Page 1

General-Purpose AC Servo

Ethernet Interface

MODEL

MR-JE-_C

SERVO AMPLIFIER

INSTRUCTION MANUAL

(PROFILE MODE)

C

Page 2

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 1

Page 3

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp

is off or not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

Always connect a magnetic contactor between the power supply and the power supply (L1/L2/L3) of the

servo amplifier, in order to configure a circuit that shuts down the power supply on the side of the servo

amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a large current may

cause smoke or a fire when the servo amplifier malfunctions.

Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the power supply (L1/L2/L3) of the servo amplifier, in order to configure a circuit that shuts

down the power supply on the side of the servo amplifier’s power supply. If a molded-case circuit breaker

or fuse is not connected, continuous flow of a large current may cause smoke or a fire when the servo

amplifier malfunctions.

When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a regenerative

transistor malfunction or the like may overheat the regenerative resistor, causing smoke or a fire.

When you use a regenerative option with an MR-JE-40C to MR-JE-100C, remove the built-in

regenerative resistor and wiring from the servo amplifier.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

A - 2

Page 4

3. To prevent injury, note the following

CAUTION

Only the power/signal specified in the Instruction Manual must be supplied/applied to each terminal.

Otherwise, an electric shock, fire, injury, etc. may occur.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, servo motor, etc., may be hot while the power is on

and for some time after power-off. Take safety measures such as providing covers to avoid accidentally

touching them by hands and parts such as cables.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the lead of the built-in regenerative resistor, cables, or connectors when carrying the servo

amplifier. Otherwise, it may drop.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the product. Otherwise, it may cause injury.

The equipment must be installed in the specified direction.

Leave specified clearances between the servo amplifier and the cabinet walls or other equipment.

Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it may cause a malfunction.

Do not drop or apply heavy impact on the servo amplifiers and the servo motors. Otherwise, injury,

malfunction, etc. may occur.

Do not strike the connector. Otherwise, a connection failure, malfunction, etc. may occur.

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Storage -20 °C to 65 °C (non-freezing)

Ambient

humidity

Storage

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude 2000 m or less above sea level (Contact your local sales office for the altitude for options.)

Vibration resistance 5.9 m/s2, at 10 Hz to 55 Hz (directions of X, Y and Z axes)

When the product has been stored for an extended period of time, contact your local sales office.

When handling the servo amplifier, be careful about the edged parts such as corners of the servo

amplifier.

Operation 0 °C to 55 °C (non-freezing)

Operation

5 %RH to 90 %RH (non-condensing)

A - 3

Page 5

r

CAUTION

The servo amplifier must be installed in a metal cabinet.

When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine are used

for disinfecting and protecting wooden packaging from insects, they cause malfunction when entering our

products. Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat method). Additionally,

disinfect and protect wood from insects before packing products.

To prevent a fire or injury from occurring in case of an earthquake or other natural disasters, securely

install, mount, and wire the servo motor in accordance with the Instruction Manual.

(2) Wiring

CAUTION

Before removing the CNP1 connector of MR-JE-40C to MR-JE-100C, disconnect the lead wires of the

regenerative resistor from the CNP1 connector.

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Make sure to connect the cables and connectors by using the fixing screws and the locking mechanism.

Otherwise, the cables and connectors may be disconnected during operation.

Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF) on the servo amplifier

output side.

To avoid a malfunction, connect the wires to the correct phase terminals (U/V/W) of the servo amplifier

and servo motor.

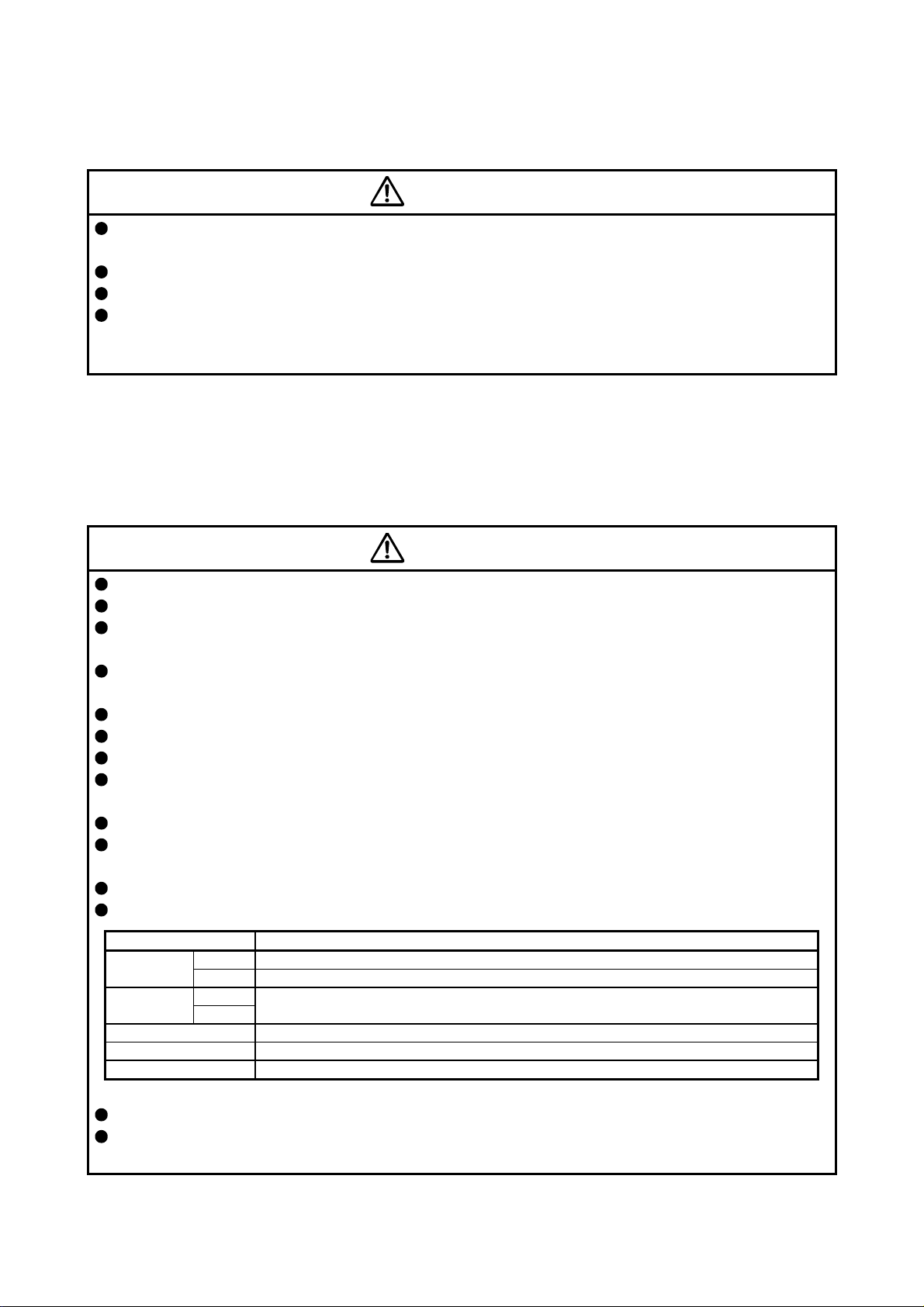

Connect the servo amplifier power output (U/V/W) to the servo motor power input (U/V/W) directly. Do

not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

The connection diagrams in this instruction manual are shown for sink interfaces, unless stated

otherwise.

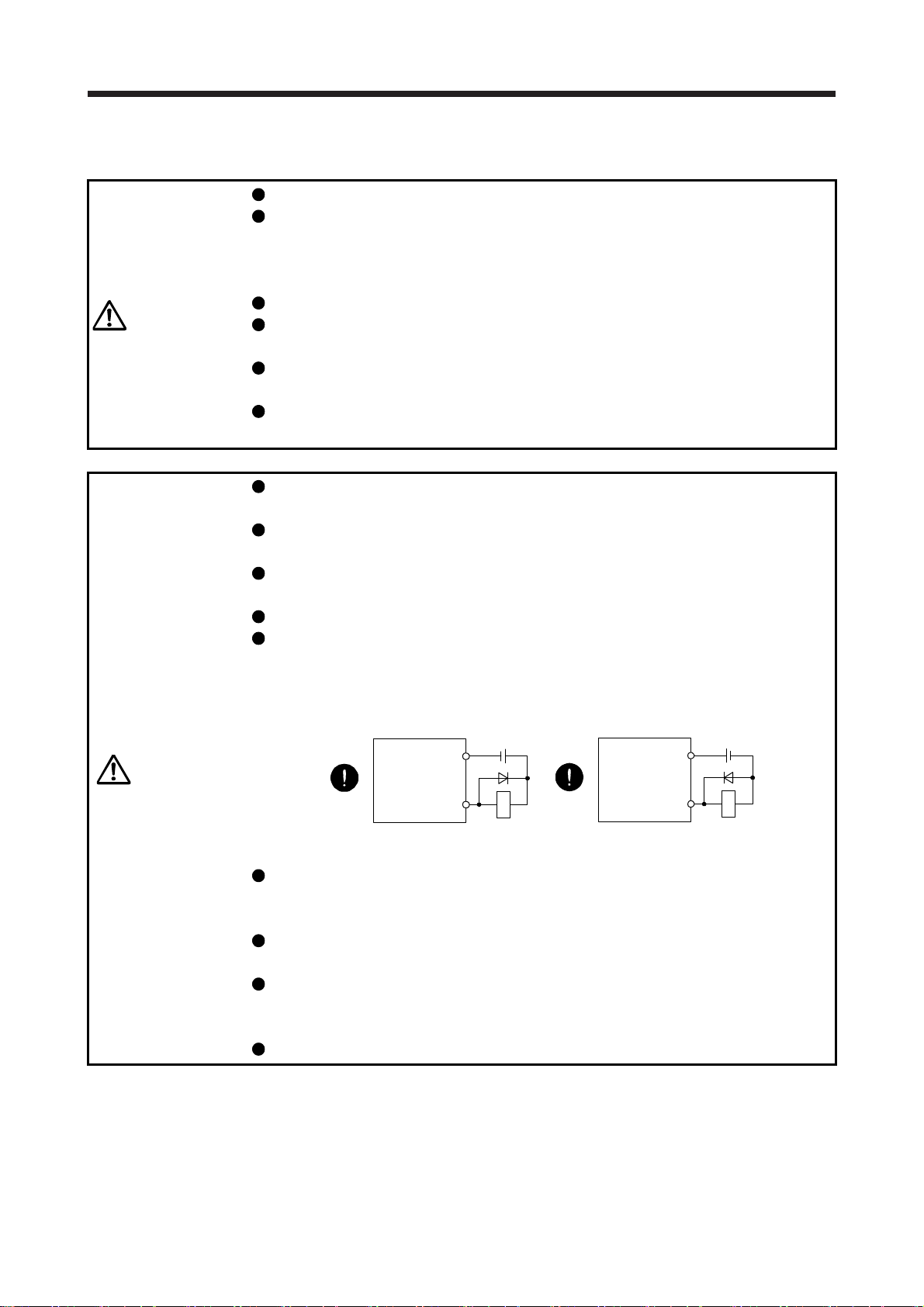

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Servo amplifier

DOCOM

Control output

signal

For sink output interface

24 V DC

RA

Servo amplifie

DOCOM

Control output

signal

For source output interface

24 V DC

RA

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo amplifier may cause a

malfunction.

A - 4

Page 6

CAUTION

Configure a circuit to turn off EM2 or EM1 when the power supply is turned off to prevent an unexpected

restart of the servo amplifier.

To prevent malfunction, avoid bundling power lines (input/output) and signal cables together or running

them in parallel to each other. Separate the power lines from the signal cables.

(3) Test run and adjustment

CAUTION

When executing a test run, follow the notice and procedures in this instruction manual. Otherwise, it may

cause a malfunction, damage to the machine, or injury.

Before operation, check the parameter settings. Improper settings may cause some machines to operate

unexpectedly.

Never adjust or change the parameter values extremely as it will make operation unstable.

Do not get close to moving parts during the servo-on status.

(4) Usage

CAUTION

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an external brake to prevent the condition.

For equipment in which the moving part of the machine may collide against the load side, install a limit

switch or stopper to the end of the moving part. The machine may be damaged due to a collision.

Do not disassemble, repair, or modify the product. Otherwise, an electric shock, fire, injury, etc. may

occur. Disassembled, repaired, and/or modified products are not covered under warranty.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent a

sudden restart. Otherwise, it may cause an accident.

Use a noise filter, etc. to minimize the influence of electromagnetic interference. Electromagnetic

interference may be given to the electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break it.

Use the servo amplifier with the specified servo motor.

Correctly wire options and peripheral equipment, etc. in the correct combination. Otherwise, an electric

shock, fire, injury, etc. may occur.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as incorrect wiring, service life, and mechanical structure (e.g. where a ball screw and

the servo motor are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft.

To ensure safety, install a stopper on the machine side.

If the dynamic brake is activated at power-off, alarm occurrence, etc., do not rotate the servo motor by an

external force. Otherwise, it may cause a fire.

A - 5

Page 7

(5) Corrective actions

CAUTION

Ensure safety by confirming the power off, etc. before performing corrective actions. Otherwise, it may

cause an accident.

If it is assumed that a power failure, machine stoppage, or product malfunction may result in a hazardous

situation, use a servo motor with an electromagnetic brake or provide an external brake system for

holding purpose to prevent such hazard.

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

If the molded-case circuit breaker or fuse is activated, be sure to remove the cause and secure safety

before switching the power on. If necessary, replace the servo amplifier and recheck the wiring.

Otherwise, it may cause smoke, fire, or an electric shock.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

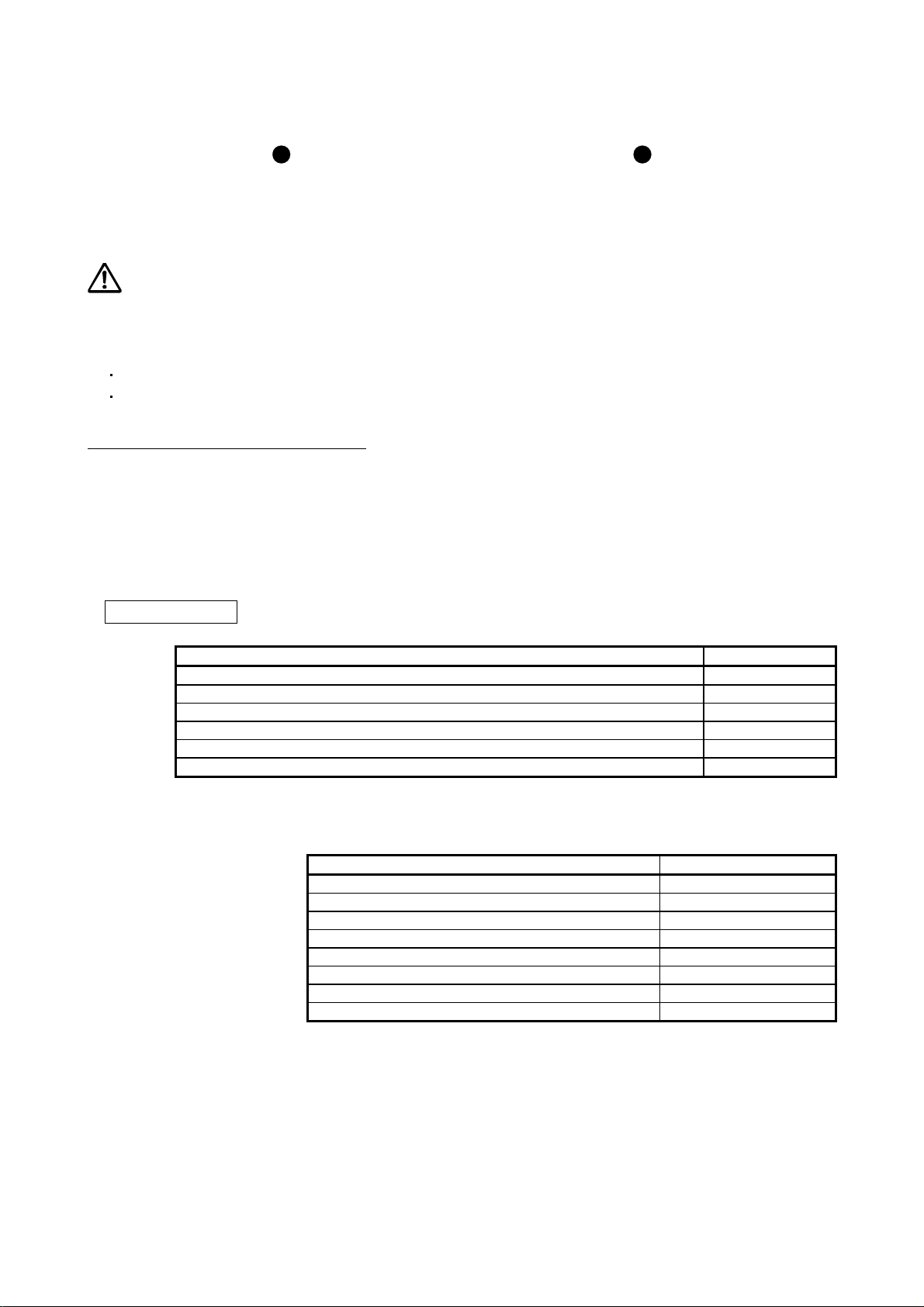

Configure an electromagnetic brake circuit which is interlocked with an external emergency stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

Contacts must be opened

with the emergency stop switch.

