Mitsubishi HD-6000 Service manual

20052005

2005

20052005

SerSer

Ser

SerSer

vicevice

vice

vicevice

MITSUBISHI ELECTRIC

ManualManual

Manual

ManualManual

SET TOP BOX

V26S CHASSIS

MODEL

HD-6000

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power Usage : 82W

• Frequency Range : VHF 54 ~ 470MHz

UHF 470 ~ 806MHz

Analog Cable - 1 ~ 125

Digital Cable - 1 ~ 135

• Antenna Input : 2 RF 75Ω unbalanced

• Tuning : 1 NTSC/A TSC/QAM

1 CableCARD™ Slot

1 NTSC for PIP

• Cabinet Dimensions : 17"(W) x 3.4"(H) x 16.8"(D)

• Weight : 27 lbs

• PVR : 120 GB Hard Disc

Approx. 12 hrs HD Recording

72 hrs SD Recording

• Analog Input : VIDEO IN JACK (RCA T ype)

Levels 1.0Vp-p 75Ω unbalanced

: AUDIO IN JACK (RCA T ype)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y , Cr, Cb (RCA T ype)

Y: 1.0 Vp-p Cr, Cb: 700mVp-p

: A TV / Y(G), Pr(R), Pb(B), H, V

Y: 1.0Vp-p with sync 75Ω (BNC)

Pr, Pb: 700mV 75Ω

H, V: 3.0Vp-p 75Ω

: VGA / R,G ,B,V ,H (15 pin D)

• Output Level : VIDEO OUT JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: COMP / Y ,Cr ,Cb

Y: 1.0 Vp-p Cr, Cb: 700mVp-p

: AUDIO OUT JACK (RCA T ype)

-4.7dBm 4.7kΩ unbalanced

• Digital : IEEE-1394 I/O Jacks

Interface : AC-3 Digtal Audio Output

: HDMI™ Input/Output

: MonitorLink

: CableCARD™ Slot

: NetCommand®

TM

Control/RS-232C

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2005 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

.

MODEL: HD-6000

CONTENTS

INTRODUCTION ................................................................................................................................5

PRODUCT SAFETY NOTICE .............................................................................................................5

SAFETY PRECAUTIONS ...................................................................................................................6

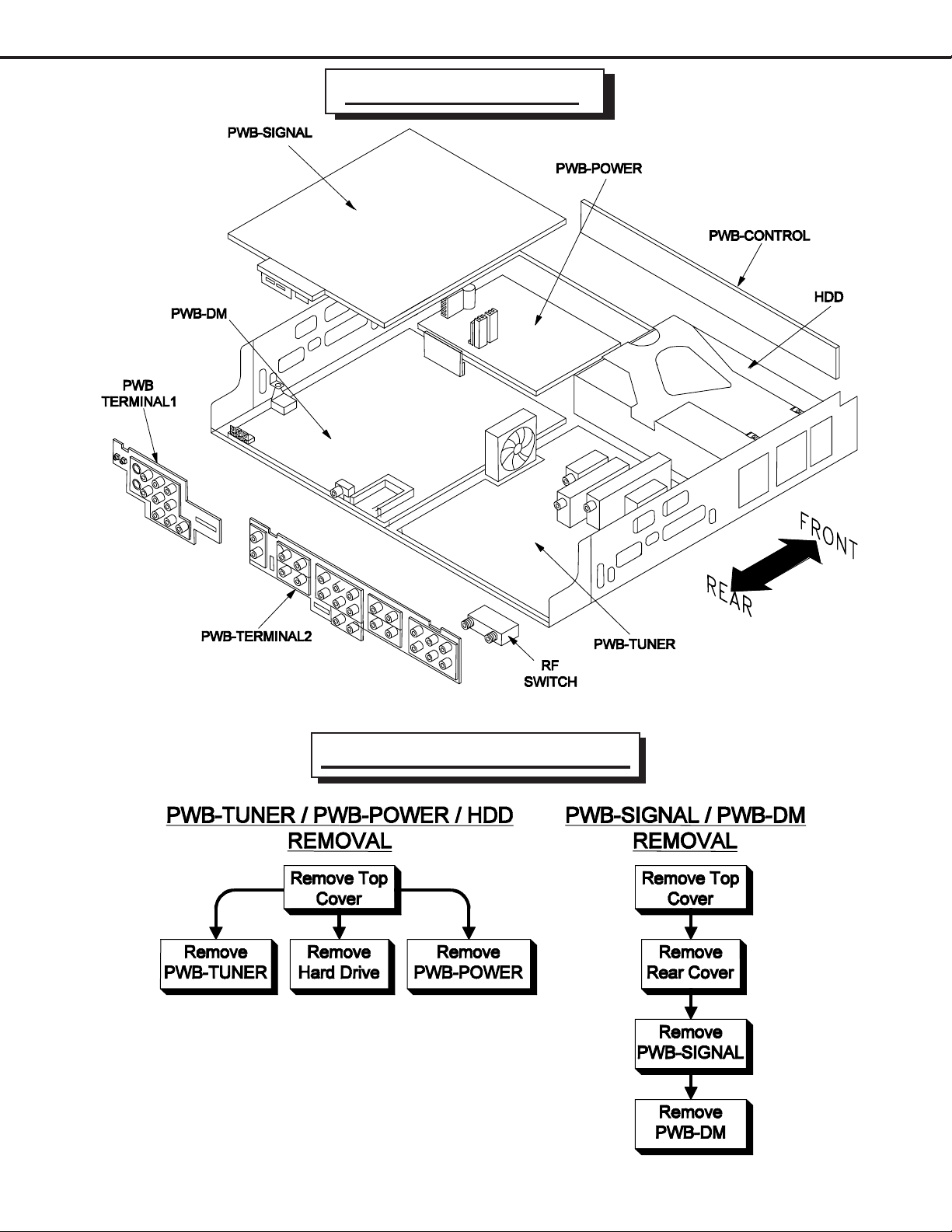

PWB-LOCA TIONS .............................................................................................................................7

DISASSEMBL Y .................................................................................................................................. 7

Disassembly Procedures Sequence ......................................................................................7

