Page 1

MITSUBISHI MGS SERIES

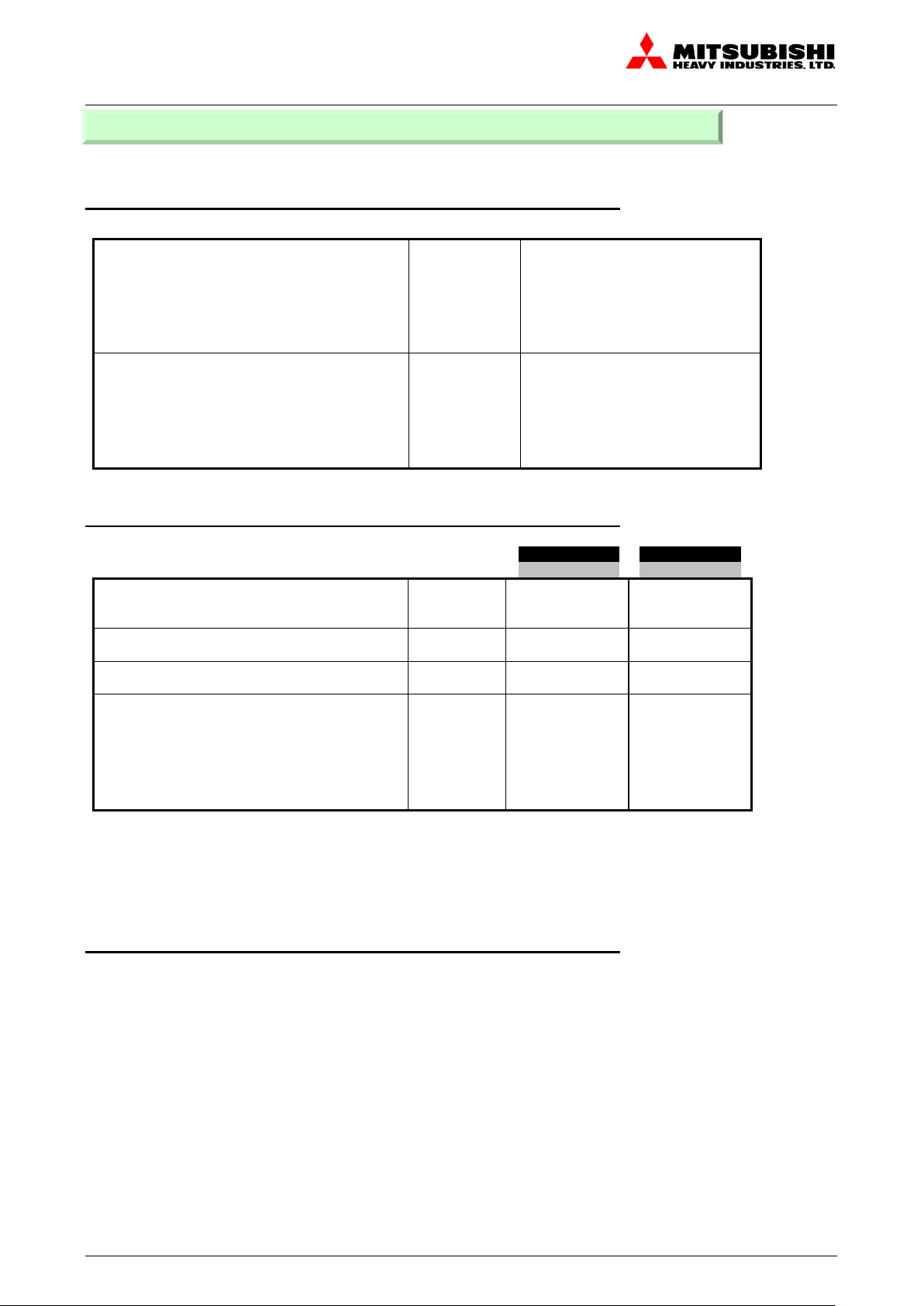

Overall dimensions

L : Length

mm

3725

W : Width

mm

1710

Total Weight (Dry)

kg

5500

Total Weight (Wet)

kg

5900

MMGGSS00665500BB

DIESEL GENERATOR SET

50Hz/1500 rpm/380V

POWER RATING (0.8 P.F.) MODEL CODE

STAND-BY 780 kVA 5S-H6G

PRIME 700 kVA 5P-H6G

MGS0650B with typical options

Voltage Variation

■ Standard Voltage 3P hase 4 Wires

380V

■ Volt ages A vailable 3Phase 4 Wires

380, 400, 415, 440, 190, 200, 208 and 220V

Note: Outputs for optional voltages may differ from standard output mentioned above.

CONDITIONS & DEFINITIONS

Stand-by: Code: S

Applicable for supplying emergency power at varying load in the event of the normal utility power interruption.

