C

MIT

SUBIS

C

HI ELECTRI

FR-A 500/FR-F 500/

FR-E 500/FR-S 500/

FR-F 700 EC

Frequency Inverter

Instruction Manual

Art. no.: 132733

01 11 2004

IB(NA)-0600081

Version C

FR-SW1-SETUP-WE

Version 3.1

MITSUBISHI ELECTRI

INDUSTRIAL AUTOMATION

INTRODUCTION

Thank you for choosing the Mitsubishi Transistorized VFD Setup Software.

This instruction manual gives handling information and precautions for use of this software.

Incorrect handling might cause an unexpected fault. Before using this product, please read this manual carefully to

use it to the optimum.

Please forward this manual to the end user.

When reading this manual, note the following:

• This manual is written on the basis that Windows

• The [return] and [enter] keys are represented by the key.

• Drive D is described as the CD-ROM drive and Drive C as the hard disk drive.

• In keyboard operation, simultaneous pressing of keys is indicated by "+".

Example: Pressing the [Alt] and [G] keys simultaneously is indicated by (Alt+G).

• The screens, parameter names, set values and so on given in this manual are written on the basis of the FRA500 series. When using the inverter of any other series, refer to the instruction manual of the used inverter.

Trademarks

• Microsoft and Windows are registered trademark or trademark of Microsoft Corporation in the United States and/

or other countries.

1) The formal name of Windows 95 is Microsoft

2) The formal name of Windows 98 is Microsoft

®

3) The formal name of Windows NT

4) The formal name of Windows

5) The formal name of Windows

6) The formal name of Windows

is Microsoft® Windows NT® operating system.

®

2000 is Microsoft® Windows® 2000 operating system.

®

Me is Microsoft® Windows® Me operating system.

®

XP is Microsoft® Windows® XP operating system.

• The DOS/V personal computer is a registered trademark of IBM Corporation.

• The "Mitsubishi Transistorized VFD Setup Software" is a registered trademark of Mitsubishi Electric Corporation.

The copyright and other rights of this software all belong to Mitsubishi Electric Corporation.

• No part of this manual may be copied or reproduced without the permission of Mitsubishi Electric Corporation.

• Other company and product names herein are the trademarks or registered trademarks of their respective owners.

®

95 (English version) is the operating system.

®

Windows® 95 operating system.

®

Windows® 98 operating system.

For Maximum Safety

• Mitsubishi vector inverters are not designed or manufactured to be used in equipment or systems in situations

that can affect or endanger human life.

• When considering this product for operation in special applications such as machinery or systems used in passenger transportation, medical, aerospace, atomic power, electric power, or submarine repeating applications,

please contact your nearest Mitsubishi sales representative.

• Although this product was manufactured under conditions of strict quality control, you are strongly advised to

install safety devices to prevent serious accidents when it is used in facilities where breakdowns of the product

are likely to cause a serious accident.

CONTENTS

1 OVERVIEW 1

1.1 Before Using This Software ................................................................................ 2

1.1.1 Packing list ................................................................................................................................ 2

1.2 Preparations for Startup...................................................................................... 3

1.2.1 System configuration ................................................................................................................. 3

1.2.2 Installing the Setup Software ..................................................................................................... 4

2 FUNCTIONS 7

2.1 Starting the VFD Setup Software........................................................................8

2.2 Settings.................................................................................................................9

2.2.1 System Settings....................................................................................................................... 11

2.2.2 Communication Settings.......................................................................................................... 12

2.2.3 Environmental Setting ............................................................................................................. 13

2.3 Parameter ........................................................................................................... 14

2.3.1 All List Format.......................................................................................................................... 14

2.3.2 Functional List Format ............................................................................................................. 17

2.3.3 Individual List Format .............................................................................................................. 18

2.3.4 Basic Settings .......................................................................................................................... 19

2.4 Monitor ................................................................................................................ 20

2.4.1 Data Display ............................................................................................................................ 20

2.4.2 Meter Display........................................................................................................................... 21

2.4.3 Oscilloscopes .......................................................................................................................... 21

2.4.4 Alarm History ........................................................................................................................... 23

2.4.5 Trace Oscilloscopes (for FR-V500 (L) series only).................................................................. 24

2.5 Diagnosis............................................................................................................ 33

2.5.1 VFD Status .............................................................................................................................. 33

2.5.2 Diagnosis ................................................................................................................................. 33

2.6 Test Running ...................................................................................................... 35

2.6.1 Test Running ........................................................................................................................... 35

2.6.2 Auto Tuning ............................................................................................................................. 35

2.7 Advanced Function............................................................................................37

2.7.1 Machine analyzer (for FR-V500 (L) series only)...................................................................... 37

2.8 Saving, Reading and Printing the Files ........................................................... 42

2.8.1 File types ................................................................................................................................. 42

2.8.2 Saving method......................................................................................................................... 42

2.8.3 Reading the file........................................................................................................................ 42

2.8.4 Printing .................................................................................................................................... 42

2.9 Help ..................................................................................................................... 43

2.9.1 Help contents........................................................................................................................... 43

2.9.2 Version information.................................................................................................................. 43

3 ERROR INDICATIONS 45

3.1 Error codes......................................................................................................... 46

3.1.1 Error code lists......................................................................................................................... 46

3.1.2 Panel-displayed errors............................................................................................................. 46

4 APPENDICES 47

4.1 Supplementary Software................................................................................... 48

4.1.1 Introduction .............................................................................................................................. 48

4.1.2 Parameter files ........................................................................................................................ 48

4.1.3 Parameter file edit software (PREDITE).................................................................................. 49

1

OVERVIEW

This chapter provides the fundamental "overview" for use of this

product.

Always read the instructions before using this software.

1.1 Before Using This Software ...........................................2

1.2 Preparations for Startup.................................................3

When using this software to make communication with the inverters, set a

value other than 0 in Pr. 122 "communication check time interval" on the

inverter's operation panel. When using the FR-A5NR, set any value other

than 0 in Pr. 336 "communication check time interval", and when using the

FR-S500 series, set any value other than 0 in the communication parameter

n6 (336) "communication check time interval".

(Refer to the inverter instruction manual for the setting method.)

1

2

3

4

1

Before Using This Software

1.1 Before Using This Software

• This software can be used effectively as a support tool for operations from startup to maintenance of the Mitsubishi transistorized inverter. The following functions can be performed efficiently on the Windows screen of a personal computer.

⋅ System setting function

⋅ Parameter editing function

⋅ Monitoring function

⋅ Diagnosis function

⋅ Test running function

⋅ File management function

⋅ Advanced function

⋅ Help function

1.1.1 Packing list

After unpacking, check that the following items are contained in the package:

Item Quantity

CD-ROM 1 disk

Instruction manual 1 book

2

Preparations for Startup

1.2 Preparations for Startup

1.2.1 System configuration

The following devices are required to use the VFD Setup Software. Configure the system in accordance with the

instruction manuals of the corresponding devices.

2)

VFD Setup Software

Communication option used

Connection cable

RS-485/RS-422

3)

Converter *1

*2

PU connector used

Connection cable

Connector: RJ45 connector

Example: Tyco Electronics Corporation 5-554720-3

Cable: Cable in compliance with EIA568

(such as 10BASE-T cable)

Example: Mitsubishi Cable Industries, Ltd.,

SGLPEV-T 0.5mm×4P

(Twisted pair cable, 4 pairs)

Distribution terminal

1)

*2

Mouse

Printer cable

Commercially available

printer

(ESC/P compatible)

Multidrop link system

Termination resistor

FR-A5NR

Power supply

*1: A converter commercially available is required when the personal computer uses the RS-232C port.

<Example of a commercially available product>

Model: FA-T-RS40 Converter (Model with connectors and cable is also available)

Mitsubishi Electric Engineering Co., Ltd.

The converter cable cannot connect two or more inverters (the computer and inverter are

connected on a 1:1 basis). Since the product is packed with the RS-232C cable and RS-485 cable

(10BASE-T + RJ-45 connector), the cable and connector need not be prepared separately.

*2: The PU connector or FR-A5NR (FR-A500 (L) / F500 (L) / V500 (L) series) can be used to make communication.

(Refer to the corresponding instruction manual for details.)

NFB

Model, Specifications, Etc.

1) Personal computer

One on which Windows 95, Windows 98, Windows NT 4.0, Windows 2000, Windows Me or Windows

XP (English version) operates

2) Mouse Mouse which can be connected to the personal computer

3) Setup software VFD Setup Software (FR-SW1-SETUP-WE)

FR-A520 (-NA), FR-A540 (-NA) (-EC) (-CH), FR-A560-NA,

FR-A520L-75K, 90K, FR-A540L-65K*, 75K to 450K (-NA) (-G-NA) (-EC) (-G-EC), FR-A540L-S-60K to

375K (-EC) (-CH), FR-A560L-NA-75K to 450K,

FR-E520-0.1K to 7.5K (-NA), FR-E540-0.4K to 7.5K (-NA) (-EC) (-CH),

FR-E520S-0.1K to 0.75K, FR-E520S-0.4K to 2.2K-EC (-CH), FR-E510W-0.1K to 0.75K (-NA),

FR-F520-0.75K to 55K (-NA), FR-F540-0.75K to 55K (-NA) (-EC) (-CH),

4) Inverter

FR-F520L-75K to 110K, FR-F540L-75K to 530K (-NA) (-EC) (-CH) (-G-CH), FR-F540L-S-75K to 400K (-CH),

FR-F720-0.75K to 55K, FR-F720-00046 to 02330 (-NA)

FR-F740-0.75K to 160K, FR-F740-00023 to 03610 (-NA) (-EC)

FR-F740-0.75K to 55K, S75K to S185K (-CH)

FR-S520-0.1K to 3.7K-R, FR-S540-0.4K to 3.7K-R (-NAR) (-ECR) (-CHR),

FR-S520S-0.1K to 1.5K-R, FR-S520S-0.2K to 1.5K-ECR (-CHR), FR-S510W-0.1K to 0.75K-R

FR-V520, FR-V540, FR-V520L-75K, FR-V540L-75K to 250K (-NA)

* For the 65K, only (-NA), (-G-NA), (-EC), and (-G-EC) are supported.

