Mitsubishi FR-K-750-U, FR-K-3700-U, FR-K-1500-U, FR-K-2200-U, FR-K-5.5K-U Instruction Manual

...

MlTSUBlSHl

VVVF TRANSISTOR INVERTER

-INSTRUCTION MANUAL-

(

208/230V

series

I

MlTSUBlSHl

ELECTRIC

FORWORD

Thank you for your purchase of Mitsubishi Multi-Purpose Inverter FREQR0L.K

.

This

is

a variable frequency power supply unit to control the speed of squirrel-cage induction motors . This in-

struction manual is intended both to explain the unit and to outline operation procedures

.

This unit

is

not difficult to operate. but incorrect operation may lead to some troubles. so read this instruction

manual carefully before operation

.

If you use to unit properly. we are sure

it

will give you many years of satisfac-

tion

.

Please make sure to attach this instruction manual to the unit when the unit

is

shipped

.

CONTENTS

1 . UNPACKING 1

2

.

TRANSPORTING 1

.........................................................

3 . INSTALLATION 1

4

.

WIRING AND POWER SUPPLY RATING

........................................

1

............................................................

4-1 Wiring 1

4-2 Power supply rating

...................................................

2

...........................................................

.

5 OPERATIONS 4

..........................................

5-1 Points to check before operations 4

5-2 Preparations before operations

............................................

4

.........................................................

5-3 Operations 5

.................................................

5-4 Operation's precautions

6

6

.

MAINTENANCE AND INSPECTION

............................................

7

7 . CONSTRUCTION AND ARRANGEMENTOF CONTROLLER PARTS

.....................

8

8

.

TROUBLESHOOTING AND COUNTERMEASURE

..................................

9

8-1 Troubleshooting chart

..................................................

9

8-2

Failures indicated by lighting of alarm indication lamps and how to deal with them

.........

13

.............................................

8-3 Measuring voltage and current

15

9

.

STANDARDSPECIFICATIONS

...............................................

17

10.

PROTECTIVEFUNCTIONS

..................................................

18

.

11 INPUT/OUTPUTTERMINAL

.................................................

19

1.

UNPACKING

After unpacking your FREQROL-K, first check the following points.

0

Refer to the name plate to confirm that the model and the output rating is indeed the one you ordered.

(See table

1)

0

Check where there has been any damage or breakage to the FREQROL-K during transportation.

If you have any doubts about the above, or find any damage to the unit, please contact your local service

representative.

Table

1

FR-K Series Configuration

Motor output (HP) 112

1

2

3

5

7.5 10

Without operation

FR-K-

FR-K- FR-K-

FR-K- FR-K- FR-K- FR-K-

panel 400-U 750-U 1500-U 2200-U 3700-U

5.5K-U 7.5K-U

With operation FR-K-

FR-K- FR-K-

FR-K- FR-K-

FR-K- FR-K-

panel 400M-U 750M-U

1500M-U 2200M-U

3700M-U 5.5KM-U 7.5KM-U

Note: The operation panel is provided with a frequency setter, a frequency meter and a FWDIREV starting

switch.

2.

TRANSPORTING

When transporting the FREQROL-K, handle

it

gently to prevent damage. There are depressions on both the

top and the bottom where the unit can be grasped, and these should be held when

it

is moved.

Do not apply too much force to the fan at the bottom of the unit. The unit is covered with a plastic case,

and care should be taken not to apply force only to this cover during transport.

a

3.

INSTALLATION

o

Place the inverter in a clean and well ventilated location. Avoid locations exposed to direct sunlight, or

subject to high temperatures, humidity, dust or corrosive gases.

0

Install the inverter securely on the wall with volts or screws, vertically so that the letters "FREQROL-K"

appears front.

0

Since the inverter does generate some heat during operations, any other equipment or parts should be

installed at least 10 cm away from up and the bottom to prevent heat confined.

The brake resistor attached to the rear of the unit also generates heat, so the unit should not be placed on

a wall with low heat resistance.

0

If your inverter is one equipped with an operation panel, take care to put

it

in a place where

it

can be

easily operated.

4.

WIRING AND POWER SUPPLY RATING

4-1

Wiring

Connect wiring correctly according to following instructions and refer to Fig. 1, Standard Wiring

Diagram.

Fow wiring of the peripheral devices such as MCCB, refer to Table

2,

Selection of Peripherals.

(1)

When the wiring cover located at the bottom of the inverter

is

pushed inward and then pulled

toward the operator, the wiring cover alone

is

removed thus exposing all terminal blocks. A

corrugated gripping surface has been provided for your convenience. Now perform wiring.

(2)

The wirings of the frequency setter, FWDIREV start switches, frequency meter and calibration

resistor of meter equipped with an operation panel in Fig. 1 have already connected.

(3) Do not wire the power cable in such a manner that the line source voltage is directly applied to

the output terminals

U,

V

and

W.

(4)

It

is

not always necessav to provide wiring to the reset switch, since the circuit can be restored

by cutting off

MCCB

or Magnetic Contactor (MS) if the output protective circuit has been

activated to stop the controller.

(5)

Since terminals P and N have been provided for brake unit and discharge resistor connections,

avoid connecting only discharge resistor, or any other equipment, to these terminals.

(6)

It

is not necessary to consider the phase sequence when connecting to terminals R, S and T.

(7)

Since the frequency setting signal current

is

extremely low

if

it

is necessary to use contacts in the

frequency setting circuit, use two pairs of parallel contacts or twin contacts for extremely low

current to prevent poor contact.

(8)

Use

shielded wires or twisted wires as the wire cable in connections to the control terminals

(terminals marked as

in Fig. 1, Standard Wiring Diagram) to prevent the control circuit from

being induced by other equipment, and also connect them away from the main circuit and high

voltage circuit (Relay sequence circuit of

230V. 115V).

Twisted wire

.~.

Shielded wire

Frequency setter Frequency setter

(9)

The output wires from the inverter are protected from short-circuiting (i.e., short-circuiting

among terminals

U,

V and W) by an overcurrent protective circuit. However, there is no protection against shortcircuit caused by accidental leakage such as grounding. Therefore, care

should be taken to position the wires so as to prevent them from making contact with the chassis,

etc.

(10) Rotation direction of the motor is counterclockwise as seen from the load side with the normal

wiring to the output terminals

U,

V and W.

