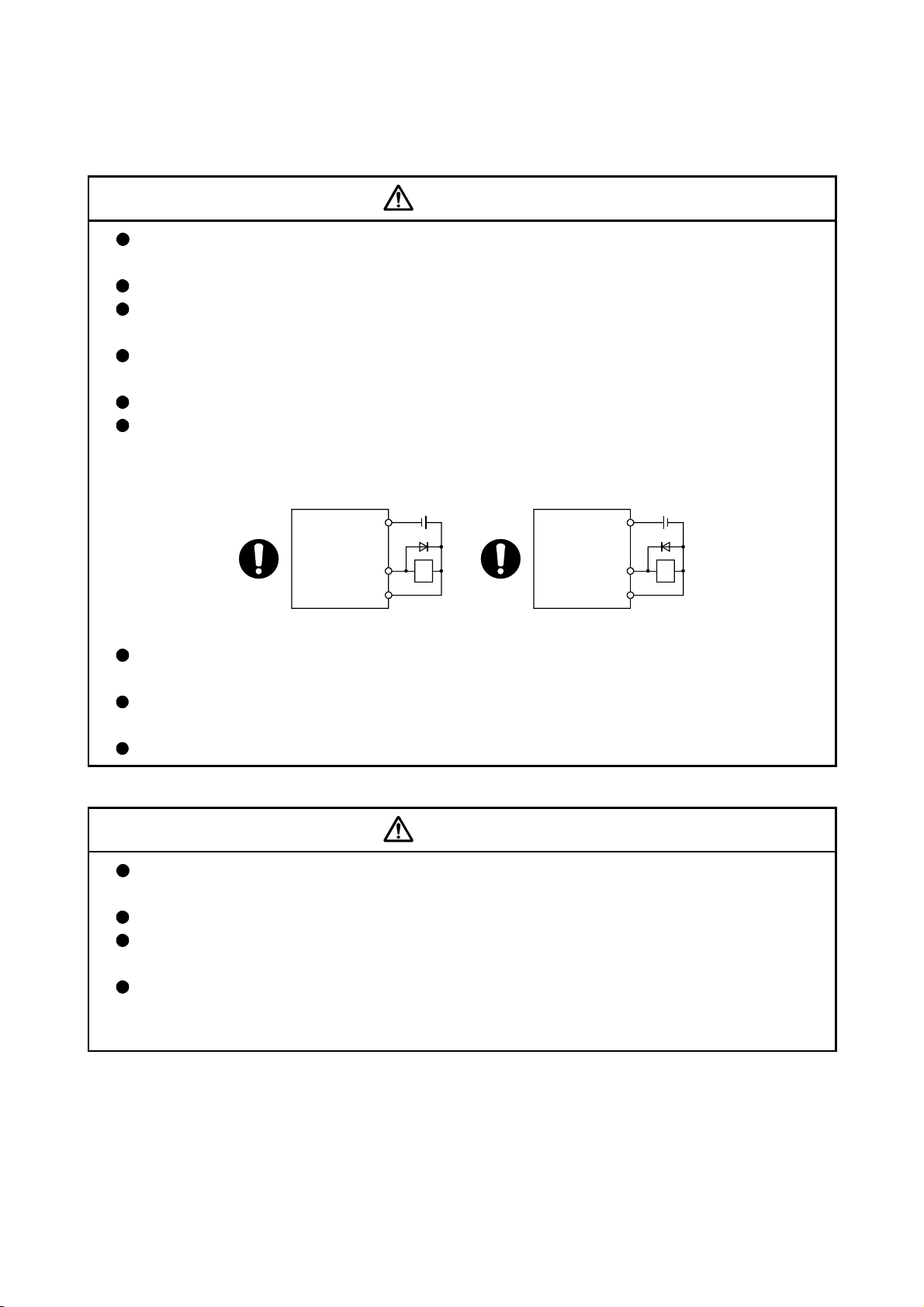

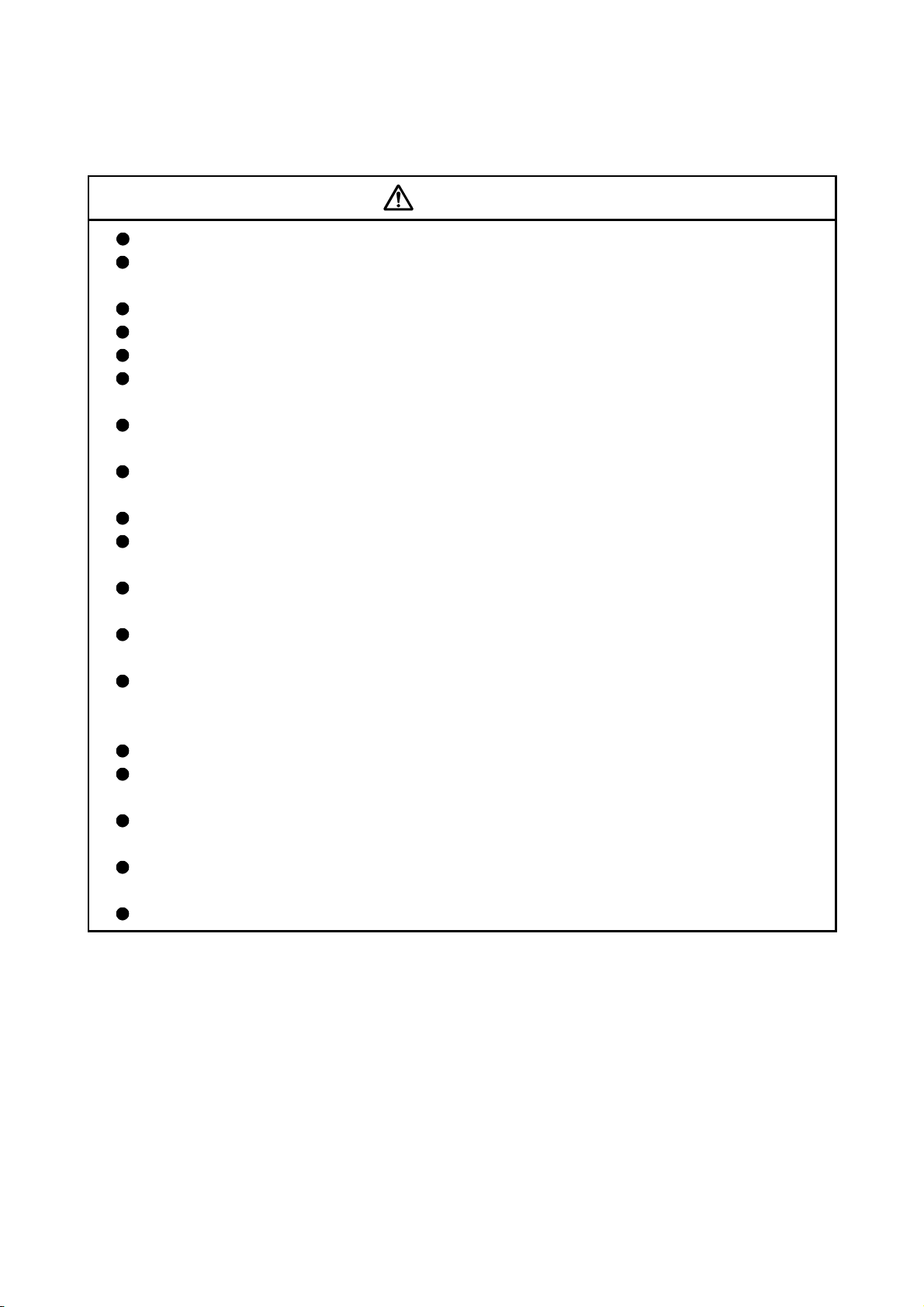

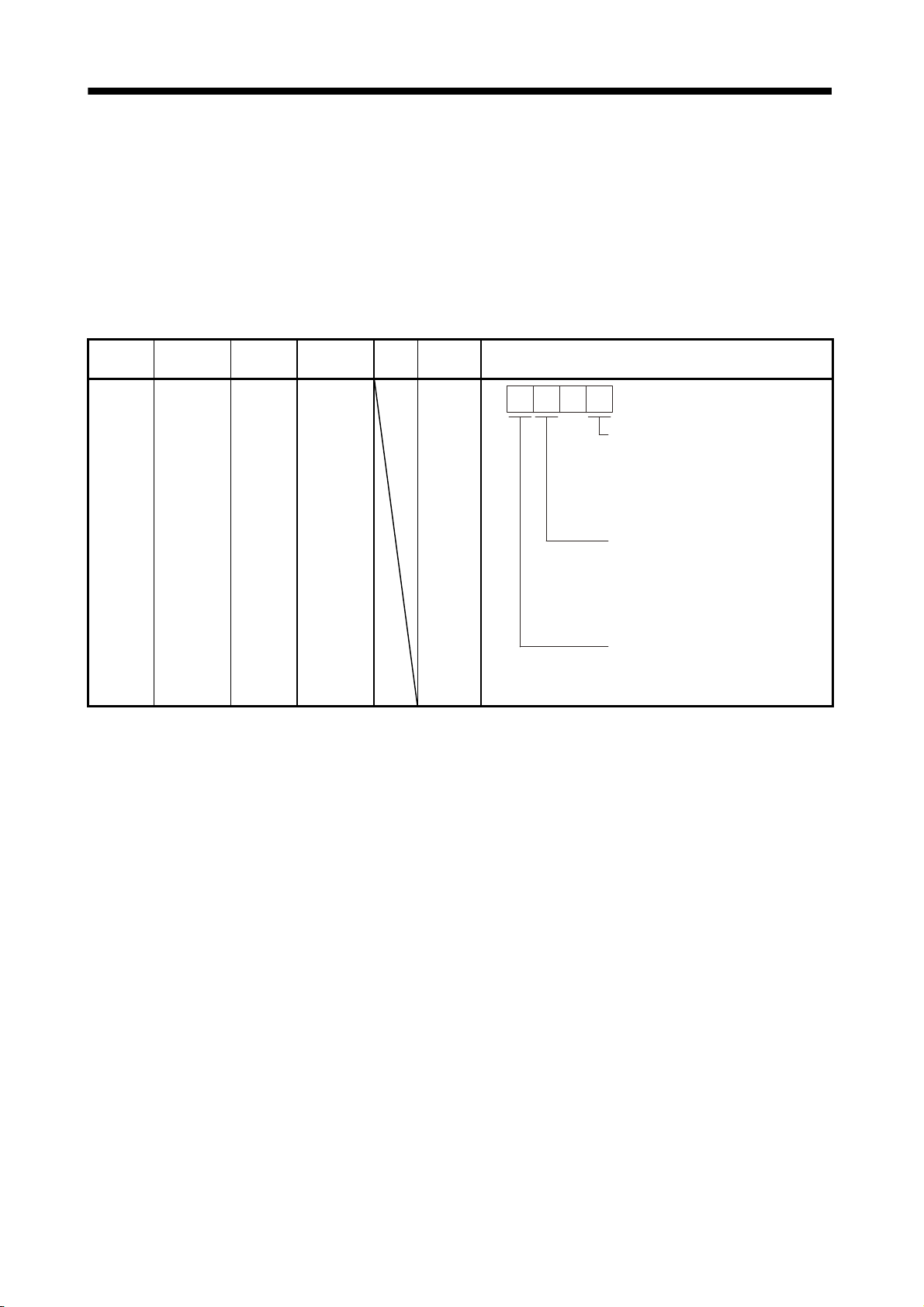

Do not mistake the direction of the surge absorbing diode installed on the DC relay for the control

signal output of brake signals, etc. Incorrect installation may lead to signals not being output

when trouble occurs or the protective functions not functioning.

Servo amplifier

DOCOM

24VDC

Servo amplifier

DOCOM

24VDC

Control output

signal

DICOM

For the sink output interface For the source output interface

RA

Control output

signal

DICOM

RA

Do not connect or disconnect the connection cables between each unit or the encoder cable

while the power is ON.

Securely tighten the cable connector fixing screws and fixing mechanisms. Insufficient fixing may

lead to the cables coming off during operation.

Do not bundle the power line or cables.

(5) Trial operation and adjustment

CAUTION

Confirm and adjust the program and each parameter before operation. Unpredictable

movements may occur depending on the machine.

Extreme adjustments and changes may lead to unstable operation, so never make them.

When using the absolute position system function, on starting up, and when the position board

or absolute value motor has been replaced, always perform a home position return.

Before starting test operation, set the parameter speed limit value to the slowest value, and

make sure that operation can be stopped immediately by the forced stop, etc. if a hazardous

state occurs.

A - 7

Page 9

(6) Usage methods

CAUTION

Immediately turn OFF the power if smoke, abnormal sounds or odors are emitted from the

position board, servo amplifier or servo motor.

Always execute a test operation before starting actual operations after the program or

parameters have been changed or after maintenance and inspection.

Do not attempt to disassemble and repair the units excluding a qualified technician whom our

company recognized.

Do not make any modifications to the unit.

Keep the effect or electromagnetic obstacles to a minimum by installing a noise filter or by using

wire shields, etc. Electromagnetic obstacles may affect the electronic devices used near the

position board or servo amplifier.

When using the CE Mark-compliant equipment, refer to this manual for the position boards and

refer to the corresponding EMC guideline information for the servo amplifiers, inverters and other

equipment.

Use the units with the following conditions.

Item Conditions

Input power According to each instruction manual.

Input frequency According to each instruction manual.

Tolerable momentary power failure According to each instruction manual.

(7) Corrective actions for errors

CAUTION

If an error occurs in the self diagnosis of the position board or servo amplifier, confirm the check

details according to the instruction manual, and restore the operation.

If a dangerous state is predicted in case of a power failure or product failure, use a servo motor

with electromagnetic brakes or install a brake mechanism externally.

Use a double circuit construction so that the electromagnetic brake operation circuit can be

operated by emergency stop signals set externally.

Shut off with servo ON signal OFF,

alarm, electromagnetic brake signal.

Servo motor

RA1

Electromagnetic

brakes

B

Shut off with the

emergency stop

signal (EMG).

EMG

24VDC

If an error occurs, remove the cause, secure the safety and then resume operation after alarm

release.

The unit may suddenly resume operation after a power failure is restored, so do not go near the

