Page 1

Page 2

Page 3

• SAFETY PRECAUTIONS •

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of

the programmable controller system, please read the user's manual of the CPU module used.

!

In this manual, the safety precautions are classified into two levels: "

!

WARNING

!

CAUTION

Under some circumstances, failure to observe the precautions given under "

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING" and "! CAUTION".

!

CAUTION" may lead to

!

WARNING

• For the operating status of each station after a communication failure, refer to Section 8.2.6 in

this manual.

Failure to do so may result in an accident due to an incorrect output or malfunction.

• When changing data of a running programmable controller from a peripheral connected to the

CPU module or from an external device such as a personal computer connected to an intelligent

function module, configure an interlock circuit in the program to ensure that the entire system

will always operate safely.

For other controls to a running programmable controller (such as program modification or

operating status change), read relevant manuals carefully and ensure the safety before the

operation.

Especially, in the case of a control from an external device to a remote programmable controller,

immediate action cannot be taken for a problem on the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to

be taken between the external device and CPU module in case of a communication failure.

A - 1 A - 1

Page 4

[Design Precautions]

!

WARNING

• Do not write any data to the "system area" of the buffer memory in each intelligent function

module.

Also, do not turn on any "use prohibited" signal that is output from the CPU module to the

intelligent function module.

Writing data to the "system area" or outputting a "use prohibited" signal may cause malfunction

of the programmable controller system.

• When setting auto refresh parameters, specify "Y" for the remote output RY refresh devices.

Specifying any other than "Y" (for example, M or L) will hold the previous device status in the

case of a CPU stop.

For how to stop a data link, refer to Section 8.3.8.

• Disconnection of a CC-Link dedicated cable may make the line condition unstable, causing

communication errors on multiple stations on the network.

Configure an interlock circuit in the program so that the system will operate safely even if these

communication errors occur on multiple stations.

Failure to do so may result in an accident due to an incorrect output or malfunction.

[Design Precautions]

!

CAUTION

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Keep a distance of 100mm or more between them.

Failure to do so may result in malfunction due to noise.

[Installation Precautions]

!

WARNING

• Shut off the external power supply for the system in all phases before mounting or removing the

module.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

A - 2 A - 2

Page 5

[Installation Precautions]

!

CAUTION

• Use the programmable controller in an environment that meets the general specifications shown

in "Safety Guidelines", the manual supplied with the CPU module or head module.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

• To interconnect modules, engage the respective connectors and securely lock the module joint

levers.

Incorrect interconnection may cause malfunction, failure, and drop of the module.

• Do not directly touch any conductive part and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

!

WARNING

• Shut off the external power supply for the system in all phases before wiring.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

• After installation and wiring, attach the included terminal cover to the product before turning it on

for operation.

Failure to do so may result in electric shock.

[Wiring Precautions]

!

CAUTION

• Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when a screw on the terminal

block comes loose, resulting in failure.

• Do not install the control lines or communication cables together with the main circuit lines or

power cables.

Failure to do so may result in malfunction due to noise.

• Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

• Tighten the terminal block screw within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

• When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable with connector, hold the connector part of the cable.

For the cable connected to the terminal block, loosen the terminal block screws.

Pulling the cable connected to the module may result in malfunction and damage to the module

or cable.

A - 3 A - 3

Page 6

[Wiring Precautions]

!

CAUTION

• Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

• A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

• For the CC-Link system, use dedicated cables that are specified by the manufacturer.

If any other cable is used, performance of the CC-Link system is not guaranteed.

Also, the maximum overall cable length and the station-to-station cable length must meet those

specified in Chapter 3.

If not, normal data communication is not guaranteed.

[Startup and Maintenance Precautions]

!

WARNING

• Do not touch any terminal while power is on.

Doing so will cause electric shock or malfunction.

• Shut off the external power supply for the system in all phases before cleaning the module or

retightening the screws on the terminal block.

Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

!

CAUTION

• Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

• Shut off the external power supply for the system in all phases before connecting or

disconnecting the module.

Failure to do so may cause the module to fail or malfunction.

• Tighten the screws on the terminal block within the specified torque range.

Undertightening can cause drop of parts or wires, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• After the first use of the module, the number of module connections/disconnections is limited to

50 times.

Exceeding the limit (in accordance with IEC 61131-2) may cause malfunction.

• Before handling the module, touch a conducting object such as a grounded metal to discharge

the static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

A - 4 A - 4

Page 7

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 5 A - 5

Page 8

• CONDITIONS OF USE FOR THE PRODUCT •

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

y Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

y Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

y Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 6 A - 6

Page 9

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-L series programmable controllers.

This manual explains the functions and programming required to use the L26CPU-BT built-in CC-Link

system master/local function and the LJ61BT11 CC-Link system master/local module (hereinafter referred to

as the L series master/local module).

Before using the product, please read this manual and the relevant manuals carefully and develop familiarity

with the functions and performance of the MELSEC-L series programmable controller to handle the product

correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability

and confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

REMARK

The program examples shown in this manual are the examples in which the L

series master/local module is assigned to the I/O No. X/Y00 to X/Y1F unless

otherwise specified. When using program samples described in the manual, the

assignment of I/O No. is required.

For the assignment of I/O No., refer to the following manual.

MELSEC-L CPU Module User's Manual (Function Explanation, Program

Fundamentals)

This manual explains the operation using GX Works2. When using GX Developer,

refer to Appendix 7.

A - 7 A - 7

Page 10

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage Directives when

incorporating the Mitsubishi programmable controller (EMC and Low Voltage Directives compliant)

into other machinery or equipment, refer to "Safety Guidelines", the manual supplied with the CPU

module or head module.

The CE mark, indicating compliance with the EMC and Low Voltage Directives, is printed on the

rating plate of the programmable controller.

(2) For the product

For the compliance of this product with the EMC and Low Voltage Directives, refer to "Safety

Guidelines", the manual supplied with the CPU module or head module.

A - 8 A - 8

Page 11

RELEVANT MANUALS

(1) CPU module user's manual

<Manual number, Model code>

MELSEC-L CPU Module User's Manual

(Hardware Design, Maintenance and Inspection)

MELSEC-L CPU Module User's Manual

(Function Explanation, Program Fundamentals)

Manual name

<SH-080890ENG, 13JZ36>

<SH-080889ENG, 13JZ35>

(2) Head module user's manual

<Manual number, Model code>

MELSEC-L CC-Link IE Field Network Head Module

User's Manual

Manual name

<SH-080919ENG, 13JZ48>

(3) Operating manual

<Manual number, Model code>

GX Works2 Version1 Operating Manual

(Common)

GX Developer Version 8 Operating Manual

Manual name

<SH-080779ENG, 13JU63 >

<SH-080373E, 13JU41>

Description

Specifications of the CPU modules, power supply module,

display unit, SD memory cards, and batteries, information on

how to establish a system, maintenance and inspection, and

troubleshooting

Functions and devices of the CPU module, and programming

Description

Specifications of the head module, procedure before the

operation, system configuration, installation and wiring, setting,

and troubleshooting

Description

System configuration, parameter settings, and online operations

(common to Simple project and Structured project) of GX

Works2

Operating methods of GX Developer, such as programming,

printing, monitoring, and debugging

A - 9 A - 9

Page 12

CONTENTS

SAFETY PRECAUTIONS..............................................................................................................................A- 1

CONDITIONS OF USE FOR THE PRODUCT .............................................................................................A- 6

INTRODUCTION............................................................................................................................................A- 7

COMPLIANCE WITH THE EMC AND LOW VOLTAGE DIRECTIVES.......................................................A- 8

RELEVANT MANUALS .................................................................................................................................A- 9

CONTENTS....................................................................................................................................................A-10

TERMS ...........................................................................................................................................................A-16

PACKING LIST...............................................................................................................................................A-18

1 CC-Link SYSTEM

1.1 About CC-Link System............................................................................................................................ 1- 1

1.2 Overview of Communication................................................................................................................... 1- 2

2 PART NAMES

3 SPECIFICATIONS

3.1 General Specifications ............................................................................................................................ 3- 1

3.2 Performance Specifications .................................................................................................................... 3- 1

3.2.1 Maximum number of connected stations ........................................................................................ 3- 3

3.2.2 Maximum overall cable distance ..................................................................................................... 3- 6

3.2.3 Ver.1.10 compatible CC-Link dedicated cable................................................................................ 3- 7

3.3 Function List ............................................................................................................................................ 3- 8

3.4 Mode Selection ....................................................................................................................................... 3-11

3.4.1 Expanded cyclic setting ................................................................................................................... 3-13

3.5 I/O Signal List .......................................................................................................................................... 3-19

3.6 Buffer Memory List .................................................................................................................................. 3-20

4 PROCEDURE BEFORE OPERATION

5 SYSTEM CONFIGURATION

5.1 System Configuration.............................................................................................................................. 5- 1

5.1.1 System configuration of the L series master/local modules ...........................................................5- 1

5.1.2 System configuration on CC-Link .................................................................................................... 5- 2

5.2 Applicable System................................................................................................................................... 5- 3

5.2.1 Applicable modules and number of connectable modules............................................................. 5- 3

5.2.2 Restrictions on use with the head module ......................................................................................5- 3

5.2.3 Precautions on the system configuration ........................................................................................5- 4

A - 10 A - 10

Page 13

6 INSTALLATION AND CONNECTION

6.1 Module Installation Environment and Position ....................................................................................... 6- 1

6.1.1 Handling precautions ....................................................................................................................... 6- 1

6.2 Hardware Test......................................................................................................................................... 6- 3

6.3 Connecting Modules with Ver.1.10 Compatible CC-Link Dedicated Cables ........................................6- 5

6.3.1 Wiring check..................................................................................................................................... 6- 7

6.4 T-Branch Connection .............................................................................................................................. 6- 9

6.4.1 T-branch system configuration ........................................................................................................6- 9

6.4.2 T-branch communication specifications list .................................................................................... 6-10

6.5 Loop Test................................................................................................................................................. 6-11

6.5.1 Loop test 1........................................................................................................................................ 6-12

6.5.2 Loop test 2........................................................................................................................................ 6-14

7 PARAMETER SETTINGS

7.1 Parameter List ......................................................................................................................................... 7- 3

7.2 Parameter Settings in Remote Net Ver.1 Mode .................................................................................... 7- 4

7.2.1 Operation setting .............................................................................................................................. 7-10

7.2.2 Station information setting ...............................................................................................................7-11

7.3 Parameter Settings in Remote Net Ver.2 Mode .................................................................................... 7-13

7.3.1 Operation setting .............................................................................................................................. 7-17

7.3.2 Station information setting ...............................................................................................................7-18

7.4 Parameter Settings in Remote Net Additional Mode ............................................................................. 7-21

7.4.1 Operation setting .............................................................................................................................. 7-26

7.4.2 Station information setting ...............................................................................................................7-27

7.5 Parameter Settings in Remote I/O Net Mode ........................................................................................7-30

7.5.1 Operation setting .............................................................................................................................. 7-33

7.6 Precautions on Parameter Setting ......................................................................................................... 7-34

8 FUNCTIONS

8.1 Basic Functions ....................................................................................................................................... 8- 1

8.1.1 Communication with remote I/O stations ........................................................................................ 8- 1

8.1.2 Communication with remote device stations................................................................................... 8- 3

8.1.3 Communication with local stations ..................................................................................................8- 8

8.1.4 Communication with intelligent device stations............................................................................... 8-15

A - 11 A - 11

Page 14

8.2 Functions for Improving System Reliability ............................................................................................. 8-22

8.2.1 Slave station cut-off function............................................................................................................ 8-22

8.2.2 Automatic return function................................................................................................................. 8-23

8.2.3 Data link status setting in case of master station programmable controller CPU failure............... 8-24

8.2.4 Setting the status of input data from a data link faulty station ........................................................8-25

8.2.5 Slave station refresh/compulsory clear setting in case of programmable controller CPU STOP . 8-27

8.2.6 Station status at error occurrence ................................................................................................... 8-29

8.2.7 Standby master function ..................................................................................................................8-31

8.2.8 Data link start by standby master station ........................................................................................8-44

8.2.9 Block guarantee of cyclic data per station....................................................................................... 8-47

8.2.10 Secured 32-bit data........................................................................................................................ 8-51

8.3 Handy Functions ...................................................................................................................................... 8-52

8.3.1 Remote device station initialization procedure registration function ..............................................8-52

8.3.2 Event issuance for the interrupt program ........................................................................................ 8-60

8.3.3 Automatic CC-Link startup............................................................................................................... 8-63

8.3.4 Reserved station function ................................................................................................................8-65

8.3.5 Error invalid station setting function................................................................................................. 8-66

8.3.6 Temporary error invalid station setting function .............................................................................. 8-67

8.3.7 Scan synchronous function.............................................................................................................. 8-69

8.3.8 Data link stop/restart ........................................................................................................................ 8-73

8.3.9 Remote I/O station points setting .................................................................................................... 8-75

8.3.10 Master station duplication error cancel function ............................................................................ 8-77

9 DEDICATED INSTRUCTIONS AND PROGRAMMING

9.1 Dedicated Instructions ............................................................................................................................ 9- 1

9.1.1 Dedicated instruction list, applicable devices, and precautions ..................................................... 9- 1