Fuel stop power in accordance with ISO15550, ISO3046/1, JISB8002-1, DIN6271 and BS5514.

Overload: not allowed

Prime: Code: P

Applicable for supply ing em erg ency p ower at varying load in t he ev ent of normal utility power inter ruption. + 10% overload

in accordance with ISO3046/1. Overload power in accordance with ISO15550, ISO3046/1, JIS8002-1, DIN6271 and

BS5514.

Conditions:

Engine ratings are based on SAE J1349 standard conditions and also apply at ISO3046/1, DIN6271 & BS5514 standard

conditions.

Fuel rates: based on A ST M D975, BS2869 and on fuel oil of 35° API (16°C or 60° F) gravity hav ing a LH V of 4 2, 78 0 kJ /kg

(18,390 Btu/lb.) when used at 29°C (85° F) and weighing 838.9 g/liter (7.001lbs./U.S. gal.).

Note: * For conditions of pri me power (P.R.P.) and additional ra ting requirements, please consul t your nearest Mitsub ish i

MGS dealer.

DIMENSION (Reference Data)

H : Height mm 1935

Page 2

MITSUBISHI MGS SERIES

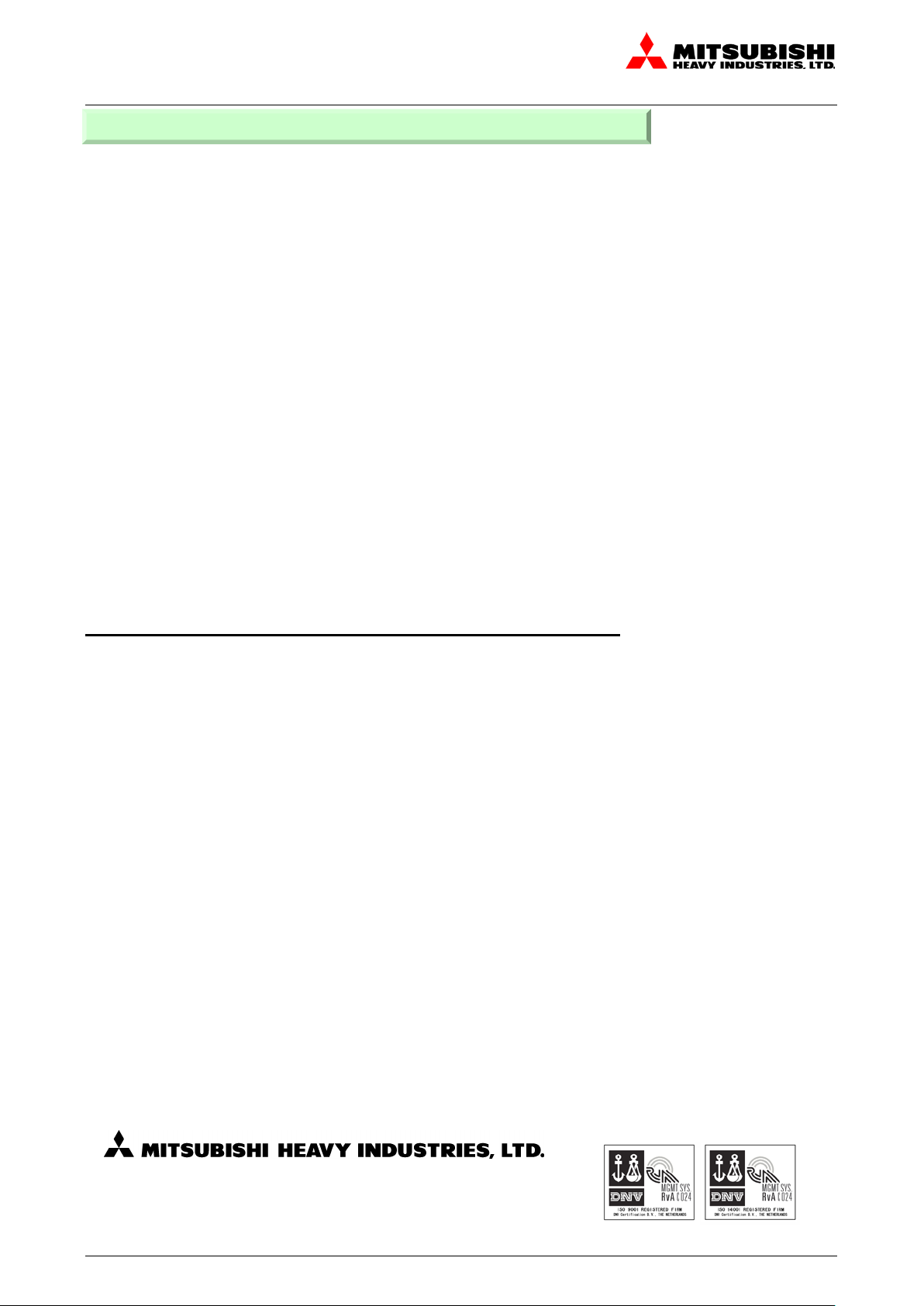

Bore

mm

170

Stroke

mm

220

Displacement

L

30

Piston speed

m/sec.

