Mitsubishi GT2512-STBA, GT2510-VTBD, GT2508-VTBD, GT2512-STBD, GT2510-VTWD General Description Manual

...

GT25 General Description

WARNING

CAUTION

WAR NI NG

WAR NI NG

CAUTION

WAR NI NG

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

WARNING

WARNING

CAUTION

CAUTION

CAUTION

WAR NI NG

CAUTION

CAUTION

CAUTION

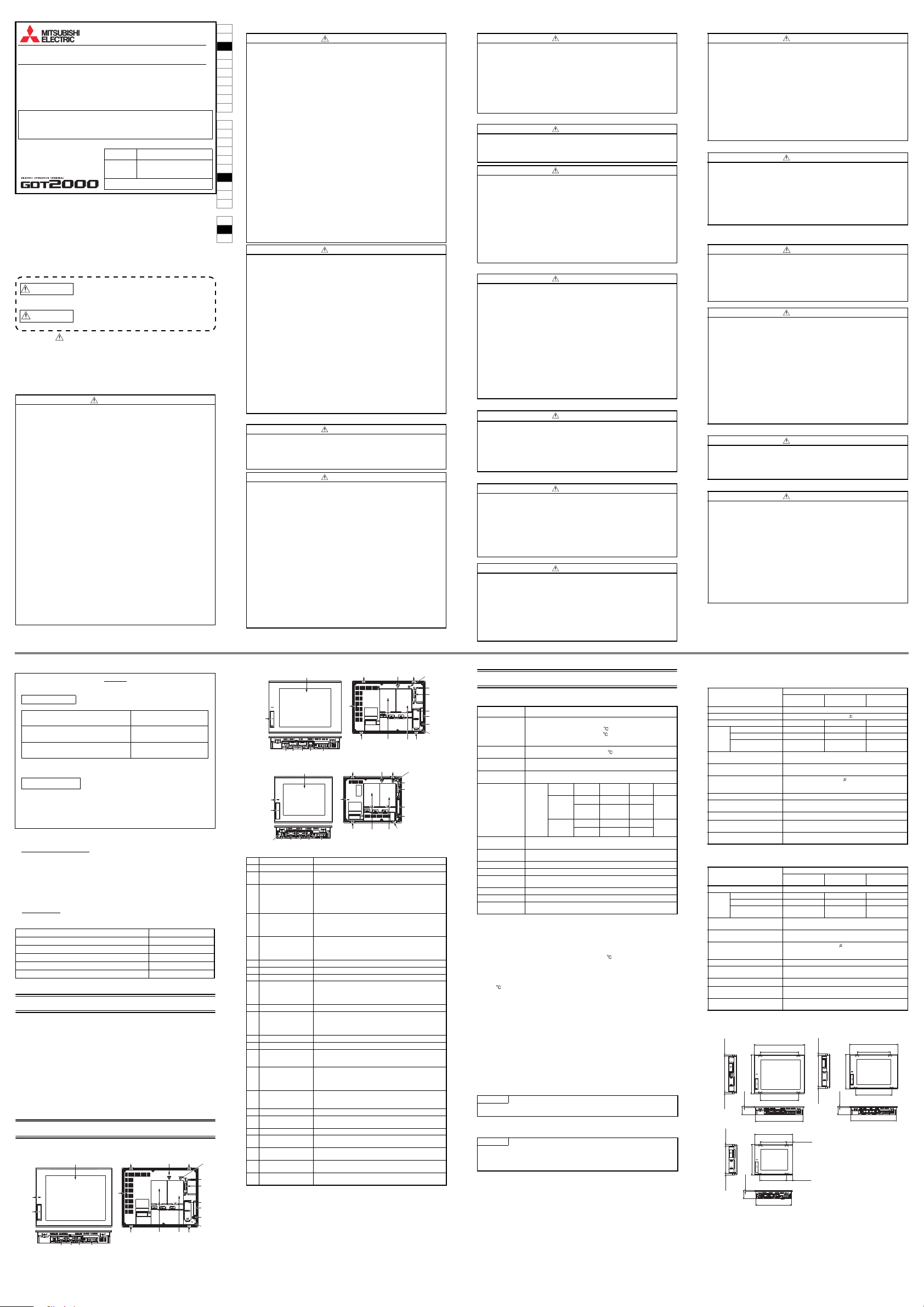

GT2512

1)2)

5)

22)

17)7)16)

8)

9)

10)

11)

12)

13)

14)

21)20) 19)

6) 6)

6) 6)

3)4)

15)

18)

GT2512-STBA

GT2510-VTBD

GT2508-VTBD

Thank you for purchasing the GOT2000 Series.

Prior to use, please read both this manual and the

detailed manual thoroughly to fully understand the

product.

(Always read these precautions before using this equipment.)

Before using this product, please read this manual and the relevant

manuals introduced in this manual carefully and pay full attention to

safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING"

and "CAUTION".

Note that the CAUTION level may lead to a serious accident

according to the circumstances.

Always follow the instructions of both levels because they are important to personal safety.

Please save this manual to make it accessible when required and

always forward it to the end user.

[DESIGN PRECAUTIONS]

Some failures of the GOT, communication unit or cable may keep the outputs

on or off.

Some failures of a touch panel may cause malf unction of the input objects

such as a touch switch.

An external monitoring circuit should be provided to check for output signals

which may lead to a serious accident.

Not doing so can cause an accident due to false outp ut or malfunction.

Do not use the GOT as the warning device that may cause a ser ious

accident.

An independent and redundant hardware or mechanic al interlock is required

to configure the device that displays and outputs se rious warning.

Failure to observe this instruction may result in an accident due to incorrect

output or malfunction.

The GOT backlight failure disables the operation on the touch s witch(s).

When the GOT backlight has a fail ure, the POWER LED blinks (orange/blue)

and the display section dims. In such a case, the input by the touch switch(s)

is disabled.

The display section of the GOT is an analog-resisti ve type touch panel.

When multiple points of the display section are touche d simultaneously, an

accident may occur due to incorrect output or ma lfunction.

Do not touch the display section in 2 points or more simultaneously.

If you touch the display section simultaneously in 2 points or mor e, the switch

that is located around the center of the touched poin t, if any, may operate.

Doing so may cause an accident due to incorrect ou tput or malfunction.

When programs or parameters of the controller (such as a PLC) that is

monitored by the GOT are changed, be sure to reset the GO T, or turn on the

unit again after shutting off the power as soon as possible.

Not doing so can cause an accident due to false outp ut or malfunction.

If a communication fault (including cable disconnection) occ urs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative.

For bus connection : The CPU becomes faulty and the GOT becomes

inoperative.

For other than bus connection : The GOT becom es inoperative.

A system where the GOT is used should be confi gured to perform any

significant operation to the system by using the switc hes of a device other

than the GOT on the assumption that a GOT communi cation fault will occur.

Not doing so can cause an accident due to false outp ut or malfunction.

GT2512-STBD

GT2510-VTWD

GT2508-VTWD

GT2510-VTBA

GT2508-VTBA

GT2510-VTWA

GT2508-VTWA

MODEL GT25-U-GD-E

Model

code

1D7MN4

IB(NA)-0800537ENG-B(1410)MEE

SAFETY PRECAUTIONS

Indicates that incorrect handling may cause

hazardous conditions, resulting in death or

severe injury.

Indicates that incorrect handling may cause

hazardous conditions, resulting in medium or

slight personal injury or physical damage.