4-2

Power

supply

rating

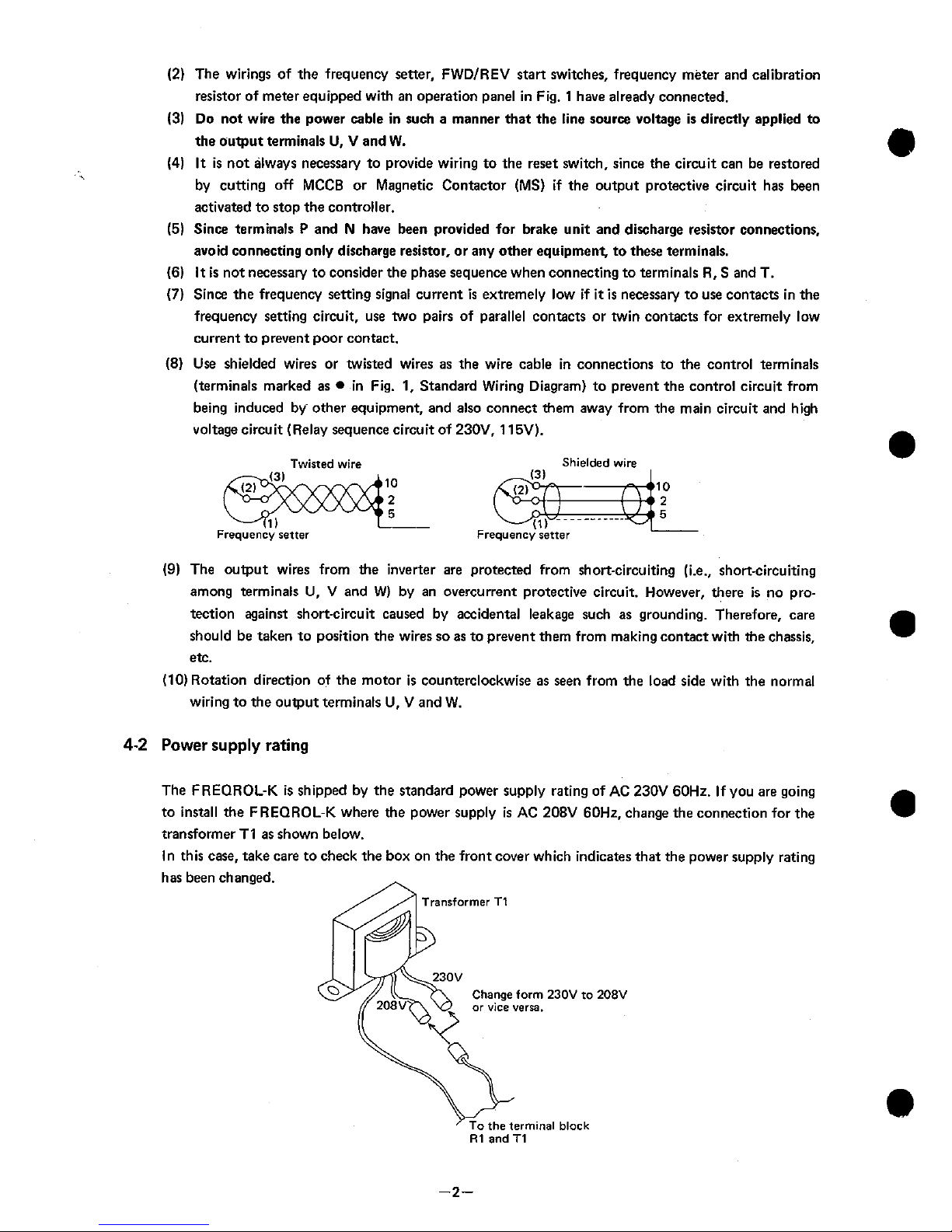

The FREQROL-K is shipped by the standard power supply rating of

AC

230V 60Hz. If you are going

to install the FREQROL-K where the power supply

is

AC

208V 60Hz, change the connection for the

transformer TI as shown below.

In this case, take care to check the box on the front cover which indicates that the power supply rating

has been changed.

Transformer T1

Change

form

230V

to

208V

or

vice verra.

the terminal black

R1

and

T1

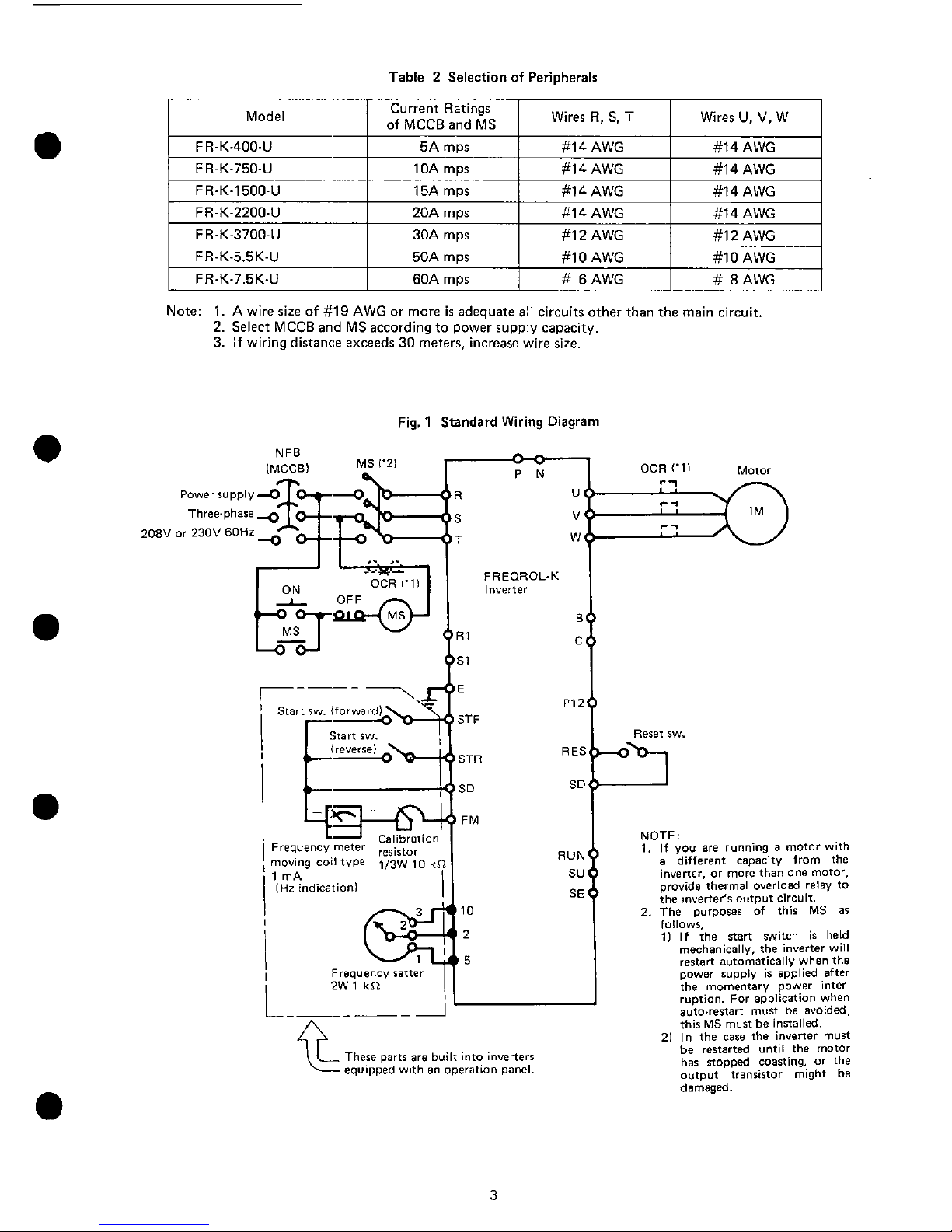

Table 2 Selection of Peripherals

Model

Current Ratings

/

of

MCCR

ad

MS

/

Wires

R,

S.

T

I

Wires

U,

V,

w

I

F

R-K400-U

F

R-K-7504

F

R-K-1500-U

Note:

1. A

wire size of

#19 AWG

or more

is

adequate all circuits other than the main circuit.

2.

Select MCCB and MS according to power supply capacity.

3.

If wiring distance exceeds

30

meters, increase wire size.

