Page 1

C

MIT

SUBIS

C

HI ELECTRI

MELSEC FX Series

Programmable Logic Controllers

User's Manual

Art. no.: 138030

15 04 2003

JY992D93401

Version D

FX2N-10PG

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

Page 2

Model FX2N-10PG Pulse Output Block

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of the FX

and understood before attempting to install or use the unit.

-10PG Pulse Output Block. It should be read

2N

• Further information can be found in the FX

Series HARDWARE MANUAL, FX

2N

2NC

HARDWARE MANUAL and THE FX SERIES OF PROGRAMMABLE CONTROLLER

PROGRAMMING MANUAL ΙΙ.

• If in doubt at any stage of the installation of FX

-10PG Pulse Output Block always consult

2N

a professional electrical engineer who is qualified and trained to the local and national

standards which apply to the installation site.

• If in doubt about the operation or use of FX

-10PG Pulse Output Block please consult the

2N

nearest Mitsubishi Electric distributor.

• This manual is subject to change without notice.

Series

Page 3

Model FX2N-10PG Pulse Output Block

Model FX

2N

-10PG Pulse Output Block

USER’S MANUAL

Manual number : JY992D93401

Manual revision : D

Date : April 2003

i

Page 4

Model FX2N-10PG Pulse Output Block

ii

Page 5

Model FX2N-10PG Pulse Output Block

FAX BACK

Mitsubishi has a world wide reputation for its efforts in continually developing and pushing back

the frontiers of industrial automation. What is sometimes overlooked by the user is the care

and attention to detail that is taken with the documentation. However, to continue this process

of improvement, the comments of the Mitsubishi users are always welcomed. This page has

been designed for you, the reader, to fill in your comments and fax them back to us. We look

forward to hearing from you.

Fax numbers: Your name: ...................................................

Mitsubishi Electric.... .....................................................................

America (01) 847-478-2253 Your company: .............................................

Australia (02) 638-7072 .....................................................................

Germany (0 21 02) 4 86-1 12 Your location:................................................

Spain (34) 93-589-1579 .....................................................................

United Kingdom (01707) 278-695

Please tick the box of your choice

!

!

!

!

!

!

Good

Ye s

Tidy

Ye s

Ye s

Good

What condition did the manual arrive in?

Will you be using a folder to store the manual?

What do you think to the manual presentation?

Are the explanations understandable?

Which explanation was most difficult to understand: ..................................................................

....................................................................................................................................................

Are there any diagrams which are not clear?

If so,which: ..................................................................................................................................

What do you think to the manual layout?

If there one thing you would like to see improved, what is it? .....................................................

....................................................................................................................................................

....................................................................................................................................................

Could you find the information you required easily using the index and/or the contents, if

possible please identify your experience: ...................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

!

Minor damage

!

No

!

Unfriendly

!

Not too bad

!

No

!

Not too bad

!

Unusable

!

Unusable

!

Unhelpful

Do you have any comments in general about the Mitsubishi manuals? .....................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

Thank you for taking the time to fill out this questionnaire. We hope you found both the product

and this manual easy to use.

iii

Page 6

Model FX2N-10PG Pulse Output Block

iv

Page 7

Model FX2N-10PG Pulse Output Block

Guidelines for the Safety of the User and Protection of the FX2N-10PG Pulse

Output Block

This manual provides information for the use of the FX2N-10PG Pulse Output Block. The

manual has been written to be used by trained and competent personnel. The definition of

such a person or persons is as follows;

a) Any engineer who is responsible for the planning, design and construction of automatic

equipment using the product associated with this manual should be of a competent

nature, trained and qualified to the local and national standards required to fulfill that

role. These engineers should be fully aware of all aspects of safety with regards to

automated equipment.

b) Any commissioning or service engineer must be of a competent nature, trained and

qualified to the local and national standards required to fulfill that job. These engineers

should also be trained in the use and maintenance of the completed product. This

includes being completely familiar with all associated documentation for the said product.

All maintenance should be carried out in accordance with established safety practices.

c) All operators of the completed equipment (see Note) should be trained to use this

product in a safe manner in compliance to established safety practices. The operators

should also be familiar with documentation which is associated with the operation of the

completed equipment.

Note :

Note: the term ‘completed equipment’ refers to a third party constructed device which

contains or uses the product associated with this manual.

Notes on the Symbols Used in this Manual

At various times throughout this manual certain symbols will be used to highlight points of

information which are intended to ensure the users personal safety and protect the integrity of

equipment. Whenever any of the following symbols are encountered its associated note must

be read and understood. Each of the symbols used will now be listed with a brief description of

its meaning.

Hardware Warnings

1) Indicates that the identified danger

2) Indicates that the identified danger could

WILL

cause physical and property damage.

POSSIBLY

cause physical and property

damage.

3) Indicates a point of further interest or further explanation.

Software Warnings

4) Indicates special care must be taken when using this element of software.

5) Indicates a special point which the user of the associate software element should

be aware of.

6) Indicates a point of interest or further explanation.

v

Page 8

Model FX2N-10PG Pulse Output Block

• Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to

understanding the text, not to guarantee operation. Mitsubishi Electric will accept no

responsibility for actual use of the product based on these illustrative examples.

• Please contact a Mitsubishi Electric distributor for more information concerning applications

in life critical situations or high reliability.

Trademark registration

The company names and product names described in this manual are the registered names

and trademarks of the relevant companies.

vi

Page 9

Model FX2N-10PG Pulse Output Block

Associated Manuals

This manual describes the handling and operation of MELSEC-FX Series FX

-10PG Pulse

2N

Output Block. For the configuration and commands of the system, also refer to the manuals of

the following PLC. Before operation, read this manual and the manuals of the PLC thoroughly

and be sure you sufficiently understand their specifications for proper operation.

Also, be sure that the manual is provided to the end user.

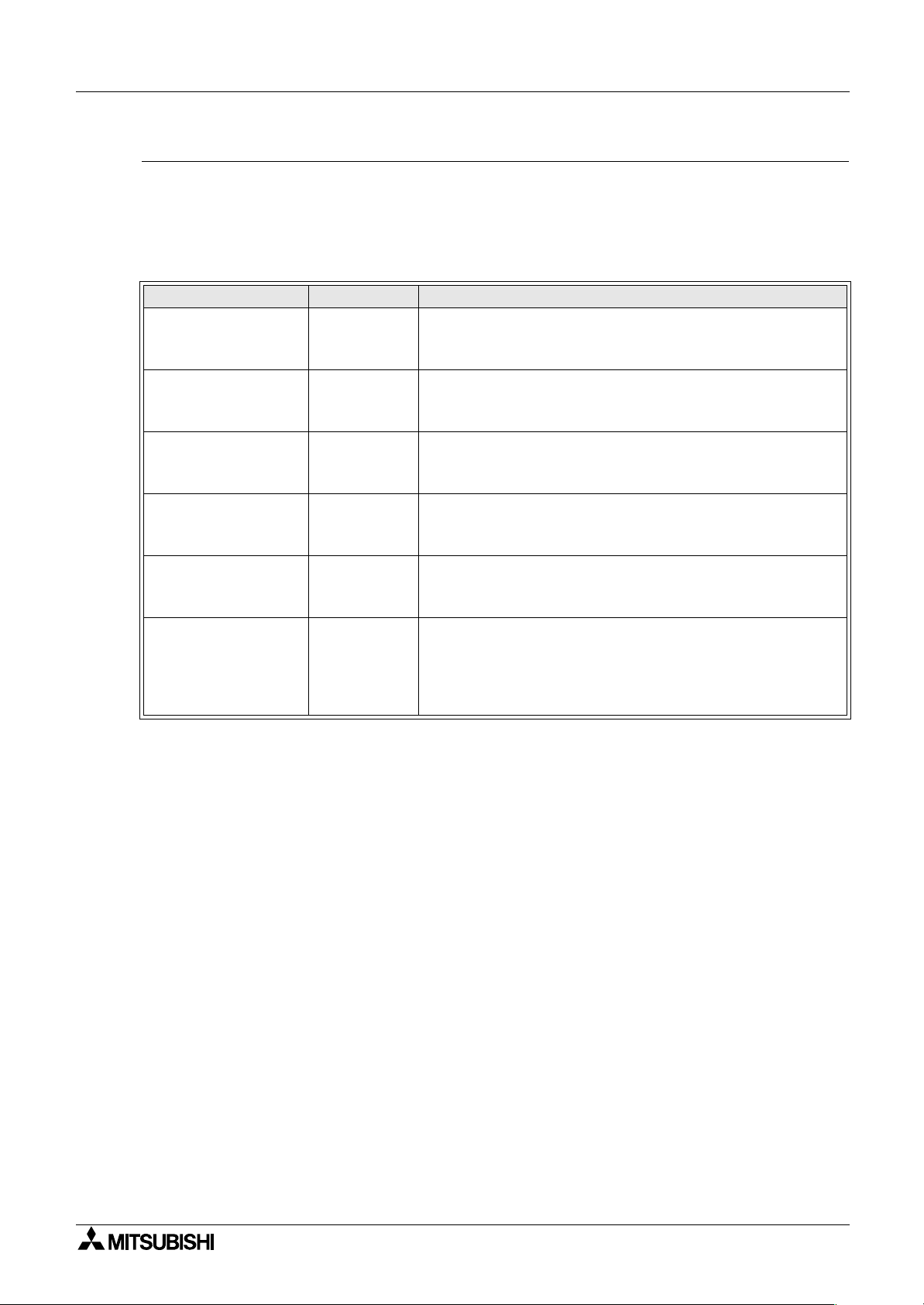

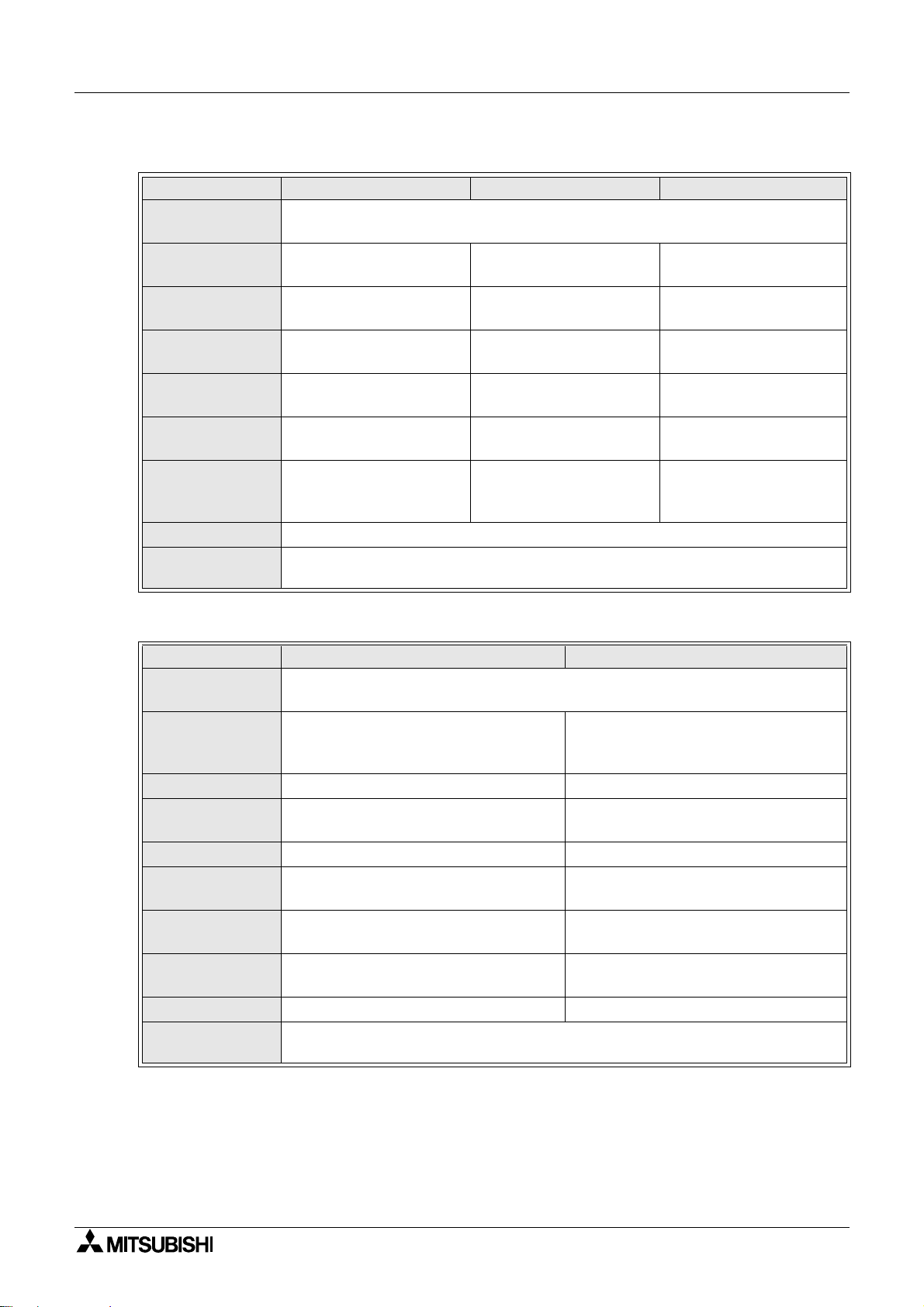

Manual name Manual No. Description

2N

-10PG

FX

USER'S MANUAL

(this manual)

2N

FX

-10PG

Installation Manual

(in same package)

2N

FX

HARDWARE MANUAL

(in same package)

2N

c (D/UL)

FX

HARDWARE MANUAL

(in same package)

2N

FX

c (DSS/DS)

HARDWARE MANUAL

(in same package)

THE FX SERIES OF

PROGRAMMABLE

CONTROLLER

PROGRAMMING

MANUAL

ΙΙ

JY992D93401

JY992D91901

JY992D66301

JY992D87201

JY992D76401

JY992D88101

The manual explains the details of the hardware regarding the

specifications, wiring, installation, etc. of the FX

2N

-10PG

Series PLC.