1

2

3

Products with the Cl.I, DIV.2 mark on the rating plate are suitable for use in

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

Class I, Division 2, Groups A, B, C and D hazardous locations, or

nonhazardous locations only.

This mark indicates that the product is certifie d for use in the Class I,

Division2 environment where flammable gase s, vapors, or liquids are not

likely to exist under normal conditions.

When using the products in the Class I, Division 2 e nvironment, observe the

following to reduce the risk of explosion.

• This device is open-type and is to be install ed in an enclosure suitable for

the environment and require a tool or key to open.

• Warning - Explosion Hazard - Substitution of any com ponent may impair

suitability for Class I, Division 2.

• Warning - Explosion Hazard - Do not disconnect equipment unle ss power

has been removed or the area is known to be non- hazardous.

• The side interface and extension interface of this equipment cann ot be used

in Class I, Division 2 environments.

Les produits marqués Cl.I, DIV.2 sur la plaque signalétique peuvent être

utilisés en Class I, Division 2, local dangereux de groupe A, B, C et D, ou

uniquement en local non dangereux.

Ce logo indique que le produit est homologué pour utilisation en

environnement de Class I, Division 2 où, dans des circonstances anormales,

il peut y avoir présence de gaz, vapeurs ou liquides inflammables.

Si le produit est utilisé en environnement de Clas s I, Division 2, observer les

précautions suivantes pour réduire le risque d 'explosion.

• Cet appareil est de type ouvert et il doit être installé dans une enceinte

appropriée à l'environnement et ne pouvant être o uverte qu'au moyen

d'une clé ou d'un outil.

• Avertissement - Danger d'explosion - Toute substitution de composant

peut compromettre l'aptitude à l'utilisation en Cla ss I, Division 2.

• Avertissement - Danger d'explosion - Ne pas déconnecter l'équipement

quand le circuit est sous tension, ni avant de d'êtr e assuré de l'absence

d'atmosphère inflammable.

• L’interface latérale et l’interface d’extension de cet équipemen t ne

peuvent être utilisées dans les environnements de Classe I, Division 2.

Do not bundle the control and communication cables with main-circui t, power

or other wiring.

Run the above cables separately from such wiring and kee p them a minimum

of 100mm apart.

Not doing so noise can cause a malfunction.

Do not press the GOT display section with a pointed material a s a pen or

driver.

Doing so can result in a damage or failure of the dis play section.

When the GOT is connected to the Ethernet network, the available IP

address is restricted according

to the system configuration.

• When multiple GOTs are connected to the Ethernet network :

Do not set the IP address (192.168.3.18) for the GOTs and the controllers in

the network.

• When a single GOT is connected to the Ethernet n etwork :

Do not set the IP address (192.168.3.18 ) for the controllers except the GOT

in the network.

Doing so can cause the IP address duplication. The duplication can

negatively affect the communication of the device with th e IP address

(192.168.3.18).

The operation at the IP address duplication depe nds on the devices and the

system.

Turn on the controllers and the network devices to be ready for

communication before they communicate with the GOT.

Failure to do so can cause a communication error on the GOT.

When the GOT is subject to shock or vibration, or some colors appear on the

screen of the GOT, the screen of the GOT might flicker.

[MOUNTING PRECAUTIONS]

Be sure to shut off all phases of the external power supply used by the

system before mounting or removing the GOT main un it to/from the panel.

Not doing so can cause the unit to fail or malfunction.

Be sure to shut off all phases of the external power supply used by the

system before mounting or removing the option unit o nto/from the GOT.

Use the GOT in the environment that satisfies the general speci fications

described in this manual.

Not doing so can cause an electric shock, fire, mal function or product

damage or deterioration.

When mounting the GOT to the control panel, tighten the mounting screws in

the specified torque range (0.36 N•m to 0.48 N• m) with a Phillips-head

screwdriver No.2.

Undertightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malf unction due to the

damage of the screws or the GOT.

When mounting a unit on the GOT, tighten the mounting screws in the

following specified torque range.

When loading the communication unit or option unit other than wireless LAN

unit to the GOT, fit it to the connection interface of the GOT and tighten the

mounting screws in the specified torque range (0 .36 N•m to 0.48 N•m) with a

Phillips-head screwdriver No.2.

When loading the wireless LAN unit to the GOT, fit it to the side interface of

GOT and tighten the mounting screws in the specif ied torque range (0.10

N•m to 0.14 N•m) with a Phillips-head screwdriver No.1.

When the GOT is installed vertically, its side interface is positioned o n the

bottom.To prevent the falling of the wireless LAN communication unit from the

side interface, install or remove the unit while holding it with hands.

Under tightening can cause the GOT to drop, short circuit or malfunction.

Overtightening can cause a drop, failure or malfu nction due to the damage of

the screws or unit.

When closing the USB environmental protection cover, fix the cover to the

GOT by pushing the [PUSH] mark on the latch firmly to comply with the

protective structure.

Remove the protective film of the GOT.

When the user continues using the GOT with the protective film, the film may

not be removed.

Operate and store the GOT in environments without direct sunlig ht, high

temperature, dust, humidity, and vibrations.

When using the GOT in the environment of oil or chemicals, u se the

protective cover for oil.Failure to do so may cause failure or malfunction due

to the oil or chemical entering into the GOT.

[WIRING PRECAUTIONS]

Be sure to shut off all phases of the external power supply used by the

system before wiring.

Failure to do so may result in an electric shoc k, product damage or

malfunctions.

Make sure to ground the FG terminal and LG terminal of the GOT p ower

supply section to the protective ground conductors de dicated to the GOT with

a ground resistance of 100 Ω or less.

When tightening the terminal screws, use a Phillips-head screwd river No.2.

Terminal screws which are not to be used must be tightened always at torque

0.5 N•m to 0.8 N•m.

Otherwise there will be a danger of short circuit agai nst the solderless

terminals.

Use applicable solderless terminals and tighten them with the specified

torque. If any solderless spade terminal is used, i t may be disconnected

when the terminal screw comes loose, resulting in failu re.

Correctly wire the GOT power supply section after confirming the rated

voltage and terminal arrangement of the product.

Not doing so can cause a fire or failure

[WIRING PRECAUTIONS]

Tighten the terminal screws of the GOT power supply section i n the specified

torque range (0.5 N•m to 0.8 N•m). Undertighten ing can cause a short circuit

or malfunction.Overtightening can cause a short circu it or malfunction due to

the damage of the screws or the GOT.

Exercise care to avoid foreign matter such as chips and wire offcuts entering

the GOT. Not doing so can cause a fire, failure or malfunction.

The module has an ingress prevention label on its top to preven t foreign

matter, such as wire offcuts, from entering the module during wiring.

Do not peel this label during wiring.Before starting system operation, be sure

to peel this label because of heat dissipation.

Plug the communication cable into the GOT interface or the connecto r of the

connected unit, and tighten the mounting screws and the terminal screws in

the specified torque range.Undertightening ca n cause a short circuit or

malfunction.Overtightening can cause a short c ircuit or malfunction due to the

damage of the screws or unit.

Plug the QnA/ACPU/Motion controller(A series) bus connec tion cable by

inserting it into the connector of the connected u nit until it "clicks".

After plugging, check that it has been inserted snug ly.

Not doing so can cause a malfunction due to a contact faul t.

[TEST OPERATION PRECAUTIONS]

Before performing the test operations of the user creation monito r screen

(such as turning ON or OFF bit device, changing the word device current

value, changing the settings or current values of the timer or counter, and

changing the buffer memory current value), read through th e manual

carefully and make yourself familiar with the oper ation method.

