Page 1

VRF INVERTER MULTI-SYSTEM AIR-CONDITIONERS

(OUTDOOR UNIT)

Manual No. '14

• KX-SM-202

Standard series

Single use (Used also for combination)

FDC280KXZE1, 335KXZE1, 400KXZE1, 450KXZE1, 475KXZE1, 500KXZE1, 560KXZE1

Combination use

FDC615KXZE1, 670KXZE1, 735KXZE1, 800KXZE1, 850KXZE1, 900KXZE1, 950KXZE1, 1000KXZE1,

1060KXZE1, 1120KXZE1, 1200KXZE1, 1250KXZE1, 1300KXZE1, 1350KXZE1,1425KXZE1,

1450KXZE1, 1500KXZE1, 1560KXZE1, 1620KXZE1, 1680KXZE1

KXZ series

(Heat pump type)

Corrosion protection treatment series (Non-CE Marking models)

Single use (Used also for combination)

FDCS280KXZE1, 335KXZE1, 400KXZE1, 450KXZE1, 475KXZE1, 500KXZE1, 560KXZE1

Combination use

FDCS615KXZE1, 670KXZE1, 735KXZE1, 800KXZE1, 850KXZE1, 900KXZE1, 950KXZE1, 1000KXZE1,

1060KXZE1, 1120KXZE1, 1200KXZE1, 1250KXZE1, 1300KXZE1, 1350KXZE1,1425KXZE1,

1450KXZE1, 1500KXZE1, 1560KXZE1, 1620KXZE1, 1680KXZE1

SERVICE MANUAL

(1) Regarding the Indoor unit series, refer to the No.'14

•

KX-DB-206

(2) Regarding the Duct Connected-High static Pressure-type Outdoor Air Processing Unit Series

(FDU500〜1800FKXE6), refer to the DATA BOOK No.'08

•

KX-DB-122

•

Note:

Page 2

'14 • KX-SM-202

CONTENTS

1. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ..................... 1

1.1 Remote control (Option parts) ................................................................... 1

1.2 Operation control function by the wired remote control ............................. 4

1.3 Operation control function by the indoor control ....................................... 9

1.4 Operation control function by the outdoor control ................................... 22

2. SYSTEM TROUBLESHOOTING PROCEDURE ............................................. 66

2.1 Basics of troubleshooting ........................................................................ 66

2.2 Explanation of troubleshooting ................................................................ 67

2.3 Contents of troubleshooting .................................................................... 68

2.4 Outdoor unit control PCB replacement procedure ................................ 124

2.5 Outdoor unit inverter PCB replacement procedure ............................... 126

2.6 Outdoor unit transistor module replacement procedure ........................ 128

3. ELECTRICAL WIRING .................................................................................. 131

4. PIPING SYSTEM ............................................................................................ 134

5. APPLICATION DATA .................................................................................... 137

5.1 Installation of outdoor unit ..................................................................... 137

5.2 Instructions for installing the branch pipe set ........................................ 162

5.3 Procedure to attach or remove the front panel ...................................... 166

Page 3

– 1 –

'14 • KX-SM-202

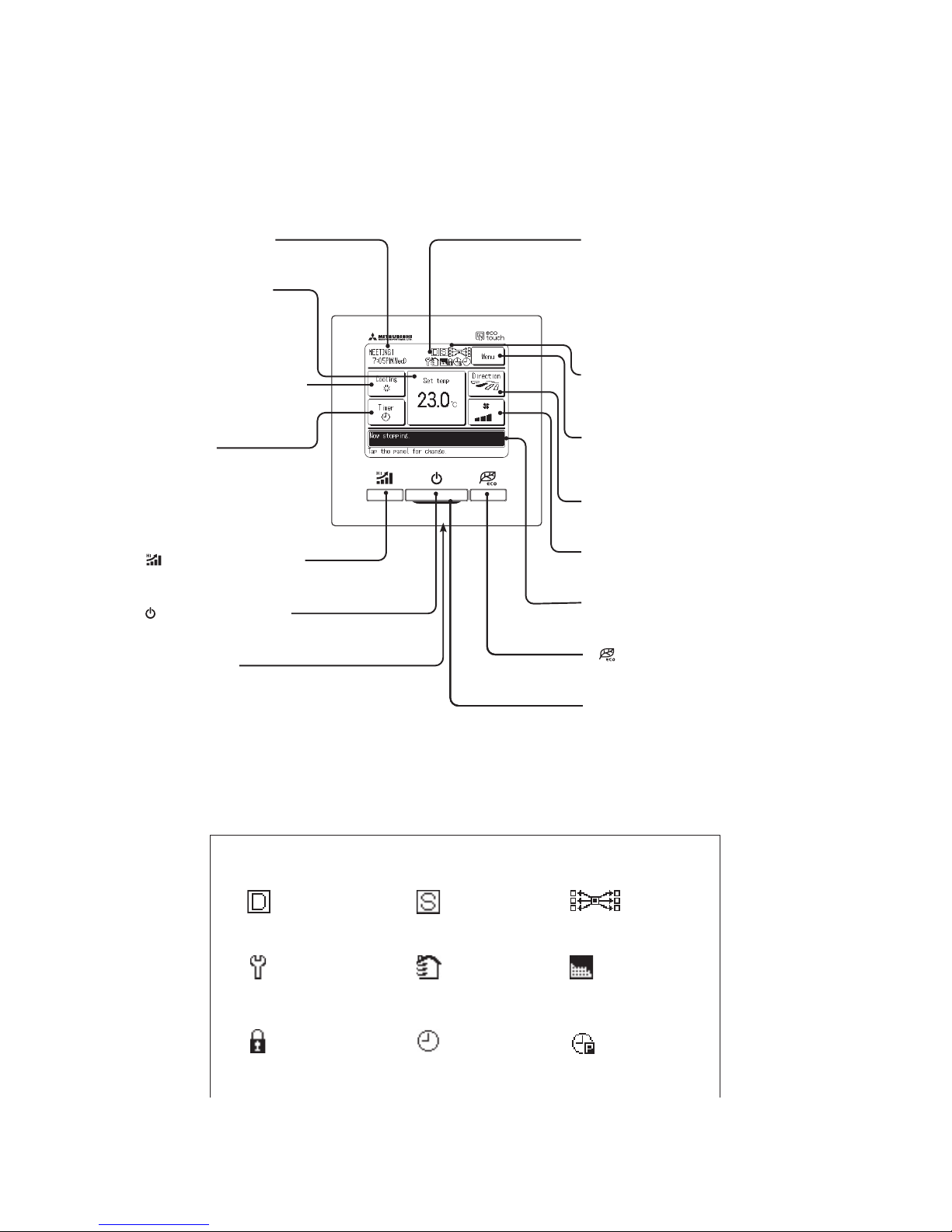

⑤LCD display (With backlight)

④Operation lamp

This lamp lights in green (yellow-green) during

operation. It changes to red if any error occurs.

⑥USB port (mini-B)

USB connector (mini-B) allows connecting to a

personal computer.

For operating methods, refer to the instruction

manual attached to the software for personal

computer (eco-touch remote control RC-EX1,

utility software).

②switch (High Power switch)

Pushing this button starts the high power

operation.

A tap on the LCD lights the backlight.

The backlight turns off automatically if there is no

operation for certain period of time.

Lig hti ng perio d o f the ba ckl ight lig hting ca n b e

changed.

If the backlight is ON setting, when the screen

is tapped while the backlight is turned off, the

backlight only is turned on.(Op erati ons w ith

switches ①,② and ③ are excluded.)

③ switch (Energy Saving switch)

Pushing this button starts the energy-saving

operation.

⑬Fan speed change button

Displays the fan speed which is selected currently.

Tap this button to change the fan speed.

⑨Menu button

When setting or changing other than the following

⑩-⑭, tapthemenubutton.When menu items are

displayed, select one and set.

⑫Flap direction button

Displays the flap direction which is selected currently.

Tap this button to change the flap direction.

⑦Clock, R/C name display

Displays the current time and

the name of R/C

⑪Change set temp button

Displays the temperature which

is set currently.Tap this button

to change the set temperature.

⑩Change operation mode button

Displays the operation mode which

is selected currently. Tap this button

to change the operation mode.

⑭Timer button

Displays simplified contents of the

timer which is set currently.

(When two or more timers are set,

contents of the timer which will be

operated immediately after is

displayed.)

Tap this button to set the timer.

①switch (Run/Stop switch)

One push on the button starts operation

and another push stops operation.

⑧Icon display

Each icon is displayed when one of following settings

is going on.(It is referring to the following figure for

details.)

⑮Message display

Status of air conditioner operation and messages of

the R/C operations etc.are displayed.

When the demand control

is effective.

When setting is made

from the sub R/C.

When the central control

(Optional) is running.

When the periodical

inspection is necessary.

During the ventilation

operation

When ”filter sign” is up.

When the Permission/

Prohibition setting is made.

When the peak-cut timer is setWhen the weekly timer

is set.

⑧Icon display

Each icon is displayed when one of following settings is going on.

Touch panel system, which is operated by tapping the LCD screen with a finger, is employed for any operations

other than the ① Run/Stop, ② High power and ③ Energy-saving switches.

All icons are shown for the sake of explanation.

Model RC-EX1A

1.

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

1.1 Remote control (option parts)

(1) Wired remote control

Page 4

– 2 –

'14 • KX-SM-202

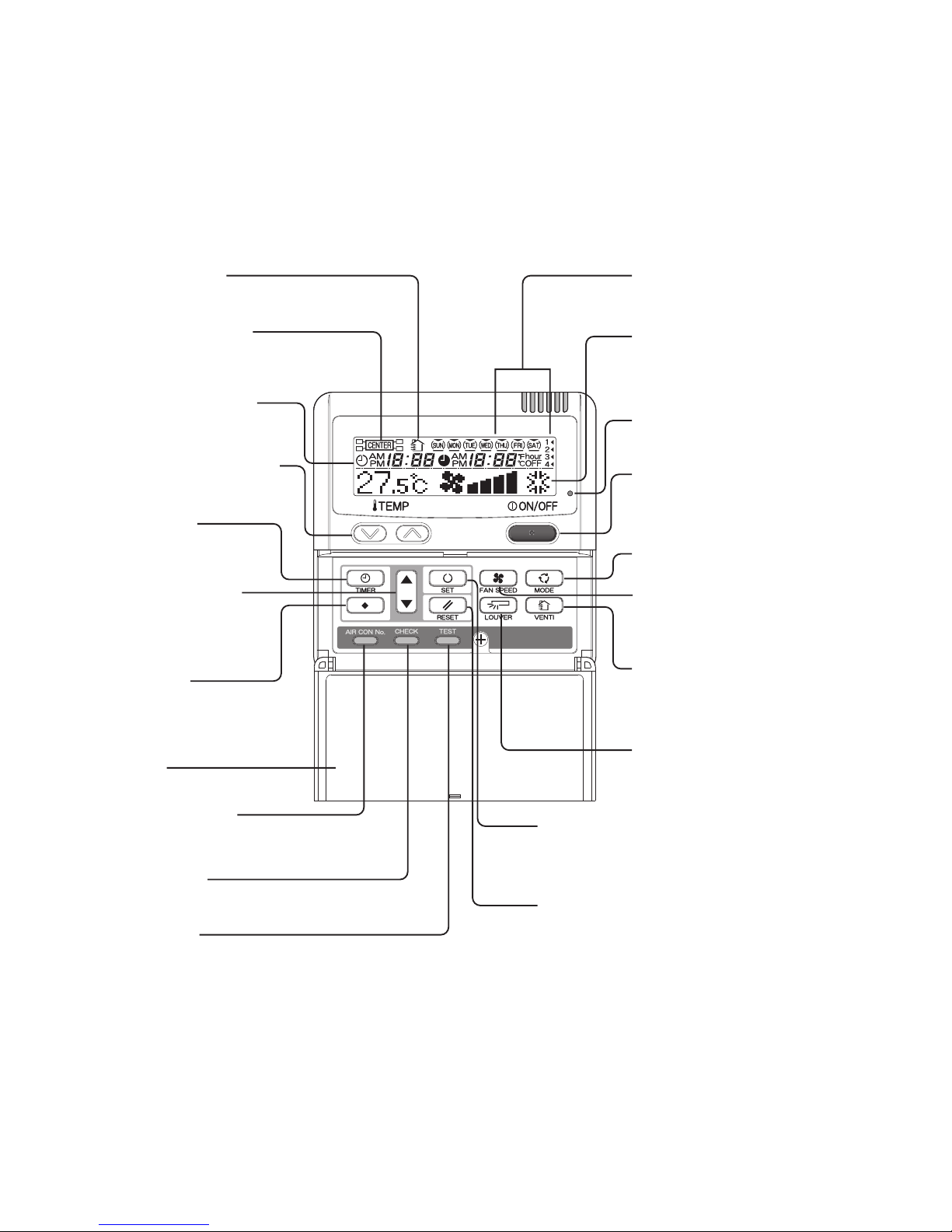

(1) Wired remote control

Model RC-E5

The figure below shows the remote control with the cover opened. Note that all the items that may be displayed in

the liquid crystal display area are shown in the figure for the sake of explanation.

Characters displayed with dots in the liquid crystal display area are abbreviated.

* All displays are described in the liquid crystal display for explanation.

The figure below shows the remote control with the cover opened.

Ventilaion display

Displayed during ventilation operation

Central control display

Displayed when the air conditioning system is

controlled by centralized remote control.

Timer operation display

Displays the timer operation setting.

Temperature setting buttons

These buttons are used to set the

temperature of the room.

Timer button

This button is used to set

the timer mode.

Timer setting buttons

These buttons are used to set

the timer mode and the time.

ESP button

This button is used to

select the auto static

pressure adjustment mode.

Cover

AIR CON No. button

Display the indoor unit number connected to this

remote control.

CHECK button

This button is used at servicing.

TEST button

This button is used during test operation.

Weekly timer display

Displays the settings of the

weekly timer.

Operation setting display area

Displays setting temperature, airflow

volume, operation mode and oparation

message.

Operation/check indicator light

During oparation: Lit in green

In case of error: Flashing in red

Operation/stop button

This button is used to operate and stop

the air conditioning system.

Press the button once to operate the

system and press it once again to stop

the system.

MODE button

This button is used to change the

operation mode.

FAN SPEED button

This button is used to set the airflow

volume.

VENT button

This button is used to operate external

ventilator.

LOUVER button

This button is used to operate/stop the

swing louver.

SET button

●

This button is used to fix the setting.

●

This button is used to set the silent mode.

RESET button

●

Press this button while making settings to go back to the

previous operation.

●

This button is also used to reset the "FILTER CLEANING" display.

(Press it after cleaning the air filter)

Page 5

– 3 –

'14 • KX-SM-202

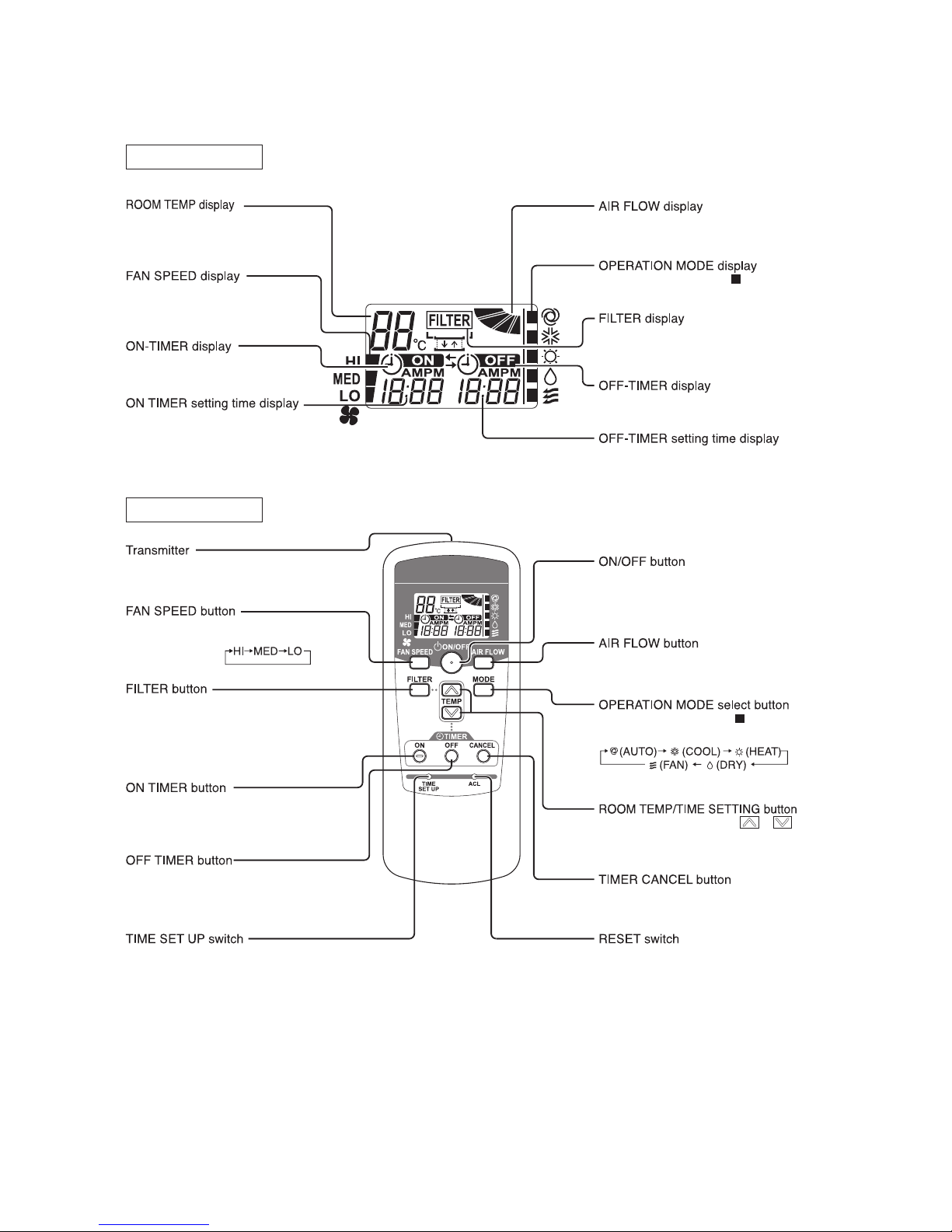

(2) Wireless remote control

* All displays are described in the liquid crystal display for explanation

Indication section

Operation section

Indicates set temperature.

