Mitsubishi GT1030-HBL, GT1030-HWD, GT1030-HWL, GT1030-HBDW, GT1030-HWDW General Description Manual

...

JY997D25301T

Side

B

Side

JAPANESE

A

Side

ENGLISH

B

GT1030-HD(W)/HD(W)2/HL(W)

GT10 General Description

Manual Number JY997D25301T

Date Oct. 2016

This manual describes the specifications of the product. Before use, read this

manual and manuals of relevant products fully to acquire proficiency in handling

and operating the product. Make sure to learn all the product information, safety

information, and precautions.

And, store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

Registration

The company name and the product name to be described in this manual are the

registered trademarks or trademarks of each company.

Effective Oct. 2016

Specifications are subject to change without notice.

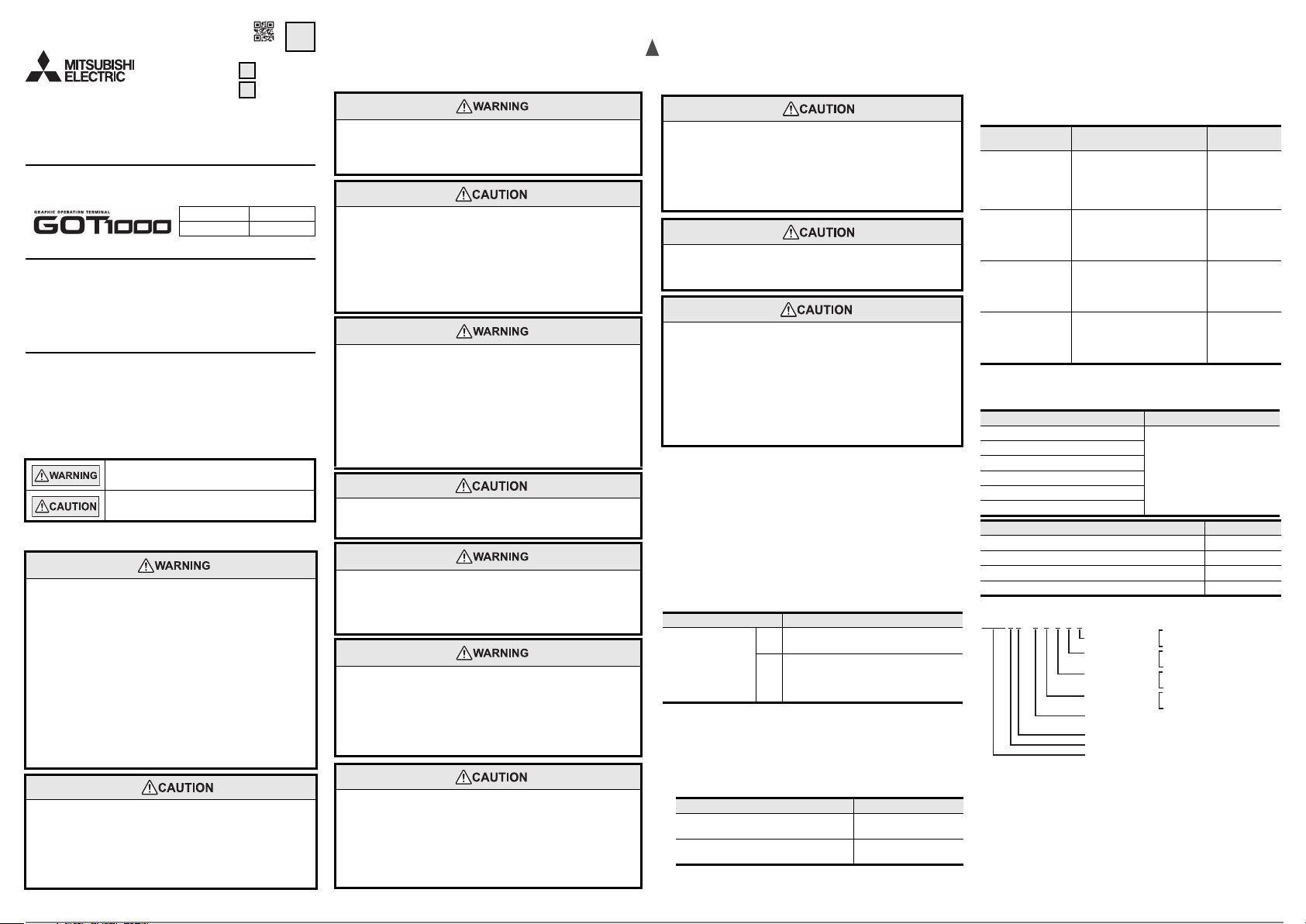

Safety Precaution

Before using this product, please read this manual and the relevant manuals introduced

