I

M'TSuB'SH'

Programmable

Controller

MELSEC

F2

SERIES

INSTRUCTION MANUAL

I

F2-60MR

0

This manual provides technical information and guidance on the installation and

rise

of

the Mitsubishi

Fz

series Programmable Controller and

its

extension unit.

e

Users should ensure that the

detail

of

this manual

is

studied and understood

before attempting

to

install or use the units.

0

Information concerning the programming

of

the system, using the programmer

unit,

is

covered

in

a separate manual.

MWSUBISHI

ELECTRIC

CORPORATION

TABLE

1.

2. PRELIMINARY WIRINGS

3. INPUT HANDLING

4. OUTPUT HANDLING

5.

6. F2-.(IOAW/AP

7. LNSTALLATION AND ENVIRONMENT

8.

QF

CONTENTS

INTRODUCTION

F2

series

PC

1-1 Descriptions of

1-2 Basic models

1-3

Extension unit selection

1-4 Peripherals

2-1

Powersupply..

2-2

Grounding..

2-3

RUN/STOP mode terminals

2-4 RUN output terminals

2-5 DC24V terminals

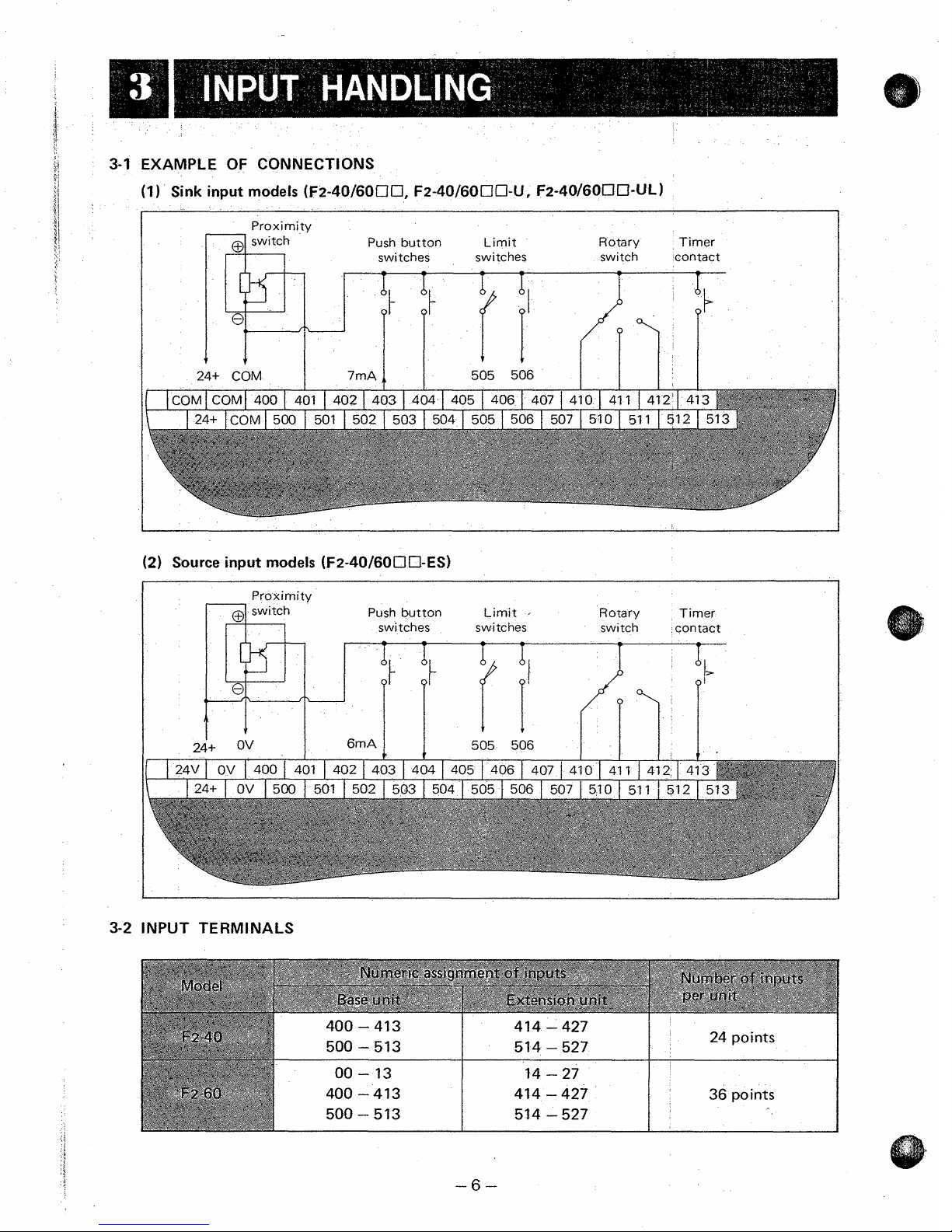

3-1 Example

3-2 Input terminals..

3-3 Input circuit specifications

3-4

Cautions.