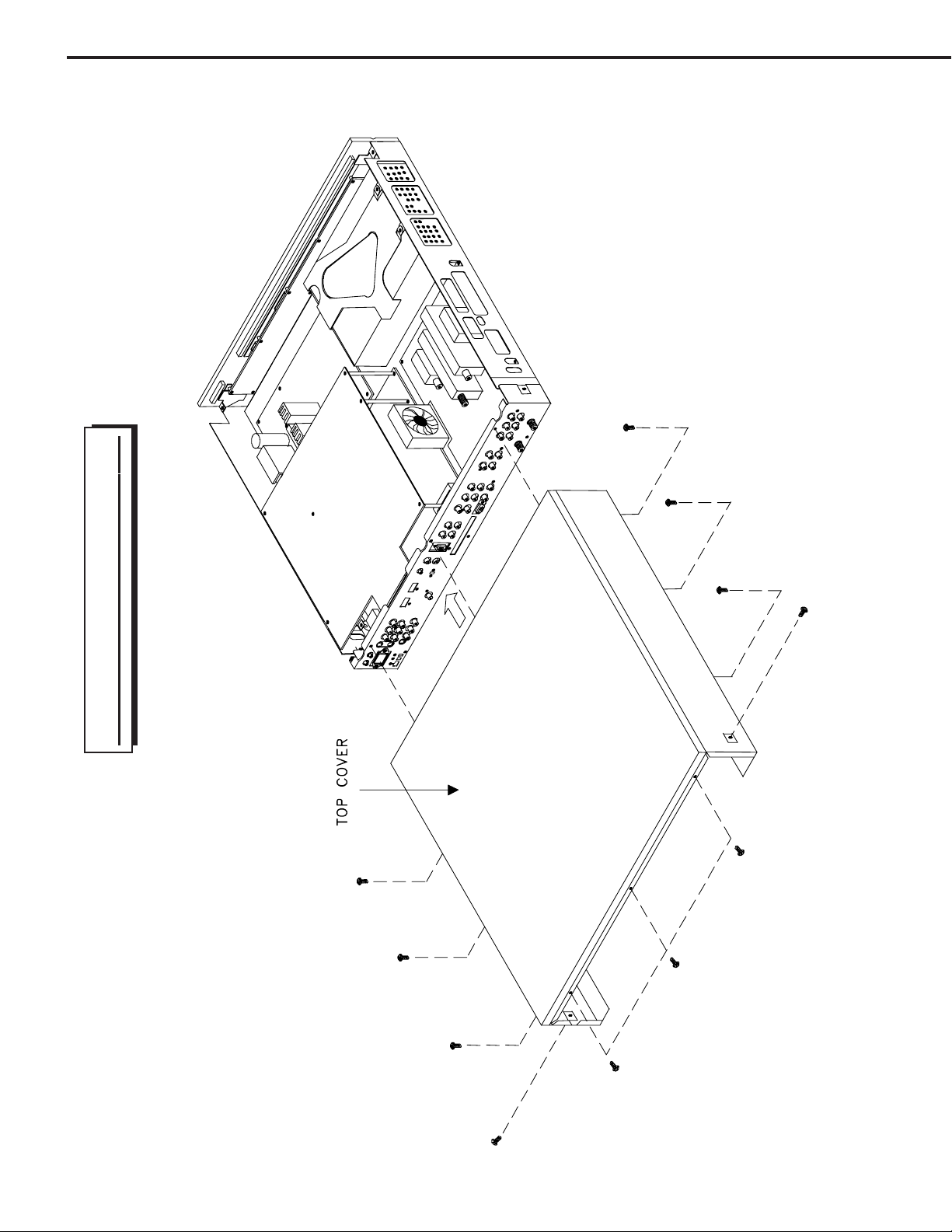

T op Cover removal ..................................................................................................................8

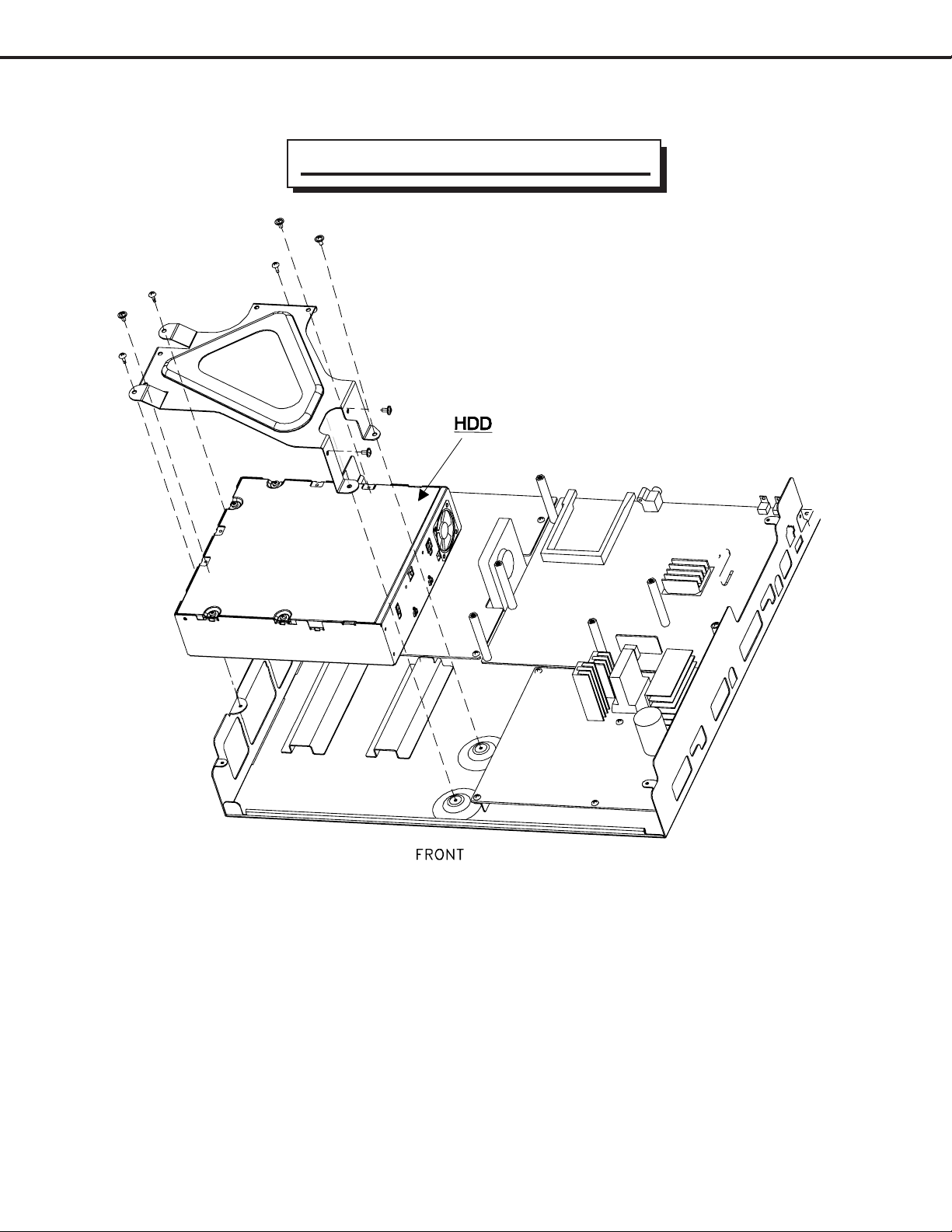

HDD (Hard Drive) removal....................................................................................................... 9

