Page 1

BACKUP

Service Manual

ENGINE

1992

-

1993

FOREWORD

The information contained in this service manual

has been prepared for the professional automotive

technician involved in daily repair operations. Information in this manual is divided into groups by

engine models. Each group is further divided to

address individual components within the group.

These groups contain general information, specification, removal and installation, disassembly and

reassembly procedures for the components. The

first page of each group contains an alphabetical

index to assist in finding the location of the

component. The information, descriptions and specifications were in effect at the time this manual

was released.

GROUP INDEX

Introduction

Engine

4Gl

463

466 <1992>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

mm

. . . . . . . . . . . . . . . . . . . . . . . .

mm

This

BACKUP DSM manual IS to be used ONLY as a BACKUP. Please DO NOT REDISTRIBUTE

WHOLE SECTIONS.

a GENUINE DSM MANUAL. It CANNOT BE considered a REPLACEMENT (Unless your original

manual was lost or destroyed.)

Please See

Mitsubishi Motors Co[poration reserves the right to make changes

dew?

or to make addltlons to or improvements in its products

impoang

previously manufactured.

This

BACKUP was sold to you under the fact that you do

README.N

any obligations upon itself to install them on its products

or

READMEHTML

Thank you. G~mm~emymanual@hotma~l.com

VOLUNTARY TECHNICIAN

CERTIFICATION THROUGH

for

additional Information.

WE SUPPORT

National

lnstit~te

AUTOMOTIVE

SERVICE

EXCELLENCE

for

indeed

OWN

WIthout

469

6G7

4G6 <1993>

in

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*..

m

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

CCT

@ qgg2

M&ubi&i Motors Corporation

Printed in Japan

Page 2

Page 3

INTRODUCTION

CONTENTS

:,

ENGINE MODEL TABLE

EXPLANATION OF MANUAL CONTENTS

FORM-IN-PLACE GASKET

Disassembly

Form-In-Place Gasket Application

Surface

Preparation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . ..I................

._......................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

. . . . . . . .

2

6

6

6

6

SPECIAL TOOL NOTE

TORQUE REFERENCES

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..I.....

1.

:

._

.

5

5

,

‘-:

:

Page 4

2

INTRODUCTION

EXPLANATION OF MANUAL CONTENTS

0

Maintenance and Servicing Procedures

(1) A diagram of the component parts is

provided near the front of each section in

order to give the reader a better under-

standing of the installed condition of

component parts.

(2) The numbers provided within the diagram

indicate the sequence for maintenance

and servicing procedures; the symbol

indicates a non-reusable part; the tighten-

ing torque is provided where applicable.

m

Removal steps:

l Disassembly steps:

0

Installation steps:

l Reassembly steps:

I

The part designation number corresponds

to the number in the illustration to indicate

removal steps.

The part designation number corresponds

to the number in the illustration to indicate

disassembly steps.

Specified in case installation is impossible

in reverse order of removal steps. Omitted if installation is possible in reverse

order of removal steps.

Specified in case reassembly is

ble

in reverse order of disassembly

Omitted if reassembly is possible

verse order of disassembly steps.

ia

im$ossi-

Classification of Major Maintenance/

Service Points

When there are major points relative to maintenance and servicing procedures (such as essential

maintenance and service points, maintenance and

service standard values, information regarding the

use of special tools, etc.), these are arranged

together as major maintenance and service points

and explained in detail.

GAO:

Indicates that there are essential points for

removal or disassembly.

I)A4:

Indicates that there are essential points for

installation or reassembly.

Symbols for Lubrication, Sealants and

Adhesives

Information concerning the locations for

tion and for application of sealants and adhesives

is provided, by using symbols, in the diagram of

component parts, or on the page following the

component parts page, and explained.

lubrica-

&

. . Grease

(multrpurpose grease unless there is

a brand or type specified)

. . . . .

Sealant or adhesive

. . . . .

i

:m

Brake fluid, automatic transmission

fllid

or air conditioning compressor

. . . . . Engine oil or gear oil

I

TSB Revision

Page 5

INTRODUCTION

Indicates the

section title.

3

Denotes non-reusable

This number corresponds to the

number appearing in “Removal

steps”, “Disassembly steps”,

stallation steps” or “Reassembly

steps”

Operating procedures, cautions,

etc. on removal, installation, disassembly and reassembly are described.

“ln-

I

I

TSB Revision

Page 6

4

ENGINE MODEL TABLE - 1992

Engine

Series,

4Gl

4G3

4G6

INTRODUCTION

4G9

6G7

4693

6672

6G72 3.0 (183)

6G72

Turbo

1.8

(1

IO)

3.0(I83)

3.0 (183)

ENGINE MODEL TABLE - 1993

In-line,

6O”V.

SOHC

6O”V.

DOHC

6O“V.

DOHC

SOHC

(per bank)

(per bank)

(per bank)

E$po

LRV

bgmante,

h&ntero,

Diamante, 3000GT

4 3000GT

.K

c:

Truck

4G9

6G7

4664

4G93

6672

6672

6G72

Turbo

.

2.4(146)

1.8 (1

IO)

3.0 (I 83)

3.0 (183)

3.0 (183)

1

TSB Revision

In-line, SOHC

In-line, SOHC

6O”V.

SOHC

(per bank)

6O”V,

DOHC 4

(per bank)

6O”V.

DOHC

(per bank)

4

4

2

4

E$po-LRV.

@age,

Diamante,

Mhtero,

C$mante,

3600GT

Expo LRV

Expo

Truck

3000GT

Page 7

SPECIAL TOOL NOTE

INTRODUCTION

.

1

6

Please refer to the special tool cross reference chart which is located in the service manual at the beginning of

each group, for a cross reference from the MMC special tool number to the special tool number that is

available in your market.

iiS *‘l

*.j,

l”

“...!: ‘/’

TORQUE REFERENCES

General tightening torque is as shown in the following table.

The specific part tightening torque is shown at the beginning of each group.

Flange bolt

Heaid.

i-MC 7

ft.lbS.

Size mm

(dia. x pitch)

5 x 0.8

6x

1.0

8 x 1.25

10x1.25

12x

1.25

14x1.5

Bolt with spring washer

Head mark 4 Head mark 7 Head mark 10 Head mark 4

Nm

ft.lbs. Nm ft.lbs. Nm ft.lbs. Nm ft.lbs. Nm

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE TIGHTENED IN PLASTIC AREA

A new type of bolts, to be tightened in plastic area, is currently used in

tightening method for the bolts is different from the conventional one. Be sure to observe the

so’me

parts of the engine. The

method

described in the text when tightening the bolts.

Service limits are provided for the bolts. Make sure that the service limits described in the text are strictly

observed.

l Areas where the bolts are in use:

(1) Cylinder head bolts

(2)

Main bearing cap bolts

(3) Connecting rod cap bolts

Remarks:

The bolts in

The bolts in (3) apply to the

l Tightening Method

After tightening the bolts to the specified torque, tighten them another

(1)

and (2) apply to the

4G15, 4G6 <1993>

4G6 <I 993>

and

and

4G93

4693

engines.

engines.

90”

or 180” (twice 90”). The

tightening method varies on different areas. Observe the tightening method described in the text.

TSB Revision

Page 8

INTRODUCTION

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket

serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead size,

continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick a bead, on

the other hand, could be squeezed out of location, causing blocking or narrowing of the fluid feed line. To

eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to apply the gasket evenly

without a break, while observing the correct bead size.

The

FIPG

used in the engine is a room temperature vulcanization (Rn/) type and is supplied in a loo-gram

tube (Part No. MD970389 or

atmospheric air, it is normally used in the metallic flange areas. The FIPG, Part No.

for sealing both engine oil and coolant, while Part No. 997110 can only be used for engine oil sealing.

Disassembly

The parts assembled with the

cases, however, the sealant between the joined surfaces may have to be broken

mallet or similar tool. A flat gasket scraper may be lightly hammered in between the joined surfaces. In this

case, however, care must be taken to prevent damage to the joined surfaces.

MD9971 10).

FIPG

can be easily disassembled without use of a special method. In some

Since the

RTV

(FIPG)

is in use. To ensure that the gasket fully

hardens as it reacts with the moisture in the

MD970389,

bylightly

can be used

striking with a

Surface

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper or

wire brush. Check to ensure that the surfaces to which the

are no oils, greases and foreign substances deposited on the application surfaces. Do:not forget to remove

the old sealant remaining in the bolt holes.

Form-In-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedure is very simple

as in the case of a conventional precut gasket.

Applied

circumference with a completely continuous bead. The

the

make sure that the gasket is applied to the required area only.

The

when applying the FIPG.