3-5

AC input handlings

4-1 Relay output models

4-2 Triac

4-3 Transistor output models {Sink output)

4-4 Transistor output models (Source output)

4-5 Output circuit specifications

F2-40AC

5-1

5-2

5-3 Indications and

6-1

6-2

6-3

6-4

7-1 Installation

7-2 Extension cable

7-3 Environment

7-4

7-5

7-6 Peripheral installation 21

DIAGNOSIS AND MAfNTENANCE

8-1

8-2

8-3 Maintenance

(HIGH

Installation

Connections

F2-40AW

F2-40AP Installation

Indications and DIP switch settings

Signal transmission

Electrical noise interference

Wirings..

Preliminary checks 22

Diagnosis

of

base unit & extension unit

......................................

............................................

....................................

..................................

of

connections.

............................................

.................................................

..........................................

(SSR)

output models

SPEED

COUNTER INTERFACE) HANDLfNG

.....................................

of

input circuit

DIP

switch settings

(PC

LINK INTERFACE) HANDLINGS

Instidlation

..........................................

.....................................

..................................

..................................

.....................................

..........................................

................................................

................................................

.....................................

...........................

.......................................

l........

.:.

.......

...........................

........

1

.........................................

........

.......................................

......................................

..........................................

...........................

.I.

........

.............................

-t*

.................

- * -

.....................................

*!

- * - * -

.....................................

................................

..........................................

.....................................

.....................

.........

.......

i..

.........

........

....................................

.........................................

-.;.

-;.

........

- * -

- -

....

-

1

1

2

2

3

5

5

5

5

6

6

7

7

8

9

10

11

*

12

13

15

16

16

17

17

18

18

20

20

20

20

21

-

22

23

Appendix

1.

SPEC

IF

2.

OUTLINES

ICATIONS

AND DIMENSIONS..

...........................................

...............................

24

25

I,

I

1-1

1-2

DESCRlPTlONS

OF

F2

SERtES

PC

The Mitsubishi

F2

series

of

programma bte controllers and auxiliary equipments are higher version

models

to

the F series and are ideal

for

small industrial process controt requirements and machines.

The

1/0

capacity

is

120 points max. per unit,

but

240

11'0s

can be covered by tinkage operation.

A separate ranges the

G

series and K series are available for larger and more complex application

requirements.

BASfC

MODELS

OF

BASE

UNIT

&

EXTENSION

UNfT

Nomenclatures

of

Base

&

Extension

Unit

Model

Fz

-

a

D

..

D

Ct

111

It

II

ir

Expl.

F2

-

40

M

R

-

E

S

I

It

tI

indicates the number

of

inputs/outputs 40 or

60

indicates type

of

the unit

indicates type

of

output

R:

Relay,

S:

SSR,

T:

Transistor

specifies power supply voltage rating

M:

Base

Unit or

E:

Extension Unit

N/A

.......

U&

u

L......

E

. . .

.

.

,

,

D

.

. . . . .

.

indicates type

N/A

_......

s

AI

.......

A2

.......

ss

. . .

. . .

.

. . .. . ..

100/1

IOVAC 200/220VAC

1

10/1

ZOVAC 220/240VAC

110/220VAC, 220/240VAC

24V DC

3f

input/output connections

24VDC sink input and sink output

24VDC source input and sink output

100/120VAC source input and sink output

220/240VAC source input and sink

output

24VDC source input and source output

-1-

I

F2-20H

G

P-80

FZ

F-ROM-1

F

-20P-CAB

F2 -40AC

F2 -40AW

F2-40AP

13

EXTENSION UNIT SELECTION

Program Loader

Graphic programmer

EP-ROM cassette

Remote cable

Adaptor (High speed counter input interface)

Adaptor (Wire

I

ink operation interface)

Adaptor (Optical fiber link operation interface)

I

The F2-40M

has

wo

extension ports and F2-60M has three extension ports where extension units

are connected. According to the requirements

of

t/O

numbers and other additional functions, select

the units within following applicable models;

Output:

16

Input:

4

Output:

6

).

"

12,

"

8

"

24,

*'

16

*'

24,

"

16

Output:

24

r'

36,

"

24

4

point

Analog

timer

unit

Positioning

counter module

14

PERIPHERALS

According to different function requirements far the peripheral equipments, wide range

of

periph-

erats are provided

as

follows;

1

F-2OP-E

I

Handy programmer

I

F2

-20P-E

(High function)

F-20MW

1

ROM

writer

t

?I

?I

1

GP-80ROW

I

"

"

(High function)

I

Above peripherals can

afso

be used for

the F series

PC

except F2-40AC, F2-40AW and F24OAP.

.-2-

Example

(-U

of

Type)

sink DC

input

model

(F2-40/6000,

RUN

-

F2-40/60cfU-U)

Example

1

2-1

of

source

?0/120VAC

POWER

DC

or

SUPPLY

Power supply voltage

input model

...............

(F2-40/60CICl-ES)

R

IJN

AC 110/120V

type models)

ACI 10/120V +IO%

model)

Power consumption

DC

24V

output capacity

j

(External power source) (Exctude the power

.................

