Mitsubishi MELSEC-L02CPU-P, MELSEC-L06CPU-P, MELSEC-L06CPU, MELSEC-L02CPU, MELSEC-L02SCPU-P User Manual

...Page 1

MELSEC-L CPU Module User's Manual

(Built-In I/O Function)

-L02SCPU

-L02SCPU-P

-L02CPU

-L02CPU-P

-L06CPU

-L06CPU-P

-L26CPU

-L26CPU-P

-L26CPU-BT

-L26CPU-PBT

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) Machine OPR (Original Point Return) of the positioning function is controlled by two kinds of data:

an OPR direction and an OPR speed. Deceleration starts when the near-point dog signal turns on.

If an incorrect OPR direction is set, motion control may continue without deceleration. To prevent

machine damage caused by this, configure an interlock circuit external to the programmable

controller.

(3) When the CPU module detects an error during control by the positioning function, the motion

slows down and stops.

(4) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(5) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC-L CPU Module User's Manual

(Hardware Design, Maintenance and Inspection).

(6) Outputs may remain on or off due to a failure of a component such as a transistor in an output

circuit. Configure an external circuit for monitoring output signals that could cause a serious

accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● For the operating status of each station after a communication failure, refer to relevant manuals for

each network. Incorrect output or malfunction due to a communication failure may result in an

accident.

2

Page 5

[Design Precautions]

WARNING

● When changing data from a peripheral device connected to the CPU module during operation,

configure an interlock circuit in the program to ensure that the entire system will always operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding. Especially, when a remote programmable controller is controlled by an external

device, immediate action cannot be taken if a problem occurs in the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit in the program, and determine

corrective actions to be taken between the external device and CPU module in case of a

communication failure.

● An absolute position restoration by the positioning function may turn off the servo-on signal (servo off)

for approximately 20ms, and the motor may run unexpectedly. If this causes a problem, provide an

electromagnetic brake to lock the motor during absolute position restoration.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

3

Page 6

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection). Failure to

do so may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Do not directly touch any conductive parts and electronic components of the module. Doing so can

cause malfunction or failure of the module.

● Securely connect an extension cable to the connectors of a branch module and an extension module.

After connections, check that the cable is inserted completely. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module or SD memory

card. Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG terminal of the programmable controller with a ground resistance of 100

or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when a terminal block screw comes loose,

resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause short

circuit, fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● To use the high-speed counter function, ground the shield cable on the encoder side (relay box).

Always ground the FG and LG terminals to the protective ground conductor. Failure to do so may

cause malfunction.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block.

Wiring and replacement of a power supply module must be performed by qualified maintenance

personnel with knowledge of protection against electric shock.

For wiring methods, refer to the MELSEC-L CPU Module User's Manual (Hardware Design,

Maintenance and Inspection).

5

Page 8

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock.

Doing so will cause the battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws. Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operating

status change) for the running CPU module from the peripheral device connected, read relevant

manuals carefully and ensure the safety. Improper operation may damage machines or cause

accidents.

● Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause drop

of the component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or

module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module, display unit, and terminal block), the number of

connections/disconnections is limited to 50 times (in accordance with IEC 61131-2). Exceeding the

limit may cause malfunction.

● After the first use of the SD memory card, do not insert/remove the memory card more than 500 times.

Exceeding the limit may cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation by the positioning function, set a low speed value for the speed limit

parameter so that the operation can be stopped immediately upon occurrence of a hazardous

condition.

6

Page 9

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations. (For details on battery regulations in EU

member states, refer to the MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance

and Inspection).)

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. (For details on the regulated

models, refer to the MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection).)

7

Page 10

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

8

Page 11

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-L series programmable controllers.

This manual describes the functions of the external I/O interface of the LCPU and programming.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-L series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

