Page 1

MELSEC-Q/L AnyWireASLINK Master Module

User's Manual

-QJ51AW12AL

-LJ51AW12AL

Page 2

Page 3

COPYRIGHT

This document is protected by the law of copyright, whereby all rights established therein remain with the company

Mitsubishi Electric Corporation. Reproduction of this document or parts of this document is only permissible within the

limits of the legal determination of Copyright Law. Alteration or abridgement of the document is not permitted without

the explicit written approval of the company Mitsubishi Electric Corporation.

PRECAUTIONS REGARDING WARRANTY AND

SPECIFICATIONS

The QJ51AW12AL and LJ51AW12AL were jointly developed and manufactured by Mitsubishi and Anywire

Corporation.

Note that there are some precautions regarding warranty and specifications of this product.

Warranty

Other programmable controller

Item QJ51AW12AL, LJ51AW12AL

Repair term after discontinuation of

production

(e.g. MELSEC-Q series)

1 year 7 years

products

Application of the EMC Directive

Item QJ51AW12AL, LJ51AW12AL

Applicable EMC standard

*1 The master module with a serial number where the sixth digit is "2" or later complies with this standard.

Application of the UL/cUL standards

Item QJ51AW12AL, LJ51AW12AL

Applicable UL standard/cUL standard

*2 The master module with a serial number where the sixth digit is "3" or later complies with this standard.

EN61131-2

*2

UL508

CSA22.2

Other programmable controller

products

(e.g. MELSEC-Q series)

*1

*2

EN61131-2

Other programmable controller

products

(e.g. MELSEC-Q series)

UL508

CSA22.2

1

Page 4

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

2

Page 5

Precautions for using the QJ51AW12AL

[Design Precautions]

WARNING

● An AnyWireASLINK system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or connecting a personal computer with an

intelligent function module to modify data of a running programmable controller, configure an interlock

circuit in the program to ensure that the entire system will always operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding.

Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to be

taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to the

intelligent function module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them. Failure to do so may result in malfunction due to

noise.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

Page 6

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the user's

manual for the CPU module used.

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

● To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect interconnection may cause malfunction, failure, or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module with

a screw.

● Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module.

Failure to do so may result in damage to the product.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less.

Failure to do so may result in electric shock or malfunction.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Do not apply the 24VDC power before wiring the entire AnyWireASLINK system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Connect a 24VDC external power supply to the device(s) in an AnyWireASLINK system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

5

Page 8

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws.

Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

6

Page 9

Precautions for using the LJ51AW12AL

[Design Precautions]

WARNING

● An AnyWireASLINK system has no control function for ensuring safety.

● When connecting a peripheral with the CPU module or connecting a personal computer with an

intelligent function module to modify data of a running programmable controller, configure an interlock

circuit in the program to ensure that the entire system will always operate safely.

For other forms of control (such as program modification or operating status change) of a running

programmable controller, read the relevant manuals carefully and ensure that the operation is safe

before proceeding.

Especially, when a remote programmable controller is controlled by an external device, immediate

action cannot be taken if a problem occurs in the programmable controller due to a communication

failure.

To prevent this, configure an interlock circuit in the program, and determine corrective actions to be

taken between the external device and CPU module in case of a communication failure.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an output signal from the CPU module to the

intelligent function module. Doing so may cause malfunction of the programmable controller system.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm or more between them. Failure to do so may result in malfunction due to

noise.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing the

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

7

Page 10

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines provided with the CPU module or head module. Failure to do so may result in electric

shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Tighten the screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

8

Page 11

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 ohms or less.

Failure to do so may result in electric shock or malfunction.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

● Do not apply the 24VDC power before wiring the entire AnyWireASLINK system. If the power is

applied before wiring, normal data transmission is not guaranteed.

● Connect a 24VDC external power supply to the device(s) in an AnyWireASLINK system.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them.

If not, dangling cable may swing or inadvertently be pulled, resulting in damage to the module or

cables or malfunction due to poor contact.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable connected to the terminal block, loosen the terminal screw.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

9

Page 12

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws.

Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module.

Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module and terminal block), do not connect/disconnect the product

more than 50 times (in accordance with IEC 61131-2).

Exceeding the limit may cause malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body.

Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

10

Page 13

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above restrictions, Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

11

Page 14

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-Q or -L series programmable controllers.

This manual describes the functions and programming of the QJ51AW12AL AnyWireASLINK master module and

LJ51AW12AL AnyWireASLINK master module.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-Q or -L series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

Unless otherwise specified, this manual describes the program examples in which the I/O numbers of X/Y10 to X/Y2F are

assigned for a master module. I/O numbers must be assigned to apply the program examples introduced in this manual to

an actual system.

For I/O number assignment, refer to the following.

User's Manual (Function Explanation, Program Fundamentals) for the CPU module used

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• User's manual for the CPU module or head module used

• Safety Guidelines (This manual is included with the CPU module, base unit, or head module.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to Page 113, Appendix 4.

12

Page 15

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

<SH-080483ENG, 13JR73>

QnUCPU User's Manual (Function Explanation, Program Fundamentals)

<SH-080807ENG, 13JZ27>

Qn(H)/QnPH/QnPRHCPU User's Manual (Function Explanation, Program

Fundamentals)

<SH-080808ENG, 13JZ28>

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance

and Inspection)

<SH-080890ENG, 13JZ36>

MELSEC-L CPU Module User's Manual (Function Explanation, Program

Fundamentals)

<SH-080889ENG, 13JZ35>

(2) Head module user's manual

Manual name

<manual number (model code)>

MELSEC-L CC-Link IE Field Network Head Module User's Manual

<SH-080919ENG, 13JZ48>

Description

Specifications of the hardware (CPU modules, power supply

modules, base units, batteries, and memory cards), system

maintenance and inspection, and troubleshooting

Functions and devices of the CPU module, and programming

Functions and devices of the CPU module, and programming

Specifications of the CPU modules, power supply modules,

display unit, SD memory cards, and batteries, information on

how to establish a system, maintenance and inspection, and

troubleshooting

Functions and devices of the CPU module, and programming

Description

Specifications, procedures before operation, system

configuration, installation, wiring, settings, and troubleshooting

of the head module

(3) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

(4) Others

Manual name

<manual number (model code)>

iQ Sensor Solution Reference Manual

<SH-081133ENG, 13JV28>

Description

System configuration, parameter settings, and online

operations of GX Works2, which are common to Simple

projects and Structured projects

Description

Operating methods of iQ Sensor Solution, such as

programming and monitoring

13

Page 16

CONTENTS

CONTENTS

COPYRIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PRECAUTIONS REGARDING WARRANTY AND SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CHAPTER 1 FEATURES 20

1.1 AnyWireASLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 2 PART NAMES 23

CHAPTER 3 SPECIFICATIONS 25

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2.1 Performance list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3.2.2 Number of parameters to set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.2.3 Communication performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 List of I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 List of Buffer Memory Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

CHAPTER 4 PROCEDURES BEFORE OPERATION 35

CHAPTER 5 SYSTEM CONFIGURATION 37

5.1 Overall Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.1 System configuration of the master module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1.2 System configuration of AnyWireASLINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.2 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2.1 QJ51AW12AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

5.2.2 LJ51AW12AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

5.3 Compatible Software Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

CHAPTER 6 INSTALLATION AND WIRING 43

6.1 Installation Environment and Position of the Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.2.1 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6.2.2 Connection of slave modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.2.3 Power supply to the AnyWireASLINK system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

6.3 Check before Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

14

Page 17

6.4 Power-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 Terminating Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CHAPTER 7 VARIOUS SETTINGS 53

7.1 Master Module Operation Mode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.1.1 Master module addition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

7.1.2 Switch setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.1.3 Auto refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

7.2 Slave Module Address Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7.3 Automatic Address Detection Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.3.1 Performing the automatic address detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

7.3.2 Interlock program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

7.3.3 Automatic address detection execution timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.4 Automatic Reading of the System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

CHAPTER 8 FUNCTIONS 62

8.1 Bit Transmission Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Transmission Cable Short Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.3 Disconnected Transmission Cable Location Detection Function . . . . . . . . . . . . . . . . . . . . . . . 63

8.4 Transmission Cable Voltage Drop Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.5 Parameter Access Error Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.6 Same ID Used Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.7 Module with No ID Setting Detection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.8 Reading and Writing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.9 Backup/Restoring Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

CHAPTER 9 PROGRAMMING 75

9.1 Correlations Between Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9.2 System Using the QJ51AW12AL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.2.1 When using a module in the ordinary system configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .76

9.2.2 When connecting a module in a remote I/O station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

9.3 System Using the LJ51AW12AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.3.1 When using a module in the ordinary system configuration. . . . . . . . . . . . . . . . . . . . . . . . . . .85

9.3.2 When connecting a module to a head module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

CHAPTER 10 TROUBLESHOOTING 92

10.1 Before Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.2 Check by Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10.3 Checking with Module's Detailed Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

10.4 Checking with Buffer Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.5 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.6 Troubleshooting of the Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.7 Troubleshooting of the Slave Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

15

Page 18

APPENDICES 101

Appendix 1 Details of I/O Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Appendix 1.1 Input signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Appendix 1.2 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Appendix 2 Details of Buffer Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Appendix 3 Checking the Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix 4 EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix 4.1 Measures to comply with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Appendix 4.2 Requirements for compliance with the Low Voltage Directive . . . . . . . . . . . . . . . . . . 115

Appendix 5 When Using GX Developer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix 5.1 Operating GX Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix 6 Precautions for Creating Program for Slave Module Parameter Access . . . . . . . . . . . 118

Appendix 6.1 Program examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Appendix 7 Functions Added and Modified with Version Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . 123

