Page 1

General-Purpose AC Servo

MODEL

HF-KN

HF-SN

SERVO MOTOR INSTRUCTION MANUAL

C

Page 2

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain or inspect the equipment until you

have read through this Instruction Manual and appended documents carefully. Do not use the equipment

until you have a full knowledge of the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

A - 1

Page 3

1. To prevent electric shock, note the following

WARNING

Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp

turns off. Otherwise, an electric shock may occur. In addition, when confirming whether the charge lamp

is off or not, always confirm it from the front of the servo amplifier.

Ground the servo amplifier and servo motor securely.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and servo motor until they have been installed. Otherwise, it

may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

CAUTION

Install the servo motor on incombustible material. Installing it directly or close to combustibles will lead to

a fire.

Provide an adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo motor.

3. To prevent injury, note the following

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal. Otherwise, a

burst, damage, etc. may occur.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

The servo motor, etc. may be hot while power is on or for some time after power-off. Take safety

measures, e.g. provide covers, to avoid accidentally touching the parts (cables, etc.) by hand.

The surface temperature of the servo motor may exceed 100 ˚C depending on its mounting and

operating conditions.

During operation, never touch the rotor of the servo motor. Otherwise, it may cause injury.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a malfunction, injury,

electric shock, etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of product packages is not allowed.

A - 2

Page 4

CAUTION

Do not carry the servo motor by holding the cables, shaft, encoder, or connector.

Install the servo amplifier and the servo motor in a load-bearing place in accordance with the Instruction

Manual.

Do not get on or put heavy load on the equipment.

The equipment must be installed in the specified direction.

Do not install or operate the servo amplifier and servo motor which have been damaged or have any

parts missing.

Do not block intake and exhaust areas of the servo motor with a cooling fan. Otherwise, it may cause a

malfunction.

Do not drop or strike the servo motor. Isolate it from all impact loads.

Securely fix the servo motor to the machine. If being attached insecurely, the motor may come off during

operation.

When handling the servo motor, be careful about the edged parts such as the corners of the servo motor.

Be sure to measure the motor vibration level with the servo motor mounted on the machine when

checking the vibration level. A great vibration may cause the early damage of a bearing, encoder, and

brake. The great vibration may also cause the poor connector connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform

with a measurement device to check that no vibration occurs. If the vibration occurs due to high gain, the

vibration may cause the early damage of the servo motor.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotor of the servo motor

during operation.

Never hit the servo motor or shaft, especially when coupling the servo motor to the machine. Otherwise,

the encoder may malfunction.

Do not subject the servo motor shaft to more than the permissible load. Otherwise, the shaft may break.

When you keep or use the equipment, please fulfill the following environment.

Item Environment

Operation 0 ˚C to 40 ˚C (non-freezing)

Ambient temperature

Operation 80 %RH or less (non-condensing)

Ambient humidity

Altitude 1000 m or less above sea level

HF-KN series X, Y: 49 m/s2

Vibration resistance

HF-SN52/HF-SN102/HF-SN152 X, Y: 24.5 m/s2

Ambience

Storage -15 ˚C to 70 ˚C (non-freezing)

Storage 90 %RH or less (non-condensing)

Indoors (no direct sunlight), free from corrosive

gas, flammable gas, oil mist, dust, and dirt

HF-SN202/HF-SN302 X: 24.5 m/s2 Y: 49 m/s2

A - 3

Page 5

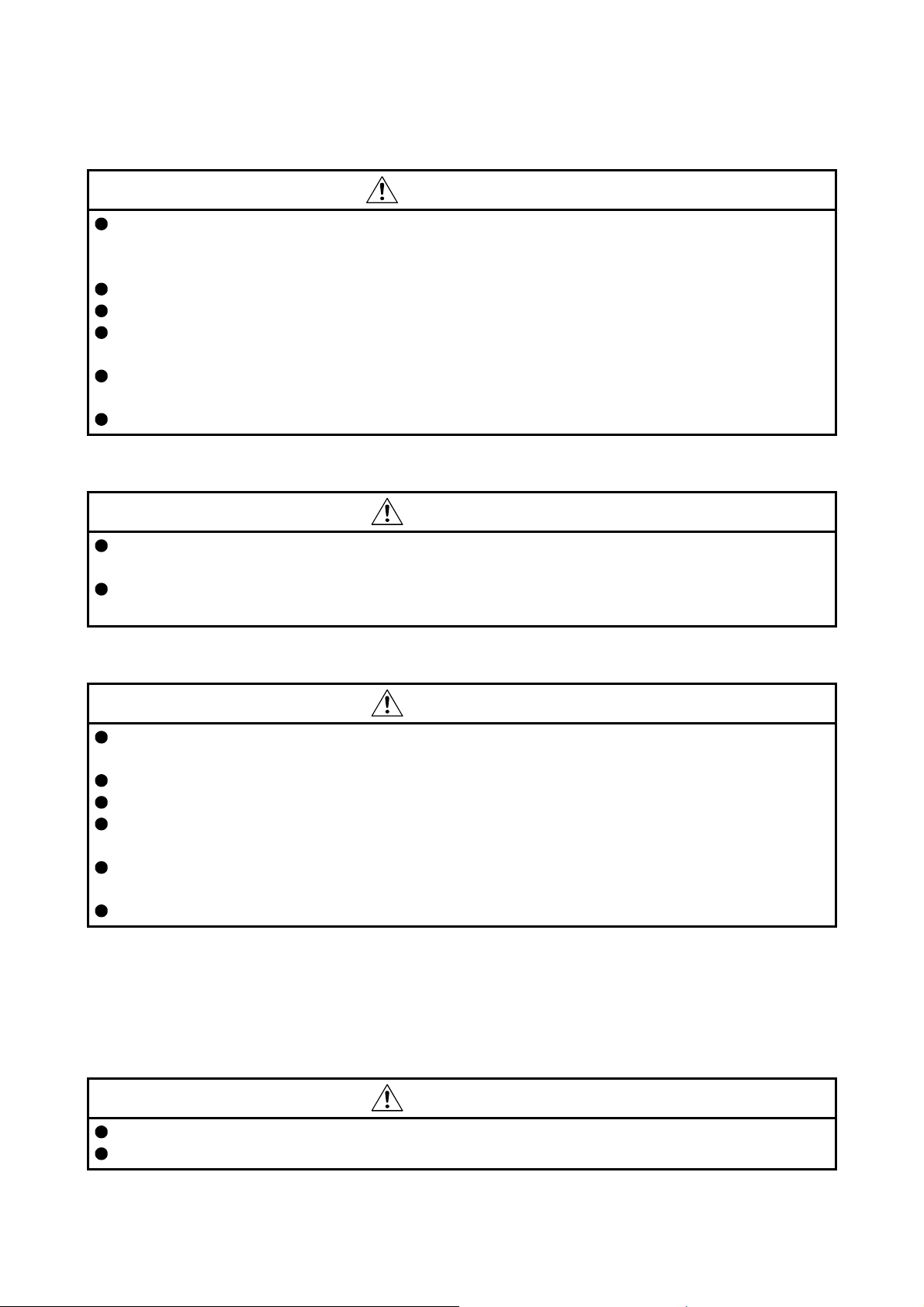

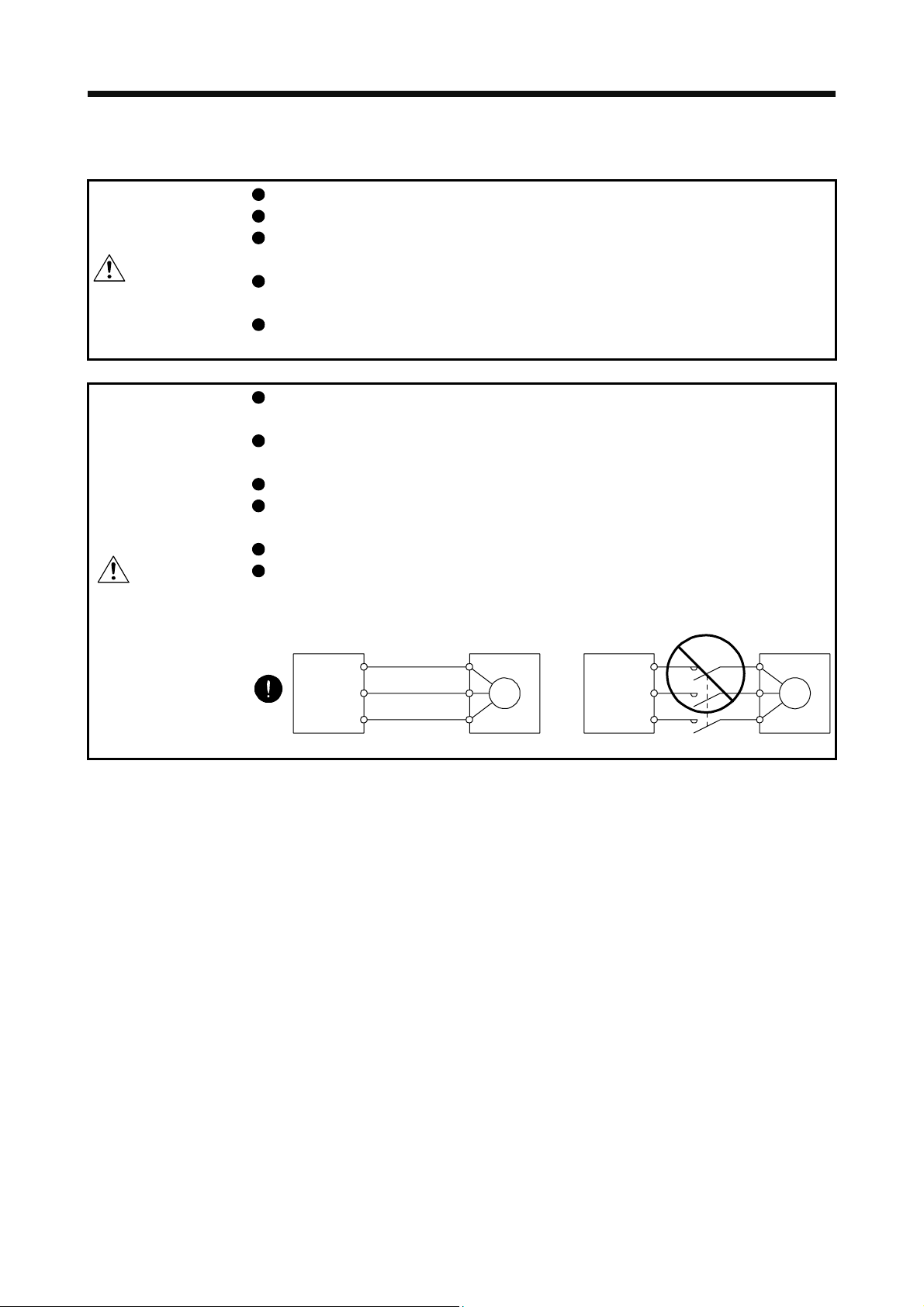

(2) Wiring

CAUTION

Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly.

Do not install a power capacitor, surge killer, or radio noise filter (FR-BIF option) on the servo amplifier

output side.

To avoid a malfunction, connect the wires to the correct phase terminals (U, V, and W) of the servo

amplifier and servo motor.

Connect the servo amplifier power output (U, V, and W) to the servo motor power input (U, V, and W)

directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Do not connect AC power supply directly to the servo motor. Otherwise, it may cause a malfunction.

When the cable is not tightened enough to the terminal block, the cable or terminal block may generate

heat because of the poor contact. Be sure to tighten the cable with specified torque.

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

W

M

(3) Test run and adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to operate

unexpectedly.

Never make a drastic adjustment or change to the parameter values as doing so will make the operation

unstable.

(4) Usage

CAUTION

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an external brake to prevent the condition.

Do not scratch the coated surface with hard objects nor clean the coated surface with an organic solvent.

Doing so may scuff the surface.

Do not disassemble, repair, or modify the equipment.

Use the servo amplifier with the specified servo motor.

The electromagnetic brake on the servo motor is designed to hold the motor shaft and should not be

used for ordinary braking.

For such reasons as service life and mechanical structure (e.g. where a ball screw and the servo motor

are coupled via a timing belt), the electromagnetic brake may not hold the motor shaft. To ensure safety,

install a stopper on the machine side.

A - 4

Page 6

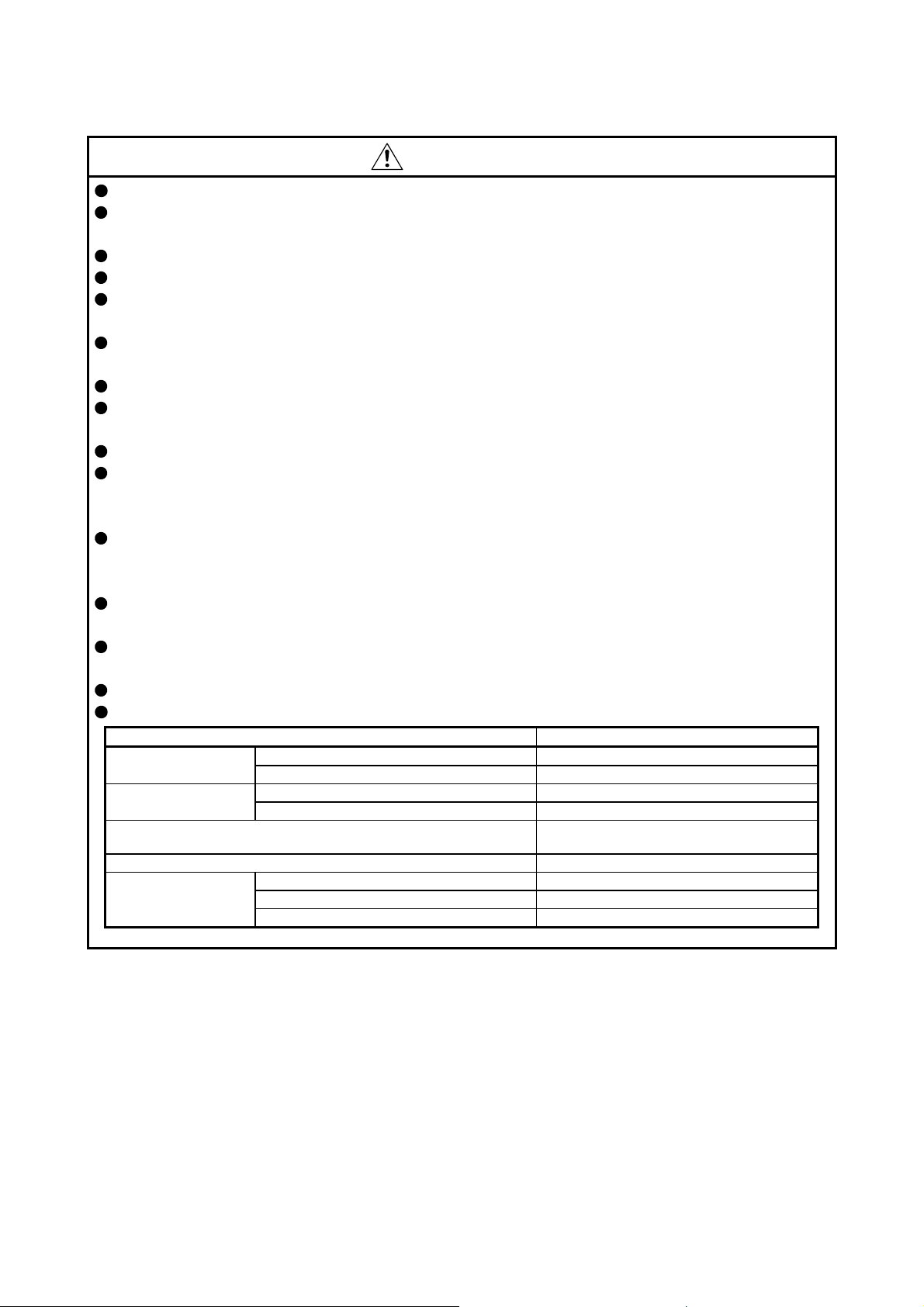

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may occur due to a power failure or product malfunction,

use a servo motor with an electromagnetic brake or external brake to prevent the condition.

Configure an electromagnetic brake circuit so that it is activated also by an external EMG stop switch.

Contacts must be opened when ALM

(Malfunction) or MBR (Electromagnetic

brake interlock) turns off.

Contacts must be opened

with the EMG stop switch.

Servo motor

B

Electromagnetic brake

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Provide an adequate protection to prevent unexpected restart after an instantaneous power failure.

RA

24 V DC

(6) Storage

CAUTION

Note the followings when storing the servo motor for an extended period of time (guideline: three or more

months).

Always store the servo motor indoors in a clean and dry place.

If it is stored in a dusty or damp place, make adequate provision, e.g. cover the whole product.

If the insulation resistance of the winding decreases, check how to store the equipment.

Though the motor is rust-proofed before shipment using paint or rust prevention oil, rust may be

produced depending on the storage conditions or storage period.

If the servo motor is to be stored for longer than six months, apply rust prevention oil again especially to

the machined surfaces of the shaft, etc.

Before using the product after storage for an extended period of time, hand-turn the servo motor output

shaft to confirm that nothing is wrong with the servo motor. When the servo motor is equipped with an

electromagnetic brake, make the above check after releasing the electromagnetic brake with the brake

power supply.

When the product has been stored for an extended period of time, contact your local sales office.

(7) General instruction

To illustrate details, the equipment in the diagrams of this Instruction Manual may have been drawn

without covers and safety guards. When the equipment is operated, the covers and safety guards must

be installed as specified. Operation must be performed in accordance with this Instruction Manual.

A - 5

Page 7

DISPOSAL OF WASTE

Please dispose a servo motor and other options according to your local laws and regulations.

