Page 1

MELSOFT

FR Configurator

INSTRUCTION MANUAL

VFD SETUP SOFTWARE

FR-SW2-SETUP-WE

-Windows® (English) Version-

OVERVIEW

FUNCTIONS

TROUBLE

INDICATIONS

APPENDICES

1

2

3

4

Page 2

INTRODUCTION

Thank you for choosing the Mitsubishi Transistorized VFD Setup Software.

This instruction manual gives handling information and precautions for use of this software. Incorrect handling might

cause an unexpected fault. Before using this product, please read this manual carefully to use it to the optimum.

Please forward this manual to the end user.

When reading this manual, note the following:

• This manual is written on the basis that Windows

• The [return] and [enter] keys are represented by the key.

• Drive D is described as the CD-ROM drive and Drive C as the hard disk drive.

• The screens, parameter names, set values and so on given in this manual are written on the basis of the FR-A700

series. When using the inverter of any other series, refer to the instruction manual of the used inverter.

Trademarks

• Microsoft, Windows and Excel are registered trademark or trademark of Microsoft Corporation in the United States

and/or other countries.

1)The formal name of Windows

2)The formal name of Windows

3)The formal name of Windows

4)The formal name of Windows

5)The formal name of Excel is Microsoft

®

98 is Microsoft® Windows® 98 operating system.

®

2000 is Microsoft® Windows® 2000 operating system.

®

Me is Microsoft® Windows® Me operating system.

®

XP is Microsoft® Windows® XP operating system.

®

Excel for Windows®.

• The "FR Configurator" is a registered trademark of Mitsubishi Electric Corporation.

The copyright and other rights of this software all belong to Mitsubishi Electric Corporation.

• No part of this manual may be copied or reproduced without the permission of Mitsubishi Electric Corporation.

• Other company and product names herein are the trademarks and registered trademarks of their respective owners.

• SPREAD

Copyright (C) 2004 FarPoint Technologies, Inc.

• LEADTOOLS

Copyright (C) 1991-2005 LEAD Technologies, Inc.

®

XP Professional (English version) is the operating system.

For Maximum Safety

• This product is not designed or manufactured to be used in equipment or systems in situations that can affect or

endanger human life.

• When considering this product for operation in special applications such as machinery or systems used in passenger

transportation, medical, aerospace, atomic power, electric power, or submarine repeating applications, please contact your nearest Mitsubishi sales representative.

• Although this product was manufactured under conditions of strict quality control, you are strongly advised to install

safety devices to prevent serious accidents when it is used in facilities where breakdowns of the product are likely to

cause a serious accident.

<Abbreviations>

PU ............................................... Operation panel (FR-DU07) and parameter unit (FR-PU04/

FR-PU07)

Inverter................................... Mitsubishi inverter FR-A/F700 series

Pr. .......................................... Parameter Number

PU operation.......................... Operation using the PU (FR-DU07/FR-PU04/FR-PU07).

External operation.................. Operation using the control circuit signals

1

Page 3

CONTENTS

1 OVERVIEW 1

1.1 Before Using This Software ....................................................................................... 2

1.1.1 Packing Confirmation ..................................................................................................................... 2

1.2 Preparations for Startup............................................................................................. 3

1.2.1 System configuration ...................................................................................................................... 3

1.2.2 Compatible inverters....................................................................................................................... 3

1.2.3 System configuration ...................................................................................................................... 4

1.2.4 Installation of FR Configurator........................................................................................................ 7

1.2.5 Uninstallation of FR Configurator ................................................................................................. 10

1.2.6 When connecting USB for the first time (FR-A700 series) ........................................................... 10

2 FUNCTIONS 13

2.1 Starting FR Configurator .......................................................................................... 14

2.2 Menu list................................................................................................................... 15

2.3 Saving, Reading and Printing the Files.................................................................... 16

2.3.1 File types ...................................................................................................................................... 16

2.3.2 Saving method.............................................................................................................................. 16

2.3.3 Reading the file............................................................................................................................. 17

2.3.4 Printing ......................................................................................................................................... 17

2.4 Explanation of Screen.............................................................................................. 18

2.4.1 Tool bar ........................................................................................................................................ 18

2.4.2 System list .................................................................................................................................... 19

2.4.3 Status bar ..................................................................................................................................... 20

2.5 Operation Mode Setting of the Inverter.................................................................... 21

2.5.1 Operation mode setting ................................................................................................................ 21

2.5.2 Communication device setting of personal computer ................................................................... 22

2.6 FR Configurator Setting [Setting] ............................................................................. 23

2.6.1 System setting .............................................................................................................................. 23

2.6.2 Communication settings ............................................................................................................... 25

2.6.3 Environmental Setting .................................................................................................................. 26

2.7 Parameter Setting [Parameter] ................................................................................ 27

2.7.1 Displaying all parameters [All List Format] ................................................................................... 28

2.7.2 Displaying the parameters function-by-function [Functional List Format] ..................................... 33

2.7.3 Registering a parameter to the user group [Individual List Format].............................................. 34

2.7.4 Parameter automatic settings [Basic Settings] ............................................................................. 35

2.7.5 Allocating functions to I/O terminals of the inverter [I/O Terminal Allocation] ............................... 36

I

Page 4

2.7.6 Converting parameters automatically at the replacement of the conventional model [Convert Func-

tion] ............................................................................................................................................... 38

2.8 Monitoring Inverter Status [Monitor] ......................................................................... 43

2.8.1 Displaying monitor data on analog meter [Data Display].............................................................. 43

2.8.2 Monitoring the status of I/O terminal [I/O Terminal Monitor] ......................................................... 44

2.8.3 Monitoring by waveform [Oscilloscopes] ...................................................................................... 45

2.8.4 Listing the inverter status of all stations [Status Monitor].............................................................. 53

2.9 Inverter Failure Check [Diagnosis] ........................................................................... 54

2.9.1 Checking main circuit status [VFD Status].................................................................................... 54

2.9.2 Listing the occurred alarm [Alarm History].................................................................................... 55

2.9.3 Check of inverter part replacement indication [Life check] ........................................................... 56

2.9.4 Estimating the cause of faults [Trouble shoot] .............................................................................. 57

2.10 Test Running............................................................................................................ 58

2.10.1 Test Running ................................................................................................................................ 58

2.10.2 Maximize the motor performance [Auto Tuning]........................................................................... 59

2.11 Advanced Function...................................................................................................61

2.11.1 Machine Analyzer (Vector Control only) ....................................................................................... 61

2.12 Help.......................................................................................................................... 66

2.12.1 Help contents................................................................................................................................ 66

2.12.2 Product information....................................................................................................................... 67

CONTENTS

3 TROUBLE INDICATIONS 69

3.1 Error codes............................................................................................................... 70

3.1.1 Error code lists.............................................................................................................................. 70

3.1.2 Panel-displayed errors.................................................................................................................. 70

4 APPENDICES 71

4.1 Supplementary Software.......................................................................................... 72

4.1.1 Introduction ................................................................................................................................... 72

4.1.2 Parameter files (ine) ..................................................................................................................... 72

4.1.3 Use of PrEdit (Parameter file edit software) ................................................................................. 73

II

Page 5

1 OVERVIEW

This chapter provides the fundamental "overview" for use of this

product.

Always read the instructions before using this software.

1.1 Before Using This Software..................................... 2

1.2 Preparations for Startup ..........................................3

When using this software to make communication with the inverters set 9999 in Pr. 123

PU communication waiting time setting and Pr. 337 RS-485 communication waiting time

setting. When using the PU connector, set a value other than 0 in Pr. 122 PU

communication check time interval on the inverter's operation panel. When using the RS-

485 terminal, set a value other than 0 in Pr. 336 communication check time interval. When

using the USB connector to make communication (available for FR-A700 series only),

set a value other than 0 in Pr. 548 USB communication check time interval. (Refer to the

inverter instruction manual for the setting method.)

1

1

2

3

4

Page 6

Before Using This Software

1.1 Before Using This Software

This software can be used effectively as a support tool for operations from startup to maintenance of the Mitsubishi

transistorized inverter. The following functions can be performed efficiently on the personal computer.

• System setting function

• Parameter editing function

• Monitoring function

• Diagnosis function

• Test running function

• File management function

• Advanced function

• Help function

1.1.1 Packing Confirmation

After unpacking, check that the following items are contained in the package:

Item Quantity

CD-ROM 1 disk

Install manual 1 book

2

Page 7

Preparations for Startup

1.2 Preparations for Startup

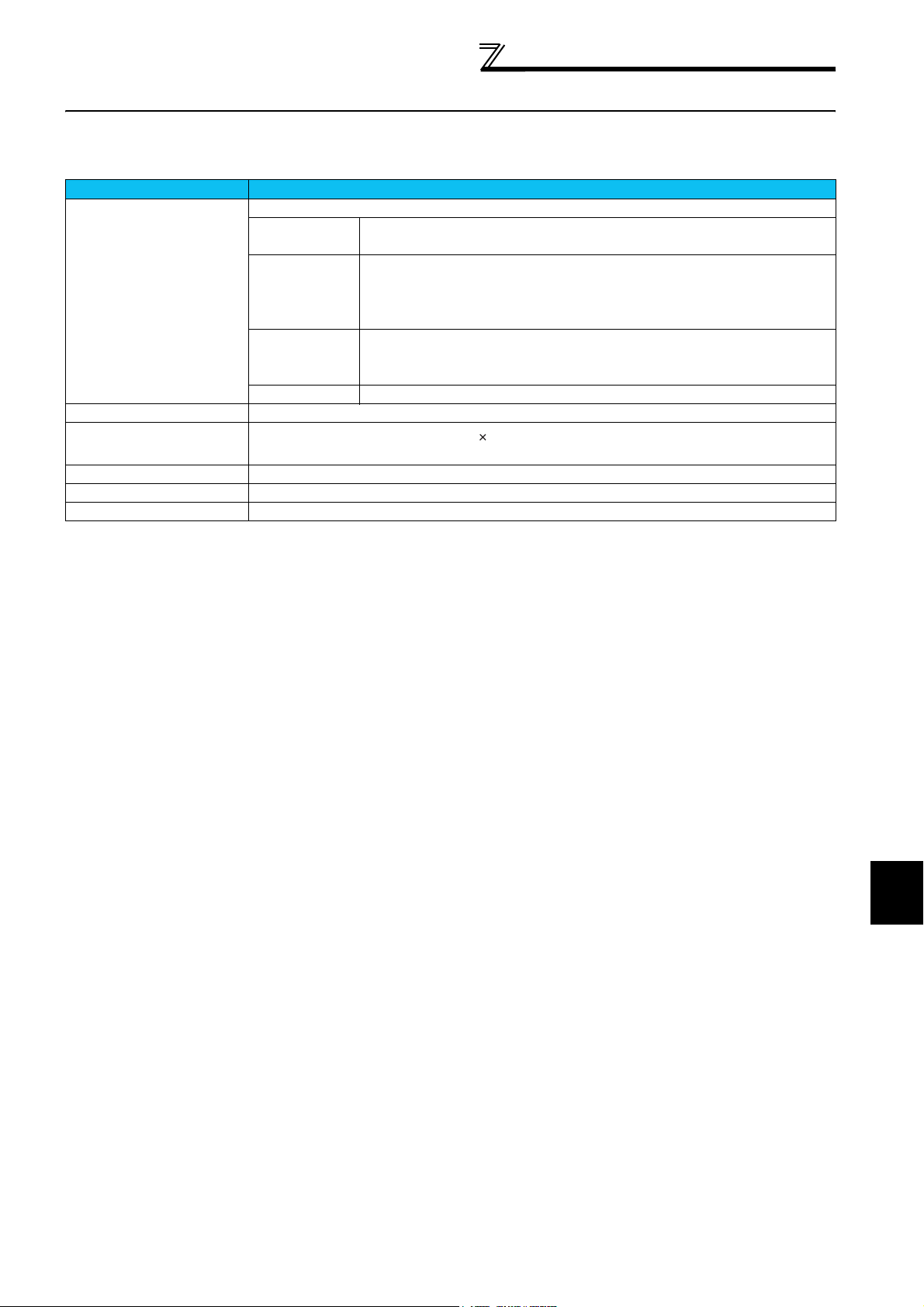

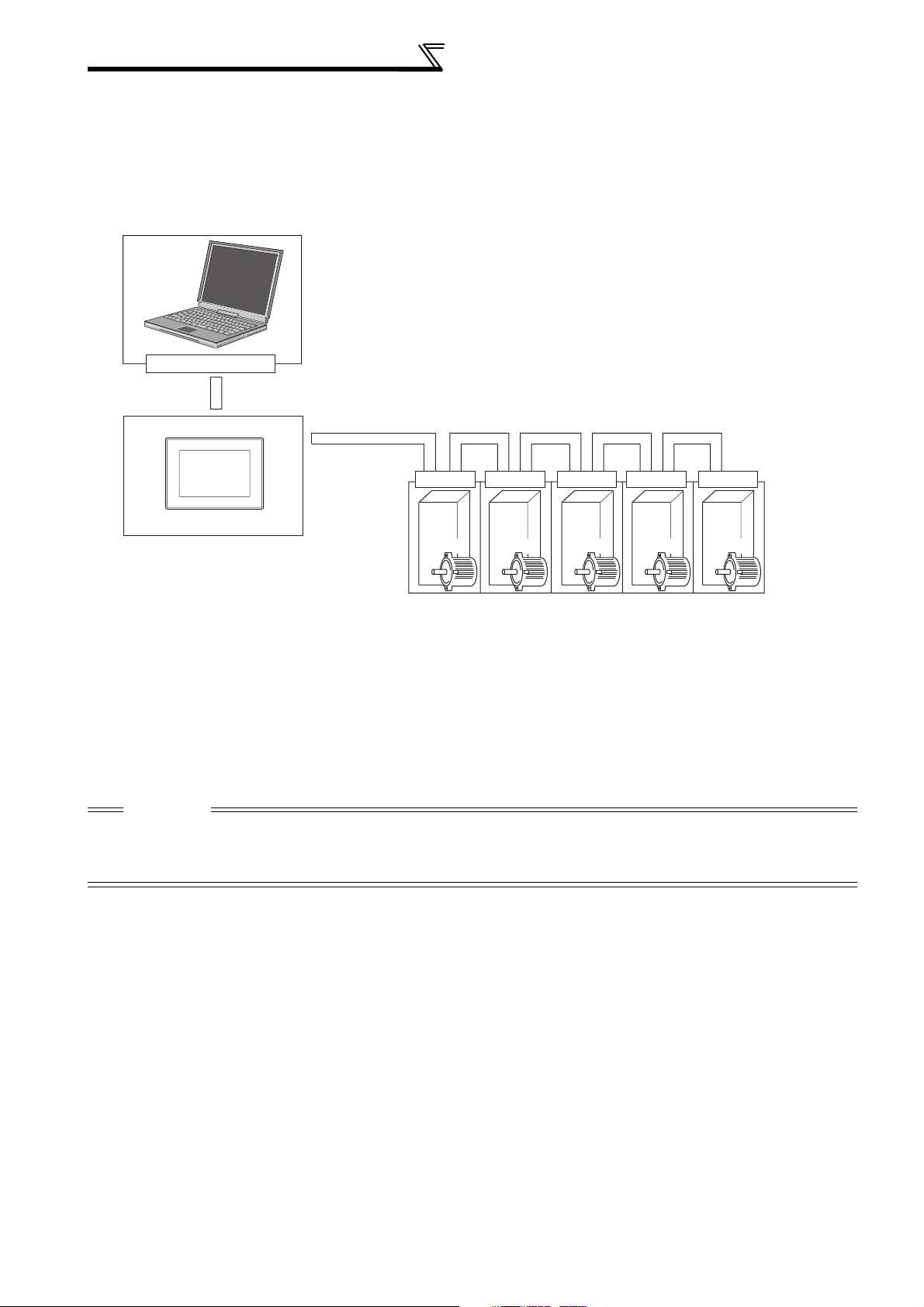

1.2.1 System configuration

Components Description*1

Personal computer*2 IBM PC/AT compatible machine with CD-ROM drive (for installation), USB port *3 or RS-232C port

OS Windows® XP Professional, Windows® XP Home Edition, Windows® 2000

Professional, Windows® Me, Windows® 98 (English)

Pentium® 133MHz or more (Windows® 98‚ Windows® 2000 Professional)

Processor

Memory

Hard disk Free area of 50MB or more

Software Internet Explorer 4.0 or more

Display

Keyboard Connectable to the above PC

Mouse Connectable to the above PC

Printer Connectable to the above PC

Applicable to display at resolution of 800 600 or more, and High Color (16 bits). Connectable to the

above PC.

