Page 1

/

u

♦

INSTRUCTIONS

AND

PARTS

MITSUBISHI

INDUSTRIAL

SEWING

MODEL:

MACHINE

LZ-207

EMBROIDERY

BOOK

FOR

A

..•Mr

MITSUBISHI

ELECTRIC

CORPORATION

Page 2

Merits

Specifications

I.

Preparation

1.

Location

2.

Mounting

3.

Mounting

4.

Connection

5.

Mounting

6.

Mounting

7.

Mounting

8.

Mounting

9.

Note

n.

Gist

of

operation

1.

Selection

2.

Attaching

3.

Wind

4.

Ad.iustment

5.

Insertion

6.

Insertion

7.

Threading

8.

Changing

9.

Adjustment

10.

To

11.

Operation

12.

Adjustment

13.

Tension

14.

Tension

15.

Tension

16.

Adjustment

m.

Adjustment

1.

Timing

2.

Adjustment

3.

Adjustment

4.

Removal

5.

Regulation

IV.

Maintenance

1.

Lubrication

2,

Cleaning

for

for

thread

make

sewing

of

the

of

machine

of

motor

of

of

bobbin

of

spool

and

of

oil

the

of

thread

of

of

of

the

and

of

of

needle

of

stitches

of

of

of

threads

of

under

of

upper

of

of

needle

of

of

of

shuttle

of

INDEX

machine.

head

motor

lever

winder

stand

regulation

drop

pan

first

operation

needle

on

the

bobbin

bobbin

removal

upper

winder

bobbin

thread

basic-line

zig-zag

in a fixed

embroidery

needle

plate

thread

thread

auxiliary

and

shuttle

needle

needle

basic-line

bar

race

occurrence

and

treadle

of

knee

regulating

into

bobbin

of

the

bobbin

amplitude.

width

upper

thread

race

amplitude

of

amplitude

case

case

tension

motion

in

mechanism

into

the

regulator

straight

Page

shuttle

race

sewing ....

2

3

4

4

4

4

4

4

5

5

6

6

6

7

7

8

8

9

9

10

10

10

11

11

11

11

12

13

14

14

14

14

15

15

V.

Trouble

VI.

Parts

and

book

repairing

-1-

j0

20

Page 3

MERITS

Tl

11 ' -

ZIG-ZAG

The

maximum

can

embroider

easy

and

NEEDLE

Needle

center

amplitudes,

STITCH

Shuttle

correct

So,

even

sewing.

AUXILIARY

THREAD

The

auxiliary

with

each

fear

of

ful

embroidery.

QUIET

Timing

So,

quiet

WIDTH

smooth

BASIC-LINE POSITION

basic-line

and

right

SKIPPING

race

timing

at

TENSION

machine

uneven

OPERATION

belt

operation

AVAILABLE

zig-zag

beautiful

more

is

for

the

UPPER-THREAD

upper-thread

sewing,

is

amplitude

patterns.

by

knee

position

by

lever

beautiful

PREVENTER

designed

thread

maximum

rotation

thread

used

to

is

ensured.

mechanism.

setting

transmit

IS

of a needle

can

be

only.

and

varied

to

rotate

hooking

zig-zag

TENSION

tension

feeds

smoothly

snapping,

rotation

12. 7 mm{V2")

is

12. 7 mm

Zig-zag

CAN

changed

EQUIPPED

in

in

order

amplitude,

regulator

amplitude

BE

CHANGED

easily

In

combination

embroidery

variant

to

prevent

REGULATOR

which

the

thread.

etc., and

of

upper

(V2"')

can

be

adjusted

in 3 positions:

with

the

can

be

sewn.

speeds

you

you

motion

stitch

can

works

So,

can

and

lower

skipping.

get

beautiful

STABILIZES

in

connection

there

enjoy

yo''^

left,

zig-zag

and

to

is

no

beauti

shafts.

GREAT

Main

up

with

CONVENIENT

Needle

hole

ence

ZIG-ZAG

When

locknut

the

sewing

DURABILITY

parts

are

super

plate

partis

in

various

you

sew

without

and

made

of

finish,

is

designed

SEWING

which

REPLACEMENT

spring

in

applied

IS

in a definite

any

fear

enjoy

beautiful

special

fit-in

bush

sewings.

POSSIBLE

alloy

ensure

type

type

zig-zag

of

changing

sewing.

steel

well

long

and

smooth

OF

NEEDLE

and

its

replacement

in

order

to

IN A DEFINITE

amplitude,

the

zig-zag

heat-treated

use.

PLATE

is

easy.

give

facility

WIDTH

you

can

amplitude

and

and

keep

worked

Needle

conveni

it

by

through

Page 4

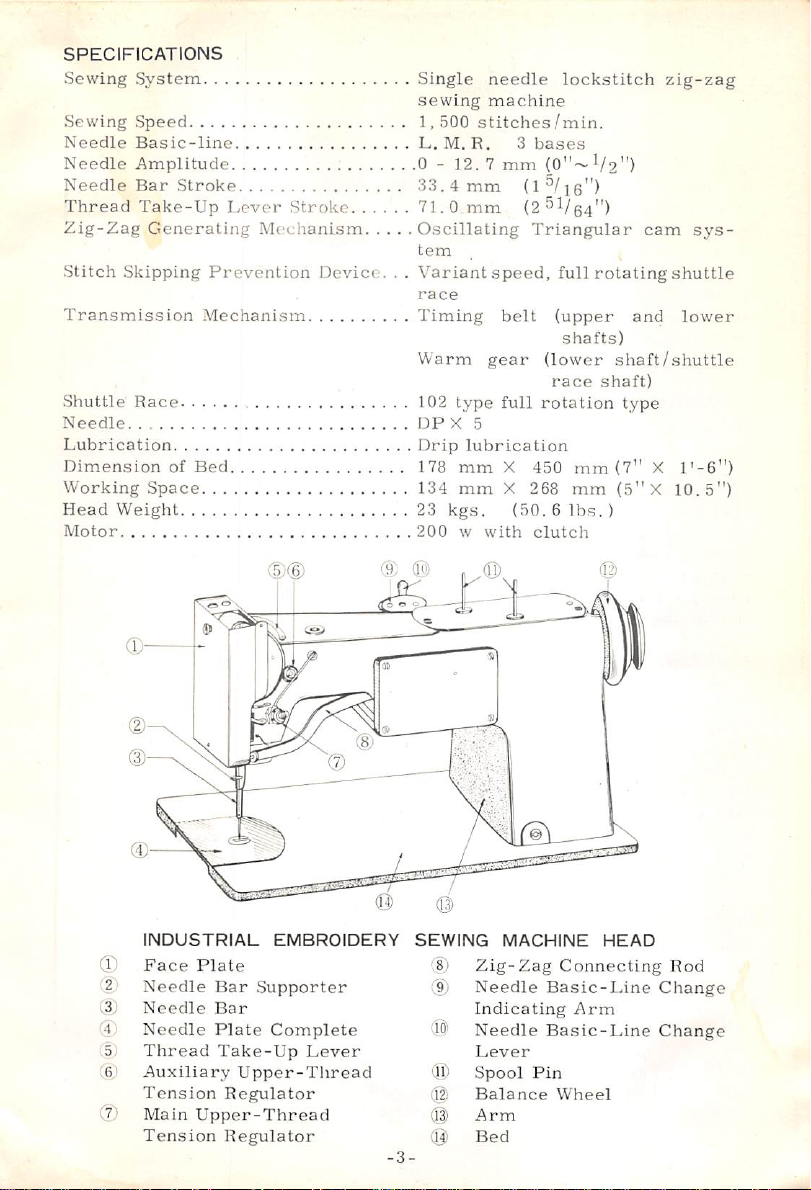

SPECIFICATIONS

Sewing

Sewing

Needle

Needle

Needle

Thread

Zig-Zag

Stitch

System

Speed

Basic-line

Amplitude

Bar

Stroke

Take-Up

Generating

Skipping

Transmission

Shuttle

Needle

Lubrication

Dimension

Working

Head

Motor

Race

of

Space

Weight

Lever

Mechanism

Prevention

Mechanism

Bed

Stroke

Device.

