MELSEC-L High-Speed Counter Module

User's Manual

-LD62

-LD62D

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Do not write any data to the "system area" of the buffer memory in the intelligent function module.

Also, do not use any "use prohibited" signals as an input signal from the CPU module to the intelligent

function module.

Doing so may cause malfunction of the programmable controller system.

● Outputs may remain on or off due to a failure of a transistor for external output. Configure an external

circuit for monitoring output signals that could cause a serious accident.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 150mm or more between them. Failure to do so may result in malfunction

due to noise.

1

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the Safety

Guidelines provided with the CPU module or head module. Failure to do so may result in electric

shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Do not directly touch any conductive parts and electronic components of the module. Doing so can

cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

2

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 or less. Failure to do so may result in electric shock or malfunction.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Connectors for external devices must be crimped with the tool specified by the manufacturer or must

be correctly soldered.

Incomplete connections may cause short circuit, fire, or malfunction.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● Tighten the connector screws within the specified torque range.

Undertightening can cause drop of the screw, short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, fire, or

malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part.

For the cable with connector, hold the connector part of the cable.

Pulling the cable connected to the module may result in malfunction or damage to the module or

cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● Ground the shield cable on the encoder side (relay box). Always ground the FG and LG terminals to

the protective ground conductor. Failure to do so may cause malfunction.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block. Wiring and

replacement of a power supply module must be performed by qualified maintenance personnel with

knowledge of protection against electric shock. For wiring methods, refer to the MELSEC-L CPU

Module User's Manual (Hardware Design, Maintenance and Inspection).

3

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the connector screws. Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a fire.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● After the first use of the product (module and display unit), do not connect/disconnect the product

more than 50 times (in accordance with IEC 61131-2). Exceeding the limit may cause malfunction.

● Tighten the connector screws within the specified torque range. Undertightening can cause drop of

the component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or

module, resulting in drop, short circuit, or malfunction.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

4

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or serious accident;

and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the PRODUCT for the

case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED TO ANY AND ALL

RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY

INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE

OPERATED OR USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR

WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL

BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any other cases in which the

public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of a special quality

assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator and Escalator,

Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for Recreation and Amusement, and

Safety devices, handling of Nuclear or Hazardous Materials or Chemicals, Mining and Drilling, and/or other

applications where there is a significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the PRODUCT in one or

more of the Prohibited Applications, provided that the usage of the PRODUCT is limited only for the specific

applications agreed to by Mitsubishi and provided further that no special quality assurance or fail-safe, redundant or

other safety features which exceed the general specifications of the PRODUCTs are required. For details, please

contact the Mitsubishi representative in your region.

5

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi MELSEC-L series programmable controllers.

This manual describes the functions and programming of a high-speed counter module.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-L series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Relevant modules: LD62, LD62D

Unless otherwise specified, this manual describes the program examples in which the I/O numbers of X/Y00 to X/Y0F are

assigned for a high-speed counter module.

For I/O number assignment, refer to the following.

MELSEC-L CPU Module User's Manual (Function Explanation, Program Fundamentals)

Operating procedures are explained using GX Works2. When using GX Developer or GX Configurator-CT, refer to the

following.

• When using GX Developer or GX Configurator-CT ( Page 120, Appendix 5)

6

COMPLIANCE WITH EMC AND LOW VOLTAGE

DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC and Low Voltage Directives when incorporated

into other machinery or equipment, certain measures may be necessary. Please refer to one of the following

manuals.

• MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

• MELSEC-L CC-Link IE Field Network Head Module User's Manual

• Safety Guidelines (This manual is included with the CPU module or head module.)

The CE mark on the side of the programmable controller indicates compliance with EMC and Low Voltage

Directives.

(2) Additional measures

To ensure that this product maintains EMC and Low Voltage Directives, please refer to Page 37, Section 6.2.1

(4).

7

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

MELSEC-L CPU Module User's Manual (Hardware Design,

Maintenance and Inspection)

<SH-080890ENG, 13JZ36>

MELSEC-L CPU Module User's Manual (Function Explanation,

Program Fundamentals)

<SH-080889ENG, 13JZ35>

(2) Head module user's manual

Manual name

<manual number (model code)>

MELSEC-L CC-Link IE Field Network Head Module User's Manual

<SH-080919ENG, 13JZ48>

(3) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

<SH-080779ENG, 13JU63>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

Description

Specifications of the CPU modules, power supply modules, display

unit, branch module, extension module, SD memory cards, and

batteries, information on how to establish a system, maintenance

and inspection, and troubleshooting

Functions and devices of the CPU module, and programming

Description

Specifications, procedures before operation, system configuration,

installation, wiring, settings, and troubleshooting of the head module

Description

System configuration, parameter settings, and online operations of

GX Works2, which are common to Simple projects and Structured

projects

Operating methods of GX Developer, such as programming,

printing, monitoring, and debugging

8

Memo

9

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

COMPLIANCE WITH EMC AND LOW VOLTAGE DIRECTIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHAPTER 1 HIGH-SPEED COUNTER MODULE 15

1.1 Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CHAPTER 2 PART NAMES 18

CHAPTER 3 SPECIFICATIONS 20

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 Number of parameters that can be set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 List of I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 List of Buffer Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

CHAPTER 4 PROCEDURES BEFORE OPERATION 29

CHAPTER 5 SYSTEM CONFIGURATION 31

5.1 Overall Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 Applicable System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2.1 Restrictions when the high-speed counter module is connected to the head module . . . . . . .33

CHAPTER 6 INSTALLATION AND WIRING 34

6.1 Installation Environment and Installation Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.2.1 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

6.2.2 Connectors for external devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.2.3 Interface with external devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.2.4 Connectable encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

6.3 Examples of Wiring Between the High-Speed Counter Module and an Encoder . . . . . . . . . . . 47

6.4 Examples of Wiring Between a Controller and External Input Terminals . . . . . . . . . . . . . . . . . 49

6.5 Examples of Wiring with External Output Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CHAPTER 7 SETTINGS 53

7.1 Adding a Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.2 Switch Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10

7.3 Intelligent Function Module Detailed Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.4 Parameter Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.5 Auto Refresh. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

CHAPTER 8 FUNCTIONS 58

8.1 Pulse Input Modes and Counting Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1.1 Types of pulse input modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

8.1.2 Setting a counting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

8.1.3 Reading the present value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Selecting Counter Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.2.1 Linear counter function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

8.2.2 Ring counter function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

8.3 Coincidence Output Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

8.4 Preset Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

8.5 Counter Function Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

8.5.1 Reading the counter function selection count value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

8.5.2 Count error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

8.6 Count Disable Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.7 Latch Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