Pentium® 150MHz or more (Windows® Me)

Pentium® 300MHz or more (Windows® XP Professional‚ Windows® XP Home

Edition)

24MB or more (Windows® 98)

32MB or more (Windows® Me‚ Windows® 2000 Professional)

128MB or more (Windows® XP Professional‚ Windows® XP Home Edition)

*1 Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

Pentium is a registered trademark of Intel Corporation

*2 FR Configurator may not normally operate according to PC used.

*3 The setup using the USB port is available for FR-A700 series only.

1.2.2 Compatible inverters

FR Configurator is compatible with the following inverters.

• FR-A700 series

• FR-F700 series

1

OVERVIEW

3

Page 8

Preparations for Startup

1.2.3 System configuration

The following devices are required to use the FR Configurator. Configure the system in accordance with the instruction

manuals of the corresponding devices.

Mouse

FR Configurator

USB connector used

USB connector

*2*3

RS-232C

PU connector used

*2

Converter

Connection cable

Connector: RJ45 connector

Example: Tyco Electronics Corporation

Cable: Cable in compliance with EIA568

Example: Mitsubishi Cable Industries, Ltd.,

5-554720-3

(such as 10BASE-T cable)

SGLPEV-T 0.5mm 4P

(Twisted pair cable, 4 pairs)

PU connector

USB connector

Connection cable

RS-485/RS-422

RS-485 terminal RS-485 terminal RS-485 terminal RS-485 terminal RS-485 terminal

Inverter Inverter Inverter Inverter Inverter

*1: A converter commercially available is required when the

personal computer uses the RS-232C port.

<Example of a commercially available product>

1) Model: FA-T-RS40 Converter (Model with connectors

and cable is also available)

Mitsubishi Electric Engineering Co., Ltd.

2) Model: DINV-CABV (with connectors and cable)

Diatrend Corp.

The converter cable cannot connect two or more inverters (the

computer and inverter are connected on a 1:1 basis). Since the

product above is packed with the RS-232C cable and RS-485

cable (10BASE-T + RJ-45 connector), the cable and connector

need not be prepared separately. Contact a maker for details of

the product.

*1

RS-485 terminal used

*4

Multidrop link system

*2: The PU connector, RS-485 terminal or USB connector

(FR-A700 series only) can be used to make

communication.

(Refer to the corresponding instruction manual for details.)

*3: The communication using USB connector (available for FR-

A700 series only) cannot connect two or more inverters. (the

personal computer and inverter are connected on a 1:1 basis)

Also, the communication using USB HUB can not be made.

*4: Overall length of connection cable: 500m

*2

Commercially available

printer

Inverter

4

Page 9

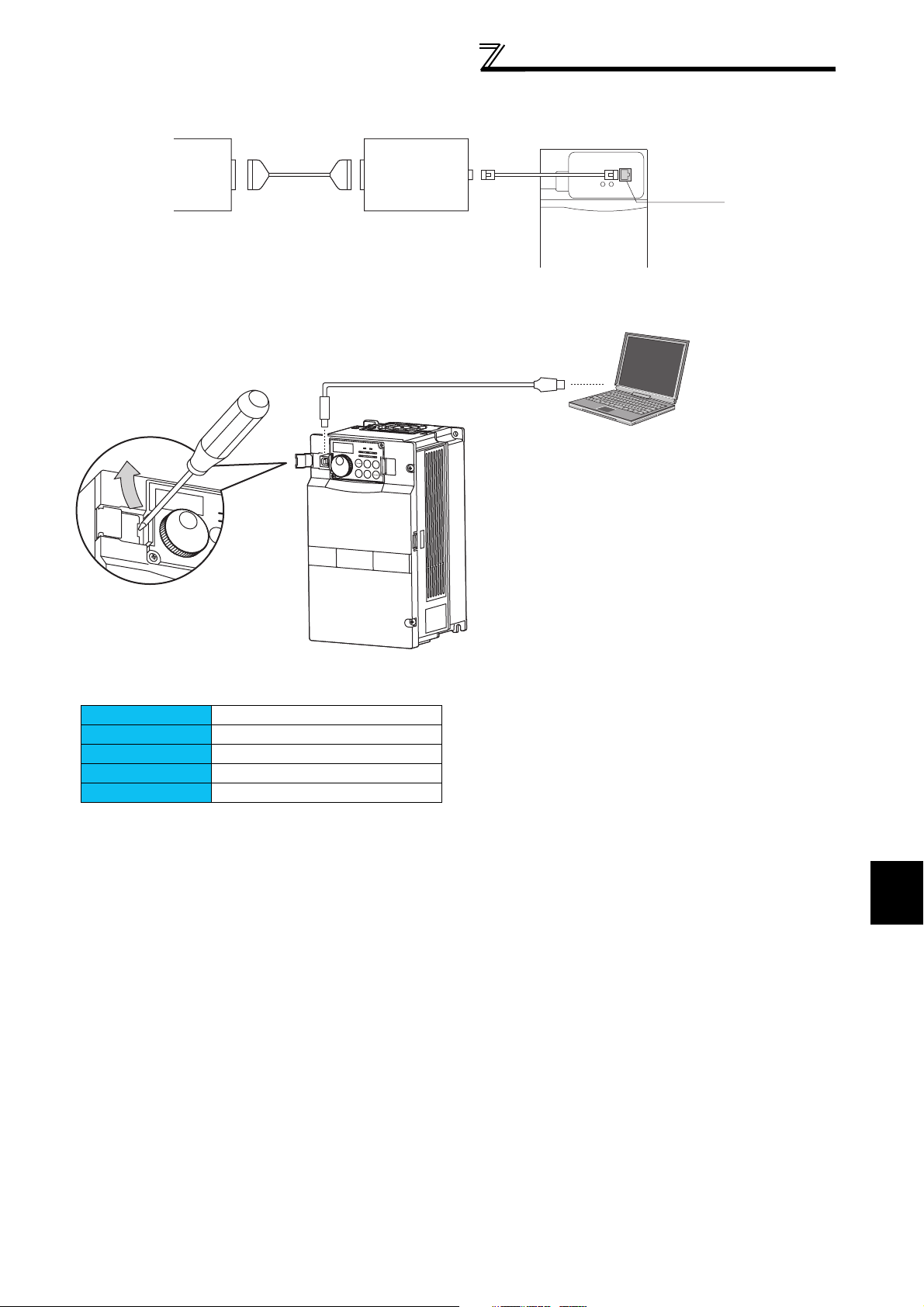

[Connection example between converter and inverter (PU connector)]

Preparations for Startup

Personnel computer

RS-232C

port

RS-232C

cable

[Connection of USB cable and USB connector]

FA-T-RS40

(RS-232CRS-485

converter)

USB cable

RS-485

cable

USB connector

Inverter

PU connector

Removal of cover

Hook the dent with a flat blade screw

driver, etc. and push it up to open the

cover.

Interface

Transfer speed

Wiring length

Connector

Power supply

Conforming to USB 1.1

12Mbps

Maximum 5m

USB connector (B receptacle)

Supplied by self-power

1

OVERVIEW

5

Page 10

Preparations for Startup

[Connection via GOT (FA transparent function)]

The FA transparent function allows the sequence programs of the Mitsubishi PLC to be read, written and monitored from a PC

connected via a GOT.

Using FA transparent function of GOT1000 series, communication with inverter via GOT is enabled.

• RS-232C or USB connection is used between FR Configurator and GOT

• RS-422 is used between GOT and inverter

USB connector or RS-232C

*1: GOT RS-422 communication unit (GT15-RS4-9S) is

required.

*2: USB or RS-232C(one from Port 1 to Port 9) can be used

for communication port, and setting must be made in

Communication settings screen of the FR Configurator

(Can not use multiple Ports simultaneously).

The personal computer and GOT is connected on a 1:1

basis. Also the communication using USB HUB can not

be made.

*2

RS-422 terminal is used

*1

*4

RS-485 terminal

Inverter Inverter Inverter Inverter Inverter

*3: Up to 10 inverters can be connected with RS-422

*4: Refer to GOT1000 Series Connection Manual for the

Up to 10 inverters

connection. Inverter station number can be set from 0 to

31.

compatible version of the GOT and details of RS-422

connection.

*3

RS-485 terminalRS-485 terminalRS-485 terminalRS-485 terminal

CAUTION

Do not perform the following operation during FA transparent function is valid and FR Configurator is ONLINE.

1. Online operation (project download, etc.) from GT Designer/GT Designer2 to GOT

2. Online operation to the PLC CPU by using FA transparent function of GX Developer

Inverter

6

Page 11

Preparations for Startup

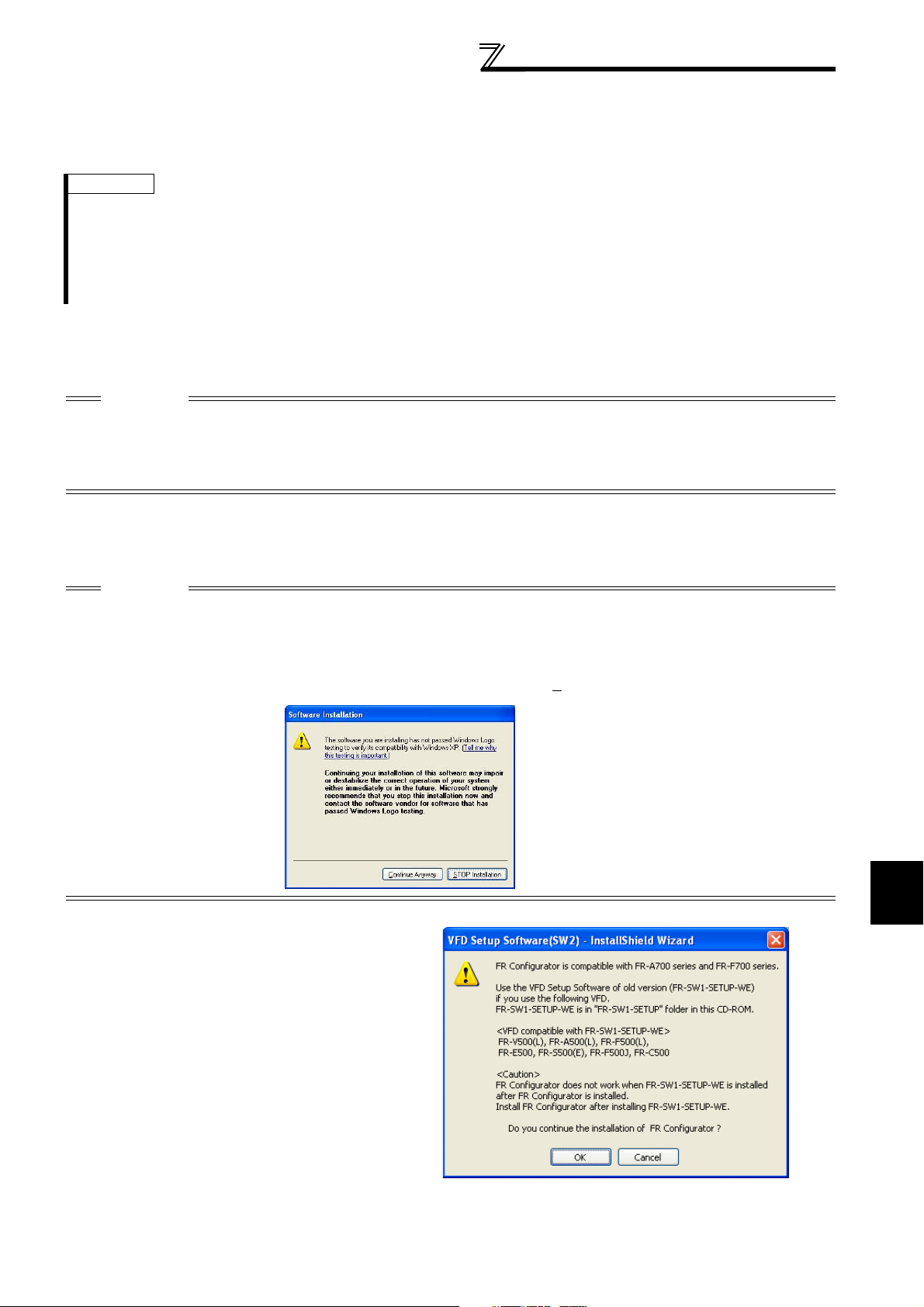

1.2.4 Installation of FR Configurator

To use the FR Configurator (FR-SW2-SETUP-WE), the files included in the setup disks must be installed onto the personal

computer.

REMARKS

FR configurator is installed in a different folder from that of the old version inverter setup software. The old version inverter setup software

can be also used continuously.

However, when installing the old version inverter setup software after the installation of FR Configurator, FR Configurator will not operate.

In this case, uninstall FR Configurator (refer to page 10) and then install it again.

If the older version of the FR Configurator is installed (version information can be checked in "About VFD Setup S/W" screen, refer to page

67), uninstall the older version, and then install the new version of the FR Configurator.

To install the old version of the FR configurator, use the setup program (SETUP.EXE) on the Setup Disk . The setup program

creates a directory on the specified hard disk and copies the required files.

CAUTION

Since the files in the Setup Disk are compressed, the FR-Configurator will not operate by merely copying the files. Always use the setup

•

program to install the software.