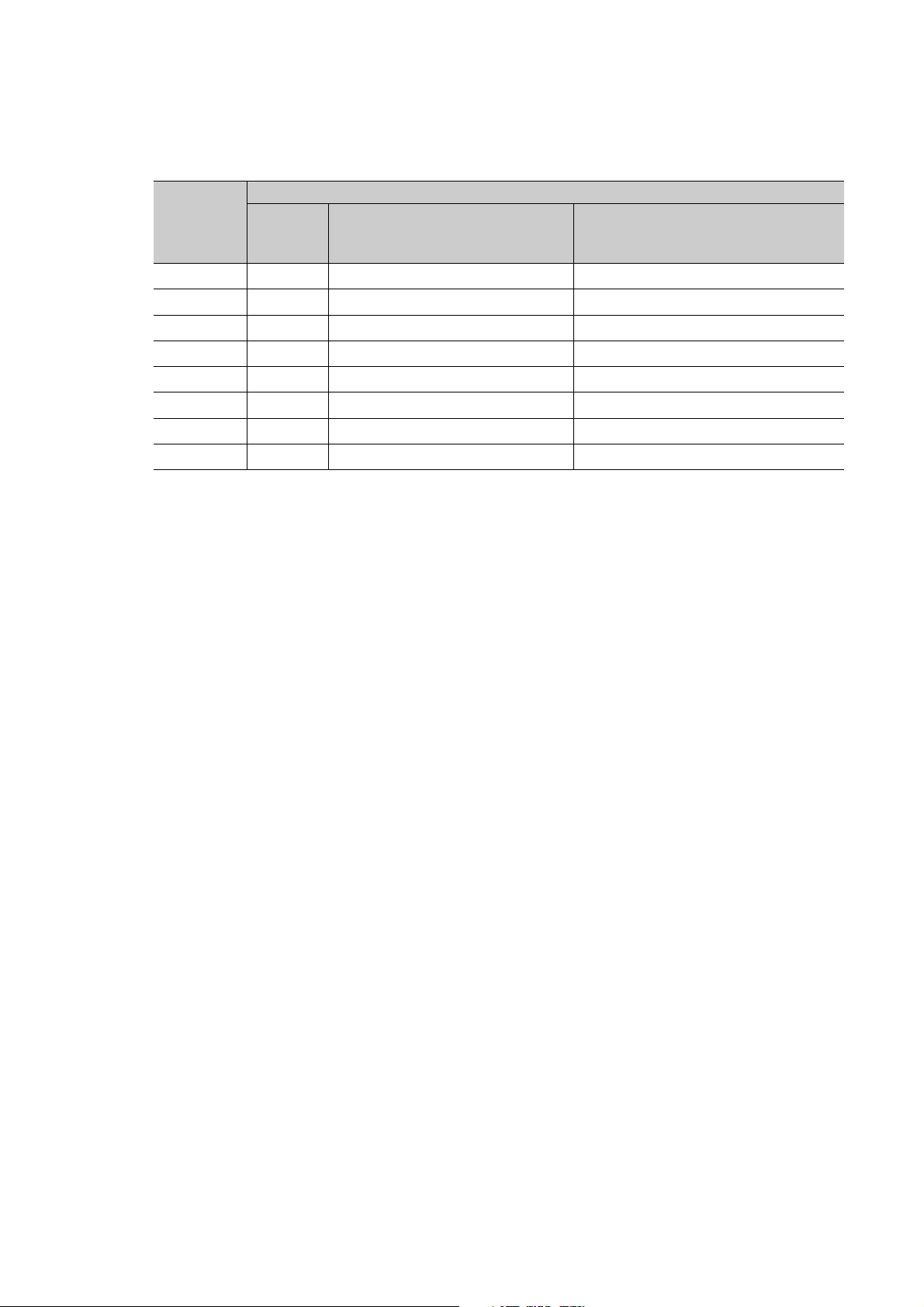

Relevant CPU modules

CPU module Model

LCPU

● This manual describes only built-in I/O functions for the CPU module. For the functions except for built-in I/O functions of

the CPU module, refer to the following.

MELSEC-L CPU Module User's Manual (Function Explanation, Program Fundamentals)

MELSEC-L CPU Module User's Manual (Built-In Ethernet Function)

QnUDVCPU/LCPU User's Manual (Data Logging Function)

● Unless otherwise specified, this manual describes examples of assigning from X0 to XF for input numbers and from Y0 to

Y7 for output numbers in each function. For I/O number assignment, refer to the following.

MELSEC-L CPU Module User's Manual (Function Explanation, Program Fundamentals)

● Unless otherwise specified, Chapter 7 POSITIONING FUNCTION in this manual is described as using examples of the

setting, special relay, special register, dedicated instruction, error code and warning code supported for Axis 1.

● Unless otherwise specified, Chapter 8 HIGH-SPEED COUNTER FUNCTION in this manual is described as using

examples of the setting, special relay, special register, dedicated instruction, error code and warning code supported for

CH1.

L02SCPU, L02SCPU-P, L02CPU, L02CPU-P, L06CPU, L06CPU-P, L26CPU, L26CPU-P,

L26CPU-BT, L26CPU-PBT

9

Page 12

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection)

<SH-080890ENG, 13JZ36>

MELSEC-L CPU Module User's Manual (Function Explanation, Program

Fundamentals)

<SH-080889ENG, 13JZ35>

MELSEC-L CPU Module User's Manual (Built-In Ethernet Function)

<SH-080891ENG, 13JZ37>

QnUDVCPU/LCPU User's Manual (Data Logging Function)

<SH-080893ENG, 13JZ39>

(2) Programming manual

Manual name

<manual number (model code)>

MELSEC-Q/L Programming Manual (Common Instruction)

<SH-080809ENG, 13JW10>

Description

Specifications of the CPU modules, power supply modules, display unit,

branch module, extension module, SD memory cards, and batteries,

information on how to establish a system, maintenance and inspection,

and troubleshooting

Functions and devices of the CPU module, and programming

The built-in Ethernet function of the CPU module

The data logging function of the CPU module

Description

Detailed description and usage of instructions used in programs

(3) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

System configuration, parameter settings, and online operations of GX

Works2, which are common to Simple projects and Structured projects

Operating methods of GX Developer, such as programming, printing,

monitoring, and debugging

(4) I/O module and intelligent function module manual

Manual name

<manual number (model code)>

MELSEC-L I/O Module User's Manual

<SH-080888ENG, 13JZ34>

Specifications and troubleshooting of the I/O module

Description

Description

10

Page 13

Memo

11

Page 14

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHAPTER 1 OVERVIEW 20

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS 22

CHAPTER 3 GENERAL-PURPOSE INPUT FUNCTION 31

CHAPTER 4 GENERAL-PURPOSE OUTPUT FUNCTION 33

CHAPTER 5 INTERRUPT INPUT FUNCTION 35

CHAPTER 6 PULSE CATCH FUNCTION 39

CHAPTER 7 POSITIONING FUNCTION 42

7.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.1.1 Procedure for performing the positioning function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.2 Connection to External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.2.1 I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

7.2.2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7.3 Parameter Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3.1 Positioning parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.5 Checking Current Position and Operation Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.6 OPR Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.6.1 Machine OPR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

7.6.2 Fast OPR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

7.6.3 Forced off of Axis 1 OPR request (SM1842) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

7.6.4 Precautions on Axis 1 OPR request (SM1842) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

7.7 Positioning Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.7.1 Start of positioning control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

7.7.2 Position control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

7.7.3 Speed/position switching control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.7.4 Current value change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

7.7.5 Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

7.8 Multiple Axes Simultaneous Start Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

7.9 JOG Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

7.10 Sub Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.10.1 OPR retry function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

7.10.2 Speed limit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12

Page 15

7.10.3 Speed change function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

7.10.4 Software stroke limit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

7.10.5 Hardware stroke limit function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

7.10.6 Target position change function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

7.10.7 Acceleration/deceleration processing function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

7.10.8 Stop processing function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

7.11 Absolute Position Restoration Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.12 Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

7.12.1 Details of dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

7.12.2 Precautions on dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

7.13 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

7.14 Errors and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

7.15 Monitoring with a Programming Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

CHAPTER 8 HIGH-SPEED COUNTER FUNCTION 179

8.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

8.1.1 Procedure for performing the high-speed counter function . . . . . . . . . . . . . . . . . . . . . . . . . .181

8.2 Connecting to External Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

8.2.1 I/O signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

8.2.2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

8.3 Parameter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

8.3.1 Common settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .193

8.4 Normal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8.4.1 Preset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .202

