Mitsubishi FR-S520E-0.1K-NA, FR-S520E-0.75K-NA, FR-S520E-0.2K-NA, FR-S520E-0.4K-NA, FR-S520E-1.5K-NA Instruction Manual

...

FR-S520E-0.1K to 3.7K-NA

FR-S540E-0.4K to 3.7K-NA

FR-S510WE-0.1K to 0.75K-NA

1

2

3

FR-S500E-NA

TRANSISTORIZED INVERTER INSTRUCTION MANUAL (BASIC)

TRANSISTORIZED INVERTER

FR-S500

INSTRUCTION MANUAL (BASIC)

CONTENTS

CONNECTION OF PERIPHERAL DEVICES ............................................. 2

1.1 Basic configuration ...................................................................................... 2

INSTALLATION METHOD.......................................................................... 5

2.1 Installation of the inverter............................................................................. 5

SPECIFICATIONS OF WIRING AND TERMINALS ................................... 6

3.1 Terminal connection diagram ...................................................................... 6

3.2 Main circuit................................................................................................... 7

3.3 Control circuit............................................................................................. 11

DRIVE THE MOTOR ................................................................................. 18

4.1 Step of operation ....................................................................................... 18

4.2 Run and operation ..................................................................................... 19

4.3 Operation by the start command from the operation panel (PU operation

mode)........................................................................................................ 21

Thank you for choosing this Mitsubishi transistorized inverter.

If this is the first time for you to use the FR-S500 series, please read through this instruction manual (basic)

carefully and use the inverter safely.

If you are going to use the inverter for higher-level applications, the FR-S500 instruction manual (detailed)

[IB(NA)-0600209ENG] is separately available from where you purchased the inverter or a Mitsubishi sales

representative.

1

2

3

4

This instruction manual (basic) provides handling information and precautions for use

of the equipment.

Please forward this instruction manual (basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read

through this instruction manual (basic) and appended documents carefully and can

use the equipment correctly. Do not use the inverter until you have a full knowledge

of the equipment, safety information and instructions.

In this instruction manual (basic), the safety instruction levels are classified into

"WARNING" and "CAUTION".

WARNING

CAUTION

Note that even the level may lead to a serious consequence

according to conditions. Please follow the instructions of both levels because they are

important to personnel safety.

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may cause

physical damage only.

CAUTION

1. Electric Shock Prevention

WARNING

z While power is on or when the inverter is running, do not open the front cover. You

may get an electric shock.

z Do not run the inverter with the front cover or wiring cover removed. Otherwise,

you may access the exposed high-voltage terminals or the charging part of the

circuitry and get an electric shock. Also, the inverter's ability to withstand

earthquakes will deteriorate.

z Even if power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric shock.

z Before starting wiring or inspection, check to make sure that the 3-digit LED inverter

monitor is off, wait for at least 10 minutes after the power supply has been switched

off, and check to make sure that there are no residual voltage using a tester or the

like.

z This inverter must be grounded. Grounding must conform to the requirements of

national and local safety regulations and electrical codes. (JIS, NEC section 250,

IEC 536 class 1 and other applicable standards)

z Any person who is involved in the wiring or inspection of this equipment should be

fully competent to do the work.

z Always install the inverter before wiring. Otherwise, you may get an electric shock

or be injured.

z Perform setting dial and key operations with dry hands to prevent an electric

shock.

z Do not subject the cables to scratches, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

z Do not change the cooling fan while power is on. It is dangerous to change the

cooling fan while power is on.

z When you have removed the front cover, do not touch the connector above the 3-

digit monitor LED display. Otherwise, you get an electrick shock.

A-1

2. Fire Prevention

CAUTION

z Install the inverter on an incombustible wall without holes, etc. Installing the inverter

directly on or near a combustible surface could lead to a fire.

z If the inverter has become faulty, switch off the inverter power. A continuous flow of

large current could cause a fire.

z Do not connect a resistor directly to the DC terminals P, N. This could cause a fire.

3. Injury Prevention

CAUTION

z Apply only the voltage specified in the instruction manual to each terminal to

prevent damage, etc.

z Always connect to the correct terminal to prevent damage, etc.

z Always make sure that polarity is correct to prevent damage, etc.

z While power is on or for some time after power-off, do not touch the inverter as it is

hot and you may get burnt.

4. Additional Instructions

Also note the following points to prevent an accidental failure, injury, electric shock,

etc.

(1) Transportation and installation

CAUTION

z When carrying products, use correct lifting gear to prevent injury.

z Do not stack the inverter boxes higher than the number recommended.

z Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the instruction manual.

z Do not install or operate if the inverter is damaged or has parts missing.

z When carrying the inverter, do not hold it by the front cover or setting dial; it may

fall off or fail.

z Do not stand or rest heavy objects on the inverter.

z Check the inverter mounting orientation is correct.

z Prevent other conductive bodies as screws and metal fragments or other

flammable substance as oil from entering the inverter.

z As the inverter is a precision instrument, do not drop or subject it to impact.

z Use the inverter under the following environmental conditions: This could cause

the inverter damage.

Ambient

Temperature

Ambient humidity 90%RH maximum (non-condensing)

Storage

temperature

Atmosphere

Environment

Altitude/

vibration

-10°C to +50°C (14°F to 122°F) (non-freezing)

-20°C to +65°C (-4°F to 149°F) *

Indoors (free from corrosive gas, flammable gas, oil mist,

dust and dirt)

2

Max.1000m (3280.80 feet) above sea level 5.9m/s

(conforming to JIS C 60068-2-6)

or less

*Temperatures applicable for a short time, e.g. in transit.

A-2

(2) Wiring

CAUTION

z Do not fit capacitive equipment such as power factor correction capacitor, radio

noise filter (option FR-BIF(-H)) or surge suppressor to the output of the inverter.

z The connection orientation of the output cables U, V, W to the motor will affect the

direction of rotation of the motor.

(3) Trial run

CAUTION

z Check all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

2

z When the load GD

output current may vary when the output frequency is in the 20Hz to 30Hz range.

If this is a problem, set the Pr.72 "PWM frequency selection" to 6kHz or higher.

(When setting the PWM to a higher frequency, check for noise or leakage current

problem and take countermeasures against it.)

(4) Operation

is small (at the motor GD or smaller) for 400V from 1.5K to 3.7K, the

WARNING

z When you have chosen the retry function, stay away from the equipment as it will

restart suddenly after an alarm stop.

z Since the [STOP] key is valid only when functions are set (refer to page 55),

provide a circuit and switch to make an emergency stop (power off, mechanical

brake operation for emergency stop, etc) separately.

z Make sure that the start signal is off before resetting the inverter alarm. A failure to

do so may restart the motor suddenly.

z The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

z Do not modify the equipment.

z Do not perform parts removal which is not instructed in this manual. Doing so may

lead to fault or damage of the inverter.

A-3

CAUTION

z The electronic thermal relay function does not guarantee protection of the motor

from overheating.

z Do not use a magnetic contactor on the inverter input for frequent starting/stopping

of the inverter.

z Use a noise filter to reduce the effect of electromagnetic interference. Otherwise

nearby electronic equipment may be affected.

z Take measures to suppress harmonics. Otherwise power supply harmonics from

the inverter may heat/damage the power capacitor and generator.

z When a 400V class motor is inverter-driven, please use an insulation-enhanced

motor or measures taken to suppress surge voltages. Surge voltages attributable to

the wiring constants may occur at the motor terminals, deteriorating the insulation of

the motor.

z When parameter clear or all clear is performed, reset the required parameters

before starting operations. Each parameter returns to the factory setting.

z The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

z In addition to the inverter's holding function, install a holding device to ensure safety.

z Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

(5) Emergency stop

CAUTION

z Provide a safety backup such as an emergency brake which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

z When the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage to internal parts of the inverter, etc. Identify the cause of the trip,

then remove the cause and power on the breaker.

z When any protective function is activated, take the appropriate corrective action,

then reset the inverter, and resume operation.

(6) Maintenance, inspection and parts replacement

CAUTION

z Do not carry out a megger (insulation resistance) test on the control circuit of the

inverter.

(7) Disposing of the inverter

CAUTION

z Treat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual (basic) show the inverter

without a cover, or partially open. Never operate the inverter in this manner. Always replace

the cover and follow this instruction manual (basic) when operating the inverter.

A-4

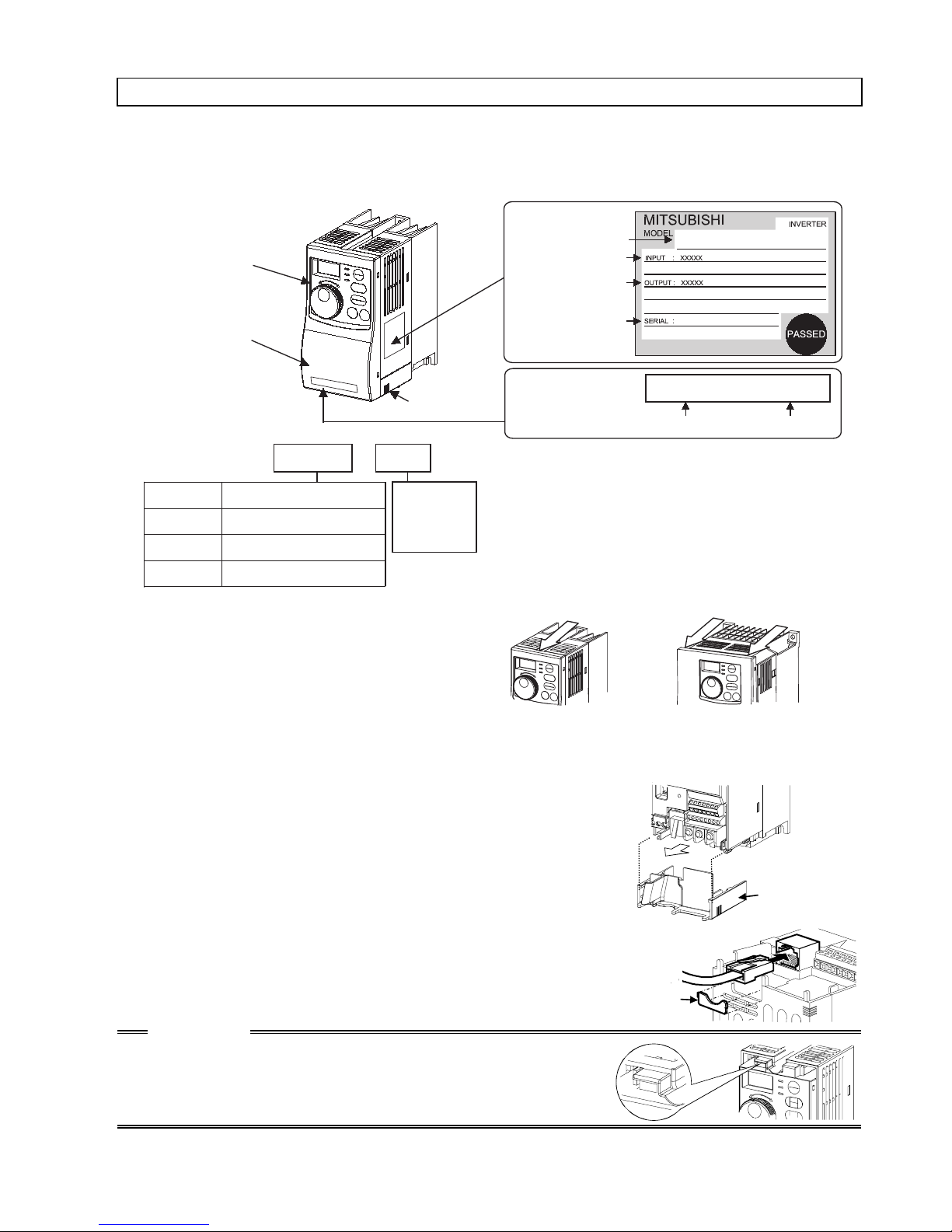

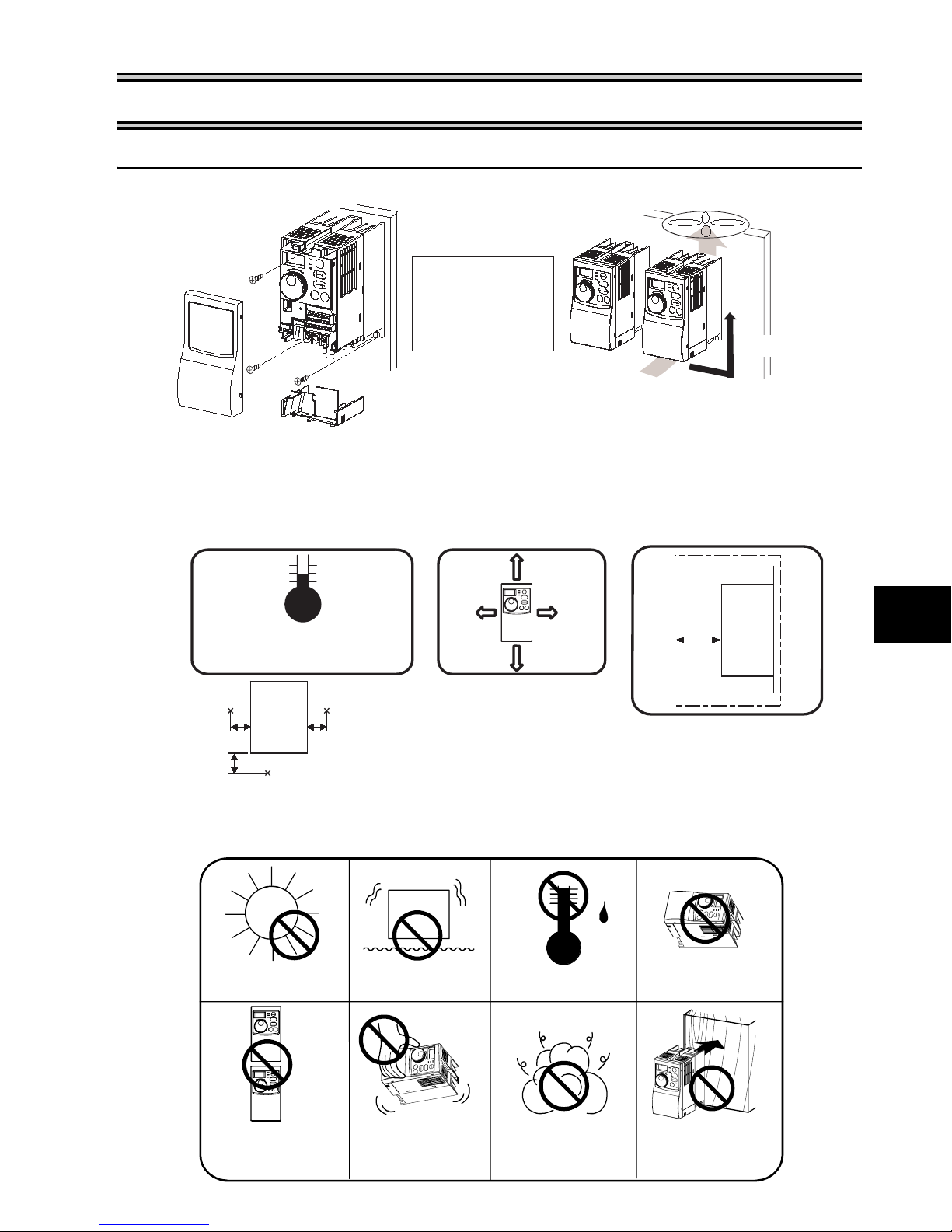

Product Checking and Parts Identification

A

A

Unpack the inverter and check the capacity plate on the front cover and the rating

plate on the inverter side face to ensure that the product agrees with your order and

the inverter is intact.

Parts and name plate

Operation panel

Front cover

Wiring cover

Inverter type

Symbol

S520E

S540E

S510WE

FR

Three-phase 200V class

Three-phase 400V class

Single-phase 100V class

S520E

-

Voltage class

0.1

- K - NA

Inverter

capacity

"kW"

z Removal and reinstallation of the

front cover

Remove the front cover by pulling it

toward you in the direction of arrow.

To reinstall, match the cover to the

inverter front and install it straight.

Rating plate

Inverter type

Input rating

Output rating

Serial number

Capacity plate

Inverter type Serial number

FR-S520E-0.1K to 0.75K-NA

FR-S510WE-0.1K to 0.4K-NA

FR-S520E-0.1K-NA XXXXXX

FR-S520E-0.1K-NA

FR-S520E-1.5K to 3.7K-N

FR-S540E-0.4K to 3.7K-N

FR-S510WE-0.75K-NA

z Removal and reinstallation of the wiring cover

The cover can be removed easily by pulling it toward

you.

To reinstall, fit the cover to the inverter along the guides.

z RS-485 communication connector

When using the RS-485 connector to wire the cable, you

can cut off the tab of the wiring cover to wire it. (Cutting off

the tab will provide protective structure IP10.)

CAUTION

The connector above the operation panel is for

manufacturer use. Do not touch it as doing so may

cause an electric shock.

