Page 1

Distributed by

MITSUBISHI ELECTRIC

INSTALLATION INSTRUCTIONS

Perfect for and other A/C and plumbing applications and installations.

WWW.LINE-HIDE.COM

No. LIOCA 100710M

PROTECT

PRO TECT

&BEA UTIFY

& BEA UTIFY

Page 2

INSTALLATION INSTRUCTIONS

WARNING! Before you begin . . .

Whenever you’re working with tools, it’s a good idea

to wear appropriate safety gear: helmet, protective goggles, and gloves. If

you’re working high above the ground, be sure that you have sound footing.

Installing Line-Hide

Your Line-Hide installation will go smoothly if you follow — in

order

— the steps outlined in these instructions: determine layout; install entry fittings and joint bases; install Line

insert Lineset: assemble tube, and assemble joints. When

you’ve finished, caulk the lineset entry and exit points on the

wall to ensure the protection of the Lineset and of the building.

Step 1: Layout

Identify the inlet and outlet points for the Lineset

you’ll be installing within the Line-Hide

product, and determine the simplest

and most appropriate route for the

installation to follow. In most cases you’ll want your installation

to run perfectly vertical and nearly horizontal (a slight grade will

enable condensate lines to drain) and adhere to 90 degree

turns. Sketching your installation on a contractor worksheet or

graph paper will help you to determine how much tubing and

how many elbows, joints, and other pieces you will need.

Try to adhere to a grid defined

by parallel and perpendicular

lines and 90-degree angles

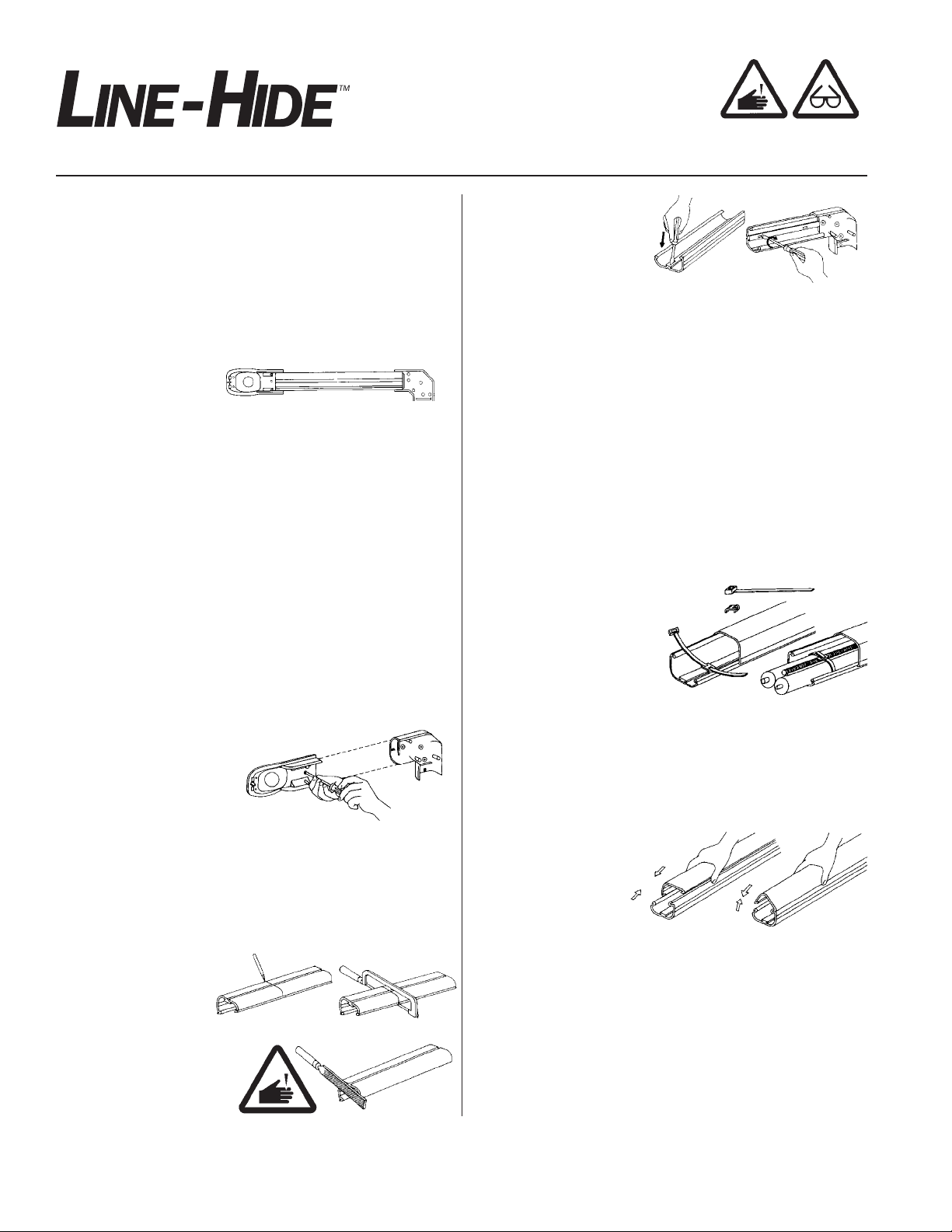

Step 2: Install Entry Fittings and Joint Bases

Most Line-Hide entry fittings and joints (including elbows)