Single

sewing

1,500

stitches/min.

L.

M.

R. 3 bases

0 - 12. 7 mm

33.4

mm

71.0

mm

Oscillating

tem

. .

Variant

race

Timing

Warm

102

type

DP X 5

Drip

lubrication

178

mm

134

mm

23

kgs.

200 w with

needle

machine

(0"~

(1

/le")

(2^V64")

Triangular

speed,

belt

(upper

gear

(lower

race

full

rotation

X

450

X

268

(50. 6 lbs.)

clutch

lockstitch

V2")

cam

full

rotating

and

shafts)

shaft/shuttle

shaft)

type

mm

(7" X l'-6")

mm

(5"X

zig-zag

sys

shuttle

lower

10.5")

2

(32

(4.

■5;

(6,1

C7)

INDUSTRIAL

Face

Plate

Needle

Needle

Needle

Thread

Auxiliary

Tension

Main

Tension

Bar

Bar

Plate

Upper-Thread

(D®

EMBROIDERY

Supporter

Complete

Take-Up

Upper-Thread

Regulator

Regulator

Lever

@

-3-

SEWING

®

(9)

(©

®

(g;

®

(g)

^

MACHINE

Zig-Zag

Needle

Indicating

Needle

Lever

Spool

Pin

Balance

Arm

Bed

(12)

HEAD

Connecting

Basic-Line

Arm

Basic-Line

Wheel

Rod

Change

Change

Page 5

I.

PREPARATION

1.

LOCATION

In

order

your

sewing

machine

floor.

2.

MOUNTING

Accessory

on

the

back

Then,

3.

Motor

the

MOUNTING

is

washers

to

pass

balance

Then

connect

cord

extended

(Turn

runs

in

the

the

to

should

hinges

head

mounted

and

the

wheel

switch

correct

FOR

OF

THE

ensure

machine

be

OF

MACHINE

are

of

the

is

set

OF

MOTOR

nuts

on a position

belt

straight

slot

power

from

on

direction.

SEWING

MACHINE

smooth

without

set

to

be

bed

on

with

and

motor

supply

switch.

and

check

directionofsewingmachine

side

facing

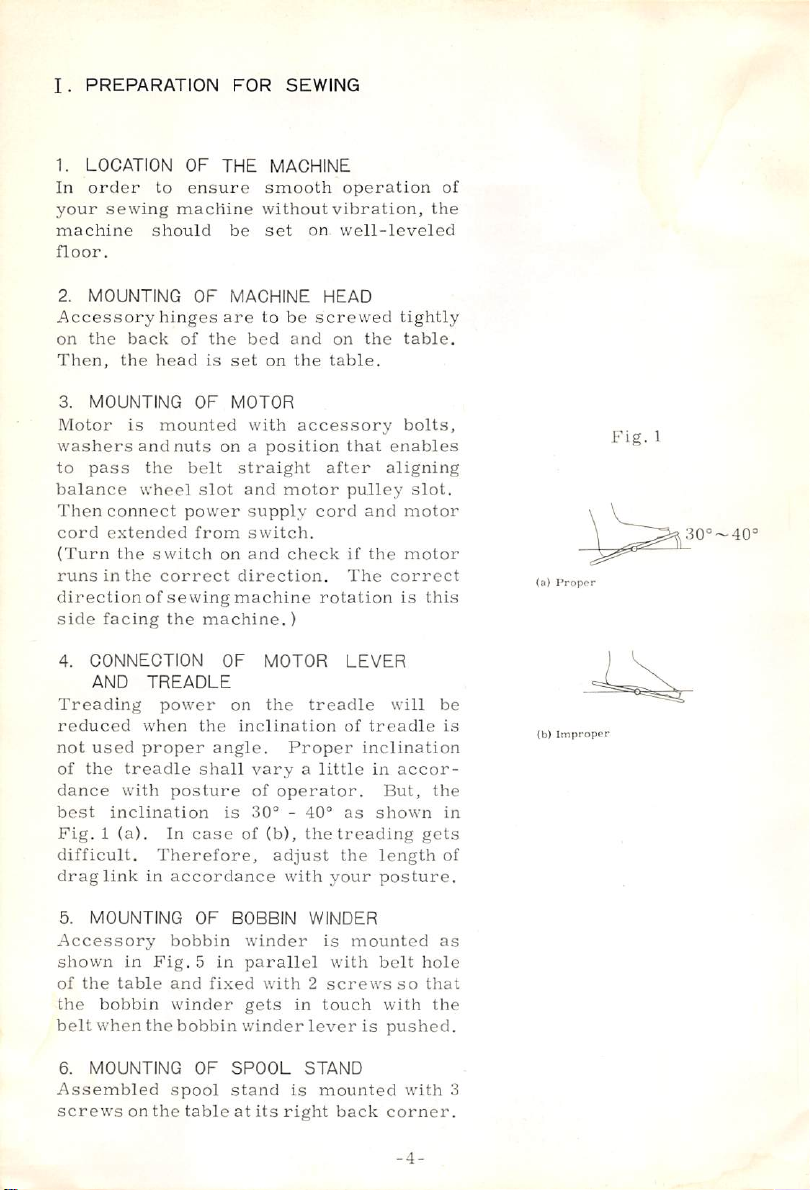

4.

CONNECTION

AND

Treading

reduced

not

used

of

the

dance

best

Fig. 1 (a).

difficult.

drag

link

the

TREADLE

power

when

proper

treadle

with

posture

inclination

In

Therefore,

in

accordance

machine.)

OF

on

the

inclination

angle.

shall

vary a little

of

is

30® - 40®

case

of

MOTOR

the

Proper

operator.

(b),

adjust

with

operation

vibration,

on.

well-leveled

HEAD

screwed

and

on

the

the

table.

accessory

that

after

pulley

cord

and

if

The

rotation

LEVER

treadle

of

inclination

as

the

treading

the

your

tightly

table.

bolts,

enables

aligning

slot.

motor

the

motor

correct

is

will

treadle

in

accor

But,

shown

length

posture.

of

the

this

be

is

the

in

gets

of

(a)

(b)

Prcippr

Improper

Fig.

1

30®~40=

5.

MOUNTING

Accessory

shown

of

the

belt

6.

in

the

table

bobbin

when

MOUNTING

Assembled

screws

on

OF

bobbin

Fig. 5 in

and

fixed

winder

the

bobbin

OF

spool

the

table

BOBBIN

winder

parallel

with 2 screws

gets

in

winder

SPOOL

stand

is

at

its

right

WINDER

is

with

touch

lever

STAND

mounted

back

mounted

belt

so

with

is

pushed.

with

corner.

