MITSUBISHI ELECTRIC

Frequency

Inverter

FR-F 740 EC/E1

Technical Catalogue

2004/2005

The new FR-F 740 inverter series

The new FR-F 740 frequency inverters are available with outputs

from 0.75 – 630 kW and are ideal for applications with pump and

The Power-Saving

Inverters

fan drives.

They use a 3-phase AC power supply and have an output

frequency range of 0.5 – 400 Hz.

Further Publications within the Factory Automation Range

Technical Catalogues Frequency Inverters

Product catalogue for frequency inverters and accessories

of the FR-S 500, FR-E 500 and FR-A 500 series

Technical

Catalogues

Additional Services

You will find current information on updates, alterations, new items and technical support on MITSUBISHI ELECTRIC's web pages

(www.mitsubishi-automation.com).

The products section of the MITSUBISHI home site includes various documents for the whole product range offered by MITSUBISHI ELECTRIC

as well as the current version of this catalogue. All manuals and catalogues can be downloaded for your convenience. Manuals and catalogues are

available in multiple language. Please check for availability.

Technical Catalogues MELSERVO and Motion Controllers

Product catalogues for MR-J2 series amplifiers, servo motors

and motion controllers with SSCNET connection

PLC Technical Catalogues

Product catalogues for programmable logic controllers and

accessories for the MELSEC series

Networks Technical Catalogue

Product catalogue for Master and Slave modules as well as

accessories for the use of programmable logic controllers in

open networks and MELSEC networks

HMI Technical Catalogue

Product catalogue for operator terminals, process visualisation and

programming software as well as accessories

About this product catalogue

Due to the constantly growing product range, technical alteration, and new or changed characteristical features, this catalogue is updated

frequently.

Texts, figures and diagrams shown in this product catalogue are intended exclusively for explanation and assistance in planning and ordering the fre

quency inverter series FR-F 700 EC/E1 and the associated accessories. Only the manuals supplied with the units are relevant for installation, commis

sioning and handling of the units and accessories. The information given in these documentations must be read before installation and commission

ing of the units or software.

Should questions arise with regard to the planning of modules described in this product catalogue, do not hesitate to contact your nearest office

listed on the last page of this document.

© MITSUBISHI ELECTRIC EUROPE B.V. 11/2004 (1st edition)

2

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

-

-

-

FREQUENCY INVERTER FR-F 740 EC/E1

YSTEM DESCRIPTION

S

Introduction to the FR-F740 series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

웇

Energy conservation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

웇

Control functions and communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

웇

Operation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

웇

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

웇

Terminal assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

웇

OPERATION

Control panel FR-DU07 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

웇

Control panel FR-PU04. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

웇

PARAMETERS

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

웇

CONTENTS

PROTECTIVE FUNCTIONS

웇 Overview of protective functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

웇 Resetting methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

APPLICATIONS

웇 Examples of applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ACCESSORIES

웇 Overview of internal and external options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

