Page 1

20052005

2005

20052005

SerSer

Ser

SerSer

vicevice

vice

vicevice

MITSUBISHI ELECTRIC

ManualManual

Manual

ManualManual

SET TOP BOX

V26K CHASSIS

MODEL

HD-4001

RECEIVER/CONTROLLER

FOR MODELS LT-3280 & LT-3780

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Power Usage

• Frequency Range : VHF 54 ~ 470MHz

• Antenna Input : 2 RF 75Ω unbalanced

• Tuning : 1 NTSC/A TSC/QAM

• Cabinet Dimensions : 17"(W) x 3.7"(H) x 17.25"(D)

• Weight : 12.8 lbs

• Analog Input : VIDEO IN JACK (RCA Type)

Levels 1.0Vp-p 75Ω unbalanced

: 82W

UHF 470 ~ 806MHz

Analog Cable - 1 ~ 125

Digital Cable - 1 ~ 135

1 CableCARD™ Slot

1 NTSC for PIP

: AUDIO IN JACK (RCA T ype)

-4.7dBm 43kΩ unbalanced

: S-VIDEO IN JACK

(Y/C separate type)

Y:1.0 Vp-p C:0.286Vp-p(BURST)

75Ω unbalanced

: COMP / Y , Cr, Cb (RCA T ype)

Y: 1.0 Vp-p Cr, Cb: 700mVp-p

• Output Level : VIDEO OUT JACK (RCA T ype)

1.0Vp-p 75Ω unbalanced

: AUDIO OUT JACK (RCA T ype)

-4.7dBm 4.7kΩ unbalanced

• Digital : IEEE-1394 I/O Jacks

Interface : AC-3 Digtal Audio Output

: HDMI™ Input

: MonitorLink

: CableCARD™ Slot

: NetCommand®

.

TM

Control/RS-232C

• Design specifications are subject to change without notice.

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2005 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

MODEL: HD-4001

CONTENTS

INTRODUCTION ................................................................................................................................5

PRODUCT SAFETY NOTICE .............................................................................................................5

SAFETY PRECAUTIONS ...................................................................................................................6

PWB-LOCA TIONS .............................................................................................................................7

DISASSEMBL Y .................................................................................................................................. 8

T op Cover removal ..................................................................................................................8

PWB-SIGNAL & PWB-TERMINAL Removal........................................................................... 9

Signal Bracket Removal ....................................................................................................... 10

Rear Panel Removal............................................................................................................. 11

Card Reader Removal & Front Panel Removall .....................................................................12

ELECTRICAL ADJUSTMENTS ........................................................................................................ 13

Equipment .................................................................................................................................... 13

Option Menu / Initialization Defaults / AV Defaults......................................................................... 1 4

LED Diagnostics ........................................................................................................................... 15

Remote Control Operational Mode ................................................................................................15

Circuit Adjustment Mode ...............................................................................................................16

Transfering data ............................................................................................................................ 17

Adjustment Items List................................................................................................................... 17

Adjustment Procedures ................................................................................................................18

Test Points .......................................................................................................................... 18

Main-Y Gain......................................................................................................................... 18

Sub-Y Gain .......................................................................................................................... 19

Sub Picture Offset ...............................................................................................................19

CHIP P ARTS REPLACEMENT ......................................................................................................... 20

REPLACEMENT P ARTS .................................................................................................................. 21

Parts Ordering ..............................................................................................................................21

Critical and Warranty Parts Designation........................................................................................21

Parts T olerance Codes.................................................................................................................. 21

SERVICE PARTS LIST ....................................................................................................................22

CIRCUITRY BLOCK DIAGRAMS ..................................................................................................... 31

St andby Power Supplies ............................................................................................................... 31

PWB-DM Power Supplies ............................................................................................................. 32

PWB-SIGNAL Switched Power Supplies ......................................................................................32

Tuners & Analog Video Select Circuitry......................................................................................... 33

Digital Video Signal Path .............................................................................................................. 34

Sync Signal Selection..........................................................................................................

Sync Signal Output Path .............................................................................................................. 35

Sound Signal Path ........................................................................................................................36

Control Circuitry ............................................................................................................................ 37

Command Input Circuitry............................................................................................................... 38

Macrovision Detection................................................................................................................... 38

......... 35

Page 3

Page 4

MODEL: HD-4001

Part 2

Schematic Diagrams

CONTENTS Page

SCHEMA TIC DIAGRAMS

Overall PWB Interconnect Diagram .................................................................................................1

POWER / E2P / CONTROL / MV Decoder] ....................................................................................2

TERMINAL-1 / TERMINAL-2 [Inputs / Outputs] ...............................................................................3

SIGNAL-1 [Video Switch]................................................................................................................4

SIGNAL-2 [Decoder / Switch]..........................................................................................................5

SIGNALS-3 [Micro} .........................................................................................................................6

SIGNAL-4 [TVGO] ..........................................................................................................................7

SIGNAL-5 [MPEG Encoder]............................................................................................................8

SIGNAL-6 [HDMI RX] ...................................................................................................................... 9

SIGNAL-7 [HDMI TX]..................................................................................................................... 10

SIGNAL-8 [Video Output]............................................................................................................. 11

SIGNAL-9 [IR232] ......................................................................................................................... 12

TUNER-1 [ATSC / NTSC Tuner] .................................................................................................... 13

TUNER-2 [Main A TSC / NTSC Demodulators] ...............................................................................14

PWB LA YOUT DIAGRAMS .............................................................................................................. 15

Page 4

Page 5

MODELS: HD-4001

INTRODUCTION

This service manual provides service instructions for STB model HD-4001 which uses the V26K chassis. Service

personnel should read this manual thoroughly before servicing these chassis.

This service manual includes:

1. Safety Precautions

2. Assembly and disassembly instructions.

3. Servicing printed circuit boards (PCBs).

4. Electrical adjustments.

5. Chip parts replacement procedures.

6. Circuit path diagrams.

The parts list section of this service manual includes:

1. Cabinet and screen parts.

2. Electrical parts.

Schematic and block diagrams of the above listed models are included in this service manual for better understanding

of the circuitry . PCB drawings are also included for easy location of part s and test points.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by

using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified in this service manual.

Electrical components having such features are identified by shading on the schematic diagrams and by bold type in

the parts list of this service manual. and by marking on the supplementary sheet for this chassis to be issued subsequently. The replacement for any safety part should be identical in value and characteristics.

CableCARD is a trademark of Cable T elevision Laboratories, Inc.

TV Guide On Screen is a registered trademark of Gemstar Development Corp.

HDMI is a trademark of HDMI Licensing, LLC.

Page 5

Page 6

MODELS: HD-4001

SAFETY PRECAUTIONS

NOTICE: Observe all cautions and safety related notes located inside the receiver cabinet and on the

receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard

from the receiver's power supplies. Work on the receiver should not be attempted by anyone who is

not thoroughly familiar with the precautions necessary when working on high voltage equipment.

2. When service is required, observe the original lead dress. Extra precaution should be taken to

assure correct lead dress in the high voltage area. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

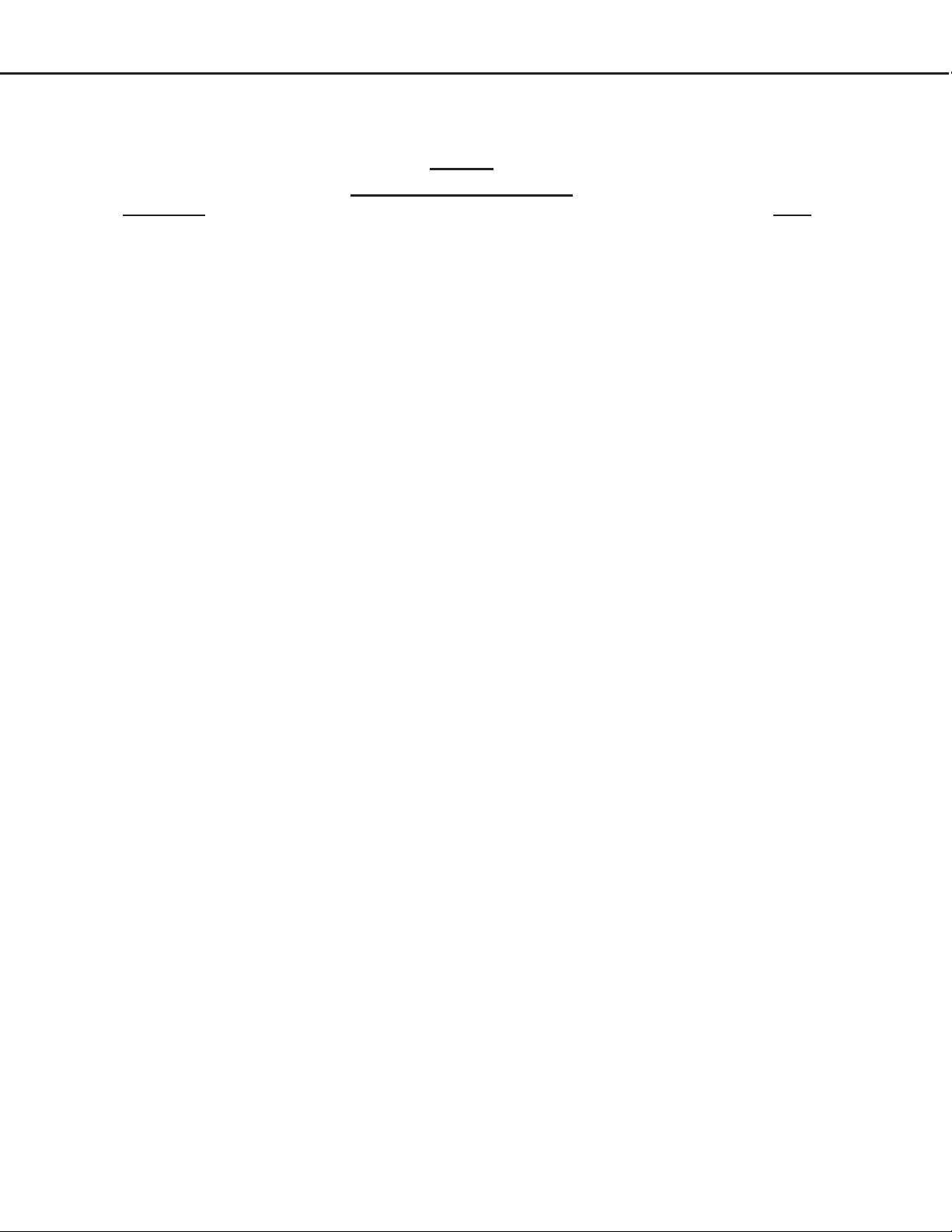

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed met al part

(i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay , control shaft s, etc.), particularly any

exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a

return path to the chassis should be a minimum of 1Mega Ohm. Any resistance below this value indicates an

abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after

connection, and with the switching devices of the receiver in their operating positions, measure

the leakage current for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the

switching devices of the receiver in their operating positions, measure the leakage current for both

positions of switch S2. Repeat the current measurements of items 1 and 2 after the receiver has

reached thermal stabilization. The leakage current must not exceed 0.5 milliampere (mA).

Page 6

Page 7

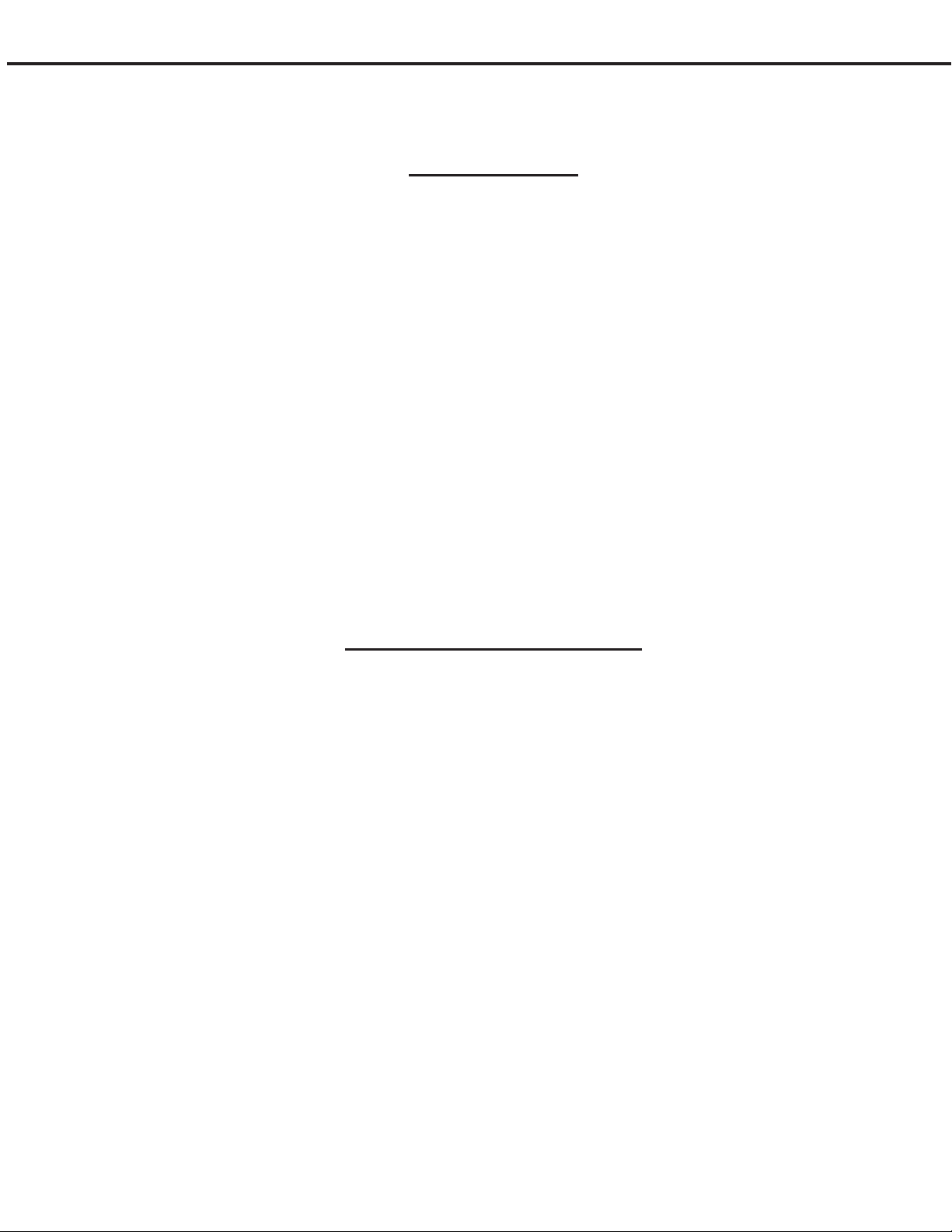

MODELS: HD-4001

PWB-LOCATION

PWB

CONTROL

PWB

POWER

FAN

PWB

CARD

READER

PWB-SIGNAL

(Top)

