Page 1

MELSEC-L CPU Module User's Manual

(Function Explanation, Program Fundamentals)

-L02SCPU

-L02SCPU-P

-L02CPU

-L02CPU-P

-L06CPU

-L06CPU-P

-L26CPU

-L26CPU-P

-L26CPU-BT

-L26CPU-PBT

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

1

Page 4

[Design Precautions]

WARNING

● Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable controller.

Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Emergency stop circuits, protection circuits, and protective interlock circuits for conflicting

operations (such as forward/reverse rotations or upper/lower limit positioning) must be configured

external to the programmable controller.

(2) Machine OPR (Original Point Return) of the positioning function is controlled by two kinds of data:

an OPR direction and an OPR speed. Deceleration starts when the near-point dog signal turns on.

If an incorrect OPR direction is set, motion control may continue without deceleration. To prevent

machine damage caused by this, configure an interlock circuit external to the programmable

controller.

(3) When the CPU module detects an error during control by the positioning function, the motion

slows down and stops.

(4) When the programmable controller detects an abnormal condition, it stops the operation and all

outputs are:

• Turned off if the overcurrent or overvoltage protection of the power supply module is activated.

• Held or turned off according to the parameter setting if the self-diagnostic function of the CPU

module detects an error such as a watchdog timer error.

(5) All outputs may be turned on if an error occurs in a part, such as an I/O control part, where the

CPU module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to "General Safety Requirements" in the MELSEC-L CPU Module User's Manual

(Hardware Design, Maintenance and Inspection).

(6) Outputs may remain on or off due to a failure of a component such as a transistor in an output

circuit. Configure an external circuit for monitoring output signals that could cause a serious

accident.

● In an output circuit, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

● Configure a circuit so that the programmable controller is turned on first and then the external power

supply. If the external power supply is turned on first, an accident may occur due to an incorrect output

or malfunction.

● Configure a circuit so that the external power supply is turned off first and then the programmable

controller. If the programmable controller is turned off first, an accident may occur due to an incorrect

output or malfunction.

● For the operating status of each station after a communication failure, refer to relevant manuals for

each network. Incorrect output or malfunction due to a communication failure may result in an

accident.

2

Page 5

WARNING

● When changing data from a peripheral connected to the CPU module to the running programmable

controller, configure an interlock circuit in the program to ensure that the entire system will always

operate safely. For other forms of control (such as program modification or operating status change)

of a running programmable controller, read the relevant manuals carefully and ensure that the

operation is safe before proceeding. Especially, when a remote programmable controller is controlled

by an external device, immediate action cannot be taken if a problem occurs in the programmable

controller due to a communication failure. To prevent this, configure an interlock circuit in the program,

and determine corrective actions to be taken between the external device and CPU module in case of

a communication failure.

● An absolute position restoration by the positioning function may turn off the servo-on signal (servo off)

for approximately 20ms, and the motor may run unexpectedly. If this causes a problem, provide an

electromagnetic brake to lock the motor during absolute position restoration.

[Design Precautions]

CAUTION

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Keep a distance of 100mm or more between them. Failure to do so may result in malfunction

due to noise.

● During control of an inductive load such as a lamp, heater, or solenoid valve, a large current

(approximately ten times greater than normal) may flow when the output is turned from off to on.

Therefore, use a module that has a sufficient current rating.

● After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size. Design circuits so

that the entire system will always operate safely, regardless of the time.

[Installation Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may result in electric shock or cause the module to fail or malfunction.

3

Page 6

[Installation Precautions]

CAUTION

● Use the programmable controller in an environment that meets the general specifications in the

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection). Failure to

do so may result in electric shock, fire, malfunction, or damage to or deterioration of the product.

● To interconnect modules, engage the respective connectors and securely lock the module joint levers

until they click. Incorrect interconnection may cause malfunction, failure, or drop of the module.

● Do not directly touch any conductive parts and electronic components of the module. Doing so can

cause malfunction or failure of the module.

● Securely connect an extension cable to the connectors of a branch module and an extension module.

After connections, check that the cable is inserted completely. Poor contact may cause malfunction.

● When using an SD memory card, fully insert it into the SD memory card slot. Check that it is inserted

completely. Poor contact may cause malfunction.

● Do not directly touch any conductive parts and electronic components of the module or SD memory

card. Doing so can cause malfunction or failure of the module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or cause the module to fail or malfunction.

● After installation and wiring, attach the included terminal cover to the module before turning it on for

operation. Failure to do so may result in electric shock.

4

Page 7

[Wiring Precautions]

CAUTION

● Individually ground the FG terminal of the programmable controller with a ground resistance of 100

or less. Failure to do so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range.

If any spade solderless terminal is used, it may be disconnected when a terminal block screw comes

loose, resulting in failure.

● Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly. Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire

or failure.

● Connectors for external devices must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered. Incomplete connections may cause short circuit, fire, or

malfunction.

● Securely connect the connector to the module.

● Do not install the control lines or communication cables together with the main circuit lines or power

cables. Failure to do so may result in malfunction due to noise.

● Place the cables in a duct or clamp them. If not, dangling cable may swing or inadvertently be pulled,

resulting in damage to the module or cables or malfunction due to poor contact.

● Check the interface type and correctly connect the cable. Incorrect wiring (connecting the cable to an

incorrect interface) may cause failure of the module and external device.

● Tighten the terminal block screws within the specified torque range. Undertightening can cause short

circuit, fire, or malfunction. Overtightening can damage the screw and/or module, resulting in drop,

short circuit, fire, or malfunction.

● When disconnecting the cable from the module, do not pull the cable by the cable part. For the cable

with connector, hold the connector part of the cable. For the cable connected to the terminal block,

loosen the terminal screw. Pulling the cable connected to the module may result in malfunction or

damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the module. Such foreign matter can

cause a fire, failure, or malfunction.

● A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not remove the film during wiring. Remove it for heat

dissipation before system operation.

● To use the high-speed counter function, ground the shield cable on the encoder side (relay box).

Always ground the FG and LG terminals to the protective ground conductor. Failure to do so may

cause malfunction.

● Mitsubishi programmable controllers must be installed in control panels. Connect the main power

supply to the power supply module in the control panel through a relay terminal block.

Wiring and replacement of a power supply module must be performed by qualified maintenance

personnel with knowledge of protection against electric shock.

For wiring methods, refer to the MELSEC-L CPU Module User's Manual (Hardware Design,

Maintenance and Inspection).

5

Page 8

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Correctly connect the battery connector. Do not charge, disassemble, heat, short-circuit, solder, or

throw the battery into the fire. Also, do not expose it to liquid or strong shock.

Doing so will cause the battery to produce heat, explode, ignite, or leak, resulting in injury and fire.

● Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal block screws or connector screws. Failure to do so may result in electric

shock.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operating

status change) for the running CPU module from the peripheral connected, read relevant manuals

carefully and ensure the safety. Improper operation may damage machines or cause accidents.

● Do not disassemble or modify the module. Doing so may cause failure, malfunction, injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the programmable controller. Failure to do so

may cause malfunction.

● Shut off the external power supply (all phases) used in the system before mounting or removing a

module. Failure to do so may cause the module to fail or malfunction.

● Tighten the terminal block screws or connector screws within the specified torque range.

Undertightening can cause drop of the component or wire, short circuit, or malfunction. Overtightening

can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

● After the first use of the product (module, display unit, and terminal block), the number of

connections/disconnections is limited to 50 times (in accordance with IEC 61131-2). Exceeding the

limit may cause malfunction.

● After the first use of the SD memory card, do not insert/remove the memory card more than 500 times.

Exceeding the limit may cause malfunction.

● Do not drop or apply shock to the battery to be installed in the module. Doing so may damage the

battery, causing the battery fluid to leak inside the battery. If the battery is dropped or any shock is

applied to it, dispose of it without using.

● Before handling the module, touch a conducting object such as a grounded metal to discharge the

static electricity from the human body. Failure to do so may cause the module to fail or malfunction.

● Before testing the operation by the positioning function, set a low speed value for the speed limit

parameter so that the operation can be stopped immediately upon occurrence of a hazardous

condition.

6

Page 9

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations. (For details on battery regulations in EU

member states, refer to the MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance

and Inspection).)

[Transportation Precautions]

CAUTION

● When transporting lithium batteries, follow the transportation regulations. (For details on the regulated

models, refer to the MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection).)

7

Page 10

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

8

Page 11

INTRODUCTION

Remark

Thank you for purchasing the Mitsubishi Electric MELSEC-L series programmable controllers.

This manual describes the memory maps, functions, and devices of the CPU module, and programming.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-L series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to an actual system, ensure the applicability and

confirm that it will not cause system control problems.

Relevant CPU modules

CPU module Model

LCPU

This manual does not describe the details of the instructions, error codes, special relay (SM), and special register (SD).

● For the instructions, refer to the following.

MELSEC-Q/L Programming Manual (Common Instruction)

● For the error codes, special relay(SM), and special register (SD), refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