FR-K-2200-U

FR-K-3700-U

FR-K-5.5K-U

FR-K-7.5K-U

Fig. 1 Standard Wiring Diagram

5A

mps

10A

mps

15A

m~s

NFB

IMCCBI

MS 1'21

/L

9

20A

mps

30A

mps

50A

mps

60A

mps

Calibratiot

Frequency meter

moving coil type

113~

10

k

1 mA

(Hz indication]

#14 AWG

#I

4 AWG

#14 AWG

Frequency setter

2W

1

kSL

#14 AWG

#14 AWG

#14 AWG

#14 AWG

#I

2

AWG

#lo

AWG

#

6 AWG

-

-

1

OCR ('11 Motor

#14 AWG

#12 AWG

#I0 AWG

#

8

AWG

FREOROL-K

Inverter

I

STF

Reret aw.

STR

SD SD

FM

are

built into inverters

an

operation panel.

NOTE:

1.

If you

are

running a motor with

a

different capacity from the

inverter,

or

more than one motor.

~rovide thermal overload relay to

the inverter's

output circuit.

2. The purpores of this MS

as

follows,

11 If the nsrt switch is held

meCnanlCB

v,

tne

nverter

w

I

restart a.tomat'ca

v

nnon

the

mner

I.OD~Y

I

am

e0

after

..

.

.

.

the momentary power interruption. For application when

auto.restart must be avoided.

this MS must be inrtalled.

21 In the

case

the inverter must

be restarted until the motor

has sopped coasting,

or

the

output transinor might be

damaged.

5.

OPERATIONS

5-1

Points

to

check before operations

After installation and wiring of FREQROL-K

is

completed, check the following points before opera-

ting.

If insulation

is

to be checked with a megger, perform only the test between controller and grounding.

Never perform a megger test between the inverter's terminals.

Also do not perform a megger ten on the control circuit terminals.

Refer to section

6

for details on megger insulation tests.

(1)

Check whether wiring conforms to the standard wiring diagram.

(2) Check for points short-circuited by broken wire, etc.

(3)

Check if any wire is strained.

(4) Check tightness of screws, of terminals and other fasteners.

(5) Check motor load conditions.

5-2

Preparations before

operations

When inspection is completed, open the setting panel flap on the inverter front panel and make the

following setting.

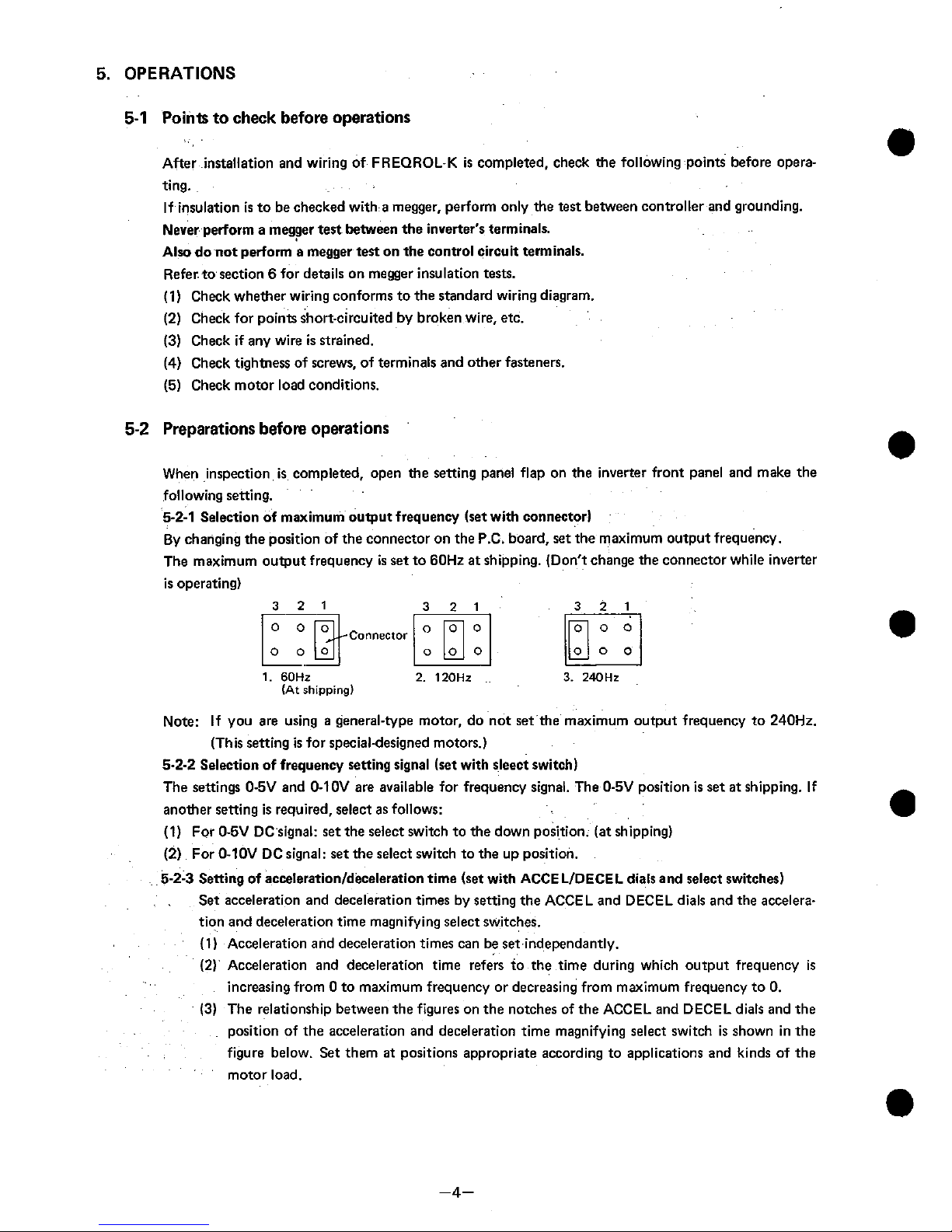

5-2-1

Selection of maximum output frequency (set with connector)

By changing the position of the connector on the P.C. board,

set

the maximum output frequency.

The maximum output frequency

is

set to 60Hz at shipping. (Don't change the connector while inverter

is operating)

1.

60Hz

(At

shipping)

Note: If you are using a general-type motor, do not set the maximum output frequency to 240Hz.

(This setting

is

for specialdesigned motors.)

5-2-2

Selection of frequency setting signal (set with sleect switch)

The settings O-5V and 0-10V are available for frequency signal. The 0-5V position is set at shipping. If

another setting is required, select as follows:

(1) For 0-5V DC signal:

set

the select switch to the down position. (at shipping)

(2) For 0-10V DC signal: set the select switch to the up position.

