Page 1

General-Purpose AC Servo

SSCNET /H Interface AC Servo

MODEL

MR-J4-_B_(-RJ)

SERVO AMPLIFIER

INSTRUCTION MANUAL

J

Page 2

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until

you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not

use the equipment until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 1

Page 3

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and others.

Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp is off or

not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

Do not operate switches with wet hands. Otherwise, it may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

During power-on or operation, do not open the front cover of the servo amplifier. Otherwise, it may cause

an electric shock.

Do not operate the servo amplifier with the front cover removed. High-voltage terminals and charging

area are exposed and you may get an electric shock.

Except for wiring and periodic inspection, do not remove the front cover of the servo amplifier even if the

power is off. The servo amplifier is charged and you may get an electric shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo amplifier, servo motor, and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to smoke or a fire.

Always connect a magnetic contactor between the power supply and the main circuit power supply (L1,

L2, and L3) of the servo amplifier, in order to configure a circuit that shuts down the power supply on the

side of the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a

large current may cause smoke or a fire when the servo amplifier malfunctions.

Always connect a molded-case circuit breaker, or a fuse to each servo amplifier between the power

supply and the main circuit power supply (L1, L2, and L3) of the servo amplifier, in order to configure a

circuit that shuts down the power supply on the side of the servo amplifier’s power supply. If a moldedcase circuit breaker or fuse is not connected, continuous flow of a large current may cause smoke or a

fire when the servo amplifier malfunctions.

When using the regenerative resistor, switch power off with the alarm signal. Otherwise, a regenerative

transistor malfunction or the like may overheat the regenerative resistor, causing smoke or a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and servo motor.

3. To prevent injury, note the following

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal. Otherwise, a

burst, damage, etc. may occur.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

A - 2

Page 4

CAUTION

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, servo motor, etc. may be hot while power is on or for

some time after power-off. Take safety measures, e.g. provide covers, to prevent accidental contact of

hands and parts (cables, etc.) with them.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric

shock, fire, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

Do not hold the front cover when transporting the servo amplifier. Otherwise, it may drop.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the equipment.

The equipment must be installed in the specified direction.

Leave specified clearances between the servo amplifier and the cabinet walls or other equipment.

Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

Do not block the intake and exhaust areas of the servo amplifier. Otherwise, it may cause a malfunction.

Do not drop or strike the servo amplifier and servo motor. Isolate them from all impact loads.

When you keep or use the equipment, please fulfill the following environment.

Items Environment

Ambient

temperature

Storage -20 °C to 65 °C (non-freezing)

Ambient

humidity

Storage

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, and dirt

Altitude Max. 1000 m above sea level

Vibration resistance 5.9 m/s2 at 10 Hz to 55 Hz (directions of X, Y, and Z axes)

When the equipment has been stored for an extended period of time, consult your local sales office.

When handling the servo amplifier, be careful about the edged parts such as corners of the servo

amplifier.

The servo amplifier must be installed in the metal cabinet.

When fumigants that contain halogen materials such as fluorine, chlorine, bromine, and iodine are used

for disinfecting and protecting wooden packaging from insects, they cause malfunction when entering our

products. Please take necessary precautions to ensure that remaining materials from fumigant do not

enter our products, or treat packaging with methods other than fumigation (heat method).Additionally,

disinfect and protect wood from insects before packing products.

Operation 0 °C to 55 °C (non-freezing)

Operation

90 %RH or less (non-condensing)

A - 3

Page 5

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Do not install a power capacitor, surge killer, or radio noise filter (FR-BIF-(H) option) on the servo

amplifier output side.

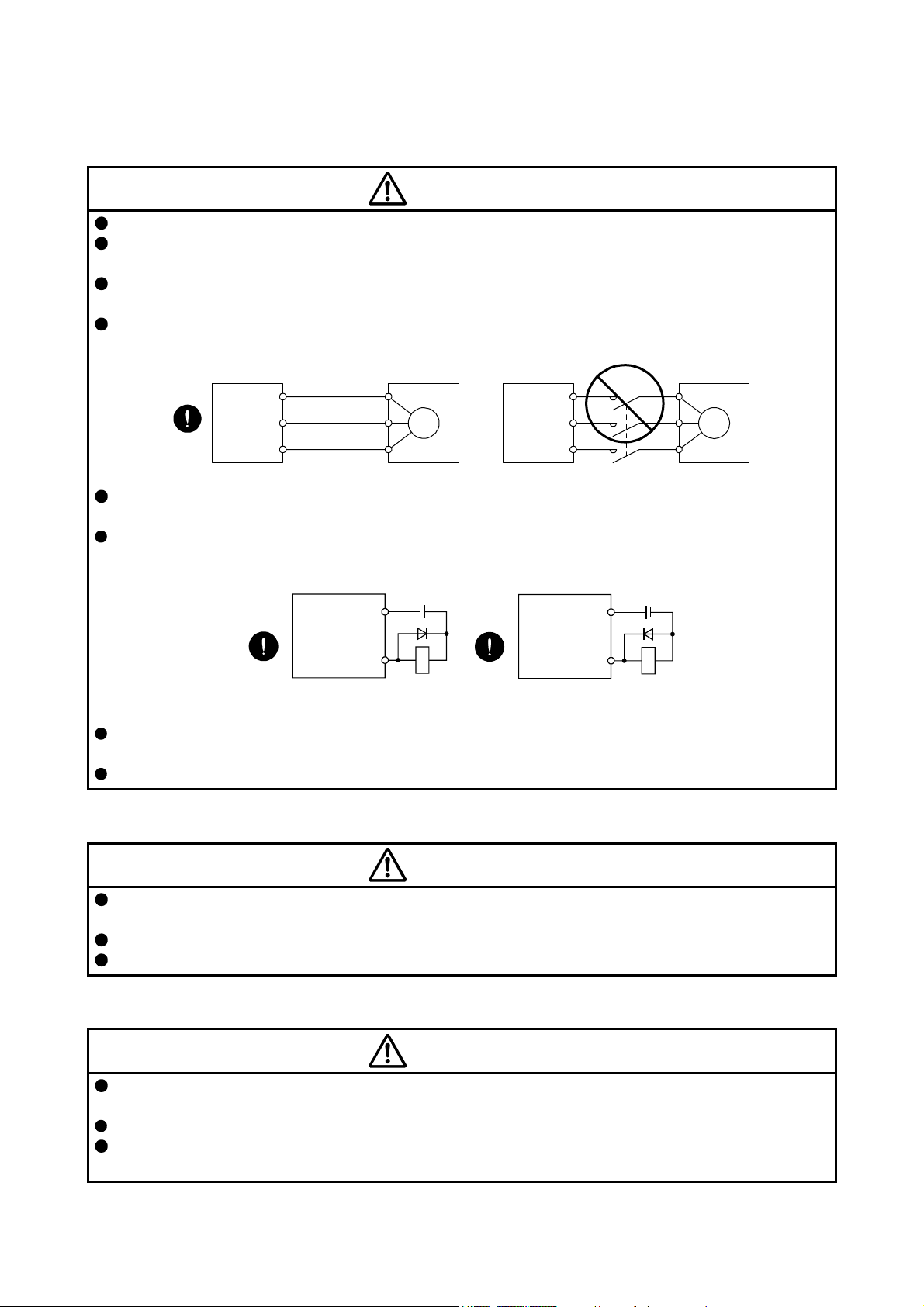

To avoid a malfunction, connect the wires to the correct phase terminals (U, V, and W) of the servo

amplifier and servo motor.

Connect the servo amplifier power output (U, V, and W) to the servo motor power input (U, V, and W)

directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

The connection diagrams in this instruction manual are shown for sink interfaces, unless stated

otherwise.

The surge absorbing diode installed to the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Servo amplifier

DOCOM

Control output

signal

For sink output interface

24 V DC

RA

Servo amplifier

24 V DC

DOCOM

Control output

signal

For source output interface

RA

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

Connecting a servo motor for different axis to the U, V, W, or CN2 may cause a malfunction.

(3) Test run and adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

Never adjust or change the parameter values extremely as it will make operation unstable.

Do not close to moving parts at servo-on status.

(4) Usage

CAUTION

Provide an external emergency stop circuit to ensure that operation can be stopped and power switched

off immediately.

Do not disassemble, repair, or modify the equipment.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off in order to prevent a

sudden restart. Otherwise, it may cause an accident.

A - 4

Page 6

CAUTION

Use a noise filter, etc. to minimize the influence of electromagnetic interference. Electromagnetic

interference may be given to the electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break it.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor

are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety,

install a stopper on the machine side.

(5) Corrective actions

CAUTION

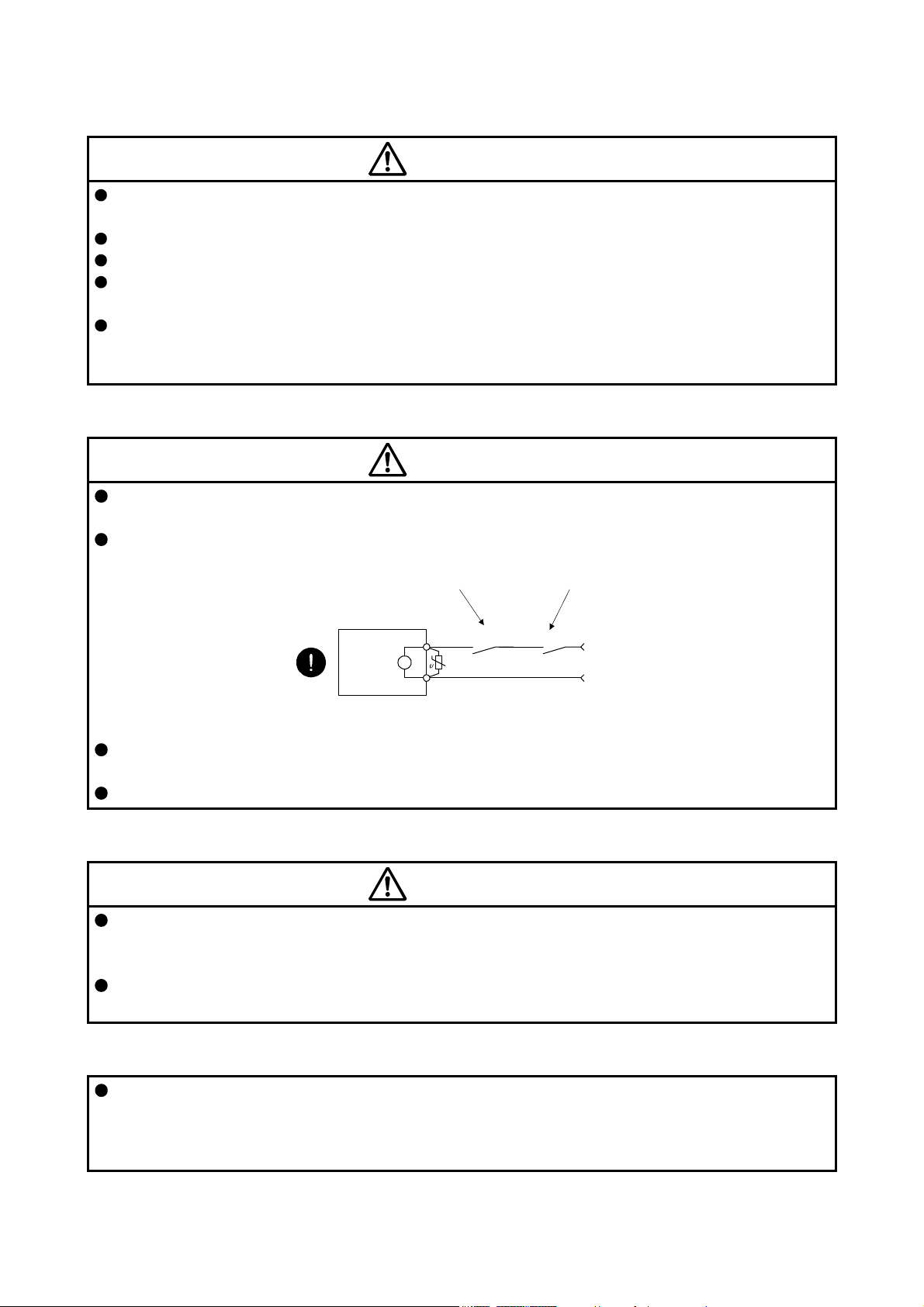

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an electromagnetic brake or external brake to prevent the condition.