Wiring cover

Tab

1

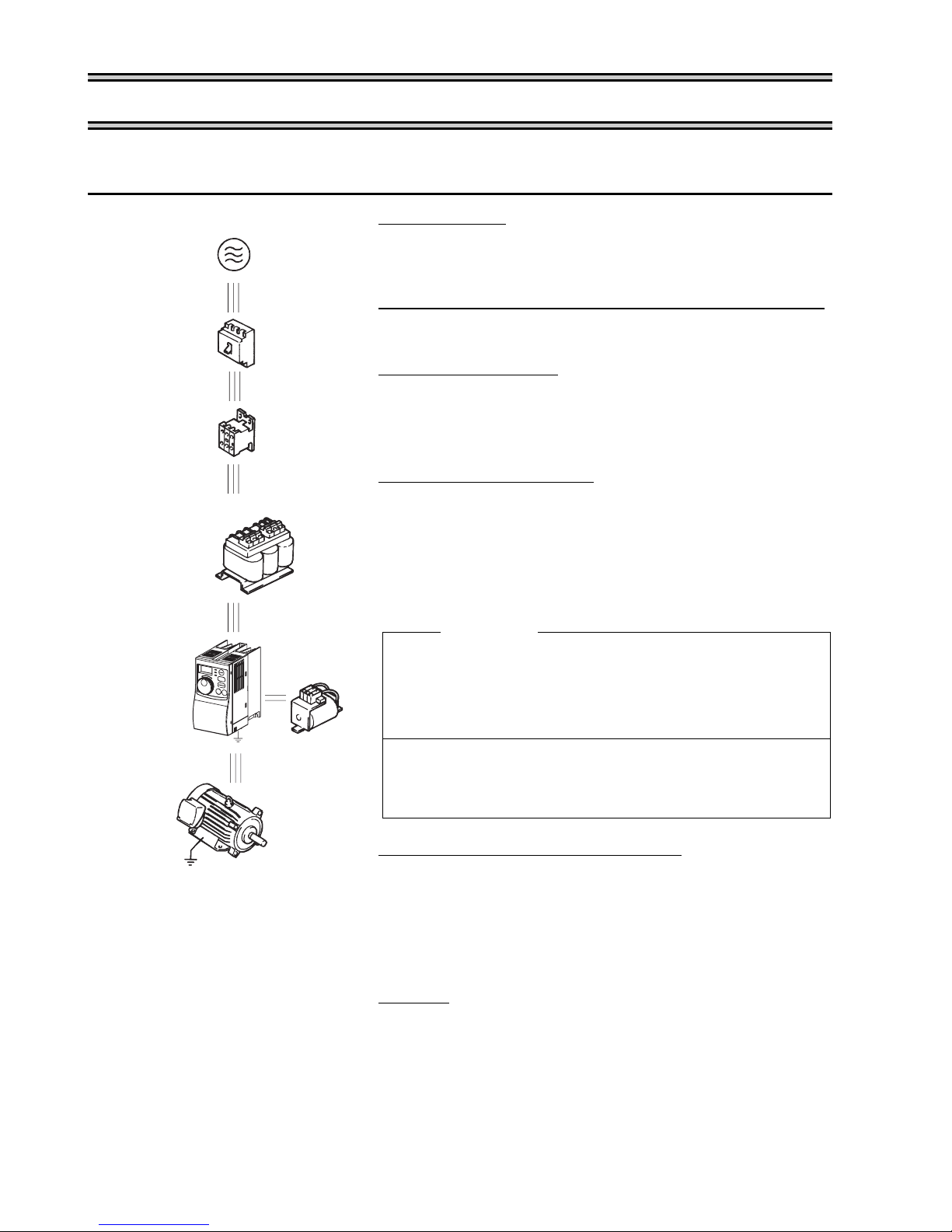

Basic configuration

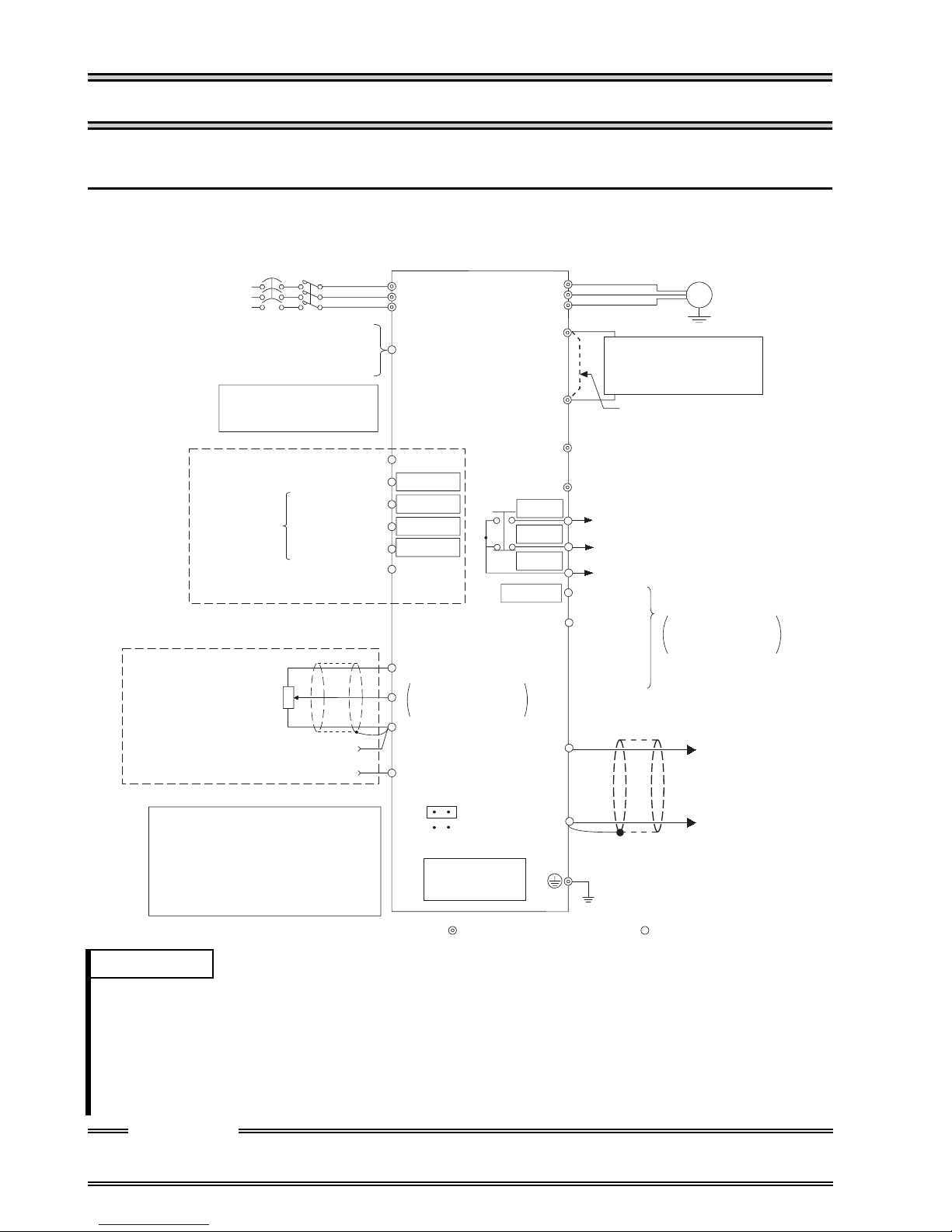

1. CONNECTION OF PERIPHERAL DEVICES

1.1 Basic configuration

Power supply

Use within the permissible power supply

specifications of the inverter. (Refer to page 76.)

No-fuse breaker or earth leakage circuit breaker

The breaker must be selected carefully since an in-

(NFB)

or (ELB)

(MC)

AC reactor

(FR-HAL

/FR-BAL)

rush current flows in the inverter at power on.

Magnetic contactor

Install for your safety. Do not use this magnetic

contactor to start and stop the inverter. Doing so will

cause the inverter life to be shorten. (Refer to page

17.)

Installation of a reactor

A reactor must be used when the power harmonics

measure is taken, power factor is to be improved or

the inverter is installed near a large supply system

(500kVA or more and wiring distance within 10 m

(32.8 feet)).

Make the selection carefully.

Inverter

(FR-S500E)

Ground

Motor

Ground

DC reactor

(FR-HEL

/FR-BEL)

Inverter

The life of the inverter is influenced by ambient

temperature. Check the ambient temperature.

Epecially when mounting the inverter inside an

enclosure, take cautions of the ambient

temperature. (Refer to page 80.)

Wrong wiring might lead to damage of the inverter.

The control signal wires must be kept fully away

from the main circuit to protect them from noise.

(Refer to page 6.)

Devices connected to the output

Do not install a power factor correction capacitor,

surge suppressor or radio noise filter on the output

side of the inverter.

When installing a no-fuse breaker on the output side

of the inverter, contact each manufacturer for

selection of the no-fuse breaker.

Ground

To prevent an electric shock, always ground the

motor and inverter.

For reduction of induction noise from the power line

of the inverter, it is recommended to wire the ground

cable by returning it to the ground terminal of the

inverter.

(For details of noise reduction techniques, refer to

the instruction manual (detailed).)

2

Basic configuration

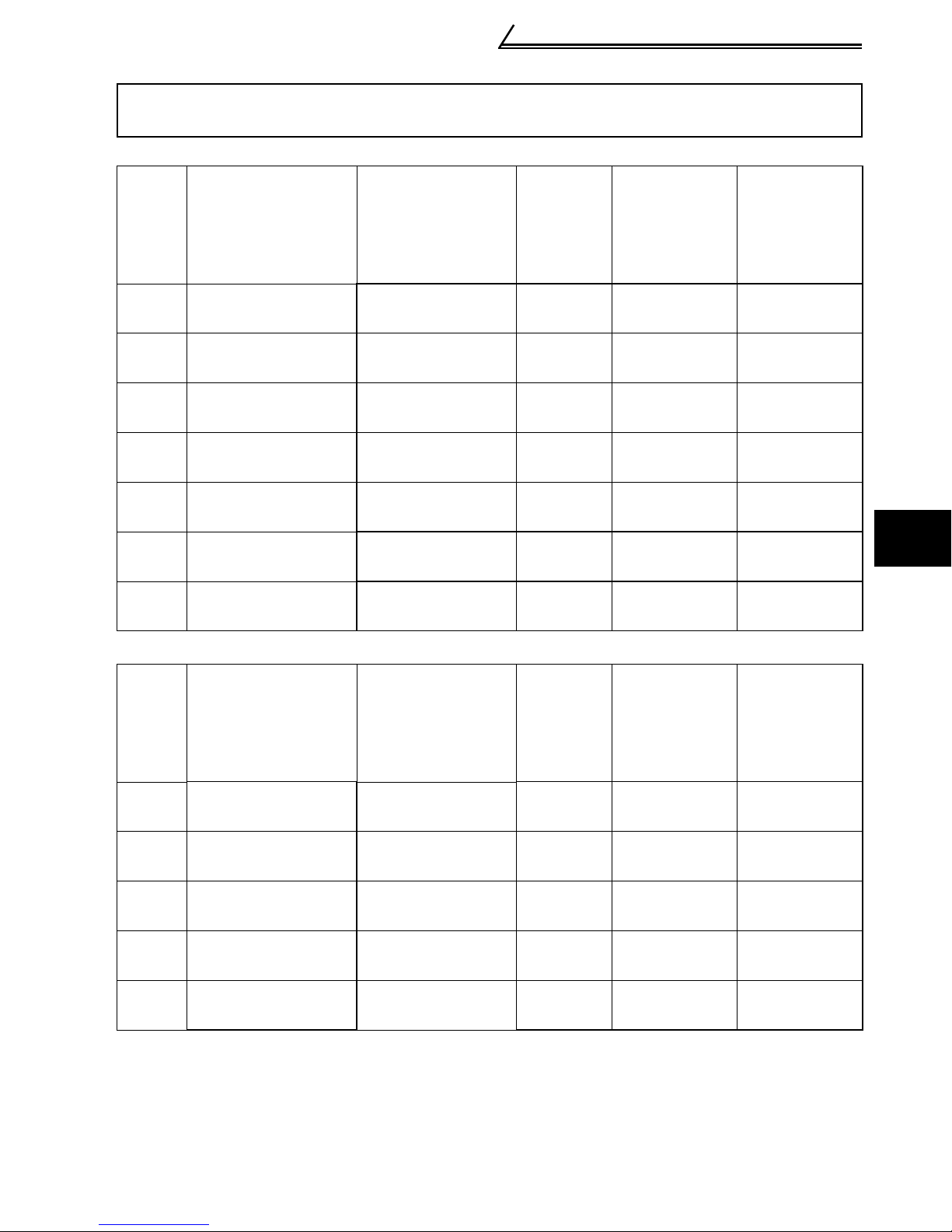

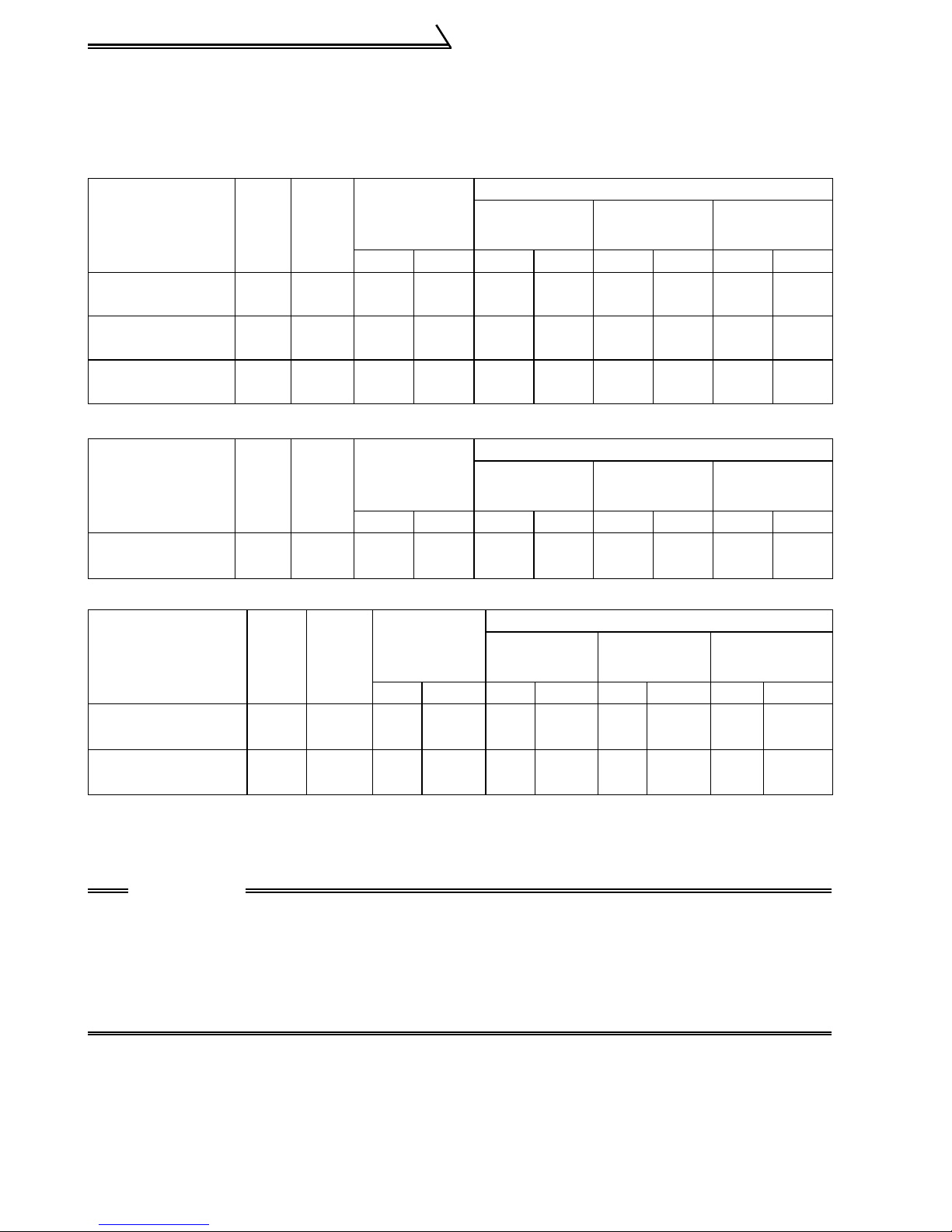

Selection of peripheral devices (selection changes with the power input

specifications of the inverter)

1) Three-phase 200V power input

Motor

Output

(kW

(HP))

0.1

(1/8)

0.2

(1/4)

0.4

(1/2)

0.75

(1)

1.5

(2)

2.2

(3)

3.7

(5)

Applied Inverter

Type

FR-S520E-0.1K-NA

FR-S520E-0.2K-NA

FR-S520E-0.4K-NA

FR-S520E-0.75K-NA

FR-S520E-1.5K-NA

FR-S520E-2.2K-NA

FR-S520E-3.7K-NA

No-fuse Breaker

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (*2, 4)

30AF/5A S-N10 0.4 (*3) 0.4 (*3)

30AF/5A S-N10 0.4 (*3) 0.4 (*3)

30AF/5A S-N10 0.4 0.4

30AF/10A S-N10 0.75 0.75

30AF/15A S-N10 1.5 1.5

30AF/20A S-N10 2.2 2.2

30AF/30A

Magnetic

Contactor

(MC)

(Refer to

page 17)

S-N20,

S-N21

AC Reactor

FR-HALFR-BAL-

K

K

3.7 3.7

DC Reactor

FR-HELFR-BEL-

K

K

1

2) Three-phase 400V power input

Motor

Output

(kW

(HP))

0.4

(1/2)

0.75

(1)

1.5

(2)

2.2

(3)

3.7

(5)

Applied Inverter

Type

FR-S540E-0.4K-NA

FR-S540E-0.75K-NA

FR-S540E-1.5K-NA

FR-S540E-2.2K-NA

FR-S540E-3.7K-NA

No-fuse Breaker

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (*2, 4)

30AF/5A S-N10 H0.4 H0.4

30AF/5A S-N10 H0.75 H0.75

30AF/10A S-N10 H1.5 H1.5

30AF/15A S-N10 H2.2 H2.2

30AF/20A

Magnetic

Contactor

(MC)

(Refer to

page 17)

S-N20,

S-N21

AC Reactor

FR-HAL-K

FR-BAL-K

H3.7 H3.7

DC Reactor

FR-HEL-K

FR-BEL-K

CONNECTION OF PERIPHERAL DEVICES

3

Basic configuration

3) Single-phase 100V power input

Motor

Output

(kW

(HP))

Applied Inverter

Type

(NFB *1, 4) or

Earth Leakage

Circuit Breaker

(ELB) (*2, 4)

No-fuse Breaker

0.1

(1/8)

0.2

(1/4)

0.4

(1/2)

0.75

(1)

FR-S510WE-0.1K-NA

FR-S510WE-0.2K-NA

FR-S510WE-0.4K-NA

FR-S510WE-0.75K-NA

30AF/10A S-N10 0.75

30AF/15A S-N10 1.5

30AF/20A

30AF/30A

*1. •Select the NFB according to the inverter power supply

capacity.

