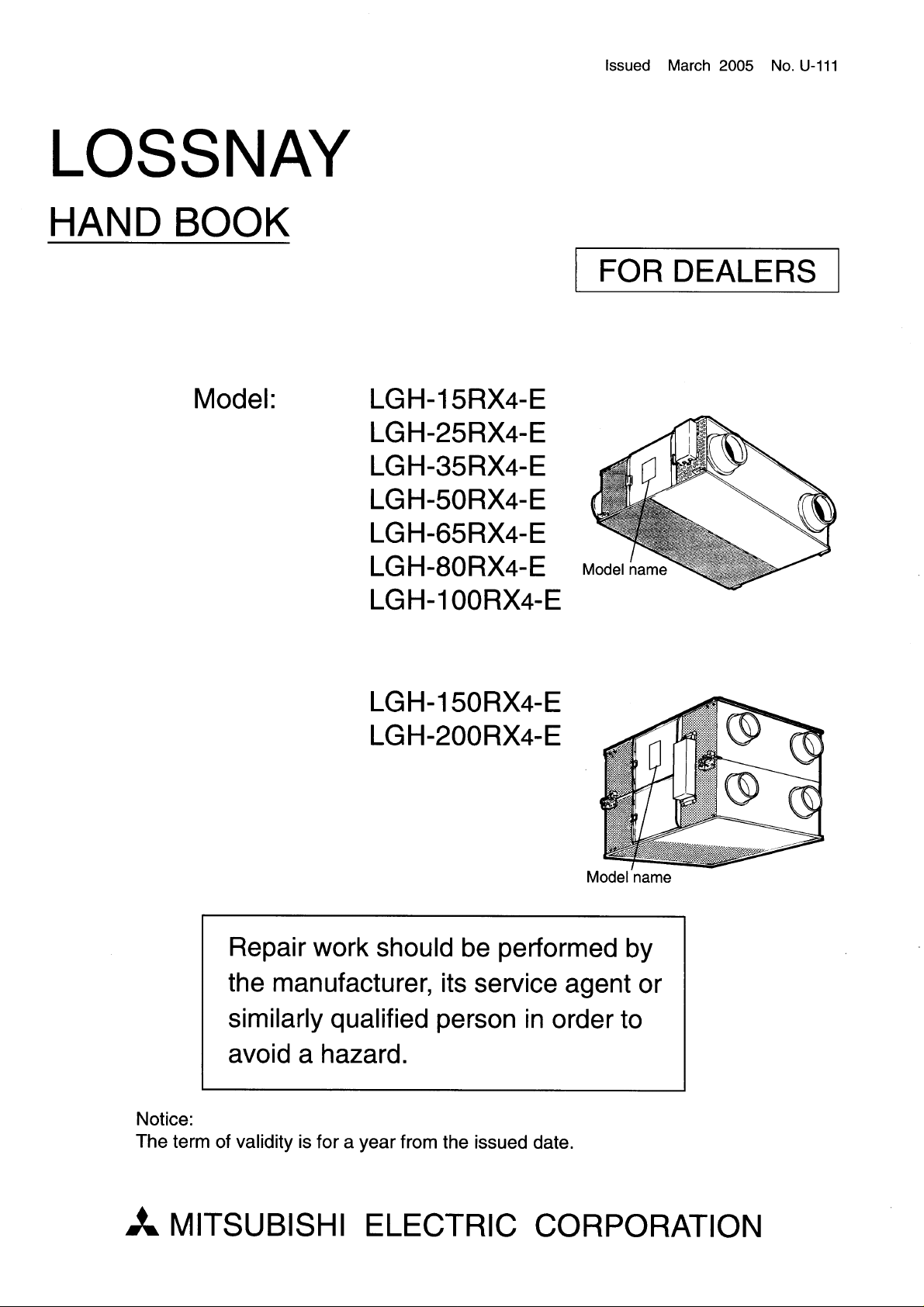

Page 1

Page 2

Contents

Safety precautions........................................................................3

1. Specifications ....................................................................... 4-8

2. Dimensions ........................................................................ 9-17

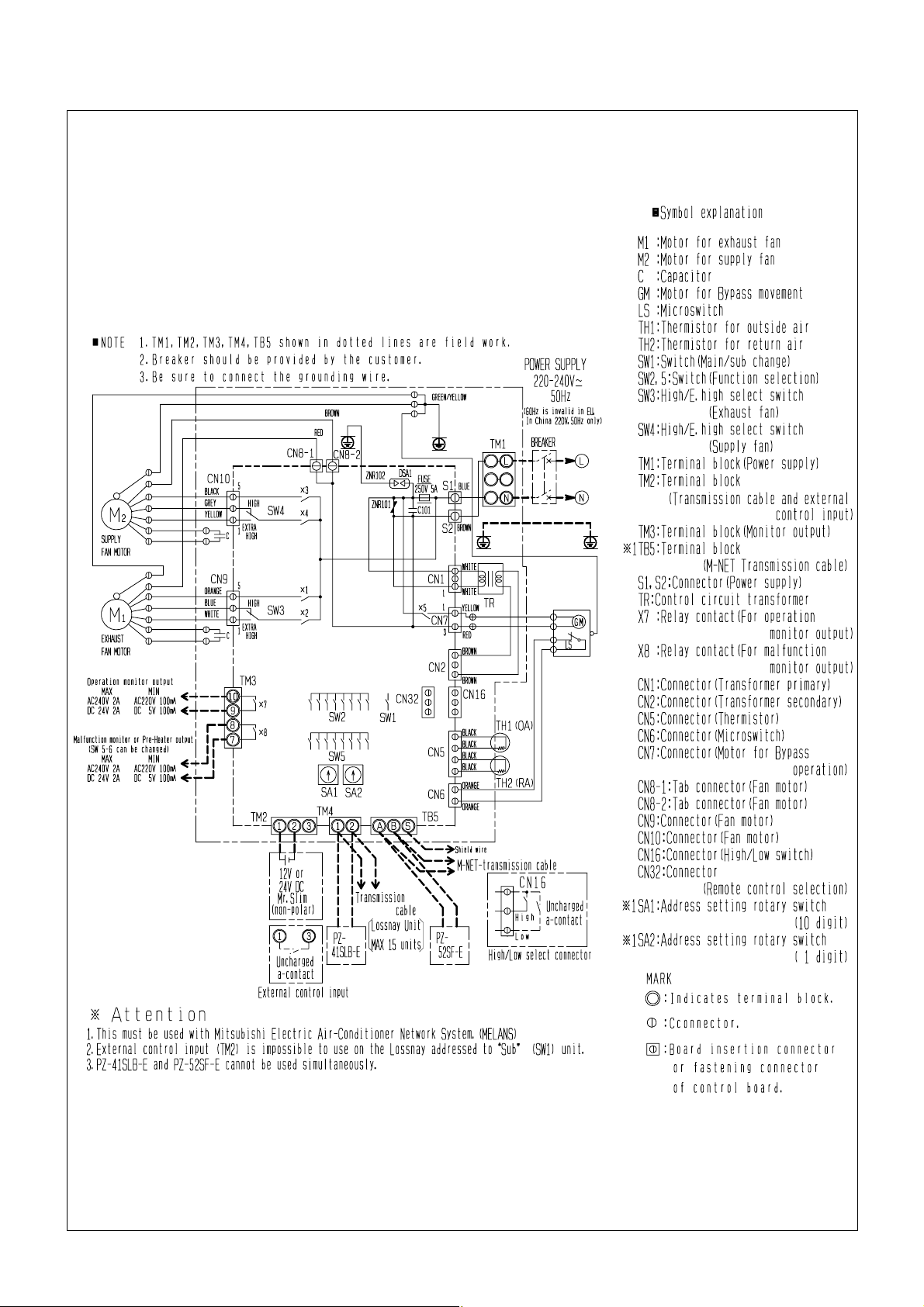

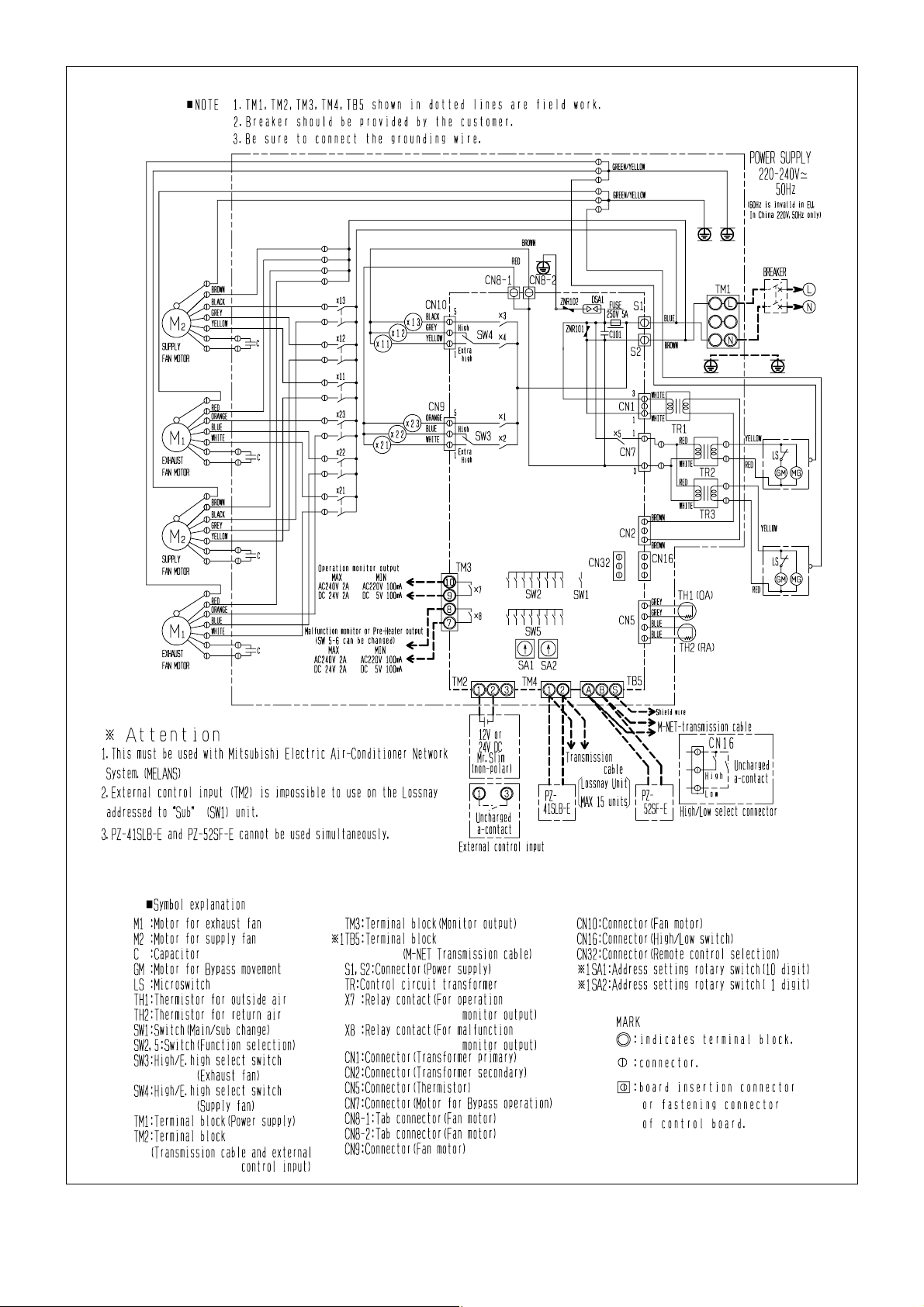

3. Wiring diagrams ............................................................... 18-19

4. Troubleshooting ............................................................... 20-34

4-1 Service Flow.............................................................. 20-21

4-2 Items to Check .......................................................... 22-33

4-3 Circuit Test Point............................................................. 34

5. Overhaul procedures........................................................ 35-39

5-1 Blower Parts.............................................................. 35-36

5-2 Damper Movement Motor Part (All units available)........ 37

5-3 Circuit Board Part...................................................... 37-39

6. Parts list ........................................................................... 40-76

LGH-15RX4-E ............................................................... 41-44

LGH-25RX

4-E ............................................................... 45-48

LGH-35RX

4-E ............................................................... 49-52

LGH-50RX

4-E ............................................................... 53-56

LGH-65RX

4-E ............................................................... 57-60

LGH-80RX

4-E ............................................................... 61-64

LGH-100RX

4-E ............................................................. 65-68

LGH-150RX

4-E ............................................................. 69-72

LGH-200RX

4-E ............................................................. 73-76

Page 3

♦♦

Turn off the power supply

Be sure to shut off the breaker before disassembling the unit for repair.

(Failure to heed this warning may result in elec-

tric shock.)

♦♦

Use proper parts and tools

For repair, be sure to use the parts listed in the service

parts list of the applicable unit model and

use the proper tools.

(Failure to heed this warning may result in elec-

tric shock, fire and/or bodily injury.)

♦♦

Proper electric work

Use the electric wires designated for electric work, and

conduct electric work in accordance with the "Electric

Installation Engineering Standard," the "Indoor Wiring

Regulations," and the Installation Work

Guide.

(Incomplete connection or wiring installation may

result in electric shock and/or fire.)

♦♦

Replace damaged and/or degraded parts

Be sure to replace the power-supply cord and lead wire

in the event that they are damaged and/or

degraded.

(Failure to heed this warning may result in elec-

tric shock and/or fire.)

♦♦

Check insulation

Be sure to measure the insulation resistance once the

repair work is complete, and turn on the power supply

after verifying that an insulation resistance

of at least 10MΩ is obtained.

(If an insulation problem exists, it may result in

electric shock.)

Safety precautions

●Please be sure to read the following safety precautions thoroughly before commencing with the maintenance

work, and conduct the inspection and repair of the product in a safe manner.

●The types and levels of danger that may arise if the product is handled incorrectly are described by using the

warning symbols shown below.

♦♦

Electric shock

If you must inspect the circuitry while the

power is on, do not touch the live parts.

(Failure to heed this warning may result in elec-

tric shock.)

♦♦

Modification is prohibited

Do not modify the unit.

(Failure to heed this warning may result in elec-

tric shock, fire and/or bodily injury.)

Incorrect handling of the product may result in serious injury

or death.

♦♦

Caution for bodily injury

Do not conduct any work at a location

where you do not have a sure footing.

(Failure to heed this caution may result in a fall.)

♦♦

Wear gloves

Wear gloves when conducting work.

(Failure to heed this caution may result in injury

to your hands from sharp metal or other edges.)

•Inspect the grounding, and repair it if incomplete.

●Make sure that the product operates correctly upon completion of repair. Clean the product as well as the surrounding area, and then notify the customer of the completion of repair.

Incorrect handling of the product may result in serious injury

or damage to properties including buildings and equipment.

Request during repair

—3—

Warning

Caution for

electric shock

Prohibited

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Be sure to follow

this instruction.

Caution

Prohibited

Be sure to follow

this instruction.