Servo motor

B

Electromagnetic brake

To prevent an electric shock, injury, or fire from occurring after an earthquake or other natural disasters,

ensure safety by checking conditions, such as the installation, mounting, wiring, and equipment before

switching the power on.

RA

U

24 V DC

(6) Maintenance, inspection and parts replacement

CAUTION

Make sure that the emergency stop circuit operates properly such that an operation can be stopped

immediately and a power is shut off by the emergency stop switch.

It is recommended that the servo amplifier be replaced every 10 years when it is used in general

environment.

When using a servo amplifier whose power has not been turned on for a long time, contact your local

sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

A - 6

Page 8

DISPOSAL OF WASTE

Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and

regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier may malfunction when the

EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

Compliance with global standards

For the compliance with global standards, refer to app. 3 of "MR-JE-_C Servo Amplifier Instruction Manual".

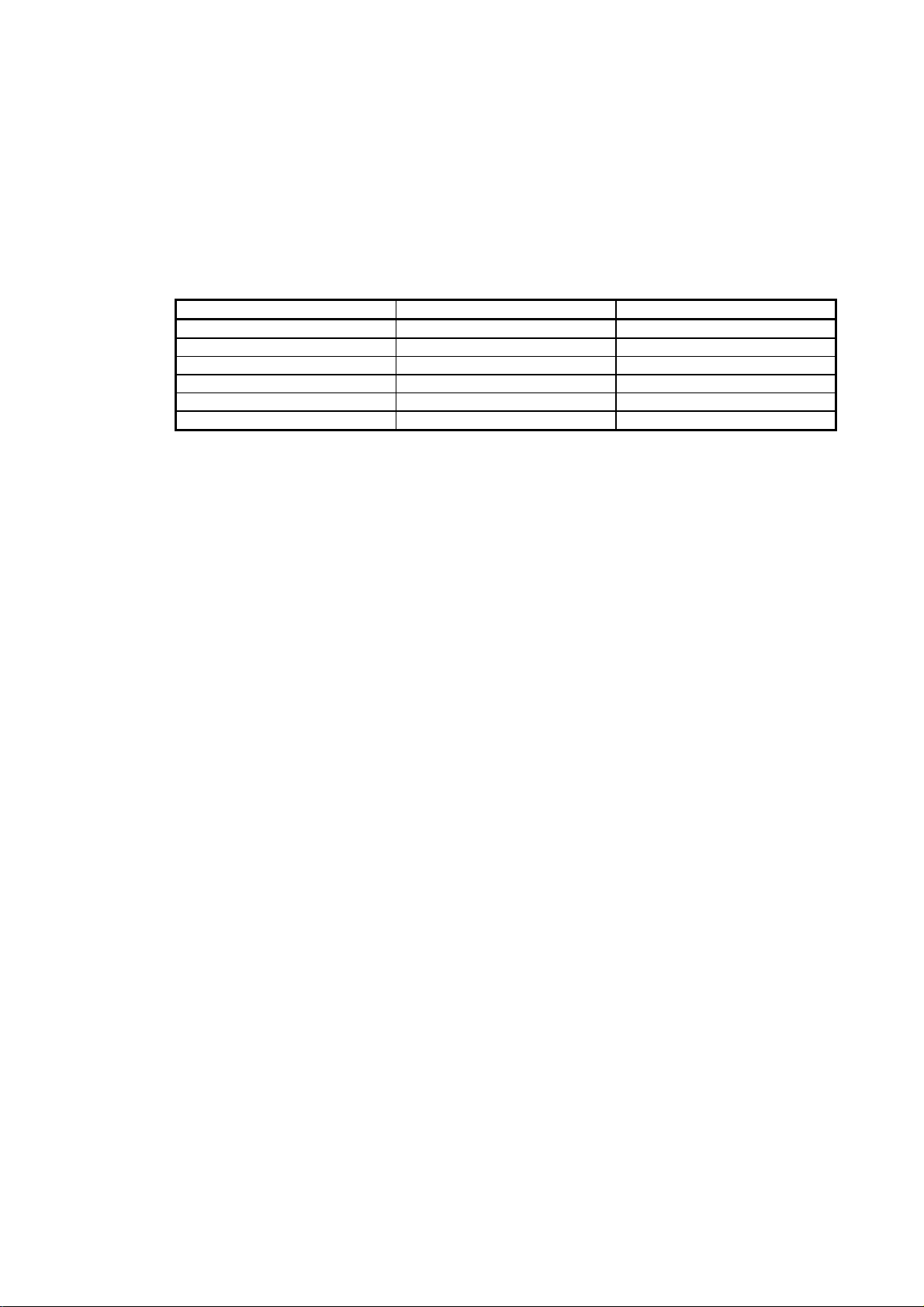

«About the manual»

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare

them to use the servo safely.

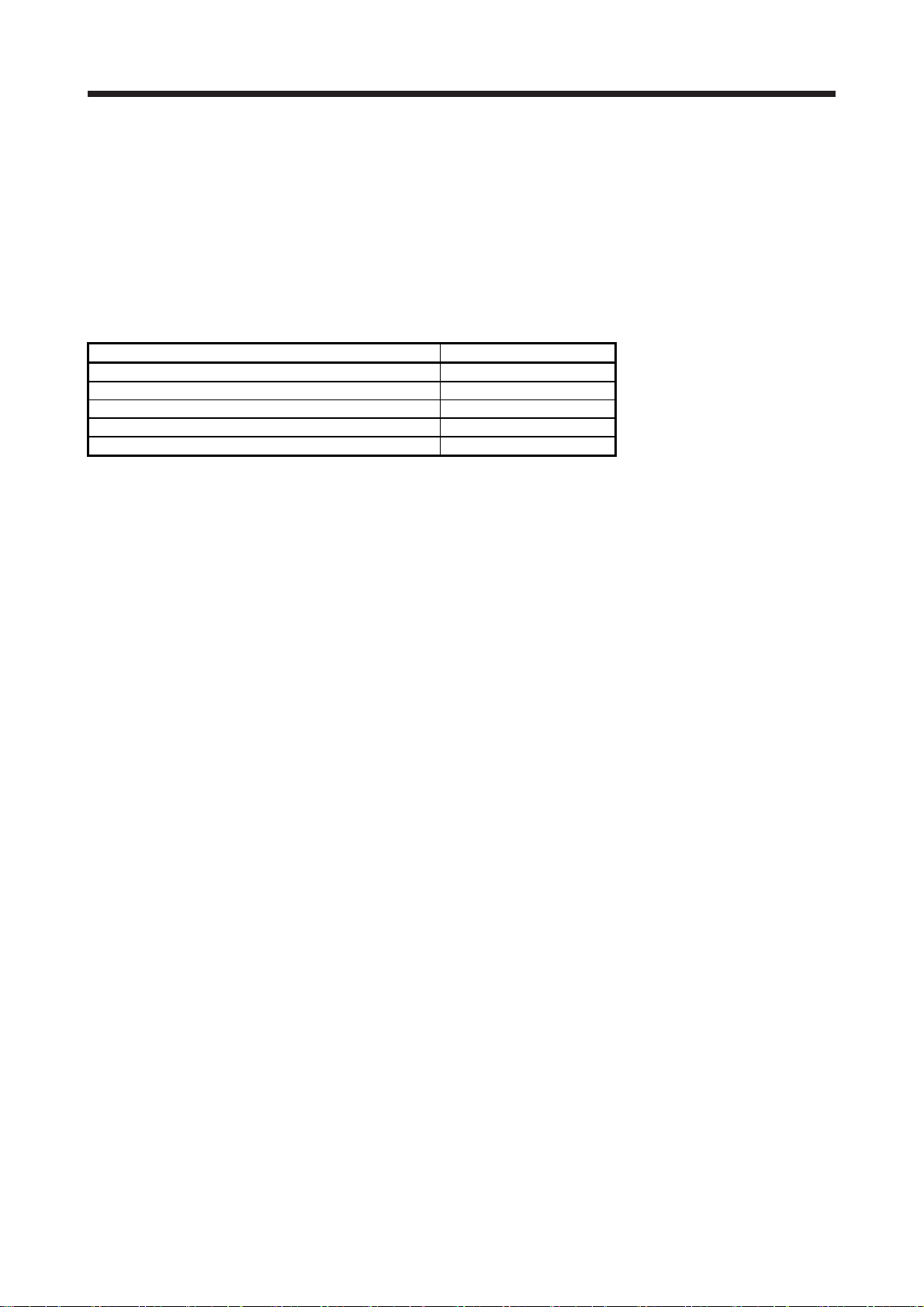

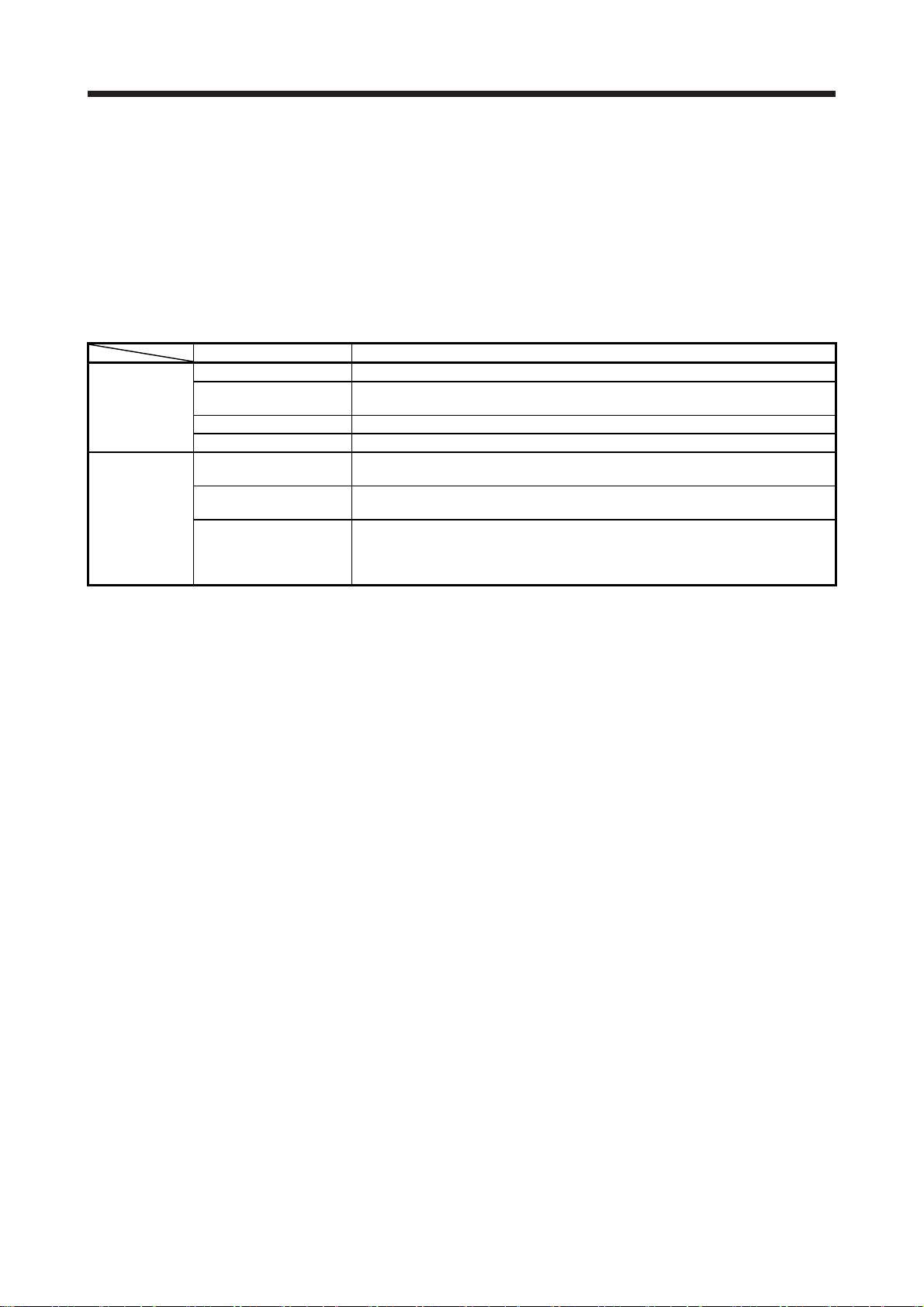

Relevant manuals

Manual name Manual No.

MELSERVO MR-JE-_C Servo Amplifier Instruction Manual SH(NA)030257ENG

MELSERVO-JE Servo Amplifier Instruction Manual (Troubleshooting) SH(NA)030166ENG

MELSERVO MR-JE-_C Servo Amplifier Instruction Manual (Positioning Mode) SH(NA)030277ENG

MELSERVO MR-JE-_C Servo Amplifier Instruction Manual (Network) SH(NA)030256ENG

MELSERVO HG-KN/HG-SN Servo Motor Instruction Manual SH(NA)030135ENG

MELSERVO EMC Installation Guidelines IB(NA)67310ENG

This Instruction Manual does not describe the following items. Refer to the section of the detailed explanation

field for details. "MR-JE-_C" means "MR-JE-_C Servo Amplifier Instruction Manual".

INSTALLATION MR-JE-_C chapter 2

NORMAL GAIN ADJUSTMENT MR-JE-_C chapter 6

SPECIAL ADJUSTMENT FUNCTIONS MR-JE-_C chapter 7

TROUBLESHOOTING MR-JE-_C chapter 8

DIMENSIONS MR-JE-_C chapter 9

CHARACTERISTICS MR-JE-_C chapter 10

OPTIONS AND PERIPHERAL EQUIPMENT MR-JE-_C chapter 11

ABSOLUTE POSITION DETECTION SYSTEM (Note) MR-JE-_C chapter 12

Note. For the communication-based absolute position transfer system, refer to "MR-JE-_C

Servo Amplifier Instruction Manual (Network)".

Item Detailed explanation

A - 7

Page 9

«Cables used for wiring»

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 °C.