Preparation

FIPG

is to be applied is flat.‘ Make sure that there

5

FIPG

bead should be of the specified size and without breaks. Also be sure

FIPG

can be wiped away unless it is hardened. While

FIPG

is still moist (in less than 15 minutes), mount the parts in position. When the parts are mounted,

FIPG

application procedure may vary on different areas. Observe the procedure described in the text

toencircle

the bolt hole

TSB Revision

Page 9

4G15

CONTENTS

BRACKET

CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE

CYLINDER HEAD AND VALVES

EXHAUST MANIFOLD AND

WATER PUMP

FRONT CASE AND OIL PUMP

FUEL AND EMISSION PARTS

GENERAL INFORMATION

GENERAL SPECIFICATIONS

GENERATOR AND IGNITION SYSTEM

................................................................

........................................................

........................

....................................................

............................

............................

................................

............................

........

53

51

33

28

39

22

14

INTAKE

PISTON AND CONNECTING ROD

ROCKER ARMS AND CAMSHAFT

SEALANT

SERVICE SPECIFICATIONS

SPECIAL TOOLS

THROlTLE

TIMING

2

TORQUE SPECIFICATIONS

5

MANIFOLD

................................................................

BODY

BELT

............................................

....................

....................

................................

....................................................

................................................

........................................................

................................

26

43

30

11

6

12

24

17

10

Page 10

IlA-2

4Gl

ENGINE - General Information

GENERAL INFQRMATION

ENGINE SECTIONAL VIEW

TSB Revision

3

1

EN0086

Page 11

4Gl

ENGINE

-

General Information

TSB Revision

1

Page 12

VA-4

4Gl

ENGINE - General Information

UBRICATION

SYSTEM

0’

t7;

ii

I

P

‘Z

:

ii

OTJ

09

1

TSB Revision

Page 13

4Gl

ENGINE - General Specifications

GENERAL SPECIFICATIONS

Items

We

Number of cylinders

Combustion chamber

Total displacement

Cylinder bore

Piston stroke

Compression ratio

Valve timing

(): Camshaft identification mark

Intake valve

Opens

Closes

Exhaust valve

Opens

Closes

Lubrication system

Oil pump type

Cooling system

Water pump type

EGR valve

Injector type and number

Injector identification No.

Fuel regulated pressure kpa (psi)

Throttle bore mm (in.)

Throttle position sensor

Closed throttle position switch

Y’

1: up to 1992 models

“2:

From 1993 models

.---

cm3 (cu.in.)

mm (in.)

mm (in.)

BTDC

ABDC

BBDC

ATDC

Specifications

In-line OHV, SOHC

4

Pentroof

1,468 (89.58)

75.5 (2.972)

82 (3.228)

9.2

(1 I*’

14”

51” 53”

51” 57”

14”

Pressure feed, full-flow filtration

Trochoid type

Water-cooled forced circulation

Centrifugal impeller type

Single type

Electromagnetic, 4

BDH182

335 (47.6)

46(1.811)

dariable

Contact type, within idle speed control

Movable contact type within throttle position sensor*’

type

(6)**

15”

15”

resistor type

motor”

1

TSB Revision

I

Page 14

1

IA-6

4Gl

ENGINE - Service Specifications

SERVICE SPECIFICATIONS

Items

Cylinder head

Flatness of gasket surface

Grinding limit of gasket surface

t

Total resurfacing depth of both cylinder

head and cylinder block

Overall height

Oversize rework dimensions of valve guide hole

(both intake and exhaust)

0.05

(.002)

0.25(.010)

0.50

(.020)

Oversize rework dimensions of intake valve

seat ring hole (primary)

0.3

(.012)

0.6(.024)

Oversize rework dimensions of intake valve

seat ring hole (secondary)

0.3

(.012)

0.6

(.024)

Oversize rework dimensions of exhaust valve

seat ring hole

0.3

(.012)

0.6

(.024)

Camshaft

Cam height

Intake

Exhaust 39.10 (1.5394)

Journal diameter

3il

clearance

Standard value

d.05 (.0020)

106.9-107.1 (4.209-4.217)

12.05-12.07 (.4744-.4752)

12.25-

12.27

12.50-12.52 (.4921 -.4929)

27.42-27.44(1.0795-1.0803)

27.72-27.74(1.0913-1.0922)

32.43-32.45

32.73-32.75

35.43-35.45(1.3949-1.3957)

35.73-35.75(1.4067-1.4075)

38.78 (1.5268)

45.93-45.94(1.8083-1.8087)

0.06-0.10(.0024-.0039)

(.4823-.4831)

(1.2768-1.2776)

(1.2886-1.2894)

“”

Limit

0.2(.008)

"0.2

3

1

“1

'$

1,

I)

1

1:

!

(.008)

38.28

38.60(1.5197)

mm (in.)

(1.5071)

qockerarm

.D.

3ocker

arm-to-shaft clearance

qockerarmshaft

I.D.

3verall

length

Intake

Exhaust

TSB Revision

18.91

-18.93(.7445-.7453)

0.01

-0.04(.0004-.0016)

18.89-18.90(.7437-.7441)

365(14.37)

346(13.62)

0.1

(.004)

Page 15

Items

Valve

Overall length

Intake

Exhaust

Stem diameter

Intake

Exhaust

Face angle

Thickness of valve head (margin)

Intake

Exhaust

Stem-to-guide clearance

Intake

Exhaust

Valve clearance

Intake

Exhaust

4Gl

ENGINE - Service Specifications

Standard value

100.75 (3.9665)

101.05 (3.9783)

6.57 - 6.58

6.53 - 6.55

(2587 - .2591)

(2571 - .2579)

45” - 45”30’

1 .o

(.039)

1.5

l.059)

0.02 - 0.05

0.05 - 0.09

0.07

0.09

(0008 - .0020)

(.0020 - .0035)

(.0028)

Up to 1992 models

(.0035)

From 1993 models

0.17 (0067)

Limit

0.5

(020)

1 .o (.039)

0.10

(.0039)

0.15

(.OOSS)

mm (in.)

.,_ ..“.. ..“_

.

.

1 t..

,-i

,

-7, ,i ,,- <

i

7/

Valve spring

Free height

Intake

Exhaust

-oad/installed

height

Intake

Exhaust

3ut-of-squareness

halve

guide

3verall

length

Intake

Exhaust

.D.

I.D.

;ervice size

‘Tess-in

lalve

;eat

lalve

temperature

seat

angle

contact width

Gnkage

iervice size

N/mm

(Ibs./in.)

46.1 (1.815)

46.8 (1.843)

230/40

(51/I

.57)

290140

(64/l

.57)

Max. 2”

44 ( 1.732)

49.5 (1.949)

6.60 - 6.62

12.055 - 12.065

0.05

(.002),

(.2598 - .2606)

(4746 - .4750)

0.25

(.Ol).

Room temperature

43”30’ - 44”

0.9 - 1.3

0.3

LO1 2),

(035 - .051)

0.6

(024)

0.50 (02) oversize

oversize

45.1 (1.776)

45.8 (1.803)

4”

0.2

(.008)

. .

\-TSR

Revision

I

Page 16

IIA-8

4Gl

ENGINE - Service Specifications

mm (in.)

Items

Piston

O.D.

Piston-to-cylinder clearance

Service size

Piston ring

End gap

No. 1 ring

No. 2 ring

Oil ring

Ring-to-ring groove clearance

No. 1 ring

No. 2 ring

Service size

Piston pin

O.D.

Press-in load N (psi)

Press-in temperature

Standard value

75.48 - 75.50 (2.9716 - 2.9724)

0.02 - 0.04

0.25

oversize

0.20 - 0.40 l.0079 -

0.20 - 0.35

0.20 - 0.70

0.03 - 0.07

0.02 - 0.06 f.0008 -

0.25

(.Ol),

oversize

18.003 -

5,000 - 15,000 (1 ,102 - 3,307)

Room temperature

(0008 - .0016)

t.01).

0.50

(.02),

(.0079 - .0138)

LOO79 - .0276)

(.0012 - .0028)

0.50

(.02),

18.005 l.7088 -

0.75

.0157)

.0024)

0.75

(.03),

(.03),

.7089)

1

1

.OO

.OO

(.04)

(04)

Limit

0.8

(.031)

0.8

f.031)

1 .o i.039)

0.1

(.004)

0.1 i.004)

Connecting rod

Big end center-to small end center length

Bend

Twist

Big end side clearance

Crankshaft

End play

Journal O.D.

Pin O.D.

