MR-J5

Mitsubishi Electric AC Servo System

User's Manual

(Adjustment)

-MR-J5-_G_

-MR-J5W_-_G

-MR-J5-_A_

SAFETY INSTRUCTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

medium or slight injury.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

(Please read the instructions carefully before using the equipment.)

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you have read

through this manual, Installation guide, and appended documents carefully. Do not use the equipment until you have a full

knowledge of the equipment, safety information and instructions.

In this manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

Note that the CAUTION level may lead to a serious consequence depending on conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

In this manual, instructions at a lower level than the above, instructions for other functions, and so on are classified into

"POINT".

After reading this guide, keep it accessible to the operator.

1

[Installation/wiring]

WARNING

● To prevent an electric shock, turn off the power and wait for 15 minutes or more before starting wiring

and/or inspection.

● To prevent an electric shock, ground the servo amplifier.

● To prevent an electric shock, any person who is involved in wiring should be fully competent to do the

work.

● To prevent an electric shock, mount the servo amplifier before wiring.

● To prevent an electric shock, connect the protective earth (PE) terminal (the terminal marked with the

symbol) of the servo amplifier to the protective earth (PE) of the cabinet.

● To prevent an electric shock, do not touch the conductive parts.

[Setting/adjustment]

WARNING

● To prevent an electric shock, do not operate the switches with wet hands.

[Operation]

WARNING

● To prevent an electric shock, do not operate the switches with wet hands.

[Maintenance]

WARNING

● To prevent an electric shock, any person who is involved in inspection should be fully competent to do

the work.

● To prevent an electric shock, do not operate the switches with wet hands.

2

ABOUT THE MANUAL

This manual covers the following servo amplifiers.

• MR-J5-_G_/MR-J5W_-_G/MR-J5-_A_

In this manual, the servo amplifier names are abbreviated as shown below.

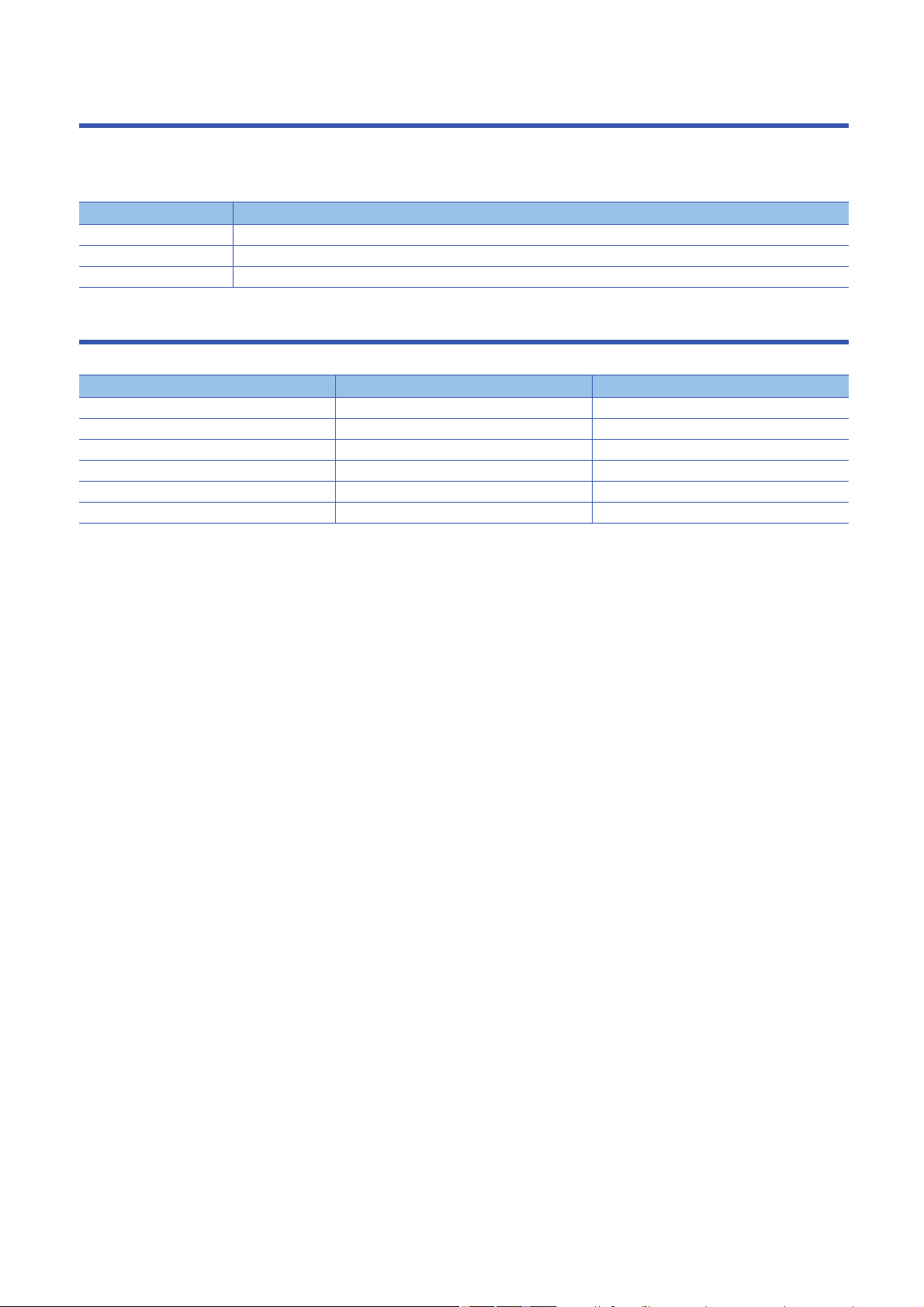

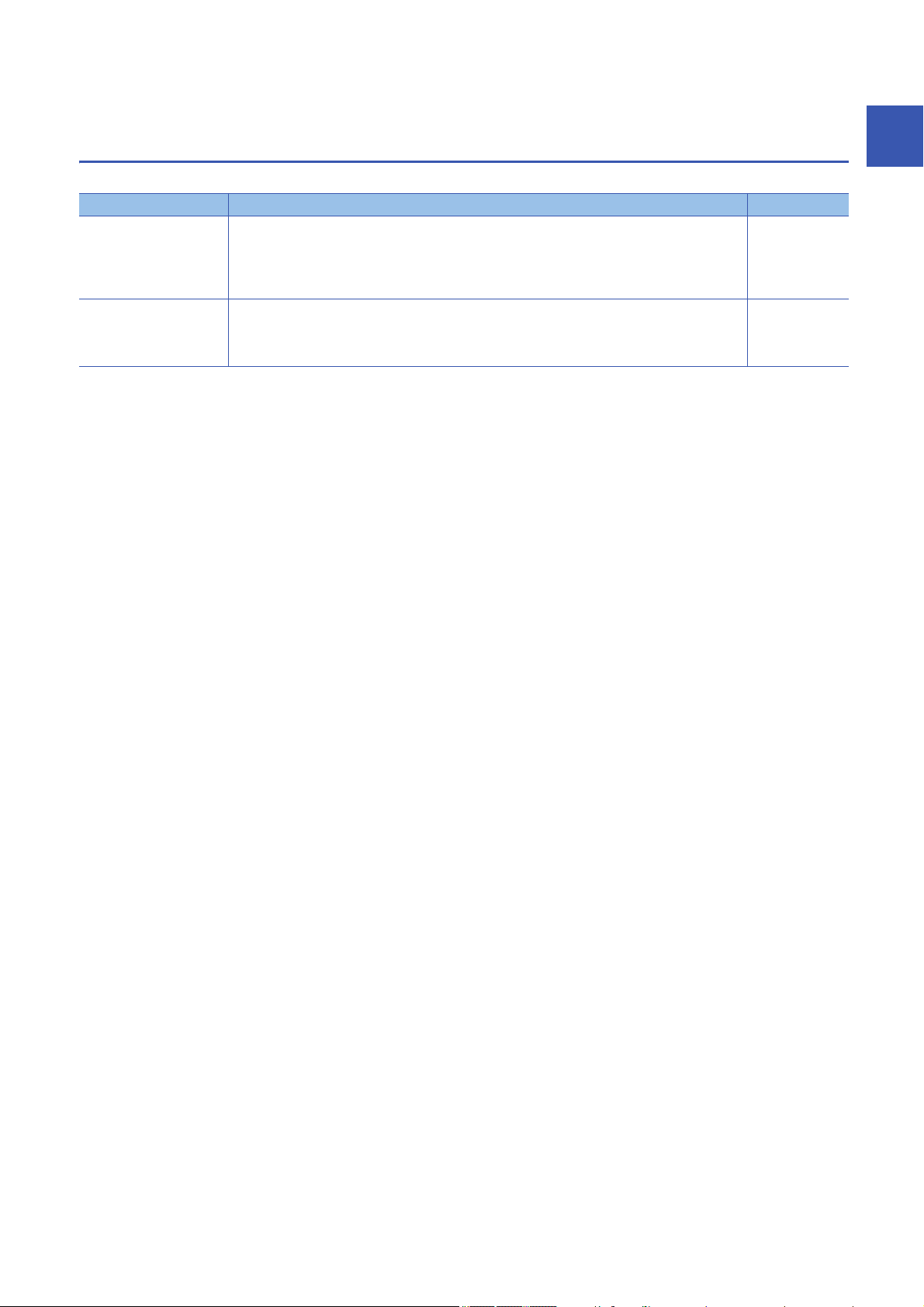

Symbol Servo amplifier

[G] MR-J5-_G_

[WG] MR-J5W_-_G

[A] MR-J5-_A_

U.S. CUSTOMARY UNITS

U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

-4

kg•m2)] 5.4675 [oz•inch2]

3

CONTENTS

SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

ABOUT THE MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

U.S. CUSTOMARY UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CHAPTER 1 ADJUSTMENT FUNCTION TYPES 7

1.1 Adjustment function available to servo amplifier alone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functions to automatically adjust machine stability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjustment functions to suppress vibration and to obtain a high level of responsiveness . . . . . . . . . . . . . . . . . . 8

Manual adjustment functions to obtain the maximum performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Adjustment functions available in combination with MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CHAPTER 2 ADJUSTMENT PROCEDURE 10

CHAPTER 3 ADJUSTMENT METHOD 12

3.1 Quick tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Restrictions on quick tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Precautions on quick tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting method for quick tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation of quick tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Errors in quick tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 One-touch tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Restrictions on one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Instructions on one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

One-touch tuning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Progress display during one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Servo parameters adjusted with one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

One-touch tuning stop method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

One-touch tuning error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Initializing one-touch tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.3 Auto tuning mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Restrictions on auto tuning mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Instructions on auto tuning mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjustment procedure by auto tuning mode 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Responsiveness setting in auto tuning mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Operation of auto tuning mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.4 Auto tuning mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Precautions on auto tuning mode 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Adjustment procedure by auto tuning mode 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Responsiveness setting in auto tuning mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Operation of auto tuning mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.5 2 gain adjustment mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjustment procedure of 2 gain adjustment mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Operation of 2 gain adjustment mode 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.6 2 gain adjustment mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Adjustment procedure of 2 gain adjustment mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Operation of 2 gain adjustment mode 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.7 Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Adjustment procedure of velocity mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . 45

4

Adjustment procedure of position mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3.8 Load to motor inertia ratio monitor mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Precautions on load to motor inertia ratio monitor mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Adjustment procedure of load to motor inertia ratio monitor mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Operation of load to motor inertia ratio monitor mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CHAPTER 4 VIBRATION SUPPRESSION FUNCTION 50

4.1 Filter setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2 Machine resonance suppression filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Machine resonance suppression filter restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Machine resonance suppression filter precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Machine resonance suppression filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operation of machine resonance suppression filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.3 Adaptive filter II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Restrictions on adaptive tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Precautions for adaptive filter II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

How to set adaptive filter II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Adaptive tuning procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.4 Shaft resonance suppression filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Shaft resonance suppression filter restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Shaft resonance suppression filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.5 Low-pass filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Low-pass filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operation of low-pass filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.6 Robust filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Robust filter restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Robust filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4.7 Advanced vibration suppression control II. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Advanced vibration suppression control restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Advanced vibration suppression control precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Advanced vibration suppression control setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Advanced vibration suppression control adjustment method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4.8 Command notch filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Command notch filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.9 Vibration tough drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Vibration tough drive restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Vibration tough drive precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Vibration tough drive setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Operation of vibration tough drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

CONTENTS

CHAPTER 5 GAIN SWITCHING FUNCTION 73

5.1 Restrictions on gain switching [G] [WG]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.2 Restrictions on gain switching [A] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.3 Precautions on gain switching [G] [WG]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4 Precautions on gain switching [A]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.5 Setting method for gain switching. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Servo parameters for setting the gain switching condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Servo parameters that are changeable with the gain switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Related objects [G] [WG] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.6 Examples of gain switching operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5

Gain switching by servo motor speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Gain switching by signals (CDP/C_CDP/CDP2/C_CDP2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Gain switching by command directions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Gain switching by servo motor speed and gain switching 2 (C_CDP2) [G] [WG] . . . . . . . . . . . . . . . . . . . . . . . . 86

When "Switching time constant disabled" of "Gain switching time constant disabling condition selection" is

selected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

When "Return time constant disabled" of "Gain switching time constant disabling condition selection" is selected

87

CHAPTER 6 SPEED FEED FORWARD CONTROL FUNCTION 88

6.1 Method for setting the speed feed forward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

CHAPTER 7 OVERSHOOT SUPPRESSION CONTROL 90

7.1 Restrictions on the overshoot suppression control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.2 Settings of the overshoot suppression control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

CHAPTER 8 SLIGHT VIBRATION SUPPRESSION CONTROL 92

8.1 Restrictions on the slight vibration suppression control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.2 Settings of the slight vibration suppression control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

8.3 Operation of slight vibration suppression control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

CHAPTER 9 UNBALANCED TORQUE OFFSET 94

9.1 Setting unbalanced torque offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Automatic setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Manual setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

CHAPTER 10 MODEL ADAPTIVE CONTROL 96

10.1 Setting model adaptive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.2 Disabling model adaptive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Instructions on disabling model adaptive control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

How to disable model adaptive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

CHAPTER 11 PATH CONTROL FUNCTION 98

11.1 Path tracking model adaptive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Setting the path tracking model adaptive control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Operation of path tracking model adaptive control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

11.2 Lost motion compensation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Restrictions on lost motion compensation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Setting the lost motion compensation function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Method for the lost motion compensation adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

6

1 ADJUSTMENT FUNCTION TYPES

Precautions

A servo amplifier is equipped with various servo parameters that can be used to adjust operation status. To maximize the

machine's performance , these servo parameters are required to be set in accordance with the machine's characteristic. The

gain adjustment is set to "Auto tuning mode 1" at the factory setting. Use each adjustment function to improve the

responsiveness.

• MR-J5-_G_-RJ and MR-J5-_A_-RJ will be available in the future.

• When using the torque mode, gain adjustment is not required.

• Before adjusting gains, check that your machine has not been operated at the maximum torque of the servo motor. If

operated in excess of the maximum torque, the machine may vibrate and operate unexpectedly. In addition, adjust gains

taking into account that each machine is different. It is recommended to keep the torque of the servo motor generated

during operation to be under 90 % of the maximum torque of the servo motor.