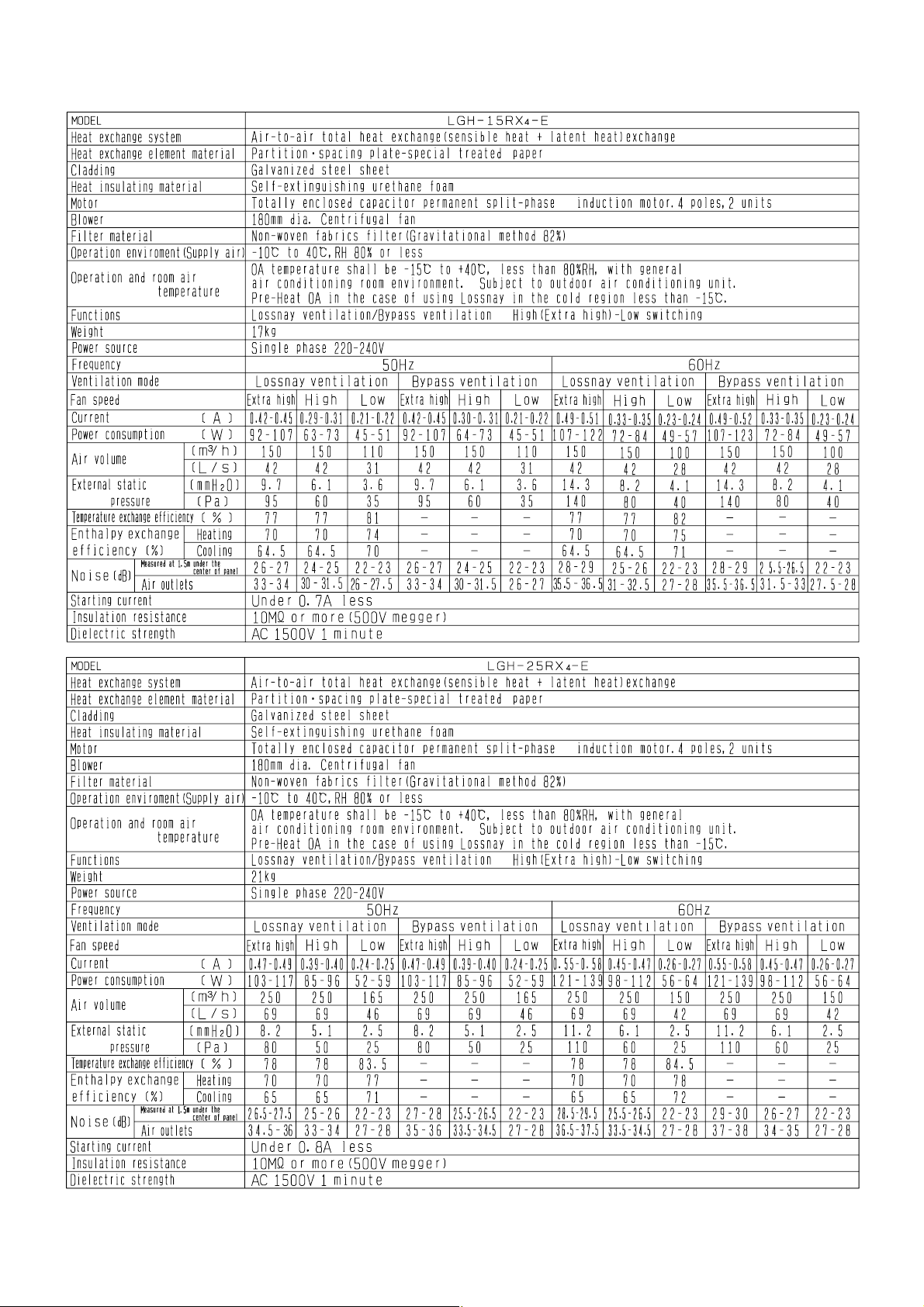

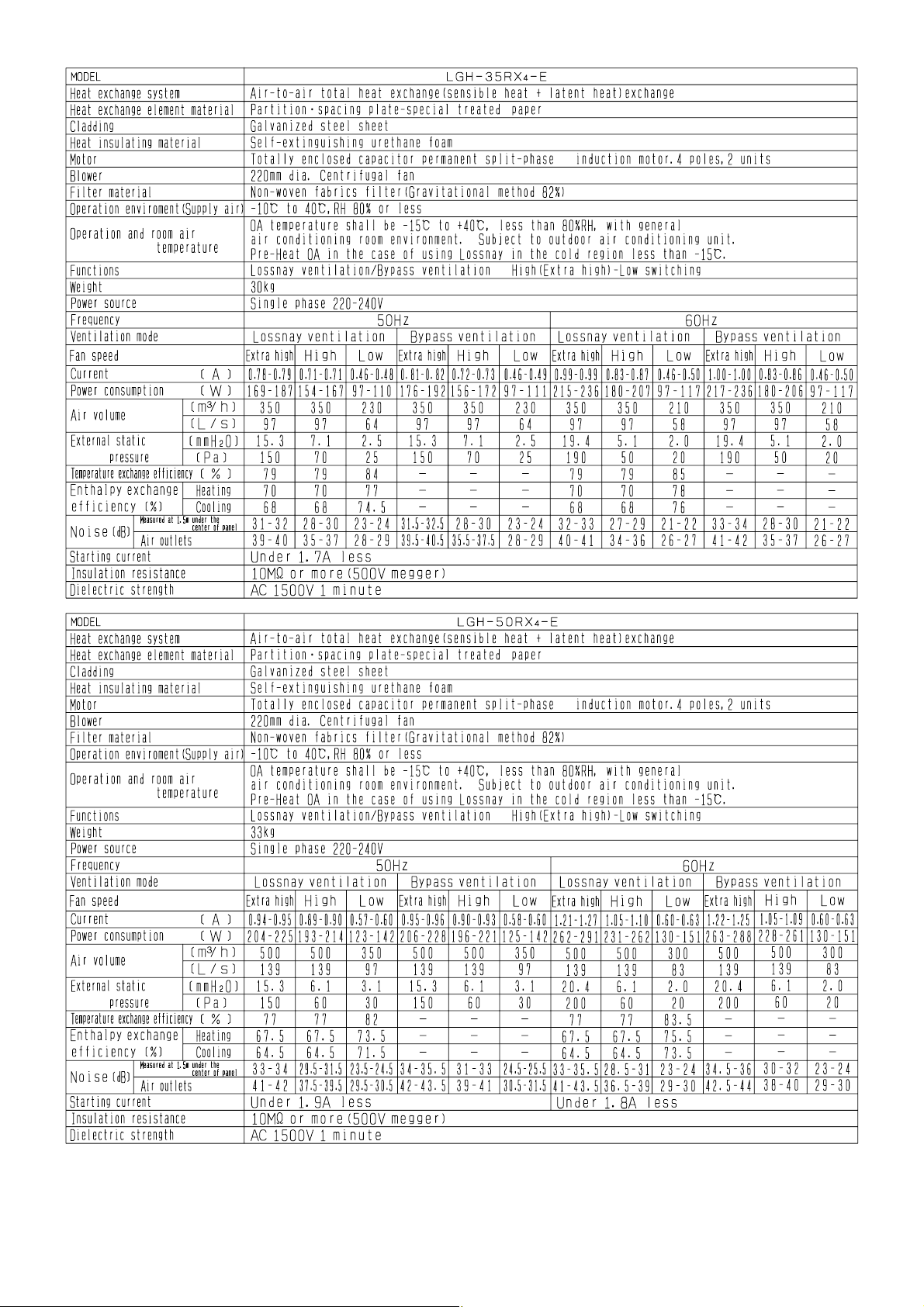

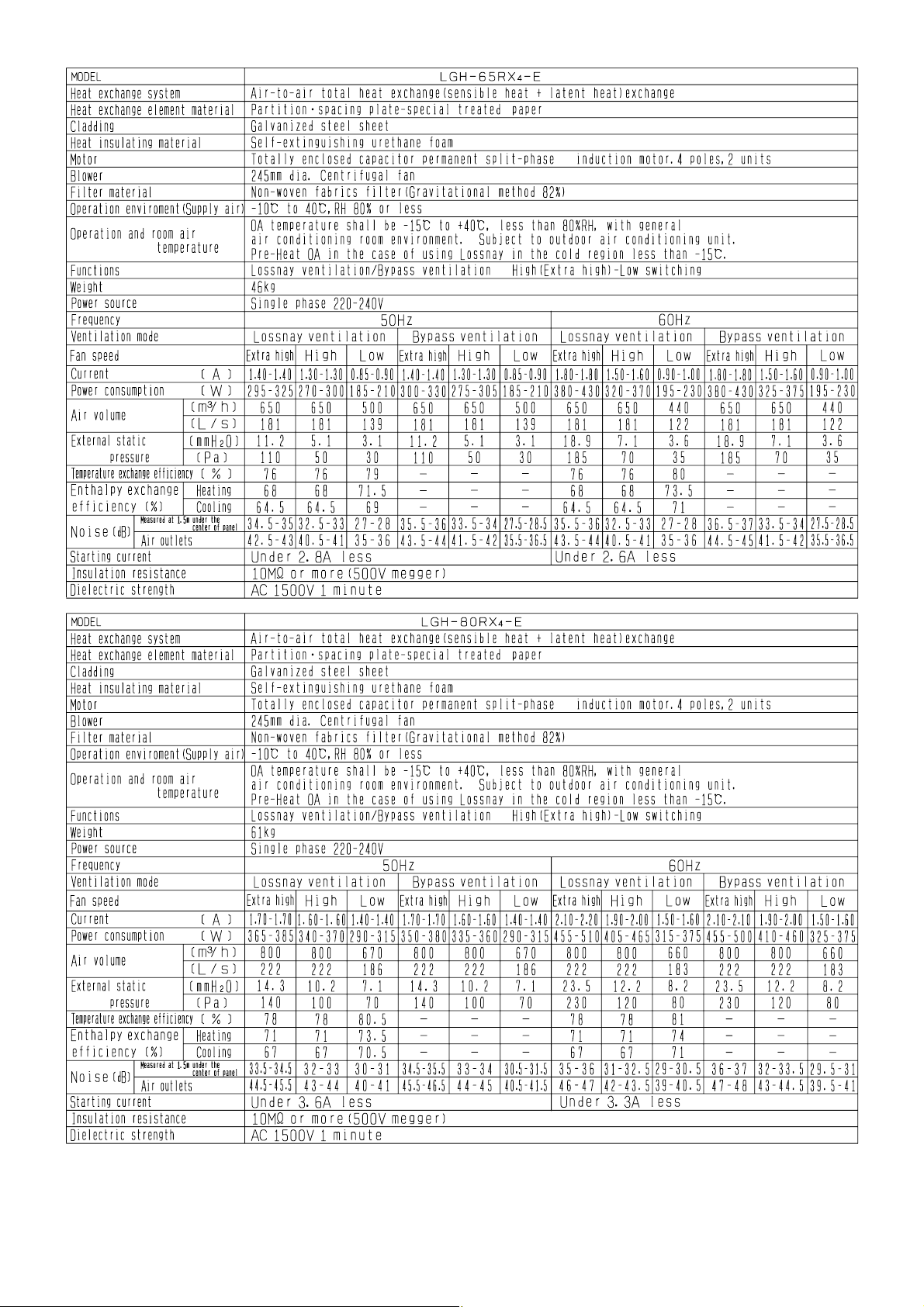

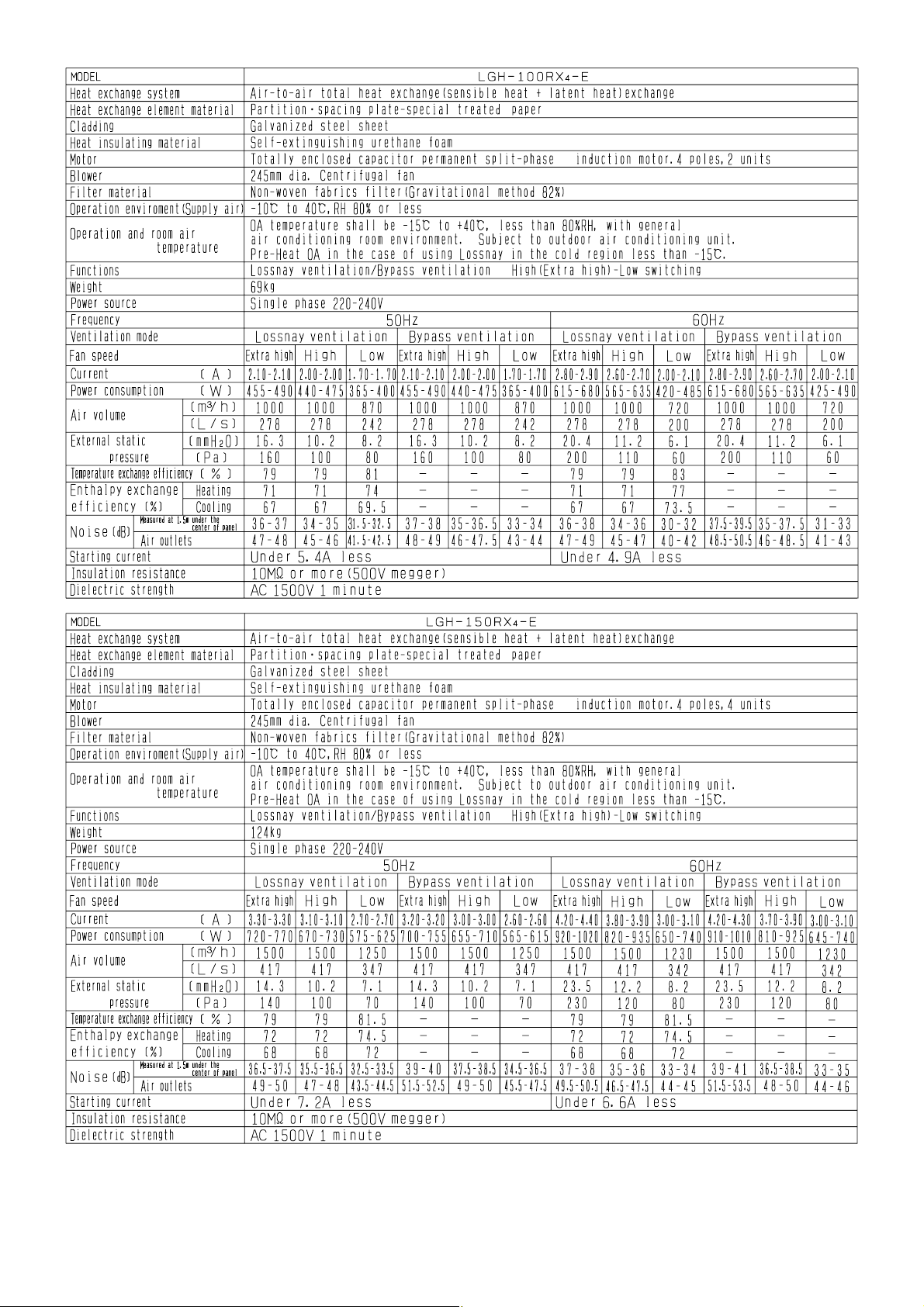

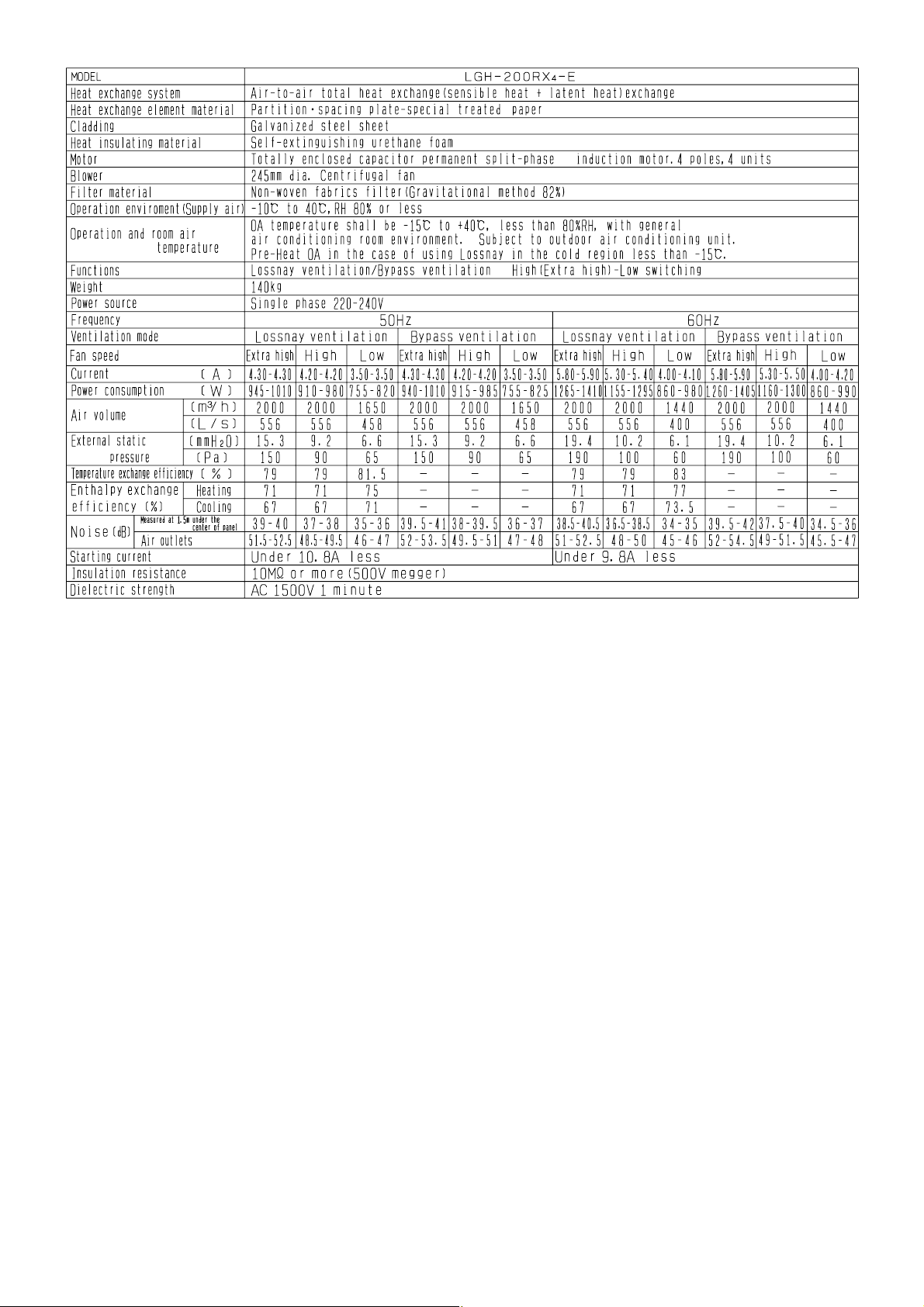

Page 4

—4—

1. Specifications

Page 5

—5—

Page 6

—6—

Page 7

—7—

Page 8