• Install the software in accordance with the Windows installation procedure.

• For uninstallation method, refer to page 10.

Installation procedure

The following describes the procedures for installing the FR Configurator to a personal computer.

CAUTION

Close any other applications that have already been started.

•

• When installing to Windows 2000/XP (Professional/Hope Edition) OS, login as a user name with administrator authority (Administrator

authorization) and install it.

• If an inverter is connected by the USB cable, disconnect the USB cable.

• If the following verification screen is displayed during the installation, click [Continue(C

(1) Insert the CD-ROM to the drive of which CD-ROM

can be read. When the screen shown on the right is

displayed, click [OK] to continue the installation of the

FR Configurator.

)] to continue the installation.

1

OVERVIEW

7

Page 12

Preparations for Startup

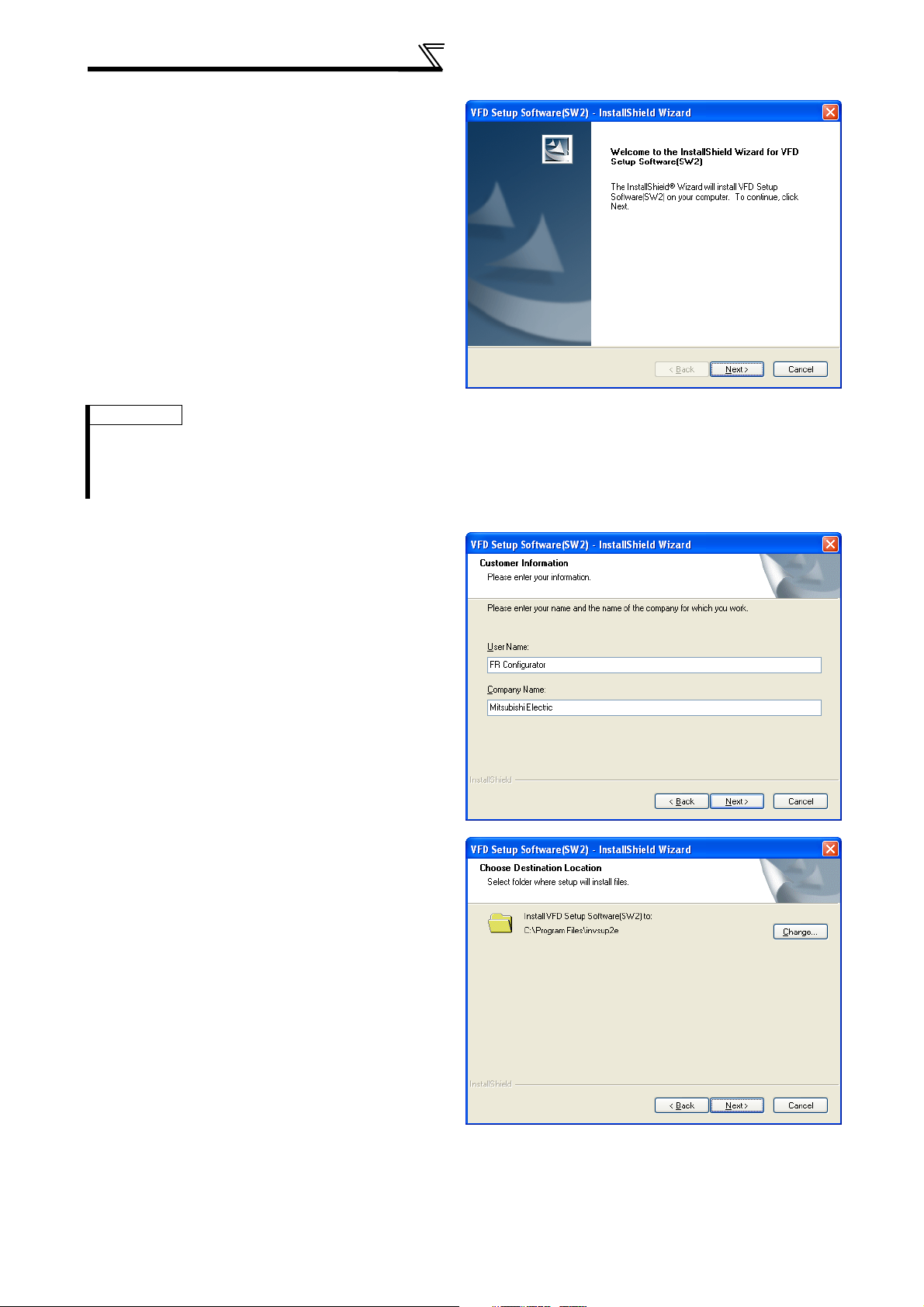

(2) The screen shown right is displayed.

Click the "Next" button.

REMARKS

The above screen can be displayed with double-clicking the icon of CD-ROM drive or the following procedure.

(1) Choose the [Execute it by specifying a file name (R)] command from [Start] menu.

(2) The display of [Execute it by specifying a file name (R)] appears.

(3) Input "D:\SETUP" (with one-byte characters) to "Name (O)" and click the "OK" button. (When CD-ROM drive is D drive)

(3) Enter a user name and company name in one byte

characters.

After entering, click the "Next" button.

(4) Check the installation destination folder and click

"Next" button.

When changing the installation destination, click

"Change..." and change it.

8

Page 13

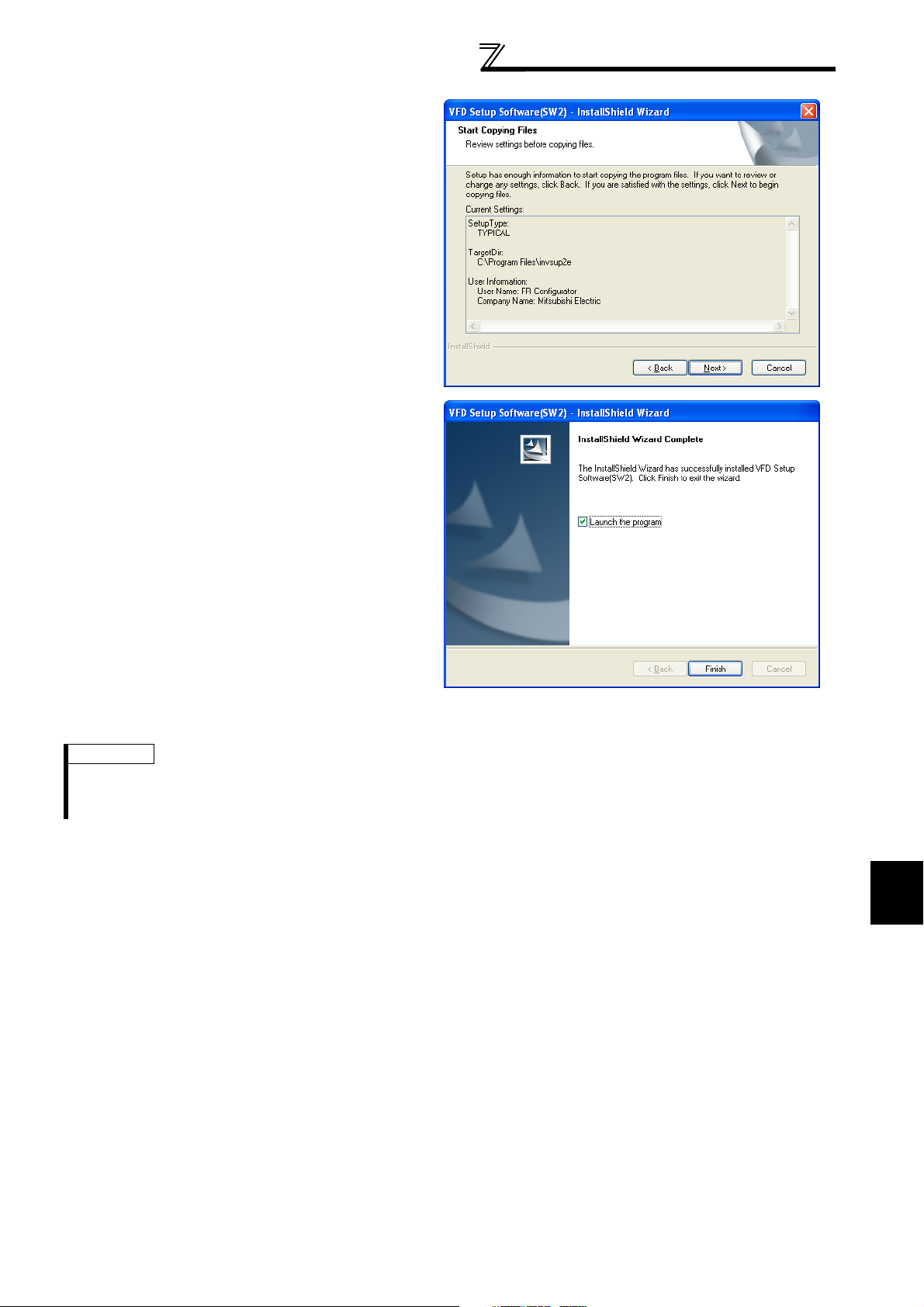

(5) Check the settings, and click "Next" if there is no

problem.

When changing the settings, click "<Back" and

correct them.

(6) The installation is completed.

Click the "Finish" button to finish.

By checking "Launch the program", the program will

start right after the "Install Shield Wizard" is finished.

Preparations for Startup

(7) When the installation is finished, a shortcut is created in the [Start] menu.

REMARKS

If the user does not have the administrator authority (Administrator authorization) with Windows XP/2000 OS, the installation cannot be

made.

Login as a user with administrator authority and start the installation again.

1

OVERVIEW

9

Page 14

Preparations for Startup

1.2.5 Uninstallation of FR Configurator

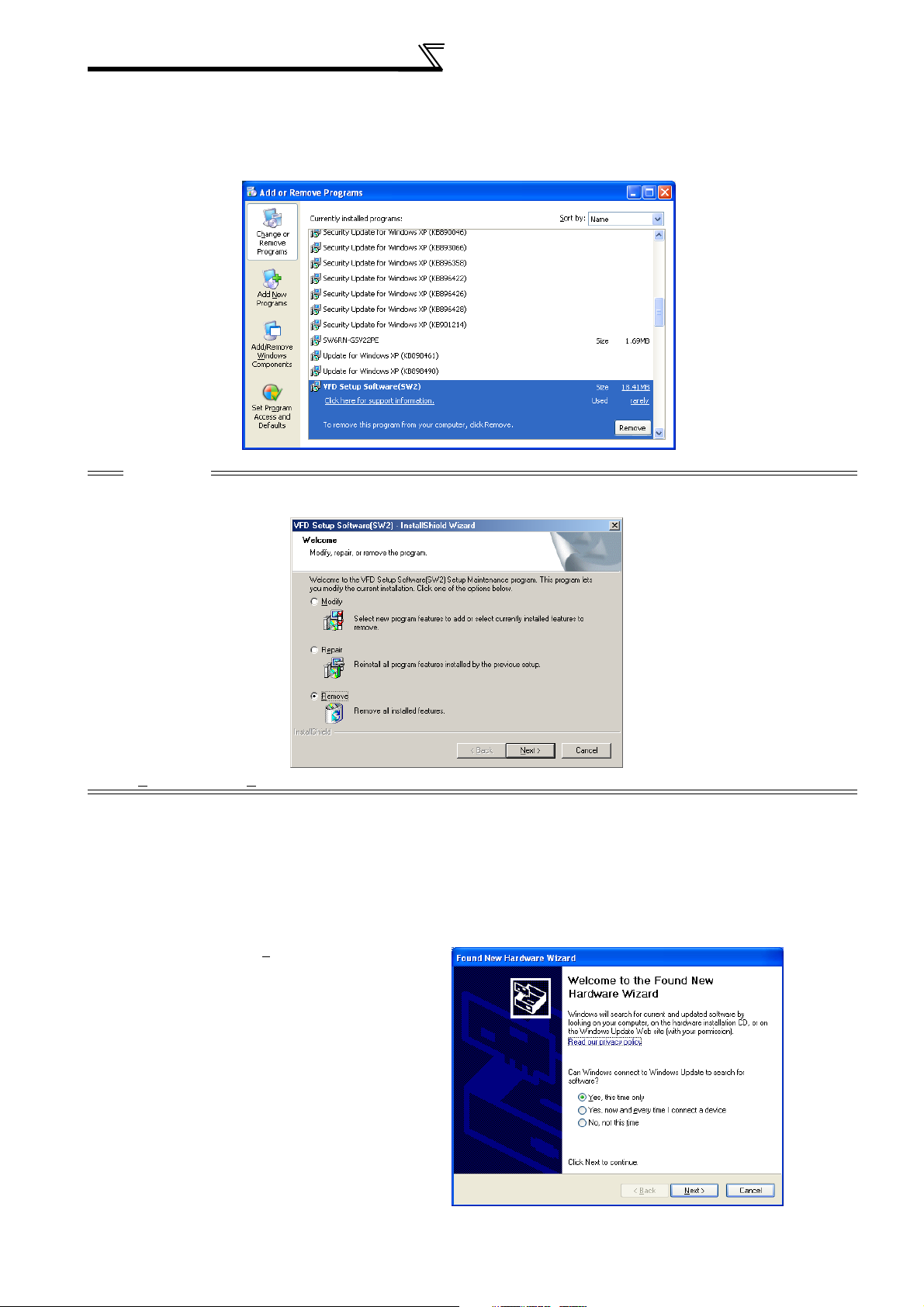

Select "Add or Remove Programs" from [Start] - [Setting] - [Control panel] and display the following screen.

Select "VFD Setup Software(SW2)" and click the "Remove" button to execute the uninstallation.

CAUTION

If the operation system is Windows 98SE or Windows Me, the following screen appears during the uninstallation.

Select [Remove] and click [Next>] to proceed the uninstallation.