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10-4 kg•m2)] 5.4675 [oz•inch2]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

A - 8

Page 10

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1- 4

1.1 Profile mode specification list ........................................................................................................... 1- 2

2. SIGNALS AND WIRING 2- 1 to 2- 6

2.1 I/O signal connection example .......................................................................................................... 2- 3

2.2 Connectors and pin assignment ....................................................................................................... 2- 4

2.3 Signal (device) explanations ............................................................................................................. 2- 5

2.4 Power-on sequence .......................................................................................................................... 2- 5

3. STARTUP 3- 1 to 3- 2

3.1 Startup .............................................................................................................................................. 3- 1

4. PARAMETERS 4- 1 to 4-34

4.1 Parameter list .................................................................................................................................... 4- 1

4.1.1 Basic setting parameters ([Pr. PA_ _ ]) ...................................................................................... 4- 2

4.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) ............................................................................... 4- 3

4.1.3 Extension setting parameters ([Pr. PC_ _ ]) .............................................................................. 4- 5

4.1.4 I/O setting parameters ([Pr. PD_ _ ]) ......................................................................................... 4- 7

4.1.5 Extension setting 2 parameters ([Pr. PE_ _ ]) ............................................................................ 4- 8

4.1.6 Extension setting 3 parameters ([Pr. PF_ _ ]) ........................................................................... 4-10

4.1.7 Positioning control parameters ([Pr. PT_ _ ]) ............................................................................ 4-11

4.2 Detailed list of parameters ............................................................................................................... 4-13

4.2.1 Basic setting parameters ([Pr. PA_ _ ]) ..................................................................................... 4-13

4.2.2 Extension setting parameters ([Pr. PC_ _ ]) ............................................................................. 4-17

4.2.3 I/O setting parameters ([Pr. PD_ _ ]) ........................................................................................ 4-19

4.2.4 Extension setting 2 parameters ([Pr. PE_ _ ]) ........................................................................... 4-21

4.2.5 Positioning control parameters ([Pr. PT_ _ ]) ............................................................................ 4-23

4.3 Software limit ................................................................................................................................... 4-30

4.4 How to set the electronic gear ......................................................................................................... 4-30

4.4.1 Electronic gear setting for the profile mode .............................................................................. 4-30

4.5 Restrictions on using objects/registers ............................................................................................ 4-33

4.5.1 Restrictions on input devices .................................................................................................... 4-33

4.5.2 Restrictions on objects/registers ............................................................................................... 4-33

5. CiA 402 DRIVE PROFILE 5- 1 to 5- 8

5.1 State machine control of the servo amplifier .................................................................................... 5- 2

5.1.1 Function description ................................................................................................................... 5- 2

5.1.2 Related objects/registers............................................................................................................ 5- 4

5.1.3 Directions for use ....................................................................................................................... 5- 6

5.2 Control mode .................................................................................................................................... 5- 7

5.2.1 Function description ................................................................................................................... 5- 7

5.2.2 Related objects/registers............................................................................................................ 5- 8

1

Page 11

6. SERVO MOTOR DRIVING 6- 1 to 6-44

6.1 Homing mode (hm) ........................................................................................................................... 6- 1

6.1.1 Function description ................................................................................................................... 6- 1

6.1.2 Related objects/registers............................................................................................................ 6- 2

6.1.3 Directions for use ....................................................................................................................... 6- 9

6.2 Profile position mode (pp) ................................................................................................................ 6-32

6.2.1 Function description .................................................................................................................. 6-32

6.2.2 Related objects/registers........................................................................................................... 6-32

6.2.3 Directions for use ...................................................................................................................... 6-35

6.3 Profile velocity mode (pv) ................................................................................................................ 6-36

6.3.1 Function description .................................................................................................................. 6-36

6.3.2 Related objects/registers........................................................................................................... 6-36

6.3.3 Directions for use ...................................................................................................................... 6-39

6.4 Profile torque mode (tq) ................................................................................................................... 6-41

6.4.1 Function description .................................................................................................................. 6-41

6.4.2 Related objects/registers........................................................................................................... 6-41

6.4.3 Directions for use ...................................................................................................................... 6-43

7. APPLICATION OF FUNCTIONS 7- 1 to 7- 2

7.1 Infinite feed function .......................................................................................................................... 7- 1

2

Page 12

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

This instruction manual describes the items required for using the MR-JE-_C servo amplifier in the profile

mode. For details of the objects/registers and communication, refer to "MR-JE-_C Servo Amplifier Instruction

Manual (Network)".

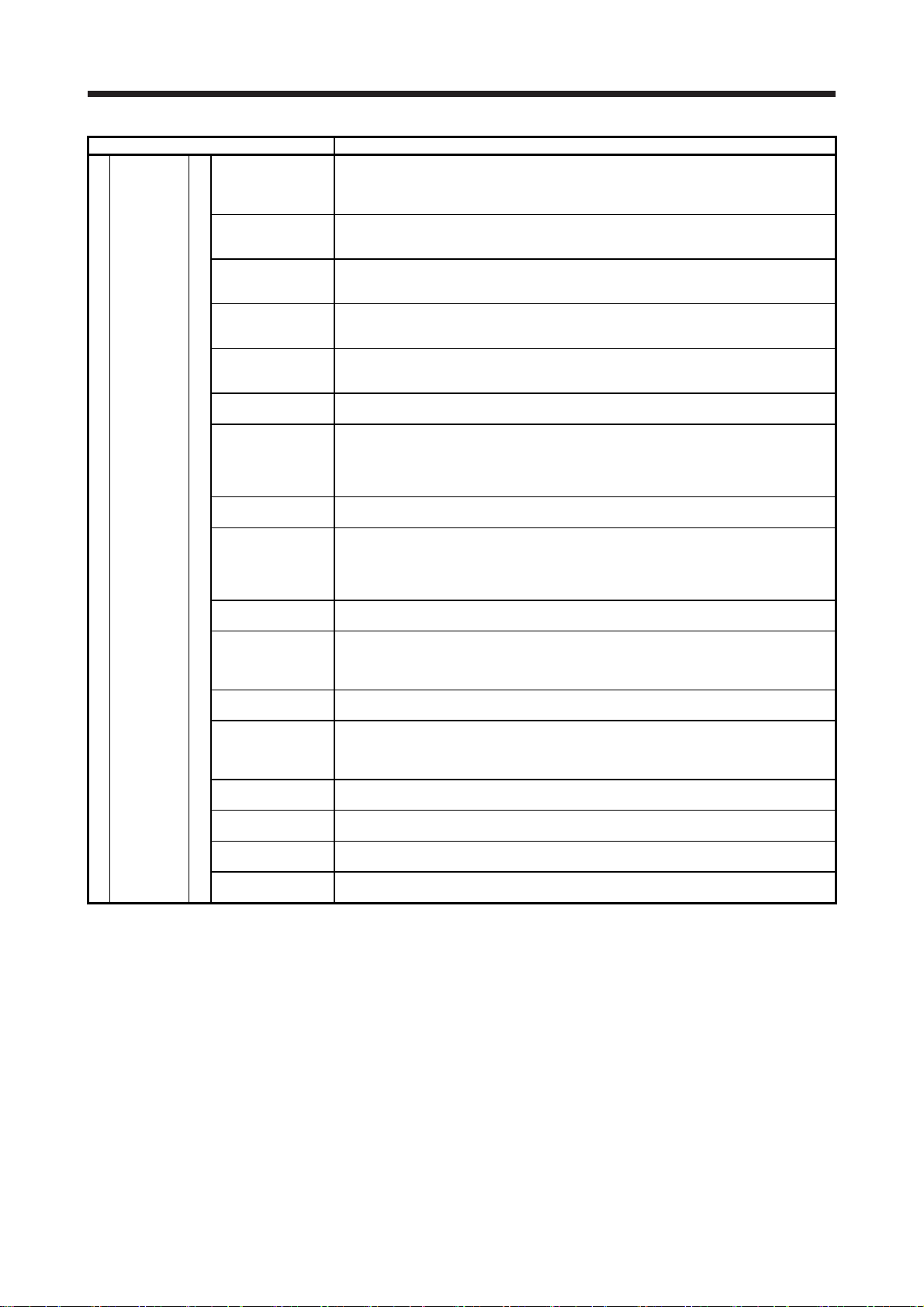

The items shown in the following table are the same with the contents of "MR-JE-_C Servo Amplifier

Instruction Manual”. For details, refer to each section indicated in the detailed explanation field. "MR-JE-_C"

means "MR-JE-_C Servo Amplifier Instruction Manual".