• If the torque of the servo motor reaches the torque limit value, even if the gain is changed, the response of the servo motor

does not change and the gain adjustment cannot perform accurately.

• When using a linear servo motor, replace the wording of the sentence as follows.

Load to motor inertia ratio → Load to motor mass ratio

Torque → Thrust

1.1 Adjustment function available to servo amplifier

1

alone

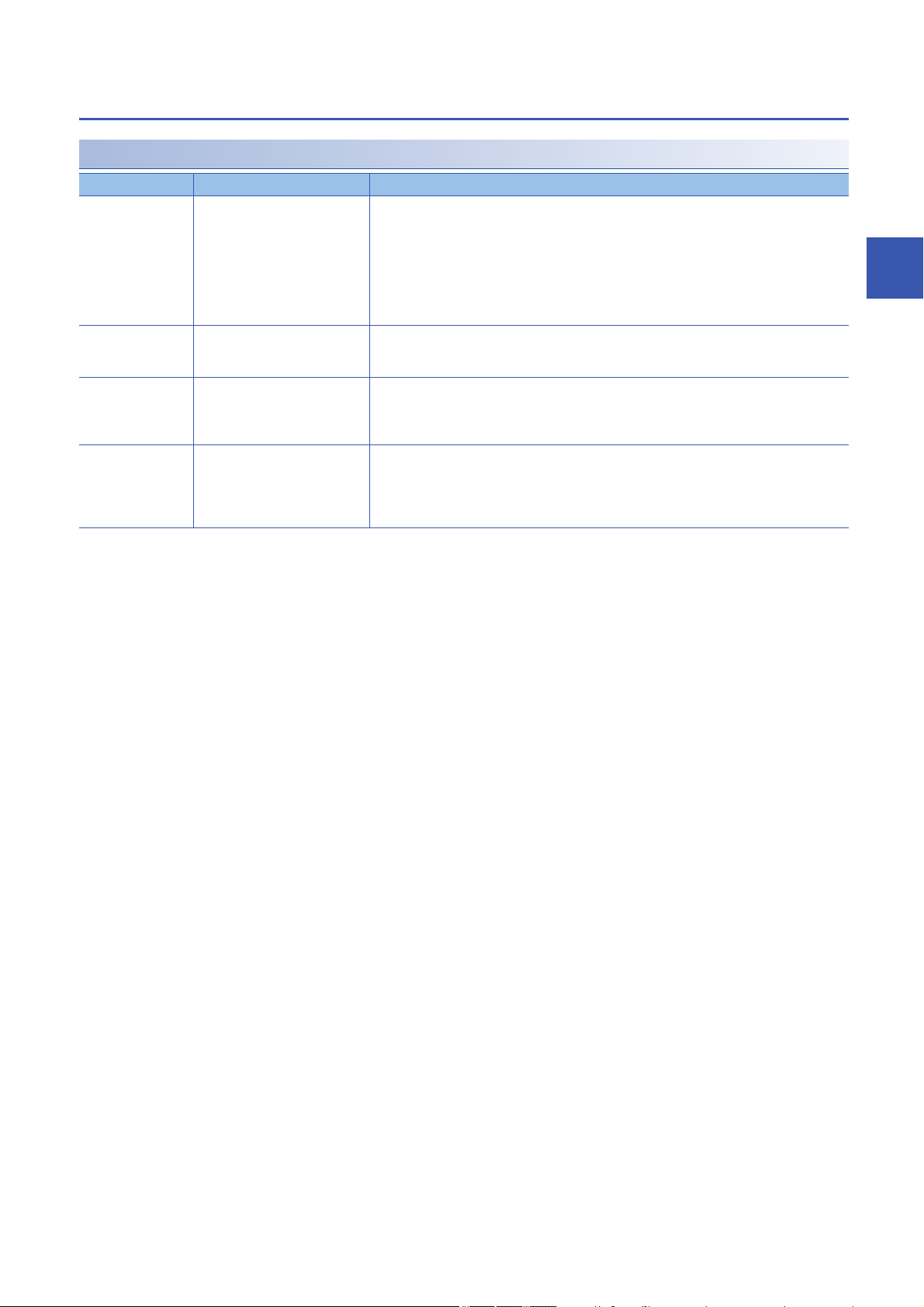

The following table shows the adjustment functions available to servo amplifier alone.

Functions to automatically adjust machine stability

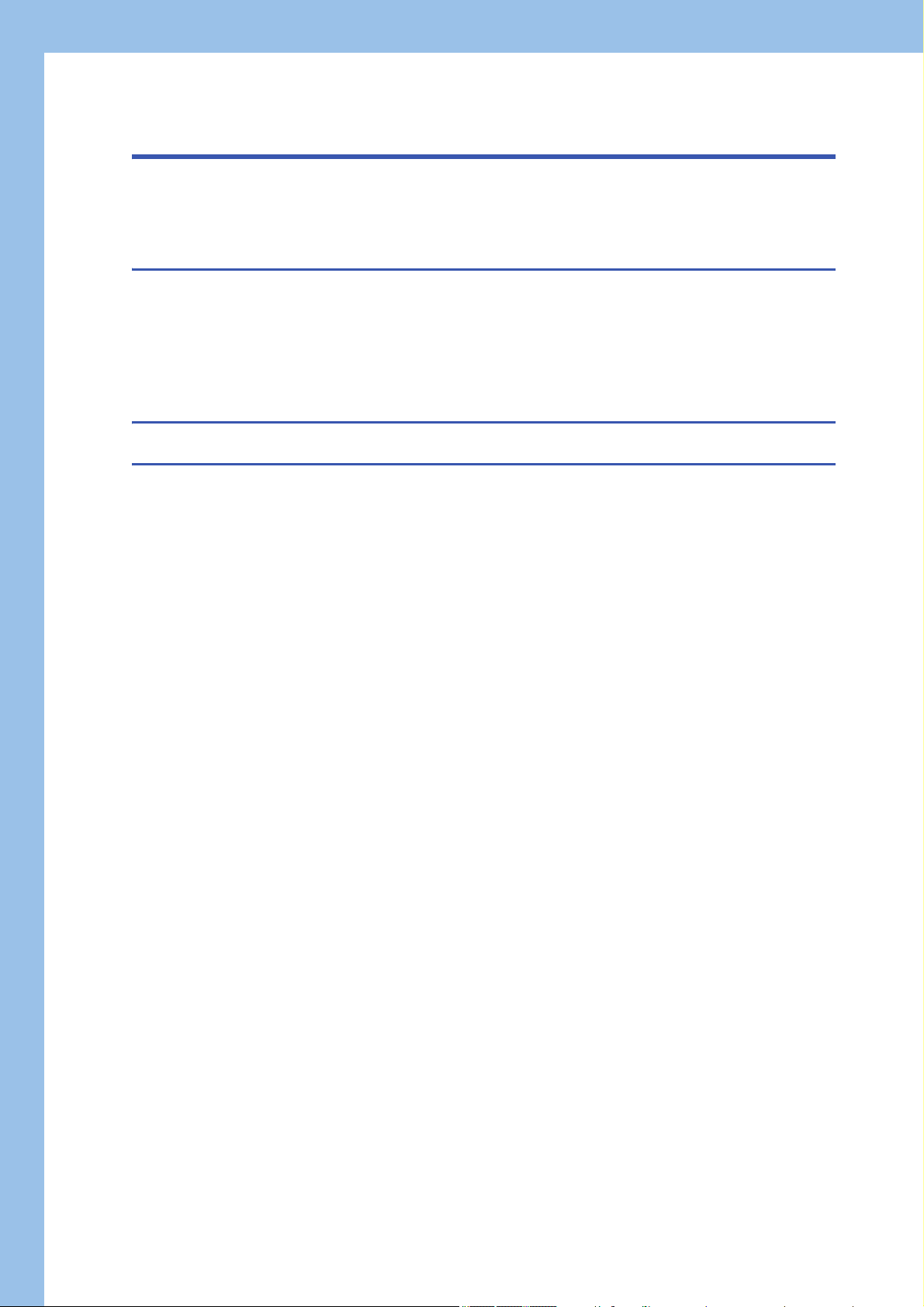

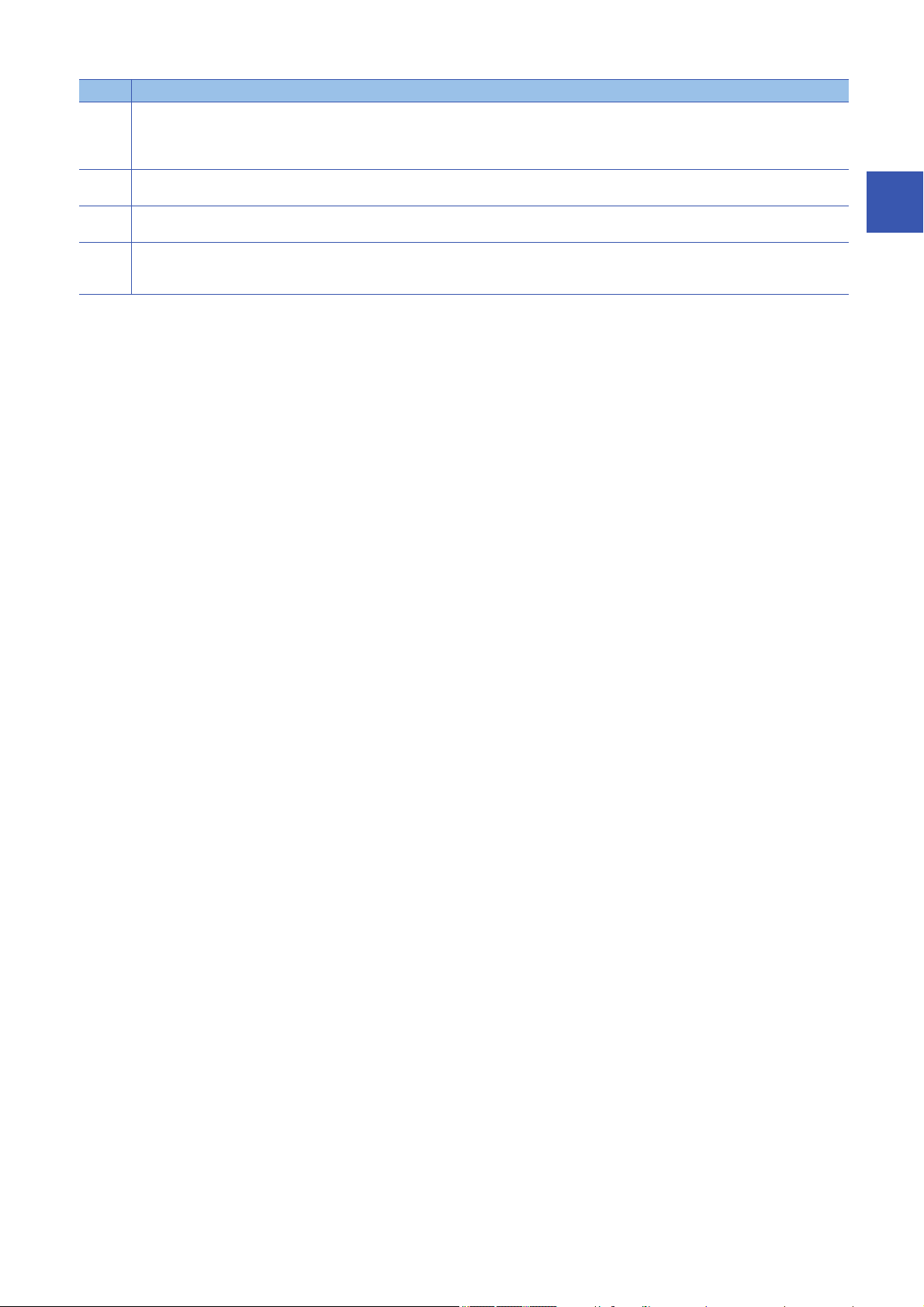

Adjustment function Outline Reference

Quick tuning Use this function to prioritize reduction of the overshoot rather than shortening the settling time. An

adjustment is enabled without the positioning operation.

Auto tuning mode 1 Use this function to adjust the machine while checking the response waveform when the load to motor

inertia ratio of the device is unknown. Also use this function when the load to motor inertia ratio of a

machine varies during operation.

Auto tuning mode 2 Use this function to adjust the machine while checking the response waveform when the load to motor

inertia ratio of the device is known.

2 gain adjustment mode 1 Use this function for auto tuning a machine that requires path accuracy improvement, such as XY table

and tandem mechanism, and to suppress inter-axis interference.

2 gain adjustment mode 2 Use this function to adjust settling time and overshoot amount after the quick tuning or one-touch tuning

was performed.

Page 12

Quick tuning

Page 37 Auto

tuning mode 1

Page 41 Auto

tuning mode 2

Page 43 2

gain adjustment

mode 1

Page 44 2

gain adjustment

mode 2

1 ADJUSTMENT FUNCTION TYPES

1.1 Adjustment function available to servo amplifier alone

7

Adjustment functions to suppress vibration and to obtain a high level of responsiveness

Adjustment function Outline Reference

One-touch tuning Use this function to reduce settling time within the designated In-position range. Page 16 One-

touch tuning

Machine resonance

suppression filter

Adaptive filter II Use this function to adjust the machine resonance suppression filter automatically. Page 53

Robust filter When the load to motor inertia ratio of a machine is 10 times or more, use this function to more increase

Advanced vibration

suppression control II

Command notch filter Use this function to suppress vibration easily, if the vibration during setting is large at high-speed

Use this function if machine resonance occurs when the response level in the auto tuning and manual

mode is increased.

the response level of the machine.

Use this function to reduce settling time as the vibration is being suppressed, if the vibration during setting

is large at high-speed positioning.

positioning.

Page 50

Machine

resonance

suppression filter

Adaptive filter II

Page 59

Robust filter

Page 60

Advanced

vibration

suppression

control II

Page 66

Command notch

filter

Manual adjustment functions to obtain the maximum performance

Adjustment function Outline Reference

Manual mode Use this function if the performance of the quick tuning, one-touch tuning, and auto tuning is not

satisfactory.