machine. (Design the machine so that personal safety can be ensured even if the machine

restarts suddenly.)

A - 8

Page 10

(8) Maintenance, inspection and part replacement

CAUTION

Perform the daily and periodic inspections according to the instruction manual.

Perform maintenance and inspection after backing up the program and parameters for the

position board and servo amplifier.

Do not place fingers or hands in the clearance when opening or closing any opening.

Periodically replace consumable parts such as batteries according to the instruction manual.

Do not touch the lead sections such as ICs or the connector contacts.

Before touching the position board, always touch grounded metal, etc. to discharge static

electricity from human body. Failure to do so may cause the position board to fail or malfunction.

Do not directly touch the position board's conductive parts and electronic components.

Touching them could cause an operation failure or give damage to the position board.

Do not place the position board or servo amplifier on metal that may cause a power leakage or

wood, plastic or vinyl that may cause static electricity buildup.

Do not perform a megger test (insulation resistance measurement) during inspection.

When replacing the position board or servo amplifier, always set the new position board

settings correctly.

When the position board or absolute value motor has been replaced, carry out a home position

return operation from the user program. Failing to do so may cause position displacement.

After maintenance and inspections are completed, confirm that the position detection of the

absolute position detector function is correct.

Do not drop or impact the battery installed to the module.

Doing so may damage the battery, causing battery liquid to leak in the battery. Do not use the

dropped or impacted battery, but dispose of it.

Do not short circuit, charge, overheat, incinerate or disassemble the batteries.

The electrolytic capacitor will generate gas during a fault, so do not place your face near the

position board or servo amplifier.

The electrolytic capacitor and fan will deteriorate. Periodically replace these to prevent secondary

damage from faults. Replacements can be made by our sales representative.

Lock the control panel and prevent access to those who are not certified to handle or install

electric equipment.

Do not burn or break a position board and servo amplifier. Doing so may cause a toxic gas.

A - 9

Page 11

(9) About processing of waste

When you discard position board, servo amplifier, a battery (primary battery) and other option articles,

please follow the law of each country (area).

CAUTION

This product is not designed or manufactured to be used in equipment or systems in situations

that can affect or endanger human life.

When considering this product for operation in special applications such as machinery or systems

used in passenger transportation, medical, aerospace, atomic power, electric power, or

submarine repeating applications, please contact your nearest Mitsubishi sales representative.

Although this product was manufactured under conditions of strict quality control, you are strongly

advised to install safety devices to forestall serious accidents when it is used in facilities where a

breakdown in the product is likely to cause a serious accident.

(10) General cautions

All drawings provided in the instruction manual show the state with the covers and safety

partitions removed to explain detailed sections. When operating the product, always return the

covers and partitions to the designated positions, and operate according to the instruction

manual.