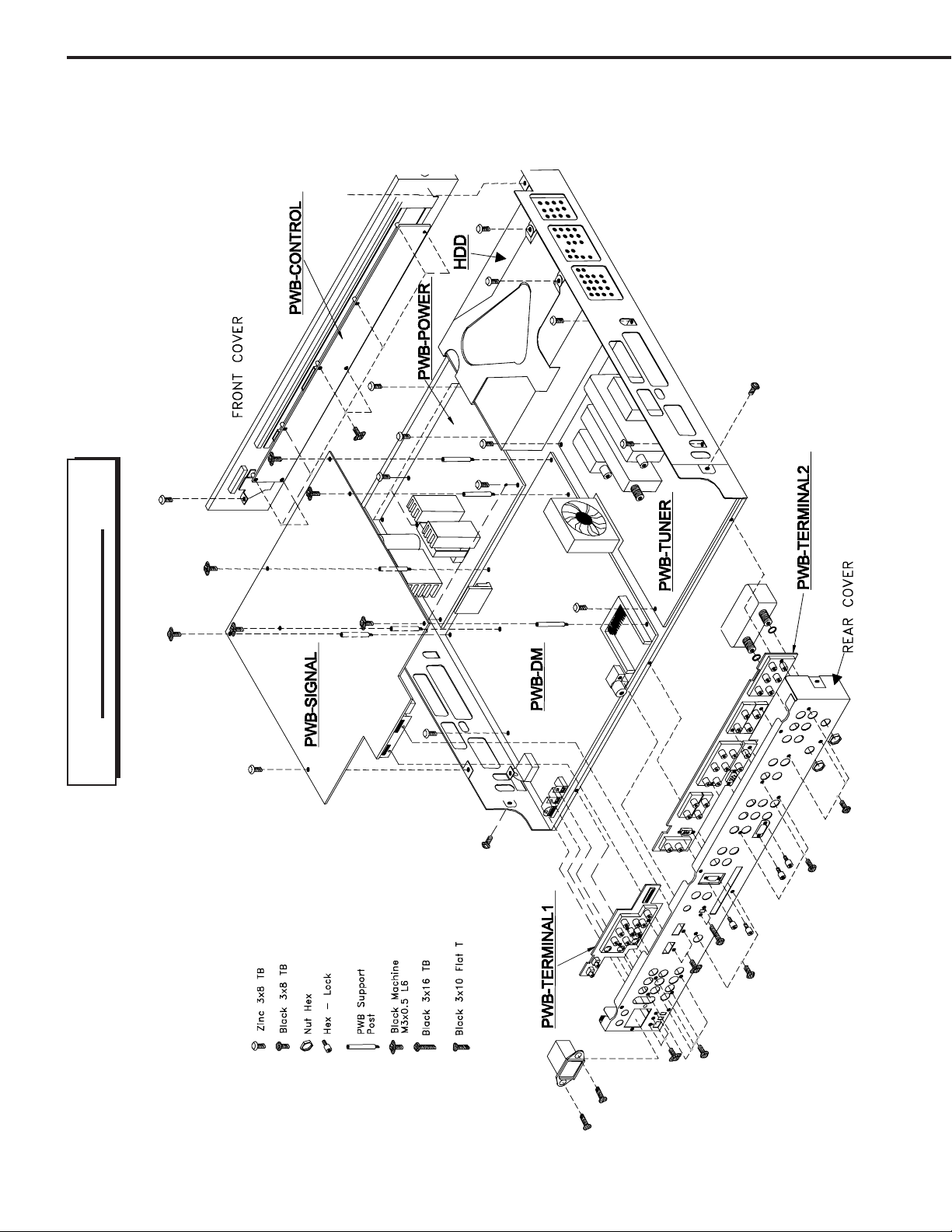

PWB’S removal ...................................................................................................................10

ELECTRICAL ADJUSTMENTS ........................................................................................................ 11

Equipment .................................................................................................................................... 11

Option Menu / Initialization Defaults / AV Defaults......................................................................... 1 2

LED Diagnostics ........................................................................................................................... 13

Remote Control Operational Mode ................................................................................................13

Circuit Adjustment Mode ...............................................................................................................14

Transfering data ............................................................................................................................ 15

Adjustment Items List................................................................................................................... 15

Adjustment Procedures ................................................................................................................16

Test Points .......................................................................................................................... 16

Main-Y Gain......................................................................................................................... 16

Sub-Y Gain .......................................................................................................................... 17

Sub Picture Offset ...............................................................................................................17

CHIP P ARTS REPLACEMENT ......................................................................................................... 18

REPLACEMENT P ARTS .................................................................................................................. 19

Parts Ordering ..............................................................................................................................19

Critical and Warranty Parts Designation........................................................................................19

Parts T olerance Codes.................................................................................................................. 19

SERVICE PARTS LIST ....................................................................................................................20

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 29

St andby Power Supplies ............................................................................................................... 29

PWB-DM Power Supplies ............................................................................................................. 30

PWB-SIGNAL Switched Power Supplies ......................................................................................30

Video Select Circuitry ...................................................................................................................31

Video Output Circuitry................................................................................................................... 32

Sync Signal Selection................................................................................................................... 33

Sync Signal Output Path .............................................................................................................. 34

Record Signal Path....................................................................................................................... 34

Sound Signal Path ........................................................................................................................35

Control Circuitry ............................................................................................................................ 36

Command Input Circuitry............................................................................................................... 37

Macrovision Detection................................................................................................................... 37

PWB-DM Signal Path ...................................................................................................................38

Page 3

MODEL: HD-6000

Part 2

Schematic Diagrams

CONTENTS Page

SCHEMA TIC DIAGRAMS

Overall PWB Interconnect Diagram .................................................................................................1

POWER / E2P / CONTROL / MV Decoder] ....................................................................................2

TERMINAL-1 / TERMINAL-2 [Inputs / Outputs] ...............................................................................3

SIGNAL-1 [Video Switch]................................................................................................................4

SIGNAL-2 [Decoder / Switch]..........................................................................................................5

SIGNALS-3 [Micro} .........................................................................................................................6

SIGNAL-4 [TVGO] ..........................................................................................................................7

SIGNAL-5 [MPEG Encoder]............................................................................................................8

SIGNAL-6 [HDMI RX] ...................................................................................................................... 9

SIGNAL-7 [HDMI TX]..................................................................................................................... 10

SIGNAL-8 [Video Output]............................................................................................................. 11

SIGNAL-9 [IR232] ......................................................................................................................... 12

TUNER-1 [ATSC / NTSC Tuner] .................................................................................................... 13

TUNER-2 [Main A TSC / NTSC Demodulators] ...............................................................................14

PWB LA YOUT DIAGRAMS .............................................................................................................. 15

Page 4

MODELS: HD-6000

INTRODUCTION

This service manual provides service instructions for STB model HD-6000 which uses the V26S chassis. Service

personnel should read this manual thoroughly before servicing these chassis.

This service manual includes:

1. Safety Precautions

2. Assembly and disassembly instructions.

3. Servicing printed circuit boards (PCBs).

4. Electrical adjustments.

5. Chip parts replacement procedures.

6. Circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Schematic and block diagrams of the above listed models are included in this service manual for better understanding

of the circuitry . PCB drawings are also included for easy location of p arts and test points.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagrams and by bold type in

the parts list of this service manual. and by marking on the supplementary sheet for this chassis to be issued subsequently. The replacement for any safety part should be identical in value and characteristics.