TERMINAL1

PWB

PWB-DM

(Under Signal)

Page 7

PWB

TUNER

PWB

TERMINAL2

Page 8

MODELS: HD-4001

DISASSEMBLY

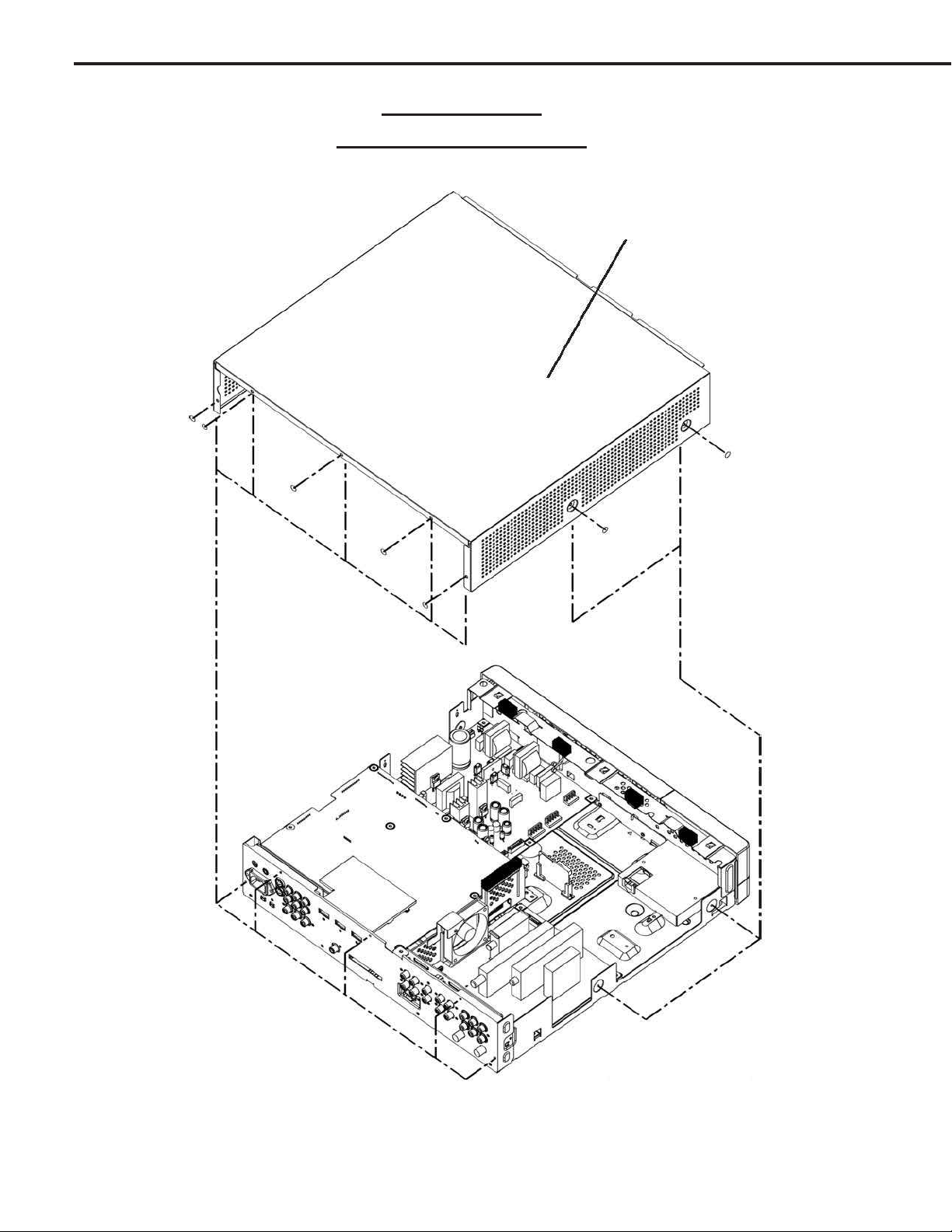

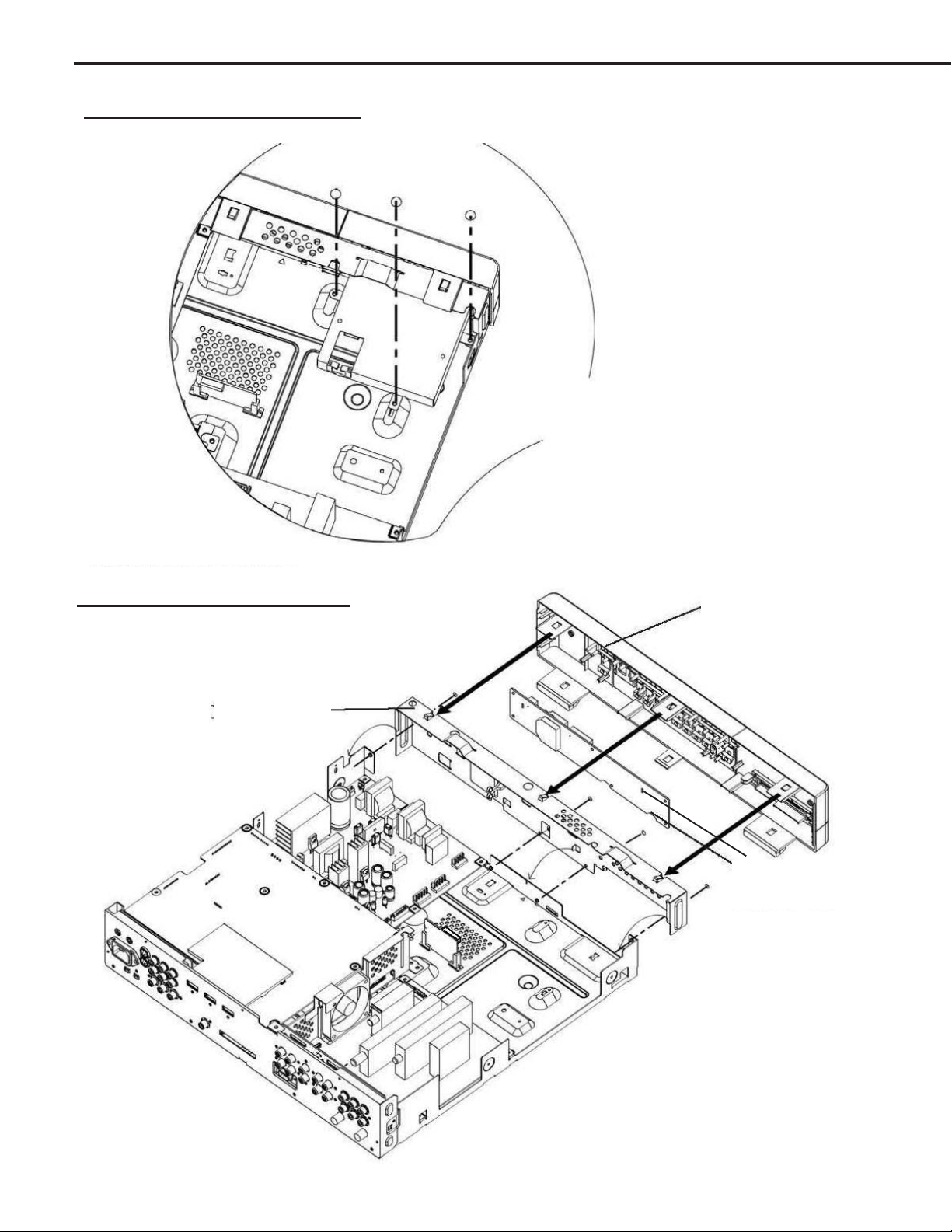

TOP COVER REMOVAL

Top Cover

Page 8

Page 9

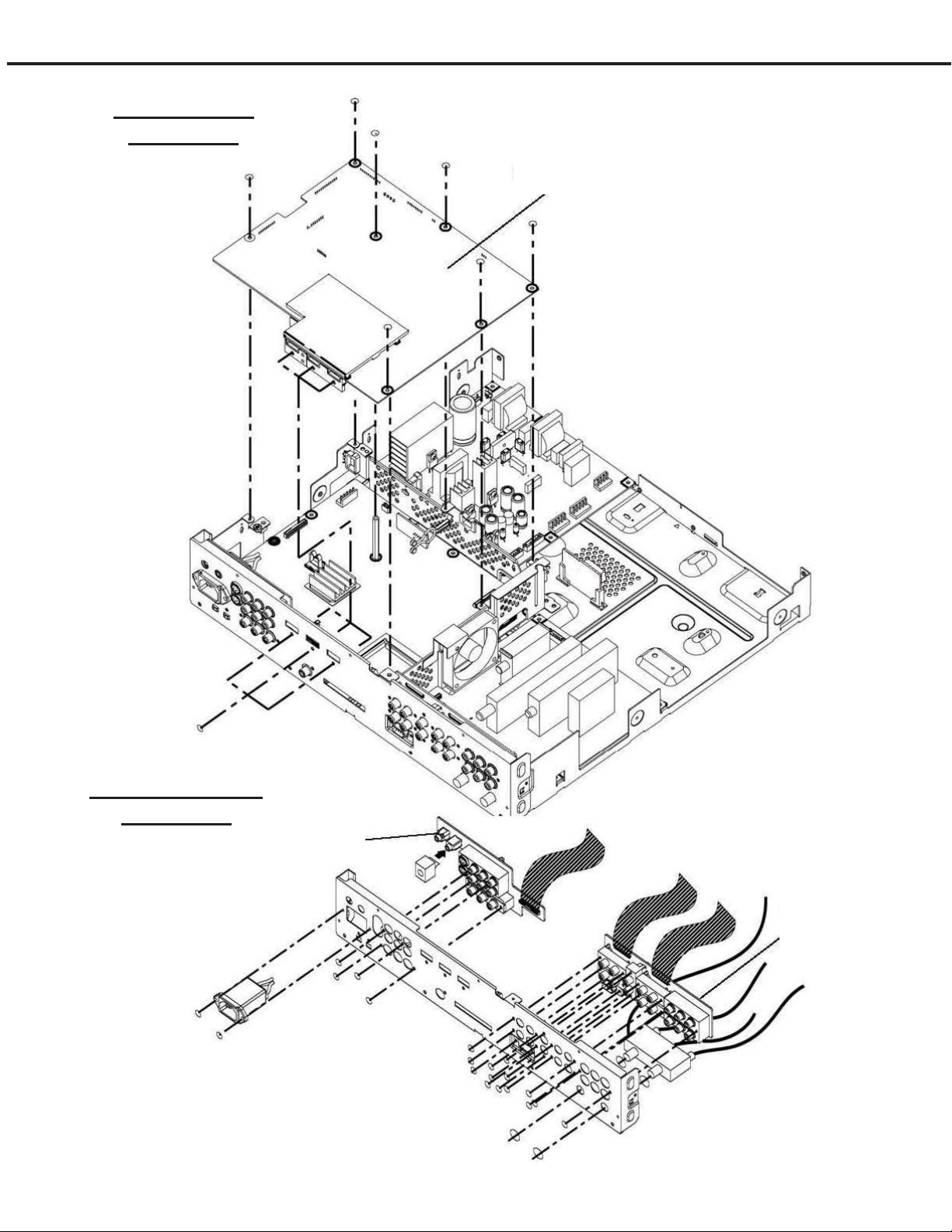

SIGNAL-PWB

REMOVAL

MODELS: HD-4001

SIGNAL

PWB

PWB-SIGNAL

TERMINAL-PWB

REMOVAL

PWB

TERMINAL1

PWB

TERMINAL2

Page 9

Page 10

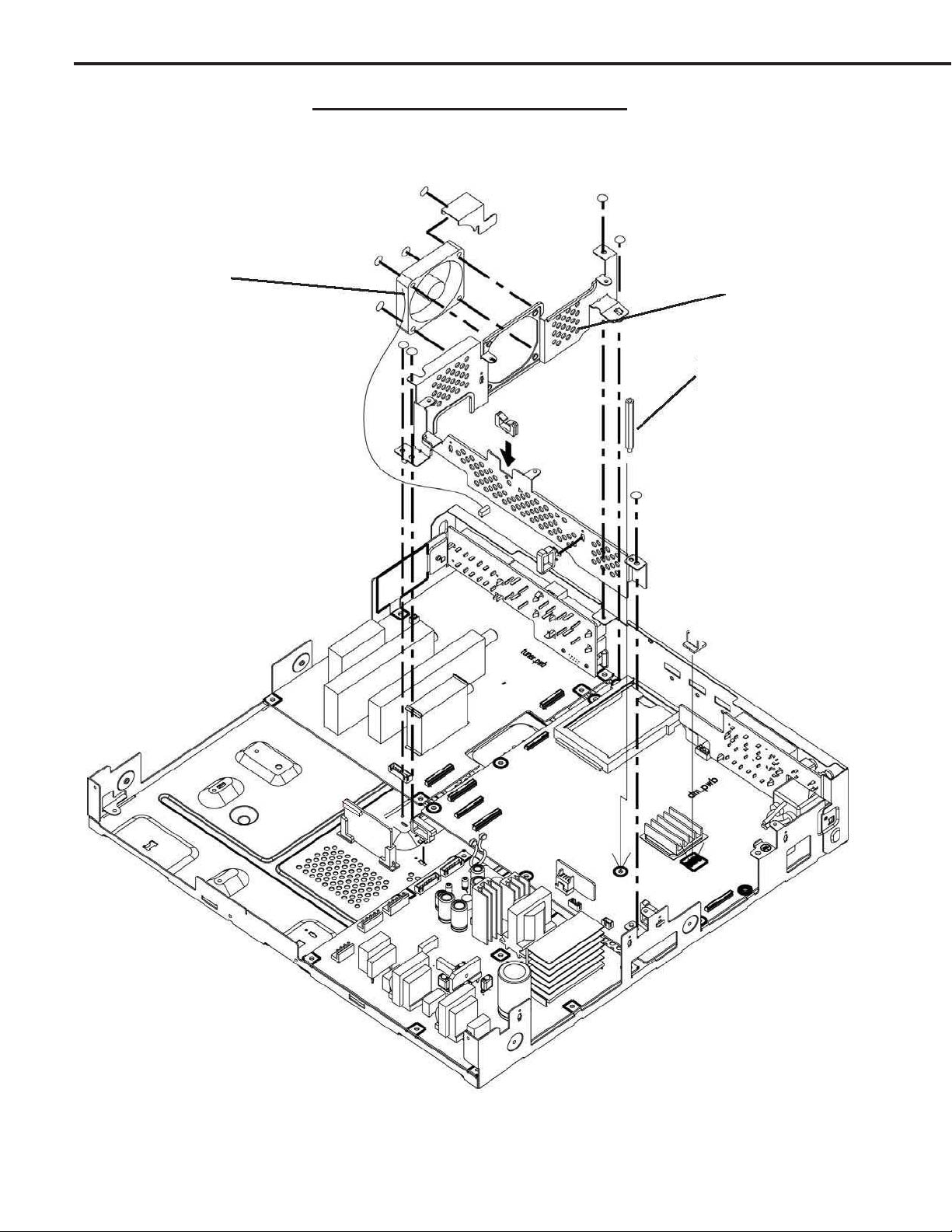

MODELS: HD-4001

SIGNAL BRACKET REMOVAL

FAN

SIGNAL

BRACKET

PWB

Support

Post

Page 10

Page 11

MODELS: HD-4001

REAR PANEL REMOVAL

Page 11

PWB

FAN

Page 12

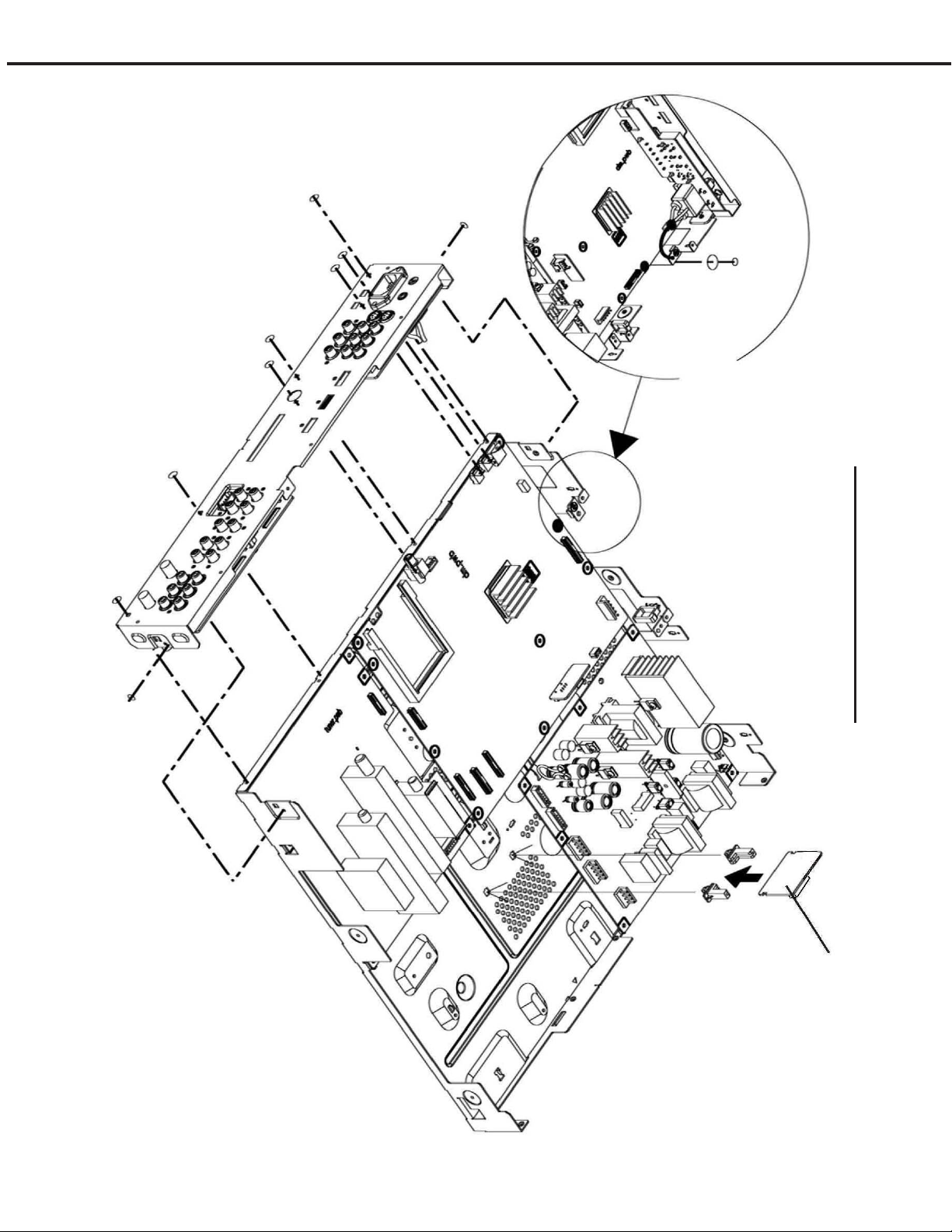

CARD READER REMOVAL

MODELS: HD-4001

FRONT PANEL REMOVAL

FRONT

Front bracket

BRACKET

FRONT

COVER

Front Cover

(Remove Lower

snaps first)

Control PWB

PWB

CONTROL

Page 12

Page 13

MODEL: HD-4001

ELECTRICAL ADJUSTMENTS

Note: Perform only the adjustments required.

Do not attempt an alignment if proper equipment is not available.

Test Equipment

• Oscilloscope (Unless otherwise specified, use 10:1 probes)

• Signal Generator (both SD and HD capable)

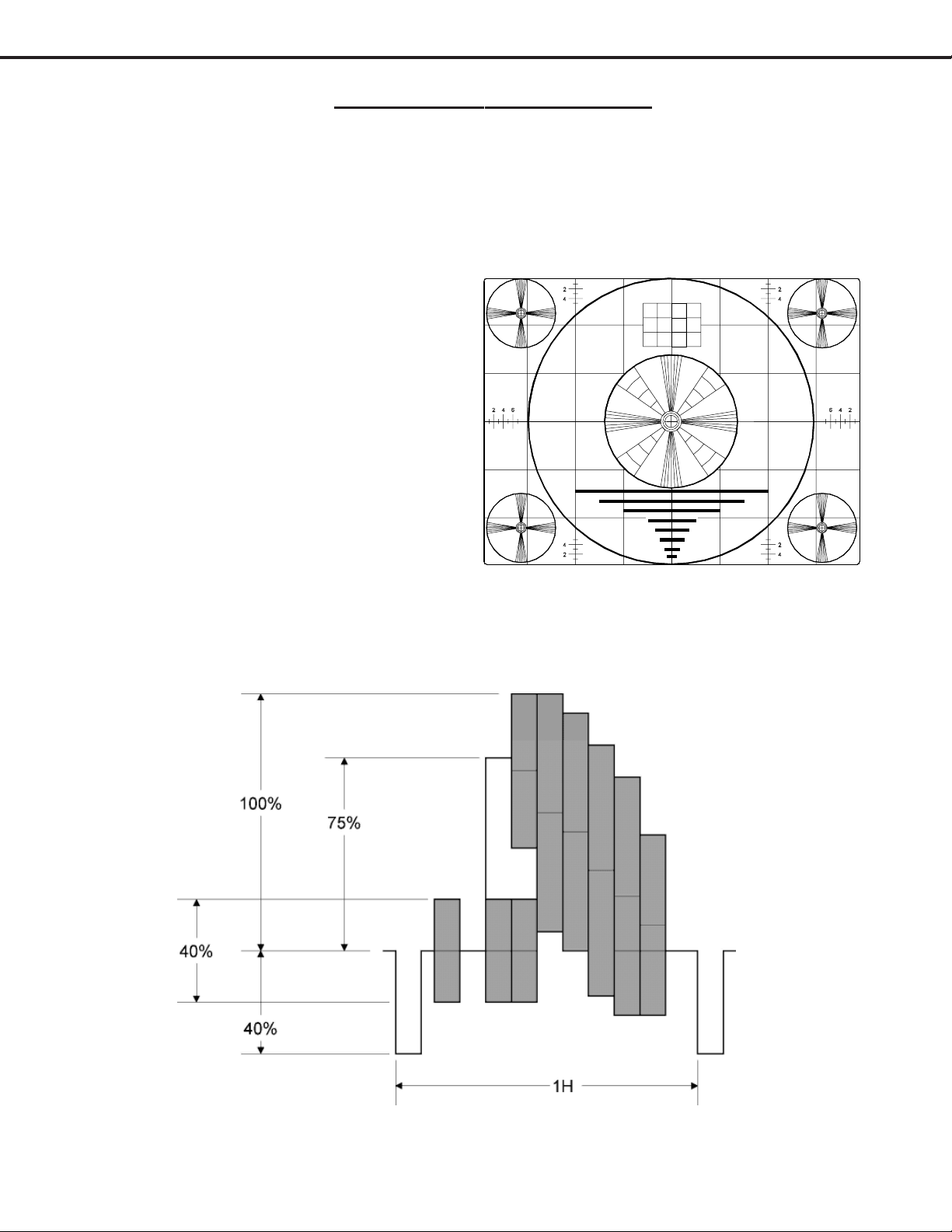

Test Signal

A. Monoscope Signal

Note: If you do not have

a monoscope signal source,

connect the unit to a VCR

and play a Monoscope

*alignment tape.

(* Part Number: 859C568060)

B. Color Bar Signal

Use the color bar signal shown

below , unless otherwise specified

in this manual.

Monoscope Signal

Page 13

Page 14

MODEL: HD-4001

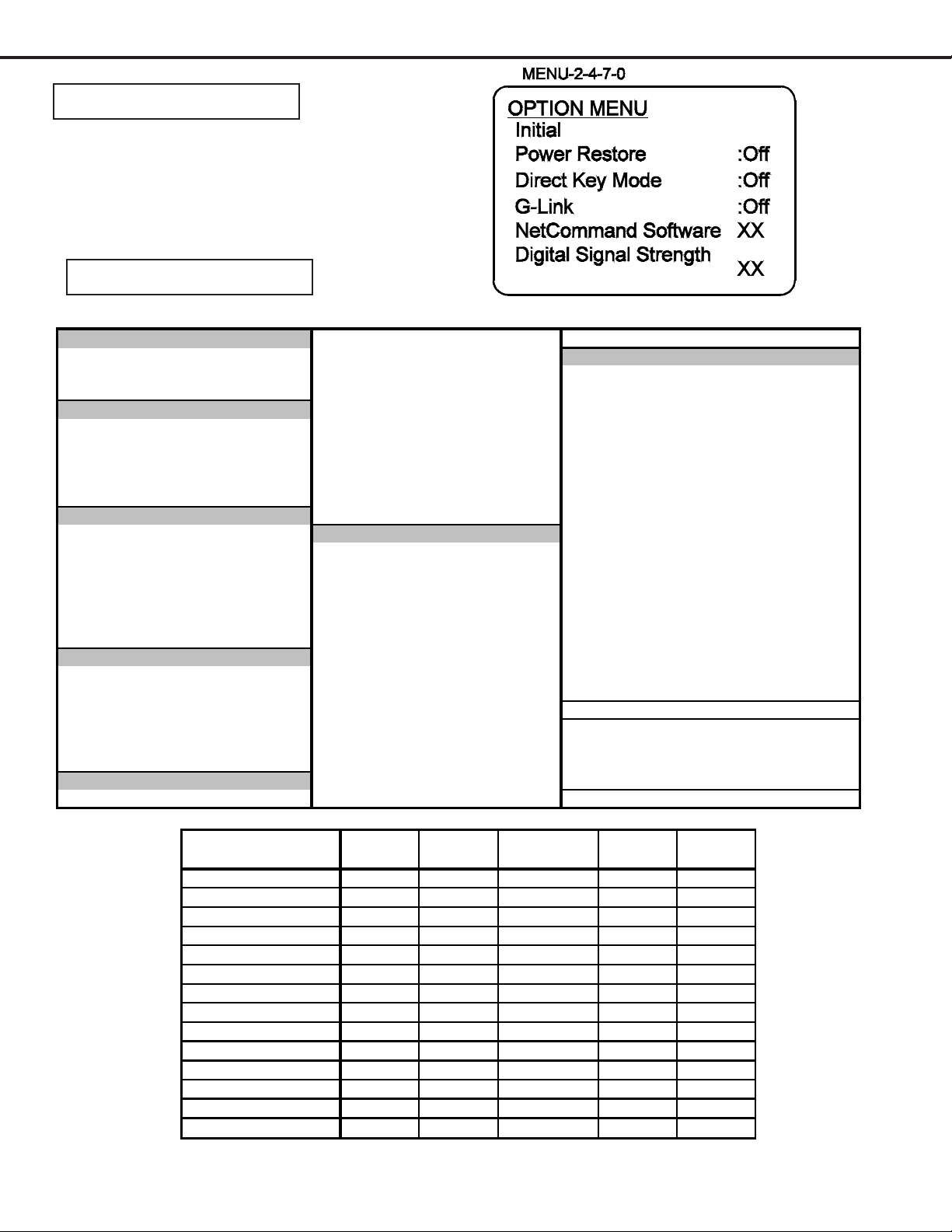

V

OPTION MENU

1. Press the “MENU” button on the remote hand unit.

2. Press the buttons “2”, “4”, “7” and “0” in order.

(The screen will change to the option menu.)

DEFAULTS

Defaults After Initialization

Captio ns Menu (conti nued)Setup Menu

Language :English Background :Gray

Color Balance -- Digital Captions :On if Mute A/V Memory Reset :Ant-1

Side Bar Color :Gray Appearance :Default Audio

NetCommand Menu

