Page 1

Mitsubishi Electric AC Servo System

MR-J5

User's Manual

(Troubleshooting)

-MR-J5-_G_

-MR-J5W_-_G

-MR-J5-_A_

Page 2

Page 3

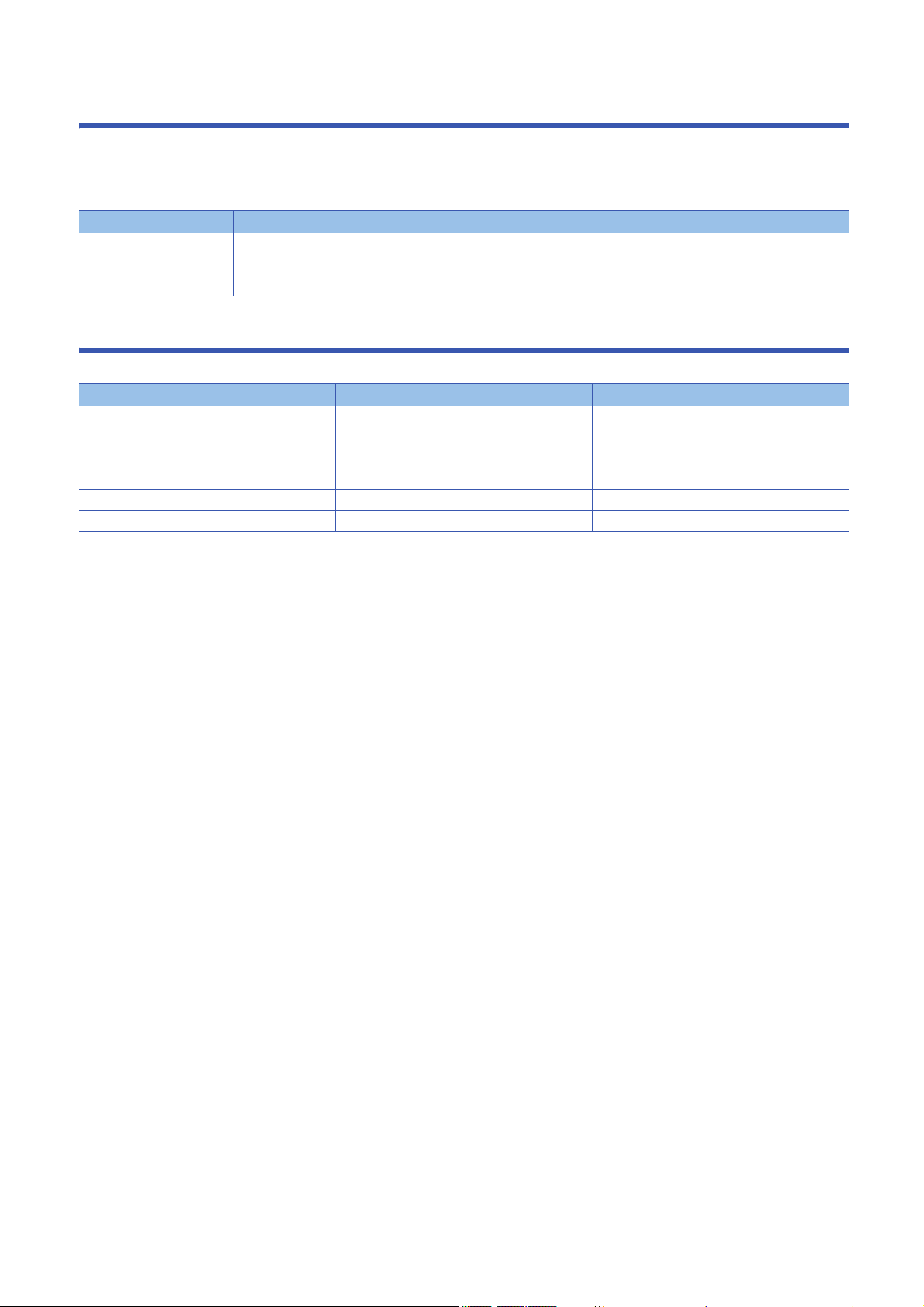

About the manual

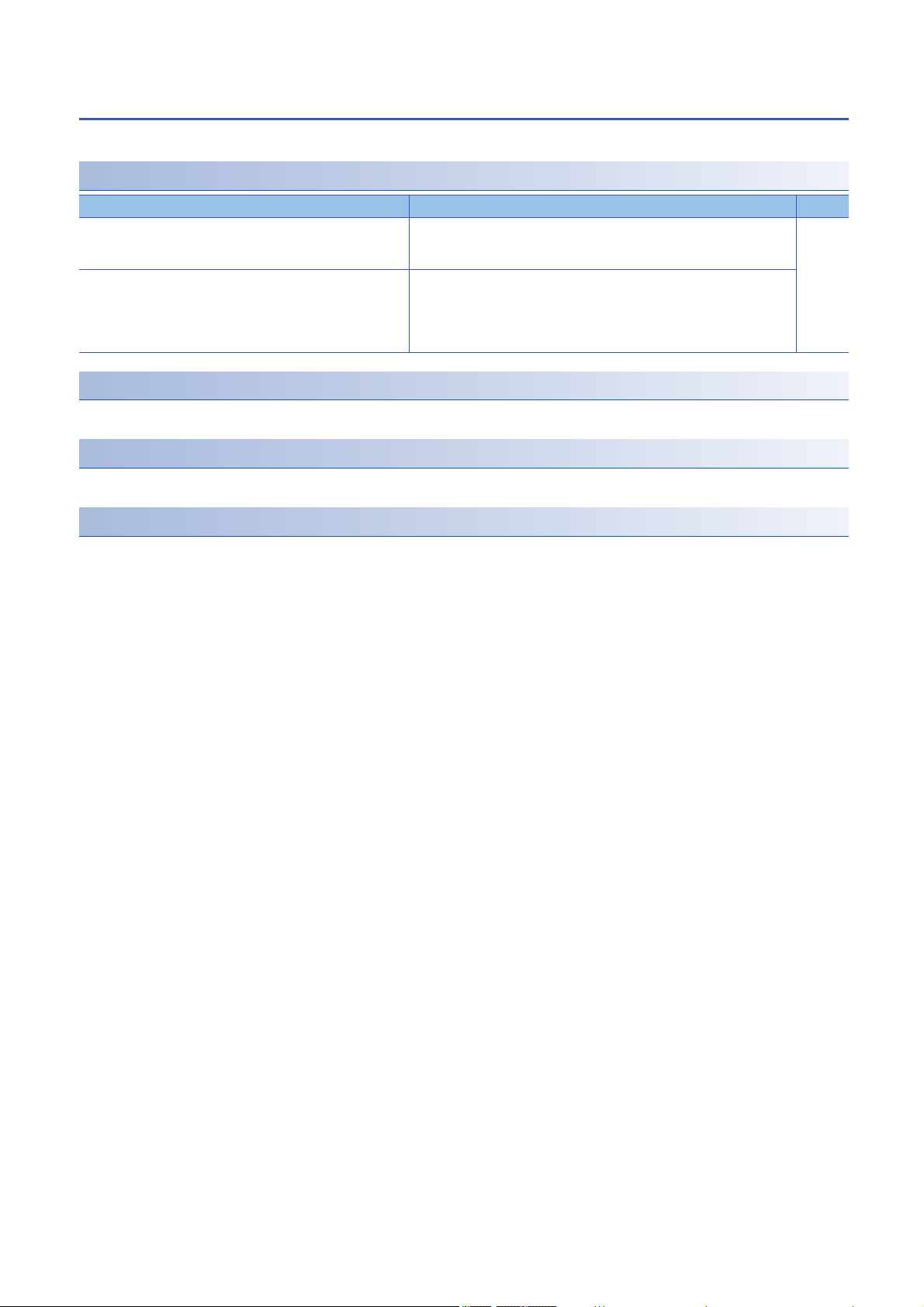

This manual covers the following servo amplifiers. These include servo amplifiers with optional units.

MR-J5-_G_/MR-J5W_-_G/MR-J5-_A_

In this manual, the servo amplifier names are abbreviated as shown below.

Symbol Servo amplifier

[G] MR-J5-_G_

[WG] MR-J5W_-_G

[A] MR-J5-_A_

U.S. CUSTOMARY UNITS

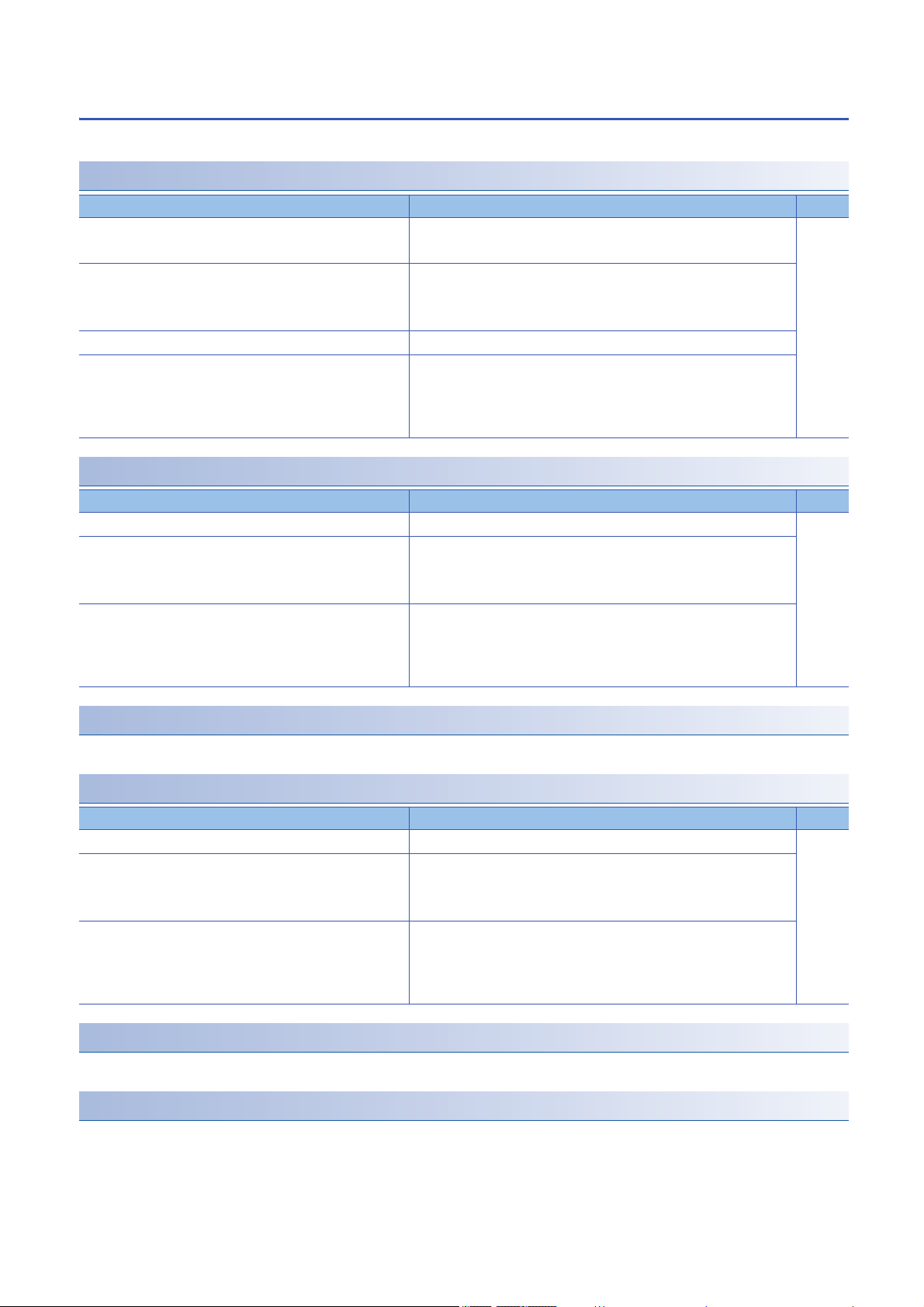

U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

-4

Moment of inertia 1 [(× 10

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

kg•m2)] 5.4675 [oz•inch2]