L02SCPU, L02SCPU-P, L02CPU, L02CPU-P, L06CPU, L06CPU-P, L26CPU, L26CPU-P,

L26CPU-BT, L26CPU-PBT

9

Page 12

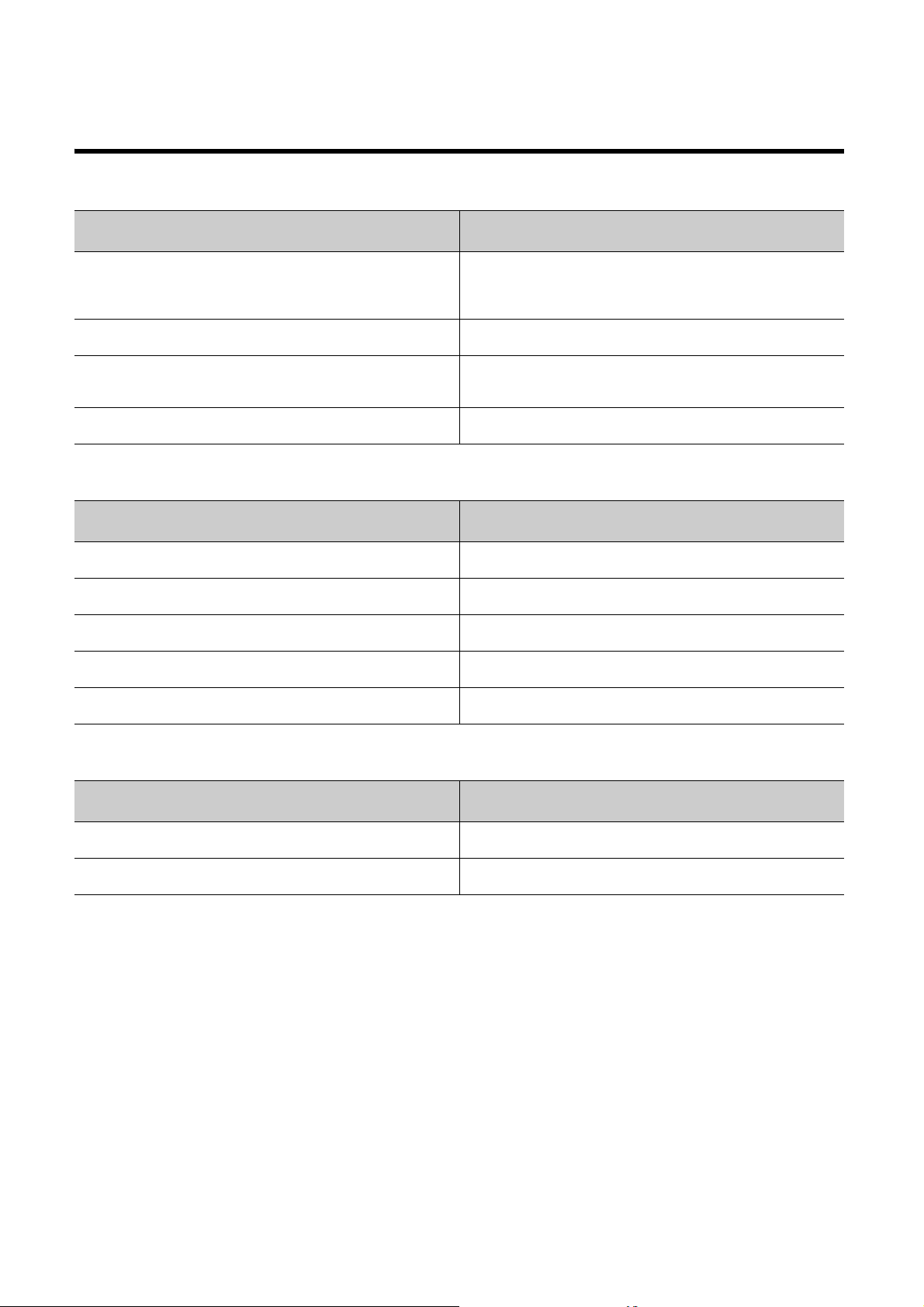

RELEVANT MANUALS

(1) CPU module user's manual

Manual name

<manual number (model code)>

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and

Inspection)

<SH-080890ENG, 13JZ36>

MELSEC-L CPU Module User's Manual (Built-In Ethernet Function)

<SH-080891ENG, 13JZ37>

MELSEC-L CPU Module User's Manual (Built-In I/O Function)

<SH-080892ENG, 13JZ38>

QnUDVCPU/LCPU User's Manual (Data Logging Function)

<SH-080893ENG, 13JZ39>

(2) Programming manual

Manual name

<manual number (model code)>

MELSEC-Q/L Programming Manual (Common Instruction)

<SH-080809ENG, 13JW10>

MELSEC-Q/L/QnA Programming Manual (SFC)

<SH-080041, 13JF60>

MELSEC-Q/L Programming Manual (MELSAP-L)

<SH-080076, 13JF61>

MELSEC-Q/L Programming Manual (Structured Text)

<SH-080366E, 13JF68>

MELSEC-Q/L/QnA Programming Manual (PID Control Instructions)

<SH-080040, 13JF59>

Description

Specifications of the CPU modules, power supply modules, display unit,

branch module, extension module, SD memory cards, and batteries,

information on how to establish a system, maintenance and inspection, and

troubleshooting

The built-in Ethernet function of the CPU module

The general-purpose I/O function, interrupt input function, pulse catch

function, positioning function, and high-speed counter function of the CPU

module

The data logging function of the CPU module

Description

Detailed description and usage of instructions used in programs

System configuration, specifications, functions, programming, and error codes

for SFC (MELSAP3) programs

System configuration, specifications, functions, programming, and error codes

for SFC (MELSAP-L) programs

System configuration and programming using structured text language

Dedicated instructions for PID control

(3) Operating manual

Manual name

<manual number (model code)>

GX Works2 Version 1 Operating Manual (Common)

GX Developer Version 8 Operating Manual

<SH-080779ENG, 13JU63>

<SH-080373E, 13JU41>

Description

System configuration, parameter settings, and online operations of GX

Works2, which are common to Simple projects and Structured projects

Operating methods of GX Developer, such as programming, printing,

monitoring, and debugging

10

Page 13

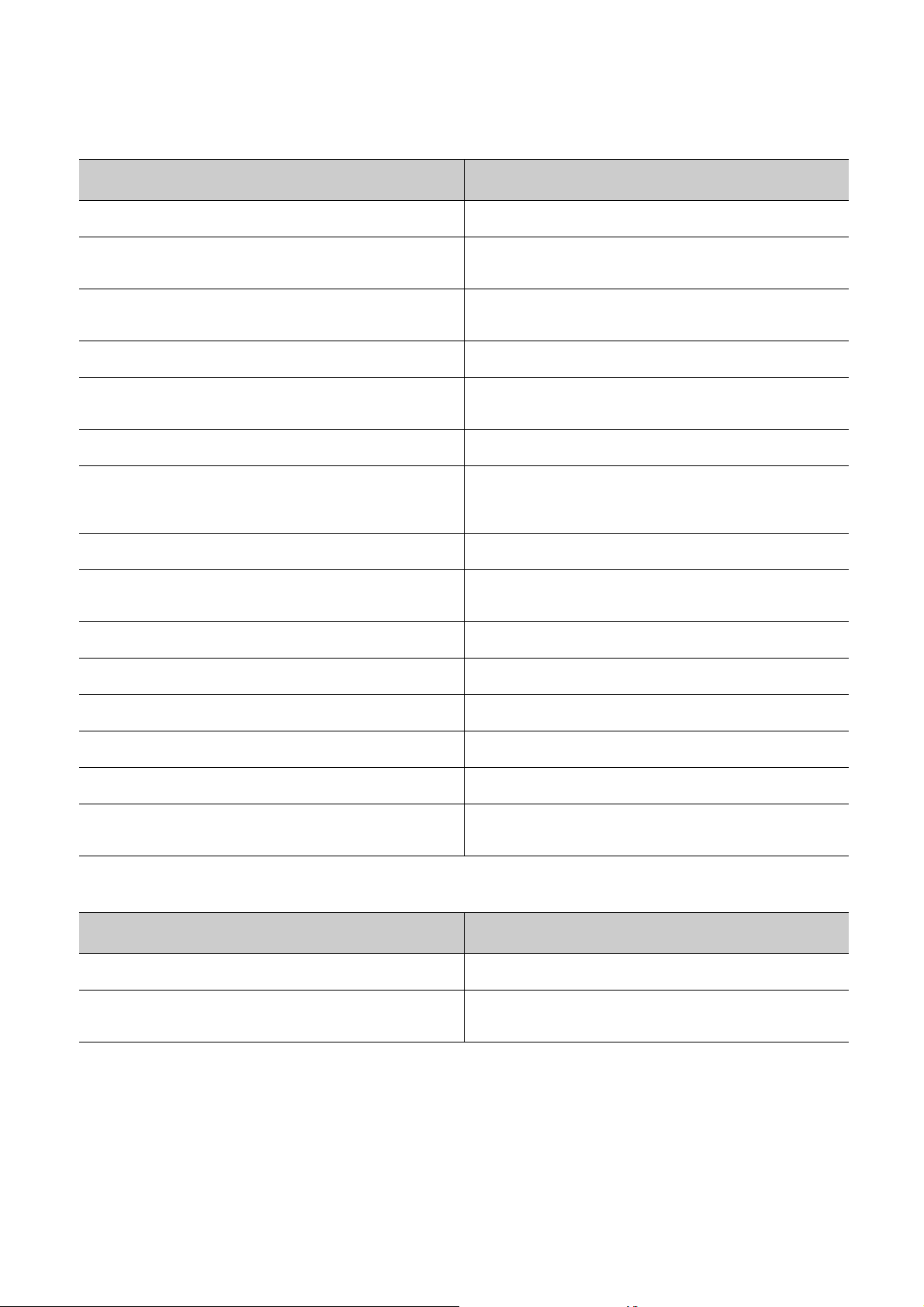

(4) I/O module and intelligent function module manual

Manual name

<manual number (model code)>

MELSEC-L I/O Module User's Manual

<SH-080888ENG, 13JZ34>

MELSEC-L Ethernet Interface Module User's Manual (Basic)

<SH-081105ENG, 13JZ73>

MELSEC-L Serial Communication Module User’s Manual (Basic)

<SH-080894ENG, 13JZ40>

MELSEC Communication Protocol Reference Manual

<SH-080008, 13JF89>

MELSEC-L CC-Link System Master/Local Module User's Manual

<SH-080895ENG, 13JZ41>

MELSEC-L CC-Link/LT Master Module User's Manual

<SH-081012ENG, 13JZ65>

MELSEC-L CC-Link IE Field Network Master/Local Module User's Manual

<SH-080972ENG, 13JZ54>

MELSEC-L Analog-Digital Converter Module User's Manual

<SH-080899ENG, 13JZ42>

MELSEC-L Dual Channel Isolated High Resolution Analog-Digital Converter

Module User's Manual

<SH-081103ENG, 13JZ72>

MELSEC-L Digital-Analog Converter Module User's Manual

<SH-080900ENG, 13JZ43>

MELSEC-L Analog Input/Output Module User's Manual

<SH-081167ENG, 13JZ87>

MELSEC-L LD75P/LD75D Positioning Module User's Manual

<SH-080911ENG, 13JZ46>

MELSEC-L High-Speed Counter Module User's Manual

<SH-080920ENG, 13JZ49>

MELSEC-L Temperature Control Module User's Manual

<SH-081000ENG, 13JZ64>

MELSEC-L Multiple Input (Voltage/Current/Temperature) Module User's

Manual

<SH-081365ENG, 13JZ76>

Specifications and troubleshooting of the I/O module

Specifications, procedures for data communication with external devices, line

connection (open/close), fixed buffer communication, random access buffer

communication, and troubleshooting of the Ethernet module

System configuration, specifications, procedures before operation, data

communication methods (basic), and troubleshooting of the serial

communication module

Details of MELSEC communication protocol (MC protocol) that is used for

data communication between a target device and a CPU module

Settings, specifications, handling, data communication methods, and

troubleshooting of the built-in CC-Link function of the CPU module or the CCLink system master/local module