• Install one NFB per inverter.

Magnetic

Contactor

(MC)

(Refer to

page 17)

S-N20,

S-N21

S-N20,

S-N21

AC Reactor(*3)

FR-HALFR-BAL-

K

K

2.2

3.7

NFB

NFB INV

DC Reactor (*5)

FR-HELFR-BEL-

K

K

INV

*2. For installations in the United States or Canada, the circuit breaker must be inverse

time or instantaneous trip type.

*3. The power factor may be slightly lower.

*4. When the breaker on the inverter primary side trips, check for the wiring fault (short

circuit), damage to internal parts of the inverter, etc. Identify the cause of the trip,

then remove the cause and power on the breaker.

*5. The single-phase 100V power input model does not allow the DC reactor to be fitted.

IM

IM

4

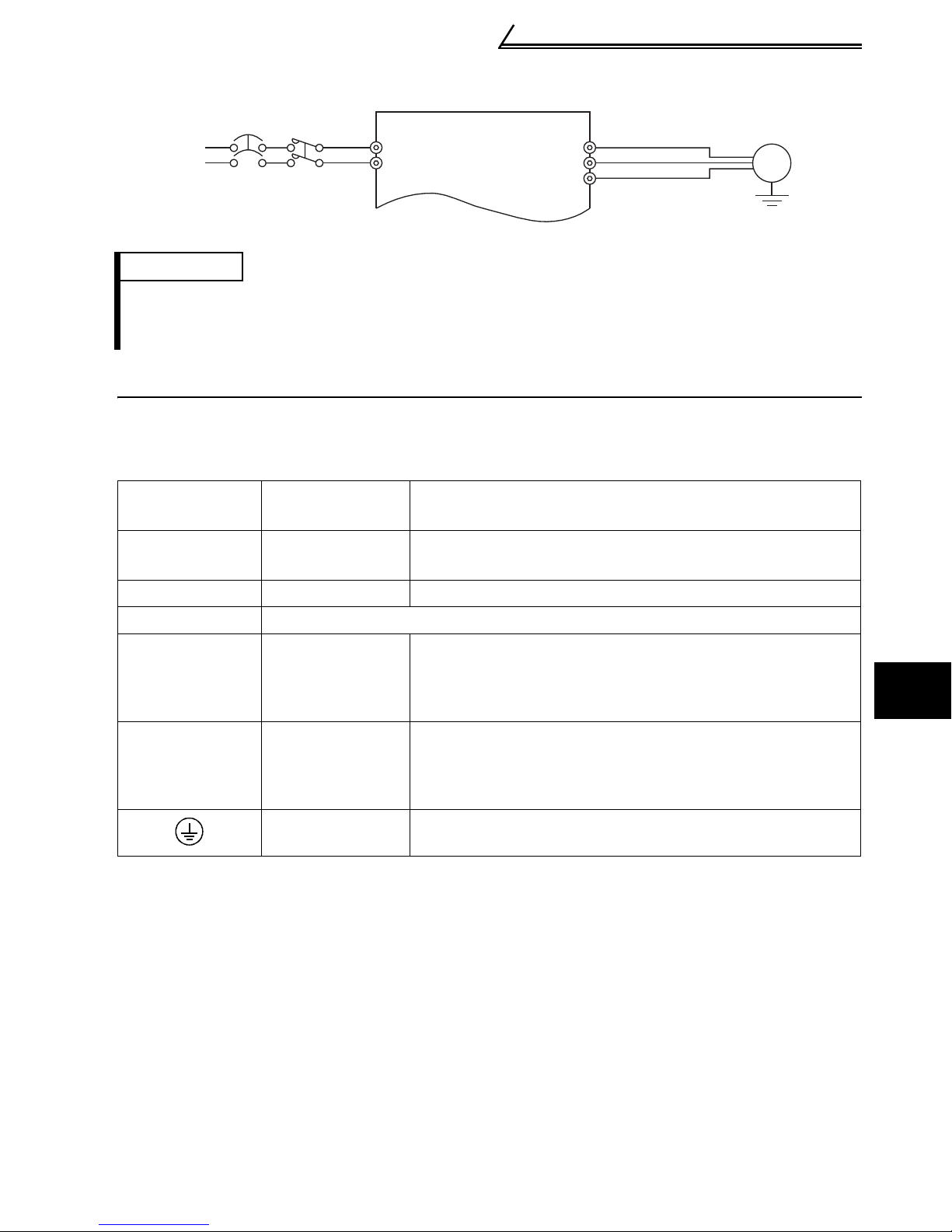

2. INSTALLATION METHOD

g

2.1 Installation of the inverter

Enclosure surface mounting Encasing multiple inverters

Fix the front

cover and wiring

cover after

removing them.

Leave enough clearances

and provide coolin

z Install the inverter under the following conditions.

measures.

Installation of the inverter

Vertical

When containing two or more

inverters, install them in parallel

and provide cooling measures.

Temperature: -10°C to 50°C

(14°F to 122°F)

Humidity: 90%RH maximum

5cm

5cm

(1.97inches)

Ambient temperature

and humidity

Measurement

position

Inverter

Measurement position

5cm

(1.97inches)(1.97inches)

Clearances (front)

1cm

(0.39inch)

or more

10cm

(3.94inches)

or more

These clearances are also

necessary for changing the

cooling fan. (

more is provided with a

cooling fan.

10cm

(3.94inches)

or more

1cm

(0.39inch)

or more

The 1.5K or

)

Clearances (side)

5cm

(1.97inches)

or more

Inverter

z Inverter consists of precision mechanical and electronic parts. Never install or

handle it in any of the following conditions as doing so could cause an operation

fault or failure.

Direct sunlight

Vibration

(5.9m/s

2

or more)

High temperature,

high humidity

Horizontal placement

2

INSTALLATION METHOD

Vertical mounting

(when mounted

inside enclosure)

Transportation

by holding front

cover or dial

Oil mist, flammable

gas, corrosive gas,

fluff, dust, etc.

5

Mounting to

combustible material

Terminal connection diagram

3. SPECIFICATIONS OF WIRING AND TERMINALS

3.1 Terminal connection diagram

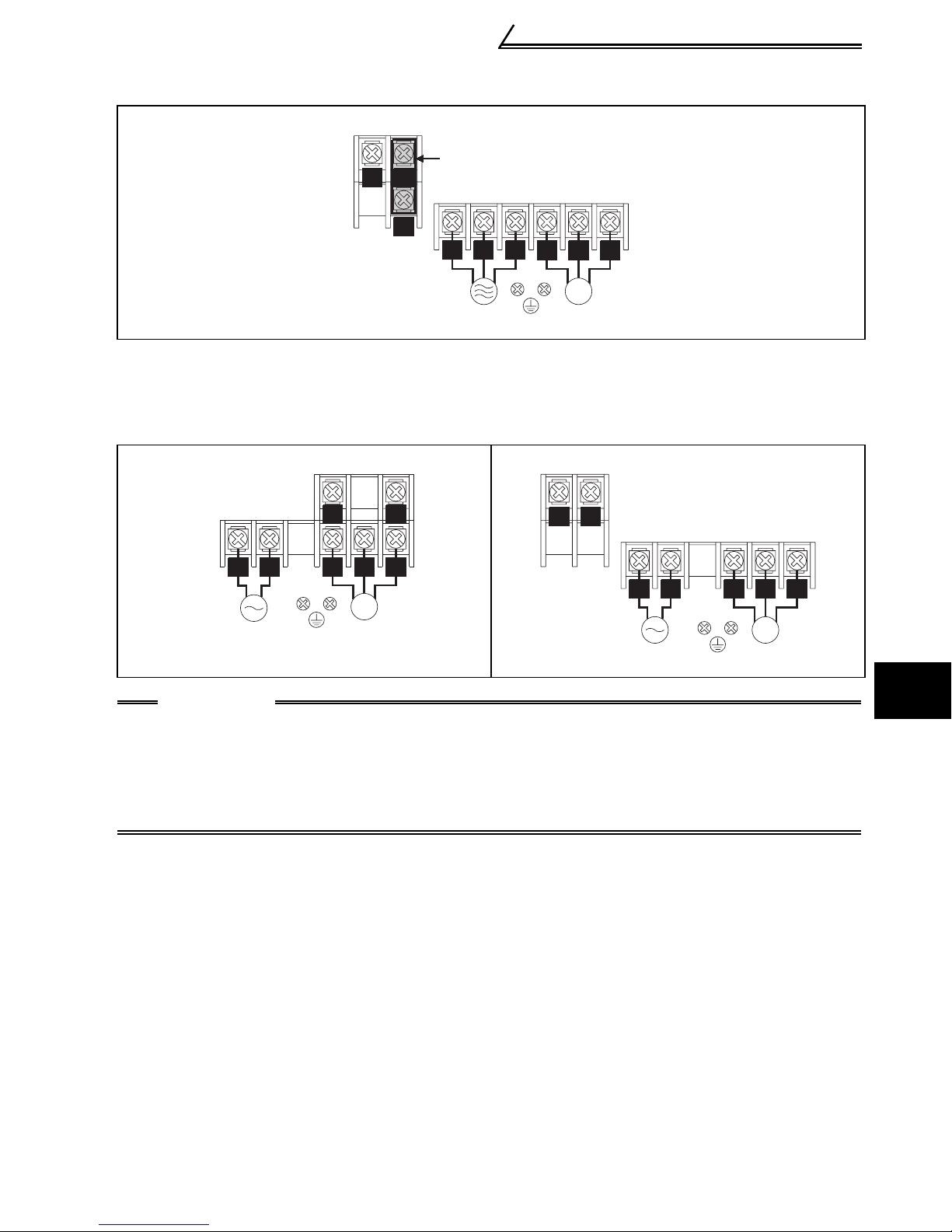

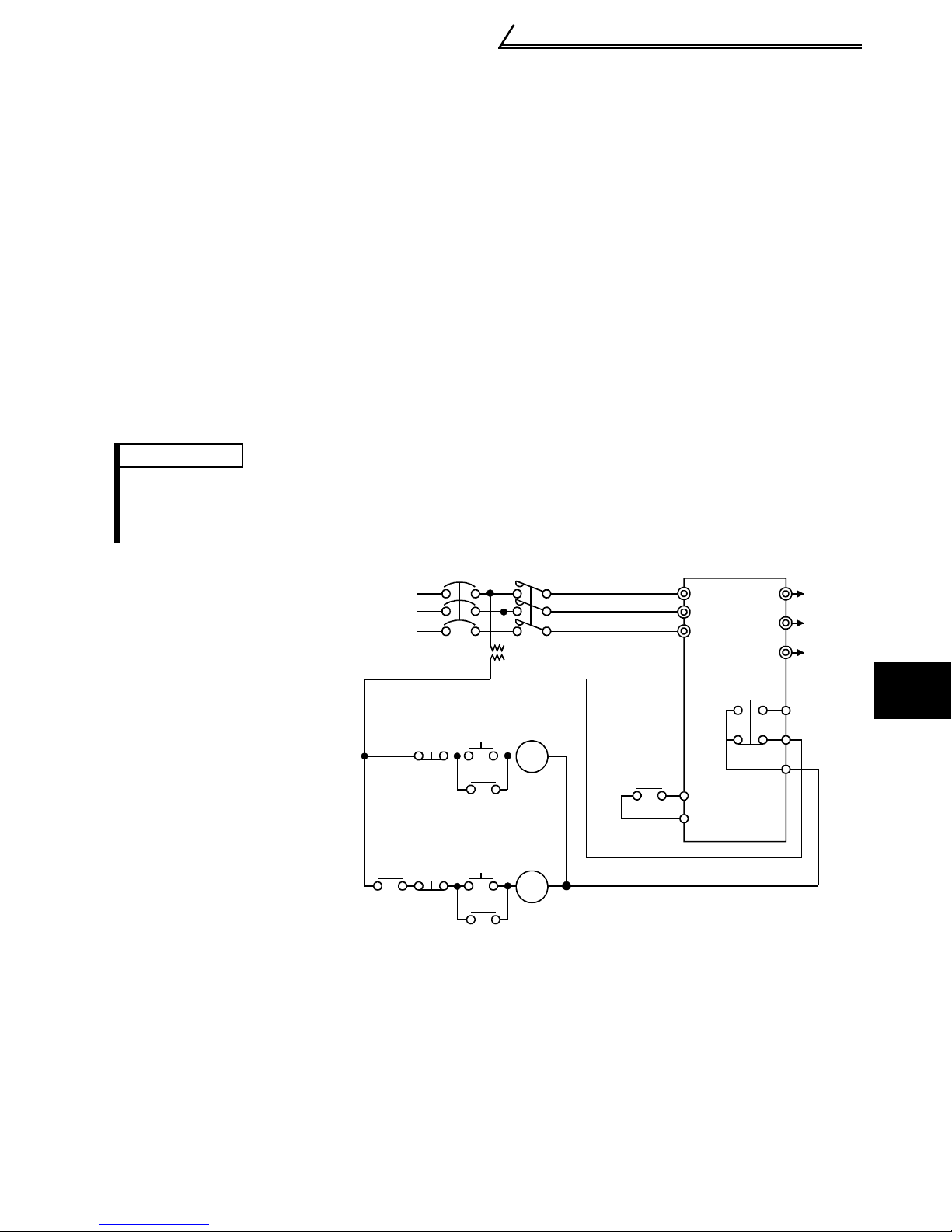

z Three-phase 200V power input

z Three-phase 400V power input

NFB MC

Three-phase AC

power supply

External transistor common

24VDC power supply

Contact input common (source)

Take care not to short

terminals PC-SD.

Forward rotation start

Control input

signals

(No voltage

input allowed)

Frequency setting signals (Analog)

Frequency setting

potentiometer

1/2W1kΩ

Reverse rotation start

Multi-speed

selection

Contact input common

3

*4

1

Current input(-)

4 to 20mADC(+)

When using the current input as

the frequency setting signal, set

"4" in any of Pr. 60 to Pr. 63 (input

terminal function selection), assign

AU (current input selection) to any

of terminals RH, RM, RL and STR

and turn on the AU signal.

High speed

Middle speed

Low speed

2

Inverter

R/L1

S/L2

T/L3

PC

STF

STR

*5

*5

RH

*5

RM

RL

*5

SD

10

(+5V)

0 to 5VDC

2

0 to 10VDC

5

(Common)

4

(4 to 20mADC)

SINK

*3

SOURCE

RS-485

Connector

*1

*2

*6

*6

*6

*6

RUN

Selected

U

V

W

P1

P/+

N/-

PR

A

B

C

SE

AM

Running

Open

collector

output

common

5

Motor

IM

Ground

DC reactor

(FR-HEL/BEL: Option)

Jumper:

jumper when DC reactor

is connected.

Alarm output

Remove this

Operation status

output

Open collector

outputs

(+)

Analog signal

output

(0 to 5VDC)

(-)

Ground

REMARKS

*1. The N/- terminal is not provided for the FR-S520E-0.1K to 0.75K-NA.

*2. The PR terminal is provided for the FR-S520E-0.4K to 3.7K-NA. (not used)

*3. You can switch the position of sink and source logic. (Refer to page 15.)

*4. When the setting potentiometer is used frequently, use a 2W1kΩ potentiometer.

*5. The terminal functions change with input terminal function selection (Pr. 60 to Pr. 63). (Refer to page 54.)

(RES, RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, X14, X16, (STR) signal selection)

*6. The terminal function changes according to the setting of output terminal function selection (Pr. 64, Pr. 65).

(Refer to page 54.) (RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL, Y93, Y95, LF, ABC signal selection)

CAUTION

To prevent a malfunction due to noise, keep the signal cables more than 10cm away

from the power cables.

Control circuit terminalMain circuit terminal

6

z Single-phase 100V power input

Main circuit

NFB

Power

supply

MC

R/L1

S/L

Motor

U

2

V

W

IM

Ground

REMARKS

•To ensure safety, connect the power input to the inverter via a magnetic contactor and earth leakage

circuit breaker or no-fuse breaker, and use the magnetic contactor to switch power on-off.

•The output is three-phase 200V.

3.2 Main circuit

3.2.1 Explanation of main circuit terminals

Term inal

Symbol

R/L1, S/L2,

T/L3 (*1)

Terminal Name Description

AC power input

Connect to the commercial power supply.

U, V, W Inverter output

PR (*2)

P/+, N/−

P/+, P1

Brake unit

connection

DC reactor

connection

Ground

*1. When using single-phase power input, terminals are R/L1 and S/L2.

*2. The PR terminal is provided for the FR-S520E-0.4K to 3.7K-NA.

Connect a three-phase squirrel-cage motor.

Do not use PR terminal.

Connect the brake unit (BU), power regeneration

common converter (FR-CV) or high power factor

converter (FR-HC). (The N/- terminal is not provided for

the FR-S520E-0.1K to 0.75K-NA.)

Remove the jumper across terminals P - P1 and connect

the optional DC reactor (FR-HEL(-H)/FR-BEL(-H)).

(The single-phase 100V power input model cannot be

connected.)

For grounding the inverter chassis. Must be grounded.