Indicates the status of swing louver.

Indicates selected operation with .

Indicates for two seconds when FILTER

button is pressed.

Indicates when OFF-TIMER is set.

Indicates OFF-TIMER setting time. Indicates the

current time when the OFF-TIMER is not set.

When this is pressed once, the unit starts to

operate and when this is pressed once again,

it stops operating.

Used to swing the louver.

Every time this button is pressed, displays switch

as below.

Sets room temperature by pressing or button.

Sets time when setting the time.

Used to cancel the TIMER SETTINGS.

Used to reset the microcomputer.

Indicates the selected airflow volume

Indicates when ON-TIMER is set.

Indicates the ON-TIMER setting time.

Nothing displayed when ON-TIMER is

not set.

Sends signal to the air conditioner.

Every time this button is pressed, the mode is

switched as below.

Used to reset (turn off) the filter sign.

Press the button only after completing

the filter cleaning.

Sets ON TIMER operation.

Sets OFF TIMER operation.

Sets current time.

Page 6

– 4 –

'14 • KX-SM-202

1.2 Operation control function by the wired remote control

Cooling Fan

Dry Heating

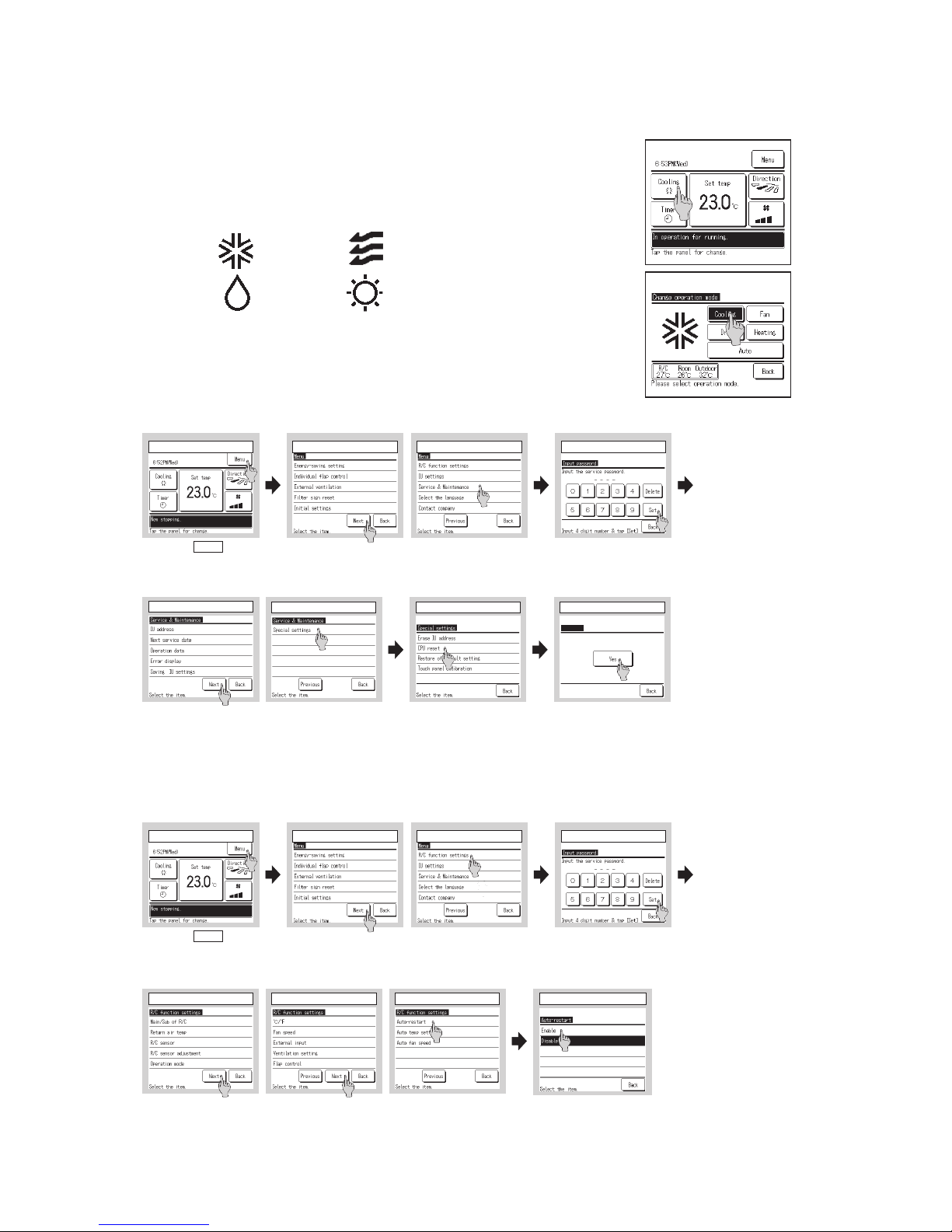

(1) Switching sequence of the operation mode switches of remote control

(a) Tap the change operation mode button on the TOP screen.

(b) When the change operation mode screen is displayed, tap the button of desired mode.

(c) When the operation mode is selected, the display returns to the TOP screen.

Icons displayed have the following meanings.

Notes(1) Operation modes which cannot be selected depending on combinations of IU and

OU are not displayed.

Notes(2) Whe n the Au to is selected, the cool ing a nd heati ng swi tching o perat ion is

performed automatically according to indoor and outdoor temperatures.

(2) CPU reset

Reset CPU from the remote control as follows.

(3) Power failure compensation function (Electric power supply failure)

Enable the Auto-restart function from the remote control as follows.

①Tap the Menu button

on the TOP screen.

②,③ Main menu screen is displayed.

Tap the “Service & Maintenance” on the menu screen.

④Display the service

password input screen.

Enter the service password

(4-digit number).

①TOP screen ②Menu screen 1 ③ Menu screen 3 ④ Service password input

①Tap the Menu button

on the TOP screen.

②,③ Main menu screen is displayed.

Tap the “Service & Maintenance” on the menu screen.

④Display the service

password input screen.

Enter the service password

(4-digit number).

①TOP screen ②Menu screen 1 ③ Menu screen 3 ④ Service password input

⑤

Service & maintenance menu 1

⑥

Service & maintenance menu 2

⑤,⑥ Service & maintenance menus are displayed.

⑦ Special settings

⑦Special settings

CPU reset : Micr ocompu ters of IU

and OU connected are reset

(State of restoration after

power failure).

⑧CPU reset

All microcomputers on the R/C operated,

other R/Cs, IUs and OUs are reset (State

of restoration after power failure).

Tap [Yes] to reset CPU

⑤,⑥,⑦Display the R/C setting menu screens.

⑤R/C setting menu 1 ⑥R/C setting menu 2 ⑦R/C setting menu 3

⑱ Auto-restart

Enable : It returns to the state be fore the supply

power fai lure as soon as the p ower is

restored (After the end of the primary

control at the power on).

Disable : It stops after the restoration of power

supply, regardless the state of operation

before the power failure.

⑱Auto-restart

Set the state of operation to be started when the

power supply is restored after a power failure.

⑧ CPU reset

CPUreset

Restartafterreset

IfOK,

tap[Set.

]

Model RC-EX1A

Page 7

– 5 –

'14 • KX-SM-202

• Since it memorizes always the condition of remote control, it starts operation according to the contents of memory no

sooner than normal state is recovered after the power failure. Although the auto swing stop position and the timer mode are

cancelled, the weekly timer setting is restored with the holiday setting for all weekdays.

After recovering from the power failure, it readjusts the clock and resets the holiday setting for each weekday so that the

setting of weekly timer becomes effective.

• Content memorized with the power failure compensation are as follows.

Note (1) Items (f), (g) and (h) are memorized regardless whether the power failure compensation is effective or not while the setting of silent mode is cancelled

regardless whether the power failure compensation is effective or not.

(a)

At power failure – Operating/stopped

If it had been operating under the off timer mode, sleep timer mode, the state of stop is memorized. (Although the

timer mode is cancelled at the recovery from power failure, the setting of weekly timer is changed to the holiday

setting for all weekdays.)

(b)

Operation mode

(c)

Airowvolumemode

(d)

Room temperature setting

(e)

Louver auto swing/stop

However, the stop position (4-position) is cancelled so that it returns to Position (1).

(f)

“Remote control function items” which have been set with the remote control function setting (“Indoor function

items” are saved in the memory of indoor unit.)

(g)

Upper limit value and lower limit value which have been set with the temperature setting control

(h)

Sleep timer and weekly timer settings (Other timer settings are not memorized.)

Page 8

– 6 –

'14 • KX-SM-202

⑥ Operation and setting from remote control

A: Refer to the in struction manual for RC-EX series.

B: Refer to the in stallation manual for RC-EX series.

C: Loading a utili ty software vie Internet

○: Nearly same fun ction setting and operations are possible.

△: Similar functio n setting and operations are possible.

Description

RC-EX

series

RC-E4

RC-E5

1. Remote Control network

1

1

2

3

4

5

6

7

8

9

Control plural indoor units

by a single remote control

A remote controller can control plural indoor units up to 16 (in one group of remote control network). An address is set to each indoor unit.

○ ○

2

A maximum of two remote controllers (include option wireless) can be connected to one indoor unit. Set one to "Master" and the other to "Slave".

B ○

2. TOP screen, Switch manipulati on A

Menu "Control", "Settings", or "Details" can be selected. (3.-19.) A

Operation mode "Cooling", "Heating", "Fan" or "Dry" can be set. A

Set temp. "Set temperature" can be set by 0.5℃ interval. A

○A "Air flow direction". [Individual flap control setting] can be set. Air flow direction

Fan speed "Fan speed" can be set. A

Timer setting "Timer operation" can be set. A

ON/OFF "On/Off operation of the system" can be done. A

○

○

○

○

○

High power SW "High power operation" or "Normal operation" can be selected. A

Energy-saving SW "Energy-saving operation" or "Normal operation" can be selected. A

3.Energy-sa ving setting [メニュー] 1番目 A

1

△

2 Peak-cut timer

[Administrator password]

3 Automatic temp. set back

[Administrator password]

△

4. Individual flap contro l setting [メニュー] 3番目 A

The moving range (the positions of upper limit and lower limit) of the flap for individual air outlet port can be set. A

5. Ventilation [メニュー] 4番目

1

External ventilation

(In combination with

ventilator)

On/Off operation of the external ventilator can be done.

・The settings of [Interlock] with AC (air-conditioner), [Single operation] of ventilator or operation [invalid] of ventilation can be done through

[Ventilation settings] in the [Remote controller] menu.

○

○A

A

A

A

Master/slave setting of remote

controllers

Setting & display item

Individual flap control setting

Auto OFF timer

[Administrator password]

For preventing the timer from keeping ON, set hours to stop operation automatically with this timer.

・The selectable range of setting time is from 30 to 240 minutes (10minutes interval)

・When setting is "Valid", this timer will activate whenever the ON timer is set.

Power consumption can be reduced by restricting the maximum capacity.

Set the [Start time], the [End time] and the capacity limit % (Peak-cut %).

・4-operation patterns per day can be set at maximum.

・The setting time can be changed by 5-minutes inter val.

・The selectable range of capacity limit % (Peak-cut %) is from 0% to 40-80% (20% interval).

・Holiday setting is available.

After the elapse of the set time period, the current set temp. will be set back to the [Set back temp.]

・The setting can be done in cooling and heating mode respectively.

・The selectable range of the set time is from 20 min. to 120 min. (10 min. interval).

・Set the [Set back temp.] by 1℃ interval.

6.Filter sign r eset [メニュー] 7番目 A

○

1 Filter sign reset B

2 Setting next cleaning date A

7.Initial set tings

[メニュー] 8番目

1 Clock setting △

2 Date and time display A

A

3 Summer time A

4 Contrast A

5 Backlight A

6 Controller sound A

8.Timer setting s

[メニュー] 9番目 A

1

Set On timer by hour

・The period of set time can be set within the range of 1hour-12hours (1hr interval).

・The operation mode, set temp and fan speed at starting operation can be set.

2 Set Off timer by hour

・The period of set time can be set within the range of 1hour-12hours (1hr interval).

3 Set On timer by clock

・The set clock time can be set by 5 minutes interval.

・[Once (one time only)] or [Everyday] operation can be switched.

・The operation mode, set temp and fan speed at starting operation can be set.

4 Set Off timer by clock

・The set clock time can be set by 5 minutes interval.

・[Once (one time only)] or [Everyday] operation can be switched.

5 Confirmation of timer settings A

[メニュー] 10番目

1 Weekly timer

[Administrator password]

△

・8-operation patterns per day can be set at a maximum.

・The setting clock time can be set by 5 minutes inter val.

・Holiday setting is available.

・The operation mode, set temp and fan speed at starting operation can be set.

△

△

[メニュー]?[次ページ] 1番目

1

When leaving home for a long period like a vacation leave, the unit can be operated to maintain the room temperature not to be hotter in summer or not to be colder in winter.

・The judgment to switch the operation mode (Cooling⇔Heating) is done by the both factors of the set temp. and outdoor air temp.

・The set temp. and fan speed can be set.

△

△

△

△

A

A

A

A

A

A

Home leave mode

[Administrator password]

9.Weekly timer

10.Home leave mode

The filter sign can be reset.

The next cleaning date can be set.

When select [Valid], the +1hour adjustment of current time can be set.When select [Invalid], the [Summer time] adjustment can be reset.

The current date and time can be set or revised.

[Display] or [Hide] the date and/or time can be set, and the [12H] or [24H] display can be set.

The contrast of LCD can be adjusted higher or lower.

Switching on/off a light can be set and the period of the lighting time can be set within the range of 5sec-90sec (5sec interval).

It can set with or without [Controller sound (beep sound)] at touching panel.

The period of time to start operation after stopping can be set.

The period of time to stop operation after starting can be set.

The clock time to start operation can be set.

The clock time to stop operation can be set.

Status of timer settings can be seen.

On timer and Off timer on weekly basis can be set.

⑥ Operation and setting from remote control (continued)

Description

[Administrator password]

1

Enable/Disable setting ・Enable/Disable setting of operation can be set. [On/Off] [Change set temp.] [Change operation mode] [Change air flow direction]

[Individual flap control setting][Fan speed] [High power operation] [Energy-saving operation] [Timer settings] [Weekly timer setting]

・Request for administrator password can be set. [Individual flap control setting][Weekly timer][Energy-saving setting][Home leave mode][Administrator settings]

2

Silent mode timer The period of time to operate the outdoor unit by prioritizing the quietness can be set.

・The [Start time] and the [End time] for operating outdoor unit in silent mode can be set. ・The period of the operation time can be set once a day by 5 minutes interval.

3 Setting temp. range The upper/lower limit of indoor temp. setting range can be set.

・The limitation of indoor temp. setting range can be set for each operation mode in cooling and heating.

4 Temp. increment setting The temp increment setting can be changed by 0.5℃ or 1.0℃. A

5

RC display setting

Register [Room name] [Name of I/U]

Display [indoor temp.] or not.

Display [inspection code] or not.

Display [Heating stand-by] [Defrost operation] [Auto cooling/heating] or not

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

Change administrator password The administrator password can be changed. (Default setting is "0000")

The administrator password can be reset.

[Service password]

Installation date The [Installation date] can be registered.

・

When registering the [Installation date], the [Next service date] is displayed automatically. (For changing the [Next service date]. please refer the item of [Service & Maintenance].)

Service contact The [Service contact] can be registered and can be displayed on the RC.

・The [Contact company] can be registered within 10 characters. ・The [Contact phone] can be registered within 13 digits.

Test run

Cooling test run

On/Off operation of the test run can be done.

The [Cooling test run] can be done at 5℃ of set temp. for 30 minutes. ○

Drain pump test run Only the drain pump can be operated. ○

Compressor Hz fixed oper ation

The [Test run] operation can be done with fixed compressor Hz set by installer. ○

Static pressure adjust ment In case of combination with only the ducted indoor unit which has a function of static pressure adjustment, the static pressure is adjustable.