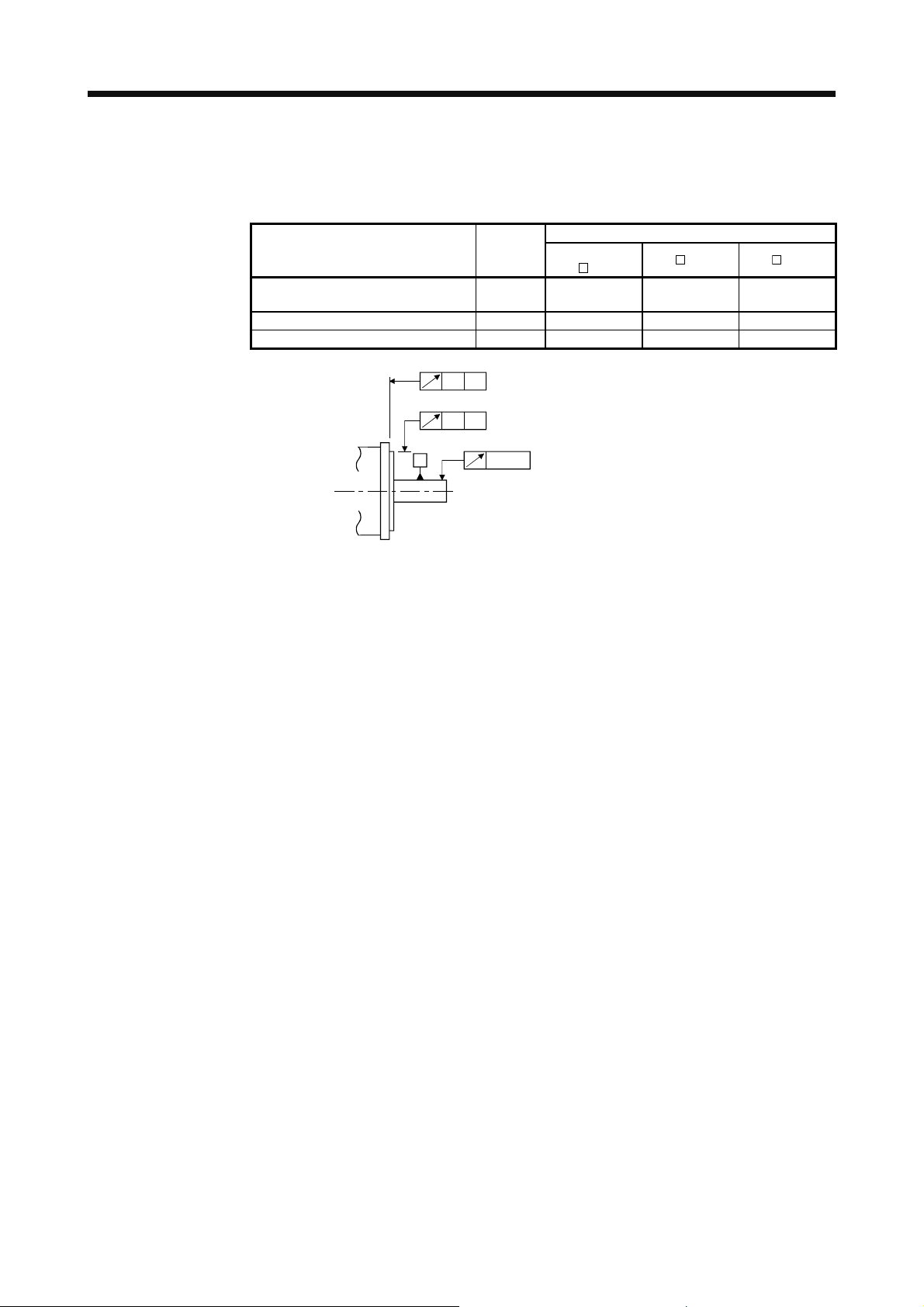

«U.S. customary units»

U.S. customary units are not shown in this manual. Convert the values if necessary according to the

following table.

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [in]

Torque 1 [N•m] 141.6 [oz•in]

Moment of inertia 1 [(× 10-4 kg•m2)] 5.4675 [oz•in2]

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

Quantity SI (metric) unit U.S. customary unit

A - 6

Page 8

CONTENTS

1. INTRODUCTION 1- 1 to 1- 4

1.1 Rating plate....................................................................................................................................... 1- 1

1.2 Parts identification............................................................................................................................. 1- 1

1.3 Electromagnetic brake ...................................................................................................................... 1- 2

1.4 Servo motor shaft shapes................................................................................................................. 1- 4

2. INSTALLATION 2- 1 to 2- 8

2.1 Mounting direction............................................................................................................................. 2- 2

2.2 Load mounting/dismounting precautions.......................................................................................... 2- 3

2.3 Permissible load for the shaft ........................................................................................................... 2- 4

2.4 Protection from oil and water ............................................................................................................ 2- 4

2.5 Cable................................................................................................................................................. 2- 5

2.6 Servo motor with oil seal................................................................................................................... 2- 5

2.7 Inspection items ................................................................................................................................ 2- 6

2.8 Parts having service lives ................................................................................................................. 2- 6

2.9 Machine accuracies .......................................................................................................................... 2- 7

3. CONNECTORS USED FOR SERVO MOTOR WIRING 3- 1 to 3- 6

3.1 Selection of connectors .................................................................................................................... 3- 1

3.2 Wiring connectors (connector configurations A/B/C)........................................................................ 3- 2

3.3 Wiring connectors (connector configurations D/E/F/G) .................................................................... 3- 3

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR 4- 1 to 4- 8

4.1 Connection instructions .................................................................................................................... 4- 2

4.2 Wiring................................................................................................................................................ 4- 3

4.2.1 HF-KN series servo motor.......................................................................................................... 4- 3

4.2.2 HF-SN series servo motor.......................................................................................................... 4- 5

4.3 Selection example of wires ............................................................................................................... 4- 7

5. WIRING OPTION 5- 1 to 5-22

5.1 Cable/connector sets ........................................................................................................................ 5- 1

5.1.1 Combinations of cable/connector sets....................................................................................... 5- 2

5.1.2 Cable and connector list............................................................................................................. 5- 3

5.2 Encoder cable/connector sets .......................................................................................................... 5- 6

5.3 Servo motor power cable................................................................................................................. 5-17

5.4 Electromagnetic brake cable ........................................................................................................... 5-19

5.5 Wires for option cables .................................................................................................................... 5-20

6. HF-KN SERIES 6- 1 to 6-16

6.1 Model designation............................................................................................................................. 6- 1

6.2 Combination list of servo motors and servo amplifiers ..................................................................... 6- 1

6.3 Standard specifications..................................................................................................................... 6- 2

6.3.1 Standard specifications list......................................................................................................... 6- 2

1

Page 9

6.3.2 Torque characteristics................................................................................................................ 6- 3

6.4 Electromagnetic brake characteristics.............................................................................................. 6- 4

6.5 Servo motors with special shafts ...................................................................................................... 6- 5

6.5.1 Key shaft (with 2 round end key) ............................................................................................... 6- 5

6.5.2 D cut shaft .................................................................................................................................. 6- 5

6.6 Servo motor with oil seal................................................................................................................... 6- 6

6.7 Mounting connectors ........................................................................................................................ 6- 6

6.8 Dimensions ....................................................................................................................................... 6- 8

6.8.1 Standard (without an electromagnetic brake) ............................................................................ 6- 8

6.8.2 With an electromagnetic brake ................................................................................................. 6-12

7. HF-SN SERIES 7- 1 to 7-10

7.1 Model designation............................................................................................................................. 7- 1

7.2 Combination list of servo motors and servo amplifiers ..................................................................... 7- 1

7.3 Standard specifications..................................................................................................................... 7- 2

7.3.1 Standard specifications list......................................................................................................... 7- 2

7.3.2 Torque characteristics................................................................................................................ 7- 3

7.4 Electromagnetic brake characteristics.............................................................................................. 7- 4

7.5 Servo motors with special shafts ...................................................................................................... 7- 5

7.6 Servo motor with oil seal................................................................................................................... 7- 5

7.7 Dimensions ....................................................................................................................................... 7- 6

7.7.1 Standard (without an electromagnetic brake) ............................................................................ 7- 6

7.7.2 With an electromagnetic brake .................................................................................................. 7- 8

APPENDIX App. - 1 to App. - 9

App. 1 Servo motor ID codes ..........................................................................................................App.- 1

App. 2 Manufacturer list ..................................................................................................................App.- 1

App. 3 Compliance with the CE marking......................................................................................... App.- 2

App. 4 Compliance with UL/CSA standard .....................................................................................App.- 3

App. 5 Selection example of servo motor power cable................................................................... App.- 4

App. 6 Connector dimensions .........................................................................................................App.- 5

2

Page 10

1. INTRODUCTION

)

1. INTRODUCTION

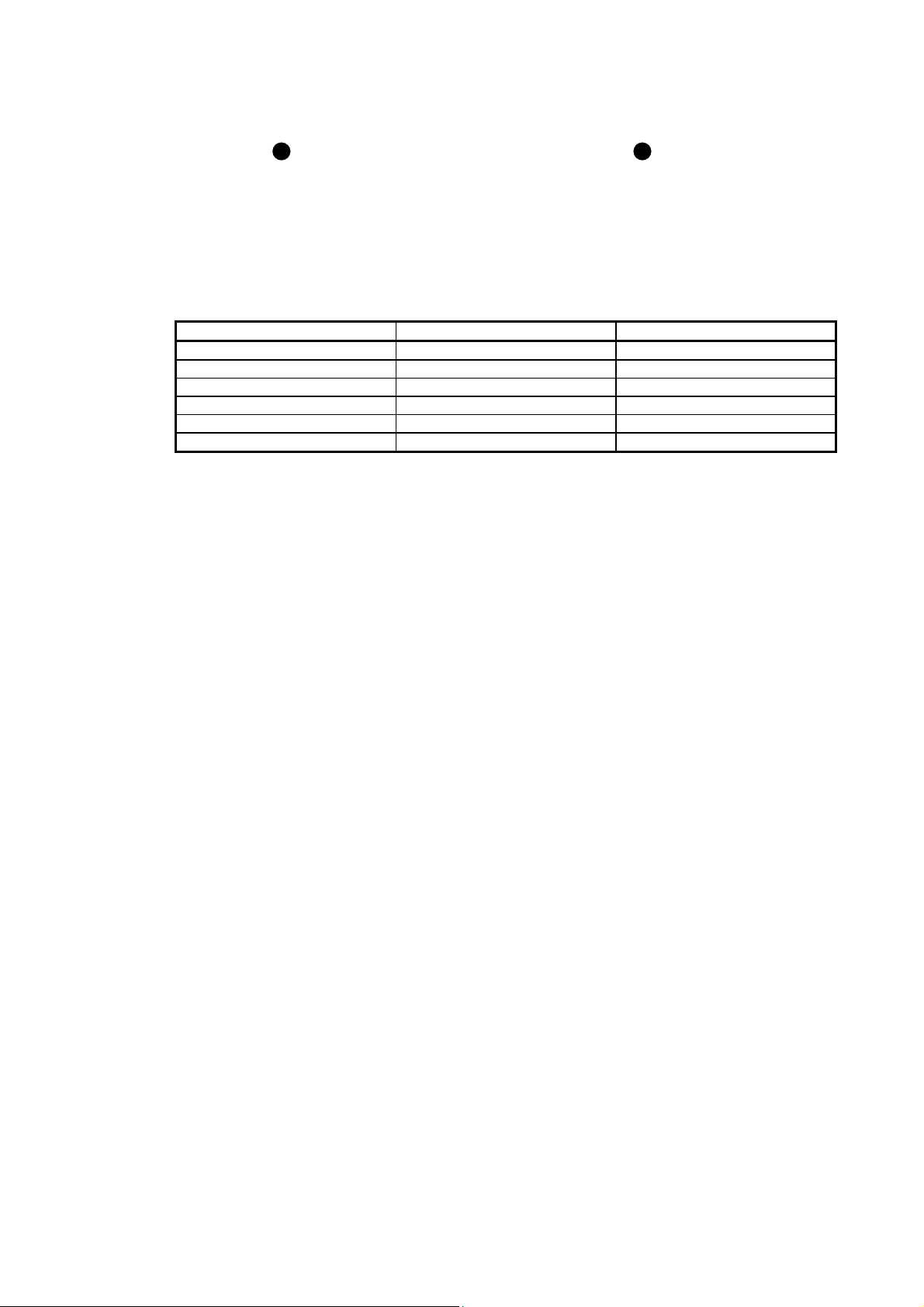

1.1 Rating plate

1.2 Parts identification

Model

Input power and insulation class

Rated output and applied standard

Rated speed and mass

(Note 2)

Note 1. Production year and month of the servo motor are indicated in a serial number on

the rating plate.

The year and month of manufacture are indicated by the last two digits of the year

and one digit of the month [1 to 9, X (10), Y (11), and Z (12)].

For July 2012, the Serial No. is like, "SER. _ _ _ _ _ _ _ _ _ 127".

2. Products approved by Certification Bodies are marked. The marks depends on the

Certification Bodies.