9.1.2 G(P).RIRD ........................................................................................................................................9- 3

9.1.3 G(P).RIWT........................................................................................................................................ 9- 9

9.1.4 G(P).RIRCV...................................................................................................................................... 9-15

9.1.5 G(P).RISEND ................................................................................................................................... 9-20

9.1.6 G(P).RIFR ........................................................................................................................................ 9-25

9.1.7 G(P).RITO ........................................................................................................................................9-28

9.1.8 G(P).RLPASET ................................................................................................................................ 9-31

9.2 Precautions on Programming ................................................................................................................. 9-46

10 EXAMPLE OF COMMUNICATION BETW EEN THE MASTER STATION AND

REMOTE I/O STATIONS

10.1 When Remote I/O Net Mode is Used................................................................................................. 10- 1

10.1.1 Configuring a system ...................................................................................................................10- 1

10.1.2 Parameter setting......................................................................................................................... 10- 3

10.1.3 Creating a program ...................................................................................................................... 10- 5

10.1.4 Performing the data link............................................................................................................... 10- 7

A - 12 A - 12

Page 15

11 EXAMPLE OF COMMUNICATION BETW EEN THE MASTER STATION AND

REMOTE DEVICE STATIONS

11.1 When Remote Net Ver.1 Mode is Used ............................................................................................. 11- 1

11.1.1 Configuring a system ...................................................................................................................11- 1

11.1.2 Parameter setting......................................................................................................................... 11- 3

11.1.3 Creating a program ...................................................................................................................... 11- 7

11.1.4 Performing the data link............................................................................................................... 11-10

11.2 When Remote Net Ver.2 Mode is Used ............................................................................................. 11-12

11.2.1 Configuring a system ...................................................................................................................11-12

11.2.2 Parameter setting......................................................................................................................... 11-15

11.2.3 Creating a program ...................................................................................................................... 11-19

11.2.4 Performing the data link............................................................................................................... 11-23

11.3 When Remote Net Additional Mode is Used ..................................................................................... 11-25

11.3.1 Configuring a system ...................................................................................................................11-25

11.3.2 Parameter setting......................................................................................................................... 11-28

11.3.3 Creating a program ...................................................................................................................... 11-32

11.3.4 Performing the data link............................................................................................................... 11-36

12 EXAMPLE OF COMMUNICATION BETW EEN THE MASTER STATION AND

LOCAL STATIONS

12.1 When Remote Net Ver.1 Mode is Used ............................................................................................. 12- 1

12.1.1 Configuring a system ...................................................................................................................12- 1

12.1.2 Setting the master station parameters ........................................................................................12- 2

12.1.3 Setting the local station parameters ............................................................................................ 12- 4

12.1.4 Creating a program ...................................................................................................................... 12- 6

12.1.5 Performing the data link............................................................................................................... 12-10

12.2 When Remote Net Ver.2 Mode is Used ............................................................................................. 12-12

12.2.1 Configuring a system ...................................................................................................................12-12

12.2.2 Setting the master station parameters ........................................................................................12-13

12.2.3 Setting the local station parameters ............................................................................................ 12-15

12.2.4 Creating a program ...................................................................................................................... 12-19

12.2.5 Performing the data link............................................................................................................... 12-22

12.3 When Remote Net Additional Mode is Used ..................................................................................... 12-24

12.3.1 Configuring a system ...................................................................................................................12-24

12.3.2 Setting the master station parameters ........................................................................................12-25

12.3.3 Setting the local station parameters ............................................................................................ 12-27

12.3.4 Creating a program ...................................................................................................................... 12-31

12.3.5 Performing the data link............................................................................................................... 12-34

13 COMMUNICATION BETWEEN THE MASTER STATION AND

INTELLIGENT DEVICE STATIONS

A - 13 A - 13

Page 16

14 EXAMPLE OF COMMUNICATION WHEN USING THE HEAD MODULE

14.1 System Configuration Example .......................................................................................................... 14- 1

14.2 Image of Link Scan and Link Refresh by Cyclic Transmission ......................................................... 14- 2

14.3 Parameter Settings ............................................................................................................................. 14- 3

14.3.1 Setting parameters of the CC-Link IE field network master station ........................................... 14- 3

14.3.2 Setting parameters of the head module ...................................................................................... 14- 5

14.4 Program Example of CC-Link IE Field Network Master Station........................................................ 14- 8

15 TROUBLESHOOTING

15.1 Troubleshooting Procedures .............................................................................................................. 15- 2

15.1.1 Flowcharts for troubleshooting by LEDs ...................................................................................... 15- 2

15.1.2 Flowcharts for troubleshooting by GX Works2 ............................................................................15- 4

15.2 List of Problems .................................................................................................................................. 15- 9

15.2.1 When disconnecting a slave station............................................................................................ 15- 9

15.2.2 When cyclic data are faulty.......................................................................................................... 15-14

15.2.3 When transient data are faulty..................................................................................................... 15-17

15.2.4 When operation of the master station is faulty............................................................................ 15-18

15.3 Error Codes ......................................................................................................................................... 15-19

15.3.1 How to check error codes............................................................................................................ 15-19

15.3.2 Error code list ............................................................................................................................... 15-23

15.4 CC-Link Diagnostics ...........................................................................................................................15-33

15.4.1 Host monitoring/Other station monitoring ................................................................................... 15-33

15.4.2 Loop test/Obtain transmission speed setting .............................................................................. 15-36

15.4.3 Status logging .............................................................................................................................. 15-38

15.4.4 Creating a check sheet ................................................................................................................15-40

15.4.5 H/W information ........................................................................................................................... 15-42

APPENDIXES

Appendix 1 Details of the I/O Signals .......................................................................................................App- 1

Appendix 2 Buffer Memory Details ...........................................................................................................App- 3

Appendix 3 Link Special Relays and Registers (SB/SW) ........................................................................App-21

Appendix 3.1 Link special relays (SB) ..................................................................................................App-22

Appendix 3.2 Link special registers (SW).............................................................................................App-28

A - 14 A - 14

Page 17

Appendix 4 Data Link Processing Time ...................................................................................................App-40

Appendix 4.1 Link scan time .................................................................................................................App-40

Appendix 4.2 Transmission delay time of master station

Appendix 4.3 Transmission delay time of master station

(Ver.1 compatible slave station) ..................................................................................App-46

Appendix 4.4 Transmission delay time of master station

(Ver.2 compatible slave station) ..................................................................................App-48

Appendix 4.5 Transmission delay time of master station

(Ver.1 compatible slave station) ..................................................................................App-50

Appendix 4.6 Transmission delay time of master station

(Ver.2 compatible slave station) ..................................................................................App-52

Appendix 4.7 Transmission delay time of master station

Appendix 4.8 Processing time for dedicated instructions of master station

Appendix 4.9 Processing time for dedicated instructions of local station

Appendix 4.10 Processing time for dedicated instructions of master station

device station................................................................................................................App-60

Appendix 4.11 Link refresh time of master station/local station ..........................................................App-62

Appendix 5 How to Confirm the Serial No. and Function Version...........................................................App-66

Appendix 6 Differences Between the L Series Master/Local Module and QJ61BT11N ........................App-67

Appendix 6.1 Specification comparisons..............................................................................................App-67

Appendix 6.2 Precautions when utilizing the program.........................................................................App-67

Appendix 7 When Using the GX Developer.............................................................................................App-68

Appendix 7.1 Compatible software package........................................................................................App-68

Appendix 7.2 Operation comparison ....................................................................................................App-68

Appendix 8 External Dimensions..............................................................................................................App-74

remote I/O station .................................App-44

remote device station

remote device station

local station

local station

intelligent device station .......................App-54

local station...............App-55

local station ..................App-58

intelligent

INDEX

REVISIONS

WARRANTY

A - 15 A - 15

Page 18

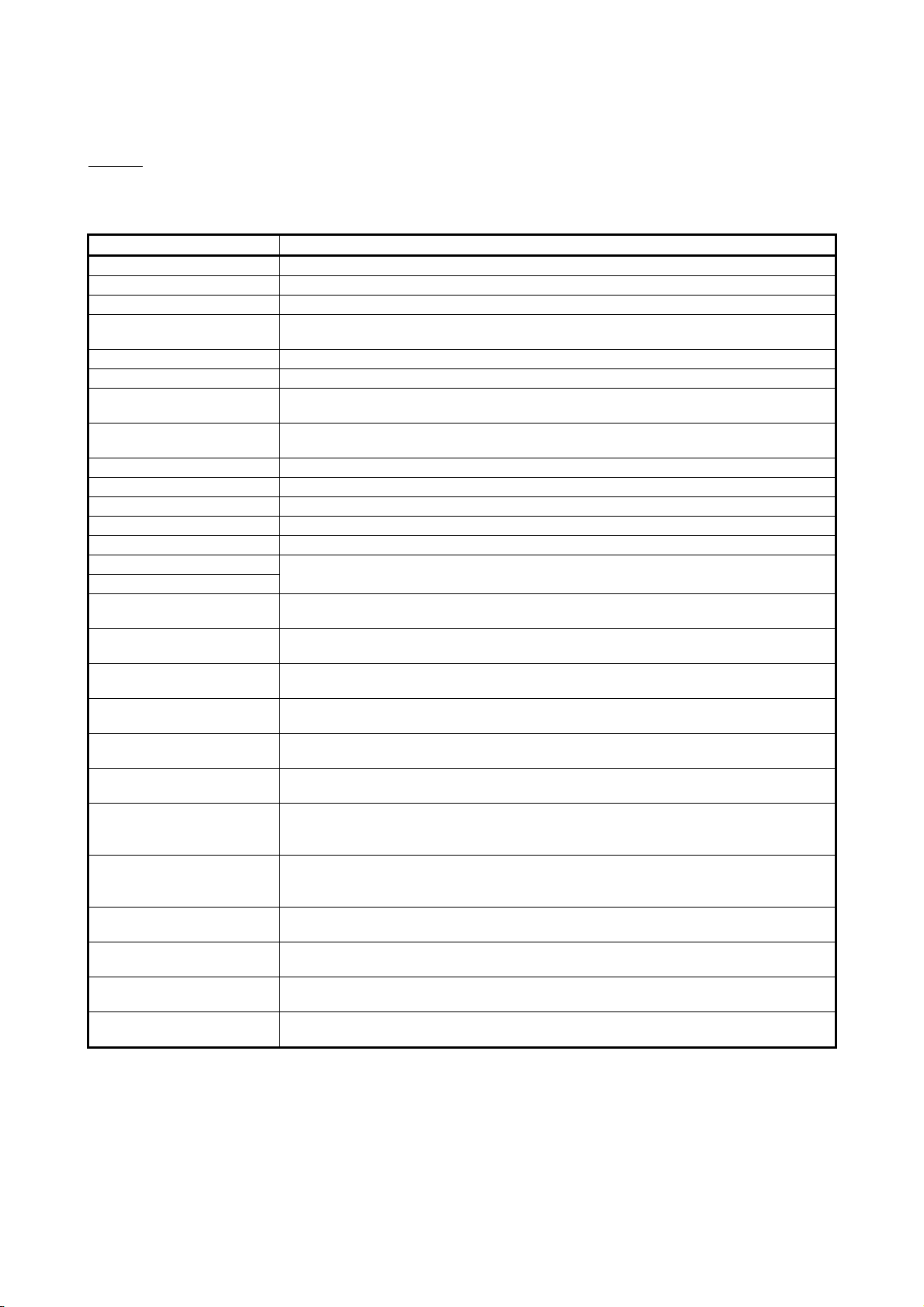

TERMS

The following shows the terms used in this manual.

Term

LJ61BT11

Built-in CC-Link function

L series master/local module

Master/local module

Master module

Local module

Remote module

Intelligent device module

AnUCPU

QnACPU

QCPU

LCPU

Head module

GX Works2

GX Developer

Intelligent function module

Special function module

Cyclic transmission

Transient transmission

Master station

Local station

Remote I/O station

Remote device station

Remote station

Intelligent device station

Standby master station

Slave station

Abbreviation for the LJ61BT11 CC-Link system master/local module.

Abbreviation for the L26CPU-BT built-in CC-Link system master/local function.

Generic term for the Built-in CC-Link function and LJ61BT11.

Generic term for the L series master/local module, QJ61BT11N, A1SJ61BT11, and

A1SJ61QBT11.

Generic term for master/local modules when they are used as master station.

Generic term for master/local modules when they are used as local station.

Generic term for AJ65BTB1-16D, AJ65SBTB1-16D, AJ65BT-64AD, AJ65BT-64DAV,

AJ65BT-64DAI, and GT15-J61BT13.

Generic term for the stations that can perform transient transmission, such as the

AJ65BT-R2N (including local module).

Another term for the MELSEC-AnU series CPU module.

Another term for the MELSEC-QnA series CPU module.

Another term for the MELSEC-Q series CPU module.

Another term for the MELSEC-L series CPU module.

Abbreviation for the LJ72GF15-T2 CC-Link IE field network head module

Product name of the software package for the MELSEC programmable controllers.

Generic term for MELSEC-Q/L series modules which have functions other than I/O, such

as A/D, D/A conversion module.

Generic term for MELSEC-QnA/A series modules which have functions other than I/O,

such as A/D, D/A conversion module.