8.8 Sampling Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

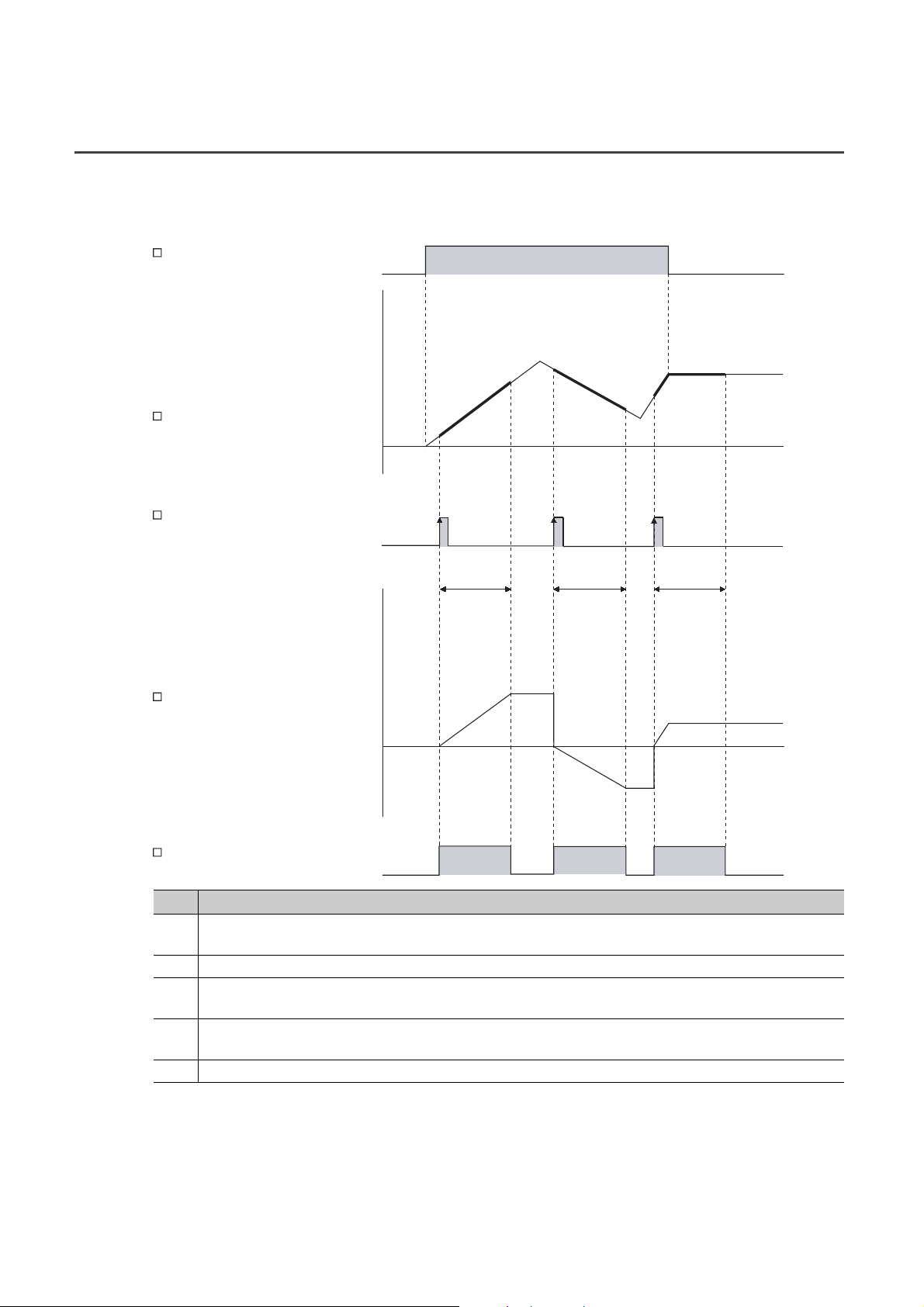

8.9 Periodic Pulse Counter Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

CHAPTER 9 DISPLAY UNIT 83

9.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9.2 Menu Transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9.3 List of Setting Value Change Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

CHAPTER 10 PROGRAMMING 88

10.1 Using the Module in Standard System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

10.2 Connecting the Module to the Head Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

10.3 Program Example with the Coincidence Detection Interrupt Function . . . . . . . . . . . . . . . . . . 106

CHAPTER 11 TROUBLESHOOTING 108

11.1 Error Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11.2 The Module Does Not Start Counting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.3 The Module Does Not Correctly Count Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.4 Coincidence Output Function Does Not Correctly Operate . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.5 Coincidence Detection Interrupt Does Not Occur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.6 Present Value Cannot be Replaced with the Preset Value. . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.7 Pulse Waveform Shaping Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

APPENDICES 112

Appendix 1 Details of I/O Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11

Appendix 1.1 Input signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix 1.2 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Appendix 2 Details of Buffer Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Appendix 3 Checking Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Appendix 4 Differences Between L Series and Q Series Modules . . . . . . . . . . . . . . . . . . . . . . . . . 119

Appendix 5 When Using GX Developer and GX Configurator-CT . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Appendix 5.1 GX Developer operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Appendix 5.2 GX Configurator-CT operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Appendix 6 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

INDEX 128

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

12

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example (for GX Works2) is provided below.

13

TERMS

Unless otherwise specified, this manual uses the following terms.

Term Description

High-speed counter module Another term for the MELSEC-L series high-speed counter module

Head module Abbreviation for the LJ72GF15-T2 CC-Link IE Field Network head module

Display unit A liquid crystal display to be attached to the CPU module

Programming tool Generic term for GX Works2 and GX Developer

GX Works2

GX Developer

GX Configurator-CT A setting and monitoring tool added in GX Developer (for high-speed counter modules)

Buffer memory

The product name of the software package for the MELSEC programmable controllers

A memory in an intelligent function module, where data (such as setting values and monitoring values)

exchanged with a CPU module are stored

PACKING LIST

The following items are included in the package of this product. Before use, check that all the items are included.

High-speed counter module

14

Module

Before Using the Product

CHAPTER 1 HIGH-SPEED COUNTER MODULE

CH1

CH2

Encoder (pulse generator)

Encoder

(pulse generator)

Temporarily stops the inverter. (Coincidence output)

CHAPTER 1 HIGH-SPEED COUNTER MODULE

This chapter describes the application and the features of the high-speed counter module.

1.1 Application

The high-speed counter module is capable of counting the number of inputs of a high-speed pulse that cannot be

measured by a sequence using general-purpose input modules.

1

1.1 Application

15

1.2 Features

(1) Offering counting capability over the wide range from -2147483648 to

2147483647

• The module stores a count value in 32-bit signed binary.

• The number of channels is two.

(2) Switching the maximum counting speed

For the LD62D, 500k/200k/100k/10k can be switched and for the LD62, 200k/100k/10k can be switched, thereby

achieving an error-free count even if a pulse has a gradual rising/falling edge.

(3) Allowing selection of pulse input

The pulse input mode can be selected from the following: 1-phase multiple of 1, 1-phase multiple of 2, 2-phase

multiple of 1, 2-phase multiple of 2, 2-phase multiple of 4, and CW/CCW.

(4) Allowing selection of counter types

Either one of the following counter types can be selected.

(a) Linear counter type

This type is capable of counting pulses ranging from -2147483648 to 2147483647 and detects an overflow if

this range is exceeded.

(b) Ring counter type

This type counts pulses repeatedly under the range of the ring counter upper limit value and the ring counter

lower limit value.

(5) Permitting coincidence output

Outputting on/off signals or initiating an interrupt program is possible at the timing when a coincidence output

point, which is set arbitrarily beforehand, matches the current value in comparison with each other.

(6) Allowing selection from the four counter functions

One of the following functions can be selected for use.

(a) Count disable function

This function makes the pulse count stop by inputting a signal while CH Count enable command (Y4, YC) is

on.