1

Page 4

CONTENTS

About the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

U.S. CUSTOMARY UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

CHAPTER 1 SERVO AMPLIFIER TROUBLESHOOTING 5

1.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 The list of alarm No./warning No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Explanation of the lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Handling methods for alarms/warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

[AL. 010_Undervoltage]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

[AL. 011_Switch setting error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

[AL. 012_Memory error 1 (RAM)] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

[AL. 013_Clock error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

[AL. 014_Control process error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

[AL. 016_Encoder initial communication error 1]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

[AL. 017_Board error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

[AL. 019_Memory error 3] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

[AL. 01A_Servo motor combination error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

[AL. 01E_Encoder initial communication error 2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

[AL. 01F_Encoder initial communication error 3]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

[AL. 020_Encoder normal communication error 1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

[AL. 021_Encoder normal communication error 2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

[AL. 024_Main circuit error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

[AL. 025_Absolute position erased]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

[AL. 027_Initial magnetic pole detection error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

[AL. 028_Linear encoder error 2]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

[AL. 02A_Linear encoder error 1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

[AL. 02B_Encoder counter error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

[AL. 030_Regenerative error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

[AL. 031_Overspeed]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

[AL. 032_Overcurrent] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

[AL. 033_Overvoltage]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

[AL. 035_Command frequency error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

[AL. 037_Parameter error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

[AL. 03A_Inrush current suppression circuit error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

[AL. 042_Servo control error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

[AL. 045_Main circuit device overheat] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

[AL. 046_Servo motor overheat] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

[AL. 047_Cooling fan error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

[AL. 050_Overload 1]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

[AL. 051_Overload 2]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

[AL. 052_Excessive error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

[AL. 054_Oscillation detection] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

[AL. 056_Forced stop error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

[AL. 063_STO timing error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

[AL. 068_STO diagnosis error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

[AL. 069_Command error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

[AL. 086_Network communication error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

[AL. 088_Watchdog 1]/[AL. 888_Watchdog 1]/[AL. 88888_Watchdog 1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

2

Page 5

[AL. 08E_Serial communication error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

[AL. 090_Homing incomplete warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[AL. 091_Servo amplifier overheat warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

[AL. 092_Battery cable disconnection warning]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

[AL. 093_ABS data transfer warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

[AL. 095_STO warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

[AL. 096_Home position setting warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

[AL. 098_Software position limit warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

[AL. 099_Stroke limit warning]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

[AL. 09B_Excessive error warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

[AL. 09E_Network warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

[AL. 09F_Battery warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

[AL. 0E0_Excessive regenerative error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

[AL. 0E1_Overload warning 1]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

[AL. 0E2_Servo motor overheat warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

[AL. 0E3_Absolute position counter warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

[AL. 0E5_ABS time-out warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

[AL. 0E6_Servo forced stop warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

[AL. 0E8_Cooling fan speed reduction warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

[AL. 0E9_Main circuit off warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

[AL. 0EA_ABS servo-on warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

[AL. 0EB_The other axis error warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

[AL. 0EC_Overload warning 2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

[AL. 0ED_Output watt excess warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

[AL. 0F0_Tough drive warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

[AL. 0F2_Drive recorder warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

[AL. 0F3_Oscillation detection warning] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

[AL. 0F7_Machine diagnosis warning]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

[AL. 118_Encoder diagnosis]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

[AL. 119_Memory error 4] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

[AL. 11A_Servo motor constant error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

[AL. 130_Regenerative error 2] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

[AL. 139_Open phase error] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

[AL. 168_STO function error]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[AL. 188_Watchdog 2]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

[AL. 1E9_Open phase warning]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

[AL. 1F8_Memory warning 1] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

1.4 Trouble which does not trigger an alarm/warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

The display shows "A" (unconnected to the controller) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

The display shows "r##" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

The display shows "TST". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

The display shows "off" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

The display is turned off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

The servo motor does not operate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

The increase in the servo motor speed is insufficient or excessive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

The servo motor vibrates with low frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

An unusual noise is occurring in the servo motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

The servo motor vibrates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Poor speed accuracy (Unstable speed of servo motor) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

The machine vibrates unsteadily when it stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Overshoot/undershoot occurs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

. . . . . . . . . . . . . . . 96

CONTENTS

3

Page 6

The servo motor starts moving immediately after the power-on of the servo amplifier or servo-on . . . . . . . . . 105

The home position deviates at the homing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

The position deviates during operation after the homing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

In the absolute position detection system, a position mismatch occurs at power restoration . . . . . . . . . . . . . . 107

Communication with the servo amplifier fails using MR Configurator2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Electromagnetic brake went out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Electromagnetic brake cannot be released. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Coasting distance of the servo motor became longer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

4

Page 7

1 SERVO AMPLIFIER TROUBLESHOOTING

Precautions

Precautions

• MR-J5-_G_-RJ and -MR-J5-_A_-RJ will be available in the future.

• In MR-J5, the alarm No. and warning No. are changed to be shown with three digits followed by one digit indicating the

detailed No., which were shown with two digits and one detailed No. in MR-J4 series.

1.1 Outline

When an error occurs in the servo system, the corresponding alarm and warning is displayed. When an alarm occurs, ALM

(Malfunction) turns off.

When an alarm or warning is displayed, take appropriate measures according to the following:

Page 13 Handling methods for alarms/warnings

Restrictions

• The following alarms are not recorded in the alarm history.

[AL. 010.1 Voltage drop in the control circuit power]

[AL. 037 Parameter error]

• With exception of [AL. 0F0 Tough drive warning], warnings are not recorded in the alarm history.

1

• As soon as an alarm occurs, switch to the servo-off status and shut off the main circuit power supply.

• Cool the equipment for approximately 30 minutes.

• The alarm canceling method in [AL. 042 Servo control error] can be changed with [Pr. PL04.3 [AL. 042 Servo control error]

detection controller reset condition selection].

• If an alarm which is related to the communication error with the controller occurs, resetting the communication may not

cancel the alarm.

• The alarms which have "○" in the safety reset column of the alarm list must be canceled while all the safety observation

functions have stopped. The alarms cannot be canceled unless all the safety observation functions have stopped.

• After performing the check/action, cycle the power of the servo amplifier.

• If the alarm remains active even after the check/action of each alarm of detail number, the servo amplifier may be

malfunctioning. Replace the servo amplifier, and then check the repeatability.

• If the malfunction continues even after replacing the servo amplifier, there is a possibility that there is an abnormality in the

surrounding area.

• To prevent unexpected operation, when [AL. 25 Absolute position erased] occurs, perform homing again.

• To prevent malfunctions of the servo amplifier and servo motor, when any of the following alarms occurs, do not deactivate

the alarm repeatedly to resume. Remove the cause of occurrence and allow 30 minutes or more for cooling, and then

resume the operation.

[AL. 030 Regenerative error]

[AL. 045 Main circuit device overheat]

[AL. 046 Servo motor overheat]

[AL. 050 Overload 1]

[AL. 051 Overload 2]

• To prevent malfunctions of the servo amplifier and servo motor, when any of the following warnings occurs, do not cycle the

power of the servo amplifier repeatedly to resume. If the power of the servo amplifier is switched off/on during the warnings,

allow more than 30 minutes for cooling before resuming operation.

[AL. 091 Servo amplifier overheat warning]

[AL. 0E0 Excessive regenerative warning]

[AL. 0E1 Overload warning 1]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.1 Outline

5

Page 8

• When [AL. 0E6 Servo forced stop warning], [AL. 0E9 Main circuit off warning], [AL. 0EA ABS servo-on warning], or [AL.

0EB The other axis error warning] occurs, the servo amplifier is changed to servo-off status. If any other warning occurs,

the operation can still be continued, but an alarm may occur.