Serial number (Note 1) and IP rating

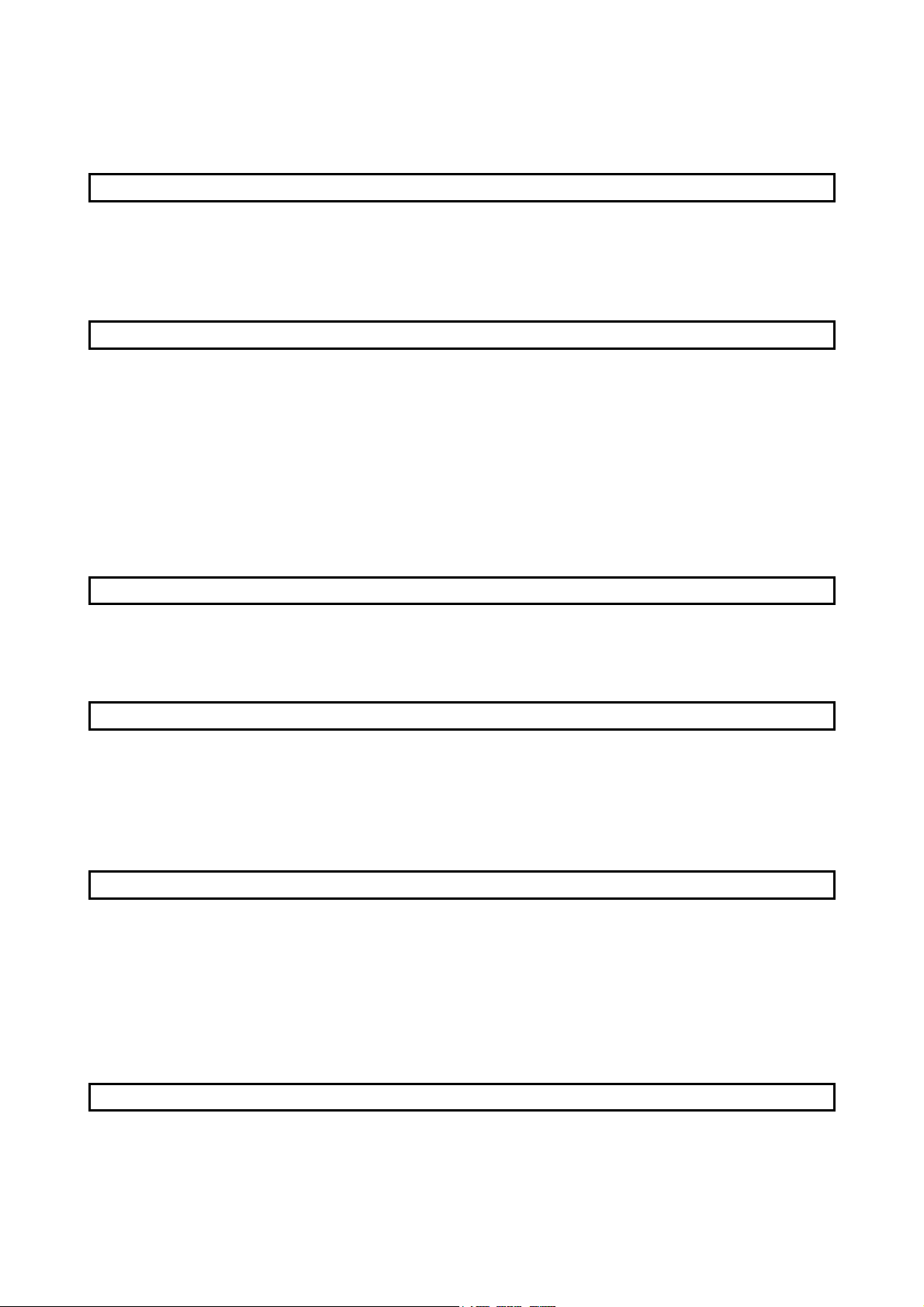

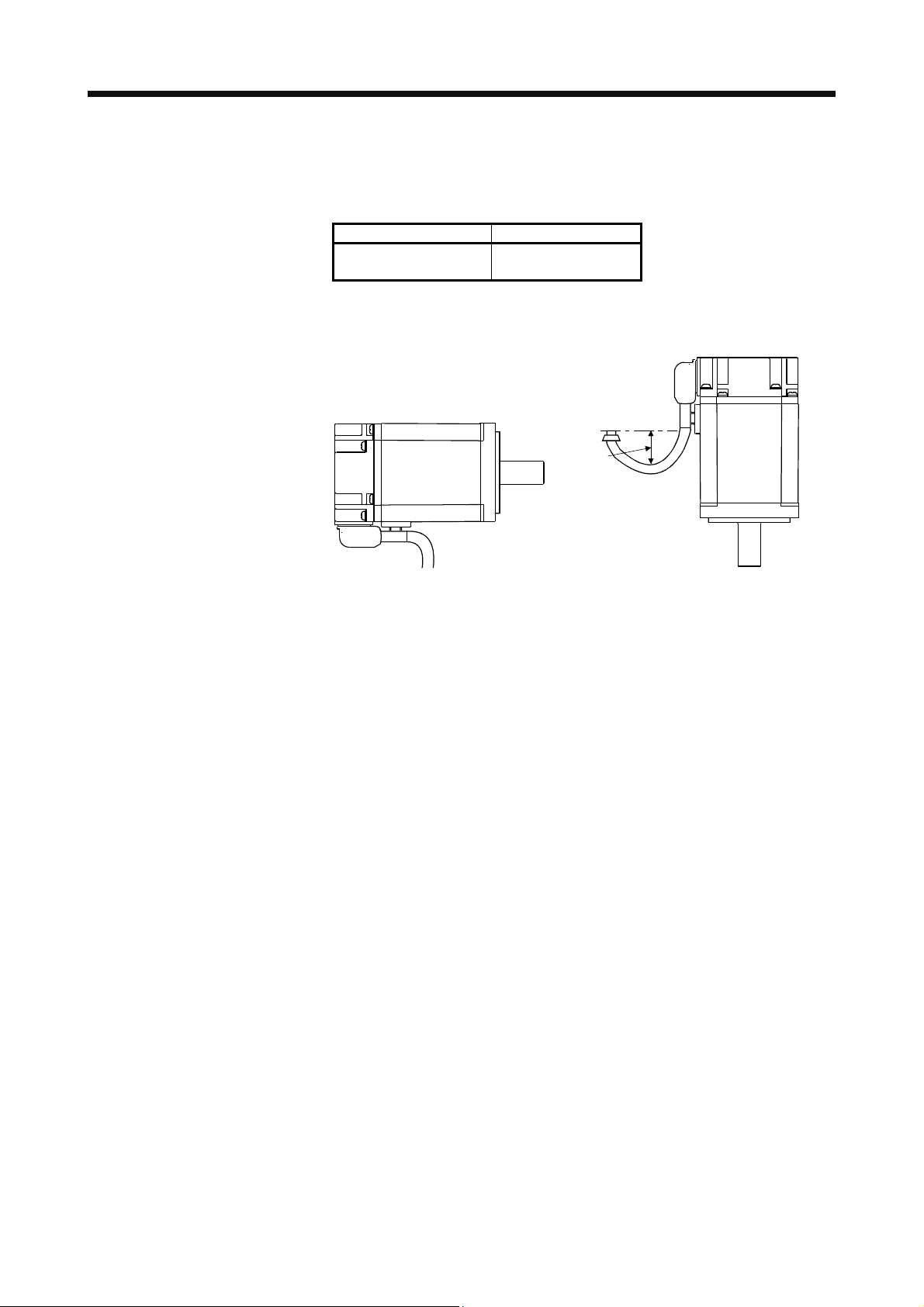

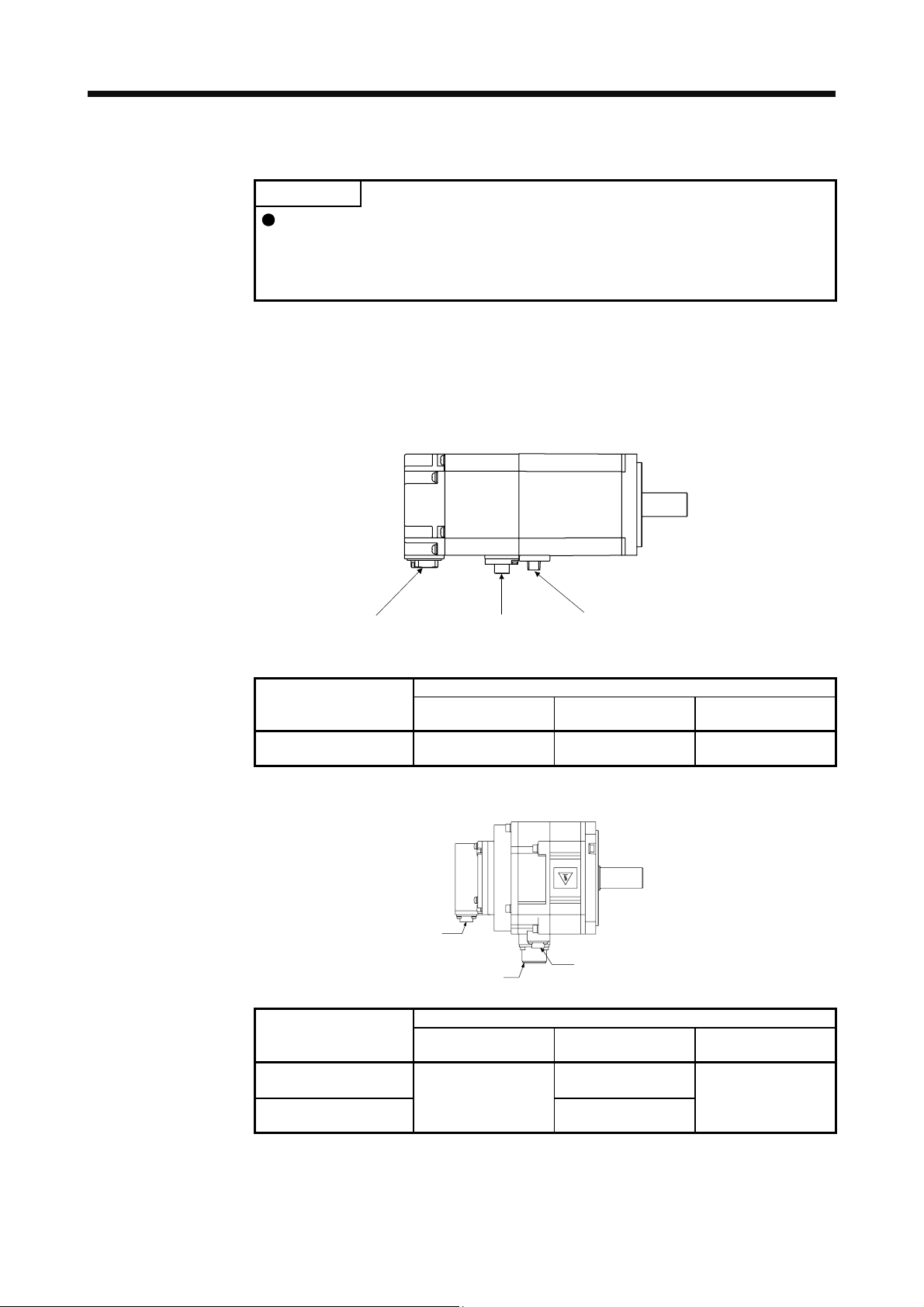

(1) HF-KN series servo motor

(2) HF-SN series servo motor

Power cable (Note 1, 2)

Power lead (U/V/W)

Grounding lead

Encoder cable (Note 1)

Encoder

Servo motor shaft

Note 1. The encoder cable and power supply cable are options.

2. An electromagnetic brake cable is separately required for the servo motor with an

electromagnetic brake.

Power supply connector (Note

Power supply (U/V/W)

Grounding ( )

Encoder connector

Encoder

Servo motor shaft

Note. The servo motor with an electromagnetic brake has the electromagnetic brake

connector separately.

1 - 1

Page 11

1. INTRODUCTION

1.3 Electromagnetic brake

The electromagnetic brake is provided to prevent a drop at a power failure or

servo alarm occurrence during vertical drive or to hold a shaft at a stop. Do not

use it for normal braking (including braking at servo-lock).

The electromagnetic brake has a time lag. Use the electromagnetic brake so that

servo motor control starts after the electromagnetic brake has completely opened.

Be sure to check the operation delay time with a real machine.

Configure an electromagnetic brake circuit so that it is activated also by an

CAUTION

The servo motor with an electromagnetic brake can be used to prevent a drop in vertical lift applications or to

ensure double safety at an emergency stop, for example. When operating the servo motor, supply power to

the electromagnetic brake to release the brake. Switching power off enables the brake.

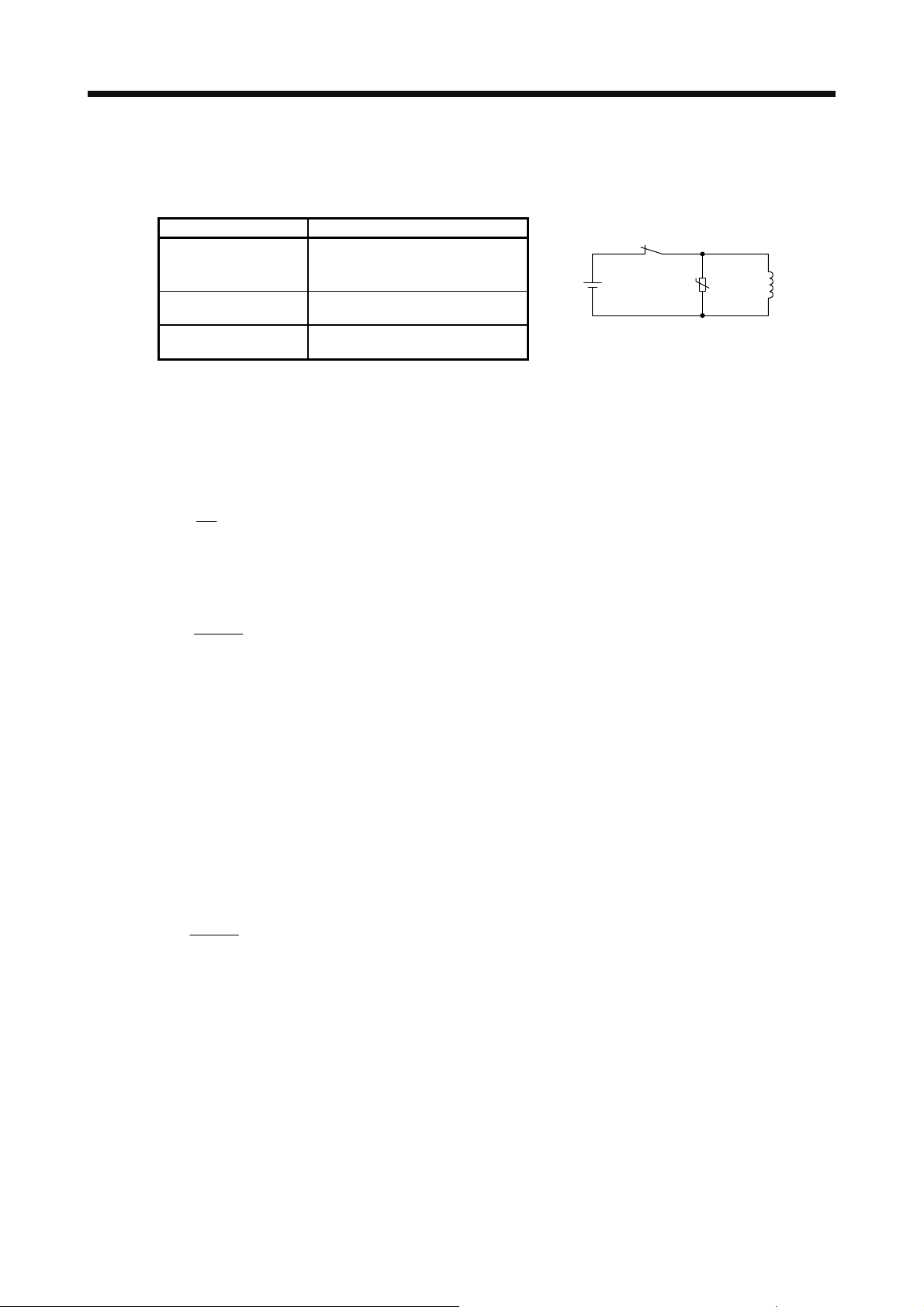

(1) Electromagnetic brake power supply

Prepare the following power supply for use with the electromagnetic brake only. The electromagnetic

brake terminals (B1 and B2) have no polarity.

24 V DC

power supply for

electromagnetic brake

external EMG stop switch.

For details of the circuit configuration and timing chart, refer to each servo

amplifier instruction manual.

While the electromagnetic brake is opened, the motor may be raised to high

temperature regardless of driving.

The life will be shorten under sudden acceleration/deceleration conditions.

B1

Switch

VAR

B

U

24 V DC

or

power supply for

electromagnetic brake

Switch

VAR

B1

B

U

B2

Electromagnetic brake

The surge absorber (VAR) must be installed between B1 and B2. For the selection and example of

surge absorbers, refer to "Electromagnetic brake characteristic" in the chapter of each servo motor

series.

When you use a diode for a surge absorber, the electromagnetic braking time will be longer.

(2) Sound generation

Though the brake lining may rattle during operation, it poses no functional problem.

If braking sounds, it may be improved by setting the machine resonance suppression filter in the servo

amplifier parameters. For details, refer to each servo amplifier instruction manual.

B2

Electromagnetic brake

1 - 2

Page 12

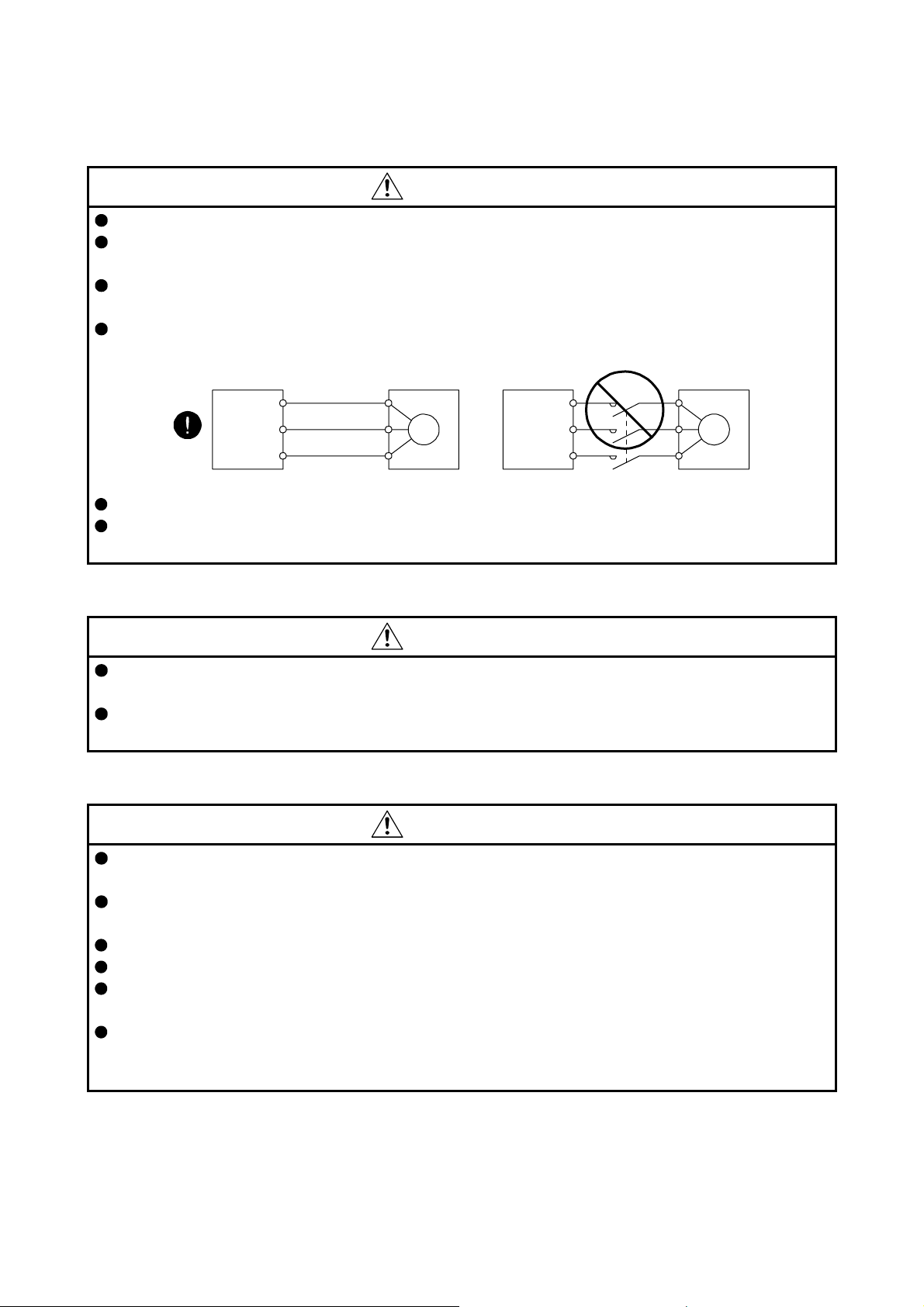

1. INTRODUCTION

y

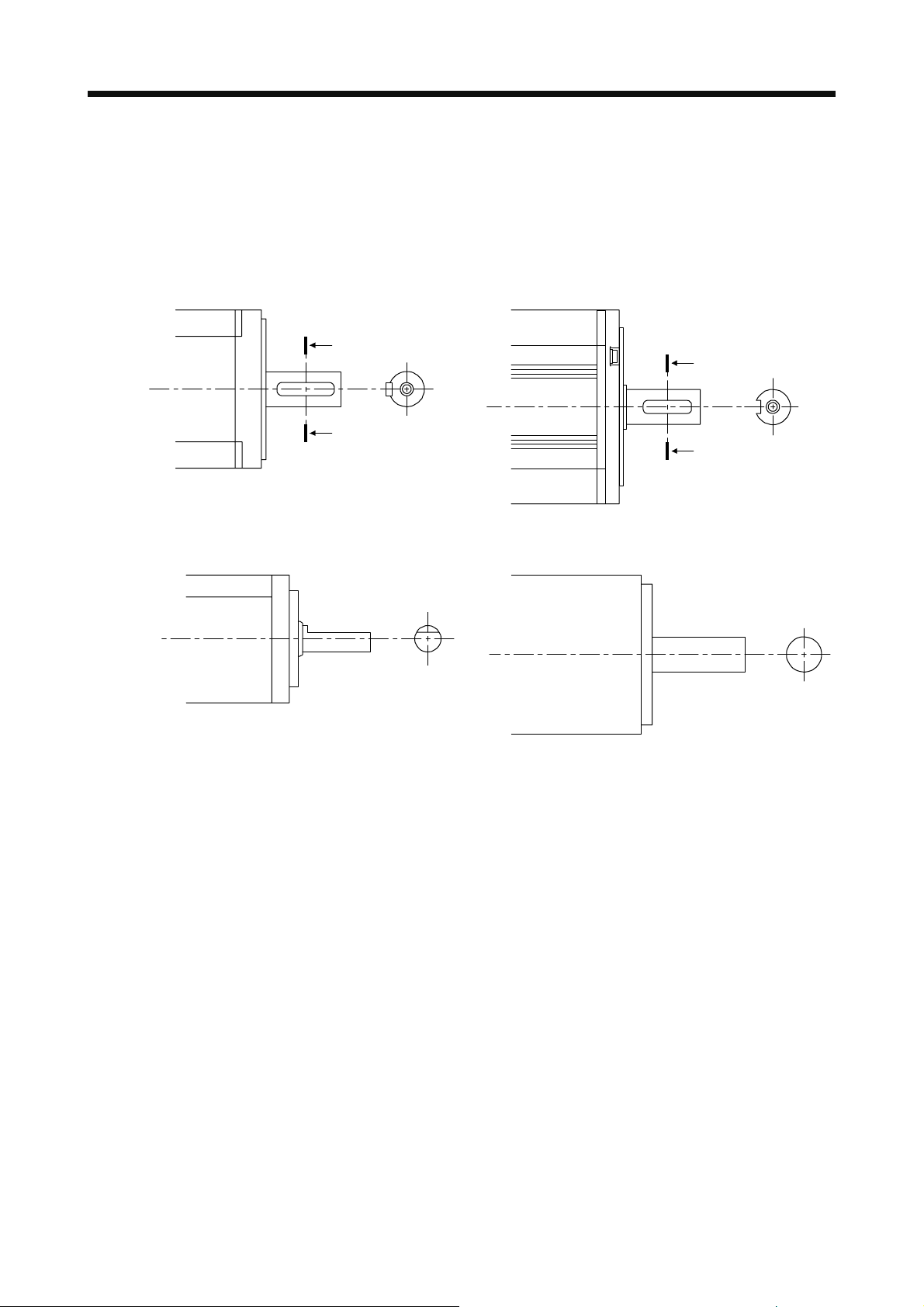

(3) Selection of surge absorbers for electromagnetic brake circuit

The following shows an example how to select a varistor with a surge absorber.

