Page 1

For R407C Refrigerant

2004

Mineral Oil Recovery Work Manual

HEAD OFFICE: MITSUBISHI DENKI BLDG., 2-2-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Issued in April 2004 MEE03K197

Printed in Japan

New publication effective April 2004

Specifications subject to change without notice.

This product is designed and intended for use in the residential, commer-

cial and light-industrial environment.

The product at hand is • Low Voltage Directive 73/23/EEC

based on the following • Electromagnetic Compatibility Directive 89/

EU regulations: 336/EEC

•Pressure Equipment Directive 97/23/EC

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

Replace Multi Mineral Oil Recovery Work Manual PUHY-YREM-A

Page 2

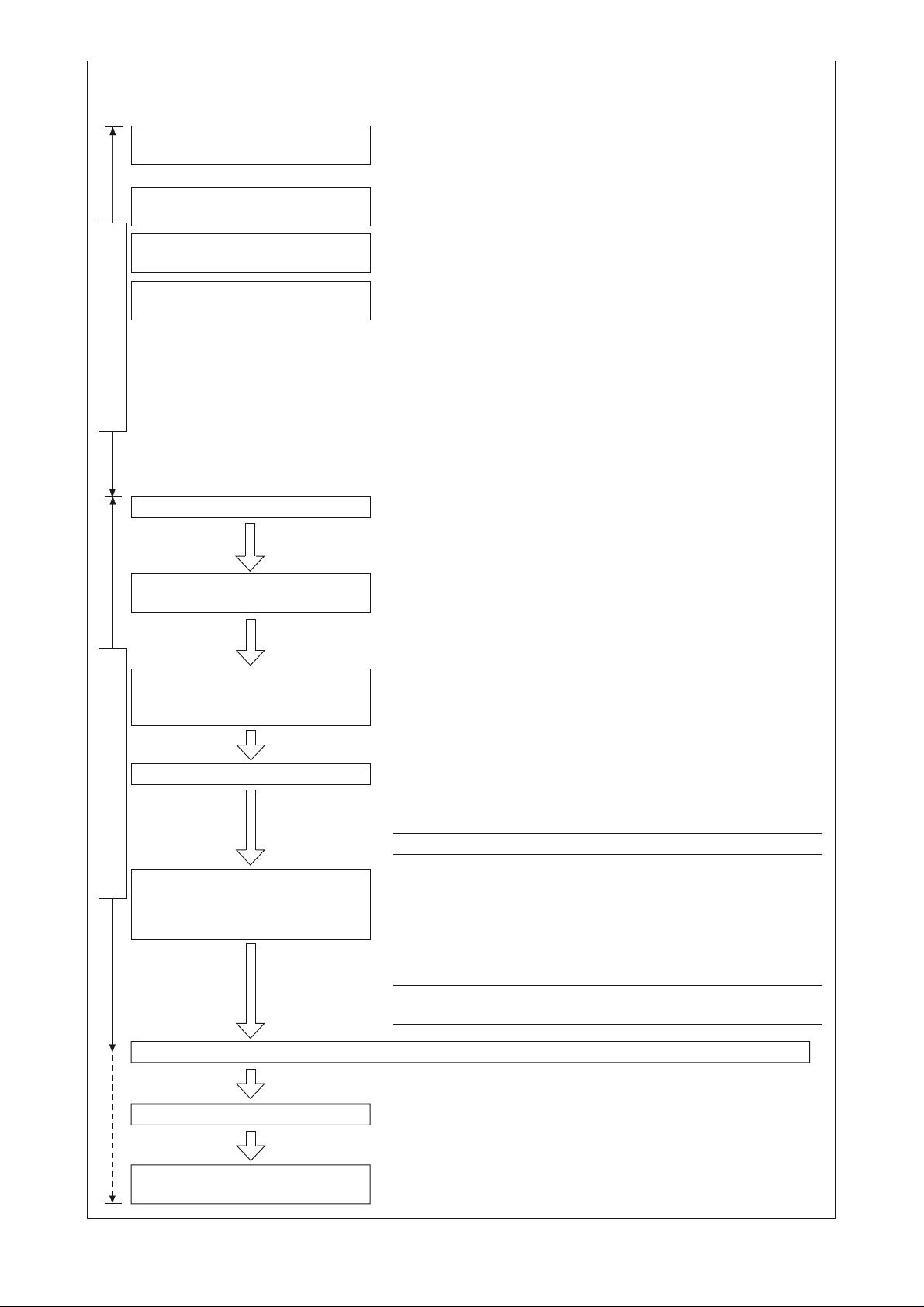

Cautions For REPLACE MULTI Installation Work

Flow of installation work in the field Items to be observed

•Please note that our Corporation is not liable to the reliability of existing piping,

wiring and power system for reuse (in relation with the gas leak of piping, partially

defective/disconnection of wiring, deteriorated insulation, characteristic faults due

to worn out system).

•For limitation on the refrigerant piping and applicable piping diameter, check the

existing piping for reuse in accordance with the specified check sheet by referring to product catalogs and this manuals for judgement to reuse.

•If vapor condensation was found in the past, check the thermal insulation.

•Any portion suffering condensation dripping, check the deterioration of the insulation, and repair the insulation materials if required.

•When the copper piping is seriously deteriorated, do not use parts with verdigris

or black spots.

•For reusing the existing control wiring between the outdoor unit, and remote controller, check the wire type , size or the like , based on the chec k sheet to judge the

possibility.

•Even when the above does not meet the item on the check sheet, existing wiring

may be reused depending on the number of connecting indoor units and piping

length. Ask us for details.

•For the power source system, employ the voltage and number of phase meeting

the outdoor unit, indoor unit and adopt the breaker capacity and wiring size based

on the power source wiring connection diagram.

•When the existing power source system (including the power source wiring) is

used, check the system for deterioration and damages.

•Check the refrigerating machine oil used in the existing system. (As is found at

the oil inspection), if the refrigerating machine oil used in the existing system is

mineral oil, use the ester oil sampling kit for inspection.

•When the length of piping for reuse is unknown, additional refrigerant charge is

to be calculated based on the quantity of recovered refrigerant. For this reason,

you are kindly requested to recover all refrigerant inside the existing outdoor/

indoor units and extended piping to check and record the quantity. (The standard of additional refrigerant is (Quantity of R22 recovered - Charged quantity of

existing outdoor unit + 3kg). Adjust the refrigerant quantity after mineral oil recovery operation.)

■ Outdoor unit

•Confirm the space around the outdoor unit.

(Verifying the installation space of the oil trap kit)

■ Turn the power source on, and confirm the normality of the system

•Check the remote controller or outdoor unit for error display.

•Run the indoor unit for fan operation after turning the remote controller on, and

check the air feeding and direction.

Do not run the compressor until finishing the mineral oil recovery operation.

■Mount the valves to the field piping (extended piping). (The ball valve is attached

to the outdoor unit.)

■Execute an airtight test to check the existing piping for deterioration or leaking.

■Calculate the quantity required by the extended piping, and charge the addi-

tional refrigerant. Make sure to enter the value in the additional refrigerant charge

column on the label of the outdoor unit.

■If the refrigerant charge is insufficient, enter the value also.

Without applying any operation, keep the ball v alves of the outdoor unit c losed

before mineral oil recovery operation.

It is necessary to charge refrigerant in a rated quantity and adjust the quantity.

Be sure to execute when the piping length is unknown.

For detail, consult the agent of your dealer.

Enter required items in the request form of REPLACE MULTI mineral oil recovery work.

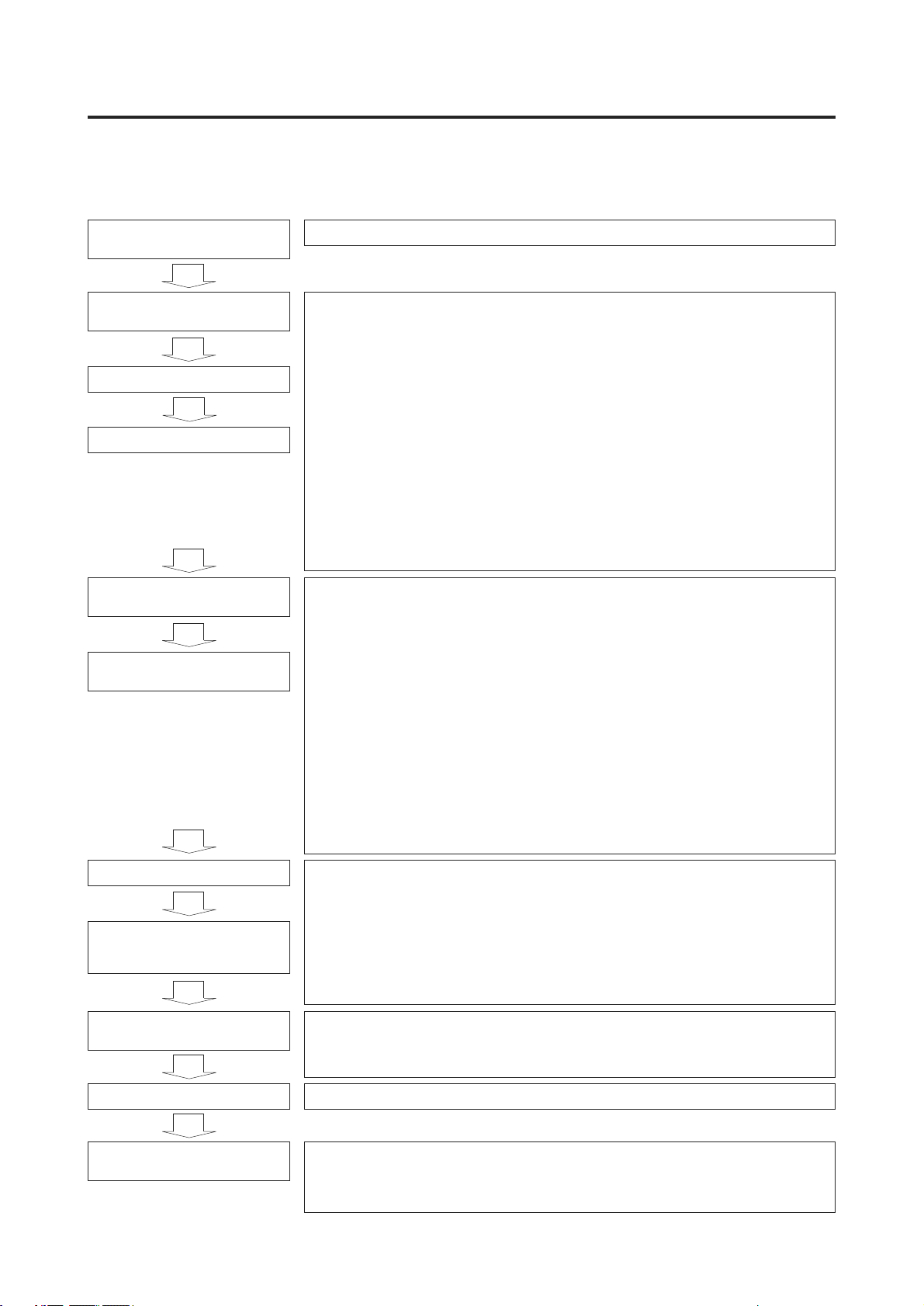

During local installation work

Before local installation work

Confirming the possibility of existing

refrigerant piping for reuse

Confirming the possibility of existing

control wiring for reuse

Confirming the possibility of existing

power source system for reuse

Confirming the objective range for

replacing

Recovering the refrigerant of old system

Removing the outdoor/indoor units, remote controllers, etc.

Installing the outdoor/indoor units, remote

controllers, etc., and executing electrical

work

Setting the address, checking the system

Executing the piping work (mounting of

ball valve).

Air tightening and evacuating the existing

piping and charging refrigerant

Operating mineral oil recovery

Executing test run and adjustment (for

final verification of operation).

Page 3

Safety Precautions

• Before installing the unit, make sure you read all the “Safety precautions”.

• The “Saf ety precautions” provide very important points regarding safety. Make sure you follow

them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock (This symbol is displayed on the

main unit label.) <Color: Yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning

Ask your dealer or specialized contractor for

installation.

•If your own installation w ork is improper, fire, electric

shock or water leakage may result.

Connect wiring using the specified cable and fasten it securely to prevent the external force of

the cable from being transferred to the terminal

connecting sections.

•Improper connection or fastening may cause heat

generation or fire.

Conduct specified installation work durable

against strong winds around buildings.

•Improper installation work can cause trouble i.e. the

unit toppling over.

Never attempt to repair the unit. For repair,

ask your dealer.

•Improper repair may result in water leakage, electric

shock or fire.

Do not touch the heat exchanger fins.

•Improper handling may cause cuts.

When refrigerant gas is leaked during work,

conduct ventilation.

•If refrigerant gas comes into contact with fire, it may

cause the generation of poisonous gases.

Please conduct correct installation work by

observing this Installation Manual.

•Improper installation work may result in water leakage, electric shock or fire.

Conduct all electrical work by a licensed engineer according to “Technical Standard relating to Electrical Facility,” “Wiring Regulation of Power Company,” and instructions in

this Manual, and always use an exclusive circuit.

•Insufficient power source capacity or improper installation may cause electric shock or fire.

When installing or moving the unit, do not

charge other than the specified refrigerant

(R407C) into the refrigeration cycle.

•Air if mixed generates abnormally high pressure inside the refrigeration cycle which may damage the

unit.

Do not reconstruct or reset the protection

devices.

•If the protection devices like the pressure switch or

thermal switch is forcibly operated by short circuiting, or parts other than that specified by Mitsubishi

Electric are used, fire or explosion may be caused.

Page 4

Before Conducting Mineral Oil Recovery Operation

Caution

Turn the power source on 12 hours or mor e

before starting operation.

• Otherwise trouble may be caused. Do not turn the

power off during the operating season.

Do not operate the unit without the panels or

guard.

•Touching the rotating parts, high temperature parts

or high voltage may cause personal injury such as

burns or electric shock.

Do not operate switches with wet fingers.

•Electric shock may be caused.

Do not turn off the power source immediately

after stopping.

• Be sure to wait for 5 minutes or more. Otherwise

water leakage or troubles may be caused.

Do not touch the refrigerant piping during

operation or immediately after stopping with

bare hands.

• The refrigerant piping or the refrigerant circuit parts

of the compressor during operation or immediately

after stopping may have low or high temperature.

Touching with bare hands may cause a burn or frostbite.

Do not run the outdoor unit during a test run until

finishing the mineral oil recovery operation.

• The indoor unit fan will run.

Caution to Mineral Oil Recovery Operation

Warning

Caution

Be sufficiently careful to avoid the oil trap

kit, falling or toppling over.

• If this happens the oil trap kit may be damaged and

refrigerant piping may malfunction.

• Falling down during flushing operation causes the

leak of refrigerant from the joint which is dangerous

if contacts it human body.

After flushing operation, check the residual pressure inside the oil trap kit with a pressure gauge.

If the residual pressure is exceeding 0.294MPa,

recover refrigerant inside the oil trap kit to reduce

the pressure to within 0.2 ~ 0.294MPa.

• Under high inner pressure, pressure rises during

storing, inducing a dangerous situation.

• Under low inner pressure, water content or foreign

matter enters during storing, causing corrosion to

the oil trap kit which may cause troubles.

Be careful not to expose the oil trap kit unit

(especially electrical parts) to rain water.

• The electrical parts if wet with rain water may cause

machine trouble.

• The electrical parts if wet with rain water may cause

electrical shock.

Conduct oil recovery from the oil recovery service valve outdoor or at a place with good ventilation. Use leather gloves when opening the oil recovery service valve and open it slowly.

