Page 1

June 2008

Air to Water (ATW) Heat pump,

Interface (I/F) and Flow temp. controller (FTC)

Technical manual

CONTENTS

1. What is ATW heat pump? .......................................................2

2. Heat pump unit_General information ...................................4

3. System design ......................................................................15

4. Interface (I/F) ........................................................................23

5. Flow temp. controller (FTC) .................................................55

6. Requirements........................................................................90

7. System example ...................................................................91

Page 2

What is ATW heat pump?1

1-1. Compare with conventional fossil fuel boiler

• Heat pumps produce water at 30°C – 60°C

• Ideal for underfl oor heating

• Average underfl oor heating circuit 35°C

• Fossil fuel boilers heat water to 80°C

• Flow temp in rads design temp approx 70°C

• Heat pumps can still be used with radiators

• Larger surface area to emit heat from lower temp water

1-2. Points to notice

1-2-1. Design (Radiator sizing)

• Careful consideration must be given to appropriate application of this technology to maximise its benefi ts – it will not suit all

properties, especially many retrofi ts

• Heat emitters may need to be larger

• Lower fl ow temperatures maximise COP

• Various regulations apply to the design and installation of such systems

• Because the fl ow temp. of heat pump is low compare to fossile fuel boiler, the temperature difference between the primary (fl ow

water) and secondary (room air) becomes little, it makes the heat emission little.

To emit the same amount of heat energy, it is needed to select the radiator that has a larger surface area.

Be especially careful of the surface area when you design the radiator.

1-2-2. Defrost

Note: Occasionally, vapor that is made by the defrost operation may seem as if smoke come up from the outdoor unit.

1-2-3. Water Pressure loss (for packaged type outdoor unit)

• Water pressure lose of the heat exchangers are as follows.

Be aware of the infl uence when you design total pipng system.

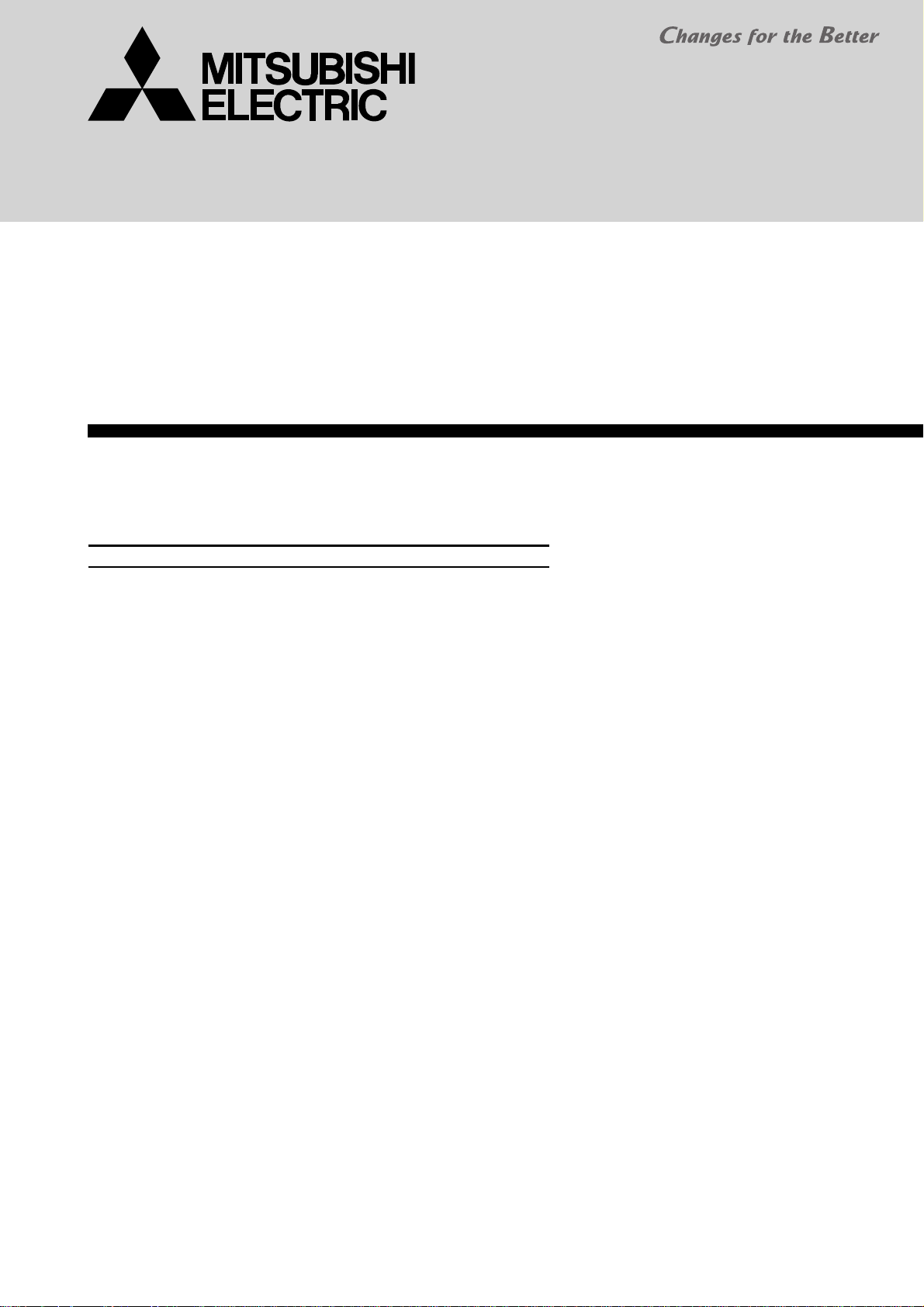

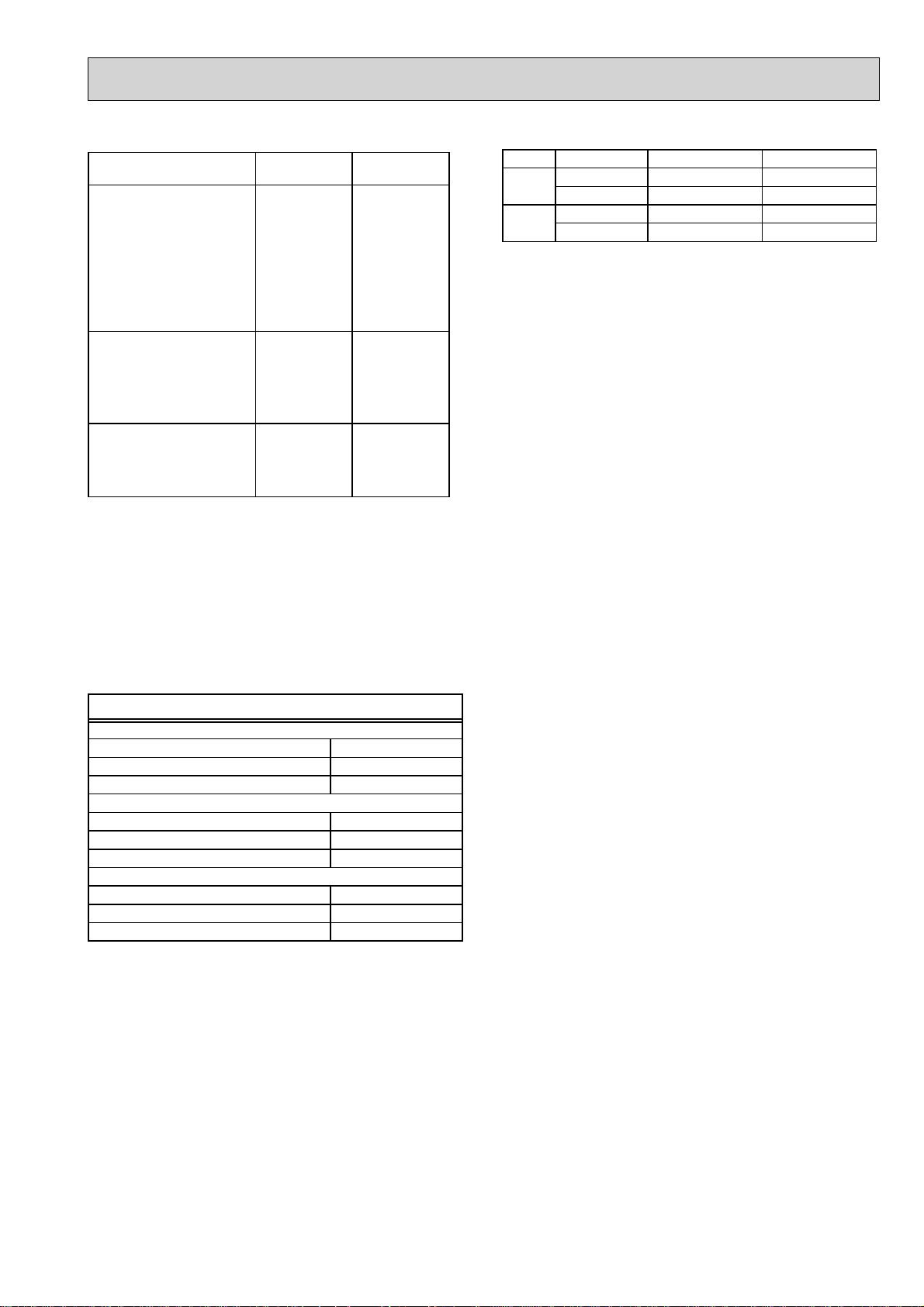

Hex for PUHZ-W50VHA (ACH30-30Plates)

Secondary (Water - side)

Flow rate (L/min) 5 10 15 20 25 30

Pressure Loss (kPa) 1.7 6.0 12.4 20.9 31.4 43.8

Pressure loss (kPa)

50

45

40

35

30

25

20

15

10

5

0

51015202530

Flow rate (L/min)

2

Page 3

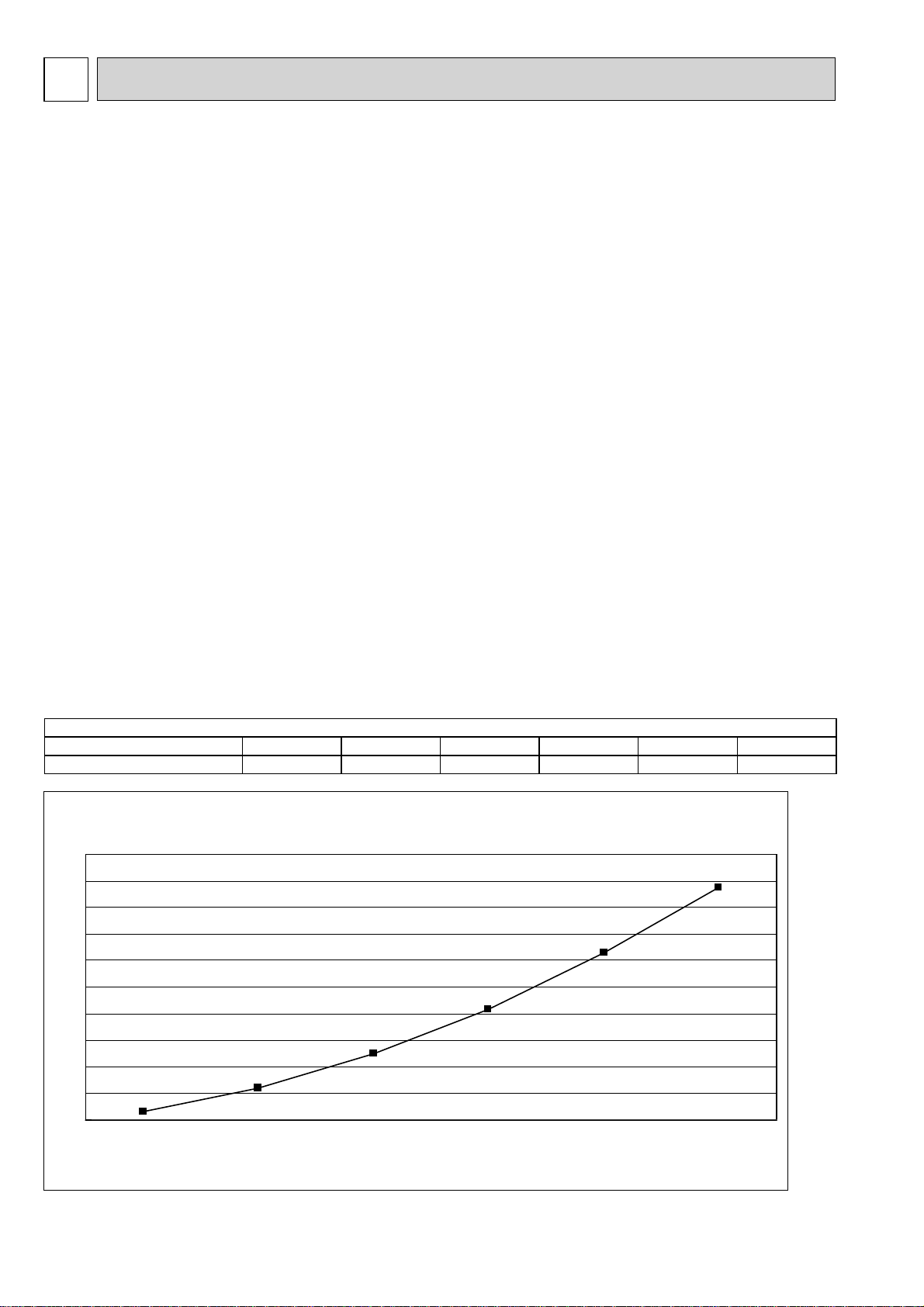

Hex for PUHZ-W85VHA (ACH30-40Plates)

Secondary (Water - side)

Flow rate (L/min) 5 10 15 20 25 30

Pressure Loss (kPa) 1.0 3.6 7.5 12.5 18.8 26.2

Pressure loss (kPa)

30.0

25.0

20.0

15.0

10.0

5.0

0.0

51015202530

Flow rate (L/min)

Hex for PUHZ-W112, 140VHA / YHA (ACH50-50Plates)

Secondary (Water - side)

Flow rate (L/min) 15 30 45 60 75 90

Pressure Loss (kPa) 1.3 4.9 10.9 19.3 29.9 42.8

Pressure loss (kPa)

45.0

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0.0

15 30 45 60 75 90

Flow rate (L/min)

33

Page 4

Heat pump unit_General information2

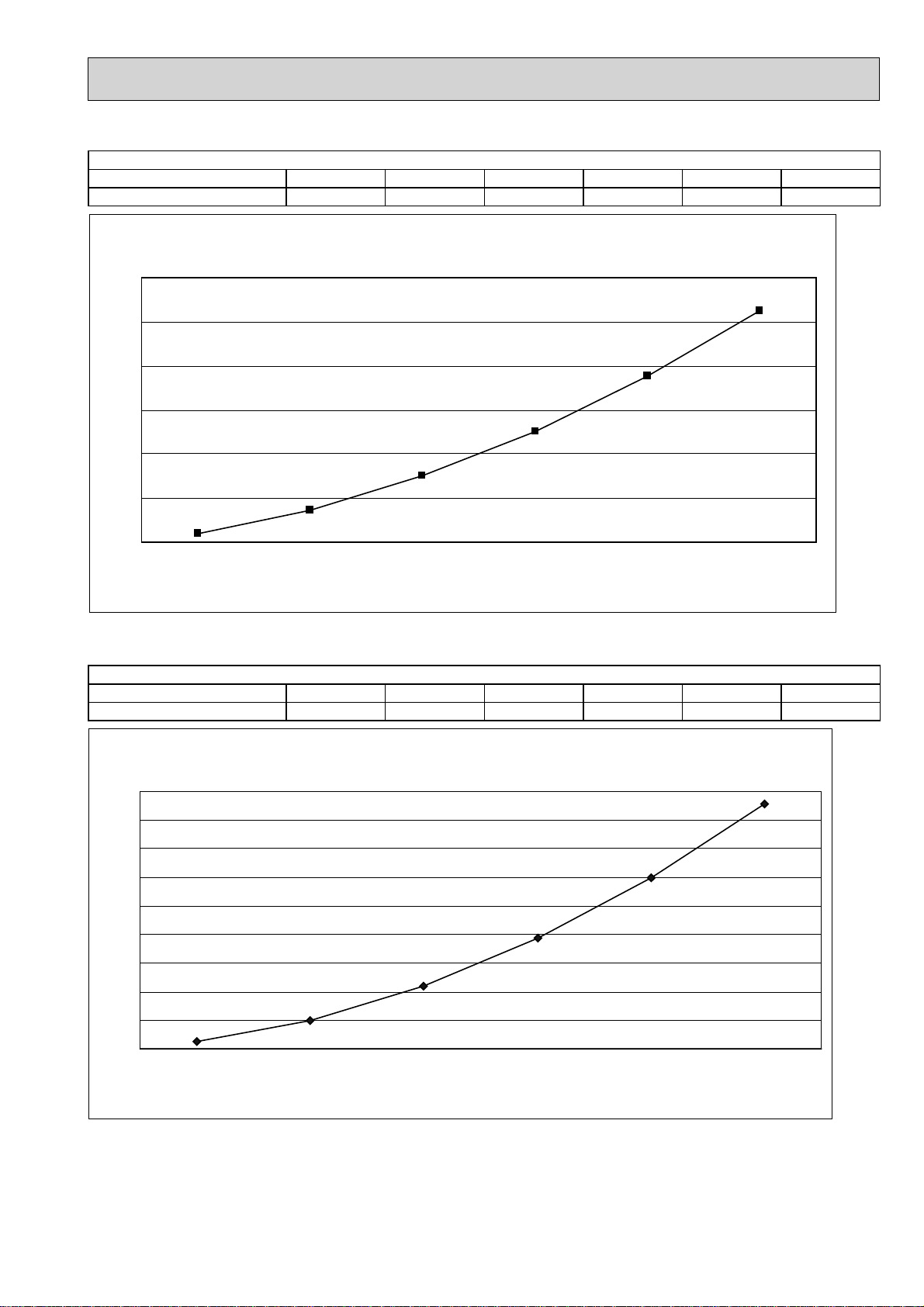

2-1. Line-up

2-1-1. Outdoor unit for Air to water

(1) Packaged type: The Air to Water outdoor unit with a plate HEX (refrigerant-water) inside

Connectable models

Capacity

( HP )

2 PUHZ-W50VHA — — —

3 PUHZ-W85VHA — — —

4 — — — PUHZ-HW112YHA

5 — — PUHZ-HW140VHA PUHZ-HW140YHA

1-phase 3-phase 1-phase 3-phase

(2) Split type: The standard outdoor unit without a plate HEX (refrigerant-water) inside

Connectable models

Capacity

( HP )

2.5 PUHZ-RP60VHA3#1 — — —

3 PUHZ-RP71VHA3#1 — PUHZ-HRP71VHA(2) —

4 PUHZ-RP100VHA3#1 PUHZ-RP100YHA3#1 PUHZ-HRP100VHA(2) PUHZ-HRP100YHA(2)

5 PUHZ-RP125VHA2#2 PUHZ-RP125YHA2#2 — PUHZ-HRP125YHA(2)

6 PUHZ-RP140VHA2#2 PUHZ-RP140YHA2#2 — —

* Outdoor units (PUHZ-RP or PUHZ-P) other than the above-mentioned become possible by connecting TH5 ( 2-phase refrig-

erant temp. thermistor ) with the interface only for Air to Air use.

1-phase 3-phase 1-phase 3-phase

Packaged models ZUBADAN-Packaged models

Split Replace inverter models Split ZUBADAN models

2-1-2. Air to Air application

INTER FACE MODEL NAME PAC-IF011B-E / PAC-IF010-E

AUTO

STEP *1

MANUAL

STEP *2

MANUAL STEP MODE is New function of INTER FACE (Fixed capacity = Compressor frequency (Hz) fi xed mode) .

<Old models : The models that are not described in the table above.>

*1: With(Auto-mode)+(SW2-6 is OFF)+(2phase thermistor), all A-control outdoor units are able to connect to PAC-IF010/

*2: With(Manual-mode)+(SW2-6 is OFF)+(2phase thermistor), from following RP type outdoor units are able to connect to

OUTDOOR UNIT 35 50 60 71 100 125 140 200 250

PUHZ-HRP — — — VHA(2) V/YHA(2) YHA(2) — — —

PUHZ-RP VHA3 VHA3 VHA3 VHA3 V/YHA3 V/YHA2 V/YHA2 YHA2 YHA2

PUHZ-P — — — — VHA2 VHA2 VHA2 YHA YHA

SUZ-KA VA VA VA VA — — — — —

PUH-P — — — V/YHA V/YHA YHA YHA MYA MYA

OUTDOOR UNIT 35 50 60 71 100 125 140 200 250

PUHZ-HRP — — — VHA V(Y)HA YHA — — —

PUHZ-RP VHA3 VHA3 VHA3 VHA3 V/YHA3 V/YHA2 V/YHA2 YHA2 YHA2

2 Phase (Gas/Liquid) pipe thermistor is required (TH5).

Also, Interface P.C.B. SW2-6 need to be set "OFF (No LEV self control mode)" .

011B-E only for Air to Air use.

PAC-IF010/011B-E only for Air to Air use.