Page 5

MODELS: HD-6000

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

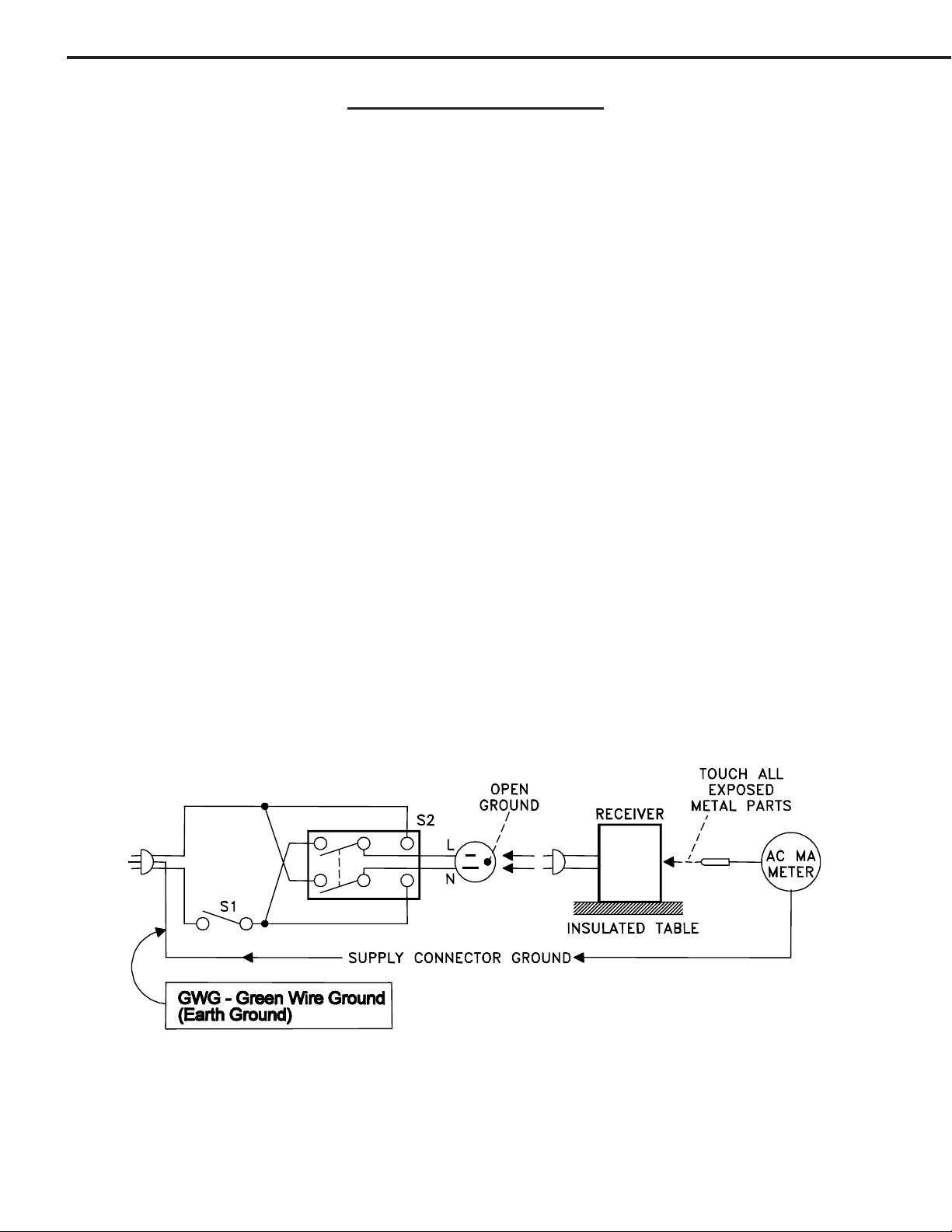

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal part

(i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay , control shaf ts, etc.), particularly any

exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a

return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value indicates an

abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately af ter closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

MODELS: HD-6000

PWB LOCATIONS

Disassembly Sequence

Page 7

MODELS: HD-6000

TOP COVER REMOVAL

Page 8

MODELS: HD-6000

HDD (Hard Drive) Removal

NOTE: Prior to HDD replacement, perform the prodedure

“Replacing the HDD” described on page 15.

Page 9

MODELS: HD-6000

PWB Removal

Page 10

MODEL: HD-6000

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

Test Equipment

• Oscilloscope (Unless otherwise specified, use 10:1 probes)

• Signal Generator (both SD and HD capable)

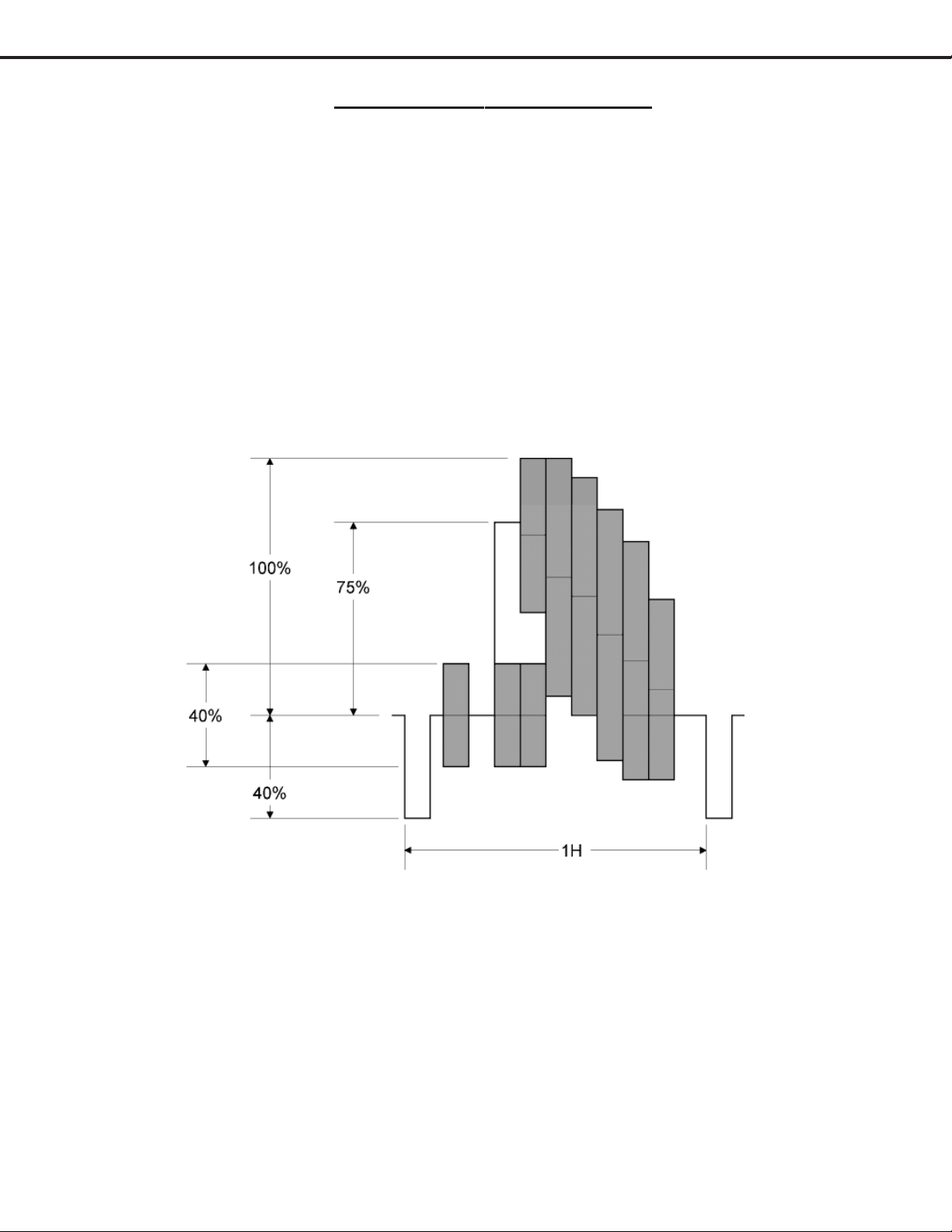

Test Signal

A. Color Bar Signal

Use the color bar signal shown below , unless otherwise specified in this manual.