11

Compression ratio 14

Lubricating oil capacity L 100

Coolant capacity without radiator

L

55

Coolant pump external resistance

m water

5.0

Coolant pump flow rate

L/min

670

Cooling fan airflow rate

m3/min

720

Cooling fan air flow restriction

kPa

0.1

Allowable exhaust back pressure

kPa

6.0

Exhaust flange size (internal diameter)

mm

200

Gross Engine Power*

kWm

668

605

Brake mean effective pressure

MPa

1.8

1.6

Regenerative absorption

kW

64

64

Noise Level at 1 m

dB(A)

106

104

(excluding: intake, exhaust & fan)

Fuel consumption load 100%*

L/hr.

162

147

Fuel consumption load 75%*

L/hr.

121

111

Combustion air inlet flow rate

m3/min

56

51

Exhaust gas flow rate

m3/min

147

133

Heat rejection to coolant

kW

404

366

Heat rejection to exhaust

kW

476

438

Heat rejection to atmosphere from engine

kW

48

44

Heat rejection to atmosphere from generator

kW

41

36

STAND-BY

780 kVA

PRIME

700 kVA

MGS SERIES DIESEL ENGINE: MITSUBISHI S6R2-PTA-S

DIESEL GENERATOR SET

MGS0650B

L-6, 4 stroke-cycle water-cooled, turbocharged and aftercooled

ENGINE SPECIFICATIONS & TECHNICAL DATA

Ambient air temperature

ENGINE OPERATING DATA

Exhaust gas temperature

* WITH FAN basis.

Deration for engine

Altitude: 2.5% per 300m (1000ft) above 1,500m

Temperature: 2% per 5℃ (9°F) above 40℃

ENGINE STANDARD EQUIPMENT

Aftercooler

Turbocharger filter

Structure ste el bas e

Crankcase breather

Charging alternator

Lubricating oil cooler

Fuel filters, full flow paper element

Fuel transfer pump, gear driven, plunger type

Electronic type governor

Jacket water pump, gear driven

Lubricating oil filter, full flow paper element

Lubricating oil pump, gear driven

Exhaust dry manifold

Radiator, blower fan, fan drive

Manual shutoff

24V DC electric starting motor

℃

℃

40

510 500

Page 3

MITSUBISHI MGS SERIES

Generator volts L1-N, L2-N, L3-N

Engine cooling water temperature (°C & °F)

Generator volts L1-L2, L2-L3, L3-L1

Battery volts

Generator amps L1, L2, L3

Engine hours run

Generator Earth Current

Generator Load kW, kVA, kVar

Generator Frequency Hz

Generator Load kWh, kVAh, kVarh

Engine speed RPM

Power Factor

Engine oil pressure (PSI & Bar)

Generator Phase Sequence

Shutdown alarm

Generator high current

Warning alarm

Over voltage (AC)

High coolant temperature

Under voltage (AC)

Low oil pressure

Over voltage (DC)

Charge fail

Under voltage (DC)

Over-speed

Auxiliary indication

Under-speed

Auxiliary alarm (warning or shutdown)

Electrical trip

Common alarm

Fail to stop

Over frequency

Under frequency

High engine temperature

Over frequency

Low oil pressure

Under frequency

Fail to start

Oil pressure sender open circuit

Over-speed

Loss of speed signal

High voltage

High Crankcase internal pressure (MGS-C Continuous only)

Low voltage

Emergency Stop

Remote start present

Lubrication oil filter clogged

Generator ready

Electrical trip

MGS SERIES 7310 GENERATOR CONTROL PANEL

DIESEL GENERATOR SET

MGS0650B

T ype & Design

MGS standard 7310 programmable microprocessor control-automatic start/stop panel, generator breaker control,

indicating the operational status and fault conditions; automatically shutting down the engine and indicating the engine

failure by means of LCD display and LEDs on the front panel.