PUHZ-RP35V, 50V, 60V, 71V,100V/Y,125V/Y,140V/YHA2

PUHZ-RP200Y, 250YHA

²

¹

4

Page 5

2-1-3. Reference manual

Outdoor unit Service

PUHZ-W50VHA

PUHZ-W85VHA

PUHZ-HW112YHA

PUHZ-HW140VHA

PUHZ-HW140YHA

PUHZ-RP60VHA3#1

PUHZ-RP71VHA3#1

PUHZ-RP100VHA3#1

PUHZ-RP125VHA2#2

PUHZ-RP140VHA2#2

PUHZ-RP100YHA3#1

PUHZ-RP125YHA2#2

PUHZ-RP140YHA2#2

PUHZ-HRP71VHA(2)

PUHZ-HRP100VHA(2)

PUHZ-HRP100YHA(2)

PUHZ-HRP125YHA(2)

manual

OCH439 OCB439

OC374 OC374

OCH425 OCB425

Parts catalog

I/F

FTC

2-2. Data

2-2-1. Packaged type

Refer to each model's service manual.

2-2-2. Split

[1]

Specifi cations(Reference data(connect to plate heat exchanger))

Rating conditions

Nominal operating condition

Heating (A2/W35)

Outside air temperature (Dry-bulb) +2

Outside air temperature (Wet-bulb) +1

Water temperature (inlet/outlet) +30/+35

Heating (A7/W35)

Outside air temperature (Dry-bulb) +7

Outside air temperature (Wet-bulb) +6

Water temperature (inlet/outlet) +30/+35

Heating (A7/W45)

Outside air temperature (Dry-bulb) +7

Outside air temperature (Wet-bulb) +6

Water temperature (inlet/outlet) +40/+45

:

:

:

:

:

:

:

:

:

Type Model name Parts catalog

cased PAC-IF011B-E OCB427

PCB only PAC-IF010-E —

cased PAC-IF021B-E OCB427

PCB only PAC-IF020-E —

55

Page 6

(1) PUHZ-HRP • V/YHA2

Outdoor unit

Model name PUHZ-HRP71VHA2

Power supply

(Phase, Voltage, Frequency)

Breaker size A 32

Nominal water fl ow L/min 22.9

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Outdoor unit

Model name

Power supply

(Phase, Voltage, Frequency)

Breaker size A 40 / 16

Nominal water fl ow L/min 32.1

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Heating

(A7/W55)

Outdoor unit

Model name PUHZ-HRP125YHA2

Power supply

(Phase, Voltage, Frequency)

Breaker size A 16

Nominal water fl ow L/min 40.1

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Capacity kW 8.00

COP 3.24

Power input 2.47

Capacity kW 8.00

COP 4.40

Power input 1.82

Capacity kW 8.00

COP 3.24

Power input 2.47

Capacity kW 11.20

COP 3.02

Power input 3.71

Capacity kW 11.20

COP 4.26

Power input 2.63

Capacity kW 11.20

COP 3.24

Power input 3.46

Capacity kW 11.20

COP 2.40

Power input 4.67

Capacity kW 14.00

COP 2.70

Power input 5.19

Capacity kW 14.00

COP 4.22

Power input 3.32

Capacity kW 14.00

COP 3.20

Power input 4.38

1[, 230V, 50Hz

PUHZ-HRP100VHA2 /

PUHZ-HRP100YHA2

1[, 230V, 50Hz /

3[, 400V, 50Hz

3[, 400V, 50Hz

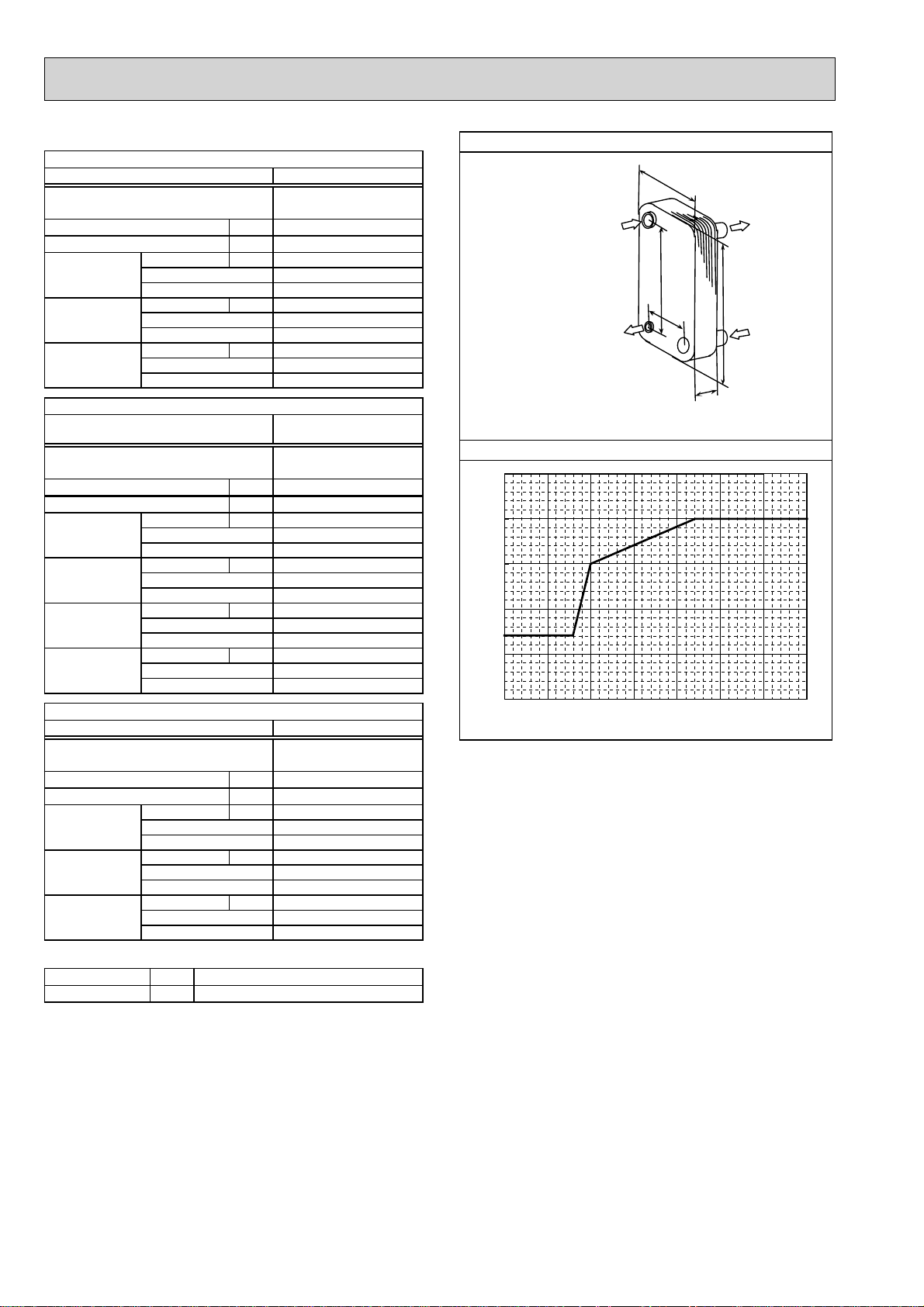

Guaranteed operating range (Outdoor)

Heating

Cooling

:

:

-25 ~ +35

-5 ~ +46

Plate heat exchanger

ALFA LAVAL

ACH50

A: 50 mm

B: 466 mm

Ref.IN

(Heating)

w

Water OUT

B

W: 112 mm

H: 526 mm

D: 130 mm

50 plates

Ref.OUT

(Heating)

A

H

Water IN

D

Refrigerant pipng length from outdoor unit to

heat exchanger (Water HEX): 5m

Maximum outlet water temperature

65

]

60

55

50

45

Maximum outlet water temptemperature [°C

40

-25 -20

-15 -10 -5 0 5 10

Ambient temperature [°C]

The performance might be decreased by the refrigerant

pipng length, insulation of refrigerant pipng and

heat exchanger (Water HEX).

6

Page 7

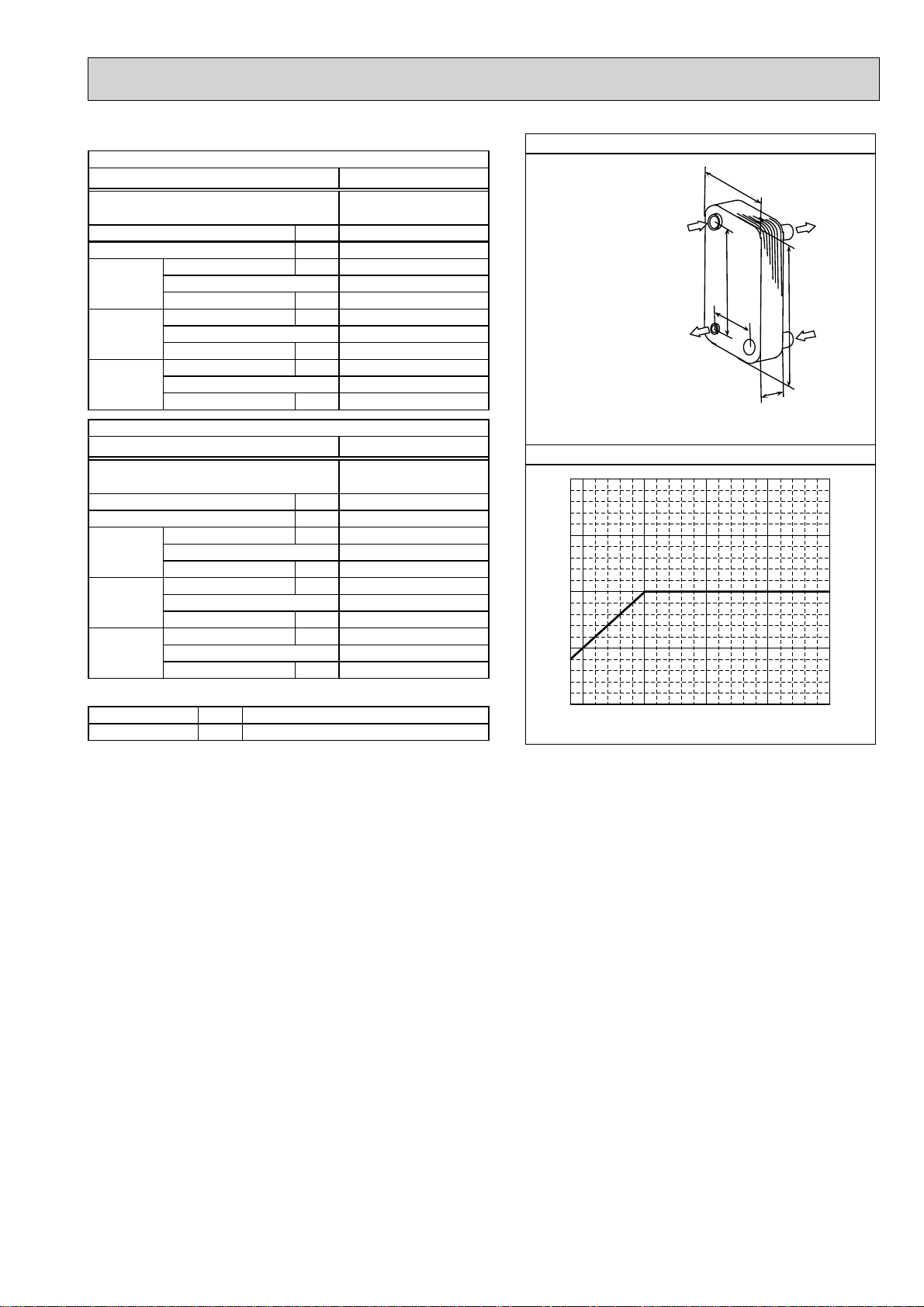

(2) PUHZ-RP • VHA3/YHA3(2)

Outdoor unit

Model name PUHZ-RP60VHA3#1

Power supply

(Phase, Voltage, Frequency)

Breaker size A 25

Nominal water fl ow L/min 20.1

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Outdoor unit

Model name PUHZ-RP71VHA3#1

Power supply

(Phase, Voltage, Frequency)

Breaker size A 25

Nominal water fl ow L/min 22.9

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Capacity kW 6.80

COP 2.94

Power input kW 2.31

Capacity kW 7.00

COP 4.29

Power input kW 1.63

Capacity kW 7.00

COP 3.27

Power input kW 2.14

Capacity kW 7.50

COP 2.92

Power input kW 2.57

Capacity kW 8.00

COP 4.21

Power input kW 1.90

Capacity kW 8.00

COP 3.20

Power input kW 2.50

1[, 230V, 50Hz

1[, 230V, 50Hz

Guaranteed operating range (Outdoor)

Heating

Cooling : -5 ~ +46

:

-11 ~ +35

Plate heat exchanger

ALFA LAVAL

ACH50

A: 50 mm

B: 466 mm

Ref.IN

(Heating)

w

Water OUT

B

W:112 mm

H: 526 mm

D: 82 mm

30 plates

Ref.OUT

(Heating)

A

H

Water IN

D

Refrigerant pipng length from outdoor unit to

heat exchanger (Water HEX): 5m

Maximum outlet water temperature

65

]

60

55

50

Maximum outlet water temptemperature [°C

45

-10 -5 0 5 10

Ambient temperature [°C]

The performance might be decreased by the refrigerant

pipng length, insulation of refrigerant pipng and

heat exchanger (Water HEX).

7

Page 8

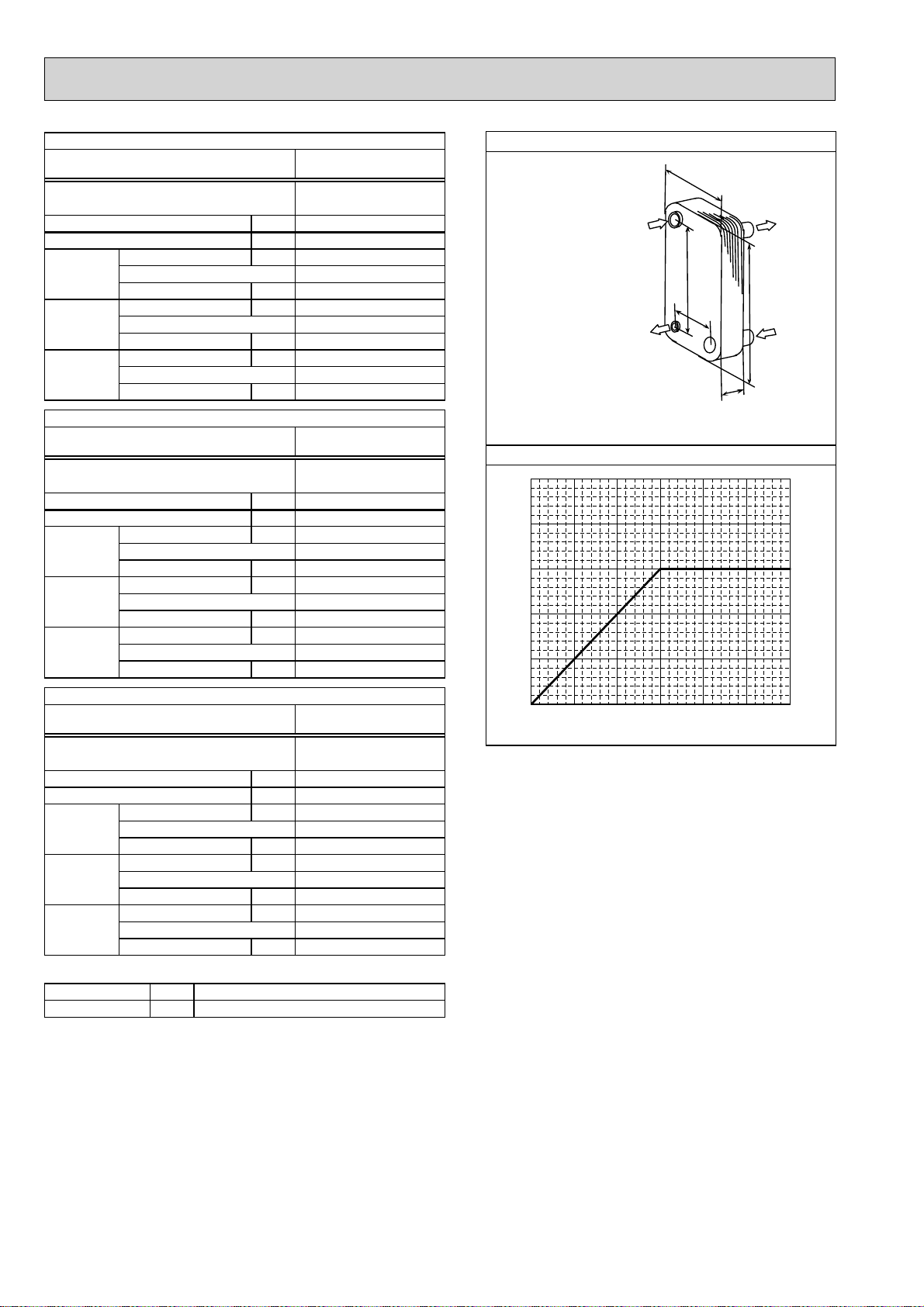

Outdoor unit

Model name

Power supply

(Phase, Voltage, Frequency)

Breaker size A 32 / 16

Nominal water fl ow L/min 32.1

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Outdoor unit

Model name

Power supply

(Phase, Voltage, Frequency)

Breaker size A 32/16

Nominal water fl ow L/min 40.1

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Outdoor unit

Model name

Power supply

(Phase, Voltage, Frequency)

Breaker size A 40/16

Nominal water fl ow L/min 45.9

Heating

(A2/W35)

Heating

(A7/W35)

Heating

(A7/W45)

Capacity kW 10.50

COP 2.90

Power input kW 3.62

Capacity kW 11.20

COP 4.21

Power input kW 2.66

Capacity kW 11.20

COP 3.20

Power input kW 3.50

Capacity kW 11.50

COP 2.70

Power input kW 4.26

Capacity kW 14.00

COP 4.15

Power input kW 3.37

Capacity kW 14.00

COP 3.10

Power input kW 4.51

Capacity kW 11.70

COP 2.69

Power input kW 4.35

Capacity kW 16.00

COP 3.90

Power input kW 4.10

Capacity kW 16.00

COP 3.00

Power input kW 5.34

PUHZ-RP100VHA3#1 /

PUHZ-RP100YHA3#1

1[, 230V, 50Hz /

3[, 400V, 50Hz

PUHZ-RP125VHA2#2 /

PUHZ-RP125YHA2#2

1[, 230V, 50Hz /

3[, 400V, 50Hz

PUHZ-RP140VHA2#2 /

PUHZ-RP140YHA2#2

1[, 230V, 50Hz /

3[, 400V, 50Hz

Guaranteed operating range (Outdoor)

Heating

Cooling

:

:

-20 ~ +35

-5 ~ +46

Plate heat exchanger

ALFA LAVAL

ACH50

A: 50 mm

B: 466 mm

Ref.IN

(Heating)

w

Water OUT

B

W:112 mm

H: 526 mm

D: 130 mm

50 plates

Ref.OUT

(Heating)

A

H

Water IN

D

Refrigerant pipng length from outdoor unit to

heat exchanger (Water HEX): 5m

Maximum outlet water temperature

65

]

60

55

50

45

Maximum outlet water temptemperature [°C

40

-20 -15

-10 -5 0 5 10

Ambient temperature [°C]

The performance might be decreased by the refrigerant

pipng length, insulation of refrigerant pipng and

heat exchanger (Water HEX).