-4-

as

hole

that

the

3

Page 6

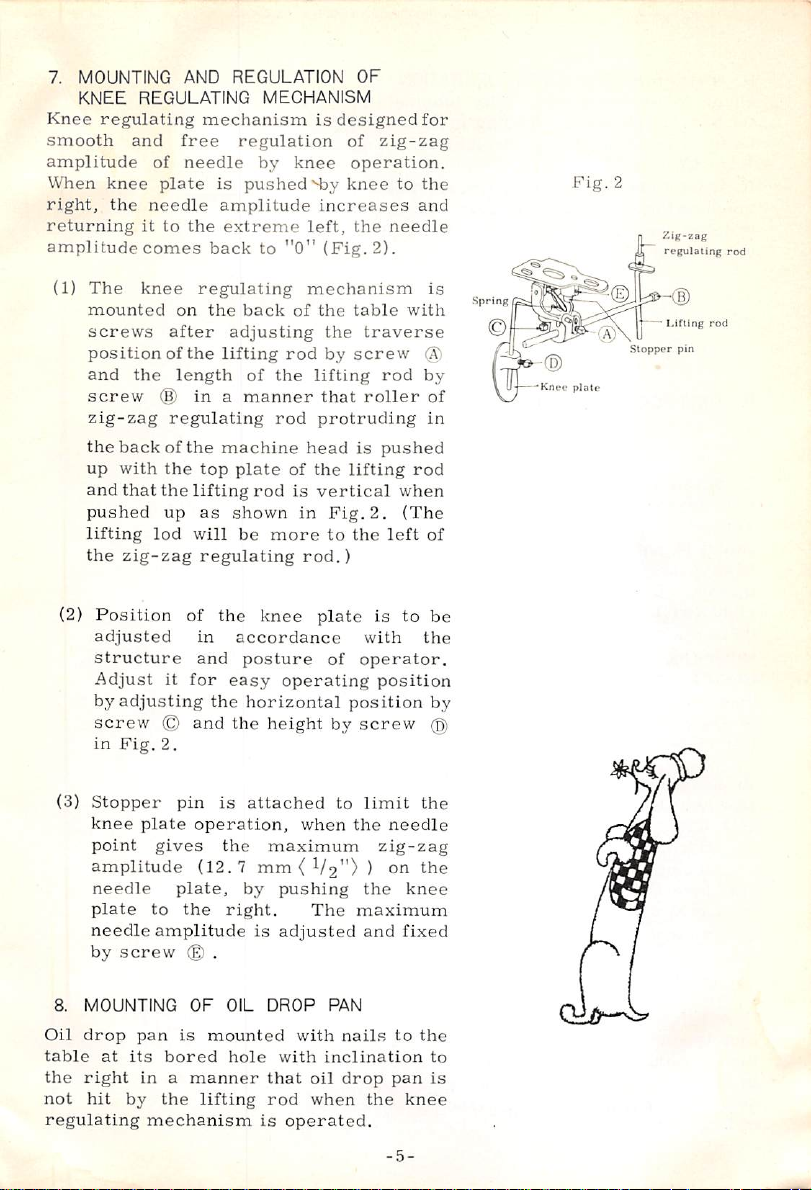

7.

MOUNTING

KNEE

REGULATING

Knee

regulating

smooth

and

amplitude

When

knee

right,

the

returning

amplitude

(1)

The

mounted

screws

position

and

the

screw

zig-zag

the

back

up

with

and

that

pushed

lifting

the

zig-zag

(2)

Position

adjusted

structure

Adjust

by

adjusting

screw © and

in

Fig.

AND

mechanism

free

of

needle

plate

needle

it

to

the

comes

knee

back

regulating

on

the

after

of

the

length

®

in a manner

regulating

of

the

the

top

the

lifting

up

as

lod

will

regulating

of

in

and

it

for

the

2.

REGULATION

MECHANISM

regulation

by

knee

is

pushed

amplitude

extreme

to

"O"

back

of

adjusting

lifting

of

rod

the

rod

machine

plate

of

rod

is

shown

be

the

in

more

knee

accordance

posture

easy

operating

horizontal

the

height

OF

is

designedfor

of

zig-zag

operation.

SDy

knee

increases

left,

the

needle

(Fig.

2).

mechanism

the

table

the

traverse

by

screw

lifting

that

rod

roller

protruding

head

is

pushed

the

lifting

vertical

Fig.

2.

to

the

left

rod.)

plate

is

with

of

operator.

position

position

by

screw

to

the

and

with

rod

when

(The

to

is

@

by

of

in

of

be

the

by

@

Spring

Knpr

Fig.

plate

2

7.1g-Z8g

Stopper

regulating

Lifting

rod

pin

rod

(3)

Stopper

knee

point

amplitude

needle

plate

needle

by

8.

MOUNTING

Oil

drop

table

at

the

right

not

hit

regulating

pin

plate

operation,

gives

(12.7

plate,

to

the

amplitude

screw © .

OF

pan

is

its

bored

in a manner

by

the

lifting

mechanism

is

attached

the

maximum

mm{

by

right.

is

OIL

DROP

mounted

hole

that

rod

is

to

when

the

V2") ) on

pushing

The

adjusted

PAN

with

nails

with

inclination

oil

drop

when

operated.

limit

needle

zig-zag

the

knee

maximum

and

fixed

to

pan

the

knee

-5-

the

the

the

to

is

Page 7

9.

NOTE

Prior

the-parts

to

the

Page

In

order

machine

stitches

FOR

to

the

requiring

item,

15.

to

ensure

for a long

approx.

operation,

concerning

using a machine.

n.

GIST

1.

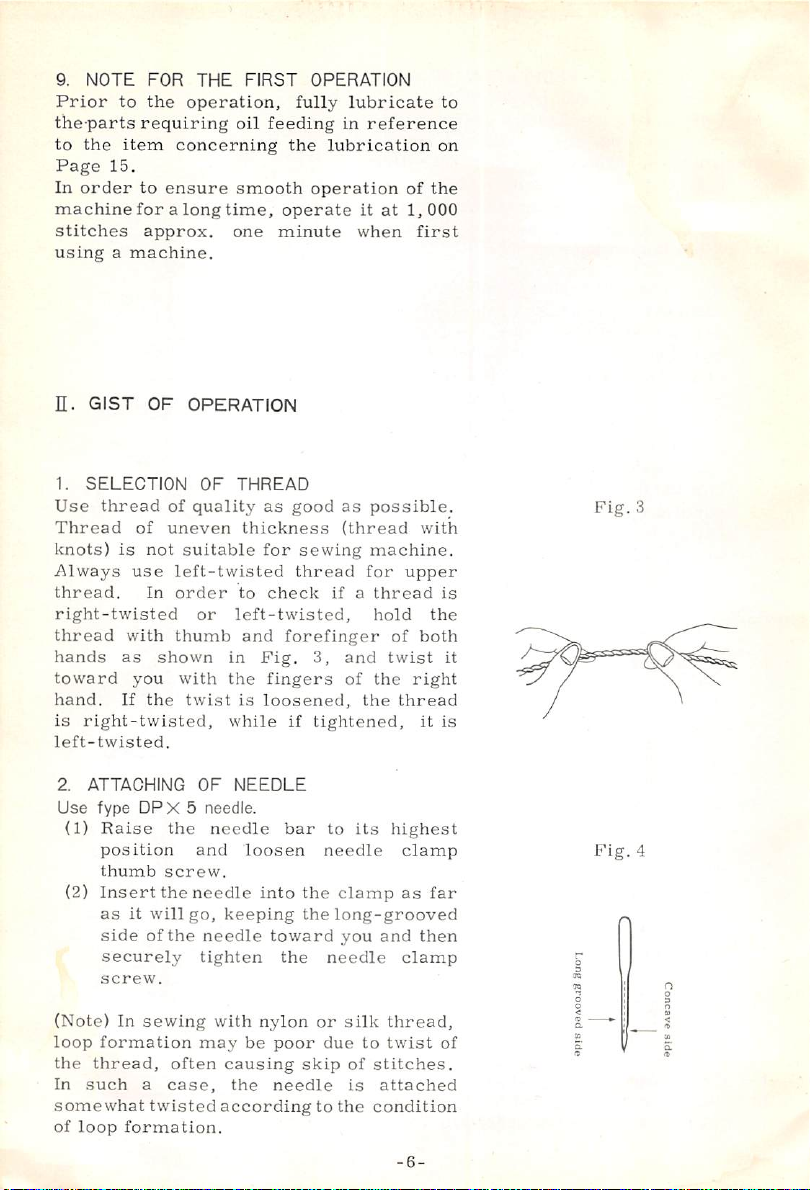

SELECTION

Use

Thread

knots)

Always

thread.

right-twisted

thread

hands

toward

hand.

is

right-twisted,

left-twisted.

OF

thread

of

is

not

use

In

with

as

you

If

the

OPERATION

of

uneven

suitable

left-twisted

order

thumb

shown

with

twist

THE

FIRST

oil

feeding

smooth

time,

one

OF

THREAD

quality

as

thickness

for

to

check

or

left-twisted,

and

in

Fig.

the

fingers

is

loosened,

while

OPERATION

fully

lubricate

in

reference

the

lubrication

operation

operate

minute

good

it

when

as

(thread

sewing

thread

for

if a thread

forefinger

3, and

of

the

if

tightened,

to

on

of

the

at

1,000

first

possible.

with

machine.

upper

is

hold

the

of

both

twist

it

the

right

thread

it

is

Fig.