웇

Noise filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

웇

Reactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

웇

Brake units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

웇

External brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

DIMENSIONS

웇

Control panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

웇

Frequency inverters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

웇

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

웇

Reactors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

웇

Brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

웇

Brake units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

APPENDIX

웇

Order form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

웇

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

3

SYSTEM DESCRIPTION

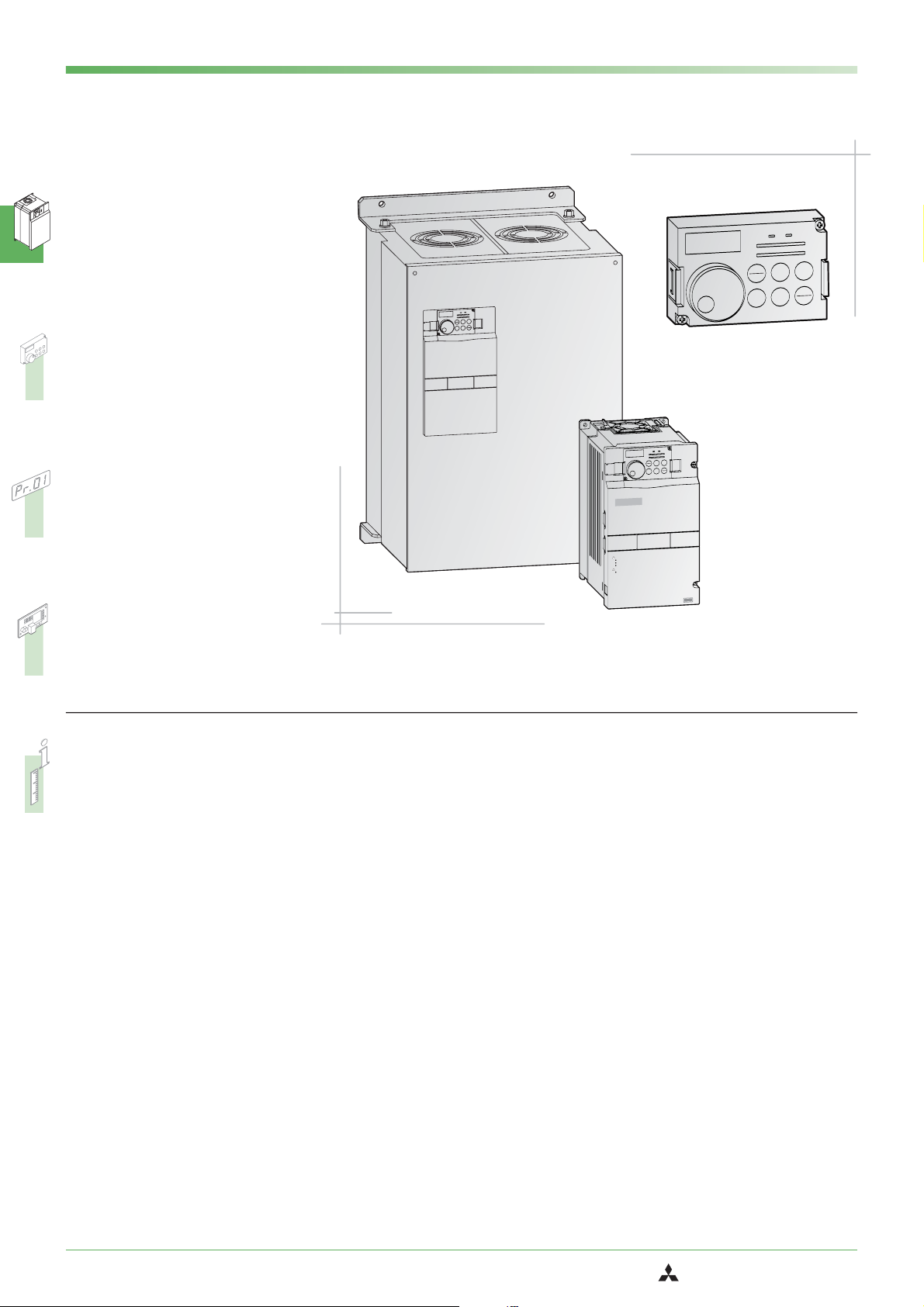

The FR-F 740 Frequency Inverter

Mitsubishi Electric’s FR-F 740 series is a

completely new range of frequency invert

ers with truly exceptional power conserva

tion capabilities. These inverters are ideal

for pumps, ventilation fans and applica

tions with reduced overload requirements

such as:

Air conditioning systems, e.g. in building

management

Air extraction systems

앬

Fans and blowers

앬

Hydraulics systems

앬

Compressors

앬

Sewage and drains systems

앬

Ground water pumps

앬

Heat pumps

앬

Drive systems with high idling rates

앬

These inverters are very user-friendly and

they are available with output ratings

matched to users’ real needs.

The FR-F 740 is available in versions with

outputs from 0.75 – 640 kW. All the inver

ters in the series are designed for connecti

on to 3~ 380–480 V/500 V (50/60Hz) power

supplies.

The output frequency range is 0.5 – 400 Hz.

-

-

-

-

P.R UN

MON

Hz

8888

P.RUN

MON

Hz

NET

EXT

A

PU

FWD

V

REV

PU

FWD

REV

EXT

STOP

SET

MODE

RESET

FR-DU07

P.RUN

MON

Hz

NET

EXT

A

PU

FWD

V

REV

PU

FWD

REV

EXT

STOP

SET

MODE

RESET

FR-DU07

MITSUBISHI

700

FREQROL-F

ock

h

rics

t

.

ofinjury and elec

k

!

DANGER:Ris

-

Readthe manual

latefrom s

o

Is

reproper earth c

u

Ens

!

CAUTION:Ris

Mountthe inverter on a non-c

FR–F740–2.2K

pplyand wait 10 minutes before remov

u

offire

k

e

ionsbefore us

t

ruc

t

fetyins

a

hes

t

ndfollow

a

ver.

o

ngthis c

i

ion

t

nnec

o

.

e

rfac

u

ibles

t

mbus

o

400V

A

V

EXT

MODE

NET

EXT

PU

FWD

REV

PU

FWD

REV

STOP

SET

RESET

FR-DU07

Proven Technology with Advanced New Capabilities

Innovative performance

optimisation

The drive performance of the FR-F 740

series is optimised for the special needs of

fan and pump applications. Drives in appli

cations like these are characterised by a

load torque curve that increases by the

square of the motor speed (variable curve).

Of course, these frequency inverters can

also be used for standard applications with

constant load curves and a maximum over

load of 150%.

The outstanding features and characteris

tics of the FR-F 740 series include:

앬

Power-saving mode with display of the

energy savings

앬

-

PID control

앬

Extended PID control with sleep and

multi-motor switching functions

앬

Flexible 5-point V/f curve

앬

Continued operation after brief power

failures

-

앬

Automatic restart after instantaneous

power failures

앬

Flying start

앬

PTC temperature sensor input

-

앬

Switch motor to direct mains operation

앬

Active current limiting

앬

Optimum excitation control

앬

Regeneration avoidance function

앬

Traverse function

앬

Disable defined frequency ranges

앬

Selectable 2nd parameter set for differ

-

ent load characteristics

앬

Network support

4

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

Intelligent Technology that Cuts Power Consumption

SYSTEM DESCRIPTION

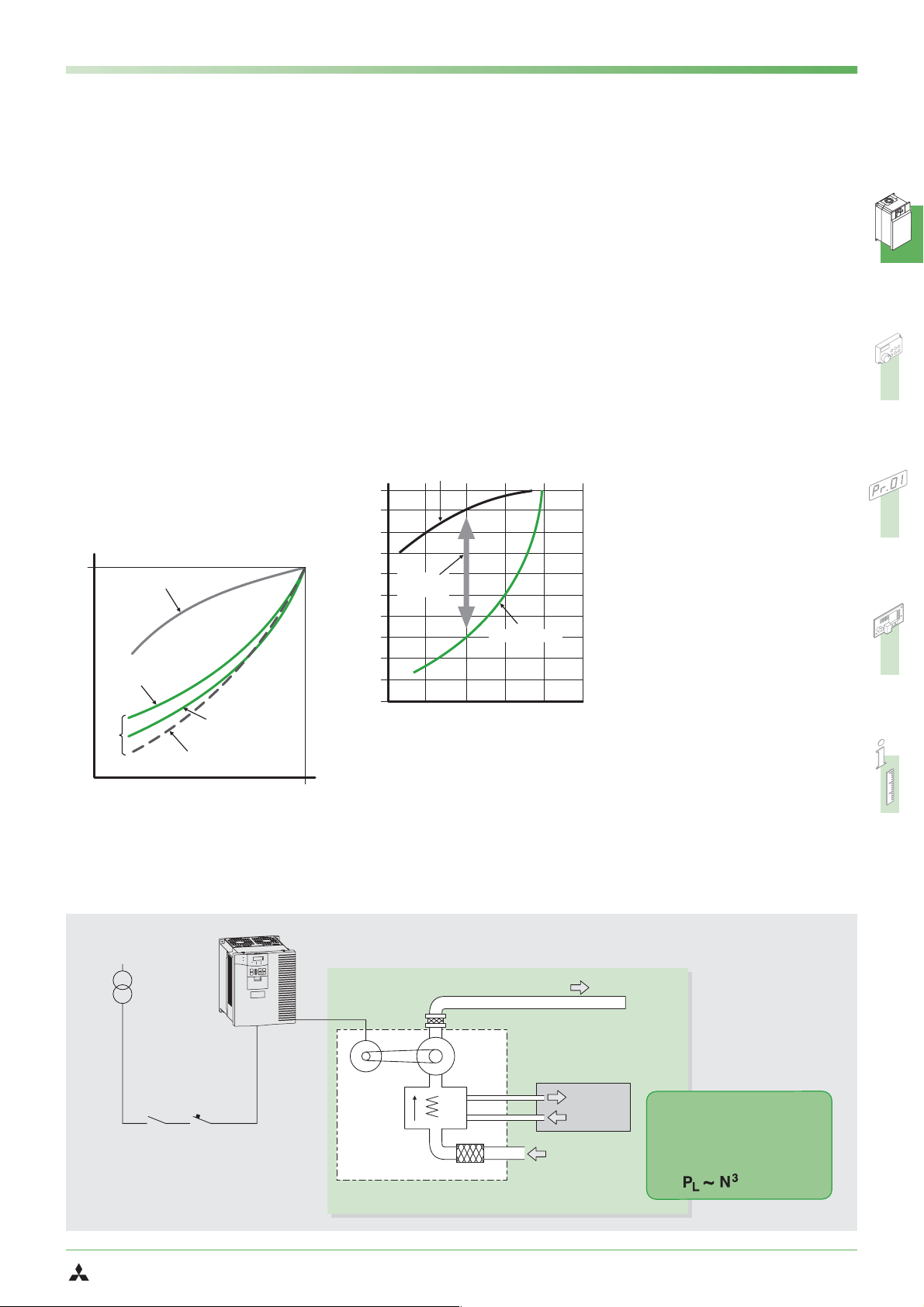

Saving power with Mitsubishi

frequency converters

Reducing consumption and optimising the

utilisation of our valuable energy resources

is one of the greatest global environmental

challenges of our age.

Energy conservation mode is a standard

feature of the intelligent controller. It dyna

mically adjusts the voltage to motor requi

rements, eliminating unnecessary power

losses, which helps to further reduce po

wer consumption. Frequency inverters are

particularly effective at conserving energy

when they are used to control pumps and

fans.

Theamountofenergyconservation(hyste

resis) depends on the speed/torque fluc

tuations. The graph below provides an im

pressive example of the results of

intelligent control in a fan system.

100

Power consumption (%)

Mechanical solution

Constant torque

pattern (Pr. no.14 = 0)

Reduced torque

control

Frequency inverter

Rotational speed (= air quantity) (%)

pattern (Pr. no.14 = 1)

Energy conservation mode

(Pr.no.14=1,Pr.no.60=9)

-

-

1000

How do frequency inverters

conserve energy?

The illustration below shows a blower sys

tem in which the air flow is regulated by

controlling the motor with a frequency in

verter instead of with a damper on the ex

haust side.

The graph below compares the motor po

wer consumption of the frequency inverter

and damper solutions. At a flow rate of

60% the curve shows that the frequency

inverter system consumes a full 60% less

power than the motor with the damper

system.

-

-

Damper control (exhaust side)

100

90

80

70

60

Conserved

energy

50

40

30

Power consumption (%)

20

10

0

0 40 80 10060

Inverter control

Air quantity (%)

Potential savings

In addition to the ecological benefits fre

quency inverters can also save a great deal

of money by radically cutting power con

sumption.

-

-

Example:

Based on the graph on the left and an elec

-

tricity price of 14 cents per kWh, the follo

wing savings can be achieved with a sys

tem using a 75 kW motor:

Conventional mechanical solution

앬

At an air throughput of 60% the power

consumption is 90%, resulting in the

following annual costs:

75 kW x 0.9 x €0.14 x 24 h x 365 days

= €82,782

Frequency inverter solution

앬

At an air throughput of 60% the power

consumption is 30%, resulting in the

following annual costs:

75 kW x 0.3 x €0.14 x 24 h x 365 days

= €27,594

This means that the inverter solution saves

€55,188 per year compared to the conventional mechanical system!

Clearly, a frequency inverter will pay for

itself in a very short time – and one must

also remember that the potential savings

increase with the power ratings of the

motors used.

Energy savings control

The effect of energy savings can be confirmed using the control panel, via the

output terminals (CA, AM) and via net

works (network option required) with the

newly developed energy saving monitor.