• If done in a closed space, suffocation can be caused.

• Opening the oil recovery service valve fully and

quickly allows oil to splash, which is dangerous.

• As the oil recovered is of low temperature, frostbite

may be caused if it touches skin.

When the oil trap kit is transported while lying sideways, do not place any thing on the

sheet metal of the kit.

• Otherwise, the sheet metal or inner piping may be

deformed leading to breakage.

Before removing the oil trap kit after flushing operation, make sure to discharge and

process the oil recovered from the oil recovery service valve.

• If it is not discharged, the oil accumulated inside will

flow out during flushing operation hindering proper

recovery of mineral oil thus leading to machine

trouble.

For inspection, use the ester oil sampling kit

when the refrigerating machine oil used in the

existing unit is mineral oil.

(

Confirm the type of refrigerating machine oil used in the

existing unit by reading the name plate or the like.

)

• Proper checking can not be executed if not using the

kit meeting the refrigerating machine oil used by the

existing unit. This possibly causes machine trouble.

Page 5

Precautions for Devices that Use R407C Refrigerant

Caution

Use refrigerant piping made of phosphorus

deoxidized copper and copper alloy seamless pipes and tubes. In addition, be sure

that the inner and outer surfaces of the pipes

are clean and free of hazardous sulphur, oxides, dust/dirt, shaving particles, moisture,

or any other contaminant.

•Contaminants on the inside of the refrigerant piping

may cause the refrigerating machine oil to deteriorate.

Store the piping to be used during installation indoors and keep both ends of the piping sealed until just before brazing. (Store

elbows and other joints in a plastic bag.)

•If dust, dirt, or water enters the refrigerant cycle,

deterioration of the oil and compressor trouble may result.

Use ester oil, ether oil or alkylbenzene (small

amount) as the refrigerating machine oil to

coat flares and flange connections.

•The refrigerating machine oil will degrade if it is mixed

with a large amount of mineral oil.

Use liquid refrigerant to seal the system.

•If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change

and performance may drop.

Do not use other refrigerant other than

R407C.

•Use of other refrigerants (R22 for example) may deteriorate refrigerating machine oil due to chlorine

generation.

Use a vacuum pump with reverse flow protection.

•Otherwise the vacuum pump oil will reversely flow

into the refrigerant circuit causing the possible deterioration of the refrigerating machine.

Do not use the following tools used for conventional refrigerant.

(Gauge manifold, Charging hose, Gas leak

detector, Reverse flow protector, Cap for refrigerant charge, Refrigerant recovery device)

•Mixing of conventional refrigerant /refrigerating machine oil may cause to deteriorate the refrigerating

machine oil.

•Mixing with water may cause deterioration of the refrigerating machine oil.

•As this refrigerant does not contain chloride, the gas

leak detector for conventional refrigerant gas can not

be used.

Do not use a charging cylinder.

•Use of a charging cylinder changes the composition

of refrigerant resulting in possible performance deterioration.

More careful management is required for the

tools than that for the conventional.

•Dust, trash or water content if mixed into the refrigerant circuit may cause to deteriorate the refrigerating machine oil.

Caution to Equipment Used for Replacing

Caution

Do not operate the valve before conducting

mineral oil recovery operation.

Operating valves before conducting mineral oil recovery operation may cause a deterioration in the performance of mineral oil recovery.

For mineral oil recovery operation, the system controller and MA remote controller may

be required to be remove sometimes.

•Improper handling can lead to an inability to perform

oil recovery operation.

• For removal, follow the instruction displayed on the

PC for mineral oil recovery.

• Mount the controllers again after finishing the oil recovery operation.

Observe a safe distance from the indoor unit

fan which runs during the mineral oil recovery operation.

Working in the surrounding of the indoor unit fan can

cause personal injury.

Record the quantity of refrigerant replenished.

(Enter into the column for replenished refrigerant

quantity on the label of the indoor unit.)

•Missing the description may deteriorate the performance of mineral oil recovery.

•Malfunction or poor cooling/heating may also be

caused.

During the mineral oil recovery operation, an

error display may be shown on the remote

controller or system controller.

•When an error display was shown during mineral oil

recovery operation, reset the error display after finishing the operation.

To conduct the refrigerant recovery/evacuation of the inside of exiting piping, choose

tools only used with R407C e.g. charging hose.

• Using a charging hose for R407C causes it to mix

the conventional refrigerating machine oil leading to

the deterioration of refrigerating machine oil.

Page 6

Before Conducting Installation Work/Electrical Work

Caution

Do not install the unit at a place where combustible gas can possibly be generated.

•Leaked combustible gas if stagnated around the unit

may cause explosion.

Do not use the unit in a special atmosphere.

•Use in an atmosphere containing high levels of oil,

steam or sulfide gas may seriously degrades the performance or damage parts.

Do not install the unit on a material which is

not designed to be wet.

•If liquid drips from the oil trap kit, apply centralised

drainage work to the oil trap kit.

Apply grounding work securely.

• Do not connect the grounding line to gas pipe, city

water pipe, lightning rod or telephone grounding line.

Improper grounding may cause electric shock.

For the power source wiring, refrain from

giving tensile force to the wiring.

•Disconnection, heat generation or fire may be

caused.

Make sure to mount a leak breaker to the

power source.

•Otherwise electric shock may be caused.

Be sufficiently careful in transporting products.

•Do not transport a product with a weight exceeding

20kg by a single person.

•Some products are packed with PP band. Do not

use it as a means of transporting.

•During transport cuts may be caused by the fin surface of the heat exchanger , please refrain from touching it without gloves.

Do not use the same switch or the like for

plural outdoor units.

Otherwise, malfunction, heat generation or fire may

be caused.

When installing the unit in hospitals or communication equipment plants, prepare measures to prevent noise generation beforehand.

•The noise may cause the erroneous operation or

failure and may give negative eff ect to medial equipment or communication equipment to disturb medical treatment on human bodies or hinders image

broadcasting or generates noise.

Check possibility for the reuse of existing

refrigerant piping by observing this manual.

• The conventional refrigerating machine oil is con-

tained inside existing piping and some residual oil

deteriorates oil recovery performance which may

lead to the deterioration of refrigerating machine oil.

• The piping specification (diameter, length , height

difference) out of the use specified range may hinder

the mineral oil recovery performance, possibly leading to deterioration of refrigerating machine oil.

Do not use breakers or fuses other than that

with correct capacities.

•Use of a fuse with excessively large capacity or wire/

copper wire may cause troubles or fire.

For the power source wiring, use wire with

rated current capacity.

•Otherwise an electric leak, heat generation or fire

may be caused.

When using existing wiring (for power source

or transmission) or switches, check them for

disconnection and deterioration beforehand.

•Otherwise an electric leak, heat generation or fire

may be caused.

Dispose the packing materials properly.

• As the packing materials are using metal products

or wooden pieces such as nails, nail wounds may

be caused if it is improperly treated. Please observe

caution to avoid this from occuring.

•Dispose the polyethylene bag for packing only after

tearing. Otherwise a suffocation accident may be

caused by children play with the disposed bag.

Be sure to mount the valve to the field piping

(extended piping).

After mineral oil recovery, the oil trap kit can not be

removed disabling air conditioning operation.

Provide thermal insulation to the valve on the

field piping (extended piping) properly.

•Insufficient thermal insulation generates condensation that may cause to deteriorate the performance.

• Provide thermal insulation (including lagging) after

recovering mineral oil.

Page 7

I. Outline of Equipment .................................................................................................................... 10

1. Combination of units ...................................................................................................................... 10

2. Temperature range allowing mineral oil recovery operation .......................................................... 10

3. Items to be observed ..................................................................................................................... 10

II. Product Specification.................................................................................................................... 11

1. Outdoor unit ................................................................................................................................... 11

(1) Specification table

(2) External dimension

2. Oil trap kit ....................................................................................................................................... 13

(1) Specification table

(2) External dimension

III. Outline of Flushing Operation .......................................................................................................... 14

I. Parts Provided with Oil Trap Kit ................................................................................................. 17

1. Verifying the parts provided ........................................................................................................... 17

II. Carrying/Storing the Oil Trap Kit................................................................................................ 18

1. Transportation by vehicles ............................................................................................................. 18

2. Carrying-in/carrying-out ................................................................................................................. 18

3. Storing............................................................................................................................................ 18

III. Work Procedure of Mineral Oil Recovery Operation ............................................................ 19

1. Work flow ....................................................................................................................................... 19

2. Items to be checked before work ................................................................................................... 21

3. Installation space and range of oil trap kit...................................................................................... 23

(1) Restrictions

4. Refrigerant piping work .................................................................................................................. 24

4-1 Piping connection before flushing operation

4-2 Piping connection after flushing operation

5. Electrical wiring work ..................................................................................................................... 30

5-1 Wiring connection before flushing operation

5-2 Wiring connection after flushing operation

6. Connection work on rainy days ...................................................................................................... 31

7. Flushing operation ......................................................................................................................... 32

(1) Installation method of S/W

(2) Items to be confirmed before flushing operation

(3) Starting and finishing of flushing operation

(4) Mounting method of low outdoor temperature hood

IV.Work Procedure at Oil Inspection.............................................................................................. 45

1. Oil inspection after mineral oil recovery ......................................................................................... 45

(1) Oil sampling method

(2) Measuring method and judgement of refractive index

(3) Measures to be taken at oil inspection (No Good)

V. Mineral Oil Recovery Operation Data (Reference Data)........................................................... 53

1. Standard data (During flushing operation) .....................................................................................53

CONTENTS

System Design

Caution to REPLACE MULTI Installation Work

Safety Precautions

Installation / Operation Work

Simplified Judgment for Reuse of Existing Piping/Wiring

I. Judgment for Reuse of Existing Piping ..................................................................................... 2

1. Reusing CITY MULTI air conditioner system .................................................................................. 2

2. Reusing other makes or Mitsubishi other than CITY MULTI ........................................................... 2

II. Connection Range of Deformed Piping

..................................................................................... 4

III.

Judgment for Reuse of Existing Transmission Line Wiring................................................. 5

Page 8

I. Construction of Oil Trap Kit......................................................................................................... 55

1. External appearance (with panel removed) ................................................................................... 55

2. Refrigerant circuit ........................................................................................................................... 56

3. Control box..................................................................................................................................... 57

II. Electrical Wiring Diagram ............................................................................................................ 58

III. Refrigerant Circuit Diagram ..............................................................................................59

1. Entire refrigerant circuit diagram at mineral oil recovery................................................................ 59

2. Refrigerant circuit diagram of oil trap kit ........................................................................................ 60

IV. Function List of Major Parts ........................................................................................................ 61

1. Outdoor unit ................................................................................................................................... 61

2. Oil trap kit ....................................................................................................................................... 62

3. Indoor unit ...................................................................................................................................... 63

V. Control of Mineral Oil Recovery Operation ............................................................................. 64

1. Initial control................................................................................................................................... 64

2. Control of solenoid valves.............................................................................................................. 64

3. Frequency control .......................................................................................................................... 65

4. Oil return control (Electronic expansion valve <SLEV> ) ............................................................... 66

5. Outdoor fan control ........................................................................................................................ 66

6. Sub-cooling coil control (Electronic expansion valve <LEV1>)...................................................... 66

7. Detecting circulation composition (CS circuit)................................................................................67

8. Distributed washing control and flow rate control (Indoor unit) ...................................................... 67

9. Indoor unit fan control .................................................................................................................... 67

VI. Operation Flow Chart.................................................................................................................... 68

1. Flushing operation ......................................................................................................................... 68

2. Flow chart of flushing operation ..................................................................................................... 69

VII. Troubleshooting ............................................................................................................................. 70

1. List of checking code ..................................................................................................................... 70

2. Self-diagnosis and countermeasure for malfunction and failure indicated by PC.......................... 72

3. Investigation of transmission wave shape/noise............................................................................ 87

4. Troubleshooting for major parts of outdoor unit and indoor unit .................................................... 97

5. Inverter......................................................................................................................................... 105

6. Control circuit ................................................................................................................................111

VIII. Monitor Display of Mineral Oil Recovery Operation by Outdoor Board LED.............. 112

1. How to view LED for service monitor ........................................................................................... 112

2. Synoptic table of the monitor display of mineral oil recovery operation by outdoor board LED ... 112

IX. Maintenance and Checking ....................................................................................................... 113

1. Maintenance and checking period ............................................................................................... 113

2. Maintenance and checking procedure for major parts for the oil trap kit ..................................... 114

3. Procedure for maintenance and checking of the portable refractometer ..................................... 118

4. Cautions when replacing the outdoor unit main board................................................................. 118

X. Information on Rating Plate....................................................................................................... 119

Service, Maintenance / Inspection

Page 9

I. Judgment for Reuse of Existing Piping ..................................................................................... 2

1. Reusing CITY MULTI air conditioner system .................................................................................. 2

2. Reusing other makes or Mitsubishi other than CITY MULTI ........................................................... 2

II. Connection Range of Deformed Piping ..................................................................................... 4

III.

Judgment for Reuse of Existing Transmission Line Wiring ................................................. 5

Simplified Judgment for Reuse

of Existing Piping/Wiring

-1-

Page 10

I. Judgment for Reuse of Existing Piping

Both the checking of gas leak inside existing piping and the verification of reliability relating to piping strength

belong to the scope of field work as same as in the past. Therefore, we are not liable to the quality of existing

piping.

Before starting the work, it is necessary to confirm that the existing piping in question owns the rated strength

(relating to the material, thickness, and corroded portions, if any).

Points to be observed for simplified judgment to reuse existing piping

1. Reusing CITY MULTI air conditioner system

The existing piping can basically be reused if no problem was found during your use in the past.

(Please check whether the trouble was caused by gas leak or it required frequent refrigerant replenishment.)

(1) Change to same capacity → Usable as it is

(2) Change to different capacity → Check whether the piping diameter, piping length, height difference, etc.

are within our operating range.

2. Reusing other makes or Mitsubishi other than CITY MULTI

(1) Check whether the packaged air conditioner used in the past was in operational trouble or not.

(Please check whether the trouble was caused by gas leak or it required frequent refrigerant replenish-

ment.)

(2) Confirm the type of refrigerating machine oil used by the existing facility.

SUNISO, MS, HAB, Barrel Freeze, Freol are acceptable. For other refrigerating machine oil than the

above, ask our factory in each case.

(3) The branch types of T-fitting, Y-branch and header branching are acceptable.

The branch pipe applied with pressure loss (like the multi-distributor of SLIM) can not be used. Replace-

ment with new branch pipe is required in this case.

Estimate the branch configuration and piping size depending on the maker name, model name and con-

necting quantity of existing products.

(4) Confirm that the piping diameter, piping length, height difference, etc. are within our operating range.