..........

less

than 24VA (F2-40),

0.1A

or

AC

220/240V

or

AC 220/240V +IO%

less

(F2-40DC input model),

to

non-voltage contacts)

I1

zigz

50/60Hz

50/60Hz

than 40VA (F2-60)

0.2A

(F2-60DC input

(-4,

-ES

(-UL

model)

I

type

-3-

Example

of

sink

DC

input

model(F2-40/60C1lJ-D)

RUN

Earth

-

POWER

24VDC

/L

f-b

7

I

I

r'

I

A

m

m

Ah

TI

I

ri

7

*

Ensure that the input

[=I

terminal

is

connected to the power

@

terminal

as

illustrated above.

Example

of

source

DC

input model

(F2-40/60DCI-DS)

*

Ensure that the input

1-

terminal

is

connected to the power,

0

terminal

as

iltustrated

above.

POWER

SUPPLY

Power

supply

voltage

. . . . . . .

24VDCk8V

-4-

(1)

Connect a power supply cable of the correct rating to the base unit and extension unit (if used)

as

illustrated. Supply voltages should be

as

specified.

supply switch which can be used when the ROM cassette

(2) The power consumption of the base unit

is

less

than 25VA to F2-40 and 40VA to

however, this does not include the power consumption of any external load.

(3) The power must be switched off when the ROM

cassette

from the unit.

to

(4) The, power supply

the extension (if used) shall be connected to same

base unit.

..

-

GROUNDING

2-2

(1)

The unit must be grounded

as

illustrated. The extension unit

same line of base unit.

(2) Resistance should be

less

than

100G.

(3) Grounding must not be shared with any high power equipment such

RUN/STOP MODE TERMINALS

2-3

I

i

is

ommended to provide, power

j

F2-60

loaded on the base unit or unloaded

(if

ON/OFF

used)

also

as

a

motor system.

switch,for the

be grounded with

These terminals should

button)

as

illustrated.

The RUN mode

system).

When the STOP mode

are turned off and timers, plus the 128 of

and

64

of

the auxiliary relays,

battery support.

When the 'STOP' switch

external facilities be provided in

AC

input models,

TERMINALS

2-4

in case of

RUN

OUTPUT

(1

)

A relay contact

normal run mode, but

etc

ference,

(2)

This facifity

It

is

(3) Output load of the relay

performed through an extra relay.

be

connected to key switches or other suitable control devices

is

used when the programmabie controller

is

used (or there

state

is

on,

all

case

see

section

L-dor

is

provided between these two terminals inside. The contact

is

switched off

is

switched off in STOP mode.

is

a

power failure of

192

auxiliary relays are reset. However,

relays and some special auxiliary relays are maintained by

outputs will be

of

emergencies

'OFF'.

to

3-5.

U

if

CPU

error might be caused from electrical nqise inter-

is

running a program (controlling

more

than 20m/sec.), aflioutputs

However

it

support and back up

used to make an emergency stop circuit or warning circuit.

is

less

than 35VA. For loads over the rated limit, operation should be

ail

counters

is

recommended that

this

facility.

is

switched on

(push

a

at

2-5

DC24V

TERMINALS

In case

of

the sink input models, input devices

terminals and the

24+

imity switches or photo sensors.

In case

of

the source input models, non-voltage contact devices are powered from the

terminals and the 24V terminals have extra power capacity for

specified.

If the extension unit

unit. The

Any

COM

external power must not be supplied to

is

terminals

of

non-voltage contacts are powered from input

terminals provide DC24V power for input sensor devices such

the

input sensor devices

as

prox-

24V

as

used, connect the DC24V terminals between the base unit and extension

are

also

connected in the same manner.

these

terminafs.

-5-

!

3-1

EXAMPLE

OF

CONNECTIONS

(1)

Sink input modefs (F2-40/60170, F2-40/6OOO-U, F2-40/6OUO-UL)

Proxi mi ty

K

24+

Push button Limit Rotary Timer

switches switches switch contact

(2)

Source input modefs ~FZ-~O/~OCICI-ES)

Proximity

Push button Limit

I

switches switches

6mA

505

506

24+

ov

Rotary Timer

switch contact

3-2

lNPU1

TERMINALS

-6-

3-3

INPUT CIRCUIT SPECIFICATIONS

Operation

current

__ ~

1

OC24V Input DC24V Input

(Sink input)

DC4mA Min.

OFF-'ON DC4mA Min.

I

I

Response

time

lnpuf

Input circuit

OFF-'ON Approx.

l0m.sec

Approx. 10m.sec

ON-+OFF

Approx. 5m.sec Approx. 5rnsec

DC24V

=k

4V

DC24V 5 4V

(Self-supply) (Self-supply)

Rated input voltage

I

I

I I

I

Insulation Photocoupler insulation

lnout

AC2mA Max. AC2mA Max.

Approx. 15m sec

Approx.

8m

sec

Approx.

t5m

sec

Approx.

8m

sec

I

Indication

1

LED turns ON when input

is

activated.

3-4

CAUTlONS

(I)

Connect input control devices,

e.g.

limit switches, push butto&, to the input terminations

as

specified.

(2) In case of sink input models, non-voltage contact devices are powered from the input terminals

and the 24V terminal points can be used to power external transistors such

as

proximity

switches.