(b) Latch counter function

This function latches the current value of a counter at the time of input of a signal.

(c) Sampling counter function

Of input signals, this function counts pulses that are input during a time specified beforehand.

(d) Periodic pulse counter function

While signals are input, this function stores the current value and previous value of a counter at each pre-

specified period.

16

CHAPTER 1 HIGH-SPEED COUNTER MODULE

(7) Executing the preset function and the counter function selection via external

control signals

• Applying a voltage to the preset input terminal allows the preset function to be performed.

• Applying a voltage to the function start input terminal allows the counter function selection to be performed.

(8) Easy settings with GX Works2

GX Works2 allows Initial settings and auto refresh settings to be configured on the window, resulting in the

reduction of programs and making it easier to check the status of module settings and operation.

1

1.2 Features

17

CHAPTER 2 PART NAMES

The following table lists the part names of the high-speed counter module.

1)

7)

1)

No. Name Description

1) Module joint levers Levers for connecting two modules

2) A LED On: A voltage is being applied to the phase A pulse input terminal.

3) B LED On: A voltage is being applied to the phase B pulse input terminal.

4) DEC. LED On: Pulses are being counted down.

5) FUNC. LED On: A voltage is being applied to the function start input terminal.

6) DIN rail hook A hook used to mount the module to a DIN rail

7)

8) Serial number display Displays the serial number printed on the rating plate.

Connector for external

devices (40 pins)

8)

2)

3)

4)

5)

A connector for I/O signal cables of external devices ( Page 41, Section 6.2.3)

1)

1)

6)

18

Memo

CHAPTER 2 PART NAMES

2

19

CHAPTER 3 SPECIFICATIONS

This chapter describes general specifications, performance specifications, functions, I/O signals, and buffer memory

areas.

3.1 General Specifications

For the general specifications of the high-speed counter module, refer to the following.

Safety Guidelines, provided with the CPU module or head module

20

3.2 Performance Specifications

2.5 2.5

5

(Unit : s)

55

10

(Unit : s)

50 50

100

(Unit : s)

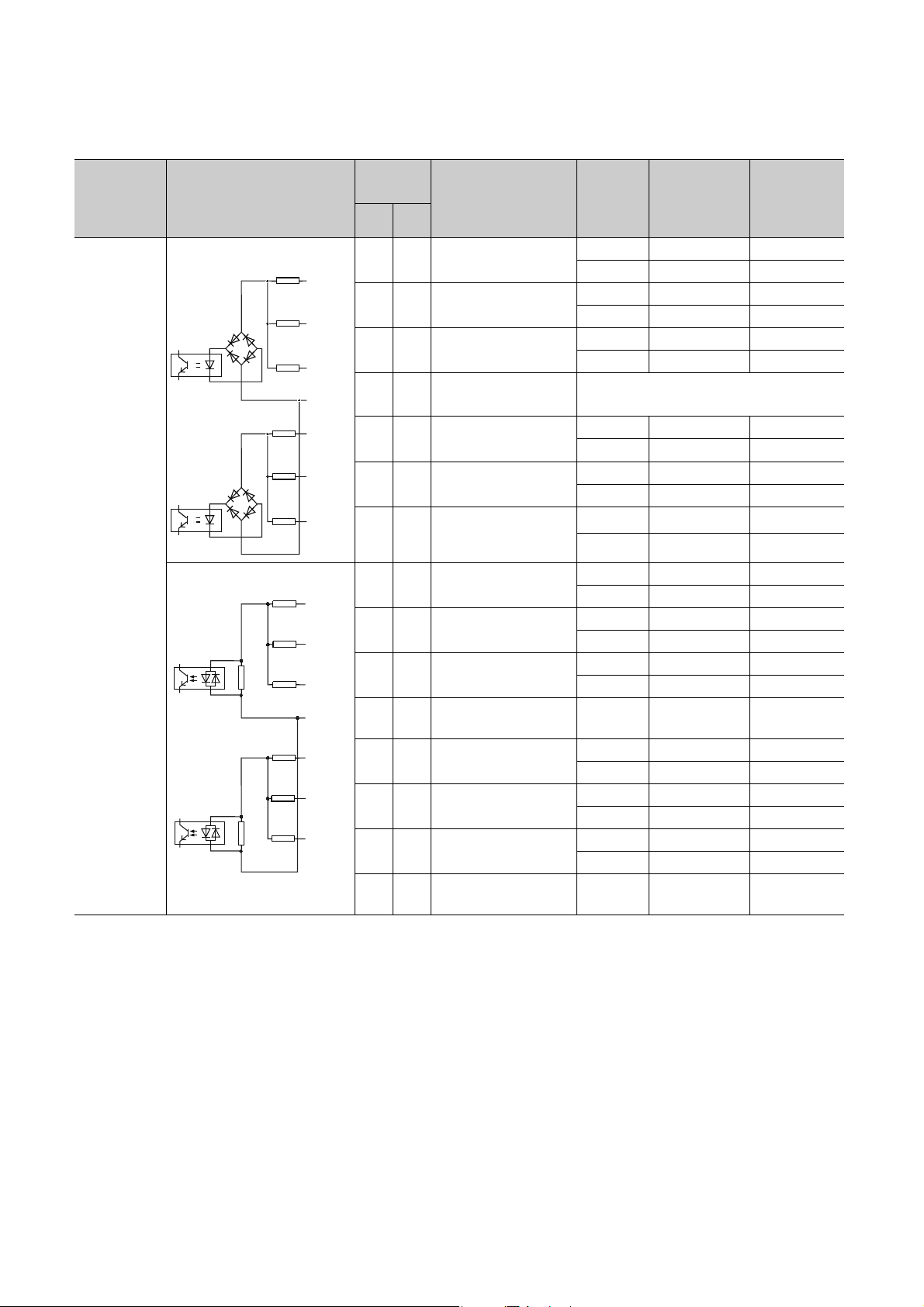

The following table describes the performance specifications of the high-speed counter module.

(1) LD62 (DC input sink output type)

CHAPTER 3 SPECIFICATIONS

Item Specifications

Counting speed switch setting

Number of occupied I/O points 16 points (I/O assignment: Intelligent, 16 points)

Number of channels 2 channels

Phase

Count input signal

Counter

Coincidence

output

External input

External output Coincidence output

Internal current consumption (5VDC) 0.31A

Weight 0.13kg

Signal level

(A, B)

Counting speed

(maximum)

Counting range 32-bit signed binary (-2147483648 to 2147483647)

Type UP/DOWN preset counter + Ring counter functions

Minimum count pulse

width

(duty ratio 50%)

Comparison range 32-bit signed binary

Comparison result

Preset

Function start

*1

*2

200k (100k to 200kPPS) 100k (10k to 100kPPS) 10k (10kPPS or less)

1-phase input (1 multiple/2 multiples), 2-phase input (1 multiple/2 multiples/4 multiples),

CW/CCW input

5/12/24VDC 2 to 5mA

200kPPS 100kPPS 10kPPS

(Minimum phase difference

in 2-phase input 1.25s)

Transistor (sink type) output, 2 points/channel

(Minimum phase difference

in 2-phase input 2.5s)

Setting value < Count value

Setting value = Count value

Setting value > Count value

5/12/24VDC

2 to 5mA

12/24VDC 0.5A/point, 2A/common

(Minimum phase difference

in 2-phase input 25s)

3

3.2 Performance Specifications

21

*1 The value can be configured in intelligent function module switch setting.

tt

*2 The counting speed is affected by the pulse rise/fall time.