Dut-of-roundness and taper of journal and pin

3il

clearance of journal

3il

clearance of pin

Cylinder

Ilatness

Grinding

3verall

block

.D.

of gasket surface

limit of gasket surface

Total resurfacing depth of both cylinder

block and cylinder head

height

130.95-

0.05

0.1

0.10 - 0.25

0.05-0.18 (.0020- .0071)

48 (1.89)

42 (1.65)

0.005 (.0002)

0.02 - 0.05

0.02 - 0.05

75.50 - 75.53 (2.9724 - 2.9736)

0.05 i.002)

255.9 - 256.1

131.05 (5.1555-5.1594)

(.0020)

(.004)

(.0039 - .0098)

(.0008 - .0020)

(.0008 - .0020)

(10.075 - 10.083)

0.4

f.016)

0.3

(.012)

0.1 i.004)

0.1

(.004)

0.1 i.004)

*0.2

(.008)

TSB

Revision

Page 17

Items

Oil

pump

Tip clearance

Side clearance

Body clearance

Drive belt deflection

New belt

Used belt

Injector

Coil resistance

Throttle position sensor

Resistance

Idle speed control motor

Coil resistance

Idle air control motor

Coil resistance

fI?

kR

rc1

0

4Gl

ENGINE - Service Specifications

Standard value

0.03 - 0.08

0.04-0.10(.0016-.0039)

O.lO-0.18(.0039-.0071)

5.5 -7.0

8.0

(.32)

13 - 16

3.5-6.5

5 - 35 at

28 - 33 at

LOOI

(.22 - .28)

at

20°C (68°F)

20°C (68°F)

20°C (68°F)

2 -

.0031)

Limit

0.35

rn:fq,

(in,

i ,I :, i /

.’

(.Orl38)

Idle speed control motor position sensor

Resistance

kfi

4-6

1

TSB Revision

Page 18

1

IA-IO

4Gl

ENGINE - Torque Specifications

TORQUE SPECIFICATIONS

Generator and ignition system

Oil level gauge guide mounting bolt

Water pulley bolt

pump

Generator brace bolt

Generator brace mounting bolt

Generator pivot nut

Crankshaft bolt

Crankshaft pulley bolt

Spark plug

Distributor

Timing belt

Engine support bracket, left

Tensioner bolt

Camshaft sprocket bolt

Fuel and emission parts

Throttle body mounting bolts

Fuel rail mounting bolts

Fuel regulator bolts

pressure

EGR valve (California) mounting bolts

Nm

11

9

14

24

23

85

14

25

12

36

24

70

19

12

9

13

ftlbs.

-

8

7

10

17

17

61

10

18

9

i

ii 26

17

51

14

‘7

9

7

9

Throttle body

Throttle position sensor attaching bolts

Intake manifold

Cable bracket bolt

Engine coolant temperature gauge unit

Engine coolant temperature sensor

Therm0

flater

Thermostat housing bolt and nut

Intake manifold stay bolt

Engine support bracket stay

Intake manifold bolt and nut

Exhaust manifold and water pump

Exhaust manifold cover “A” bolt

Exhaust manifold cover “A” and

Exhaust manifold cover “B” bolt

Exhaust manifold nut

Vater inlet pipe bolt

Vater

Ixygen

switch

outlet fitting bolt

bolt

pump

sensor

“B”

mounting bolt

2.0

14

11

30

8

19

18

22

36

18

30

9

24

18

14

14

45

1.5

11

8

22

6

14

13

16

26

13

22

7

18

13

11

11

33

jocker

arms and camshaft

jocker cover bolt

locker arm shaft bolt

iocker arm lock nut

TSB Revision

1.8

32

15

1.3

24

11

Page 19

461

ENGINE - Torque Specifications / Sealant

Cylinder head and valves

Cylinder head bolt

Front case and oil pump

pan

Oil drain plug

pan

Oil bolt

Oil screen bolt

Oil relief valve plug

Front case bolt

Oil pump cover screw

Piston and connecting rod

Connecting rod cap nut

Crankshaft, flywheel and drive plate

Flywheel and drive plate

Rear plate bolt

Bell housing cover bolt

Oil seal case bolt

Bearing cap bolt

3il switch

pressure

Nm

73

40

7

19

45

I4

IO

20 +

135

11

9

11

53

19

I/4

turns

ft.lbs.‘, I. ‘-,.‘.,;

53

29

5

14

33

11

8

14.5 +

98

8

7

8

38

14

l/4

turns

$8;

_.”.c

Bracket

Exhaust pipe support bracket

Engine support bracket, front

7011

stopper bracket, front

3011

stopper bracket, rear

SEALANT

Items

Therm0

Engine coolant temperature sensor

Engine coolant temperature gauge unit

Oil pan

Oil pressure switch threads

switch

36

60

65

120

Specified sealant

3M

Nut Locking part No. 4171 or equivalent

3M

Nut Locking part No. 4171 or equivalent

3M

ATD Part No. 8660 or equivalent

Mitsubishi Genuine Part No. MD970389 or equivalent

3M ATD Part No. 8660 or equivalent

26

43

47

87

Quantity

As required

As required

As required

As required

As required

TSB Revision

Page 20

1

IA-12

SPECIAL TOOLS

Tool

4Gl

ENGINE - Special Tools

MD99801 1

Crankshaft rear

oil seal installer

Crankshaft front

oil seal installer

MD99871

Camshaft oil seal

3

MD99801 I-01

MD998713-01

Installation of crankshaft rear oil seal

Installation of camshaft oil seal

TSB Revision

Removal of oil pan

ompresslon 0

,.

i

.

.

Page 21

4Gl

ENGINE - Special Tools

Valve stem seal

compressor

Flywheel stopper

1

TSB Revision

Page 22

4Gl

1 IA-14

ENGINE - Generator and Ignition System

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

*

_,

12 Nm

9

ftJp3.

14 Nm

10 ft.lbs.

Ji

I

24Nr;l

17

ft.lbs.

9Nm

7

23 Nm

” Rm/b=-

I

n

\!

I

85 Nm

81

ft.lbs.

1

TSB Revision

1

Removal steps

1,

Oil level gauge

2. Oil level gauge guide

3. O-ring

+C4

4. Drive belt

5. Water pump pulley

6. Generator brace

7. Generator

(IA!) +B4

8. Crankshaft bolt

9. Special washer

IO. Crankshaft pulley

11. Damper pulley

12. Spark plug cable

13.

Spark

*A4 ‘ll.

;.s;;$butor

.

-

plug

1

EN0325

Page 23

461

ENGINE

-

Generator and Ignition System

REMOVAL SERVICE POINT

OAo

CRANKSHAFT BOLT REMOVAL

(I) Using the special tool, hold the drive plate or flywheel.

(2) Remove the crankshaft bolt.

INSTALLATION SERVICE POINTS

r)A4

DISTRIBUTOR ASSEMBLY INSTALLATlOy

(1) Turn the crankshaft to bring the No. I cylinder piston to the

top dead center on compression stroke.

(2) Align the mating mark on

thedistributor

housing with that

on the coupling key.

/

1

EL004

(3) Install the distributor with the coupling key fitted in the

keyway at the end of the camshaft.

r)64

CRANKSHAFT BOLT INSTALLATION

(I) Using the special tool, hold the drive plate or flywheel.

(2) Install the crankshaft bolt.

1 EN0326

F

#c4

(I) Adjust the belt deflection with the adjusting bolt to the

1

EN029'

1

TSB Revision

DRIVE BELT TENSION ADJUSTMENT

standard value.

Standard value:

New belt

Used belt

5.5 - 7.0 mm

8.0 mm

(.32

in.)

(.22 - .28

in.)

Page 24

4Gl

ENGINE - Generator and Ignition System

6EN059E

(2)

Or using a tension gauge, adjust the tension to the standard

value.

Standard value:

New belt 500

Used belt 400 N (88 Ibs.)

(3) Tighten the lock bolt to the specified torque.

(4) Tighten the nut for pivot bolt to th$ specified torque.

6EN0591

-

700

N (116 -

154

Ibs.)

1

TSB Revision

I

I

Page 25

461

TIMING BELT

REMOVAL AND INSTALLATION

ENGINE - Timing Belt

2bnhll

17

ft.lbs.

d

7

8

I

Removal steps

1. Timing belt upper cover

2. Timing belt lower cover

@I$ eC4

OBO

$I$

3. Timing belt

4. Engine support bracket, left

5. Tensioner spring

+B4

6. Tensioner

7. Crankshaft sprocket

8. Flange

*A4

9. Camshaft sprocket bolt

10. Camshaft sprocket

TSB Revision

1

EN0327

I

Page 26

461

ENGINE

-

Timing Belt

REMOVAL SERVICE POINTS

OAo

TIMING BELT REMOVAL

(1) Mark belt running direction for reference in reinstallation.

(2) Loosen the tensioner bolts and move the tensioner toward

the water pump.

(3) Remove the timing belt.

NOTE

(1)

Water or oil on the belt shortens its life drastically, so

the removed timing belt, sprocket, and tensioner must

be kept free from oil and water. Do not immerse parts in

cleaning solvent.

(2) If there is oil or water on any part, check the front case

oil seal, camshaft oil seal and

4Bo

CRANKSHAFT SPROCKET

~

wfter

pump for leaks.

,

REldOVAL

r-

@o

CAMSHAFT SPROCKET BOLT LOOSENING

INSPECTION

TIMING BELT

Replace belt if any of the following conditions exist.

(1) Hardening of back rubber side is glossy without resilience

and leaves no indent when pressed with fingernail.

