Page 1

♦

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

Model

classes

INSTRUCTION

FOR

OPERATION

MANUAL

Page 2

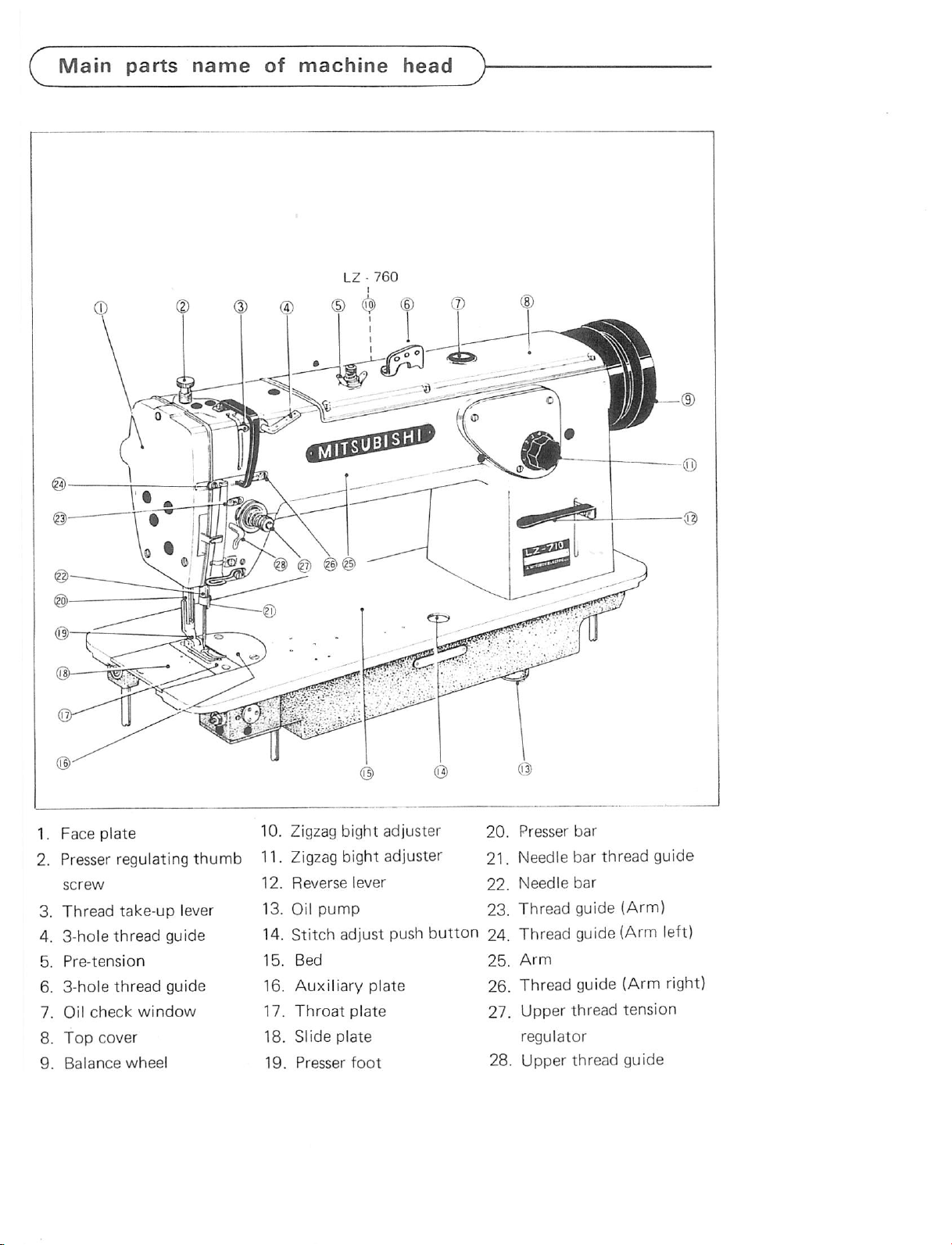

Main

parts

name

of

machine

LZ•760

(I)

(5^

head

(6)

Face

1.

2.

3.

4.

5.

6.

7.

8.

9.

plate

Presser regulating

screw

Thread

3-ho!e

Pre-tension

3-hole

Oil

Top

Balance

take-up

thread

thread

check

cover

wheel

guide

guide

window

thumb

lever

10. Zigzag

11. Zigzag bight

12.