InverterInverterInverterInverterInverter

4) Inverters

Motors

1

OVERVIEW

3

Preparations for Startup

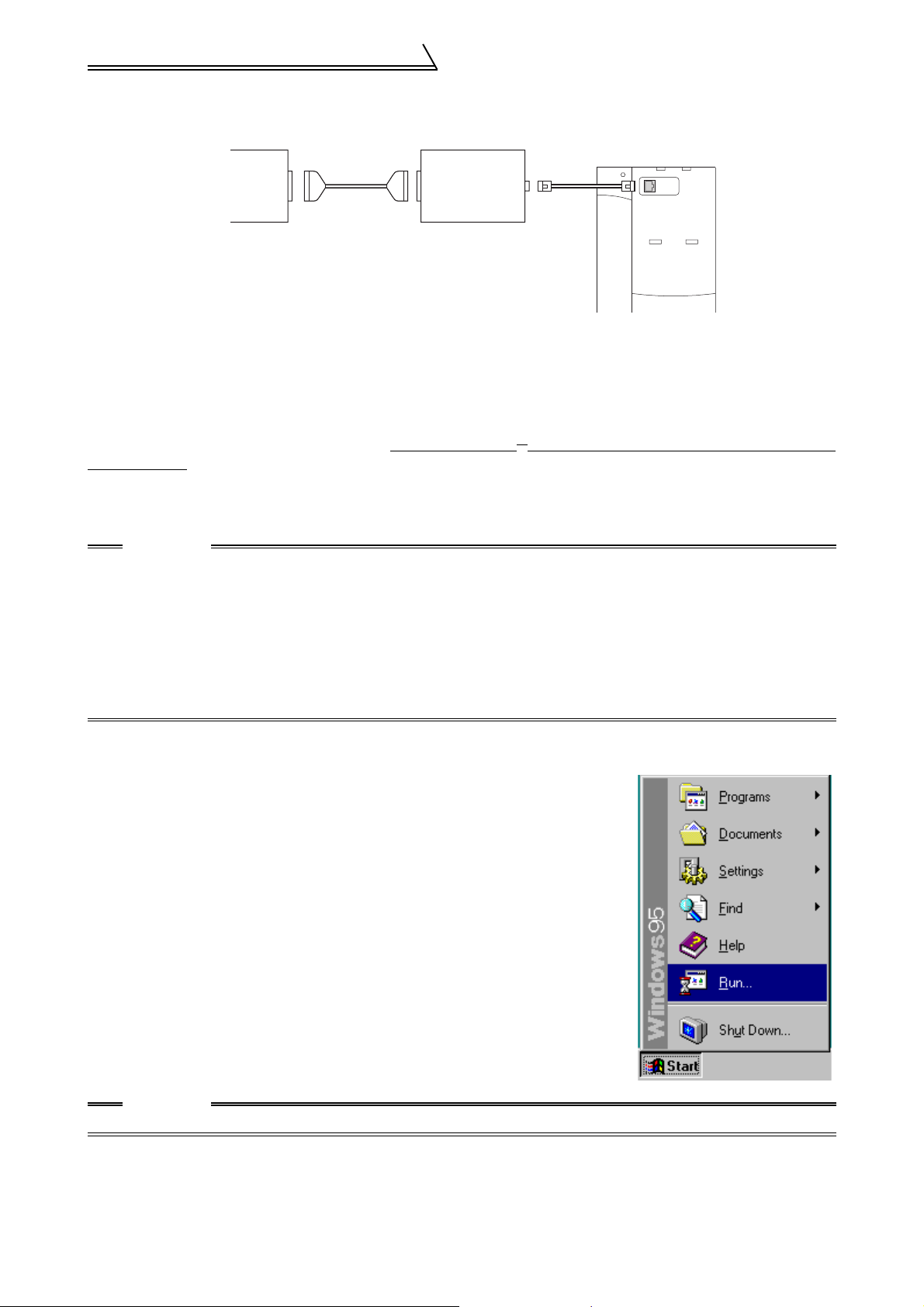

[Connection example between converter and inverter (PU connection port)]

Personal computer

RS-232C

port

RS-232C

cable

FA-T-RS40

(RS-232C-RS-485

converter)

RS-485

cable

Inverter

PU

connection

port

1.2.2 Installing the Setup Software

To use the VFD Setup Software (FR-SW1-SETUP-WE), the files included in the setup disks must be installed onto

the personal computer.

When using an old version inverter setup software, move the setting file you have created from the default folder

where the file is placed to another folder. Also, be sure to uninstall

setup software.

To install the VFD Setup Software, use the setup program (SETUP.EXE) on the Setup Disk (CD-ROM). The setup

program creates a directory on the specified hard disk and copies the required files.

CAUTION

1. Since the files in the Setup Disk are compressed, the VFD Setup Software will not operate by merely

copying the files. Always use the setup program to install the software.

2. Install the software in accordance with the Windows installation procedure.

3. When installing on Windows 95, be sure to install Microsoft DCOM95 for Windows 95, Version 1.3

before installing setup software. You can download DCOM95 for Windows 95, Version 1.3 from the following website of Microsoft Corporation. Note that URL is subject to variation.

http://www.microsoft.com/com/

4. For uninstallation, use [Uninstall] of the inverter setup software or [Setting] of the [Start] menu-[Add/

Remove Programs Properties] of [Control panel].

*4

the old version software before installing a new

•

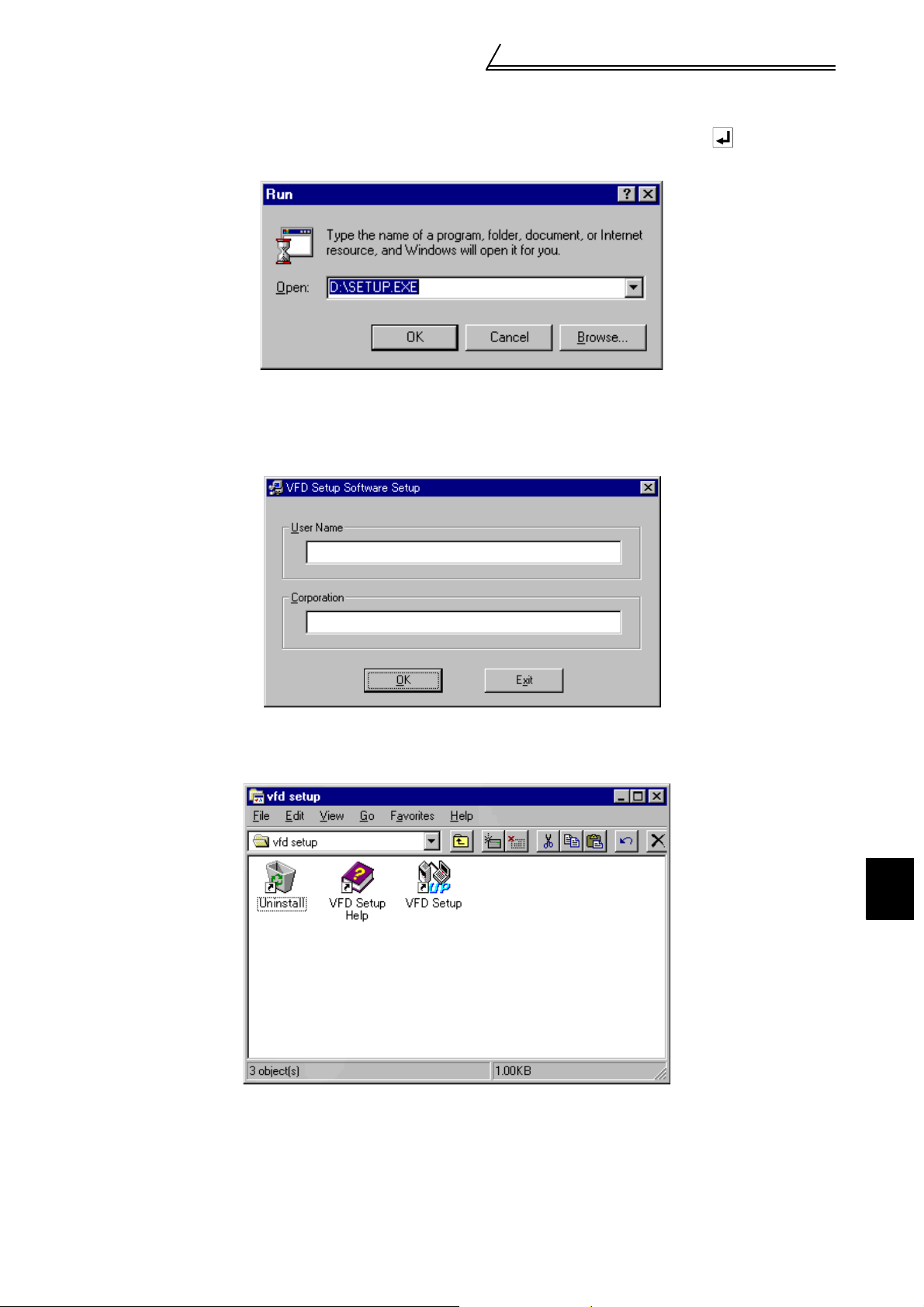

Installation procedure

Use the following procedure to register (install) the VFD Setup Software onto the

hard disk drive of the personal computer:

(1) Insert the CD-ROM into the CD-ROM drive.

(2) Press the [Start] button and choose the [Run] command.

CAUTION

Close any other applications that have already been started.

4

Preparations for Startup

(3) Running the installation program

1) The [Run] dialog box appears.

2) Type "D:\SETUP" (use half-size letters) in [Open] and click the [OK] button or press the key. (When the

CD-ROM drive is drive D)

3) After that, perform operation in accordance with the setup guide (screen).

(4) When file copying is over, the following screen appears. Always enter the user and company names and click

the [OK] button.

Installation is not completed unless the user and company names are entered.

(5) When installation is finished, the "Uninstall", "VFD Setup S/W" and "VFD Setup S/W Help" icons are registered

and the following screen appears.

1

OVERVIEW

5

MEMO

6

2

FUNCTIONS

This chapter describes the "functions" for use of this product.

Always read the instructions before using this software.

2.1 Starting the VFD Setup Software...................................8

2.2 Settings..........................................................................9

2.3 Parameter....................................................................14

2.4 Monitor.........................................................................20

2.5 Diagnosis.....................................................................33

2.6 Test Running................................................................35

2.7 Advanced Function......................................................37

2.8 Saving, Reading and Printing the Files........................42

2.9 Help .............................................................................43

1

2

3

4

7

Starting the VFD Setup Software

2.1 Starting the VFD Setup Software

Start the VFD Setup Software with "INVSUPE.EXE".

CAUTION

Start only one VFD setup software program.