Configure an electromagnetic brake circuit so that it is activated also by an external EMG stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

Contacts must be opened

with the EMG stop switch.

Servo motor

B

Electromagnetic brake

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

RA

24 V DC

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor of the servo amplifier will deteriorate. To prevent a secondary

accident due to a malfunction, it is recommend that the electrolytic capacitor be replaced every 10 years

when it is used in general environment. Please contact your local sales office.

When using a servo amplifier whose power has not been turned on for a long time, contact your local

sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Specifications and

Instruction Manual.

A - 5

Page 7

DISPOSAL OF WASTE

Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and

regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If

the total number of the following operations exceeds 100,000, the servo amplifier may malfunction when the

EEP-ROM reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

STO function of the servo amplifier

When using the STO function of the servo amplifier, refer to chapter 13.

For the MR-J3-D05 safety logic unit, refer to appendix 5.

Compliance with global standards

For the compliance with global standards, refer to appendix 4.

A - 6

Page 8

«About the manuals»

You must have this Instruction Manual and the following manuals to use this servo. Ensure to prepare

them to use the servo safely.

Relevant manuals

Manual name Manual No.

MELSERVO MR-D30 INSTRUCTION MANUAL (Note 5) SH(NA)030132

MELSERVO MR-J4-DU_(-RJ)/MR-CR55K_ INSTRUCTION MANUAL (Note 6) SH(NA)030153

MELSERVO-J4 SERVO AMPLIFIER INSTRUCTION MANUAL (TROUBLESHOOTING) SH(NA)030109

MELSERVO Servo Motor Instruction Manual (Vol. 3) (Note 1) SH(NA)030113

MELSERVO Linear Servo Motor Instruction Manual (Note 2) SH(NA)030110

MELSERVO Direct Drive Motor Instruction Manual (Note 3) SH(NA)030112

MELSERVO Linear Encoder Instruction Manual (Note 2, 4) SH(NA)030111

EMC Installation Guidelines IB(NA)67310

Note 1. It is necessary for using a rotary servo motor.

2. It is necessary for using a linear servo motor.

3. It is necessary for using a direct drive motor.

4. It is necessary for using a fully closed loop system.

5. It is necessary for using a functional safety unit MR-D30.

6. It is necessary for using an MR-J4-DU_B_(-RJ) drive unit and MR-CR55K_ converter unit.

«Wiring»

Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 °C.

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

Moment of inertia 1 [(× 10-4 kg•m2)] 5.4675 [oz•inch2]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

A - 7

Page 9

MEMO

A - 8

Page 10

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-52

1.1 Summary ........................................................................................................................................... 1- 1

1.2 Function block diagram ..................................................................................................................... 1- 3

1.3 Servo amplifier standard specifications ........................................................................................... 1-13

1.4 Combinations of servo amplifiers and servo motors ....................................................................... 1-19

1.5 Function list ...................................................................................................................................... 1-21

1.6 Model designation ............................................................................................................................ 1-23

1.7 Structure .......................................................................................................................................... 1-24

1.7.1 Parts identification ..................................................................................................................... 1-24

1.7.2 Removal and reinstallation of the front cover............................................................................ 1-37

1.8 Configuration including peripheral equipment ................................................................................. 1-39

2. INSTALLATION 2- 1 to 2- 8

2.1 Installation direction and clearances ................................................................................................ 2- 2

2.2 Keeping out of foreign materials ....................................................................................................... 2- 3

2.3 Encoder cable stress ........................................................................................................................ 2- 4

2.4 SSCNET III cable laying ................................................................................................................... 2- 4

2.5 Inspection items ................................................................................................................................ 2- 6

2.6 Parts having service lives ................................................................................................................. 2- 7

3. SIGNALS AND WIRING 3- 1 to 3-44

3.1 Input power supply circuit ................................................................................................................. 3- 3

3.1.1 200 V class ................................................................................................................................. 3- 4

3.1.2 400 V class ................................................................................................................................ 3-10

3.1.3 100 V class ................................................................................................................................ 3-14

3.2 I/O signal connection example ......................................................................................................... 3-15

3.2.1 For sink I/O interface ................................................................................................................. 3-15

3.2.2 For source I/O interface ............................................................................................................ 3-17

3.3 Explanation of power supply system ............................................................................................... 3-18

3.3.1 Signal explanations ................................................................................................................... 3-18

3.3.2 Power-on sequence .................................................................................................................. 3-19

3.3.3 Wiring CNP1, CNP2, and CNP3 ............................................................................................... 3-20

3.4 Connectors and pin assignment ...................................................................................................... 3-24

3.5 Signal (device) explanations ............................................................................................................ 3-25

3.5.1 Input device ............................................................................................................................... 3-25

3.5.2 Output device ............................................................................................................................ 3-26

3.5.3 Output signal ............................................................................................................................. 3-27

3.5.4 Power supply ............................................................................................................................. 3-27

3.6 Forced stop deceleration function ................................................................................................... 3-28

3.6.1 Forced stop deceleration function ............................................................................................. 3-28

3.6.2 Base circuit shut-off delay time function ................................................................................... 3-29

3.6.3 Vertical axis freefall prevention function ................................................................................... 3-30

3.6.4 Residual risks of the forced stop function (EM2) ...................................................................... 3-30

3.7 Alarm occurrence timing chart ......................................................................................................... 3-31

3.7.1 When you use the forced stop deceleration function ................................................................ 3-31

1

Page 11

3.7.2 When you do not use the forced stop deceleration function ..................................................... 3-32

3.8 Interfaces ......................................................................................................................................... 3-33

3.8.1 Internal connection diagram ...................................................................................................... 3-33

3.8.2 Detailed explanation of interfaces ............................................................................................. 3-34

3.8.3 Source I/O interfaces ................................................................................................................ 3-36

3.9 SSCNET III cable connection .......................................................................................................... 3-37

3.10 Servo motor with an electromagnetic brake .................................................................................. 3-39

3.10.1 Safety precautions .................................................................................................................. 3-39

3.10.2 Timing chart ............................................................................................................................ 3-40

3.11 Grounding ...................................................................................................................................... 3-44

4. STARTUP 4- 1 to 4-20

4.1 Switching power on for the first time ................................................................................................. 4- 2

4.1.1 Startup procedure ...................................................................................................................... 4- 2

4.1.2 Wiring check ............................................................................................................................... 4- 3

4.1.3 Surrounding environment ........................................................................................................... 4- 6

4.2 Startup .............................................................................................................................................. 4- 6

4.3 Switch setting and display of the servo amplifier .............................................................................. 4- 8

4.3.1 Switches ..................................................................................................................................... 4- 8

4.3.2 Scrolling display ........................................................................................................................ 4-11

4.3.3 Status display of an axis ........................................................................................................... 4-12

4.4 Test operation .................................................................................................................................. 4-14

4.5 Test operation mode ........................................................................................................................ 4-14

4.5.1 Test operation mode in MR Configurator2 ................................................................................ 4-15

4.5.2 Motor-less operation in controller .............................................................................................. 4-18

5. PARAMETERS 5- 1 to 5-54

5.1 Parameter list .................................................................................................................................... 5- 1

5.1.1 Basic setting parameters ([Pr. PA_ _ ]) ...................................................................................... 5- 2

5.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) ............................................................................... 5- 3

5.1.3 Extension setting parameters ([Pr. PC_ _ ]) .............................................................................. 5- 4

5.1.4 I/O setting parameters ([Pr. PD_ _ ]) ......................................................................................... 5- 6

5.1.5 Extension setting 2 parameters ([Pr. PE_ _ ]) ............................................................................ 5- 7

5.1.6 Extension setting 3 parameters ([Pr. PF_ _ ]) ............................................................................ 5- 8

5.1.7 Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) ................................................ 5- 9

5.2 Detailed list of parameters ............................................................................................................... 5-11

5.2.1 Basic setting parameters ([Pr. PA_ _ ]) ..................................................................................... 5-11

5.2.2 Gain/filter setting parameters ([Pr. PB_ _ ]) .............................................................................. 5-22

5.2.3 Extension setting parameters ([Pr. PC_ _ ]) ............................................................................. 5-35

5.2.4 I/O setting parameters ([Pr. PD_ _ ]) ........................................................................................ 5-42

5.2.5 Extension setting 2 parameters ([Pr. PE_ _ ]) ........................................................................... 5-48

5.2.6 Extension setting 3 parameters ([Pr. PF_ _ ]) ........................................................................... 5-51

5.2.7 Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) ............................................... 5-52

6. NORMAL GAIN ADJUSTMENT 6- 1 to 6-18

6.1 Different adjustment methods ........................................................................................................... 6- 1

6.1.1 Adjustment on a single servo amplifier ...................................................................................... 6- 1

6.1.2 Adjustment using MR Configurator2 .......................................................................................... 6- 2

2

Page 12

6.2 One-touch tuning .............................................................................................................................. 6- 3

6.2.1 One-touch tuning flowchart ........................................................................................................ 6- 3

6.2.2 Display transition and operation procedure of one-touch tuning ............................................... 6- 4

6.2.3 Caution for one-touch tuning ...................................................................................................... 6- 8

6.3 Auto tuning ........................................................................................................................................ 6- 9

6.3.1 Auto tuning mode ....................................................................................................................... 6- 9

6.3.2 Auto tuning mode basis ............................................................................................................. 6-10

6.3.3 Adjustment procedure by auto tuning ....................................................................................... 6-11

6.3.4 Response level setting in auto tuning mode ............................................................................. 6-12

6.4 Manual mode ................................................................................................................................... 6-13

6.5 2 gain adjustment mode .................................................................................................................. 6-16

7. SPECIAL ADJUSTMENT FUNCTIONS 7- 1 to 7-38

7.1 Filter setting ...................................................................................................................................... 7- 1

7.1.1 Machine resonance suppression filter ....................................................................................... 7- 2

7.1.2 Adaptive filter II ........................................................................................................................... 7- 5

7.1.3 Shaft resonance suppression filter ............................................................................................. 7- 7

7.1.4 Low-pass filter ............................................................................................................................ 7- 8

7.1.5 Advanced vibration suppression control II ................................................................................. 7- 8

7.1.6 Command notch filter ................................................................................................................ 7-13

7.2 Gain switching function .................................................................................................................... 7-15

7.2.1 Applications ............................................................................................................................... 7-15

7.2.2 Function block diagram ............................................................................................................. 7-16

7.2.3 Parameter .................................................................................................................................. 7-17

7.2.4 Gain switching procedure ......................................................................................................... 7-20

7.3 Tough drive function ........................................................................................................................ 7-24

7.3.1 Vibration tough drive function.................................................................................................... 7-24

7.3.2 Instantaneous power failure tough drive function ..................................................................... 7-26

7.4 Compliance with SEMI-F47 standard .............................................................................................. 7-30

7.5 Model adaptive control disabled ...................................................................................................... 7-33

7.6 Lost motion compensation function ................................................................................................. 7-34

7.7 Super trace control .......................................................................................................................... 7-37

