Page 1

Mitsubishi Industrial Robot

CR750-Q/CR751-Q series controller

iQ Platform Supporting

Extended Function Instruction Manual

CRnQ-700 series controller

BFP-A8787-F

Page 2

Page 3

All teaching work must be carried out by an operator who has received special

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

Safety Precautions

CAUTION

CAUTION

WARNING

CAUTION

DANGER

CAUTION

CAUTION

CAUTION

training. (This also applies to maintenance work with the power source turned

ON.)

Enforcement of safety training

For teaching work, prepare a work plan related to the methods and procedures

of operating the robot, and to the measures to be taken when an error occurs

or when restarting. Carry out work following this plan. (This also applies to

maintenance work with the power source turned ON.)

Preparation of work plan

Prepare a device that allows operation to be stopped immediately during

teaching work. (This also applies to maintenance work with the power source

turned ON.)

Setting of emergency stop switch

During teaching work, place a sign indicating that teaching work is in progress

on the start switch, etc. (This also applies to maintenance work with the power

source turned ON.)

Indication of teaching work in progress

Provide a fence or enclosure during operation to prevent contact of the

operator and robot.

Installation of safety fence

Establish a set signaling method to the related operators for starting work, and

follow this method.

Signaling of operation start

As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

Indication of maintenance work in progress

Before starting work, inspect the robot, emergency stop switch and other

related devices, etc., and confirm that there are no errors.

Inspection before starting work

Page 4

The points of the precautions given in the separate "Safety Manual" are given below.

DANGER

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

Refer to the actual "Safety Manual" for details.

When automatic operation of the robot is performed using multiple control

devices (GOT, programmable controller, push-button switch), the interlocking of

operation rights of the devices, etc. must be designed by the customer.

Use the robot within the environment given in the specifications. Failure to do

so could lead to a drop or reliability or faults. (Temperature, humidity,

atmosphere, noise environment, etc.)

Transport the robot with the designated transportation posture. Transporting

the robot in a non-designated posture could lead to personal injuries or faults

from dropping.

Always use the robot installed on a secure table. Use in an instable posture

could lead to positional deviation and vibration.

Wire the cable as far away from noise sources as possible. If placed near a noise

source, positional deviation or malfunction could occur.

Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to

personal injuries or damage if the robot is started with external commands.

Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

After editing the program, always confirm the operation with step operation

before starting automatic operation. Failure to do so could lead to interference

with peripheral devices because of programming mistakes, etc.

Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to

do so could lead to personal injuries.

Never carry out modifications based on personal judgments, or use nondesignated maintenance parts.

Failure to observe this could lead to faults or failures.

Page 5

When the robot arm has to be moved by hand from an external area, do not

WARNING

CAUTION

CAUTION

DANGER

DANGER

DANGER

DANGER

DANGER

CAUTION

place hands or fingers in the openings. Failure to observe this could lead to

hands or fingers catching depending on the posture.

Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during

automatic operation, the robot accuracy could be adversely affected. Moreover,

it may interfere with the peripheral device by drop or move by inertia of the arm.

Do not turn off the main power to the robot controller while rewriting the

internal information of the robot controller such as the program or parameters.

If the main power to the robot controller is turned off while in automatic

operation or rewriting the program or parameters, the internal information of the

robot controller may be damaged.

Do not connect the Handy GOT when using the GOT direct connection function

of this product. Failure to observe this may result in property damage or bodily

injury because the Handy GOT can automatically operate the robot regardless

of whether the operation rights are enabled or not.

Do not connect the Handy GOT to a programmable controller when using an iQ

Platform compatible product with the CR7xx-Q controller. Failure to observe

this may result in property damage or bodily injury because the Handy GOT can

automatically operate the robot regardless of whether the operation rights are

enabled or not.

Do not remove the SSCNET III cable while power is supplied to the multiple

CPU system or the servo amplifier. Do not look directly at light emitted from

the tip of SSCNET III connectors or SSCNET III cables of the Motion CPU or

the servo amplifier. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

Attach the cap to the SSCNET III connector after disconnecting the SSCNET

III cable. If the cap is not attached, dirt or dust may adhere to the connector

pins, resulting in deterioration connector properties, and leading to malfunction.

Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not

being released. In order to prevent errors occurring, please be sure to check

that all functions (such as the teaching box emergency stop, customer emer

gency stop, and door switch) are working properly after the wiring setup is com

pleted.

-

-

Page 6

Use the network equipments (personal computer, USB hub, LAN hub, etc)

CAUTION

confirmed by manufacturer. The thing unsuitable for the FA environment

(related with conformity, temperature or noise) exists in the equipments

connected to USB. When using network equipment, measures against the noise,

such as measures against EMI and the addition of the ferrite core, may be

necessary. Please fully confirm the operation by customer. Guarantee and

maintenance of the equipment on the market (usual office automation

equipment) cannot be performed.

Page 7

*CR751-D or CR751-Q controller

CAUTION

PE terminal

Grounding screw

Controller

ACIN connector

AC200V AC200V

Primary

Secondary

PE terminal

Grounding screw

123 123

ACIN connector

ACIN connector

Note 2)

Note 1) Crimping swage is recommended for connecting the attachment ACIN connector (soldering is also possible)

Recommendation compression tools: 234171-1(Tyco Electronics)

Note 2) The earth leakage breaker is the customer preparation. Always use the cover below.

Recommendation: For single primary power supply .........NV30FAU-2P-10A-AC100-240V-30mA, (Cover: TCS-05FA2)

For three primary power supply .......... NV30FAU-3P-10A-AC100-240V-30mA, (Cover: TCS-05FA3)

Note 3) If necessary, as shown in the figure, connects the noise filter between ACIN terminal blocks and primary power supply.

(Recommended noise filter: SUP-EL20-ER6 *OKAYA ELECTRIC INDUSTRIES)

Controller

<4> LINE/LOAD

<3> LINE/LOAD

<1> LINE/LOAD

<2> LINE/LOAD

Noise filter

Label

ACIN connector or

power cable

(Attachment)

Note 1)

For three phaseFor single phase

Three phase Single phase

Earth leak

-

age breaker

(NV)

Note 3)

* The controller is an

example.

Notes of the basic component are shown.

Please install the earth leakage breaker in the primary side supply power supply

of the controller of CR751-D or CR751-Q because of leakage protection.

1) Please prepare the following: Leakage current breaker (with the terminal cover), cable for connecting the

primary power supply (AWG #14 (2mm

2

or above).

(3.5mm

The secondary power cable (with the ACIN connector) for single phase or three phase power is supplied with

the product to match the specifications. When you build a cable suitable for your environment using the ACIN

connector and the ACIN terminal supplied, prepare a secondary power cable (AWG #14 (2mm

2) Confirm that the primary power matches the specifications.

3) Confirm that the primary power is OFF and that the earth leakage breaker power switch is OFF.

4) Connect the secondary power cable.

a) When using the supplied power cable with the ACIN connector

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

b) When building a power cable using the ACIN connector and the ACIN terminals supplied

Connect the ACIN terminals with the secondary power cable (prepared by customers), and insert the ACIN

terminals to the ACIN connector pins with the following numbers. Crimping caulking is recommended to

connect the ACIN terminals.

For single phase: 1 and 3

For three phase: 1, 2, and 3

Refer to the figure above and connect the cable from the secondary side of the earth leakage breaker.

5) Connect this ACIN connector to the ACIN connector on the front of the controller.

6) Connect the grounding cable to the PE terminal. (M4 screw)

7) Connect the primary power cable to the primary side terminal of the earth leakage breaker.

2

or above), cables to ground the primary power supply (AWG #12

2

) or above).

Page 8

Revision history

Date of print Specifications No. Details of revisions

2009-12-04 BFP-A8787-* • First edition created.

2012-03-05 BFP-A8787-A • CR750-Q/CR751-Q series controller were added.

2012-12-05 BFP-A8787-B • The statement about trademark registration was added.

2014-08-06 BFP-A8787-C • The cover and corporate logo mark of this manual was changed.

• The statement about trademark registration was modified.

2014-12-16 BFP-A8787-D • Correction of errors in a timing chart was corrected.

2015-03-10 BFP-A8787-E • The new function of software version R3p was added.

2017-05-10 BFP-A8787-F • Contact information of the authorized representative was updated.

• Correction of errors in “(3) Hand control image” was corrected.

• The corporate logo mark of illustrations in this manual was changed.

Long-precision integer number and single-precision real number can be used

for reading/writing of numeric value variables.

Page 9

*Introduction

• No part of this manual may be reproduced by any means or in any form, without prior consent

from Mitsubishi.

• The contents of this manual are subject to change without notice.

• The specifications values are based on Mitsubishi standard testing methods.

• The information contained in this document has been written to be accurate as much as possi-

ble. Please interpret that items not described in this document "cannot be performed." or "alarm

may occur".

Please contact your nearest dealer if you find any doubtful, wrong or skipped point.

•This specifications is original.

• Microsoft, Windows, Windows XP, Windows Vista, Windows 7, Windows 8, Windows 8.1 are

either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

• Windows®XP, Windows Vista®, Windows® 7, Windows® 8, Windows® 8.1 are either product

names of Microsoft Corporation in the United States.

• Ethernet is registered trademarks or trademarks of Xerox Corporation in the United States.

• All other company names and production names in this document are the trademarks or regis-

tered trademarks of their respective owners.

Copyright(C) 2009-2017 MITSUBISHI ELECTRIC CORPORATION

Thank you for buying the industrial robot MELFA manufactured by Mitsubishi Electric.

This document provides the instructions for iQ Platform supporting extended functions. Our

extended functions allows the sequencer easily to monitor the robot through shared memory

between sequencer and robot, set up data, and operate the robot without a program (sequencer

direct performance). This document provides the detailed description of data configuration of shared

memory, monitoring, and operating procedures.

Please carefully read and fully understand this document before making use of the extended functions.

