TRANSISTORIZED INVERTER

INSTRUCTION MANUAL

PARAMETER UNIT

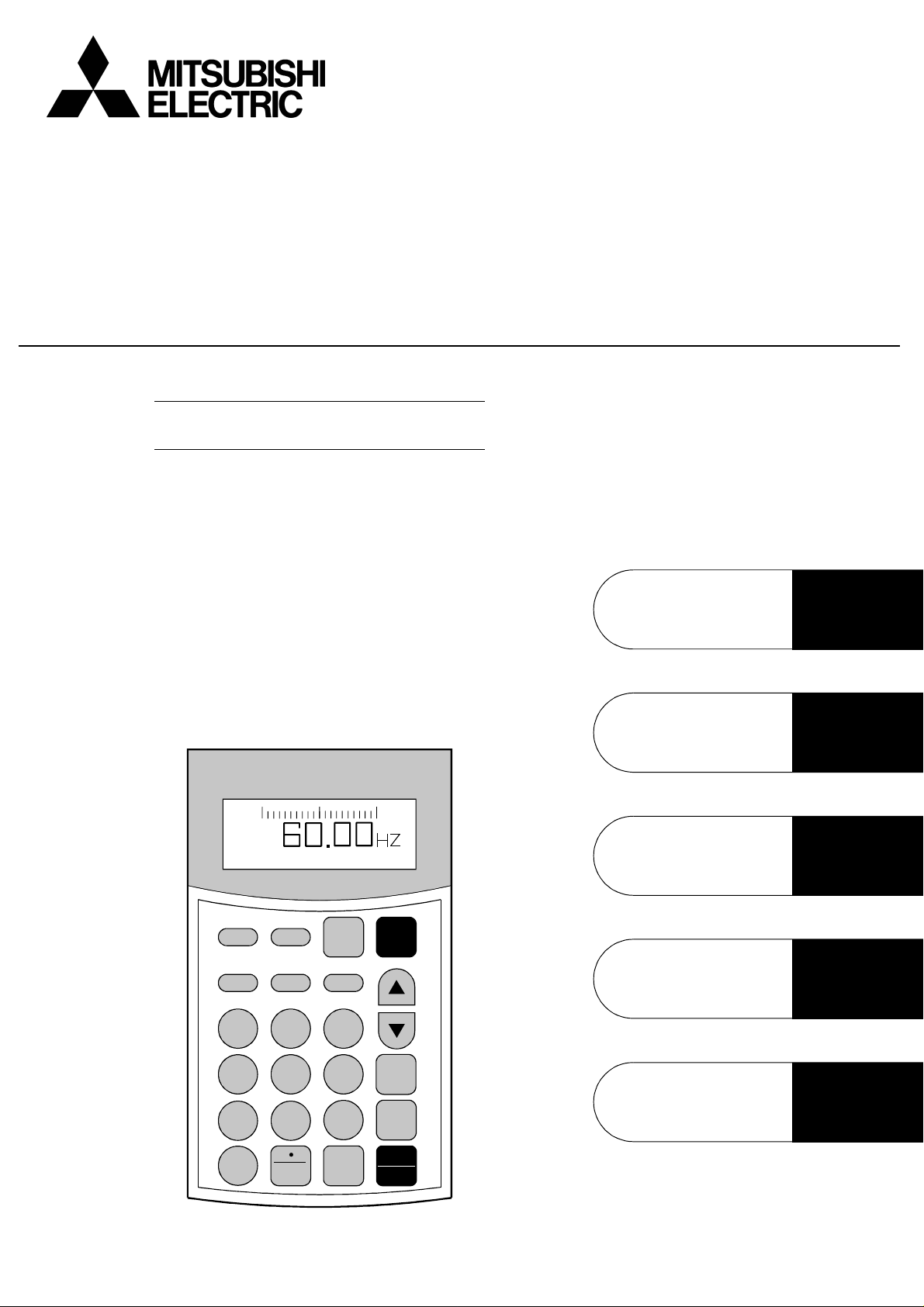

FR-PU04

FR-PU04

STF FWD PU

SETMON

789

PARAMETER UNIT

EXT

ESCHELP SHIFT

PU

PRE-OPERATION

INFORM ATI ON

FUNCTIONS

HELP

OPERATION

Chapter 1

Chapter 2

Chapter 3

Chapter 4

456

12

0

READ

WRITE

FWD

3

RESET

REV

STOP

SPECIFICATION

Chapter 5

Thank you for choosing the Mitsubishi transistorized inverter option unit.

This instruction manual gives handling information and precautions for use of this

equipment. Incorrect handling might cause an unexpected fault. Before using the

equipment, please read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This instruction manual uses the International System of Units (SI). The measuring

units in the yard and pound system are indicated in parentheses as reference

values.

This section is specifically about safety matters.

Do not attempt to install, operate, maintain or inspect this product until you have

read through this instruction manual and appended documents carefully and can use

the equipment correctly. Do not use this product until you have a full knowledge of

the equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into "WARNING"

and "CAUTION".

Assumes that incorrect handling may cause hazardous

WARNING

CAUTION

Note that the

to conditions. Please follow the instructions of both levels because they are

important to personnel safety.

CAUTION

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may

cause physical damage only.

level may lead to a serious consequence according

A - 1

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

! Do not run the inverter with the front cover removed. Otherwise, you may access

exposed high voltage terminals or charging devices and get an electric shock.

! Any person who is involved in the wiring or inspection of this equipment should

be fully competent to do the work.

! Always install the inverter before wiring. Otherwise, you may get an electric

shock or be injured.

! Operate the keys with dry hands to prevent an electric shock.

2. Additional Instructions

To prevent injury, damage or product failure, please note the following points.

(1)

Transportation and mounting

CAUTION

! Do not install and operate the parameter unit (FR-PU04) if it is damaged or has

parts missing.

! Do not stand or rest heavy objects on this equipment.

! Check the inverter mounting orientation is correct.

! The parameter unit (FR-PU04) is a precision device. Do not drop it or subject it

to impact.

! Use the product under the following environmental conditions:

Environment Conditions

Ambient tem perature -10°C to +50°C (non-freezing)

Ambient humidit y 90%RH or less (non-condensing)

Storage temperature -20°C to +65°C *

Ambience

Altitude, vibration

* Temperatures applicable for a short time, e.g. in transit.

Indoors (free from corrosive gas, flammable gas, oil mist, dust

and dirt)

Max. 1000m above sea level, 5.9m/s

JIS C 0040)

2

or less (conforming to

A - 2

(2)

Test operation and adjustment

CAUTION

! Before starting operation, confirm and adjust the parameters. A failure to do so

may cause some machines to make unexpected motions.

(3)

Usage

WARNING

! The

! Make sure that the start signal is off before resetting the alarm. A failure to do so

! Do not modify the equipment.

STOP

key is only valid when function setting has been made. Provide an

RESET

emergency stop switch separately.

may restart the motor suddenly.

CAUTION

! When parameter clear or all parameter clear is performed, each parameter

returns to the factory setting. Re-set the required parameters before starting

operation.

(4)

Corrective actions for alarm

CAUTION

! Provide safety backup devices, such as an emergency brake, to protect

machines and equipment from hazard if the parameter unit (FR-PU04) becomes

faulty.

(5)

Disposal

CAUTION

! Treat as industrial waste.

(6)

General instruction

All illustrations given in this manual may have been drawn with covers or safety

guards removed to provide in-depth description. Before starting operation of the

product, always return the covers and guards into original positions as specified

and operate the equipment in accordance with the manual.

A - 3

- CONTENTS -

1 PRE-OPERATION INFORMATION 1

1.1 Overview....................................................................................................................1

1.1.1 Appearance and parts identification...................................................................... 1

1.1.2 Explanation of the keys......................................................................................... 1

1.2 Installation and Removal............................................................................................ 3

1.2.1 Installation............................................................................................................. 3

(1) Installation to the inverter

-NA -EC -CHS500

(2) Using the connection cable (FR-CB2) for connection................................................3

1.2.2 Removal................................................................................................................ 4

(1) Removal from the inverter

-NA -EC -CHS500

(2) Removal when the connection cable (FR-CB2) is used............................................4

1.3 Parameters to Be Checked First................................................................................ 5

1.3.1 PU display language selection (Pr. 145)............................................................... 5

1.3.2 PU buzzer control (Pr. 990)................................................................................... 5

1.3.3 PU contrast adjustment (Pr. 991).......................................................................... 5

A500

A500

F500

-CHF500J

-CHF500J

C500

F500

C500

-NA -EC -CHE500

...........................................................3

-NA -EC -CHE500

...........................................................4

Contents

2 FUNCTIONS 6

2.1 Monitoring Function.................................................................................................... 6

2.1.1 Display overview................................................................................................... 6

(1) Main monitor............................................................................................................. 6

(2) PU level meter

-CHF500J

(3) Rotation direction monitoring....................................................................................6

(4) Operating status indication........................................................................................6

(5) Operation mode indication........................................................................................7

(6) Unit indication ...........................................................................................................7

(7) Alarm indication........................................................................................................7

2.1.2 Using the

2.1.3 Setting the first priority screen (first screen).......................................................... 8

2.1.4 Using the

SHIFT

HELP

A500

C500

key to change the main screen.................................................... 8

key to change the main screen

-NA -EC -CHE500

2.1.5 Using the “PU main display data selection parameter” to change the screen..... 10

F500

................................................................................................6

-NA -EC -CHS500

-NA -EC -CHE500

A500

-CHF500J

F500

C500

-NA -EC -CHS500

....................... 9

I

2.2 Frequency Setting.................................................................................................... 11

2.2.1 Direct setting....................................................................................................... 11

2.2.2 Step setting......................................................................................................... 11

2.2.3 Precautions for frequency setting........................................................................ 12

2.3 Setting and Changing the Parameter Values........................................................... 13

2.3.1 Direct setting....................................................................................................... 13

2.3.2 Step setting......................................................................................................... 14