A - 10

Page 12

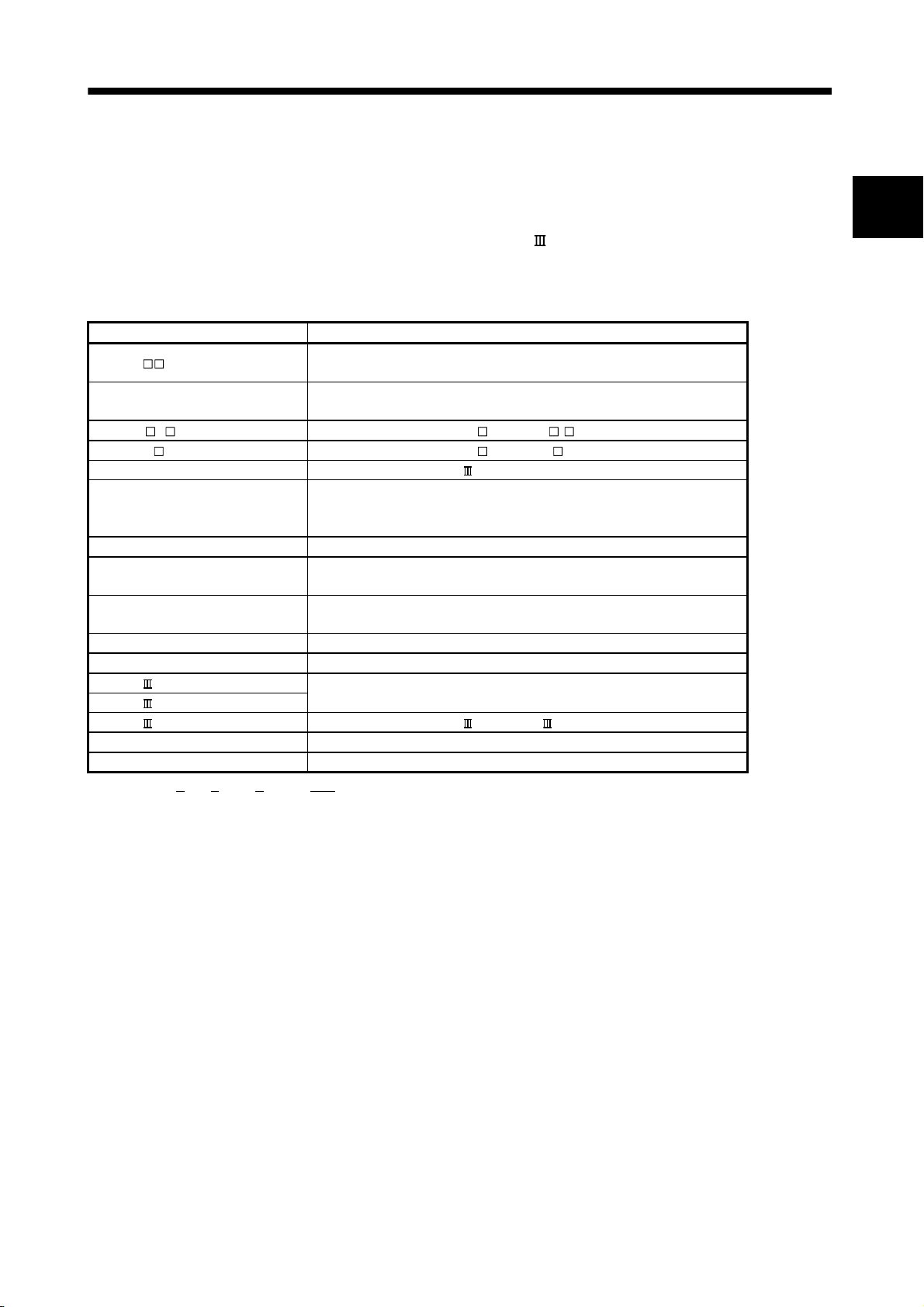

REVISIONS

The manual number is given on the bottom left of the back cover.

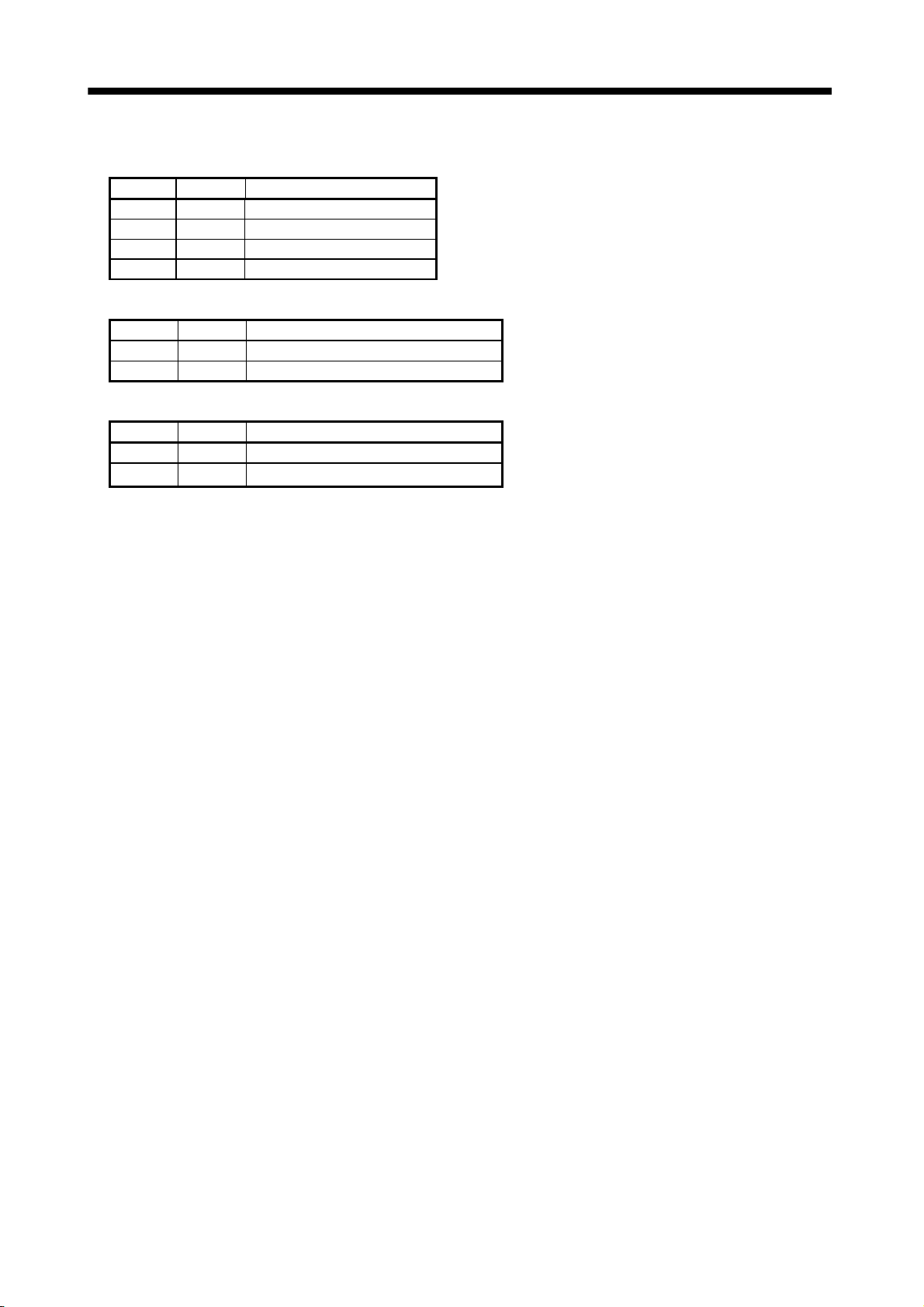

Print Date Manual Number Revision

Dec., 2013 IB(NA)-0300223-A First edition

Dec., 2014 IB(NA)-0300223-B [Additional model]

MR-MC240, MR-MC241

[Additional function]

Speed-torque control, Mark detection, Continuous operation to torque

control, External forced stop disabled

[Additional correction]

Alarm history, Home position return change while system is running,

High speed monitor position droop, Table map, Log data (event code

list, information for each event), Parameters (servo parameters,

control parameters), Monitor number (operation information), Alarm

number (system alarm, operation alarm), Supplementary explanation

for the use of linear servo system, Supplementary explanation for the

use of SSCNET

compatible servo amplifier, Connector exterior

dimensions

Japanese Manual Number IB(NA)-0300222

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent

licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property

rights which may occur as a result of using the contents noted in this manual.

© 2013 MITSUBISHI ELECTRIC CORPORATION

A - 11

Page 13

INTRODUCTION

Thank you for choosing the Mitsubishi position board MR-MC210/MR-MC211/MR-MC240/MR-MC241.

Before using the equipment, please read this manual carefully to develop full familiarity with the functions

and performance of the position board you have purchased, so as to ensure correct use.