include a base and a cover. Once you’ve determined where

your joints will be, install the bases. If you’re installing on wood,

simply position the base, and fasten it to the wall, using wood

screws. Don’t overtighten, or you’ll risk cracking the plastic.

For installations on a brick wall, mark the location for

each screw, and drill an anchor hole

using a masonry bit; then use

appropriate anchors and

screws.

Tube base;

To attach the Line Tube

base to the wall, first use

the tip of a screwdriver to

make a hole in the central

rib of the base (thin spots

are moulded in to accommodate installation). Then put a screw

through the hole in the tube, and tighten it to the wall. Be careful not to overtighten, for you may distort the tube. For the

smaller sizes (the 60 and 75 series), place screws approximately every twelve inches. For the larger sizes (the 100 and 140

series), use screws approximately every six inches.

Step 4: Install the Lineset

Unwind insulated refrigerant lines, and place into straight portion

of the tube. When installing insulated refrigerant pipe into a corner, adjust the pipe to the shape of the joint, and gently bend the

insulated refrigerant pipe without forcing it. Bending too quickly

can cause kinks in insulated refrigerant pipe and can pinch drain

pipe. Also try to avoid compressing the pipe insulation.

A Saddle Band (NV-S short or

NV-L long) can be used to fasten the insulated refrigerant

pipe, drain pipe, and electric

cable together in the Line

Tube. The saddle snaps to the

central rib of the tube base.

Thread the band through the

saddle and around the piping and cable, and pull it tight. This procedure will help to keep the pipes and wiring in place.

As a general rule, use one saddle band for every three feet (one

meter) of tube.

Step 3:

Measure the distance between the molded stops of each joint

base, and determine the length of tube needed. Line-Hide Line

ube is manufactured in six-and-one-half-foot (two-meter)

T

lengths so some straight runs are fabricated using two or more

lengths of tube and a socket/coupling.

o

T

the appropriate length;

then draw a perpendicu

lar guideline across the

tube. Use a hacksaw to cut

the tube along the line, and

then use a file to smooth the

cut edge.

LIOCA 10/07 10M ©2007 Mitsubishi Electric and Electronics USA, Inc., HVAC

Install Line

cut tube, measure and mark

Tube Base

-

Step 5: Assemble

the Line

When the Lineset is in

position, attach the tube

cover to the base. Slip

the lip on the short

edge of the cover into the trough on the high edge of the base.

Then squeeze the short end of the base while pushing the long

edge of the cover inward so that the lip and the trough engage.

Step 6: Assemble the Joints

With the Line Tube completely assembled, return to each joint,

and complete assembly

base; line up the holes; then secure cover to bases with the

stainless steel screws provided.

T

ube

. Position the cover of each joint over its

Page 3

Installation Instructions for

Specific Items

Wall Cover Inlet (NW):

Use where piping penetrates the wall.

Align wall cover base with hole in the

wall, and fasten to wall with appropriate screws. After completing tube

assembly, push the

tube downward (in

the direction of the

arrows) after aligning

the base with the

stopper built-in to the

top portion of wall

cover. This process will temporarily fasten wall cover.

Simple Wall Cover (NY):

One-piece inlet is used where refrigerant piping penetrates the

building wall.

Locate cover over Lineset, and mark mounting holes. Mount

and secure Line Tube to wall. Carefully bend refrigerant tubing,

drain and/or wiring into Line Tube. Place a bead of caulk on the

wall cover flange. Place Simple Wall Cover over wall opening,

and secure with appropriate screws and anchors.

Elbows – 90 degree horizontal (NE) and vertica l

(NC), 45 degree horizontal (NM) and vertical (NU),

and univeral horizonal (NX) and vertical (NZ):

Use where piping from the outdoor unit rises vertically or turns

horizontally along the wall.

Position the elbow base on the

wall where it will be fastened, and

attach to the wall with appropriate

screws. After installing tube, align

the elbow cover to the elbow

base, and attach with the stainless

steel screws provided.

