Mitsubishi FR-K-750-U, FR-K-3700-U, FR-K-1500-U, FR-K-2200-U, FR-K-5.5K-U Instruction Manual

...

MlTSUBlSHl

VVVF TRANSISTOR INVERTER

-INSTRUCTION MANUAL-

(

208/230V

series

I

MlTSUBlSHl

ELECTRIC

FORWORD

Thank you for your purchase of Mitsubishi Multi-Purpose Inverter FREQR0L.K

.

This

is

a variable frequency power supply unit to control the speed of squirrel-cage induction motors . This in-

struction manual is intended both to explain the unit and to outline operation procedures

.

This unit

is

not difficult to operate. but incorrect operation may lead to some troubles. so read this instruction

manual carefully before operation

.

If you use to unit properly. we are sure

it

will give you many years of satisfac-

tion

.

Please make sure to attach this instruction manual to the unit when the unit

is

shipped

.

CONTENTS

1 . UNPACKING 1

2

.

TRANSPORTING 1

.........................................................

3 . INSTALLATION 1

4

.

WIRING AND POWER SUPPLY RATING

........................................

1

............................................................

4-1 Wiring 1

4-2 Power supply rating

...................................................

2

...........................................................

.

5 OPERATIONS 4

..........................................

5-1 Points to check before operations 4

5-2 Preparations before operations

............................................

4

.........................................................

5-3 Operations 5

.................................................

5-4 Operation's precautions

6

6

.

MAINTENANCE AND INSPECTION

............................................

7

7 . CONSTRUCTION AND ARRANGEMENTOF CONTROLLER PARTS

.....................

8

8

.

TROUBLESHOOTING AND COUNTERMEASURE

..................................

9

8-1 Troubleshooting chart

..................................................

9

8-2

Failures indicated by lighting of alarm indication lamps and how to deal with them

.........

13

.............................................

8-3 Measuring voltage and current

15

9

.

STANDARDSPECIFICATIONS

...............................................

17

10.

PROTECTIVEFUNCTIONS

..................................................

18

.

11 INPUT/OUTPUTTERMINAL

.................................................

19

1.

UNPACKING

After unpacking your FREQROL-K, first check the following points.

0

Refer to the name plate to confirm that the model and the output rating is indeed the one you ordered.

(See table

1)

0

Check where there has been any damage or breakage to the FREQROL-K during transportation.

If you have any doubts about the above, or find any damage to the unit, please contact your local service

representative.

Table

1

FR-K Series Configuration

Motor output (HP) 112

1

2

3

5

7.5 10

Without operation

FR-K-

FR-K- FR-K-

FR-K- FR-K- FR-K- FR-K-

panel 400-U 750-U 1500-U 2200-U 3700-U

5.5K-U 7.5K-U

With operation FR-K-

FR-K- FR-K-

FR-K- FR-K-

FR-K- FR-K-

panel 400M-U 750M-U

1500M-U 2200M-U

3700M-U 5.5KM-U 7.5KM-U

Note: The operation panel is provided with a frequency setter, a frequency meter and a FWDIREV starting

switch.

2.

TRANSPORTING

When transporting the FREQROL-K, handle

it

gently to prevent damage. There are depressions on both the

top and the bottom where the unit can be grasped, and these should be held when

it

is moved.

Do not apply too much force to the fan at the bottom of the unit. The unit is covered with a plastic case,

and care should be taken not to apply force only to this cover during transport.

a

3.

INSTALLATION

o

Place the inverter in a clean and well ventilated location. Avoid locations exposed to direct sunlight, or

subject to high temperatures, humidity, dust or corrosive gases.

0

Install the inverter securely on the wall with volts or screws, vertically so that the letters "FREQROL-K"

appears front.

0

Since the inverter does generate some heat during operations, any other equipment or parts should be

installed at least 10 cm away from up and the bottom to prevent heat confined.

The brake resistor attached to the rear of the unit also generates heat, so the unit should not be placed on

a wall with low heat resistance.