8.4.2 Coincidence output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .205

8.4.3 Coincidence detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

8.4.4 Counter function selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

8.5 Frequency Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

8.6 Rotation Speed Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

8.7 Pulse Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

8.8 PWM Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

8.9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

8.10 Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

8.10.1 Details of dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

8.10.2 Precautions on dedicated instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .257

8.11 Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

8.12 Errors and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

8.13 When the LCPU Stops Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

8.14 Monitoring with a Programming Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

APPENDICES 269

Appendix 1 Processing Time of Each Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Appendix 2 Connection Examples with Servo Amplifiers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix 2.1 Connection examples with servo amplifiers manufactured by Mitsubishi . . . . . . . . .271

13

Page 16

Appendix 2.2 Connection examples with stepping motors manufactured by ORIENTAL MOTOR

CO.,LTD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Appendix 2.3 Connection examples with servo amplifiers manufactured by Panasonic Corporation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .277

Appendix 2.4 Connection examples with servo amplifiers manufactured by SANYODENKI CO.,LTD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .279

Appendix 2.5 Connection examples with servo amplifiers manufactured by YASKAWA Electric

Corporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

INDEX 281

INSTRUCTION INDEX 284

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

14

Page 17

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example (for GX Works2) is provided below.

15

Page 18

Pages describing instructions are organized as shown below.

Descriptions of

setting data and data type

Instruction name

Structure of the instruction

in the ladder mode

shows the devices

applicable to the instruction

Descriptions of

control data (if any)

Execution condition of the instruction

Setting side

User

: Device value is set by the user.

System: Device value is set by

the CPU module.

C

error codes

For the errors not described in

this manual, refer to the following.

MELSEC-Q/L Programming

Manual (Common Instruction)

Simple program example(s)

and descriptions of the devices used

Detailed descriptions

of the instruction

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

onditions for the error and

16

Page 19

• Instructions can be executed under the following conditions.

Execution condition Any time During on On the rising edge During off On the falling edge

Symbol No symbol

• The following devices can be used.

Internal device

Setting

data

Applicable

*1

device

(system, user)

Bit Word Bit Word

X, Y, M, L,

S, M, F, B,

SB, FX, FY

*2

T, ST, C, D,

W, SD, SW,

FD, @

File

register

R, ZR U\G ZK, H, E, $

*1 For details on each device, refer to the following.

MELSEC-L CPU Module User's Manual (Function Explanation, Program Fundamentals)

*2 FX and FY can be used for bit data only, and FD for word data only.

*3 In the "Constant" and "Others" columns, a device(s) that can be set for each instruction is shown.

Link direct device

J\

Intelligent

function module

device

U\G

Index

register

Zn

Constant *3Others

P, I, J,

U, D, X,

DY, N,

BL, TR,

BL\S,V

• The following data types can be used.

Data type Description

Bit Bit data or the start number of bit data

BIN 16-bit 16-bit binary data or the start number of word device

BIN 32-bit 32-bit binary data or the start number of double-word device

BCD 4-digit Four-digit binary-coded decimal data

BCD 8-digit Eight-digit binary-coded decimal data

Real number Floating-point data

Character string Character string data

Device name Device name data

*3

17

Page 20

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

CPU module The abbreviation for the MELSEC-L series CPU module

Power supply module The abbreviation for the MELSEC-L series power supply module

Branch module The abbreviation for the MELSEC-L series branch module

Extension module The abbreviation for the MELSEC-L series extension module

END cover A cover to be attached to the right side of the rightmost MELSEC-L series module

Display unit A liquid crystal display to be attached to the CPU module

Extension cable The abbreviation for the MELSEC-L series extension cable

LCPU Another term for the MELSEC-L series CPU module

Programming tool A generic term for GX Works2 and GX Developer

GX Works2

GX Developer

Encoder One of the pulse generators that converts input data into binary data (on and off)

Near-point dog

Servo on

Servo motor

Stepping motor

Zero signal PG0 of a pulse generator (encoder), that is detected once in one rotation

Drive unit (servo amplifier)

Pulse generator

Warning

PWM

The product name of the software package for the MELSEC programmable controllers

A switch used in positioning systems, placed in front of the starting point of a workpiece When this switch

turns on, the feed speed is switched to creep speed. Therefore, the deceleration time is required while this

switch is on.

A signal that indicates the normal status of a servo amplifier. A servo amplifier is operable only when this

signal is on.

A motor that rotates according to a command. This motor is highly responsive, therefore frequent and rapid

start and stop are available with high precision.

DC and AC type motors are available. Feedback control is available with the included pulse generator that

detects the number of rotations.

A motor that rotates by the predetermined angle for every pulse. The number of rotations is proportional to

the number of pulses.

A small power motor is applied, and it rotates accurately without feedbacks. Do not overload the motor,

otherwise it will be out of step.

A unit used to amplify the power and control the motor in the operation by the positioning function since the

signals, such as pulses, that are output from the CPU module are low voltage and small current.

The unit, also called a servo amplifier, is provided with a servomotor and step motor.

A device that generates pulses. For example, by attaching this device on a motor axis, pulses can be

generated by the rotation of the axis.

Different from an error, a warning is a minor error that does not terminate or stop the operation even if it is

detected.

The abbreviation for pulse-width modulation, a method of changing a ratio of on width to off width of a pulse

wave

18

Page 21

Memo

19

Page 22

CHAPTER 1 OVERVIEW

The LCPU supports the following built-in I/O functions. The built-in I/O functions allow constructing a small-scale

system using the LCPU alone because dedicated modules for these functions are not required. Therefore, the system

cost can be reduced.

• General-purpose input function

• General-purpose output function

• Interrupt input function

• Pulse catch function

• Positioning function

• High-speed counter function

General-purpose input function, interrupt input function, and

pulse catch function

General-purpose

output function

Positioning function

High-speed counter

function

20

Page 23

CHAPTER 1 OVERVIEW

(1) Number of points used for each function

X0 to XF and Y0 to Y7 are sorted for each function.