2.3.3 Function-by-function parameter setting

-NA -EC -CHS500

2.3.4 User parameter registration and deletion

-NA -EC -CHS500

(1) Confirmation ...........................................................................................................16

(2) Registration.............................................................................................................17

(3) Deletion...................................................................................................................18

2.3.5 Precautions for setting write................................................................................ 18

2.4 Calibration of the Meter (Frequency Meter).............................................................. 19

2.4.1 Calibration of the FM terminal

-NA -EC -CHS500

2.4.2 Calibration of the AM terminal

-NA -EC -CHS500

2.5 Adjustment of the frequency setting signals "bias" and "gain" ................................. 23

2.5.1 Adjustment procedure

-NA -EC -CHS500

(1) Adjust only the bias and gain frequencies and not adjust the voltage ..................... 24

A500

-CHF500J

-CHF500J

A500

-CHF500J

-CHF500J

F500

-CHF500J

A500

C500

C500

F500

C500

F500

C500

C500

A500

........................................................ 15

A500

........................................................ 16

........................................................ 19

........................................................ 20

........................................................ 23

F500

F500

-NA -EC -CHE500

-NA -EC -CHE500

-NA -EC -CHE500

-NA -EC -CHE500

-NA -EC -CHE500

(2) Any point is adjusted with a voltage applied across terminals 2-5........................... 26

(3) Any point is adjusted without a voltage applied across terminals 2-5......................28

2.6 Copy and Verify Functions....................................................................................... 30

2.6.1 Copying the parameter settings.......................................................................... 30

2.6.2 Verifying the parameters..................................................................................... 31

3 HELP 32

3.1 Overview of the Help Functions ............................................................................... 32

3.1.1 Help function menu............................................................................................. 32

3.1.2 Help function display data................................................................................... 33

3.2 Operation Procedures for the Help Functions.......................................................... 36

II

3.2.1 Monitor function................................................................................................... 36

3.2.2 Selection of PU operation (direct input)............................................................... 38

3.2.3 Selection of the PU jog operation mode

-NA -EC -CHS500

(1) Calling from the help function menu........................................................................39

(2) Calling the key operation guide directly...................................................................39

-CHF500J

C500

A500

........................................................ 39

F500

-NA -EC -CHE500

3.2.4 Parameters.......................................................................................................... 40

(1) "2 Pr. List"...............................................................................................................41

(2) Display of "3 Set Pr. List"

-NA -EC -CHS500

(3) Display of "4 Def. Pr. List"

-NA -EC -CHS500

(4) Display of "5 Def. Pr. List 2"

-NA -EC -CHS500

A500

A500

A500

F500

-CHF500J

-CHF500J

-CHF500J

C500

F500

C500

F500

C500

-NA -EC -CHE500

.........................................................42

-NA -EC -CHE500

.........................................................42

.........................................................42

-NA -EC -CHE500

3.2.5 Parameter Clear.................................................................................................. 43

3.2.6 Alarm History....................................................................................................... 44

3.2.7 Alarm Clear......................................................................................................... 45

3.2.8 Inverter Reset...................................................................................................... 46

Contents

3.2.9 Troubleshooting

-CHF500J

(1) Troubleshooting guidance....................................................................................... 48

3.2.10 Selectop

A500

-CHF500J

C500

C500

A500

F500

F500

............................................................................................ 47

-NA -EC -CHE500

............................................................................................ 51

-NA -EC -CHE500

-NA -EC -CHS500

-NA -EC -CHS500

3.2.11 Option................................................................................................................ 52

3.3 Other Precautions.................................................................................................... 53

3.3.1 Precautions for parameter unit operation............................................................ 53

(1) Precautions for the digit count and decimal point of input value.............................. 53

(2) Other indications.....................................................................................................53

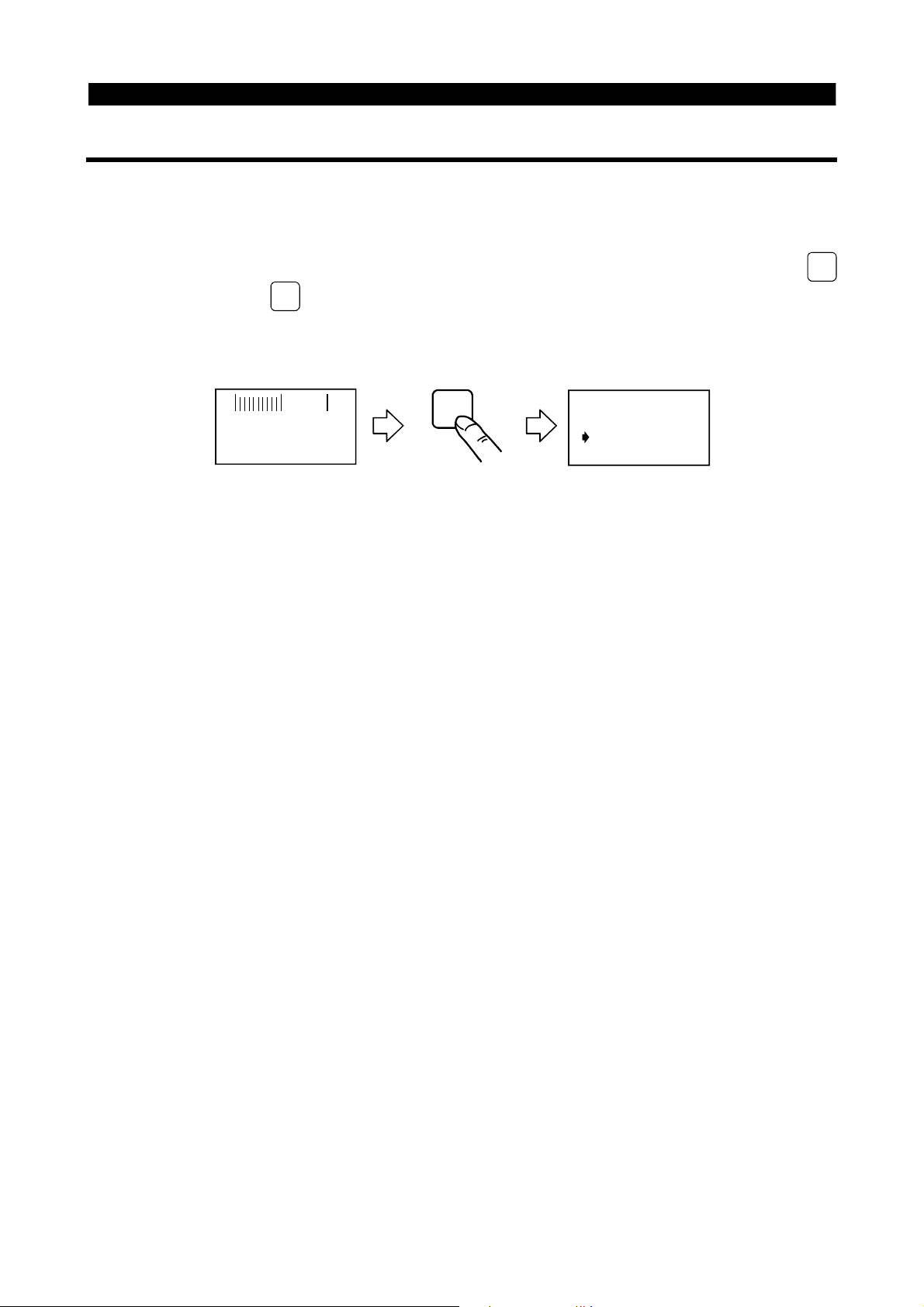

(3) Power-on indication.................................................................................................53

4 OPERATION 54

4.1 Operation Modes...................................................................................................... 54

4.1.1 How to select the operation mode....................................................................... 54

(1) Switching from external operation mode [EXT] to PU operation mode [PU]....................54

(2) Switching from PU operation mode [PU] to external operation mode [EXT] ......................... 54

(3) Switching to the external / PU combined operation mode.......................................54

4.2 PU Operation ........................................................................................................... 56

III

4.2.1 Ordinary operation............................................................................................... 56

4.2.2 PU jog operation

-CHF500J

4.3 Combined Operation (Operation using external input signals and PU).................... 58

4.3.1 Entering the start signal from outside and setting the running frequency from the

PU (Pr. 79=3)...................................................................................................... 58

4.3.2 Entering the running frequency from outside and making start and stop from the

PU (Pr. 79 = 4).................................................................................................... 59

4.3.3 Entering the start signal and multi-speed signal from outside and setting multiple

speeds from the PU ............................................................................................ 60

C500

A500

............................................................................................ 57

F500

-NA -EC -CHE500

-NA -EC -CHS500

5 SPECIFICATION 61

5.1 Specifications........................................................................................................... 61

5.1.1 Standard specifications....................................................................................... 61

5.1.2 Outline drawing................................................................................................... 62

5.1.3 Panel cutting drawing.......................................................................................... 62

IV

CHAPTER 1

PRE-OPERATION

INFORMATION

This chapter provides the basic "pre-operation information

(overview)" for use of this product.

Always read the instructions before using the equipment

1.1 Overview.....................................................................1

1.2 Installation and Removal.............................................3

1.3 Parameters to Be Checked First.................................5

The FR-PU04 can be used with the Mitsubishi transistorized

inverters. However, there are restrictions on some functions

depending on the model.

Note that the following representations are used in this

manual.

