Page 1

Page 2

Page 3

Lossnay Unit

Page 4

i

CONTENTS

CHAPTER 1 Ventilation for Healthy Living

1. Necessity of Ventilation ...................................................................................................................................... 2

2. Ventilation Standards .......................................................................................................................................... 4

3. Ventilation Method .............................................................................................................................................. 5

4. Ventilation Performance ...................................................................................................................................... 8

5. Outdoor Air (ventilation) Load .............................................................................................................................. 10

CHAPTER 2 Lossnay Construction and Principle

1. Construction and Features of Lossnay .............................................................................................................. 16

2. Construction and Principle of Core ...................................................................................................................... 16

3. Calculation of the Total Heat Recovery Efficiency .............................................................................................. 18

4. What is a Psychrometric Chart? ........................................................................................................................ 19

5. Calculation of Lossnay Heat Recovery .............................................................................................................. 20

CHAPTER 3 General Technical Considerations

1. Lossnay Heat Recovery Effect ............................................................................................................................ 22

2. Example Heat Recovery Calculation .................................................................................................................. 24

3. Calculation of Lossnay Economical Effects ........................................................................................................ 26

4. Psychrometric Chart .......................................................................................................................................... 28

5. The Result of No Virus (phage) Cross Contamination for the Lossnay Core and Determining

Resistance of the Lossnay Core to Molds .......................................................................................................... 29

6. Flame-proofing Properties of Lossnay Core ...................................................................................................... 31

7. Lossnay Core’s Soundproofing Properties Test .................................................................................................. 33

8. Change in Lossnay Core Over Time .................................................................................................................. 34

9. Comparison of Heat Recovery Techniques ........................................................................................................ 36

CHAPTER 4 Characteristics

1. How to Read the LGH Series Lossnay Characteristic Curves ............................................................................ 40

2. Calculating the Static Pressure Loss .................................................................................................................. 40

3. How to Obtain Efficiency from Characteristic Curves ........................................................................................ 44

4. Sound .................................................................................................................................................................. 45

5. NC Curves (LGH-RX

4 Series) ............................................................................................................................ 51

6. List of Models ...................................................................................................................................................... 54

CHAPTER 5 System Design Recommendations

1. Lossnay Usage Conditions ................................................................................................................................ 58

2. Noise Value of Lossnay with Built-in Fans .......................................................................................................... 59

3. Attachment of Air Filter ...................................................................................................................................... 59

4. Duct Construction .............................................................................................................................................. 59

5. By-pass Ventilation ............................................................................................................................................ 59

6. Transmission Rate of Various Gases and Related Maximum Workplace Concentration .................................. 60

7. Solubility of Odors and Toxic Gases, etc., in Water and Effect on Lossnay Core .............................................. 61

8. Positioning of the Supply/Exhaust Fans and the Air Transmission Rate

(excluding moisture resistant total heat recovery units) ...................................................................................... 62

9. Combined Operation with other Air Conditioners ................................................................................................ 63

10. Automatic Ventilation Switching .......................................................................................................................... 64

11.Vertical Installation of LGH Series ...................................................................................................................... 65

12. Installation of Supplementary Fan Devices After Lossnay Unit .......................................................................... 66

Page 5

ii

CHAPTER 6 Examples of Lossnay Applications

1. Large Office Building .......................................................................................................................................... 68

2. Medium Size Office Building .............................................................................................................................. 71

3. Multipurpose Tenant Building .............................................................................................................................. 74

4. Urban Small-Scale Building ................................................................................................................................ 77

5. Hospitals ............................................................................................................................................................ 78

6. Schools .............................................................................................................................................................. 80

7. Hotels (convention halls, wedding halls) ............................................................................................................ 82

8. Public Halls (combination facilities such as day-care centres) .......................................................................... 85

CHAPTER 7 Installation Considerations

1. LGH-Series Lossnay Ceiling Embedded-Type (LGH-RX

4 Series) ...................................................................... 86

2. Building Lossnay Unit Horizontal-type (LU-500) ................................................................................................ 89

CHAPTER 8 Filtering for Freshness

1. Necessity of Filters .............................................................................................................................................. 92

2. Data Regarding Dust .......................................................................................................................................... 92

3. Calculation Table for Dust Collection Efficiency of Each Lossnay Filter ............................................................ 93

4. Comparison of Dust Collection Efficiency Measurement Methods .................................................................... 95

5. Calculation of Dust Concentration ...................................................................................................................... 97

6. Certificate in EU .................................................................................................................................................. 97

CHAPTER 9 Service Life and Maintenance

1. Service Life ........................................................................................................................................................ 100

2. Cleaning the Lossnay Core and Pre-filter .......................................................................................................... 100

CHAPTER 10 Ventilation Standards in Each Country

1. Ventilation Standards in Each Country ................................................................................................................ 102

2. U.S. ...................................................................................................................................................................... 103

3. U.K....................................................................................................................................................................... 103

CHAPTER 11 Lossnay Q and A .......................................................................................................................... 106

Page 6

Page 7

CHAPTER 1

Ventilation for Healthy Living

Page 8

2

CHAPTER 1 ● Ventilation for Healthy Living

Fresh outdoor air must be introduced constantly at a set ratio in an air conditioning system. This fresh air is introduced to be

mixed with the return air from the room, to adjust the temperature and humidity, supply oxygen, reduce body and other odors,

remove tobacco smoke and to increase the cleanness of the air.

The standard ventilation (outdoor air intake) volume is determined according to the type of application, estimated number of

persons in the room, room area, and relevant regulations. Systems which accurately facilitate these requirements are

increasingly being required to be installed in buildings.

1. Necessity of Ventilation

The purpose of ventilation is basically divided into “oxygen supply”, “cleaning of air”, “temperature control” and “humidity

control”. Cleaning of the air includes the elimination of “odors”, “gases”, “dust” and “bacteria”. The needs of ventilation are

divided into “personal comfort”, “assurance of environment for animals and plants”, and “assurance of environments for

machinery and constructed materials”.

In Japan legal regulations regarding ventilation are set in the Building Srandard Law Enforcement Ordinance and the “Building

Management Law” for securing a sanitary environment in buildings. These are in general agreeance with similar regulations in

other countries.

1.1 Room air environment in buildings

In Japan, the Building Management Law, a law concerning the sanitary environment of buildings, designates eleven

applications including offices, shops, and schools with a total floor area of 3,000 m

2

or more, as buildings. According to this

law maintenance and management of the ventilation and water supply and discharge according to the Environmental

Sanitation Management Standards is obligatory.

The following table gives a specific account of buildings in Tokyo.

(Tokyo Food and Environment Guidance Center Report)

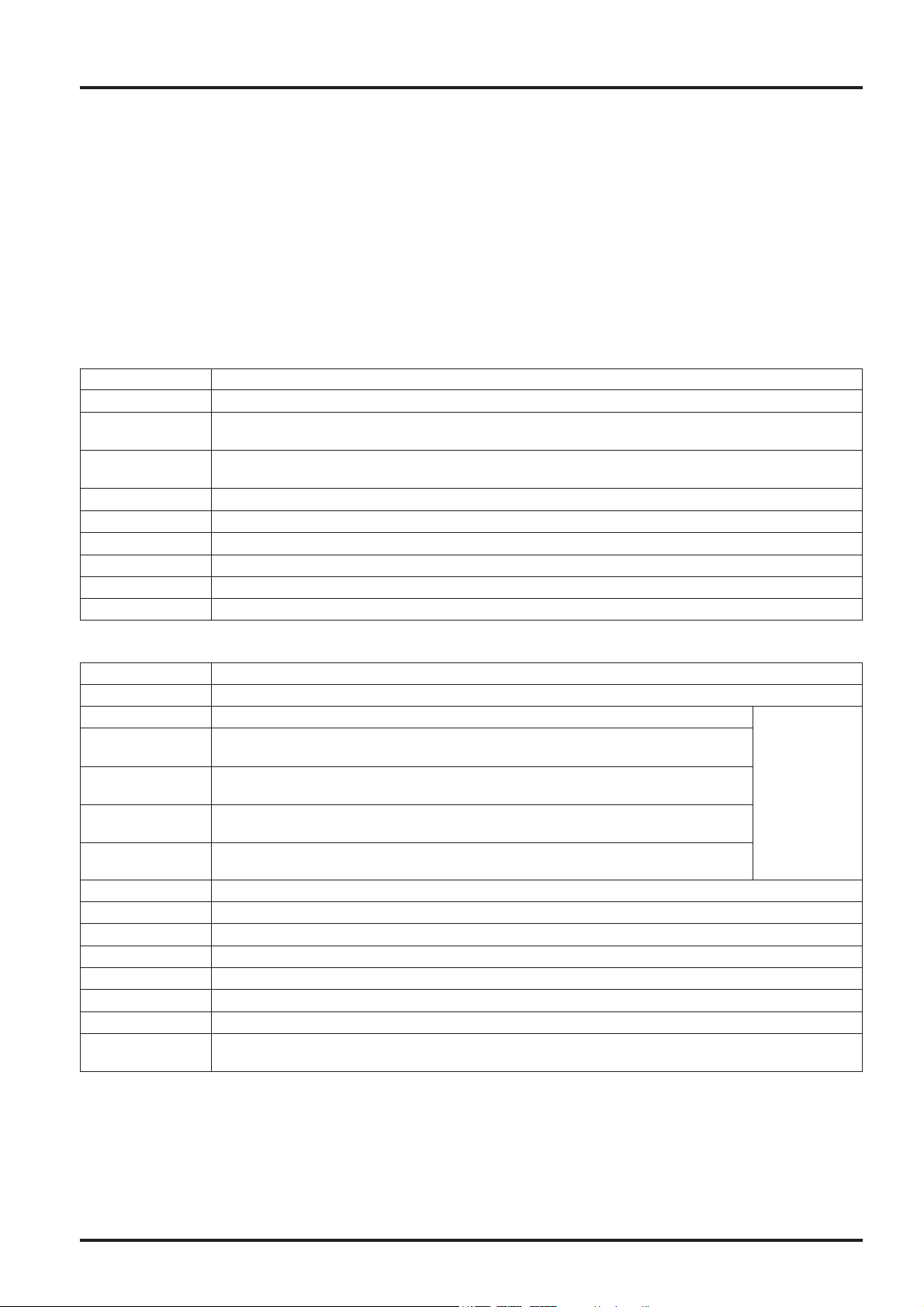

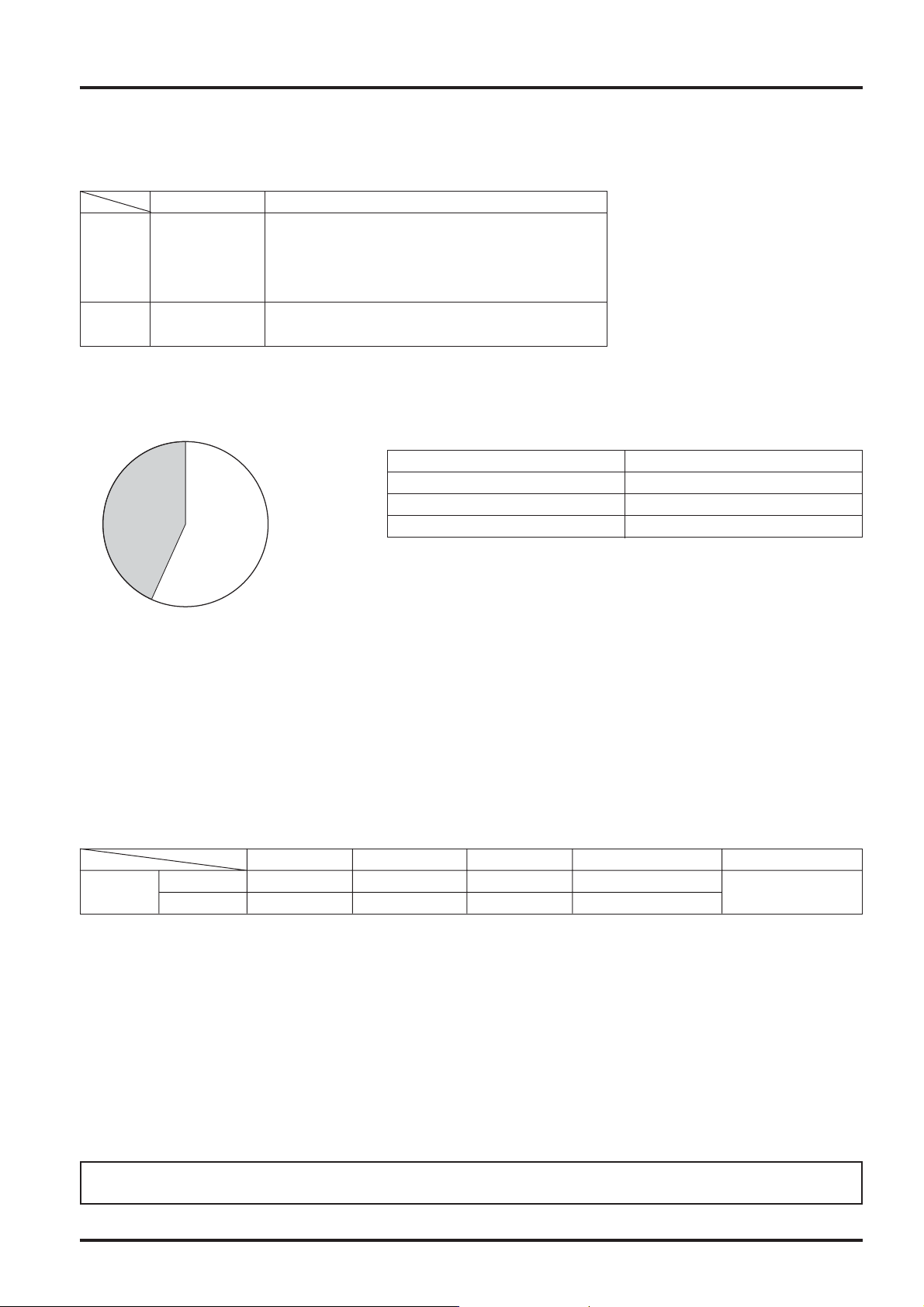

Specific Account of Buildings in Tokyo (March, 2003)

Note: Excludes buildings with an expanded floor space of 3,000 to 5,000 m

2

in particular areas.

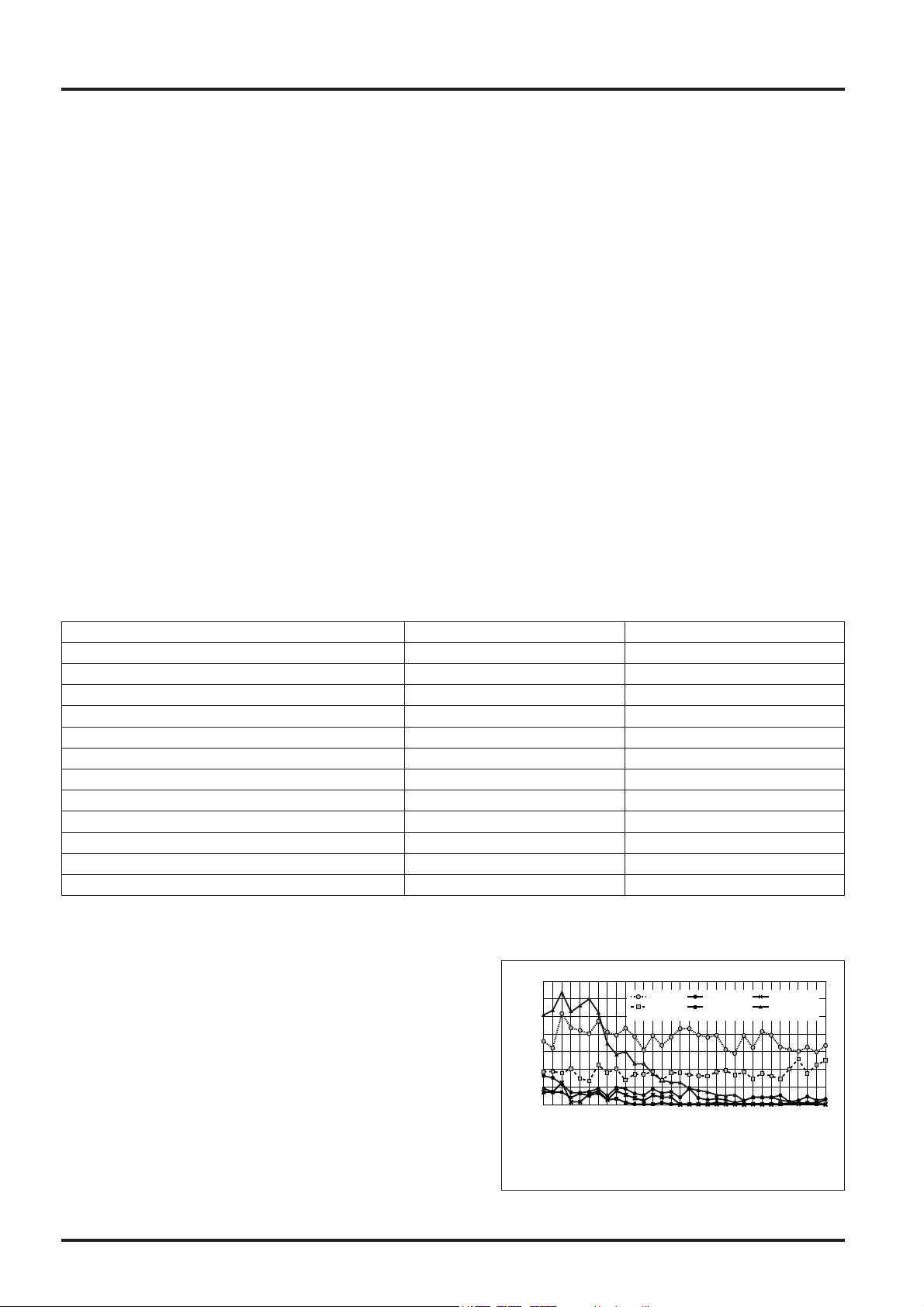

The ratio of results of the air quality measurement public

inspection and the standard values that were not met (percentage

of unsuitability) for the approximately 500 buildings examined in

1980 is shown in the chart at the right.