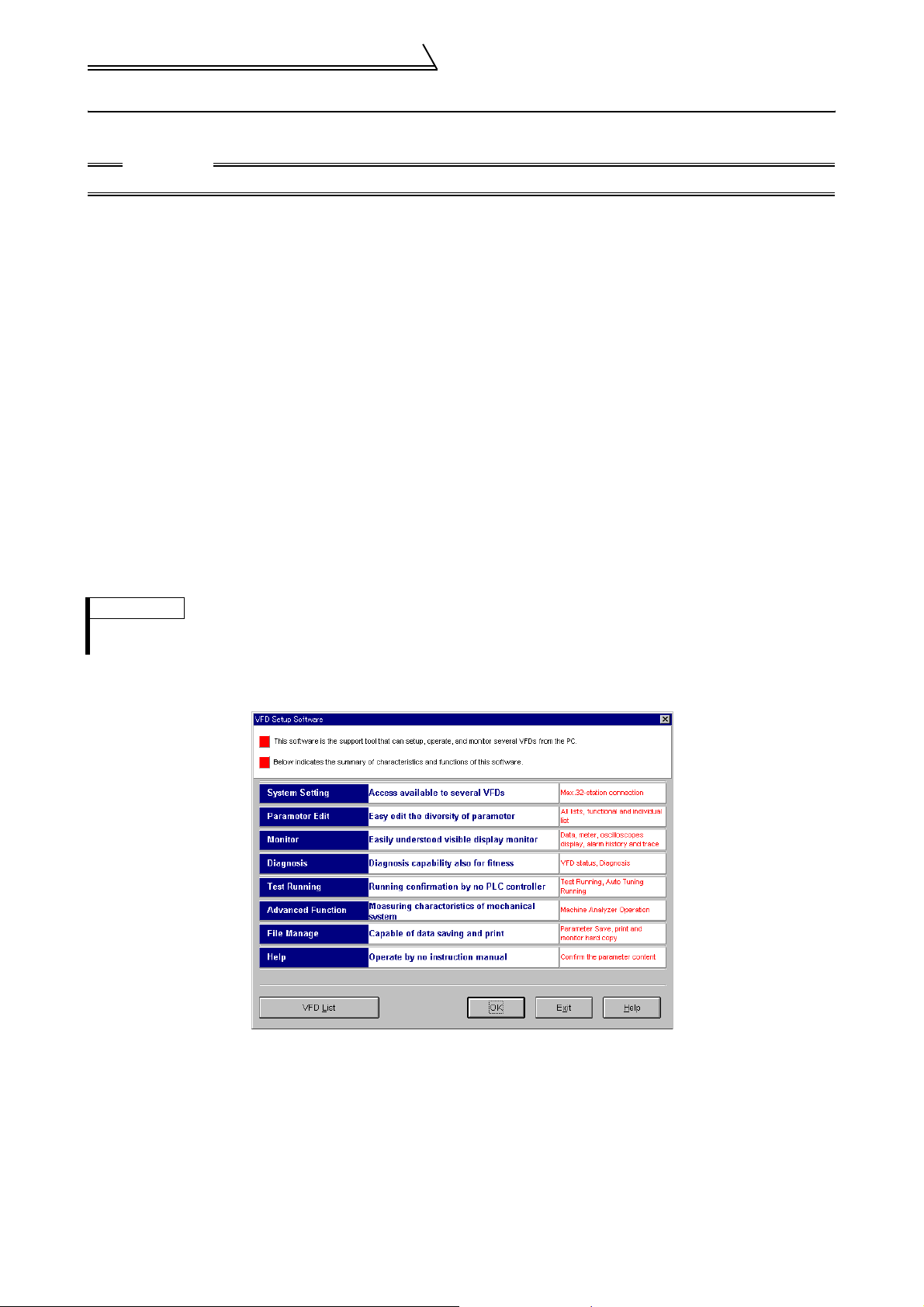

<Primary screen>

REMARKS

If check box "next time no disp." is checked, the above screen will not be displayed from the next time.

To display it again, check the check box "Display the initial screen", see section "2.2.3 Environmental Setting" (refer to page 13).

<Initial screen>

8

2.2 Settings

When you press the [OK] button on the initial screen, the following screen appears:

Settings

(1) Menu list

This software has the following functions:

Menu Pull-Down Menu Function/Operation

O

pen Ctrl+O Opens a file.

C

lose Closes the screen.

S

File

(Alt+F)

ettings

S

(Alt+S)

P

arameter

(Alt+P)

onitor

M

(Alt+M)

Diagn

osis

(Alt+N)

Test Running

(Alt+T)

Advanced function

(Alt+V)

indow

W

(Alt+W)

H

elp

(Alt+H)

ave Ctrl+S Saves data.

Save A

s Ctrl+A Save data with a new name.

P

rint Ctrl+P Selects printing.

Ex

it Performs exiting procedure.

S

ystem Settings Sets the model, capacity (size) and option type. (Stations 00 to 31)

Communicat

Environmental Settings

A

ll list Format Shows and sets the parameter list.

F

unctional List Format Shows and sets the related parameters function-by-function.

I

ndividual list Format

B

asic Settings

ata Display Shows four pieces of data (up to four stations) in terms of values.

D

M

eter Display Shows four pieces of data (up to four stations) in terms of meter deflections.

O

scilloscopes Shows four pieces of data (up to four stations) in terms of waveforms.

A

larm History Shows the alarm history of all inverter stations connected.

T

race Oscilloscopes Analyzes various types of data.

V

FD Status Shows various data of all stations connected in real time in terms of values.

Diagnosis

est Running

T

A

uto Tuning

achine Analyzer

M

C

ascade Display Overlapping Windows.

T

ile Display Windows are side-by-side.

ontents Various help functions (parameter explanations, function explanations, etc.)

C

About VFD Setup S/W

ion Settings Sets serial communication information.

1)

2) 3) 4)

5)

6) 7)

Sets the directory where data will be stored and sets re-display of the initial

screen.

You can register or delete a total of 32 parameters out of all parameters to

or from two different user groups.

You can set the parameters required for starting up the inverter without

being aware of parameter numbers.

Examine the estimated cause of the alarm in accordance with the alarm

display.

Gives the operation command from the personal computer to actually test

run the inverter.

Performs auto tuning in accordance with the motor connected to the

inverter.

Measures the response frequency characteristic of speed relative to the

motor torque of the machine.

Version information (copyright, version information, user and company

names, etc.)

8)

2

FUNCTIONS

9

Settings

(2) Description of various buttons and indications

1) Node

The station number selected is displayed.

2) [EX

T] (Alt+X), [PU] (Alt+U) and [LNK] (Alt+L) buttons

You can choose the inverter operation mode for online operation.

⋅ [EXT] button: External operation mode

⋅ [PU] button: PU operation mode

⋅ [LNK] button: Computer link operation mode

3) The operation mode and error codes appear. (Refer to page 46 for the error codes.)

Operation mode indications

⋅ EXT............................ External operation mode

⋅ PU.............................. PU operation mode

⋅ EXT JOG ................... External jog mode

⋅ PU JOG ..................... PU jog mode

⋅ LNK............................ Computer link mode

⋅ PU EXT...................... PU-external combined mode

⋅ TIME .......................... Time scheduled operation

⋅ SP.............................. Special mode

⋅ No Node..................... Time-out occurred in the online mode

In any other case, the error number at NAK error occurrence appears.

⋅ When an alarm occurs, the operation mode and error codes are displayed in red.

⋅ To display a warning, the operation mode and warning appear.

4) [O

NLINE/OFFLINE] (Alt+O) button

⋅ [ONLINE] (online) button: Online operation mode

⋅ [OFFLINE] (offline) button: Offline operation mode

Click the corresponding button to select the online or offline mode.

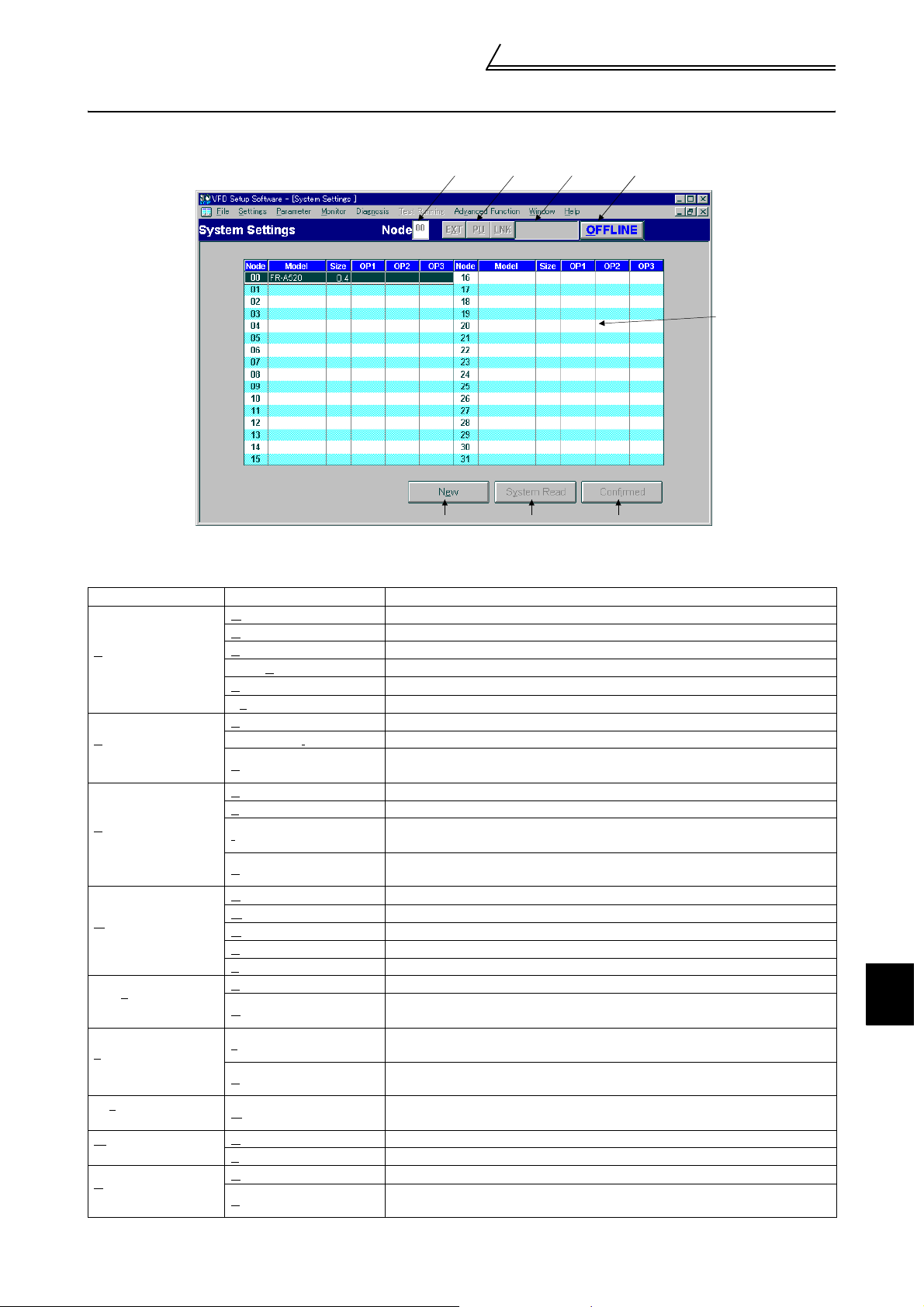

5) System settings

You can set the environment of the inverters of stations 00 to 31.