3

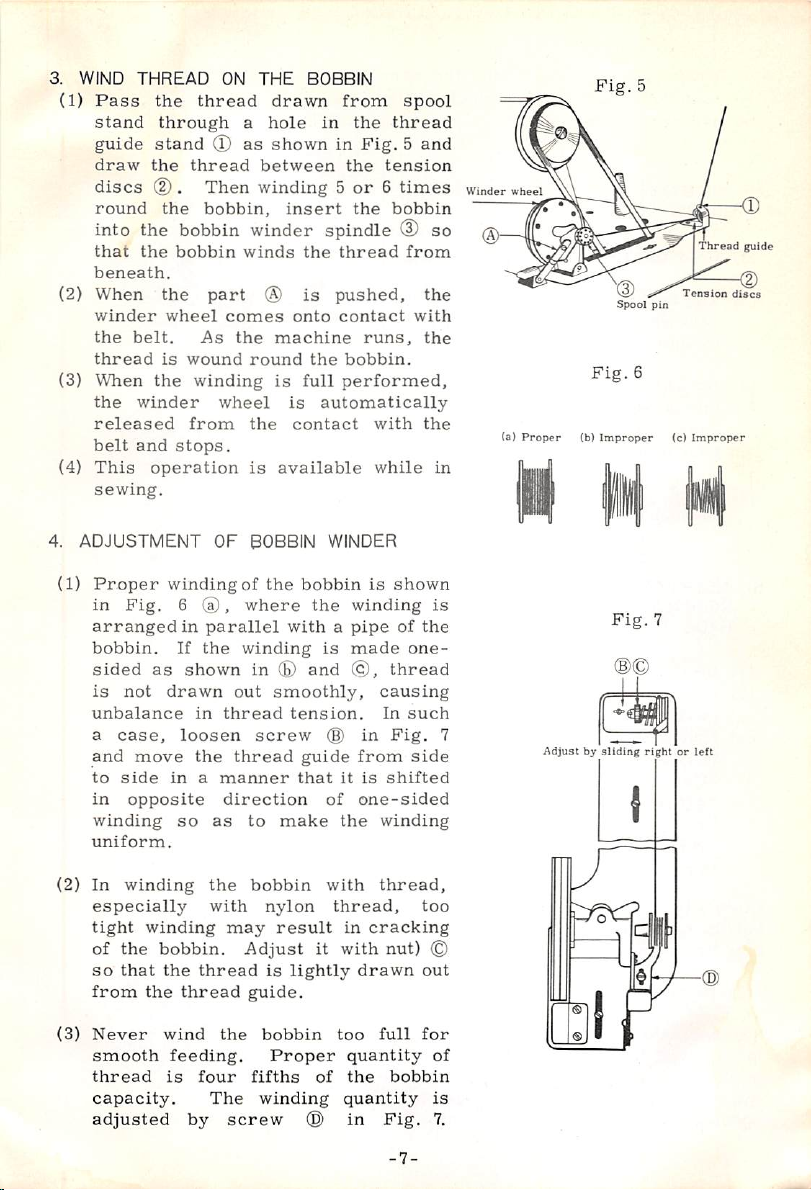

2.

ATTACHING

Use

type

(1)

Raise

position

thumb

(2)

Insert

as

it

side

securely

screw.

(Note)

loop

the

In

In

formation

thread,

such a case,

somewhat

of

loop

formation.

OF

NEEDLE

DPX 5 needle.

the

needle

and

loosen

screw.

the

will

of

the

needle

go,

into

keeping

needle

tighten

sewing

twisted

with

may

often

nylon

be

causing

the

according

bar

needle

the

the

toward

the

or

poor

due

skip

needle

to

to

its

highest

clamp

clamp

as

long-grooved

you

and

then

needle

the

silk

thread,

to

twist

of

stitches.

is

attached

condition

clamp

-6-

Fig.

far

of

4

Page 8

3.

WIND

(1)

Pass

stand

guide

draw

discs

round

into

that

beneath.

(2)

When

winder

the

thread

(3)

When

the

released

belt

(4)

This

sewing.

4.

ADJUSTMENT

(1)

Proper

in

arranged

bobbin.

sided

is

unbalance

a

and

to

in

winding

uniform.

THREAD

the

ON

thread

through a hole

stand ® as

the

thread

(D . Then

the

bobbin,

the

bobbin

the

bobbin

the

part ® is

wheel

belt.

winder

and

is

the

stops.

wound

from

As

winding

wheel

operation

OF

winding

Fig. 6 ®,

in

parallel

If

the

as

shown

not

drawn

in

case,

move

side

loosen

the

in a manner

opposite

so

as

THE

BOBBIN

drawn

shown

between

from

in

in

the

the

Fig. 5 and

winding 5 or 6 times

insert

winder

winds

the

spindle

the

thread

pushed,

comes

thread

direction

the

machine

round

is

is

the

is

available

BOBBIN

of

the

where

with a pipe

winding

in

(E)

out

smoothly,

screw

thread

to

make

onto

contact

runs,

the

bobbin.

full

performed,

automatically-

contact

with

while

WINDER

bobbin

and

the

is

is

winding

made

©,

causing

tension.

(§)

in

guide

from

that

it

is

of

one-sided

the

spool

thread

tension

bobbin

(D

so

from

the

with

the

the

in

shown

is

of

the

one

thread

In

such

Fig.

side

shifted

winding

Winder

7

wheel

(b)

Pro

per

Adjust

Fig.

Fig.

(b)

Improper

by

sliding

5

Spool

6

Fig.

pin

(c)

7

right

Thread

Tension

Improper

or

left

guide

discs

(2)

In

especially

tight

of

so

from

(3)

Never

smooth

thread

capacity.

adjusted

winding

winding

the

that

the

the

with

may

bobbin.

the

thread

thread

wind

the

feeding.

is

four

The

by

screw

bobbin

nylon

result

Adjust

is

lightly

guide.

bobbin

Proper

fifths

winding

©

with

thread,

in

it

with

drawn

too

quantity

of

the

quantity

in

thread,

too

cracking

nut)

©

out

full

for

of

bobbin

is

Fig.

-7-

7.

