Page 1

MITSUBISHI

Building Air Conditioning Control System

Maintenance Tools for MN converter & G-50A

- Advanced -

Operating Manual

Contents

Page

1 Foreword

1.1 Introduction of Maintenance Tools 1

1.2 Required Operating Environment 4

1.3 Installation 5

1.4 Starting and Ending the Application

9

2 Terms for Each Section

2.1 Design of Screen 22

2.2 Operating Method 22

3 On-Line Monitor Operation Method

3.1 On-Line Monitor Screen Transfer 23

3.2 Function Chart 24

3.3 Address Search Method 24

3.4 Main Screen 26

3.5 Function Selection Operations 27

3.6 Connecting Information 27

3.7 Operation Monitor 29

3.8 Malfunction Log 37

3.9 Optional Setting 39

3.10

Operation Control 42

3.11

Free contact of indoor unit 44

4 Off-Line Monitor Operating Method

4.1 Off-Line Monitor Screen Transfer 46

4.2 Function Chart 47

4.3 Operation Monitor 48

4.4 System Information 52

4.5 Monitoring of Pre-error Data 53

4.6 Filing Operation 54

4.7 Offline on Wide area access mode 57

5 File Names

5.1 System Information Data 58

5.2 Operating Status Monitor Data 58

5.3 Pre-error Data 58

5.4 Text Convert Data 58

6 How to change setting of Firewall 59

7 Troubleshooting? 64

Before using Maintenance Tools, read this manual thoroughly to ensure correct operation.

WT03939X09

Page 2

1

1.1 Introduction of Maintenance Tools

The Maintenance Tools are comprised of the On-Line Monitor and the Off-Line Monitor.

The following two connection methods are available in the Online Monitoring.

(1) Monitoring by connecting the maintenance tool to MN converter (CMS-MNF) via RS-232C.

(2) Monitoring through the central controller (G-50) by connecting the maintenance tool to LAN.

A brief explanation of each of their function is provided here.

* To use the maintenance tool via G-50 (Network), license registration for the G-50 to be used is necessary.

Purchasing the license No. for each G-50 to be used, conduct the license registration through the Web

browser (http://[IP address of the G-50A]/ administrator.html). After selecting "Maintenance tool" of the

optional function on the Web Browser Screen displayed, enter the purchased license No..

For the detail of the license registration, see Chapter 4 [Registering a License for Optional Functions] of

Central Controller Model: G-50A Web Browser Operation Manual (For manager).

1.1.1 On-Line Monitor(via MN converter)

The On-Line Monitor is connected to the unit by a MN Converter (CMS-MNF) and can monitor such areas

as system data, unit data and operating data.

(1) In case for local connection

Connecting PC installed with the maintenance tool to M-NET transmission line via MN Converter allows

conducting various monitoring and setting from the maintenance tool.

(2) In case for remote connection

Using a modem and remotely connecting PC installed with the maintenance tool to MN Converter via

public telephone circuit allow conducting various monitoring and setting as same in the case of local

connection.

*For the remote connection utilizing MN Converter, an isolator is required to be inserted between

the modem and MN Converter.

For detail, please see Installation Manual-annexing of MN Converter (CMS-MNF).

1 Foreword

MN Converter

RS-232C

M-NET

M-NET

M-NET

RS-232C

RS-232C

MN Converter

Maintenance

Tools PC

Maintenance

Tools PC

MODEM

MODEM

Public

network

Page 3

2

1.1.2 On-Line Monitor(via G-50)

The On-Line Monitor is connected to the unit by the central controller(G-50A) and can monitor such areas

as system data, unit data and operating data.

(1) In case for local connection

By directly connecting the PC installed with Maintenance Tools and G-50A through LAN, various

monitoring/setting can be performed from the Maintenance Tools.

(2)-1 In case for remote connection (Dialup connection mode)

By connecting the PC installed with Maintenance Tools and G-50A through public network remotely,

various monitoring/setting can be performed from the Maintenance Tools.

(2)-2 In case for remote connection (E-mail connection mode)

Under E-mail connection mode, communication can be executed with G-50A through E-mail transmission

via mail server. All communication with G-50A is converted into E-mail in this case.

Maintenance

Tools PC

G-50

A

LAN

HUB

M-NET

M-NET

MODEM etc

Public

network

Dial-up

Router

Maintenance

Tool PC

HUB

G-50A

LAN

Maintenance

LAN

G-50

A

POP

Internet

Provider 2

A

ccess point

Provider 1

A

ccess point

Provider1

Mail server

Provider2

Mail server

SMTP

POP

SMTP

Mail server

Mail server

E-mail

E-mail

Notice

•To use the E-mail connection mode, the version of G-50 should be above 2.60.

•When using E-mail connection mode, the local G-50A is required to be initially set with Maintenance Tool and

the mail address by the G-50A initial setting tool.

- For each mail address, it is required to obtain and set an exclusive one. To transmit mail via an internet

provider, obtain the mail address from the provider. When a mail server is existing on the LAN, obtain the

mail address from the LAN administrator.

- Set the [Pop receive interval] within 3 minutes. However to monitor operating status [Operation Monitor], set it within 1

minute.

- Setting of initial information to G-50A can not be executed from Maintenance Tool. Make sure to set it from the G-50A

initial setting tool locally. If dialup connection environment is available, it can be set from a remote position.

(For detail, please refer to 6-1 Mail Basic Setting in the instruction manual of the G-50A initial setting tool.)

• The communication speed under E-mail connection mode largely depends on the transfer rate of each mail

server. Under the circumstance, the action of Maintenance Tool may take a lot of time under some internet

environments or routing mail servers.

Page 4

3

1.1.3 Off-Line Monitor

The Off-Line Monitor can display, print information obtained by the On-Line Monitor.

In the case of connection monitoring utilizing G-50, the operation monitor data collected by G-50A will be

transmitted to remote mail servers periodically if the [Operation monitor - mail communication mode] of

online mode is adapted.

Using this function allows to collect and monitor the operation monitor data without continually connecting

the maintenance tool.

*For the setting of the [Operation monitor - mail communication mode], refer to 3.7.1 and 4.3.3 description.

*Image of the [Operation monitor - mail communication mode]

1.1.4 Wide area access mode

The “Wide area access mode" has been located starting from Ver4.06(D).

Under the "Wide area access mode," the access method for remote connection can be registered to the

database of each customer enabling easy online connection with the air conditioning system of the customer

desired to be accessed.

[Remote access method]

- LAN : Accessing by directly connecting Maintenance Tool PC and G-50A with LAN (WAN).

- Dialup : Accessing by dialup connection to G-50A via public network.

- E-mail : Accessing by E-mail communication to G-50A via mail server.

- Modem (MN Converter) : Accessing by connecting Modem to MN Converter via public telephone

circuit.

After the online connection performed by any of the above methods, you may use the similar function as that

obtainable in the normal online connection.

While under the offline mode, customer information will be provided to the monitored data enabling only to

select a specified customer for display.

MODEM etc

Internet

Provider 2

A

ccess point

Public

network

Dial-up

Router

Maintenance

LAN

G-50

A

Provider 1

A

ccess point

Provider1

Mail server

Operation monitor data

automatic mail transmit

Operation monitor mail

data ac

q

uisition

Collecting the operation

monitoring data of

air conditioners

Provider2

Mail server

Notice

•This differs from the E-mail connection mode of (2)-2 in 1.1.2 On-Line Monitor (via G-50).

Page 5

4

1.2 Required Operating Environment

This manual refers to Windows® 2000 as Windows 2000, and Windows® XP as Windows XP.

Trademarks

MS, Microsoft, Microsoft logo, and Windows are registered trademarks and trade names of Microsoft

Corporation.

Each company may use as registered trademarks and trade names the product names used in this

manual.

1.2.1 Hardware Requirements

The computer must be IBM compatible on DOS/V and capable of satisfying the following requirements.

- OS .................... Windows2000 or WindowsXP (Recommended English version *1)

- CPU .................... PentiumIII 500 MHz (Recommended 1GHz or more)

- RAM .................... Minimum 128 MB (Recommended 256MB or more)

- HDD .................... Available space 5 GB or more *2

- LCD .................... Display resolution:XGA(1024x768) or more

Unit should be equipped with a pointing device, such as a mouse pointer or track ball.

1.2.2 Required Materials

The following materials are needed for operating the Maintenance Tools :

(1) In case of routing via MN converter

MN Converter (CMS-MNF), Personal Computer, RS-232 (cross), and modem in the case of remote

connection, are required. RS-232 C is to be straight cable in this case.

For detail, please see Installation Manual-annexing of MN Converter (CMS-MNF).

(2) In case of routing via G-50

G-50, personal computer, LAN cable (Straight) and HUB.

A dial-up router is required for remote communication. For the dial-up router to be used, employ that

allowing data communication by receiving external telephone transmission.