Set the model, capacity and options for these inverters.

6) [Ne

w] button (Alt+E)

Used to make new system settings.

7) [Sy

stem Read] button (Alt+Y)

Used to batch-read all inverters in the system with which the personal computer communicates.

8) [Confi

rmed] button (Alt+I)

You can register the data specified in the system settings. Always confirm the entry with the [Confirmed] button when you have changed the setting of the system configuration manually.

10

Settings

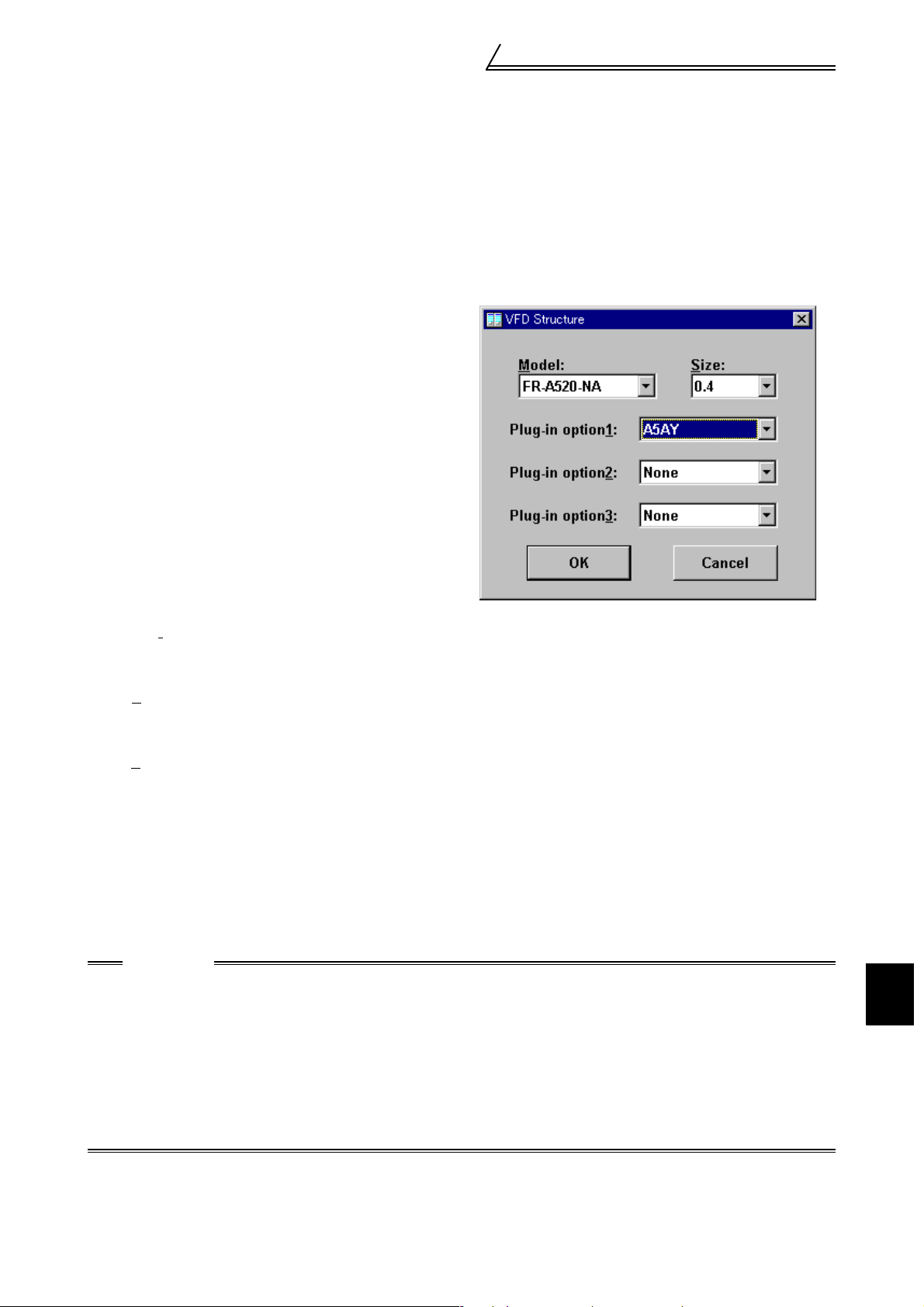

2.2.1 System Settings

This screen appears when you start this software and press the [OK] button on the initial screen.

On this screen, set the station numbers, models, capacities and plug-in options of the inverters connected. Inverters

can be set to stations 0 to 31.

(1) Station selection (Ctrl+N)

Click the required station number. That line is then chosen.

(2) Selection of model, capacity and options

When you double-click the selected line, the "VFD

Structure" panel (as shown on the right) appears. Set

the model, capacity and options and press the [OK]

button to complete the settings. Using the same procedure, set all inverter stations which connected.

(3) [Confi

After setting all stations, pressing the Confirmed button completes the system settings.

rmed] button (Alt+I)

(4) [New] button (Alt+E)

Press the New button to initialize (clear) the system settings/communication settings being edited.

(5) [System Read] button (Alt+Y)

Before pressing the [System Read] button, press the [ONLINE/OFFLINE] button to change the mode indication

to [ONLINE] and select the online operation mode. In the online operation mode, the personal computer is

switched to the inverter communication status and clicking the [System Read] button reads the models, capacities and options of all stations (stations 0 to 31) and displays the stations connected (with which the personal

computer can communicate).

After reading, the settings are registered automatically.

When the system settings have not yet been made, the read stations are displayed. When the system settings

have already been registered, check is performed. If the check result is different from the read data, select

whether different points are displayed and changed or not.

CAUTION

1. When the [Cancel] button is clicked during [System Read], the system setting made until then is verified.

2. • When the [System Read] button is pressed, the 100V or 200V class of the FR-E500 series is dis-

played as the FR-E520-NA, the 400V class as the FR-E540-NA.

• When the [System Read] button is pressed, the 100V class of the FR-S500 series as the 200V class.

• During [System Read] of the FR-F520 and the FR-F540(L), the models are displayed as the FR-F520-

NA and the FR-F540(L)-NA.

• During [System Read] of the FR-F540L-G-CH, the model is displayed as the FR-F540L-S-CH and the

capacity is the value one rank lower.

When the model and the capacity differ, change them manually.

2

FUNCTIONS

11

Settings

4

2.2.2 Communication Settings

The VFD Setup Software uses the serial port of the personal computer to control the inverters through serial

communication. Its communication settings must be the same as those of the inverter. (The initial values of the

setup software have been matched with the factory settings of the inverter.)

When you start this software, the initial screen appears. Pressing the [OK] button displays the system setting

screen. Choosing the [Settings] → [Communication settings] command on the menu bar. The screen then shows

the following dialog box, where various communication settings can be made.

Communication settings will be described below:

1)

2)

3)

)

5)

6)

7)

8)

(1) Screen explanations

The values in parentheses are initial values.

1) Co

mmunication Port (1)

Choose the communication port of the personal computer.

2) B

aud Rate (19200)

Set the communication speed.

3) Data L

4) P

5) S

6) D

7) I

8) T

ength (8)

Set the data bit length.

arity Check (Even)

Specify the parity bit.

top Bit (2)

Set the stop bit length.

elimiter (CR)

Specify the delimiter at the data trailer.

nterrogate Time [sec] (1)

Set the interval at which data transmission (operation mode indication and error check) is always made to

the inverter.

ime Out [msec] (1000)

Set the time from when data is transferred from the personal computer to the inverter until when the personal

computer receives a reply from the inverter. If a reply is not given after the preset time has passed, the "timeout" error is displayed.

The above set values depend on the inverter connected. Set them after confirming the set values of the

communication function parameters of the inverter.

(2) Button settings

1) [OK] button

Recognizes the settings on the communication screen and returns to the system setting screen.

2) [Cancel] button

Cancels the communication settings and returns to the system setting screen.

3) [Re

flect Default] button

Used to omit the setting of the values specified in communication settings from the next time onward.

4) [Default R

Used to read the default values. The value is as set with the [Reflect Default] button.

5) [Initial V

This button is used to return the communication setting to the initial value (factory setting of the inverter).

ead] button

alue] button

12

Settings

(3) Inverter communication settings

The values set for communication depend on the inverter and connection method.

Inverter Connection Method Operation mode Setting Range

FR-A520(-NA)

FR-A520L

FR-A540(-NA)

(-EC) (-CH)

FR-A540L (-NA)

(-G-NA) (-EC)

(-G-EC) (-S-EC)

(-S-CH)

FR-A560-NA

FR-A560L-NA

FR-F520 (-NA)

FR-F520L

FR-E520 (-NA)

FR-E520S (-EC)

(-CH)

FR-S520-R

FR-S520S-R

FR-S520S-ECR

(-CHR)

CAUTION

When making communication with the inverters, set a value other than 0 in Pr. 122 "communication

check time interval" on the inverter's operation panel. For the FR-A5NR, set any value other than 0 in Pr.

336 "communication check time interval", and for the FR-S500 series, set any value other than 0 in the

communication parameter n6 (336) "communication check time interval".

(Refer to the inverter instruction manual for the setting method.)

FR-F540 (-NA)

(-EC) (-CH)

FR-F540L (-NA)

(-EC) (-CH)

(-G-CH) (-S-CH)

FR-F720 (-NA)

FR-F740 (-NA)

(-EC) (-CH)

FR-V520

FR-V520L

FR-V540

FR-V540L (-NA)

FR-E510W (-NA)

FR-E540 (-NA)

(-EC) (-CH)

FR-S510W-R

FR-S540-R (-NAR)

(-ECR) (-CHR)

⋅ When PU

connector (RSPU connector

(RS-485 connector)

or

FR-A5NR

PU connector

(RS-485 connector)

RS-485 connector LINK mode

485 connector)

is connected PU

mode

⋅ When FR-A5NR

is connected

LINK mode

PU mode

[Node] Station 0 to 31

[Baud rate] 4800, 9600, 19200 bps

[Stop bit] 1 bit, 2 bits

[Data length] 7 bits, 8 bits

[Parity bit] None, odd, even

[Delimiter] None, CR, CR+LF

(4) Interrogate time

Set the interval at which data is always sent or received to or from the inverter.

It must be set to at least 2 seconds shorter than the communication check time interval setting of the inverter. If

its setting is longer than the communication check time interval setting, the inverter will come to an alarm stop.

CAUTION

The setting of short interrogate time may slow down the response of the menus and buttons on each

window depending on the operating model and communication speed.

