FX-2DA

SPECIAL FUNCTION BLOCK

USER'S GUIDE

JY992D52801C

This manual contains text, diagrams and explanations which will guide the reader in the correct installation

and operation of the FX-2DA special function block and should be read and understood before attempting

to install or use the unit.

Further information can be found in the FX PROGRAMMING MANUAL and FX SERIES HARDWARE

MANUAL.

1

●

The FX-2DA analog special function block has two output channels. The output channels take a digital value

and output an equivalent analog signal. This is called a D/A conversion. The FX-2DA has a maximum

resolution of 12 bits.

●

The selection of voltage or current based input/output is by user wiring. Analog ranges of -10 to 10V

(resolution: 5mV), and/or 4 to 20mA (resolution: 20µA) maybe selected.

●

FX programmable controllers versions 2.0 or later (those with serial number 13XXXX or larger) are

required; as these units have the TO/FROM applied instructions in their instruction set. Data transfer

between the FX-2DA and the FX base unit is by buffer memory exchange. There are 32 buffer memories

(each of 16 bits) in the FX-2DA.

●

The FX-2DA occupies 8 points of I/O on the FX, FX2C expansion bus. The 8 points can be allocated from

either inputs or outputs. The FX-2DA draws 30mA from the 5V rail of the base unit or powered extension

unit.

INTRODUCTION

1.1 External dimensions Weight : Approx. 0.5kg (1.1 lbs) Dimensions : mm (inches)

2

Extension cable

and connector

Any connection to these terminals

may damage the FX-2DA.

M3.5 (0.14)

terminal screws

24V LED

63 (2.48)

73 (2.87)

Wiring

D-A LED

125 (4.92)

140 (5.51)

1

0 (

0.39)

95 (3.74)

Groove for

35mm (1.38)

wide DIN rail

2-5.5mm (0.22)

hole

DC24V ±10% 130mA

Class 3

Grounding

(100 Ω or less)

*4

PC

+24V

0V

DC/DC

converter

FX-2DA special function block

Extension cable

*1 Use a twisted pair shielded cable for the analog

output. This cable should be wired away from

power lines or any other lines which could induce

noise.

*2 Apply 1-point grounding at the load side of the

output cable (class 3 grounding: 100 Ω or less). If

electrical noise is caused from grounding,

disconnect from grounding.

*3 If electrical noise or a voltage ripple exists at the

output, connect a smoothing capacitor of 0.1 to

0.47 µF, 25V.

Voltage output

V

+

V

I

I

V

V

I

I

*1

+

-

+

-

Current output

+

-

*1

*2

*2

Inverter,

etc.

*3

Recorder,

etc.

AG

+15V

-15V

CH1

CH2

*4 Connect the ground terminal on the FX-2DA with

the ground terminal on the base unit of the

programmable controller. Use class 3 grounding

on the base unit, if available.

Caution;

(a) The same output channel cannot drive current

and voltage output loads at the same time!

(b) Shorting the voltage output terminals may da-

mage the unit!

3

INSTALLATION NOTES AND USAGE

3.1 Environment specification

Item

Environment specifications

3.2 Power supply specifications

Item

Analog circuits

Digital circuits

3.3 Performance specifications

Item

Voltage or current outputs can be individually selected with each output

Max. convertible

output range

Digital input

(external load: 1kΩ

Voltage = -2048 to +2047

Same as those for the FX base unit

24V DC ±10% 130mA

(external power supply)

(internal power supply from base unit)

Voltage output

terminal. There are a total of 2 output points.

DC -10V to +10V

to 1MΩ)

(external load: 500 Ω or less)

Specification

Specification

5V DC, 30mA

Current output

DC+4mA to +20mA

Current = 0 to +1000

Resolution

Overall accuracy

Conversion speed

5mV (10V full scale 1/2000)

±1% full scale (10V range)

20µA (20mA full scale 1/1000)

±1% full scale (20mA range)

18ms for 2 channels (normal speed), 3.5ms for 2 channels (high speed).

Analog output continued...

Factory Presets

Load:

ΩΩ

= 10k

(voltage

Ω

ΩΩ

Output)

ΩΩ

= 250

Ω

(current

ΩΩ

Output)

Analog output

-2000 -1000

-2048

-10.24V

+10V

+ 5V

+10.235V

0 +1000 +2000

- 5V

Digital input

-10V

+2047

+20mA

Analog output

+ 4mA

Gain and offset can be adjusted using the procedure described in chapter 4.