Function Available range

General-purpose input

function

General-purpose output

function

Interrupt input function 0 to 16 points (input signal) 0 to 16 points

Pulse catch function 0 to 16 points (input signal) 0 to 16 points

High-speed counter

*1

function

Positioning function

0 to 16 points (input signal) 0 to 16 points

0 to 8 points (output signal) 0 to 8 points

0 to 2CH

• Input signal: 0 to 5 points (points/channel) (depending on

settings)

• Output Signal: 0 to 2 points (points/channel) (depending on

settings)

0 to 2 axes

• Input signal: 0 to 6 points (points/axis) (depending on

*1

settings)

• Output signal: 2 to 3 points (points/axis) (depending on

settings)

• When using only one

channel: 0 to 5 points

• When using two channels

simultaneously: 0 to 10 points

• When using only one axis: 0

to 6 points

• When using two axes

simultaneously: 0 to 12 points

Input Output

*1 Assignment of some signals used for the high-speed counter function and positioning function (such as A phase, B

phase, and near-point dog) are fixed. When using these functions, no signal can be assigned in place of the signals.

Number of points

• When using only one

channel: 0 to 2 points

• When using two channels

simultaneously: 0 to 4 points

• When using only one axis: 2

to 3 points

• When using two axes

simultaneously: 4 to 6 points

1

21

Page 24

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS

60

4

01020304050

10

16

55

14

6

12

8

Ambient temperature ( )

Input voltage:

24VDC

Input voltage: 28.8VDC

(16 points, 55 )

(8 points, 55 )

(16 points, 45 )

2

0

Input voltage:

26.4VDC

Simultaneous on points (point)

This chapter describes internal circuits, pin numbers and corresponding signal names, and specifications of external

I/O interface. For connectors used for external wiring, refer to MELSEC-L CPU Module User's Manual (Hardware

Design, Maintenance and Inspection).

(1) Input specifications

Item Specifications

Signal name

Rated input voltage

Rated input current 6.0mA (TYP.) (at 24VDC) 4.1mA (TYP.) (at 24VDC)

ON voltage/ON current 19.0V or higher/5.0mA or higher 19.0V or higher/3.5mA or higher

OFF voltage/OFF current 8V or lower/1.5mA or lower 8V or lower/1.0mA or lower

Input resistance 3.8k 5.6k

Off On

Response time

Withstand voltage 510VAC for 1 minute between input terminal and internal power supply (altitude: 0 to 2000m)

Insulation resistance 10M or higher between input terminals and internal power supply (500VDC insulation resistance tester)

Wiring method for common Independent common 10 points/common

On Off

24VDC (+20%/-15%, ripple ratio

Depending on the setting value of the input response time setting

24V input Differential input 24V input

within 5%)

High-speed input (IN0 to IN5) Standard input (IN6 to INF)

24VDC (+20%/-15%, ripple ratio

(0.01ms

EIA Standard RS-422-A

Differential line driver level

(AM26LS31 (Manufactured by

Texas Instruments Incorporated)

or equivalent)

*2

/0.1ms/0.2ms/0.4ms/0.6ms/1ms)

Depending on the setting value of

the input response time setting

(0.1ms*1/1ms/5ms/10ms/20ms/70

within 5%)

ms)

*1 The response time at turning on off of input devices can take 0.2ms even if the input response time is set to "0.1ms".

*2 The response time can take 0.02ms even if the input response time is set to "0.01ms".

The following shows a temperature derating curve for the input signal.

22

Page 25

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B09

B08

B07

B06

B05

B04

B03

B02

B01

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A09

A08

A07

A06

A05

A04

A03

A02

A01

(2) Output specifications

Item Specifications

Signal name Output (OUT0 to OUT7)

Rated load voltage 5 to 24VDC

Maximum load current 0.1A/point

Maximum voltage drop at ON 0.2V (TYP.)

Leakage current at OFF 0.1mA or lower

Response time

On 1s or less (rated load, resistive load)

Off 1s or less (rated load, resistive load)

Withstand voltage 510VAC for 1 minute between output terminal and internal power supply (altitude: 0 to 2000m)

Insulation resistance

Wiring method for common

10M or higher between output terminals and internal power supply (500VDC insulation resistance

tester)

L02SCPU, L02CPU, L06CPU, L26CPU, L26CPU-BT: 8 points/common (sink type)

L02SCPU-P, L02CPU-P, L06CPU-P, L26CPU-P, L26CPU-PBT: 8 points/common (source type)

(3) Signal assignment of the connector for external devices

2

Viewed from the front of the module

23

Page 26

(4) Internal circuits

(a) L02SCPU, L02CPU, L06CPU, L26CPU, L26CPU-BT

Classification

Input

Output

External wiring

Fuse

24VDC

24VDC

24VDC

24VDC

Load

Load

Load

Load

5 to 24VDC

Pin number Internal circuit

A20

*1

B20

B19 A19

3.6k

1/2W

680

1/10W

220

B18 A18

B17 A17

3.6k

1/2W

B16 A16

*1

680

1/10W

220

B15 A15

*1

B14 A14

B13 A13

3.6k

1/2W

680

1/10W

220

B12 A12

B11 A11

B10 A10

5.6k

1/3W

B09 A09

B08 A08

B07 A07

B06 A06

5.6k

1/3W

5.6k

1/3W

5.6k

1/3W

5.6k

1/3W

B05 A05

B04 A04

B03 A03

B02 A02

B01 A01

1k

1/10W

1k

1/10W

1k

1/10W

1k

1/10W

1k

1/10W

Insulating

element

Insulating

element

Insulating

element

Insulating

element

Signal name

B line

High-speed 24V

input (IN0-24V)

High-speed

differential

input (IN0-DIFF)

High-speed

input common

(IN0-COM)

High-speed 24V

input (IN1-24V)

High-speed

differential

input (N1-DIFF)

High-speed

input common

(IN1-COM)

High-speed 24V

input (IN4-24V)

High-speed

differential

input (IN4-DIFF)

High-speed

input common

(IN4-COM)

High-speed 24V

input (IN2-24V)

High-speed

differential

input (IN2-DIFF)