6

1 SERVO AMPLIFIER TROUBLESHOOTING

1.1 Outline

Page 9

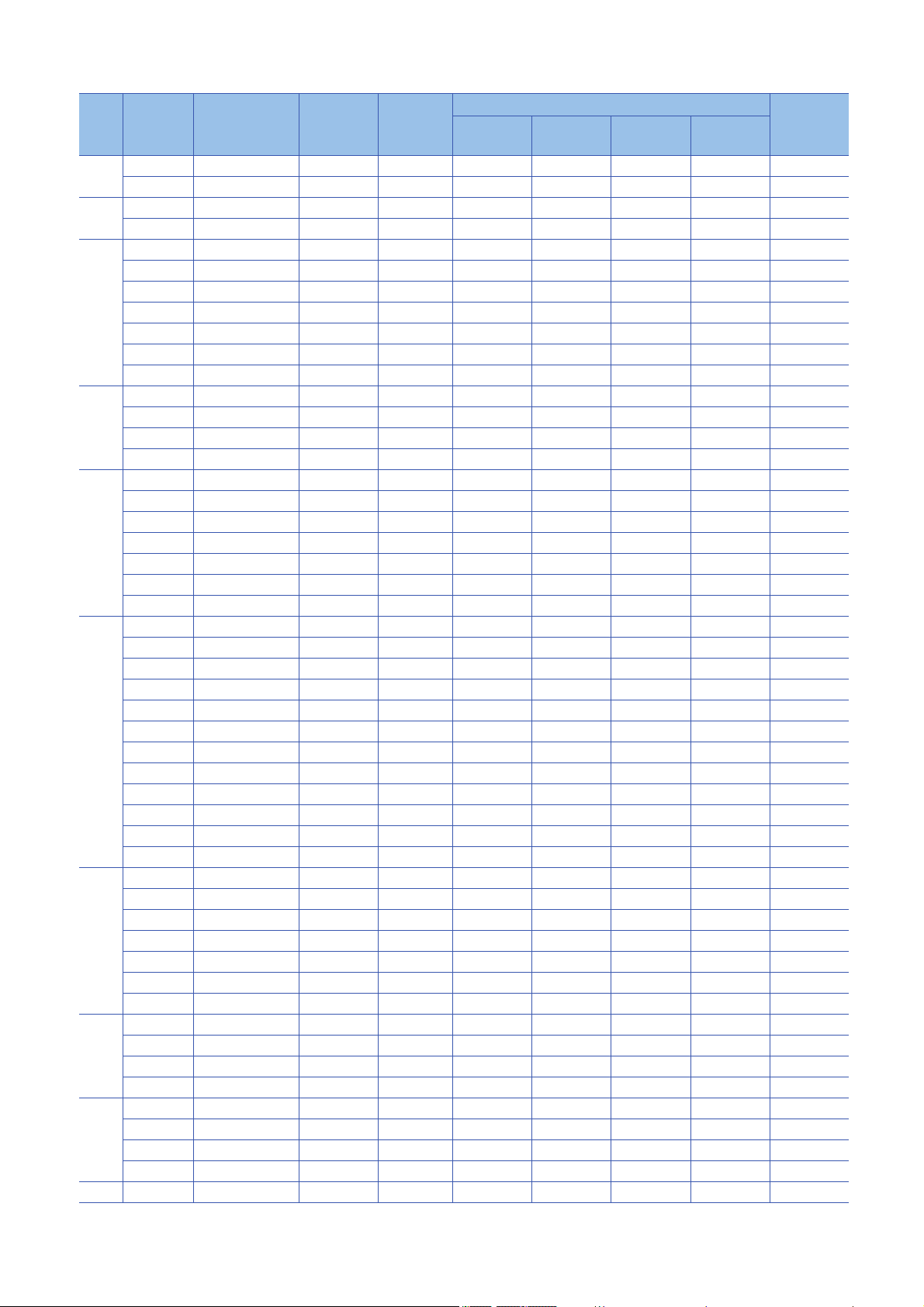

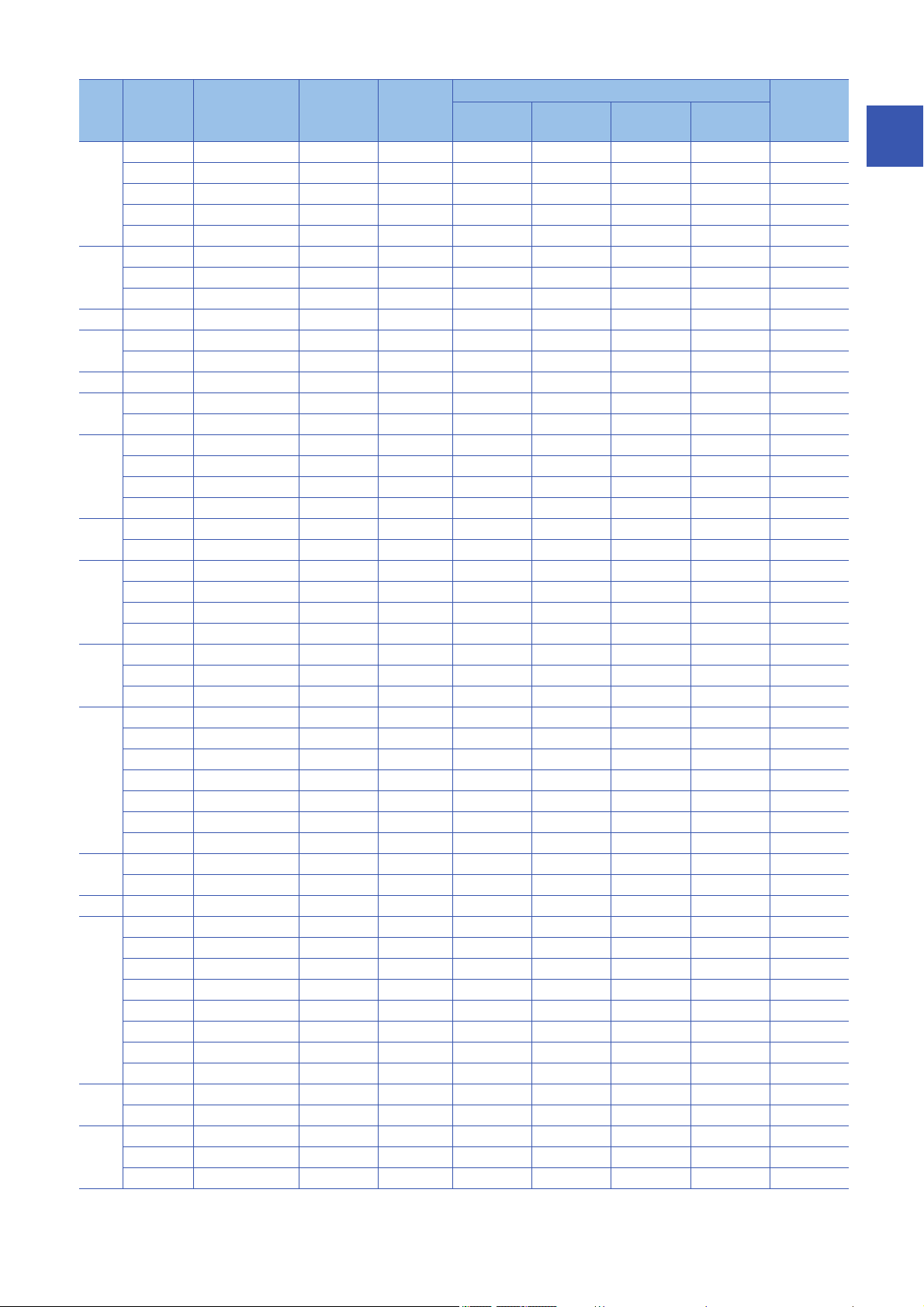

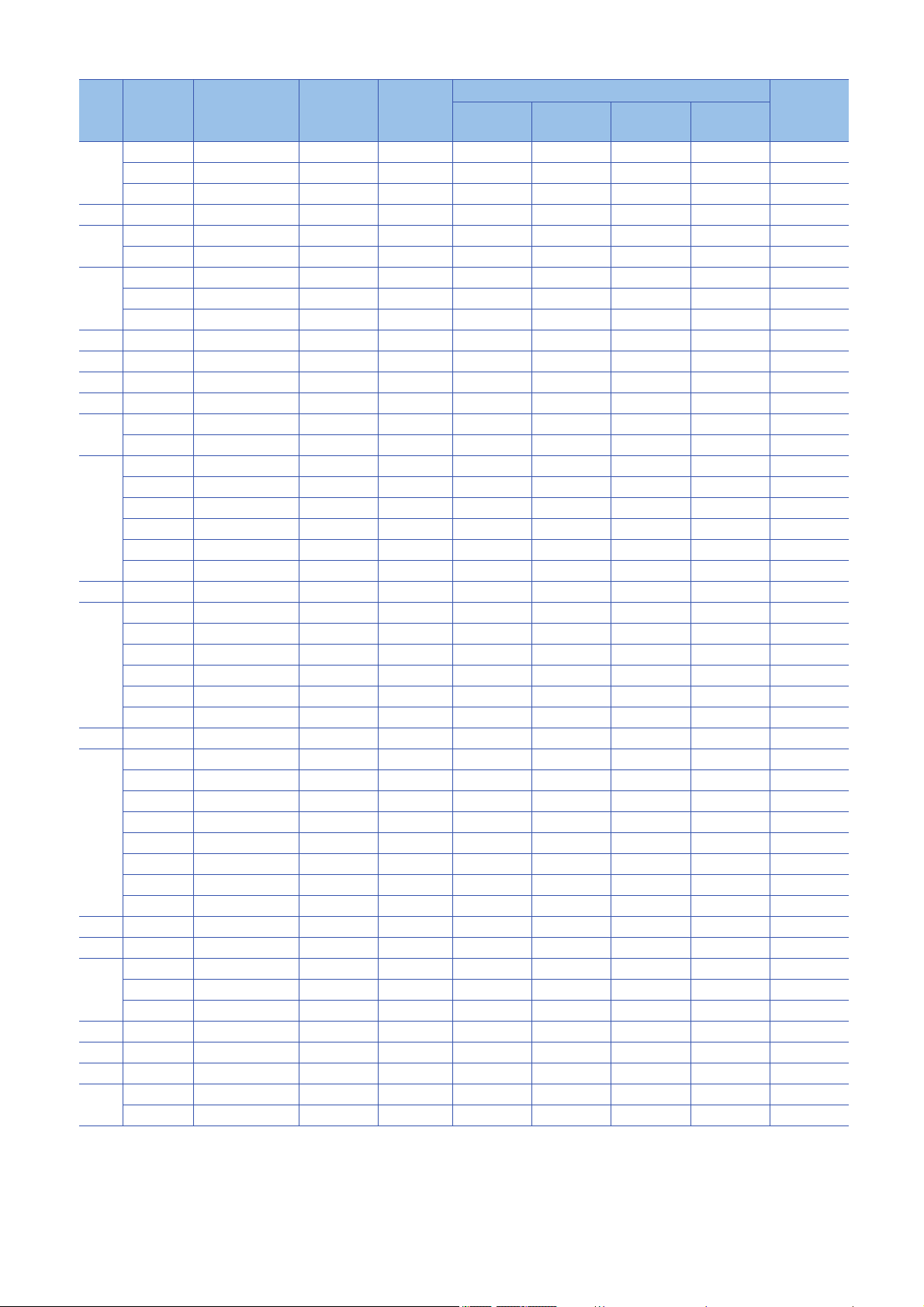

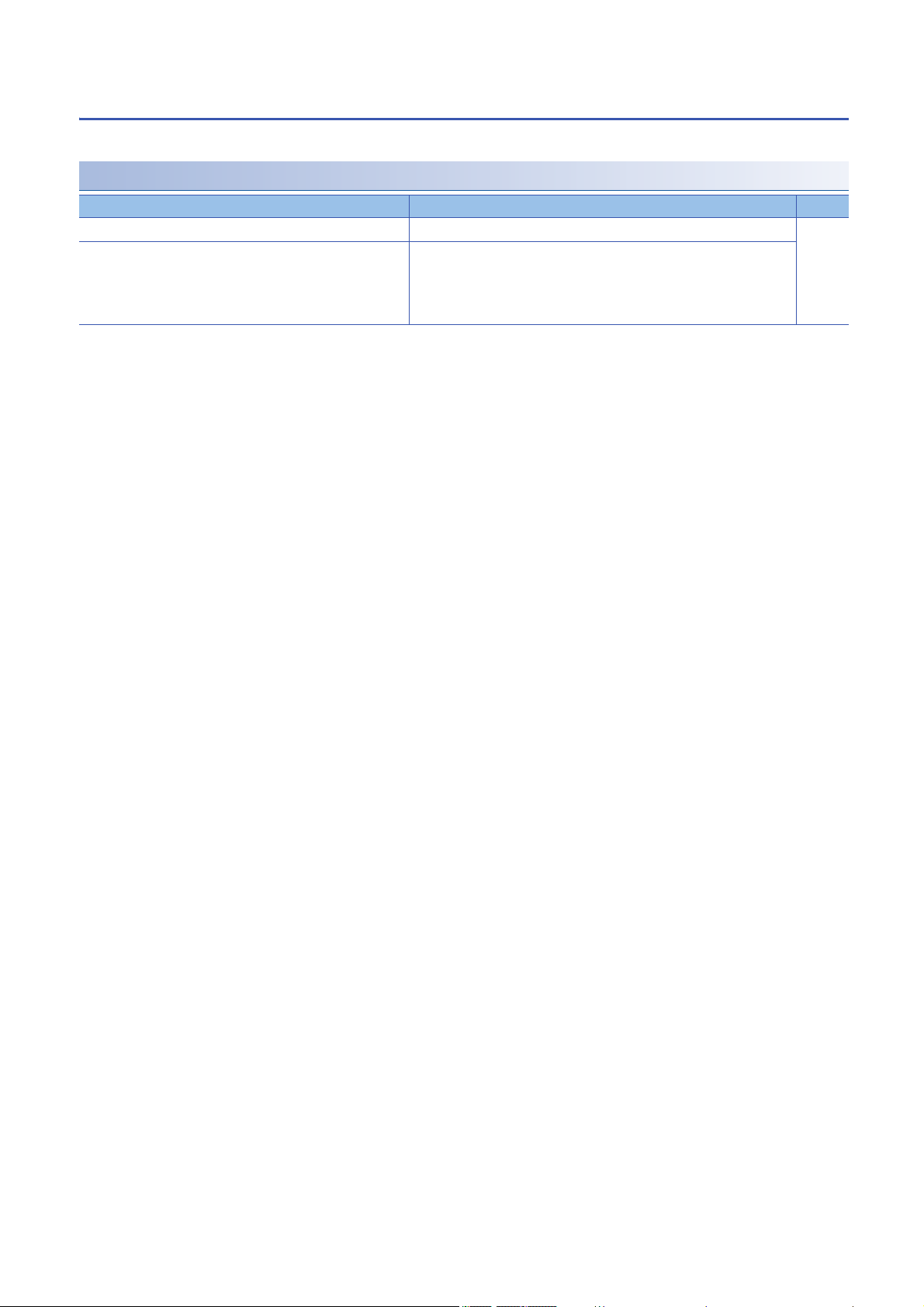

1.2 The list of alarm No./warning No.

Explanation of the lists

Motor stop method

For the alarms and warnings in which "SD" is written in the stop method column, the servo motor stops with the dynamic

brake after forced stop deceleration. For the alarms and warnings in which "DB" or "EDB" is written in the stop method

column, the servo motor stops with the dynamic brake.

■ Stop method at occurrence of alarms/warnings

MR-J5 servo amplifier has the following stop methods:

DB: Dynamic brake stop (for a servo amplifier without the dynamic brake, the servo motor coasts)

SD: Forced stop deceleration

These stop methods are applicable when [Pr. PA04] is set to the initial value. With [Pr. PA04], the stop methods can be

changed from SD to DB.

■ Specific stop methods

For MR-J5-_G_ servo amplifiers (I/O mode), quick stop or slow stop can be selected with [Pr. PD12].

For MR-J5-_A_ servo amplifiers, quick stop or slow stop can be selected with [Pr. PD30].

Alarm deactivation

After the cause of the alarm has been removed, the alarm can be deactivated by the methods marked "○" in the alarm

deactivation column. Alarms are deactivated by alarm reset, communication reset, or power cycling. Alarms can be canceled

by software reset, instead of power cycling.

Refer to "Alarm function" in the following manual.

MR-5 User's Manual (Function)

1

Stop system

This stop system is applicable only for MR-J5W_-_G.

This indicates which axis to stop when an alarm or a warning occurs.

Each axis: Only the axis where the alarm or warning occurred will stop.

All axes: All axes will stop.

Motor stop warning

A warning with "○" indicates that a servo motor to stop when the warning occurs. When the servo motor stop warning occurs,

WNGSTOP (Motor stop warning) is turned on.