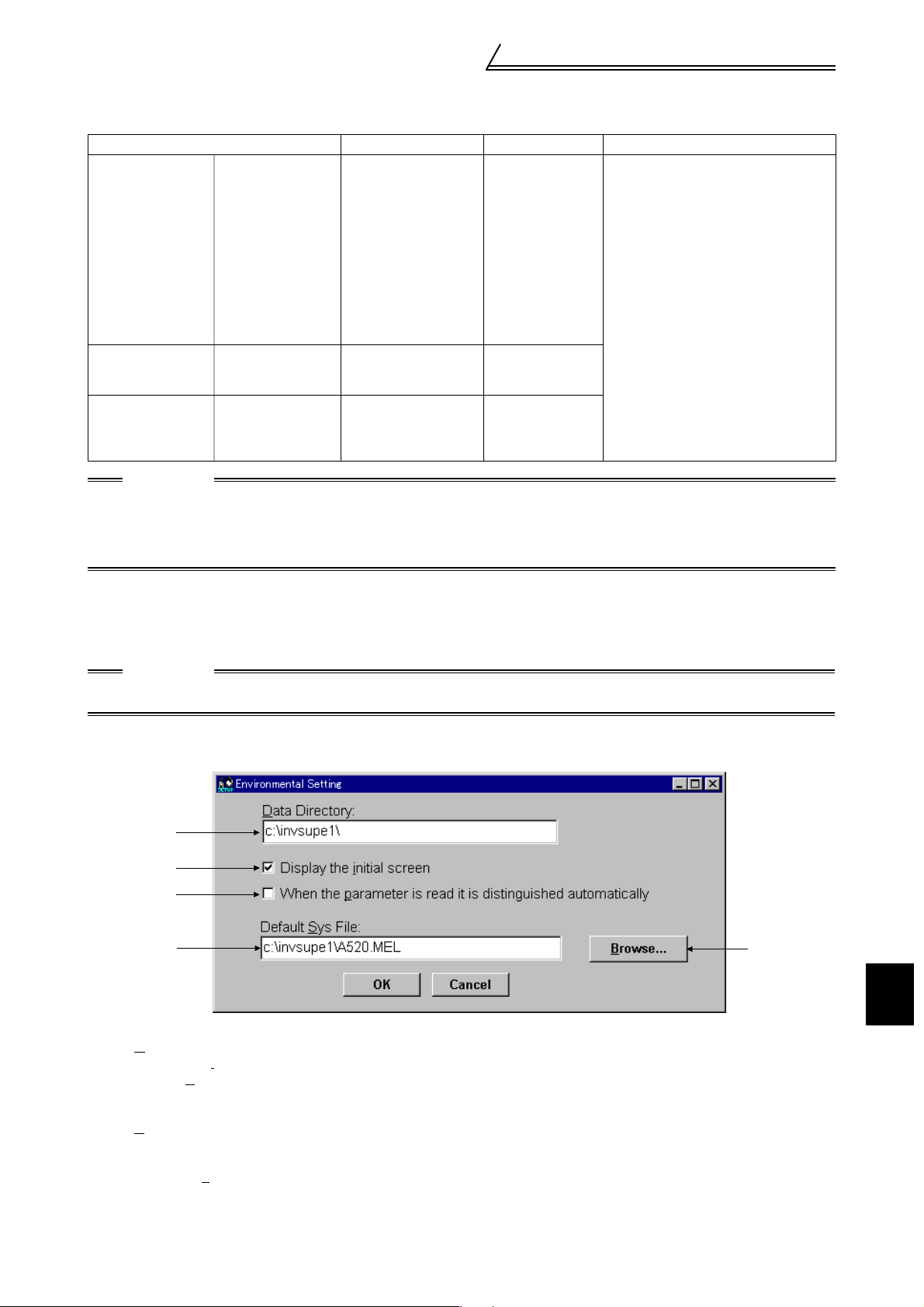

2.2.3 Environmental Setting

You can specify the data directory (place where data is saved) and default system file.

1)

2)

5)

3)

(1) Screen explanations

1) Data Directory..................................... You can change the directory where data will be saved.

2) Display the i

3) Default S

4) B

rowse................................................ Default system file browsing button.

5) When the p

distinguished automatical.........................Turn on the check box to hide the parameters read-disabled for parameter

nitial screen.....................Checking the check box displays the initial screen.

ys File .................................. Shows the system file (*.MEL) which is automatically set when

starting of the software.

There is no default registered.

Shows the file selection common dialog and displays the chosen file

name in the default system file text box.

arameter is read it is

batch-read or batch-verify from the error panel. (Refer to page 16)

4)

2

FUNCTIONS

13

Parameter

2.3 Parameter

When system settings are complete, you can choose menu parameters.

Choose the [Parameter] → [All List Format], [Functional List Format], [Individual List Format] or [Basic Settings]

command in the menu to select the corresponding format, and set parameters. Any parameter setting is changed by

first entering new data in the Updated column and then pressing the [Write] or [Blk Write] button. The new data is

then displayed in the Current setting column, which shows the current settings of the inverter.

2.3.1 All List Format

By choosing the [Parameter] → [All List Format] command in the menu, all parameters of the inverter are displayed

as a list. When changing any parameter setting, enter a new value in the required parameter column and press the

key to register it.

1) 2) 3)

4)

6) 7) 8) 9) 10) 11) 12) 13) 14)

(1) Buttons and indications common to various parameter setting screens

1) Node (Ctrl+N) ............................. Indicates the inverter station number to be set (only the station numbers

registered in the system settings may be selected.)

2) Inverter operation mode ............. Used to choose/display the operation mode of the selected inverter station

number.

3) O

nline/offline (Alt+O) .................. To read/write the parameter values of the inverter, select the online opera-

tion mode.

4) Setting Range............................. Indicates the setting range of the selected parameter.

5) Pr J

mp (Alt+J),

update

d Val (Alt+E)..................... Shows the number and new value of the selected parameter. Values may

be entered directly into these columns.

6) D

etail Information (Alt+D,F1) ...... Shows the function explanation of the selected parameter.

5)

14

Parameter

7) Change List (Alt+G) .................... Lists the parameters with the present set values which have been changed

from the initial values.

8) Parameter initialization (Alt+R)... Initializes the parameters of the inverter. (The communication parameters

are not initialized.)

Choose the clearing method from among "P

ser Clear" on the following panel and click the [OK] button to exe-

and "U

cute clear.

arameter Clear", "All Clear"

CAUTION

Changing the Pr. 21 setting automatically switches the minimum setting increments of the acceleration/

deceleration time-related parameters (Pr. 7, Pr. 8, Pr. 16, Pr. 45, Pr. 46, Pr. 110, Pr. 111, Pr. 264, Pr.265).

(Increments are 0.1s when Pr. 21=0, 0.01s when Pr. 21=1)

The acceleration deceleration time-related parameters differ according to the inverter. Refer to the

inverter manual for details.

9) Copy

10) B

11) R ea

12) Blk C

13) Blk

14) Wri

(Alt+Y) .................................. ⋅ System setting file (*.MEL)

Used to copy the parameter list as

a file to the inverter. Choose the

system setting file (*.MEL) and

click the [OK] button to display the

panel shown on the right. Making

selections at "Copy" and "Node"

and clicking the [OK] button reads

the parameter settings and sets

them to the Updated column.

Therefore, by performing block

write after that, they are copied to the inverter. (Parameter copy cannot be

made between different models.)

⋅Parameter setting file (*.PRM)

Choosing the parameter setting file (*.PRM) displays the present settings

in the Updated value field of the screen. (When only the present settings

are saved)

When there are both the present settings and updated values, display the

parameter copy panel (shown above) and select the values to be copied.

lk Read (Alt+B) ....................... Reads all parameters of the selected inverter station number.

d (Alt+A) ............................. Reads the data of the parameter numbers selected on the screen.

heck (Alt+C) ..................... Batch-checks the parameters of the inverter against those of the personal

computer.

write (Alt+K) ........................ Writes new parameter values to the inverter.

(When there are no values in the Updated value field, the screen for

selecting whether the present settings will be written or not appears. Perform operation following the screen prompts.)

te (Alt+I)............................... Writes the data of the parameter numbers selected on the screen.

2

FUNCTONS

15

Parameter

CAUTION

If an error occurred during "block read", "block check" or "block write", the parameter list appears on the

panel. Double-clicking the error number in the displayed list shows the details of the error definition on

the panel.

[When the p

Turning on this check box automatically judges the read-disabled parameters and hide them from the

read error panel.

arameter is read it is distinguished automatically]

16

Parameter

2.3.2 Functional List Format

By choosing the [Parameter] → [Functional List Format] command in the menu, the parameters are displayed as a function list.

For parameter setting and changing, values may only be written in the online operation mode.

When changing any parameter setting, enter a new value in the required parameter column and press the key to register it.

13)

11) 12)

1)

7)

14) 15) 16)

2) 3)

9)

8)

10)

4)

5)

(1) Various panel indications

• FR-A500(L)/F500(L)/E500/S500 series

1) Terminal allocation...................... Lists the parameters concerned with the control circuit terminals.

2) Magnetic flux vector.................... Lists only the parameters for magnetic flux vector control.

3) Intelligent .................................... Shows the parameters related to the intelligent mode in which the inverter

4) Calibration .................................. Lists the parameters related to the calibration of the FM and AM terminals

5) Option ......................................... Lists the parameters of the values related to the options.

6) Special running........................... Lists the parameters such as the functions used by making pre-selection.

7) Motor torque ............................... Lists the parameters related to motor torque.

8) Frequency settings ..................... Lists the parameters related to frequency.

9) Acceleration/deceleration ........... Lists the parameters related to acceleration/deceleration.

10) Protection.................................. Lists the parameters related to the protective functions.

11) Monitor ...................................... Lists the parameters related to the monitoring function.

12) Brake......................................... Lists the parameters related to braking.

13) Pr J

• FR-V500 series

1) Terminal allocation...................... Lists the parameters concerned with the control circuit terminals.

2) V/F control .................................. Lists only the parameters used to exercise V/F control.

4) Calibration .................................. Lists the parameters related to the calibration of the DA1 and DA2 termi-

5) Option ......................................... Lists the parameters of the values related to the options.

6) Special running........................... Lists the parameters such as the functions used by making pre-selection.

7) Motor .......................................... Lists the parameters related to the motor.

8) Speed setting.............................. Lists the parameters related to the speed.

9) Acceleration/deceleration ........... Lists the parameters related to acceleration/deceleration.

10) Protection.................................. Lists the parameters related to the protective functions.

11) Monitor ...................................... Lists the parameters related to the monitoring function.

12) Brake......................................... Lists the parameters related to braking.

13) Pr J

14) Speed control............................ Lists the parameters related to speed control.

15) Torque control ........................... Lists the parameters related to torque control.