High-speed

input common

(IN2-COM)

High-speed 24V

input (IN3-24V)

High-speed

differential

input (IN3-DIFF)

High-speed

input common

(IN3-COM)

High-speed 24V

input (IN5-24V)

High-speed

differential

input (IN5-DIFF)

High-speed

input common

(IN5-COM)

Standard input common

(INCOM)

Standard input

Standard input

(IN6)

Standard input

Standard input

(IN8)

Standard input

Standard input

(INA)

Standard input

Standard input

(INC)

Standard input

Standard input

(INE)

Output (OUT0)

Output (OUT2)

Output (OUT4)

Output (OUT6)

Output (OUT1)

Output (OUT3)

Output (OUT5)

Output (OUT7)

Output common (OUTCOM)

*2

A line

(IN7)

(IN9)

(INB)

(IND)

(INF)

24

*1 High-speed inputs can be connected based on the 24V input mode or differential input mode.

*2 For signal names when using the positioning function or high-speed counter function, refer to the following.

• Positioning function: Page 51, Section 7.2.1

• High-speed counter function: Page 182, Section 8.2.1

Page 27

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS

Classification

B line

A line

Input

B20

A20

B19 A19

B18 A18

B17 A17

B16 A16

B15 A15

B14 A14

B13 A13

B12 A12

B11 A11

B10 A10

B09 A09

B08 A08

B07 A07

B06 A06

Output

B05 A05

B04 A04

B03 A03

B02 A02

B01 A01

3.6k

1/2W

680

1/10W

220

3.6k

1/2W

680

1/10W

220

3.6k

1/2W

680

1/10W

220

5.6k

1/3W

5.6k

1/3W

5.6k

1/3W

5.6k

1/3W

5.6k

1/3W

1k

1/10W

1k

1/10W

1k

1/10W

1k

1/10W

1k

1/10W

Insulating

element

Insulating

element

Insulating

element

Insulating

element

Pin number Internal circuit

Signal name

*2

Load

Load

Load

Load

5 to 24VDC

Fuse

External wiring

*1

*1

*1

24VDC

24VDC

24VDC

24VDC

High-speed

24V input

(IN0-24V)

High-speed

24V input

(IN2-24V)

High-speed

differential input

(IN0-DIFF)

High-speed

differential input

(IN2-DIFF)

High-speed

input common

(IN0-COM)

High-speed

input common

(IN2-COM)

High-speed

24V input

(IN1-24V)

High-speed

24V input

(IN3-24V)

High-speed

differential input

(IN1-DIFF)

High-speed

differential input

(IN3-DIFF)

High-speed

input common

(IN1-COM)

High-speed

input common

(IN3-COM)

High-speed

24V input

(IN4-24V)

High-speed

24V input

(IN5-24V)

High-speed

differential input

(IN4-DIFF)

High-speed

differential input

(IN5-DIFF)

High-speed

input common

(IN4-COM)

High-speed

input common

(IN5-COM)

Standard input common

(INCOM)

Standard input

(IN6)

Standard input

(IN8)

Standard input

(INA)

Standard input

(INC)

Standard input

(INE)

Standard input

(IN7)

Standard input

(IN9)

Standard input

(INB)

Standard input

(IND)

Standard input

(INF)

Output

(OUT0)

Output

(OUT2)

Output

(OUT4)

Output

(OUT6)

Output

(OUT1)

Output

(OUT3)

Output

(OUT5)

Output

(OUT7)

Output common

(OUT24V)

(b) L02SCPU-P, L02CPU-P, L06CPU-P, L26CPU-P, L26CPU-PBT

2

*1 High-speed inputs can be connected based on the 24V input mode or differential input mode.

*2 For signal names when using the positioning function or high-speed counter function, refer to the following.

• Positioning function: Page 51, Section 7.2.1

• High-speed counter function: Page 182, Section 8.2.1

25

Page 28

(5) I/O connector pin numbers and corresponding I/O signals

Pin

number

B20

B18 A18

B17

B15 A15

B14

B12 A12

B11 Input common A11 Input common

B10 Standard X6 A10 Standard X7

B09 Standard X8 A09 Standard X9

B08 Standard XA A08 Standard XB

B07 Standard XC A07 Standard XD

B06 Standard XE A06 Standard XF

B05

B04

B03

B02

B01

Cate-

gory

Input

Output

Typ e

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

Correspondence

for line driver

X0

X1

X4

Y0 A05

Y2 A04

Y4 A03

Y6 A02

O

utput common

Corresponding

I/O signal

*1

Pin

number

A20

A17

A14

A01

Cate-

gory

Input

Output

Typ e

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

High-

speed

Correspondence

for line driver

X2B19 A19

X3B16 A16

X5B13 A13

Y1

Y3

Y5

Y7

Output common

Corresponding

*1

I/O signal

*1 B01 and A01 are used as negative common on the L02SCPU, L02CPU, L06CPU, L26CPU, and L26CPU-BT, while they

are used as positive common on the L02SCPU-P, L02CPU-P, L06CPU-P, L26CPU-P, and L26CPU-PBT.

26

Page 29

(6) Input signal assignment

External

input

signal

X0 (High-

speed)

X1 (High-

speed)

X2 (High-

speed)

X3 (High-

speed)

X4 (High-

speed)

X5 (High-

speed)

X6

(Standard)

X7

(Standard)

X8

(Standard)

X9

(Standard)

XA

(Standard)

XB

(Standard)

XC

(Standard)

XD

(Standard)

XE

(Standard)

XF

(Standard)

Generalpurpose

input

Interrupt

input

*1

*1

*1

*1

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS

: Selectable, : No combination

Function

Pulse catch High-speed counter Positioning

Counter CH1 A Phase

Counter CH1 B Phase

Counter CH2 A Phase

Counter CH2 B Phase

Counter CH1 Z Phase

Counter CH2 Z Phase

Counter CH1 Function Input

Counter CH2 Function Input

Counter CH1 Latch Counter

Counter CH2 Latch Counter

*3

*3

*3

*3

*3

*3

*1

*1

*1

*1

*2

*2

*2

*2

*2

*2

Axis #1 Zero Signal

Axis #2 Zero Signal

Axis #1 External Command Signal

Axis #2 External Command Signal

Axis #1 Drive Module READY Signal

Axis #2 Drive Module READY Signal

Axis #1 Near-point Dog Signal

Axis #2 Near-point Dog Signal

Axis #1 Upper Limit Signal

Axis #2 Upper Limit Signal

Axis #1 Lower Limit Signal

Axis #2 Lower Limit Signal

*3

*3

*3

*3

2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*2

*1 When using CH1 for the high-speed counter function, X0 and X1 cannot be used as interrupt inputs. Also, when using

CH2 for the high-speed counter function, X2 and X3 cannot be used as interrupt inputs. Other functions such as the

general-purpose input can be used.