Page 27

461

ENGINE - Timing Belt

Peeling

Cracks

Roundededge

Abnormal wear

(Fluffy strand)

Rubber exposed

1

EN024E

8EN006;

Cracks on

(2)

Cracks or

(3)

Cracks on

(4)

(5) Cracks on

(6)

Abnormal wear of belt sides. The sides are normal if they

rubber back

peeling of canvas

rib root

belt sides

are sharp as if cut by a knife.

(7) Abnormal wear on teeth

(8) Missing tooth

Water

pump

Tooth missing

and canvas fiber

MIT308239

/

8EN006

I

01

PO281

INSTALLATION SERVICE

I)A4

CAMSHAFT SPROCKET BOLT TIGHTENING

I)B4

TENSIONER INSTALLATION

(I)

Move the tensioner pulley toward the water pump and

POIFTS

tighten the tensioner mounting bolts.

1 EN0003

TSB Revision

Page 28

11

A-20

4Gl

ENGINE - Timing Belt

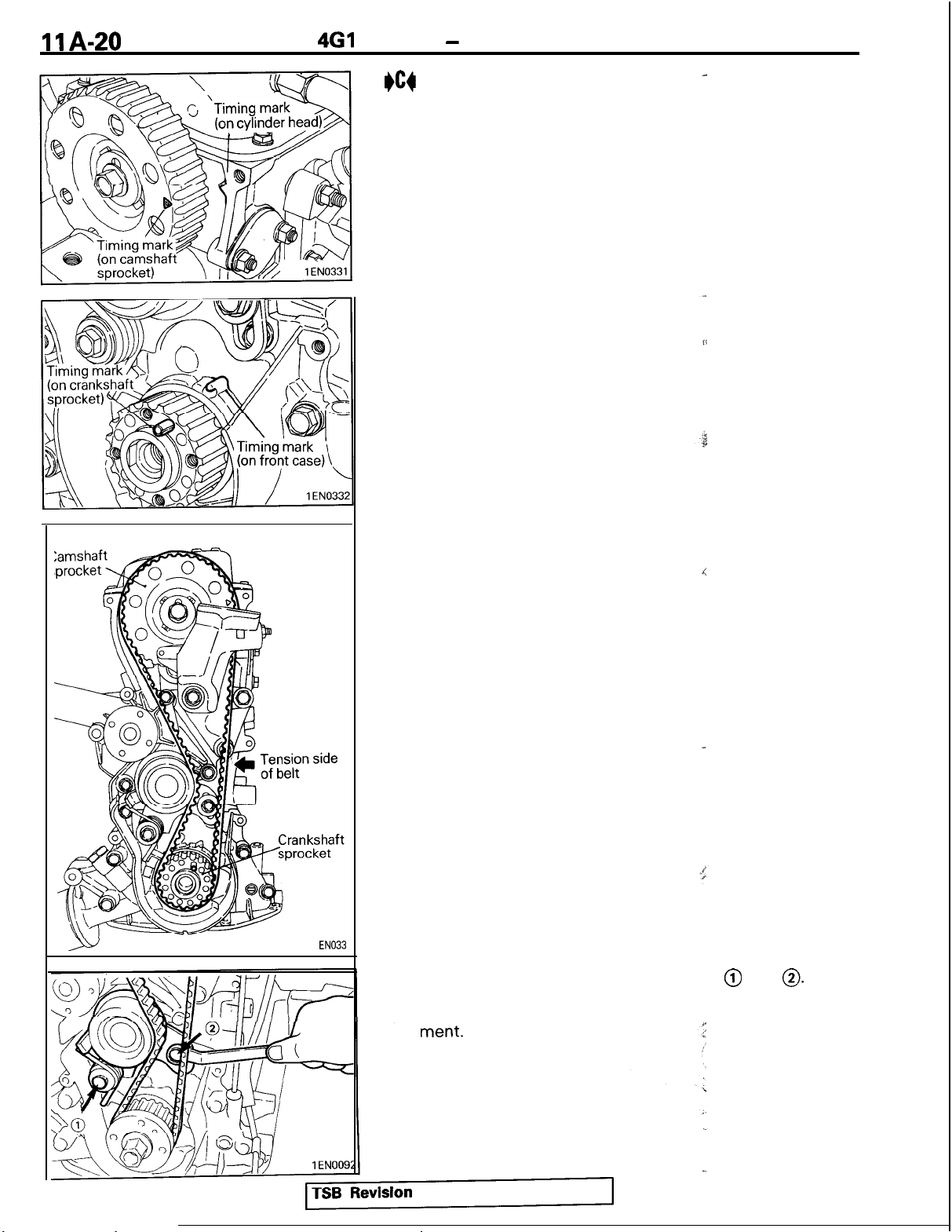

I)cg

TIMING BELT INSTALLATION

(1) Align the timing marks on the camshaft sprocket and the

crankshaft sprocket with their timing marks.

-

1

EN033

(2) Set the timing belt first on crankshaft sprocket and then

keeping the tension side belt tight, set on the camshaft

sprocket.

(3) Loosen the tensioner mounting bolts @ and

(4) Check that the belt completely meshes with the sprocket.

Also check the timing marks on the sprockets for align-

4

0.

Page 29

4Gl

ENGINE - Timina Belt

\

Tensioner slot side

il

1

ENOOOE

(5) Turn the crankshaft clockwise by 3 crankshaft

teeth.

(6) Tighten bolt @ first and then bolt 0. If bolt @ is tightened

first, the tensioner will turn together with the bolt, resulting

in an overtensioned belt.

(7) Check the belt tension. Hold the tensioner and ‘timing belt

together by hand and give the belt a slight thumb pressure

at a point level with tensioner center. Make sure that belt

cog crest comes as deep as about

slot side tensioner bolt head.

l/4

of the width of the

s@Cxket

I

ll4of

bolt head

1

EN025

TSB

Revision

Page 30

461

IIA-22

ENGINE - Fuel and Emission Parts

FUEL AND EMISSION PARTS

REMOVAL AND INSTALLATION

19 Nm

;;

14

ft.lbs.

TSB Revision

Removal steps

1.

Throttle body

2.

Gasket

3. Injectors and fuel rail

4.

eB4 ;.

*A4

*A4

Insulator

Fuw&ressure regulator

7:

Insulator

8. Injector clip

9.

Injector

10.

O-ring

11.

Grommet

12.

Fuel rail

13. EGR valve (For California)

14.

Gasket

1 EN0238

Page 31

461

ENGJNE - Fuel and Emission Parts

INSPECTION

INJECTORS

(1) Using an ohmmeter (circuit tester), test for,

between terminals of injector; the circuit should be closed.

If failure is detected, replace the injector.

Standard value: 13 - 16 Cn [at

6FU192C

EGR VALVE

(1) Check the EGR valve for sticking or carbon deposits.

If such conditions exist, clean or replace the EGR valve.

(2) Connect a hand vacuum pump to the nipple of the EGR

valve and plug the other nipple.

(3) Apply a vacuum of 500 mmHg (19.7

that vacuum is maintained. If there is a leak, replace the

EGR valve.

In addition, check the valve for its opening and closing

6EM038~

motion by applying and removing vacuum.

20°C (68”F)l

in.Hg)

to make sure

‘,.$

::.

:.

‘I’ ,L

cont$u~ty,

1

EN025C

INSTALLATION SERVICE POINTS

#A4

(1) Before installing an injector, the rubber O-ring must be

(2) Install injector top end into the fuel rail. Be

(3) Install injector clip by sliding open ends onto both injector

I)64

(1) Before installing the pressure regulator, the O-ring must be

INJECTORS / INJECTOR

lubricated with a

*drop

of clean engine oil to aid in

CLIP INSTALLATICjbi

installation.

careful

not

damage O-ring during installation.

and fuel rail.

FUEL PRESSURE REGULATOR INSTALLATION

lubricated

a drop of clean engine oil to aid in

yjth

installation.

to

6FUO71,

TSB Revision

Page 32

4Gl

1

M-24

ENGINE - Throttle Body

THROTTLE BODY

DISASSEMBLY AND REASSEMBLY

Up to 1992 models

1

2Nm

1.4 ftlbs.

Disassembly steps

4ArJ bA4 1.

From 1993 models

Throttle position sensor

2.

Idle

speed control motor

3. Throttle valve set screw

4. Throttle body

“p

2Nm

1.4

ft.lbs.

6FU1292

Disassembly steps

8:;

I)A4

I.

Throttle position sensor

2.

Idle arr

control motor

4BO

3. O-ring

4. Throttle body

5. Fixed speed adjusting screw

]

TSB Revision

1 EN0336

Page 33

461

ENGINE - Throttle Bodv

Closed throttle position switch*

Throttle

Throttle position

sensor output

*

From 1993 models

Dosition

Throttle position

sensor connector

DISASSEMBLY

6Ab

THROTTLE POSITION SENSOR AND

CONTROL MOTOR

SERVJCE

POINTS

/ IDLE

IDLE

SPEED

AIR CONTROL IMOTOR

REMOVAL

(1)

DO not disassemble the sensor and motor.

(2)

DO

not immerse in solvent the sensor and motor to clean.