During test operation, never change the data of the devices which are used to

perform significant operation for the system.

False output or malfunction can cause an accident.

[STARTUP/MAINTENANCE PRECAUTIONS]

When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfuncti on.

Correctly connect the battery connector.Do not charge, disassemble, heat,

short-circuit, solder, or throw the battery into the fire.Doing so will cause the

battery to produce heat, explode, or ignite, resulti ng in injury and fire.

Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases.Not switching the p ower off in all phases can

cause a unit failure or malfunction.Undertighten ing can cause a short circuit

or malfunction.Overtightening can cause a short circu it or malfunction due to

the damage of the screws or unit.

Do not disassemble or modify the unit.

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the unit directly.

Doing so can cause a unit malfunction or failure.

The cables connected to the unit must be run in ducts or clamped.

Not doing so can cause the unit or cable to be damaged due to the dangling,

motion or accidental pulling of the cables or can cause a malfunct ion due to a

cable connection fault.

When unplugging the cable connected to the unit, do not hold and pul l from

the cable portion.Doing so can cause the unit or cable to be damaged or can

cause a malfunction due to a cable connection faul t.

Do not drop the module or subject it to strong shock. A module damage ma y

result.

Do not drop or give an impact to the battery mounted to the unit.

Doing so may damage the battery, causing the battery fluid to leak inside the

battery.If the battery is dropped or given an impact, dispose of it without

using.

Before touching the unit, always touch grounded metals, etc. to dis charge

static electricity from human body, etc.

Not doing so can cause the unit to fail or malfunction.

Use the battery manufactured by Mitsubishi Electric Corporation.

Use of other batteries may cause a risk of fire or expl osion.

Dispose of used battery promptly.

Keep away from children.Do not disassemble and do not dispose of in fire.

Be sure to shut off all phases of the external power supply before r eplacing

the battery or using the dip switch of the te rminating resistor.Not doing so can

cause the unit to fail or malfunction by static electricity.

[TOUCH PANEL PRECAUTIONS]

For the analog-resistive film type touch panels, normally the adjustment is not

required.

However, the difference between a touched position and the object position

may occur as the period of use elapses.

When any difference between a touched position and the object position

occurs, execute the touch panel calibration.

When any difference between a touched position and the object pos ition

occurs, other object may be activated.

This may cause an unexpected operation due to incorrect output or

malfunction.

[PRECAUTIONS WHEN THE DATA STORAGE IS IN

USE]

If the SD card is removed from drive A of the GOT while being a ccessed by

the GOT, the GOT may stop processing data for about 20 seconds.The GOT

cannot be operated during this period. The function s that run in the

background including a screen updating, alarm, l ogging, scripts, and others

are also interrupted.Since this interruption makes an impact to the system

operation, it might cause failure.After checking th e light off of SD card access

LED, remove the SD card.

If the data storage is removed from the GOT while being accessed by th e

GOT, the data storage and files may be damaged.Before removing the data

storage from the GOT, check the SD card access LED, system signal, or

others to make sure that the data storage is not accessed.

When inserting a SD card into the GOT, make sure to close the SD card

cover. Failure to do so causes the data not to be read or written.

When removing the SD card from the GOT, make sure to support the SD card

by hand as it may pop out.Failure to do so may c ause the SD card to drop

from the GOT, resulting in a failure or break.

When inserting a USB device into a USB interface of the GO T, make sure to

insert the device into the interface firmly.Failure to do so may cause the USB

device to drop from the GOT, resulting in a failure or break

Before removing the USB device from the GOT, follow the procedure for

removal on the utility screen of the GOT. After the successful completion

dialog is displayed, remove the USB dev ice by hand carefully.Failure to do so

may cause the USB device to drop from the GO T, resulting in a failure or

break.

[DISPOSAL PRECAUTIONS]

When disposing of this product, treat it as industrial waste .

When disposing of batteries, separate them from other wastes according to

the local regulations.

(Refer to the GOT2000 Series User’s Manual (Hardware) for details of the

battery directive in the EU member states.)

[TRANSPORTATION PRECAUTIONS]

When transporting lithium batteries, make sure to treat them based on the

transport regulations.

(Refer to the GOT2000 Series User’s Manual (Ha rdware) for details of the

regulated models.)

Make sure to transport the GOT main unit and/or relevant unit(s ) in the

manner they will not be exposed to the impact exceedin g the impact

resistance described in the general specifications of this manual, as they are

precision devices.

Failure to do so may cause the unit to fail.

Check if the unit operates correctly after transportation.

When fumigants that contain halogen materials such as fluorine, chlori ne,

bromine, and iodine are used for disinfecting and p rotecting wooden

packaging from insects, they cause malfunction when ent ering our products.

Please take necessary precautions to ensure that rem aining materials from

fumigant do not enter our products, or treat packaging with methods oth er

than fumigation (heat method).

Additionally, disinfect and protect wood from insects before packing products.

The following shows manuals relevant to this product.

Manual

Detailed Manual

Manual name

GOT2000 Series User’s Manual

(Hardware)

GOT2000 Series User’s Manual (Utility)

For detailed manuals, refer to the PDF manuals stored in the DVD-ROM for the

drawing software used.

Manual number

(Model code)

SH-081194ENG

(1D7MJ5)

SH-081195ENG

(1D7MJ6)

Relevant Manuals

For relevant manuals, refer to the Help or the PDF m anuals stored in the DVDROM for the drawing software used.

The latest manuals are also available from MITS UBISHI ELECTRIC FA Global

Website (http://www.MitsubishiElectric.co.jp/fa/).

© 2014MITSUBISHI ELECTRIC CORPORATION

Before using the GOT

Connect the connector of the GOT to the connector of t he battery.

Refer to the GOT2000 Series User’s Ma nual (Hardware) for the connection

instructions.

For details on the GOT specifications, installing ins tructions, wiring, maintenance

and inspection, or checking procedure for the versi on and the compatible standard,

refer to the GOT2000 Series User’s Manual (Hardwa re).

Packing List

The GOT product package includes the following:

Battery (GT11-50BAT) (Attached to the GOT) 1

Description Quantity

GT25 1

Installation fitting 4

GT25 General Description (This manual) 1

GT25 本体概要説明書

1. FEATURES

(1) Abundant standard equipment

• Variety of connection with FA devices

• SD card interface compatible with the S DHC card having a large capacity

and allowing high-speed communication

• Connection with va rious peripheral devices with the USB host

(2) Improved usability

• Abundant troublesho oting

• Easy and clear s creen creation

• PC-like operation s creen

• Support for the v ertical installation

(3) Enhanced compatibility with Mitsubishi FA devices

(4) Easy replacement]

(5) LED backlight

(6) Various extended functions supported

2. Part Names and Settings

The following shows the part names for GT2512, GT2510 a nd GT2508.

GT2510

1)2)

6) 6)

18)

3)4)

6)6)17)

22)21)20) 19)

23)

7)

GT2508

5)

1)2)

6) 6)

18)

3)4)

6) 6)17)

22)21)20) 19)

23)

15)

No. Name Description

1) Display screen Displays the utility and the user-created screen.