The

capacity of 24V

DC

source

is

rated by

0.1

Amp

(F2-40)

and 0.2 Amp

(FZ-60)

from 24V

terminal in addition to each 7mA from

all

input terminals.

(3)

In case of source input modefs, non-voltage contact devices are powered from the 24V termi-

nals and the current rating

at

each input terminal

is

24VDC, 6mA. The control devices should

be specified accordingly.

The 24V terminal points can also be used to power externaf transistors such

as

proximity

switches.

Totaf

of

0.1

Amp (F2-40) and 0.2 Amp

(F2-60)

current by two 24V terminals can be used for

such transistors in addition to each

6mA

suppty to

all

input terminals.

If further more power

is

requested, use an externaf power source of

16

to

36V DC.

The

OV

terminals

are

used for negatives of 24V

DC

source.

(4)

If

transistor circuits, such

as

proximity switches, are connected to input terminals and have

a

parallel or series resistance, their parallel should be more than

10OKL-l

and their series resistance

less

than

1

KO2.

(5)

Three common terminals

are

connected internally and are common. However, thte base and

extension unit commons are not linked unless connected together externalfy

as

detailed in

other section.

The common terminal

is

also used for

a

negative

of

24V

DC

source.

(6)

For the sake of convenience and appearance and to avoid damage of failure, input wires should

be bound or cabled together.

It:

is

recommended

that

input wires are not longer than 20 meters for the general use, However,

the tength can be longer but depends upon the conditions of the noise environment and voltage

drop.

-7-

3-5

AC

INPUT

HANDLINGS

(F2-40/60OO-C1A1,

A2)

When

no

contacr

input

devises such

as

proximity

switches

or

photo

sensors are connected

to

input

terminals, be aware that the leakage current may activate the

input

signal

incorrectly.

Where the leakage current

is

more than

2mA,

it

may prove necessary

to

provide additional

bleeder resister

or

CR

circuit (ex.

0.5yF

+

IOOSt),

otherwise use

input

devices

with

tow

leakage

current

less

than

2mA.

Run

stop

switch switch Limit switch

1

IO/

I20V

-

(Example:

F2-40MR-UAi

1

4-1

RELAY

OUTPUT

MODELS

(FZ-40/6OO

R,

-0U)

4

4

points

corn mo

4

4

points

n

common

points

common

points

common

\-\/u-

4

points

common

4 points

common common

4 points

4

points

common

points

common common

4

points

4

Connect external load devices e.g. contactors, pilot lamps, solenoid (electromagnetic) valves, etc.,

to

output terminations of the base unit and extension unit

As

shown in the above figure, four common terminals are provided for the output terminations.

As

these commons are not linked and cover each four

types

of

block

share one type

power can

be

used as shown in the above exampte as far as the output terminals

of

power.

(if

output

used).

terminals

in

their block, different

in

t

a

-9-

0

Normal open relay contacts are connected internally

to

the output terminals

on

the base and

extension units, The ratings

of

the contacts are

2A

at

24V

DC,

110/120V AC, 220/240V

AC.

These ratings apply

for

resistive loads

(COS

(6

=

1

.O).

The durability data of output relay

is

stated in other section

(4-5).

0

Each internai contact

is

protected by a residual current circuit. When the contact is closed,

its

current leakage will normally be less than 1 .lmA

at

220V

AC

or 0.55mA at

21OV

AC.

However,

it

is possible that this might have

some

effect on external loads.

Where the external current demand

is

very low,

it

may prove necessary

to

provide additional

parallel resistance because

of

the influence

of

leakage (see section

4-5).

e

When using the controller in a direct current circuit,

it

is recommende'd

to

connect a free whee!

diode in paratlel

to

the inductive load.

@

4-2

TRIAC

(SSR)

OUTPUT

MODELES

(F2-40/60cIS,

-DU)

1'09"

1

44

0

I

4 4

1

1

4 4

2

I

44 3

r:2

I

444 f 44 5 f 4 4 6 I 447

1

54

0

1

54

t

1

54

2

I

5 43

IC,??

I

5441 5451 546 1 547

I

2

4

points

4

points

common common

4

points

common

4

points

common

4

points

4

points

4

points

4

points

4

points

4

points

common

common

common

common common common

-

10-

I

Connect external load devices e.g. contactors, pilot lamps, sotenoid (electromagnetic)

to output terminations of the base unit and extension unit (if used).

As

As these commons are not linked and cover each four output terminals in their block, different

types of power can be used

block share one type

The load limitation of the triac

collective output load should no exceed

24OV.

For inductance loads, the rated coil of magnetic contactors

12OV

be required. For lamp loads above

Each triac

residual current circuit. With the triac

2.2mA

It

4-3

TRANSfSTOR

shown in the above figure, common terminals are provided

as

of

power.

shown in the above example

(SSR)

outputs

8A

across

is

1A

for each individual output, but the total

all

16

as

outputs

sl-tould

or 100VA

at

AC

is

not possible to operate triac output card

at

AC 220/240V. If the coil toad

(SSR)

inside the

220V. However,

OUTPUT

MODELS

is

over these limits, then an externa1)relay

IOOW,

unit

will withstand moderate surge currents, and

it

is

(F2-40/60CIT,

an external relay will atso be required.