—8—

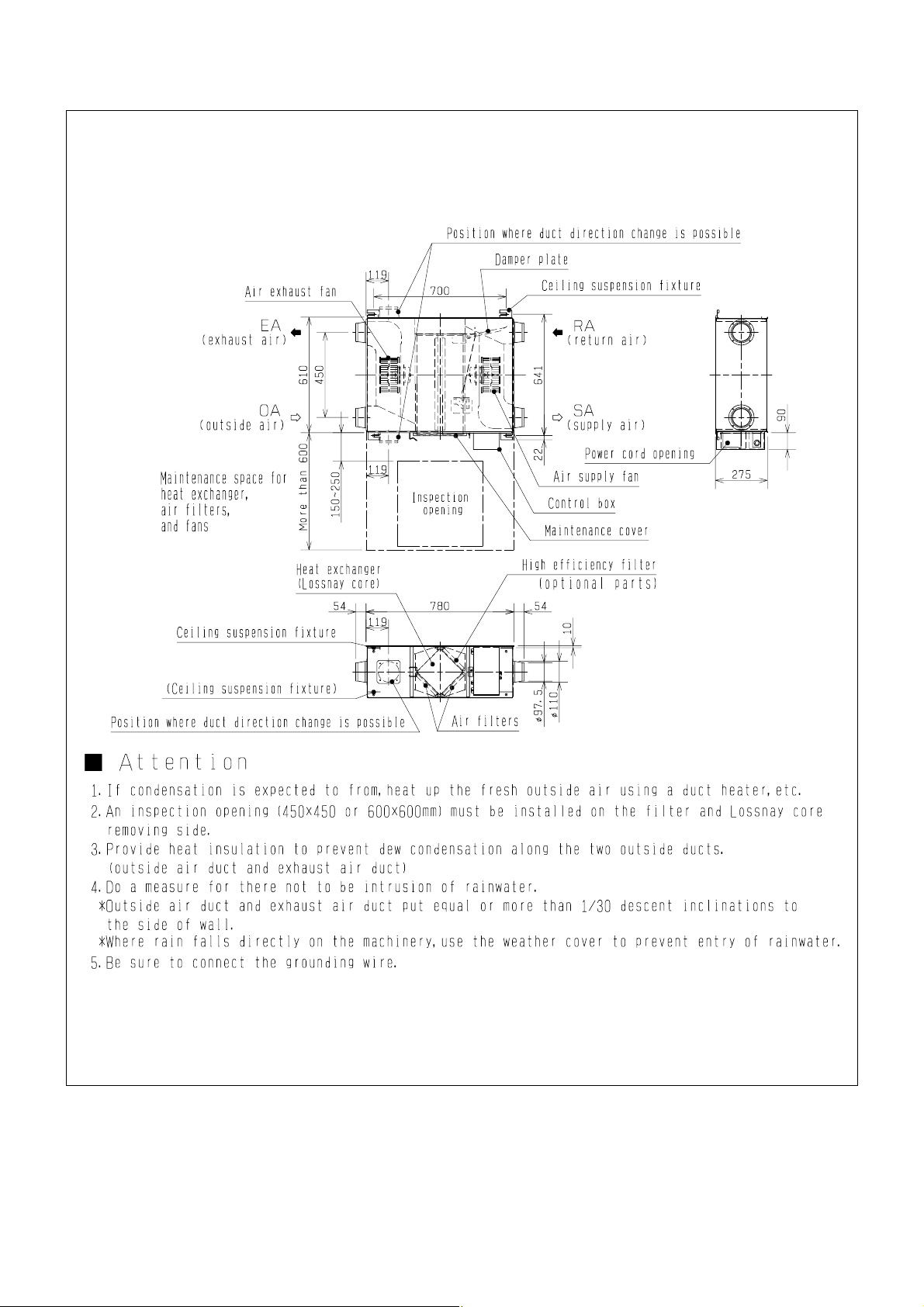

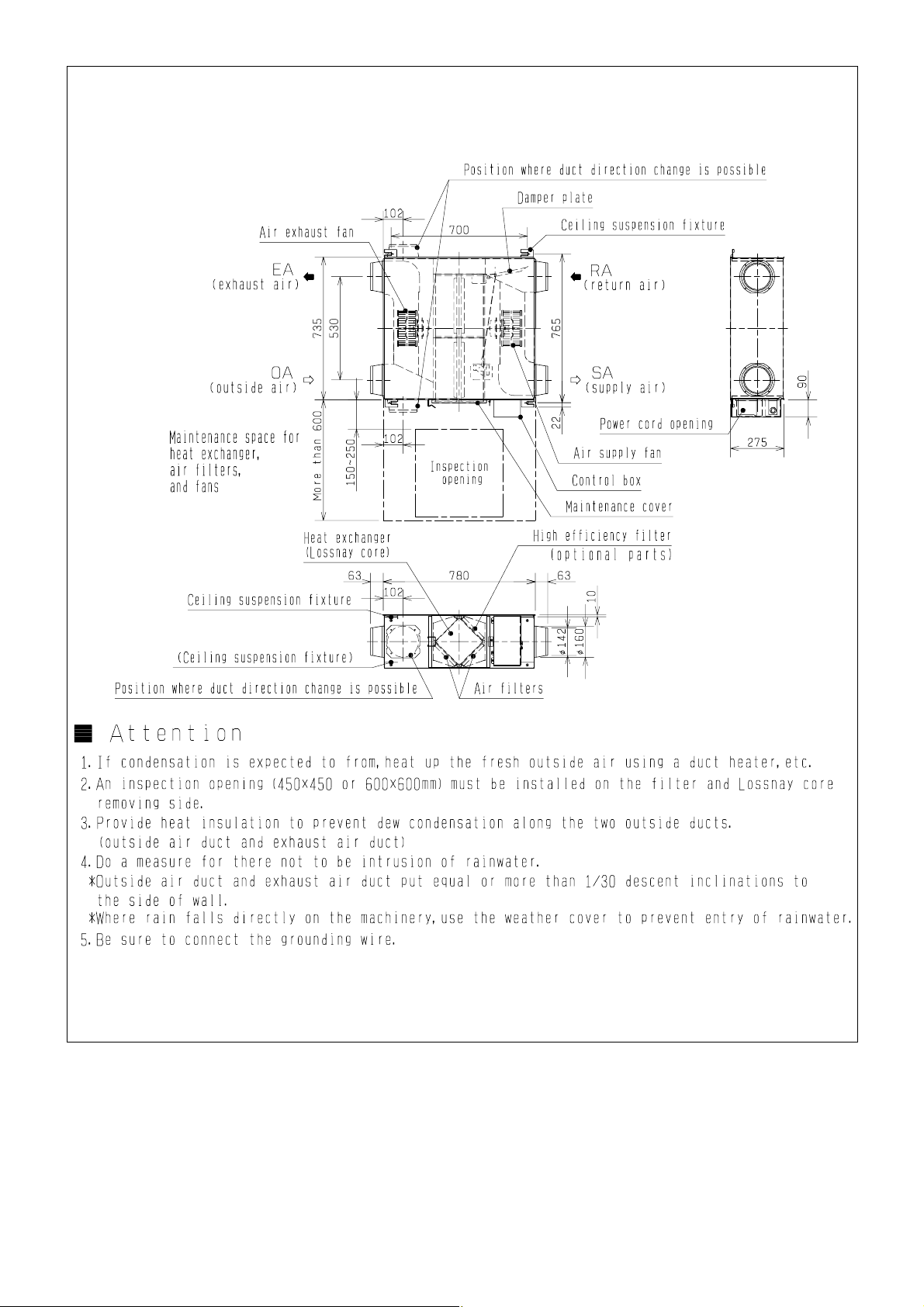

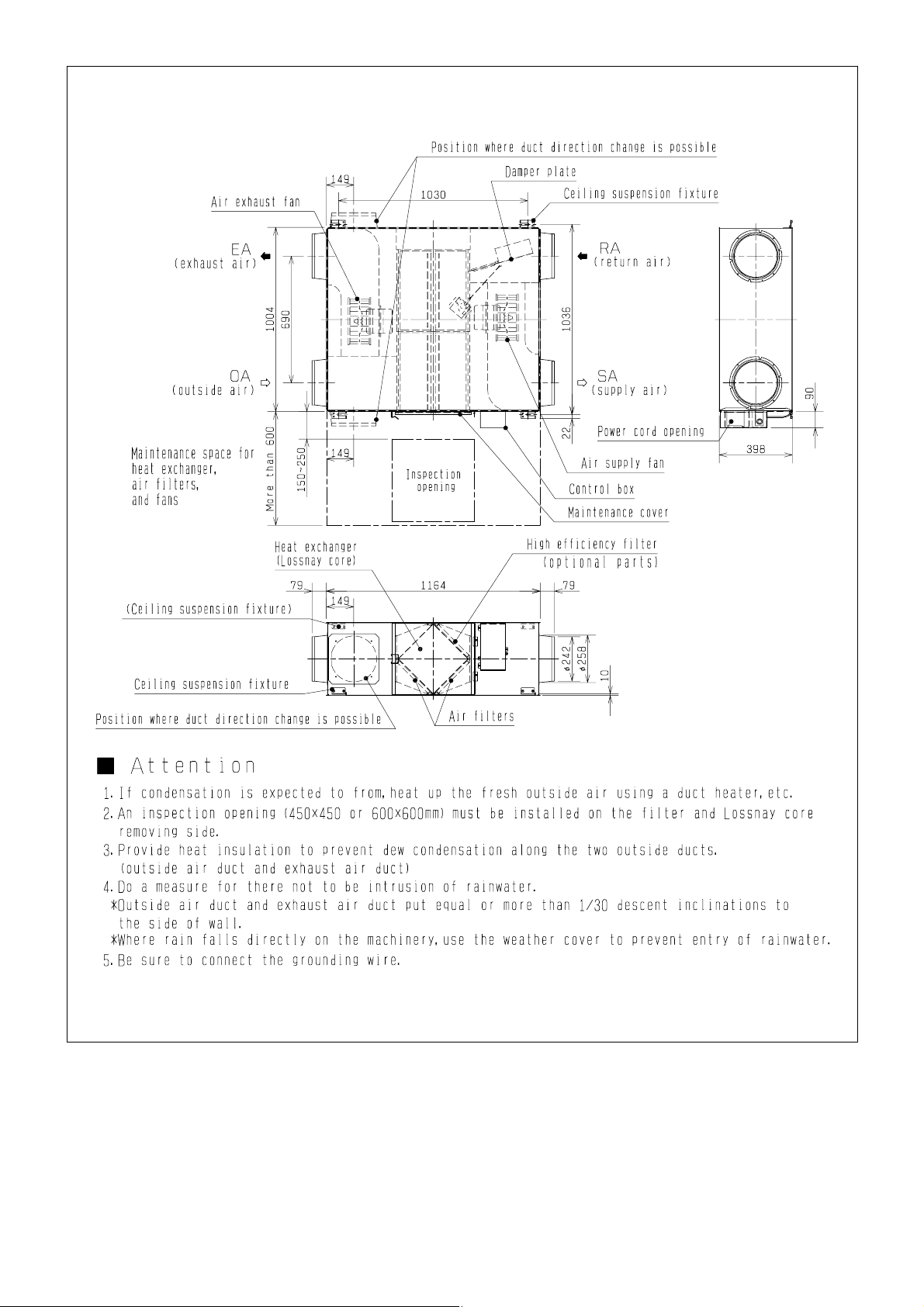

Page 9

Unit (mm)

LGH-15RX4-E

2. Dimensions

—9—

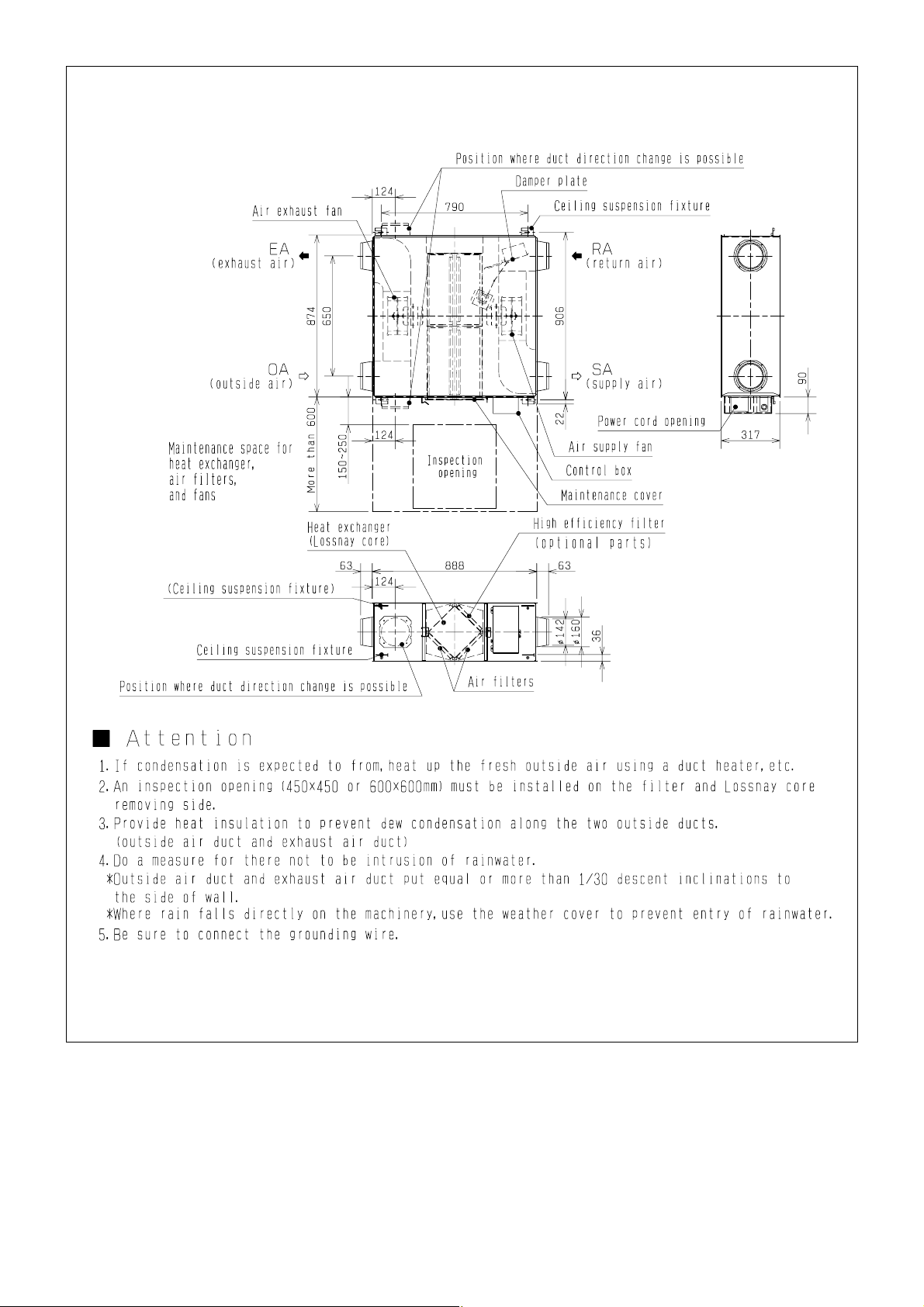

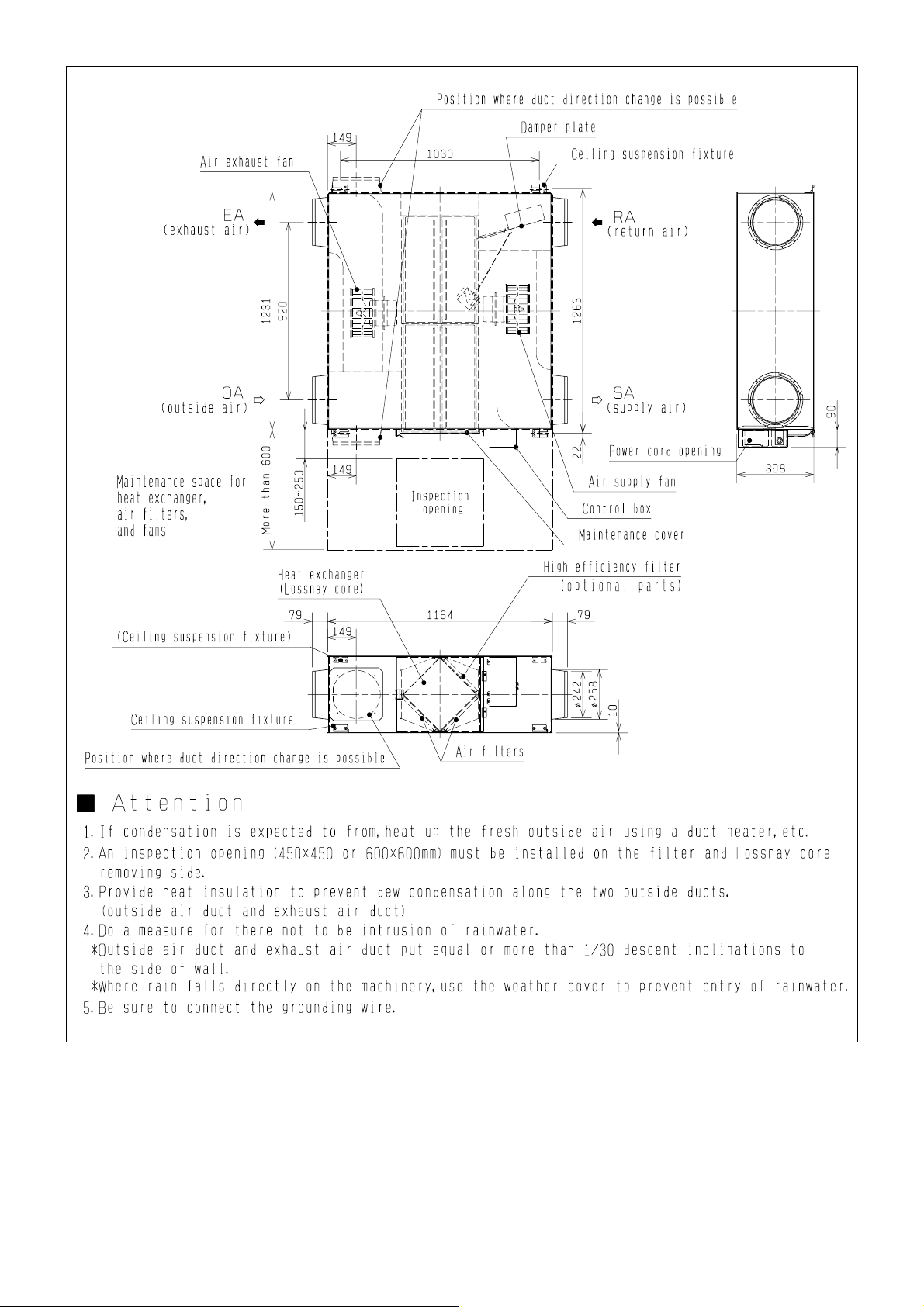

Page 10

Unit (mm)