There was a large decrease in unsuitable percentages of floating

particles, but there was almost no change in temperature and

carbon dioxide. Values for temperature, ventilation, and carbon

monoxide almost entirely cleared the standard values, and are

excluded. The study from 2002 shows the item with the highest

percentage of unsuitability as temperature with 2.7%, followed by

carbon dioxide at 22.8%.

70

60

50

40

30

20

10

0

Percentage of unsuitability (%)

76 77 78 79 80 8171 72 73 74 75

82

83 84

85

86

87

88 899091 92 93 94 95 96 97 98 99 00 01 02

(year)

relative humidity

carbon dioxide

temperature

carbon monoxide

ventilation

floating particles

(tobacco smoke)

Percentage of unsiutability of air quality by year

(From reference data in the 2003 edition of the “Water Supply

Division, Dept. of Localized PublicHealth, Tokyo Metropolitan

Government, Bureau of Public Health”)

Number of buildings %

Offices 1,467 56.7

Shops 309 22.0

Department Stores 63 2.4

Schools 418 16.2

Inns 123 4.8

Theaters 86 3.3

Libraries 12 0.5

Museums 11 0.4

Assembly Halls 63 2.4

Art Museums 8 0.3

Amusement Centers 27 1.0

Total 2,587 100.0

Page 9

3

CHAPTER 1 ● Ventilation for Healthy Living

Effect of carbon monoxide (CO) 10,000 ppm = 1%

Concentration (ppm)

Effect of concentration changes

0.01 - 0.2 Standard atmosphere.

5 Considered to be the long-term tolerable value.

10

The Building Standard Law of Japan, Law for Maintenance of Sanitation in Buildings.

Environmental standard 24-hour average.

20

Considered to be the short-term tolerable value.

Environmental standard 8-hour average.

50

Tolerable concentration for labor environment.

(Japan Industrial Sanitation Association)

100

No effect for 3 hours. Effect noticed after 6 hours.

Headache, illness after 9 hours; harmful for long-term but not fatal.

200 Light headache in the forehead in 2 to 3 hours.

400 Headache in the forehead, nausea in 1 to 2 hours; headache in the back of head in 2.5 to 3 hours.

800 Headache, dizziness, nausea, convulsions in 45 minutes. Comatose in 2 hours.

1,600 Headache, dizziness in 20 minutes. Death in 2 hours.

3,200 Headache, dizziness in 5 to 10 minutes. Death in 30 minutes.

6,400 Death in 10 to 15 minutes.

12,800 Death in 1 to 3 minutes.

Several 10,000 ppm

This level may be found in automobile exhaust.

(Several %)

Apprpx. 5 ppm is

an annual

average value in

city areas.

This value may

exceed 100 ppm

near roads, in

tunnels and

parking areas.

Concentration (%) Standards and effect of concentration changes

Approx. 21 Standard atmosphere.

20.5

Ventilation air volume standard will be a guideline where concentration does not decrease more than 0.5%

from normal value. (The Building Standard Law of Japan)

20 - 19

An oxygen deficiency of this amount does not directly endanger life in a normal air pressure, but if there is a

combustion device in the area, the generation of CO will increase rapidly due to incomplete combustion.

18 Industrial Safety and Health Act. (Hypoxia prevention regulations.)

16 Normal concentration in exhaled air.

16 - 12 Increase in pulse and breathing resulting in dizziness and headaches.

15 Flame in combustion devices will extinguish.

12 Threat to life in short term.

7 Fatal

In the case of Japan, an Instruction Guideline based on these regulations has been issued, and unified guidance is carried out.

Part of the Instruction Guideline regarding ventilation is shown below.

●

The fresh outdoor air intake must be 10 m or higher from ground level, and be distanced appropriately from the exhaust air

outlet. (Neighbouring buildings must also be considered.)

●

The fresh outdoor air intake volume must be 25 to 30 m3/h·person in design.

●

An air volume measurement hole must be installed at an effective position to measure the treated air volume of the

ventilating device.

●

The position and shape of the supply diffuser and return grille must be selected so the air environment in the room is

distributed evenly.

1.2 Effect of air contamination on human bodies

Effect of oxygen (O2

) concentration

Page 10

4

CHAPTER 1 ● Ventilation for Healthy Living

Effect of carbon dioxide (CO2)

Note: According to Facility Check List published by Kagekuni-sha.

1.3 Effect of air contamination in buildings

●

Dirtiness of interior

New ceilings, walls and ornaments will turn yellow in one to two years. This is caused by dust and the tar in tobacco smoke.

2. Ventilation Standards

The legal standards for ventilation differ according to each country. Please follow the standards set by the country. In the US,

Ashrae revised their standards in 1989 becoming more strict.

In Japan, regulations are set in the The Building Standard Law of Japan Enforcement Ordinance, the so-called “Building

Management Law” for securing a sanitary environment in buildings. According to the Building Standards Law, a minimum of

20 m

3

/h per person of ventilation air is required.

Concentration (%) Effect of concentration changes

0.03 (0.04) Standard atmosphere.

0.04 - 0.06 City air.

0.07 Tolerable concentration when many people stay for long time.

0.10

General tolerable concentration.

The Building Standard Law of Japan, Law for Maintenance of Sanitation in Buildings.

0.15 Tolerable concentration used for ventilation calculations.

0.2 - 0.5 Observed as relatively poor.

0.5 or more Observed as the poorest.

0.5 Long-term safety limits (U.S. Labor Sanitation) ACGIH, regulation of laborer offices.

2 Depth of breathing and inhalation volume increases 30%.

3Work and physical functions deteriorate, breathing doubles.

4 Normal exhalation concentration.

4 - 5

The respiratory center is stimulated; depth and times of breathing increases. Dangerous if breathed in for a

long period. If an O

2 deficiency also occurs, trouble will occur sooner and be more dangerous.

8

When breathed in for 10 minutes, breathing difficulties, redness in the face and headaches will occur.

The trouble will worsen when there is also a deficiency of O

2.

18 or more Fatal

There is no toxic level in

CO2 alone.

However, these tolerable

concentrations are a

guideline of the

contamination estimated

when the physical and

chemical properties of

the air deteriorate in

proportion to the increase

of CO

2.

Page 11

5

CHAPTER 1 ● Ventilation for Healthy Living

3. Ventilation Method

3.1 Ventilation class and selection points

An appropriate ventilation method must be selected according to the purpose.

Ventilation is composed of “Supply air” and “Exhaust air” functions. These functions are classified according to natural flow or

mechanical ventilation using a fan (forced ventilation).

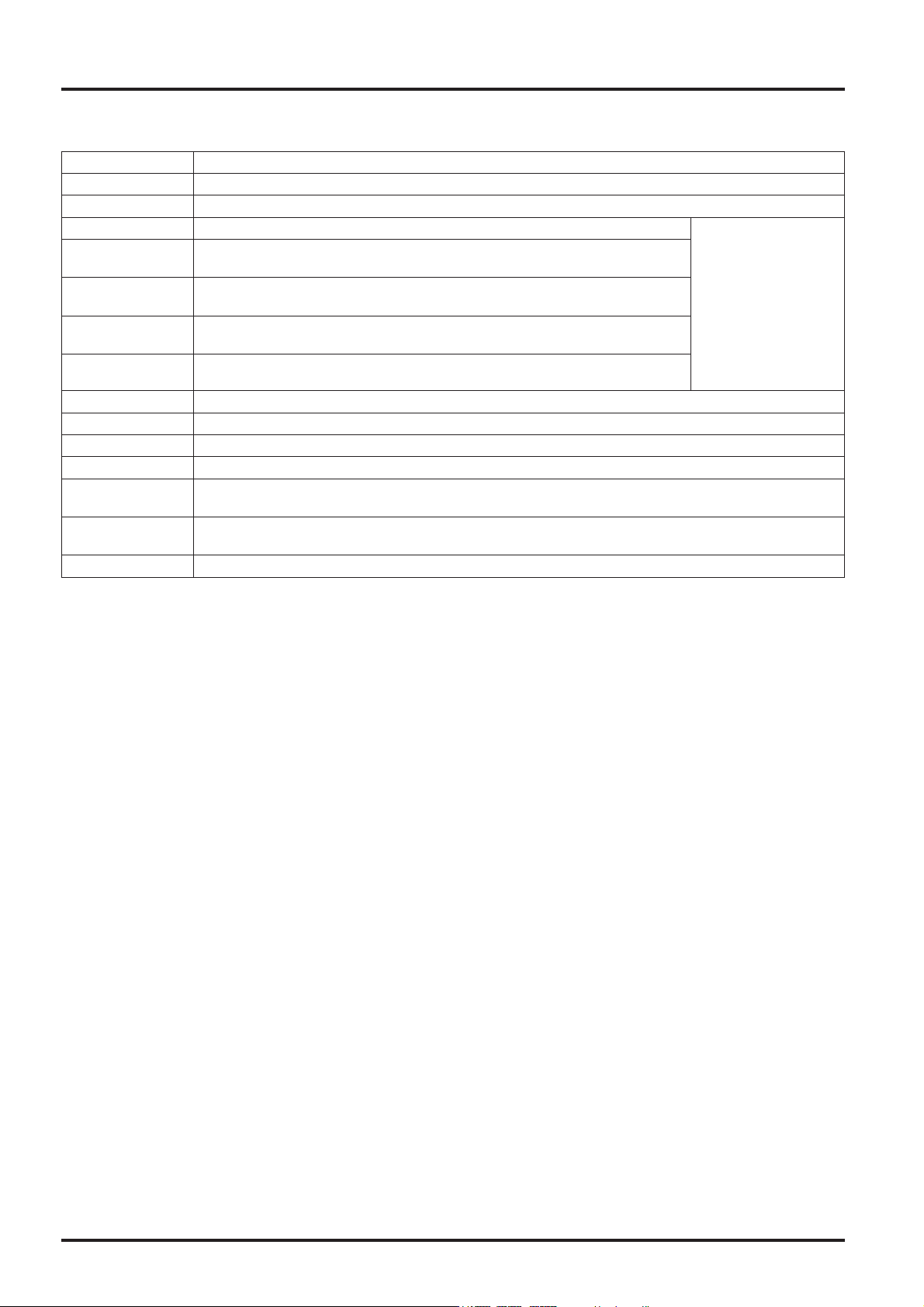

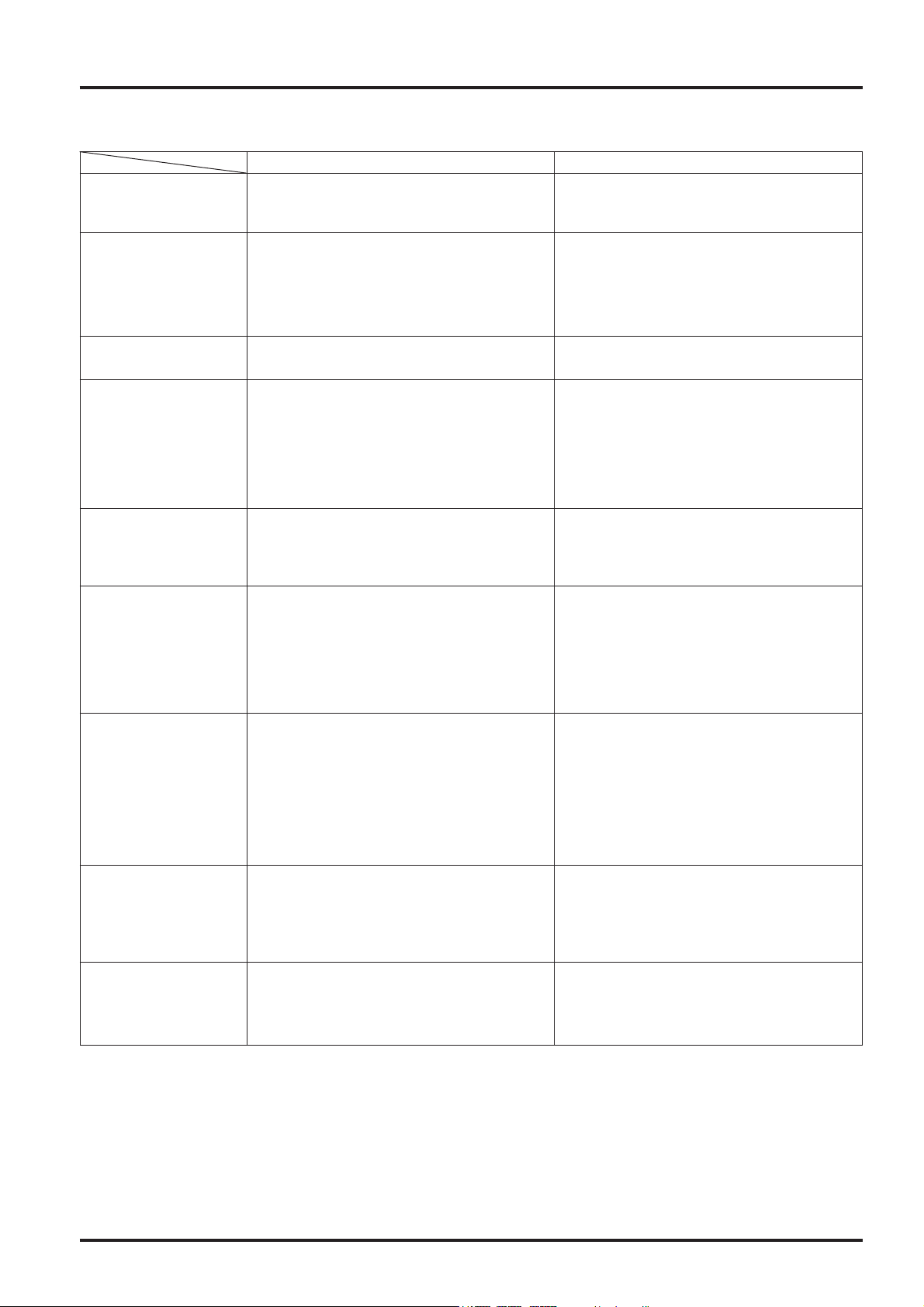

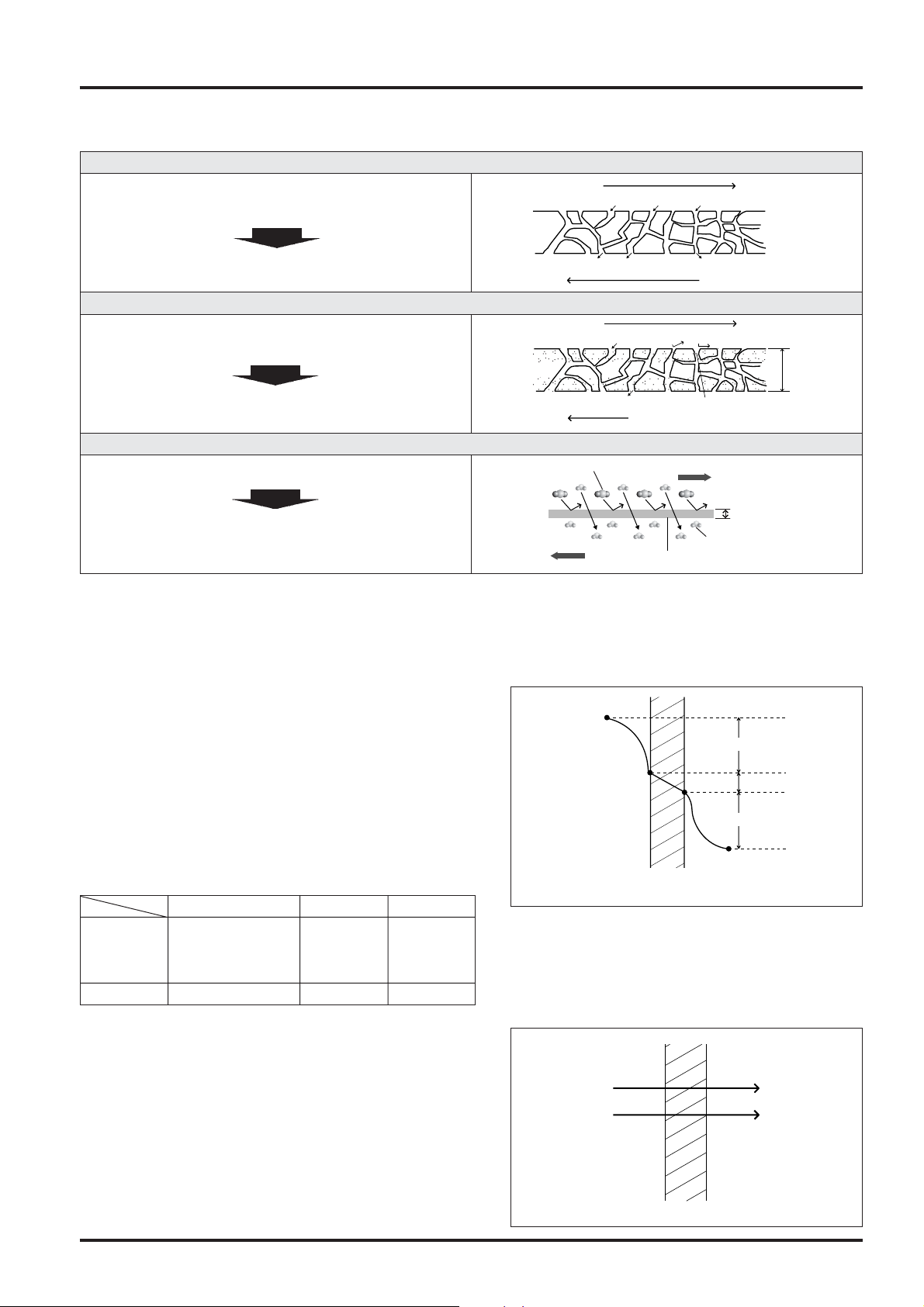

Classification of mechanical ventilation

Classification of ventilation (according to Building Standards Law)

1. Class 1 ventilation

Fresh outdoor air is mechanically

brought in and simultaneously the

stale air in the room is mechanically

discharged.