Transmission method by which data of remote I/O and remote registers are refreshed

periodically.

Transmission method by which 1:1 communication can be performed with the target

specified and at any timing.

Station that controls the data link system.

One master station is required for each system.

Station having a programmable controller CPU and the ability to communicate with the

master and other local stations.

Remote station that handles bit data only. (Performs input and output with external

devices.)

(AJ65BTB1-16D, AJ65SBTB1-16D)

Remote station that handles bit and word data. (Performs input and output with external

devices, and analog data conversion.)

(AJ65BT-64AD, AJ65BT-64DAV, AJ65BT-64DAI)

Generic term for remote I/O station and remote device station. (Controlled by the master

station)

Generic term for the stations that can perform transient transmission, such as the

AJ65BT-R2N (including local stations).

Backup station for data link control when the link to the master station is disconnected

due to a programmable controller CPU or power supply problem.

Generic term for remote I/O station, remote device station, local station, intelligent

device station and standby master station.

Description

A - 16 A - 16

Page 19

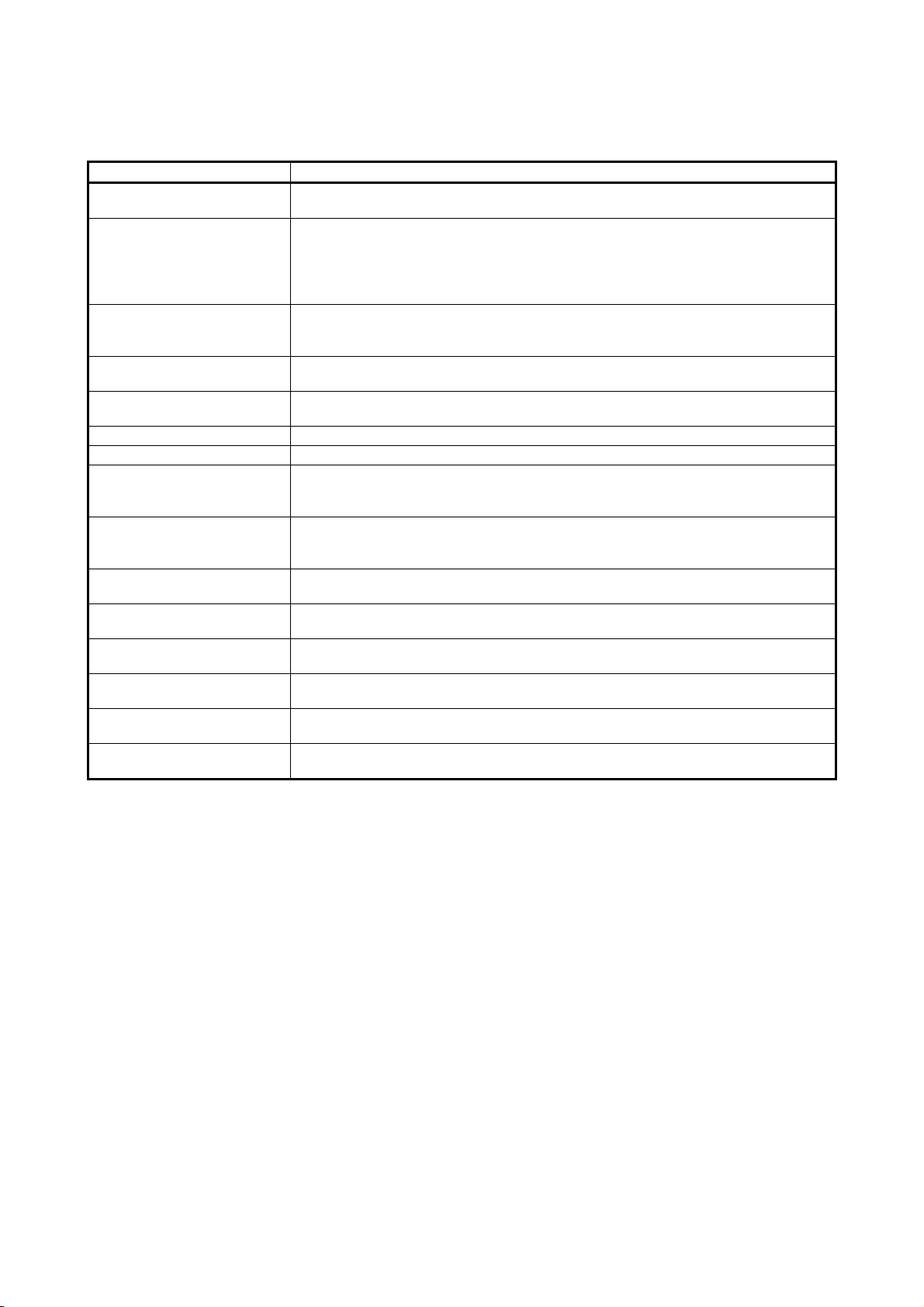

Term

Remote I/O net mode

Remote net mode

Remote net ver.1 mode

Remote net ver.2 mode

Remote net additional mode

Ver.1 compatible slave station

Ver.2 compatible slave station

SB

SW

RX

RY

RWw

RWr

Online

Offline

Description

Dedicated mode for sending and receiving data to and from remote I/O stations at high

speed.

Mode that allows communication with all stations on CC-Link (remote I/O station,

remote device station, local station, intelligent device station, and standby master

station).

There are three different modes: remote net ver.1 mode, remote net ver.2 mode, and

remote net additional mode.

Mode in which complete compatibility with the conventional module (ver.1 compatible

station) is achieved.

Select this mode when the number of link points need not be increased.

Select this mode when increasing the number of link points and configuring a new

system.

Select this mode when adding a ver.2 compatible station to the existing system

configured by only ver.1 compatible station to increase the number of link points.

Slave station compatible with the remote net ver.1 mode.

Slave station compatible with the remote net ver.2 mode.

Link special relay (for CC-Link)

Bit information that indicates the module operating status and data link status of the

master station/local station.

Link special register (for CC-Link)

16-bit information that indicates the module operating status and data link status of the

master station/local station.

Remote input (for CC-Link)

Information input in bit units from the slave station to the master station.

Remote output (for CC-Link)

Information output in bit units from the master station to the slave station.

Remote register (Write area for CC-Link)

Information output in 16-bit units from the master station to the slave station.

Remote register (Read area for CC-Link)

Information input in 16-bit units from the slave station to the master station.

Status that remote net ver.1 mode, remote net ver.2 mode, remote net additional mode

or remote I/O net mode is selected in the mode setting of network parameter.

Status that offline, loop test or H/W test is selected in the mode setting of network

parameter.

A - 17 A - 17

Page 20

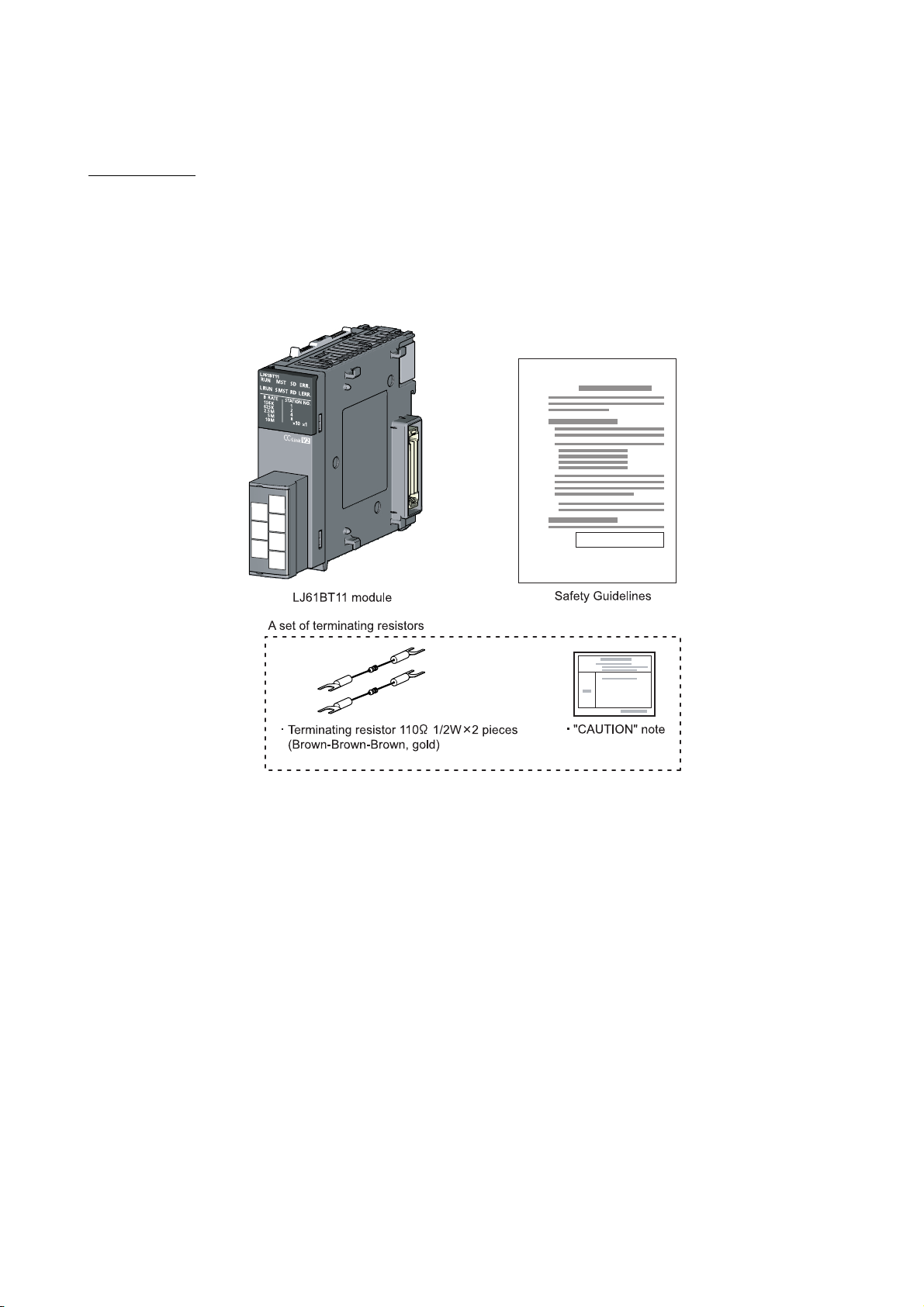

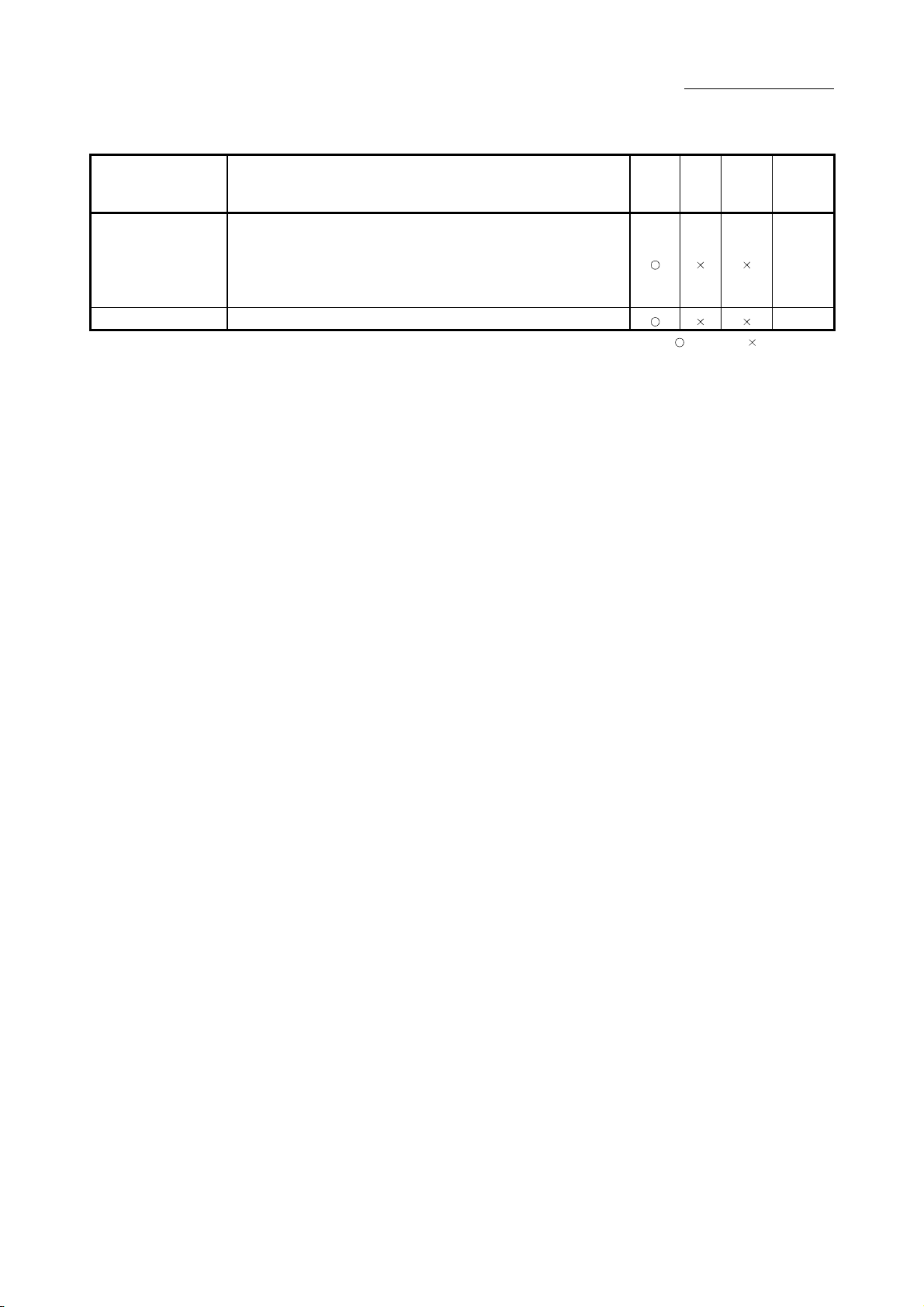

PACKING LIST

The LJ61BT11 package contains the following items. Before using the product, check if all of them are in the

package.