LGH-25RX4-E

—10—

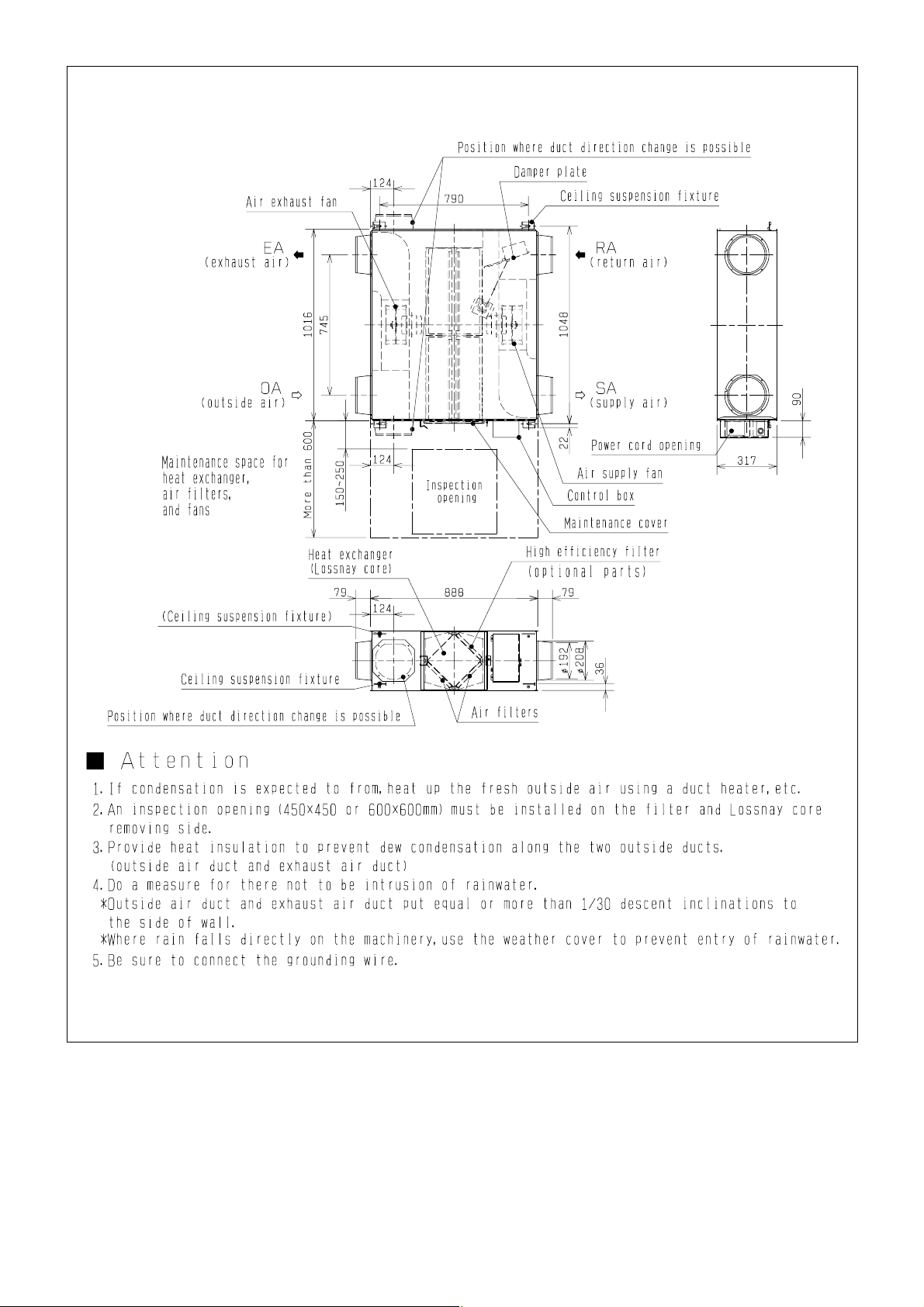

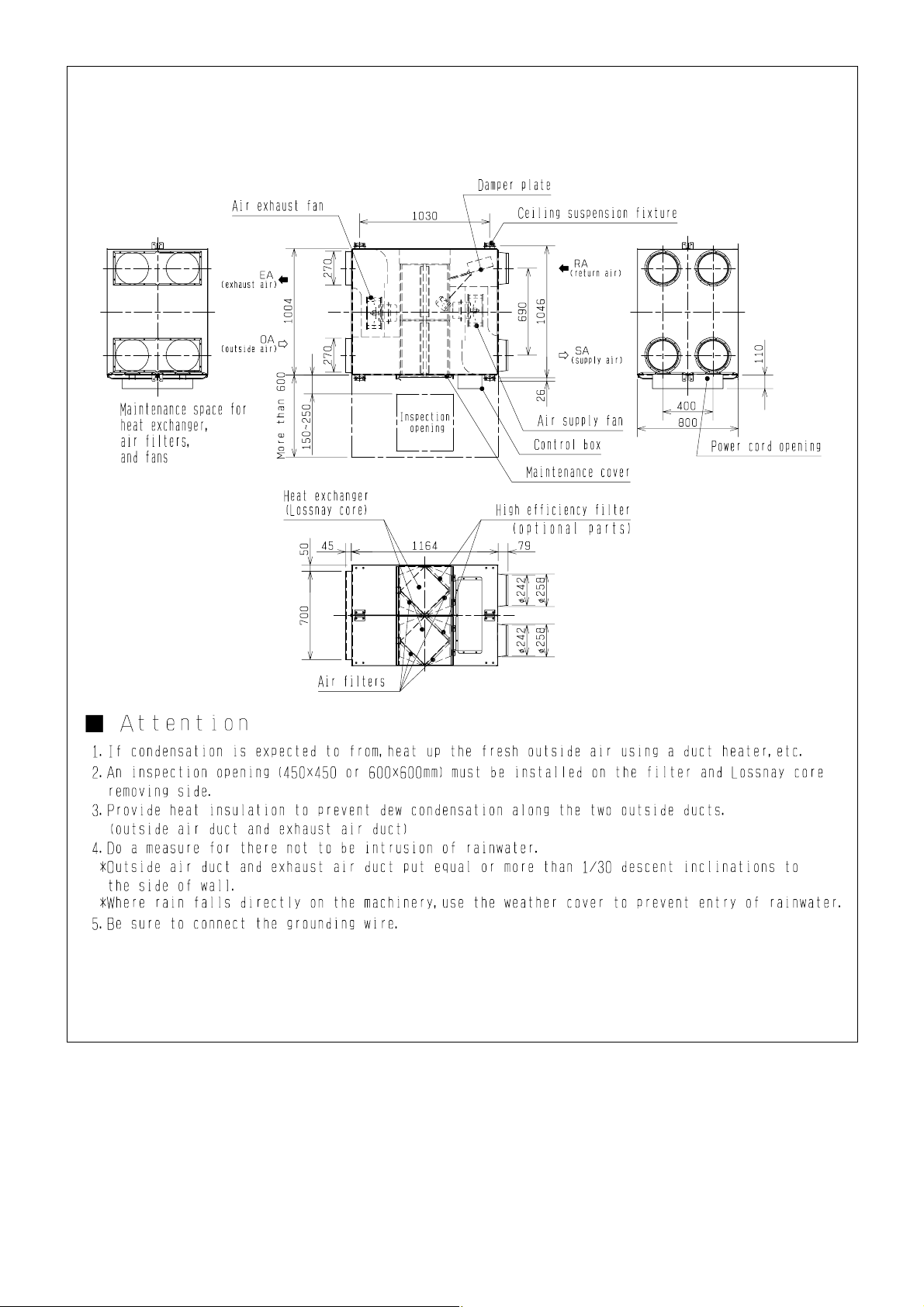

Page 11

Unit (mm)

LGH-35RX4-E

—11—

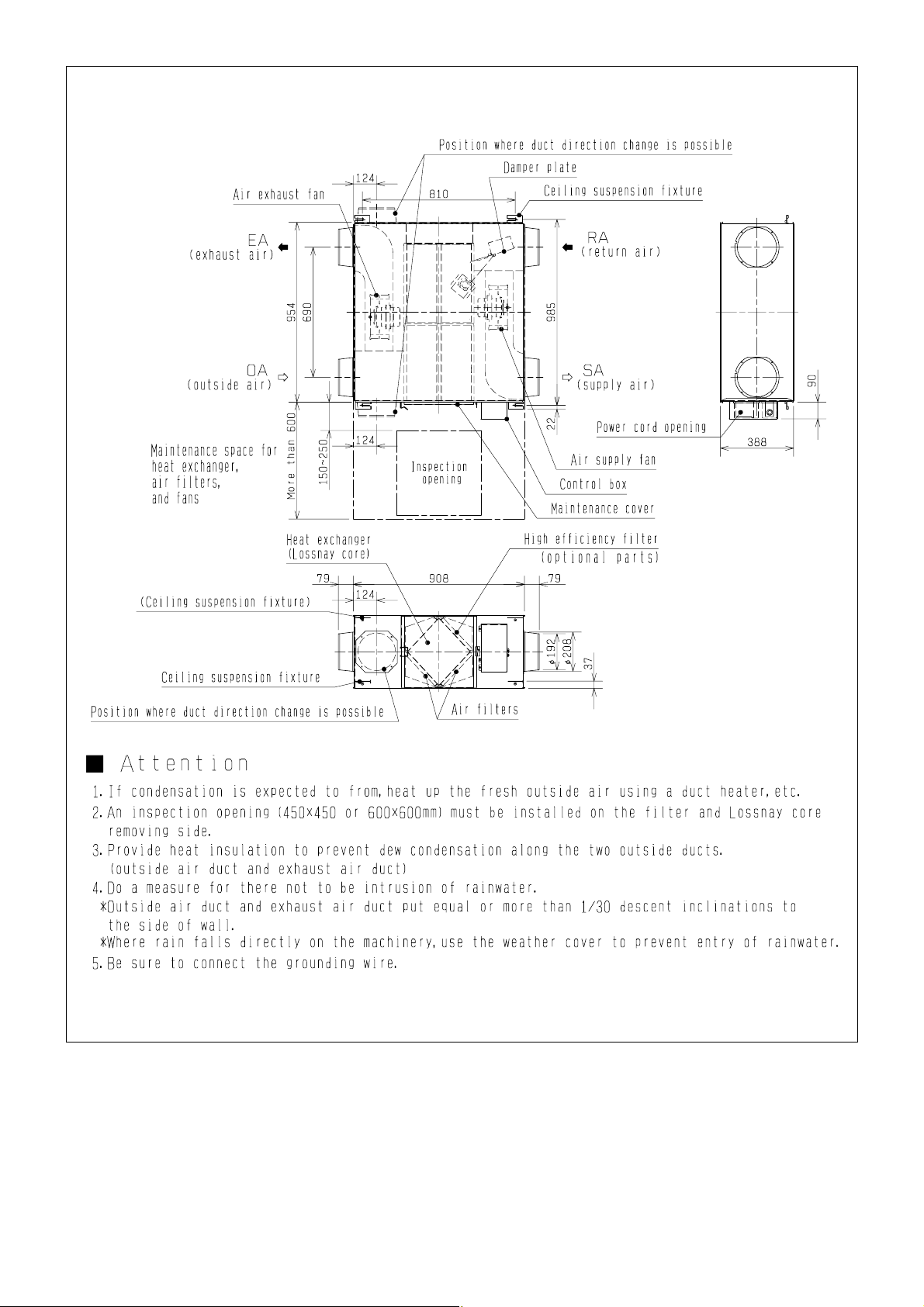

Page 12

—12—

Unit (mm)

LGH-50RX4-E

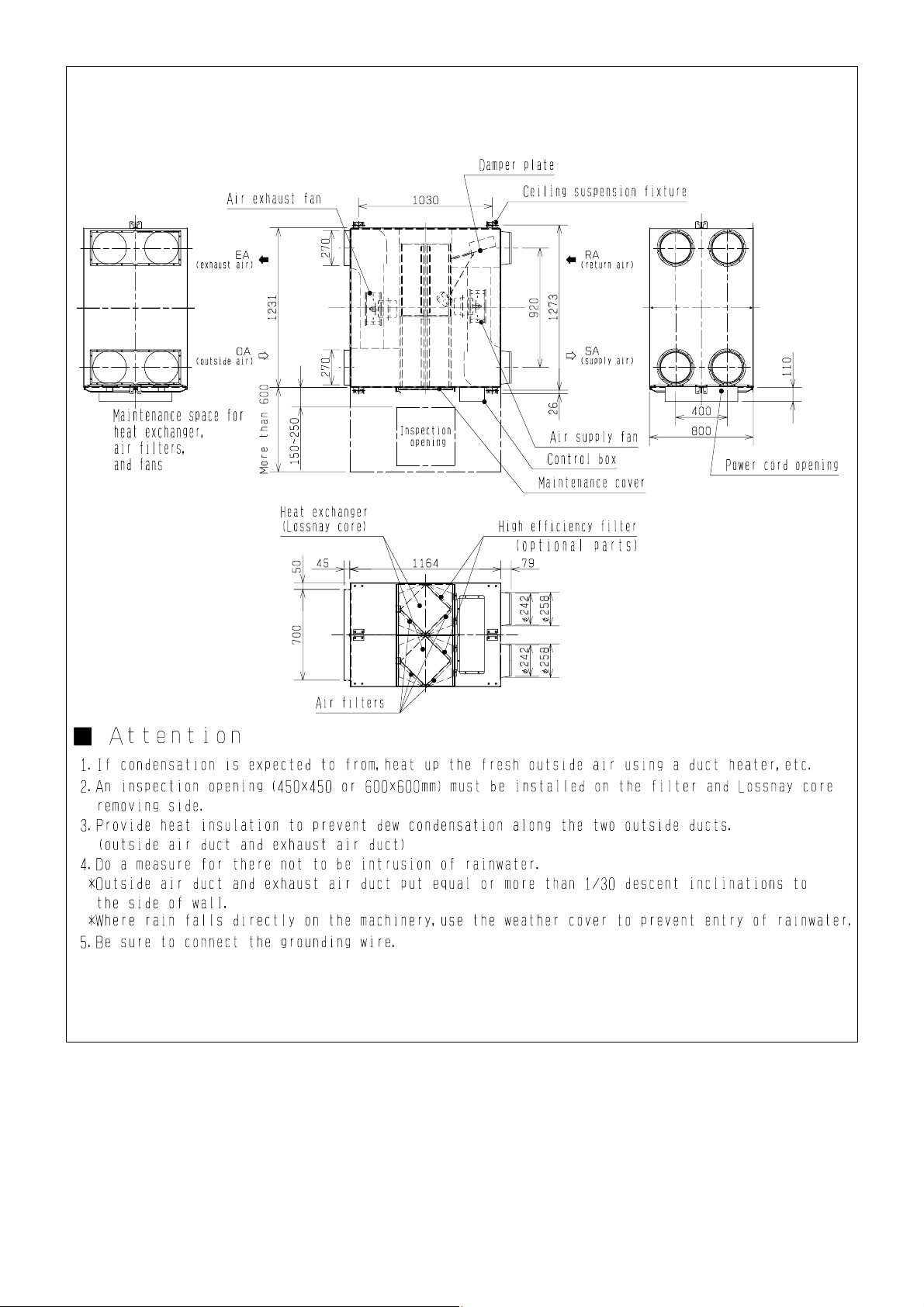

Page 13

Unit (mm)

LGH-65RX4-E

—13—

Page 14

—14—

Unit (mm)

LGH-80RX4-E

Page 15

Unit (mm)

LGH-100RX4-E

—15—

Page 16

—16—

Unit (mm)

LGH-150RX4-E

Page 17

Unit (mm)

LGH-200RX4-E

—17—

Page 18

3. Wiring diagrams

LGH-15RX4-E,LGH-25RX4-E,LGH-35RX4-E,LGH-50RX4-E,LGH-65RX4-E,LGH-80RX4-E,LGH-100RX4-E

—18—

Page 19

LGH-150RX4-E,LGH-200RX4-E

—19—

Page 20

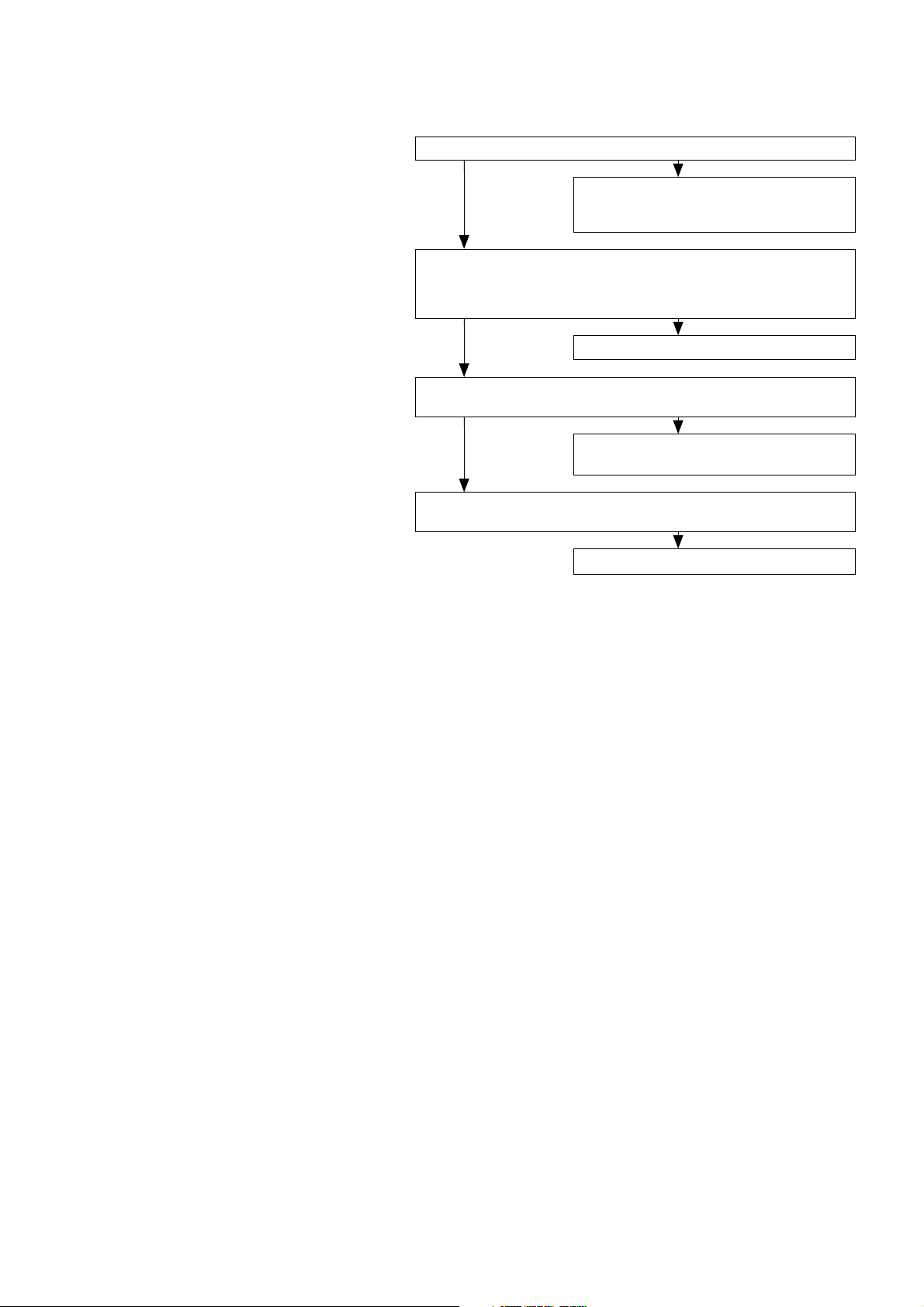

4. Troubleshooting

4-1 Service Flow

Confirmation items

1 Condition of trouble – remote controller dis-

play, etc.

2 Frequency of trouble – date of start of opera-

tion and occurrence

3 Occurrence timing

4 Existence of drawings, equipment (including

controllers and equipment sold separately),

cables, wiring, and settings.

Applicable models

Lossnay

LGH-15 to 200RX

4-E

Remote controller

PZ-41SLB-E

PZ-52SF-E

Trouble Mode 1 The system will not start properly.

• Check the initialization checklist from

installation to operation (table 1-1).

• Check the system checklist (table 1-2).

Trouble Mode 2

• The check code display appears on the

remote controller.

• The LED of the Lossnay circuit board is

blinking.

Check with the check code list (table 2).

Trouble Mode 3

The remote controller does not operate or

operates irregularly.

The Lossnay does not operate or operates

irregularly.

Trouble Mode 4

Check with the remote controller checklist

(table 3).

Check with the Lossnay checklist (table 4).

Precautions when diagnosing malfunctions

● When removing a transistor or printed circuit board, make sure the breaker is thrown.

● When removing the circuit board, always hold it at both ends and remove carefully so as not to apply force to the surface

mounted parts.

● When removing the circuit board, be careful of the metal edges on the board.

● When removing or inserting the connectors for the circuit board, hold the entire housing section. Never pull on the lead

wires.

● When servicing, be sure to recreate the malfunction 2 to 3 times before starting repairs.