Settings, specifications, handling, data communication methods, and

troubleshooting of the CC-Link/LT master module

Overview of CC-Link IE Field Network, and specifications, procedures before

operation, system configuration, installation, wiring, settings, functions,

programming, and troubleshooting of the MELSEC-L series CC-Link IE Field

Network master/local module

System configuration, specifications, settings, and troubleshooting of the

analog-digital converter module

System configuration, specifications, settings, and troubleshooting of the dual

channel isolated high resolution analog-digital converter module

System configuration, specifications, settings, and troubleshooting of the

digital-analog converter module

System configuration, specifications, settings, and troubleshooting of the

analog input/output module

System configuration specifications settings and troubleshooting of the

positioning module

System configuration specifications settings and troubleshooting of the highspeed counter module

System configuration specifications settings and troubleshooting of the

temperature control module

System configuration, specifications, settings, and troubleshooting of the

multiple input module

Description

(5) Others

Manual name

<manual number (model code)>

iQ Sensor Solution Reference Manual

CC-Link IE Field Network Basic Reference Manual

<SH-081133ENG, 13JV28>

<SH-081684ENG, 13JX62>

Description

Operating methods of iQ Sensor Solution, such as programming and

monitoring

Specifications, procedures before operation, system configuration,

programming, functions, parameter settings, and troubleshooting of CC-Link

IE Field Network Basic

11

Page 14

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PART 1 PROGRAMMING

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING 20

1.1 System Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.2 Creating a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.3 Creating a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.3.1 Prior knowledge for creating a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

1.3.2 How to create a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1.4 Converting a Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

1.5 Writing a Project to the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1.5.1 Formatting a memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

1.5.2 Writing to the CPU module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

1.6 Checking an Operation of the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

1.7 Saving a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

CHAPTER 2 APPLICATION OF PROGRAMMING 31

2.1 Memory and Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.1 Memory configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.1.2 Parameter-valid drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.1.3 Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2.2 I/O Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.2.1 Concept of I/O number assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2.2.2 I/O number assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

2.3 Scan Time Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.3.1 Initial processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

2.3.2 Refresh processing of input/output modules or intelligent function modules . . . . . . . . . . . . . .46

2.3.3 Program operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

2.3.4 END processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

2.4 Operation Processing of the CPU Module for Each Operating Status . . . . . . . . . . . . . . . . . . . 48

2.5 Operation Processing During Momentary Power Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.6 Processing of Inputs and Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.6.1 Refresh processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

2.6.2 Direct processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

2.7 Interrupt Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.8 Executing Multiple Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.8.1 Initial execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

2.8.2 Scan execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

2.8.3 Standby type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

12

Page 15

2.8.4 Fixed scan execution type program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

2.8.5 Changing the program execution type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

2.9 Boot Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

2.10 Programming Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

2.11 Communications with Intelligent Function Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

PART 2 FUNCTIONS

CHAPTER 3 CPU MODULE FUNCTIONS 82

3.1 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3.2 Constant Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

3.3 Watchdog Timer (WDT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

3.4 Latch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

3.5 Initial Device Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.6 Service Processing Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

3.7 Output Mode at Operating Status Change (STOP to RUN) . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.8 Input Response Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

3.9 Error Time Output Mode Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.10 PLC Operation Mode at H/W Error Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.11 Security Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.11.1 File Password 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

3.11.2 Remote Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

3.12 Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.12.1 Remote RUN/STOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

3.12.2 Remote PAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

3.12.3 Remote RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

3.12.4 Remote Latch Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

3.13 Scan Time Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

3.14 Program List Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

3.15 Interrupt Program List Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

3.16 Monitor condition setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

3.17 Local Device Monitor/Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

3.18 External Input/Output Forced On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.19 Executional Conditioned Device Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.20 Sampling Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

3.21 Realtime Monitor Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

3.22 Writing Programs in RUN Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

3.22.1 Online change (ladder mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

3.22.2 Online change (files) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

3.22.3 Precautions for online change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

3.23 Debug from Multiple Programming Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

3.23.1 Simultaneous monitoring from multiple programming tools . . . . . . . . . . . . . . . . . . . . . . . . . .159

3.23.2 Online change from multiple programming tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .160

3.24 Self-Diagnostic Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

13

Page 16

3.25 Error Clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

3.26 LED Control Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

3.26.1 Methods for turning off the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

3.26.2 LED indication priority . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

3.27 Module Error Collection Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

3.28 Latch Data Backup to Standard ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

3.28.1 Latch data backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .176

3.28.2 Restoring backup data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

3.29 Writing/Reading Device Data to/from Standard ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

3.30 Module Model Name Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

3.31 CPU Module Change Function with SD Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

3.31.1 Backup to SD memory card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

3.31.2 Backup data restoration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .192

3.32 Clock Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

3.33 Battery Life-Prolonging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

3.34 Memory Check Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

3.35 Program Cache Memory Auto Recovery Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

3.36 Project Data Batch Save/Load Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

3.36.1 Batch save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .203

3.36.2 Batch load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

3.37 Predefined Protocol Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

3.37.1 Communications via Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

3.37.2 Communications via RS-232 and RS-422/485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216

3.38 Serial Communication Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

3.39 iQ Sensor Solution Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

CHAPTER 4 DISPLAY UNIT FUNCTIONS 236

4.1 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

4.2 CPU Monitor/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

4.2.1 Device monitor/test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .241

4.2.2 Device clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .249

4.2.3 Forced on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .251

4.2.4 Scan time monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .254

4.2.5 Built-in I/O function monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .255

4.2.6 Error display/clear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259

4.3 CPU Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

4.3.1 Clock setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .263

4.4 Module Monitor/Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

4.4.1 Buffer memory monitor/test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .265

4.5 Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

4.5.1 Initial setting change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .270

4.6 User Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

4.7 Memory Card Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

4.7.1 File list/delete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .274

4.7.2 Free space display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .279

4.7.3 Batch save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .280

14

Page 17

4.7.4 Batch load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .281

4.8 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

4.8.1 Language setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .283

4.8.2 Contrast adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .284

4.8.3 Lighting period setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .285

4.8.4 Pop-up display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .286

PART 3 DEVICES, CONSTANTS

CHAPTER 5 DEVICES 288

5.1 Device List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

5.2 Internal User Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

5.2.1 Input (X) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

5.2.2 Output (Y). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .293

5.2.3 Internal relay (M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

5.2.4 Latch relay (L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

5.2.5 Link relay (B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .294

5.2.6 Annunciator (F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .295

5.2.7 Link special relay (SB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

5.2.8 Edge relay (V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .298

5.2.9 Step relay (S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .299

5.2.10 Timer (T, ST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .299

5.2.11 Counter (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

5.2.12 Data register (D). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .311

5.2.13 Link register (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .312

5.2.14 Link special register (SW) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

5.3 Internal System Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

5.3.1 Function devices (FX, FY, FD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .314

5.3.2 Special relay (SM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .316

5.3.3 Special register (SD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .316

5.4 Link Direct Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

5.5 Module Access Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

5.5.1 Intelligent function module device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .320

5.6 Index Register/Standard Device Register (Z). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

5.6.1 Index Register (Z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .322

5.6.2 Standard device register (Z). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .323

5.6.3 Saving and restoration of the index register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .324

5.7 File Register (R, ZR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

5.8 Extended Data Register (D) and Extended Link Register (W) . . . . . . . . . . . . . . . . . . . . . . . . 330

5.9 Nesting (N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

5.10 Pointer (P). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

5.10.1 Local pointer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .337

5.10.2 Common pointer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .338

5.11 Interrupt Pointer (I) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

5.12 Other Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

15

Page 18

5.12.1 SFC block device (BL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .340

5.12.2 I/O No. specification device (U) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .340

5.12.3 Macro instruction argument device (VD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .341

CHAPTER 6 CONSTANTS 342

6.1 Decimal Constant (K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

6.2 Hexadecimal Constant (H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 342

6.3 Real Number (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

6.4 Character String (" "). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 343

CHAPTER 7 CONVENIENT USAGE OF DEVICES 344

7.1 Global Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 344

7.2 Local Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 345

APPENDICES 350

Appendix 1 Parameter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350

Appendix 1.1 List of parameter numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .350

Appendix 1.2 PLC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .353

Appendix 1.3 Network parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .374

Appendix 1.4 Remote password setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .375

Appendix 2 Added and Changed Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376

Appendix 3 CPU Module Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378

Appendix 3.1 Time required for each processing in a scan time . . . . . . . . . . . . . . . . . . . . . . . . . . .378

Appendix 3.2 Factors that increase the scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .385

Appendix 3.3 Realtime monitor function processing time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .388

Appendix 4 Data Used in the CPU Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 389

Appendix 5 Character Codes Available in the Display Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 391

Appendix 6 Differences Between LCPU and QnUCPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 403

Appendix 6.1 Specifications comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .403

Appendix 6.2 Precautions for utilizing programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .404

Appendix 7 Precautions for Using GX Works2 and Differences with GX Developer . . . . . . . . . . . . 405

Appendix 8 Device Point Assignment Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 406