A500 F500

Usable Unusable Unusable Usable

E500

-NA -EC -CH

S500

-NA -EC -CH

UnusableUsable

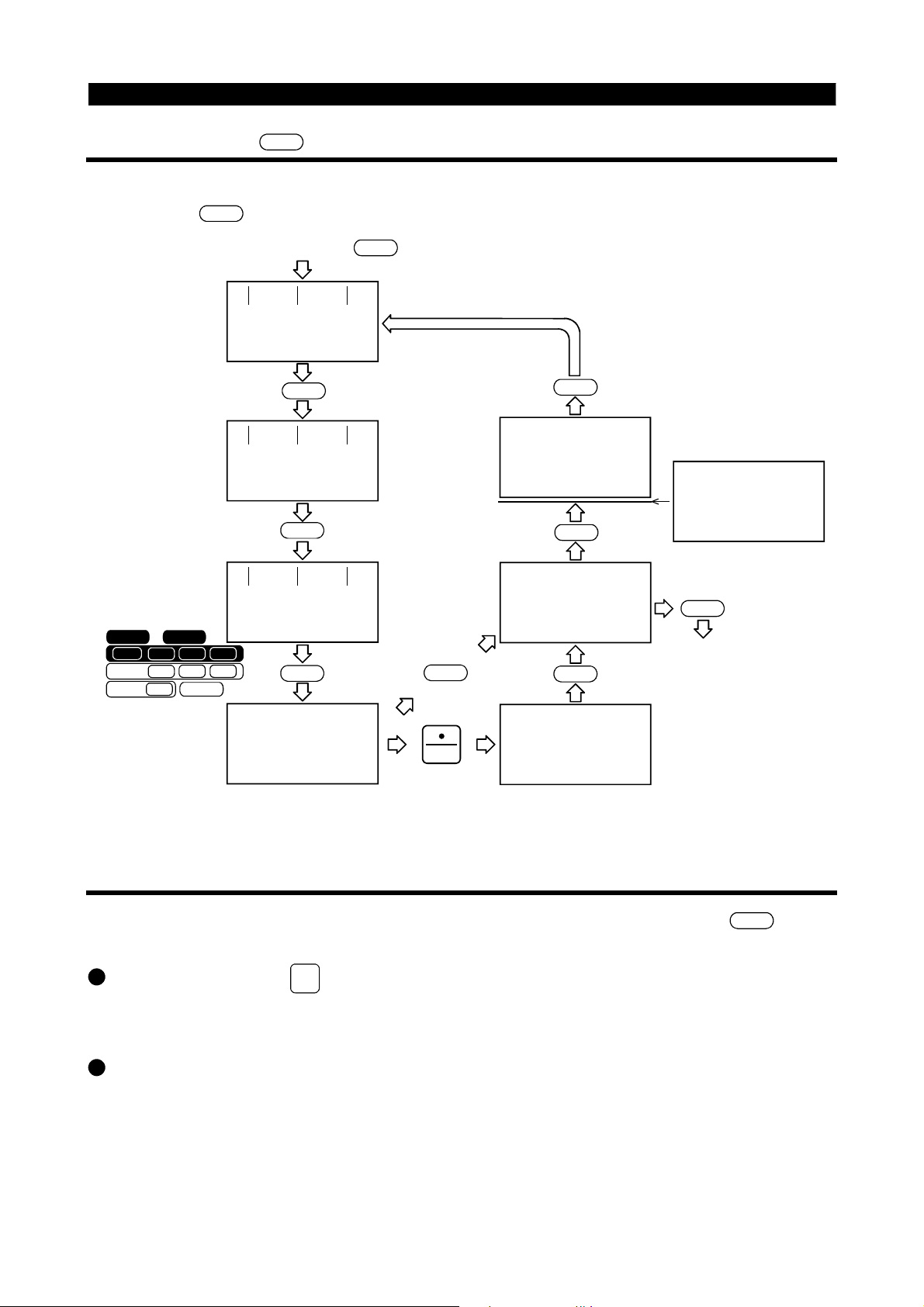

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

1.1 Overview

y

PRE-OPERATION INFORMATION

1 PRE-OPERATION INFORMATION

1.1 Overview

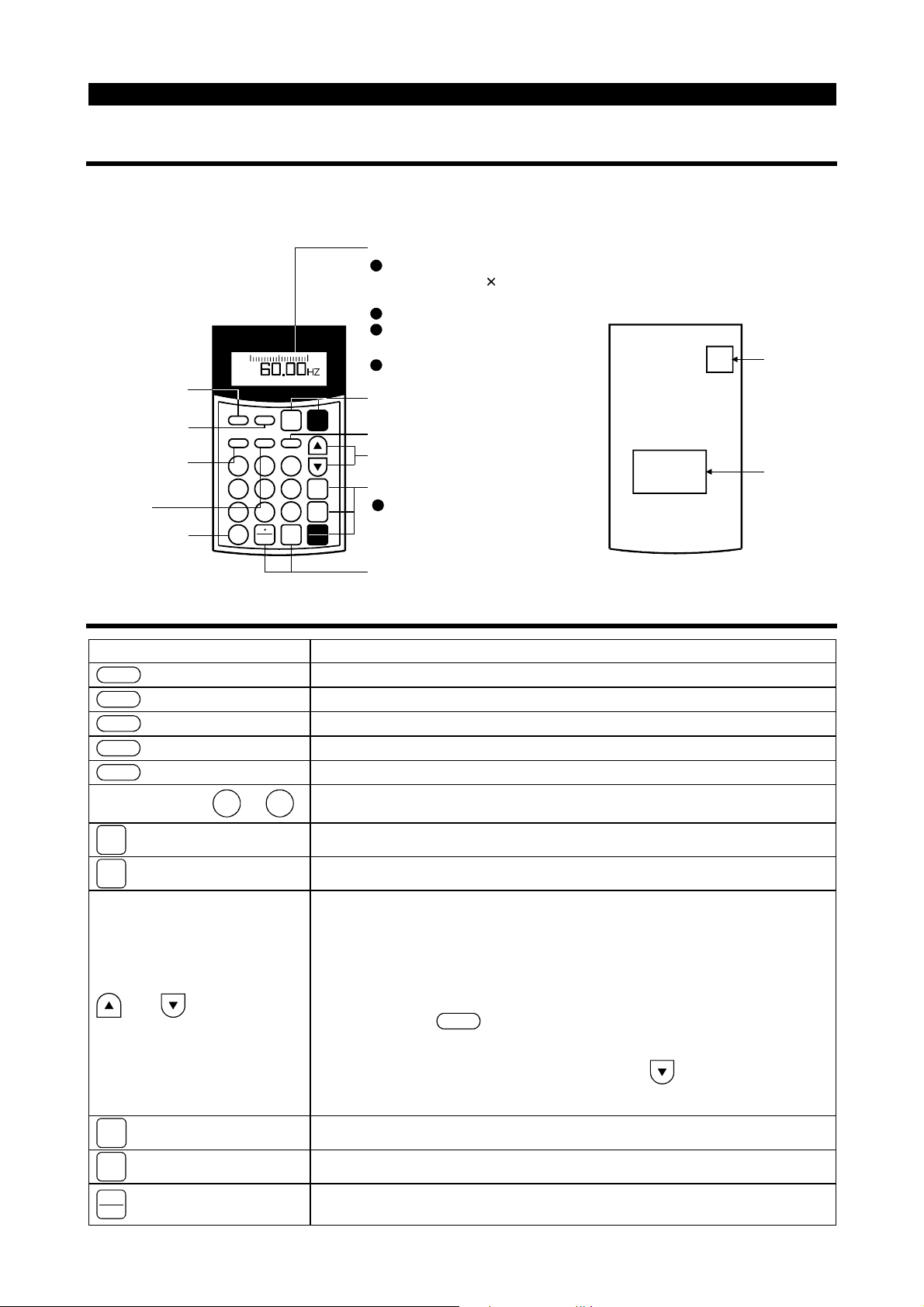

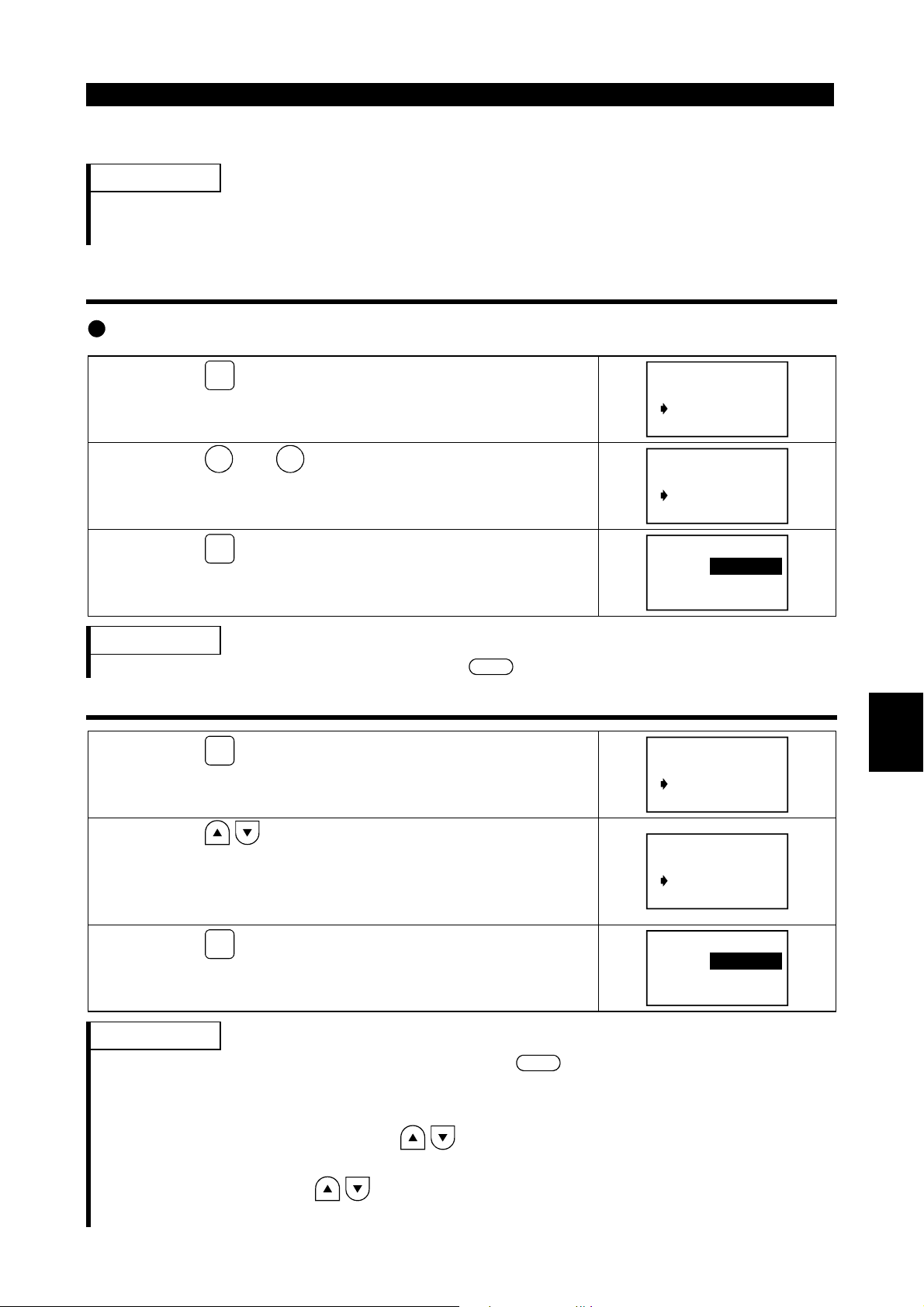

1.1.1 Appearance and parts identification

Unpack the parameter unit from the carton, check the name plate on the back, and

make sure that the product has not been damaged before using the equipment.