16) Position control ......................... Lists the parameters related to position control.

mp (Alt+J),

Update

mp (Alt+J),

Update

d Val (Alt+E) .................. Show the selected parameter number and its new value. Values may be

d Val (Alt+E) .................. Show the selected parameter number and its new value. Values may be

performs operation after setting appropriate parameters automatically.

and the bias/gain adjustments of the frequency setting voltage (frequency

setting current).

entered directly into these columns.

nals and the bias/gain adjustment of the speed setting voltage (speed setting current).

entered directly into these columns.

6)

2

FUNCTONS

17

Parameter

2.3.3 Individual List Format

By choosing the [Parameter] → [Individual List Format] command in the menu, you can select two different user

groups ("User Group 1", "User Group 2").

To these user groups, you can register a total of 32 parameters from among all parameters. Click the [Edit Reg.]

button. The following panel appears.

(1) Description of individual list editing operation

1) Registration ................................. Choose the items to be registered in the "Parameter List" and press the

[Add>>>] button to register them to the "I

2) Deletion ....................................... Choose the items to be deleted in the "I

[<<<Delete] button to delete them.

ndividual List".

ndividual List" and press the

After choosing the parameters, pressing the [OK] button completes the user setting and displays the individually

selected list in the following panel. To save the individual list, choose the [File] → [Save] command from the

menu to save it.

18

Parameter

2.3.4 Basic Settings

Choosing the [Parameter] → [Basic Settings] command in the menu displays the following screen.

By entering data into the items shown on the screen, you can set the parameters without being aware of the parameter numbers.

(1) Setting of each specification

Set the specification of each item in the Specification column. When the [Click] button is provided, clicking it displays choices. Make selection and click the [OK] button.

60Hz is the maximum setting for operation speed.

(2) Registration of the specifications

After entering the specifications of all items, press the [Confirmed] button to register them. Pressing the [Confirmed] button displays the following panel.

By pressing the [OK] button, the parameters are set automatically and the new values of the parameters that

may be set automatically are displayed.

(3) Parameter setting

When the automatic settings of the parameters are registered, the following panel appears.

To write the new parameter values to the inverter, press the [Blk Write] button.

19

2

FUNCTONS

Monitor

2.4 Monitor

Choosing the [Monitor] - [Data Display], [Meter Display], [Oscilloscopes], [Alarm History] or [Trace Oscilloscopes]

command in the menu allows you to select the corresponding monitor item.

2.4.1 Data Display

Data Display shows four different signals (those of up to four stations) as numerical values in real time. The input

and output statuses of the control terminals can also be monitored.

Choosing the [Monitor] → [Data Display] command from the menu displays the following screen:

1) 2) 5) 6)

7)

4) 3)

Explanation of the buttons and indications

1) Node setting

You can enter the station number specified in "System Settings" or use the [ / ] button to choose the station number.

2) Display items

Choose the items to be displayed in the menu.

3) Start/Stop (Alt+A)

After pressing the [ONLINE/OFFLINE] button to display [ONLINE], click the [Start] button to start monitoring.

(The function of this button toggles depending upon the mode.)

Click this button during monitoring to stop monitoring.

4) Hold (Alt+D)

Clicking the [Hold

Click this button during holding to cancel hold.

5) Present value

Shows the real-time monitor value.

6) Maximum value

Shows the maximum value of the monitor value. Once monitoring is stopped, the maximum value is cleared.

7) I/O status

When you have chosen "Input Status" or "Output Status" in "Display Item", the I/O status (ON or OFF) is displayed. (ON: red, OFF: gray)

] button holds the data being monitored. In this state, the data can also be saved.

20

Monitor

2.4.2 Meter Display

Meter Display shows four different signals (those of up to four stations) as meters in real time. Meter Display

handles show only data which can be indicated by meter deflections.

Choosing the [Monitor] → [Meter Display] command shows the following screen:

Max Val.

Present Val.

1)

2)

Perform operation as with Data Display.

The meter scales are automatically adjusted. After the parameters are batch-read, they are set to the optimum values.

Panel display

1) Meter display

Shows monitor values on the meters.

The present value is indicated by the black pointer and the maximum value by the red pointer.

2) Meter full-scale

Shows the full-scale value of the meter display. It can be changed by entering a new value.

2.4.3 Oscilloscopes

Oscilloscopes show four different signals, which had been received from the inverter beforehand, as waveforms on

the personal computer screen.

Choosing the [Monitor] → [Oscilloscopes] command from the menu displays the following screen:

2

21

FUNCTIONS

Monitor

[Operating procedure]

1) Se

tting (Alt+E)

Pressing the [Settings] button shows the "Measurement Conditions" panel.

a. Choose the station number and measurement item.

b. Trigger signal setting

Choose the outside, inside or alarm trigger. For "Outside

Trigger", pressing the [Measurement Start] button starts measurement. For "Inside Trigger", since the signal from the

inverter is used as a trigger signal, set the station number

measurement signal, timing, trigger terminal and conditions.

For "Alarm Trigger", the alarm occurrence signal of the

inverter is used as a trigger signal. In this case, the trigger

settings valid are the station number and timing only.

[Timing] ...................... Choose the displayed data from among "Before", "During" and "After" the trigger

signal.

[Sampling Time] ......... Set the interval of importing data. (100 to 60000msec)

[Conditions] ................ Choose the "Rise" or "Down" timing when the trigger is activated.

c. After setting the measurement conditions, press the [OK] button. The screen returns to Oscilloscopes

and the station numbers and measurement items set appear.

2) Measurement sta

rt (Alt+A)

Press the [ONLINE] button. For "Inside Trigger", press the [Measurement Start] button to start the importing

of data. On a trigger condition match, waveforms are displayed on the screen. For "Outside Trigger", pressing the [Measurement Start] button starts the importing of data endlessly. After completion or (suspension),

press the [Play Back] button to display the data.

3) Sc

ale Change (Alt+C)

To change the vertical and horizontal axis scales of the displayed waveforms, press the [Scale Change] button to display the "Scale Change" panel, on which the scales are to

be changed.

The full-scale values on the vertical axes and time axes

(horizontal axes) of the displayed waveforms of the four

channels (four stations) can be changed.

Specify the sampling count as the unit for the time axis (horizontal axis).

(Reference) Time converting method

: [sampling count] × [sampling interval]

+ [personal computer processing time] + [data importing time]

4) Play B

ack (Alt+B)

You can play back the measured oscilloscope data.

a. By pressing the [Play Back] button after the end of measurement, the oscilloscope data can be played

back. When the waveforms are being displayed, the screen is blanked once and the waveforms are then

played back.

b. You can play back saved oscilloscope data. By choosing [File] → [Open] to read the data, the waveforms

appear (are loaded).

22

2.4.4 Alarm History

Alarm History displays the history of eight past alarms of all inverter stations connected.

Choosing the [Monitor] → [Alarm History] command from the menu displays the following screen.

3)

5) 4) 1)

Explanation of the buttons and indications

1) Block Read (Alt+B)

Press the [ONLINE/OFFLINE] button to show [ONLINE] and then click the [B

alarm history of all stations specified in the system settings.

2) Alarm History

Lists the station numbers specified in the system settings and their history of eight past alarms.

3) Alarm Explanation

Clicking the alarm display column in the alarm history list shows the explanation of that alarm.

4) Alarm C

Clicking the [Alarm C

5) VFD R

Clicking the [VFD R

lear (Alt+C)

lear] button clears the alarm history of the chosen station inverter.

eset (Alt+R)

eset] button resets the chosen station inverter.

lock Read] button to display the

Monitor

2)

23

2

FUNCTIONS

Monitor

A

2.4.5 Trace Oscilloscopes (for FR-V500 (L) series only)

The FR-V500 (L) series allows you to trace various data by setting Pr. 520 to Pr. 536 and Pr. 538.

Using the trace function of the setup software, you can set the parameters on the trace function setting screen and

analyze the traced data. The trace function is available for the FR-V500 (L) series only.

When using the trace function, the trace option unit T-TRC50 need to be fitted to the inverter. Install the trace option

unit T-TRC50 in Slot 1 of the inverter. If you install it in Slot 2 or 3, operation is not performed. The traced data are

stored in the memory of the trace option unit T-TRC50.

<Installation>

(1) Make sure that the input power of the inverter is OFF.

(2) Insert the option unit connector into the connector of the inverter securely. At this time, also insert the option fix-

ing holes securely.

Refer to the following diagram for the position of Slot 1. Push the option unit securely into the option fixing hook.

(3) Fix the two left and right places of the option unit to the inverter securely with the accessory mounting screws. If

the screw holes do not line-up, the connector may not have been inserted securely. Check for insecure insertion.

Trace option unit

ccessory screw

(2 pcs.)

Option side

connector

Inverter

(without cover)

Slot 1

Inverter side connector

Slot 2

Option fixing hook

Slot 3

The slots 1, 2, and 3 are provided

with an option fixing hook.

CAUTION

1. You cannot use more than one same option units.

2. Option error (E.OP1) is displayed if the inverter does not recognize the mounted option.

(1) Trace function oscilloscope screen

Choosing the [Monitor] → [Trace Oscilloscopes] command in the menu displays the following screen.

To use the trace function, you need to make trace function setting. Click the [Settings] button 14 to make trace

function setting. (Refer to page 27 for details of the trace function setting screen.)

1)

2)

13) 15)

12)

11)

14)

10)

9)

3)

7)

5)

8)

4)

6)

Trace function oscilloscope screen

24

Monitor

•Explanation of the buttons and indications

1) Channel setting indication

Shows a data name according of the setting of each channel. The indication is blanked when no data is set.

2) Screen spli

You can choose any of one to four way splits. (Initial setting: One way split)

3) Channel indication

Clicking the channel of the data you want to display shows the data assigned to the clicked channel.

4) Terminal signal indication

Clicking [ ] displays a list of terminal signals to enable setting. Unset signal names are blanked.

Up to four terminal signals can be displayed simultaneously.

The input/output terminal signals can be displayed only when the input/output terminal signal data are

included in the CH1 to CH10 data.

STF, STR, DI1, DI2, DI3, DI4, OH, RES DO1, DO2, DO3, ABC

5) CH signal screen/Terminal signal screen switchover

Clicking here alternates between the channel (CH) indication (3) and terminal signal indication (4).

6) Scroll

Clicking here shifts the whole screen left to right.

7) Scale adjustment

Click [ ]/[ ] to adjust the scale. The adjustable range is 50% to 400%. (Initial setting: 100%)

8) Data indication

Clicking [ ] and choosing the channel from the list displays on the screen the data value of the selected

channel at the point of the cursor A.

