Mitsubishi Electric HC5, HC5W Service Manual

2013

CAUTION

Before servicing this chassis, it is important that the service person reads the “SAFETY PRECAUTIONS” and “PRODUCT

SAFETY NOTICE” in this service manual.

Copyright © 2013 Mitsubishi Electric Corporation All Rights Reserved.

Pb Solder, Pb Joints, Pb PCA

This product uses lead-free solder

on the circuit boards. For repairing

circuit boards, see "Precautions for

resoldering" in this Service Manual.

MODEL

HC5/

HC5W

These model are RoHS-compliant. Provide

servicing referring to “NOTES FOR SERVICING

RoHS-COMPLIANT PRODUCTS” described in

the service manual.

HOME THEATER PROJECTOR

- 2 -

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS

Follow the notes and instructions below when servicing RoHS-compliant

products.

1. For RoHS-compliant products, be sure to use RoHS-compliant service parts.

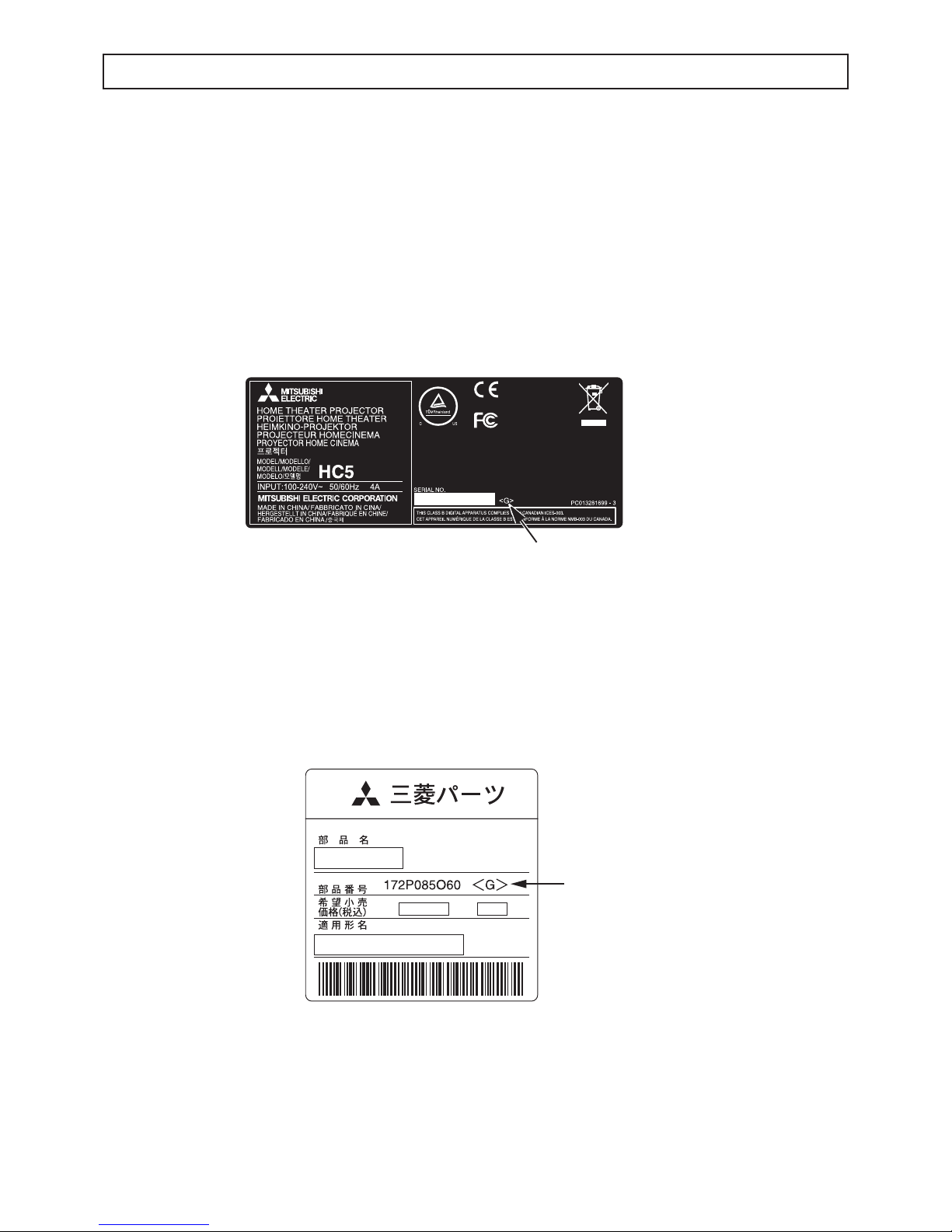

2. Check the presence of <G> marking on the rating plate to distinguish RoHScompliant product from non-RoHS-compliant product.

<G> marking

With <G> marking: RoHS-compliant product

Without <G> marking: Non-RoHS-compliant product

<Sample>

3. Labels of RoHS-compliant service parts bear <G> marking for identifi cation purpose.

<Sample>

4. Don’t use non-RoHS-compliant parts with RoHS-compliant products.

5. Service parts for RoHS-compliant products are listed in the parts catalog contained

in the service manual.

Parts Name

Model Name

Parts No.

E05R

Mark position

Mark position

- 3 -

SPECIFICATIONS

• Weight and dimensions shown are approximate.

• Design and specifications are subject to change without

notice.

• Rated power supply

: 100-240 V AC, 50/60 Hz

• Power consumption

: 4.0A

• Display technology : 0.61 inch SXRDTM panel

• Pixels : 1,920x1,080= 2,073,600 pixels

• Projection lens

: F=3.2-3.9, f=21.4-38.5 mm

• Light source lamp : 230 W

• Picture Size

:

50-200 inch (16:9)

• PC compatibility :

1,920 x 1,080

• Video compatibility

: NTSC / NTSC 4.43 / PAL (including PAL-M, N)

/ SECAM / PAL-60

Component Video(480i/p, 576i/p, 720p, 1080i/p)

• S-Video input : Luminance signal;

1.0 Vp-p 75Ω (negative sync)

Chroma signal;

0.286 Vp-p 75Ω (burst signal)

• Video input

: 1.0 Vp-p 75Ω(negative sync)

• Analog RGB input : RGB: 0.7 Vp-p 75Ω(negative sync)

YPbPr/YCbCr: Y-> 1.0 Vp-p (negative sync)

PbPr/CbCr-> 0.7 Vp-p

HD/CS: TTL level(positive or negative)

VD: TTL level(positive or negative)

• Digital input

: HDMI interface (TMDS single link)

• Control connector :

Serial terminal (RS-232C) (D-sub 9 pin)

• Outside dimensions : 482 x 215 x 530mm (width x height x depth)

• Weight

: 14.5kg

• Operating temperature

: 5°C - 35°C

- 4 -

CONTENTS

– FILE “COVERPGE” –

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS ............................................................................... 2

SPECIFICATIONS ................................................................................................................................................. 3

CONTENTS ........................................................................................................................................................... 4

– FILE “DIAGNO” –

DIAGNOSIS INFORMATION ................................................................................................................................. 1

STATUS LED indicator ..................................................................................................................................... 1

SPECIFICATION OF INPUT SIGNALS IN EACH INPUT OF THE PROJECTOR ................................................ 2

– FILE “EXPOSED” –

TRADE MARK, REGISTERED TRADEMARK ...................................................................................................... 1

PRODUCT SAFETY NOTICE ............................................................................................................................... 1

SAFETY PRECAUTIONS ...................................................................................................................................... 2

PRECAUTIONS FOR RESOLDERING ................................................................................................................. 3

PCB LOCATION .................................................................................................................................................... 4