Page 11

MODEL: HD-6000

V

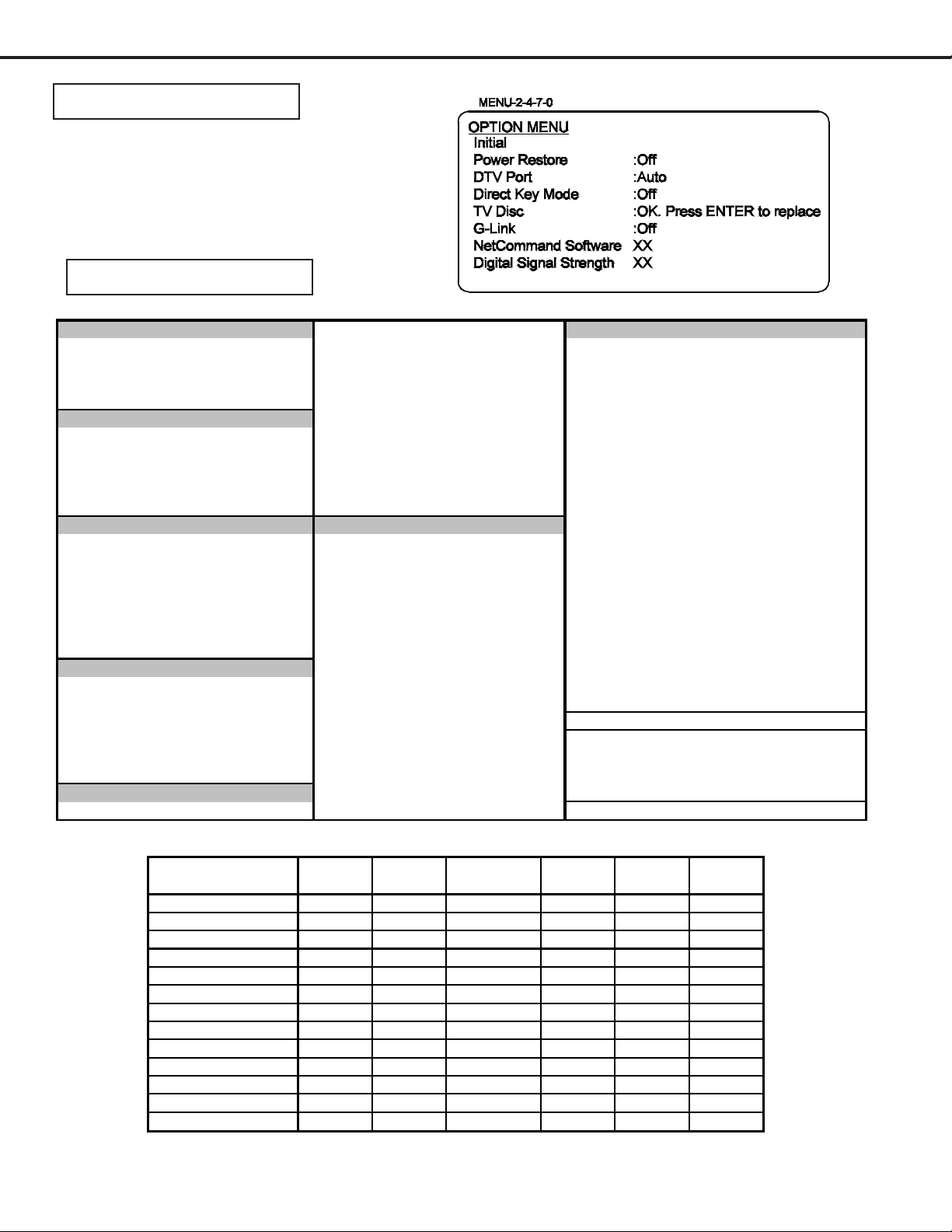

OPTION MENU

1. Press the “MENU” button on the remote hand unit.

2. Press the buttons “2”, “4”, “7” and “0” in order.

(The screen will change to the option menu.)

DEFAULTS

Defaults After Initialization

Audio / VideoCaptions Menu (continued)Setup Menu

Language :English Background :Gray A/V Memory Reset :Ant-1

Color Balance - - Digital Captions :On if Mute Audio

TV Pause :On Requ est Appear ance :Default Bas s :50%

Side Bar Color :Gray Digital S ettings Treble :50%

NetCommand Menu

Edit -- Size :Large Surround :Off

Transport Menu :On Color :W hite Sub W oofer :On

Default PVR -- Background :Black Listen To (Analog Only) :Stereo

Icon Order -- Opacity :Translucent Level Sound :On

Analog Quality :High Bac kground Opacity :Translucent Languag e (Digital Onl y) :English

Anten na Menu

Antenna :1 V-Chiip :Off Contrast :50%

Memorize -- TV Rating :TV-PG Brightness :50%

Prefer Digital -- FV-Fantasy Violence :Enable Sharpness :50%

Channel :3 D-Sexual Dialog :Enable Color :50%

Memory :Deleted L-Adult Language :Enable Tint :50%

Name -- S-Sexua l Situations :Enable Video noise :Standard

SQV -- V-Violence :Enable Film Mode (Auto) :On

Time Menu

Clock Setting :Manual Movie Rat ing :PG Fix/Variable :Variable

Time :12:00AM V-Chip Time Scan Rate Setting :Automatic

Date :1/01/00 Start :12:00pm

Time Zone :Eastern Stop :12:00pm PIP Sourc e :A nt-1 003

Daylight Savings Time :Applies Lock by Time PIP Position :Lower Right

Timer -- Lock by Time :Off POP Pos ition :Right Half

Captions Menu

Analog Captions :On if Mute Unlock Time :12:00pm

Font :Font 3 Balance :50%

V-Chip Lock Menu

Programs Not Rated :Enable Video Mute :On

Lock Time :12:00pm

Video

TV Volume

PIP/POP Format

Format

:30%

:Double Window

:Stretch

A/V Re se t Defaults

A/V Function Ant 1/2 Input 1/2

Contrast Center Center Center Center Center Center

Brightness Center Center Center Center Center Center

Sharpness

Color Center Center Center Center Center C enter

Tint Center Center Center Center Center C enter

ideo noise

Film Mode (Auto) On On On N/A On N/A

Bass

Treble

Balance Center Center Center Center Center Center

Surround

Listen To

Level Sound On On On On On On

NOTE: Front Panel A/V Reset, resets all A/V Memory settings.

Center Center Center N/A Center C enter

Standard Standard Standard N/A Standard N/A

Center Center Center Center Center Center

Center Center Center Center Center Center

Off Off Off Off Off Off

Stereo N/A N/A N/A N/A N /A

User Menu A/V Reset, resets only the selected input A/V settings.

Component

1/2/DTV

Page 12

VGA HDMI 1394

MODEL: HD-6000

A. A/V Memory

Each of the external inputs has its own Audio/Video Memory. A change in an A/V setting at a specific input is

stored in memory for that specific input.

B. A/V Reset

1. Press the GUIDE and FORMA T buttons on the front panel to reset all A/V Memories to default.

2. The AV Reset in the user’s menu initializes only the selected input’s A/V Memory.

LED Indicator Diagnostics

The “POWER/TIMER” LED provides an indication of the sets operation, and the possible cause of a malfunction.