8. TROUBLESHOOTING 8- 1 to 8- 8

8.1 Explanation for the lists ..................................................................................................................... 8- 1

8.2 Alarm list ........................................................................................................................................... 8- 2

8.3 Warning list ....................................................................................................................................... 8- 7

8.4 Troubleshooting at power on ............................................................................................................ 8- 8

9. OUTLINE DRAWINGS 9- 1 to 9-22

9.1 Servo amplifier .................................................................................................................................. 9- 1

9.2 Connector ........................................................................................................................................ 9-20

10. CHARACTERISTICS 10- 1 to 10-14

10.1 Overload protection characteristics .............................................................................................. 10- 1

10.2 Power supply capacity and generated loss .................................................................................. 10- 5

10.3 Dynamic brake characteristics ...................................................................................................... 10- 8

3

Page 13

10.3.1 Dynamic brake operation ....................................................................................................... 10- 8

10.3.2 Permissible load to motor inertia when the dynamic brake is used ...................................... 10-11

10.4 Cable bending life ........................................................................................................................ 10-12

10.5 Inrush currents at power-on of main circuit and control circuit .................................................... 10-13

11. OPTIONS AND PERIPHERAL EQUIPMENT 11- 1 to 11-106

11.1 Cable/connector sets .................................................................................................................... 11- 1

11.1.1 Combinations of cable/connector sets ................................................................................... 11- 2

11.1.2 MR-D05UDL3M-B STO cable ................................................................................................ 11- 6

11.1.3 SSCNET III cable ................................................................................................................... 11- 7

11.1.4 Battery cable/junction battery cable ....................................................................................... 11- 9

11.2 Regenerative options ................................................................................................................... 11-10

11.2.1 Combination and regenerative power ................................................................................... 11-10

11.2.2 Selection of regenerative option ........................................................................................... 11-12

11.2.3 Parameter setting .................................................................................................................. 11-15

11.2.4 Selection of regenerative option ........................................................................................... 11-15

11.2.5 Dimensions ........................................................................................................................... 11-20

11.3 FR-BU2-(H) brake unit ................................................................................................................. 11-24

11.3.1 Selection................................................................................................................................ 11-24

11.3.2 Brake unit parameter setting ................................................................................................. 11-25

11.3.3 Connection example ............................................................................................................. 11-26

11.3.4 Dimensions ........................................................................................................................... 11-34

11.4 FR-RC-(H) power regeneration converter ................................................................................... 11-37

11.5 FR-CV-(H) power regeneration common converter .................................................................... 11-41

11.5.1 Model designation ................................................................................................................. 11-42

11.5.2 Selection................................................................................................................................ 11-42

11.6 Junction terminal block PS7DW-20V14B-F (recommended) ...................................................... 11-50

11.7 MR Configurator2 ........................................................................................................................ 11-51

11.7.1 Specifications ........................................................................................................................ 11-51

11.7.2 System configuration ............................................................................................................. 11-52

11.7.3 Precautions for using USB communication function ............................................................. 11-53

11.8 Battery ..................................................................................................................

........................ 11-54

11.8.1 Selection of battery ............................................................................................................... 11-54

11.8.2 MR-BAT6V1SET battery ....................................................................................................... 11-54

11.8.3 MR-BAT6V1BJ battery for junction battery cable ................................................................. 11-58

11.8.4 MR-BT6VCASE battery case ................................................................................................ 11-62

11.8.5 MR-BAT6V1 battery .............................................................................................................. 11-68

11.9 Selection example of wires .......................................................................................................... 11-69

11.10 Molded-case circuit breakers, fuses, magnetic contactors ....................................................... 11-73

11.11 Power factor improving DC reactors .......................................................................................... 11-75

11.12 Power factor improving AC reactors .......................................................................................... 11-77

11.13 Relay (recommended) ............................................................................................................... 11-80

11.14 Noise reduction techniques ....................................................................................................... 11-81

11.15 Earth-leakage current breaker ................................................................................................... 11-88

11.16 EMC filter (recommended) ........................................................................................................ 11-91

11.17 External dynamic brake ............................................................................................................. 11-95

11.18 Heat sink outside mounting attachment (MR-J4ACN15K/MR-J3ACN) ................................... 11-101

4

Page 14

12. ABSOLUTE POSITION DETECTION SYSTEM 12- 1 to 12- 6

12.1 Summary ....................................................................................................................................... 12- 1

12.1.1 Features ................................................................................................................................. 12- 1

12.1.2 Structure ................................................................................................................................. 12- 2

12.1.3 Parameter setting ................................................................................................................... 12- 2

12.1.4 Confirmation of absolute position detection data ................................................................... 12- 2

12.2 Battery ........................................................................................................................................... 12- 3

12.2.1 Using MR-BAT6V1SET battery .............................................................................................. 12- 3

12.2.2 Using MR-BAT6V1BJ battery for junction battery cable ........................................................ 12- 4

12.2.3 Using MR-BT6VCASE battery case ....................................................................................... 12- 5

13. USING STO FUNCTION 13- 1 to 13-14

13.1 Introduction ................................................................................................................................... 13- 1

13.1.1 Summary ................................................................................................................................ 13- 1

13.1.2 Terms related to safety .......................................................................................................... 13- 1

13.1.3 Cautions ................................................................................................................................. 13- 1

13.1.4 Residual risks of the STO function ......................................................................................... 13- 2

13.1.5 Specifications ......................................................................................................................... 13- 3

13.1.6 Maintenance ........................................................................................................................... 13- 4

13.2 STO I/O signal connector (CN8) and signal layouts ..................................................................... 13- 4

13.2.1 Signal layouts ......................................................................................................................... 13- 4

13.2.2 Signal (device) explanations .................................................................................................. 13- 5

13.2.3 How to pull out the STO cable ............................................................................................... 13- 5

13.3 Connection example ..................................................................................................................... 13- 6

13.3.1 Connection example for CN8 connector ................................................................................ 13- 6

13.3.2 External I/O signal connection example using an MR-J3-D05 safety logic unit .................... 13- 7

13.3.3 External I/O signal connection example using an external safety relay unit ......................... 13- 9

13.3.4 External I/O signal connection example using a motion controller ....................................... 13-10

13.4 Detailed description of interfaces ................................................................................................ 13-11

13.4.1 Sink I/O interface ................................................................................................................... 13-11

13.4.2 Source I/O interface .............................................................................................................. 13-13

14. USING A LINEAR SERVO MOTOR 14- 1 to 14-32

14.1 Functions and configuration ......................................................................................................... 14- 1

14.1.1 Summary ................................................................................................................................ 14- 1

14.1.2 Servo system with auxiliary equipment .................................................................................. 14- 2

14.2 Signals and wiring ......................................................................................................................... 14- 6

14.3 Operation and functions ................................................................................................................ 14- 8

14.3.1 Startup .................................................................................................................................... 14- 8

14.3.2 Magnetic pole detection ........................................................................................................ 14-11

14.3.3 Home position return ............................................................................................................. 14-19

14.3.4 Test operation mode in MR Configurator2 ............................................................................ 14-23

14.3.5 Operation from controller ...................................................................................................... 14-24

14.3.6 Function................................................................................................................................. 14-26

14.3.7 Absolute position detection system ....................................................................................... 14-28

14.4 Characteristics ............................................................................................................................. 14-29

14.4.1 Overload protection characteristics ...................................................................................... 14-29

14.4.2 Power supply capacity and generated loss .......................................................................... 14-30

5

Page 15

14.4.3 Dynamic brake characteristics .............................................................................................. 14-31

14.4.4 Permissible load to motor mass ratio when the dynamic brake is used ............................... 14-32

15. USING A DIRECT DRIVE MOTOR 15- 1 to 15-22

15.1 Functions and configuration ......................................................................................................... 15- 1

15.1.1 Summary ................................................................................................................................ 15- 1

15.1.2 Servo system with auxiliary equipment .................................................................................. 15- 2

15.2 Signals and wiring ......................................................................................................................... 15- 3

15.3 Operation and functions ................................................................................................................ 15- 4

15.3.1 Startup procedure .................................................................................................................. 15- 5

15.3.2 Magnetic pole detection ......................................................................................................... 15- 6

15.3.3 Operation from controller ...................................................................................................... 15-14

15.3.4 Function................................................................................................................................. 15-15

15.4 Characteristics ............................................................................................................................. 15-17

15.4.1 Overload protection characteristics ...................................................................................... 15-17

15.4.2 Power supply capacity and generated loss .......................................................................... 15-19

15.4.3 Dynamic brake characteristics .............................................................................................. 15-20

16. FULLY CLOSED LOOP SYSTEM 16- 1 to 16-26

16.1 Functions and configuration ......................................................................................................... 16- 1

16.1.1 Function block diagram .......................................................................................................... 16- 1

16.1.2 Selecting procedure of control mode ..................................................................................... 16- 3

16.1.3 System configuration .............................................................................................................. 16- 4

16.2 Load-side encoder ........................................................................................................................ 16- 6

16.2.1 Linear encoder ....................................................................................................................... 16- 6

16.2.2 Rotary encoder ....................................................................................................................... 16- 6

16.2.3 Configuration diagram of encoder cable ................................................................................ 16- 6

16.2.4 MR-J4FCCBL03M branch cable ............................................................................................ 16- 8

16.3 Operation and functions ................................................................................................................ 16- 9

16.3.1 Startup .................................................................................................................................... 16- 9

16.3.2 Home position return ............................................................................................................. 16-16

16.3.3 Operation from controller ...................................................................................................... 16-19

16.3.4 Fully closed loop control error detection functions................................................................ 16-21

16.3.5 Auto tuning function .............................................................................................................. 16-22

16.3.6 Machine analyzer function .................................................................................................... 16-22

16.3.7 Test operation mode ............................................................................................................. 16-22

16.3.8 Absolute position detection system under fully closed loop system ..................................... 16-23

16.3.9 About MR Configurator2 ....................................................................................................... 16-24

17. APPLICATION OF FUNCTIONS 17- 1 to 17-70

17.1 J3 compatibility mode ................................................................................................................... 17- 1

17.1.1 Outline of J3 compatibility mode ............................................................................................ 17- 1

17.1.2 Operation modes supported by J3 compatibility mode .......................................................... 17- 2

17.1.3 J3 compatibility mode supported function list ........................................................................ 17- 2

17.1.4 How to switch J4 mode/J3 compatibility mode ...................................................................... 17- 5

17.1.5 How to use the J3 compatibility mode ................................................................................... 17- 6

17.1.6 Cautions for switching J4 mode/J3 compatibility mode ......................................................... 17- 7

17.1.7 Cautions for the J3 compatibility mode .................................................................................. 17- 7

6

Page 16

17.1.8 Change of specifications of "J3 compatibility mode" switching process ................................ 17- 9

17.1.9 J3 extension function ............................................................................................................ 17-12

17.2 Master-slave operation function .................................................................................................. 17-59

17.3 Scale measurement function ....................................................................................................... 17-63

17.3.1 Functions and configuration .................................................................................................. 17-63

17.3.2 Scale measurement encoder ................................................................................................ 17-66

17.3.3 How to use scale measurement function .............................................................................. 17-69

APPENDIX App.- 1 to App.-50

App. 1 Peripheral equipment manufacturer (for reference) .............................................................. App.- 1

App. 2 Handling of AC servo amplifier batteries for the United Nations Recommendations on the

Transport of Dangerous Goods ............................................................................................ App.- 1

App. 3 Symbol for the new EU Battery Directive .............................................................................. App.- 3

App. 4 Compliance with global standards ........................................................................................ App.- 3

App. 5 MR-J3-D05 Safety logic unit ................................................................................................ App.-19

App. 6 EC declaration of conformity ................................................................................................ App.-37

App. 7 How to replace servo amplifier without magnetic pole detection ......................................... App.-39

App. 8 Two-wire type encoder cable for HG-MR/HG-KR ................................................................ App.-40

App. 9 SSCNET III cable (SC-J3BUS_M-C) manufactured by Mitsubishi Electric System & Service

............................................................................................................................................. App.-42

App. 10 Analog monitor ..................................................................................................................... App.-42

App. 11 Special specification ............................................................................................................. App.-47

App. 12 Driving on/off of main circuit power supply with DC power supply ...................................... App.-49

7

Page 17

MEMO

8

Page 18

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

The Mitsubishi MELSERVO-J4 series general-purpose AC servo has further higher performance and higher

functions compared to the previous MELSERVO-J3 series.