2) Touch Pane

USB interface

3)

(Host/Front face)

USB interface (Device

4)

/Front face)

5) POWER LED

6) Unit installation fitting Mounting fixtures for fixing the GOT to the control panel

1

7) Reset switch Hardware reset switch

8) Installation switch Used for OS installations at the GOT startup

9) SD card access LED

10) SD card interface For installing a SD card

11) SD card cover

12) Battery holder Houses the battery

13) Side interface For installing a communic ation unit

USB interface

14)

(Host/Back face)

Hole for attaching a

15)

cable clamp

Terminating resistor

16)

setting switch

(Inside cover)

17) Extension interface For installing a communic ation unit or an option unit

Vertical installation

18)

arrow mark

19) Power terminal Power input terminal, LG terminal, FG terminal

20) Ethernet interface

21) RS-232 interface

22) RS-422/485 interface

USB interface (Device/

23)

Back face)

For operating the touch switches in the utility and the usercreated screen

For connecting a USB mou se, connecting a USB keyboard,

data transfer, and data storage

(connector type: TYPE-A)

(Only GT2512-STBA/D, GT2510-VTBA/D

VTBA/D)

For connecting a personal computer (connector type: MiniB)

(Only GT2512-STBA/D, GT2510-VTBA/D

VTBA/D)

Lit in blue : Power is properly supplied.

Lit in orange : Screen saving

Blinks in orange/blu e : Backlight failure

Not lit : Power is not supplied

Lit: SD card mounted

Blinking: SC card accessed

No lit: SD card not mounted or SD card mounted

(removable)

With a switching function for accepting and stopping the

access to the SD card

When the cover is opened : Acc ess is prohibited

When the cover is closed : Access is allowed

For connecting a USB mou se, connecting a USB keyboard,

data transfer, and data storage

(connector type: TYPE-A)

Hole for attaching a cab le clamp for preventing USB cable

from being pulled out

(Recommended product: RSG-1 30-V0 made by

KITAGAWA INDUSTRIES CO.,LTD)

For switching on and off of the terminating resistor for the

RS-422/485 communication port (Default (Off))

For the vertical installation, install the GOT so that the arrow

points upward.

For communicating with a co ntroller or connecting a

personal computer (conne ctor type: RJ-45 (modular jack))

For communicating with a controller (Connector type: D s ub

9-pin (male))

For communicating with a controller (Connector type: D s ub

9-pin (female))

For connecting personal co mputers (connector type: Mini-B)

(Only GT2510-VTWA/D, GT2508-VTWA/D)

16)

7)

16)

8)

9)

10)11)12)

13)

14)

and GT2508-

and GT2508-

8)

9)

10)

11)

12)

13)

14)

15)

3. Specifications

3.1 General Specifications

Item Specifications

Operating ambient

*1

temperature

Température

ambiante de

fonctionnement

Storage ambient

temperature

Operating ambient

humidity

Storage ambient

humidity

Vibration resistance

Shock resistance

Operating

atmosphere

Operating altitude

Installation location Inside control panel

Overvoltage

category

Pollution degree

Cooling method Self-cooling

Grounding

*1: The operating ambient temperature incl udes the temperature inside the

*2: When mounting a MELSECNET/H communic ation unit (GT15-J71LP23-25,

*3: Do not use or store the GOT under pr essure higher than the atmospheric

*4: This indicates the section of the power supply to which the equipment is

*5: This index indicates the degree to which conductive material is generated in the

*1

10 to 90% RH, non-condensing

10 to 90% RH, non-condensing

Complian

t with JIS

B 3502

and IEC

61131-2

Compliant with JIS B 3502 and IEC 61131-2 147 m/s

No greasy fumes, corrosive gas, flammable gas, excessive

conductive dust, and dire ct sunlight (Same as storage atmosphere)

*3

*4

*5

enclosure of the control panel to which the GOT is installed.

La température ambiante de fonctionnement inclut la te mpérature à l'intérieur

du boîtier du tableau de commande sur lequel le GOT est installé.

GT15-J71BR13), or CC-Link communication unit (GT1 5-J61BT13), the

operating ambient temperature must be reduced

values described in general specifications.

Lors du montage d'un module communication MELSECNET/H (GT15J71LP23-25, GT15-J71BR13) ou du module de communication CC-Link

(GT15-J61BT13), la température ambiante de fonctionnem ent doit être réduite

de 5 par rapport aux valeurs maximales décrites dans les spécifications

générales.

pressure of altitude 0m (0ft.).

Failure to observe this instruction may c ause a malfunction.

When an air purge is made inside the control panel by adding pressure, there

may be a clearance between the surface sheet and the screen making it difficult

to use the touch panel, or the sheet may come off.

assumed to be connected between the public electric al power distribution

network and the machinery within the premises.

Category II applies to equipment for which electrical powe r is supplied from

fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300 V is 2500 V.

environment where the equipment is used.

In pollution degree 2, only non-conductive pollu tion occurs but temporary

conductivity may be produced due to condensa tion.

Point

Refer to the GOT2000 Series User’s Manual (Hardware) for details on the performance

specifications of each GOT.

Frequency Acceleration

Under

intermitten

t vibration

Under

continuou

8.4

s vibration

3 times each in X, Y and Z direct ions

Type D grounding (100Ω or l ess).

Connect to panel if unable to ground.

*2

0 to 55

*2

0 à 55

-20 to 60

5 to 8.4Hz

8.4

5 to 8.4Hz

2000 m (6562 ft) max.

-

to150Hz

9.8m/s

-

to 150Hz

4.9m/s

II or less

2 or less

5 against the maximum

2

2

Half-

amplitude

3.5mm

-

1.75mm

-

Sweep

10 times

each in X,

Y and Z

directions

2

(15G),

count

-

3.2 Power Supply Specifications

The following indicates the power supply s pecifications for GT25.

Note

Operation at momentary failure

• If an instantaneous power failure occurs in the power supply and continues for more

than the permissible period, the GOT will be reset.

• Make sure to power on the unit more than 5 seconds after power-off.

3.2.1 For GOTs powered from the 100 to 240VAC

power supply

Item

Power supply voltage Power supply voltage AC100 to 240VAC (+10%, -15%)

Power frequency 50/60Hz 5%

Max. apparent power 80VA 80VA 70VA

maximum load 35W or less 34W or less 31W or less

Power

Stand alone 14W 12W 11W

consum

Stand alone with

ption

backlight off

Inrush current

Allowable momentary power

failure time

Noise immunity

Dielectric wit hstand voltage 1500VAC for 1 minute across po wer terminals and earth

Insulation resistance

Applicable wire size 0.75[mm

Applicable solderless terminal

Applicable tightening torque

(Terminal block terminal screw)

GT2512-STBA

60A or less (2ms, operating ambient temperature 25,

1,500Vp-p noise voltag e, 1 s noise width (when

measuring with a noise si mulator under 25 to 60Hz

noise frequency)

10M or more across powe r terminals and earth by a

500V DC insulation resistance te ster

Solderless terminal for M3 screw RAV1.25-3, V2-S3.3,

Specifications

GT2510-VTBA,

GT2510-VTWA

7W 7W 7W

maximum load)

20 ms or less (100VAC or more)

V2-N3A, FV2-N3A

0.5[N•m] to 0.8[N•m]

2

] to 2[mm2]

GT2508-VTBA,

GT2508-VTWA

3.2.2 For GOTs powered from the 24VDC power

supply

Item

Power supply voltage DC24V (+25%, -20%)

maximum load 37W or less 33W or less 31W or less

Power

Stand alone 13W 10W 8W

consum

Stand alone with

ption

backlight off

Inrush current

Allowable momentary power

failure time

Noise immunity

Dielectric withstand voltage 350VAC for 1 minute across power terminals and earth