2. Class 2 ventilation

Fresh outdoor air is mechanically

brought in and the exhaust air is

discharged from the exhaust air

outlet (natural).

3. Class 3 ventilation

The stale air in the room is

mechanically discharged and

simultaneously fresh outdoor air is

mechanically introduced from the

supply air diffuser (natural).

Ex. of application

•Ventilation of air

conditioned rooms.

(buildings, hospitals,

etc.)

•Ventilation of room

not facing an outer

wall. (basement,

etc.)

•Ventilation of large

room. (office, large

conference room,

hall, etc.)

• Surgery theatre.

• Clean rooms.

• Foodstuff processing

factories.

• Local ventilation in

kitchens.

•Ventilation of hot

exhaust air from

machine room, etc.

•Ventilation of humid

exhaust air from

indoor pools, bathrooms, etc.

• General simple

ventilation.

System effect

By changing the

balance of the supply

fan and exhaust fan’s

air volumes, the

pressure in the room

can be balanced

freely, and the

interrelation with

neighboring spaces

can be set freely.

As the room is

pressurized, the flow

of odors and dust,

etc., from neighboring

areas can be

prevented.

The exhaust air is

removed from a local

position in the room,

and dispersion of the

stale air can be

prevented by applying

an entire negative

pressure.

Design and construction

properties

•

An ideal design in which

the supply air diffuser

and exhaust air outlet

position relation and air

volume, etc., can be set

freely is possible.

•A system which adjusts

the temperature and

humidity of the supply

air diffuser flow to the

room environment can

be incorporated.

•

The supply and

exhaust volume can be

set freely according to

the changes in

conditions.

• The position and

shape of the supply

air diffuser can be

set.

• The temperature and

humidity of the

supply air diffuser

flow can be set

accordingly, and

dust can be removed

as required.

•Effective exhausting

of dispersed stale air

generation sites is

possible from a local

exhaust air outlet.

•Ventilation in which

the air flow is not felt

is possible with the

supply air diffuser

setting method.

Selection points

• Accurate supply air

diffuser can be

maintained.

• The room pressure

balance can be

maintained.

• The supply air

diffuser temperature

and humidity can be

adjusted and dust

treatment is

possible.

• The pressure is

positive.

•

The supply air diffuser

temperature and

humidity can be

adjusted, and dust

treatment is possible.

•

The positional relation

of the exhaust air

outlet to the supply air

diffuser is important.

• The room pressure

is negative.

• Local exhaust is

possible.

•Ventilation without

dispersing stale air is

possible.

•Ventilation with

reduced air flow is

possible.

•

The positional relation

of the exhaust air

outlet to the supply air

diffuser is important.

Supply

air

diffuser

Exhaust

fan

Exhaust

air

outlet

Exhaust

fan

Exhaust

fan

Stale

air

Fresh

outdoor

air

Supply Exhaust Ventilation volume Room pressure

Class 1 Mechanical Mechanical Random (constant) Random

Class 2 Mechanical Natural Random (constant) Positive pressure

Class 3 Natural Mechanical Random (constant) Negative pressure

Class 4 Natural Mechanical & natural Limited (inconstant) Negative pressure

Page 12

1) System operation with cassette-type air conditioner

2) System operation with ceiling embedded-type air conditioner

3) Independent operation with ceiling suspended-type air conditioner

6

CHAPTER 1 ● Ventilation for Healthy Living

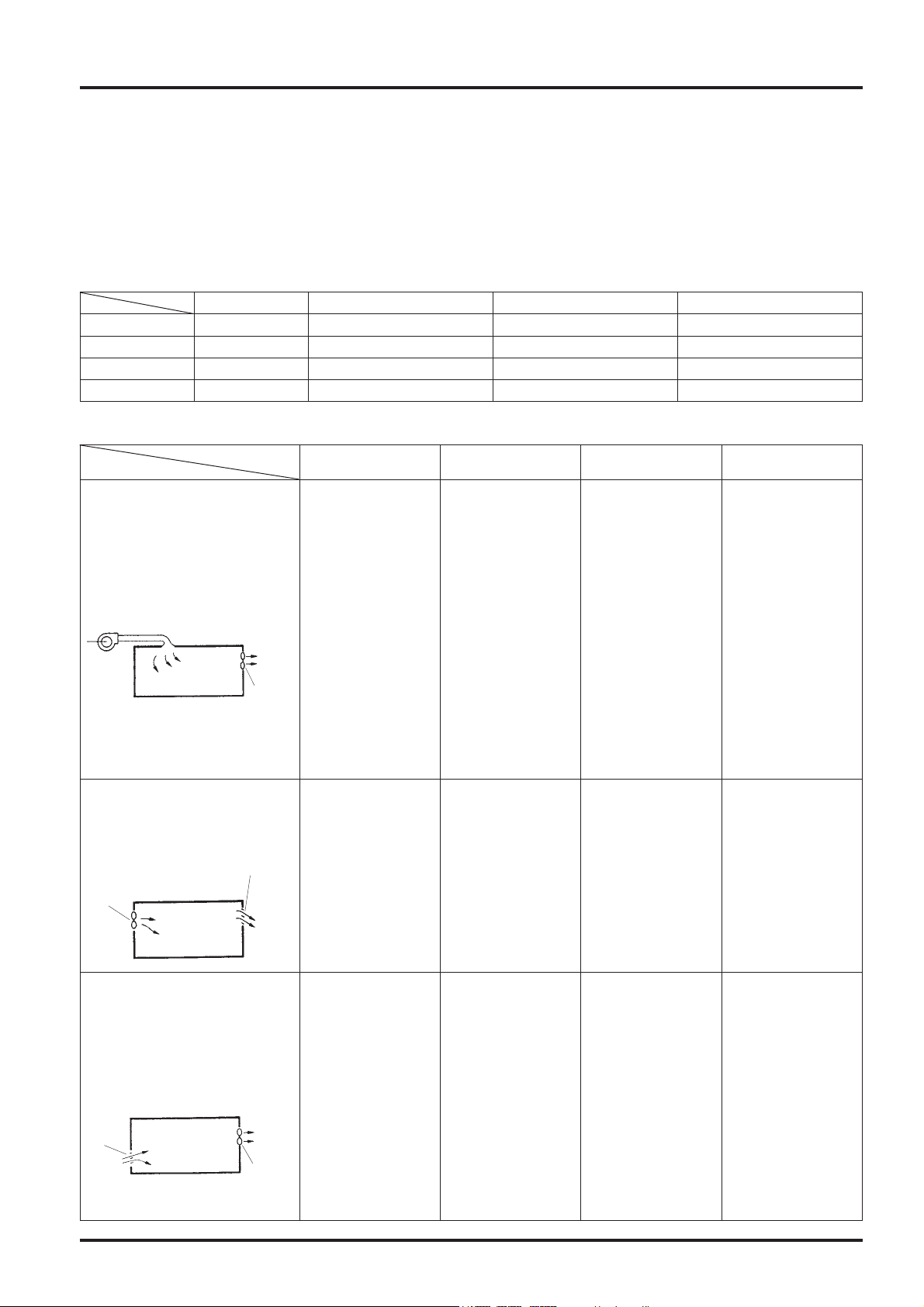

3.2 Comparison of ventilation methods

There are two main types of ventilation methods.

Centralized ventilation method

This is mainly used in large buildings, with the fresh outdoor air intake being installed in one machine room. For this method,

primary treatment of the fresh outdoor air, such as heat recovery to the intake air and dust removal is performed being

distribution to the building by ducts.

Independent zoned ventilation method

This is mainly used in small to medium sized buildings, with areas being ventilated using fresh outdoor air intakes formed of

independent ventilation devices. The rate of use of this method has recently increased as independent control is becoming

ever more feasible.

Centralized ventilation method Independent zoned ventilation method

Air intake

(fresh out-

door air)

Filters

Air exhaust

(stale air)

Cassette-type package air

conditioner or fan coil unit

Cassette-type or ceiling

suspended-type package air

conditioner or fan coil unit

Exhaust grill

Ceiling recessedtype Lossnay

Exhaust air

Fresh outdoor air

Finished ceiling

Exhaust air

Fresh outdoor air

Finished ceiling

Lossnay

Supply fan

Exhaust

Each unit

Ceiling embedded-type package

air conditioner or fan coil unit

Ceiling recessedtype Lossnay

Exhaust grill

Exhaust air

Fresh outdoor air

Finished ceiling

Ceiling recessedtype Lossnay

Exhaust grill

Supply grill

Page 13

7

CHAPTER 1 ● Ventilation for Healthy Living

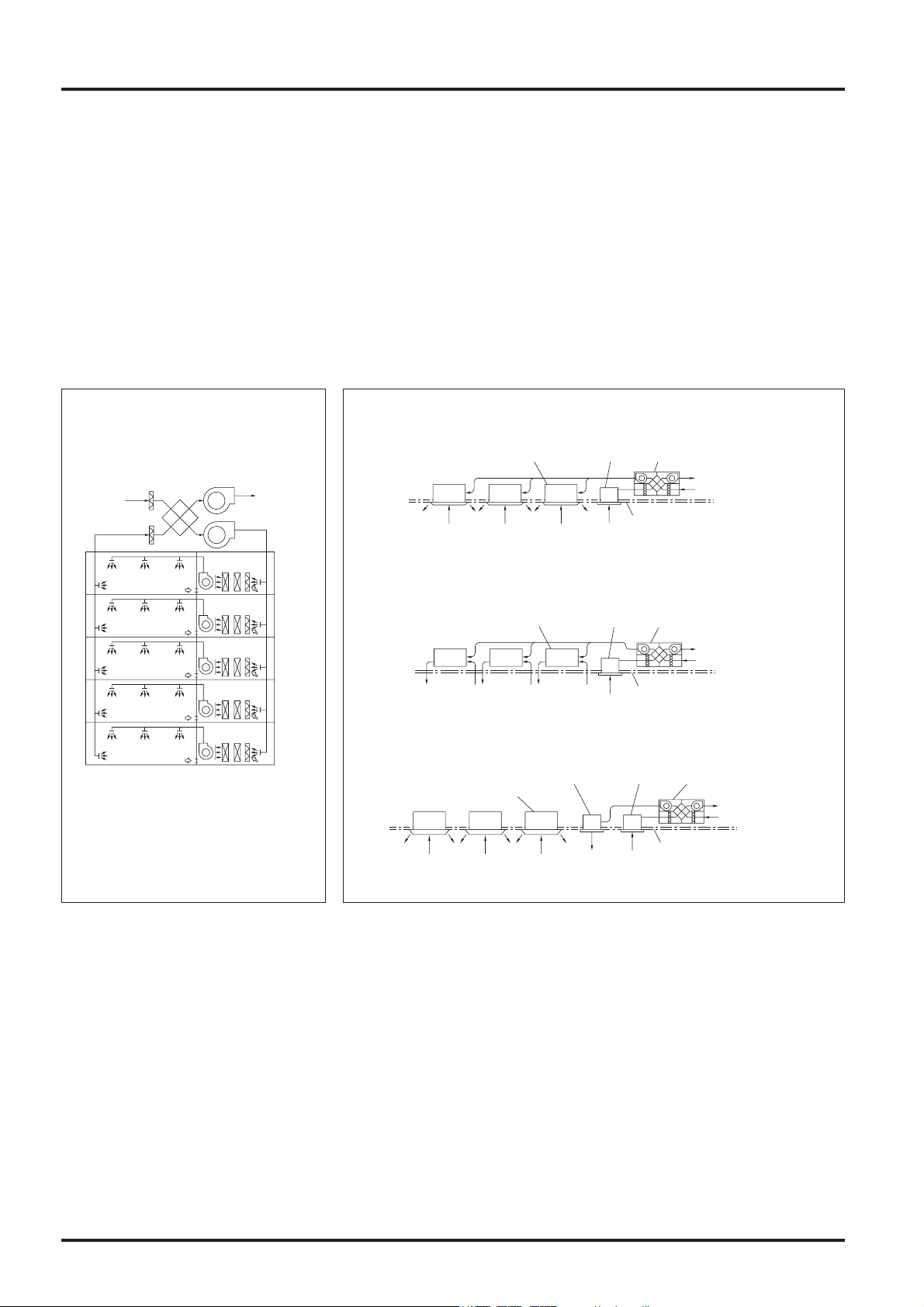

Comparison of centralized ventilation method and independent zoned ventilation method

Centralized ventilation method

The air transfer distance is long thus requiring

much fan power.

• Independent equipment room is required.

• Duct space is required.

• Penetration of floors with vertical shaft is not

desired in terms of fire prevention.

Generalized per system.

• Design of outer wall is not lost.

• The indoor supply air diffuser and return grille

can be selected freely for an appropriate design.

As there are many common-use areas, if the

building is a tenant building, an accurate

assessment of operating cost is difficult.

• As the usage time setting and ventilation volume

control, etc., is performed in a central monitoring

room, the user’s needs may not be met

appropriately.

•A large amount of ventilation is required even

for a few persons.

• An ideal supply air diffuser and return grille

position can be selected as the supply air

diffuser and return grilles can be laid out freely.

• The only noise in the room is the aerodynamic

sound.

• Anti-vibration measures must be taken as the

fan in the equipment room is large.

• Centralized management is easy as it can be

performed in the equipment room.

• The equipment can be inspected at any time.

• Large as the entire system is affected.

• Immediate inspection can be performed in the

equipment room.

Fan power

Installation space

Zoning

Designability

Clarification of costs

Controllability

Comfort

Maintenance and

management

Trouble correspondence

Independent zoned ventilation method

As the air transfer distance is short, the fan power

is small.

• Independent equipment room is not required.

• Piping space is required only above the ceiling.

Can be utilised for any one area.

• The number of intakes and exhaust air outlets

on the outer wall will increase; design must be

considered.

• The design will be fixed due to the installation

fittings, so the design of the intakes and exhaust

air outlets must be considered.

Invoicing for each zone separately is possible,

even in a tenant building.

• The user in each zone can operate the ventilator

freely.

• The ventilator can be operated even during offpeak hours.

• Consideration must be made of the noise from

the main unit.

• Anti-vibration measures are often not required

as the unit is compact and the vibration

generated can be dispersed.

•Work efficiency is poor as the equipment is not

centrally located.

• An individual unit can be inspected only when

the room it serves is vacant.

• Limited as only independent units are affected.

• Consultation with the tenant is required prior to

inspection of an individual unit.

Page 14

8

CHAPTER 1 ● Ventilation for Healthy Living

4. Ventilation Performance

The ventilation performance is largely affected by the installation conditions. Ample performance may not be achieved unless

the model and usage methods are selected according to the conditions.

Generally, the ventilation performance is expressed by “Air volume” and “wind pressure (static pressure)”, and these are

necessary when considering ventilation.

4.1 Air volume

Air volume expresses the volume of air exhausted (or supplied) by the unit in a given period. Generally, this is expressed as

m

3

/hr (hour).