INDEX 407

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 410

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 413

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 414

16

Page 19

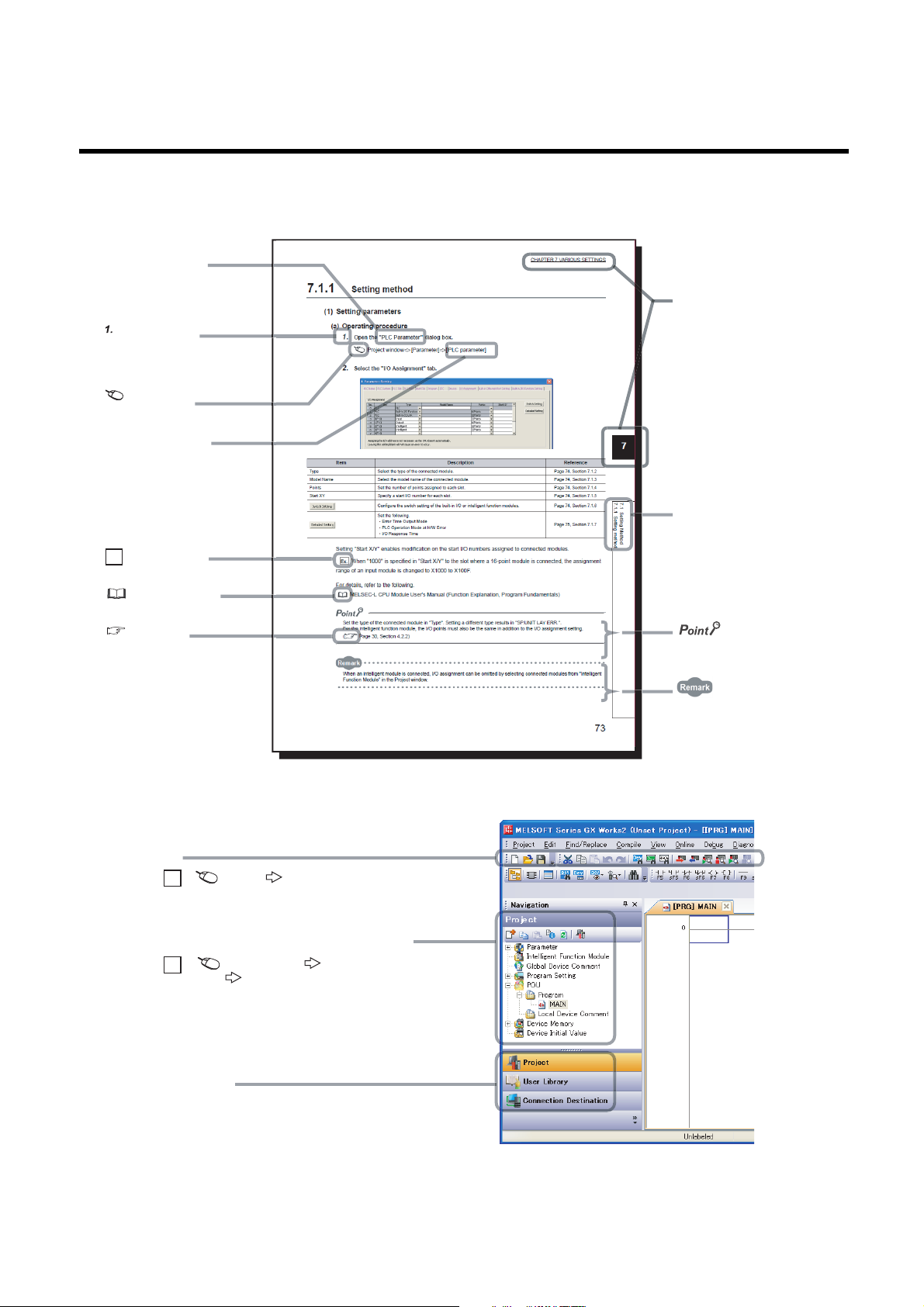

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

*1 The mouse operation example (for GX Works2) is provided below.

17

Page 20

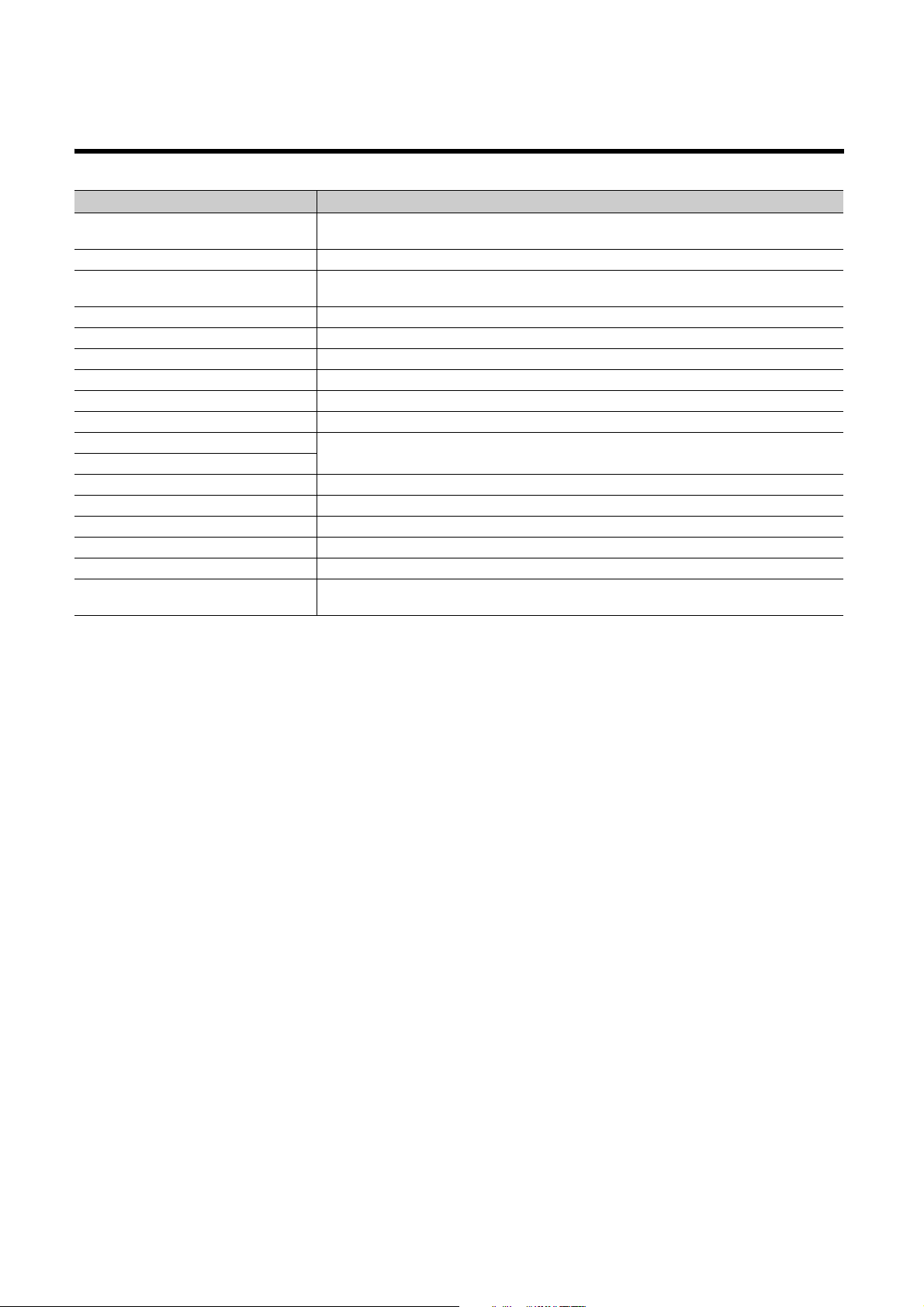

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

Battery

Branch module The abbreviation for the MELSEC-L series branch module

Built-in Ethernet port LCPU

CPU module The abbreviation for the MELSEC-L series CPU module

Display unit A liquid crystal display to be attached to the CPU module

END cover A cover to be attached to the right side of the rightmost MELSEC-L series module

Extension block A block where an extension module is connected in an extension system

Extension cable The abbreviation for the MELSEC-L series extension cable

Extension module The abbreviation for the MELSEC-L series extension module

GX Works2

GX Developer

LCPU Another term for the MELSEC-L series CPU module

Main block A block where a CPU module is connected in an extension system

Power supply module The abbreviation for the MELSEC-L series power supply module

Programming tool A generic term for GX Works2 and GX Developer

QnUCPU Another term for the MELSEC-Q series Universal model QCPU

SD memory card

A battery to be installed in the CPU module and used for backing up data such as the standard RAM data

and latch device data in case of power failure. The Q6BAT and Q7BAT are available.

A generic term for the L02CPU, L02CPU-P, L06CPU, L06CPU-P, L26CPU, L26CPU-P, L26CPU-BT, and

L26CPU-PBT

The product name of the software package for the MELSEC programmable controllers

Secure Digital Memory Card, which is a flash memory device. The NZ1MEM-2GBSD, NZ1MEM-4GBSD,

NZ1MEM-8GBSD, NZ1MEM-16GBSD, L1MEM-2GBSD, and L1MEM-4GBSD are available.

18

Page 21

PART 1 PROGRAMMING

In this part, fundamental knowledge of programming is described.

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . 19

CHAPTER 2 APPLICATION OF PROGRAMMING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

19

Page 22

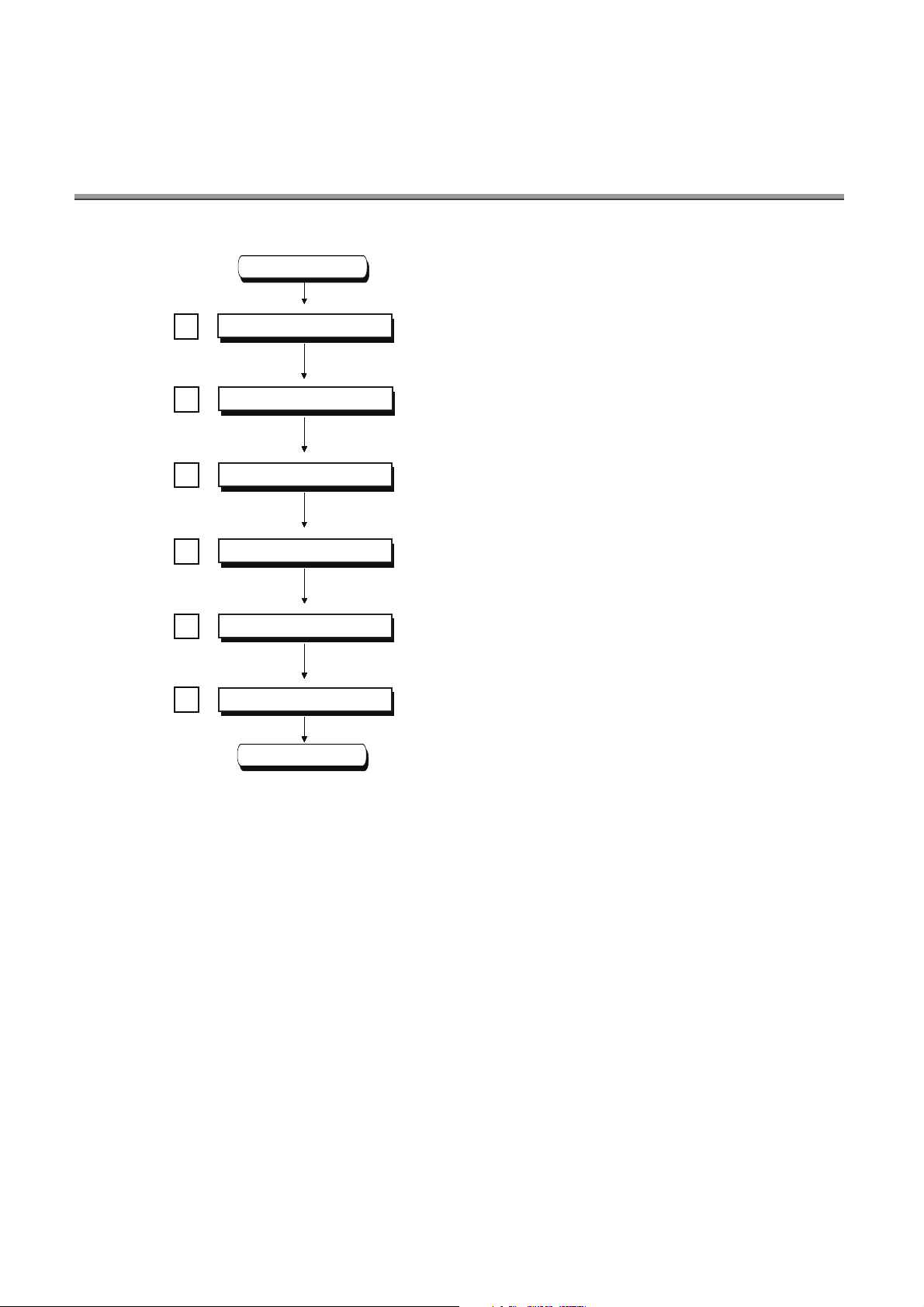

CHAPTER 1 BASIC PROCEDURE FOR

Creating projects

Creating programs

Converting programs

Writing projects

Checking operations

PROGRAMMING

This chapter describes the basic procedure for programming.