0

If your inverter is one equipped with an operation panel, take care to put

it

in a place where

it

can be

easily operated.

4.

WIRING AND POWER SUPPLY RATING

4-1

Wiring

Connect wiring correctly according to following instructions and refer to Fig. 1, Standard Wiring

Diagram.

Fow wiring of the peripheral devices such as MCCB, refer to Table

2,

Selection of Peripherals.

(1)

When the wiring cover located at the bottom of the inverter

is

pushed inward and then pulled

toward the operator, the wiring cover alone

is

removed thus exposing all terminal blocks. A

corrugated gripping surface has been provided for your convenience. Now perform wiring.

(2)

The wirings of the frequency setter, FWDIREV start switches, frequency meter and calibration

resistor of meter equipped with an operation panel in Fig. 1 have already connected.

(3) Do not wire the power cable in such a manner that the line source voltage is directly applied to

the output terminals

U,

V

and

W.

(4)

It

is

not always necessav to provide wiring to the reset switch, since the circuit can be restored

by cutting off

MCCB

or Magnetic Contactor (MS) if the output protective circuit has been

activated to stop the controller.

(5)

Since terminals P and N have been provided for brake unit and discharge resistor connections,

avoid connecting only discharge resistor, or any other equipment, to these terminals.

(6)

It

is not necessary to consider the phase sequence when connecting to terminals R, S and T.

(7)

Since the frequency setting signal current

is

extremely low

if

it

is necessary to use contacts in the

frequency setting circuit, use two pairs of parallel contacts or twin contacts for extremely low

current to prevent poor contact.