*1 About OS

Fundamentally, it corresponds to OS of each country. However, separators of time and date differ in

each language. This separator may affect a maintenance tool.

It recommends using it by English OS and Regional options setup, changing into English area form.

Or it recommends using it, changing date separator into [/] and time separator into [:].

*2 About Hard Disk Space

The hard disk space recommended above is only the amount required for installing the maintenance

application. Additional space will be required if the operating data is also to be stored on the hard disk.

A

ccordingly, there may not be enough memory to store operating data if the maintenance system is

installed in a computer with limited hard disk memory.

* NOTE

TG-2000A and Maintenance Tool cannot operate with the same personal computer.

Page 6

5

1.3 Installation

There are two Maintenance Tool setup methods:

Method 1) New setup.(See Section 1.3.1)

Method 2) Upgrading with existing setup.(See Section 1.3.2)

1.3.1 Setting Up the Maintenance Tools (New setup)

To set up Maintenance Tools, follow the 3 steps below.

Step 1) Setting up of MSDE

Step 2) Setting up of database

Step 3) Setting up of

Maintenance Tools

Step 1) Setting up the MSDE

Execute “SETUP.exe” located in SetUp ¥1_MSDE4VS

in the

folder of CD-ROM.

Double clicking on “SETUP.exe” with the explorer displays the

MSDE setup screen as shown right.

PC is reset automatically after completing installation of MSDE.

After closing other application software, click [OK] and start

installation.

* To stop setting up, click on [Cancel] button.

The setting up processing requires for about 2-3minutes

.

If processing progresses to 100%, the screen in the right will be

displayed. Clicking on [OK] resets PC automatically. Please

carry out STEP2 after PC's starting.

Step 2) Setting up the database

Execute “Setup.bat” located in the folder of

SetUp ¥2_DB_SETUP

” of CD-ROM.

Double clicking on “Setup.bat” with the explorer displays

the command prompt screen.

The setting up processing ends within about 10 seconds

- 3 minutes

.

After ending of the setting up, “Press any key to continue …”

is displayed. Pressing any key closes the command prompt

screen.

Request

•For setting up, be sure to practice 3 steps in order.

Otherwise, Maintenance Tools will not operate normally.

•Before setting up, be sure to log in with the log-in name authorized as administrator.

Notice

•Before Setting up the MSDE, restart your computer and Ending software for application program

and Anti-Virus.

: After finishing Step 1, PC restarts automatically.

(Restarting PC is essential before going to Step 2.)

Notice

A

fter setting up MSDE, PC is designed to automatically reset. However, if this setting up is executed without

finishing other application software, PC may not be reset automatically. In this case, reset PC manually. Afte

r

restarting, go to Step 2. Without restarting PC, Maintenance Tool can not be set up unless replacing OS

itself.

Caution

Please refer to also 1.3.4 RE:

Change of computer name on PC.

Page 7

6

Step 3) Setting up the Maintenance Tools

Set up the application of this

Maintenance Tools. Please read the guide shown on the screen carefully

to proceed the setting up.

(1) Starting the setup program

1) Start setup.exe.

Execute “setup.exe” located in

SetUp ¥3_MNTTOOL

folder of CD-ROM.

Double clicking on “setup.exe” with the explorer displays

“Welcome” screen. Please confirm the caution shown on

the screen before setting up.

2) Confirm the display contents, and select [Next] button.

If no problem was found on the content, click [Next] button.

* To stop setting up, click on [Cancel] button.

(2) Confirming the Installation folder

1) Confirm the installation folder and select [Next] button.

Confirm the folder on which this program should be

installed. To change the installation folder (C drive only),

Use [Previous] button. After confirming the installation

folder, click on [Next] button.

* Clicking on [Cancel] button stops installation procedure.

(3) Confirming the installation start

1) Confirm the starting and select [Next] button.

Clicking on [Next] button starts installation.

* Clicking on [Cancel] button stops installation.

(4) Confirming the completion of Maintenance Tools setup

1) Select [Close] button.

Click on [Close] button on the Installation Complete screen.

After completing installation, restart your computer.

Keep the CD-ROM used with you carefully.

Request

•After installing Maintenance Tools, be sure to restart

your computer.

Notice

During database setting, the process may be observed as stopped for a while. However, it is still unde

r

operation internally. Wait for some time until "Press any key to continue - - - -" appears without doing

anything.

*Do not stop the set up procedure by pressing

at the upper right of the screen.

Page 8

7

1.3.2 Running Maintenance Tool Upgrade

The following describes how to upgrade the Maintenance Tool.

Step 1) Ending the Maintenance Tool

Step 2) Uninstalling the Maintenance Tool :Restart your computer after completing the STEP 2.

Step 3) Upgrade the Database

Step 4) Upgrade the Maintenance Tool :Restart your computer after completing the STEP 4.

Step 1) Ending the Maintenance Tool

End the Maintenance Tool program.

*Refer to 1.4.5 Ending the Maintenance Tool

Step 2) Uninstalling the Maintenance Tool

Uninstall the Maintenance Tool program.

* Refer to 1.3.3 Uninstalling the Maintenance Tool

Step 3) Upgrade the Database

Execute "Setup.bat" located in VerUp ¥1_DB_UPDATE

folder of CD-ROM.

Double clicking on "Setup.bat" with the explorer displays the command prompt screen.

The setting up processing ends within about 10 seconds

and the screen closes.

When the set up processing is completed, [Press any key to continue …] will be displayed at the bottom

of the screen. Please wait for this display.

About 10 seconds - 3 minutes are required to complete the set up processing.

The screen will be closed by pressing any button after completing the processing with the display of

[Press any key to continue …].

Step 4) Upgrade the Maintenance Tool

Execute "setup.exe" located in VerUp ¥2_MNTTOOL_UPDATE

folder of CD-ROM.

Double clicking on "setup.exe".

*The Maintenance Tool program version upgrading procedure is the same as new setup.

Refer to 1.3.1 Step 3) Setting up the Maintenance Tool.

Request

•For setting up, be sure to practice 4 steps in order.

Otherwise, Maintenance Tools will not operate normally.

Request

• After uninstalling Maintenance Tool program, be sure to restart your computer.

Request

• After installing Maintenance Tool program, be sure to restart your computer.

Notice

During database setting, the process may be observed as stopped for a while. However, it is still unde

r

operation internally. Wait for some time until "Press any key to continue - - - -" appears without doing

anything.

*Do not stop the set up procedure by pressing

at the upper right of the screen.

Page 9

8

1.3.3 Uninstalling the Maintenance Tools

The method to uninstall the application of the [Maintenance Tools] once installed is given below.

(1) Uninstalling the Maintenance Tools

1) Confirm the ending of Maintenance Tools.

Confirm that Maintenance Tools program has been ended.

If not, end the program.

*For the ending method, refer to Chapter 1.4.5.

2) Start [Add/Remove Programs].

Click on [Add/Remove Programs] from [Control panel] to

start.

3) Select [Maintenance Tool for windows 2000 and XP]

and press [Change & Remove] button.

Select [Maintenance Tool for windows 2000 and XP] from the application, and click on [Remove]

button.

The deletion of Maintenance Tools application starts.

4) Ending the [Add/Remove Programs].

After ending the deletion of application, end [Add/Remove Programs].

1.3.4 RE: Change of computer name on PC

Do not change the computer name after the Maintenance tool has been setup.

Maintenance tool will not run properly if changed, and may require the OS to be installed again.

Notice

•Recommend not to delete the common components.

•There are folders and files that can not be deleted with this uninstalling.

(Example:C:¥Program files¥Mnttool32)

Page 10

9

1.4 Starting and Ending the Application

1.4.1 Starting the Maintenance Tool

(1) Connect the computer and G-50A(MN Converter) and

air conditioner.

(2) Click on “Start

”, and then click on ”Programs”.

(3) Click on “Maintenance Tool for Windows2000 & XP

” in

the “Maintenance Tool

” folder.

(4) The Title Screen will soon appear.

In addition, the message of [This unit can be changed

into °F and pounds/inch

2

. Do you change them?] is

displayed, and the temperature is set into °F if is

clicked on, while into °C if is clicked on.

*After upgrade, if a maintenance tool is started for the first

time, conversion processing of a database may be

performed. In this case, "Now, Converting database! "

and a progress state are displayed.

*The capacity to store the data obtained by the maintenance

tool counts for 2G-bite maximum.

When the remaining storage capacity is insufficient at

starting, Warning Screen will appear.

In this case, move to OFF- Line Screen to delete

unnecessary data.

(5) Thereafter, the selection screen of Monitor mode is

displayed. Selecting the mode to be adapted.

Normal mode

a) ON LINE MODE

- MN CONVERTER

When on-line monitoring is adapted to air conditioning

system by connecting MN Converter [Refer to 1.4.2.1.]