Edit -- Font :Font 3 Treble :50%

Transpor t Menu :O n Size :Large Balance :50%

Default PVR -- Col o r :White Surround :Off

Icon Order -- Background :Black Listen To (Analog Only) :Stereo

Analog Quality :High Opacity :Tran slucent Level Sound :On

An t enna Menu

Antenna :1 Video

Memorize -- V-Chiip :Off Contrast :50%

Prefer Digital -- TV Rating :TV-PG Brightness :50%

Channel :3 FV-Fantasy Violenc e :Enable Sharpness :50%

Memory :Deleted D-Sexual Dialog :Enable Color :50%

Name -- L-Adult Language :Enable Tint :50%

SQV -- S-Sexual Situations :Enable Video noise :Standard

Time Menu

Clock Setting :Manual Programs N ot R ate d :Enable Video Mute :On

Time :12:00AM Movie Rating :PG Back Lig ht :100%

Date :1 /0 1/00 V-C h ip Time

Time Zone :Eastern Start :12:00pm

Daylight Savings Time :Applies Stop :12:00pm PIP Position :Lower Right

Timer --

Captions Menu

Analog Captions :O n if M ut e Lock Time :12:0 0pm

Digital Settings Bass :50%

Background Opacity :Translucent Language (Digital Only) :English

V-Chip Lock Menu

V-Violence :Enable Film Mode (Auto) :On

Lock by Time

Lock by Time :Of f PIP/POP Format :Double Window

Unlock Time :12:00pm

Audio / Video

TV Volume

PIP Source

POP Posi ti on

Format

:30%

:Ant-1 003

:Right Half

:Stretch

A/ V Function Ant 1 /2 Input 1/2

Contrast

Brightness

Sharpness

Color

Tint

ideo no is e

Backlight

Film Mo de ( Auto)

Bass

Treble

Balance

Surround

Listen To

Level Soun d

Center Center Center Center Center

Center Center Center Center Center

Center Center Center Center Center

Center Center Center Center Center

Center Center Center Center Standard

Standard Standard Standard Standard Standard

Max Max Max Max Max

On On On On On

Center Center Center Center Center

Center Center Center Center Center

Center Center Center Center Center

Off Off Off Off Off

Stereo N/A N/A N/A N/A

On On On On On

Component

1/2

HDMI 1/2 1394

NOTE: User Menu A/V Reset, resets only the selected input A/V settings.