● If a malfunction of the printed circuit board is suspected, check for disconnected wires in the print pattern, burnt parts or dis-

coloration.

● If the printed circuit board is replaced, make sure that the switch settings on the new board are the same as the old board.

—20—

Page 21

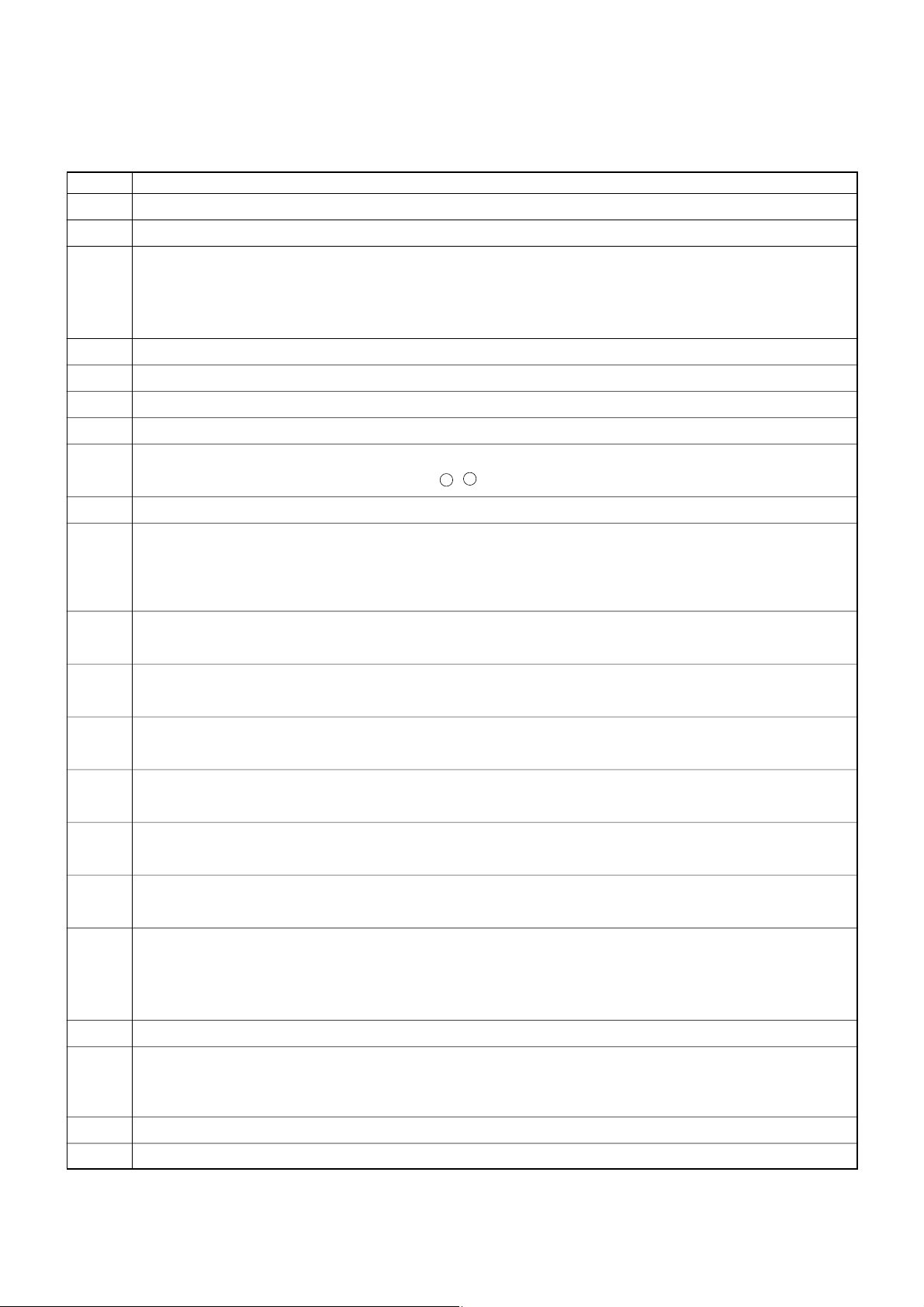

Error List

Unit error

——

Error item

—

«

«««

««

«

«««

«

«

—

—

«

—

«««

————

—

—

—

—

« «««

—

—

«« «

«« «

—

«« ««

—

«« «

—

«« «

«

—

«« «

2 times

3 times

4 times

8 times

—

—

—

—

—

—

—

9 times

—

—

—

—

—

6 times

—

—

8 times

1 - 5

times

LED 6

turn off

—

4000/4116

*1)

3602

*2)

5101

3126

0900

6600

6607

6608

6607/6608

6602/6603/

6604

—

6608

• Cancellation

• Cancel damper operation

• Other controls as normal

•

Lossnay ventilation

fixed (for “Auto” modes)

•

Other controls as normal

•

The Pre-heat output

(X8) turns OFF

• Fan: High speed

• Lossnay ventilation fixed

—

—

—

• Cancellation

—

—

• Cancellation

Fan motor

operation

device error

Damper motor

error

OA

temperature

sensor error

Pre-heat error

«««

—

«

5 times —5102

•

Lossnay ventilation

fixed (for “Auto” modes)

•

Other controls as normal

RA

temperature

sensor error

Test operation

Dual address

No ACK

No response

Controller

communication

error

Communication

circuit error

««« ««

9 times —

6801

*3)

• Restricted to ON/OFF

Local transmission cable communication

error

Polarity not set

PZ-41SLB-E

communication error

ClassificationCommunication error

Measures taken by

Lossnay

Remote

controller

display

error

code

LED 1

(green)

Display

(No. of

blinks)

LED 2

(red)

Display

(No. of

blinks)

Error

monitor

output

*4)

Reset

power

supply

Change

address

Stop

↓

Start

Error

delete

Cancellation measures

*1) “4000” is displayed on PZ-41SLB-E only.

*2) This error is not generated in the LGH-150RX

4, LGH-200RX4 model.

*3) “6801” is displayed on the M-NET controllers only.

*4) Since the error monitor output will turn into the preheat output if SW5-6 is turned ON, it becomes impossible to use it.

—21—

Page 22

Do the capacity of the main power supply on/off unit and wiring span meet specification?

Checkpoint

1

No.

2 Is the specified power supplied to the Lossnay power terminal (TM1)?

3 Is the wiring length of the transmission cable within specifications?

When using PZ-41SLB-E: Overall extension within 500 m

When using M-NET: Maximum power supply length within 200 m, maximum distance between ends

within 500 m

4 Does the transmission cable meet regulations? (Type, diameter)

5 Is the transmission cable wired at least 5 cm away from the power supply cable?

6 Are multiple transmission or signal cables wired to the same power cable duct?

7 Are multiple transmission cables wired with multi core cables?

8 Is the transmission cable connected to the terminal unit?

(PZ-41SLB-E to TM4 1, 2; M-NET to TB5

A , B )

9 Is the transmission cable securely connected to the Lossnay terminal unit?

10 When not using M-NET

If using 1 Lossnay unit, is the Main/Sub change switch (SW1) on the Lossnay circuit board set to “Main”?

If using 2 or more Lossnay units, is the Main/Sub switch set to “Main” on only one unit, and the other units are set

to “Sub”?

11 When using M-NET

Is the address switch on the Lossnay circuit board (SA1, SA2) set to the correct number?

12 When using external control input

Do the specifications of the external signal match specifications of signals that can be input to the Lossnay?

13 When the external input signal is a pulse signal

Is the pulse input switch (SW2-2) on the Lossnay circuit board set to ON?

14 When the external signal is 12V DC, 24V DC, or Mr. Slim (A-control or K-control) signal

Is it connected to 1, 2 on the Lossnay external control input terminal unit (TM2)?

15 When the external signal is an uncharged a-contact signal

Is it connected to 1, 3 on the Lossnay external control input terminal unit (TM2)?

16 When M-NET is not being used

Is the external input signal connected to the Lossnay set to “Main”?

17 Is the signal cable length within wiring specifications?

12V DC, 24V DC signal: Within limitation of the external device

Uncharged a-contact signal: Within 500 m

Mr. Slim (A-control or K-control) signal: Within 500 m

18 Is the signal cable wired at least 5 cm away from the power supply cable?

19 Is the output capacity of the Lossnay operation monitor/malfunction monitor (pre-heat output) within specifications?

Operation monitor output: Maximum 240V AC/24V DC 2A, minimum 220V AC/5V DC 100 mA

Maifunction monitor output/pre-heat output:Maximum 240V AC/24V DC 2A, minimum 220V AC/5V DC100 mA

20 Are the power supply cable, transmission cable, signal cable, etc., securely connected to the proper terminals?

21 Are the settings for the Mai/Sub switch, address switch, and function select switch correct?

4-2 Items to Check

(1)Trouble Mode 1: The system will not start properly.

Initialization checklist from installation to operation (Table 1-1)

After checking the system, check the points below up to operation.

—22—

Page 23

22 When pre-heat output output is used, turn the SW5-6 ON.

There is no method of turning ON the pre-heat output without changing OA temperature.

The first check of the installation

(1) Make the power supply of the heater turned off.

(2) Short-circuit the pre-heater output with a lead etc.

(3) Check weather the relay contact by the side of the heate rturns on.

The pre-heat output is never closed even if abnormalities, such as drawing out the OA/RA thermistor connector,

occur.

« Check the power supply to the

Lossnay.

« Set the Main/Sub (SW1) switch

to “Main.”

« Check the length of the trans-

mission cable wiring.

« Connect the transmission cable

to TM4 12.

« Change to the PZ-41SLB-E

remote controller.

1

No.

Remote controller

display does not

appear.

« Power is not supplied to the Lossnay, or power

outside specifications is connected.

« When using only 1 Lossnay, the Main/Sub switch

(SW1) on the Lossnay circuit board is set to “Sub.”

« The overall wiring length of the transmission cable

is longer than specifications (longer than 500 m).

« The remote controller is connected to TB5 (M-NET

transmission cable).

« PZ-52SF-E is connected to the Lossnay local

remote controller.

2 Remote controller

does not operate

(Communication error

display)

« When using multiple Lossnay units, the Main/Sub

switch (SW1) on the Lossnay circuit board of the

second or following unit is set to “Main.”

« The overall wiring length of the transmission cable

is longer than specifications (longer than 500 m).

« Multiple transmission cables are wired with multi

core cables.

«

Set the Main/Sub switch (SW1) of

the second and following Lossnay

units to “Sub.”

« Check the length of the trans-

mission cable wiring.

« For the applied transmission

cable, wire the transmission

cables away from the other

transmission cable.

3 Interlocked operation

with external device

does not occur.

« The type of external signal does not match the

connected terminal unit (charged, uncharged, Mr.

Slim signal).

« The type of external signal does not match the

pulse input switch (SW2-2) setting (level signal,

pulse signal).

« The external device signal is not being input.

« The external device and signal cable wiring is

longer than specifications

12V DC, 24V DC: Longer than limitations of

external device

Uncharged a-contact: Longer than 500 m

Mr. Slim signal: Longer than 500 m

« The Delayed Start mode is set at the remote con-

troller (PZ-41SLB-E).

« The ON Interlocked Operation mode or OFF

Interlocked Operation mode is set at the remote

controller (PZ-41SLB-E).

« When using multiple Lossnay units, the external

control input signal is connected to a unit with the

“Sub” setting made.

«

Check the connection to the external control input terminal (TM2) for

the type of external signal.

«

Check the type of external signal

and the setting of the pulse input

switch (SW2-2).

« Check the external device.

« Check the length of the signal

cable wiring.

« Check the Delayed Start mode

setting at the remote controller

(PZ-41SLB-E).

« Check the Interlocked Operation

mode setting at the remote controller (PZ-41SLB-E).

« Connect the external control

input signal to the Lossnay unit

set to “Main.”

Symptom Cause Corrective action

System checklist

1Use this checklist when using a PZ-41SLB-E or an external device (Table 1-2-1)

—23—

Checkpoint

No.

Page 24

« Turn the SW5-6 ON.

« Operate onry below -5˚C.

4

No.

Pre-heat control does

not work.

« SW5-6 is OFF.

« OA temprature is larger than -5˚C.

Symptom Cause Corrective action

2System checklist when using the M-NET (Table 1-2-2)

« Check the Lossnay address, and

set for an address corresponding to interlocked operation.

« Check the length of the trans-

mission cable wiring.

«

Change to the PZ-52SF-E remote

controller (PZ-41SLB-E can not

be used with the M-NET).

1

No.

Does not interlock with

City Multi. (The Lossnay

cannot be operated by

the ventilation switch on

the ME remote controller,

MA remote controller, or

MELANS.)

« The Lossnay is not set for interlocked opera-

tion, or is set for interlocked operation at the

wrong address.

« The length of the M-NET transmission cable

wiring from the outdoor unit or the system’s

overall wiring length is longer than specifications. (Longer than 200 m from the outdoor

unit, longer than 500 m between ends.)

« PZ-41LSB-E is connected to the Lossnay local

remote controller.

Symptom Cause Corrective action

2 Cannot operate using the

MELANS or Lossnay

remote controller.

« The address that has been set for the group in

MELANS and the address for the Lossnay are

different.

« The length of the M-NET transmission cable

wiring from the power supply unit or the system’s overall wiring length is longer than specifications. (Longer than 200 m from the power

supply unit, longer than 500 m between ends.)

« PZ-41LSB-E is connected to the Lossnay local

remote controller.

« Check the registered address in

MELANS.

« Check the length of the trans-

mission cable wiring.

«

Change to the PZ-52SF-E remote

controller (PZ-41SLB-E can not be

used with a M-NET system).

3 A unit should operate

independently by

MELANS or the Lossnay

remote controller, but it

interlocks with another

City Multi unit.

« It has been set for interlocked operation with

the City Multi unit.

« Cancel the interlocked operation

setting.

4 Cannot perform group

settings for the Lossnay

using MELANS, ME

remote controller, or MA

remote controller. (The

remote controller shows

“88” at the time of registration.)

« Power is not supplied to the Lossnay, or power

outside specifications is connected.

« The M-NET transmission cable is connected to

TM4 12.

« The transmission cable is not properly con-

nected to the MELANS or the City Multi.

«

The length of the transmission cable wiring is longer than

specifications (longer than maximum 200 m from the

power supply unit, longer than 500 m between

ends.)

«

Check the power for the Lossnay

and perform the registration again.

« Connect the transmission cable

to TB5

A , B .

« Check the transmission cable

connection.

« Check the length of the trans-

mission cable wiring.

—24—

5 When power is supplied

to the system, the

Lossnay remote controller continues to display “HO” and does not

start. (Group registration

information disappears.)

« The Group setting was made on a Lossnay

remote controller in a system connected to a

system controller.

« The length of the transmission cable wiring is

longer than specifications (longer than maximum 200 m from the power supply unit, longer

than 500 m between ends.)

«

In a system connected to MELANS,

make the group setting with the

MELANS (Do not make the group setting with the Lossnay remote controller).

« Check the length of the trans-

mission cable wiring.

Page 25

«

Check remote control unit number

limitations when using a power

supply unit.

« Check the length of the trans-

mission cable wiring.

6 When power is supplied

to the system, the

remote control display

goes blank and the system does not start.

« Over the number of units that can be controlled

with the Lossnay remote controller.

« The length of the transmission cable wiring is

longer than specifications (longer than maximum 200 m from the power supply unit, longer

than 500 m between ends.)

No.

Symptom Cause Corrective action

—25—

7

The power display “”

does not display when

power is supplied to the

system.

1 When using City Multi and Lossnay interlocked

system (connected to the indoor unit system)

« The transmission cable is not correctly con-

nected to the Lossnay remote controller.

« The power is not turned on for the outdoor unit.

« The length of wiring for the outdoor unit’s M-

NET transmission cable is longer than specification (longer than 200 m).

« Check the transmission cable

connection.

«

Check the power to the outdoor unit.

« Check the length of the trans-

mission cable wiring.

2 When using a Lossnay individual system or

City Multi and Lossnay interlocked system connected to the central system.

« The power supply unit is not connected to the

transmission cable.

« The power to the power supply unit is not

turned on.

« The length of wiring of the M-NET transmission

cable from the power supply unit is longer than

specification (longer than 200 m).

« Connect to the power supply

unit.

« Check the power to the power

supply unit.

« Check the length of the trans-

mission cable wiring.

« Check the power to the Lossnay.

« Check the Lossnay remote con-

troller address registration with

the MELANS (“HO displays for 3

– 10 minute when electricity is

supplied to the system).

« Connect the transmission cable

to TB5

A , B .

« Check the Lossnay registration

with the Lossnay remote controller.

8

The “HO” on the remote

controller continues to

flash when the power is

supplied to the system.

« Lossnay is Not supplied with specified power.

« The address for the Lossnay remote controller

does not have a group setting at the MELANS.

« The M-NET transmission cable is connected to

TM2 56.

«

For a Lossnay individual system with no

MELANS,

Lossnay registration has not been

performed by the Lossnay remote controller.

9 “LC 6608” displays on

the remote controller and

the Lossnay does not

operate.

« The remote controller is PZ-41LSB-E and con-

nected to the TB5

A , B .

« Change to the PZ-52SF-E

remote controller (PZ-41SLB-E

can not be used with a M-NET

system).

10 The operation specified

by the system controller

differs from the operation

of the Lossnay.

« The remote controller is PZ-41SLB-E and con-

nected to the TM4 1-2.

« Change to the PZ-52SF-E

remote controller (PZ-41SLB-E

can not be used with a M-NET

system).