Further select Remote connection to conduct remote

connection. [Refer to 1.4.2.2.]

- G50(LAN)

When on-line monitoring is adapted to air conditioning

system via G-50 by connecting the maintenance tool to

LAN. [Refer to 1.4.3.1.] For remote connection, select

either “Dialup connection mode” or “E-mail connection

mode”. [Refer to 1.4.3.2., 1.4.3.3.]

b) OFF LINE MODE

- Offline analysis

When offline analysis is adapted to the data collected under ON-LINE MODE [Refer to 1.4.4.]

Wide area access mode

The detail is described in the item 1.4.5.

Page 11

10

1.4.2 Starting the On-Line Monitor(MN Converter connection)

1.4.2.1 In case for local connection

This will be used when online monitoring is adapted to air conditioning system by connecting the

maintenance tool and MN Converter locally. The maintenance tool, MN Converter and air conditioning

system should be connected beforehand.

(1) Clicking "MN CONVERTER" on the selection screen of

Monitor mode selects "Local connection" simultaneously.

Select the model name of the connected MN Converter

and the COM port No. of the connected RS-232C. Last

click .

1.4.2.2 In case for remote connection

This will be used when online monitoring is adapted to air conditioning system by using a modem, and

connecting the maintenance tool and MN Converter with public telephone circuit remotely. The setting up of

the modem for Windows (modem at the remote site side) and the initial setting up (modem connecting MN

Converter at the local side. For detail, refer to (3).) are previously required. The connection of the modem,

public telephone circuit and local MN Converter is necessary.

* For a description of the on-site air conditioner system connection method, refer to the MN Converter

Operation Manual.

* If communication does not have for 10 minutes in remote connection, "Timeout occurred!" will be

displayed, if O.K. is pushed, a telephone circuit will be cut automatically and the Maintenance tool will be

ended.

(1) After clicking "MN CONVERTER" on the selection screen

of Monitor mode, and click "REMOTE CONNECTION."

For MN Converter, "CMS-MNF-B" will automatically be

selected. Then select COM port No. of RS-232C

connected with equipment (like a modem) for connection

to public telephone line.Last click .

*MN Converter to be locally installed should be

"CMS-MNF-B." Remote connection can not be

performed with "CMS-MNF."

(2) Next the screen to set remote connection will appear. In

order to conduct the initial setting (AT command setting) of

the modem to be used, click , and to initiate

remote connection, click .

*Insert an isolator between the local MN Converter and

modem for insulation. Inserting the isolator reduces the number of lines used by the internal wiring of

RS-323C. For this reason, it is required to select before the remote connection to

change the setting information on the modem to be installed at the local side.

For detail, see Installation Manual-annexing of MN Converter (CMS-MNF).

Page 12

11

(3) Initial setting of modem

For the modem to be installed at the local side (MN Converter side), initial setting should be applied

before connecting remotely. To apply the initial setting of the modem, click on the

remote setting screen.

The Connection Modem Initial Setting Screen will appear. A modem that is already initialized does

not have to be re-initialized.

The explanation of the operation only is described here. For the detail of the setting content, see

Installation Manual-annexing of MN Converter (CMS-MNF).

(a) Explanation of screen

-Select a registered modem setup file at the Select

Initial Settings File Box. The contents of the selected

file will be listed below the selection box.

-Click on and the modem will be set up

according to the contents selected at the selection

box.

(AT commands are sent to the modem.)

Check if transfer with the modem is normal at the

Transfer with Modem Status Screen.

- Click on to initialize another modem.

Send the initialize command and register the transfer

contents for the modem at the AT Command

Transmit Screen. [Refer to (b)]

- Click on to delete the selected modem

settings from the registered settings. When the

number of registrations limit is exceeded, delete the unwanted contents. [Refer to (b)]

- Click on to return to the Connection Setting Screen.

(b) Perform new modem setup.

- Enter the command (you want to set) you want to

send

to the modem at the AT command input text.

Then click on to send the entered AT

command to the modem. The response from the

modem will appear below the entered AT command.

Check the contents.

- After transmission to the modem is complete, click

on . The contents sent to the modem will be

registered as an initialize file. (Registered in the setup

file list of the Connection Modem Initial Setting

Screen.) At this time, do not forget to enter the registration name. Up to ten items can be

registered. If ten items are already registered, new items cannot be registered. Delete unwanted

items using the Connection Modem Initial Setting Screen.

- Click on to return to the Connection Modem Initial Setting Screen.

Page 13

12

(4) Initiating the remote connection

To initiate the remote connection, click

on the remote setting screen.

The Customer Selection Screen will appear. This screen

connects to the on-site remote modem.

(a) When the addressee has already been registered, select

the customer name to be connected in "Select customer

name box" and then click to initiate

connection.

In the case of initial connection or to change to a new addressee, click .

Then the Customer Information Registration Screen will appear.

(b) Enter Customer name of the field addressee, enter the type of the telephone circuit to be used and the

telephone number of the addressee, and click . The set content will be registered.

* The contents transmitted to the modem vary in the

chosen Line type.

Pay attention to the following.

When PB is chosen, "ATDT" is added before the

telephone number.

For example, when a telephone number is

0123456789,

"ATDT0123456789" is transmitted to the modem.

It becomes the following when "DP", "NONE" are

chosen in the same way.

DP --- ATDP0123456789

NONE --- ATD0123456789

When a circuit connection is impossible in the case

of above three which as well, "ELSE" is used.

When "ELSE" is chosen, nothing is added to before the telephone number.

Input a command for the circuit connection from the beginning.

For example, "ATD0,0123456789" is transmitted to the modem when "ATD0,0123456789" is

inputted in the telephone number column.

When the one except for the "ELSE” is chosen, only a number can be inputted in the telephone

number column.

The information for up to 100 customers can be registered. When the information for 100

customers has been registered, new customer information cannot be registered. Delete the

unwanted customer information using the customer selection screen.

(c) Check the contents, then click on .

The Connection Status Indication Screen will appear.

Connect the line. When you want to disconnect the line,

click on .

The line will be disconnected.

Page 14

13

1.4.3 Starting the On-Line Monitor(G-50 connection)

* To use the maintenance tool via G-50 (Network), license registration for the G-50 to be used is necessary.

Purchasing the license No. for each G-50 to be used, conduct the license registration through the Web

browser (http://[IP address of the G-50A]/ administrator.html). After selecting "Maintenance tool" of the

optional function on the Web Browser Screen displayed, enter the purchased license No..

For the detail of the license registration, see Chapter 4 [Registering a License for Optional Functions] of

Central Controller Model: G-50A Web Browser Operation Manual (For manager).

* To use the maintenance tool via G-50 (Only for LAN mode and Dialup connection mode), please check a

setup of Internet Connection Firewall of PC. If the FIREWALL function is used, communication will be

normally impossible with G-50A, and normal data will not be displayed.

For detail, please refer to [6. How to change setting of Firewall] on Page 57.

In the case of permanently installing an anti-virus software and always started under this environment, the

fire wall function of this software may be activated sometimes. In such case, The normal communication with

G-50 will be hindered not displaying data normally. When operating Maintenance Tool, finish the anti-virus

software once or remove the fire wall function.

1.4.3.1 In case for local connection

In the case when on line monitoring is applied to air conditioning system via G-50 by connecting the

maintenance tool to LAN locally.