-

-

-

-

-

-

Application with potential for power savings

Power

supply

3-phase 400 V

POWER

ALARM

EXT

MON

REV

REV

MODE

SET

RESET

DATAPORT

MITSUBISHI

0

0

F5

Hz

A

V

PU

FWD

FWD

STOP

Frequency inverter

Motor

Heat

exchanger

Example of air handling unit

MITSUBISHI ELECTRIC

Belt

Duct

Blower

Air filter

Exhaust

Cold source (chiller)

Heat source (heat pump)

Cold/hot

water

Air

The power PLrequired for a

fan or pump is proportional

to the cube of the rotational

speed

FR-F 740 EC/E1

5

SYSTEM DESCRIPTION

Intelligent Motor Control Functions

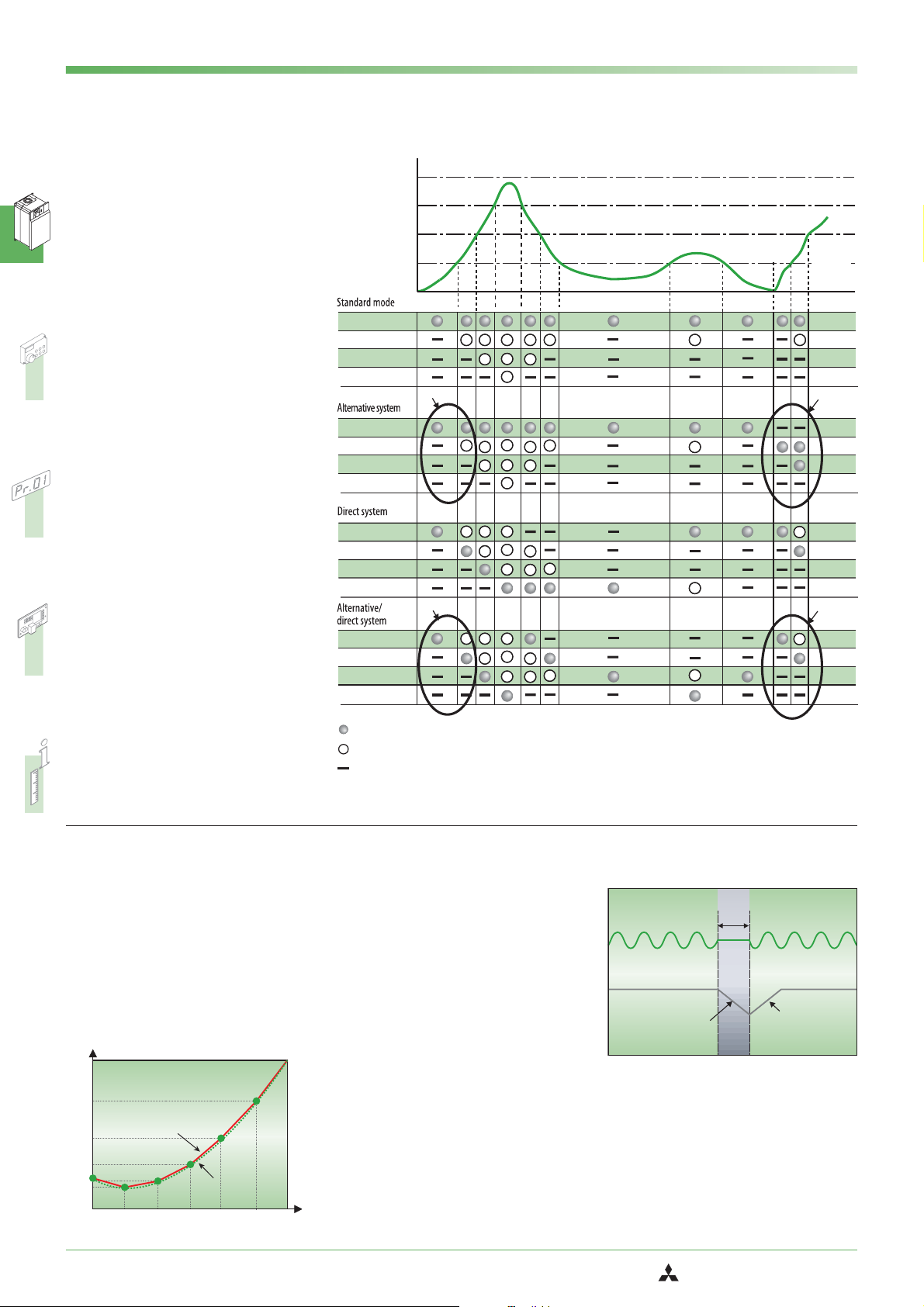

Extended PID control

The FR-F 740 series supports extended PID

control. This feature makes it possible to

connect the process status signal to the fre

quency inverter as a voltage signal

(0–10 V DC) or a current signal

(0/4–20 mA DC) and then use the analog

input calibration function of the inverter to

compensate minor controller-related fluc

tuations.

In addition to this the frequency inverter

can also control up to four motors succes

sively. This function is programmable; for

example, you can program it so that only

one motor is frequency-controlled and the

others are switched on and off under direct

mains power as required, or you can alter

nate between direct mains power and

frequency control for all four motors.

The graph on the right illustrates this multimotor switching function with a typical ex

ample.

When implementing an application like

this you must plan the necessary number

of magnetic power contactors and the required number of output signal terminals

on the inverter. Care must also be taken to

ensure that the mains power is never switched to the inverter output.