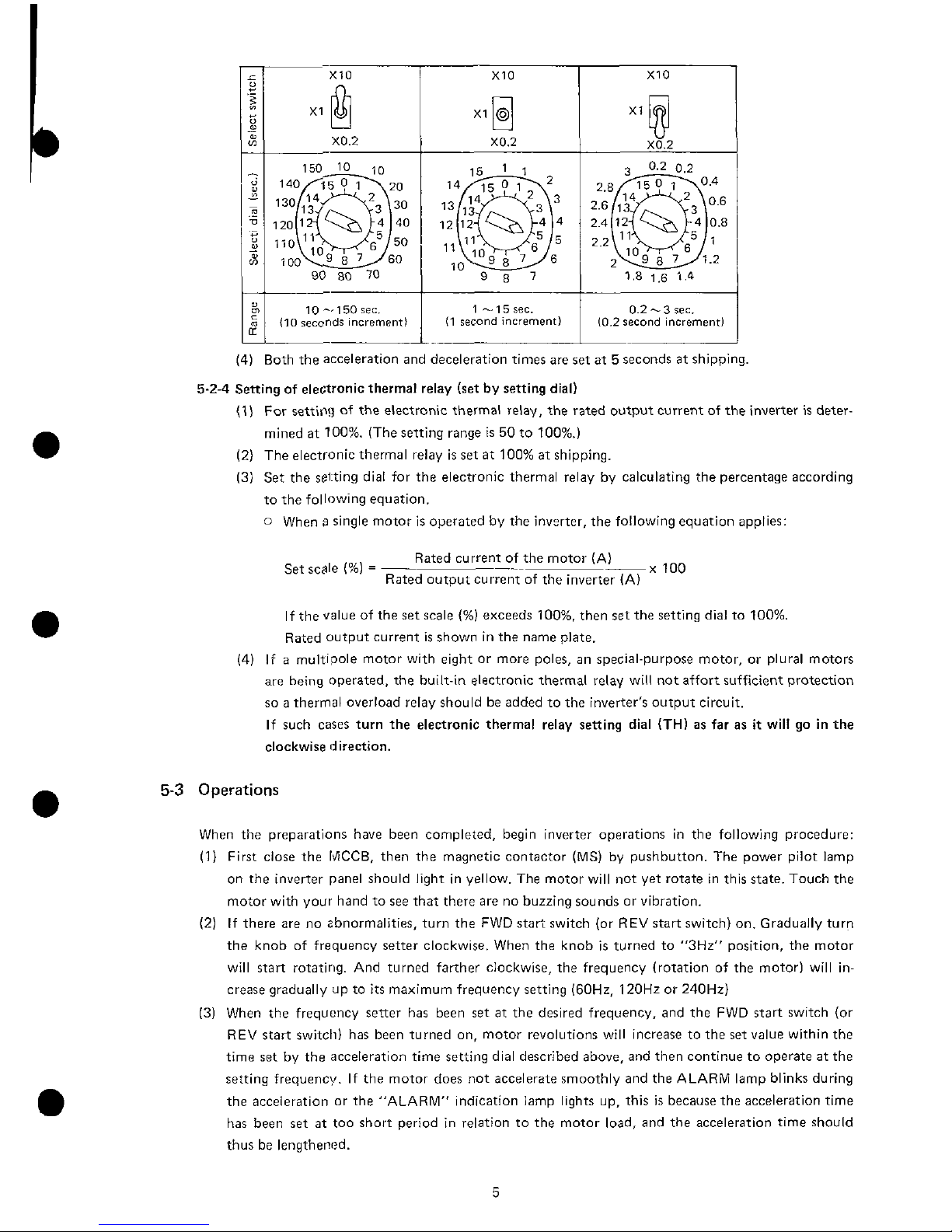

5-2-3

Setting of

accelerationldeceleration

time (set with ACCE LIDECEL dials and select switches)

Set acceleration and deceleration times by setting the ACCEL and DECEL dials and the acceleration and deceleration time magnifying select switches.

(1) Acceleration and deceleration times can be

set

independantly.

(2)

Acceleration and deceleration time refers to the time during which output frequency

is

increasing from 0 to maximum frequency or decreasing from maximum frequency to 0.

(3)

The relationship between the figures on the notches of the ACCEL and DECEL dials and the

position of the accelerat~on and deceleration time magnifying select switch

is

shown in the

figure below. Set them

at

positions appropriate according to applications and kinds of the

motor load.

10 -150

rec.

110

secor~ds

increment)

0.2

-3

sec.

10.2

second

increment1

(4) Both the acceleration and deceleration times are set at 5 seconds at shipping.

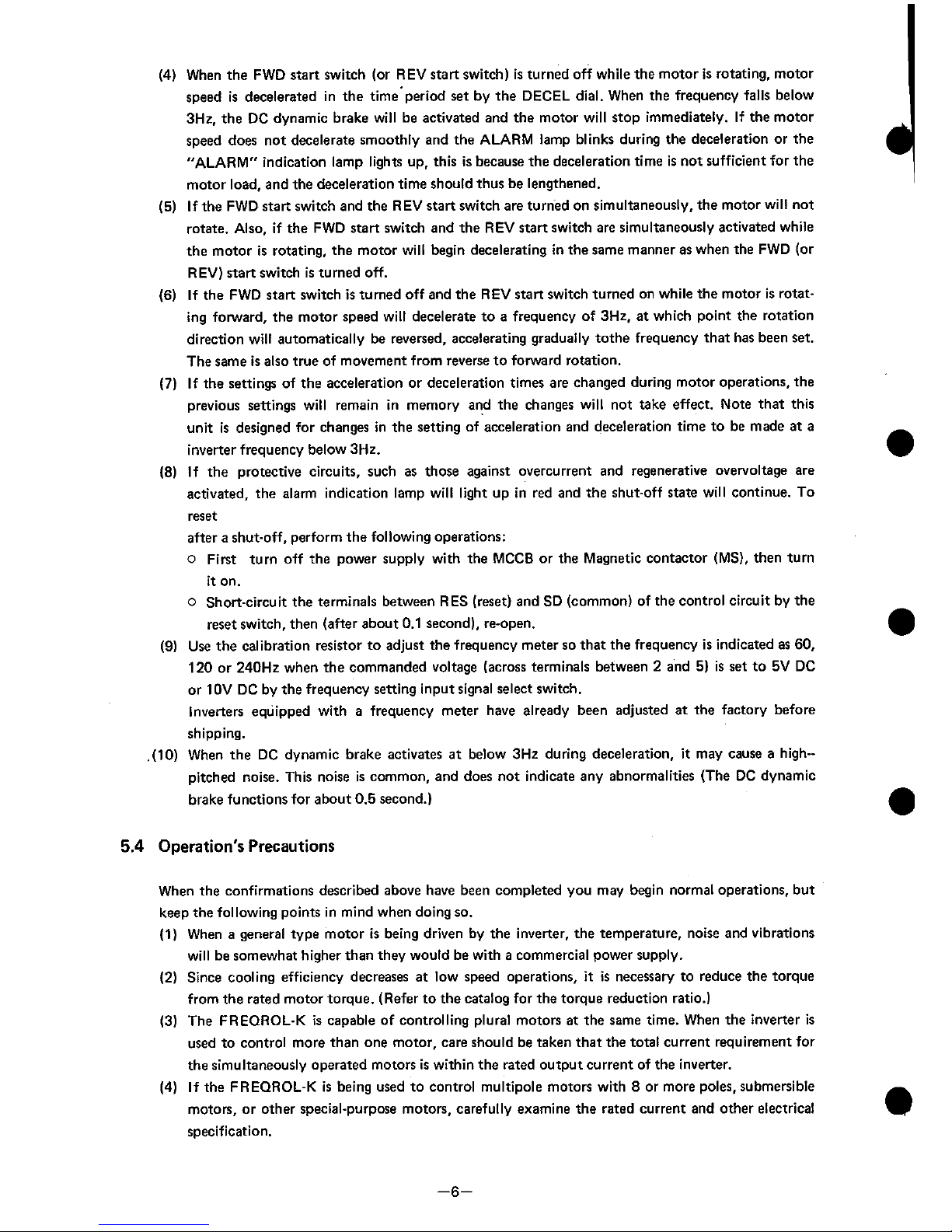

5-2-4 Sening of electronic thermal relay (set by setting dial)

(1) For setting of the electronic thermal relay, the rated output current of the inverter is deter-

mined at 100%. (The setting range

is

50 to loo%.)