Target controller of this document

This document supports the robot controller below:

• CR750-Q/CR751-Q series controller: ... Ver. R3 or later

• CRnQ-700 series controller: ................. Ver. N8 or later

Robot language MELFA BASIC V or later

Page 10

Contents

Page

1 Overview ......................................................................................................................................... 1-1

1.1 Shared Memory Extended Function List ................................................................................... 1-1

1.2 Features .................................................................................................................................... 1-2

1.3 Shared Memory Configuration .................................................................................................. 1-4

1.3.1 Memory Configuration for Valid/Invalid Extended Function ................................................ 1-4

1.3.2 Memory Map of Extended Function Area ........................................................................... 1-5

2 Preparation for Using Extended Function ....................................................................................... 2-6

2.1 Operation flow ........................................................................................................................... 2-6

2.1.1 Set up Sequencer's Multiple CPUs ..................................................................................... 2-7

2.1.2 Set up Robot's Multiple CPUs ............................................................................................. 2-8

2.1.3 Set up Parameter for Selecting Shared Memory Extended Function ................................. 2-9

2.1.4 Check Robot Language Setting ........................................................................................ 2-10

2.1.5 Allocation Example of Shared Memory ............................................................................. 2-11

(1) Multiple CPU Configuration with One Sequencer plus One Robot ................................ 2-11

(2) Multiple CPU Configuration with One Sequencer plus Three Robots ............................ 2-13

3 Monitor Robot Information ............................................................................................................ 3-17

3.1 Operation Flow ........................................................................................................................ 3-18

3.1.1 Select Monitoring Items .................................................................................................... 3-19

3.1.2 Select Target Mecha ......................................................................................................... 3-19

3.1.3 Timing Chart ..................................................................................................................... 3-20

3.1.4 Sample Ladder ................................................................................................................. 3-21

3.2 Monitoring Item ....................................................................................................................... 3-23

3.2.1 Monitor Operation Control Setting Values ........................................................................ 3-23

3.2.2 Monitor Activities ............................................................................................................... 3-25

3.2.3 Monitor Current and Aimed Positions ............................................................................... 3-26

3.2.4 Monitor Position and Joint Information ............................................................................. 3-28

(1) Select Position and Joint Data ....................................................................................... 3-28

(2) Position and Joint Data .................................................................................................. 3-30

3.2.5 Monitor Maintenance Information ..................................................................................... 3-33

4 Reads/Writes Robot's Variables ................................................................................................... 4-34

4.1 Function Description ............................................................................................................... 4-34

4.2 Operation Flow ........................................................................................................................ 4-34

4.3 How to Operate Variables ....................................................................................................... 4-35

4.3.1 Data List ............................................................................................................................ 4-35

(1) Sequencer output data ................................................................................................... 4-35

(2) Robot output data ........................................................................................................... 4-36

(3) Completion status ........................................................................................................... 4-37

(4) Data description ............................................................................................................. 4-37

4.3.2 Timing Chart ..................................................................................................................... 4-39

4.3.3 Sample Ladder ................................................................................................................. 4-40

5 Read Current Line of Robot Program ........................................................................................... 5-42

5.1 Function Description ............................................................................................................... 5-42

5.2 Operation flow ......................................................................................................................... 5-42

5.3 How to Operate Program ........................................................................................................ 5-43

5.3.1 Data List ............................................................................................................................ 5-43

5.3.2 Timing Chart ..................................................................................................................... 5-47

5.3.3 Sample Ladder ................................................................................................................. 5-48

6 Set up Robot's Maintenance ..................................................................................................

6.1 Function Description ............................................................................................................... 6-50

6.2 Operation flow ......................................................................................................................... 6-50

6.3 How to Operate Maintenance ................................................................................................. 6-51

....... 6-50

i

Page 11

Contents

Page

6.3.1 Data List ............................................................................................................................ 6-51

6.3.2 Timing Chart ..................................................................................................................... 6-53

6.3.3 Sample Ladder ................................................................................................................. 6-54

7 Read Robot Information ................................................................................................................ 7-56

7.1 Function Description ............................................................................................................... 7-56

7.2 Operation flow ......................................................................................................................... 7-56

7.3 How to Operate Robot Information ......................................................................................... 7-57

7.3.1 Data List ............................................................................................................................ 7-57

7.3.2 Timing Chart ..................................................................................................................... 7-60

7.3.3 Sample Ladder ................................................................................................................. 7-61

8 Perform Sequencer Direct ............................................................................................................ 8-63

8.1 Sequencer Direct Performance Function ................................................................................ 8-63

8.2 Operation flow ......................................................................................................................... 8-64

8.2.1 Parameter Setting ............................................................................................................. 8-65

8.2.2 Teaching ........................................................................................................................... 8-66

(1) Position Data .................................................................................................................. 8-66

(2) Position Teaching in Position Box (R32TB) ................................................................... 8-67

8.2.3 Prepare to Perform Sequencer Direct .............................................................................. 8-71

8.3 How to Operate Sequencer Direct .......................................................................................... 8-72

8.3.1 Operation Command ........................................................................................................ 8-72

(1) Sequencer output ................................................................................................................................................... 8-72

(2) Robot output .............................................................................................................................................................. 8-74

(3) Data description ............................................................................................................. 8-74

8.3.2 Timing Chart for Performing Operation Command ........................................................... 8-81

(1) Perform Operation (Normal Operation) .......................................................................... 8-81

(2) Operation Command Is Impracticable: ........................................................................... 8-82

(3) Suspend/Resume Operation .......................................................................................... 8-83

(4) Support on Occurrence of Error ..................................................................................... 8-84

(5) Suspension when Robot's External Operation Authority Gets Invalid ............................ 8-85

(6) Cancel Based on Command Request OFF Signal ......................................................... 8-86

8.3.3 Sample Ladder for Performing Operation Command ....................................................... 8-87

8.3.4 Control Robot Hand .......................................................................................................... 8-89

(2) Mapping hand signal with parameter HANDTYPE ......................................................... 8-90

(3) Hand control image ........................................................................................................ 8-91

8.3.5 Timing Chart for Robot Hand Control ............................................................................... 8-93

8.3.6 Sample Ladder for Robot Hand Control ........................................................................... 8-98

8.4 Samples ................................................................................................................................ 8-100

8.4.1 Robot Program ............................................................................................................... 8-100

8.4.2 Sample Ladder Program ................................................................................................. 8-101

8.4.3 Sample Operation Setting in GOT Screen ...................................................................... 8-109

8.5 Precautions for Sequencer Direct Performance ................................................................... 8-113

8.5.1 Requirements ................................................................................................................. 8-113

8.5.2 Running together with Program ...................................................................................... 8-113

8.5.3 Prohibit Program Startup with always Running Program ................................................ 8-113

8.5.4 Robot Language Setting ................................................................................................. 8-113

8.5.5 Operation Panel Display ................................................................................................. 8-114

9 Shared Memory Extended Function Relevant Parameter .......................................................... 9-115

9.1 Parameter of Selecting Shared Memory Extended Function ................................................ 9-115

9.2 Function Definition Parameter .............................................................................................. 9-117

10 Extended Function Relevant Error List ................................................................................... 10-118

ii

Page 12

1Overview

Note)

Note) The figure is the DU-700 series drive unit. The DU750-Q/DU751-Q series drive unit is also the same.

Monitor information

Operate robot

Instruct robot operation

Instruct robot operation

Sequence program

Shared

memory

1 Overview

These specifications describe the functions (sequencer direct performances) which extend the shared

memory in CR750-Q/CR751-Q series and CRnQ-700 series robot controller, exchange various robot information between sequencer and robot through the extended shared memory, and operate the robot without a

robot program.

Note: These shared memory extended functions only support MELFA-BASIC V or later. They do not support

MELFA-BASIC IV.

(For more information, refer to Page 10, "2.1.4 Check Robot Language Setting")

Sequencer direct performance does not support mecha 2 and 3 for multiple mecha. It supports additional axis.

1.1 Shared Memory Extended Function List

These shared memory extended functions are largely classified into monitoring and operation functions.

Monitoring function periodically updates and outputs the data in shared memory on the robot. Operation

function outputs a request from the sequencer to the robot as needed and exchanges the data. Shared

memory extended functions also provide a direct performance function to directly operate the robot.

No Item Description

1 Monitor-

ing function

2 Monitor activities Monitors the robot's activities (current

3 Monitor current and

4 Monitor general position

Monitor operation control setting values

aimed positions

and joint information

Monitors the setting values relating to

operation control command and operation control.

speed, arrival factor to the aimed position, etc.)

Monitors current and aimed positions of

robot.

Monitors various position type data (orientation at collision, etc.) and joint type

data (current value, load factor, etc.)

5 Monitor maintenance

information

Monitors the maintenance information

(battery and grease remaining times).

I/F btwn

Robots

Motoring output

(Robot side periodically updates

the data in

shared memory)

Update Cycle

7.1msec

7.1msec

7.1msec

It may differ according to each item.

Refer to Page 28,

"3.2.4 Monitor Position and Joint Information".

Depending on the

parameter MFINTVL

1-1Shared Memory Extended Function List

Page 13

1Overview

No Item Description

6 Operation

function

7 Read program's current

8 Set up maintenance Resets the servomotor information.

9 Read error information Reads detailed error information (pro-

10 Read product information Reads the robot's product information

11 Perform sequencer direct Operates the robot from the sequencer

Read/write variables Reads/ writes variables used in the

robot's program.

line

Reads currently performing line of the

robot program on a per line basis (up to

128 characters).

gram name, occurred line, etc.)

(model name, version, and serial number).

through shared memory

I/F btwn

Robots

Request reply

method

(The robot side

answers by the

output request of

the sequencer,

and delivers the

data on the

shared memory)

Update Cycle

Responds within 1s

(It may vary according to the load status

of robot control)

1.2 Features

(1) Fulfilling functions to monitor and operate robot from GOT. Advances T/B and PC-less solution.

→ Various functions can be performed by reading/ writing the data in shared memory from GOT.