0 1000

Digital input

Specification

Photo-coupler isolation between analog and digital circuits.

DC/DC converter isolation of power from FX base unit.

No isolation between analog channels.

8 points taken from the FX expansion bus

(can be either inputs or outputs)

Item

Isolation

Number of occupied I/O

points

ATTENTION FOR WHEN SWITCHING SYSTEM ON/OFF

Due to the inevitable timing difference of the DC24V for the analog circuits and other power lines of the

base unit, the output of the FX-2DA special function block may behave erroneously before settling down

to operational conditions in approximately 1sec. Therefore, ensure that this behavior is taken into account

such that the end performance of the system is not degraded.

(example)

Power switch

Miscellaneous

DC24V

supply

FX-2DA special

function block

cut analog lines

before switching

External analog

machine

3.4 Allocation of buffer memories (BFM)

BFM

*# 0

*# 1

*# 2

# 3-# 4

*# 5

# 6

*# 7

# 8-#19

contents

channel Initialization (Default = H00)

channel 1

channel 2

Reserved

Last data reset (Default = 0)

Reserved

selection of A-D

conversion speed

see note

When set to 0, normal

speed is selected 18ms

When set to 1, high

speed is selected 3.5ms

Reserved

In BFM's (buffer memory) with an “ * ”, data

can be written from the programmable controller using the TO command.

These BFM's should always be given when the

programmable controller goes from STOP to

RUN. Buffer memory (BFM's) are reset to their

default settings upon power on.

BFM

*#20

*#21

*#22

*#23

*#24

#25-#28

#29

#30

#31

b3 b2 b1 b0

Reset all to default default value: 0

Gain/offset adjust prohibit

Pro-

Permit

Initial value (0,1)

Offset/gain

G2 O2 G1 O1

hibit

setting command

Offset data (in mV or µA units)

default value: 0

Gain data (in mV or µA units)

default value: 5,000

Reserved

Error status (See next page)

Identification code K3010 (See next page)

Reserved

●

The buffer memory also handles information

used to adjust the gain and offsets of the FX2DA unit. Status of the unit such as errors

are also available.

●

From BFM #29 and #30, data can be read

via the FROM command.

●

Offset value : the actual output value when

the digital input is 0.

●

Gain value : the actual output value when

the digital input is +1000.

(1) Channel Selection

Switching between voltage and current output modes. The value of BFM #0 switches the analog output

between voltage and current on channels CH1 and CH2. It takes the form of a 2-character HEX number.

The least significant character controls CH1 and the other controls CH2.

Control of each O HEX character of

HOO

O=0 Voltage output (-10V to +10V)

Example : H10 CH1 : Voltage output CH2 Current output

:

:

O=1 Current output (+4mA to +20mA)

:

:

(2) Last data reset

If the programmable controller is changed to the STOP state, the FX-2DA will continue to output the last

value. To reset the output to the offset value, set the HEX characters of BFM #5 to one of the appropriate

settings below:

H01 : CH2=Hold, CH1=Reset

H10 : CH2=Reset, CH1=Hold

H11 : CH2=Reset, CH1=Reset

Both channels are held when BFM #5 = H00.

(3) Digital to Analog conversion speed change

By writing 0 or 1 into BFM #7 of the FX-2DA, the speed at which D-A conversion is performed can be

changed. However the following points should be noted:

Note :

●

The conversion speed does not depend on the number of channels being used.

●

On power up, the FX-2DA is set for normal speed conversion and BFM #7 contains 0.

(4) Adjusting Gain and Offset Values

(a)

When BFM #20 is set to K1, all settings in the buffer memory are reset to their default settings. This

allows the buffer memory settings to be set from the beginning again when many settings have

been corrupted.

(b)

If (b1, b0) of BFM #21 is set to (1, 0), gain and offset adjustments are prohibited. This is to prevent

inadvertent misuse by the operator. To adjust the gain and offset, (b1, b0) of BFM #21 must have

the values (0, 1). The default is set at (0, 1).

(c)

Each time a TO instruction is used to send data to BFM #22 (gain/offset setting command), the

designated gain and offsets of each channel (G2 O2 G1 O1) are adjusted with the values in

BFM #23 and #24. This action causes the adjustments to be written to internal non-volatile EEPROM

memory. Limit this action to as little as possible to preserve the life of the EEPROM memory.