The number of pulses that can be counted depending on the counting speed is as follows. Note that the count may be

incorrect when pulses with long rise/fall time are counted.

Counting speed switch

setting

200k 100k 10k

Rise/fall time Both 1- and 2-phase inputs

t = 1.25s or less 200kPPS 100kPPS 10kPPS

t = 2.5s or less 100kPPS 100kPPS 10kPPS

t = 25s or less 10kPPS 10kPPS

t = 500s 500PPS

(2) LD62D (differential input sink output type)

Item Specifications

Counting speed switch setting

*1

500k (200k to

500kPPS)

Number of occupied I/O points 16 points (I/O assignment: Intelligent, 16 points)

Number of channels 2 channels

1-phase input (1 multiple/2 multiples), 2-phase input (1 multiple/2 multiples/4 multiples),

(AM26LS31 (manufactured by Texas Instruments Incorporated) or equivalent)

500kPPS 200kPPS 100kPPS 10kPPS

Count input signal

Phase

Signal level

(A, B)

Counting speed

(maximum)

*2

Counting range 32-bit signed binary (-2147483648 to 2147483647)

Type UP/DOWN preset counter + Ring counter functions

200k (100k to

200kPPS)

CW/CCW input

EIA Standard RS-422-A

Differential line driver level

100k (10k to

100kPPS)

10k (10kPPS or less)

Counter

2

5

Minimum count pulse

width

(duty ratio 50%)

11

(Unit : s)

(Minimum phase

difference in 2-phase

input 0.5s)

2.5 2.5

(Unit : s)

(Minimum phase

difference in 2-phase

input 1.25s)

Comparison range 32-bit signed binary

Coincidence

output

Comparison result

Setting value < Count value

Setting value = Count value

Setting value > Count value

External input

Preset

Function start

External output Coincidence output

(EIA Standard RS-422-A differential line driver can be connected.)

Transistor (sink type) output, 2 points/channel

5/12/24VDC 2 to 5mA

12/24VDC 0.5A/point, 2A/common

Internal current consumption (5VDC) 0.36A

Weight 0.13kg

22

10

55

(Unit : s)

(Minimum phase

difference in 2-phase

input 2.5s)

100

50 50

(Unit : s)

(Minimum phase

difference in 2-phase

input 25s)

CHAPTER 3 SPECIFICATIONS

*1 The value can be configured in intelligent function module switch setting.

*2 The counting speed is affected by the pulse rise/fall time.

The number of pulses that can be counted depending on the counting speed is as follows. Note that the count may be

incorrect when pulses with long rise/fall time are counted.

Counting speed switch

setting

Rise/fall time Both 1- and 2-phase inputs

t = 0.5s or less 500kPPS 200kPPS 100kPPS 10kPPS

t = 1.25s or less 200kPPS 200kPPS 100kPPS 10kPPS

t = 2.5s or less 100kPPS 100kPPS 10kPPS

t = 25s or less 10kPPS 10kPPS

t = 500s 500PPS

500k 200k 100k 10k

tt

3

3.2.1 Number of parameters that can be set

Configure the parameters of the initial setting and the auto refresh of the high-speed counter module within the number

of parameters that can be set to the CPU module or head module, including the number of parameters set for other

intelligent function modules. For the number of parameters that can be set to the CPU module and head module, refer

to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

(1) Number of high-speed counter module parameters

The following number of parameters can be set for one high-speed counter module.

Model Initial setting Auto refresh

LD62 8 14 (maximum number of parameters)

LD62D 8 14 (maximum number of parameters)

3.2 Performance Specifications

3.2.1 Number of parameters that can be set

23

(2) Checking the number of parameters

The number of parameters set for the intelligent function module and the maximum number of parameters can be

checked by the following operation.

Project window [Intelligent Function Module] Right-click [Intelligent Function Module

Parameter List]

1) 2) 3) 4)

No. Description

1) The total number of parameters that have been selected under "Initialization (Count)"

2) The maximum number of parameters for initial setting

3) The total number of parameters that have been selected under "Auto Refresh (Count)"

4) The maximum number of parameters for auto refresh setting

24

3.3 Function List

The following table lists the functions of the high-speed counter module.

Item Description Reference

Linear counter function

Ring counter function

Coincidence

output function

Preset function

Counter function

selection

Coincidence

detection

interrupt

function

Count disable

function

Latch counter

function

Sampling

counter function

Periodic pulse

counter function

This function counts pulses between -2147483648 and 2147483647 and detects an

overflow if the count value is outside the range.

This function repeatedly counts pulses between the ring counter upper limit value

and the ring counter lower limit value.

This function compares the present counter value with the preset coincidence output

point setting value and outputs on or off signal when they match.

This function outputs an interrupt signal to the CPU module and starts an interrupt

program when the present counter value matches with the preset coincidence output

point setting value.

This function overwrites the present counter value with the preset value.

This function is performed by a program or an external control signal (preset input).

This function stops counting pulses while CH Count enable command (Y4, YC) is

on.

This function stores the present counter value to the buffer memory when the

counter function selection start command signal is input.

This function is performed by a program or an external control signal (function input).

This function counts pulses input during the specified sampling period after the

counter function selection start command is input and stores the counter value to the

buffer memory.

This function is performed by a program or an external control signal (function input).

This function stores the present and previous counter values to the corresponding

buffer memory areas at the preset cycle while the counter function selection start

command signal is input.

CHAPTER 3 SPECIFICATIONS

Page 64,

Section 8.2.1

Page 65,

Section 8.2.2

Page 68,

Section 8.3

Page 73,

Section 8.4

Page 78,

Section 8.6

Page 79,

Section 8.7

Page 80,

Section 8.8

Page 81,

Section 8.9

3

3.3 Function List

● These functions can be used together.

However, select either the linear counter function or the ring counter function and any one of the counter functions from

counter function selection.

● The preset function and the function selected from counter function selection can also be performed by the following

external inputs.

• To use the preset function, apply a voltage to the preset input terminal.

• To use any function of the counter function selection, apply a voltage to the function start input terminal.

25

3.4 List of I/O Signals

The following table lists the I/O signals of the high-speed counter module.

For details on the I/O signals, refer to the following.

• Details of I/O signals ( Page 112, Appendix 1)

Input signal Output signal

Device No. Signal name Device No. Signal name

X0 Module READY Y0

X1 CH1 Counter value large (point No.1) Y1 CH1 Preset command

X2 CH1 Counter value coincidence (point No.1) Y2 CH1 Coincidence signal enable command

X3 CH1 Counter value small (point No.1) Y3 CH1 Down count command

X4 CH1 External preset request detection Y4 CH1 Count enable command

X5 CH1 Counter value large (point No.2) Y5

X6 CH1 Counter value coincidence (point No.2) Y6

X7 CH1 Counter value small (point No.2) Y7

X8 CH2 Counter value large (point No.1) Y8

X9 CH2 Counter value coincidence (point No.1) Y9 CH2 Preset command

XA CH2 Counter value small (point No.1) YA CH2 Coincidence signal enable command

XB CH2 External preset request detection YB CH2 Down count command

XC CH2 Counter value large (point No.2) YC CH2 Count enable command

XD CH2 Counter value coincidence (point No.2) YD

XE CH2 Counter value small (point No.2) YE

XF Use prohibited YF

CH1 Coincidence signal No.1 reset

command

CH1 External preset detection reset

command

CH1 Counter function selection start

command

CH1 Coincidence signal No.2 reset

command

CH2 Coincidence signal No.1 reset

command

CH2 External preset detection reset

command

CH2 Counter function selection start

command

CH2 Coincidence signal No.2 reset

command

26

● The I/O numbers (X/Y) above apply when the start I/O number of the high-speed counter module is set to "0".