Reverse

13.

Oil

14. Stitch adjust push button 24. Thread guide (Arm left)

15.

16.

17.

Throat

18.

Slide

19.

bight

pump

Bed

Auxiliary

plate

Presser

lever

plate

plate

foot

adjuster

adjuster

20.

21.

22.

23.

25.

Presser

Needle

Needle

Thread

Arm

bar

bar

thread

bar

guide (Arm)

26. Thread guide (Arm right)

27. Upper

regulator

28.

Upper

thread

thread

tension

guide

guide

Page 3

How

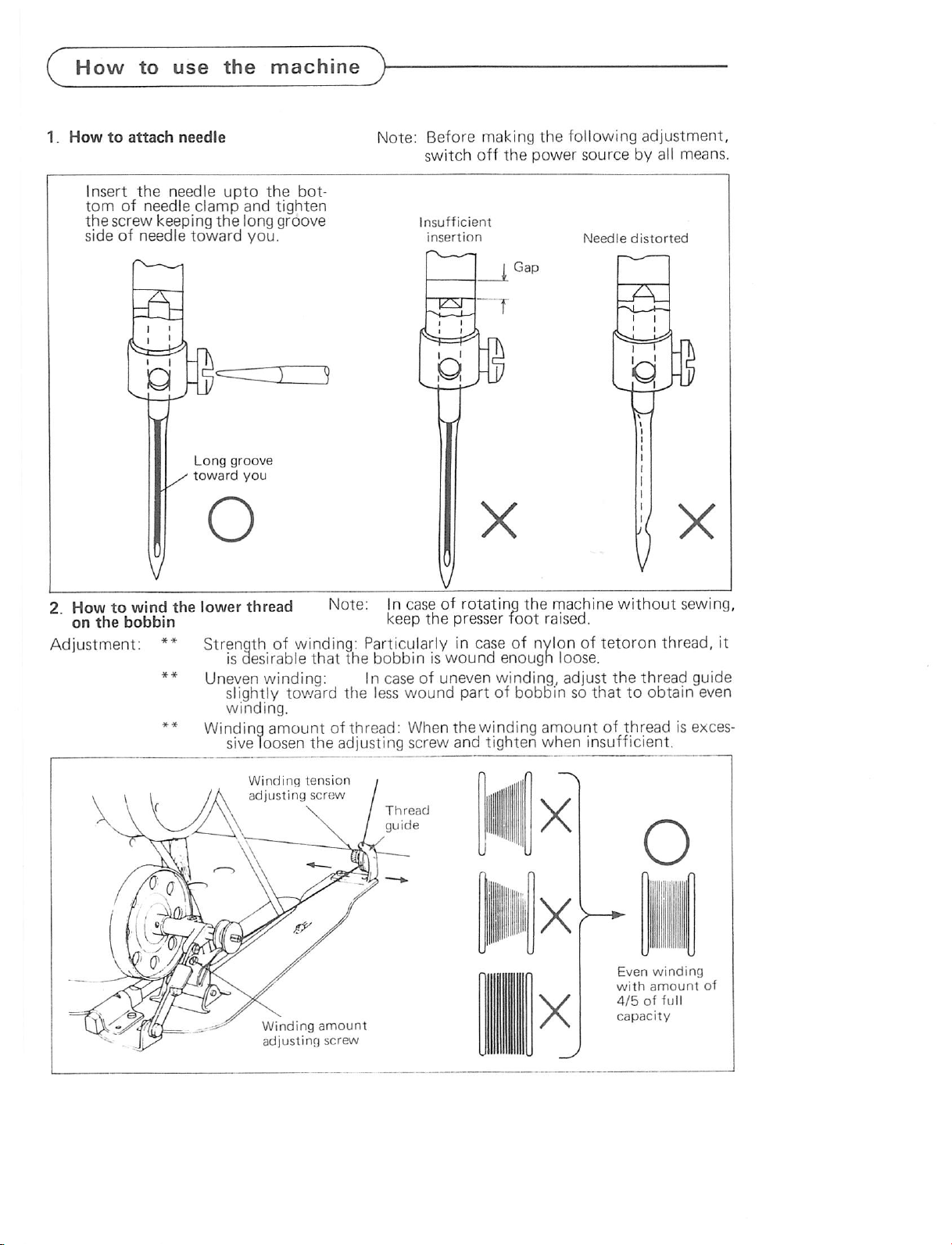

1.