MR-J4-_B_ servo amplifier is connected to controllers, including a servo system controller, on the highspeed synchronous network SSCNET III/H. The servo amplifier directly receives a command from a

controller to drive a servo motor.

MELSERVO-J4 series compatible rotary servo motor is equipped with 22-bit (4194304 pulses/rev) highresolution absolute encoder. In addition, speed frequency response is increased to 2.5 kHz. Thus, faster and

more accurate control is enabled as compared to MELSERVO-J3 series.

MR-J4-_B_ servo amplifier operates MELSERVO-J4 series compatible rotary servo motors, linear servo

motors, and direct drive motors as standard.

With one-touch tuning and real-time auto tuning, you can automatically adjust the servo gains according to

the machine.

The tough drive function and the drive recorder function, which are well-received in the MELSERVO-JN

series, have been improved. The MR-J4 servo amplifier supports the improved functions. Additionally, the

preventive maintenance support function detects an error in the machine parts. This function provides strong

support for the machine maintenance and inspection.

SSCNET III/H achieves high-speed communication of 150 Mbps full duplex with high noise immunity due to

the SSCNET III optical cables. Large amounts of data are exchanged in real-time between the controller and

the servo amplifier. Servo monitor information is stored in the upper information system and is used for

control.

On the SSCNET III/H network, the stations are connected with a maximum distance of 100 m between them.

This allows you to create a large system.

The MR-J4-_B_ servo amplifier supports the Safe Torque Off (STO) function. When the MR-J4W_-B servo

amplifier is connected to a SSCNET III/H-compatible servo system controller, in addition to the STO function,

the servo amplifier also supports the Safe Stop 1 (SS1), Safe Stop 2 (SS2), Safe Operating Stop (SOS),

Safely-Limited Speed (SLS), Safe Brake Control (SBC), and Safe Speed Monitor (SSM) functions.

The MR-J4W_-B servo amplifier has a USB communication interface. Therefore, you can connect the servo

amplifier to the personal computer with MR Configurator2 installed to perform the parameter setting, test

operation, gain adjustment, and others.

In MELSERVO-J4 series, servo amplifiers with CN2L connector is also available as MR-J4-_B_-RJ. By using

CN2L connector, an A/B/Z-phase differential output method external encoder can be connected to the servo

amplifier. In a fully closed loop system, a four-wire type external encoder is connectable as well. The

following table indicates the communication method of the external encoder compatible with MR-J4-_B_ and

MR-J4-_B_-RJ servo amplifiers.

1 - 1

Page 19

1. FUNCTIONS AND CONFIGURATION

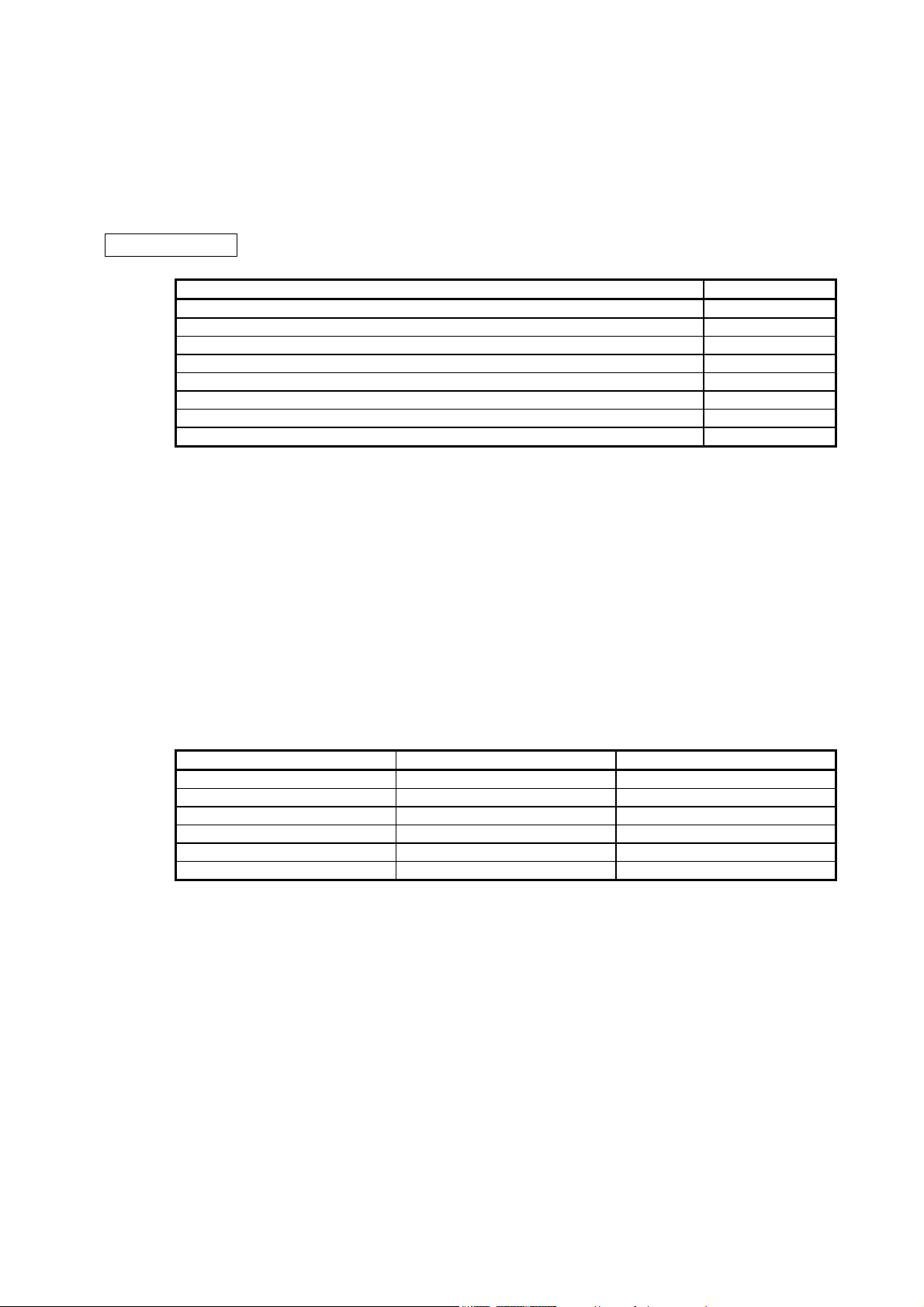

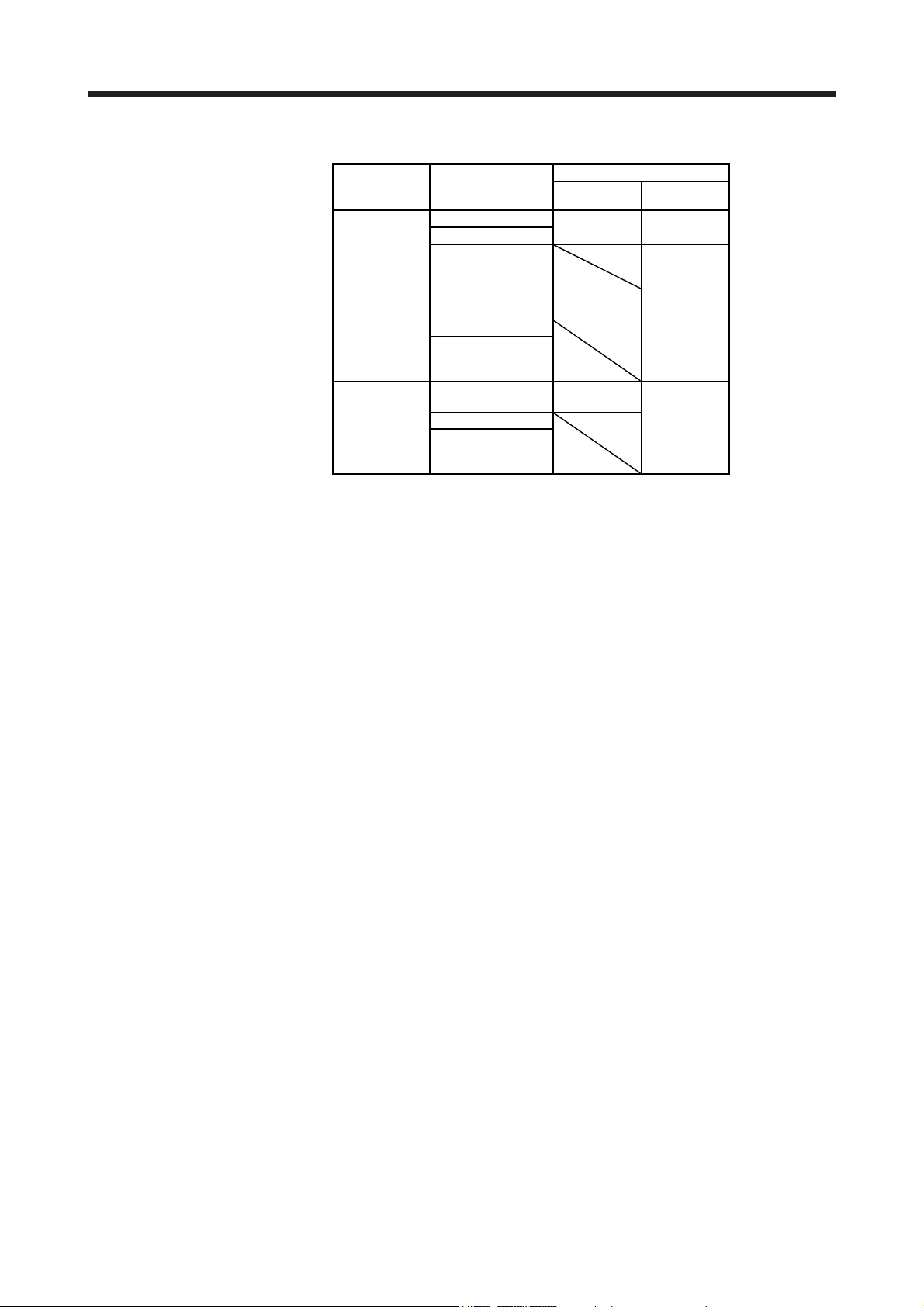

Table 1.1 Connectors to connect from external encoders

Operation

mode

Linear servo

motor system

Fully closed

loop system

Scale

measurement

function

Note 1. The MR-J4THCBL03M branch cable is necessary.

2. The MR-J4FCCBL03M branch cable is necessary.

3. When the communication method of the servo motor encoder is four-wire type,

MR-J4-_B_ cannot be used. Use an MR-J4-_B_-RJ.