Combinations of servo amplifiers and servo motors MR-JE-_C section 1.4

Function list MR-JE-_C section 1.5

Model designation MR-JE-_C section 1.6

Structure (parts identification) MR-JE-_C section 1.7

Configuration including peripheral equipment MR-JE-_C section 1.8

Item Detailed explanation

1 - 1

Page 13

1. FUNCTIONS AND CONFIGURATION

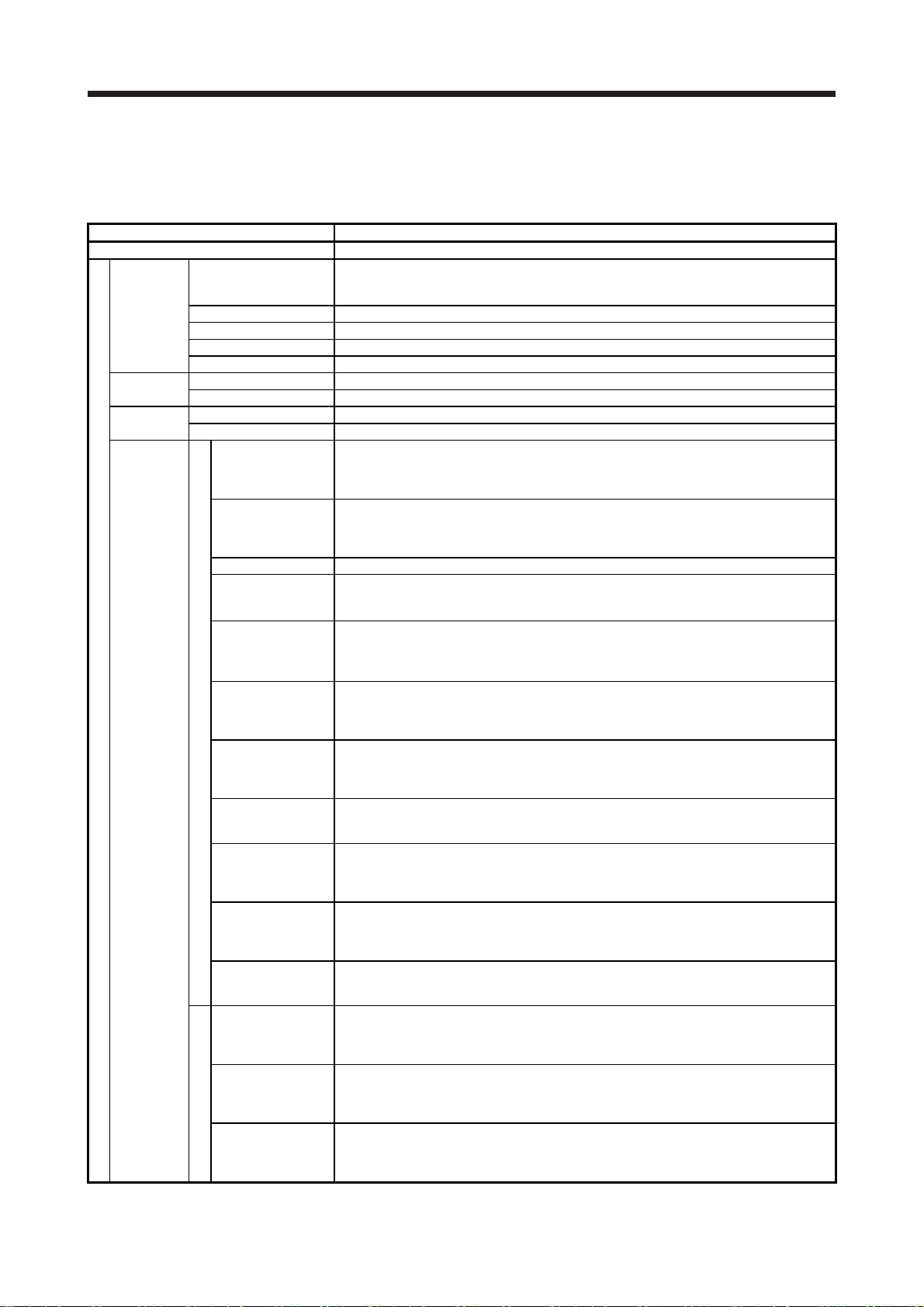

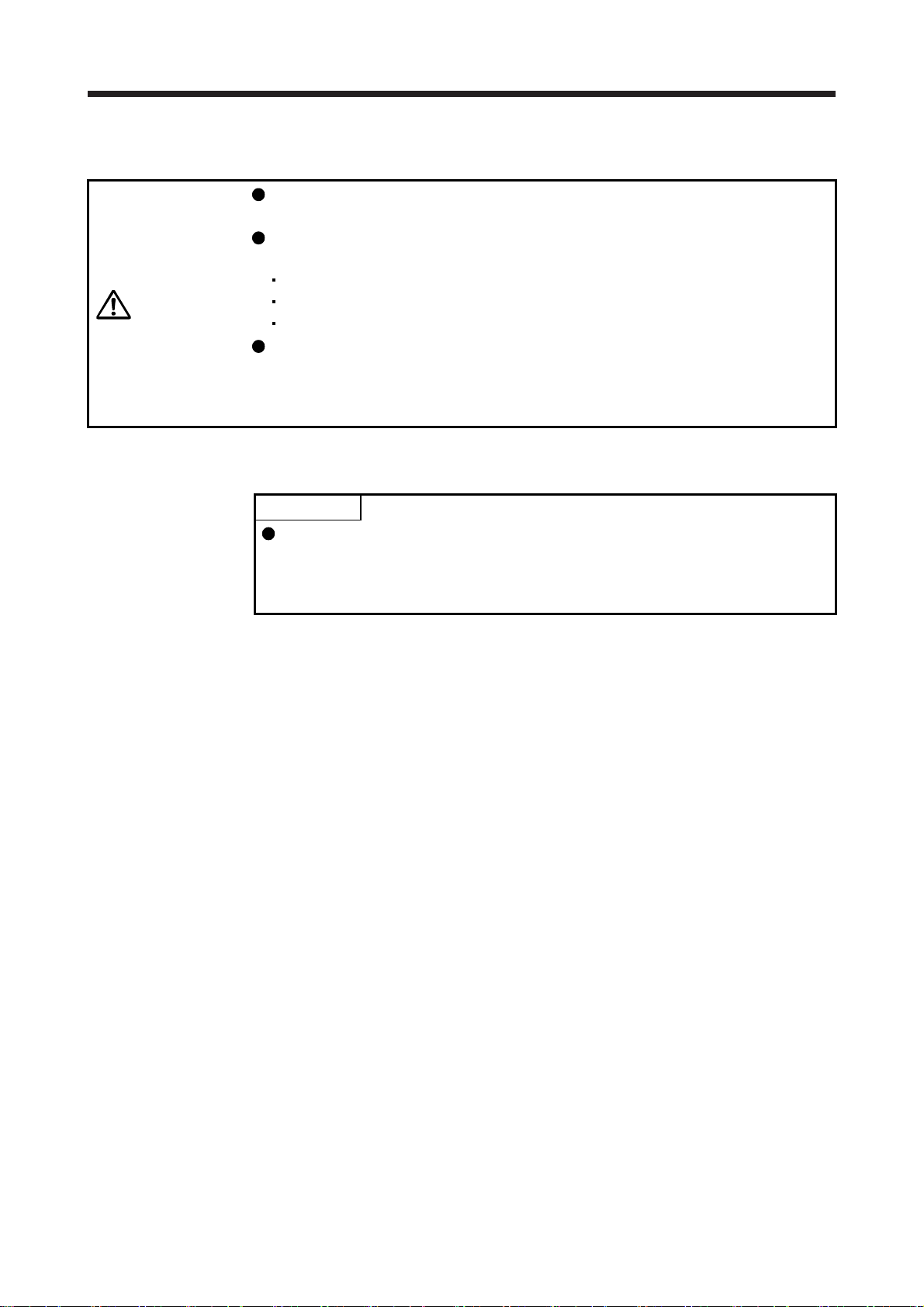

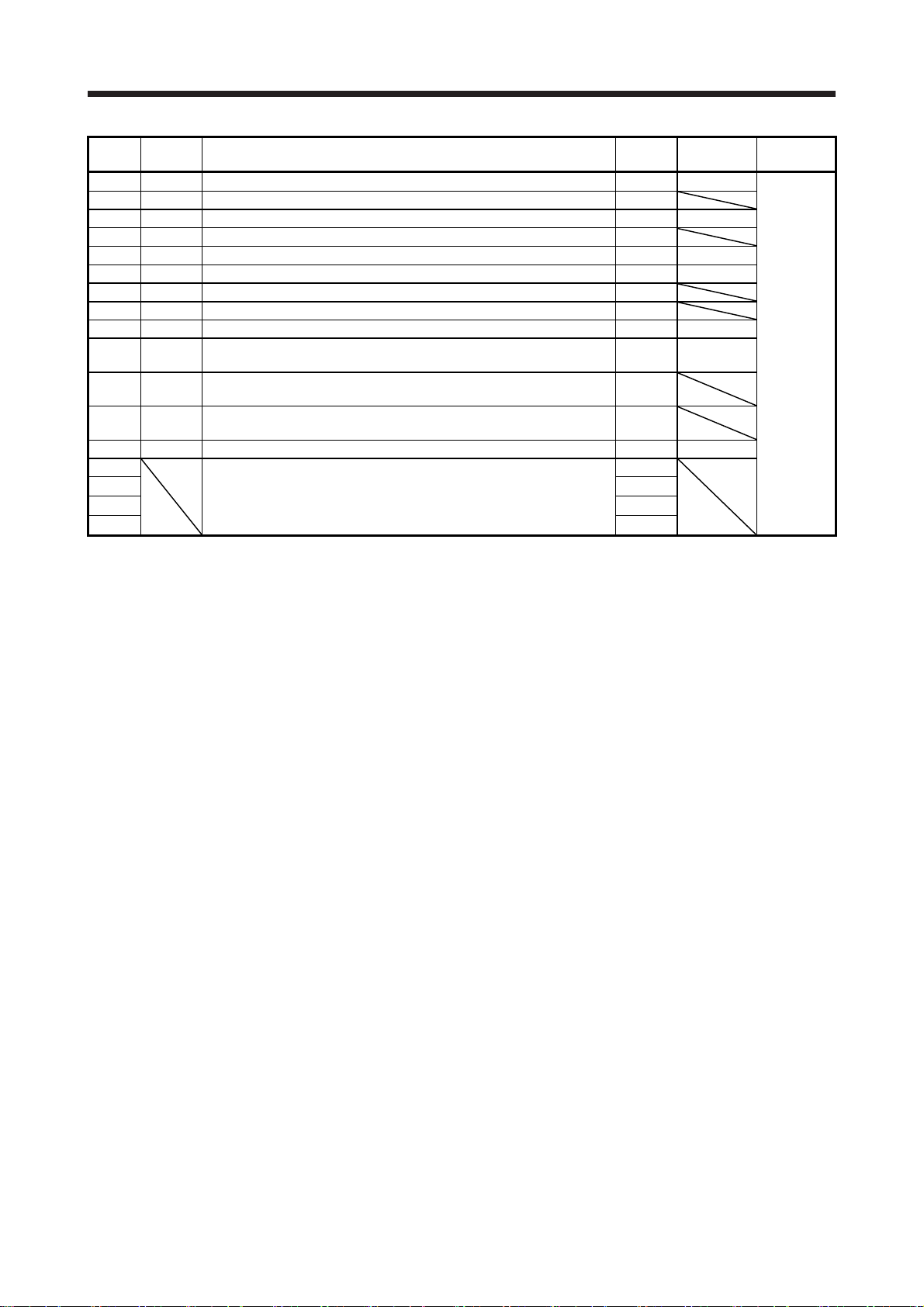

1.1 Profile mode specification list

Only the specifications of the profile mode are listed here. For other specifications, refer to section 1.3 of

"MR-JE-_C Servo Amplifier Instruction Manual".

Profile mode

Profile

position mode

Profile

velocity mode

Profile torque

mode

Data set type The current position is set as the home position.

Stopper type

Home position

Homing mode

Homing on positive

Homing on negative

Item Description

Servo amplifier model MR-JE-_C

Command position range

Command multiplication Electronic gear A/B multiple, A: 1 to 16777215, B: 1 to 16777215, 1/27649 < A/B < 8484

In-position range setting 0 pulse to ±65535 pulses (command pulse unit)

Error excessive ±3 revolutions

Torque limit Set with parameters or objects/registers.

Command speed range -21474836.48 r/min to 21474836.47 r/min (Clamped at the permissible speed)

Torque limit Set with parameters or objects/registers (Clamped at the maximum torque).

Command torque range -3276.8% to 3276.7% (Clamped at the maximum torque)

Speed limit Set with parameters or objects/registers (Clamped at the permissible speed).

Manufacturer-specific

Dog type

(Rear end detection,

Z-phase reference)

Count type

(Front end detection,

Z-phase reference)

(Stopper position

reference)

ignorance

(servo-on position as

home position)

Dog type

(Rear end detection,

rear end reference)

Count type

(Front end detection,

front end reference)

Dog cradle type

Dog type last Z-phase

reference

Dog type front end

reference

Dogless Z-phase

reference

CiA 402 type

Homing on positive

home switch and index

pulse

(method 3)

home switch and index

pulse

(method 4)

home switch and index

pulse

(method 5)

Deceleration starts at the front end of the proximity dog. After the rear end is passed, the position

specified by the first Z-phase signal, or the position of the first Z-phase signal shifted by the specified

home position shift distance is used as the home position. If the stroke end is detected during home

position return, the direction of movement is reversed.

At the front end of the proximity dog, deceleration starts. After the front end is passed, the position

specified by the first Z-phase signal after the set distance or the position of the Z-phase signal shifted

by the set home position shift distance is set as a home position. If the stroke end is detected during

home position return, the direction of movement is reversed.

A workpiece is pressed against a mechanical stopper, and the position where it is stopped is set as

the home position. If the stroke end is detected during home position return, [AL. 90 Home position

return incomplete warning] occurs.

The current position at servo-on is set as a home position. A home position can be set without

switching to the home position return mode (Homing Mode).

Deceleration starts from the front end of the proximity dog. After the rear end is passed, the position

is shifted by the travel distance after proximity dog and the home position shift distance. The position

after the shifts is set as the home position. If the stroke end is detected during home position return,

the direction of movement is reversed.

Deceleration starts from the front end of the proximity dog. The position is shifted by the travel

distance after proximity dog and the home position shift distance. The position after the shifts is set

as the home position. If the stroke end is detected during home position return, the direction of

movement is reversed.

A position, which is specified by the first Z-phase signal after the front end of the proximity dog is

detected, is set as the home position. If the stroke end is detected during home position return, the

direction of movement is reversed.

After the front end of the proximity dog is detected, the position is shifted away from the proximity dog

in the reverse direction. Then, the position specified by the first Z-phase signal or the position of the

first Z-phase signal shifted by the home position shift distance is used as the home position. If the

stroke end is detected during home position return, the direction of movement is reversed.

Starting from the front end of the proximity dog, the position is shifted by the travel distance after

proximity dog and the home position shift distance. The position after the shifts is set as the home

position. If the stroke end is detected during home position return, the direction of movement is

reversed.

The position specified by the first Z-phase signal, or the position of the first Z-phase signal shifted by

the home position shift distance is used as the home position. If the stroke end is detected during

home position return, [AL. 90 Home position return incomplete warning] occurs.

Same as the dog type last Z-phase reference home position return. Note that if the stroke end is

detected during home position return, [AL. 90 Home position return incomplete warning] occurs.

Same as the dog cradle type home position return. Note that if the stroke end is detected during

home position return, [AL. 90 Home position return incomplete warning] occurs.

Same as the dog type last Z-phase reference home position return. Note that if the stroke end is

detected during home position return, [AL. 90 Home position return incomplete warning] occurs.

Setting range of feed length: -999999 to 999999 [pulse],

Setting range of rotation angle: -360.000 to 360.000 [degree]

Set with objects/registers.

1 - 2

Page 14

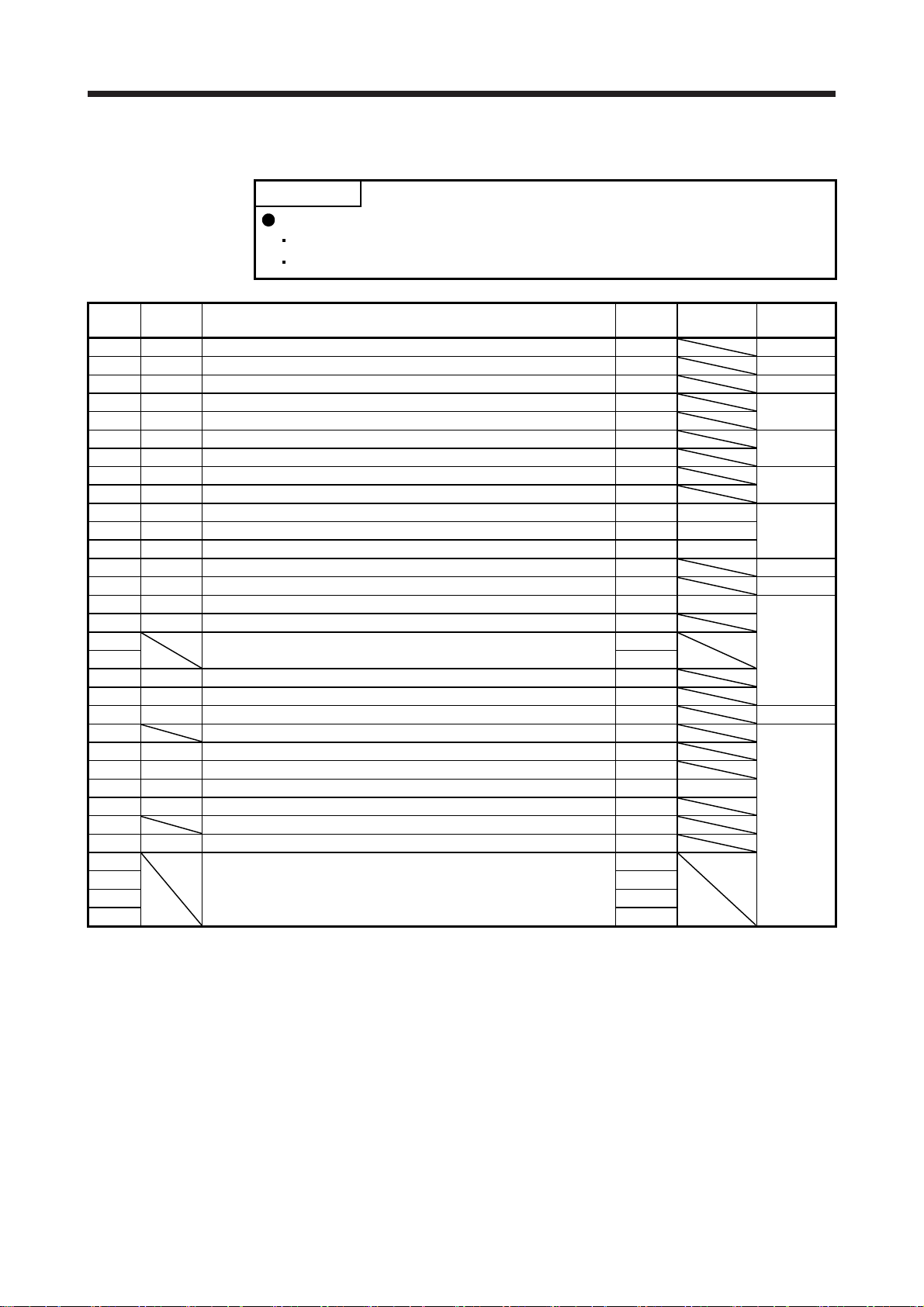

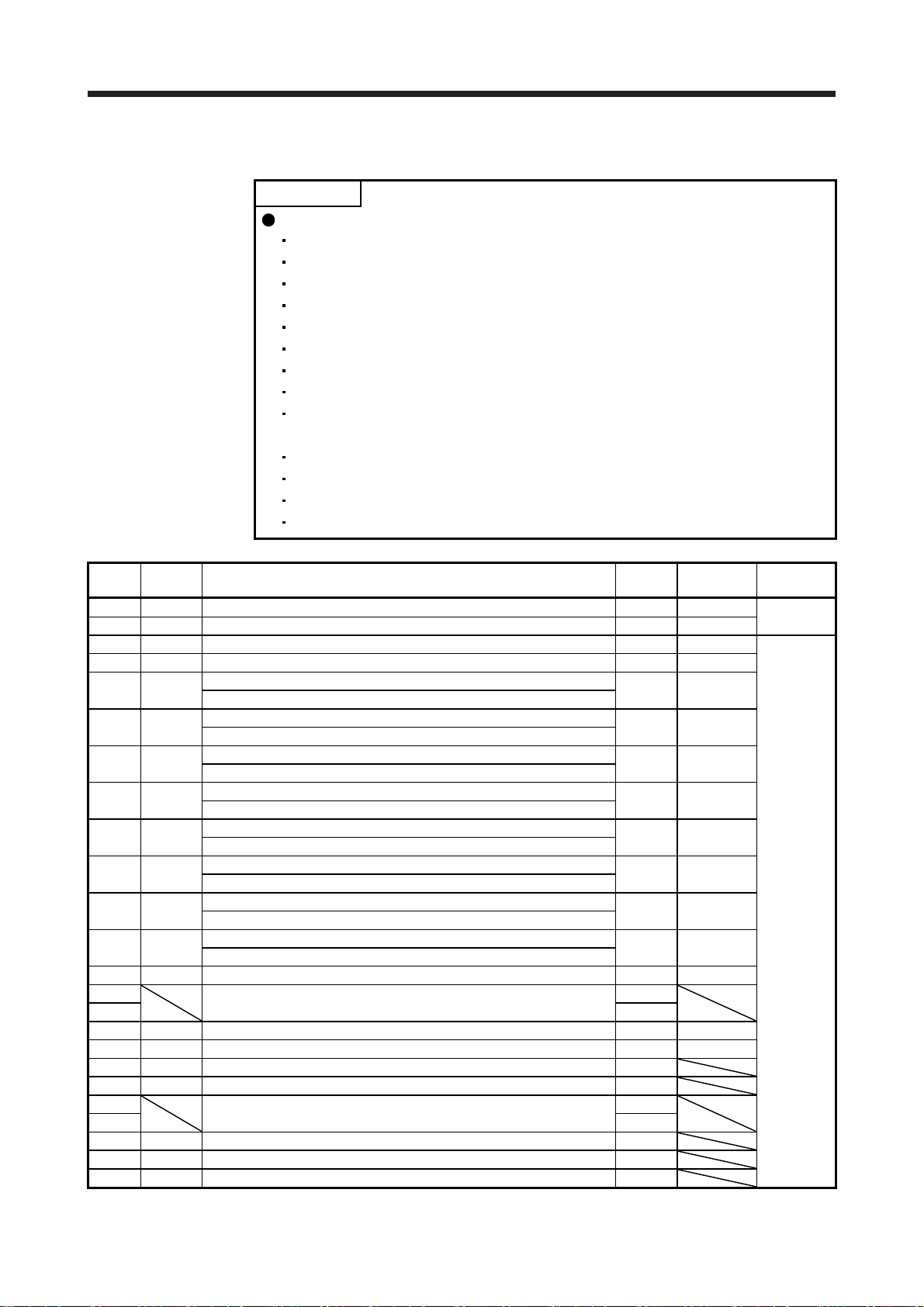

1. FUNCTIONS AND CONFIGURATION

Profile mode

Homing on home

Homing without index

Homing without index

Homing mode

Homing without index

Homing without index

Homing on index pulse

Homing on index pulse

Homing on current

Homing on current

Item Description

CiA 402 type

Homing on negative

home switch and index

pulse

(method 6)

Homing on home

switch and index pulse

(method 7)

Homing on home

switch and index pulse

(method 8)

Homing on home

switch and index pulse

(method 11)

switch and index pulse

(method 12)

pulse (method 19)

Homing without index

pulse (method 20)

pulse (method 21)

Homing without index

pulse (method 22)

pulse (method 23)

Homing without index

pulse (method 24)

pulse (method 27)

Homing without index

pulse (method 28)

(method 33)

(method 34)

position (method 35)

position (method 37)

Same as the dog cradle type home position return. Note that if the stroke end is detected during

home position return, [AL. 90 Home position return incomplete warning] occurs.