(2) The electronic thermal relay is

set

at 100% at shipping.

(3) Set the setting dial for the electronic thermal relay by calculating the percentage according

to the following equation.

0

When s single motor is operated by the inverter, the following equation applies:

Rated current of the motor (A)

Set scale

(%)

=

-

x

100

Rated output currentof the inverter (A)

If the value of the

set

scale

(%)

exceeds 100%. then

set

the setting dial to 100%.

Rated output current

is

shown in the name plate.

(4)

If a multipole motor with eight or more poles, an special-purpose motor, or plural motors

are

being

operated, the built-in electronic thermal relay will not affort sufficient protection

so a thermal overload relay should be added to the inverter's output circuit.

If such cases turn the electronic thermal relay setting dial

(TH)

as far as

it

will go in the

clockwise direction.

5-3

Operations

When the preparations have been completed, begin inverter operations in the following procedure:

(1) First close the

MCCB,

then the magnetic contactor (MS) by pushbutton. The power pilot lamp

on the inverter panel should light in yellow. The motor will not yet rotate in this state. Touch the

motor with your hand to see that there are no buzzing sounds or vibration.

(2) If there are no zbnormalities, turn the FWD start switch (or REV start switch) on. Gradually turn

the knob of frequency setter clockwise. When the knob is turned to

"3Hz" position, the motor

will start rotating. And turned farther clockwise, the frequency (rotation of the motor) will increase gradually ap to

its

maximum frequency setting (60Hz. 120Hz or 240Hz)

(3) When the frequency setter has been

set

at the desired frequency, and the FWD start switch (or

REV start switch) has been turned on, motor revolutions will increase to the set value within the

time

set

by the acceleration time setting dial described above, and then continue to operate at the

setting frequency. If the motor does not accelerate smoothly and the ALARM lamp blinks during

the acceieration or the "ALARM" indication lamp lights up, this is because the acceleration time

has been

set

at too short period in relation to the motor load, and the acceleration time should

thus be lengthened.

(4) When the FWD start switch (or REV start switch) is turned off while the motor is rotating, motor

speed is decelerated in the time'period set by the DECEL dial. When the frequency falls below

3Hz. the DC dynamic brake will be activated and the motor will stop immediately. If the motor

speed does not decelerate smoothly and the ALARM lamp blinks during the deceleration or the

"ALARM" indication lamp lights up, this is because the deceleration time

is

not sufficient for the

motor load, and the deceleration time should thus be lengthened.

(5) If the FWD start switch and the REV start switch are turned on simultaneously, the motor will not

rotate. Also, if the FWD start switch and the REV start switch are simultaneously activated while

the motor

is

rotating, the motor will begin decelerating in the same manner as when the FWD (or

REV) start switch

is

turned off.

(6) If the FWD start switch is turned off and the REV start switch turned on while the motor is rotat-

ing

forward, the motor speed will decelerate to a frequency of 3Hz. at which point the rotation

direction will automatically be reversed, accelerating gradually tothe frequency that has been set.

The same is also true of movement from reverse to forward rotation.

(7)

If the settings of the acceleration or deceleration times are changed during motor operations, the

previous settings will remain in memory and the changes will not take effect. Note that this

unit

is

designed for changes in the setting of acceleration and deceleration time to be made at a

inverter frequency below 3Hz.

(8) If the protective circuits, such as those against overcurrent and regenerative overvoltage are

activated, the alarm indication lamp will light up in red and the shut-off state will continue. To

reset

after a shut-off, perform the following operations:

0

First turn off the power supply with the MCCB or the Magnetic contactor (MS), then turn

it

on.

0

Short-circuit the terminals between RES (reset) and SD (common) of the control circuit by the

reset switch, then (after about 0.1 second), re-open.

(9)

Use the calibration resistor to adjust the frequency meter so that the frequency

is

indicated as 60,

120 or 240Hz when the commanded voltage (across terminals between 2 and 5)

is

set to 5V DC

or 10V DC by the frequency setting input signal select switch.

Inverters equipped with a frequency meter have already been adjusted at the factory before

shipping.

(10) When the DC dynamic brake activates at below

3Hz during deceleration,

it

may cause a highpitched noise. This noise is common, and does not indicate any abnormalities (The DC dynamic

brake functions for about 0.5 second.)

5.4

Operation's Precautions

When the confirmations described above have been completed you may begin normal operations, but

keep the following points in mind when doing so.

(1)

When a general type motor is being driven by the inverter, the temperature, noise and vibrations

will be somewhat higher than they would be with a commercial power supply.

(2) Since cooling efficiency decreases at low speed operations,

it

is

necessary to reduce the torque

from the rated motor torque. (Refer to the catalog for the torque reduction ratio.)

(3) The FREQROL-K is capable of controlling plural motors at the same time. When the inverter is

used to control more than one motor, care should be taken that the total current requirement for

the simultaneously operated motors

is

within the rated output current of the inverter.

(4) If the FREQROL-K

is

being used to control multipole motors with 8 or more poles, submersible

motors. or other special-purpose motors, carefully examine the rated current and other electrical

specification.

(5)

Do not add a capacitor nor surge absorber to the output circuit of the inverter. This may activate

the overcurrent protection.

(6)

If you are using a motor with mechanical brakes, the brake exciting circuit should not be connected to the inverter output, and make certain theat brake action can be affected after turning

off the inverter's power supply.

(7)

If using motors of different capacity or special-purpose motors, or if more than one motor is being

used simultaneously, add

a

thermal overload relay to the inverter output circuit to protect the

motor from being burned up. In this case turn the electronic thermal relay setting dial (TH) on

the operation panel as far as

it

will go in the clockwise direction.

(8)

Th= FR-K-400 can also be used with a single phase power supply, but when doing so be sure to

connect the power supply to terminals R and

S.

(9)

Since the built-in brake resistor will cause temperature increases, mount

it

on noninflammable

materials such as metal or concrete.

6.

MAINTENANCE AND INSPECTION

The FREQROL-K is the static type, so almost no daily maintenance is required. The following maintenance

practices should, however, be observed.

(1)

Since the capacitor in the inverter remains charged at high voltage for a while after the inverter is turned

off, perform inspections only after charge indication lamp "CHARGE" goes out. Also, the cooling fan

will continue to run for some time after the power has been turned off, so be careful to keep hands away

from this area.

(2)

From time to time, inspect the inverter for dust and dirt accumulated inside, and clean

it

if there is a

buildup.

(3)

Check the tightness of terminal block screws and mounting screws. If they come any loose, tighten

them securely. Make certain there are no defects in the wiring parts or components. Replace defective

wiring part if found, or contact your service representative.

(4) Megger test

a)

When performing a megger test on the external equipment, remove all inverter terminals so that the

test voltage will not be applied to the inverter.

b)

Perform megger tests only for the main circuit of the inverter as shown in Fig.

2.

Do not apply the

test voltage to the control circuit.

c)

TO check the FFiEQROL-K control circuit, use a multimeter (set to high resistance range position).

Do not use a megger or buzzer.

Fig.

2

Megger Test

-

Earth

terminal

7.