Page 14

Page 15

MODEL: HD-4001

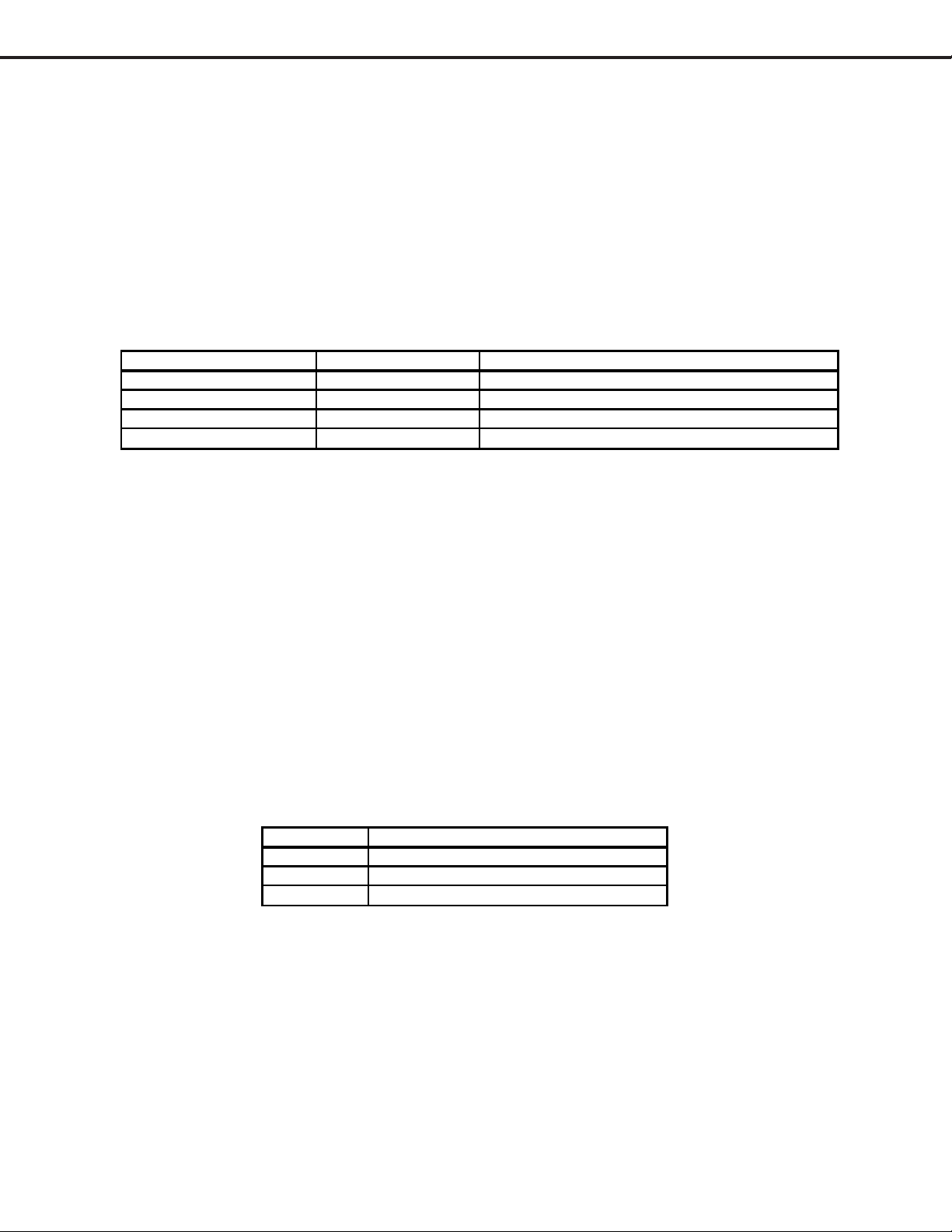

A. A/V Memory

Each of the external inputs has its’ own Audio/Video Memory. A change in an A/V setting at a specific input is

stored in memory for that specific input.

B. A/V Reset

The AV Reset in the user’s menu initializes only the selected input’s A/V Memory .

LED Indicator Diagnostics

The “POWER/TIMER” LED provides an indication of the sets operation, and the possible cause of a malfunction.

1. Initial Control Circuitry Check

Immediately after the TV is connected to an AC power source:

LED Indi c a t ions Condit ions Probable C aus e

Off After AC is applied Standby Power Supply or TV µPC not running

Fast Bllink for 70 sec. After AC is applied Normal DM µPC is booting up

Fast Blink (doesn't stop) After AC is applied DM µPC failed to boot up

Slow Blink Set in Off Normal - Timer is set for Automatic Turn ON

2. Error Code Operational Check

Note: The Set T op Box must be in “Shut Down” and not have been switched Of f, to perform the Error Code

Operational Check. When the unit is switched Off, the code automatically resets to “12” No Error .

Pressing the front panel “DEVICE” and “MENU” buttons at the same time, and holding for 5 seconds,

activates the Error Code Mode. The LED flashes denoting a two digit Error Code, or indicating no problem

has occured since the last Initalization.

Note: The front panel buttons must be used, NOT those on the Remote Control.

• The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

• The flashing then pauses for approximately 1/2 second.

• The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

• The Error Code is repeated a total of 5 times.

Example: If the Error Code is “23”, the LED will flash two times, pause, and then flash three times.

4. Error Codes

The Error Code designations indicating malfunction, or no malfunction, are listed below:

Error Code Prob able Cause

12 Normal Operation - No Error Detected

35 Fan Stopped

41 Short Detected

Remote Control Operational Modes

There are two Remote Hand Unit Operational Modes, “Standard” and “NetCommandTM”. The Remote is initially

in the “Standard” mode. The “NetCommandTM” mode is used when controlling Home Theater devices using

NetCommandTM. To change the Remote Operational Mode:

• Set the Remote to the CABLE/DBS/DTV Layer.

• Point the Remote away from the STB.

• To change to “Netcommand

TM

” ... Hold the “Power” button and press “1-9-7” in sequence.

Page 15

Page 16

MODEL: HD-4001

CIRCUIT ADJUSTMENTS

:

Electrical Adjustments

Electrical Adjusment s are performed in Service Adjustment Mode.

1. Activating the adjustment mode

1. Press the “MENU” button on a remote hand unit.

(The “MENU” display will appear .)

2. Press the buttons “2”, “4”, “5” and “7” in that order . (The screen will change to the adjustment mode.)

If not changed to the adjustment mode, repeat steps 1 and 2.

2. Adjustment Function Selection

Use the “AUDIO” button to select a specific Adjustment Function.

AD9883A

Functions

SMTX MMTX

3. Adjustment Selection

Use the “VIDEO” button to select a specific elecrtrical ajustment.

4. Adjusting Data

After selecting an adjustment item, use the “UP” and “DN” buttons to change adjustment data.

ª If the “UP” button is pressed, the adjustment data increases.

ª If the “DN” button is pressed, the adjustment data decreases.

5. Saving data

Press “ENTER” to save the adjustment data in memory .

The display characters go red for approx. one second in this step.

Note: If the circuit adjustment mode is terminated without pressing

“ENTER”, changes in adjustment data are not saved.

6. T erminating the circuit adjustment mode

Press the “MENU” button on the remote hand unit twice to terminate the adjustment mode.

Note: The adjustment mode can be also terminated by turning the

power off.

Page 16

Page 17

MODEL: HD-4001

A

Transferring Data

1 ) Enter the Service Adjustment Mode ... Press “MENU-2-4-5-7”

2 ) Press “0” when in the Service Mode ... Three choices appear at the top of the screen.

3 ) User UP & DN keys to highlight the desired choice, the Press “ENTER”

Data Transfer Definiti ons

Display Description

Backup DVC files to CF Copies Alignment data to compact flash

Restore DVC files from CF Loads Alignment data from compact flash

Copy WB Alignment Used to transfer WB data from signal E2P to DM E2P

SERVICE MODE - Adjustment Items and Initial Data Values

MAIN MATRIX

Item # Abbrev. Description Data Range Initial Data

1 TNTM Main Tint adjustment 0~63 28

4 COLM Main Color adjustment 0~63 20

14 YDRM Main Y gain control 0~31 5

18 UPDM Main Pb Pedestal adjustment 0~15 7

19 VPDM Main Pr Pedestal adjustment 0~15 7

SUB MATRIX

Item # Abbrev. De scri pt ion Data Range Initial Data

1 TNTS Sub Tint adjustment 0~63 28

4 COLS Sub Color adjustment 0~63 18

14 YDRS Sub Y gain control 0~31 5

18 UPDS Sub Pb Pedestal adjustment 0~15 7

19 VPDS Sub Pr Pedestal adjustment 0~15 7

AD9883

Item # A bbrev. Description Data Range Initial Data

12 ROFF Red Offset 0~127 55

14 BOFF Blue Offset 0~127 59

Page 17

Page 18

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

MODEL: HD-4001

Purpose:

TEST POINTS

Symptom:

[Video Circuit]

1. Main-Y Gain

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TPMY

------

------Color bars

External Input

TPSY

Purpose:

Symptom:

1. Supply a Color Bars with 100% white signal to an External Input.

2. Connect a scope to TPY.

3. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the MMTX function (AUDIO button).

5. Select adjust item #14 YDRM (VIDEO button).

6. Set the data so the waveform at TPY is 0.7 Vp-p ±0.03 Vp-p (ADJUST buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

T o set the main picture Y level

Incorrect analog source main picture brightness level.

TPY

PWB-SIGNAL (Partial)

TPSY

Page 18

TPY

Page 19

[Video Circuit]

Purpose:

MODEL: HD-4001

To set the sub picture Y level

2. Sub-Y Gain

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

Oscilloscope

TPSY

------

------Color bars

External Input

Symptom:

Incorret analog source sib picture brightness level.

1. Supply a Color Bars with 100% white signal to an External Input. Select this

input as the sub picture source.

2. Connect a scope to TPSY.

3. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the SMTX function (AUDIO button).

5. Select adjust item #14 YDRS (VIDEO button).

6. Set the data so the waveform at TPSY equals the main-y signal. (ADJUST

buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

PWB-SIGNAL (Partial)

TPSY

TPY

[Video Circuit]

3. Sub Picture Offset

Measuring

Instrument

Test Point

Ext. Trigger

Measuring

Range

Input Signal

Input Terminal

----

----

------

------Full White Raster

External Input

Purpose:

Symptom:

T o match sub picture white to main picture white

Sub picture white differs from white in the main picture.

1. Supply a full white raster signal to an External Input.

2. Select the white raster as the source for both the main and sub pictures.

3. Use the PIP/POP buttion to select the Single PIP mode.

4. Enter the Alignment Mode (MENU-2-4-5-7)

4. Select the AD9883A function (AUDIO button).

5. Select item #12 ROFF and #14 BOFF (VIDEO button).

6. Set the data fore items #12 and #14 so the sub picture white is close to that in

the main picture. (ADJUST buttons).

7. Press “ENTER” to save data.

8. Press “MENU” twice to exit the service mode.

Page 19

Page 20

MODELS: HD-4001

CHIP PARTS REPLACEMENT

Some resistors, shorting jumpers (0 Ohm resistors),

ceramic capacitors, transistors and diodes are chip parts.

The following precautions should be taken when replacing

these parts.

Cautions:

1. Use a fine tipped, well insulated soldering iron

(approximately 30 watts), and tweezers.

2. Melt the solder and remove the chip parts

carefully so as not to tear the copper foil from

the printed circuit board.

3. Discard removed chips; do not reuse them.

4. Do not apply heat for more than 3 (three)

seconds to new chip parts.

5. Avoid using a rubbing stroke when soldering.

6. T ake care not to scratch, or damage the chip

parts when soldering.

7. Supplementary cementing is not required.

Chip Parts Removal (Resistors, Capacitors, etc.)

1. Grasp the part with tweezers. Melt the solder

at both sides alternately , and remove one side

of the part with a twisting motion.

2. Melt the solder at the other side and remove

the part.

Chip Parts Removal (T ransistors)

1. Melt the solder of one lead and lift the side of

that lead upward.

2. Simultaneously melt the solder of the other

two leads and lift the part from the PCB.

Replacement

1. Presolder the contact points on the circuit

pattern.

2. Press the part downward with tweezers and

apply the soldering iron as shown.

PAGE 20

Page 21

MODELS: HD-4001

REPLACEMENT PARTS

Parts Ordering

T o expedite delivery of replacement p arts orders, specify the following:

1. Model Number/Serial Number

2. Part Number and description

3. Quantity

Note: Unless complete information is supplied, delay in processing of orders will result.

Critical and Warranty Parts Designation

Critical Electrical Components are indicated by Bold Type in the Parts List, and in the schematic

diagrams by shading.

Warranty Return Parts are indicated in the Parts List with an (*).

Parts T olerance Codes

Refer to the following chart for tolerance characteristics of electrical components.