-

-

-

-

-

Q max

Q3

Q2

Q1

Motor 1 (M1)

Motor 2 (M2)

Motor 3 (M3)

Motor 4 (M4)

Motor 1 (M1)

Motor 2 (M2)

Motor 3 (M3)

Motor 4 (M4)

Motor 1 (M1)

Motor 2 (M2)

Motor 3 (M3)

Motor 4 (M4)

Motor 1 (M1)

Motor 2 (M2)

Motor 3 (M3)

Motor 4 (M4)

*

*1

*2

Flow rate

Time

*1

*

*2

Flexible 5-point V/f curve

The integrated flexible 5-point V/f curve

enables you to match the torque curve

perfectly to the characteristics of your

machine.

Together, the optimum excitation control

feature and the 5-point V/f curve achieve

significantly increased power savings.

V/f characteristic

V/F5

V/f pattern

Voltage

V/F1

0

V/F4

V/F3

V/F2

Base frequency

Torque

characteristic

Inverter controlled operation

Conventional operation

Stop

Automatic restart after instantane

ous power failures

In pump and fan applications normal ope

ration can be continued automatically af

ter brief power failures. The system simply

reactivates the coasting motor and auto

matically accelerates it back up to its

setpoint speed.

The graphic on the right shows how the

frequency inverter can respond to a brief

power outage. Instead of coasting down

completely and stopping, the motor is au

tomatically “caught” by the frequency in

verter and re-accelerated back up to its

previous speed.

* After switching the magnetic contactor the motor start

sequence switches from M1->M2->M3 to M2->M3->M1

-

-

-

Power supply

Output frequency

Deceleration

IPF

-

-

-

Restart

acceleration

6

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

Innovative Features and Functions

SYSTEM DESCRIPTION

Flying start

Gentle restart of a rotating motor (e.g. fan

rotated by a draft), also in the opposite di

rection.

PTC temperature sensor input

The motor’s internal PTC temperature sen

sor can be connected to the inverter di

rectly. In combination with the electronic

temperature monitoring system this provi

des effective protection for the motor.

Active current limiting

Tried and tested capabilities like the active

current limiting feature have been retai

ned. The characteristics of the current limi

ter have now been further improved to

prevent unwanted triggering in response

to overcurrents. Transient overcurrents, for

example those generated when a motor

coasting in reverse is restarted or when an

input contactor is closed, will no longer

cause unwanted triggering of the current

limiter.

-

Magnetic flux vector control

The integrated motor flux vector control

system makes it possible to achieve high

torques, even at low motor speeds.