Change auto-address The set address of each indoor unit decided by auto-address setting method can be changed to any other address. (For multiple KX units only) B

Address setting of Main IU

[Service password]

Main/Sub RC setting The setting of [Main/Sub RC] can be changed. B

RC sensor

The [Valid/Invalid] setting of [RC sensor] can be done. Respective setting in cooling and heating is available.

RC sensor adjustment The offset value of [RC sensor] sensing temp. can be set respectively in heating and cooling.

・The setting range of offset value is ±3℃ both in cooling and heating.

Operation mode The [Valid/Invalid] setting of [Auto][Cooling][Heating] and [Dry] can be done respectively. B

Fan speed The setting of [Fan speed] can be done from following patterns.・1-speed, 2-speeds (Hi-Me), 2-speeds (Hi-Lo), 3-speeds, 4-speeds. B

External input The applicable range ([Individual] or [All units]) of CnT input to the multiple indoor units connected in one control system.

・[Individual] : Only the unit received CnT input signal.・[All units] : All the units connected to one control system received CnT input signal.

Ventilation setting The setting of [Invalid] operation of ventilator, [Interlock] with AC or [Independent] of ventilator can be selected.

・When setting [Interlock], the operation of external ventilator is interlocked with the operation of AC ・When setting [Independent], only the operation of external ventilator is available.

Flap control The [Flap control] method can be switched to[Stop at fixed position] or [Stop at any position]・[Stop at fixed position] : Stop the flap at a certain position

among the designated 4 positions.・[Stop at any position] : Stop the flap at any arbitrary position just after the stopping command from RC was sent.

Auto-restart The operation control method after recovery of power blackout happened during operation can be set. B

Auto temp. setting [Valid] or [Invalid] of [Auto temp. setting] can be selected. B

Auto fan speed setting [Valid] or [Invalid] of [Auto fan speed setting] can be selected. B

Main indoor unit address can be set.

・Only the Main indoor unit can change operation mode and the Sub indoor units dominated by the Main indoor unit shall follo w.

・The Main indoor unit can domain 10 indoor units a t a maximum.

12.Installer settings

13.RC function settings

Setting & display item

11. Administrato r settings

[Service password]

High ceiling The fan tap of indoor fan can be changed. ・[Standard] [High ceiling 1] [High ceiling 2] can be selected. B

Filter sign The setting of filter sign display timer can be done from following patterns. B

External input 1

The content of control by external input can be changed.・The selectable contents of control are [On/Off] [Permission/Prohibition] [Cooling/heating] [Emergency stop]

External input 1 signal The type of external input signal ([Level input]/[Pulse input]) can be changed. B

External input 2 ・The selectable contents of control are [On/Off] [Permission/Prohibition] [Cooling/heating] [Emergency stop] B

External input 2 signal The type of external input signal ([Level input]/[Pulse input]) can be changed. B

Heating thermo-off tem p. adjust.

The judgment temp. of heating thermo-off can be adjusted within the range from 0 to +3℃(1℃ interval) B

Return air sensor adjus t. The sensing temp. of return air temp. sensor built in the indoor unit can be adjusted within the range of ±2℃. B

Fan control i n heating t hermo OFF

The fan control method at heating thermo-off can be changed.・The selectable fan control methods are [Low] [Set fan speed] [Intermittent] [Stop]. B

Anti-frost temp. The judgment temp. of anti-frost control for the indoor unit in cooling can be changed to [Temp. High] or [Temp. Low]. B

Anti-frost control When the anti-frost control of indoor unit in cooling is activated, the fan speed can be changed.

Drain pump operation In any operation mode in addition to cooling and dry mode, the setting of drain pump operation can be done. B

Residual fan operation in cooling

The time period of residual fan operation after stopping in cooling mode can be set. B

Residual fan operation in heating

The time period of residual fan operation after stopping or thermo-off in heating mode can be set. B

Intermittent fan opera tion in hea ting

The fan operation rule following the residual fan operation after stopping or thermo-off in heating mode can be set. B

Fan circulat or operatio n In case that the fan is operated as the circulator, the fan control rule can be set. B

Control pressure adjust . (For OA processing uni t only)

When only the OA processing units are operated, control pressure value can be changed. B

Auto operation mode The [Auto rule selection] for switching the operation mode automatically can be selected from 3 patterns. B

Thermo. rule setting When selecting [Outdoor air temp. control], the judgment temp can be offset by outdoor temp.. B

Auto fan speed control

Under the [Auto fan speed control] mode, the switching range of fan speed can be selected from following 2 patterns [Auto 1] [Auto 2]. ・[Auto 1] : Hi ⇔Me⇔Lo・[Auto 2] : P-hi⇔Hi⇔Me ⇔Lo

[Service password]

1

2

3

4

5

6

IU address No. Max. 16 indoor units can be connected to one remote control, and all address No. of the connected indoor units can be displayed.

・The indoor unit conforming to the address No. can be identified by selecting the address No. and tapping [Check] to operate the indoor fan.

Next service date The [Next service date] can be registered.・The [Next service date] and [Service contact] is displayed on the [Periodical check] message screen. AB

Operation data Total 39 items of [Operation data] for indoor unit and outdoor unit can be displayed. B

Error history [Date and time of error occurred] [I/U address] [Error code] for Max. 16 latest cases of error history can be displayed. B

Display anomaly data The operation data just before the latest error stop can be displayed. B

Reset periodical check The timer for the periodical check can be reset. B

Saving I/U settings The I/U settings memorized in the indoor PCB connected to the remote control can be saved in the memory of the remote control.

Special settings [Erase I/U address] [CPU reset] [Initializing] [Touch panel calibration] B

14. I/U settings

15.Service & Maintenance

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

(4) Operation and setting from remote control

Page 9

– 7 –

'14 • KX-SM-202

⑥ Operation and setting from remote control (continued)

Description

[Administrator password]

A

1

Enable/Disable setting ・Enable/Disable setting of operation can be set. [On/Off] [Change set temp.] [Change operation mode] [Change air flow direction]

[Individual flap control setting][Fan speed] [High power operation] [Energy-saving operation] [Timer settings] [Weekly timer setting]

・Request for administrator password can be set. [Individual flap control setting][Weekly timer][Energy-saving setting][Home leave mode][Administrator settings]

2

Silent mode timer The period of time to operate the outdoor unit by prioritizing the quietness can be set.

・The [Start time] and the [End time] for operating outdoor unit in silent mode can be set. ・The period of the operation time can be set once a day by 5 minutes interval.

3 Setting temp. range The upper/lower limit of indoor temp. setting range can be set.

・The limitation of indoor temp. setting range can be set for each operation mode in cooling and heating.

4 Temp. increment setting The temp increment setting can be changed by 0.5℃ or 1.0℃. A

5

RC display setting

Register [Room name] [Name of I/U]

Display [indoor temp.] or not.

Display [inspection code] or not.

Display [Heating stand-by] [Defrost operation] [Auto cooling/heating] or not

○

△

△

△

△

○

6

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

Change administrator password The administrator password can be changed. (Default setting is "0000")

The administrator password can be reset.

A

B

[Service password]

B

Installation date The [Installation date] can be registered.

・

When registering the [Installation date], the [Next service date] is displayed automatically. (For changing the [Next service date]. please refer the item of [Service & Maintenance].)

B

Service contact The [Service contact] can be registered and can be displayed on the RC.

・The [Contact company] can be registered within 10 characters. ・The [Contact phone] can be registered within 13 digits.

Test run

Cooling test run

On/Off operation of the test run can be done.

The [Cooling test run] can be done at 5℃ of set temp. for 30 minutes. ○

Drain pump test run Only the drain pump can be operated. ○

Compressor Hz fixed oper ation

The [Test run] operation can be done with fixed compressor Hz set by installer. ○

Static pressure adjust ment In case of combination with only the ducted indoor unit which has a function of static pressure adjustment, the static pressure is adjustable.

Change auto-address The set address of each indoor unit decided by auto-address setting method can be changed to any other address. (For multiple KX units only) B○△

Address setting of Main IU

[Service password]

B

Main/Sub RC setting The setting of [Main/Sub RC] can be changed. B

RC sensor

The [Valid/Invalid] setting of [RC sensor] can be done. Respective setting in cooling and heating is available.

B

RC sensor adjustment The offset value of [RC sensor] sensing temp. can be set respectively in heating and cooling.

・The setting range of offset value is ±3℃ both in cooling and heating.

B

Operation mode The [Valid/Invalid] setting of [Auto][Cooling][Heating] and [Dry] can be done respectively. B

Fan speed The setting of [Fan speed] can be done from following patterns.・1-speed, 2-speeds (Hi-Me), 2-speeds (Hi-Lo), 3-speeds, 4-speeds. B

External input The applicable range ([Individual] or [All units]) of CnT input to the multiple indoor units connected in one control system.

・[Individual] : Only the unit received CnT input signal.・[All units] : All the units connected to one control system received CnT input signal.

B

Ventilation setting The setting of [Invalid] operation of ventilator, [Interlock] with AC or [Independent] of ventilator can be selected.

・When setting [Interlock], the operation of external ventilator is interlocked with the operation of AC ・When setting [Independent], only the operation of external ventilator is available.

B

Flap control The [Flap control] method can be switched to[Stop at fixed position] or [Stop at any position]・[Stop at fixed position] : Stop the flap at a certain position

among the designated 4 positions.・[Stop at any position] : Stop the flap at any arbitrary position just after the stopping command from RC was sent.

B

Auto-restart The operation control method after recovery of power blackout happened during operation can be set. B

○

○

△

○

○

○

○

○

○

Auto temp. setting [Valid] or [Invalid] of [Auto temp. setting] can be selected. B

Auto fan speed setting [Valid] or [Invalid] of [Auto fan speed setting] can be selected. B

△B

B

B

B

A

A

A

A

Main indoor unit address can be set.

・Only the Main indoor unit can change operation mode and the Sub indoor units dominated by the Main indoor unit shall follo w.

・The Main indoor unit can domain 10 indoor units a t a maximum.

12.Installer settings

13.RC function settings

Setting & display item

11. Administrator settings

RC-EX

series

RC-E4

RC-E5

[Service password]

B

High ceiling The fan tap of indoor fan can be changed. ・[Standard] [High ceiling 1] [High ceiling 2] can be selected. B

Filter sign The setting of filter sign display timer can be done from following patterns. B

External input 1

The content of control by external input can be changed.・The selectable contents of control are [On/Off] [Permission/Prohibition] [Cooling/heating] [Emergency stop]

B

External input 1 signal The type of external input signal ([Level input]/[Pulse input]) can be changed. B

External input 2 ・The selectable contents of control are [On/Off] [Permission/Prohibition] [Cooling/heating] [Emergency stop] B

External input 2 signal The type of external input signal ([Level input]/[Pulse input]) can be changed. B

Heating thermo-off tem p. adjust.

The judgment temp. of heating thermo-off can be adjusted within the range from 0 to +3℃(1℃ interval) B

Return air sensor adjus t. The sensing temp. of return air temp. sensor built in the indoor unit can be adjusted within the range of ±2℃. B

Fan control i n heating t hermo OFF

The fan control method at heating thermo-off can be changed.・The selectable fan control methods are [Low] [Set fan speed] [Intermittent] [Stop]. B

Anti-frost temp. The judgment temp. of anti-frost control for the indoor unit in cooling can be changed to [Temp. High] or [Temp. Low]. B

Anti-frost control When the anti-frost control of indoor unit in cooling is activated, the fan speed can be changed.

B

Drain pump operation In any operation mode in addition to cooling and dry mode, the setting of drain pump operation can be done. B

Residual fan operation in cooling

The time period of residual fan operation after stopping in cooling mode can be set. B

Residual fan operation in heating

The time period of residual fan operation after stopping or thermo-off in heating mode can be set. B

Intermittent fan opera tion in hea ting

The fan operation rule following the residual fan operation after stopping or thermo-off in heating mode can be set. B

Fan circulat or operatio n In case that the fan is operated as the circulator, the fan control rule can be set. B

Control pressure adjust . (For OA processing uni t only)

When only the OA processing units are operated, control pressure value can be changed. B

○

○

○

○

△

△

○

○

○

○

○

○

○

○

Auto operation mode The [Auto rule selection] for switching the operation mode automatically can be selected from 3 patterns. B

Thermo. rule setting When selecting [Outdoor air temp. control], the judgment temp can be offset by outdoor temp.. B

Auto fan speed control

Under the [Auto fan speed control] mode, the switching range of fan speed can be selected from following 2 patterns [Auto 1] [Auto 2]. ・[Auto 1] : Hi ⇔Me⇔Lo・[Auto 2] : P-hi⇔Hi⇔Me⇔Lo

B

[Service password]

B

1

2

3

4

5

6

IU address No. Max. 16 indoor units can be connected to one remote control, and all address No. of the connected indoor units can be displayed.

・The indoor unit conforming to the address No. can be identified by selecting the address No. and tapping [Check] to operate the indoor fan.

B

Next service date The [Next service date] can be registered.・The [Next service date] and [Service contact] is displayed on the [Periodical check] message screen. AB

Operation data Total 39 items of [Operation data] for indoor unit and outdoor unit can be displayed. B

Error history [Date and time of error occurred] [I/U address] [Error code] for Max. 16 latest cases of error history can be displayed. B

Display anomaly data The operation data just before the latest error stop can be displayed. B

Reset periodical check The timer for the periodical check can be reset. B

Saving I/U settings The I/U settings memorized in the indoor PCB connected to the remote control can be saved in the memory of the remote control.

B

Special settings [Erase I/U address] [CPU reset] [Initializing] [Touch panel calibration] B

○

○

△

○

△

△

Confirmation of Inspect ion The address No, of anomalous indoor/outdoor unit and error code are displayed.

USB connection Weekly timer setting and etc., can be set from PC.

C

A

17.PC connection

14. I/U settings

15.Service & Maintenance

16.Inspection

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Page 10

– 8 –

'14 • KX-SM-202

Model RC-E5

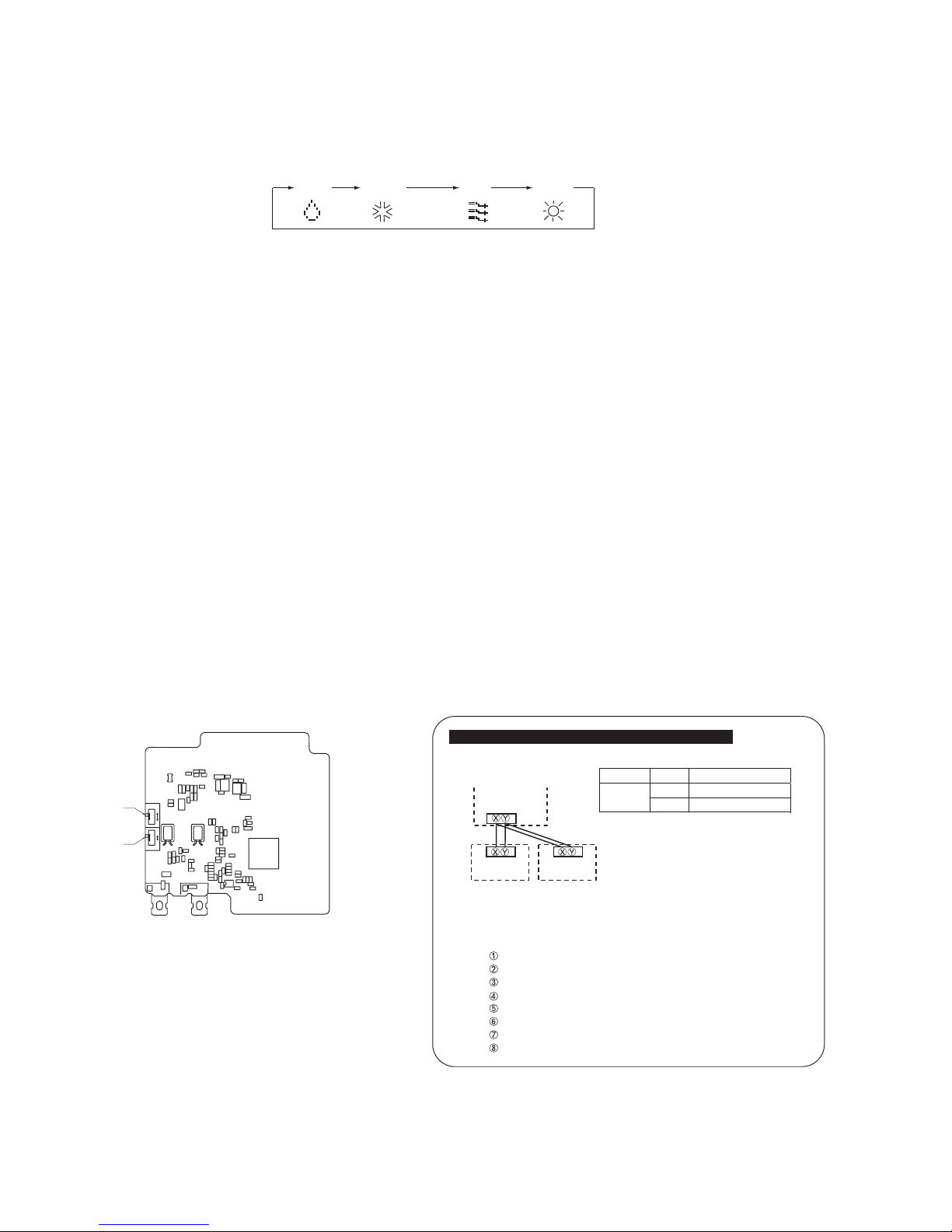

(1) Switching sequence of the operation mode switches of remote control

DRY COOL FAN HEAT

(2) CPU reset

This functions when “CHECK” and “ESP” buttons on the remote control are pressed simultaneously. Operation is same as that

of the power supply reset.