All vertical elbows — NC, NU, NZ

— are reversible for use in both

inside and outside corner applica

tions. Cover screws can be inserted in either direction required.

-Joint (NT):

T

Use where piping branches off.

To change tube size, use the appropriate adapter set.

Contents of Accessory Adapter Sets

NT-75 75mm-60mm adapter 2 sets

NT-100 100mm-60mm adapter 2 sets

100mm-75mm adapter 2 sets

NT-140 140mm-100mm adapter 2 sets

-

Fit the accessory adapter base

appropriate for the proper size tube

into the

T-Joint to wall with the appropriate

screws. After tube base is

installed and the lineset

positioned, and the tube

cover snapped on, attach

theT-Joint cover to the

T-Joint base with the stainless steel screws provided.

T-Joint base. Fasten base of

Socket/Coupling (NS):

Use to lengthen and extend

tubes and to prevent tube

cover from sliding.

Mark the length of the tube;

then position the socket base

so that the tube will abut the

molded plastic stop of the

socket; then attach the socket

to the wall with appropriate screws. After installing tube, align

cover with holes in socket base, and fasten with the stainless

steel screws provided.

Variant Socket/Reducer (NJ):

Use to connect Line Tubes of different sizes.

Before attaching base to wall, determine that the converter corresponds to the varying tube sizes you’ll be joining and that it is

oriented properly on the wall. Then attach with the appropriate

screws. Locate Line Tubes, and install covers. Place socket

covers over base; align holes, and fasten with stainless steel

screws provided.

Flexible Joint (NF):

Use where piping bends over protrusion (such

as side molding) on wall.

If your installation requires the use of flexible

joint,

not split.

piping, and secure it in place.

o connect flexible joint to Line

T

joint into the end of tube base, and fasten it with appropriate

screws.

flexible joint.

against the tube to make a tight, strong connection. When the

assembly is complete, snap the tube cover onto the tube base

so that the end of the flexible joint is concealed.

ALL IT FIRST

INST

Simply slide the flexible joint over the

o help ensure a tight fit, compress the bellows of the

T

After the flexible joint is released, it will expand

. Fle

le joints are

xib

ube, slide end of the flexible

T

©2007 Mitsubishi Electric and Electronics USA, Inc., HVAC LIOCA 10/07 10M

Page 4

End Socket (NR):

Use to accommodate

arious lineset combi-

v

nations.

Before attaching the

end socket, determine

which of the various

openings will best accommodate your

Then remove the extra levels of plastic

lineset.

on the end socket. To do this procedure, score

the plastic with a utility knife (make sure you’re

wearing gloves) where you want to break it.

end socket in one hand, use pliers to grip the excess plastic,

and snap it off (make sure you’re wearing safety goggles, as

the plastic can break in unexpected ways). Use a file to smooth

any rough edges.

Attempting to snap the plastic without scoring it first will

NOTE:

likely crack the end socket.

With the excess plastic removed, attach the base with screws;

install the tube, and attach the cover. See the socket/coupling

instructions for more details.

Then, holding the

Universal Elbow, Horizontal (NX) and Vertical (NZ):

Use to change duct direction at an angle beween 45 and 90

degrees.

When elbow is angled at 0 to

15 degrees, break off the

protrusion inside the universal

elbow using pliers (as shown

at right) in the direction of the arrow.

For turns less than

15 degrees, remove

this plastic protrusion

Corner Cap/Soffit Entry Fitting (NA):

Use where piping

comes through ceiling,

wall, etc.

With Line Tube in

place, locate the bot

tom of the corner cap

against the wall, and

attach with appropri

ate screws. Then snap the top portion to the bottom portion and

attach it to the base with the stainless steel screws provided.

-

Lineset

-

exterior

wall

Wall Entry Fitting (NK):

Use to provide a good seal where

tube comes through wall.

Simply fit the bottom and top portions around the inlet hole in the

wall, and attach with appropriate

screws. Wall Entry Fitting may be

trimmed to fit by scoring the bottom portion, then snapping off

the excess plastic.

Caulking

To help ensure that the lineset remains free of corrosion and

mildew resulting from excess moisture, use caulking to seal

around the Line-Hide product where the lineset exits and enters

the wall.

WARNING: Flying fragments of plastic may pose

a hazard when breaking

off the protrusion inside

the universal elbow. Be

sure to wear safety glasses and gloves, and make sure that

others in the area are wearing appropriate safety gear as well.

LIOCA 10/07 10M ©2007 Mitsubishi Electric and Electronics USA, Inc., HVAC

3400 Lawrenceville-Suwanee Road

Suwanee, GA 30024

phone 678-376-2900

fax 678-376-3540

e-mail line-hide@hvac.mea.com

www.line-hide.com

Loading...

Loading...