Insulation resistance

Applicable wire size 0.75[mm

Applicable solderless terminal

Applicable tightening torque

(Terminal block terminal screw)

GT2512-STBD

5A or less (20ms, operati ng ambient temperature 25,

500Vp-p noise voltage, 1 s noise width (when

measuring with a noise si mulator under 25 to 60Hz

noise frequency)

10M or more across powe r terminals and earth by a

500V DC insulation resistance te ster

Solderless terminal for M3 screw RAV1.25-3, V2-S3.3,

Specifications

GT2510-VTBD,

GT2510-VTWD

6W 6W

maximum load)

10 ms or less

V2-N3A, FV2-N3A

0.5[N•m] to 0.8[N•m]

2

] to 2[mm2]

GT2508-VTBD,

GT2508-VTWD

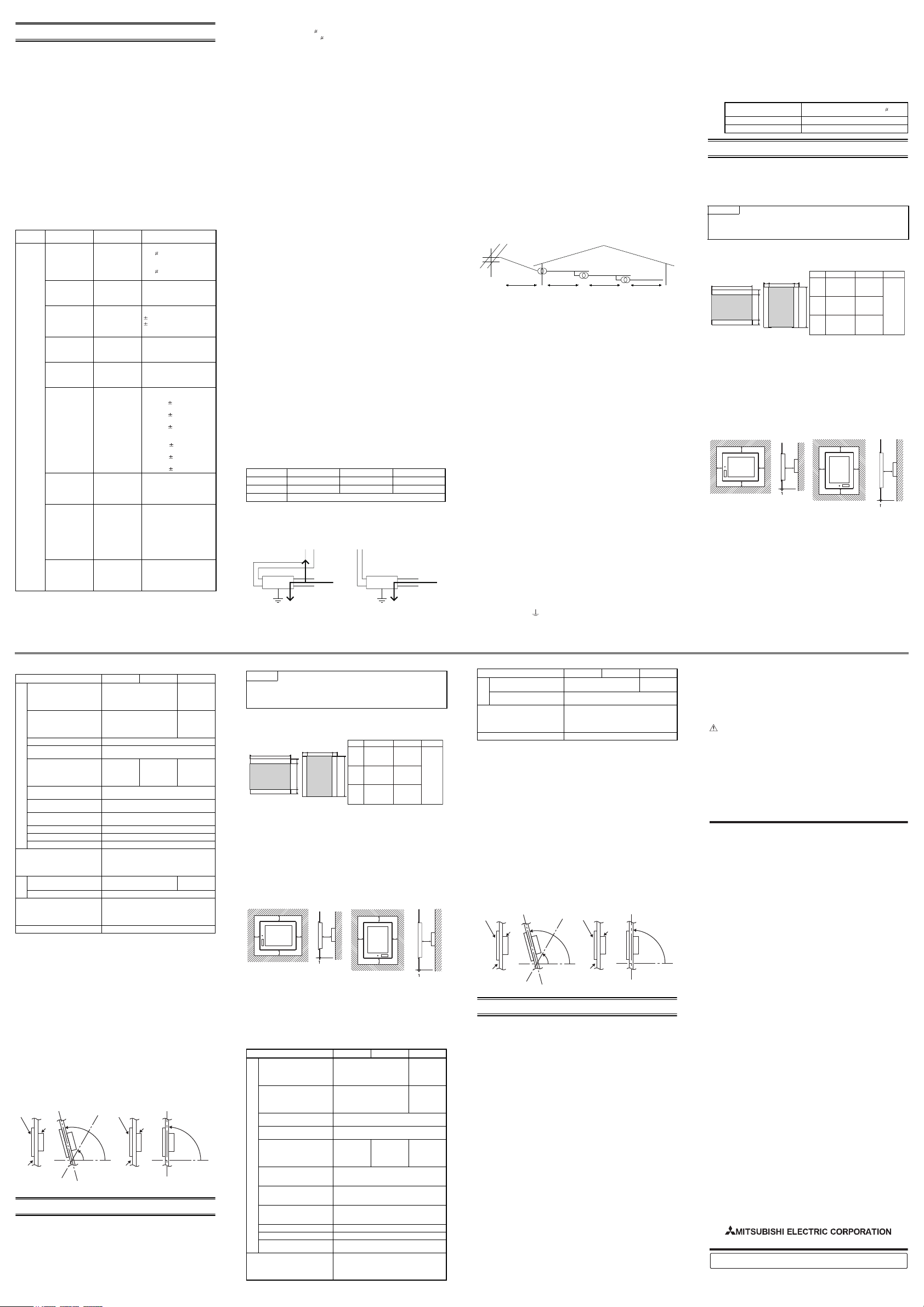

3.3 External Dimensions

GT2512

10

(0.39)

227 (8.94)

10

(0.39)

GT2508

10

(0.39)

175 (6.89)

10

(0.39)

52

52

6

(2.05)

6

(2.05)

246 (9.69)

(0.24)

241 (9.49)

166 (6.54)

194 (7.64)

(0.24)

226 (8.90)

316 (12.44)

241 (9.49)

241 (9.49)

301 (11.85)

171.6

(6.76)

GT2510

10

199 (7.83)

10

37.5

(1.48)

37.5

(1.48)

Unit : mm (inch)

(0.39)

(0.39)

52

218 (8.58)

6

(0.24)

(2.05)

303 (11.93)

208 (8.19)

228 (8.98)

288 (11.34)

4. EMC AND LOW VOLTAGE DIRECTIVE

Unité : mm (pouce)

*Épaisseur du panneau : 1,6 à 4mm

(0,06 à 0,16 pouce)

GOT

A

B

GT

2510

GT

2508

289 (11.38)

227 (8.94)

+2 (0.08)

0 (0)

+2 (0.08)

0 (0)

200 (7.87)

176 (6.93)

+2 (0.08)

0 (0)

+2 (0.08)

0 (0)

GT

2512

302 (11.89)

+2 (0.08)

0 (0)

228 (8.98)

+2 (0.08)

0 (0)

B

B

Horizontal

Vertical

A

C

C

C

C

A

C

10

(0.39)

ou plus

For the products sold in European countries, the conformance to the

EMC Directive, which is one of the European Directives, has been a

legal obligation since 1996. Also, conformance to the Low Voltage.

Directive, another European Directives, has been a legal obligation since

1997.

Manufacturers who recognize their products must conform to the EMC

and Low Voltage Directive are required to declare that their products

conform to these Directives and put a "CE mark" on their products.

• Authorized representative in Europe

Authorized representative in Europe is shown below.

Name :Mitsubishi Elec tric Europe BV

Address :Gothaer strase 8, 40880 Ratingen, Germany

4.1 Requirements to Meet EMC Directive

EMC Directives are those which require "any strong electromagnetic

force is not output to the external.:Emission (electromagnetic

interference)" and "It is not influenced by the electromagnetic wave from

the external.: Immunity (electromagnetic sensitivity)".

Items4.1.1 through4.1.3 summarize the precautions to use GOT and

configure the mechanical unit in order to match the EMC directives.

Though the data described herein are produced with our best on the

basis of the requirement items and standards of the restrictions gathered

by Mitsubishi, they do not completely guaranteed that all mechanical unit

manufactured according to the data do not always match the above.

4.1.1 EMC directive

The standards of the EMC Directive are shown below.

Applied

standard

EN61131-2

: 2007

*1: The GOT is an open type device (device ins talled to another device) and must

*2: QP (Quasi-Peak): Quasi-peak value, Mean: Average value

Test standard Test details Standard value

Electromagnetic

*1

*1

emissions from the

*1

product are

measured.