4.2 Wind pressure

When a piece of paper is placed in front of a fan and let go, the piece of paper will be blown away. The force that blows the

paper away is called the wind pressure, and this is normally expressed in units of Pa. The wind pressure is divided into the

following three types:

4.2.1 Static pressure

This is the force that presses the surroundings when the air is still such as in an automobile tyre or rubber balloon. For

example, in a water gun, the hydraulic pressure increases when pressed by a piston, and if there is a small hole, the water

sprays out with force. The pressure of this water is equivalent to the static pressure for air. The higher the pressure is, the

further the water (air) can be sprayed.

4.2.2 Dynamic pressure

This expresses the speed at which air flows, and can be thought of as the force at which a typhoon presses against a building.

4.2.3 Total pressure

This is the total force that wind has, and is the sum of the static pressure and dynamic pressure.

Page 15

9

CHAPTER 1 ● Ventilation for Healthy Living

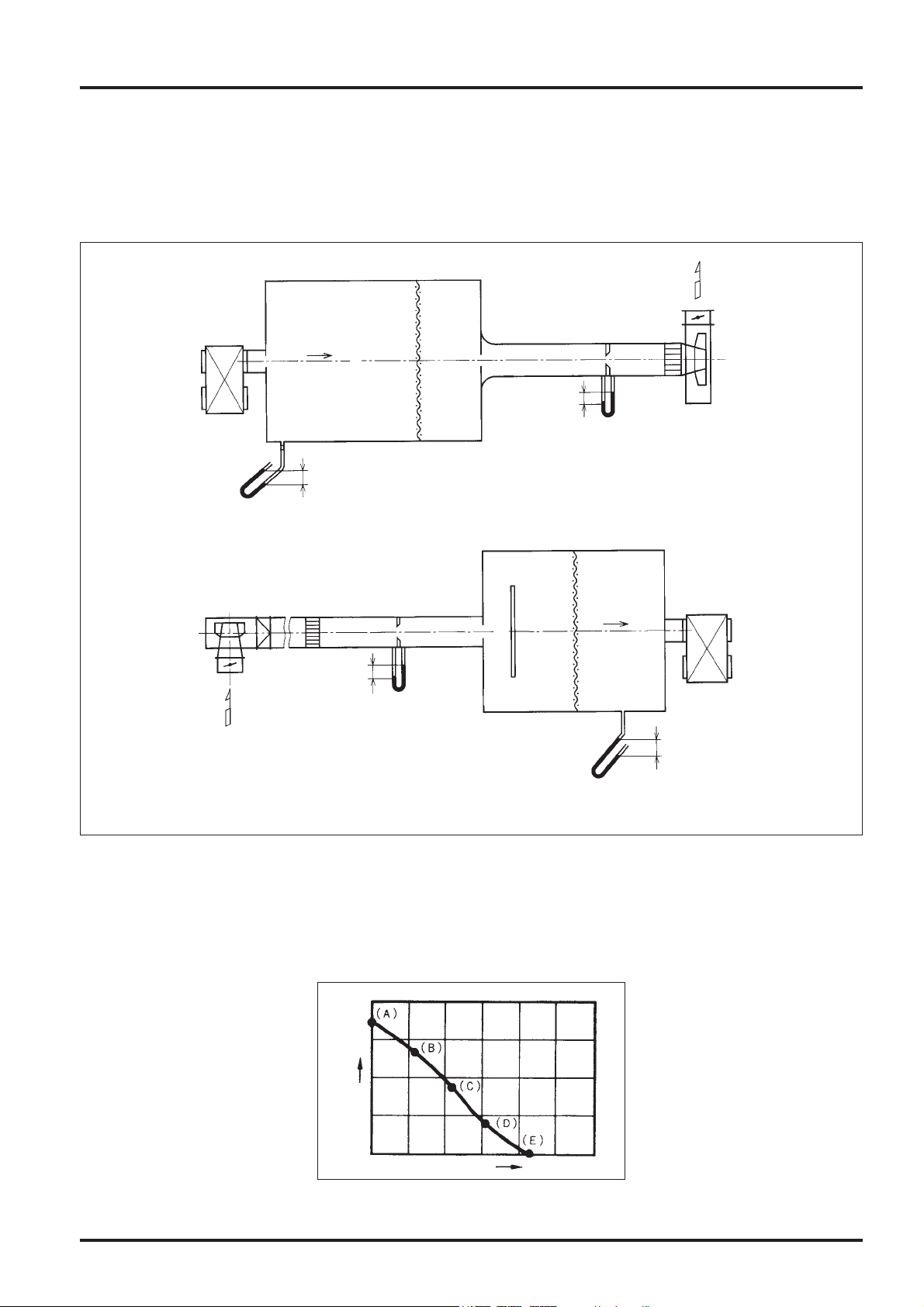

4.3 Measurement of the air volume and wind pressure

Mitsubishi measures the machine’s air volume and wind pressure with a device as shown below according to the Japan

Industrial Standards (JIS B 8628).

Measuring device using orifice (JIS B 8628 standards)

Static pressure (

H

)

Air volume (Q)

Measurement method

The unit is operated with the throttle device fully closed. There is no air flow at this time, and the air volume is 0. The maximum

point of the static pressure (A point, the static pressure at this point is called the totally closed pressure) can be obtained. Next,

the throttle device is gradually opened, the auxiliary fan is operated, and the middle points (points B, C and D) are obtained.

Finally, the throttle device is completely opened, and the auxiliary fan is operated until the static pressure in the chamber

reaches 0. The maximum point of the air volume (point E, the air volume at this point is called the fully opened air volume) is

obtained. The points are connected as shown below, and are expressed as air volume, static pressure curves (Q-H curve).

Connection

Wind dispersing place

Connection

Rectifying

grid

Rectifying

grid

Supply

Air

(SA)

Chamber

Return

Air

(RA)

Rectifying

net

Rectifying

net

Wind gauge

duct path

Orifice

Wind gauge

duct path

Orifice

Damper

Blower

Blower

Test unit

Test unit

Static pressure in chamber

(Static pressure measurement)

Static pressure in chamber

(Static pressure measurement)

Pressure

difference before

and after orifice

(Air volume

measurement)

A) When measuring the supply air volume (with the orifice plate)

B) When measuring the return air volume (with the orifice plate)

Page 16

10

CHAPTER 1 ● Ventilation for Healthy Living

5. Outdoor Air (ventilation) Load

5.1 How to calculate each approximate load

The outdoor air load can be calculated with the following formula if the required outside air intake volume Q m3/h to be

introduced is known:

(Outdoor air load) = γ · Q

F · (iO - iR)

= γ [kg/m

3

] × S [m2] × k × n [person/m2] × Vf [m3/h·person] × (iO - iR): ∆i [kJ/kg]

γ : Specific gravity of air - 1.2 kg/m

3

S:Building’s airconditioned area

k:Thermal coefficient; generally 0.7 - 0.8.

n:The average population concentration is the inverse of the occupancy area per person. If the number of persons in the

room is unclear, refer to the Floor space per person table below.

Vf : Outdoor air intake volume per person

Refer to the Required outdoor air intake volume per person table below.

i

O : Outdoor air enthalpy - kJ/kg

iR

: Indoor enthalpy - kJ/kg

Floor space per person table (m

2

)

(According to the Japan Federation of Architects and Building Engineers Associations)

Required outdoor air intake volume per person table (m

3

/h·person)

Caution

The application of this table to each type of room should be carefully considered in relation to the degree of smoking in

the room.

Office building

Department store, shop

Restaurant

Teatre or

Average Crowded Empty

cinema hall

General design 4 - 7 0.5 - 2 0.5 - 2 5 - 8 1 - 2 0.4 - 0.6

value

5 3.0 1.0 6.0 1.5 0.5

Application example

Required ventilation volume

Degree of smoking

Recommended value Minimum value

Broker’s office

Extremely heavy Newspaper editing room 85 51

Conference room

Quite heavy

Bar

51 42.5

Cabaret

Heavy

Office

25.5

17

Restaurant 20

Light

Shop

25.5 17

Department store

None

Theatre 25.5 17

Hospital room 34 25.5

Page 17

11

CHAPTER 1 ● Ventilation for Healthy Living

Cooling load per unit area

When the volume of outdoor air per person is 25 m

3

/h, and the number of persons per 1 m2is 0.2, the cooling load will be

approximately 157.0 W/m

2

.

How these values are determined can be seen as follows:

● Outdoor air load

Air conditions <Standard design air conditions in Tokyo>

Example calculations of determining ventilation load during both cooling and heating are given as follows:

5.2 Ventilation load during cooling (in general office building)

● Classification of cooling load

(a) is the heat infiltrating the room, and often is 30 to 40% of the entire cooling load.

(b) is the heat generated in the room.

(c) is applies only when reheating is necessary.

(d) is the heat generated when outdoor air is mixed into part of the supply air diffuser volume and introduced into the room.

The outdoor air is introduced to provide ventilation for the people in the room, and is referred to as the ventilating load.

Typical load values (during cooling)

Type of load Load

Outdoor air load 53.0 W/m

2

Indoor

People 26.4 W/m

2

generated heat

Lighting equipment 30.0 W/m

2

Indoor infiltration heat 47.6 W/m

2

Total 157.0 W/m

2

Conditions: Middle floor of a general office building facing south.

Class

Heat from walls (q

WS)

(a) Indoor infiltration heat Heat from glass

from direct sunlight (qGS)

from conduction & convection (qGS)

Accumulated heat load in walls (q

SS)

Generated heat from people

Sensible heat (q

HS)

(b) Indoor generated heat

Latent heat (qHL)

Genarated heat from electrical equipment

Sensible heat (q

ES

)

Latent heat (q

EL)

(c) Reheating load (q

RL)

(d) Outdoor air load

Sensible heat (q

FS)

Latent heat (qFL

)

}

}

}

}

Dry bulb temp.

Relative humidity

Wet bulb temp. Enthalpy Enthalpy difference

Cooling

Outdoor air 33 °C 63% 27 °C 85 kJ/kg

31.8 kJ/kg

Indoors 26 °C 50% 18.7 °C 53.2 kJ/kg

When the load per floor area of 1 m2with a ventilation volume of 25 m3/h·person is calculated with the above air conditions,

the following is obtained:

Outdoor air (ventilation) load = 1.2 kg/m

3

(Specific gravity of air) × 0.2 persons/m2(no. of persons per 1 m2)

× 25 m

3

/h·person (outdoor air volume) × 31.8 kJ/kg (air enthalpy difference indoors/outdoors) = 190.8 kJ/h·m2(530 W/m2)

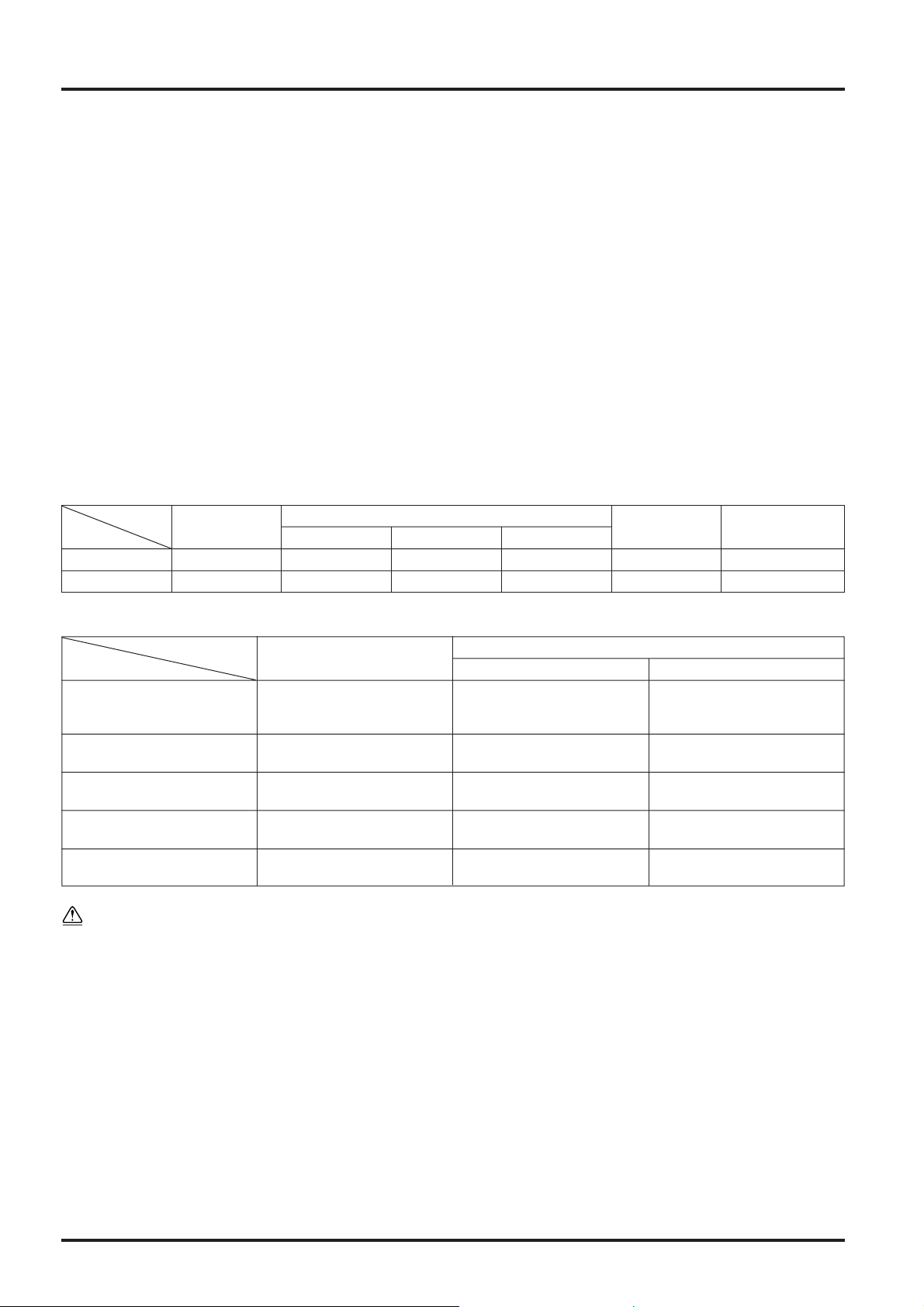

The Lossnay recuperates approximately 70% of the exhaust air load and saves on approximately 20% of the total load.

Outdoor air

load 33.8%

53.0 W/m

2

Indoor

infiltration

heat 30.3%

47.6 W/m

2

Indoor

generated heat

(people, lighting

equipment) 35.9%

56.4 W/m

2

156.5 W/m

2

Page 18

12

CHAPTER 1 ● Ventilation for Healthy Living

● Determining internal heat gain

When classifying loads, the internal heat gain (indoor generated heat + indoor infiltration heat) will be the value of the outdoor

air load subtracted from the approximate cooling load when it is assumed that there is no reheating load.

(Internal heat gain)

= 157.0 W/m

2

– 53.0 W/m2= 104.0 W/m

2

●

This value of internal heat gain is based on assumptions for typical loads. To determine individual levels of internal heat

gain, the following is suggested:

● Indoor generated heat

(1) Heat generated from people

Heat generation design value per person in office

Sensible heat (SH)= 63.0 W·person

Latent heat (LH) = 69.0 W·person

Total heat (TH) = 132.0 W·person

The heat generated per 1 m

2

of floor space is

(heat generated from people)

= 132.0 W·person × 0.2 person/m

2

= 26.4 W/m

2

(2) Heat generated from electrical equipment (lighting)

The approximate value of the room illuminance and power for lighting for a general office with illuminance of 300 350 Lux, is 20 - 30 W/m

2

.

● Indoor infiltration heat

This is the heat that infiltrates into the building from outside. This can be determined by subtracting the amount of heat

generated by people and lighting from the internal heat gain.

(Indoor infiltration heat)

= 104.0 – (26.4 + 30.0) = 47.6 W/m

2

The Lossnay recuperates approximately 70% of the outdoor air load and saves on approximately 20% of the total load.

Page 19

13

CHAPTER 1 ● Ventilation for Healthy Living

5.3 Ventilation load during heating

●

Classification of heating load

Class

Heat lost from walls (q

WS)

(a)

Indoor heat

Heat lost from glass (q

GS)

loss

Heat loss from conduction & convection (q

GS)

Accumulated heat load in walls (q

SS)

(b)

Outdoor air

Sensible heat (q

FS)

load

Latent heat (q

FL)

During heating, the heat generated by people and electrical equipment in the room can be subtracted from the heating load.

However, as the warming up time at the start of heating is short, this generated heat may be ignored in some cases.

Percentage of load

Internal heat loss

In terms of load classification, the internal heat loss is the value of the outdoor air load subtracted from the approximate

heating load.

Internal heat loss = 133.7 W/m

2

– 56.0 W/m2= 77.7 W/m

2

Heating load per unit area

When the outdoor air volume per person is 25 m

3

/h, and the number of persons per 1 m2is 0.2 persons, the approximate

heating load will be approximately 133.7 W/m

2

.