in this manual carefully and pay full attention to safety to handle the product correctly.

The precautions given in this manual are concerned with this product.

In this manual, the safety precautions are ranked as "WARNING" and

"CAUTION".

Depending on circumstances, procedures indicated by "CAUTION" may also be

linked to serious results.

In any case, it is important to follow the directions for usage.

DESIGN PRECAUTIONS

Some failures of the GOT or cable may keep the outputs on or off.

An external monitoring circuit should be provide d to check for output signals

which may lead to a serious accident.

Not doing so can cause an accident due to false output or malfunction.

If a communication fault (including cable disconnection) occurs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative.

A system where the GOT is used should be configured to perform any

significant operation to the sys tem by using the switches of a devi ce other

than the GOT on the assumption that a GOT communication fault will occur.

Not doing so can cause an accident due to false output or malfunction.

Do not use the GOT as the warning device that may cause a serious accident.

An independent and redundant hardware or mechanical interlock is required to

configure the device that displays and outputs serious warning.

Failure to observe this instruction may result in an accident due to incorrect

output or malfunction.

Incorrect operation of the touch switch(s) may lead to a serious accident if the

GOT backlight is gone out. When the GOT backlight goe s out, causes the

monitor screen to appear blank, while the input of the touch switch(s) remains

active. This may confuse an operator in thinking that the GOT is in

"screensaver" mode, who then tries to release the GOT from this mode by

touching the display section, which may cause a touch switch to operate.

DESIGN PRECAUTIONS

Do not bundle the control and communication cables with main-circuit, power

or other wiring.

Run the above cables separately from such wiring and keep them a minimum

of 100mm (3.94in.) apart.Not doing so noise can cause a malfunction.

Do not press the GOT display section with a pointed material as a pen or

driver. Doing so can result in a damage or failure of the display section.

Before connecting to GOT, turn ON the controller to enable the

communication. When the communication of controller is not ava ilable, a

communication error may occur in GOT.

2008 MITSUBISHI ELECTRIC CORPORATION

(Read these precautions before using.)

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or slight personal injury

or physical damage.

MOUNTING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before mounting or removing the GOT to/from the panel.

Not doing so can cause the unit to fail or malfunction.

When installing the battery wear an earth band etc. to avoid the static electricity.

The static electricity can cause the unit to fail or malfunction.

MOUNTING PRECAUTIONS

Use the GOT in the environment that satisfies the general specifications

described in this manual. Not doing so can cause an electric shock, fire,

malfunction or product damage or deterioration.

When mounting the GOT to the control panel, tighten the mounting screws in the

specified torque range. Undertightening can cause the GOT to drop, short circ uit

or malfunction, and deteriorate the waterproof effect and oilproof effect.

Overtightening can cause a drop , short circuit or malfunction du e to the damage

of the screws or the GOT, and deteriorate the waterproof effect and oilproof effect

due to distortion of the protective cover for oil, GOT or panel.

When using the GOT in the environment of oil or chemicals, use the protective

cover for oil. Failure to do so may cause f ailure or malfunction due to the oil or

chemical entering into the GOT.

WIRING PRECAUTIONS

Be sure to shut off all phases of the external power supply used by the system

before wiring. Failure to do so may result in an electric shock, product damage or

malfunctions.

Please make sure to ground FG terminal of the GOT power supply section by

applying 100 or less which is used exclusively for the GOT. Not doing so may

cause an electric shock or malfunction.

Correctly wire the GOT power supply section after confirming the rated voltage

and terminal arrangement of the product. Not doing so can cause a fire or failure.