Gain switching function Use this function for:

Speed feed forward Use this function to improve path accuracy by decreasing droop pulses at the constant speed. Page 88

Overshoot suppression

function

Slight vibration suppression

function

Unbalanced torque offset Use this function for freefall prevention on vertical axis at servo-on. Page 94

Path tracking model

adaptive control

Lost motion compensation

function

1) Reducing the stop settling time

2) Increasing the gain during servo-lock while suppressing vibration sound during rotation

3) When load fluctuation is large

Use this function to decrease the overshoot. Page 90

Use this function to suppress vibration at a servo motor stop. Page 92

Use this function to suppress overshoot in path control. Page 98 Path

Use this function to suppress quadrant projections at speed switching in path control. Page 99 Lost

Page 45

Manual mode

Page 73

GAIN

SWITCHING

FUNCTION

SPEED FEED

FORWARD

CONTROL

FUNCTION

OVERSHOOT

SUPPRESSION

CONTROL

SLIGHT

VIBRATION

SUPPRESSION

CONTROL

UNBALANCED

TORQUE

OFFSET

tracking model

adaptive control

motion

compensation

function

8

1 ADJUSTMENT FUNCTION TYPES

1.1 Adjustment function available to servo amplifier alone

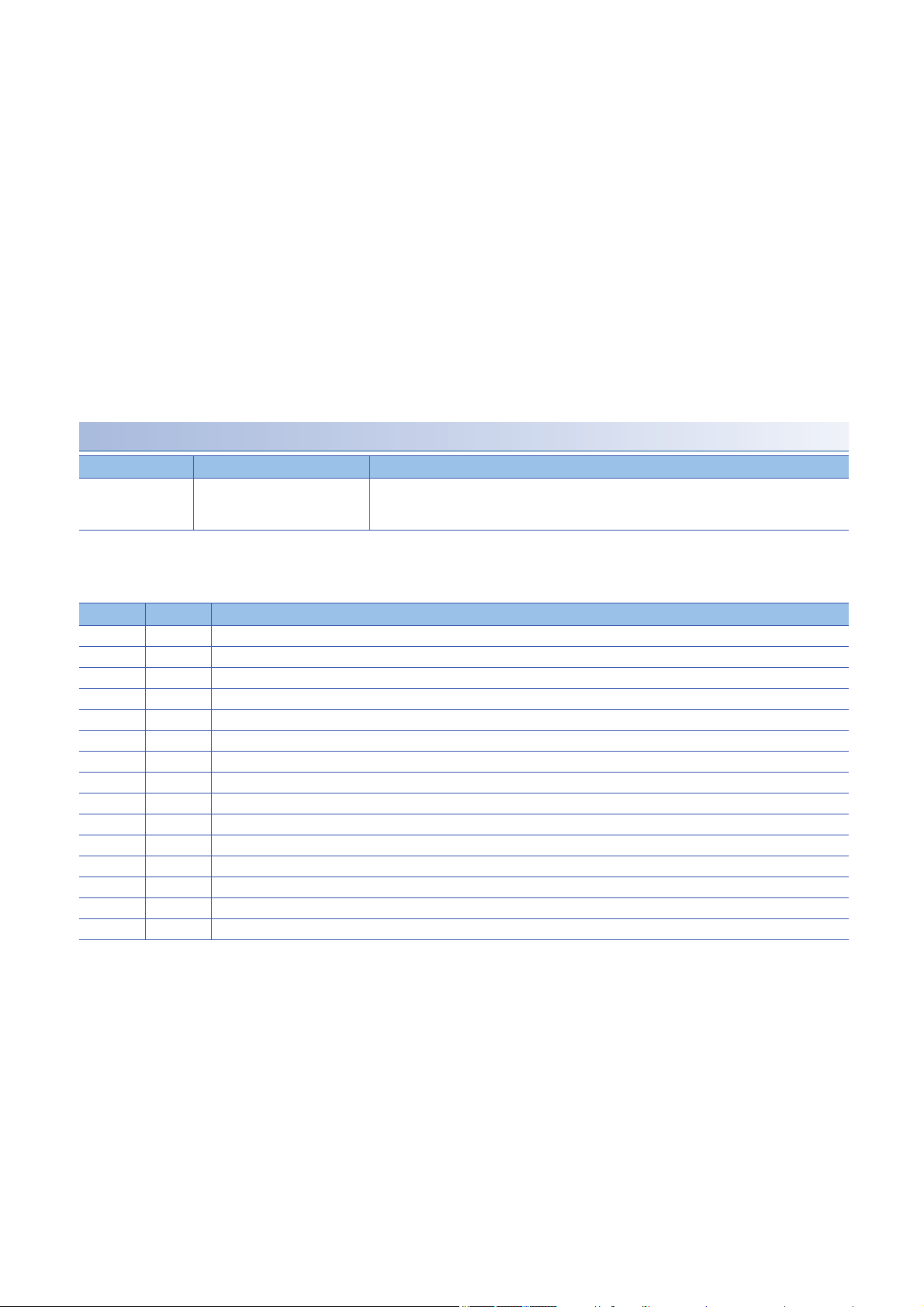

1.2 Adjustment functions available in combination

with MR Configurator2

By combining with MR Configurator2 and a servo amplifier, the following adjustment functions can be used additionally.

Adjustment function Outline Reference

Machine analyzer Use this function to accurately adjust the mechanical resonance suppression filter, when the characteristic

One-touch tuning in the

amplifier command method

of mechanical resonance is known.

With the machine and servo motor connected, the characteristic of the mechanical system can be

measured by giving a random vibration command from a personal computer to the servo amplifier, and by

measuring the responsiveness of the machine.

Use this function to prioritize time reduction of settling and gain adjustment over overshoot suppression.

To generate an optimum command inside the servo amplifier and perform the one-touch tuning, input the

travel distance (permissible travel distance) on MR Configurator2 that avoids collision with the machine

when driving the servo motor.

Page 16 One-

touch tuning

1

1 ADJUSTMENT FUNCTION TYPES

1.2 Adjustment functions available in combination with MR Configurator2

9

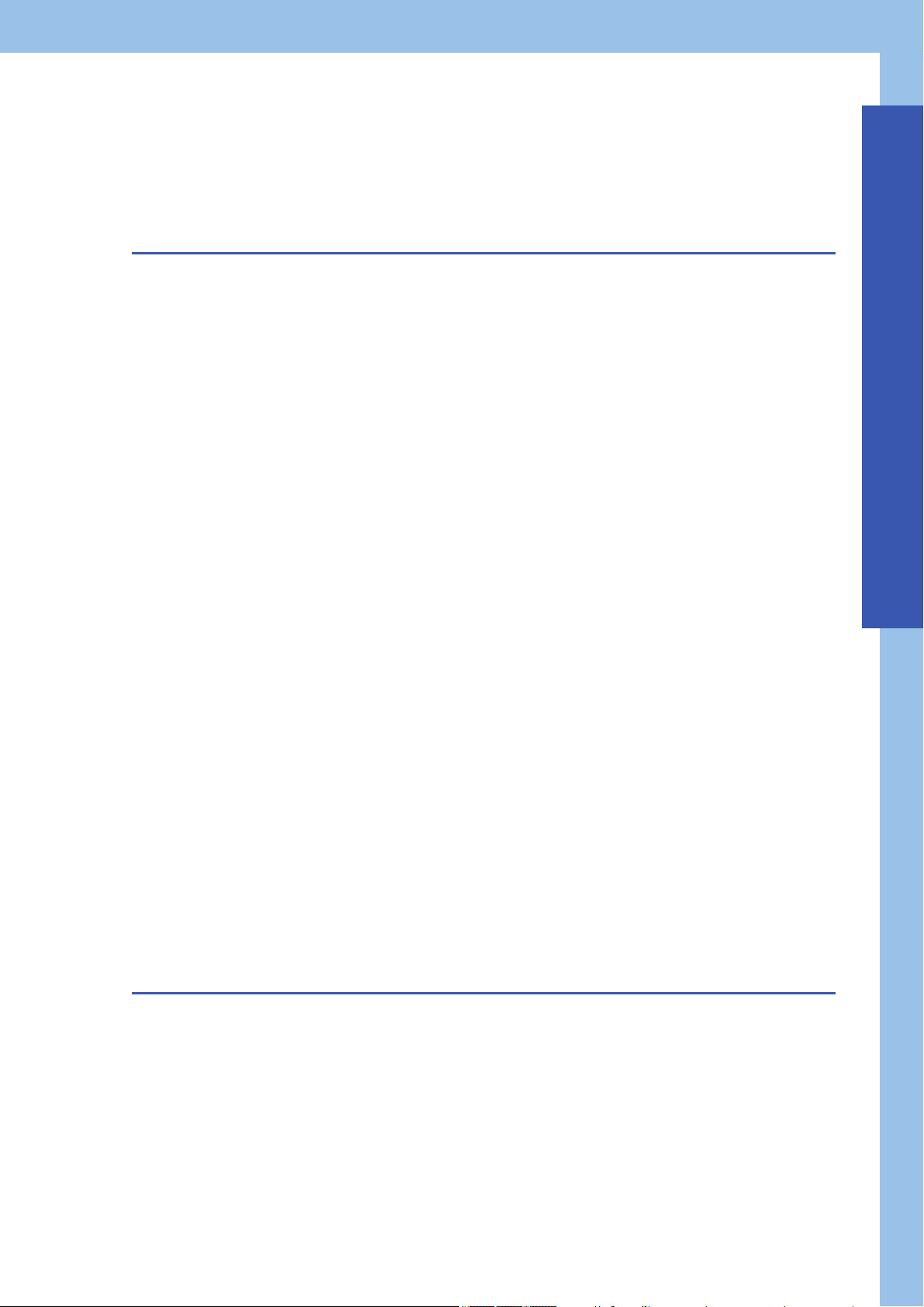

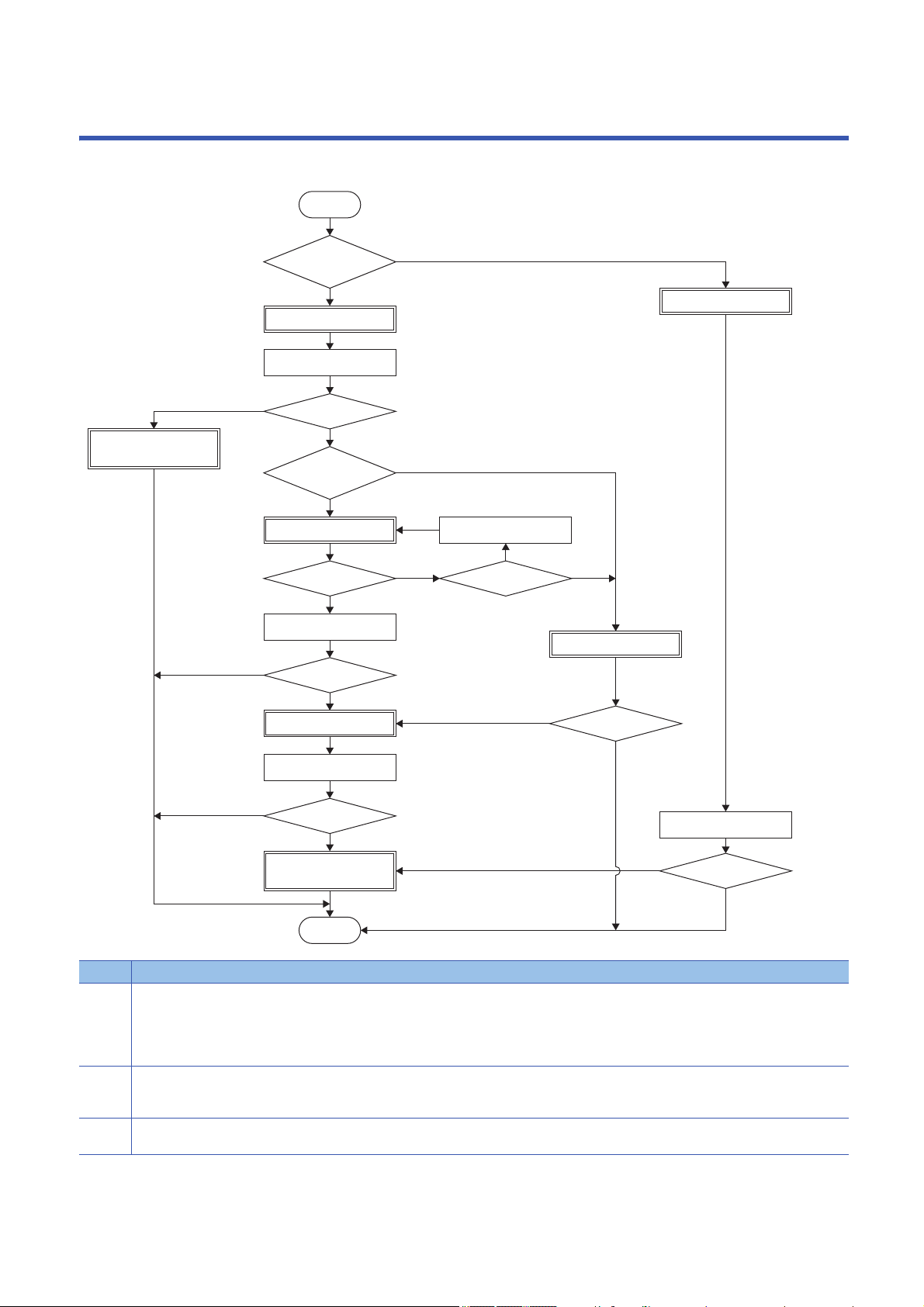

2 ADJUSTMENT PROCEDURE

Yes

Yes

No

No

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

No

(7)

(6)

(5)

(4)

(3)

(2)

(1)

Start

Is the system for

Interpolation of 2 or

more axes?

2 gain adjustment mode 1

Quick tuning

Operation

Is the adjustment

satisfactory?

Load to motor inertia ratio

monitor mode

Adjustment for large load fluctuation

Is load fluctuation

large during operation?

One-touch tuning Handling the error

Is handling an error

possible?

Successfully completed?

Operation

Auto tuning

Is the adjustment

satisfactory?

2 gain adjustment mode 2

Is the adjustment

satisfactory?

Operation

Is the adjustment

satisfactory?

Operation

Manual adjustment

Resonance suppression

function

Is the adjustment

satisfactory?

End

Adjust the servo amplifier with the following procedure.

No. Instructions

(1) Change [Pr. PA08.0 Gain adjustment mode selection] to "0".

(2) This mode can adjust the servo amplifier without driving the servo motor.

(3) Change the mode to the load to motor inertia ratio monitor mode if the adjustment result of the quick tuning has no problem.

2 ADJUSTMENT PROCEDURE

10

Use this mode to set the same setting value in [Pr. PB07 Model control gain] to all axes when performing interpolation such as path control or

tandem drive for a system with 2 axes or more.

Do not use this for other purposes.

Page 43 2 gain adjustment mode 1

Adjust the servo amplifier with this mode when not executing the interpolation control.

Page 12 Quick tuning

Page 12 Quick tuning

No. Instructions

(4) To start the one-touch tuning, push the "Start" button for one-touch tuning on the engineering tool during the positioning operation.

Use this adjustment if the conditions for the quick tuning are not fulfilled. A higher response level than that of the quick tuning can be obtained,

enabling a quicker positioning.

Page 16 One-touch tuning

(5) Set [Pr. PA08.0 Gain adjustment mode selection] to "1" or "2".

Page 37 Auto tuning mode 1

(6) [Pr. PA08.0 Gain adjustment mode selection] is automatically set to "4" (2 gain adjustment mode 2) once the one-touch tuning is complete.

Page 16 One-touch tuning

(7) Set [Pr. PA08.0 Gain adjustment mode selection] to "3".

Use the manual adjustment for fast settling or high accuracy path control.

Page 45 Manual mode

2

2 ADJUSTMENT PROCEDURE

11

3 ADJUSTMENT METHOD

3.1 Quick tuning

To use quick tuning, set [Pr. PA08.0 Gain adjustment mode selection] to "5". When the SON is on, the servo amplifier adjusts

the gain. The characteristic of quick tuning is shown as follows:

• Effective when to reduce the overshoot rather than to shorten the settling time because of the ability to reduce the

overshoot regardless of the machine type or the load size

• Adjustment available without the positioning operation

Restrictions on quick tuning

Quick tuning is not available in the following situations:

• During one-touch tuning

• In torque control

• When using adaptive filter II

Precautions on quick tuning

• Do not use quick tuning in a tandem system.