The manual explains the specifications, installation, etc. of the

2N

FX

-10PG Pulse Output Block.

The manual explains the details of the hardware regarding the

specifications, wiring, installation, etc. of the FX2N Series

PLC.

The manual explains the details of the hardware regarding the

specifications, wiring, installation, etc. of the FX

2NC

(D/UL)

Series PLC.

The manual explains the details of the hardware regarding the

specifications, wiring, installation, etc. of the FX

2NC

(DSS/DS)

Series PLC.

The manual explains the commands of FX

2N

and FX

2NC

Series.

Of the manuals listed above, THE FX SERIES OF PROGRAMMABLE CONTROLLER

PROGRAMMING MANUAL ΙΙ are not packed with the product.

If necessary, contact your dealer to request the desired manual.

FX

-10PG Installation Manual, FX2N Handy Manual and FX

2N

Handy Manual are packed

2NC

with each product.

vii

Page 10

Model FX2N-10PG Pulse Output Block

viii

Page 11

Model FX2N-10PG Pulse Output Block Contents

1. Introduction .........................................................................................1-1

1.1 Product outline.................................................................................................1-1

2. Outside dimensions and component names.......................................2-1

2.1 Outside d ime n s io n s .............. .. ............. .. ............. ... .. ............. .. .............. .. .. .......2-1

2.2 LED display......................................................................................................2-2

2.3 Pin layout and assignment...............................................................................2-3

2.3.1 Applicable connector and cable size...................................... ...... ....... ................2-4

3. Installation........................................................................................... 3-1

3.1 DIN rail installation...........................................................................................3-1

3.2 Direct installation..............................................................................................3-1

4. System configuration.................................................... ............ ...........4-1

4.1 Connection with PLC ....................................................................................... 4-1

4.2 Applicable PLC ................................................................................................4-2

5. Specifications......................................................................................5-1

5.1 Environmental specifications ...........................................................................5-1

5.2 Power supply specifications.............................................................................5-1

5.3 Performance specifications..............................................................................5-1

5.4 Input specifications..........................................................................................5-2

5.5 Output specifications........................................................................................5-2

6. Wiring..................................................................................................6-1

6.1 Input output circuit............................................................................................6-1

6.2 Input wiring.......................................................................................................6-4

6.2.1 START, DOG, X0, X1, S/S.............. ....... ...... ....................................... ...... ....... ...6-4

6.2.2 A-phase +, A-phase -, B-phase +, B-phase - ......................................................6-5

6.2.3 PGO+, PGO-.......................................................................................................6-6

6.3 Output wiring....................................................................................................6-7

6.3.1 VIN+, VIN-, FP+, FP-, RP+, RP- .........................................................................6-7

6.3.2 CLR+, CLR-.........................................................................................................6-8

6.4 Connection with stepping motor.......................................................................6-9

6.5 Connection with Model MR-C Servo Motor....................................................6-10

6.6 Connection with Model MR-J Servo Motor ....................................................6-11

6.7 Connection with Model MR-J2 (-Jr, -Super) Serv o Motor..............................6-12

6.8 Connection with Model MR-H Servo Motor....................................................6-13

7. Buffer memory (BFM)..........................................................................7-1

7.1 BFM list............................................................................................................ 7-1

7.2 Details o f BF M ................. .. .............. .. .. ............. .. .............. .. ............. .. ... ...........7-5

7.2.1 BFM#1, #0 Maximum speed ..............................................................................7-5

7.2.2 BFM#2 Bias speed.............................................................................................7-5

7.2.3 BFM#4, #3 Jog speed........................................................................................7-5

7.2.4 BFM#6, #5 Zero return speed (high speed) ....................................................... 7-5

7.2.5 BFM#7 Zero return speed (creep).......................................................................7-5

7.2.6 BFM#8 Zero-point signal number........................................................................7-5

7.2.7 BFM#10, #9 Zero-point address........................................................................7-6

7.2.8 BFM#11 Acceleration time.................................................................................7-6

7.2.9 BFM#12 Deceleration time.................................................................................7-6

7.2.10 BFM#14, #13 Target address I...........................................................................7-6

7.2.11 BFM#16, #15 Operation speed I........................................................................7-6

7.2.12 BFM#18, #17 Target address II.........................................................................7-7

7.2.13 BFM#20, #19 Operation speed II.....................................................................7-7

7.2.14 BFM#21 Override setting ................................................................................... 7-7

7.2.15 BFM#23, #22 Operation speed current value ....................................................7-7

7.2.16 BFM#25, #24 Current address...........................................................................7-7

7.2.17 BFM#26 Operation commands .......................................................................... 7-8

ix

Page 12

Model FX2N-10PG Pulse Output Block Contents

7.2.18 BFM#27 Operation pattern...............................................................................7-11

7.2.19 BFM#28 Status information..............................................................................7-13

7.2.20 BFM#29 m code..............................................................................................7-13

7.2.21 BFM#30 Machine model code..........................................................................7-13

7.2.22 BFM#33, #32 pulse rate...................................................................................7-14

7.2.23 BFM#35, #34 Feed rate ...................................................................................7-14

7.2.24 BFM#36 Parameters ........................................................................................7-14

7.2.25 BFM#37 Error code..........................................................................................7-19

7.2.26 BFM#38 Terminal information..........................................................................7-19

7.2.27 BFM#40, #39 Current address........................................................................7-19

7.2.28 BFM#42, #41 Manual pulse generator input current value ..............................7-19

7.2.29 BFM#44, #43 Manual pulse generator input frequency ...................................7-20

7.2.30 BFM#45 Manual pulse generator input electronic gearing (numerator)...........7-20

7.2.31 BFM#46 Manual pulse generator input electronic gearing (denominator) .......7-20

7.2.32 BFM#47 Input response of manual pulse generator ........................................7-20

7.2.33 BFM#64 Version information............................................................................7-20

7.2.34 BFM#98 Table start No. ...................................................................................7-20

7.2.35 BFM#99 Executing table No.............................................................................7-20

7.2.36 BFM#100 and later BFM for program with table system.................................7-20

8. Operation pattern................................................................................8-1

8.1 General items for positioning operation...........................................................8-1

8.1.1 Outline of positioning operation...........................................................................8-1

8.1.2 STOP command process....................................................................................8-2

8.1.3 Overlapped command of operation modes .........................................................8-3

8.1.4 Small travel...................................... ....... ...................................... ....... ...... ....... ...8-3

8.1.5 Forward/reverse limits.........................................................................................8-5

8.1.6 Cautions for use of mechanical system/compound system units........................8-6

8.2 Jog opera ti on ..................... ... .. ............. .. .. ... ............. .. .. .............. .. .. .. ............. ...8-7

8.2.1 Outline of jog operation.......................................................................................8-7

8.2.2 Speed change during jog operation ....................................................................8-8

8.3 Machine zero return.........................................................................................8-9

8.3.1 Outline of zero return...........................................................................................8-9

8.3.2 Zero return direction............................................................................................8-9

8.3.3 Polarity of dog input.............................................................................................8-9

8.3.4 Count start timing............................................... ....... ...... ....... ...... ....... ...... ..........8-9

8.3.5 Zero return speed..............................................................................................8-10

8.3.6 Zero return completed flag................................................................................8-10

8.3.7 Change of zero return speed.............................................................................8-10

8.3.8 Data set type zero return...................................................................................8-10

8.3.9 Dog search function ..........................................................................................8-11

8.3.10 Forced ON/OFF of CLR signal..........................................................................8-11

8.4 1st-speed positioning operation........................... ..........................................8-12

8.4.1 Outline of 1st-speed positioning operation........................................................8-12

8.4.2 Operation speed................................................................................................8-12

8.4.3 Address instruction............................................................................................8-12

8.4.4 Rotation direction ............... ....... ...... ....... ...... ...... ....... ....................................... .8-12

8.4.5 Positioning complete flag ..................................................................................8-13

8.4.6 STOP command................................................................................................8-13

8.5 Interrupt 1st-speed positioning operation.......................................................8-14

8.5.1 Outline of interrupt 1st-speed positioning operation..........................................8-14

8.5.2 Operation speed................................................................................................8-14

8.5.3 Address instruction............................................................................................8-14

8.5.4 Rotation direction ............... ....... ...... ....... ...... ...... ....... ....................................... .8-14

8.5.5 Positioning complete flag ..................................................................................8-15

8.5.6 STOP command................................................................................................8-15

8.6 2nd-speed positioning operation....................................................................8-16

x

Page 13

Model FX2N-10PG Pulse Output Block Contents

8.6.1 Outline of 2nd-speed positioning operation.......................................................8-16

8.6.2 Operation speed................................................................................................8-16

8.6.3 Address instruction............................................................................................8-16

8.6.4 Rotation direction ............... ....... ...... ....... ...... ...... ....... ....................................... .8-17

8.6.5 Positioning complete flag (BFM#28 b6) ............................................................8-17

8.6.6 STOP command................................................................................................8-17

8.7 Interrupt 2nd-speed positioning operation ......................... ............................8-18

8.7.1 Outline of interrupt 2nd-speed positioning operation.........................................8-18

8.7.2 Operation speed................................................................................................8-18

8.7.3 Address instruction............................................................................................8-18

8.7.4 Rotation direction ............... ....... ...... ....... ...... ...... ....... ....................................... .8-19

8.7.5 Positioning complete flag (BFM#28 b6) ............................................................8-19

8.7.6 STOP command................................................................................................8-19

8.8 Interrupt stop operation..................................................................................8-20

8.8.1 Outline of interrupt stop operation.....................................................................8-20

8.8.2 Operation speed................................................................................................8-20

8.8.3 Address instruction............................................................................................8-20

8.8.4 Rotation direction ............... ....... ...... ....... ...... ...... ....... ....................................... .8-20

8.8.5 Positioning complete flag ..................................................................................8-21

8.8.6 STOP command................................................................................................8-21

8.9 Table operation................................... ...........................................................8-22

8.9.1 Outline of table operation ..................................................................................8-22

8.9.2 Assignment of tables and BFM Nos....... ...................................... ....... ...... ....... .8-24

8.9.3 Operation example 1 (continuous operation)....................................................8-24

8.9.4 Operation example 2 (position-to-speed operation)..........................................8-25

8.9.5 Operation example 3 (step-advance operation)................................................8-26

8.10 Variable-speed operation . ..............................................................................8-27

8.10.1 Outline of variable-speed operation ..................................................................8-27

8.10.2 Operation speed................................................................................................8-27

8.10.3 Rotation direction ................................... ...... ...... ....... ....................................... .8-28

8.10.4 STOP command................................................................................................8-28

8.11 Manual pulse generator input operation........................................................8-29

8.11.1 Outline of manual pulse generator input operation ...........................................8-29

8.11.2 Pulse output valid range....................................................................................8-30

8.11.3 Manual pulse generator input current value......................................................8-30

8.11.4 Manual pulse generator input frequency...........................................................8-30

8.11.5 Manual pulse generator Electronic gearing (numerator).................................8-30

8.11.6 Manual pulse generator Electronic gearing (denominator) .............................8-30

8.11.7 Manual pulse generator response.....................................................................8-30

9. Program example................................................................................9-1

9.1 Outline of FROM/TO commands .....................................................................9-1

9.2 Length feed operation (1st-speed positioning).................................................9-2

9.2.1 Operation explanation.........................................................................................9-3

9.2.2 Device assignment (PLC)....................................................................................9-6

9.2.3 Sequence program..............................................................................................9-7

9.3 Multi-speed operation (table operation)...........................................................9-9

9.3.1 Operation explanation.......................................................................................9-10

9.3.2 Device assignment (PLC)..................................................................................9-13

9.3.3 Sequence program............................................................................................9-15

10. Diagnostics........................................................................................10-1

10.1 D iagnostics LED .......................... .. ................................................................10-1

10.2 Diagnostics (BFM#37) ......................................... .. .. .. .. .. ...............................10-3

10.3 D iagnostics PLC .......................... .. ................................................................10-4

xi

Page 14

Model FX2N-10PG Pulse Output Block Contents

xii

Page 15

Model FX2N-10PG Pulse Output Block

1. Introduction

1.1 Product outline

FX2N-10PG Pulse Output Block (hereafter abbreviated as FX2N-10PG, Pulse Output Block or

PGU) is a special block to output a maximum 1MHz pulse array and drive a single-axis

stepping motor or servo motor.