(3) Power failure compensation function (Electric power supply failure)

• This becomes effective if “Power failure compensation effective” is selected with the setting of remote control function.

• Since it memorizes always the condition of remote control, it starts operation according to the contents of memory no

sooner than normal state is recovered after the power failure. Although the auto swing stop position and the timer mode are

cancelled, the weekly timer setting is restored with the holiday setting for all weekdays.

After recovering from the power failure, it readjusts the clock and resets the holiday setting for each weekday so that the

setting of weekly timer becomes effective.

• Content memorized with the power failure compensation are as follows.

Note (1) Items (f), (g) and (h) are memorized regardless whether the power failure compensation is effective or not while the setting of silent mode is cancelled

regardless whether the power failure compensation is effective or not.

(a)

At power failure – Operating/stopped

If it had been operating under the off timer mode, sleep timer mode, the state of stop is memorized. (Although the

timer mode is cancelled at the recovery from power failure, the setting of weekly timer is changed to the holiday

setting for all weekdays.)

(b)

Operation mode

(c)

Airowvolumemode

(d)

Room temperature setting

(e)

Louver auto swing/stop

However, the stop position (4-position) is cancelled so that it returns to Position (1).

(f)

“Remote control function items” which have been set with the remote control function setting (“Indoor function

items” are saved in the memory of indoor unit.)

(g)

Upper limit value and lower limit value which have been set with the temperature setting control.

(h)

Sleep timer and weekly timer settings (Other timer settings are not memorized.)

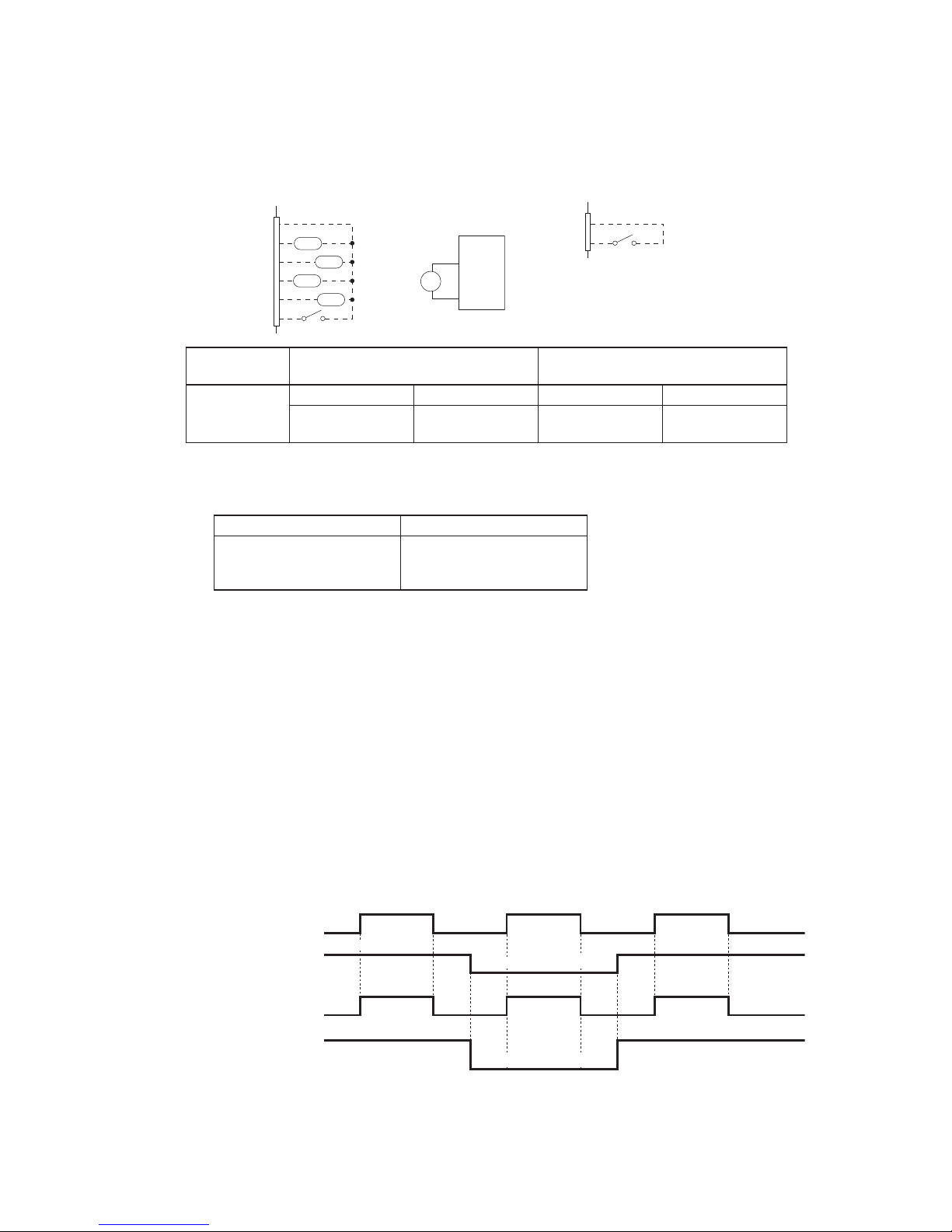

[Parts layout on remote control PCB]

X

Y

SW2

SW1

A

B

M

S

親

子

SW1

SW2

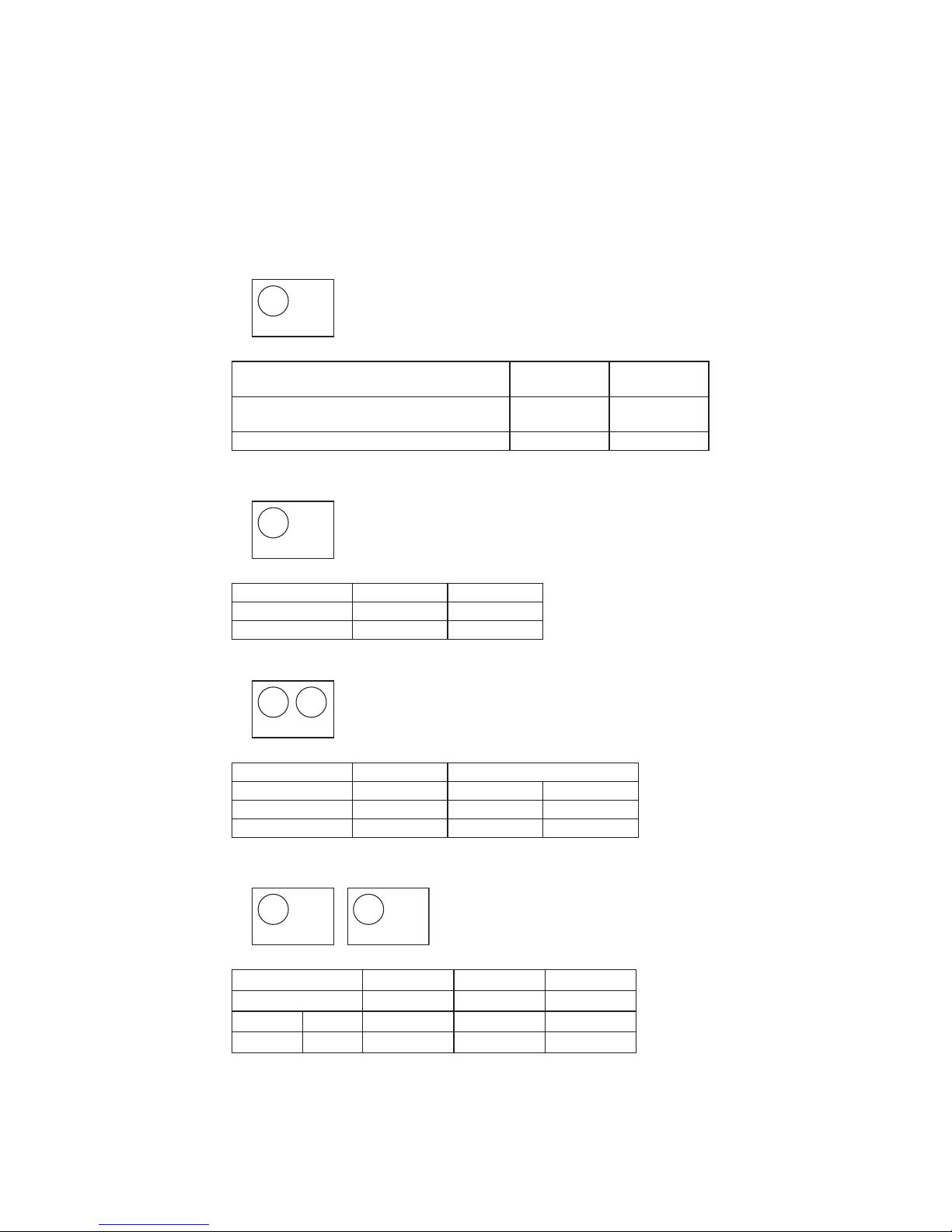

Master/ slave setting when more than one remote controls are used

A maximum of two remote controls can be connected to one indoor unit (or one group of indoor units.)

Remote control cord (no polarity)

Remote control

SW1 "Master"

Switch Setting Contents

M Master remote control

SW1

S Slave remote control

Remote control

SW1 "Slave"

Indoor units

Note (1) Don’t change SW2 because it is not used normally.

Caution

When using multiple remote controls, the following dispiays or settings

cannot be done with the slave remote control. It is available only with

the master remote control.

Louver position setting (set upper or lower limit of swinging range)