For the packaged items for L26CPU-BT, refer to MELSEC-L CPU Module User's Manual (Hardware Design,

Maintenance and Inspection).

A - 18 A - 18

Page 21

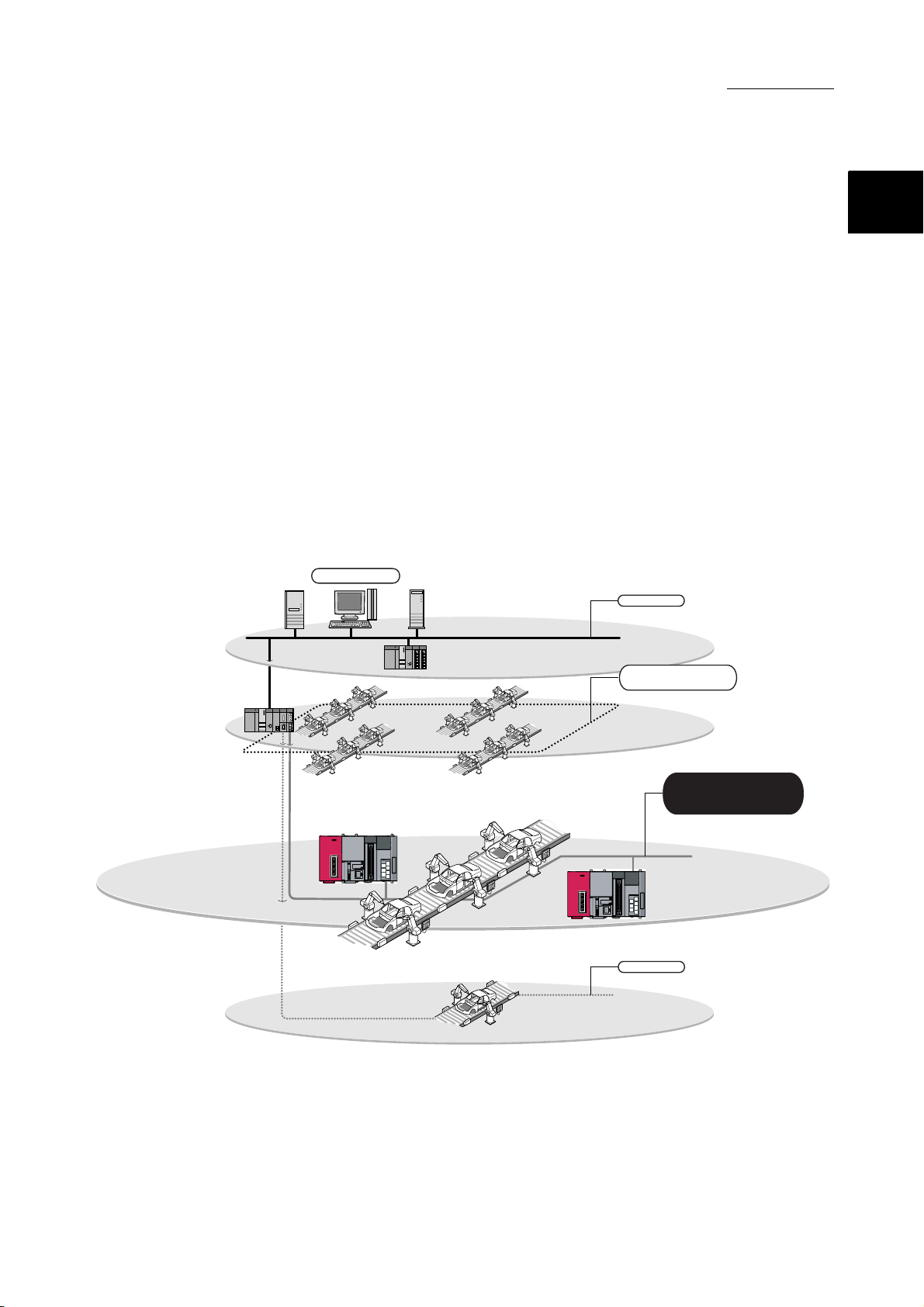

1 CC-Link SYSTEM

1 CC-Link SYSTEM

1.1 About CC-Link System

The CC-Link system is a system that connects distributed modules such as I/O modules,

intelligent function modules, and special function modules using dedicated cables so that

these modules can be controlled by a programmable controller CPU.

(1) By connecting each module separately to equipment such as a conveyor line or a

machine, the number of wires can be reduced in the entire system.

(2) Each module’s on/off information of input/output and numeric data can easily be

sent and received at high-speed.

(3) By connecting multiple programmable controller CPUs, a simple distributed

system can be configured.

(4) Since various devices from Mitsubishi's partner manufacturers can be connected,

the system can provide flexible solutions depending on the user’s requirements.

GX Works2

Ethernet

In factory (information control)

1

CC-Link IE

controller network

Between lines (production control)

CC-Link

In line (equipment control)

CC-Link/LT

In board and equipment

(device control and I/O control)

1 - 1 1 - 1

Page 22

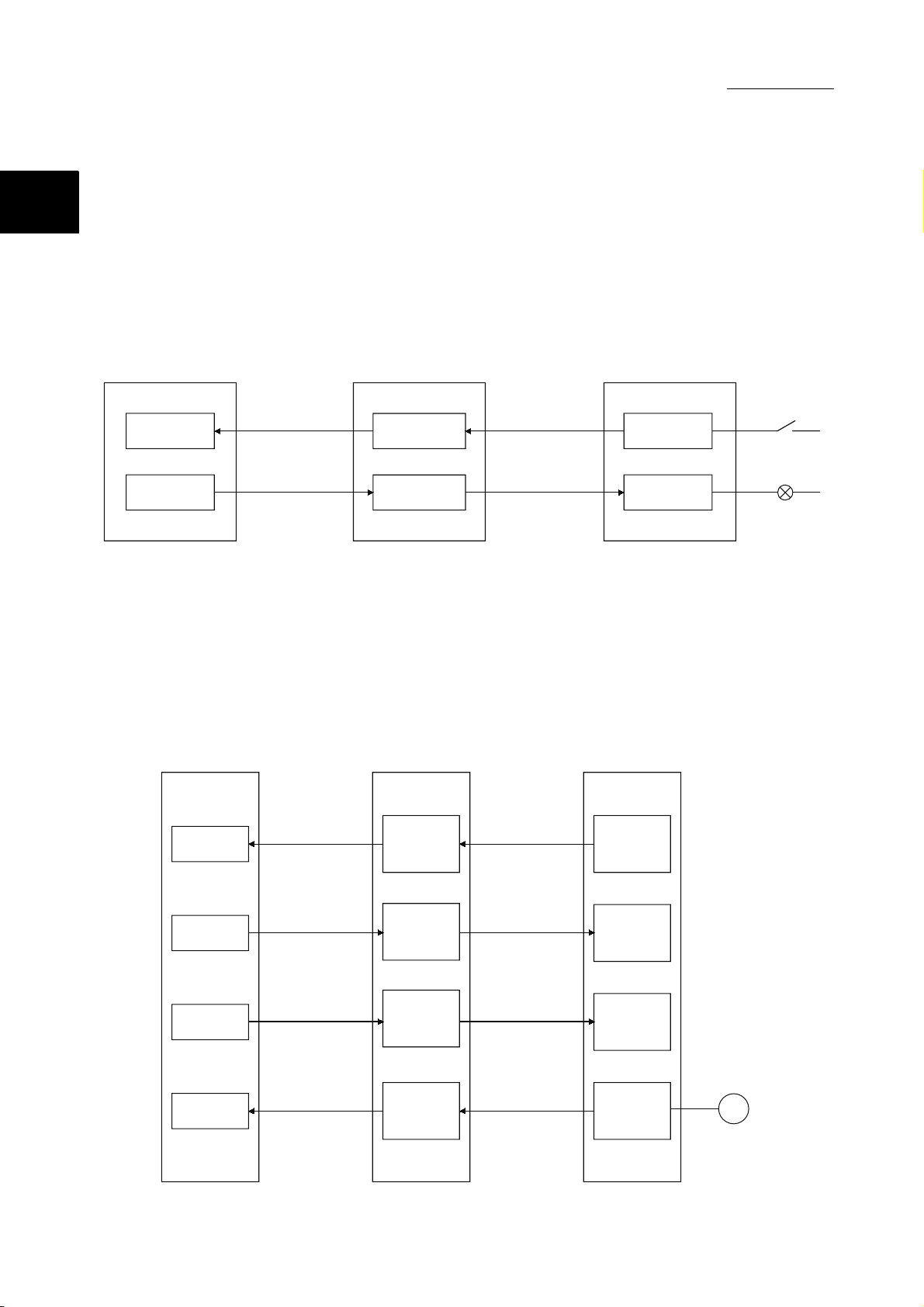

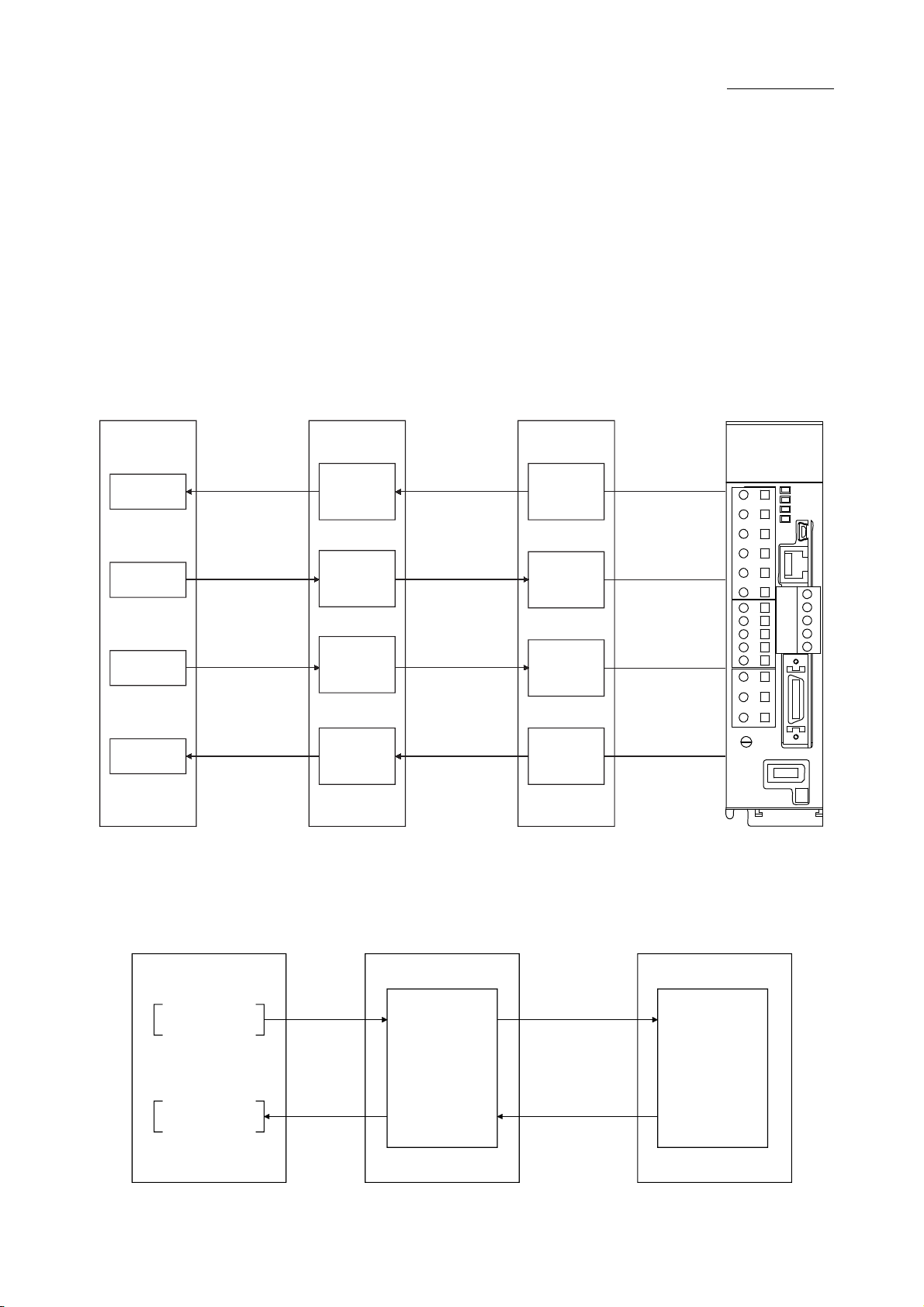

1.2 Overview of Communication

1 CC-Link SYSTEM

1

The overview of CC-Link communication is described below.