Same as the dog type last Z-phase reference home position return.

Same as the dog cradle type home position return.

Same as the dog type last Z-phase reference home position return. The direction of rotation is

opposite to that of the method 7.

Same as the dog cradle type home position return. The direction of rotation is opposite to that of the

method 8.

Same as the dog type front end reference home position return. Note that if the stroke end is

detected during home position return, [AL. 90 Home position return incomplete warning] occurs.

Although this type is the same as the dog cradle type home position return, the stop position is not on

the Z-phase. Starting from the front end of the dog, the position is shifted by the travel distance after

proximity dog and the home position shift distance. The position after the shifts is set as the home

position. If the stroke end is detected during home position return, [AL. 90 Home position return

incomplete warning] occurs.

Same as the dog type front end reference home position return. Note that if the stroke end is

detected during home position return, [AL. 90 Home position return incomplete warning] occurs.

Although this type is the same as the dog cradle type home position return, the stop position is not on

the Z-phase. Starting from the front end of the dog, the position is shifted by the travel distance after

proximity dog and the home position shift distance. The position after the shifts is set as the home

position. If the stroke end is detected during home position return, [AL. 90 Home position return

incomplete warning] occurs.

Same as the dog type front end reference home position return.

Although this type is the same as the dog cradle type home position return, the stop position is not on

the Z-phase. Starting from the front end of the dog, the position is shifted by the travel distance after

proximity dog and the home position shift distance. The position after the shifts is set as the home

position.

Same as the dog type front end reference home position return.

Although this type is the same as the dog cradle type home position return, the stop position is not on

the Z-phase. Starting from the front end of the dog, the position is shifted by the travel distance after

proximity dog and the home position shift distance. The position after the shifts is set as the home

position.

Although this type is the same as the dogless Z-phase reference home position return, the creep

speed is applied as the movement start speed.

Although this type is the same as the dogless Z-phase reference home position return, the creep

speed is applied as the movement start speed.

The current position is set as the home position. This type can be executed not in the Operational

enabled state.

The current position is set as the home position. This type can be executed not in the Operational

enabled state.

1 - 3

Page 15

1. FUNCTIONS AND CONFIGURATION

MEMO

1 - 4

Page 16

2. SIGNALS AND WIRING

r

2. SIGNALS AND WIRING

Any person who is involved in wiring should be fully competent to do the work.

Before wiring, turn off the power and wait for 15 minutes or more until the charge

lamp of the servo amplifier is off. Otherwise, an electric shock may occur. In

addition, when confirming whether the charge lamp is off or not, be sure to look at

the lamp from the front of the servo amplifier.

WARNING

CAUTION

Ground the servo amplifier and servo motor securely.

Do not attempt to wire the servo amplifier and servo motor until they have been

installed. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it

may cause an electric shock.

To avoid an electric shock, insulate the connections of the power supply

terminals.

Before removing the CNP1 connector from MR-JE-40C to MR-JE-100C,

disconnect the lead wires of the regenerative resistor from the CNP1 connector.

Wire the equipment correctly and securely. Otherwise, the servo motor may

operate unexpectedly, resulting in injury.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc., may

occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc., may occur.

The surge absorbing diode installed to the DC relay for control output should be

fitted in the specified direction. Otherwise, the converter unit and the drive unit will

malfunction and will not output signals, disabling the emergency stop and other

protective circuits.

Servo amplifier

DOCOM

Control output

signal

For sink output interface

24 V DC

RA

Servo amplifie

Control output

signal

For source output interface

DOCOM

24 V DC

RA

Use a noise filter, etc., to minimize the influence of electromagnetic interference.

Electromagnetic interference may affect the electronic equipment used near the

servo amplifier.

Do not install a power capacitor, surge killer or radio noise filter (optional FR-BIF)

with the power line of the servo motor.

When using the regenerative resistor, shut the power off with an alarm signal.

Otherwise, a transistor fault or the like may overheat the regenerative resistor,

causing a fire.

Do not modify the equipment.

2 - 1

Page 17

2. SIGNALS AND WIRING

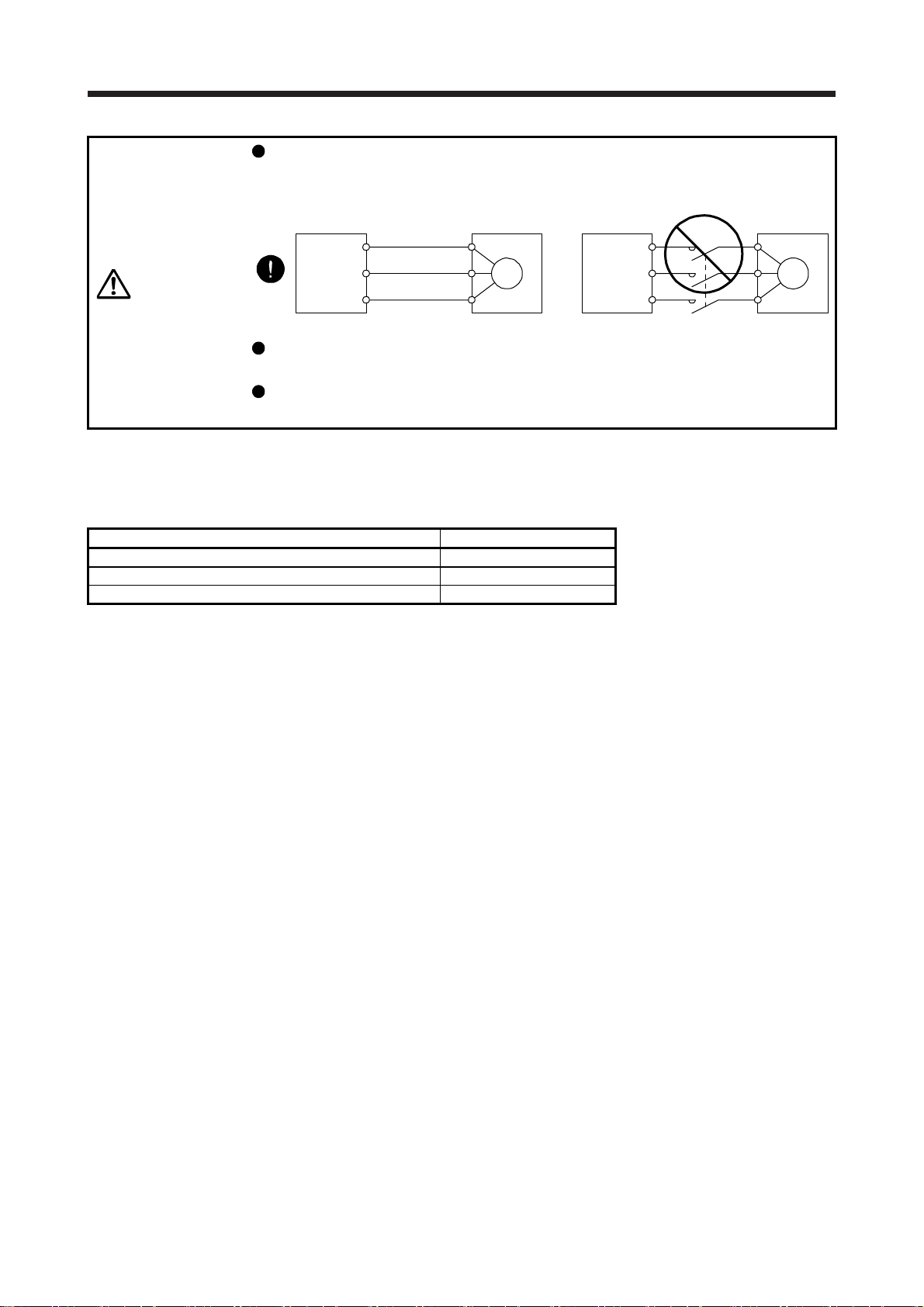

Connect the servo amplifier power output (U/V/W) to the servo motor power input

(U/V/W) directly. Do not connect a magnetic contactor and others between them.

Otherwise, it may cause a malfunction.

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

M

W

CAUTION

Servo amplifier

U

V

W

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo

amplifier may cause a malfunction.

Before wiring, switch operation, etc., eliminate static electricity. Otherwise, it may

cause a malfunction.

The items shown in the following table are the same with the contents of "MR-JE-_C Servo Amplifier

Instruction Manual”. For details, refer to each section indicated in the detailed explanation field. "MR-JE-_C"

means "MR-JE-_C Servo Amplifier Instruction Manual".

Item Detailed explanation

Connection example of power circuit MR-JE-_C section 3.1

Explanation of power supply system MR-JE-_C section 3.3

Signal (device) explanations MR-JE-_C section 3.5

2 - 2

Page 18

2. SIGNALS AND WIRING

A

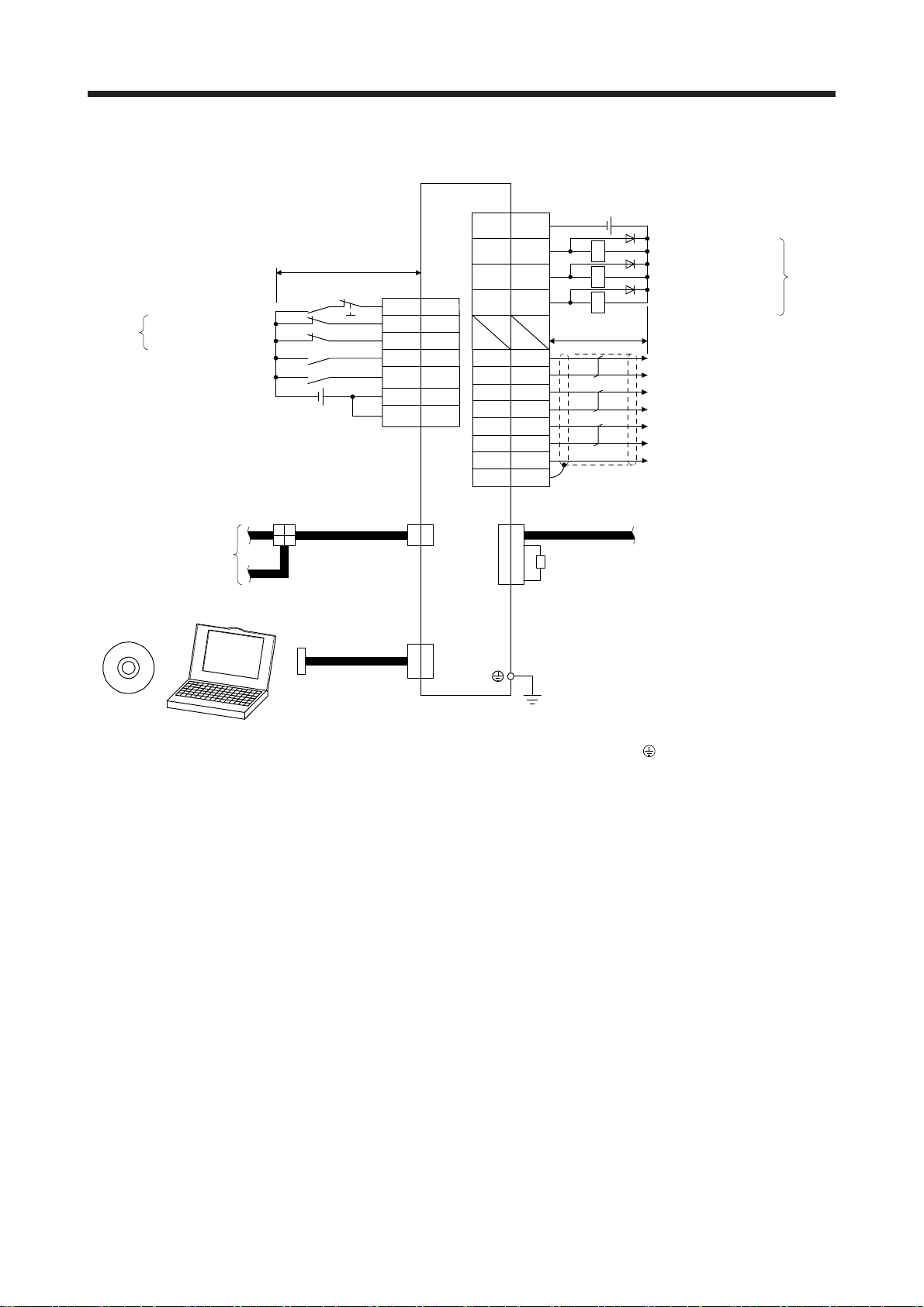

2.1 I/O signal connection example

Servo amplifier

Forced stop2 (Note 3)

Forward rotation

(Note 5)

CC-Link IE Field Network

Basic, SLMP or Modbus/

TCP

(Note 10, 12, 13)

(Note 7)

MR Configurator2

stroke end

Reverse rotation

stroke end

Proximity dog

Touch probe 1

Personal

computer

+

(Note 8)

Power supply

(Note 4, 11)

Switching

hub

10 m or less

24 V DC

Ethernet cable

USB cable

(option)

EM2

LSP

LSN

DOG

TPR1

DICOM

OPC

CN3

17

15 ALM

CN3

1

3

4

2

6

(Note 15)

5

18

(Note 15)

CN1 CN6

CN5

22 INP

13 LZ

26

11 LA

24 LAR

12 LB

25 LBR

23 LG

Plate

DOCOM

LZR

SD

(Note 1)

24 V DC (Note 4, 11)

(Note 2)

RA1

RA2

RA3

10 m or less

(Note 14)

Malfunction (Note 6)

Encoder Z-phase pulse

(open collector)

In-position

Encoder Z-phase pulse

(differential line driver)

Encoder A-phase pulse

(differential line driver)

Encoder B-phase pulse

(differential line driver)

Control common

Modbus RTU

(Note 10, 12, 13)

(Note 9)16 OP

Note 1. To prevent an electric shock, be sure to connect the protective earth (PE) terminal (marked ) of the servo amplifier to the

protective earth (PE) of the cabinet.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output

signals, disabling EM2 (Forced stop 2) and other protective circuits.

3. The forced stop switch (normally closed contact) must be installed.

4. Supply 24 V DC ± 10% to interfaces from outside. The total current capacity of these power supplies must be 300 mA or lower.

300 mA is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number

of I/O points. Refer to section 3.9.2 (1) of "MR-JE-_C Servo Amplifier Instruction Manual" that gives the current value

necessary for the interface. The illustration of the 24 V DC power supply is divided between input signal and output signal for

convenience. However, they can be configured by one.

5. When starting operation, always turn on EM2 (Forced stop 2), LSP (Forward rotation stroke end) and LSN (Reverse rotation

stroke end) (normally closed contact).

6.

LM (Malfunction) turns on in normal alarm-free condition (normally closed contact). When this signal is switched off (at

occurrence of an alarm), the output of the programmable controller should be stopped by the sequence program.

7. Use SW1DNC-MRC2-_. MR-JE-_C Servo Amplifier Instruction Manual section 11.4

8. Configure a circuit to turn off EM2 when the power is turned off to prevent an unexpected restart of the servo amplifier.

9. You can change devices of these pins with [Pr. PD30], [Pr. PD31], [Pr. PD32], and [Pr. PD38].

10. For communication function, refer to the "MR-JE-_C Servo Amplifier Instruction Manual (Network)”.

11. This diagram shows sink I/O interface.

12. Modbus/TCP can be used on servo amplifiers with software version A3 or later. Modbus RTU can be used on servo amplifiers

with software version A4 or later.

13. Ethernet communication (CC-Link IE field network Basic, SLMP and Modbus/TCP) and RS-485 communication (Modbus RTU)

are exclusively independent functions. Only the communication function selected in [Pr. PN08] "Select communication

function" can be used.

14. If this servo amplifier is the last axis, connect a 150 Ω resistor between DA and DB, and terminate the servo amplifier. For

details, refer to the "MR-JE-_C Servo Amplifier Instruction Manual (Network)”.

15. When CN3-6 pin is used as the input device of sink interface, supply + of 24 V DC to CN3-18 pin (OPC: power input for opencollector sink interface).