MARK B C D F G J K

Tolerance % ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2 ± 5 ± 10

MARK M N V X Z P Q

Tolerance %

MARK M N V X Z

Tolerance (pF) ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2

± 20 ± 30 ± 10 + 40 + 80 + 100 + 30

-20 -20 - 0 -10

PAGE 21

Page 22

MODELS: HD-4001

Ref # Part # Part Name & Description [#]

INTEGRA TED CIRCUITS

IC2001 276P257010 IC-C-MOS - Sil9031CTU

IC201 1 261P837010 TR-CHIP - UPA672T

IC2020 275P981010 IC-C-MOS - 24LCS22AT/SN

IC2021 275P981010 IC-C-MOS - 24LCS22AT/SN

IC2040 271P071010 IC - BA033SFP

IC2051 261P837010 TR-CHIP - UPA672T

IC2070 261P837010 TR-CHIP - UPA672T

IC2080 271P072040 IC - LD29150DT18R

IC2090 275P718010 IC-C-MOS - TC74HC4053FT

IC2091 261P837010 TR-CHIP - UPA672T

IC2092 275P718010 IC-C-MOS - TC74HC4053FT

IC2093 261P837010 TR-CHIP - UPA672T

IC2C00 275P989010 IC-C-MOS - MAX3223ECAP

IC2C01 276P020010 IC-C-MOS - SN74LVC2G14DBVR

IC2C02 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC2C03 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC2K01 271P061010 IC - CXA2189Q

IC2L00 271P078010 IC - MM1566AJBE

IC2L70 270P938010 IC - MC33202D

IC2M01 275P947010 IC-C-MOS - UPD64083

IC2M02 272P379020 IC - LM1881MX (NSC)

IC3B01 270P938010 IC - MC33202D

IC3C01 276P146010 IC-C-MOS - CS5340-CZR

IC3E01 276P147010 IC-C-MOS - CS8405A-CZR

IC3E02 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC3E03 275P356010 IC-C-MOS - TC74VHCU04FT

IC3J01 271P060010 IC - CXA2188Q

IC54Z1 275P657050 IC-C-MOS - 24LC256T-I/SN

IC54Z3 276P174010 IC-C-MOS - AT24C512N-10S1-2.7

IC54Z4 270P880010 IC - 24LC64I/SN

IC5A01 276P114010 IC-C-MOS - SiI 9190

IC5A03 261P837010 TR-CHIP - UPA672T

IC5G01 271P071010 IC - BA033SFP

IC5H01 270P998010 IC-C-MOS - LM317EMP

IC5J01 275P778010 IC-C-MOS - AD7196AKS

IC5J10 279P069030 IC - SN74LVTH244APW

IC5J20 276P187010 IC-C-MOS - ICS574MIT

IC5P01 276P148010 IC-C-MOS - ispMACH -4128V-5T100C

IC5T01 270P997010 IC-C-MOS - SM5301AS

IC5U01 271P099010 IC - LD29150PT50R

IC7A00 276P244060 M306V7FGFP#U0-V26K1

IC7A01 275P533010 IC-C-MOS - M24C64WM6T

IC7A02 270P706020 IC - MAX823REUK

IC7A04 275P718010 IC-C-MOS - TC74HC4053FT

IC7D00 275P278010 IC-C-MOS - TC74LVX14FT

IC7D01 270P818020 IC - CXA3506R

IC7DA1 267P176010 HIC - AF-9412

IC7DB0 270P677010 IC - BA033FP

IC7DC0 270P992010 IC - BA18BC0FP

IC7E01 275P894010 IC-C-MOS - AD9883AKST-110

IC7E02 275P663030 IC-C-MOS - M4A3-32/32-5VC-48

IC7H00 276P106010 IC-C-MOS - MB87M1823PFV-ES-BND

IC7K21 270P831010 IC-C-MOS - OPA2350PA

IC7M00 276P091010 IC-C-MOS - M12L64322A-6T

IC7N01 275P682010 IC-C-MOS - TC74VCX16244FT

IC7N02 275P682010 IC-C-MOS - TC74VCX16244FT

IC7P01 275P943030 IC-C-MOS - PIC18F252T-I/SO030

IC7P03 263P154010 IC-C-MOS - SN74HC132DB

IC7P04 271P023010 IC - SN74CBTD1G125DBVR

Ref # Part # Part Name & Description [#]

IC7P30 275P718010 IC-C-MOS - TC74HC4053FT

IC7P31 271P023010 IC - SN74CBTD1G125DBVR

IC8001 276P030030 IC-C-MOS - 215H31AGA12H

IC8002 270P706020 IC - MAX823REUK

IC8003

IC8004 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC8101 271P033010 IC - LP2996MRX

IC8102 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8103 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8104 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8105 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC81A1 270P991010 IC - IRU3037CS

IC81A2 261P135010 FET-HEX - IRF7313

IC81A3 270P879030 IC - SC1566I5M-2.5TR

IC81A4 270P992010 IC - BA18BC0FP

IC81A5 270P879030 IC - SC1566I5M-2.5TR

IC81A6 270P037020 IC - MIC29301-5.0BU

IC81A7 270P999010 IC - NJM2370R09

IC8205 276P042010 IC-C-MOS - MIC2544-1BM

IC821 1 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8212 276P029020 IC-C-MOS - NT5DS16M16BT-5T

IC8280 275P955010 IC-C-MOS - RTC-8564JE

IC8301 275P677010 IC-C-MOS - SN74LVC573APWR

IC8302 275P677010 IC-C-MOS - SN74LVC573APWR

IC8303 275P677010 IC-C-MOS - SN74LVC573APWR

IC8304 274D105090 D105A9

IC8305 275P956020 IC-C-MOS - MD2811-D32-V3

IC8307 275P983010 IC-C-MOS - XR16L2750CM

IC8308 276P077010 IC-C-MOS - ST013T

IC8309 275P660020 IC-C-MOS - CS4341-KSR

IC8310 275P270010 IC-C-MOS - M66010GP

IC831 1 275P769010 IC-C-MOS - TC74AC157FT

IC8313 276P145010 IC-C-MOS - MSP4440G QI-C13

IC8314 275P677010 IC-C-MOS - SN74LVC573APWR

IC8315 275P464010 IC-C-MOS - TC7WH14FK

IC8316 276P064010 IC-C-MOS - SN74LVC1G125DBV

IC8317 275P786010 IC-C-MOS - TC7SA08FU

IC8401 275P624010 IC-C-MOS - TSB42AA4

IC8402 275P686010 IC-C-MOS - TSB41AB3PFP

IC8501 275P679010 IC-C-MOS - TC74LCX74FT

IC8502 275P124040 IC-C-MOS - SN74LVC245APWR

IC8503 275P677010 IC-C-MOS - SN74LVC573APWR

IC8504 271P036020 IC - TPS2221PWPR

IC8505 275P677010 IC-C-MOS - SN74LVC573APWR

IC8506 276P065020 IC-C-MOS - CIMAX(103563)

IC8507 275P680010 IC-C-MOS - TC74VCX257FT

IC8508 275P675010 IC-C-MOS - SN74LV125APWR

IC8509 271P036020 IC - TPS2221PWPR

IC8600 275P983010 IC-C-MOS - XR16L2750CM

IC8601 275P122020 IC-C-MOS - SN74LV32APWR

IC8602 275P676010 IC-C-MOS - SN74LVC139APWR

IC8705 275P769010 IC-C-MOS - TC74AC157FT

IC8706 276P145010 IC-C-MOS - MSP4440G QI-C13

IC8707 276P089010 IC-C-MOS - TC7W66FU

IC8708 271P072030 IC - LD29150DT50

IC8709 271P082010 IC - LD1117DT12

IC8710 271P072010 IC - LD29150DT25

IC871 1 295P527010 TUNER-NTSC DEMODULATOR

IC8712 276P109010 IC-C-MOS - CS4334-KS

IC8713 270P938010 IC - MC33202D

276P064010 IC-C-MOS - SN74LVC1G125DBV

PAGE 22

Page 23

MODELS: HD-4001

Ref # Part # Part Name & Description [#] Ref # Part # Part Name & Description [#]

IC8719 271P023010 IC - SN74CBTD1G125DBVR

IC8720 271P023010 IC - SN74CBTD1G125DBVR

IC8721 270P677030 IC - BAO9FP

IC8722 271P064010 IC - TA75S01F

IC8723 271P072020 IC - LD29150DT33

IC8724 275P278010 IC-C-MOS - TC74LVX14FT

IC8800 270P877010 IC - UPC3217GV

IC8801 270P877010 IC - UPC3217GV

IC8802 275P464010 IC-C-MOS - TC7WH14FK

IC8805 270P988010 IC-OP AMP - LM358M

IC8806 271P039010 IC-C-MOS - NXT2003 100C

IC8A00 275P980010 IC-C-MOS - SAA7115HL

IC8A01 275P982020 IC-C-MOS - MT48LC2M32B2P-7

IC8A02 276P111010 IC-C-MOS - AK5353VT

IC8A03 276P112010 IC-C-MOS - BCM7040 KQL

IC8E00 276P175010 IC-C-MOS - SAA7119E

IC8G00 276P254020 M306H2MC-517FP#10

IC8G01 270P706010 IC - MAX823

IC8G02 271P023010 IC - SN74CBTD1G125DBVR

IC8G03 276P020010 IC-C-MOS - SN74LVC2G14DBVR

IC8G04 271P023010 IC - SN74CBTD1G125DBVR

IC8G05 275P443010 IC-C-MOS - TC7SET08H

IC8G06 271P023010 IC - SN74CBTD1G125DBVR

IC8H01 270P658030 IC - CXA2019AQ/T4

IC8H02 271P079010 IC - CXA2181Q

IC8H10 271P071020 IC - BA09SFP

IC8H20 271P099010 IC - LD29150PT50R

IC8T01 270P658030 IC - CXA2019AQ/T4

IC8T02 271P079010 IC - CXA2181Q

IC9A20 267P175010 HIC - STR-W6735

IC9A21 270P816010 IC - NJM431L

IC9C10 271P010010 IC - RT9172-18CG

IC9C10 271P072020 IC - LD29150DT33

IC9C21

IC9C41 271P072030 IC - LD29150DT50

IC9M01 270P677010 IC - BA033FP

IC9M02 270P992020 IC - BA25BC0FP

IC9M03 271P071020 IC - BA09SFP

IC9M04 271P099010 IC - LD29150PT50R

271P072020 IC - LD29150DT33

TRANSISTORS

CHIP Type Transistors (Listed by Part No.)

Part No. Description

260P806010 DTA124EK/UN21 1 2

260P817030 2SA1037K-S

260P817050 2SA1037K-R,S/2SB709AI-R,S

260P817080 2SA1037K-R,S

260P818030 2SC2412K-S

260P818050 2SC2412K-R,S/2SD601AI-R,S

260P818080 2SC2412K-R,S

260P836090 2SC3326-A,B

260P846030 DTC143ZKA T146

261P801010 2SA1252-5,6

Conventional Transistors (By Ref #)

Ref # Part # Part Name & Description

Q7E03 261P114010 TR - 2SA1585STPR

Q8800 261P026010 TR - 2SC3356

DIODES

D2301 262P805050 D-CHIP - UDZS5.1B

D2770 262P805050 D-CHIP - UDZS5.1B

D2H01 262P075010 DIODE - RSB6.8S

D2H02 262P075010 DIODE - RSB6.8S

D5A65 262P802010 D-CHIP - 1SS302

D5A66 262P802010 D-CHIP - 1SS302

D7A00 264P828010 D-CHIP - DAN202U/MA142WK

D7K21 268P110010 PHOTO-DIODE - SFH2505FA

D7K22 264P045080 DIODE - 1S2076A/1S2471OM

D7L20 262P075010 DIODE - RSB6.8S

D7L21 262P099010 DIODE-LE-CHIP - SML01 1BBT

D81A1 264P828010 D-CHIP - DAN202U/MA142WK

D81A2 264P828010 D-CHIP - DAN202U/MA142WK

D81A3 264P828010 D-CHIP - DAN202U/MA142WK

D81A4 262P090010 DIODE - M1FP3

D81A5 264P458050 DIODE - RD3.9EB1

D8201 264P846010 D-CHIP - MA732

D8202 264P846010 D-CHIP - MA732

D8203 264P846010 D-CHIP - MA732

D8204 264P846010 D-CHIP - MA732

D8280 264P808010 DIODE-CHIP - DAN202K

D8701 262P132010 DIODE - MA2Z077

D8702 262P132010 DIODE - MA2Z077

D8703 262P132010 DIODE - MA2Z077

D8704 262P132010 DIODE - MA2Z077

D8800 262P089010 DIODE - MA2S728

D8801 262P071070 DIODE-LE - SML-210FT

D8802 262P071070 DIODE-LE - SML-210FT

D8803 262P071070 DIODE-LE - SML-210FT

D8H10 264P045080 DIODE - 1S2076A/1S2471OM

D9A01 262P031010 DIODE - D6SB80

D9A02 264P045080 DIODE - 1S2076A/1S2471OM

D9A03 264P461050 DIODE - EQA02-06B/RD5.6EB3

D9A04 264P045080 DIODE - 1S2076A/1S2471OM

D9A20 264P045080 DIODE - 1S2076A/1S2471OM

D9A21 264P899010 DIODE - BYV26E

D9A23 264P045080 DIODE - 1S2076A/1S2471OM

D9A24 264P045080 DIODE - 1S2076A/1S2471OM

D9A25 264P045080 DIODE - 1S2076A/1S2471OM

D9A26 262P128010 DIODE - FSH05A06

D9A27 262P127010 DIODE - FSH05A03L

D9A28 264P045080 DIODE - 1S2076A/1S2471OM

D9A29 264P045080 DIODE - 1S2076A/1S2471OM

D9A30 264P470070 DIODE - EQA02-32B/RD33EB3

D9A41 264P045080 DIODE - 1S2076A/1S2471OM

D9A42 264P045080 DIODE - 1S2076A/1S2471OM

D9A44 264P045080 DIODE - 1S2076A/1S2471OM

COILS

L1H01 321C114010 COIL-RF - 2200MH-J

L1H02 325C241030 COIL-CHIP - 10MH-K

L1H51 321C114010 COIL-RF - 2200MH-J

L1H52 325C241030 COIL-CHIP - 10MH-K

L201 1 409P777080 EMI-F-CHIP - BLM21P221S

L2012 409P777080 EMI-F-CHIP - BLM21P221S

L2061 409P777080 EMI-F-CHIP - BLM21P221S

L2071 409P777080 EMI-F-CHIP - BLM21P221S

PAGE 23

Page 24

MODELS: HD-4001

Ref # Part # Part Name & Description [#]

L21 11 409P777080 EMI-F-CHIP - BLM21P221S

L2121 409P777080 EMI-F-CHIP - BLM21P221S

L2141 409P777080 EMI-F-CHIP - BLM21P221S

L2151 409P777080 EMI-F-CHIP - BLM21P221S

L2231 325C462050 COIL-PEAKING 100uH-j

L231 1 409P777080 EMI-F-CHIP - BLM21P221S

L2321 409P777080 EMI-F-CHIP - BLM21P221S

L2331 409P777080 EMI-F-CHIP - BLM21P221S

L2361 409P777080 EMI-F-CHIP - BLM21P221S

L2371 409P777080 EMI-F-CHIP - BLM21P221S

L2381 409P777080 EMI-F-CHIP - BLM21P221S

L2391 409P777080 EMI-F-CHIP - BLM21P221S

L2441 325C462050 COIL-PEAKING 100uH-j

L271 1 409P777080 EMI-F-CHIP - BLM21P221S

L2761 409P777080 EMI-F-CHIP - BLM21P221S

L2801 409P777080 EMI-F-CHIP - BLM21P221S

L2821 325C461000 COIL-PEAKING 5.6uH-J

L2831 409P777080 EMI-F-CHIP - BLM21P221S

L2901 409P777080 EMI-F-CHIP - BLM21P221S

L2902 409P777080 EMI-F-CHIP - BLM21P221S

L2C03 325C146090 COIL-CHIP - 33MH-J

L2H00 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2H01 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J00 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J01 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J20 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J21 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J22 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2J23 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L2K01 325C241030 COIL-CHIP - 10MH-K