Setting indoor unit functions

Setting temperature range

Operation data display

Error data display

Silent mode setting

Test operation of drain pump

Remote control sensor setting

Page 11

– 9 –

'14 • KX-SM-202

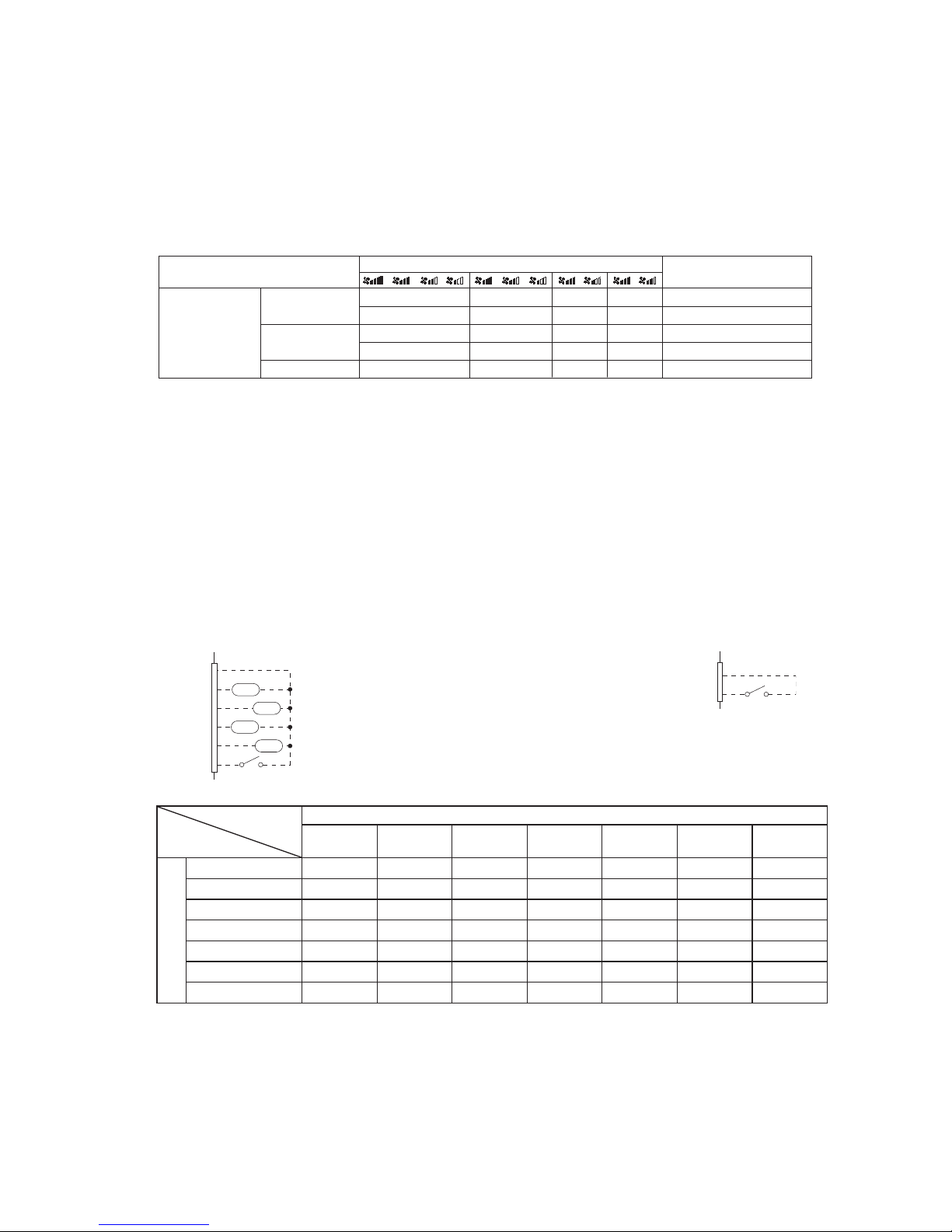

1.3 Operation control function by the indoor control

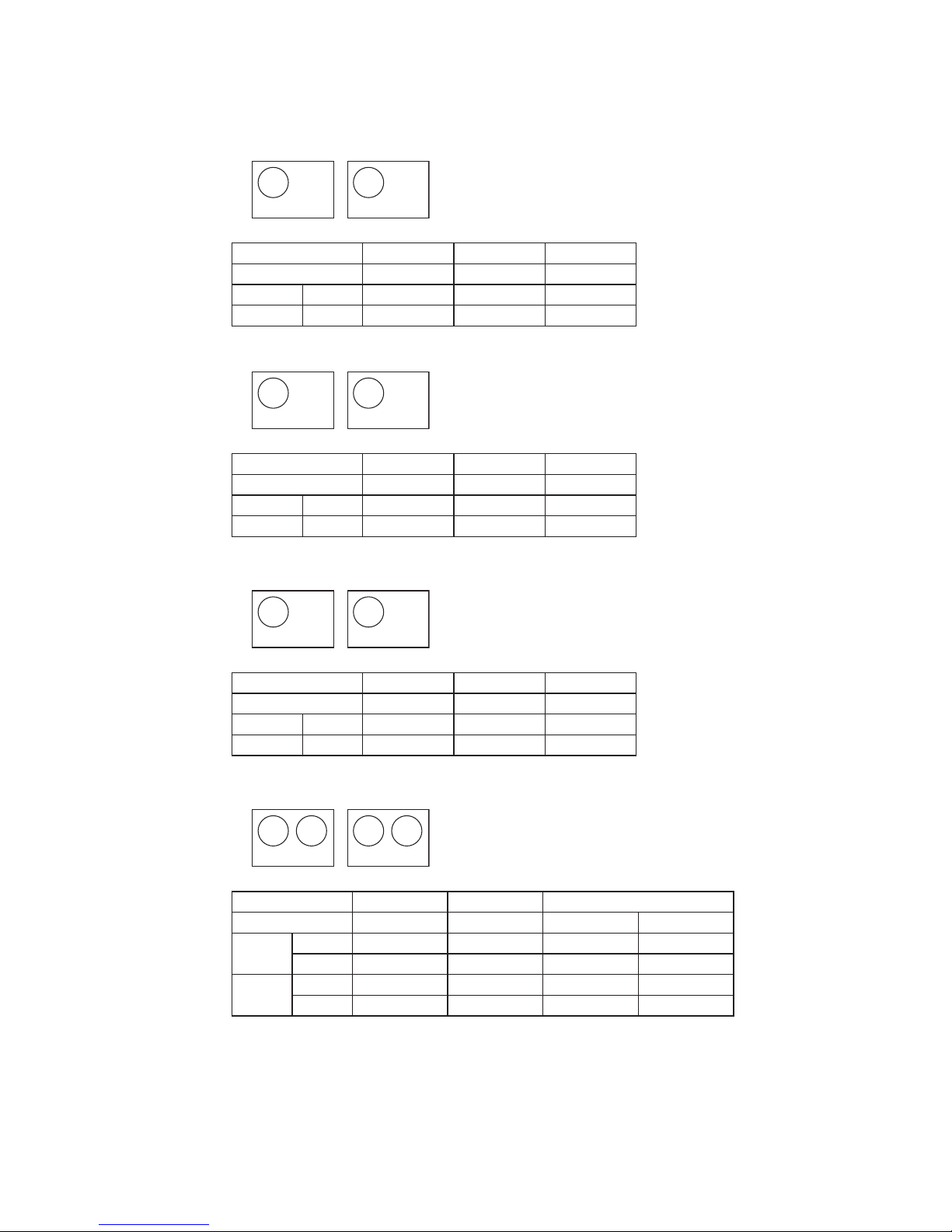

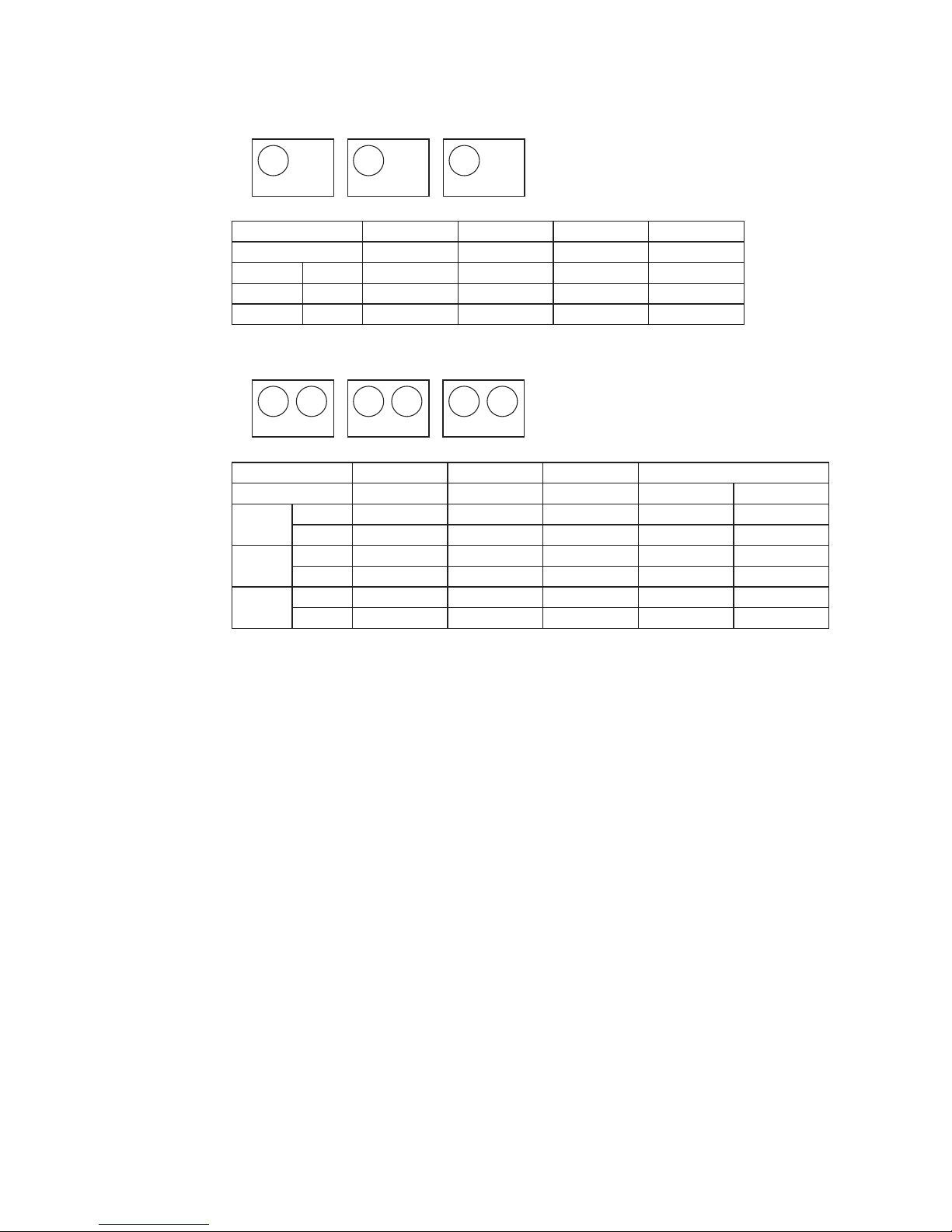

(1) Operations of functional items during cooling/heating

Cooling Heating

Dehumidifying

Fan

Operation

Functional item

Thermostat

ON

Thermostat

ON

Thermostat

OFF

Thermostat

OFF

Hot start

(Defrost)

Compressor

4-way valve

Outdoor unit fan

Indoor unit fan

Drain pump

(3)

(2)

(2)

/

/

()

()

/

/

/

/

Thermostat ON:

Thermostat OFF:

(2)

/

(2)

Note (1) : Operation : Stop /: Turned ON/OFF by the control other than the room temperature control.

(2) ON during the drain motor delay control.

(3) Drain pump ON setting may be selected with the indoor unit function setting of the wired remote control.

(2) Dehumidifying operation

Return air temperature thermistor [Th

I-A (by the remote control when the remote control thermistor is enabled)] controls

the indoor temperature environment simultaneously.

(a) Operation is started in the cooling mode. When the difference between the return air temperature and the setting

temperature is 2°C or less, the indoor unit fan tap is brought down by one tap. That tap is retained for 3 minutes

after changing the indoor unit fan tap.

(b) If the return air temperature exceeds the setting temperature by 3°C during dehumidifying operation, the indoor unit

fan tap is raised. That tap is retained for 3 minutes after changing the indoor unit fan tap.

(c) If the thermostat OFF is established during the above control, the indoor unit fan tap at the thermostat ON is retained

so far as the thermostat is turned OFF.

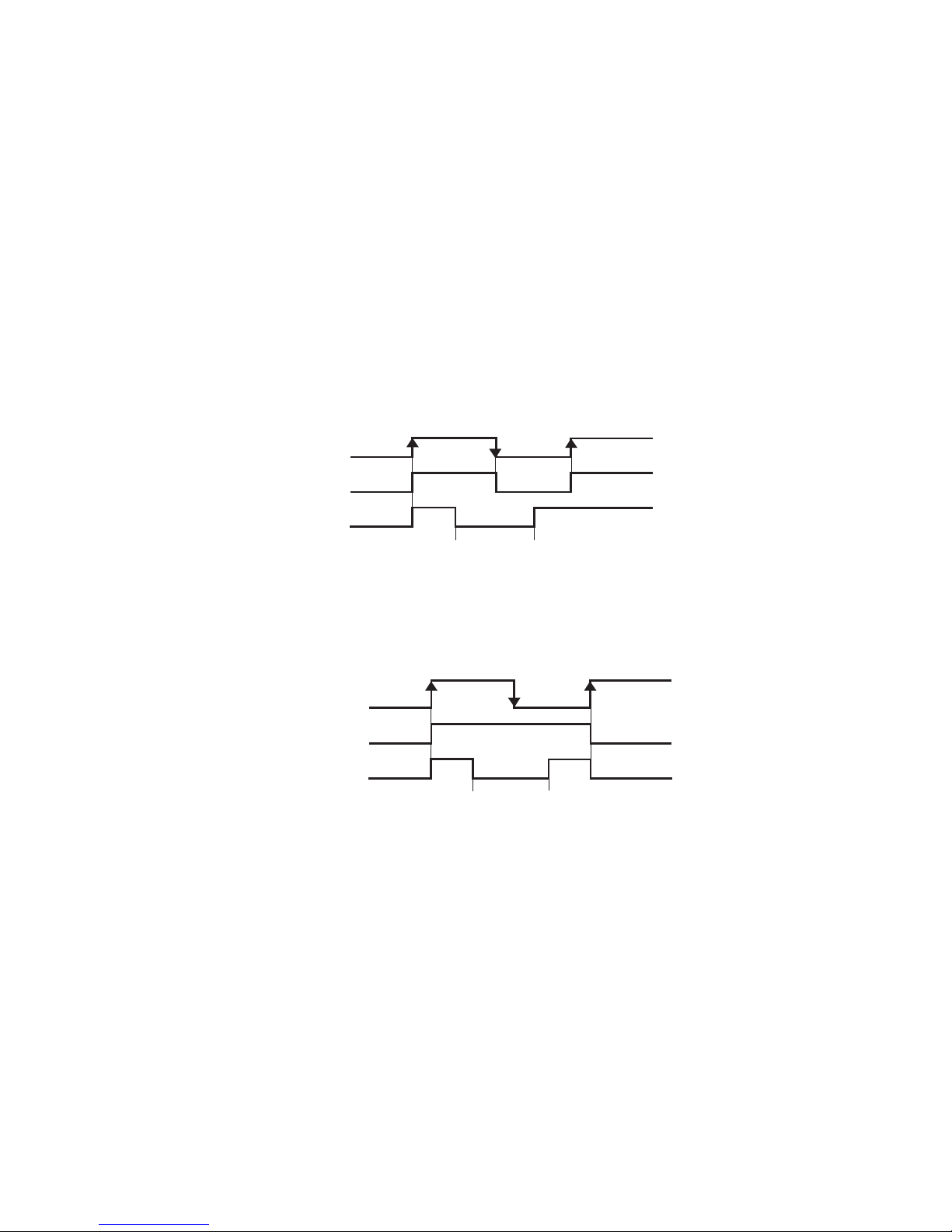

(3) Timer operation

(a) RC-EX1A

(i) Sleep timer

Set the time from the start to stop of operation. The time can be selected in the range from 30 to 240 minutes (in the

unit of 10-minute).

Note (1) Enable the “Sleep timer” setting from the remote control. If the setting is enabled, the timer operates at every time.

(ii) Set OFF timer by hour

Set the time to stop the unit after operation, in the range from 1 to 12 hours (in the unit of hour).

(iii) Set ON timer by hour

Set the time to start the unit after the stop of operation, in the range from 1 to 12 hours (in the unit of hour). It is

allowed also to set simultaneously the indoor temperature, operation mode, air flow rate and warm-up enabled/

disabled.

(iv) Set ON timer by clock

Set the time to start operation. The time can be set in the unit of 5-minute. This setting can be activated only once

oratevery time. It is allowed alsotosetsimultaneouslytheindoor temperature, operation mode, air owrateand

warm-up enabled/disabled.

Note (1) It is necessary to set the clock to use this timer.

(v) Set OFF timer by clock

Set the time to stop operation. The time can be set in the unit of 5-minute. This setting can be activated only once or

at every time.

Note (1) It is necessary to set the clock to use this timer.

(vi) Weekly timer

Set the ON or OFF timer for a week. Up to 8 patterns can be set for a day. The day-off setting is provided for

holidays and non-business days.

Note (1) It is necessary to set the clock to use the weekly timer.

Page 12

– 10 –

'14 • KX-SM-202

(vii)

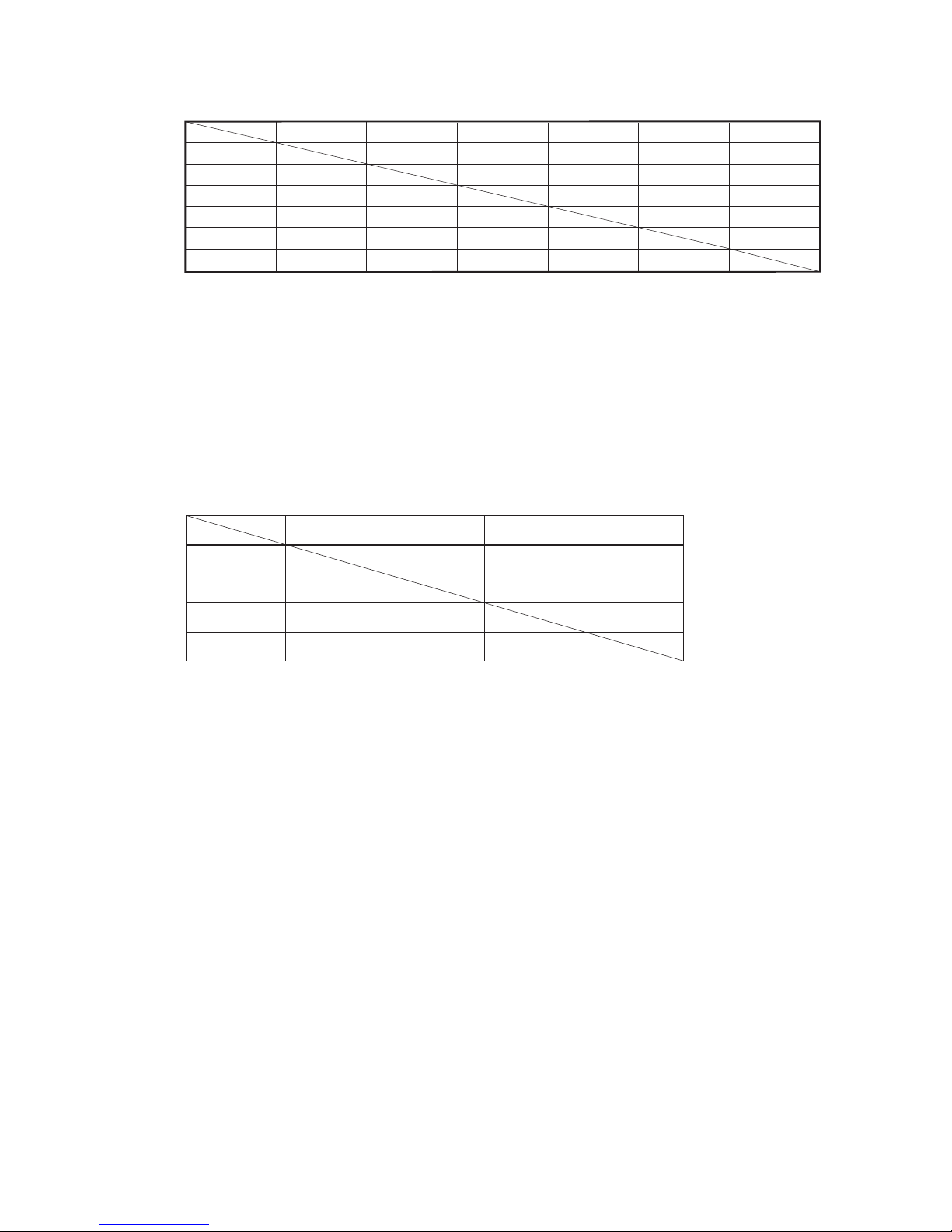

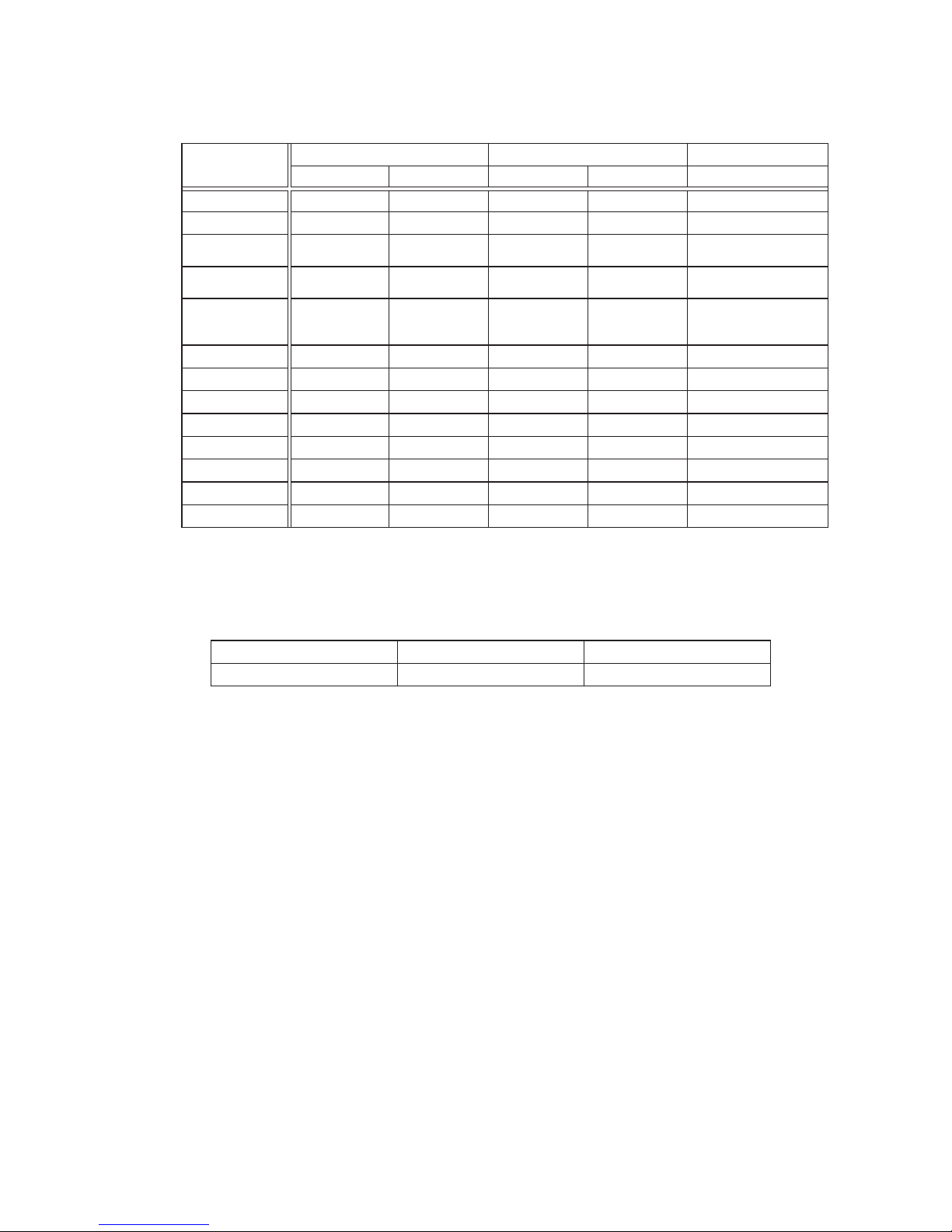

Combination of patterns which can be set for the timer operations

Note (1) : Allowed : Not

Sleep time

Sleep time

Set OFF timer by hour

Weekly timer

Set ON timer by hour

Set OFF timer by clock

Set ON timer by clock

Set OFF timer by hour

Set ON timer by hour

Set OFF timer by clock

Set ON timer by clock

Weekly timer

(b) RC-E5

(i) Sleep timer

Set the duration of time from the present to the time to turn off the air-conditioner.