Monitor section

Wide liquid crystal screen

(13 characters 4 lines,

with backlight)

Interactive parameter setting

Monitor mode

selection key

Setting mode

selection key

Help mode

selection key

Shift key

Function and

number keys

(0 to 9)

FR-PU04

7

4

1

0

PARAMETER UNIT

STF FWD PU

SETMON

EXT

ESCHELP

SHIFT

89

56

23

WRITE

READ

PU

FWD

REV

STOP

RESET

Help function, troubleshooting

guidance.

21 different monitor data

(frequency, current, power, etc.)

Operation mode selection key

Escape key

Frequency changing keys

Operation command keys

Keys used to command

forward rotation, reverse

rotation and stop (reset at

alarm occurrence).

Write, read ke

s

Connector

Model

1.1.2 Explanation of the keys

Key Description

SET

key

MON

key

ESC

key

HELP

key

SHIFT

key

Number keys (0 to 9)

EXT

key

PU

key

and keys

Used to select the parameter setting mode.

Used to display the main monit or.

Operation cancel key.

Used to select the help mode.

Used to shift to the next item in the setting or m onitoring mode.

Used to enter a frequency, parameter number or set value.

Used to select the external operation mode.

Used to select the PU operation mode.

Used to keep on increasing or decreasing the running

frequency. Hold down to vary the frequency.

Press either of these keys on the setting mode screen to change

the parameter setting sequent ially.

On the monitoring, parameter or help menu screen, t hese keys

are used to move the cursor.

Hold down the

advance or return the display screen one page.

SHIFT

key and press either of these keys to

FWD

REV

STOP

RESET

key

key

key

In the parameter copy or verify mode, the

key is used as a

verify k ey.

Forward rotation command key.

Reverse rotation command key.

•

Stop command key.

•

Used as a reset key when an alarm occurs.

1

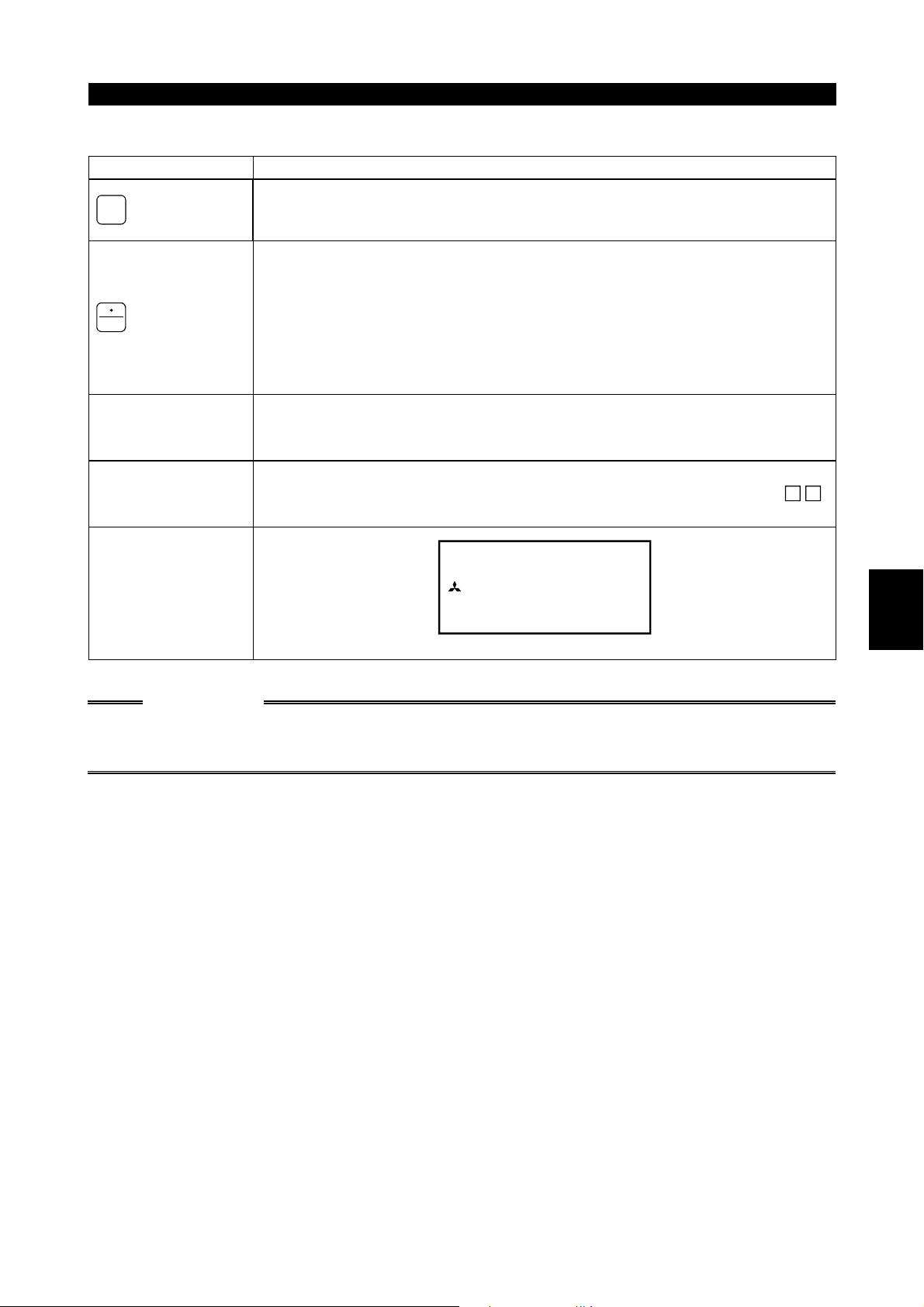

Key Description

WRITE

key

key

READ

Display

Connector

PRE-OPERATION INFORMATION

• Used to write a set value in the setting mode.

• Used as a clear key in the all parameter clear or alarm history clear

mode.

Used also as a decimal point key.

Used as a parameter number read key in the setting mode.

Used as an item select key on the m enu screen such as parameter list

or monitoring list.

Used as an alarm definition display key in the alarm history display

mode.

Used as a command voltage read key in the calibration mode.

13 character × 4 line liquid crystal display screen shows monitoring

data, such as frequency, motor current and I/O terminal states, as well

as troubleshooting guidance and other information.

Used for connection of the parameter unit with the inverter. You may

either connect the unit directly or use the connection cable (FR-CB2 )

for connection.

FR-PU04

Model

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

CAUTION

1.Do not use a sharp-pointed tool to push the keys.

2.The display is a liquid crystal display. Do not press your fingers against the display.

