General-Purpose AC Servo

General-Purpose Interface AC Servo

MODEL

MR-JE-_A

SERVO AMPLIFIER

INSTRUCTION MANUAL

E

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 1

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp

is off or not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

Always connect a magnetic contactor between the power supply and the power supply (L1, L2, and L3)

of the servo amplifier, in order to configure a circuit that shuts down the power supply on the side of the

servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a large

current may cause smoke or a fire when the servo amplifier malfunctions.

Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the main circuit power supply (L1, L2, and L3) of the servo amplifier, in order to configure a

circuit that shuts down the power supply on the side of the servo amplifier’s power supply. If a moldedcase circuit breaker or fuse is not connected, continuous flow of a large current may cause smoke or a

fire when the servo amplifier malfunctions.

When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a regenerative

transistor malfunction or the like may overheat the regenerative resistor, causing smoke or a fire.

When you use a regenerative option with an MR-JE-40A to MR-JE-100A, remove the built-in

regenerative resistor and wiring from the servo amplifier.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

3. To prevent injury, note the following

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal. Otherwise, a

burst, damage, etc. may occur.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, servo motor, etc. may be hot while power is on or for

some time after power-off. Take safety measures, e.g. provide covers, to avoid accidentally touching the

parts (cables, etc.) by hand.

A - 2

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the lead wire of the regenerative resistor when transporting the servo amplifier.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the equipment.

The equipment must be installed in the specified direction.

Leave specified clearances between the servo amplifier and the cabinet walls or other equipment.

Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it may cause a malfunction.

Do not drop or strike the servo amplifier and servo motor. Isolate them from all impact loads.

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Ambient

temperature

Storage -20 ˚C to 65 ˚C (non-freezing)

Ambient

humidity

Storage

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude 1000 m or less above sea level

Vibration resistance 5.9 m/s2, at 10 Hz to 55 Hz (directions of X, Y and Z axes)

When the product has been stored for an extended period of time, contact your local sales office.

When handling the servo amplifier, be careful about the edged parts such as corners of the servo

amplifier.

The servo amplifier must be installed in a metal cabinet.

When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine are used

for disinfecting and protecting wooden packaging from insects, they cause malfunction when entering our

products. Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat method). Additionally,

disinfect and protect wood from insects before packing products.

Operation 0 ˚C to 55 ˚C (non-freezing)

Operation

90 %RH or less (non-condensing)

A - 3

r

(2) Wiring

CAUTION

Before removing the CNP1 connector of MR-JE-40A to MR-JE-100A, disconnect the lead wires of the

regenerative resistor from the CNP1 connector.

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF) on the servo amplifier

output side.

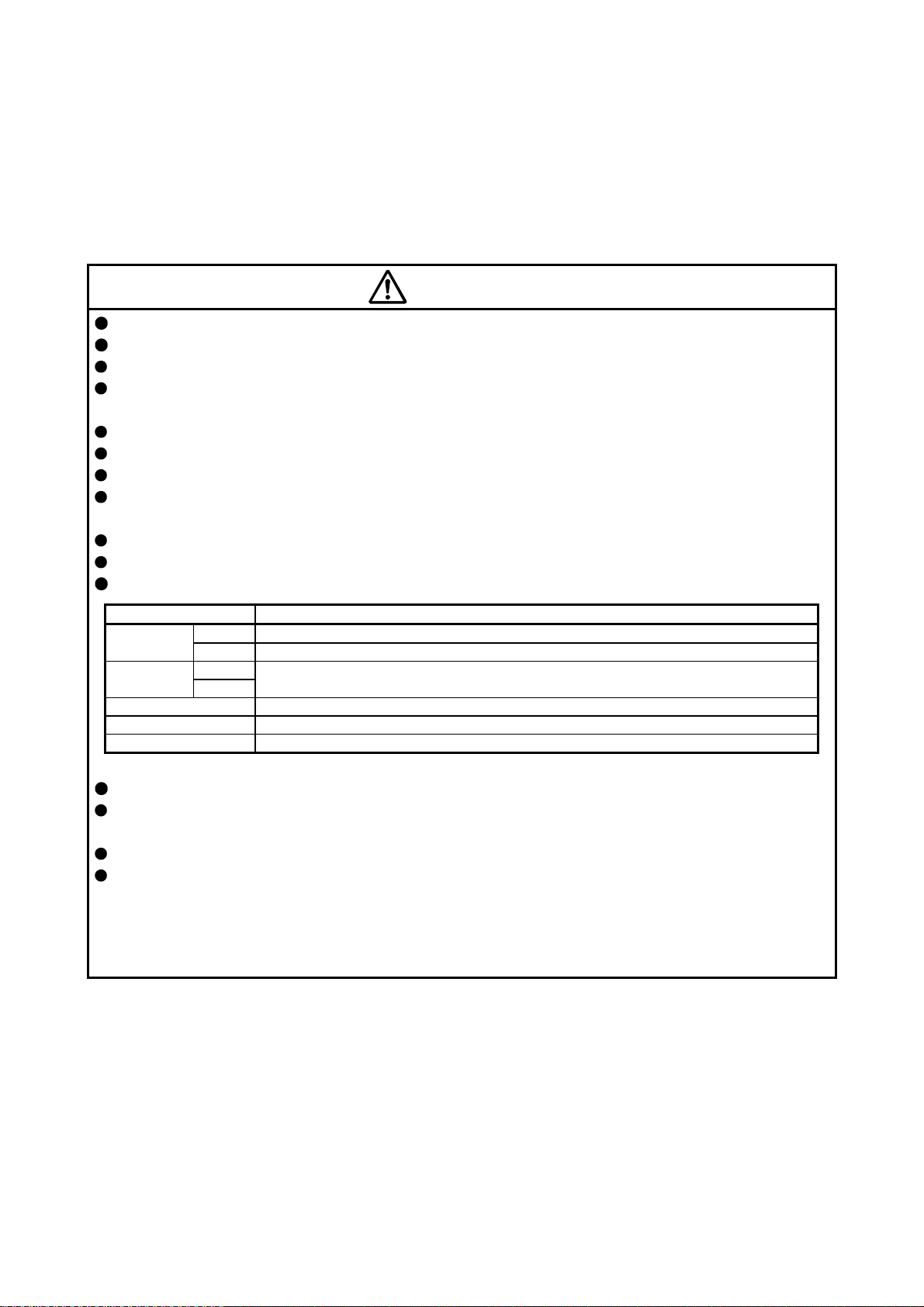

To avoid a malfunction, connect the wires to the correct phase terminals (U, V, and W) of the servo

amplifier and servo motor.

Connect the servo amplifier power output (U, V, and W) to the servo motor power input (U, V, and W)

directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

The connection diagrams in this instruction manual are shown for sink interfaces, unless stated

otherwise.

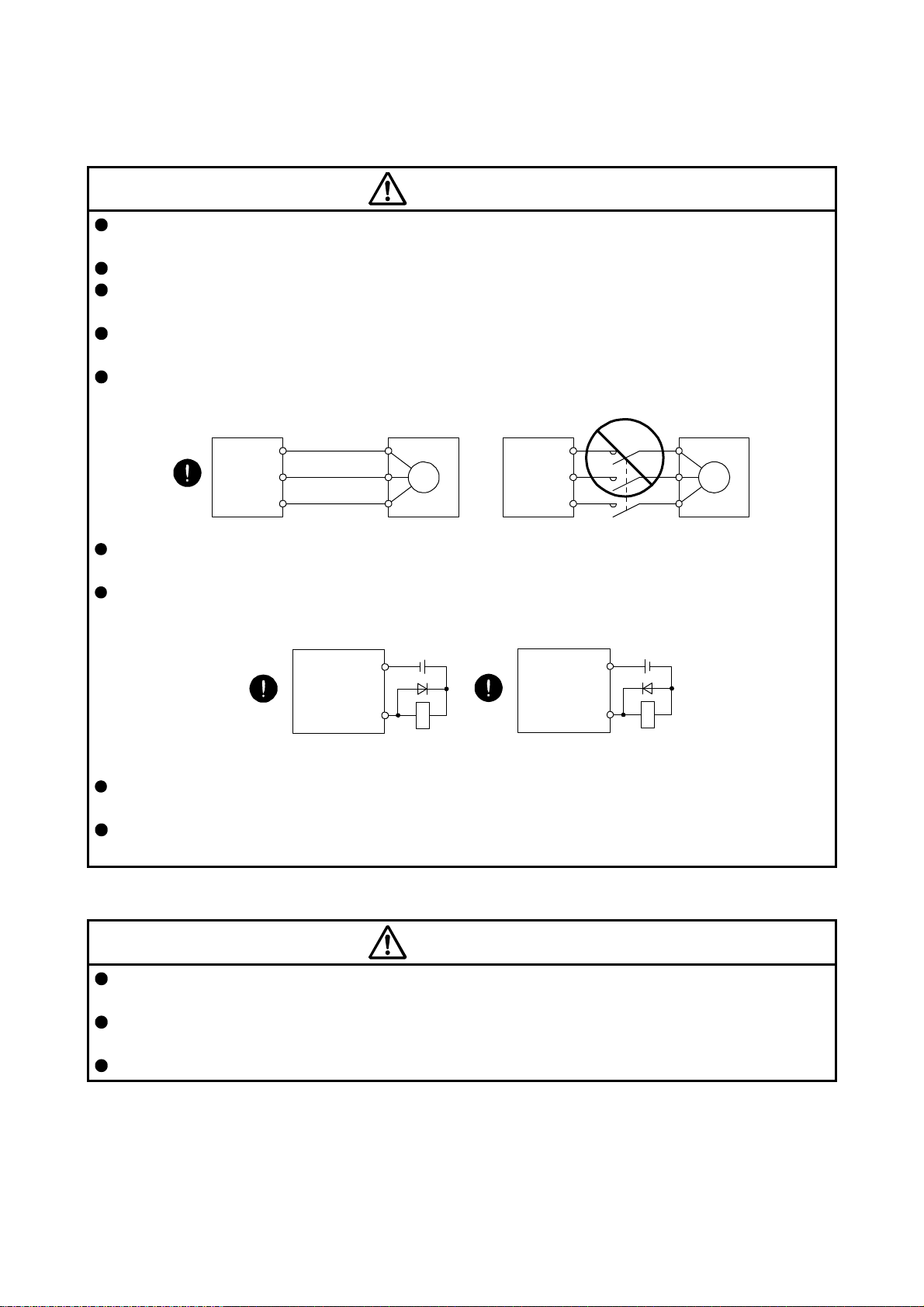

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Servo amplifier

DOCOM

Control output

signal

For sink output interface

24 V DC

RA

Servo amplifie

DOCOM

Control output

signal

For source output interface

24 V DC

RA

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo amplifier may cause a

malfunction.

(3) Test run and adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to operate

unexpectedly.

Never make a drastic adjustment or change to the parameter values as doing so will make the operation

unstable.

Do not get close to moving parts during the servo-on status.

A - 4

(4) Usage

CAUTION

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an external brake to prevent the condition.

Do not disassemble, repair, or modify the equipment.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent a

sudden restart. Otherwise, it may cause an accident.

Use a noise filter, etc. to minimize the influence of electromagnetic interference. Electromagnetic

interference may be given to the electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break it.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor

are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety,

install a stopper on the machine side.

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an electromagnetic brake or external brake to prevent the condition.

Configure an electromagnetic brake circuit so that it is activated also by an external EMG stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

Servo motor

B

Electromagnetic brake

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

Contacts must be opened

with the EMG stop switch.

RA

24 V DC

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor of the servo amplifier will deteriorate. To prevent a secondary

accident due to a malfunction, it is recommend that the electrolytic capacitor be replaced every 10 years

when it is used in general environment. For replacement, please contact your local sales office.

When using a servo amplifier whose power has not been turned on for a long time, contact your local

sales office.

A - 5

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

DISPOSAL OF WASTE

Please dispose a servo amplifier and other options according to your local laws and regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier may malfunction when the

EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

Compliance with global standards

Refer to appendix 2 for the compliance with global standard.

Using HF-KN series and HF-SN series servo motors

For the combinations and characteristics when using HF-KN series and HF-SN series servo motors, refer to

appendix 5.

«About the manual»

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare

them to use the servo safely.

Relevant manuals

Manual name Manual No.

MELSERVO-JE Servo Amplifier Instruction Manual (Troubleshooting) SH(NA)030166

MELSERVO-JE-_A Servo Amplifier Instruction Manual (Positioning Mode) SH(NA)030150

MELSERVO-JE-_A Servo Amplifier Instruction Manual (Modbus-RTU Protocol) SH(NA)030177

MELSERVO HG-KN/HG-SN Servo Motor Instruction Manual SH(NA)030135

EMC Installation Guidelines IB(NA)67310

«Cables used for wiring»

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 ˚C.