● The use prohibited signal above is used by the system and is not available for users. If used (turned on) by a user, the

performance of the high-speed counter module is not guaranteed.

3.5 List of Buffer Memory Areas

The following table lists the buffer memory areas of the high-speed counter module.

For details on the buffer memory areas, refer to the following.

• Details of Buffer Memory Areas ( Page 116, Appendix 2)

Address

(decimal)

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

31

32

33

34

35

36

37

38

39

Address

(hexadecimal)

0

H

1

H

2

H

3

H

4

H

5

H

6

H

7

H

8

H

9

H

A

H

B

H

C

H

D

H

E

H

F

H

10

H

11

H

12

H

13

H

14

H

15

H

16

H

17

H

18

H

1F

H

20

H

21

H

22

H

23

H

24

H

25

H

26

H

27

H

Name

CH1 Preset value (L)

CH1 Preset value (H)

CH1 Present value (L)

CH1 Present value (H)

CH1 Coincidence output point No.1 (L)

CH1 Coincidence output point No.1 (H)

CH1 Coincidence output point No.2 (L)

CH1 Coincidence output point No.2 (H)

CH1 Overflow detection 0 R

CH1 Counter function selection 0 R/W

CH1 Sampling/periodic time setting 0 R/W

CH1 Sampling/periodic counter flag 0 R

CH1 Latch count value (L)

CH1 Latch count value (H)

CH1 Sampling count value (L)

CH1 Sampling count value (H)

CH1 Periodic pulse count previous value (L)

CH1 Periodic pulse count previous value (H)

CH1 Periodic pulse count present value (L)

CH1 Periodic pulse count present value (H)

CH1 Ring counter lower limit (L)

CH1 Ring counter lower limit (H)

CH1 Ring counter upper limit (L)

CH1 Ring counter upper limit (H)

System area to to

CH2 Preset value (L)

CH2 Preset value (H)

CH2 Present value (L)

CH2 Present value (H)

CH2 Coincidence output point No.1 (L)

CH2 Coincidence output point No.1 (H)

CH2 Coincidence output point No.2 (L)

CH2 Coincidence output point No.2 (H)

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

CHAPTER 3 SPECIFICATIONS

Initial value

*1

Read/write

*2

3

0R/W

0R/W

0R

0R

*3

*3

*3

*3

0R/W

0R/W

0R/W

0R/W

0R

0R

0R

3.5 List of Buffer Memory Areas

0R

*3

*3

*3

*3

0R

0R

0R

0R

0R/W

0R/W

0R/W

0R/W

0R/W

0R/W

0R

0R

*3

*3

*3

*3

0R/W

0R/W

0R/W

0R/W

27

Address

(decimal)

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

63

*1 This value is set when the high-speed counter module is powered on or the CPU module is reset.

*2 Whether a value can be read from/written to a program or not is indicated.

*3 Read or write values in 32-bit signed binary. (Be sure to use two words at a time.)

Address

(hexadecimal)

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

3F

R: Readable

W: Writable

Name

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

CH2 Overflow detection 0 R

CH2 Counter function selection 0 R/W

CH2 Sampling/periodic time setting 0 R/W

CH2 Sampling/periodic counter flag 0 R

CH2 Latch count value (L)

CH2 Latch count value (H)

CH2 Sampling count value (L)

CH2 Sampling count value (H)

CH2 Periodic pulse count previous value (L)

CH2 Periodic pulse count previous value (H)

CH2 Periodic pulse count present value (L)

CH2 Periodic pulse count present value (H)

CH2 Ring counter lower limit (L)

CH2 Ring counter lower limit (H)

CH2 Ring counter upper limit (L)

CH2 Ring counter upper limit (H)

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

*3

Initial value

*1

Read/write

0R

0R

0R

0R

0R

0R

0R

0R

0R/W

0R/W

0R/W

0R/W

*2

System area to to

H

● The system areas listed above and the areas not listed above are used by the system and are not available for users. If

data are written by a user, the performance of the high-speed counter module is not guaranteed.

● Buffer memory data in the high-speed counter module are initialized when the high-speed counter module is powered on

or the CPU module is reset. To save the necessary data, read/write the data by executing the FROM/DFRO/TO/DTO

instructions in the program or performing auto refresh to the device data.

28

CHAPTER 4 PROCEDURES BEFORE OPERATION

Start

Module installation

Connect the high-speed counter module.

Wiring

Connect an external device to the high-speed counter module.

Add the model name of the high-speed counter module.

Adding the model name of the intelligent function module

Switch setting

Set a pulse input mode, counting speed, and counter type.

Set an output mode if a CPU stop error occurs and CPU module

operation mode if a high-speed counter module error is detected.

Intelligent function module detailed setting

NO

YES

Use intelligent function module parameters?

Configure the parameter and auto refresh settings.

Parameter setting and auto refresh setting

Programming and debugging

Create and check a program.

CHAPTER 4 PROCEDURES BEFORE OPERATION

This chapter lists the procedures before operation.

( Page 31, Section 5.1)

( Page 35, Section 6.2, Page 47, Section 6.3, Page 49,

Section 6.4)

( Page 53, Section 7.1)

4

( Page 54, Section 7.2)

( Page 55, Section 7.3)

( Page 56, Section 7.4, Page 57, Section 7.5)

( Page 88, CHAPTER 10)

29

Memo

30

CHAPTER 5 SYSTEM CONFIGURATION

Power supply module CPU module

Display unit

(optional)

END cover

Connector

High-speed counter module

CHAPTER 5 SYSTEM CONFIGURATION

This chapter describes the overall configuration, number of connectable modules, and compatible software versions of

the high-speed counter module.

5.1 Overall Configuration

The following figures show examples of system configuration using the high-speed counter module.

(1) When connected to the CPU module

5

5.1 Overall Configuration

31

(2) When connected to the head module

Power supply module END cover

Connector

Head module High-speed counter module

32

CHAPTER 5 SYSTEM CONFIGURATION

5.2 Applicable System

(1) Number of connectable modules

For the number of connectable modules, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

(2) Compatible software versions

For compatible software versions, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

5.2.1 Restrictions when the high-speed counter module is

connected to the head module

5

The restrictions are as follows:

• The coincidence detection interrupt function cannot be used.

• Due to the link scan time, a delay occurs. This delay causes variations if the processing is carried out with

counter values that are input using a program. Thoroughly examine the system to make sure that it will not

cause controllability problem.

5.2.1 Restrictions when the high-speed counter module is connected to the head module

5.2 Applicable System

33

CHAPTER 6 INSTALLATION AND WIRING

This chapter describes installation and wiring of the high-speed counter module.