1

2

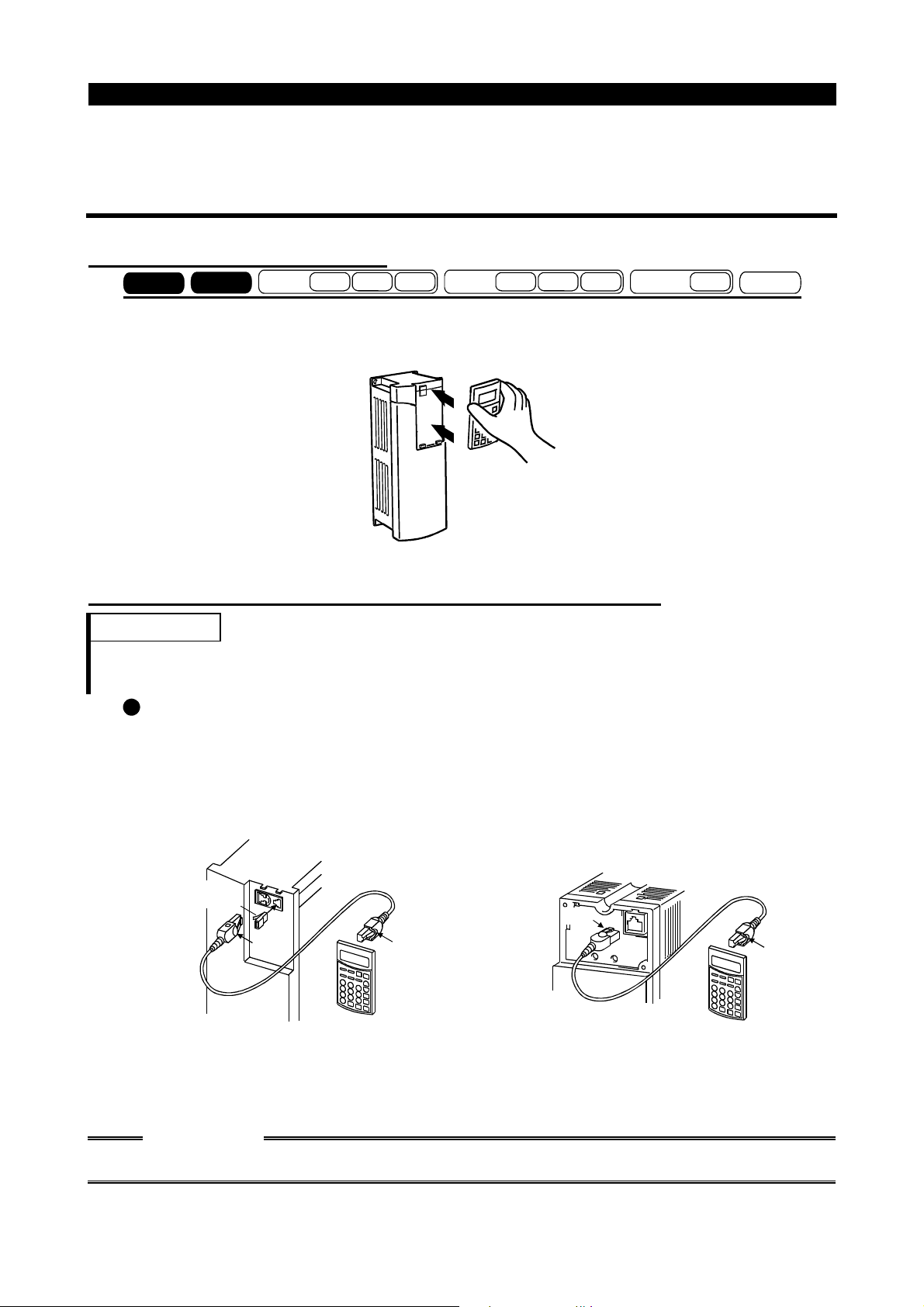

1.2 Installation and Removal

PRE-OPERATION INFORMATION

1.2 Installation and Removal

To ensure safety, install and remove the parameter unit after switching the power off.

1.2.1 Installation

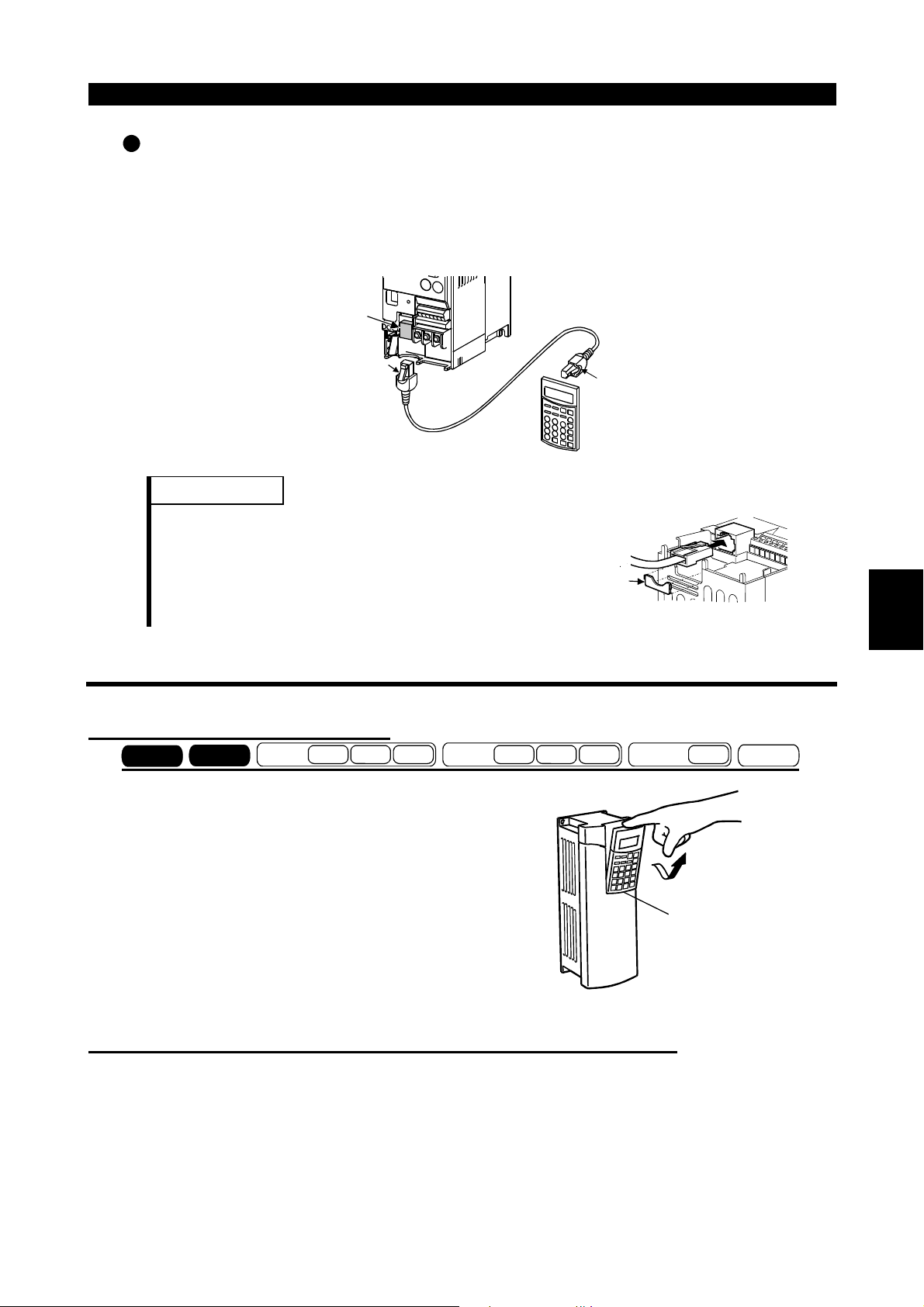

(1) Installation to the inverter

A500

1) Remove the operation panel (FR-DU04) and accessory cover.

2) Insert the parameter unit straight and fit it securely.

F500

-NA -EC -CHE500

-NA -EC -CHS500

-CHF500J

C500

(2) Using the connection cable (FR-CB2) for connection

REMARKS

For details of the connection cable (FR-CB2), refer to the connection cable (FR-CB2)

instruction manual.

When connecting to the FR-A500/ F500/ E500 series.

1) Remove the operation panel.

2) Insert the cable plugs securely into the connectors of the inverter and

parameter unit (FR-PU04) along the cable guides until the stoppers are

actuated.

Joint connector

Tab

Tab

Tab

Tab

FR-A500 / F500 series. FR-E500 series.

CAUTION

Install the operation panel only when the front cover is installed.

3

PRE-OPERATION INFORMATION

When connecting to the FR-S500/ F500J/ C500 series.

1) Remove the front cover.

2) Insert the cable plugs securely into the connectors of the inverter and

parameter unit (FR-PU04) along the cable guides until the tabs snap into

place.

connector

Tab

REMARKS

You can cut off the hook of the wiring cover

to perform the wiring.

You can insert or pull the connector with

the front cover installed.

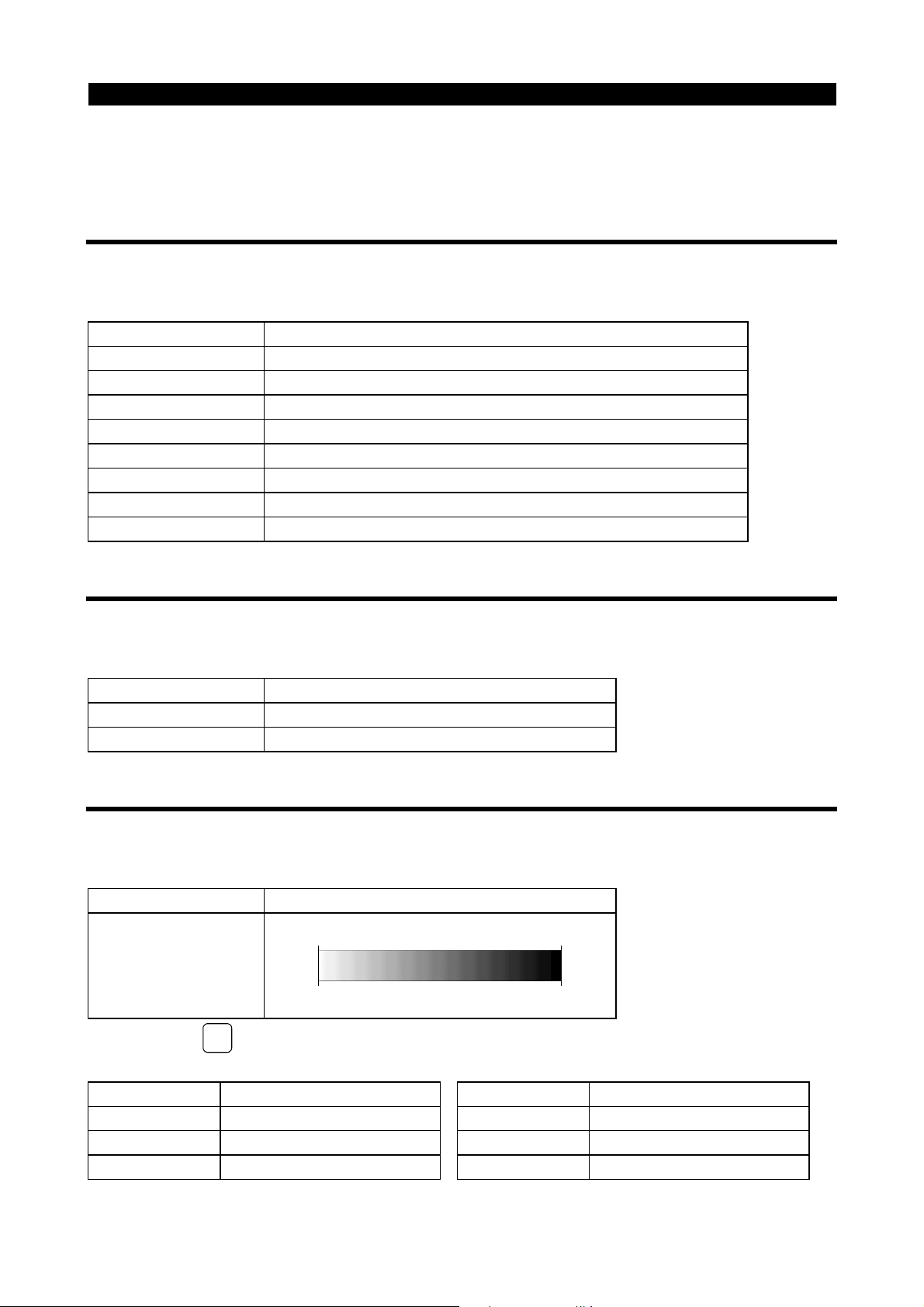

1.2.2 Removal

(1) Removal from the inverter

A500

Hold down the top button of the FR-PU04

F500

-NA -EC -CHE500

Tab

hook

1

-NA -EC -CHS500

-CHF500J

C500

and pull the parameter unit toward you,

using the catches as a support.