Item, index of judgment for reusing of existing piping

Piping diameter, length

Type of refrigerating

machine oil

Air tightness

Distributor configuration

Thermal insulation

Piping system

Pipe thickness

None

Maker, type (model name), year of manufacturing

Operability of previous unit

Maker, type (model name), year of manufacturing

None

None

Refer to DATA BOOK

SUNISO, MS, HAB, Barrel Freeze, Freol

No pressure drop by leaving for one day after

pressurizing to 2.98Mpa

T-fitting, Y-fitting, Header branching

No peeling off of thermal insulation and caulking

Unit height difference should be within the standard

of typical unit

Pipe thickness equivalent to the standard of each

country

Items Judgment standard Indirect material for judgment

-2-

Page 11

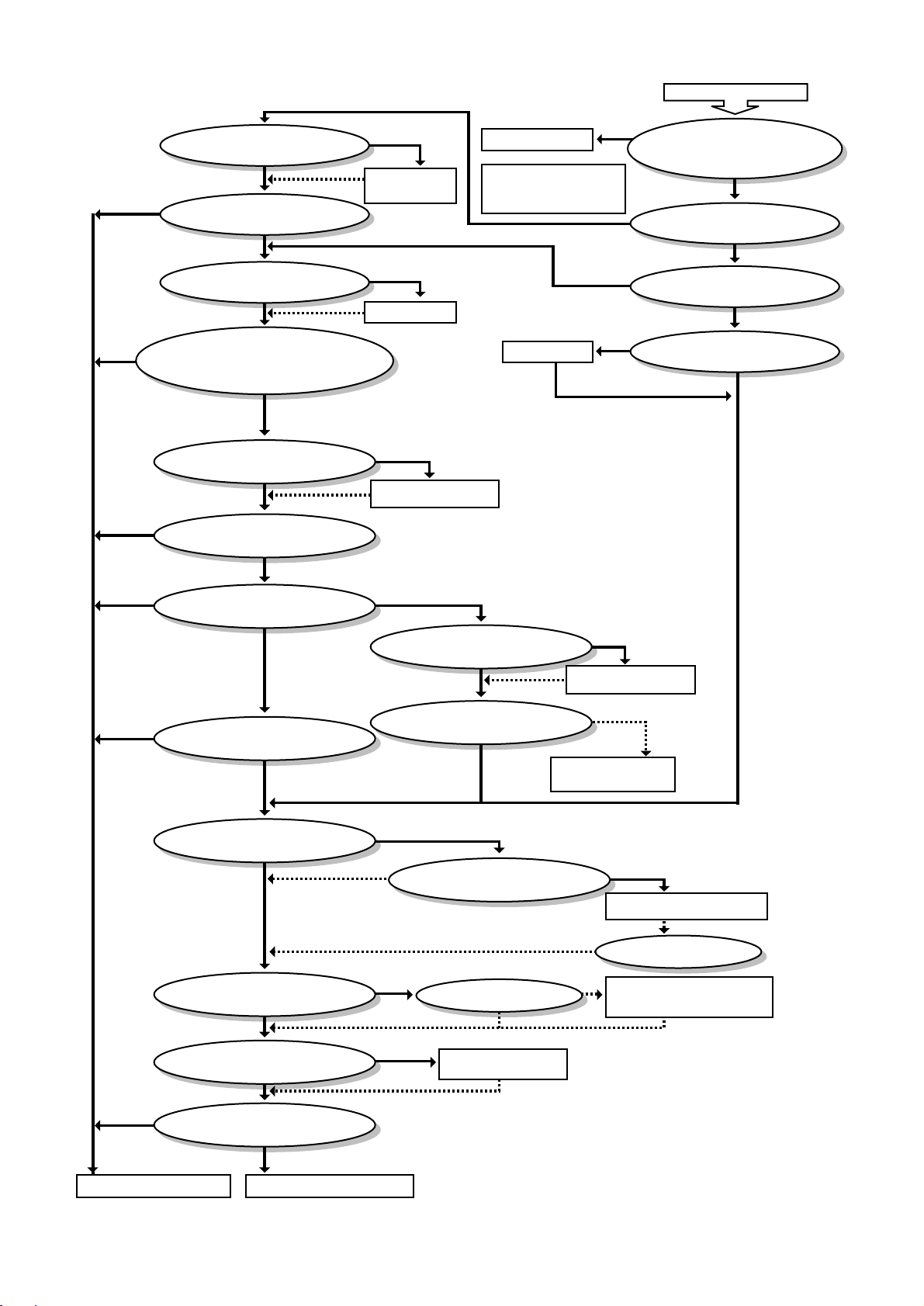

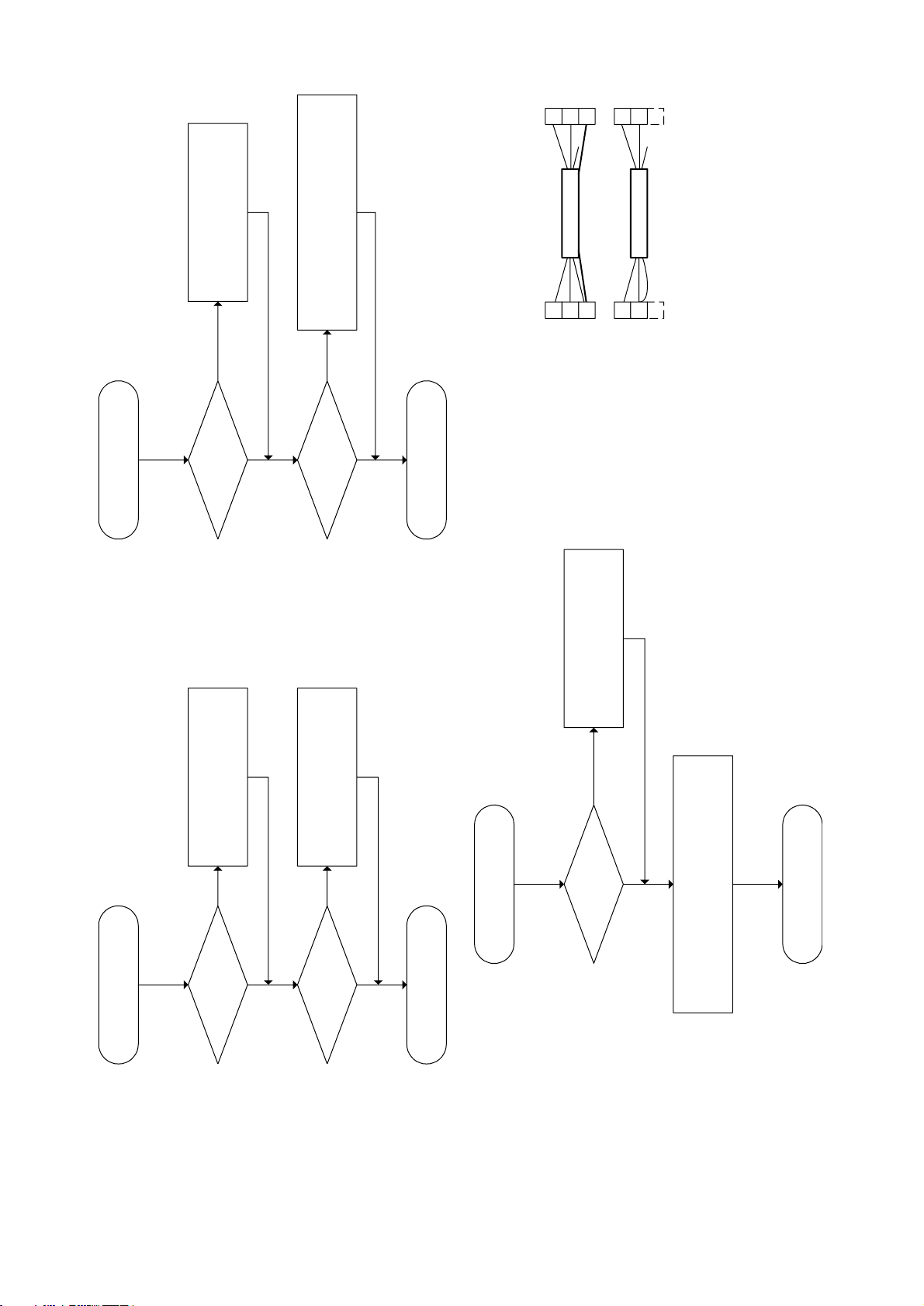

Start

In the piping planned for reuse,

are the outdoor and indoor

units connected?

Is the old unit Mitsubishi?

Do you wish to replace with our

Building Multi in the same capacity?

Do you know the piping

diameter/length?

Simplified judgment for reuse of existing piping (Flow)

Do you know the type of refrigerating

machine oil used by the old unit?

Is it SUNISO, MS, HAB,

Barrel Freeze or Freol?

Can you find the height

difference between outdoor and indoor

units, and between indoor units?

Is the height difference between

indoor and outdoor units less than

50m (40m when outdoor unit locates below

indoor unit), and that between indoor units

less than 15m maximum?

Do you know the piping

diameter/length?

Do the piping diameter and piping

length match our standard?

Do you know the configuration of

the branch piping?

Is the branch pipe of T, Y

or header branching?

Is a gas leak found?

Is there any branching pipe

not connected with indoor unit?

Is the thermal insulation of

piping peeling off ?

Is the rated strength

(material, thickness, corroded portion

if any) kept?

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

YES

Check it by

asking the maker.

Please check it.

Install new piping.

As the piping left alone

may allow the entry of

dust or the like, refrain

to reuse such piping.

Please investigate.

Please investigate

in the field.

Please investigate

in the field.

Change the branch pipe

with that specified by us.

Check the air tightness

in the field.

Is the air tightness of

the piping proper?

Isolate the branching pipe from

the refrigerant circuit during

mineral oil recovery work.

Use new piping. Existing piping can be used.

NO

NO

NO

NO

YES

YES

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Do you know the maker,

type and model name?

Judge the possibility of

reuse by checking the configuration

while referring to the standard.

Was the old unit operated before

replacement without refrigerant leak?

Can you cut off the

branching pipe?

Provide proper thermal

insulation.

-3-

Page 12

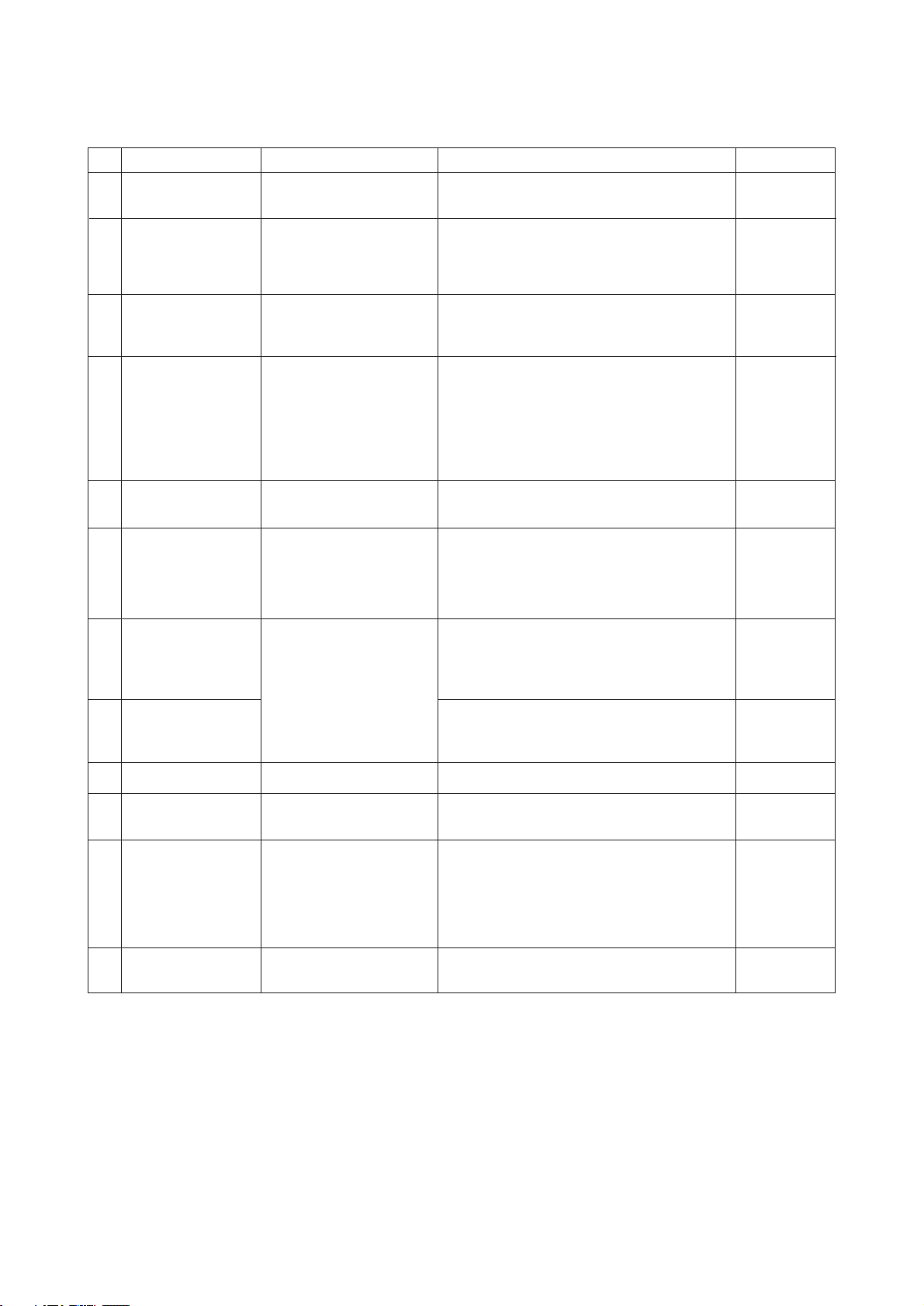

II. Connection Range of Deformed Piping

1. List of possibility to connect deformed piping (Chart)

(1) Outdoor – First branch [A section (Y series)]

Table-1

: Normal piping

: Usable (without performance deterioration)

● : Usable (with performance deterioration: Refer to DATA BOOK)

: Usable (with rule on refrigerant charge: Refer to the formula to judge refrigerant

charge on the next page.)

▲ : Usable (with limitation on piping length)

◆ : Possible for liquid piping of

φ

9.52

x : Not connectable

❉ : Limitation on mineral oil recovery work process

This list is presented just for your reference, even the item marked x may be acceptable occasionally depending on the specific field piping condition. Therefore, please

ask the factory individually in such case.

Gas pipe

φ

15.88

φ

19.05

φ

22.2

φ

25.4

φ

28.58

φ

31.75

φ

38.1

Liquid pipe

φ

9.52

φ

12.7

φ

15.88

φ

19.05

φ

22.2

(2) Branch – indoor [a ~ f sections]

Table-2 List of possibility to connect indoor unit/deformed piping

Formula to judge refrigerant charge:

For the case marked , it is necessary to take measures to reduce the piping length slightly, to raise the selecting model or reduce

the number of connected indoor units.

• Y series

M = 0.3 x L1 + 0.2 x L2 + 0.12 x L3 + 0.06 x L4 + 0.024 x L5 < 17.4

L1 : Piping length (m) of φ19.05mm

L2 : Piping length (m) of φ15.88mm

L3 : Piping length (m) of φ12.7mm

L4 : Piping length (m) of φ9.52mm

L5 : Piping length (m) of φ6.35mm

Gas pipeφ12.7

φ

15.88

φ

19.05

φ

22.2

φ

25.4

φ

28.58

φ

31.75

φ

38.1

Liquid pipe

φ

6.35

φ

9.52

φ

12.7

φ

15.88

φ

19.05

P20 P25 P32 P40 P50 P63 P71 P80 P100 P125 P140 P200 P250

xx xx xxx

xxx xx

xxxxx xx

xxxxxxx❉❉❉ x

xxxxxxxx x❉❉

xxxxxxxx xxx

xxxxxxxx xxxxx

xxxxxxxx xxxxx

xx xx xxx

xx

xxxxxxxx xxxxx

(within 25m) (within 15m)

P200 P250

x

x

x

x

x

❉

x

x

xx

xx

xx

x

x

-4-

Page 13

1. Remote controller line (MA remote controller)

(1) Length m

(2) Wire diameter mm

2

(3) Number of wire (number of pole) Pole

(4) Type of wire (Shielded wire used/not used) Used / Not used

2. Remote controller line (M-NET remote controller)

(1) Length ❉1 m

(2) Wire diameter mm

2

(3) Number of wire (number of pole) Pole

(4) Type of wire (Shielded wire used/not used) Used / Not used

3. Remote controller line (System controller)

(1) Length ❉1 m

m

m

(2) Wire diameter mm

2

(3) Number of wire (number of pole) Pole

(4) Type of wire (Shielded wire used/not used) Used / Not used

(5)

System controller connection

Indoor / Centralized

Indoor system/centralized system

4. Indoor-outdoor transmission line

(1) Refrigerant system Single/Plural Single / Plural

(2) Transmission line farthest length

(3) Wire diameter mm

2

(4) Number of wire (Number of pole) Pole

(5) Type of wire (Shielded wire used/not used) Used / Not used

(6) Number of connected indoor units Unit

5. Centralized transmission line

(1) Transmission line farthest length

(2) Wire diameter mm

2

(3) Number of wire (Number of pole) Pole

(4) Type of wire (Shielded wire used/not used) Used / Not used

6. Availability of system diagram YES / NO

(Please try to obtain it much as possible.)