Page 26

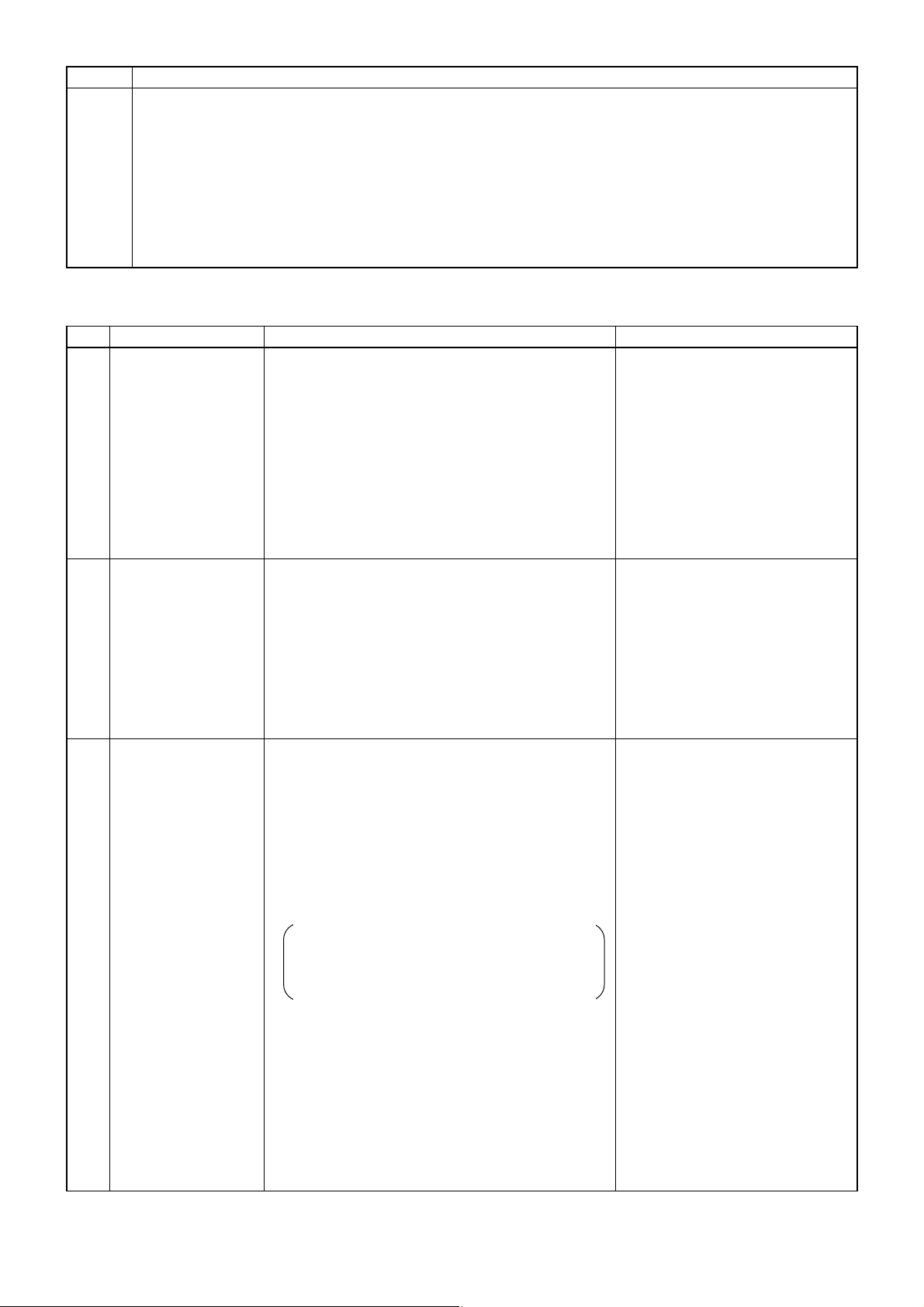

0.25S 0.25S 0.25S

5S

OFF

ON

Error display example: Fan motor operation device error

1Checklist of error codes displayed on the PZ-41SLB-E and LED displays(Table2-1)

(2)Trouble Mode 2

●An error code displays on the remote controller.

●Lossnay circuit board LED is flashing or lit up.

An error code displayed on the remote controller (PZ-41SLB-E, PZ-52SF-E) or the M-NET controller and blinking

or illumination of LED1 (green) or LED2 (red) on the circuit board shows the type of error. The LED blink interval

is 0.25 seconds for both on and off. The display duration is approximately 5 seconds.

LC 6608

Error code

*1

—

LED1

(green)

—

LED 2

(red)

Lossnay

communication

error

«

When using multiple Lossnay units, the

main/sub setting has not been made

for the second unit and following units.

« Multiple transmission cables have

been wired using multi core wires.

« Transmission cable and power cable

are too close.

« Transmission cable is not securely

connected.

« The length of wiring of the transmis-

sion cable is longer than specification (longer than 500 m).

«

Turn off the main power supply and set

the Main/Sub switch (SW1) (first unit to

main, second and following units to sub).

« Wire the transmission cable away

from the other transmission cable.

«

Wire the transmission cable at least 5

cm away from the power supply cable.

« Check the transmission cable con-

nection.

« Check the length of the transmission

cable wiring.

Symptom Cause Corrective action

RC6608

SRC 6608

——

Communica

tion error

between

remote controllers

(when 2

remote controllers are

connected)

« Multiple transmission cables have

been wired using multi core wires.

« Transmission cable and power sup-

ply cable are too close.

« Transmission cable is not securely

connected.

« The length of wiring of the transmis-

sion cable is longer than specification (longer than 500 m).

« Wire the transmission cable away

from the other transmission cable.

«

Wire the transmission cable at least 5

cm away from the power supply cable.

« Check the transmission cable con-

nection.

« Check the length of the transmission

cable wiring.

LC 0900

SLC 0900

——Lossnay

trial operation

« Trial operation switch on the

Lossnay circuit board (SW 2-1 or

SW 2-3) is set to ON board.

« Check the test operation switch.

LC 4000

SLC 4000

2

blinks

—

Fan motor

operation

device error

« Lossnay fan will not stop. « Replace the table.

LC 3602

SLC 3602

3

blinks

— Damper

related

error

« Damper board operation is not cor-

rect.

« Connectors for the damper unit are

not correctly connected.

« Remove the load and check or

move the damper board by hand.

«

Check the connection of the lead wire’s

connectors and the circuit con

nector.

LC 5101

SLC 5101

4

blinks

—

OA thermistor related

error

« Connectors for the thermistor are

not correctly connected.

« Check the connection of the lead

wires connectors and the circuit

connector.

LC 5102

SLC 5102

5

blinks

—

RA thermistor related

error

« Connectors for the thermistor are

not correctly connected.

« Check the connection of the lead

wires connectors and the circuit

connector.

—26—

Page 27

Error code*1LED1

(green)

LED 2

(red)

———

*2

8

blinks

— Pre-heat

error

« In order that the OA temperature

might not rise up, intermittent operation started.

« After turnig ON the pre-heat output

(X8), when the OA temperature

becomes larger than 15

˚C within

15 minutes.

« SW5-6 ON without preheating

installation

« Check whether the heater power is

supplied. Check whether the wiring

is correct. If not above-mentioned,

the heater capacity is too small. The

heater capacity needs to be looked

again.

«

Since the heater capacity is too large,

the OA temperature rises up too

much. The heater capacity needs to

be looked again.

« Turn SW5-6 OFF, when no preheat-

ing installation.

——— 9

blinks

— Remote

controller

communication

error

« Multiple transmission cables have

been wired using multi core wires.

« Transmission cable and power sup-

ply cable are too close.

« Transmission cable is not securely

connected.

« The length of wiring of the transmis-

sion cable is longer than specification (longer than 500 m).

« Wire the transmission cable away

from the other transmission cable.

«

Wire the transmission cable at least 5

cm away from the power supply cable.

« Check the transmission cable con-

nection.

« Check the length of the transmission

cable wiring.

“Filter” blink-

ing

——

Warning to clean air

filter by comulative

operation time

« Interval for cleaning Lossnay air fil-

ter has elapsed.

« After cleaning the air filter press the

“Filter” button on the remote controller 2 times.

“HO” blinking blink-

ing

— System is

starting

«

LED1 blinks at 1 second intervals during

starting operation (maximum of 45 seconds.)

« There is no error.

Symptom Cause Corrective action

*1 LC: Lossnay set to Main SLC: Lossnay set to Sub RC, SRC: remote controller (PZ-41SLB-E)

*2 The errror message is NOT displayed for the PZ-41SLB-E Lossnay remote controller.

—27—

2Checklist of error codes displayed on the PZ-52SF-E, M-NET controllers, and LED displays(Table2-2)

Error code*1LED1

(green)

LED 2

(red)

Symptom Cause Corrective action

6600 — 6

blinks

Multiple

address error

«

There is another unit with the same

address setting.

« Check the addresses of devices in

the system.

6607

6608

— 8

blinks

No ACK error

No answer

error (MNET communication

error)

«

Power supply to Lossnay is not turned on.

« Lossnay address was changed.

« Multiple transmission cables have

been wired using multi core wires.

« Transmission cable is not securely

connected.

«

The length of wiring of the transmission

cable is longer than specifications (longer

than maximum 200 m from the power supply unit, longer than 500 m between ends).

« Check the power to the Lossnay.

« Check the Lossnay address.

« Wire the transmission cable away

from the other transmission cable.

« Check the transmission cable con-

nection.

« Check the length of the transmission

cable wiring.

0900 ——Lossnay

trial operation

« Trial operation switch on the

Lossnay circuit board (SW 2-1 or

SW 2-3) is set to ON.

« Check the trial operation switch.

4116 2

blinks

—

Fan motor

operation

device error

« Lossnay fan will not stop. « Replace the table.

3602 3

blinks

— Damper

related

error

« Damper board operation is not cor-

rect.

« Connectors for the damper unit are

not correctly connected.

« Remove the load and check or

move the damper board by hand.

«

Check the connection of the lead wires

connectors and the circuit connector.

Page 28

5101 4

blinks

—

OA thermistor related

error

« Connectors for the thermistor are

not correctly connected.

« Check the connection of the lead

wires connectors and the circuit

connector.

5102 5

blinks

—

RA thermistor related

error

« Connectors for the thermistor are

not correctly connected.

« Check the connection of the lead

wires connectors and the circuit

connector.

3126 8

blinks

—

Pre-heat

error

« In order that the OA temperature

might not rise up, intermittent operation started.

« After turnig ON the pre-heat output

(X8), when the temprature become

larger than 15

˚C within 15 min-

utes.

« SW5-6 ON without preheating

installation

« Check whether the heater power is

supplied. Check whether the wiring

is correct. If not above-mentioned,

the heater capacity is too small. The

heater capacity needs too be looked

again.

«

Since the heater capacity is too large,

the OA temperature rises up too

much. The heater capacity needs to

be looked again.

« Turn SW5-6 OFF, when no preheat-

ing installation.

6602

6603

6604

— 1 - 5

blinks

Communic

ation circuit section

error

« Error with transmission cable.

« Controller where error originally

occurred is defective.

« Lossnay board is defective.

« Check transmission cable relations.

« Check the controller where the error

occurred.

« Replace the circuit board.

——— — Lit No M-NET

connection

information

« Lossnay does not have Group set-

ting (registration) made.

« Check the Lossnay address and

confirm that the group setting is

made.

Filter blinking ——

Warning to clean air

filter by comulative

operation time

« Interval for cleaning Lossnay air fil-

ter has elapsed.

« After cleaning the air filter press the

“Filter” button on the remote controller 2 times.

——— Lit — In delayed

start operation

« Delayed start operation is set at the

function select switch (SW 5-1) on

the Lossnay circuit board.

« There is no error.

——— LED6 (red)

off

No power

to M-NET

transmission cable

« Power supply is not supplied to the

M-NET transmission cable.

« Wiring length of the transmission

cable is from the power supply unit

or the outdoor unit is longer than

specification (maximum extension

200 m).

« Check the connection of the power

supply unit, outdoor unit and transmission cable.

« Check the length of the transmission

cable wiring.

Error code*1LED1

(green)

LED 2

(red)

Symptom Cause Corrective action

*1 The letters “LC” that display with the error code show a Lossnay unit type, and the number in the third column shows the

address.

—28—

Page 29

(3)

Trouble Mode 3: The remote controller does not operate or operates irregularly.

1Checklist for when using the PZ-41SLB-E (Table 3-1)

1

No.

Nothing displays on the

LCD.

« Transmission cable is connected to the wrong

terminal

« No Lossnay is set to “Main.”

« Power supply to the Lossnay is not turned on.

« Lossnay is connected to a power supply with a

rating outside specification.

« Transmission cable is not securely connected.

«

The length of wiring of the transmission cable is

longer than specification (longer than 500 m).

«

Check the transmission cable

connection (connected to TM4

on the Lossnay board).

« Turn off the main power supply

and set the Main/Sub switch

(SW1) (first unit to main, second

and following units to sub).

«

Check the power supply to the Lossnay.

« Check the power supply.

« Check the transmission cable

connection.

« Check the length of the trans-

mission cable wiring.

2

Starts or stops, or the

display changes, by

itself.

« Multiple transmission cables have been wired

using multi core wires.

« Transmission cable and power supply cable

are too close.

«

Wire the transmission cable away from

the other transmission cable.

«

Wire the transmission cable at least 5

cm away from the power supply

cable.

3 Displays a error code

that is not in the check

list.

« Letters on the remote controller LCD are dim.

« The release of the Delay Start button or the

Filter Reset button is not good.

« Replace the remote control.

« Replace the remote control.

4 Cannot stop the Lossnay

with the remote controller

(display shows “Interlocked”).

« External priority ON/OFF setting is made. « Check the interlocked operation

mode setting.

5 Cannot switch fan speed

with the remote controller.

« High/Low change input (CN16) is ON.

« The function select switch (SW2-4.5) on the

Lossnay circuit has the fixed high or fixed low

speed set.

« Check the High/Low change

input (CN16).

« Check the function select switch

(SW 2-4.5)

6 Lossnay operates when

the main power supply

turns on and the remote

controller displays.

« Main power supply was cut during Lossnay

operation.

« Stop the Lossnay with the

remote controller, then wait at

least 10 second and turn off the

main power supply .

Symptom Cause Corrective action

—29—

2Checklist for when using PZ-52SF-E (Table 3-2)

1

No.

Nothing displays on the

LCD.

« Transmission cable is connected to the wrong

terminal

« There is no power supply unit (for Lossnay

only systems).

« The power supply unit is not turned on.

« Transmission cable is not securely connected.

« Wiring length of the transmission cable is from

the power supply unit or the outdoor unit is

longer than specifications (maximum extension

200 m).

« Check the transmission cable

connection (connected to

A , B

of terminal unit TB5 on the

Lossnay board).

« Install the power supply unit.

« Check the power to the power

supply unit.

« Check the transmission cable

connection.

« Check the length of the trans-

mission cable wiring.

Symptom Cause Corrective action

Page 30

« After supplying power to the sys-

tem, HO blinks for a maximum of

about 10 minutes.

(This is not an error.)

«

Make the group setting (registration). If using a system with a system controller, register at the system controller. If there is only the

Lossnay remote controller, register

at the remote controller.

« Check the group setting at the

MELANS.

« Check the power supply to the

Lossnay.

« Check the power supply.

« Check the transmission cable

connection (connected to

A , B

of terminal unit TB5 on the

Lossnay board).

« Check the Lossnay address.

« If the board has been replaced,

reset the group settings.

« Check the length of the trans-

mission cable wiring.

2

No.

Displays “HO” and does

not start.

« It is less than 10 minutes since the power was

supplied to the system.

« Group setting (registration) has not been

made.

«

Remote control address has not been registered

in the group setting by the system controller.

« Power supply to the Lossnay is not turned on.

« Lossnay is connected to a power supply with a

rating outside specification.

« Lossnay transmission cable connection termi-

nal is wrong.

« Lossnay address was changed.

« Lossnay board was changed.

«

The length of wiring of the transmission cable is longer

than specifications (longer than maximum 200 m from

the power supply unit, longer than 500 m between ends).

3 Cannot register the

Lossnay from the remote

controller or the controller.

« Power supply to the Lossnay is not turned on.

« Lossnay is connected to a power supply with a

rating outside specification.

« Transmission cable to the Lossnay is not con-

nected.

« Lossnay transmission cable connection termi-

nal is wrong.

« Lossnay address is wrong.

«

The length of wiring of the transmission cable is longer

than specifications (longer than maximum 200 m from

the power supply unit, longer than 500 m between ends).

« Check the power supply to the

Lossnay.

« Check the power supply.

« Check the transmission cable

connection.

« Check the transmission cable

connection (connected to

A , B

of terminal unit TB5 on the

Lossnay table).

« Check the Lossnay address.

« Check the length of the trans-

mission cable wiring.

4

Starts or stops, or the display changes, by itself.

« Set for interlocked operation with City Multi. « Cancel interlocked operation set-

ting.

5

Displays a error code that

is not in the checklist.

« Letters on the remote controller LCD are dim. « Replace the remote controller.

6

Cannot stop the Lossnay

with the remote controller

(display shows “Central”).

« “Cancel Operation” setting is made from the

MELANS.

« External priority ON/OFF setting is made.

« Remote/nearby switch input (CN32) is set to

“Remote.”

« Check the settings of the

MELANS.

« Check the interlocked operation

mode setting.

« Check the remote/nearby

change input (CN32).

Symptom Cause Corrective action

—30—

Page 31

(4)Trouble Mode 4: The Lossnay does not operate or operates irregularly.

1Lossnay checklist (Table 4).

1

No.

The fan does not operate.

The fan does not operate

normally.

« Connectors for the fan connection or connec-

tors for the control circuit section connection

are not secure.

« Power supply is not supplied to the Lossnay, or

power outside specifications is connected.

« Lossnay group setting is not made by using the

M-NET. (LED2 lights)

« Check the lead wire connectors

and the control circuit section

connectors.

« Check the power supply.

« Check the Lossnay address and

the group setting (LED2 lights

when not using M-NET. This is

no error.)

3 Fan will not stop. « The trial operation switch (SW 2-1) is ON. «

Check the test operation switch (SW2-1).

2 Interlocked operation

with external device

(air conditioner) does not

occur.

« The type of external signal does not match the

connected terminal unit (charged, uncharged,

Mr. Slim signal).

« The type of external signal does not match the

pulse input switch (SW2-2) setting (level signal, pulse signal).

« The external device signal is not being input.

« The external device and signal cable wiring is

longer than specifications

(12V DC, 24V DC:

Longer than limitations

of external device

Uncharged a-contact: Longer than 500 m

Mr. Slim signal: Longer than 500 m)

« The Delayed Start mode is set at the remote

controller (PZ-41SLB-E) or the function select

switch (SW 5-1) on the Lossnay circuit board.

« The ON Interlocked Operation mode or OFF

Interlocked Operation mode is set at the

remote controller (PZ-41SLB-E) or the function

select switch (SW 5-7,8) on the Lossnay circuit

board.

« When using multiple Lossnay units, the exter-

nal control input signal is connected to a unit

with the “Sub” setting made.

« In a group of multiple Lossnay units with the M-

NET, the external control input signal is connected to a Lossnay unit other than the one

with the smallest address.

« There is a communication error with the

remote controller or controller.

«

Check the external signal type and the

external control input terminal (TM2)

connection.

«

Check the external signal type and

the pulse input switch (SW2-2)

setting.

« Check the external device.

« Check the wiring length of the

signal cable.

«

Check the delayed start settings of

the remote controller (PZ41SLB-E)

and the function select switch

(SW5-1).