(1) Remote I/O station communication

The remote I/O station is a remote station that handles bit data only.

The ON/OFF information of a switch or indicator lamp is sent or received using

the remote input RX and remote output RY (refer to Section 8.1.1).

Programmable

controller CPU

Master station

Remote I/O station

X

Y

Automatic refresh

Automatic refresh

Remote input

RX

Remote output

RY

Link scan

Link scan

Input

Output

(2) Remote device station communication

Programmable

controller CPU

The remote device station is a remote station that handles bit and word data.

Signals for handshaking with the remote device station (initial request, error

occurred flag, etc.) are communicated using the remote input RX and remote

output RY. The setting data to the remote device station are communicated using

remote registers RWw and RWr (refer to Section 8.1.2).

Master station

Remote device station

X

Automatic refresh

Remote

input

(RX)

Link scan

Remote

input

(RX)

Y

Automatic refresh

W

Automatic refresh

W

Automatic refresh

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

Link scan

Link scan

Link scan

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

V

Voltmeter

1 - 2 1 - 2

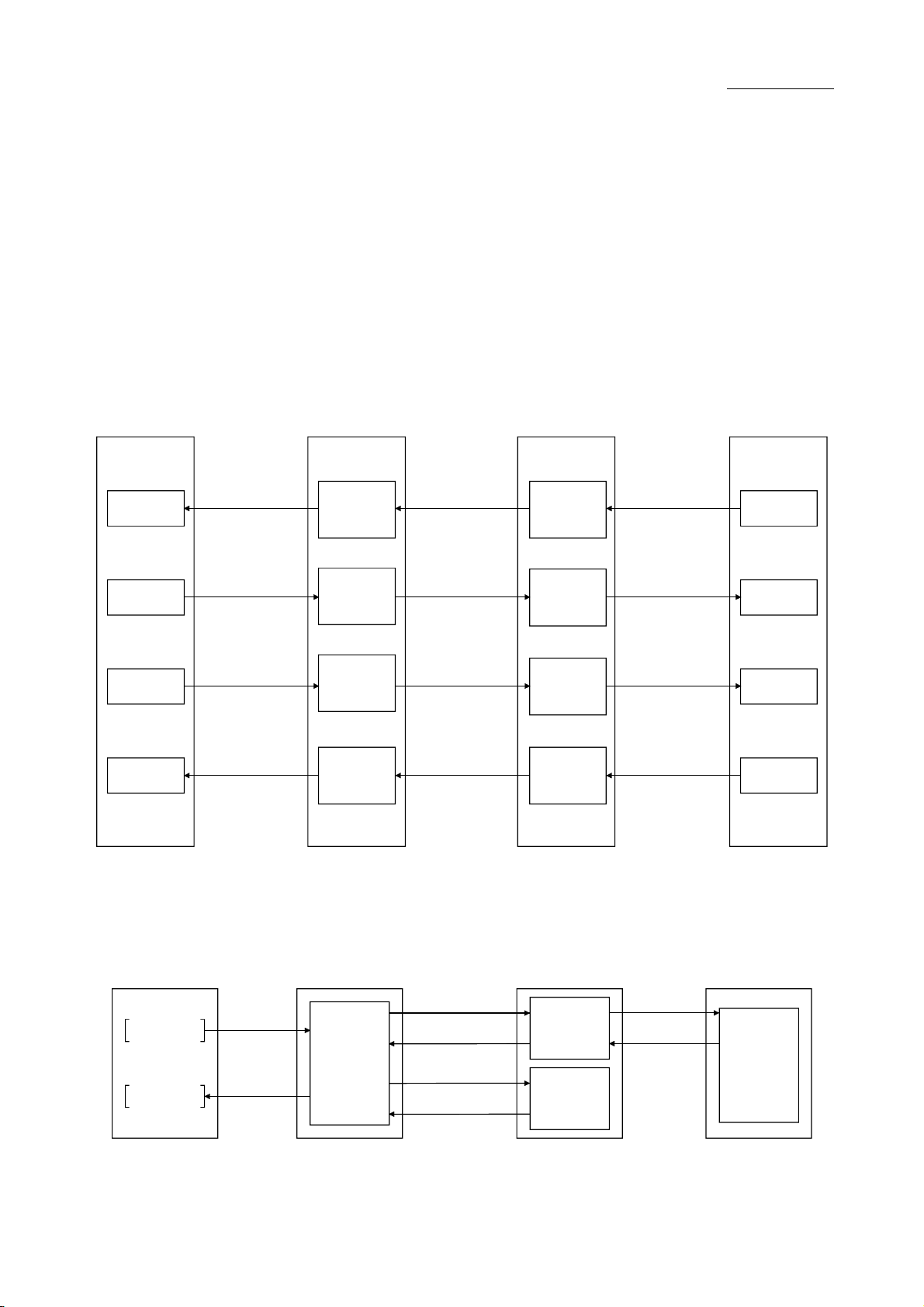

Page 23

Programmable

controller CPU

1 CC-Link SYSTEM

(3) Local station communication

The local station is a station having a programmable controller CPU and the

ability to communicate with the master and other local stations.

Communication between a master station and a local station uses two types of

transmission methods: cyclic transmission and transient transmission (refer to

Section 8.1.3).

(a) Cyclic transmission

Data communication between programmable controller CPUs can be

performed in N:N mode using bit data (remote input RX and remote output

RY) and word data (remote registers RWw and RWr).

Master station

Local station

Programmable

controller CPU

Programmable

controller CPU

X

Y

W

W

G(P).RIWT

G(P).RIRD

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

Remote

input

(RX)

Remote

output

(RY)

Remote

register

(RWw)

Remote

register

(RWr)

Link scan

Link scan

Link scan

Link scan

Remote

output

(RY)

Remote

input

(RX)

Remote

register

(RWr)

Remote

register

(RWw)

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

(b) Transient transmission

Read (G(P).RIRD) or write (G(P).RIWT) operation of the local station buffer

memory and CPU device can be performed at any timing.

Programmable

Master station

Transient

transmission

area

Transient transmission

Transient transmission

Transient transmission

Transient transmission

Local station

Transient

transmission

area

Buffer

memory

controller CPU

Y

X

W

W

W

1 - 3 1 - 3

Page 24

Programmable

controller CPU

1 CC-Link SYSTEM

(4) Intelligent device station communication

The intelligent device station is a station that can handle bit and word data.

Communication between a master station and an intelligent device station uses

two types of transmission methods: cyclic transmission and transient

transmission (refer to Section 8.1.4).

(a) Cyclic transmission

Signals for handshaking with the intelligent device station (positioning start,

positioning complete, etc.) are communicated using the remote input RX and

remote output RY. Numeric data (positioning start number, present feed

value, etc.) is communicated using remote registers RWw and RWr.

Master station

Intelligent device station

Servo amplifier

X

Y

W

W

Automatic refresh

Automatic refresh

Automatic refresh

Automatic refresh

Remote

input

RX

Remote

output

RY

Remote

register

RWw

Remote

register

RWr

Link scan

Link scan

Link scan

Link scan

Remote

input

RX

Remote

output

RY

Remote

register

RWw

Remote

register

RWr

(b) Transient transmission

Reading (G(P).RIRD) or writing (G(P).RIWT) of buffer memory data in an

Programmable

controller CPU

intelligent device station is available at any timing.

Master station

Intelligent device station

G(P).RIWT

Transient

transmission

area

G(P).RIRD

Transient transmission

Buffer memory

Transient transmission

1 - 4 1 - 4

Page 25

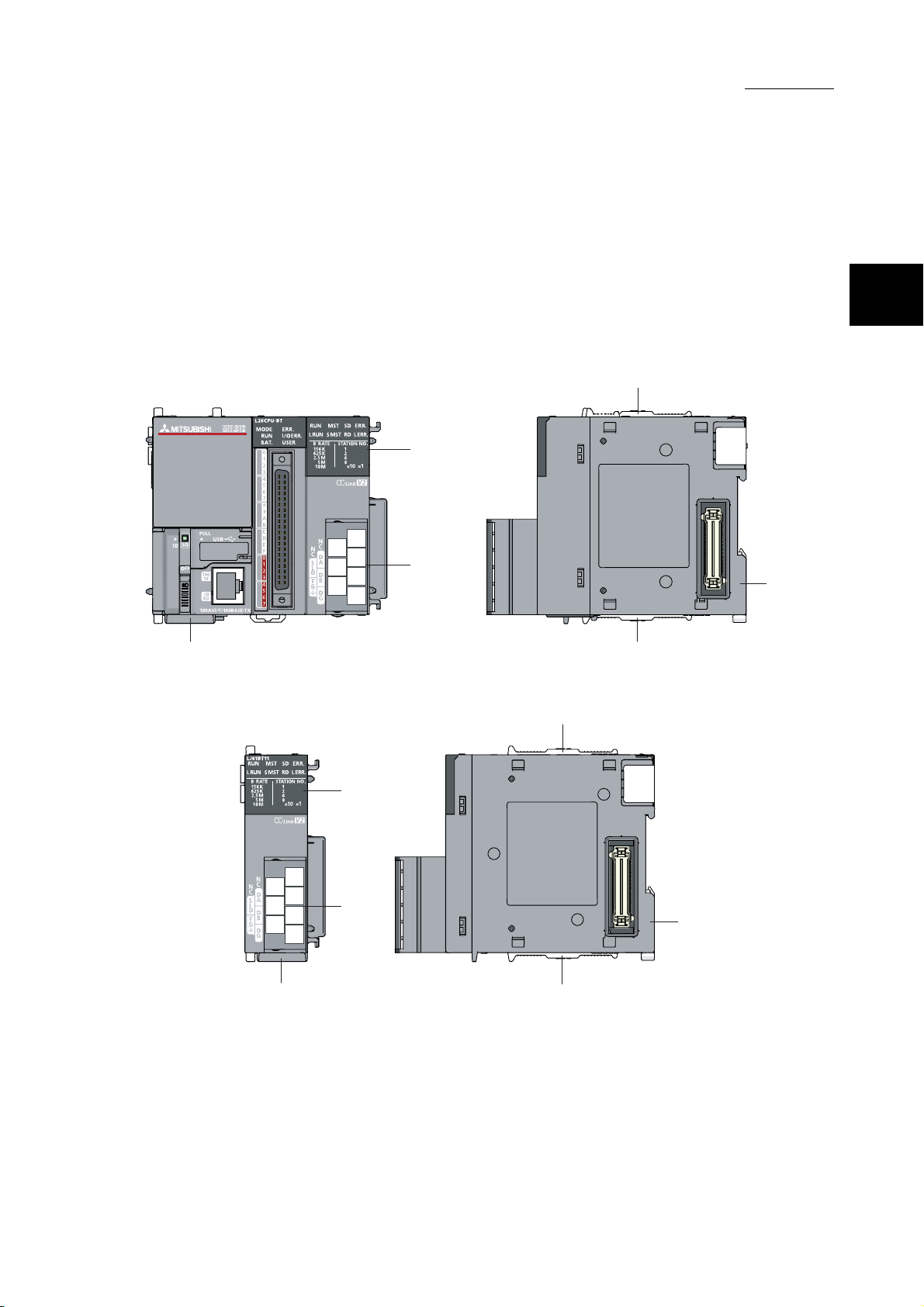

2 PART NAMES

2. PART NAMES

The following describes the parts names of the L series master/local modules.