8

Page 9

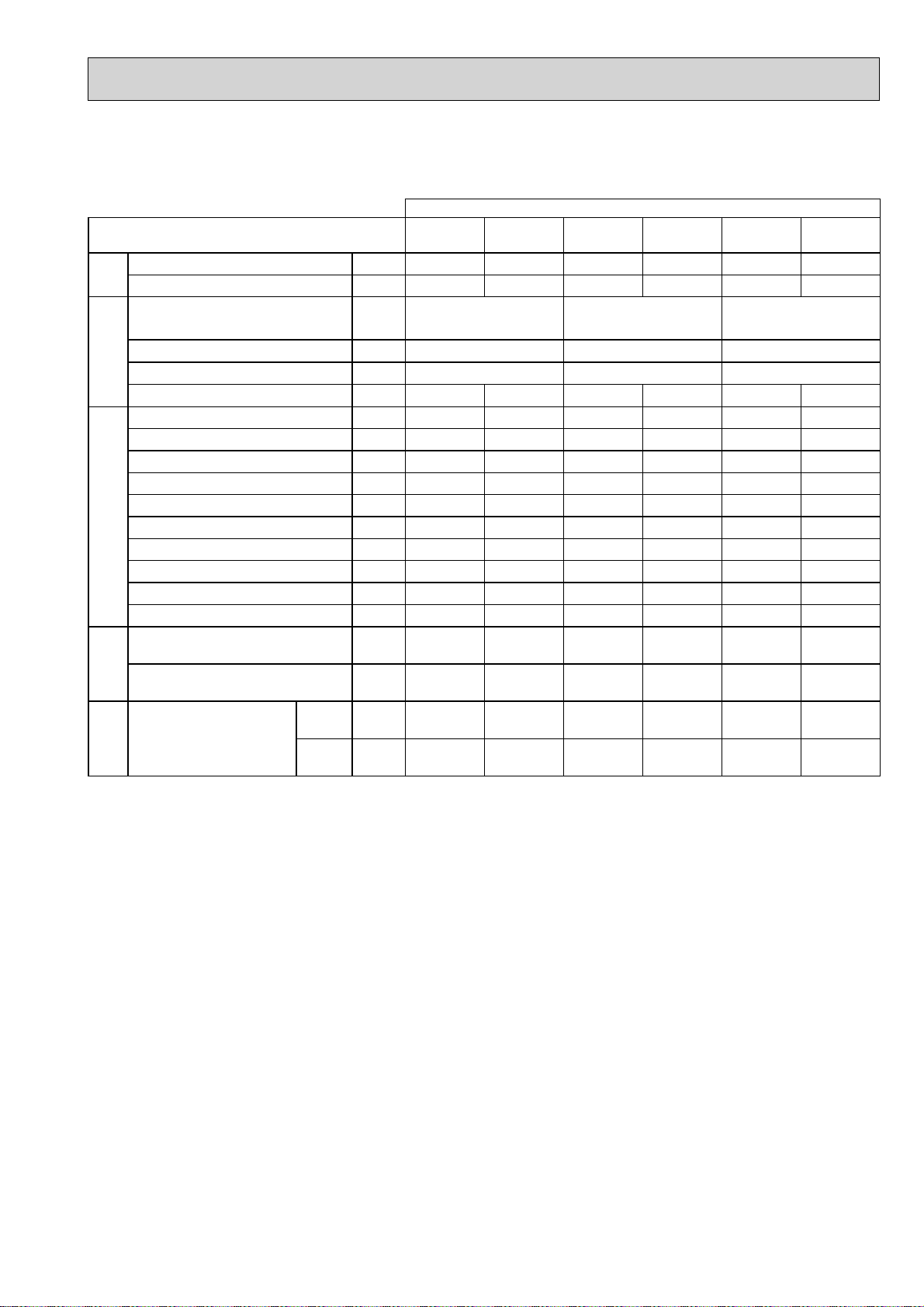

[2]

Standard operation data <Split> Reference data (connect to Plate HEX)

(1) PUHZ-HRP • V/YHA2

Mode

Capacity W 7,100 8,000 10,000 11,200 12,500 14,000

Total

Input kW 2.20 1.82 3.67 2.61 4.80 3.50

Outdoor unit PUHZ-HRP71VHA2

Phase, Hz 1, 50 1/3, 50 3, 50

Voltage V 230 230 / 400 400

Electrical circuit

Current A 9.9 8.2 16.5/5.6 11.7/4.0 7.3 5.3

Discharge pressure MPa 2.4 2.0 2.6 2.1 2.8 2.3

Suction pressure MPa 0.8 0.7 0.8 0.7 0.8 0.7

Discharge temperature

Condensing temperature

Suction temperature

Evaporating temperature

Evaporator inlet temperature

Refrigerant circuit

Evaporator outlet temperature

Condenser inlet temperature

Condenser outlet temperature

Cooling

(A35/W7)

:

:

:

:

:

:

:

:

70 60 78 63 84 70

42 35 46 36 47 39

12 6 11 4 10 3

525251

5—5—5—

5—5—5—

—55—60—65

—33—31—30

Heating

(A7/W35)

ACH50-50 plates

Cooling

(A35/W7)

PUHZ-HRP100VHA2/

PUHZ-HRP100YHA2

Heating

(A7/W35)

Cooling

(A35/W7)

PUHZ-HRP125YHA2

Heating

(A7/W35)

Flow volume L/min 20.4 22.9 28.7 34.4 35.8 40.1

Water

Outlet water temperature

conditions

D.B.

Intake air temperature

Outdoor

conditions

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/F)

W.B.

:

:

:

735735735

35 7 35 7 35 7

24 6 24 6 24 6

9

Page 10

(2) PUHZ-RP • VHA3/YHA3(2)

Mode

Capacity W 6,000 7,000 6,600 8,000 9,100 11,200

Total

Input kW 2.31 1.63 2.59 1.90 3.31 2.66

Outdoor unit PUHZ-RP60VHA3#1 PUHZ-RP71VHA3#1

Phase, Hz 1, 50 1, 50 1/3, 50

Voltage V 230 230 230 / 400

Current A 10.3 7.2 11.4 8.4 14.5 / 5.1 11.8 / 4.1

Electrical circuit

Discharge pressure MPa 2.7 2.1 2.7 2.2 2.6 2.1

Suction pressure MPa 0.8 0.7 0.8 0.7 0.8 0.7

Discharge temperature

Condensing temperature

Suction temperature

Evaporating temperature

Evaporator inlet temperature

Refrigerant circuit

Evaporator outlet temperature

Condenser inlet temperature

Condenser outlet temperature

:

:

:

:

:

:

:

:

ACH50-30 plates ACH50-50 plates

Cooling

(A35/W7)

70 65 70 66 74 65

45 36 45 36 44 36

454265

515151

6—6—5—

5—5—5—

—56—57—58

—34—33—35

Heating

(A7/W35)

Cooling

(A35/W7)

Heating

(A7/W35)

Cooling

(A35/W7)

PUHZ-RP100VHA3#1/

PUHZ-RP100YHA3#1

Heating

(A7/W35)

Flow volume L/min 17.2 20.1 18.9 22.9 26.1 32.1

Water

Outlet water temperature

conditions

D.B.

Intake air temperature

Outdoor

conditions

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/F)

W.B.

:

:

:

7 35 7 35 7 35

357357357

246246246

10

Page 11

ACH50-50 plates

Mode

Capacity W 12,000 14,000 12,500 16,000

Input kW 5.10 3.37 5.38 4.10

Total

Outdoor unit

Phase, Hz 1 / 3, 50 1 / 3, 50

circuit

Voltage V 230 / 400 230 / 400

Electrical

Current A 22.4 / 7.6 15.0 / 5.2 23.6 / 8.1 18.2 / 6.2

Discharge pressure MPa 2.8 2.1 2.8 2.2

Suction pressure MPa 0.7 0.7 0.7 0.7

Discharge temperature

Condensing temperature

Suction temperature

Evaporating temperature

Evaporator inlet temperature

Evaporator outlet temperature

Refrigerant circuit

Condenser inlet temperature

Condenser outlet temperature

Flow volume L/min 34.4 40.1 35.8 45.9

:

:

:

:

:

:

:

:

Cooling

(A35/W7)

PUHZ-RP125VHA2#2/

PUHZ-RP125YHA2#2

80 69 81 67

46 36 46 36

3431

5-15-1

6—6—

5—5—

—63—61

—35—34

Heating

(A7/W35)

Cooling

(A35/W7)

PUHZ-RP140VHA2#2/

PUHZ-RP140YHA2#2

Heating

(A7/W35)

Water

Outlet water temperature

conditions

D.B.

Intake air temperature

Outdoor

conditions

The unit of pressure has been changed to MPa based on international SI system.

The conversion factor is : 1(MPa)=10.2(kgf/F)

W.B.

:

:

:

735735

357357

246246

11

Page 12

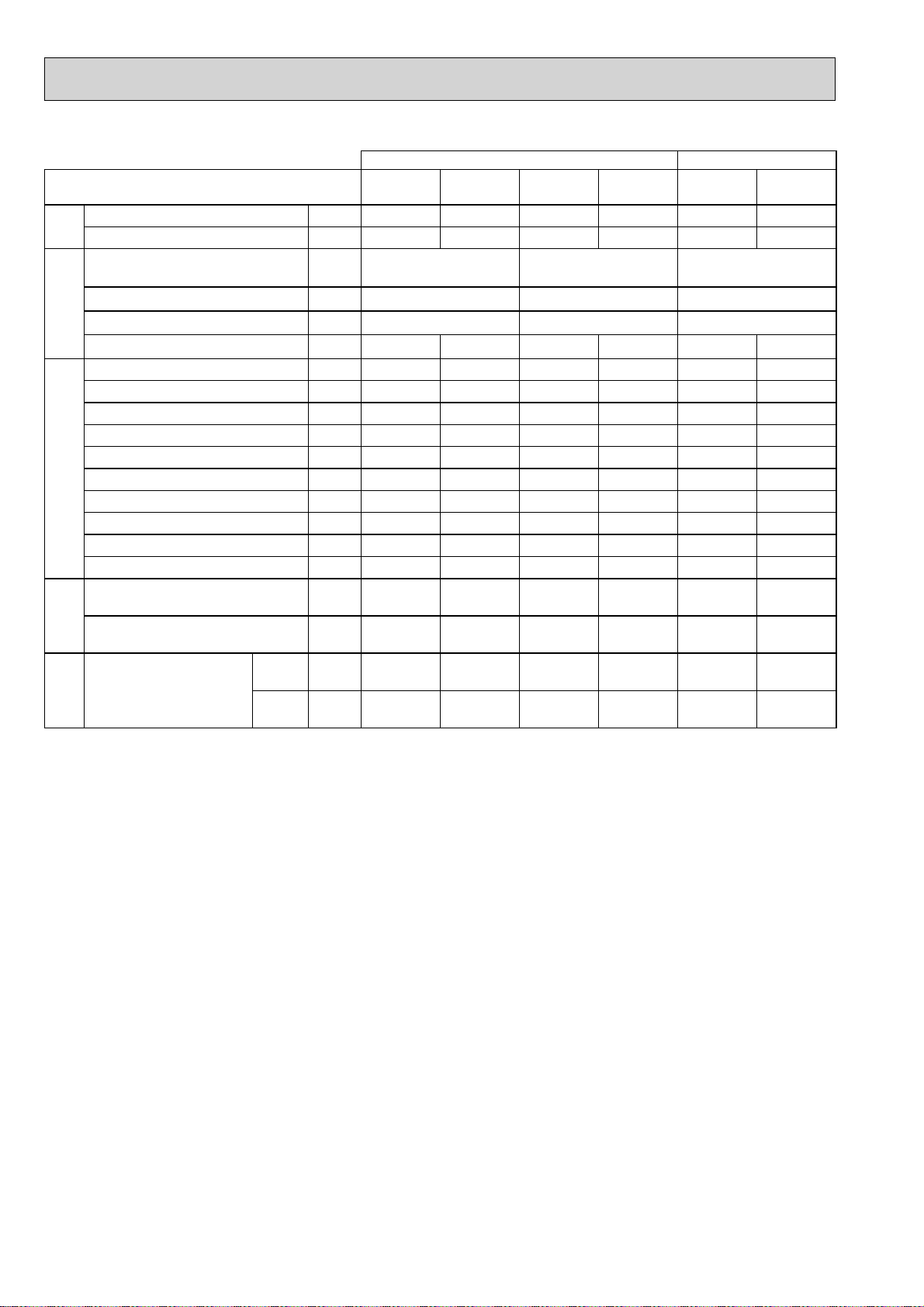

[4]

Capacity correction curves (Refrigerant pipng length)

Cooling and heating capacity is lowered according to pipe length. Capacity can be obtained by referring to the capacity curves

below.

Cooling

100

Heating

95

90

85

80

Capacity ratio [%]

75

Note: The permitted pipe length is up to 55m for RP 60, 71 model.

The permitted pipe length is up to 80m for HRP71 and 100~ 140 model.

70

5 101520253035404550556065707580

Corrected pipe length [m]

[5]

Refrigerant circuit diagram (Representative pattern)

PUHZ-HRP

Water OUT

Plate HEX

Water IN

•

Thermistor TH1

(Outlet water)

Thermistor TH2

(Liquid pipe)

V/YHA2 + Plate HEX (ACH50) + FTC (TH1/2)

Ball valve

Refrigerant

GAS pipe

connection

(5/8 inch)

Linear

expansion valve B

Refrigerant

LIQUID pipe

connection

(3/8 inch)

Stop valve

(with service port)

Strainer

#50

Charge plug

(Low pressure)

Strainer

#100

Strainer

#100

Solenoid valve

(Four-way valve)

Power

receiver

Linear

expansion valve C

Low pressure

switch 63L

Strainer

#100

Cooling 60 models

P-sensor

Charge plug

(High pressure)

Muffler

Strainer

#100

Compressor

Heat exchanger

High pressure

switch 63H

Thermistor

TH32

(Outdoor pipe)

Thermistor TH4

(Discharge)

Linear expansion valve A

Injection port

Heat interchange circuit

Heating

Cooling 71 model

Cooling 100 model

Cooling 125 model

Cooling 140 model

Thermistor TH7

(Outdoor)

Thermistor

TH6

(Outdoor

2-phase pipe)

Thermistor TH3

(Outdoor pipe)

Distributor

Thermistor TH33

Strainer

#100

Refrigerant flow in cooling

Refrigerant flow in heating

(Outdoor pipe)

Restrictor

valve

Bypass

valve

Replace

filter

Strainer

#100

12

Page 13

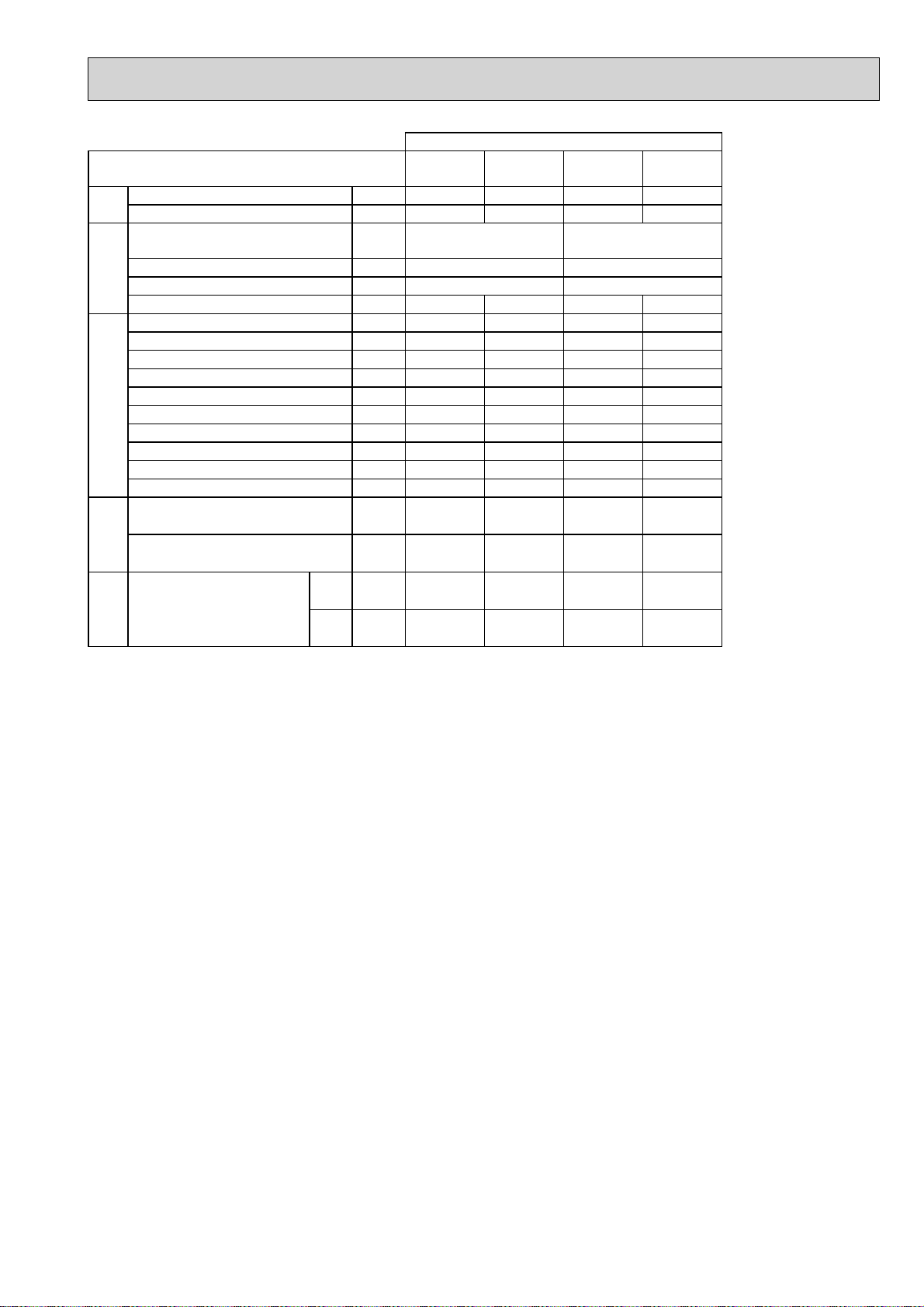

[6]

Notifi cation to design/select HEX (Refrigerant - Water)

• Specifi cations of AHU and compatibility with regulations must be confi rmed by your company.

• Selection of an apporopriate AHU (with appropriate specifi cations to match those of units

connected to the AHU such as confi guration, dimension, life-span, vibration, noise level,

or features) must be made by your company.

• Mitsubishi Electric shall not be liable for any damage to the entire system or the AHU main

body caused by connected AHU with wrong specifi cation or wrong usage of AHU.

• Mitsubishi Electric shall not be liable for any damage to the outdoor units caused by AHU damage.

( AHU : hydro box or refrigerant - water HEX )

Heat exchanger

(1) Withstanding pressure

Designed pressure of outdoor unit is 4.15 MPa. Following must be satisfi ed for burst pressure of connecting application.

Burst pressure : More than 12.45 MPa (3 times more than designed pressure)

(2) Performance

Secure the heat exchanger capacity which meets the following conditions. If the conditions are not met, it may result in

malfunction caused by the protection operation or the outdoor unit may be turned off due to the operation of protection

system.

1. Evaporate temperature is more than 4: in max. frequency operation under *1 the cooling rated conditions.

2. In case of hot water supply, condense temperature is less than 58: in max. frequency operation with the outside temperature 7:D.B./6:W.B.

*1. Outdoor: 35:D.B./24:W.B.

(3) Heat exchanger internal capacity

Heat exchanger internal capacity must be within the capacity range shown below. If the heat exchanger below the minimum capacity is connected, it may result in the back fl ow of liquid or the failure of the compressor.

If the heat exchanger above the maximum capacity is connected, it may result in the defi ciency in performance due to lack

of refrigerant or overheating of the compressor.

Minimum capacity : 10 х Model capacity [J] / Maximum capacity : 30 х Model capacity [J]

e.g. When connecting to PUHZ-HRP100 VHA2

Minimum capacity : 10 х 100 =1000

Maximum capacity : 30 х 100 =3000

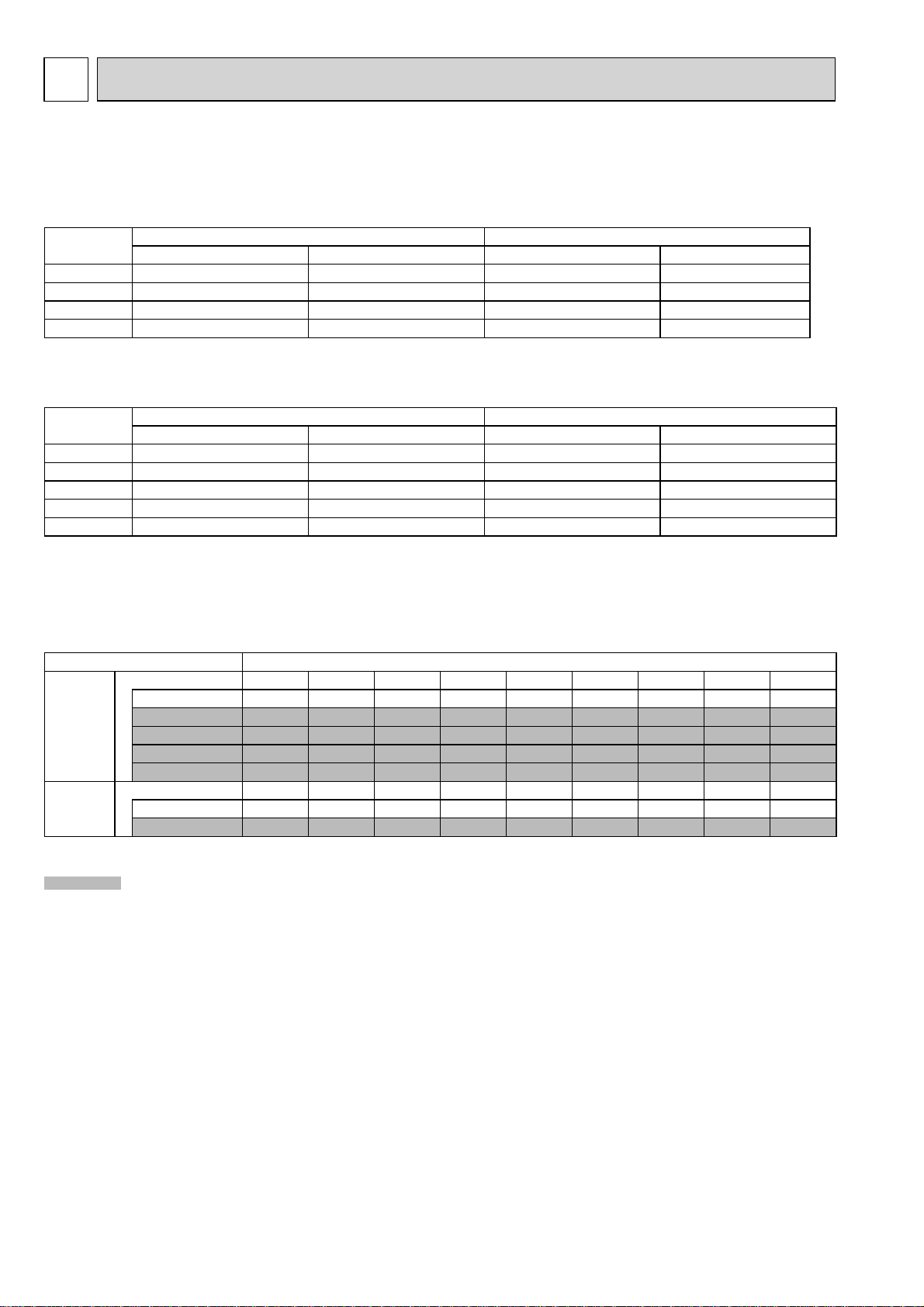

Model capacity 60(2.5HP) 71(3HP) 100(4HP) 125(5HP) 140(6HP)

Maximum capacity [J] 1800 2130 3000 3750 4200

Minimum capacity [J] 600 710 1000 1250 1400

J

J

Warranty for SPILIT solution

(4) Contamination maintenance

1. Wash the inside of heat exchanger to keep it clean. Be sure to rince not to leave fl ux. Do not use chlorine detergent for

wash.