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

7

Page 10

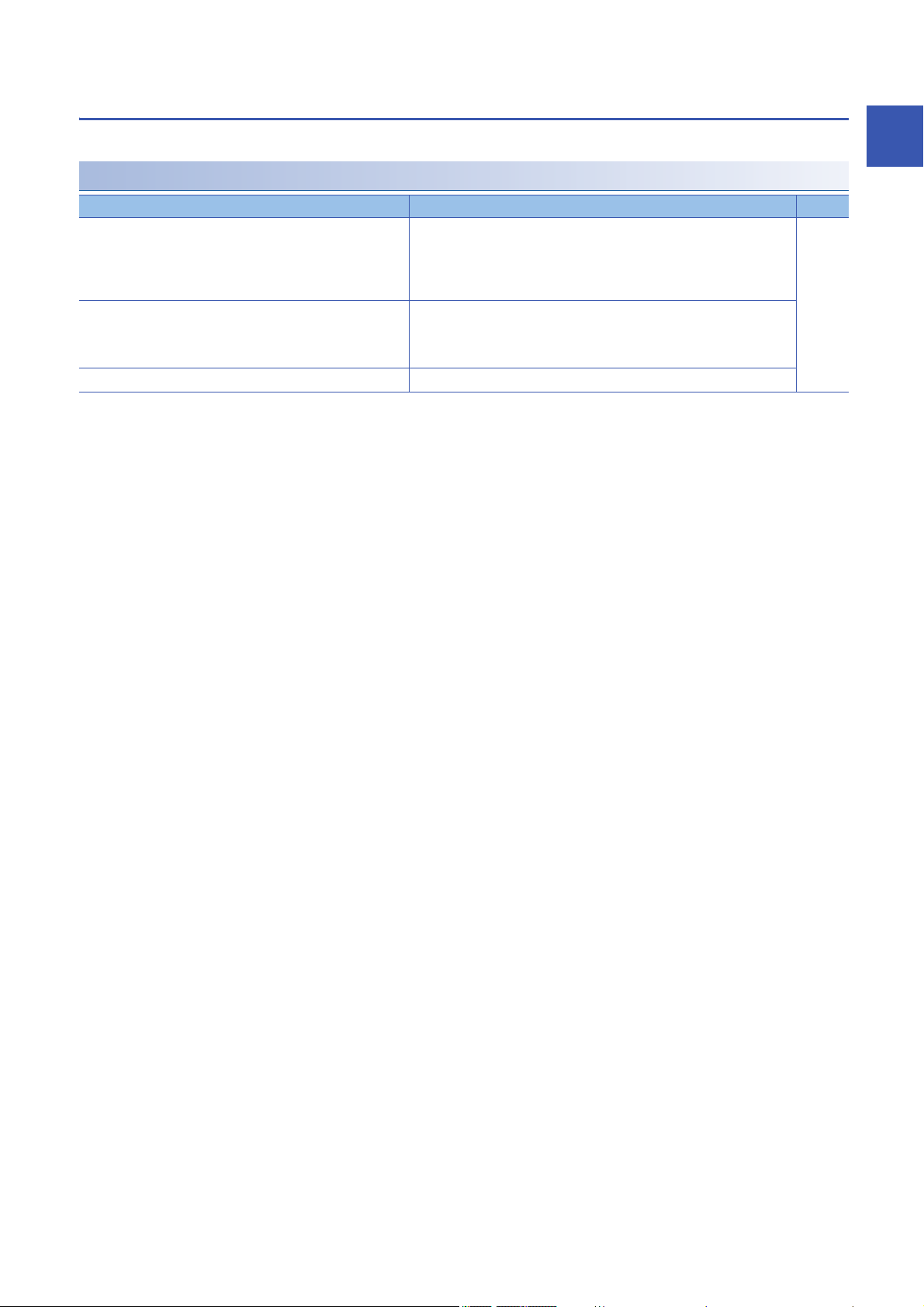

No. Detail No. Alarm/Warning Motor stop

method

010 010.1 Alarm EDB All axes

010.2 Alarm SD All axes

011 011.1 Alarm DB All axes

011.2 Alarm DB All axes

012 012.1 Alarm DB All axes

012.2 Alarm DB All axes

012.4 Alarm DB All axes

012.5 Alarm DB All axes

012.6 Alarm DB All axes

012.7 Alarm DB All axes

012.8 Alarm DB All axes

013 013.1 Alarm DB All axes

013.2 Alarm DB All axes

013.4 Alarm DB All axes

013.5 Alarm DB All axes

014 014.1 Alarm DB All axes

014.2 Alarm DB All axes

014.3 Alarm DB All axes

014.4 Alarm DB All axes

014.5 Alarm DB All axes

014.8 Alarm DB All axes

014.9 Alarm DB All axes

016 016.1 Alarm DB Each axis

016.2 Alarm DB Each axis

016.3 Alarm DB Each axis

016.5 Alarm DB Each axis

016.6 Alarm DB Each axis

016.7 Alarm DB Each axis

016.A Alarm DB Each axis

016.B Alarm DB Each axis

016.C Alarm DB Each axis

016.D Alarm DB Each axis

016.E Alarm DB Each axis

016.F Alarm DB Each axis

017 017.1 Alarm DB All axes

017.3 Alarm DB All axes

017.4 Alarm DB All axes

017.5 Alarm DB All axes

017.6 Alarm DB All axes

017.7 Alarm DB All axes

017.9 Alarm DB All axes

019 019.1 Alarm DB All axes

019.2 Alarm DB All axes

019.3 Alarm DB All axes

019.6 Alarm DB All axes

01A 01A.1 Alarm DB Each axis

01A.2 Alarm DB Each axis

01A.5 Alarm DB Each axis

01A.6 Alarm DB Each axis

01E 01E.1 Alarm DB Each axis

Stop

system

Alarm deactivation Motor stop

Safety

reset

Alarm

reset

Communic

ation reset

Power

cycling

warning

8

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

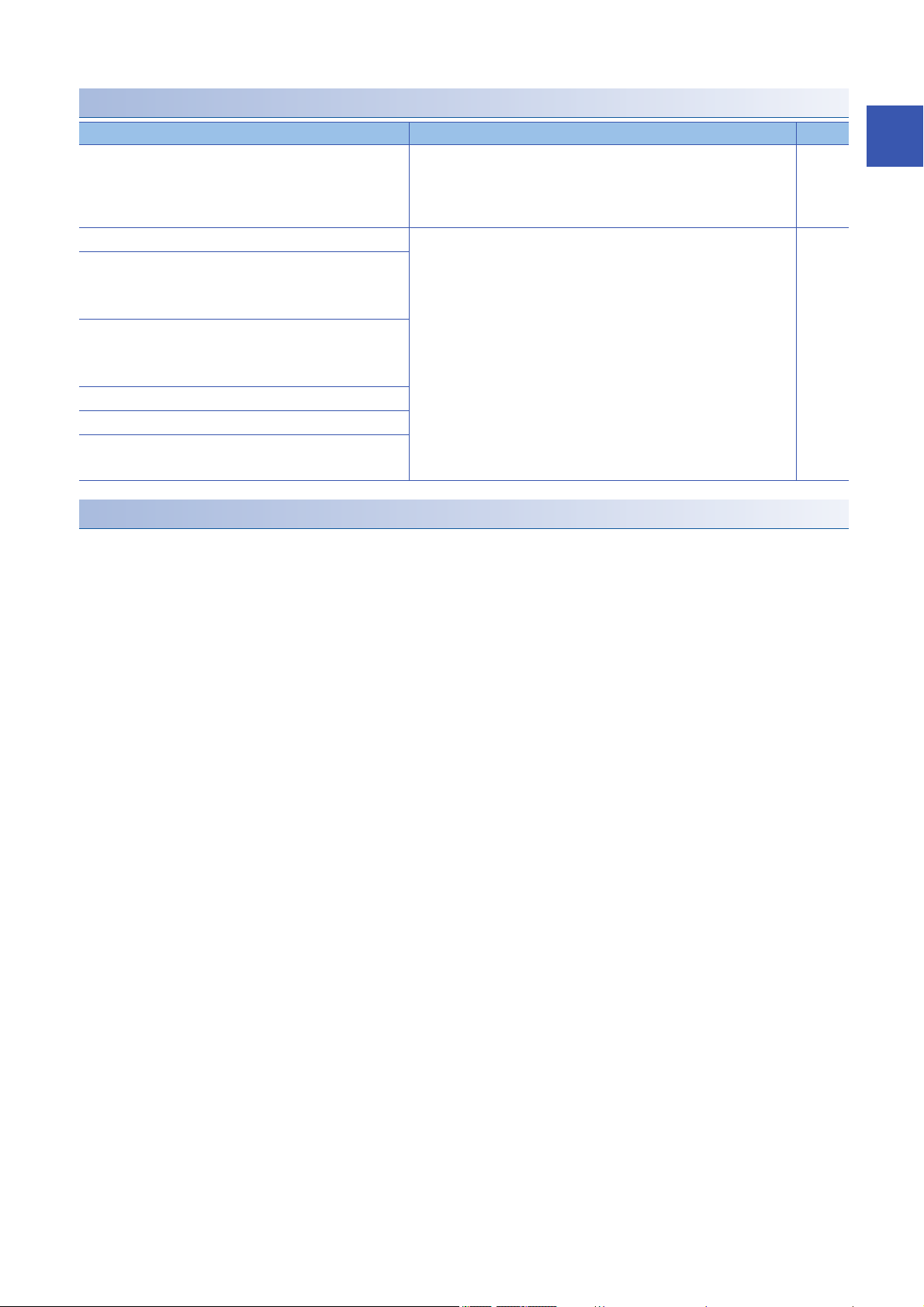

Page 11

No. Detail No. Alarm/Warning Motor stop

method

01F 01F.1 Alarm DB Each axis

020 020.1 Alarm EDB Each axis

020.2 Alarm EDB Each axis

020.3 Alarm EDB Each axis

020.5 Alarm EDB Each axis

020.6 Alarm EDB Each axis

020.7 Alarm EDB Each axis

021 021.1 Alarm EDB Each axis

021.2 Alarm EDB Each axis

021.3 Alarm EDB Each axis

021.4 Alarm EDB Each axis

021.5 Alarm EDB Each axis

021.6 Alarm EDB Each axis

024 024.1 Alarm DB All axes

024.2 Alarm DB All axes

025 025.1 Alarm DB Each axis

027 027.1 Alarm DB Each axis

027.2 Alarm DB Each axis

027.3 Alarm DB Each axis

027.4 Alarm DB Each axis

027.5 Alarm DB Each axis

027.6 Alarm DB Each axis

027.7 Alarm DB Each axis

028 028.1 Alarm EDB Each axis

02A 02A.1 Alarm EDB Each axis

02A.2 Alarm EDB Each axis

02A.3 Alarm EDB Each axis

02A.4 Alarm EDB Each axis

02A.5 Alarm EDB Each axis

02A.6 Alarm EDB Each axis

02A.7 Alarm EDB Each axis

02A.8 Alarm EDB Each axis

02B 02B.1 Alarm EDB Each axis

02B.2 Alarm EDB Each axis

030 030.1 Alarm DB All axes

030.2 Alarm DB All axes

030.3 Alarm DB All axes

031 031.1 Alarm SD Each axis

032 032.1 Alarm DB All axes

032.2 Alarm DB All axes

032.3 Alarm DB All axes

032.4 Alarm DB All axes

033 033.1 Alarm EDB All axes

035 035.1 Alarm SD Each axis

037 037.1 Alarm DB Each axis

037.2 Alarm DB All axes

037.6 Alarm DB Each axis

037.7 Alarm DB Each axis

03A 03A.1 Alarm EDB All axes

Stop

system

Alarm deactivation Motor stop

Safety

reset

Alarm

reset

Communic

ation reset

Power

cycling

warning

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

9

Page 12

No. Detail No. Alarm/Warning Motor stop

method

042 042.1 Alarm EDB Each axis

042.2 Alarm EDB Each axis

042.3 Alarm EDB Each axis

045 045.1 Alarm EDB All axes

045.2 Alarm EDB All axes

046 046.1 Alarm SD Each axis

046.2 Alarm SD Each axis

046.3 Alarm SD Each axis

046.4 Alarm SD Each axis

046.5 Alarm DB Each axis

046.6 Alarm DB Each axis

047 047.1 Alarm SD All axes

047.2 Alarm SD All axes

050 050.1 Alarm SD Each axis

050.2 Alarm SD Each axis

050.3 Alarm SD Each axis