1. Initial Control Circuitry Check

Immediately after the TV is connected to an AC power source:

LED Indi c a tions Cond itions Probable C a use

Off After AC is applied Standby Power Supply or TV µPC not running

Fast Bllink for 70 sec. After AC is applied Normal DM µPC is booting up

Fast Blink (doesn't stop) After AC is applied DM µPC failed to boot up

Slow Blink Set in Off Normal - Timer is set for Automatic Turn ON

2. Error Code Operational Check

Note: The Set T op Box must be in “Shut Down” and not have been switched Of f, to perform the Error Code

Operational Check. When the unit is switched Off, the code automatically resets to “12” No Error .

Pressing the front panel “DEVICE” and “MENU” buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The LED flashes denoting a two digit Error Code, or indicating no problem

has occured since the last Initalization.

Note: The front panel buttons must be used, NOT those on the Remote Control.

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

• The Error Code is repeated a total of 5 times.

Example: If the Error Code is “35”, the LED will flash three times, pause, and then flash five times.

4. Error Codes

The Error Code designations indicating malfunction, or no malfunction, are listed below:

Error Code Probable Cause

12 Normal Operation - No Error Detected

35 Fan Stopped

41 Short Detected

Remote Control Operational Modes

There are two Remote Hand Unit Operational Modes, “Standard” and “NetCommandTM”. The Remote is initially

in the “Standard” mode. The “NetCommandT” mode is used when controlling Home Theater devices using

NetCommand. T o change the Remote Operational Mode:

• Set the Remote to the CABLE/DBS/DTV Layer.

• Point the Remote away from the STB.

• To change to “Netcommand” ... Hold the “Power” button and press “1-9-7” in sequence.

• To change to “S tandard” ... Hold the “Power” button and press “0-0-0” in sequence.

Page 13

MODEL: HD-6000

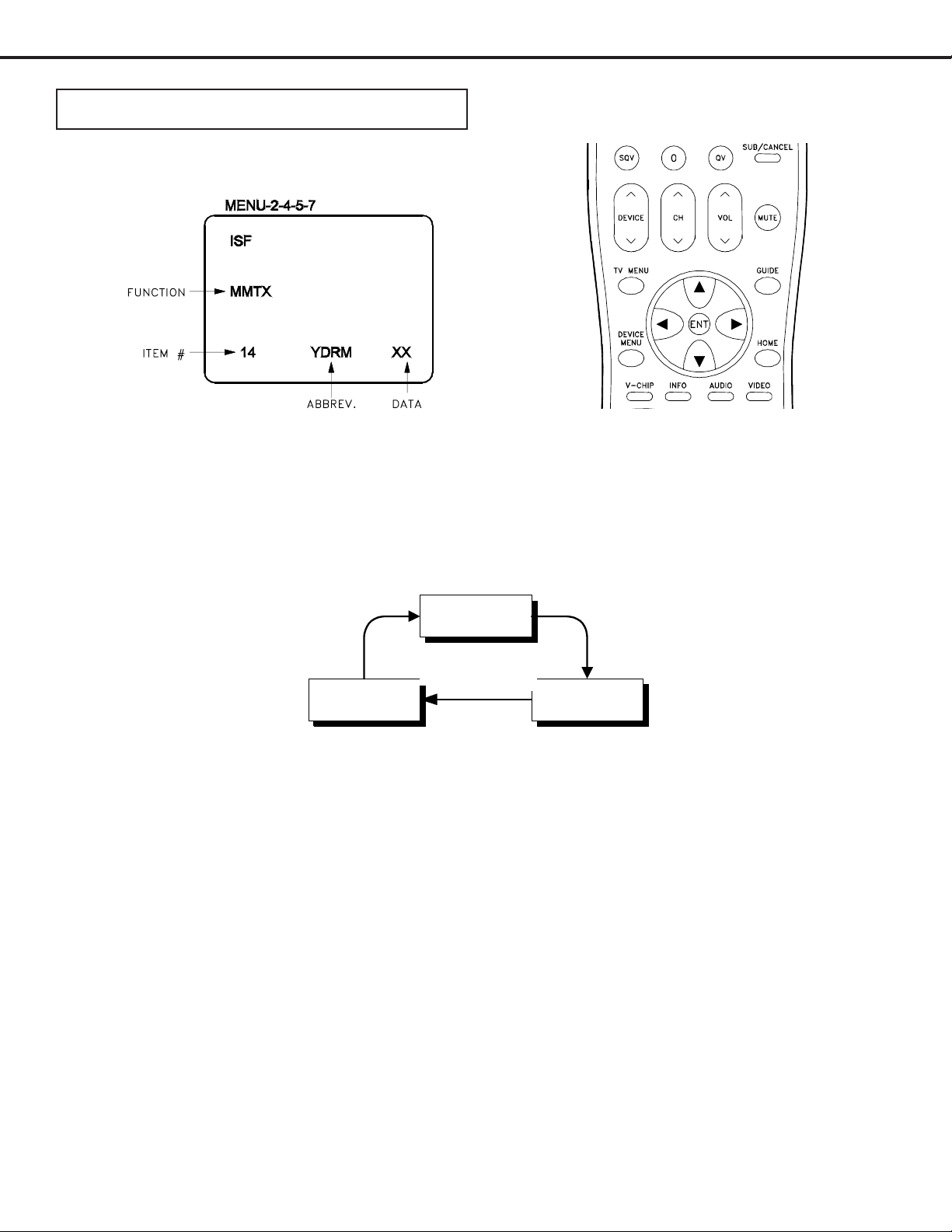

CIRCUIT ADJUSTMENTS

Electrical Adjustments

Electrical Adjusments are performed in Service Adjustment Mode.

1. Activating the adjustment mode

1. Press the “MENU” button on a remote hand unit.

(The “MENU” display will appear .)

2. Press the buttons “2”, “4”, “5” and “7” in that order . (The screen will change to the adjustment mode.)

If not changed to the adjustment mode, repeat steps 1 and 2.

2. Adjustment Function Selection

Use the “AUDIO” button to select a specific Adjustment Function.

AD9883A

Functions

SMTX MMTX

3. Adjustment Selection

Use the “VIDEO” button to select a specific elecrtrical ajustment.

4. Adjusting Data

After selecting an adjustment item, use the “UP” and “DN” buttons to change adjustment data.

ª If the “UP” button is pressed, the adjustment data increases.

ª If the “DN” button is pressed, the adjustment data decreases.

5. Saving data

Press “ENTER” to save the adjustment data in memory .

The display characters go red for approx. one second in this step.

Note: If the circuit adjustment mode is terminated without pressing

“ENTER”, changes in adjustment data are not saved.

6. T erminating the circuit adjustment mode

Press the “MENU” button on the remote hand unit twice to terminate the adjustment mode.

Note: The adjustment mode can be also terminated by turning the

power off.