Appendix 8 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

INDEX 126

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

16

Page 19

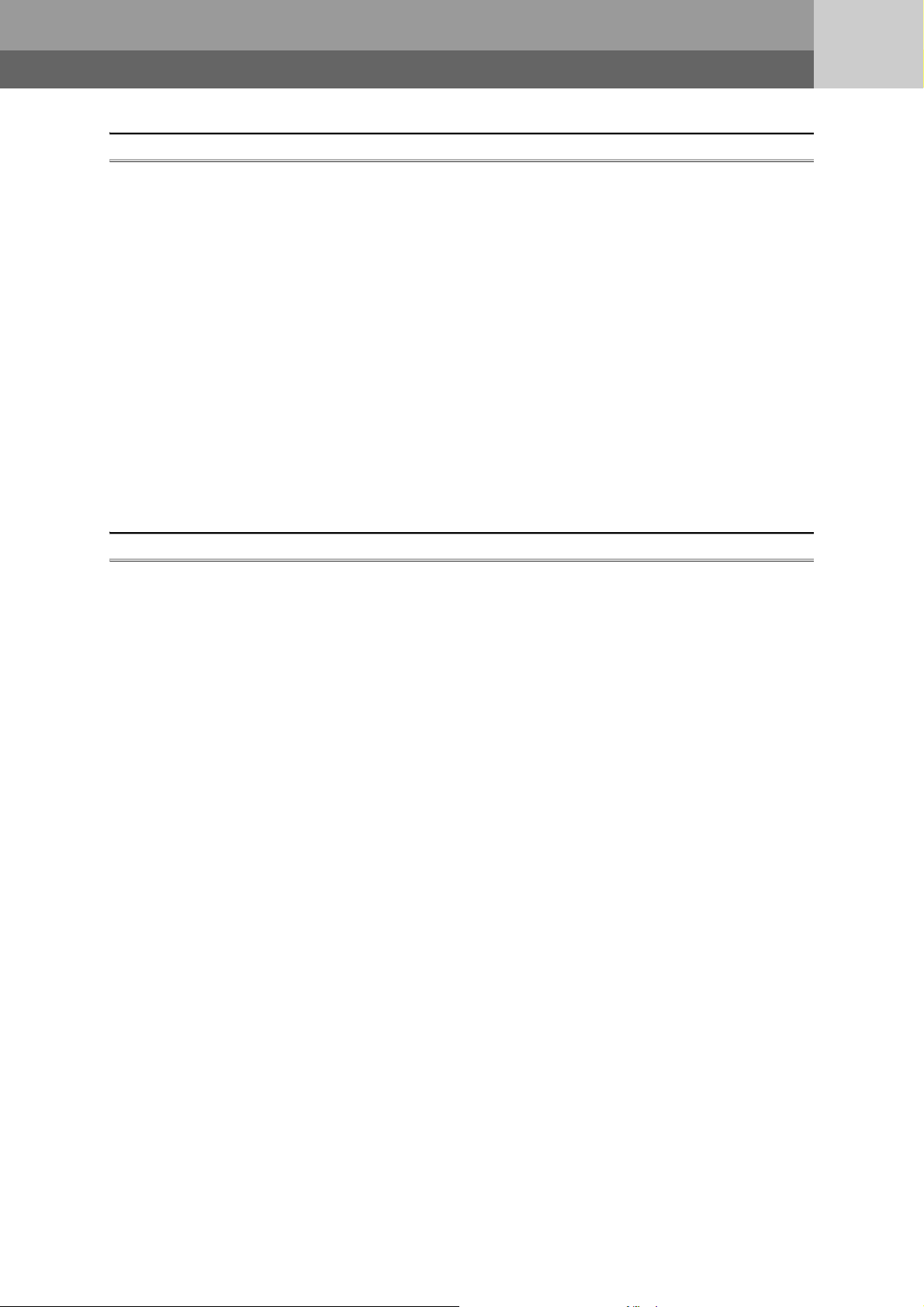

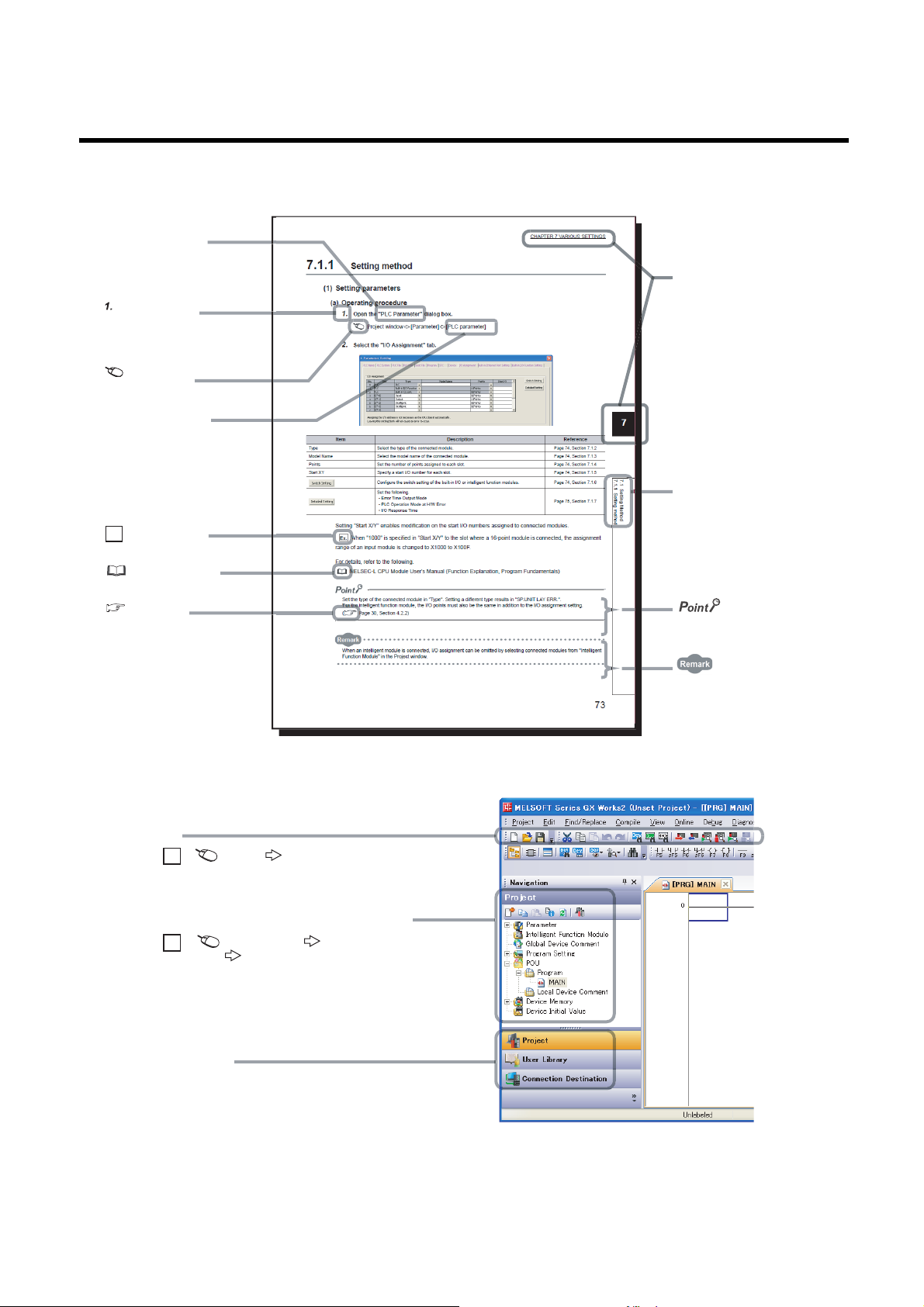

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example (for GX Works2) is provided below.

Menu bar

Ex.

A window selected in the view selection area is displayed.

Ex.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

In the Project window, expand [Parameter] and

select [PLC Parameter].

[Parameter]