It can be selected from 10 steps in the range from “OFF 1 hour later” to “OFF 10 hours later”. After the sleep timer

setting, the remaining time is displayed with progress of time in the unit of hour.

(ii) OFF timer

Time to turn OFF the air-conditioner can be set in the unit of 10 minutes.

(iii) ON timer

Time to turn ON the air-conditioner can be set. Indoor temperature can be set simultaneously.

(iv) Weekly timer

Timer operation (ON timer, OFF timer) can be set up to 4 times a day for each weekday.

(v) Timer operations which can be set in combination

Timer

OFF timer

ON timer

Weekly timer

Timer

OFF timer

ON timer

Weekly timer

Note (1) : Allowed : Not

Item

Item

(2) Since the ON timer, sleep timer and OFF timer are set in parallel, when the times to turn ON and OFF the airconditioner are duplicated, the setting

of the OFF timer has priority.

(4) Remote control display during the operation stop

When the operation is stopped (the power supply is turned ON), it displays preferentially the “Room temperature”, “Center/

Remote”, “Filter sign”, “Inspection” and “Timer operation”.

(5) Hot start (Cold draft prevention at heating)

(a) Operating conditions

When either one of following conditions either of (i) to (iv), the hot start control is performed.

(i) From stop to heating operation

(ii) From cooling to heating operation

(iii) From heating thermostat OFF to ON

(iv) After completing the defrost control (only on units with thermostat ON)

(b) Contents of operation

(i) Indoor fan motor control at hot start

1) Within 7 minutes after starting heating operation, the fan mode is determined depending on the condition of

thermostat (fan control with heating thermostat OFF).

a) Thermostat OFF

i) Operates according to the fan control setting at heating thermostat OFF.

ii) Even if it changes from thermostat OFF to ON, the fan continues to operate with the fan control at thermostat

OFF till the heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 35°C or higher.

iii) When the heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 35°C or higher, the fan

operateswiththesetairowvolume.

Page 13

– 11 –

'14 • KX-SM-202

b) Thermostat ON

i) When the heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 25°C or lower, the fan is

turned OFF and does not operate.

ii) When the heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 25°C or higher, the fan

operates with the fan control at heating thermostat OFF.

iii) When the heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 35°C or higher, the fan

operateswiththesetairowvolume.

c) Ifthe fan controlatheatingthermostat OFFissetat the “Setairowvolume”(from the remotecontrol),the

fanoperateswiththesetairowvolumeregardlessofthethermostatON/OFF.

2) Once the fan motor is changed from OFF to ON during the thermostat ON, the indoor fan motor is not turned

OFF even if the heat exchanger thermistor detects lower than 25

°C.

Note (1) When the defrost control signal is received, it complies with the fan control during defrosting.

3) Once the hot start is completed, it will not restart even if the temperature on the heat exchanger thermistor drops.

(ii) During the hot start, the louver is kept at the horizontal position.

(iii) When the fan motor is turned OFF for 7 minutes continuously after defrosting, the fan motor is turned ON regardless

of the temperatures detected with the indoor heat exchanger thermistors (ThI-R1, R2).

(c) Ending condition

(i) If one of following conditions is met during the hot start control, this control is terminated, and the fan is operated with

thesetairowvolume.

1) Heat exchanger thermistor (ThI-R1 or R2, whichever higher) detects 35

°C or higher.

2) It has elapsed 7 minutes after starting the hot start control.

(6) Hot keep

Hot keep control is performed at the start of the defrost control.

(a) Control

(i) When the indoor heat exchanger temperature (detected with ThI-R1 or R2) drops to 35°C or lower, the speed of

indoor fan is changed to the lower tap at each setting.

(ii) During the hot keep, the louver is kept at the horizontal position.

(b) Ending condition

Whentheindoorfan isatthe lowertapat eachsetting,itreturnsto thesetairow volumeastheindoorheatexchanger

temperature rises to 45°C or higher.

(7) Auto swing control (FDT, FDTC, FDTW, FDTS, FDE only)

(a) RC-EX1A

(i) Louver control

1) To operate the swing louver when the air conditioner is operating, press the “Direction” button on the TOP screen of

remote control. The wind direction select screen will be displayed.

2) Toswingthelouver,touchthe“Autoswing”button.Theloverwillmoveupanddown.Toxtheswinglouverata

position, touch one of [1] - [4] buttons. The swing lover will stop at the selected position.

3) Louver operation at the power on with a unit having the louver 4-position control function

The louver swings one time automatically (without operating the remote control) at the power on.

This allows the microcomputer recognizing and inputting the louver motor (LM) position.

(ii) Automatic louver level setting during heating

At the hot start and the heating thermostat OFF, regardless whether the auto swing switch is operated or not (auto

swing or louver stop), the louver takes the level position (in order to prevent blowing of cool wind). The louver position

display LCD continues to show the display which has been shown before entering this control.

(iii) Louver free stop control

If you touch the “Menu” → “Next” → “R/C settings” buttons one after another on the TOP screen of remote control,

the “Flap control” screen is displayed. If the free stop is selected on this screen, the louver motor stops upon receipt of

the stop signal from the remote control. If the auto swing signal is received from the remote control, the auto swing will

start from the position before the stop.

Page 14

– 12 –

'14 • KX-SM-202

(b) RC-E5

(i) Louver control

1) Press the “LOUVER” button to operate the swing louver when the air conditioner is operating.

“SWING ” is displayed for 3 seconds and then the swing louver moves up and down continuously.

2) Toxtheswinglouverataposition,pressonetimethe“LOUVER”buttonwhiletheswinglouverismovingsothat

four stop positions are displayed one after another per second.

When a desired stop position is displayed, press the “LOUVER” button again. The display stops, changes to show

the “STOP 1

” for 5 seconds and then the swing louver stops.

3) Louver operation at the power on with a unit having the louver 4-position control function

The louver swings one time automatically (without operating the remote control) at the power on.

This allows inputting the louver motor (LM) position, which is necessary for the microcomputer to recognize the

louver position.

Note (1) If you press the “LOUVER” button, the swing motion is displayed on the louver position LCD for 10 second. The display changes to the

“SWING ” display 3 seconds later.

(ii) Automatic louver level setting during heating

At the hot start with the heating thermostat OFF, regardless whether the auto swing switch is operated or not (auto

swing or louver stop), the louver takes the level position (In order to prevent the cold start). The louver position display

LCD continues to show the display which has been shown before entering this control.

(iii) Louver-free stop control

When the louver-free stop has been selected with the indoor function of wired remote control “ POSITION”, the

louver motor stops when it receives the stop signal from the remote control. If the auto swing signal is received from the

remote control, the auto swing will start from the position where it was before the stop.

Note (1) When the indoor function of wired remote control “ POSITION” has been switched, switch also the remote control function “

POSITION” in the same way.

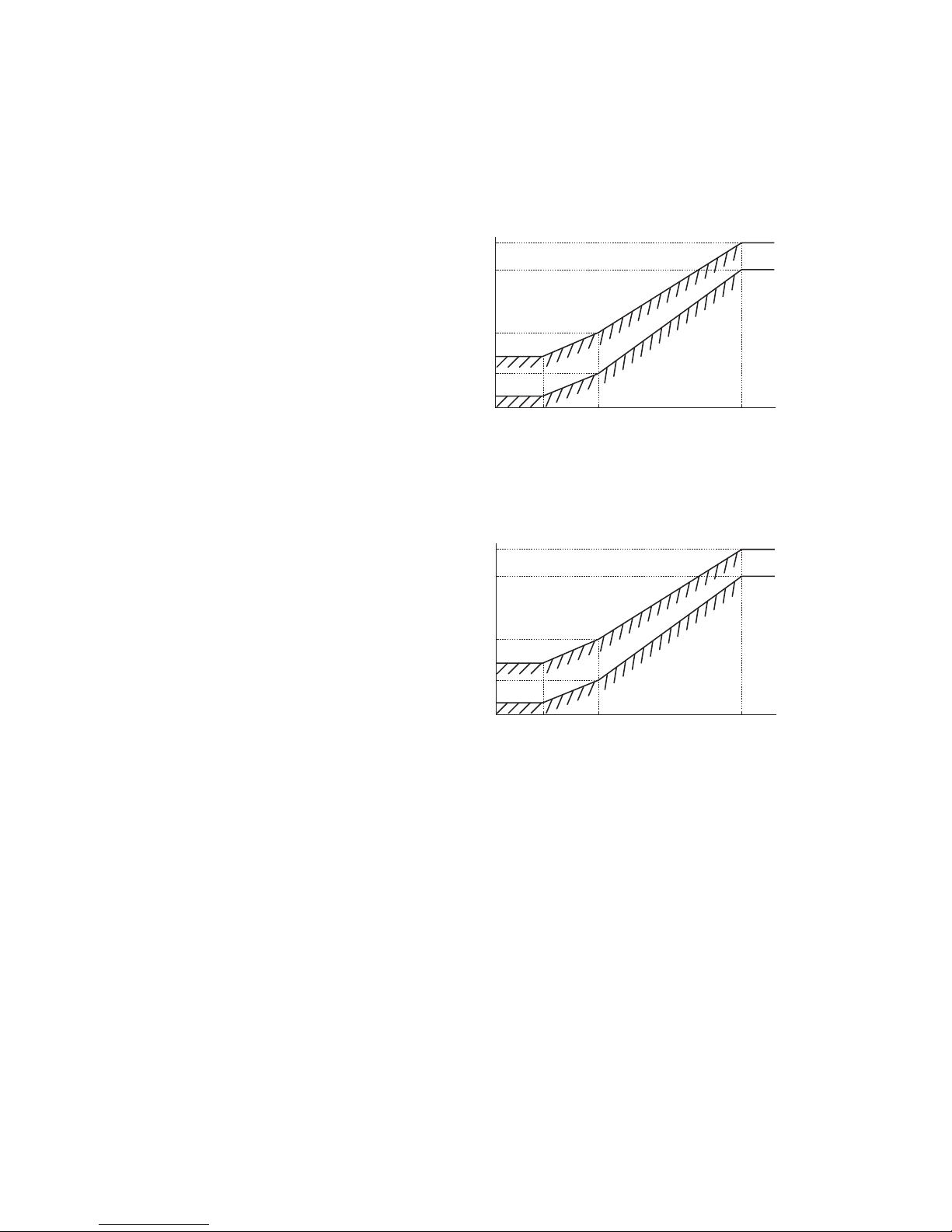

(8) Thermostat operation

(a) Cooling

(i) Thermostat is operated with the room temperature control.

(ii) Thermostat is turned ON or OFF relative to the set room temperature as shown below.

(iii) Thermostat is turned ON when the room temperature is in the range of -1 < Set temperature < +1 at the start of cooling

operation (including from heating to cooling).

(b) Heating

(i) Thermostat is operated with the room temperature control.

(ii) Thermostat is turned ON or OFF relative to the set room temperature as shown below.

(iii) Thermostat is turned ON when the room temperature is in the range of -1 < Set point < +1 at the start of cooling opera-

tion (including from cooling to heating).

Thermostat OFF

Set room temperature

Temperature drop

Temperature rise

-1

+1

Thermostat ON

Thermostat OFF

Heater OFF

Temperature rise

Temperature drop

Thermostat ON

Set room temperature

-1

+1

-1

+1

Heater ON

3C

◦

Page 15

– 13 –

'14 • KX-SM-202

(c) Fan control during heating thermostat OFF

(i) Following fan controls during the heating thermostat OFF can be selected with the indoor function setting of the wired

remote control.

① Low fan speed (Factory default), ② Set fan speed, ③ Intermittence, ④ Fan OFF

(ii) When the “Low fan speed (Factory default)” is selected, the following taps are used for the indoor fans.

・ For AC motor : Lo tap

・ For DC motor : ULo tap

(iii) When the “Set fan speed” is selected, it is operated with the set fan speed also in the thermostat OFF condition.

(iv) If the “Intermittence” is selected, following controls are performed:

1) If the thermostat is turned OFF during the heating operation, the indoor unit fan motor stops.

2) IndoorfanOFFisxedfor5minutes.Afterthe5minutes,theindoorfanisoperatedatLoorULofor2minutes.

In the meantime the louver is controlled at level.

3) After operating at Lo or ULo for 2 minutes, the indoor fan moves to the state of 1) above.

4) If the thermostat is turned ON, it moves to the hot start control.

5) When the heating thermostat is turned OFF, the remote control displays the temperature detected at the fan stop

and revises the temperature later when the indoor fan changes from Lo or ULo to stop.

The remote control uses the operation data display function to display temperatures and updates values of

temperature even when the indoor fan is turned OFF.

6) When the defrosting starts while the heating thermostat is turned OFF or the thermostat is turned OFF during

defrosting, the indoor fan is turned OFF. (Hot keep or hot start control takes priority.) However, the suction

temperature is updated at every 7-minute.

7) When the heating thermostat is turned ON or the operation is changed to another mode (including stop), this

control is stopped immediately, and the operating condition is restored.

(v) When the “Fan OFF” is selected, the fan on the indoor unit of which the thermostat has been turned OFF, is turned OFF.

The same occurs also when the remote control sensor is effective.

(d) Fan control during cooling thermostat OFF

(i) Following fan controls during the cooling thermostat OFF can be selected with the indoor function setting of the wired

remote control.

① Low fan speed, ② Set fan speed (Factory default), ③ Intermittence, ④ Fan OFF

(ii) When the “Low fan speed” is selected, the following taps are used for the indoor fans.

・ For AC motor : Lo tap

・ For DC motor : ULo tap

(iii) When the “Set fan speed” is selected, it is operated with the set fan speed also in the thermostat OFF condition.

(iv) If the “Intermittence” is selected, following controls are performed:

1) If the thermostat is turned OFF during the cooling operation, the indoor unit fan motor stops.

2) IndoorfanOFFisxedfor5minutes.Afterthe5minutes,theindoorfanisoperatedatLoorULofor2minutes.

3) After operating at Lo or ULo for 2 minutes, the indoor fan moves to the state of 1) above.

4) If the thermostat is turned ON, the fan starts operation at set fan speed.

5) When the cooling thermostat is turned OFF, the remote control displays the temperature detected at the fan stop

and revises the temperature later when the indoor fan changes from Lo or ULo to stop.

By using operation data display function at wireless remote control, the tempenature as displayad and the value is

updated including the fan stops.

6) When the cooling thermostat is turned ON or the operation is changed to another mode (including stop), this

control is stopped immediately, and the operating condition is restored.

(v) When the “Fan OFF” is selected, the fan on the indoor unit of which the thermostat has been turned OFF, is turned OFF.

The same occurs also when the remote control sensor is effective.

Page 16

– 14 –

'14 • KX-SM-202

(9) Filter sign

As the operation time (Total ON time of ON/OFF switch) accumulates to 180 hours

(1)

, “FILTER CLEANING” is displayed on

the remote control. (This is displayed when the unit is in trouble and under the centralized control, regardless of ON/OFF)

Note(1)Timesettingforthelter signcanbemadeasshownbelow usingtheindoor functionofwiredremotecontrol“FILTERSIGNSET”.(Itis setatTYPE1

at the shipping from factory.)

Filter sign setting

TYPE 1

TYPE 2

TYPE 3

TYPE 4

Function

Setting time: 180 hrs (Factory default)

Setting time: 600 hrs

Setting time: 1,000 hrs

Setting time: 1,000 hrs (Unit stop)

(2)

(2) After the setting time has elapsed, the “FILTER CLEANING” is displayed and, after operating for 24 hours further (counted also during the stop), the unit

stops.