CONTENTS

Safety Precautions ......................................................................................................................................... A- 1

Revisions ........................................................................................................................................................A-11

Contents .........................................................................................................................................................A-12

About Manuals ................................................................................................................................................A-21

1. SUMMARY 1- 1 to 1-24

1.1 Summary ................................................................................................................................................... 1- 1

1.2 Features..................................................................................................................................................... 1- 6

1.3 Specifications ............................................................................................................................................ 1- 9

1.3.1 General specifications ........................................................................................................................ 1- 9

1.3.2 List of specifications of position board .............................................................................................. 1-10

1.4 Name of each section .............................................................................................................................. 1-13

1.4.1 Name of parts for PCI bus compatible position board ..................................................................... 1-13

®

1.4.2 Name of parts for PCI Express

bus compatible position board ..................................................... 1-15

1.5 Bus interface ............................................................................................................................................. 1-17

1.5.1 Configuration register ........................................................................................................................ 1-17

1.5.2 Dual port memory map...................................................................................................................... 1-19

1.5.3 Module information ............................................................................................................................ 1-20

1.6 SSCNET

cables .................................................................................................................................... 1-22

1.7 Forced stop input terminal ....................................................................................................................... 1-23

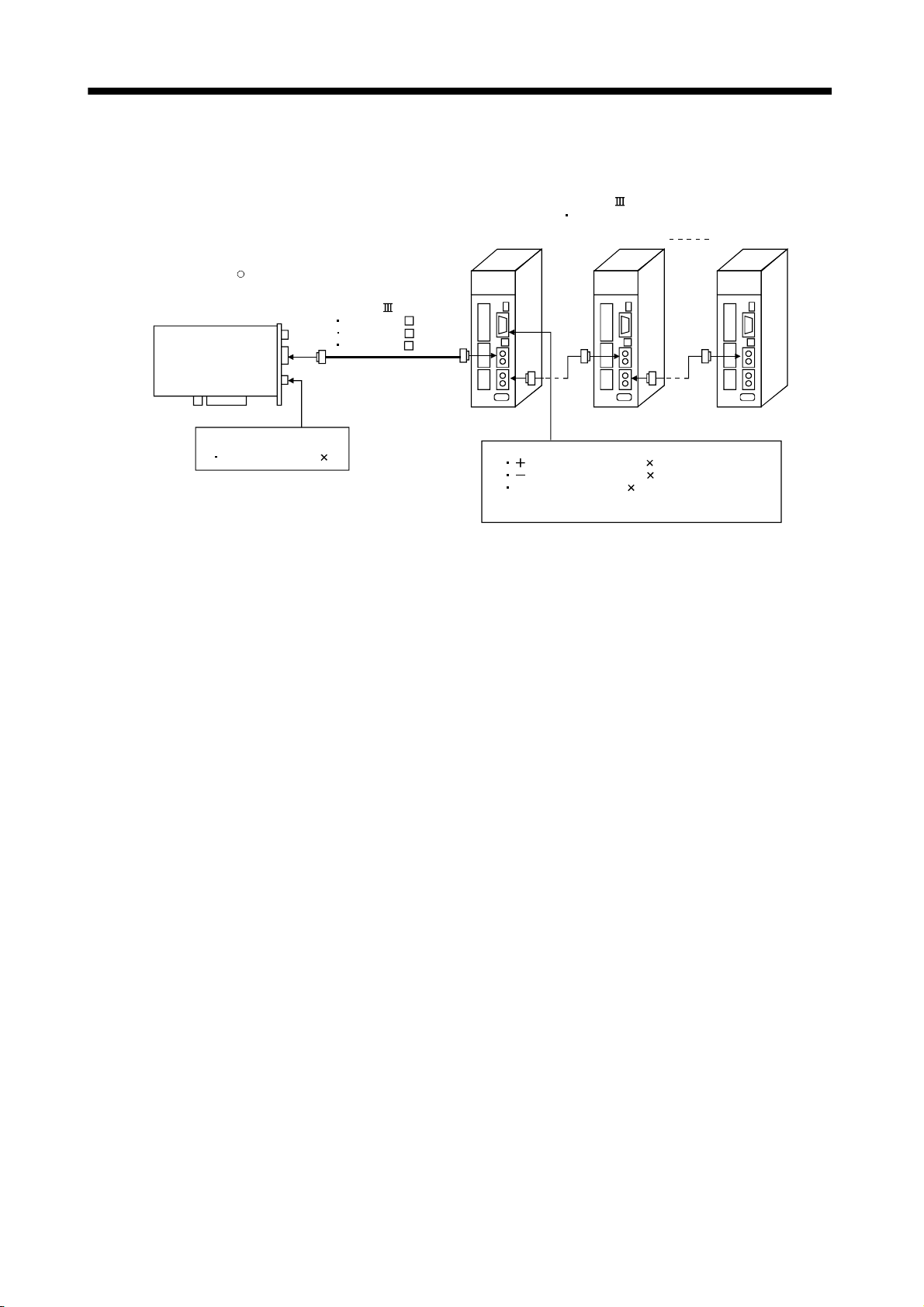

2. SYSTEM CONFIGURATION 2- 1 to 2- 8

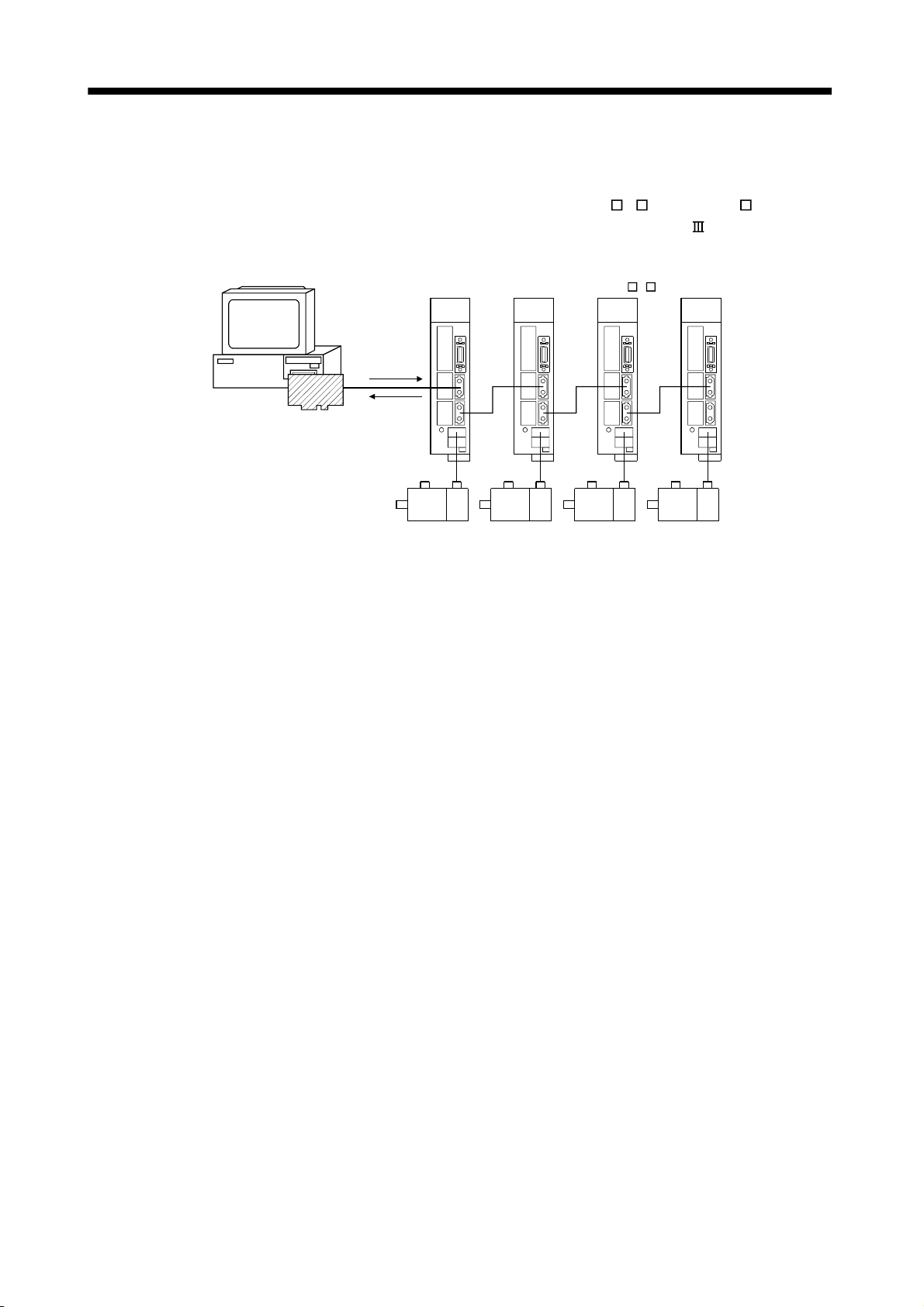

2.1 Position board configuration ..................................................................................................................... 2- 1