(a) Selection conditions

Electromagnetic brake

specification

Desired suppression

voltage

Durable surge

application time

(b) Tentative selection and verification of surge absorber

1) Maximum allowable circuit voltage of varistor

Tentatively select a varistor whose maximum allowable voltage is larger than Vb [V].

2) Brake current (Ib)

Ib =

3) Energy (E) generated by brake coil

E =

4) Varistor limit voltage (Vi)

From the energy (E) generated in the brake coil and the varister characteristic diagram, calculate

the varistor limit voltage (Vi) when the brake current (Ib) flows into the tentatively selected varistor

during opening of the circuit.

Vi is favorable when the varistor limit voltage (Vi) [V] is smaller than the desired suppressed

voltage (Vs) [V].

If Vi is not smaller than Vs, reselect a varistor or improve the withstand voltage of devices.

5) Surge current width (τ)

Given that the varistor absorbs all energies, the surge current width (τ) will be as follows.

τ =

6) Examining surge life of varister

From the varistor characteristic diagram, find the guaranteed current value (Ip) in which the

number of the surge application life is N at the surge current width (τ). Calculate the guaranteed

current value (Ip) ratio to brake current (Ib).

If an enough margin is ensured for Ip/Ib, the number of the surge application life N [time] can be

considered as favorable.

(4) Others

A leakage magnetic flux will occur at the shaft end of the servo motor equipped with an electromagnetic

brake. Note that chips, screws and other magnetic substances are attracted.

Item Condition

R [Ω]: Resistance

L [H]: Inductance

Vb [V]: Power supply voltage

Vs [V] or less

N times

Vb

[A]

R

2

L × lb

[J]

2

E

Vi × lb

[S]

Rela

24 V DC

U

Varistor

Brake coil

1 - 3

Page 13

1. INTRODUCTION

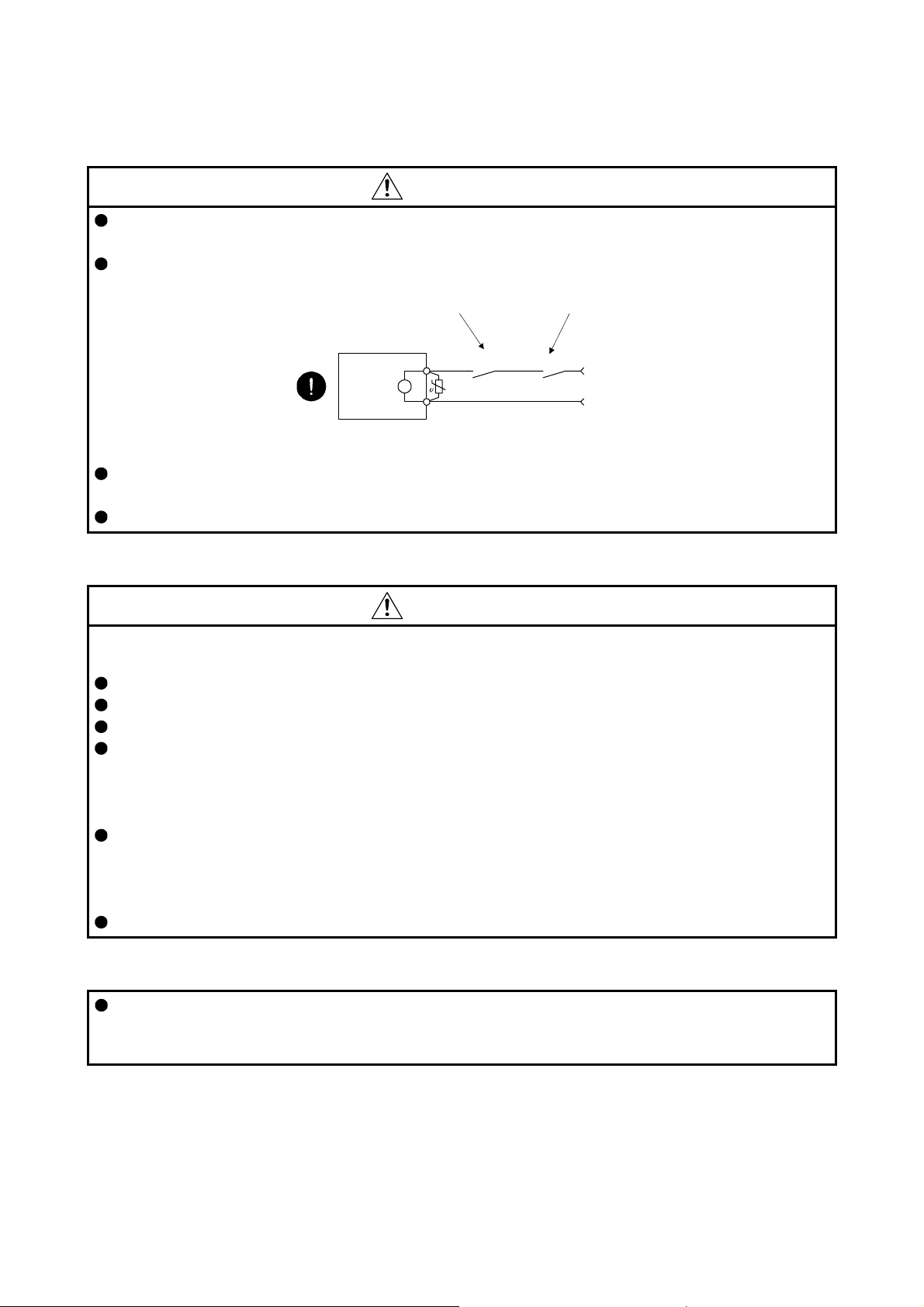

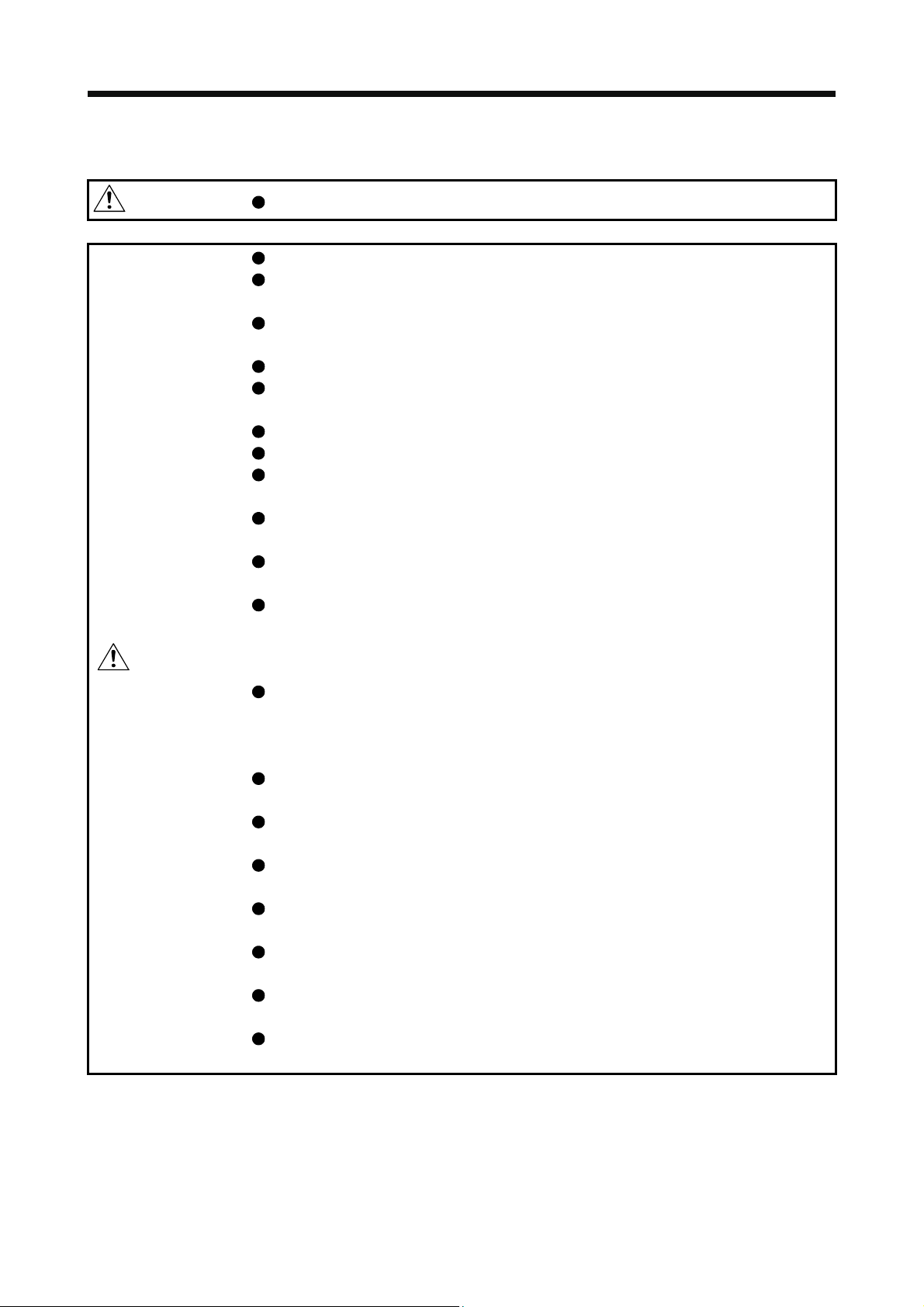

1.4 Servo motor shaft shapes

In addition to the straight shaft, the key shaft and D cut shaft are available as the servo motor shafts.

The key shaft and D cut shaft cannot be used in very frequent start/stop applications.

Since we cannot warrant the servo motor against fracture and similar accidents attributable to a loose key,

use a friction coupling, etc. when coupling the shaft with a machine.

The shaft shape of the standard servo motor changes depending on the series and capacity. Refer to the

chapter of the servo motor series.

A

A

A

Shaft section view AA

A

Shaft section view AA

Key shaft (with 2 round end key) Key shaft (without key)

D cut shaft Straight shaft

1 - 4

Page 14

2. INSTALLATION

2. INSTALLATION

WARNING

CAUTION

To prevent electric shock, ground each equipment securely.

Stacking in excess of the specified number of product packages is not allowed.

Install the equipment on incombustible material. Installing it directly or close to

combustibles will lead to a fire.

Install the servo amplifier and the servo motor in a load-bearing place in

accordance with the Instruction Manual.

Do not get on or put heavy load on the equipment. Otherwise, it may cause injury.

Use the equipment within the specified environment. For the environment, refer to

the specifications of the servo motor series.

Do not drop or strike the servo motor. Isolate it from all impact loads.

Do not install or operate a faulty servo motor.

Do not carry the servo motor by holding the cables, shaft, encoder, or connector.

Otherwise, it may cause a malfunction or injury.

Use the eyebolts of the servo motor to only transport it. Do not use the eyebolts to

transport the servo motor when it is mounted on a machine.

Securely fix the servo motor to the machine. If being attached insecurely, the

motor may come off during operation, leading to injury.

Be sure to measure the motor vibration level with the servo motor mounted on the

machine when checking the vibration level. A great vibration may cause the early

damage of a bearing, encoder, and brake. The great vibration may also cause the

poor connector connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and

the speed waveform with a measurement device to check that no vibration

occurs. If the vibration occurs due to high gain, the vibration may cause the early

damage of the servo motor.

Never hit the servo motor or shaft, especially when coupling the servo motor to

the machine. Otherwise, the encoder may malfunction.

When coupling a load to the servo motor, do not use a rigid coupling. Doing so

can cause the shaft to break and the bearing to wear out.

Balance the load to the extent possible. Not doing so can cause vibration during

servo motor operation or damage the bearings and encoder.

Take safety measures, e.g. provide covers, to prevent accidental access to the

rotor of the servo motor during operation.

Do not subject the servo motor shaft to more than the permissible load.

Otherwise, the shaft may break, leading to injury.

When the product has been stored for an extended period of time, contact your

local sales office.

When handling the servo motor, be careful about the edged parts such as the

corners of the servo motor.

2 - 1

Page 15

2. INSTALLATION

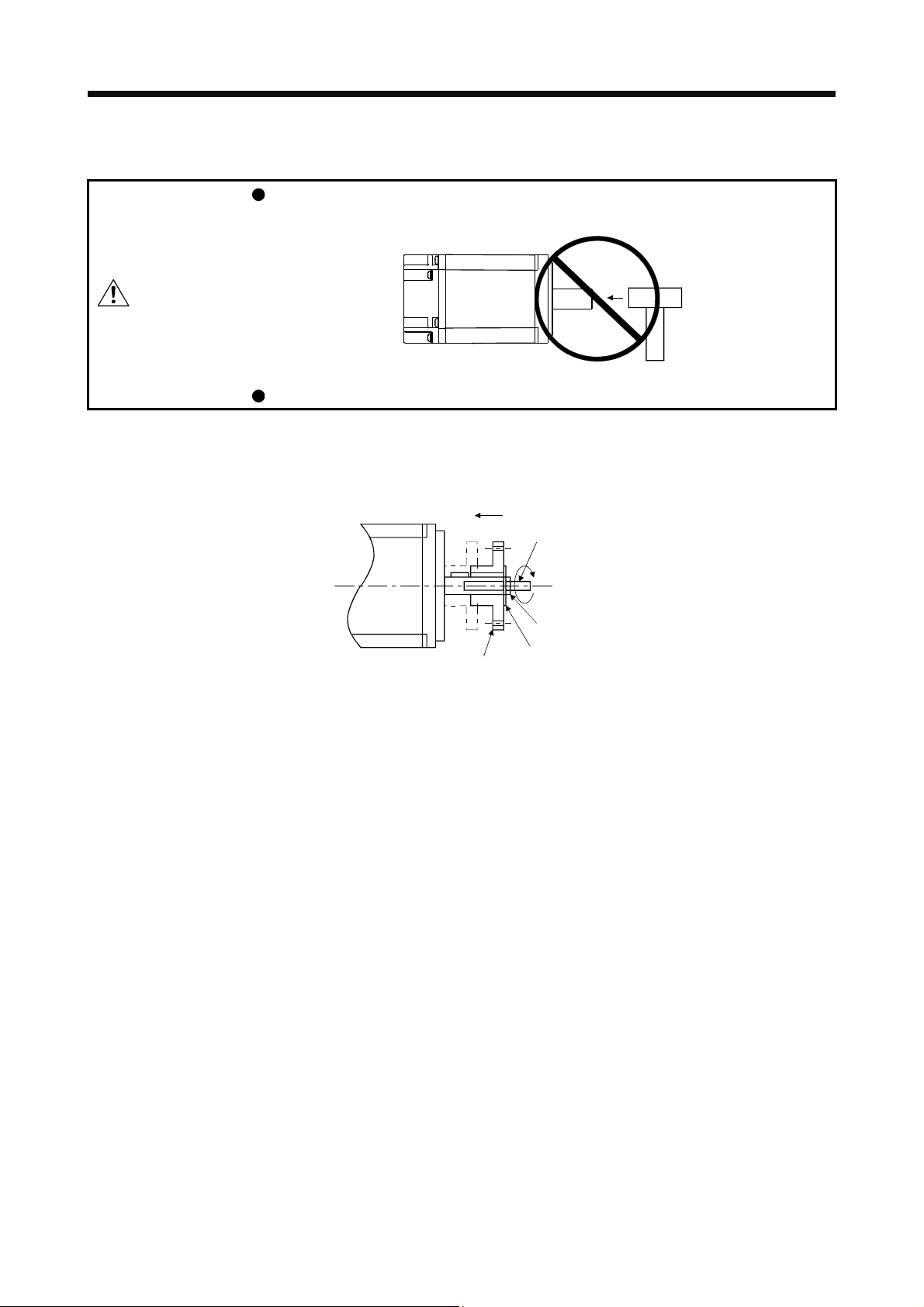

2.1 Mounting direction

(1) Standard servo motor

The following table indicates the mounting direction of the standard servo motor.