Introduction 1

1) FX

-10PG controls the positioning operation of one single-axis stepping motor or servo

2N

motor per unit.

2) FX

or FX

2N

Series PLC is connected to read and write the data with FROM/TO

2NC

commands.

3) A pulse array of max. 1MHz can be output. (Differential line driver output)

Cautions regarding design

• To make sure the entire system operates safely even when problems such as a faulty

external power supply, PLC, or FX

circuits outside the PLC and FX

2N

Otherwise, improper operation or wrong output may cause an accident.

1) The emergency stop circuit, protective circuit, in terlock circ uit against machi ne breakage ,

etc. must be provided as circuits outside the PLC and FX

2) If the PLC or FX

-10PG Pulse Output Block detects any problem using the self-

2N

diagnosis function for the watchdog timer errors and input value errors, or if any trouble

occurs in the input/output control area, etc. which cannot be detected by the PLC CPU,

output control may sometimes become impossible .Be sure to design the ext ernal circu it s

and mechanisms to operate the machine safely in such cases.

-10PG Pulse Output Block occurs, provide safety

2N

-10PG Pulse Output Block.

-10PG.

2N

3) If any relay, transistor, triac, etc. in the output unit of the FX

-10PG Pulse Output Block

2N

or PLC malfunctions, the output may sometimes be kept on or off .

Design the external circuits and mechanisms to operate the machine safely regarding

output signals which may lead to a serious accident.

Cautions regarding disposal

• When disposing of the product, handle it as industrial waste.

1-1

Page 16

Model FX2N-10PG Pulse Output Block Introduction 1

MEMO

1-2

Page 17

Model FX2N-10PG Pulse Output Block

Outside dimensions and component names 2

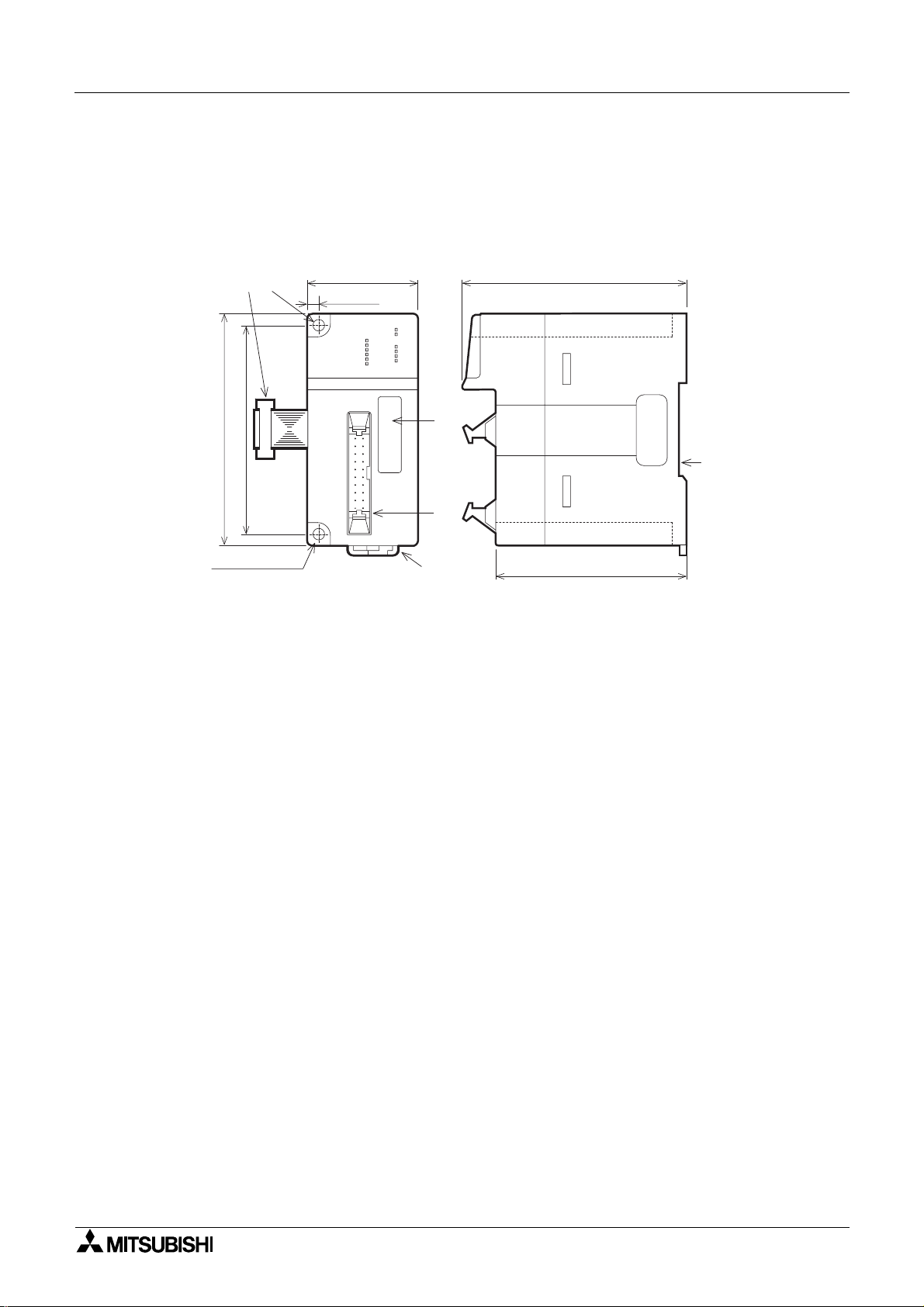

2. Outside dimensions and component names

2.1 Outside dimensions

Unit: mm (inches)

b)a)

43(1.69")

4(0.16")

FX2N-10P G

START

DOG

X0

X1

φ

φ

POW ER

ERROR

PGO

FP

RP

A

CLR

B

87(3.43")

c)

90(3.54")

80(3.15")

f )

d)

4.5(φ0.18")

2-φ

e)

74(2.91")

External color: Munsell 0.08GY/7.64/0.81 Mass (Weight): Approx. 0.2kg (0.44lbs)

Accessories : Special block No. label

a) Extension cable

b) Direct mounting hole (2 - φ4.5/0.18”)

c) Extension port

d) Input/output port

e) DIN rail mounting hook

f) DIN rail mounting groove (DIN rail: DIN46277 35mm (1.38”) wide)

2-1

Page 18

Model FX2N-10PG Pulse Output Block Outside dimensions and component names 2

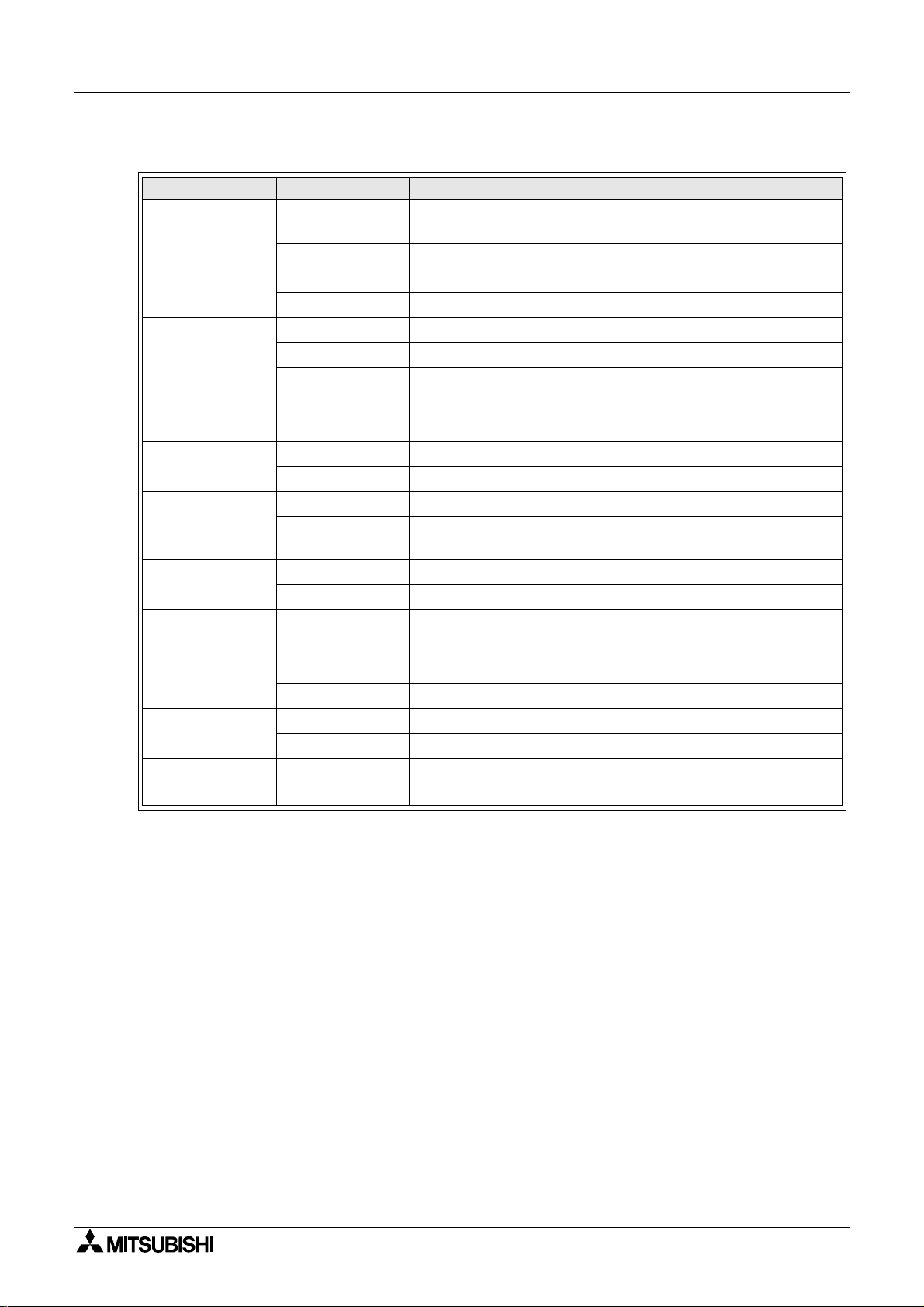

2.2 LED display

LED name State Display content

5V DC is not supplied through the extension cable from the

PLC.

CLR signal is output (when the origin point return is

completed)

POWER

START

ERROR

FP

RP

CLR

DOG

PG0

φ

A

φ

B

X0,X1

Unlit

Lit 5V DC is supplied through the extension cable from the PLC.

Unlit Start input off

Lit Start input on

Unlit Normal operation

Blinking Error occurred

Lit CPU error occurred

Unlit Forward pulse or pulse array interrupted.

Blinking Forward pulses or pulse array is being output.

Unlit Reverse pulse or directional output interrupted.

Blinking Reverse pulses or directional output is being output.

Unlit CLR signal is not output.