Tighten the terminal screws of the GOT power supply section in the specified

torque range. Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage of the

screws or the GOT.

Exercise care to avoid foreign matter such as chips and wire offcuts entering the

GOT. Not doing so can cause a fire, failure or malfunction.

WIRING PRECAUTIONS

Plug the communication cable into the connector of the connected unit and

tighten the mounting and terminal screws in the specified torque range.

Undertightening can cause a short circuit or malfunction. Overtightening can

cause a short circuit or malfunction due to the damage of the screws or unit.

TEST OPERATION

PRECAUTIONS

Before performing the test operations of the user creation monitor screen (such as

turning ON or OFF bit device, changing the word device current value, changing

the settings or current values of the timer or counter), read through the manual

carefully and make yourself familiar with the operation method.

During test operation, never change the data of the devices which are used to

perform significant operation for the system . False output or malfunction can

cause an accident.

STARTUP/MAINTENANCE

PRECAUTIONS

When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

Connect the battery correctly.

throw the battery into the fire.

generate heat, burst or take fire, resulting in injuries or fires.

Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases. Not switching the power off in all phases can cause

a unit failure or malfunction . Undertightening can cau se a short circuit or

malfunction. Overtightening can cause a short circuit or malfunction due to the

damage of the screws or unit.

STARTUP/MAINTENANCE

PRECAUTIONS

Do not disassemble or modify the unit.

Doing so can cause a failure, malfunction, injury or fire.

Do not touch the conductive and electronic parts of the unit directly.

Doing so can cause a unit malfunction or failure.

The cables connected to the unit must be run in ducts or clamped.

Not doing so can cause the unit or cable to be damaged due to the dangling,

motion or accidental pulling of the cables or can cause a malfunction due to a

cable connection fault.

When unplugging the cable connected to the unit, do not hold and pull the cable

portion. Doing so can cause the uni t or cable to be damaged or can cause a

malfunction due to a cable connection fault.

Do not discharge, disassemble, heat, short, solder or

Incorrect handling may cause the battery to

STARTUP/MAINTENANCE

PRECAUTIONS

Do not drop or apply any impact to the battery.

If any impact has been applied, discard the battery and never use it.

The battery may be damaged by the drop or impact.

Before touching the unit, always touch grounded metal, etc. to discharge static

electricity from human body, etc.

Not doing so can cause the unit to fail malfunction.

Replace battery with GT11-50BAT by Mitsubishi electric Co. only.

Use of another battery may present a risk of fire or explosion.

Dispose of used battery promptly.

Keep away from children. Do not disassemble and do not dispose of in fire.

DISPOSAL PRECAUTIONS

When disposing of the product, handle it as industrial waste.

When disposing of batteries, separate them from other wastes according to the

local regulations. (For details of the battery directive in EU member states, refer

GOT User’s Manual.)

TRANSPORTATION

PRECAUTIONS

When transporting lithium batteries, make sure to treat them based on the

transport regulations. (Refer to User's Manual for details of the regurated

models.)

Before transporting the GOT, turn the GOT power on and check that the battery

voltage status is normal on the Time setting & display screen (utilities screen). In

addition, confirm that the adequate battery life remains on the rating plate.

Transporting the GOT with the low battery v oltage or the battery the reached

battery life may unstabilize the backup data unstable during transportation.

Make sure to transport the GOT main unit and/or relevant unit(s) in the manner

they will not be exposed to the impact exceeding the impact resistance

described in the general specifications of this manual, as they are precision

devices. Failure to do so may cause the unit to fail.

Check if the unit operates correctly after transportation.

Compliance with EC directive (CE Marking)

This note does not guarantee that an entire mechanical module produced in

accordance with the contents of this note will comply with the following standards.

Compliance to EMC directive for the entire mechanical module should be checked by

the user / manufacturer. For more details please contact the local Mitsubishi Electric

sales site.

Attention

This product is designed for use in industrial applications.

Requirement for Compliance with EMC directive

The following products have shown compliance through direct testing (to the

identified standards) and design analysis (forming a technical construction file) to the

European Directive for Electromagnetic Compatibility (2004/108/EC) when used as

directed by the appropriate documentation.