Start

Check column

Create projects with GX Works2.

( Page 22, Section 1.2)

Create programs.

( Page 23, Section 1.3)

Convert created programs into ones that can be processed by

the CPU module.

( Page 25, Section 1.4)

Write the projects to the CPU module.

For the first use of the CPU module, format the used memory

beforehand.

( Page 26, Section 1.5)

Debug the programs using the monitoring function.

( Page 28, Section 1.6)

Saving projects

End

Save the projects.

( Page 30, Section 1.7)

20

Page 23

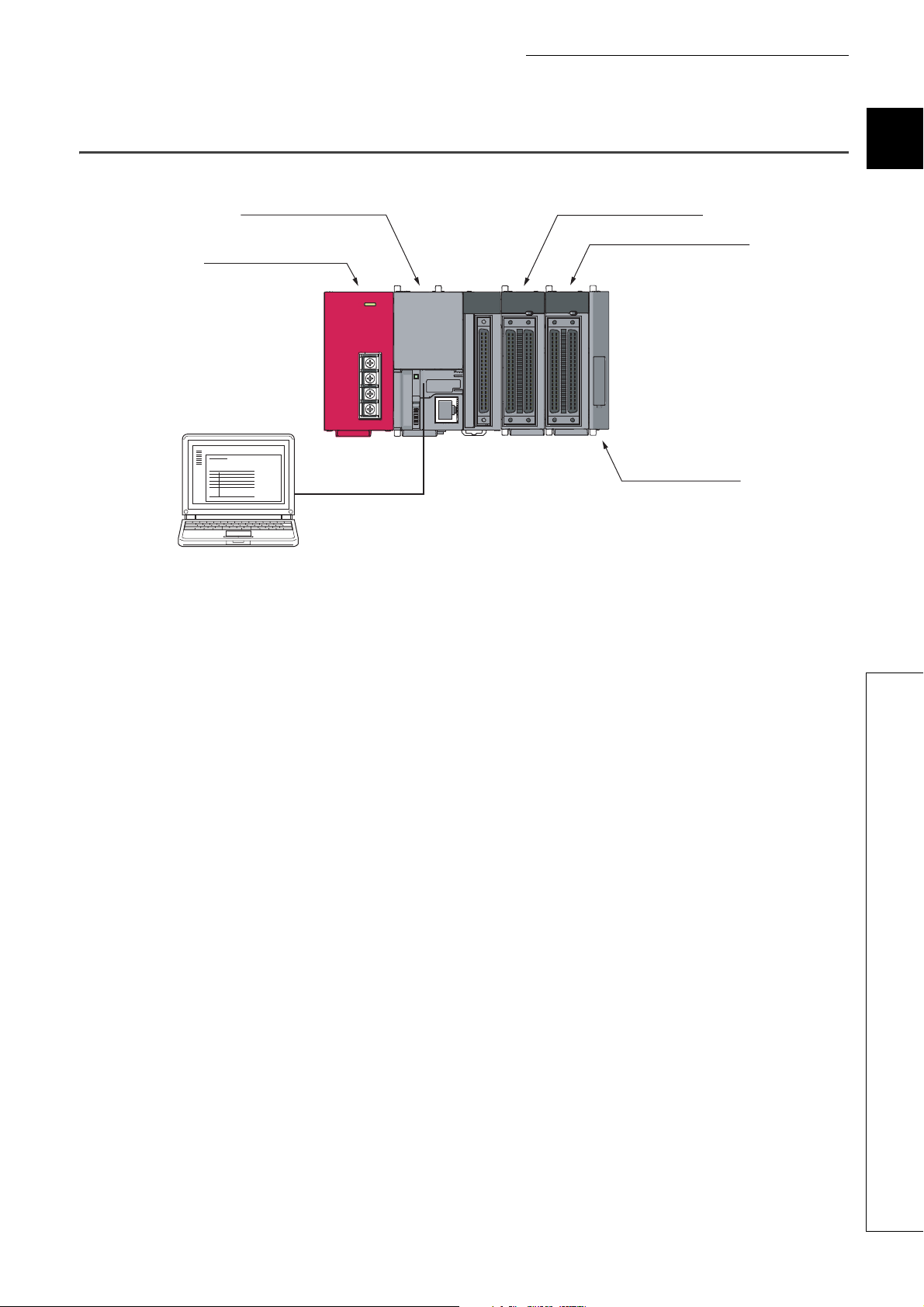

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING

CPU module (L02CPU)

Power supply module (L61P)

GX Works2

Input module (LX42C4)

Output module (LY42NT1P)

END cover (L6EC)

USB connection

1.1 System Configuration Example

The following system configuration is used for description throughout this chapter.

*1 Wiring of the power supply module and I/O modules are omitted in this illustration.

1

1.1 System Configuration Example

21

Page 24

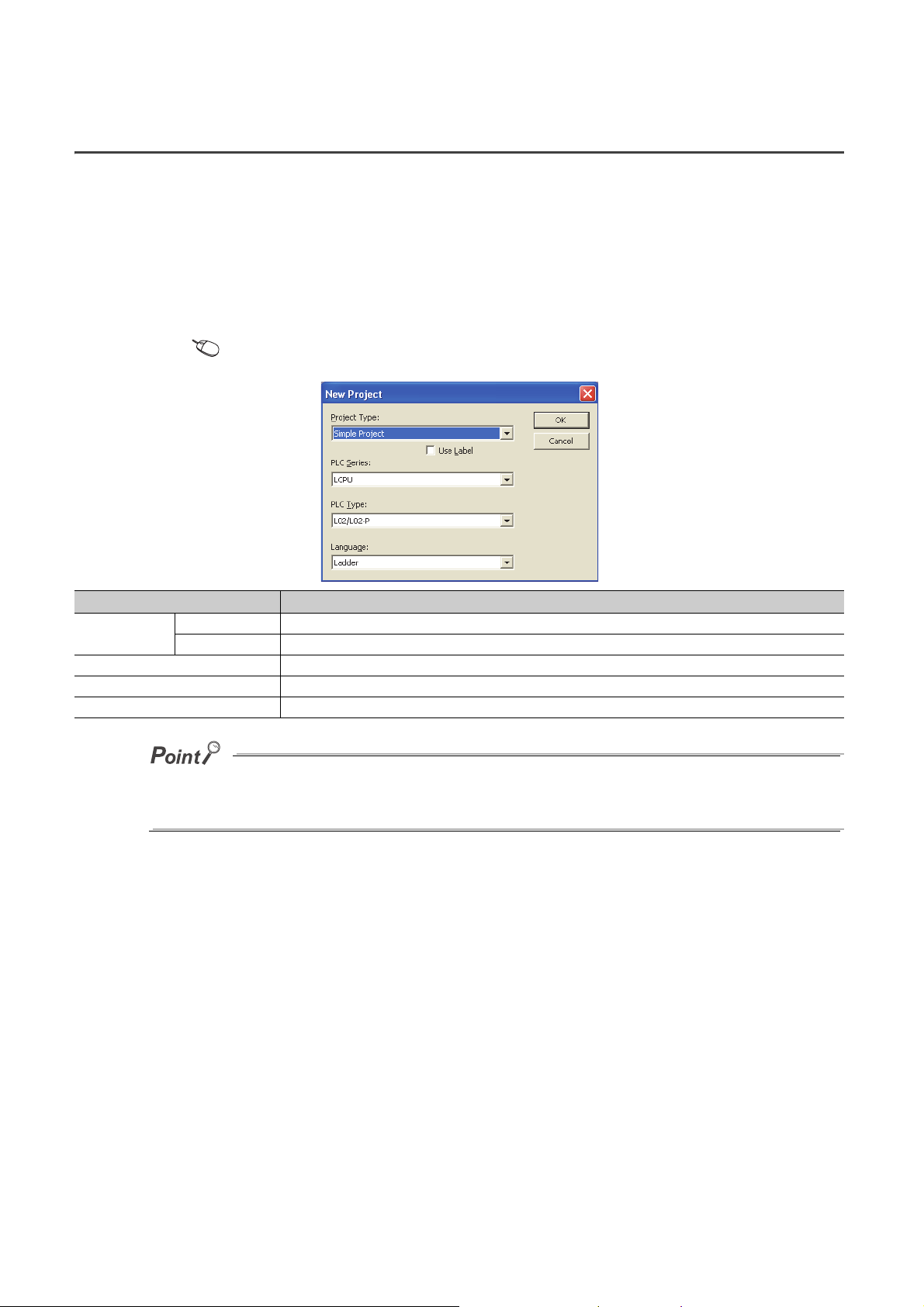

1.2 Creating a Project

A project is a set of information, such as programs and parameters, which is necessary to operate a programmable

controller.

The following two projects are available.

• Simple project

• Structured project

Create a new project using GX Works2.

[Project] [New...]

Item Description

Project Type

PLC Series Select a series of the CPU module to use in the project. In this chapter, "LCPU" is selected.

PLC Type Select a type of the CPU module (CPU module model) to use in the project. In this chapter, "L02/L02-P" is selected.