7. Existence of noise trouble on the unit before replacement YES / NO

(In case of YES, enter the trouble detail into the

column of remarks.) ❉2

8. Is the noise generation from high harmonics medical YES / NO

equipment estimated? (In case of YES, enter your

apprehensions in detail into the column of remarks.) ❉2

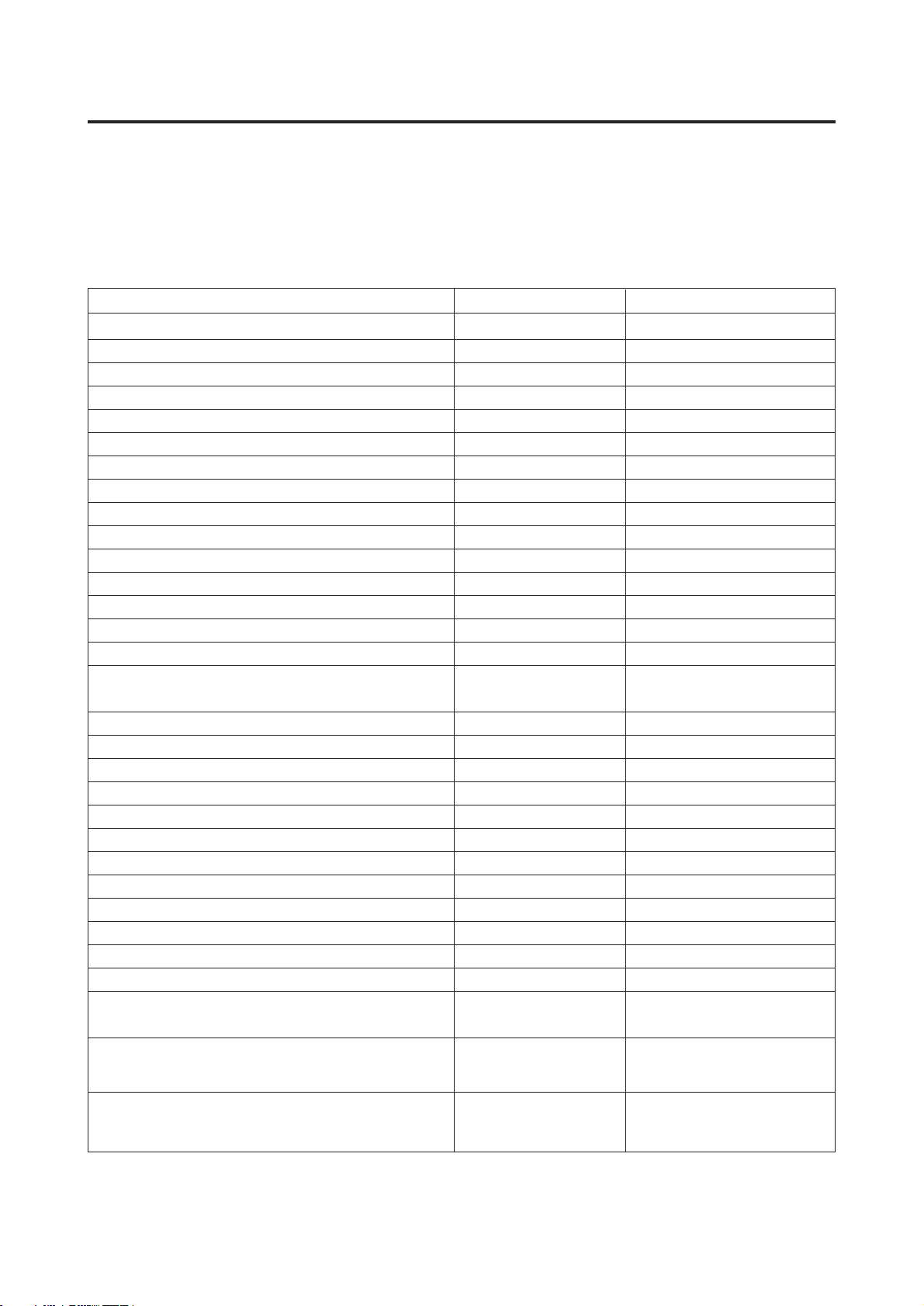

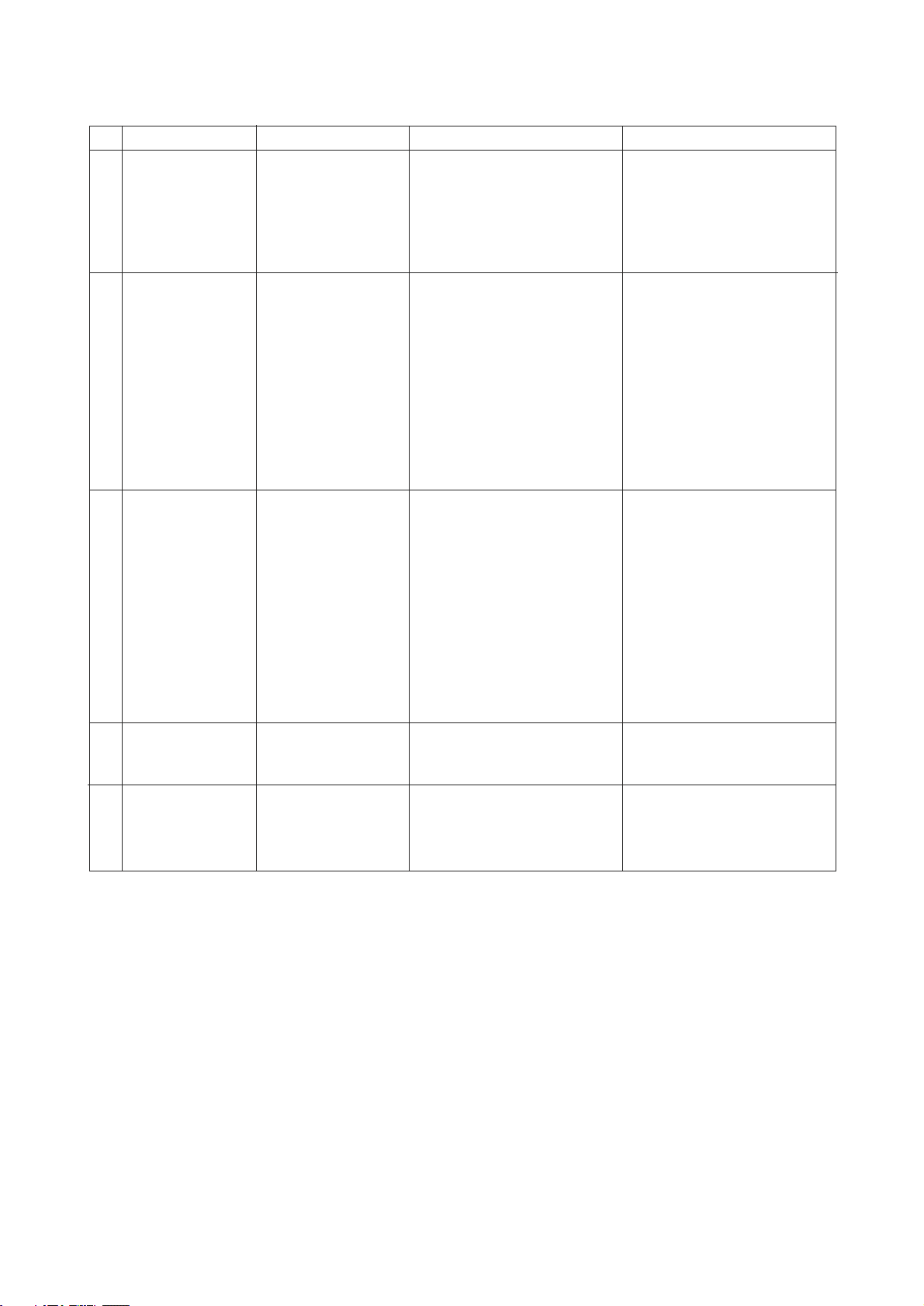

III.

Judgment for Reuse of Existing Transmission Line Wiring

To study on the reuse of existing transmission line, please refer to the flow shown later starting from the next

page.

For the reuse of existing transmission line, enter the necessary items into the check list, obtain the system

diagram and contact our dealer.

Check list for reuse of existing transmission line wiring

Checking item Result Remarks

❉1 Include the portion of the remote controller length (M-NET/System controller) exceeding 10m into the figure of the transmission line

length (Indoor-outdoor, centralized).

❉2 Regarding the judgment and countermeasure on noise, please contact our dealer.

❉1

❉1

-5-

Page 14

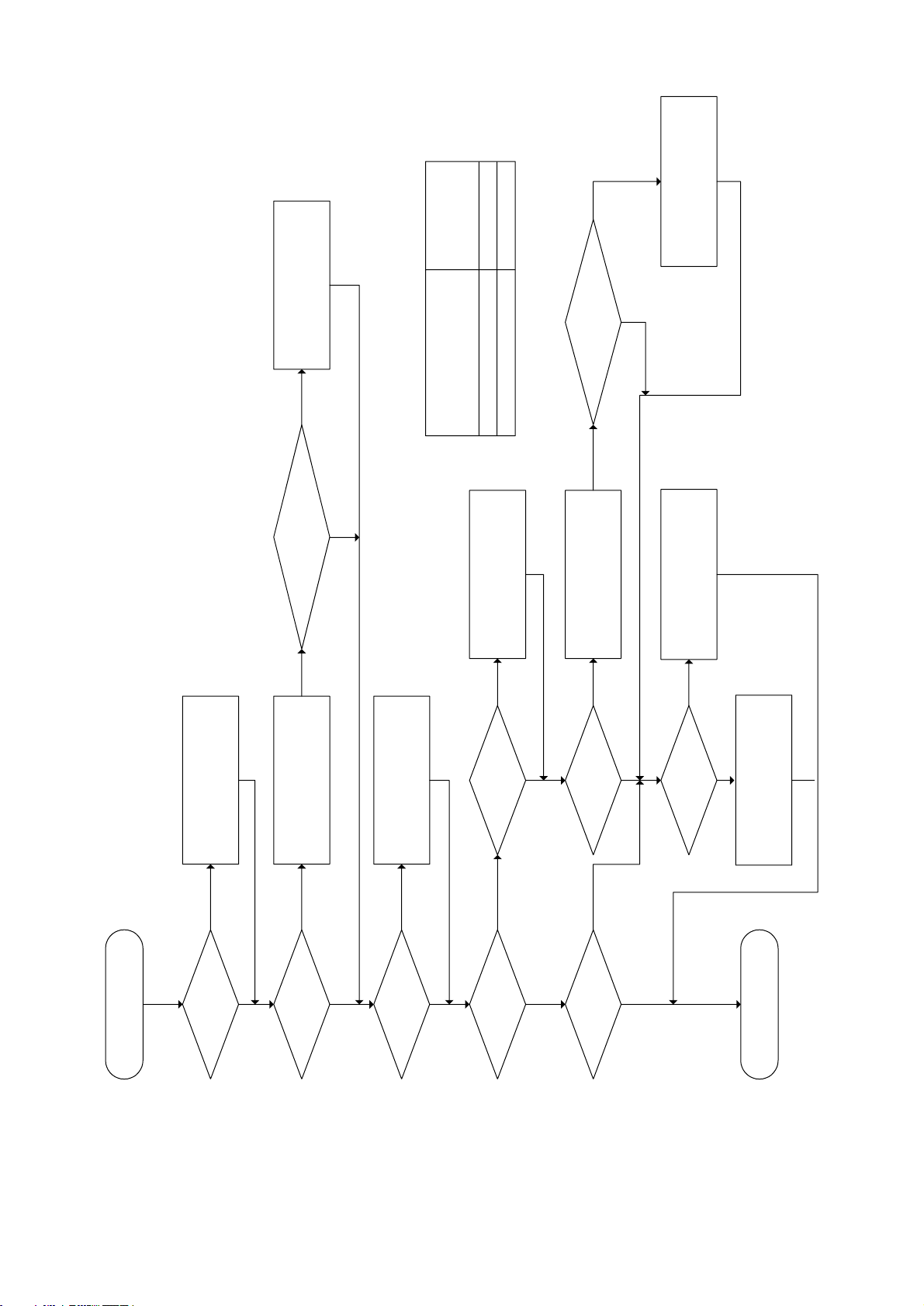

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

ABS

ABS

ABS

ABS

Arrange the wire not

used as shown in Fig. A.

Arrange MA remote controller

line length below 200m.

Check MA remote

controller line

Number of wire (pole)

= 2 ?

Remote controller

line length

≤ 200m?

To transmission

line checking

Arrange the wire not used

as shown in Fig. A.

Check system controller

remote controller line

Number of wire (pole)

= 2 ?

• Include a portion of wire length exceeding 10m into

the figure of the transmission line farthest length.

❉1

• Make the wire diameter and type as same as that of

transmission line.

To transmission

line checking

Check M-NET remote

controller line

Number of wire (pole)

= 2 ?

Remote controller

line length ≤10m?

To transmission

line checking

Arrange the wire not

used as shown in Fig. A.

• Include a portion of wire length exceeding 10m

into the figure of the indoor-outdoor transmis-

sion line length.

❉1

• Make the wire diameter and type the same as

that of the indoor-outdoor transmission line.

Power supply unit

(outdoor unit,

power supply

device, etc.) side

Fig. A Arrangement of wire not used

For the power supply unit (outdoor unit, power supply de-

vice, etc.) side, connect shielded wire to the terminal for

shielded wire, unshielded wire to the terminal for signal,

and open the other ends.

Insulate the opened ter

minals securely.

Shielded wire

Unshielded wire

-6-

Page 15

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

NO

YES

NO

YES

YES

NO

Table A Usable wire diameter for centralized

system transmission line

❉1 Include a portion of remote controller (M-NET/System controller) wire length exceeding 10m into the figure of the transmission line

(indoor-outdoor / centralized systems) length.

❉2 Ask our dealer for the judgment and countermeasure on noise.

Arrange the indoor-outdoor

transmission line farthest

length less than 200m.

Confirming the number of indoor

units and the indoor-outdoor trans-

mission line farthest length, read the

usable wire diameter from the graph.

Arrange the wire not used

as shown in Table A.

Centralized

transmission line farthest

length ≤ 500m?

❉

1

C

entralized

transmission line wire dia-

meter ≥ 1.25mm

2

?

Shielded wire?

Connect the shielded wire to the

outdoor unit (power supply unit)

side for grounding.

The diameter of

the wire used is thicker than that read

from the B graph.

Replace the indoor-outdoor

transmission line by that with

a diameter over 1.25mm

2

.

Arrange the centralized

transmission line farthest length

less than 500m.

Confirming the centralized trans-

mission line farthest length, read

the usable wire diameter from

Table A.