Clean them with shop towel.

aB0

THROlTLE

BODY REMOVAL

(1) Do not remove the throttle valve.

(2) Check if the vacuum port or passage is clogged. Use

compressed air to clean the vacuum passage.

REASSEMBLY SERVICE POINT

/

round

View

P

7FUO535

P

+A4 THROTTLE

POSITION SENSOR INSTALLATION

(1) Check correct installation of the throttle position sensor.

While moving the throttle lever in both open and close

directions, check to see that resistance between terminals

@ and @ or @ and @ changes. If the resistance changes

smoothly, the throttle position sensor has been installed

correctly.

1 EN024S

TSB Revision

Page 34

llA-26

4Gl

ENGINE - Intake Manifold

INTAKE MANIFOLD

REMOVAL AND INSTALLATION

8Nm

Gft.!bs.

14

Nm

IO ft.lbs.

A*

Removal steps

I.

Water hose

eC4

2. Engine coolant temperature gauge unit

eB4

3. Engine coolant temperature sensor

*AiJ

4. Thermoswitch

5. Water outlet fitting

6. Water outlet fitting gasket

7. Thermostat

8. Outer cable bracket

9. Inner cable bracket

10.

Engine hanger

11. Thermostat housing

12. Intake manifold stay

13. Engine support bracket stay (From 1993

models)

14. Intake manifold

15. Intake manifold gasket

18Nm

13

ftlbs.

For

k:E

AIT

-18Nm

13

ft.lbs.

/

. .

[

TSB Revision

I

Page 35

Sealant

Sealant

4Gl

ENGINE

lEN033E

-

Intake Manifold

INSTALLATION SERVICE POINTS

#A4

SEALANT APPLICATION TO

Specified sealant:

3M

Nut Locking Part No. 4171 or equivalent

I)B4

SEALANT APPLICATION TO ENGINE COOLANT

-

TEMPERATURE GAUGE UNIT

Specified sealant:

3M ATD Part No. 8660 or equivalent

THERM0 SWIT&

,-

(” *f ‘; : i’<, ‘* ; *

. .

,,

Sealant

9EN009;

9EN0091

I)c4

SEALANT APPLICATION TO ENGINE COOLANT

TEMPERATURE SENSOR

Specified sealant:

3M

Nut Locking Part No. 4171 or equivalent

1

TSB Revision

Page 36

1

IA-28

461

ENGINE

Exhaust Manifold and Water

-

EXHAUST MANIFOLD AND WATER PUMP

REMOVAL AND INSTALLATION

14

10

Nm

ft.lbs.

Pump*

7

30 Nm

22

ft.lbs.

9Nm’

7 klbs.

1

-

14 Nm

10

ftlbs.

Removal steps

1.

Exhaust manifold cover “A”

2. Oxygen sensor - [1992,1993 (FED)

3. Engine hanger

4. Exhaust manifold

5. Exhaust manifold cover “B”

6. Exhaust manifold gasket

7. Water hose

+A4

8. Water inlet pipe

*AC

9. O-ring

10.

Water pump

11. Water pump gasket

models1

1 EN0339

TSB Revision

Page 37

4Gl

ENGINE - Exhaust Manifold and Water Pump

O-ring

I

Water inlet pipe

Water

pump

6EN0594

INSTALLATION SERVICE POINT

I)A4

WATER PIPE / O-RING INSTALLATION.

(1)

Wet the O-ring (with water) to

Caution

Keep the O-ring free of oil or grease

facilitateFas-6embly.

‘.‘ ) & p

:.

TSB

Revision

Page 38

1 IA-30

461

ENGINE

Rocker Arms and Camshaft

-

ROCKER ARMS AND CAMSHAFT

REMOVAL AND INSTALLATION

1.8Nm

1.3ft.lbs.

‘_

1

I

32

Nm

23

ft.lbs.

TSB Revision

Removal steps

1.

Breather hose

2. PCV hose

3. Rocker cover

4. Rocker cover gasket

)C4

5. Oil seal

6. Rocker arm and rocker arm shaft

eB4

7. Rocker arm and rocker arm shaft

#Bd

8. Rocker arm “D”

9. Wave washer

10. Spacer

11. Rocker arm “C”

12. Rocker arm shaft (exhaust side)

13. Rocker arm “B”

14. Rocker arm spring

15. Rocker arm “A”

16. Rocker arm shaft (intake side)

17. Adjusting screw

18. Nut

+A4

19. Camshaft

1

EN0340

Page 39

461

ENGINE - Rocker Arms and Camshaft

INSPECTION

CAMSHAFT

(1) Measure the cam height.

Standard value:

38.78

39.10 mm

38.28 mm (1.5071 in.)

38.60 mm (1.5197 in.)

1

EN009s

Intake

Exhaust

Limit:

Intake

Exhaust

ROCKER ARM

l

Check the roller surface. If any dents, damage or seizure is

evident, replace the rocker arm.

l

Check rotation of the roller. If it does not rotate smoothty or

if looseness is evident, replace the rocker arm.

l

Check the inside diameter. If damage or seizure is

replace the rocker arm.

l Check the screw end for wear. If considerable wear is

evident, replace the adjusting screw.

mti

(1.5268 ‘in.)

(1.53& Sii.)

qfq/&&l

.:-

_j

*

”

,

evident,

C

Timing belt side

Wave washer

Bolt hole

center

1

EN005:

1 EN0342

INSTALLATION SERVICE POINTS

I)A4

CAMSHAFT INSTALLATION

(1)

Position the dowel pin of the camshaft as shown in the

illustration.

I)B4

(1)

ROCKER ARM AND ROCKER ARM SHAFT

INSTALLATION

install

the rocker arm shaft assembly wnlle

respecuny LIW

illustrated positions.

NOTE

Make sure that the bolt hole center is offset toward the

indicated side with respect to the rocker arm shaft

centerline.

. .

+c4

TSB Revision

OIL SEAL INSTALLATION

Page 40

1

IA-32

4Gl

ENGINE

-

Rocker Arms and Camshaft

Intake 1 Intake 2

/

Exhaust 1

’ /

Exhaust 2

Exhaust 3

Exhaust 4

lEN015t

lEN0122

VALVE CLEARANCE ADJUSTMENT

~

(1) Position the No. 1 cylinder at the top dead center on

compression stroke.

(2) Adjust the valve clearance at the points shown in the

illustration.

(3) Loosen the adjusting screw locknut’.

(4) Using a feeler gauge, adjust the valve clearance by turning

the adjusting screw.

Standard value: on cold engine

Intake

Exhaust

0.07 mm

0.09 mm

0.17 mm

(.0028

(.0035

(.0067

in.) Up to 1992 models

in.) From 1993 models

in.)

(5) While holding the adjusting screw with a screwdriver,

tighten the lock nut.

(6) Rotate clockwise the crankshaft one complete turn (360”

1

degrees).

(7) Adjust the valve clearance at the points shown in the

illustration.

(8) Repeat steps (3) to (5) to adjust the valve clearance of

remaining valves.

Intake 3 Intake 4

-.----

lEN0156

TSB Revision

Page 41

4Gl

ENGINE - Cylinder Head and Valves

CYLINDER HEAD AND VALVES

REMOVAL AND INSTALLATION

2-

73 Nm

53

ft.lbs.

Removal steps

(JAI) #E4

(IBI) #Q

(IBM) bC4

$I$ #A4

@I$ #A4

1. Cylinder head bolt

2. Cylinder head, valve assembly

I)D4

3. Cylinder head gasket

4. Retainer lock

5. Valve spring retainer

#B4

6. Valvespring

7. Intake valve (primary)

8. intake valve (secondary)

9. Retainer lock

10.

Valve spring retainer

+B4

11. Valve spring

12. Exhaust valve

13. Valve stem seal

14. Valve spring seat

15. Valve stem seal

16. Valve spring seat

17. Intake valve guide

18. Exhaust valve guide

19. Intake valve seat (primary)

20.

Intake valve seat (secondary)

21. Exhaust valve seat

22. Cylinder head

1ENOlOl

TSB Revision

Page 42

1 IA-34

461

ENGINE - Cvlinder Head and Valves

REMOVAL SERVICE POINTS

(IAN

CYLINDER HEAD BOLT REMOVAL

OBo

RETAINER LOCK REMOVAL

(1) Store the removed valves, springs and other parts, tagged

to indicate their cylinder No. and location to aid reassembly.

j

$0

(1) Do not reuse removed valve stem seals.

INSPECTION

CYLINDER HEAD

(1) Check the cylinder head gasket

(2) If the service limit is exceeded, correct to meet specifica-

TSB Revision

VALVE STEM SEAL REMOVAL

&$-face

using a straightedge and

Standard value: 0.05 mm

Limit: 0.2 mm

tion.

Grinding limit:

* Total resurfacing depth of

cylinder block

Cylinder head height

106.9

-

(.008

*0.2 mm

107.1 mm (4.209 - 4.217 in.)

thicknessygauge.