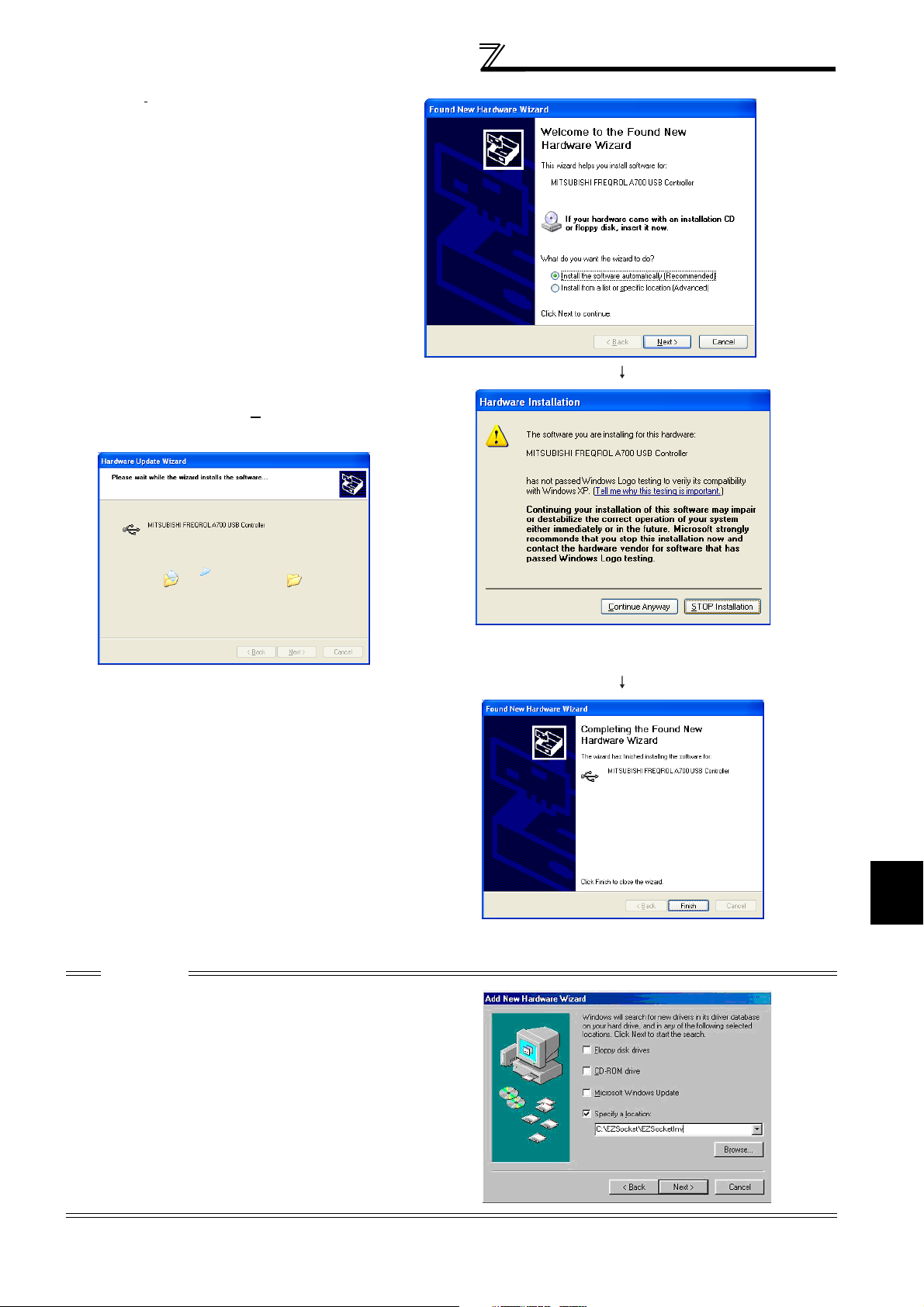

1.2.6 When connecting USB for the first time (FR-A700 series)

If a personal computer and inverter are connected via USB for the first time with the inverter power on, Found New Hardware

Wizard is displayed.

The following additional wizard is displayed for Windows 98SE/Me/XP only.

For Windows 2000, it is automatically detected.

(1) Check the radio button "Yes, this time only" and click

the "Next" button.

10

Page 15

(2) Check "Install the software automatically

(Recommended)" and click the "Next" button.

(3) If the screen shown on the right is displayed when

using Windows XP, click [Continue Anyway] to start

the installation.

Preparations for Startup

(4) The installation of driver is completed.

Click "Finish" to complete.

CAUTION

When the dialogue box shown on right appeared while using

Windows 98SE and Windows Me, check the "Specify a

location" and specify "C:\EZSocket\EZSocketInv", and then

click "Next>" button.

If the FRA700.inf file is not in the folder above, search the

FRA700.inf file and specify that folder.

1

OVERVIEW

11

Page 16

MEMO

12

Page 17

2 FUNCTIONS

This chapter describes the "functions" of this product.

Always read the instructions before using this software.

2.1 Starting FR Configurator..........................................14

2.2 Menu list ..................................................................15

2.3 Saving, Reading and Printing the Files ...................16

2.4 Explanation of Screen .............................................18

2.5 Operation Mode Setting of the Inverter ...................21

2.6 FR Configurator Setting [Setting] ............................23

2.7 Parameter Setting [Parameter]................................ 27

2.8 Monitoring Inverter Status [Monitor] ........................ 43

2.9 Inverter Failure Check [Diagnosis] ..........................54

2.10 Test Running ...........................................................58

2.11 Advanced Function.................................................. 61

2.12 Help ......................................................................... 66

13

1

2

3

4

Page 18

Starting FR Configurator

2.1 Starting FR Configurator

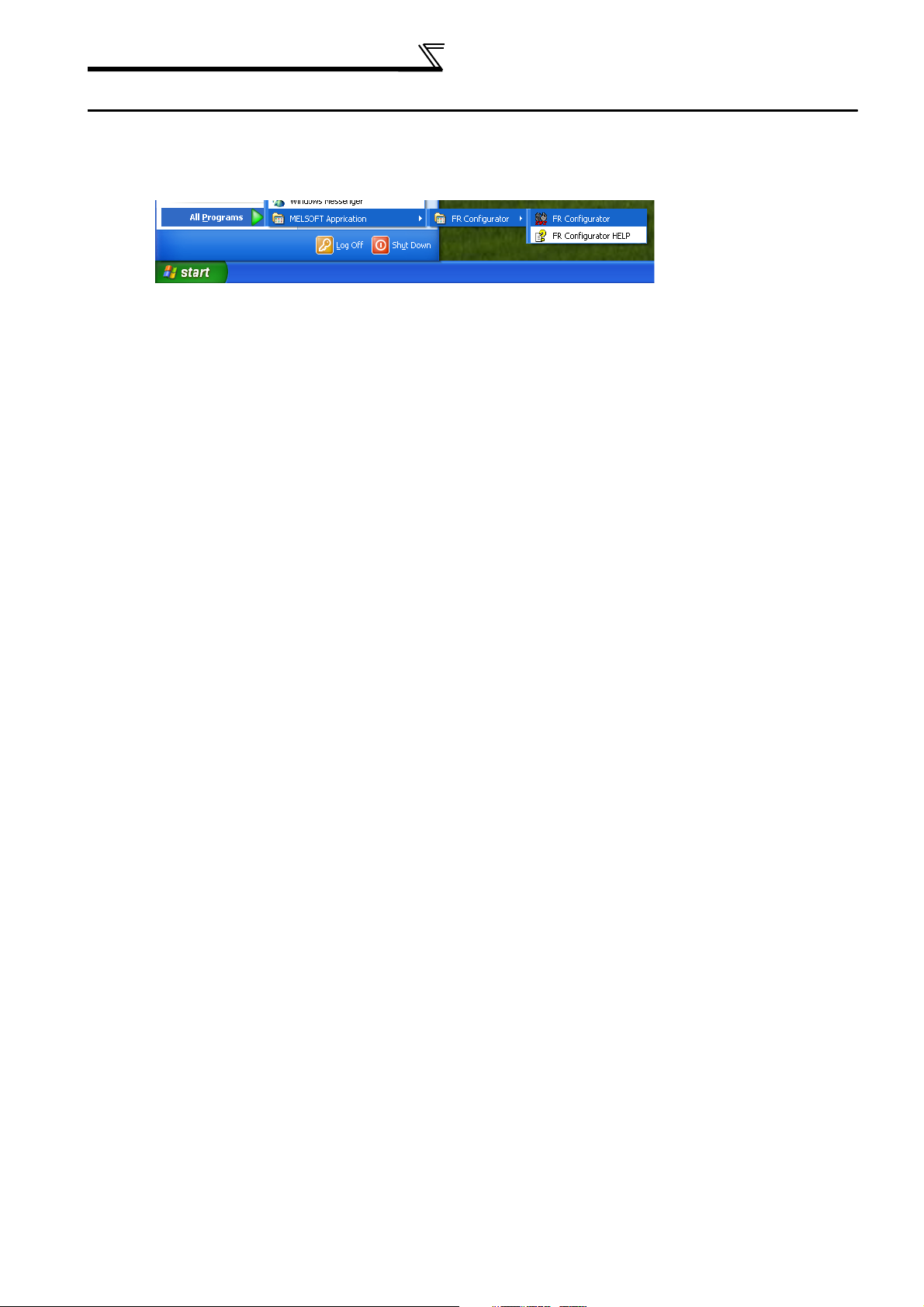

Click [Start] , point to [All Programs] , point to [MELSOFT application] , point to [FR Configurator] and then click [FR

Configurator] to start FR Configurator.

14

Page 19

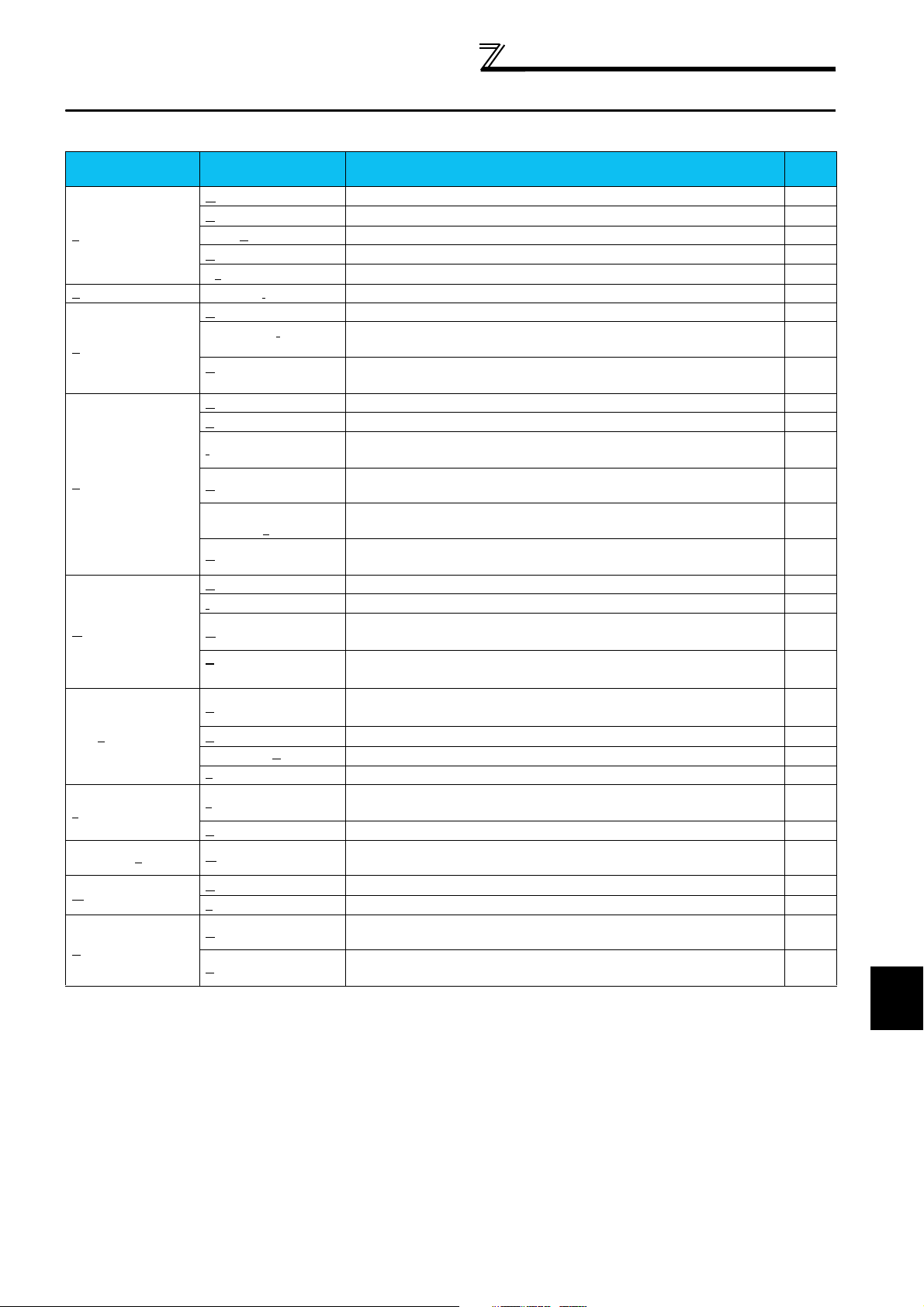

2.2 Menu list

This software has the following functions:

Menu list

Menu Pull-Down Menu Function/Operation

Open (Ctrl+O) Opens a file.

Close Closes the screen.

File

Save As (Ctrl+A) Saves data.

Print (Ctrl+P) Selects printing.

Exit Exit FR Configurator.

V

iew System list Displays a system list. 19

System Settings Sets the model, capacity and option type. (Stations 00 to 31)

S

ettings

Communication

Settings

Environmental

Settings

Sets communication information.

Set the place for saving data (directory) and the operation at the start-up.

All List Format Shows the parameter list, and parameter setting can be made.

Functional List Format Shows and sets the related parameters function-by-function.

A total of 32 parameters out of all parameters can be registered to two

different user groups to be managed.

The parameters required for starting up the inverter can be set without

being aware of parameter numbers.

Assigns functions to the inverter I/O terminals.

Converts the parameter settings automatically at replacement from the

conventional mode

P

arameter

Individual List Format

Basic Settings

I/O terminals

Allocations

Convert Function

Data Display Shows four pieces of data (up to 4 signals) in terms of meter deflections.

Monitors the status of the inverter I/O terminals. 44

3 analog signals and 4 digital signals (up to 7 signals) can be output in

waveform.

Lists the operation status, operation mode and error existence of all inverter

stations.

Shows various data of all stations connected in real time in terms of

values.

Displays the alarm history of all inverters connected.

Displays inverter part replacement indication.

Estimates the cause of faults from the situation.

Gives the operation command from the personal computer to actually test

run the inverter.

Performs auto tuning.

Measures the response frequency characteristic of speed relative to the

motor torque of the machine.

Overlapping Windows.

Windows are side-by-side.

Explains the use of FR Configurator and the description of parameters,

etc.

Version information (copyright, version information, user and company

names, etc.)