17

Page 20

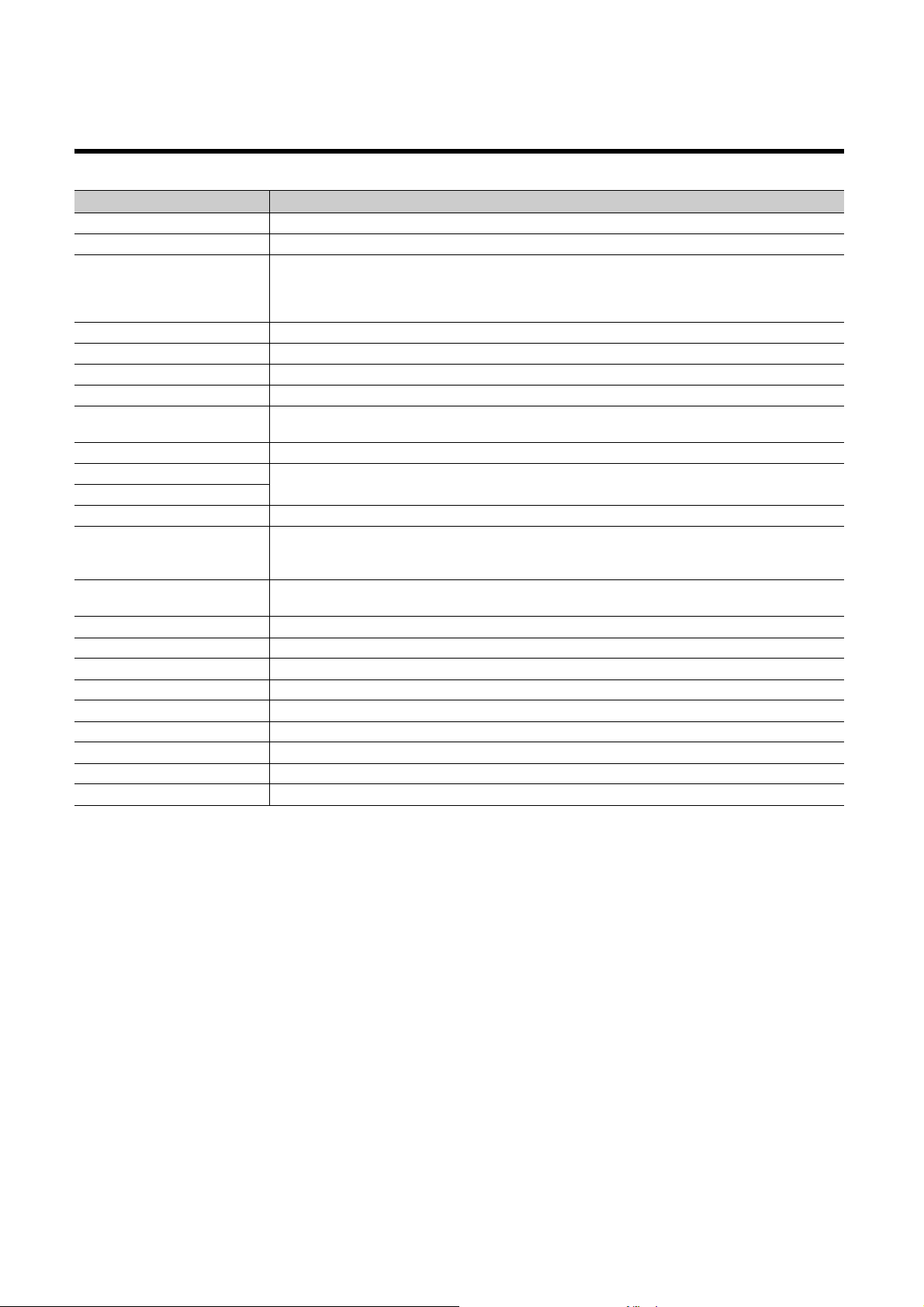

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

Address A parameter assigned to a slave module to identify each node on the AnyWireASLINK network

Address writer A hand-held device to read/write parameters (including addresses) from/to a slave module

A system where sensors at the end of a control system are connected to a programmable controller in the most

AnyWireASLINK

AnyWireASLINK bridge module A generic term for the NZ2AW1C2AL and NZ2AW1GFAL

AnyWireASLINK master module A generic term for the RJ51AW12AL, QJ51AW12AL, and LJ51AW12AL

ASLINKAMP A generic term for sensor amplifiers that have an AnyWireASLINK interface

ASLINKER A generic term for I/O devices that have an AnyWireASLINK interface

Buffer memory

CPU module A generic term for the MELSEC-Q and -L series CPU modules

GX Developer

GX Works2

Head module The abbreviation for the LJ72GF15-T2 CC-Link IE Field Network head module

ID

Intelligent function module

Master module A generic term for the QJ51AW12AL and LJ51AW12AL

MELSEC-L series The abbreviation for the Mitsubishi programmable controller MELSEC-L series

MELSEC-Q series The abbreviation for the Mitsubishi programmable controller MELSEC-Q series

Power cable (24V, 0V) A cable that connects a master module to a 24VDC external power supply

Programming tool A generic term for GX Works2 and GX Developer

Slave module A generic term for modules that communicate data with a master module

Terminating unit A waveform shaper

Transmission cable (DP, DN) A signal cable that connects a slave module to a master module

Transmission cycle time A data sampling interval

suitable way.

With this system, a bridge module can detect sensor disconnection and a user can set the I/O operations of a slave

module on a bridge module without using I/O areas of the CPU module.

A memory in an intelligent function module, where data (such as setting values and monitoring values) exchanged

with a CPU module are stored

The product name of the software package for the MELSEC programmable controllers

A parameter to identify whether the module is an input module or output module based on its address

Output slave module ID: Address

Input slave module/I/O combined slave module ID: Address + 200

A MELSEC-Q/L series module that has functions other than input and output, such as an A/D converter module and

D/A converter module

H

18

Page 21

PACKING LIST

QJ51AW12AL Before Using the Product

LJ51AW12AL Before Using the Product

The following items are included in the package of this product. Before use, check that all the items are included.