3

SPECIFICATIONS OF WIRING AND TERMINALS

7

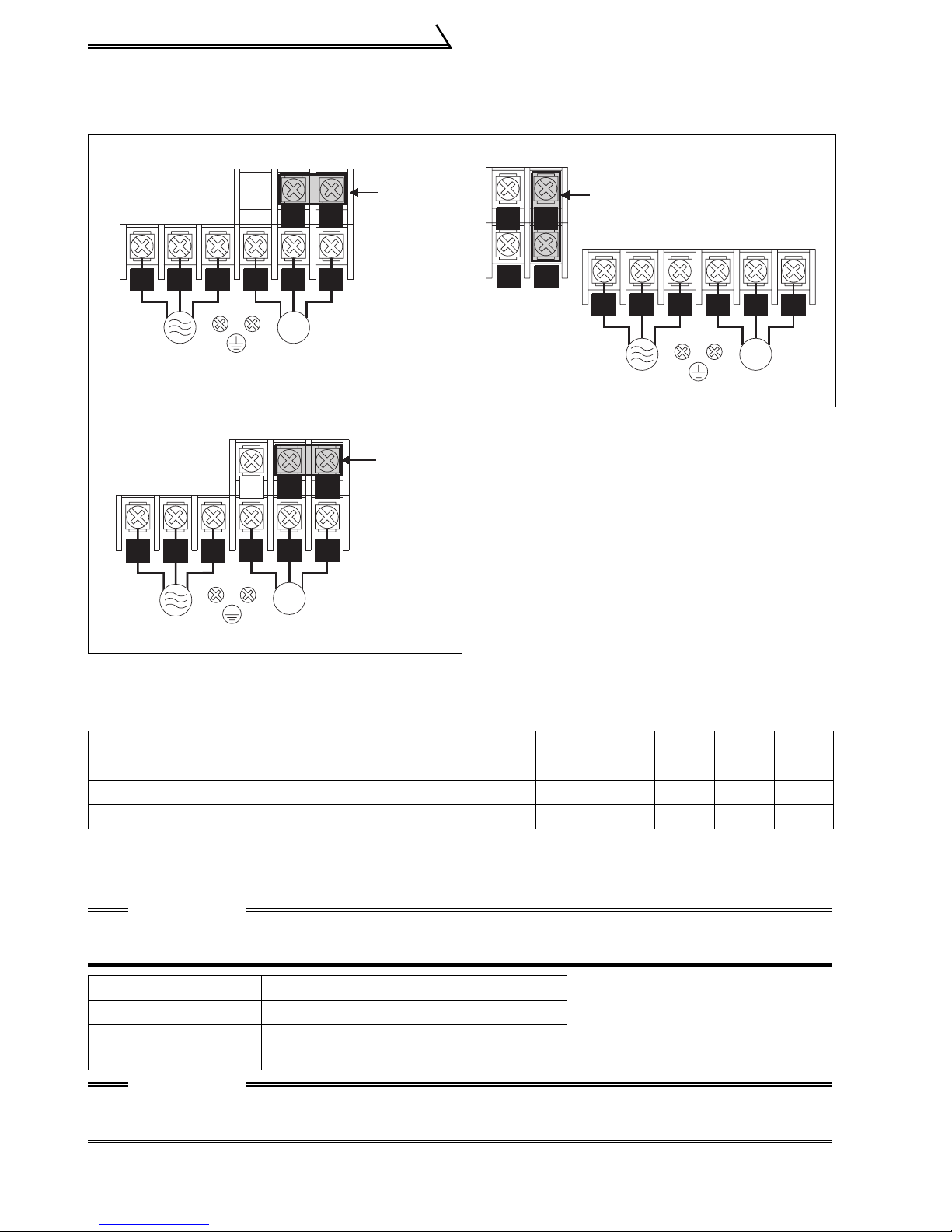

Main circuit

r

r

3.2.2 Terminal block layout

1) Three-phase 200V power input

• FR-S520E-0.1K, 0.2K-NA • FR-S520E-1.5K, 2.2K, 3.7K-NA

P/+

P1

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

• FR-S520E-0.4K, 0.75K-NA

P1

IM

P/+

R/L1 S/L2

T/L3

Power supply

PR

U V W

Motor

Jumpe

Jumpe

N/-

PR

P/+

P1

Jumper

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

<When single-phase power is applied to three-phase power input inverter

(FR-S520E-0.1K to 3.7K-NA only)>

•Reduce the output current.

FR-S520E- K-NA inverter 0.1 0.2 0.4 0.75 1.5 2.2 3.7

Rated output current (A) 0.4 0.8 1.5 2.5 4.0 5.0 7.0

Power supply capacity (kVA) 0.4 0.8 1.5 2.5 4.5 5.5 9.0

AC input current (A) 1.1 2.4 4.5 6.4 11.2 12.9 17.4

•Set m9 (Pr. 637) "current detection filter".

Setting "801" in the manufacturer setting parameter C8 enables you to set the m9

parameter.

CAUTION

Parameters other than m9 can also be made to be displayed, but never alter these

since they are manufacturer setting parameters.

m9 Setting Description

0 Single-phase power input

- - -

(Factory setting)

Three-phase power input

CAUTION

Always return the C8 parameter to 0 (factory setting) after you have finished the

setting of m9.

8

2) Three-phase 400V power input

Main circuit

• FR-S540E-0.4K, 0.75K, 1.5K, 2.2K, 3.7K

-NA

Jumper

P/+

N/-

P1

R/L1 S/L2 T/L3

Power supply

U V W

IM

Motor

3) Single-phase 100V power input

• FR-S510WE-0.1K, 0.2K, 0.4K-NA • FR-S510WE-0.75K-NA

R/L1 S/L2

Power supply

P/+N/-

U V W

IM

Motor

N/-

P/+

R/L1 S/L2

Power supply

U V W

IM

Motor

CAUTION

•Make sure the power cables are connected to the R/L1, S/L2, T/L3 of the inverter.

Never connect the power cable to the U, V, W of the inverter. (Phase need not be

matched)

•Connect the motor to U, V, W. At this time, turning on the forward rotation switch

(signal) rotates the motor in the counterclockwise direction when viewed from the

motor shaft.

3

SPECIFICATIONS OF WIRING AND TERMINALS

9

Main circuit

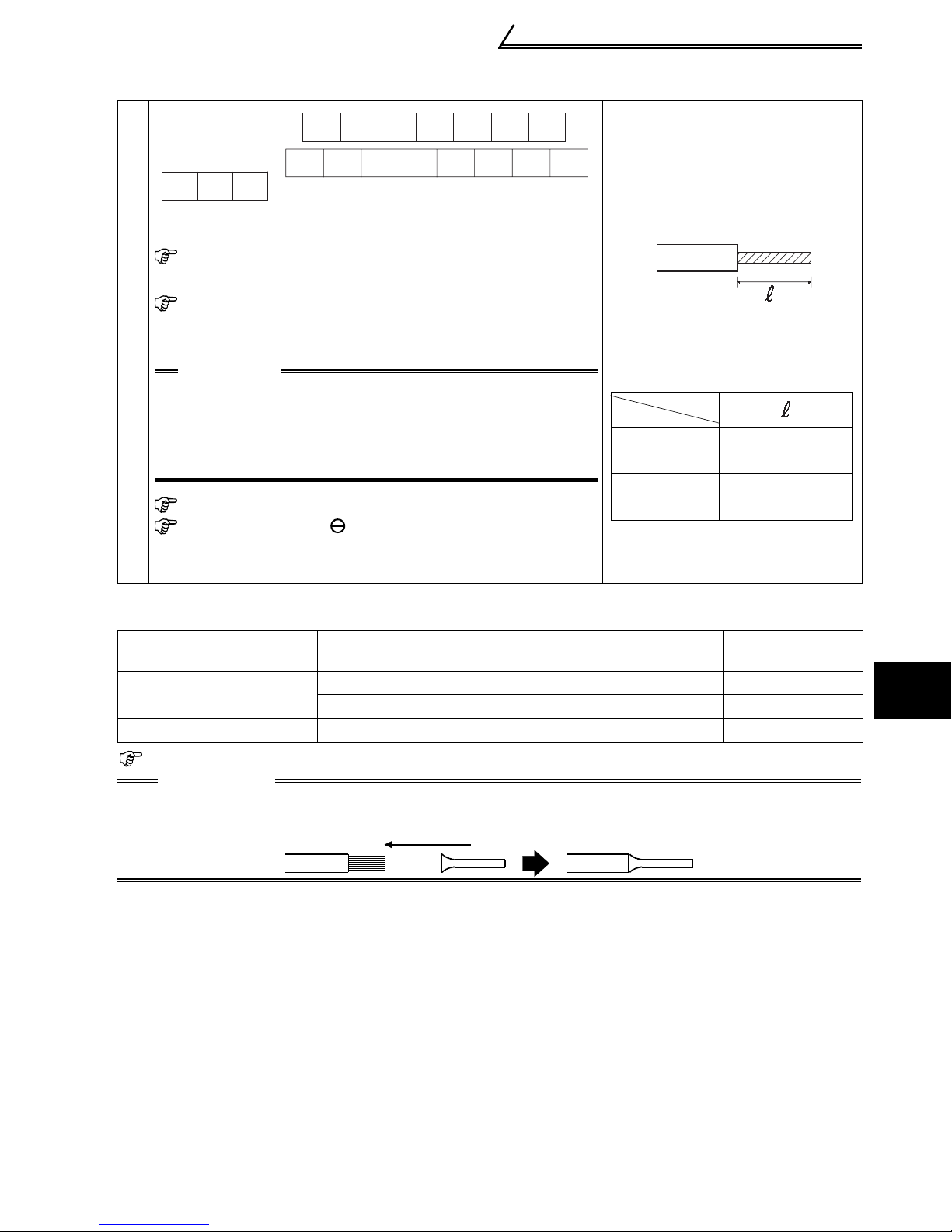

3.2.3 Cables, wiring length, and crimping terminals

The following table indicates a selection example for the wiring length of 20m (65.62

feet).

1) Three-phase 200V power input

Cable Size

AWG

R, S, T

U, V, W

Cable Size

AWG

PVC cable

(mm

R, S, T

U, V, W

PVC cable

(mm

2

)

2

)

Applied Inverter

FR-S520E-0.1K

to 0.75K-NA

FR-S520E-

1.5K, 2.2K-NA

FR-S520E-

3.7K-NA

Ter-

minal

Screw

size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

Tightening

Torque

⋅

m

N

Crimping

R, S, T U, V, W

2) Three-phase 400V power input

Applied Inverter

FR-S540E-0.4K

to 3.7K-NA

Ter-

minal

Screw

size

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

Tightening

Torque

⋅

m

N

Crimping

R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W R, S, T U, V, W

Termi nal

Termi nal

HIV cable

(mm

R, S, T

HIV cable

(mm2)

2

)

U, V, W

3) Single-phase 100V power input

Cable Size

AWG

PVC cable

2

(mm

)

Applied Inverter

FR-S510WE-

0.1K

to 0.4K-NA

FR-S510WE-0.75KNA

Termi -

nal

Screw

size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

Tightening

Torqu e

⋅

m

N

Crimping

Terminal

HIV cable

2

(mm

)

R, S U, V, W R, S U, V, W R, S U, V, W R, S U, V, W

z Wiring length

100m (328.08 feet) maximum. (50m (164.04 feet) maximum for the FR-S540E-

0.4K-NA.)

CAUTION

•When the wiring length of the 0.1K and 0.2K of the three-phase 200V and

single-phase 100V class and the 0.4K and 0.75K of the three-phase 400V class

is 30m (98.43 feet) or more, set the carrier frequency to 1kHz.

•When automatic torque boost is selected in Pr. 98 "automatic torque boost

selection (motor capacity)", the wiring length should be 30m (98.43 feet)

maximum. (Refer to page 57.)

10

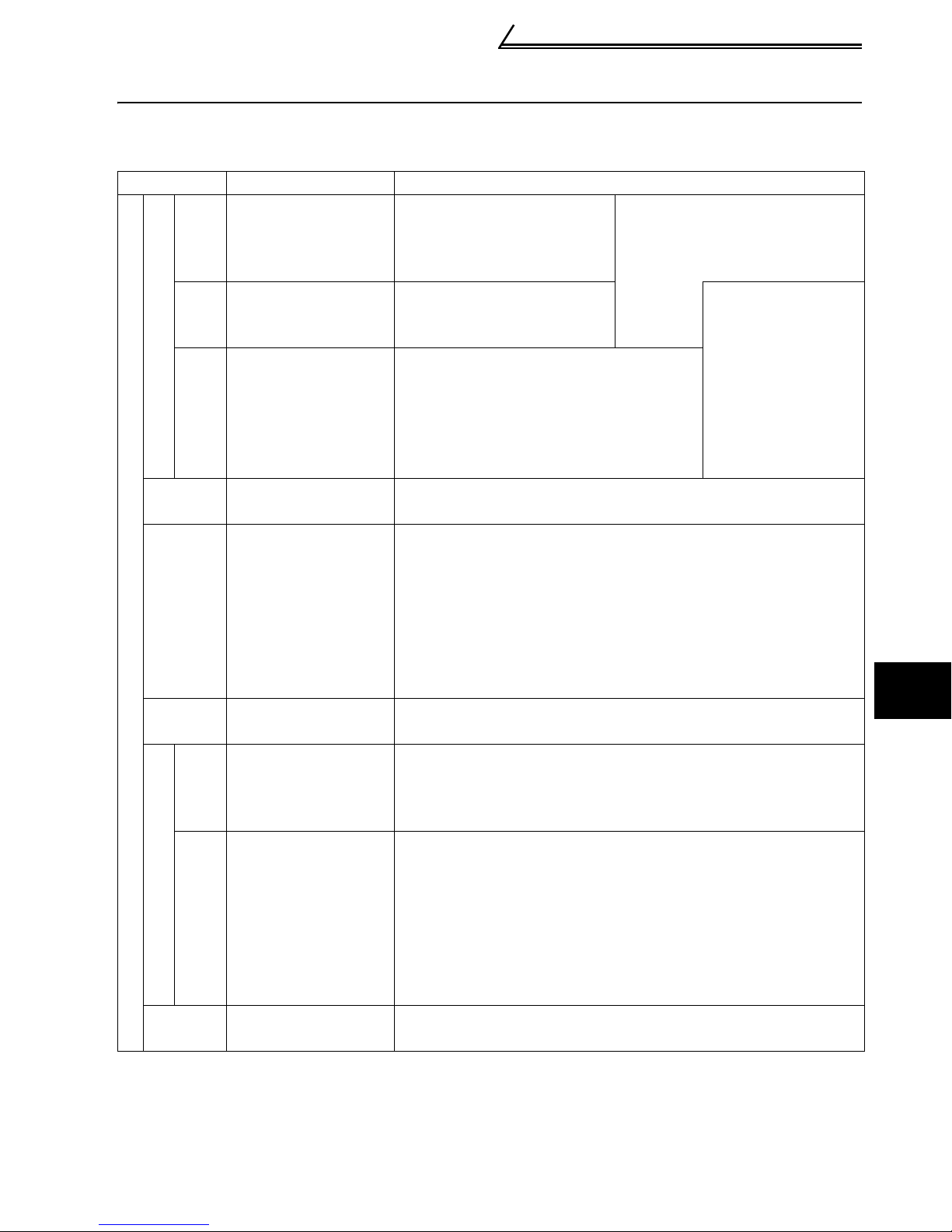

3.3 Control circuit

3.3.1 Explanation of control circuit terminals

Symbol Terminal Name Definition

When the STF and STR

signals are turned on

simultaneously, the stop

command is given.

Input signals

STF

STR

RH

Contact input

RM

RL

SD

(*1)

PC

(*1)

10

Frequency setting

5

Forward rotation

start

Reverse rotation

start

Multi-speed

selection

Contact input

common (sink)

External

transistor

common, 24VDC

power supply,

contact input

common (source)

Frequency setting

power supply

Frequency setting

2

(voltage signal)

Frequency setting

4

(current signal)

Frequency setting

input common

Turn on the STF signal to

start forward rotation and

turn it off to stop.

Turn on the STR signal to

start reverse rotation and

turn it off to stop.

Turn on the RH, RM and RL signals in

appropriate combinations to select

multiple speeds.

The priorities of the speed commands

are in order of jog, multi-speed setting

(RH, RM, RL, REX) and AU.

Common to the contact input terminals (STF, STR, RH, RM,

RL). (*6)

When connecting the transistor output (open collector output),

such as a programmable controller (PLC), connect the positive

external power supply for transistor output to this terminal to

prevent a malfunction caused by undesirable currents.

This terminal can be used as a 24VDC, 0.1A power output

across terminals PC-SD.

When source logic has been selected, this terminal serves

as a contact input common.

5VDC, Permissible load current 10mA.

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output

frequency at 5V (10V) and makes input and output proportional.

Switch between 5V and 10V using Pr. 73 "0-5V, 0-10V selection".

Input resistance 10kΩ. Maximum permissible input voltage 20V

Input 4 to 20mADC. It is factory set at 0Hz for 4mA and at

60Hz for 20mA.

Maximum permissible input current 30mA. Input resistance

approximately 250Ω.

Turn ON signal AU for current input.

Turning the AU signal on makes voltage input invalid. Use any of

Pr. 60 to Pr. 63 (input terminal function selection) to set the AU

signal.

Common terminal for the frequency setting signals

(terminal 2, 4) and indicator connection (terminal AM). (*6)

Control circuit

The terminal

functions change

with input terminal

function selection

(Pr. 60 to Pr.63).