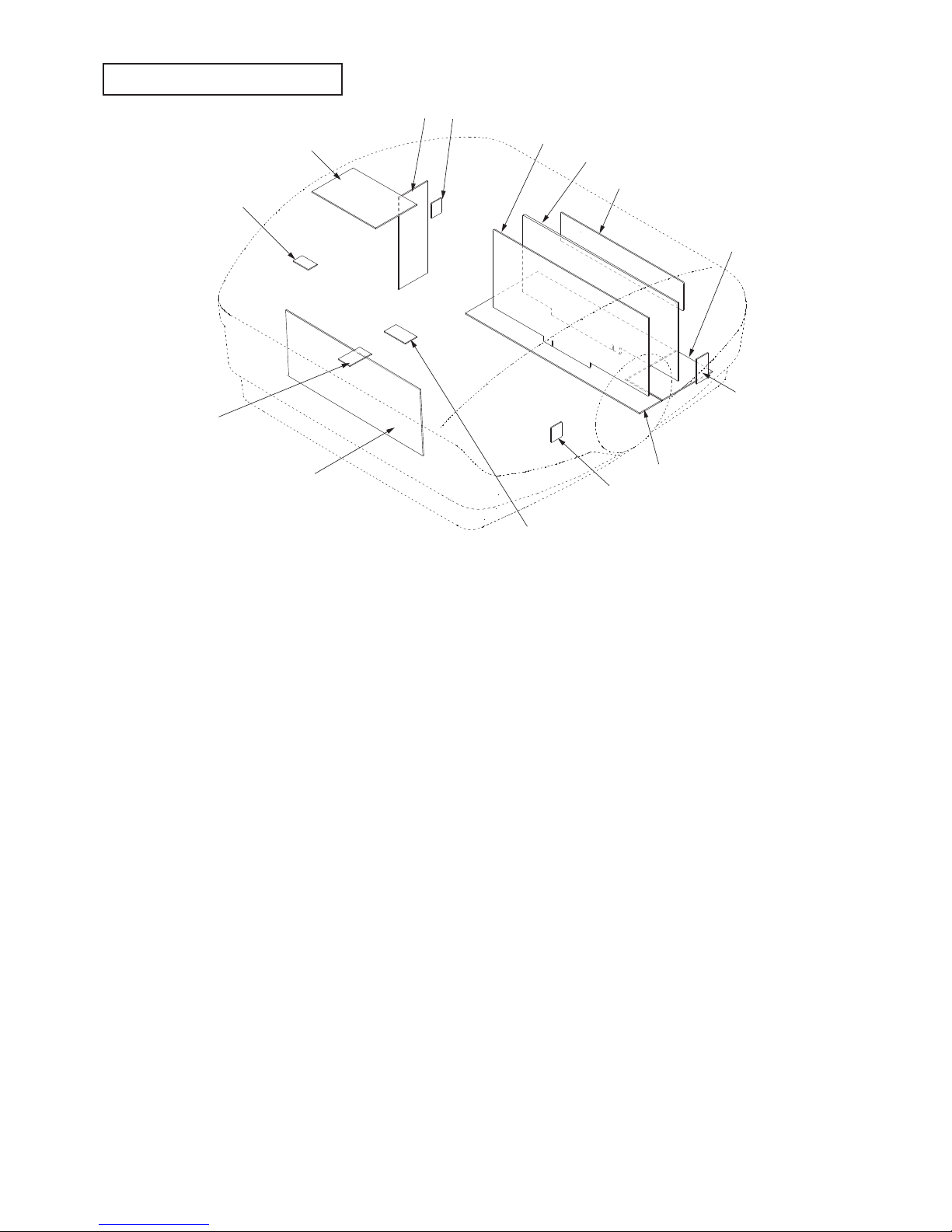

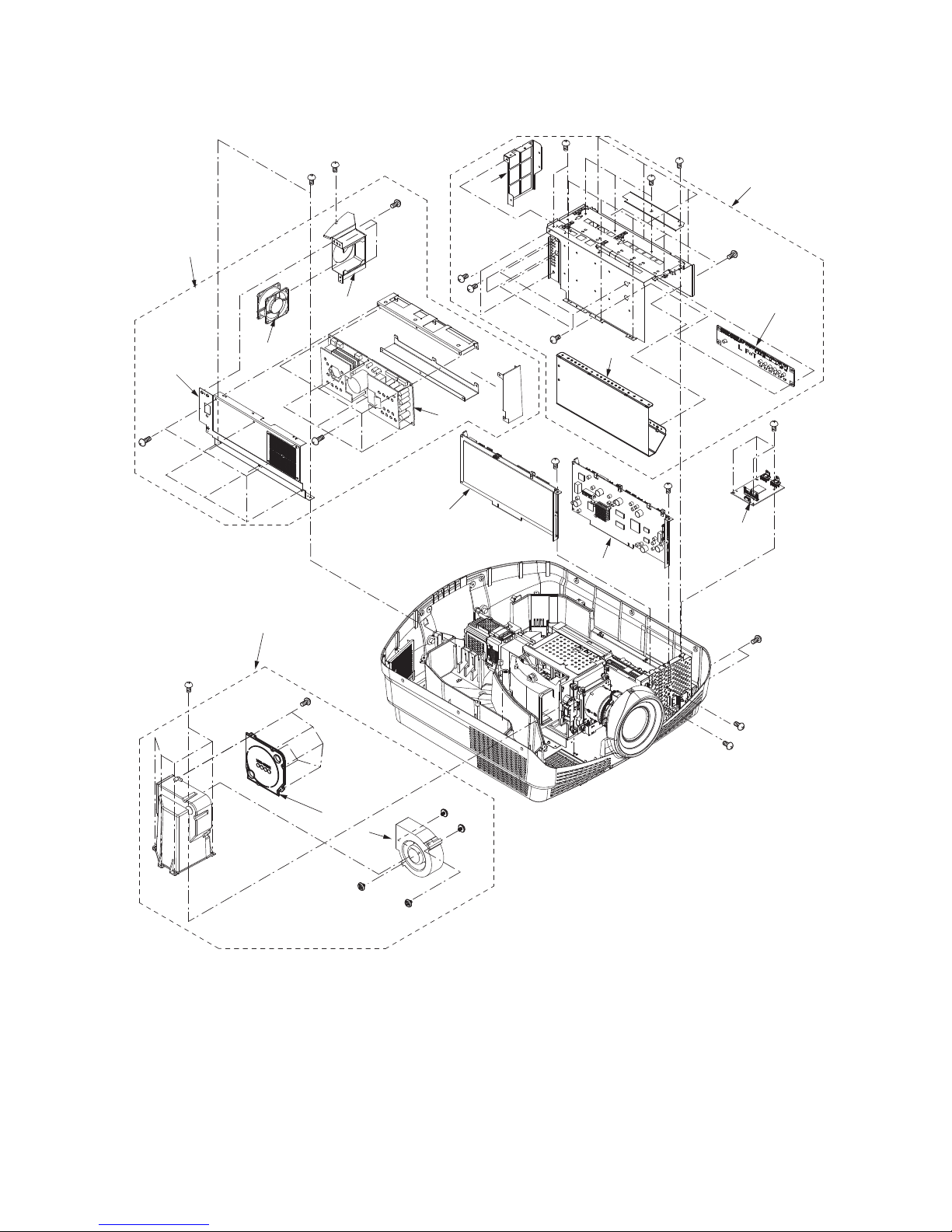

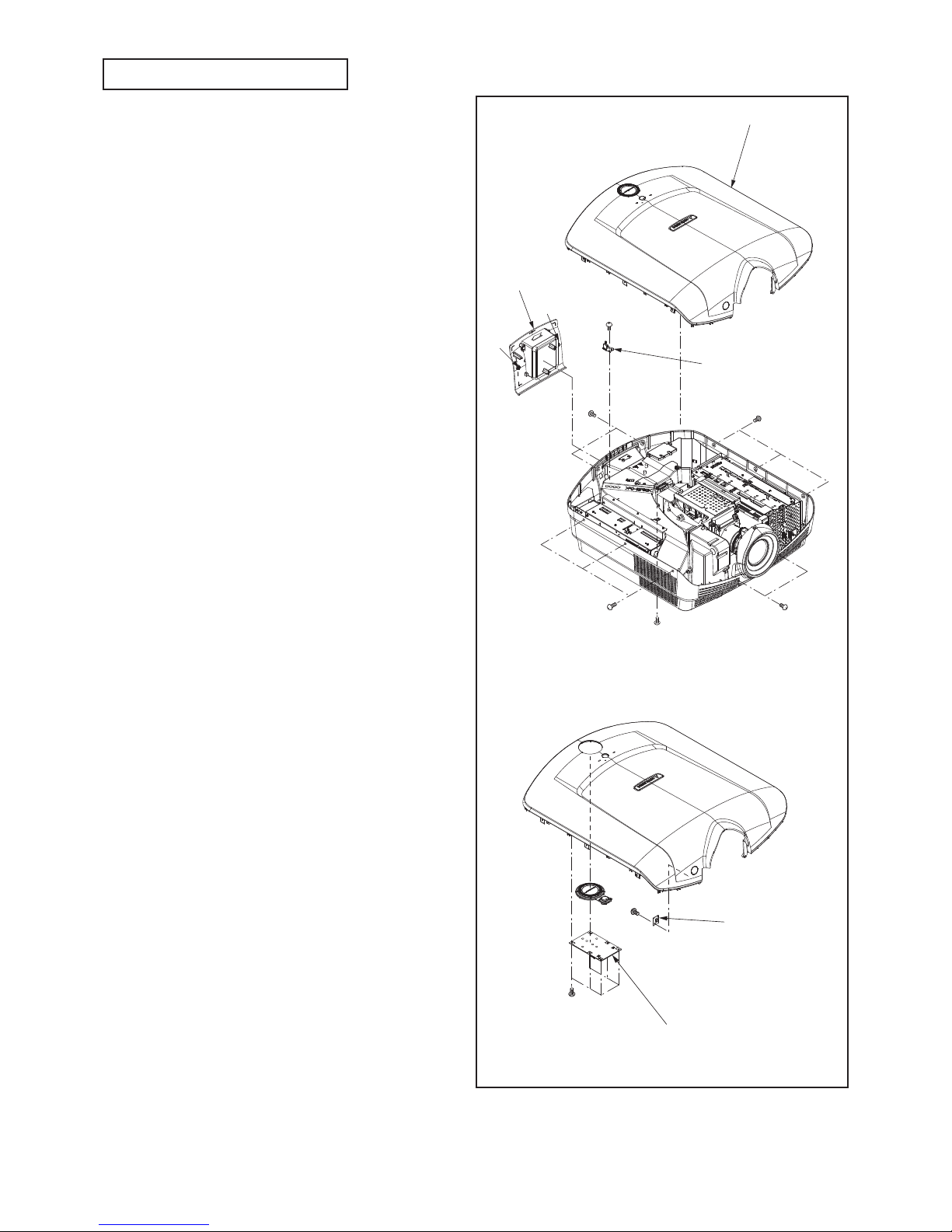

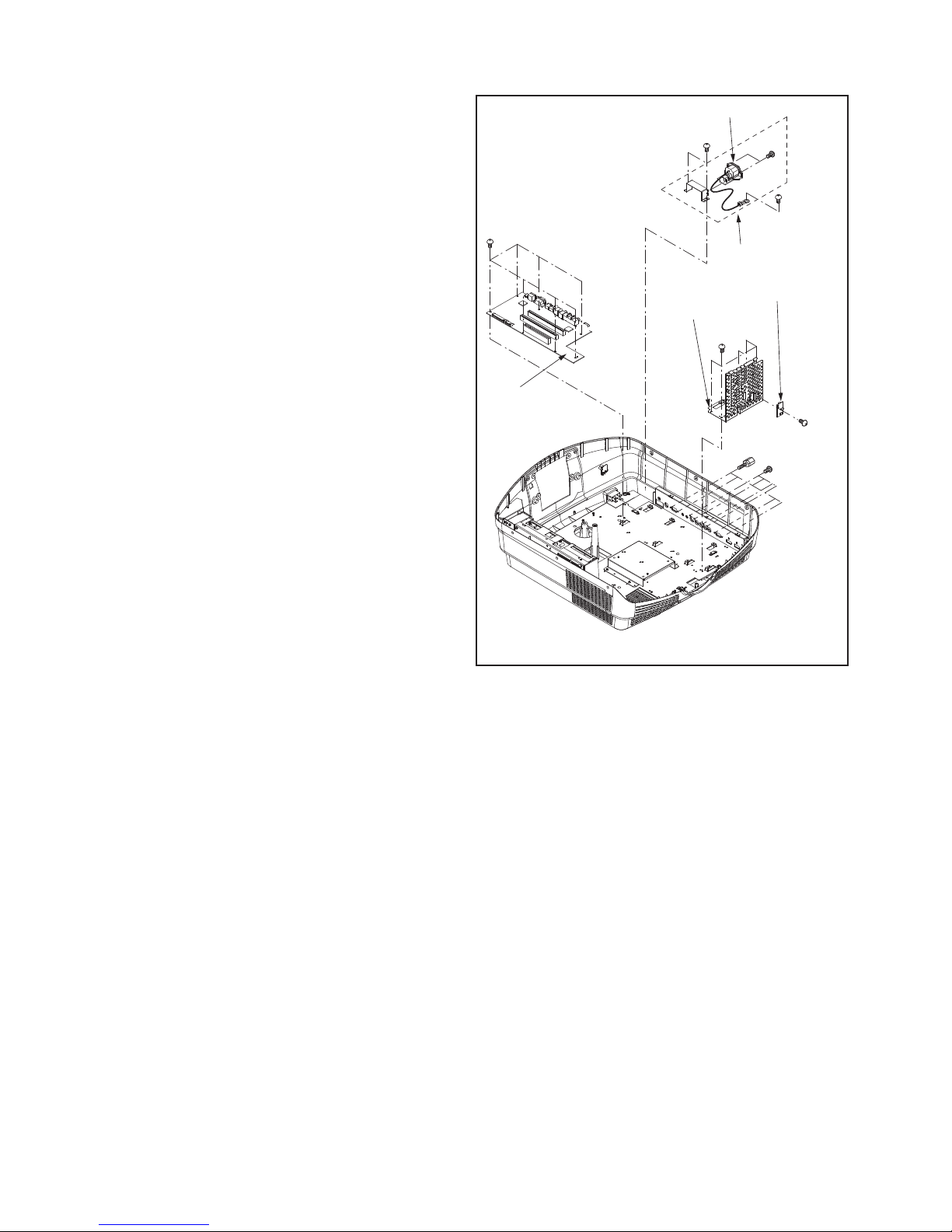

EXPOSED VIEW ................................................................................................................................................... 6

Chassis ASSY 1 ............................................................................................................................................... 6

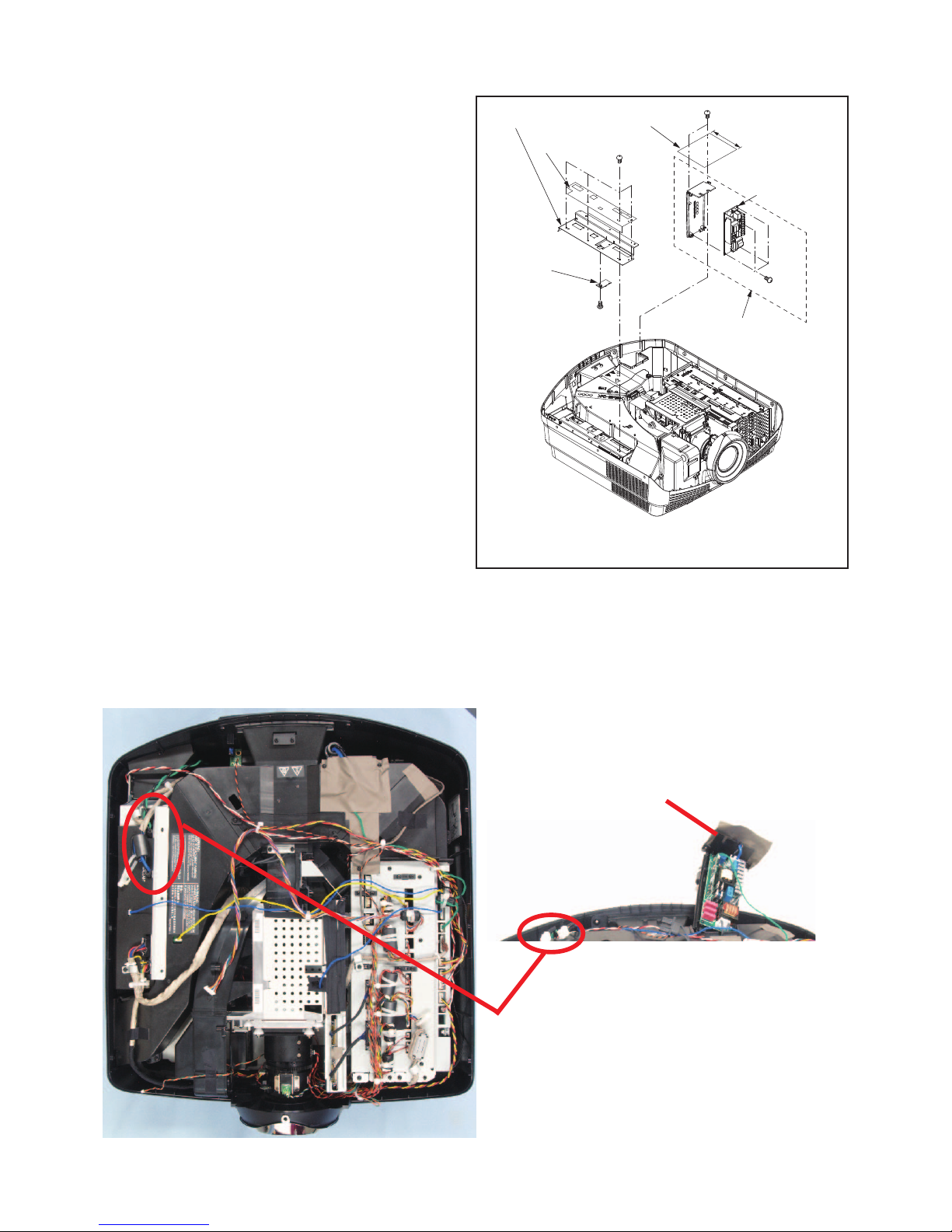

Chassis ASSY 2 ............................................................................................................................................... 8

Chassis ASSY 3 ............................................................................................................................................... 10

DISASSEMBLY ..................................................................................................................................................... 12

1. Removal of the Top cover ASSY .................................................................................................................. 12

2. Removal of the KEY SWITCH PCB ASSY ................................................................................................... 12

3. Removal of the IR PCB ASSY (FRONT)...................................................................................................... 12

4. Removal of the LAMP COVER PCB ASSY ................................................................................................. 12

5. Removal of the TEMP SENSOR PCB ASSY (POWER) .............................................................................. 13

6. Removal of the LAMP POWER PCB ASSY ................................................................................................. 13

7. Removal of the TEMP SENSOR PCB ASSY (OUTLET) ............................................................................. 14

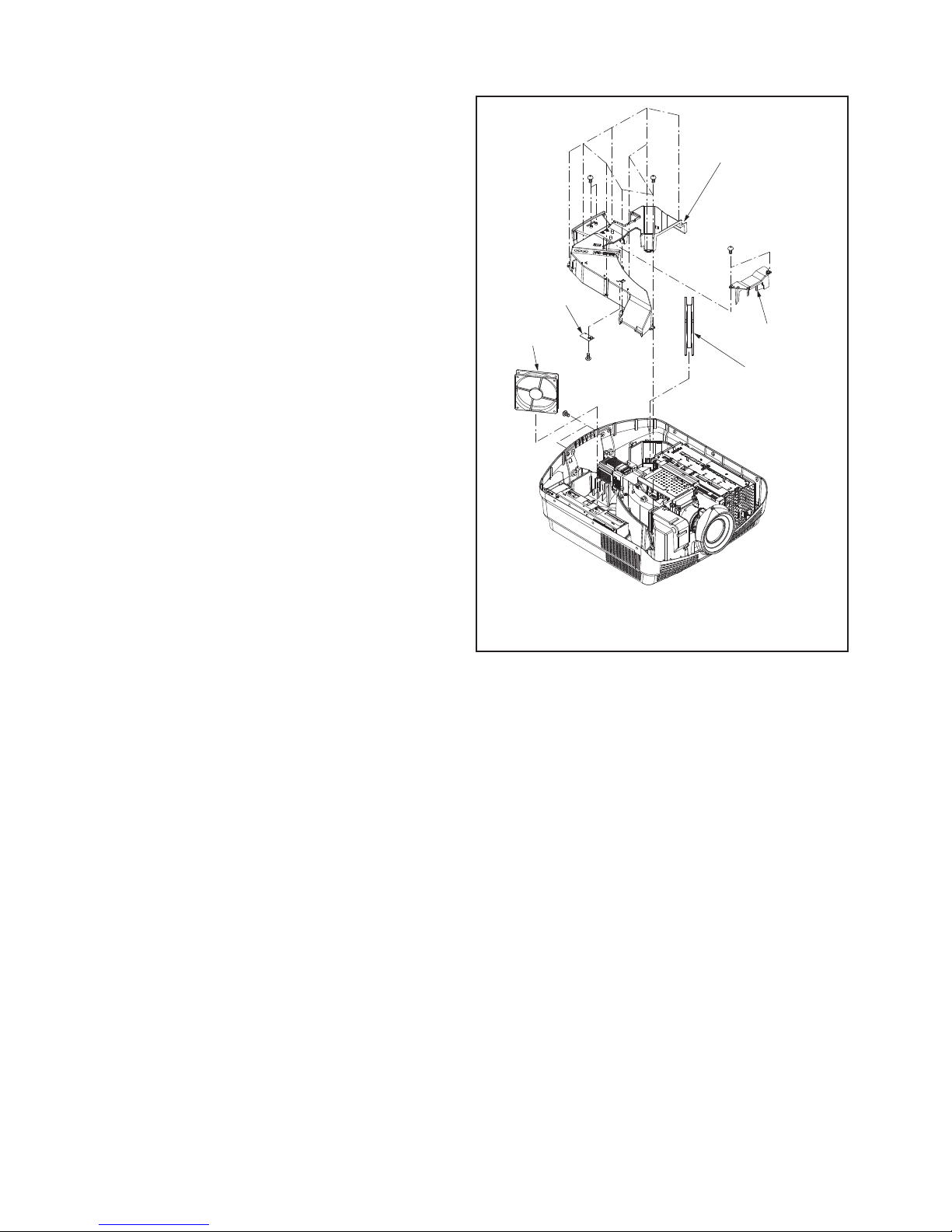

8. Removal of the Fan (Inlet) / Fan (Outlet) ..................................................................................................... 14

9. Removal of the Power fan ........................................................................................................................... 15

10. Removal of the POWER PCB ASSY ......................................................................................................... 15

11. Removal of the Duct fan (Inlet) .................................................................................................................. 16