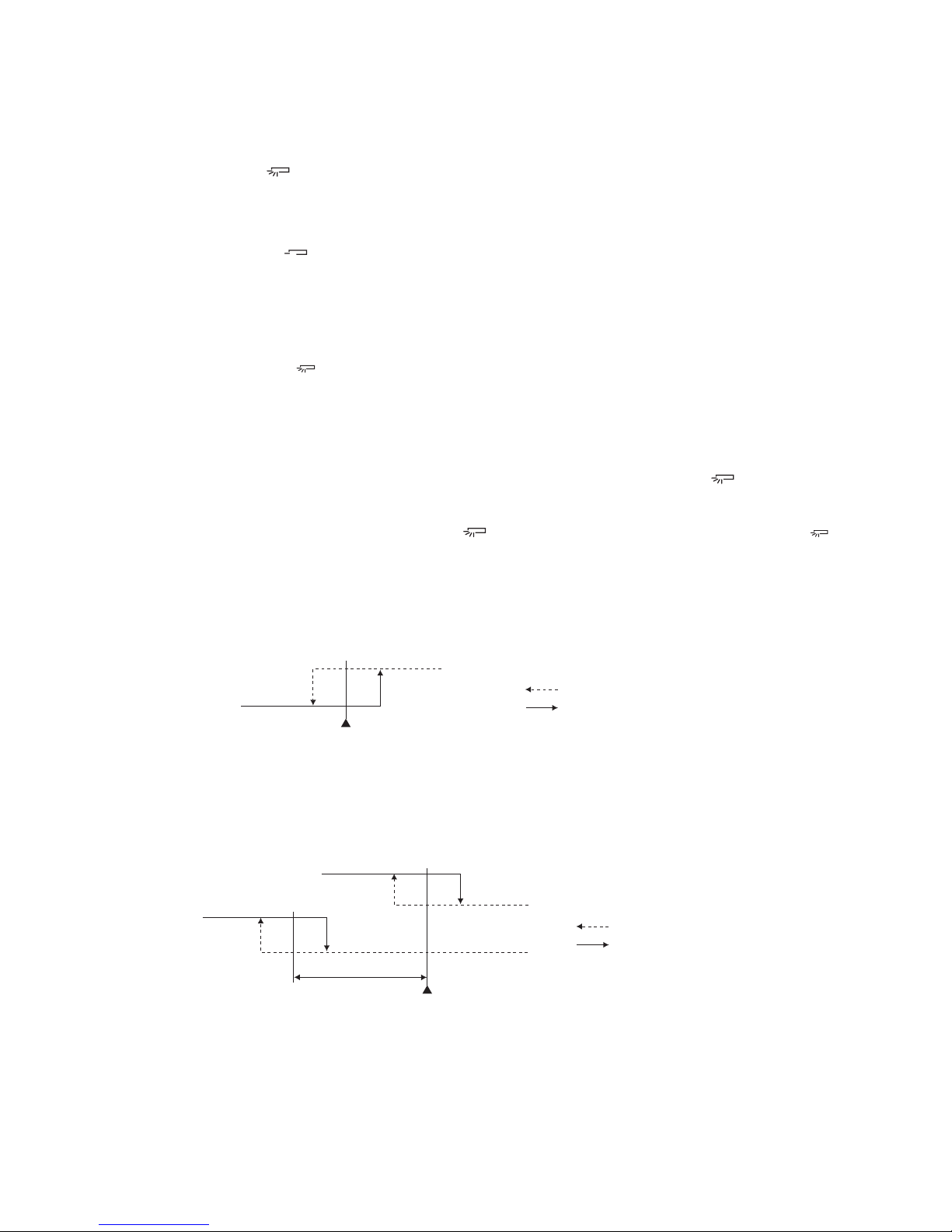

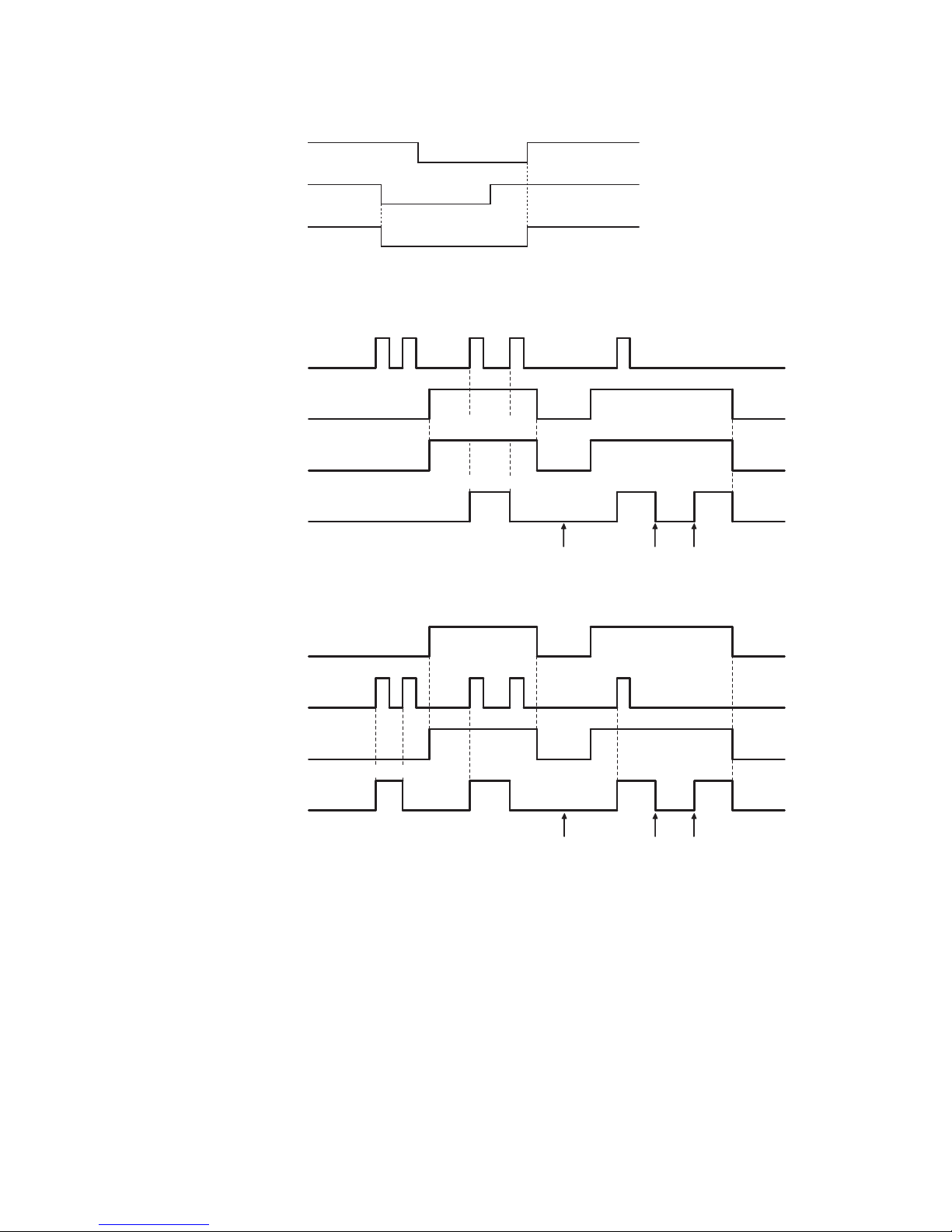

(10) Compressor inching prevention control

(a) Once the indoor unit thermostat has been turned ON, the thermostat is not turned OFF for 2 minutes (*1) after the

compressor ON even if the thermostat is turned OFF at the state of (9).

Thermostat ON/OFF with this control

2 minutes2 minutes

OFF

ON

ON

ON

Stopped by remote control, etc.

*1

*1Even when the thermostat of another indoor

unit is turned ON after the compressor ON,

the thermostat is not turned OFF for 2 minutes

after the compressor ON.

*1

OFF

OFF

3 minutes delay

Thermostat OFF in the condition of (9)

Compressor

Indoor unit A

Thermostat

Indoor unit B

Thermostat

(11) Drain pump control

(a) This control is operated when the inverter frequency is other than 0 Hz during the cooling operation and automatic

cooling and dehumidifying operations.

(b) Drain pump ON condition continues for 5 minutes even when it enters the OFF range according to (i) above after turning

the drain pump ON, and then stops. The 5-minute delay continues also in the event of anomalous stop.

(c) The drain pump is operated with the 5-minute delay operation when the compressor is changed from ON to OFF.

(d) Even in conditions other than the above (such as heating, fan, stop, cooling thermostat OFF), the drain pump control is

performed by the drain detection.

(e) Following settings can be made using the indoor function setting of the wired remote control.

(i)

(ii)

(iii)

(iv)

Note (1) Values in 〔

〕

are for the RC-EX1A model.

ާStandardin cooling & dryި: Drain pump is run during cooling and dry.

ާOperate in standard & heatingި: Drain pump is run during cooling, dry and heating.

ާOperate in heating & fanި: Drain pump is run during cooling, dry, heating and fan.

ާOperate in standard & fanި: Drain pump is run during cooling, dry and fan.

(b) When the oil return control has started while the thermostat is turned ON, the thermostat is not turned OFF even if the

thermostat OFF condition is met during the oil return control.

Page 17

– 15 –

'14 • KX-SM-202

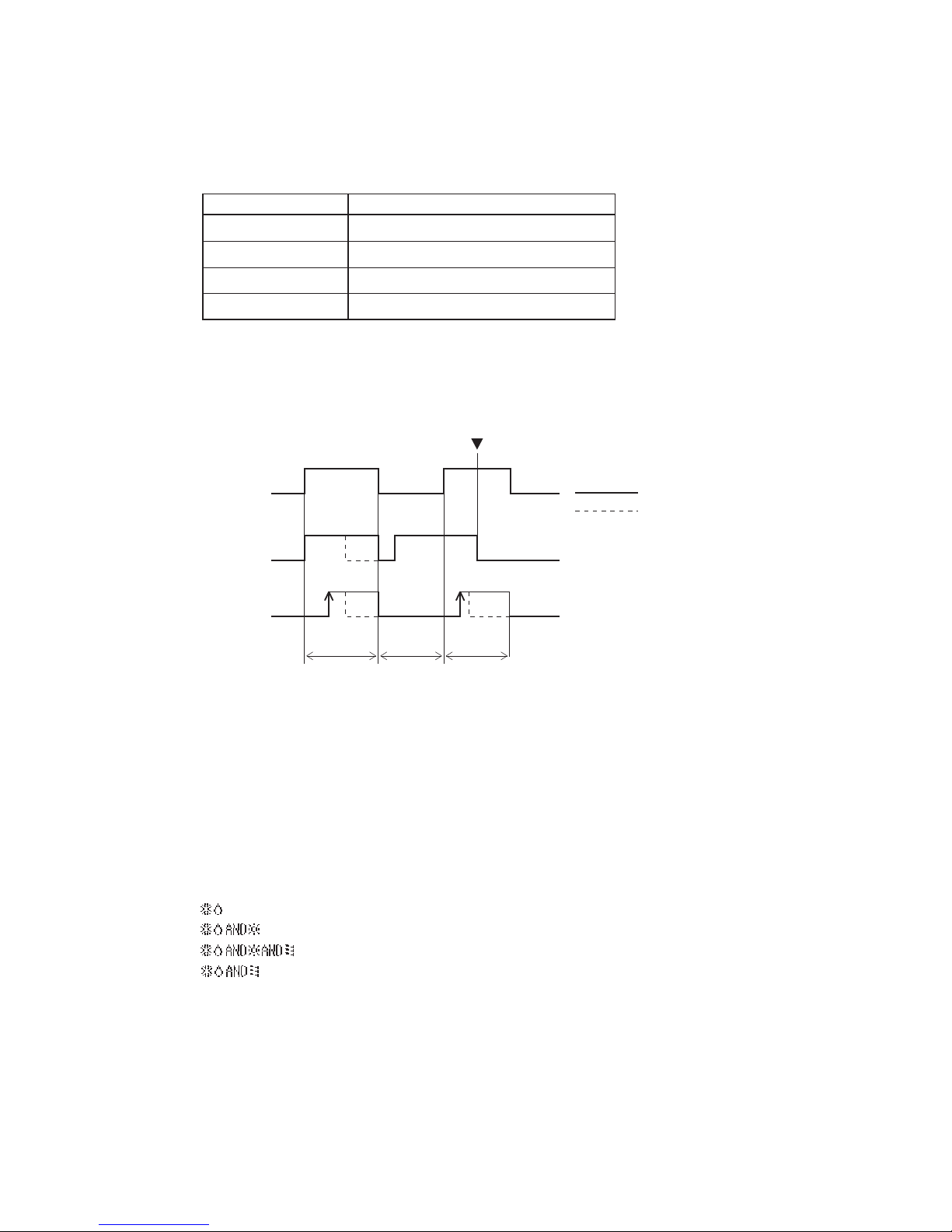

(12) Drain motor (DM) control

(a)

DraindetectionswitchisturnedONorOFFwiththeoatswitch(FS)andthetimer.

[

*

1]Draindetectionswitchisturned“ON”whentheoatswitch“Open”isdetectedfor3secondscontinuouslyinthe

drain detectable space.

[

*

2]Draindetectionswitchisturned“OFF”whentheoatswitch“Close”isdetectedfor10secondscontinuously.

(i) It detects always from 30 seconds after turning the power ON.

1) There is no detection of anomalous draining for 10 seconds after turning the drain pump OFF.

2) Turning the drain detection switch “ON” causes to turn ON the drain pump forcibly.

3) Turning the drain detection switch “OFF” releases the forced drain pump ON condition.

Normal state

[*1] [*2]

Normal state

Drain detection switch ON

Stop

(1)

Indoor unit operation mode

Control A

Control B

Compressor ON

Compressor OFF

Cooling Dry HeatingFan

(2)

Note (1) Including the stop from the cooling, dehumidifying, fan

and heating, and the anomalous stop

(2) Including the “Fan” operation according to the

mismatch of operation modes

(i) Control A

1) Iftheoatswitchdetectsanyanomalousdrainingcondition,theunitstopswiththeanomalousstop(displaysE9)

and the drain pump starts. After detecting the anomalous condition, the drain motor continues to be ON.

2) Itkeepsoperatingwhiletheoatswitchisdetectingtheanomalouscondition.

(ii) Control B

If the oat switch detects any anomalous drain condition, the drain motor is turned ON for 5 minutes, and at 10

seconds after the drain motor OFF it checks the oat switch. If it is normal, the unit is stopped under the normal

mode or, if there is any anomalous condition, E9 is displayed and the drain motor is turned ON. (The ON condition is

maintained during the drain detection.)

(b)

Indoor unit performs the control A or B depending on each operating condition.

(13) Operation check/drain pump test run operation mode

(a)

If the power is turned on by the dip switch (SW7-1) on the indoor PCB when electric power source is supplied, it enters the

mode of operation check/drain pump test run. It is ineffective (prohibited) to change the switch after turning power on.

(b) When the communication with the remote control has been established within 60 seconds after turning power on by the

dip switch (SW7-1) ON, it enters the operation check mode. Unless the remote control communication is established, it

enters the drain pump test run mode.

Note (1) To select the drain pump test run mode, disconnect the remote control connector (CNB) on the indoor PCB to shut down the remote control

communication.

(c) Operation check mode

There is no communication with the outdoor unit but it allows performing operation in respective modes by operating the

remote control.

(d) Drain pump test run mode

As the drain pump test run is established, the drain pump only operates and during the operation protective functions by

the microcomputer of indoor unit become ineffective.