(*3)

3

SPECIFICATIONS OF WIRING AND TERMINALS

11

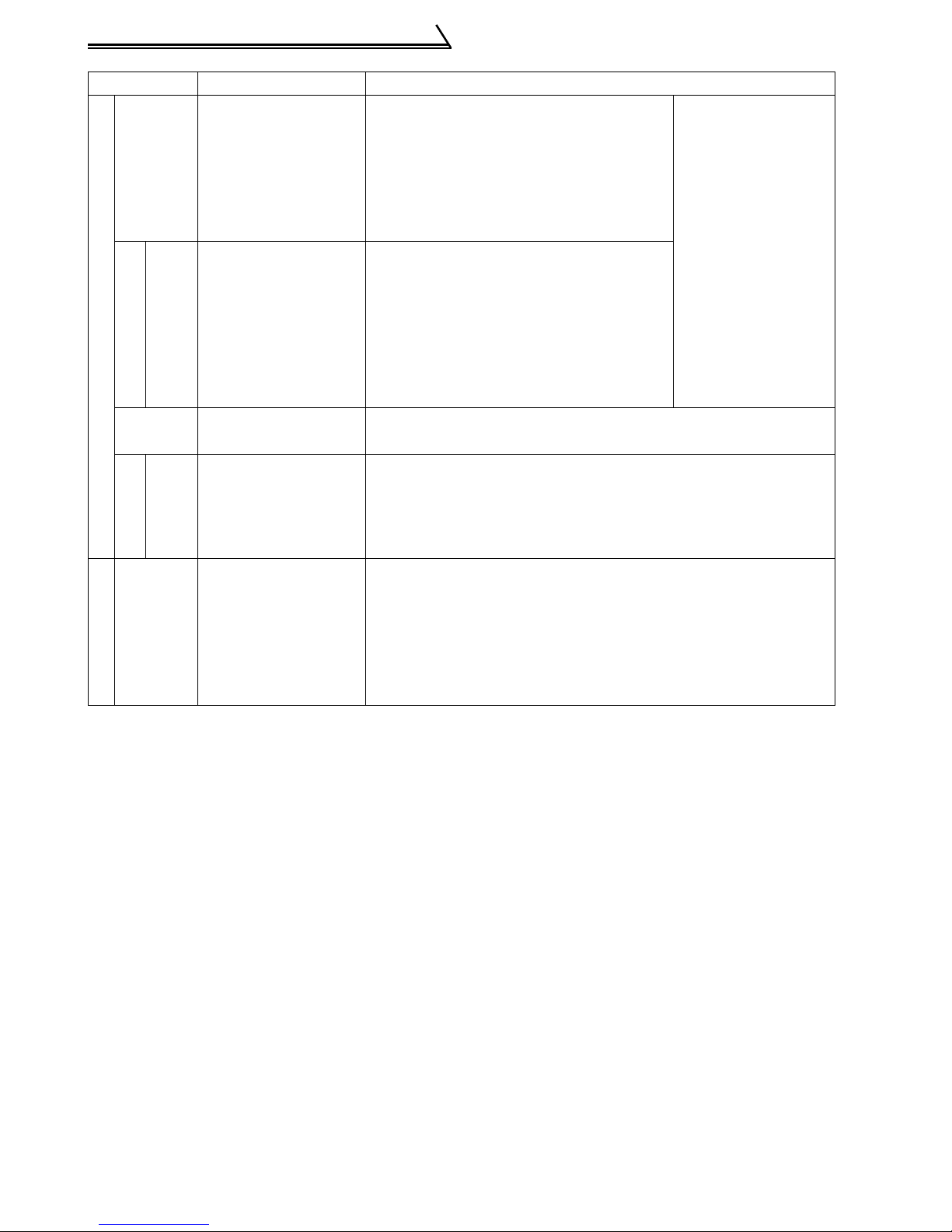

Control circuit

Symbol Terminal Name Definition

Changeover contact output indicates

that the inverter protective function has

Output signals

A

B

C

RUN

Open collector

SE

AM

Indicator

Alarm output

Inverter

running

Open collector

common

Analog signal

output

activated and the output stopped.

230VAC 0.3A, 30VDC 0.3A. Alarm:

discontinuity across B-C (continuity

across A-C), Normal: continuity across

B-C (discontinuity across A-C).(*5)

Switched low when the inverter output

frequency is equal to or higher than the

starting frequency (factory set to 0.5Hz

variable). Switched high during stop or

DC injection brake operation. (*2)

Permissible load 24VDC 0.1A (a

voltage drop is 3.4V maximum when

the signal is on)

Common terminal for inverter running terminal RUN.

The output signal across terminals AM-5 is factory set to about

5VDC at 60Hz and is proportional to the corresponding output

frequency.

Frequency permissible load current 1mA

Output signal 0 to 5VDC

The function of the

terminals changes

according to the

output terminal

function selection

(Pr. 64, Pr.65).

(*4)

(*6)

Using the parameter unit connection cable (FR-CB201 to

205), the parameter unit (FR-PU04) can be connected.

Communication operation can be performed using RS-485.

For details of RS-485 communication, refer to the

separately available instruction manual (detailed).

——

RS-485

connector

Communication

*1. Do not connect terminals SD and PC each other or to the ground.

For sink logic (factory setting), terminal SD acts as the common terminal of contact input.

For source logic, terminal PC acts as the common terminal of contact input. (Refer to the

separately available instruction manual (detailed) for switching method.)

*2. Low indicates that the open collector output transistor is on (conducts). High indicates

that the transistor is off (does not conduct).

*3. RL, RM, RH, RT, AU, STOP, MRS, OH, REX, JOG, RES, X14, X16, (STR) signal

selection (Refer to page 54.)

*4. RUN, SU, OL, FU, RY, Y12, Y13, FDN, FUP, RL, Y93, Y95, LF, ABC signal selection

(Refer to page 54.)

*5. To be compliant with the European Directive (Low Voltage Directive), the operating

capacity of relay outputs (A, B, C) should be 30VDC 0.3A.

*6. Terminals SD, SE and 5 are isolated from each other. Do not ground.

12

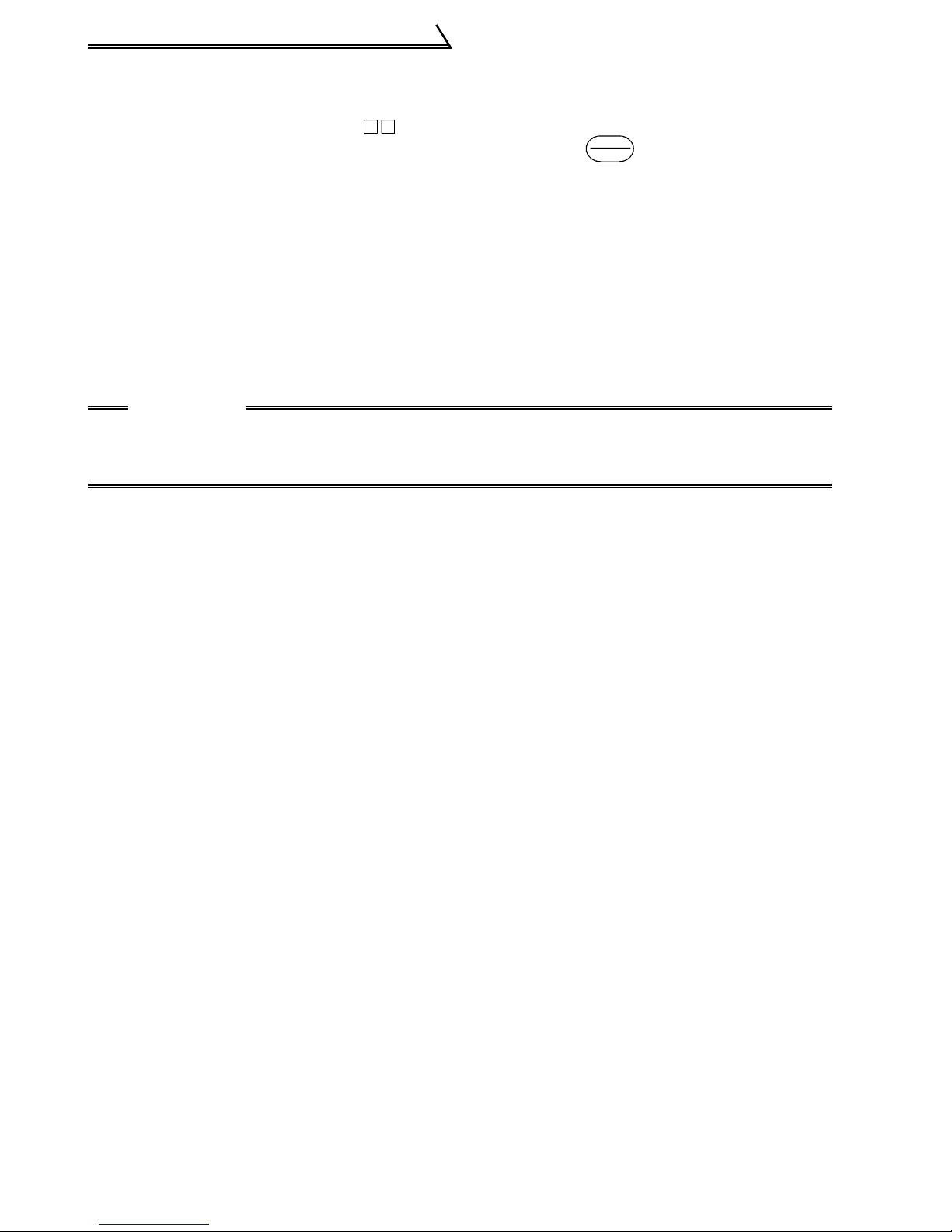

Control circuit

3.3.2 Arrangement and wiring of control circuit terminals

PC

SE RUN 10 2 5 4

SD

AB

SD STF STR RM RH

C

RL AM

Loosen the terminal screw and insert the cable into the

terminal.

Cable stripping size

Screw size: M3 (A, B, C terminals),

M2 (other than the above)

Tightening torque: 0.5N•m to 0.6N•m (A, B, C terminals)

0.22N•m to 0.25N•m (other than the

above)

CAUTION

Wire the stripped cable after

twisting it to prevent it from

becoming loose.

In addition, do not solder it. *

Undertightening can cause cable

disconnection or malfunction. Overtightening

can cause a short circuit or malfunction due

to damage to the screw or unit.

Cable size: 0.3mm

Screwdriver: Small flat-blade screwdriver

Control circuit terminal block

2

to 0.75mm

2

ABC

terminals

Other than

the above

Tip thickness: 0.4mm (0.02 inch)

Tip width: 2.5mm (0.10 inch)

*Information on bar terminals

Introduced products (as of August, 2005): Phoenix Contact Co.,Ltd.

Terminal Screw Size

M3 (A, B, C terminal)

M2 (Other than the above) Al 0.5-6WH A 0.5-6 0.3 to 0.5

Bar Terminal Model

(With Insulation Sleeve)

Al 0.5-6WH A 0.5-6 0.3 to 0.5

Al 0.75-6GY A 0.75-6 0.5 to 0.75

Bar Terminal Model

(Without Insulation Sleeve)

6mm

(0.24 inch)

5mm

(0.20 inch)

Wire Size (mm2)

3

Bar terminal crimping tool: CRIMPFOX ZA3 (Phoenix Contact Co., Ltd.)

CAUTION

When using the bar terminal (without insulation sleeve), use care so that the

twisted wires do not come out.

SPECIFICATIONS OF WIRING AND TERMINALS

13

Control circuit

3.3.3 Connection to RS-485 connector

(1) When connecting the parameter unit

Use the optional FR-CB2 . When the parameter unit (FR-PU04) is used,

operation from the operation panel is not accepted. ( is valid)

(2) RS-485 communication

Using the RS-485 connector, you can perform communication operation from a

personal computer etc. By connecting the RS-485 connector to computers such

as personal computer and FA with a communication cable, you can run/monitor

the inverter and read/write parameter values using a user program. For further

details, refer to the instruction manual (detailed).

· Conforming standard: EIA-485 (RS-485)

· Transmission format: Multi-drop link

· Communication speed: Maximum 19200 bps

· Overall extension: 500m (1640.42 feet)

CAUTION

Do not plug the connector to a computer LAN board, fax modem socket, telephone modular connector etc. As they are different in electrical specifications,

the inverter may be damaged.

STOP

RESET

14

Control circuit

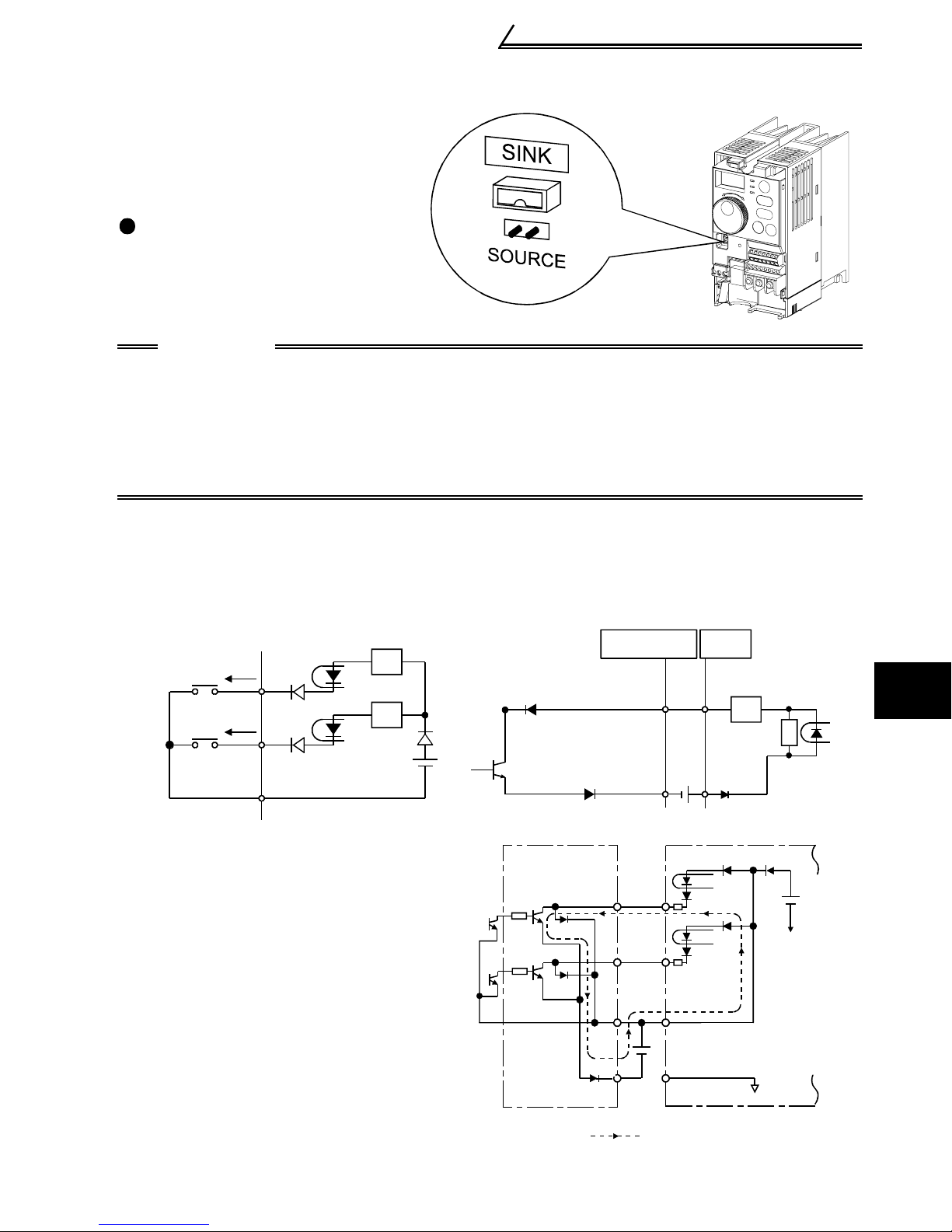

3.3.4 Changing the control logic

The input signals are set to sink

logic.

To change the control logic, the

jumper connector under the setting

dial must be moved to the other

position.

Change the jumper connector

position using tweezers, a pair of

long-nose pliers etc.

Change the jumper connector

position before switching power on.

CAUTION

•Make sure that the front cover is installed securely.

•The front cover is fitted with the capacity plate and the inverter unit with the

rating plate. Since these plates have the same serial numbers, always replace

the removed cover onto the original inverter.

•The sink-source logic change-over jumper connector must be fitted in only

one of those positions. If it is fitted in both positions at the same time, the

inverter may be damaged.

1) Sink logic type

• In this logic, a signal switches on when a current flows from the corresponding signal

input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the

open collector output signals.

Power supply

STF

STR

SD

• Connecting a positive terminal of the

R

R

external power supply for transistor

output to terminal PC prevents a

malfunction caused by an undesirable

current. (Do not connect terminal SD

AY40

transistor

output module

1

2

RUN

SE

STF

STR

AX40Inverter

1

R

R

9

24VDC

Inverter

24VDC

(SD)

of the inverter with terminal 0V of the

external power supply. When using

terminals PC-SD as a 24VDC power

supply, do not install an external

power supply in parallel with the

inverter. Doing so may cause a

9

9

10

24VDC SD

PC

malfunction in the inverter due to an

undesirable current.)