For mounting in the horizontal direction, it is recommended to set the connector section downward.

When installing the servo motor vertically or obliquely, provide a connection and trap for the cable.

Servo motor series Mounting direction

HF-KN

HF-SN

May be installed in any

direction.

Cable trap

(2) Servo motor with an electromagnetic brake

The servo motor with an electromagnetic brake can also be installed in the same orientation as the

standard servo motor. When the servo motor with an electromagnetic brake is installed with the shaft

end at top, the brake plate may generate sliding sound but it is not a fault.

2 - 2

Page 16

2. INSTALLATION

2.2 Load mounting/dismounting precautions

During assembling, the shaft end must not be hammered. Otherwise, the encoder

may malfunction.

CAUTION

Do not process the shaft to avoid damage to the encoder and bearing.

(1) When mounting a pulley to the servo motor with a key shaft, use the screw hole in the shaft end. To fit

the pulley, first insert a double-end stud into the screw hole of the shaft, put a washer against the end

face of the coupling, and insert and tighten a nut to force the pulley in.

Servo motor

Double-end stud

Nut

Pulley

Washer

(2) For the shaft without a key, use a friction coupling or the like.

(3) When removing the pulley, use a pulley remover to protect the shaft from hard load and or impact.

(4) To ensure safety, fit a protective cover or the like on the rotary area, such as the pulley, mounted to the

shaft.

(5) When a threaded shaft end part is needed to mount a pulley on the shaft, please contact your local sales

office.

(6) The direction of the encoder on the servo motor cannot be changed.

(7) When mounting the servo motor, use spring washers, etc. and fully tighten the bolts so that they do not

become loose due to vibration.

2 - 3

Page 17

2. INSTALLATION

2.3 Permissible load for the shaft

CAUTION

For the permissible shaft load specific to the servo motor, refer to the chapter of the servo motor series.

(1) Use a flexible coupling and adjust the misalignment of the shaft to less than the permissible radial load.

(2) When using a pulley, sprocket or timing belt, select a diameter that will fit into the permissible radial load.

(3) Excess of the permissible load can cause the bearing life to reduce and the shaft to break.

(4) The load indicated in this section is static load in a single direction and does not include eccentric load.

Make eccentric load as small as possible. Not doing so can cause the servo motor to be damaged.

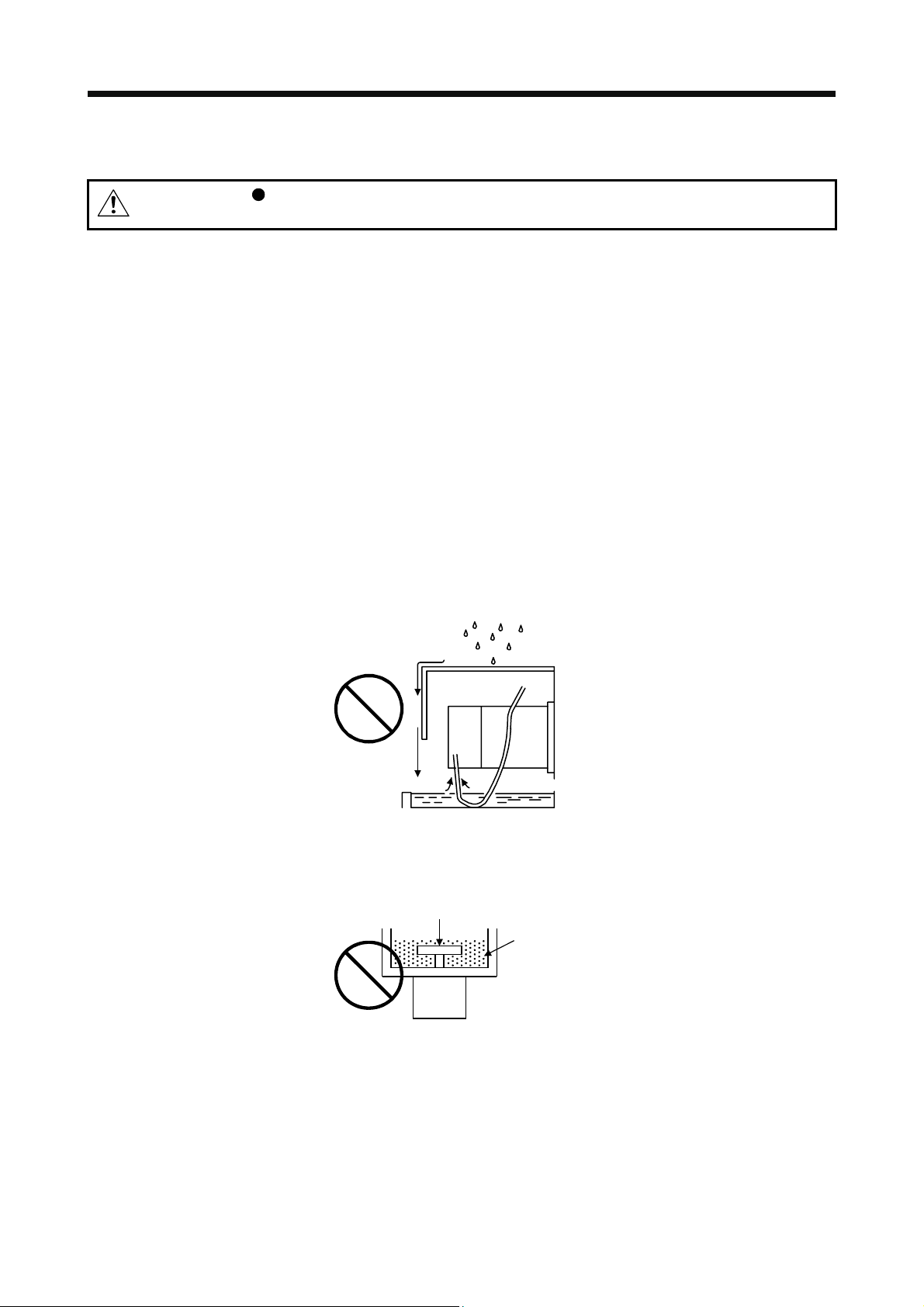

2.4 Protection from oil and water

Do not use a rigid coupling as it may apply excessive bending load to the shaft of

the servo motor, leading the shaft to break and the bearing to wear out.

Provide adequate protection to prevent foreign matter, such as oil from entering the servo motor shaft. When

installing the servo motor, consider the items in this section.

(1) Do not use the direct drive motor with its cable soaked in oil or water.

Cover

Servo

motor

Oil/water pool

Capillary phenomenon

(2) When the servo motor is to be installed with the shaft end at top, provide measures so that it is not

exposed to oil and water entering from the machine side, gear box, etc.

Gear

Lubricating oil

Servo motor

(3) If oil such as coolant drops on the servo motor, the sealant, packing, cable and others may be affected

depending on the oil type.

(4) In the environment where the servo motor is exposed to oil mist, oil, water, grease and/or like, a

standard specifications servo motor may not be usable. Please contact your local sales office.

2 - 4

Page 18

2. INSTALLATION

2.5 Cable

The power supply and encoder cables routed from the servo motor should be fixed to the servo motor to

keep them unmovable. Otherwise, the cable may disconnect. In addition, do not modify the connectors,

terminals and others at the ends of the cables.

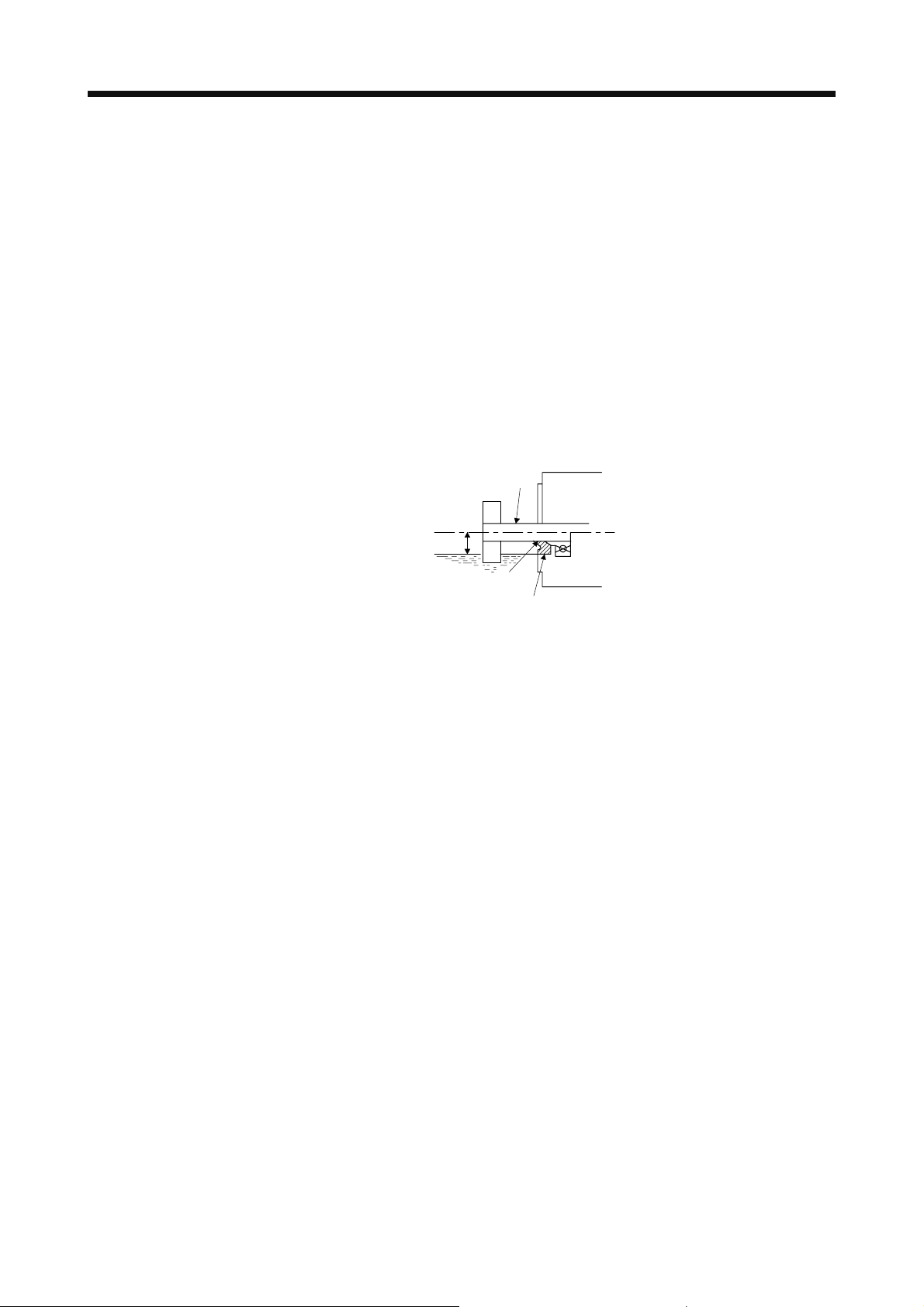

2.6 Servo motor with oil seal

For the servo motor with oil seal, the oil seal prevents the entry of oil into the servo motor. Make sure to

install it according in this section.

The functions have no problem even if the servo motor with oil seal may sound during operation.

(1) Pressure and oil level

Install the servo motor horizontally, and set the oil level in the gear box to be lower than the oil seal lip

always. If the oil level is higher than the oil seal lip, the oil that entered into the servo motor may cause

any failure.

Shaft

Gear

Servo motor

Height above oil level h

Lip

Oil seal

High pressure against the oil seal causes the abrasion and makes the life be short. Keep constant

internal pressure by equipping a ventilator to the gear box.

(2) Temperature

High temperature against the oil seal lip makes the life be short. Avoid exposing the oil seal lip to high

temperature oil since applicable temperature of the material is up to 100 ˚C and temperature of the oil

seal lip rises within 10 ˚C to 15 ˚C at maximum rotation.

2 - 5

Page 19

2. INSTALLATION

2.7 Inspection items

WARNING

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Otherwise, an electric shock may

occur. In addition, when confirming whether the charge lamp is off or not, always

confirm it from the front of the servo amplifier.

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your local sales office.

CAUTION

It is recommended that the following points periodically be checked.

(1) Check the bearings, brake section, etc. for unusual noise.

(2) Check the cables and the like for scratches or cracks. Especially when the cable is movable, perform

periodic inspections according to operating conditions.

(3) Check the servo motor shaft and coupling for misalignment.

(4) Check the power supply connector and encoder connector tightening screws for looseness.

2.8 Parts having service lives

Service lives of the following parts are listed below. However, the service life vary depending or operating

methods and environment. If any fault is found in the parts, they must be replaced immediately regardless of

their service lives. For parts replacement, please contact your local sales office.

(1) Bearings

When the motor is run at rated speed under rated load, bearings should be exchanged in 20,000 to

30,000 hours as a guideline. This differs on the operating conditions. The bearings must also be

changed if unusual noise or vibration is found during inspection.

(2) Oil seal

Oil seals must be changed in 5,000 hours of operation at rated speed as a guideline. They must also be

changed if oil leakage, etc. is found during inspection.

The functions have no problem even if an oil seal may sound during operation.

Do not disassemble and/or repair the equipment on customer side.

Part name Life guideline

Bearings 20,000 hours to

30,000 hours

Encoder 20,000 hours to

30,000 hours

Oil seal 5000 hours

2 - 6

Page 20

2. INSTALLATION

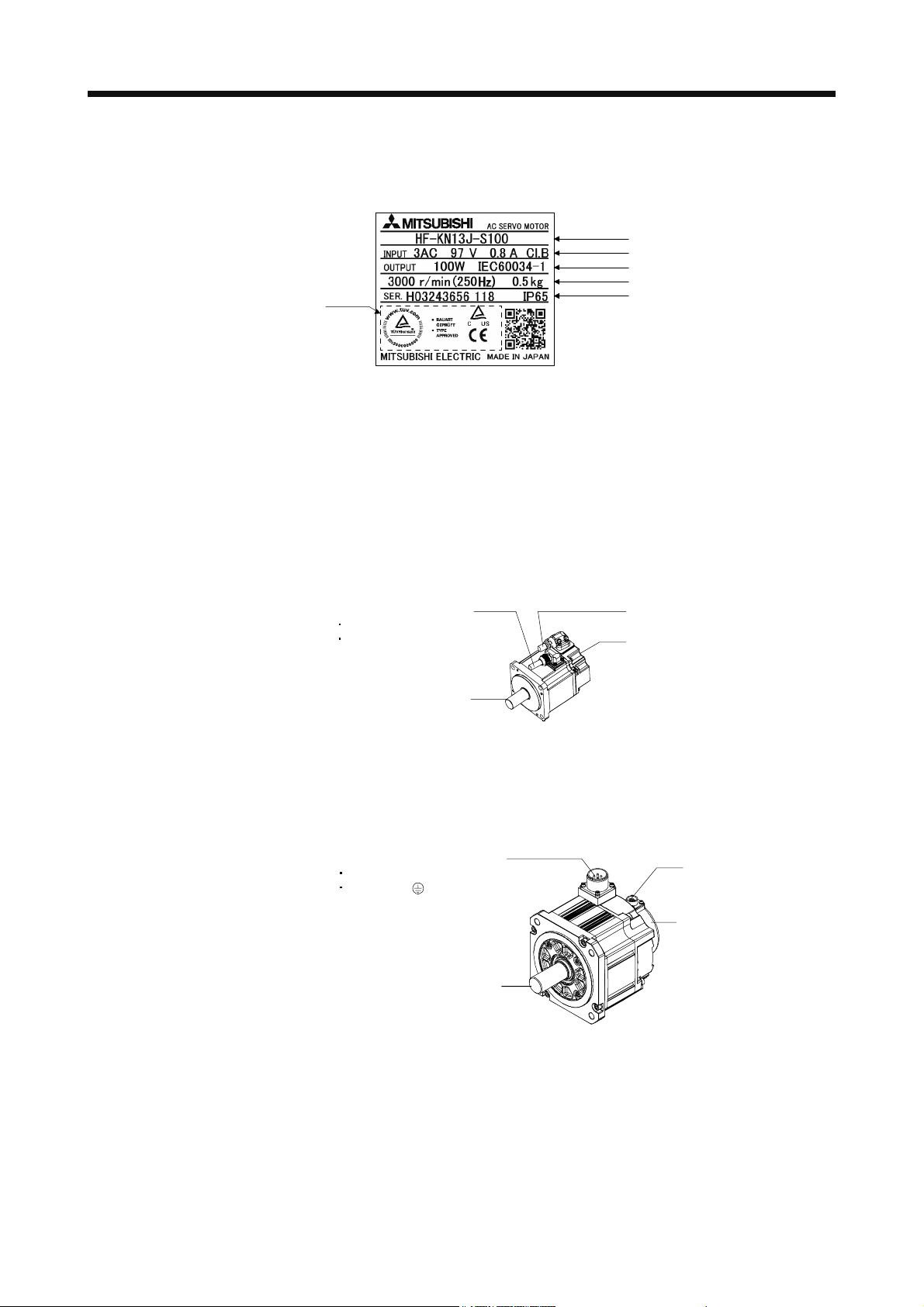

2.9 Machine accuracies

The following table indicates the machine accuracies of the servo motor around the output shaft and

mounting. (except the optional products)

Accuracy [mm]

Runout of flange surface to output

shaft

Runout of fitting OD of flange surface b) 0.04 0.04 0.06

Runout of output shaft end c) 0.02 0.02 0.03

Measuring

position

a) 0.05 0.06 0.08

Less than

100

a)

A

b)

A

A

c)

Flange size

130 176

2 - 7

Page 21

2. INSTALLATION

MEMO

2 - 8

Page 22

3. CONNECTORS USED FOR SERVO MOTOR WIRING

r

3. CONNECTORS USED FOR SERVO MOTOR WIRING

POINT

The IP rating indicated is the connector's protection against ingress of dust and

water when the connector is connected to a servo amplifier or servo motor. If the

IP rating of the connector, servo amplifier and servo motor vary, the overall IP

rating depends on the lowest IP rating of all components.