(d)

Gain and offset values in BFM #23 #24 are set in units of mV or µA. Due to the resolution of the unit,

the actual response will be in steps of 5mV or 20µA.

(5) Status information BFM #29

Bit

When any of b1 to b3 is ON D/A conversion

b 0 : error

is stopped for the error channel

Offset/Gain data in EEPROM is corrupted or

b 1 : Offset/Gain error

adjustment error

b 2 : Power abnormality

b 3 : Hardware error

b 8 : Not READY

FX-2DA MODE switch is not set to READY.

DC 24V power supply failure

D/A converter or other hardware failure

Digital input value or analog output is outside

b10: Range error

the specified range.

b12: Offset/Gain adjust

Prohibit-(b1, b0) of BFM #21 is set at (1, 0).

prohibit

Bits b4 to b7, b9, b11 and b13 are undefined.

ON

OFF

No error

Offset/Gain data normal

Power supply normal

Hardware normal

READY mode

Analog output value is normal.

Permit-(b1, b0) of BFM #21 is

set at (1, 0).

(6) Model code number BFM #30

The identification code for a Special Block is read using the FROM command.

The identification code for the FX-2DA unit is K3010.

The PC can use this facility in the program to identify the special block before commencing any data trans-

fer from and to the special block.

CAUTION

●

Values of BFM #0, #5, #21, #23 and #24 are stored in EEPROM memory of the FX-2DA. BFM #23

and BFM #24 are only copied when the gain/offset setting command BFM #22 is used. Also, BFM

#20 causes resetting of the EEPROM memory. The EEPROM has a life of about 10,000 cycles

(changes), so do not use programs which frequently change these BFMs.

●

Because of the time needed to write to the EEPROM memory, a delay of 300ms is required between

instructions that cause a change to the EEPROM.

Therefore, a delay timer should be used before writing to the EEPROM a second time.