Controls & Monitori ng

◆ Mode selection & start engine button with interlock key switch system

◆ Menu navigation button

◆ LCD display for: AC amperage-each phase and earth current, AC voltage-each phase and neutral, Frequency Hz,

Operation hours run, Lub. Oil pressure, Cooling water temperature, Generator Load kW/kVA/kVar, Generator Load

kWh/kVAh/kVarh

◆ Operation status LED indicators

◆ CB control buttons

◆ Mute/Lamp test button

◆ Voltage adjuster

◆ Speed adjuster

◆ Emergency stop pushbutton

◆ Provided 5 outputs for status as standard equipment (Programmable 8 outputs available as option)

Safety Shutdown Protect ion and LED Indicator s

High engine temperature, Low oil pressure, Fail to start, Generator Over Speed/Frequency,

Generator Under Speed/Frequency

Generator High Voltage, Generator Low Voltage, Oil pressure sender circuit, Loss of Speed signal , Emergency stop,

Mounting

Fabricated cubicle mounted on individual bracket with anti-vibration isolator

Electrical Design

In accordance with BS EN 60950 Low Voltage Directive, BS EN 61006-2 and 61006-4 EMC Directive. The optional

interface can provide real time diagnostic facilities.

Generator Control Panel Description

■ 3 position operation mode control key switch

(ACTIVE, PANEL LOCK, STOP/RESET)

■ Manual button ■ Stop/Reset button (Manual only)

■ Auto button ■ Mute/Lamp test button (Manual only )

■ CB open button (Manual only) ■ Voltage adjusting trimmer

■ CB close button (Manual only) ■ Speed adj ust ing tr im mer

■ Start engine button (Manual only) ■ Emergency stop pushbutton

■ LCD display accessed by scroll pushbutton

■ Visual indicators on LCD display

■ Visual indication alarm and automatically shutdown

■ Operation status ind icat ed by LED

■ Pre-Programmed St artin g U nit

Automatic start/stop sequen ce timing and delay sy ste ms configur e d

via MS-Windows based software.

Page 4

MITSUBISHI MGS SERIES

MGS SERIES AC GENERATOR MODEL: MG-HC6G

DIESEL GENERATOR SET

MGS0650B

T ype & Design

MGS original design, single bearing, 4 pole, screen protected, selfexciting, self regulating and brushless with fully

connected damper windings, salient pole rotors, A.C. exciter and rotating rectifier unit. Direct coupled to engine and

pre-lubricated maintenance free bearing, direct drive centrifugal blower.

Winding Sy s t e m

Standard 12 wire reconnectable winding provides a wide range of 3 phase voltage. All windings are impregnated in

vacuum pressure impregnated with a special polyester resin.

Voltage Regulator

Fully sealed, 3 phase RMS sensing AVR with built-in protection against sustained over-excitation. This de-excites the

generator after a minimum of 5 seconds.

Permanent Magnet Generator (PMG)

Electrically isolated from the main alternator stator windings powers AVR - sustaining approx. 250~300% of short circuit

current at the AC generator output terminals for not more than 10 seconds by means of excitation voltage via AVR

Electrical Design

In accordance with BS5000 Part 3, VDE0530, UTE51100, NEMA MG1-22, CEMA, IEC34-1, CSA22.2, AS1359 and

JEC2100.

Gen Set Option Features

■ ENGINE

■ FUEL

■ COOLING

■ LUBRICATION

■ EXHAUST

■ GENERATOR

■ CONTROL PANEL

■ SWITCHGEAR

Enclosure: Drip-proof IP23

Overspeed capability: 125% for 2 minutes

Insulation: Class 'H' of IEC

Temperature rise: Class 'H'

Voltage regulation: Less than +/- 0.5% from no load to full load at any power factor between 0.8 lagging and 1.0

allowing for a 4% engine speed variation

Volta ge adjustment: +/- 6%

Wave form: Less than 5% deviation

Telephone Influence Factor (TIF): Less than 50

Telephone Harmonic factor (THF): Less than 2%

Radio interference: Suppression is in line with the provision of BS800 and VDE Class G and N

Air Cleaner, paper element dry type

Battery Kit

Battery Charger

Anchor Bolts

Fuel Day Service Tank

Oversize radiator

Heat Exchanger

Expansion Tank

Jacket Water Heater

Removal STD Radiator, Fan & Fan Drive

Lub. Oil Priming Pump

Exhaust Silencer

Exhaust Flexible Pipe

Space Heater

3 phase Sensing Auto Voltage Regulator

Power Factor Regulator

Diesel Generator Integrated Communication Synthesizer (DGICS-MII)

Auxiliary Control Panel

Remote Monitor Interface

Circuit Breaker MCCB & ACB

Reverse Power Relay

Power Systems Engine Section, Engine Sales Department

16-5, KONAN 2-CHOME, MINATO-KU, TOKY O 108-8215 JAPAN

TEL: 81-3-6716-4771 FAX: 81-3-6716-5854

Mitsubishi Heavy Industries, Ltd. serves for the customers with improved products continually.

Therefore specification and some materials will be ch ang ed with out notice.

The International System of units (SI) is used in this publication.

Loading...

Loading...