M

onitor

osis

Diagn

T

est Running

Advanced (Z

W

indow

elp

H

I/O terminal monitor

Oscilloscopes

Status Monitor

V

FD Status

larm History

A

Life Check (D

T

rouble Shoot

T

est Running

uto Tuning

A

)Machine Analyzer

C

ascade Display

T

ile Display

H

elp

About VFD Setup S/W

)

Refer to

page

17

-

16

17

-

23

25

26

28

33

34

35

36

38

43

45

53

54

55

56

57

58

59

61

-

-

66

67

2

15

FUNCTIONS

Page 20

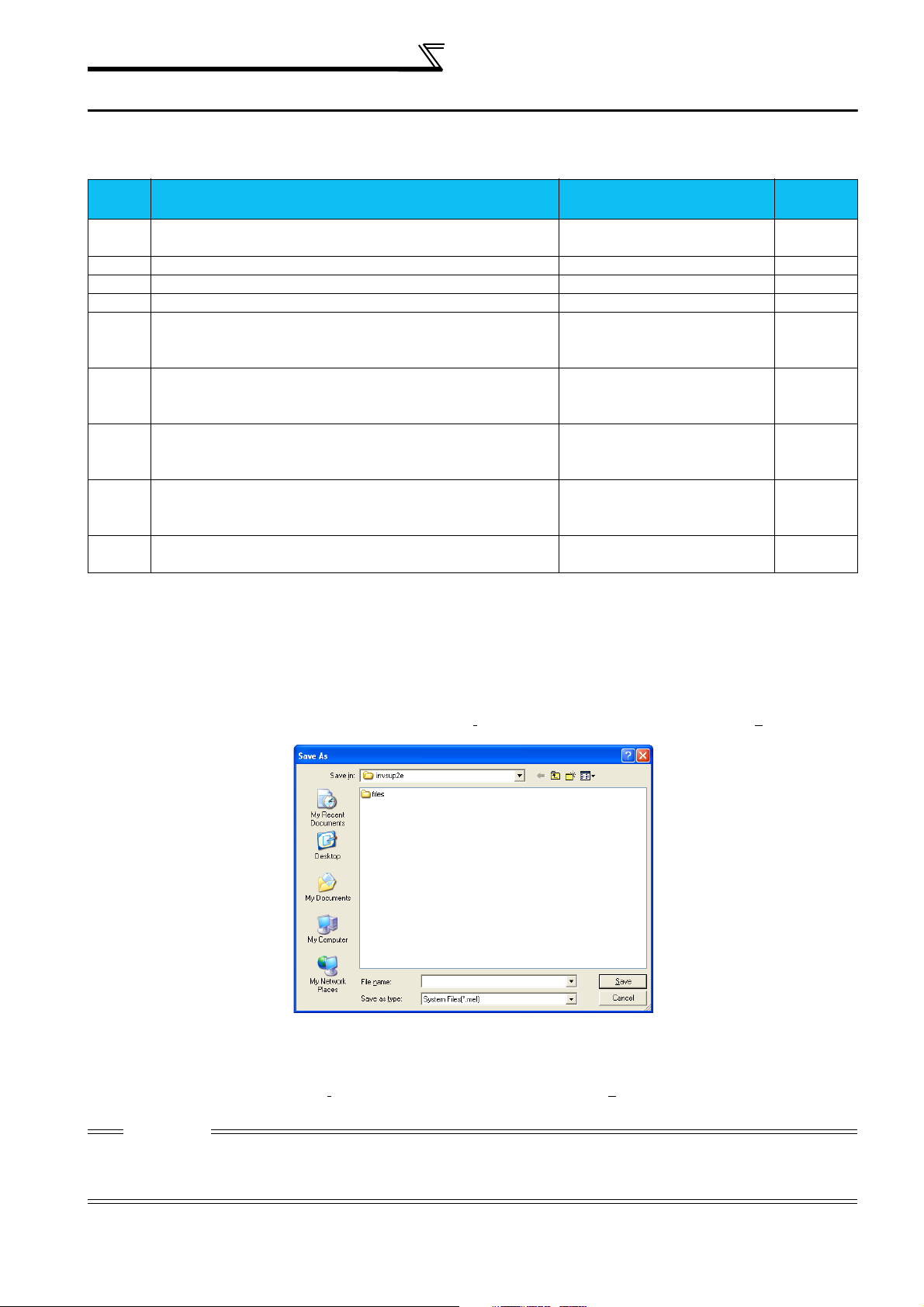

Saving, Reading and Printing the Files

2.3 Saving, Reading and Printing the Files

2.3.1 File types

Extensi

on

*.MEL

*.MMT Manages the Data Display in monitoring. (one screen) Data Display 43

*.GPI Manages the oscilloscope data in monitoring. (one screen) Oscilloscopes 45

*.JPEG Saves the oscilloscope data as images. Oscilloscopes 45

*.TXT Saves the parameter list (one station) in a text file format.

*.CSV

*.PRM

*.XLS

*.HDT

Manages the system setting and parameter lists of all stations as a

single file.

Saves the parameter list (one station) in a text file format.

Saves the oscilloscope data in a text file format.

Saves the parameter list (one station) in a text format.

Used to copy the parameter settings to other inverters (other stations).

Saves the parameter list (one station) in a Microsoft Excel file format.

(Editable with Microsoft Excel 97 or later)

Saves the frequency characteristic measurement data of Machine

Analyzer

Description Target screen

System Setting, All List Format 23, 28

All list Format, Functional List

Format, Individual List Format, Basic

Setting Format 2

All List Format, Functional List

Format, Individual List Format, Basic

Setting Format 2, Oscilloscopes

All List Format, Functional List

Format, Individual List Format, Basic

Setting Format 2

All List Format, Functional List

Format, Individual List Format, Basic

Setting Format 2

Machine Analyzer 61

Refer to

2.3.2 Saving method

page

27

27, 45

27

27

(1) *.MEL file

When the system settings or parameter lists to be saved are open, choose the [Save] command from the [File] menu. The

"Save As" panel appears. Select the file type from "Save as type", and save the file with the name in "File name" field.

(2) *.MMT, *.GPI, *.JPEG,*.HDT, *.TXT, *.CSV, *.PRM, *.XLS files

Choose the [Save] command from the [File] menu on the corresponding display screen. The "Save As" panel appears.

Select the file type from "Save as t

ype", and save the file with the name in "File name" field.

CAUTION

When saving *.TXT, *.CSV, *.PRM and *.XLS files from the Functional List Format, Individual List Format or Basic Settings format 2, only

the parameters displayed are saved.

When saving all the parameter setting values, save in all list format.

16

Page 21

Saving, Reading and Printing the Files

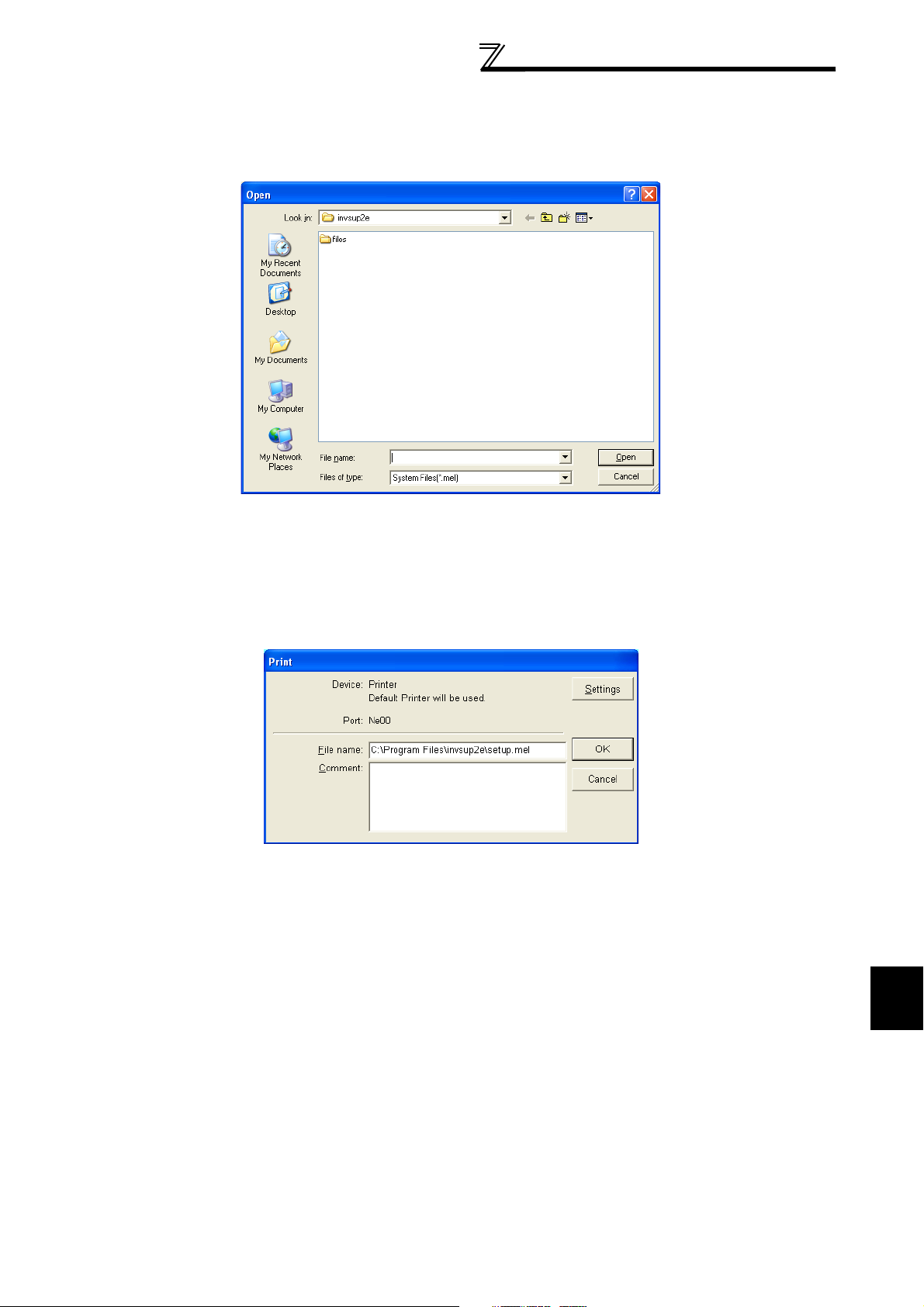

2.3.3 Reading the file

To read the saved file, choose the [Open] command from the [File] menu. The "Open" panel appears. Choose the file to

be read and click the [OK] button to read the saved data.

2.3.4 Printing

Display the screen to be printed and choosing the [Print] command in the [File] menu displays the "Print" panel. Make printer

and other settings and click the [OK] button to start printing.

When entering a comment in the comment area, the comment can be printed with it.

17

2

FUNCTIONS

Page 22

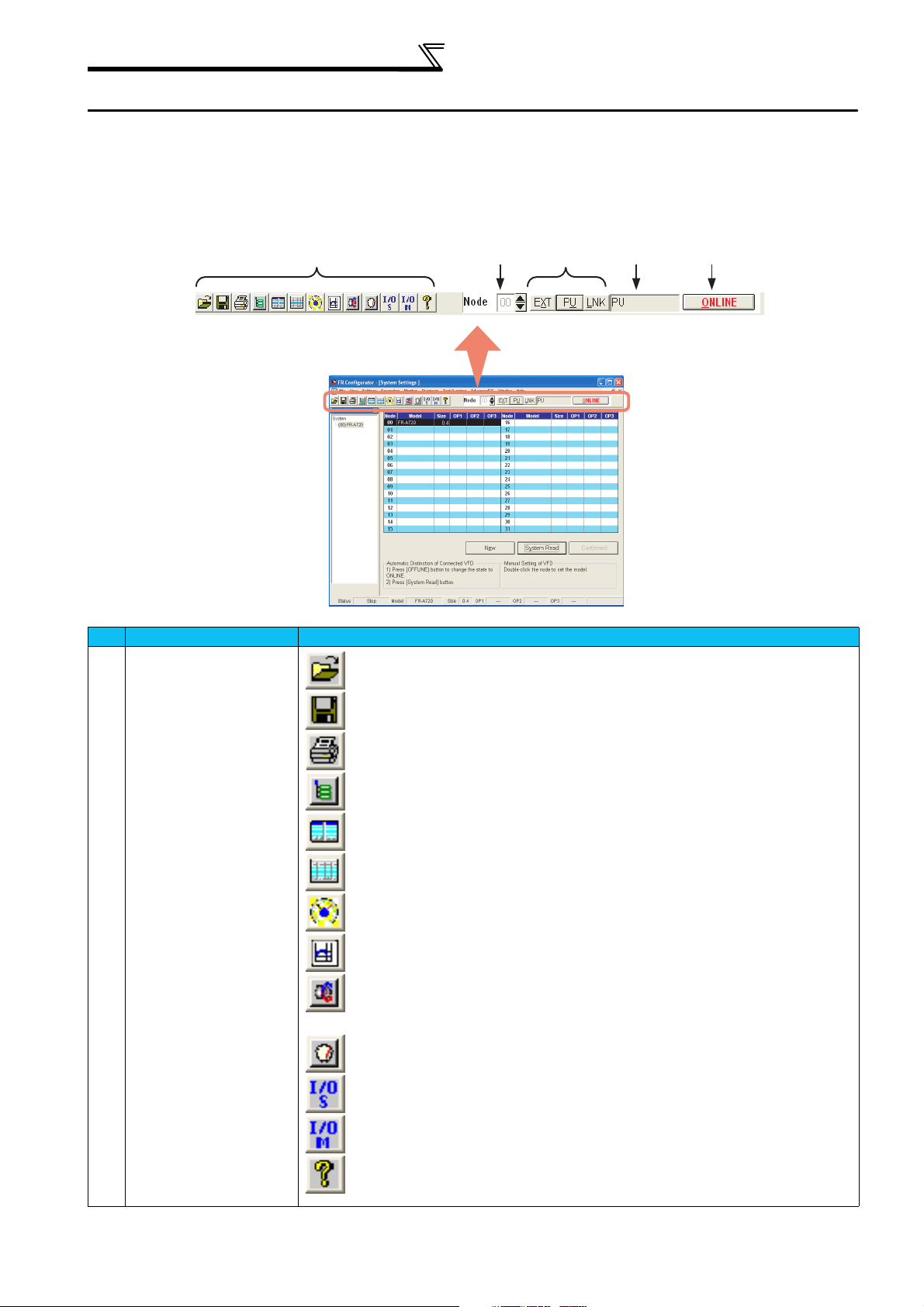

Explanation of Screen

2.4 Explanation of Screen

2.4.1 Tool bar

Tool bar is comprised of tool buttons which have functions commonly used in the menu, and the menu can be executed

quickly by clicking the icons.

In addition, selection of station number and operation mode, online/offline settings are also available.

A

No. Name Function and description

Function tool button

A

.........Opens a file.

(Refer to page 17)

.........Saves the data.

(Refer to page 16)

.........Prints.

(Refer to page 17)

.........Displays a system list.

(Refer to page 19)

.........Makes settings of model, capacity and plug-in option.

(Refer to page 23)

.........Displays a parameter list and makes a parameter setting.

(Refer to page 28)

.........Displays four data with analog meter and numerical value.

(Refer to page 43)

.........Displays data of three analog signals and four digital signals as waveform.

(Refer to page 45)

.........Gives an operation command from a personal computer and executes a test operation

on the inverter.

(Refer to page 58)

.........Executes an auto tuning.

(Refer to page 59)

.........Assigns functions to the inverter I/O terminals.

(Refer to page 36)

.........Monitors the status of the inverter I/O terminals.

(Refer to page 44)

.........Explains the use of FR Configurator and the description of parameters, etc.