9) T

A/TB

Clicking [ ]/[ ] moves the cursor to the left/right. The time indication of the cursor A on the right hand side

of [T

10) Horiz

Clicking [ ]/[ ] changes the time unit of the horizontal axis. The changing range is 10ms to 500s. (Initial

setting: 20ms)

11) R

ead Data

Clicking [Read Data] starts data read. At the same time, the following screen also appears. Clicking "Cancel" stops data read and returns to the trace function oscilloscope screen.

t selection

Input terminal signals Output terminal signals

A] also varies with the movement of the cursor A. This also applies to the operation of the cursor B.

ontal axis time unit

12) Start Trace/Stop Trace

Clicking [Start Trace]/[Stop Trace] starts/stops a trace. (At this time, write "1" in Pr. 538 "trace start/stop

selection" for a start or "0" for a stop.)

13) Trace status indication

Shows the trace status. The trace status is monitored at intervals of 500ms.

Stop, waiting for pre-trigger, waiting for trigger,

during trace, trace completed

14) Se

Indication

tting

Clicking [Setting] displays the trace function setting screen.

25

2

FUNCTIONS

Monitor

15) Reference Data

Clicking [Reference Data] shows the data display reference value setting screen.

Clicking [ ]/[ ] varies the reference value setting. Clicking [OK] changes the data reference value. Clicking

"Cancel" stops the setting and returns to the trace function oscilloscope screen.

26

Monitor

4

(2) Trace function setting screen

By changing the set values on the trace function setting screen and writing them to the parameters, you can

change the parameter settings of the inverter. (Refer to page 28 for details of the parameters.)

CAUTION

The trace function setting screen is used to only set the parameter values and not to write them. Use the

parameter check screen to write them. Click [Parameter check]. (Refer to page 32 for details of the

parameter check screen.)

1)

)

5)

2)

3)

6)

8)

9)

7)

10)

Trace function setting screen

1) Function setting [Pr. 520 to Pr. 529]

Select the data of CH1 to CH10. The selected data are displayed.

You can assign one piece of data to two or more channels.

Selecting the data changes the Pr. 520 to Pr. 529 values.

2) Sample Ti

me [Pr. 530]

Vary the sampling period. (1 = 444s)

Varying the sampling period changes the Pr. 530 value.

3) Sample M

ode [Pr. 531]

Set the number of samplings made at one time. Increasing the sampling count limits the number of data that

can be traced.

Changing the sampling mode changes the Pr. 531 value.

4) T

rigger Signal 1 [Pr. 532]

A specific signal times the start and end of a trace.

Changing the trigger signal choice 1 changes the Pr. 532 value.

5) Trig

ger Signal 2 [Pr. 533]

When you have selected "Error (trigger signal choice 2)" in the trigger signal choice 1, select the error that

will output a trigger signal.

Changing the trigger signal choice 2 changes the Pr. 533 value.

6) Trigger L

evel [Pr. 534]

A trigger is enabled when the value of the data set in the trigger signal choice 1 reaches the set trigger level

on the trigger condition.

Changing the trigger level changes the Pr. 534 value.

7) Trigger conditions [Pr. 535]

Select whether a trigger will be enabled on the "leading edge" or on the "trailing edge".

Changing the trigger condition changes the Pr. 535 value.

8) P

re-trigger [Pr. 536]

Used to trace the data before trigger.

Specify the percentage of the trigger point on the assumption that the recording starting point is 0% and the

recording end point is 100%.

Changing the pre-trigger changes the Pr. 536 value.

9) V

iew Parameter

Clicking [View Parameter] shifts to the parameter check screen.

10) Cancel

Clicking [Cancel] cancels function changing and returns to the trace function oscilloscope screen.

2

FUNCTIONS

27

Monitor

(3) Parameter list

Parameter Name Setting Range Factory Setting

52

190 DO1 terminal function selection 0 to 8, 10 to 16, 20, 25 to 27, 30 to

191 DO2 terminal function selection 1

192 DO3 terminal function selection 2

195 ABC terminal function selection 99

520 Trace data CH1

521 Trace data CH2 2 (output current)

522 Trace data CH3 3 (output voltage)

523 Trace data CH4 4 (alarm display)

524 Trace data CH5 5 (set speed)

525 Trace data CH6 15 (input status (DI))

526 Trace data CH7 16 (output status (DO))

527 Trace data CH8 50 (U phase output current)

528 Trace data CH9 51 (V phase output current)

529 Trace data CH10 52 (W phase output current)

530 Sampling period 1 to 9998 1

531 Sampling count selection 1, 2, 3, 4 1

532 Trigger source selection 1 0 to 17, 22, 31 to 34, 9999 9999

533 Trigger source selection 2

534 Trigger level 600% to 1400% (*) 1000%

535 Trigger slope selection 0, 1 0

536 Pre-trigger 0 to 100% 85%

538 Trace start/stop selection 0, 1 0

PU/DU main display data

selection

0, 5 to 12, 17 to 20, 23,

24, 32 to 35, 38, 100

(5 to 12 are invalid for FR-PU04V)

37, 39 to 44, 96 to 99,

100 to 108, 110 to 116, 120,

125 to 127, 130 to 137,

139 to 144, 196 to 199, 9999

1 to 12, 15 to 20, 23, 24,

32 to 36, 50 to 56, 9999

0 to 23, 25, 26, 29 to 40,

46 to 48, 51, 52, 9999

0

0

1 (speed)

9999

REMARKS

1. *: In Pr. 534, set the trigger level value (-400% to 400%) plus 1000.

2. When Pr. 538 = "1", you cannot write any parameter values to Pr. 520 to Pr. 536.

3. You can write parameter values to Pr. 520 to Pr. 536 and Pr. 538 if Pr. 77 = "0".

(4) Parameter details

1. Trace status (Pr. 52, Pr. 190 to Pr. 192, Pr. 195)

The trace progress status, data output status and so on can be displayed on the DU/PU monitor and output to the

external output terminals.

⋅ Pr. 52 "PU/DU main display data selection"

When "38 (trace status)" is set in Pr. 52, the trace status is displayed on the FR-DU04-1/FR-PU04V.

Monitor Display Trace Status

0Stop

1 During pre-trigger

2 Waiting for trigger

3 During trace

4 Trace completed

REMARKS

• The trace status is displayed instead of the output voltage monitor of the DU/PU main monitor.

⋅ Pr. 190 to Pr. 192, Pr. 195 "output terminal function selection"

When you set "40 (positive logic) and 140 (negative logic)" (Y40 signal: trace status) in Pr. 190 to Pr. 192 and

Pr. 195, the trace status is output from the output terminals.

Y40 Signal

40

(positive logic)

OFF ON Stop, trace completed, during data output, data output completed

ON OFF During pre-trigger, waiting for trigger, during trace

140

(negative logic)

Trace Status

28

Monitor

2. Function setting (Pr. 520 to Pr. 529)

⋅ Pr. 520 to Pr. 529 "trace data CH1 to CH10" (1 to 12, 15 to 20, 23, 24, 32 to 36, 50 to 56, 9999)

Set the data to be traced. You can set the data of CH1 to CH10.

Setting Name Setting Name Setting Name

9999 No trace data CH setting 11 Output current peak value 33* Torque current command

1 Speed 12 Converter voltage peak value 34* Motor output

2 Output current value 15 Input status (DI) 35* Feedback pulse

3 Output voltage value 16 Output status (DO) 36* Torque monitor

4 Alarm display 17* Load meter 50 U phase output current

5 Set speed 18* Motor exciting current 51 V phase output current

6 Output frequency 19 Position pulse 52 W phase output current

7* Motor torque 20 Energization time 53* Torque current

8 DC bus voltage 23 Operation time 54 U phase voltage command value

9 Regenerati ve brake duty 24 Motor load factor 55 V phase voltage command value

10 Thermal l oad f actor 32* Tor que command 56 W phase voltage command value

CAUTION

*: Data that are made invalid under V/F control. If they are traced, correct values will not be displayed.

REMARKS

The data to be traced can be assigned to two or more channels.

3. Sampling setting (Pr.530, Pr.531)

⋅ Pr.530 "Sampling period" (1 to 9998)

Change the sampling period.

Sampling period

T

=

Pr.530

×

T=444 s

µ

⋅ Pr.531 "Sampling count selection" (1 to 4)

Set the number of samplings made at one time. Increasing the sampling count limits the number of data that

can be traced.

Pr. 531 Setting Sampling Count Number of Usable Channels

1360 10

2720 4

31080 2

41440 1

CAUTION

1. Set "9999" (no trace data CH setting) in Pr. 520 to Pr. 529 of any unused channel.

2. When Pr. 531 = "2 to 4", the operating channels have the priorities of CH1, CH2 ... and the channel that

has exceeded the number of usable channels does not operate.

4. Trigger source setting (Pr.532, Pr.533)

⋅ Pr.532 "Trigger source selection 1" (0 to 17, 22, 31 to 34, 9999)

A specific signal can be used to time the start and end of a trace.

When Pr. 532 = "1 to 10", set the trigger level in Pr. 534 and Pr. 535.

Setting Trigger Source Setting Trigger Source

9999 Error (all errors) 11 STF

0 Error (any error can be selected using Pr. 533) 12 STR

1 Trace data CH1 setting data 13 RES

2 Trace data CH2 setting data 14 DI1

3 Trace data CH3 setting data 15 DI2

4 Trace data CH4 setting data 16 DI3

5 Trace data CH5 setting data 17 DI4

6 Trace data CH6 setting data 22 OH

7 Trace data CH7 setting data 31 ABC

8 Trace data CH8 setting data 32 DO1

9 Trace data CH9 setting data 33 DO2

10 Trace data CH10 setting data 34 DO3

2

CAUTION

1. A trace start trigger is made valid when Pr. 538 = "1". To trace data again after a trace start trigger, set

"1" in Pr. 538.

2. When using the input/output terminal signal as a trigger source, set any of "11 to 17, 22, 31 to 34" in Pr.

532. Do not set the trace data CH1 to 10 (Pr. 520 to Pr. 529 = "15, 16"), to which the input status/output

status has been set, as a trigger source.

29

FUNCTIONS

Monitor

⋅ Pr.533 "Trigger source selection 2" (0 to 23, 25, 26, 29 to 40, 46 to 48, 51, 52, 9999)

Pr.532 "Trigger source selection 1" = When you selected "0 (error)", choose the error that will output the trigger

signal.