4. This is used with servo amplifiers with software version A3 or later.

5. This is used with servo amplifiers with software version A8 or later.

6. Connect a thermistor to CN2.

External encoder

communication

method

Two-wire type

Four-wire type

A/B/Z-phase

differential output

method

Two-wire type

Four-wire type

A/B/Z-phase

differential output

method

Two-wire type

Four-wire type

A/B/Z-phase

differential output

method

Connector

MR-J4-_B_ MR-J4-_B_-RJ

CN2 (Note 1) CN2 (Note 1)

CN2L (Note 6)

CN2

(Note 2, 3, 4)

CN2L

CN2

(Note 2, 3, 5)

CN2L (Note 5)

1 - 2

Page 20

1. FUNCTIONS AND CONFIGURATION

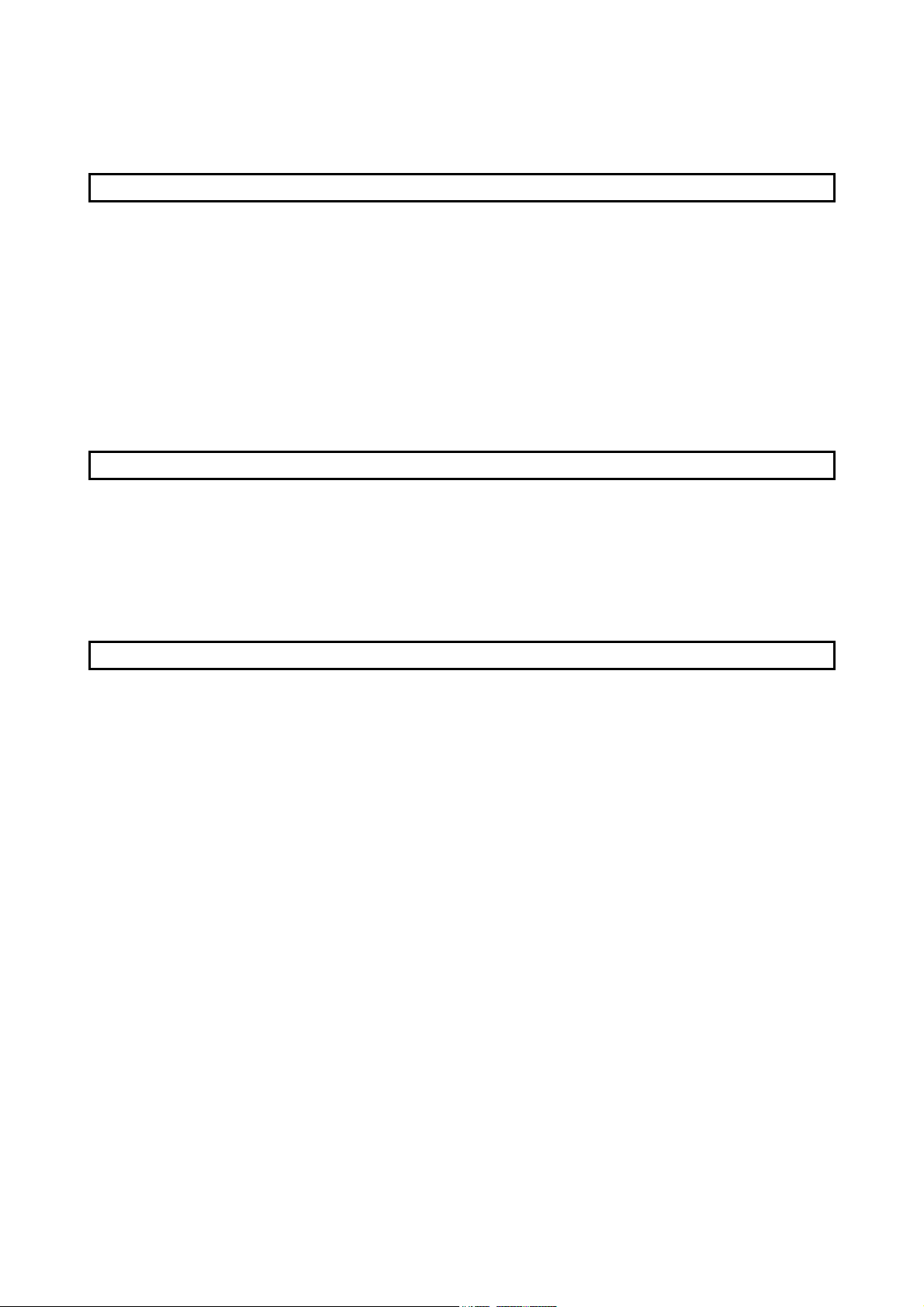

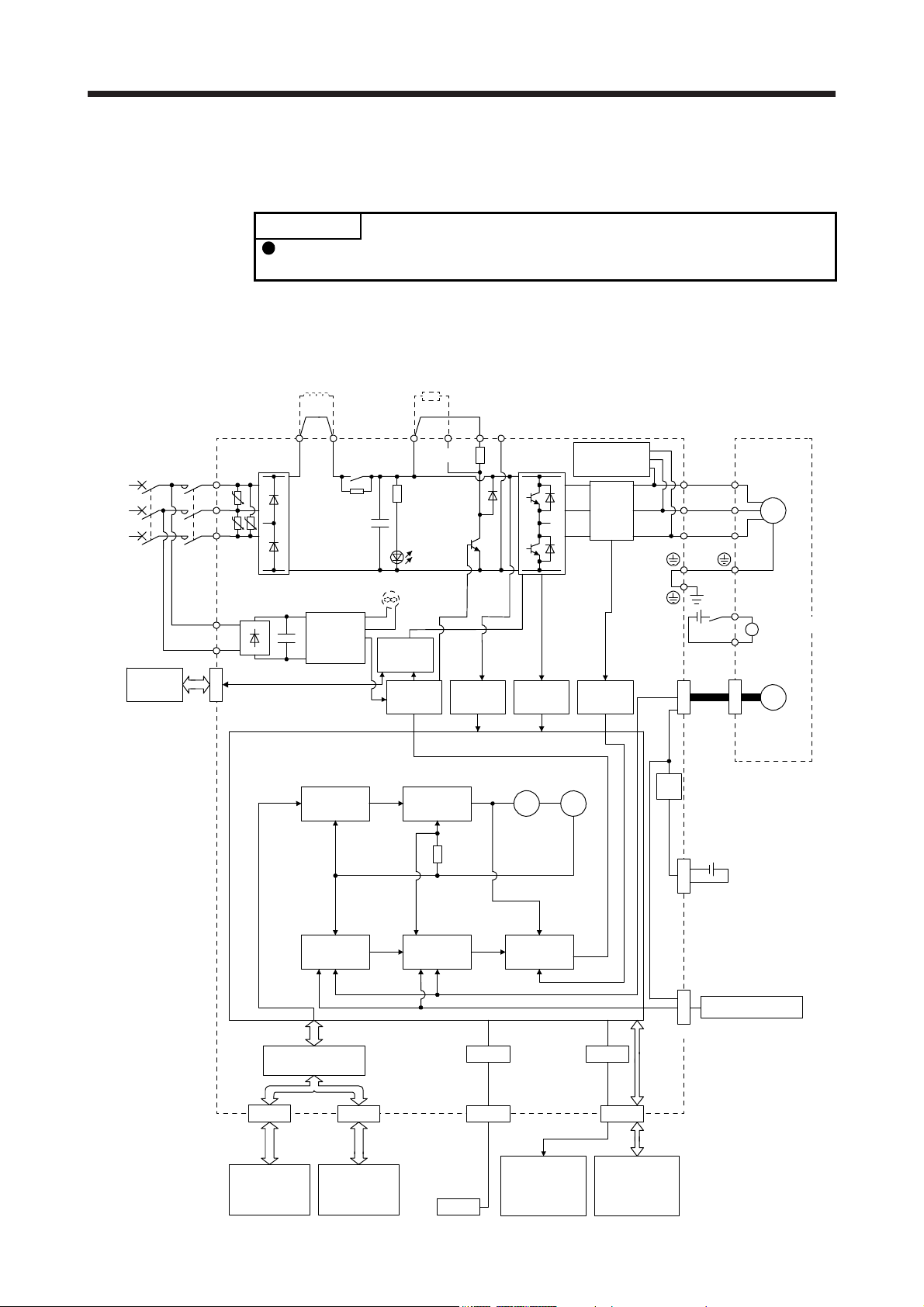

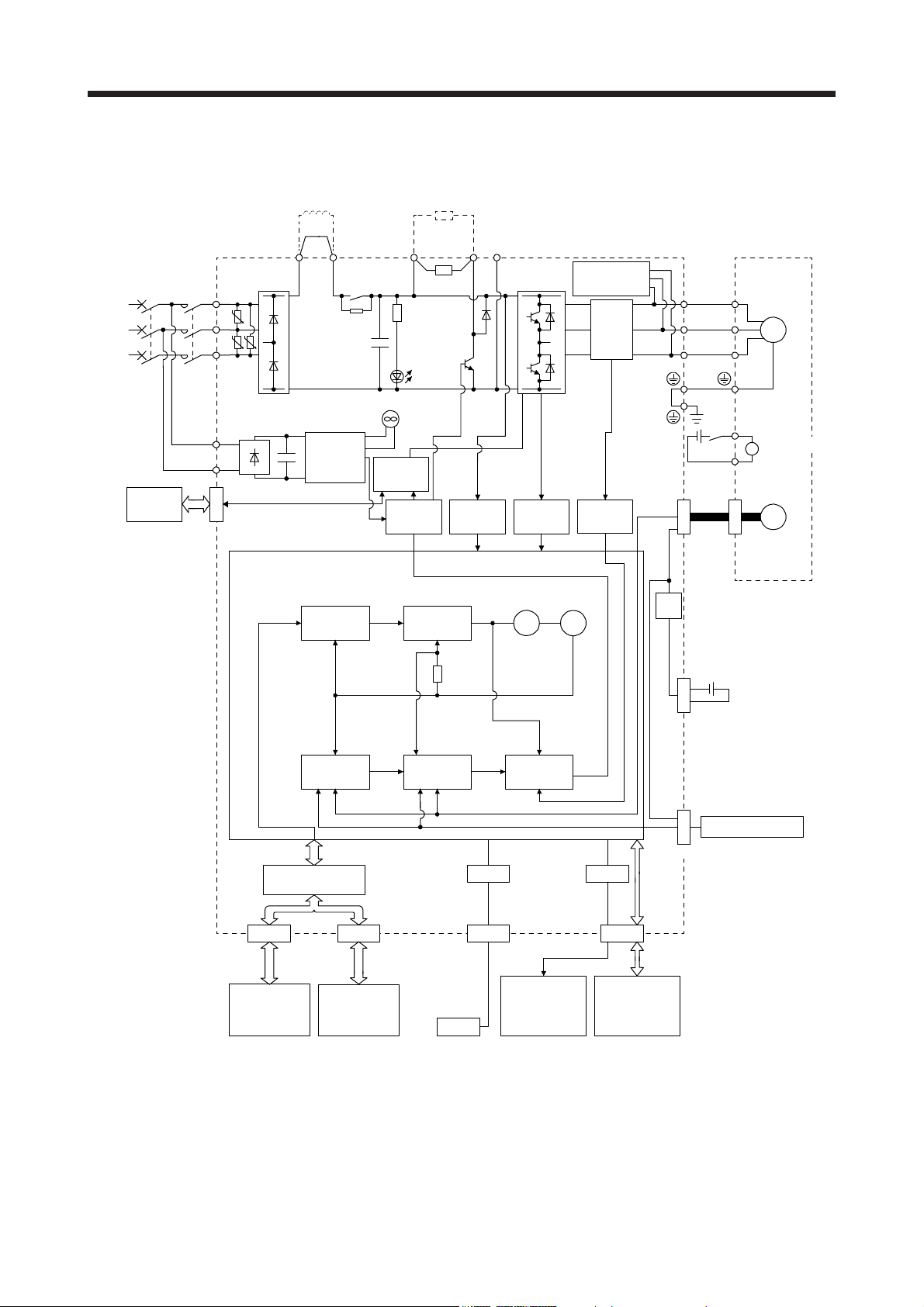

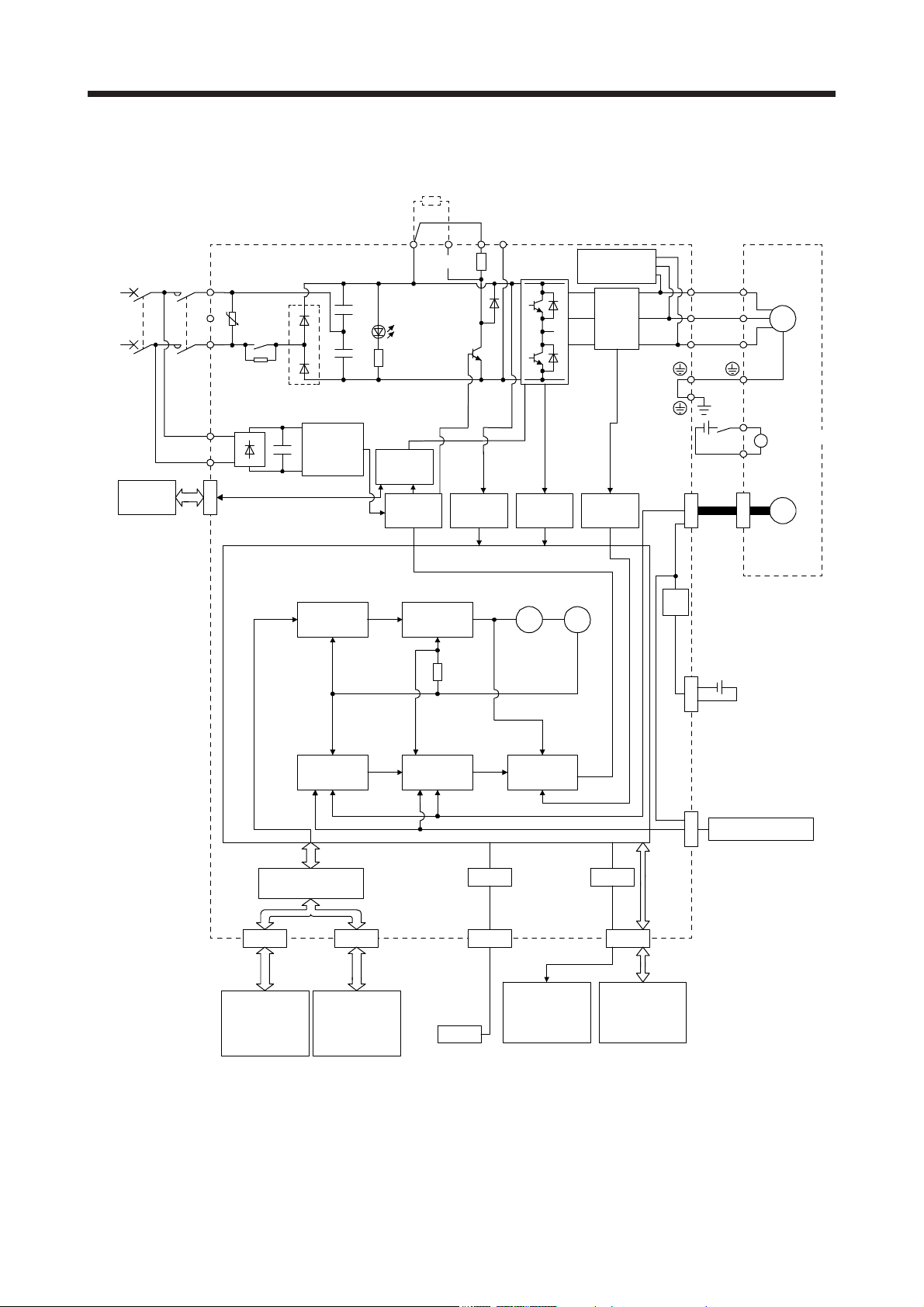

1.2 Function block diagram

The function block diagram of this servo is shown below.

Regenerative

option

(1) 200 V class

(a) MR-J4-500B(-RJ) or less

POINT

The diagram shows for MR-J4-_B_-RJ as an example. MR-J4-_B_ servo

amplifier does not have CN2L connector.

(Note 6)

Power factor improving

DC reactor

(Note 2)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

L11

L21

CN8

P3 P4

Diode

stack

Position

command

input

+

(Note 4)

Relay

Cooling fan

(Note 3)

Control

circuit

power

supply

Model

position

control

+

CHARGE

lamp

STO

circuit

Base

amplifier

P+

(Note 1)

Regenerative

TR

Model

speed

control

Voltage

detection

N-CD

Overcurrent

protection

Virtual

motor

detection

Virtual

encoder

Dynamic

brake

circuit

Current

encoder

Current

Stepdown

circuit

U

V

W

RA

24 V DC

CN2

Servo motor

U

V

W

B1

B

B2

M

Electromagnetic

brake

Encoder

position

I/F Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model position

Actual

control

Servo

amplifier

or cap

Model speed Model torque

Actual

speed

control

Personal

computer

USB

USB

CN5

Analog monitor

(2 channels)

Current

control

1 - 3

D/A

CN3

Digital I/O

control

CN4

Battery

(for absolute position

detection system)

External encoder

CN2L

(Note 5)

Page 21

1. FUNCTIONS AND CONFIGURATION

Note 1. The built-in regenerative resistor is not provided for MR-J4-10B(-RJ).

2. For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open.

Refer to section 1.3 for the power supply specifications.