Lit

Unlit DOG input off

Lit DOG input on

Unlit Zero-point input off

Lit Zero-point input on

Unlit A-phase input of manual pulse generator off

Lit A-phase input of manual pulse generator on

Unlit B-phase input of manual pulse generator off

Lit B-phase input of manual pulse generator on

Unlit Interrupt input off

Lit Interrupt input on

2-2

Page 19

Model FX2N-10PG Pulse Output Block Outside dimensions and component names 2

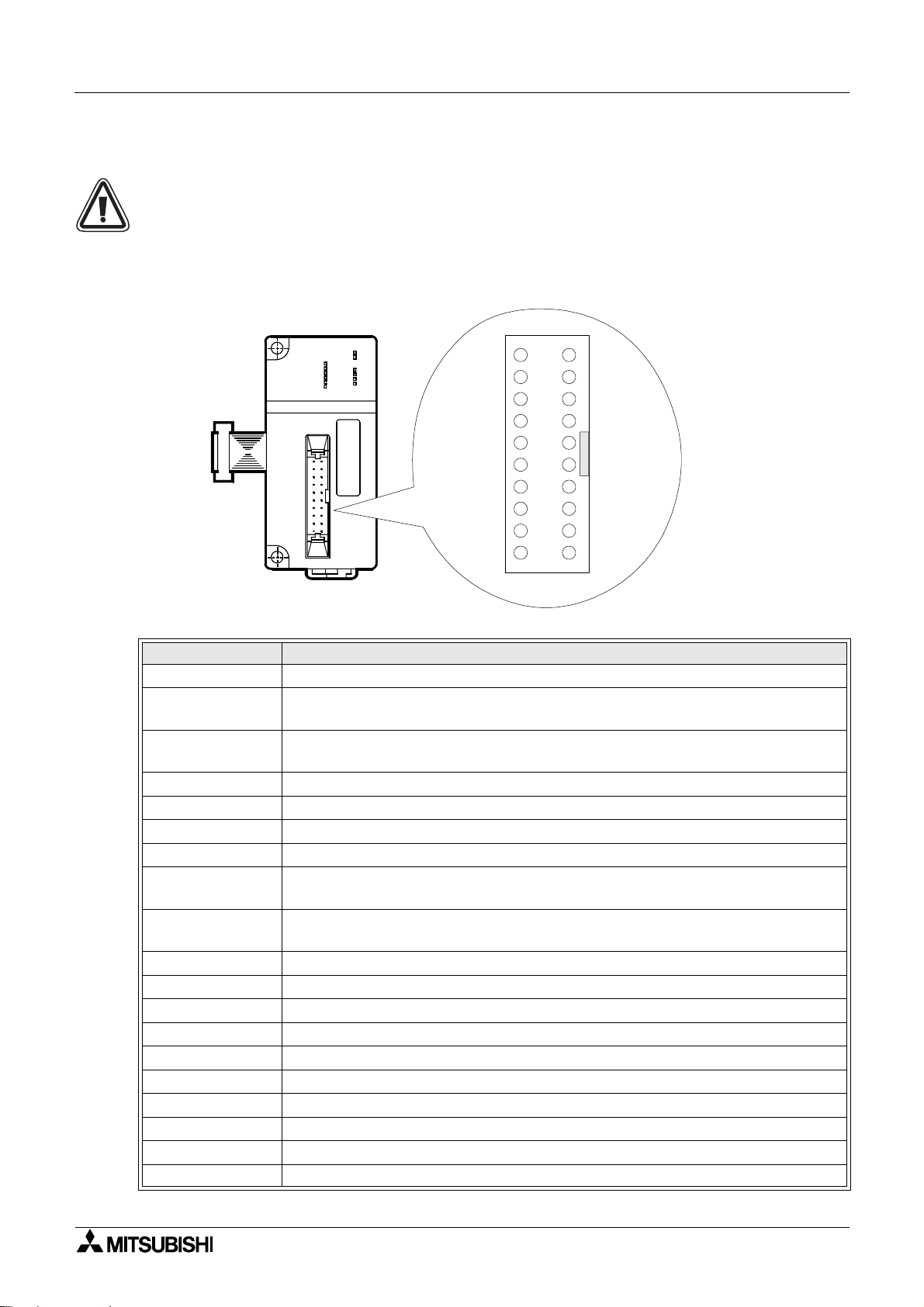

2.3 Pin layout and assignment

• The following pin layout is seen when looking at the I/O port in the FX2N-10PG from the

front face.

When an I/O cable and connecto r is prepare d by the user, the pin number mark an d

mark are different according to the connector used.

Wire correctly noting the position of notch and the direction of the connector.

I/O port in the FX2N-10P from the front face

POWER

FX2N-10PG

START

DOG

X0

X1

f

f

ERROR

PGO

FP

RP

A

CLR

B

VIN+

FP+

RP+

PG0+

CLR+

φ

A+

φ

B+

DOG

S/S

X0

VINFPRPPG0CLR-

φ

A-

φ

BSTART

S/S

X1

▲

Terminal name Content

VIN+ Power input terminal for pulse output 5V DC to 24V DC

FP+

RP+

Forward/reverse mode: Forward pulse output terminal

Pulse/direction mode: Pulse output terminal

Forward/reverse mode: Reverse pulse output termina l

Pulse/direction mode: Direction output terminal

PG0+ Zero-point signal input terminal

CLR+ Output terminal to clear the deviation counter of servo amplifier

φ

A+ A-phase input terminal of 2-phase pulse

φ

B+ B-phase input terminal of 2-phase pulse

DOG

S/S

Near-point DOG input terminal (Input terminal used for origin-point return

command)

Power input terminal (start, DOG, X0, X1) 24V DC

Pins (S/S) are internally short-circuited.

X0 Interrupt input terminal

VIN- Common terminal of VIN+

FP- Common terminal of FP+

RP- Common terminal of RP+

PG0- Common terminal of PG0+

CLR- Common terminal of CLR+

φ

A- Common terminal of A-phase input of 2-phase pulse

φ

B- Common terminal of B-phase input of 2-phase pulse

START Start input terminal

X1 Interrupt input terminal

2-3

Page 20

Model FX2N-10PG Pulse Output Block Outside dimensions and component names 2

2.3.1 Applicable connector and cable size

The connectors for the multi-wire cables are prepared as a set to allow the customer to

produce the input/output cables.

The cables and crimp tool should be prepared by the customer.

Model name and configuration of

input/output connector

Applicable cable and tool

Model name Cable size

FX

-I/O-CON-S

2C

For multi-wire cable: 5 sets

FX

-I/O-CON-SA

2C

For multi-wire cable: 5 sets

AWG22(0.3mm

AWG20(0.5mm

2

)

2

)

*1 Since it may be difficult to pass the random cable through the housing depending on the

variation of the sheath thickness, UL-1061 cable is recommended.

* Phoenix contact crimp tool.

2-4

Page 21

Model FX2N-10PG Pulse Output Block

3. Installation

Install FX2N-10PG on the right side of the basic unit, extension unit or other extension block of

FX

and FX2Nc Series PLC.

2N

For installation, install the block with DIN rail (DIN46277, 35mm (1.38inches) wide) or directly

with M4 screws.

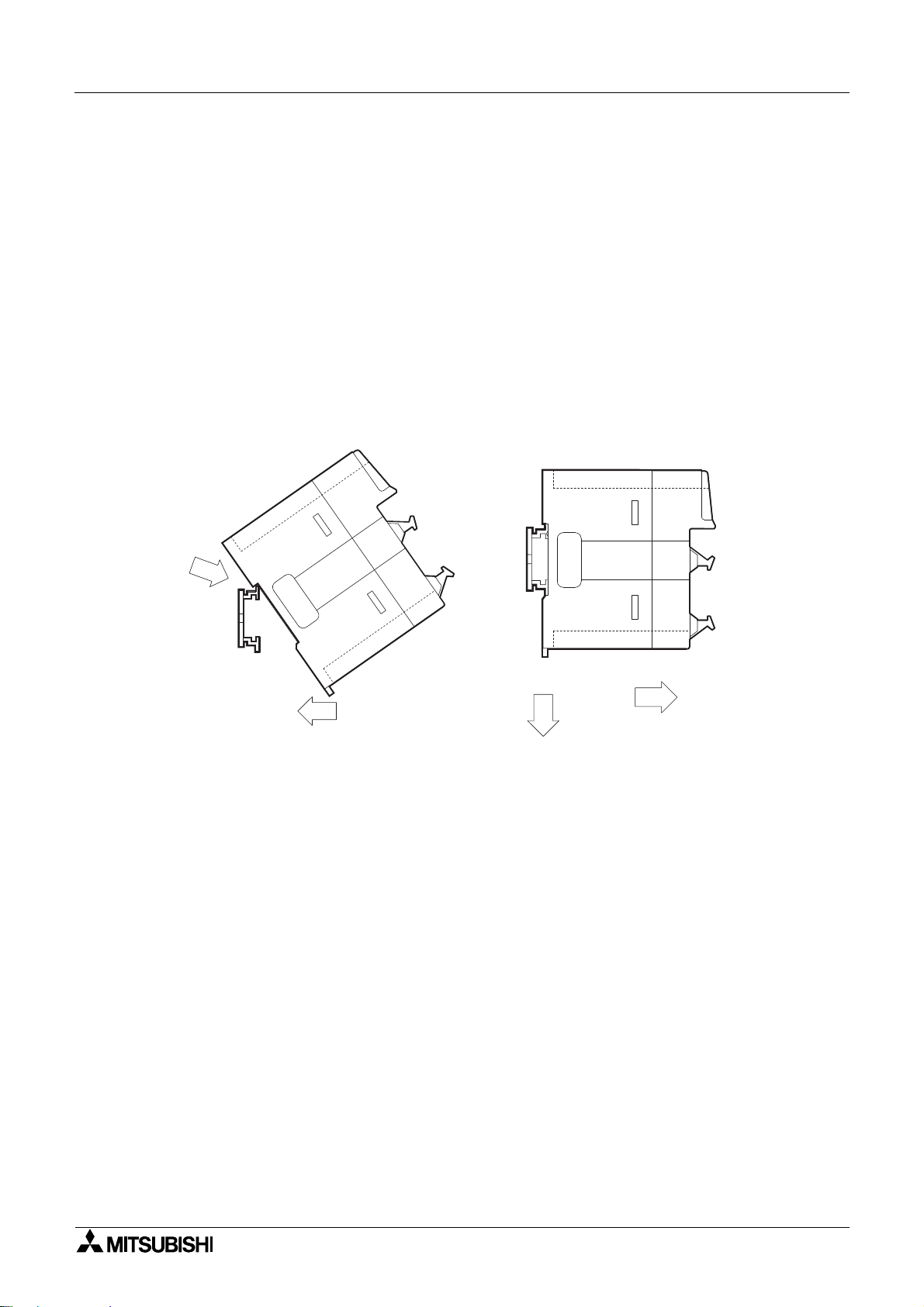

3.1 DIN rail installation

Align the upper side of the DIN rail mounting groove with t he DIN rail 1), and press the block in

2).

To remove the main body, pull out the DIN rail mounting hook downward 3), and remove the

block 4).

Installation Removal

Installation 3

1)

3.2 Direct installation

Pass M4 screws through the two mounting holes provided at the top and bottom on the left

side of FX

Provide a clearance of 1 to 2mm (0.08inches) between the units during installation.

-10PG, and install the block on the panel with the screws.

2N

2)

4)

3)

3-1

Page 22

Model FX2N-10PG Pulse Output Block Installation 3

Cautions regarding installation

1) Use the block under the envir onmental conditions specified in the manual.

Do not use the unit in a loca tion surrounded by dust, oil fumes, conductive dust, corrosive

gas or combustibl e gas, exposed to high temperature , condensation, wind or rai n, or subject

to vibration or impact.

Use in such a locati on may cause an electric shock, fire haza rd, mal functi on, or break age or

degradation of the product.

2) Before installation, wiring or similar work, be sure to switch off the external power supply to

isolate the block.

Otherwise, it may cause an electric shock or damage the product.

3) When tur ning on the power supply or operating the block after installation, wiring or similar

work, be sure to install the top cover.

4) When tapping a hole or routing a wire, prevent chips or wire chips from dropping into the

vent windows of FX

Such chips may cause a fire haza rd or malf unction.

-10PG.

2N

5) Securely fasten the extension cable to a specified connector.

If it is poorly connected, it will cause a malfunction.