*2 When this signal is not used, the input signal can be used for other functions such as the general-purpose input.

*3 When the high-speed counter function or positioning function is selected, this signal is not used for that function. This

signal can be used for another function such as the general-purpose input function.

27

Page 30

(7) Output signal assignment

: Selectable, : No combination

Function

External

output signal

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

*1 This signal must be used depending on parameter settings. When this signal is not used, the output signal can be used

for the general-purpose output function.

*2 When this signal is not used, the output signal can be used for the general-purpose output function.

*3 When the high-speed counter function or positioning function is selected, this signal is not used for that function. This

signal can be used for the general-purpose output function.

Generalpurpose

output

High-speed counter Positioning

CH1 Coincidence Output No.1

CH2 Coincidence Output No.1

CH1 Coincidence Output No.2

CH2 Coincidence Output No.2

*3

*3

*3

*3

*1

*1

*2

*2

Axis #1 Deviation Counter Clear

Axis #2 Deviation Counter Clear

Axis #1 CW/PULSE/A Phase Output

Axis #2 CW/PULSE/A Phase Output

Axis #1 CCW/SIGN/B Phase Output

Axis #2 CCW/SIGN/B Phase Output

*3

*3

*1

*1

*1

*1

*1

*1

28

Page 31

CHAPTER 2 EXTERNAL I/O SPECIFICATIONS

Remark

Remark

(8) Simplified chart of I/O signals

The following shows a simplified chart of I/O signals for the high-speed counter function and positioning function.

High-speed counter Positioning

CH1 CH2 Axis #1 Axis #2

X5

X7

X9

XB

XD

XF

Y3

Y5

Y7

X0

X1

X4

X6

X8

Y0

Y2

X2

X3

X5

X7

X9

Y1

Y3

X4

X6

X8

XA

XC

XE

Y2

Y4

Y6

(9) External input signals (X0 to XF) when using the functions

The on/off status of the external input signals (X0 to XF) are reflected to the input device (X0 to XF) in the

program when any built-in I/O functions (except the pulse catch function) is used. When the pulse catch function

is used, the input device turns on for one scan by detecting the rising edge of the external input signal ( Page

39, CHAPTER 6). When selecting positioning function or high-speed counter function, an input signal that is not

used due to settings of the functions operates as the general-purpose input.

2

The IN0 to IN F LEDs indicate status of the external input signals (X0 to XF). However, the indicating status is not affected by

turning on or off the input device (X0 to XF) in the program.

(10)External output signals (Y0 to Y7) when using the functions

The external output signals (Y0 to Y7) reflect the output status of the function selected from the general-purpose

output, positioning, and high-speed counter functions. Therefore, the output status are not affected by turning on

or off the output device (Y0 to Y7) in the program when the output signals are used for the positioning or highspeed counter function.

The output device (Y0 to Y7) do not reflect the status of the output signals used for the positioning or high-speed

counter function.

The OUT 0 to OUT 7 LEDs indicate status of the external output signals. So the output status of the output device (Y0 to Y7)

are indicated when the output signals are used for the general-purpose output function. Actual output status of the

positioning or high-speed counter function are indicated when the output signals are used for those functions. (The

indicating status is not affected by turning on or off the output device in the program.)

29

Page 32

(11)Monitoring by the programming tool

To check the I/O settings, open the "I/O Monitor" window by using the programming tool.

[Tool] [Built-in I/O Module Tool]

For details, refer to the followings. GX Works2 Version 1 Operating Manual (Common)

30

Page 33

CHAPTER 3 GENERAL-PURPOSE INPUT FUNCTION

Select a response time.

Select "General-purpose input".

CHAPTER 3 GENERAL-PURPOSE INPUT

FUNCTION

This function uses the built-in external input signals (16 points) as general-purpose inputs to read the on/off status of

external devices such as switches and sensors. The on/off status of the external input signals are refreshed to the

input device (X0 to XF) and used in programs.

(1) Parameter setting

Set the input signals and input response time values.

Project window [Parameter] [PLC Parameter] "Built-in I/O Function Setting" tab

3

(2) External input signal types

The following two types are available.

• High-speed input: X0 to X5 (6 points)

• Standard input: X6 to XF (10 points)

(3) Read timing of external input signals

The on/off status of the external input signals are refreshed to the input device (X0 to XF) at execution of the END

instruction. Therefore, a delay for one scan (maximum) occurs from when an external input signal changes until

when the input device turns on.

(4) Direct input

By using the direct input device (DX0 to DXF) for the external input signals, the external input status can be

loaded at execution of sequence instructions using the direct input device.

31

Page 34

(5) Partial refresh

The LCPU can read the current external input status by executing partial refresh using the RFS instruction to the

input device (X0 to XF). For the RFS instruction, refer to the following.

MELSEC-Q/L Programming Manual (Common Instruction)

(6) Performance specifications

The following is the performance specifications of the general-purpose output function.

Item Description

Points 10

Input voltage/current 24VDC, 4.1mA (TYP.)

Standard input

High-speed input

Minimum input response time

Input response time setting

Points 6

DC input 24VDC, 6.0mA (TYP.)