QJ51AW12AL

LJ51AW12AL

19

Page 22

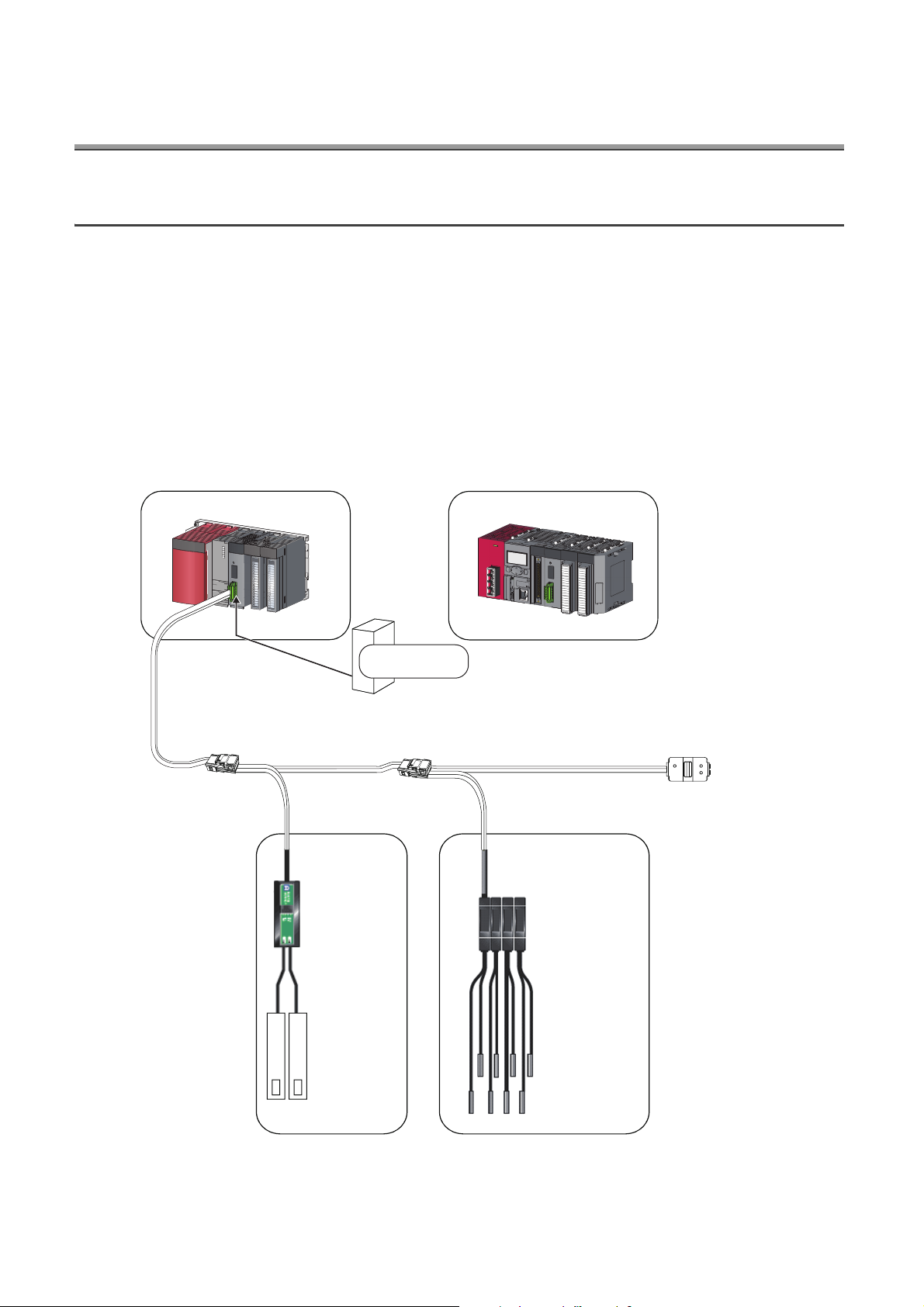

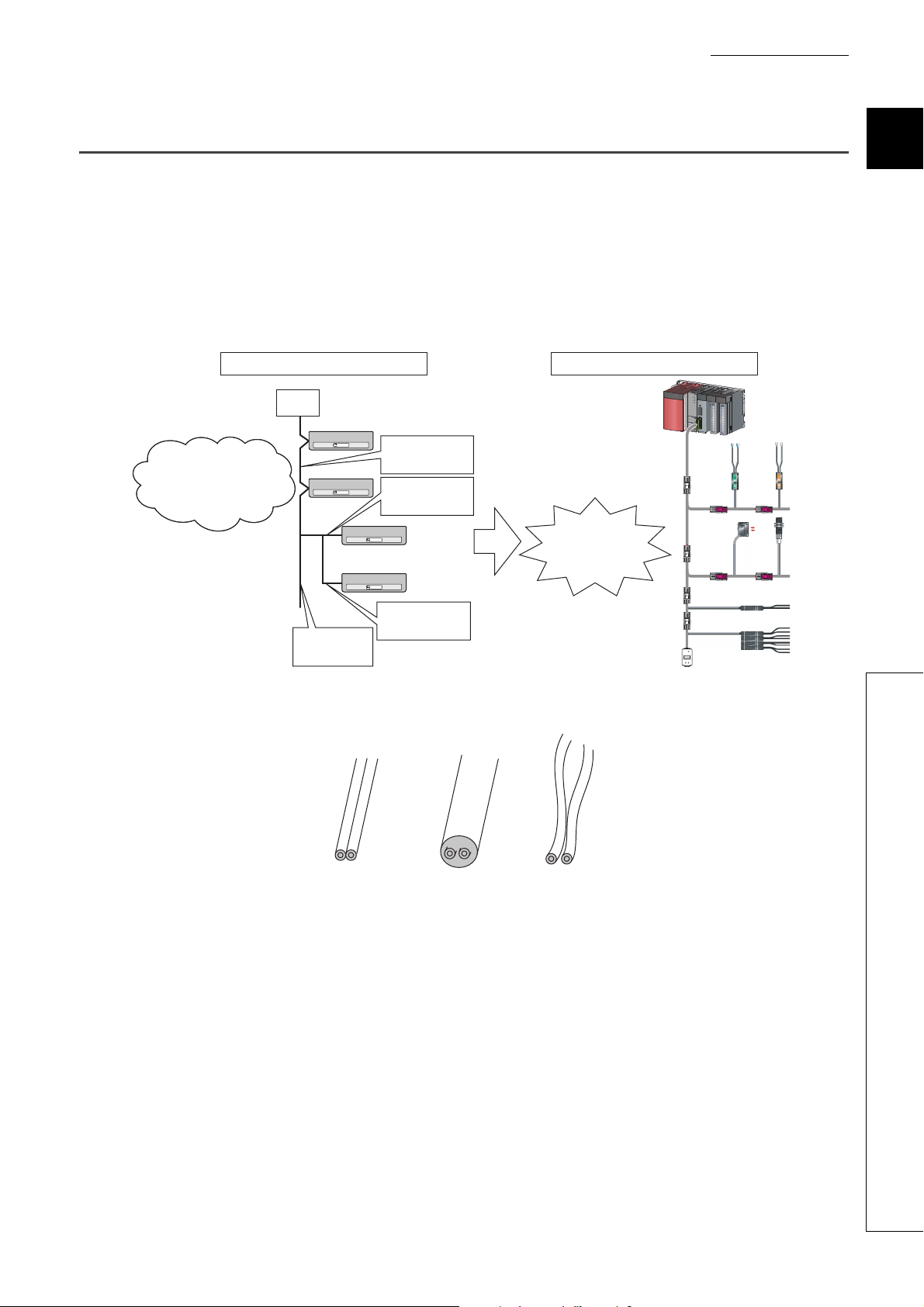

CHAPTER 1 FEATURES

ASLINKER

*1

LJ51AW12AL

ASLINKAMP

*1

24VDC

General-purpose

power supply

QJ51AW12AL

or

Cylinder,

switch, or

others

AnyWireASLINK terminating unit

*1

*

1 Manufactured by Anywire Corporation

Sensor head

1.1 AnyWireASLINK

The AnyWireASLINK is a high-speed and highly reliable system which releases the work site from complicated and

incorrect wiring.

In this network, sensors at the end of a control system are connected to a programmable controller in the optimum

form.

Furthermore, this network enables a mater module to detect sensor disconnection and enables a user to set the

operations of a slave module only using the areas, 32 points occupied, of a master module with the I/O assignment

setting.

The master module, a product of the joint development project with Anywire Corporation, allows the AnyWireASLINK

system to be constructed in a MELSEC-Q or MELSEC-L series programmable controller system.

20

Page 23

CHAPTER 1 FEATURES

Restricted

station-to-station

distance

Restricted

branch line length

Restricted number

of branches

Restricted main

line length

Standard network

Master

station

AnyWireASLINK

Adding a station to

the existing network is

hard with many

restrictions on wiring.

A station

can be added only

if the total length

is within 200m.

Flat cable

General-purpose

2-wire cable

General-purpose

wire

1.2 Features

This section describes the features of the AnyWireASLINK.

(1) Flexible wiring

The AnyWireASLINK allows flexible connections if the overall cable distance of transmission cables (DP, DN) is

within 200m.

There is no restriction about, for example, the main line length, station-to-station distance, and number of

branches.

1

(2) Single-touch cable connection and disconnection

(3) Space saving

Moreover, because of a little restrictions about cables, cables used for other networks can be used for the

AnyWireASLINK without modification, resulting in reduced wiring man-hours and cable cost.

*1 Before using, check the performance specifications. ( Page 26, Section 3.2.1)

Using a dedicated connector enables cables to be connected and disconnected with a single operation and

eases slave module addition and replacement.

*1 For wiring with the dedicated connectors, contact Anywire Corporation.

The system needs much less space because of a wide selection of small-type slave modules (manufactured by

Anywire Corporation).

*1

*1

1.2 Features

21

Page 24

(4) RAS improvement

The system start-up time can be reduced by checking whether a slave module is connected or by detecting an ID

setting error.

22

Page 25

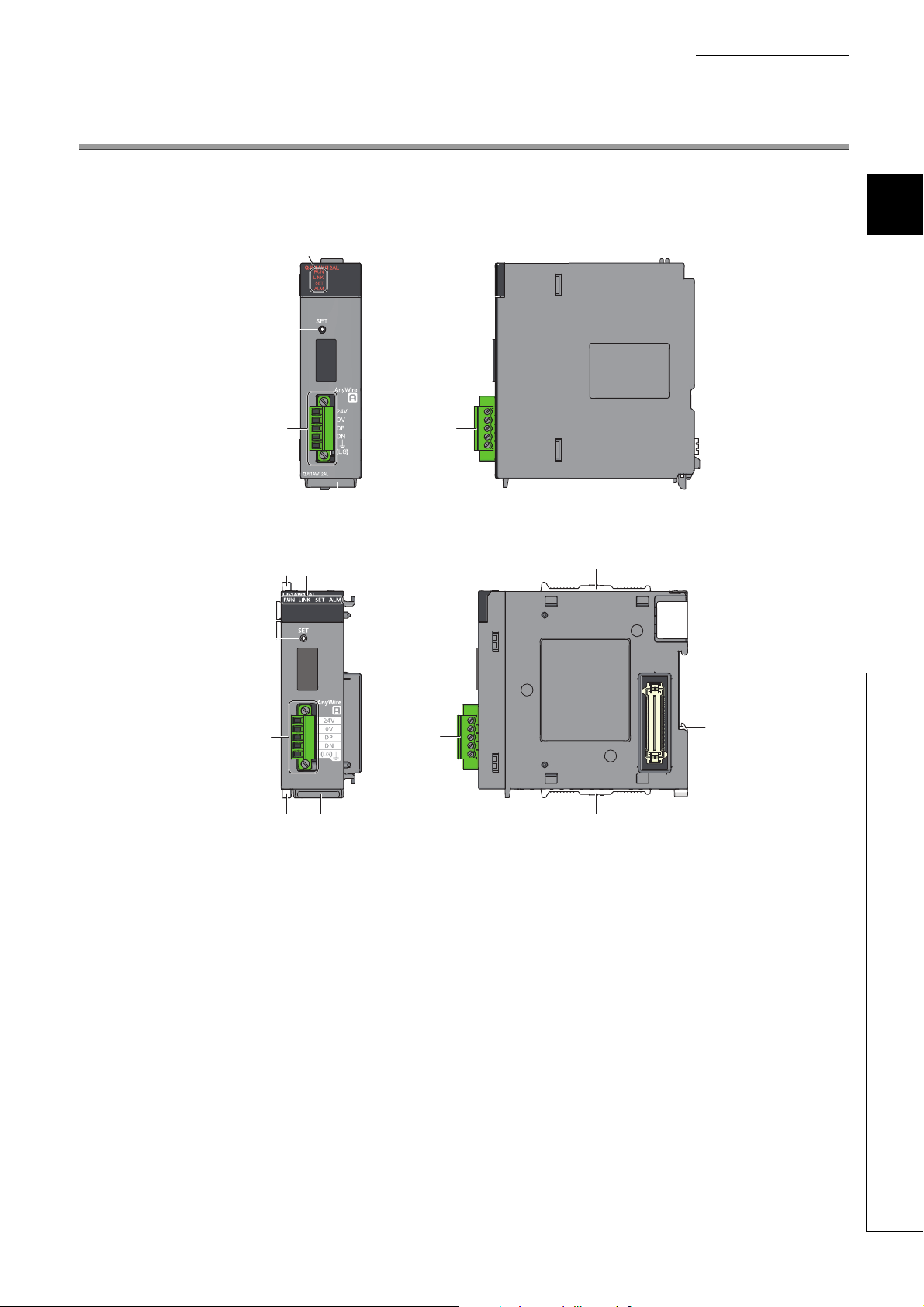

CHAPTER 2 PART NAMES

2)

3)

3)

6)

4)5) 5)

LJ51AW12AL

1)

5)

5)

This chapter describes the part names of the master module.