(Refer to page 66)

B

C

D

E

18

Page 23

Explanation of Screen

No. Name Function and description

Station number

B

selection

Operation mode

C

button

Operation mode

D

indication

Online button Switches Offline and Online by clicking. Pressing [Alt] key and [o] key can also switch Offline and Online.

E

Selects a station number to be displayed on the screen using the / button. (Only station number set

with the system setting is displayed in the displaying column.

Direct enter of displaying column is also available.

Sets the operation mode by clicking each button.

The set operation mode is displayed in the displaying column of operation mode.

Valid only when the online button is in the status.

• [EXT] (Alt+X): External operation mode

• [PU] (Alt+U): PU operation mode

• [LNK] (Alt+L): Network operation mode

• EXT: External operation mode

• PU: PU operation mode

• LNK: Network operation mode

• EXT JOG: External JOG operation mode

• PU JOG: PU JOG operation mode

• PU+EXT: External/PU combined operation mode

• No Node: when the time-out occurs in the ONLINE mode

REMARKS

• The operation mode + alarm (warning) descriptions are displayed at the alarm occurrence or during the

warning indication. Displayed in red letters at the alarm occurrence.

Example: When the overcurrent shut-off during acceleration occurs during PU operation ... PU (OC1)

When PU stop occurs during EXT operation ... EXT (PS)

At the occurrence of communication error such as NAK or the occurrence of inverter error such as out of

•

parameter range, error codes are displayed.

...Online

...Offline

(page 70)

2.4.2 System list

The system list is displayed with the system setting screen when starting FR Configurator.

The model name and station number set with the system setting are displayed on the list.

The inverter (station number) selected on the system list becomes active on thez parameter setting screen or alarm display

screen.

When the system list window is closed, select [System list] of the [Display] menu to display again.

2

19

FUNCTIONS

Page 24

Explanation of Screen

2.4.3 Status bar

AB DEC

No. Name Function and description

Status Displays the inverter operation status (Running/Stop/Off Line/Error) of selected station.

A

Model Displays the inverter model name of selected station.

B

Size Displays the inverter size of selected station.

C

OP1 Displays the name of plug-in option mounted on the inverter of selected station.

D

OP2

E

OP3

F

PLC Function status

G

(FR-A700-NA/EC series only)

(The number of plug-in options which can be mounted on an inverter differs according to the

inverter.)

Displays the state of PLC Function.

PLC Function: Stop

PLC Function: Running

PLC Function: Disabled

PLC Function: Error

F

G

20

Page 25

Operation Mode Setting of the Inverter

2.5 Operation Mode Setting of the Inverter

2.5.1 Operation mode setting

For operating the inverter using FR Configurator (parameter change, auto tuning and test operation, etc.), the operation mode

of inverter must be set. Refer to the table, and select an operation mode, which matches to each connecting method. The

selection of operation mode can be made using the tool bar. (Refer to page 18)

Connecting method

PU connector

Direct

connection

with FR

Configurator

and the

Inverter

Connection

via GOT

* When connecting a USB connector, set "3" in Pr.551 PU mode control source selection. The change for the setting value of Pr.551 becomes valid when turning on

the power next time or resetting the inverter.

(RS-485

connector)

RS-485 terminal

USB connector

(FR-A700

series only)

PU connector

(RS-485

connector)

RS-485 terminal

Operation

mode*

PU

PU

LINK Pr. 551 PU mode control source selection

PU

PU

PU

LINK Pr. 551 PU mode control source selection

Pr. 122 PU communication check time interval

Pr. 123 PU communication waiting time setting

Pr. 551 PU mode control source selection

(Factory setting)

Pr. 548 USB communication check time interval

Pr. 551 PU mode control source selection

Pr. 123 PU communication waiting time setting

Pr. 551 PU mode control source selection

Pr. 551 PU mode control source selection

(Factory setting)

Parameter setting

≠ 0 (Factory setting = 9999)

= 9999 (Factory setting)

= 2

= 1

= 3

= 2 (Factory setting)

= 2

= 1

Pr. 336 RS-485 communication check time

≠ 0

interval

Pr. 337 RS-485 communication waiting time

= 9999 (Factory setting)

setting

≠ 0 (Factory setting = 9999)

= 0

Pr. 336 RS-485 communication check time

≠ 0

interval

Pr. 337 RS-485 communication waiting time

= 0

setting

Controllability through communcation

Operation

Location

Control by RS-485 communication from PU connector

Condition

(Pr. 551

Setting)

2

(PU

connector)

Except for 2

Operation

Mode

Item

Run command (start)

Run command (stop)

Running frequency

setting

Monitor {{ { { {

Parameter write { *4 × *5 { *4 { *4 × *5

Parameter read {{ { { {

Inverter reset {{ { { {

Run command (start)

Run command (stop)

Running frequency

setting

Monitor {{ { { {

Parameter write ×

Parameter read {{ { { {

Inverter reset {{ { { {

PU

Operation

{ ×× { ×

{ *3 *3 { *3

{ × { ××

*3 *3 *3 *3 *3

External

Operation

×× × × ×

×× × × ×

*5 × *5 × *5 × *5 × *5

External/PU

Combined

Operation Mode

1

Pr. 79

= 3)

(

External/PU

Combined

Operation

Mode 2

(Pr. 79 = 4)

NET Operation

(when RS-485

terminals are

used)

*6

NET Operation

(when

communication

option is used)

*7

2

21

FUNCTIONS

Page 26

Operation Mode Setting of the Inverter

Operation

Location

RS-485 terminals

Control by communication from

Operation from the USB connector*8

Condition

(Pr. 551

Setting)

1

(RS-485

terminals)

Except for 1

3 (USB

connector)

Except for 3

Operation

Mode

PU

Operation

External

Operation

Item

Run command(start,

stop)

Running frequency

setting

Monitor {{ { { {

Parameter write { *4 × *5 { *4 { *4 × *5

Parameter read {{ { { {

Inverter reset {{ { { {

Run command

(start, stop)

Running frequency

setting

Monitor {{ { { { {

Parameter write × *5 × *5 × *5 × *5 { *4 × *5

Parameter read {{ { { { {

Inverter reset ×× × × {

Run command

(start, stop)

Running frequency

setting

Monitor {{ { { {

Parameter write { *4 × *5 × *5 × *5 × *5

Parameter read {{ { { {

Inverter reset {{ { { {

Run command

(start, stop)

Running frequency

setting

Monitor {{ { { {

Parameter write × *5 × *5 × *5 × *5 × *5

Parameter read {{ { { {

Inverter reset {{ { { {

{ ×× { ×

{ × { ××

×× × × { *1 ×

×× × × { *1 ×

{ ×× { ×

{ × { ××

×× × × ×

×× × × ×

External/PU

Combined

Operation Mode

1

Pr. 79

= 3)

(

External/PU

Combined

Operation

Mode 2

(Pr. 79 = 4)

NET Operation

(when RS-485

terminals are

used)

*6

*2 ×

NET Operation

(when

communication

option is used)

*7

{: Enabled, ×: Disabled, : Some are enabled

*1 As set in Pr. 338 Communication operation command source and Pr. 339 Communication speed command source. (Refer to the inverter Instruction Manual

(applied)

*2 At occurrence of RS-485 communication error, the inverter cannot be reset from the computer.

*3 Enabled only when stopped by the PU. At a PU stop, PS is displayed on the operation panel. As set in Pr. 75 Reset selection/disconnected PU

detection/PU stop selection. (Refer to the inverter

*4 Some parameters may be write-disabled according to the Pr. 77 Parameter write selection setting and operating status. (Refer to the inverter

)

Instruction Manual (applied))

Instruction Manual (applied))

*5 Some parameters are write-enabled independently of the operation mode and command source presence/absence. When Pr. 77 = 2, write is

enabled. (Refer to the inverter

*6 When Pr. 550 NET mode operation command source selection = 1 (RS-485 terminals valid) or Pr. 550 NET mode operation command source selection =

9999 and the communication option is not fitted.

*7 When Pr. 550 NET mode operation command source selection = 0 (communication option valid) or Pr. 550 NET mode operation command source selection

= 9999 and the communication option is fitted.

*8 FR-A700 series only.

Instruction Manual (applied)) Parameter clear is disabled.

2.5.2 Communication device setting of personal computer

Make a setting for the communicating method of personal computer and inverter. Select [Communication setting] in the

[Setting] menu of the FR Configurator menu bar, and then select either "RS-232C" or "USB" from the connecting methods on

the communication setting screen.

For details, refer to page 25.

22

Page 27

FR Configurator Setting [Setting]

2.6 FR Configurator Setting [Setting]

2.6.1 System setting

The system setting is displayed when starting FR Configurator.

This section describes the setting for the station number, model, capacity and plug-in option of inverter to be connected. The

inverter can be set from 0 to 31 stations.

The connected inverter system can be also read all at once.

POINT

After adding or changing the inverter model or capacity, make sure to press the button.

A

B

C

D

23

2

FUNCTIONS

Page 28

FR Configurator Setting [Setting]

No. Name

System setting Sets the environment of inverter from 00 to 31 stations.

A

Select a model and capacity of inverter. Set a type of plug-in option when using a plug-in option.

By double-clicking on the line of station number to be set, the "VFD Structure" panel is displayed.

Set model, capacity and option, and press the [OK] button to complete the setting. With the same

procedures, set all the inverter stations to be connected.

[New] button By clicking the [New] button, the edited system setting and communication setting are initialized

B

(cleared), and a new system is set.

[System Read] button Before pressing the [System Read] button, change the system to the [online] mode by pressing the

C

[ONLINE] button. In the online mode, the system is in the status communicating with the inverter. By

clicking the [System Read] button, the models, capacities and options of all stations (0 to 31 stations)

are read, and connected (communicable) stations are displayed.

Automatically confirmed after the read.

When the system setting has been already registered, the verification is performed. When the

verification result is different from the read data, displays the result of checking, and select to change

the settings or not.

[Confirmed] button The data set the system setting can be confirmed. When the setting of the system configuration is

D

changed manually, make sure to confirm using the [Confirmed] button.

Function and description

CAUTION

• When clicking the [Cancel] button during [System Read], the verification is performed with the system setting up to the point.

• 75K or more of FR-F740-CH is displayed as "FR-F740-CHT" in the [Model] field.

REMARKS

Shortcut key on the [System setting] screen

Menu name Shortcut key*

Open Ctrl + O

Save As Ctrl + A

Print Ctrl + P

* "+" indicates that keys should be pressed at the same time.

Button name Shortcut key*

EXT Alt + X

PU Alt + U

LINK Alt + L

ONLINE/OFFLINE Alt + O

24

Page 29

FR Configurator Setting [Setting]

2.6.2 Communication settings

FR Configurator can control the inverter by communication using RS-232C port or USB port of personal computer.

Communication setting must be set same as the inverter.

When you start this software first, the initial screen appears, then displays the system setting screen. Choose the

[Communication settings] command on the [Settings] menu. The screen then shows the following dialog box, where various

communication settings can be made.

Communication settings will be described below.

POINT

The communication setting is set to the initial value of inverter.

Confirm the communication ports (1 to 9) and communication device (RS-232C/USB) of personal computer.

A

B

C

D

E

No. Name

Communication

A

port type

Communication

B

port number

Baud Rate 19200 Set the communication speed.

C

Data Length 8 Set the data bit length.

D

Parity Check Even Specify the parity bit.

E

Stop Bit 2 Set the stop bit length.

F

Delimiter CR Specify the delimiter at the data trailer.

G

Initial

value

RS-232C

Selects a communication device from either RS-232C or USB. (USB communication is available

for FR-A700 series only.)

1 Selects a communication port of personal computer.

The communication port can be checked by the following procedure.

(1) Click [Start], point to [All Programs]*, point to

[Accessories], point to [System Tools], and

then click [System Information].

* [Programs] for other than Windows XP

(2) Select [Serial]* in [Port] folder of

[Component] in the left pane.

* [Serial] is not displayed for other than Windows

2000 and XP.

(3) Check the [COM] number of "Communication

port" displayed in the right pane.

Example: "1" for "Communication port (COM1)"

(4) Set the confirmed value to the communication port of B.

F

H

I

Function and description

G

O

J

K

L

M

N

2

FUNCTIONS

25

Page 30

FR Configurator Setting [Setting]

No. Name

Initial

Function and description

value

Interrogate Time 1 Sets an interval for sending data (display and error check of the operation mode) to the inverter.

H

The value must be set 2s shorter than the communication check time interval (Pr.122, Pr.336 or

Pr.548). If it is set longer than the setting value of communication check time interval (Pr.122, Pr.

366 or Pr. 548), the inverter will come to an alarm stop.

CAUTION

If the value of Interrogate Time is set shorter, the menu or buttons of each window may

be slow to respond depending on operating model and communication speed.

Time Out* 1000 Sets the time for a personal computer to receive a response from an inverter after sending a data

I

to the inverter from the personal computer. If there is no response after the set time is passed,

"Time out" error will be displayed.

[OK] button Recognizes the setting value on the communication screen and returns to the system setting

J

screen.

[Cancel] button Cancels the communication settings and returns to the system setting screen.

K

[Reflect Default] button Used to omit the setting of the values specified in communication settings from the next time

L

onward.

[Default Read] button

M

[Initial Value] button Used to return the communication setting to the initial value.

N

GOT Transparent

O

communication

Used to read the default values. The value is as set with the [Reflect Default] button.

Check when using FA transparent function.

* When connecting with FA transparent function, set the time-out value in 500ms increments (Example: 500 / 1000 / 1500 /... / 30000).

CAUTION

When using FA transparent communication, communication error (Time Out) may occur when FR Configurator starts communication during Time

Out occurrence in GOT (when GOT is monitoring the inverter which is not connected).

In that case, set the Time Out value more than the following.

Time Out value of GOT[s] x (Retry count of GOT + 1) x 3 x1000[ms] (500ms increments)

If the value above is more than 30[s], make adjustment to "Time Out value" and "Retry count" of GOT so that the value above is less than 30[s].

2.6.3 Environmental Setting

You can specify the place for saving data (directory) and default system.

A

B

C

D

No. Name

Default Data Directory

A

System block read is done at start-up

B

When the parameter is read it is

C

distinguished automatically

Default Sys File

D

Set the folder (directory) displayed first in a data saving screen, "Save with file name", or a

opening file screen,"Open file".

Once the data is saved in a different folder, the same folder where the data is saved and opened

will be displayed when saving the data again.

Turn on the check box to execute automatically [System Read] when starting of FR Configurator. If

the default system file is registered, system block read is not performed automatically at the

startup.

Turn on the check box to hide the parameters read-disabled for parameter batch-read or batchverify from the error panel. (Refer to page 29)

Registers the system file (*.MEL) which is automatically opened when starting FR Configurator. If

the default system file is registered, system block read is not performed automatically at the

startup.

There is no default system file registered at the installation.

Function and description

26

Page 31

Parameter Setting [Parameter]

2.7 Parameter Setting [Parameter]

When system settings are completed, parameter menu can be selected.