• Some noise due to the applied vibration torque may occur during quick tuning, but the noise is not an abnormality.

• When the load to motor inertia ratio is more than 100 times, quick tuning cannot adjust the gain appropriately. Adjust the

gain by using an alternative method such as auto tuning.

• When quick tuning is enabled (performed), the time until the servo amplifier actually becomes in the servo-on state after

turning on the servo-on command gets 300 ms longer at a maximum.

• When the torque limit value is less than 30 % of the rated torque, the torque required for quick tuning cannot be generated,

and quick tuning may fail. Set the torque limit value to exceed 30 % of the rated torque for quick tuning.

• If the travel distance in quick tuning exceeds the set value in [Pr. PA34 Quick tuning - Permissible travel distance], the

quick tuning will be stopped.

• [Pr. PB11 Speed differential compensation] will be changed to the initial value if quick tuning is used.

• When friction is 30 % or more of the rated torque, quick tuning may fail. In this case, adjust the gain with one-touch tuning

or auto tuning.

12

3 ADJUSTMENT METHOD

3.1 Quick tuning

Setting method for quick tuning

How to use quick tuning

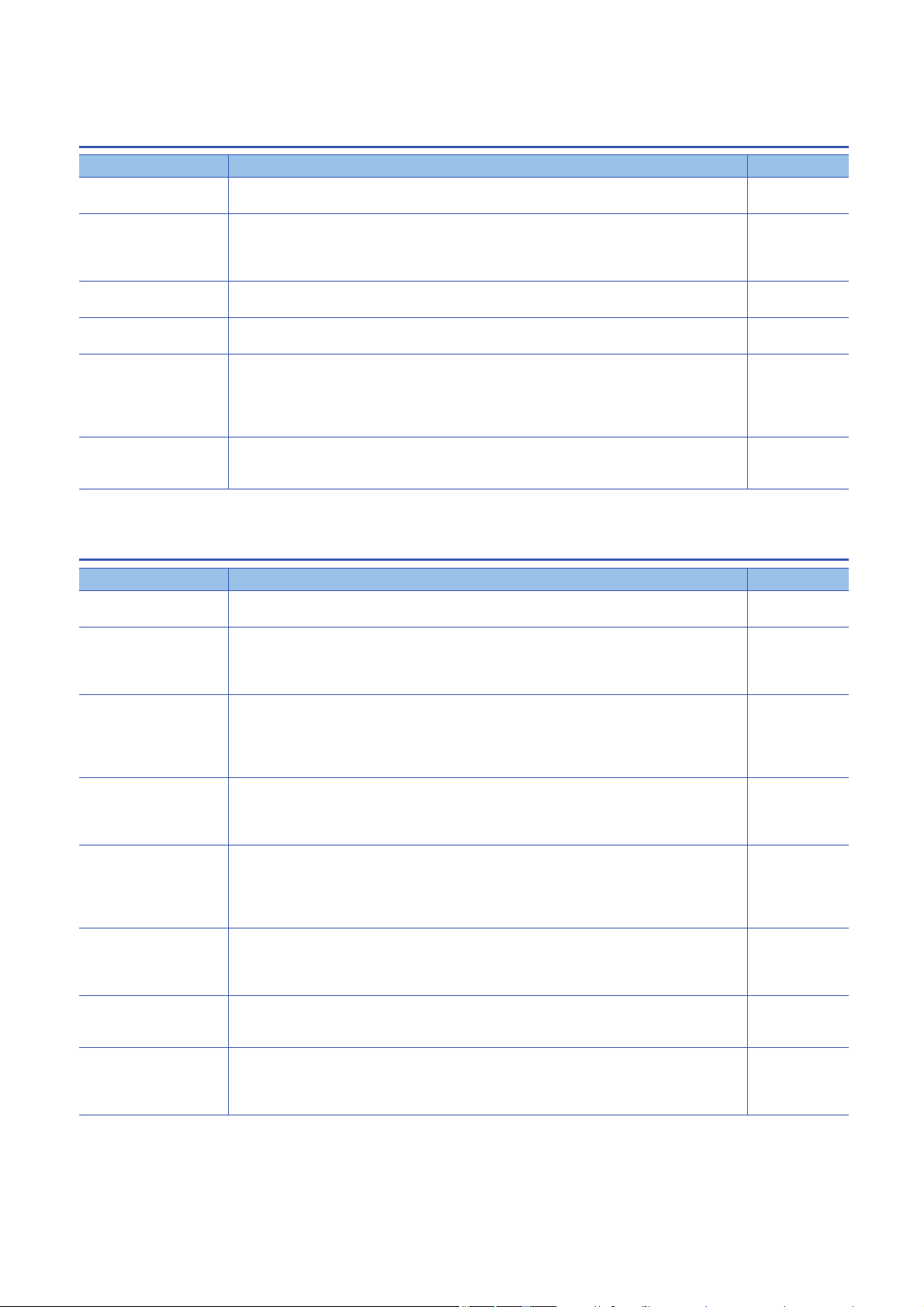

Servo parameter Name Description

PA08.0 Gain adjustment mode selection Select the gain adjustment mode. The initial value is "1".

0: 2 gain adjustment mode 1 (interpolation mode)

1: Auto tuning mode 1

2: Auto tuning mode 2

3: Manual mode

4: 2 gain adjustment mode 2

5: Quick tuning mode

6: Load to motor inertia ratio monitor mode

PA08.4 Quick tuning - Load to motor

inertia ratio setting

PA08.5 Quick tuning - Execution selection Set when to execute quick tuning. The initial value is "0".

PA34 Quick tuning - Permissible travel

distance

Execute one-touch tuning with the following procedures.

Select the load to motor inertia ratio of the equipment. The initial value is "0".

0: A load to motor inertia ratio of 30 times or less

1: A load to motor inertia ratio of 100 times or less

0: At the initial servo-on after cycling the power (Execute quick tuning at the initial servo-on after

turning on the power)

1: At every servo-on (Execute quick tuning every time the SON is turned on.)

Set the permissible travel distance in quick tuning.

If the travel distance in quick tuning exceeds the setting value, the quick tuning error occurs.

When "0" is set, the permissible travel distance of quick tuning is 1.0 rev (10 mm when using a

linear servo motor).

Setting range: 0 to 100

3

■When executing quick tuning at the initial servo-on after turning on the power

1. Switch to the servo-off status.

2. Set "5" (quick tuning) to [Pr. PA08.0].

3. Set "0" (at the initial servo-on after cycling the power) to [Pr. PA08.5].

4. Check the load to motor inertia ratio.

• When the load to motor inertia ratio is 30 times or less

Set "0" (a load to motor inertia ratio of 30 times or less) to [Pr. PA08.4].

• When the load to motor inertia ratio is over 30 times and 100 times or less, or unknown

Set "1" (a load to motor inertia ratio of 100 times or less) to [Pr. PA08.4].

5. Set the permissible travel distance for quick tuning with [Pr. PA34].

6. Switch to the servo-on status to adjust servo parameters automatically.

Quick tuning will be executed at every initial servo-on after turning on the power thereafter.

7. Set "6" (load to motor inertia ratio monitor mode) to [Pr. PA08.0] to retain the tuning results.

3 ADJUSTMENT METHOD

3.1 Quick tuning

13

■When executing quick tuning at every servo-on

1. Switch to the servo-off status.

2. Set "5" (quick tuning) to [Pr. PA08.0].

3. Set "1" (at every servo-on) to [Pr. PA08.5].

4. Check the load to motor inertia ratio.

• When the load to motor inertia ratio is 30 times or less

Set "0" (a load to motor inertia ratio of 30 times or less) to [Pr. PA08.4].

• When the load to motor inertia ratio is 100 times or less, or unknown

Set "1" (a load to motor inertia ratio of 100 times or less) to [Pr. PA08.4].

5. Set the permissible travel distance for quick tuning with [Pr. PA34].

6. Switch to the servo-on status to adjust servo parameters automatically.

Quick tuning will be executed at every servo-on thereafter.

7. Set "6" (load to motor inertia ratio monitor mode) to [Pr. PA08.0] to retain the tuning results.

How to restore servo parameters before quick tuning

Servo parameter Name Description

PA08.6 Quick tuning - Restore selection Set whether to restore the servo parameter values before quick tuning. The initial value is "0".

0: Disabled

1: Enabled

When [Pr. PA08.6] is set to "1" (Enabled), the following servo parameters return to the values before quick tuning. If quick

tuning has never been performed after power on or software reset, setting [Pr. PA08.6] to "1" only keeps the current servo

parameters.

No. Symbol Name

PB01 FILT Adaptive tuning mode (adaptive filter II)

PB07 PG1 Model control gain

PB08 PG2 Position control gain

PB09 VG2 Speed control gain

PB10 VIC Speed integral compensation

PB11 VDC Speed differential compensation

PB13 NH1 Machine resonance suppression filter 1

PB14 NHQ1 Notch shape selection 1

PB15 NH2 Machine resonance suppression filter 2

PB16 NHQ2 Notch shape selection 2

PB18 LPF Low-pass filter setting

PB23 VFBF Low-pass filter selection

PB50 NH5 Machine resonance suppression filter 5

PB51 NHQ5 Notch shape selection 5

PE41 EOP3 Function selection E-3

14

3 ADJUSTMENT METHOD

3.1 Quick tuning

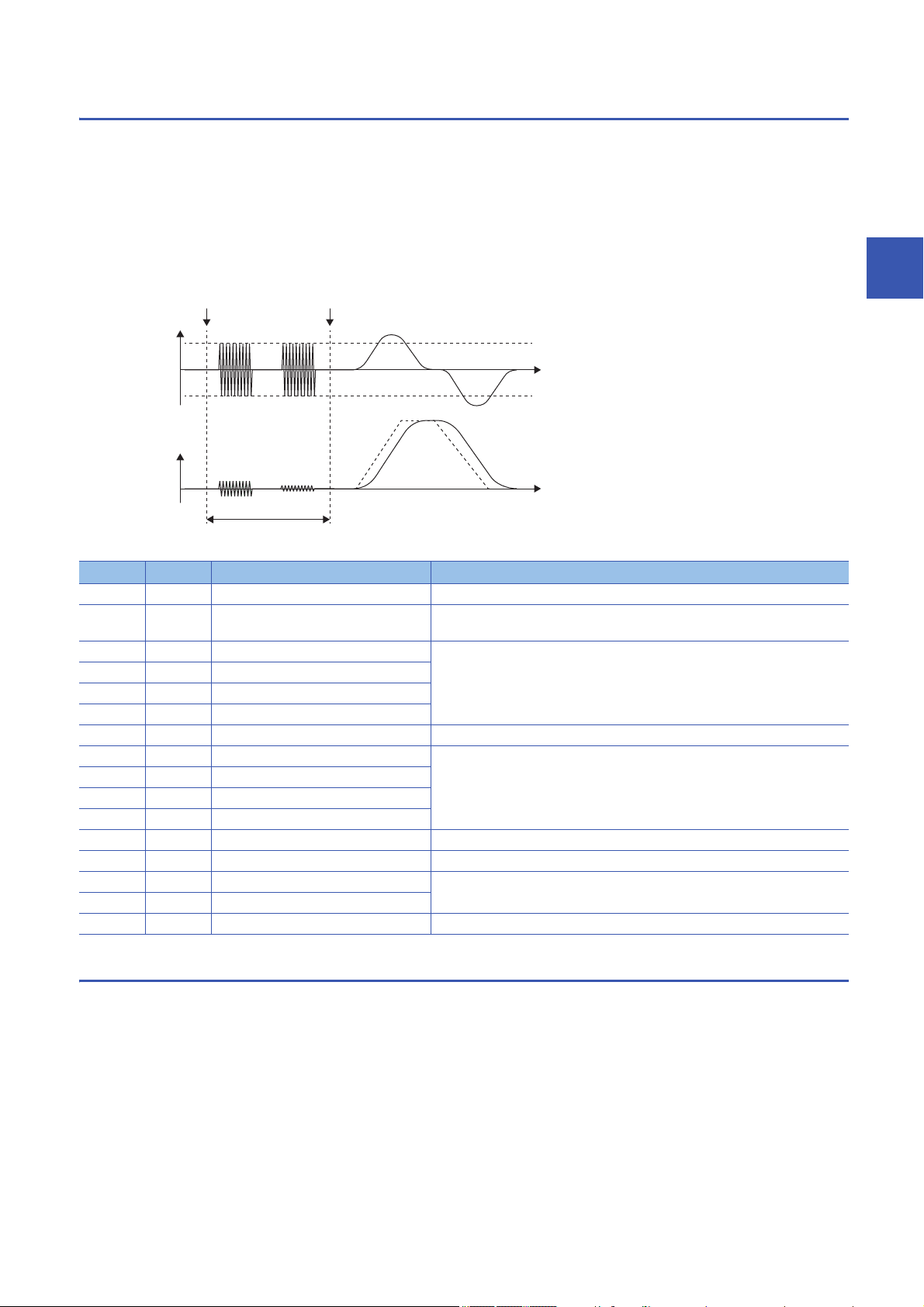

Operation of quick tuning

Start of quick tuning Gain adjustment complete

Torque

60 % of rated

torque

Time

-60 % of rated

torque

Speed

Time

Approx. 300 [ms]

When quick tuning is started, the servo amplifier applies vibration torque instantly, and adjusts each gain and the machine

resonance suppression filter by using the response from that excitation. Vibration torque is applied by 60 % at the maximum

of the rated torque. However, vibration torque is limited by the torque limit value when the torque limit value is less than 60 %

of the rated torque. The adjusting time is approximately 300 [ms]. When the magnetic pole detection is executed, quick tuning

will be started after the magnetic pole detection.

Once gain adjustment by quick tuning is complete, the gain can be changed as in the manual mode. Also, the load to motor

inertia ratio will be always estimated as in the auto tuning mode 1 after the gain adjustment.

The following servo parameters are adjusted automatically in quick tuning.

No. Symbol Name Setting value after gain adjustment

PB01 FILT Adaptive tuning mode (adaptive filter II) Automatic setting

PB06 GD2 Load to motor inertia ratio The setting value is set depending on the response waveform during servo motor

driving after gain adjustment.

PB07 PG1 Model control gain Automatic setting

PB08 PG2 Position control gain

PB09 VG2 Speed control gain

PB10 VIC Speed integral compensation

PB11 VDC Speed differential compensation Initial value

PB13 NH1 Machine resonance suppression filter 1 Automatic setting

PB14 NHQ1 Notch shape selection 1

PB15 NH2 Machine resonance suppression filter 2

PB16 NHQ2 Notch shape selection 2

PB18 LPF Low-pass filter setting Initial value

PB23.1 Low-pass filter selection 1

PB50 NH5 Machine resonance suppression filter 5 Automatic setting

PB51 NHQ5 Notch shape selection 5

PE41 EOP3 Function selection E-3 Initial value

3

Errors in quick tuning

When the following conditions are met, quick tuning may fail:

• When torque is reached to torque limit value during quick tuning

• When the travel distance in quick tuning exceeds the set value in [Pr. PA34 Quick tuning - Permissible travel distance]

When quick tuning fails, the servo parameters before quick tuning will be restored.