A - 6

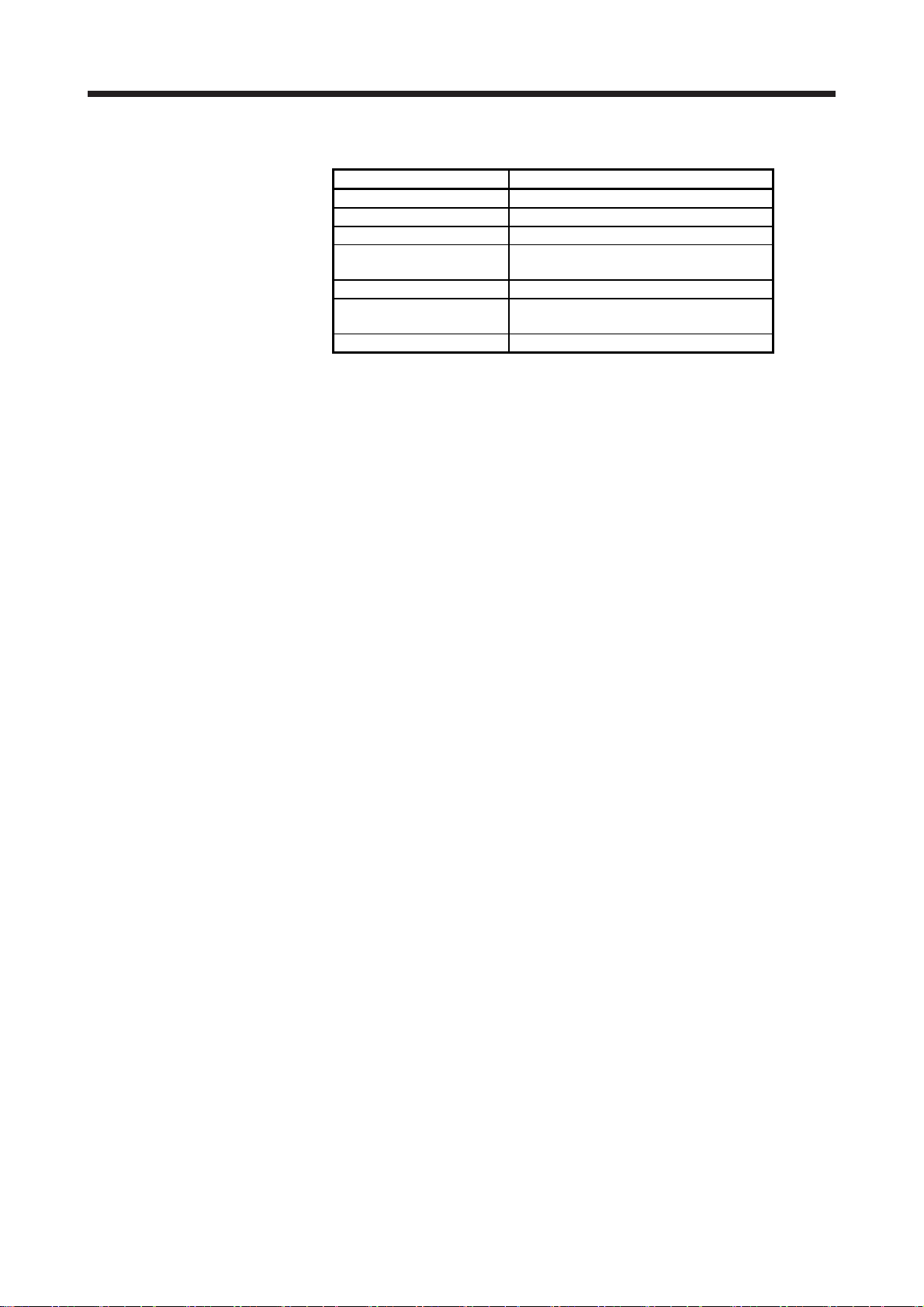

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10-4 kg•m2)] 5.4675 [oz•inch2]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

A - 7

MEMO

A - 8

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-14

1.1 Summary ........................................................................................................................................... 1- 1

1.2 Function block diagram ..................................................................................................................... 1- 2

1.3 Servo amplifier standard specifications ............................................................................................ 1- 4

1.4 Combinations of servo amplifiers and servo motors ........................................................................ 1- 6

1.5 Function list ....................................................................................................................................... 1- 7

1.6 Model designation ............................................................................................................................. 1- 9

1.7 Structure .......................................................................................................................................... 1-10

1.7.1 Parts identification ..................................................................................................................... 1-10

1.8 Configuration including peripheral equipment ................................................................................. 1-12

2. INSTALLATION 2- 1 to 2- 6

2.1 Installation direction and clearances ................................................................................................ 2- 2

2.2 Keep out foreign materials ................................................................................................................ 2- 3

2.3 Encoder cable stress ........................................................................................................................ 2- 4

2.4 Inspection items ................................................................................................................................ 2- 4

2.5 Parts having service lives ................................................................................................................. 2- 5

3. SIGNALS AND WIRING 3- 1 to 3-66

3.1 Input power supply circuit ................................................................................................................. 3- 2

3.2 I/O signal connection example .......................................................................................................... 3- 7

3.2.1 Position control mode ................................................................................................................. 3- 7

3.2.2 Speed control mode .................................................................................................................. 3-12

3.2.3 Torque control mode ................................................................................................................. 3-14

3.3 Explanation of power supply system ............................................................................................... 3-16

3.3.1 Signal explanations ................................................................................................................... 3-16

3.3.2 Power-on sequence .................................................................................................................. 3-17

3.3.3 Wiring CNP1 and CNP2 ............................................................................................................ 3-18

3.4 Connectors and pin assignment ...................................................................................................... 3-20

3.5 Signal (device) explanations ............................................................................................................ 3-23

3.6 Detailed explanation of signals ........................................................................................................ 3-31

3.6.1 Position control mode ................................................................................................................ 3-31

3.6.2 Speed control mode .................................................................................................................. 3-36

3.6.3 Torque control mode ................................................................................................................. 3-38

3.6.4 Position/speed control switching mode ..................................................................................... 3-41

3.6.5 Speed/torque control switching mode ....................................................................................... 3-43

3.6.6 Torque/position control switching mode.................................................................................... 3-45

3.7 Forced stop deceleration function ................................................................................................... 3-46

3.7.1 Forced stop deceleration function ............................................................................................. 3-46

3.7.2 Base circuit shut-off delay time function ................................................................................... 3-48

3.7.3 Vertical axis freefall prevention function ................................................................................... 3-49

3.7.4 Residual risks of the forced stop function (EM2) ...................................................................... 3-49

3.8 Alarm occurrence timing chart ......................................................................................................... 3-50

3.8.1 When you use the forced stop deceleration function ................................................................ 3-50

3.8.2 When you do not use the forced stop deceleration function ..................................................... 3-51

1

3.9 Interfaces ......................................................................................................................................... 3-52

3.9.1 Internal connection diagram ...................................................................................................... 3-52

3.9.2 Detailed explanation of interfaces ............................................................................................. 3-54

3.9.3 Source I/O interfaces ................................................................................................................ 3-58

3.10 Servo motor with an electromagnetic brake .................................................................................. 3-60

3.10.1 Safety precautions .................................................................................................................. 3-60

3.10.2 Timing chart ............................................................................................................................ 3-62

3.11 Grounding ...................................................................................................................................... 3-65

4. STARTUP 4- 1 to 4-36

4.1 Switching power on for the first time ................................................................................................. 4- 1

4.1.1 Startup procedure ...................................................................................................................... 4- 1

4.1.2 Wiring check ............................................................................................................................... 4- 2

4.1.3 Surrounding environment ........................................................................................................... 4- 3

4.2 Startup in position control mode ....................................................................................................... 4- 4

4.2.1 Power on and off procedures ..................................................................................................... 4- 4

4.2.2 Stop ............................................................................................................................................ 4- 4

4.2.3 Test operation ............................................................................................................................ 4- 5

4.2.4 Parameter setting ....................................................................................................................... 4- 6

4.2.5 Actual operation ......................................................................................................................... 4- 6

4.2.6 Trouble at start-up ...................................................................................................................... 4- 7

4.3 Startup in speed control mode .......................................................................................................... 4- 9

4.3.1 Power on and off procedures ..................................................................................................... 4- 9

4.3.2 Stop ............................................................................................................................................ 4- 9

4.3.3 Test operation ........................................................................................................................... 4-10

4.3.4 Parameter setting ...................................................................................................................... 4-11

4.3.5 Actual operation ........................................................................................................................ 4-12

4.3.6 Trouble at start-up ..................................................................................................................... 4-12

4.4 Startup in torque control mode ........................................................................................................ 4-13

4.4.1 Power on and off procedures .................................................................................................... 4-13

4.4.2 Stop ........................................................................................................................................... 4-13

4.4.3 Test operation ........................................................................................................................... 4-14

4.4.4 Parameter setting ...................................................................................................................... 4-15

4.4.5 Actual operation ........................................................................................................................ 4-15

4.4.6 Trouble at start-up ..................................................................................................................... 4-16

4.5 Display and operation sections ........................................................................................................ 4-17

4.5.1 Summary .................................................................................................................

.................. 4-17

4.5.2 Display flowchart ....................................................................................................................... 4-18

4.5.3 Status display mode .................................................................................................................. 4-19

4.5.4 Diagnostic mode ....................................................................................................................... 4-23

4.5.5 Alarm mode ............................................................................................................................... 4-25

4.5.6 Parameter mode ....................................................................................................................... 4-26

4.5.7 External I/O signal display ......................................................................................................... 4-28

4.5.8 Output signal (DO) forced output .............................................................................................. 4-31

4.5.9 Test operation mode ................................................................................................................. 4-32

5. PARAMETERS 5- 1 to 5-46

5.1 Parameter list .................................................................................................................................... 5- 1

5.1.1 Basic setting parameters ([Pr. PA_ _ ]) ...................................................................................... 5- 1

2

5.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) ............................................................................... 5- 2

5.1.3 Extension setting parameters ([Pr. PC_ _ ]) .............................................................................. 5- 3

5.1.4 I/O setting parameters ([Pr. PD_ _ ]) ......................................................................................... 5- 5

5.1.5 Extension setting 2 parameters ([Pr. PE_ _ ]) ............................................................................ 5- 6

5.1.6 Extension setting 3 parameters ([Pr. PF_ _ ]) ............................................................................ 5- 7

5.2 Detailed list of parameters ................................................................................................................ 5- 8

5.2.1 Basic setting parameters ([Pr. PA_ _ ]) ...................................................................................... 5- 8

5.2.2 Gain/filter setting parameters ([Pr. PB_ _ ]) .............................................................................. 5-17

5.2.3 Extension setting parameters ([Pr. PC_ _ ]) ............................................................................. 5-28

5.2.4 I/O setting parameters ([Pr. PD_ _ ]) ........................................................................................ 5-39

5.2.5 Extension setting 2 parameters ([Pr. PE_ _ ]) ........................................................................... 5-44

5.2.6 Extension setting 3 parameters ([Pr. PF_ _ ]) ........................................................................... 5-44

6. NORMAL GAIN ADJUSTMENT 6- 1 to 6-24

6.1 Different adjustment methods ........................................................................................................... 6- 1

6.1.1 Adjustment on a single servo amplifier ...................................................................................... 6- 1

6.1.2 Adjustment using MR Configurator2 .......................................................................................... 6- 2

6.2 One-touch tuning .............................................................................................................................. 6- 3

6.2.1 One-touch tuning flowchart ........................................................................................................ 6- 3

6.2.2 Display transition and operation procedure of one-touch tuning ............................................... 6- 5

6.2.3 Caution for one-touch tuning ..................................................................................................... 6-13

6.3 Auto tuning ....................................................................................................................................... 6-14

6.3.1 Auto tuning mode ...................................................................................................................... 6-14

6.3.2 Auto tuning mode basis ............................................................................................................. 6-15

6.3.3 Adjustment procedure by auto tuning ....................................................................................... 6-16

6.3.4 Response level setting in auto tuning mode ............................................................................. 6-17

6.4 Manual mode ................................................................................................................................... 6-18

6.5 2 gain adjustment mode .................................................................................................................. 6-22

7. SPECIAL ADJUSTMENT FUNCTIONS 7- 1 to 7-28

7.1 Filter setting ...................................................................................................................................... 7- 1

7.1.1 Machine resonance suppression filter ....................................................................................... 7- 1