QJ51AW12AL

1)

2)

3) 3)

CHAPTER 2 PART NAMES

2

4)

23

Page 26

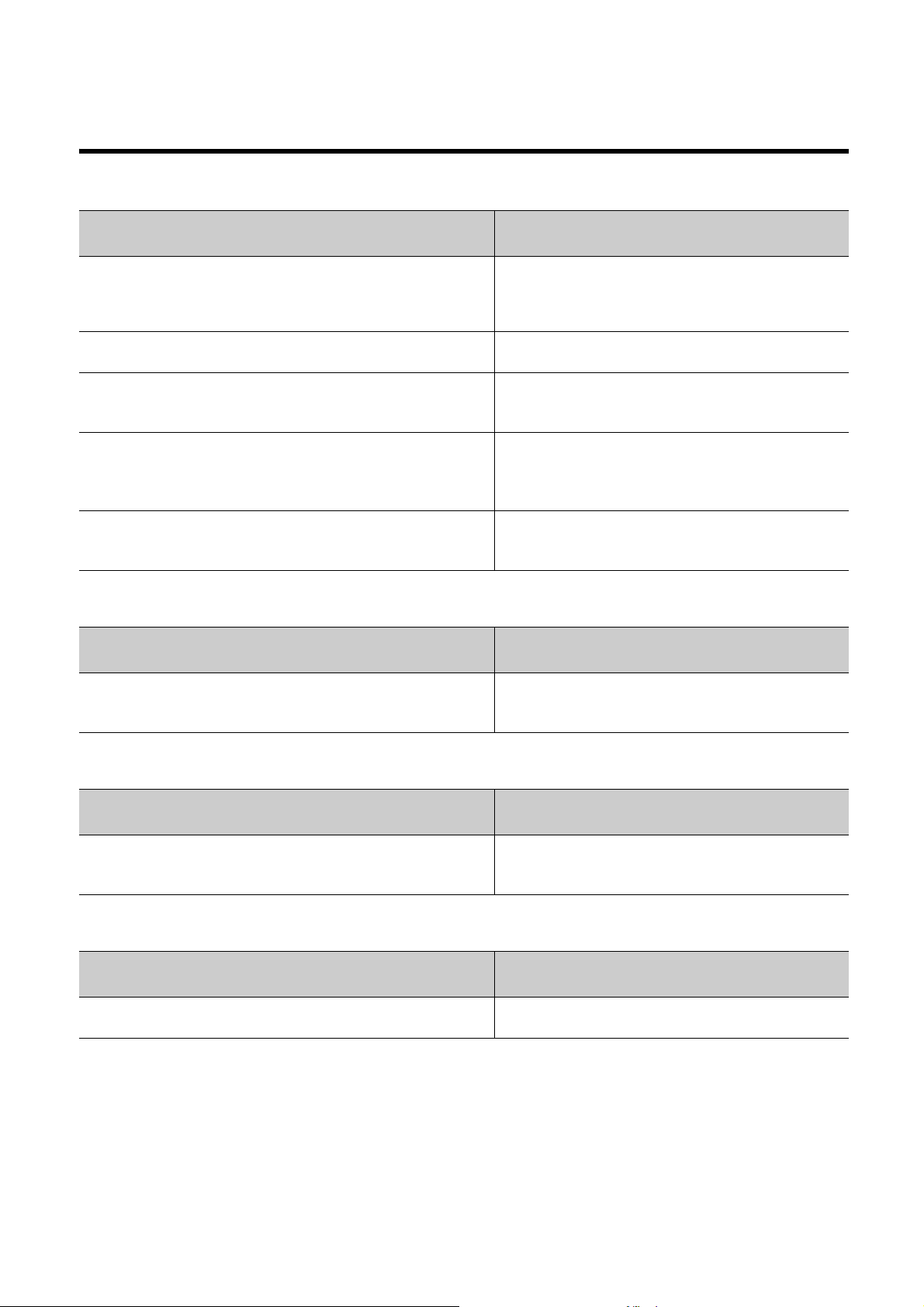

No. Name Description

The master module status is indicated by the LEDs.

LED name Description

Indicates the operating status of the master module.

RUN LED (green)

LINK LED (green)

1) LED display

SET LED (green)

ALM LED (red)

2) SET switch Switch for automatic detection of the slave module ID (address)

Transmission cable terminal

3)

block

4) Serial number display Displays the serial number printed on the rating plate

5) Module joint lever A lever for connecting modules

6) DIN rail hook A hook for mounting a module to a DIN rail

A terminal block of the AnyWireASLINK

ON: Operating normally

OFF: Master module error, 5VDC power off, or CPU module stop error

Indicates the link status of the master module.

Flashing: Communication is possible.

Off, On: Communication is not possible.

Indicates the address detection status of the master module.

On: Automatic address detection in progress

Flashing: Address write in progress

Off: Before or after automatic address detection

Indicates the alarm status of the master module.

ON: DP/DN disconnection, no response from the slave module

Slow flashing (one-second intervals): DP/DN short

Fast flashing (0.2-second intervals): 24VDC is not being supplied or the

voltage is low.

OFF: Operating normally

24

Page 27

CHAPTER 3 SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

This chapter describes the general specifications and performance specifications and lists the functions, I/O signals,

and buffer memory addresses.

3.1 General Specifications

For the general specifications of the master module, refer to the following.

"Safety Guidelines" included with the CPU module, base unit, or head module

3

3.1 General Specifications

25

Page 28

3.2 Performance Specifications

3.2.1 Performance list

The following table lists the performance specifications of the master module.

Item

Transmission clock 27.0kHz

Maximum transmission distance (total

length)

Transmission system DC power supply transmission total frame cyclic system

Connection type Bus topology (multidrop system, T-branch system, tree branch system)

Transmission protocol Dedicated protocol (AnyWireASLINK)

Error control Checksum, double-check system

Number of connected I/O points Up to 512 points (256 input points/256 output points)

Number of connectable slave modules Up to 128 (varies depending on the current consumption of each slave module)

RAS function

Transmission cable (DP, DN)

Power cable (24V, 0V)

Transmission cable supply current

Maximum number of writes to EEPROM Up to 100000 times

Internal current

consumption (5VDC)

Power supply

Number of occupied I/O points 32 points (I/O assignment: intelligent 32 points)

External dimensions 98.0mm (H) 27.4mm (W) 100.0mm (D) 90.0mm (H) 28.5mm (W) 104.5mm (D)

Weight 0.2kg

External power

supply

*1

Disconnected transmission cable location detection function, transmission cable short

• UL-listed general-purpose 2-wire cable (VCTF, VCT 1.25, 0.75, temperature rating

70 or higher)

• UL-listed general-purpose wire (1.25, 0.75, temperature rating 70 or higher)

• Dedicated flat cable (1.25, 0.75, temperature rating 90)

• UL-listed general-purpose 2-wire cable (VCTF, VCT 0.75 to 2.0, temperature

rating 70 or higher)

• UL-listed general-purpose wire (0.75 to 2.0, temperature rating 70 or higher)

• Dedicated flat cable (1.25, 0.75, temperature rating 90)

Voltage: 21.6 to 27.6VDC (24VDC -10% to +15%), ripple voltage 0.5Vp-p or lower

QJ51AW12AL LJ51AW12AL

detection function, transmission cable voltage drop detection function

When using a 1.25 cable: Up to 2A

When using a 0.75 cable: Up to 1.2A

Current consumption: Up to 0.2A

Recommended voltage: 26.4VDC (24VDC + 10%)

Module current consumption: 0.1A

Transmission cable supply current: Up to 2A

Model name

*2

200m

Voltage: 5VDC 5%

*1

26

*1 For the relationship between the total length, the wire diameter of transmission cables (DP, DN), and the transmission

cable supply current, refer to the following. On some slave modules with cables, the wire diameter of module-integrated

transmission cables (DP, DN) may be 0.75or less. However, they can be used without any problem, provided that the

diameter of the transmission cables (DP, DN) meets the requirement below.

Wire diameter of

transmission

cables (DP, DN)

1.25 Up to 2A Up to 1A Up to 0.5A

0.75 Up to 1.2A Up to 0.6A Up to 0.3A

Total length of 50m or

*2

less

Transmission cable supply current

Total length of 50m to

*2

100m

Total length of 100m to

200m

*2

Page 29

CHAPTER 3 SPECIFICATIONS

*2 For slave modules with integrated transmission cables (DP, DN), the length of the transmission cables (DP, DN) is

included in the total length.

For wiring of 50m or more with 4 wires (DP, DN, 24V, 0V), insert the noise filter for power supply cables between the

power supply and cables. For details, refer to the manual for the AnyWireFILTER (ANF-01) manufactured by Anywire

Corporation.