3.1 Selection of connectors

Use the connector configuration products given in the table as the connectors for connection with the servo

motor. Refer to section 3.2 and 3.3 for the compatible connector configuration products.

(1) HF-KN series

Encoder connecto

Electromagnetic

brake connector

Power supply connector

(2) HF-SN series

Servo motor

HF-KN_

Encoder connector

Power supply connector

Servo motor

HF-SN52/HF-SN102/

HF-SN152

HF-SN202/HF-SN302

Wiring connector

For encoder For power supply

Connector

configuration A

Connector

configuration B

For electromagnetic

brake

Connector

configuration C

Electromagnetic brake connector

Wiring connector

For encoder For power supply

Connector

Connector

configuration D

configuration E

Connector

configuration G

For electromagnetic

brake

Connector

configuration F

3 - 1

Page 23

3. CONNECTORS USED FOR SERVO MOTOR WIRING

3.2 Wiring connectors (connector configurations A/B/C)

The connectors in this section comply with UL/CSA standards.

Connector

configuration

A (for encoder) IP65

Feature

Connector: 2174053-1

(TE Connectivity)

Note. The connector to be mated.

Connector

configuration

B (for power

supply)

Feature

Connector: KN4FT04SJ1-R

IP65

Contact: ST-TMH-S-C1B-100 (A534G)

Note. The connector to be mated.

Connector Crimping tool

For ground clip: 1596970-1

For receptacle contact: 1596847-1

(TE Connectivity)

Servo motor encoder

1674339-1

(TE Connectivity)

Connector Crimping tool

HOOD/SOCKET

INSULATOR/BUSHING/

GROUND NUT

(JAE)

CT160-3-TMH5B

(JAE)

Servo motor power supply

JN4AT04NJ1

(JAE)

connector (Note)

connector (Note)

Connector

configuration

C

(for

electromagnetic

brake)

Feature

Connector: JN4FT02SJ1-R

IP65

Contact: ST-TMH-S-C1B-100 (A534G)

Note. The connector to be mated.

Connector Crimping tool

HOOD/SOCKET

INSULATOR/BUSHING/

GROUND NUT

(JAE)

Servo motor

CT160-3-TMH5B

(JAE)

electromagnetic brake

connector (Note)

JN4AT02PJ1

(JAE)

3 - 2

Page 24

3. CONNECTORS USED FOR SERVO MOTOR WIRING

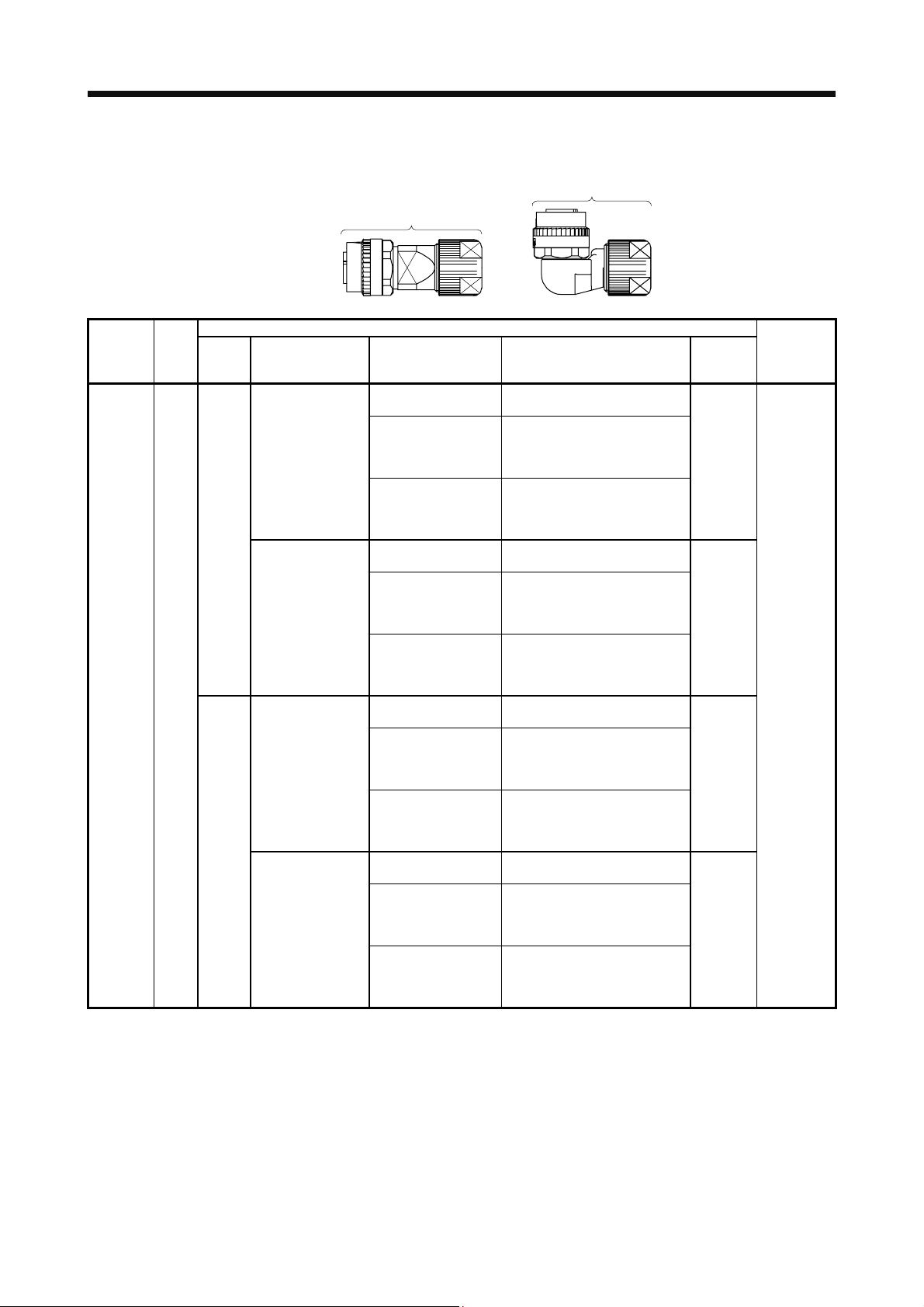

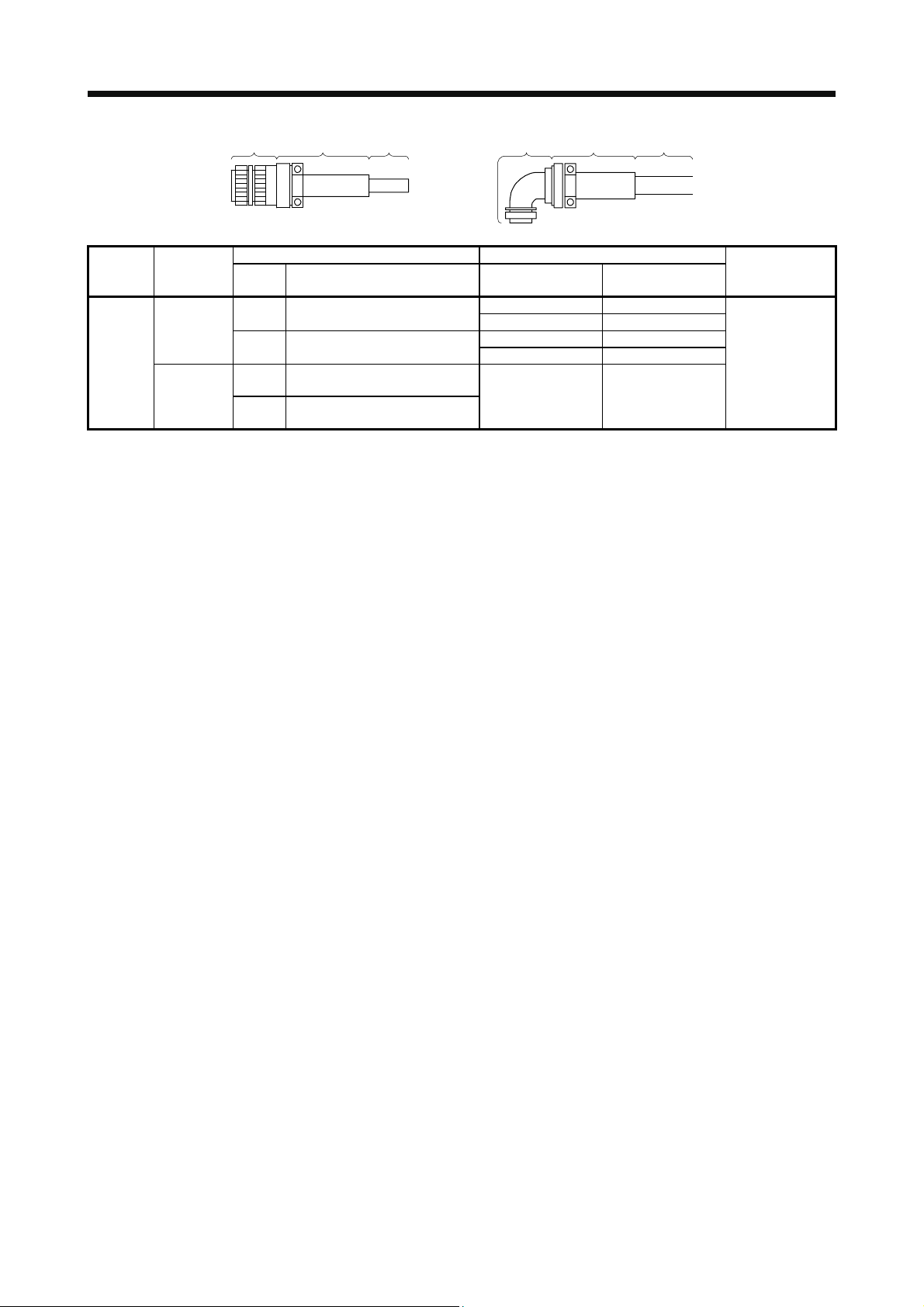

3.3 Wiring connectors (connector configurations D/E/F/G)

Angle plug

Straight plug

(one-touch connection type)

(one-touch connection type)

Connector

configuration

(for encoder)

Feature

D

IP67

Type Plug Socket contact Contact shape

CMV1-SP10S-M1

(one-touch connection

type)

Straight

CMV1-SP10S-M2

(one-touch connection

type)

CMV1-AP10S-M1

(one-touch connection

type)

Angle

CMV1-AP10S-M2

(one-touch connection

type)

Note. The connector to be mated.

Plug (DDK)

CMV1-#22ASC-S1-100

CMV1-#22ASC-C1-100

CMV1-#22ASC-C2-100

CMV1-#22ASC-S1-100

CMV1-#22ASC-C1-100

CMV1-#22ASC-C2-100

CMV1-#22ASC-S1-100

CMV1-#22ASC-C1-100

CMV1-#22ASC-C2-100

CMV1-#22ASC-S1-100

CMV1-#22ASC-C1-100

CMV1-#22ASC-C2-100

Soldering type

Applicable wire size: AWG 20 or less

Crimping type

Applicable wire size: AWG 24 to 20

The crimping tool (357J-53162T) is

required.

Crimping type

Applicable wire size: AWG 28 to 24

The crimping tool (357J-53163T) is

required.

Soldering type

Applicable wire size: AWG 20 or less

Crimping type

Applicable wire size: AWG 24 to 20

The crimping tool (357J-53162T) is

required.

Crimping type

Applicable wire size: AWG 28 to 24

The crimping tool (357J-53163T) is

required.

Soldering type

Applicable wire size: AWG 20 or less

Crimping type

Applicable wire size: AWG 24 to 20

The crimping tool (357J-53162T) is

required.

Crimping type

Applicable wire size: AWG 28 to 24

The crimping tool (357J-53163T) is

required.

Soldering type

Applicable wire size: AWG 20 or less

Crimping type

Applicable wire size: AWG 24 to 20

The crimping tool (357J-53162T) is

required.

Crimping type

Applicable wire size: AWG 28 to 24

The crimping tool (357J-53163T) is

required.

Cable OD

[mm]

(reference)

5.5 to 7.5

7.0 to 9.0

5.5 to 7.5

7.0 to 9.0

Servo motor

encoder

connector

(Note)

CM10-R10P

3 - 3

Page 25

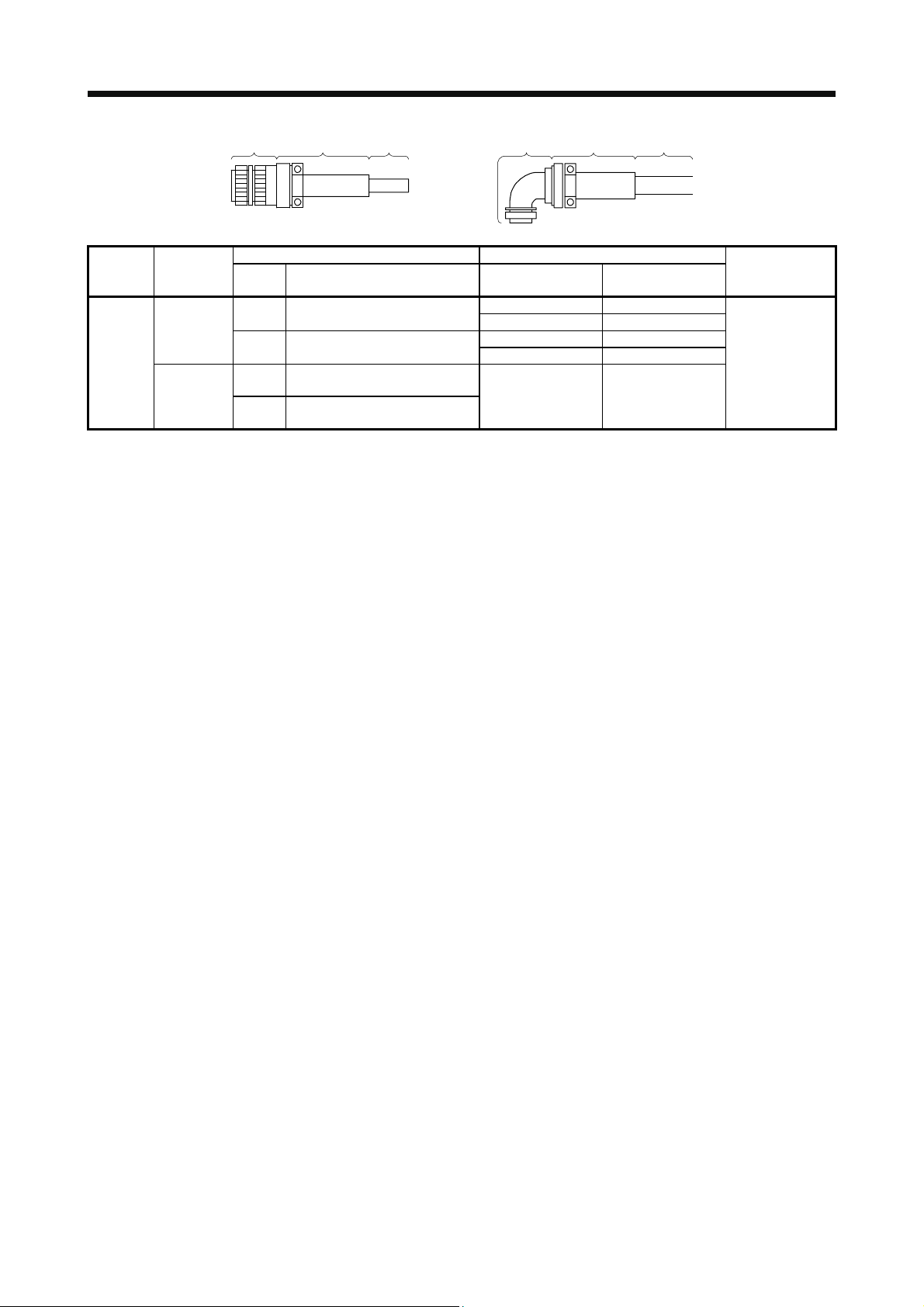

3. CONNECTORS USED FOR SERVO MOTOR WIRING

Plug Cable clamp Cable Plug Cable clamp Cable

Connector

configuration

E

(for power

supply)

Feature

IP67

EN compliant

(Note 1)

General

environment

Type Model

Straight

Angle

Straight

Angle

Note 1. Not comply with EN.