Electromagnetic

emissions from the

*1

product to the power

line is measured.

Immunity test in

which static

electricity is applied

to the cabinet of the

equipment.

Immunity test in

which field is

irradiated to the

product.

Immunity test in

which burst noise is

applied to the power

line and signal lines.

Immunity test in

which lightening

*1

surge is applied to

the product.

Immunity test in

which a noise

inducted on the

power and signal

lines is applied.

Test for checking

normal operations

under the

circumstance

exposed to the

ferromagnetic field

noise of the power

supply frequency

(50/60Hz).

Test for checking

normal operations

at instantaneous

power failure.

CISPR16-2-3

Radiated noise

CISPR16-2-1

Conducted noise

IEC61000-4-2

Electrostatic

immunity

IEC61000-4-3

Radiated

electromagnetic

field AM modulation

IEC61000-4-4

Fast transient burst

*1

noise

IEC61000-4-5

Surge immunity

IEC61000-4-6

Conducted RF

immunity

IEC61000-4-8

Power supply

frequency magnetic

field immunity

IEC61000-4-11

Instantaneous

power failure and

voltage dips

immunity

be installed in a conductive control panel.

The above test items are conducted in the condition where the GOT is installed

on the conductive control panel and combined with the Mitsubishi PLC.

30M-230MHz QP:

30dB V/m (30m in

measurement range)

230M-1000MHz QP:

37dB V/m(30m in

measurement range)

150k-500kHz QP:79dB,

Mean: 66dB

500k-30MHz QP:73dB,

Mean: 60dB

4kV Contact discharge

8kV Aerial discharge

80-1000MHz:10V/m

1.4-2GHz:3V/m

2.0-2.7GHz:1V/m

80%AM modulation@1kHz

Power line:2kV

Digital I/O(24V or high er): 1kV

(Digital I/O(24V or less))> 250V

(Analog I/O, signal lines)> 250V

AC power type

Power line (between line and

ground): 2kV

Power line (between lines)

: 1kV

Data communication port

: 1kV

DC power type

Power line (between line and

ground) : 0.5kV

Power line (between lines)

: 0.5kV

Data communication port

: 1kV

Power line: 10V

Data communication port: 1 0V

30 A/m

AC power type

0.5 cycle 0% (interval 1 to 10s)

250/300 cycle 0%

10/12 cycle 40%

25/30 cycle 70%

*2, *3

*2, *3

*2

*2

*3: The above test items are conducted in the foll owing conditions.

30M-230MHz QP : 40dB V/m (10m in measurement range)

230M-1000MHz QP : 47dB V/m (10m in measurement range)

4.1.2 Control panel

The GOT is an open type device (device installed to another device) and

must be installed in a conductive control panel.

It not only assure the safety but also has a large effect to shut down the

noise generated from GOT, on the control panel.

(1) Control Panel

(a) The control panel must be conductive.

(b) When fixing a top or bottom plate of the control panel wit h bolts,

do not coat the plate and bolt surfaces so that they will come into

contact.

And connect the door and box using a thick grounding cable in

order to ensure the low impedance under high frequency.

(c) When using an inner plate to ensure electric conductivity with the

control panel, do not coat the fixing bolt area of the inner plate

and control panel to ensure conductivity in the largest area as

possible.

(d) Ground the control panel using a thick grounding cable in order to

ensure the low impedance under high frequency.

(e) The diameter of cable holes in the control panel must be 10cm

(3.94in.). In order to reduce the chance of radio waves leaking

out, ensure that the space between the control panel and its door

is small as possible.

Paste the EMI gasket directly on the painted surface to seal the

space so that the leak of electric wave can be suppressed.

Our test has been carried out on a panel having the damping

characteristics of 37dB max. and 30dB mean (measured by 3m

method with 30 to 300MHz).

(2) Connection of power and ground wires

Ground and power supply wires for the GOT must be connected as

described below.

(a) Provide a grounding point near the GOT. Short-circuit the LG and

FG terminals of the GOT (LG: line ground, FG: frame ground)

and ground them with the thickest and shortest wire possible

(The wire length must be 30cm (11.81in.) or shorter.)

The LG and FG terminals function is to pass the noise generated

in the PC system to the ground, so an impedance that is as low

as possible must be ensured. As the wires are used to relieve the

noise, the wire itself carries a large noise content and thus short

wiring means that the wire is prevented from acting as an

antenna.

Note) A long conductor will become a more efficient antenna at

high frequency.

(b) The earth wire led from the earthing point must be twisted with

the power supply wires.

By twisting with the earthing wire, noise flowing from the power

supply wires can be relieved to the earthing. However, if a filter is

installed on the power supply wires, the wires and the earthing

wire may not need to be twisted.

4.1.3 Noise filter (power supply line filter)

The noise filter (power supply line filter) is a device effective to reduce

conducted noise. Except some models, installation of a noise filter onto

the power supply lines is not necessary. However conducted noise can

be reduced if it is installed. (The noise filter is generally effective for

reducing conducted noise in the band of 10MHz or less.) Usage of the

following filters is recommended.

Model name FN343-3/05 FN660-6/06 RSHN-2003

Manufacturer SCHAFFNER SCHAFFNER TDK

Rated current 3A 6A 3A

Rated voltage 250V

The precautions required when installing a noise filter are described

below.

(1) Do not install the input and output cables of the noise filter together

to prevent the output side noise will be inducted into the input side

cable where noise has been eliminated by the noise filer.

Input side

(power supply side)

Filter

• I nstalling the input and output cables

together will cause noise induction.

(2) Connect the noise filter's ground terminal to the control panel with

the shortest cable as possible (approx. 10cm (3.94 in.) or less).

Induction

Output side

(device side)

Input side

(power supply side)

Filter

Output side

(device side)

• Separate the input cable from the output

cable.

4.2 Requirements for Compliance with the Low

Voltage Directive

The Low Voltage Directive requires each device which operates with

power supply ranging from 50VAC to 1000V and 75VDC to 1500V to

satisfy necessary safety items.

In the Sections from 4.2.1 to 4.2.5, cautions on installation and wiring of

the GOT to conform to the Low Voltage Directive requires are described.

We have put the maximum effort to develop this material based on the

requirements and standards of the Directive that we have collected.

However, compatibility of the devices which are fabricated according to

the contents of this manual to the above Directive is not guaranteed.

Each manufacturer who fabricates such device should make the final

judgement about the application method of the Low Voltage Directive

and the product compatibility.

4.2.1 Standard subject to GOT

Standard applied to GOT : EN61131-2 Programmable controllers - Equipment

requirements and tests

EN60950-1 Safety of In formation Technology Equipment

4.2.2 Power supply

The insulation specification of the GOT was designed assuming

installation category II. Be sure to use the installation category II power

supply to the GOT.

The installation category indicates the durability level against surge

voltage generated by lightning strike.

Category I has the lowest durability; category IV has the highest

durability.

Category ICategory IICategory IIICategory IV

Category II indicates a power supply whose voltage has been reduced

by two or more levels of isolating transformers from the public power

distribution.

Installation category

4.2.3 Control panel

Because the GOT is open type equipment (device designed to be stored

within another device), be sure to use it only when installed in a control

panel.

(1) Shock Protection

In order to prevent those who are unfamiliar with power facility,

e.g., an operator, from getting a shock, make sure to take the

following measures on the control panel.