«

Check the interlocked operation mode

settings of the remote controller

(PZ41SLB-E) and the function

select switch (SW5-7, 8)

« Connect the external control

input signal to the Lossnay set to

“Main.”

« Connect the external control

input signal to the Lossnay in the

group with the lowest address.

« Check the remote controller or

controller.

Symptom Cause Corrective action

—31—

4 Lossnay operates when

main power is turned on.

« The PZ-41SLB-E is being used.

«

By using the M-NET, the power supply ON/OFF

setting is set to ON at the function select switch

(SW 2-6) on the Lossnay circuit board.

« By using the M-NET, the automatic recovery

following power supply interruption (refer to

page 61) setting is made at the function select

switch (SW 5-4) on the Lossnay circuit board.

«

When the main power supply is

turned off while the Lossnay is

operating from the remote controller, the Lossnay will resume

operation when the main power is

turned back on (this is no error).

«

Check the power supply ON/OFF

setting of the function select

switch (SW2-6).

«

Check the automatic recovery following power supply interruption

setting of the function select

switch (SW5-4).

Page 32

5

No.

Supply air fan periodically stops operating.

« When the outdoor air temperature is -10°C or

less, operation stops after a fixed period of

about 10 minutes to keep the Lossnay Core

from freezing. (Cold weather area spec)

« When connected to a Mr. Slim or a City Multi

by a duct, operation stops when the air conditioner is defrosting.

« This is no error.

« This is no error.

6 Takes in air from out-

doors during interlocked

operation with a Mr. Slim

or a City Multi, but supply

air fan doesn’t stop operating when defrosting.

« The indoor unit’s outside air intake selection is

invalid.

« Set the outdoor air intake selec-

tion of a indoor unit to “ON.”

7 The supply air fan and

exhaust fan both periodically stop operating.

« When connected to Mr. Slim or City Multi by a

duct and the function select switch (SW 5-3)

on the Lossnay circuit board is ON, operation

stops when the air conditioner is defrosting.

« Check the function select switch

(SW5-3).

8 Fan speed will not

change.

« The High/Low switching extermary input

(CN16) is set to ON.

«

The function select switch (SW2-4.5) on the Lossnay circuit board is set to the high fixed or low fixed fan speed.

« The trial operation switch (SW2-1) is turned

ON.

« Check the High/Low change

input (CN16).

« Check the function select switch

(SW2-4,5).

« Check the trial operation switch

(SW2-1).

9 Damper board does not

operate.

« The outside air temperature is less than 8°C.

« The damper board operation is defective.

« The thermistor related connectors are not

securely connected.

« The damper related connectors are not

securely connected.

« The trial operation switch (SW2-1 or SW2-3) is

turned ON.

« When using the remote controller to change

ventilation mode, there may be a delayed start

of up to 30 seconds depending on the timing.

«

Check the outdoor air temperature.

«

Remove the load and check or

move the damper board by hand.

« Check the connections of the

lead wire connectors and the circuit connectors.

« Check the connections of the

lead wire connectors and the

control circuit connectors.

« Check the trial operation switch

(SW2-1 or SW2-3).

« This is no error.

10

Operation monitor output

is late with regard to external control input ON/OFF.

« When using the PZ-41SLB-E there is a maxi-

mum delay of 7 seconds, or without using

there is a maximum delay of 3 seconds.

«

This is

no error.

11 Operation monitor output

is OFF during operation.

« When the function select switch (SW 5-2) on

the Lossnay circuit board is ON, for operation

monitor output for interlocked operation with

the supply air fan, it turns OFF when the outside air is -10°C or less or when the air conditioner is defrosting.

«

Check the function select switch

(SW5-2)

12 Delayed start operation

does not work when

Delayed start is set.

« When using the PZ-41SLB-E, the circuit func-

tion select switch is set for delayed start.

«

Set delayed start at the remote controller (the circuit board switch is not in

effect when using the PZ-41SLB-E).

13

Lossnay does not operate when

power is on even when the

power on/off setting is made.

« Using the PZ-41SLB-E. « The power supply ON/OFF set-

ting is not in effect when using

PZ-41SLB-E.

14 Interlocked operation is

different from the settings.

« When using the PZ-41SLB-E, the circuit func-

tion select switch is set for interlocked operation.

« Set interlocked operation at the

remote controller (the circuit

board switch is not in effect when

using the PZ-41SLB-E).

Symptom Cause Corrective action

—32—

Page 33

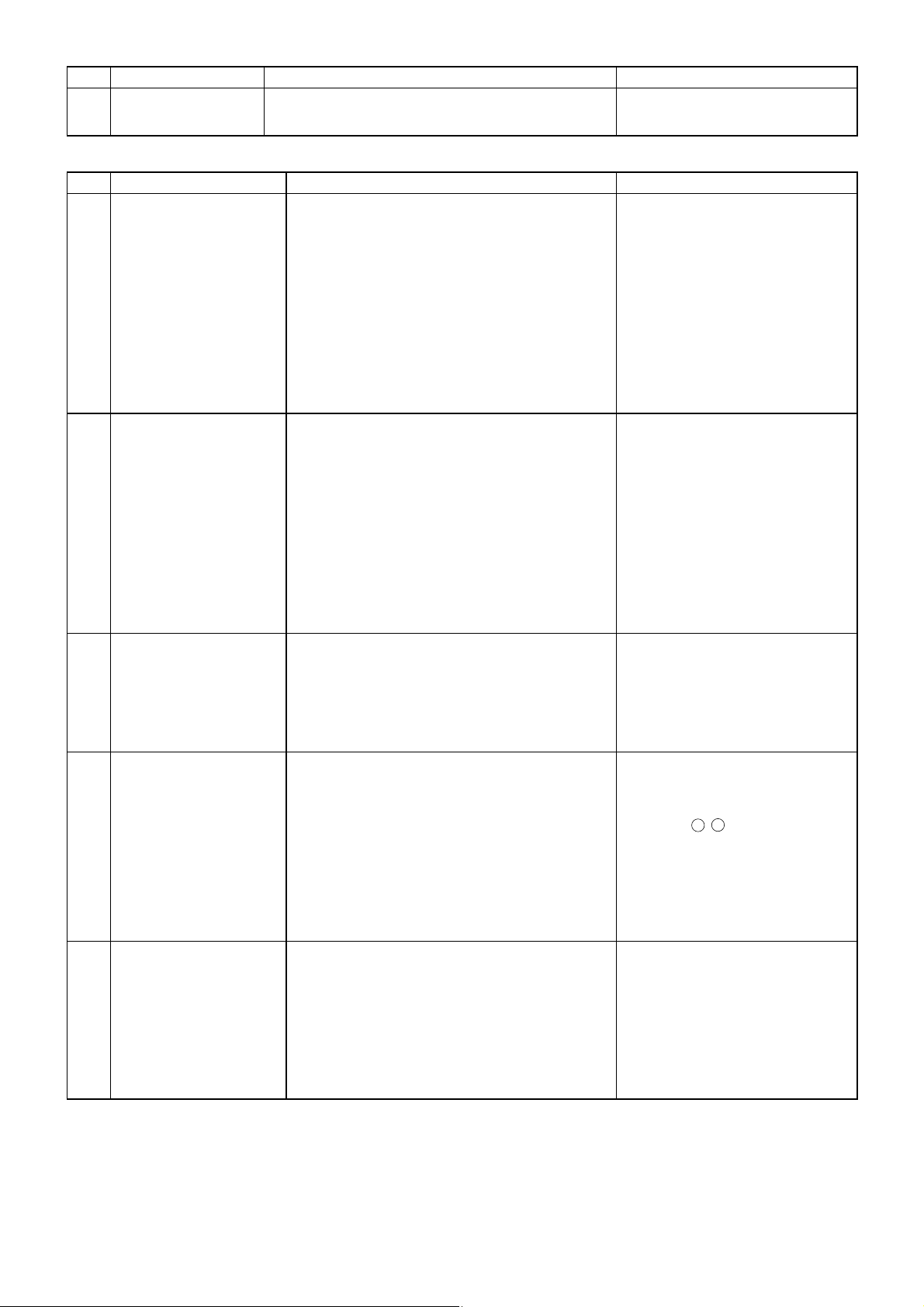

2Temperature vs. themistor resistance table

Temperature

(°C)

Resistance

value (kΩ)

Temperature

(°C)

Resistance

value (kΩ)

Temperature

(°C)

Resistance

value (kΩ)

Temperature

(°C)

Resistance

value (kΩ)

Temperature

(°C)

Resistance

value (kΩ)

-40 88.85 - ∞ -7 17.92 8 9.57 23 5.38 38 3.17

. . .

. . .

. . .

. . .

-6 17.16 9 9.20 24 5.19 39 3.06

-20 32.43 -5 16.43 10 8.84 25 5.00 40 2.96

-19 30.92 -4 15.74 11 8.49 26 4.82 41 2.86

-18 29.50 -3 15.08 12 8.17 27 4.65 42 2.77

-17 28.14 -2 14.45 13 7.85 28 4.49 43 2.68

-16 26.87 -1 13.86 14 7.55 29 4.33 44 2.59

-15 25.65 0 13.29 15 7.27 30 4.18 45 2.51

-14 24.51 1 12.74 16 6.99 31 4.03 46 2.43

-13 23.42 2 12.22 17 6.73 32 3.89 47 2.35

-12 22.39 3 11.72 18 6.48 33 3.76 48 2.28

-11 21.41 4 11.25 19 6.24 34 3.63 49 2.21

-10 20.48 5 10.80 20 6.01 35 3.51 50 2.14

-9 19.58 6 10.37 21 5.79 36 3.39

-8 18.73 7 9.96 22 5.58 37 3.28 87.5 - 0.72 - 0

—33—

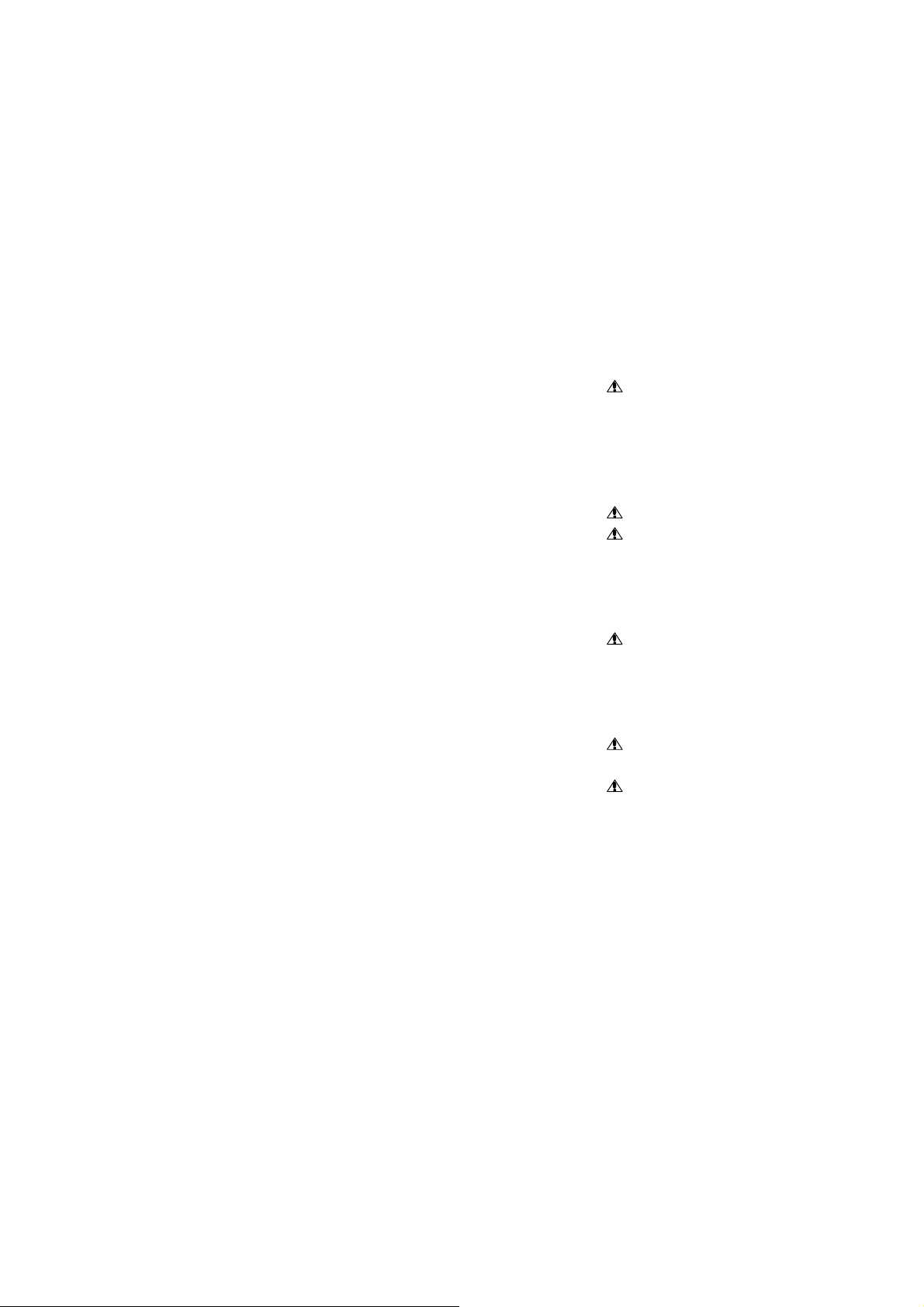

Page 34

—34—

LED1 (green)

• When blinking, there is an error with the Lossnay unit (number of blinks indicates the type of error).

• Blinks at 1 second intervals when starting.

• Lit during delayed start, normally off at other times.

LED2 (red)

• Blinking indicates M-NET communication error (number of blinks indicated the type of error).

• Lit when not connected to other M-NET units (registered).

Exhaust fan operation unit (combined)

Fuse (6.3 A/250 V)

Supply fan operation unit (combined)

Power supply

220 V to 240 V AC: up to 50 Hz

220 V AC: up to 60 Hz

(60 Hz is not used in EU)

Transformer input

Damper motor

operation unit

220 V - 240 V AC

5 V DC

12 V DC

Transformer output

11 V to 20 V AC

GND

LED4 (red)

• lit when power is

supplied to circuit

Thermistor

(outdoor air)

Thermistor

(return air)

Damper position

detector

• during Lossnay

ventilation: 12 V DC

• during by-pass

ventilation: 0 V

M-NET transmission cable (shielded)

M-NET transmission cable

(PZ-52SF-E, MELANS, power supply unit

or City Multi)

For external device

connection

During

operation: 0Ω

When

stopped: OPEN

During error/preheat: 0Ω

Normal: OPEN

Remote control switch (PZ-41SLB-E) and

Lossnay spanning transmission cable

9 V to 15 V DC

Exhaust fan operation unit

220 V to 240 V AC: up to 50 Hz

220 V AC: up to 60 Hz

Supply fan operation unit

220 V to 240 V AC: up to 50 Hz

220 V AC: up to 60 Hz

Extra

high

High Low

Extra

high

High Low

4-3 Circuit Test Point

In the case of LGH150RX

4-E and LGH-

200RX4-E, CN6 is

unconnected.

Page 35

5. Overhaul procedures

5-1 Blower Parts

1Remove the cover fixing screw.

2Pull back the hinged clip.

2Open the door and lift off of the hinge brackets.

3Remove Filters from the unit.

4Remove Cores from the unit.

LGH-15RX

4-E~LGH-100RX4-E

Hinge Maintenance Cover

LGH-15RX

4-E~LGH-100RX4-E

Core

Screw Screw

Filter

Filter

LGH-150RX

4-E,LGH-200RX4-E

Hinge Maintenance Cover

LGH-150RX

4-E,LGH-200RX4-E

Core

—35—

Page 36

5Remove screw from the core-guide,Remove core-guide.

6Remove separator from the blower portion.

7Remove screws from the motor base.

—36—

Core Guide

Separator

Motor Base Motor

Pre-assembled Blower

8Remove the pre-assembled blower.

Page 37

—37—

5-2 Damper Movement Motor Part (All units available)

1Remove (2) screws out from the damper motor cover.

2Take the damper movement motor out of the cover.

Damper Motor Cover

Damper Movement Motor

Control Cover

1Remove (3) screws from the control cover and open

the control cover.

5-3 Circuit Board Part

(1)LGH-15RX4-E~LGH-100RX4-E

Page 38

2Remove (2) screws from capacitors.

3Remove all harnesses connected to the circuit board.

—38—

Capacitors

Circuit Board

4Take the circiuit board out.

Page 39

1Remove (2) screws from the control cover and open the

control cover.

(2)

LGH-150RX4-E,LGH-200RX4-E

—39—

2Remove all harnesses connected to the circuit board.

3Take the circuit board out.

Page 40

—40—

6. Parts list

Please note the following when using the parts list.

1. When ordering parts, always indicate the part number, part name, and number of parts

required.

2. Parts are not always available, and it may take time for you to receive them.

3. There may be specification improvements or prices changes.

4. Specifications and prices are as of March 2005.

5. Parts marked are critical for safety. To maintain safety and performance, always

replace these parts with the parts prescribed.

6. The numbers that are circled in the exploded view are the same as the reference

number for the part being indicated.