Page 9

When

should

and

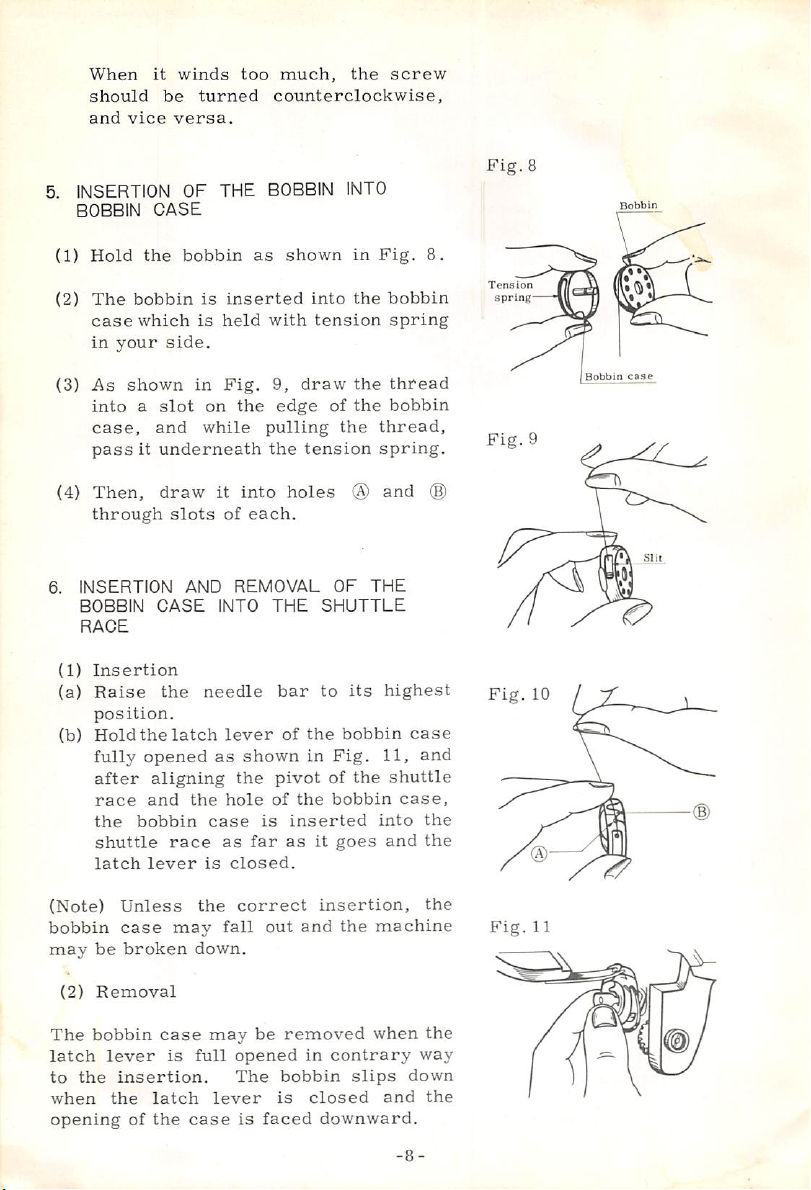

5.

INSERTION

BOBBIN

(1)

Hold

(2)

The

case

in

(3)

As

into a slot

case,

pass

it

be

vice

CASE

the

bobbin

which

your

side.

shown

and

it

underneath

winds

turned

versa.

OF

THE

bobbin

is

is

in

on

while

too

much,

counterclockwise,

BOBBIN

as

shown

inserted

held

with

Fig.

9,

draw

the

edge

pulling

the

tension

the

INTO

in

into

the

tension

the

of

the

the

screw

Fig.

8.

bobbin

spring

thread

bobbin

thread,

spring.

Fig.

Tens

ion

spring

Fig.

8

Bobbin

Bobbin

case

9

(4)

Then,

through

6.

INSERTION

BOBBIN

RAGE

(1)

Insertion

(a)

Raise

position.

(b)

Hold

fully

after

race

the

shuttle

latch

(Note)

bobbin

may

be

(2)

Removal

The

bobbin

latch

lever

to

the

when

opening

draw

slots

AND

CASE

the

the

latch

opened

aligning

and

the

bobbin

race

lever

Unless

case

may

broken

case

is

insertion.

the

latch

of

the

case

it

into

of

each.

REMOVAL

INTO

needle

lever

as

shown

the

hole

case

as

far

is

closed.

the

correct

fall

down.

may

full

opened

The

lever

is

holes

THE

bar

of

pivot

of

the

is

inserted

as

out

be

removed

bobbin

is

faced

OF

THE

SHUTTLE

to

its

the

bobbin

in

Fig.

of

the

bobbin

it

goes

insertion,

and

the

machine

when

in

contrary

slips

closed

downward.

and

highest

case

11,

and

shuttle

case,

into

the

and

the

the

the

way

down

and

the

p^g

xo

Fig.11

Page 10

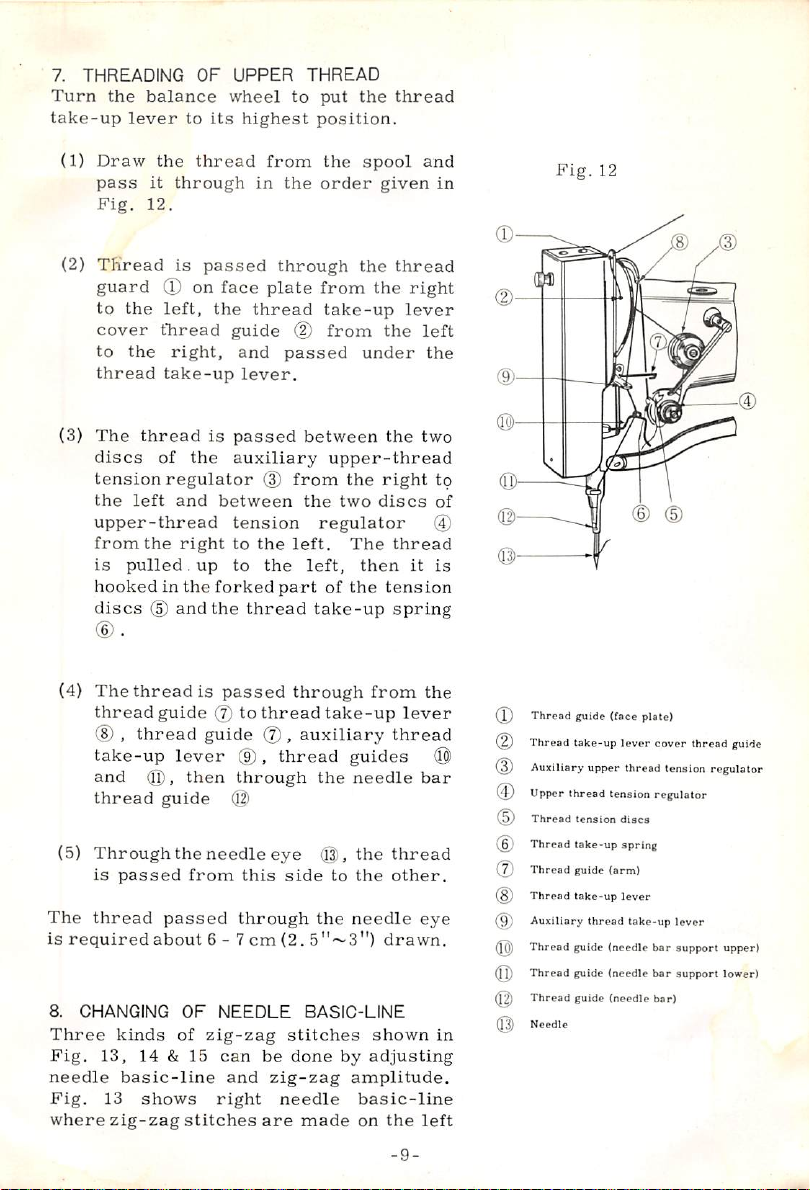

7.

THREADING

Turn

the

take-up

(1)

Draw

pass

Fig.

(2)

Thread

guard

to

cover

to

thread

(3)

The

discs

tension

the

upper-thread

from

is

hooked

discs

balance

lever

to

the

it

through

12.

is

(D

the

left,

tlaread

the

right,

take-up

thread

of

the

regulator

left

and

the

right

pulled,

in

the

(D

and

OF

UPPER

wheel

its

highest

thread

passed

on

face

the

thread

guide

and

lever.

is

passed

auxiliary

between

tension

to

up

to

forked

the

thread

THREAD

to

from

in

the

through

plate

(2)

passed

between

(3)

from

the

the

left.

the

left,

part

put

the

thread

position.

the

spool

order

from

given

the

the

take-up

from

the

thread

right

lever

under

the

upper-thread

the

right

two

discs

regulator

The

thread

then

it

of

the

tension

take-up

spring

and

in

left

the

two

to

of

is

Fig.

12

(4)

The

thread

(8) , thread

take-up

and

thread

(5)

Through

is

The

thread

is

required

8.

CHANGING

Three

Fig.

13,

needle

Fig.

13

where

zig-zag

thread

passed

kinds

basic-line

is

guide

lever

then

guide

the

from

passed

about

OF

of

14 & 15

shows

stitches

passed

(j)

to

thread

guide

(7),

(9),

through

(l|)

needle

eye

this

through

6-7

cm

NEEDLE

zig-zag

can

be

and

zig-zag

right

are

through

take-up

auxiliary

thread

the

(Q),

side

to

the

(2.