7.1.2 Adaptive filter II ........................................................................................................................... 7- 4

7.1.3 Shaft resonance suppression filter ............................................................................................. 7- 6

7.1.4 Low-pass filter ............................................................................................................................ 7- 7

7.1.5 Advanced vibration suppression control II ................................................................................. 7- 7

7.1.6 Command notch filter ................................................................................................................ 7-12

7.2 Gain switching function .................................................................................................................... 7-13

7.2.1 Applications ............................................................................................................................... 7-13

7.2.2 Function block diagram ............................................................................................................. 7-14

7.2.3 Parameter .................................................................................................................................. 7-15

7.2.4 Gain switching procedure ......................................................................................................... 7-17

7.3 Tough drive function ........................................................................................................................ 7-21

7.3.1 Vibration tough drive function.................................................................................................... 7-21

7.3.2 Instantaneous power failure tough drive function ..................................................................... 7-23

7.4 Model adaptive control disabled ...................................................................................................... 7-27

3

8. TROUBLESHOOTING 8- 1 to 8-8

8.1 Explanations of the lists .................................................................................................................... 8- 1

8.2 Alarm list ........................................................................................................................................... 8- 2

8.3 Warning list ....................................................................................................................................... 8- 6

9. DIMENSIONS 9- 1 to 9- 6

9.1 Servo amplifier .................................................................................................................................. 9- 1

9.2 Connector ......................................................................................................................................... 9- 4

10. CHARACTERISTICS 10- 1 to 10- 6

10.1 Overload protection characteristics .............................................................................................. 10- 1

10.2 Power supply capacity and generated loss .................................................................................. 10- 2

10.3 Dynamic brake characteristics ...................................................................................................... 10- 4

10.3.1 Dynamic brake operation ....................................................................................................... 10- 4

10.3.2 Permissible load to motor inertia when the dynamic brake is used ....................................... 10- 5

10.4 Cable bending life ......................................................................................................................... 10- 6

10.5 Inrush current at power-on ........................................................................................................... 10- 6

11. OPTIONS AND PERIPHERAL EQUIPMENT 11- 1 to 11-32

11.1 Cable/connector sets .................................................................................................................... 11- 1

11.1.1 Combinations of cable/connector sets ................................................................................... 11- 2

11.2 Regenerative option ...................................................................................................................... 11- 4

11.2.1 Combination and regenerative power .................................................................................... 11- 4

11.2.2 Selection of regenerative option ............................................................................................ 11- 5

11.2.3 Parameter setting ................................................................................................................... 11- 6

11.2.4 Selection of regenerative option ............................................................................................ 11- 7

11.2.5 Dimensions ........................................................................................................................... 11-11

11.3 Junction terminal block MR-TB50 ................................................................................................ 11-13

11.4 MR Configurator2 ........................................................................................................................ 11-15

11.4.1 Specifications ........................................................................................................................ 11-15

11.4.2 System requirements ............................................................................................................ 11-15

11.4.3 Precautions for using USB communication function ............................................................. 11-17

11.5 Selection example of wires .......................................................................................................... 11-18

11.6 Molded-case circuit breakers, fuses, magnetic contactors ......................................................... 11-19

11.7 Power factor improving AC reactor .............................................................................................. 11-20

11.8 Relay (recommended) ................................................................................................................. 11-21

11.9 Noise reduction techniques ......................................................................................................... 11-22

11.10 Earth-leakage current breaker ................................................................................................... 11-28

11.11 EMC filter (recommended) ........................................................................................................ 11-30

12. COMMUNICATION FUNCTION (MITSUBISHI GENERAL-PURPOSE AC SERVO PROTOCOL) 12- 1 to 12-34

12.1 Structure ....................................................................................................................................... 12- 1

12.1.1 Configuration diagram ............................................................................................................ 12- 1

12.1.2 Precautions for using RS422/USB communication function .................................................. 12- 2

12.2 Communication specifications ...................................................................................................... 12- 3

12.2.1 Outline of communication ...................................................................................................... 12- 3

4

12.2.2 Parameter setting ................................................................................................................... 12- 3

12.3 Protocol ......................................................................................................................................... 12- 4

12.3.1 Transmission data configuration ............................................................................................ 12- 4

12.3.2 Character codes ..................................................................................................................... 12- 5

12.3.3 Error codes ............................................................................................................................. 12- 6

12.3.4 Checksum .............................................................................................................................. 12- 6

12.3.5 Time-out processing............................................................................................................... 12- 6

12.3.6 Retry processing .................................................................................................................... 12- 7

12.3.7 Initialization ............................................................................................................................ 12- 7

12.3.8 Communication procedure example ...................................................................................... 12- 8

12.4 Command and data No. list .......................................................................................................... 12- 9

12.4.1 Reading command ................................................................................................................. 12- 9

12.4.2 Writing commands ................................................................................................................ 12-13

12.5 Detailed explanations of commands ............................................................................................ 12-15

12.5.1 Data processing .................................................................................................................... 12-15

12.5.2 Status display mode .............................................................................................................. 12-17

12.5.3 Parameter ............................................................................................................................. 12-18

12.5.4 External I/O signal status (DIO diagnosis) ............................................................................ 12-22

12.5.5 Input device on/off ................................................................................................................. 12-25

12.5.6 Disabling/enabling I/O devices (DIO) .................................................................................... 12-25

12.5.7 Input devices on/off (test operation) ...................................................................................... 12-26

12.5.8 Test operation mode ............................................................................................................. 12-27

12.5.9 Output signal pin on/off (output signal (DO) forced output) .................................................. 12-30

12.5.10 Alarm history ....................................................................................................................... 12-31

12.5.11 Current alarm ...................................................................................................................... 12-32

12.5.12 Software version ................................................................................................................. 12-33

APPENDIX App. - 1 to App. -17

App. 1 Peripheral equipment manufacturer (for reference) .............................................................. App.- 1

App. 2 Compliance with global standards ........................................................................................ App.- 1

App. 3 Analog monitor ..................................................................................................................... App.-11

App. 4 Low-voltage directive ........................................................................................................... App.-14

App. 5 Using HF-KN series and HF-SN series servo motors ......................................................... App.-15

App. 6 When turning on or off the input power supply with DC power supply ................................ App.-17

5

MEMO

6

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

The Mitsubishi general-purpose AC servo MELSERVO-JE series have limited functions with keeping high

performance based on MELSERVO-J4 series.

The servo amplifier has position, speed, and torque control modes. In the position control mode, the

maximum pulse train of 4 Mpulses/s is supported. Further, it can perform operation with the control modes

switched, e.g. position/speed control, speed/torque control and torque/position control. Hence, it is

applicable to a wide range of fields, not only precision positioning and smooth speed control of machine tools

and general industrial machines but also line control and tension control.

With one-touch tuning and real-time auto tuning, you can automatically adjust the servo gains according to

the machine.

The tough drive function, drive recorder function, and preventive maintenance support function strongly

support machine maintenance.

The servo amplifier has a USB communication interface. Therefore, you can connect the servo amplifier to

the personal computer with MR Configurator2 installed to perform the parameter setting, test operation, gain

adjustment, and others.

The MELSERVO-JE series servo motor equipped with an incremental encoder whose resolution is 131072

pulses/rev will enable a high-accuracy positioning.

1 - 1

1. FUNCTIONS AND CONFIGURATION

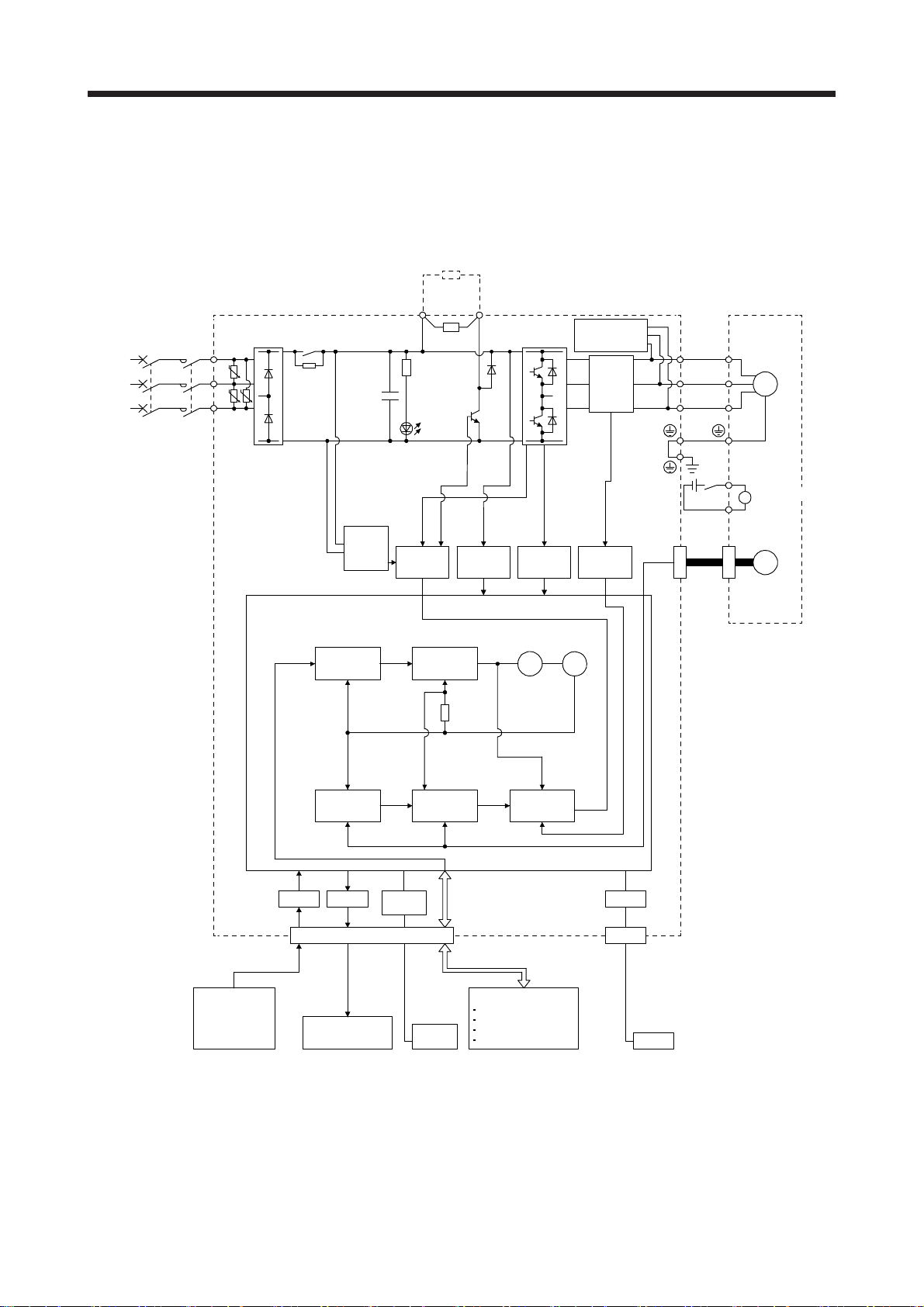

1.2 Function block diagram

The function block diagram of this servo is shown below.

(1) MR-JE-100A or less

Regenerative

option

(Note 2)

Power

supply

W

RA

24 V DC

Servo motor

U

V

B1

B

B2

Encoder

M

Electromagnetic

brake

P+

Diode

stack

MCMCCB

L1

U

L2

U U

L3

Relay

Position

command

input

Control

circuit

power

Model

position

control

Model position

(Note 1)

+

Regenerative

TR

CHARGE

lamp

Base

amplifier

Model

speed

control

Model speed Model torque

C

Voltage

detection

Overcurrent

protection

Virtual

motor

brake circuit

detection

Virtual

encoder

Dynamic

Current

encoder

Current

U

V

W

CN2

Analog

(2 channels)

Actual

position

control

CN1

Analog monitor

(2 channels)

RS-422/

RS-485

Actual

speed

control

Controller

RS-422/

RS-485

Current

I/F

D I/O control

Servo-on

Input command pulse.

Start

Malfunction, etc.

control

USBA/D D/A

CN3

Note 1. The built-in regenerative resistor is not provided for MR-JE-10A and MR-JE-20A.

2. For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open.

For the power supply specifications, refer to section 1.3.