Type :Programmable Controller (Open Type Equipment)

Standard Remark

EN61131-2 : 2007

Programmable

controllers- Equipment,

requirement and tests

For more details please contact the local Mitsubishi Electric sales site.

Notes for compliance to EMC regulation

1) General notes on the use of communication cables

Any device which utilizes a data communication function is susceptible to the

wider effects of local EMC noise. Therefore, when installing any communication

cables care should always be taken with the routing and location of those c ables.

The GOT units identified on the previous chapter are compliant with the EMC

requirement when the following communication cables are used.

GT1030-HBD/HWD/HBL/HWL/HBDW/HWDW/

HBLW/HWLW

GT1030-HBD2/HWD2/HBDW2/HWDW2

2) General notes on the use of the power cable

The GT1030-HD/HD2/HDW/HDW2 unit demand that the cable for the

power supply is 10m or less.

Compliance with all relevant aspects of the

EMI

standard. (Radiated Emissions)

Compliance with all relevant aspects of the

standard. (ESD,RF electromagnetic field, EFTB,

EMS

Surge, RF conducted disturbances and Power

frequency magnetic field)

GOT Unit Existing Cables

GT10-C30R4-8P

(For Melsec FX series PLC)

GT10-C30R2-6P

(For Melsec Q series PLC)

Associated Manuals

The following manuals are relevant to this product. When these loose manuals are

required, please consult with our local distributor.

Manual name Contents

Describes the GT10 hardware-

GT10 User's Manual

(sold separately)

GT Designer3 Version1

Screen Design Manual

(For GOT1000 Series)

(Fundamentals)1/2, 2/2

(sold separately)

GT Designer3 Version1

Screen Design Manual

(For GOT1000 Series)

(Functions) 1/2, 2/2

(sold separately)

GOT1000 Series

Connection Manual

(Mitsubishi Products)

for GT Works3

(sold separately)

*1 Stored in the GT Works3/GT Designer3 in PDF format.

For details of a PLC to be connected, refer to the PLC user's manual respectively.

relevant content such as part

names, external dimensions,

mounting, power supply wiring,

specifications, and introduction to

option devices

Describes methods of the GT

Designer3 installation operation,

basic operation for drawing and

transmitting data to GOT1000 series

*1

Describes specifications and

settings of the object functions used

in GT Designer3

*1

Describes system configurations of

the connection method applicable to

GOT1000 series and cable creation

method

*1

Manual Number

(Model Code)

JY997D24701

(09R819)

SH-080866ENG

(1D7MB9)

SH-080867ENG

(1D7MC1)

SH-080868ENG

(1D7MC2)