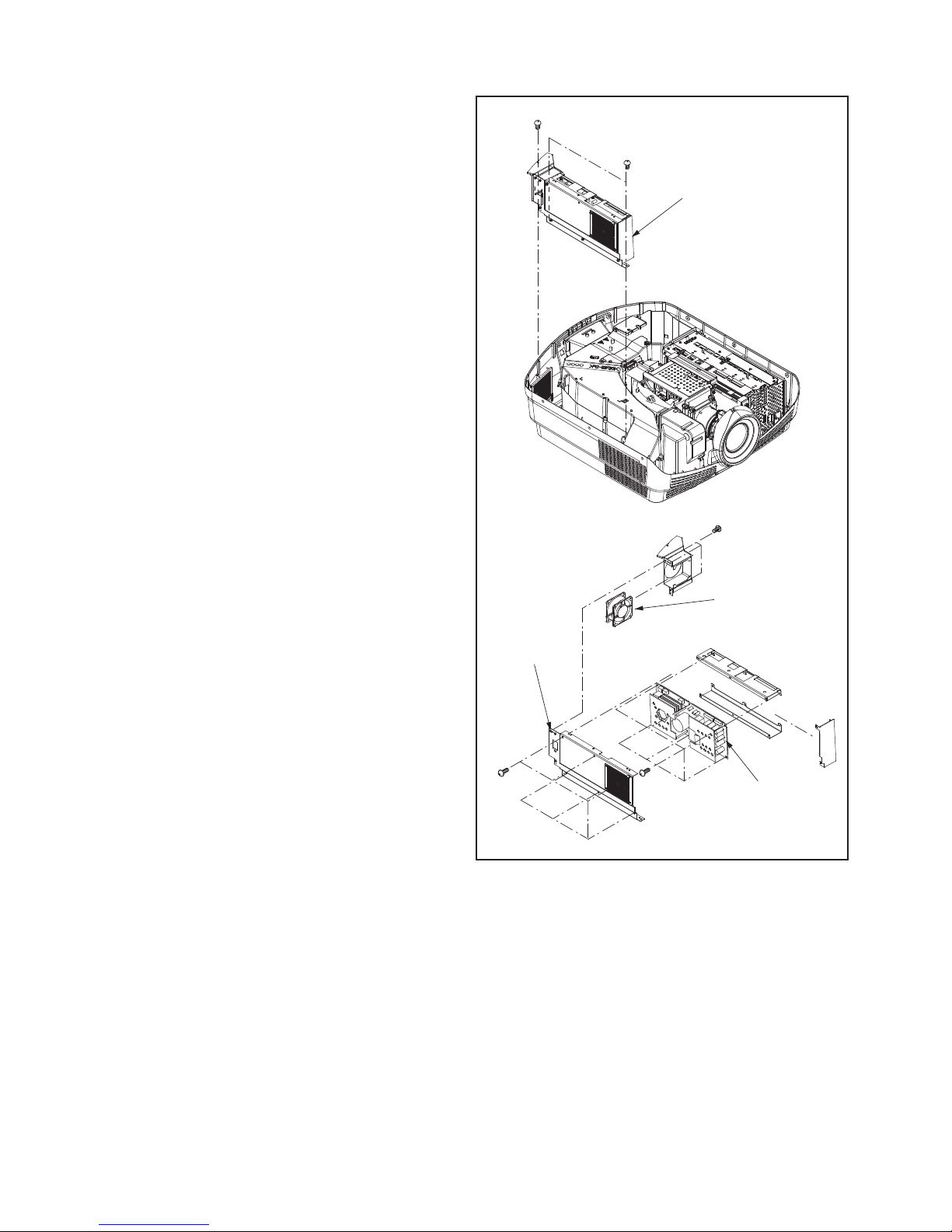

12. Removal of the LFT PCB ASSY ................................................................................................................. 17

13. Removal of the MEMC PCB ASSY ............................................................................................................ 17

14. Removal of the SCALER PCB PCB ASSY / HDMI PCB ASSY ................................................................. 17

15. Removal of the Lamp unit / Optical unit / Cooling fan (optical) .................................................................. 18

16. Removal of the IR PCB ASSY (REAR) ...................................................................................................... 19

17. Removal of the Thermostat ....................................................................................................................... 19

18. Removal of the I/O PCB ASSY / TEMP SENSOR PCB ASSY (INLET) ..................................................... 20

19. Removal of the AC inlet ............................................................................................................................. 20

LEAD DRESS ........................................................................................................................................................ 21

LABEL POSITION ................................................................................................................................................. 49

PACKING ............................................................................................................................................................... 50

– FILE “MAINTENA” –

REPLACING THE LAMP ....................................................................................................................................... 1

MAINTENANCE .................................................................................................................................................... 4

DOWNLOAD OF THE FIRMWARE ....................................................................................................................... 5

LIFE TIME OF THE CONSUMABLE PARTS ........................................................................................................ 8

– FILE “PCCONTRL” –

Controlling the projector using a personal computer ............................................................................................. 1

– FILE “PARTSLST” –

PARTS LIST .......................................................................................................................................................... 1

PCB LOCATION .............................................................................................................................................. 2

EXPOSED VIEW ............................................................................................................................................. 3

Chassis ASSY 1 ......................................................................................................................................... 3

Chassis ASSY 2 ......................................................................................................................................... 4

Chassis ASSY 3 ................................................................................................................

......................... 5

P

ACKING AND ACCESSORY ......................................................................................................................... 6

PACKING ................................................................................................................................................... 6

ACCESSORY ............................................................................................................................................. 6

ELECTRICAL PARTS AND OTHERS .............................................................................................................. 7

– FILE “SHEMATC” –

BLOCK DIAGRAM ........................................................................................................................................... B-1

SCHEMATIC DIAGRAMS ................................................................................................................................ C-1

- 1 -

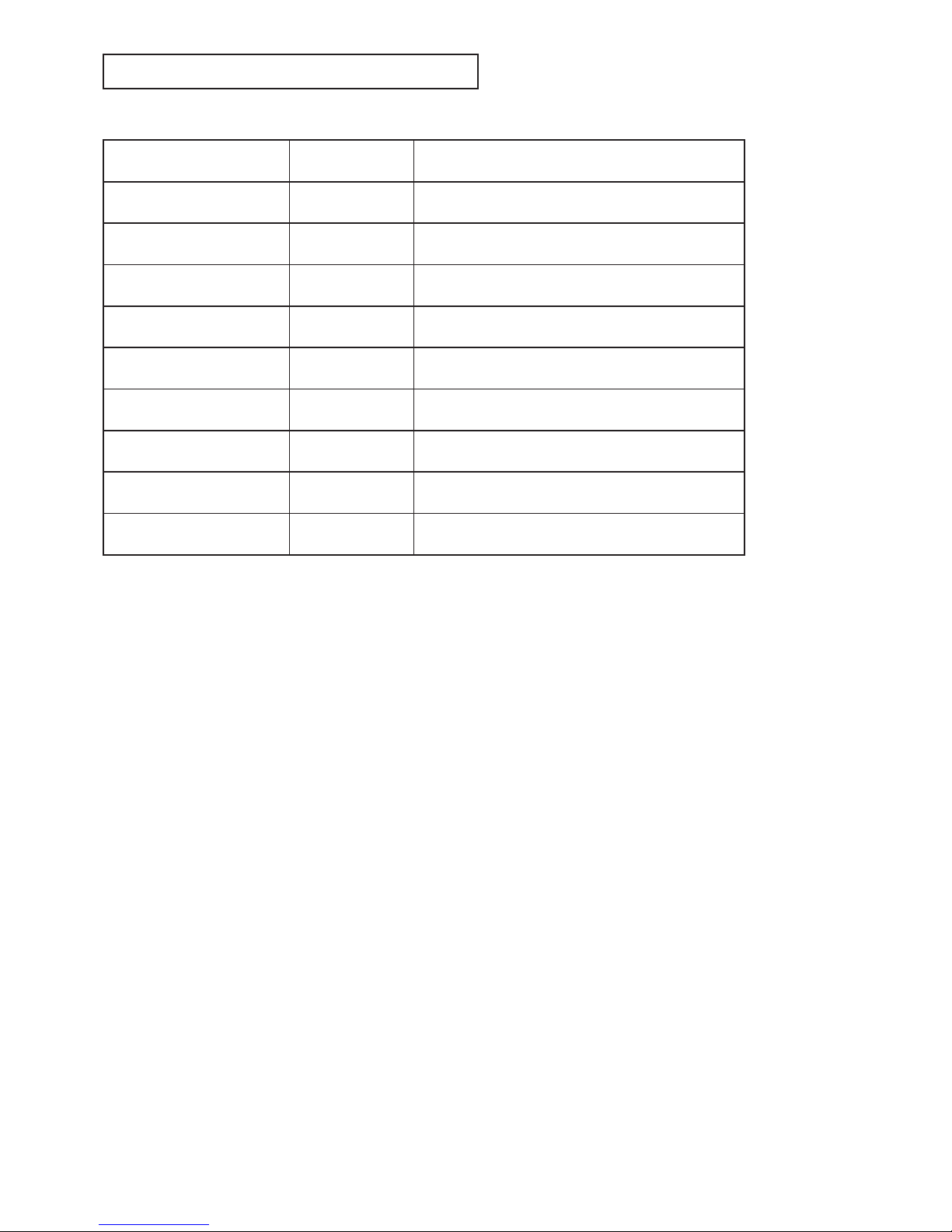

DIAGNOSIS INFORMATION

STATUS LED indicator

LED Indication Numbers of flash Failure

Red / orange alternately

1

E2PROM communication error

Green fl ash 2 Fan error

Green / orange alternately 1 Temp error

Green / orange alternately 2 PCB-MEMC error

Green / orange alternately 3 Lamp cover error (Lamp cover switch open.)

Green fl ash 1 PCB-POWER error

Orange fl ash 2 MCU-DDB communication error

Orange fl ash 3

1. Scaler doesn't finish the initial work.

2. MCU-Reon communication error

Red fl ash 1

Others error

Note : Check the STATUS LED indicator after the projector fi nishes the cooling process.

Flash (On 0.5Sec, Off 0.5Sec.)

- 2 -

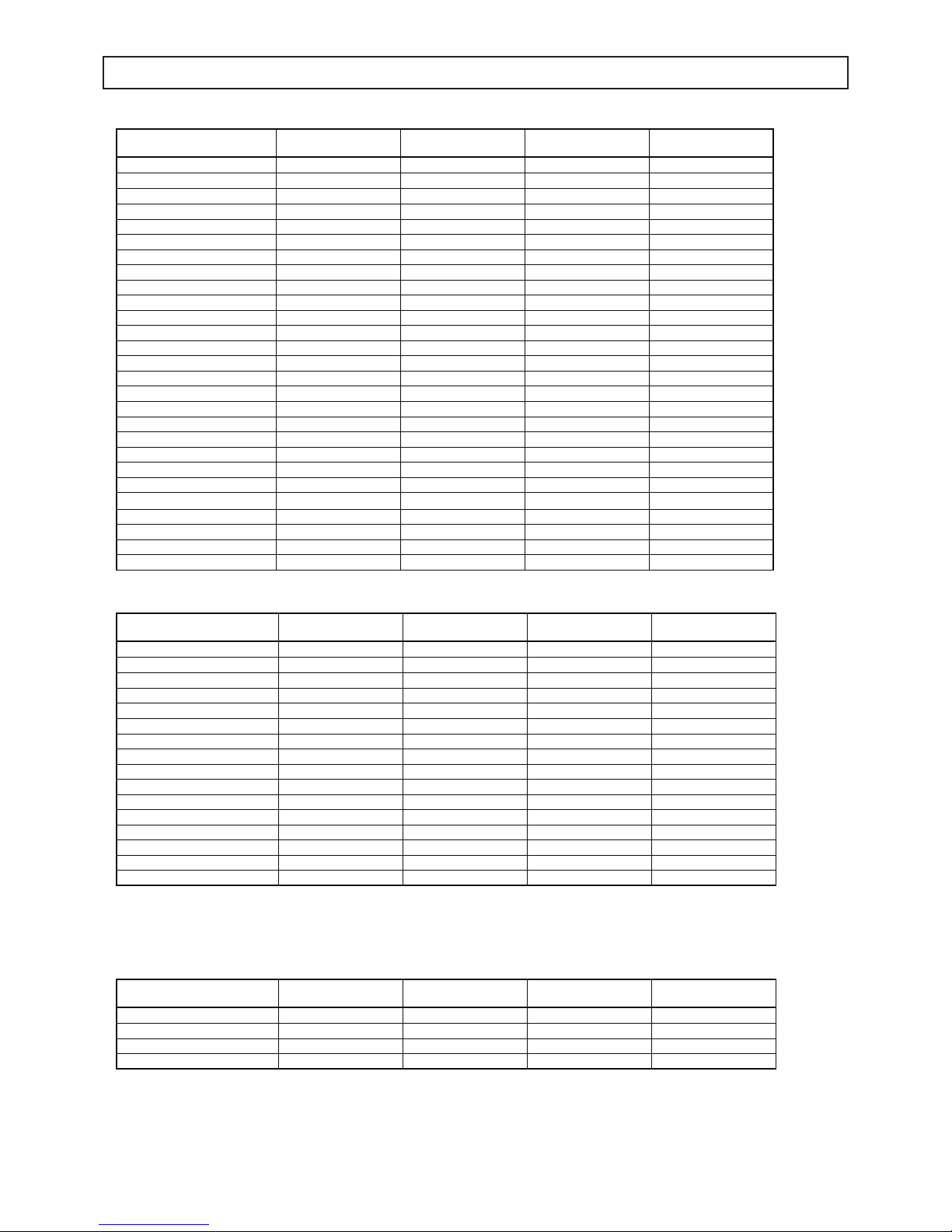

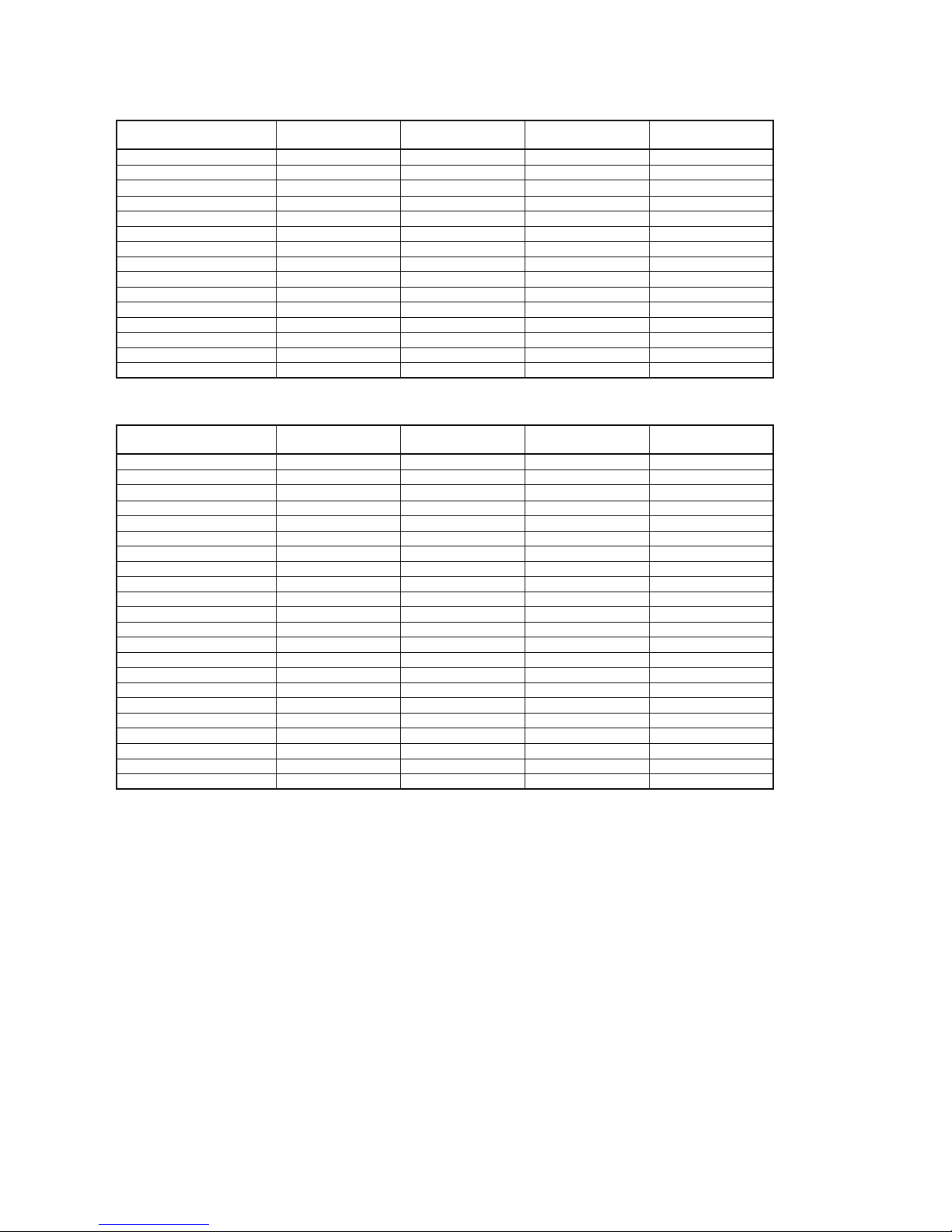

SPECIFICATION OF INPUT SIGNALS IN EACH INPUT OF THE PROJECTOR

HDMI

Signal mode

Resolution

(H x V)