(a) Store the GOT within the control panel locked, and allow only

those who are familiar with power facility to unlock the panel.

(b) Build the structure in order that the power supply will be shut off

when the control panel is opened.

(2) Dustproof and waterproof features

The control panel also provides protection from dust, water and

other substances. Insufficient ingression protection may lower the

insulation withstand voltage, resulting in insulation destruction.

The insulation in the GOT is designed to cope with the pollution

level 2, so use in an environment with pollustion level 2 or better.

Pollution level 1: An env ironment where the air is dry and conductive

Pollution level 2: An env ironment where conductive dust does not

Pollution level 3: An environment where conductive dust exits and

Pollution level 4: Continuo us conductivity may occur due to rain, snow,

dust does not exist.

usually exist, but occasional temporary condu ctivity

occurs due to the accumulated dust.

Generally, this is the level for inside the control panel

equivalent a control room or on the floor of a typical

factory.

conductivity may be generated due to t he accumulated

dust.

An environment for a typical factory floor.

etc. An outdoor environment.

4.2.4 Grounding

The following are applicable ground terminals. Use them in the grounded

state.

Be sure to ground the GOT for ensuring the safety and complying with

the EMC Directive.

Functional grounding : Improves the noise resistance.

4.2.5 External wiring

(1) External devices

When a device with a hazardous voltage circuit is externally

connected to the GOT, select a model which complies with the

Low Voltage Directive's requirements for isolation between the

primary and secondary circuits.

(2) Insulation requirements

Dielectric withstand voltages are shown in the following table.

Reinforced Insulation Withstand Voltage

(Installation Category II, source : IEC664)

Rated voltage of hazardous

voltage area

150 VAC or below 2 500V

300 VAC or below 4000V

Surge withstand voltage (1.2/50 s)

5. INSTALLATION

5.1 Control Panel Inside Dimensions for

Mounting GOT

Install the GOT on the control panel out of the way for the equipment

inside the control panel. Do not install the GOT and the unit in

prohibited areas for the installation.

Point

Applicable cable

Some cables may need to be longer than the specified dimensions when connecting to the

GOT. Therefore, consider the connector dimensions and bending radius of the cable as

well for installation.

5.2 Panel Cutting Dimensions

C

A

B

C

B

C

Horizontal

Vertical

5.3 Mounting Position

When mounting the GOT, the following clearances must be maintained

from other structures and devices.

Some cables may need to be longer than the specified dimensions when

connecting to the GOT.

Therefore, consider the connector dimensions and bending radius of the

cable as well for installation.

For the lead-in allowance for cables at the bottom of the GOT, refer to

the GOT2000 Series User’s Manual (Hardware) .

For the vertical installation, install the GOT so that the vertical installation

arrow printed on the GOT rear face points upward.

B

A

Horizontal

DE

Panel thickness:

1.6 to 4mm

C

(0.06 to 0.16 inch)

According to the dimensions in the following table, leave clearances

between the GOT and the other devices. The values enclosed in

square brackets apply to the case where no other equipment

generating radiated noise (such as a contactor) or heat is installed

near the GOT. However, keep the ambient temperature of the GOT

to 55°C or lower.

*Panel thickness : 1.6 to 4 mm

(0.06 to 0.16 inch)

GOT A B

C

302 (11.89)

GT

+2 (0.08)

2512

0 (0)

289 (11.38)

GT

+2 (0.08)

A

2510

0 (0)

227 (8.94)

GT

+2 (0.08)

2508

0 (0)

D

B

C

Vertical

(0.06 to 0.16 inch)

228 (8.98)

+2 (0.08)

0 (0)

200 (7.87)

+2 (0.08)

0 (0)

176 (6.93)

+2 (0.08)

0 (0)

Unit: mm (inch)

A

Panel thickness:

1.6 to 4mm

C

10

(0.39)

or more

E

more

more]

Unit : mm(inch)

48(1.89) or

more

[29(1.14) or

more]

23(0.91) or

more

[29(1.14) or

more]

67(2.64) or

more

50(1.97)or

more

Item

GOT only

Bus connection unit is fitted

Serial connection unit is fitted

CC-Link communication unit

(GT15-J61BT13) fitted

A

MELSECNET/H communication unit (coaxial) fitted

MELSECNET/H communication

unit(optical) fitted

CC-Link IE Controller Network

communication unit fitt ed

CC-Link IE Field Network communication unit fitted

Printer unit fitted

External I/O unit fitted

Sound output unit fitted

B

When the SD card is used

C

When the SD card is not used

D

*3

E

*1: This value is for use of the coaxial cable 3C-2V (JIS C 3501).

For specifications of the cable, refer to the GOT2000 Series Connection

Manual for a controller used.

*2: This value differs depending on the cable used.

*3: When opening or closing the battery cover: 72(2 .83) or more

*2

GT2512 GT2510 GT2508

48(1.89) or more

[18(0.71) or more]

48(1.89) or more

[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or

*1

more

[38(1.50) or

more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

48(1.89) or more[18(0.71) or more]

Horizontal: 78(3.07) or more

Vertical: 48(1.89) or more

50(1.97)or more

[20(0.79) or more]

50(1.97) or more[20(0.79) or more]

Horizontal: 50(1.97) or more

Vertical: 80(3.15) or more

100(3.94) or more[20(0.79) or more]

48(1.89) or

[45(1.77) or

[18(0.71) or more]

[18(0.71) or more]

[20(0.79) or more]

[20(0.79) or more]

5.4 Control Panel Inside Temperature and

Installation Angle

When installing the GOT to a panel, set the display section as shown

below.Using the GOT with the installation angle other than the following

deteriorates the GOT earlier.

Installing the GOT horizontally

When installing the GOT with the installation angle between 60 to 105

°, the temperature inside the control panel must be within 55 °C.

When installing the GOT with the installation angle other than

between 60 to 105 °, the temperature inside the control panel must be

within 40 °C.

Installing the GOT vertically

When the GOT is installed a 90° angle , the control panel inside

temperature must be within 55°C. When the GOT is installed at any

angle other than 90°, the control panel inside temperature must be

within 40°C.

Display section

GOT

Panel or others

Display section

105°

60°

GOT

Panel or others

Horizontal Vertical

5. INSTALLATION

5.1 Dimensions intérieures du tableau de

commande pour le montage du GOT

Installez le GOT sur le tableau de commande en laissant de l'espace

pour le dispositif à l'intérieur du tableau de commande. N'installez

pas le GOT et le module dans des zones où l'installation est interdite.

Point

Câble applicable

Certains câbles peuvent être plus longs que les dimensions spécifiées lors de la

connexion au GOT. Par conséquent, prenez également en compte les dimensions du

connecteur et le rayon de co urbure du câble pour l'installation.

5.2 Cotes de découpe du panneau

5.4 Température intérieure et angle

Lors de l'installation du GOT sur un panneau, réglez la zone d'affichage

comme indiqué ci-dessous.

5.3 Position de montage

Lors du montage du GOT, laissez les espaces suivants pour les autres

structures et dispositifs.Certains câbles peuvent être plus longs que les

dimensions spécifiées lors de la connexion au GOT.

Par conséquent, prenez également en compte les dimensions du

connecteur et le rayon de courbure du câble pour l'installation.

Pour connaître l'espace à laisser pour les câbles sous le GOT, référezvous au manuel GOT2000 Series User’s Manual (Hardware).

Pour l’installation à la verticale, installez le GOT de sorte que la flèche

d’installation à la verticale imprimée sur la face arrière du GOT pointe

vers le haut.