● Allows you to check activities, position information, and setting values of operation control command and

thereby analyze the operation in case of debugging or problem. (Monitoring current and aimed positions,

activities, and operation control setting values)

● Allows you to read and write the contents of program and variables and thereby change the robot's oper-

ation in case of debugging or problem.

● Allows you to check and set up maintenance status.

● Allows you to check error's detailed content. (Reading error information)

● Allows you to display and check various information in the robot (product, servo information, etc.)

(2) Controls peripheral devices and system according to the robot activities with the sequencer

The sequencer allows you to monitor the data in shared memory and responsively control the peripheral

device connected to the sequencer according to the monitored value.

● Allows you to control the peripheral devices by monitoring the robot's activities (current speed, arrival fac-

tor to the aimed position, etc.)

● Allows you to generate an alarm to the system and report to the upper side by monitoring the mainte-

nance and servomotor information (load factor, etc.)

(3) Analyzes the data and performs the quality control by logging the robot information through sequencer

Allows you to analyze the system data and perform the products' quality control by sending the logged robot

information in shared memory to the sequencer and upper device connected to the sequencer.

● Allows you to control the system's operating situation by logging error information.

● Allows you to perform the quality control of product assembly by logging servo monitor information (cur-

rent value, etc.)

Features 1-2

Page 14

1Overview

(4) Allows to operate the robot without learning robot language (sequencer direct performance)

● Allows to operate the robot without knowing robot language.

Allows you to operate the robot by writing predetermined setting value into the specified address in

shared memory. Therefore, this function can be fulfilled regardless of sequencer language (ladder, ST

language, SFC, etc.)

● Allows you to select either joint or linear interpolation. Also, allows you to adequately specify the robot

operations such as override, acceleration and deceleration, tool setting.

Command Action

Operation control

Definition command

Hand command

Mov Move for joint interpolation

Mvs Move for linear interpolation

Ovrd Specify the overall speed

Spd Specify the linear interpolation speed

Accel Specify the acceleration and deceleration speed

Tool Specify the tool data

Hopen/Hclose

Open/close a hand

● Allows you to operate the robot with a sense, which is familiar to the sequencer programmer, to move a

positioning unit.

● Allows you to control the system operations only with sequencer.

Makes the program management easy so that a sequencer programmer can support for the change of

system specification and the problem.

● Allows you to control the system settings only with the sequencer in the GOT screen.

A sequencer programmer can support for the change of system specification and the problem so that the

program management gets so easy.

1-3Features

Page 15

1Overview

Robot input area

(Sequencer output area)

0

511

0

511

0

511

512

1023

User area

User area

0

511

User area

User area

Extended

function area

・

・

・

Robot output area

(Sequencer input area)

0.5K

words

extended

Total 1K

word used

512

1023

Extended

function area

0.5K

words

extended

Total 1K

words used

Sequencer shared memory address (per word)

* Above notation is an offset address from the beginning

・

・

・

Sequencer shared memory address (per word)

* Above notation is an offset address from the beginning

Robot input area

(Sequencer output area)

Robot output area

(Sequencer input area)

Sequencer shared memory address (per word)

* Above notation is an offset address from the beginning.

Sequencer shared memory address (per word)

* Above notation is an offset address from the beginning.

1.3 Shared Memory Configuration

Here, describes the shared memory configuration among multiple CPUs.

1.3.1 Memory Configuration for Valid/Invalid Extended Function

To use the shared memory extended functions, enable the shared memory extended functions with the

parameter "IQMEM".

After enabling the shared memory extended functions, the shared memory is used by extending the robot I/

O area by 0.5 K word.

Extended Function Invalid

Extended Function Valid

Note) Only the user area can be referred to by robot program, signal monitor, and dedicated I/O signal allo-

cation. They cannot refer to the extended function area.

Shared Memory Configuration 1-4

Page 16

1Overview

1.3.2 Memory Map of Extended Function Area

The table below lists the memory map of extended function area in the shared memory among multiple

CPUs.

* As the sequencer address may differ according to each CPU device, the sequencer address is described

in the offset address from start address.

* When not otherwise specified, the values are stored in binary format.

(1) Robot input (sequencer output) area (2) Robot output (sequencer input) area

Shared

Memory Addr

Sequencer

Description

Addr

512 Common setting area of extended function 512 Common setting area of extended function

Sequencer direct performance area Sequencer direct performance area

600 600

Shared

Memory Addr

Sequencer

Addr

Description

Common area of operation function

Read/write variables

Reading area of program's current line

Reset area of servo monitor information

Reading area of information

700 Common area of operation function 700

Reading/ writing/ teaching area of variables

Common area of monitoring function

Reading area of program's current line Monitoring area of operation control setting

values

800 800

Monitoring area of activities

Reset area of servo monitor information

Reading area of error and product information

Common area of monitoring function

Monitoring area of general position and joint

information

(Reserved: Future extended area)

900 900 Monitoring area of general position and joint

Monitoring area of current and aimed posi-

tions

information

1000 1000

1023 1023

1024 1024

1-5Shared Memory Configuration

Monitoring area of maintenance information

(Reserved)

Page 17

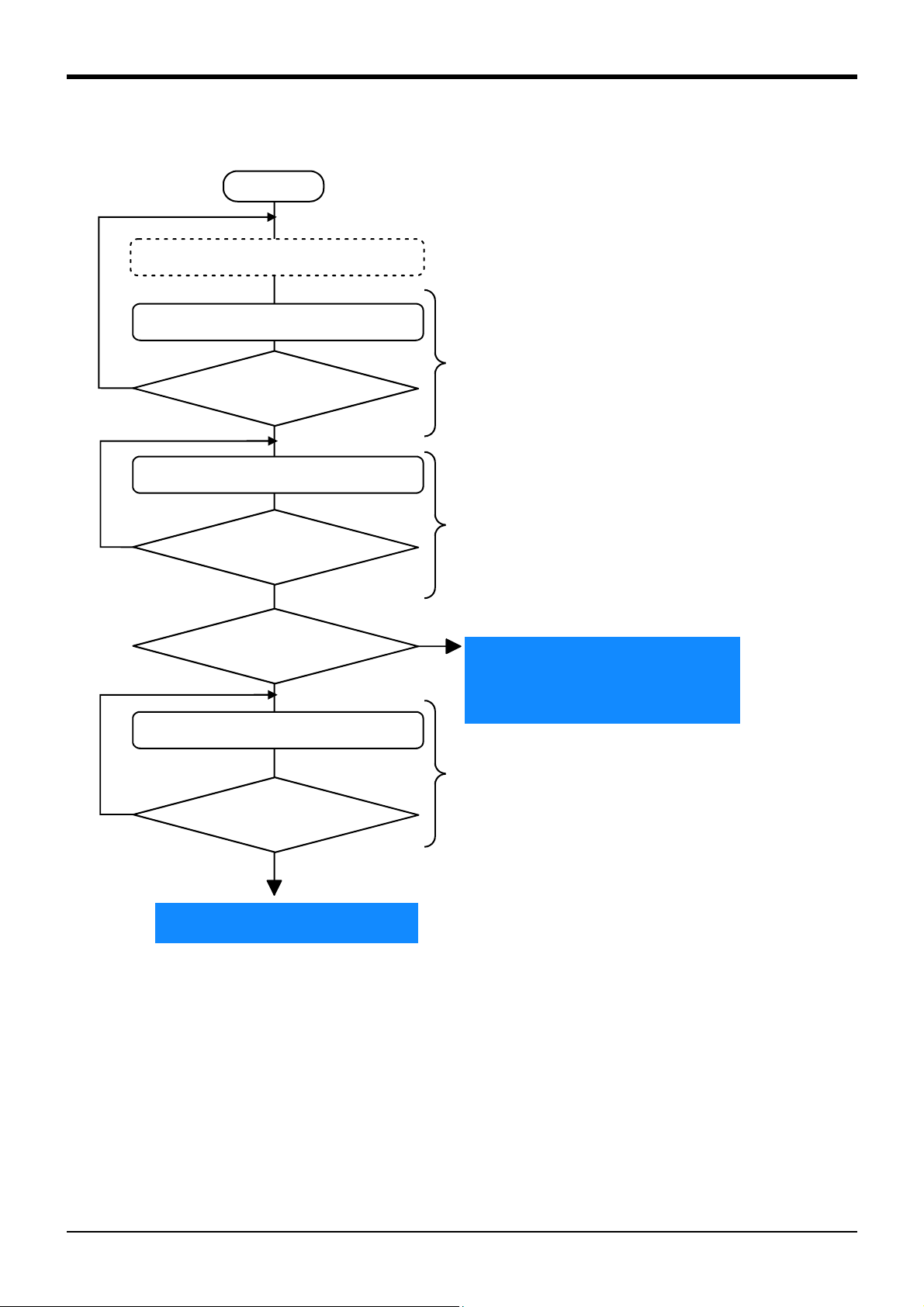

2 Preparation for Using Extended Function

…

…

…

● Sets up sequencer's parameter (multiple CPU setting).

For robot CPU, allocate 1K word of free user area in high-speed

communication area of multiple CPUs to robot's I/O area.

(Refer to Page 7, "2.1.1 Set up Sequencer's Multiple CPUs")

● Sets up multiple CPUs' parameters.

(Refer to Page 8, "2.1.2 Set up Robot's Multiple CPUs")

● Sets up parameter IQMEM.

1) To enable the extended function, set bit 0 to one.

2) To enable the sequencer direct performance, set bit 1 to one.

(Refer to Page 9, "2.1.3 Set up Parameter for Selecting Shared

Memory Extended Function")

● Set robot language to "MELFA BASIC V."

(Refer to Page 10, "2.1.4 Check Robot Language Setting")

"3Monitor Robot Information"

"4Reads/Writes Robot's Variables"

"5Read Current Line of Robot Program"

"6Set up Robot's Maintenance"

"7Read Robot Information"

"8Perform Sequencer Direct"

Set up sequencer's multiple CPUs

Start

Reset sequencer

Reset sequencer

Did the sequencer

successfully restart?