Current flow

3

SPECIFICATIONS OF WIRING AND TERMINALS

15

Control circuit

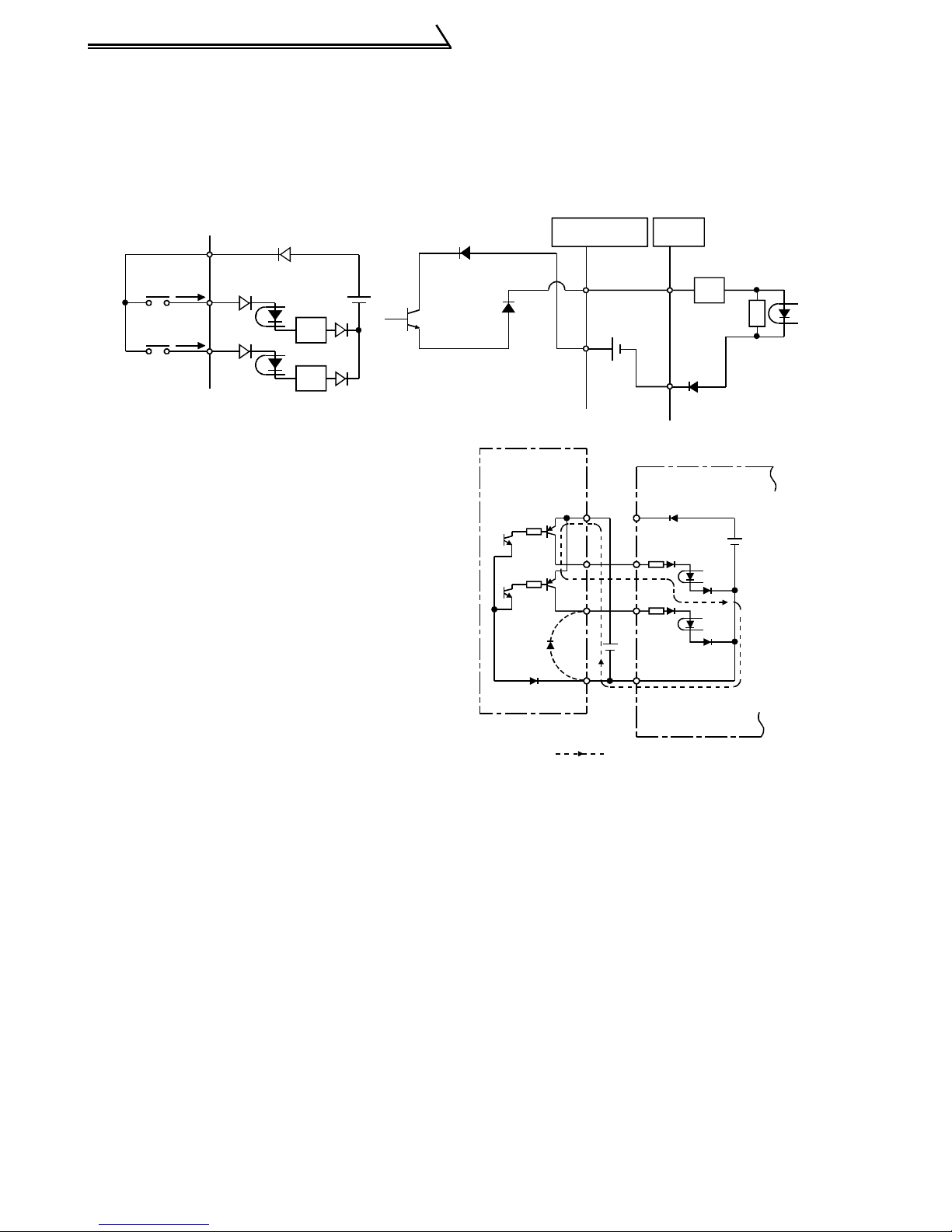

2) Source logic type

• In this logic, a signal switches on when a current flows into the corresponding signal

input terminal.

Terminal PC is common to the contact input signals. For the open collector output

signals, terminal SE is a positive external power supply terminal.

PC

Power

supply

STF

STR

R

R

• Connecting the 0V terminal of the

external power supply for transistor

output to terminal SD prevents a

malfunction caused by an undesirable

current.

AY80

transistor

output module

10

Inverter

RUN

SE

24VDC

9

1

2

PC

STF

STR

24VDC

SD

AX80

1

R

R

9

Inverter

24VDC

(SD)

Current flow

16

Control circuit

r

3.3.5 Power-off and magnetic contactor (MC)

(1) Inverter input side magnetic contactor (MC)

On the inverter's input side, it is recommended to provide an MC for the following

purposes. (Refer to page 3 for selection)

1) To release the inverter from the power supply when the inverter protective function

is activated or the drive becomes faulty (e.g. emergency stop operation)

2) To prevent any accident due to an automatic restart at restoration of power after an

inverter stop made by a power failure

3) To rest the inverter for an extended period of time

The control power supply for inverter is always running and consumes a little power.

When stopping the inverter for an extended period of time, powering off the inverter

will save power slightly.

4) To separate the inverter from the power supply to ensure safe maintenance and

inspection work

The inverter's input side MC is used for the above purpose, select class JEM1038AC3 for the inverter input side current when making an emergency stop during

normal operation.

REMARKS

The MC may be switched on/off to start/stop the inverter. However, since repeated inrush

currents at power on will shorten the life of the converter circuit (switching life is about 100,000

times), frequent starts and stops must be avoided. Turn on/off the inverter start controlling

terminals (STF, STR) to run/stop the inverter.

As shown on the right,

always use the start signal

(ON or OFF across

terminals STF or STR-SD)

to make a start or stop.

*1. When the power supply

is 400V class, install a

step-down transformer.

Power

supply

Operation ready

NFB

OFF

Start/Stop

ON

MC

MC

T (*1)

MC

RA

R/L1

S/L2

T/L3

Inverter

STF(STR)

SD

U

V

W

To

moto

A

B

C

3

(2) Handling of output side magnetic contactor

In principle, do not provide a magnetic contactor between the inverter and motor and

switch it from off to on during operation. If it is switched on during inverter operation, a

large inrush current may flow, stopping the inverter due to overcurrent shut-off. When

an MC is provided for switching to the commercial power supply, for example, switch it

on/off after the inverter and motor have stopped.

MC

Operation

OFF

RA

Inverter Start/Stop Circuit Example

RA

17

SPECIFICATIONS OF WIRING AND TERMINALS

Step of operation

Step of operation

p

4. DRIVE THE MOTOR

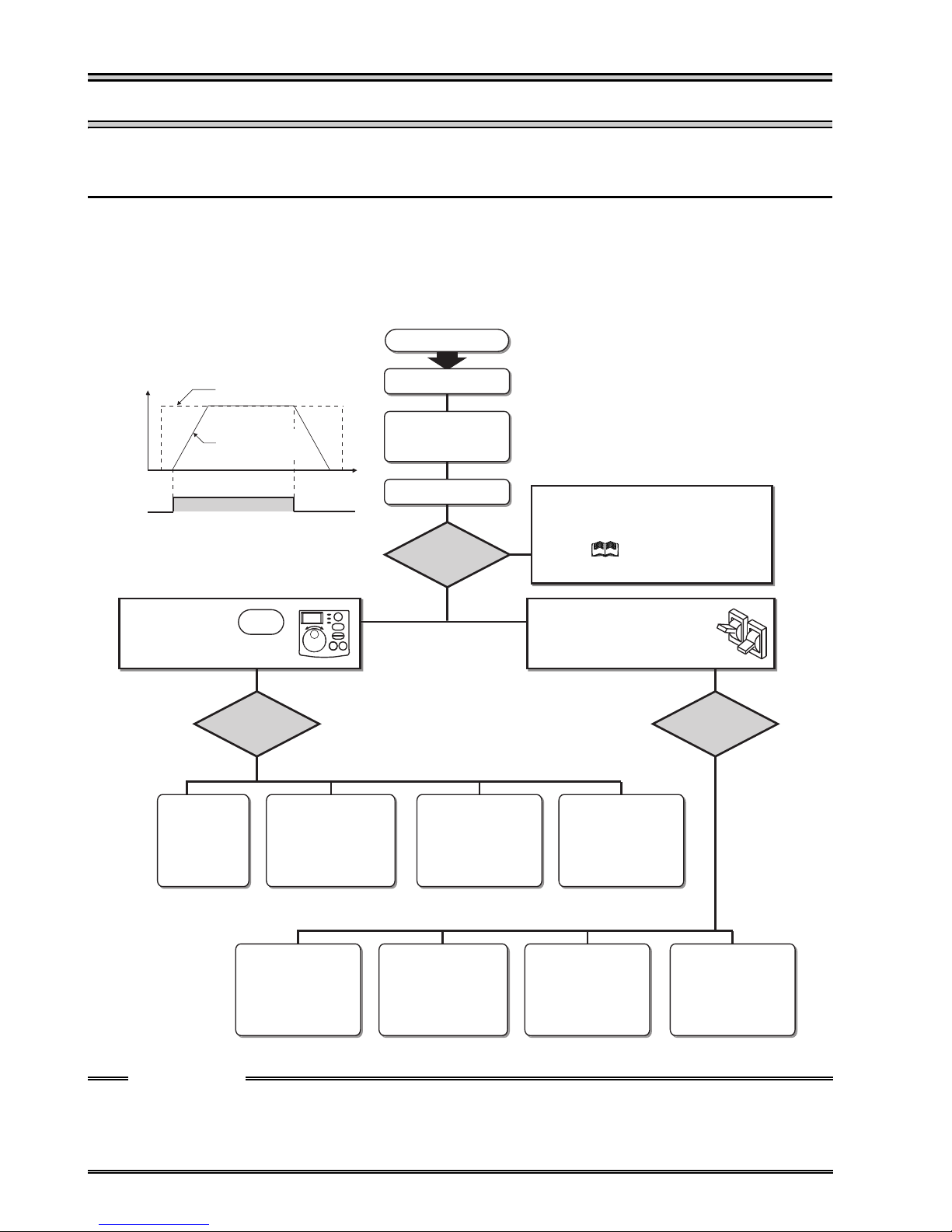

4.1 Step of operation

The inverter needs frequency command and start command. Turning the start

command on start the motor rotating and the motor speed is determined by the

frequency command.

Refer to the flow chart below to perform setting.

Step of operation

o

(Hz)

Frequency

Start

command

Start command with

on the operation panel (PU)

Set from the

operation

panel.

Frequency command

Inverter output

frequency

ON

How to

give a frequency

command?

(PU)

Time

(S)

RUN

-+

Change frequency

with ON/OFF switches

connected to terminals

(multi-speed setting)

(External)

Installation/mounting

Wiring of the power

supply and motor

System examination

How

to give a start

command?

Perform frequency

setting by a voltage

output device

(Connection across

terminals 2-5)

(External)

{Refer to page 5}

{Refer to page 8}

Start command using the RS-485

connector of the inverter

(Communication)

Refer to Instruction Manual

(detailed)

Connect a switch, relay, etc.

to the control circuit

terminal block of the inverter

to give a start command. (External)

Perform frequency

setting by a current

output device

(Connection across

terminals 4-5)

(External)

{Refer to page 21} {Refer to page 23} {Refer to page 25} {Refer to page 26}

How to

give a frequency

command?

Set from the

operation panel

(PU)

{Refer to page 28} {Refer to page 30} {Refer to page 32} {Refer to page 34}

CAUTION

Check the following items before powering on the inverter.

•Check that the inverter is installed correctly in a correct place. (Refer to page 5)

•Check that wiring is correct. (Refer to page 6)

•Check that no load is connected to the motor.

Change of frequency

with ON/OFF switches

connected to terminals

(multi-speed setting)

(External)

18

Perform frequency

setting by a voltage

output device

(Connection across

terminals 2-5)

(External)

Perform frequency

setting by a current

output device

(Connection across

Terminals 4-5)

(External)

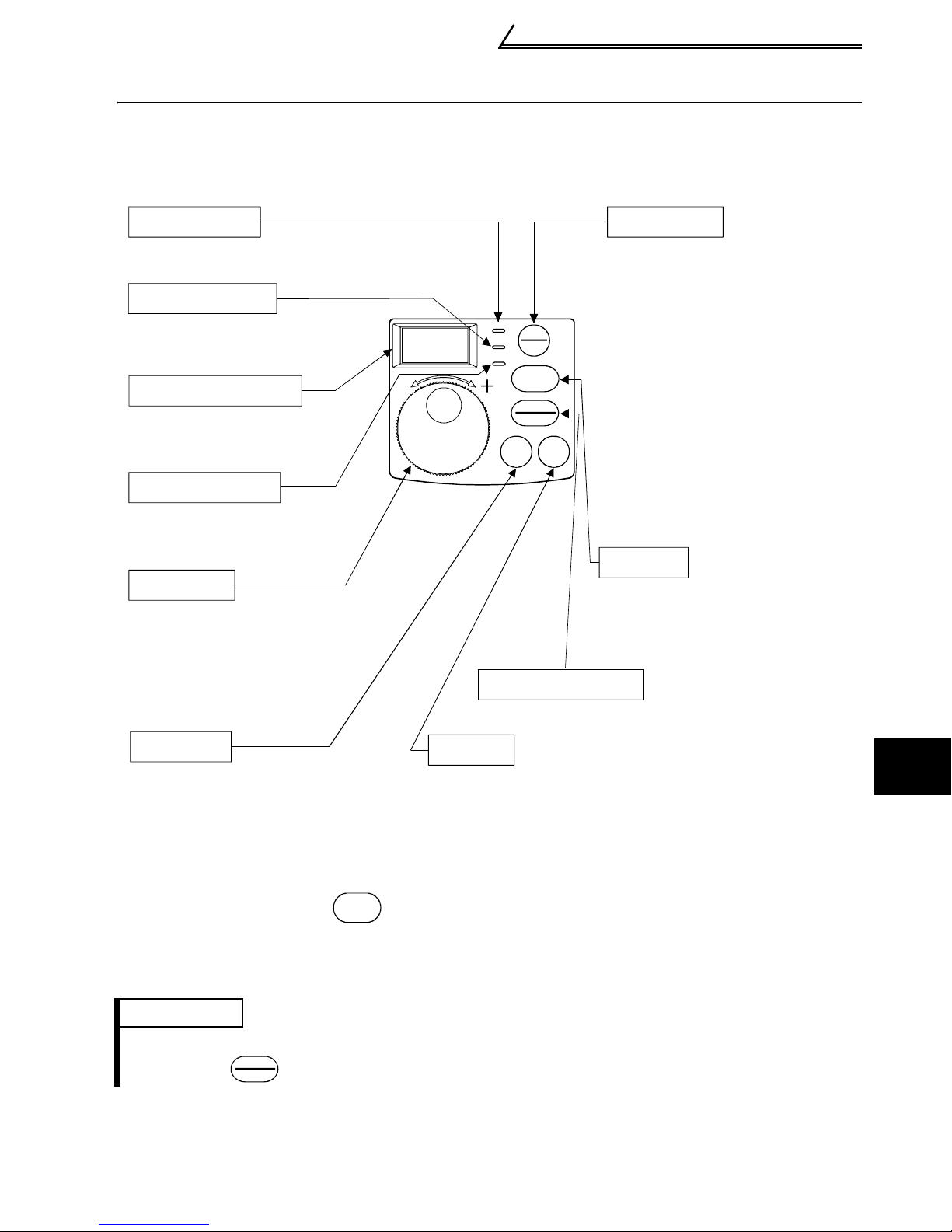

4.2 Run and operation

4.2.1 Parts of the operation panel

The operation panel cannot be removed from the inverter.

Run and operation

RUN indication

Turns on/flickers* to indicate operation.

PU indication **

Lit to indicate the PU

operation mode.

3-digit monitor LED

Shows the frequency,

parameter number, etc.

EXT indication **

Lit to indicate the external

operation mode.

Setting dial

(Setting dial: Mistubishi inverter's dial)

Used to change the frequency

setting and parameter values.

This dial cannot be removed.

PU/EXT Key

Used to switch between the

PU and external operation

mode.When using the external

RUN

PU

EXT

PU

EXT

RUN

operation mode (operation

using the separately

connected frequency setting

potentiometer and start

signal), press this key to

STOP

RESET

light up the EXT indication.

(Change the Pr. 79 value to

MODE SET

use the combined mode.)

PU: PU operation mode

EXT: External operation mode

RUN Key

Used to give the forward

rotation operation command.

Use Pr. 17 to set reverse

operation.

STOP/RESET Key

Used to stop operation or reset an alarm.

MODE Key

Used to change the setting mode.

SET Key

Used to define each setting.

* RUN indication

On: Indicates that forward rotation operation is being performed.

Slow flickering (1.4s cycle): Indicates reverse rotation

Fast flickering (0.2s cycle): Indicates that operation is not being performed

but the was pressed or the start command was given.

RUN

** PU/EXT indication

Flickers slowly in the computer link operation mode.

REMARKS

•When the parameter unit (FR-PU04) is used, operation from the operation panel is not

accepted. ( is valid)

STOP

RESET

4

DRIVE THE MOTOR

19

Run and operation

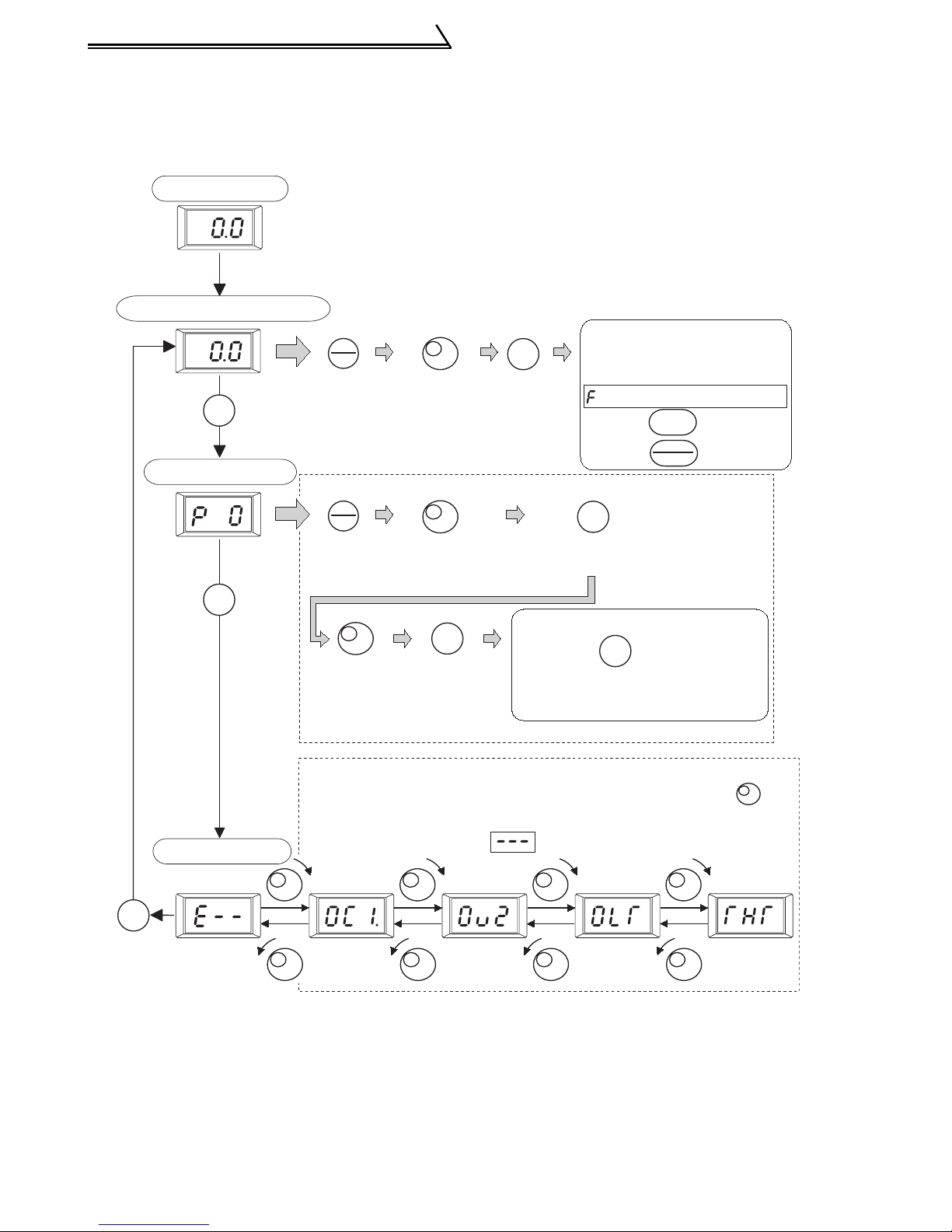

4.2.2 Basic operation

The following explains the outline of operation. (factory setting)

<Basic operation> (factory setting)

At powering on

Monitor/frequency setting

Return

Press

MODE

MODE

key.