6.1 Installation Environment and Installation Position

For precautions for installation environment and installation position, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

MELSEC-L CC-Link IE Field Network Head Module User's Manual

34

CHAPTER 6 INSTALLATION AND WIRING

6.2 Wiring

This section describes wiring of encoders and controllers to the high-speed counter module.

6.2.1 Wiring precautions

To obtain the maximum performance from the functions of the high-speed counter module and improve the system

reliability, an external wiring with high durability against noise is required.

Here are some precautions when wiring encoders and controllers.

(1) Wiring

• Different terminals are prepared depending on the voltage of the signal to be input. Connecting to a terminal

with a different voltage may cause malfunction of the module or failure of the connected devices.

• In 1-phase input, always connect a pulse input cable on the A-phase side.

• Install a fuse for each external terminal to prevent the external devices or module from being burnt out or

damaged if a load shorts in an output circuit. The following fuses have been tested by Mitsubishi.

Fuse model name Rated current Contact

312.750 0.75A

216.800 0.8A

Littlefuse KK

www.littelfuse.com

6

(2) Connectors for external devices

• Connectors for external devices must be soldered or crimped properly. A poor soldering or crimping may

result in malfunction.

• Securely connect the connectors for external devices to the connectors of the high-speed counter module,

and securely tighten the two screws.

• When removing a cable from the high-speed counter module, do not pull the cable by the cable part.

Remove a cable supporting the connector part of the cable by hand. Pulling the cable being connected to the

high-speed counter module can cause malfunction. In addition, a damage of the high-speed counter module

or cables can result.

6.2.1 Wiring precautions

6.2 Wiring

35

(3) Measures against noise

Measure 1

Measure 2

Use shielded twisted pair cables.

Use the shortest possible shielded twisted pair cables, placing them not parallel with

noise-generating power cables or I/O cables and at a distance of 150mm or more.

Measure3

Ground the shield cable on the encoder side (relay box). Always ground the FG and LG terminals

to the protective ground conductor.

To A

To B

To the high-speed

counter module

Current for encoder

A

B

24V

E

+24V

0V

E

To the encoder

Connect the shielded cable of the encoder to the shielded

cable of the shielded twisted pair cable in the relay box.

If the shielded wire of the encoder is not grounded,

ground it to the relay box as shown by the dotted lines.

• The high-speed counter module may count pulses incorrectly if pulse-like noise is input.

• For the input of high-speed pulses, take the following measures against noise:

• The following figure shows a wiring example for noise reduction.

High-speed counter module

Inverter

Programmable

controller

Install I/O cables at least

150mm away from

high voltage equipment

such as a relay or

inverter.

(Pay attention to wiring in

the control panel as well.)

Terminal

block

AC motor

Terminal

block

Avoid using a solenoid valve or inductive load together with the cable in a metallic pipe.

If a sufficient distance from the power line cannot be ensured due to duct wiring,

use shielded cables such as CVVS for the power line.

Relay box

Provide the shortest possible distance between the encoder and

relay box.

If the distance from the high-speed counter to the encoder is long,

Cart

Encoder

a voltage drop may occur. Using a measuring instrument such as

a tester on the terminal block of the relay box, check if the voltages

in the encoder operation and stop status are within the rated

voltage range. If a voltage drop is too large, increase the cable size

or use a 24VDC encoder that will consume less current.

• Ground the shielded twisted pair cable on the encoder side (relay box). (Shown here is an example of

wiring to an open collector output type encoder (24VDC).)

36

CHAPTER 6 INSTALLATION AND WIRING

(4) Requirements for compliance with the EMC and Low Voltage Directives

Take the following measures for compliance with the EMC and Low Voltage Directives.

• Install a DC power inside the control panel.

• Use a shielded cable for the DC power when the cable is extended out of the control panel.

• Keep the length of the cables between the high-speed counter module and the external devices to 30m or

less.

• Use a shielded twisted pair cable and ground the shielded part of the cable to the control panel with the

AD75CK-type cable clamping (Mitsubishi).

Inside of control panel

counter module

High-speed

20 to 30cm

AD75CK

For details on the AD75CK, refer to the following.

AD75CK-type Cable Clamping Instruction Manual

6

6.2.1 Wiring precautions

6.2 Wiring

37

• Take the following noise reduction measures when wiring a connector for external devices.

Take off the jacket of each shield and connect

the shields of the cables with conductive tapes.

Cover the wires with

an insulating tape.

Take a shield out from any of the shielded cables,

and solder it to the FG wire.

Coat the connector pins with heatshrinkable insulation

tubes to protect signal lines.

(Exposure of signal lines may cause malfunction

due to static electricity.)

Cover the wires and conductive tape

with a heatshrinkable tube.

[Example of wiring using a shielded cable]

The following figure shows an example of wiring for noise reduction using the A6CON1.

Connector

(A6CON1)

From the controller

Shielded

cable

From the encoder

To the external device

To the high-speed counter module

[Example of noise reduction measures taken to shielded cables]

Assembling the A6CON1

The length between the connector

and shielded cables should be the

shortest possible.

2

Ground the shortest possible FG wire of 2mm

or more.

(Ground it to the panel on the high-speed counter module

side.)

38

6.2.2 Connectors for external devices

(1) Precautions

• Tighten the connector screws within the specified torque range.

Screw Tightening torque range

Connector screw (M2.6) 0.20 to 0.29Nm

• Use copper wires having temperature rating of 75 or more for the connectors.

• Use UL listed connectors if necessary for UL compliance.

(2) Applicable connectors

Connectors for external devices that are applicable to the high-speed counter module need to be obtained by a

user.

The following tables list the applicable connectors, and the reference product of a crimping tool.

CHAPTER 6 INSTALLATION AND WIRING

(a) 40-pin connectors

Type Model Applicable wire size

Soldering type connector

(straight out type)

Crimping type connector

(straight type)

Soldering type connector

(dual purpose (straight/oblique) type)

The A6CON3 (IDC type connector (straight type)) cannot be used.

A6CON1 0.3 (22 AWG) (Stranded)

A6CON2 0.088 to 0.24 (28 to 24 AWG) (stranded wire)

A6CON4 0.3 (22 AWG) (Stranded)

(b) 40-pin connector crimping tool

Type Model Contact

Crimping tool FCN-363T-T005/H

For how to wire the connector and how to use the crimping tool, contact the manufacturer.

FUJITSU COMPONENT LIMITED

www.fcl.fujitsu.com/en

6

6.2 Wiring

6.2.2 Connectors for external devices

39

(3) Wiring method

Connector screw

For wiring method, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

(4) Connection procedure

1. Plugging the connector

Plug the connector into the slot on the high-speed

counter module.

2. Tightening the connector screws

Tighten the two connector screws (M2.6).

40

(5) Removal procedure

1. Removing the connector

Loosen the two connector screws and pull out the

connector from the module.

CHAPTER 6 INSTALLATION AND WIRING

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B09

B08

B07

B06

B05

B04

B03

B02

B01

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A09

A08

A07

A06

A05

A04

A03

A02

A01

6.2.3 Interface with external devices

This section lists the interface of the high-speed counter module with external devices.

(1) Terminal layout and terminal numbers of the connector for external devices

The following figure shows the terminal layout and numbers on the connector for external devices.