3

3.2.1 Performance list

3.2 Performance Specifications

27

Page 30

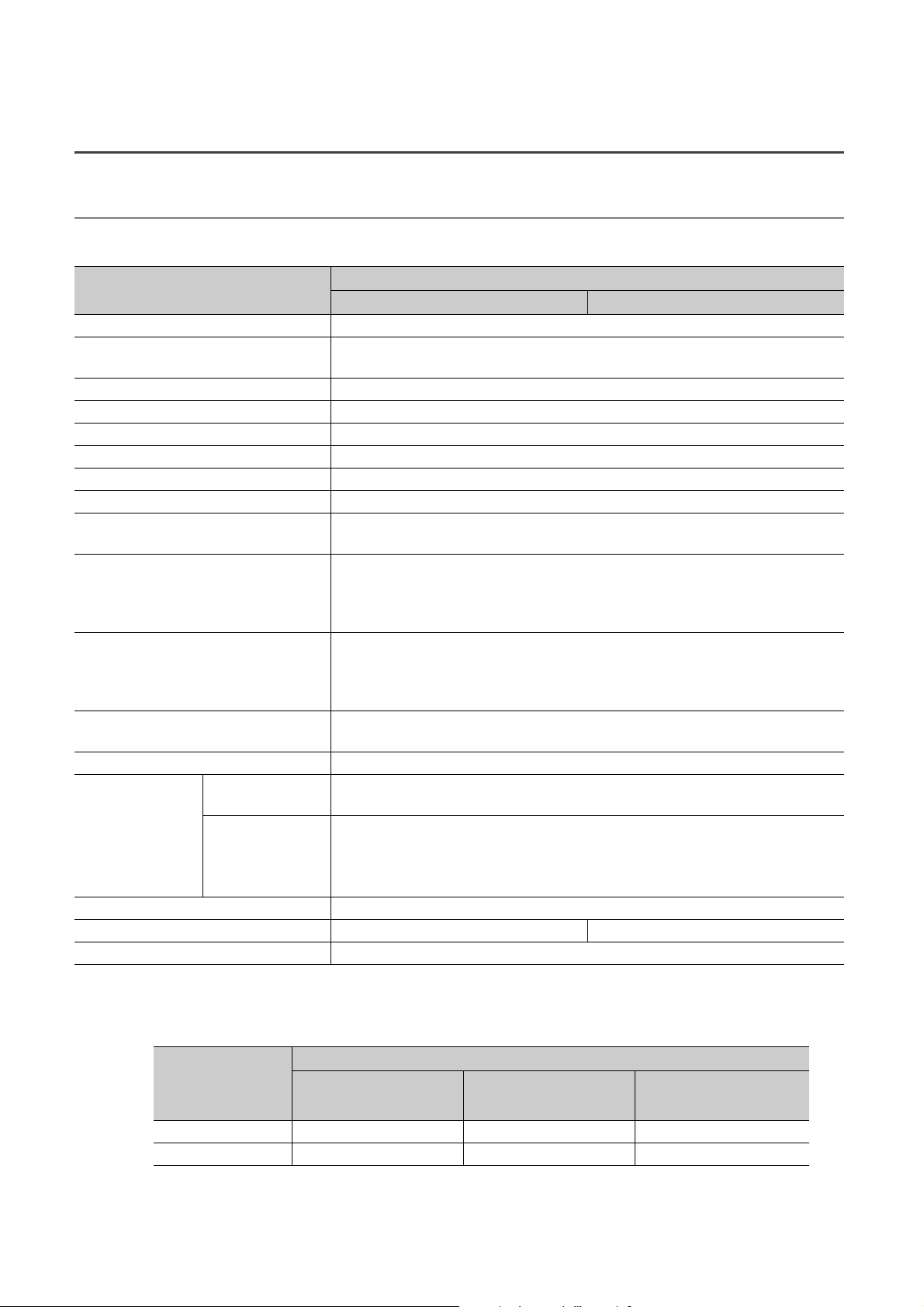

3.2.2 Number of parameters to set

1) 2) 3) 4)

As for the initial settings of a master module and the parameter settings regarding the auto refresh setting, do not set

the number of parameters, including those of other intelligent function modules, greater than the number of parameters

that can be set in a CPU module.

For the maximum number of parameters settable on the CPU module, refer to the following.

User's Manual (Hardware Design, Maintenance and Inspection) for the CPU module used

MELSEC-L CC-Link IE Field Network Head Module User's Manual

(1) The number of parameters for a master module

The master module allows the following number of parameters per module.

Target module Initial setting Auto refresh setting

QJ51AW12AL 0 (unused) 2 (maximum number of settings)

LJ51AW12AL 0 (unused) 2 (maximum number of settings)

(2) Check method

The number of parameters set in an intelligent function module and the maximum number of parameter settings

can be checked with the following operations:

Project window [Intelligent Function Module] Right click

[Intelligent Function Module Parameter List]

No. Description

1) Total number of initial setting parameters having the checkboxes checked on the window

2) Maximum number of initial parameter settings

3) Total number of auto refresh setting parameters having the checkboxes checked on the window

4) Maximum number of auto refresh setting parameters

28

Page 31

3.2.3 Communication performance

Remark

Minimum data

response time

Input data change

Input data change

Input data update

Input data update

Maximum data

response time

Sampling timing Sampling timing Sampling timing

Minimum one-transmission cycle time

Maximum two-transmission cycle time

Sampling timing Sampling timing

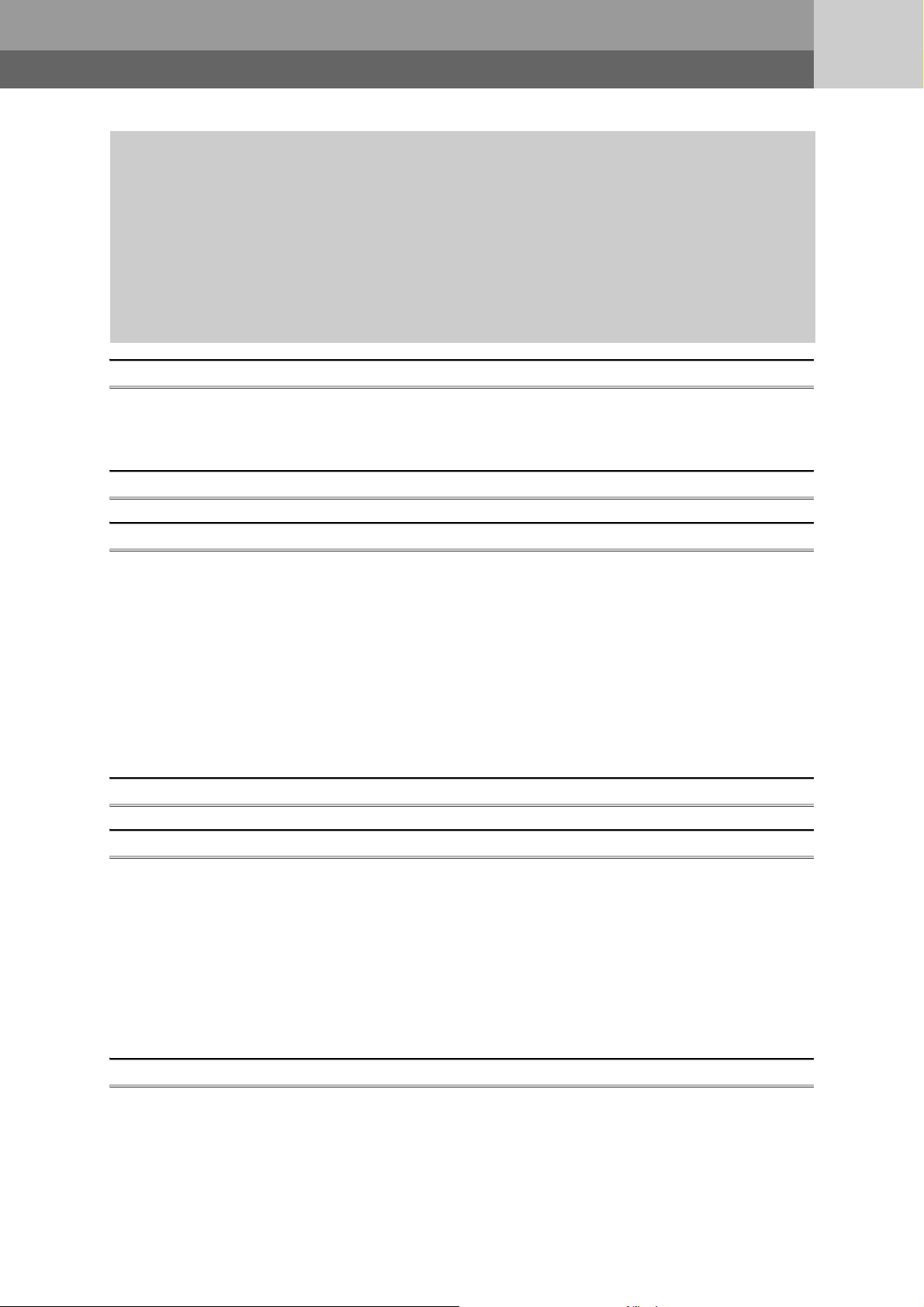

(1) Transmission cycle time

The transmission cycle time is the time required for the master module and all the slave modules to update I/O

data.

The transmission cycle time of the master module is listed in the table below.

Number of

transmission points

One transmission

cycle time

● The transmission delay time is a value between one- and two-transmission cycle time.

● To ensure the response to the input signal, provide an input signal that is longer than two-transmission cycle time.

64 points (32 input

points, 32 output

points)

2.3ms 3.5ms 5.9ms 10.6ms

128 points (64 input

points, 64 output

points)

CHAPTER 3 SPECIFICATIONS

256 points (128 input

points, 128 output points)

512 points (256 input

points, 256 output points)

3

(2) Effects of the double check system

(a) Input

Unless the same data is received twice successively on the master module side, the input area data is not

updated.

A minimum of one-transmission cycle time and a maximum of two-transmission cycle time are required as the

data response time.

Therefore, when an input signal is shorter than two-transmission cycle time, the input data may not be captured

depending on the timing.

To ensure the response, provide an input signal that is longer than two-transmission cycle time.

(b) Output

As the double check is performed on the slave module side, the time required is the same as that for input,

namely a minimum of one-transmission cycle time and a maximum of two-transmission cycle time.

3.2 Performance Specifications

3.2.3 Communication performance

29

Page 32

(3) Response delay time

Input

Slave module

AnyWireASLINK

CPU module

3) Transmission time

4) Processing time on the

master module

1) Input response time on the

slave module

2) Processing time on the

slave module

5) Processing time on the

programmable controller

The following shows the response delay time of input and output.

(a) Input response delay time

The figure below shows the time between a signal input to the slave module and the CPU module device

turning on/off.

The input response delay time is the total of 1) to 5) in the following figure.

No. Description Required time

1) Input response time on the slave module

2) Processing time on the slave module

3) Transmission time

4) Processing time on the master module 0.6ms

5)

Processing time on the programmable

controller

Refer to the manual for the slave module connected to the

system or the device connected to the slave module.

Approx. 0.2ms (The time differs depending on the slave

module.)