Parameter setting

[Parameter setting change]

Press

MODE

MODE

key.

Turn the

setting dial

to change

value.

[Operation panel is used for operation]

PU

EXT

Press

PU/EXT

key.

Turn the

setting dial

to match

SET

Press

SET key

frequency.

PU

EXT

Press

PU/EXT

key.

Turn the setting

dial to match

frequency.

SET

After setting is completed,

SET

Press SET key to

show present setting.

press the once to show

Press SET

key to

complete

alarm history, or twice to

show frequency setting screen.

setting.

Frequency setting has

been written and

completed!!

and frequency flickers.

Press to start.

Press to stop.

MODE

RUN

STOP

RESET

[Operation for displaying alarm history]

Four past alarms can be displayed with the setting dial .

(The latest alarm is ended by ".".)

Alarm history

MODE

When no alarm exists, is displayed.

Press MODE key.

20

Operation by the start command from the operation panel

(PU operation mode)

4.3 Operation by the start command from the operation panel (PU operation mode)

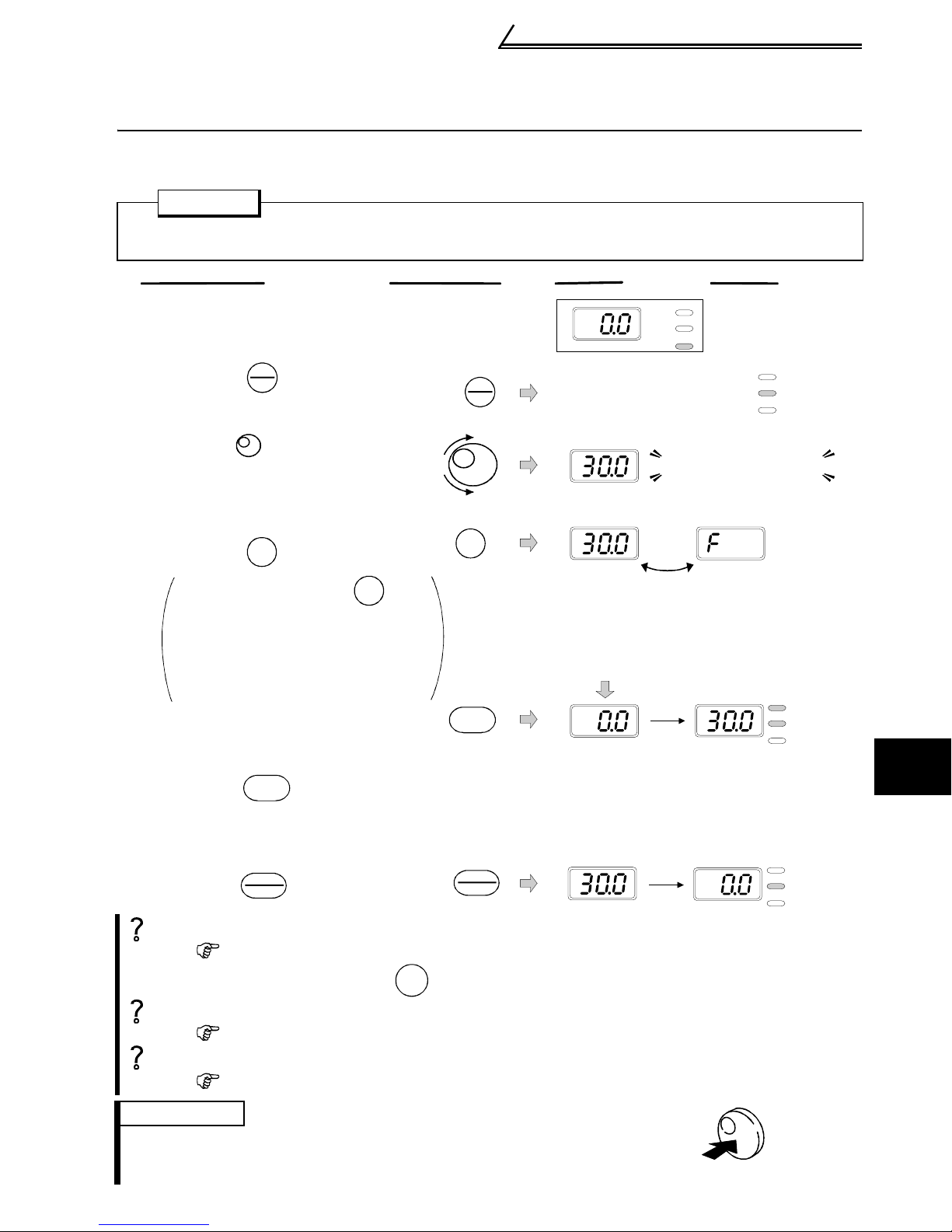

4.3.1 Setting the frequency to perform operation

(example: performing operation at 30Hz)

POINT

•Set "0" (setting dial frequency setting mode) in Pr. 53 "frequency setting

operation selection".

Operation

Screen at power-on

1.

The monitor display appears.

2.

Press the

to choose the PU

operation mode.

Turn the to show

3.

the frequency you want to set.

Flickers for about 5s.

While the value is flickering,

4.

press the to set the

frequency.

If you do not press the ,

the value flickers for about 5s and

the display then returns to 0.0

(monitor display). At this time,

return to "step 3" and set the

frequency again.

5.

After the value flickered for about

3s, the display returns to 0.0

(monitor display).

Press the to start operation.

To change the set frequency, perform

6.

the operation in above steps 3 and 4.

(Starting from the previously set frequency.)

Press the to stop.

7.

PU

EXT

SET

RUN

STOP

RESET

SET

PU

EXT

SET

RUN

STOP

RESET

Display

RUN

PU

EXT

RUN

PU indication is lit.

Flickers for about 5s.

Flicker...Frequency setting complete!!

3s later

PU

EXT

RUN

PU

EXT

RUN

PU

EXT

4

Operation cannot be performed at the set frequency ... Why?

Did you carry out step 4 within 5s after step 3?

(Did you press the within 5s after turning the setting dial?)

Setting of higher than 60Hz cannot be made ... Why?

Check to see if the Pr. 1 "maximum frequency" setting is 60Hz.

The frequency does not change by turning the setting dial ... Why?

Check to see if the operation mode selected is the external operation mode.

REMARKS

Pressing the setting dial shows the set frequency.

•The setting dial can also be used like a potentiometer to perform operation. (Refer to page 22.)

DRIVE THE MOTOR

SET

21

Operation by the start command from the operation panel

(PU operation mode)

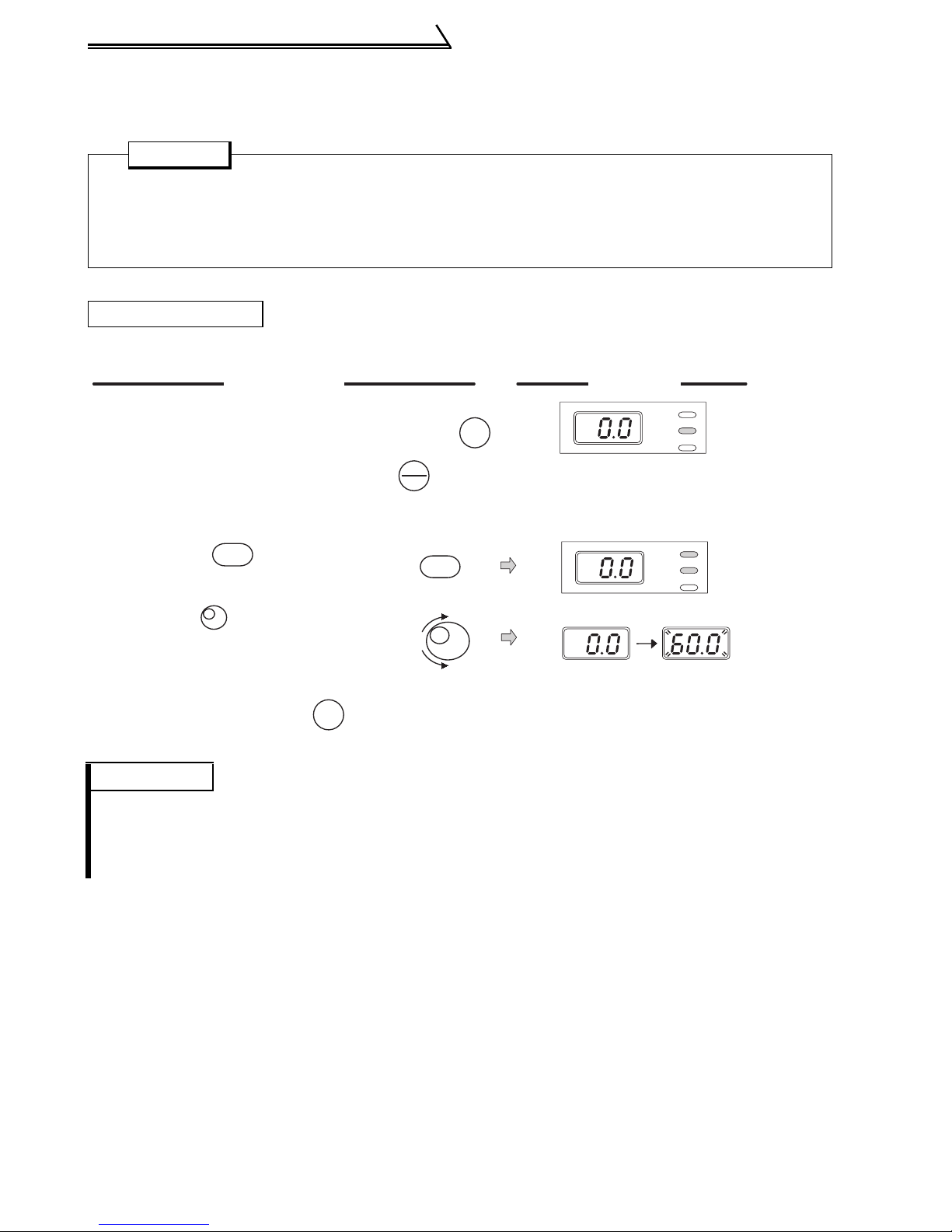

4.3.2 Using the setting dial like a potentiometer to perform

operation

POINT

•Set "1" (extended function parameter valid) in Pr. 30 "extended function

display selection".

•Set "1" (setting dial potentiometer mode) in Pr. 53 "frequency setting

operation selection".

Operation example Changing the frequency from 0Hz to 60Hz during operation

Operation

Mode/monitor check.

1.

Choose monitor/frequency monitor.

The inverter must be in the

PU operation mode.

Pr. 30 must be set to "1".

Pr. 53 must be set to "1".

Press the to start

2.

RUN

the inverter.

Turn the clockwise

3.

(Press the .)

PU

EXT

( )

RUN

MODE

Display

RUN

PU

EXT

RUN

PU

EXT

until "60.0" appears.

The flickering frequency is

the set frequency.

You need not press the .

SET

Flickers for 3s.

REMARKS

•If flickering "60.0" turns to "0.0", the Pr. 53 "frequency setting operation selection" setting may

not be "1".

•Independently of whether the inverter is running or at a stop, the frequency can be set by

merely turning the dial.

22

Operation by the start command from the operation panel

(PU operation mode)

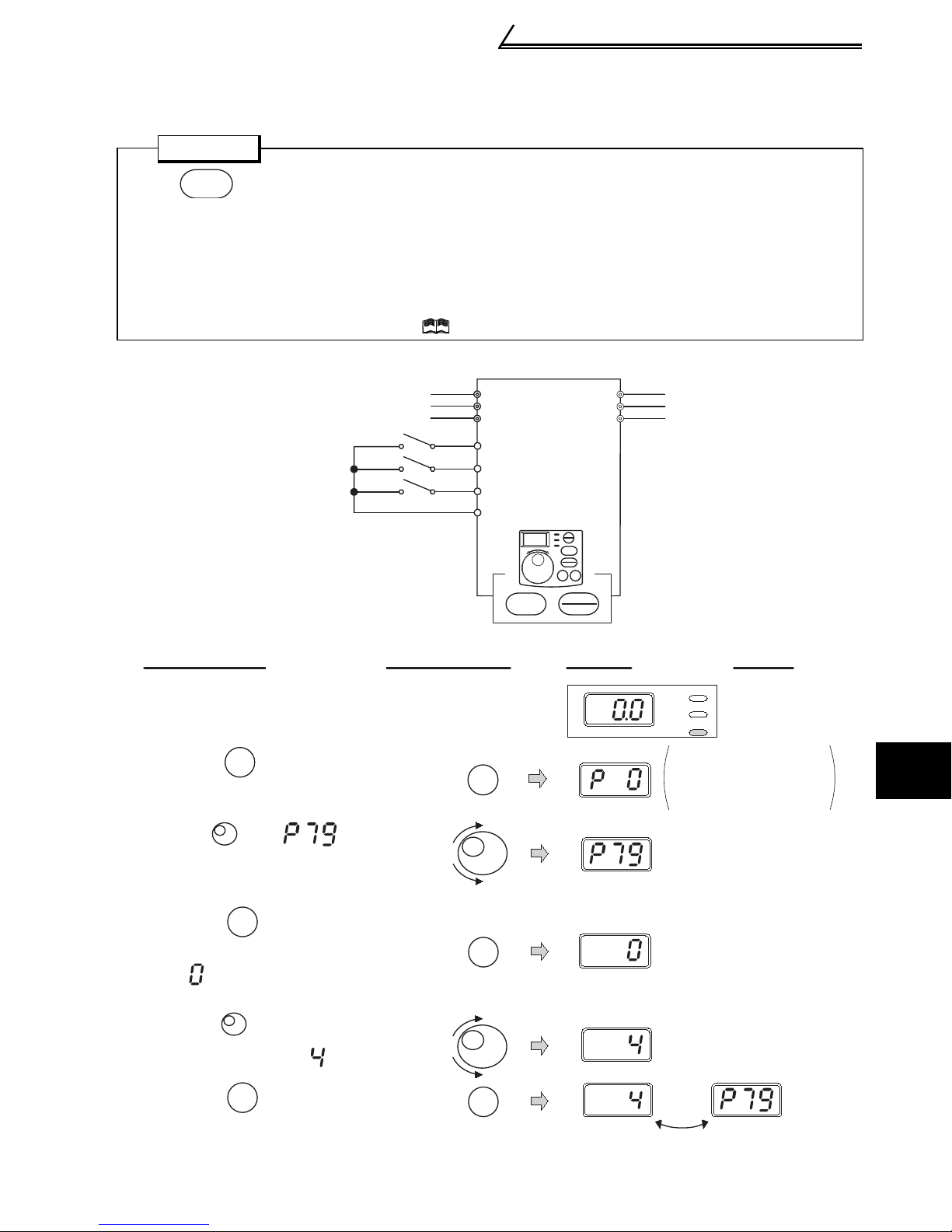

4.3.3 Use switchs to give a start command and a frequency

command (multi-speed setting)

POINT

•Use to give a start command.

RUN

•Pr. 79 "Operation mode selection" must be set to "4" (external/PU combined

operation mode 2)

•The factory setting of the terminal RH, RM, RL, are 60Hz, 30Hz, and 10Hz.

(Refer to page 44 to change frequency using Pr. 4, Pr. 5 and Pr. 6.)

•Operation at 15-speed can be performed by turning on two (or three) terminals simultaneously. (Refer to Instruction Manual (detailed).)

Inverter

Three-phase

AC power supply

High speed

Middle speed

Low speed

R

S

T

RH

RM

RL

SD

Operation

panel

㧗㧙

RUN

、

STOP

RESET

U

V

W

Motor

Operation

Screen at powering on

1.

The monitor display appears.

2.

Press to choose the

parameter setting mode.

Turn until (Pr.79)

3.

appears.

Press to read the currently

4.

set value.

" "(factory setting) appears.

Turn to change it to the

5.

setting value of " ".

Press to set.

6.

MODE

SET

SET

MODE

SET

SET

Display

RUN

PU

EXT

The parameter

number read

previously appears.

4

DRIVE THE MOTOR

Flicker

23

・・・

Parameter setting complete!!