3 ADJUSTMENT METHOD

3.1 Quick tuning

15

3.2 One-touch tuning

Precautions

By turning on the one-touch tuning during servo motor operation, the one-touch tuning performs an adjustment in accordance

with the machine characteristic. The one-touch tuning has two methods: the user command method and the amplifier

command method.

User command method

The user command method performs the one-touch tuning by inputting commands from outside the servo amplifier. Although

it is necessary to input commands from the outside of the servo amplifier, the optimum adjustment can be made by taking both

the mechanical characteristics and the commands into accounts.

Amplifier command method

The amplifier command method generates an optimum tuning command inside a servo amplifier and performs the one-touch

tuning by simply inputting travel distance (permissible travel distance) that avoids collision with the machine during servo

motor driving. The one-touch tuning in this method can be performed easier than the user command method, and does not

require to generate commands from the outside of a servo amplifier. However, MR Configurator2 is required for performing

the one-touch tuning in the amplifier command method.

• When the following servo parameters are set in [Pr. PA08.0 Gain adjustment mode selection], [Pr. PB06 Load to motor

inertia ratio/load to motor mass ratio] is estimated at the start of one-touch tuning.

"0" (2 gain adjustment mode 1 (interpolation mode))

"1" (Auto tuning mode 1)

"2" (Auto tuning mode 2)

"4" (2 gain adjustment mode 2)

"6" (Load to motor inertia ratio monitor mode)

Restrictions on one-touch tuning

The one-touch tuning cannot be performed in the following conditions.

Common restrictions on user command method and amplifier command method

• When [Pr. PA21.0 One-touch tuning - Function selection] is "0" (disabled)

• In the torque mode

• When an alarm or a warning which disrupts the motor driving occurs

• In output signal (DO) forced output and motor-less operation

Restrictions on user command method

• The one-touch tuning in the user command method cannot be performed at servo-off.

Restrictions on amplifier command method

• The one-touch tuning in the amplifier command method cannot be started during servo motor driving.

• The one-touch tuning in the amplifier command method cannot be performed when the positioning operation, JOG

operation, program operation, and test operation mode of machine analyzer function are being carried out.

16

3 ADJUSTMENT METHOD

3.2 One-touch tuning

Instructions on one-touch tuning

Instructions on amplifier command method

• Once one-touch tuning is performed, control by commands from a controller will not be available. To enable control from the

controller again, reset the controller, cycle the power of the servo amplifier, or reset software.

• Set the permissible travel distance for not to collide with a machine. In addition, the permissible travel distance may be

exceeded because of an overshoot during one-touch tuning. Therefore, set the permissible travel distance with a margin to

avoid exceeding the range of a limit switch.

• When the manual mode is selected in [Pr. PA08.0 Gain adjustment mode selection], a load to motor inertia ratio is not

estimated. Optimum acceleration/deceleration commands are generated by [Pr. PB06 Load to motor inertia ratio/load to

mass ratio] at the start of the one-touch tuning. When the load to motor inertia ratio is not accurate, optimum acceleration/

deceleration commands may not be generated, causing the tuning to fail.

• When the one-touch tuning is started by using USB communication, if the communication between MR Configurator2 and a

servo amplifier is interrupted during the tuning, both the servo motor and the tuning stop. In addition, the servo parameters

returns to the status at the start of one-touch tuning.

• When the one-touch tuning starts during the velocity mode, the mode is switched to the position mode automatically. As a

result, the tuning result may differ from the results obtained by using the speed command.

One-touch tuning procedure

3

Procedure for one-touch tuning in user command method by MR Configurator2

Perform the one-touch tuning with the following procedure.

1. Start

2. Overshoot permissible level setting

Set the permitted overshoot level for the one-touch tuning in [Pr. PA25 One-touch tuning - Permitted overshoot level].

3. Operation

Rotate a servo motor by a controller. In the user command method, the one-touch tuning cannot be performed during a servo

motor stop.

4. One-touch tuning start, mode selection

On MR Configurator2, select "One-touch tuning" from the tuning tab of MR Configurator2. Select "User command method".

5. Response mode selection

Select the response mode (High mode/Basic mode/Low mode) in the one-touch tuning window of MR Configurator2.

6. One-touch tuning execution

Click “Start” during servo motor driving.

7. One-touch tuning in progress

Gains and filters are adjusted automatically. During the process of the tuning, the progress status is displayed in % on MR

Configurator2.

8. One-touch tuning complete

Once one-touch tuning is complete, the parameters will be set automatically. If tuning did not complete properly, a tuning error

will be displayed.

Page 29 Servo parameters adjusted with one-touch tuning

9. Tuning result check

Check the tuning results.

When the tuning result is not satisfactory, the servo parameters can be returned to the value before the one-touch tuning or

the initial value.

Page 34 Initializing one-touch tuning

10. End

3 ADJUSTMENT METHOD

3.2 One-touch tuning

17

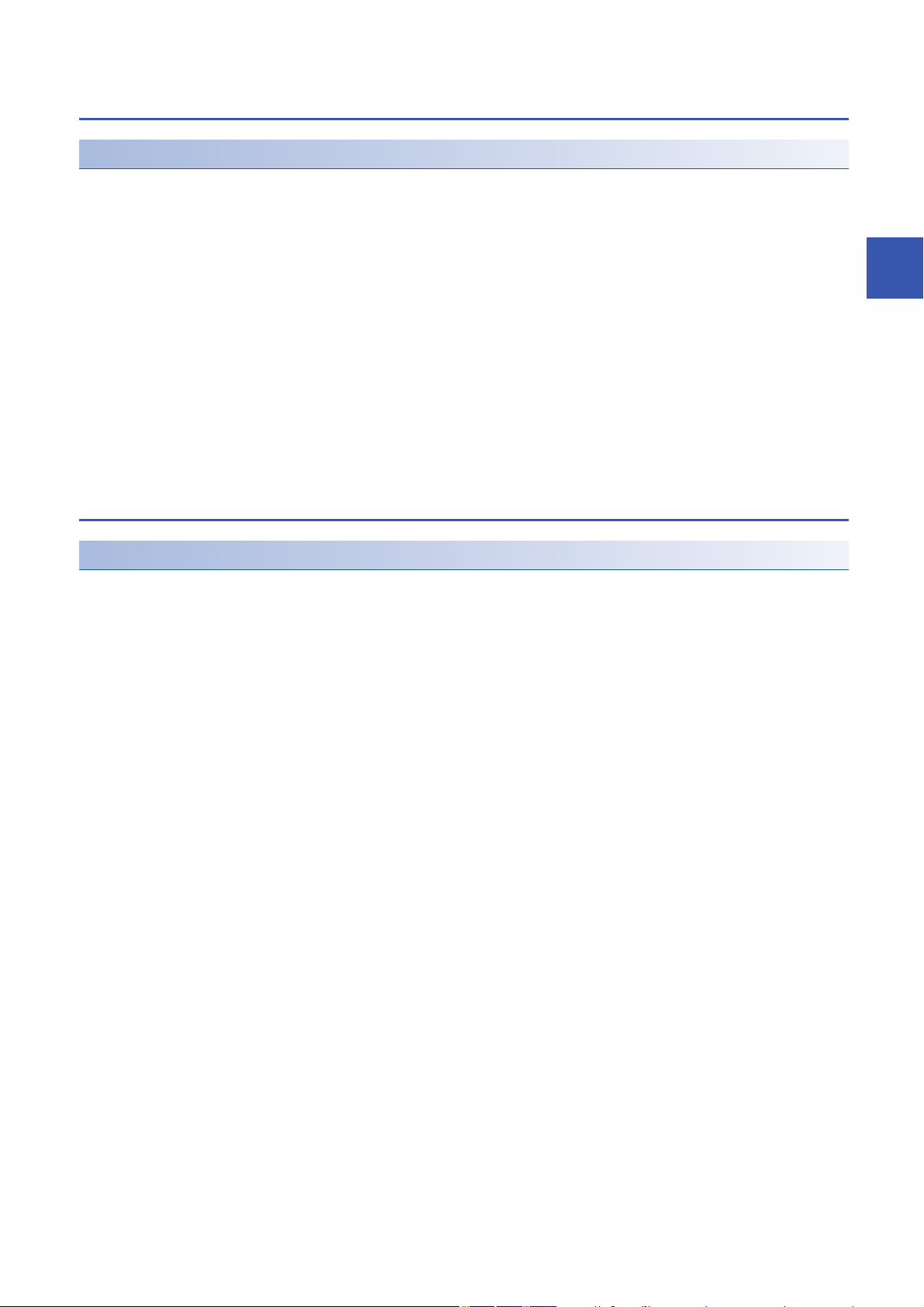

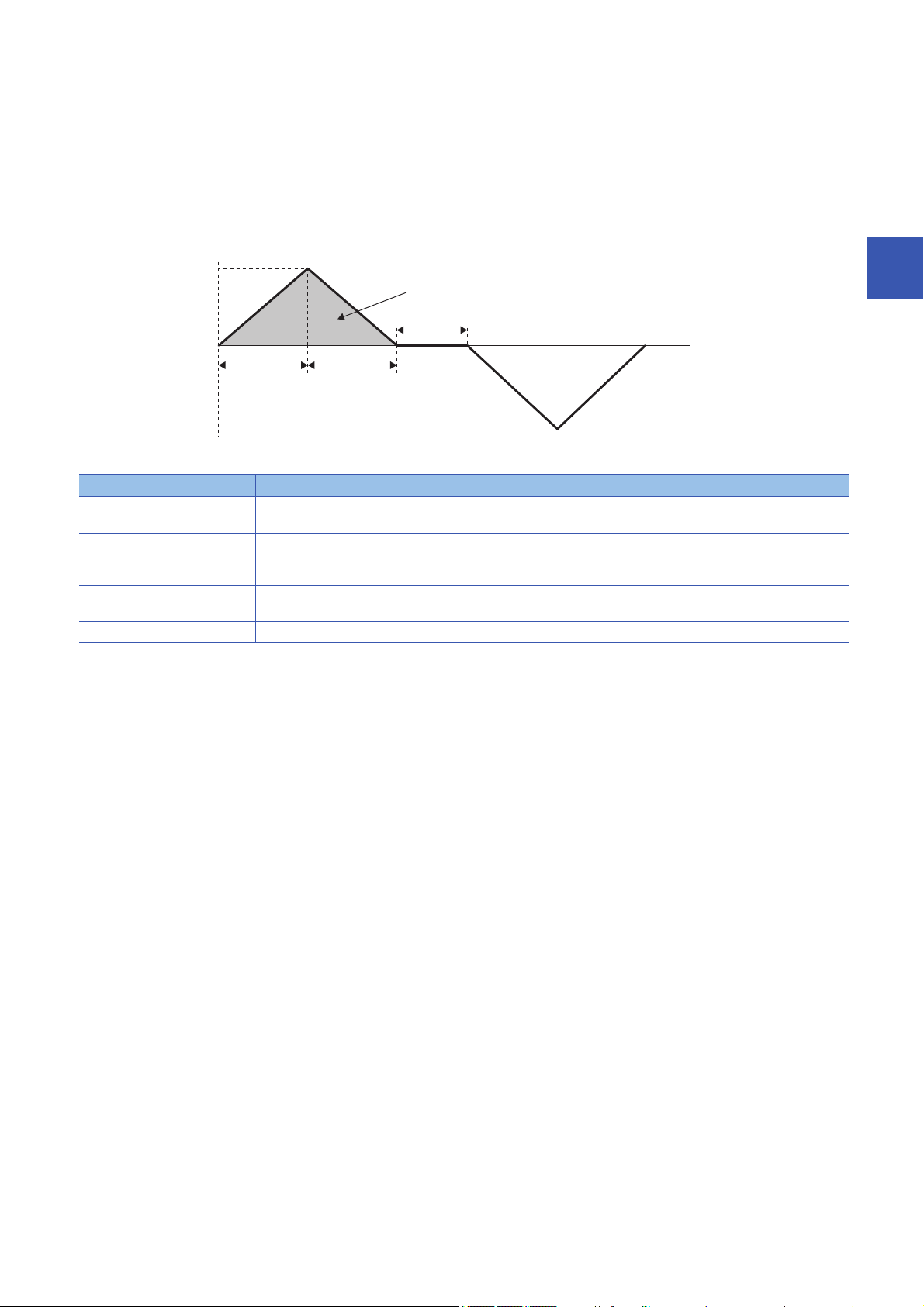

■Overshoot permissible level setting

[Pr. PA14]

[Pr. PA14]

× [Pr. PA25]

Position command frequency

Droop pulses

Reduced settling time

Increased overshoot

[Pr. PA14]

[Pr. PA14]

× [Pr. PA25]

Position command frequency Droop pulses

Reduced overshoot

Increased settling time

Set the permitted overshoot level for the one-touch tuning in [Pr. PA25 One-touch tuning - Permitted overshoot level]. The

one-touch tuning adjusts the settling time to the shortest within the range of the overshoot permissible level. Therefore, when

the value set in [Pr. PA25] is large, reduction of the settling time is prioritized. When the value set in [Pr. PA25] is small, then

reduction of the overshoot is prioritized.

• When the permitted overshoot level is high

• When the permitted overshoot level is low

18

3 ADJUSTMENT METHOD

3.2 One-touch tuning

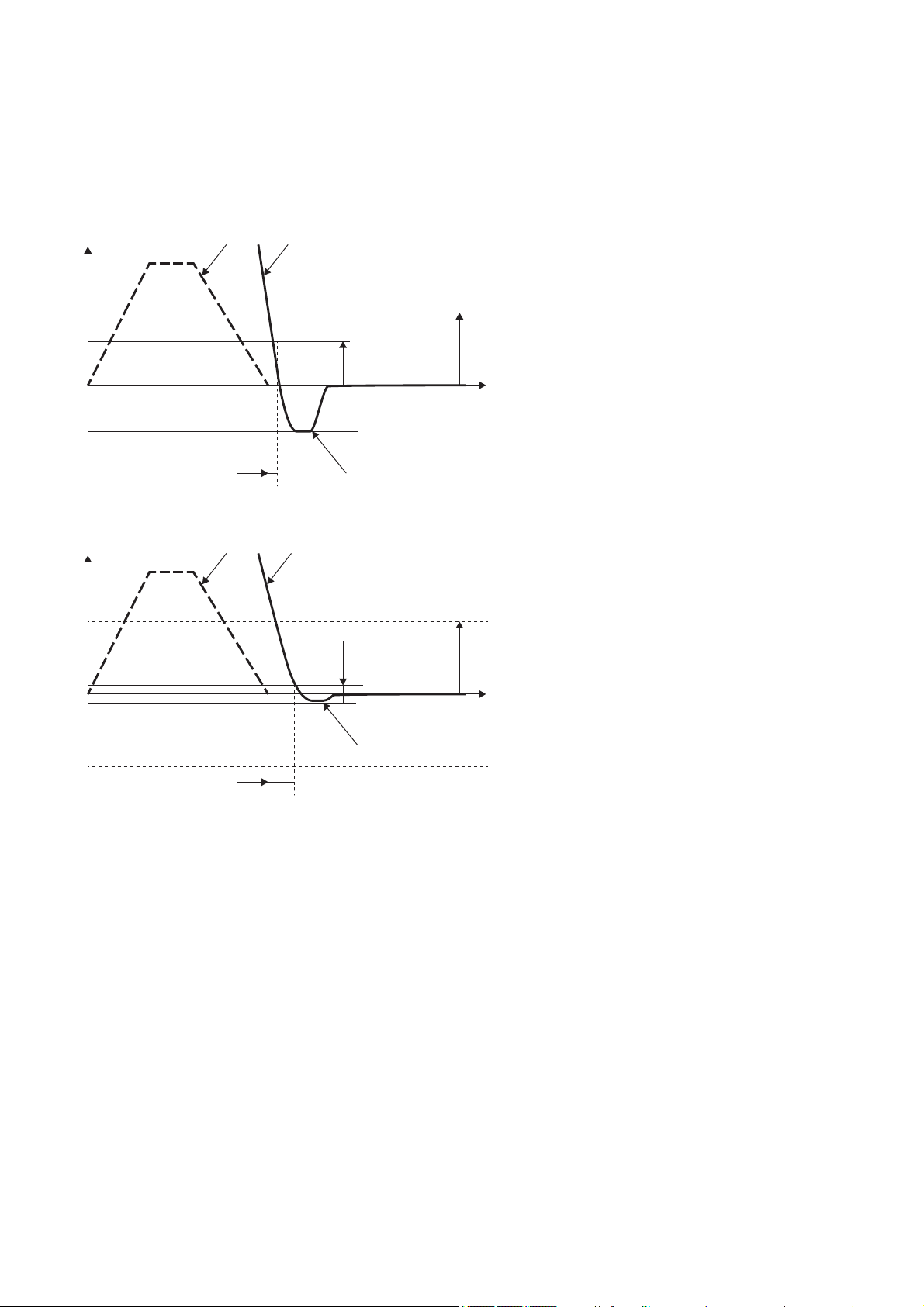

■Operation

0 r/min

One cycle time

Forward rotation

Travel distance

Dwell time

Servo motor

speed

Acceleration

time constant

Deceleration

time constant

Reverse rotation

Inputting commands to the servo amplifier that satisfy the following conditions is recommended. If the one-touch tuning is

performed with commands that do not satisfy the condition are inputted to the servo amplifier, a one-touch tuning error may

occur.