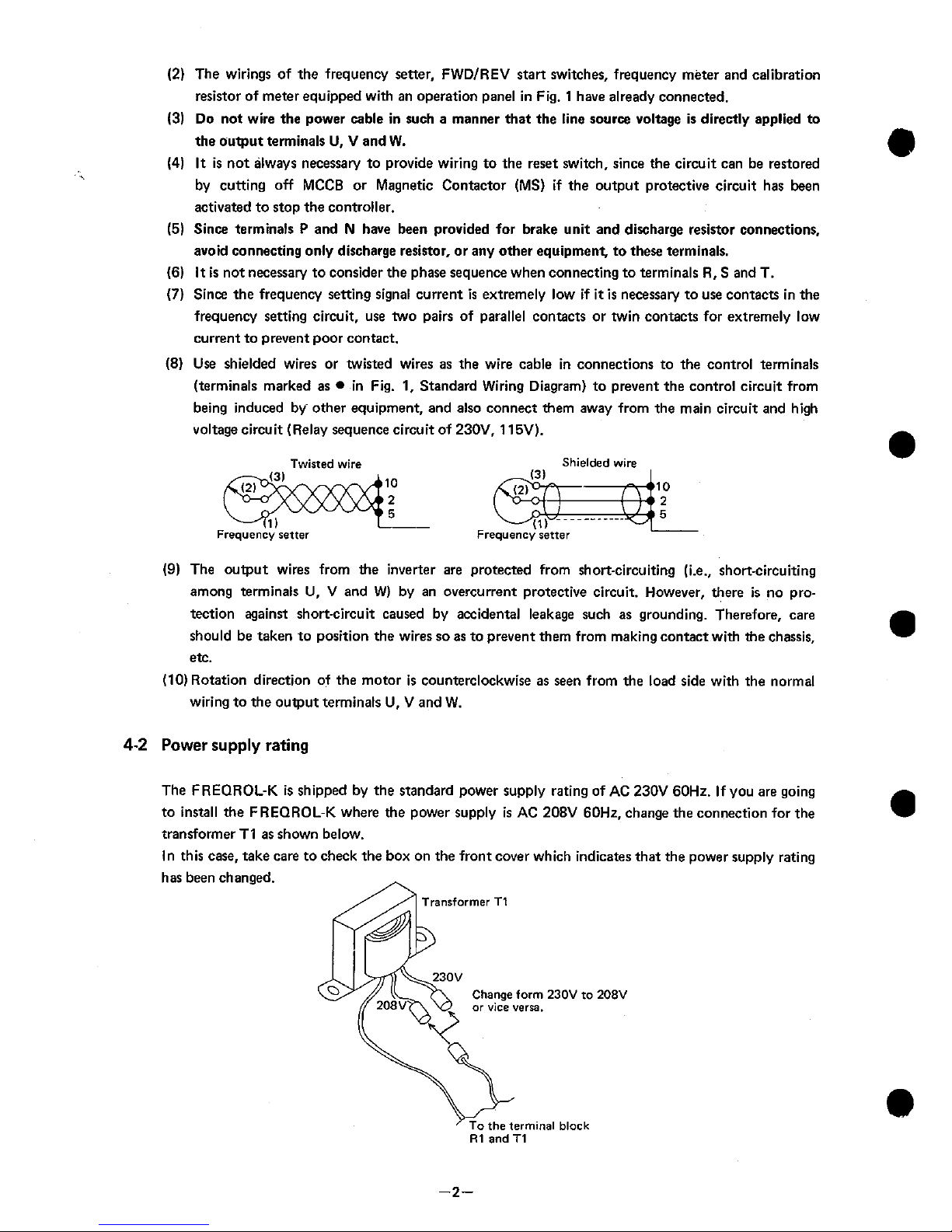

(8)

Use

shielded wires or twisted wires as the wire cable in connections to the control terminals

(terminals marked as

in Fig. 1, Standard Wiring Diagram) to prevent the control circuit from

being induced by other equipment, and also connect them away from the main circuit and high

voltage circuit (Relay sequence circuit of

230V. 115V).

Twisted wire

.~.

Shielded wire

Frequency setter Frequency setter

(9)

The output wires from the inverter are protected from short-circuiting (i.e., short-circuiting

among terminals

U,

V and W) by an overcurrent protective circuit. However, there is no protection against shortcircuit caused by accidental leakage such as grounding. Therefore, care

should be taken to position the wires so as to prevent them from making contact with the chassis,

etc.

(10) Rotation direction of the motor is counterclockwise as seen from the load side with the normal

wiring to the output terminals

U,

V and W.

4-2

Power

supply

rating

The FREQROL-K is shipped by the standard power supply rating of

AC

230V 60Hz. If you are going

to install the FREQROL-K where the power supply

is

AC

208V 60Hz, change the connection for the

transformer TI as shown below.

In this case, take care to check the box on the front cover which indicates that the power supply rating

has been changed.

Transformer T1

Change

form

230V

to

208V

or

vice verra.