When using other than shielded

wire, be careful for noise.

❉

2

Check transmission line.

Indoor-

outdoor transmission line

farthest length ≤ 200m?

❉1

Indoor-

outdoor transmission

line wire diameter

≥

125mm

2

?

Number of wire (pole)

= 2?

Single refrigerant

system?

Indoor-

outdoor transmission line

farthest length ≤ 120m?

❉1

Possible to reuse existing

transmission line

The wire

diameter of the used transmis-

sion line is thicker than that usable

in Table A?

Replace by the centralized

transmission line with a

diameter over 1.25mm

2

.

Distance from power supply

unit to outdoor unit and sys-

tem controller

Wire diameter

200m or less 0.5mm

2

or more

130m or less 0.3mm

2

or more

-7-

Page 16

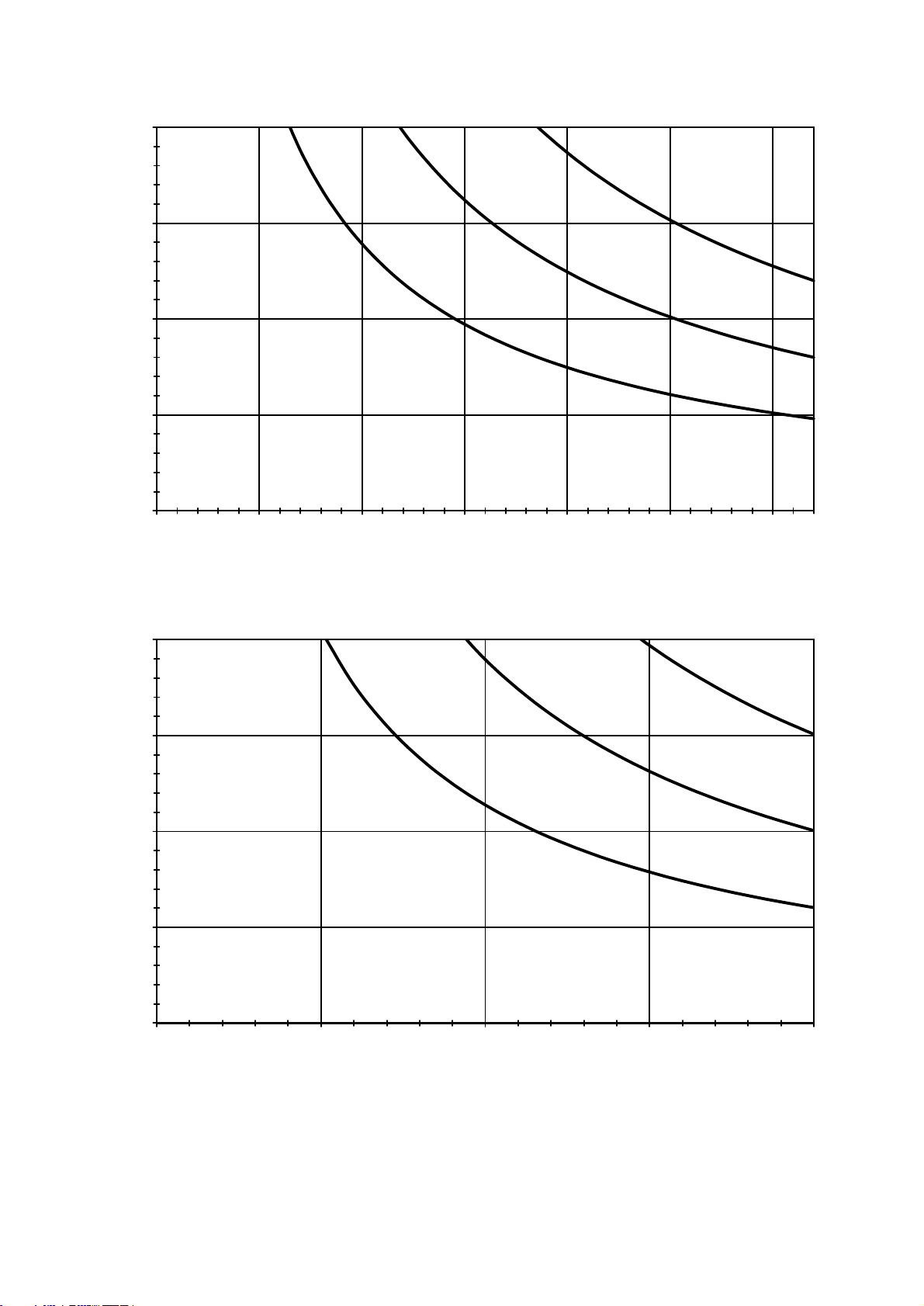

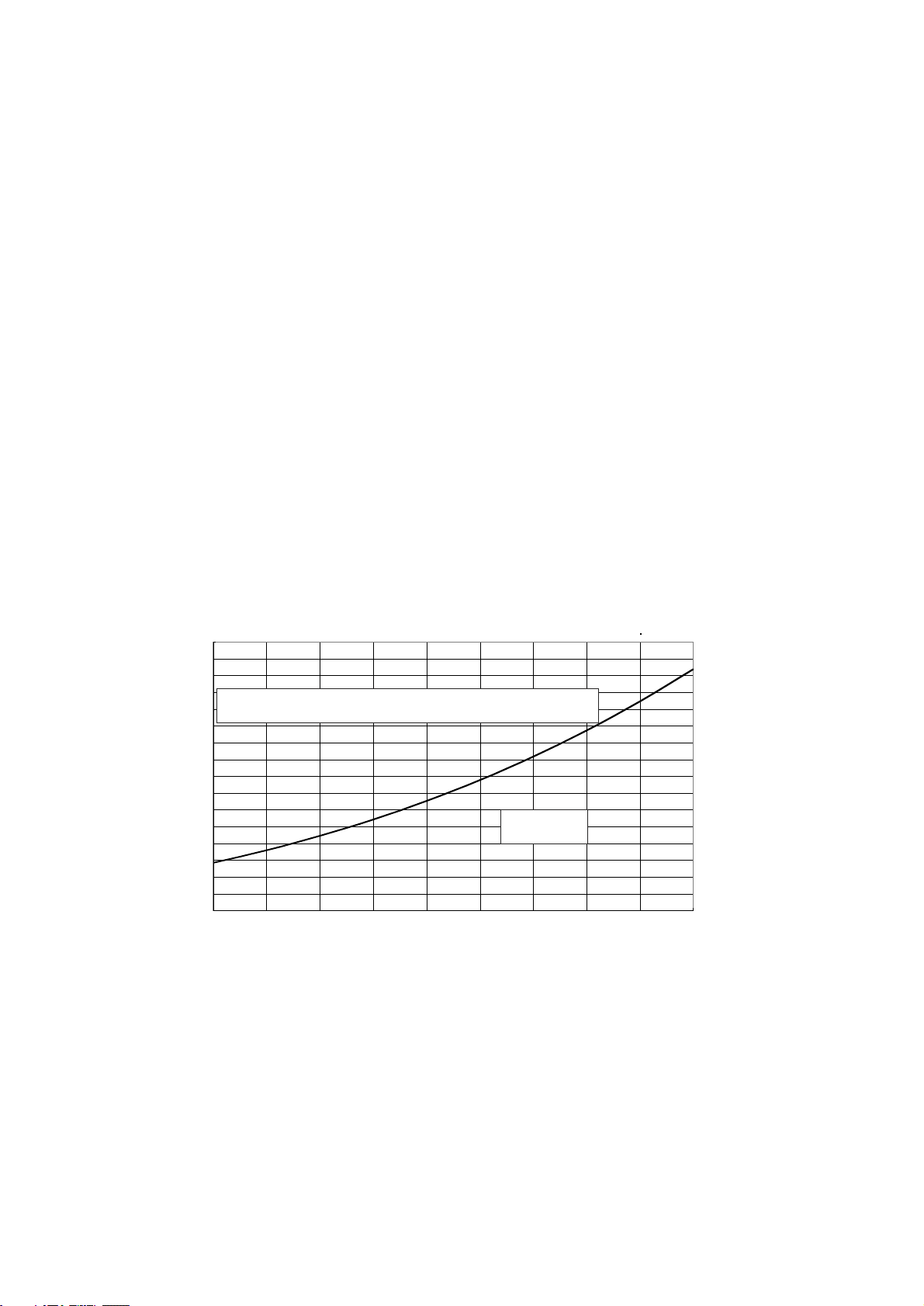

0.5mm

2

0.75mm

2

0.3mm

2

1.25mm

2

0

50

100

150

200

0 5 10 15 20

0

50

100

150

200

0 5 10 15 20 25 32

30

0.75mm

2

0.5mm

2

0.3mm

2

1.25mm

2

Fig. B Usable wire diameter

For connection with MA remote controller

Transmission line fa

rthest length (m)

Number of indoor unit

Transmission line farthest length (m)

Number of indoor unit

For connection with M-NET remote controller

-8-

Page 17

I. Outline of Equipment .................................................................................................................... 10

1. Combination of units ...................................................................................................................... 10

2. Temperature range allowing mineral oil recovery operation .......................................................... 10

3. Items to be observed ..................................................................................................................... 10

II. Product Specification ....................................................................................................... 11

1. Outdoor unit ................................................................................................................................... 11

(1) Specification table .................................................................................................................... 11

(2) External dimension ................................................................................................................... 12

2. Oil trap kit ....................................................................................................................................... 13

(1) Specification table .................................................................................................................... 13

(2) External dimension ................................................................................................................... 13

III. Outline of Flushing Operation........................................................................................... 14

System Design

-9-

Page 18

2. Temperature range allowing mineral oil recovery operation

Outdoor inlet dry bulb temperature –5 ~ 43˚C

3. Items to be observed

• Refrigerant flow sound, operating sound of solenoid valve switching

Caution Countermeasure

Install the unit at a place not affected by the

sound generated from the unit.

• RE: Effect of noise

Caution Countermeasure

During mineral oil recovery, flowing sound may be generated depending on the status of refrigerant. In addition, operating sound may be generated at the switching

of the solenoid valve.

(These symptoms do not represent abnormal states.)

As the air conditioner uses microcomputer, radiation noise

is emitted from the power source, transmission line and

unit body slightly. If the unit is installed near equipment

that amplify microscopic signals electrically (wireless microphone, medical equipment for example), these equipment may operate erroneously affected by the noise. Further installing the air conditioner near the equipment emitting strong noise (like electric discharge machine etc.)

may cause the malfunction of the air conditioner due to

the noise. In the case when such troubles are expected,

please take the countermeasure shown right.

The equipment which may likely be affected

by noise (receiver of wireless microphone or

antenna) are recommended to be install isolated from the transmission line, power source

line of the unit and the unit body.

The power source line of the equipment emitting strong noise and that of the air conditioner

should be separated, and the transmission

line, power source line and unit body should

be installed isolating each other as much as

possible.

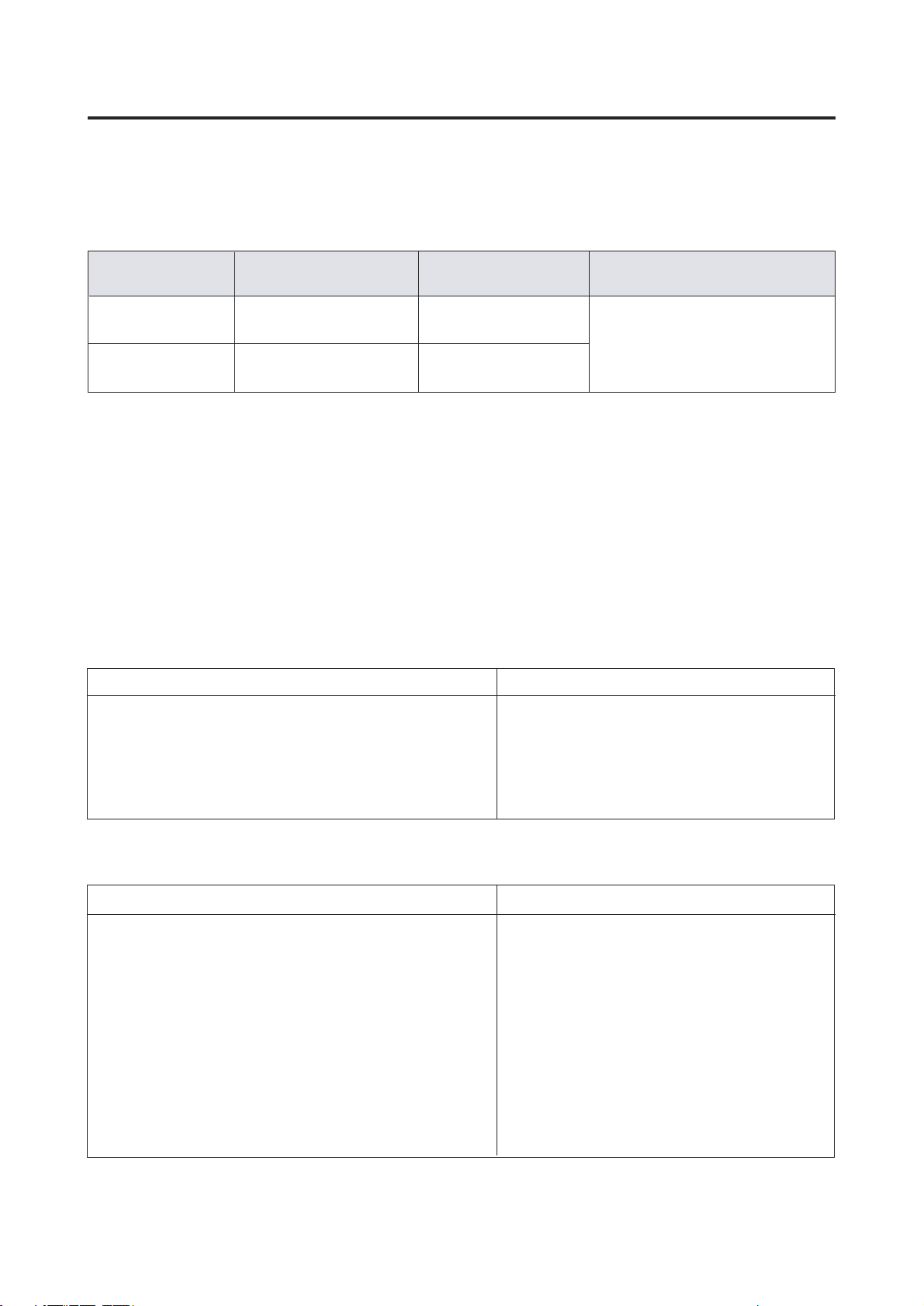

I. Outline of Equipment

1. Combination of units

The connectable units to this product are shown below.

• Cool/heat selection Y System

Outdoor unit Total capacity of connected Quantity of connectable Connectable indoor unit

model name indoor unit model names indoor unit model name

PUHY-P200YREM-A 100 ~ 260 1-set ~ 13-set

PUHY-P250YREM-A 125 ~ 325 1-set ~ 16-set

P20 ~ P250

New refrigerant series indoor unit

and ventilation relating equipment

Note: The total capacity of connected indoor unit model name represents the summed up total of the numerical figure

portion of the indoor unit model names.