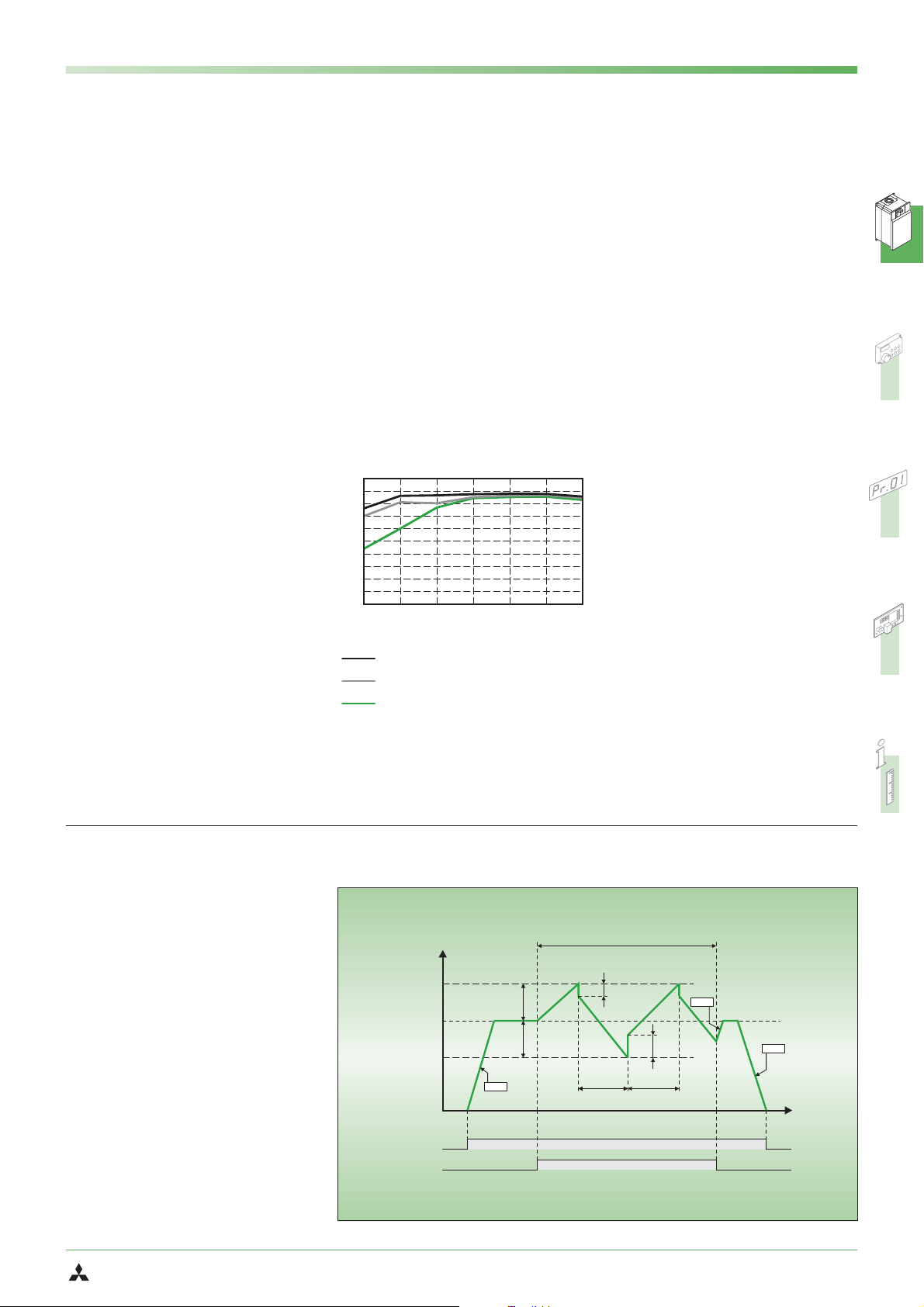

Optimum excitation control

You can also select the optimum excitation

control mode, which achieves yet more

power savings compared to conventional

inverters designed for pump and fan appli

cations.

The graph below demonstrates the kind of

improvements that are possible with this

control mode:

-

100

90

80

70

60

50

40

30

Motor efficiency (percent)

20

10

0

5% 10% 25% 50% 75% 100% 120%

Torque load (percentage of rated torque load)

Optimum excitation control mode

Standard energy saving inverter

No excitation control

Regeneration avoidance function

This function can prevent the inverter from

being shut down by regenerative overvol

tages when strong regenerative loads cau

se power to be released into the frequency

inverter (for example when braking the

motor or with loads that actively drive the

motor).

The inverter can automatically increase the

output frequency or disable the braking

-

ramp when a programmed threshold value

is reached. The response sensitivity, dyna

mics and working range are all adjustable.

For example, this function can prevent a

shutdownwithanovervoltageerrorwhen

the speed of a fan controlled by the inver

ter is increased by the draft from another

fan operating in the same ventilation duct.

The function then temporarily increases

the output frequency above the setpoint

value.

This function can also be used to brake lo

ads with the DC bus voltage, without using

braking modules.

Switching to direct mains operation

You can switch the motor to direct mains

operation by programming the contactor

relays accordingly and applying a control

signal to terminals L11 and L21 of the

inverter.

-

-

-

-

-

Traverse function

The traverse function of the FR-F740 is de

signed specifically for use in yarn-winding

applications in the textile industry.

This function performs a cyclical variation

of the output frequency as shown in the

graph on the right. The width of the fluc

tuation around the frequency setpoint va

lue and the ramp times are configurable

via setup parameters.

This function prevents the formation of the

unwanted “bands” in the wound yarn.

MITSUBISHI ELECTRIC

-

Output frequency

(Hz)

-

f0

Start/stop

signal

X37 signal

f1

f1

Pr.7

ON

ON

Traverse function

f2

t1

(Pr.596) t2 (Pr.597)

Pr.7

f3

Pr.8

FR-F 740 EC/E1

Time (s)

t(s)

7

SYSTEM DESCRIPTION

L W

ON ORKS

NETWORK

Extensive Communications Support

Extended I/Os for additional control

functions

The following I/Os are included as standard

equipment on the FR-F 740:

12 contact inputs

앬

3 analog inputs

앬

5 open collector outputs

앬

2 relay outputs

앬

2 analog outputs

앬

The contact inputs, open collector outputs

and relay outputs can all be used for a

wide range of functions.

Two of the analog inputs can be switched

from current to voltage. The switching sta

tus of the input and output terminals can

be displayed on the control panel.

Remote I/Os

Instead of using the remote I/Os of a PLC

you can use a network connection to both

read out the status of the frequency

inverter’s inputs and set its outputs.

Expansion slot

The frequency inverter has an expansion

slot that can be used to install an I/O expansion module or a network module. These modules are cards that are installed by

plugging them into the slot in the inverter.

See page 34 for a list of available modules.