2 - 3

Page 19

2. SIGNALS AND WIRING

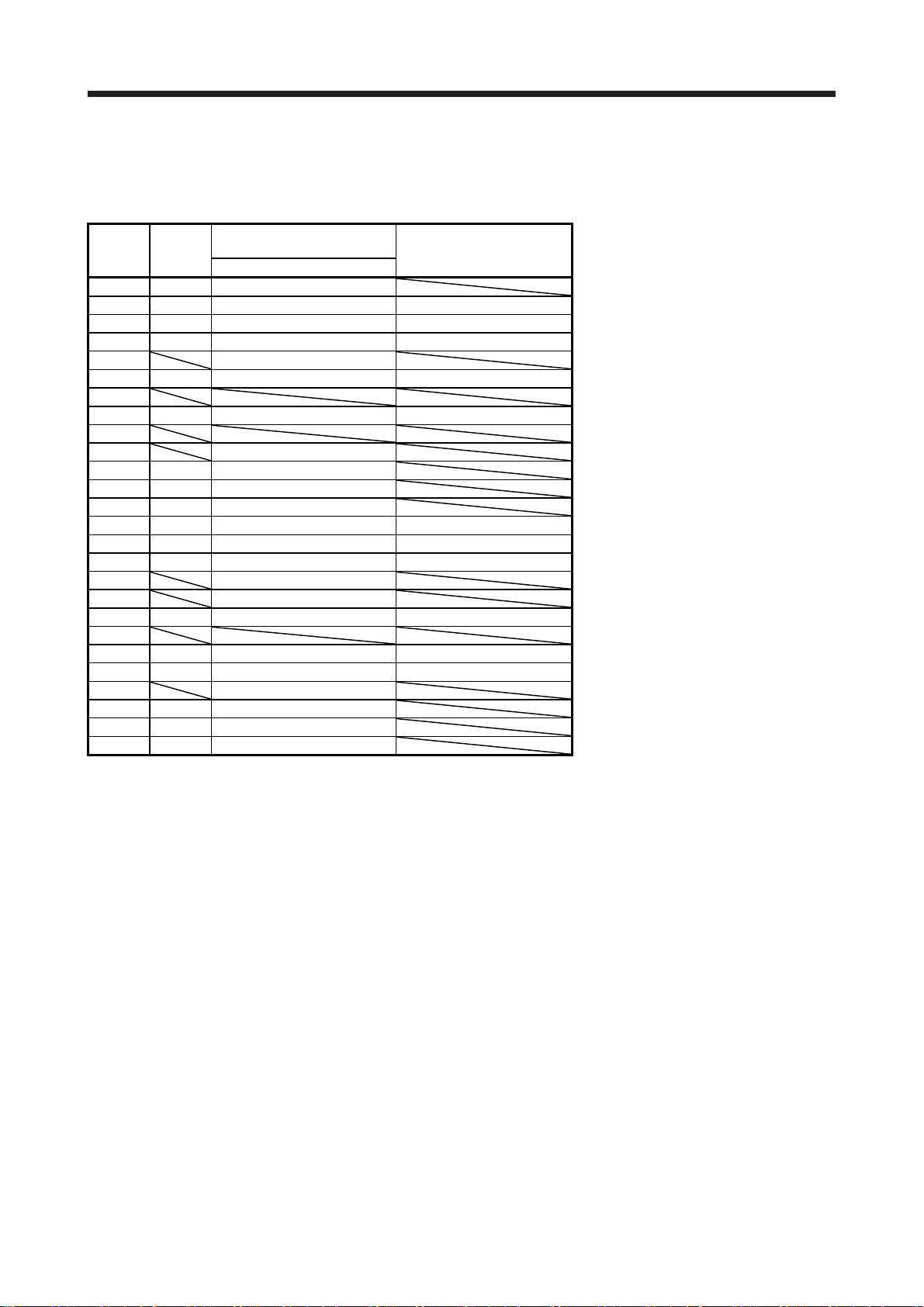

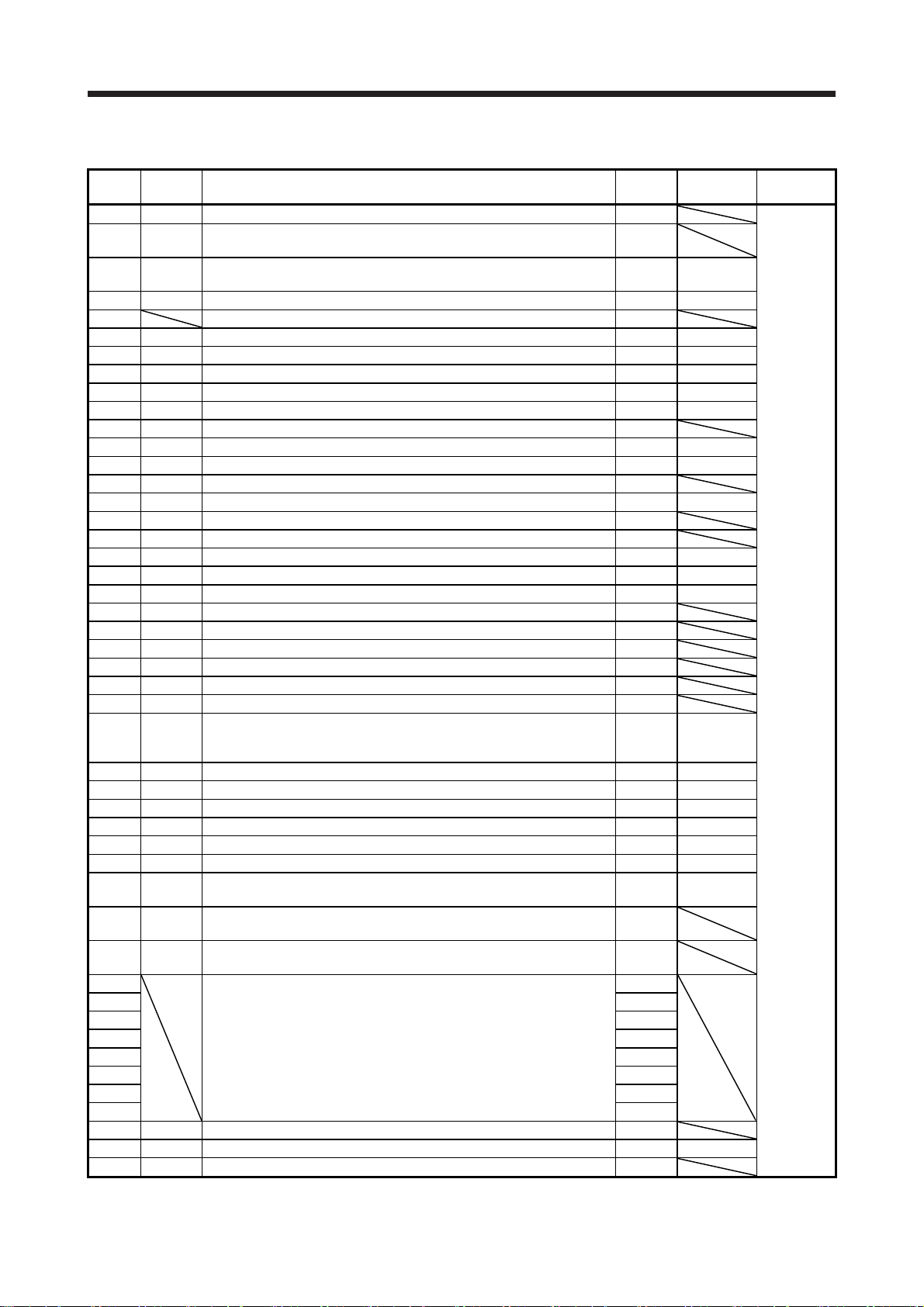

2.2 Connectors and pin assignment

For the pins which are given parameters in the related parameter column, their devices can be changed

using those parameters.

Pin No.

1 I EM2

2 I DOG PD07

3 I LSP PD10

4 I LSN PD13

5 DICOM

6 I TPR1 (Note 5) PD25

7

8 I (Note 3) PD16

9

10 LG

11 O LA

12 O LB

13 O LZ

14 O RD PD29

15 O ALM PD30

16 O OP PD31/PD38

17 DOCOM

18 OPC

19 I (Note 4) PD28

20

21 I (Note 3) PD19

22 O INP PD32

23 LG

24 O LAR

25 O LBR

26 O LZR

I/O

(Note 1)

Note 1. I: input signal, O: output signal

2. pp: Profile position mode, pv: Profile velocity mode, tq: Profile torque mode

3. Input devices are not assigned by default. Assign the input devices with [Pr. PD16] and [Pr. PD19] as necessary.

4. Input devices are not assigned by default. When using CN3-19 pin as the input device of sink interface, assign the device with

[Pr. PD28] as necessary. In addition, supply + of 24 V DC to CN3-18 pin (OPC: power input for open-collector sink interface).

5. When CN3-6 pin is used as the input device of sink interface, supply + of 24 V DC to CN3-18 pin (OPC: power input for open-

collector sink interface).

I/O signals in control modes

(Note 2)

pp/pv/tq

Related parameter

2 - 4

Page 20

2. SIGNALS AND WIRING

2.3 Signal (device) explanations

For details of the devices and I/O interfaces (symbols in I/O division column in the table) not described in the

table, refer to sections 3.5 and 3.9 in "MR-JE-_C Servo Amplifier Instruction Manual".

Device Symbol

Proximity dog DOG Turning off DOG will detect a proximity dog. The polarity for dog detection can

Connector

pin No.

be changed with [Pr. PT29].

Function and application

_ _ _ 0 Detection with off

_ _ _ 1 Detection with on

Touch probe 1 TPR1 CN3-6 The touch probe function that executes current position latch by sensor input

can be used. For details of the touch probe function, refer to "MR-JE-_C Servo

Amplifier Instruction Manual (Network)".

[Pr. PT29]

Polarity for proximity dog

detection

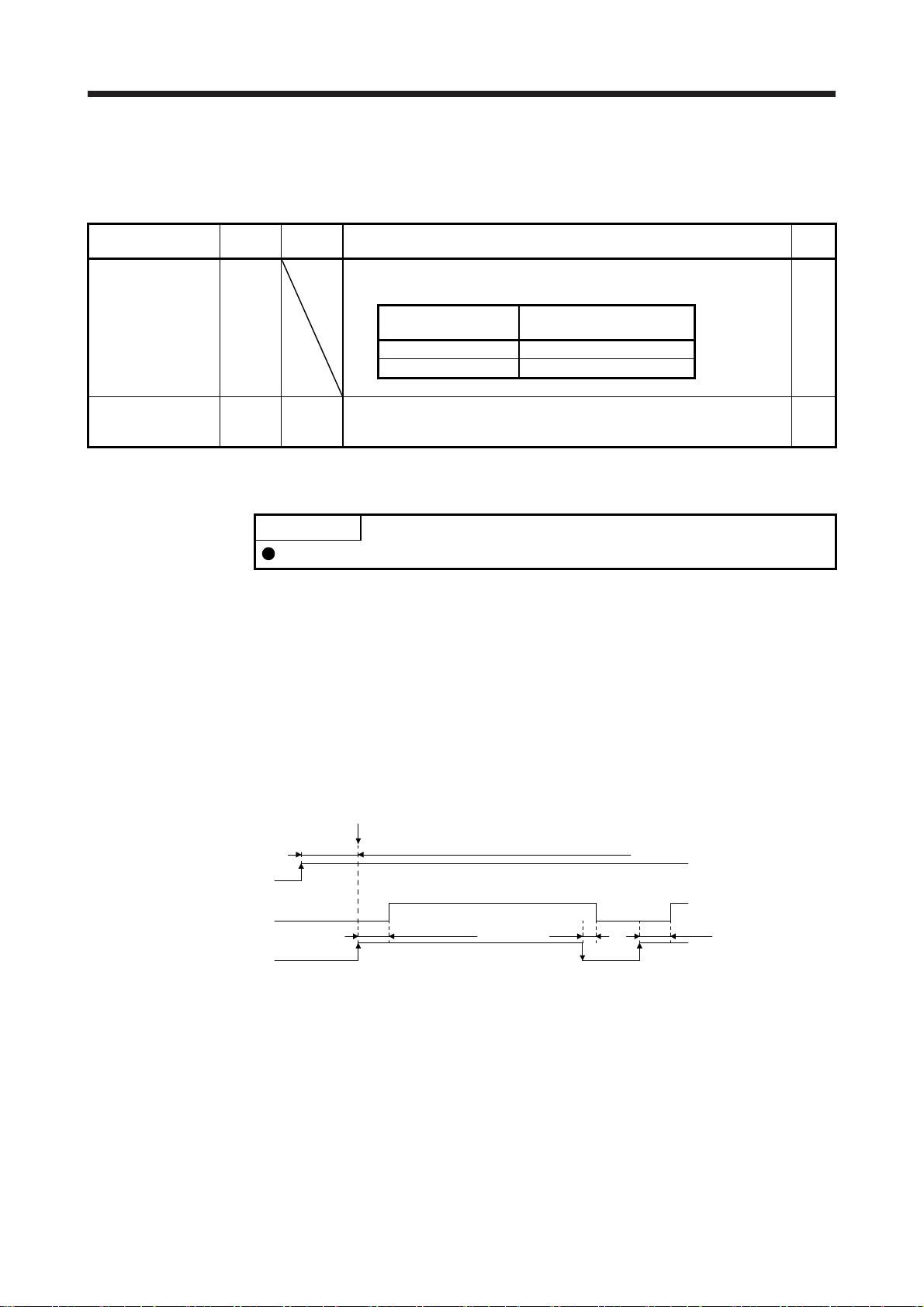

2.4 Power-on sequence

POINT

The output signal, etc. may be unstable at power-on.

I/O

division

DI-1

DI-1

(1) Power-on procedure

1) Always wire the power supply as shown in above section 3.1 of "MR-JE-_C Servo Amplifier

Instruction Manual" using the magnetic contactor with the power supply (L1/L2/L3). Configure up

an external sequence to switch off the magnetic contactor as soon as an alarm occurs.

2) The servo amplifier receives the servo-on command in 3 s to 4 s + network initial communication

time after the power supply is switched on.

(Refer to (2) in this section.)

(2) Timing chart

Power supply

Base circuit

Servo-on command

(from controller)

ON

OFF

ON

OFF

ON

OFF

Servo-on command accepted

(3 s to 4 s + network initial communication time)

95 ms 10 ms 95 ms

2 - 5

Page 21

2. SIGNALS AND WIRING

MEMO

2 - 6

Page 22

3. STARTUP

3. STARTUP

The items shown in the following table are the same with the contents of "MR-JE-_C Servo Amplifier

Instruction Manual”. For details, refer to each section indicated in the detailed explanation field. "MR-JE-_C"

means "MR-JE-_C Servo Amplifier Instruction Manual".

Switching power on for the first time MR-JE-_C section 4.1

Display and operation section MR-JE-_C section 4.5

Test operation MR-JE-_C section 4.6

Test operation mode MR-JE-_C section 4.7

3.1 Startup

Connect the servo motor with a machine after confirming that the servo motor operates properly alone.

(1) Power on

When the power is switched on, "b01" (when the identification number is 01h) appears on the servo

amplifier display.

When you use the absolute position detection system, first power-on results in [AL. 25 Absolute position

erased] and the servo-on cannot be ready. [AL. 25] can be deactivated by cycling the power.

Also, if the power is switched on when the servo motor is rotated at a speed of 3000 r/min or higher, a

position mismatch may occur due to external force or the like. Power must therefore be switched on

when the servo motor is at a stop.

(2) Parameter setting

Item Detailed explanation

POINT

The following encoder cables are of four-wire type. When using any of these

encoder cables, set [Pr. PC04] to "1 _ _ _" to select the four-wire type. An

incorrect setting will result in [AL. 16 Encoder initial communication error 1].

MR-EKCBL30M-L

MR-EKCBL30M-H

MR-EKCBL40M-H

MR-EKCBL50M-H

Set the parameters according to the structure and specifications of the machine. Refer to chapter 4 for

details.

After setting the above parameters, turn off the power as necessary. Then switch power on again to

enable the parameter values.

(3) Servo-on

Enable the servo-on with the following procedure.

(a) Turn on the power.

(b) Transmit the servo-on command with the controller.