B

C

Horizontal

Laissez les espaces entre le GOT et les autres dispositifs en fonction

des dimensions contenues dans le tableau suivant. Les valeurs entre

parenthèses s'appliquent au cas où aucun dispositif générant des

émissions sonores (comme un contacteur) ou de la chaleur n'est installé

près du GOT.

Toutefois, maintenez la température ambiante du GOT à 55°C ou moins.

GOT uniquement

Unité de connexion de bus

encastrée

Unité de connexion série

encastrée

Module de communication CC-

90°

Link (GT15-J61BT13) encastré

Module de communication

MELSECNET/H (coaxial)

A

encastré

Module de communication

MELSECNET/H (optique)

encastré

Module de communication

réseau de contrôleur CC-Link I E

encastré

Module de communication

réseau de champ CC-Link IE

encastré

Imprimante encastrée

Module d'E/S externe encas tré

Module de sortie acoustique

encastré

B

DE

A

Épaisseur du panneau :

(0,06 à 0,16 pouce)

Article

*1

*2

D

B

1,6 à 4mm

GT2512 GT2510 GT2508

48 (1,89) ou plus

[18 (0,71) ou plus]

48 (1,89) ou plus

[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou

plus

[38(1.50) ou

plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

48 (1,89) ou plus[18 (0,71) ou plus]

Horizontal: 78 (3,07) ou plus

Vertical: 48 (1,89) ou plus

A

C

Vertical

Épaisseur du panneau :

48 (1,89) ou

plus

[45 (1,77) ou

plus]

[18 (0,71) ou plus]

[18 (0,71) ou plus]

E

1,6 à 4mm

(0,06 à 0,16 pouce)

Unité : mm (pouce)

48 (1,89) ou

plus

[29 (1,14) ou

plus]

23 (0,91) ou

plus

[29 (1,14) ou

plus]

67 (2,64) ou

plus

Si l'angle d'installation est différent de celui indiqué, le GOT se détériore

plus tôt.

Installation du GOT à l’horizontale

Installation du GOT à la verticale

Horizontal Vertical

Refer to the GOT2000 Series User’s Manual (Hardware) for

maintenance and inspection for the GOT.

Article

Quand la carte SD est utilis ée

C

Quand la carte SD n'est pas

utilisée

D

*3

E

*1 : Cette valeur est utilisée pour le câble coaxial 3C-2V (JIS C 3501).

Pour connaître les spécifications du câble, référez-vous au manuel

GOT2000 Series Connection Manual for a controller used.

*2 : Cette valeur diffère selon le câble utilisé.

*3 : Pour ouvrir ou fermer le couvercle de la batterie : 72 (2,83) ou plus

d'installation du tableau de commande

Lors de l'installation du GOT avec un angle d'installation compris entre

60 et 105°, la température à l'intérieur du tableau de commande doit

être d'environ 55°C. Lors de l'installation du GOT avec un angle

d'installation non compris entre 60 et 105°, la température à l'intérieur

du tableau de commande doit être d'environ 40°C.

Lors de l’installation du GOT avec un angle de 90°, la température à

l’intérieur du panneau de commande ne doit pas dépasser 55°C. Lors

de l’installation du GOT avec tout autre angle que 90°, la température

à l’intérieur du panneau de commande ne doit pas dépasser 40°C.

Zone d'affichage

GOT

Tableau ou autres

6. MAINTENANCE AND INSPECTION

GT2512 GT2510 GT2508

50 (1,97) ou plus

[20 (0,79) ou plus]

50 (1,97) ou plus[20 (0,79) ou plus]

Horizontal: 50 (1,97) ou plus

[20 (0,79) ou plus]

Vertical: 80 (3,15) ou plus

[20 (0,79) ou plus]

100 (3,94) ou plus[20 (0,79) ou plus]

Zone d'affichage

105°

60°

GOT

Tableau ou autres

50 (1,97) ou

plus

90°

Warra nty

Mitsubishi will not be held liable for damage caused by factors found

not to be the cause of Mitsubishi; machine damage or lost profits

caused by faults in the Mitsubishi products; damage, secondary

damage, accident compensation caused by special factors

unpredictable by Mitsubishi; damages to products other than

Mitsubishi products; and to other duties.

For safe use

• This product has been manufactured as a general-purpose part for

general industries, and has not been designed or manufactured to

be incorporated in a device or system used in purposes related to

human life.

• Before using the product for special purposes such as nuclear

power, electric power, aerospace, medicine or passenger

movement vehicles, consult with Mitsubishi.

• This product has been manufactured under strict quality control.

However, when installing the product where major accidents or

losses could occur if the product fails, install appropriate backup or

failsafe functions in the system.

Country/Region Sales office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon Hills, IL 60061, U.S.A.

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria Tecnica Ltda.

Rua Correia Dias, 184, Edificio Paraiso Trade Center-8 andar

Paraiso, Sao Paulo, SP Brazil

Tel : +55-11-5908-8331

Germany Mitsubishi Electric Europe B.V. German Branch

Gothaer Strasse 8 D-40880 Ratingen, GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK Branch

Travellers Lane, Hatfield, Hertfordshire., AL10 8XB, U.K.

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian Branch

Centro Dir. Colleoni, Pal. Perseo-Ingr.2

Via Paracelso 12, I-20041 Agrate Brianza., Milano, Italy

Tel : +39-039-60531

Spain Mitsubishi Electric Europe B.V. Spanish Branch

Carretera de Rubi 76-80,

E-08190 Sant Cugat del Valles, Barcelona, Spain

Tel : +34-93-565-3131

France Mitsubishi Electric Europe B.V. French Branch

25, Boulevard des Bouvets, F-92741 Nanterre Cedex, France

Tel : +33-1-5568-5568

South Africa Circuit Breaker Industries Ltd.

Private Bag 2016, ZA-1600 Isando, South Africa

Tel : +27-11-928-2000

Hong Kong Mitsubishi Electric Automation (Hong Kong) Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, Hong Kong

Tel : +852-2887-8870

China Mitsubishi Electric Automation (China) Ltd.

4/F Zhi Fu Plazz, No.80 Xin Chang Road,

Shanghai 200003, China

Tel : +86-21-6120-0808

Taiwan Setsuyo Enterprise Co., Ltd.

6F No.105 Wu-Kung 3rd.Rd, Wu-Ku Hsiang,

Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea Mitsubishi Electric Automation Korea Co., Ltd.

1480-6, Gayang-dong, Gangseo-ku Seoul

157-200, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 Alexandra Road #05-01/02,

Mitsubishi Electric Building, Singapore 159943

Tel : +65-6470-2460

Thailand Mitsubishi Electric Automation (Thailand) Co., Ltd.

Bang-Chan Industrial Estate No.111 Moo 4, Serithai Rd,

T.Kannayao, A.Kannayao, Bangkok 10230 Thailand

Tel : +66-2-517-1326

Indonesia P.T. Autoteknindo Sumber Makmur

Muara Karang Selatan, Block A/Utara

No.1 Kav. No.11 Kawasan Industri Pergudangan

Jakarta - Utara 14440, P.O.Box 5045 Jakarta, 11050 Indonesia

Tel : +62-21-6630833

India Messung Systems Pvt, Ltd.

Electronic Sadan NO:III Unit No15, M.I.D.C Bhosari,

Pune-411026, India

Tel : +91-20-2712-3130

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Specifications subject to change without notice.

Printed in Japan, October 2014.

Loading...

Loading...