●

Outdoor air load

Air conditions <Standard design air conditions in Tokyo>

Type of load Load

Outdoor air load 56.0 W/m

2

Internal heat 77.7 W/m

2

Total 133.7 W/m

2

Conditions: Middle floor of a general office building facing south.

Dry bulb temp.

Relative humidity

Wet bulb temp. Enthalpy Enthalpy difference

Heating

Outdoor air 0 °C 50% –3 °C 5.0 kJ/kg

33.5 kJ/kg

Indoors 20 °C 50% 13.7 °C 38.5 kJ/kg

When the load per 1 m2of floor area with a ventilation volume of 25 m3/h·person is calculated with the above air conditions,

the following is obtained:

Outdoor air (ventilation) load = 1.2 kg/m

3

× 0.2 persons/m2× 25 m3/h·person × 33.5 kJ/kg = 201.0 kJ/h·m2(56 W/m2)

The Lossnay recuperates approximately 70% of the outdoor air load and saves on approximately 30% of the total load.

Outdoor

air load 41.9%

56.0 W/m

2

Indoor heat

loss 58.1%

77.7 W/m

2

133.7 W/m

2

Page 20

Page 21

CHAPTER 2

Lossnay Construction and Principle

Page 22

16

CHAPTER 2 ● Lossnay Construction and Principle

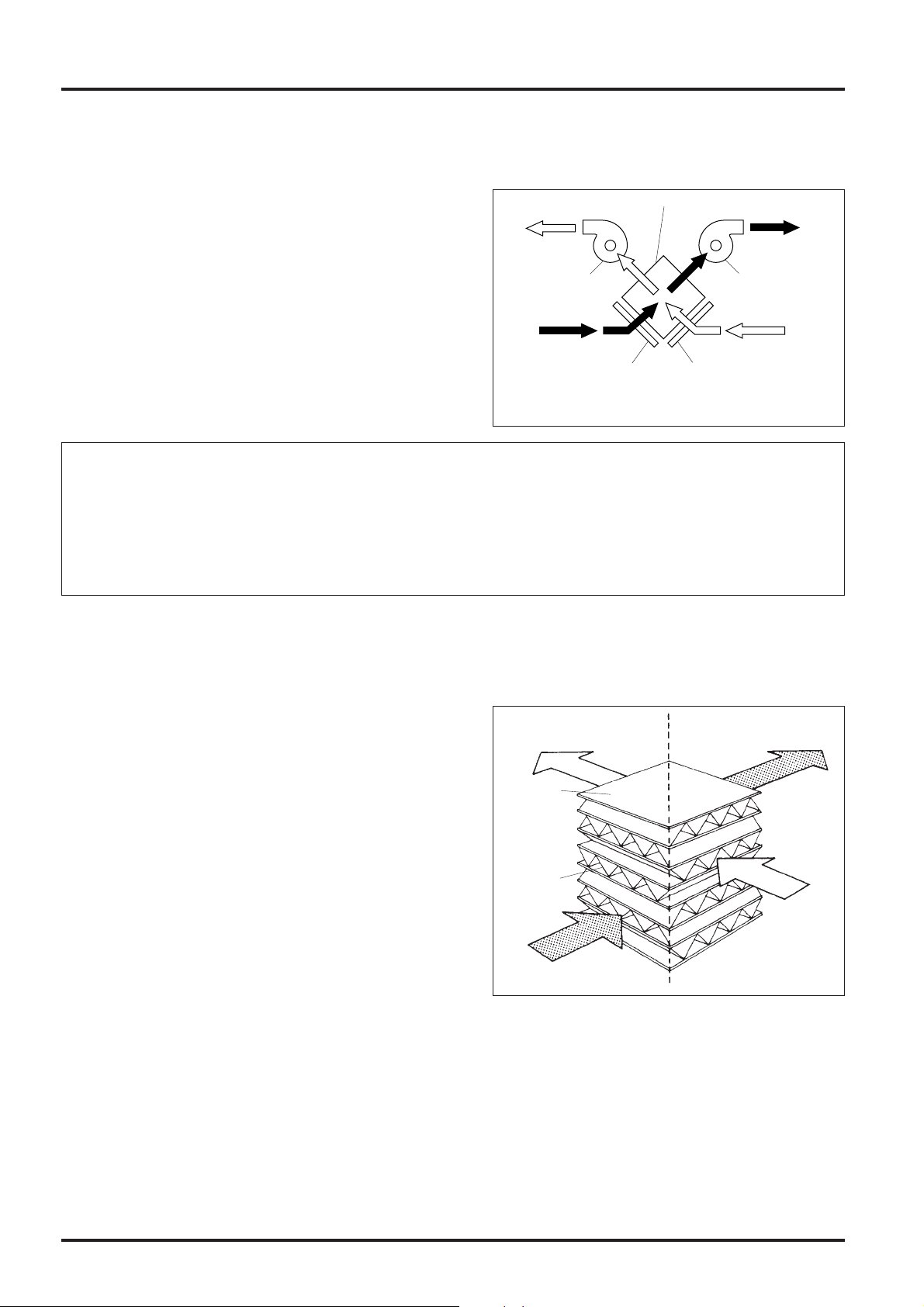

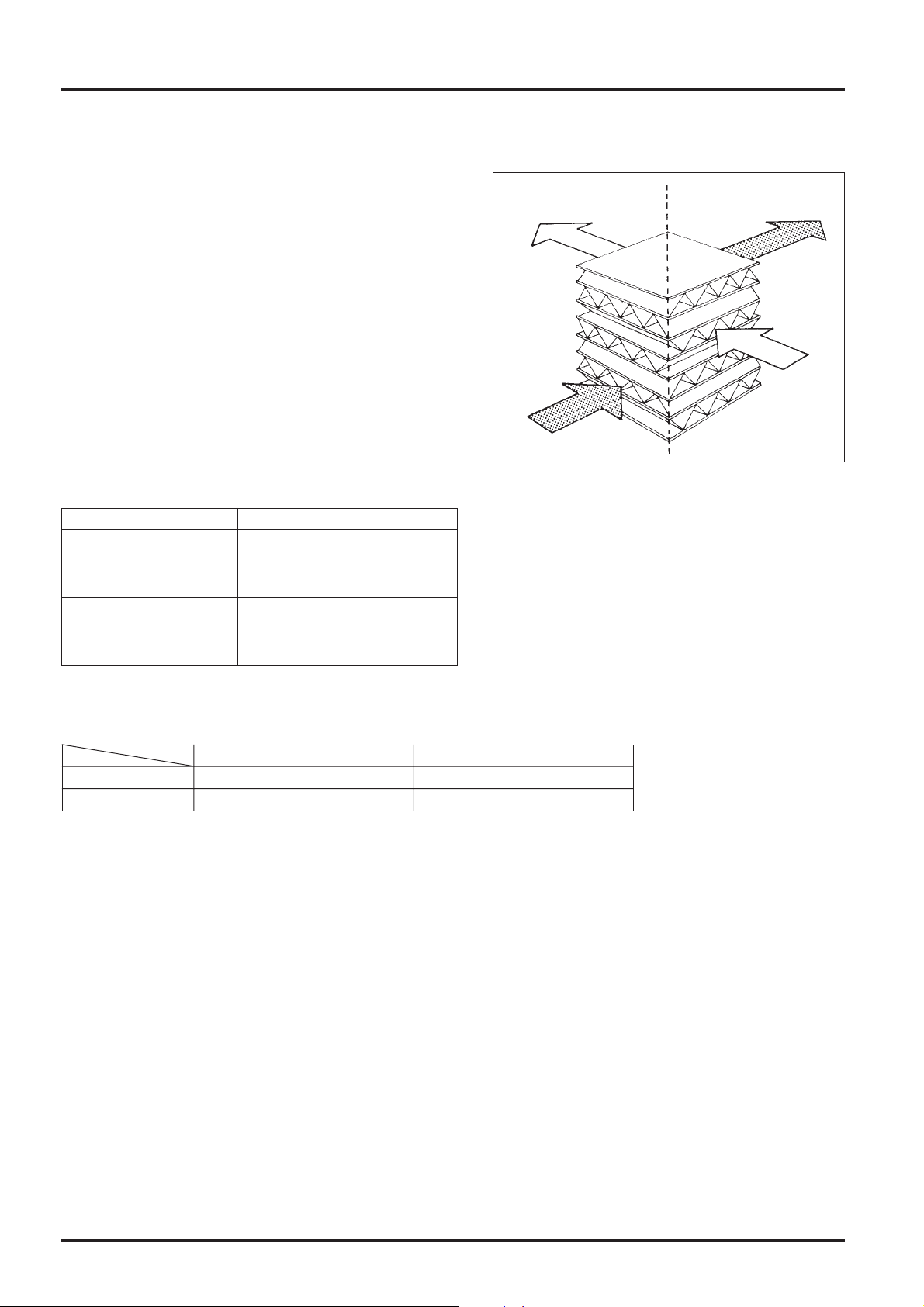

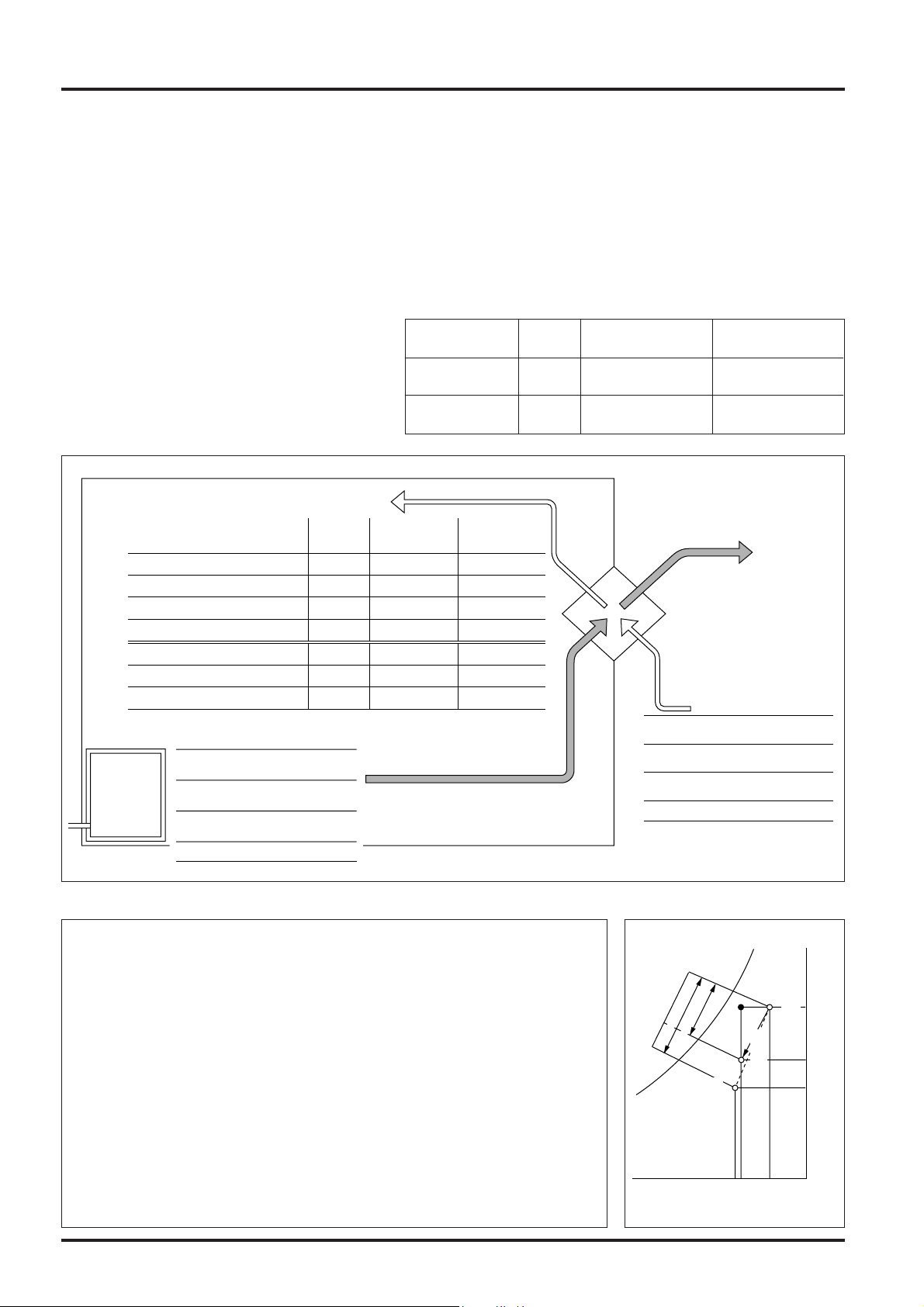

1. Construction and Features of Lossnay

● Lossnay construction

The Lossnay is constructed so that the exhaust air passage from

the indoor side to the outdoor side (RA → EA) and the fresh air

passage from the outdoor side to the indoor side (OA → SA)

cross. The Lossnay heat recovery unit (Lossnay Core) is installed

at this cross point, and recovers the heat by conduction through

the separating medium between these airflows. This enables the

heat loss during exhaust to be greatly reduced.

*RA: Return Air

EA : Exhaust Air

OA : Outdoor Air

SA : Supply Air

SA (Supply air diffuser)

Supply fan

RA (Return air)

Exhaust side filter

Lossnay Core

Intake side filter

OA (Outdoor air)

Exhaust fan

EA (Exhaust air)

Note: The dust inlet and outlet are linear in the

actual product.

Main Features of Lossnay

(1) Cooling and heating maintenance fees are saved while ventilating.

(2) The capacity and performance of the air conditioner can be reduced.

(3) Dehumidifying during summer, and humidifying during winter is possible.

(4) Comfortable ventilation is possible, (the outdoor air being adjusted to the room temperature.)

(5) Effective sound-proofing.

2. Construction and Principle of Core

● Simple construction

The Lossnay Core is a cross-flow total heat recovery unit

constructed of plates and fins made of treated paper.

The fresh air and exhaust air passages are totally separated

allowing the fresh air to be introduced without mixing with the

exhaust air.

●

Principle

The Lossnay Core uses the heat transfer properties and moisture

permeability of the treated paper. Total heat (sensible heat plus

latent heat) is transferred from the stale exhaust air to the fresh air

being introduced into the system when they pass through the

Lossnay. Try this simple experiment. Roll a piece of paper into a

tube and blow through it. Your hand holding the paper will

immediately feel warm. If cold air is blown through the tube, your

hand will immediately feel cool. Lossnay is a total heat exchanger

that utilizes these special properties of paper.

●

Treated paper

The paper partition plates are treated with special chemicals so that the Lossnay Core is an appropriate heat recovery unit for

the ventilator. This paper differs from ordinary paper, and has the following unique properties.

(1) The paper is incombustible and is strong.

(2) The paper has selective hydroscopicity and moisture permeability that permits the passage of water vapor only (including

some water-soluble gases).

(3) The paper has gas barrier properties that does not pass gases such as CO

2.

Hyper Core

The Hyper Core that utilizes the world’s thinnest* 25 µm ultra-thin film imperforate paper has been developed to further reduce

gas transfer and to improve humidity exchange efficiency. The Hyper Core is mounted to the LGX-RX

4.

(* As of January 22, 2004, in the case of a high moisture permeable material used for total heat exchange elements)

SA

Supply air diffuser

(Fresh cold or warm air)

Partition

plate

(Treated

paper)

Spacer plate

(Treated paper)

RA

Return air

(Stale cold or warm air)

Indoors Outdoors

EA

Exhaust air

(Stale air)

OA

Outdoor air

(Fresh air)

Page 23

17

CHAPTER 2 ● Lossnay Construction and Principle

A comparison of the ordinary paper and the Lossnay Core plates is as shown in the table.

Ordinary paper

Water vapor is transferred, but gas elements that are easily

dissolved in water such as CO

2

, NO2 are also transferred.

The contaminated air passes through the plates during

ventilation and returns to the room.

Treated paper

Water vapor is transferred, but gas elements such as CO

2,

NO

2 are not transferred.

The contaminated air does not almost return to the room

when ventilated.

Hyper core

The water vapor transfer rate has increased with further

reduction of gas transfer.

The rate at which the contaminated air returns to the room

has been reduced to less than 1%*, and the total heat

exchange performance has also been improved.

(* Based on data measured by Mitsubishi using a single core unit)

Low humid air

Water molecule

25 µm

Gas (CO2) molecule

Non-porous ultra-thin film material

Highly humid air

Highly humid air

Water vapor

Water vapor

CO

2 NO2

CO2 NO2

CO2 NO2Water vapor

Water vapor

Treatment

(Selective permeable film)

(Incombustible specifications)

Low humid air

Highly humid air

Cellulose

fibers

Low humid air

● Total heat recovery mechanism

Sensible heat and latent heat

The heat that enters and leaves in accordance with changing temperature (rise or drop) is called sensible heat. The heat that

enters and leaves due to the changes in a matter’s physical properties (evaporation, condensation) is called latent heat.