(.0020 jn.)

in.)

(.008 ind

bo$

(Specifieatidn

i:

;-

".

.,

for flatness by

>:

cylinder head and

when new):

Page 43

4Gl

ENGINE - Cylinder Head and Valves

VALVE

(1) Check the valve face for correct contact. If incorrect, reface

using valve

refacer.

Valve

should“ma,ke

a uniform contact

with the seat at the center of valve ‘face.

(2) If the margin is smaller than the

ser@cefimit,

replace the

valve.

Standard value:

1.0

6EN054:

Intake

Exhaust

1.5

Limit:

Intake 0.5 mm

Exhaust

1.0

mm

mm

mm

(.039

(.059

(.020

(.039

in.)

in.)

in.)

in.)

VALVE SPRING

(1) Measure the free height of the spring and, if it is smaller

than the limit, replace.

Free

height

Standard value:

Intake

Exhaust

46.1 mm

(1.815

in.)

48.8 mm (1.643 in.)

Limit:

Intake

1

I

EN0264

Exhaust

45.1 mm

45.8 mm

(1.776

(1.803

in.)

in.)

(2) Measure the squareness of the spring and, if the limit is

exceeded, replace.

Standard value: 2” or less

Limit: 4”

Valve

guide

0.9 -1.3 mm 0.9 -1.3 mm

(.035-

,051

in.)

Exhaust

44” 44”

(.035-

Intake

1

EN027!

,051

in.)

T

1

EN01 71

TSB Revision

VALVE GUIDE

(1)

Measure the clearance between the valve guide and the

valve stem. If the limit is exceeded, replace the valve guide

or the valve, or both.

Standard value:

Intake

Exhaust

0.02 - 0.05 mm

0.05 - 0.09 mm

(.OOOS -

JO20 in.)

(.0020 - .0035 in.1

Limit:

Intake

Exhaust

0.10 mm

0.15 mm I.0059 in.)

(.0039

in.)

VALVE SEAT RECONDlTlONlNG PROCEDURE

(1)

Before attempting reconditioning of the valve seat, check

the valve guide-to-valve stem clearance and replace the

valve guide if necessary.

(2) Recondition to the specified seat width and seat angle.

(3) After reconditioning, fit up the valve and valve seat using

lapping compound.

Page 44

1

IA-36

4Gl

ENGINE - Cylinder Head and Valves

0.5 - 1 mm

Oversize I.D.

f.02 - .04

in.)

0.5-

1 mm

(.02 - .04

I

in.)

1

EN0275

VALVE SEAT REPLACEMENT PROCEDURE

(1)

Cut the

valve

seat to be replaced from the inside to thin the

wall thickness. Then, remove the valve seat.

(2) Rebore the valve seat hole in cylinder head to a selected

oversize valve seat diameter.

Seat ring hole diameter: See “Service Specifications”

in page

(3) Before fitting the valve seat, either

up to approximately

using cooling spray, to prevent the

llA-6

250°C (482°F)

&at

the cylinder head

or cool the valve seat

cy%nder

head bore from

galling.

(4) Using valve seat cutter, correct

tie

valve seat to the

specified width and angle. See “VALVE SEAT RECONDITIONING PROCEDURE.”

VALVE GUIDE REPLACEMENT PROCEDURE

(1) Push out the valve guide toward the combustion chamber

side using a press.

(2) Rebore the valve guide hole in the cylinder head to the size

corresponding to the oversize valve guide to be installed.

Caution

Do not install a valve guide of the same size again.

Valve guide hole diameter: See “Service Specifica-

tions” in page

IIA-6

(3) Install the valve guide until it projects 17 mm

1ENOlOf

REASSEMBLY SERVICE POINTS

+A4

(1) Install the valve spring seat.

(2) The special tool must be used to install the valve stem seal.

TSB Revision

(67

in.) from

the cylinder head as illustrated.

NOTE

(1)

The valve guide must be installed from the upper side of

the cylinder head.

(2) Note that the intake and exhaust valve guides differ in

length: 44 mm (1.732 in.) on intake side, 49.5 mm

(1.949 in.) on exhaust side.

(3) After installation of the valve guide, install a new valve

and check that it slides

smoothly.

VALVE STEM SEAL INSTALLATION

Improper installation could result in oil leaking past the valve

guide.

Caution

Do not reuse removed valve stem seal.

;

c

Page 45

Painted end

4Gl

ENGINE - Cylinder Head and Valves

+B4

I

Spring retainer

VALVE SPRING INSTALLATION

(1)

~.s$~~;~

valve spring with the painted end on the rocker

_

Stem seal

Spring seat

6EN043i

I)c4

RETAINER LOCK INSTALLATION

(1) The valve spring, if excessively compressed, causes the

bottom end of retainer to be in contact with, and damage,

the stem seal.

+

+-

Timing belt side

I

Timing belt side

Identification mark

1

FNOlill

lEN0109

TSB

I)D4

(1) Clean both gasket surfaces of cylinder block and cylinder

(2) Do not apply sealant.

(3) Confirm the identification mark on cylinder head gasket.

I)E4

(1)

(2) Repeat the tightening sequence several times, and torque

Revision

CYLINDER HEAD GASKET

INSTALLATlON

head.

The identification mark is stamped on the top surface of the

gasket at its front end.

Identification mark

3Vll: Up to 1992 models

1CG:

From 1993 models

CYLINDER HEAD BOLT INSTALLATION

Using the special tool and a torque wrench, tighten the

bolts in the shown sequence.

the bolts to specification in the final sequence.

Page 46

1 IA-38

461

ENGINE - Cvlinder Head and Valves

TSB Revision

Page 47

4Gl

ENGINE - Front Case and Oil Pump

FRONT CASE AND OIL PUMP

REMOVAL AND INSTALLATION

45 Nm

33

ft.lbs.

I

7

Removal steps

eD4

1. Oil filter

2.

Drain plug

QAI$~C~

@I) +A4

@I) +A4

3. Drain plug gasket

4. Oil pan

5.

Oil screen

6. Oil screen gasket

7.

Relief plug

8.

Gasket

9.

Relief spring

10.

+B4

Relief plunger

11. Oil seal

12.

Front case

13. Front case gasket

14. Oil pump cover

15. Outer rotor

16. Inner rotor

TSB

lEN0165

Revision

Page 48

1

IA-40

4Gl

ENGINE - Front Case and Oil

Puma,

lEN008t

REMOVAL SERVICE POINTS

OAo

OIL PAN REMOVAL

1

(1) Knock the special tool deeply between the oil pan and the

cylinder block.

(2) Hitting the side of the special tool, slide the special tool

along the oil pan to remove it.

OBo

(I)

OUTER ROTOR / INNER ROTOR REMOVAL

Make alignment marks on the outer and inner rotors for

reference in reassembly.

INSPECTION

OIL PUMP

(1)

Check the tip clearance.

Standard value: 0.03 - 0.08 mm

.?

(.00?2 - .0031 in.)

TSB

(2) Check the side clearance.

(3) Check the body clearance.

Revision

Standard value: 0.04 - 0.10 mm

(.0016 - .0039

!

fI

?

?’

Standard value: 0.10 - 0.18 mm I.0039

Limit: 0.35

(.138

in.)

“,

i

:s

P

E

I

-

.0071

in.)

in.)

Page 49

4Gl

ENGINE - Front Case and Oil Pump

INSTALLATION SERVICE POINTS

I)A4

(1) Install the outer rotor in the same direction as before noting

INNER ROTOR / OUTER ROTOR INSTALLATION

the mark put at the time of removal. Apply engine oil to the

entire rotor surface.

I

MD998305 n’

lEN00801

eB4

\

(1) Set the special tool on the crankshaft front end and apply

CRANKSHAFT FRONT OIL SEAL INSTALLATION

engine oil to its outer circumference.

(2) Apply a light coat of engine oil to the oil seal lip and then

slide the oil seal down along the special tool by hand until it

touches the front case. Install the oil seal in the front case

using the other special tool.

TSB Revision

Page 50

4Gl

ENGINE

-

Front Case and Oil

I)c4

OIL PAN INSTALLATION

(1) Scrape clean or wire brush all

Puma

gask{t

surfaces removing all

loose material.

(2) Apply a 4 mm

pan flange.

Specified sealant:

Mitsubishi Genuine Part No.

lent

(16

in.) diameter

beid

of sealant to the oil

.F

1

‘%lD970389

or equiva-

i.

(3) The oil pan should be installed within 15 minutes after the

application of sealant.

4 mm

(.I

based sealant

6 in.) diameter

Groove

portion

Bog,hole

po

+on

t

;

J

I)04

OIL FILTER INSTALLATION

(1) Clean the filter installation surface of the filter bracket.

(2) Apply engine oil to the O-ring of the oil filter.

(3) Screw the oil filter on the bracket until the O-ring contacts

the base. Then tighten one additional turn.

TSB Revision

Page 51

4Gl

ENGINE- Piston and Connecting Rod

PISTON AND CONNECTING ROD

REMOVAL AND INSTALLATION

yl&g

. .