050.4 Alarm SD Each axis

050.5 Alarm SD Each axis

050.6 Alarm SD Each axis

051 051.1 Alarm DB Each axis

051.2 Alarm DB Each axis

052 052.1 Alarm SD Each axis

052.3 Alarm SD Each axis

052.4 Alarm SD Each axis

052.5 Alarm EDB Each axis

052.6 Alarm SD Each axis

054 054.1 Alarm EDB Each axis

056 056.2 Alarm EDB Each axis

056.3 Alarm EDB Each axis

063 063.1 Alarm DB All axes

063.2 Alarm DB All axes

068 068.1 Alarm DB All axes

069 069.1 Alarm SD Each axis

069.2 Alarm SD Each axis

069.3 Alarm SD Each axis

069.4 Alarm SD Each axis

069.5 Alarm SD Each axis

069.6 Alarm SD Each axis

086 086.1 Alarm SD All axes

086.2 Alarm SD All axes

086.3 Alarm SD All axes

086.5 Alarm SD All axes

086.6 Alarm SD All axes

088 088.1/088/

888/88888

088.2 Alarm DB All axes

088.4 Alarm DB All axes

088.8 Alarm DB All axes

Alarm DB All axes

Stop

system

Alarm deactivation Motor stop

Safety

reset

Alarm

reset

Communic

ation reset

Power

cycling

warning

10

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

Page 13

No. Detail No. Alarm/Warning Motor stop

method

08E 08E.1 Alarm SD All axes

08E.2 Alarm SD All axes

08E.3 Alarm SD All axes

08E.4 Alarm SD All axes

08E.5 Alarm SD All axes

090 090.1 Warning DB Each axis

090.2 Warning DB Each axis

090.5 Warning DB Each axis

091 091.1 Warning

092 092.1 Warning

092.3 Warning

093 093.1 Warning DB

095 095.1 Warning DB Each axis

095.2 Warning DB Each axis

096 096.1 Warning

096.2 Warning

096.3 Warning

096.4 Warning

098 098.1 Warning

098.2 Warning

099 099.1 Warning

099.2 Warning

099.4 Warning

099.5 Warning

09B 09B.1 Warning

09B.3 Warning

09B.4 Warning

09E 09E.2 Warning SD All axes

09E.3 Warning SD All axes

09E.4 Warning SD All axes

09E.5 Warning SD All axes

09E.6 Warning SD All axes

09E.7 Warning SD All axes

09E.8 Warning SD All axes

09F 09F.1 Warning

09F.2 Warning

0E0 0E0.1 Warning

0E1 0E1.1 Warning

0E1.2 Warning

0E1.3 Warning

0E1.4 Warning

0E1.5 Warning

0E1.6 Warning

0E1.7 Warning

0E1.8 Warning

0E2 0E2.1 Warning

0E2.2 Warning

0E3 0E3.1 Warning

0E3.2 Warning

0E3.5 Warning

Stop

system

Alarm deactivation Motor stop

Safety

reset

Alarm

reset

Communic

ation reset

Power

cycling

warning

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

11

Page 14

No. Detail No. Alarm/Warning Motor stop

method

0E5 0E5.1 Warning

0E5.2 Warning

0E5.3 Warning

0E6 0E6.1 Warning SD All axes

0E8 0E8.1 Warning

0E8.2 Warning

0E9 0E9.1 Warning DB All axes

0E9.2 Warning DB All axes

0E9.3 Warning DB All axes

0EA 0EA.1 Warning Each axis

0EB 0EB.1 Warning DB Each axis

0EC 0EC.1 Warning

0ED 0ED.1 Warning

0F0 0F0.1 Warning

0F0.3 Warning

0F2 0F2.1 Warning

0F2.2 Warning

0F2.3 Warning

0F2.4 Warning

0F2.5 Warning

0F2.6 Warning

0F3 0F3.1 Warning

0F7 0F7.1 Warning

0F7.2 Warning

0F7.3 Warning

0F7.4 Warning

0F7.5 Warning

0F7.6 Warning

118 118.1 Alarm DB All axes

119 119.1 Alarm DB All axes

119.2 Alarm DB All axes

119.3 Alarm DB All axes

119.4 Alarm DB All axes

119.5 Alarm DB All axes

119.6 Alarm DB All axes

119.7 Alarm DB All axes

119.8 Alarm DB All axes

11A 11A.1 Alarm DB Each axis

130 130.1 Alarm DB All axes

139 139.1 Alarm SD All axes

139.2 Alarm DB Each axis

139.3 Alarm DB Each axis

168 168.1 Alarm DB All axes

188 188.1 Alarm DB All axes

1E9 1E9.1 Warning

1F8 1F8.1 Warning

1F8.2 Warning

Stop

system

Alarm deactivation Motor stop

Safety

reset

Alarm

reset

Communic

ation reset

Power

cycling

warning

12

1 SERVO AMPLIFIER TROUBLESHOOTING

1.2 The list of alarm No./warning No.

Page 15

1.3 Handling methods for alarms/warnings

Remove the cause of the alarm and warning in accordance with this section. MR Configurator2 can be used as reference for

the cause of a warning.