3-2

Page 23

Model FX2N-10PG Pulse Output Block

4. System configuration

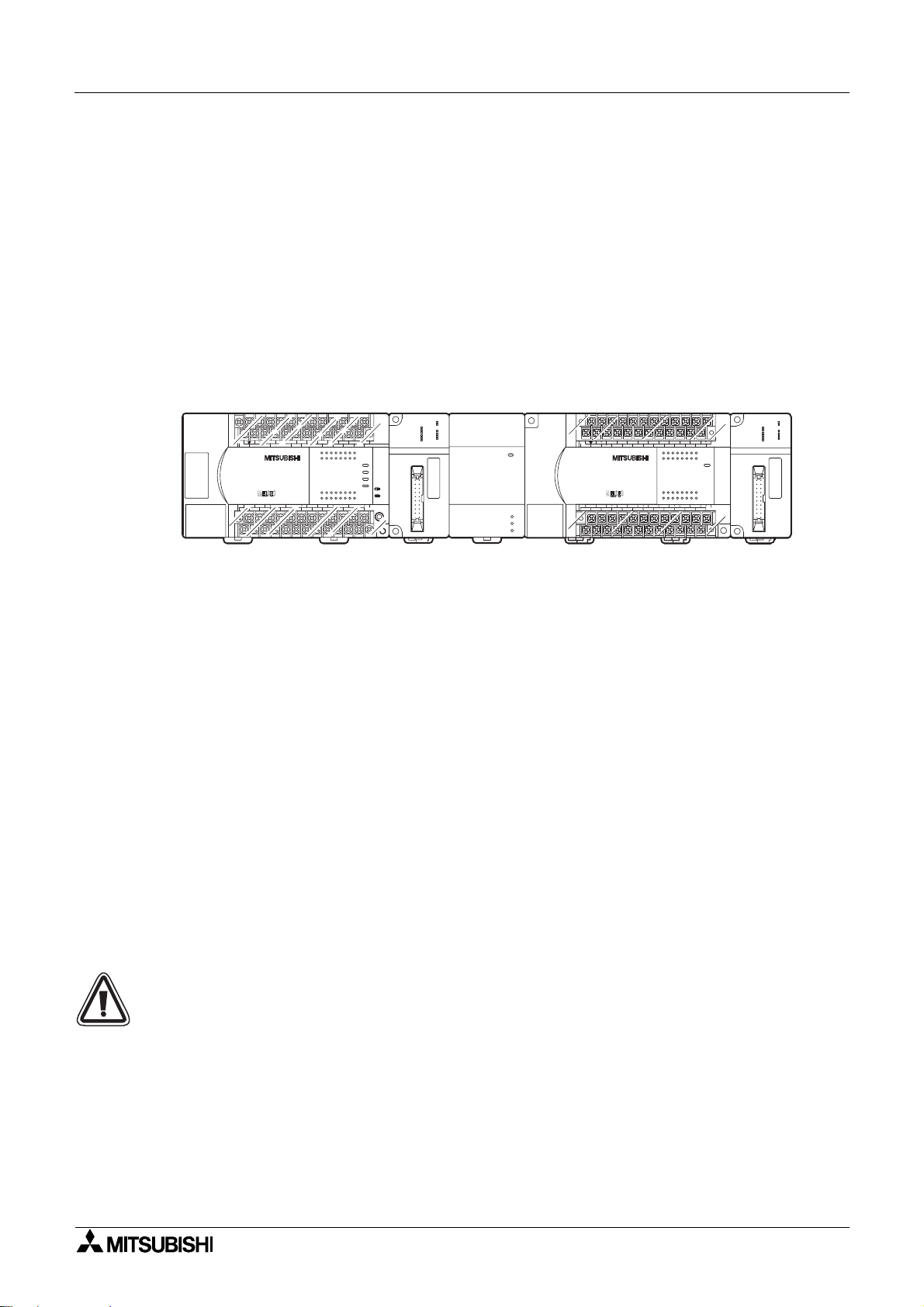

4.1 Connection with PLC

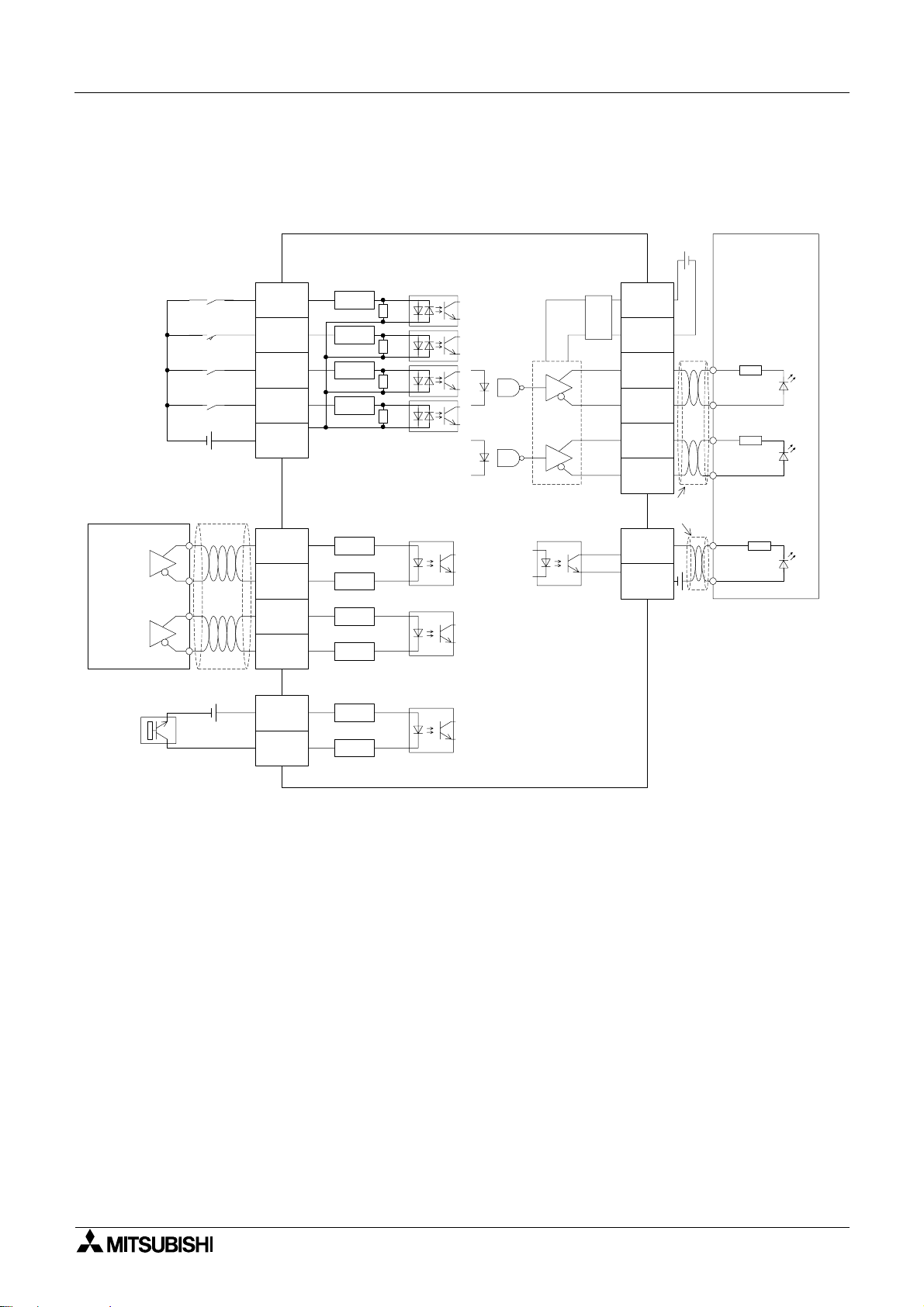

The PLC is connected to FX2N-10PG with the extension cable.

FX

-10PG is handled as a special unit of the PLC and is sequentially given the special unit

2N

number of 0 to 7 from the u nit which is the nearest to P LC. (The unit No. is instructed with

FROM/TO commands.)

For details of the input/output assignment of PLC, refer to the manual of FX

PLC.

System configuration 4

2N

, FX

2NC

Series

START

DOG

X0

X1

A

f

fB

FX2N -2 L C

POWER

ERROR

PGO

FP

RP

CLR

FX2N-2 L C

FX2N-3 2 E R

FX

Y7

FX2N-10 P G

POW ER

Special

2N -1 0 P G

START

DOG

X0

X1

A

f

fB

block

No.2

(X020 to X 037)

X0

X6 X0 X2 X4 X6

COM X4

POW ER

24V

OUT1

OUT2

Special

L X1X3X5X7

(Y020 to Y 037)

24+N

X3X2X1

FX2N-3 2 E R

X5

X7

IN

01234567

OUT

76543210

72456130

72456130

Y4Y5Y6

COM4COM2Y4Y5Y6Y7 COM3Y0Y1Y2Y3COM1Y0Y1Y2Y3

block

No. 1

Series PLC and a maximum of 4 units can

2N

-CNV-IF is required.

2NC

-65EC/FX0N-30EC extension cable and FX2N-

0N

POWER

ERROR

PGO

FP

RP

CLR

FX2N -3 2 M R

14 171510 12 13

1611

1611 1514 1710 12 13

Y14

Y15

72456130

POW ER

RUN

BATT.V

PROG .E

72456130

CPU.E

FX2N -1 0 P G

FX2N-10 P G

Special

(X000 to X 017)

24+N

FX2N-3 2M R

Y4Y5Y6

X10 X14 X16

X7

X3X2X1

IN

OUT

Y10

Y12

COM3

Y11

Y13Y1Y2Y3

COM X4

LX13X15

(Y000 to Y 017)

block

No. 0

• A maximum of 8 units can be connected to FX

be connected to FX

• When connected to FX

Series PLC.

2NC

Series PLC, FX

2NC

• For extension, the separately available FX

CNV-BC are used.

One extension cable can be used per system.

• The number of occupied I/O points of the FX

-10PG is 8. The total number of I/O points of

2N

the basic unit, extension unit and extension block and the occupied poin ts of the special

block must not exceed the max. number of the I/O points of the basic unit (256 points for

FX

and FX

2N

2NC

).

• The assignment of the I/O number of the PLC is shown in the parentheses. The I/O

connectors and occupied points of FX

-10PG are not included during assignment of I/O

2N

numbers of the PLC.

Turn OFF the power at first, then connect/disconnect the cab le such as an extension cable.

If you connect/disconnect a cable while the power is supplied, the unit may fail or malfunction.

4-1

Page 24

Model FX2N-10PG Pulse Output Block System configuration 4

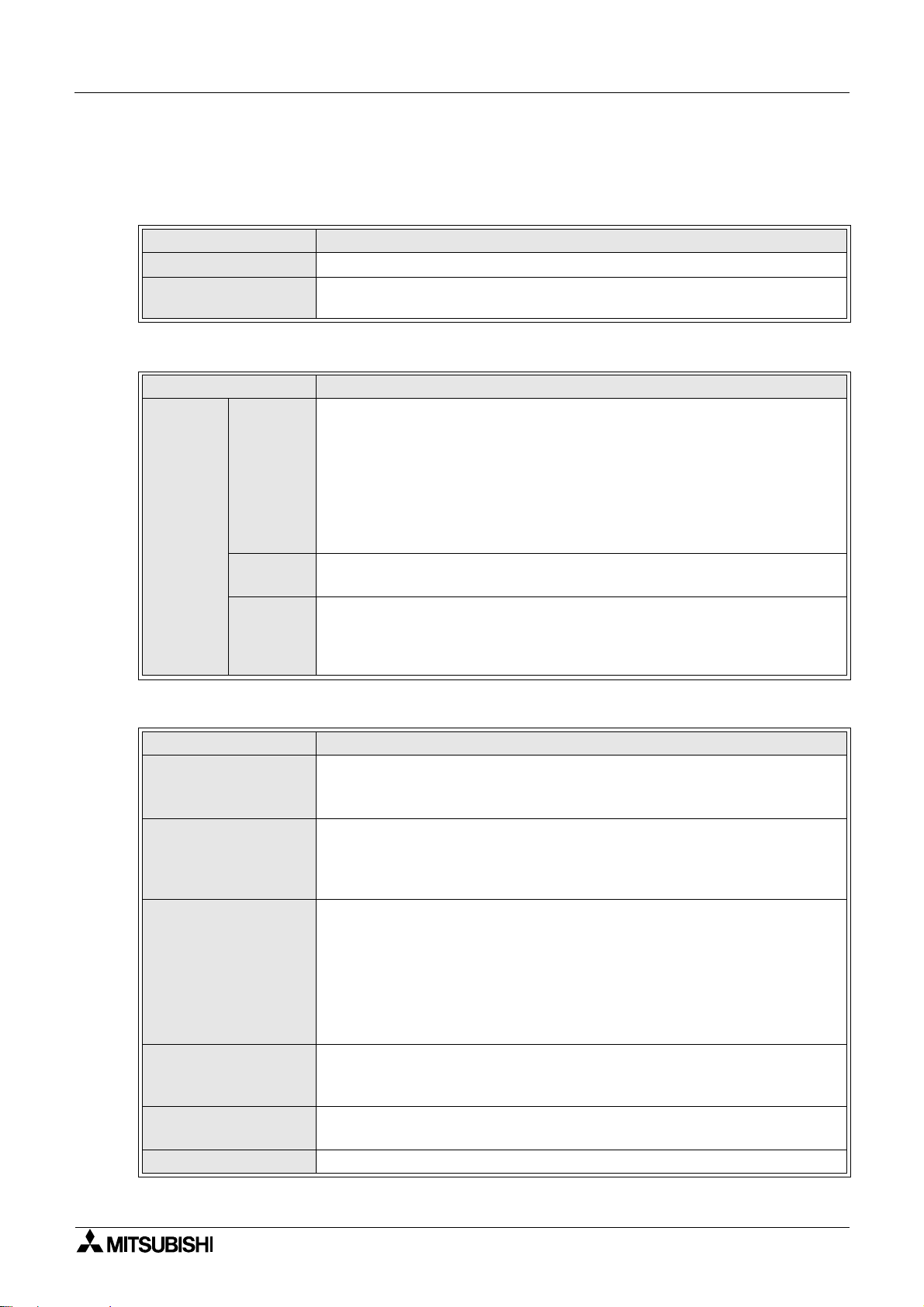

4.2 Applicable PLC

Series name Applicable version

2N

Series All versions

FX

2NC

FX

Series All versions

For connection to FX

2NC

, FX

2NC

-CNV-IF is necessary.