Horizontal frequency

(kHz)

Vertical frequency

(Hz)

Normal mode

(H x V)*1

480i60.00Hz(Double Rate) - 15.75 60.00 1440x1080

480i59.94Hz(Double Rate) - 15.73 59.94 1440x1080

576i50.00Hz(Double Rate) - 15.63 50.00 1440x1080

480p 60.00Hz - 31.50 60.00 1440x1080

480p 59.94Hz - 31.47 59.94 1440x1080

576p 50.00Hz - 31.25 50.00 1440x1080

720p 60.00Hz - 45.00 60.00 1920x1080

720p 59.94Hz - 44.96 59.94 1920x1080

720p 50.00Hz - 37.50 50.00 1920x1080

1080i 60.00Hz - 33.75 60.00 1920x1080

1080i 59.94Hz - 33.72 59.94 1920x1080

1080i 50.00Hz - 28.13 50.00 1920x1080

1080p 60.00Hz - 67.50 60.00 1920x1080

1080p 59.94Hz - 67.43 59.94 1920x1080

1080p 50.00Hz - 56.25 50.00 1920x1080

1080p 24.00Hz - 27.00 24.00 1920x1080

1080p 23.98Hz - 26.97 23.98 1920x1080

VGA 60.00Hz 640x480 31.50 60.00 1440x1080

VGA 59.94Hz 640x480 31.47 59.94 1440x1080

SVGA 60Hz 800x600 37.88 60.00 1440x1080

XGA/60Hz 1024x768 48.36 60.00 1440x1080

WXGA 60Hz 1280x768 47.76 60.00 1800x1080

WXGA+ 60Hz 1440x900 55.92 60.00 1728x1080

SXGA+ 60 1400x1050 65.32 59.98 1440x1080

SXGA 60Hz 1280x1024 63.98 60.00 1350x1080

WSXGA+ 60Hz 1680x1050 65.22 60.00 1728x1080

WUXGA 60Hz 1920x1200 74.04 59.95 1728x1080

HDMI-3D

Signal mode Resolution

(H x V)

Horizontal frequency

(kHz)

Vertical frequency

(Hz)

Normal mode

(H x V)*1

Frame Packing 720p50 - 50.00 75.00 1920x1080

Frame Packing 720p59 - 59.94 89.91 1920x1080

Frame Packing 720p60 - 60.00 90.00 1920x1080

Frame Packing 1080p23 - 23.98 53.95 1920x1080

Frame Packing 1080p24 - 24.00 54.00 1920x1080

Side-by-Side 1080p50(Half ) - 50.00 56.25 1920x1080

Side-by-Side 1080p59(Half ) - 59.94 67.43 1920x1080

Side-by-Side 1080p60(Half ) - 60.00 67.50 1920x1080

Side-by-Side 1080i50(Half ) - 50.00 28.13 1920x1080

Side-by-Side 1080i60(Half ) - 60.00 33.75 1920x1080

Side-by-Side 1080i59(Half ) - 59.94 33.72 1920x1080

Top-and-Bottom 1080p24 - 24.00 27.00 1920x1080

Top-and-Bottom 1080p23 - 23.98 26.97 1920x1080

Top-and-Bottom 720p50 - 50.00 37.50 1920x1080

Top-and-Bottom 720p60 - 60.00 45.00 1920x1080

Top-and-Bottom 720p59 - 59.94 44.96 1920x1080

Video / S-Video

Signal mode Resolution

(H x V)

Horizontal frequency

(kHz)

Vertical frequency

(Hz)

Normal mode

(H x V)*1

NTSC(3.58/4.43) 712x483 15.73 59.94 1440x1080

PAL/PAL-N 702x575 15.63 50.00 1440x1080

PAL-M 712x483 15.73 59.94 1440x1080

SECAM 702x575 15.63 50.00 1440x1080

- 3 -

*1 This mode shows the display area when Aspect Ratio in

the Screen menu is set to Standard.

Important:

r Some computers aren’t compatible with the projector.

r The projector’s maximum resolution is 1920 x 1080

pixels. It may not display images of higher resolutions

than 1920 x 1080 correctly.

r If the resolution and frequency of your computer

aren’t shown on the table, nd the compatible

resolution and frequency by changing the resolution

of your computer.

r This projector supports only 5 lines format (R, G, B, H,

V) in Computer input and does not support 4 lines

format (R, G, B, Composite Sync).

Component

Signal mode Resolution

(H x V)

Horizontal frequency

(kHz)

Vertical frequency

(Hz)

Normal mode

(H x V)*1

480i 60.00Hz - 15.75 60.00 1440x1080

480i 59.94Hz - 15.73 59.94 1440x1080

576i 50.00Hz - 15.63 50.00 1440x1080

480p 60.00Hz - 31.50 60.00 1440x1080

480p 59.94Hz - 31.47 59.94 1440x1080

576p 50.00Hz - 31.25 50.00 1440x1080

720p 60.00Hz - 45.00 60.00 1920x1080

720p 59.94Hz - 44.96 59.94 1920x1080

720p 50.00Hz - 37.50 50.00 1920x1080

1080i 60.00Hz - 33.75 60.00 1920x1080

1080i 59.94Hz - 33.72 59.94 1920x1080

1080i 50.00Hz - 28.13 50.00 1920x1080

1080p 60.00Hz - 67.50 60.00 1920x1080

1080p 59.94Hz - 67.43 59.94 1920x1080

1080p 50.00Hz - 56.25 50.00 1920x1080

PC Signal

Signal mode Resolution

(H x V)

Horizontal frequency

(kHz)

Vertical frequency

(Hz)

Normal mode

(H x V)*1

VGA 60 640x480 31.50 60.00 1440x1080

VGA 72 640x480 37.90 72.00 1440x1080

VGA 75 640x480 37.50 75.00 1440x1080

VGA 85 640x480 43.30 85.00 1440x1080

SVGA 56 800x600 35.20 56.00 1440x1080

SVGA 60 800x600 37.90 60.00 1440x1080

SVGA 72 800x600 48.10 72.00 1440x1080

SVGA 75 800x600 46.90 75.00 1440x1080

SVGA 85 800x600 53.70 85.00 1440x1080

XGA 60 1024x768 48.40 60.00 1440x1080

XGA 70 1024x768 56.50 70.00 1440x1080

XGA 75 1024x768 60.02 75.03 1440x1080

XGA 85 1024x768 68.70 85.00 1440x1080

WXGA 60 1280x768 47.76 60.00 1800x1080

WXGA+ 60 1440x900 55.92 60.00 1728x1080

SXGA 60 1280x1024 63.98 60.02 1440x1080

SXGA+ 60 1400x1050 64.74 59.95 1350x1080

WSXGA+ 60 1680x1050 65.22 60.00 1728x1080

1920x1080@60 1920x1080 67.50 60.00 1920x1080

MAC13" 640x480 35.00 66.67 1440x1080

MAC16" 832x624 49.11 75.09 1440x1080

MAC19" 1024x768 60.24 74.93 1440x1080

- 1 -

Microsoft Windows 95/98/Me/Vista/XP are either registered trademarks or trademarks of Microsoft Corporation in the United

States and/or other countries.

Other brand or product names are trademarks or registered trademarks of their respective holders.

TRADEMARK, REGISTERED TRADEMARK

Many electrical and mechanical parts in the projector have special safety related characteristics. These characteristics are

often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by using replacement

components rated for higher voltage, etc. Replacement parts which have these special safety characteristics are identifi ed in

this service manual. Electrical components having such features are identifi ed by shading on the schematic diagram and the

parts list of this service manual and by the supplementary sheet for this chassis to be issued subsequently.

PRODUCT SAFETY NOTICE

- 2 -

Europe, other than USA

NOTICE: Observe all cautions and safety related notes located inside the cabinet and on the chassis.

Warning

1. An isolation transformer should be used between the projector and the AC supply point before any test/service is

performed on a LIVE chassis projector.

2. Operation of this projector outside the cabinet or with the cover removed, involves a shock hazard from the projector

power supplies. Work on the projector should not be attempted by anyone who is not thoroughly familiar with precautions

necessary when working on high voltage equipment.

3. When service is required, observe the original lead dressing. Extra precaution should be given to assure correct lead

dressing in the high voltage area. Where a short-circuit has occurred, replace those components that indicate evidence of

overheating.

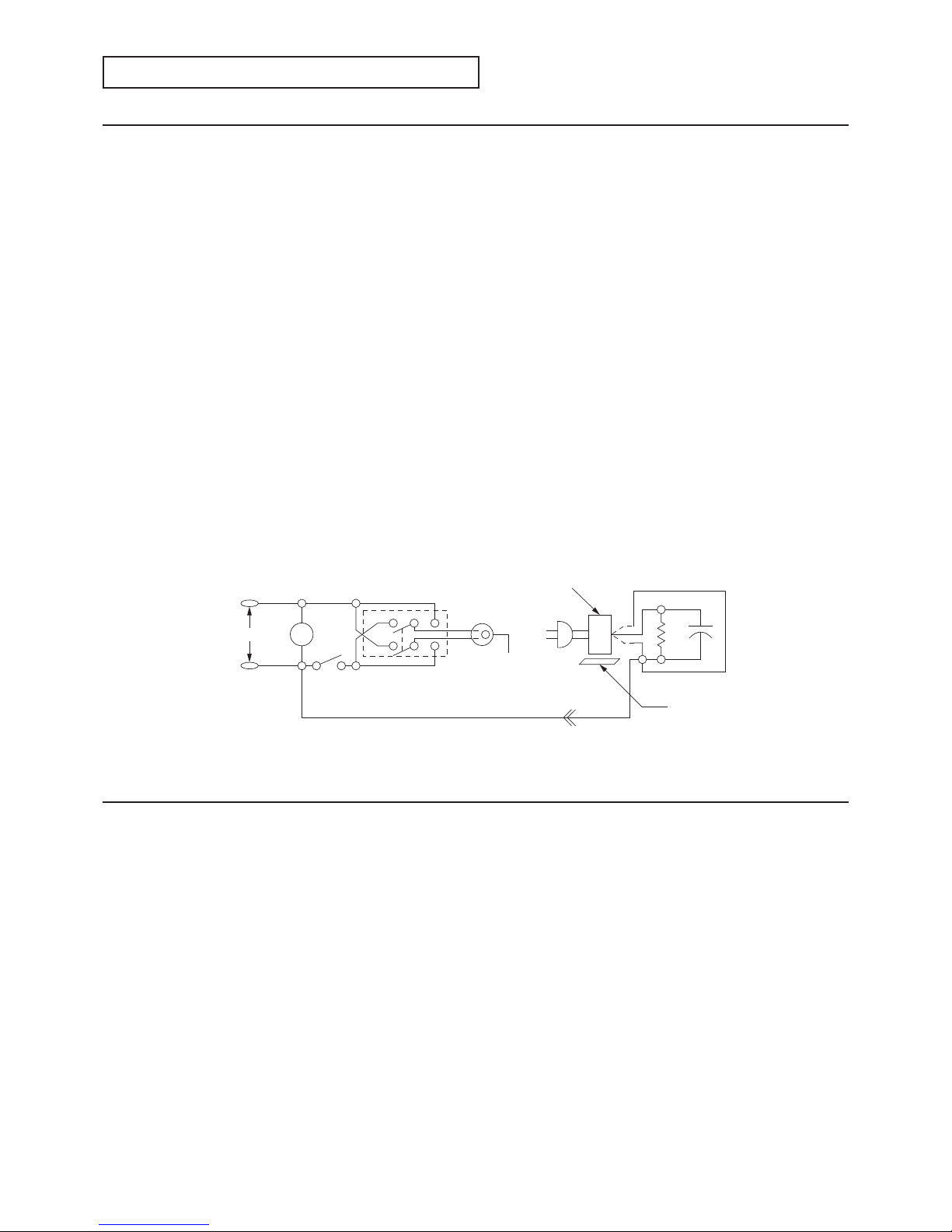

Leakage current cold check

Before returning the projector to the customer, it is recommended that leakage current be measured according to the

following methods.

With the AC plug removed from the AC source, place a jumper across the two AC plug prongs. Turn the projector AC switch

on. Using an 500 V D.C. Insulation Tester, connect one lead to the jumpered AC plug and touch the other lead to each

exposed metal part (screwheads, etc.), particularly any exposed metal part having a return path to the chassis. Exposed

metal parts having a return path to the chassis should have a minimum resistance reading of 4 M

Ω

. Any resistance below this

value indicates an abnormality which requires corrective action.

V

S1

S2

GH

(grounding)

open

Grounding supply conductor

B

Insulating table

Projector

A

AC milliammeter

Figure

A

C 100 to 240 V

North america

NOTICE: Observe all cautions and safety related notes located inside the cabinet and on the chassis.

Warning

1. Operation of this projector outside the cabinet or with the cover removed presents a shock hazard from the projector

power supplies.

2. When a short-circuit has occurred, replace those components that indicate evidence of overheating.

3. Grounding circuit continuity is vital for safe operation of equipment. Do not remove ground connection while the power

cord is still connected to the supply. Disconnect supply before servicing.