Select the [All List Format], [Functional List Format], [Individual List Format], or [Basic Settings] command in the [Parameter]

menu to select the corresponding format, and set parameters. Any parameter setting is changed by first entering new data in

the Updated Val column and then pressing the [Write] or [Blk Write] button. The new data is then displayed in the Present

Setting column. The Present setting column shows the current setting value of the inverter.

Using [I/O terminals Allocation] allows to change or assign the functions of the inverter I/O terminals by selecting from the list.

Using [Convert Function], the parameters of the conventional model inverter can be automatically converted to those of FR-

A700/F700 series.

The communication settings of the inverter must be set before setting parameters. (Refer to page 21)

Saving a file

By selecting [Save] in the [File] menu, a list can be saved.

• MEL file (.mel) ................................... A file saved in MEL format can be opened with FR Configurator afterward.

• PRM file (.prm)..................................A file saved in PRM format can be opened with FR Configurator afterward.

• TXT/CSV file (.txt/.csv)...................... When saved in TXT/CSV format, the file is saved in a text format.

• XLS file (.xls).....................................When saved in XLS format, the file is saved in Microsoft Excel format.

The file can be opened with Microsoft Excel.

27

2

FUNCTIONS

Page 32

Parameter Setting [Parameter]

2.7.1 Displaying all parameters [All List Format]

By selecting the [All List Format] command in the [Parameter] menu or clicking of the tool button, all parameters of the

inverter are displayed as a list. When changing any parameter setting, enter a new value in the parameter column to be

changed, and press the key to set it.

A

B

C

D

EF GH IJ K

REMARKS

By pressing the [F1] key (function key), the explanation (HELP) of selected parameter can be displayed.

No. Name Function and description

Pr Jmp Displays a selected parameter number.

A

Input the parameter number and press key to jump to the designated parameter column.

Setting Range Displays the setting range for a selected parameter.

B

Parameter display area Displays a parameter list.

C

After entering data in the Updated Val Column, the parameter setting value can be changed by

pressing the [Write] or [Blk Write] button. After the parameter writing, the new data is displayed in

the Present Setting column.

If the parameter setting value has been changed from the initial value, the NO. column is displayed

in green.

Word Search Letters inputted in Word Search field is searched among the parameter name. (The sensitivity of

D

one byte character set or 2 byte character set is ignored.)

28

Page 33

Parameter Setting [Parameter]

No. Name Function and description

Change List Displays parameters of which Present Setting value has changed from the Factory Setting as a list.

E

Pr Init Clears (initializes) the parameters of the inverter. (The communication parameters are not

F

initialized.)

Choose the clearing method from "Parameter Clear" or "All Clear" on the following panel and click

the [OK] button to execute clear.

Blk Read Reads all parameters of the selected inverter station number.

G

Read Reads the data of the parameter numbers selected on the screen.

H

Blk Check Batch-checks the parameters of the inverter against those of the personal computer.

I

Blk Write Writes new parameter values to the inverter.

J

(When there are no values in the Updated Val field, the screen for selecting whether the present

settings will be written or not appears. Perform operation following the screen.)

Write Writes the data of the parameter numbers selected on the screen.

K

CAUTION

• If an error occurred during "block read", "block check" or "block write", the parameter list appears on the panel. Double-clicking the error

number in the displayed list shows the details of the error definition on the panel.

[When the parameter is read it is distinguished automatically]

Turning on this check box automatically judges the read-disabled parameters and hides them from the Read Error panel from the next read.

• Changing the Pr. 21 setting automatically switches the minimum setting increments of the acceleration/deceleration time-related

parameters (Pr. 7, Pr. 8, Pr. 16, Pr. 44, Pr. 45, Pr. 110, P r. 111, Pr. 264, Pr. 265).

(Increments are 0.1s when Pr. 21=0, 0.01s when Pr. 21=1).

The acceleration deceleration time-related parameters differ according to the inverter. Refer to the inverter Instruction Manual (applied) for

details.

• When the setting of Pr. 37, Pr. 71, Pr. 81, Pr. 144, Pr. 450, Pr. 505 or Pr. 811 has been changed, the setting value (setting increments) of

related parameters may be changed.

If the setting value is changed, perform [Blk Read] to reflect the setting value of the inverter in parameter display area.

Refer to the inverter Instruction Manual (applied) for details of the parameters.

2

FUNCTIONS

29

Page 34

Parameter Setting [Parameter]

(1) FM/CA/AM calibration

The full scale of terminal FM/CA, terminal AM can be calibrated.

The dedicated adjustment screen is used for terminal FM/CA/AM calibration (Pr. 900, Pr. 901).

Press the [Click] button in the parameter list to show the FM/CA/AM terminal adjustment panel.

FM/CA/AM calibration is enabled during the ONLINE mode only.

<Calibration method>

1) Set to the ONLINE mode.

2) Set the monitor with using Pr. 54 FM/CA terminal function selection (Pr. 158 AM terminal function selection).

3) Press the [Click] button in Pr. 900/Pr. 901 row to show the FM/CA/AM terminal adjustment panel.

4) Input the running frequency in the full-scale state, and press [Selected].

5) Press [FWD]/[REV] to start the inverter.

6) Calibrate the scale of the meter in the full-scale state with the / button.

7) Press [Fin.[Stop]] button after adjustment to write the calibration value to the inverter.

To cancel the calibration, press the [Cancel] button.

30

Page 35

Parameter Setting [Parameter]

(2) Calibration of frequency (torque) setting voltage (current)

The dedicated adjustment screen is used for the calibration of frequency setting voltage (current) bias/gain (Pr. 902 to Pr. 905,

Pr. 917 to Pr. 920, Pr. 932, Pr. 933).

Press the [Click] button in the parameter list to show the frequency setting voltage (current) bias/gain setting panel.

The frequency setting voltage (current) bias/gain setting is enabled during the ONLINE mode only.

<Setting method>

1) Set to the ONLINE mode.

2) Press the [Click] button in Pr. 902 to Pr. 905, Pr. 917 to Pr. 920, Pr. 932, Pr. 933 row to show the Parameter (Terminal 2(4)

frequency setting bias/gain (speed/torque/flux) ) setting panel.

3) Choose the Adjustment method from 3 Adjustment method check button.

(a) Without Voltage/Current

Check "Without Voltage/Current" and input setting frequency or torque command value.

(b) With Voltage/Current

Check "With Voltage/Current", input setting frequency or torque command value, and then adjust the external

potentiometer.

(c) Set Any Point without Voltage/Current

Check "Set Any Point without Voltage/Current" and input the setting frequency or the torque command, and the setting

voltage (current).

2

4) Press [OK] button to write the calibration value to the inverter. To cancel the calibration, press the [Cancel] button.

31

FUNCTIONS

Page 36

Parameter Setting [Parameter]

(3) CA terminal calibration (FR-A700-EC/CH, FR-F700-EC/NA/CH)

The dedicated adjustment screen is used for the calibration of the Current output bias/gain signal/current (Pr. 930, Pr. 931).

Press the [Click] button in the parameter list to show the Current output bias/gain signal/current setting panel.

The Current output bias/gain signal/current setting is enabled during the ONLINE mode only.

<Setting method>

1) Set to the ONLINE mode.

2) Press the [Click] button in Pr. 930, Pr. 931 Current output bias/gain signal/current panel.

3) Choose the Adjustment method from 2 Adjustment method check button.

(a) Set the output signal value

Check "Set the output signal value" and input setting signal value.

(b) Set the current value

Check "Set the current value", input Setting signal value and Setting current value.

4) Press [OK] button to write the calibration value to the inverter. To cancel the calibration, press the [Cancel] button.

32

Page 37

Parameter Setting [Parameter]

2.7.2 Displaying the parameters function-by-function [Functional List Format]

By selecting the [Functional List Format] command in the [Parameter] menu, the parameters are displayed as a functional list.

Click the function name tab to display the parameter related to the function name.

For parameter setting and changing, values may only be written in the online mode.

When changing any parameter setting, enter a new value in the Updated Val column and press the key to register it.

The function list differs according to the inverter.

(1) FR-A700 series

Function Description

Basic function Displays the parameters related to the basic function.

F setting Displays the parameters related to frequency.

Acc/Dec Displays the parameters related to acceleration/deceleration.

V/F Displays the parameters related to V/F characteristic.

Protection Displays the parameters related to the protective function.

Operation mode Displays the parameters related to the operation mode.

Monitor Displays the parameters related to the monitoring function.

Brake Displays the parameters related to frequency, time and others at braking.

Terminal Displays the parameters related to the control circuit terminals.

Additional func. Displays the parameters related to the additional function.

Maintenance Displays the parameters related to the maintenance of the inverter.

M.F. vector Displays the parameters related to the advanced magnetic flux vector control.

Vector Displays the parameters related to the vector control.

Calibration Displays the parameters for the calibration of the FM and AM terminals, and the bias/gain setting of the

frequency (torque) setting voltage and the frequency (torque) setting current.

Communication Displays the parameters related to the communication operation.

Option Displays the parameters related to the options.

(2) FR-F700 series

Function Description

Motor,Torque Displays the parameters related to motor and torque.

F Settings Displays the parameters related to frequency.

Acc/Dec Displays the parameters related to acceleration/deceleration.

Protection Displays the parameters related to the protective function.

Monitor Displays the parameters related to the monitoring function.

Brake Displays the parameters related to frequency, time and others at braking.

Terminal Alloc Displays the parameters related to the control circuit terminals.

M.F.Vector Displays the parameters related to the simple Magnetic flux vector control (M.F.Vector).

Intelligent Displays the parameters related to the intelligent mode in which the inverter performs operation after setting

appropriate parameters automatically.

Calibration Displays the parameters for the calibration of the FM and AM terminals, and the bias/gain setting of the

frequency setting voltage and the frequency setting current.

Option Displays the parameters related to the options.

Sp Running Displays the parameters related to the special running used after selecting the communication related settings,

etc. in advance.

2

FUNCTIONS

33

Page 38

Parameter Setting [Parameter]

2.7.3 Registering a parameter to the user group [Individual List Format]

By using the [Individual List Format] command on the [Parameter] menu, two different user groups ("User Group 1", "User

Group 2") can be selected. For these user groups, a total of 32 parameters from among all parameters can be registered.

Click the [Edit Reg.] button. The following panel appears.

C

A

D

No. Name Function and description

Parameter List Displays a parameter list.

A

Individual List Displays parameters to be registered to the user groups.

B

Add Select the items to be registered in the "Parameter List (P)" and press the [Add>>>] button

C

to register them to the "Individual List (K

Delete Select the items to be deleted in the "Individual List (K)" and press the [<<<Delete] button to

D

delete them.

)".

B

After selecting the parameters, pressing the [OK] button completes the user setting and displays the individually selected list

in the following panel. To save the individual list, select the [Save] command from the [File] menu and save it to the system

file.

34

Page 39

Parameter Setting [Parameter]

2.7.4 Parameter automatic settings [Basic Settings]

Selecting the [Basic Settings] command in the [Parameter] menu displays the following screen.

By entering the items shown on the screen, parameters can be set without being aware of the parameter numbers.

C

A

No. Name Function and description

Area for entering the specifications Enter the specification of each item. 60Hz is the maximum setting for operation speed. The

A

illustration shown right on the screen changes according to the specifications entered.

[Click] button Clicking this button displays a window to choose each specifications. Make a selection and

B

click the [OK] button.

Confirmed After entering the specifications of all

C

items, press the [Confirmed] button to

register them. Pressing the

[Confirmed] button displays the panel

on the right.

By pressing the [OK] button, the parameters are set automatically and the new values of the

parameters that may be set automatically are displayed and the following panel appears.

To write the new parameter values to the inverter, press the [Blk Write] button.

B

2

CAUTION

Only V/F Control can be selected in [VFD running system] field when LD or SLD is selected.

35

FUNCTIONS

Page 40

Parameter Setting [Parameter]

2.7.5 Allocating functions to I/O terminals of the inverter [I/O Terminal Allocation]

Selecting the [I/O Terminals Allocation] command on the [Parameter] menu or the tool button selects the I/O terminals

from the list and allows to change or assign the functions of the inverter I/O terminals to them.

B

A

C

E

F

No. Name Function and description

Inverter input terminal function

A

selection

Inverter output terminal function

B

selection

FR-A7AR terminal function

C

selection

FR-A7AY terminal function

D

selection

Monitor/Allocation

E

Selects the signal name from the list and assigns the function to the corresponding input

terminal.

Selects the signal name from the list and assigns the function to the corresponding output

terminal.

Checking the check box sets to negative logic.

Selects the signal name from the list and assigns the function to the output terminal of the

corresponding plug-in option (FR-A7AR).

(When the plug-in option settings have not yet been made by system settings, the setting

cannot be changed.)

Selects the signal name from the list and assigns the function to the output terminal of the

corresponding plug-in option (FR-A7AY).

Checking the check box sets to negative logic.

(When the plug-in option settings have not yet been made by system settings, the setting

cannot be changed.)

When monitoring the signal, click to change to "I/O Terminal Monitor"

screen. Refer to page 44 for "I/O Terminal Monitor".

D

Click to return to "I/O Terminal Allocation" screen and the signal monitoring

can not be made.

36

Page 41

Parameter Setting [Parameter]

No. Name Function and description

Allocation/Monitor start

F

Clicking lists the parameters, and clicking OK writes the parameter setting

values to the inverter.

When the terminal monitor screen appears by clicking , the button becomes

. Clicking the button starts monitoring.

REMARKS

After displaying and checking the parameter list allocated by clicking the "Allocation" button, write the parameters to the inverter.

• Since the parameter cannot be read when Pr.160 0, display the Pr.160 setting change check screen, and click OK to display the

parameter list.

2

For details of I/O terminals functions, refer to the inverter manual.

FUNCTIONS

37

Page 42

Parameter Setting [Parameter]

2.7.6 Converting parameters automatically at the replacement of the conventional model [Convert Function]

By selecting the [Convert Function] command in the [Parameter] menu, the parameters of the conventional model inverter can

be automatically converted to those of FR-A700/F700 series of the same model type.

Source inverter Target inverter

FR-A520, FR-A520L, FR-V520, FR-V520L FR-A720

FR-A540, FR-A540L, FR-A540L-G, FR-V540, FR-V540L FR-A740

FR-F520, FR-F520L FR-F720

FR-F540, FR-F540L, FR-F540L-G, FR-F540L-S FR-F740

CAUTION

If the model type of the source inverter and the target inverter is different (Example: converting NA to EC, etc.), convert can not be made.

C

A

B

D

E

F

G

H

[Source inverter setting section]

No. Name Function and description

Source model selection setting Turning on the checkbox to select the model and the capacity from the list.

A

Source model selection Selects the model of source inverter from the list in the combo box.

B

Source capacity selection Selects the capacity of source inverter from the list in the combo box.

C

Parameter file conversion setting Turning on the checkbox makes the parameter file input field valid. Input the storage place

D

for the parameter file (PRM file).

Connected inverter selection

E

[Fixation] button

F

Source model/capacity display Displays the model and capacity of the read parameter.