2. Be sure that the amount of contamination per unit cubic content of heat transfer pipe is less than the following amount.

Example) In case of [ 9.52mm

Residual water : 0.6M/C, Residual oil : 0.5M/C, Solid foreign object : 1.8M/

Note:

• Install the hydraulic fi lter at the water intake.

• Use the inlet water of higher than 5 ˚C and lower than 55 ˚C.

• The water in a system should be clean and with pH value of 6.5-8.0.

• The followings are the maximum values;

Calcium : 100mg/L

Chlorine : 100mg/L

Iron/manganese : 0.5mg/L

• Refrigerant pipe diameter from outdoor unit to refrigerant-water HEX (Only for SPLIT type)

Use the pipe with same diameter size as the refrigerant pipe connection diameter of outdoor unit.(Refer to outdoor

unit installation manual.)

• Make sure to perform the frozen prevention measure for water pipe system.(Water piping insulation, back-up pump

system, using of a certain % ethylene glycol instead of normal water)

[Reference]

TB142 has for “Forced Comp. OFF” function as the EXTERNAL INPUT(Contact signal).

To input the abnormal signal of water pump or the abnormal lowering of water fl ow amount with non-voltage contact

signal makes the outdoor unit stop forcibly. For details, refer to each part of I/F or FTC on this manual.

C

13

Page 14

• The water velocity in pipes should be kept within certain limits of material to avoid erosion,corrosion and excessive

noise generation.

Be aware, and take care of , that local velocities in small pipes, bends and similar obstructions can exceed the values

of previous page.

e.g.) Copper : 1.5m/s

Warning

• Use clean enough water which meets water quality standards. The deterioration of water quality may result in the system breakdown or the water leakage.

• Never use anything other than water as a medium. It may cause a fi re or an explosion.

• Do not use heated or cooled water that is produced by the air to water heat pump directly for drinking or cooking.

There is a risk to damage your health. There is also a risk that installing the water heat exchanger may corrode if the

necessary water quality for air to water heat pump system cannot be maintained. If you wish to use the heated or

cooled water from the heated pump for these purposes, take measure such as to the second heat exchanger within

the water piping system.

Reference data

Required specifi cation and performance of Plate Heat Exchanger.

Required specifi cation

Refrigerant type R410A

Refrigerant side

Water side

Burst pressure 12.45MPa (4.15MPa ×3) or more

Frozen performance Satisfy an initial performance since 5 times or more of deep freezing.

Heat cycle 70,000 times or more…Temperature difference: about 50K

Endurance pressure 72,000 times or more…Pressure difference: 3.3MPa (0 ↔ 3.3MPa)

Normal (designed) pressure 4.15MPa

Operating temperature -20~100

Refrigerant type Clean water

Normal (designed) pressure 1.5MPa

Operating temperature -20~90: (No freezing)

:

Required performance

< For 2.5~3 HP >

Required performance of Plate Heat Exchanger kW 9.0 9.0

Inlet temperature degC 75 100 Gas pipe: [12.7mm

Refrigerant side

(R410A)

Water side

* For heating mode, used at counter fl ow direction between refrigerant fl ow and water one.

< For 4~6 HP >

Required performance of Plate Heat Exchanger kW 14.0 14.0

Refrigerant side

(R410A)

Water side

* For heating mode, used at counter fl ow direction between refrigerant fl ow and water one.

Condensing temperature degC 39.5 63.5 Liquid pipe: [9.52mm

Subcool degC 2 2

Max. pressure loss kPa 50 50

Inlet temperature degC 30 55 Inlet / outlet pipe: [28.6mm

Outlet temperature degC 35 60

Water fl ow volume L/min 25.8 25.8

Max. pressure loss kPa 50 50

Inlet temperature degC 75 100 Gas pipe: [15.88mm

Condensing temperature degC 39.5 63.5 Liquid pipe: [9.52mm

Subcool degC 2 2

Max. pressure loss kPa 50 50

Inlet temperature degC 30 55 Inlet / outlet pipe: over [28.6mm

Outlet temperature degC 35 60

Water fl ow volume L/min 40.1 40.1

Max. pressure loss kPa 50 50

14

Page 15

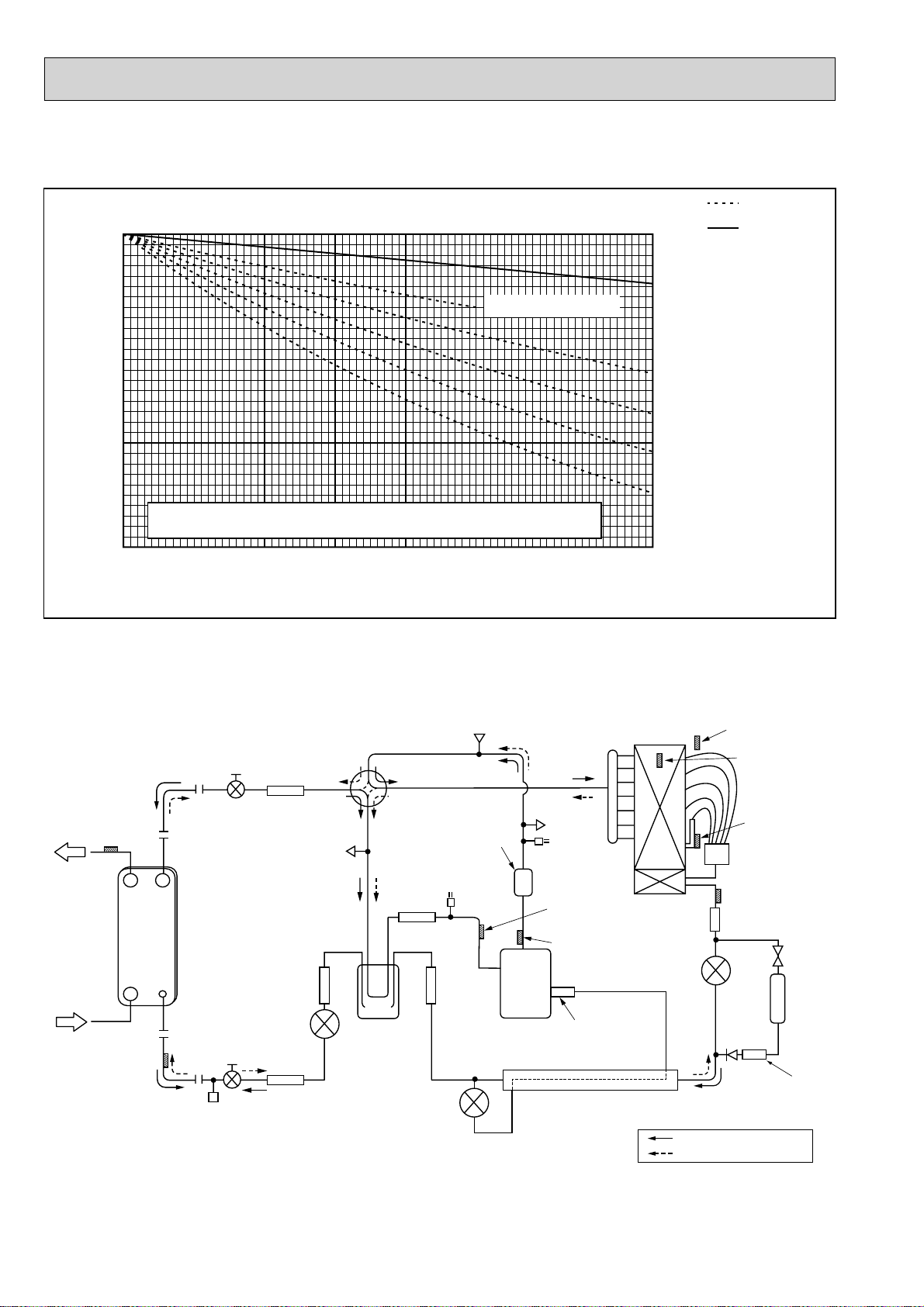

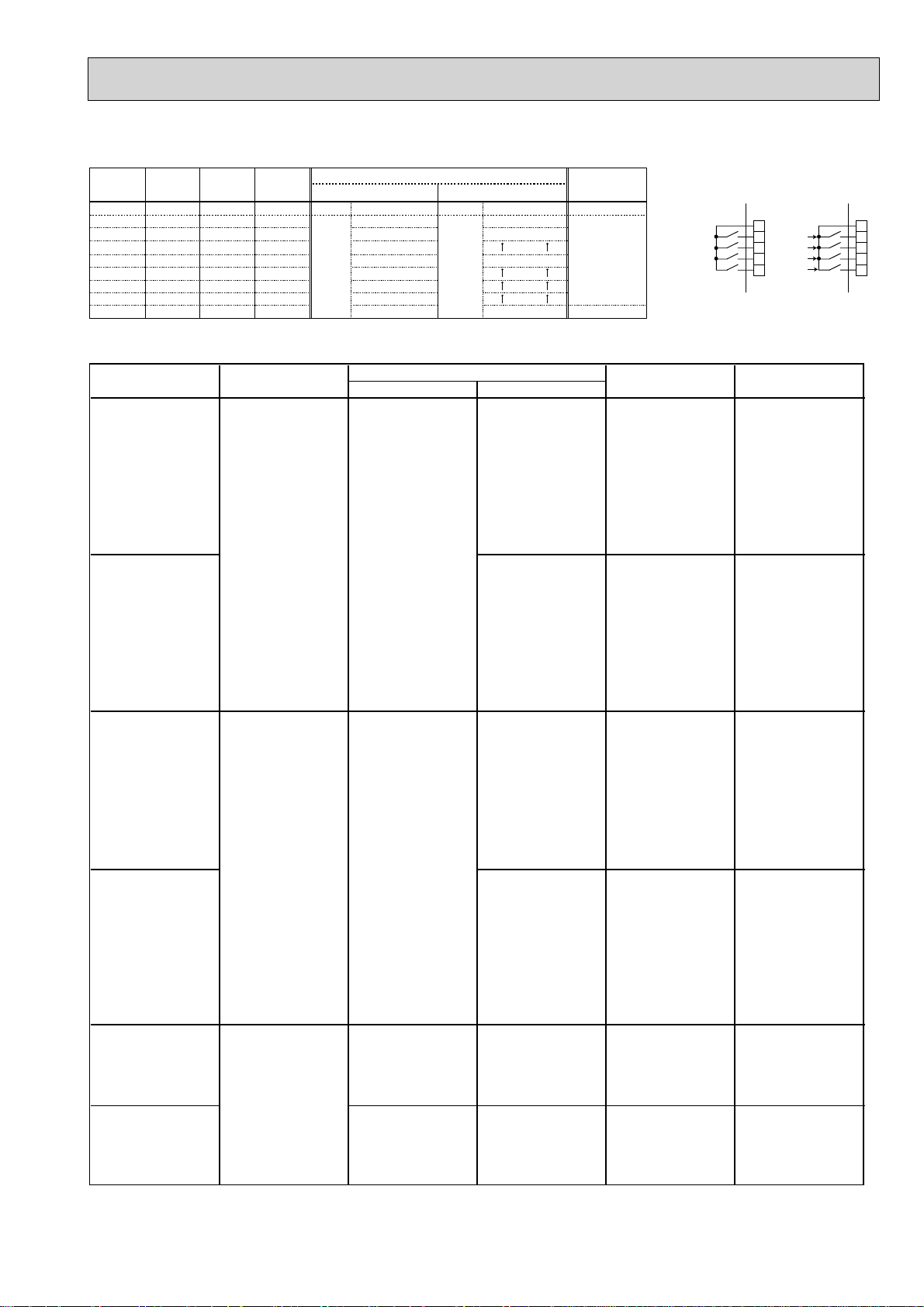

System design3

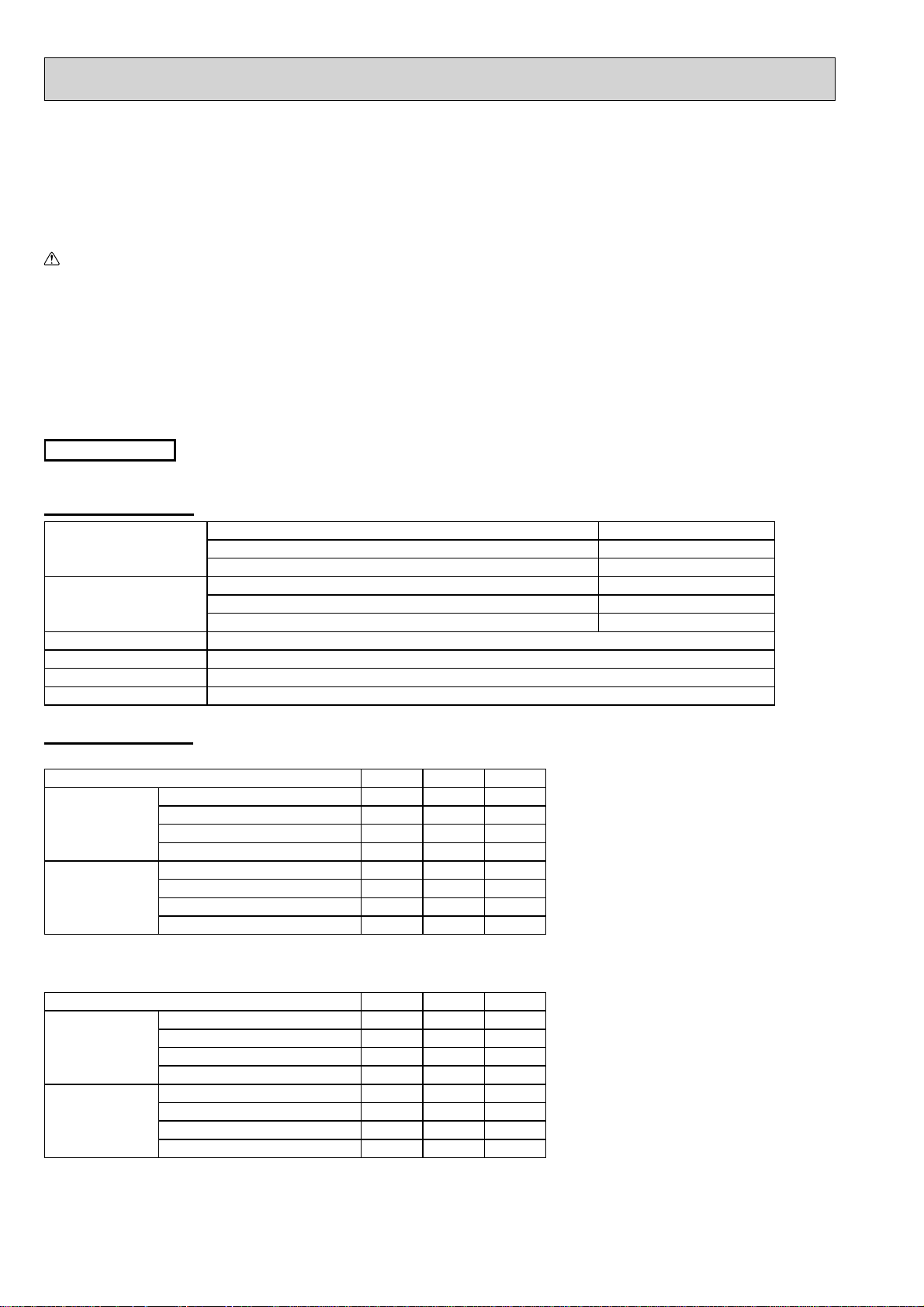

3-1. System type

* with step I/F by digital/analog signals

* with FTC simple/basic/analog temp.

Application Capacity control For Model name Type

Local controller

Air to Air

I/F

Local controller

Air to Water

FTC

* PAC-IF010-E, PAC-IF020-E : PCB 10pcs/set

3-2. Combination of remote controller

Remote controller model Connected object Connectability

PAR-21MAA (Standard) I/F

PAR-W21MAA (Only for FTC) I/F NG (Continue to indicate “PLEASE WAIT”)

PAR-20MAA (Standard) I/F NG (Continue to indicate “PLEASE WAIT”)

(Old ) FTC NG (Continue to indicate “PLEASE WAIT”)

Manufacturer PAC-IF010-E *

Individual installer PAC-IF011B-E Cased

Manufacturer PAC-IF010-E * PCB only

Individual installer PAC-IF011B-E Cased

STEP I/F

Manufacturer PAC-IF010-E * PCB only

Individual installer PAC-IF011B-E Cased

Manufacturer PAC-IF020-E *

Individual installer PAC-IF021B-E Cased with R/C

FTC

OK

FTC NG (Continue to indicate “PLEASE WAIT”)