L2K09 325C241030 COIL-CHIP - 10MH-K

L2K58 325C241030 COIL-CHIP - 10MH-K

L2K67 325C241030 COIL-CHIP - 10MH-K

L2K71 325C241030 COIL-CHIP - 10MH-K

L2K80 409P777080 EMI-F-CHIP - BLM21P221S

L2K81 409P777080 EMI-F-CHIP - BLM21P221S

L2K90 325C241030 COIL-CHIP - 10MH-K

L2K91 325C241030 COIL-CHIP - 10MH-K

L2K99 409P777080 EMI-F-CHIP - BLM21P221S

L2L12 409P777080 EMI-F-CHIP - BLM21P221S

L2L13 409P777080 EMI-F-CHIP - BLM21P221S

L2L70 409P865080 EMI-F-CHIP - BLM18PG6

L2M21 325C241030 COIL-CHIP - 10MH-K

L2M30 409P777080 EMI-F-CHIP - BLM21P221S

L2M31 409P777080 EMI-F-CHIP - BLM21P221S

L2M35 325C241050 COIL-CHIP - 15MH-K

L2M36 325C241030 COIL-CHIP - 10MH-K

L2M38 409P777080 EMI-F-CHIP - BLM21P221S

L2M40 325C241030 COIL-CHIP - 10MH-K

L2M41 325C461080 COIL-PEAKING - 27MH-K

L2M42 325C241030 COIL-CHIP - 10MH-K

L2M45 409P777080 EMI-F-CHIP - BLM21P221S

L2M46 409P777080 EMI-F-CHIP - BLM21P221S

L2M50 325C461000 COIL-PEAKING - 5.6MH-K

L2M53 325C241030 COIL-CHIP - 10MH-K

L2M70 325C241030 COIL-CHIP - 10MH-K

L2M71 325C461080 COIL-PEAKING - 27MH-K

L2M77 325C241030 COIL-CHIP - 10MH-K

L2M81 409P777080 EMI-F-CHIP - BLM21P221S

Ref # Part # Part Name & Description [#]

L3A01 409P777080 EMI-F-CHIP - BLM21P221S

L3A02 409P777080 EMI-F-CHIP - BLM21P221S

L3A04 409P777080 EMI-F-CHIP - BLM21P221S

L3A05 409P777080 EMI-F-CHIP - BLM21P221S

L3A07 409P777080 EMI-F-CHIP - BLM21P221S

L3A08 409P777080 EMI-F-CHIP - BLM21P221S

L3A09 409P777080 EMI-F-CHIP - BLM21P221S

L3J00 409P777080 EMI-F-CHIP - BLM21P221S

L5A01 409P777080 EMI-F-CHIP - BLM21P221S

L5A18 409P777080 EMI-F-CHIP - BLM21P221S

L5A29 409P777080 EMI-F-CHIP - BLM21P221S

L5A32 409P777080 EMI-F-CHIP - BLM21P221S

L5A35 409P777080 EMI-F-CHIP - BLM21P221S

L5G01 409P777080 EMI-F-CHIP - BLM21P221S

L5G02 409P777080 EMI-F-CHIP - BLM21P221S

L5H01 409P777080 EMI-F-CHIP - BLM21P221S

L5H02 409P777080 EMI-F-CHIP - BLM21P221S

L5H03 409P777080 EMI-F-CHIP - BLM21P221S

L5H04 409P777080 EMI-F-CHIP - BLM21P221S

L5H05 409P777080 EMI-F-CHIP - BLM21P221S

L5H06 409P777080 EMI-F-CHIP - BLM21P221S

L5H07 409P777080 EMI-F-CHIP - BLM21P221S

L5H08 409P777080 EMI-F-CHIP - BLM21P221S

L5H09 409P777080 EMI-F-CHIP - BLM21P221S

L5J01 409P865090 EMI-F-CHIP - BLM11A121S

L5J10 409P865090 EMI-F-CHIP - BLM11A121S

L5J20 409P865090

L5J35 409P865090 EMI-F-CHIP - BLM11A121S

L5P04 103P509050 R-M-CHIP - 1/16W 0OHM

L5P05 103P509050 R-M-CHIP - 1/16W 0OHM

L5P06 103P509050 R-M-CHIP - 1/16W 0OHM

L5P12 409P865090 EMI-F-CHIP - BLM11A121S

L5T01 409P865090 EMI-F-CHIP - BLM11A121S

L7A16 409P777050 EMI-F-CHIP - BLM21B201S

L7A19 409P777050 EMI-F-CHIP - BLM21B201S

L7A73 409P777050 EMI-F-CHIP - BLM21B201S

L7A85 409P777050 EMI-F-CHIP - BLM21B201S

L7A88 409P777050 EMI-F-CHIP - BLM21B201S

L7A90 409P777050 EMI-F-CHIP - BLM21B201S

L7A91 409P777050 EMI-F-CHIP - BLM21B201S

L7A92 409P777050 EMI-F-CHIP - BLM21B201S

L7A99 409P777050 EMI-F-CHIP - BLM21B201S

L7D16 325C420070 COIL-CHIP - 10MH-K

L7DA7 325C420070 COIL-CHIP - 10MH-K

L7DF4 409P777080 EMI-F-CHIP - BLM21P221S

L7DF8 325C420070 COIL-CHIP - 10MH-K

L7E00 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L7E01 409P777080 EMI-F-CHIP - BLM21P221S

L7E01 409P876040 EMI-F-CHIP - CNF20C221S/CKD510JB1H221S

L7E33 409P777080 EMI-F-CHIP - BLM21P221S

L7E34 325C421030 COIL-CHIP - 100MH-K LOW-R

L7E42 325C241050 COIL-CHIP - 15MH-K

L7E69 325C421030 COIL-CHIP - 100MH-K LOW-R

L7H01 409P777080 EMI-F-CHIP - BLM21P221S

L7H04 409P777080 EMI-F-CHIP - BLM21P221S

L7H29 409P777080 EMI-F-CHIP - BLM21P221S

L7H49 409P777080 EMI-F-CHIP - BLM21P221S

L7H66 409P777080 EMI-F-CHIP - BLM21P221S

L7H73 409P777080 EMI-F-CHIP - BLM21P221S

L7H76 409P777080 EMI-F-CHIP - BLM21P221S

EMI-F-CHIP - BLM1 1A121S

PAGE 24

Page 25

MODELS: HD-4001

Ref # Part # Part Name & Description [#] Ref # Part # Part Name & Description [#]

L7J13 409P777080 EMI-F-CHIP - BLM21P221S

L7J38 409P777080 EMI-F-CHIP - BLM21P221S

L7J44 409P777080 EMI-F-CHIP - BLM21P221S

L7K01 325C421030 COIL-CHIP - 100MH-K LOW-R

L7K02 325C421030 COIL-CHIP - 100MH-K LOW-R

L7M90 409P777080 EMI-F-CHIP - BLM21P221S

L7N01 409P777080 EMI-F-CHIP - BLM21P221S

L7N41 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N42 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N43 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N44 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N45 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N46 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N47 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N48 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N49 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N50 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N51 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N52 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N53 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N54 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N55 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N56 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N57 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N58 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N59 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N60 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N61 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N62 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N63 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N64 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N65 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N66 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N67 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N68 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N70 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7N71 409P955020 EMI-F-CHIP - BLM18BB220SN1

L7P00 409P777080 EMI-F-CHIP - BLM21P221S

L7P14 409P777050 EMI-F-CHIP - BLM21B201S

L7P20 409P777050 EMI-F-CHIP - BLM21B201S

L7P30 409P777050 EMI-F-CHIP - BLM21B201S

L8001 409P865080 EMI-F-CHIP - BLM18PG6

L8002 409P865080 EMI-F-CHIP - BLM18PG6

L8003 409P865080 EMI-F-CHIP - BLM18PG6

L8004 409P865080 EMI-F-CHIP - BLM18PG6

L8005 409P865080 EMI-F-CHIP - BLM18PG6

L8006 409P865080 EMI-F-CHIP - BLM18PG6

L8007 409P865080 EMI-F-CHIP - BLM18PG6

L8008 409P865080 EMI-F-CHIP - BLM18PG6

L8009 409P777080 EMI-F-CHIP - BLM21P221S

L8012 409P865080 EMI-F-CHIP - BLM18PG6

L8013 409P865080 EMI-F-CHIP - BLM18PG6

L8017 409P865020 EMI-F-CHIP - BLM11A601S

L8018 409P865020 EMI-F-CHIP - BLM11A601S

L81A1 321C140060 COIL-RF - 2.7MH-M

L81A2 351P250010 COIL-CHOKE - GSTC6018-100M

L81A3 409P777080 EMI-F-CHIP - BLM21P221S

L81A4 321C140060 COIL-RF - 2.7MH-M

L81A5 321C140060 COIL-RF - 2.7MH-M

L81A6 409P777080 EMI-F-CHIP - BLM21P221S

L81A7 409P865080 EMI-F-CHIP - BLM18PG6

L81A8 409P777080 EMI-F-CHIP - BLM21P221S

L8202 409P777080 EMI-F-CHIP - BLM21P221S

L8203 409P777080 EMI-F-CHIP - BLM21P221S

L8206 351P265010 COIL-CHOKE-CHIP - ACM2012

L8280 409P865080 EMI-F-CHIP - BLM18PG6

L8301 409P865080 EMI-F-CHIP - BLM18PG6

L8304 325C501010 COIL-CHIP - ALQM21NNR47K10

L8305 325C501010 COIL-CHIP - ALQM21NNR47K10

L8307 409P865080 EMI-F-CHIP - BLM18PG6

L8309 409P865080 EMI-F-CHIP - BLM18PG6

L8310 409P865080 EMI-F-CHIP - BLM18PG6

L831 1 409P865080 EMI-F-CHIP - BLM18PG6

L8312 409P865080 EMI-F-CHIP - BLM18PG6

L8314 409P865080 EMI-F-CHIP - BLM18PG6

L8315 409P865080 EMI-F-CHIP - BLM18PG6

L8320 409P865080 EMI-F-CHIP - BLM18PG6

L8321 409P865080 EMI-F-CHIP - BLM18PG6

L8322 409P865080 EMI-F-CHIP - BLM18PG6

L8323 409P865080 EMI-F-CHIP - BLM18PG6

L8324 409P865080 EMI-F-CHIP - BLM18PG6

L8326 409P865080 EMI-F-CHIP - BLM18PG6

L8329 409P865080 EMI-F-CHIP - BLM18PG6

L8331 409P865080 EMI-F-CHIP - BLM18PG6

L8332 409P865080 EMI-F-CHIP - BLM18PG6

L8333 409P865080 EMI-F-CHIP - BLM18PG6

L8401 409P865080 EMI-F-CHIP - BLM18PG6

L8403 409P777080 EMI-F-CHIP - BLM21P221S

L8404 409P777080 EMI-F-CHIP - BLM21P221S

L841 1 351P265020 COIL-CHIP - ACM2012-201-2P

L8412 351P265020 COIL-CHIP - ACM2012-201-2P

L8413 351P265020

L8414 351P265020 COIL-CHIP - ACM2012-201-2P

L8415 351P265020 COIL-CHIP - ACM2012-201-2P

L8416 351P265020 COIL-CHIP - ACM2012-201-2P

L8501 409P865080 EMI-F-CHIP - BLM18PG6

L8502 409P777080 EMI-F-CHIP - BLM21P221S

L8503 409P865080 EMI-F-CHIP - BLM18PG6

L8504 409P777080 EMI-F-CHIP - BLM21P221S

L8505 409P865080 EMI-F-CHIP - BLM18PG6

L8506 409P777080 EMI-F-CHIP - BLM21P221S

L8507 409P865080 EMI-F-CHIP - BLM18PG6

L8508 409P865080 EMI-F-CHIP - BLM18PG6

L8509 409P865080 EMI-F-CHIP - BLM18PG6

L8510 325C241050 COIL-CHIP - 15MH-K

L8700 325C412050 COIL-CHIP - 100MH-J

L8701 325C420030 COIL-CHIP - 2.2MH-M

L8702 325C420030 COIL-CHIP - 2.2MH-M

L8703 325C420030 COIL-CHIP - 2.2MH-M

L8704 325C420030 COIL-CHIP - 2.2MH-M

L8705 325C412050 COIL-CHIP - 100MH-J

L8706 409P923060 EMI-F-CHIP - BLM21B272S

L8707 409P923060 EMI-F-CHIP - BLM21B272S

L8717 325C420030 COIL-CHIP - 2.2MH-M

L8718 325C420030 COIL-CHIP - 2.2MH-M

L8719 409P777080 EMI-F-CHIP - BLM21P221S

L8722 325C420030 COIL-CHIP - 2.2MH-M

L8723 409P923060 EMI-F-CHIP - BLM21B272S

L8725 409P923060 EMI-F-CHIP - BLM21B272S

L8726 409P923060 EMI-F-CHIP - BLM21B272S

COIL-CHIP - ACM2012-201-2P

PAGE 25

Page 26

MODELS: HD-4001

Ref # Part # Part Name & Description [#]