2.1.1 MR-MC210 system configuration ...................................................................................................... 2- 1

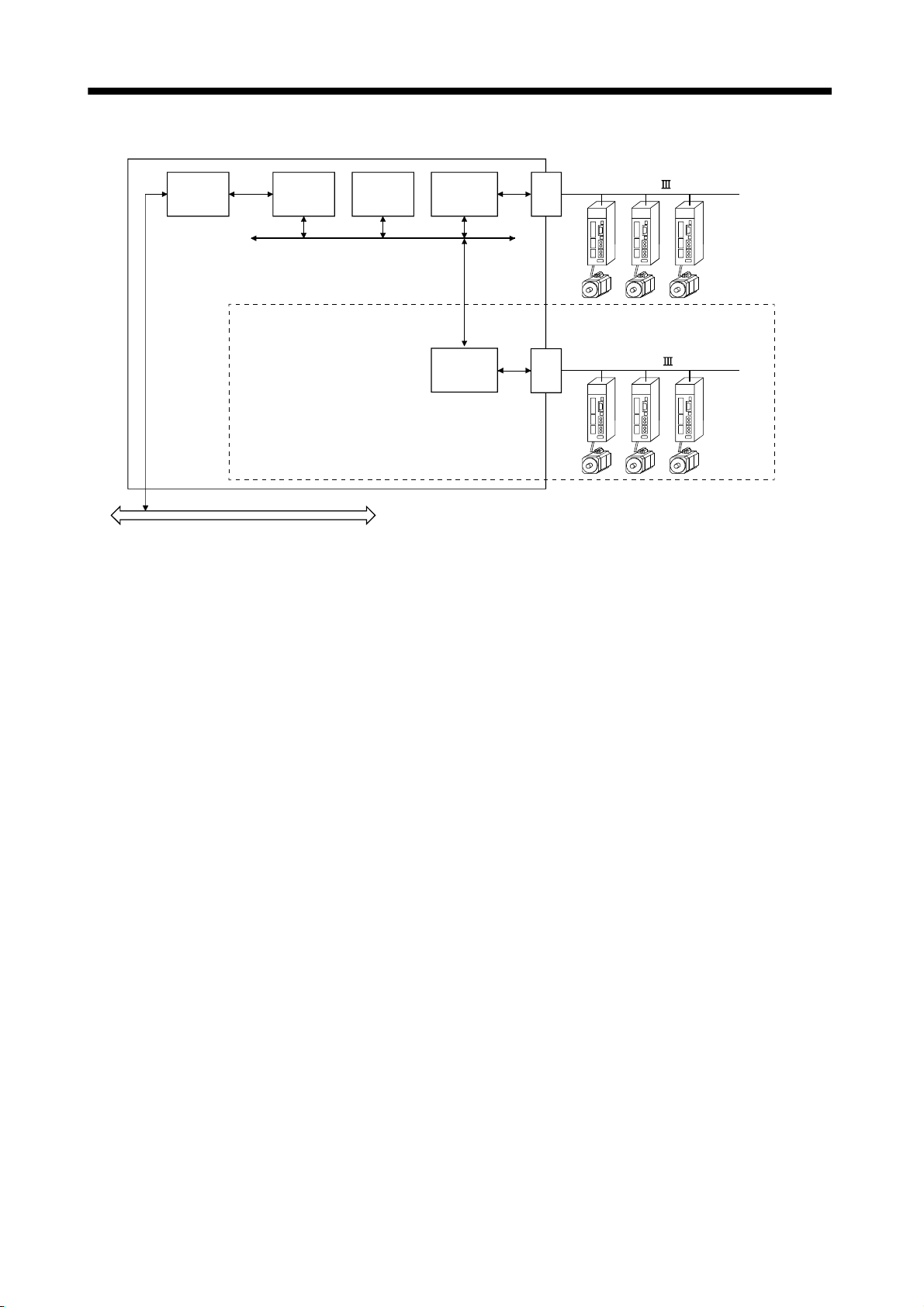

2.1.2 MR-MC211 system configuration ...................................................................................................... 2- 2

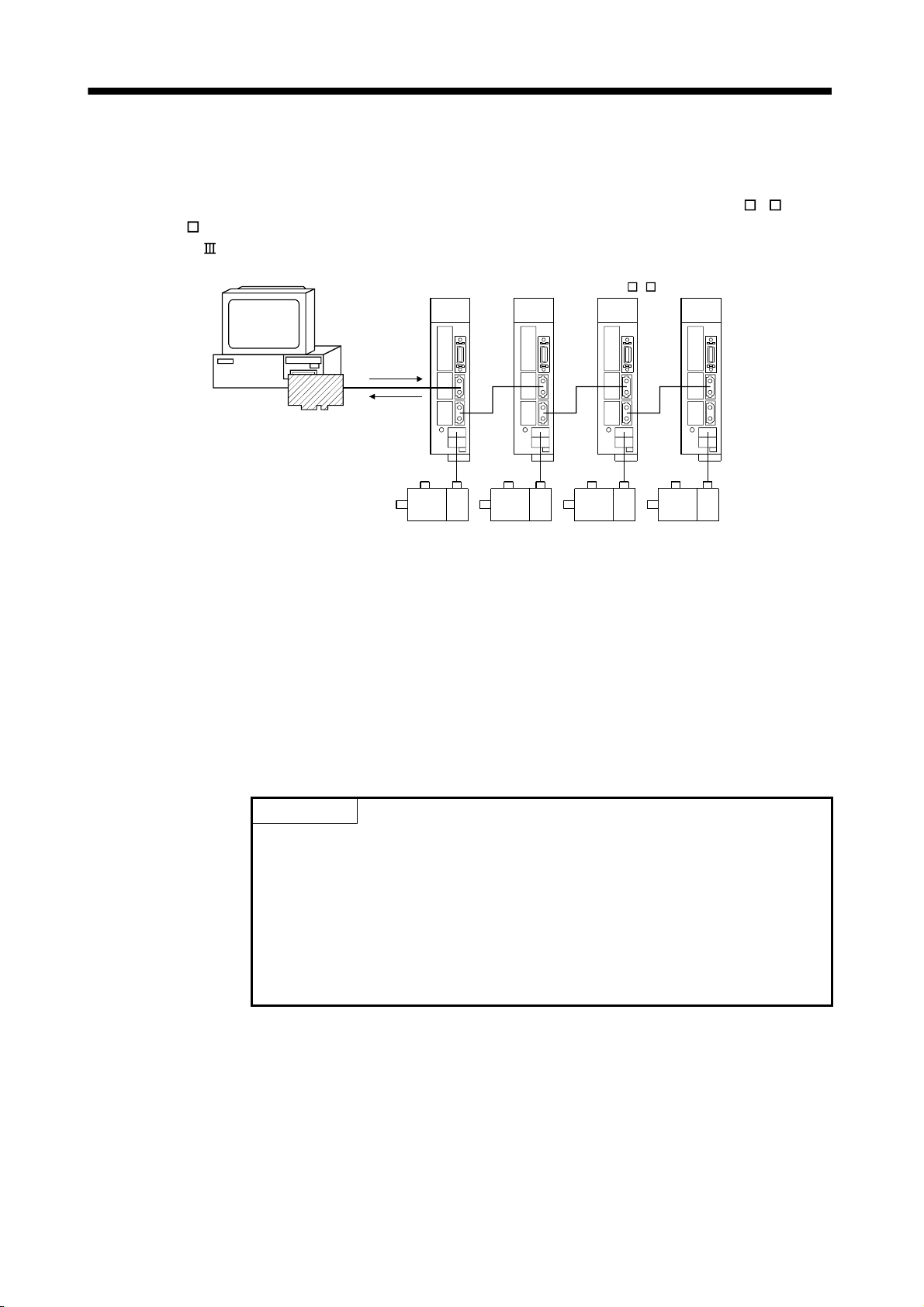

2.1.3 MR-MC240 system configuration ...................................................................................................... 2- 3