[AL. 010_Undervoltage]

• The voltage of the control circuit power supply has dropped.

• The voltage of the main circuit power supply has dropped.

[AL. 010.1_Voltage drop in the control circuit power]

Cause Check/action method Model

1. The control circuit power supply connection is

incorrect.

2. The voltage of the control circuit power supply

is low.

3. The power was cycled before the internal

control circuit power supply stopped.

4. An instantaneous power failure lasted for

longer than the specified time.

• When [Pr. PA20.2 SEMI-F47 function selection] is set to "0"

(Disabled), the specified time is 60 ms.

• When [Pr. PA20.2] is set to "1" (Enabled), the value set in [Pr.

PF25 SEMI-F47 function - Instantaneous power failure detection

time (instantaneous power failure tough drive - detection time)]

is the specified time.

Check the connection of the control circuit power supply.

Refer to "Connection example of power supply circuit" in the following manual.

MR-J5 User's Manual (Hardware)

Check if the voltage of the control circuit power supply is equal to or lower than

the specified value.

200 V class: 160 V AC

After shutting off the servo amplifier power supply, make sure that the sevensegment LED of the servo amplifier is turned off, and then cycle the power.

Check if the power supply has a problem.

After checking, cycle the power of the servo amplifier.

[A]

[G]

[WG]

1

[AL. 010.2_Voltage drop in the main circuit power]

Cause Check/action method Model

1. The main circuit power supply wiring is

disconnected.

2. The wiring between P3 and P4 is

disconnected.

3. The voltage of the main circuit power supply is

low.

4. When this alarm occurs, the bus voltage is low

at acceleration.

5. The fuse is disconnected.

6. The power supply capacity is insufficient.

7. Main circuit capacitor has deteriorated.

8. The servo amplifier is malfunctioning.

Check the main circuit power supply wiring.

Refer to "Connection example of power supply circuit" in the following manual.

MR-J5 User's Manual (Hardware)

Check the wiring between P3 and P4.

Refer to "Connection example of power supply circuit" in the following manual.

MR-J5 User's Manual (Hardware)

Check if the voltage of the main circuit power supply is equal to or lower than

the specified value. When the voltage is equal to or lower than the specified

value, increase the voltage of the main circuit power supply.

• 200 V class: 160 V AC

Check if the bus voltage during acceleration is lower than the specified value.

If the bus voltage is lower than the specified value, increase the acceleration

time constant or the power supply capacity.

• 200 V class: 200 V DC

Check the charge light after a certain period of time.

Check that the specified power supply capacity is satisfied.

After checking the operation time and ambient temperature, replace the servo

amplifier if the main circuit capacitor has reached its life.

Refer to "Parts having life" in the following manual.

MR-J5-A User's Manual (Introduction)

MR-J5-G/MR-J5W-G User's Manual (Introduction)

Check the value of the bus voltage. When the bus voltage is lower than the

specified value though the voltage of the main circuit power supply is within

specifications, replace the servo amplifier.

• 200 V class: 200 V DC

[A]

[G]

[WG]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

13

Page 16

[AL. 011_Switch setting error]

• The setting of the DIP switch is incorrect.

• The setting of the rotary switch is incorrect.

[AL. 011.1_Rotary switch setting error]

Cause Check/action method Model

1. Each selected network has its settable range,

and the values set with the rotary switches

(SW1/SW2) were set out of the range.

Check the settings of the rotary switches (SW1/SW2).

When the value set with the rotary switch and the actual value do not match,

the servo amplifier may be malfunctioning. Replace the servo amplifier.

Specifications on the setting of the rotary switches vary depending on each

network.

Refer to "Switch setting and display of the servo amplifier" in the following

manual.

MR-J5-G/MR-J5W-G User's Manual (Introduction)

[AL. 011.2_Disabling control axis setting error]

Cause Check/action method Model

1. The setting of the disabling control axis switch

is incorrect.

Check the setting of the disabling control axis switch.

Refer to "Switch setting and display of the servo amplifier" in the following

manual.

MR-J5-G/MR-J5W-G User's Manual (Introduction)

If the above case does not apply, the servo amplifier may be malfunctioning.

Replace the servo amplifier.

[G]

[WG]

[WG]

14

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 17

[AL. 012_Memory error 1 (RAM)]

• The internal parts of the servo amplifier (RAM) have malfunctioned.

[AL. 012.1_RAM error 1]

Cause Check/action method Model

1. The internal parts of the servo amplifier has

malfunctioned.

2. There is an abnormality in the surrounding

environment.

Noise from the power supply may have caused the failure. Disconnect the

cables except for the control circuit power supply, and then check the

repeatability. If the failure continues, the servo amplifier may have

malfunctioned. Replace the servo amplifier.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[AL. 012.2_RAM error 2]

Page 15 [AL. 012.1_RAM error 1]

[AL. 012.4_RAM error 4]

Page 15 [AL. 012.1_RAM error 1]

[AL. 012.5_RAM error 5]

Page 15 [AL. 012.1_RAM error 1]

1

[AL. 012.6_RAM error 6]

Page 15 [AL. 012.1_RAM error 1]

[AL. 012.7_RAM error 7]

Page 15 [AL. 012.1_RAM error 1]

[AL. 012.8_RAM error 8]

Page 15 [AL. 012.1_RAM error 1]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

15

Page 18

[AL. 013_Clock error]

• The internal parts of the servo amplifier have malfunctioned.

• A clock transmitted from the controller has an error.

[AL. 013.1_CPU error 1]

Cause Check/action method Model

1. The internal parts of the servo amplifier have

malfunctioned.

2. A clock transmitted from the controller has an

error.

3. The servo amplifier of the next axis is

malfunctioning.

4. There is an abnormality in the surrounding

environment.

[AL. 013.2_CPU error 2]

Page 16 [AL. 013.1_CPU error 1]

Noise from the power supply may have caused the failure. Disconnect the

cables except for the control circuit power supply, and then check the

repeatability. If the failure continues, replace the servo amplifier.

Check if this alarm occurs when the servo amplifier is connected to the

controller. If the alarm occurs, replace the controller.

Replace the servo amplifier of the next axis, and then check the repeatability.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[G]

[WG]

[A]

[G]

[WG]

[AL. 013.4_CPU error 4]

Page 16 [AL. 013.1_CPU error 1]

[AL. 013.5_CPU error 5]

Page 16 [AL. 013.1_CPU error 1]

16

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 19

[AL. 014_Control process error]

• The process did not complete within the specified time.

• The internal parts of the servo amplifier (communication IC) have malfunctioned. [G]

[AL. 014.1_Control process error 1]

Cause Check/action method Model

1. The servo parameter setting is incorrect.

2. There is an abnormality in the surrounding

environment.

3. The servo amplifier is malfunctioning.

Set the servo parameter to a value before the alarm occurrence, and then

check the repeatability.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

Replace the servo amplifier.

[A]

[G]

[WG]

[AL. 014.2_Control process error 2]

Cause Check/action method Model

1. A synchronous signal error transmitted from

the controller occurred.

2. The servo parameter setting is incorrect.

3. There is an abnormality in the surrounding

environment.

4. The servo amplifier is malfunctioning.

Replace the controller, and then check the repeatability. [G]

Set the servo parameter to a value before the alarm occurrence, and then

check the repeatability.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

Replace the servo amplifier.

[WG]

[A]

[G]

[WG]

1

[AL. 014.3_Control process error 3]

Page 17 [AL. 014.1_Control process error 1]

[AL. 014.4_Control process error 4]

Page 17 [AL. 014.1_Control process error 1]

[AL. 014.5_Control process error 5]

Page 17 [AL. 014.1_Control process error 1]

[AL. 014.8_Control process error 8]

Page 17 [AL. 014.1_Control process error 1]

[AL. 014.9_Control process error 9]

Page 17 [AL. 014.1_Control process error 1]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

17

Page 20

[AL. 016_Encoder initial communication error 1]

• An error has occurred in the communication between an encoder and servo amplifier.

[AL. 016.1_Encoder initial communication - Receive data error 1]

Cause Check/action method Model

1. There is an error in the encoder cable.

2. When using an A/B/Z-phase differential output

linear encoder on the servo motor side, the

servo amplifier is not compatible with the A/B/

Z-phase differential output linear encoder.

3. When using an A/B/Z-phase differential output

linear encoder on the servo motor side, the A/

B/Z-phase differential output linear encoder is

connected incorrectly.

4. The servo amplifier is malfunctioning.

5. The encoder is malfunctioning.

6. There is an abnormality in the surrounding

environment.

Check if the encoder cable is disconnected, shorted, or incorrectly wired.

If the encoder cable is malfunctioning, replace or repair the cable.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Check if the servo amplifier is compatible with the A/B/Z-phase differential

output linear encoder.

Refer to "Corresponding linear encoder list" in the following manual.

MR-J5 Partner's Encoder User's Manual

Check if the wiring of the A/B/Z-phase differential output linear encoder is

correct. Check that the encoder is wired to PSEL.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Replace the servo amplifier. [A]

Replace the servo motor.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[A]

[G]

[G]

[WG]

[AL. 016.2_Encoder initial communication - Receive data error 2]

Page 18 [AL. 016.1_Encoder initial communication - Receive data error 1]

[AL. 016.3_Encoder initial communication - Receive data error 3]

Cause Check/action method Model

1. Axis not used is not set as disabled-axis.

2. The encoder cable is disconnected.

3. The servo parameter setting of communication

method is incorrect.

[A]: [Pr. PC22.3 Encoder cable communication method selection]

[G] [WG]: [Pr. PC04.3 Encoder cable communication method

selection]

4. There is an error in the encoder cable.

5. When using an A/B/Z-phase differential output

linear encoder on the servo motor side, the

connection with the linear encoder is incorrect.

6. The voltage of the control circuit power supply

has become unstable.

7. The servo amplifier is malfunctioning.

8. The encoder is malfunctioning.

9. There is an abnormality in the surrounding

environment.

Set the axis not used to disabled with disabling control axis switch (SW3-2/

SW3-3/SW3-4).

Check if the encoder cable is connected correctly. [A]

Check the setting value of the servo parameter.

Check if the encoder cable is disconnected or shorted. If the encoder cable is

malfunctioning, replace or repair the cable.

Check if the wiring of the A/B/Z-phase differential output linear encoder is

correct. Check that the encoder is wired to PSEL.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Check the voltage of the control circuit power supply.