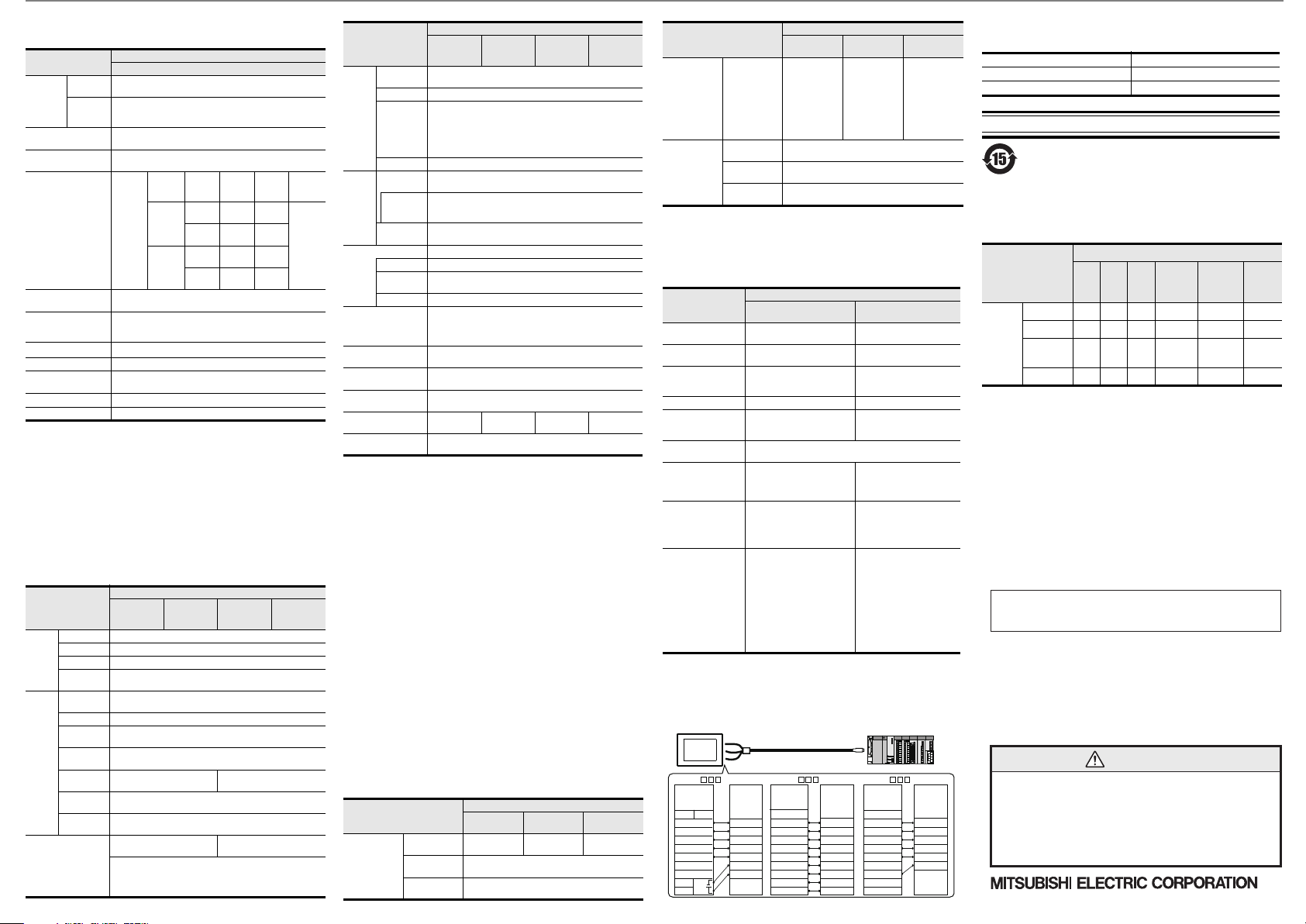

Bundled Items

GT1030-HBD/HWD

GT1030-HBD2/HWD2

GT1030-HBL/HWL

GT1030-HBDW/HWDW

GT1030-HBDW2/HWDW2

GT1030-HBLW/HWLW

PLC Communication Connector 1

Panel Mounting Bracket (with M4 20 screws) 4

Panel Mounting Packing 1

GT10 General Description (This manual) 1

Explanation of the GOT model name

GT10 3 0 -

Model Name Remark

GOT main unit

(The maintenance supplies below

are packed with the product.)

Maintenance Supplies Quantity

* * * * *

Interface type for

communication with PLC

Backlight type

Power type

Panel color type

Display device type

Display color type

Screen size type

GOT1000 series GT10

2:RS-232

Blank:RS-422

W:white/red/pink

Blank:green/red/orange

D:24VDC

L:5VDC

B:Black

W:White

H:STN monochrome

0:Monochrome(black/white)

3:4.5"

(High contrast)

1. Specifications

1.1 General Specifications

Item

Display

Operating

section

ambient

Other than

tempera-

display

ture

section

Storage ambient

temperature

Operating/Storage

ambient humidity

Vibration resistance

Shock resistance

Operating atmosphere

Operating altitude

Installation location Inside control panel

Overvoltage

*2

category

Pollution degree

Cooling method Self-cooling

*1 Do not use or store the GOT under p ressure higher than the atmospheric

pressure of altitude 0m (0ft.). Failure to observe this instruction may cause a

malfunction.

When the air inside the control panel is purg ed by pressurization, the surface

sheet may be lifted by high pressure. As a result, the touch panel may be

difficult to press, and the sheet may be peeled off.

*2 This indicates the section of the power supply to which the equipment is

assumed to be connected betw een the public electrical power dist ribution

network and the machinery within the premises.