6

6.2 Wiring

6.2.3 Interface with external devices

41

(2) LD62 (DC input sink output type)

6.8kΩ

A20,A13

B20,B13

A19,A12

B19,B12

A18,A11

B18,B11

A17,A10

1/3W

3.9kΩ

1/4W

330Ω

1/4W

6.8kΩ

1/3W

3.9kΩ

1/4W

330Ω

1/4W

10kΩ

1/3W

5.6kΩ

1/10W

2kΩ

1/8W

10kΩ

1/3W

5.6kΩ

1/10W

2kΩ

1/8W

1kΩ

1/10W

1kΩ

1/10W

B17,B10

A16,A09

B16,B09

A15,A08

B15,B08

A14,A07

B14,B07

I/O

classification

Internal circuit

Terminal

*1

number

Signal name Operation

CH1 CH2

A20 A13

B20 B13

Phase A pulse input

24V

Phase A pulse input

12V

A19 A12 Phase A pulse input 5V

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 4.5 to 5.5V 2 to 5mA

Off 2V or less 0.1mA or less

Input voltage

(guaranteed

value)

B19 B12 ABCOM

Operating

current

(guaranteed

value)

Input

A18 A11

B18 B11

Phase B pulse input

24V

Phase B pulse input

12V

A17 A10 Phase B pulse input 5V

B17 B10 Preset input 24V

A16 A09 Preset input 12V

B16 B09 Preset input 5V

A15 A08 CTRLCOM

B15 B08 Function start input 24V

A14 A07 Function start input 12V

B14 B07 Function start input 5V

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 4.5 to 5.5V 2 to 5mA

Off 2V or less 0.1mA or less

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 4.5 to 5.5V 2 to 5mA

Off 2V or less 0.1mA or less

Response

time

Off to on

0.5ms or less

On to off

1ms or less

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 4.5 to 5.5V 2 to 5mA

Off 2V or less 0.1mA or less

Response

time

Off to on

0.5ms or less

On to off

1ms or less

42

CHAPTER 6 INSTALLATION AND WIRING

I/O

classification

Output

Terminal

*1

Internal circuit

A06,A05

B06,B05

B02,B01

A02,A01

*1 The terminals A03, A04, B03, and B04 are not assigned.

*2 Coincidence output derating (on ratio) is as follows.

number

CH1 CH2

A06 A05

B06 B05

B02, B01 12/24V • Input voltage: 10.2 to 30V

A02, A01 0V

100

90

80

70

60

50

ON ratio (%)

40

30

010 5550403020

Ambient temperature ( )

Signal name Operation

EQU1

(coincidence output

point No.1)

EQU2

(coincidence output

point No.2)

Input voltage

(guaranteed

value)

• Operating voltage: 10.2 to 30V

• Maximum load current: 0.5A/point,

2A/common

• Maximum voltage drop at on: 1.5V

• Response time

Off to on: 0.1ms or less

On to off: 0.1ms or less (rated load, resistive

load)

• Current consumption: 43mA

(TYP., 24VDC and all points on/common)

• Common to all channels

*2

Operating

current

(guaranteed

value)

6

6.2 Wiring

6.2.3 Interface with external devices

43

(3) LD62D (differential input sink output type)

+5V +5V

27kΩ

1/10W

4.7kΩ

1/10W

100Ω

1/2W

4.7kΩ

1/10W

27kΩ

1/10W

A20,A14

B20,B14

Line

receiver

Digital

isolator

+5V +5V

27kΩ

1/10W

4.7kΩ

1/10W

100Ω

1/2W

4.7kΩ

1/10W

27kΩ

1/10W

A19,A13

B19,B13

Line

receiver

Digital

isolator

1kΩ

1/10W

10kΩ

1/3W

5.6kΩ

1/10W

680Ω

1/10W

A16,A10

B16,B10

A15,A09

B15,B09

Terminal

I/O

classification

Internal circuit

CH1 CH2

number

*1

Signal name Operation

Input voltage

(guaranteed

value)

Operating

current

(guaranteed

value)

Input

1kΩ

1/10W

10kΩ

1/3W

5.6kΩ

1/10W

680Ω

1/10W

A18,A12

B18,B12

A17,A11

B17,B11

A20 A14 Phase A pulse input

B20 B14 Phase A

pulse input

A19 A13 Phase B pulse input

B19 B13 Phase B pulse input

A18 A12 Preset input 24V

B18 B12 Preset input 12V

A17 A11 Preset input 5V

B17 B11 PRSTCOM

A16 A10 Function start input 24V

B16 B10 Function start input 12V

A15 A09 Function start input 5V

B15 B09 FUNCCOM

EIA Standard RS-422-A Line receiver

(AM26C32 (manufactured by Texas

Instruments Incorporated) or equivalent)

The line receiver specifications are as follows:

• VIT + Differential input on voltage

(H level threshold voltage) 0.2V

• VIT - Differential input off voltage

(L level threshold voltage) - 0.2V

• Vhys hysteresis voltage (VIT +- VIT -) 60mV

(Current type line driver cannot be used.)

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 2.5 to 5.5V 2 to 5mA

Off 1V or less 0.1mA or less

Response

time

Off to on

0.5ms or less

On to off

1ms or less

On 21.6 to 26.4V 2 to 5mA

Off 5V or less 0.1mA or less

On 10.8 to 13.2V 2 to 5mA

Off 4V or less 0.1mA or less

On 2.5 to 5.5V 2 to 5mA

Off 1V or less 0.1mA or less

Response

time

Off to on

0.5ms or less

On to off

1ms or less

44

CHAPTER 6 INSTALLATION AND WIRING

A06,A05

B06,B05

B02,B01

A02,A01

I/O

classification

Output

Terminal

*1

Internal circuit

*1 The terminals A03, A04, A07, A08, B03, B04, B07, and B08 are not assigned.

*2 Coincidence output derating (on ratio) is as follows.

number

CH1 CH2

A06 A05

B06 B05

B02, B01 12/24V • Input voltage: 10.2 to 30V

A02, A01 0V

100

90

80

70

60

50

ON ratio (%)

40

30

010 5550403020

Ambient temperature ( )

Signal name Operation

EQU1

(coincidence output

point No.1)

EQU2

(coincidence output

point No.2)

• Operating voltage: 10.2 to 30V

• Maximum load current: 0.5A/point,

2A/common

• Maximum voltage drop at on: 1.5V

• Response time

Off to on: 0.1ms or less

On to off: 0.1ms or less (rated load, resistive

load)

• Current consumption: 43mA

(TYP., 24VDC and all points on/common)

• Common to all channels

Input voltage

(guaranteed

value)

*2

Operating

current

(guaranteed

value)

6

6.2 Wiring

6.2.3 Interface with external devices

45

6.2.4 Connectable encoders

Encoders that can be connected to the high-speed counter module are as follows.

(1) To the LD62

• Open collector output type encoder

• CMOS level voltage output type encoder

(Check that the encoder output voltage meets the specifications of the LD62.)

(2) To the LD62D

• Line driver output type encoder

(Check that the encoder output voltage meets the specifications of the LD62D.)

The following encoder cannot be used with the high-speed counter module.