(1) Temperature (sensible heat) recovery

1) Heat conduction and heat passage is performed through a

partition plate from the high temperature to low temperature

side.

2) As shown on the right, the heat recovery efficiency is affected

by the resistance of the boundary layer, and for the Lossnay

there is little difference when compared to materials such as

copper or aluminium which also have high thermal

conductivity.

Heat resistance coefficients

t1

t2

Ra1

Ra2

Rp

Partition plate

Ra1+Ra2

»Rp

Treated paper Cu Al

Ra

1 10 10 10

Rp 1 0.00036 0.0006

Ra

2 10 10 10

Total 21 20.00036 20.0006

(2) Humidity (latent heat) recovery

●

Water vapor is moved through the partition plate from the

high humidity to low humidity side by means of the

differential pressure in the vapor.

High humidity side

Low humidity side

Partition plate

120µm

Page 24

18

CHAPTER 2 ● Lossnay Construction and Principle

3. Calculation of the Total Heat Recovery Efficiency

The Lossnay Core’s heat recovery efficiency can be considered

using the following three transfer rates:

(1) Temperature (sensible heat) recovery efficiency

(2) Humidity (latent heat) recovery efficiency

(3) Enthalpy (total heat) recovery efficiency

The heat recovery effect can be calculated if two of the above

efficiencies is known. (The temperature and enthalpy efficiencies

are indicated in the applicable catalogue.)

●

Each recovery efficiency can be calculated with the formulas

given below.

●

When the supply air volume and exhaust air volume are equal,

the heat recovery efficiencies on the supply and exhaust sides

are the same.

●

When the supply air volume and exhaust air volume are not

equal, the total heat recovery efficiency is low if the exhaust

volume is lower, and high if the exhaust volume is higher.

Refer to the Heat Recovery Efficiency Correction Curve in the

applicable catalogue for more details.

SA

Supply air

(Fresh cold or warm air)

RA

Return air

(Stale cold or warm air)

Indoors Outdoors

EA

Exhaust air

(Stale air)

OA

Outdoor air

(Fresh air)

Item Formula

Temperature recovery

efficiency (%)

ηt =

t (

OA

) - t (SA)

× 100

t (

OA) - t (RA)

Enthalpy recovery

efficiency (%)

ηi =

i (

OA) - i (SA)

× 100

i (

OA

) - i (RA)

η: Efficiency (%)

t: Dry bulb temperature (°C)

i: Enthalpy (kJ/kg)

Calculation of air conditions after passing through Lossnay

If the Lossnay heat recovery efficiency and the conditions of the room and outdoor air are known, the conditions of the air

entering the room and the air exhausted outdoors can be determined with the following formulas.

Supply side Exhaust side

Temperature t

SA = tOA - (tOA - tRA) · ηttEA = tRA + (tOA - tRA) · ηt

Enthalpy i

SA = iOA - (iOA - iRA) · ηiiEA = iRA + (iOA - iRA) · ηi

Page 25

19

CHAPTER 2 ● Lossnay Construction and Principle

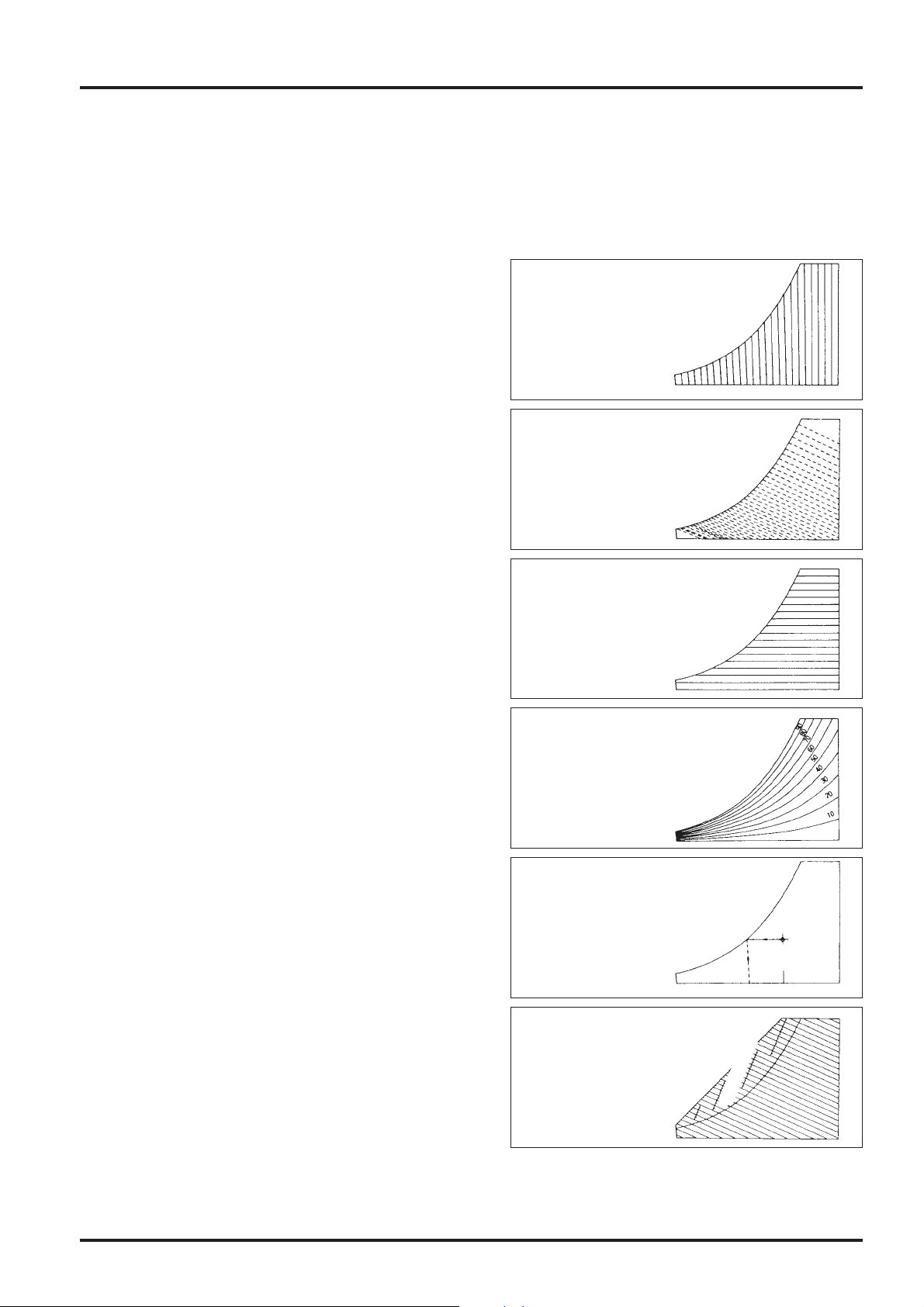

4. What is a Psychrometric Chart?

The chart which shows the properties of humid air is called a psychrometric chart. The psychrometric chart can be used to find

the (1) Dry bulb temperature, (2) Wet bulb temperature, (3) Absolute humidity, (4) Relative humidity, (5) Dew point and (6)

Enthalpy (total heat) of a certain air condition. If two of these values are known beforehand, the other values can be found

with this chart. The way that the air will change when it is heated, cooled, humidified or dehumidified can also be seen easily

on the chart.

(1) Dry bulb temperature t (°C)

Generally referred to as standard temperature this is

measured with a dry bulb thermometer (conventional

thermometer). The obtained value is the dry bulb

temperature.

(2) Wet bulb temperature t’ (°C)

When a dry bulb thermometer’s heat sensing section is

wrapped in a piece of wet gauze and an ample air flow

(3 m/s or more) is applied, the heat applied to the wet bulb by

the air and the heat of the water vapor that evaporates from

the wet bulb will balance at an equal state. The temperature

indicated at this time is called the wet bulb temperature.

(3) Absolute humidity x (kg/kg’)

The weight (kg) of the water vapor that corresponds to the

weight (kg’) of the dry air in the humid air is called the

absolute humidity.

(4) Relative humidity ϕ (%)

The ratio of the water vapor pressure Pw in the humid air and

the water vapor pressure Pws in the saturated air at the same

temperature is called the relative humidity. This is obtained

with the following formula:

ϕR = P

W/PWS × 100

(5) Dew point t” (°C)

The water content in the air will start to condense when air is

cooled.

The dry bulb temperature at this time is called the dew point.

(6) Enthalpy i (kJ/kg)

Physical matter has a set heat when it is at a certain

temperature and state. This retained heat is called the

enthalpy, with dry air at 0 °C being set at 0.

Temperature (°C)

Absolute humidity x (kg/kg’)

Wet bulb temperature

(dew point) t’ (°C)

Relative humidity ϕ (%)

The dew point t” of the air at point A is the

temperature of the point at the same absolute humidity

as point A on the saturation curve.

t” °C dew point

Enthalpy i (kJ/kg)

A

t”

Parallel to absolute

temperature scale line

Page 26

20

CHAPTER 2 ● Lossnay Construction and Principle

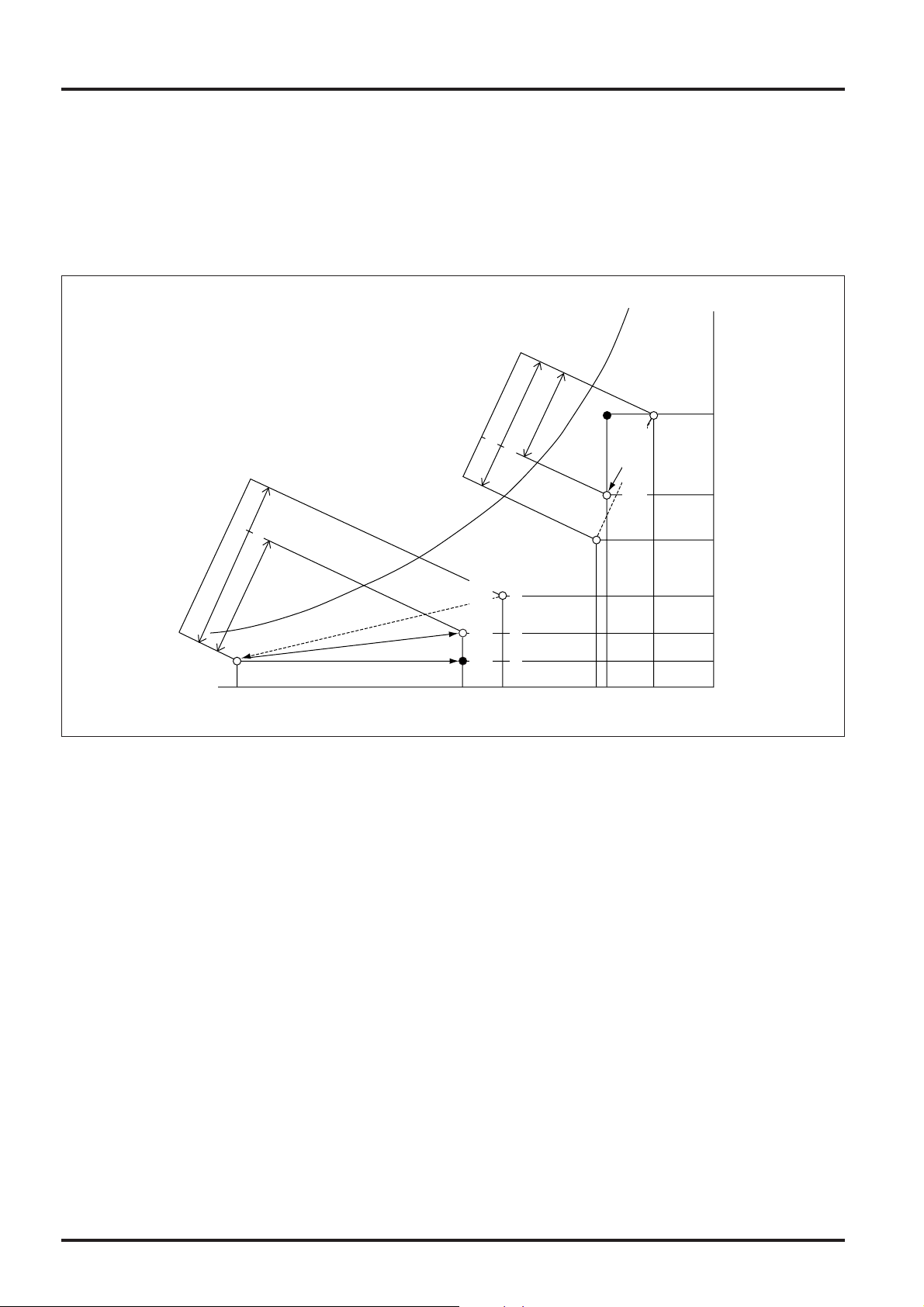

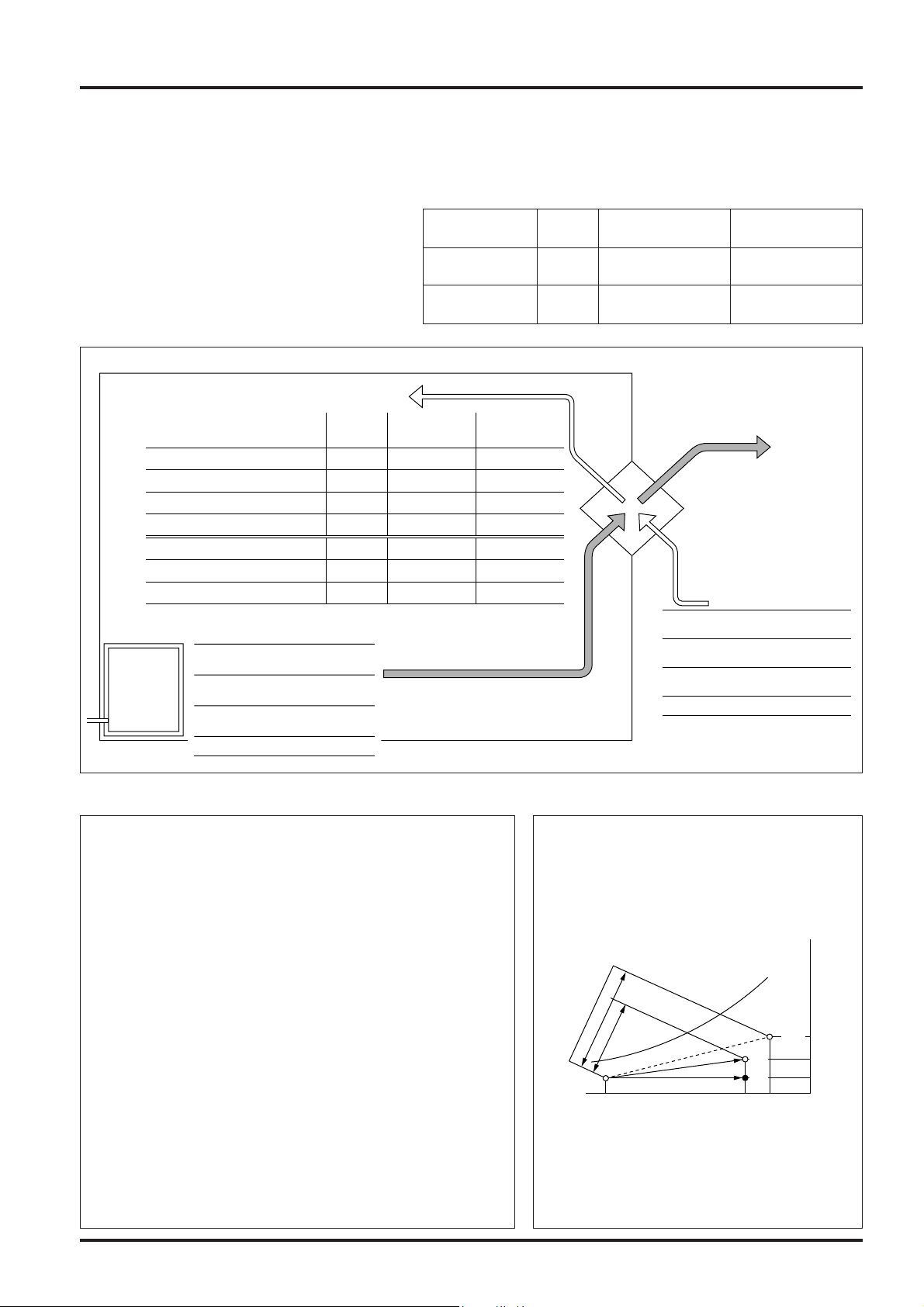

5. Calculation of Lossnay Heat Recovery

The following figure shows the conditions of various air states when fresh air is introduced through the Lossnay Core. If a

conventional sensible heat recovery unit is used alone and is assumed to have the same heat recovery efficiency as Lossnay,

the condition of the air supplied to the room is expressed by point A in the figure. This point shows that the air is very humid in

summer and very dry in winter.