3. Servo amplifiers MR-J4-70B(-RJ) or more have a cooling fan.

4. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

5. This is for MR-J4-_B-RJ servo amplifier. MR-J4-_B servo amplifier does not have CN2L connector.

6. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

1 - 4

Page 22

1. FUNCTIONS AND CONFIGURATION

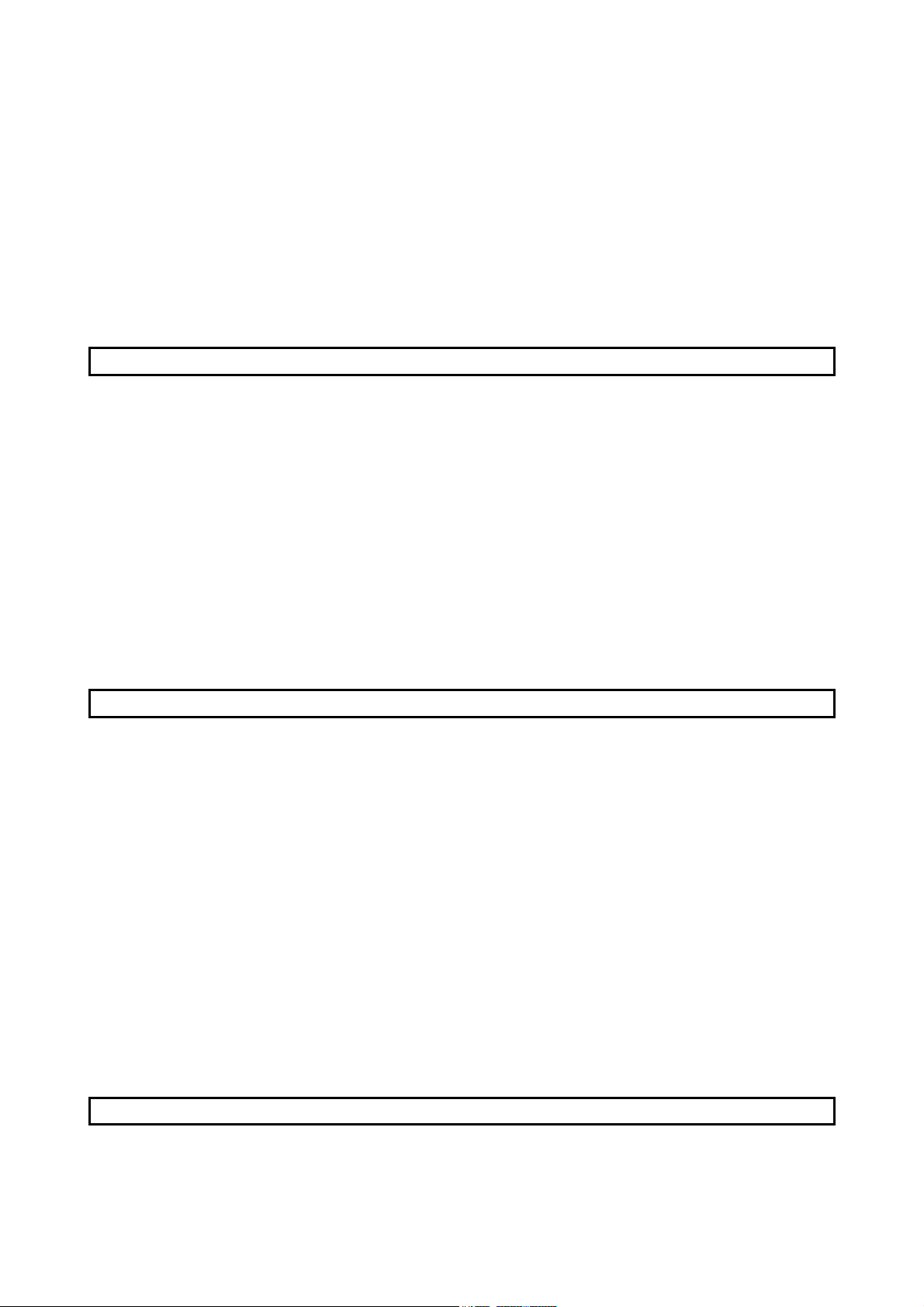

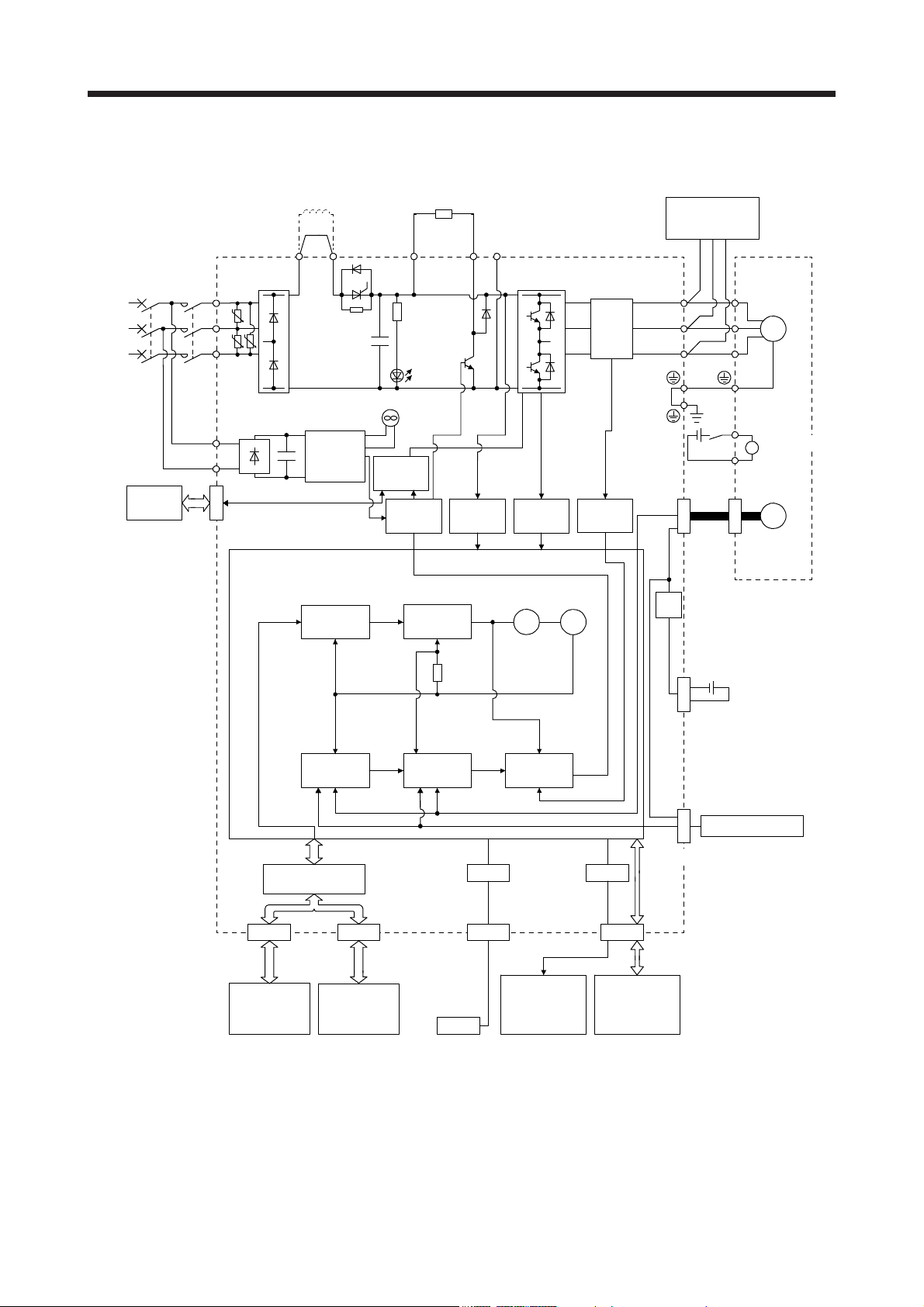

(b) MR-J4-700B(-RJ)

(Note 4)

Power factor improving

DC reactor

Regenerative

option

(Note 1)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

L11

L21

CN8

P3 P4

Diode

stack

Position

command

input

+

(Note 2)

Relay

Cooling fan

Control

circuit

power

supply

Model

position

control

+

CHARGE

lamp

STO

circuit

Base

amplifier

P+

Regenerative

TR

Model

speed

control

Voltage

detection

N-C

Overcurrent

Virtual

motor

protection

detection

Virtual

encoder

Dynamic

brake

circuit

Current

encoder

Current

Stepdown

circuit

U

V

W

RA

24 V DC

CN2

Servo motor

U

V

W

B1

B

B2

M

Electromagnetic

brake

Encoder

CN4

Battery

(for absolute position

detection system)

External encoder

CN2L

(Note 3)

position

I/F Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model position

Actual

control

Servo

amplifier

or cap

Model speed Model torque

Actual

speed

control

Current

control

USB

CN5

Personal

computer

Analog monitor

(2 channels)

USB

D/A

CN3

Digital I/O

control

Note 1. Refer to section 1.3 for the power supply specifications.

2. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