Language Select a language of the program data to use for the new project. In this chapter, "Ladder" is selected.

When performing communication between a programming tool and a CPU module through GOT or a network module, check

the PLC type because the modules could be connected with wrong model names. If the modules are connected with wrong

model names, data may not be written or read properly.

Select a type of project to create. In this chapter, "Simple Project" is selected.

Use Label Select this checkbox when using a label for programming. In this chapter, this is not selected.

22

Page 25

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING

Device

Constant

1.3 Creating a Program

1.3.1 Prior knowledge for creating a program

(1) Device and constants

Devices and constants, such as shown below, are used for creating a program. ( Page 288, CHAPTER 5)

(2) Concept of I/O numbers

I/O numbers are automatically assigned.

Power

supply

module

CPU

module

0000

to

000F

Input

module

64

points

X0010

to

X004F

Output

module

64

points

Y0050

to

Y008F

1.3.1 Prior knowledge for creating a program

1

1.3 Creating a Program

Users can also assign I/O numbers according to their purposes. ( Page 41, Section 2.2)

(3) Program configuration

A main routing program, subroutine program, ( Page 46, Section 2.3.3), and interrupt program ( Page

56, Section 2.7) can be included in a program.

23

Page 26

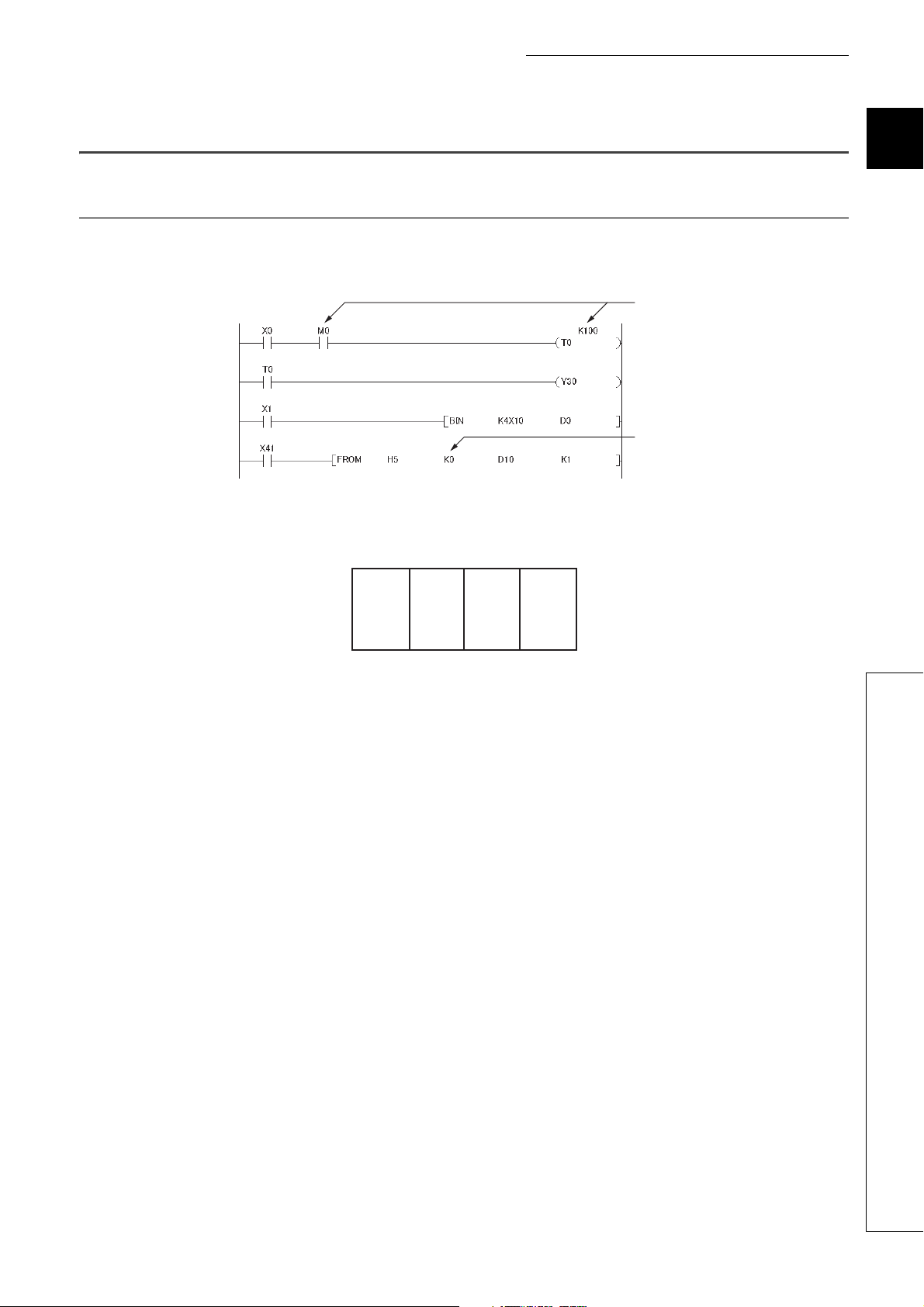

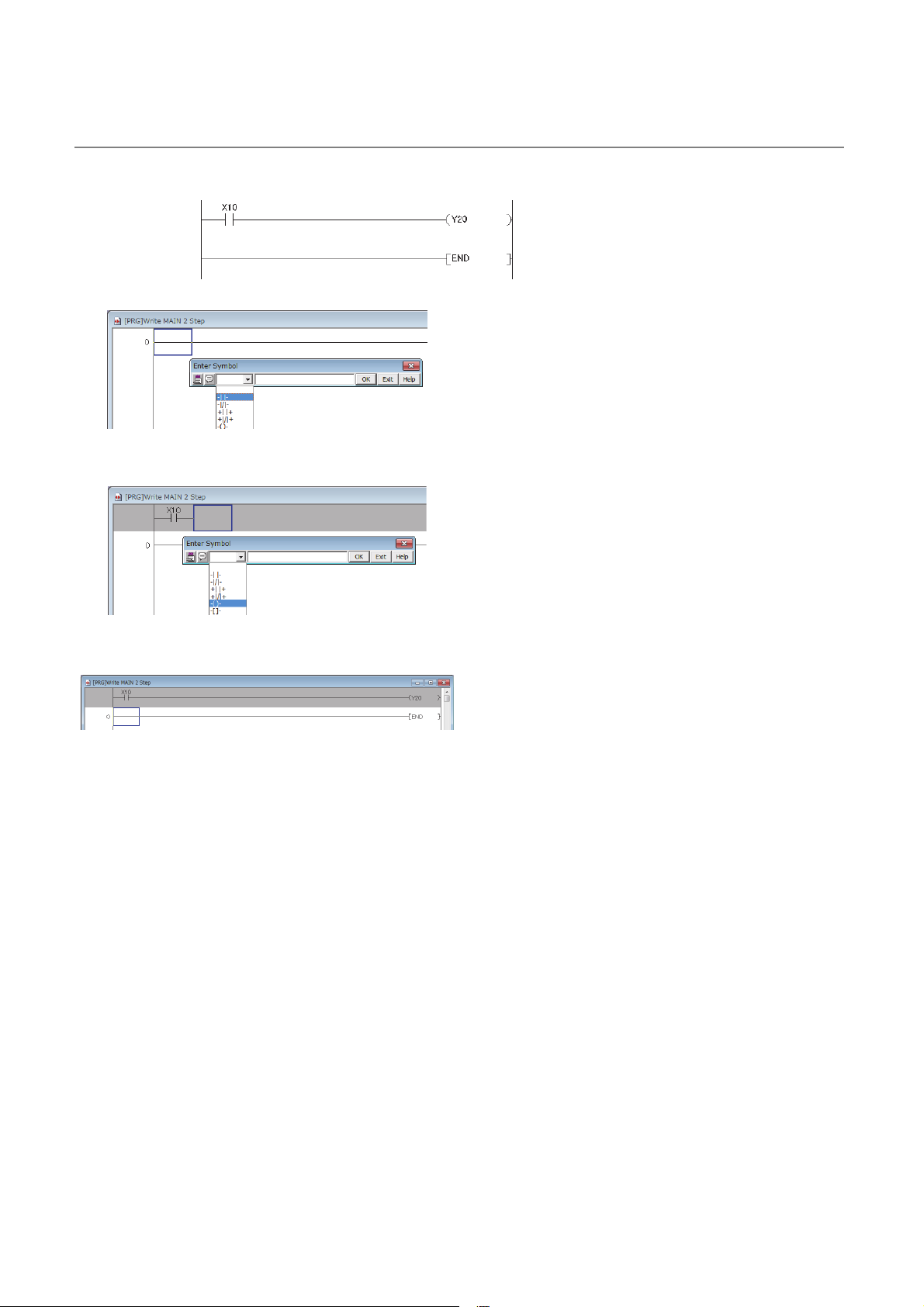

1.3.2 How to create a program

This section shows how to create the following sample program.

When X10 is turned on, Y20 turns on.

1. To enter X10, type X10 at the original cursor

position and select the contact shown in the left

figure.

2. To enter Y20, type Y20 and select the coil shown in

the left figure.

The program has been created. In the next procedure, convert the program.

24

Page 27

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING

1.4 Converting a Program

Operation of a program is defined after converting its ladder.

[Compile] [Build]

The program has been converted. In the next procedure, write the program to a CPU module.

● To use a label, the program must be compiled.

GX Works2 Version 1 Operating Manual (Common)

● After modifying a program, it must be compiled.

1

1.4 Converting a Program

25

Page 28

1.5 Writing a Project to the CPU Module

Write the project (the program and parameters described in Section 1.4.) to the CPU module. Note that, when the

program is new, the memory ( Page 31, Section 2.1.1) is formatted so that a program can be written to it.