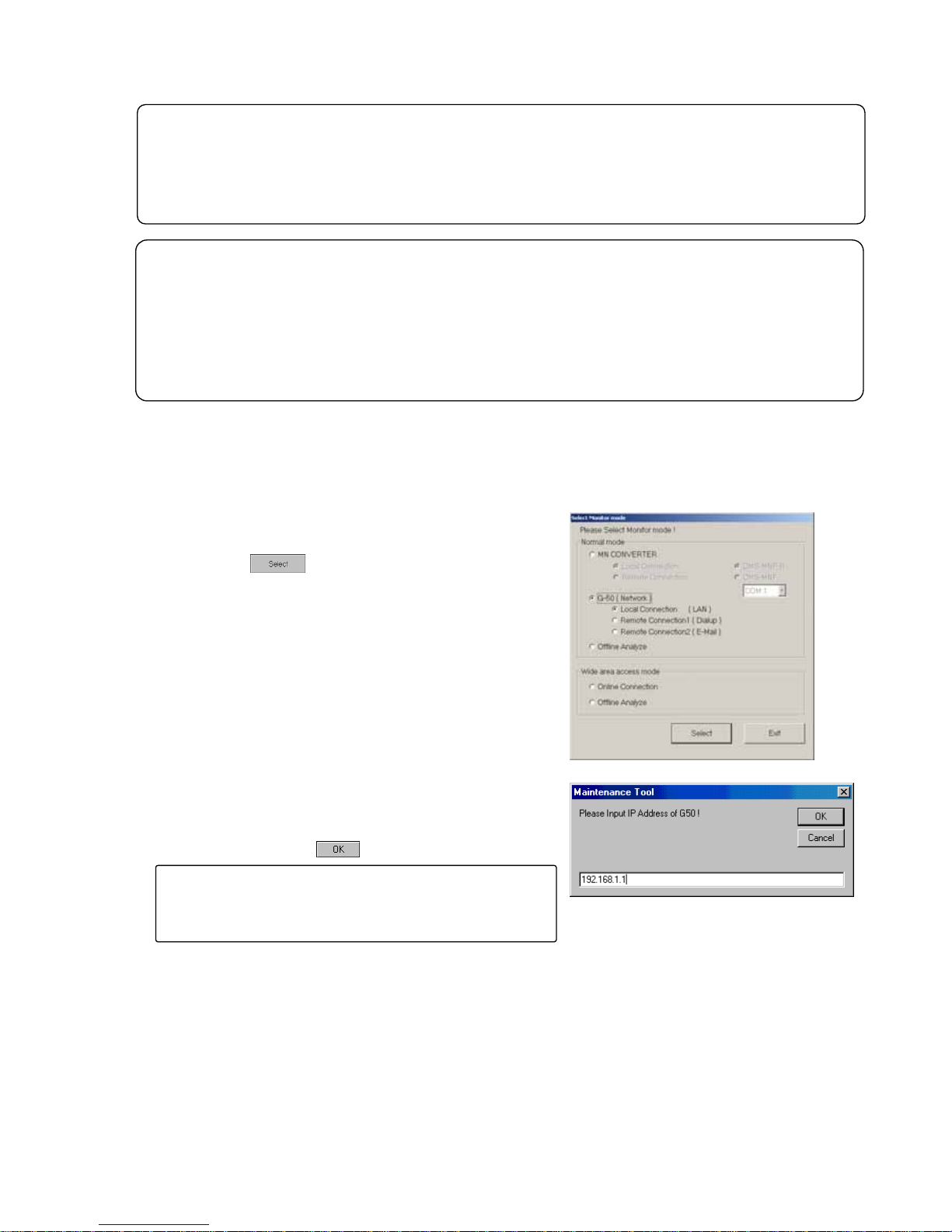

(1) Clicking "G-50(Network)" on the selection screen of

Monitor mode selects "Local connection" simultaneously.

Last click " ."

(2) Next IP address input screen is displayed. Here,input IP

address of G-50A connected to the air conditioning

system of which operating information is desired to

monitor, and click on .

Request

It is required to set to the IP address in the same system with

G-50 to be connected to Maintenance Tool PC from

[Control Panel].

Page 15

14

1.4.3.2 In case for remote connection (Dialup)

In the case when on line monitoring is applied to local air conditioning system (with G-50 installed) from the

maintenance tool in the remote place via public telephone circuit.

* When utilizing Remote connection (Dialup),please prepare MODEM and DIAL-UP ROUTER (of a type

allowing data communication by receiving external telephone transmission) for the connection with the

public circuit in addition to the components used by Local connection (LAN).

For the system composition, please refer to the system diagram of (2)-1 in 1.1.2.

To use Remote connection (Dialup), it is previously required to register MODEM onto Windows and set

the information on the receiver (the dial-up router at G-50A in the field) of the telephone transmission

onto the dial-up connection screen.

* If communication does not have for 10 minutes in remote connection, "Timeout occurred!" will be

displayed, if O.K. is pushed, a telephone circuit will be cut automatically and the Maintenance tool will be

ended.

(1) After clicking "G-50(Network)" on the selection screen of

Monitor mode, and click "REMOTE CONNECTION(Dialup)."

Last click " ."

(2) Next Remote Monitor screen is displayed.

Here select the connection name of the dial-up router at

G-50A in the field desired to be remotely connected.

It is being set previously on the dial-up connection

screen. Then input Dial-up user name and Dial-up

password to connect with the dial-up router,and click

on .

After connecting to the telephone circuit, on-line monitoring

can be performed as same as the case when connected with LAN.

Page 16

15

1.4.3.3 In case for remote connection (E-mail)

In the case when on line monitoring is applied to local air conditioning system (with G-50 installed) from the

maintenance tool in the remote place via mail server.

(1) After clicking "G-50(Network)" on the selection screen of

Monitor mode, and click "REMOTE CONNECTION(E-mail)."

Last click " ."

(2) The mail connection setting screen is displayed.

Here, set the mail information on G-50A to be connected,

and that on the Maintenance Tool.

A

ll communication to G-50 is converted in E-mail in this case.

Notice

For each mail address, it is required to obtain and set an

exclusive one. To transmit mail via an internet provider, obtain

the mail address from the provider. When a mail server is

existing on the LAN, obtain the mail address from the LAN

administrator.

(a)Setting of the mail information on G-50

A

1) To assign the G-50A connected in the past

After assigning “Customer name” from the pull down menu, select G-50 name.”

2) To connect to new G-50A

Click to open the address book, and register and select the mail address of G-50A.

*The 10 Customer names in the past are displayed on the pull down menu. To assign earlier G-50A,

open the address book to select.

Notice

•To use the E-mail connection mode, the version of G-50 should be above 2.60.

•When using E-mail connection mode, the local G-50A is required to be initially set with Maintenance Tool and

the mail address by the G-50A initial setting tool.

- For each mail address, it is required to obtain and set an exclusive one. To transmit mail via an internet

provider, obtain the mail address from the provider. When a mail server is existing on the LAN, obtain the

mail address from the LAN administrator.

- Set the [Pop receive interval] within 3 minutes. However to monitor operating status [Operation Monitor], set it within 1

minute.

- Setting of initial information to G-50A can not be executed from Maintenance Tool. Make sure to set it from the G-50A

initial setting tool locally. If dialup connection environment is available, it can be set from a remote position.

(For detail, please refer to 6-1 Mail Basic Setting in the instruction manual of the G-50A initial setting tool.)

•The communication speed under E-mail connection mode largely depends on the transfer rate of each mail

server. Under the circumstance, the action of Maintenance Tool may take a lot of time under some internet

environments or routing mail servers.

•For the system composition, please refer to the system diagram of (2)-2 in 1.1.2.

Page 17

16

[Entering order]

1) Preparing the Customer folder

Pressing displays the input screen of customer name,

and then enter the name.

The setting can also be made from the file menu or

the sub-menu displayed by right-clicking.

Further deletion processing can be made with or

Del-key, and rename processing with button.

2) Name and address setting of G-50A

Double-clicking at a position desired to enter provides the

input mode.

Set the name and address accordingly.

*Be sure to set the name of G-50A also.

The deleting processing can be executed with the ,

Del-key, or Edit menu. It can also be performed by the Delete

setting of the sub menu displayed by right-clicking.

(b) Address book

The mail address of G-50A for each project can be registered.

As shown in the sample examples, register the name and mail address of G-50A after preparing the

[

Customer name] folder.

[Selection order]

-Selection of G-50A to be connected with Click the customer name folder desired to connect to open

the address book of the project.

After fitting the cursor to the name of address of G-50A, click [SELECT] button.

(c)Advanced setting screen

Clicking [Open Advanced] opens Advanced screen where the mail information about Maintenance Tool may be

set.

When the mail information about Maintenance Tool has not been set, Advanced screen is displayed always under

opened state.

- Setting of mail information on Maintenance Tool

1) POP server (Receiving)

- POP server address

Set the IP address of the receiving mail server (POP3)

of Maintenance Tool or domain name.

- POP account

Set the POP account (user ID) for mail receiving.

- POP password

Set the user password for mail receiving.

- POP receive interval

Select the mail receiving interval.

The default value represents 5sec.

It can be selected within a range of 5 ~180sec.

Extend the interval when the server is crowded.

2) SMTP server (Transmitting)

- SMTP server address

Set the IP address of transmitting mail server of

Maintenance Tool.

3) Mail address

- Set the mail address of Maintenance Tool.

Clicking [Close Advanced] closes Advanced screen.

(3) After setting the mail information about the G-50 connected and that about Maintenance Tool, click [CONNECT].

Page 18

17

1.4.4 Starting the Off-Line Monitor

When offline analysis is adapted to the data collected under ONLINE MODE.

(1) Clicking "Offline Analyze" on the selection screen of Monitor

mode. Last click " ."

1.4.5 Using the Wide area access mode

Under the "Wide area access mode," the access method for remote connection can be registered to the

database of each customer enabling easy online connection with the air conditioning system of the customer

desired to be accessed.

[Remote access method]

- LAN : Accessing by directly connecting Maintenance Tool PC and G-50A with LAN (WAN).

- Dialup : Accessing by dialup connection to G-50A via public network.

- E-mail : Accessing by E-mail communication to G-50A via mail server.