5"~3")

BASIC-LINE

stitches

done

by

needle

made

from

the

lever

thread

guides

needle

the

the

needle

shown

adjusting

amplitude.

basic-line

on

(0)

bar

thread

other.

eye

drawn.

the

left

-9-

in

Thread

Thread

0)

Auxiliary

(J)

Upper

Thread

Thread

(7)

Thread

Thread

@

Auxiliary

^

Thread

Thread

^

Thread

(13)

Needle

guide

(face

take-up

upper

tliread

tension

tension

take-up

guide

iann)

take-up

thread

guide

(needle

guide

(needle

guide

(needle

plate]

lever

cover

thread

tension

regulator

discs

spring

lever

take-up

lever

bar

support

t»r

support

bar)

thread

guide

regulator

upper)

lower)

Page 11

side

of

the

zig-zag

on

Fig.

zig-zag

of

basic-line

Fig.

operated.

needle

set

the

needle

hole © .

on

®

the

is

you

When

stitches

the

both

15

shows

stitches

the

basic-line.

16

on

basic-line

the

lever @ to

needle

basic-line

the

adjusted

is

set

stitches

set

on

the

can

get

it

is

machine),

in

Fig.

15.

9.

ADJUSTMENT

basic-line.

are

sides

of

the

left

needle

are

made

To

as

shown

the

back

To

operate

change

the

basic-line

change

Then,

you

on

the

as

left

the

stitches

set

on

can

the

lever © can

position.

center

shown

hole

the

get

OF

Fig.

14

shows

made

required,

in

equal

needle

change

above, a lever

of

knob

proper

basic-line.

basic-line

on

the

right

the

the

machine

lever @ ,

(B)

in

position

and

knob ® to

When

hole,

in

Fig.

(facing

as

shown

right

hole

the

stitches

ZIG-ZAG

the

you

14.

the

machine),

in

(facing

as

AMPLITUDE

that

width

where

side

needle

in

is

draw

FiglS,

of

set

the

bracket

be

fixed

lever

can

get

When

it

Fig.

13.

the

shown

Fig.13

Fig.

14

Fig.

15

Zig-zag

to

easy

of

the

of

sewing

to

the

10.

In

amplitude,

operate

amplitude

of

stitch,

Now,

amplitude.

11.

Put

frame,

position,

neath

thread

balance

amplitude

12. 7 mm

and

free

knee

regulating

with a fixed

next

item.

TO

MAKE

order

to

loosen

the

to

and

you

can

OPERATION

cloth into

raise

put

the

needle.

end

by

wheel

(0"~

V2")-

by

STITCHES

get

stitches

thumb

knee

the

necessary

tighten

sew

OF

accessory

the

the

embroidery

Holding

the

left

toward

can

be

adjusted

It

can

operating

mechanism.

zig-zag

IN A FIXED

in a fixed

nut © in

plate

until

the

thumb

in

the

EMBROIDERY

needle

at

lightly

hand,

turn

you,

and

from

be

adjusted

the

knee

In

width,

Fig.

the

zig-zag

nut

fixed

zig-zag

embroidery

its

highest

frame

under

the

slowly

the

-10-

plate

case

refer

WIDTH

needle

16,

needle

width

©)

upper

the

upper

0

Fig.

16

.

Page 12

thread

thread.

the

the

the

dery

by

tionrequires

better

enced

12.

Needle

spring

When

adjust

needle

left.

13.

Usually,

tensions

are

loos

Tension

conditions

thread,

required

comes

Then,

two

threads,

two

threads

drawing

frame

the

knee

have

with

ADJUSTMENT

plate

action

the

the

plate ® in

TENSION

the

are,

sewn.

of

thread

of

zig-zag

to

on

and

plate

some

good

the

is

needle

needle

Proper

threads

of

adjust

out

you

twined

can

with

start

to

After 2 or 3 stitches,

free

and

embroider

cloth

by

moving

regulating

zig-zag

mechanism.

skilfulness

practice

machine.

attached

so

as

does

OF

THREADS

less

the

in

use,

tobe

OF

NEEDLE

on

to

be

not

position

Fig.

17

upper

and

better

tension

stitch

varies

i.e.

kind

width,

it

each

good

the

removed

drop

by

to

under

zig-zag

does

on

according

of

etc., so

situation.

the

under

sew

holding

along

the

embroi

width

This

opera-

and

you

had

experi

PLATE

head

with

easily.

smoothly,

sliding

the

right

thread

stitches

not

be

the

cloth.

materials,

it

set

the

or

too

to

is

Fig.

17

a

14.

TENSION

Tension

(0.

35 - 0,

and

15 - 20 g {0.

medium

the

tension,

regulating

and

to

decrease

15.

TENSION

Tension

regulated

tension

regulator

made

spring

(1)

by

action

Pressure

In

almost

available

of

the

OF

UNDER

of

under

thread

52

oz)

for

52 - 0.

and

thick

turn

screw ® in

turn

OF

UPPER

of

the

upper

by

adjusting

discs

in

the

and

then

adjusting

range

of

Tension

all

merely

tension

THREAD

should

sewing

70

materials.

the

bobbin

Fig.

it

counterclockwise,

THREAD

thread

the

pressure

upper-thread

fine

regulation

the

thread

and

strength.

Discs

cases,

by

discs.

proper

adjusting

To

be

thin

materials

oz)

for

To

case

18

clockwise

is

tension

increase

10 - 15

sewing

increase

tension

roughly

of

the

tension

is

to

be

take-up

is

pressure

the

-11-

g

Fig.18

Thread

tension

spring

Page 13

tension,

(2)

thumb

to

decrease,

Thread

Proper

take-up

the

hook

turn

nut

Take-Up

position

spring

upper

turns

adjustment,

Fig.

20

and

to

clockwise

(Tighten

adjustment)

(3)

Thread

Approximate

for

spring.

and

split

clockwise

counterclockwise

(Tighten

adjustment)

16.

ADJUSTMENT

THREAD

In

case

tension

of

it

is

lever

auxiliary

begins

position

from

take-up

thread

back

of

screw

When

early,

busing a little.

ments,

thread

enjoy

tension

important

Take-Up

the

strength

Loosen

insert

of

the

TENSION

that

regulator

released

gets

near

upper-thread

to

press

of 3 mm - 6

the

highest

lever.

is

too

the

tension

in a notched

release

adjust

unlike

tension

beautiful

of

thread.

in

embroidering.

the

(F'

in

Fig.

turn

starts

thread

round

loosen

turn

the

or

fast

the

20 g (0.

a

screw

tension

to

decrease

fast

the

OF

the

auxiliary

is

duly

when

its

highest

the

position

When

late,

loosen

bush

of

the

it

by

After

usual

regulator

sewing

tension

19

it

counterclockwise.

Spring

is

where

hooked

180

regulating

clockwise

Action

the

the

action

by

the

degrees.

screw

stopper ® either

counterclockwise.

screw

Spring

screw © in

to

AUXILIARY

Strength

70

oz)

of

thread

driver

stud.

the

increase

screw

REGULATOR

is

standard

take-up

Fig.

into

Turn

strength

it.

(©

UPPER-

upper-thread

adjusted,

the

thread

position.

tension

upper

mm

(V8"~V4")

release

discs

showed

upper

loosening

these

adjustment

with

This

regulator

thread

of

the

of

the

locknut

in

Fig.

in

thread

the

correct

of

only,

the

is

the

Fig.

you

and

Range

thread

when

shuttle

For

C

in

after

21

the

it

and

after

tension

take-up

This

at

the

down

thread

upper

at

the

22

and

22.

is

too

noched

adjust

upper-

can

lightest

most

Fig.19

to

Fig.20

\

Fig.

Thread

spring

Fig.22

to

Lock

to

<icc

Trnaion

(Thread

btnppc

21

take-up,

loos

nut

quicker

(Pressure

regulating

ldke>up

Thread

of

to

spring

take-up

Tension

to

tighten

tension

increase

thumb

action

spring

to

Notched

discs)

nut

range)

strength)

decrea.se

stud

bushing

-12-

Page 14

in.

ADJUSTMENT

1.