(2) Removal when the connection cable (FR-CB2) is used

Hold down the tab at the cable end and gently pull the plug.

4

Catches

1.3 Parameters to Be Checked First

k

PRE-OPERATION INFORMATION

1.3 Parameters to Be Checked F irst

Change the following parameter settings as required.

For the changing procedures, refer to page 13.

1.3.1 PU display language selection (Pr. 145)

By setting the Pr. 145 "PU display language selection" value, you can select the

language displayed on the parameter unit.

Pr. 145 Setting Display Language

0 Japanese (factory setting of Japanese domestic version)

1 English (factory setting of NA version)

2German

3 French

4 Spanish

5 Italian

6 Swedish

7 Finnish

1.3.2 PU buzzer control (Pr. 990)

By setting the Pr. 990 "PU buzzer control" value, you can select to either generate or

mute the "beep" which sounds when you press any of the parameter unit keys.

Pr.990 Setting Description

0 No sound

1 Sound generated (factory setting)

1.3.3 PU contrast adjustment (Pr. 991)

By setting the Pr. 991 "PU contrast adjustment" value, you can adjust the contrast of

the parameter unit LCD.

Pr. 991 Setting

"0" "63"

0 to 63

Light

Dar

Note: If the

Inverter Pr. 991 factory setting Inverter Pr. 991 factory setting

FR-A500 53 FR-S500 58

FR-F500 53 FR-F500J 58

FR-E500 58 FR-C500 58

WRITE

key is not pressed, the PU contrast setting is not stored.

5

CHAPTER 2

FUNCTIONS

This chapter describes the "functions" for use of this

product.

Always read the instructions before using the equipment.

2.1 Monitoring Function........................................................6

2.2 Frequency Setting.........................................................11

2.3 Setting and Changing the Parameter Values................ 13

Chapter 1

2.4 Calibration of the Meter (Frequency Meter)..................19

2.5 Adjustment of the frequency setting signals

"bias" and "gain"...........................................................23

2.6 Copy and Verify Functions ............................................30

Chapter 2

Chapter 3

Chapter 4

Chapter 5

2.1 Monitoring Function

2 FUNCTIONS

2.1 Monitoring Function

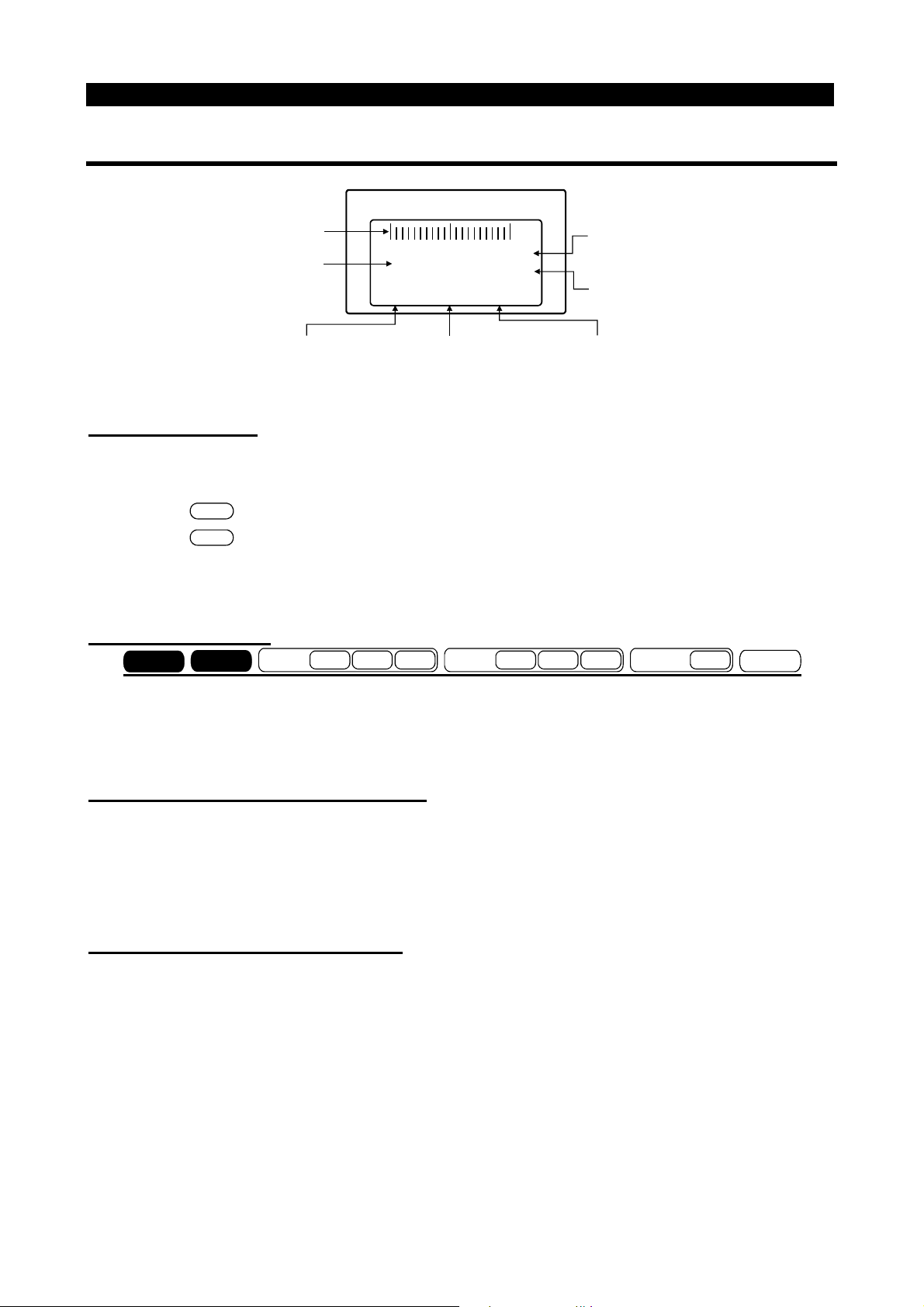

2.1.1 Display overview

FUNCTIONS

(2) PU level meter

(1) Main monitor

(3) Rotation direction

monitoring

120.00

STF FWD PU

(4) Operating status

indication

OL

Hz

(5) Operating mode

(7) Alarm indicatio n

(6) Unit indication

indication

(1) Main monitor

Shows the output frequency, output current, output voltage, alarm history and other

monitor data.

SHIFT

• Using the

• Using the

key to change to the next screen (refer to page 8)

HELP

key to change to the next screen (refer to page 9)

• Using Pr. 52 "PU main display data selection" to change the main screen (refer to

page 10)

(2) PU level meter

A500

F500

-NA -EC -CHE500

-NA -EC -CHS500

-CHF500J

C500

Setting the Pr. 53 "PU level display data selection" displays the data selected on the

5% graduated level meter.

Refer to the inverter instruction manual for details.

(3) Rotation direction monitoring

Indicates the direction of rotation of the motor.

STF: Forward rotation

STR: Reverse rotation

- - - : No command or both STF and STR on

(4) Operating status indication

Shows the operating status of the inverter.

STOP: During stop

FWD : During forward rotation

REV : During reverse rotation

JOGf : During job forward ratation

JOGr : During jog reverse rotation

6

(5) Operation mode indication

Displays the status of the operation mode.

EXT : External operation mode

PU : PU operation mode

EXTj : External jog mode

PUj : PU jog mode

NET : Link operation mode

PU+E: External / PU combined operation mode

PRG : Programmed operation mode

(6) Unit indication

Shows the unit of the main monitor.

(7) Alarm indication

Displays an inverter fault as an alarm.

FUNCTIONS

CAUTION

This function varies with the inverter model.