the terminal black

R1

and

T1

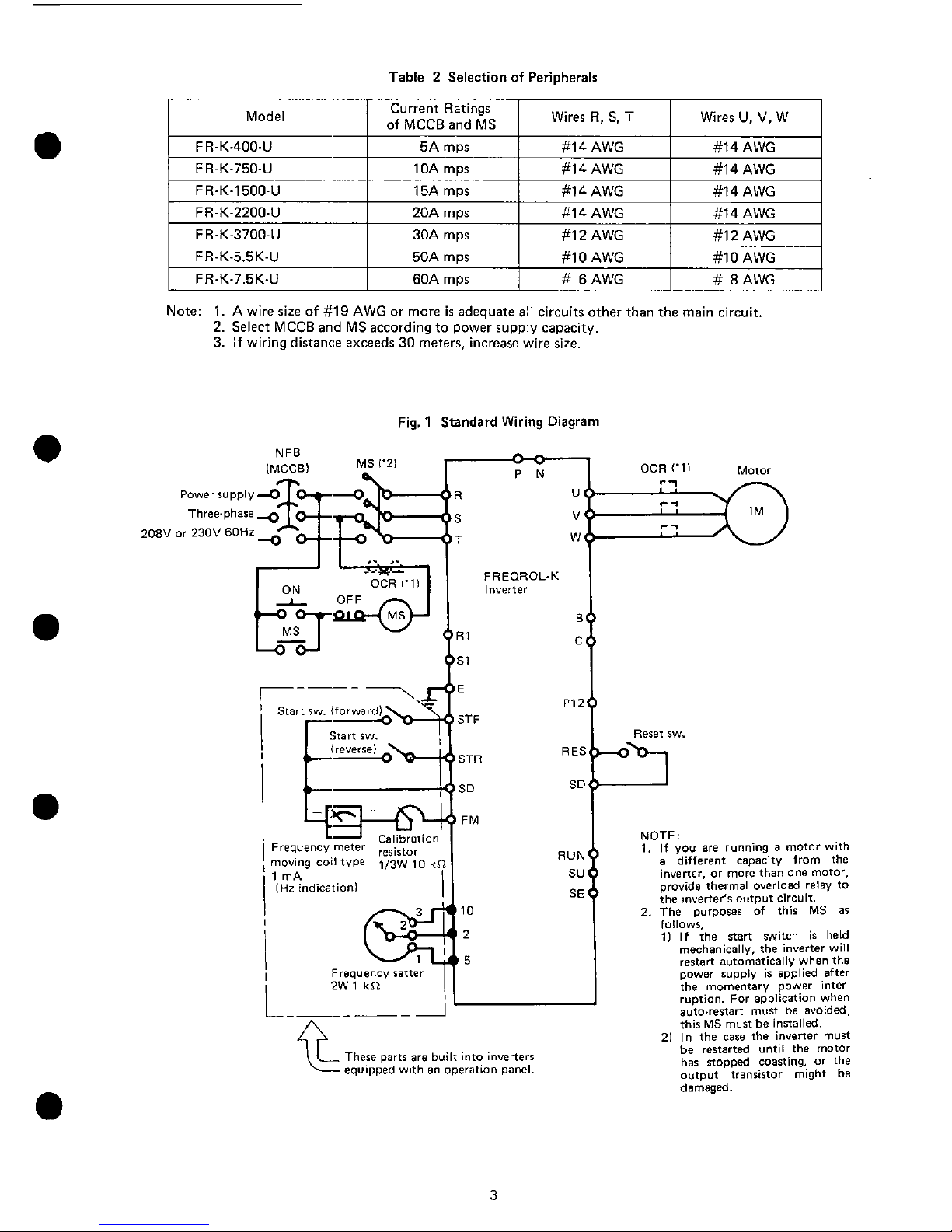

Table 2 Selection of Peripherals

Model

Current Ratings

/

of

MCCR

ad

MS

/

Wires

R,

S.

T

I

Wires

U,

V,

w

I

F

R-K400-U

F

R-K-7504

F

R-K-1500-U

Note:

1. A

wire size of

#19 AWG

or more

is

adequate all circuits other than the main circuit.

2.

Select MCCB and MS according to power supply capacity.

3.

If wiring distance exceeds

30

meters, increase wire size.

FR-K-2200-U

FR-K-3700-U

FR-K-5.5K-U

FR-K-7.5K-U

Fig. 1 Standard Wiring Diagram

5A

mps

10A

mps

15A

m~s

NFB

IMCCBI

MS 1'21

/L

9

20A

mps

30A

mps

50A

mps

60A

mps

Calibratiot

Frequency meter

moving coil type

113~

10

k

1 mA

(Hz indication]

#14 AWG

#I

4 AWG

#14 AWG

Frequency setter

2W

1

kSL

#14 AWG

#14 AWG

#14 AWG

#14 AWG

#I

2

AWG

#lo

AWG

#

6 AWG

-

-

1

OCR ('11 Motor

#14 AWG

#12 AWG

#I0 AWG

#

8

AWG

FREOROL-K

Inverter

I

STF

Reret aw.

STR

SD SD

FM

are

built into inverters

an

operation panel.

NOTE:

1.

If you

are

running a motor with

a

different capacity from the

inverter,

or

more than one motor.