4-2

Page 25

Model FX2N-10PG Pulse Output Block

5. Specifications

5.1 Environmental specifications

Item Specifications

Withstand voltage

Items except above

5.2 Power supply specifications

Item Specifications

Input

signal

Drive

power

supply

Inner

control

Output

signal

500V AC One minute (between all external terminals and ground terminal)

Same as the environmental specifications of the connected PLC

(Refer to the PLC manual.)

START, DOG, X0, X1 terminals: 24V DC+/-10%

Current consumption 32mA or less

PGO terminal: 3 to 5.5V DC Current consumption 20mA or less

VIN terminal: 5 to 24V DC Current consumption 100mA or less for 5V,

70mA or less for 24V

Each current can be supplied from the external power supply. (START, DOG,

X0, X1 terminals can be supplied from the service power supply (24+

terminal) of the PLC.)

5V DC Current consumption 120mA Power is supplied through the

extension cable from the PLC.

FP, RP terminals (Power supplied from VIN terminal 5 to 24V DC):

Set 25mA or less.

CLR: 5 to 24V DC Set 20mA or less.

Each is supplied from the servo amplifier or external power supply.

Specifications 5

5.3 Performance specifications

Item Specifications

Number of control

axes

Speed command

Position command

Positioning program

Number of I/O

occupied points

Start time

• One axis per unit

(Max. 8 units and 4 units can be connected to FX

FX

2NC

• The operation speed is set with the buffer memory.

• It can be operated at the pulse frequency of 1Hz to 1MHz.

• Hz, cm/min, 10 deg/min and inch/min are selectable for the command

unit.

• The travel is set with the buffer memory.

• The pulse converted value is in the range of -2,147,483,648 to

2,147,483,647. Pulse, mm, mdeg and 10

• The absolute position instruction and relative position instruction are

selectable.

• The magnification rates of 10

position data.

• Positioning is done in the PLC program.

(Data read-/writing and operation mode selection are instructed with

FROM/TO commands.)

• 8 points (Input or output.)

• 1 to 3ms

Series PLC respectively.)

0

, 101, 102 and 103 are settable for the

Series PLC and

2N

-4

inch are usable for the unit.

5-1

Page 26

Model FX2N-10PG Pulse Output Block Specifications 5

5.4 Input specifications

φφφφ

φφφφ

A,

Item START, DOG, X1

Number of input

points

Input signal

voltage

Signal format

Input signal

current

Input ON

sensitivity

Input OFF

sensitivity

Input receiving

speed

Circuit insulation

Operation

indication

Three control input points (START, DOG, PG0), two interrupt input points (X0, X1)

2-phase pulse input point (φA, φB)

24V DC ± 10% 3.0 to 5.5V DC 3.0 to 5.5V DC

Contact or open collector

transistor

6.5 ± 1mA 6 to 20mA 6 to 20mA

4.5mA or more 6.0mA or more 6.0mA or more

1.5mA or less 1mA or less 1mA or less

0.1ms or less

(1.0ms or less for DOG)

Photocoupler insulation

LED is lit when input is ON.

Differential line driver or

open collector transistor

2-phase pulse

30,000Hz or less

(Duty 50%)

B

Differential line driver or

open collector transisto r

Pulse width 50ms or more

PG0

5.5 Output specifications

Item Pulse output section Clear signal (CLR)

Number of output

points

Output system

Output type

Rated load

voltage

Max. load current

VIN current

consumption

Max. voltage drop

during ON

Leak current

during ON

Output frequency

Operation

indication

Three output points (FP, RP, CLR)

Forw ard pulse (FP) / reverse pulse (RP)

or pulse (PLS) / direction (DIR) is

selectable.

Differential line driver output NPN open collector transistor output

VIN 5 to 24V DC VIN 5 to 24V DC

25mA or less 20mA or less

24V DC: 70mA 5V DC: 100mA

FP+, RP+ Max. 1MHz 20 to 25ms

LED is lit when output is ON.

When zero return operation is

completed, it is turned on.

(Output pulse width: 20ms)

1.5V or less

0.1mA or less

5-2

Page 27

Model FX2N-10PG Pulse Output Block

6. Wiring

6.1 Input output circuit

Input terminal FX2N-10PG

Manual pulse

generator

7mA/24V DC

7mA/24V DC

7mA/24V DC

7mA/24V DC

24V DC

Shielded cable

A phase

START

DOG

X0

X1

S/S

φ

A+

3.3k

3.3k

3.3k

3.3k

120

Wiring 6

5 to

VIN+

VIN-

FP+

FP-

RP+

RP-

CLR+

24V DC

Shielded

cable

Servo amplifier

drive unit

Output terminal

Ω

Ω

Ω

Ω

AM26LS31 or equivalent

Differential line driver

Ω

5V

25mA or less

2-phase pulse

Frequency

30kHz or less

5V DC

20mA or less

B phase

A-

φ

B+

φ

B-

PG0+

PG0-

120

120

120

120

120

φ

• For the pin layout, refer to Section 2.3.

Ω

Ω

Ω

Ω

Ω

CLR-

5 to 24V DC

20mA or less

6-1

Page 28

Model FX2N-10PG Pulse Output Block Wiring 6

• Install a safety circuit outside the FX2N-10PG so that the entire system conservatively

operates even if an abnormality occurs in the external power supply or a failure occurs in

the FX

-10PG.

2N

1) Make sure to construct an emergency stop circuit, protection circuit, interlock circuit for

reverse operations such as normal rotation and reverse rotation and interlock circuit to

prevent damages of a machine for upper limit/lower limit, etc. outside the FX

-10PG.

2N

2) When the CPU in the detects an abnormality such as a watch dog timer error by the selfdiagnosis circuit, all outputs turn off. When an abnormality occurs in the I/O control area

which cannot be detected by the CPU in the FX

-10PG, output control may be disabled.

2N

Design external circuits and the structure so that the entire system conservatively

operates in such cases.

3) Do not lay signal cable near to high voltage power cable or house them in the same

trunking duct. Effects of noise or surge inductio n may occur. Keep signal cables a safe

distance of more than 100 mm (4”) from these power cables.

4) Where output signal lines are used over an extended distance consideration for voltage

drop and noise interference should be made.

5) Fix cables so that any stress is not directly applied on the terminal block or the cable

connection area.

6) When a failure occurs in a transistor etc. in the FX

-10PG, outputs may keep ON or

2N

OFF.

For output signals which may lead to severe accidents, design external circuits and the

structure so that the entire system conservatively operates.

• Make sure to shut down the power supplies of all phases on the outside before starting

installation or wiring.

If the power supplies are not shut down, you may get electrical shock or the unit may be

damaged.

• Never touch any terminals while the power is supplied.

If you touch a terminal while the power is supplied, you may get electrical shock or the

unit may malfuncti on.

• Turn off the power at first, then start cleaning or tighten terminals.

If you perform cleaning or tightening while the power is supplied, you may get electrical

shock.

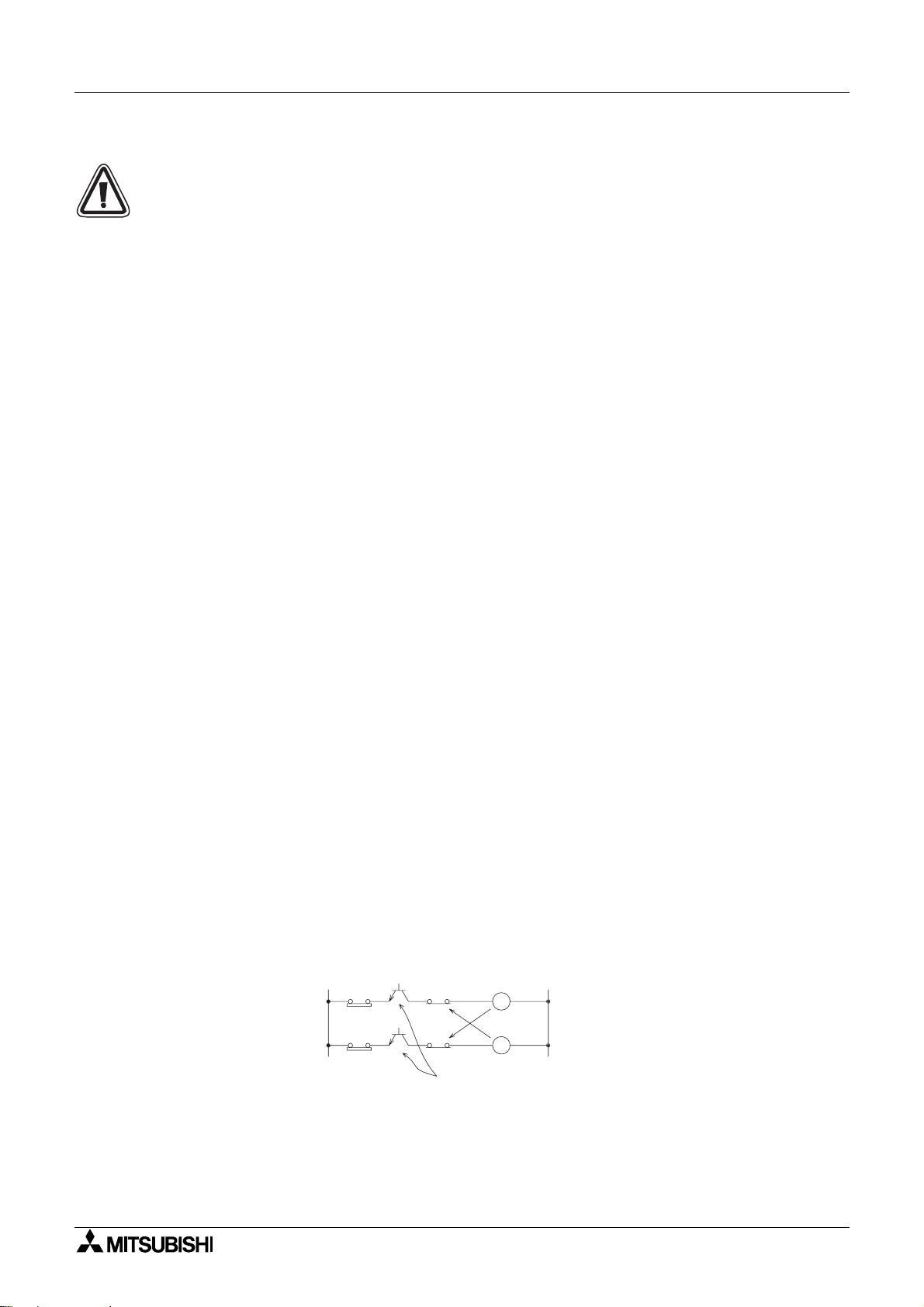

• For pairs of inputs such as forward/reverse contacts which would pose a hazard if turned

ON simultaneously, provide external interlocks, in addition to interlocks in the program

inside the positioning unit, to ensure that they cannot be turned ON simultaneously.