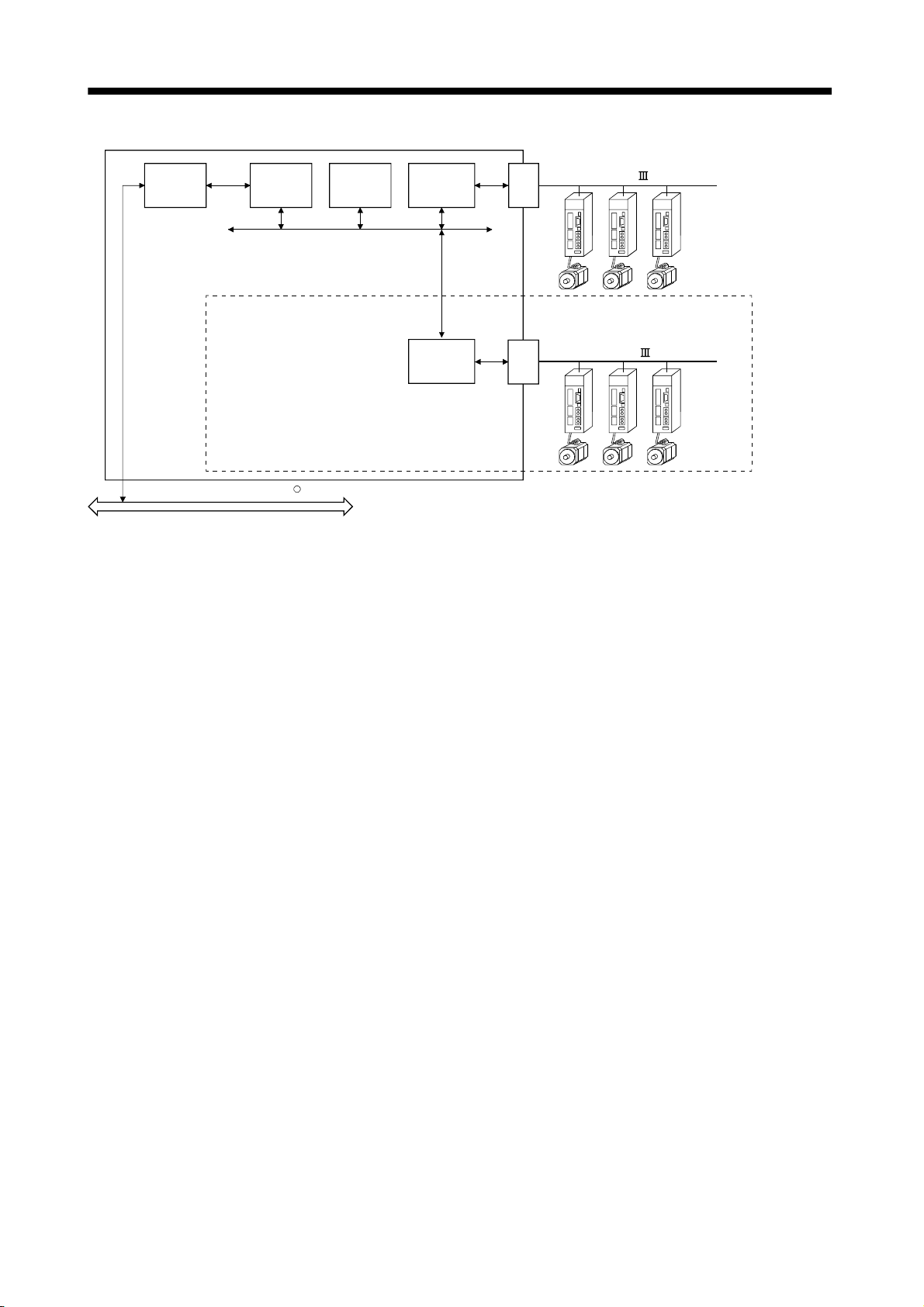

2.1.4 MR-MC241 system configuration ...................................................................................................... 2- 4

2.2 System configuration equipment .............................................................................................................. 2- 5

2.3 Checking serial number and operating system software version ............................................................ 2- 6

2.3.1 Checking serial number ..................................................................................................................... 2- 6

2.3.2 Checking software version ................................................................................................................. 2- 6

2.4 Restrictions by the Software's Version ..................................................................................................... 2- 7

3. INSTALLATION AND WIRING 3- 1 to 3- 6

3.1 Board installation ....................................................................................................................................... 3- 1

3.1.1 Instructions for handling ..................................................................................................................... 3- 1

3.1.2 Installation environment ..................................................................................................................... 3- 1

3.2 Connection and disconnection of cable.................................................................................................... 3- 2

3.2.1 SSCNET

cable ................................................................................................................................ 3- 2

A - 12

Page 14

3.2.2 Forced stop input cable ...................................................................................................................... 3- 6

4. SYSTEM STARTUP 4- 1 to 4-18

4.1 Startup procedures .................................................................................................................................... 4- 1

4.2 Check of wiring and ambient environm ent ............................................................................................... 4- 2

4.3 Position board setting ................................................................................................................................ 4- 3

4.4 Servo amplifier setting ............................................................................................................................... 4- 4

4.5 Parameter setting ...................................................................................................................................... 4- 6

4.5.1 Parameter initialization ....................................................................................................................... 4- 6

4.5.2 System option 1 setting ...................................................................................................................... 4- 7

4.5.3 System option 2 setting ...................................................................................................................... 4- 9

4.5.4 Control option 1 setting ..................................................................................................................... 4-10

4.5.5 Axis No. assignment.......................................................................................................................... 4-11

4.5.6 Sensor input option setting................................................................................................................ 4-13

4.5.7 Vendor ID and type code setting ...................................................................................................... 4-16

4.6 System startup processing ...................................................................................................................... 4-17

5. OPERATIONAL FUNCTIONS 5- 1 to 5-42

5.1 JOG operation ........................................................................................................................................... 5- 2

5.1.1 Summary ............................................................................................................................................ 5- 2

5.1.2 Start operation method ....................................................................................................................... 5- 2

5.1.3 Resuming operation ........................................................................................................................... 5- 3

5.2 Incremental feed ........................................................................................................................................ 5- 4

5.2.1 Summary ............................................................................................................................................ 5- 4

5.2.2 Start operation method ....................................................................................................................... 5- 5

5.3 Automatic operation .................................................................................................................................. 5- 6

5.3.1 Summary ............................................................................................................................................ 5- 6

5.3.2 Start operation method ....................................................................................................................... 5- 7

5.3.3 Auxiliary command ............................................................................................................................. 5- 8

5.3.4 Other axes start specification ............................................................................................................ 5-15

5.3.5 S-curve ratio ...................................................................................................................................... 5-15

5.4 Linear interpolation ................................................................................................................................... 5-16

5.4.1 Summary ........................................................................................................................................... 5-16

5.4.2 Settings .............................................................................................................................................. 5-18

5.4.3 Start operation method ...................................................................................................................... 5- 19

5.4.4 Processing for exceeding speed limit for each axis ......................................................................... 5-20

5.4.5 Restrictions ........................................................................................................................................ 5-21

5.5 Home position return ................................................................................................................................ 5-22

5.5.1 Summary ........................................................................................................................................... 5-22

5.5.2 Home position return method ........................................................................................................... 5-24

5.5.3 Start operation method ...................................................................................................................... 5- 25

5.5.4 Home position return using a dog method ....................................................................................... 5-27

5.5.5 Home position return using a data set method ................................................................................ 5-29

5.5.6 Home position return using a stopper method ................................................................................. 5-29

5.5.7 Home position return using a dog cradle method ............................................................................ 5-30

5.5.8 Home position return using a limit switch combined method........................................................... 5-32

5.5.9 Home position return using a limit switch front end method ............................................................ 5-32

5.5.10 Home position return using a dog front end method ...................................................................... 5-33

A - 13

Page 15

5.5.11 Home position return using a Z-phase detection method .............................................................. 5-35

5.5.12 Home position return using a scale home position signal detection method ................................ 5-38

5.5.13 Home position return using a scale home position signal detection method 2 ............................. 5-39

5.6 Home position reset function (data set function) ..................................................................................... 5-40

6. APPLICATION FUNCTIONS 6- 1 to 6-146

6.1 Command units ......................................................................................................................................... 6- 1

6.1.1 Position command unit - electronic gear ........................................................................................... 6- 1

6.1.2 Settings ............................................................................................................................................... 6- 3

6.1.3 Setting example of electronic gears .................................................................................................. 6- 3

6.1.4 Restrictions ......................................................................................................................................... 6- 4

6.2 Speed unit ................................................................................................................................................. 6- 5

6.2.1 Settings ............................................................................................................................................... 6- 5

6.2.2 Setting example of speed units .......................................................................................................... 6- 6

6.2.3 Speed limit .......................................................................................................................................... 6- 6

6.3 Acceleration/deceleration .......................................................................................................................... 6- 7

6.3.1 Linear acceleration/deceleration ........................................................................................................ 6- 7

6.3.2 Smoothing filter ................................................................................................................................... 6- 8

6.3.3 Start up speed validity ........................................................................................................................ 6- 8