CONSTRUCTION AND ARRANGEMENT OF INVERTER PARTS

I

As noted above, wiring requires only the removal of the wiring cover at the bottom of the inverter. To

inspect the inverter's interior, however, proceed as follows:

(1)

When the wiring cover

is

removed, the plastic cover's two set screws will be exposed. Remove these

screws and slide the plastic cover upward.

(2)

The

P.C.

board of the control circuit has been attached by set screws (for inverters below class FR-K-

3700-U) or the board support (for FR-K-5.5K-U and FR-K-7.5K-U).

Fig.

3

Type

FR-K-400-U

to

FR-K-3700-U

Fig.

4

Type

FR-K-5.5K-U and FR-K-7.5K-U

Control circuit terminal arrangement

TR?

Control circuit terminal arrangement

TB4

8.

TROUBLESHOOTING AND COUNTERMEASURE

In the unlikely event that there should,be problems with the inverter or

its

should lose any of its functions,

use the troubleshooting chart below to identify the cause and apply the appropriate countermeasure.

If

your

problem

is

not described below, the inverter

is

out of order, one of the parts has been damaged or if you have

any other problem not dealt with here, contact with your local service representation.

8-1

Troubleshooting Chart

(1)

Motor does not run

START

ii

Note

1.

power supply has been

Are MCCB (ELB), MS.

Yes

terminals R and S, S

etc. turned

on?

Defective MCCB (ELBI

or

and

T.T and

S.

MS,

or

wiring trouble

lamp lit

up?

pacity transformer?

Inverter trouble

Cooling fan trouble

tion relay of radiation

Ventilation obstruction fan. Remove

Set reret rwitch lbetween terminals

Is reset switch "ON"? RES and SD) to

"OFF"

1s

voltage

across

termi-

t

yes

.(

Defective

reret

switch

nals RES

and

SD below

Transistor falls to function when energized.

14V?

L

No

lcont'd

on

next right page1

(cont'd from left pagel

I

No

I

Are

terminals STF and

Either STF or STR should

be

STR both ON?

continuity; not both.

J,

No

1s

voltage across termi-

nals STF lor STRI and

Poor start switch contact

SD greater than

1V7

,

Transistor fsilr to function when energized.

Has voltage been applied

P

to motor terminals

U

Has voltage been applied Yes

and V, V and

W,

and

W

>

to frequency command

Inverter trouble

,and

U?

J

terminals 2and 5?

I

v

Is

voltage across termi-

%,-

I

nalr 5 and

10

5V (or

trouble or wiring

trouble

Motor overload

Motor trouble

Magnetic brake does not open.

.

Motor trouble

Note

0:

ELL3 = Earth Leakage

Braker

Wiring trouble

Note 1: Out of voltage should

be

within

f

10%

of rated voltage.

Note

2:

Is

thermal overload relay IOCRI connected.

Note

3:

Imbalanced should be within

1%

of maximum output voltage.

Note

3.

Is

three-phase voltage

out of balance?

I

Yes

>

Is voltage still unbalan-

ced after disconnecting Inverter trouble

motor terminals.

(2)

Motor buzzes and does not run.

Note

4.

A

Does

frequency meter fail

to change

even

though

frequency setter has been

turned to increase?

Is output voltage

across

terminals U and

V. V

and W,

and

W and

U

Inverter trouble

out

of

balance?

Overload

causer

activation

Increase inverter capacity

of protection againat stalls.

and motor capacity.

Motor

trouble

Note

4:

Examine this with motor disconnected

(3)

Motor runs

at

constant speed and cannot be controlled.

/-,

OV

to

5~ lor

from

1~

to

Frequency

rener

trouble

10Vl

across

terminals

2

and

5

even

after

freque-

ncy setter has been tur-

ned

on?

No

Inverter trouble

(4)

Motor overheats.

u

Ir motor overloaded?

Yes

Lighten the load

or

increase capacity of motor and

No

Does

motor

run

at

low

speeds for long periods

Lighten the load

or

ventilate the motor from

of time?

or

increasecapacity of motor

and

inverter.

&

Note.

6

I

I

IS

output voltage among

terminals

U

and

V,

V

and W, Wand U out Of

Inverter trouble

balance?

Is

there any obstruction

to

motor cooling? Remove obstruction.

Inverter trouble

Note

5:

Overload should

be

below

110%

of motor rated current

l60Hz. 220V

ACI.

Note

6:

Proper balance

is

not more

1%

of maximum output voltage.

(5)

Motor

does

not

run

smoothly

Note

7.

Does problem occur Is accelerationldecele- ngthen acceleration1

during acceleration/ ration time

too

short?

deceleration time.

deceleration?

I

Does output voltage

fluctuctuate?

Load

4

too heavy.

Increase capacity of

motor and inverter.

\L

Is voltage out of balance

amaung terminals

U

and

yes

V,

V

and

W.

W

and

U?

NO

Har there been

a

load Yes

Minimize load variation

or

attach flywheel to motor.

vibration?

Run

with load vaciation.

Is there any backlash in

chain, gear. etc.?

Improve mechanical parts.

No

Capacitor

for

constant

Has inverter been

used

output voltage has been

for

5t0

10

years?

used beyond service life.

Inverter trouble

Note

7:

Anivatlon

of

protectton function against stalls causes unstable

acceleratianldeceleratian

8-2

Failures Indicated

by

Lighting of Alarm Indication Lamps and How to Deal with Them

The protective functions can be activated by various conditions, as shown below. If an alarm indication

lamp lights up,

it

is

important to keep your head and examine the cause of the problem, and then to

apply the appropriate countermeasure.

Alarm

Uarm

ndication

amp "ON'

Cause

Acceleration time

is

too

short.

Inverter's output circuit

is

turned on and off.

Peak load reached

nstan-ianeously.

Load

is

too heavy

Built-in brake is being

lsed too frequently.

-.

:Ither a capacitor for

lower factor improvement

lr a capacitor for surge

jbsorber has been inserted

3t

inverter's output circuit.

jhort-circuit or ground

'ault in the output circuit

)f the inverter.

Motor

is

turned on again

luring free running (runnin

sf

inertia force after power

ias been turned off).

Description

Check whether the magneti

contactor has been turned

on after the inverter start

signal (ST) went ON.

Even after acceleration timt

has been lengthened, motor

hardly runs before the alarn

indication lamp lights up.

(The electronic thermal

relay has been activated dut

to overload or overheating

caused by low speed operations, thus turning alarm

indication lamp on.)

Deceleration may be done

in several stages. If the

maximum number

all~wabl~

is exceeded, however, this

will increase the frequency

of use of the brake, and an

alarm indication lamp will

come on.

There is an overcurrent

because impedence of

capacitor is small against

high frequency.

Ground faults do not alway

cause an overcurrent trip

(OCT) state. If a ground

fault occurs, it may lead to

inverter trouble.

Since inverter starts operation at

3H2,

motor runs by

regenerative operation,

which generates overcurreni

Countermeasure

Lengthen acceleration1

deceleration time.

Correct sequence if wrong.

If

it

is

necessary to turn on

and off of inverter's output

circuit, increase the capacit

of inverter by five times or

more.

Adjust machine so that

peak load

is

not reached.

Increase capacity of in-

verter by

1

or 2 class.

Since static friction torque

is

larger than the torque of

motors under

3Hz

at startup, increase capacity of

motor and inverter. Lighter

the load or change operations partern.

Either lengthen the deceleration time or lessen its

frequency. Add an external brake unit.