Carry out the functions described in

chapters 3 to 8

● Carry out the reset operation of sequencer or reset the sequencer

by turning ON the power.

2.1 Operation flow

2Preparation for Using Extended Function

Operation flow 2-6

Page 18

2Preparation for Using Extended Function

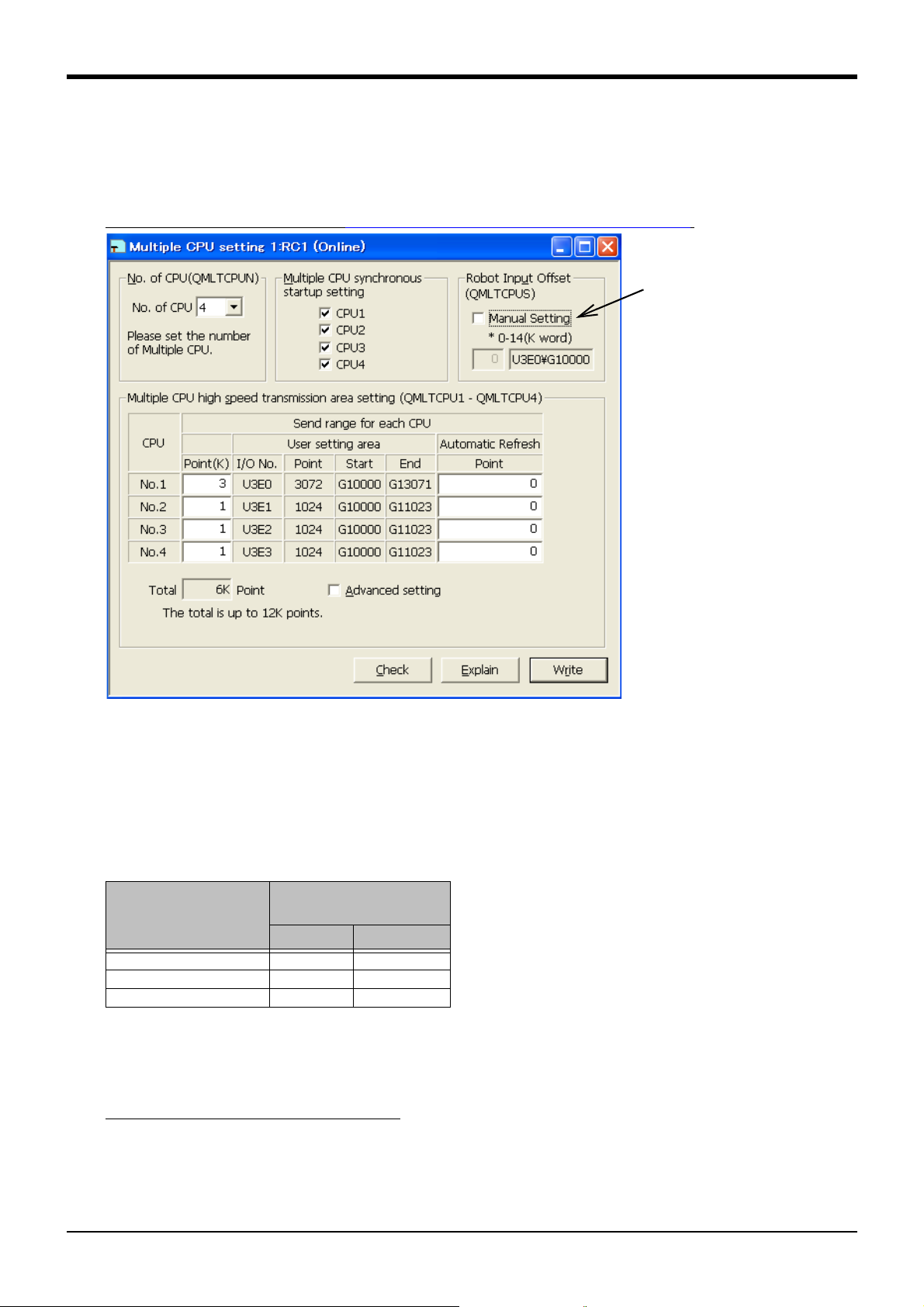

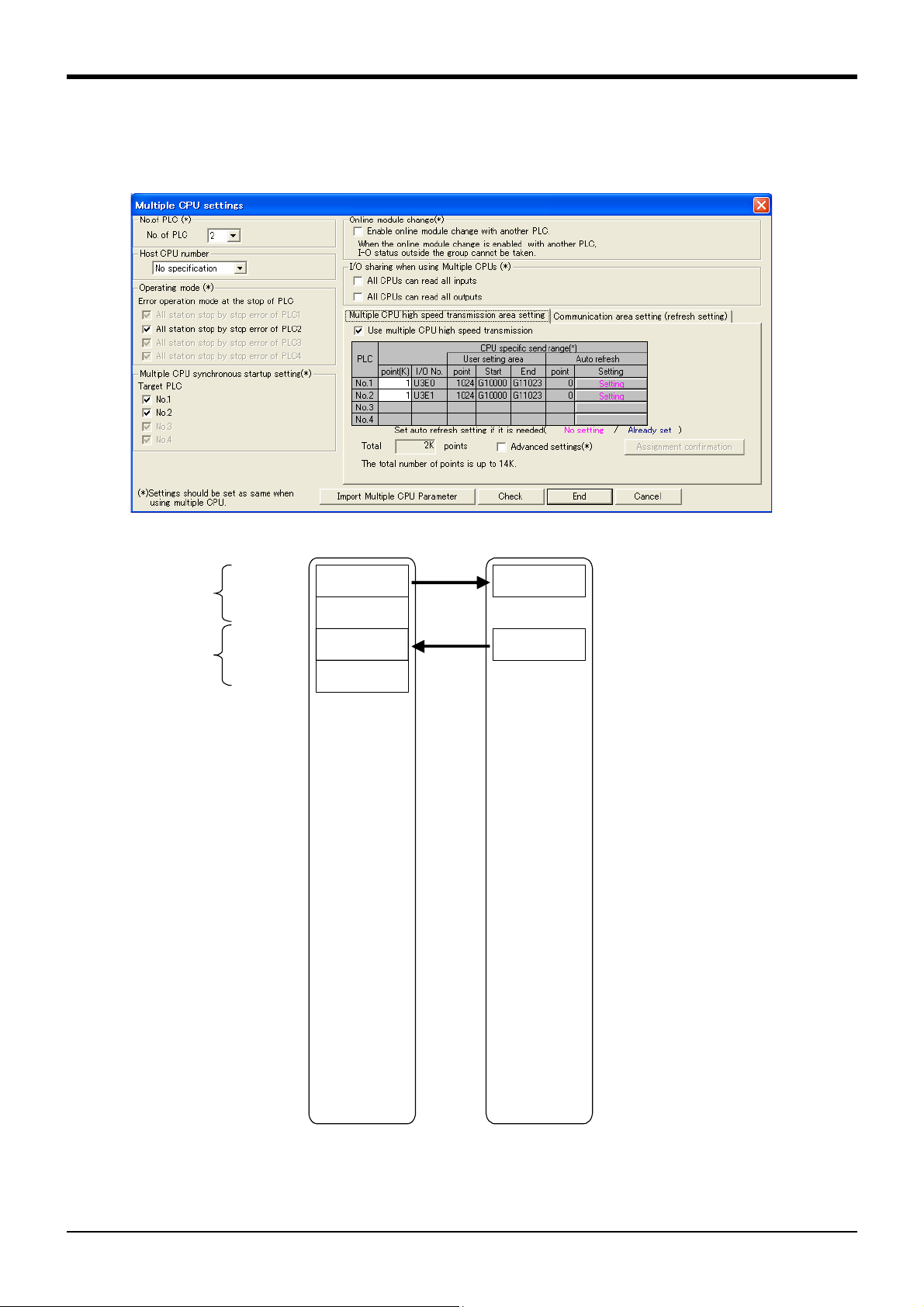

2.1.1 Set up Sequencer's Multiple CPUs

Here, sets up the multiple CPU setting as a sequencer's PC parameter. Also refer to the description of

sequencer link I/O functions described in Supplement volume "Instruction Manual, Detailed Description of

Functions and Operations."

GX-Developer multiple CPU setting screen (three robots. The shared memory extended functions are valid

in all robots)

Setting Item Description Setting Value

CPU quantity Set up the quantity of CPU units used in multiple CPU

system.

Synchronous startup

among multiple CPUs

High-speed communication area setting among

multiple CPUs

Automatic refresh setting Set up this when the device data is automatically

Set up this to synchronize the startup times of CPU

units in multiple CPU system.

* Because the robot CPU takes a dozen second for

startup, select the synchronize startup

Set up this when the data is transferred by using the

high-speed communication area

CPUs.

The necessary area for robot is as follows:

Shared memory extended functions are valid:

Robot input area: 1.0K

Robot output area: 1.0K

Shared memory extended functions are invalid:

Robot input area: 0.5K

Robot output area: 0.5K

refreshed by using the high-speed communication area

among multiple CPUs.

* Robot CPU is not supported. Always set this to zero.

Note1)

among multiple

Note1) For information about multiple CPUs and high-speed communication area among multiple CPUs, refer to the QCPU

manual (QCPU User Manual, Multiple CPU System).

Note2) Because the area is set up in 1K unit, allocate 1K even in case of 0.5K.

2 - 4

Required for check

<Shared memory extended functions are valid:>

Device #1: Sum of the size (1K) of the data to be

sent to the robot and the size of the data to be

sent to other devices

Robot device: Set 1K for it

Other devices: Set its own transmission size

<Shared memory extended functions are invalid:>

Device #1: Sum of the size (0.5K) of the data to be

sent to the robot and the size of the data to be

sent to other devices

Robot device: Set 1K for it

Other devices: Set its own transmission size

Note 2: Because the area is set up in 1K unit, allocate 1K even in case of 0.5K.