When an instantaneous power failure is occurring in the control circuit power

supply, review the power supply environment.

Replace the servo amplifier.

Replace the servo motor.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[WG]

[G]

[WG]

[A]

[G]

[A]

[G]

[WG]

18

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 21

[AL. 016.5_Encoder initial communication - Transmission data error 1]

Page 18 [AL. 016.1_Encoder initial communication - Receive data error 1]

[AL. 016.6_Encoder initial communication - Transmission data error 2]

Page 18 [AL. 016.1_Encoder initial communication - Receive data error 1]

[AL. 016.7_Encoder initial communication - Transmission data error 3]

Page 18 [AL. 016.1_Encoder initial communication - Receive data error 1]

[AL. 016.A_Encoder initial communication - Process error 1]

Cause Check/action method Model

1. The servo amplifier is malfunctioning.

2. The encoder is malfunctioning.

3. There is an abnormality in the surrounding

environment.

Replace the servo amplifier. [A]

Replace the servo motor.

Check the power supply for noise. If there is noise, take countermeasures to

reduce the noise.

Check if the connector is shorted.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[G]

[WG]

[AL. 016.B_Encoder initial communication - Process error 2]

Page 19 [AL. 016.A_Encoder initial communication - Process error 1]

1

[AL. 016.C_Encoder initial communication - Process error 3]

Page 19 [AL. 016.A_Encoder initial communication - Process error 1]

[AL. 016.D_Encoder initial communication - Process error 4]

Page 19 [AL. 016.A_Encoder initial communication - Process error 1]

[AL. 016.E_Encoder initial communication - Process error 5]

Page 19 [AL. 016.A_Encoder initial communication - Process error 1]

[AL. 016.F_Encoder initial communication - Process error 6]

Page 19 [AL. 016.A_Encoder initial communication - Process error 1]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

19

Page 22

[AL. 017_Board error]

• A part in the servo amplifier is malfunctioning.

[AL. 017.1_Board error 1]

Cause Check/action method Model

1. The current detection circuit is malfunctioning.

2. There is an abnormality in the surrounding

environment.

Check that this alarm occurs in the servo-on status. If the alarm occurs, the

servo amplifier may have malfunctioned. Replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[AL. 017.3_Board error 2]

Page 20 [AL. 017.1_Board error 1]

[AL. 017.4_Board error 3]

Cause Check/action method Model

1. The recognition signal of the servo amplifier

was not read properly.

2. There is an abnormality in the surrounding

environment.

Disconnect the cables except for the control circuit power supply, and then

check the repeatability. If the failure continues, the servo amplifier may have

malfunctioned. Replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[A]

[G]

[WG]

[AL. 017.5_Board error 4]

Cause Check/action method Model

1. Rotary switches (SW1/SW2) are

malfunctioning.

2. There is an abnormality in the surrounding

environment.

After checking the conditions of the rotary switches, cycle the power, and then

check the repeatability. If the failure continues, the servo amplifier may have

malfunctioned. Replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[G]

[WG]

[AL. 017.6_Board error 5]

Cause Check/action method Model

1. The DIP switch (SW3) is malfunctioning.

2. There is an abnormality in the surrounding

environment.

After checking the conditions of the DIP switch, cycle the power, and then

check the repeatability. If the failure continues, the servo amplifier may have

malfunctioned. Replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause. If there is noise, take countermeasures to

reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[G]

[WG]

[AL. 017.7_Board error 7]

Page 20 [AL. 017.4_Board error 3]

20

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 23

[AL. 017.9_Board error 8]

Cause Check/action method Model

1. There is an abnormality in the surrounding

environment.

2. The servo amplifier is malfunctioning.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

Replace the servo amplifier.

[G]

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

21

Page 24

[AL. 019_Memory error 3]

• The internal parts of the servo amplifier (Flash-ROM) have malfunctioned.

[AL. 019.1_Flash-ROM error 1]

Cause Check/action method Model

1. The Flash-ROM is malfunctioning.

2. There is an abnormality in the surrounding

environment.

[AL. 019.2_Flash-ROM error 2]

Page 22 [AL. 019.1_Flash-ROM error 1]

[AL. 019.3_Flash-ROM error 3]

Page 22 [AL. 019.1_Flash-ROM error 1]

[AL. 019.6_Flash-ROM error 6]

Page 22 [AL. 019.1_Flash-ROM error 1]

Noise from the power supply may have caused the failure. Disconnect the

cables except for the control circuit power supply, and then check the

repeatability. If the failure continues, replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

22

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 25

[AL. 01A_Servo motor combination error]

• The combination of the servo amplifier and servo motor is incorrect.

• The combination of the servo amplifier and servo motor constant file is incorrect.

[AL. 01A.1_Servo motor combination error 1]

Cause Check/action method Model

1. The servo amplifier and the servo motor have

been connected incorrectly.

2. [Pr. PA17 Servo motor series setting] and [Pr.

PA18 Servo motor type setting] were not set

based on the servo motor to be used.

3. The encoder is malfunctioning.

Refer to "Specifications" in the following manual.

MR-J5-A User's Manual (Introduction)

MR-J5-G/MR-J5W-G User's Manual (Introduction)

Check if [Pr. PA17] and [Pr. PA18] are set correctly.

Replace the servo motor.

[A]

[G]

[WG]

[AL. 01A.2_Servo motor control mode combination error]

Cause Check/action method Model

1. The combination of the servo amplifier to be

used and the setting of [Pr. PA01.1 Operation

mode selection] is not appropriate.

Check the [Pr. PA01.1] setting. [A]

[G]

[WG]

[AL. 01A.5_Servo motor combination error 3]

1

Cause Check/action method Model

1. A servo motor, other than the one that was

connected at the startup of the absolute

position detection system, is connected.

2. At occurrence of [AL. 025 Absolute position

erased], the power was supplied after shutting

off without leaving the servo motor for 5 s.

3. The servo motor was replaced.

4. The servo amplifier is malfunctioning.

5. The encoder is malfunctioning.

6. Something near the device caused it.

Check if a servo motor other than the one that was connected at the startup of

the absolute position detection system is connected. If connected, re-connect

to the servo motor that was connected at the startup of the absolute position

detection system.

After changing the setting value of [Pr. PA03.1 Servo motor replacement

preparation] to "1" (enabled), cycle the power and then deactivate [AL. 01A

Servo motor combination error]. Perform homing again.

After changing the setting value of [Pr. PA03.1] to "1" (enabled), cycle the

power and then deactivate [AL. 01A]. Perform homing again.

Replace the servo amplifier.

Replace the servo motor.

Take countermeasures against its cause.

[A]

[G]

[WG]

[AL. 01A.6_Servo motor combination error 4]

Cause Check/action method Model

1. A scale measurement encoder, other than the

one that was connected at the startup of the

absolute position detection system, is

connected.

2. The servo amplifier is malfunctioning.

3. The scale measurement encoder is

malfunctioning.

4. Something near the device caused it.

Connect the scale measurement encoder that was connected at the startup of

the absolute position detection system.

Replace the servo amplifier.

Replace the scale measurement encoder.

Take countermeasures against its cause.

[A]

[G]

[WG]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

23

Page 26

[AL. 01E_Encoder initial communication error 2]

• The encoder is malfunctioning.

[AL. 01E.1_Encoder malfunction]

Cause Check/action method Model

1. The encoder is malfunctioning.

2. There is an abnormality in the surrounding

environment.

Replace the servo motor. [A]

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[G]

[WG]

24

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 27

[AL. 01F_Encoder initial communication error 3]

• The connected encoder is not compatible with the servo amplifier.

[AL. 01F.1_Incompatible encoder]

Cause Check/action method Model

1. Incompatible servo motor or linear encoder

was connected to the servo amplifier.

2. The software version of the servo amplifier

does not support the servo motor or linear

encoder.

3. The encoder is malfunctioning.

Refer to "Specifications" in the following manual.

MR-J5-A User's Manual (Introduction)

MR-J5-G/MR-J5W-G User's Manual (Introduction)

Refer to "Corresponding linear encoder list" in the following manual.

MR-J5 Partner's Encoder User's Manual

Refer to "Corresponding linear encoder list" in the following manual.

MR-J5 Partner's Encoder User's Manual

Replace the servo motor.

[A]

[G]

[WG]

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

25

Page 28

[AL. 020_Encoder normal communication error 1]

• An error has occurred in the communication between an encoder and servo amplifier.

[AL. 020.1_Encoder normal communication - Receive data error 1]

Cause Check/action method Model

1. There is an error in the encoder cable.

2. The external conductor of the encoder cable is

not connected to the ground plate of the

connector.

3. The servo parameter setting of communication

method is incorrect.

[A]: [Pr. PC22.3 Encoder cable communication method selection]

[G] [WG]: [Pr. PC04.3 Encoder cable communication method

selection]

4. The servo amplifier is malfunctioning.

5. The encoder is malfunctioning.

6. There is an abnormality in the surrounding

environment.

Check if the encoder cable is disconnected or shorted.

If there is a malfunction, repair or replace the cable.

When an A/B/Z-phase differential output linear encoder is used, check if the

linear encoder is wired correctly.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Check if the external conductor of the encoder cable is connected to the

ground plate of the connector.

Refer to "Ground plate connection" in the following manual.

Rotary Servo Motor User's Manual (HK series)

Refer to "Parameter detail list" in the following manual.

MR-J5-A User's Manual (Parameters)

MR-J5-G/MR-J5W-G User's Manual (Parameters)

Replace the servo amplifier.

Replace the servo motor.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[AL. 020.2_Encoder normal communication - Receive data error 2]

Page 26 [AL. 020.1_Encoder normal communication - Receive data error 1]

[AL. 020.3_Encoder normal communication - Receive data error 3]

Page 26 [AL. 020.1_Encoder normal communication - Receive data error 1]

[AL. 020.5_Encoder normal communication - Transmission data error 1]

Cause Check/action method Model

1. When an A/B/Z-phase differential output linear

encoder is used, the wiring of the linear

encoder has an error.

2. There is an error in the encoder cable.

3. The external conductor of the encoder cable is

Check if the A/B-phase pulse signals (PA, PAR, PB, and PBR) of the encoder

cable are disconnected or shorted.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Page 26 [AL. 020.1_Encoder normal communication - Receive data error

1]

[A]

[G]

[WG]

not connected to the ground plate of the

connector.

4. When an A/B/Z-phase differential output linear

encoder is used, the servo parameter setting

is incorrect.

5. The servo amplifier is malfunctioning.

6. The encoder is malfunctioning.

7. There is an abnormality in the surrounding

environment.

26

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 29

[AL. 020.6_Encoder normal communication - Transmission data error 2]

Cause Check/action method Model

1. When an A/B/Z-phase differential output linear

encoder is used, the wiring of the linear

encoder has an error.

2. There is an error in the encoder cable.

3. The external conductor of the encoder cable is

not connected to the ground plate of the

connector.