Personal

computer

USB

1 - 2

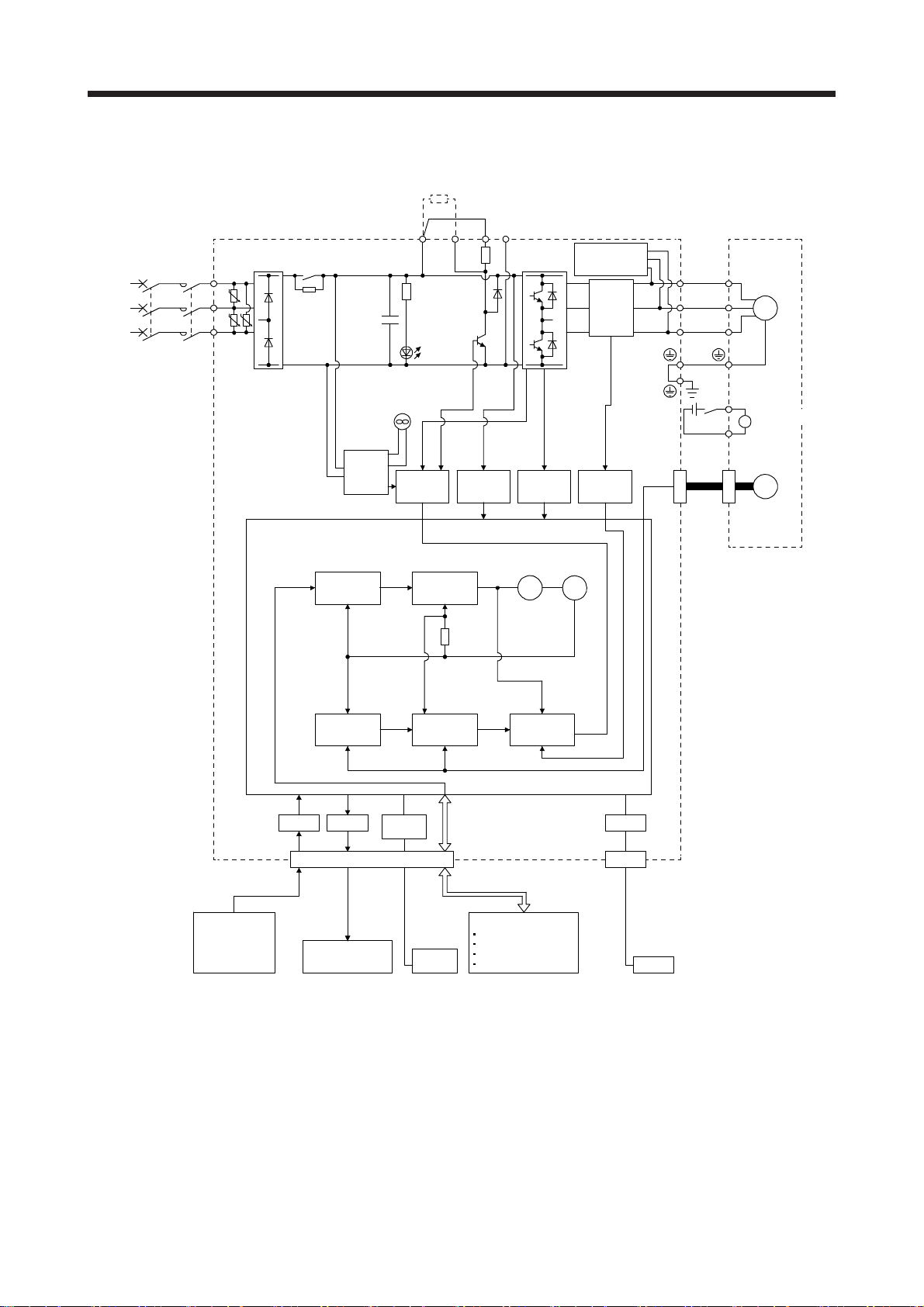

1. FUNCTIONS AND CONFIGURATION

(2) MR-JE-200A or more

Regenerative

option

(Note 1)

Power

supply

W

RA

24 V DC

Servo motor

U

V

B1

B

B2

Encoder

M

Electromagnetic

brake

N- (Note 2)CDP+

Diode

stack

MCMCCB

L1

U

L2

U U

L3

Relay

Position

command

input

Control

circuit

power

Model

position

control

Model position

+

CHARGE

lamp

Cooling fan

Base

amplifier

Regenerative

TR

Voltage

detection

Model

speed

control

Model speed Model torque

Overcurrent

protection

Virtual

motor

brake circuit

detection

Virtual

encoder

Dynamic

Current

encoder

Current

U

V

W

CN2

Analog

(2 channels)

Actual

position

control

CN1

Analog monitor

(2 channels)

RS-422/

RS-485

Actual

speed

control

Controller

RS-422/

RS-485

Note 1. For the power supply specifications, refer to section 1.3.

2. This is for manufacturer adjustment. Leave this open.

Current

I/F

D I/O control

Servo-on

Input command pulse.

Start

Malfunction, etc.

control

USBA/D D/A

CN3

Personal

computer

USB

1 - 3

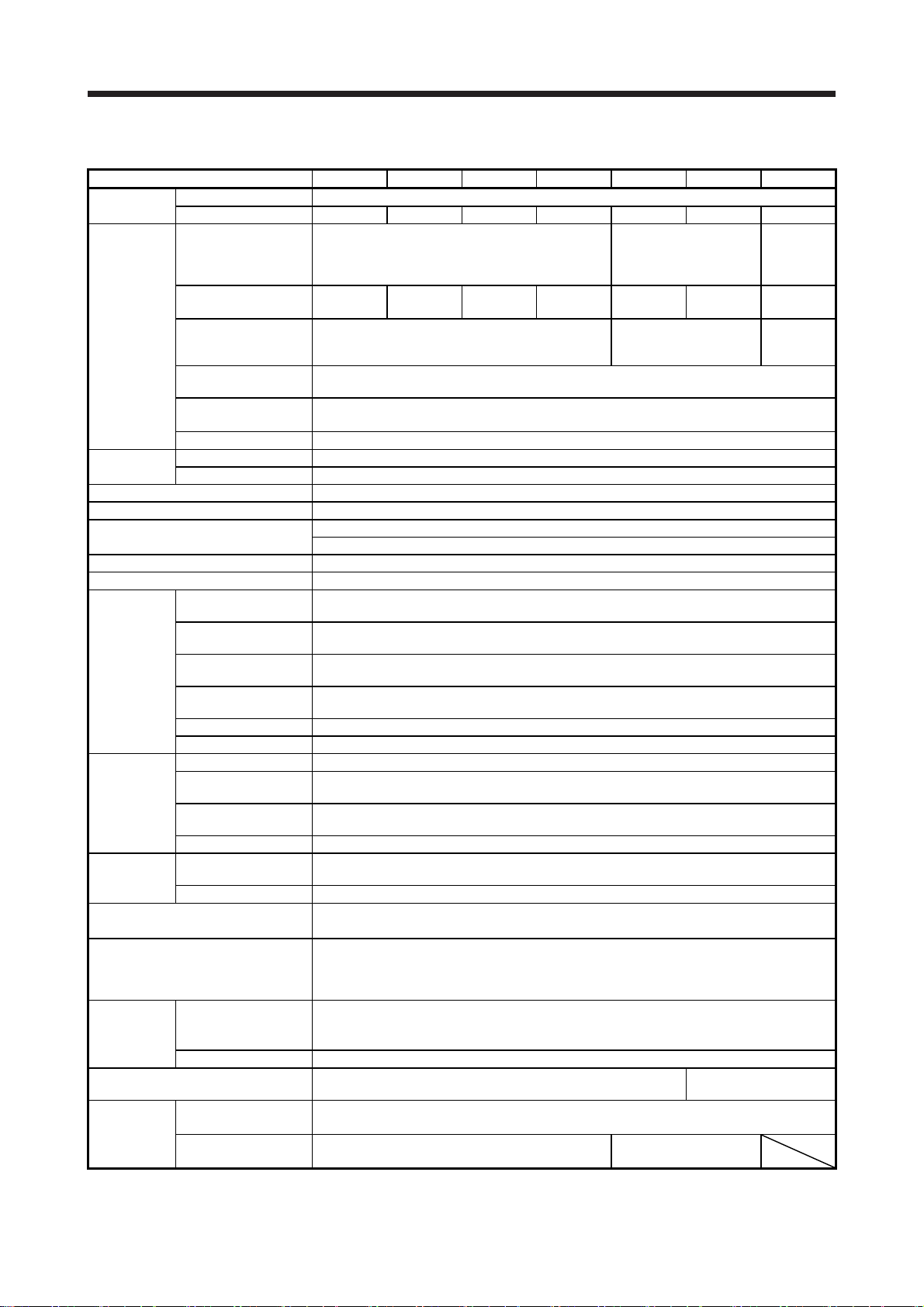

1. FUNCTIONS AND CONFIGURATION

1.3 Servo amplifier standard specifications

Model: MR-JE- 10A 20A 40A 70A 100A 200A 300A

Output

Power supply

input

Interface

power supply

Control method Sine-wave PWM control, current control method

Dynamic brake Built-in

Communication function

Encoder output pulses Compatible (A/B/Z-phase pulse)

Analog monitor Two channels

Position

control mode

Speed control

mode

Torque

control mode

Positioning mode

Protective functions

Compliance

to global

standards

Structure (IP rating) Natural cooling, open (IP20)

Close

mounting

(Note 2)

Rated voltage 3-phase 170 V AC

Rated current [A] 1.1 1.5 2.8 5.8 6.0 11.0 11.0

Voltage/Frequency

Rated current

(Note 5)

Permissible voltage

fluctuation

Permissible frequency

fluctuation

Power supply capacity

[kVA]

Inrush current [A] Refer to section 10.5.

Voltage 24 V DC ± 10%

Current capacity [A] (Note 1) 0.3

Max. input pulse

frequency

Positioning feedback

pulse

Command pulse

multiplying factor

In-position range

setting

Error excessive ±3 revolutions

Torque limit Set by parameter setting or external analog input (0 V DC to +10 V DC/maximum torque)

Speed control range Analog speed command 1: 2000, internal speed command 1: 5000

Analog speed

command input

Speed fluctuation ratio

Torque limit Set by parameter setting or external analog input (0 V DC to +10 V DC/maximum torque)

Analog torque

command input

Speed limit Set by parameter setting or external analog input (0 V DC to 10 V DC/rated speed)

CE marking

UL standard UL 508C

3-phase power supply

input

1-phase power supply

input

3-phase or 1-phase 200 V AC to 240 V AC, 50

[A]

0.9 1.5 2.6 3.8 5.0 10.5 14.0

3-phase or 1-phase 170 V AC to 264 V AC

Within ±5%

Refer to section 10.2.

USB: connection to a personal computer or others (MR Configurator2-compatible)

RS-422/RS-485: Connection to controller (1: n communication up to 32 axes) (Note 4, 7)

4 Mpulses/s (for differential receiver) (Note 3), 200 kpulses/s (for open collector)

Encoder resolution (resolution per servo motor revolution): 131072 pulses/rev

Electronic gear A:1 to 16777215, B:1 to 16777215, 1/10 < A/B < 4000

0 to ±10 V DC/rated speed (The speed at 10 V is changeable with [Pr. PC12].)

±0.01% or less (load fluctuation 0% to 100%), 0% (power fluctuation ±10%), ±0.2% or less

(ambient temperature 25 °C ± 10 °C) when using analog speed command

0 V DC to ±8 V DC/maximum torque (input impedance 10 kΩ to 12 kΩ)

Refer to section 1.1 of "MR-JE-_A Servo Amplifier Instruction Manual (Positioning Mode)"

The positioning mode is available with servo amplifiers with software version B7 or later.