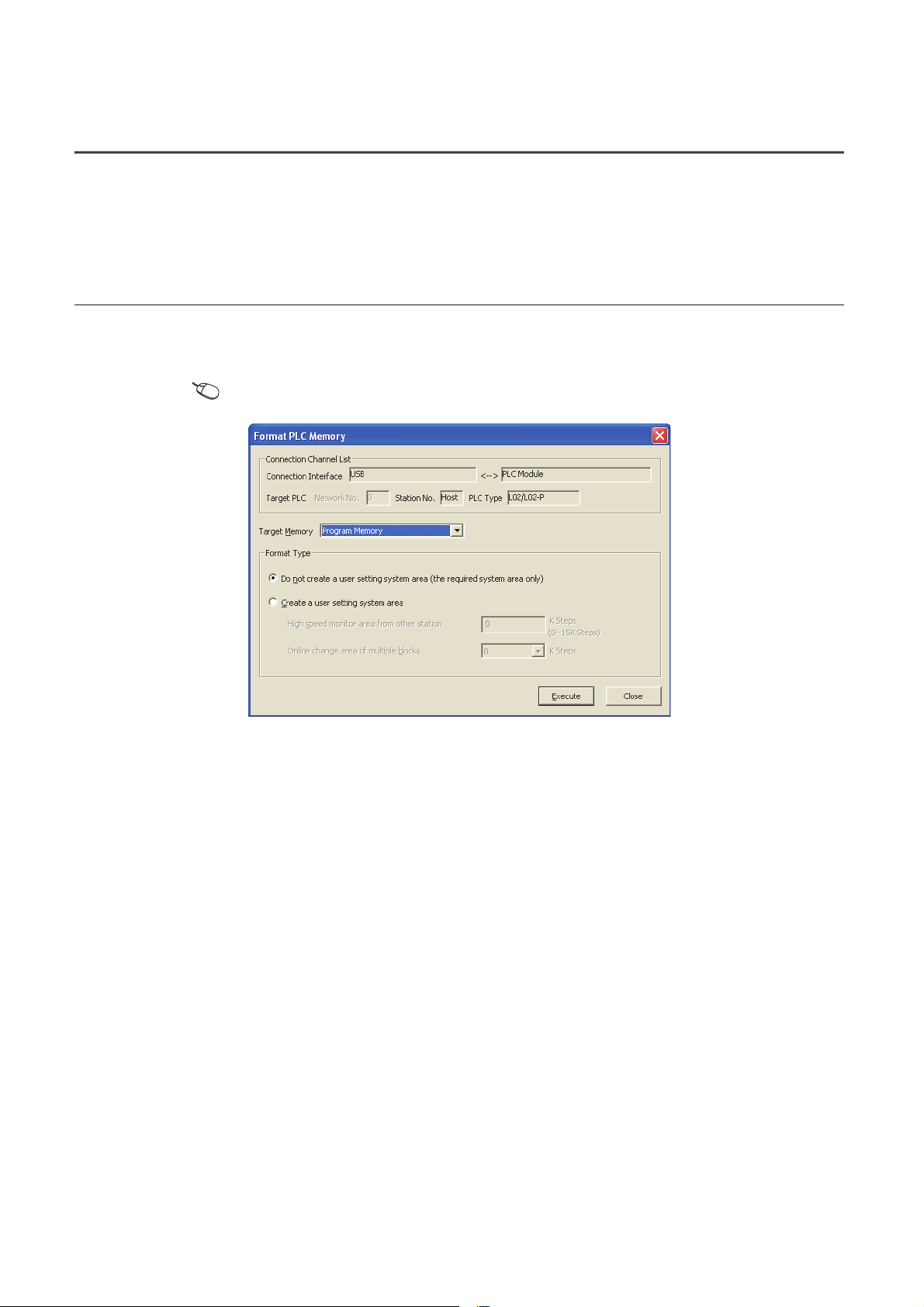

1.5.1 Formatting a memory

To format a memory, open the "Format PLC Memory" dialog box. In this chapter, a program memory is formatted so

that a program can be written to it.

[Online] [PLC Memory Operation] [Format PLC Memory...]

To check the capacity of the memory after formatting, open the "Online Data Operation" dialog box.

26

Page 29

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING

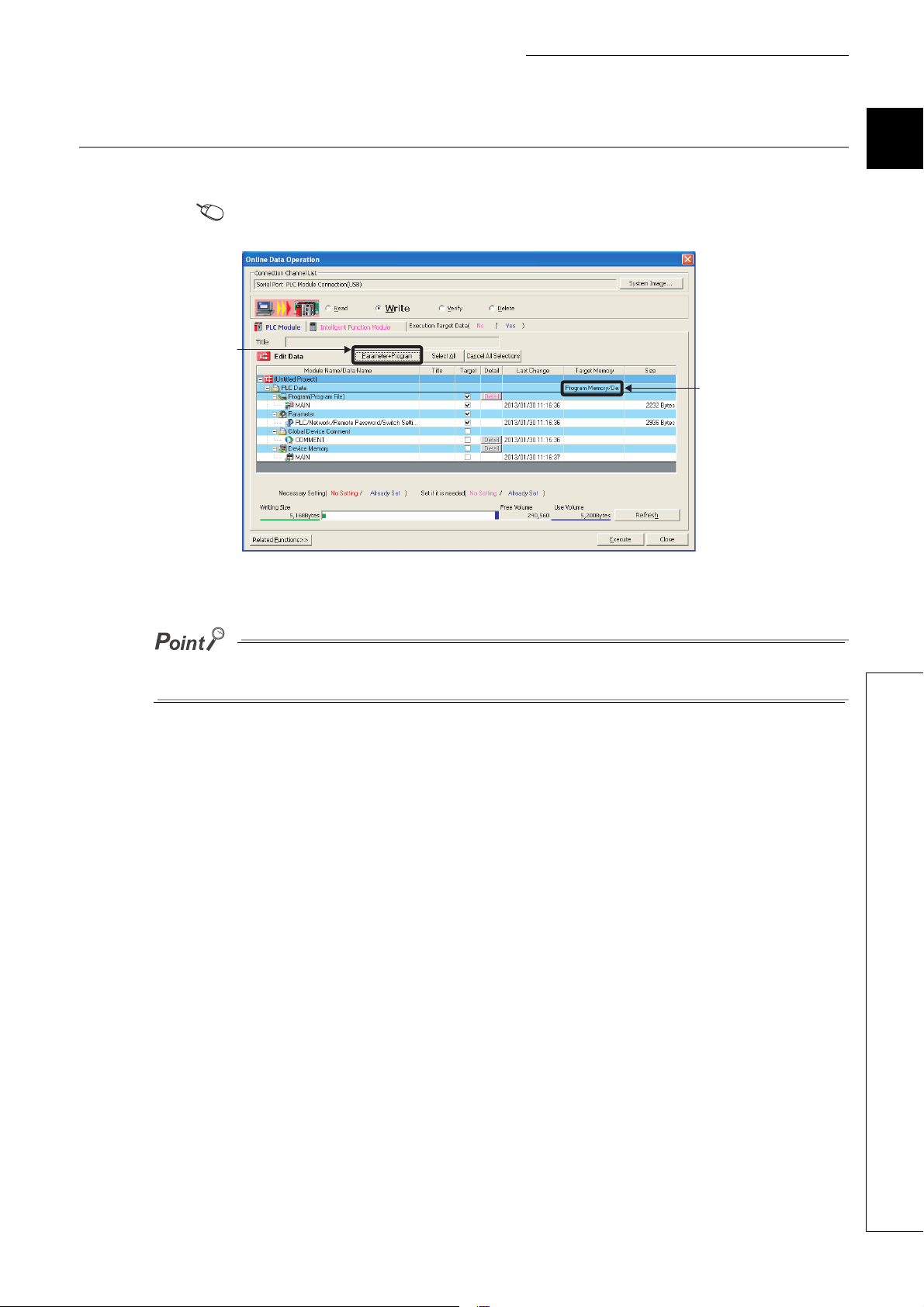

1) Select the program

memory.

2) Click this button to

select the parameter

and program

checkboxes

automatically.

1.5.2 Writing to the CPU module

Open the "Online Data Operation" dialog box. In this chapter, a project is written to the program memory.

[Online] [Write to PLC...]

1

The project has been written. In the next procedure, execute the program.

Note that parameter setting is required to operate CPU modules. In this chapter, the procedure for parameter setting is not

introduced since default values are used.( Page 350, Appendix 1)

1.5 Writing a Project to the CPU Module

1.5.2 Writing to the CPU module

27

Page 30

1.6 Checking an Operation of the CPU Module

On (green)

Off

Flashing (red)

MODE:

RUN :

ERR. :

On (green)

Off

Flashing (red)

MODE:

RUN :

ERR. :

MODE:

RUN :

ERR. :

On (green)

Off

Off

MODE:

RUN :

ERR. :

On (green)

On (green)

Off

To check an operation, execute the program written to the CPU module. In this chapter, operation is checked through

the monitoring screen of GX Works2.

(1) Executing a program

Before operating the CPU module, data written to the CPU module must be validated. To validate, power off and

then on or reset the CPU module.

1. Before resetting the CPU module, check the current

LED status.

2. Move the switch on the front of the CPU module to

the RESET position. (One second or longer)

3. Hold the switch until the ERR. LED turns off after

flashing.

In the next procedure, run the CPU module. To run, use the switch on the CPU module.

4. Move the switch to the RUN position.

When the RUN LED is lit green, the program is being executed successfully.

By remote operation, CPU modules can be operated without using switches. ( Page 112, Section 3.12)

28

Page 31

CHAPTER 1 BASIC PROCEDURE FOR PROGRAMMING

Enter a device to be

turned on or off.

(2) Checking operation

Conductivity and power distribution status of contacts and coils can be checked by switching GX Works2 to the

monitor mode.

[Online] [Monitor] [Start Monitoring]

When X0 and X1 are turned on, Y10 turns on. (to turn on X0 and X1, place the cursor on them and double-click

while holding the key.) While contacts and coils are conducting, they are shown in blue.

Alternatively, device states can be checked through a display unit. ( Page 241, Section 4.2.1)

Debug can be performed by forcibly turn on or off devices in the "Modify Value" dialog box.

[Debug] [Modify Value...]

Shift

1

1.6 Checking an Operation of the CPU Module

For details on current value changing, refer to the following.

GX Works2 Version 1 Operating Manual (Common)

If a program is edited during debugging, the program can be written to the CPU module even while the CPU

module is in the RUN status. ( Page 158, Section 3.23)

29

Page 32

1.7 Saving a Project

To save a project, open the "Save As" dialog box.

[Project] [Save As...]

Item Description

Enter the storage destination folder (drive or path) of the workspace. Folders can be browsed for selection by

Save Folder Path

Workspace/Project List Select a workspace. Double-click "Workspace" to display a project list.

Workspace Name Enter a name for the workspace.

Project Name Enter a name for the project.

*1

Titl e

*1 Projects can also be saved without titles.

clicking the button.

Enter a title for the project.

30

Page 33

CHAPTER 2 APPLICATION OF PROGRAMMING

<Drive 3>

Standard RAM

(SRAM)

<Drive 4>

Standard ROM

(flash ROM)

<Drive 0>

Program

memory

(flash ROM)

Inside CPU module

Programming tool

1) Data are written to the program

cache memory first.