4

DEFINING GAIN AND OFFSET

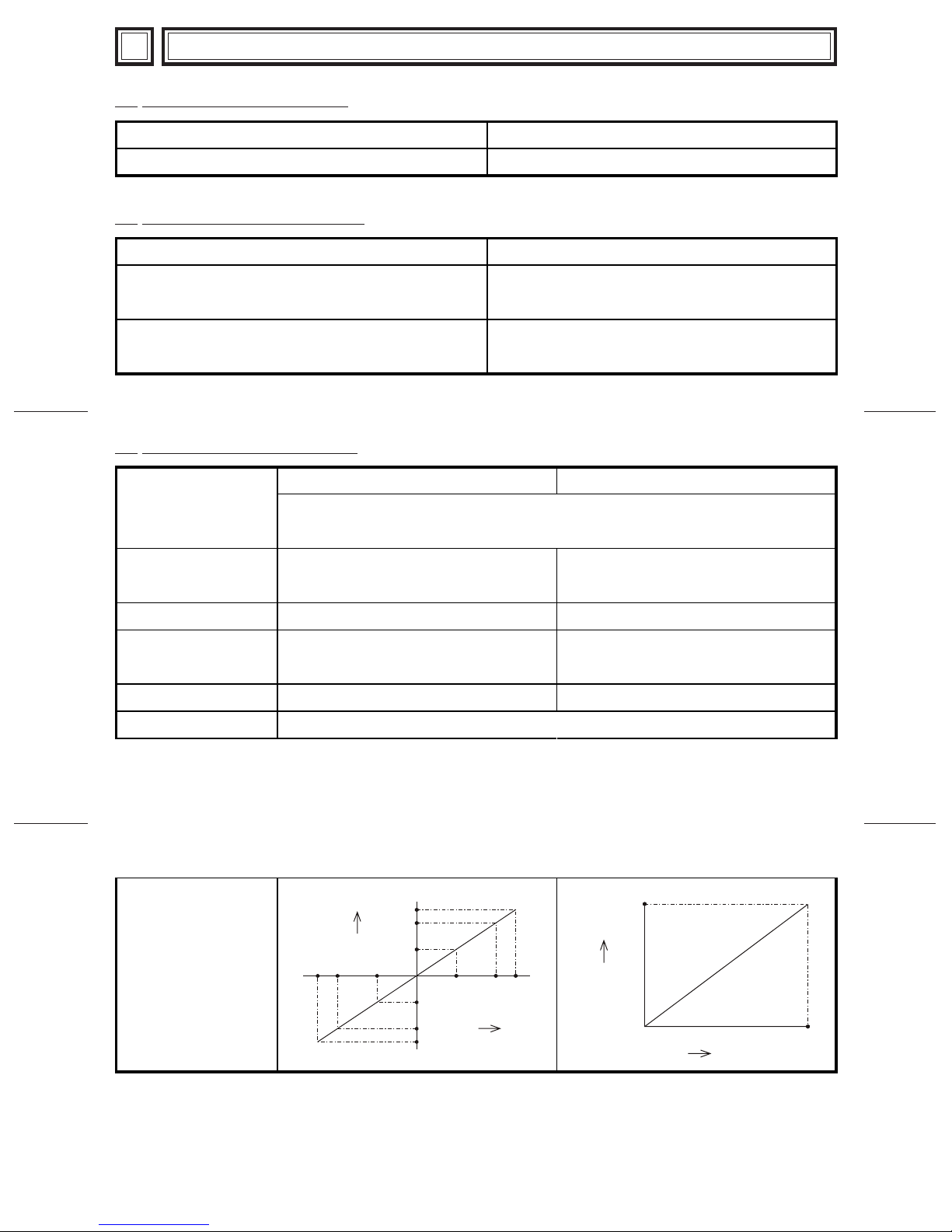

(d)

(e)

(f)

Digital

Offset value

1000

(a)

Digital

(b)

(c)

〈〈

〈GAIN

〈〈

〉〉

〉

〉〉

Analog

Gain value

Gain is the angle or slope of the calibration line

identified at a digital value of 1000.

(a) Large gain– low reading resolution

(b) Zero gain-– default 5V or 20mA

(c) Small gain – high reading resolution

〈〈

〈OFFSET

〈〈

〉〉

〉

〉〉

Analog

Digital value 0

Offset is the 'Potion' of the calibrated line, identified

at a digital value of 0.

(d) Positive offset

(e) Zero offset – default (4-20mA default is 4mA)

f

( ) Negative offset

Offset and gain can be used independently or together. Reasonable offset ranges are -5V to +5V or

-20mA to 20mA, and gain-offset difference 1V to 15V or 4mA to 32mA. Gain and offset can be adjusted by

software in the FX base unit (see program example 2) or by the switches on the FX-2DA (with the aid of a

voltmeter/ammeter).

●

Bit device's b0, b1 of the gain/offset BFM (#21) should be set to 0, 1 to allow adjustment.

Once adjustment is complete these bit device should be set to 1, 0 to prohibit any further changes.

●

Channel initialization (BFM #0) should be set to the nearest range, i. e. voltage/current etc.

1. Power up the system the FX base unit can be in either RUN or STOP mode.

2. Connect the load and voltmeter or ammeter to the CH1 terminals.

3. Set the FX-2DA MODE switch to output CH1.

4. Press the OFFSET button once. The offset value is output. Use the UP/DOWN switch to reach the desired

offset value.

5. Press the GAIN button once. The gain value is output. Use the UP/DOWN switch to reach the desired

offset value.

6. Repeat operations 3 to 5 for each channel you wish to use.

7. Set the FX-2DA MODE switch to READY to complete gain and offset adjustment.

NOTE : If the MODE switch is not set to a channel number, the FX-2DA is regarded as being in the

READY status and no adjustments can be made.

5 EXAMPLE PROGRAM

5.1 Basic program

In the following example, channel CH1 is set to voltage output, while CH2 is set to current output. The FX2DA unit is connected at the position of special function block No.1. If the programmable controller is

changed to the STOP mode, the last data sent will remain and the outputs will hold.

M8000

RUN

monitor

M1

FROM(P)

●

Set CH1 setting to D0

●

Set CH2 setting to D1

TO

K1

CMP

K1

K3010

K30

(-2,000 to +2,000)

( 0 to +1,000)

K1

D4

D4

D0

K1

M0

K1H10K0K1TO(P)

K2

The ID code for the special function block at position

“1”is read from BFM #30 of that block and stored at

D4 in the FX base unit. This is compared to check the

block is an FX-2DA, if OK M1 is turned ON. These

two program steps are not strictly needed to perform

an analog output. They are however a useful check

and are recommended as good practice.

The analog output channels (CH1, CH2) are set up

by writing H10 to BFM #0 of the FX-2DA.