2. The connector to be mated.

Plug (DDK) Cable clamp (DDK)

Cable OD

[mm] (reference)

CE05-6A18-10SD-D-BSS

Applicable wire size: AWG 14 to 12

CE05-8A18-10SD-D-BAS

Applicable wire size: AWG 14 to 12

D/MS3106B18-10S

Applicable wire size: AWG 14 to 12

D/MS3108B18-10S

Applicable wire size: AWG 14 to 12

8.5 to 11 CE3057-10A-2-D

10.5 to 14.1 CE3057-10A-1-D

8.5 to 11 CE3057-10A-2-D

10.5 to 14.1 CE3057-10A-1-D

14.3 or less

(bushing ID)

Model

D/MS3057-10A

Servo motor power

supply connector

(Note 2)

MS3102A18-10P

3 - 4

Page 26

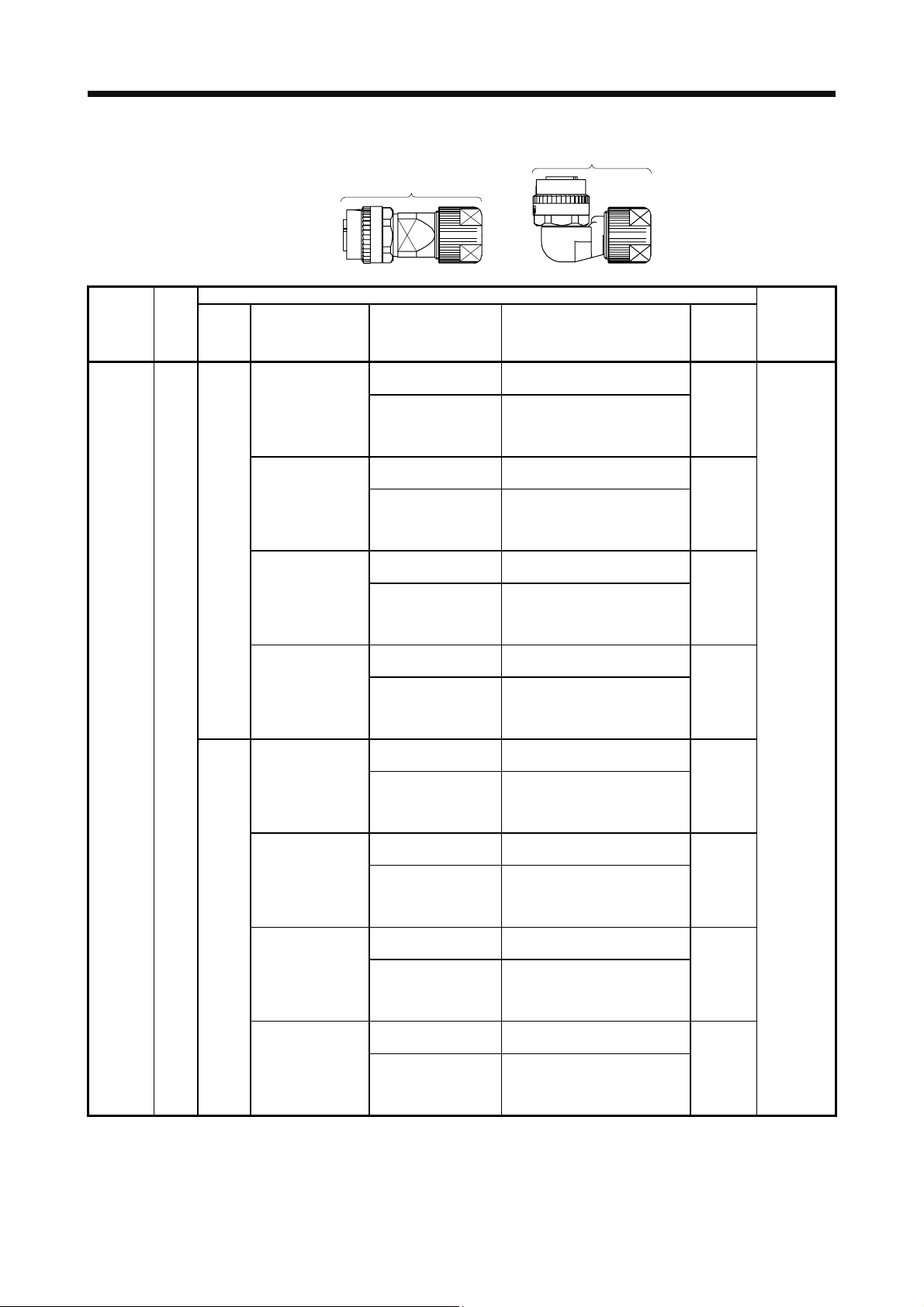

3. CONNECTORS USED FOR SERVO MOTOR WIRING

Connector

configuration

(for

electromag

netic

brake)

Feature

F

IP67

Type Plug Socket contact Contact shape

CMV1-SP2S-S

(one-touch connection

type)

CMV1-SP2S-M1

(one-touch connection

type)

Straight

CMV1-SP2S-M2

(one-touch connection

type)

CMV1-SP2S-L

(one-touch connection

type)

CMV1-AP2S-S

(one-touch connection

type)

CMV1-AP2S-M1

(one-touch connection

type)

Angle

CMV1-AP2S-M2

(one-touch connection

type)

CMV1-AP2S-L

(one-touch connection

type)

Note. The connector to be mated.

Straight plug

(one-touch connection type)

Plug (DDK)

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

CMV1-#22BSC-S2-100

CMV1-#22BSC-C3-100

(one-touch connection type)

Angle plug

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Soldering type

Applicable wire size: AWG 16 or less

Crimping type

Applicable wire size: AWG 20 to 16

The crimping tool (357J-53164T) is

required.

Cable OD

[mm]

(reference)

4.0 to 6.0

5.5 to 7.5

7.0 to 9.0

9.0 to 11.6

4.0 to 6.0

5.5 to 7.5

7.0 to 9.0

9.0 to 11.6

Servo motor

electromagnetic

brake

connector

(Note)

CM10-R2P

3 - 5

Page 27

3. CONNECTORS USED FOR SERVO MOTOR WIRING

Plug Cable clamp Cable Plug Cable clamp Cable

Connector

configuration

G

(for power

supply)

Feature

IP67

EN compliant

(Note 1)

General

environment

Type Model

Straight

Angle

Straight

Angle

Note 1. Not comply with EN.

2. The connector to be mated.

Plug (DDK) Cable clamp (DDK)

Cable OD

[mm] (reference)

CE05-6A22-22SD-D-BSS

Applicable wire size: AWG 10 to 8

CE05-8A22-22SD-D-BAS

Applicable wire size: AWG 10 to 8

D/MS3106B22-22S

Applicable wire size: AWG 10 to 8

D/MS3108B22-22S

Applicable wire size: AWG 10 to 8

9.5 to 13 CE3057-12A-2-D

12.5 to 16 CE3057-12A-1-D

9.5 to 13 CE3057-12A-2-D

12.5 to 16 CE3057-12A-1-D

15.9 or less

(bushing ID)

Model

D/MS3057-12A

Servo motor power

supply connector

(Note 2)

MS3102A22-22P

3 - 6

Page 28

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

Any person who is involved in wiring should be fully competent to do the work.

Ground the servo motor securely.

Do not attempt to wire the servo motor until it has been mounted. Otherwise, it

WARNING

CAUTION

may cause an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it

may cause an electric shock.

To avoid an electric shock, insulate the connections of the power supply

terminals.

Wire the equipment correctly and securely. Otherwise, the servo motor may

operate unexpectedly, resulting in injury.

Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may

occur.

Ensure that polarity (+/-) is correct. Otherwise, a burst, damage, etc. may occur.

Do not install a power capacitor, surge killer or radio noise filter (FR-BIF option)

with the power line of the servo motor.

Do not modify the equipment.

Connect the servo amplifier power output (U, V, and W) to the servo motor power

input (U, V, and W) directly. Do not let a magnetic contactor, etc. intervene.

Otherwise, it may cause a malfunction.

Servo amplifier

U

V

W

Servo motor

U

V

W

Servo motorServo amplifier

U

M

V

W

U

V

M

W

4 - 1

Page 29

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

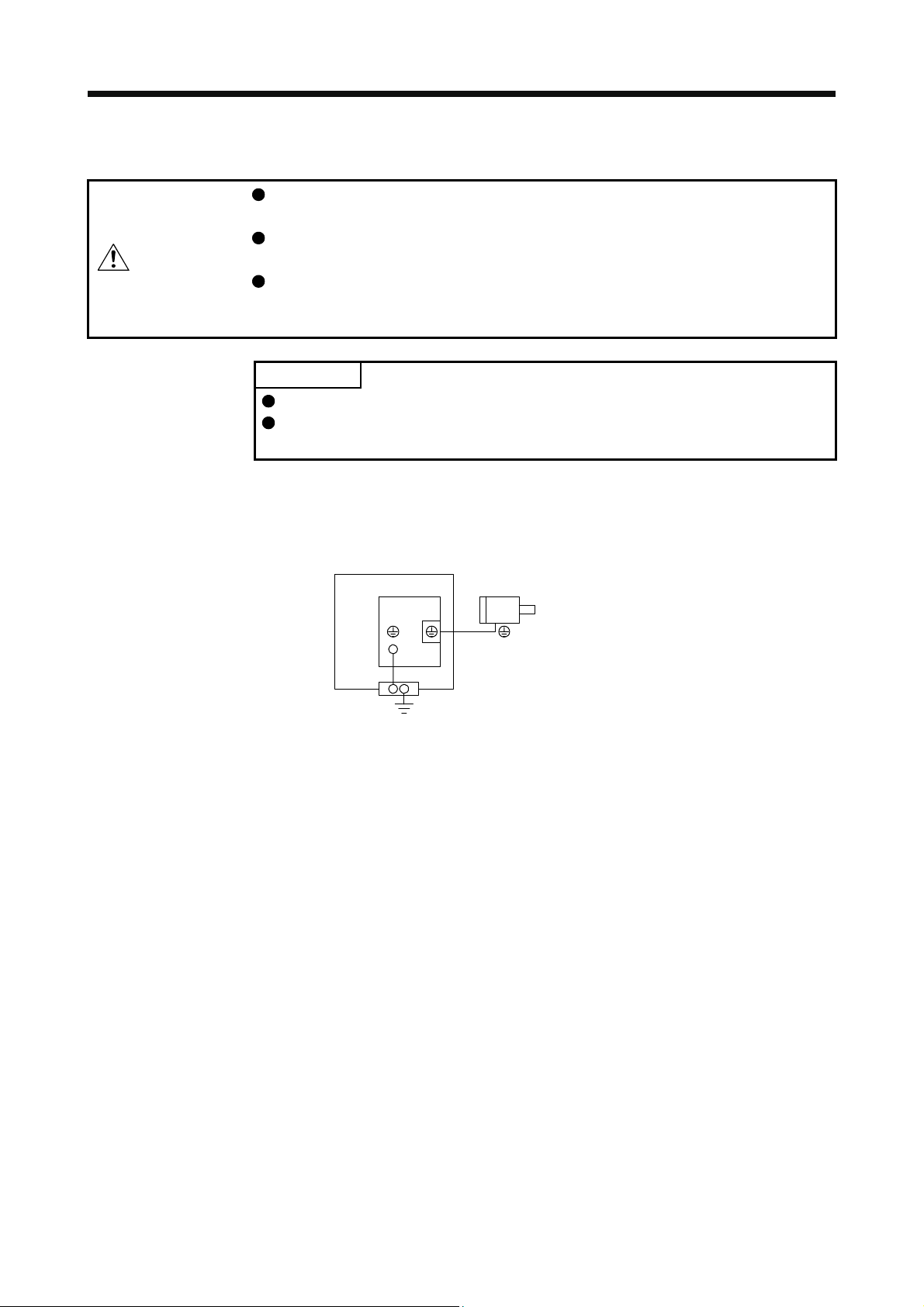

4.1 Connection instructions

To avoid a malfunction, connect the wires to the correct phase terminals (U, V,

and W) of the servo amplifier and servo motor.

Do not connect AC power supply directly to the servo motor. Otherwise, it may

cause a malfunction.

CAUTION

For grounding, connect the grounding lead wire from the servo motor to the protective earth (PE) terminal of

the servo amplifier, and then connect the wire from the servo amplifier to the ground via the protective earth

of the cabinet. Do not connect the wire directly to the protective earth of the cabinet.

Do not use the 24 V DC interface power supply for the electromagnetic brake.

Always use the power supply designed exclusively for the electromagnetic brake.

Otherwise, it may cause a malfunction.

POINT

Refer to chapter 5 for the selection of the encoder cable.

Refer to the chapter of the servo motor series for the selection of a surge

absorber for the electromagnetic brake.

Cabinet

Servo motorServo amplifier

PE

terminal

(Note)

Note. The number of PE terminals of the servo amplifier differs depending on the amplifier

types.

4 - 2

Page 30

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

4.2 Wiring

To wire to the servo amplifier, use connectors packed with the amplifier or optional connectors. For servo

amplifier terminals, refer to each servo amplifier instruction manual.

4.2.1 HF-KN series servo motor

(1) Servo motor power supply cable wiring diagrams

(a) When cable length is 10 m or less

10 m or less

MR-PWS1CBL_M-A1-L

MR-PWS1CBL_M-A2-L

(Note) CNP2

U

V

MR-PWS1CBL_M-A1-H

MR-PWS1CBL_M-A2-H

(Red)

(White)

(Black)

(Green/yellow)

Servo motorServo amplifier

U

V

WW

M

(b) When cable length exceeds 10 m

When the cable length exceeds 10 m, fabricate an extension cable as shown below. In this case, the

motor power supply cable should be within 2 m.

Refer to section 4.3 for the wire used for the extension cable.

(Note 1) CNP2

U

V

Note 1. The name and shape of connector differ depending on the servo amplifier types.

2. Use of the following connectors is recommended when ingress protection (IP65) is necessary.

Note. The name and shape of connector differ depending on the servo amplifier types.

50 m or less 2 m or less

Extension cable

(Note 2)

a) Junction connector for

extension cable

MR-PWS1CBL2M-A1-L

MR-PWS1CBL2M-A2-L

MR-PWS1CBL2M-A1-H

MR-PWS1CBL2M-A2-H

MR-PWS2CBL03M-A1-L

MR-PWS2CBL03M-A2-L

(Red)

(White)

(Black)

(Green/yellow)

(Note 2)

b) Junction connector for

motor power supply cable

Servo motorServo amplifier

U

V

WW

M

Junction connector

a) Junction connector for

extension cable

b)

Junction connector for

motor power supply cable

Connector: RM15WTPZ-4P(71)

Cord clamp: JR13WCC-5(72)

(Hirose Electric)

Connector: RM15WTJZ-4S(71)

Cord clamp: JR13WCC-8(72)

(Hirose Electric)

Description IP rating

IP65

Numeral changes depending on the cable OD.

IP65

Numeral changes depending on the cable OD.

4 - 3

Page 31

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

(2) Electromagnetic brake cable wiring diagrams

(a) When cable length is 10 m or less

10 m or less

MR-BKS1CBL_M-A1-L

MR-BKS1CBL_M-A2-L

(Note 3)

24 V DC power supply

for electromagnetic

brake

Note 1. Connect a surge absorber as close to the servo motor as possible.

2. There is no polarity in electromagnetic brake terminals (B1 and B2).

3. Do not use the 24 V DC interface power supply for the electromagnetic brake.

4. Create the circuit in order to shut off by interlocking with the emergency stop switch.

(Electromagnetic

brake interlock)

When fabricating the electromagnetic brake cable MR-BKS1CBL-_M-H, refer to section 5.4 and

section 5.5.

(b) When cable length exceeds 10 m

When the cable length exceeds 10 m, fabricate an extension cable as shown below. In this case, the

electromagnetic brake cable should be within 2 m.

Refer to section 4.3 for the wire used for the extension cable.

(Note 5)

24 V DC power supply

for electromagnetic

brake

(Electromagnetic

brake interlock)

MBR

MBR

ALM

(Malfunction)

50 m or less

Extension cable

(To be fabricated)

ALM

(Malfunction)

(Note 4)

(Note 1)

(Note 3)

(Note 1)

MR-BKS1CBL_M-A1-H

MR-BKS1CBL_M-A2-H

U

MR-BKS1CBL2M-A1-L

MR-BKS1CBL2M-A2-L

MR-BKS1CBL2M-A1-H

MR-BKS1CBL2M-A2-H

MR-BKS2CBL03M-A1-L

MR-BKS2CBL03M-A2-L

U

AWG 20

AWG 20

2 m or less

AWG 20

AWG 20

Servo motor

(Note 2)

B1

B

B2

Servo motor

(Note 4)

B1

B

B2

(Note 2)

a) Junction connector for

extension cable

Note 1. Connect a surge absorber as close to the servo motor as possible.

2. Use of the following connectors is recommended when ingress protection (IP65) is necessary.

(Note 2)

b) Junction connector for

electromagnetic brake cable

Junction connector Description IP rating

a)

Junction connector for

extension cable

b)

Junction connector for

electromagnetic brake cable

3. Create the circuit in order to shut off by interlocking with the emergency stop switch.

4. There is no polarity in electromagnetic brake terminals (B1 and B2).

5. Do not use the 24 V DC interface power supply for the electromagnetic brake.

CM10-CR2P- (DDK)

Wire size: S, M, L

CMV1-SP2S- (DDK)

Wire size: S, M1, M2, L

IP65

IP65

4 - 4

Page 32

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

4.2.2 HF-SN series servo motor

Refer to section 4.3 for the wires used for wiring.

(1) Wiring

50 m or less

(Note 4) CNP2

U

V

W

Servo motorServo amplifier

U

V

W

M

(Note 2)

24 V DC power supply

for electromagnetic

brake

Note 1. There is no polarity in electromagnetic brake terminals (B1 and B2).

2. Do not use the 24 V DC interface power supply for the electromagnetic brake.

3. Create the circuit in order to shut off by interlocking with the emergency stop switch.

4. The name and shape of connector differ depending on the servo amplifier types.

MBR

(Electromagnetic

brake interlock)

RA2

ALM

(Malfunction)

RA1

(Note 3)

RA3

B1

U

B2

B

(Note 1)

4 - 5

Page 33

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

(2) Connector

The connector fitting the servo motor is prepared as optional equipment. Refer to section 5 for details of

the options. For types other than those prepared as optional equipment, refer to chapter 3.