Robot device: Set zero point for it

Other devices: To use automatic refresh function,

set its score and target device

Note2)

2-7Operation flow

Page 19

2Preparation for Using Extended Function

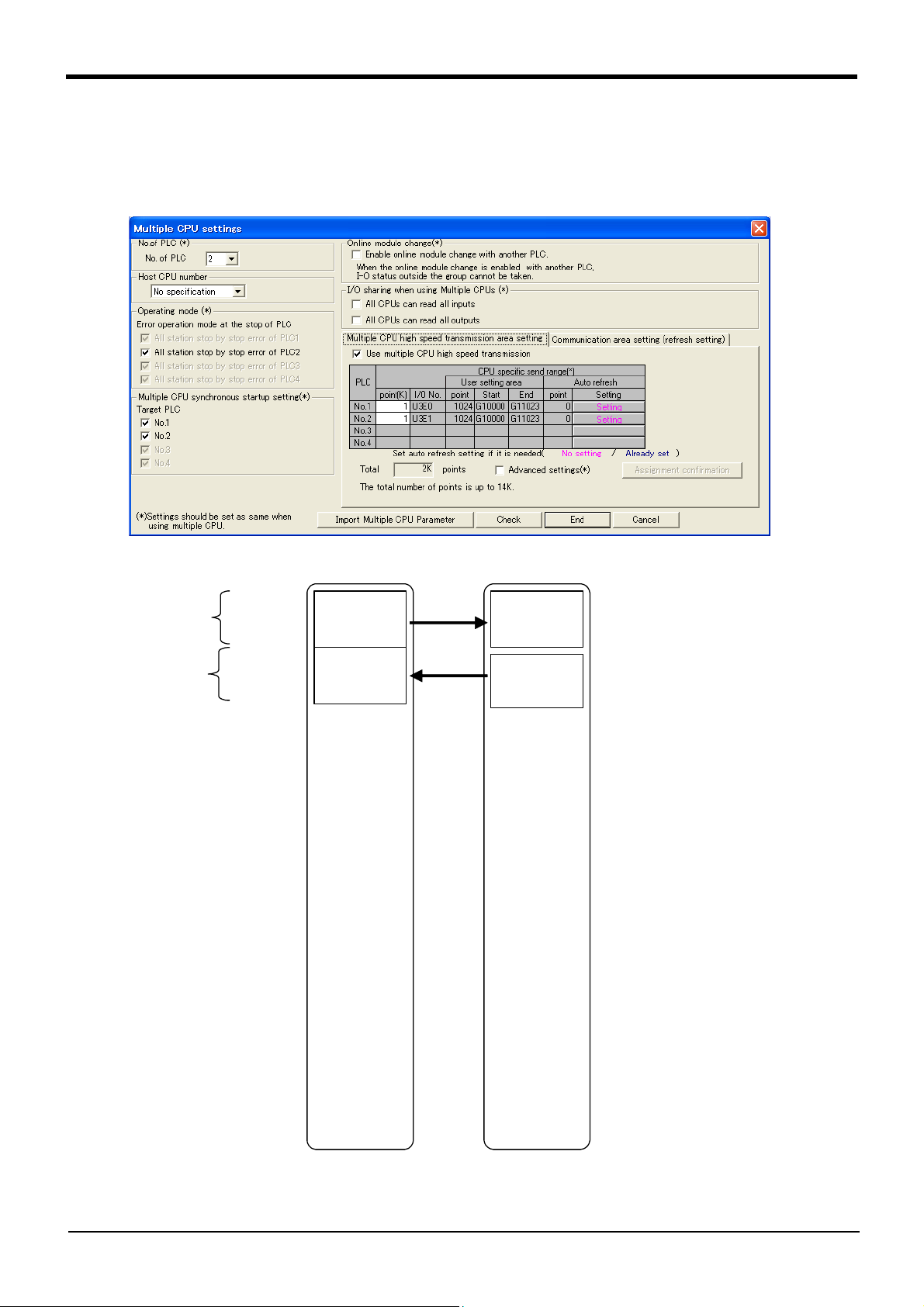

RT-ToolBox2 multiple CPU setting screen (three robots. Shared memory extended functions are valid in

all robots)

The multiple CPU input

offset parameter

"QMLTCPUS" can also

be set.

About input offset parameter (QMLTCPUS)

Sets up the offset of robot's input signals in multiple CPUs in 1K word unit.

For example, when QMLTCPUS is set to one, the start address of robot's input area is an address

(U3E0\G11024) offset by 1K word from the start address of transmission area of device #1 (sequencer).

When QMLTCPUS is set to -1 (initial value), the start address of robot's input area is as listed in the table

above.

2.1.2 Set up Robot's Multiple CPUs

Here, sets up the multiple CPUs as a robot's parameter. In the description below, parameter setting screen

of RT ToolBox 2 illustrates this setting. This can also be set up by specifying the parameter name in the

teaching box's parameter setting screen.

Set the same value as specified in

Page 7, "2.1.1 Set up Sequencer's Multiple CPUs".

[Start address of robot input offset]

The Table 2-1 lists the start addresses of robot input area in the robot's initial setting (multiple CPU input off-

set parameter "QMLTCPUS" is set to "-1") (The start address changes according to whether the shared

memory extended functions are enabled or not).

Table 2-1:Start address of robot input area when the multiple CPU input offset parameter is initial value

Shared Memory Extended

Device No

Device #2 (robot 1) 0K 0K

Device #3 (robot 2) 0.5K 1.0K

Device #4 (robot 3) 1.0K 2.0K

Functions

Invalid Valid

The start address of robot's input area may differ, when the valid/invalid setting for shared memory extended

function may differ in other devices or when a unit other than robot is installed. In these cases, set up the

multiple CPU input offset parameter (QMLTCPUS).

For setting example, refer to Page 11, "2.1.5 Allocation Example of Shared Memory".

Operation flow 2-8

Page 20

2Preparation for Using Extended Function

Set both bits 0, 1 of

parameter IQMEM to 1

External program

variable

External program

variable for

sequencer direct

performance

(For instructing

robot location)

Sequencer direct performance is

valid

Sequencer direct performance is

invalid

:

Extend external

program variable

Set either bit 0, 1 of

parameter IQMEM to 0

Extend and delete

external program

variable

External program

variable

System state

variable

System state

variable

Set both bits 0, 1 of

parameter IQMEM to 1

Set either bit 0, 1 of

parameter IQMEM to 0

+

System state

variable for

sequencer direct

performance

Extend system state

variable

Extend and delete

system state

variable

Robot controller's internal memory

+

CAUTION

2.1.3 Set up Parameter for Selecting Shared Memory Extended Function

The parameter "IQMEM" for selecting the shared memory extended function is 16bit data. Set the bit 0 to

one to use the extended functions (monitoring, operation functions). Set the bit 1 to one to use the

sequencer direct performance function. Both bits can be set to one.

For information on how to set up a parameter, refer to Supplement volume "Instruction Manual, Detailed

Description of Functions and Operations."

Array Qty

Character

Qty

ger

Description Factory Default

Set validity (1)/ invalidity (0) for the function.

Sets each bit by allocating a function to each bit.

0000000000000000 bit2-15: Not used

|+- bit0: Use the shared memory

extended function

+-- bit1: Sequencer direct

performance function

0000000000000000

Parameter

Select shared

memory extended

function

Parameter

Name

IQMEM 1 digit inte-

To use the shared memory extended functions and sequencer direct performance functions, set each bit as

follows:

Bit 1 Bit 0

Use the shared memory extended function 0 1

Use the sequencer direct performance function 1 1

When using the sequencer direct performance function, robot's internal memory is extended as follows:

:

2-9Operation flow

When the sequencer direct performance function is valid, external program variable

and system state variable areas are extended in the robot controller (extended variables). When the function gets invalid, the extended variable area is cleared. Consequently, after the sequencer direct performance function was enabled once, the

robot location was taught, and the data was set, when the parameter is turned back,

be aware that the previous teaching and setting data will disappear.

Page 21

2Preparation for Using Extended Function

CAUTION

2.1.4 Check Robot Language Setting

The shared memory extended functions can be carried out only when the robot language is set to MELFABASIC V.

Check the value of robot language setting parameter "RLNG".

To use the shared memory extended function, set the parameter "RLNG" to 2.

For information on how to set up a parameter, refer to Supplement volume "Instruction Manual, Detailed

Description of Functions and Operations."

Parameter

Robot language RLNG 1 digit inte-

Parameter

Name

Array Qty

Character

Qty

ger

Description Factory Default

Select the robot language to be used:

2: MELFA-BASIC V

1: MELFA-BASIC IV

2

The robot controller's factory default is MELFA-BASIC V. But, when you have selected MELFA-BASIC IV, an

error "L3994" or "L3996" occurs on controller startup.

When the robot language setting is changed from MELFA-BASIC V to MELFABASIC IV, the extended variable area is cleared. Consequently, be aware that the

teaching and setting data for shared memory extended function/ sequencer direct

performance function will disappear.

Operation flow 2-10

Page 22

2Preparation for Using Extended Function

Transmission

area of Device #1

(for Device #2)

(sequencer)

Transmission

area of Device

#1, 3K word

(1K x 3)

Transmission

area of Device

#2, 1K word

Extended Function: Valid

Robot input

Robot output

Transmission

area of Device #2

U3E0\G10000

U3E1\G10000

2.1.5 Allocation Example of Shared Memory

(1) Multiple CPU Configuration with One Sequencer plus One Robot

1) Case 1: Robot: Extended function is enabled, input offset parameter is initial value

The robot uses each 1K word for I/O.

Device #1

Device #2 (robot 1)

2-11Operation flow

Page 23

2Preparation for Using Extended Function

Transmission

area of Device #1

Device #1

(sequencer)

Transmission

area of Device

#1, 2K word

(0.5K x 4)

(Empty)

Transmission

area of Device

#2, 1K word

(0.5K x 2)

Transmission

area of Device #2

(Empty)

Robot input

Robot output

Device #2 (robot 1)

Extended Function: Invalid

U3E0¥G10000

U3E1¥G10000

U3E0¥G10512

U3E1¥G10512

2) Case 2: Robot: Extended function is disabled, input offset parameter is initial value

The robot uses each 0.5K word for I/O.