'off'

current leakage

possible that this might have some effect on external loads.

on

DC

toads.

-17)

is

SINK

for

far

as

at

AC

be within 50VA

less

than 1.2mA

OUTPUT

valves,

the output terminations.

the output terminals in

110/120V or

at

is

protqcted bv

at

AC 120V or

TYPE

AC

AC

etc.,

220/

110/

will

a

a

I

i

?

1

DC24V 0 14301 431

/4321433143414351436f437[53015311532[5331534i

2A

d

t

P

b

4

535[536[5371

DC24V

0

I

DC24VO 31 33 35 37 431 433 435 437 531 533 535 537 DC24VO

40 42 44 46 440 442 444 446 540 542 544 546

DC24VO

41

43 45 47 441 443 445 447

541

543 545 547

DC24V

@

0

Connect external load devices

e.g.

contactors, pilot lamps, solenoid (electromagnetic)

valves,

etc.,

0

The load limitation

of

the transistor outputs

is

1A

for

each individual ouiput, but the collective

output toad should not exceed

2A

per 4 points

at

DC

24V.

8

Due to surge current limitations lamp loads should be within 3W.

0

When other load are connected to a output termination in addition to lamp load, the totaf collec-

tive

output load should be

as

specified with reference to following table.

to output terminations

of

the base unit and extension unit.

i

\

2w

6W

1w

I

16W

I

I

0

24W

I

0

The external DC power supply should be

DC

24V

+15%/-30%.

0

2A

rated back-up fuses or protectors are recommended per each four outputs

'to

prevent damage

to the circuit boards

of

the PC in the event of a short circuit fault in one of the external circuits.

4-4

TRANSISTOR OUTPUT

MODELS

(F2-40/600T-ESS)

SOURCE OUTPUT

TYPE

1

130 I 32 I34 136 1 14301432143414361 15301532153415361

I

1

I

DC24VO 41 43 45 47 441 443

445

447 541 543 545 547

DC24VQ

-

12

-

Connect external load devices e.g. contactors, pilot lamps, solenoid (electromagnetic)

to output terminations of the base unit and extension unit (if used).

The

load

limitation

output load should not exceed

Due to surge current limitations lamp loads should be within

When other load are connected

tive

output load should be

of

the transistor outputs

2A

per 4 points

to

a

output termination in addition to lamp load, the total collec-

as

specified with reference to following table.

is

at

1A

DC

for

each individual output, but

24V.

3W.

2w

1w

0

The

external

2A rated back-up fuses or protectors are recommended per each four outputs to prevent damage

to the circuit boards of the

4-5

OUTPUT CIRCUIT SPECIFICATIONS

~~

Output circuit

DC

power supply

Relay Output

should

PC

in the event

6W

16W

24W

be

DC

24V

of

a

Triac Output

i

+I

5%/-30%.

short circuit fault in one

Transistor Output

(Sink output)

of

the external ,circuits.

Transistor Output

(Source output)

External power source

Rated output current

(Resistance load)

Lamp load

Rush

current

Leakage current

Min. Load

(Inductive load)

Response

time

Circuit insulation

Indications

Less

than 250VAC

I30VDC

2AIpoint

Detailed below

tOOW

1OAICycle

0.55mA111 OVAC

l.lmAl220VAC

0.2VAlllOAC

0.8VAl220VAC

Approx. 5m.sec

Approx l0m.sec

Relay

insulation

LED

(When relay

is

activated)

coil

80-240VAC

tA1point but 2A

4

points toral

per

50VA

(1

loll

1

OOVA (220/240VAC)

lOOW

1 OAICycle

1 .lmAIllOVAC

2.2mA1220VAC

0.4VAIl TOVA

1.6VAl220VAC

Less than 1m.sec

1Om.szc Max.

Photo-triac

LED (When triac is

activated)

20VAC)

+?O%

24vDc-30%

IA/point but 2A

per

4

points total

24W (24VDC)

3W (Detailed in

Section

4-3)

BAllOms

-

Less than 1m.sec

Less than 1 msec

Photo-coupler

LED (When photo-

coupler is activated)

+lo%

24VDC-30F

tA/point but 2A

4

points total

per

24W (24VDC)

3W (Detailed in

Section 4-4)

SA11

Oms

-

I

Less than Irn.sec

Less than 1m.sec

Phot ocoupler

LED (When photo-

coupler is activated)

!

-13-

The basic

unit

and extension

unit

have the output power ratings indicated in the above table. For

loads over the rated maximum limits shown, operation should be perforhed through

an

extra

relay, capable of handling the load. Loads under the minimum limits shown

will

need

an

additional

surge absorber circuit (approx.

O.1pF

+

1OOSt)

to prevent incorrect operation due

to

leakage currents

ftowing

in

the output circuits.

Less than

35VA

Less than

80VA

Less than

120VA

on

I

Back-up fuses or circuit protectors are recommended on output circuits to prevent damage to the

circuit boards of the

PC

in

the event

of

a short circuit fault

in

an

external output circuit.