-10-

Page 19

II. Product Specification

1. Outdoor unit

(1) Specification table

Y Series

Power source

Cooling capacity ❉1kW

Heating capacity kW

Power

Cooling kW

input

Heating kW

Cooling A

Current

Heating A

Refrigerant/Lubricant

Type x quantity

Compressor Motor output kW

Starting system

Crankcase heater W

Type x Quantity

Fan Airflow rate m3/min

Motor output kW

High pressure protection

Protection

Compressor

devices

Fan

Inverter

Refrigerant

Gas pipe mm

piping diameter

Liquid pipe mm

Noise level ❉2 dB(A)

External finish

High mm

External

Width mm

dimension

Depth

Net weight kg

Operating temperature range

Matters deserving special mention

Outdoor unit model name PUHY-P200YREM-A PUHY-P250YREM-A

Electrical

characteristic

3N~ 380/400/415V 50/60Hz

22.4 28.0

25.0 31.5

6.32 8.54

6.80 8.95

10.6/10.1/9.7 14.4/13.6/13.2

11.4/10.9/10.5 15.1/14.3/13.8

R407C/MEL32

Hermetic x 1

6.8

Inverter start

45 (240V) 45 (240V)

Propeller fan x 1

200 200

0.38 0.38

2.94MPa

Over current protection • over heat protection

Thermal switch

Over current protection • thermal protection

φ

25.4

φ

28.58

φ

12.7

φ

12.7

56 57

Pre-coated galvanized sheets

(MUNSELL 5Y 8/1 or similar)

1755 1755

990 990

840 840

239 239

A pipe of φ28.58 can be used for the gas pipe

Note : 1. Cooling/heating capacity indicates the maximum value at operation under the following condition.

❉1 Cooling Indoor : 27˚CDB/19˚CWB Outdoor : 35˚CDB

Heating Indoor : 20˚CDB Outdoor 7˚CDB/6˚CWB

Piping length : 7.5m

❉2 It is measured in anechoic room.

Indoor : 15˚CWB~24˚CWB

Outdoor : –5˚CDB~43˚CDB

(0˚CDB~43˚CDB with outdoor unit at lower position)

Indoor : 15˚CDB~27˚CDB

Outdoor : –15˚CWB~15.5˚CWB

mm

5.3

-11-

Page 20

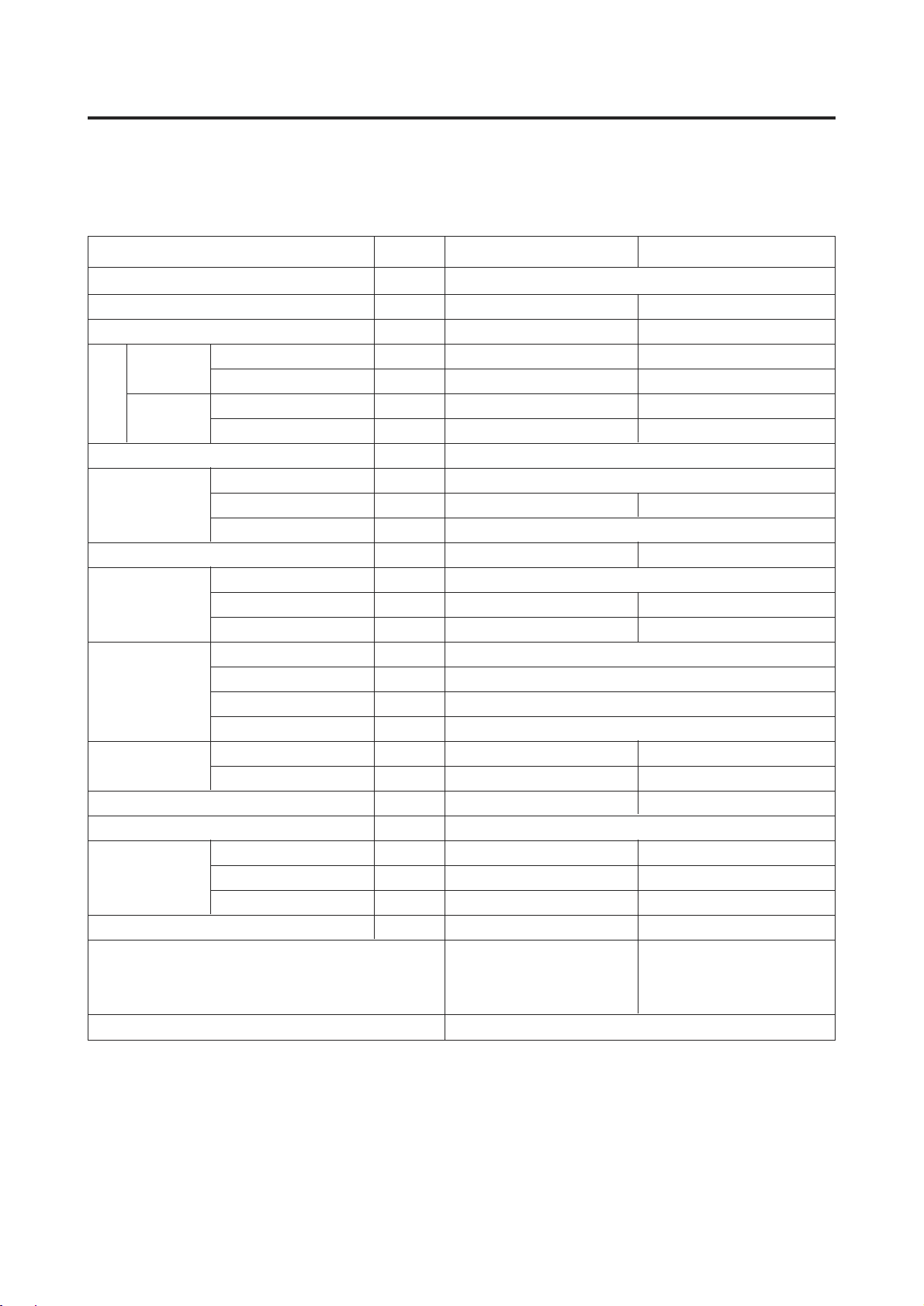

1755

25 160

73 80

Knockout hole

Bottom piping hole

<Bottom wiring hole>

237

198

2✕2-14✕20

Oval hole

910

(15)880(bolt hole)

15

560(bolt hole)

215 (215)

990

840

80

16531

79

70

48 100

194

4080

7560

251100

234

149

40

X

X

Cross section X-X

Note1

Y

Y

Cross section Y-Y

50

12 5

75778

121

Plane view

Air outlet

Rear view

Air

inlet

Air

inlet

Right side view

Knockout hole

Service panel

Knockout hole

Front piping hole

<Front wiring hole>

Front view

Refrig. service

valve(gas)

<flange>

Knockout hole

Left piping hole

Left side view

Knockout hole

1490

Knockout hole

<Front side hole for

the power supply>

78

99

813

590 55

(2) External dimensions

Models PUHY-P200, P250YREM-A Unit: mm

φ

27 Knockout hole

<Left side hole for the

control wiring>

Refrig. service

valve (liquid)

φ

12.7<flare>

φ

40 Knockout hole

<Left side hole for

the power supply>

φ

40 Knockout hole

<Bottom side hole for

the power supply>

φ

27 Knockout hole

<Bottom side hole for

the control wiring>

Conn. pipe

200:

φ

25.4 <brazed>

250:

φ

28.58<brazed>

315:

φ

31.75<brazed>

<Accessories>

• Refrigerant <gas> connecting pipe

............. 1 pc.

(The connecting pipe is fixed with the unit)

• Packing for connecting pipe

........................ 1 pc.

(Attached near ball valve)

• Wiring mounting board

................................

1 pc.

• Conduit mounting plate

(Painting the same color as the unit body)

φ

40,

φ

33,

φ

27 ....................................

Each 1 pc.

• Tapping screw 4 x 10 .................................

6 pcs

• Parts of mineral oil recovery

....................... 1 set

Note:

1. Please leave a space under the outdoor unit for

the piping. When you connect the piping from

the bottom.

(Please be careful not to close the hole of the

bottom plate by the basement.)

-12-

Page 21

787

65

90

1091

999

559

92

130

272

507577

336

845

75777

A

N L

M1 M2 S

❉1 The packing is provided for 5 pcs. (mineral oil recovery for 1 time). Please purchase additional packing if required.

(Service parts code : R61 F14 514, Service model name code : P321009X01)

❉2 Service parts code : R61 M03 622, Service model name code : W650296G01

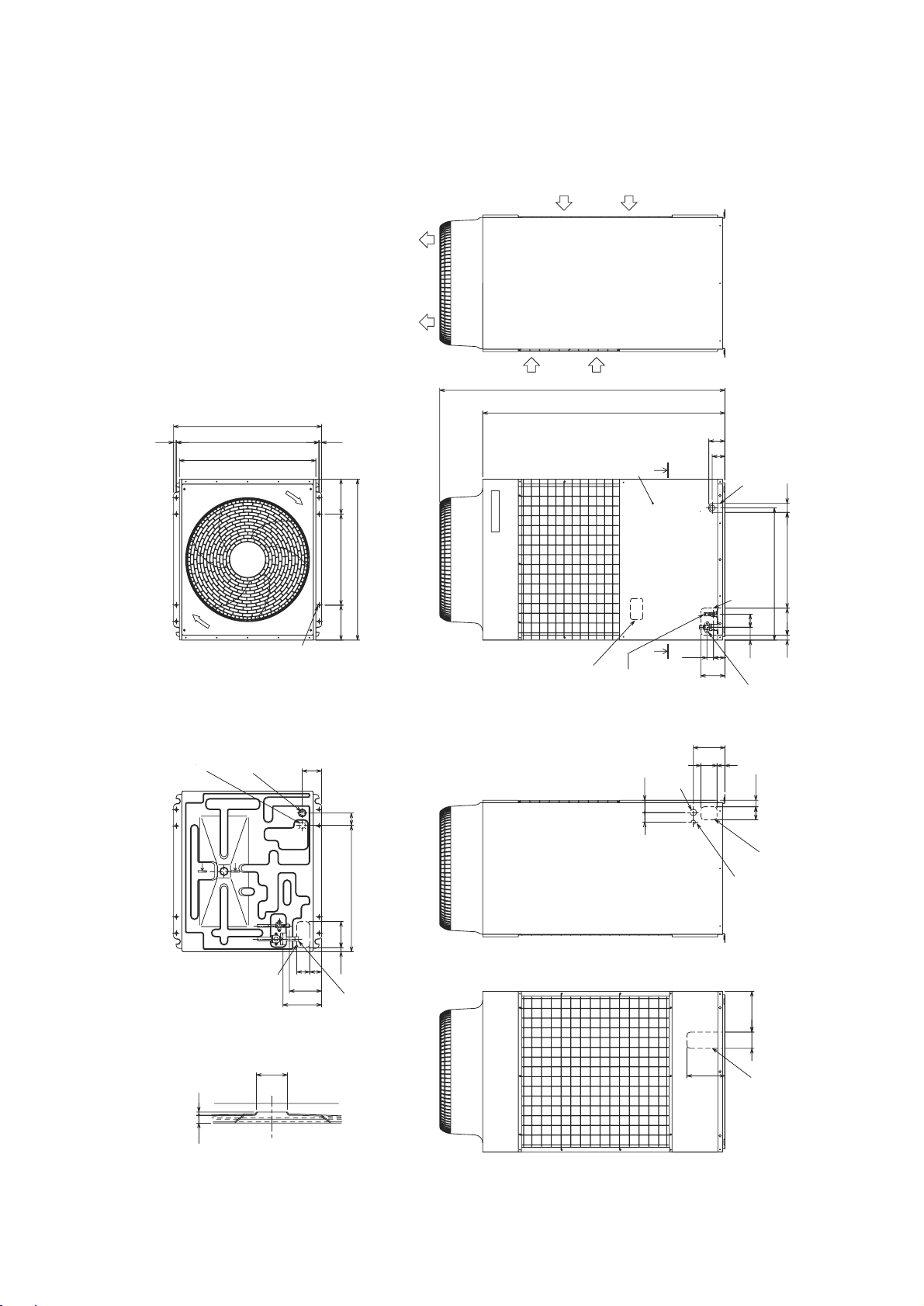

(2) External dimension

Notes: 1. For the connection and operation control of the oil

trap kit, you are kindly requested to obtain our approval.

2. Make the piping length between the oil trap kit and

the outdoor unit 5m or less. <The optional flexible

hose (2m) is prepared by Mitsubishi.>

2. Oil trap kit

(1) Specification table

Oil trap kit model name PAC-KP90VCLU

Power source ~N 220/230/240V 50Hz

Electrical

Power consumption kW 0.049

characteristic

Current A 0.20/0.21/0.22

External finish Galvanized steel sheets

Height mm

mm

mm

1091

External dimension Width 336

Depth 757

Ball valve side

High pressure mm

φ

12.7 Flare connection

Refrigerant piping

(at outdoor unit)

Low pressure mm

φ

28.58 Flange connection

Fitting side

High pressure mm

φ

15.88 Flare connection

(at extended piping)

Low pressure mm

φ

19.05 Flare connection

Net weight kg 76

Accessories

Packing ❉1, Hood for low OA ❉2

Pipe 1,Pipe 2, Saddle, Packing, Screw

Power source

terminal block cover

Refrigerant service

valve <outdoor unit

low pressure side>

φ

28.58 <flange>

Refrigerant service

valve <outdoor unit

low pressure side>

φ

19.05 <flare>

Terminal for PC

connection

<RS-232C>

Refrigerant service

valve <outdoor unit

high pressure side>

φ

12.7 <flare>

Refrigerant service

valve <outdoor unit

high pressure side>

φ

15.88 <flare>

Pressure gauge

Refrigerant service

valve <oil recovery>

φ

6.35 <flare>

Transmission terminal block Power source terminal block (TB01)

(TB02)