TIMING

OF

NEEDLE

AND

SHUTTLE

RACE

Fig.23

Tip

of

shuttle

hook

Timing

the

and

with

mark

standard

the

shuttle

the

supporter

the

middle

tude

is

at

DP X 5

as

its

mark

the

turning

that

the

raised

position

a

timing

lowest

(Note)

kind

mentioned.

the

is

To

the

that

to

when

left

upper

used,

follows.

lowest

are

needle

the

the

center

3.2

as

position

mark

part

Adjustment

of

materials,

shuttle

to

be

make

shuttle

the

tip

the

upper

the

or

to

thread.

in

the

of

proper

race

lowest

when

the

position

"0".

the

When

position,

to

match

bar

supporter.

balance

tip

of

the

line

of

the

mm

shown

of

under

matches

of

the

Clearance

hook

and

adjusted

sure

of

race,

of

the

part

needle

the

right,

needle

timing

is

adjusted

tip

of

needle

and

the

So,

in

case

standard

the

needle

the

lines

with

wheel

shuttle

needle

(V0")

in

Fig.

line

from

23.

approximately

needle

bar

varies

but

the

standard

between

the

needle

as

0.05

timing

it

is

necessary

shuttle

basic-line

hook

of

the

to

catch a loop

bar

which

of

the

to

the

needle

basic-line

zig-zag

of

the

adjustment

bar

on

two

the

lowest

Then,

adjust

toward

hook

match

when

the

its

In

this

of

the

needle

supporter.

according

is

the

side

(Fig.

mm

of

the

needle

to

passes

needle

is

eye,

set

shows

needle

match

bar

is

ampli

needle

goes

timing

tip

by

you

so

with

needle

lowest

case,

bar

to

the

to

the

above

tip

24)

approx.

and

confirm

close

even

to

the

of

the

in

is

to

of

of

The

Fig.

Tip

of

Fig.25

Needle

connecting

lowest

24

shuttle

bar

position

hook

stud

0.

05mm

Less

3.

ttian

2mm

raised

(^/b")

(1)

Height

releasing

connecting

tighten

(2)

Timing

needle

adjusting

wheel

the

adjustment,

of

the

screw

after

of

is

screws

(under)

shuttle

needle

stud

in

adjusted.

the

shuttle

adjusted

in

Fig. 2 6

race

the

screw

®

Fig.

in

by

is

adjusted

of

needle

25

race

by

the

timing

and

hand.

should

by

bar

which

and

is

the

releasing

belt

turning

After

be

Fig.

26

Timing

yldjusting

be

screw

tightened.

-13-

Page 15

(3)

For

adjustment

the

tip

needle

shaft

When

are

in

part

too

large,

you

by

the

screw

2.

ADJUSTMENT

To

make

the

each

needle

to

move

right

or

to

loosening

®

of

the

and

turn

the

wise

or

counterclockwise.

ment,

fast.

3.

the

ADJUSTMENT

AMPLITUDE

i\mplitude

before

so

parallel

ring

cam.

shown

releasing

(Note)

is

the

important,

with

of

helical

It

is

in

the

When

harmed.

of

the

side,

release

bushing

the

needle

touch

©

and

pull

hand

for

©

OF

uniform

basic-line,

slightly

the

left.

the

set

needle

eccentric

set

screw

OF

MOTION

motion

needle

for

the

needle

gear

necessary

Fig.

28

zig-zag

the

needle

of

clearance

shuttle

set

screw © in

and

with,

when

the

hook

the

the

push

the

shuttle

correction

NEEDLE

the

needle

it

the

needle

For

the

screw

bar

of

support

pin ® to

must

NEEDLE

of

the

needle

penetration

it

gives

influence

motion.

on

the

main

to

adjust

when

the

needle

shaft

helical

amplitude

between

and

shuttle

race

Fig.

shuttle

the

race

screw

clearance

race

toward

and

tighten

BASICLINE

dropping

is

necessary

bar

to

adjustment,

eccentric

in

Fig.

the

clock

i^fter

adjust

be

tightened

BAR

bar

should

into

the

clotli.

to

ildjustment

shaft

the

triangular

bar

gear

motion

the

27.

is

on

the

pin

25

the

and

gets

set

is

Fig.27

Shuttle

Shuttle

Fig.

Fig.29

be

adjusted

Timing

motion

is

helical

cam

to

screw.

too

low,

race

hook

stoppe

28

' ® ®

of

of

the

done

by

gear

to

be

its

lowest

sometimes

Left

needle

Middle

needle

Right

needle

so

as

to

this

motion

shuttle

changing

on

triangular

in

the

position

position

the

basic-line

basic-line

basic-line

finish

race

gea

cloth

is

in

by

4.

REMOVAL

(1)

Remove

(2)

When

forward.

of

screw

shuttle

5.

REGULATION

Putting a sheet

toward

needle

you

traces

OF

screw

screw

©

race

by

SHUTTLE

©

©

is

When

it

after

is

loosened.

OF

OCCURRENCE

of

paper

hand

to

appears

RACE

of

Fig.

removed,

is

too

tight

screw

on

make

in

double

27

and

the

to

©

is

OF

the

needle

needle

points,

disconnect

shuttle

be

drawn

shuttle

race

out,

lightly

can

hook

be

loosened 2 or 3 times,

AMPLITUDE

plate,

traces

loosen

-14-

on

screw

IN

turn

the

STRAIGHT

the

balance

paper.

(a)

tap

in

stopper.

drawn

the

head

then

SEWING

wheel

When

Fig.

29

out

the

the

in

Page 16

a

projection

regulate

become

ment

and

so

single

of

zig-zag

loosening

regulation

line

on

the

IV.

MAINTENANCE

on

that

is

given

left

the

back

the

double

point

by

adjusting

screw

for

or

on

the

up

and

©

the

right.

of

the

pointed

down

arm

.

The

needle

arm

and

traces

move

tightening

same

basic-

Fig.

30

For a long

condition,

required.

1.

LUBRICATION

The

most

important

is

lubrication.

of

the

machine

and

tear. A plenty

(1)

Parts

(a)

Lubricate

Fig.

30,

(b)

Lubricate

marked

into

the

(c)

Dust

required

the

dust

is

not

(d)

After

slightly

soak

of

lubricate

revolving

out.

Into

and

each

after

arm.

use

of

the

constant

and

care

If

you

neglect

shortens

of

oil

is

and

Quantity

in

the

31,

32 & 33.

5-6

drops

Q—^

parts

marked

on

parts

should

absorbs

efficient

lubricating,

for

into

groove,

taking

where

be

oil

on

the

operate

about 1 minute

the

motion

into

take

the

main

link

in

the

off a lid

machine

good

of

the

it,

in

care

machine

the

with a heavy

required

of

Lubrication

arrowed

and

into

1-2

always.

parts

the

^

lubrication

cleaned

and

the

dust.

away,

lubrication

the

machine

so

parts.

the

shuttle

the

bobbin

shaft helical

arm.

lubricate

on

the

top

good

wear

parts

drops

as

In

race

gear

of

is

life

in

is

for

to

case

case

the

Fig.31

Fig.32

Fig.33

2.

CLEANING

Clean

shuttle

which

away

race

will

occasionally

parts

cause

poor

and

thread

dust

each

covering

thread

tension.

-15-

path

Page 17

V.

Trouble

Faulty

Condition

1.

Stitch

Skipping

and

repairing

(1)

a.

b.

c.

(2)

a.

b.

c.

(3)

Faulty

Causes

Faulty

Bent

Poor

soft)

Needlenot

ing

needle

needle

quality

thread

Faulty

mounting

Not

sufficiently

Gap

Needle

Faced

direction

Point

hook

broken.

is

in

of

tip

is

Proper

(too

match

needle

inserted

remains

twisted

wrong

shuttle

dull

or

Replace

Replace

with

with

quality.

Replace

thread

Insert

Face

with

thickness.

to

the

the

side-ways;

observing

of

nylon

Mount

grooved

concave

Correct

stone

or

needle

side

side

or

replace

loop

the

Remedy

new

needle

needle

fullest

needle

twist

slightly

condition

tetoron

so

faces

faces

tip

with

needle.

of

matching

depth.

eye

directly

in

thread.

that

the

left

the

with

new

better

while

case

long

and

right.

grind

one.