Transmission cycle time 2

The transmission cycle time differs depending on the number

of transmission points. ( Page 29, Section 3.2.3 (1))

Sequence scan time 2

30

Page 33

CHAPTER 3 SPECIFICATIONS

Output

(b) Output response delay time

The figure below shows the time between the CPU module device turning on/off and a signal output from the

slave module turning on/off.

The output response delay time is the total of 1) to 5) in the following figure.

Output

Slave module

5) Output response time

on the slave module

4) Processing time on the

slave module

Output

3

AnyWireASLINK

CPU module

1) Processing time on the

programmable controller

3) Transmission time

2) Processing time on the

master module

No. Description Required time

1)

2) Processing time on the master module 0.6ms

3) Transmission time

4) Processing time on the slave module

5) Output response time on the slave module

Processing time on the programmable

controller

Sequence scan time

Transmission cycle time 2

The transmission cycle time differs depending on the number

of transmission points. ( Page 29, Section 3.2.3 (1))

Approx. 0.04ms (The time differs depending on the slave

module.)

Refer to the manual for the slave module connected to the

system or the device connected to the slave module.

(4) Parameter access response time

The parameters of the AnyWireASLINK provide the monitoring information of the slave module or the entire

system and the setting information of the slave module.

Parameter data are synchronized between the buffer memory of the master module and the slave module at a

cycle different from that of the I/O data.

Use the following calculation formulas to obtain the parameter access response time.

3.2 Performance Specifications

3.2.3 Communication performance

[Update interval time of an automatically updated parameter]

Number of AnyWireASLINK connection IDs transmission cycle time 3

[Time required for reading a parameter]

Number of target IDs transmission cycle time 27

[Time required for writing a parameter]

Number of target IDs transmission cycle time 39

31

Page 34

3.3 Function List

The following table lists the functions of the master module.

Item Description Reference item

Bit transmission function

Parameter reading function

Parameter writing function

Automatic address detection function

Transmission cable short detection

function

Disconnected transmission cable

location detection function

Transmission cable voltage drop

detection function

Parameter access error detection

function

Same ID used detection function

Module with no ID setting detection

function

Backup/restoring function

Performs input and output of up to 512 points (256 input points and 256

output points) between the master module and the slave module.

Reads the parameters of a slave module connected to the master module

without delaying the AnyWireASLINK bit transmission.

Writes the parameters of a slave module connected to the master module

without delaying the AnyWireASLINK bit transmission.

The master module detects or stores the ID (address) of the connected

slave module when the SET switch on the front of the master module is

pressed. (Alternatively a specific bit can be used.)

Detects a short in DP-DN cables. Page 62, Section 8.2

Detects the location of DP-DN cable disconnection. Page 63, Section 8.3

Monitors a voltage drop in the 24VDC external power supply. Page 64, Section 8.4

Detects an error upon reading or writing of the setting values of the slave

module.

Checks whether the same ID is used for multiple slave modules. The

LEDs of the relevant slave modules are forcibly turned on.

Detects slave modules with no ID assigned (default ID). Page 68, Section 8.7

Backs up various information of the connected slave module into the SD

memory card of the CPU module.

Restores the information backed up on the SD memory card of the CPU

module into the connected slave module.

Page 62, Section 8.1

Page 69, Section 8.8

Page 69, Section 8.8

Page 57, Section 7.3

Page 65, Section 8.5

Page 67, Section 8.6

Page 74, Section 8.9

32

Page 35

CHAPTER 3 SPECIFICATIONS

3.4 List of I/O Signals

The following table lists the signals input or output between the CPU module and the master module.

For details on the I/O signals, refer to Page 101, Appendix 1.

Signal direction: Master module to CPU module Signal direction: CPU module to master module

Device number Signal name Device number Signal name

Xn0 Module READY Yn0 Error flag clear command

Xn1 DP/DN short error Yn1

Xn2 Use prohibited

Xn3

Xn4 DP/DN disconnection error

Xn5 to XnF Use prohibited

X(n+1)0 Slave module alarm signal Y(n+1)0

X(n+1)1

X(n+1)2 Parameter access error Y(n+1)2

X(n+1)3 Use prohibited

X(n+1)5 to X(n+1)F Use prohibited

Transmission cable voltage drop

error

Parameter access completion

flag

Y(n+1)3 to Y(n+1)F Use prohibitedX(n+1)4 Automatic address detection flag

Yn2 to YnF Use prohibited

Y(n+1)1

Automatic address detection

command

Parameter access request

command for the slave module

Parameter batch read command

for the slave module

Parameter batch write command

for the slave module

3

3.4 List of I/O Signals

33

Page 36

3.5 List of Buffer Memory Addresses

Buffer memory is for data communications between the master module and the CPU module.

When the CPU module is reset or the system is powered off and on, the data in the buffer memory are set back to the

default (initial values).

The following table lists the buffer memory addresses for the master module.

For details on the buffer memory, refer to Page 104, Appendix 2.

Buffer memory address

Decimal Hexadecimal

to F

0 to 15

16 to 4095

4096 to 4111

4112 to 8191

8192

8193 to 8320

8321 to 8959

8960

8961 to 9215

9216

9217 to 9344

9345 to 9983

9984

9985 to 10112

10113 to 10255

10256

10257

10258 to 10319

10320

10321

10322 to 10495

10496 to 10751

10752 to 11007

11008 to 11263

11264 to 12287

12288 to 18431

18432 to 32767

0

H

10

H

1000

1010

2000

2001

2081

2300

2301

2400

2401

2481

2700

2701

2781

2810

2811

2812

2850

2851

2852

2900

2A00

2B00

2C00

3000

4800

to FFF

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

to 100F

to 1FFF

to 2080

to 22FF

to 23FF

to 2480

to 26FF

to 2780

to 280F

to 284F

to 28FF

to 29FF

to 2AFF

to 2BFF

to 2FFF

H

to 47FF

to 7FFF

Item

Input information area Read only

H

H

H

H

H

Number of the connected modules Read only

H

Number of the IDs of the connected modules Read only

H

H

H

H

H

Connected module ID information storage area Read only

Parameter access target module ID specification Read and write

H

H

H

H

H

H

H

Parameter storage location memory number (output) Read only

Parameter storage location memory number (input) Read only

System reserved

Output information area Read and write

System reserved

Number of the error IDs Read only

Error ID information storage area Read only

System reserved

System reserved

System reserved

Number of the alarm IDs Read only

Alarm ID information storage area Read only

System reserved

Latest error code storage area Read only

Latest error ID storage area Read only

System reserved

Parameter access setting Read and write

System reserved

System reserved

System reserved

Parameter storage area Read and write

System reserved

Allowable

operation

(Read/write)

34

If data are written in the system reserved area, it may cause malfunction of the programmable controller system.

Page 37

CHAPTER 4 PROCEDURES BEFORE OPERATION

Start

Checkbox

Master module mounting/connecting

Mount or connect the master module.

Slave module installation

Install the slave module in the control panel or machine.

Wiring

Connect each module using transmission lines (DP, DN) and power

cables (24V, 0V).

System power-on

Check the following before powering on the system:

Whether the master module is properly mounted or connected

Proper voltage supply to the power supply module of the programmable

controller and 24V and 0V terminals of the master module

Whether the switch on the CPU module is set to STOP

Whether each module is properly wired

Transmission distance

Set the address of the slave module.

Address setting

CHAPTER 4 PROCEDURES BEFORE OPERATION

This chapter describes the procedure from module mounting/connecting to system operation.

MELSEC-L CC-Link IE Field

User's manual for the slave

Page 43, Section 6.2

User's Manual (Hardware

Design, Maintenance and

Inspection) for the CPU

module used

Network Head Module User's

Manual

module used (manufactured by

Anywire Corporation)

4

Page 51, Section 6.4

Page 55, Section 7.2

35

Page 38

Operation mode setting for the master module

Set the number of transmission points for the master module.

Automatic address detection

Save the address of the slave module in the EEPROM of the master

module.

Page 53, Section 7.1

Page 57, Section 7.3

Parameter setting

Set the parameters of the slave module.

System operation

Operate the system.

End

Page 69, Section 8.8

36

Page 39

CHAPTER 5 SYSTEM CONFIGURATION

Master module

Power supply module

CPU module

Power supply module CPU module Master module

Display unit

(optional)

END cover

CHAPTER 5 SYSTEM CONFIGURATION

This chapter describes the overall configuration, system configuration of the master module, system configuration of

AnyWireASLINK, and applicable systems.

5.1 Overall Configuration

5.1.1 System configuration of the master module

This section describes the system configuration of the master module.

(1) QJ51AW12AL

The following system configuration of the QJ51AW12AL is used for explanation purpose.

(2) LJ51AW12AL

The following system configurations of the LJ51AW12AL are used for explanation purpose.

(a) When connected to the CPU module

5

5.1 Overall Configuration

5.1.1 System configuration of the master module

37

Page 40

(b) When connected to the head module

Power supply module CPU module Master module END cover

38

Page 41

CHAPTER 5 SYSTEM CONFIGURATION

ASLINKER

*1

LJ51AW12AL

ASLINKAMP

*1

24VDC

General-purpose

power supply

QJ51AW12AL

or

Cylinder,

switch, or

others

AnyWireASLINK terminating unit

*1

*

1 Manufactured by Anywire Corporation

Sensor head

5.1.2 System configuration of AnyWireASLINK

The following figure shows the system configuration of AnyWireASLINK.

5

For the number of connectable slave modules, refer to the following.

Page 26, Section 3.2.1

5.1 Overall Configuration

5.1.2 System configuration of AnyWireASLINK

39

Page 42

5.2 Applicable Systems

Remark

This section describes applicable systems.