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic thermal),

servo motor overheat protection, encoder error protection, regenerative error protection,

undervoltage protection, instantaneous power failure protection, overspeed protection, and

Possible

Possible Impossible

Hz/60 Hz

0 pulse to ±65535 pulses (command pulse unit)

error excessive protection

LVD: EN 61800-5-1

EMC: EN 61800-3

MD: EN ISO 13849-1, EN 61800-5-2, EN 62061

3-phase or 1-phase

200 V AC to 240 V AC,

50 Hz/60 Hz (Note 6)

3-phase or 1-phase

170 V AC to 264 V AC

(Note 6)

Force cooling, open

3-phase

200 V AC to

240 V AC,

50 Hz/60 Hz

3-phase

170 V AC to

264 V AC

(IP20)

1 - 4

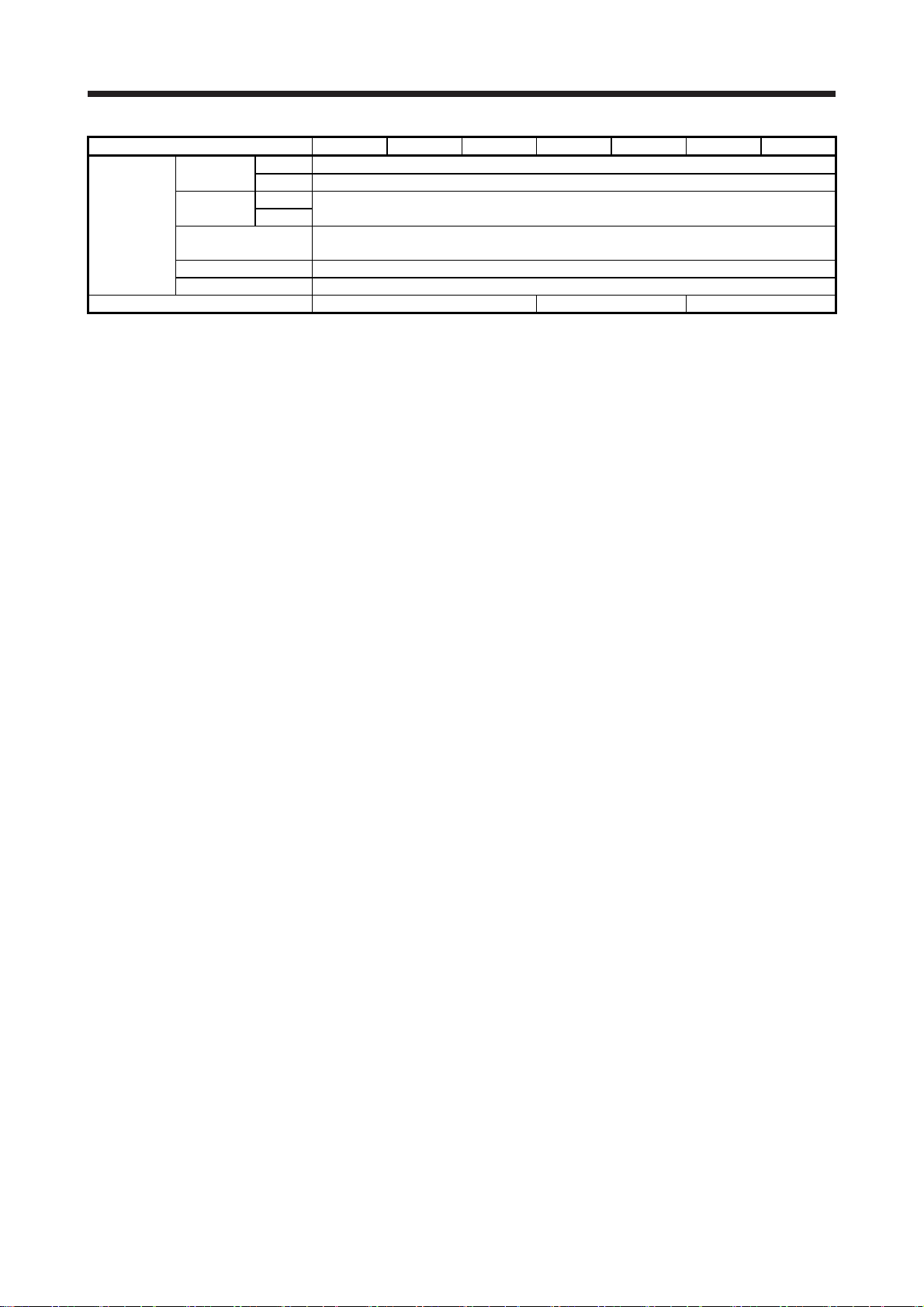

1. FUNCTIONS AND CONFIGURATION

/s

Model: MR-JE- 10A 20A 40A 70A 100A 200A 300A

Ambient

temperature

Ambient

Environment

Mass [kg] 0.8 1.5 2.1

humidity

Ambience

Altitude 1000 m or less above sea level

Vibration resistance 5.9 m/s2, at 10 Hz to 55 Hz (directions of X, Y and Z axes)

Note 1. 0.3 A is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of

I/O points.

2. When closely mounting the servo amplifier of 3.5 kW or less, operate them at the ambient temperatures of 0 °C to 45 °C or at

75% or smaller effective load ratio.

3. 1 Mpulse/s or lower commands are supported in the initial setting. When inputting commands over 1 Mpulse/s and 4 Mpulses

or lower, change the setting in [Pr. PA13].

4. The RS-422 communication function is supported by servo amplifier manufactured in December 2013 or later. Refer to section

1.6 (1) for the year and month of manufacture.

5. These are current values for 3-phase power supply.

6. When using 1-phase 200 V AC to 240 V AC power supply, operate the servo amplifier at 75% or smaller effective load ratio.

7. The RS-485 communication function is available with servo amplifiers manufactured in May 2015 or later. Refer to section 1.6

(1) for the year and month of manufacture.

Operation 0 °C to 55 °C (non-freezing)

Storage -20 °C to 65 °C (non-freezing)

Operation

Storage

free from corrosive gas, flammable gas, oil mist, dust, and dirt

90 %RH or less (non-condensing)

Indoors (no direct sunlight),

1 - 5

1. FUNCTIONS AND CONFIGURATION

1.4 Combinations of servo amplifiers and servo motors

Servo amplifier Servo motor

MR-JE-10A HG-KN13_

MR-JE-20A HG-KN23_

MR-JE-40A HG-KN43_

MR-JE-70A HG-KN73_

MR-JE-100A HG-SN102_

MR-JE-200A HG-SN152_

MR-JE-300A HG-SN302_

HG-SN52_

HG-SN202_

1 - 6

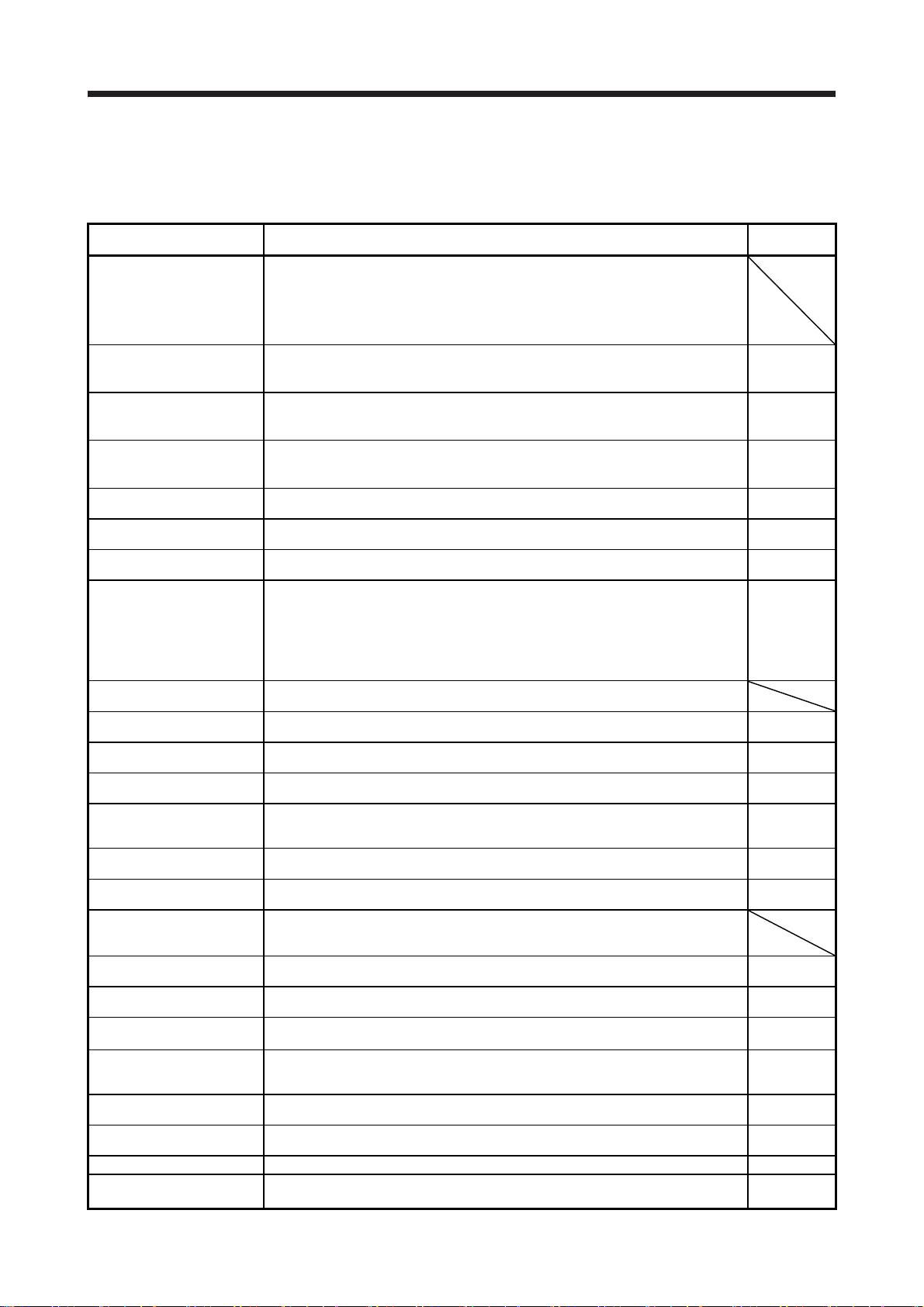

1. FUNCTIONS AND CONFIGURATION

1.5 Function list

The following table lists the functions of this servo. For details of the functions, refer to each section

indicated in the detailed explanation field.

Function Description

This function achieves a high response and stable control following the ideal model.

The two-degree-of-freedom-model model adaptive control enables you to set a

Model adaptive control

Position control mode This servo is used as a position control servo.

Speed control mode This servo is used as a speed control servo.

Torque control mode This servo is used as a torque control servo.

Position/speed control switch

mode

Speed/torque control switch

mode

Torque/position control switch

mode

Positioning mode

High-resolution encoder

Gain switching function

Advanced vibration

suppression control II

Machine resonance

suppression filter

Shaft resonance suppression

filter

Adaptive filter II

Low-pass filter

Machine analyzer function

Robust filter

Slight vibration suppression

control

Electronic gear Input pulses can be multiplied by 1/10 to 4000.

S-pattern

acceleration/deceleration time

constant

Auto tuning

Regenerative option

Alarm history clear Alarm history is cleared. [Pr. PC18]

Output signal selection

(device settings)

response to the command and response to the disturbance separately.

Additionally, this function can be disabled. Refer to section 7.4 for disabling this

function. Used by servo amplifiers with software version B4 or later. Check the

software version using MR Configurator2.

Using an input device, control can be switched between position control and speed

control.

Using an input device, control can be switched between speed control and torque

control.

Using an input device, control can be switched between torque control and position

control.

In this mode, MR-JE-_A servo amplifiers are used in with point table or program

method. For details, refer to "MR-JE-_A Servo Amplifier Instruction Manual

(Positioning Mode)." The positioning mode is available with servo amplifiers with

software version B7 or later.

High-resolution encoder of 131072 pulses/rev is used for the encoder of the servo

motor compatible with the MELSERVO-JE series.

You can switch gains during rotation and during stop, and can use an input device to

switch gains during operation.

This function suppresses vibration at the arm end or residual vibration. Section 7.1.5

This is a filter function (notch filter) which decreases the gain of the specific frequency

to suppress the resonance of the mechanical system.

When a load is mounted to the servo motor shaft, resonance by shaft torsion during

driving may generate a mechanical vibration at high frequency. The shaft resonance

suppression filter suppresses the vibration.

Servo amplifier detects mechanical resonance and sets filter characteristics

automatically to suppress mechanical vibration.

Suppresses high-frequency resonance which occurs as servo system response is

increased.

Analyzes the frequency characteristic of the mechanical system by simply connecting

an MR Configurator2 installed personal computer and servo amplifier.

MR Configurator2 is necessary for this function.

This function provides better disturbance response in case low response level that

load to motor inertia ratio is high for such as roll send axes.

Suppresses vibration of ±1 pulse produced at a servo motor stop. [Pr. PB24]

Speed can be increased and decreased smoothly. [Pr. PC03]

Automatically adjusts the gain to optimum value if load applied to the servo motor

shaft varies.

Used when the built-in regenerative resistor of the servo amplifier does not have

sufficient regenerative capability for the regenerative power generated.

ST1 (Forward rotation start), ST2 (Reverse rotation start), and SON (Servo-on) and

other input device can be assigned to any pins.