Inductive

toad

of

Relay

Output

Appticabte toads to the output relays are subject to the frequency

of

operations. According to our

life test data, followings are given for

a

reference

of

the relay durability level;

UP

to

3,000,000

UP

to

1,000,000

up

to

200,000

I

--

5-1

I

NSTAL

LATI

ON

'ER

1)

Connect a connector

PC.

the

2)

Fit the hooks in

the

PC.

3)

Slide the plastic cover upward ,to remove

the cover.

4) Connect the input wires to the terminals

and adjust the

DIP

of

the F2-4OAC to

the

installation holes

switch.

of

I

-

15-

3

5-2

CONNECTIONS

OF

INPUT CIRCUIT

Example

of

proximity

switch

lt---ll---

Proximity

switch

Pulse:

2KMz

Max

(ON:

0.25ms,

OFF:

0.25ms)

5-3

INDICATIONS AND DIP-SWITCH SETTINGS

Terminals

LED

indications:

1

.......

Mode selection tM470)

2

.......

Up/down selection (M471)

3

.......

Start (M472)

4

.......

input signal

DIP switch

setthgs:

SWI

.......

Switch

ON

only when 5VDC

is

used for input device.

SW2

.......

Switch

ON

only when 12VDC

is

used for input device.

SW3

.......

Switch

ON

only when 24VDC

is

used for input device.

SW4

.......

Switch

ON

only when input filter

is

required.

-16-

"_

..........

.....

...

.....

.............

yl_

..,...

.-,--

,~-..,"

I

6-1

FZ-4OAW

(WIRE

LINK) INSTALLATION

Attach the

Connect two

sealing twist are connected

The cable length shall be less than

suppty cables

6-2

FZQOAP (OPTICAL

unit

units

to

Fz-40 A

the

PC

in

with

a twist-pair cable as illustrated (SA

W

the same manner

to

the earth terminals

10

or

other such electrical apparatus

FIBER

Optical

connectors

LINK) INSTALLATION

/

as

the F2-40AC (Section5-1).

of

the

meters (approx.

to

avoid electrical noise interference.

Optical

to

SA,

SB

PCs.

35

feet) and keep away

F2-40A

to

SB),

W

and

from

both

ends

of

high voltage

Attach the

Connect

The cable length shall be less than

The optical fiber cables and opticaf connectors are

specifications and

unit

two

to

units

the PC

with

supply

in

the same manner as the F2-40AC (Section

optical plastic fiber cables as illustrated

50

meters (approx.

shall be inquired

to

Mitsubishi agent.

160

not

feet).

included

-17-

5-1

).

(R

to

T,

T

to

R).

in

the attachment. The material

6-3

INDICATIONS

AND

DIP-SWITCH

SETTINGS

6-4

(Expt. F2-40AW)

LED indicatigns:

1

.......

Power supply

2

.......

Linkage

RUN

3

.......

Signal transmission

4

.......

Transmission error

DIP

switch settings:

SW1

.......

Switch

OFF

at any time.

SW2

.......

Switch

ON

at any time.

SW3

.......

Since

two

PC

units must be identified

for

the signal handlings mentioned

in

the next

section

64,

the

SW3

makes identifications

of

both

PCs

as follows:

ON

.......

Side A PC (Master)

OFF

.....

Side

B

PC

(Slave)

SW4

.......

Switch

ON

to

transmit

32

points

of

signals

or

switch

OFF

to

transmit

16

points

of

signals.

SIGNAL TRANSMSSION

For the linkage operations

of

two

PCs,

certain auxiliary retays are shared

with

both

PCs

and the

signal transmissions are as follows:

(I

)

32

Points Transmission

Side

B

(Slave)

PC

Side

A

(Master)

PC

I

Receiving

Side

B

PC

can activate the auxiliary relays

M100-Ml37

subjectively and Side

A

PC

receives the

data

to

share

with

the contacts

in

the program.

On

other hand auxijiary relays

M140-MI77

are

activated

by

Side

A

PC

and the data is shared

by

Side

B

PC

with

the contacts.

(Auxiliary reiay

M100-M137

cannot

be

activated

by

Side

A

PC

and

M140--177

cannot be

activated

by

Side

B

PC.)

j

I

Receiving

1

In

Side

Ref.

1)

2)

Side B (Slave)

M140-Ml57

the same manner

B

PC

and M140-157

Linkage operation

expected to

It

takes approx. 7.2m.sec

time

of

receive

signal transmission

PC

as

32

point transmission, auxiliary relays

is

activated by Side

of

32/?6

from another

I

16

points

A

PC.

points

for

is

is

also availabte. But the auxiliary relays

PC

must not be activated for the coit.

the signal transmission between the

7.2m;sec

plus

a

execution time

Side

A

(Master)

M100-Ml17

PCs.

of

the

PC.

PC

are activated by

of

which data

Maximum delay

is

I

i

I

i

i

i

I

~

!

I

-19-

7-'!

INSTALLATION

Screw

4-M4

Screw

4-M5

F2-40:

F2-60:

Screw

hole

pitch

240(9.45)

335(

I

3.19)

h-

d-3.N

eo!

2s

..

..