~rovide thermal overload relay to

the inverter's

output circuit.

2. The purpores of this MS

as

follows,

11 If the nsrt switch is held

meCnanlCB

v,

tne

nverter

w

I

restart a.tomat'ca

v

nnon

the

mner

I.OD~Y

I

am

e0

after

..

.

.

.

the momentary power interruption. For application when

auto.restart must be avoided.

this MS must be inrtalled.

21 In the

case

the inverter must

be restarted until the motor

has sopped coasting,

or

the

output transinor might be

damaged.

5.

OPERATIONS

5-1

Points

to

check before operations

After installation and wiring of FREQROL-K

is

completed, check the following points before opera-

ting.

If insulation

is

to be checked with a megger, perform only the test between controller and grounding.

Never perform a megger test between the inverter's terminals.

Also do not perform a megger ten on the control circuit terminals.

Refer to section

6

for details on megger insulation tests.

(1)

Check whether wiring conforms to the standard wiring diagram.

(2) Check for points short-circuited by broken wire, etc.

(3)

Check if any wire is strained.

(4) Check tightness of screws, of terminals and other fasteners.

(5) Check motor load conditions.

5-2

Preparations before

operations

When inspection is completed, open the setting panel flap on the inverter front panel and make the

following setting.

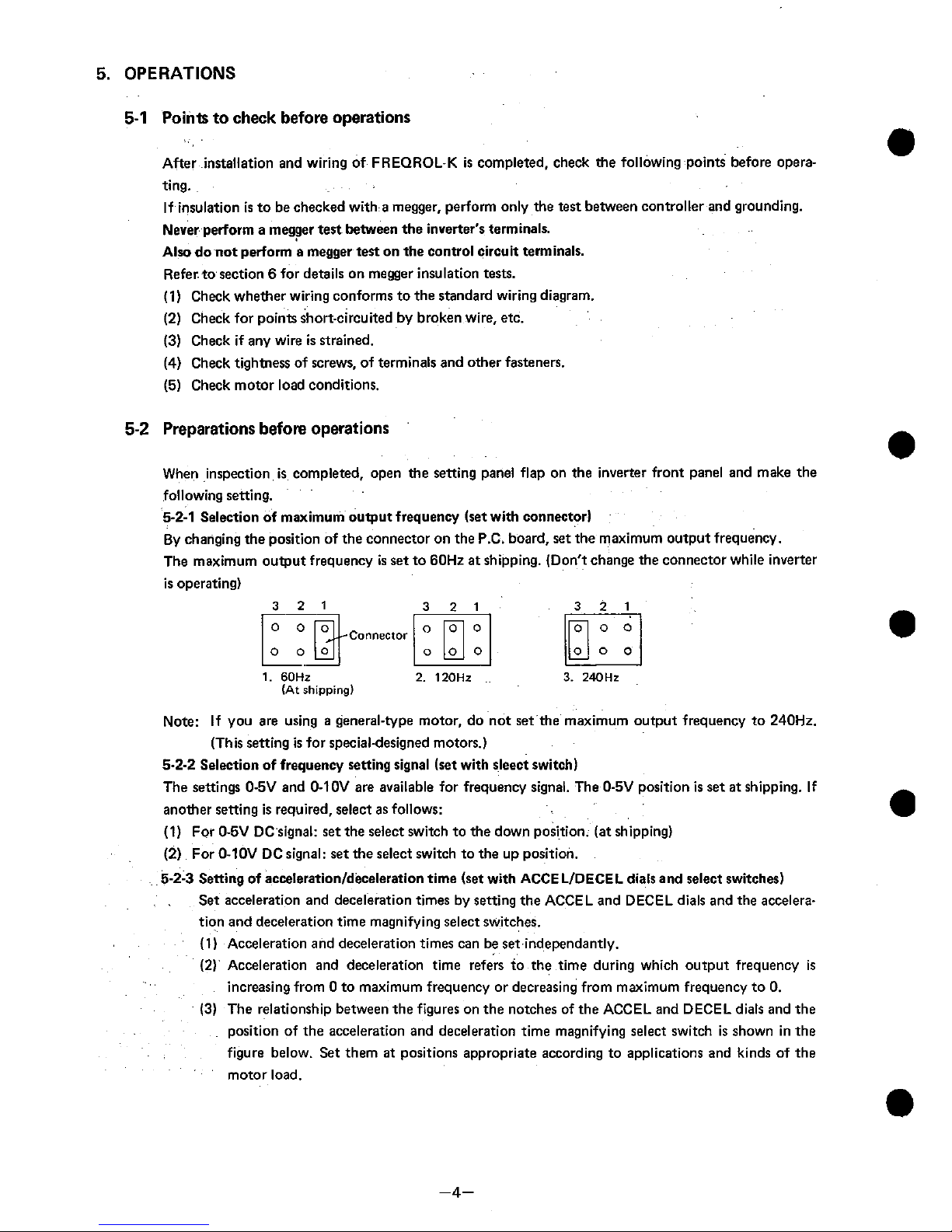

5-2-1

Selection of maximum output frequency (set with connector)

By changing the position of the connector on the P.C. board,

set

the maximum output frequency.

The maximum output frequency

is

set to 60Hz at shipping. (Don't change the connector while inverter

is operating)

1.

60Hz

(At

shipping)

Note: If you are using a general-type motor, do not set the maximum output frequency to 240Hz.

(This setting

is

for specialdesigned motors.)

5-2-2

Selection of frequency setting signal (set with sleect switch)

The settings O-5V and 0-10V are available for frequency signal. The 0-5V position is set at shipping. If

another setting is required, select as follows:

(1) For 0-5V DC signal:

set

the select switch to the down position. (at shipping)

(2) For 0-10V DC signal: set the select switch to the up position.