L8727 409P923060 EMI-F-CHIP - BLM21B272S

L8729 409P923060 EMI-F-CHIP - BLM21B272S

L8730 409P923060 EMI-F-CHIP - BLM21B272S

L8736 409P923060 EMI-F-CHIP - BLM21B272S

L8737 409P865080 EMI-F-CHIP - BLM18PG6

L8738 409P777080 EMI-F-CHIP - BLM21P221S

L8739 409P923060 EMI-F-CHIP - BLM21B272S

L8800 409P936050 EMI-F-CHIP - HS800

L8801 409P936050 EMI-F-CHIP - HS800

L8802 409P936050 EMI-F-CHIP - HS800

L8803 409P936050 EMI-F-CHIP - HS800

L8804 409P936050 EMI-F-CHIP - HS800

L8807 325C414090 COIL-CHIP - 0.68MH-J

L8809 325C410040 COIL-CHIP - 1.8MH-J

L8914 409P923060 EMI-F-CHIP - BLM21B272S

L8915 409P865060 EMI-F-CHIP - BLM11B141S

L8A00 409P777080 EMI-F-CHIP - BLM21P221S

L8A02 409P777080 EMI-F-CHIP - BLM21P221S

L8A04 409P777080 EMI-F-CHIP - BLM21P221S

L8A05 409P777080 EMI-F-CHIP - BLM21P221S

L8A06 409P777080 EMI-F-CHIP - BLM21P221S

L8A07 409P777080 EMI-F-CHIP - BLM21P221S

L8A08 409P777080 EMI-F-CHIP - BLM21P221S

L8A10 409P777080 EMI-F-CHIP - BLM21P221S

L8A11 325C241030 COIL-CHIP - 10MH-K

L8A99 409P777080 EMI-F-CHIP - BLM21P221S

L8E00 409P777080 EMI-F-CHIP - BLM21P221S

L8E01 409P777080 EMI-F-CHIP - BLM21P221S

L8E02 409P777080 EMI-F-CHIP - BLM21P221S

L8E03 409P777080 EMI-F-CHIP - BLM21P221S

L8G00 409P777080 EMI-F-CHIP - BLM21P221S

L8G01 409P777080 EMI-F-CHIP - BLM21P221S

L8H00 409P777080 EMI-F-CHIP - BLM21P221S

L8H01 409P777080 EMI-F-CHIP - BLM21P221S

L8H03 409P777080 EMI-F-CHIP - BLM21P221S

L8H05 409P777080 EMI-F-CHIP - BLM21P221S

L8H13 409P777080 EMI-F-CHIP - BLM21P221S

L8H24 409P777080 EMI-F-CHIP - BLM21P221S

L8H25 409P777080 EMI-F-CHIP - BLM21P221S

L8H32 409P777080 EMI-F-CHIP - BLM21P221S

L8H82 409P777080 EMI-F-CHIP - BLM21P221S

L8H83 409P777080

L8H84 409P777080 EMI-F-CHIP - BLM21P221S

L8H85 409P777080 EMI-F-CHIP - BLM21P221S

L8H87 409P777080 EMI-F-CHIP - BLM21P221S

L8H88 409P777080 EMI-F-CHIP - BLM21P221S

L8H90 409P777080 EMI-F-CHIP - BLM21P221S

L8H91 409P777080 EMI-F-CHIP - BLM21P221S

L8T03 409P777080 EMI-F-CHIP - BLM21P221S

L8T05 409P777080 EMI-F-CHIP - BLM21P221S

L8T13 409P777080 EMI-F-CHIP - BLM21P221S

L8T24 409P777080 EMI-F-CHIP - BLM21P221S

L8T25 409P777080 EMI-F-CHIP - BLM21P221S

L8T32 409P777080 EMI-F-CHIP - BLM21P221S

L9A20 321C141030 COIL-RF - 10MH-K

L9A21 321C141030 COIL-RF - 10MH-K

L9A22 321C141030 COIL-RF - 10MH-K

L9A23 321C141030 COIL-RF - 10MH-K

L9D00 351P266010 LINE-FILTER - ELF22V050BN

L9D01 351P266020 LINE-FILTER - ELF22V025A

EMI-F-CHIP - BLM21P221S

Ref # Part # Part Name & Description [#]

LC202 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC203 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC208 409P876020 EMI-F-CHIP - CNF20C470S/CKD510JB1H470S

LC8001 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8002 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC81A1 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8300 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8301 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8302 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8303 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8304 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8305 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8306 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8307 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8308 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8309 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8310 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8312 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8313 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8314 409P945010

LC8315 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8316 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8317 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8318 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8319 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8320 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8321 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8322 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8323 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8501 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8502 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8503 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8504 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8505 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8506 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8507 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8508 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8509 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC851 1 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8512 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8514 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8515 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8516 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8517 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8518 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8519 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8520 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8521 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8522 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8523 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8524 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8525 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8526 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8527 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8528 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8529 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8530 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8531 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8603 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8604 409P945010 EMI-F-CHIP - NFL21SP506X13CD

EMI-F-CHIP - NFL21SP506X13CD

PAGE 26

Page 27

MODELS: HD-4001

Ref # Part # Part Name & Description [#] Ref # Part # Part Name & Description [#]

LC8605 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LC8606 409P945010 EMI-F-CHIP - NFL21SP506X13CD

LF7D02 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D04 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D06 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D08 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D10 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D12 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D14 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D16 409P945020 EMI-F-CHIP - NFL21SP106X1C3D

LF7D18 409P945020 EMI-F-CHIP - NFL21SP106X1C3D

LF7D20 409P945020 EMI-F-CHIP - NFL21SP106X1C3D

LF7D22 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7D24 409P944010 EMI-F-CHIP - NFL21SP107X1

LF7H13 409P865020 EMI-F-CHIP - BLM11A601S

LF7H14 409P865020 EMI-F-CHIP - BLM11A601S

LF7H22 409P865020 EMI-F-CHIP - BLM11A601S

LF7H24 409P865020 EMI-F-CHIP - BLM11A601S

TRANSFORMERS

T2310 409P961010 CHIP-FILTER - ACM2012D-9002P

T2320 409P961010 CHIP-FILTER - ACM2012D-9002P

T2330 409P961010 CHIP-FILTER - ACM2012D-9002P

T2340 409P961010 CHIP-FILTER - ACM2012D-9002P

T2830 409P961010 CHIP-FILTER - ACM2012D-9002P

T2860 409P961010 CHIP-FILTER - ACM2012D-9002P

T2910 409P961010 CHIP-FILTER - ACM2012D-9002P

T2961 409P961010 CHIP-FILTER - ACM2012D-9002P

T5A21 409P961010 CHIP-FILTER - ACM2012D-9002P

T5A24 409P961010 CHIP-FILTER - ACM2012D-9002P

T5A27 409P961010 CHIP-FILTER - ACM2012D-9002P

T5A30 409P961010 CHIP-FILTER - ACM2012D-9002P

T9A20 350P824010 TRANS-PWR - ER35TM075

V ARIABLE RESISTORS

RV231 1 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2321 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2331 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2341 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2351 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2361 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2371 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2381 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2401 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV241 1 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2761 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2771 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2831 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2841 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2861 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2871 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV291 1 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2921 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2961 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV2971 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A21 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A22 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A24 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A25 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A27 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A28 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A30 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV5A31 265P804010 VARISTOR-CHIP - 0603 PULSE GUARD

RV9D00 265P100020 VAR - ERZV10D271CS

RESISTORS

CHIP Type Resistors (Listed by Value)

Part No. Value Part No. Value

103P509050 1/16W 0OHM 103P502060 1/16W 1.2K-J

103P409050 1/8W 0OHM 103P492080 1/16W 1.3K-F

103P489050 1/4W 00HM 103P492090 1/16W 1.5K-F

103P508040 1/16W 2.2-J 103P502070 1/16W 1.5K-J

103P508080 1/16W 4.7-J 103P472090 1/8W 1.5K-F

103P509000 1/16W 6.8-J 103P493010 1/16W 1.8K-F

103P500010 1/16W 10-J 103P502080 1/16W 1.8K-J

103P793000 1/16W 16-F 103P493020 1/16W 2K-F

103P910040 1/16W 18-J 103P493030 1/16W 2.2K-F

103P400050 1/10W 22-J 103P502090 1/16W 2.2K-J

103P500050 1/16W 22-J 103P402090 1/8W 2.2K-J

103P910050 1/16W 22-Jx4 103P493040 1/16W 2.4K-F

103P500060 1/16W 27-J 103P493050 1/16W 2.7K-F

103P400070 1/10W 33-J 103P503000 1/16W 2.7K-J

103P500070 1/16W 33-J 103P493060 1/16W 3K-F

103P910070 1/16W 33-Jx4 103P493070 1/16W 3.3K-F

103P793080 1/16W 36F 103P503010 1/16W 3.3K-J

103P500080 1/16W 39-J 103P503020 1/16W 3.9K-J

103P794010 1/16W 47-F 103P494000 1/16W 4.3K-F

103P500090 1/16W 47-J 103P494010 1/16W 4.7K-F

103P844030 1/16W 56-D 103P503030 1/16W 4.7K-J

103P501000 1/16W 56-J 103P494020 1/16W 5.1K-F

103P911000 1/16W 56-Jx4 103P494030 1/16W 5.6K-F

103P401000 1/10W 56-J 103P503040 1/16W 5.6K-J

103P501010 1/16W 68-J 103P814040 1/16W 6.2K-D

103P489090 1/4W 75-J 103P494050 1/16W 6.8K-F

103P794060 1/16W 75-F 103P503050 1/16W 6.8K-J

103P509090 1/16W 75-J 103P494070 1/16W 8.2K-F

103P501020 1/16W 82-J 103P503060 1/16W 8.2K-J

103P401030 1/10W 100-J 103P494090 1/16W 10K-F

103P501030 1/16W 100-J 103P503070 1/16W 10K-J

103P501040 1/16W 120-J 103P913070 1/16W 10K-Jx4

103P810050 1/16W 150-D 103P495010 1/16W 12K-F

103P490050 1/16W 150-F 103P503080 1/16W 12K-J

103P501050 1/16W 150-J 103P495020 1/16W 13K-F

103P490070 1/16W 180-F 103P495030 1/16W 15K-F

103P490080 1/16W 200-F 103P503090 1/16W 15K-J

103P490090 1/16W 220-F 103P495050 1/16W 18K-F

103P501070 1/16W 220-J 103P504000 1/16W 18K-J

103P481070 1/4W 220-J 103P504010 1/16W 22K-J

103P491000 1/16W 240-F 103P495080 1/16w 24K-F

103P501080 1/16W 270-J 103P495090 1/16W 27K-F

103P471010 1/8W 270-F 103P504030 1/16W 33K-J

103P491020 1/16W 300-F 103P496010 1/16W 33K-F

103P491030 1/16W 330-F 103P504040 1/16W 39K-J

103P501090 1/16W 330-J 103P504050 1/16W 47K-J

103P491040 1/16W 360-F 103P496060 1/16W 51K-F

103P491050 1/16W 390-F 103P496070 1/16W 56K-F

103P502000 1/16W 390-J 103P504060 1/16W 56K-J

103P491070 1/16W 470-F 103P504070 1/16W 68K-J

103P502010 1/16W 470-J 103P497030 1/16W 100K-F

PAGE 27

Page 28

MODELS: HD-4001

Ref # Part # Part Name & Description [#]

Part No. Value Part No. Value

103P491080 1/16W 510-F 103P504090 1/16W 100K-J

103P491090 1/16W 560-F 103P497050 1/16W 120K-F

103P502020 1/16W 560-J 103P505000 1/16W 120K-J

103P492010 1/16W 680-F 103P505030 1/16W 220K-J

103P502030 1/16W 680-J 103P498020 1/16W 240K-F

103P492030 1/16W 820-F 103P505050 1/16W 330K-J

103P502040 1/16W 820-J 103P505090 1/16W 680K-J

103P492050 1/16W 1K-F 103P506000 1/16W 820K-J

103P502050 1/16W 1K-J 103P506010 1/16W 1M-J

103P492070 1/16W 1.2K-F

RESISTORS

Conventional Resistors (By Ref #)

Ref # Part # Part Name & Description

R2814 103C398040 R-METAL-P - 3W 2.2-K

R2816 103C298010 R-METAL-CP - 3W 1.2-J

R2817 103C288040 R-METAL-CP - 2W 2.2-J

R2H15 103C180020 R-METAL - 2W 12-J

R2H16 103C180020 R-METAL - 2W 12-J

R5G01 103C398050 R-METAL-P - 3W 2.7-K

R7E12 103C178010 R-METAL - 1W 1.2-J

R7K36 103P710090 R-CARBON - 1/4W 47-J

R8798 103C288040 R-METAL-CP - 2W 2.2-J

R8H10 103C298050 R-METAL-CP - 3W 2.7-J

R8H20 103P719050 R-CARBON - 1/4W 0OHM (MAX 3A)

R9A02 109P179010 R-CEMENT-PLATE - 6.8-J

R9A03 109C010010 R-COMP - 1/2W 1M-K

R9A05 109C010010 R-COMP - 1/2W 1M-K

R9A06 109C010010 R-COMP - 1/2W 1M-K

R9A09 103P145030 R-CARBON - 1/2W 220K-J

R9A11 103P145030 R-CARBON - 1/2W 220K-J

R9A18 103P145020 R-CARBON - 1/2W 180K-J

R9A20 103P144020 R-CARBON - 1/2W 27K-J

R9A21 103P144020 R-CARBON - 1/2W 27K-J

R9A22 103C187030 R-METAL - 2W 0.27-J

R9A25 103P142050 R-CARBON - 1/2W 1K-J

R9A26 109D151090 R-CARBON - 1/4W 33-J

R9A27 109D151050 R-CARBON - 1/4W 75-J

R9A38 103P144090 R-CARBON - 1/2W 100K-J

R9D00 109D036020 R-COMP - 1/2W 4.7M-K

R9M00 103C288030 R-METAL-CP - 2W 1.8-J

CAPACITORS

CHIP Type Capacitors (Listed by Value)

Part No. Value Part No. Value

154P340010 CK50V 1P-C 141P142050 B25V 0.022M-K

154P340030 CK50V 2P-C 141P142090 B25V 0.047M-K

154P340060 CK50V 5P-C 141P143020 B16V 0.082M-K

154P340080 CH50V 7P-C 141P143030 B16V 0.1M-K

154P341010 CH50V 10P-C 141P139030 B25V 0.1M-K

154P341030 CH50V 12P-J 141P144020 F25V 0.1M-Z

154P341050 CH50V 15P-J 141P134090 F50V 0.1M-Z

154P341070 CH50V 18P-J 141P135080 F50V/25V 0.1M-Z

154P341090 CH50V 22P-J 141P138080 B25V 0.33M-K

154P342010 CH50V 27P-J 141P146080 B10V 0.47M-K

154P352020 SL50V 27P-J 141P139090 B16V 0.47M-K

154P342030 CH50V 33P-J 181P526010 50V 1M-M

Ref # Part # Part Name & Description [#]