Check if the Z-phase pulse signals (PZ and PZR) of the encoder cable are

disconnected or shorted.

Refer to "A/B/Z-phase differential output linear encode" in the following

manual.

MR-J5 Partner's Encoder User's Manual

Page 26 [AL. 020.1_Encoder normal communication - Receive data error 1][A]

[A]

[G]

[G]

[WG]

4. When an A/B/Z-phase differential output linear

encoder is used, the servo parameter setting

is incorrect.

5. The servo amplifier is malfunctioning.

6. The encoder is malfunctioning.

7. There is an abnormality in the surrounding

environment.

[AL. 020.7_Encoder normal communication - Transmission data error 3]

Page 26 [AL. 020.1_Encoder normal communication - Receive data error 1]

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

27

Page 30

[AL. 021_Encoder normal communication error 2]

• The encoder detected an error signal.

[AL. 021.1_Encoder data error 1]

Cause Check/action method Model

1. An excessive speed or acceleration was

detected due to an oscillation or other factors.

2. The external conductor of the encoder cable is

not connected to the ground plate of the

connector.

3. The encoder is malfunctioning.

4. There is an abnormality in the surrounding

environment.

Decrease the control gain, and then check the repeatability. If the error does

not repeat, use the encoder with a lower gain.

Check if the external conductor of the encoder cable is connected to the

ground plate of the connector.

Refer to "Ground plate connection" in the following manual.

Rotary Servo Motor User's Manual (HK series)

Replace the servo motor.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[AL. 021.2_Encoder data update error]

Cause Check/action method Model

1. The encoder is malfunctioning.

2. The external conductor of the encoder cable is

not connected to the ground plate of the

connector.

3. There is an abnormality in the surrounding

environment.

Replace the servo motor. [A]

Check if the external conductor of the encoder cable is connected to the

ground plate of the connector.

Refer to "Ground plate connection" in the following manual.

Rotary Servo Motor User's Manual (HK series)

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[G]

[WG]

[AL. 021.3_Encoder data waveform error]

Page 28 [AL. 021.2_Encoder data update error]

[AL. 021.4_Encoder non-signal error]

Cause Check/action method Model

1. A signal of the encoder has not been input.

2. The external conductor of the encoder cable is

not connected to the ground plate of the

connector.

3. There is an abnormality in the surrounding

environment.

Check if the encoder cable is wired correctly. [A]

Check if the external conductor of the encoder cable is connected to the

ground plate of the connector.

Refer to "Ground plate connection" in the following manual.

Rotary Servo Motor User's Manual (HK series)

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause.

If there is noise, take countermeasures to reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[G]

[WG]

[AL. 021.5_Encoder hardware error 1]

Page 28 [AL. 021.2_Encoder data update error]

[AL. 021.6_Encoder hardware error 2]

Page 28 [AL. 021.2_Encoder data update error]

28

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 31

[AL. 024_Main circuit error]

• A ground fault occurred on the servo motor power lines.

• A ground fault occurred on the servo motor.

[AL. 024.1_Ground fault detected at hardware detection circuit]

Cause Check/action method Model

1. A ground fault or short occurred in the servo

motor power cable.

2. A ground fault occurred on the servo motor.

3. The main circuit power supply cable and servo

motor power cable have been shorted.

4. The servo amplifier is malfunctioning.

5. There is an abnormality in the surrounding

environment.

Check if the servo motor power cable has been shorted. If short occurs,

replace the servo motor power cable.

After disconnecting the servo motor power cables on the servo motor side,

check the insulation between phases (U, V, W, and ). If short occurs,

replace the servo motor.

After shutting off the power, make sure that the main circuit power cable and

the motor power cable are not in contact with each other. If the cables are

contacting, correct the wiring.

Check that this alarm occurs as the servo motor power cables (U / V / W) are

disconnected. If the alarm occurs, replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause. If there is noise, take countermeasures to

reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

[AL. 024.2_Ground fault detected by software detection function]

Cause Check/action method Model

1. A ground fault or short occurred in the servo

motor power cable.

2. A ground fault occurred on the servo motor.

3. The main circuit power supply cable and servo

motor power cable have been shorted.

4. The servo amplifier is malfunctioning.

5. There is an abnormality in the surrounding

environment.

Check if the servo motor power cable has been shorted. If short occurs,

replace the servo motor power cable.

After disconnecting the servo motor power cables on the servo motor side,

check the insulation between phases (U, V, W, and ). If short occurs,

replace the servo motor.

After shutting off the power, make sure that the main circuit power cable and

the motor power cable are not in contact with each other. If the cables are

contacting, correct the wiring.

Check that this alarm occurs as the servo motor power cables (U / V / W) are

disconnected. If the alarm occurs, replace the servo amplifier.

Check the noise, ambient temperature, and others, and implement appropriate

countermeasures for the cause. If there is noise, take countermeasures to

reduce the noise.

Refer to "Noise reduction techniques" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

1

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

29

Page 32

[AL. 025_Absolute position erased]

• The absolute position data have errors.

• Power was switched on for the first time in the absolute position detection system.

[AL. 025.1_Servo motor encoder - Absolute position erased]

Cause Check/action method Model

1. Power was switched on for the first time in the

absolute position detection system.

2. The servo motor, which is different from servo

motor that had been connected on the battery-

less absolute position encoder loaded servo

motor that has been connected on startup of

the absolute position detection system, was

incorrectly connected.

3. After the control circuit power supply was shut

off, the battery was removed in either of the

following situations:

• When using an MR-BAT6V1SET(-A) battery or MR-BT6VCASE

battery case, CN4 of the servo amplifier was disconnected with

the control circuit power supply off.

4. The power was shut off in either of the

following situations:

• When using an MR-BAT6V1SET(-A) battery or MR-BT6VCASE,

the power was shut off with the battery disconnected from CN4.

5. The battery voltage is low. The battery is

exhausted.

6. The voltage dropped considerably in the

encoder cable wired to the battery.

7. A battery cable is malfunctioning.

8. There is a loose connection of the encoder

cable on the servo motor side.

9. When using direct drive motor, the absolute

position storage unit is not connected.

10. The servo amplifier is malfunctioning.

11. The encoder is malfunctioning.

When the power was switched on for the first time after the absolute position

detection system is set, check that the battery is mounted correctly before

homing.

When a servo motor with a batteryless absolute position encoder is used, wait

for 5 s in the alarm occurrence, and then cycle the power. Perform homing.

Connect the servo motor that was connected at the startup of the absolute

position detection system. Start up the absolute position detection system

again.

If the battery was disconnected as described in the left column, check that the

battery is mounted correctly before homing.

If the power supply was shut off as described in the left column, check that the

battery is mounted correctly before homing.

If the power supply was not shut off as described in the left column, check if

the following cases apply:

When MR-BAT6V1SET(-A) or MR-BT6VCASE is used, see 6.

Check the battery voltage with a tester. If the voltage is lower than 3 V DC,

replace the battery.

Check if recommended cable is used for the encoder cable.

Refer to "Optional power cable" in the following manual.

Rotary Servo Motor User's Manual (HK series)

Check for a loose connection with a tester.

If there is a loose connection, use a recommended cable.

Check for a loose connection with a tester. Measure the voltage on the servo

motor side.

If there is a loose connection, repair or replace the encoder cable.

Refer to "Encoder cable combination" in the following manual.

MR-J5 Direct Drive Motor User's Manual

Replace the servo amplifier.

Replace the servo motor.

[A]

[G]

[WG]

30

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

Page 33

[AL. 027_Initial magnetic pole detection error]

• The initial magnetic pole detection cannot be performed properly.

[AL. 027.1_Initial magnetic pole detection - Abnormal termination]

Cause Check/action method Model

1. A moving part collided against the machine.

2. The wiring of the servo motor power cable is

incorrect.

3. The linear encoder resolution setting differs

from the setting value.

4. The mounting direction of the linear encoder is

incorrect.

5. An excitation level of the magnetic pole

detection voltage level is small.

If the moving part collides, move the start position of the magnetic pole

detection.

Check the motor power cable for abnormality.

Refer to "Power cable wiring diagram" in the following manual.

MR-J5 Linear Servo Motor User's Manual

Refer to "Direct drive motor power cable wiring diagram" in the following

manual.

MR-J5 Direct Drive Motor User's Manual

Check the setting of [Pr. PL02 Linear encoder resolution setting - Numerator]

and [Pr. PL03 Linear encoder resolution setting - Denominator].

Check the polarities of the linear encoder and the linear servo motor.

If the mounting direction is incorrect, mount the encoder correctly. Change the

setting of "Encoder pulse count polarity selection" as required.

[A]: [Pr. PC45.0 Encoder pulse count polarity selection]

MR-J5-A User's Manual (Parameters)

[G] [WG]: [Pr. PC27.0 Encoder pulse count polarity selection]

MR-J5-G/MR-J5W-G User's Manual (Parameters)

Refer to "Setting of linear encoder direction and linear servo motor direction" in

the following manual.

MR-J5 User's Manual (Hardware)

• When in position detection method

Check if the travel distance in the magnetic pole detection is small. If the travel

distance is small, set a larger value in [Pr. PL09 Magnetic pole detection Voltage level].

• When in minute position detection method

Check if the travel distance in the magnetic pole detection is large, or if a

vibration is occurring. If the travel distance is large or a vibration is occurring,

refer to the magnetic pole detection method, and review the setting of [Pr.

PL17.0 Response selection] and [Pr. PL17.1 Load to motor mass ratio/load to

motor inertia ratio selection].

Refer to "Magnetic pole detection" in the following manual.

MR-J5 User's Manual (Hardware)

[A]

[G]

[WG]

1

[AL. 027.2_Initial magnetic pole detection - Time out error]

Cause Check/action method Model

1. Servo-on was enabled when the primary side

of linear servo motor and rotor of direct drive

motor was not stopped.

2. Only one of the limit switches is on during

magnetic pole detection.

In the magnetic pole detection, only one of the

limit switches is turned off.

3. The excitation level in the magnetic pole

detection is small.

Stop the linear servo motor and the direct drive motor, and then turn the servoon again.

Check the limit switches and remove the cause.

Move the start position of the magnetic pole detection.

• When in position detection method

Check if the travel distance in the magnetic pole detection is small. If the travel

distance is small, set a larger value in [Pr. PL09 Magnetic pole detection Voltage level].

[A]

[G]

[WG]

1 SERVO AMPLIFIER TROUBLESHOOTING

1.3 Handling methods for alarms/warnings

31

Page 34

[AL. 027.3_Initial magnetic pole detection - Limit switch error]

Cause Check/action method Model

1. In the magnetic pole detection, both limit

switches are turned off.

2. When using a direct drive motor in a system

where the motor rotates one revolution or

more, the following stroke limit signals are not

disabled with a servo parameter.