FTC OK

PCB only

PCB only

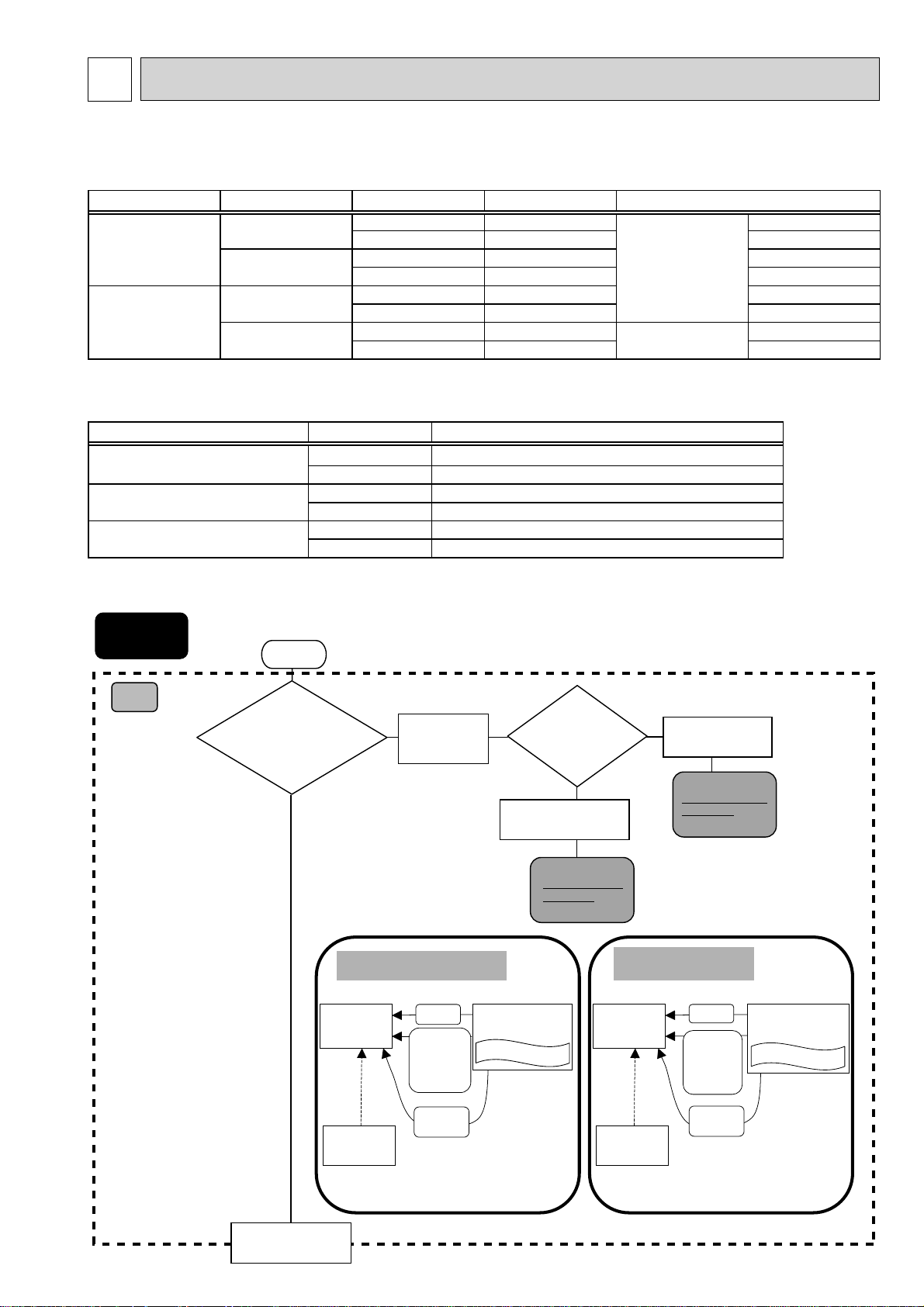

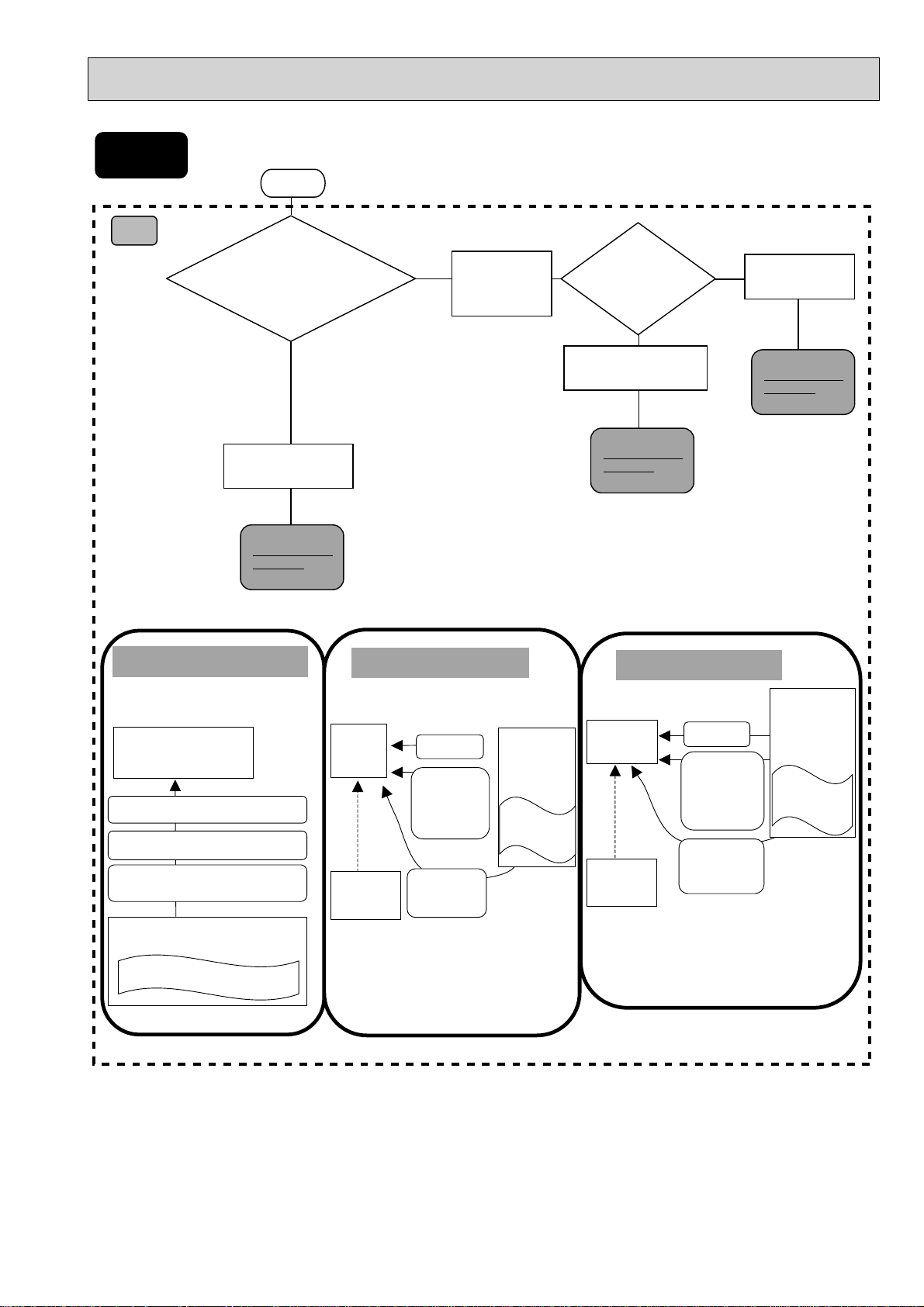

3-3. Flow chart to check system type

ATW

application

IF

start

Variable capacity

request signals for

Heat Pump is

calculated...

DIGITAL STEP

SYSTEM

IF PCB System controller

By local

controller

(your side)

By Non-voltage

Contact signals

ON/OF

Operation

mode

-Heating

-Cooling

capacity

signals

protocol is...

digital step

(non-voltage contact)

Your system is

DIGITAL STEP

SYSTEM

(IF)

(locally supplied)

End user interface

Analog

(0-10v/4-20mA…)

Your system is

ANALOG STEP

SYSTEM

(IF)

ANALOG STEP

SYSTEM

By Non-voltage

IF PCB System

Contact signals

ON/OF

Operation

mode

-Heating

-Cooling

controller

(locally supplied)

End user interface

By our FTC

Remote

for maintenance

- to check error code

Capacity

steps

By Non-voltage

Contact signals

1515

Capacity

Remote

For maintenance purpose

- analog signal parameters

steps

By Analog signal

4-20mA / 1-5V / 0-10V

Continued to next page.

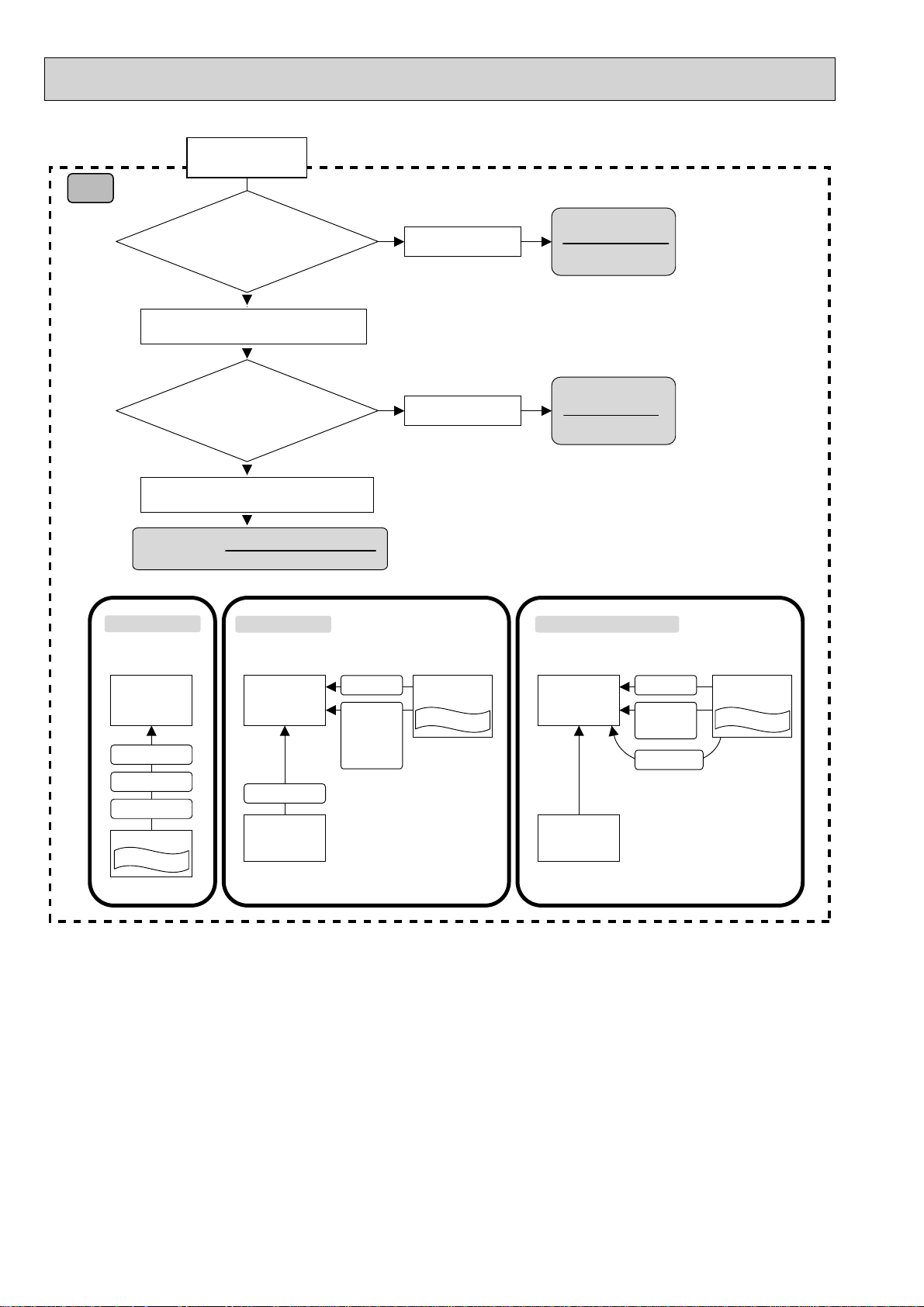

Page 16

FTC

By our FTC

Heat Pump switch ON/OFF

and the operation mode

change is done…

By remote controller

Your system is

SIMPLE SYSTEM.

(FTC)

By external signals from local controller

(non-voltage contact signals)

Your system is

‘Target flow temperature’ is set…

By remote controller

BASIC SYSTEM.

(FTC)

By external signals from local controller

(Analog signal:4-20mA/ 1-5V/ 0-10V)

Your system is ANALOG TEMP. SYSTEM.

(FTC)

SIMPLE SYSTEM BASIC SYSTEM

By Non-voltage

Contact signals

FTC PCB BOX FT C PCB BOX FTC PCB BOX

ON/OFF

Operation mode

Target flow temp.

Remote controller

End user interface

Target flow temp.

Remote controller

Topreset

- target temp. for eachmode

- target temp. parameters

ON/OFF

Operation mode

- Heating

- Heating ECO

- Hot water

- Anti freeze

- Cooling

System controller

(locally supplied)

End user interface

ANALOG TEMP. SYSTEM

Remote controller

Topreset

- analog signal parameters

By Non-voltage

Contact signals

ON/OFF

Operation mode

- Heating +

- Cooling

Target flow temp.

Analog signal

4-20mA/1-5V/0-10V

+In this system,

• Heating ECO mode of FTC is

not available.

• It is NOT necessary to switch

operation mode to realize

Hot water mode, Anti freeze

mode and Heating ECO mode.

Simply change the target temp.

by Analog signal.

System controller

(locally supplied)

End user interface

16

Page 17

ATA

application

IF

start

Variable capacity

request signals for

Heat Pump is

calculated...

By local

controller

(your side)

capacity

signals

protocol is...

Analog

(0-10v/4-20mA…)

AUTO STEP SYSTEM

IF PCB

ON/OFF

Operation mode

Target retern air temp.

Remote controller

End user interface

By our IF

Your system is

AUTO STEP

SYSTEM

(IF)

DIGITAL STEP SYSTEM

By Non-voltage

Contact signals

IF

PCB

Remote

controller

for

maintenance

- to check

error code

ON/OF

Operation

mode

-Heating

-Cooling

Capacity

steps

By Non-voltage

Contact signals

System

controller

(locally

suppliied)

End user

interface

digital step

(non-voltage contact)

Your system is

DIGITAL STEP

SYSTEM

(IF)

ANALOG STEP SYSTEM

By Non-voltage

Contact signals

IF

PCB

Remote

controller

For

maintenance

purpose

- analog signal

Your systemis

ANALOG STEP

SYSTEM

(IF)

System

controller

ON/OF

Operation

mode

-Heating

-Cooling

Capacity

steps

By Analog

signal

4-20mA / 1-5V / 0-10V

(locally

suppliied)

End user

interface

17

Page 18

6

5

2

1

1

8

1

2

1

8

1

8

4

3

TH1

OFF/ONOFF/ON

OFF/ON

OFF/ON

TB61

TH2

6

5

214

3

+

TB62

Adjustable resistor

4-20mA/1-5V/0-10V

Wired Remote Controller

(For Maintenance)

6

5

2

1

4

3

8

7

10

9

11

13

12

14

6

5

2

1

4

3

8

7

10

9

11 13

12 14

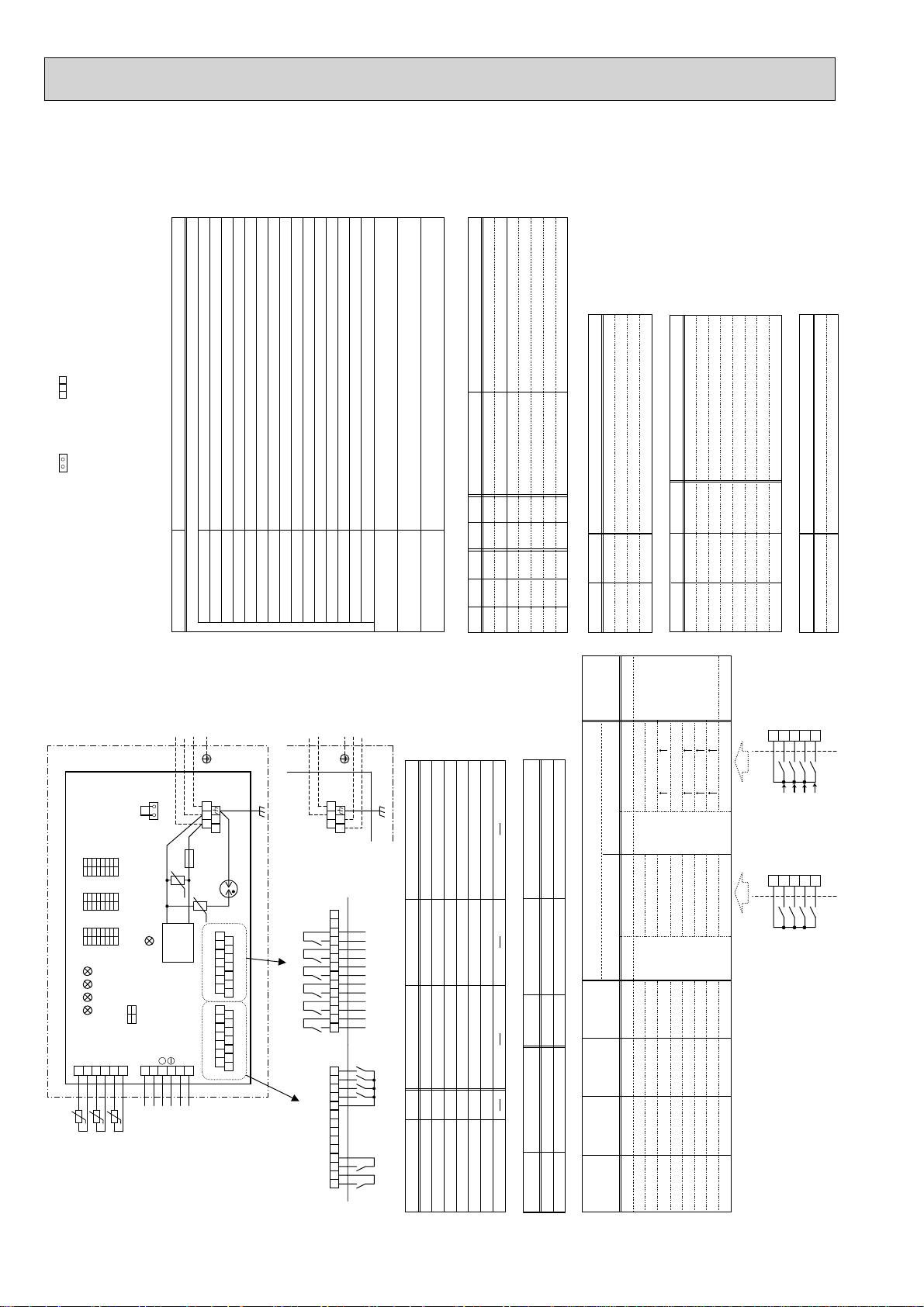

TB142 TB141

(External Output)

(External Input)

L

N

S1 S2 S3

L

N

S1 S2 S3

TB6

DC311~

339V

FUSE

SW6

LED1

RECTIFICATION

LED2

LED3

LED4

LED5

CNS2

(RED)

Interface controller

TO OUTDOOR UNIT

U

U

DSA

21

SYMBOL

INTERFACE CONTROLLER

TB6

TB141

TB142

TB62

TB61

LED1

LED2~5

FUSE

SW1

SW2

SW3

SW6

ZNR01,02

DSA

X1

~

X6

TH1

TH2

TH5

NAME

TERMINAL BLOCK(INTERFACE/OUTDOOR CONNECTING LINE)

TERMINAL BLOCK (External Output)

TERMINAL BLOCK (External Input REMOTE SWITCH)

TERMINAL BLOCK (External Input)

THERMISTOR(TARGET, PIPE)

POWER SUPPLY(I/F)

OPERATION INDICATION

FUSE(T3.15AL250V)

SWITCH(Input selection of inverter capacity setting) *See table 4.

SWITCH(Function switch)*See table 5 and 6.

SWITCH(LED2~5 Display setting)

SWITCH(4-20mA/1-5V/0-10V switch)*See table 4.

VARISTOR

SURGE ABSORBER

RELAY

TARGET TEMP. THERMISTOR

(0

/15k, 25/5.2k DETECT)

PIPE TEMP . THERMIST OR/LIQUID

(0

/15k, 25/5.2k DETECT)

PIPE TEMP . THERMIST OR/2-PHASE

(0

/15k, 25/5.2k DETECT)

TB6

TO OUTDOOR UNIT

POWER SUPPLY

~/N

21354678

TB141

11

10

9

121314

ZNR01

ZNR02

21354678

TB142

I/F

9

X1 X2 X3 X4 X5 X6

Item

Operation Output

Error Output

Comp. Output

Defrost Output

Mode(Cool) Output

Mode(Heat) Output

(OUT1)

(OUT2)

(OUT3)

(OUT4)

(OUT5)

(OUT6)

(OUT7)

X1X2X3X4X5

X6

ON

ErrorONONONON

OFF

Normal

OFF(Comp. OFF)

OFF

OFF

OFF

(Comp. ON)

(Defrosting)

(Cooling)

(Heating)

TB141

1-2

3-4

5-6

7-8

9-10

11-12

13-14

Refer to table 1.

table 1

*1(Fig.1)

Refer to table 2, 3.

Remark

SW2-1, SW2-2: ON is valid.

ON

Forced Comp. OFF

Heating

OFF

Normal

Cooling

Item

Forced Comp. OFF

Fixed operation mode

TB142

1-2 (IN1)

3-4 (IN2)

table 2

Step for capacity setting

TB142

10-11

(COM-IN5)

TB142

10-12

(COM-IN6)

TB142

10-13

(COM-IN7)

TB142

10-14

(COM-IN8)

Remark

Auto mode

OFF

Fixed capacity

(Hz fixed)

mode

table 3

TB142

I/F

1110121314

1110121314

At site

4bit8 switch

OFF

~AUTO

TB142

I/F

At site

Step1

Step4

Step7

AUTO

SW1-1

OFFONONONOFFONOFF

SW2-3

OFFONOFFONOFFONOFF

ON

OFFONOFFONOFFONOFFONOFF

OFF

OFFONON

OFF

OFFONON

OFF

OFF

OFF

OFF

OFFONONONON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

OFF 0%

Step1 10%

Step2 20%

Step3 30%

Step4 50%

Step5 70%

Step6 80%

Step7 100%

Auto

OFF 0%

Step1 10%

Step4 50%

Step7 100%

Auto

[OFF]

[ON]

[OFF]

[ON]

SW2-4

OFF

OFFONON

OFF

OFFONON

SW2-5

OFF

OFF

OFF

OFFONONONON

Details

Not fixed (Remote controller setting)

Cooling 19 ˚C/Heating 17 ˚C FIX

20 ˚C FIX

22 ˚C FIX

24 ˚C FIX

26 ˚C FIX

28 ˚C FIX

Cooling 30 ˚C / Heating 28 ˚C FIX

SW1-2

OFF

OFFONON

OFF

OFF

ON

SW2-1

OFFONOFF

ON

SW2-2

OFF

OFFONON

SW1-3

OFF

OFF

OFF

OFFONON

ON

SW6-1

OFF

OFFONOFF

OFF

OFF

OFF

SW6-2

OFF

OFFONON

OFF

OFF

OFF

Input

TypeA

(4bit-8 setting)

TypeB

(1bit-1 setting)

4-20mA

1-5V

0-10V

0-10k

No input(Auto mode)

Step for capacity setting

OFF/Step 1/Step 2/

...

/Step 7/Auto

OFF/Step 1/Step 4/Step 7/Auto

OFF/Step 1/Step 2/

...

/Step 7

OFF/Step 1/Step 2/

...

/Step 7

OFF/Step 1/Step 2/

...

/Step 7

OFF/Step 1/Step 2/

...

/Step 7/Auto

Only Auto mode

table 4 SW1, SW6 : Input selection of inverter capacity setting

table 5 SW2-1/2-2 : Fixed operation mode

Details

Not FIX

(Depending on Remote controller setting)

[Cooling]FIX

[Heating]FIX

External input(Depending on TB142-3,4)

1. SymboIs used in wiring diagram are, : Connector, : Terminal block.

2. Interface controller and outdoor connecting wires have poIarities, make sure to match

terminal numbers(S1, S2, S3) for correct wirings.

3. Since the outdoor side electric wiring may change, be sure to check the outdoor unit

electric wiring diagram for servicing.

4. This diagram shows the wiring of Interface controller and outdoor connecting wires.(specification of 230V),

adopting superimposed system of power and signal.

*1 : When work to supply power separately to Interface controller and outdoor units was applied, refer to Fig 1.

*2 : Remove the short-circuited connector CNS2 when work to supply power separately to

Interface controller and outdoor units was applied.