The air supplied to the room with Lossnay is indicated by point S in the figure. The air is precooled and dehumidified in the

summer and preheated and humidified in the winter before it is introduced to the room.

iSA

iOA

tOA tSA

A

S

O

R

i

RA

iSA

iOA

tRA tRA

S

R

AO

t

SA tOA

XOA

XSA

XRA

XRA

XSA

XOA

iRA

The quantity of heat recovered by using the Lossnay Core can be calculated with the following formula.

Total heat recovered: qT = γ · Q · (iOA - iSA) [W]

= γ · Q · (i

OA - iRA) × ηi

Where γ = Specific weight of air under standard conditions 1.2 (kg/m

3

)

Q= Treated air volume (m

3

/h)

t= Temperature (°C)

x= Absolute humidity (kg/kg’)

i= Enthalpy (kJ/kg)

η = Heat recovery efficiency (%)

●

Suffix meanings

OA : Outdoor air

RA : Return air

SA : Supply air

Enthalpy (kJ/kg)

Outdoor air load

Lossnay Core heat recovery

Enthalpy (kJ/kg)

Outdoor air load

Lossnay Core heat recovery

Outdoor air

condition in

winter

Supply air condition of

the Lossnay

Supply air condition of

the Lossnay

Room air

condition

in summer

Outdoor air condition

in summer

Absolute

humidity (kg/kg’)

Room air condition in winter

Dry bulb temperature (°C)

Page 27

CHAPTER 3

General Technical Considerations

Page 28

1. Lossnay Heat Recovery Effect

1.1 Comparison of outdoor air load of various ventilators

Examples of formulas to compare the heat recovered and outdoor air load when ventilating with the Lossnay (total heat

recovery unit), sensible heat recovery ventilation (sensible HRV) and conventional ventilators are shown below.

(1) Cooling during summer

Conditions

●

Model LGH-100R type

●

Heat recovery efficiency table (%)

(at 50Hz, high speed) (For summer)

●

Ventilation rate: 1000 m3/h

(specific gravity of air

ρ

= 1.2 kg/m3)

22

CHAPTER 3 ● General Technical Considerations

Lossnay Sensible HRV

Conventional

ventilator

Temperature

79 79 –

(sensible heat)

Enthalpy

67 19* –

(total heat)

hOA

hSA

hRA

84.6

63.4

52.9

tOA

33

tSA

27.5

tRA

26

R

S

AO

X

OA

0.0201

XSA

0.0140

XRA

0.0105

●

Lossnay

(Supply air diffuser temperature)

tSA = 33°C – (33°C – 26°C) × 0.79 = 27.5°C

(Supply air diffuser enthalpy)

hSA = 84.6 – (84.6 – 52.9) × 0.67 = 63.4 kJ/kg

Heat recovered

(84.6 – 63.4) × 1.2 × 1,000 = 25,440 kJ/h = 7.07 kW

Outdoor air load

(63.4 – 52.9) × 1.2 × 1,000 = 12,600 kJ/h = 3.5 kW

●

Sensible HRV

(Supply air diffuser temperature)

tSA = 78.9°C – (33°C – 26°C) × 0.79 = 27.5°C

(Supply air diffuser enthalpy)

hSA

= kJ/kg (from psychrometric chart)

Heat recovered

(85.0 – 78.9) × 1.2 × 1,000 = 7,320 kJ/kg = 2.03 kW

Outdoor air load

(78.9 – 53.2) × 1.2 × 1,000 = 30,840 kJ/h = 8.56 kW

[Calculated enthalpy recovery efficiency 2.03 ÷ (2.03 + 8.56) × 100 = 19]

●

Conventional ventilator

If a conventional ventilator is used, the heat recovered will be 0 as the supply air

diffuser is equal to the outdoor air.

The outdoor air load is:

(84.6 – 52.9)

×

1.2 ×1,000 = 38,040 kJ/h = 10.6 kW

Calculation example Summer conditions

Absolute humidity (kg/kg’)

Room air condition in summer

Outdoor air condition

in summer

Supply air condition

of the Lossnay

Dry bulb temperature (°C)

Lossnay heat recovery

Outdoor air load

Enthalpy

(kJ/kg)

Supply air

Room air

Air

conditioner

Lossnay Sensible HRV

Conventional

ventilator

Dry bulb

temperature

Absolute

humidity

Relative

humidity

Enthalpy

26°C

27.5 27.5 33

14.0 20.1 20.1

61 86 63

63.4 78.9 84.6

7.1 20.0 0

3.5 8.6 10.6

33 81 100

10.5 g/kg’

50%

52.9 kJ/kg

Outdoor air

Exhaust air

Dry bulb

temperature

Absolute

humidity

Relative

humidity

Enthalpy

33°C

20.1 g/kg’

63%

84.6 kJ/kg

Dry bulb temperature (°C)

Absolute humidity (g/kg’)

Relative humidity (%)

Enthalpy (kJ/kg)

Outdoor air load (kW)

Outdoor air load ratio (%)

Total heat recovered (kW)

* Calculated volume under below conditions.

Page 29

(2) Heating during winter

Conditions:

●

Model LGH-100R type

●

Heat recovery efficiency table (%)

(at 50Hz, high speed) (For winter)

●

Ventilation rate: 1000 m3/h

(Specific gravity of air

ρ

= 1.2 kg/m3)

23

CHAPTER 3 ● General Technical Considerations

Lossnay Sensible HRV

Conventional

ventilator

Temperature

79 79 –

(sensible heat)

Enthalpy

71 47* –

(total heat)

Supply air

Room air

Air

conditioner

Lossnay Sensible HRV

Conventional

ventilator

Dry bulb

temperature

Absolute

humidity

Relative

humidity

Enthalpy

20°C

15.8 15.8 0

5.1 1.9 1.9

46 17 50

28.7 20.7 4.7

8 5.3 0

3.3 5.9 5.6

29 47 100

7.2 g/kg’

50%

38.5 kJ/kg

Outdoor air

Exhaust air

Dry bulb

temperature

Absolute

humidity

Relative

humidity

Enthalpy

0°C

1.9 g/kg’

50%

4.7 kJ/kg

Dry bulb temperature (°C)

Absolute humidity (g/kg’)

Relative humidity (%)

Enthalpy (kJ/kg)

Outdoor air load (kW)

Outdoor air load ratio (%)

Total heat recovered (kW)

●

Lossnay

(Supply air diffuser temperature) tSA=

(20°C – 0°C) × 0.79 + 0°C = 15.8°C

(Supply air diffuser

enthalpy)

hSA=

(38.5 – 4.7) × 0.71 + 4.7

=

28.7 kJ/kg

Heat recovered (28.7 – 4.7) × 1.2 × 1,000

= 28,800 kJ/h = 8.0 kW

Outdoor air load (38.5 – 28.7) × 1.2 × 1,000

=

11,760 kJ/h = 3.3 kW

●

Sensible HRV

(Supply air diffuser temperature) tSA=

(20°C – 0°C) × 0.79 + 0°C = 15.8°C

(Supply air diffuser

enthalpy)

hSA=

20.7 kJ/kg

(from psychrometric chart)

Heat recovered (20.7 – 4.7) × 1.2 × 1,000

= 19,200 kJ/h = 5.3 kW

Outdoor air load (38.5 – 20.7) × 1.2 × 1,000

= 21,360 kJ/h = 5.9 kW

[Calculated enthalpy recovery efficiency 5.3 ÷ (5.3 + 5.9) × 100 = 47]

●

Conventional ventilator

If a conventional ventilator is used, the supply air diffuser is the same

as the outdoor air and the exhaust is the same as the room air.

Thus the heat recovered is 0 kcal and the outdoor air load is

(38.5 – 4.7) × 1.2 × 1,000 = 40,560 kJ/h = 11.3 kW

Calculation example Winter conditions

hRA

iOA

tOA

0

tSA

15.8

tRA

20

R

S

O

A

X

RA 0.0072

XSA 0.0051

XOA 0.0019

hSA

38.5

4.7

28.7

Absolute humidity (kg/kg’)

Outdoor air

condition in

winter

Room air condition

in winter

Supply air condition

of the Lossnay

Dry bulb temperature (°C)

Lossnay

heat recovery

Outdoor air load

Enthalpy

(kJ/kg)

* Calculated volume under below conditions.

Page 30

24

CHAPTER 3 ● General Technical Considerations

2. Example Heat Recovery Calculation

(1) Setting of conditions

(Note: Tokyo Power, industrial power 6 kV supply)

●

Return air volume (RA) = 8,000 m3/Hr

●

Outdoor air volume (OA) = 8,000 m3/Hr

●

Air volume ratio (RA/OA) = 1.0

●

Air conditions

(2) Selection of Lossnay model (select from treatment air volume catalogue)

●

Model name: LGH-100RX4 × 8 unit

●

Processing air volume per unit RA = 8,000 m3/Hr, OA = 8,000 m3/Hr, Air volume ratio (RA/OA) = 1.0

●

Heat recovery efficiency : Heat recovery efficiency = 79%, Enthalpy recovery efficiency (cooling) = 67%,

Enthalpy recovery efficiency (heating) = 71%

●

S

tatic pressure loss (unit-type) RA = 100 Pa, OA = 100 Pa (Note: Each motors are High notch)

●

Power consumption (pack-type) = 440W × 8 unit

= 3.52 kW

(3) State of indoor supply air

(4) Outdoor air load and heat recovered

(5) Recovered money (power rates)

Units When Heating When Cooling

Operation time (h/yr)

10h/day × 26 days/mo. × 5 mo./yr. = 1,300 h/yr 10h/day × 26 days/mo. × 4 mo./yr. = 1,040 h/yr

Electricity fee

(yen/kWh)

16.22 17.84

Capacity per

(kW/kW) 3.1 2.6

1 kW of electricity

Energy unit cost

(yen/kWh)

16.22/3.1 = 5.23 17.84/2.6 = 6.86

Season Winter heating Summer cooling

Item

Dry bulb temp

.Wet bulb temp.

Relative humidity

Absolute humidity

Enthalpy h Mark

Dry bulb temp.

Wet bulb temp.

Relative humidity

Absolute humidity

Enthalpy h Mark

DB [°C] WB [°C] RH [%]

× [kg/kg (DA)]

[kJ/kg (DA)]

in page 25 DB [°C] WB [°C] RH [%]

× [kg/kg (DA)]

[kJ/kg (DA)]

in page 25

Outdoors

0 –2.7 50 0.0018 4.7

1

33 27.1 63 0.0202

85.0 (20.3)

3

Indoors 20 13.8 50 0.0072 38.5

2

26 18.7 50 0.0105

53.0 (12.7)

4

Heating Cooling

= { 20 (Indoor temperature) – 0 (outdoor air temperature)} × = 33

(Outdoor air temperature) – { 33 (outdoor air temperature) –

Temperature [°C] 0.79 (heat recovery efficiency) + 0 (outdoor air temperature) 26 (indoor temperature)} × 0.79 (heat recovery efficiency)

= 15.8 = 27.5

Enthalpy

= {38.5 (Indoor enthalpy) – 4.7 (outdoor air enthalpy)} × = 85 (Outdoor air enthalpy) – { 85 (outdoor air enthalpy) –

[kJ/kg (DA)]

0.71 (enthalpy recovery efficiency) + 4.7(outdoor air enthalpy)

53

(indoor enthalpy)} × 0.67 (enthalpy recovery efficiency)

= 28.7 = 63.6

Numerical value obtained •Dry-bulb temperature = 15.8 °C •Wet-bulb temperature = 9.9 °C•Dry-bulb temperature = 27.5 °C •Wet-bulb temperature = 21.8 °C

from above equation and •Relative humidity = 46% •Absolute humidity = 0.005 kg/kg (DA)•Relative humidity = 61% •Absolute humidity = 0.014 kg/kg (DA)

psychometric chart•Enthalpy = 28.7 kJ/kg (DA) (page 25,

5

)

•

Enthalpy = 63.3 kJ/kg (DA) (page 25, 6)

Heating Cooling

Fresh air load without

= 1.2 (Air specific gravity) × 8,000 (outdoor air volume) × = 1.2 (Air specific gravity) × 8,000 (outdoor air volume) ×

Lossnay (q

1)

{ 38.5 (indoor enthalpy) – 4.7 (outdoor air enthalpy) } { 85.0 (outdoor air enthalpy) – 53.2 (indoor enthalpy) }

= 324,480 kJ/h = 90.1 kW = 307,200 kJ/h = 85.3 kW

= 90.1 (Outdoor air load) (q

1) × = 85.3 (Outdoor air load) (q1) ×

Outdoor air load with

{ 1 – 0.71 (enthalpy recovery efficiency)} { 1 – 0.67 (enthalpy recovery efficiency) }

Lossnay (q

2)

= 26.1kW = 28.2 kW

or or

=

Air specific gravity × outdoor air volume × (indoor enthalpy – indoor blow enthalpy)

=

Air specific gravity × outdoor air volume × (indoor enthalpy – indoor blow enthalpy)

= q1 – q2 = q1 – q2

= 90.1 - 26.1 = 85.3 - 28.2

Heat recovered (q

3)

= 64.0 kW = 57.1 kW

or or

= Outdoor air load (q1) × enthalpy recovery efficiency = Outdoor air load (q1) × enthalpy recovery efficiency

•

Outdoor air load = 90.1 kW = 100%

•

Outdoor air load =85.3 kW = 100%

Outdoor air load (%)•Outdoor air load with Lossnay = 26.1 kW = 29%

•

Outdoor air load with Lossnay = 28.2 kW = 33%

•

Heat recovered = 64.0 kW = 71%

•

Heat recovered = 57.1 kW = 67%

Heating Cooling

=

Heat recovered: kW ×Unit price yen/W ×operation time Hr/year = Heat recovered: kW × Unit price yen/W × operation time Hr/year

Yearly saved money = 64.0 kW × 5.23 yen/kWh × (1,300hr/year) = 57.1 kW × 6.86 yen × (1,040hr/year)

= 435,100 yen = 407,374 yen

Remarks If recovered heat is converted to electricity : heating = 64.0 kW/3.1 = 20.6 kW/h cooling = 57.1 kW/2.6 = 22.0 kW/h