3. This is for MR-J4-_B-RJ servo amplifier. MR-J4-_B servo amplifier does not have CN2L connector.

4. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

1 - 5

Page 23

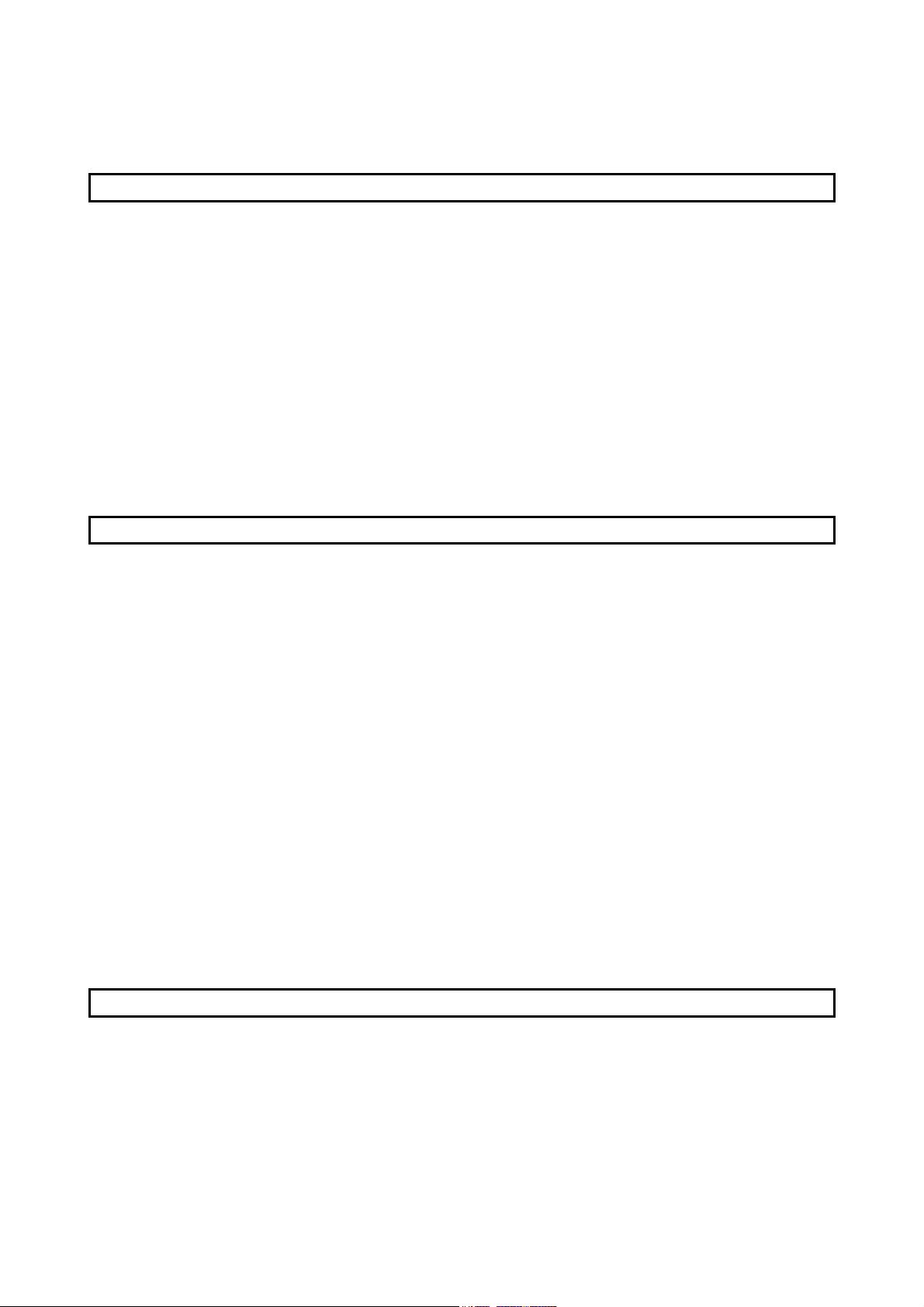

1. FUNCTIONS AND CONFIGURATION

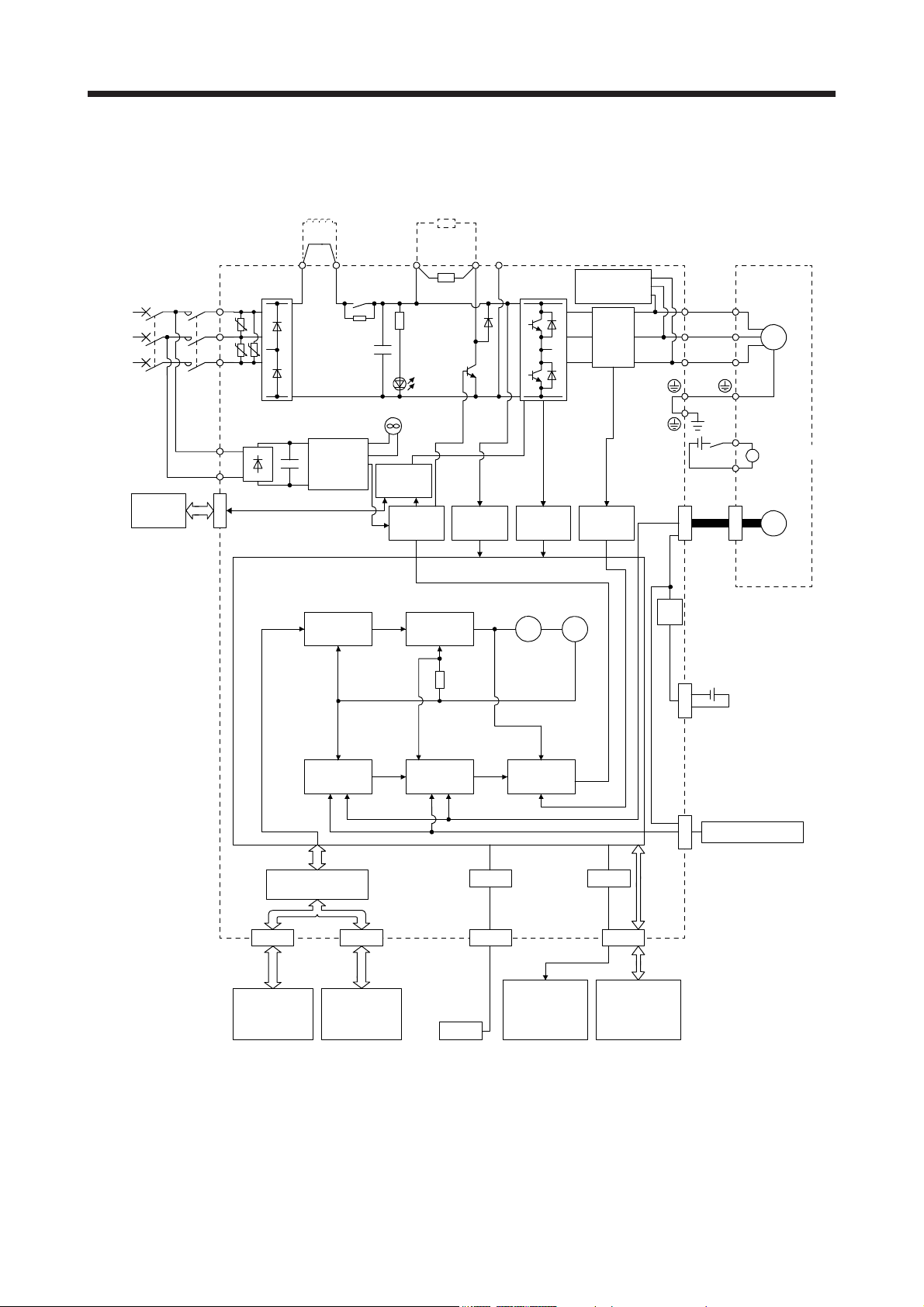

(c) MR-J4-11KB(-RJ)/MR-J4-15KB(-RJ)/MR-J4-22KB(-RJ)

(Note 1)

Power

supply

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

(Note 5)

Power factor improving

DC reactor

P3 P4

Diode

stack

External regenerative

regenerative option

(Note 2)

Thyristor

+

resistor or

P+

Regenerative

TR

(Note 4, 6)

External dynamic

brake (optional)

N-C

U

Current

encoder

V

W

Servo motor

U

V

M

W

STO

switch

L11

L21

CN8

Position

command

input

Cooling fan

Control

+

circuit

power

supply

Model

position

control

Actual

position

control

I/F Control

CHARGE

STO

circuit

Base

amplifier

Model position

lamp

Overcurrent

protection

Virtual

motor

Model

speed

control

Voltage

detection

Model speed Model torque

Actual

speed

control

Current

control

USB

detection

Virtual

encoder

Current

D/A

RA

24 V DC

CN2

Stepdown

circuit

CN4

Battery

(for absolute position

detection system)

External encoder

CN2L

(Note 3)

B1

Electromagnetic

B

brake

B2

Encoder

CN1A CN1B

Servo system

controller or

servo amplifier

Servo

amplifier

or cap

Personal

computer

USB

CN5

Analog monitor

(2 channels)

CN3

Digital I/O

control

1 - 6

Page 24

1. FUNCTIONS AND CONFIGURATION

Note 1. Refer to section 1.3 for the power supply specifications.

2. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

3. This is for MR-J4-_B-RJ servo amplifier. MR-J4-_B servo amplifier does not have CN2L connector.

4. Use an external dynamic brake for this servo amplifier. Failure to do so will cause an accident because the servo motor does

not stop immediately but coasts at an alarm occurrence for which the servo motor does not decelerate to stop. Ensure the

safety in the entire equipment. For alarms for which the servo motor does not decelerate to stop, refer to chapter 8.

5. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

6. The external dynamic brake cannot be used for compliance with SEMI-F47 standard. Do not assign DB (Dynamic brake

interlock) in [Pr. PD07] to [Pr. PD09]. Failure to do so will cause the servo amplifier to become servo-off when an

instantaneous power failure occurs.

1 - 7

Page 25

1. FUNCTIONS AND CONFIGURATION

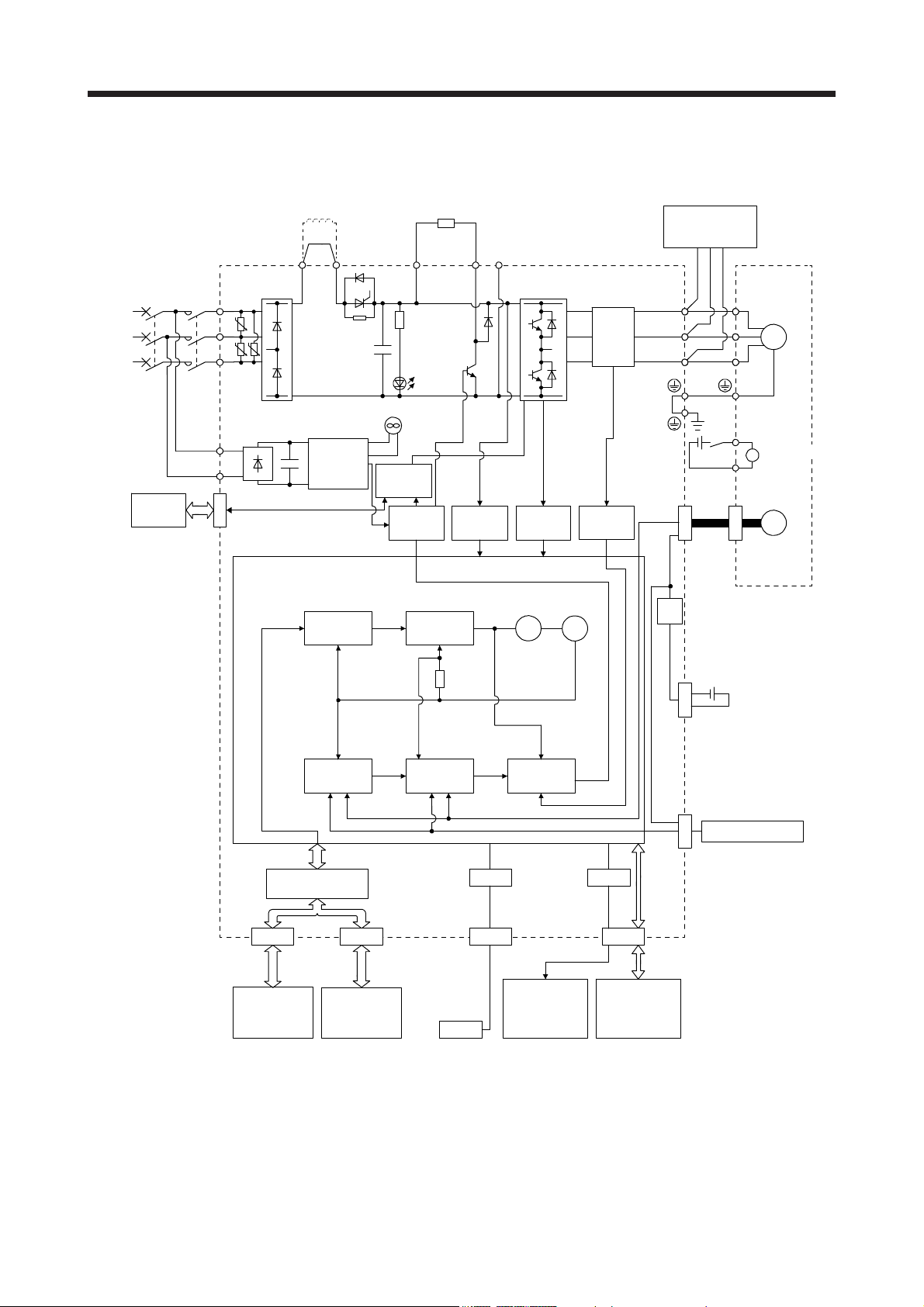

(2) 400 V class

(a) MR-J4-350B4(-RJ) or less

(Note 5)

Power factor

improving

DC reactor

Regenerative

option

(Note 1)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

L11

L21

CN8

P3 P4 (Note 3)

Diode

stack

+

Position

command

input

Relay

(Note 2)

Control

circuit

power

supply

Model

position

control

+

Cooling fan

STO

circuit

Base

amplifier

P+

Regenerative

TR

Charge

lamp

Model

speed

control

Voltage

detection

N-CD

Overcurrent

protection

Virtual

motor

detection

Virtual

encoder

Dynamic

brake

circuit

Current

detector

Current

Stepdown

circuit

U

V

W

RA

24 V DC

CN2

Servo motor

U

V

W

B1

B

B2

M

Electromagnetic

brake

Encoder

CN4

Battery

(For absolute

position detection

system)

External encoder

CN2L

(Note 4)

position

IF Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model position

Actual

control

Servo

amplifier

or cap

Model speed Model torque

Actual

speed

control

Current

control

USB

CN5

Personal

computer

Analog monitor

(2 channels)

USB

D/A

CN3

Digital I/O

control

Note 1. Refer to section 1.3 for the power supply specification.

2. Servo amplifiers MR-J4-200B4(-RJ) or more have a cooling fan.

3. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

4. This is for MR-J4-_B4-RJ servo amplifier. MR-J4-_B4 servo amplifier does not have CN2L connector.

5. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

1 - 8

Page 26

1. FUNCTIONS AND CONFIGURATION

(b) MR-J4-500B4(-RJ)/MR-J4-700B4(-RJ)

(Note 4)

Power factor

improving

DC reactor

Regenerative

option

(Note 1)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

L11

L21

CN8

P3 P4 (Note 2)

Diode

stack

+

Position

command

input

Relay

Control

circuit

power

supply

Model

position

control

+

Cooling fan

STO

circuit

Base

amplifier

P+

Regenerative

TR

Charge

lamp

Model

speed

control

Voltage

detection

N-C

Overcurrent

Virtual

motor

protection

detection

Virtual

encoder

Dynamic

brake

circuit

Current

detector

Current

Stepdown

circuit

U

V

W

RA

24 V DC

CN2

Servo motor

U

V

W

B1

B

B2

M

Electromagnetic

brake

Encoder

CN4

Battery

(For absolute

position detection

system)

External encoder

CN2L

(Note 3)

position

IF Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model position Model speed Model torque

Actual

control

Actual

speed

control

USB

CN5

Servo

amplifier

or cap

Personal

computer

USB

Analog monitor

(2 channels)

Current

control

D/A

CN3

Digital I/O

control

Note 1. Refer to section 1.3 for the power supply specification.

2. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

3. This is for MR-J4-_B4-RJ servo amplifier. MR-J4-_B4 servo amplifier does not have CN2L connector.

4. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

1 - 9

Page 27

1. FUNCTIONS AND CONFIGURATION

(c) MR-J4-11KB4(-RJ)/MR-J4-15KB4(-RJ)/MR-J4-22KB4(-RJ)

(Note 1)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

U U

L3

L11

L21

CN8

(Note 5)

Power factor

improving

DC reactor

P3 P4 (Note 2)

Diode

stack

Control

+

circuit

power

supply

Thyristor

Cooling fan

External

regenerative resistor

or

regenerative option

P+

+

Regenerative

TR

Charge

lamp

STO

circuit

Base

amplifier

Voltage

detection

N-C

Overcurrent

protection

Current

detector

Current

detection

(Note 4, 6)

External

dynamic brake

(optional)

U

V

W

W

RA

24 V DC

CN2

Servo motor

U

V

M

B1

Electromagnetic

B

brake

B2

Encoder

Position

command

input

position

position

IF Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model

control

Model position

Actual

control

Servo

amplifier

or cap

Virtual

motor

encoder

Model

speed

control

Model speed Model torque

Actual

speed

control

Current

control

USB

CN5

Personal

computer

Analog monitor

(2 channels)

USB

Virtual

D/A

CN3

Digital I/O

control

Stepdown

circuit

CN4

Battery

(For absolute

position detection

system)

CN2L

(Note 3)

External encoder

1 - 10

Page 28

1. FUNCTIONS AND CONFIGURATION

Note 1. Refer to section 1.3 for the power supply specification.

2. MR-J4 servo amplifier has P3 and P4 in the upstream of the inrush current suppression circuit. They are different from P1 and

P2 of MR-J3 servo amplifiers.

3. This is for MR-J4-_B4-RJ servo amplifier. MR-J4-_B4 servo amplifier does not have CN2L connector.

4. Use an external dynamic brake for this servo amplifier. Failure to do so will cause an accident because the servo motor does

not stop immediately but coasts at an alarm occurrence for which the servo motor does not decelerate to stop. Ensure the

safety in the entire equipment. For alarms for which the servo motor does not decelerate to stop, refer to chapter 8.

5. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used.

When not using the power factor improving DC reactor, short P3 and P4.

6. The external dynamic brake cannot be used for compliance with SEMI-F47 standard. Do not assign DB (Dynamic brake

interlock) in [Pr. PD07] to [Pr. PD09]. Failure to do so will cause the servo amplifier to become servo-off when an

instantaneous power failure occurs.

1 - 11

Page 29

1. FUNCTIONS AND CONFIGURATION

(3) 100 V class

Regenerative

option

(Note 2)

Power

supply

STO

switch

Servo amplifier

MCMCCB

L1

U

L2

L11

L21

CN8

Relay

Diode stack

Position

command

input

+

Control

circuit

power

supply

Model

position

control

U

V

W

RA

Servo motor

M

B1

Electromagnetic

B

brake

B2

P+

(Note 1)

N-CD

Dynamic brake

circuit

U

+

Charge

lamp

Regene-

+

rative TR

Current

encoder

V

W

24 V DC

STO

circuit

Base

amplifier

Voltage

detection

Overcurrent

protection

Current

detection

CN2

Encoder

Model

speed

control

Virtual

encoder

Virtual

Stepdown

circuit

motor

Model speed Model torque

Actual

speed

control

Current

control

USB

CN5

Personal

computer

Analog monitor

(two channel)

USB

D/A

CN3

Digital I/O

control

IF Control

CN1A CN1B

Servo system

controller or

servo amplifier

Model position

Actual

position

control

Servo

amplifier

or cap

Note 1. The built-in regenerative resistor is not provided for MR-J4-10B1(-RJ).

2. Refer to section 1.3 for the power supply specifications.

3. This is for MR-J4-_B1-RJ servo amplifier. MR-J4-_B1 servo amplifier does not have CN2L connector.

CN4