ONOFF

TypeA TypeB

At site

*2 Remove the

short-circuited connector

CNS2.

table 6 SW2-3/2-4/2-5 : Fixed set temperature [For Auto mode]

t°

t°

SW3SW2SW1

1110

12

13

14

{

{

{

{

SW2-6

OFF

ON

table 7 SW2-6 : setting TH5

Details

Connect TH5

Not connect TH5 (Initial setting)

TH5

t°

(

(

(

3-4. Wiring diagram

(1) PAC-IF011B-E(I/F)

18

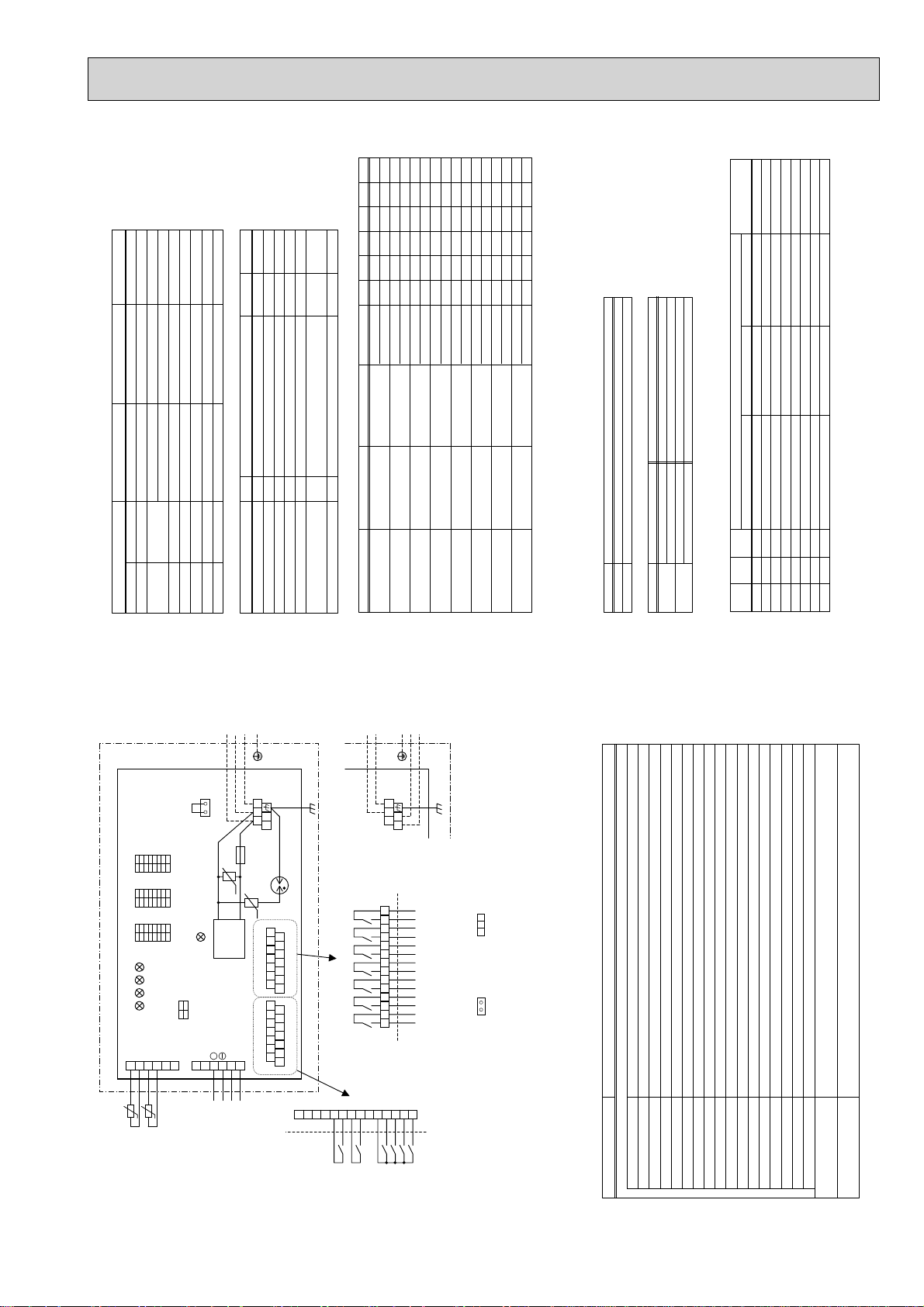

Page 19

6

5

2

1

1

8

1

2

1

8

1

8

4

3

TH1

OFF/ONOFF/ON

OFF/ON

OFF/ON

TB61

*6TH2

6

5

214

3+

TB62

4-20mA/1-5V/0-10V

WiredRemoteController

6

5

2

1

4

3

8

7

10

9

11

13

12

14

6

5

2

1

4

3

8

7

10

9

1113

12 14

TB142 TB141

(ExternalOutput)

(ExternalInput)

LN

S1 S2 S3

LN

S1 S2 S3

TB6

DC311〜

339V

FUSE

SW6

LED1

RECTIFICATION

LED2

LED3

LED4

LED5

CNS2

(RED)

FLOWTEMP.CONTROLLER(FTC)

TOOUTDOORUNIT

U

U

DSA

21

SYMBOL

FLOWTEMP.CONTROLLER(FTC)

TB6

TB141

TB142

TB62

TB61

LED1

LED2

LED3

LED4,5

FUSE

SW1

SW2

SW3

SW6

ZNR01,02

DSA

X1〜X7

TH1

TH2

NAME

TERMINALBLOCK(FTC/OUTDOORUNITCONNECTINGLINE)

TERMINALBLOCK(ExternalOutput)

TERMINALBLOCK(ExternalInputContactsignal)

TERMINALBLOCK(ExternalInputAnalogsignal)

TERMINALBLOCK(Thermistor)

POWERSUPPLY(FTC)

POWERSUPPLY(WIREDREMOTECONTROLLER)

TRANSMISSION(FTC-OUTDOORUNIT)

NOTINUSE

FUSE(T3.15AL250V)

SWITCH*SeeTable3,4and6.

SWITCH

SWITCH*SeeTable5.

SWITCH(4-20mA/1-5V/0-10Vswitch)*SeeTable3.

VARISTOR

SURGEABSORBER

RELAY

ACTUALFLOWWATERTEMP.THERMISTOR(Waterpiping)

(0℃/15kΩ,25℃/5.2kΩDETECT)

PIPETEMP.THERMISTOR/LIQUID(Refrigerantpiping)

(0℃/15kΩ,25℃/5.2kΩDETECT)

TB6

TOOUTDOORUNIT

POWERSUPPLY

〜/N

21354678

TB141

11

10

9

12 13 14

ZNR01

ZNR02

X1X2X3X4X5X X76

OFF

Normal

ForcedComp.OFF

OFF

OFF

OFF

OFF

OFF

(IN1)

(IN2)

(IN3)

(IN4)

(COM-IN5)

(COM-IN6)

(COM-IN7)

(COM-IN8)

Remark

Notinuse

Notinuse

SW3-6=OFF

SW3-6=ON

ON

ForcedComp.OFF

Normal

Cooling

Heating

HeatingECO

HotWater

Anti-Freeze

TB142

1-2

3-4

5-6

7-8

10-11

10-12

10-13

10-14

X1X2X3X4X5X6X7

(OUT1)

(OUT2)

(OUT3)

(OUT4)

(OUT5)

(OUT6)

(OUT7)

OFF

OFF

Normal

OFF

OFF

OFF

OFF

ONONErrorONONONON

Item

OperationOutput

ErrorOutput

Comp.Output

DefrostOutput

Mode(Cooling)Output

Mode(Heating/HeatingECO/

HotWater/Anti-Freeze)Output

TB141

1-2

3-4

5-6

7-8

9-10

11-12

13-14

RefertoTable2.

Table1Externalinput(Contactsignal)

Table2Externaloutput

*1(Fig.1)

Referto

Table1.

SW1-6

OFF

OFF

OFF

OFFONONONON

SW1-7

OFFONOFFONOFFONOFF

ON

SW1-8

OFF

OFFONON

OFF

OFFONON

Heating/HeatingECO/HotWater

Upper55℃/lower20℃

Upper60℃/lower20℃*7

Upper50℃/lower20℃

Anti-Freeze

Upper45℃/lower5℃

Upper45℃/lower5℃

Upper45℃/lower5℃

Cooling

Upper25℃/lower5℃

Upper25℃/lower5℃

Upper25℃/lower5℃

Temperaturetable

SW2-1〜8,SW3-1〜3

Table*8Table*8

SW3-6

OFF

ON

TB142No.5-6input

OFF(open)

ON(short)

OFF(open)

ON(short)

Table3SW1,SW6:Inputselection

Table5SW3-6LogicofForcedcomp.OFFexternalsignal(TB1425-6)

*7.DontusethissettingwhenusingtheSPLITtypeoutdoorunit.

*8.Refertoinstallationmanual.

Item

Normal

ForcedComp.OFF

ForcedComp.OFF

Normal

SW1-3

OFF

ON

Operationmode

Heating/HeatingECO/Hotwater/Anti-freeze/Cooling

Heating/HeatingECO/Hotwater/Anti-freeze

Table4SW1-3ProhibitionofCoolingmode

*3.0〜2mA:STOP

*4.0〜0.5V:STOP

*5.Thesignalofexternalinputispriortothesignalofwiredremotecontroller.

*6.SPLITtype:thestandardoutdoorunitwithoutaplateHEX(refrigerant-waterHEX)inside.

PACKAGEDtype:theAirtowateroutdoorunitwithaplateHEX(refrigerant-waterHEX)inside.

(ItisnotnecessarytoconnecttoTH2.)

1.SymboIsusedinwiringdiagramare, :Connector, :Terminalblock.

2.FTCandoutdoorunitconnectingwireshavepoIarities,makesuretomatchterminalnumbers(S1,

S2,S3)forcorrectwirings.

3.Sincetheoutdoorunitsideelectricwiringmaychange,besuretochecktheoutdoorunitelectric

wiringdiagramforservicing.

4.ThisdiagramshowsthewiringofFTCandoutdoorunitconnectingwires(specificationof230V),

adoptingsuperimposedsystemofpowerandsignal.

*1:WhenworktosupplypowerseparatelytoFTCandoutdoorunitwasapplied,refertoFig1.

*2:Removetheshort-circuitedconnectorCNS2whenworktosupplypowerseparatelytoFTC

andoutdoorunitwasapplied.

*2Removethe

short-circuited

connectorCNS2.

Table6SW1-6,7,8 Settemperaturerange

SW1-6=OFF Settemperaturerangewithwiredremotecontroller

SW1-6=ON SettemperaturetablewithDIPswitchofFTC

BH79L347H01

t。t

。

SW3SW2SW1

{

{

{

TB142

FTC

FTC

11

10

12

13

14

Atsite

Atsite

HeatingECO

→

Anti-Freeze

→

HotWater

→

Heating

→

65789

213

4

ForcedComp.OFF→

Cooling→

ON/OFFInput

Externalinput

(non-voltagecontact)

Externalinput

(non-voltagecontact)

Externalinputor

4-20mA*3

Externalinputor

1-5V*4

Externalinput

Externalinputand

Wiredremotecontroller

Externalinputand

Wiredremotecontroller

Wiredremotecontroller

ChangemodeInput

Externalinput

(non-voltagecontact)

Externalinput

(non-voltagecontact)

Externalinput

(non-voltagecontact)

Externalinput

(non-voltagecontact)

Externalinput

(non-voltagecontact)

Externalinputand

Wiredremotecontroller

Externalinputand

Wiredremotecontroller

Wiredremotecontroller

ChangeTEMP. Input

DIPswitchonPCB

SW2-1〜8,SW3-1〜3

Wiredremotecontroller

4-20mA

1-5V

0-10V

DIPswitchonPCB

SW2-1〜8,SW3-1〜3

Wiredremotecontroller

Wiredremotecontroller

Outdoorunit*6

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SPLITtype

PACKAGEDtype

SW1-1ONONONON

OFF

OFF

OFF

OFFONON

OFF

OFF

OFF

OFF

OFF

OFF

SW1-2

OFF

OFF

OFF

OFFONONONONONON

OFF

OFF

OFF

OFF

OFF

OFF

SW1-5

OFFONOFFONOFFONOFFONOFFONOFFONOFFONOFF

ON

SW1-6ONON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFFONON

OFF

OFF

OFF

OFF

SW6-1

OFF

OFF

OFF

OFFONON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

SW6-2

OFF

OFF

OFF

OFFONONONON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Temperaturerangewithwiredremotecontroller

*5

*5

(

(

(2) PAC-IF021B-E(FTC)

19

Page 20

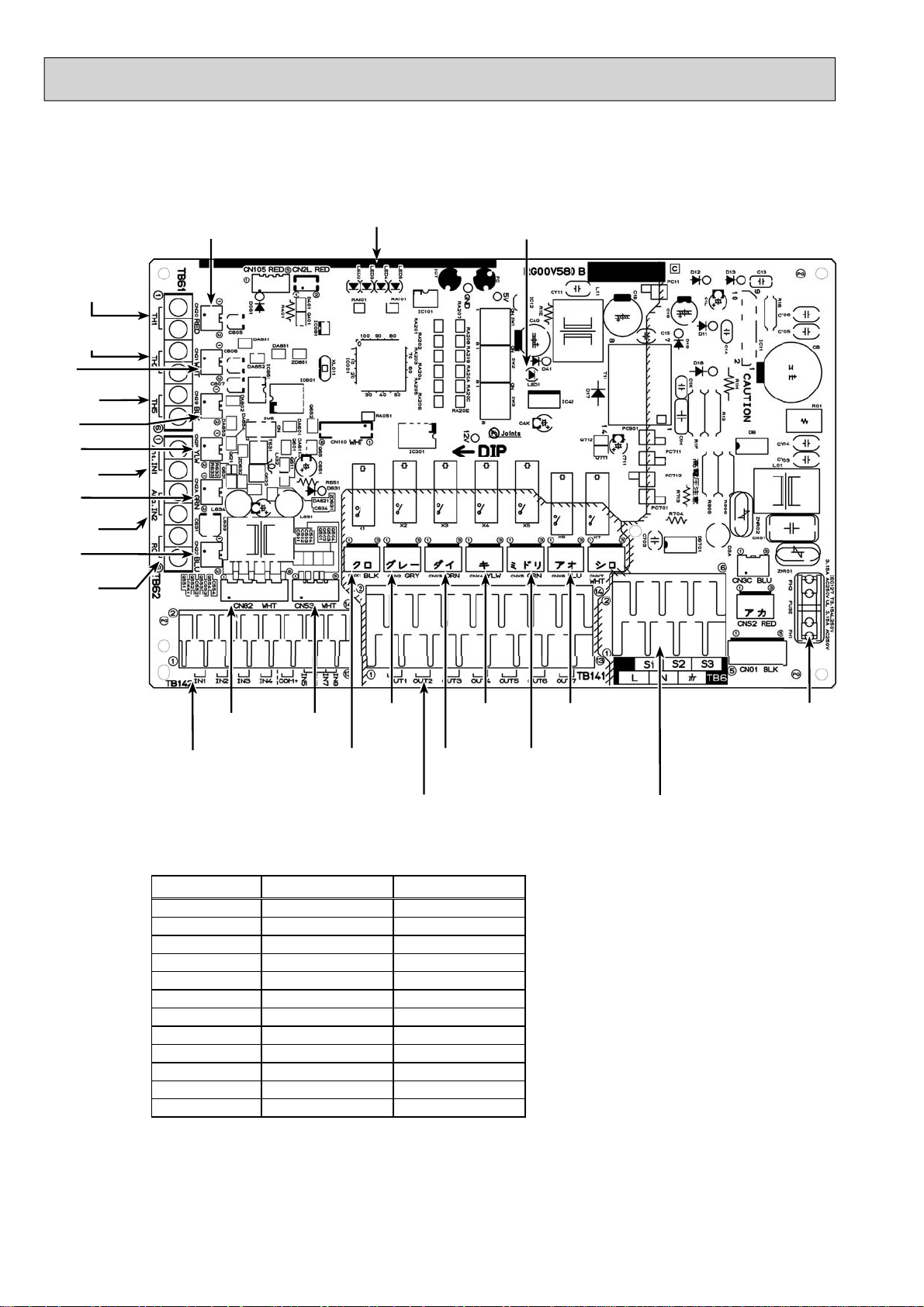

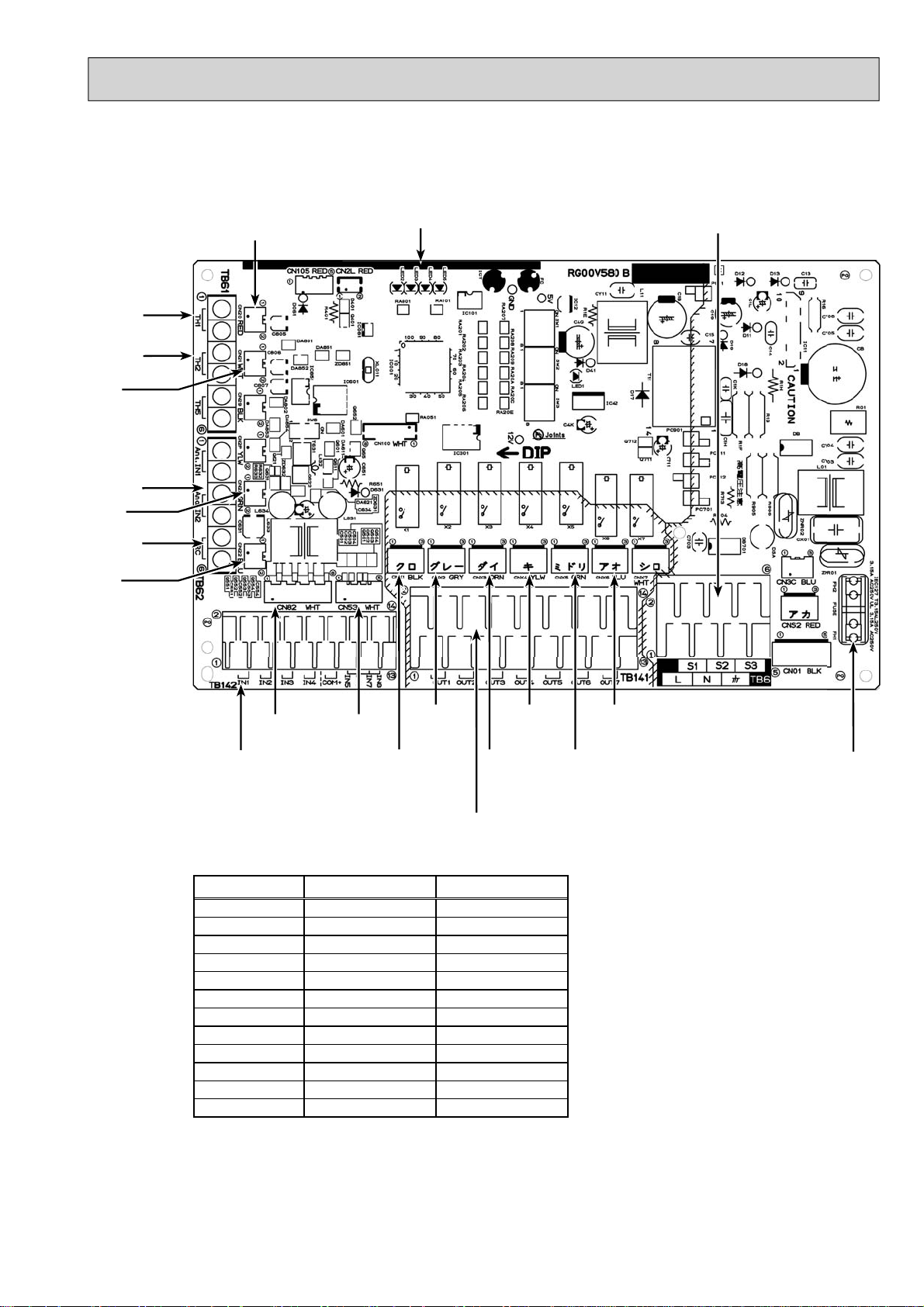

3-5. PCB diagram(Test point )

(1) PAC-IF011B-E, PAC-IF010-E

TB61 1-2

Thermistor (TH1)

TB61 3-4

Thermistor (TH2)

CN21

Thermistor (TH2)

TB61 5-6

Thermistor (TH5)

CN29

Thermistor (TH5)

CN2P

Adjustable resistor

TB62 1-2

Adjustable resistor

CN2A

4-20mA/1-5V/0-10V

TB62 3-4

4-20mA/1-5V/0-10V

CN22

Wired remote

controller

TB62 5-6

Wired remote

controller

CN20

Thermistor (TH1)