- - - : Normal

OL : Stall (current)

oL : Stall (voltage)

RB : Regenerative brake pre-alarm

TH : Electronic overcurrent protection pre-alarm

PS : PU stop

2

7

FUNCTIONS

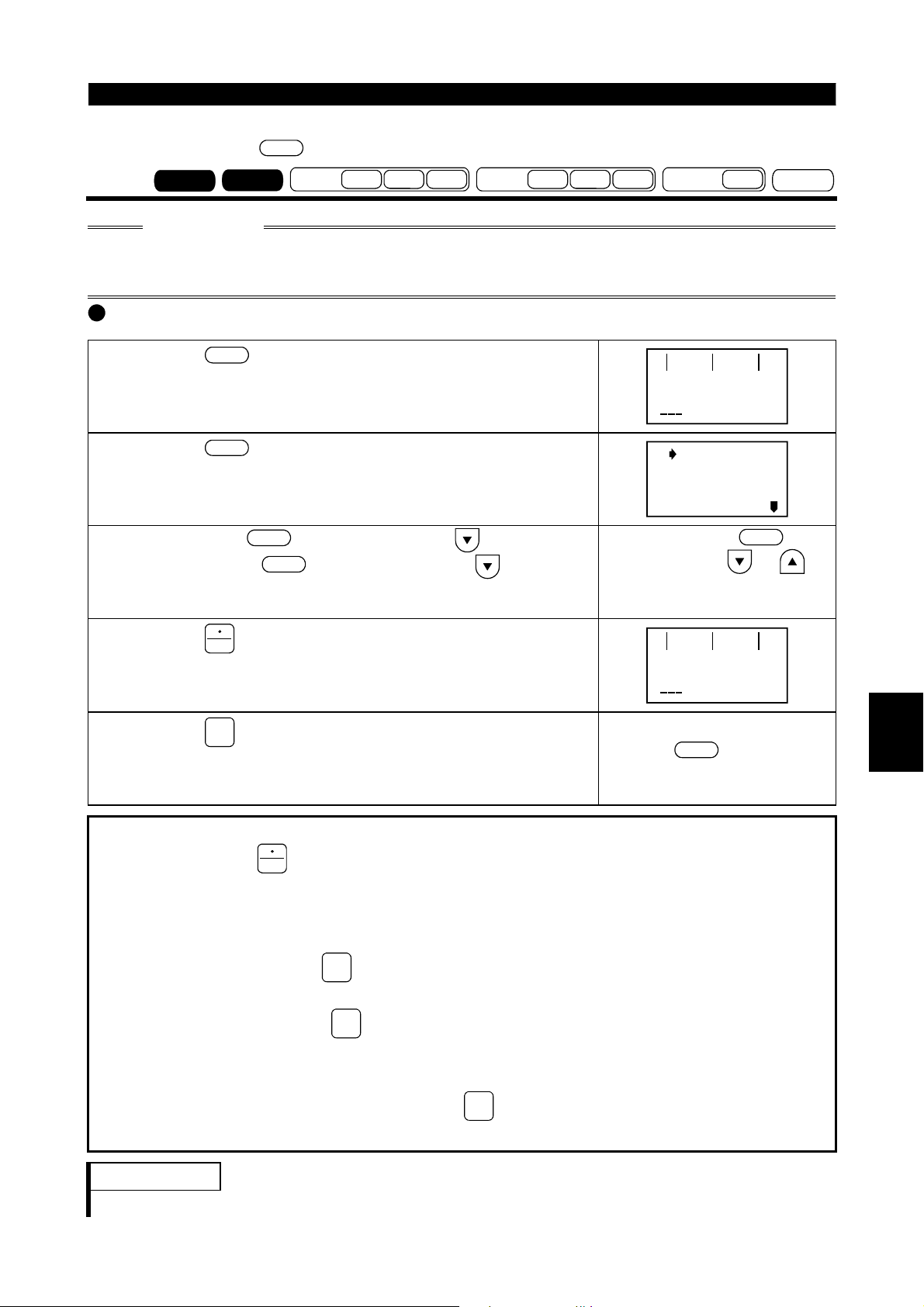

2.1.2 Using the

SHIFT

key to change the main screen

When "0" (factory setting) is set in Pr. 52 "PU main display data selection", merely

SHIFT

pressing the

Switch power on or press key.

First priority

monitor

(Output

frequency

monitor)

(Output current

monitor)

(Output voltage

monitor)

A500

E500

S500 -NA -EC -CH

F500J -CH

(Alarm history

monitor)

F500

-NA -EC - C H

C500

key calls 6 different monitor screens in sequence.

MON

First

0.00

STOP EXT

---

SHIFT

Second

0.00

STOP EXT

---

SHIFT

Third(*)

STOP EXT

---

SHIFT

Fourth

ALARM HISTORY

<READ>

0.0

Hz

(3-step monitor)

A

Up to 3 monitor

data types are

displayed in line

from top of the

left column.

V

(Selective

monitor)

SHIFT

READ

SHIFT

Sixth

0.00Hz

0.00A

0.0V

--- STOP EXT

SHIFT

Fifth

OTHERS

<HELP>

SHIFT

1 UVT 5

2 UVT 6

3 7

4 8

Setting the first

priority monitor

sets it here.

HELP

Refer to page 9

*For the FR-S500 series, the third monitor is also output current monitor.

2.1.3 Setting the first priority screen (first screen)

Set the screen which appears first when power is switched on or the

pressed.

When you press the

WRITE

key with any screen other than ALARM HISTORY and

OTHERS being displayed, that screen is set as the first priority screen and will be

displayed first.

You cannot set "15 I/P Signal", "16 O/P Signal" or multiple simultaneous screens as

the first priority screen.

8

MON

key is

FUNCTIONS

F500

HELP

key to change the main screen

-NA -EC -CHE500

-NA -EC -CHS500

-CHF500J

C500

2.1.4 Using the

A500

CAUTION

The functions vary with the inverter model. (Refer to page 32 for details of the help

functions.)

Example: Select the output current peak value monitor.

1) Press the

The parameter unit is placed in the monitoring mode.

2) Press the

The monitoring list appears.

3) Hold down the

then release the

(Moves the cursor to Peak I.)

MON

HELP

key.

key.

SHIFT

key and press the key twice,

SHIFT

key, and press the key twice.

0.00

STOP PU

1 Frequency

2 Current

3 Voltage

4 Alarm His

......Hold down

press the

key to shift the screen

one page.

SHIFT

Hz

and

or

4) Press the

The screen shown on the right appears.(*1)

5) Press the

The screen in step 4) is set as the first priority screen.

(*2)

READ

WRITE

key.

key.

0.00

STOP EXT

A

......Subsequently press

SHIFT

the

key to call

another monitor

screen.

*1. The selective monitor screen is not yet the first priority screen in the above step

4) when the

key was pressed. Hence, the selected item is erased from

READ

memory as soon as the power is switched off or another operation mode (such

as external operation) is selected.

In this case, the item must be selected again in the above procedure.

WRITE

When you press the

key to select the first priority screen, the selected item

is stored in memory.

WRITE

*2. In step 5) where the

key was pressed in the above setting example, the

"output current peak" selected here is first displayed with priority when the other

operation mode is switched to the monitoring mode. To give first priority to

WRITE

another monitor screen, press the

key with that monitor screen being

2

displayed. (Refer to page 8.)

REMARKS

Refer to page 32 for details of the help functions.

9

FUNCTIONS

When "current monitor" or "power monitor" is selected

Note that any current or power not more than 5% of the rated inverter current cannot

be detected and displayed.

Example:When a small motor is used with a large-capacity inverter (a 0.4kW motor is

used with a 55kW inverter), power monitor is inoperative.

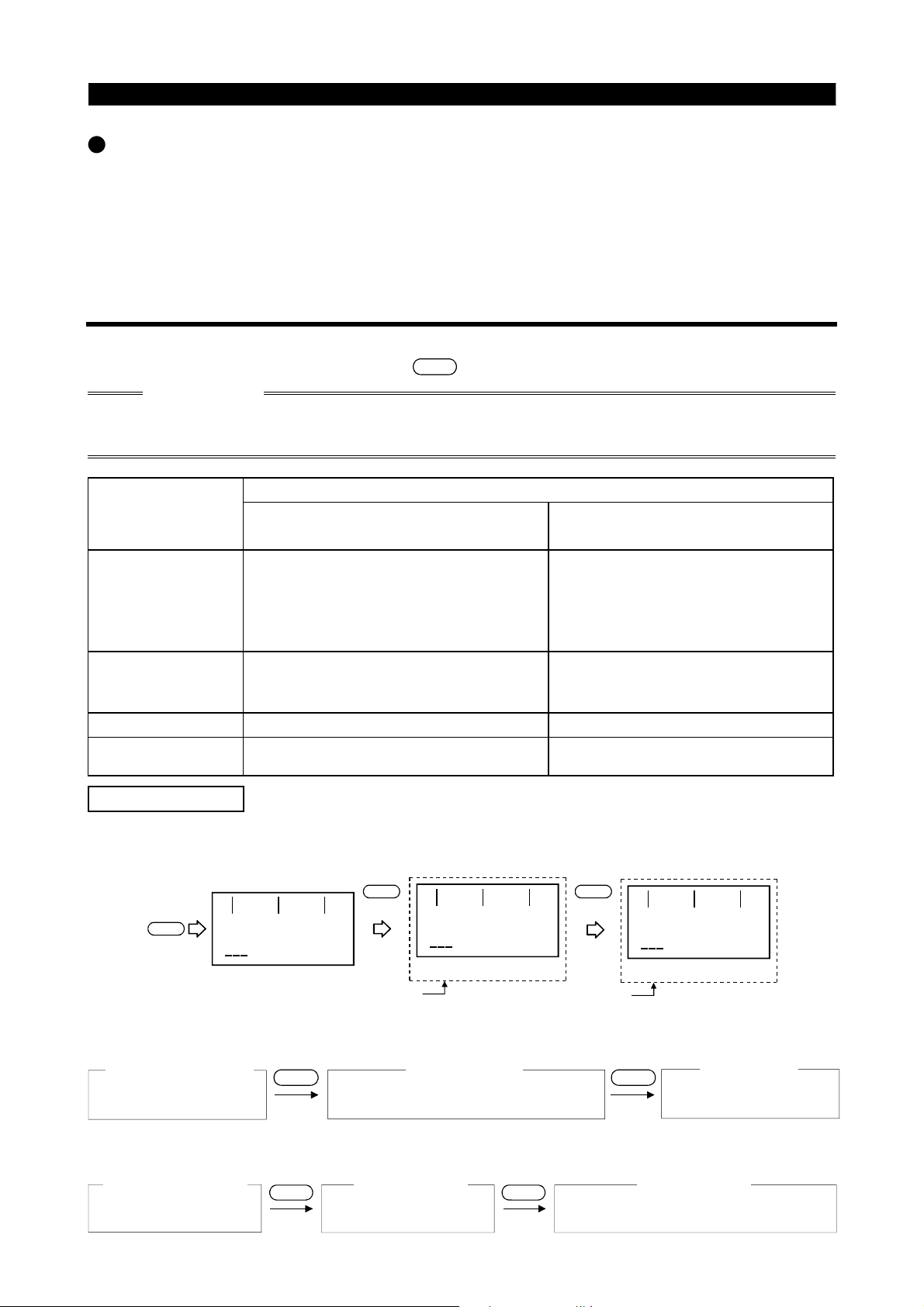

2.1.5 Using the “PU main display data selection parameter” to change the screen

By setting the Pr. 52 value, you can change the "second" and "third" screen displays

SHIFT

from the first priority screen using the

CAUTION

The functions vary with the inverter model. (Refer to the inverter instruction manual

for details of the “PU main display data selection parameter”.)