Removal steps

OAo $1 k khecting

3. Connecting rod bearing

*iI4

4. Piston and connecting rod

5. Connecting rod bearing

eC4

6. Piston ring No. 1

eC4

7. Piston ring No. 2

I)B4

8. Oil ring

oBoeA 9. Piston pin

10.

Piston

11. Connecting rod

12. Bolt

rod cap

TSB Revision

-

‘.

1

EN0245

Page 52

IlA-44

4Gl

ENGINE

-

Piston and Connecting Rod

Piston pin setting tool

ylinder No.

MIT21

6941

DENOOM

DISASSEMBLY

OAo

CONNECTING ROD CAP REMOVAL

(1)

Mark the cylinder number on the side of the connecting rod

big end for correct reassembly.

(IBM

PISTON PIN REMOVAL

Item

No.

1

2

3

4

5

6

7

8

9

10

11

,SERVlCE

Part No.

MIT310134

MIT310136

MIT310137

MIT310138

MIT310139

MIT310140

MIT310141

MIT310142

M IT48

143

2 16943

10396

POINT6

Description

Base

Piston Support

Connecting Rod Guide Pin

Connecting Rod Guide Pin

Connecting Rod Guide Pin

Piston Support

Connecting Rod Guide Pin

Piston Support

Press Pin

Stop Screw

Nut

Press pin

$Mgg

h

, Piston pin

Front mark

Connecting rod

de

pin

7EN042E

(2) Select the correct piston support for your

above.) Fit the piston support onto the base. Place the base

on the press support blocks.

(3)

Insert

the press pin through the piston pin hole. Select the

correct connecting rod guide pin. (See above.) Thread the

guide pin onto the threaded portion of the press pin.

(4) Position the piston assembly on the piston support in the

press. With the press pin up as shown in the illustration,

insert the guide pin through the hole in the piston and

through the hole in the piston support.

(5)

Press the piston pin out of the assembly.

IMPORTANT: To avoid piston damage,

l

The piston support must seat squarely against the

piston.

l

Verify that the piston pin will

in the piston support.

(6)

Remove the piston pin from the

qide

f$ess

applrcatron.

9

through the hole

pin.

1

(See

7EN042E

ivision

Page 53

Piston

kg

End gap

5EN0066

6EN0548

INSPECTION

PISTON RING

(1)

Check for side clearance.

If the limit is exceeded, replace the ring or piston, or both.

Standard value:

No. 1

No. 2

Limit: 0.1 mm

0.03 - 0.07 mm (A012 -

0.02 - 0.08 mm

(.004

in.)

(&IO8 - .0024.‘in.)

(2) insert the piston ring into the cylinder bore. Force the ring

down with a piston, the piston crown being in contact with

the ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a

If the end gap is excessive, replace the piston ring.

Standard value:

No. 1

No. 2

Oil

0.20 - 0.40 mm

0.20 - 0.35 mm

0.20 - 0.70 mm

(.0079 - .0157

(-0079 - .0138

(.0079 - .0276

Limit:

No. 1, No. 2 0.8 mm

Oil

1.0 mm

(.031

(.038

in.)

in.)

.0028 h.)

thickne$s

in.)

in.)

in.)

gauge.

&llT;E;yFT

(1)

Remove oil from crankshaft pin and connecting rod bearing.

PlN

OIL CLEARANCE (PLASTIC GAUGE

(2) Cut the plastic gauge to the same length as the width of

bearing and place it on a crankshaft pin in parallel with its

axis.

(3)

Install the connecting rod cap carefully and tighten the bolts

to specified torque.

(4) Carefully remove the connecting rod cap.

(5) Measure the width of the plastic gauge at its widest part by

using a scale printed on the plastic gauge package.

Standard value: 0.02 - 0.05 mm

Limit: 0.1 mm

(.004

in.)

(.OOOS - AI020

in.)

1

TSB Revision

I

Page 54

11 A-46

4Gl

ENGINE

-

Piston and Connecting Rod

7EN0421

REASSEMBLY SERVICE

I)A4

PISTON PIN INSTALLATION

(I)

Thread the stop screw and lock nut

Fit the correct piston support on the top of the base.

the press pin, threaded end up, into

support until the press pin touches

(2) Using the graduations on the press

POINTS-

asiembly

,’

into the base.

t?re

hole in the piston

e

stop screw.

n,

adjust the stop

Insert

screw to the correct depth of 49 mm (1.93 in.)

(3) Place the base on the press support blocks.

(4) Slide the piston pin over the threaded end of the press pin,

and thread the correct guide pin up against it.

(5) Coat the piston pin with oil, and with the connecting rod

held in position, slide the guide pin through the piston and

the connecting rod.

(6) Press the piston pin through the connecting rod until the

guide pin contacts the stop screw.

(7) Remove the piston assembly from the base. Remove the

guide pin and the press pin from the assembly.

IMPORTANT: Due to production tolerance variations, it

is necessary to visually inspect t@ piston pin depth

after installation to verify that the piston pin is

centered. Adjust if necessary.

‘*

7EN042:

TSB Revision

3

Page 55

4Gl

ENGINE - Piston and Connecting Rod

*6+

OIL RING INSTALLATION

(1)

Fit the oil ring spacer into the piston ring groove.

NOTE

The side rails and spacer may be installed in either direction.

I

1

EN027;

Side rail gap

1

EN026E

7EN045:

(2) Install the upper side rail.

To install the side rail, first fit one end of the rail into the

piston groove, then press the remaining portion into

position by finger. See illustration.

Caution

Do not use piston ring expander when installing the

side rail.

(3) Install the lower side rail in the same procedure as

described in step (2).

(4) Make sure that the side rails move smoothly in either

direction.

I)c4

PISTON RING No. 2 / PISTON RING

iuo.

1 IN-

STALLATION

(1)

Using piston ring expander, fit No. 2 and then No. 1 piston

ring into position.

NOTE

(1) Note the difference in shape between

No.‘l,

and No. 2

piston rings.

(2) Install piston rings No. 1 and No. 2 with their side having

marks facing up (on the piston crown side).

-l

No. 2

and

spa&gap

,

No. 1

I

rinq qap

Identification mark

stamped

1’

Barrel

type

Identification mark stamped

1

L

No. 2

Taper type

1

No.

6EN054!

TSB Revision

EN027t

1

side

I)D4

PISTON AND CONNECTING ROD ASSEMBLY IN-

STALLATION

(1)

Apply engine oil to the piston surface, piston rings, and oil

ring.

(2) Align the gaps of piston rings and oil ring (side rails and

spacer) as shown in the illustration.

Page 56

IlA-48

461

ENGINE

-

Piston and Connecting Rod

Timing belt

c3

side

ront mark

1

EN0247

(3) Rotate crankshaft so that the crank

pi^n

is on the center of

the cylinder bore.

(4) Use suitable thread protectors on

theconnecting

rod bolts

before inserting piston and connecting rod assembly into

the cylinder block.

Care must be taken not to nick the crank pin.

(5) Using a suitable piston ring compressor. tool, install the

piston and connecting rod assembly

I)E4

CONNECTING ROD CAP

(1) Verifying the mark made during

ir#o

the cylinder block.

INST&LLATION

dis$ssembly,

install the

bearing cap to the connecting rod. If the connecting rod is

new with no index mark, make sure

notches come on the same side

th@

the bearing locking

as-,

shown.

e

(2) Make sure that connecting rod big end side clearance

meets the specification.

Standard value: 0.10 - 0.25 mm

Limit: 0.4 mm

(.018

in.)

f.0039 - .00!38

3

in.)

I)F4

(1) Since the connecting rod bolts and nuts are torqued using a

(2) Install the connecting rod cap on the big end of connecting

(3) Before installing the nuts the threads-should be oiled with

(4) Install both nuts on each bolt finger tight, then alternately

(5) Tighten the nuts to 20 Nm (14.5

TSB Revision

CONNECTING ROD CAP NUT

[NSTALLATION

new procedure, they should be examined BEFORE reuse. If

the bolt threads are “necked down” the bolts should be

replaced.

Necking can be checked by running a

I”

&rt

with fingers to the

full length of the bolt’s thread. If the nut does not run down

smoothly the bolt should be replaced.

rod.

engine oil.

torque each nut to assemble the cap properly.

ft.lbs.)

and plus

l/4

(90”)

turn.

t

Page 57

461

ENGINE

-

Crankshaft, Flywheel and Drive Plate

CRANKSHAFT, FLYWHEEL AND DRIVE PLATE

REMOVAL AND INSTALLATION

., 135.Nm

19 Nm

l4 fi*‘bfm

184%

11 Nm

8

ft.lbs.

8

I fL

.Y fths-

Al,

3

\

135Nm

- 6 ft.lbk.

53 Nm

38

1

TSB Revision

I

ft.lbs.

Removal steps

1.

Flywheel bolt

2.

Flywheel

3. Drive plate bolt

4.