6.3.4 S-curve acceleration/deceleration (Sine acceleration/deceleration) ................................................ 6- 9

6.4 Servo off ................................................................................................................................................... 6-13

6.5 Forced stop ............................................................................................................................................... 6-14

6.6 Stop operation .......................................................................................................................................... 6-15

6.7 Rapid stop operation ................................................................................................................................ 6-16

6.8 Limit switch (stroke end) .......................................................................................................................... 6-17

6.9 Software limit ............................................................................................................................................ 6-18

6.10 Interlock .................................................................................................................................................. 6-20

6.11 Rough match output ............................................................................................................................... 6-22

6.12 Torque limit ............................................................................................................................................. 6-23

6.13 Command change .................................................................................................................................. 6-24

6.13.1 Speed change ................................................................................................................................. 6-24

6.13.2 Change of time constants ............................................................................................................... 6-25

6.13.3 Position change ............................................................................................................................... 6-26

6.14 Backlash ................................................................................................................................................. 6-32

6.15 Position switch ........................................................................................................................................ 6-33

6.16 Completion of operation signal .............................................................................................................. 6-34

6.17 Interference check function .................................................................................................................... 6-40

6.17.1 Interface ........................................................................................................................................... 6-42

6.17.2 Interference check operation image diagram ................................................................................. 6-43

6.17.3 Checks prior to start up ................................................................................................................... 6-44

6.17.4 Operation check .............................................................................................................................. 6-45

6.18 Home position search limit ..................................................................................................................... 6-48

6.18.1 Summary ......................................................................................................................................... 6-48

6.18.2 Set items .......................................................................................................................................... 6-48

6.18.3 Home position search limit operation example .............................................................................. 6-49

6.19 Gain changing ........................................................................................................................................ 6-50

6.20 PI-PID switching ..................................................................................................................................... 6-52

6.21 Absolute position detection system ....................................................................................................... 6-53

6.21.1 Parameters ...................................................................................................................................... 6-53

A - 14

Page 16

6.21.2 Processing procedure ..................................................................................................................... 6-54

6.21.3 Sequence example ......................................................................................................................... 6-56

6.22 Home position return request ................................................................................................................ 6-58

6.23 Other axes start ...................................................................................................................................... 6-60

6.23.1 Summary ......................................................................................................................................... 6-60

6.23.2 Settings ............................................................................................................................................ 6-60

6.23.3 Interface ........................................................................................................................................... 6-66

6.23.4 Operation example .......................................................................................................................... 6-69

6.24 High response I/F ................................................................................................................................... 6-73

6.24.1 Summary ......................................................................................................................................... 6-73

6.24.2 Interface ........................................................................................................................................... 6-74

6.24.3 Fast start operation ......................................................................................................................... 6-75

6.24.4 Interrupt processing high speed completion .................................................................................. 6-76

6.25 In-position signal .................................................................................................................................... 6-77

6.26 Digital input/output ................................................................................................................................. 6-78

6.26.1 Summary ......................................................................................................................................... 6-78

6.26.2 Interface ........................................................................................................................................... 6-79

6.27 Servo amplifier general input/output ...................................................................................................... 6-80

6.27.1 Summary ......................................................................................................................................... 6-80

6.27.2 Settings ............................................................................................................................................ 6-82

6.28 Dual port memory exclusive control ...................................................................................................... 6-85

6.28.1 Summary ......................................................................................................................................... 6-85

6.28.2 Exclusive control of digital output ................................................................................................... 6-85

6.29 Pass position interrupt............................................................................................................................ 6-87

6.29.1 Summary ......................................................................................................................................... 6-87

6.29.2 Pass position interrupt setting method ........................................................................................... 6-88

6.29.3 Interface ........................................................................................................................................... 6-89

6.29.4 Operation example ........................................................................................................................ 6-100

6.30 Mark detection ...................................................................................................................................... 6-104

6.30.1 Summary ....................................................................................................................................... 6-104

6.30.2 Interface ......................................................................................................................................... 6-108

6.30.3 Function details ............................................................................................................................. 6-116

6.30.4 Operation example ........................................................................................................................ 6-118

6.31 Continuous operation to torque control ............................................................................................... 6-121

6.31.1 Summary ....................................................................................................................................... 6-121

6.31.2 Interface ......................................................................................................................................... 6-123

6.31.3 Control mode switch ...................................................................................................................... 6-134

6.31.4 Operation timing ............................................................................................................................ 6-136

6.31.5 Operation during continuous operation to torque control mode .................................................. 6-140

6.31.6 Stop factors during continuous operation to torque control ......................................................... 6-141

6.31.7 Combinations of continuous operation to torque control and other functions ............................. 6-143

6.31.8 Restrictions on servo amplifier functions ..............................................................................

........ 6-145

XILIARY FUNCTION 7- 1 to 7-108

AU

7.

7.1 Reading/writing parameters ...................................................................................................................... 7- 1

7.1.1 Writing par ameters ............................................................................................................................. 7- 1

7.1.2 Reading parameters ........................................................................................................................... 7- 3

7.2 Changing parameters at the servo ........................................................................................................... 7- 4

7.3 Alarm and system error ............................................................................................................................. 7- 6

A - 15

Page 17

7.4 Monitor function ......................................................................................................................................... 7- 8

7.4.1 Summary ............................................................................................................................................ 7- 8

7.4.2 Monitor latch function ........................................................................................................................ 7-10

7.5 High speed monitor function .................................................................................................................... 7-11

7.5.1 Summary ........................................................................................................................................... 7-11

7.5.2 Monitor latch function ........................................................................................................................ 7-12

7.6 Interrupt .................................................................................................................................................... 7-13

7.6.1 Interrupt sequence ............................................................................................................................ 7-13

7.6.2 Interrupt conditions ............................................................................................................................ 7-15

7.6.3 Factor of interrupt .............................................................................................................................. 7-16

7.6.4 Interrupt processing example............................................................................................................ 7-24

7.7 User watchdog function ........................................................................................................................... 7-25

7.8 Software reboot function .......................................................................................................................... 7-26

7.9 Parameter backup .................................................................................................................................... 7-27

7.10 Test mode ............................................................................................................................................... 7-31

7.10.1 Structural diagram ........................................................................................................................... 7-31

7.10.2 Test operation mode ....................................................................................................................... 7-32

7.11 Reconnect/disconnect function .............................................................................................................. 7-33

7.11.1 Disconnection function summary .................................................................................................... 7-33

7.11.2 Reconnect function summary ......................................................................................................... 7-34

7.11.3 Interface ........................................................................................................................................... 7-35

7.11.4 Disconnection method..................................................................................................................... 7-36

7.11.5 Reconnection method ..................................................................................................................... 7-37

7.11.6 Restrictions ...................................................................................................................................... 7-38

7.12 Sampling ................................................................................................................................................. 7-39

7.12.1 Summary ......................................................................................................................................... 7-39

7.12.2 Command/status bit ........................................................................................................................ 7-40

7.12.3 Command/status data ..................................................................................................................... 7-43

7.12.4 Sampling setting write/read ............................................................................................................. 7-46

7.12.5 Details for sampling function settings ............................................................................................. 7- 47

7.12.6 Number of sampled points .............................................................................................................. 7-53

7.12.7 Sampling items ................................................................................................................................ 7-54

7.12.8 Sampling trigger .............................................................................................................................. 7-60

7.12.9 Sampling data read ......................................................................................................................... 7-63

7.12.10 Timing chart for sampling function ................................................................................................ 7-65

7.13 Log .......................................................................................................................................................... 7-74

7.13.1 Summary ......................................................................................................................................... 7-74

7.13.2 Log data details ............................................................................................................................... 7-75

7.13.3 Event code list ................................................................................................................................. 7-76

7.13.4 Information for each event .............................................................................................................. 7-78

7.13.5 Log function interface ...................................................................................................................... 7-87

7.13.6 Timing chart for reading of log data ................................................................................................ 7-90

7.13.7 Log acquiring selection ................................................................................................................... 7-90

7.14 Operation cycle monitor function ........................................................................................................... 7-91

7.14.1 Summary ................................................................................................................

2 Interface ........................................................................................................................................... 7-91

4.