Input voltage/current

Minimum input response time

Input response time setting

Differential

input

*1

Depending on the setting value of the input response

time

*2

0.1ms

/1ms/5ms/10ms/20ms/70ms

EIA Standard RS-422-A Differential line driver level

(AM26LS31 (manufactured by Texas Instruments

Incorporated) or equivalent)

Depending on the setting value of the input response

time

0.01ms*3/0.1ms/0.2ms/0.4ms/0.6ms/1ms

*1 The shorter the input response time is, the more the module is susceptible to noise. When setting the input response

time, check that the module will not be affected by noise. For details on measures against noise, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

*2 The response time at turning on off of input devices can take 0.2ms even if the input response time is set to "0.1ms".

*3 The response time can take 0.02ms even if the input response time is set to "0.01ms".

32

Page 35

CHAPTER 4 GENERAL-PURPOSE OUTPUT FUNCTION

Select "General Output".

Select an error time output mode.

CHAPTER 4 GENERAL-PURPOSE OUTPUT

FUNCTION

This function uses the built-in external output signals (8 points) as general-purpose outputs for external devices such

as lamps. By turning on/off the output device (Y0 to Y7) in programs, the LCPU can output the signals externally.

(1) Parameter setting

Set the output signals and error time output mode.

Project window [Parameter] [PLC Parameter] "Built-in I/O Function Setting" tab

4

(2) External output timing

On/off status of the output device are refreshed to the external outputs (Y0 to YF) at execution of the END

instruction. Therefore, a delay for one scan (maximum) occurs from when an external device turns on/off in

programs until when the on/off status is refreshed to the external output.

(3) Direct output

When using the output device (Y0 to Y7) for the direct output device (DY0 to DY7), on/off status of the device are

refreshed to the external outputs by using the instruction such as the SET instruction.

(4) Partial refresh

The output device status (only specified range) is refreshed to the external output by executing partial refresh

using the RFS instruction to the output device (Y0 to Y7) ( MELSEC-Q/L Programming Manual (Common

Instruction)).

33

Page 36

(5) Error time output mode

Select the output mode (Hold or Clear) for the output status of the output device (Y0 to Y7) when an error to stop

the program occurs. (This is not the setting for outputs to the output modules and the intelligent function modules.

For details on the error time output mode setting for modules, refer to the following. MELSEC-L CPU Module

User's Manual (Function Explanation, Program Fundamentals)

(6) Performance specifications

The following is the performance specifications of the general-purpose output function.

Description

Item

Output type Sink type Source type

Points 8

Output voltage/current 5 to 24VDC, 0.1A

Response time

On 1s or less (rated load, resistive load)

Off 1s or less (rated load, resistive load)

L02SCPU, L02CPU, L06CPU,

L26CPU, L26CPU-BT

L02SCPU-P, L02CPU-P, L06CPU-P,

L26CPU-P, L26CPU-PBT

34

Page 37

CHAPTER 5 INTERRUPT INPUT FUNCTION

Select "Interrupt input".

Select a response time.

Select an interrupt

processing condition.

CHAPTER 5 INTERRUPT INPUT FUNCTION

This function executes an interrupt program when triggered by the input signal (X0 to XF).

(1) Parameter setting

Set the input signals, input response time values, and interrupt processing condition.

Project window [Parameter] [PLC Parameter] "Built-in I/O Function Setting" tab

5

35

Page 38

(2) Interrupt pointer assignment and interrupt priority

The following shows interrupt pointers corresponding to input signals (X0 to XF).

I/O signal Interrupt pointer

X0 I0 5

X1 I1 6

X2 I2 7

X3 I3 8

X4 I4 9

X5 I5 10

X6 I6 11

X7 I7 12

X8 I8 13

X9 I9 14

XA I10 15

XB I11 16

XC I12 17

XD I13 18

XE I14 19

XF I15 20

*1 The priority 1 to 4 are used for interrupt pointers I28 to I31 (interrupt by build-in timers).

Priority

*1

Interrupt pointer numbers can be changed. ( Page 37, (2) (a))

36

Page 39

CHAPTER 5 INTERRUPT INPUT FUNCTION

Ex.

(a) Changing the interrupt pointer numbers

1. Click the button in the "PLC System" tab.

Project window [Parameter] [PLC Parameter] "PLC System" tab

2. Set the interrupt pointer start No., interrupt pointer count, start I/O No., and start SI No.

3. Click the button to exit.

When assigning the interrupt inputs X0 and X1 to the interrupt pointers I50 and later

5

• Precautions

When the range of interrupt input that is specified in the "Intelligent Function Module Interrupt Pointer

Setting" and the interrupt input is not selected for the built-in I/O function in the range, "PARAMETER

ERROR" (error cord: 3000) occurs. The following shows a correct example and an incorrect example of

assigning the interrupt inputs to the interrupt pointers I50 and later as shown above.

• Correct example

As shown below, the interrupt inputs are set within the range specified in "Intelligent Function Module

Interrupt Pointer Setting", so the error will not occur.

Input signal function selection: Interrupt input is set to X0 and X1.

• Incorrect example

As shown below, input signal X2 and X3 are set to the interrupt inputs, but no interrupt input is set within

the range specified in "Intelligent Function Module Interrupt Pointer Setting", so the error will occur.

Input signal function selection: X2 and X3 are set to the interrupt inputs.

37

Page 40

(3) Interrupt processing condition

The following table lists three types of conditions to execute the interrupt programs by the interrupt inputs.

Interrupt processing

condition

Rising edge The interrupt program is executed at the rising edge of the interrupt input signal.

Falling edge The interrupt program is executed at the falling edge of the interrupt input signal.

Rising edge + Falling

edge

The interrupt program is executed at both the rising edge and the falling edge of the interrupt

input signal.

Description

When the condition is set to "Rising edge + Falling edge", an interrupt factor occurred during execution of an

interrupt program is held only once, and the second and subsequent factors are ignored. When the second rising

edge (falling edge) of the signal is detected after the falling edge (rising edge) during execution of the interrupt

program due to the first one, the second one cannot execute the interrupt program. To avoid this, keep an enough

interval between on and off of the interrupt input.

In addition, a continuous interrupt input of signals with a short ON width and OFF width causes frequent halts of

the main routine program. Adjust the ON width and OFF width for interrupt input not to interfere with the

execution of the main routine program.