As the transmission score is set yet in 1K word unit, the transmission score setting is as follows:

Operation flow 2-12

Page 24

2Preparation for Using Extended Function

Transmission

area of Device #1

(for Device #2)

Device #1

(sequencer)

Transmission

area of Device

#1, 3K word

(1K x 3)

Transmission

area of Device

#2, 1K word

Device #2 (robot 1)

Extended Function:

Vali d

Device #3 (robot 2)

Extended Function:

Val id

Device #4 (robot 3)

Extended Function:

Vali d

Transmission

area of Device #1

(for Device #3)

Transmission

area of Device #1

(for Device #4)

Transmission

area of Device

#3, 1K word

Transmission

area of Device

#4, 1K word

Robot input

Robot output

Robot input

Robot output

Robot input

Robot output

Transmission

area of Device #3

Transmission

area of Device #4

Transmission

area of Device #2

U3E0\G10000

U3E0\G11024

U3E0\G12048

U3E1\G10000

U3E2\G10000

U3E3\G10000

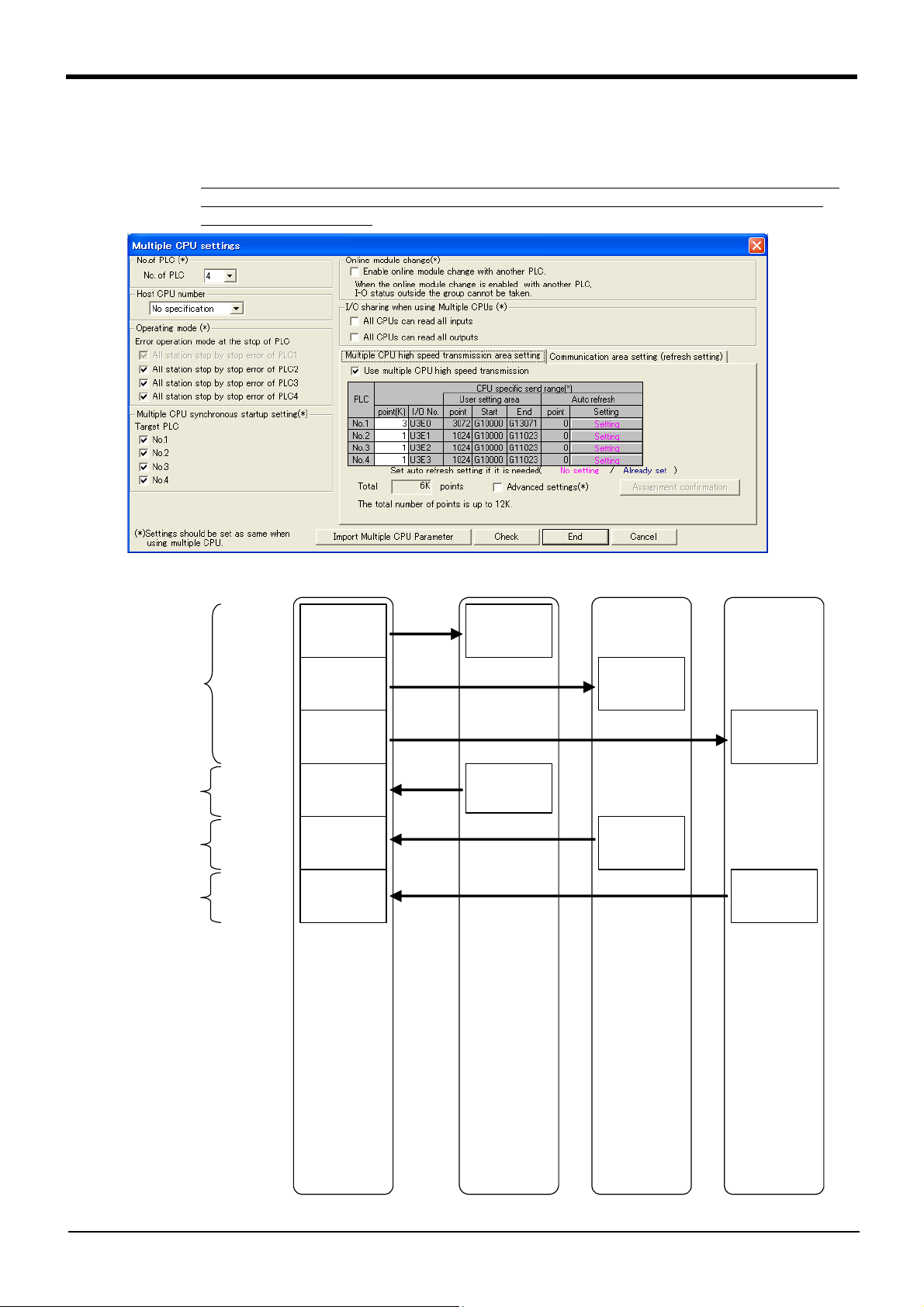

(2) Multiple CPU Configuration with One Sequencer plus Three Robots

1) Case 1: All robots: Extended function is enabled, input offset parameter is initial value

All robots use each 1K word for I/O.

The beginning of robot 2 input area starts at 1.0K offset from the beginning of shared memory

address, and the beginning of robot 3 input area starts at 2.0K offset from the beginning of

shared memory address.

2-13Operation flow

Page 25

2Preparation for Using Extended Function

Transmission area of Device #1

(for Device #2)

Device #1

(sequencer)

Transmission area of Device #1

(for Device #3)

Transmission area of Device #1

(for Device #4)

Transmission

area of Device

#1, 2K word

(0.5K x 4)

(Empty)

Transmission

area of Device

#2, 1K word

(0.5K x 2)

Transmission area

of Device #2

(Empty)

Transmission area

of Device #3

(Empty)

Transmission area

of Device #4

(Empty)

Transmission

area of Device

#3, 1K word

(0.5K x 2)

Transmission

area of Device

#4, 1K word

(0.5K x 2)

Robot input

Robot output

Robot input

Robot output

Robot input

Robot output

Device #2 (robot 1)

Extended Function:

Invalid

Device #3 (robot 2)

Extended Function:

Invalid

Device #4 (robot 3)

Extended Function:

Invalid

U3E0\G10000

U3E0\G10512

U3E0\G11024

U3E1\G10000

U3E2\G10000

U3E3\G10000

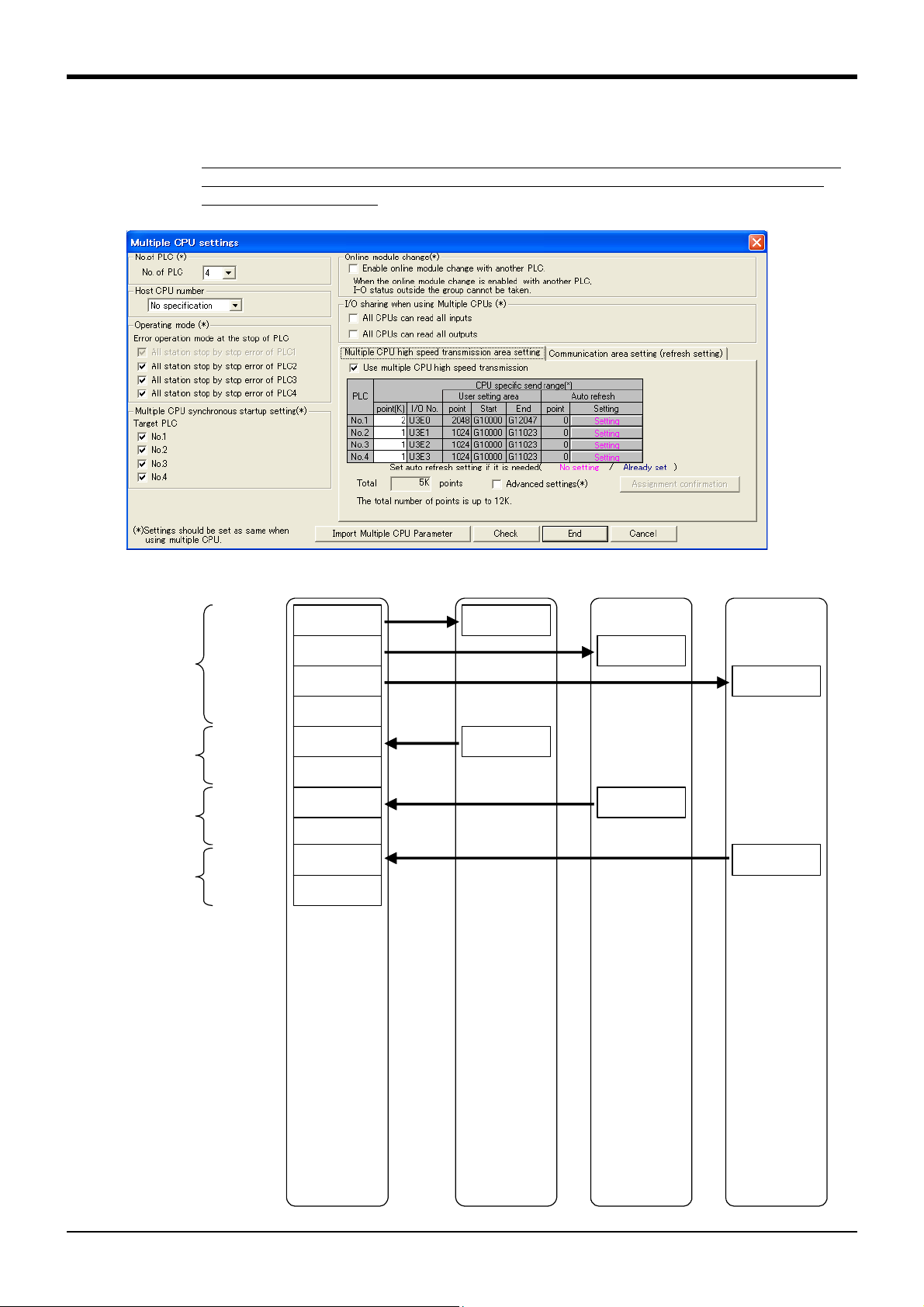

2) Case 2: All robots: Extended function is disabled, input offset parameter is initial value

All robots use each 0.5K word for I/O.