Detailed

explanation

Section 3.2.1

Section 3.6.1

Section 4.2

Section 3.2.2

Section 3.6.2

Section 4.3

Section 3.2.3

Section 3.6.3

Section 4.4

Section 3.6.4

Section 3.6.5

Section 3.6.6

MR-JE-_A

Servo

Amplifier

Instruction

Manual

(Positioning

Mode)

Section 7.2

Section 7.1.1

Section 7.1.3

Section 7.1.2

Section 7.1.4

[Pr. PE41]

[Pr. PA06]

[Pr. PA07]

Section 6.3

Section 11.2

[Pr. PD03] to

[Pr. PD20]

1 - 7

1. FUNCTIONS AND CONFIGURATION

Function Description

Output signal selection

(device settings)

Output signal (DO) forced

output

Command pulse selection Command pulse train form can be selected from among three different types. [Pr. PA13]

Torque limit Servo motor torque can be limited to any value.

Speed limit Servo motor speed can be limited to any value.

Status display Servo status is shown on the 5-digit, 7-segment LED display. Section 4.5.3

External I/O signal display On/off statuses of external I/O signals are shown on the display. Section 4.5.7

Automatic VC offset

Alarm code output If an alarm has occurred, the corresponding alarm number is outputted in 3-bit code. Chapter 8

Test operation mode

Analog monitor output Servo status is outputted in terms of voltage in real time.

MR Configurator2

One-touch tuning

Tough drive function

Drive recorder function

Servo amplifier life diagnosis

function

Power monitoring function

Machine diagnosis function

Modbus-RTU communication

function

The output devices including MBR (Electromagnetic brake interlock) can be assigned

to certain pins of the CN1 connector.

Output signal can be forced on/off independently of the servo status.

Use this function for checking output signal wiring, etc.

Voltage is automatically offset to stop the servo motor if it does not come to a stop

when VC (Analog speed command) or VLA (Analog speed limit is 0 V.

Jog operation, positioning operation, motor-less operation, DO forced output, and

program operation

MR Configurator2 is required for the positioning operation and program operation.

Using a personal computer, you can perform the parameter setting, test operation,

monitoring, and others.

Gain adjustment is performed just by one click on a certain button on MR

Configurator2 or operation section.

This function makes the equipment continue operating even under the condition that

an alarm occurs.

The tough drive function includes two types: the vibration tough drive and the

instantaneous power failure tough drive.

This function continuously monitors the servo status and records the status transition

before and after an alarm for a fixed period of time. You can check the recorded data

on the drive recorder window on MR Configurator2 by clicking the "Graph" button.

However, the drive recorder will not operate on the following conditions.

1. You are using the graph function of MR Configurator2.

2. You are using the machine analyzer function.

3. [Pr. PF21] is set to "-1".

You can check the cumulative energization time and the number of on/off times of the

inrush relay. This function gives an indication of the replacement time for parts of the

servo amplifier including a capacitor and a relay before they malfunction.

MR Configurator2 is necessary for this function.

This function calculates the power running energy and the regenerative power from

the data in the servo amplifier such as speed and current. Power consumption and

others are displayed on MR Configurator2.

From the data in the servo amplifier, this function estimates the friction and vibrational

component of the drive system in the equipment and recognizes an error in the

machine parts, including a ball screw and bearing.

MR Configurator2 is necessary for this function.

The Modbus protocol uses dedicated message frames for the serial communication

between a master and slaves. The dedicated message frames have functions for

reading and writing data, and users can write parameters from servo amplifiers and

check the operation status of the servo amplifiers by using this function.

Detailed

explanation

[Pr. PD24] to

[Pr. PD28]

Section 4.5.8

Section 3.6.1

(5)

[Pr. PA11]

[Pr. PA12]

Section 3.6.3

(3)

[Pr. PC05] to

[Pr. PC11]

Section 4.5.4

Section 4.5.9

[Pr. PC14],

[Pr. PC15]

Section 11.4

Section 6.2

Section 7.3

[Pr. PA23]

MR-JE-_A

Servo

Amplifier

Instruction

Manual

(Modbus-RTU

Protocol)

1 - 8

1. FUNCTIONS AND CONFIGURATION

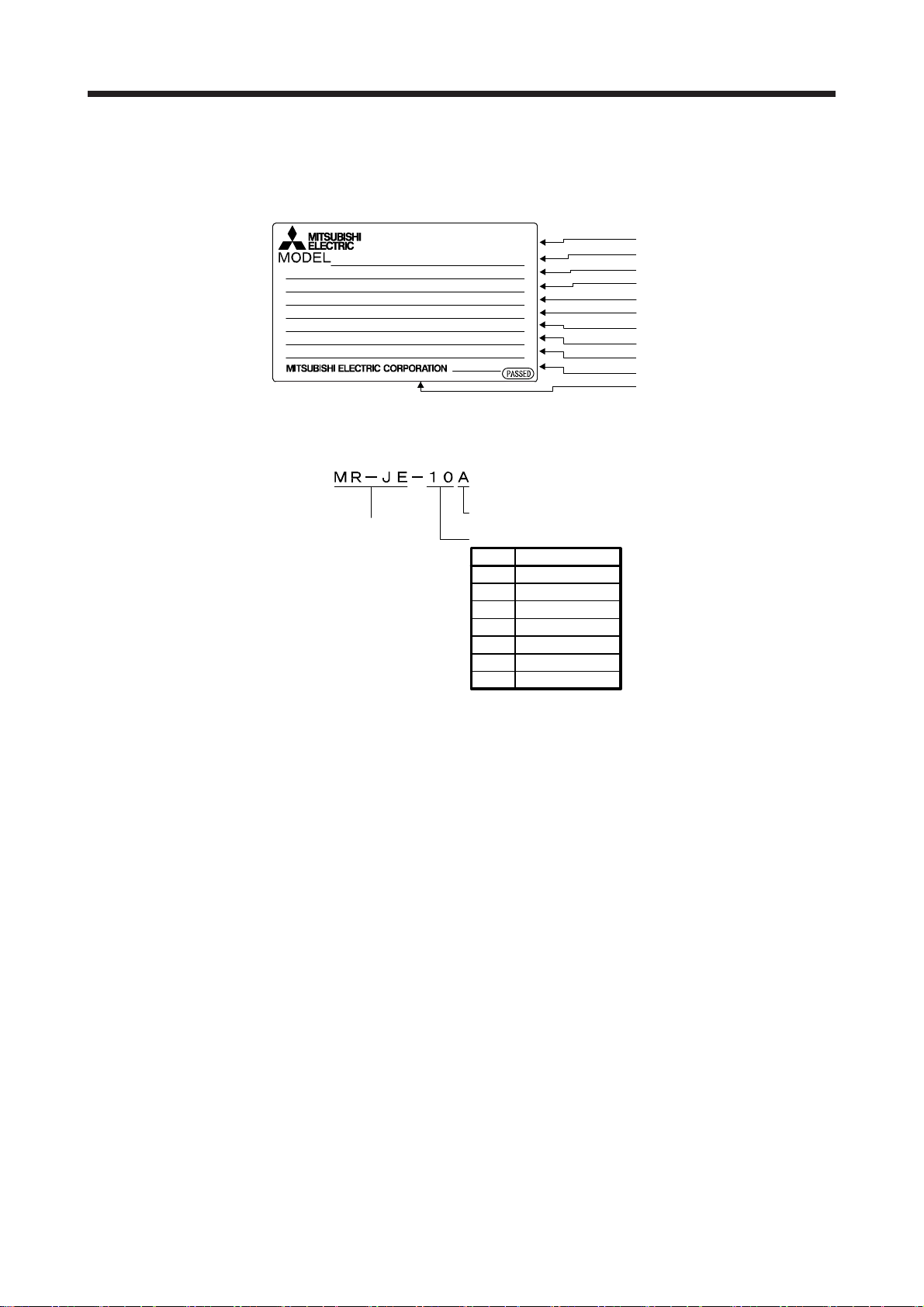

1.6 Model designation

(1) Rating plate

The following shows an example of rating plate for explanation of each item.

AC SERVO

SER. S4Y001001

MR-JE-10A

POWER

: 100W

INPUT

: 3AC/200-240V 0.9A/1.5A 50/60Hz

OUTPUT

: 3PH170V 0-360Hz 1.1A

STD.: IEC/EN61800-5-1 MAN.: IB(NA)0300194

Max. Surrounding Air Temp.: 55°C

IP20

KCC-REI-MEK-TC300A745G51

TOKYO 100-8310, JAPAN MADE IN JAPAN

DATE: 2014-11

(2) Model

The following describes what each block of a model name indicates.

General-purpose interface

Series

Rated output

Symbol Rated output [kW]

10 0.1

20 0.2

40 0.4

70 0.75

100 1

200 2

300 3

Serial number

Model

Capacity

Applicable power supply

Rated output current

Standard, Manual number

Ambient temperature

IP rating

KC certification number

The year and month of manufacture

Country of origin

1 - 9

1. FUNCTIONS AND CONFIGURATION

1.7 Structure

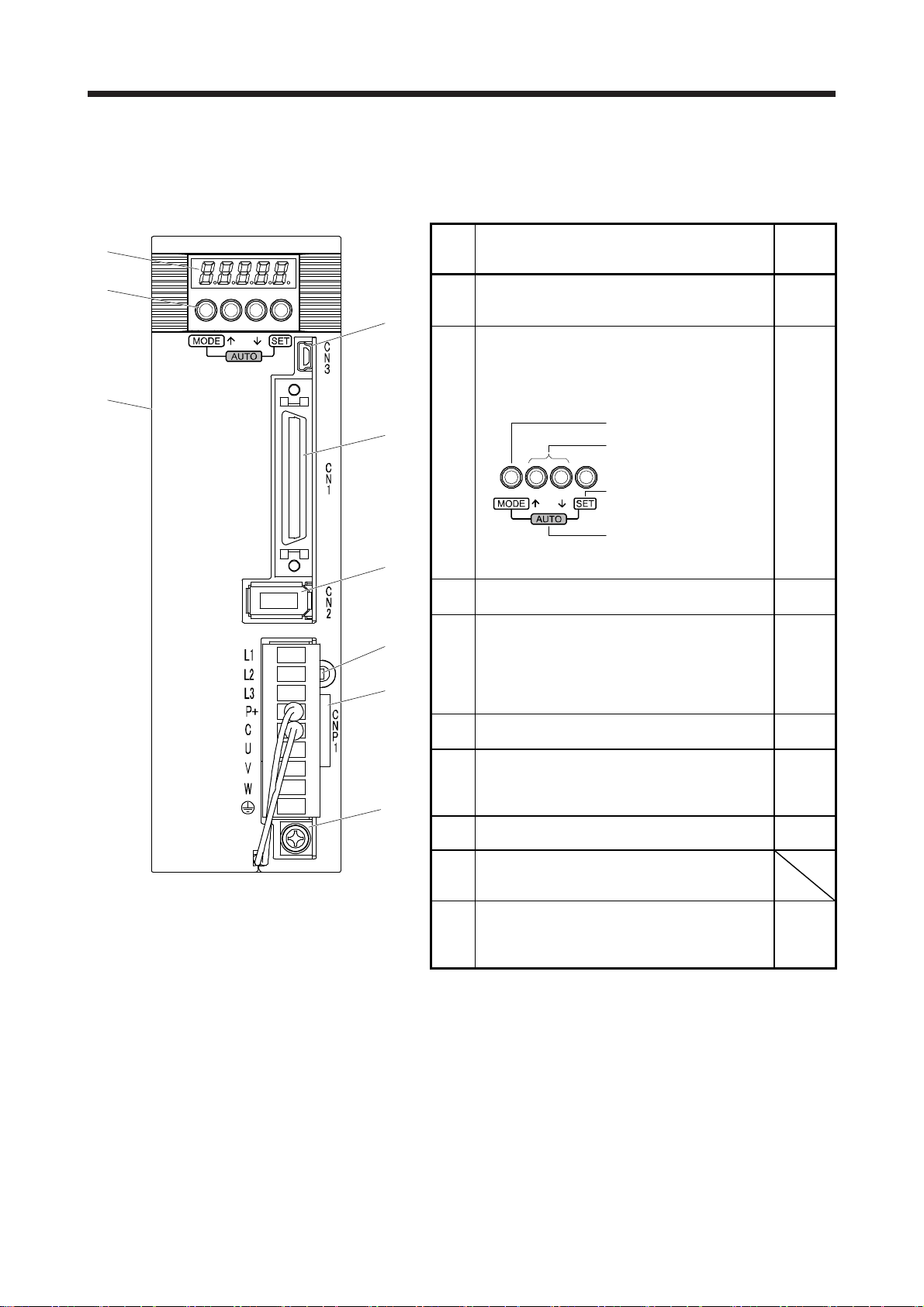

1.7.1 Parts identification

(1) MR-JE-100A or less

(1)

(2)

(3)

(7)

Side

(4)

No. Name/Application

(1)

(2)

Display

The 5-digit, 7-segment LED shows the servo status

and the alarm number.