Leakage current check

Before returning the projector to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold check

With the AC plug removed from the AC 100 to 240 V, place a jumper across the two AC plug prongs. Turn the projector

AC switch on. Using an ohm-meter, connect one lead to the AC plug and touch the other lead to each exposed metal

part (metal cabinet, screwheads, metal overlays, etc.), particularly any exposed metal part having a return path to the

chassis. Exposed metal parts having a return path to the chassis should have a minimum resistance reading of 1 M

Ω

. Any

resistance below this value indicates an abnormality which requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

2. Hot check

Use the circuit in fi gure to perform this test.

(1) With switch S1 open, connect the projector to the measuring circuit. Immediately after connection, measure the

leakage current using both positions of switch S2, and with the switching devices in the projector in all of their

operating positions.

(2) Switch S1 is then closed, energizing the projector. Immediately after closing the switch, measure the leakage current

using both positions of switch S2, and with the switching devices in the projector in all of their operating positions.

Current measurements of items (1) and (2) are to be repeated after the projector has reached thermal stabilization.

The leakage current must not be more than 0.5 milliampere.

SAFETY PRECAUTIONS

- 3 -

Lead-free solder is handled in a different way from eutectic solder. See below for details.

How to distinguish circuit boards using lead-free solder from those using

eutectic solder

Circuit boards using lead-free solder

A mark of Solder, Joints, PCA or LFS (for limited marking space) is printed near the board assembly number on

the component side.

Circuit boards using eutectic solder

Circuit boards using eutectic solder are divided into two groups.

- Boards having no mark of

Solder, Joints, PCA or LFS (for limited marking space) near the board assembly

number.

- Boards having a mark of

Solder, Joints, PCA or LFS (for limited marking space) that is painted out by a

feltpen near the board assembly number.

* Only when there is a limited marking space on the board,

Solder may be indicated as S, Joints as J, and

PCA as P.

* Circuit boards using lead-free solder and those using eutectic solder may be used together in the same product.

Instructions for resoldering

- For circuit boards using lead-free solder, use lead-free solder.

- For circuit boards using eutectic solder, use eutectic solder.

- Separate the soldering iron for lead-free solder from that for eutectic solder completely for use.

(It is prohibited to use a same soldering iron for lead-free solder and eutectic solder.)

- For lead-free solder, it is advisable to use a soldering iron of at least 40 W because lead-free solder has a melting point

approx. 35°C higher than that of eutectic solder as conventionally used. For wire solder, use M705ESC made by Senju

Metal Industry Co., Ltd.

- To remove solder, you can use desoldering wires for eutectic solder as conventionally used.