Details of A-section

Caster

<stopper side>

Piping

cover

Handle

Caster <swivel side>

with stopper

Valve

cover

-13-

Page 22

0 20 40 60 80 100 120

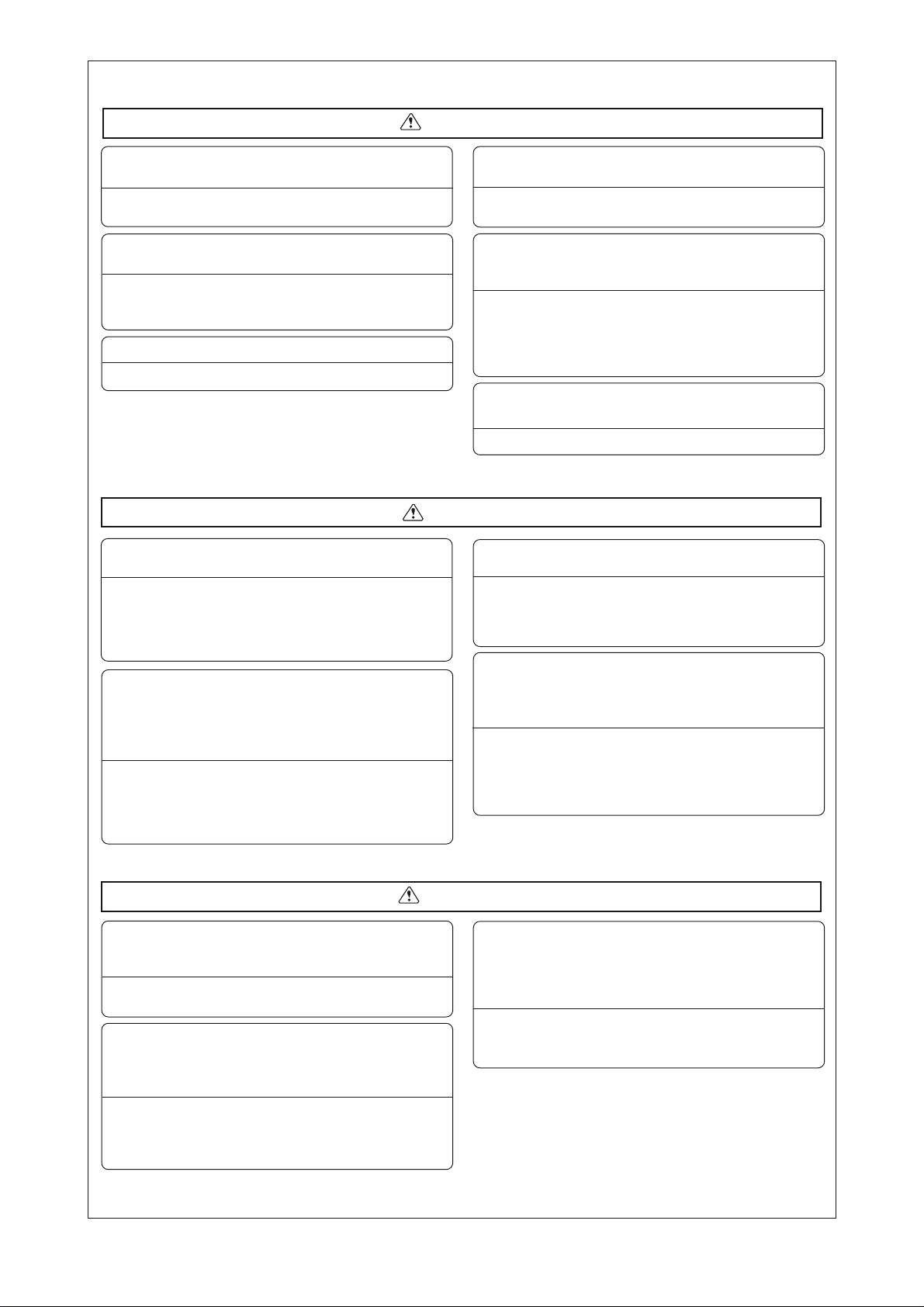

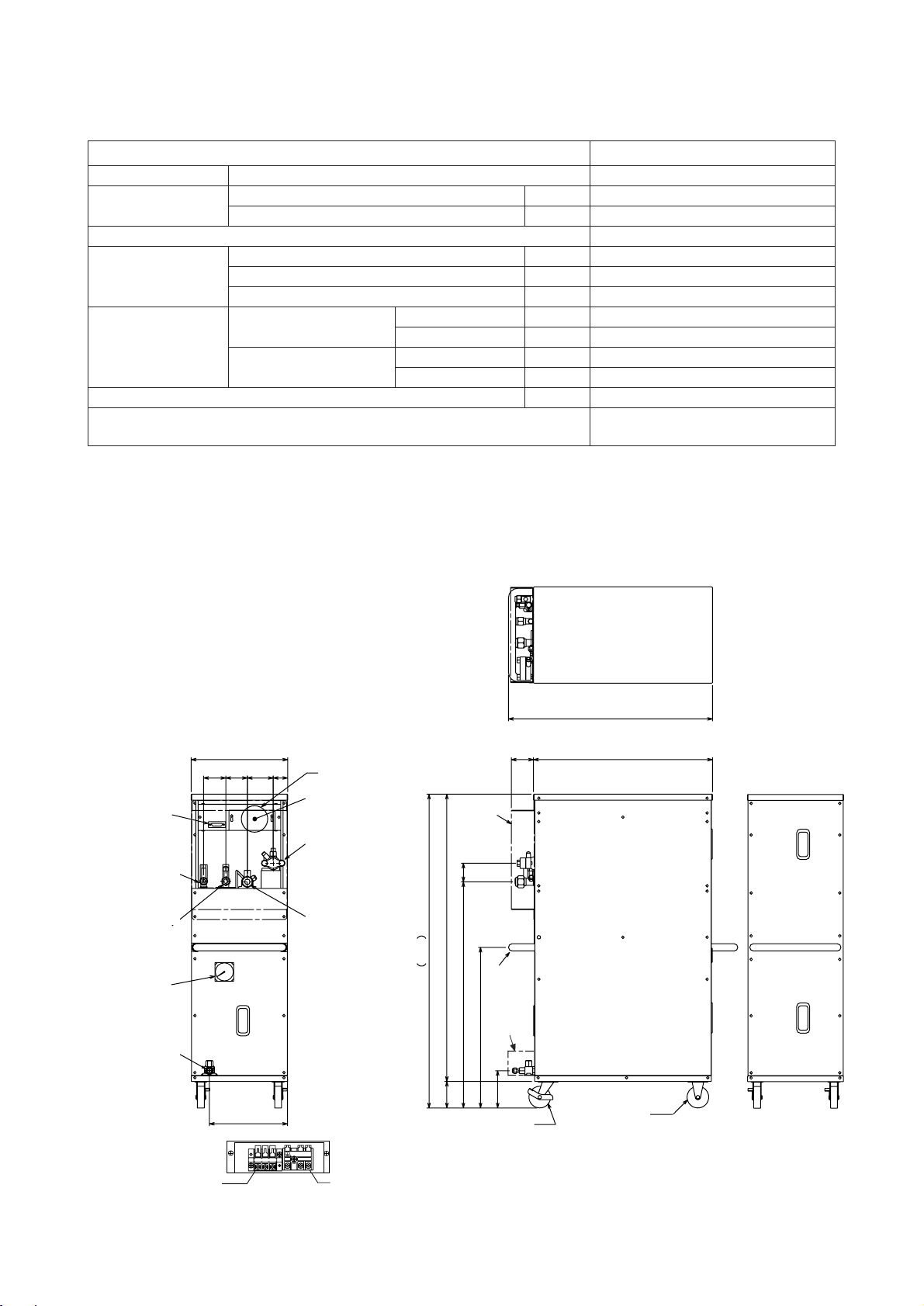

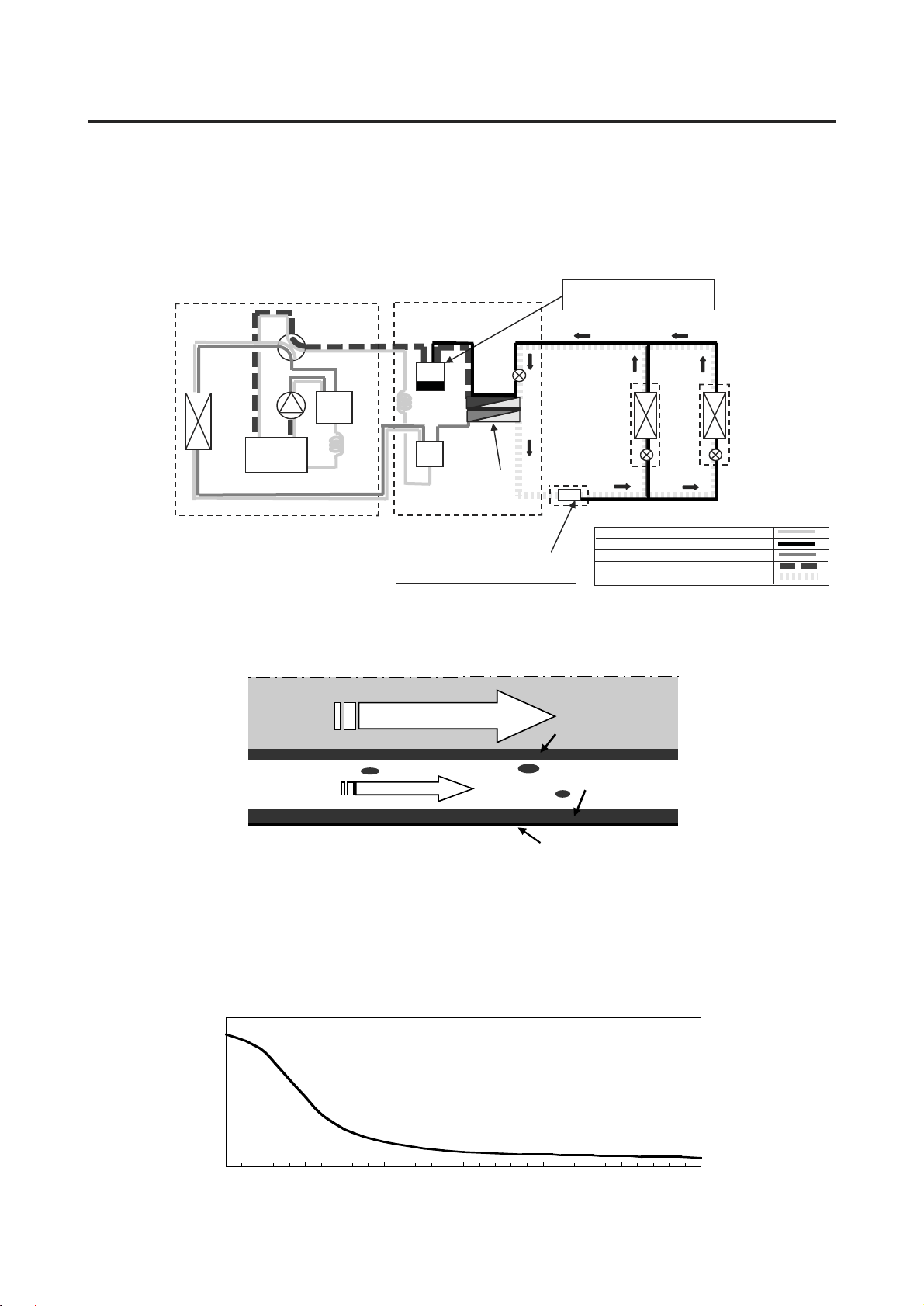

III. Outline of Flushing Operation

Install the oil trap kit between the outdoor unit and extended piping. Operation of the outdoor unit is in cooling

mode, feeding the R407C charged in the system under a gas/liquid two-phase state from the oil trap kit heat

exchanger. By feeding the refrigerant in the gas/liquid two-phase state into the existing piping, the residual

mineral oil inside the existing extended piping can be recovered into the oil trap kit. Feeding oil fluidity solution

from upstream of the existing piping can maintain or even increase the fluidity of residual mineral oil, thus

allowing the mineral oil to flow through the indoor units.

The mineral oil used as the refrigerating machine oil of conventional refrigerant (R22) systems are oils mostly

incompatible with new refrigerant (R407C). By flowing R407C to piping attached with mineral oil, the mineral oil

is forced out and peeled off from the pipe wall by the shearing force applied between the mineral oil and

refrigerant liquid. Then it is carried out while floating on the surface of refrigerant liquid. If it is under gas/liquid

2-phase state at this moment, the liquid refrigerant will be accelerated by gas refrigerant flowing at high speed

in the center of the pipe. Thanks to this accelerated flow, the mineral oil inside piping can be collected quickly.

Outdoor unit Oil trap kit

4-way valve

Outdoor

heat exchanger

Oil

separator

Accumulator

Oil trap

Throttle

Oil

separator

Refrigerant heat

exchanger

Separates and recovers oil

with fluidity solution.

Outdoor unit

Indoor heat

exchanger

Indoor unit

throttle

Mineral oil

fluidity solution

Promotes flushing by lowing the

viscosity of the oil.

Flow of ester

Flow of mineral oil

Flow of refrigerant (hot gas)

Flow of refrigerant (low pressure gas)

Flow of refrigerant

(gas/liquid 2-phase refrigerant)

Principle of recovery by refrigerant under gas/liquid 2-phase state incompatible with mineral oil

(❉ mark portion above)

Piping center

Refrigerant gas

(R407C)

Floating layer of

mineral oil

Refrigerant liquid

(R407C)

Mineral oil attached

to wall surface

Pipe wall of refrigerant piping

Residual quantity

Flushing time (min)

Longest extended piping : 100m

Maximum extended length : 220m

(Liquid/gas going and returning for 440m)

Residual oil quantity in piping against flushing time

Replace tank

❉

-14-

Page 23

Installation / Operation Work

I. Parts Provided with Oil Trap Kit ................................................................................................. 17

1. Verifying the parts provided ........................................................................................................... 17

II. Carrying/Storing the Oil Trap Kit................................................................................................ 18

1. Transportation by vehicles ............................................................................................................. 18

2. Carrying-in/carrying-out .................................................................................................................. 18

3. Storing ............................................................................................................................................ 18

III. Work Procedure of Mineral Oil Recovery Operation ............................................................ 19

1. Work flow ....................................................................................................................................... 19

2. Items to be checked before work ................................................................................................... 21

3. Installation space and range of oil trap kit ...................................................................................... 23

(1) Restrictions

4. Refrigerant piping work .................................................................................................................. 24

4-1 Piping connection before flushing operation

4-2 Piping connection after flushing operation

5. Electrical wiring work ..................................................................................................................... 30

5-1 Wiring connection before flushing operation

5-2 Wiring connection after flushing operation

6. Connection work on rainy days ...................................................................................................... 31

7. Flushing operation ......................................................................................................................... 32

(1) Installation method of S/W

(2) Items to be confirmed before flushing operation

(3) Starting and finishing of flushing operation

(4) Mounting method of low outdoor temperature hood

IV. Work Procedure at Oil Inspection .............................................................................................. 45

1. Oil inspection after mineral oil recovery ......................................................................................... 45

(1) Oil sampling method

(2) Measuring method and judgment of refractive index

(3) Measures to be taken at oil inspection (Failure to pass oil inspection test) (No Good)

V. Mineral Oil Recovery Operation Data (Reference Data) ........................................................... 53

1. Standard data (During flushing operation) .....................................................................................53

-15--16

Page 24

-

Page 25

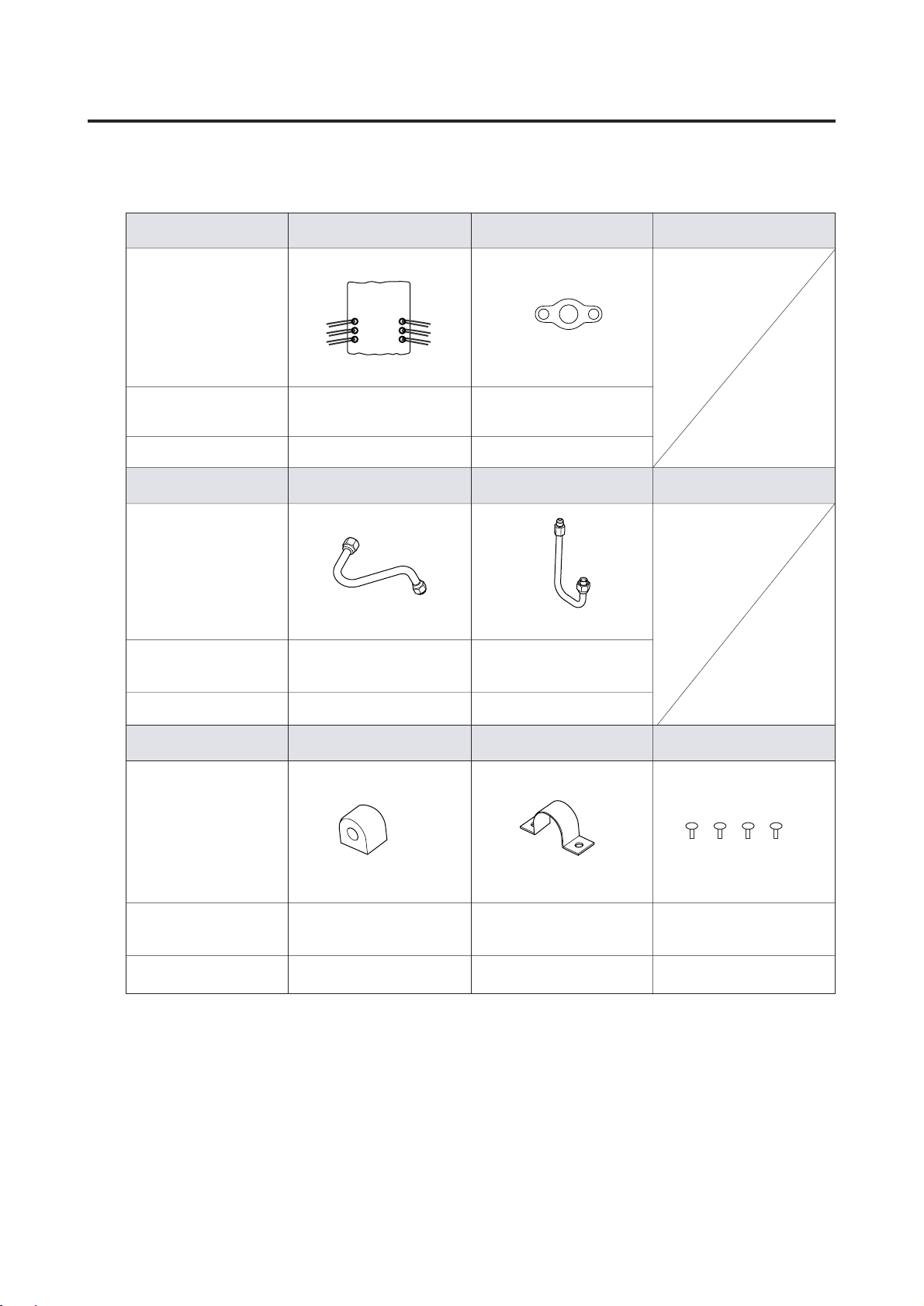

I. Parts Provided with Oil Trap Kit

1. Verifying the parts provided

Please confirm that the following parts are provided with this oil trap kit.