- Modem (MN Converter) : Accessing by connecting Modem to MN Converter via public telephone

circuit.

After the online connection performed by any of the above methods, you may use the similar function as that

obtainable in the normal online connection.

While under the offline mode, customer information will be provided to the monitored data enabling only to

select a specified customer for display.

Note :

Even when connecting under the wide area access mode, cautions will be applied as same as under the

normal connection mode. You are kindly requested to observe the cautions described in the connection

method under normal mode as well. (1.4.1 - 1.4.3)

Page 19

18

1.4.5.1 Online Connection

(1) Clicking “Online Connection (Wide area access mode)”on the

section screen of Monitor mode.

Last click " ."

(2) The customer registration screen will be displayed.

Register customer information in the order of

[1] -> [2] -> [3] hierarchically.

[1] Area name

[2] Customer name

[3] Air conditioning system name

& connection method

(a) Creating the [Area name] folder

1) When [Wide Area] is being focussed, the

sub-menu will be displayed by right-clicking.

2) Select [Create Area …].

3) As the screen to enter the AREA name appears,

set a proper Area name and press [OK] to

create the Area folder.

(b) Creating the [Customer name] folder

1) Right-clicking the [Area name folder] to be

registered displays the sub-menu.

2) Select [Create Custormer …].

3) As the screen to enter the Customer name

appears, set a proper customer name.

* In addition to the above mouse operation, the creation of [AREA name] and [Customer name] can be

set from the menu bar (File)

or tool bar (Figure).

By applying the same operation procedure(right-clicking, menu bar, tool bar), each folder can be

deleted. Also the name of each folder can be changed.

Caution :

If a folder is deleted, all information (customer name, air conditioning system name, etc.) will be

deleted similarly.

Page 20

19

(c) Setting the [Air conditioning system name]

1) Under the state when the [Customer name

folder] desired to be set on the air conditioning

system is focussed, the sub-menu will be

displayed by right-clicking the air conditioning

system list at the right screen.

2) Selecting [Create ...] displays [Setting screen of

air conditioning system].

[Setting screen of air conditioning system]

1) Set the system name.

2) Select the method to connect with the system.

- To connect by using LAN (WAN)

, enter the IP

address of G-50 to be connected. (Same as

1.4.3.1)

- To connect by using Dial-up

, select the

[Connection name] of dialup router of the local

G-50 being previously set on the dialup

connection screen of Windows. And enter [User

name] and [Password] for the connection with

the dialup router, and lastly enter the IP address

of G-50. (Same as1.4.3.2)

- To connect under E-mail mode

, enter the

E-mail address of G-50 to be connected.(Refer

to1.4.3.3.)

- To connect remotely with MN Converter and

Modem, select [Modem(MN Converter)].

3) Enter special notes if any on the comment column.

After entering and selecting the above, press [OK].

Set various information as required by repeating the items

(a)-(c) above.

Using the area selecting section allows you to extract the

only area desired to display.

Page 21

20

(d) Other setting

You may select the mail address of maintenance tool PC itself and the Com port to be used.

* To use the E-mail mode, mail setting is essentially required.

[Mail setting of maintenance tool PC]

1)

POP server (Receiving)

- POP server address

Set the IP address of the receiving mail server(POP3)

of Maintenance Tool or domain name.

- POP account

Set the POP account (user ID) for mail receiving.

- POP password

Set the user password for mail receiving.

- POP receive interval

Select the mail receiving interval.

The default value represents 5sec.

It can be selected within a range of 5 ~180sec.

Extend the interval when the server is crowded.

2) SMTP server (Transmitting)

- SMTP server address

Set the IP address of transmitting mail server of

Maintenance Tool.

3) Mail address

- Set the mail address of Maintenance Tool.

Clicking [Close Advanced] closes Advanced screen.

[Setting of Com port]

To connect Mode, select the Com port to be used.

(3) Focussing on the air conditioning system desired to be

connected and pressing [Connect] will start the

procedure for connection. After completing the normal

connection, the screen moves to the online main screen

allowing normal online operation.

However when the connection method uses

[Modem(MN Converter)], the screen of the Modem

remote connection will appear. In this case, select the

Modem to be connected and proceed the connection

procedure.(Refer to 1.4.2.2.)

1.4.5.2 Offline Analyze

(1) Clicking “Offline Analyze (Wide area access mode)”on the

section screen of Monitor mode.

Last click " ."

Page 22

21

1.4.6 Ending the Maintenance Tool

1.4.6.1 Ending the On-Line Monitor

(1) Open the Main Screen.

(2) Click on [File

] on the menu bar.

(3) Click on [Return

] in the sub-menu.

(4) The message “Are you sure you want to finish

maintenance tool?” will appear.

Click on .

The On-Line Monitor will end and the Windows screen will

appear.

*At ending of Maintenance Tools, the telephone circuit will

automatically be disconnected.

* Clicking returns to the [selection screen of Monitor mode].

1.4.6.2 Ending the Off-Line Monitor

(1) Open the Off-line Analyze Screen.

(2) Click on .

(3) The message “Are you sure you want to finish

maintenance tool?” will appear.

Click on .

* When finishing Offline Screen immediately after deleting data,

a message of "Finishing Maintenance Tool !!" may

sometime be displayed. The internal data is now under

arrangement. Offline Screen will automatically be finished after

completing this process. Please wait a while.

* Clicking returns to the [selection screen of Monitor mode].

Page 23

22

2.1 Design of Screen

The design of the screen is shown below.

- Title Bar

Displays the title of the screen.

- Menu Bar

Displays the functions that can be performed using the current

screen.

Click on an item and a sub-menu or message screen will

appear, as shown in the illustration.

If a sub-menu appears, further function selections can be made.

- Function Display / Operating Section

Displays the contents of the screen and the operation to be performed.

2.2 Operating Method

The following operations are performed by mouse.

(1) Click

Align the mouse pointer with the desired button and press the left button on the mouse. This is known as

a click.

In general, all maintenance tool operations are performed with click operations.

(2) Drag

A drag is when the mouse pointer is moved while the left button is held down.

If you desired to check the bottom screen when two or more screens are being displayed on top of each

other, align the mouse pointer with the title bar of the top screen and drag it. The bottom screen can now

be seen.

2 Terms for Each Section

(Example of what the screen looks

like when option is clicked.)

Menu Bar

Function Display /

Operating Section

Title Bar

Page 24

23

3.1 On-Line Monitor Screen Transfer

3 On-Line Monitor Operating Method

Title Screen

Main Screen

Malfunction Log Operation Control

Connecting Information Operation Monitor

Optional Setting

Page 25

24

3.2 Function Chart

Connecting Information ----------------------- [Refer to 3.6]

This allows monitoring of the indoor units connected to the outdoor unit and of the interlock units and the

operation group SC connected to indoor units.

Operation Monitor ------------------------------- [Refer to 3.7]

This allows monitoring of the operating condition of the unit and operating data. The operation data

obtained will be shown in the form of a graph.

Utilizing the mail communication mode in addition, the operation monitoring data collected by G-50A can

periodically be transmitted to remote mail servers, and it can be referred as the off-line data later.

*The Mail communication mode can not be used with MN Converter connected.

Malfunction Log ---------------------------------- [Refer to 3.8]

This allows monitoring of the ten most recent errors of the unit.

Optional Setting ---------------------------------- [Refer to 3.9]

This allows monitoring of self-diagnosis function, operation control and pre-error data monitoring.

This also allows to monitor the response to any M-NET command transmitted to the unit. Time setting.

Operation Control -------------------------------- [Refer to 3.10]

This allows the same operation as with the remote controller.

3.3 Address Search Method

3.3.1 Address Search Method Selection

(1) Start the M-NET Maintenance Tools and the Select The Address Searching Method Screen will

appear after the Title Screen.

(2) Click on either or to select the

address search method.

* Automatic Search

The Maintenance Tools automatically searches for

and displays information about units connected to

the M-Net transmission line.

* Manual Search

The user optionally searches for the units connect to the

M-Net transmission line.

Page 26

25

3.3.2 Automatic Searching

(1) Click on and the Automatic Address

Searching Screen will appear.

- The time required to complete the automatic search

will depend on the PC.

- The address currently being searched for is

displayed as [Address

]. Up to 250 addresses can

be searched for.

- Click on to end automatic search.

The Main Screen will appear.

(2) When automatic search has ended, the Main

Screen will appear.

Returning to the Main Screen enables the [Function Buttons

].

3.3.3 Manual Searching

(1) Click on and the Main Screen will appear.

(2) Click on the [Button

] of the address desired and

searching will begin.

*Note

When a system is changed, please search an address after re-starting a Maintenance tool and G-50.

Page 27

26

3.4 Main Screen

The operations in 3.3 Address Search Method have made information about the units known.