Adaptor plate

5.

Drive plate

6.

Adaptor plate

7.

Crankshaft bushing

8. Rear plate

9. Bell housing cover

10. Oil seal case

11.

Oil seal case gasket

*Cl4

12.

Rear oil seal

13. Bearing cap bolt

*C4

14. Bearing cap

#B+

15. Crankshaft bearing, lower

16. Crankshaft

@B4

17. Crankshaft bearing, upper

#A4

18. Oil pressure switch

19. Cylinder block

I

For MIT

1

EN343

Page 58

1

IA-50

461

ENGINE

-

Crankshaft, Flywheel and Drive Plate

INSPECTION

CRANKSHAFT JOURNAL OIL CLEARANCE (PLASTIC

GAUGE METHOD)

(1) Remove oil from the crankshaft journal and the crankshaft

bearing.

(2) Install the crankshaft.

(3) Cut the plastic gauge to the same length as the width of

bearing and place it on the journal in parallel with its axis.

6EN055C

(4) Install the crankshaft bearing cap carefully and tighten the

bolts to the specified torque.

(5) Carefully remove the crankshaft bearing cap.

(6)

Measure the width of the plastic gauge at its widest part by

using a scale printed on the plastic gauge package.

Standard value: 0.02 - 0.05 mm

Limit: 0.1 mm

(.004

in.)

rr,

(.OOOS - .0020

in.)

;

i;

CYLINDER BLOCK

(1)

Using a straightedge and feeler

surface for

warpage.

Make sure

gaugzcheck

thagthe

the block top

surface is free

from gasket chips and other foreignimatters.

Standard value: 0.05 mm

Limit: 0.1 mm

(004

in.)

(.002

in.)

(2) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

(.008

in.)

The total resurfacing depth of both cylinder block

and mating cylinder head is 0.2 mm

maximum.

$

(008

in.) at

Cylinder block height (When new)?

Al

B

0

(3) Check cylinder walls for scratches

255.9 - 256.1 mm

(10.075 - lO~iO88

and

seizure. If defects

in.)

are evident, correct (rebore to an oversize) or replace.

(4) Using cylinder gauge, measure the’ cylinder bore and

cylindricity. If worn badly, correct the cylinder to an oversize

and replace the piston and piston rings. Measure at the

points shown in illustration.

i

Standard value:

Cylinder I.D.

75.50

75.53 mm

-

(2.9724 - 2.9736 in.)

Cylindricity: 0.01 mm

(0004

in.) or less

TSB Revisipn

Page 59

4Gl

ENGINE - Crankshaft, Flywheel and Drive Plate

BORING CYLINDER

(1) Oversize pistons to be used should be determined on the

basis of the largest bore cylinder.

Piston size identification

Thrust

direction

6EN055

Size

0.50

0.75

1

.OO

mm

(.02 in.) O.S.

mm

(.03

mm

(.04

in.)

in.)

OS.

OS.

Identification

0.25

0.50

0.75

1 .oo

I-

NOTE

Size mark is stamped on the piston top.

(2) Measure outside diameter of piston to be used. Measure it

in thrust direction as shown.

(3) Based on the measured piston O.D. calculate the boring

finish dimension.

I,:“.

Boring finish dimension = Piston O.D. + (clearance

between piston O.D. and cylinder) - 0.02 mm

(.OOOS

in.)

(honing margin)

(4) Bore all cylinders to the calculated boring finish dimension.

Caution

To prevent distortion that may result from temperature

rise during honing, bore cylinders, in this order: No. 2

to No. 4 to No. 1 to No. 3.

(5) Hone to the final finish dimension [piston O.D. + clearance

between piston O.D. and cylinder.]

(6) Check the clearance between piston and cylinder.

Clearance between piston and cylinder:

0.02 - 0.04 mm

(.OOOS - .0016

in.)

NOTE

When boring cylinders, finish all of four cylinders to the

same oversize, Do not bore only one cylinder to an

oversize.

lwer

Grooveless

bearing

Upper and lower bearings

(for No.

3)

Upper bearing

(for No.

1.2.4.5)

9EN0094

1

EN027

TSB

INSTALLATION SERVICE POINTS

*A+

(1)

+B4

(1)

(2) No. 1, 2, 4 and 5 lower bearings (cap side) are not provided

(3) No. 3 bearings are flanged and provided with no groove.

Revision

SEALANT APPLICATION TO OIL PRESSURE

SWITCH

Coat the threads of switch with sealant before

installirlg

the

switch.

Specified sealant: 3M ATD Part No. 8660 or equivalent

Caution

1. Keep the end of threaded portion clear of sealant.

2. Avoid an overtightening.

CRANKSHAFT BEARING INSTALLATION

No. 1, 2, 4 and 5 upper bearings (cylinder block side) are

provided with oil groove.

with oil groove.

Common bearings are used on the cap side and cylinder

block side.

Page 60

11

A-52

Timing

belt side

401

ENGINE - Crankshaft, Flywheel and Drive

I)c4

INSTALLATION OF BEARING

(1) Install according to the front mark end cap No.

NO174

Cap No.

1

EN017E

Pla$

CAP

Oil seal

Oil seal case

1

EN028C

1

EN027:

(2) After installing the bearing caps, make sure that the

crankshaft turns smoothly and the end play is correct. If the

end play exceeds the limit, replace crankshaft bearings.

Standard value: 0.05 - 0.18 mm

Limit: 0.3 mm

eD4

OIL SEAL INSTALLATION

(.012

in.)

(.0020 - .0071

in.)

TSB Revision

Page 61

4Gl

BRACKET

REMOVAL AND INSTALLATION

65

Nm

47

ft.lbs.

2

60

Nm

44

36

26

ft.1bs.h

Nm

ft.lbs.

1

/--+GFL

yy

ENGINE - Bracket

l.lA-53

Removal steps

1.

Exhaust pipe support bracket

2. Engine support bracket, front

3. Roll stopper bracket, front

4. Roll stopper bracket, rear

120

Nm

67

ftlbs.

‘\

TSB Revision

1

EN0347

I

Page 62

NOTES

Page 63

ENGINE

4637

CONTENTS

BRACKET

CRANKSHAFT, FLYWHEEL AND

DRIVE PLATE

CYLINDER HEAD AND VALVES

EXHAUST MANIFOLD AND

WATER PUMP

FRONT CASE, OIL PUMP AND OIL PAN

FUEL AND EMISSION

GENERAL INFORMATION

GENERAL SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. .

.._..............._...._..............................

f.......................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PARTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

62

58

39

32

. . . . . . . .

45

26

‘2

5

GENERATOR AND IGNITION SYSTEM

INTAKE

PISTON AND CONNECTING ROD

ROCKER ARMS AND CAMSHAFT

SEALANT

SERVICE SPECIFICATIONS

SPECIAL TOOLS

THROTTLE BODY

TIMING

TORQUE SPEClklCATlONS

MANIFOLD

................................................................

BELT

........................................................

............................................

....................

..........:.........

................................

....................................................

................................................

....................

........

..........

/.

16

30

52

34

12

6

13

28

18

10

Page 64

IIB-2

4G3

ENGINE - General Information

GENERAL INFORMATION

ENGINE SECTIONAL VIEW

1

TSB Revision

3ENOO86

I

Page 65

4G3

ENGINE - General Information

pqJp3

I

\

TSB Revision

3EN0087

Page 66

IIB-4

JBRICATION SYSTEM

4G3

ENGINE - General Information

TSB Revision

3LUOO20

Page 67

4G3

ENGINE

GENERAL SPECIFICATIONS

-

General Specifications

ptgpg

Description

Type

Number of cylinders

Combustion chamber

Total displacement

Cylinder bore

Piston stroke

Compression ratio

Valve timing:

( 1:

camshaft identification mark

Intake valve

Opens

Closes

Exhaust valve

Opens

Closes

Lubrication system

Oil pump type

Cooling system

Water pump type

EGR type

Injector type and number

Injector identification mark

Fuel regulated pressure

Throttle bore

Throttle position sensor

Closed throttle position switch

cm3

mm (in.)

mm (in.)

mm (in.)

(cu. in.)

kPa

(psi)

Specifications

In-line OHV, SOHC

4

Compact type

1.755 (107.10)

80.6 (3.17)

86 (3.39)

9.0

(AR)

20” BTDC

52” ATDC

55” BBDC

17” ATDC

Pressure feed, full-flow filtration

Involute gear type

Water-cooled forced circulation

Centrifugal impeller type

Single type

Electromagnetic 4

N210H

335 (47.6)

50 (1.969)

Variable resistor type

Contact type, within idle speed control motor

““:’:

:

: .///,.’

.

-_

.I-.: :_

I .,

.-

Page 68

IIB-6

4G3

ENGINE - Service Specifications

SERVICE SPECIFICATIONS

Standard

Cylinder head

Flatness of gasket surface

Grinding limit of gasket surface

*

Total resurfacing depth of both cylinder head

and cylinder block

Overall height