The beginning of robot 2 input area starts at 0.5K offset from the beginning of shared memory

address, and the beginning of robot 3 input area starts at 1.0K offset from the beginning of

shared memory address.

The setting is in 1K word unit as follows:

Operation flow 2-14

Page 26

2Preparation for Using Extended Function

Device #1

(sequencer)

Transmission

area of Device

#1, 2K word

(0.5K x 2, 1K x1)

Transmission

area of Device

#2, 1K word

Device #2 (robot 1)

Extended

Function: Invalid

Device #3 (robot 2)

Extended

Function: Invalid

Device #4 (robot 3)

Extended

Function: Valid

Transmission area of Device #1

(for Device #4)

Transmission

area of Device #4

Transmission

area of Device

#4, 1K word

Robot input

Robot output

Transmission area of Device #1

(for Device #2)

Robot input

Transmission

(Empty)

Robot output

Transmission area of Device #1

(for Device #3)

Transmission

(Empty)

Transmission

area of Device

#3, 1K word

Robot output

Robot input

U3E0\G10000

U3E0\G10512

U3E0\G11024

U3E1\G10000

U3E2\G10000

U3E3\G10000

Input offset parameter of

robot 3 is changed

3) Case 3: Robots 1, 2: Extended function is disabled, Robot 3: Extended function is enabled (#1)

By default, the robot 3 input area starts at 2.0K offset from the beginning of shared memory

(By default, the extended function of robots 1, 2 is also assumed to be enabled, similar to

robot 3). Therefore, the multiple CPU input offset parameter (QMLTCPUS) of robot 3 should

be set to "1."

area of Device #2

area of Device #3

2-15Operation flow

Page 27

2Preparation for Using Extended Function

Device #1

(sequencer)

Transmission

area of Device

#1, 3K word

(1K x 3)

Transmission

area of Device

#2, 1K word

Device #2 (robot 1)

Extended Function:

Invalid

Device #3 (robot 2)

Extended Function:

Invalid

Device #4 (robot 3)

Extended Function:

Val id

Transmission area of Device #1

(for Device #4)

Transmission

area of Device #4

Transmission

area of Device

#4, 1K word

Robot input

Robot output

Transmission area of Device #1

(for Device #2)

(Empty)

Robot input

Transmission

(Empty)

Robot output

Transmission area of Device #1

(for Device #3)

(Empty)

Transmission

(Empty)

Transmission

area of Device

#3, 1K word

Robot output

Robot input

U3E0\G10000

U3E0\G11024

U3E0\G12048

U3E1\G10000

U3E2\G10000

U3E3\G10000

Input offset parameter of

robot 2 is changed

4) Case 4: Robots 1, 2: Extended function is disabled, Robot 3: Extended function is enabled (#2)

This example allocates 1K area in advance so that the allocation is not changed even when

the extended function is enabled in the future, while the extended function was disabled and

the extended area was not allocated.

Empty area of 0.5K is kept at the back of each transmission area of robot 1 (for robots 2, 3).

By default, the robot 2 input area starts at 0.5K offset from the beginning of shared memory

(By default, the extended function of robots 1 is also assumed to be disabled, similar to robot

2). Therefore, the multiple CPU input offset parameter (QMLTCPUS) of robot 2 should be set

to "1".

area of Device #2

area of Device #3

Operation flow 2-16

Page 28

3Monitor Robot Information

3 Monitor Robot Information

The Table 3-1 lists the robot information monitored from sequencer.

Setting values are also monitored during performing sequencer direct.

Table 3-1:Monitoring item list

No Item Description I/F betw Robots

1 Monitor operation

control setting values

2 Monitor activities Monitors the robot's activities (current

3 Monitor current

and aimed positions

4 Monitor position

and joint information

5 Monitor mainte-

nance information

Monitors the setting values relating to

operation control command and operation control

speed, arrival factor to the aimed position, etc.)

Monitors current and aimed positions of

robot

Monitors various position type data (orientation at collision, etc.) and joint type

data (current value, load factor, etc.)

Monitors the maintenance information

(battery and grease remaining times)

Monitoring output

(Robot side periodically updates

the data in

shared memory

Update

Cycle

7.1msec

7.1msec

7.1msec

Differ according to items

Depending

on the

parameter

MFINTVL

Mecha No

Setting

○

(necessary)

○

○

○

○

Section

No

"3.2.1"

"3.2.2"

"3.2.3"

"3.2.4"

"3.2.5"

3-17

Page 29

3.1 Operation Flow

…

Refer to Page 6, "2 Preparation for Using Extended Function".

Select items to be monitored from the sequencer.

The robot outputs the signal "Function performing" of the monitoring function.

(Refer to Page 19, "3.1.1 Select Monitoring Items")

Select the mecha number from the sequencer.

The robot outputs the "Mecha No" of monitoring target.

(Refer to Page 19, "3.1.2 Select Target Mecha")

Select the position and joint data from the sequencer.

The robot outputs the "Position and joint data No" of monitoring

target.

(Refer to Page 28, "(1) Select Position and Joint Data")

Start

Prepare for Using Extended Function

Select monitoring items

Is the function selected by

the robot side?

Select mecha

Is the mecha selected by

the robot side?

Whether to monitor posi-

tion and joint information?

Select position and joint data

Is the data selected by the

robot side?

No

Yes

No

Yes

No

No

Yes

Yes

Monitoring starts

• Monitor operation control setting values

• Monitor activities

• Monitor current and aimed positions

• Monitor maintenance information

Monitoring starts

• Monitor position and joint information

3Monitor Robot Information

Operation Flow 3-18

Page 30

3Monitor Robot Information

3.1.1 Select Monitoring Items

Here, selects the monitoring functions output by the robot from the sequencer.

Only the data specified by items (set to "1") selected with each bit can be monitored. For more information

on each monitoring data, refer to Page 23, "3.2 Monitoring Item" and after.

(1) Sequencer output data

a) Word data

Sequencer Addr

(offset)

Function selection [Allocated to each bit, 0: invalid, 1: valid]

bit15 0

0000000000000000

|||||||+--bit0: (Reserved)

||||||+---bit1: (Reserved)

512

|||||+----bit2: Monitor operation control settings

||||+-----bit3: Monitor activities

|||+------bit4: Monitor current and aimed positions

||+-------bit5: Monitor position and joint information

|+--------bit6: Monitor maintenance information

+---------bit7: (Reserved)

Description Remarks

(2) Robot output data

a) Word data

Sequencer Addr

(offset)

Function performing [allocated to each bit, 0: invalid, 1: valid]

bit15 0

0000000000000000

|||||||+--bit0: (Reserved)

||||||+---bit1: (Reserved)

512

|||||+----bit2: Monitor operation control settings

||||+-----bit3: Monitor activities

|||+------bit4: Monitor current and aimed positions

||+-------bit5: Monitor position and joint information

|+--------bit6: Monitor maintenance information

+---------bit7: (Reserved)

Description Remarks

3.1.2 Select Target Mecha

Here, selects the target mecha number of monitoring data output by the robot from the sequencer.

The robot outputs the data with selected mecha number. The number (1 to 3) is selectable for mecha numbers. When the number other than 1 - 3 is specified, the data is initialized (zeros are put in the whole target

area)

(1) Sequencer output data

a) Word data

Sequencer Addr

(offset)

841 Specify a mecha number [1 - 3]

Description Remarks

(2) Robot output data

a) Word data

Sequencer Addr

(offset)

3-19Operation Flow

Description Remarks

731 Mecha number [1 - 3]

Page 31

3.1.3 Timing Chart

(1) (2) (3) (4) (5) (6) (7)

Sequencer

Specify mecha

No

Mecha No

Data for monitoring

current and

aimed positions

2

Mecha 1's

value

Mecha 2's

value

Data for monitoring

maintenance

information

Mecha 2's

value

Mecha 1's

value

The data is updated periodically while outputting

setting values (monitoring output)

Select function, bit 4

(Monitor current and

aimed positions)

Select function, bit 6

information)

Performing function, bit 4

(Monitor current and

aimed positions)

Performing function, bit 6

(Monitor maintenance

information)

value

value

Sequencer Robot

CAUTION

Robot

3Monitor Robot Information

(Monitor maintenance

1 2

1

Mecha 1's

0

1

1 0

Mecha 1's

Fig.3-1:Timing chart for selecting monitoring items and target mecha

(1) When the sequencer sets the target bit of "Select function" to "ON", the robot sets the target bit of

(2) When the sequencer sets "Specify mecha number" to one, the robot starts to update mecha 1's data.

(3) When the target bit of "Select function" is set to "ON" while the sequencer sets "Specify mecha num-

(4) When the sequencer changes "Specify mecha number", the robot outputs the data of specified

(5) When the sequencer sets "Mecha number" to other than 1 - 3, the robot clears the output data.

(6) When the sequencer re-sets "Mecha number", the robot outputs the data of target mecha.

(7) When the sequencer sets the target bit of "Select function" to "OFF", the robot sets the target bit of

"Performing function" to "ON" to start the monitoring output of target item. Here, when "Specify

mecha number" is other than 1 - 3, the robot waits to update the data.

ber", the robot starts to update the data of target item while at the same time the robot sets the target

bit of "Performing function" to "ON".

mecha.

"Performing function" to "OFF" to initialize the output data.

The synchronization of data in shared memory is guaranteed on a per 32bit (2

word) basis. But, the synchronization in the unit more than this bit cannot be guaranteed. Therefore, be aware that the position type and joint type data is guaranteed for

each axis, the data is not guaranteed as a whole.