G

Source parameter data list Lists the data of the read parameter. The setting value can be changed.

H

Turning on the check box makes the station number selection available. Specify the station

number of source inverter.

Clicking after making the source inverter setting, and then the target inverter

setting can be made.

I

J

K

N

L

M

38

Page 43

Parameter Setting [Parameter]

[Target inverter setting section]

No. Name Function and description

Target model selection Selects the model of target inverter from the list in the combo box.

I

[Start Conversion] button Clicking here starts the conversion.

J

[Save Data] button Clicking the [Save Data] button displays the [Save as] dialogue, and the parameter data is

K

saved with specifying a file.

The format of the file is Parameter file (PRM file) only.

Target model/capacity display Displays the inverter model and capacity of the converted parameter.

L

Target parameter data list Displays the converted parameter list. The setting value can be changed.

M

The number of parameters of which setting has been made are displayed in green.

[Common section]

No. Name Function and description

Simultaneous scroll of the list of

N

parameters

Checked: When either of the source or target parameter lists is scrolled, the other list is

also scrolled.

Not checked: When either of the source or target parameter lists is scrolled, the other list

does not scroll.

CAUTION

Do not change the setting of the following parameters in the Source parameter data list. Increments or setting value may not be

converted correctly.

(If the parameter setting is already changed when reading into the Source parameter data list, converting can be made correctly.)

Pr. 21, Pr. 37, Pr. 71, Pr. 81, Pr. 144, Pr. 450, Pr. 505, Pr. 811

(Refer to the inverter instruction manual for details of the parameters.)

39

2

FUNCTIONS

Page 44

Parameter Setting [Parameter]

Conversion procedure by selecting a model from a list

(1) Check "Select the model from the list" in "Set VFD from

which conversion is made" section and select the model and

capacity of the source inverter.

(2) Click .

When it is fixed, the parameters of selected model and

capacity are displayed as a list.

(3) When the parameter setting of the utilized source inverter

has been changed, input the changed value in the Set Value

column.

(4) Select the model of target inverter.

(Only models convertible with FR Configurator are

selectable)

(5) Click to display the parameter conversion result

as a list.

Input a new value in the Set Value column to change the

parameter setting value.

(6) Click to save the conversion result in the

parameter file (PRM).

(7) Display the All List Format or the Functional List Format, and

select the target inverter.

Displayed in

green when the

setting value is

changed.

When changing

the Pr.1 setting

value to "60Hz "

(8) Open the saved parameter file (PRM). Press the [ONLINE]

button to display

and click .

The parameter setting value is written in the inverter and

conversion is completed.

(9) For parameters completed in error, set them manually again

if required.

40

Page 45

Conversion procedure from parameter file

(1) Check "Convert from the parameter file" in "Set VFD from

which conversion is made" section and select the parameter

file (PRM) of source inverter saved with inverter setup

software (FR-SW0-SETUP/FR-SE1-SETUP).

(2) Click .

When it is fixed, the parameters of selected parameter file

are displayed as a list.

Input a new value in the Set Value column to change the

parameter setting value.

(3) Select the model of target inverter.

(Only models convertible with FR Configurator are

selectable)

Parameter Setting [Parameter]

Click to select the file.

(4) Click to display the parameter conversion result as a list.

Input a new value in the Set Value column to change the parameter setting value.

(5) Click to save the conversion result in the

parameter file (PRM).

(6) Display the All List Format or the Functional List Format, and

select the target inverter.

(7) Open the saved parameter file (PRM). Press the [ONLINE]

button to display

The parameter setting value is written in the inverter and

conversion is completed.

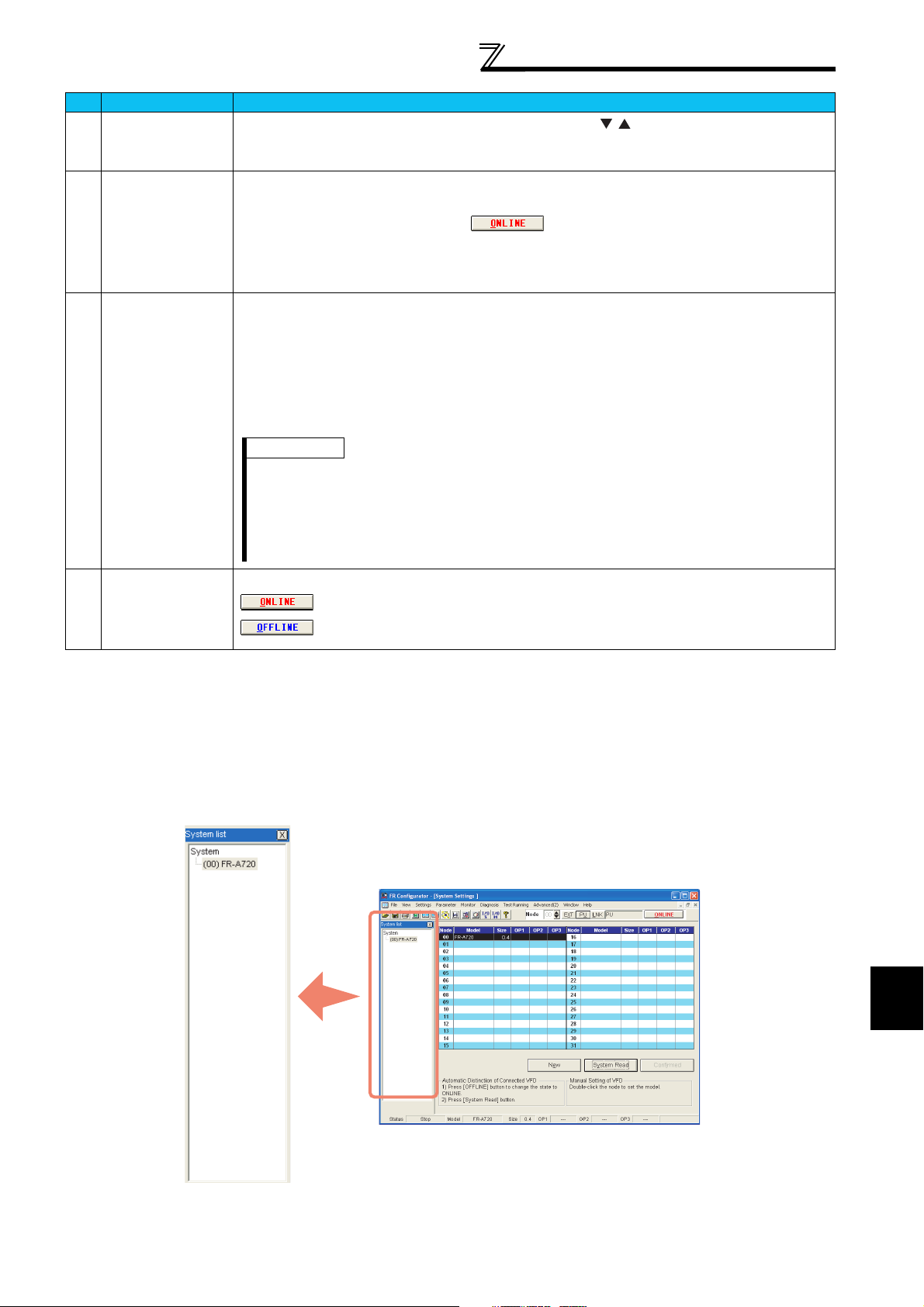

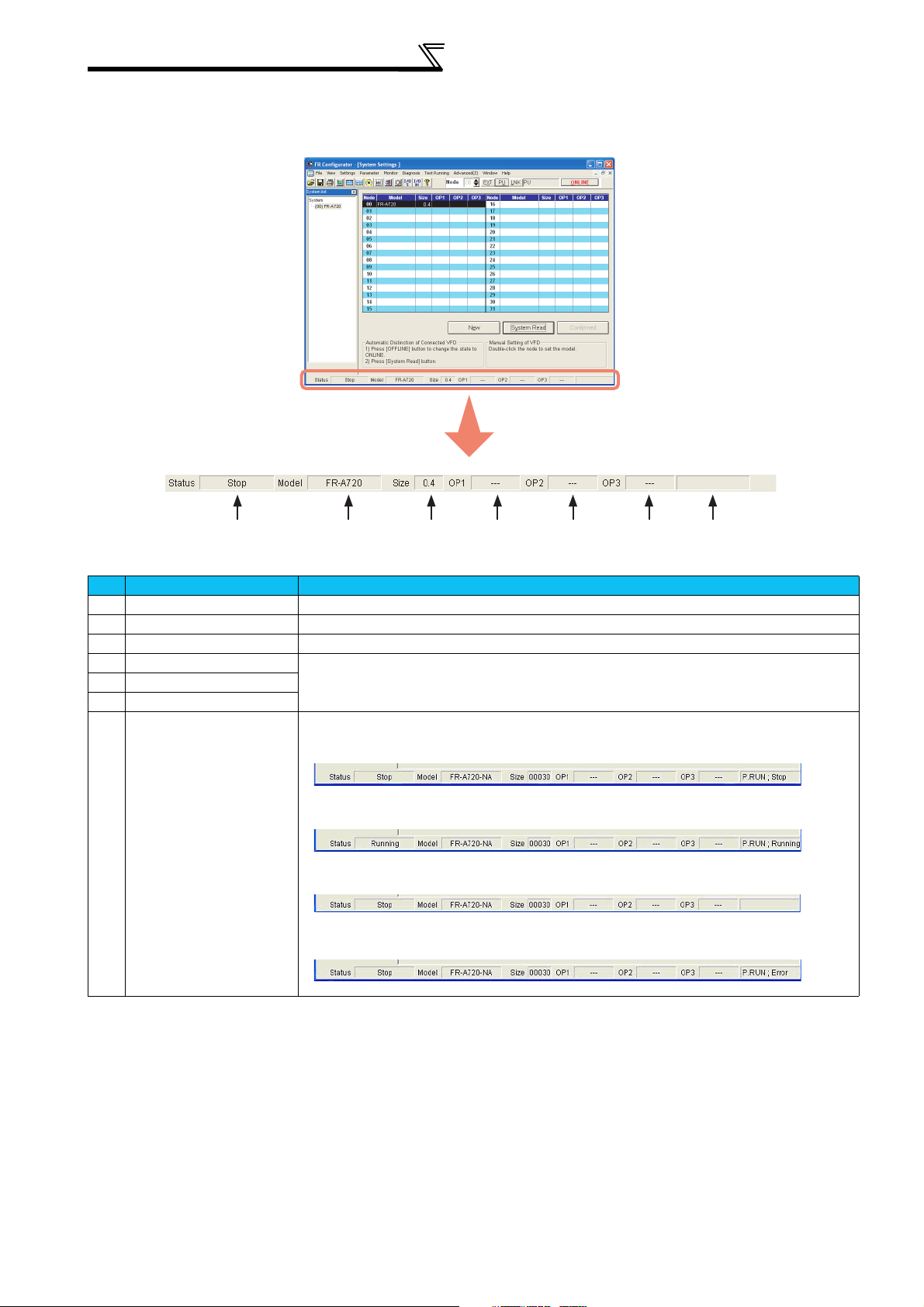

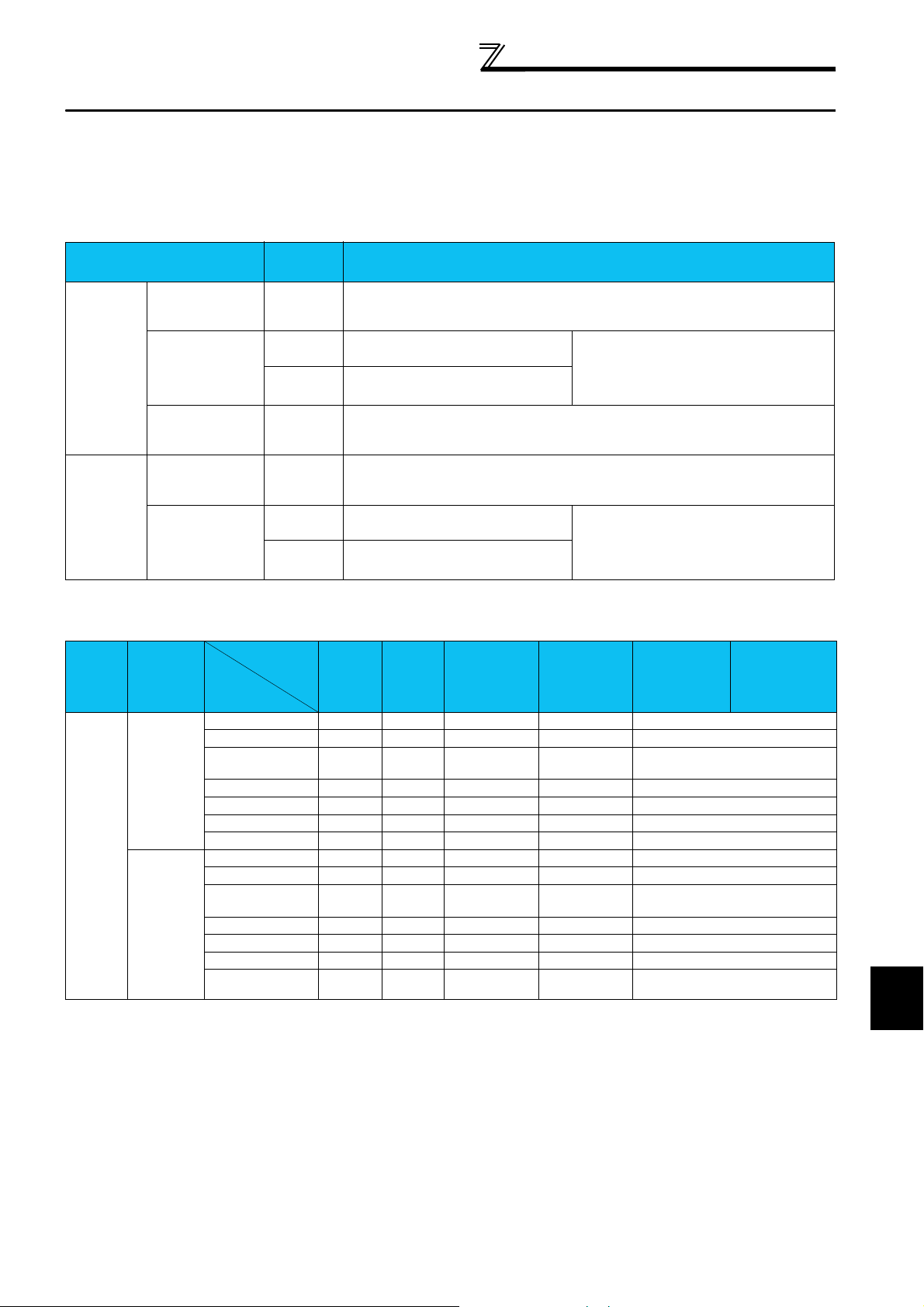

(8) For parameters completed in error, set them manually again