Description of screw abbreviations

Screw

4

× 16

Abbreviation

PC screw

PRC screw

PP screw

SW · PP screw

PPT screw

PCT screw

PTT screw

PT screw

SET screw

SQ · SET screw

P · SET screw

PMT screw

HS · SET screw

P · R · W screw

P · C · W screw

P · R · C · W screw

R · W screw

PW · PP screw

SW-PW · PP screw

Description

Cross recess flat head machine screw

Cross recess oval head machine screw

Cross recess pan head machine screw

Cross recess pan head screw with spring washer

Cross recess tapping screw

Cross recess flat head tapping screw

Cross recess truss head tapping screw

Cross recess truss head machine screw

Slotted head stop screw

Square head stop screw

Pan head stop screw

Primer truss head screw

Hexagon head stop screw

Cross recess round wood screw

Cross recess flat head wood screw

Cross recess round and flat wood screw

Slotted round wood screw

Cross recess pan head screw with small washer

Cross recess pan head machine screw with spring washer and flat washer

Screw diameter Length

Page 41

1

12 34

567 8 9101112

13 14 15 16

1

1

16

2

3

7

3

3

—41—

Model LGH-15RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. H00 000 487 PTT screw 4×8 18

2. K82 163 617 Flange 2

3. R50 476 380 Hanger 4

4. H00 189 007 PTT screw 5×10 4

5. Y50 075 707 Maintenance cover 1

6. R50 395 381 Core guide 1

7. Y50 061 717 Filter 2

8. R50 476 710 Lossnay core 1

9. R50 476 381 Core guide 1

10. R50 384 712 Cover 2

11. R50 466 344 Hinge 1

12. M34 074 017 Special screw 4×11 1

13. Y50 029 712 Fix plate 1

14. Y50 061 704 Hanger cover 4

15. R50 361 717 Sound absorbing material 1 SA

16. R50 384 617 Flange 2

Page 42

31 32 33 34 35

36 37

38 39

36

38

38

31

33

38

32

34

36

38

35

36

39

38

37

—42—

Model LGH-15RX4-E

No. Parts No. Name of part Critical Remarks Price

31. R50 331 067 Special nut 2

32. M34 398 077 Tab washer 2

33. R50 354 480 Centrifugal fan 2 φ180

34. R50 028 465 Special washer 2

35. Y50 116 451 Motor 2

36. H00 312 007 PTT screw 4×6 22

37. R50 214 708 Motor plate 4

38. H00 000 332 PTT screw 4×10 12

39. Y50 029 708 Motor base 2

Q'ty

pcs/unit

for safety

Page 43

Model LGH-15RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. R50 213 715 Damper support 1

53. M31 234 089 Special bush 2

54. R50 095 156 Pull spring 1

55. R50 213 713 Damper 1

56. Y50 061 260 Damper motor 1 220-240V

57. R50 054 225 Bush 2

58. R50 228 150 Rod 1

59. Y50 061 706 Control cover 1

60. K83 170 228 Cord band 1

61. M45 017 228 Cord band 1

62. Y50 047 216 Transformer 1 230VAC

63. Y50 116 235 Capacitor 2 1.5μF・440VAC

64. H00 011 008 PT screw 4×8(BS) 2

65. H00 013 076 Lock washer 3

66. Y50 116 706 Earth fix plate 1

67. H00 154 005 PPT screw 4×12 2

68. K81 432 236 Terminal block 1 3P ML-20

69. Y50 108 226 Insulation plate 1

70. Y50 116 707 Circuit fix plate 1

71. Y50 116 368 Wiring diagram 1

72. H00 000 003 PP screw 4×8 2

73. Y50 116 171 Circuit board 1 LG-X02-E

74. X40 139 095 Spacer 4

75. R50 477 167 Thermistor 1

76. D42 019 095 Spacer 4

77. M35 164 224 Cord clip 1

78. K82 163 225 Cord bush 2

79. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

43

Page 44

59 60 61 62 63 64 65 66 67168 69 70

1

65

1

71 72 73 74 75 76 77 78 79

51 52 53 54 55

56 57 58

57

36

36

1

—44—

Page 45

1

12 34

567 8 9101112

13 14 15 16

1

1

16

2

3

7

3

3

—45—

Model LGH-25RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. H00 000 487 PTT screw 4×8 18

2. R50 323 609 Flange 2

3. R50 476 380 Hanger 4

4. H00 189 007 PTT screw 5×10 4

5. Y50 075 707 Maintenance cover 1

6. R50 395 382 Core guide 1

7. Y50 061 718 Filter 2

8. R50 476 711 Lossnay core 2

9. R50 476 382 Core guide 1

10. R50 476 708 Cover 2

11. R50 466 344 Hinge 1

12. M34 074 017 Special screw 4×11 1

13. Y50 029 712 Fix plate 1

14. Y50 061 704 Hanger cover 4

15. R50 354 718 Sound absorbing material 1 SA

16. Y50 075 609 Flange 2

Page 46

31 32 33 34 35

36 37

38 39

36

38

38

31

33

38

32

34

36

38

35

36

39

38

37

—46—

Model LGH-25RX4-E

No. Parts No. Name of part Critical Remarks Price

31. R50 331 067 Special nut 2

32. M34 398 077 Tab washer 2

33. R50 354 480 Centrifugal fan 2 φ180

34. R50 028 465 Special washer 2

35. Y50 117 451 Motor 2

36. H00 312 007 PTT screw 4×6 22

37. R50 214 708 Motor plate 4

38. H00 000 332 PTT screw 4×10 12

39. Y50 030 707 Motor base 2

Q'ty

pcs/unit

for safety

Page 47

Model LGH-25RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. R50 213 715 Damper support 1

53. M31 234 089 Special bush 2

54. R50 095 156 Pull spring 1

55. R50 213 713 Damper 1

56. Y50 061 260 Damper motor 1 220-240V

57. R50 054 225 Bush 2

58. R50 230 150 Rod 1

59. Y50 061 706 Control cover 1

60. K83 170 228 Cord band 1

61. M45 017 228 Cord band 1

62. Y50 047 216 Transformer 1 230VAC

63. Y50 116 235 Capacitor 2 1.5μF・440VAC

64. H00 011 008 PT screw 4×8(BS) 2

65. H00 013 076 Lock washer 3

66. Y50 116 706 Earth fix plate 1

67. H00 154 005 PPT screw 4×12 2

68. K81 432 236 Terminal block 1 3P ML-20

69. Y50 108 226 Insulation plate 1

70. Y50 116 707 Circuit fix plate 1

71. Y50 116 368 Wiring diagram 1

72. H00 000 003 PP screw 4×8 2

73. Y50 116 171 Circuit board 1 LG-X02-E

74. X40 139 095 Spacer 4

75. R50 477 167 Thermistor 1

76. D42 019 095 Spacer 4

77. M35 164 224 Cord clip 1

78. K82 163 225 Cord bush 2

79. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

47

Page 48

59 60 61 62 63 64 65 66 67168 69 70

1

65

1

71 72 73 74 75 76 77 78 79

51 52 53 54 55

56 57 58

57

36

36

1

—48—

Page 49

14

12345

6 7 8 9 10 11 12

13 14 15 16

4

2

14

5

5

8

5

14

14

14

1

2

4

14

16

2

4

3

—49—

Model LGH-35RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. R50 323 609 Flange 2

2. R50 476 380 Hanger 4

3. H00 189 007 PTT screw 5×10 4

4. R50 483 705 Hanger support 4

5. Y50 061 704 Hanger cover 4

6. X50 002 707 Maintenance cover 1

7. R50 396 381 Core guide 1

8. Y50 062 717 Filter 2

9. R50 478 710 Lossnay core 2

10. R50 478 381 Core guide 1

11. R50 476 708 Cover 2

12. R50 466 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. H00 000 487 PTT screw 4×8 20

15. Y50 029 712 Fix plate 1

16. Y50 075 609 Flange 2

Page 50

31 32 33 34 35

36 37

38

38

31

33

38

32

34

36

38

35

37

—50—

Model LGH-35RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

31. R50 331 067 Special nut 2

32. M34 398 077 Tab washer 2

33. R50 351 480 Centrifugal fan 2 φ220

34. R50 478 707 Motor base 2

35. M34 706 465 Special washer 2

36. Y50 062 451 Motor 2

37. R50 351 713 Motor fix plate 2

38. H00 189 007 PTT screw 5×10 16

Page 51

Model LGH-35RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. H00 312 007 PTT screw 4×6 23

53. R50 069 156 Pull spring 1

54. R50 472 716 Damper support 1

55. M31 234 089 Special bush 2

56. R50 472 715 Damper 1

57. Y50 061 260 Damper motor 1 220-240V

58. R50 054 225 Bush 2

59. R50 231 150 Rod 1

60. Y50 061 706 Control cover 1

61. K83 170 228 Cord band 1

62. M45 017 228 Cord band 1

63. Y50 047 216 Transformer 1 230VAC

64. Y50 088 235 Capacitor 2 2.5μF・440VAC

65. H00 011 008 PT screw 4×8(BS) 2

66. H00 013 076 Lock washer 3

67. Y50 116 706 Earth fix plate 1

68. H00 154 005 PPT screw 4×12 2

69. K81 432 236 Terminal block 1 3P ML-20

70. Y50 108 226 Insulation plate 1

71. Y50 116 707 Circuit fix plate 1

72. Y50 116 368 Wiring diagram 1

73. H00 000 003 PP screw 4×8 2

74. Y50 116 171 Circuit board 1 LG-X02-E

75. X40 139 095 Spacer 4

76. R50 477 167 Thermistor 1

77. D42 019 095 Spacer 4

78. M35 164 224 Cord clip 1

79. K82 163 225 Cord bush 2

80. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

51

Page 52

60 61 62 63 64 65 66 67 681469 70 71

14

66

14

72 73 74 75 76 77 78 79 80

51 52 54 55 56

57 58 59

58

52

53

—52—

Page 53

14

12345

6 7 8 9 10 11 12

13 14 15 16

4

2

14

5

5

8

5

14

14

14

1

2

4

14

16

2

4

3

—53—

Model LGH-50RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. R50 028 610 Flange 2

2. R50 476 380 Hanger 4

3. H00 189 007 PTT screw 5×10 4

4. R50 483 705 Hanger support 4

5. Y50 061 704 Hanger cover 4

6. X50 002 707 Maintenance cover 1

7. R50 216 381 Core guide 1

8. Y50 062 718 Filter 2

9. R50 478 711 Lossnay core 2

10. R50 478 382 Core guide 1

11. R50 351 708 Cover 2

12. R50 466 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. H00 000 487 PTT screw 4×8 20

15. Y50 029 712 Fix plate 1

16. R50 429 609 Flange 2

Page 54

31 32 33 34 35

36 37

38

38

31

33

38

32

34

36

38

35

37

—54—

Model LGH-50RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

31. R50 331 067 Special nut 2

32. M34 398 077 Tab washer 2

33. R50 351 480 Centrifugal fan 2 φ220

34. R50 478 707 Motor base 2

35. M34 706 465 Special washer 2

36. Y50 062 452 Motor 2

37. R50 351 713 Motor fix plate 2

38. H00 189 007 PTT screw 5×10 16

Page 55

Model LGH-50RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. H00 312 007 PTT screw 4×6 23

53. R50 069 156 Pull spring 1

54. R50 472 716 Damper support 1

55. M31 234 089 Special bush 2

56. R50 472 715 Damper 1

57. Y50 061 260 Damper motor 1 220-240V

58. R50 054 225 Bush 2

59. R50 232 150 Rod 1

60. Y50 061 706 Control cover 1

61. K83 170 228 Cord band 1

62. M45 017 228 Cord band 1

63. Y50 047 216 Transformer 1 230VAC

64. Y50 091 235 Capacitor 2 4μF・440VAC

65. H00 011 008 PT screw 4×8(BS) 2

66. H00 013 076 Lock washer 3

67. Y50 116 706 Earth fix plate 1

68. H00 154 005 PPT screw 4×12 2

69. K81 432 236 Terminal block 1 3P ML-20

70. Y50 108 226 Insulation plate 1

71. Y50 116 707 Circuit fix plate 1

72. Y50 116 368 Wiring diagram 1

73. H00 000 003 PP screw 4×8 2

74. Y50 116 171 Circuit board 1 LG-X02-E

75. X40 139 095 Spacer 4

76. R50 477 167 Thermistor 1

77. D42 019 095 Spacer 4

78. M35 164 224 Cord clip 1

79. K82 163 225 Cord bush 2

80. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

55

Page 56

60 61 62 63 64 65 66 67 681469 70 71

14

66

14

72 73 74 75 76 77 78 79 80

51 52 54 55 56

57 58 59

58

52

53

—56—

Page 57

12 345

6 7 8 9 10 11 12

13 14 15 16

2

5

5

8

5

1

16

2

3

3

2

3

2

2

2

—57—

Model LGH-65RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. R50 028 610 Flange 2

2. H00 000 487 PTT screw 4×8 18

3. R50 479 380 Hanger 4

4. H00 189 007 PTT screw 5×10 4

5. R50 479 704 Hanger cover 4

6. R50 217 708 Meintenance cover 1

7. R50 217 381 Core guide 1

8. Y50 120 717 Filter 2

9. R50 479 710 Lossnay core 2

10. R50 479 381 Core guige 1

11. R50 351 708 Cover 2

12. R50 466 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. Y50 029 712 Fix plate 1

15. R50 357 717 Sound absorbing material 1 SA

16. R50 429 609 Flange 2

Page 58

31 32 33 34 35 36 3837

40

31

33

39

32

34

36

37

35

38

39 40 41 42 43

41

42

43

—58—

Model LGH-65RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

31. R50 218 067 Special nut(12) 2

32. K83 466 113 Special washer(12) 2

33. R50 479 480 Centrifugal fan 2 φ245

34. R50 357 707 Fan base 2

35. Y50 033 104 Key 2 5×5×11.5

36. R50 217 711 Inlet ring 2

37. H00 189 007 PTT screw 5×10 16

38. Y50 120 451 Motor 2

39. R50 263 712 Motor fix leg 4

40. R50 217 225 Bush 8

41. D40 135 095 Spacer 8

42. M34 043 080 Special washer 8

43. H00 000 606 PT screw 5×14 8

Page 59

Model LGH-65RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. R50 099 156 Pull spring 1

53. R50 472 716 Damper support 1

54. M31 234 089 Special bush 2

55. R50 472 715 Damper 1

56. Y50 061 260 Damper motor 1 220-240V

57. H00 312 007 PTT screw 4×6 2

58. R50 054 225 Bush 2

59. R50 233 150 Rod 1

60. Y50 061 706 Control cover 1

61. K83 170 228 Cord band 1

62. M45 017 228 Cord band 1

63. Y50 047 216 Transformer 1 230VAC

64. Y50 120 235 Capacitor 2 5μF・440VAC

65. H00 011 008 PT screw 4×8(BS) 2

66. H00 013 076 Lock washer 3

67. Y50 116 706 Earth fix plate 1

68. H00 154 005 PPT screw 4×12 2

69. K81 432 236 Terminal block 1 3P ML-20

70. Y50 108 226 Insulation plate 1

71. Y50 116 707 Circuit fix plate 1

72. Y50 116 368 Wiring diagram 1

73. H00 000 003 PP screw 4×8 2

74. Y50 116 171 Circuit board 1 LG-X02-E

75. X40 139 095 Spacer 4

76. R50 477 167 Thermistor 1

77. D42 019 095 Spacer 4

78. M35 164 224 Cord clip 1

79. K82 163 225 Cord bush 2

80. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

59

Page 60

60 61 62 63 64 65 66 67 681469 70 71

14

66

14

72 73 74 75 76 77 78 79 80

51 53 54 55

56 58 59

58

52

57

2

—60—

Page 61

123 45

6 7 8 9 10 11 12

13 14 15 16

4

8

2

4

16

4

3

3

3

14

—61—

Model LGH-80RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. H00 000 488 PTT screw 4×12 10

2. R50 430 609 Flange 2

3. H00 000 487 PTTscrew 4×8 18

4. R50 095 380 Hanger 4

5. H00 000 244 PT screw 6×12 16

6. X50 004 707 Maintenance cover 1

7. R50 218 381 Core guide 1

8. Y50 063 717 Filter 2

9. R50 480 710 Lossnay core 2

10. R50 480 381 Core guide 1

11. R50 358 704 Cover 2

12. R50 466 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. Y50 029 712 Fix plate 2

15. R50 358 717 Sound absorbing material 1 SA

16. Y50 021 609 Flange 2

Page 62

313233343536 3837

40

31

33

39

32

34

36

38

35

37

3940414243

41

42

43

44

44

—62—

Model LGH-80RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

31. R50 218 067 Special nut(12) 2

32. K83 466 113 Special washer(12) 2

33. R50 479 480 Centrifugal fan 2 φ245

34. H00 157 008 PT screw 6×20 8

35. M34 043 080 Special washer 8

36. D40 135 095 Spacer 8

37. R50 217 225 Bush 8

38. R50 480 707 Fan base 2

39. Y50 033 104 Key 2 5×5×11.5

40. R50 264 711 Inlet plate 2

41. R50 264 712 Motor fix leg 2

42. H00 189 007 PTT screw 5×10 16

43. Y50 121 451 Motor 2

44. H00 061 050 Nut(6) 8

Page 63

Model LGH-80RX4-E

No. Parts No. Name of part Critical Remarks Price

51. Y50 061 693 Damper motor cover 1

52. R50 074 156 Pull spring 1

53. R50 473 715 Damper support 1

54. M31 234 089 Special bush 2

55. R50 473 716 Damper 1

56. Y50 061 260 Damper motor 1 220-240V

57. H00 312 007 PTT screw 4×6 2

58. R50 054 225 Bush 2

59. R50 265 150 Rod 1

60. Y50 061 706 Control cover 1

61. K83 170 228 Cord band 1

62. M45 017 228 Cord band 1

63. Y50 047 216 Transformer 1 230VAC

64. Y50 092 235 Capacitor 2 7μF・440VAC

65. H00 011 008 PT screw 4×8(BS) 2

66. H00 013 076 Lock washer 3

67. Y50 116 706 Earth fix plate 1

68. H00 154 005 PPT screw 4×12 2

69. K81 432 236 Terminal block 1 3P ML-20

70. Y50 108 226 Insulation plate 1

71. Y50 116 707 Circuit fix plate 1

72. Y50 116 368 Wiring diagram 1

73. H00 000 003 PP screw 4×8 2

74. Y50 116 171 Circuit board 1 LG-X02-E

75. X40 139 095 Spacer 4

76. Y50 121 215 Thermistor 1

77. D42 019 095 Spacer 4

78. M35 164 224 Cord clip 1

79. K82 163 225 Cord bush 2

80. K83 223 225 Bush 1

Q'ty

pcs/unit

for safety

63

Page 64

60 61 62 63 64 65 66 67 68369 70 71

3

66

3

72 73 74 75 76 77 78 79 80

51 53 54 55

56 58 59

58

52

57

3

—64—

Page 65

123 45

6 7 8 9 10 11 12

13 14 15 16

4

8

2

4

16

4

3

3

3

14

—65—

Model LGH-100RX4-E

No. Parts No. Name of part Critical Remarks Price

Q'ty

pcs/unit

for safety

1. H00 000 488 PTT screw 4×12 10

2. R50 430 609 Flange 2

3. H00 000 487 PTT screw 4×8 18

4. R50 095 380 Hanger 4

5. H00 000 244 PT screw 6×12 16

6. X50 004 707 Maintenance cover 1

7. R50 219 381 Core guide 1

8. Y50 063 718 Filter 2

9. R50 481 710 Lossnay core 2

10. R50 481 381 Core guide 1

11. R50 358 704 Cover 2

12. R50 466 344 Hinge 1

13. M34 074 017 Special screw 4×11 1

14. Y50 029 712 Fix plate 2

15. R50 358 717 Sound absorbing material 1 SA