Operation Flow 3-20

Page 32

3Monitor Robot Information

3.1.4 Sample Ladder

Here, shows the sample ladder to retrieve current and aimed positions and maintenance information into

the internal device by specifying the monitoring item and mecha number.

[Target function]

Select monitoring items (monitoring current and aimed positions, monitoring data of maintenance infor-

mation) and mecha

[Target robot]

The target robot is robot 2 of multiple CPUs (robot's multiple CPU input offset parameter is initial value)

[Description]

When the device with desired function to be monitored is set to "ON" of monitoring request (M14) for cur-

rent and aimed positions, monitoring request (M15) for maintenance information, and device of selecting

mechas 1 - 3 (M21 - M23), target data is output to the internal device for monitoring.

The data of current and aimed positions is stored in D1000 - D1071.

The data of maintenance information is stored in D1100 - D1133.

Example:

To output the current and aimed positions data of mecha 1, set M14 and M21 to "ON" (M22 and M23 are

"OFF") to output the monitoring data to D1000 to D1071.

To output the maintenance information data of mecha 1, set M16 and M21 to "ON" (M22 and M23 are

"OFF") to output the monitoring data to D1100 to D1133.

[Device details]

M14: Request to monitor the current and aimed positions

M16: Request to monitor the maintenance information

M21: Selects mecha 1

M22: Selects mecha 2

M23: Selects mecha 3

M34: Monitoring the current and aimed positions

M36: Monitoring the maintenance information

M41: Mecha 1 selected

M42: Mecha 2 selected

M43: Mecha 3 selected

D1000 - D1071: Stores the current and aimed positions data from the robot

D1100 - D1133: Stores the monitoring data of maintenance information from the robot

3-21Operation Flow

Page 33

[Ladder]

3Monitor Robot Information

Operation Flow 3-22

Page 34

3Monitor Robot Information

3.2 Monitoring Item

3.2.1 Monitor Operation Control Setting Values

Here, periodically outputs the robot's operation control commands and the setting values for operation control to the shared memory.

(1) Monitoring data list

Sequencer Addr

(Offset)

777

778 ColLvl setting value Collision detection level, J1 axis [%: 1 - 500]

779 Collision detection level, J2 axis [%: 1 - 500]

780 Collision detection level, J3 axis [%: 1 - 500]

781 Collision detection level, J4 axis [%: 1 - 500]

782 Collision detection level, J5 axis [%: 1 - 500]

783 Collision detection level, J6 axis [%: 1 - 500]

784 (Reserved)

785 (Reserved)

794

795

796

797

798

799

800

801

802 (Reserved)

803 (Reserved)

804

Description

ColChk setting value Collision detection setting [0: Invalid/ 1: Valid (error

occurred)/ 2: Valid (error not occurred)

CMP Pos/Tool/Jnt setting values

CmpG setting value

MvTune/Prec setting values

Compliance coordinate type

[0: Invalid/ 1: Perpendicular/ 2: Tool/ 3: Joint]

Specify a compliance coordinate type [Specify target

axis with bit]

[Setting values to specify compliance axis of CMP

Pos/Tool/Jnt setting values]

The values below are set by setting up bit:

bit7 0

00000000

|||||||+---bit0:J1/X axis

||||||+----bit1:J2/Y axis

|||||+-----bit2:J3/Z axis

||||+------bit3:J4/A axis

|||+-------bit4:J5/B axis

||+--------bit5:J6/C axis

|+---------bit6:(Reserved)

+----------bit7:(Reserved)

Compliance J1/X axis gain [10

Compliance J2/Y axis gain [10

Compliance J3/Z axis gain [10

Compliance J4/A axis gain [10

Compliance J5/B axis gain [10

Compliance J6/C axis gain [10

Operation characteristic [1: Standard/ 2: Highspeed/ 3: Track preferred/ 4: Vibration restricted]

-2

: 1 - 100]

-2

: 1 - 100]

-2

: 1 - 100]

-2

: 1 - 100]

-2

: 1 - 100]

-2

: 1 - 100]

Supported

State

Var iable

Update

Cycle

7.1msec

3-23Monitoring Item

Page 35

3Monitor Robot Information

<Precautions>

● When the target mecha does not exist, outputs the data zero.

● The value below is output as ColChk:

- When multiple mechas are in use or when the element 1 of parameter COL is zero (collision detection

unavailable),

→ zero is output

- Otherwise (collision detection available):

When being in operation (including step feed, position jump operation, and sequencer direct performance),

→ the initial value is the value of element 2 of parameter COL, and then the output value is the

value changed by ColChk command.

When not being in operation (including suspension and jog operation),

→ it is set to the value of element 3 of parameter COL.

● The value below is output as ColLvl:

- When multiple mechas are in use or when the element 1 of parameter COL is zero (collision detection

unavailable) and

being in operation,

→ the initial value is the value of parameter COLLVL, and then the output value is the value

changed by ColLvl command.

When not being in operation,

→ it is the value during automatic operation is held when being in suspension, and it is the value

of parameter COLLVL when being stopped.

- Otherwise (collision detection available),

When being in operation,

→ the initial value is the value of parameter COLLVL, and then the output value is the value

changed by ColLvl command.

When not being in operation,

→ it is the value of parameter COLLVLJG.

● CMP Pos/Tool/Jnt setting values are set to zero when mechas 2, 3 are selected during using multiple

mechas.

(User mecha cannot use compliance)

Monitoring Item 3-24

Page 36

3Monitor Robot Information

3.2.2 Monitor Activities

Here, periodically outputs the robot's activities (current speed, arrival factor to the aimed position, etc.) to

the shared memory.

(1) Monitoring data list

Sequencer

Addr

Description

(offset)

810

Current instruction speed [10

811

812

Current distance remained [10

813

814

Distance between instructed and feedback positions [10

815

816 Arrival factor [%] to the current aimed position M_Ratio

Current acceleration and deceleration state

817

[0: Stopped/ 1: Accelerated/ 2: Constant speed/ 3: Decelerated]

818

Collision detection [1: Collided/ 0: Otherwise]

Going over the limit during performing compliance

819

[1: Almost go over the limit/ 0: Does not go over the limit]

820 Deviance amount between instructed and actual positions during performing

821

compliance [10

-4

mm]

-4

mm/s]

-4

mm]

Note1)

-4

mm]

Note1) Robot state variable (M_ColSts) is "1" for about 7.1ms between collision detection and servo OFF. But, the data

"1" is output to the shared memory for 1sec after the collision is detected.

Supported

State Variable

M_RSpd

M_RDst

M_Fbd

M_AclSts

M_ColSts

M_CmpLmt

M_CmpDst

Update

Cycle

7.1msec

<Precautions>

● When the target mecha does not exist, outputs the data zero.

● When the data is dependent on a slot and the slot does not exist which has the control of target mecha,

outputs the data zero. The data dependent on a slot is as follows:

• Current distance remained (M_RDst)

• Arrival factor to the current aimed position (M_Ratio)

• Current acceleration and deceleration state (M_ActSts)

3-25Monitoring Item

Page 37

3Monitor Robot Information

3.2.3 Monitor Current and Aimed Positions

Here, periodically outputs robot's current and aimed positions to the shared memory.

(1) Monitoring data list

Sequencer

Addr

(offset)

830

831

832

833

834

835

836

837

838

839

Current position (perpendicular)

840

841

842

843

844

845

846

847

848

849

850

851

852

853

854

855

856

857

858

859

Aimed position (perpendicular)

860

861

862

863

864

865

866

867

868

869

Description

X coordinate value [10-4mm/10-4deg]

Y coordinate value [10-4mm/10-4deg]

Z coordinate value [10-4mm/10-4deg]

A coordinate value [10-4mm/10-4deg]

B coordinate value [10-4mm/10-4deg]

C coordinate value [10-4mm/10-4deg]

L1 coordinate value [10-4mm/10-4deg]

L2 coordinate value [10-4mm/10-4deg]

Structure flag

Multi-turn data

X coordinate value [10-4mm/10-4deg]

Y coordinate value [10-4mm/10-4deg]

Z coordinate value [10-4mm/10-4deg]

A coordinate value [10-4mm/10-4deg]

B coordinate value [10-4mm/10-4deg]

C coordinate value [10-4mm/10-4deg]

L1 coordinate value [10-4mm/10-4deg]

L2 coordinate value [10-4mm/10-4deg]

Structure flag

Multi-turn data

Update

Cycle

7.1msec

Monitoring Item 3-26

Page 38

3Monitor Robot Information

Sequencer

Addr

(offset)

870

871

872

873

874

875

876

877

Current position (joint)

878

879

880

881

882

883

884

885

886

887

888

889

890

891

892

893

Aimed position (joint)

894

895

896

897

898

899

900

901

Description

J1 coordinate value [10-4mm/10-4deg]

J2 coordinate value [10-4mm/10-4deg]

J3 coordinate value [10-4mm/10-4deg]

J4 coordinate value [10-4mm/10-4deg]

J5 coordinate value [10-4mm/10-4deg]

J6 coordinate value [10-4mm/10-4deg]

J7 coordinate value [10-4mm/10-4deg]

J8 coordinate value [10-4mm/10-4deg]

J1 coordinate value [10-4mm/10-4deg]

J2 coordinate value [10-4mm/10-4deg]

J3 coordinate value [10-4mm/10-4deg]

J4 coordinate value [10-4mm/10-4deg]

J5 coordinate value [10-4mm/10-4deg]

J6 coordinate value [10-4mm/10-4deg]

J7 coordinate value [10-4mm/10-4deg]

J8 coordinate value [10-4mm/10-4deg]

Update

Cycle

<Precautions>

• When the target mecha and axis do not exist, outputs the data zero.

• When the origin is not established, outputs zero for the both perpendicular and joint components of current

position.

(2) Data description

[Perpendicular data]

• The unit is 10

-4

mm or 10-4deg.