Forward

lim it

Forward

Reverse

lim it

Reverse

O utput elem ent

6-2

Page 29

Model FX2N-10PG Pulse Output Block Wiring 6

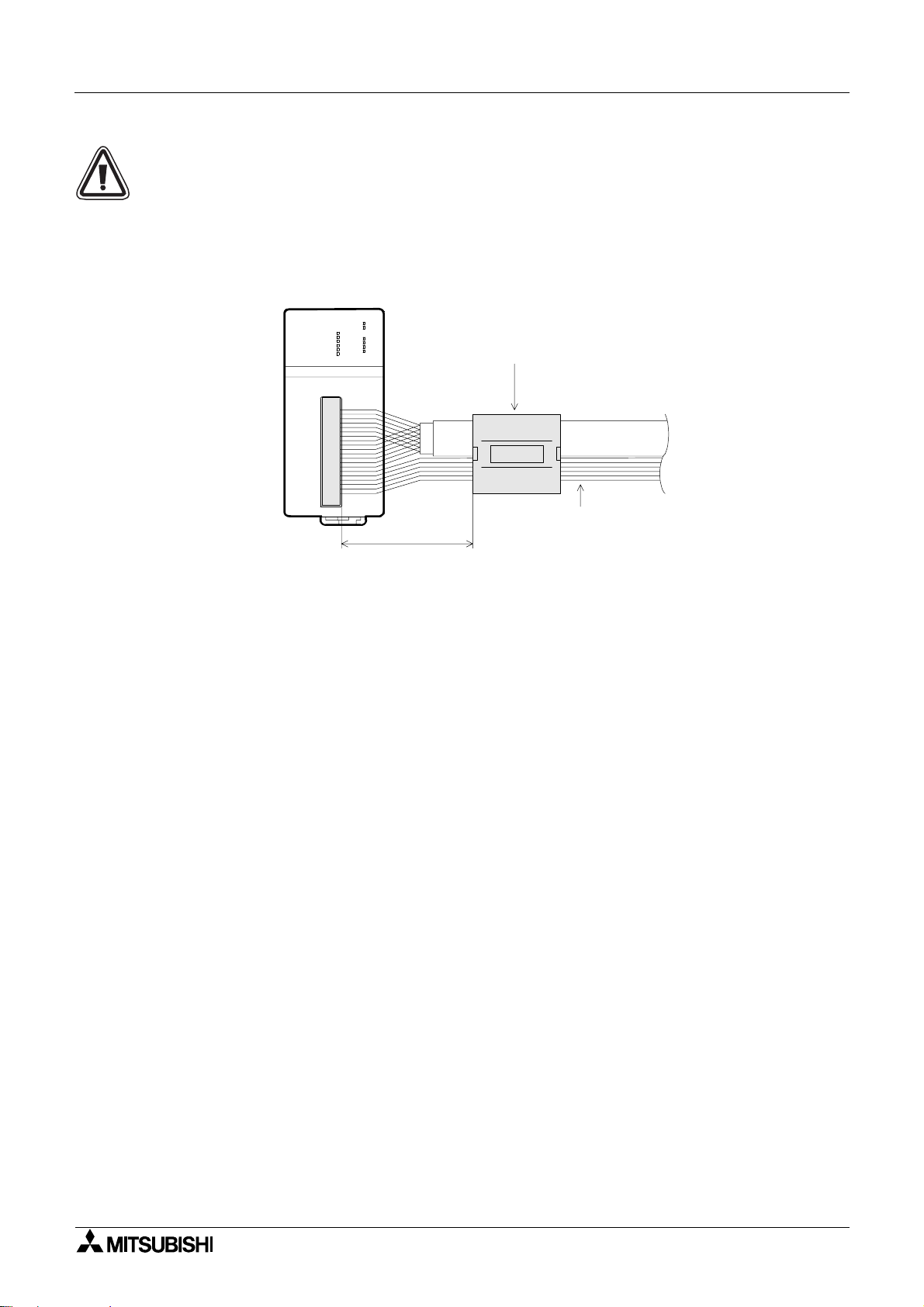

CE MEC Conformity

For compliance to EC EMC regulation it is necessary to add a Ferrite filter on the I/O cable of

the FX

-10PG.

2N

The filter should be attached below with the filter surrounding the I/O cable.

The recommended ferrite filter is the TOKIN ESD-SR-25 or equivalent. The filter should be

placesd as near to I/O port the FX

2N

-10PG

FX

POWER

ERROR

START

DOG

PGO

X0

FP

FX2N-10PG

X1

RP

fA

CLR

f

B

150mm (5.9") or less

-10PG as possible.

2N

Ferrite filter

TOKIN ESD-SR-25

TOKIN

I/O cable

6-3

Page 30

Model FX2N-10PG Pulse Output Block Wiring 6

6.2 Input wiring

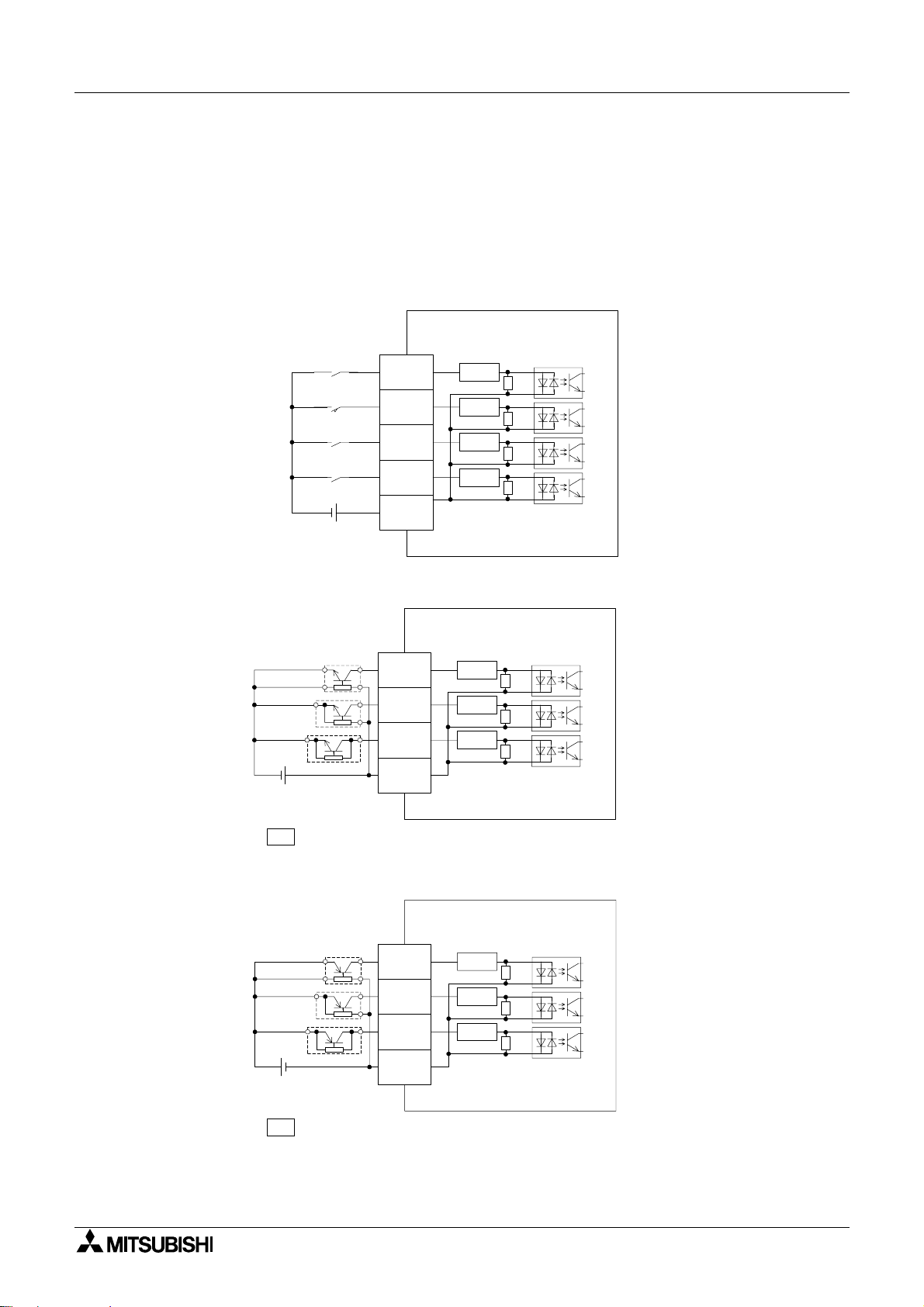

6.2.1 START, DOG, X0, X1, S/S

External power supply (24V DC) is required for terminals START, DOG, X0, X1 and S/S.

Contact output type and open collector transistor output (NPN, PNP) types of external devices

are applicable.

1) When contacts are used

FX2N-10PG

Input terminal

7mA/24V DC

START

7mA/24V DC

DOG

7mA/24V DC

X0

7mA/24V DC

X1

24V DC

S/S

3.3k

3.3k

3.3k

3.3k

Ω

Ω

Ω

Ω

2) When NPN open collector transistors are used

FX2N-10PG

Input terminal

4-wire type

3-wire type

2-wire type

24V DC

Reread terminal as START, DOG, X0 or X1 according to the application.

IN

IN

IN

IN

S/S

3.3k

3.3k

3.3k

Ω

Ω

Ω

3) When PNP open collector transistors ar e used

FX2N-10PG

Input terminal

4-wire type

3-wire type

2-wire type

24V DC

IN

IN

IN

S/S

3.3k

3.3k

3.3k

Ω

Ω

Ω

Reread terminal as START, DOG, X0 or X1 according to the application.

IN

• For the pin layout, refer to Section 2.3.

6-4

Page 31

Model FX2N-10PG Pulse Output Block Wiring 6

6.2.2 A-phase +, A-phase -, B-phase +, B-phase -

The different ial line driv er or the open co llect or tran sistor output type man ual pulse gener ator is

applicable to the terminals φA+, φA-, φB+ and φB-.

External power supply (5V DC) is required for the open collector transistor output.

1) When a differential line driver is used

FX2N-10PG

Input terminal

φ

A+

φ

A-

φ

B+

φ

B-

Manual pulse

generator

2-phase pulse

Frequency

30kHz or less

Power supply

Shielded

cable

A phase

B phase

2) When NPN open collector transistors are used

Manual pulse

generator

Shielded

cable

A phase

B phase

FX2N-10PG

Input terminal

φ

A+

φ

A-

φ

B+

φ

B-

120

120

120

120

120

120

120

120

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

5V DC

• For the pin layout, refer to Section 2.3.

6-5

Page 32

Model FX2N-10PG Pulse Output Block Wiring 6

6.2.3 PGO+, PGO-

External power supply (5V DC) is required for the terminals PGO+ and PG0-.

The external device of the differential line driver output type or open collector transistor output

(NPN/PNP) type is applicable.

1) When a differential line driver is used

FX2N-10PG

Photocoupler

PG0+

120

Ω

PG0-

Power supply

2) When NPN open collector transistor is use d

FX2N-10PG

PG0+

5V DC

20mA or less

PG0-

3) When PNP open collector transistor is use d

FX2N-10PG

PG0+

5V DC

20mA or less

PG0-

120

120

120

120

120

Ω

Photocoupler

Ω

Ω

Photocoupler

Ω

Ω

• For the pin layout, refer to Section 2.3.

6-6

Page 33

Model FX2N-10PG Pulse Output Block Wiring 6

6.3 Output wiring

6.3.1 VIN+, VIN-, FP+, FP-, RP+, RP-

The terminals VIN+, VIN-, FP+, FP-, RP+ and RP- are connected to the servo amplifier and

motor driver.

5 to 24V DC is supplied to the terminals VIN+ and VIN- from the external power supply or

servo amp lif ie r.

The terminals FP+, FP-, RP+ and RP- are used for the differential line driver output.

1) Connection to differential line receiver

2N

-10PG

FX

M26LS31 or equivalent

Differential line driver

25mA or less

Output terminal

5V

2) Connection to photocoupler

FX2N-10PG

Output terminal

5V

VIN+

VIN-

FP+

FP-

RP+

RP-

VIN+

VIN-

5 to 24V DC

Shielded

cable

5 to 24V DC

Servo amplifier

drive unit

AM262LS32 or

equivalent

Differential line

receiver

Servo amplifier

drive unit

FP+

FP-

RP+

RP-

M26LS31 or equivalent

Differential line driver

25mA or less

• For the pin layout, refer to Section 2.3.

Shielded

cable

6-7

Page 34

Model FX2N-10PG Pulse Output Block Wiring 6

6.3.2 CLR+, CLR-

The terminals CLR+ and CLR- are connected to the servo amplifier.

5 to 24V DC is supplied to the terminals CLR+ and CLR- from the external power supply or

servo amp lif ie r.

CLR+ and CLR- are used for the NPN open collector output.

FX2N-10PG

CLR+

CLR-

• For the pin layout, refer to Section 2.3.

5 to 24V DC

20mA or less

Shielded

cable

Servo amplifier

drive unit

6-8

Page 35

Model FX2N-10PG Pulse Output Block Wiring 6

6.4 Connection with stepping motor

FX2N/FX

2NC

FX2N-10PG

24V DC

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

120

120

120

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

L

N

COM

X***

X***

X***

X***

X***

X***

X***

X***

X***

START

DOG

X0

X1

S/S

A+

φ

A-

φ

φ

B+

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC

A Phase

B Phase

Class D

ground

Manual pulse

generator

Power supply

DC power type is

also available on the

PLC.

.

Pin layout of p or t in FX2N-10PG

STOP

Error reset

Forward limit

Reverse limit

Forward jog

Reverse jog

Zero return

command

Operation speed

change enable

m code OFF

command

2-phase pulse

Frequency 30kHz or less

For the power supply wiring of the driver unit

and the connection of the motor, refer to the

instruction manuals of the drive and unit.

VIN+

FP+

RP+

PG0+

CLR+

A+

φ

φ

B+

DOG

S/S

X0

.

The above pin layout is seen when looking

at the I/O port in the FX

front face.

When an I/O cable and conne ctor is

prepared by the us er, the pin number m ark

▲

mark are different according to the

and

connector used.