How

to

use

to

attach

needle

the

machine

Note:

Before

switch

making

off

the

the

power

following

source

adjustment,

by all means.

Insert

tom

of

the

screw

sideofneedle

2.

Howtowind

on

the

Adjustment:

the

needle

bobbin

needle

clamp

keeping

toward

Long

toward

the

**

upto

the

and

the

long

you.

groove

you

lower

thread

lower

thread

Strength of

Strength

bot

tighten

groove

winding:

of ^

Insufficient

insertion

Note: In caseofrotating

keep

the

presser

Particularly in

caseofnylon

the

foot

is desirable that the bobbin is wound enough loose.

Uneven winding: In

slightly tov/ard

winding.

Winding

amount of thread:

sive loosen

the

caseofuneven

the

less

wound

When

adjusting screw and tighten

winding,

partofbobbinsothattoobtain

thewinding amount of threadisexces

machine

raised.

Needle

distorted

without

of tetoron thread, it

adjust

when

the

insufficient.

thread

sewing,

guide

even

Winding

adjusting

Winding

adjusting

tension

screw

amount

screw

Thread

guide

nix

'A^r

o

Ll,

Even

winding

with

amount

4/5offull

capacity

of

Page 4

How

to

use

the

machine

3. Howtoplace

case

1. Insert

direction

4.

Threading

Raise

the

bobbin

when pull

the thread take-up

est position and

in

the

following order. istobe

the

bobbin

to

out

Bobbin

thread

and

move in

the

thread.

case

lever

the

upper

the

Bobbin

bobbin

the

arrow 3. Insert

to its

high-

thread

2. Lead

3.

the

'

Note:

the

thread

the

bobbin

latch lever.

The

thread

put

through

case

into

Latch

lever

guide (C) of

just above

the

slit 1, 2 and

hook

cotton

the

spool.

holding

Tension

g

stand

Thread

Thread

/spring

take-up

Page 5

How

5.

Adjustment

Causion;

to

of

use

zigzag

the

width

* No adjustment of zigzag width can

be

done

chine.

LZ-710

the

dial

* Adjust

cloth

during

Do

not

machine

rotates

the

worked.

operation

touch

simultaneously.

needle to be above

Needle

is

maged or bended if zigzag width is

adjusted while

into

the

4 LZ-710

Turning

and

the

zigzag width adjustable dial

setanindicating

accordingtothe

the

cloth.

needle is inserted

line

"A'

required zigzag width.

machine

of

the

dial

operating,

may

to

the

when

be

scale

ma

for

the

da

6.

Adjustmentofstitch

1. Pushing

the

push

length&backstitch

button

down

the balance wheel slowly toward you.

2. So

that

the

push

button

and

the

balance wheel running.

At

this

time

set

the

on

the

Balance Wheel with

on

the

arm

and

button

Causion: Do

when

will be broken if

7.

Adjustmentofpressure on presser

Pressure

shown

not

operating

on

the

in Fig.

touch

the

the

presser

justedinaccordance

sewn.

light

Pressure

For

weight

material

(weaken).

goes

down

graduationofthe

the

then

release

the

push

machine.

The

pushbutton

Indicating

rrk

footisto

with

materialstobe

regulating

^

thumb

For

heavy

material

and

turn

further

dial

marking

the

push

button

machine

ispushed.

foot

be

screw

weight

(tighten)

ad

8.

♦

LZ-760

Loosen

the

arrowtothe

the

nut

by

box

indicating

spanner

number.

Box

and

spanner

Adjustmentoffeed dog

set

height

Feed

1

Arrow

Feed

bar

Number

Indicating

of

180°onthe

Eccentric

pin(D

Indicating

mark

canbeadjusted

sideofarrowdirection

Arrow

mark

within

on

dog

direction

the

feed

limits

bar.

Page 6

ow

to

use

the

C2

9.

Adjustment

thread

o

10.

Upper

**

Upper

the

**

Upper

tension

For

special fabric sewing

thread,

tained by adjusting

erating range of

♦

Adjustment

* Adjustment of strength of

take-up

1.

Loosen

thread

2. It adjusts the strength of

take-up

thread

the Fig. (It obtained

strength in more 180 degrees turning

when

from 0 pressure.)