Remove them. If they

have been factory-set, care

should be taken not to

forget to remove them.

It

is recommended to

insert a reactor into the

input circuit in order to

improve the power factor.

Locate the short-circuited

points and apply the appropriate countermeasure.

Restart the motor only

after

it

has stopped completely.

In automatic operation, use

a timer to start the motor

after

it

has stopped completely.

Alarm

Alarm

indication

lamp "ON"

Cause

I

Description

Activation of the

temperature detection

relay of the rediation fin.

External noise.

When the fin for cooling

power modules

is

overheated, the temperature

sensor activates to stop

output

Consider the possibility

of external noise when

the alarm indication lamp

lights up for causes other

than these described above.

t

Countermeasure

Instantaneous power

failure.

Cooling fan trouble or

ventilation obstruction in

radiation fin has caused a

rise

in temperature, so

remove those troubles.

Twisted wire or shield

wire are used fo the frequency setting signal circuit

(10,

2.5).

Shield wire

should be connected to

terminal

"5

only and do

not connect shield wire

with grounding or around

terminal of other circuit

(i.e., instrumentation

circuit).

Reset the inverter and

restart

it.

If you wish to

keep the alarm state on

display, use an external

circuit.

If there has been an in

stantaneous power failure

for

15

msec or more, and

the power supply has been

restored before the motor

has stopped after a free

running, overcurrent may

occur.

Note: If you cannot identify the trouble even after checking all the points listed above, try discon-

necting the motor from the inverter. If the alarm indication lamp still comes on, there has been

a breakdown in the inverter.

8-3

Measuring Voltage

and

Current

Since the primary and secondary voltage and current contain high frequency, data may differ depending upon the instrument used and the circuit to be measured.

If you use

a

measuring instrument for commercial frequency, select one listed in Table 3 and measure

the circuit as shown in Fig.

5

Variation of the indicated value are shown in Fig.

6.

However, even measuring instruments of the same

accuracy may be inconsistent because of differences in factors such as manufacturer, model type or

year made, etc.

FR-K

Inverter

7

Fig. 5 Points to be Measured and Examples of Measuring Instruments

Example: Output voltage

of

inverter

Motor rating:

3.7

kW

4P

FR-K.3700-U

Inverter

Take

the indicated

value

of

rectifier type voltmeter

as

100%.

4

Rectifier type

k

Moving-iron type

Electrothermic type

Fig. 6 Variation of Indicated Value Depending on the Type of the

Measuring Instrument

Table 3 Terminals to be Measured and Measuring Instrument

Item

Supply voltage: V1

Current at power supply:

I1

Terminals to be measured

Across terminals R and S,

Sand T, and T and R.

Line current at terminals

R, S and T.

Terminals R, Sand T and

across terminals R and S,

and S and T.

Power at power supply:

P1

Power factor at power

supply: Pfl

Measuring instrument

Moving-iron type

9:

fi

Moving-iron type

Electro-dynamo-

meter type

Measure supply voltage (Vl), current at power supply (11) and power at powet

supply (PI

),

and calculate power factor using equation shown below:

Remarks (reference value)

Commercial voltage:

230V

P

=

WII

+

Wn

Voltage at output: V2

Pfl

=

PI

fiV1

.

I1

100%

Difference between each

Across terminals

U

and V,

V and W, and Wand

U.

phase should be within

10%

Rectifier type

+

(Moving-iron type

is

not available)

Current at output: 12

Below rated current of

inverter

Difference between each

phase should be within

10%.

Line current at terminals

U,

V and W.

Power at output: P2

Moving-iron type

Terminals

U,

V and W and

Electro-dynamo-

across terminals

U

and V,

$

meter type

and V and W.

Power factor at output:

Pf2

Calculate in a similar manner as for power supply, using the following equation:

Output of converter Across terminals P and

N

Moving-coil type

(such as multi-

meter)

Charge lamp lights up

when voltage is

10V DC

or more.

1.35 x v1

Maximum 380V DC

during regeneration.

0 to 5V DC

I

3

Movinwcoil tvpe

Frequency setting signal Across terminals 2 and

5

(such

is

multi-.

W

meter)

(internal resistance

5 0 kCl or more)

Power supply for frequency setting

Across terminals 10 and 5

Across terminals FM and

SD

About 5 V DC at

maximum

frequenq

(when frequency

meter is connected.)

Open: 13V DC to

19V DC

ON voltage:

1

V

DC or

less

OFF voltage:

13V DC or more

Power supply fot

frequency

Forward operation signal Across terminals STD and

SD

Reverse operation signal

Across terminals STR and

SD

Reset Across terminals RES and

SD

Base shut-off (alarm)

signal

Across terminals Band C

Moving-coil type

(such as multimeter)

Measuring continuity

Continuity when power

supply is shut off or

during normal operations.

9.

STANDARD SPECIFICATIONS

FR-K- FR-K- FR-K- FR-K- FR-K- FR-K- FR-K400-U

/

750-U 1500-U 2200-U

2.700-U

/

55K-U

7.5K.U

I

Nominal output (HP)

-

Output capacity (kVA)

-

Rated output current (A)

Maximum output voltage

Power source requirement (kVA)

ilVeight (kg)

Construction Totally enclosed type

1

Enclosed type

Voltagelfrequency

Allowable voltage regulation

Allowable frequency regulation

Control method Sinusoidal PWM,

Voltage-control

Frequency range

1

:

10

(6 - 60Hr) or

1 : 20 (6 - 120Hz) or 1 : 40 (6 - 240Hz) selectable

(Operation starts at 3Hz)

Frequency resolution

(Hzlmaximum frequency)

Frequency accuracy

Voltageifrequency ratio

VoltagefFrequency ratio is constant until 60Hz.

Voltage

is

constant above 60Hz

7-

;

Overcurrent resistance

I

Frequency setting signal

150% for one minute

0 - 5V DC, 0 - 10V DC changeable

i

i

Acceleration1deceleration time

0.2

-

3.0 rec. (in 0.2 sec. increments),

1

-

15 sec. (in 1 sec. increments),

10

-

150 sec. (in 10 sec. increments) selectable

Regenerative braking torque Over 70% of rated motor torque (short time rating)

Protection against stalls caused by overcurrent, protection against stalls

caused by regenerative overvoltage, overcurrent protection,

regenerativ,

overvoltage protection, overload protection (electronic thermal relay),

instantaneous power failure, thermo detect of the heatsink (*3), alarm

against overload.

Protective functions

-1 O•‹C to +40•‹C

-1 0•‹C to +50•‹C

(To be free from freezing)

(To be free

from freezing)

Ambient temperature

Ambient humidity

Below 90% (To be free from condensation)

To be free from

To

be free from corrosive gas

corrosive gas

and dust

.

--

Less than 1,000 m

Atmosphere

Altitude

Vibration Less than 0.5G

phase power supply

of

200V 50Hz. 2001220V

AC

60Hz.

ncy

resolution

at

accelerationldeceleration

is

one

half

of

table

value.

ipped with

thermo

detect

of

the heatrink.

17

10.

PROTECTIVE FUNCTION

The protective functions listed below are built into the FR-K Series inverters.

When the protective circuits are activated, output is stopped by shutting off the base of the transistor so that

the modules are protected. This will cause the motor to stop after a brief free run. To start again,

it

is neces-

sary to either reset by using the reset terminal "RES", or to turn off and on the power.