UU-

mm

(inch)

The base unit and extension unit can be mounted with suitable screws direct

by using the four corner holes provided.

DIN

raii mounting kit

Do

not attempt to install the equipment on the floor surface or ceiling

is

available for

F2-40

models.

rise.

Do

not fail to install the equipment

in

case

unit through

boards of the

7-2

EXTENSION CABLE

(1)

Extension cables of

of

mounting the unit on the wall surface, beware

the

ventilation opening etc. Conductive trashes may cause damage to the circuit

PC

or

operation faiiure,

0.6

meter (1.97

on

the wall surface.

feet)

length

(2) The extension cables used to connect the basic unit and

a

400,

distance

500

are marked to each extensi,on port, and the ports

rate from any other cables or wires by

(3)

l/O

assignment numbers e,g.

00,

with same npmber shall be connected between the base unit and extension unit,

Labels of

00,

400

and

500

are attached to the base unit for the usage

F-20E.

7-3

ENV!RONMENT

of

are

attached in the

an

of

30mm

to

any flat surface

to

avoid temperature

conductive Trashes falling into the

F2-40E

and

F2-60E

unit.

extension unit should be kept sepa-

(1.2

inch)

at

least.

of

F-4T,

F-1OER or

White the

F

series

PC

is

suitable for most industrial sitcztions,

hostile environments associated with extremes of damp, dust, temperature, corrosive

or mechanical impact. The unit should not be installed in

to rise to above

50°C

(122'F) and a space of some 50mm

unit for heat dissipation.

7-4

ELECTRICAL

NOISE

1NTERFERENCE

To avoid electrical noise interference from some external apparatus, the unit should not be installed

near high voltage supply cables or other such electrical apparatus. Input and output wires must be

kept separate and away from any power supply cables or high voltage cables.

it

should not be used in excessively

gases,

vibration

a

situation where <he temperature

(2

inches) shoutd be allowed around the

-

20

-

is

likely

7-5

WIRINGS

led together

(2)

It

is

recommended that input and output wires are not fonger than

general use. However the length can be longer but depends upon the conditions

environment and voltage drop.

(3)

DC

cable and

(4)

External emergency stop circuit or interlocks for dangerous contactor such

AC

cable should not be bound together.

shall be provided in addition to the

(5)

If

internal power fuse should be cut

may not recover the unit.

7-6

PERIPHERAL INSTALLATION

(1

}

The power must be switched

(2) When F2-20P-E or F-20P-E

the programme must be

nd appearance and to avoi

as

well

as

output wires.

PC

sequence.

in

a

event

off

when the

is

plugged on the

MONITOR

mode.

ROM

PC

20

meters

of

wrong voltage supply, the fuse replacement

cassette

during the

is

loaded or unloaded.

PC

power

is

ON.

(65

feet) for the

of

the noise

as

forward/reverse

The slide switch

I

i

1

of

-21

,

,

-

,

INARY

ope

CHECKS

the unit,

it

is

advisable to carry out

the following checks:

a.

That the power and ground leads are properly con-

nected.

b. That input and output leads

and not entangled.

load according to

c.

that output loads and input contacts are within the

specification

(It

is

is

input and output assignment.)

I

imits detailed earlier.

are

property connected

worthwhile numbering each

d. That program/monitor mode on the programming

panel and RUN/STOP mode on the base unit are

properly

e.

That the extension cable

f.

Programmes can be checked and monitored by using

set.

is

properly connected.

the facility available on the programming panet for

this purpose.

8-2

DIAGNOSIS

r

Power

jndi$Or

supply

RUN

indicator

Battery vot

i

CPU.

PROG. ERROR

indicator

I

tage indicator

ERROR

I

The base unit's

(1

1

Power Supply t ndication

LED

is

under apparent power, open the fuse cover and check the fuse. If the

LEDs

illumination indicates that the power

the unit may be faulty.

(2)

Run indication,

ff the run

unit

(3)

Battery

is

faulty.

LED

is

in 'run' mode then (assuming

tf the battery

ry relay

(4)

Program Error tndication

CPU

I

)

M76

is

ERROR

Programming errofs

Timer or counter without constant

a.

b. Grammatic error in a program

c,

Circuit error in a program

2)

Battery voltage drop

3}

Sum-check error, which may be caused by nois? interference or conductive debris falling

into the unit.

In this

case,

ty of conductive debris, and try to operate again

enable the following conditions to be checked:

is

'on'. If the

.

is

not illuminated when the programming panel

all

wiring connections

LED

iltuminates, replace the battery immediately. At same time, a special auxitia-

turned

LED

ON.

flickers when following errors are caused:

LED

fails to illuminate when the unit

PC

will

not recover,

is

turned to 'monitor' and the

to

be correct),

it

is

likely the unit

K

check the program, battery voltage indication, electrical noise source or posibili-

after

the power reset.

'

22

-

(5)

CPU Error Indication

CPU

ERROR

LED

is

turned

ON

in

following case:

1) CPU execution error

is

caused

by

noise interference or conductive trashes fallen

2)

ROM

cassette

is

toaded or unloaded when the PC power

is

turned

ON.

3)

Watchdog timer error

is

caused if program execution time

is

more than

0.1

second.

unit.

into the

a.