Item Description

Travel distance Set 100 pulses or more in the encoder pulse unit. Setting less than 100 pulses causes the one-touch tuning error "C_04".

Servo motor speed Set 50 r/min (mm/s) or higher. Setting less than 50 r/min may cause the one-touch tuning error "C_05".

Acceleration time constant

Deceleration time constant

Dwell time Set 200 ms or more. If the value is small, the one-touch tuning error "C_04" may occur.

One cycle time Set 30 s or less. Setting over 30 s causes the one-touch tuning error "C_04".

Set the time to reach 2000 r/min (mm/s) to 5 s or less.

Set an acceleration time constant/deceleration time constant so that the acceleration/deceleration torque is 10 % or more

of the rated torque. The estimation accuracy of the load to motor inertia ratio improves as the acceleration/deceleration

torque is larger, and the one-touch tuning result is closer to the optimum value.

3

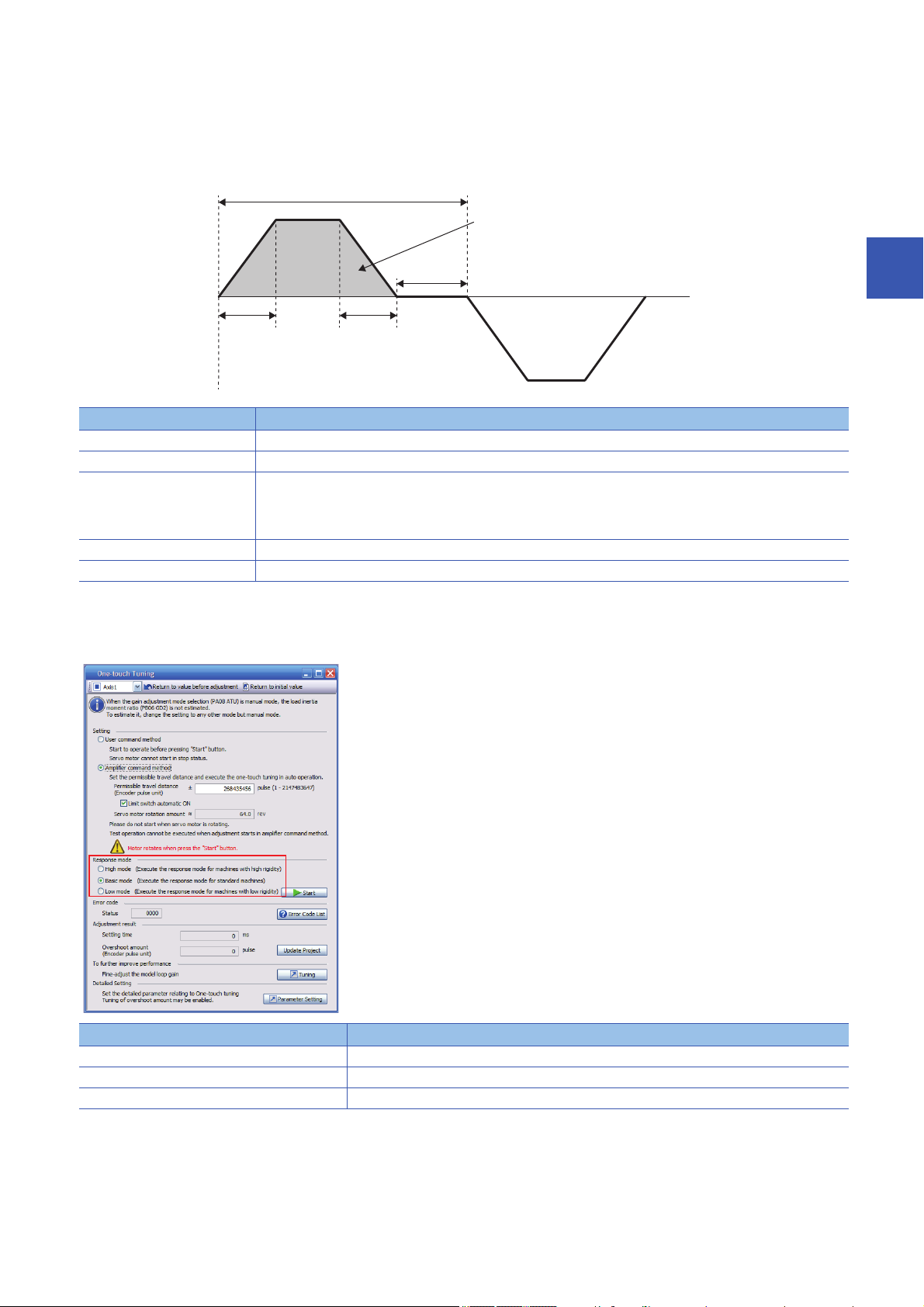

■Command method and response mode selection

Select the user command method in the one-touch tuning window of MR Configurator2 and then select a response mode from

three modes. If no vibration sound occurs during tuning, perform the one-touch tuning again in the high response mode.

Item Description

High mode This mode is for a high-rigid system.

Basic mode This mode is for a standard system.

Low mode This mode is for a low-rigid system.

3 ADJUSTMENT METHOD

3.2 One-touch tuning

19

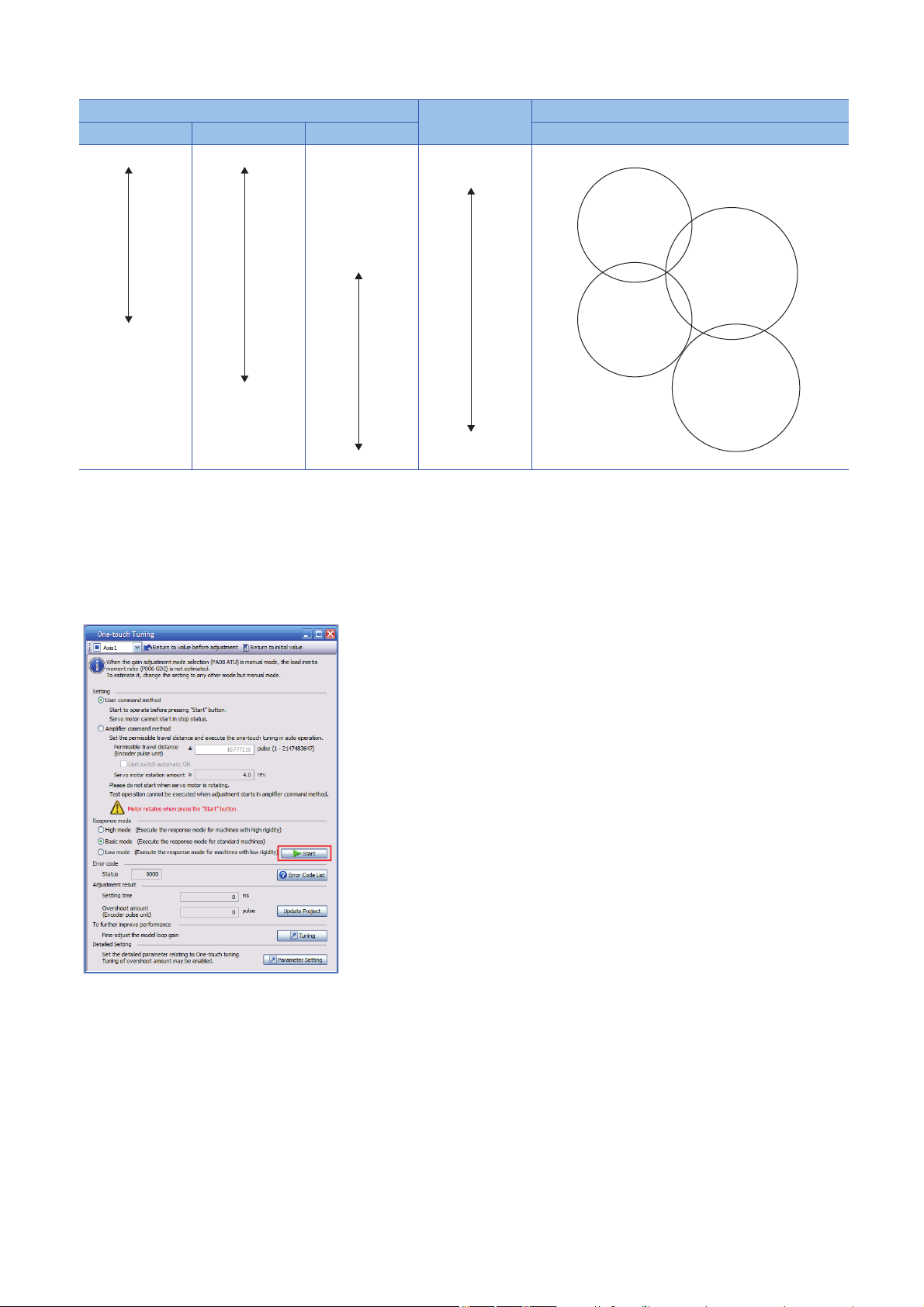

Refer to the following table for selecting a response mode.

Low response

High response

Response mode Responsiveness Machine characteristic

Low mode Basic mode High mode Guidelines for corresponding mode and machinery

Arm robot

General machine tool

Conveyor

Precision working

machine

Inserter

Mounter

Bonder

■One-touch tuning execution

Clicking "Start" after selecting a response mode starts the one-touch tuning in the user command method.

Page 19 Command method and response mode selection

For the one-touch tuning in the user command method, clicking "Start" during a servo motor stop causes "C_02" or "C_04"

shown at the status of the error code. (Refer to the following for the error code.)

Page 31 One-touch tuning error

20

3 ADJUSTMENT METHOD

3.2 One-touch tuning

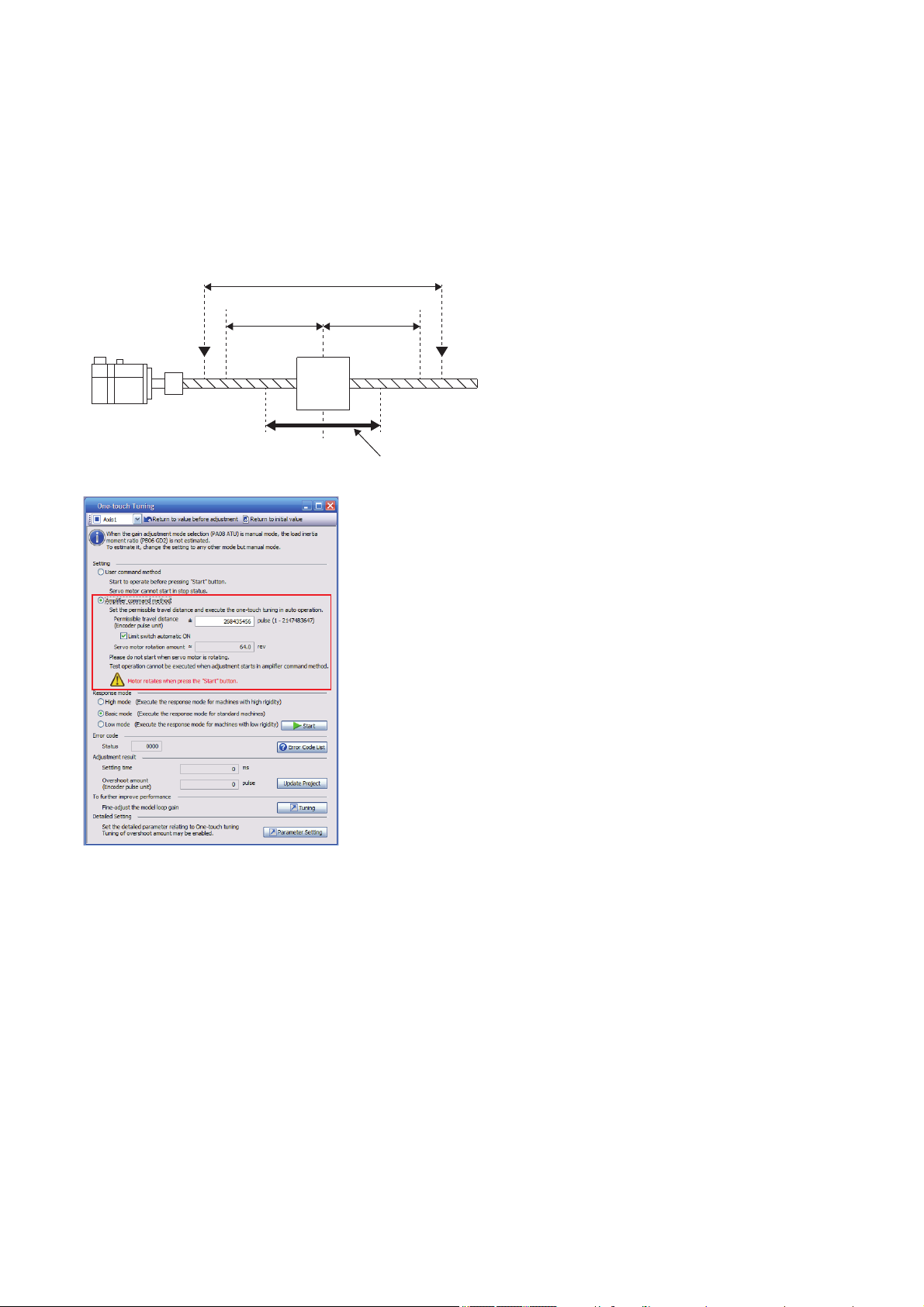

Procedure of one-touch tuning in the amplifier command method with MR

Configurator2

Perform the one-touch tuning with the following procedure.