Page 14

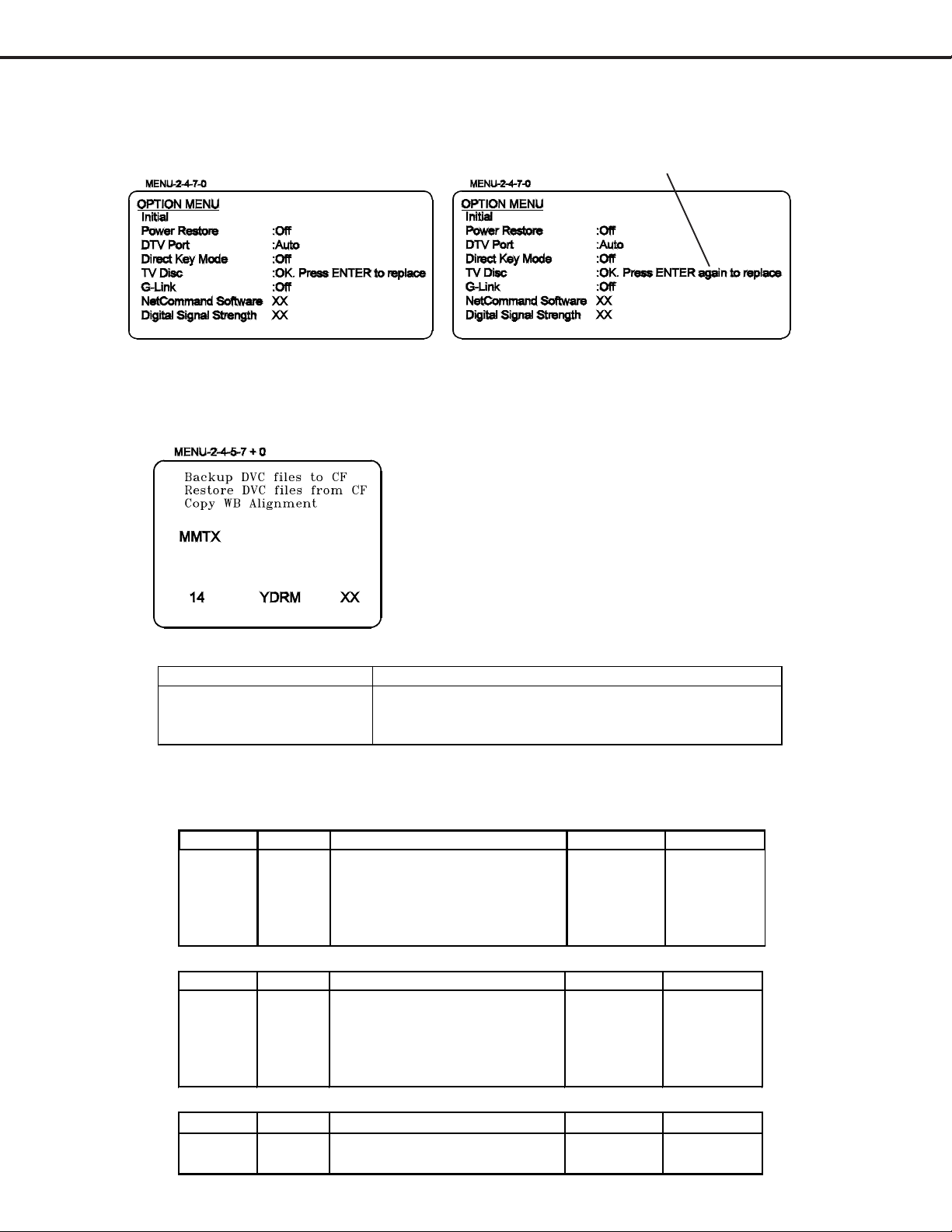

MODEL: HD-6000

A

Replacing the HDD

Prior to replacing the HDD Assembly , perform the following step s.

1 ) Disconnect all external IEEE1394 devices.

2 ) Enter the Option Menu ... Press “MENU-2-4-7-0”

3) Select TV Disc. Press “Enter.” Wait for confirmation and press “Enter” again.

Transferring Data

1 ) Enter the Service Adjustment Mode ... Press “MENU-2-4-5-7”

2 ) Press “0” when in the Service Mode ... Three choices appear at the top of the screen.

3 ) User UP & DN keys to highlight the desired choice, the Press “ENTER”

Data Transfer Defini tions

Display Description

Bac k up DVC files to CF Copies A li gnment dat a to c ompact flas h

Restore DVC files from CF Loads A lignm ent data from com pac t flash

Copy WB Alignment Used t o transfer WB data from si gnal E2P to DM E 2P

SERVICE MODE - Adjustment Items and Initial Data Values

MAIN MATRIX

Item # Abbrev. Descript ion Data Range Initial Data

1 TNTM Main Tint adjustment 0~63 28

4 COLM Main Color adjustment 0~63 20

14 YDRM Main Y gain control 0~31 5

18 UPDM Main Pb Pedestal adjustment 0~15 7

19 VPDM Main Pr Pedestal adjustment 0~15 7

SUB MATRIX

Item # A bbr ev. Desc ription Data Range Initial Data

1 TNTS Sub Tint adjustment 0~63 28

4 COLS Sub Color adjustm ent 0~63 18

14 YDRS Sub Y gain control 0~31 5

18 UPDS Sub Pb Pedestal adjustment 0~15 7

19 VPDS Sub Pr Pedestal adjustment 0~15 7

AD9883

Item # Abbrev. Description Data Range Initial Data

12 ROFF Red Offset 0~27 55

14 BOFF Blue Offset 0~27 59

Page 15

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

MODEL: HD-6000

Purpose:

TEST POINTS

Symptom:

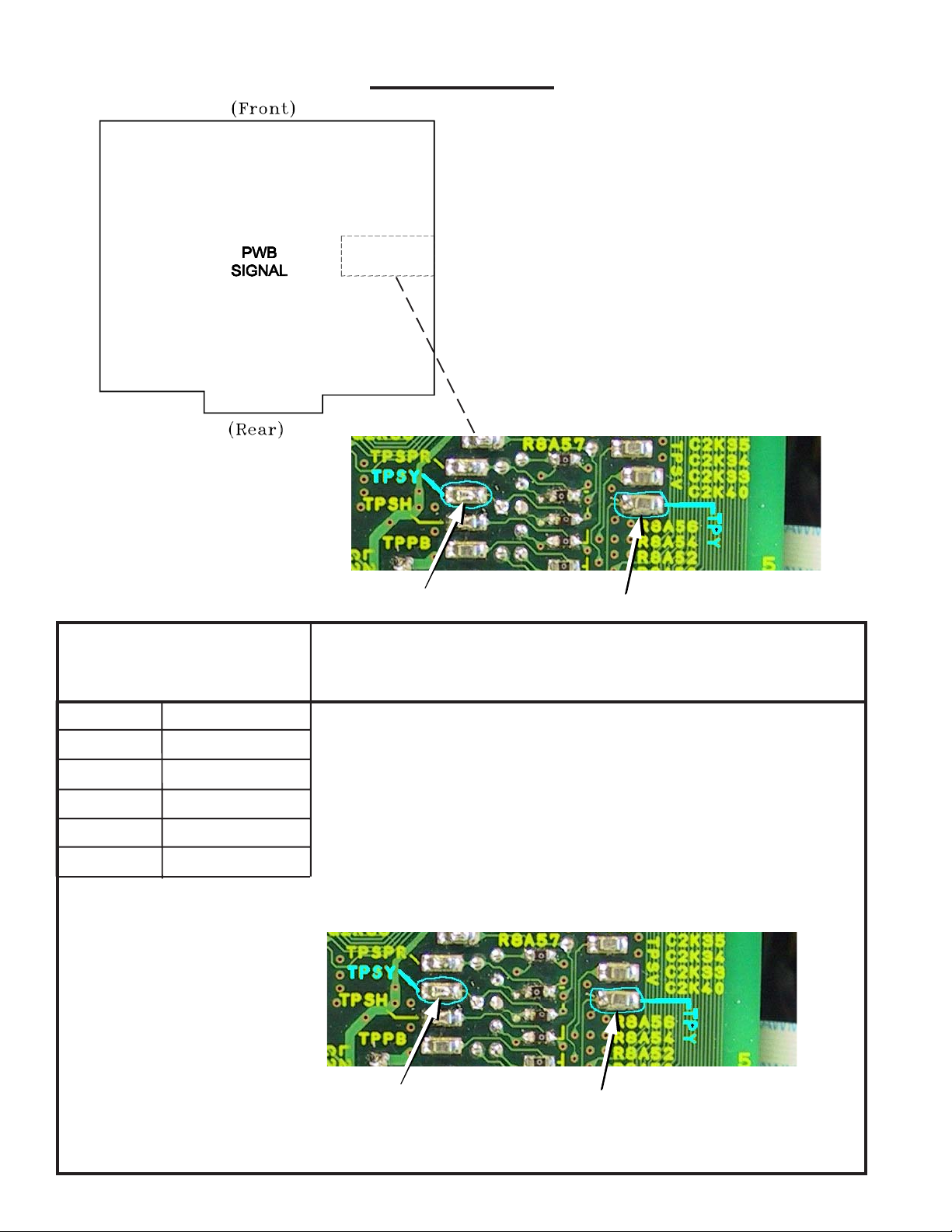

PWB-SIGNAL (Partial)

[Video Circuit]

1. Main-Y Gain

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TPY

------

------Color bars

External Input

TPSY

Purpose:

Symptom:

1. Supply a Color Bar pattern with 100% white signal to an External Input. Select

the Color Bars as the source (Device button).

2. Connect a scope to TPY (Main Luminance).

3. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the MMTX function (AUDIO button).

5. Select adjust item #14 YDRM (VIDEO button).

6. Set the data so the waveform at TPY is 0.7 Vp-p ±0.03 Vp-p (ADJUST buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

T o set the main picture Y level

Incorrect analog source main picture brightness level.

TPY

PWB-SIGNAL (Partial)

TPSY

TPY

Page 16

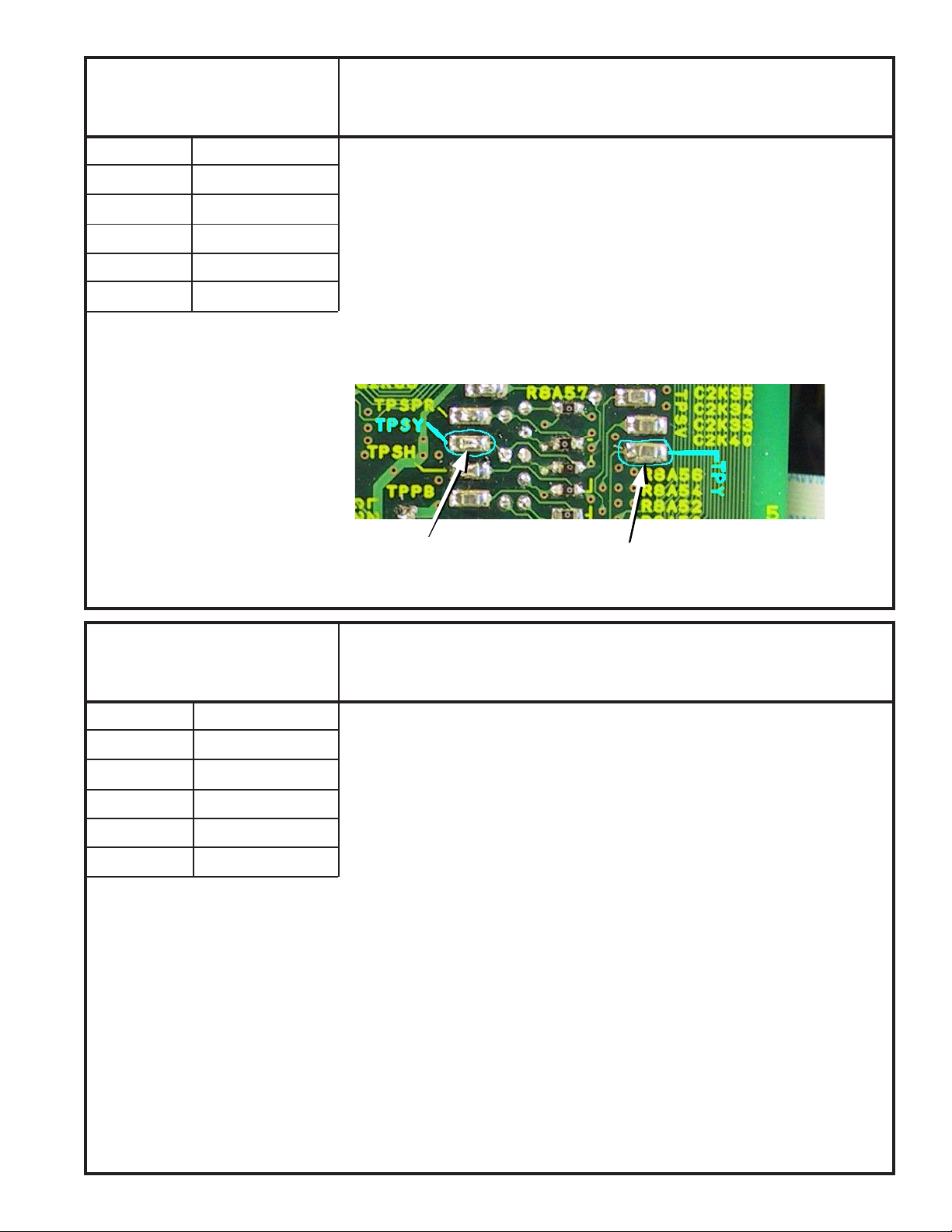

[Video Circuit]

Purpose:

MODEL: HD-6000

To set the sub picture Y level

2. Sub-Y Gain

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TPY & TPSY

------

------Color bars

External Input

Symptom:

Incorrect analog source sub picture brightness level.

1. Supply a Color Bar pattern with 100% white signal to an External Input.

2. Select the Color Bars as the source for both the main and sub pictures.

2. Connect a scope to TPY (Main Luminance) & TPSY (Sub Luminance).

3. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the SMTX function (AUDIO button).

5. Select adjust item #14 YDRS (VIDEO button).

6. Set the data so the waveform at TPSY equals TPY. (ADJUST buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

PWB-SIGNAL (Partial)

TPSY

TPY

[Video Circuit]

3. Sub Picture Offset

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

----

----

------

------Full White Raster

External Input

Purpose:

Symptom:

T o match sub picture white to main picture white

Sub picture white differs from white in the main picture.

1. Supply a full white raster signal to an External Input.

2. Select the White raster as the source for both the main and sub pictures.

3. Use the PIP/POP buttion to select the Single PIP mode.

4. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the AD9883A function (AUDIO button).

5. Select item #12 ROFF and #14 BOFF (VIDEO button).

6. Set the data fore items #12 and #14 so the sub picture white is close to that in

the main picture. (ADJUST buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

Page 17

Loading...

Loading...