(1) L26CPU-BT

For parts other than those for the built-in CC-Link functions, refer to the following

manual.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection)

4)

1)

2)

2

5)

4)3)

(2) LJ61BT11

1)

2)

3) 4)

4)

5)

2 - 1 2 - 1

Page 26

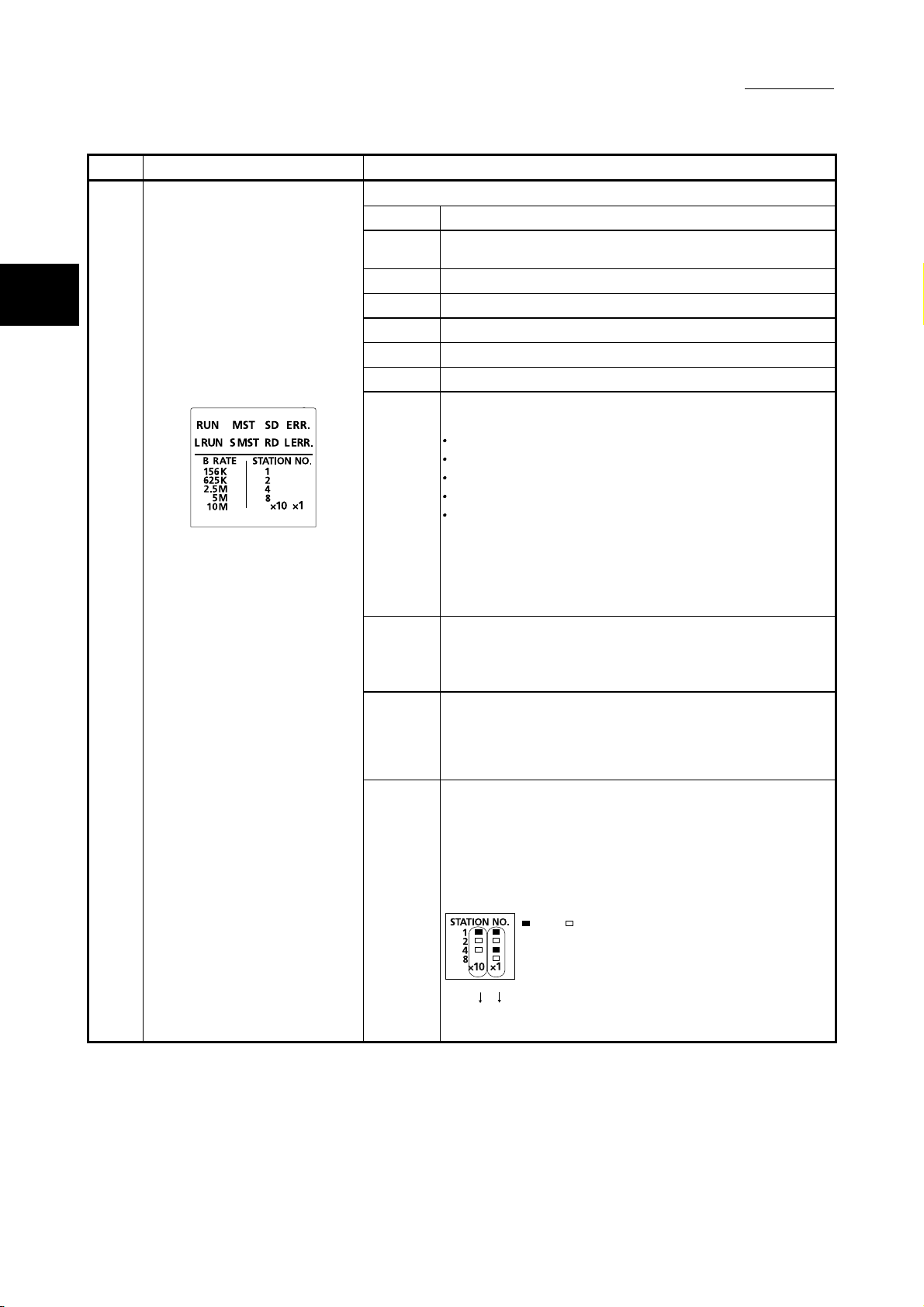

Number Name Description

2

1) LED indicators

The data link status can be checked with each ON/OFF status.

LED name Description

RUN

L RUN On: Data link is being executed

MST On: Operating as a master station. (in data link control)

S MST On: Operating as a standby master station. (in standby status)

SD On: Data being sent

RD On: Data being received

ERR.

L ERR.

B RATE

STATION

NO.

On : Operating normally

Off : Watchdog timer error

On: All stations have a communication error

This LED also turns on when the following errors occur.

There are more than one master station on the same line.

There is an error in the parameter settings.

The data link monitoring timer was activated.

The cable is disconnected.

The transmission path is affected by noise.

To check the source of the error, refer to Section 15.3.

Or, refer to Appendix 3.2 for details on SW0058 (detailed LED

display status).

Flashing: A communication error station identified, or remote

station No. duplicated.

On : Communication error (host)

Flashing: The terminating resistor is not attached. The module or

CC-Link Ver.1.10 compatible cable is affected by

noise.

On : Operating at the indicated transmission speed.

All off: Transmission speed auto following up

(When succeeded, the LED of the followed transmission

speed turns on.)

The module station number setting is indicated.

<Range>

Master station : 0 (All off)

Local station and standby master station : 1 to 64

(Example) When the station number 15 is indicated

: On : Off

2 PART NAMES

5

10

10 + 5 = 15

2 - 2 2 - 2

Page 27

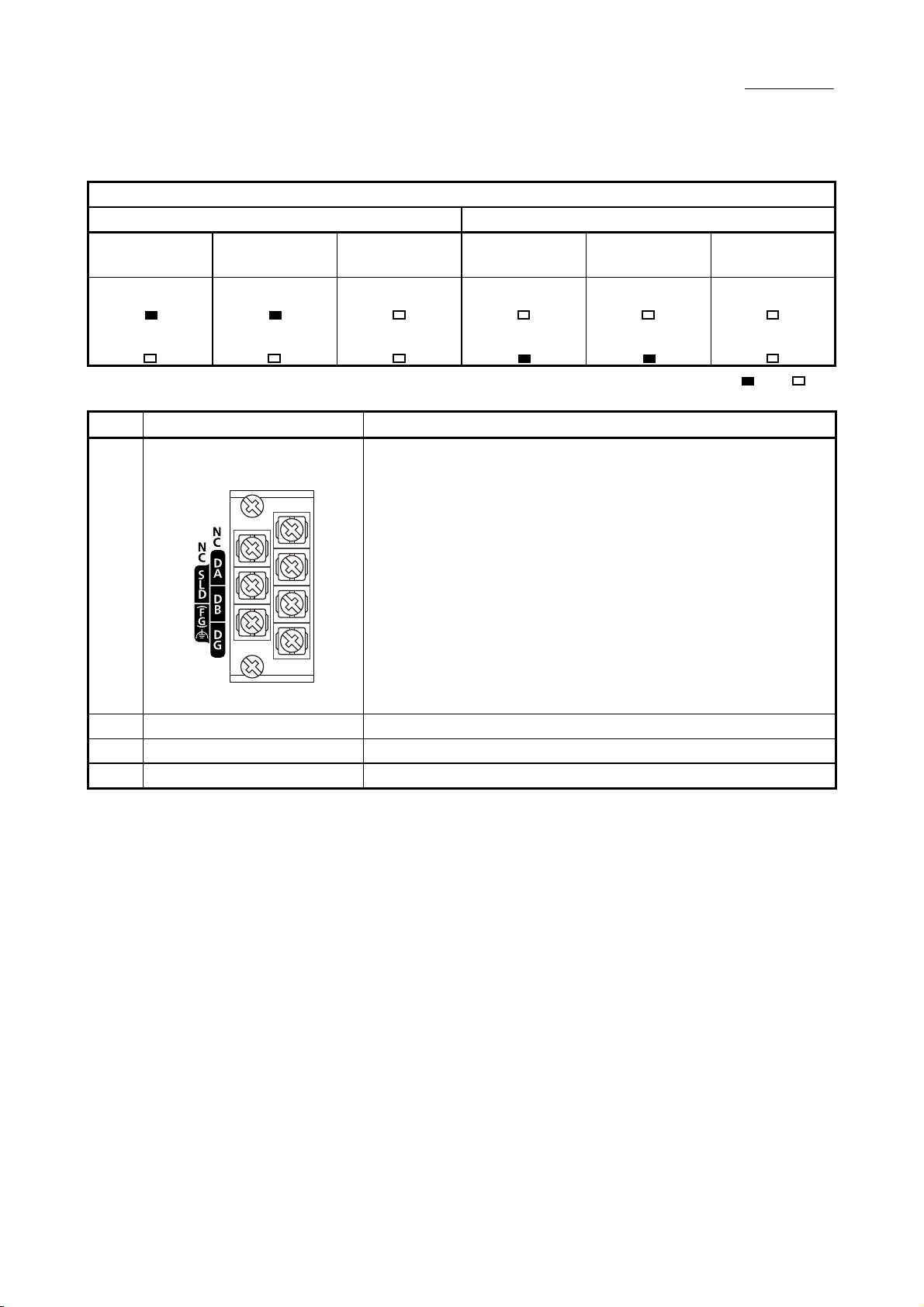

Operating as a master station (data link control) Operating as a standby master station (standby)

Master station

MST

S MST

Station type and ON/OFF status of the "MST" and "S MST" LEDs

Operating status

Standby master

station

MST

S MST

Local station Master station

MST

S MST

MST

S MST

Standby master

station

S MST

MST

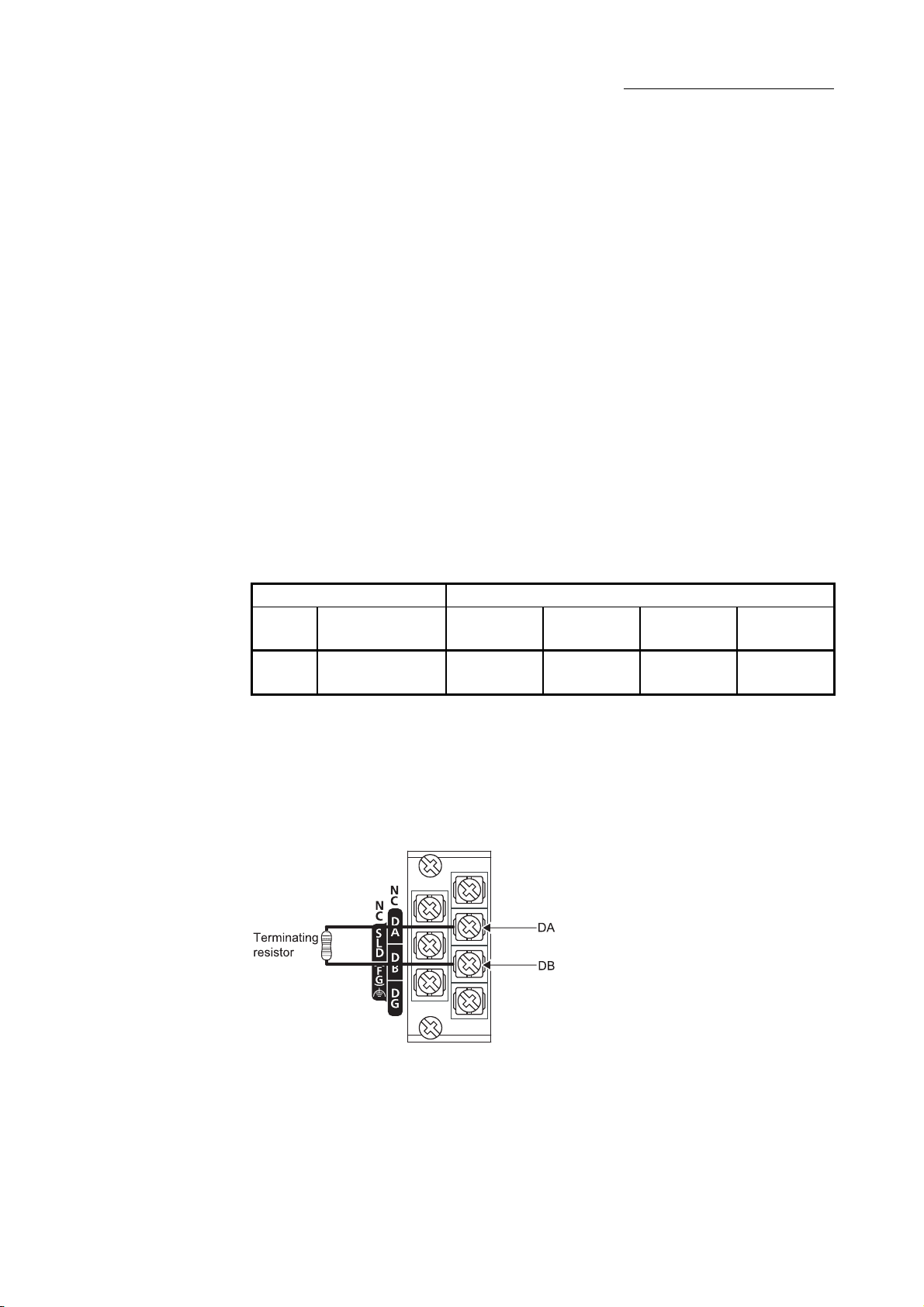

Number Name Description

2) Terminal block

A CC-Link dedicated Ver.1.10 compatible cable is connected for data linking.

For the connection method, refer to Section 6.3.

Terminals SLD and FG are connected inside the module.

Since a 2-piece type terminal block is used, the module can be replaced

without disconnecting the signal lines to the terminal block.

(Shut off the external power supply for the system in all phases before

replacing the module.)

2 PART NAMES

Local station

MST

S MST

: On, : Off

3) Serial No. display part Displays the serial No. of the rating plate.

4) Module joint lever Fixes the connected modules.

5) DIN rail hook Used to install the module to the DIN rail.

2 - 3 2 - 3

Page 28

3 SPECIFICATIONS

3 SPECIFICATIONS

3.1 General Specifications

This chapter provides the specifications of the L series master/local modules.

For the general specifications of the L series master/local modules, refer to the

following manual.