PRECAUTIONS FOR RESOLDERING

- 4 -

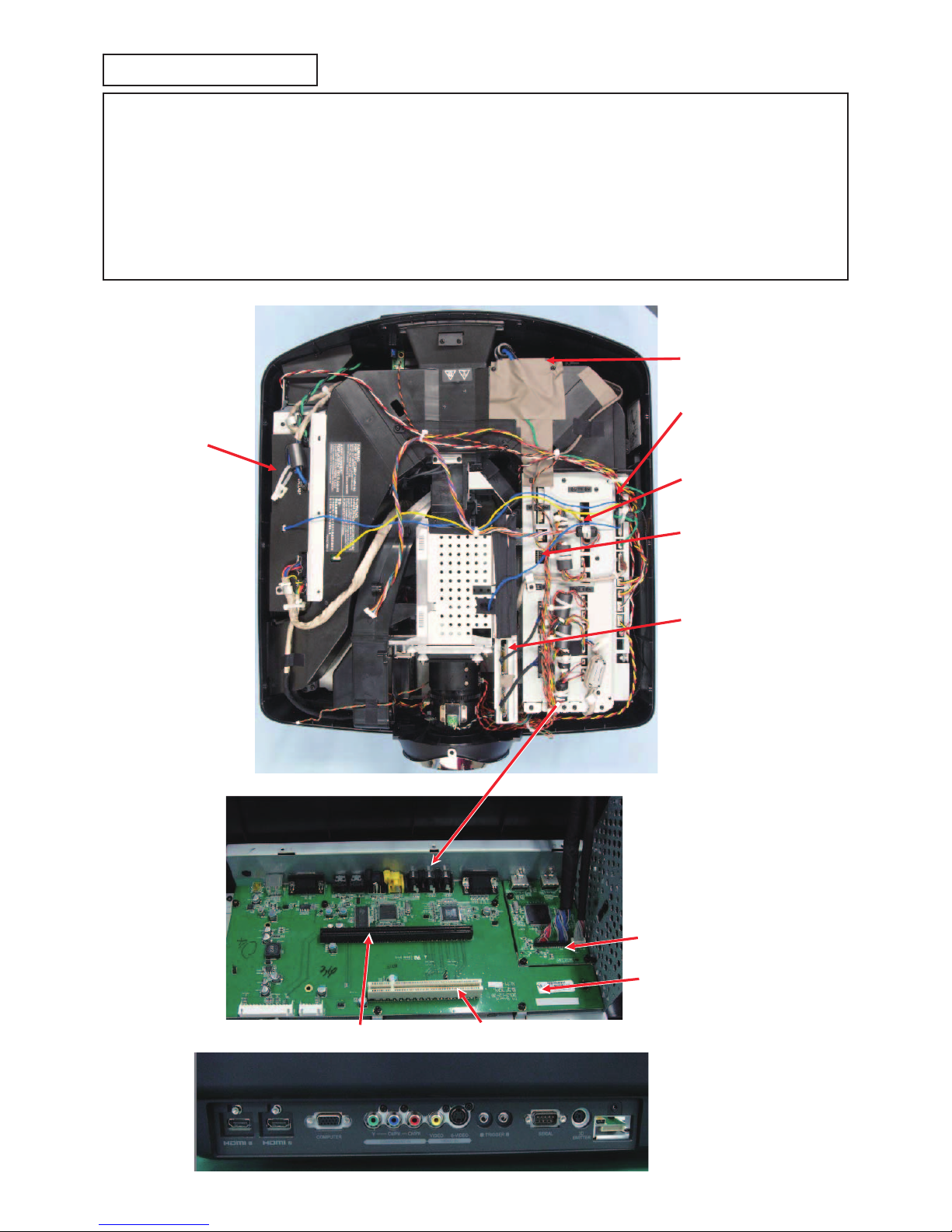

PCB LOCATION

Fig.1

4

8

1

3

5

2

6

7

11

10

9

12

13

14

- 5 -

Parts list : See page 2 of PARTS LIST

Item No. Part name

1 I/O PCB ASSY

2 TEMP SENSOR PCB ASSY (INLET)

3 HDMI PCB ASSY

4 LFT PCB ASSY

5 SCALER PCB ASSY

6 MEMC PCB ASSY

7 IR PCB ASSY (REAR)

8 LAMP POWER PCB ASSY

9 KEY SWITCH PCB ASSY

10 LAMP COVER PCB ASSY

11 TEMP SENSOR PCB ASSY (POWER)

12 POWER PCB ASSY

13 TEMP SENSOR PCB ASSY (OUTLET)

14 IR PCB ASSY (FRONT)

Table 1

- 6 -

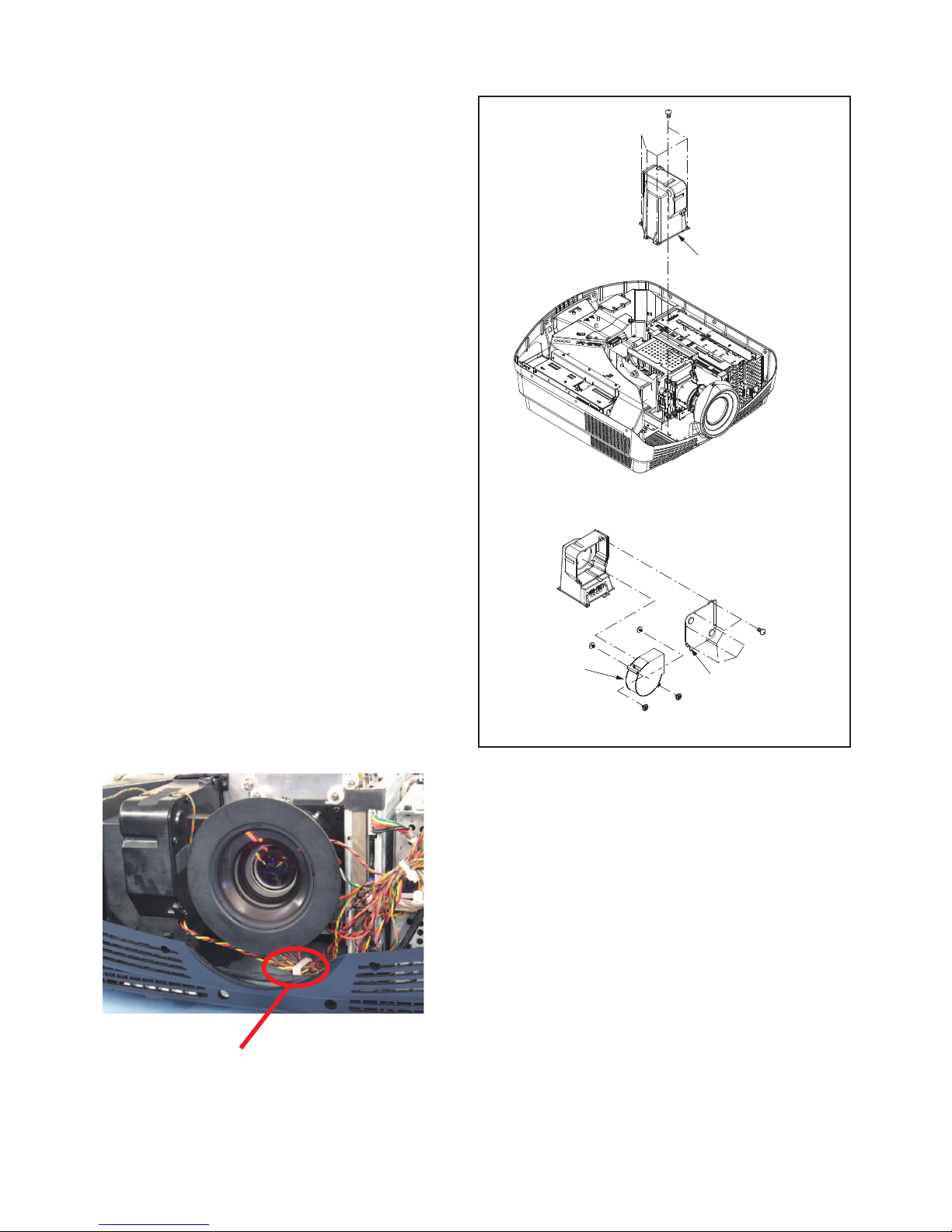

Chassis ASSY 1

Fig.2-1

3

8

9

7

7

77

7

7

7

7

Hx1

14

13

Nx4

Qx11Ex2

Jx1

Gx1

6

10

15

18

20

Px2

17

5

4

Fx6

2

Ax2

16

Rx1

Qx2

Cx2

Kx4

11

12

Lx1

Cx3

Bx1

Cx3

Dx2

1

Mx2

Hx1

Hx1

Hx1

Hx1

Hx1

Hx1

Hx1

19

EXPOSED VIEW

- 7 -

Part name Number of screw

1.Lens cap None

2.Lamp cover unit Ax2, Ex2

3.Top cover ASSY Bx1, Cx8, Dx2

4.KEY SWITCH PCB ASSY Fx6

5.Key ASSY None

6.IR PCB ASSY(Front) Gx1

7.Cover holder Hx8

8.WW Logo inlay None

9.Top cover unit None

10.LAMP COVER PCB ASSY Jx1

11.Power shield plate 1 Kx4

12.TEMP SENSOR PCB ASSY (POWER) Lx1

13.Lamp power sheet Mx2

14.Lamp power ASSY Mx2

15.LAMP POWER PCB ASSY Nx4

16.Optical cover Px2

17.Top duct ASSY Qx13

18.TEMP SENSOR PCB ASSY (OUTLET) Rx1

19.Fan(Inlet) None

20.Fan(Outlet) None

21.Power sheet Kx3

Table 2-1

Parts list : See page 3 of PARTS LIST

- 8 -

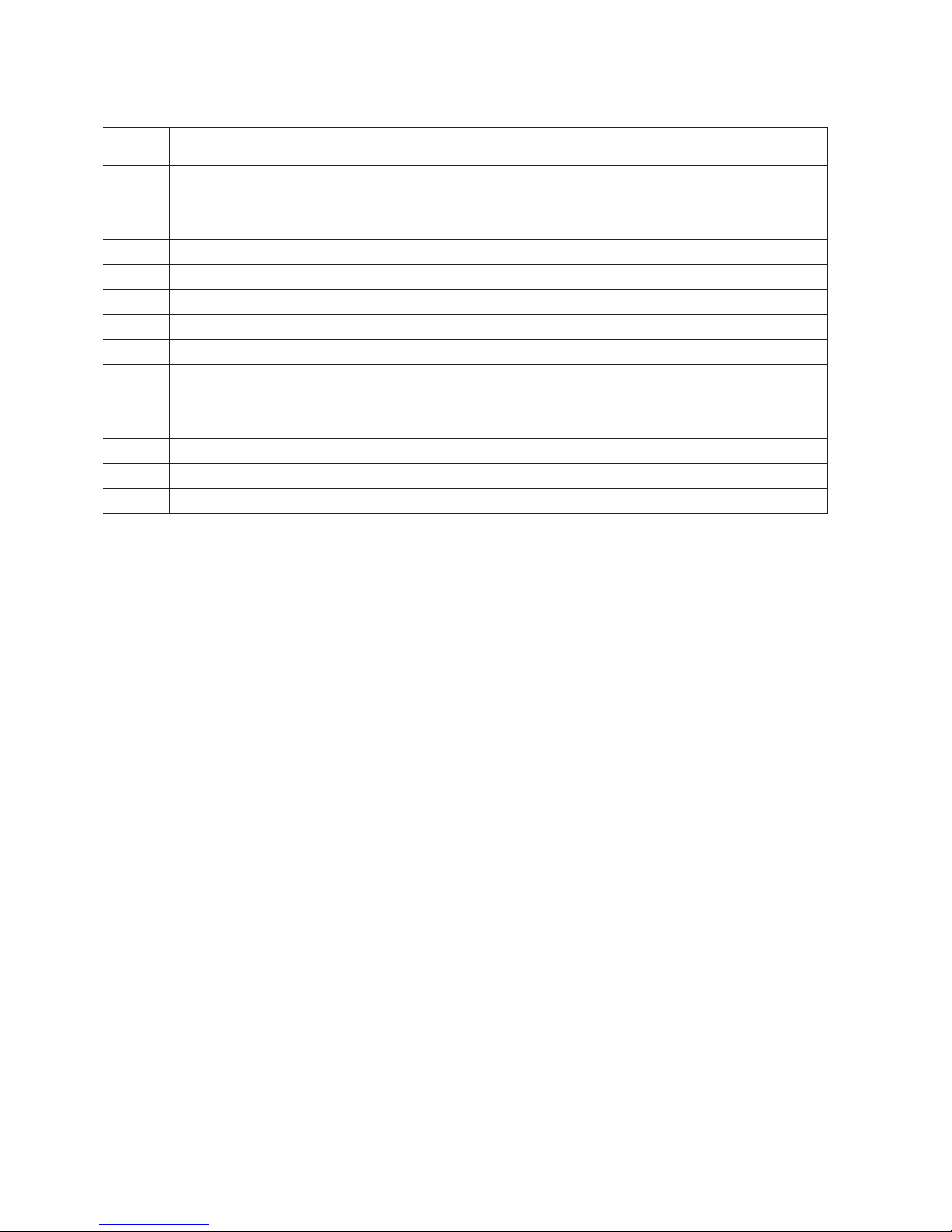

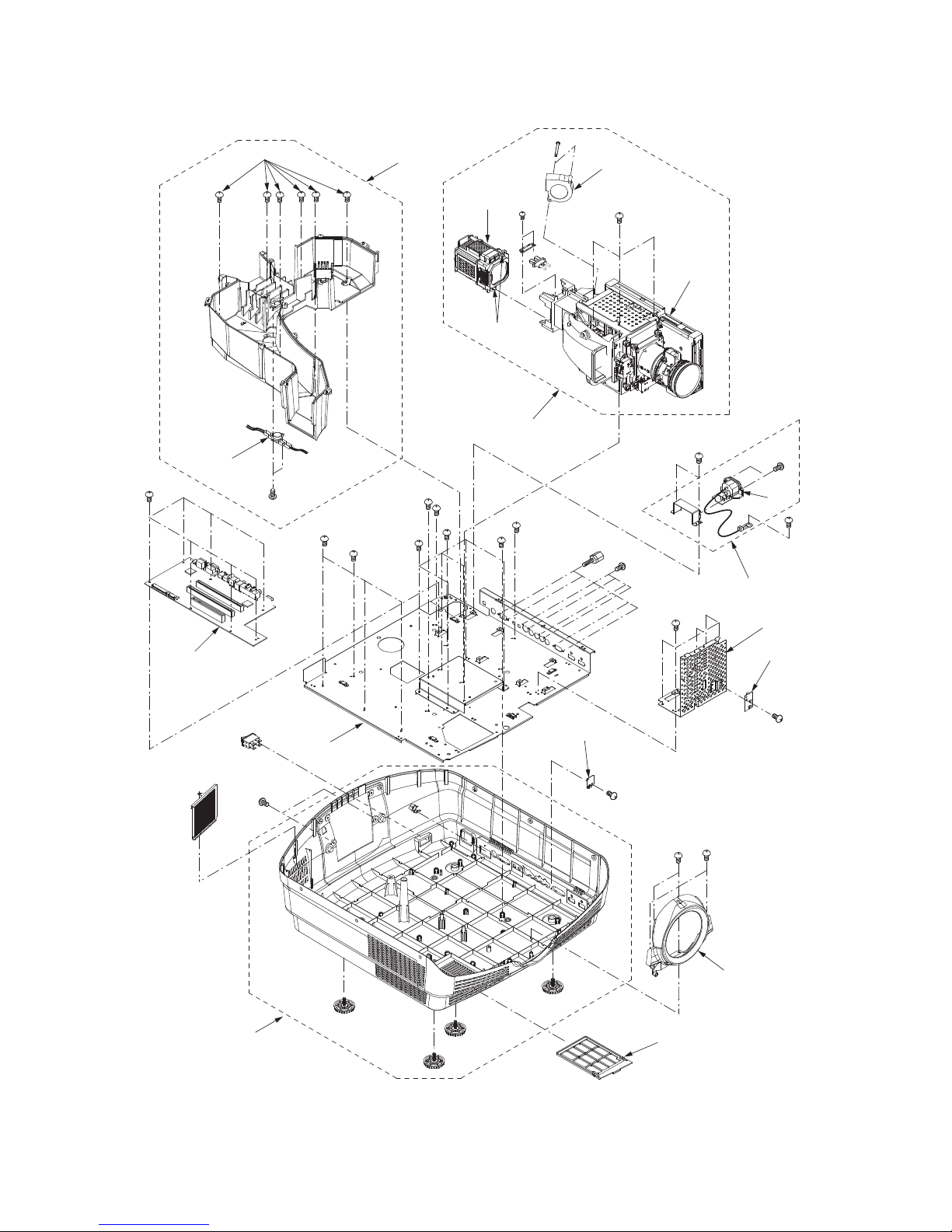

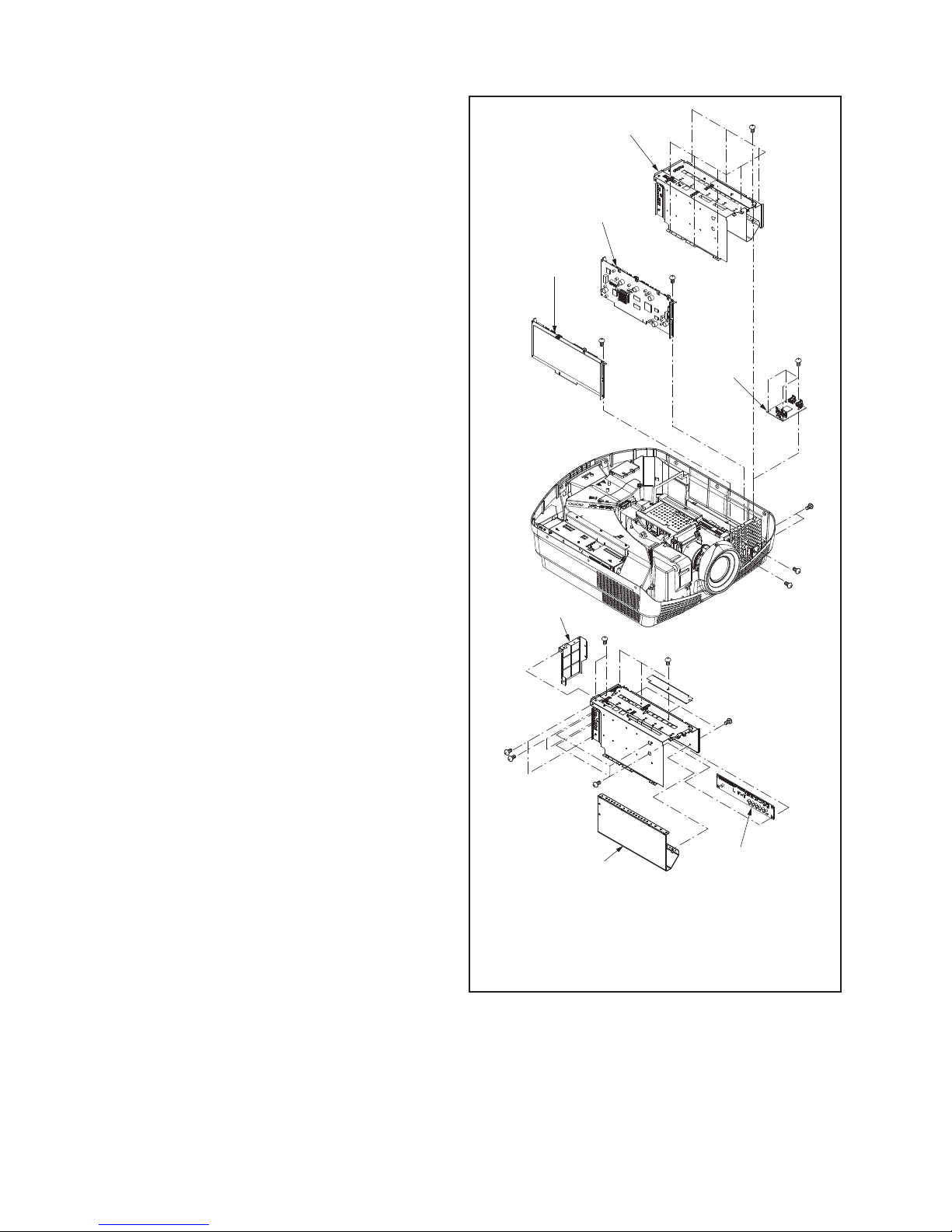

Chassis ASSY 2

Fig.2-2

Ax2

1

Bx1

2

Cx3

3

4

Dx6

Ex6

5

6

Fx5

7

Gx6

8

9

Hx8

10

Jx3

Jx2

Kx2

Kx2

11

Jx3

12

Lx4

13

14

15

Mx1

Mx1

Nx1

Nx1

Px2

Qx4

- 9 -

Part name Number of screw

1.Power unit Ax2, Bx1

2.Power fan holder ASSY Cx3

3.Power fan None

4.Power shield plate 2 Dx6

5.POWER PCB ASSY Ex6

6.Duct unit (Inlet) Fx5

7.Duct cover (Inlet) Gx6

8.Duct fan (Inlet) None

9.MEMC/scaler shield plate ASSY Hx8

10.Scaler shield plate 1 Jx8

11.Scaler shield plate 2 Kx4

12.LFT PCB ASSY Lx4

13.MEMC PCB ASSY Mx2

14.SCALER PCB ASSY Nx2

15.HDMI PCB ASSY Px2, Qx4

Table 2-2

Parts list : See page 3 of PARTS LIST

- 10 -

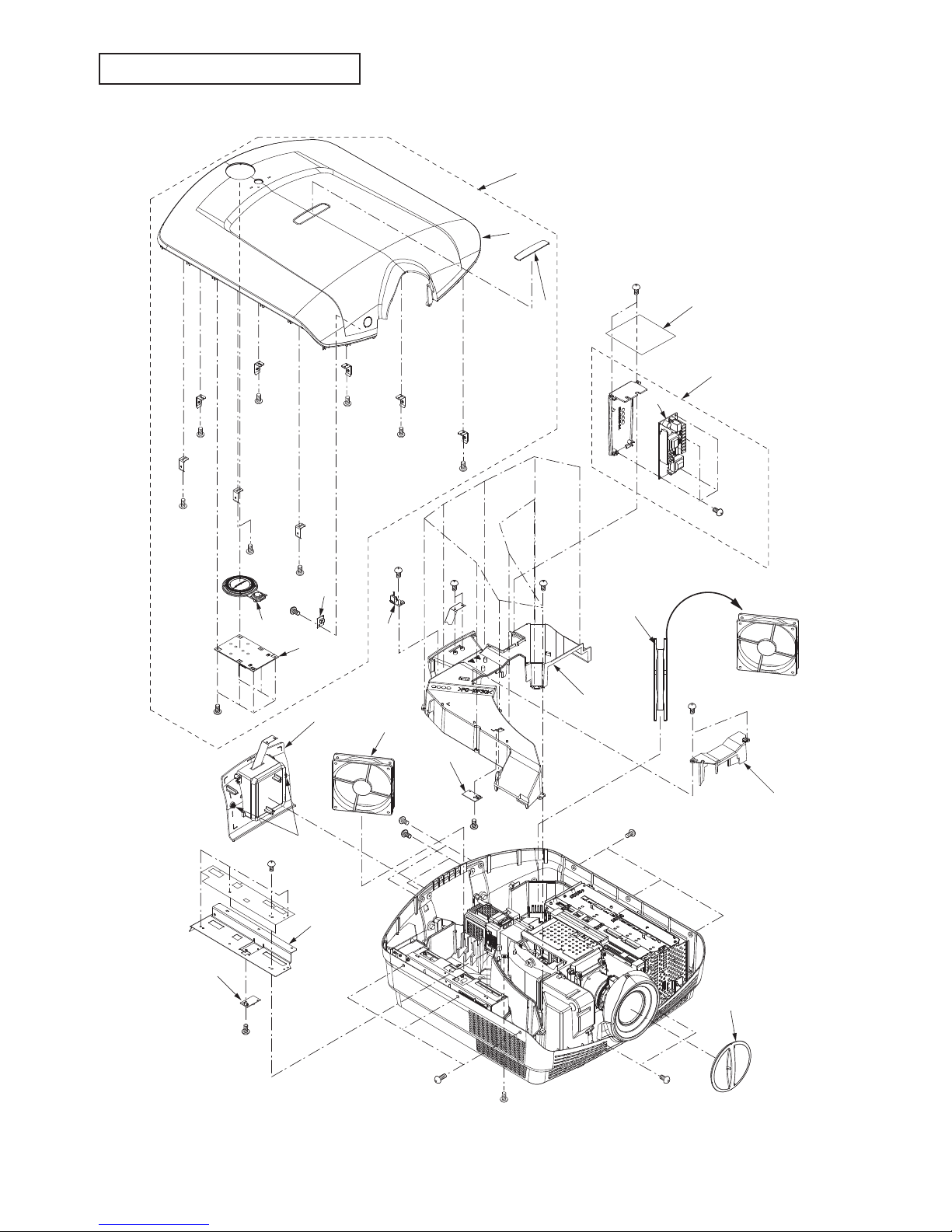

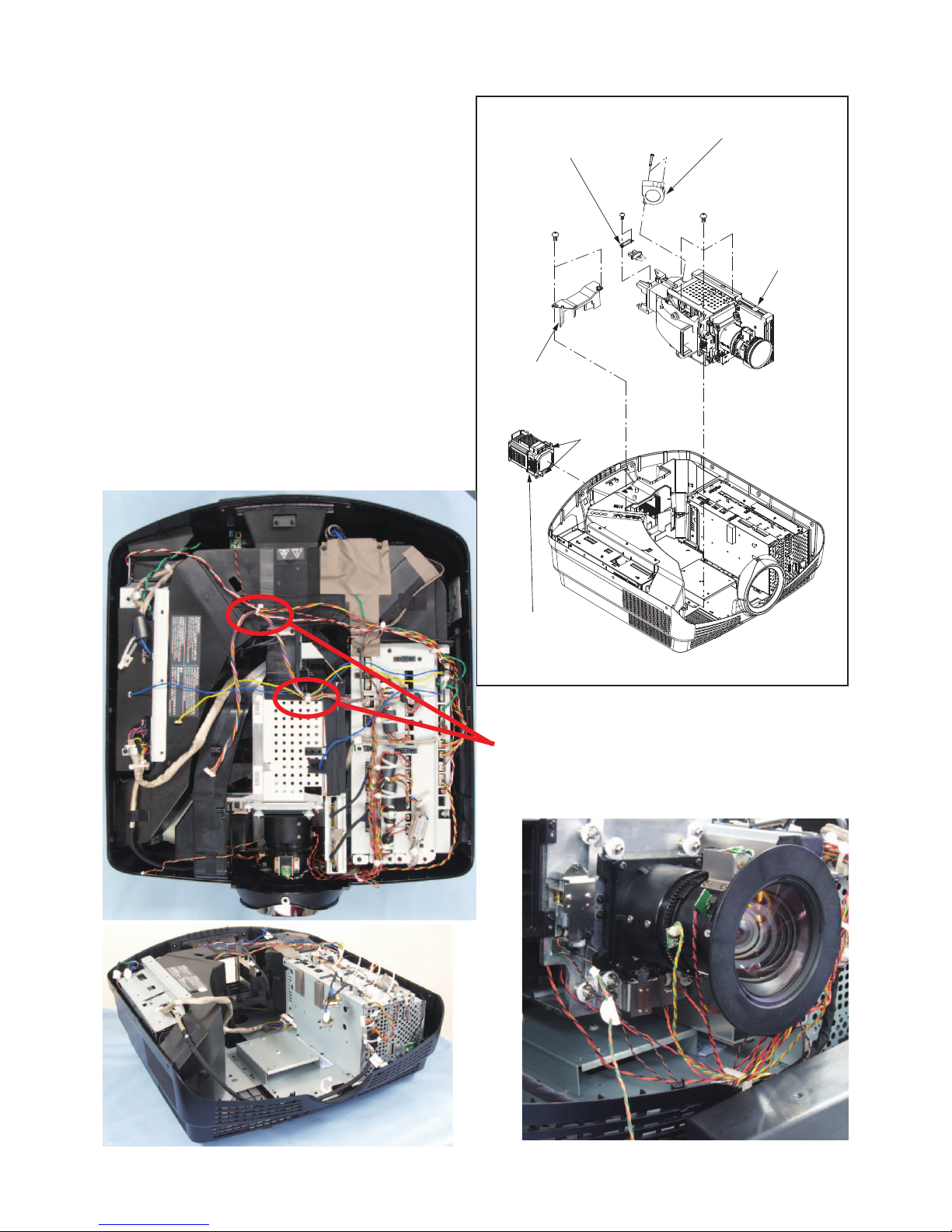

Chassis ASSY 3

Fig.2-3

Ax6

1

Bx2

2

Cx2

3

Dx1

4

5

Ex2

Fx1

Gx2

6

7

8

Hx3

Jx2

Kx2

9

10

Lx4

Mx4

Nx7

11

12

Px5

Qx1

13

Rx2

Rx2

14

15

15

15

15

16

Sx3

Sx5

Sx1

Sx1Sx1

Sx1

Sx1

Sx1

17

Tx2

- 11 -

Part name Number of screw

1.Bottom duct ASSY Ax6, Bx2

2.Thermostat Cx2

3.IR PCB ASSY (REAR) Dx1

4.AC inlet ASSY Ex2, Fx1

5.AC inlet Gx2

6.Optical ASSY Hx3

7.Lamp unit Jx2

8.Cooling fan (optical) Kx2

9.Optical unit Tx2

10.I/O PCB ASSY Lx4, Mx4, Nx7

11.HDMI shield plate Px5

12.TEMP SENSOR PCB ASSY (INLET) Qx1

13.Lens cover unit Rx4

14.Filter None

15.Adjustment foot None

16.Bottom plate Sx14

17.Bottom cover unit None

Table 2-3

Parts list : See page 4 of PARTS LIST

- 12 -

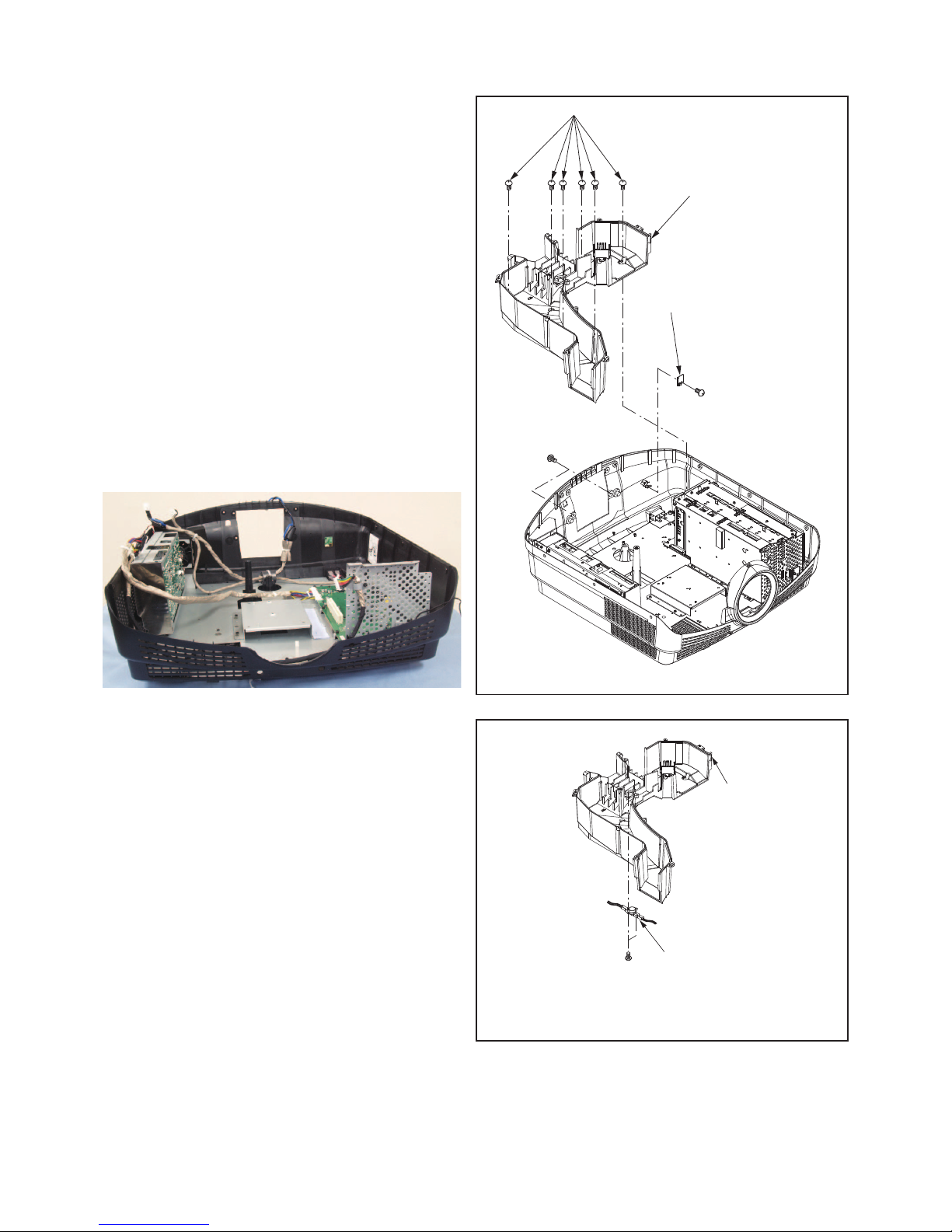

Fig.3-1

Note : On the lead connector, the connector name

isn't indicated. When disconnecting the lead

connector, place labels (

INDEX LABELs

) bearing

the reference markings (connector names) near

the lead connectors and the connectors on the

board to prevent wrong disconnection. After

re-connecting the lead connectors, remove the

labels. To disassemble the product, it is required to

cut the BAND KMs that clamp the lead connectors.

Therefore, when re-assembling the product,

prepare and use the specified BAND KMs. For

the part number of the BAND KM, refer to PARTS

LIST.

For the reference markings of the lead connectors,

see pages D23 to D26.

For the connector names of the fans and motors,

see pages D35 to D48.

1.

Removal of the Top cover ASSY

1. Loose the two screws (a) and remove the Lamp cover

ASSY as shown in Fig. 3-1.

2. Remove the screw (b), eight screws (c) and two screws

(d) as shown in Fig. 3-1.

3. Disconnect the connector on the KEY SWITCH PCB

ASSY and remove the Top cover ASSY as shown in Fig.

3-1.

2.

Removal of the KEY SWITCH PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the six screws (f) and KEY SWITCH PCB ASSY

as shown in Fig. 3-1.

3.

Removal of the IR PCB ASSY (FRONT

)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Disconnect the connector on the IR PCB ASSY

(FRONT) as shown in Fig. 3-1.

3. Remove the screw (g) and IR PCB ASSY (FRONT) as

shown in Fig. 3-1.

4. Removal of the LAMP COVER

PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Disconnect the connector on the LAMP COVER PCB

ASSY as shown in Fig. 3-1.

3. Remove the screw (e) and LAMP COVER PCB ASSY as

shown in Fig. 3-1.

ax1

cx2

cx3

cx3

dx2

bx1

ex1

ax1

Top cover ASSY

LAMP COVER

PCB ASSY

Lamp cover unit

DISASSEMBLY

fx6

gx1

KEY SWITCH PCB ASSY

IR PCB ASS

Y

(FRONT)

- 13 -

ax4

bx1

dx4

cx2

70mm

Lamp power

sheet

LAMP POWER

PCB ASSY

Lamp power ASSY

TEMP SENSOR

PCB ASSY

(POWER)

Power shield

plate 1

Power sheet

Fig.3-2

5. Removal of the TEMP SENSOR

PCB ASSY (POWER)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the four screws (a) and Power shield plate 1 as

shown in Fig. 3-2.

3. Disconnect the connector on the TEMP SENSOR PCB

ASSY (POWER) as shown in Fig. 3-2.

4. Remove the screw (b) and TEMP SENSOR PCB ASSY

(POWER) as shown in Fig. 3-2.

6. Removal of the LAMP POWER

PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the two screws (c) and Lamp power ASSY as

shown in Fig. 3-2.

Note) The LAMP POWER SHEET has no screw holes.

Insert the screw, piercing the LAMP POWER

SHEET.

3. Disconnect all connectors on the LAMP POWER PCB

ASSY as shown in Fig. 3-2.

4. Remove the four screws (d) and LAMP POWER PCB