Protection against stalls

caused by overcurrent

Protection against stalls

caused by regenerative

overvoltage

Overcurrent protection

Regenerative overvoltage

protection

Instantaneous power failurl

protection

Overload protection

(electronic thermal relay)

Overload alarm

Thermo defect of the

heatsink

lote: When the overcurren

tection

is

activated,

;

magnetic contactor

(

to retain the alarm

independently. In or

and

Sl,

and connect

t

P

an

MZ

disl

de~

the

If an overcurrent more than 150% of the rated current occurs during acceleration,

the freauencv increase is stopped and freauencv

is

keot until the load current has

been reduced, thus preventing the inverte; from the stall.

If

an overcurrent larger

than 150% of the rated current occurs during normal operations (at constant

speed), the frequency is decreased until the load current has been reduced, thus

preventing the inverter from the stall. When the load current has been decreased

below

156%. frequency will be increased again and acceleration will be continued

to reach the set frequency level.

This protective circuit detects any regenerative energy during deceleration, so

tha

the frequency decrease will be stopped until the output voltage of the capacitor

has been reduced, thus preventing the inverter from the stall. When the regenerative energy has been reduced, frequency will be decreased again and deceleration

continued.

If an overcurent

larue than 200% of rated outout current is detected throuuh the

output current, the-overcurrent protection circuit will

be

activated to cut

iff

the

transistor circuit and keep

it

off. (When an overcurrent protection circuit has beel

activated, the alarm indication lamp will light up.)

(Activation of the overcurrent protection circuit is caused mainly by a power

supply decrease, extreme load inertial

(GDz

1,

extremely short preset acceleration

time, or a short-circuit in the inverter secondary circuit, so to remove the trouble

and restore the circuit examine all possible failure.)

When an overvoltage is caused by regenerative energy at the converter output, the

protection circuit is activated to cut off the transistor circuit and keep

it

off. (An

alarm indication lamp will light up in such cases.)

(Activation of the rGeneratLe overvoltage protection circuit

is

caused mainly by

an extremely short preset deceleration time, so lengthen the preset deceleration

time or consider using the optional brake unit.)

If a power failure continues for

15

msec or more, the instantaneous power failure

protection circuit

is

activated to cut off the transistor circuit and keep it off. (An

alarm indicator will light up in such cases.)

If the power failure

is

within 15 msec, the protection circuit will not work and th

control circuit will continue operation.

Any overload while the motor

is

running under its rated condition or overheating

at low speed running

is

detected by an electronic thermal relay, which cuts off thl

transistorcircuitand keeps itoff. (Alarm indication lamp will Iightup insuch cases.)

(Check the cause of the overload and either lighten the load, change the opera-

tions pattern or reconsider the capacity of inverter and motor.)

If the motor becomes overloaded, an alarm indication lamp will go on and off. If

overload increases further. the overcurrent protection function will be activated.

If the alarm indicator goes on and off during

accelerationldeceleration,

preset to

longer

accelerationldeceleration

times. If an alarm indication begins blinking

during fixed speed operation, lighten the load or reconsider the capacity of

inverter and motor.

When the heat sink is overheated through a decrease in the cooling effect of the

semiconductor, the temperature

sensor~is activated to stop the function and

output of the power element and to keep them off. (An alarm indicator will light

up in such cases.)

l~xamine the cooling fan and the ambient temperature.)

However. inverters below tvoe FR-K-750 are not provided with this function,

A

~rotection, regenerative overvoltage protection, or instantaneous power failure pro-

alarm indicator lamp lights up and that state will be retained. However, when the

i)

is opened by an alarm signal, the alarm display will not be retained. If you wish

play, design the circuit so that main circuit and control circuit are configurated

r

to retain the display of an alarm, disconnect control circuit power terminal R1

!separate power.

11.

INPUT/OUTPUT

TERMINAL

Description

7

Terminal

symbol

Terminal name

Rating

When FR-K-400 is used with single-phase power

supply, connect

it

at terminals R and S.

R.S.T.

E

U.V.W.

4C powered supply

nput terminal

--

Sround terminal

Be sure to ground both inverter and the panel box

which encloses

inverier.

--

Output terminals for

notor

Connection for three-phase induction motor.

I

3utput terminals for

:onverter

Terminals for connection of regenerative brake

unit.

Never connect anything other than brake unit to

these terminals.

'ower supply terninal for frequency

setting

5V DC

?

0.01V DC

Allowable load

current:

6

mA

Use these terminals as power supplies for external

setters such as the variable resistor for frequency

Setting (motor speed setting).

Terminals for inpilt

iignal of frequency

lnput resistor

11

ka? 1 kc2

lnput resistor 2.5

kc2

Open voltage

14 to 20V DC

Optoelectronic

isolator

Controllable by

means of opencollector.

Maximum frequency

(60Hz. 120Hz, or 240Hzl

is obtained at 5V (1OV).

STF-SD

STR-SD

lnput terminal for

forward start signal

Forward start by closing terminals between STF

and SD, stoppage by opening them

Reverse start by closing terminals between STR

SD, stoppage by opening them.

Closing terminals between STF and SD, and STR

SD simultaneously causes stop command.

lnput termial for

-everse start signal

3utput terminal for

irequency meter

~

~~

-

Appromixately 5V DC is obtained at maximum

frequencies (60Hz. 120H2, or 240Hz) and output

voltage

is in proportion with the frequencies.

Connect moving-coil type ampere meter

(DC

1 mA) with terminals FM and SD. Use calibration

variable resistor 10K 1/3W by inserting

it

in series

FM-SD

Allowable load

current: 1 mA

Optoelectronic iso!ator output voltage

form

is

oulse.

RES-SD

B-C

Input terminal fol

;ignal

lnput resistor 4.7

kc2

Open voltage

14 to 20V DC

Optoelectronic isolator

Controllable by

means of opencontroller

For resetting emergency stop of the inverter

caused by the activation of protection circuit.

Resetting initializes each part of the control

circuit immediately, and the circuit to inverter and

converter

is

shut off. To give this reset command,

it

is necessav to short-circuit across terminals RES

and SD for 0.1 second or more. Initial reset is

automatically performed inside the controller

0.2 to 0.4 seconds later after power up.

-

Contact output

230V AC 0.3A

cos@

=

0.4

30V DC 0.3A

3utput terminal for

alarm

Normally closed contact that provides alarm signal

when protective circuit is activated.

When this signal is provided, power to the converter and inverter are cut off and the motor will

stop after free running.

symbol

Terminal

I

Terminal name

Rating

Description

RUN-SE

SU-SE

Output terminal

controller operations

Output terminal for

correspondence of

frequencies

Power supply terminal for control

circuit

Open-collector of

transistor

Allowable load

23V

DC

0.1A

Exclusive terminal for

manufacturer check

Open-collector:

L

...

when the commanded frequency

is

above

3H

H

...

normally

Use power supply

24V

DC

with ripple voltage

within 10%.

Output terminal that indicates whether the actual

frequency corresponds to the preset frequency:

Open-collector:

L

...

corresponds

H ...

does not correspond

These terminals are connected internally with

input terminals

R and S. To retain an alarm

display, disconnect from terminals

R and S, and

connect external control circuit power supply

with terminals R1 and S1.

Fig.

7

Black Diagram

IB

INA)

64525-8

185031

ROD

Printed

in

Jaoan

S~ecification rubiect to

chanae

withnur

novice

Loading...

Loading...