"Safety Guidelines", the manual supplied with the CPU module or head module

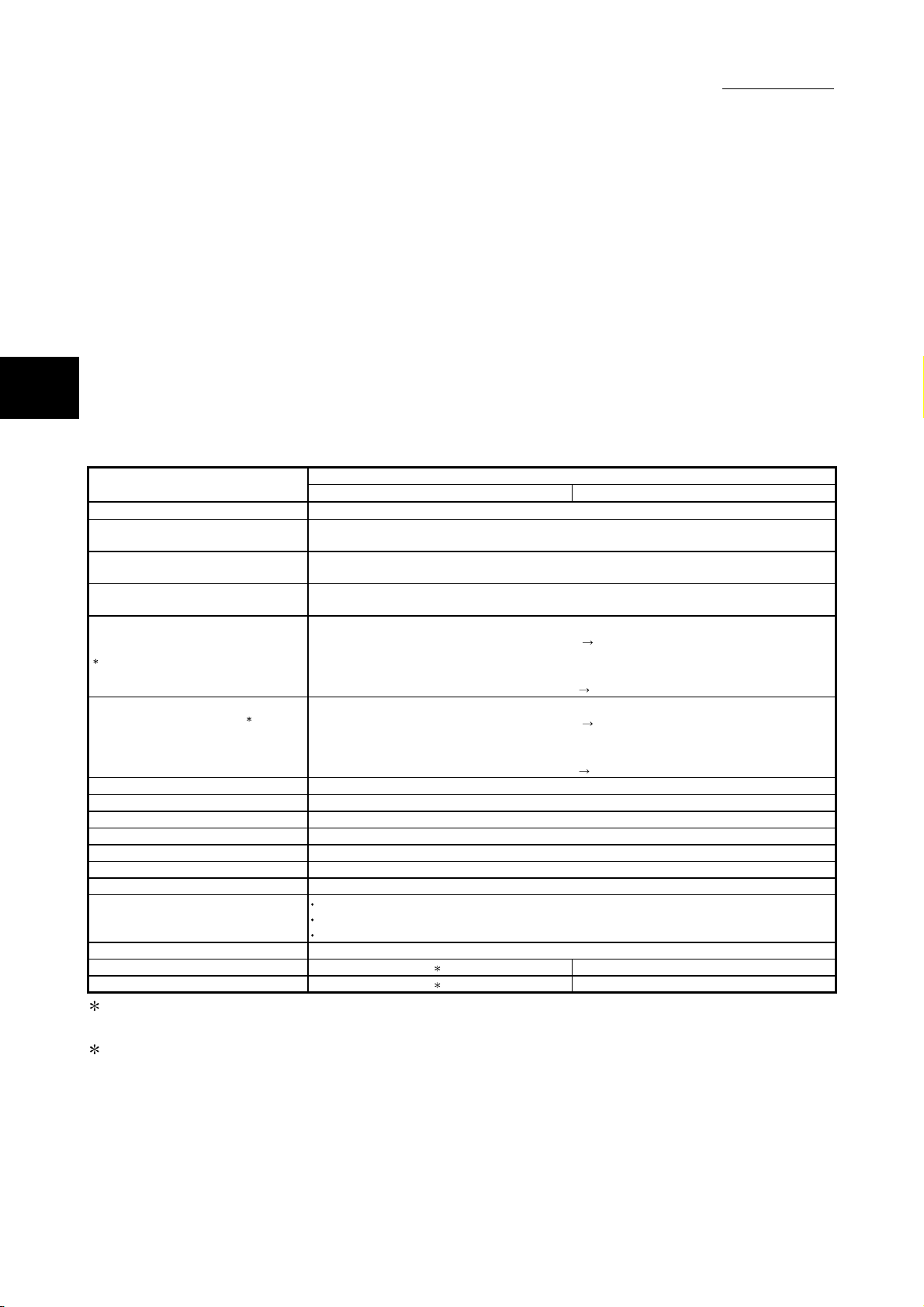

3.2 Performance Specifications

3

Transmission speed Can be selected from 156 kbps/ 625 kbps/ 2.5 Mbps/ 5 Mbps/ 10 Mbps

Maximum overall cable distance

(Maximum transmission distance)

Maximum number of connected stations

(master station)

Number of occupied stations

(local station)

Maximum number of link points per system

1

Number of link points per station 1

(remote station/local station/intelligent device

station/standby master station)

Communication method Broadcast polling method

Synchronous method Frame synchronization method

Encoding method NRZI method

Transmission path Bus (RS-485)

Transmission format Conforms to HDLC

Error control system CRC (X16 + X12 + X5 + 1)

Connection cable Ver.1.10 compatible CC-Link dedicated cable

RAS function

Number of occupied I/O points 32 points (I/O assignm ent: Intelligent 32 points)

5V DC internal current consumption 2 0.46A

Weight 2 0.15kg

Item

The following shows the performance specifications of the L series master/local

module.

Specification

Built-in CC-Link function LJ61BT11

Varies according to the transmission speed (Refer to Section 3.2.2)

64 (Refer to S ection 3.2.1)

1 to 4 stations

The number of stations can be switched by GX Works2 parameter setting.

Remote I/O (RX, RY) : 2048 points

Remote register (RWw) : 256 points (master station remote device station/local station/ intelligent

device station/standby master station)

Remote register (RWr) : 256 points (remote device station/local station/ intelligent device station/standby

Remote I/O (RX, RY) : 32 points (local station is 30 points)

Remote register (RWw) : 4 points (master station remote device station/local station/ intelligent

Remote register (RWr) : 4 points (remote device station/local station/ intelligent device station/standby

Automatic return function

Slave station cut-off function

Error detection by the link special relay/register

master station

device station/standby master station)

master station

master station)

master station)

1 Indicates the number of link points in remote net ver.1 mode. For the number of link points in remote net

Ver.2 mode and remote net additional mode, refer to Section 3.2 (1).

2 For the 5V DC internal current consumption and weight, refer to the following manual.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

3 - 1 3 - 1

Page 29

3 SPECIFICATIONS

(1) Number of link points in remote net ver.2 mode or remote net

Item Specifications

Maximum No. of link points per system

Expanded cyclic setting Single Double Quadruple Octuple

No. of link

points per

station

Number

of link

points per

number of

occupied

stations

Remote I/O (RX/RY)

Remote register (RWw) 4 points 8 points 16 points 32 points

Remote register (RWr) 4 points 8 points 16 points 32 points

Occupies

1 station

Occupies

2 stations

Occupies

3 stations

Occupies

4 stations

additional mode

Remote I/O

(RX/RY)

Remote

register (RWw)

Remote

register (RWr)

Remote I/O

(RX/RY)

Remote

register (RWw)

Remote

register (RWr)

Remote I/O

(RX/RY)

Remote

register (RWw)

Remote

register (RWr)

Remote I/O

(RX/RY)

Remote

register (RWw)

Remote

register (RWr)

Remote I/O (RX/RY) : 8192 points

Remote register (RWw) : 2048 points (master station

station/local station/intelligent device

station/standby master station)

Remote register (RWr) : 2048 points (remote device station/local

station/intelligent device station/standby

master station

32 points

(30 points

for local

station)

32 points 32 points 64 points 128 points

4 points 8 points 16 points 32 points

4 points 8 points 16 points 32 points

64 points 96 points 192 points 384 points

8 points 16 points 32 points 64 points

8 points 16 points 32 points 64 points

96 points 160 points 320 points 640 points

12 points 24 points 48 points 96 points

12 points 24 points 48 points 96 points

128 points 224 points 448 points 896 points

16 points 32 points 64 points 128 points

16 points 32 points 64 points 128 points

32 points

(30 points

for local

station)

master station)

64 points

(62 points

for local

station)

remote device

128 points

(126 points

for local

station)

3

3 - 2 3 - 2

Page 30

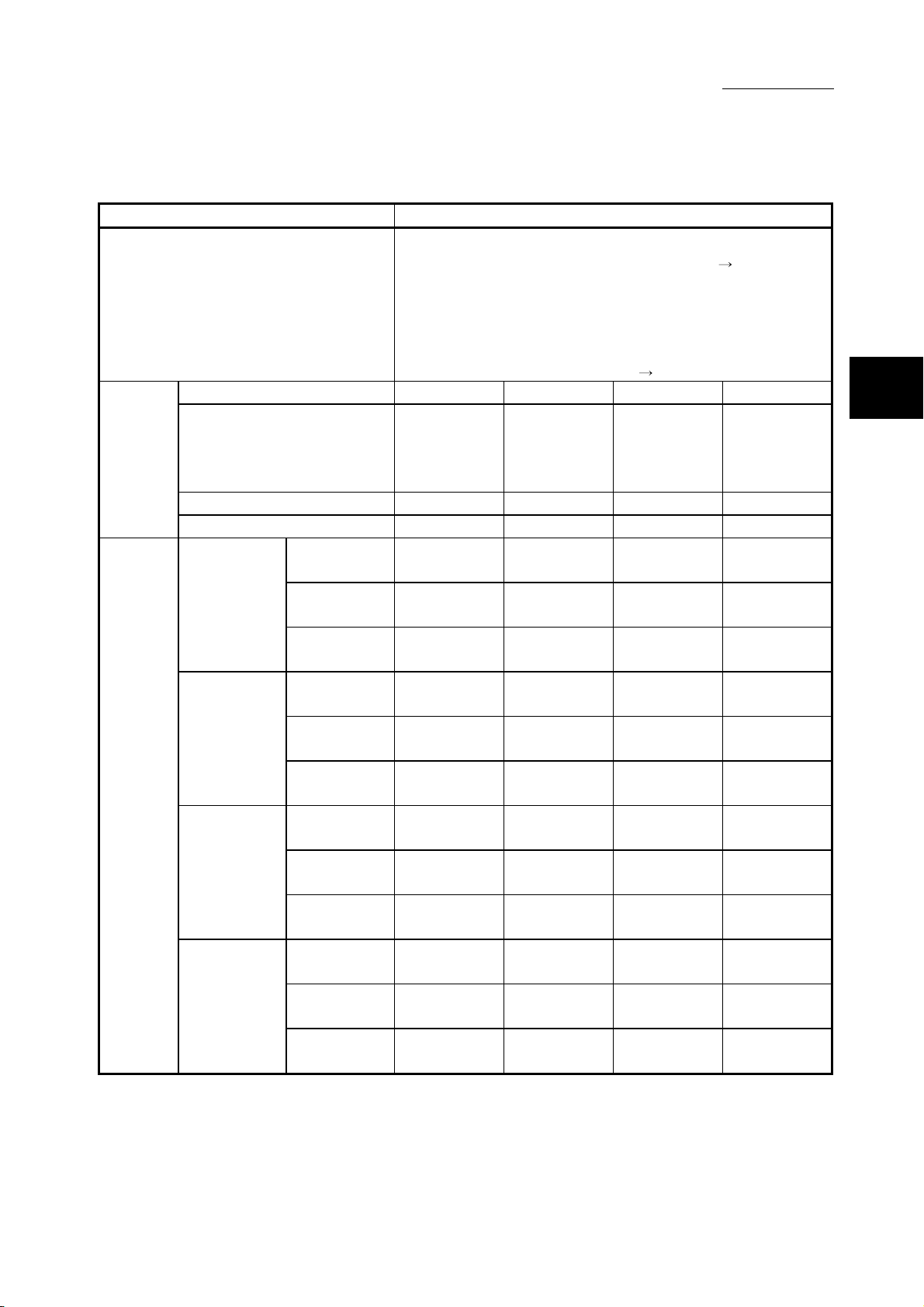

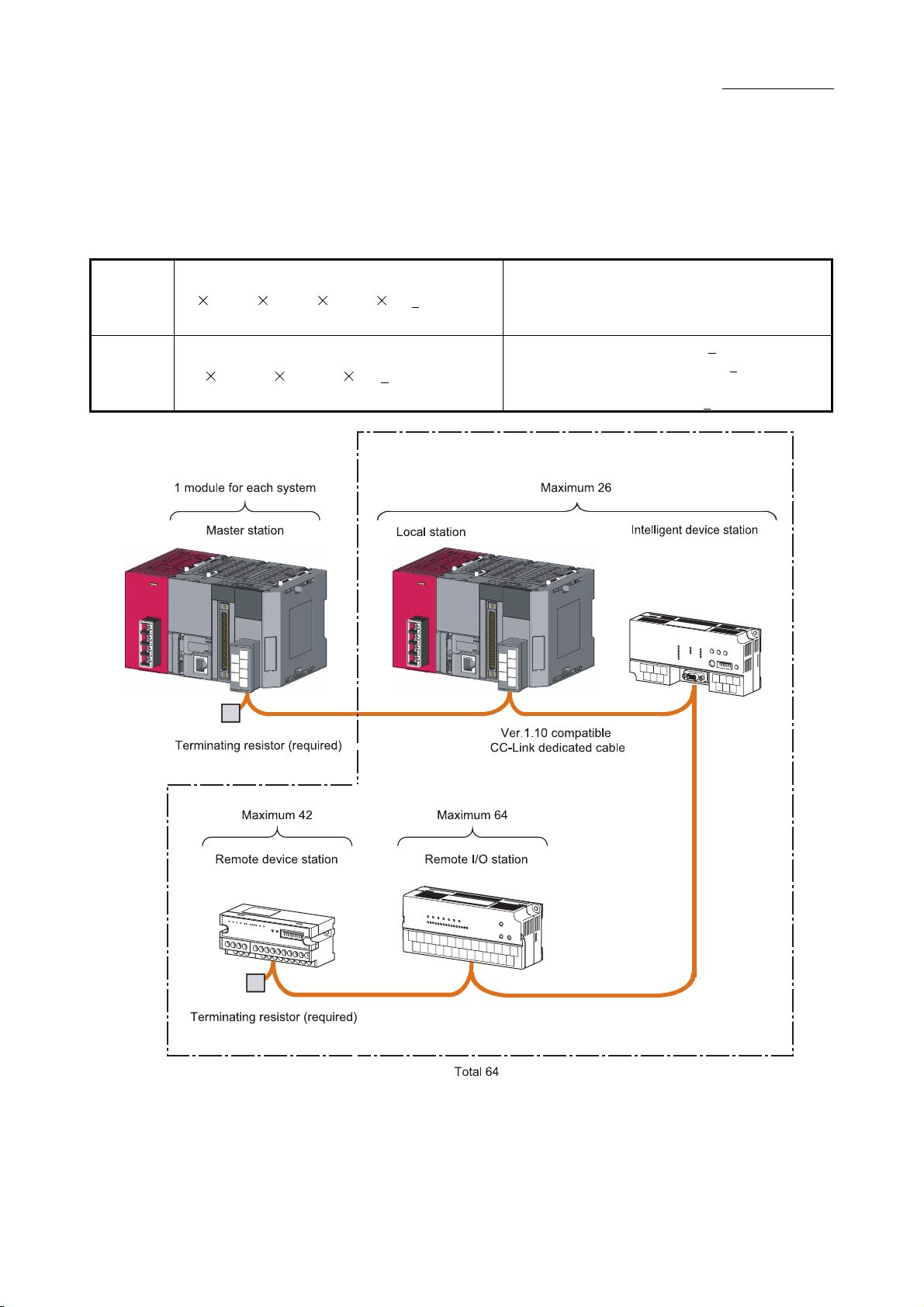

3.2.1 Maximum number of connected stations

(1) Remote net ver.1 mode

A total of 64 slave stations can be connected to a single master station.