ASSY as shown in Fig. 3-2.

Note) The Lamp power sheet is not reusable.

Lamp power ASSY

LEAD DRESS

To remove the LAMP POWER PCB ASSY, disconnect the

connector and loosen the lead wire.

- 14 -

bx2

cx11

cx2

dx1

ax2

Top duct ASSY

TEMP SENSOR

PCB ASSY

(OUTLET)

Optical cover

Fan (Inlet)

Fan

(Outlet)

Optical cover

Fig.3-3

7. Removal of the TEMP SENSOR

PCB ASSY (OUTLET)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the two screws (a) and Optical cover as shown

in Fig. 3-3.

5. Remove the two screws (b), thirteen screws (c) and Top

duct ASSY as shown in Fig. 3-3.

6. Disconnect the connector on the TEMP SENSOR PCB

ASSY (OUTLET) as shown in Fig. 3-3.

7. Remove the screw (d) and TEMP SENSOR PCB ASSY

(OUTLET) as shown in Fig. 3-3.

8. Removal of the Fan (Inlet) / Fan

(Outlet)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the Top duct ASSY according to “7. Removal of

the TEMP SENSOR PCB ASSY (OUTLET)”.

5. Disconnect the connectors on the LFT PCB ASSY as

shown in Fig. 3-6.

6. Remove the Fan (Inlet), Fan (Outlet) as shown in Fig.

3-3.

- 15 -

ax2

dx6

ex6

cx3

bx1

Power unit

Power fan

POWER PCB ASSY

Power shield

plate 2

Fig.3-4

9. Removal of the Power fan

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the two screws (a), screw (b) and Power unit as

shown in Fig. 3-4.

4. Disconnect the connector on the LFT PCB ASSY as

shown in Fig. 3-6.

5. Remove the three screws (c) and Power fan as shown in

Fig. 3-4.

10. Removal of the POWER PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Power unit according to “9. Removal of the

Power fan”.

4. Remove the six screws (d) and Power shield plate 2 as

shown in Fig. 3-4.

5. Disconnect all connectors on the POWER PCB ASSY as

shown in Fig. 3-4.

6. Remove the six screws (e) and POWER PCB ASSY as

shown in Fig. 3-4.

- 16 -

Fig.3-5

11. Removal of the Duct fan (Inlet)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the five screws (a) and Duct unit (Inlet) as

shown in Fig. 3-5.

3. Remove the six screws (b) and Duct cover (Inlet) as

shown in Fig. 3-5.

4. Disconnect the connector on the LFT PCB ASSY as

shown in Fig. 3-6.

5. Remove Duct fan (Inlet) as shown in Fig. 3-5.

ax5

bx6

Duct unit (Inlet)

Duct cover

(Inlet)

Duct fan (Inlet)

LEAD DRESS

To remove the Duct cover (Inlet), release the clamper.

- 17 -

Fig.3-6

ax8

bx3

bx3

dx4

ex1

ex1

fx1

fx1

gx2

hx4

bx2

cx2

cx2

HDMI PCB

ASSY

MEMC PCB

ASSY

SCALER PCB ASSY

Memc/Scaler shield

plate ASSY

Scaler shield plate 2

Scaler shield plate 1

LFT PCB

ASSY

12. Removal of the LFT PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the eight screws (a) and Memc/Scaler shield

plate ASSY as shown in Fig. 3-6.

3. Remove the eight screws (b) and Scaler shield plate 1

as shown in Fig. 3-6.

4. Remove the four screws (c) and Scaler shield plate 2 as

shown in Fig. 3-6.

5. Disconnect all connectors on the LFT PCB ASSY as

shown in Fig. 3-6.

6. Remove the four screws (d) and LFT PCB ASSY as

shown in Fig. 3-6.

13. Removal of the MEMC PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Memc/Scaler shield plate ASSY according

to “12. Removal of the LFT PCB ASSY”.

3. Disconnect all connectors on the MEMC PCB ASSY as

shown in Fig. 3-6.

4. Remove the two screws (e) and MEMC PCB ASSY as

shown in Fig. 3-6.

14. Removal of the SCALER PCB

ASSY / HDMI PCB ASSY

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Memc/Scaler shield plate ASSY according

to “12. Removal of the LFT PCB ASSY”.

3. Disconnect all connectors on the SCALER PCB ASSY

as shown in Fig. 3-6.

4. Remove the two screws (f) and SCALER PCB ASSY as

shown in Fig. 3-6.

5. Disconnect the connectors on the HDMI PCB ASSY as

shown in Fig. 3-6.

6. Remove the two screws (g), four screws (h) and HDMI

PCB ASSY as shown in Fig. 3-6.

- 18 -

15. Removal of the Lamp unit /

Optical unit / Cooling fan (optical)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

3. Remove the Duct unit (Inlet) according to “11. Removal

of the Duct fan (Inlet) ”.

4. Loose the two screws (a) and remove the Lamp unit as

shown in Fig. 3-7.

5. Remove the two screws (b) and Optical cover as shown

in Fig. 3-7.

6. Remove the two screws (e) , plate and lead wire as

shown in Fig. 3-7.

7. Disconnect all connectors on the Optical unit as shown

in Fig. 3-7.

8. Remove the three screws (c) and Optical unit as shown

in Fig. 3-7.

9. Remove the two screws (d) and Cooling fan (optical) as

shown in Fig. 3-7.

Fig.3-7

ax2

bx2

cx3

dx2

ex2

Cooling fan

(optical)

Optical cover

Lamp unit

Optical unit

Plate

To remove the Optical unit, cut the clamper.

LEAD DRESS

- 19 -

16. Removal of the IR PCB ASSY (REAR)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the Top duct ASSY according to “7. Removal of

the TEMP SENSOR PCB ASSY (OUTLET)”.

5. Remove the Duct unit (Inlet) according to “11. Removal

of the Duct fan (Inlet) ”.

6. Remove the Duct unit (Inlet) according to “15. Removal

of the Lamp unit / Optical unit / Cooling fan (optical)”.

7. Remove the six screws (a), two screws (b) and Bottom

duct ASSY as shown in Fig. 3-8.

8. Disconnect the connector on the IR PCB ASSY (REAR)

as shown in Fig. 3-8.

9. Remove the screw (c) and IR PCB ASSY (REAR) as

shown in Fig. 3-8.

17. Removal of the Thermostat

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the Top duct ASSY according to “7. Removal of

the TEMP SENSOR PCB ASSY (OUTLET)”.

5. Remove the Duct unit (Inlet) according to “11. Removal

of the Duct fan (Inlet) ”.

6. Remove the Optical unit parts according to “15. Removal

of the Lamp unit / Optical unit / Cooling fan (optical)”.

7. Remove the Bottom duct ASSY according to “

16.

Removal of the IR PCB ASSY (REAR)

”.

8. Disconnect the connector on the

Thermostat

as shown in

Fig. 3-9.