Inverter

FR-A500 series

FR-F500 series

FR-E500 series -

FR-S500/F500J/

C500 series

Setting values displayed in place

of output current monitor

17 (load meter)

18 (motor excitation current)

24 (motor load factor)

17 (load meter)

24 (motor load factor)

--

key.

Pr. 52 Setting

Setting values displayed in

place of output vol t age monitor

19 (position pulse)

20 (cumulative energization time)

22 (orientation status)

23 (actual operation time)

25 (cumulative power)

20 (cumulative energization time)

23 (actual operation time)

25 (cumulative power)

23 (actual operation time)

Factory setting

* The monitor displayed at powering on is the first priorit y monitor.

Refer to page 8 for the setting method of the first priority monitor.

MON

First prio rity m o n ito r

0.00

STOP EXT

(Output frequency monitor)

First

Hz

SHIFT SHIFT

Second monitor Third monitor

0.00

STOP EXT

(Output current monitor)

1)

Second

A

(Output voltage monitor)

2)

0.0

V

STOP EXT

Third

1) For the set value of "17, 18, 24", their monitors are displayed at the second monitor

instead of output current monitor.

First priority monitor Second monitor

Output frequency

monitor

SHIFT SHIFT

Monitor of the set value

of "17, 18, 24"

Third monitor

Output voltage monitor

2) For the set value of "19 to 23, 25", their monitors are displayed at the third monitor

instead of output voltage monitor.

First priority monitor

Output frequency

monitor

SHIFT SHIFT

Second monitor

Output current

monitor

Second monitor

Monitor of the set value

of "19 to 23, 25"

10

2.2 Frequency Setting

FUNCTIONS

2.2 Frequency Setting

Make this setting in the PU operation mode.

REMARKS

The external start signal (STF or STR) must not be ON to switch from external

operation mode to PU operation mode.

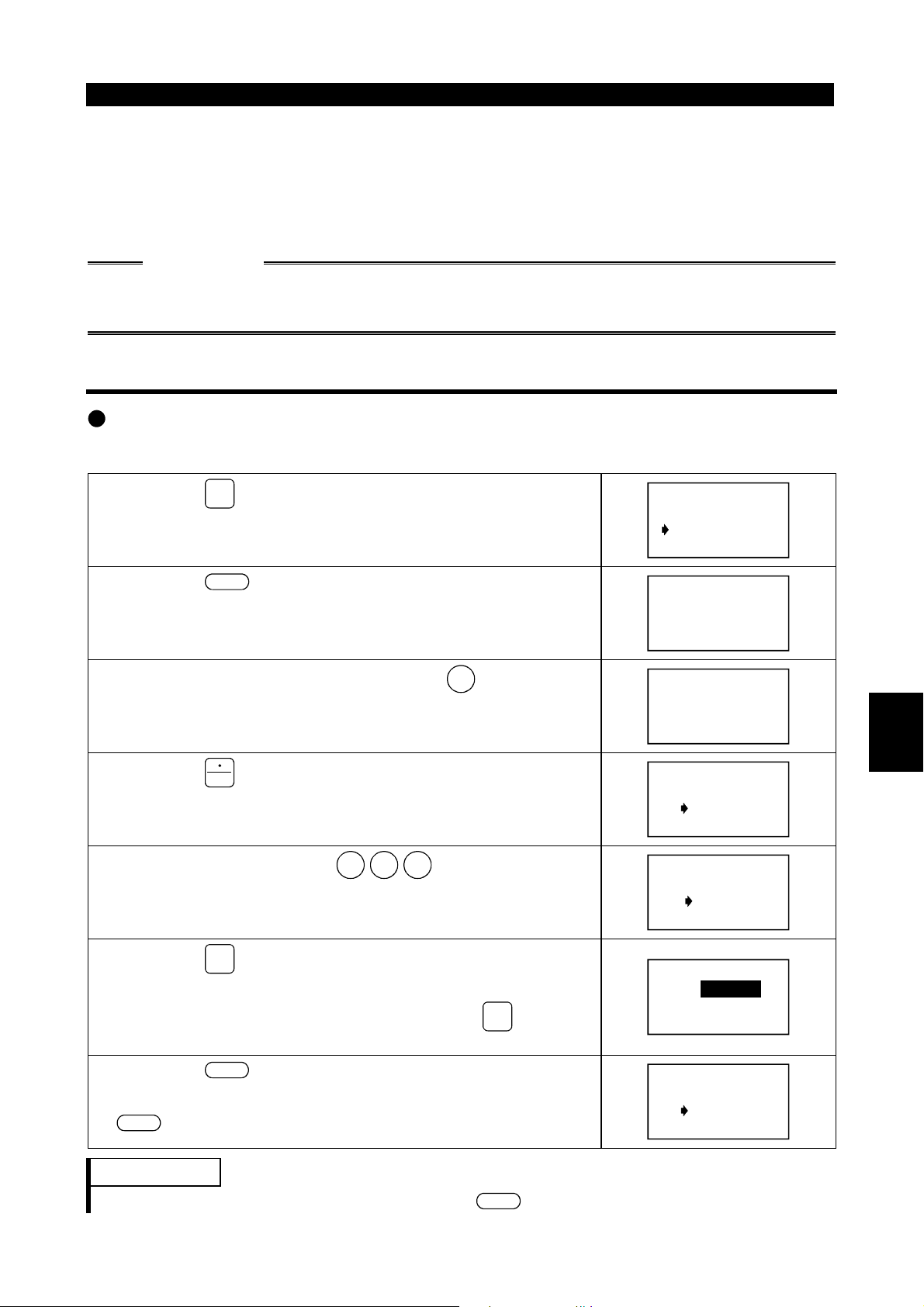

2.2.1 Direct setting

Operation procedure (Changing from 0Hz setti ng to 60Hz setting)

1) Press the PU key. .......The frequency setting

screen appears.

2) Press the 6 and

0

.......Enter 60Hz.

keys.

(Remarks)

3) Press the

WRITE

key. .......Register the 60Hz

setting. (Setting

complete)

REMARKS

If you entered an incorrect value, press the

ESC

key to return to the pre-entry state.

2.2.2 Step setting

1) Press the PU key. .......The frequency setting

screen appears.

DIRECTLY

Set 0.00Hz

DIRECTLY

Set 0.00Hz

60Hz

DIRECTLY

60.00Hz

Completed

2

DIRECTLY

Set 0.00Hz

2) Press the / key to enter any value (60.00Hz).

(Remarks 1)

You can set any value between the maximum frequency

DIRECTLY

Set 0.00Hz

60.00Hz

(Pr. 1) and minimum frequency (Pr. 2).

3) Press the

WRITE

key. .......Register the 60Hz

setting. (Setting

complete)

DIRECTLY

60.00Hz

Completed

REMARKS

1. If you entered an incorrect value, press the

ESC

key to return to the pre-entry

state.

2. During operation, you can also make the step setting to change the running

frequency. If you operate the / key in the monitor mode, however, the

frequency will not stop when you release the key but will further increase (or

decrease). (Since the

/ key is used to vary the preset frequency, the varied

frequency will differ from the output frequency.)

11

FUNCTIONS

2.2.3 Precautions for frequency setting

1) Pr. 79 "operation mode selection" must have been set to make the "PU operation

mode" valid.

2) In the monitor mode, you cannot make the setting directly (refer to page 11) to set

the running frequency. Perform the step setting (refer to page 11) and press the

key, or press the PU key to deselect the monitor mode before starting frequency

setting.

WRITE

Monitor mode

30.00

FWD PU

STF

Hz

Deselect monitor

mode

PU

Frequency setting

screen

DIRECTLY

Set 30.00Hz

12

2.3 Setting and Changing the Parameter Values

FUNCTIONS

2.3 Setting and Changing the Par ameter Values

The inverter has a number of parameters. Using the PU, you can choose parameters

required for operation and set and/or change their values as appropriate according to

the load and running conditions. Set "1" in Pr. 77 "parameter write inhibit selection" to

inhibit write.

CAUTION

The functions vary with the inverter. (Refer to the inverter instruction manual for

details of the parameters.)

2.3.1 Direct setting

Operation procedure (Example: Reading and writing the Pr. 8

"deceleration time" value)

1) Press the PU key.

The frequency setting screen appears.

2) Press the

SET

key.

The parameter unit enters the parameter setting mode.

3) Press the required parameter number 8.

The screen on the right appears.

4) Press the

READ

key.

The current setting appears on the display.

5) Enter the required value (

1 8 0

). (Example: To set

to 180s)

A new setting appears on the display.(*)

DIRECTLY

Set 0.00Hz

SETTING MODE

Set

FOR PR. List

<HELP>

SETTING MODE

Pr.

NO.

Pr. NO.

<READ>

8 De c. T1

5. 0S

8 Dec. T1

5. 0S

180S

8

2

6) Press the

WRITE

key.

The setting is stored into memory.

If an error is displayed when you press the

WRITE

to page 47.

7) Press the

SHIFT

key to move to the next parameter

(Pr. 9) and call the current setting. Then, press the

SHIFT

key to advance to the next parameter.

REMARKS

*If you entered an incorrect value, press the

ESC

13

8 Dec. T1

180. 0S

key, refer

Completed

9 Se t THM

2. 55A

key to return to the pre-entry state.

Loading...

Loading...