The [Unit Attributes

] are displayed on top of the address buttons.

The Function Buttons are now enabled at this time.

(1) Click on an address [Button] displaying attributes

and information about that unit will be displayed in

the [Unit Information Display Columns

].

(2) The menu bar will display [File

], [Option] ,[Print] and [Help].

- Click on [File

] and ”Save System Information” and “Return” sub-menu can be selected.

Click on “Save System Information” and the message “Are you sure you want to save the System

Information?” will appear.

Clicking displays the screen to save data. Change the data name as required and save it.

You may enter your comment also.

Click on to return to the Main Screen.

[Refer to 5.1 System Information Data.]

Click on “Return” to end the operation of the On-line monitor.

[Refer to 1.4.5.1 Ending the On-Line Monitor ]

- Click on [Option

] and “Automatic searching” and the “Stop mail communication” sub-menus can be

selected. * At the connection of MN Converter, “Stop mail communication” is not displayed.

Click on “Automatic searching ” and the message “Start the automatic searching. Is it OK?” will

appear.

Click on to perform automatic searching or click on to return to the Main Screen.

For more information about automatic searching, refer to [3.3 Address Search Method 3.3.2

Automatic Searching].

Click on “Stop mail communication” ,and the Stop mail communication Screen will appear.

Clicking on stops the mail transfer processing of operation

monotor data to remote mail servers.

After a while, the setting completion message appears. Clicking on

returns to the main screen.

Clicking on returns to the main screen directly.

- Clicking on [Print] prints out the display currently shown on the screen.

- Click on [Help

] and "Explanation of Terminology" and "Operation Method" sub-menus can be

selected.

[Refer to 3.6 Connecting Information 3.6.2 (2) ”Menu Bar” ]

Page 28

27

3.5 Function Selection Operations

(1) First, click on the desired [Function Selection

Button].

(2) Next, click on the Unit to Operate

.

(3) The screen will move to the various operation

screens.

(4) If the wrong function selection button is clicked, click

on that button once again and the other function

selection buttons will be enabled.

3.6 Connecting Information

* Items Performed Here

- Indoor units connected to outdoor units, interlock units and the operation group SC (such as system

controller and remote controller) connected to indoor units can be monitored here.

- Select and double-click the interlock units and operation group SC (remote controller only), the

Connecting Information Screen will display as a pop-up menu.

The screen displays addresses and attributes of the units connected to the select unit.

3.6.1 Screen Transfer Operation

(1) Click on on the Main Screen.

(2) Click on the for the outdoor unit to be monitored.

- Only outdoor units can be selected.

(3) Momentarily, the message “Monitoring! Please wait

for a moment.” will appear.

* NOTE

Even with the direct expansion type, when units other than outdoor units are selected by

(2), the screen returns to the Main Screen (where it waits for function selection input).

*Note

"Stop mail communication" is a function to stop the operation monitor mail transmission of G-50 under [mail

communication mode] set in Chapter 3.7. It has no relation with (2)-2 E-mail connection mode of 1.1.2

On-line Monitor (via G-50).

Page 29

28

(4)Momentarily, the Connecting Information Screen

will appear.

(5)Click on to end the Connecting

Information Screen.

(6)The message ”Finish the Connecting Information”

will appear.

Click on to end or click on to

continue.

Click on and the Main Screen appears.

3.6.2 Screen Functions and Operation

(1) Double-click on the interlock unit and operation

group SC (remote controller), the Operation

System SC Connecting Information Screen (in

case operation group SC) will appear as a pop-up

menu.

The screen displays addresses and attributes of each connected unit.

(2)”Menu Bar”

[Return

] and [Help] appear in the menu bar.

Click on [Return] to end the Connecting Information Screen and return to the Main Screen.

Click on [Help] and the Help Screen appear.

- Click on "Contents" and the index for the Help Screen

appear.

- Click on "Back" and the unit returns to its previous

operating state.

- Click on "Print" and the currently displayed screen is

printed. (Caution: Do not print while on-line. There is a

chance that it could interfere with operation.)

- Click on "Term" and Explanation of Terminology

Screen appear.

Abbreviations, codes and other terms are explained on

the explanation of terminology screen.

* NOTE

The BC controller(BC),Subsidiary outdoor unit(OS) are indicated in the outdoor unit column.

3.6.2(2)

(5)

Page 30

29

3.7 Operation Monitor

* Items Performed Here

- Monitors the operating condition and operating data of the current units every minute.

This information can be displayed and saved.

* When an excessively large number of the objective unit for monitoring exists, the monitoring interval may

exceed 1 minute (70s, 80s, ---).

* The capacity to store the data obtained by the maintenance tool counts for 2G-bite maximum.When the

remaining storage capacity is getting insufficient during Operation Monitoring, Warning Screen will

appear. In this case, suspend the Operation Monitoring, move to Offline screen and delete

unnecessary data to keep a proper capacity.

3.7.1 Screen Transfer Operation

(1) Click on on the Main Screen.

(2) Click on the unit to be monitored.

If only outdoor unit is selected here, the operating data for the units connected to the outdoor unit

will be automatically monitored.

The maximum number which can carry out a monitor changes with selected models.

An error message will appear if the limited number of units is exceeded.

The standard of the number which can carry out a monitor.

* When only Outdoor Unit is selected.

- One (1) Outdoor Unit + 50 Indoor Units.

- One (1) Outdoor Unit + Three (3) OC Sub Controller (BC,BS,OS…) + 50 Indoor Units.

* When only Indoor Units are selected, 50 Units.

(3) After the units to be monitored have been selected, click

on .

(4) The message “Monitoring! Please w ait for a moment.” will

appear.

After a while, the screen to select monitor method appears.

* In "MN converter connection", it shifts to (7).

(5)

When desiring to observe the operation data immediately,

select [Realtime Monitor Mode] and then click on .

Select [Mail communication Mode] to observe the operation

data by the off-line monitor later, after mail-transmitting the

operation data beforehand by using the mail transmission

function.

When it is judged that monitoring with one minute cycle may

not be performed because of many units to be monitored, a

message of [The monitoring cycle will be [* *] seconds

due to too many IC units for monitoring. ---] will be

displayed automatically. To continue the monitoring, click

[YES], while to suspend it once to reduce the quantity o

f

units for monitoring, click [NO]. Reduction of one IC can

minimize the cycle time by about one second.

Page 31

30

When [Mail communication Mode] is selected, the setting

items of mail communication will be displayed.

- From: Mail Address

Set the mail address of the G-50A in the [From: Mail

Address] field. When sending mail via an ISP, set the mail

address allocated by the ISP. When the mail server

resides on the LAN, obtain the mail address from the LAN

administrator.

* When sending mail via an ISP, a user contract with the ISP is required.

- To: Mail Address

Set the mail addresses of the recipients to which mail is sent.

* The mail address of recipient (To:) acquires and sets up the address only for maintenance tools.

- SMTP Server IP

Set the mail server IP address in the Mail Server Information [SMTP Server IP] field. When sending

mail via an ISP, set the ISP address of the ISP mail server. When the mail server resides on the

LAN, obtain the IP address from the LAN administrator.

* If the only information available on the ISP mail server is a domain name, use a PC to connect to

the Internet, open a DOS prompt and type “ping domain name”. Set the IP address that is displayed

as the ping response.

- Monitor Finish Data

Set the date of monitor data transmit period.

- Mail Sending Interval

Set the transmit interval of monitor data (max 240 min).

Then click on .

After a while, it returns to the main screen, but the mail transmission to remote receivers will be

performed by G-50A automatically.

* At the connection of MN Converter “the screen to select monitor method” is not displayed. Real-time

Monitor Mode is always commenced not allowing to use [Mail communication Mode].

(6) In the case of real time monitoring, the message “Monitoring. Please wait for a moment.” will

appear again.

(7)

Momentarily, the Operation Status Monitor Screen

will appear.

3.7.2(1

)

Page 32

31

(8)

Click on to end the Operating Status Monitor Screen.

The message “Finish the operation status monitor” will appear.

Click on to end or click on to not end.

Clicking displays the screen to save data.

Change the data name as required and save it. You

may enter your comment also.

Clicking does not allow the data to be saved.

Returning to the main screen.

3.7.2 Screen Functions and Operations

- The operating condition and operating data are displayed every minute.

- The [Current Time

] is displayed. The [Monitor ID] is displayed when saving data.

[Refer to 5.2 Operation Status Monitor Data]

(1) ”Operation Buttons”

allows operation in the same manner as a remote controller.

[Refer to 3. 10 Operation Control]

Click on to end the operation status monitor and return to the Main Screen.

[Refer to 3.7.1(8)]

(2) ”Menu Bar”

[Return], [Print], [Graph] and [Help] are displayed on the menu bar.

- Click on [Return] to end the Operation Status Monitor

and return to the Main Screen.