LED2~5 LED1

Power supply

CN82

External input

Remote switch

TB142

External input

Remote switch

CN53

External input

Remote switch

PAC-IF011B-E PAC-IF010-E

TB6

TB141

TB142

TB61

TB62

CNX1~CNX6 —

CN20

CN21

CN29

CN2P

CN2A

CN22

: mounting

Ο

—

: unmounting

CNX2

Error Output

CNX1

Operation Output

TB141

External output

CNX4

Defrost Output

CNX3

Comp.Output

CNX5

Mode(Cool)Output

ΟΟ

Ο

—

ΟΟ

ΟΟ

ΟΟ

Ο

ΟΟ

ΟΟ

ΟΟ

ΟΟ

ΟΟ

ΟΟ

CNX6

Mode(Heat)Output

TB6

Interface/outdoor

connecting

FUSE

T3,15AL250V

20

Page 21

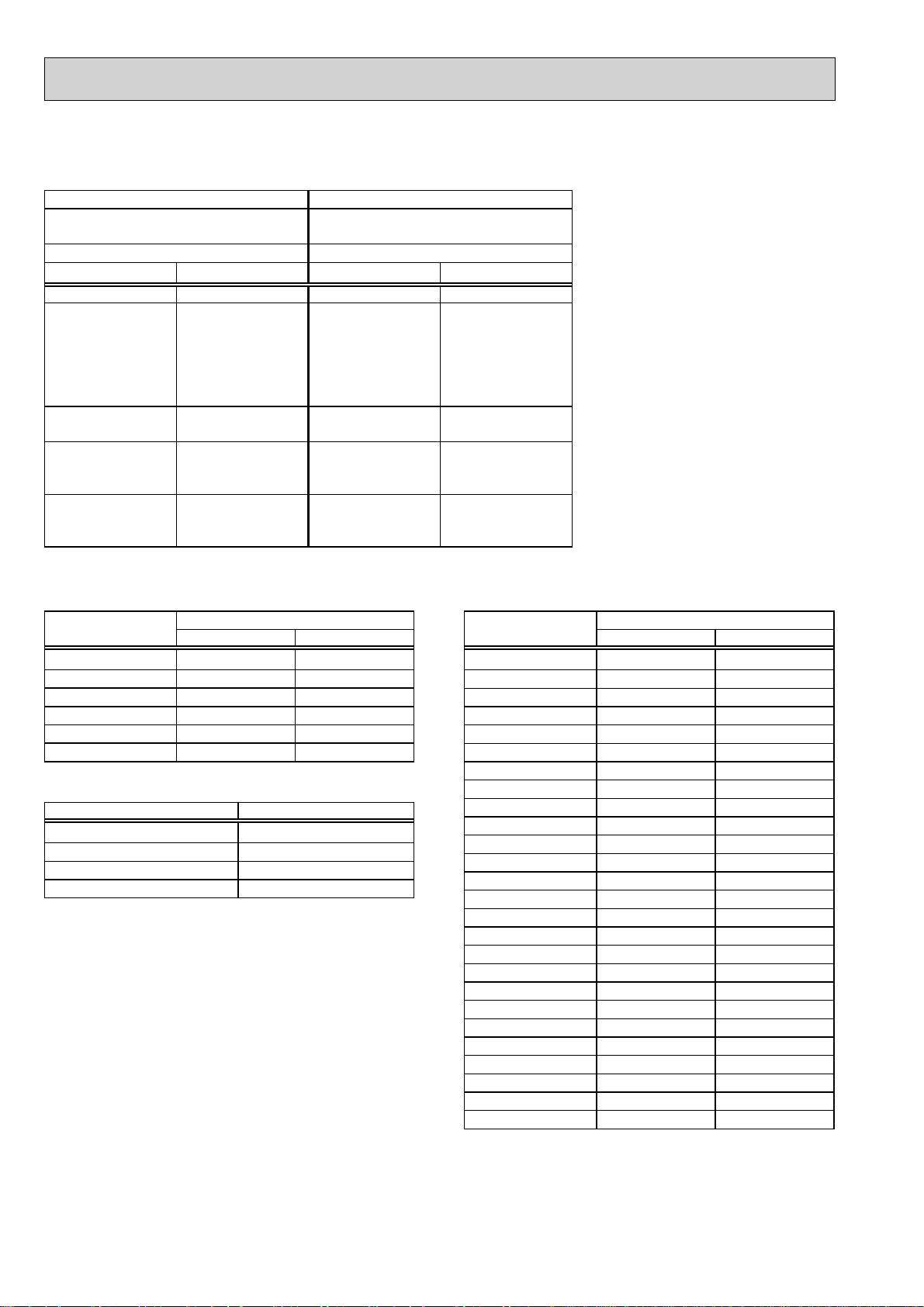

(2) PAC-IF021B-E(FTC), PAC-IF020-E

CN20

Thermistor (TH1)

TB61 1-2

Thermistor (TH1)

TB61 3-4

Thermistor (TH2)

CN21

Thermistor (TH2)

TB62 3-4

4-20mA/1-5V/0-10V

CN2A

4-20mA/1-5V/0-10V

TB62 5-6

Wired remote

controller

CN22

Wired remote

controller

LED2,3

TB6

FTC/outdoor unit

connecting

CN82

External input

TB142

External input

CN53

External input

PAC-IF021B-E PAC-IF020-E

TB6

TB141

TB142

TB61

TB62

CNX1~CNX6 —

CN20

CN21

CN29

CN2P

CN2A

CN22

: mounting

Ο

—

: unmounting

CNX2

Error Output

CNX1

Operation Output

CNX4

Defrost Output

CNX3

Comp.Output

TB141

External output

CNX5

Mode(Cooling)Output

ΟΟ

Ο

—

ΟΟ

ΟΟ

ΟΟ

Ο

ΟΟ

ΟΟ

ΟΟ

ΟΟ

ΟΟ

ΟΟ

CNX6

Mode(Heating/Heating

ECO/Hot Water/Anti-Freeze)Output

FUSE

T3,15AL250V

21

Page 22

3-6. Specifi cation of connectors

Please connect wiring with either of the terminal bed or the connector.

Parts on the PCB are different depending on the model.

PCB ONLY Cased

PAC-IF010-E

PAC-IF020-E

Parts on PCB Parts on PCB

TERMINAL BED CONNECTOR TERMINAL BED CONNECTOR

TB6 TB6

CNX1

CNX2

CNX3

CNX4

CNX5

CNX6

TB142 CN82

CN53

TB61 CN20

CN21

CN29

TB62 CN2P

CN2A

CN22

The following terminal bed and the connector is the same signals, meaning.

PAC-IF011B-E

PAC-IF021B-E

TB141

TB142

TB61 CN20

CN21

CN29

TB62 CN2P

CN2A

CN22

TB6

TERMINAL BED

TB6-L — —

TB6-N — —

TB6-PE — —

TB6-S1 — —

TB6-S2 — —

TB6-S3 — —

Specifi cation of connectors (Manufacture: J.S.T. Mfg. Co., Ltd.)

CONNECTOR NAME HOUSING

CNX1 ~ 6 VHR-3N

CN82 XAP-08V-1

CN53 XAP-05V-1

CN20,21,29,2P,2A,22 XAP-02V-1

Contact pin : According to the wiring size select the correct

contact pin by yourself.

CONNECTOR

NAME PIN No.

TB141, TB142, TB61

TERMINAL BED

TB141-1,2 CNX1 1,3pin

TB141-3,4 CNX2 1,3pin

TB141-5,6 CNX3 1,3pin

TB141-7,8 CNX4 1,3pin

TB141-9,10 CNX5 1,3pin

TB141-11,12 CNX6 1,3pin

TB142-1 CN82 1pin

TB142-2 CN82 2pin

TB142-3 CN82 3pin

TB142-4 CN82 4pin

TB142-5 CN82 5pin

TB142-6 CN82 6pin

TB142-7 CN82 7pin

TB142-8 CN82 8pin

TB142-9 CN53 5pin

TB142-10 CN53 5pin

TB142-11 CN53 1pin

TB142-12 CN53 2pin

TB142-13 CN53 3pin

TB142-14 CN53 4pin

TB61-1,2 CN20 1,2pin

TB61-3,4 CN21 1,2pin

TB61-5,6 CN29 1,2pin

TB62-1,2 CN2P 1,2pin

TB62-3,4 CN2A 1,2pin

TB62-5,6 CN22 1,2pin

CONNECTOR

NAME PIN No.

22

Page 23

Interface (I/F)4

CONTENTS

1. System outline ..................................................................................24

2. System structure ...............................................................................24

3. Power supply ....................................................................................28

4. Connecting thermistor.......................................................................30

5. Interface controller switch setting .....................................................31

6. Input specifi cations ...........................................................................32

7. Output specifi cations ........................................................................33

8. LED display detail .............................................................................34

9. Maintenance information ..................................................................35

10. Central control ..................................................................................52

11. Outlines and dimensions ..................................................................53

12. Troubleshooting ................................................................................ 54

Notes on system controller side in I/F connection system

(1)Please do not transmit “STEP 0” during defrost operation.

Defrost operation might be interrupted, and frost remain.

(Please demand the planned capacity step even when the system controller receives defrost signal from the heat

pump (outdoor unit)).

(2)Please do not transmit “STEP 0” when the outdoor unit(H/P) is abnormal.

Abnormal detection data is reset, and an Abnormal point cannot be confi rmed.

2323

Page 24

1. System outline

With PAC-IF011B-E, local units can be connected with the outdoor units manufactured by MITSUBISHI ELECTRIC.

The commands, such as Remote switch, Varistor, 4-20mA/1-5V/0-10V and etc., allow the inverter outdoor unit to operate, to

stop and to switch capacity.

By outputting the operation state, the interface can be connected with the local unit.Also, the interface can be connected with

wired remote controller for maintenance so that the maintenance information is obtained.

Only the outdoor units with self-controlled S/W are connectable.

2. System structure

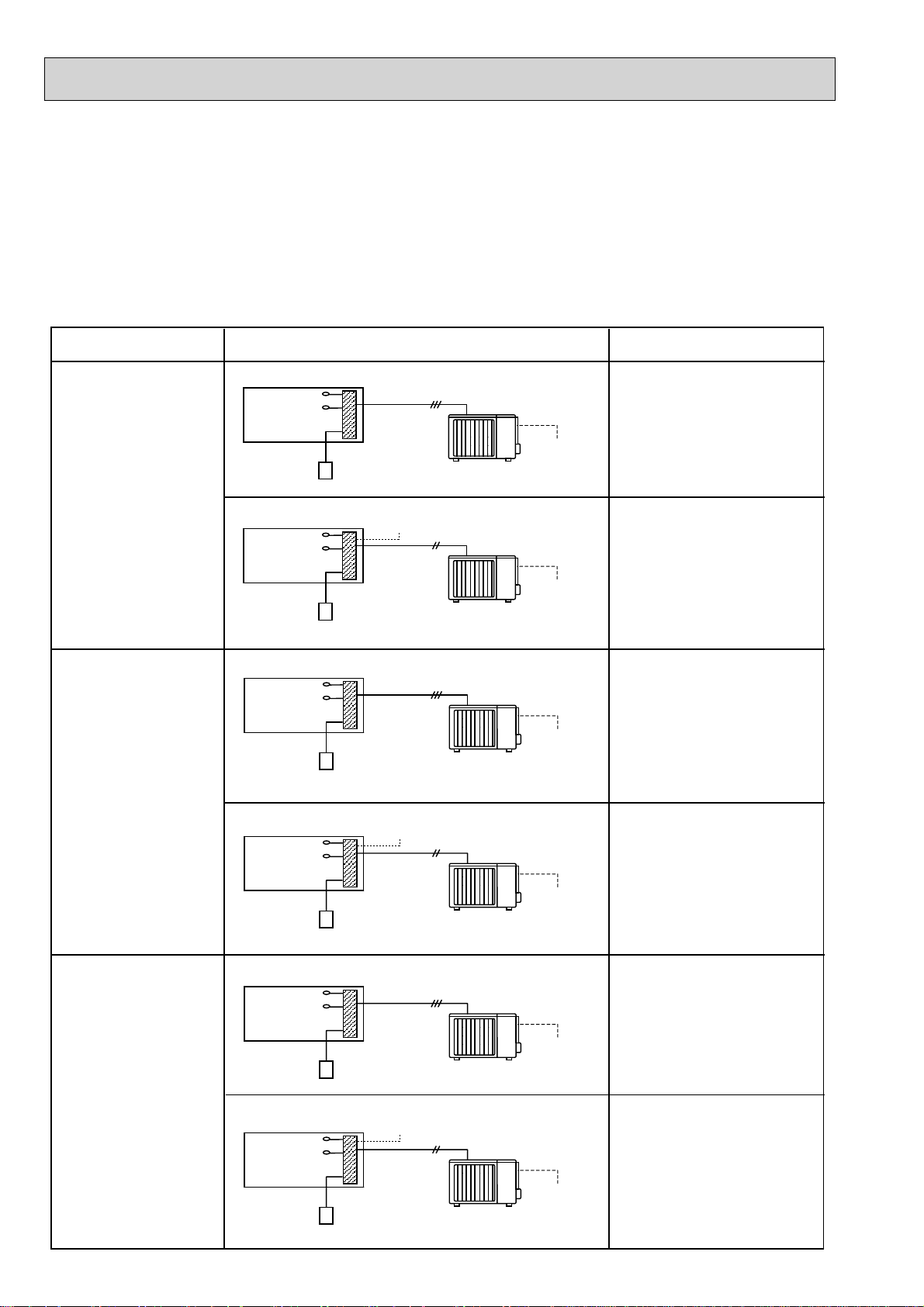

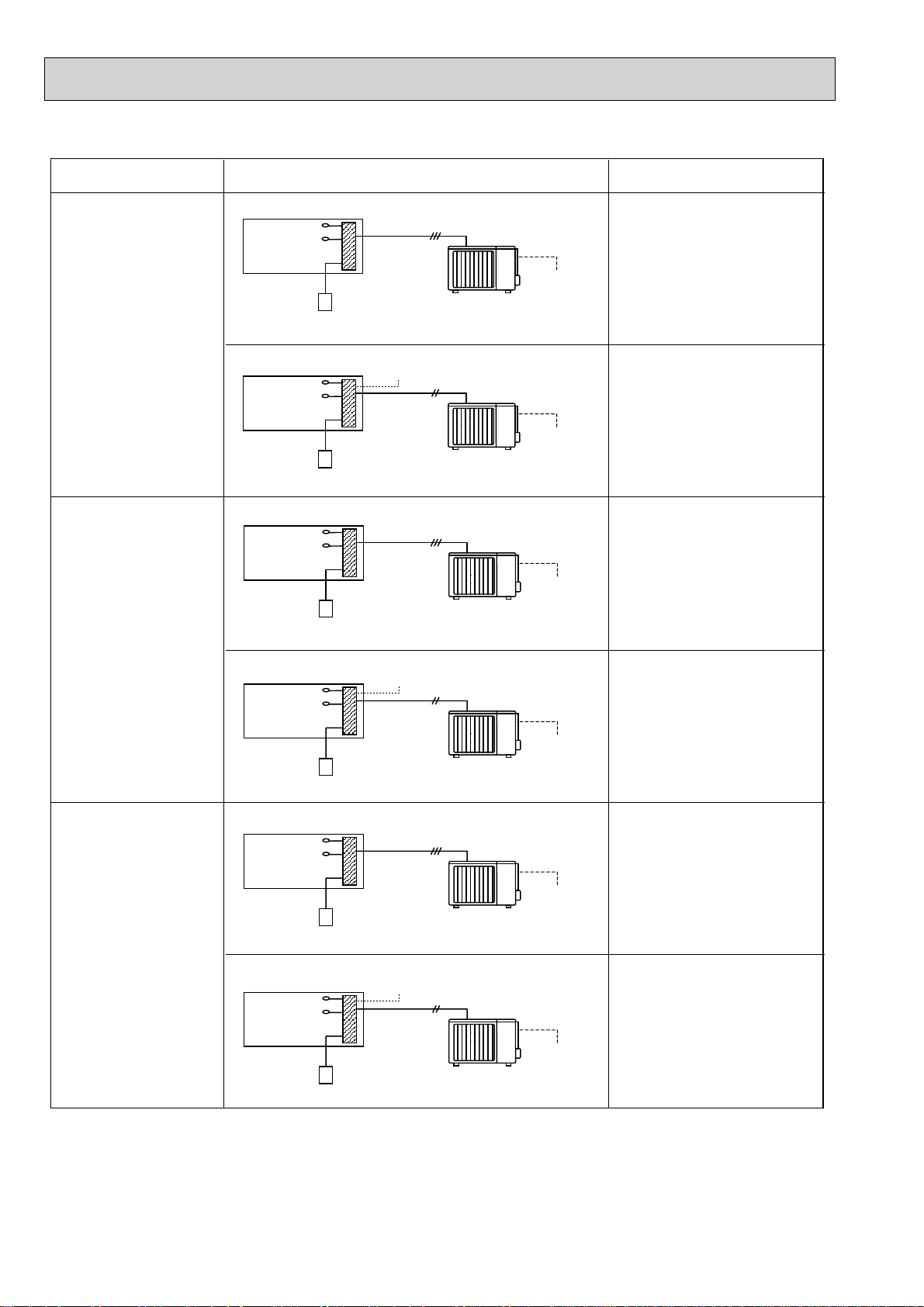

System structure(1)

Outdoor unit capacity switch

Remote switch

Capacity switch of outdoor

unit according to the remote

switch

When auto stop being set,

the difference between room

temperature and set

temperature of interface,

and the pipe temperature

switch the capacity of

outdoor unit automatically.

Wired remote controller

(Auto step mode only)

The difference between

room temperature and set

temperature of wired remote

controller, and the pipe

temperature switch the

capacity of outdoor unit

automatically.

As with the remote controller

for air conditioner, the

interface performs ON/OFF

operation, and changes

operation mode (cooling,

heating ,fan) and set

temperature.

Adjustable resistor(0-10k)

Capacity switch of outdoor

unit according to the

adjustable resistor

System diagram Power supply specifications

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Wired

remote controller

Intake temp.

Liquid pipe temp.

Local unit

Wired

remote controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller Adjustable resistor

Interface controller

Remote switch

Power line

Interface controller

Remote switch

Interface controller

PAR-21MAA

Power line

Interface controller

PAR-21MAA

Interface controller

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

Power supplied from outdoor unit

Power supply for interface

controller is supplied from the

outdoor unit.

Refer to 3.1.

Separate interface/outdoor unit

power supplies

Power supply for interface

controller and power supply for

outdoor unit are supplied from the

different source.(Common power

source for local unit and interface

controller)

Refer to 3.2.

Power supplied from outdoor unit

Power supply for interface

controller is supplied from the

outdoor unit.

Refer to 3.1.

Separate interface/outdoor unit

power supplies

Power supply for interface

controller and power supply for

outdoor unit are supplied from the

different source.(Common power

source for local unit and interface

controller)

Refer to 3.2.

Power supplied from outdoor unit

Power supply for interface

controller is supplied from the

outdoor unit.

Refer to 3.1.

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Power line

Interface controller

Adjustable resistor

A transmission line/Power line

Power line

Outdoor unit

24

Separate interface/outdoor unit

power supplies

Power supply for interface

controller and power supply for

outdoor unit are supplied from the

different source.(Common power

source for local unit and interface

controller)

Refer to 3.2.

Page 25

Note:

• REMOTE SWITCH Type A (4bit - 8 setting) / Type B (1bit -1 setting)

TB142

10-11

(COM-IN5)

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

TB142

10-12

(COM-IN6)

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

TB142

10-13

(COM-IN7)

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

TB142

10-14

(COM-IN8)

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

Step for capacity setting *

TypeA TypeB

OFF 0%

[OFF]

[ON]

Step1 10%

Step2 20%

Step3 30%

Step4 50%

Step5 70%

Step6 80%

Step7 100%

Auto step

[OFF]

[ON]

OFF 0%

Step1 10%

Step4 50%

Step7 100%

Auto step

Remark

OFF

Fixed capacity

(Hz fixed)

mode

Auto step mode

Type A Type B

I/F

At site

4 bit 8 switch

OFF~AUTO

step

{

10

11

12

13

14

TB142

At site

Step1

Step4

Step7

AUTO

step

I/F

10

11

12

13

14

TB142

* The actual capacity will be slightly different from the numerial data in this table depending on conditions such as the ambient

temperature.

Attachment of sensor

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Interface controller

switch setting

2 patterns can be

set.

(Refer to NOTE 1.)

Type A

SW1-1:OFF

SW1-2:OFF

SW1-3:OFF

SW6-1:OFF

SW6-2:OFF

Type B

SW1-1:ON

SW1-2:OFF

SW1-3:OFF

SW6-1:OFF

SW6-2:OFF

Other switches are

to be set according

to the site.

Refer to 5 for details.

Interface controller specifications

Input and wiring Output and wiring

Type A

Refer to 7.

OFF/Step1/Step2/

···Step7/Auto step

Type B

OFF/Step1/Step4/

Step7/Auto step

Refer to 6 for details.

Refer to 7.

Other functions/setting

Maintenance

Refer to 8, 9.

Refer to 8, 9.

Connection with

BMS/MELANS

Not available

Not available

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary depending

on the type of the

outdoor unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary depending

on the type of the

outdoor unit.

SW1-1:OFF

SW1-2:ON

SW1-3:ON

SW6-1:OFF

SW6-2:OFF

Other switches are

to be set according

to the site.

Refer to 5 for details.

SW1-1:OFF

SW1-2:OFF

SW1-3:ON

SW6-1:OFF

SW6-2:OFF

Other switches are

to be set according

to the site.

Refer to 5 for details.

TB62

Connect the wired

remote

controller wire to

No.5-6

Wiring

Wire NO.×size(mm

2×0.3(Non-polar)

Max. 500m

Circuit rating

DC12V

The figure is NOT

always against the

ground.

Only the operation

with remote

controller is valid.

(External signal is

invalid)

Refer to 6.

Refer to 6.

2

)

Refer to 7.

Refer to 7.

Refer to 7.

Refer to 7.

Refer to 8, 9.

Refer to 8, 9.

Refer to 8, 9.

Refer to 8, 9.

Available

Refer to 10.

Connect adaptor to

outdoor unit.

M-NET converter

PAC-SF80MA-E

A-Control sub

Interface

PAC-SK82SI-E

Available

Refer to 10.

Connect adaptor to

outdoor unit.