Category II applies to equipment for which ele ctrical power is supplied from

fixed facilities.

The surge voltage withstand l evel for up to the raged voltage of 300 V is 2500 V.

*3 This index indicates the degree to which conductive material is generated in

the environment where the equipment is used.

In pollution degree 2, only non-conductive pollution occurs but temporary

conductivity may be produced due to condensation.

GT1030-HD/HD2/HL/HDW/HDW2/HLW

0 to 50C

0 to 55C (When mounted horizontally), 0 to 50C (When

mounted vertically)

-20 to 60C

10 to 90% RH, non-condensing (The w et bulb temperature

is 39C or less.)

Conforms

to JIS

B3502

and

IEC61131

-2

Conforms to JIS B3502, IEC 61131-2 (147m/s

half-wave pulse, 3 times each in the X, Y, and Z directions.)

Must be free of lamp black, corrosive gas, flammable gas,

or excessive amount of electro conductive dust particles

and must be no direct sunlight. (Same as for saving)

*1

2000 m (6562 ft) max.

II or less

*3

2 or less

1.2 Performance Specifications

Item

Type STN monochrome (white/black) liquid crystal

Screen size 4.5"

Display

*

section

Resolution 288 96 dots (Horizontal format)

1

Display size

Display

character

Display color Monochrome (white/black)

Display angle

Contrast

Display

*

adjustment

section

1

Intensity of

LCD only

Intensity

adjustment

Life

Backlight (no

replacement required)

GT1030-

HD/HD2

W109.42(4.3) H35.98(1.41) [mm](inch) (Horizontal

format)

16-dot standard font: 36 characters 6 lines, 12-dot

standard font: 48 characters 8 lines (Horizontal format)

Left/Right: 30 degrees, Top: 20 degrees, Bottom: 30

degrees (Horizontal format)

16-level adjustment

200 [cd/m

8-level adjustment

Approx. 50,000h. (Time for display intensity to become 1/5

at operating ambient temperature of 25C)

LED with 3 available colors

(green, red, orange)

Backlight status (colors, ON/BLINK/OFF) control,

Adjustable screensaver activation time

Setting the system information enables

backlight status

Specifications

Acceler-

ation

-- 3.5mm

2

9.8m/s

--

2

4.9m/s

Half-

ampli-

tude

--

1.75mm

--

2

Under

intermittent

vibration

Under

continuous

vibration

Fre-

quency

5 to

8.4Hz

8.4 to

150Hz

5 to

8.4Hz

8.4 to

150Hz

Specifications

GT1030-

2

] (in green) 500 [cd/m2] (in white)

GT1030-

HL

HDW/

HDW2

LED with 3 available colors

(white, red, pink)

*2

PLC to control the

Sweep

Count

10 times

each in

and Z

direc-

, 11 ms, Sine

GT1030-

HLW

Item

Number of

touch keys

Key size Minimum 16 16 dots (per key)

Simultaneous

Touch

pressing of

panel

two (or

more) areas

(2-point

press)

Life 1 million times or more (operating force 0.98N max.)

*3

C drive

Life

(Number of

Memory

write times)

X, Y

tions

D drive

Type Magnesium maganese dioxide lithium primary battery

Battery

Backup

target

Life Approx. 5 years (Operating ambient temperature of 25)

Buzzer output

(a buzzer that sounds

when touch keys are

pressed)

Environmental

protective structure

External dimensions

Panel cutting

dimensions

Weight (Excluding

mounting fixtures)

Compatible software

package

*1 Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal

display panel. It is impossible to completely avoid this symptom, as t he liquid

crystal display comprises of a great number of display elements. Flickers may

be observed depending on the display color.

Please note that these dots appear due to its characteristic and are not

caused by product defect.

Flickers and partial discoloration may be generated on the liquid crystal

display panel due to the display contents or the contrast adjustment.

However, please note that these phenomena appear due to its characteristic

and are not caused by product defect.

There is a difference in the display brightness and the color tones between

liquid crystal display panels. When using multiple liquid crystal display panels,

please note that there is an individual difference between them.

A crosstalk (shadow as an extension of the display) may appear on the liquid

crystal display panel. Please note that it appears due to its characteristic.