(D0 → BFM #1 (output to CH1))

(D1 → BFM #2 (output to CH2))

K4M10

FROM

NO

error

K1

M18M10

READY

K29

M20

Output

range

normal

K1

M3

The operational status of the FX-2DA is read from

BFM #29 and output as bit devices at the FX base

unit.

Output data normal

5.2 Using gain and offset in a program

I/O characteristics of the FX-2DA can be adjusted by changing the gain and offset parameters. These can

be changed by the switches of the FX-2DA with the aid of Voltage & Current meters or simply changed by

writting these settings from the programmable controller.

Only the gain and offset values in the memory of the FX-2DA need be adjusted. A voltmeter or an ammeter

for the analog output is not needed. A program for the programmable controller will be needed however.

The following is an example; changing the offset value to 0mA and gain value to 20mA on output channel

CH2 of the FX-2DA connected as block No.1.

Example: Adjusting gain/offset via software settings

X010

M0

TO(P)

K1

K0

H10

M0SET

K1

●

Adjustment start.

●

(H10) → BFM #0 (initialize input channels)

In the program shown at left, the programmable

controller should be in RUN status, and MODE

switch of the FX-2DA in the READY position.

TO(P)

K1

K21

K1

K1

●

(K1) → BFM #21

BFM #0 should be of HEX value H10, and (b1,

b0) of BFM #21 should be (0, 1).

T0

T1

TO(P)

TO(P)

TO(P)

TO(P)

K1

K1

K1

K1

K23

K24

K22

K21

K0

K20000

HC

RST

K2

K1K0K22K1TO

T0

K1

K1

K1

M0

K1

K4

●

(K0) → BFM #22 (offset/adjust)

Reset adjust bits.

●

(K0) → BFM #23 (offset)

This statement may be omitted if BFM #23 is already

at its default value.

●

(K20000) → BFM #24 (gain)

●

(HC) → BFM #22 (offset/gain set)

A delay of 300ms may be needed between setting

BFM #0 and #22 (see section 3.4“caution”)

●

Adjustment end.

●

(K2) → BFM #21

BFM #21 gain/offset adjust prohibit.

6

DIAGNOSTICS

6.1 Preliminary checks

1. Check whether the output wiring and/or expansion cables are properly connected on FX-2DA analog special

function block.

2. Check that the FX system configuration rules have not been broken, i.e. the number of blocks does not

exceed 8 and the total system I/O is equal or less than 256 I/O.

3. Ensure that the correct operating range has been selected for the application.

4. Check that the MODE switch on the FX-2DA panel is set to the READY position.

5. Check that there is no power overload on either the 5V or 24V power source, remember the loading on

the FX base unit or a powered extension unit varies according to the number of extension blocks or

special function blocks connected.

6. Pit the main processing unit into RUN.

6.2 Error checking

If the FX-2DA special function block does not seem to operate normally, check the following items.

●

Check the status of the POWER LED.

Lit. : The extension cable is properly connected.

Otherwise : Check the connection of the extension cable.

●

Check the external wiring.

●

Check the status of“24V”LED (top right cover of the FX-2DA).

Lit. : FX-2DA is OK, 24V DC power source is OK.

Otherwise : Possible 24V DC power failure, if OK then possible FX-2DA failure.

●

Check the status of th“D/A”LED (top right cover of the FX-2DA)

Lit. : D/A conversion is proceeding normally

Otherwise : Check buffer memory #29 (error status). If any bits (b2 and b3) are ON, then this is why the D/A LED

is OFF.

Guidelines for the safety of the user and protection of

the FX-2DA special function block

●

This manual has been written to be used by trained and competent personnel. This is defined

by the European directives for machinery, low voltage and EMC.

●

If in doubt at any stage during the installation of the FX-2DA always consult a professional

electrical engineer who is qualified and trained to the local and national standards. If in doubt

about the operation or use of the FX-2DA please consult the nearest Mitsubishi Electric distributor.

●

Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

●

All examples and diagrams shown in this manual are intended only as an aid to understanding

the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

use of the product based on these illustrative examples.

JY992D52801C

Manual number : JY992D52801

Manual revision : C

Data : AUGUST 1996

HEAD OFFICE : MITSUBISHI DENKI BLDG MARUNOUCH TOKYO 100 TELEX : J24532 CABLE MELCO TOKYO

HIMEJI WORKS : 840, CHIYODA CHO, HIMEJI, JAPAN

Effective AUG. 1996

Specifications are subject

to change without notice.

Loading...

Loading...