5.2.1 QJ51AW12AL

(1) Applicable modules and base units, and the number of connectable modules

(a) Connecting a QJ51AW12AL to a CPU module

For the CPU modules, the number of modules, and base units applicable to the QJ51AW12AL, refer to the

user's manual for the CPU module used.

Note the following when the QJ51AW12AL is used with a CPU module.

• Depending on the combination with other modules or the number of mounted modules, power supply

capacity may be insufficient. Pay attention to the power supply capacity before mounting modules, and if

the power supply capacity is insufficient, change the combination of the modules.

• Mount a module within the number of I/O points for the CPU module. If the number of slots is within the

available range, the module can be mounted on any slot.

When using a C Controller module, refer to the user's manual for the C Controller module.

(b) Connecting a QJ51AW12AL in a MELSECNET/H remote I/O station

For the MELSECNET/H remote I/O station, the number of modules, and base units applicable to the

QJ51AW12AL, refer to the Q Corresponding MELSECNET/H Network System Reference Manual (Remote I/O

network).

(c) Connecting the QJ51AW12AL to an RQ extension base unit

When connecting the QJ51AW12AL to an RQ extension base unit, refer to the MELSEC iQ-R Module

Configuration Manual.

(2) Compatibility with a multiple CPU system

The QJ51AW12AL is compatible with a multiple CPU system from the first product.

When using the QJ51AW12AL in a multiple CPU system, refer to the following.

QCPU User's Manual (Multiple CPU System)

(3) Online module change

The QJ51AW12AL does not support online module change.

40

Page 43

5.2.2 LJ51AW12AL

(1) Number of connectable modules

For the number of connectable modules, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

(2) Precautions for the system configuration

(a) Rated output current (5VDC)

The total current consumption upon system configuration must not exceed the rated output current (5VDC) of

the power supply module of the programmable controller. For the specifications of the power supply module,

refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

CHAPTER 5 SYSTEM CONFIGURATION

5

5.2 Applicable Systems

5.2.2 LJ51AW12AL

41

Page 44

5.3 Compatible Software Version

The system which uses a master module is compatible with the software package as follows.

A programming tool is required when a master module is used.

Software Version

GX Works2 Version 1.98C or later

42

Page 45

CHAPTER 6 INSTALLATION AND WIRING

CHAPTER 6 INSTALLATION AND WIRING

This chapter describes the installation and wiring of the master module.

6.1 Installation Environment and Position of the Master

Module

For the precautions for the installation environment and position of the master module, refer to the following.

User's Manual (Hardware Design, Maintenance and Inspection) for the CPU module used

MELSEC-L CC-Link IE Field Network Head Module User's Manual

6.2 Wiring

(1) Descriptions of terminals

6

Terminal Description

24V

0V

DP AnyWireASLINK transmission signal terminals

DN

LG

Power supply terminal for driving the transmission circuit for the AnyWireASLINK system.

Connect to a 24VDC external power supply.

DP: Transmission cable (+), DN: Transmission cable (-)

Connect to the DP and DN terminals on the slave module or terminating unit.

Connected to the neutral point of the noise filter inserted between the 24V and 0V terminals.

Ground the LG terminal with the functional ground terminal (FG terminal) on the programmable

controller at a single point.

6.1 Installation Environment and Position of the Master Module

43

Page 46

(2) Transmission cable terminal block

Model name Applicable tightening torque

MC 1,5/5-STF-3,81

*1 Use the one manufactured by PHOENIX CONTACT GmbH & Co. KG. (For contact, visit www.phoenixcontact.com.)

*1

Classification Name Wire diameter Type Material

UL-listed general-purpose 2-wire

cable (VCTF, VCT)

Transmission

cable (DP, DN)

Power supply

cable (24V, 0V)

UL-listed general-purpose wire

Dedicated flat cable

UL-listed general-purpose 2-wire

cable (VCTF, VCT)

UL-listed general-purpose wire 0.75 to 2.0

Dedicated flat cable

0.2Nm to 0.3Nm

1.25

0.75

1.25

0.75

1.25

0.75

0.75 to 2.0 Stranded wire

1.25

0.75

Stranded wire

Stranded

wire/single

wire

Stranded wire 90

Copper

wire

Temperature

rating

70 or higher

90

70 or higher

To tighten the terminal block, a flathead screwdriver having a tipped size of 0.4 2.5mm is required.

Before removing the transmission cable terminal block, check that the terminal block mounting screws on both

ends are completely loosened (removed from the socket).

Pulling the terminal block with excessive force while the terminal block mounting screws on both ends are still

tightened may damage the devices.

Before connecting the terminal block, check that there are no short-circuits due to the disconnected or frayed

wires and tighten the terminal block mounting screws at both ends securely. (Tightening torque: 0.2 to 0.3Nm)

(3) Cable processing

Bare cables can be connected to the transmission cable terminal block; however, for safety reasons, it is

recommended to connect cables using bar solderless terminals.

Use UL-listed solderless terminals and, for processing, use a tool recommended by their manufacturer.

Typ e Model name

Bar

solderless

terminal

*1 When connecting two cables to one terminal, connect the two cables together to the TWIN bar solderless terminal.

*2 When TWIN bar solderless terminals are used, the maximum wire diameter is 0.75.

AI 0,75-8 GY Processing of a 0.752 wire

AI 1,5-8 BK Processing of a 1.252 wire

*1

AI-TWIN 2 0,75-8 GY Processing of two 0.75 wires

Application

*2

PHOENIX CONTACT GmbH & Co. KG

(www.phoenixcontact.com)

Contact

44

Page 47

6.2.1 Wiring precautions

The following shows the wiring precautions in the AnyWireASLINK system.

• In the AnyWireASLINK system, signals and power are supplied to a slave module with two types of

transmission cables; DP and DN. Therefore, using a stranded wire of 1.25 or larger for the main line is

recommended.

• Wires such as general-purpose wires, cabtyre cables, and flat cables can be used.

• Do not run multiple transmission cables (DP, DN) using a multicore cable. Running multiple transmission

cables (DP, DN) together may cause noise, resulting in a malfunction.

CHAPTER 6 INSTALLATION AND WIRING

DP

DN

DP

DN

• The voltage should not fall below the lower limit of the allowable voltage range due to the voltage drop

caused by the cable. If the voltage falls below the lower limit, malfunctions may occur.

• Do not connect soldered cables directly to the terminals. Doing so may loosen the screws, resulting in a poor

contact.

• Use a crimping tool to connect a cable to a bar solderless terminal.

• Before inserting a bar solderless terminal, check the shapes of the wire insertion opening and bar solderless

terminal. Then, insert the terminal in the correct orientation. Inserting a bar solderless terminal wider than the

wire insertion opening may damage the terminal block. ( Page 44, Section 6.2 (3))

DP

DN

DP

DN

6

6.2.1 Wiring precautions

6.2 Wiring

45

Page 48

6.2.2 Connection of slave modules

Master module

A

Terminating

unit

Slave

module

Slave

module

Slave

module

Slave

module

C

B

Tree-type T-branch

Multidrop

(1) Connection type

• The maximum transmission distance in the AnyWireASLINK stand-alone system is 200m, which is the total

cable length including the main line and branch line (branch). (It varies depending on the wire diameter of

the transmission cables (DP, DN) or the transmission cable supply current.)

• Tree branch, T-branch, and multidrop connections are usable in the AnyWireASLINK system.

• Up to 128 slave modules can be connected.

The total length of the transmission distance for the AnyWireASLINK system can be calculated from A + B + C.

Note that the total length should not exceed the maximum transmission distance or the total length set for the system to

branch lines.

46

Page 49

CHAPTER 6 INSTALLATION AND WIRING

6.2.3 Power supply to the AnyWireASLINK system

(1) Method of supplying the power to the slave module

Connect a 24VDC external power supply to the master module.

The power consumed in the internal control circuits of all the slave modules and the external load power

connected to non-isolated slave modules are supplied collectively from the 24VDC external power supply

connected to the master modules.

( Page 26, Section 3.2)

(2) Scope of the power supply with transmission cables (DP and DN)

The current consumption of the system must satisfy all the conditions specified by the following calculation

formulas 1) to 3) for each master module.

Condition Calculation formula Description

Ihin: Current consumption of the non-isolated input slave module/I/O combined slave

module

Iho: Current consumption of the non-isolated output slave module

Izdin: Current consumption of the isolated input slave module/I/O combined slave

module

I(A) = (Ihin x m) + (Iho x n) + (Izdin x

1)

p) + (Izdo x q) The maximum value

of transmission cable supply current

Izdo: Current consumption of the isolated output slave module

m: Number of connected non-isolated input slave modules/I/O combined slave

modules

n: Number of connected non-isolated output slave modules

p: Number of connected isolated input slave modules/I/O combined slave modules

q: Number of connected isolated output slave modules

6

For details, refer to Page 48, Section 6.2.3 (2) (a).

2)

3)

Vm(V) - V(V) 20V

Vm(V) - V(V) The lowest

allowable voltage of the connected

load

Vm: Supply voltage for the master module

V: Cable-to-cable voltage drop

For details, refer to Page 50, Section 6.2.3 (2) (b).

6.2.3 Power supply to the AnyWireASLINK system

6.2 Wiring

47

Page 50

(a) Description of the condition 1)

Non-isolated slave module

Control circuit

Power supply

generation

Connected load

24VDC external

power supply

24V 0V

24V 0V

24VL 0VL 01 n

DP DN

DP DN

Master module

• Constants related to the non-isolated slave module (Ihin, Iho)

For the non-isolated slave module, the current required for the internal control circuit and the connected

load is supplied over transmission cables (DP, DN).

Ihin(A) = Current consumption of the non-isolated input slave module/I/O combined slave module