Operation section

Used to perform status display, diagnostic, alarm,

and parameter setting operations. Push the "MODE"

and "SET" buttons at the same time for 3 s or more

to switch to the one-touch tuning mode.

Used to change the mode.

Used to change the

display or data in each

mode.

Used to set data.

Detailed

explanati

on

Section

4.5

Section

4.5

Section

6.2

To the one-touch tuning

mode

Section

11.4

Section

3.2

Section

3.4

Chapter

12

Section

3.4

Section

3.1

Section

3.3

1.6

Section

3.1

Section

3.3

Bottom

(9)

(5)

(8)

(6)

USB communication connector (CN3)

(3)

Connect with the personal computer.

I/O signal connector (CN1)

Digital I/O signal, analog input signal, analog

monitor output signal, and RS-422/RS-485

(4)

communication controller are connected.

Encoder connector (CN2)

(5)

Used to connect the servo motor encoder.

Power connector (CNP1)

Input power supply, built-in regenerative resistor,

(6)

regenerative option, and servo motor are connected.

Rating plate Section

(7)

Charge lamp

(8)

When the main circuit is charged, this will light up.

While this lamp is lit, do not reconnect the cables.

Protective earth (PE) terminal

Grounding terminal

(9)

1 - 10

1. FUNCTIONS AND CONFIGURATION

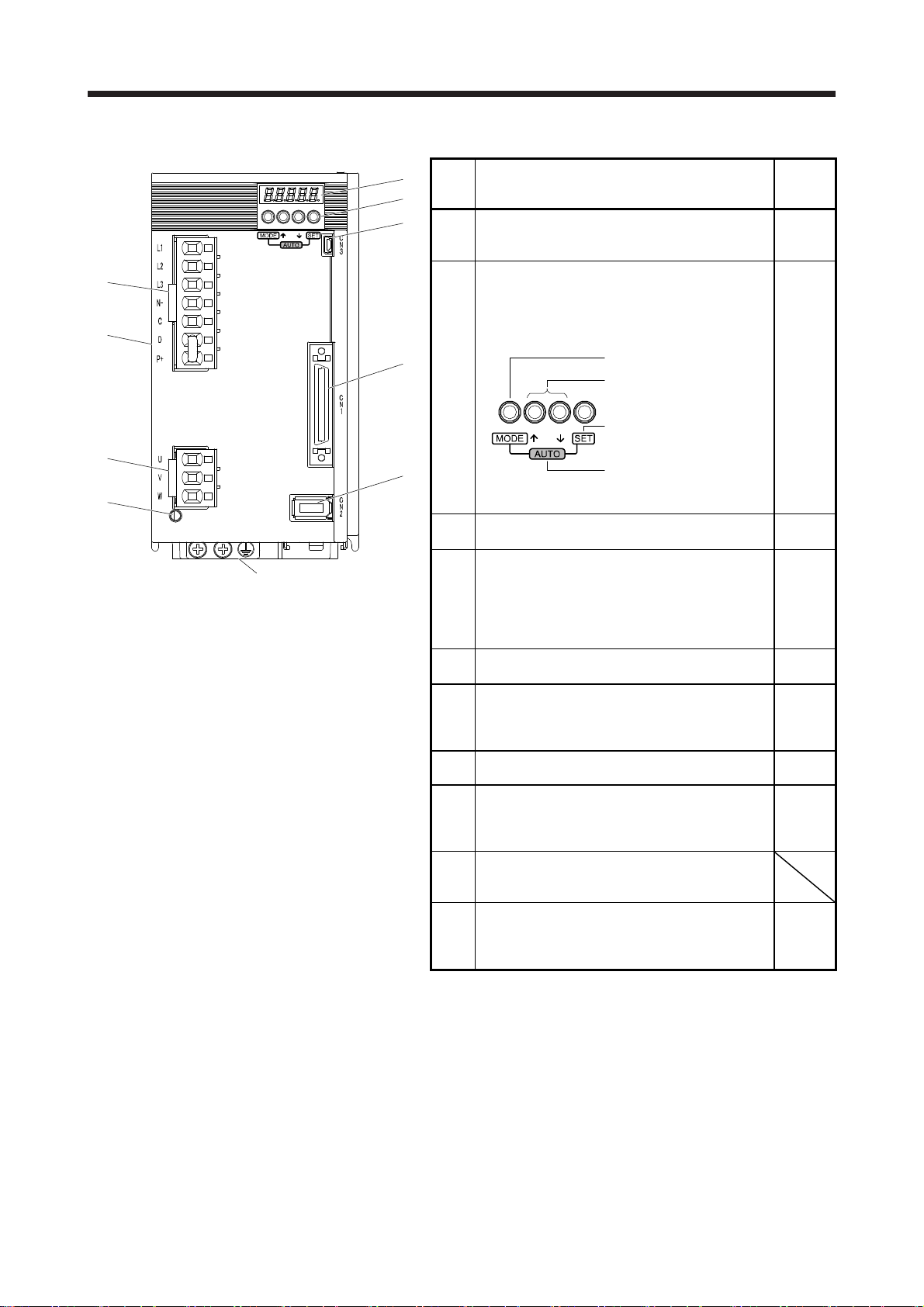

(2) MR-JE-200A or more

(1)

No. Name/Application

(2)

(3)

(1)

(6)

(7)

Side

(4)

(2)

Display

The 5-digit, 7-segment LED shows the servo status

and the alarm number.

Operation section

Used to perform status display, diagnostic, alarm,

and parameter setting operations. Push the "MODE"

and "SET" buttons at the same time for 3 s or more

to switch to the one-touch tuning mode.

Used to change the mode.

Used to change the

display or data in each

mode.

Used to set data.

Detailed

explanati

on

Section

4.5

Section

4.5

Section

6.2

(8)

(9)

(10)

Bottom

(5)

To the one-touch tuning

mode

USB communication connector (CN3)

(3)

Connect with the personal computer.

I/O signal connector (CN1)

Digital I/O signal, analog input signal, analog

monitor output signal, and RS-422/RS-485

(4)

communication controller are connected.

Encoder connector (CN2)

(5)

Used to connect the servo motor encoder.

Power connector (CNP1)

Input power supply and regenerative option are

(6)

connected.

Rating plate Section

(7)

Servo motor power connector (CNP2)

Connect the servo motor.

(8)

Charge lamp

(9)

When the main circuit is charged, this will light up.

While this lamp is lit, do not reconnect the cables.

Protective earth (PE) terminal

Grounding terminal

(10)

Section

11.4

Section

3.2

Section

3.4

Chapter

12

Section

3.4

Section

3.1

Section

3.3

1.6

Section

3.1

Section

3.3

Section

3.1

Section

3.3

1 - 11

1. FUNCTIONS AND CONFIGURATION

A

1.8 Configuration including peripheral equipment

CAUTION

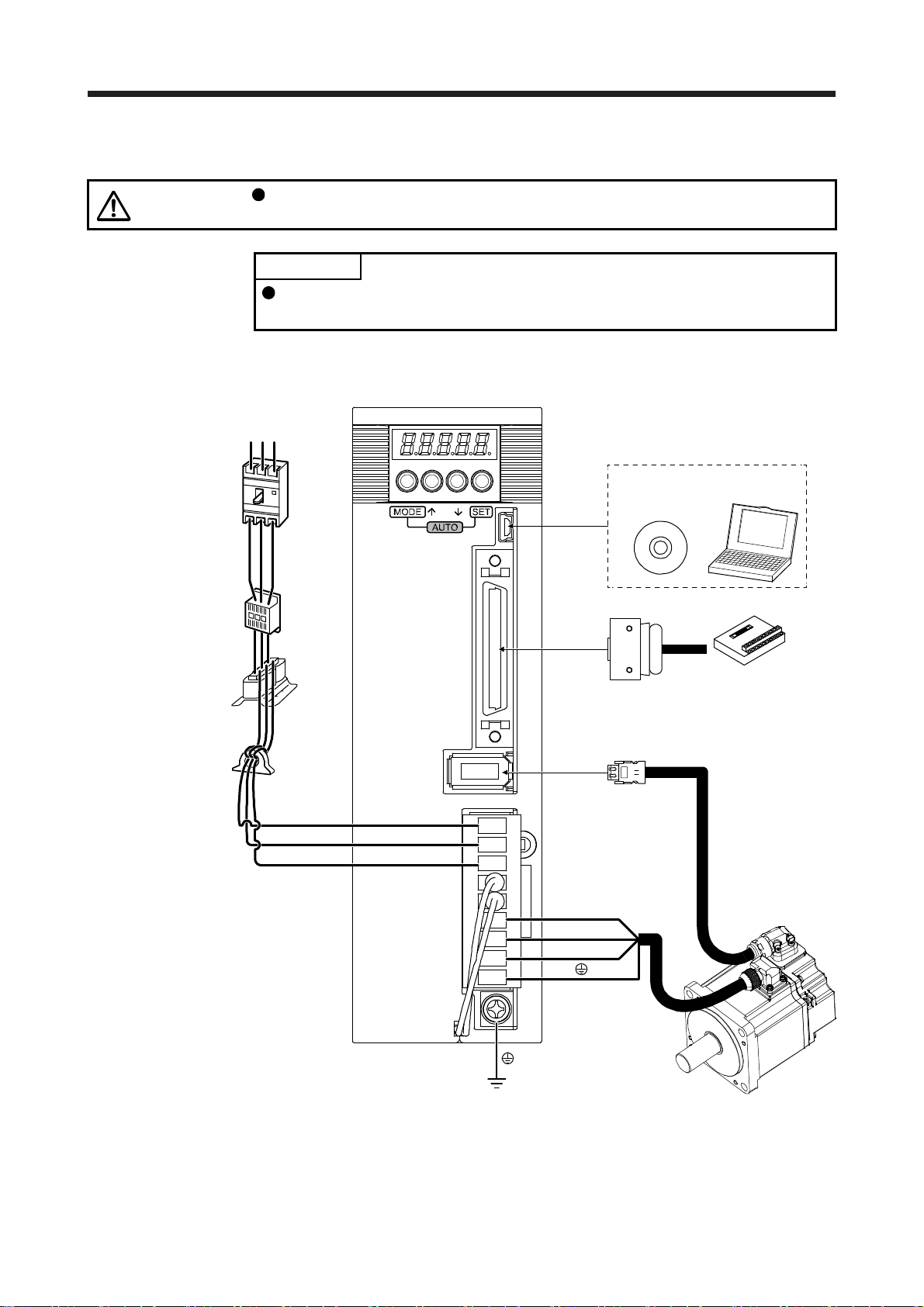

(1) MR-JE-100A or less

The diagram shows MR-JE-40A.

Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo

amplifier may cause a malfunction.

POINT

Equipment other than the servo amplifier and servo motor are optional or

recommended products.

(Note 1)

Power

supply

Molded-case

circuit breaker

(Note 2)

Magnetic

contactor

(MC)

Power factor

improving AC

reactor

(FR-HAL)

Line noise

filter

(FR-BSF01)

RST

Personal

computer

MR Configurator2

CN3

CN1

Junction terminal block

CN2

L1

L2

L3

U

V

W

Note 1. A 1-phase 200 V AC to 240 V AC power supply may be used with the servo amplifier of MR-JE-70A or less. For 1-phase 200 V

C to 240 V AC, connect the power supply to L1 and L3. Leave L2 open. For the power supply specifications, refer to section

1.3.

2. Depending on the power supply voltage and operation pattern, bus voltage can decrease. This can shift the mode to the

dynamic brake deceleration during forced stop deceleration. When dynamic brake deceleration is not required, slow the time to

turn off the magnetic contactor.