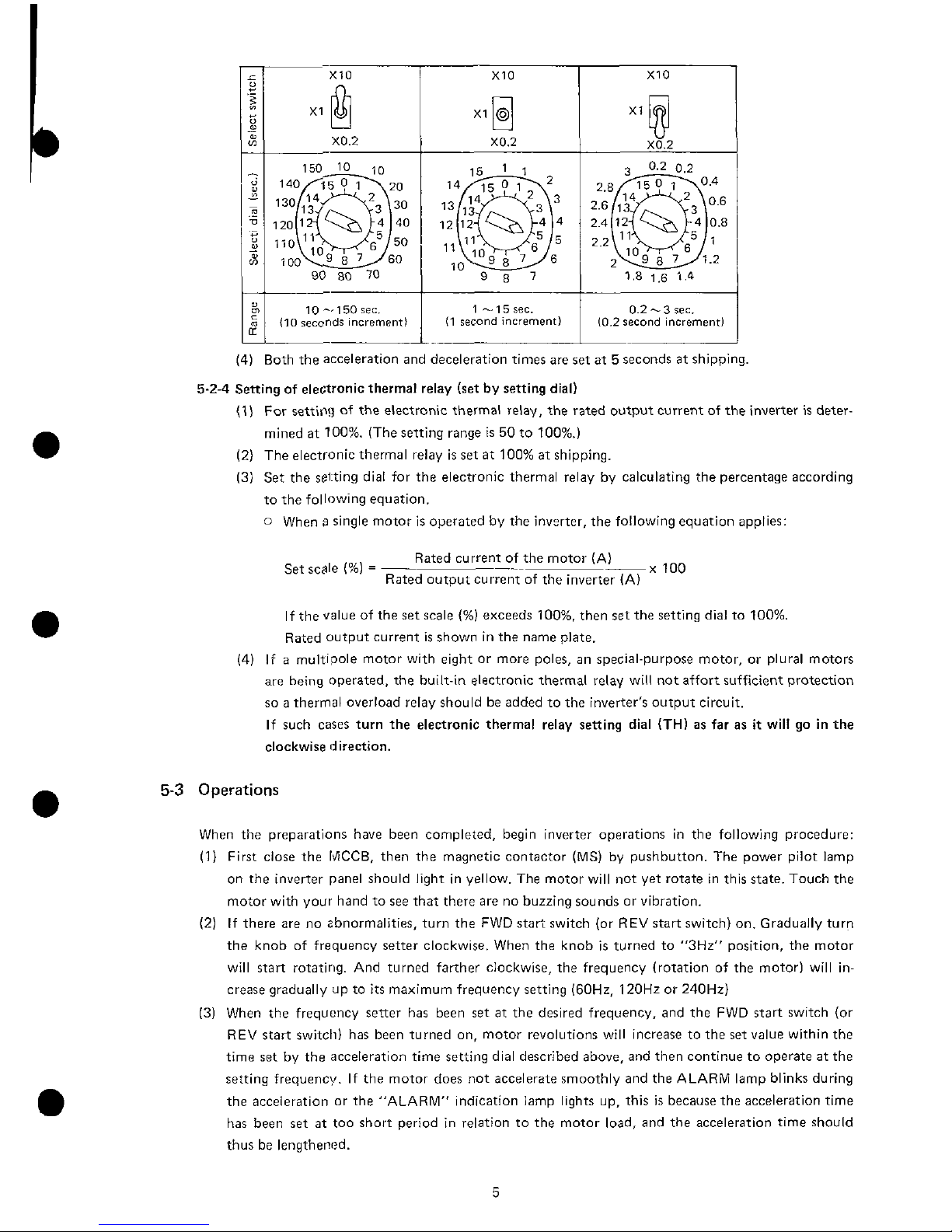

5-2-3

Setting of

accelerationldeceleration

time (set with ACCE LIDECEL dials and select switches)

Set acceleration and deceleration times by setting the ACCEL and DECEL dials and the acceleration and deceleration time magnifying select switches.

(1) Acceleration and deceleration times can be

set

independantly.

(2)

Acceleration and deceleration time refers to the time during which output frequency

is

increasing from 0 to maximum frequency or decreasing from maximum frequency to 0.

(3)

The relationship between the figures on the notches of the ACCEL and DECEL dials and the

position of the accelerat~on and deceleration time magnifying select switch

is

shown in the

figure below. Set them

at

positions appropriate according to applications and kinds of the

motor load.

10 -150

rec.

110

secor~ds

increment)

0.2

-3

sec.

10.2

second

increment1

(4) Both the acceleration and deceleration times are set at 5 seconds at shipping.

5-2-4 Sening of electronic thermal relay (set by setting dial)

(1) For setting of the electronic thermal relay, the rated output current of the inverter is deter-

mined at 100%. (The setting range

is

50 to loo%.)

(2) The electronic thermal relay is

set

at 100% at shipping.

(3) Set the setting dial for the electronic thermal relay by calculating the percentage according

to the following equation.

0

When s single motor is operated by the inverter, the following equation applies:

Rated current of the motor (A)

Set scale

(%)

=

-

x

100

Rated output currentof the inverter (A)

If the value of the

set

scale

(%)

exceeds 100%. then

set

the setting dial to 100%.

Rated output current

is

shown in the name plate.

(4)

If a multipole motor with eight or more poles, an special-purpose motor, or plural motors

are

being

operated, the built-in electronic thermal relay will not affort sufficient protection

so a thermal overload relay should be added to the inverter's output circuit.

If such cases turn the electronic thermal relay setting dial

(TH)

as far as

it

will go in the

clockwise direction.

5-3

Operations

When the preparations have been completed, begin inverter operations in the following procedure:

(1) First close the

MCCB,

then the magnetic contactor (MS) by pushbutton. The power pilot lamp

on the inverter panel should light in yellow. The motor will not yet rotate in this state. Touch the

motor with your hand to see that there are no buzzing sounds or vibration.