M-NET converter

PAC-SF80MA-E

A-Control sub

Interface

PAC-SK82SI-E

Not available

Not available

25

Page 26

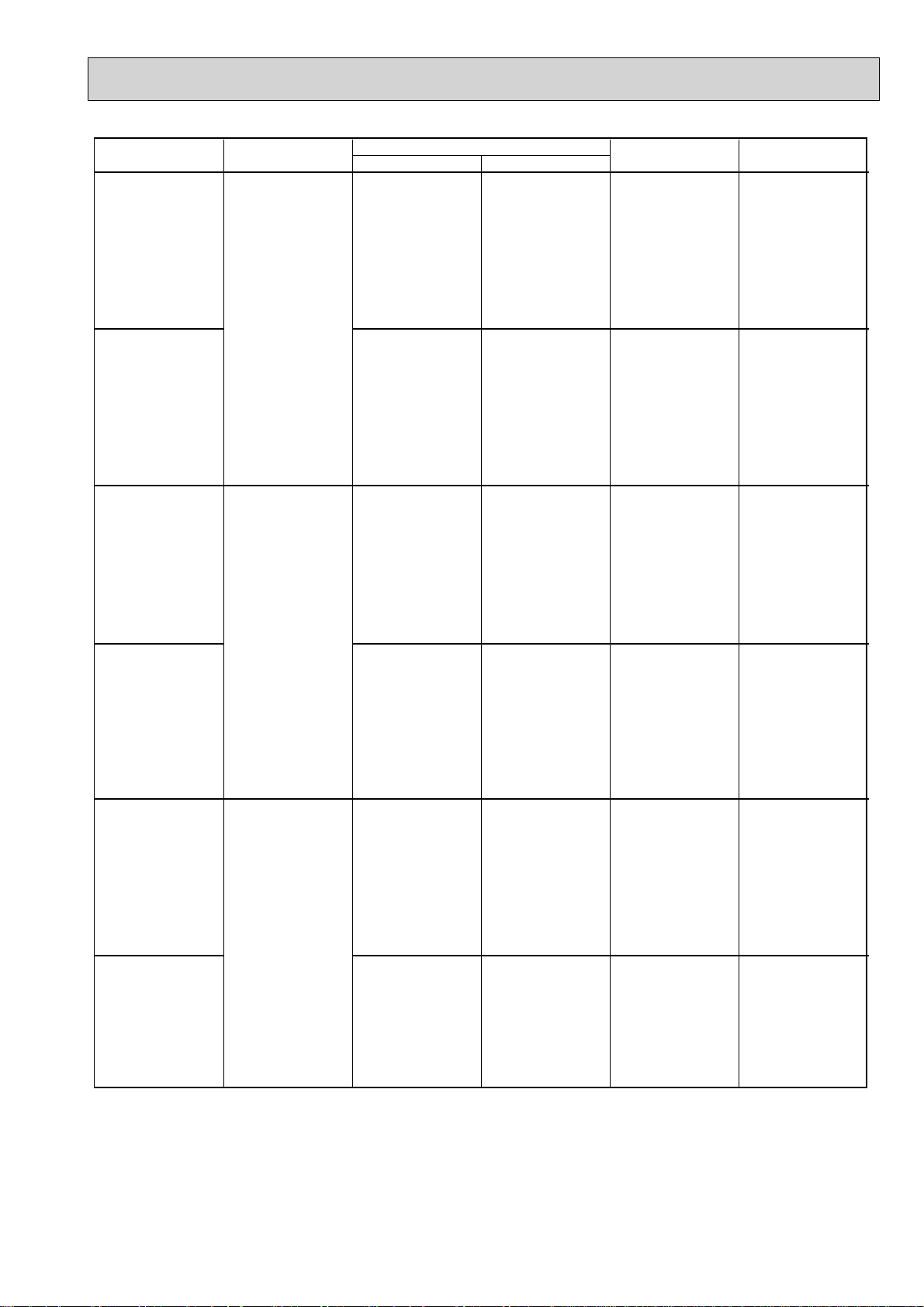

System structure(2)

Outdoor unit capacity switch

4-20mA

Capacity switch of outdoor

unit according to the signal

of 4-20mA

1-5V

Capacity switch of outdoor

unit according to the signal

of 1-5V

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller

System diagram Power supply specifications

Power supplied from outdoor unit

A transmission line/Power line

Power supply for interface

controller is supplied from the

outdoor unit.

Refer to 3.1.

Interface controller

4-20mA

Power line

Outdoor unit

Separate interface/outdoor unit

Power line

A transmission line/Power line

power supplies

Power supply for interface

controller and power supply for

Interface controller

4-20mA

Power line

Outdoor unit

outdoor unit are supplied from the

different source.

(Common power source for local

unit and interface controller)

Refer to 3.2.

Power supplied from outdoor unit

A transmission line/Power line

Power supply for interface

controller is supplied from the

outdoor unit.

Interface controller

1-5V

Power line

Outdoor unit

Refer to 3.1.

0-10V

Capacity switch of outdoor

unit according to the signal

of 0-10V

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Intake temp.

Liquid pipe temp.

Local unit

Local controller

Power line

Interface controller

1-5V

Interface controller

0-10V

Power line

Interface controller

0-10V

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

A transmission line/Power line

Power line

Outdoor unit

Separate interface/outdoor unit

power supplies

Power supply for interface

controller and power supply for

outdoor unit are supplied from the

different source.

(Common power source for local

unit and interface controller)

Refer to 3.2.

Power supplied from outdoor unit

Power supply for interface

controller is supplied from the

outdoor unit.

Refer to 3.1.

Separate interface/outdoor unit

power supplies

Power supply for interface

controller and power supply for

outdoor unit are supplied from the

different source.

(Common power source for local

unit and interface controller)

Refer to 3.2.

26

Page 27

Attachment of sensor

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Interface controller

switch setting

SW1-1:ON

SW1-2:ON

SW1-3:OFF

SW6-1:ON

SW6-2:ON

Other switches are

to be set according

to the site.

Refer to 5 for details.

Interface controller specifications

Input and wiring Output and wiring

Refer to 6.

Refer to 6.

Refer to 7.

Refer to 7.

Other functions/setting

Maintenance

Refer to 8, 9.

Refer to 8, 9.

Connection with

BMS/MELANS

Not available

Not available

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

SW1-1:ON

SW1-2:ON

SW1-3:OFF

SW6-1:OFF

SW6-2:ON

Other switches are

to be set according

to the site.

Refer to 5 for details.

SW1-1:OFF

SW1-2:OFF

SW1-3:ON

SW6-1:OFF

SW6-2:OFF

Other switches are

to be set according

to the site.

Refer to 5 for details.

Refer to 6.

Refer to 6.

Refer to 6.

Refer to 7.

Refer to 7.

Refer to 7.

Refer to 8, 9.

Refer to 8, 9.

Refer to 8, 9.

Not available

Not available

Not available

Refer to 4.

Pipe-thermistor/

2-phase might be

neccessary

depending on the

type of the outdoor

unit.

Refer to 6.

27

Refer to 7.

Refer to 8, 9.

Not available

Page 28

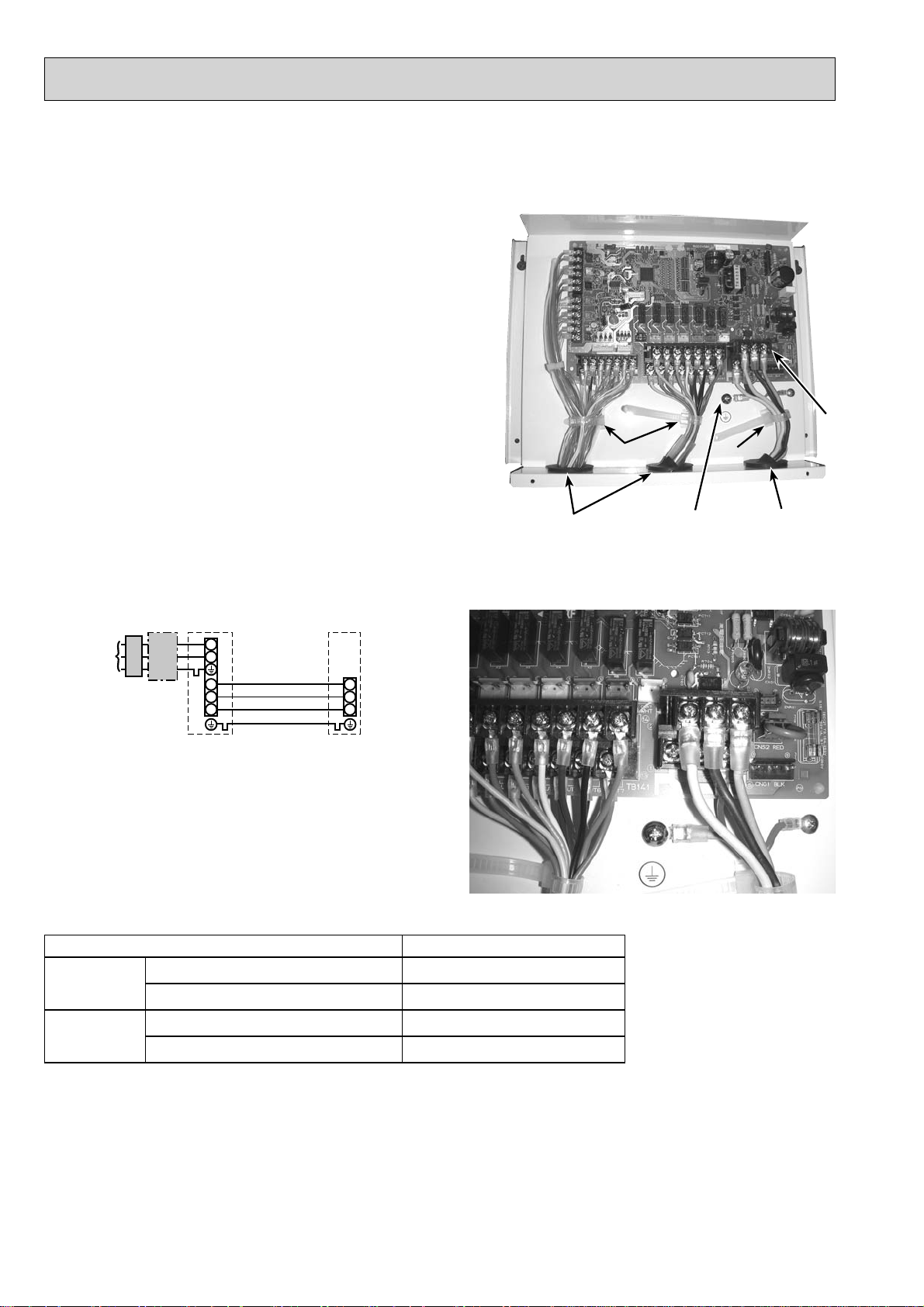

3. Power Supply

Interface controller is applicable to both methods of interface unit power supplied from outdoor unit, and of separate interface

unit/outdoor unit power supplies. Choose one according to the site.

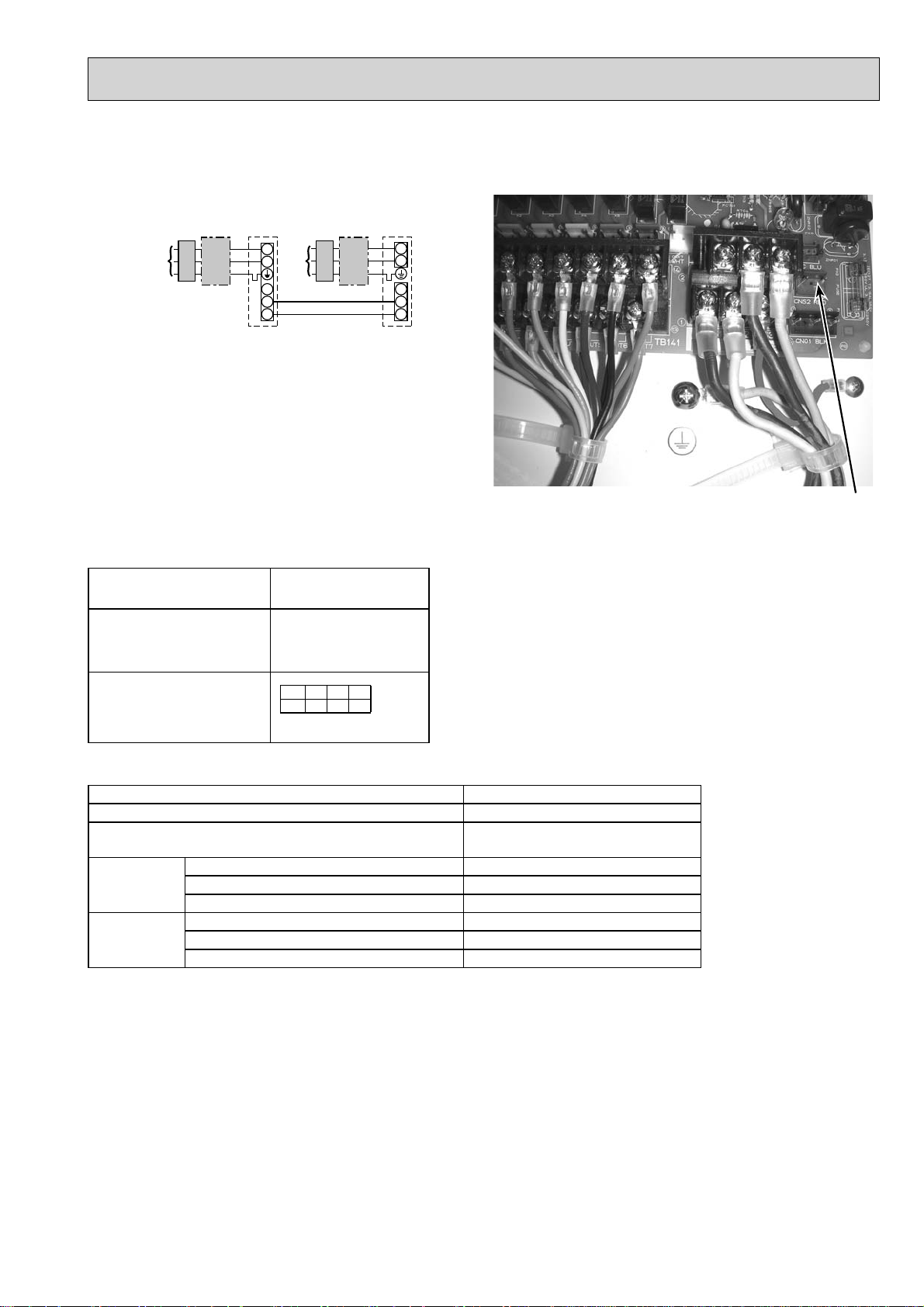

(Photo. 3-1)

Inlet for control cable

A

Inlet for power

B

Clamp

C

Interface / Outdoor unit connecting terminals

D

Earth terminal

E

D

A

3.1. Interface unit power supplied from outdoor unit (Photo 3-2)

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

D

L

ABC

N

S1

S2

S3

E

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Interface unit/outdoor unit connecting cables

F Interface unit

F

S1

S2

S3

C

Photo.3-1

C

E

B

Photo.3-2

Interface unit model PAC-IF011B-E

)

2

Interface unit-Outdoor unit *1 3× 1.5 (polar)

size

Interface unit-Outdoor unit earth *1 1 × Min.1.5

Wiring

(mm

Wire No.×

Interface unit-Outdoor unit S1-S2 *2 AC 230 V

rating

Circuit

*1. Max. 80 m

*2. The fi gures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are not electrically insulated by the transformer or other device.

Interface unit-Outdoor unit S2-S3 *2 DC24 V

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cables and interface unit/outdoor unit connecting cables shall not be lighter than polychloroprene sheathed fl exible cable. (Design 60245 IEC 57)

3. Install an earth longer than other cables.

28

Page 29

3.2. Separate interface unit/outdoor unit power supplies

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

D

L

N

A

CB

GEB

S1

S2

S3

C

F

L

N

S1

S2

S3

A Outdoor unit power supply

B Earth leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Interface unit/outdoor unit connecting cables

F Interface unit

G Interface unit power supply

If the interface and outdoor units have separate power supplies, refer to the table below.

Separate power supply

specifi cations

Interface unit controller connector (CNS2) connection

change

Disconnected

Photo. 3-3

CNS2

Outdoor unit DIP switch settings (when using separate interface unit/outdoor unit power

supplies only)

ON

OFF

Set the SW8-3 to ON.

12

3

(SW8)

Interface unit model PAC-IF011B-E

Interface unit power supply ~/N (Single Phase), 50 Hz, 230 V

Interface unit input capacity

Main switch (Breaker)

)

Interface unit power supply & earth 3 × Min. 1.5

2

Interface unit-Outdoor unit *2 2 × Min. 0.3

size

Wire

No.×

Wiring

(mm

Interface unit-Outdoor unit earth –

*1 16 A

Interface unit L-N *3 AC230V

Interface unit-Outdoor unit S1-S2 *3 –

rating

Circuit

*1. A breaker with at least 3.0mm contact separation in each pole shall be provided. Use earth leakage breaker (NV).

*2. Max. 120 m

*3. The fi gures are NOT always against the ground.

Interface unit-Outdoor unit S2-S3 *3 DC24V

Notes: 1. Wiring size must comply with the applicable local and national code.

2. Power supply cables and interface unit/outdoor unit connecting cables shall not be lighter than polychloroprene sheathed fl exible cable. (Design 60245 IEC 57)

3. Install an earth longer than other cables.

29

Page 30

4. Connecting thermistor

4.1 Connecting thermistor cable

Connect the thermistor for the interface controller.

When the thermistor cables are too long, cut it to the appropriate length.

Do not bind it in the interface unit.

1. Target temp. thermistor (TH1)

Connect the thermistor for the target temp. to 1 and 2 on

the terminal block (TB61) on the interface controller.

2. Pipe temp. thermistor / Liquid (TH2)

Connect the thermistor for the pipe temp. to 3 and 4 on

the terminal block (TB61) on the interface controller.

3. Pipe temp. thermistor / 2-phase (TH5).

Connect the thermistor for the 2-phase temp. to 5 and 6

on the terminal block (TB61) on the interface controller.

Set the DIP switch 2-6 to OFF of the interface controller.

Caution:

Do not route the thermistor cables together with power cables.

The sensor part of the thermistor should be installed where user must not touch.

(It is separated by the supplementary insulation from where user may touch.)

TB61

TH1

TH2

TH5

Photo. 4-1

4.2 Thermistor position

< Target temp. thermistor (TH1) > (Used only in *auto step mode (Only for Air to Air applications))

1. Put thermistor(TH1) where average intake temperature for heat exchanger can be detected.

2. It is better to put thermistor(TH1) where radiant heat from heat exchanger can be avoided.

To use this interface for manual step control, put a fi xed resistor of 4~10kΩ instead of thermistor.(TH1 on the terminal block

TB61)

* Auto step mode: In this mode, the capacity step of the outdoor unit is controlled automatically to let the target (intake)

temperature reach the set temperature.(Only for air to air application)

< Liquid pipe thermistor (TH2) >

1. Put thermistor(TH2) where liquid refrigerant pipe temperature can be detected.

2. It is better to protect the thermistor(TH2) with heat insulating materials not to be affected by the ambient temperature, etc.

3. In case that the refrigerant is distributed by distributor, put thermistor(TH2) before the distributor.

< 2 phase pipe (condensing/evaporating) thermistor (TH5) >

*Only for Air to Air application (Refer to page.4)

*Only in AUTO STEP mode of the I/F (Refer to page.4)

1. 2 phase pipe thermistor must be located where the 2 phase (condensing / evaporating) temperature of HEX can be meas-

ured.

2. Preferably, it should be insulated to avoid any infl uences by the ambient air temperature and so.

3. It must be located where it does NOT measure hot gas/subcool liquid temperature in heating mode.

4. If HEX is divided into several paths, 2 phase pipe thermistor should be put on the upper path.(Liquid refrigerant tends to stay

in the lower path when HEX works as a condenser, and the improper temperature may possibly be picked up.)

5. 2 phase thermistor should be located in the middle of the path. If it is impossible to put it in the middle, it should be put a bit

inlet side of condenser. Do NOT move it too much to the inlet side, however, as it may possibly pick up hot gas temperature.

(Never put it on the outlet side of condenser as it may pick up subcool liquid temperature.)

30

Page 31

<Thermistor Characteristic graph>

Thermistor for

lower temperature

Target temperature thermistor (TH1)

Pipe temperature thermistor/liquid (TH2)

Pipe temperature thermistor / 2-phase (TH5)

Thermistor R0 =15k" ± 3%

Fixed number of B =3480 ± 2%

Rt =15exp { 3480 (

1

273+t

–

1

273

) }

< Thermistor for lower temperature >

50

40

30

20

Resistance (k)

0: 15k

10: 9.6k

20: 6.3k

25: 5.4k

30: 4.3k

40: 3.0k

"

"

10

"

"

'

"

0

-20-100 1020304050

Temperature ()

5. Interface controller switch setting

Set the switches following the system specifi cations below.

Switch1. Switch6 : Input selection of inverter capacity setting

Input SW 1-1 SW 1-2 SW 1-3 SW 6-1 SW 6-2 Step for capacity setting

REMOTE SWITCH

Type A (4bit-8 setting)

REMOTE SWITCH

Type B (1bit-1 setting)

4-20mA ON ON OFF ON ON OFF/Step1/Step2/…/Step7

1-5V ON ON OFF OFF ON OFF/Step1/Step2/…/Step7

0-10V OFF OFF ON OFF OFF OFF/Step1/Step2/…/Step7

0-10kΩ ON OFF ON OFF OFF OFF/Step1/Step2/…/Step7/Auto step

No input (AUTO mode) OFF ON ON OFF OFF Only Auto step mode