When the display section is seen from the outside of the display angle, the

display color seems like it has changed.

Please note that it is due to its char acteristic. Please note that the response

time, brightness and color of the liquid crystal display panel may vary

depending on the usage environmental temperature.

Especially in the low temperature environment, the display response

becomes slow due to the characteristics of the STN liquid crystal.

Please check the display response in advance for using this product.

Please note that the response in low temperatures tend to be slower as a

characteristic of the liquid crystal display panel.

When the same screen is displayed for a long time, an incidental color or

partial discoloration is generated on the screen due to heat damage, and it

may not disappear.

To prevent heat damage, the screen saver function is effective.

For details of the screen saver function, refer to the following.

GT10 User's Manual

*2 For the details of system information, refer to the following.

GT Designer3 Version1 Screen Design Manual

*3 ROM in which new data can be written without deleting the written data.

*4 Note that this does not guarantee all users' operation environment.

In addition, the product may no t be used in environments under exp osition of

oil or chemicals for a long period of time, or in environments filled with oil-mist.

1.3 Communication Specifications

Item

Communication

standard

PLC

communication

Transmission

speed

Connector

shape

Specifications

GT1030-

HD/HD2

GT1030-

HL

GT1030-

HDW/

HDW2

Maximum 50 keys/screen (Matrix resistive film touch panel)

Enable

Flash memory ROM (Internal), for storing Project data

(1.5M bytes or less), OS

100,000 times

SRAM (Internal), for storing alarm history, recipe data and

time action setting value

GT11-50BAT lithium battery

Clock data, alarm history and recipe data

Single tone (LONG/ SHORT/ OFF adjustable)

Equivalent to IP67 (JEM1030) (front section)

*4

W145(5.7) H76(2.99) D29.5(1.16)[mm](inch) (Excluding

mounting fixtures) (Horizontal format)

W137(5.39) H66(2.59) [mm](inch) (Horizontal format)

0.3kg 0.28kg 0 .3kg 0.28kg

GT Designer3 Version1.19V or later

Specifications

GT1030-

HD/HDW

RS-422/485

1ch

GT1030-

HD2/HDW2

HL/HLW

RS-232 1ch RS-422 1ch

115,200/57,600/38,400/19,200/9,600/4,800bps

Connector terminal block 9-pins

GT1030-

HLW

GT1030-

Item

PLC

communication

PC

communica-

*2

tion

*1 Set the terminating resistor selector switch of the GOT i n accordance with the

*2 Project data upload/download, OS installation, Transparent function

1.4 Power Supply Specifications

(For details on power supply wiring, such as the allowable cable size and tightening

torque, refer to the additional manual, "GT10 User's Manual".)

Input power supply

voltage

Fuse (built-in, not

exchangeable)

Power consumption,

(At backlight off)

Terminating

resistor

Communication

standard

Trans miss ion

speed

Connector

shape

connection type when adopting GOT multidrop connection.

For details of GOT multidrop connection, refer to the following.

GOT1000 Series Connection Manual (Mitsubishi Products) for GT Works3

Item

GT1030-HD/HD2/HDW/

24VDC (+10% -15%),

ripple voltage 200mV or less

0.5A --

2.2W (90mA/24VDC) or less,

(1.7W (70mA/24VDC) or less)

GT1030-

HD/HDW

Open/110/

330 (Switched

by

terminating

resistor selector

*1

switch)

(At factory

shipment:

330)

RS-232 1ch

115,200/57,600/38,400/19,200/9,600/4,800bps

MINI DIN 6-pins (Female)

HDW2

Specifications

GT1030-

HD2/HDW2

-- --

Specifications

GT1030-HL/HLW

5VDC (5%),

supplied from the PLC

1.1W (220mA/5VDC) or

less, (0.6W (120mA/5VDC)

or less)

GT1030-

HL/HLW

Inrush current 18A or less (26.4VDC) 1ms --

Permissible

instantaneous power

failure time

Noise immunity

Dielectric withstand

voltage

Insulation resistance

Grounding

*1 The GOT continues to operate even upon 5ms or shorter instantaneous

power failure. The GOT stops operating if there is extended power failure or

voltage drop, while it automatically resumes operation as soon as the power is

restored.