- Click on [Print] and then select “Print screen” from

the sub-menu.

The hard copy of the screen will be printed from the

connected printer.

- Clicking [Graph] displays a message of “Make the

graph to data ?”.

To graphing, click , while to return to the

operation monitor screen without graphing,

Click .

- Click on [Help] and an explanation about "Terminology" and "Operation Method" will be displayed.

[Refer to 3.6 Connecting Information 3.6.2 (2)”Menu Bar”]

Page 33

32

* About LM ADAPTER

Operation Monitor

Item Performed Here

Operation status of LM ADAPTER, current values of network variable and configration property,setting status of

switch or the like.

[Refer to 3.7 Operation Monitor]

1 Screen Transfer Operation

To move to the screen monitoring LM ADAPTER operation,

select LM ADAPTER from the main screen.

(LM ADAPTER is expressed by )

When LM ADAPTER is selected,you may not monitor

other units.

Same operation procedure as that of other units is applicable

to other main screens.

2 Screen Functions and Operations

- The operating condition and operating data are displayed every minute.

- [Current time] will be displayed.During a time when saving data,[Monitor ID] will also be displayed.

[Refer to 5.2 Operation Status Monitor Data.]

(1)[Operation Button]

[Operation control] will not be displayed.

Click on [Return] to end the operation status monitor and return to the Main Screen.[Refer to 3.7.1(8)]

(2)[Menu Bar]

[Return] , [Print] , [Graph] and [Help] are displayed on the menu bar.

Neither [Graph] nor [Ref.] may be used. Other menus are same as that of other units.

Menu Bar

Operation Button

Page 34

33

3 Introduction to the screen

Display Contents

<Function set switch>

Set status of function selector switch

0:OFF setting 1:ON setting

<Extension switch>

Set status of extension function selector switch

0:OFF setting 1:ON setting

<M-NET address switch>

Set status of M-NET address switch on LM ADAPTER

SWU1:The units digit SWU2:The tens digit

<Control flag>

Internal processing status of LM ADAPTER

FLAG:Control flag status

ERROR:Error flag status

[M]:M-NET communication processing flag

[LON]:LonWorks communication processing flag

0:Reset 1:Set

<General input>

General input status of LM ADAPTER

0:Normal 1:Detecting

<Power failure flag>

Indicating power failure detecting status of LM

ADAPTER

0:Powering 1:Interrupting

<Binding status : nvoOnOff_n>

Binding information on operation command input

0:No binding

1:Binding

Unit address

(Unit digit)

Unit address(Tens digit)

Page 35

34

Display Contents

<Binding status : nvoOnOff_n>

Binding information on operation status output

0:No binding

1:Binding

<IC connection status>

Connection status of air conditioner(indoor unit)

0:Not connected

1:Connected

<nv Transmitting/receiving data>

Latest value of network variables

[Rcv] Received value of operation command input

[Snd] Output value of operation status

St : state field data

V1 : value field data

<nci set value>

Set value of configuration property

Unit address

(Tens digit)

Display example

[Rcv] [Snd]

St Vl St Vl

stopping 00 00 00 00

Operating 01 C8 0 1 C8

Unit address(Tens digit)

Unit address

(Unit digit)

Unit address(Tens digit)

Unit address

(Unit digit)

Unit address(Unit digit)

Page 36

35

3.7.3 Trend graph

Clicking at 3.7.2 (2) [GRAPH] displays Trend Graph Screen.

(1) Procedure for graphing

(a)Click [Option] on the menu bar.

(b)The sub-menu of "Graph detail setting" and "Other setting"

will be displayed. Click "Graph detail setting" to set each

item of the graph.

*Note

Without setting of each item on "Graph detail setting,"

no graph can be displayed.

(The graph detail setting is explained in (c) and other setting is in (d).)

(c) Graph Detail Setting Screen will be displayed.

1) Click your desired number (from Graph 1 ~ 5) for

graphing.

*Note

The number of the graph selected represents

the ordinate.

2) Select [Unit] desired to be graphed.

3) Select [Source] (Data item) desired to be graphed.

4) Set [Upper limit, Lower limit] of data. You may also

set to [Auto-scale].

- When the data exceeds the high limit value or low limit value being set under [Auto-scale] setting,

the above value is replaced by the exceeded value in the setting. When the high limit value and low

limit value are set before entering, 10 will be set to the high limit value and 0 will be to the low limit

value automatically.

5) [Graph upper limit, Graph lower limit] (Ordinate display

position/range) may be acceptable as it is. Setting is

required when the display position/range is desired to

change.

(To display over the entire screen, enter 100 to the

graph high limit position, while 0 to the low limit position.)

*Note

The input of the upper limit value/lower limit value and

graph upper limit position/lower limit position can be

entered by the ten keys for numerical input besides the

entering by the key board.

6) Click after completing all setting to return to Trend Graph Screen.

(d) Conducting the "Other setting"

With "Other setting," the optional function to facilitate graph

observation can be set.

Click [Option] on the menu bar. Click "Other setting."

Other Setting Screen will be displayed.

1) Moving [Scroll bar] by dragging or clicking changes

the value of the horizontal grid line from 0 to 4. The horizontal grid line will be displayed on the

graph in a number of the value above.

*The sampling time can not be set by on-line.

6

)

5

)

Upper limit value/graph upper limit position

Lower limit value/Graph lower limit position

Page 37

36

2) Clicking returns to Trend Graph Screen

displaying the horizontal grid line in the number being

set to the graph.

(e) Starting the graph

Clicking initiates monitoring to graph the data for

each one minute. The sampling time to allow graphing by

online system is limited to 500 minutes maximum. If 500

minutes are exceeded, the data of old time is eliminated by

the excess time.

(2) Screen function and operation

- The current monitor data is displayed on [Lower column].

- Clicking [Graph number] makes the graph line bold.

- [Current time] is displayed.

- Clicking suspends the monitoring.

At suspension, [Scaler] will be displayed on the graph.

Dragging the scaler displays the data on the scaler at the

current value column and [Time] at the under part of the graph

number.

- Moving [Scroll bar] by dragging or clicking moves the

display range of the graph.

can be operated as same as the local remote

controller.

[Refer to 3.10 Operation control.]

* Here, BC operation cannot be carried out.

- Clicking clears the graph being displayed. The set values of the graph setting items and other

setting items will remain unchanged.

(3) Ending the graph

To finish Trend Graph Screen and return to Operation Status Monitor Screen, click [Return] on the

menu bar or click . A message of [Finish the trend graph and return to the monitor?] will be

displayed. For returning, click , while not returning, click . Clicking returns to

Operation Status Monitor Screen.

(3)

[Graph number]

Page 38

37

3.8 Malfunction Log

* Items Performed Here

- The malfunction log of the most recent 10 cases (except operation group SC)

3.8.1 Screen Transfer Operation

(1) Click on from the function selection buttons on the Main Screen.

(2) Click on the units to be monitored (except operation group SC).

(3) The message “Monitoring. Please wait for a moment.” will appear.

(4) Momentarily, the Malfunction Log Screen will appear.

If the number of incidents in the malfunction log is

less than ten, [--] will appear in the attribute column

and [FFFF] will appear in the code column.

* Error detailed No.

Error detailed No. may be displayed on the right of

an error code by the model which carries out

a monitor.

Refer to the service handbook for the implications of

detailed No.

* When the monitor of the unit with a simple clock

function is carried out, the time which malfunction

generated, or the time when it was integrated to

unusual generating is displayed.

- When the unit has received a setup of time: The time which malfunction generated is displayed.

- When the unit has not received the setup of time: The addition time from a power supply injection

when malfunction occur is displayed.

Note : While the power supply of a unit turns off, time does not count the simple clock function of a unit.

Therefore, the display of the time which malfunction generated, and addition time will be a mere

rough standard.

* About a flag display

- When a flag is “1” : The state which the power supply does not turn off after receiving a setup of time.

- When a flag is “0” : A setup of time is not received. Or the state which the power failure generated

after receiving a setup of time.

* About PC Time/Unit Time

- PC Time : The present time set as the maintenance tool PC.

- Unit Time : The present time which carried out the monitor from the unit with a simple clock function.

Note : When the system controller which transmits a setup of time to a unit periodically is not

connected, a year and moon data are not updated. In this case, the date column of unit time

maybe counted up till the 9999th.

3.8.2(3

)

3.8.2(2)

3.8.2(1)

Page 39

38

(5) Click on to end the Malfuncion Log Screen.

The message “Close the malfunction log display? ” will be displayed.

Click on to end or click on to not end.

is clicked, the Main Screen is returned.

Note: When G-50A is connected to the system, the malfunction log of OC is eliminated.

Please check the malfunction log in G-50 to check the malfunction log of OC.

3.8.2 Screen Functions and Operations

(1) Click on and the Address Change Screen appear.