Wire correct ly noting the position of notch

and the directio n of the connector .

VINFPRPPG0CLR-

A-

φ

φ

BSTART

S/S

X1

2N

-10PG from the

Ω

120

Ω

120

Ω

120

5V

AM26LS31 or equivalent

Differential line

driver 25mA or less

φ

B-

PG0+

PG0-

VIN+

VIN-

FP+

FP-

RP+

RP-

CLR+

CLR-

Shielded

cable

5V DC

5 to 4V DC

Shielded cable

CW-

CW+

CCW-

CCW+

Drive unit

Stepping

motor

6-9

Page 36

Model FX2N-10PG Pulse Output Block Wiring 6

6.5 Connection with Model MR-C Servo Motor

FX

/FX

2N

2NC

FX2N-10PG

24V DC

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

120

120

120

120

120

120

5V

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

L

N

COM

X***

X***

X***

X***

X***

X***

X***

X***

X***

START

DOG

X0

X1

S/S

A+

φ

A-

φ

φ

B+

φ

B-

PG0+

PG0-

VIN+

VIN-

FP+

FP-

RP+

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC

A Phase

B Phase

Shielded

cable

Class D

ground

Manual pulse

generator

Power supply

DC power type is

also available on the

PLC.

.

Pin layout of por t in FX2N-10PG

STOP

Error reset

Forward limit

Reverse limit

Forward jog

Reverse jog

Zero return

command

Operation speed

change enable

m code OFF

command

2-phase pulse

Frequency 30kHz or less

For the power supply wiring of the servo

amplifier and the connection of the motor,

refer to the instruction manual and technical

data of the servo amplifier.

CN1 CN1

11

1

4

CN1

16

9

10

7

VIN+

FP+

RP+

PG0+

CLR+

A+

φ

φ

B+

DOG

S/S

X0

.

The above pin layout is seen when looking

at the I/O port in the FX

front face.

When an I/O cable and connec tor is

prepared by the us er, the pin number m ar k

▲

mark are different according to the

and

connector used.

Wire correct ly noting the position of notch

and the direction of the connector.

Servo amplifier

SD

V+

OP

V5

PP

PG

NP

ALM

V5

SG

SON

LSP

LSN

VINFPRPPG0CLR-

A-

φ

φ

BSTART

S/S

X1

2

CN1

16

12

17

15

14

2N

-10PG from the

RA1

5V DC

AM26LS31 or equivalent

Differential line

driver 25mA or less

RP-

CLR+

CLR-

Shielded cable

8

CN1

13

12

NG

CR

SG

6-10

Page 37

Model FX2N-10PG Pulse Output Block Wiring 6

6.6 Connection with Model MR-J Servo Motor

FX

/FX

2N

2NC

FX2N-10PG

24V DC

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

120

120

120

120

120

120

5V

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

L

N

COM

X***

X***

X***

X***

X***

X***

X***

X***

X***

START

DOG

X0

X1

S/S

A+

φ

A-

φ

φ

B+

φ

B-

PG0+

PG0-

VIN+

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC/7mA

A Phase

B Phase

Shielded

cable

5 to

24V DC

Class D

ground

24V DC

Manual pulse

generator

Power supply

DC power type is

also available on the

PLC.

.

Pin layout of por t in FX2N-10PG

STOP

Error reset

Forward limit

Reverse limit

Forward jog

Reverse jog

Zero return

command

Operation speed

change enable

m code OFF

command

2-phase pulse

Frequency 30kHz or less

For the power supply wiring of the servo

amplifier and the connection of the motor,

refer to the instruction manual and technical

data of the servo amplifier.

CN1

18

5V DC

6

12

CN1

35

VIN+

FP+

RP+

PG0+

CLR+

A+

φ

φ

B+

DOG

S/S

X0

.

The above pin layout is seen when looking

at the I/O port in the FX

front face.

When an I/O cable and conne ctor is

prepared by the us er, the pin number m ark

▲

mark are different according to the

and

connector used.

Wire correct ly noting the position of notch

and the directio n of the connector.

Servo amplifier

SD

LG

OP

VDD

VIN

ZSP

VINFPRPPG0CLR-

A-

φ

φ

BSTART

S/S

X1

CN1

34

26

2N

-10PG from the

AM26LS31 or equivalent

Differential line

driver 25mA or less

VIN-

FP+

FP-

RP+

RP-

CLR+

CLR-

Shielded cable

34

20

19

22

21

CN1

32

15

VIN

PP

PG

NP

NG

CR

SG

PF

ALM

RES

SON

LSP

LSN

SG

25

27

CN1

29

28

30

31

15

RA1

6-11

Page 38

Model FX2N-10PG Pulse Output Block Wiring 6

6.7 Connection with Model MR-J2 (-Jr, -Super) Servo Motor

FX

/FX

2N

2NC

FX2N-10PG

24V DC

Ω

3.3k

3.3k

Ω

3.3k

Ω

3.3k

Ω

3.3k

Ω

3.3k

Ω

Ω

3.3k

Ω

3.3k

Ω

3.3k

3.3k

Ω

Ω

3.3k

Ω

3.3k

Ω

3.3k

120

Ω

120

Ω

Ω

120

Ω

120

Ω

120

120

Ω

5V

AM26LS31 or equivalent

Differential line

driver 25mA or less

L

N

COM

X***

X***

X***

X***

X***

X***

X***

X***

X***

START

DOG

X0

X1

S/S

A+

φ

A-

φ

φ

B+

φ

B-

PG0+

PG0-

VIN+

VIN-

FP+

FP-

RP+

RP-

CLR+

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC/7mA

A Phase

B Phase

Shielded

cable

5 to

24V DC

Class D

ground

24V DC

Manual pulse

generator

Power supply

DC power type is

also available on the

PLC.

.

Pin layout of por t in FX2N-10PG

STOP

Error reset

Forward limit

Reverse limit

Forward jog

Reverse jog

Zero return

command

Operation speed

change enable

m code OFF

command

2-phase pulse

Frequency 30kHz or less

For the power supply wiring of the servo

amplifier and the connection of the motor,

refer to the instruction manual and technical

data of the servo amplifier.

CN1A

Case

5

15

CN1B

3

CN1A

9

3

13

2

12

CN1A

8

VIN+

FP+

RP+

PG0+

CLR+

A+

φ

φ

B+

DOG

S/S

X0

.

The above pin layout is seen when looking

at the I/O port in the FX

front face.

When an I/O cable and conne ctor is

prepared by the us er, the pin number m ark

▲

mark are different according to the

and

connector used.

Wire correct ly noting the position of notch

and the directio n of the connector.

Servo amplifier

SD

LZ

LZR

VDD

COM

PP

PG

NP

NG

CR

VDD

ZSP

TLC

ALM

EMG

SON

LSP

LSN

VINFPRPPG0CLR-

A-

φ

φ

BSTART

S/S

X1

CN1B

3

19

6

18

CN1B

15

5

16

17

2N

-10PG from the

RA1

CLR-

Shielded cable

SG

10

SG

10

6-12

Page 39

Model FX2N-10PG Pulse Output Block Wiring 6

6.8 Connection with Model MR-H Servo Motor

FX

/FX

2N

2NC

FX2N-10PG

24V DC

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

120

120

120

120

120

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

Ω

L

N

COM

X***

X***

X***

X***

X***

X***

X***

X***

X***

START

DOG

X0

X1

S/S

A+

φ

A-

φ

φ

B+

φ

B-

PG0+

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC/7mA

24V DC

A Phase

B Phase

Shielded

cable

Class D

ground

Manual pulse

generator

Power supply

DC power type is

also available on the

PLC.

.

Pin layout of por t in FX2N-10PG

STOP

Error reset

Forward limit

Reverse limit

Forward jog

Reverse jog

Zero return

command

Operation speed

change enable

m code OFF

command

2-phase pulse

Frequency 30kHz or less

For the power supply wiring of the servo

amplifier and the connection of the motor,

refer to the instruction manual and technical

data of the servo amplifier.

CN1

50

8

VIN+

FP+

RP+

PG0+

CLR+

A+

φ

φ

B+

DOG

S/S

X0

.

The above pin layout is seen when looking

at the I/O port in the FX

front face.

When an I/O cable and conne ctor is

prepared by the us er, the pin number m ark

▲

mark are different according to the

and

connector used.

Wire correct ly noting the position of notch

and the directio n of the connector.

Servo amplifier

SD

LZ

VDD

ZSP

VINFPRPPG0CLR-

A-

φ

φ

BSTART

S/S

X1

CN1

22

23

2N

-10PG from the

120

Ω

5V

AM26LS31 or equivalent

Differential line

driver 25mA or less

PG0-

VIN+

VIN-

FP+

FP-

RP+

RP-

CLR+

CLR-

5 to

24V DC

Shielded cable

9

CN1

22

20

10

11

35

36

CN1

37

17

LZR

VDD

VIN

PP

PPR

NP

NPR

CR

SG

PF

ALM

EMG

EMG

SON

SON

LSP

RES

LSP

LSN

SG

24

48

CN1

46

12

15

38

34

40

RA1

6-13

Page 40

Model FX2N-10PG Pulse Output Block Wiring 6

MEMO

6-14

Page 41

Model FX2N-10PG Pulse Output Block

7. Buffer memory (BFM)

7.1 BFM list

Buffer memory (BFM) 7

BFM No. Name Content and setting range

-2,147,483,648 to 2,147,483,467

#1 #0 Max. speed

#2 Bias speed

#4 #3 Jog speed

#6 #5

#10 #9 Zero point address

#14 #13 Target address

#16 #15 Operation speed

#18 #17 Target address

#20 #19 Operation speed

#23 #22

#25 #24 Current address -2,147,483,648 to 2,147,483,467

Zero return speed

(high speed)

Zero return speed

#7

(creep)

Zero-point signal

#8

number

(S-shaped control)

#11 Acceleration time

#12 Deceleration time

Ι

ΙΙ

#21 Override setting 1 to 30,000

Current value,

operation speed

#26 Operation command Refer to 7.2.17

#27 Operation pattern Refer to 7.2.18

(The pulse-converted value of

1 to 1,000,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

0 to 30,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

1 to 1,000,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

1 to 1,000,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

0 to 30,000Hz)

0 to 32.767

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

-2,147,483,648 to 2,147,483,467)

1 to 5,000ms (trapezoidal control)

64 to 5,000ms (S-shaped control)

1 to 5,000ms (trapezoidal control)

64 to 5,000ms (S-shaped control)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

-2,147,483,648 to 2,147,483,467)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

Ι

1 to 1,000,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

-2,147,483,648 to 2,147,483,467)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

ΙΙ

1 to 1,000,000Hz)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

1 to 1,000,000Hz)

Initial

value

500,000

0

10,000

500,000

1,000

1

0

100

100

0

500,000

0

100,000

1000

0

0

H000

H000

Unit Attribute

User

unit

User

unit

User

unit

User

unit

User

unit

Pulse R/W

User

unit

ms R/W

ms R/W

User

unit

User

unit

User

unit

User

unit

0.1% R/W

×

User

unit

User

unit

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

R

R/W

R/W

R/W

7-1

Page 42

Model FX2N-10PG Pulse Output Block Buffer memory (BFM) 7

BFM No. Name Content and setting range

#28 Status information Refer to 7.2.19

#29 M code

#30 Machine model code K5120

#31 Not usable.

#33 #32 Pulse rate 1 to 999,999 PLS/REV

#35 #34 Feed rate 1 to 999,999 µm/REV

#36 Parameter Refer to 7.2.24

#37 Error code Occured error code is stored.

#38 Terminal information

Current address

#40 #39

#42 #41

#44 #43

#48 to #63 Not usable.

#65 to #97 Not usable.

#101 #100

#103 #102

#104

(pulse converted

value)

Manual pulse

generator input

current value

Manual pulse

generator input

frequency

Electronic gear

(numerator) for

#45

manual pulse

generator input

Electronic gear

(denominator) for

#46

manual pulse

generator input

Manual pulse

#47

generator input

response

#64

Version information

#98

Table start No.

#99

Executing table No.

Position information

(Table No. 0)

Speed information

(Table No. 0)

m code information

(Table No. 0)

During M code ON : 0 to 32,767

During M code OFF: -1

ON/OFF information of the terminal

input is stored.

-2,147,483,648 to 2,147,483,467

-2,147,483,648 to 2,147,483,467

0 to ±30,000

1 to 32,767

1 to 32,767

1, 2, 3, 4, 5

(Low response → High response)

0 to 199

-1 to 199

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

-2,147,483,648 to 2,147,483,467)

-2,147,483,648 to 2,147,483,467

(The pulse-converted value of

1 to 1,000,000Hz)

-1 to 32,767

Operation

#105

information (Table

-1 to 4

No. 0)

Initial

value

-1