9. Remove the two screws (a) as shown in Fig. 3-9.

Fig.3-8

ax6

cx1

bx2

IR PCB

ASSY (REAR)

Bottom duct ASSY

ax2

Bottom duct ASS

Y

Thermostat

Fig.3-9

LEAD DRESS

- 20 -

ax4

bx4

cx7

dx5

ex1

gx2

hx1

fx2

AC inlet

AC inlet ASSY

HDMI shield

plate

I/O PCB ASSY

TEMP SENSOR PCB

ASSY (INLET)

18. Removal of the I/O PCB ASSY /

TEMP SENSOR PCB ASSY (INLET)

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the Top duct ASSY according to “7. Removal of

the TEMP SENSOR PCB ASSY (OUTLET)”.

5. Remove the Duct unit (Inlet) according to “11. Removal

of the Duct fan (Inlet) ”.

6. Remove the Memc/Scaler shield plate ASSY according

to “12. Removal of the LFT PCB ASSY”.

7. Remove the MEMC PCB ASSY according to “13.

Removal of the MEMC PCB ASSY”.

8. Remove the SCALER PCB ASSY, HDMI PCB ASSY

according to “14. Removal of the SCALER PCB ASSY/

HDMI PCB ASSY”.

9. Remove the optical parts according to “15. Removal of

the Lamp unit / Optical unit/Cooling fan(optical)”.

10. Remove the Bottom duct ASSY according to “16.

Removal of the IR PCB ASSY (REAR)”.

11. Remove the four screws (a), four screws (b), seven

screws (c) and HDMI PCB ASSY as shown in Fig. 3-10.

12. Remove the five screws (d) and HDMI shield plate as

shown in Fig. 3-10.

13. Disconnect the connector on the TEMP SENSOR PCB

ASSY (INLET) as shown in Fig. 3-10.

14. Remove the screw (e) and TEMP SENSOR PCB ASSY

(INLET) as shown in Fig. 3-10.

19. Removal of the AC inlet

1. Remove the Top cover ASSY according to “1. Removal

of the Top cover ASSY”.

2. Remove the Power shield plate 1 according to “5.

Removal of the TEMP SENSOR PCB ASSY (POWER)”.

3. Remove the Lamp power ASSY according to “6.

Removal of the LAMP POWER PCB ASSY”.

4. Remove the Top duct ASSY according to “7. Removal of

the TEMP SENSOR PCB ASSY (OUTLET)”.

5. Remove the Duct unit (Inlet) according to “11. Removal

of the Duct fan (Inlet) ”.

6. Remove the Optical parts according to “15. Removal of

the Lamp unit / Optical unit/Cooling fan(optical)”.

7. Remove the Bottom duct ASSY according to “16.

Removal of the IR PCB ASSY (REAR)”.

8. Remove the I/O PCB ASSY according to “18. Removal

of the I/O PCB ASSY / TEMP SENSOR PCB ASSY

(INLET)”.

9. Remove the two screws (d), screw (e), two screws (f)

and AC inlet as shown in Fig. 3-10.

Fig.3-10

- 21 -

Note : The inner wires are clamped so that they do not come close to heat generating or high voltage parts. After

servicingroute all wires in their original position.

Note : On the lead connector, the connector name isn't indicated. When disconnecting the lead connector, place

labels (

INDEX LABELs

) bearing the reference markings (connector names) near the lead connectors and the

connectors on the board to prevent wrong disconnection. After re-connecting the lead connectors, remove

the labels (

INDEX LABELs

) . To disassemble the product, it is required to cut the BAND KMs that clamp the lead

connectors. Therefore, when re-assembling the product, prepare and use the specified BAND KMs. For the part

number of the BAND KM, refer to PARTS LIST.

For the reference markings of the lead connectors, see pages D23 to D26.

For the connector names of the fans and motors, see pages D35 to D48.

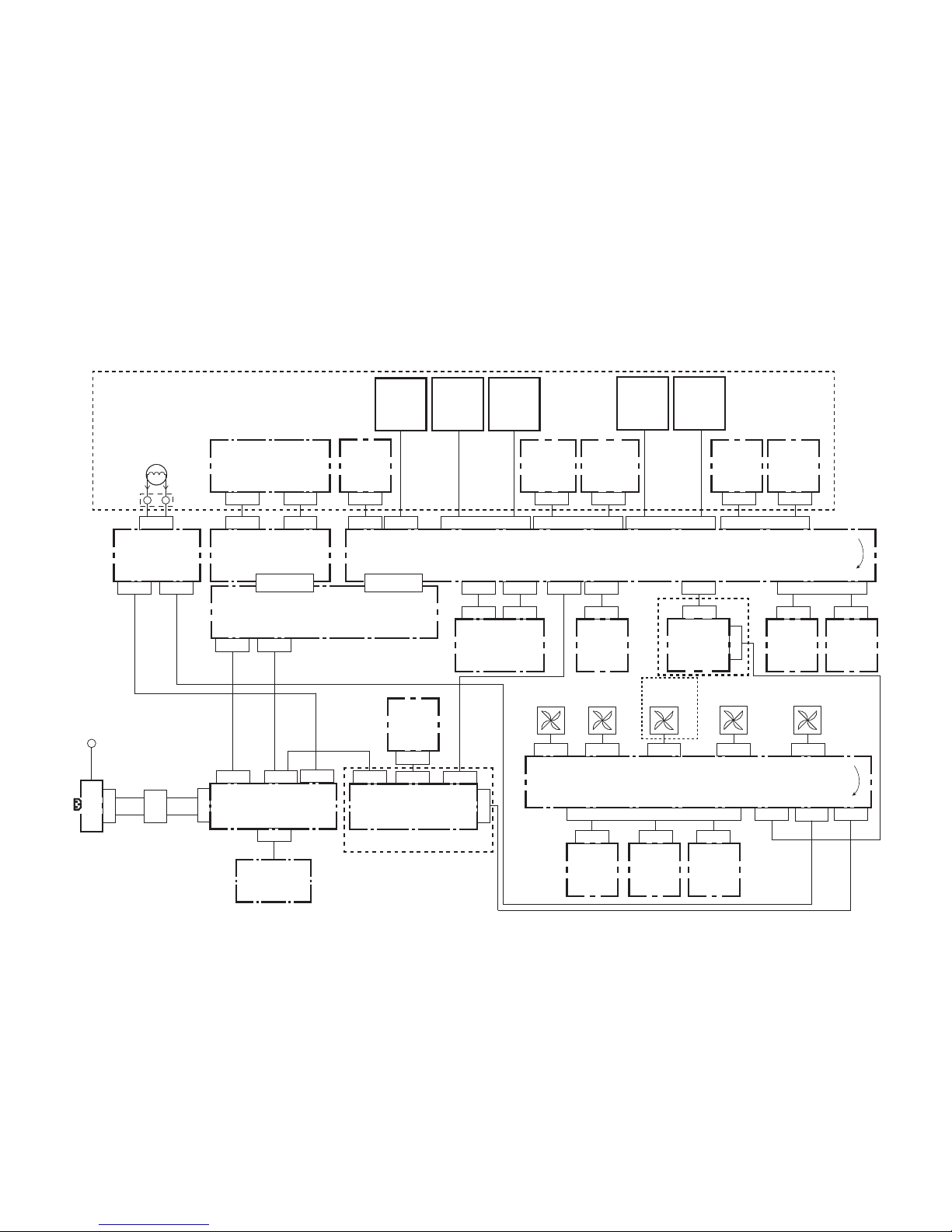

LEAD DRESS

Top view

LFT PCB ASSY

SCALER PCB ASSY

MEMC PCB ASSY

Y-pro PCB ASSY

DDB PCB ASSY

LAMP POWER PCB ASSY

POWER PCB ASSY

HDMI PCB ASSY

I/O PCB ASSY

MEMC SOCKET

SCALER SOCKE

- 22 -

ZZ-3

ZZ-50 ZZ-49

ZZ-18

ZZ-48

ZZ-26 ZZ-24

ZZ-25

ZZ-100 ZZ-101

ZZ-33

ZZ-47

ZZ-54

ZZ-46

ZZ-43

ZZ-102

ZZ-104ZZ-103

ZZ-27

ZZ-23

ZZ-37

ZZ-38

ZZ-51

ZZ-29

ZZ-40ZZ-42

ZZ-300

ZZ-34

ZZ-55

ZZ-39

ZZ-41

ZZ-13

ZZ-53 ZZ-52

ZZ-32

ZZ-19

ZZ-31 ZZ-30

KEY

SWITCH

PCB

ASSY

IR PCB

ASSY

(FRONT)

TEMP

SENSOR

PCB ASSY

(INLET)

TEMP

SENSOR

PCB ASSY

(OUTLET)

TEMP

SENSOR

PCB ASSY

(POWER)

LAMP

COVER

PCB ASSY

IR PCB

ASSY

(REAR)

HORIZONTAL

SHIFT

MOTOR

VERTICAL

SHIFT

MOTOR

ZZ-202

ZOOM

MOTOR

FOCUS

MOTOR

ZZ-201

ZZ-16

VERTICAL

ROTARY

ENCODER

PCB ASSY

SCALER PCB ASSY

MEMC PCB ASSY

LAMP POWER

PCB ASSY

Y-pro PCB ASSY

I/O PCB ASSY

LFT PCB ASSY

DDB PCB ASSY

POWER PCB ASSY

HDMI PCB ASSY

DUCT FAN

(INLET)

POWER

FAN

COOLING

FAN

FAN

(INLET)

FAN

(OUTLET)

ZZ-17

HORIZONTAL

ROTARY

ENCODER

PCB ASSY

ZZ-15

THERMOSTAT

ZZ-14

IRIS1

MOTOR

PCB ASSY

ZZ-2

ZZ-7

ZZ-21

ZOOM

PI SENSOR

PCB ASSY

ZZ-22

FOCUS

PI SENSOR

PCB ASSY

ZZ-20

ZZ-28

ZZ-200

FILTER

MOTOR

ZZ-11

ZZ-12

FILTER

SENSOR

ASSY

ZZ-4

ZZ-9 ZZ-10

ZZ-44

ZZ-45

ZZ-6

ZZ-5

power

switch

AC

inlet

ZZ-301

Chassis

GND

ZZ-35

ZZ-36

ZZ-1

ZZ-8

*1

*1

*1

*1

SOCKT

LAMP

Connection diagram

ZZ-○○○○ : Reference number of the lead connector, not the connector name on the board.

*1 : Optical unit section

- 23 -

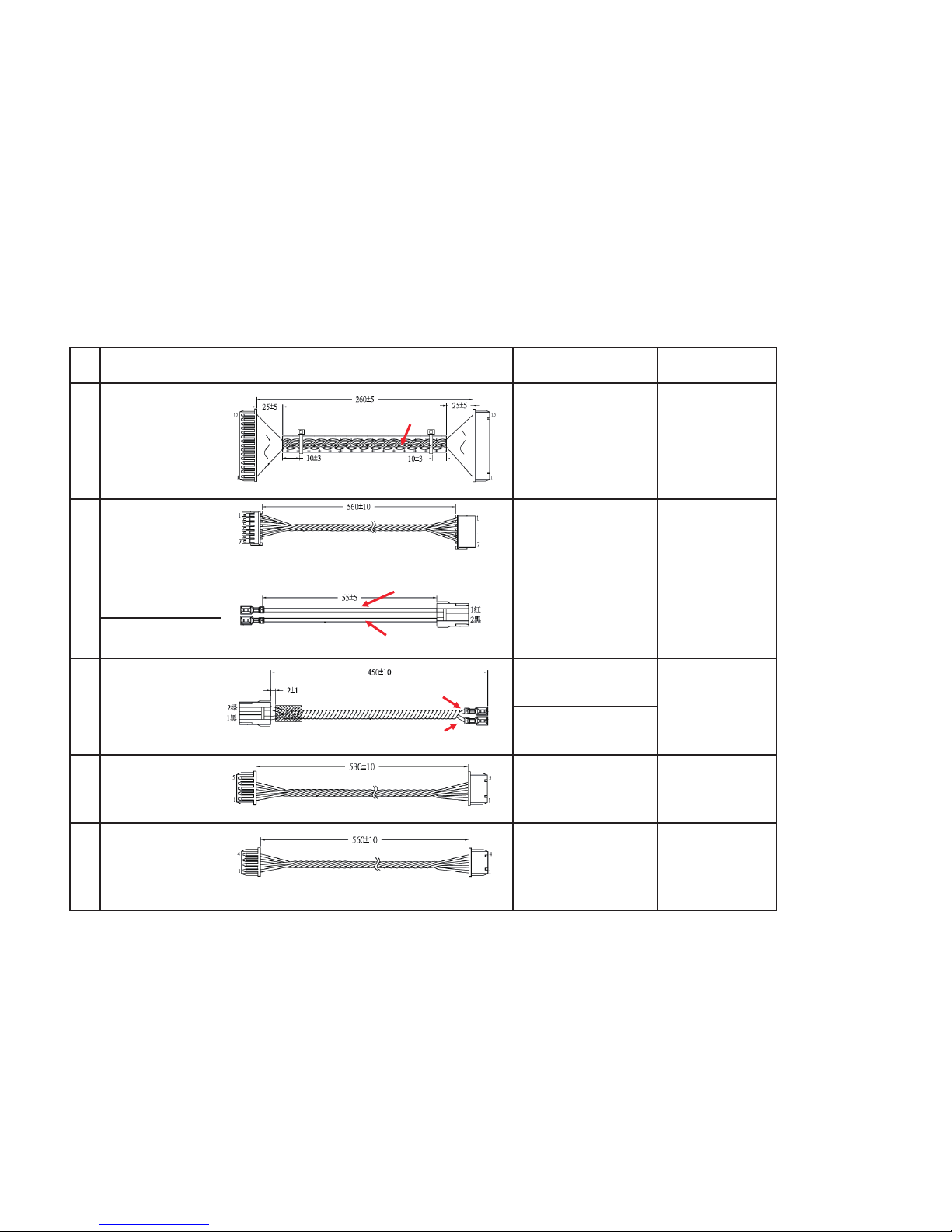

LEAD CONNECTOR

No.

Reference number for

connector insertion

Lead connector

Reference number for

connector insertion

Page describing the

connection

1

SCALER PCB ASSY : (6)

[ZZ-1]

DDB PCB ASSY : (6)

(OPTICAL UNIT)

[ZZ-2]

35

2

SCALER PCB ASSY : (10)

[ZZ-3]

DDB PCB ASSY : (5)

(OPTICAL UNIT)

[ZZ-4]

39

power switch-1

[ZZ-5]

power switch-2

[ZZ-6]

THERMOSTAT

[ZZ-9]

THERMOSTAT

[ZZ-10]

5

SCALER PCB ASSY : (1)

[ZZ-11]

FILTER SENSOR ASSY

(OPTICAL UNIT)

[ZZ-12]

37

6

SCALER PCB ASSY : (8)

[ZZ-13]

IRIS1 MOTOR PCB ASSY

(OPTICAL UNIT)

[ZZ-14]

39

32

32

AC INLET PCB ASSY-1

[ZZ-7]

POWER PCB ASSY : (2)

[ZZ-8]

3

4

Green

Black

Red

Black

Orange / Red / Brown / Black / open

Orange / RedBrown / Black

Yellow /Yellow / Black / Orange / Red /

Black / o

p

en

Brown

Loading...

Loading...