Condition 1 {(1 a) + (2 b) + (3 c) + (4 d)} ≤ 64

Condition 2 {(16 A) + (54 B) + (88 C)} ≤ 2304

However, the following conditions must all be satisfied.

3 SPECIFICATIONS

a: Number of modules occupying 1 station

b: Number of modules occupying 2 stations

c: Number of modules occupying 3 stations

d: Number of modules occupying 4 stations

A: Number of remote I/O stations ≤

B: Number of remote device stations ≤

C: Number of local stations, standby master stations

and intelligent device stations ≤

64

42

26

3 - 3 3 - 3

Page 31

(2) Remote net ver.2 mode, remote net additional mode

A total of 64 slave stations can be connected to a single master station.

{(a + a2 + a4 + a8)

Condition 1

Condition 2

Condition 3

Condition 4 {(16 A) + (54 B) + (88 C) } ≤ 2304

+ (b + b2 + b4 + b8)

+ (c + c2 + c4 + c8) 3

+ (d + d2 + d4 + d8) 4} ≤ 64

32) + (a2 32) + (a4 64) + (a8 128)}

[{(a

+ {(b 64) + (b2 96) + (b4 192) + (b8 384)}

96) + (c2 160) + (c4 320) + (c8 640)}

+ {(c

+ {(d 128) + (d2 224) + (d4 448) + (d8 896)}] ≤ 8192

4) + (a2 8) + (a4 16) + (a8 32)}

[{(a

8) + (b2 16) + (b4 + 32) + (b8 64)}

+ {(b

+ {(c 12) + (c2 24) + (c4 48) + (c8 96)}

+ {(d 16) + (d2 32) + (d4 64) + (d8 128)}] ≤ 2048

However, the following conditions must all be satisfied.

2

3 SPECIFICATIONS

a: The total number of ver.1 compatible slave

stations that occupy 1 station, and ver.2

compatible slave stations that occupy 1 station

which are set to “Single”.

b: The total number of ver.1 compatible slave

stations that occupy 2 stations, and ver.2

compatible slave stations that occupy 2 stations

which are set to “Single”.

c: The total number of ver.1 compatible slave

stations that occupy 3 stations, and ver.2

compatible slave stations that occupy 3 stations

which are set to “Single”.

d: The total number of ver.1 compatible slave

stations that occupy 4 stations, and ver.2

compatible slave stations that occupy 4 stations

which are set to “Single”.

a2: The number of ver.2 compatible stations that

occupy 1 station which are set to “Double”.

b2: The number of ver.2 compatible stations that

occupy 2 stations which are set to “Double”.

c2: The number of ver.2 compatible stations that

occupy 3 stations which are set to “Double”.

d2: The number of ver.2 compatible stations that

occupy 4 stations which are set to “Double”.

a4: The number of ver.2 compatible stations that

occupy 1 station which are set to “Quadruple”.

b4: The number of ver.2 compatible stations that

occupy 2 stations which are set to “Quadruple”.

c4: The number of ver.2 compatible stations that

occupy 3 stations which are set to “Quadruple”.

d4: The number of ver.2 compatible stations that

occupy 4 stations which are set to “Quadruple”.

a8: The number of ver.2 compatible stations that

occupy 1 station which are set to “Octuple”.

b8: The number of ver.2 compatible stations that

occupy 2 stations which are set to “Octuple”.

c8: The number of ver.2 compatible stations that

occupy 3 stations which are set to “Octuple”.

d8: The number of ver.2 compatible stations that

occupy 4 stations which are set to “Octuple”.

A: Number of remote I/O stations ≤

B: Number of remote device stations ≤

C: Number of local stations, standby master

stations and intelligent device stations ≤

64

42

26

3 - 4 3 - 4

Page 32

3 SPECIFICATIONS

3 - 5 3 - 5

Page 33

3.2.2 Maximum overall cable distance

The relation of the transmission speed and maximum overcall cable distance when

configuring the entire system with products compatible with CC-Link Ver.1.10 or higher

and Ver.1.10 compatible CC-Link dedicated cables is shown below.

For the identification of the CC-Link Version, refer to the installation manual issued by

the CC-Link Partner Association.

3 SPECIFICATIONS

Version 1.10 compatible CC-Link dedicated cable (terminating resistor of 110Ω used)

Transmission speed Station-to-station cable length Maximum overall cable distance

156kbps 1200m

625kbps 900m

2.5Mbps 400m

5Mbps 160m

10Mbps

20cm or longer

100m

3 - 6 3 - 6

Page 34

3.2.3 Ver.1.10 compatible CC-Link dedicated cable

Use Ver.1.10 compatible CC-Link dedicated cables for the CC-Link system.

If a cable other than the Ver.1.10 compatible CC-Link dedicated cable is used, the

performance of the CC-Link system cannot be guaranteed.

For the specifications of the Ver.1.10 compatible CC-Link dedicated cables or any

other inquiries, visit the following website:

CC-Link Partner Association: http://www.cc-link.org/

REMARK

For details, refer to the CC-Link cable wiring manual issued by CC-Link Partner

Association.

3 SPECIFICATIONS

3 - 7 3 - 7

Page 35

3 SPECIFICATIONS

3.3 Function List

The following shows the function list of the L series master/local module.

Item Description Reference

Communication with remote I/O

stations

Communication with remote device

stations

Communication with local stations

Communication with intelligent

device stations

Item Description Reference

Slave station cut-off function

Automatic return function

Data link status setting when the

master station programmable

controller CPU has an error

Setting the status of input data from

a data link faulty station

Slave station refresh/compulsory

clear setting in case of

programmable controller CPU

STOP

Standby master function

Data link start by standby master

station

Block guarantee of cyclic data per

station

Guarantee of 32-bit data

3 - 8 3 - 8

(1) List of the "basic functions"

Performs on/off data communication with remote I/O stations. Section 8.1.1

Performs on/off data and numeric data communication with

remote device stations.

Performs on/off data and numeric data communication with local

stations.

Performs communication with intelligent device station, by cyclic

transmission, and transient transmissions.

(2) List of the "functions for improving system reliability"

Disconnects a slave station that cannot continue the data link

due to a reason such as power off, so that data link can continue

among normal slave stations only.

When a slave station, which has been disconnected from the

network due to a reason such as power off, returns to the normal

status, it automatically joins the data link.

Sets whether to stop or continue the data link when an error that

stops the operation occurs at the master station programmable

controller CPU in the system that has no standby master station.

When "Continue" is set, the diagnostics of the master station can

be performed from local stations.

Sets whether to clear or hold the input data (remote input RX)

from a station that detected a data link error due to a reason

such as power off.

Sets whether to refresh or forcibly clear output data (remote

output RY) to the slave stations when the programmable

controller CPU comes to STOP.

When "Clears Compulsorily" is set, the remote output RY turns

off when the operation stops due to STOP of programmable

controller CPU or due to an error occurrence.

Continues the data link by switching the control to the standby

master station when a problem occurs in the master station.

Starts data link when either of the master or standby master

station is turned on.

Guarantees the consistency of the cyclic data for each slave

station.

Guarantees the 32-bit data of the remote register (RWr/RWw)

between programmable controller CPU and the master/local

station.

Section 8.1.2

Section 8.1.3

Section 8.1.4

Section 8.2.1

Section 8.2.2

Section 8.2.3

Section 8.2.4

Section 8.2.5

Section 8.2.7

Section 8.2.8

Section 8.2.9

Section 8.2.10

Page 36

Item Description Reference

Remote device station initialization

procedure registration function

Event issuance for the interrupt

program

Automatic CC-Link startup

Reserved station function

Error invalid station setting function

Temporary error invalid station

setting function

Scan synchronous function

Data link stop/restart

Remote I/O station points setting

Master station duplication error

cancel function

Transmission speed auto following

setting

Status logging

(3) List of the "handy functions"

Programs for the initial setting become unnecessary, since the

initial settings in the remote device station are set at the network

parameter. The initial settings in the remote device station can

be configured easily.

Since the interrupt program of the programmable controller CPU

is executed according to the established event issuance

conditions, high speed data receive processing can be made

without being influenced by the sequence scan.

The CC-Link starts automatically, only by turning the power on,

and the operation at the system construction can be checked.

By setting slave stations that will be connected in the future as

reserved stations, they will not be treated as data link faulty

stations.

Prevents slave stations that may be powered off in the system

configuration from being treated as data link faulty stations by

setting the network parameters.

Changes slave stations without detecting errors during online

operation.

Also, prevents slave stations, which are turned off in the system

configuration, from being treated as data link faulty stations

temporarily.

Selects whether to synchronize or not the link scan with

sequence scan.

In the synchronous mode, the link scan is performed

synchronously with the sequence scan. Therefore, the output

data can be sent in high speed.

In the asynchronous mode, the link scan is performed not

synchronized to the sequence scan. Therefore, a high speed link

scan can be performed independent of the sequence scan.

Stops or restarts the data link that is being executed.

By stopping the data link, the program debug can be performed

efficiently, since data from other stations are not received, and

data are not sent from the host station.

Allows the I/O points of the remote I/O stations to be selected

from among 8 points, 16 points and 32 points, reducing the

number of reserved points.

The refresh device points of the programmable controller CPU

and the link refresh time can be saved.

Master station duplication errors can be canceled without turning

the power supply off to on, or without resetting the

programmable controller CPU.

When the host station is a local station or a standby master

station, an auto following occurs according to the transmission

speed of the master station, what eliminates setting errors of the

transmission speed.

Logs the data link status of all stations.

When multiple stations repeat normal/faulty, or when determined

stations and later repeat normal/faulty, this function enables

easy identification of the causes, such as contact failure of the

cable, or the noise occurrence location.

3 SPECIFICATIONS

Section 8.3.1

Section 8.3.2

Section 8.3.3

Section 8.3.4

Section 8.3.5

Section 8.3.6

Section 8.3.7

Section 8.3.8

Section 8.3.9

Section 8.3.10

Section 7.2 (2)

Section 15.4.3

3 - 9 3 - 9

Page 37

Item Description Reference

Transient transmission

(4) List of the "functions for transient transmission"

Specifies a target and communicates with it at any timing when

required.

3 SPECIFICATIONS

Section 9.1

3 - 10 3 - 10

Page 38

3.4 Mode Selection

CC-Link

Ver.1/

Ver.2

Ver.1

Ver.2

Mode

Remote I/O net

mode

Remote net ver.1

mode

Remote net

additional mode

Remote net ver.2

mode

3 SPECIFICATIONS

There are two different CC-Link versions: Ver.1 and Ver.2, and the L series

master/local modules are Ver.2-compatible modules.

The L series master/local modules have four types of modes for various systems.

(1) Overview of the modes

Connectable station

type

Remote I/O station

Remote I/O station

Remote device station

Intelligent device

station

Local station

Standby master station

Select this mode when the system consists of only

the master station and remote I/O stations.

Since the cyclic transmission speed is high, the

link scan time can be reduced.

Mode for complete compatibility with the

conventional module (Ver.1 compatible station).

Select this mode when the number of link points

need not to be increased.

Select this mode

when the number

of link points

need to be

increased.

Overview Reference

Section 3.4 (1) (a)

—

Select this mode when adding a

Ver.2 compatible slave station

to the existing Ver.1 system.

Select this mode when

configuring a new system.

Section 3.4.1 (2)