7.1

7.14.3 Operation timing .............................................................................................................................. 7-92

7.15 External forced stop disabled ................................................................................................................ 7-94

7.15.1 Summary ......................................................................................................................................... 7-94

7.15.2 Interface ........................................................................................................................................... 7-94

......................... 7-91

A - 16

Page 18

7.15.3 Setting method ................................................................................................................................ 7-94

7.16 Amplifier-less axis function .................................................................................................................... 7-95

7.16.1 Summary ......................................................................................................................................... 7-95

7.16.2 Interface ........................................................................................................................................... 7-95

7.16.3 Control details .................................................................................................................................. 7-96

7.17 Alarm history function............................................................................................................................. 7-97

7.17.1 Summary ......................................................................................................................................... 7-97

7.17.2 Alarm history data details ................................................................................................................ 7-98

7.17.3 Interface ......................................................................................................................................... 7-103

7.17.4 Timing chart for alarm history read ............................................................................................... 7-106

7.17.5 Alarm history initialization pr ocedure ............................................................................................ 7-107

7.17.6 List of system errors that do not apply to alarm history storage .................................................. 7-107

8. TANDEM DRIVE 8- 1 to 8-32

8.1 Drive modes .............................................................................................................................................. 8- 1

8.1.1 Synchronous mode ............................................................................................................................ 8- 2

8.1.2 Non-synchronous micro-adjustment control mode ........................................................................... 8- 2

8.1.3 Changing of drive mode ..................................................................................................................... 8- 3

8.2 Parameter settings .................................................................................................................................... 8- 4

8.2.1 Designation of tandem drive axes ..................................................................................................... 8- 4

8.2.2 Servo parameters ............................................................................................................................... 8- 4

8.2.3 Control parameters ............................................................................................................................. 8- 4

8.3 Axis data classifications ............................................................................................................................ 8- 5

8.3.1 Only data from master axis is valid .................................................................................................... 8- 5

8.3.2 Individual data for master axis/slave axis .......................................................................................... 8- 5

8.4 Tandem drive axis operation .................................................................................................................... 8- 6

8.4.1 Home position return during tandem drive ........................................................................................ 8- 6

8.4.2 JOG operation during tandem drive ................................................................................................. 8-24

8.4.3 Incremental feed while using tandem drive ...................................................................................... 8-25

8.4.4 Automatic operation during tandem drive ......................................................................................... 8-26

8.4.5 Linear interpolation during tandem drive .......................................................................................... 8-27

8.5 Servo on and servo off during tandem drive axis operation ................................................................... 8-29

8.6 Tandem drive axis limit switch ................................................................................................................. 8-30

8.7 Tandem drive axis software limit ............................................................................................................. 8-31

8.8 Tandem drive interference check ............................................................................................................ 8-31

8.9 Tandem drive axis servo alarms .............................................................................................................. 8-32

8.10 Deviation monitoring function ................................................................................................................ 8-32

9. INTERFACE MODE 9- 1 to 9-40

9.1 Summary ................................................................................................................................................... 9- 1

9.2 Combinations with functions ..................................................................................................................... 9- 2

9.3 Parameters ................................................................................................................................................ 9- 4

9.4 Interface ..................................................................................................................................................... 9- 6

9.5 Control method ......................................................................................................................................... 9-11

9.5.1 Control mode ..................................................................................................................................... 9-11

9.5.2 Position control mode ........................................................................................................................ 9-12

9.5.3 Speed control mode .......................................................................................................................... 9-14

9.5.4 Torque control mode ......................................................................................................................... 9-16

A - 17

Page 19

9.5.5 Control method for interrupt output invalid ....................................................................................... 9-18

9.5.6 Control method for interrupt output valid .......................................................................................... 9- 21

9.5.7 Procedure for switching control mode .............................................................................................. 9-26

9.5.8 Examples of switching control mode ................................................................................................ 9-28

9.6 Interrupt output cycle ................................................................................................................................ 9-31

9.7 Command data update cycle ................................................................................................................... 9-32

9.8 Servo off ................................................................................................................................................... 9-33

9.9 Home position return ................................................................................................................................ 9-34

9.10 Coordinate management ....................................................................................................................... 9-36

9.10.1 Incremental system ......................................................................................................................... 9-36

9.10.2 Absolute position system ................................................................................................................ 9-38

9.11 Precautions............................................................................................................................................. 9-40

10. TABLE MAP 10- 1 to 10-52

10.1 Table list ................................................................................................................................................ 10- 1

10.2 System information ............................................................................................................................... 10- 3

10.3 System command/status table ............................................................................................................. 10- 5

10.4 Factor of interrupt ................................................................................................................................. 10-17

10.5 System configuration information table ............................................................................................... 10-25

10.6 Axis data ............................................................................................................................................... 10-26

10.6.1 Axis data command table .............................................................................................................. 10-26

10.6.2 Axis data status table .................................................................................................................... 10-33

10.7 Servo parameter change number ........................................................................................................ 10-41

10.8 Point number offset .............................................................................................................................. 10-45

10.9 Command buffers ................................................................................................................................. 10-46

10.10 Digital input/output table .................................................................................................................... 10-48

10.11 Mark detection command/status table .............................................................................................. 10-49

10.12 Mark detection data tables ................................................................................................................. 10- 50

10.13 Continuous operation to torque control data table ............................................................................ 10-51

11. PARAMETERS 11- 1 to 11-36

11.1 System parameters ............................................................................................................................... 11- 2

11.2 Servo parameters .................................................................................................................................. 11- 4

11.2.1 Servo amplifier MR-J4(W

11.3 Control parameters .............................................................................................................................. 11-22

12. MONITOR NUMBER 12- 1 to 12-20

12.1 Servo information (1)............................................................................................................................. 12- 1

12.2 Servo information (2)............................................................................................................................. 12- 3

12.3 Operation information ........................................................................................................................... 12- 8

12.4 Operation information (double word) ................................................................................................... 12-11

12.5 System information .............................................................................................................................. 12-12

12.6 Servo parameter information ............................................................................................................... 12-1 4

13. ALARM NUMBER 13- 1 to 13-12

13.1 System alarm ........................................................................................................................................ 13- 1

13.2 Servo alarm ........................................................................................................................................... 13- 2

13.3 Operation alarm..................................................................................................................................... 13- 4

13.4 System error ......................................................................................................................................... 13-11

)- B .................................................................................................... 11- 4

A - 18

Page 20

14. EMC AND LOW VOLTAGE DIRECTIVES 14- 1 to 14- 6

14.1 Requirements for compliance with the EMC directive ......................................................................... 14- 1

14.1.1 Standards relevant to the EMC directive ....................................................................................... 14- 2

14.1.2 Installation instructions for EMC directive ..................................................................................... 14- 3

14.1.3 Parts of measure against noise ..................................................................................................... 14- 5

14.2 Requirements for compliance with the low voltage directive ............................................................... 14- 6

APPENDIX App.- 1 to App.-82

App. 1 Supplementary explanation for the use of linear servo system .................................................. App.- 1

App. 1.1 Position board ........................................................................................................................ App.- 1

App. 1.2 Position board utility software ................................................................................................ App.- 1

App. 1.3 Servo amplifier ....................................................................................................................... App.- 1

App. 1.4 Operations and functions of the linear servo system ........................................................... App.- 2

App. 2 Supplementary explanation for the use of fully closed loop system ........................................... App.-13

App. 2.1 Position board ........................................................................................................................ App.-13

App. 2.2 Position board utility software ................................................................................................ App.-13

App. 2.3 Servo amplifier ....................................................................................................................... App.-13

App. 2.4 Operations and functions of the fully closed loop control ..................................................... App.-14

App. 3 Supplementary explanation for the use of direct drive servo system ......................................... App.-21

App. 3.1 Position board ........................................................................................................................ App.-21

App. 3.2 Position board utility software ................................................................................................ App.-21

App. 3.3 Servo amplifier ....................................................................................................................... App.-21

App. 3.4 Operations and functions of the direct drive servo system .................................................. App.-22

App. 4 Supplementary explanation for the use of multiple-axis servo amplifier (MR-J4W

App. 4.1 Position board ........................................................................................................................ App.-28

App. 4.2 Position board utility software ................................................................................................ App.-28

App. 4.3 Servo amplifier ....................................................................................................................... App.-28

App. 4.4 Operations and functions of the servo amplifier ................................................................... App.-28

App. 5 Supplementary explanation for the use of SSCNET

(MR-J3(W)-

App. 5.1 Position board ........................................................................................................................ App.-30

App. 5.2 Position board utility software ................................................................................................ App.-30

App. 5.3 Connectable units .................................................................................................................. App.-30

App. 5.4 System setting ....................................................................................................................... App.-31

App. 5.5 System configuration ............................................................................................................. App.-31

App. 5.5.1 System configuration diagram ....................................................................................... App.-31

App. 5.6 Axis No. setting ...................................................................................................................... App.-32

App. 5.6.1 Servo amplifier setting .................................................................................................... App.-32

App. 5.7 Parameter setting .................................................................................................................. App.-33

App. 5.7.1 System option 1 setting .................................................................................................. App.-33

App. 5.8 Control option 1 setting .......................................................................................................... App.-35

App. 5.9 Axis No. assignment .............................................................................................................. App.-36