When the servo-on status is enabled, the servo amplifier is ready to operate and the servo motor is

locked.

3 - 1

Page 23

3. STARTUP

(4) Home position return

Always perform home position return before starting positioning operation.

(5) Stop

If any of the following situations occurs, the servo amplifier suspends and stops the operation of the

servo motor.

Turn off the servo-on command after the servo motor has stopped, and then switch the power off.

Refer to section 3.10 in "MR-JE-_C Servo Amplifier Instruction Manual" for the servo motor with an

electromagnetic brake.

Controller

Servo amplifier

Note 1. This is for CC-Link IE Field Network Basic. If an error occurs, RX (n + 3) F is set to "0" (cyclic communication ready turns off).

2. Refer to "MELSERVO-JE Servo Amplifier Instruction Manual (Troubleshooting)" for details of alarms and warnings.

Operation/command Stopping condition

Servo-off command The base circuit is shut off, and the servo motor coasts.

Ready-off command

Quick stop command The servo motor decelerates to a stop.

Error occurrence (Note 1) The servo motor decelerates to a stop.

Alarm occurrence

EM2 (Forced stop 2) off

LSP (Forward rotation

stroke end) off or LSN

(Reverse rotation stroke

end) off

The base circuit is shut off and the dynamic brake operates to bring the servo motor to

a stop.

The servo motor decelerates to a stop. With some alarms; however, the dynamic

brake operates to stop the servo motor. (Note 2)

The servo motor decelerates to a stop. [AL. E6 Servo forced stop warning] occurs. In

the torque control mode, EM2 functions the same as EM1

The servo motor stops immediately and will be servo locked. Operation in the

opposite direction is possible.

3 - 2

Page 24

4. PARAMETERS

4. PARAMETERS

CAUTION

4.1 Parameter list

Never make a drastic adjustment or change to the parameter values as doing so

will make the operation unstable.

Do not change the parameter settings as described below. Doing so may cause

an unexpected condition, such as failing to start up the servo amplifier.

Changing the values of the parameters for manufacturer setting

Setting a value out of the range

Changing the fixed values in the digits of a parameter

When you write parameters with the controller, make sure that the identification

No. of the servo amplifier is set correctly. Otherwise, the parameter settings of

another identification No. may be written, possibly causing the servo amplifier to

be an unexpected condition.

POINT

To enable a parameter whose symbol is preceded by *, cycle the power after

setting it. However, the time will be longer depending on a setting value of [Pr.

PF25 Instantaneous power failure tough drive - Detection time] when

"instantaneous power failure tough drive selection" is enabled in [Pr. PA20].

Refer to chapter 5 in "MR-JE-_C Servo Amplifier Instruction Manual" for the parameters with "MR-JE-_C" in

the detailed explanation field.

4 - 1

Page 25

4. PARAMETERS

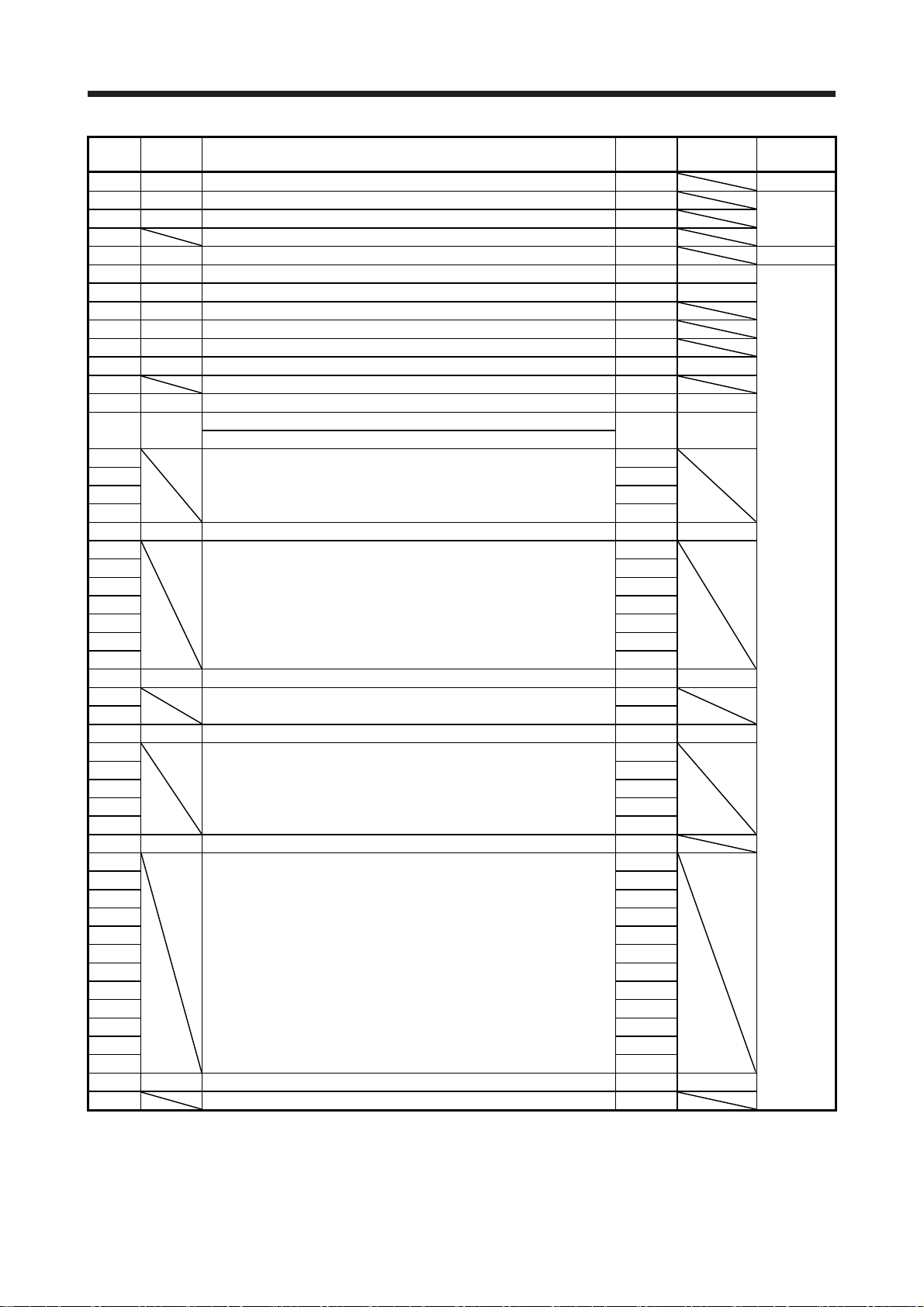

4.1.1 Basic setting parameters ([Pr. PA_ _ ])

POINT

The following parameters cannot be used in the profile mode.

[Pr. PA05 Number of command input pulses per revolution]

[Pr. PA13 Command pulse input form]

No. Symbol Name

PA01 *STY Operation mode 1000h Section 4.2.1

PA02 *REG Regenerative option 0000h MR-JE-_C

PA03 *ABS Absolute position detection system 0000h Section 4.2.1

PA04 *AOP1 Function selection A-1 2000h MR-JE-_C

PA05 *FBP Number of command input pulses per revolution 10000

PA06 CMX Electronic gear numerator (command pulse multiplication numerator) 1 Section 4.2.1

PA07 CDV Electronic gear denominator (command pulse multiplication denominator) 1

PA08 ATU Auto tuning mode 0001h MR-JE-_C

PA09 RSP Auto tuning response 16

PA10 INP In-position range 100 [pulse] Section 4.2.1

PA11 TLP Forward rotation torque limit 1000.0 [%]

PA12 TLN Reverse rotation torque limit 1000.0 [%]

PA13 *PLSS Command pulse input form 0100h MR-JE-_C

PA14 *POL Rotation direction selection 0 Section 4.2.1

PA15 *ENR Encoder output pulses 4000 [pulse/rev] MR-JE-_C

PA16 *ENR2 Encoder output pulses 2 1

PA17 For manufacturer setting 0000h

PA18 0000h

PA19 *BLK Parameter writing inhibit 00AAh

PA20 *TDS Tough drive setting 0000h

PA21 *AOP3 Function selection A-3 0001h Section 4.2.1

PA22 For manufacturer setting 0000h MR-JE-_C

PA23 DRAT Drive recorder arbitrary alarm trigger setting 0000h

PA24 AOP4 Function selection A-4 0000h

PA25 OTHOV One-touch tuning - Overshoot permissible level 0 [%]

PA26 *AOP5 Function selection A-5 0000h

PA27 For manufacturer setting 0000h

PA28 *AOP6 Function selection A-6 0000h

PA29 For manufacturer setting 0000h

PA30 0000h

PA31 0000h

PA32 0000h

Initial

value

Unit

Detailed

explanation

4 - 2

Page 26

4. PARAMETERS

4.1.2 Gain/filter setting parameters ([Pr. PB_ _ ])

No. Symbol Name

PB01 FILT Adaptive tuning mode (adaptive filter II) 0000h MR-JE-_C

PB02 VRFT Vibration suppression control tuning mode (advanced vibration

suppression control II)

PB03 PST Position command acceleration/deceleration time constant (position

smoothing)

PB04 FFC Feed forward gain 0 [%]

PB05 For manufacturer setting 500

PB06 GD2 Load to motor inertia ratio 7.00 [Multiplier]

PB07 PG1 Model loop gain 15.0 [rad/s]

PB08 PG2 Position loop gain 37.0 [rad/s]

PB09 VG2 Speed loop gain 823 [rad/s]

PB10 VIC Speed integral compensation 33.7 [ms]

PB11 VDC Speed differential compensation 980

PB12 OVA Overshoot amount compensation 0 [%]

PB13 NH1 Machine resonance suppression filter 1 4500 [Hz]

PB14 NHQ1 Notch shape selection 1 0000h

PB15 NH2 Machine resonance suppression filter 2 4500 [Hz]

PB16 NHQ2 Notch shape selection 2 0000h

PB17 NHF Shaft resonance suppression filter 0000h

PB18 LPF Low-pass filter setting 3141 [rad/s]

PB19 VRF11 Vibration suppression control 1 - Vibration frequency 100.0 [Hz]

PB20 VRF12 Vibration suppression control 1 - Resonance frequency 100.0 [Hz]

PB21 VRF13 Vibration suppression control 1 - Vibration frequency damping 0.00

PB22 VRF14 Vibration suppression control 1 - Resonance frequency damping 0.00

PB23 VFBF Low-pass filter selection 0100h

PB24 *MVS Slight vibration suppression control 0000h

PB25 *BOP1 Function selection B-1 0000h

PB26 *CDP Gain switching function 0000h

PB27 CDL Gain switching condition 10 [kpulse/s]/

PB28 CDT Gain switching time constant 1 [ms]

PB29 GD2B Load to motor inertia ratio after gain switching 7.00 [Multiplier]

PB30 PG2B Position loop gain after gain switching 0.0 [rad/s]

PB31 VG2B Speed loop gain after gain switching 0 [rad/s]

PB32 VICB Speed integral compensation after gain switching 0.0 [ms]

PB33 VRF11B Vibration suppression control 1 - Vibration frequency after gain switching 0.0 [Hz]

PB34 VRF12B Vibration suppression control 1 - Resonance frequency after gain

switching

PB35 VRF13B Vibration suppression control 1 - Vibration frequency damping after gain

switching

PB36 VRF14B Vibration suppression control 1 - Resonance frequency damping after

gain switching

PB37

PB38 0.00

PB39 0.00

PB40 0.00

PB41 0000h

PB42 0000h

PB43 0000h

PB44 0.00

PB45 CNHF Command notch filter 0000h

PB46 NH3 Machine resonance suppression filter 3 4500 [Hz]

PB47 NHQ3 Notch shape selection 3 0000h

For manufacturer setting 1600

Initial

value

0000h

0 [ms]

0.0 [Hz]

0.00

0.00

Unit

[pulse]/

[r/min]

Detailed

explanation

4 - 3

Page 27

4. PARAMETERS

No. Symbol Name

PB48 NH4 Machine resonance suppression filter 4 4500 [Hz] MR-JE-_C

PB49 NHQ4 Notch shape selection 4 0000h

PB50 NH5 Machine resonance suppression filter 5 4500 [Hz]

PB51 NHQ5 Notch shape selection 5 0000h

PB52 VRF21 Vibration suppression control 2 - Vibration frequency 100.0 [Hz]

PB53 VRF22 Vibration suppression control 2 - Resonance frequency 100.0 [Hz]

PB54 VRF23 Vibration suppression control 2 - Vibration frequency damping 0.00

PB55 VRF24 Vibration suppression control 2 - Resonance frequency damping 0.00

PB56 VRF21B Vibration suppression control 2 - Vibration frequency after gain switching 0.0 [Hz]

PB57 VRF22B Vibration suppression control 2 - Resonance frequency after gain

switching

PB58 VRF23B Vibration suppression control 2 - Vibration frequency damping after gain

switching

PB59 VRF24B Vibration suppression control 2 - Resonance frequency damping after

gain switching

PB60 PG1B Model loop gain after gain switching 0.0 [rad/s]

PB61 For manufacturer setting 0.0

PB62 0000h

PB63 0000h

PB64 0000h

Initial

value

0.0 [Hz]

0.00

0.00

Unit

Detailed

explanation

4 - 4

Page 28

4. PARAMETERS

4.1.3 Extension setting parameters ([Pr. PC_ _ ])

POINT

The following parameters cannot be used in the profile mode.

[Pr. PC04 Torque command time constant]

[Pr. PC05 Internal speed command 1/internal speed limit 1]

[Pr. PC06 Internal speed command 2/internal speed limit 2]

[Pr. PC07 Internal speed command 3/internal speed limit 3]

[Pr. PC08 Internal speed command 4/internal speed limit 4]

[Pr. PC09 Internal speed command 5/internal speed limit 5]

[Pr. PC10 Internal speed command 6/internal speed limit 6]

[Pr. PC11 Internal speed command 7/internal speed limit 7]

[Pr. PC12 Analog speed command - Maximum speed/Analog speed limit Maximum speed]

[Pr. PC13 Analog torque command maximum output]

[Pr. PC32 Command input pulse multiplication numerator 2]

[Pr. PC33 Command input pulse multiplication numerator 3]

[Pr. PC34 Command input pulse multiplication numerator 4]

No. Symbol Name

PC01 STA Acceleration time constant 0 [ms] Section 4.2.2

PC02 STB Deceleration time constant 0 [ms]

PC03 STC S-pattern acceleration/deceleration time constant 0 [ms] MR-JE-_C

PC04 TQC Torque command time constant 0 [ms]

PC05 SC1 Internal speed command 1 100.00 [r/min]

Internal speed limit 1

PC06 SC2 Internal speed command 2 500.00 [r/min]

Internal speed limit 2

PC07 SC3 Internal speed command 3 1000.00 [r/min]

Internal speed limit 3

PC08 SC4 Internal speed command 4 200.00 [r/min]

Internal speed limit 4

PC09 SC5 Internal speed command 5 300.00 [r/min]

Internal speed limit 5

PC10 SC6 Internal speed command 6 500.00 [r/min]

Internal speed limit 6

PC11 SC7 Internal speed command 7 800.00 [r/min]

Internal speed limit 7

PC12 VCM Analog speed command - Maximum speed 0.00 [r/min]

Analog speed limit - Maximum speed

PC13 TLC Analog torque command maximum output 100.0 [%]

PC14

PC15 0000h

PC16 MBR Electromagnetic brake sequence output 0 [ms]

PC17 ZSP Zero speed 50 [r/min]

PC18 *BPS Alarm history clear 0000h

PC19 *ENRS Encoder output pulse selection 0000h

PC20

PC21 0000h

PC22 *COP1 Function selection C-1 0020h

PC23 *COP2 Function selection C-2 0000h

PC24 *COP3 Function selection C-3 0000h

For manufacturer setting 0000h

For manufacturer setting 0

Initial

value

Unit

Detailed

explanation

4 - 5

Page 29

4. PARAMETERS

No. Symbol Name

PC25 *COP4 Function selection C-4 0000h Section 4.2.2

PC26 *COP5 Function selection C-5 0000h MR-JE-_C

PC27 *COP6 Function selection C-6 0000h

PC28 For manufacturer setting 0000h

PC29 *COP8 Function selection C-8 0120h Section 4.2.2

PC30 STA2 Acceleration time constant 2 0 [ms] MR-JE-_C

PC31 STB2 Deceleration time constant 2 0 [ms]

PC32 CMX2 Command input pulse multiplication numerator 2 1

PC33 CMX3 Command input pulse multiplication numerator 3 1

PC34 CMX4 Command input pulse multiplication numerator 4 1

PC35 TL2 Internal torque limit 2 1000.0 [%]

PC36 For manufacturer setting 0000h

PC37 VCO Analog speed command offset 0 [mV]

PC38 TPO Analog torque command offset 0 [mV]

Analog torque limit offset

PC39

PC40 0

PC41 0

PC42 0

PC43 ERZ Error excessive alarm detection level 0 [rev]

PC44

PC45 0000h

PC46 0

PC47 0

PC48 0

PC49 0

PC50 0000h

PC51 RSBR Forced stop deceleration time constant 100 [ms]

PC52

PC53 0

PC54 RSUP1 Vertical axis freefall prevention compensation amount 0 [0.0001 rev]

PC55

PC56 100

PC57 0000h

PC58 0

PC59 0000h

PC60 *COPD Function selection C-D 0000h

PC61 For manufacturer setting 0000h

PC62 0000h

PC63 0000h

PC64 0000h

PC65 0000h

PC66 0

PC67 0

PC68 0

PC69 0

PC70 0

PC71 0040h

PC72 0000h

PC73 ERW Error excessive warning level 0 [rev]

PC74 For manufacturer setting 0000h

For manufacturer setting 0

For manufacturer setting 0000h

For manufacturer setting 0

For manufacturer setting 0

Initial

value

Unit

Detailed

explanation

4 - 6

Page 30

4. PARAMETERS

No. Symbol Name

PC75 FEWL Following error output level 0000h 10-3 [degree]/

PC76 FEWH 00C0h

PC77 FEWF Following error output filtering time 10 [ms]

PC78 For manufacturer setting 0000h MR-JE-_C

PC79 0000h

PC80 0000h

Initial

value

Unit

[pulse]

4.1.4 I/O setting parameters ([Pr. PD_ _ ])

POINT

The following parameters cannot be used in the profile mode.