2. Wiring of connection cable

The diagram below shows cable assignment for GOT port.

Cables: GT10-CR4-8P, GT10-CR4-2P, GT10-CR2-6P

GOT PLC

GT10-C R4-8P

GOT

(terminal

block)

24V

5V

SDA

SDB

RDA

RDB

SG

RSA

RSB

CSA

CSB

Within 5ms --

*1

Noise voltage: 1000Vp-p, Noise width: 1 s (by noise

simulator of 30 to 100Hz noise frequency)

500VAC for 1 minute

(between the GOT’s power

supply terminals and the

GOT’s grounding terminal)

10M or larger by insulation

resistance tester (between the

GOT’s power supply terminals

and the GOT’s grounding

terminal)

Grounding with a ground

resistance of 100 Ω or less by

using a ground cable that has

a cross-sectional area of 0.1 4

2

(solid wire), 0.14

to 1.5 mm

2

to 1.0 mm

(stranded wire), or

0.25 to 0.5 mm

with an insulation sleeve).

If impossible, connect the

ground cable to the control

panel.

Untied

wire

color

Brown

Red

Orange

Yellow

Green

Black

White

-

+

2

(rod terminal

PLC connection cable

GT10-C R4-25P

GOT

SDA

SDB

RDA

RDB

SG

RSA

RSB

CSA

CSB

24V

Untied

Orange

Yellow

Purple

(terminal

block)

wire

color

Brown

Red

Green

Blue

Black

White

--

--

--

GT10-C R2-6P

GOT

(terminal

block)

24V

SD

RD

ER

DR

SG

RS

CS

NC

NC

Untied

wire

color

Brown

Red

Blue

Yellow

Green

Purple

User-made cable is necessary, depending on the PLC.

For the detail, refer to GOT1000 Series Connection Manual (Mitsubishi Products) for

GT Works3.

Cable jacket to remove 7mm (0.27")

Tightening torque 0.22 to 0.25 N

m

Recommended Tool (Screwdriver) SZS 0.4 2.5 (Phoenix Contact Inc.)

「电器电子产品有害物质限制使用标识要求」的表示方式

Note: This symbol mark is for China only.

含有有害6物质的名称,含有量,含有部品

本产品中所含有的有害6 物质的名称,含有量,含有部品如下表所

示。

产品中有害物质的名称及含量

有害物质

部件名称

铅

(Pb)汞(Hg)镉(Cd)

六价铬

(Cr(VI))

多溴联苯

(PBB)

多溴

二苯醚

(PBDE)

外壳 ○ ○ ○ ○ ○ ○

印刷基板 × ○ ○ ○ ○ ○

显示器

背光灯

GOT

(CCFL)

○×○ ○ ○ ○

电缆 × ○ ○ ○ ○ ○

本表格依据SJ/T 11364的规定编制。

○:表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572

规定的限量要求以下。

×:表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T

26572规定的限量要求。

This manual confers no industrial property rights or any rights of any other

kind, nor does it confer any patent licenses. Mitsubishi Electric Corporation

cannot be held responsible for any problems involving industrial property rights

which may occur as a result of using the contents noted in this manual.

Warranty

Exclusion of loss in opportunity and secondary loss from warranty liability

Regardless of the gratis warranty term, Mitsubishi shall not be liable for

compensation to:

(1) Damages caused by any cause found not to be the responsibility of

Mitsubishi.

(2) Loss in opportunity, lost profits incurred to the user by Failures of Mitsubishi

products.

(3) Special damages and secondary damages whether foreseeable or not,

compensation for accidents, and compensation for damages to products

other than Mitsubishi products.

(4) Replacement by the user, maintenance of on-site equipment, start-up test run

and other tasks.

For safe use

This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in

a device or system used in purposes related to human life.

Before using the product for special purposes such as nuclear power, electric

power, aerospace, medicine or passenger movement vehicles, consult with

Mitsubishi Electric.

This product has been manufactured under strict quality control. However

when installing the product where major accidents or losses could occur if the

product fails, install appropriate backup or failsafe functions in the system.

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Loading...

Loading...