Setting Indication Code Setting Indication Code

9999 No error E.0 21 CPU error E.CPU

0 Overcurrent shutoff during acceleration E.OC1 22 Fan fault FN

1

2 Overcurrent shutoff during deceleration E.OC3 25 Excessive acceleration deviation detection E.OSD

3

4

5

6 Motor overload shutoff E.THM 31 Brake sequence error 3 E.MB3

7 Inverter overload shutoff E.THT 32 Brake sequence error 4 E.MB4

8

9 Undervoltage protection E.UVT 34 Brake sequence error 6 E.MB6

10 Brake transistor alarm detection E.BE 35 Brake sequence error 7 E.MB7

11

12 External thermal operation E.OHT 37 Operation panel power supply short circuit E.CTE

13 Stall prevention E.OLT 38 Lost output phase failure protection E.LF

14 Option alarm E.OPT 39 P12 alarm E.P12

15 Option slot 1 alarm E.OP1 40 Encoder phase error E.EP

16 Option slot 2 alarm E.OP2 46 Error 1 E.E1

17 Option slot 3 alarm E.OP3 47 Error 2 E.E2

18 Parameter storage device alarm E.PE 48 Error 3 E.E3

19 Parameter unit disconnection E.PUE 51 Error 6 E.E6

20 Retry count excess E.RET 52 Error 7 E.E7

5. Trigger level setting (Pr.534, Pr.535)

A trigger is enabled when the value of the data set in Pr. 532 "Trigger source selection 1" reaches the trigger level

set in Pr. 534 on the trigger condition set in Pr. 535.

This setting is made valid when Pr. 532 = "1 to 10".

Overcurrent shutoff during

constant speed

Regenerative overvoltage shutoff

during acceleration

Regenerative overvoltage shutoff

during constant speed

Regenerative overvoltage shutoff

during deceleration

Momentary voltage

interruption protection

Output side ground fault

overcurrent protection

E.OC2 23 Fin overheat E.FIN

E.OV1 26 Open cable detection E.ECR

E.OV2 29 Brake sequence error 1 E.MB1

E.OV3 30 Brake sequence error 2 E.MB2

E.IPF 33 Brake sequence error 5 E.MB5

E.GF 36 24VDC power output short circuit E.P24

REMARKS

Set the trigger level (Pr. 534, Pr. 535) when Pr. 532 = "1 to 10". However, the trigger level is made invalid when the channel

where "4: alarm display" is set to the trace data CH setting (Pr. 520 to Pr. 529) is used as a trigger source.

⋅ Pr.534 "

Trigger level" (-400% to 400%)

Refer to the following table for calculation of the trigger level.

Trigger Data

Speed Pr.55

Output current value Pr.56 Input status (DI) --- Feedback pulse 0×ffff/4

Output voltage value 400V/800V Output status (DO) --- Torque monitor Pr.866

Alarm display 1 Load meter Pr.866 U phase output current Rated current

Set speed Pr.55 Motor exciting current 4096/rating V phase output current Rated current

Output frequency 120 Position pulse 0× ffff/4 W phase output current Rated current

Motor torque Pr.866 Energization time 0×ffff/4 Torque current Rated current

DC bus voltage 500V/1000V Operation time 0× ffff/4

Regenerative brake duty 100% Motor load factor 100%

Thermal load factor 100% Torque command Rated current

Output current peak value Pr.56 Torque current command Rated current

Reference

Val ue

Trigger Data

Converter voltage peak

value

Reference

Value

400V/800V Motor output

Trigger Data

U phase voltage

command value

V phase voltage

command value

W phase voltage

command value

Reference

Value

Inverter

capacity

400V/800V

400V/800V

400V/800V

CAUTION

When setting the trigger level on the setup software, set it within the range -400% to 400%. When directly

setting the parameter (Pr. 534) of the inverter, set the calculated trigger level plus 1000 (600% to 1400%).

30

⋅ Pr.535 "Trigger condition"

Select whether a trigger will be enabled on the "leading edge" or on the "trailing edge".

Pr. 535 Setting Function

0 Trigger is enabled on the leading edge.

1 Trigger is enabled on the trailing edge.

Time

Trigger point

Trigger point

Monitor

Trigger data

Trigger level

(Pr.534)

Leading edge

(Pr.535=0) (Pr.535=1)

Trigger data

Trigger level

(Pr.534)

Trailing edge

6. Pre-trigger (Pr.536)

⋅ Pr.536 "Pre-trigger" (0 to 100%)

Used to trace the data before a trigger.

Specify the percentage of the trigger point on the assumption that the recording starting point is 0% and the

recording end point is 100%.

<Example>

Pr.536 = "85%"

Pre-trigger

85%

Trigger point

Recording length

Trace record

15%

Time

CAUTION

If a trigger occurs during a pre-trigger, the trigger signal is not made valid. The trigger signal is made

valid after the pre-trigger time zone has ended.

7. Trace start, stop (Pr.538)

⋅ Pr.538 "Trace start/stop selection"

Select the start or stop of a trace.

On completion of a trace, Pr. 538 is automatically set to "0".

Pr. 538 Setting Description

0 Trace stop/completion

1 Trace start

CAUTION

When "1" is set in Pr. 538, the previous trace data is deleted.

31

2

FUNCTIONS

Monitor

)

(5) Parameter check

1) 2)

3)

4

Parameter check screen

1) Present setting

Parameter value currently stored in the inverter.

2) Updated value

New parameter value set using the trace function.

3) OK

Checking the parameter setting and clicking [OK] writes that value to the parameter.

Completion of write returns to the trace function oscilloscope screen.

4) NG

Clicking [NG] returns to the trace function setting screen without write to the parameter being performed.

32

Diagnosis

2.5 Diagnosis

2.5.1 VFD Status

Choosing the [Diagnosis] → [VFD Status] command in the menu displays the following screen.

CAUTION

This command can be chosen in the online mode only.

VFD Status: Displays the output current, output voltage, DC link V, Regenerative brake duty, THM factor, Power on

Time and Running Time data of all inverter stations specified in the system settings in real time. The

data can also be locked by pressing the [Hold] button (Alt+D). The values displayed can be switched

between absolute value indication and % indication (Alt+V).

CAUTION

The FR-E500 series or FR-S500 series displays only the output currents/output voltages.

2.5.2 Diagnosis

Choosing the [Diagnosis] → [Diagnosis] command from the menu displays the following screen:

CAUTION

This command can be chosen in the online mode only.

Alarm

Diagnosis (Alarm): Click the [B

have occurred. By clicking the corresponding item, its comment appears.

•Alarm C

Clicking the [Alarm C

•VFD R

Clicking the [VFD R

lear (Alt+C)

lear] button clears the alarm history of the chosen station inverter.

eset (Alt+R)

eset] button resets the chosen station inverter.

lock Read] button (Alt+B) to batch-read the information of the inverters where alarms

33

2

FUNCTIONS

Diagnosis

No Alarm

Diagnosis (No Alarm): Shows the diagnosis items. When you choose the corresponding item, the panel appears.

Enter data in accordance with the display. As a result, the estimated cause, etc. is shown.

For diagnosing the running status, the online mode must be selected.

[Alarm occurrence in online mode]

If an inverter alarm has occurred in the online mode, the following panel appears:

Clicking the [Y

Clicking the [H

CAUTION

The above alarm panel appears only once in the online mode.

Once you have closed the alarm panel, it will not appear even during alarm occurrence. By changing the

online mode to the offline, then to the online again, however, the panel will appear again if an alarm has

occurred.

es] button shows the Diagnosis (Alarm) screen.

elp] button shows the alarm detail help.

34

Test Running

2.6 Test Running

2.6.1 Test Running

Choosing the [Test Running] → [Test Running] command from the menu displays the following screen.

CAUTION

This command can be chosen in the online mode only.

Operation procedure

1)Set the station number of the inverter to be run and the operation mode (PU or LNK (Link) operation).

2)Enter the running frequency (running speed for the FR-V500 (L) series) and press the key to confirm.

3)Click the [JOG FWD] (Shift+F5) or [JOG REV] (Shift+F6) button. The motor rotates while the button is being

pressed. The output frequency (speed for the FR-V500 (L) series), output voltage and output current are monitored on the screen.

CAUTION

1. If your inverter is the FR-E500 series, set any value other than "0" in Pr. 146 "frequency setting command selection".

2. When selecting [JOG REV (Shift+F6)] for the FR-S500 series, set "---" in Pr. 63 "STR terminal function

selection". Setting other than "---" does not enable [JOG REV (Shift+F6)].

3. The inverter stops if the F6 key is pressed and then released while the inverter is running with [JOG

FWD (shift+F5)].

Likewise, the inverter also stops if the F5 key is pressed and then released during running with [JOG

REV (shift+F6)].

2.6.2 Auto Tuning

Choosing the [Test Running] → [Auto Tuning] command from the menu enables auto tuning. You have to set the

auto tuning parameters in advance. If they have not been set, the following screen appears:

2

35

FUNCTIONS

Test Running

<Operation procedure>

1) Set the station number of the inverter to be run and the operation mode (PU or LNK (Link) operation).

2) Confirmation of the auto tuning parameters

Clicking the [Check] button (Alt+C) shows the parameters on the screen in a dialog box.

After entering all parameter set values, click the [Blk

inverter.

3) Click the [FWD

The LED block and monitor screen display the auto tuning status.

When Pr. 96 = "101", the motor is rotated. The motor stops on completion of auto tuning. If the auto tuning

has failed, follow the dialog box instructions.

CAUTION

1. In the offline mode, test running and auto tuning cannot be performed.

2. Before starting test running, check and if necessary adjust the parameters. Not doing so may cause

some machines to perform unexpected operation.

3. Provide safety backup devices such as emergency brakes to ensure that the machinery and equipment are not put in hazardous conditions if the inverters become faulty.

4. Auto tuning is not available for the FR-F500 (L) series and FR-S500 series. (Can be displayed on the

screen.)

] (Alt+D) or [REV] (Alt+R) button.

Write] button to write the new parameter values to the

36

Advanced Function

2.7 Advanced Function

2.7.1 Machine analyzer (for FR-V500 (L) series only)

Machine analyzer reads and analyzes the torque and speed data available when the inverter oscillates the motor at

random torque for about 0.5 to 4 seconds.

This allows measurement of the response frequency characteristic of speed relative to the motor torque of the

machine so that you can grasp the frequency at which the mechanical system has the resonance point.

CAUTION

1. The machine analyzer function is available for only the system that can perform PLG vector control

with the FR-V500 (L) series.

2. The machine analyzer function is not performed in any of the following cases.

⋅ During inverter operation

⋅ When the second motor is selected (Pr. 450 ≠ "9999")

⋅ When the control mode is other than the PLG vector control mode (Pr. 800 ≠ "0 to 5")

(1) Machine analyzer screen

Choosing the [Advanced function] → [Machine analyzer] command in the menu displays the following screen.

Before starting machine analyzer operation, set the oscillation conditions and oscillation mode.

2)

3)

4)

1)

5)

6)

Machine analyzer screen

•Various buttons, status indications

1) Waveform data

Frequency characteristic measurement results are displayed in the board chart (gain, phase).

2) Start

Used to start Machine analyzer.

3) Stml C

4) Stml Mod

5) Resonance point, opposite resonance point cursors

6) Y-axis Scale Optimiz

ondition

Set the oscillation conditions for Machine analyzer.

e

Set the oscillation mode for Machine analyzer.