Servo motor

HF-SN52/HF-SN102/

HF-SN152

HF-SN202/HF-SN302

Encoder Power

CM10-R10P

(DDK)

The followings show the encoder connector, power connector, and electromagnetic brake connector

viewed from the connection side.

Encoder connector

CM10-R10P

Power supply connector

MS3102A18-10P

MS3102A22-22P

Terminal

7

10

9

8

3

6

2

5

1

4

No.

1 MR A U

2 MRR B V

3 C W

4

5 LG

6

7

8 P5

9

10 SHD

Signal

CD

AB

Terminal

No.

D

Servo motor-side connectors

MS3102A18-10P

MS3102A22-22P

Electromagnetic brake connector

Signal

(PE)

Electromagnetic

CM10-R2P

Terminal

No.

12

1

2

Note. For the motor

brake

CM10-R2P

(DDK)

with an

electromagnetic

brake, supply

electromagnetic

brake power

(24 V DC).

There is no

polarity.

Signal

(Note)

B1

(Note)

B2

4 - 6

Page 34

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

4.3 Selection example of wires

POINT

Wires indicated in this section are separated wires. When using a cable for

power line (U, V, and W) between the servo amplifier and servo motor, use a

600 V grade EP rubber insulated chloroprene sheath cab-tire cable (2PNCT).

For selection of cables, refer to appendix 6.

To comply with the UL/CSA standard, use the wires shown in appendix 4 for

wiring. To comply with other standards, use a wire that is complied with each

standard.

Selection condition of wire size is as follows.

Construction condition: One wire is constructed in the air.

Wire length: 30 m or less

The following diagram shows the wires used for wiring. Use the wires given in this section or equivalent.

Servo amplifier

1) Servo motor power lead

U

V

W

Servo motor

U

V

Motor

W

2) Electromagnetic

brake lead

B1

Electromagnetic

brake

B2

Encoder

Encoder cable

When using the 600 V Grade heat-resistant polyvinyl chloride insulated wire (HIV wire)

Wire size selection examples for HIV wires are indicated below.

Table 4.1 Wire size selection example 2 (HIV wire)

Servo motor

HF-KN13

HF-KN23

HF-KN43

HF-KN73

HF-SN52

HF-SN102

HF-SN152

HF-SN202

Note. It is for 10 m wire length. When fabricating an extension cable, use 1.25 mm2 (AWG 16).

HF-SN302 3.5 (AWG 12)

1) U/V/W/

0.75 (AWG 18) (Note) 0.5 (AWG 20) (Note)

1.25 (AWG 16)

2 (AWG 14)

Wires [mm2]

2) B1/B2

1.25 (AWG 16)

4 - 7

Page 35

4. CONNECTION OF SERVO AMPLIFIER AND SERVO MOTOR

MEMO

4 - 8

Page 36

5. WIRING OPTION

5. WIRING OPTION

Before connecting options, turn off the power and wait for 15 minutes or more

WARNING

CAUTION

5.1 Cable/connector sets

until the charge lamp turns off. Otherwise, an electric shock may occur. In

addition, when confirming whether the charge lamp is off or not, always confirm it

from the front of the servo amplifier.

Use specified peripheral equipment and options. Otherwise, it may cause a

malfunction or fire.

POINT

The IP rating indicated for cables and connectors is their protection against

ingress of dust and water when they are connected to a servo amplifier or servo

motor. If the IP rating of the cable, connector, servo amplifier and servo motor

vary, the overall IP rating depends on the lowest IP rating of all components.

Purchase the cable and connector options indicated in this section.

5 - 1

Page 37

5. WIRING OPTION

r

5.1.1 Combinations of cable/connector sets

(1) HF-KN series servo motor

Servo amplifier

(Note)

CNP2

CN2

Direct connection (cable length 10 m or less, IP65)

13)14)15)16)

Junction connection (cable length more than 10 m, IP65)

24)25)

26)

Junction connection (cable length more than 10 m, IP20)

19)20)

22)23)

17)18)

Note. The name and shape of connector differ depending on the servo amplifier types. For connector details, refer to each

servo amplifier instruction manual.

(2) HF-SN series servo motor

Servo amplifie

(Note)

CNP2

CN2

To 24 V DC power supply

for electromagnetic brake

7)8)9)10)

1)2)3)4)

Power supply

connector

21)

11)12)

5)6)

Electromagnetic

brake connector

26)31)

Servo

motor

HF-KN

Encoder

connector

24)25)

29)30)

27)28)

Power supply

connector

Note. The name and shape of connector differ depending on the servo amplifier types. For connector details, refer to each

servo amplifier instruction manual.

Electromagnetic

brake connector

Servo motor

HF-SN

Encoder

connector

5 - 2

Page 38

5. WIRING OPTION

5.1.2 Cable and connector list

No. Product Model Description Remarks

1) Servo motor

power cable

2) Servo motor

power cable

3) Servo motor

power cable

4) Servo motor

power cable

5) Servo motor

power cable

6) Servo motor

power cable

7) Electromagnetic

brake cable

8) Electromagnetic

brake cable

9) Electromagnetic

brake cable

10) Electromagnetic

brake cable

MRPWS1CBL_MA1-L (Note)

Cable length:

2/5/10 m

MRPWS1CBL_MA1-H (Note)

Cable length:

2/5/10 m

MRPWS1CBL_MA2-L (Note)

Cable length:

2/5/10 m

MRPWS1CBL_MA2-H (Note)

Cable length:

2/5/10 m

MRPWS2CBL03M

-A1-L (Note)

Cable length:

0.3 m

MRPWS2CBL03M

-A2-L (Note)

Cable length:

0.3 m

MRBKS1CBL_MA1-L

Cable length:

2/5/10 m

MRBKS1CBL_MA1-H

Cable length:

2/5/10 m

MRBKS1CBL_MA2-L

Cable length:

2/5/10 m

MRBKS1CBL_MA2-H

Cable length:

2/5/10 m

Refer to section 5.3 for details.

Refer to section 5.3 for details.

Refer to section 5.3 for details.

Refer to section 5.3 for details.

Refer to section 5.4 for details.

Refer to section 5.4 for details.

Power supply connector

HF-KN series

Power supply connector

HF-KN series

Power supply connector

HF-KN series

Power supply connector

HF-KN series

Electromagnetic brake connector

HF-KN series

Electromagnetic brake connector

HF-KN series

IP65

Load-side

lead

EN

compliant

IP65

Load-side

lead

Long

bending life

EN

compliant

IP65

Opposite

to loadside lead

EN

compliant

IP65

Opposite

to loadside lead

Long

bending life

EN

compliant

IP55

Load-side

lead

EN

compliant

IP55

Opposite

to loadside lead

EN

compliant

IP65

Load-side

lead

IP65

Load-side

lead

Long

bending life

IP65

Opposite

to loadside lead

IP65

Opposite

to loadside lead

Long

bending life

5 - 3

Page 39

5. WIRING OPTION

r

r

No. Product Model Description Remarks

11) Electromagnetic

brake cable

12) Electromagnetic

brake cable

13) Encoder cable MR-

14) Encoder cable MR-

15) Encoder cable MR-

16) Encoder cable MR-

17) Encoder cable MR-

18) Encoder cable MR-

MRBKS2CBL03MA1-L

Cable length:

0.3 m

MRBKS2CBL03MA2-L

Cable length:

0.3 m

J3ENCBL_MA1-L (Note)

Cable length:

2/5/10 m

J3ENCBL_MA1-H (Note)

Cable length:

2/5/10 m

J3ENCBL_MA2-L (Note)

Cable length:

2/5/10 m

J3ENCBL_MA2-H (Note)

Cable length:

2/5/10 m

J3JCBL03MA1-L (Note)

Cable length:

0.3 m

J3JCBL03MA2-L (Note)

Cable length:

0.3 m

Refer to section 5.4 for details.

Refer to section 5.4 for details.

Refer to section 5.2 (1) for details.

Refer to section 5.2 (1) for details.

Refer to section 5.2 (3) for details.

Electromagnetic brake connecto

HF-KN series

Electromagnetic brake connecto

HF-KN series

Encoder connector

HF-KN series

Encoder connector

HF-KN series

Encoder connector

HF-KN series

Encoder connector

HF-KN series

IP55

Load-side

lead

IP55

Opposite

to loadside lead

IP65

Load-side

lead

IP65

Load-side

lead

Long

bending life

IP65

Opposite

to loadside lead

IP65

Opposite

to loadside lead

Long

bending life

IP20

Load-side

lead

IP20

Opposite

to loadside lead

19) Encoder cable MR-EKCBL_M-

L

Cable length:

20/30 m

20) Encoder cable MR-EKCBL_M-

H

Cable length:

20/30/40/50 m

21) Encoder

connector set

MR-ECNM

Refer to section 5.2 (3) for details.

HF-KN series

Refer to section 5.2 (2) for details.

IP20

HF-KN series

Refer to section 5.2 (2) for details.

IP20

Long

bending life

IP20

5 - 4

Page 40

5. WIRING OPTION

r

No. Product Model Description Remarks

22) Encoder cable MR-

J3JSCBL03MA1-L (Note)

Cable length:

0.3 m

Refer to section 5.2 (4) for details.

23) Encoder cable MR-

J3JSCBL03MA2-L (Note)

Cable length:

0.3 m

Refer to section 5.2 (4) for details.

24) Encoder cable MRJ3ENSCBL_ML (Note)

Cable length:

2/5/10/20/30 m

25) Encoder cable MRJ3ENSCBL_MH (Note)

Cable length:

2/5/10/20/30/40

/50 m

26) MR-J3SCNS

Encoder

connector set

27) Power connector

set

28) Power connector

set

29) Electromagnetic

brake connector

set

30) Electromagnetic

brake connector

set

31) Encoder

Connector set

(Note)

HF-KN/HF-SN series

MR-PWCNS4 Plug: CE05-6A18-10SD-D-BSS

MR-PWCNS5 Plug: CE05-6A22-22SD-D-BSS

MR-BKCNS1

(Note)

MR-BKCNS1A

(Note)

MR-J3SCNSA

(Note)

HF-KN/HF-SN series

Refer to section 5.2 (5) for details.

IP67

Refer to section 5.2 (5) for details.

Cable clamp: CE3057-10A-1-D

(DDK)

Applicable cable

Applicable wire size: 2 mm

Cable outer diameter: 10.5 mm to 14.1 mm

Cable clamp: CE3057-12A-1-D

(DDK)

Applicable cable

Applicable wire size: 5.5 mm

Cable outer diameter: 12.5 mm to 16 mm

Straight plug: CMV1-SP2S-L

Socket contact: CMV1-#22BSC-S2-100

(DDK)

Angle plug: CMV1-AP2S-L

Socket contact: CMV1-#22BSC-S2-100

(DDK)

2

to 3.5 mm

(AWG 14 to 12)

2

to 8 mm

(AWG 10 to 8)

Encoder connecto

HF-KN series

Encoder connector

HF-KN series

HF-SN52/HF-SN102/

HF-SN152

2

HF-SN202/HF-SN302

2

HF-SN series

HF-SN series

IP65

Load-side

lead

IP65

Opposite

to loadside lead

IP67

Standard

flexlife

Long

bending life

IP67

IP67

EN

compliant

IP67

EN

compliant

IP67

IP67

IP67

HF-SN series

Refer to section 5.2 (5) for details.

Note. The cable and the connector set may contain different connectors but still usable.

5 - 5

Page 41

5. WIRING OPTION

5.2 Encoder cable/connector sets

POINT

For the CN2-side connector, securely connect the shielded external conductor

of the cable to the ground plate and fix it to the connector shell.

(1) MR-J3ENCBL_M-_-_

These cables are encoder cables for the HF-KN series servo motors. The numbers in the cable length

field of the table indicate the symbol filling the underline "_" in the cable model. The cables of the lengths

with the symbols are available.

Cable model

MR-J3ENCBL_M-A1-L 2 5 10 IP65 Standard

MR-J3ENCBL_M-A1-H 2 5 10 IP65

MR-J3ENCBL_M-A2-L 2 5 10 IP65 Standard

MR-J3ENCBL_M-A2-H 2 5 10 IP65

Ground plate

Cable length

2 m 5 m

Cable

Screw

IP rating Bending life Application

10 m

Long

bending life

Long

bending life

Load-side lead for HF-KN servo

motor

Opposite to load-side lead for HFKN servo motor

5 - 6

Page 42

5. WIRING OPTION

(a) Connection of servo amplifier and servo motor

MR-J3ENCBL_M-A1-L

MR-J3ENCBL_M-A1-H

Servo amplifier

CN2

Cable model 1) CN2-side connector 2) Encoder-side connector

MR-J3ENCBL_M-A1-L

MR-J3ENCBL_M-A1-H

MR-J3ENCBL_M-A2-L

MR-J3ENCBL_M-A2-H

Receptacle: 36210-0100PL

Shell kit: 36310-3200-008

(3M or equivalent)

2

LG 8

1

P5

View seen from wiring side. (Note)

Note. Do not connect anything to the pins shown as

6

4

MRR

5

3

MR

10 is provided for manufacturer adjustment. If it is connected with any

other pin, the servo amplifier cannot operate normally.

10

9

7

1)

MR-J3ENCBL_M-A2-L

MR-J3ENCBL_M-A2-H

1)

Connector set: 54599-1019

(Molex)

2

4

MRR

LG

or

1P53

MR

View seen from wiring side. (Note)

or

8610

5

79

. Especially, pin

2)

Servo motor

HF-KN

2)

Servo motor

HF-KN

Connector: 2174053-1

Crimping tool for ground clip:

1596970-1

Crimping tool for receptacle

contact: 1596847-1

(TE Connectivity)

SHD

9

7

5MR

3P5

1

View seen from wiring side.

(Note)

Note. Do not connect anything

to the pins shown as

.

(b) Cable internal wiring diagram

CN2-side

connector

Encoder-side

connector

8

6LG

MRR

4

2

P5

LG

MR

MRR34

Plate

SD

1

2

9

P5

3

LG

6

5

4

2

9

MR

MRR

SHD

5 - 7

Page 43

5. WIRING OPTION

(2) MR-EKCBL_M-_

POINT

The following encoder cables are of four-wire type.

MR-EKCBL30M-L

MR-EKCBL30M-H

MR-EKCBL40M-H

MR-EKCBL50M-H

When using these encoder cables, refer to each servo amplifier instruction

manual.

The servo amplifier and the servo motor cannot be connected by these cables alone. The servo motorside encoder cable (MR-J3JCBL03M-_-L) is required.

The numbers in the cable length field of the table indicate the symbol filling the underline "_" in the cable

model. The cables of the lengths with the symbols are available.

Cable model

MR-EKCBL_M-L 20

MR-EKCBL_M-H 20

Note. Four-wire type cable

(a) Connection of servo amplifier and servo motor

Cable length

20 m 30 m 40 m 50 m

(Note)

30

(Note)

30

IP20 Standard

(Note)

(Note)

40

50

IP rating Bending life Application

For HF-KN servo motor

Use in combination with MR-

J3JCBL03M-_-L.

IP20

Long

bending life

Servo amplifier

CN2

1)

Cable model 1) CN2-side connector 2) Junction connector

MR-EKCBL_M-L

MR-EKCBL_M-H

Receptacle: 36210-0100PL

Shell kit: 36310-3200-008

(3M)

2

LG

15

P5

View seen from wiring side. (Note)

Note. Do not connect anything to the pins shown as

6

4

MRR

37

MR

10 is provided for manufacturer adjustment. If it is connected with any

other pin, the servo amplifier cannot operate normally.

8

MDR

MD

10

9

MR-EKCBL_M-L

MR-EKCBL_M-H

Connector set: 54599-1019

(Molex)

428610

or

13 79

P5 MR

View seen from wiring side. (Note)

MRR

LG

MDR

5

MD

. Especially, pin

MR-J3JCBL03M-A2-L

Cable length: 0.3m

2)

Housing: 1-172161-9

Connector pin: 170359-1

Crimping tool: 91529-1

(TE Connectivity or equivalent)

Cable clamp: MTI-0002

(Toa Electric Industrial)

123

MR

456

MD

789

P5

View seen from wiring side.

MRR

CONT

MDR

LG SHD

Servo motor

HF-KN

5 - 8

Page 44

5. WIRING OPTION

(b) Internal wiring diagram

MR-EKCBL20M-L

CN2-side

connector

Junction

connector

MR-EKCBL30M-L

CN2-side

connector

Junction

connector

P5

LG

MR

MRR34

Plate

SD

CN2-side

connector

P5

LG

1

2

9

(Note)

MR-EKCBL20M-H

1

2

7

8

1

2

3

9

Junction

connector

7

8

P5

LG

MR

MRR

SHD

P5

LG

P5

LG

1

2

MR

MRR34

MD

MDR 8 5

SD

P5

LG

7

9

Plate

MR-EKCBL30M-H

MR-EKCBL40M-H

MR-EKCBL50M-H

CN2-side

connector

1

2

(Note)

7

8

1

2

4

3

6 CONT

9

Junction

connector

7

8

P5

LG

MR

MRR

MD

MDR

SHD

P5

LG

MR

MR

MRR34

SD

9

Plate

(Note)

1

MRR

2

3

9

SHD

MR

MRR34

MD

MDR

Plate

SD

7

85

9

(Note)

1

MR

2

MRR

4

MD

MDR

3

6

CONT

9

SHD

Note. When fabricating, it is not necessary to wire this.

When fabricating the cable, use the wiring diagram corresponding to the length indicated below.

Cable bending life

Standard MR-EKCBL20M-L MR-EKCBL30M-L

Long bending life MR-EKCBL20M-H MR-EKCBL30M-H

Less than 30 m 30 m to 50 m

Applicable wiring diagram

MR-EKCBL40M-H

MR-EKCBL50M-H

5 - 9

Page 45

5. WIRING OPTION

(c) When fabricating the encoder cable

When fabricating the cable, prepare the following parts, and fabricate it according to the wiring

(3) MR-J3JCBL03M-_-L