(4) Interrupt enable/disable

Use the EI instruction to enable the interrupt. Also, use the DI instruction to disable interrupt, and the IMASK

instruction to mask the interrupt program. ( MELSEC-Q/L Programming Manual (Common Instruction))

(5) Performance specifications

The following is the performance specifications of the interrupt input function.

Item Description

Points 10

Input voltage/current 24VDC, 4.1mA (TYP.)

Standard input

High-speed

input

*1 The response time at turning on off of input devices can take 0.2ms even if the input response time is set to "0.1ms".

*2 The response time can take 0.02ms even if the input response time is set to "0.01ms".

Minimum input response time

Input response time setting

Points 6

DC input 24VDC, 6.0mA (TYP.)

Input voltage/current

Minimum input response time

Input response time setting

Differential

input

Depending on the setting value of the input response

time setting

*1

0.1ms

/1ms/5ms/10ms/20ms/70ms

EIA Standard RS-422-A Differential line driver level

(AM26LS31 (manufactured by Texas Instruments

Incorporated) or equivalent)

Depending on the setting value of the input response

time setting

*2

0.01ms

/0.1ms/0.2ms/0.4ms/0.6ms/1ms

38

Page 41

CHAPTER 6 PULSE CATCH FUNCTION

Program

External input signal

X0

Input device

X0

0 step END

0 step END

0 step

1) Input signal ON

2) ON for 1 scan

OFF

OFF

CHAPTER 6 PULSE CATCH FUNCTION

This function can catch pulse signals that the general-purpose input function cannot catch because the on time is

shorter than the scan time.

(1) Parameter setting

Set the input signals and input response time values.

Project window [Parameter] [PLC Parameter] "Built-in I/O Function Setting" tab

Select a response time.

Select "Pulse Catch".

6

(2) Basic operation of the pulse catch function

The function turns on the input device for one scan after detecting a pulse signal, and turns off the input device

during the END processing.

(a) Operation when using an input signal (X0) as the pulse catch function

The input device turns on for one scan after detecting a rising edge of the external input signal (X0).

39

Page 42

(b) Operation when detecting more than one pulse in one scan

External

input signal

X0

1 scan

1): Interrupt program execution

2): Interrupt program execution in the next scan

3): If a pulse is input after completion of the interrupt program by

1), the interrupt program is executed at time after the next.

Interrupt program

1)

2)

3)

OFF

Program

External input signal

X0

Input device

X0

0 step END

0 step

END

0 step

0 step

END

1) Input signal ON

ON for 2 scans

3) Input signal ON

4) ON for 1 scan2) ON for 1 scan

OFF

OFF

Second pulse and later are ignored. Input pulse signals at intervals of one scan or more.

0 step END

0 step END

Program

1) Input signal ON

0 step

External input signal

X0

Input device

X0

OFF

OFF

These pulses are ignored.

2) ON for 1 scan

To count the second and third pulse inputs, use the interrupt input function. However, if the third pulse is detected before the

end of the execution of the interrupt program, the pulse cannot be counted.

(c) Operation when detecting same pulse in two scans or more

The input device turns on for scans by the number of detected pulses. Input pulse signals at intervals of one

scan or more.

40

Page 43

CHAPTER 6 PULSE CATCH FUNCTION

(d) Operation when detecting a pulse that has on width of two scans or more

The input device turns on for one scan.

0 step END

0 step

Program

0 step

END

External input signal

X0

Input device

X0

OFF

OFF

1) Input signal ON

2) ON for 1 scan

(3) Detectable pulse width

Pulse width that meets the following condition can be detected.

ON or OFF width of the pulse input > Input response time

When the condition is not met, the pulse cannot be detected correctly. Set the input response time values to meet

the condition.

(4) Precautions

Avoid the following actions for the input device (X0 to XF) that is set to the pulse catch function.

Otherwise, the input device does not turn on correctly for one scan after detecting a pulse.

• Use of the direct device (DX)

• Execution of the instruction that performs input refresh at execution, such as RFS, COM, CCOM(P), and

MTR

6

(5) Performance specifications

The following is the performance specifications of the pulse catch function.

Item Description

Points 10

Input voltage/current 24VDC, 4.1mA (TYP.)

Standard input

High-speed input

*1 The response time at turning on off of input devices can take 0.2ms even if the input response time is set to "0.1ms".

*2 The response time can take 0.02ms even if the input response time is set to "0.01ms".

Minimum input response time

Input response time setting

Points 6

DC input 24VDC, 6.0mA (TYP.)

Input voltage/current

Minimum input response time

Input response time setting

Differential input

Depending on the setting value of the input response

time setting

*1

0.1ms

/1ms/5ms/10ms/20ms/70ms

EIA Standard RS-422-A Differential line driver level

(AM26LS31 (manufactured by Texas Instruments

Incorporated) or equivalent)

Depending on the setting value of the input response

time setting

*2

0.01ms

/0.1ms/0.2ms/0.4ms/0.6ms/1ms

41

Page 44

CHAPTER 7 POSITIONING FUNCTION

Mechanical system

Hardware stroke

upper limit switch

Workpiece

Workpiece

Near-point

watchdog

Near-point

watchdog

Drive unit

Drive unit

Servo motor

Servo motor

Hardware stroke

lower limit switch

Hardware stroke

upper limit switch

Hardware stroke

lower limit switch

Motor power

cable

Motor power

cable

Encoder cable

Encoder cable

Programming tool LCPU

7.1 Overview

(1) Definition

This function is used to move a table, machining target, tool, or other moving body (workpiece) at a specified

speed with the purpose of stopping it accurately at a target position.

(2) Features

The positioning function is controlled by dedicated instructions.

(a) 2-axis control

Two drive units (two motors) can be connected and two coordinates can be controlled independently or

simultaneously.

(b) OPR (Original point return)

Six types of OPR methods are available. A near-point dog (OP sensor) can be used to establish the OP

(position that becomes the starting point of each control) and "address" of this position. (Machine OPR) OPR

can also be performed automatically within the range defined by the upper and lower limit switches. (OPR retry

function)

(c) Target position and speed

• The workpiece can be moved to the target position based on a specified address or movement amount.

(Position control)