Support for integration in larger

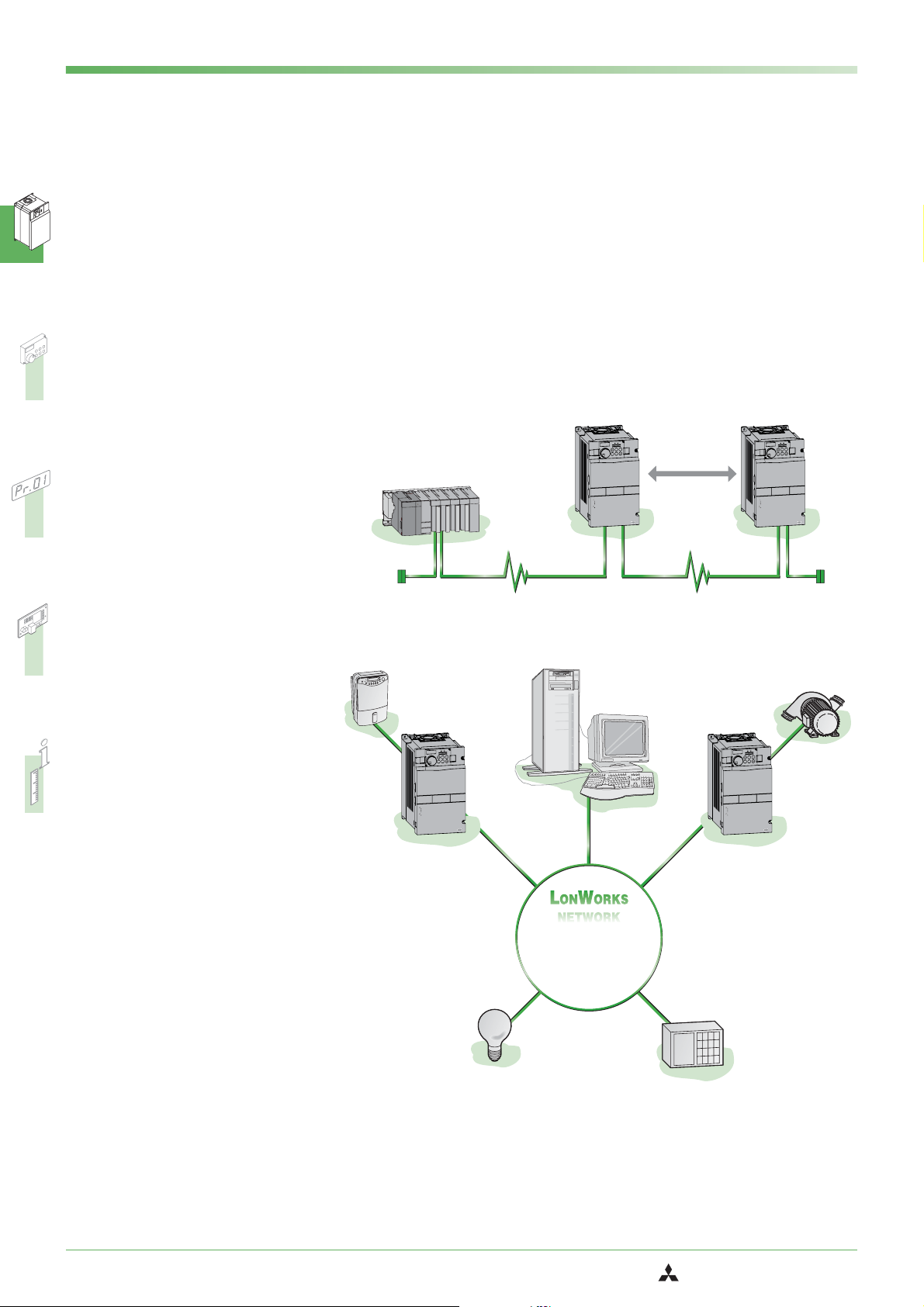

networks

Open communications with standard indu

strial bus systems can be implemented ea

sily with optional expansion cards.

This makes it possible to integrate the fre

quency inverter in large-scale automation

systems.

-

PLC system

(e.g. Mitsubishi System Q)

1

Air conditioner

The following networks are supported by

the FR-F 740:

CC-Link

앬

Profibus/DP

앬

-

-

DeviceNet

앬

LON Works

앬

RS485 and Modbus RTU (standard)

앬

You can find a description of the network

cards on page 34.

FR-F 740

P.RUN

MON

Hz

NET

T

EX

A

PU

FWD

V

REV

PU

FWD

REV

EXT

OP

T

S

SET

MODE

RESET

FR-DU07

MITSUBISHI

700

FREQROL-F

!

DANGER:Riskofinjury and electric shock

Readthemanual andfollow the safety instructions before use.

Isolatefromsupplyand wait 10 minutes before removing this cover.

Ensureproperearth connection

!

CAUTION:Riskoffire

Mounttheinverteron a non-combustible surface.

400V

FR–F740–2.2K

FR-A7NC

CC-Link Network

PC for network

management

Up to 42

inverters

FR-F 740

MITSUBISHI

FREQROL-F

!

DANGER:Riskofinjury and electric shock

Readthemanual andfollow the safety instructions before use.

Isolatefromsupplyand wait 10 minutes before removing this cover.

Ensureproperearth connection

!

CAUTION:Riskoffire

Mounttheinverteron a non-combustible surface.

FR–F740–2.2K

700

ON

M

Hz

EXT

A

PU

V

REV

PU

R

EXT

SET

MODE

P.RUN

NET

FWD

FWD

V

E

STOP

RESET

FR-DU07

Pump

400V

FR-A7NC

Extended networking capabilities

The inverter comes with two serial ports as

standard equipment for integration in an

automation network. You can connect a

standard RJ45 network cable to the PU con

nector. there are also RS-485 terminals insi

de the inverter unit for connection to a mul

tidrop network via a normal cable, which

enables inexpensive networking of up to 32

nodes.

In addition to the Mitsubishi protocol you

can also use the Modbus RTU (binary) pro

tocol.

Programming via USB

You can configure the setup parameters

and monitor the frequency inverter via an

USB port with the optional USB 1.1

module.

FR-F 740

P.RUN

MON

Hz

NET

EXT

A

PU

FWD

V

REV

PU

FWD

REV

EXT

STOP

SET

MODE

RESET

FR-DU07

MITSUBISHI

700

FREQROL-F

400V

FR-A7NL

ON ORKS

L W

NETWORK

-

-

-

!

DANGER:Riskofinjury and electric shock

Readthemanual andfollow the safety instructions before use.

Isolatefromsupplyand wait 10 minutes before removing this cover.

Ensureproperearth connection

!

CAUTION:Riskoffire

Mounttheinverteron a non-combustible surface.

FR–F740–2.2K

-

FR-F 740

MON

Hz

A

PU

V

REV

PU

EXT

MODE

MITSUBISHI

700

FREQROL-F

!

DANGER:Riskofinjury and electric shock

Readthemanual andfollow the safety instructions before use.

Isolatefromsupplyand wait 10 minutes before removing this cover.

Ensureproperearth connection

!

CAUTION:Riskoffire

Mounttheinverteron a non-combustible surface.