Servo motor

1 - 12

1. FUNCTIONS AND CONFIGURATION

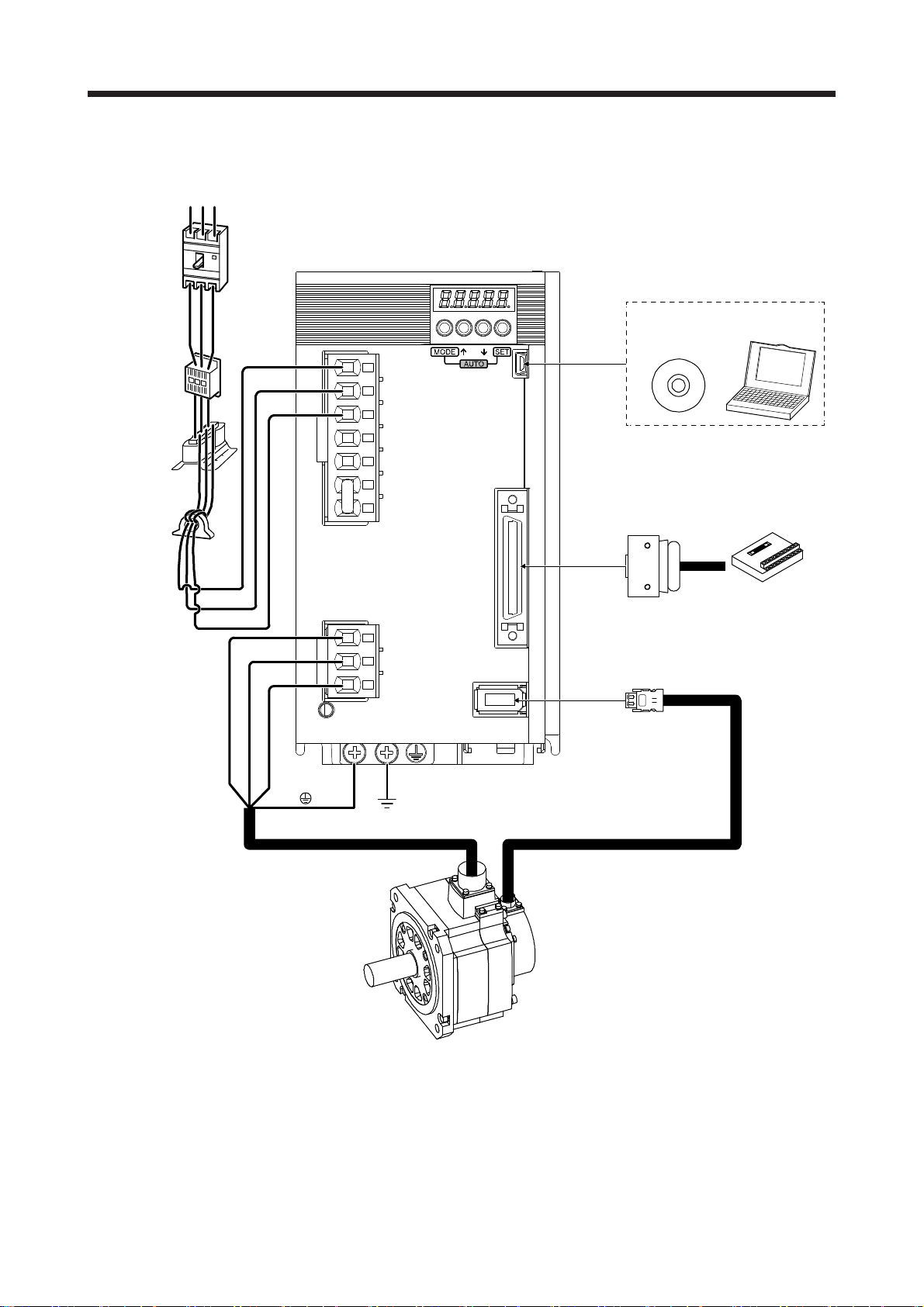

(2) MR-JE-200A or more

The diagram shows MR-JE-200A.

(Note 1)

Power

supply

Molded-case

circuit breaker

(Note 2)

Magnetic

contactor

(MC)

Power factor

improving AC

reactor

(FR-HAL)

Line noise

filter

(FR-BSF01)

RS T

CN3

MR Configurator2

Personal

computer

L1

L2

L3

CN1

Junction terminal block

U

V

W

CN2

Servo motor

Note 1. For the power supply specifications, refer to section 1.3.

2. Depending on the power supply voltage and operation pattern, bus voltage can decrease. This can shift the mode to the

dynamic brake deceleration during forced stop deceleration. When dynamic brake deceleration is not required, slow the time to

turn off the magnetic contactor.

1 - 13

1. FUNCTIONS AND CONFIGURATION

MEMO

1 - 14

2. INSTALLATION

2. INSTALLATION

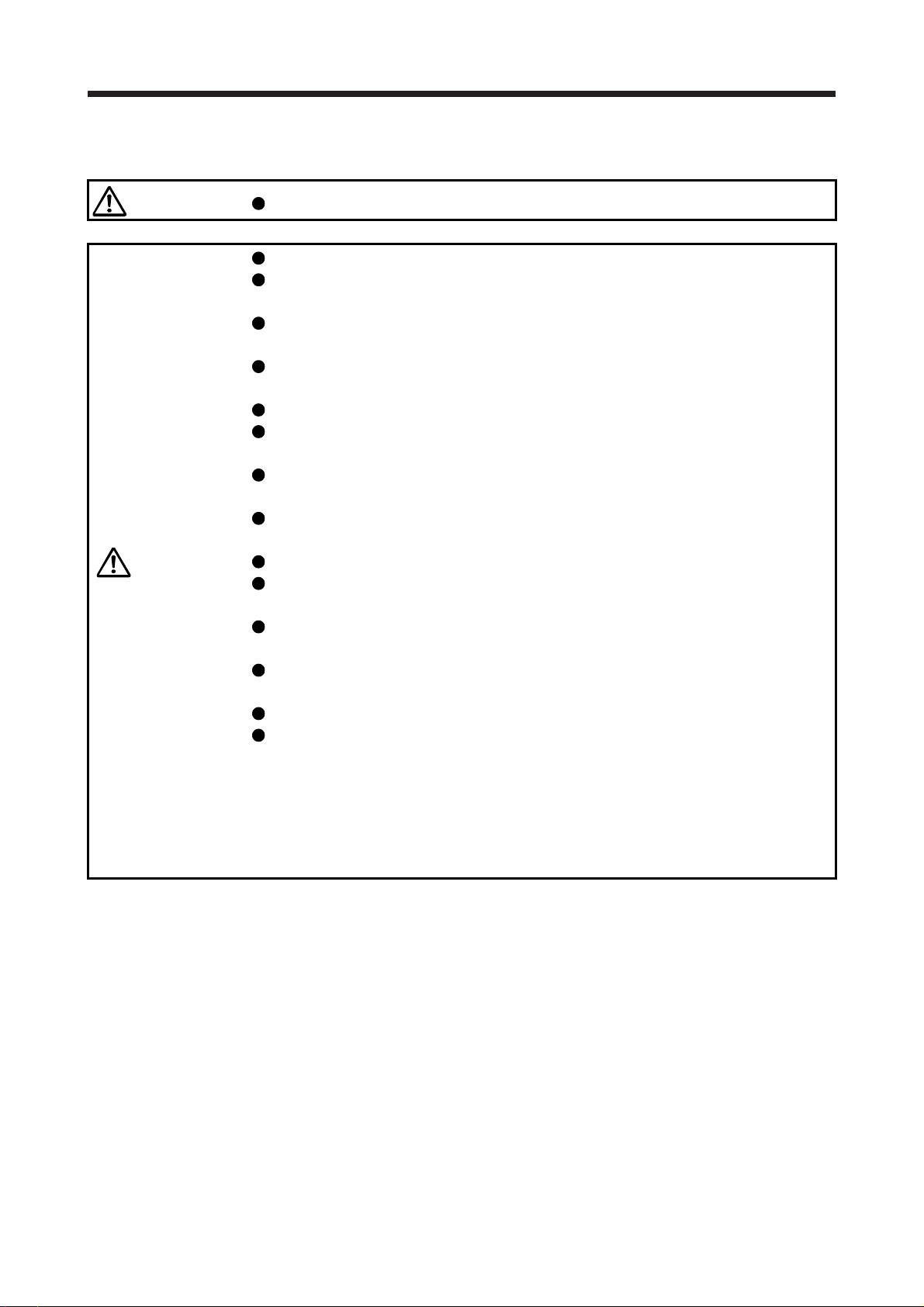

WARNING

CAUTION

To prevent electric shock, ground each equipment securely.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the lead wire of the regenerative resistor when transporting the servo

amplifier.

Install the equipment on incombustible material. Installing them directly or close to

combustibles will lead to a fire.

Install the servo amplifier and the servo motor in a load-bearing place in

accordance with the Instruction Manual.

Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

Use the equipment within the specified environment. For the environment, refer to

section 1.3.

Provide an adequate protection to prevent screws and other conductive matter, oil

and other combustible matter from entering the servo amplifier.

Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it

may cause a malfunction.

Do not drop or strike the servo amplifier. Isolate it from all impact loads.

Do not install or operate the servo amplifier which has been damaged or has any

parts missing.

When the product has been stored for an extended period of time, contact your

local sales office.

When handling the servo amplifier, be careful about the edged parts such as

corners of the servo amplifier.

The servo amplifier must be installed in a metal cabinet.

When fumigants that contain halogen materials such as fluorine, chlorine,

bromine, and iodine are used for disinfecting and protecting wooden packaging

from insects, they cause malfunction when entering our products. Please take

necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat

method). Additionally, disinfect and protect wood from insects before packing

products.

2 - 1

2. INSTALLATION

2.1 Installation direction and clearances

The equipment must be installed in the specified direction. Otherwise, it may

CAUTION

MR-JE-40A to MR-JE-100A have a regenerative resistor on their back face. The regenerative resistor

generates heat of 100 ˚C higher than the ambient temperature. Please fully consider heat dissipation,

installation position, etc. when mounting it.

(1) Installation clearances of the servo amplifier

(a) Installation of one servo amplifier

10 mm

or more

cause a malfunction.

Leave specified clearances between the servo amplifier and the cabinet walls or

other equipment. Otherwise, it may cause a malfunction.

Cabinet Cabinet

40 mm

or more

Servo

amplifier

10 mm

or more

Wiring allowance

80 mm

or more

Top

Bottom

40 mm

or more

2 - 2

2. INSTALLATION

(b) Installation of two or more servo amplifiers

POINT

Close mounting is possible depending on the capacity of the servo amplifier.

Refer to section 1.3 for availability of close mounting.

Leave a large clearance between the top of the servo amplifier and the cabinet walls, and install a

cooling fan to prevent the internal temperature of the cabinet from exceeding the environment.

When mounting the servo amplifiers closely, leave a clearance of 1 mm between the adjacent servo

amplifiers in consideration of mounting tolerances. In this case, keep the ambient temperature within

0 ˚C to 45 ˚C or use the servo amplifier with 75% or less of the effective load ratio.

Cabinet

Cabinet

30 mm

or more

100 mm or more

10 mm or more

30 mm

or more

40 mm or more

Leaving clearance Mounting closely

1 mm

100 mm or more

1 mm

40 mm or more

(2) Others

When using heat generating equipment such as the regenerative option, install them with full

consideration of heat generation so that the servo amplifier is not affected.

Install the servo amplifier on a perpendicular wall in the correct vertical direction.

2.2 Keep out foreign materials

30 mm

or more

Top

Bottom

(1) When drilling in the cabinet, prevent drill chips and wire fragments from entering the servo amplifier.

(2) Prevent oil, water, metallic dust, etc. from entering the servo amplifier through openings in the cabinet or

a cooling fan installed on the ceiling.

(3) When installing the cabinet in a place where toxic gas, dirt and dust exist, conduct an air purge (force

clean air into the cabinet from outside to make the internal pressure higher than the external pressure) to

prevent such materials from entering the cabinet.

2 - 3

2. INSTALLATION

2.3 Encoder cable stress

(1) The way of clamping the cable must be fully examined so that bending stress and cable's own weight

stress are not applied to the cable connection.

(2) For use in any application where the servo motor moves, fix the cables (encoder, power supply, and

brake) with having some slack from the connector connection part of the servo motor to avoid putting

stress on the connector connection part. Use the optional encoder cable within the bending life range.

Use the power supply and brake wiring cables within the bending life of the cables.

(3) Avoid any probability that the cable sheath might be cut by sharp chips, rubbed by a machine corner or

stamped by workers or vehicles.

(4) For installation on a machine where the servo motor moves, the flexing radius should be made as large

as possible. Refer to section 10.4 for the bending life.

2.4 Inspection items

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Otherwise, an electric shock may

WARNING

CAUTION

It is recommended that the following points periodically be checked.

(1) Check for loose terminal block screws. Retighten any loose screws.

(2) Check the cables and the like for scratches or cracks. Inspect them periodically according to operating

conditions especially when the servo motor is movable.

(3) Check that the connector is securely connected to the servo amplifier.

(4) Check that the wires are not coming out from the connector.

(5) Check for dust accumulation on the servo amplifier.

(6) Check for unusual noise generated from the servo amplifier.

occur. In addition, when confirming whether the charge lamp is off or not, always

confirm it from the front of the servo amplifier.

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your local sales office.