Page 31

25

CHAPTER 3 ● General Technical Considerations

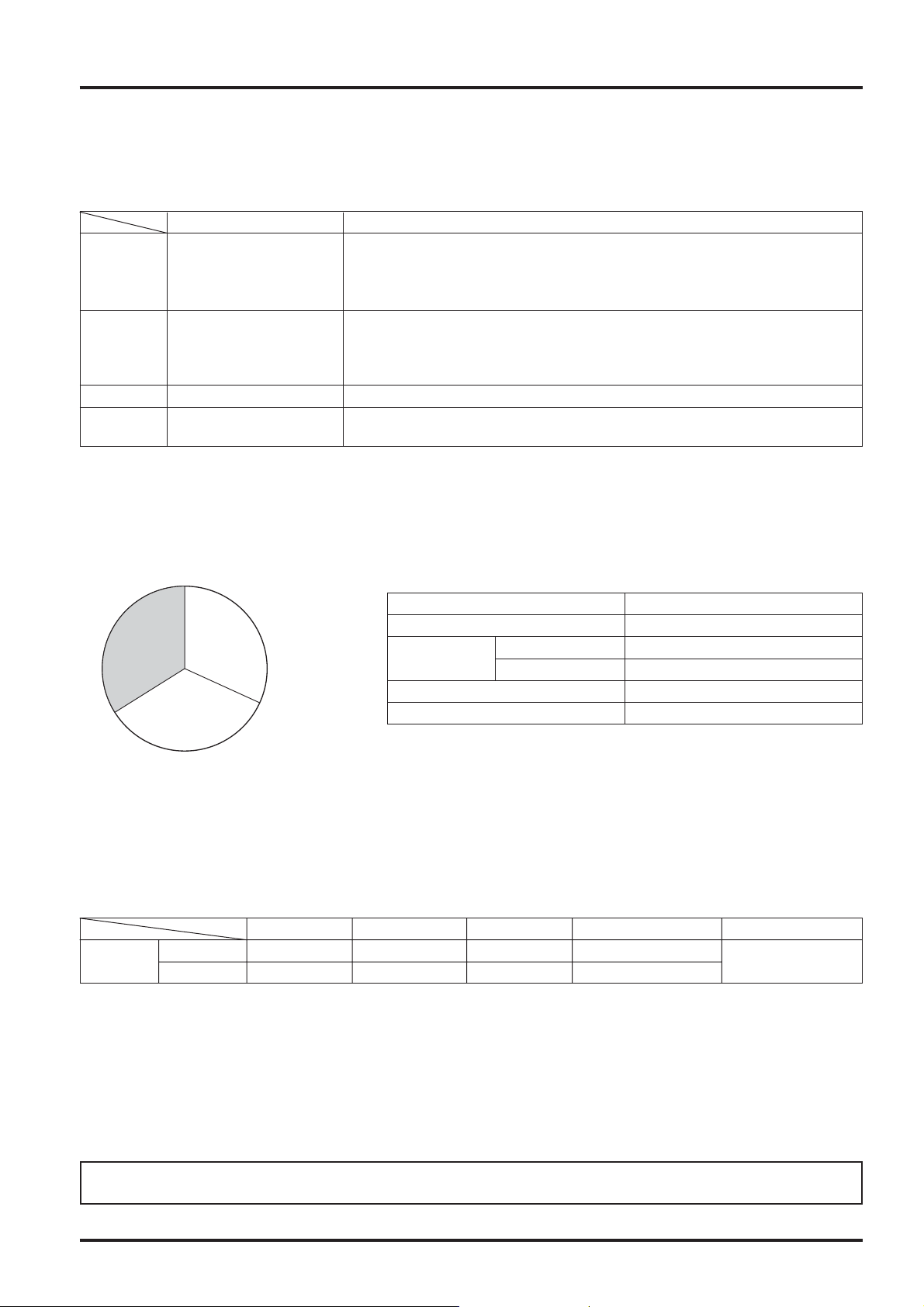

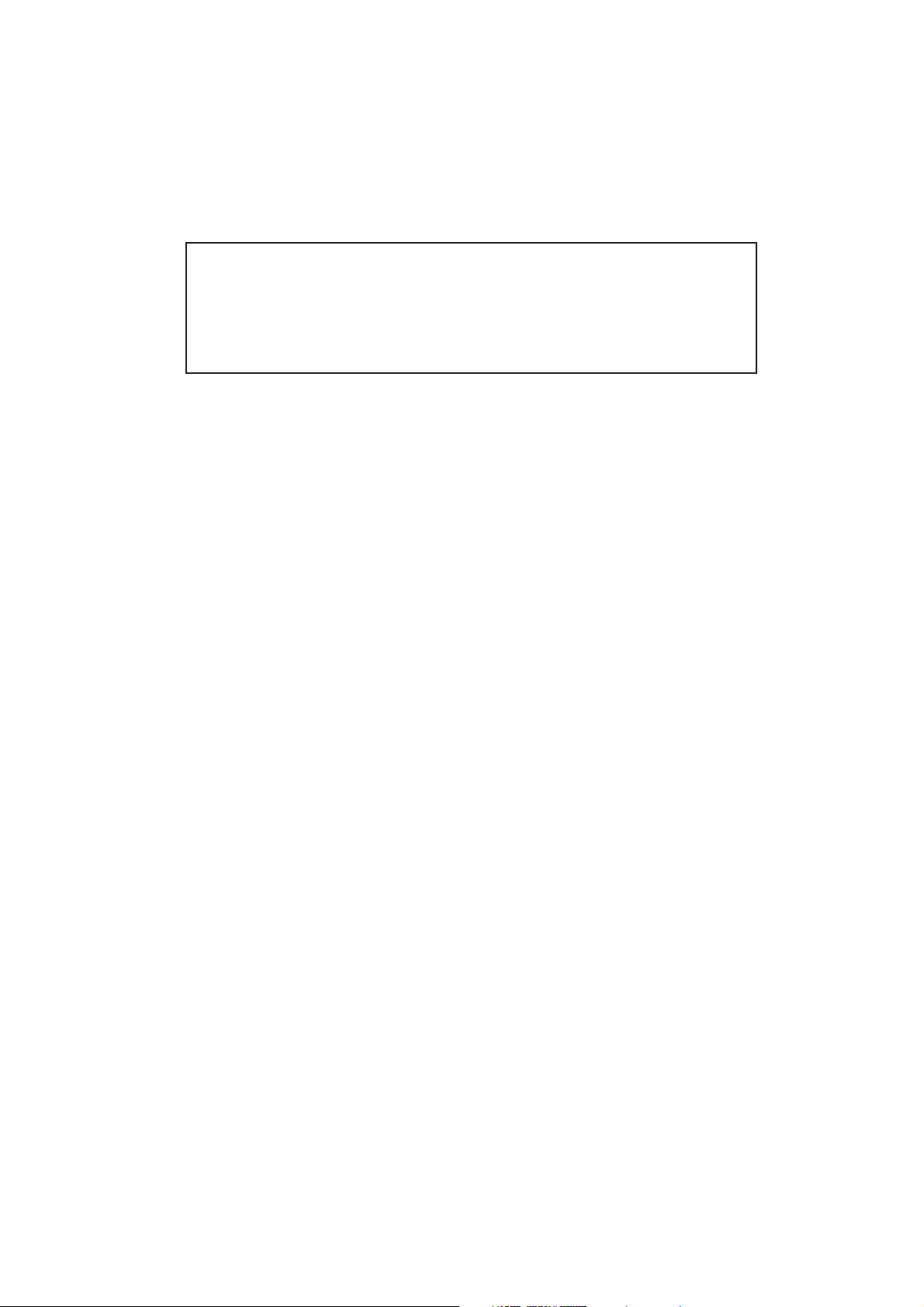

●

Psychrometric chart for calculating Lossnay economical effect

The following can be determined from the above calculation results:

●

Saving of 64.0 kW of the heating load, and 57.1 kW of the cooling load is possible.

The heat source equipment and related ventilator capacity that is equivalent to this saved amount can be reduced, thus the

operation and maintenance costs can also be saved.

●

Approximately 430,000 yen can be saved in operation and maintenance costs during heating and 400,000 yen during

cooling, for a total savings of approximately 830,000 yen.

28.7

38.5

53.2

63.3

85.0

4.7

0 15.8 20 26 33

0.0018

0.005

0.0072

0.0105

0.0146

0.0203

27.5

0.00.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.009

0.010

0.011

0.012

0.013

0.014

0.015

0.016

0.017

0.018

0.019

0.020

0.021

0.022

0.023

0.024

0.025

0.026

0.027

0.028

0.029

0.030

0.031

0.032

0.033

0.034

0.035

0.036

0.037

0.1

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

T.FUJITA

1987

VaporpressurePw[kPa]

Absolutehumidity x [kg/kg(DA)]

50494847464544434240 41393837363534333230 31292827262524232220 21191817161514131210 11987654320–1–2–3–4–9–10

0.75 0.76 0.77 0.78 0.79 0.80 0.81 0.82 0.83 0.84 0.85 0.86 0.87 0.88 0.89 0.90 0.91

–7–8 –5–6 1

18

19

20

55

60

65

70

22

21

23

24

25

75

80

26

27

85

90

28

29

95

100

105

110

31

115

120

33

32

34

35

125

30

50

45

40

35

11

10

9

8

7

6

4

5

3

2

1

0

–1

–2

–4

–5

–5

0

5

10

90

80

70

60

50

40

30

25

60

55

65

70

75

80

85

95

90

85

80

75

70

65

60

55

ψ50

ψ50

45

40

40

45

35

30

25

20

15

10

5

35

30

25

20

15

20

10

5

15

15

25

30

20

–8

10

5

0

15

20

25

30

12

13

14

15

16

17

±

∞

–40000

40000

20000

15000

10000

7000

6000

5000

4500

4200

4000

3800

–20000

–10000

–5000

–2000

–1000

–500

0

500

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

3800

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Comparativeenthalpy

h[kJ/kg(DA)]

Humid air psychrometric chart

(-10 to +50°C, atmospheric pressure 101.325 kPa)

Heatwaterratio

u = ––[kJ/kg]

dh

dx

Sensibleheatratio

SFH

Saturation [%]

0.94

0.92

0.93

0.96

0.95

Wetbulbtemperaturet'[°C]

Drybulbtemperaturet[°C]

Relativehum

idity[%]

Chilled

Water

Specificcapacityv [m

3

/kg(DA)]

1

5

2

4

6

3

Page 32

26

CHAPTER 3 ● General Technical Considerations

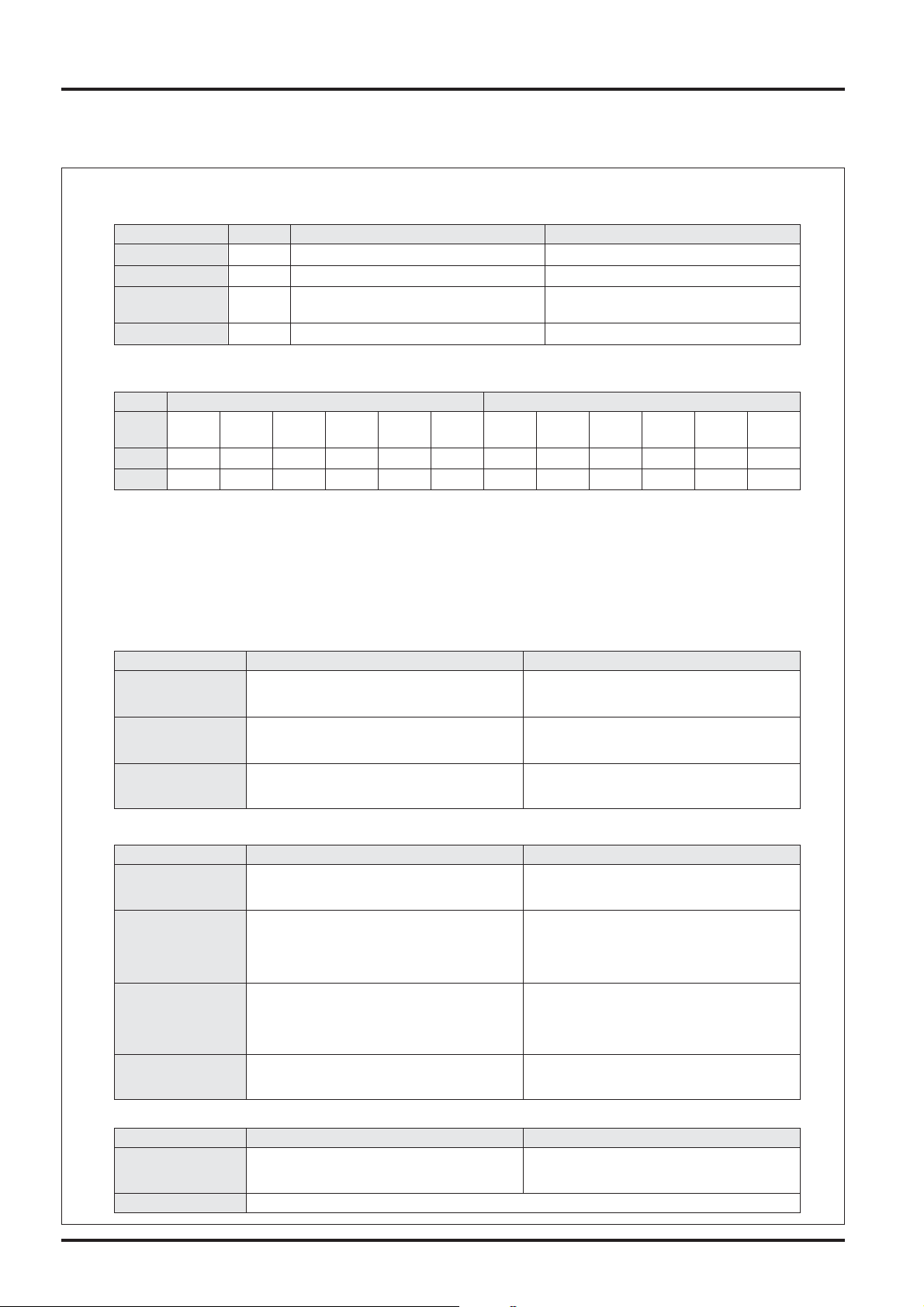

3. Calculation of Lossnay Economical Effects

The following is a sample questionnaire from which it is possible to assess the economical benefits of using the Lossnay in

particular applications.

(1) Setting of conditions

●

Return air volume (RA) = m3/Hr

●

Outdoor air volume (OA) = m3/Hr

●

Air volume ratio (RA/OA) =

●

Air conditions

●

Operation time: Heating = hours/day × days/month × months/year = hours/year

Cooling = hours/day × days/month × months/year = hours/year

●

Energy: Heating = Type: Electricity Cost: yen/kWh

Cooling = Type: Electricity Cost: yen/kWh

Power rates: Winter: yen/kWh Summer: yen/kWh

(2) Selection of Lossnay model (select from treatment air volume catalog)

●

Model name:

●

Processing air volume per unit RA = m3/Hr, OA = m3, Air volume ratio (RA/OA) =

●

Heat recovery efficiency :

Heat recovery efficiency = %,

Enthalpy recovery efficiency (cooling) = %,

Enthalpy recovery efficiency (heating) = %

●

Static pressure loss (unit-type) RA= Pa OA = Pa (Note: Each with filters)

●

Power consumption (pack-type) = none because of unit type

(3) State of indoor blow air

Season Winter heating Summer cooling

Dry bulb Wet bulb Relative Absolute Enthalpy Dry bulb Wet bulb Relative Absolute Enthalpy

Item temp. temp. humidity humidity i kJ/kg temp. temp. humidity humidity i kJ/kg

DB [°C] WB [°C] RH [%]×[kg/kg’] (kcal/kg’) DB [°C] WB [°C] RH [%]×[kg/kg’] (kcal/kg’)

Outdoors

Indoors

Heating Cooling

= (Indoor temperature – outdoor air temperature) × = Outdoor air temperature – (outdoor air

Temperature [°C]

heat recovery efficiency + outdoor air temperature – indoor temperature) ×

temperature heat recovery efficiency

==

= (Indoor enthalpy – outdoor air enthalpy) × = Outdoor air enthalpy – (outdoor air

Enthalpy [kJ/kg]

enthalpy recovery efficiency + outdoor air enthalpy – indoor enthalpy) ×

enthalpy enthalpy recovery efficiency

==

Numerical value

●

Dry-bulb temperature = °C

●

Dry-bulb temperature = °C

obtained from above

●

Wet-bulb temperature = °C

●

Wet-bulb temperature = °C

equation and

●

Relative humidity = %

●

Relative humidity = %

psychometric chart

●

Absolute humidity = kg/kg’●Absolute humidity = kg/kg’

●

Enthalpy = kg/kg●Enthalpy = kg/kg

Page 33

27

CHAPTER 3 ● General Technical Considerations

(4) Outdoor air load and heat recovery

Heating Cooling

Fresh air load without

= Air specific gravity × outdoor air volume = Air specific gravity × outdoor air volume

Lossnay (q1)

× (indoor enthalpy

–

outdoor air enthalpy) × (outdoor air enthalpy – indoor enthalpy)

==

= Outdoor air load (q

1) = Outdoor air load (q1)

× ( 1 – enthalpy recovery efficiency) × ( 1 – enthalpy recovery efficiency)

Outdoor air load with = =

Lossnay (q

2)or or

= Air specific gravity × outdoor air volume = Air specific gravity × fresh air volume

× (indoor enthalpy

–

indoor blow enthalpy) × (indoor blow enthalpy – indoor enthalpy)

=q

1

–

q

2 =q1

–

q2

=

–

=

–

Heat recovery (q3)

==

or or

= Outdoor air load (q

1)=Outdoor air load (q1)

× enthalpy recovery efficiency × enthalpy recovery efficiency

● Outdoor air load = W = % ● Outdoor air load = W = %

Outdoor air load (%)

● Outdoor air load with Lossnay ● Outdoor air load with Lossnay

= W = % = W = %

● Heat recovered = W = % ● Heat recovered = W = %

(5) Recovered money (power rates)

Heating Cooling

=

Heat recovered: kW × Unit price ¥/kWh ×

=

Heat recovered: kW × Unit price ¥/kWh ×

Yearly saved money

operation

time Hr/year = kW ×

¥

/

kWh

×

operation

time Hr/year = kW ×¥/

kWh

×

(

yen)

= Hr/year = Hr/year

==

Page 34

28

CHAPTER 3 ● General Technical Considerations

4. Psychrometric Chart

0.00.000

0.001

0.002

0.003

0.004

0.005

0.006

0.007

0.008

0.009

0.010

0.011

0.012

0.013

0.014

0.015

0.016

0.017

0.018

0.019

0.020

0.021

0.022

0.023

0.024

0.025

0.026

0.027

0.028

0.029

0.030

0.031

0.032

0.033

0.034

0.035

0.036

0.037

0.1

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

5.5

Vapor pressure Pw [kPa]

Absolute humidity x [kg/kg(DA)]

50494847464544434240 41393837363534333230 31292827262524232220 21191817161514131210 11987654320–1–2–3–4–9–10

0.75 0.76 0.77 0.78 0.79 0.80 0.81 0.82 0.83 0.84 0.85 0.86 0.87 0.88 0.89 0.90 0.91

–7–8 –5–6 1

18

19

20

55

60

65

70

22

21

23

24

25

75

80

26

27

85

90

28

29

95

100

105

110

31

115

120

33

32

34

35

125

30

50

45

40

35

11

10

9

8

7

6

4

5

3

2

1

0

–1

–2

–4

–5

–5

0

5

10

90

80

70

60

50

40

30

25

60

55

65

70

75

80

85

95

90

85

80

75

70

65

60

55

50

50

45

40

40

45

35

30

25

20

15

10

5

35

30

25

20

15

20

10

5

15

15

25

30

20

–8

10

5

0

15

20

25

30

12

13

14

15

16

17

–40000

40000

20000

15000

10000

7000

6000

5000

4500

4200

4000

3800

–20000

–10000