Part No. Value Part No. Value

154P342050 CH50V 39P-J 141P134070 B16V 1M-K

154P342070 CH50V 47P-J 141P135070 F16V 1M-Z

154P342070 CH50V 47P-J 141P142020 B50V 0.012M-K

154P342090 CH50V 56P-J 141P144060 F25V 1M-Z

154P343010 CH50V 68P-J 141P147020 B10V/6.3V 1M-K

154P343050 CH50V 100P-J 181P526020 50V 2.2M-M

154P343070 CH50V 120P-J 141P147040 B6.3V 2.2M-K

154P344010 CH50V 180P-J 141P133010 B10V 3.3M-M

141P140010 B50V 220P-K 181P808070 16V 4.7M-M

154P344030 CH50V 220P-J 181P532020 16V 4.7M-M 105C

154P354040 SL50V 220P-J 181P524090 35V 4.7M-M 105C

154P344050 CH50V 270P-J 141P147060 B6.3V 4.7M-K

141P140050 B50V 470P-K 181P508080 16V 10M-M

154P345010 CH50V 470P-J 181P522030 16V 10M-M 105C

154P345030 CH25V 560P-J 181P532030 BP16V 10M-M 105C

154P345050 CH25V 680P-J 181P525000 35V 10M-M 105C

154P345070 CH25V 820P-J 181P522040 16V 22M-M 105C

141P140090 B50V 1000P-K 181P520010 6.3V 22M-M 105C

141P143050 F50V 1000P-Z 181P502060 16V 47M-M

/B50V 1000P-K 181P500030 6.3V 47M-M

154P345090 CH25V 1000P-J 181P520030 6.3V 47M-M

141P141010 B50V 1500P-K 181P522060 6V 47M-M

141P141030 B50V 2200P-K 181P502070 16V 100M-M

141P141050 B50V 3300P-K 181P520040 6.3V 100M-M

141P141070 B50V 4700P-K 181P528010 4V 220M-M 105C

141P142000 B50V 8200P-K 181P500060 6.3V 220M-M

141P143080 F50V 0.01M-Z 181P520050 6.3V 220M-M 105C

141P142010 B50V 0.01M-K

141P133080 B50V 0.01M-Z

CAPACITORS AND TRIMMERS

Conventional Capacitors (By Ref #)

Ref # Part # Part Name & Description

C1H05 172P262010 C-M-POLY - 50V 0.047M-J

C1H55 172P262010 C-M-POLY - 50V 0.047M-J

C2L03 181P351080 C-ELEC - 10V 1000M-M

C2M28 181P351080 C-ELEC - 10V 1000M-M

C2M29 181P351080 C-ELEC - 10V 1000M-M

C2824 181P351050 C-ELEC 10V 220M-M

C5A01 141P140090 C-CER-CHIP - B50V 1000P-K

C7A00 154P345050 C-CER-CHIP - CH25V 680P-J

C81A2 181P182030 C-ELEC - 16V 1000M-M 105C

C81A3 181P182030 C-ELEC - 16V 1000M-M 105C

C81B3 181P182030 C-ELEC - 16V 1000M-M 105C

C81B4 181P182030 C-ELEC - 16V 1000M-M 105C

C8281 189P197020 C-ELE-DBL-LA - FM0H473Z/EECS5R5T473Z

C8702 181P355090 C-ELEC - 50V 100M-M

C8703 181P185060 C-ELEC - 50V 10M-M 105C

C8705 181P184020 C-ELEC - 35V 100M-M

C8708 181P185090 C-ELEC - 50V 47M-M 105C

C8710 181P181000 C-ELEC - 10V 330M-M 105C

C8717 181P352060 C-ELEC - 16V 330M-M

C8719 181P352060 C-ELEC - 16V 330M-M

C8720 181P185060 C-ELEC - 50V 10M-M 105C

C8725 181P352060 C-ELEC - 16V 330M-M

C8727 181P181000 C-ELEC - 10V 330M-M 105C

C8729 181P352060 C-ELEC - 16V 330M-M

C8733 181P352060 C-ELEC - 16V 330M-M

PAGE 28

Page 29

MODELS: HD-4001

Ref # Part # Part Name & Description [#] Ref # Part # Part Name & Description [#]

C8736 181P185060 C-ELEC - 50V 10M-M 105C

C8738 181P352060 C-ELEC - 16V 330M-M

C8742 181P185060 C-ELEC - 50V 10M-M 105C

C8748 181P185060 C-ELEC - 50V 10M-M 105C

C8749 181P184020 C-ELEC - 35V 100M-M

C8751 181P185060 C-ELEC - 50V 10M-M 105C

C8754 181P184020 C-ELEC - 35V 100M-M

C8760 181P352030 C-ELEC - 16V 47M-M

C8761 181P352060 C-ELEC - 16V 330M-M

C8765 181P352030 C-ELEC - 16V 47M-M

C8772 181P181000 C-ELEC - 10V 330M-M 105C

C8773 181P353020 C-ELEC - 25V 10M-M

C8780 181P353060 C-ELEC - 25V 330M-M

C8786 181P352030 C-ELEC - 16V 47M-M

C8788 181P352060 C-ELEC - 16V 330M-M

C8790 181P355030 C-ELEC - 50V 3.3M-M

C8792 181P353020 C-ELEC - 25V 10M-M

C8795 181P352030 C-ELEC - 16V 47M-M

C8797 181P353060 C-ELEC - 25V 330M-M

C8798 181P353060 C-ELEC - 25V 330M-M

C87A0 181P353060 C-ELEC - 25V 330M-M

C87A1 181P353060 C-ELEC - 25V 330M-M

C87A3 181P353060 C-ELEC - 25V 330M-M

C87A4 181P353060 C-ELEC - 25V 330M-M

C87A7 181P353060 C-ELEC - 25V 330M-M

C87C1 181P184020 C-ELEC - 35V 100M-M

C87C4 181P350050 C-ELEC - 6.3V 470M-M

C8840 181P185060 C-ELEC - 50V 10M-M 105C

C8844 181P185060 C-ELEC - 50V 10M-M 105C

C8845 181P185060 C-ELEC - 50V 10M-M 105C

C8847 181P185060 C-ELEC - 50V 10M-M 105C

C8848 181P185060 C-ELEC - 50V 10M-M 105C

C8852 181P185060 C-ELEC - 50V 10M-M 105C

C8853 181P185060 C-ELEC - 50V 10M-M 105C

C9A08 189P185090 C-CER - AC250V E2200P-M

C9A09 189P185090 C-CER - AC250V E2200P-M

C9A10 189P185090 C-CER - AC250V E2200P-M

C9A11 189P185090 C-CER - AC250V E2200P-M

C9A13 189P152070 C-M-POLY - 250VAC 0.01M-M

C9A14 189P152050 C-M-POLY - 250VAC 4700P-M

C9A20 154P232020 C-CER - B1KV 1000P-K

C9A21 181P355050 C-ELEC - 50V 10M-M

C9A25 172P138010 C-POLY - 50V 4700P-J

C9A26 185D122050 C-ELEC - H200V 1000M-M

C9A29 181P355050 C-ELEC - 50V 10M-M

C9A30 181P355050

C9A32 181P735040 C-ELEC - 25V 1500M-M

C9A33 181P735040 C-ELEC - 25V 1500M-M

C9A34 154P400050 C-CER - B1KV 1000P-K

C9A35 181P735010 C-ELEC - 25V 470M-M

C9A37 181P734000 C-ELEC - 16V 2200M-M 105C

C9A38 181P734000 C-ELEC - 16V 2200M-M 105C

C9A41 181P732010 C-ELEC - 10V 1000M-M 105C

C9A43 172P262050 C-M-POLY - 50V 0.1M-J

C9D00 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D01 189P153040 C-M-POLY - 250VAC 0.1M-M

C9D02 189P153040 C-M-POLY - 250VAC 0.1M-M

CF8H01 299P128010 OSC-CERAMIC - CSB500F2

CF8T01 299P128010 OSC-CERAMIC - CSB500F2

C-ELEC - 50V 10M-M

SWITCHES

S7L20 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L21 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L22 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L23 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L24 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L25 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L26 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L27 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L28 432P109010 SW-KEY BOARD - KSHS61 1BT

S7L29 432P109010 SW-KEY BOARD - KSHS61 1BT

SF8800 296P171010 SAW-FILTER - X6892D

SF8801 296P172010 SAW-FIL TER - X7303P

MISCELLANEOUS

242D540040 CABLE - RF PIN-PLUG 150mm

242D540050 CABLE - RF PIN-PLUG 100mm

242D540060 CABLE - RF F-TYPE 160mm

246C468020 AC-INLET

299P254020 IR-EMITTER, 4-HEAD - T-IR-02 W/

299P278020 FAN EFB0612LA-R00

305P703010 2RF-SWITCH

411D064010 FERRITE CORE - HF57SH35X0.8

938P038010 CARD-READER-UNIT

F9A01 283P144080 FUSE - 125V 5A

F9A21 283P144090 FUSE - 125V 10A

F9A22 283P144090 FUSE - 125V 10A

F9D00 283D131040 FUSE - S10A 125A

HR1 452C410010 CONNECTOR-HDMI

HR2 452C410010 CONNECTOR-HDMI

HT 452C410010 CONNECTOR-HDMI

J8301 440C393030 PIN-JACK-BOARD-1P

J8402 451P246010 JACK-1394 - MINI

J8403 451P246010 JACK-1394 - MINI

K9A50 287P111030 RELAY-POWER - LKS1AF-12V

PB 452C411020 CONNECTOR-PCCARD

PC9A21 268P058020 PHOTO-COUPLER - ON3131-R/

ON3161-R

PC9A50 268P058020 PHOTO-COUPLER - ON3131-R/

ON3161-R

PJ2J00 440C438010 PIN-JACK-BOARD

PJ2J01 440C438020 PIN-JACK-BOARD

PJ2J04 440C433020 PIN-JACK-BOARD

PJ2J05 440C433010 PIN JACK BOARD

PJ2J09 440C433020 PIN-JACK-BOARD

PJ2J10 440C433020 PIN-JACK-BOARD

PJ2J11 440C433020 PIN-JACK-BOARD

PJ2J14 452C393010 CONNECTOR-DSUB

PJ2J20 440C433020 PIN-JACK-BOARD

PJ2J21 451C269010 AUDIO-JACK

PJ2J22 451C242010 JACK-MICROPHONE

TU8700 295P490040 TUNER-TV - ENA46914P4A

TU8701 295P523020 TUNER-NTSC/ATSC

TU8702 295P524010 TUNER-OOB

X2001 285P457010 QUARTZ-CRYSTAL-UNIT

X2K51 285P029030 QTZ-CRYST - 4.000 MHZ

X2M47 285P374050 QTZ-CRYST - 20.000MHZ

X3E51 285P451010

X7A13 285P434020 QTZ-CRYST - 16.000MHZ

QTZ-CRYST - 12.288MHz

PAGE 29

Page 30

MODELS: HD-4001

Ref # Part # Part Name & Description [#]

X7J10 285P335050 QTZ-CRYST - 80.000MHZ

X7P09 285P434010 QTZ-CRYST - 8.000MHZ

X8001 285P441040 QTZ-CRYST - 26.1621MHZ

X8301 285P434060 QTZ-CRYST - 14.7456MHZ

X8302 285P441030 QTZ-CRYST - 14.31818MHZ

X8303 285P413010 QTZ-CRYST - 18.432MHZ

X8401 285P431020 QTZ-CRYST - 54.000MHZ

X8402 285P410020 QTZ-CRYST - 24.576MHZ

X8613 285P434060 QTZ-CRYST - 14.7456MHZ

X8701 285P413010 QTZ-CRYST - 18.432MHZ

X8800 285P453010 QTZ-CRYST - 25.140MHZ

X8A00 285P387010 QTZ-CRYST - 24.576MHz

X8A01 285P446010 QTZ-CRYST - 83.33MHZ

X8E00 285P387010 QTZ-CRYST - 24.576MHz

X8G00 285P374040 QTZ-CRYST - 10.000MHZ

X8G01 285P374020 QTZ-CRYST - 3.579545MHZ

X8H12 299P259010 OSC-CERAMIC - CSALA2M6964ZF01-B0

X8H14 285P029030 QTZ-CRYST - 4.000 MHZ

X8H26 285P374020 QTZ-CRYST - 3.579545MHZ

X8T12 299P259010 OSC-CERAMIC - CSALA2M6964ZF01-B0

X8T14 285P029030 QTZ-CRYST - 4.000 MHZ

X8T26 285P374020 QTZ-CRYST - 3.579545MHZ

Z7K02 938P031010 UNIT-PREAMP - GP1UM263RK

Z81A1 283P128050 FUSE-CHIP - AC125/100V 4A

Z81A2 283P128050 FUSE-CHIP - AC125/100V 4A

Z81A3 283P128050 FUSE-CHIP - AC125/100V 4A

Z81A4 283P128050 FUSE-CHIP - AC125/100V 4A

Ref # Part # Part Name & Description [#]

PRINTED CIRCUIT BOARDS

934C127001 ASSY-PWB-TUNER

934C171001 ASSY-PWB-POWER

934C172001 ASSY-PWB-TERMINAL1

934C173001 ASSY-PWB-TERMINAL2

934C174001 ASSY-PWB-CONTROL

934C175001 ASSY-PWB-DM

934C176001 ASSY-PWB-E2P

934C177001 ASSY-PWB-SIGNAL

934C215001 ASSY-PWB-FAN

COSMETIC P ARTS

701B531020 PANEL-FRONT

710A145020 P ANEL-TOP

ACCESSORIES

242D525010 CABLE - AUDIO - AC3

246C293010 CORD - AC-POWER

290P118020 REMOTE CONTROL

I/QR HD4001 GUIDE - QR

I/B HD4001 IB PCTV

246C472010 CABLE - 9P SUB

246C505020 CABLE - HDMI

PAGE 30

Page 31

MODEL: HD-4001

Standby Supplies

Page 31

Page 32

MODEL: HD-4001

PWB-DM Power Supplies

PWB-SIGNAL Switched Supplies

Page 32

Page 33

MODEL: HD-4001

Tuners & Analog Video

Select Circuitry

Page 33

Page 34

MODEL: HD-4001

Digital Video Signal Path

Page 34

Page 35

MODEL: HD-4001

Sync Signal Selection

Sync Output Path

Page 35

Page 36

MODEL: HD-4001

Sound Signal Path

Page 36

Page 37

MODEL: HD-4001

Control Circuitry

Page 37

Page 38

MODEL: HD-4001

Command Input Circuitry

Macrovision Detection

Page 38

Page 39

B

C

I

A

D

E

F

G

H

FAN

FANSTOP

VCCOUT

GND

FANSTOP

+12V

GND

Card

Reader

564321 1512118 161410 1379

17 18

19

* NOTES

TERMINAL 1

2473

5

7

9

114612

13

14

15616

17818

195020

21 22

23 24

GND

Y-IN2

GND

V-IN2

GND

SW-IN2

GND

GND

L-IN1

GND

R-IN1

GND

GND

C-IN1

GND

Y-IN1

GND

V-IN1

GND

SW-IN1

GND

1

R-IN2

25 26

27 28

441045

48449

29

SYSTEM5-OUT

30 31

32 33

34 35

36 37

38 39

40 41

42 43

1211

987654312

10

2019

1716151413

18

GND

GND

GND

GLINK_RXD

GND

GLINK_TXD

GND

SYS5_GLINK

GND

GND

GND

R-MOUT

GND

L-MOUT

GND

GND

GND

GND

V-MOUT

GND

GND

L-IN2

GND

GND

GND

C-IN2

N.C.N.C.

TA

N.C.

N.C.

30 31 32 33 34 35 36 37 38 39 4010111122133144155166177188199 20212223242526272829

GND