[Pr. PD05 Input device selection 1L]

[Pr. PD06 Input device selection 1M]

[Pr. PD08 Input device selection 2L]

[Pr. PD09 Input device selection 2M]

[Pr. PD11 Input device selection 3L]

[Pr. PD12 Input device selection 3M]

[Pr. PD14 Input device selection 4L]

[Pr. PD15 Input device selection 4M]

[Pr. PD17 Input device selection 5L]

[Pr. PD18 Input device selection 5M]

[Pr. PD23 Input device selection 7L]

[Pr. PD24 Input device selection 7M]

[Pr. PD26 Input device selection 8L]

[Pr. PD27 Input device selection 8M]

Detailed

explanation

Section 4.2.2

No. Symbol Name

PD01 *DIA1 Input signal automatic on selection 1 0000h MR-JE-_C

PD02 For manufacturer setting 0000h

PD04 0000h

PD05 *DI1L Input device selection 1L 0202h

PD06 *DI1M Input device selection 1M 0202h

PD07 *DI1H Input device selection 1H 002Bh Section 4.2.3

PD08 *DI2L Input device selection 2L 0A0Ah MR-JE-_C

PD09 *DI2M Input device selection 2M 0700h

PD10 *DI2H Input device selection 2H 000Ah Section 4.2.3

PD11 *DI3L Input device selection 3L 0B0Bh MR-JE-_C

PD12 *DI3M Input device selection 3M 0800h

PD13 *DI3H Input device selection 3H 000Bh Section 4.2.3

PD14 *DI4L Input device selection 4L 0703h MR-JE-_C

PD15 *DI4M Input device selection 4M 3807h

PD16 *DI4H Input device selection 4H 0000h Section 4.2.3

PD17 *DI5L Input device selection 5L 0806h MR-JE-_C

PD18 *DI5M Input device selection 5M 2008h

PD19 *DI5H Input device selection 5H 0000h Section 4.2.3

Initial

value

Unit

Detailed

explanation

PD03 0000h

4 - 7

Page 31

4. PARAMETERS

No. Symbol Name

PD20

PD21 0000h

PD22 0000h

PD23 *DI7L Input device selection 7L 0000h

PD24 *DI7M Input device selection 7M 0000h

PD25 *DI7H Input device selection 7H 002Ch Section 4.2.3

PD26 *DI8L Input device selection 8L 0000h MR-JE-_C

PD27 *DI8M Input device selection 8M 0000h

PD28 *DI8H Input device selection 8H 0000h

PD29 *DO1 Output device selection 1 0002h

PD30 *DO2 Output device selection 2 0003h

PD31 *DO3 Output device selection 3 0000h

PD32 *DO4 Output device selection 4 0004h

PD33 For manufacturer setting 0000h MR-JE-_C

PD34 *DIF Input filter setting 0004h

PD35 *DOP1 Function selection D-1 0101h Section 4.2.3

PD36 For manufacturer setting 0000h MR-JE-_C

PD37 *DOP3 Function selection D-3 0000h

PD38 *DOP4 Function selection D-4 3000h Section 4.2.3

PD39 *DOP5 Function selection D-5 0000h MR-JE-_C

PD40 For manufacturer setting 0000h

PD41 *TPOP Touch probe function selection 0000h Section 4.2.3

PD42

PD43 0000h

PD44 0000h

PD45 0000h

PD46 0000h

PD47 0000h

PD48 0000h

For manufacturer setting 0000h

For manufacturer setting 0

Initial

value

Unit

4.1.5 Extension setting 2 parameters ([Pr. PE_ _ ])

Detailed

explanation

MR-JE-_C

Section 4.2.3

MR-JE-_C

No. Symbol Name

PE01

PE02 0000h

PE03 0000h

PE04 0

PE05 0

PE06 0

PE07 0

PE08 0

PE09 0000h

PE10 0000h

PE11 0000h

PE12 0000h

PE13 0000h

PE14 0111h

PE15 20

PE16 0000h

PE17 0000h

PE18 0000h

For manufacturer setting 0000h

Initial

value

Unit

Detailed

explanation

MR-JE-_C

4 - 8

Page 32

4. PARAMETERS

No. Symbol Name

PE19

PE20 0000h

PE21 0000h

PE22 0000h

PE23 0000h

PE24 0000h

PE25 0000h

PE26 0000h

PE27 0000h

PE28 0000h

PE29 0000h

PE30 0000h

PE31 0000h

PE32 0000h

PE33 0000h

PE34 0

PE35 0

PE36 0.0

PE37 0.00

PE38 0.00

PE39 0

PE40 0000h

PE41 EOP3 Function selection E-3 0000h

PE42

PE43 0.0

PE44 LMCP Lost motion compensation positive-side compensation value selection 0 [0.01%] Section 4.2.4

PE45 LMCN Lost motion compensation negative-side compensation value selection 0 [0.01%]

PE46 LMFLT Lost motion filter setting 0 [0.1 ms]

PE47 TOF Torque offset 0 [0.01%]

PE48 *LMOP Lost motion compensation function selection 0000h

PE49 LMCD Lost motion compensation timing 0 [0.1 ms]

PE50 LMCT Lost motion compensation non-sensitive band 0 [pulse]/

PE51

PE52 0000h

PE53 0000h

PE54 0000h

PE55 0000h

PE56 0000h

PE57 0000h

PE58 0000h

PE59 0000h

PE60 0000h

PE61 0.00

PE62 0.00

PE63 0.00

PE64 0.00

For manufacturer setting 0000h

For manufacturer setting 0

For manufacturer setting 0000h

Initial

value

Unit

[kpulse]

Detailed

explanation

MR-JE-_C

MR-JE-_C

4 - 9

Page 33

4. PARAMETERS

4.1.6 Extension setting 3 parameters ([Pr. PF_ _ ])

No. Symbol Name

PF01

PF02 0000h

PF03 0000h

PF04 0

PF05 0

PF06 0000h

PF07 1

PF08 1

PF09 *FOP5 Function selection F-5 0003h

PF10

PF11 0000h

PF12 10000

PF13 100

PF14 100

PF15 2000

PF16 0000h

PF17 10

PF18 0000h

PF19 0000h

PF20 0000h

PF21 DRT Drive recorder switching time setting 0 [s]

PF22 For manufacturer setting 200

PF23 OSCL1 Vibration tough drive - Oscillation detection level 50 [%]

PF24 *OSCL2 Vibration tough drive function selection 0000h

PF25 CVAT Instantaneous power failure tough drive - Detection time 200 [ms]

PF26

PF27 0

PF28 0

PF29 0000h

PF30 0

PF31 FRIC Machine diagnosis function - Friction judgment speed 0 [r/min]

PF32

PF33 0000h

PF34 0000h

PF35 0000h

PF36 0000h

PF37 0000h

PF38 0000h

PF39 0000h

PF40 0

PF41 0

PF42 0

PF43 0

PF44 0

PF45 0000h

PF46 0

PF47 0000h

PF48 0000h

For manufacturer setting 0000h

For manufacturer setting 0000h

For manufacturer setting 0

For manufacturer setting 50

Initial

value

Unit

Detailed

explanation

MR-JE-_C

4 - 10

Page 34

4. PARAMETERS

4.1.7 Positioning control parameters ([Pr. PT_ _ ])

No. Symbol Name

PT01 *CTY Command mode selection 0300h Section 4.2.5

PT02 For manufacturer setting 0001h

PT03 *FTY Feeding function selection 0000h Section 4.2.5

PT04 For manufacturer setting 0000h

PT05 ZRF Home position return speed 100.00 [r/min] Section 4.2.5

PT06 CRF Creep speed 10.00 [r/min]

PT07 ZST Home position shift distance 0 10-3 [degree]/

PT08 For manufacturer setting 0

PT09 DCT Travel distance after proximity dog 0 10-3 [degree]/

PT10 ZTM Stopper type home position return stopper time 100 [ms]

PT11 ZTT Stopper type home position return torque limit value 15.0 [%]

PT12 For manufacturer setting 0

PT13 100.00

PT14 0

PT15 LMPL Software limit + 0000h 10-3 [degree]/

PT16 LMPH 0000h 10-3 [degree]/

PT17 LMNL Software limit - 0000h 10-3 [degree]/

PT18 LMNH 0000h 10-3 [degree]/

PT19 For manufacturer setting 0000h

PT20 0000h

PT21 0000h

PT22 0000h

PT23 0

PT24 0

PT25 0

PT26 *TOP2 Function selection T-2 0000h Section 4.2.5

PT27 For manufacturer setting 0000h

PT28 8

PT29 *TOP3 Function selection T-3 0000h Section 4.2.5

PT30 For manufacturer setting 0000h

PT31 0000h

PT32 0000h

PT33 0000h

PT34 0000h

PT35 0000h

PT36 0000h

PT37 10

PT38 0000h

PT39 100

PT40 0

PT41 ORP Home position return inhibit function selection 0000h Section 4.2.5

PT42 For manufacturer setting 0

PT43 0

PT44 0000h

Initial

value

Unit

[pulse]

[pulse]

[pulse]

[pulse]

[pulse]

[pulse]

Detailed

explanation

Section 4.2.5

Section 4.2.5

4 - 11

Page 35

4. PARAMETERS

No. Symbol Name

PT45 HMM Home position return method 37 Section 4.2.5

PT46 For manufacturer setting 0000h

PT47 0000h

PT48 0000h

PT49 TQS Torque slope 0.0 [%/s] Section 4.2.5

PT50 PVC Profile speed command 100.00 [r/min]

PT51 MPVC Maximum profile speed 20000.00 [r/min]

PT52 VLMT Speed limit 500.00 [r/min]

PT53 For manufacturer setting 0000h

PT54 0000h

PT55 0000h

PT56 0000h

PT57 ZSTH Home position shift distance (extension parameter) 0 10-3 [degree]/

PT58 For manufacturer setting 0

PT59 DCTH Travel distance after proximity dog (extension parameter) 0 10-3 [degree]/

PT60 *TOP8 Function selection T-8 0000h

PT61 HMA Home position return acceleration time constant 0 [ms]

PT62 HMB Home position return deceleration time constant 0 [ms]

PT63 ZSP2L Zero speed 2 level 50.00 [r/min]

PT64 ZSP2F Zero speed 2 filtering time 10 [ms]

PT65 INP2R In-position 2 output range 100 10-3 [degree]/

PT66 INP2F In-position 2 output filtering time 10 [ms]

PT67 SA2R Speed reached 2 output range 20.00 [r/min]

PT68 SA2F Speed reached 2 output filtering time 10 [ms]

PT69 For manufacturer setting 0000h

PT70 0000h

PT71 0000h

PT72 0000h

PT73 0000h

PT74 0000h

PT75 0000h

PT76 0000h

PT77 0000h

PT78 0000

PT79 0000

PT80 0000

Initial

value

Unit

[pulse]

[pulse]

[pulse]

Detailed

explanation

Section 4.2.5

Section 4.2.5

4 - 12

Page 36

4. PARAMETERS

4.2 Detailed list of parameters

POINT

For parameters which are not described in this section, refer to chapter 5 of

"MR-JE-_C Servo Amplifier Instruction Manual".

Set a value to each "x" in the "Setting digit" columns.

4.2.1 Basic setting parameters ([Pr. PA_ _ ])

No./symbol/

name

PA01

*STY

Operation

mode

_ _ x _ For manufacturer setting 0h

_ x _ _ 0h

x _ _ _ 1h

PA03

*ABS

Absolute

position

detection

system

_ _ x _ For manufacturer setting 0h

_ x _ _ 0h

x _ _ _ 0h

Setting

digit

_ _ _ x Control mode selection

To use the profile mode, select "9" (Profile mode (pp/pv/tq)).

0: Position control mode (P)

1: Position control mode and speed control mode (P/S)

2: Speed control mode (S)

3: Speed control mode and torque control mode (S/T)

4: Torque control mode (T)

5: Torque control mode and position control mode (T/P)

6: Positioning mode (point table method) (CP)

8: Positioning mode (indexer method) (PS)

9: Profile mode (pp/pv/tq)

_ _ _ x Absolute position detection system selection

Set this digit when using the absolute position detection system.

0: Disabled (used in the incremental system)

2: Enabled (absolute position detection system)

Setting "1" will trigger [AL. 37].

Function

Initial

value

[unit]

0h

0h

4 - 13

Page 37

4. PARAMETERS

No./symbol/

name

PA06

CMX

Electronic

gear

numerator

(command

pulse

multiplication

numerator)

Setting

digit

Set an electronic gear numerator.

To enable the parameter, select "Electronic gear (0 _ _ _)" of "Electronic gear selection" in [Pr.

PA21].

In the profile mode, cycle the power to enable the parameter.

The following shows a standard of the setting range of the electronic gear.

1

27649

If the set value is outside this range, noise may be generated during acceleration/deceleration or

operation may not be performed at the preset speed and/or acceleration/deceleration time

constants.

<

CMX

CDV

< 8484

Function

Number of command input pulses per revolution

([Pr. PA05] "1000" to "1000000")

Initial

value

[unit]

1

PA07

CDV

Electronic

gear

denominator

(command

pulse

multiplication

denominator)

PA10

INP

In-position

range

Command

pulse train

Electronic gear selection

(x _ _ _ ) ([Pr. PA21])

"0" (initial value)

"1"

Pt (servo motor resolution): 131072 pulses/rev

Electronic gear

([Pr. PA06]/[Pr. PA07])

CMX

CDV

Pt

FBP

+

Deviation

counter

-

Be sure to set the electronic gear with servo-off state to prevent unexpected operation due to

improper setting.

This parameter corresponds to "Motor revolutions (Index: 6091h, Sub: 1)". When this parameter is

mapped to the link device of CC-Link IE Field Network Basic, the value written with MR

Configurator2 is overwritten by the controller. Thus, do not write a value with MR Configurator2.

Setting range: 1 to 16777215

Set an electronic gear denominator.