In this case, turn the

PC

power

OFF

and switch

ON

again

(power reset).

If

the

PC

operation

is

recovered, check the electrical noise source or possibility of conductive trashes.

b. If the CPU

ERROR

LED

flickers after power reset, check the pragram error in the same

manner

as

former item (Section

8-2(4)).

c. If the CPU ERROR

LED

is

still

turned

ON,

check the program execution time.

In case of failure of the input

LEDs

to illuminate, check the

ON/OFF

status in the program

with programmer, and check whether input switching device works properly. Beware following

possibilities

:

(6)

input Indications

a.

If current rating of input device

is

too large, contact error may be caused.

b. When the bleed resister for external

LED

indication

is

provided in parallel to the input

device, the

PC

input may be turned

ON

incorrectly because

of

the leakage current.

c. The

PC

may not accept

the

input signal which

is

shorten than PC execution time.

(7)

Output fndication

If outputs fail to function, beware following cases might be caused:

a.

In

case

the very low current device

is

connected to the relay output or triac output

PC

models, the output device may be activated incorrectly because of the

PC

leakage current.

b. The short circuit and large current load may cause the damage of the

PC

relay contact or

damage

of

triac and transistor device in the PC, which cause output failure.

8-3

MAINTENANCE

(1)

Periodical Check

The

PC

does not contain wasting component except a lithium battery and output relays.

The battery life

is

approx. 5 years

(1

year warranty) and relay life

is

subjected to the frequency

of operations and current

level

(see

the section of output handling).

The battery

is

replaced in the manner stated below.

The units installation should be checked to ensure that

it

has not been contaminated by dust or

other contaminations, also that

all

terminal connections are

stilt

tight.

The unit should not be installed in

a

situation where

the

temperature

is

likely

to

rise

to above

5OoC

(122°F).

(2)

Battery Renewat

a.

The program

RAM

memory and a part of software functions are backed by a non-chargeable

lithium battery, of which discharge life

is

more than five years

(1

year warranty). When the

battery voftage runs tow,

LED

indicator

on

the base unit

is

itfuminated. However, regardless

of

its

condition,

it

is

recommended that the battery be replaced every five years.

b.

To

renew the battery, remove a pannel cover

of

the base unit and renew the battery within

30

seconds, while an inside capacitor supports the memories.

-23-

f

1

!

>

I

i

i

1

I

Power-failure compensation

Ambient temperature

Storage temperature

Ambient humidity

Vi bration resistance

fa

tion resistance

In su

Insulation withstand voltage

CPU

Memory

Method

Program language

Instructions

Program capacity

Execution speed

Memory

CPU

Self-d iagnostics

Battery

DC24V+8V

:

FZ-40: 25VA, FZ-60: 40VA

:

20m.sec.

:

0-55OC (32- 13loF)

:

-15-65OC

:

85%

(no condensation)

:

10 - 55H42,0.5rnm (Max. 2G1

:

5MCl (5OOVDC)

:

1500VAC, 1 minu.

:

Stored program, Repeated arithmetic

:

Relay and logic sym bok

:

Sequenciat instructions

Step-ladder instructions

Functional instructions

:

1000 steps

:

Average 7p.sec/step

:

C-MOS RAM standard, EP-ROM option

:

p.p

8031

:

Sum-check, watch-dog timer, battery voltage,

(-D, - DS

(5-

149OF)

Type)

:

:

:

35

2:

i

-rota'

power supply voltage, etc.

:

Lithium battery

57

~~

__

~

Functional

Number

Number

of

of

output

input

Input sensor power

Timers

Counters (backed by battery)

Auxiliary relays

No

battery back-up

Backed by battery

State

JM

P/EJP

:

F2-40 (Base unit): 24 points (W/RUN, STOP inputs)

(Base

F2-60

F2-40 (Base unit): 16 points

F2-60

:

F2-40 (Base unit): 24VDC 0.25A total (All inputs turned OFF)

~2-60

:

0.1

-

-

0.01

:

1

-

999:

:

128 points (M100- M277)

:

64

points (M300 - M377)

:

40 points (M600 - M647)

:

64 points (M700 - M777)

unit): 36 points (W/RUN, STOP inputs)

(Base

unit):

(W/RUN

24

points (W/RUN contact)

contact)

(Base unit): 24VDC 0.43A total (ditto)

999

sec.

timer: 24 points

99.9

sec. timer: 8 points (3 digits)

32

points Up/down available

-

24

-

(3

digits)

OUTLINES

AND

DIMENSIONS

I

Fz-60M

BASE

UNIT

mm

(inch)

350 (13.78)

d

..

..

~

7-

I

-M3.5

screw terminals

I

F2-40M BASE

UNIT

I

110

(4.33)

(o.43)

-+I--

,

-I-,,

i,

(0.197)

Weight

2.7

kg

(5.95

Ibs}

FZ-60E

EXTENSION

UNIT

350

113.78)

110

(4.33)

335

(13.19)

,

-25-

3

J

Y992D02801

C

(ROD)

The specifications and designs

are

subject to change without notice.

--

Loading...

Loading...