(2) If there are no zbnormalities, turn the FWD start switch (or REV start switch) on. Gradually turn

the knob of frequency setter clockwise. When the knob is turned to

"3Hz" position, the motor

will start rotating. And turned farther clockwise, the frequency (rotation of the motor) will increase gradually ap to

its

maximum frequency setting (60Hz. 120Hz or 240Hz)

(3) When the frequency setter has been

set

at the desired frequency, and the FWD start switch (or

REV start switch) has been turned on, motor revolutions will increase to the set value within the

time

set

by the acceleration time setting dial described above, and then continue to operate at the

setting frequency. If the motor does not accelerate smoothly and the ALARM lamp blinks during

the acceieration or the "ALARM" indication lamp lights up, this is because the acceleration time

has been

set

at too short period in relation to the motor load, and the acceleration time should

thus be lengthened.

(4) When the FWD start switch (or REV start switch) is turned off while the motor is rotating, motor

speed is decelerated in the time'period set by the DECEL dial. When the frequency falls below

3Hz. the DC dynamic brake will be activated and the motor will stop immediately. If the motor

speed does not decelerate smoothly and the ALARM lamp blinks during the deceleration or the

"ALARM" indication lamp lights up, this is because the deceleration time

is

not sufficient for the

motor load, and the deceleration time should thus be lengthened.

(5) If the FWD start switch and the REV start switch are turned on simultaneously, the motor will not

rotate. Also, if the FWD start switch and the REV start switch are simultaneously activated while

the motor

is

rotating, the motor will begin decelerating in the same manner as when the FWD (or

REV) start switch

is

turned off.

(6) If the FWD start switch is turned off and the REV start switch turned on while the motor is rotat-

ing

forward, the motor speed will decelerate to a frequency of 3Hz. at which point the rotation

direction will automatically be reversed, accelerating gradually tothe frequency that has been set.

The same is also true of movement from reverse to forward rotation.

(7)

If the settings of the acceleration or deceleration times are changed during motor operations, the

previous settings will remain in memory and the changes will not take effect. Note that this

unit

is

designed for changes in the setting of acceleration and deceleration time to be made at a

inverter frequency below 3Hz.

(8) If the protective circuits, such as those against overcurrent and regenerative overvoltage are

activated, the alarm indication lamp will light up in red and the shut-off state will continue. To

reset

after a shut-off, perform the following operations:

0

First turn off the power supply with the MCCB or the Magnetic contactor (MS), then turn

it

on.

0

Short-circuit the terminals between RES (reset) and SD (common) of the control circuit by the

reset switch, then (after about 0.1 second), re-open.

(9)

Use the calibration resistor to adjust the frequency meter so that the frequency

is

indicated as 60,

120 or 240Hz when the commanded voltage (across terminals between 2 and 5)

is

set to 5V DC

or 10V DC by the frequency setting input signal select switch.

Inverters equipped with a frequency meter have already been adjusted at the factory before

shipping.

(10) When the DC dynamic brake activates at below

3Hz during deceleration,

it

may cause a highpitched noise. This noise is common, and does not indicate any abnormalities (The DC dynamic

brake functions for about 0.5 second.)

5.4

Operation's Precautions

When the confirmations described above have been completed you may begin normal operations, but

keep the following points in mind when doing so.

(1)

When a general type motor is being driven by the inverter, the temperature, noise and vibrations

will be somewhat higher than they would be with a commercial power supply.

(2) Since cooling efficiency decreases at low speed operations,

it

is

necessary to reduce the torque

from the rated motor torque. (Refer to the catalog for the torque reduction ratio.)

(3) The FREQROL-K is capable of controlling plural motors at the same time. When the inverter is

used to control more than one motor, care should be taken that the total current requirement for

the simultaneously operated motors

is

within the rated output current of the inverter.

(4) If the FREQROL-K

is

being used to control multipole motors with 8 or more poles, submersible

motors. or other special-purpose motors, carefully examine the rated current and other electrical

specification.

Loading...

Loading...