*

of

tension

Well

balanced

stitch

thread

tension

threadisadjusted

lower

thread

thread

tension

regulating

the

desired

thread

of thethread

spring.

the

screw

tension

tension

the

Standard

Light material about 20g

Medium

Heavy material

stud.

spring by

stud

take-up

tensionisas

material

machine

X

tension.

thumb

tension

the

according

is adjusted by

nut.

with

can

strength and op

take-up spring.

take-up

"A"

of

turning

"B"

as

about

spring

fitsto stopper

follows.

....

about

about

In

case

too

strongorlower

is

too

weak

special

be

spring

the

thread

the

upper

the

thread

the

upper

shown

25g

30g

to

ob

25g

>

upper

in

thread

thread

is

X

In

too

is

too

case

weak

upper

strong

thread

or

lower

thread

/

is

Thread

tension

nut

^"^trengthen

Weaken

Strengthen

Weaken

*

11.

Lower

Thread

spring

thread

tension

tension

Strengthen

Standardoflower

1. Bobbin case should have a bobbin with

regular amount of the

.

It is

that

the

standard tension of

the

bobbin

thread

tension

cotton

the

case will be fallen

slowly when holding the end of the

/ K

Weaken

A

Lower

thread

/

canbeadjusted

screw

A.

tension

by

threadasshowninthe

In

cases

of

light fabrics . .

medium

are

best

fabrics

provided.

10

20

of

Fig.

20g

30g

Rotation

bobbin

(10~log)

thread

thread

Page 7

^Precaution

Lubrication—1

Before

the

ing

ume

would

plenish oil

starting

position (K) of oil tank. While

you

are requestedtocheck

periodically,

come

less

upto

to

the

before

operate

and

than

startingtooperate^

pour

in case

the

position

position (H).

L Oil

screw

oil

operat

the

oil vol

volume

removing

3. Adjustment of lubrication to the hook

Loosen

to

to

tighten

loosen

the

nut®

and

more

less

Loosen

turn

the

screw

upto

(L) re

2.

Lubrication

When starting

to

sew initially and after

kept idle for a long time without

is essentialtooil enough

holesinthe

Condition

While

sarytocheck

tion

through

red

of

oil

operating

the

Rubber

plug

colored

lubrication

the

the

condition of oil lubrica

oil check

4. Replacementofoil filter

In

case

oil

back

out

of

order

flow

duetowaste

through

rubber

machine

window.

capability

plug.

it is neces

Oil

window

becomes

thread,

starch, etc., clean or replace the filter

fixedonthe

endofoil

back

flow

using

the

check

fabric

pipe.

it

oil

5.

Periodical

*

Remove

clean

Feed

the

cleaning

the

feed

dog

throat

dog.

Tighten

svy

plate

and

* Lay down

and

clean

TlknfuwtfaS/C—

Oil

flow

the

machine head

the

hook.

ol ^

back

pipe

Hook

* Lay

and

screen.

Oil

pump

screen

Oil

flow

down

clean

back

pipe

y

Filter5mm

the

the

about

machine head

oil

pump

Page 8

^

Specifications^-

MODEL

For

Speed

Needle

Presser

Max.

bar

foot

stitch

stroke

lift

length

Spaceatrightofneedle

Hook

Zigzag

actuator

Max.

widthofbight

Needle

Reverse

lever

LZ-710.11

regular

4,500

32.3

7

4

mm

mm

mm

260

mm

DP2-57

eccentric

0 ~ 5

Schmetz

zigzag

s.p.m.

(1-9/32")

(9/32")

(5/32")

(10-1/4")

(auto-lubrication)

mm

(0 ~

5/32")

19:13

SKF

Singer 135x7 #11

Organ DPx5 #11

equipped

70

LZ-760-11

3-stitch

3,500

same

same

same

same

same

grooved

zigzag

s.p.m.

cam

overall9mm

same

135x7

DPx5

same

#11

#11

(11/32")

LZ-760-11-D

Blind

stitches

3,000

s.p.m.

same

same

same

same

same

grooved

0 ~ 5

mm

same

135x7

DPx5

same

zigzag

cam

(0~5/32")

#11

#11

A

MITSUBISHI

HEAD OFFICE MITSUBISHI DENKI BLDG MARUNOUCHI. TOKYO

ELECTRIC

CORPORATION

100

TELEX

J24532

CABLE MELCO TOKYO

WT00526X02

Loading...

Loading...