(4)

Clearance

ween

ttle

needle

(5)

Position

too

(6)

race

a.

Shuttle

b.

point

hook

high

Needle

not

properly

advanced

Shuttle

delayed

too

and

of

tip

large

of

needle

or

low

shuttle

meeting

race

race

bet

shu

and

too

too

-16-

Correct

so

that

0.

05mm

i^djust

mark

in

13)

Correct

so

that

to

center

needle

lowest

is

position.

shuttle

the

clearance

(about

by

needle

hair

regulating

bar.

shuttle

shuttle

line

raised

hook

of

hook

race

(See

position

will

thickness).

timing

(See

page

position

tip

comes

needle

3.

2mm

when

from

page

be

13)

Page 18

Faulty

Condition

2.

Loose

Stitches

(1)

Pressure

tension

enough

(2)

Weak

take-up

(3)

Small

operation

thread

spring

(4)

Weak

thread

(5)

Thread

not

a.

Non-uniform

thread

b.

Hand-wound

is

used

c.

Dust

discs

d.

Improper

excessive

of

bobbin

e.

Dust

case

f.

Thread

spring

case

bent

g.

Bobbin

improperly

Causes

tension

uniform

thickness

in

thread

in

of

distorted

discs

thread

spring

range

take-up

under-

strength

spool

tension

winding

bobbin

tension

bobbin

inserted

not

or

on

or

of

of

of

i^djust

by

regulating

right

little

strengthen.

item

15)

Strengthen

tension

stud

Strengthen

fabrics

page

Increase

the

15)

Adjust

ning

bobbin

14)

Use

Use

Hand-wound

draw-out

(large

12,

item

by

left.

(See

while

thread

case

quality

machine-wound

of

Disassemble

tension

tension

and

tension

of

Rewind

winding

with

7,

Remove

Correct

one.

Check

correct.

polish

tension

bobbin

item

regulator

regulating

stud

discs.

bobbin

capacity

3).

dust.

or

bobbin

(See

Remedy

turning

thumb

by

little

(See

by

gradually

to

when

sewing

stitches)

15)

turning

page

gradually

tension

(See

page

machine

spool

thread.

upper-thread

by

thread-path

and

inner

up

pipe.

replace

insertion

page

tension

nut

to

in

order

page

turning

the

right.

stopper

12,

tighte

screw

11,

thread.

spool.

offers

removing

thumb

surface

to

80%

in

parallel

(See

il^nfi

with

8,

item

the

to

12,

thick

(See

to

item

of

item

poor

nut

of

of

page

new

if

5)

-17-

Page 19

Faulty

Condition

3.

Break

thread

of

(1)

Improper

a.

Poor

b.

Use

twisted

thread

c.

Thread

for

(2)

Improper

a.

Bent

b.

Poor

needle

eye

c.

Needle

improperly

d.

Needle

for

Causes

quality

of

needle

needle

finish

thread

thread

right-

upper-

too

large

needle

groove

mounted

too

thin

of

or

Replace

of

good

ununiform

cannot

Change

Replace

thickness.

Replace

Replace

quality.

Refer

(2),

Replace

be

with

to

page

with

with

with

Skipped

with

Remedy

with

machine

quality.

thickness

used.

left-twisted

thread

new

needle.

needle

stitches,

17.

suitable

thread

Thread

or

knotty

thred.

in

proper

of

better

item

needle.

in

(3)

Upper-thread

tension

(4)

Action

take-up

too

(5)

Thread

spring

quick

too

of

take-up

too

strong

thread

spring

strong

-18-

Weaken

tension

to

the

used

recheck

stitches)

15)

Delay

stopper

12,

Weaken

to

the

used

recheck

stitches)

regulating

left

to

prevent

the

to

item

by

left

to

prevent

(Seepage

tension

the

(See

action

15)

the

(If

strong

loose

causes

page,

the

left

turning

(If

strong

loose

cause

by

thumb

tension

stitches,

of

12

by

turning

(See

tension

tension

stitches,

of

12,

item

turning

nut

is

loose

item

the

page

stud

is

loose

15)

Page 20

Faulty

Condition

Causes

Remedy

Break

thread

of

(6)

Shuttle

bobbin

race

or

case

Correct

with

grindstone.

injured

(7)

(8)

(9)

Needle

needle

injured

Ununiform

strength

Needle

race

not

properly

and

hole

thread

shuttle

meeti

on

plate

-g

Polish

needle

caused

moved

tion,

Refer

(5),

Correct

race

item

hole

or

plate.

if

material

during

or

if

bent

to

Loose

page

17.

the

mounting

1)

replace

{Injury

is

sewing

needle

stitches,

position

(See

with

may

forcibly

opera

is

used.)

item

of

shuttle

page

new

be

13,

-19-

Page 21

MEMO

Page 22

71

PARTS

BOOK

Industrial

Remarks : Whenorderingparts,

and

its

figure

ZIG-ZAG

number.

be

sure

Sewing

to

include

Machine

model

number,

parts

number

Page 23

.lD

-22-

CO

Page 24

Arm

bed

and

its

accessories

Fig

Parts

Na

1

W110516

2

W322326

3

B509091

4

W500211

5

W448583

6

W445617

7

W500906

8

W444138

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

415206

B422836

W501728

W500149

W453519

W501925

W452939

B509179

B659592

W451064

NaO X 5

W450620

B503846

W502386

W452915

W452912

W502365

W502366

W452913

Fig

Parts

Ni

28

W445933

29

W502367

30

W452914

31

W500655

32

W500307

33

W452909

34

W500994

35

B509264

W44S942

36

W501391

37

38

W446986

39

W447016

40

W445933

41

W447017

42

W446985

43

W501296

44

W444076

45

W501297

46

47

48

49

50

51

52

53

Nal5

W452917

W452918

W452919

W500591

W452920

W502368

W500370

Page 25

-24-

Page 26

I

Main

Fig

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

shaft

Parts

W322327

W446384

W500006

W452922

W452925

W501391

W452924

B508971

W452921

W500076

W446385

W446386

W500833

D

FX

W452927

W445883

W444138

B509087

W445881

W452923

W452926

W500294

and

Na

5

its

accessories

Fig

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

Na

Parts

B503851

W500306

W502371

W500036

W502372

W501167

W446397

W501168

W501017

W322328

W446457

B411094

W446560

B509256

W447023

W320112

B509060

B509054

W501177

W452932

B504016

Na

W452928

76

Page 27

138

137

1

' 119

139

108

^

n

'106

125

116

148

<2/146

Page 28

Fig

100

101

102

103

104

105

99

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

Na

Parts

W322330

W446387

W500089

W452940

W452941

B504016

W446456

W500036

W501167

W448092

B503842

W452942

W452943

B509069

B 8 S

B508961

W502374

W452944

W452945

W452946

W452947

B509289

Ml

Fig

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

^

Parts

W502378

W452952

W452954

W501845

W501009

W500102

B504016

W452955

W502382

W502383

W502384

W501758

W501031

W502379

B509064

W502380

W501550

W452949

W501540

W500245

W452950

W445925

Na

W452948

121

W502377

122

W502376

123

146

147

148

W445940

W500092

W501022

Page 29

-28-

Page 30

Lower

Fig

Na

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

shaft & Ralating

Parts

Na

W452956

B508961

B 8 S

W502373

B508959

W502385

B509177

W322331

W452957

W444138

B509060

W446142

W500509

W452929

B509069

W452930

B509088

hook

mechanism

Fig

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

Na

Parts

W501385

W500996

W452935

W447004

W500149

W446376

W501176

W501183

W446420

W452937

W452938

B508852

Na

W446142

166

167

B509087

168

W452933

169

W452931

170

W452937

Page 31

MEMO

Page 32

♦

MITSUBISHI

No.

12

2-CHOME

ELECTRIC

MARUNOUCHI

CORPORATION

CHIYODA-KU

TOKYO

JAPAN

Loading...

Loading...