Click on to change the address.

The unit attributes are displayed at this time.

(If there is no unit at the address given, the attributes are not

given.)

Once the address has been set, click on .

The units are changed.

If there is no unit at the address given, the message “Unit doesn’t

exist in this address. Retry again.” will appear.

Click on to return to the Address Change Screen.

(2) Click on and the message “Clear the malfunction log. Is it OK?” will appear.

Click on to clear or click on to not clear.

(3) ”Menu Bar”

The menu bar displays [File

] and [Help].

- By clicking [File

] and then selecting “Save as …” from the sub-menu, the Malfunction Log data will

be output and saved in the CSV format. This data can not be viewed on the offline screen.

- Click on [File

] and then select “Return“ from the sub-menu to end the Malfunction Log Screen

and return to the Main Screen.

- Click on [Help] and an explanation about "Terminology" and "Operation Method" will be appear.

[Refer to 3.6 Connecting Information 3.6.2 (2)”Menu Bar”]

* The error history being memorized by G-50 can also be monitor-displayed.

(Display can not be performed when connecting with MN Converter.)

The system controllers other than G-50 can not provide the monitoring of error history.

Page 40

39

3.9 Optional Setting

* Items Performed Here

- Self-Diagnosis Monitoring : The self-diagnosis function (LED for service monitor) to be performed

with Dip-SW on the circuit board of the outdoor unit can be monitored.

- Operation Control : Controlling of unit operation can be performed in the same manner as a

remote controller.

-

Sending Command : Allows to monitor the response for any M-NET command transmitted

to the unit.

-

Monitoring of Pre-error Data : The operation status of the unit (OC/OS) until generating an error can

be monitored in a unit of minute.

- Date / Time Setting : A setup of the present time can be performed to outdoor unit.

(It is used for the time when abnormalities occurred.)

(1) Click on from the function selection buttons on the Main Screen.

(2) Click on the units to be monitored or operated.

(3) The Optional Setting Screen will be appear.

Click on [Item

] to be monitored or operated.

- Click on and the Address Change Screen

appears.

[Refer to 3.8 Malfunction Log 3.8.2 (1)]

- The sending/receiving data are displayed on the

[Lower Column].

(4) Click on to end the Optional Setting Screen

and return to the Main Screen.

3.9.1 Self-Diagnosis Monitoring

(1) Click on and the Self-Diagnosis

Monitoring Screen will appear.

(2) Set the self-diagnosis SW value with .

For the set value, use the No.

on the List of LED monitor

display of the Service Handbook for each unit.

(3) After setting the set value, click on .

The self-diagnosis LED display will be shown with flag or

numerial value.

If the unit other than the outdoor unit or the set value being not

corresponded is sended, the characters “Not corresponded”

and “Attribute and Version” are displayed.

(4) Click on to end the Self-Diagnosis Monitoring Screen and return to the Optional

Setting Screen.

3.9.2 Operation Control

[Refer to 3.10 Operation Control]

Page 41

40

3.9.3 Sending Command

(1) Click on and the Sending

Command Screen

will appear.

(2) Input M-NET command desired to transmit by

clicking on the button.

Direct input from the keyboard is also possible.

(3) After inputting command, click on . Response command is displayed on [Answer] column.

(4) Click on to end the Sending

Command Screen and return to the Optional Setting Screen.

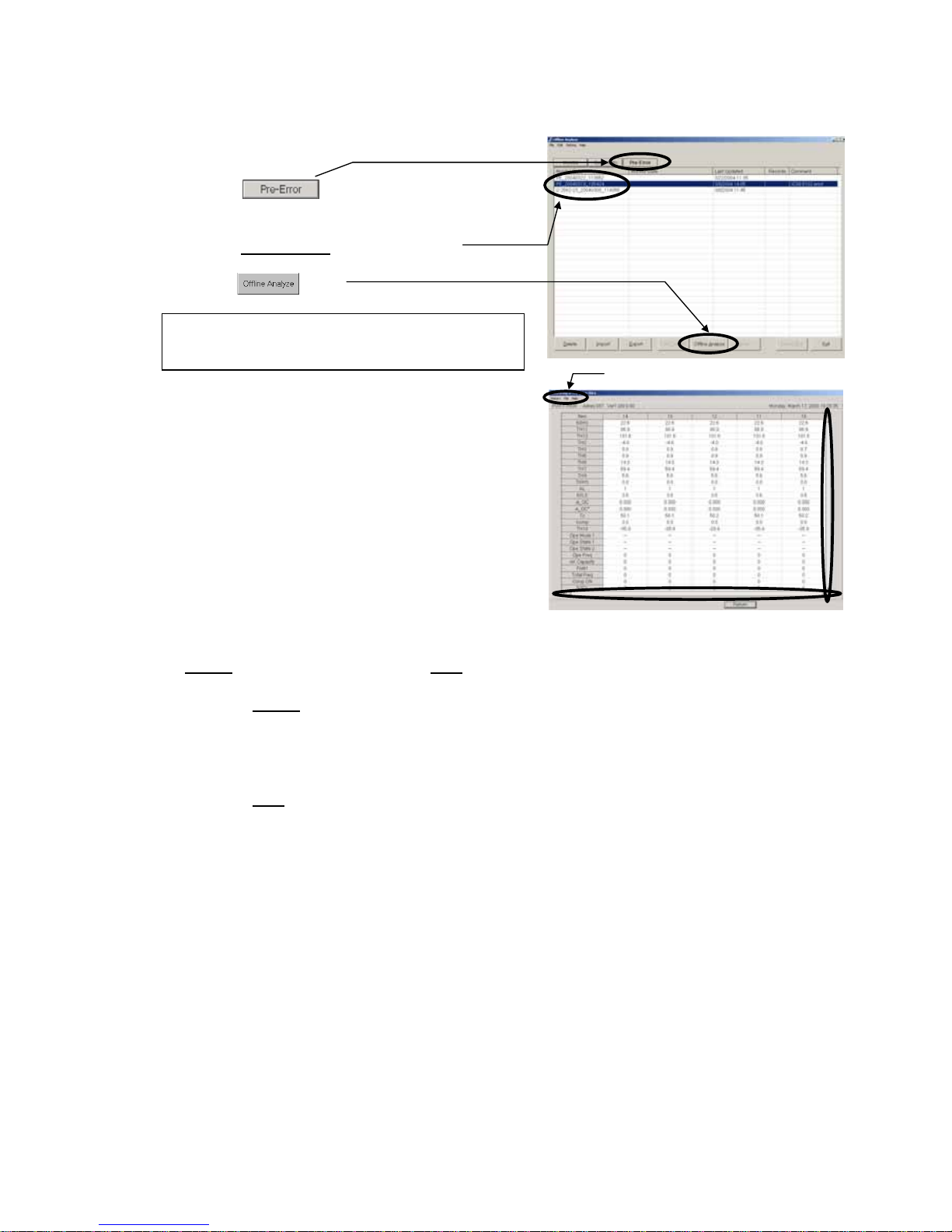

3.9.4 Monitoring of Pre-error Data

(1) Click on and the Pre-error Data

Screen will appear.

- When it chooses except the outdoor unit or

constant speed unit (OS), the message of

“This model doesn’t have the function of

Monitoring of Pre-error.

” is displayed not allowing

operation.

(2) As the screen opens, the monitoring of the data of

the selected unit before error occurred will

automatically be started.

(3) After ending the monitoring, the data of the selected unit before error occurred is displayed in a unit of

minute on Pre-error Data Screen.

Each figure on the upper column indicates a number of minute before generating an error respectively.

The change of the display content is performed with Up/down, left/right scroll bar.

The number of displayed items and that of the stored data (per minute) differ depending on the

selected item.

(4) ”Menu Bar”

The menu bar displays [Return

] and [Help].

- Click on [Return

] to end the Pre-error Data Screen and return to the Optional Setting

Screen.

As the screen to save data will appear, change the data

name as required and save it. You may enter your

comment also.

After saving, return to the Optional Setting Screen.

- Click on [Help] and an explanation about "Terminology" and

"Operation Method" will be displayed.

[Refer to 3.6 Connecting Information 3.6.2 (2)”Menu Bar”

]

* NOTE

Use this function after obtaining the knowledge of M-NET command.

Page 42

41

3.9.5 Date / Time Setting

(1) Click on . The Date / Time Setting

Screen opens and the present time of PC is displayed.

* When the unit which does not correspond to a setup of

time is chosen, the message of "This function is not

available" is displayed, and it cannot set up.

(2) A click of sets the time currently displayed to a unit.

* The time to set up can also be changed on a screen. Cursor is united with a change point and

a numerical value is inputted.

(3) Click on to end the Date / Time Setting Screen and return to the Main Screen.

Page 43

42

3.10 Operation Control

* Items Performed Here