Name (1) Hood (for low OA) (2) Packing

Appearance

Storing position Provided at the control Provided at the control

box bottom box bottom

Quantity 1 pc. 5 pcs.

Name (3) Piping 1 (4) Piping 2

Appearance

Storing position Provided inside Provided inside

piping cover piping cover

Quantity 1pc. 1pc.

Name (5) Rubber mount (6) Saddle (7) Screw

Appearance

Storing position

Provided at the control Provided at the control Provided at the control

box bottom box bottom box bottom

Quantity 1pc. 1pc. 4pcs.

Inner diameter Outer diameter

φ

23

φ

35

(1) Service parts code : R61 M03 622, Service model name code : W650296G01

(2) The packing is provided for 5 pcs. (mineral oil recovery for 1 time). Please purchase additional

packing if required. (Service parts code : R61 F14 514, Service model name code : P321009X01)

-17-

Page 26

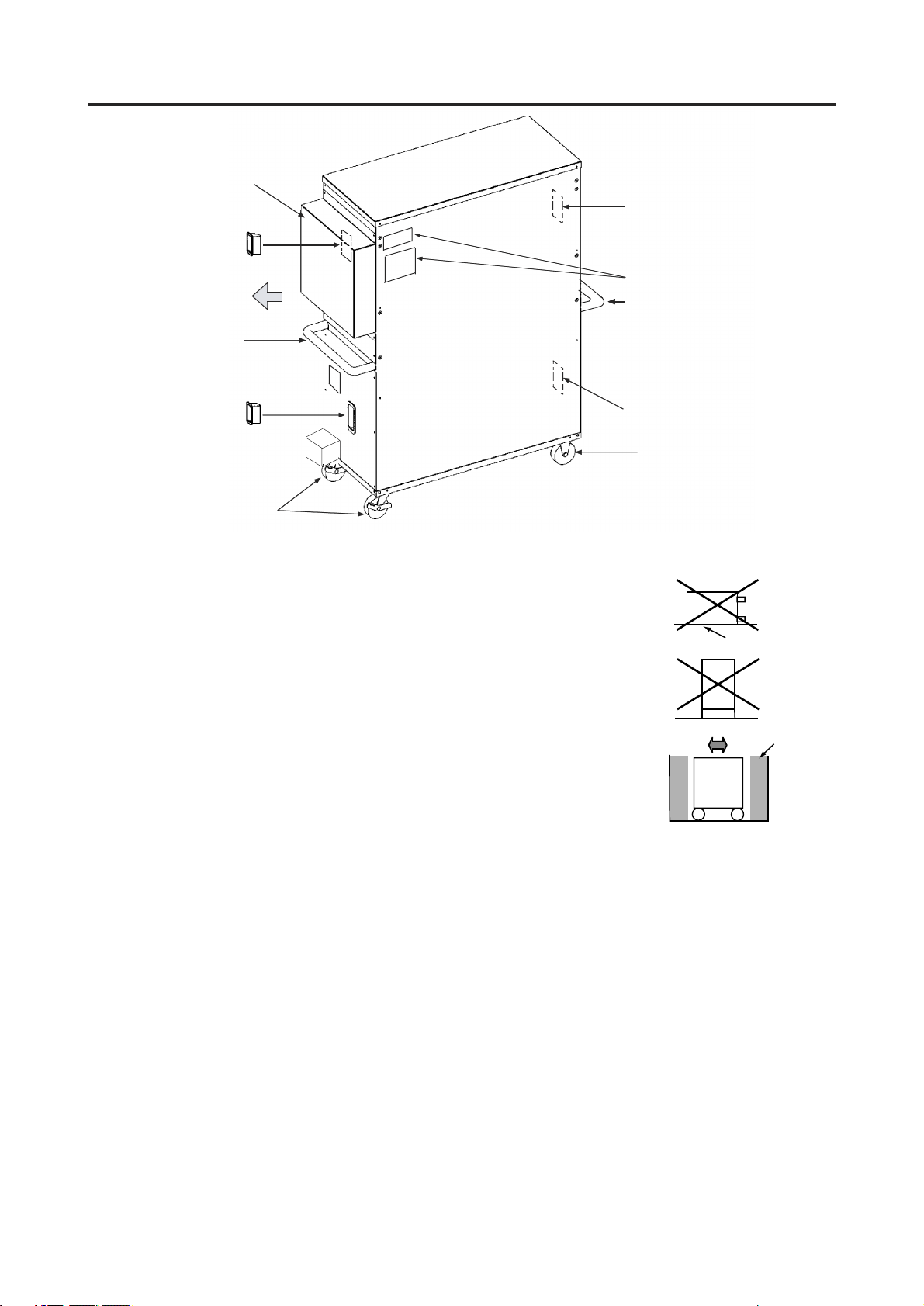

II. Carrying/Storing the Oil Trap Kit

1. Transportation by vehicles

For the transportation by vehicles, ensure that sufficient care has been paid to the withstanding force of the product. However, please observe the items below and pay careful

attention to prevent the product from falling down or being damaged.

(1) When carrying the product while being laid down, locate the name plate on the up-

side.

Do not place any goods on the sheet metal surface.

Reason : The letters on the name plate can not be read. The inner piping may be

deformed leading to damage.

(2) Do not locate the piping cover downward.

Reason : The service valve is damaged causing possible gas leak.

(3) Carrying the product while locating the caster downward causes unstable condition

leading to falling down due to the vibration during transportation. Provide a measure

to prevent falling down.

2. Carrying-in / carrying-out

The product is mounted with the parts for transportation, including one handle, knobs (at 5 places) and casters (at swivel

side and stopper side). For the carrying-in and -out of the product, locate it horizontally (with the name plate at the upper

side) or vertically and pay careful attention to prevent it from falling or dropping due to obstacles. Refrain from locating the

piping cover facing downward. (If dropped, the service valve may be damaged.)

3. Storing

When storing the product, observe the items below.

(1) Store in a cool and dark place avoiding direct exposure to solar radiation. (Storing temperature less than 60˚C)

(2) Store the oil trap kit fixed with the stopper locating the caster in the downward facing position.

(3) Store the oil trap kit, flexible tube and branch piping kit mounted with the cap previously provided. (to prevent the entry

of dirt, dust and water)

(4) Store the oil trap kit, flexible tube with their original packing.

Do not lose the packing materials as they are to be used for storing.

Oil trap kit : Applied corrugated cardboard to upper part, wooden frames to lower part and fixed with PP band.

Flexible tube : Packed with corrugated cardboard

Piping cover

Knob

❉Unscrewing the screws

(at 4 spots) allows using

the handle.

Handle

Caster with stopper (swivel side)

Knob

Name plate

For the unit with a handle instead

of knobs, the handle can be dismantled by removing the upper/

lower panels and M8 bolts (2 pcs.)

fixing the handle. Do not operate

the unit with the upper/lower panels removed.

Knob

Knob

Caster (stopper side)

Surface with

name plate

Fixing material

-18-

Page 27

Check the necessary parts (P20) & check the work preparation (P21).

1. Turn the outdoor unit power source off.

2. Mount the replace tank to the oil trap kit..

3. Connect the outdoor unit, valve mounted to the extended piping and oil trap kit with piping

(flexible tube).

4. Conduct airtight test and evacuation the piping (flexible tube) between the outdoor unit,

valve mounted to the extended piping and oil trap kit.

5. Open the ball valve. (in the order of oil trap kit (1)~(4), extended piping, outdoor unit (1) and

(4).)

6. For the oil trap kit, apply from L

1 and N of outdoor unit supply or a separate 220~240V

supply power source of the outdoor unit and the transmission line from the outdoor unit TB3.

7. Connect the oil trap kit and PC.

8. The system controller and MA remote controller may be required to be remove.

For detail, refer to 1~5 : Piping connection, 6

•7 Piping connection.

❉ When conducting mineral recovery work the next day, close all service valves of the out-

door unit, valve mounted to the extended piping and oil trap kit to finish the work, and open

all service valves immediately before starting flushing operation. (Otherwise mineral recovery time is extended due to prolonged start-up time, or the oil traped inside the kit is overflown hindering the normal mineral oil recovery.)

1. Apply power source to the outdoor unit, and confirm the completion of the start-up.

2. Check the operating sound caused by the ON/OFF of the solenoid valves.

3. Through the PC operation, drive the outdoor unit compressor to recover mineral oil inside the

extended piping. The recovery time requires for 1.5 ~ 3 hours. (Outdoor temperature below

20˚C, the low outdoor air hood should be fitted to the outdoor unit.)

However under low outdoor temperature, flushing operation may be required again due to

insufficient refrigerant.

❉ When the frequency or low pressure drops less than the rated value due to insufficient

refrigerant and the such like, the time required for the mineral oil recovery may exceed 3

hours. For detail, refer to P36.

4. Prevent the outdoor unit and oil trap kit from being exposed to rain directly.

5. Close the service valves of the outdoor unit and the valve mounted to the extended piping (4

positions).

6. Close the service valves of the oil trap kit (at 4 spots).

7. Turn off the power source of the outdoor unit once.

8. After flushing operation, recover mineral oil by opening the oil recovery service valve.

❉ The mineral oil recovered by flushing operation should be extracted each time from the oil

trap kit. During the work, observe that the pressure is staying within 0.049 ~ 0.294MPa.

1. Remove piping (flexible tube) and wiring between the outdoor unit, remove valves mounted

to the extended piping and oil trap kit.

2. Remove the oil trap kit.

3. After reconnecting the piping kit (field work) to the outdoor unit, execute evacuation.

4. Open the ball valve (in the order of extended piping, outdoor unit (1)

and (4).)

5. Mount the system controllers and MA remote controller previously removed.

❉ After removing the oil trap kit, confirm the inner pressure with a pressure gauge.

❉ Do not store the oil trap kit at a place exposed directly to solar radiation, but store in a cool

and dark place.

After recovering oil, conduct ordinary air conditioning operation, and check the cooled air (heated

air) and the operating condition of the compressor.

❉ The test run and adjustment work are not included. Execute them separately if

required.

This belongs to the field work category. Execute it after flushing.

1. For the inspection of oil, use suitable kit for the refrigerating machine oil used by the existing

unit. (Mineral oil : Ester collection kit)

2. When the recovery of mineral oil is insufficient, ester oil, etc. should be added.

❉ Note: Only in rare cases.

III. Work Procedure of Mineral Oil Recovery Operation

1. Work flow

For P200 • P250YREM-A

Work flow Items to be verified

Carry in the oil trap kit (1 set),

replace tank, PC and tools.

Install the oil trap kit, replace

tank and PC.

Perform air tightness test

Evacuate the piping (Flexible tube)

Apply flushing inside of the exiting

piping.

Recover mineral oil inside the

oil trap kit.

Remove the oil trap kit.

Connect the piping kit processed

there, and evacuate inside of the

piping kit.

Confirm operation

(compressor starting).

Execute test run & adjustment.

Inspect oil one month after

operation.

-19-

Page 28

Built-in solenoid valve, pressure sensor,

pressure gauge, service valve

φ

12.7 (2 pcs.), each 1 pc. of φ19.05 and φ28.58

(

φ

19.05 is for short copper pipe [requires φ28.58

–φ19.05 connection])

5 pcs. (outdoor unit 2 pcs. valve mounted to the extended piping 2 pcs., oil trap kit 1 pc.)

[provided inside oil trap kit]

Equipment:

DOS-V machine (suitable for PC-98NX or later)

CD ROM equipped

CPU : 300MHz or larger (recommended)

Memory : 64Mbyte or larger (recommended)

HDD : 40Mbyte or larger (recommended)

O/S : Windows95, 98, NT 4.0, 2000, ME, XP

Exclusive S/W for Replace

(Caution : Install on PC before mineral oil recovery.)

RS-232C cross cable (within 15m)

Oil trap kit connector specification : D-SUB25 Pin type

female connector (DTE)

(Caution: Select RS-232 cable depending on the type

of the serial interface of PC.)

φ

1.5mm2 or more

Power supply cord parts of appliances for heat source

shall not be lighter than polychloroprene sheathed

flexible cord (design 245IEC57)

φ

1.25mm2 or more

2-core cable (VCTF, VCTEK, CVV, CVS, VVR, VVF,

VCT or shielded wire CVVS/CPEVS)

Vessel with more than 2L capacity is required.

Refrigerant piping/wiring system diagrams are

required for each system

Vessel (1 pc.), bottles (2 pcs. 1 pc. with oil charged)

Mineral oil fluidity solution

Mineral Oil Recovery Operation

Parts List

Parts name Application Specification (quantity) Remarks

(1) Oil trap kit

(PAC-KP90VCLU)

(2) Flexible tube

(PAC-KP80FPP,

PAC-KP-82FPP,

PAC-KP83FPP)

(3) Packing

(4) PC (Field supply)

(5) Software

(6) Connecting cable

(field supply)

(7) Power source wiring

(field supply)

(8) Control wiring

(field supply)

(9) Oil pan (field supply)

(10) Refrigerant piping,

Wiring system diagram

(11) Ester oil check kit

(PAC-KP95ECK)

(Use when the refrigerating machine oil used

by conventional system

is the mineral oil.)

(12) Replace tank

(PAC-KP01RTK)

Mineral oil recovery

device

Piping connection between

oil trap kit and outdoor unit

and the valve mounted to the

extended piping

Connection between (2) flange

and outdoor unit

Mineral oil recovery

operation control

Mineral oil recovery

operation software

RS-232C connection of

oil trap kit and PC

Connection to oil trap kit

(Jumper from outdoor unit)

Mineral oil recovery vessel

Verification of connection with

system controller, others

To judge proper oil recovery

at oil inspection about one

month after flushing operation

executed

To lower the viscosity of

residual mineral oil

1 set

1 set

1 set for

1 outdoor unit

-20-

Page 29

1) Check whether outdoor unit is being powered.

2) Check the insulation resistance

between power source terminal

and ground for over 1.0MΩ.

1) Confirm the ball valve of outdoor

unit is fully closed.

2) Confirm the ball valve of oil trap

kit is fully closed.

1) Check whether system controller

is connected to indoor/outdoor

transmission line.

2) The system controller that turns

the power source off when turning