● TTL level voltage output type encoder

46

CHAPTER 6 INSTALLATION AND WIRING

A20(A13)

24V

B20(B13)

12V

A19(A12)

5V

B19(B12)

ABCOM

Phase A

Shield

OUT

E

+24V

LD62

A18(A11)

24V

B18(B11)

12V

A17(A10)

5V

Phase B

Shield

OUT

E

+24V

0V

+24V

0V

24VDC

External power supply

Shielded twisted pair cable

Shielded twisted pair cable

Encoder

In parentheses, terminal numbers of channel 2 are shown.

24V

ABCOM

LD62

0V

24VDC

External

power supply

OUT

Encoder

+24V

0V

E

Shielded twisted pair cable

Shield

Phase A

24V

ABCOM

LD62

OUT

0V

24VDC

External

power supply

Encoder

+24V

0V

E

Shielded twisted pair cable

Shield

Phase A

Because currents flow in

the same direction in the

shielded twisted pair cable,

canceling effect will be lost

and electromagnetic

induction may occur.

6.3 Examples of Wiring Between the High-Speed Counter

Module and an Encoder

(1) Example of wiring with an open collector output type encoder (24VDC)

6

For the wiring between the RD62 and an encoder, separate the power supply cables and the signal cables. The following

figures show its examples:

● Example of correct wiring

● Example of inappropriate wiring

6.3 Examples of Wiring Between the High-Speed Counter Module and an Encoder

47

(2) Example of wiring with a voltage output type encoder (5VDC)

A20(A13)

24V

B20(B13)

12V

A19(A12)

5V

B19(B12)

ABCOM

Phase A

E

LD62

A18(A11)

24V

B18(B11)

12V

A17(A10)

5V

Phase B

0V

0V

External power supply

E

GND

OUT

+5V

5VDC

GND

OUT

Shielded twisted pair cable

Shielded twisted pair cable

Encoder

Shield

Shield

In parentheses, terminal numbers of channel 2 are shown.

(3) Example of wiring with a line driver (equivalent to AM26LS31) encoder

Encoder

A

A

E

B

B

E

VCCVCC

0V

Phase

A

Phase

B

Digital

isolator

Digital

isolator

LD62D

External power supply

A

A20(A14)

A

B20(B14)

B

A19(A13)

B

B19(B13)

0V

Shielded twisted pair cable

Shield

Shielded twisted pair cable

Shield

In parentheses, terminal numbers of channel 2 are shown.

48

CHAPTER 6 INSTALLATION AND WIRING

A18(A12)

24V

B18(B12)

12V

A17(A11)

5V

B17(B11)

PRSTCOM

Preset

Shield

OUT

E

+12V

ControllerLD62D

Shield

OUT

E

+12V

12VDC

A16(A10)

24V

B16(B10)

12V

A15(A09)

5V

B15(B09)

FUNCCOM

Function start

Shielded twisted pair cable

Shielded twisted pair cable

B17(B10)

24V

A16(A09)

12V

B16(B09)

5V

A15(A08)

CTRLCOM

Preset

Shield

OUT

E

+12V

ControllerLD62

Shield

OUT

E

+12V

12VDC

B15(B08)

24V

A14(A07)

12V

B14(B07)

5V

Function start

Shielded twisted pair cable

Shielded twisted pair cable

In parentheses, terminal numbers of channel 2 are shown.

In parentheses, terminal numbers of channel 2 are shown.

6.4 Examples of Wiring Between a Controller and External

Input Terminals

(1) When the controller (sync load type) has a voltage of 12VDC

6

6.4 Examples of Wiring Between a Controller and External Input Terminals

49

(2) When the controller (source load type) has a voltage of 5VDC

Preset

Function start

24V

B17(B10)

12V

A16(A09)

5V

B16(B09)

CTRLCOM

A15(A08)

24V

B15(B08)

12V

A14(A07)

5V

B14(B07)

ControllerLD62

Shielded twisted pair cable

OUT

GND

Shield

Shielded twisted pair cable

E

OUT

GND

Shield

E

In parentheses, terminal numbers of channel 2 are shown.

5VDC

Preset

Function start

24V

A18(A12)

12V

B18(B12)

5V

A17(A11)

PRSTCOM

B17(B11)

24V

A16(A10)

12V

B16(B10)

5V

A15(A09)

FUNCCOM

B15(B09)

ControllerLD62D

Shielded twisted pair cable

OUT

GND

Shield

Shielded twisted pair cable

E

OUT

GND

Shield

E

In parentheses, terminal numbers of channel 2 are shown.

5VDC

50

(3) When the controller is a line driver type

A18(A12)

24V

B18(B12)

12V

A17(A11)

5V

B17(B11)

PRSTCOM

Preset

Shield

OUT

E

Controller

A16(A10)

24V

B16(B10)

12V

A15(A09)

5V

B15(B09)

FUNCCOM

Function start

Shield

OUT

E

OUT

OUT

Shielded twisted pair cable

Shielded twisted pair cable

LD62D

In parentheses, terminal numbers of channel 2 are shown.

CHAPTER 6 INSTALLATION AND WIRING

6

6.4 Examples of Wiring Between a Controller and External Input Terminals

51

6.5 Examples of Wiring with External Output Terminals

Load

Load

A06(A05)

B06(B05)

A02, A01

B02, B01

EQU1

EQU2

0V

12/24V

10.2 to

30VDC

Fuse*

1

Fuse*

1

LD62, LD62D

In parentheses, terminal numbers of channel 2 are shown.

To use the coincidence output terminal (EQU), an external power supply of 10.2 to 30VDC is required to drive the

internal photocoupler. The following figure shows the wiring example:

(1) For the high-speed counter module (sink output type)

*1 Install a fuse for each external terminal to prevent the external devices or module from being burnt out or damaged if a

load shorts in an output circuit.

52

CHAPTER 7 SETTINGS

This chapter describes how to configure settings of the high-speed counter module.

● After writing the contents of the new module, parameter settings, and auto refresh settings into the CPU module, reset

the CPU module and switch its status as STOP RUN STOP RUN, or turn off and on the power supply to activate

the settings.

● After writing the contents of the switch settings, reset the CPU module or turn off and on the power supply to activate the

settings.

7.1 Adding a Module

Add the model name of the high-speed counter module used for the project.

CHAPTER 7 SETTINGS

(1) How to add a module

Open "New Module".

Project window [Intelligent Function Module] Right-click [New Module...]

Item Description

Module Selection

Mount Position

Title Setting Title Enter a title.

Module Type Select "Counter Module".

Module Name Select the model name of the module to be connected.

Mounted Slot No. Select the number of the slot where the module is mounted.

Specify start XY

address

7

7.1 Adding a Module

The start I/O number (hexadecimal) of the module mounted on the slot set to

"Mounted Slot No." is displayed. This item can be set by user.

53

7.2 Switch Setting

Set a pulse input mode, counting speed, and counter type for each channel.

(1) Setting method

Open "Switch Setting".

Project window [Intelligent Function Module] Model name [Switch Setting]

Item Description Setting value

Pulse input mode Select a pulse input mode for each channel.

Select a counting speed for each channel.

Counting speed setting

Counter format Select a counter type for each channel.

500kpps can be selected for the LD62D

only.

• 1-Phase Multiple of 1 (default)

• 1-Phase Multiple of 2

• CW/CCW

• 2-Phase Multiple of 1