1. Start

2. Moving to tuning start position

Move the moving part to the center of the movable range.

3. Overshoot permissible level setting

Set the permitted overshoot level for the one-touch tuning in [Pr. PA25 One-touch tuning - Permitted overshoot level].

4. One-touch tuning start, mode selection

On MR Configurator2, select "One-touch tuning" from the tuning tab of MR Configurator2. Select "Amplifier command

method".

5. Permissible travel distance input

In the one-touch tuning window of MR Configurator2, input a maximum travel distance to move the moving part at one-touch

tuning.

6. Response mode selection

Select the response mode (High mode/Basic mode/Low mode) in the one-touch tuning window of MR Configurator2.

7. One-touch tuning execution

Click the "Start" button to start the one-touch tuning during a servo motor stop. On starting the tuning , the servo motor

reciprocates automatically. Performing the one-touch tuning during a servo motor rotation causes an error. Once performed,

the one-touch tuning in the amplifier command method cannot be controlled by commands from the controller.

8. One-touch tuning in progress

Gains and filters are adjusted automatically. During the process of the tuning, the progress status is displayed in % on MR

Configurator2.

9. One-touch tuning complete

Once one-touch tuning is complete, the parameters will be set automatically. When the tuning is not completed normally, a

tuning error is displayed.

Page 29 Servo parameters adjusted with one-touch tuning

3

10. Tuning result check

Check the tuning results.

When the tuning result is not satisfactory, the servo parameters can be returned to the value before the one-touch tuning or

the initial value. Refer to the following.

Page 34 Initializing one-touch tuning

11. Controller reset, servo amplifier power cycling

After executing the one-touch tuning, to restore the control from the controller, reset the controller or cycle the power of the

servo amplifier.

12. End

■Overshoot permissible level setting

Refer to the following for the settings of overshoot permissible level.

Page 18 Overshoot permissible level setting

3 ADJUSTMENT METHOD

3.2 One-touch tuning

21

■Mode selection and permissible travel distance input

Movable range

Permissible travel

distance

Permissible travel

distance

Limit switch Limit switch

Moving

part

Servo motor

Starting position

of tuning

Movable range at tuning

Select "Amplifier command method" in the one-touch tuning window of MR Configurator2. Input permissible travel distance of

the amplifier command method. For the fully closed loop control mode, input permissible travel distance in the load-side

resolution unit. For other control modes, input it in the servo motor-side resolution unit. In the amplifier command method, a

servo motor drives in a range between "current value ± permissible travel distance". Input the value of the permissible travel

distance as large as possible within a range that the movable part does not collide against the machine. Inputting a small

permissible travel distance decreases the possibility that the moving part collides against the machine. However, the

estimation accuracy of the load to motor inertia ratio may be lower, resulting in inaccurate tuning.

■Response mode selection

Refer to the following for response mode.

Page 19 Command method and response mode selection

22

3 ADJUSTMENT METHOD

3.2 One-touch tuning

■One-touch tuning execution

0 r/min

Servo motor

speed

*1

Travel distance

*1

Forward rotation

Dwell time

*1

Servo motor

speed

Acceleration time

constant

*1

Deceleration time

constant

*1

Reverse rotation

Clicking "Start" after selecting a response mode starts the one-touch tuning in the amplifier command method.

Page 19 Command method and response mode selection

In servo-off status, clicking "Start" for the one-touch tuning in the amplifier command method, servo-on is automatically

enabled and the one-touch tuning starts. For the one-touch tuning in the amplifier command method, an optimum tuning

command as follows is generated inside the servo amplifier after servo-on. Then the one-touch tuning is performed with the

servo motor reciprocating.

*1 These items are automatically generated in the servo amplifier.

Item Description

Travel distance An optimum travel distance is automatically set in the range not exceeding the user-inputted permissible travel distance

with MR Configurator2.

Servo motor speed [A]: A speed not exceeding 1/2 of the rated speed and the overspeed alarm detection level is automatically set.

[G] [WG]: A speed not exceeding 1/2 of the rated speed and the overspeed alarm detection level ([Pr. PC08]) is

automatically set.

Acceleration time constant

Deceleration time constant

Dwell time A dwell time in which the one-touch tuning error "C004" does not occur will be automatically set.

An acceleration time constant/deceleration time constant is automatically set so as not to exceed 60 % of the rated torque

and the torque limit value set at the start of one-touch tuning in the amplifier command method.

3

3 ADJUSTMENT METHOD

3.2 One-touch tuning

23

Procedure of one-touch tuning via controller [G] [WG]

Perform the one-touch tuning with the following procedure.

1. Start

2. Overshoot permissible level setting

Set the in-position range for one-touch tuning in [Pr. PA25 One-touch tuning - Permitted overshoot level].

3. Operation

Rotate a servo motor by a controller. The one-touch tuning via a controller cannot be performed during a servo motor stop.

4. Response mode setting, one-touch tuning execution

To perform the one-touch tuning, write the value of the response mode (High mode/Basic mode/Low mode) in [One-touch

tuning mode (Obj. 2D50h)].

5. One-touch tuning in progress

Gains and filters are adjusted automatically. During one-touch tuning, the progress is returned to [One-touch tuning Status

(Obj. 2D51h)] in %.

6. One-touch tuning complete

Check whether the one-touch tuning is completed normally with [One-touch tuning mode (Obj. 2D50h)]. Once one-touch

tuning is complete, each parameter will be set automatically. When the tuning is not completed normally, a tuning error is

returned in [One-touch tuning Error Code (Obj. 2D54h)]. Refer to the following.

Page 34 Initializing one-touch tuning

7. Tuning result check

Check the tuning results.

If the tuning result is not satisfactory, the servo parameters can be returned to the value before the one-touch tuning or the

initial value with [One-touch tuning Clear (Obj. 2D53h)]. Refer to the following.

Page 34 Initializing one-touch tuning

8. End

24

3 ADJUSTMENT METHOD

3.2 One-touch tuning

■Object registration

Register the following objects when performing the one-touch tuning.

Index Sub Object Name Data

Type

2D50h 0 VAR One-touch tuning mode U8 rw 0 Setting "1", "2", or "3" starts one-touch

2D51h 0 VAR One-touch tuning Status I8 ro 0 Regardless of whether the one-touch tuning

2D52h 0 VAR One-touch tuning Stop U16 wo 0 Writing "1EA5h" stops one-touch tuning.

2D53h 0 VAR One-touch tuning Clear U16 wo 0 Servo parameters that were changed in the

2D54h 0 VAR One-touch tuning Error

Code

U16 ro 0 The following shows the details of the one-

Access Default Description

tuning. After one-touch tuning is completed,

the setting value automatically changes to

"0".

0: During one-touch tuning stop

1: Basic mode

2: High mode

3: Low mode

is properly completed or not, the setting

value is 100 % at the completion.

Unit: %

one-touch tuning can be restored to the

original status.

0000h: Restores factory setting

0001h: Restores the value before one-touch

tuning

When servo parameters are restored, the

setting value of the restored servo

parameter is stored to the EEP-ROM.

touch tuning error codes.

0000h: Properly completed

C_00h: Tuning canceled

C_01h: Overshoot exceeded

C_02h: Servo OFF during tuning

C_03h: Control mode error

C_04h: Time-out

C_05h: Load to motor inertia ratio

miscalculated

C_06h: Servo amplifier built-in command

start error

C_07h: Servo amplifier built-in command

generation error

C_08h: Stop signal

C_09h: Parameter

C_0Ah: Alarm

C00Fh: One-touch tuning disabled

3

■Overshoot permissible level setting

Refer to the following for the settings of an overshoot permissible level.

Page 18 Overshoot permissible level setting

■Operation

Refer to the following for operation.

Page 19 Operation

■Response mode selection

Refer to the following for response mode.

Page 19 Command method and response mode selection

3 ADJUSTMENT METHOD

3.2 One-touch tuning

25

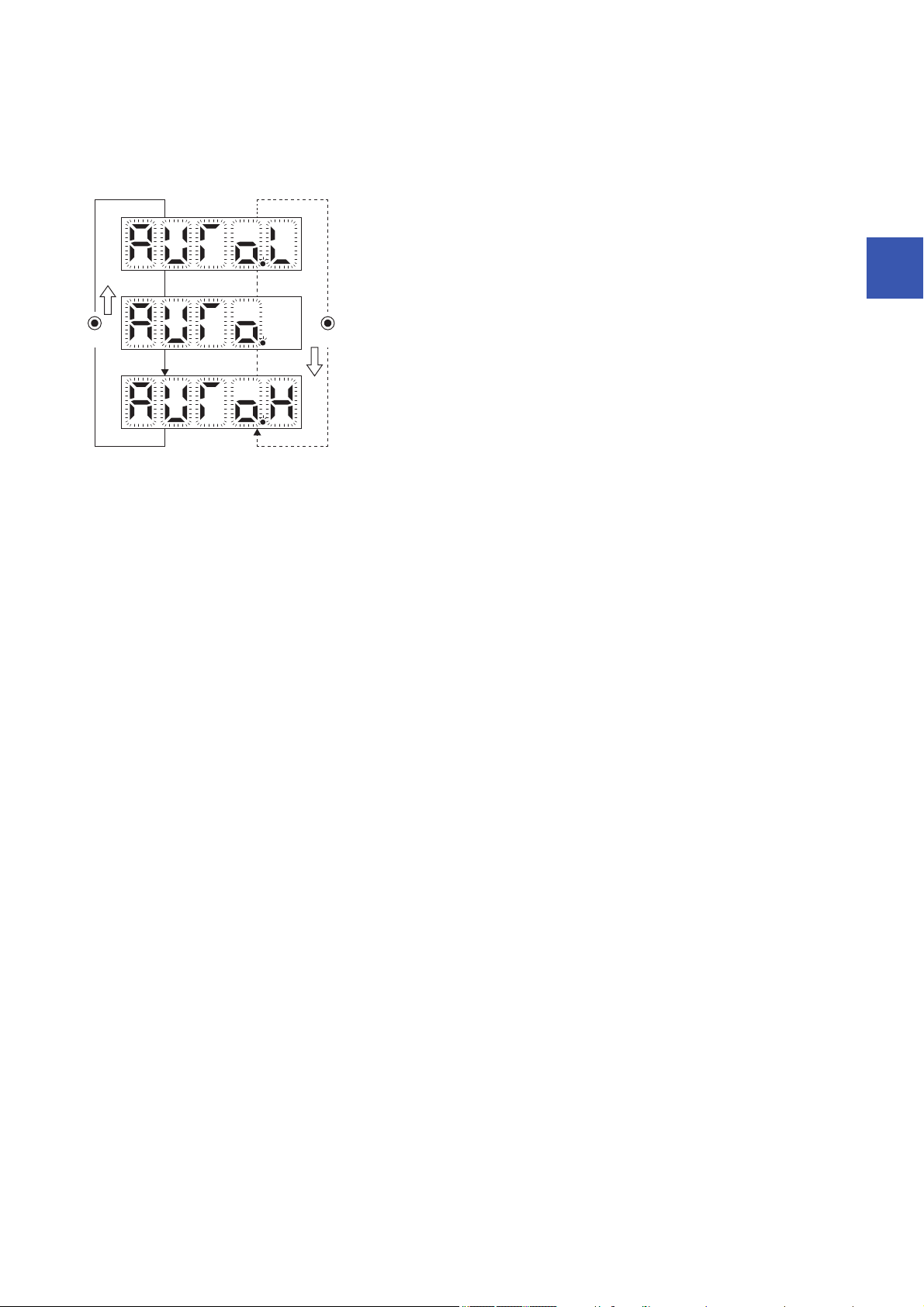

One touch adjustment procedure with push button [A]

Perform the one-touch tuning with the following procedure.

1. Start

2. Overshoot permissible level setting

Set the in-position range for one-touch tuning in [Pr. PA25 One-touch tuning - Permitted overshoot level].

3. Operation

Rotate a servo motor by a controller. In the user command method, the one-touch tuning cannot be performed during a servo

motor stop.

4. Switching to one-touch tuning mode

Push "MODE" during motor driving to switch to the initial screen ("AUTO.") of the one-touch tuning. While "AUTO" is being

displayed, push the "SET" button for 2 s or more to switch to the response mode selection ("AUTO.").

By pushing "MODE" and "SET" at the same time for 3 s or more, switching to the response mode selection ("AUTO.") can be

done without going through the initial display of the one-touch tuning ("AUTO").

5. Response mode selection

Push the "UP" or "DOWN" , and select either one of the response mode from "AUTO.H" (High mode), "AUTO." (Basic mode),

and "AUTO.L" (Low mode).

6. One-touch tuning execution

Push "SET" to start the one-touch tuning. Push the "SET" during servo motor driving.

7. One-touch tuning in progress

Gains and filters are adjusted automatically. During the process of tuning, the progress status is displayed in % on the display

(five-digit, seven-segment LED).

8. One-touch tuning complete

Once one-touch tuning is complete, each parameter will be set automatically. When the tuning is not completed normally, a

tuning error is displayed. Refer to the following.

Page 34 Initializing one-touch tuning

9. Tuning result check

Check the tuning results.

When the tuning result is not satisfactory, the servo parameters can be returned to the value before the one-touch tuning or

the initial value.

Page 34 Initializing one-touch tuning

10. End

■Overshoot permissible level setting

Refer to the following for the settings of the overshoot permissible level.

Page 18 Overshoot permissible level setting

■Operation

Refer to the following for operation.

Page 19 Operation

26

3 ADJUSTMENT METHOD

3.2 One-touch tuning

■Response mode selection

DOWN

UP

Response mode selection display

Low mode : This mode is for a low-rigid system.

Basic mode : This mode is for a standard system.

High mode : This mode is for a high-rigid system.

Select a response mode of the one-touch tuning from three modes with the "UP" button or the "DOWN" button. Refer to the

following for guidelines of response mode.

Page 19 Command method and response mode selection

■One-touch tuning execution

After the response mode is selected, pushing "SET" starts one-touch tuning.

Page 19 Command method and response mode selection

3

3 ADJUSTMENT METHOD

3.2 One-touch tuning

27

Progress display during one-touch tuning

On MR Configurator2

In servo-off status, clicking "Start" for one-touch tuning in the amplifier command method, servo-on is automatically enabled

and the one-touch tuning starts. For the one-touch tuning in the amplifier command method, an optimum tuning command is

generated inside the servo amplifier after servo-on. Then the one-touch tuning is performed with the servo motor

reciprocating. After the tuning is completed or canceled, the servo amplifier is automatically switched to the servo-off status.

When the servo-on command has been input from outside, the servo amplifier maintains the servo-on state.

During one-touch tuning, the progress status is displayed in the progress window as follows. One-touch tuning completes

when the progress reaches 100 %.

Completing the one-touch tuning starts the writing of servo parameters to the servo amplifier. Also, the following dialog is

displayed after completing the one-touch tuning. Select whether or not to reflect the tuning result in the project.

After the one-touch tuning is completed, "0000" is displayed in the status of the error code. Settling time and overshoot

amount are displayed in "Adjustment result".