2) After writing to the program

cache memory, the data are

automatically transferred to

the program memory.

Program

cache

memory

(SRAM)

CHAPTER 2 APPLICATION OF PROGRAMMING

This chapter describes applications of programming.

2.1 Memory and Files

2.1.1 Memory configuration

The following table lists the memory configuration of the CPU module.

CPU module Memory configuration

L02SCPU, L02SCPU-P Program memory, standard RAM, standard ROM

L02CPU, L02CPU-P, L06CPU, L06CPU-P, L26CPU, L26CPU-P,

L26CPU-BT, L26CPU-PBT

(1) Program memory

This memory stores programs and parameters required in processing of the CPU module.

(a) Processing a program

When a program is executed, data in the program memory are transferred to the program cache memory*1 at

the following timings.

• Initial processing at power-on

• Initial processing at reset

Program memory, standard RAM, standard ROM, SD memory card

2.1.1 Memory configuration

2

2.1 Memory and Files

*1 The program cache memory is used for program operations.

(b) Writing to the program memory

When a program is written to the program memory, it is temporarily written to the program cache memory, and

then automatically transferred back to the program memory.

While the CPU module is in the RUN status, automatic data transfer to the program memory can be disabled by setting.

( Page 153, Section 3.22.3)

31

Page 34

(c) Transfer confirmation to the program memory

Program transfer to the program memory can be checked by the following.

• On the dialog box below

• SM681 and SD681

Whether the transfer is in execution or complete can be checked by SM165.

(2) Standard RAM

This memory stores file register files, local device files, sampling trace files, and module error collection files.

(3) Standard ROM

This memory stores data such as device comments and PLC user data.

(4) SD memory card

This memory stores programs and parameters. To execute a program stored in the SD memory card, perform a

boot operation. ( Page 74, Section 2.9)

An SD card memory is required when using the data logging function.

(5) Memory capacity

The following table shows the memory capacity of each memory.

CPU module Program memory Standard RAM Standard ROM SD memory card

L02SCPU, L02SCPU-P

L02CPU, L02CPU-P

L06CPU, L06CPU-P 240K bytes

L26CPU, L26CPU-P,

L26CPU-BT, L26CPU-PBT

80K bytes 128K bytes 512K bytes

1040K bytes 2048K bytes

768K bytes

1024K bytes

Capacity of the SD memory card

used

32

Page 35

CHAPTER 2 APPLICATION OF PROGRAMMING

(6) Memory and data to be stored

: Storable, : Not storable

Program

File type

Memory

Drive 0 Drive 3 Drive 4 Drive 2

Parameter PARAM.QPA One file per drive

Intelligent function module

parameters

Program ***.QPG

Device comment ***.QCD

Initial device value ***.QDI

File register

Local device

Sampling trace

PLC user data ***.CSV/BIN

Symbolic information

Drive heading QN.DAT

Device data storage file DEVSTORE.QST

Module error collection file

Boot setting file AUTOEXEC.QBT

Remote password 00000000.QTM

Latch data backup file LCHDAT00.QBK

Backup data file MEMBKUP0.QBP

System file for project batch

save/load

Device data file DEVDATA.QDT

Data logging setting file

Data logging file

Menu definition file MENUDEF.QDF

System file for the iQ Sensor Solution

function (data backup/restoration)

Backup data file for the iQ Sensor

Solution function (data

backup/restoration)

Predefined protocol setting file

*1

*4

IPARAM.QPA

SVLDINF.QSL

SSBRINF.QSI

Standard

RAM

*2

*2

*2

*2

Standard

ROM

SD memory card

File name and

extension (any

given name for ***)

***.QDR

***.QDL

***.QTD

*5

IERRLOG.QIE

LOGCOM.QLG,

LOG01 to 10.QLG

*3

***.CSV

*6

***.QBR

ECPRTCL.QPT,CPRT

CL.QPT

Remarks

One data per

drive

One file per

module

2.1.1 Memory configuration

2

2.1 Memory and Files

*1 Store parameters (PARAM.QPA) and intelligent function module parameters (IPARAM.QPA) in the same drive.

Otherwise the intelligent function module parameters are invalid.

*2 Only one file can be stored.

*3 This drive cannot be selected as a storage file by the data logging function. To write data to this drive, perform Write PLC

User Data.

*4 This is the data of label program configuration information.

GX Works2 Version 1 Operating Manual (Common)

*5 For Simple project (with a label): SRCINF1M.C32 and SRCINF2M.C32. For Structured project: SRCINF1I.C32 and

SRCINF2I.C32.

*6 This file name depends on the connection type of the iQ Sensor Solution data backup/restoration. ( iQ Sensor

Solution Reference Manual)

33

Page 36

2.1.2 Parameter-valid drive

CPU modules operate according to parameter settings. Systems automatically select parameters from those stored in

the drives for CPU module operation, according to the following priority order.

[Priority order]

1) Drive 0 (program memory)

2) Drive 2 (SD memory card)

3) Drive 4 (standard ROM)

● If parameters are set to be booted to an SD memory card, the above priority order is applied after the parameters are

booted to the specified destination. ( Page 74, Section 2.9)

● The parameters used by the CPU module can be checked at "Parameter Valid Drive Information" under "PLC Status

Information" on the "PLC Diagnostics" dialog box. ( Page 376, Appendix 2)

[Diagnostics] [PLC Diagnostics]

(1) Timing that the parameters take effect

The CPU module automatically searches for parameters in the following timing and operates according to the

parameters stored in the drive.

• When the CPU module is powered off and then on

• When the CPU module is reset

(2) Precautions

Note that if the parameters are written while the CPU module is in operation, the timing that the parameters take

effect varies.

(a) To write a parameter to the drive other than the one in operation:

The CPU module keeps operating according to the current parameters. When the CPU module is turned off

and then on or is reset, newly written parameters take effect according to the priority order.

(b) To write a parameter to the drive where another parameter is currently processed:

Only the device settings become effective immediately after writing is complete. To make all the parameters

effective, power off and then on or reset the CPU module.

34

Page 37

CHAPTER 2 APPLICATION OF PROGRAMMING

2.1.3 Files

For the files written to the CPU module, information such as written date, file name (if created), and file size are

appended to the file. By monitoring the file through Read from PLC, the file is displayed as shown below.

[Online] [Read from PLC...]

2

Item Description

A file name consists of a name (up to 8 one-byte or 4 two-byte characters) and an extension.

• File name: Create with uppercase characters only.

• Extension: It is automatically appended according to the specified file type.

File name

Update date The date and time when the file was written to the CPU module is displayed.

Size

The following cannot be used as a file name since they are the reserved words of Microsoft Windows

COM1 to COM9, PRN, LPT1 to LPT9, NULL, AUX, CLOCK$, and CON

When using characters, recognition of uppercase and lowercase differs depending on the memory.

• Program memory, standard RAM, standard ROM: Not case-sensitive ("ABC" and "abc" are both considered to be "ABC".)

• SD memory card: Case-sensitive

Except for file registers, at least 64 bytes are added to the capacity of the file created by a user.

To display the latest data, click the "Refresh" button.

2.1 Memory and Files

2.1.3 Files

.

35

Page 38

(1) Handling

(a) Power-off during online data operation (including reset)

Files in memory are not discarded if the CPU module is powered off or reset during online operation.

However, for SD memory cards, doing so may result in data corruption. Stop accessing to an SD memory card,

and then power off or reset the CPU module. All of SD memory card operations can be disabled by SM606 (SD

memory card forced disable instruction). For the forced disablement of SD card, refer to the following.

MELSEC-L CPU Module User's Manual (Hardware Design, Maintenance and Inspection)

(b) Simultaneous writing to the same file from multiple programming tools

While a file is being written, accessing the file from another programming tool is not allowed. Also, while a file is

being accessed, writing data to the file from another programming tool is not allowed.

To write data to the same file from multiple programming tools, perform one by one.

(c) Simultaneous accessing to different files from multiple programming tools

Up to ten different files in a CPU module can be simultaneously accessed from multiple programming tools.

(d) File access into the SD memory card

Accessing into the SD memory card with the SP.FREAD or SP.FWRITE instruction may extend the scan time

as the number of files stored in the SD memory card increases.

36

Page 39

(2) File size

The size of a file used in the CPU module depends on the file type. Calculate the rough size of each file, referring

to the following table.

File type File size (unit: byte)

Default

• L02SCPU, L02SCPU-P: 2760 (The size can be increased by parameter setting.)

• L02CPU, L02CPU-P: 2936 (The size can be increased by parameter setting.)

• L06CPU, L06CPU-P, L26CPU, L26CPU-P, L26CPU-BT, L26CPU-PBT: 2964 (The size can be increased by parameter

*1

Parameter

Intelligent function module

parameter

Program

Device comment

Initial device value

File register 2 (number of device points)

setting.)

Reference

• Boot setting 84 + (18 (number of files))

• With CC-Link setting ( MELSEC-L CC-Link System Master/Local Module User's Manual)

• With CC-Link IE Field Network setting (MELSEC-L CC-Link IE Field Network Master/Local Module User's Manual)

• With Ethernet setting ( MELSEC-L Ethernet Interface Module User's Manual (Basic))

• With remote password setting 92 + (the number of target modules 10)

76 + (28 the number of modules set) + parameter size for each utility

*3

+ 4 ((number of steps) + (number of steps reserved for online change))

228

74 + 72 + 8 + (total comment data size of each device)

Comment data size per device = 10 + 10240 a + 40 b

• a: Quotient of ((number of device points) 256)

• b: remainder of ((number of device points 256)

66 + 44 (number of settings of the initial device value) + 2 (total number of device points set to the initial device value) + 72

+ 8

70 + 6 (set device type) + (Am + Av + B + Ct + Cst + Cc) n

CHAPTER 2 APPLICATION OF PROGRAMMING

2

*1

*1

*2

*2

, Up to an increment of 172

*2

• Am, Av = (((a1 + a2) 16) - ((a1 + 1) 16) + 1) 2

•B = b 2

• Ct, Cst, Cc = ((((c1 + c2) 2) 16) - ((c1 2 + 1) 16) + 1) 2 + c2 2

Local device

Sampling trace file

PLC user data Depends on the value and the number of data

Source information Depends on the specifications of the programming tool

Drive heading 72

Device data storage file

Module error collection file 76 + 64 (64 (value set for the number of storable errors))

System file for project batch

save/load

Device data file

*4

*5

• Am, Av: Save area sizes of M (internal relay) and V (edge relay), respectively