Operation by the start command from the operation panel

(PU operation mode)

Mode/monitor check

7.

Press twice to choose the

MODE

monitor/frequency monitor.

MODE

RUN

PU

EXT

Press the start switch .

8.

RUN

RUN flickers.

When the frequency command is

not given, it flickers.

Turn on the low speed switch (RL).

9.

The output frequency

increases to 10Hz according

RUN

Low speed

RUN

Flickering

PU

EXT

RUN

PU

EXT

to Pr. 7 "Acceleration time".

Turn off the low speed switch (RL).

10.

The output frequency

decreases to 0Hz according

Low speed

RUN

Flickering

PU

EXT

to Pr. 8 "Deceleration time".

Turn off the start switch .

11.

RUN turns off.

STOP

RESET

STOP

RESET

RUN

PU

EXT

60Hz for the RH, 30Hz for the RM, 10Hz for the RL are not output when they are

turned on ... Why?

Check for the setting of Pr. 4, Pr. 5, and Pr. 6 once again.

Check for the setting of Pr. 1 "Maximum frequency" and Pr. 2 "Minimum fre-

quency" once again. (Refer to page 44.)

Check that Pr. 60 "RL terminal function selection" = "0", Pr. 61 "RM terminal

function selection" = "2", Pr. 62 "RH terminal function selection" and Pr. 59

"Remote function selection" = "0". (all are factory setting)

[RUN] lamp is not lit ... Why?

Check that wiring is correct. Check the wiring once again.

Check for the Pr. 79 setting once again. (Pr. 79 must be set to "4".)

(Refer to page 44)

Change the frequency of the terminal RL, RM, and RH. ...How?

Refer to page 44 to change the running frequency at each terminal in Pr. 4

"Multi-speed setting(high speed)", Pr. 5 "Multi-speed setting (middle speed)",

and Pr. 6 "Multi-speed setting (low speed)".

24

Operation by the start command from the operation panel

r

(PU operation mode)

4.3.4 Perform frequency setting by analog (voltage input)

POINT

•Use to give a start com-

RUN

mand.

•Pr. 79 "Operation mode selection"

must be set to "4" (external/PU

combined operation mode 2)

Operation

Screen at powering on

1.

The monitor display appears.

2.

Change the Pr. 79 setting to " ".

(Refer to page 23 for change of the setting.)

Mode/monitor check

3.

Press twice to choose the

monitor/frequency monitor.

Start

4.

Press the start switch .

Operation status indication of RUN flickers.

Acceleration → constant speed

5.

Turn the volume (frequency setting

potentiometer) clockwise slowly to full.

The frequency value on the indication

increases according to Pr. 7 "Acceleration

time" until 60.00Hz is displayed.

6.

7.

MODE

RUN

Deceleration

Turn the volume (frequency setting

potentiometer) counterclockwise

slowly to full.

The frequency value on the indication

decreases according to "Pr. 8 Deceleration

time" until 0.00Hz is displayed and

operation status indication of RUN flickers.

The motor stops.

Stop

Press .

STOP

RESET

Operation status indication of RUN

turns off.

[Connection diagram]

Three-phase

AC power supply

Frequency setting

potentiometer

MODE

RUN

STOP

RESET

Flicker

・・・

T/L3

Parameter setting complete

Inverter

R/L1

S/L2

Operation

10

2

5

RUN

Display

RUN

PU

EXT

RUN

Flickering

PU

EXT

RUN

PU

EXT

RUN

Flickering

PU

EXT

RUN

PU

EXT

panel

㧗㧙

、

RUN

PU

EXT

STOP

RESET

U

V

W

Moto

4

DRIVE THE MOTOR

Change the frequency (60Hz) of the maximum value of potentiometer (at 5V)

Adjust the frequency in Pr. 38 "frequency setting voltage gain frequency".

(Refer to page 40)

Change the frequency (0Hz) of the minimum value of potentiometer (at 0V)

Adjust the frequency in calibration parameter C2 "frequency setting voltage

bias frequency". (Refer to Instruction Manual (detailed).)

25

Operation by the start command from the operation panel

r

(PU operation mode)

4.3.5 Perform frequency setting by analog (current input)

POINT

•Assign the AU signal to any of the terminal RH, RM, RL, or STR and turn on

the AU signal.

•Pr. 62 and Pr. 39 are extended function parameters. Set "1" in Pr. 30. (Refer to

page 48.)

•Set "4" (external/PU combined operation mode 2) in Pr. 79 "operation mode"

[Connection diagram ]

Three-phase AC

power supply

Current input selection

Current output

frequency setting

device

(4 to 20mADC)

[AU signal assignment]

Assign the AU signal to any of the RL, RM, RH or STR terminal.

(example) Assign the AU signal to the RH terminal.

Set

"4"

Confirm the RUN indication and

1.

operation mode indication.

The inverter must be

at a stop.

The inverter must be

in the PU operation mode.

Press the to choose

2.

the parameter setting mode.

Turn the until (Pr. 62)

3.

appears.

Inverter

R/L1

S/L2

T/L3

U

V

W

AU signal

(RH terminal)

SD

4 (+)

5 (-)

Operation Panel

㧗㧙

、

STOP

RESET

RUN

(AU signal) in Pr. 62 "RH terminal function selection".

Operation

MODE

(Press the .)

PU

EXT

MODE

Display

Moto

RUN

PU

EXT

The parameter

number read

previously

appears.

Press the to read

4.

the currently set value.

"

" (factory setting) appears.

Turn the to change it to

5.

the set value of " ".

Press the to set

6.

the value.

SET

SET

REMARKS

•Refer to page 46, 51 for other parameters' setting.

•Refer to page 54 for details of Pr. 62 "RH terminal function selection".

SET

SET

Flicker...AU signal assignment complete!!

26

Operation by the start command from the operation panel

[Perform frequency setting by analog (current input) ]

(PU operation mode)

Operation

7.

Change the Pr.79 setting to " ".

(Refer to page 23 for change of the

setting.)

Mode/monitor check

8.

MODE

Press twice to choose the

monitor/frequency monitor.

Start

9.

Check that the current input selection

signal (AU) is on.

Press the start switch .

RUN of operation status indication flickers.

Acceleration → constant speed

10.

Perform 20mA input.

The frequency value on the

indication increases according

to Pr.7 "Acceleration time"

until 60.00Hz is displayed.

RUN

Flicker

MODE

RUN

Output of the

adjustment meter

(4 to 20mADC)

Display

・・・

Parameter setting complete!!

RUN

PU

EXT

RUN

Flickering

PU

EXT

RUN

PU

EXT

Deceleration

11.

Perform 4mA input.

The frequency value on the

indication decreases according

to Pr.8 "Deceleration time" until

0.00Hz is displayed and the

operation status indication of RUN flickers.

The motor stops.

12.

Stop

Press .

RUN of the operation status indication

turns off.

STOP

RESET

Output of the

adjustment meter

(4 to 20mADC)

STOP

RESET

RUN

Flickering

PU

EXT

RUN

PU

EXT

Change the frequency (60Hz) at the maximum value of potentiometer (at 20mV)

Adjust the frequency in Pr. 39 "Frequency setting current gain frequency".

(Refer to page 41)

Change the frequency (0Hz) at the minimum value of potentiometer (at 4mA)

Adjust the frequency in calibration parameter C5 "frequency setting current

bias frequency". (Refer to Instruction Manual (detailed).)

4

DRIVE THE MOTOR

27

Operation by the start command of the terminal block

r

(external operation)

4.4 Operation by the start command of the terminal

block (external operation)

4.4.1 Use the set frequency set by the operation panel

(Pr.79=3)

POINT

•Switch terminal STF(STR)-SD on to give a start command.

•Set "3" in Pr. 79 (External/PU combined operation mode 1).

•Refer to page 21 for the set frequency by the operation panel.

[

Connection diagram

Forward rotation start

Reverse rotation start

]

Three-Phase

AC power supply

Inverter

R

S

T

STF

STR

SD

Operation panel

U

V

W

Moto

Operation

Screen at powering on

1.

The monitor display appears.

2.

Press to choose the

parameter setting mode.

Turn until (Pr.79)

3.

appears.

Press to read the currently

4.

set value.

" " (factory setting) appears.

MODE

SET

MODE

SET

㧗㧙

Set frequency

Display

RUN

PU

EXT

The parameter

number read

previously appears.

Turn to change it to the setting

5.

value of " ".

Press to set.

6.

SET

SET

Flicker

28

・・・

Parameter setting complete!!

e

Mode/monitor check

7.

Press twice to choose the

MODE

monitor/frequency monitor.

Turn the start switch (STF or

8.

STR) on.

The motor runs at the frequency

set in the set frequency mode

of the operation panel.

Turn to change running frequency.

9.

Display the frequency you want to set.

The frequency flickers for about 5s.

ON

MODE

Forward

rotation

Operation by the start command of the terminal block

Reverse

rotation

(external operation)

RUN

PU

EXT

RUN

PU

EXT

Flickers for about 5s

While the value is flickering,

10.

press to set the frequency.

If you do not press , the value

flickers for about 5s and the display

SET

SET

SET

Flicker

・・・

Parameter setting complet

then returns to 0.00 (display) Hz.

At this time, return to "Step 8" and

set the frequency again.

Forward

Turn the start switch (STF or

11.

STR) off.

rotation

Reverse

rotation

The motor decelerates according

to Pr. 8 "Deceleration time" to stop.

OFF

Stop

REMARKS

•To make a reverse rotation start, Pr. 63 "STR terminal function selection" must be set to "---".

(factory setting)

•When Pr. 79 "Operation mode selection" is set to "3", multi-speed operation (refer to page 30)

is also made valid.

4

When the inverter is stopped by of the operation panel,

and

1. Turn the start switch (STF or STR) off.

2. The display can be reset by .

RUN

PU

EXT

STOP

RESET

Flickering

are displayed alternately.

PU

EXT

29

DRIVE THE MOTOR

Operation by the start command of the terminal block

e

(external operation)

4.4.2 Use switches to give a start command and a frequency

command (multi-speed setting)

POINT

•Start command by terminal STF (STR)-SD

•Frequency command by terminal RH, RM, RL-SD.

•[EXT] must be lit. (When [PU] is lit, switch it to [EXT] with .)

•The initial values of the terminals RH, RM, RL, are 60Hz, 30Hz, and 10Hz. (Use

Pr. 4, Pr. 5, and Pr. 6 to change.)

•Operation at 15-speed can be performed by turning two (or three) terminals

simultaneously. (Refer to the instruction Manual(detailed).)

PU

EXT

[Connection diagram]

Three-phase

AC power supply

Forward

rotation start

Reverse

rotation start

High speed

Middl speed

Low speed

Changing

example

Set "50Hz" in Pr. 4 "Multi-speed setting (high speed)" and turn on terminal

RH and STF (STR)-SD to operate.

R

S

T

STF

STR

RH

RM

RL

SD

Inverter

U

V

W

Operation

Power on →operation mode check

1.

For the factory setting, the inverter operates

in the external operation mode [EXT] when

powering on. Check that the operation

command indication is [EXT].

If not displayed, press to change to the

external [EXT] operation mode. If the operation

mode still does not change, set Pr. 79 to change

to the external operation mode.

2.

Press to choose the parameter

MODE

setting mode.

(Refer to page 46)

Motor

MODE

(Hz)

Output frequency

RH

RM

RL

ON

Speed 1

(High speed)

Speed 2

(Middle speed)

Speed 3

(Low speed)

ON ON ON ON

ON

Speed 5

Speed 6

Speed 4

ON ON

Display

RUN

EXT

The parameter

number read

previously appears.

Speed 7

Tim

ON

ONONON

PU

Turn until . (Pr. 4) appears.

3.

Press to read the currently set value.

4.

SET

" " (factory setting) appears. (60.0Hz)

SET

30

Turn to change it to the seting

5.

value of " ". (50.0Hz)

Operation by the start command of the terminal block

(external operation)

Press to set.

6.

SET

SET

Flicker

Mode/monitor check

7.

Press twice to choose the

MODE

monitor/frequency monitor.

Turn on the high speed

8.

switch (RH).

Turn the start switch (STF or STR) on.

9.

50Hz appears.

30Hz appears when RM is on and

10Hz appears when RL is on.

10.

Stop

Turn the start switch (STF or STR) off.

The motor stops according to Pr. 8

"Deceleration time".

[EXT] is not lit even when is pressed ...Why?

PU

EXT

MODE

High speed

ON

Forward rotation

ON

Forward rotation

OFF

・・・

Parameter setting complete!!

RUN

PU

EXT

Middle speed

Low speed

Reverse rotation

Reverse rotation

RUN

PU

EXT

Stop

Switchover of the operation mode with is valid when Pr. 79 = "0" (initial

PU

EXT

value).

60Hz, 30Hz and 10Hz are not output from RH, RM and RL respectively when they are

turned on. ...Why?

Check for the setting of Pr. 4, Pr. 5, and Pr. 6 once again.

CHeck for the setting of Pr. 1 "Maximum frequency" and Pr. 2 "MInimum fre-

quency" once again. (Refer to page 44)

Check for the Pr. 79 setting once again. (Pr. 79 must be set to "0" or "2".) (Refer to

page 44)

Check that Pr. 60 "RL termianl function selection" = "0", Pr. 61 "RM terminal func-

tion selection" = "1", Pr. 62 "RH termianl function selection" = "2" and Pr. 59

"Remote function selection" = "0". (factory setting)

[RUN] is not lit. ...Why?

Check that wiring is correct. Check it again.

To make a reverse rotation start, check that "---" is set in Pr. 63 "STR terminal func-

tion selection"? (factory setting)

How is the frequency setting from 4 to 7 speed?

The setting differs according to Pr. 24 to Pr. 27 (multi-speed setting). Refer to

Instruction Manual (detailed).

REMARKS

External operation is fixed by setting "2" (external operation mode) in Pr. 79 "Operation mode

selection" when you do not want to take time pressing or when you want to use the cur-

rent operation command and frequency command. (Refer to page 46)

PU

EXT

4

DRIVE THE MOTOR

31

Operation by the start command of the terminal block

(external operation)

4.4.3 Perform frequency setting by analog (voltage input)

[Connection diagram]

(The inverter supplies 5V of power to frequency setting potentiometer. (Termianl 10))

Inverter

Three-phase

AC power supply

Forward rotation

start

Reverse rotation

start

Frequency setting

potentiometer

R

S

T

STF

STR

SD

10

2

5

W

U

V

Motor

Operation

Power on → operation mode check

1.

For the factory setting, the inverter operates

in the external operation mode [EXT] when

powering on. Check that the operation command

ON

Display

RUN

PU

EXT

indication is [EXT]. If not displayed, press to

change to the external [EXT] operation mode. If the

operation mode still does not change, set Pr. 79 to

change to the external operation mode.

(Refer to page 46)

2.

Start

Turn the start switch (STF or STR) on.

Operation status indication of RUN flickers.

CAUTION

When both the forward switch and reverse

switch are on, the inverter will not start.

Also, if both switches turn on while running,

the inverter decelerates to stop.

Acceleration → constant speed

3.

Turn the volume (frequency setting

potentiometer) clockwise slowly to full.

The frequency value on the indication

ON

Forward

rotation

Reverse

rotation

RUN

Flickering

PU

EXT

RUN

PU

EXT

increases according to Pr. 7 "Acceleration

time" until 60.0Hz is displayed.

Deceleration

4.

Turn the volume (frequency setting

potentiometer) counterclockwise slowly

RUN

Flickering

PU

EXT

to full. The frequency value of the indication

decreases according to Pr. 8 "Deceleration

time" until 0.0Hz is displayed.

The motor stops.

Stop

5.

Turn the start switch (STF or STR) off.

Forward

rotation

OFF

Reverse

rotation

RUN

PU

EXT

When you want to operate in the external operation mode always at powering on or when

you want save the trouble of input, set "2" (external operation mode) in Pr. 79 "Opera-

PU

EXT

tion mode selection" to choose external operation mode always.

32

Operation by the start command of the terminal block

(external operation)

REMARKS

To make a reverse rotation start, Pr. 63 "STR terminal function selection" must be set to "---".

The motor will not rotate ... Why?

Check that [EXT] is lit.

[EXT] is valid when Pr. 79 = "0" (factory setting).

Use to lit [EXT].

PU

EXT

Check that wiring is correct. Check once again.

Change the frequency (60Hz) of the maximum value of potentiometer (at 5V)

Adjust the frequency in Pr. 38 "frequency setting voltage gain frequency".

(Refer to page 40)

Change the frequency (0Hz) of the minimum value of potentiometer (at 0V)

Adjust the frequency in calibration parameter C2 “frequency setting Voltage

bias frequency”. (Refer to Instruction Manual (detailed).)

4

DRIVE THE MOTOR

33

Operation by the start command of the terminal block

play

(external operation)

4.4.4 Perform frequency setting by analog (current input)

POINT

•Switch terminal STF(STR)-SD on to give a start command.

•Assign the AU signal to any of the terminal RH, RM, RL, or STR and turn on the

AU signal. (Refer to page 26)

•Set "2" (external operation mode) in Pr. 79 "Operation mode selection".

[Connection diagram]

Three-phase

AC power supply

Forward rotation start

Reverse rotation start

AU signal

Output of the

adjustment meter

(4 to 20mADC)

Operation

Power on → operation mode check

1.

For the factory setting, the inverter operates

in the external operation mode [EXT] when

powering on. Check that the operation

command indication is [EXT]. If not displayed,

press to change to the external [EXT] operation

mode. If the operation mode still does not change, set

Pr. 79 to change to the external operation mode.

(Refer to page 46)

R

S

T

STF

STR

AU

SD

4

(+)

5(ー)

ON

Inverter

U

V

W

Display

Motor

RUN

PU

EXT

2.

Start

Turn the start switch (STF or STR) on.

RUN of operation indication flickers.

CAUTION

When both the forward switch and reverse

switch are on, the inverter will not start.