28

3 ADJUSTMENT METHOD

3.2 One-touch tuning

On a controller [G] [WG]

One-touch tuning

in progress

The progress of the one-touch tuning is represented from 0 % to 100 %.

The decimal point moves right to left in rotation during the tuning.

Pushing the "MODE" button during the tuning switches to the status display.

Complete

Once the one-touch tuning is complete, the auto-tuned parameters

by the one-touch tuning will be written to the servo amplifier.

The progress of one-touch tuning can be checked with [One-touch tuning Status (Obj. 2D51h)] during one-touch tuning. When

the progress reaches 100 %, the one-touch tuning is completed and [One-touch tuning mode (Obj. 2D50h)] switches to "0".

With push buttons [A]

The following are displayed during the one-touch tuning.

3

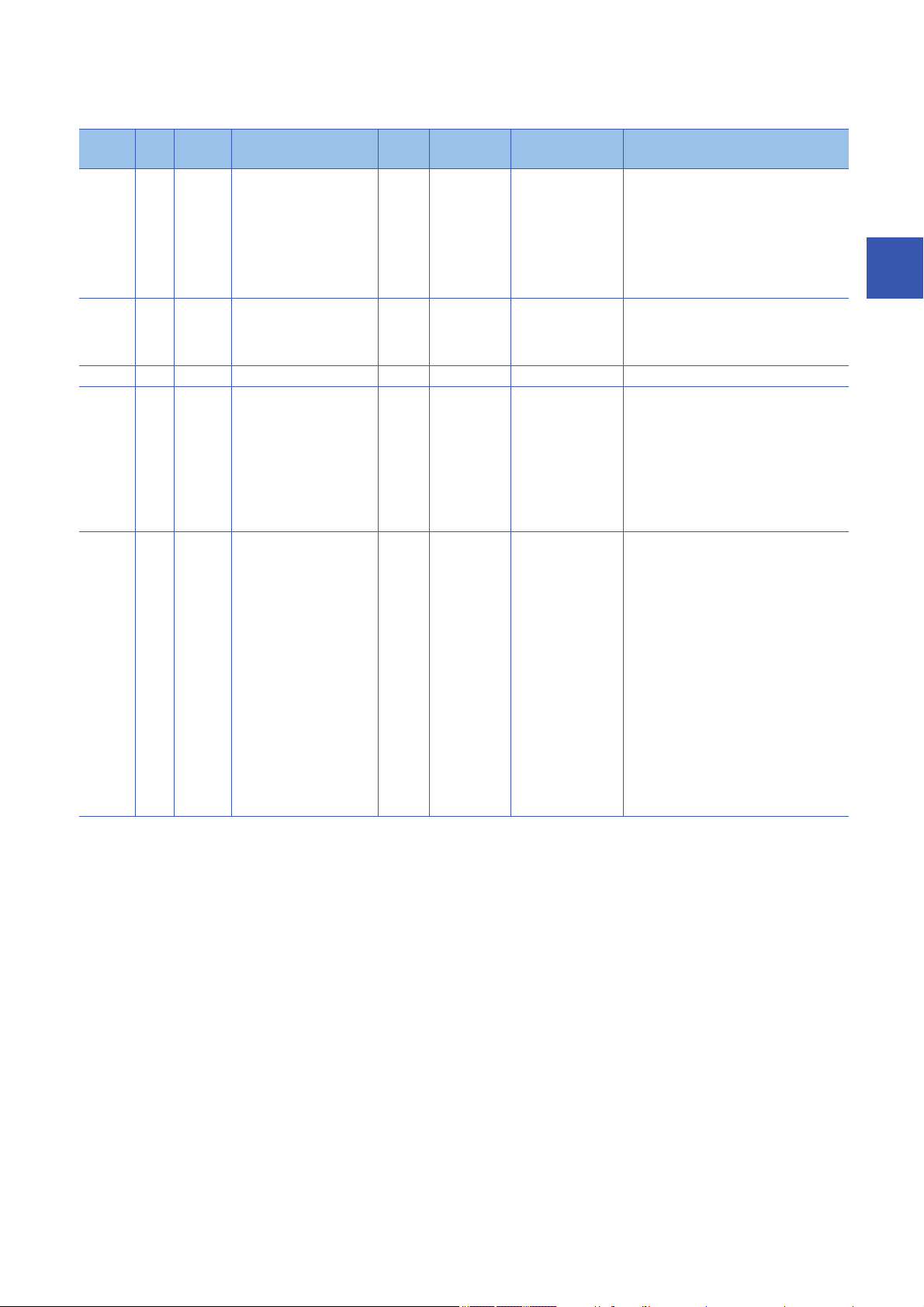

Servo parameters adjusted with one-touch tuning

The following servo parameters are set automatically with the one-touch tuning. Moreover, [Pr. PA08.0 Gain adjustment mode

selection] is set to "4" (2 gain adjustment mode 2) automatically. Other servo parameters are set to an optimum value in

accordance with the setting of [Pr. PA09 Auto tuning response].

Servo parameter Symbol Name

PA08 ATU Auto tuning mode

PA09 RSP Auto tuning response

PA24 AOP4 Function selection A-4

PB01 FILT Adaptive tuning mode (adaptive filter II)

PB02 VRFT Vibration suppression control tuning mode (advanced vibration suppression control II)

PB03 PST Position command - Acceleration/deceleration time constant (position smoothing)

PB06 GD2 Load to motor inertia ratio/load to motor mass ratio

PB07 PG1 Model control gain

PB08 PG2 Position control gain

PB09 VG2 Speed control gain

PB10 VIC Speed integral compensation

PB12 OVA Overshoot amount compensation

PB13 NH1 Machine resonance suppression filter 1

PB14 NHQ1 Notch shape selection 1

PB15 NH2 Machine resonance suppression filter 2

PB16 NHQ2 Notch shape selection 2

PB17 NHF Shaft resonance suppression filter

PB18 LPF Low-pass filter setting

PB19 VRF11 Vibration suppression control 1 - Vibration frequency

PB20 VRF12 Vibration suppression control 1 - Resonance frequency

PB21 VRF13 Vibration suppression control 1 - Vibration frequency damping

PB22 VRF14 Vibration suppression control 1 - Resonance frequency damping

PB23 VFBF Low-pass filter selection

3 ADJUSTMENT METHOD

3.2 One-touch tuning

29

Servo parameter Symbol Name

Stop symbol

Once the one-touch tuning mode is in progress, the one-touch tuning mode can be stopped

by pushing the "SET" button regardless of what is displayed on the screen.

2 s interval

The stop symbol and error code "C 000" (cancel during tuning) will be displayed by turns

with 2 s interval.

After the one-touch tuning is stopped, the servo parameters are restored to the values

at the start of the one-touch tuning.

Error code

Pushing the "SET" button will switch to the initial screen.

Initial screen

When performing the one-touch tuning again, stop the servo motor once.

PB46 NH3 Machine resonance suppression filter 3

PB47 NHQ3 Notch shape selection 3

PB48 NH4 Machine resonance suppression filter 4

PB49 NHQ4 Notch shape selection 4

PB51 NHQ5 Notch shape selection 5

PB52 VRF21 Vibration suppression control 2 - Vibration frequency

PB53 VRF22 Vibration suppression control 2 - Resonance frequency

PB54 VRF23 Vibration suppression control 2 - Vibration frequency damping

PB55 VRF24 Vibration suppression control 2 - Resonance frequency damping

PE41 EOP3 Function selection E-3

One-touch tuning stop method

On MR Configurator2

Clicking the "Stop" button during tuning stops one-touch tuning. If one-touch tuning is stopped, "C000" will be displayed in the

error code status. After the one-touch tuning is stopped, the servo parameters are restored to the values at the start of the

one-touch tuning. When performing the one-touch tuning again, stop the servo motor once. In addition, perform the one-touch

tuning after the moving part is returned to the tuning start position.

On a controller [G] [WG]

Writing "1EA5" in [One-touch tuning Stop (Obj. 2D52h)] during the one-touch tuning stops the tuning. After the one-touch

tuning is stopped, the servo parameters are restored to the values at the start of the one-touch tuning. Moreover when

performing the one-touch tuning again, stop the servo motor once.

With push buttons [A]

30

3 ADJUSTMENT METHOD

3.2 One-touch tuning

One-touch tuning error

On MR Configurator2

If a tuning error occurs during the tuning, the one-touch tuning is stopped. At this time, as the error code is displayed in the

error code status, check the cause of the tuning error. Stop the servo motor before executing one-touch tuning again. In

addition, perform the one-touch tuning after the moving part is returned to the tuning start position.

Display Name Error description Handling example

C000 Tuning canceled The "Stop" button was clicked during one-touch

C_01 Overshoot exceeded The overshoot amount is larger than the value set in

C_02 Servo OFF during tuning The one-touch tuning in the user command method

C_03 Control mode error The one-touch tuning was attempted when the

C_04 Time-out One cycle time during the operation exceeds 30 s. Set one cycle time during the operation (time from the

C_05 Load to motor inertia

ratio miscalculated

C_06 Amplifier command start

error

tuning.

[Pr. PA10 In-position range] and [Pr. PA25 Onetouch tuning - Permitted overshoot level].

was attempted during servo-off.

The servo amplifier was set to the servo-off status

during the one-touch tuning.

torque mode was selected in the control modes.

Control switching from the position mode to the

speed mode was attempted during one-touch tuning.

The command speed is slow. Set the servo motor speed to 100 r/min (mm/s) or higher. An

The dwell time during continuous operation (stop

time between commands) is short.

The estimation of the load to motor inertia ratio at the

one-touch tuning has failed.

The load to motor inertia ratio cannot be estimated

due to the effect of oscillation or others.

One-touch tuning was attempted to start by the

amplifier command method under the following

speed condition.

• Servo motor speed: 20 [r/min] or higher

• In MR-J5W-G, servo motor speed of other axes:

20 [r/min] or higher

Increase the in-position range or the overshoot permissible

level.

Perform the one-touch tuning in the user command method in

servo-on status.

Do not turn the servo off during one-touch tuning.

Select the position mode or velocity mode for the control mode,

and then perform the one-touch tuning without control

switching.

command start to the next command start) to 30 s or less.

error is less likely to occur if the command speed is higher.

Set the dwell time to 200 ms or more.

An error is less likely to occur as the setting time is longer.

Drive the servo motor under the following conditions:

• Time to reach 2000 r/min (mm/s) is the acceleration/

deceleration time constant of 5 s or less.

• Speed is 50 r/min (mm/s) or higher.

• The load to motor inertia ratio to the servo motor is 100 times

or less.

• The acceleration/deceleration torque is 10 % or more of the

rated torque.

Set [Pr. PA08.0 Gain adjustment mode selection] to "3" (manual

mode), and set the correct value of load inertia moment ratio to

[Pr. PB06 Load to motor inertia ratio], then execute the onetouch tuning.

Perform the one-touch tuning in the amplifier command method

when the servo motor is at a stop.

3

3 ADJUSTMENT METHOD

3.2 One-touch tuning

31

Display Name Error description Handling example

C_07 Amplifier command

generation error

C_08 Stop signal LSP and LSN were turned off during the one-touch

C_09 Parameter Servo parameter for manufacturer setting has been

C_0A Alarm The one-touch tuning in the amplifier command

C00F One-touch tuning

disabled

The one-touch tuning (amplifier command) was

performed when the permissible travel distance was

set to 100 [pulse] or less in the encoder pulse unit, or

the servo motor speed was set to less than 50 [r/min]

(for direct drive motors, less than 15 [r/min]) at the

load to motor inertia ratio estimation.

The overspeed alarm detection level is set where the

servo motor speed becomes 50 [r/min] or less (for

direct drive motors, 15 [r/min] or less) at the time of

load to motor inertia ratio estimation.

The torque limit value has been set to 0. Set the torque limit value greater than 0.

tuning of the amplifier command method.

EM2 was turned off during the one-touch tuning in

the amplifier command method.

changed.

method was attempted to start during an alarm or a

warning occurrence.

An alarm or a warning occurred during the one-touch

tuning in the amplifier command method.

[Pr. PA21.0 One-touch tuning function selection] is

set to "0" (disabled).

Execute one-touch tuning in the amplifier command method

after setting a permissible travel distance to be 100 [pulse] or

more in the encoder pulse unit, or setting the distance so that

the servo motor speed to be 50 [r/min] (mm/s) or more (15 [r/

min] or more for direct drive motors) at the load to motor inertia

ratio estimation.

The permissible travel distance required for estimating the load

to motor inertia ratio is two or more rotations as a guide value.

If [Pr. PA08.0 Gain adjustment mode selection] is set to "3"

(manual mode) at the start of the one-touch tuning, the load to

motor inertia ratio estimation is not performed.

If the servo motor speed cannot be set to 50 [r/min] (mm/s) or

more (15 [r/min] or more for direct drive motors) because of the

short permissible travel distance, execute one-touch tuning in

the amplifier command method while auto tuning mode [Pr.

PA08.0] is set to "3" (manual mode) which does not estimate

the load to motor inertia ratio.

When estimating the load to motor inertia ratio, set the

overspeed alarm detection level to 50 [r/min] or more (for direct

drive motors, 15 [r/min] or more).

Review the start position and the permissible travel distance of

the amplifier command method.

After ensuring safety, turn EM2 on.

Restore the servo parameters for manufacturer setting to the

initial values.

Start the one-touch tuning in the amplifier command method

when no alarm or warning occurs.

Prevent an alarm or a warning from occurring during one-touch

tuning in the amplifier command method.

Enable [Pr. PA21.0 One-touch tuning function selection] to "1"

(enabled).

The following table shows the servo parameter status after the one-touch tuning error occurred.

Error code Servo parameter after the one-touch tuning error occurrence

C0 _ _ A servo parameter is returned to the value at the start of the one-touch tuning.

C1 _ _ The following remain as the servo parameters during the one-touch tuning. Other servo parameters return to the values at

the start of the one-touch tuning.

• [Pr. PA08 Auto tuning mode (ATU)]

• [Pr. PA09 Auto tuning response (RSP)]

• [Pr. PB01 Adaptive tuning mode (adaptive filter II) (FILT)]

• [Pr. PB03 Position command acceleration/deceleration time constant (position smoothing) (PST)]

• [Pr. PB06 Load to motor inertia ratio/load to motor mass ratio (GD2)]

• [Pr. PB08 Position control gain (PG2)]

• [Pr. PB09 Speed control gain (VG2)]

• [Pr. PB10 Speed integral compensation (VIC)]

• [Pr. PB13 Machine resonance suppression filter 1 (NH1)]

• [Pr. PB14 Notch shape selection 1 (NHQ1)]

• [Pr. PB15 Machine resonance suppression filter 2 (NH2)]

• [Pr. PB16 Notch shape selection 2 (NHQ2)]

• [Pr. PB17 Shaft resonance suppression filter (NHF)]

• [Pr. PB18 Low-pass filter setting (LPF)]

• [Pr. PB23 Low-pass filter selection (VFBF)]

• [Pr. PB46 Machine resonance suppression filter 3 (NH3)]

• [Pr. PB47 Notch shape selection 3 (NHQ3)]

• [Pr. PB48 Machine resonance suppression filter 4 (NH4)]

• [Pr. PB49 Notch shape selection 4 (NHQ4)]

• [Pr. PB51 Notch shape selection 5 (NHQ5)]

• [Pr. PE41 Function selection E-3 (EOP3)]