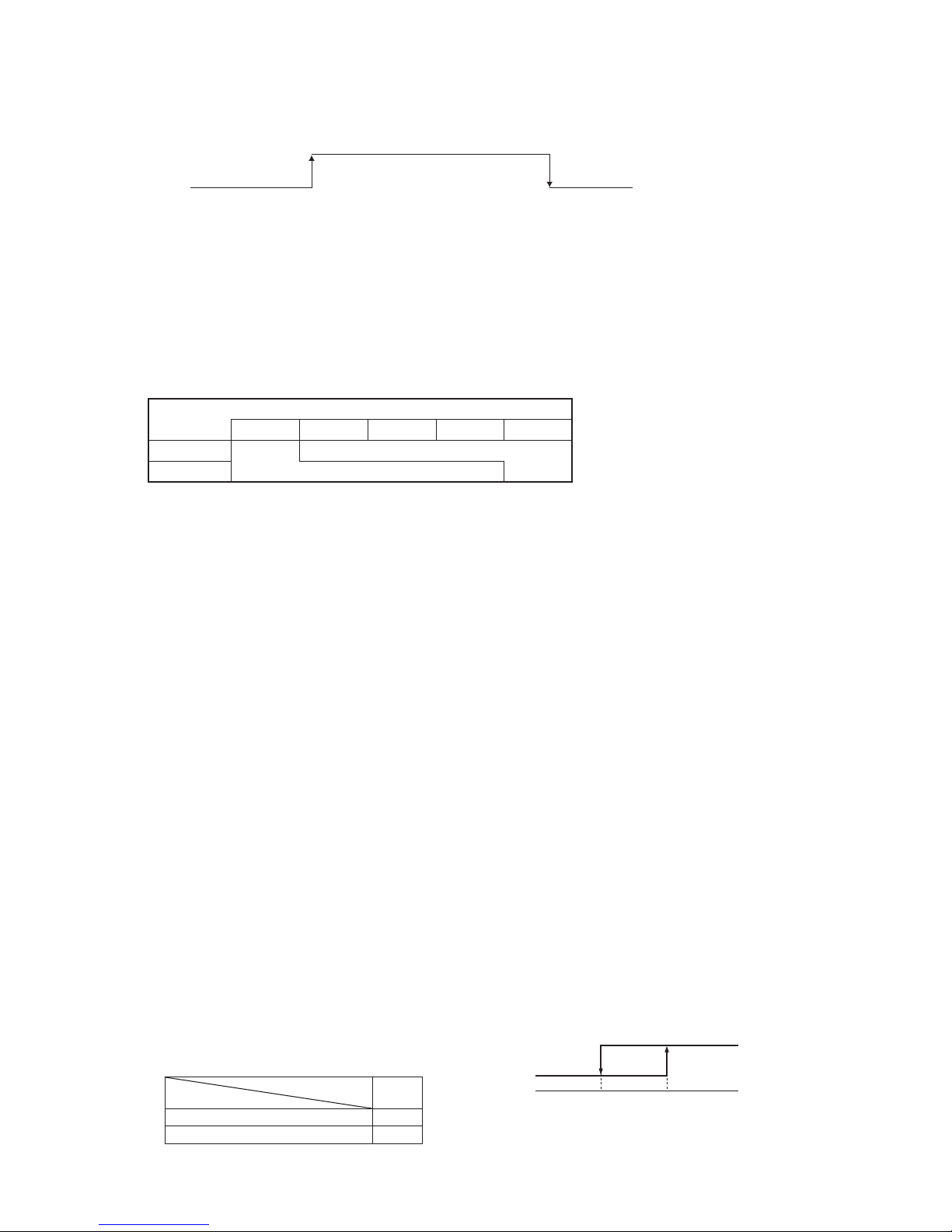

(14) Cooling, dehumidifying frost protection

To prevent frosting during cooling mode or dehumidifying mode operation, the of thermostat-OFF if the indoor heat exchanger

temperature (detected with ThI-R) drops to 1.0 °C or lower at 4 minutes after the thermostat-ON. If the indoor unit heat

exchanger temperature is 1.0 °C or lower after 5 minutes, the indoor unit is controlled thermostat-OFF. If it becomes 10°C or

higher, the control terminates. When the indoor heat exchanger temperature has become as show, the indoor unit send outdoor

unit the “Anti-frost” signal.

101.0

Indoor heat exchanger temperature (°C)

Thermostat-OFF

5 minutes

Thermostat-ON capable

SRC40~60

FDC100~140

Model

Symbol

A

4

4

1

1

1.0

1.0

2.5

2.5

B C

D

• Frost prevention temperature setting can be selected with the

indoor unit function setting of the wired remote control.

Symbol

Item

A

Temperature - Low (Factory default) 1.0

Temperature - High 2.5

Page 18

– 16 –

'14 • KX-SM-202

(15) Anomalous fan motor

(a)

After starting the fan motor, if the fan motor speed is 200min-1 or less is detected for 30 seconds continuously and 4 times

within 60 minutes, then fan motor stops with the anomalous stop (E16).

(b) If the fan motor fails to reach at -50(FDU: -500)

min

-1

less than the required speed, it stops with the anomalous stop (E20).

(16) High ceiling control

When sufficient air flow rate cannot be obtained from the indoor unit which is installed at a room with high ceiling, the air flow

rate can be increased by changing the fan tap. To change the fan tap, use the indoor unit function “FAN SPEED SET” on the

wired remote control.

--- -- --

PHi1 - Hi

PHi1 - Hi

PHi1 - Me

PHi1 - Me

PHi1 - Hi - Me

PHi1 - Hi - Me

STANDARD

HIGH SPEED1

HIGH SPEED2

FAN SPEED SET

Hi - Lo

Hi - Lo

Hi - Lo

Hi - Me Except FDT

Except FDT, FDTW, FDTS

Only FDT

Only FDT, FDTW, FDTS

Only FDT, FDTW, FDTS

Hi - Me

Hi - M

Hi - Me - Lo

Hi - Me - Lo

Hi - Me - Lo

PHi1 - PHi1 - Hi - Me

PHi2 - Hi - Me - Lo

PHi2 - PHi1 - Hi - Me

PHi1 - Hi - Me - Lo

PHi2 - Hi - Me - Lo

Indoor unit airflow setting

Series

Fan tap

Notes (1) Factory default is STANDARD.

(2) At the hot-start and heating thermostat OFF, or other, the indoor unit fan is operated at the low speed tap of each setting.

(3) This function is not able to be set with wireless remote controls or simple remote control (RCH-E3)

(17)

Abnormal temperature thermistor (return air/indoor heat exchanger) wire/short-circuit detection

(a) Broken wire detection

When the return air temperature thermistor detects -20°C or lower or the heat exchanger temperature thermistor detect

-40°C or lower for 5 seconds continuously, the compressor stops. After a 3-minute delay, the compressor restarts but,

if it is detected again within 60 minutes after the initial detection for 6 minutes continuously, stops again (the return air

temperature thermistor: E7, the heat exchanger temperature thermistor: E6).

(b) Short-circuit detection

If the heat exchanger temperature thermistor detects 70°C or higher for 5 seconds continuously at 2 minutes and 20

seconds after the compressor ON during cooling operation, the compressor stops (E6).

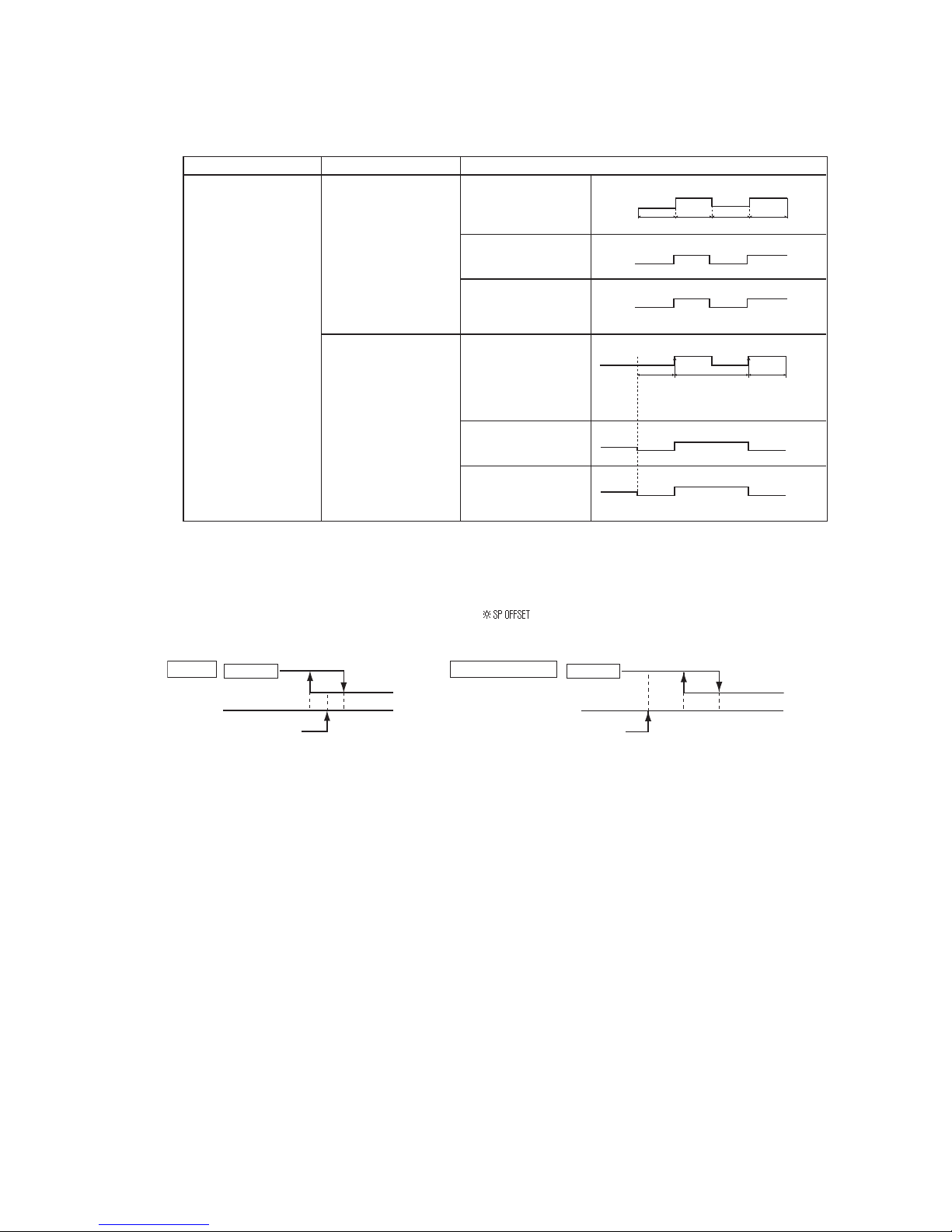

(18) External input/output control (CnT or CnTA)

Be sure to connect the wired remote control to the indoor unit. Without wired remote control remote operation by CnT is not

possible to perform.

・

CnT ・CnTA

①

Operation output (CnT-2: XR1)

②

Heating output (CnT-3: XR2)

③

Thermostat ON output (CnT-4: XR3)

④

Error output (CnT-5: XR4)

⑤

Remote operation input (CnT-6: Volt-free contact)

XR1

1

2

3

4

5

6

XR3

XR4

CnT

Blue

12V

XR2

Option

XR5

■

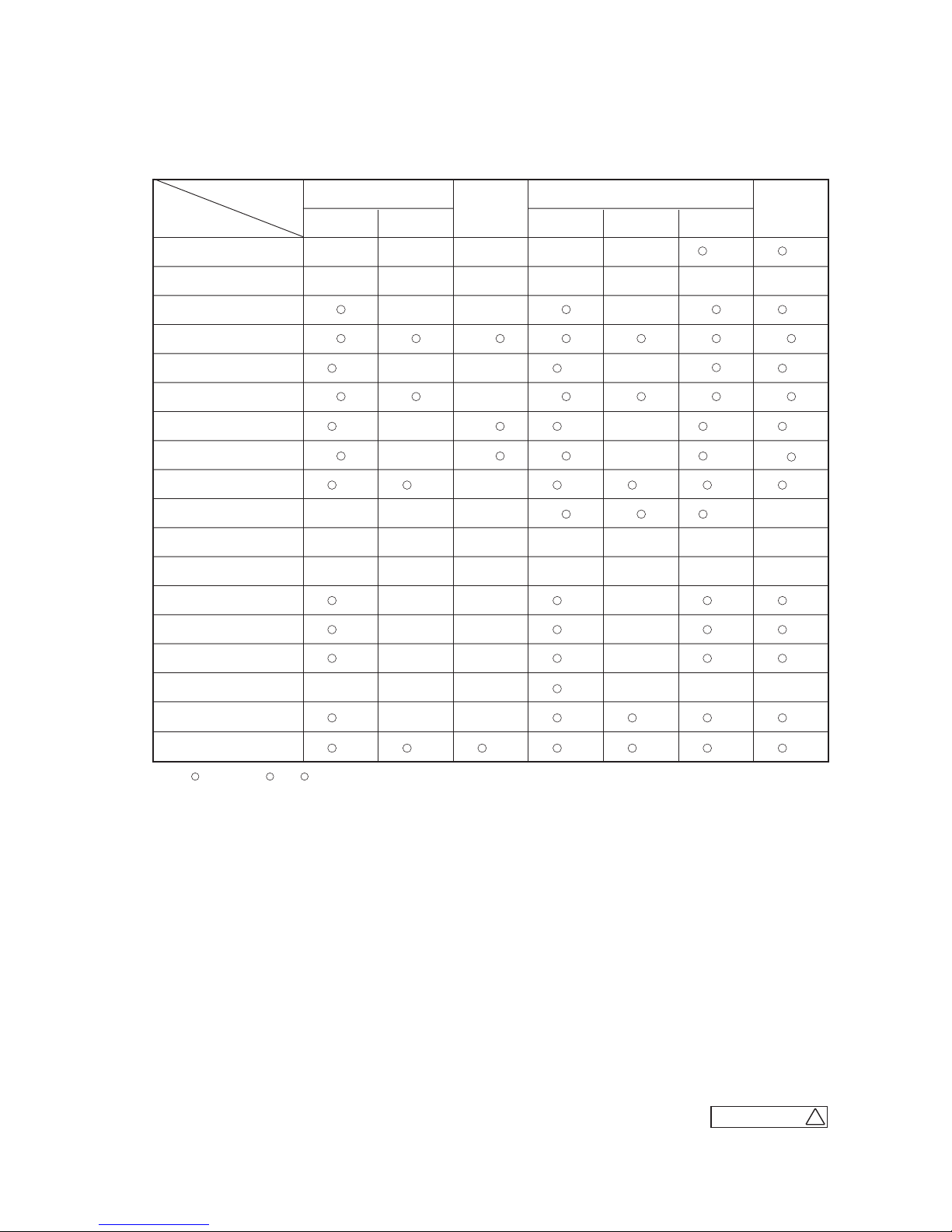

Priority order for combinations of CnT and CnTA input.

Note (1) Following operation commands are accepted when the operation prohibition is set with CnTA as indicated with *.

Individual operation command from remote control, test run command from outdoor unit and operation command from optional device, CNT input.

Reference: Explanation on the codes and the combinations of codes in the table above

1.

In case of CnT “Number”, the CnT “Number” is adopted and CnTA is invalidated.

2.

In case of CnTA “Number”, the CnTA “Number” is adopted and CnT is invalidated.

3.

In case of CnT “Number”/CnTA “Number”, the CnT “Number” and the CnTA “Number” become independent functions each other.

4.

In case of CnT “Number” + CnTA “Number”, the CnT “Number” and the CnTA “Number” become competing functions each other.

5.

In case of CnT “Number” > CnTA “Number”, the function of CnT “Number” supersedes that of CnTA “Number”.

6.

In case of CnT “Number” < CnTA “Number”, the function of CnTA “Number” supersedes that of CnT “Number”.

(The “Number” above means ① - ⑦ in the table.)

CnTA

Blue

12V

XR6

1

2

Note (1) CnTA f un ct ion can be

changed by RC-EX1A.

CnTA

①

Operation

stop level

②

Operation

stop pulse

③

Operation

permission/prohibition

④

Operation

permission/prohibition pulse

⑤

Cooling/heating

selection level

⑥

Cooling/heating

selection pulse

⑦

Emergency

stop

CnT

①

Operation stop level CnT

①

CnT

①

CnT

①

+

CnTA②CnT

①

CnT

①

/

CnTA⑤CnT

①

/

CnTA⑥CnT

①

<

CnTA

⑦

②

Operation stop pulse CnT

②

CnT

②

CnT

②

+

CnTA③CnT

②

CnT

②

/

CnTA⑤CnT

②

/

CnTA⑥CnT

②

<

CnTA

⑦

③

Operation permission/prohibition level

CnT

③

>

CnTA①CnT

③

>

CnTA②CnT

③

+

CnTA③CnT

③

CnT

③

/

CnTA⑤CnT

③

/

CnTA⑥CnT

③

<

CnTA

⑦

④

Operation permission/prohibition pulse

CnT

④

CnT

④

CnT

④

+

CnTA

③

※

CnT

④

CnT

④

/

CnTA⑤CnT

④

/

CnTA⑥CnT

④

<

CnTA

⑦

⑤

Cooling/heating selection level

CnT

⑤

/

CnTA①CnT

⑤

/

CnTA②CnT

⑤

/

CnTA

③

※

CnT

⑤

/

CnTA④CnT

⑤

CnT

⑤

CnT

⑤

/

CnTA

⑦

⑥

Cooling/heating selection pulse

CnT

⑥

/

CnTA①CnT

⑥

/

CnTA②CnT

⑥

/

CnTA③CnT

⑥

/

CnTA④CnT

⑥

CnT

⑥

CnT

⑥

/

CnTA

⑦

⑦

Emergency stop

CnT

⑦

>

CnTA①CnT

⑦

>

CnTA②CnT

⑦

>

CnTA③CnT

⑦

>

CnTA④CnT

⑦

/

CnTA⑤CnT

⑦

/

CnTA⑥CnT

⑦

+

CnTA

⑦

Page 19

– 17 –

'14 • KX-SM-202

(a) Output for external control (remote display)

Following output connectors (CnT) are provided on the indoor control PCB for monitoring operation status.

①

Operation output:

Outputs DC12V signal for driving relay during operation

②

Heating output:

Outputs DC12V signal for driving relay during heating operation

③

Thermostat ON output:

Outputs DC12V signal for driving relay when compressor is operating.

④

Error output:

Outputs DC12V signal for driving relay when anomalous condition occurs.

(b) Remote operation input

Remote operation input connector (CnT-6 or CnTA) is provided on the indoor control PCB.

However remote operation by CnT-6 or CnTA is not effective, when “Center mode” is selected by center controller.

In case of plural unit (twin, triple, double twin), remote operation input to CnT-6 or CnTA on the slave indoor unit is

invalid.

Only the “LEVEL INPUT” is acceptable for external input

, however when the indoor function setting of “Level

input (Factory default)” or “Pulse input” is selected by the function for “External input” of the wired remote control,

operation status will be changed as follows.