FR–F740–2.2K

P.RUN

NET

EXT

FWD

FWD

REV

STOP

SET

RESET

FR-DU07

400V

FR-A7NL

Open network

topology

Lighting

Security system

8

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

Environment-Friendly and Internationally Compatible

SYSTEM DESCRIPTION

Electromagnetic compatibility

New technologies have been used to signi

ficantly reduce the interference levels ge

-

nerated by this frequency inverter.

The FR-F 740 EC conforms to the strict elec

tromagnetic compatibility regulations of

the European Union (EMC Directive, Envi

ronment 2). In order to meet these stan

-

dards the FR-F700 inverters are fitted with

a new, integrated interference suppression

filter, which can easily be deactivated with

a jumper if necessary.

International standards

The inverters of the FR-F 740 EC series are

designed so that they can be used worldwide without any additional modifications

or certifications.

앬

The units conform to the international

CE, UL, cUL, Gost and CCC standards.

앬

User-selectable positive or negative

switching logic. Users can select posi

tive or negative switching logic for in

put and output signals, enabling

flexible and simple adaptation of the

units for varying world market

requirements.

앬

Extended input power voltage range:

3~ 380-480 V (up to 500 V for 01800 and

above), 50/60 Hz

Tolerance: −15%; +10%

-

-

You can also further limit the make current

and reduce network interference by fitting

the input of the inverter with an optional

AC reactor and a DC reactor, which is con

nected to special terminals on the inverter

-

unit.

The DC reactor is included as standard

equipment with models 00180 and above

andmustbeusedwiththem.

Multilingual programming/control unit

앬

(optional)

Support for a variety of international in-

앬

dustrial bus systems

앬

Internationally standardised, frequency

inverter configuration software package

for MS Windows, with multilingual user

interface

These features make the FR-F 740 EC a truly

international product that meets all relevant

standards and can be easily adjusted for na

tional requirements.

Circuit boards with two coats of pro

tective varnish

The frequency inverters with the E1 desig

nation (standard, type 02160 and above)

have circuit boards with two coats of pro

tective varnish.

This feature is available as an option for the

models up to type 01800. The twin coating

on the internal PCBs provides even better

protection against environmental influen

ces. This is particularly important in appli

cations sewage plants where the switchge

ar cabinets are exposed to aggressive

fermentation gases that can reduce the

service life of the equipment.

DIN ISO 9001 /

EN 29001

Zertifikat: 09 100 4371

-

R

C

-

-

-

-

-

-

R

SELV

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

9

SYSTEM DESCRIPTION

MON

PU

EXT

NET

FWD

P. R U N

User-friendly Operation

Easy configuration with control

panel or software

The FR-DU07 control panel is included as

standard equipment with all the inverters

of this series. It makes operation of the in

verter simple and intuitive and displays

operating parameters and alarm messa

ges. The jog shuttle “digital dial” control

provides fast and efficient access to all key

drive parameters.

The optional FR-PU04 control panel featu

res a long-life LC-display with a backlight

and integrated numeric keypad for direct

entry of operating parameters. The user

interface can be displayed in eight diffe

rent languages. This panel is designed as a

remote unit that is connected to the inver

ter with a cable. It also supports definition

of user groups with which you can imple

ment editable parameter sets that can

then be selected as required for specific

applications.

-

-

MON

Hz

EXT

A

8.8.8.8.

-

8.8.8.8.

V

PU

EXT

MODE

PU

REV

REV

SET

-

FR-DU07

In addition to control panel operation the

frequency inverter can also be connected

to a standard PC via an RS-485 port and

operated from the PC with the optional

VFD setup software package. Using this

software you can configure, operate and

monitor multiple frequency inverters, eit

her in a network or directly from a single

PC or notebook computer. (See page 21 for

more details on this software package.)

P.R U N

NET

FWD

FWD

STOP

RESET

FR-DU07

50

50

SET

SHIFT

READ

PARAMETER UNIT

8

5

2

WRITE

FR-PU04

EXT

ESC

00

00

EXT

9

6

3

EXT

Hz

Hz

PU

FWD

REV

STOP

RESET

U

P

-

R

F

MON

HELP

4

0

-

- - - STOP

- - - STOP

7

4

1

0

-

User-friendly

In addition to allowing you to enter and

display configuration and control parame

ters the integrated control panel can also

be used to monitor and display current

operating data and alarm messages. The

information is output on a 4-digit LED dis

play.

You can monitor all the current status pa

rameters of both the inverter itself and the

connected motor. Problems and mal

-

functions are indicated by error codes.

One-touch operation

Simple and intuitive configuration and

operation save both time and money. The

control panel’s jog shuttle “digital dial”

control provides much faster access to all

key drive parameters than would be possi

ble with conventional buttons and keys.

You can also use the dial to continuously

adjust the speed of the connected motor.

5

-

justing a para

meter with the

jog shuttle

-

-

Example: Ad-

Removable panel with parameter

-

copy function

The control panel is removable and can

also be connected installed remotely, for

example in the door of a switchgear cabi

net. It also features a useful copy function

with which you can copy the parameter

settings of one frequency inverter to

another.

4

-

3

2

1

Hz

MON

A

PU

V

REV

PU

EXT

MODE

EXT

REV

SET

6

P.R U N

NET

FWD

7

FWD

STOP

RESET

FR-DU07

8

Alarm log

The control panel stores an alarm log for

up to 8 alarm messages that can be dis

played and checked on the panel. The

alarm details in the log include frequency,

current, voltage and cumulative operating

time at the time of the alarm.

Switch between direct and external

control

The frequency inverter can be controlled

directly via the control panel (PU mode) or

via external signals (EXT mode).

-

Hz

A

V

PU

EXT

MODE

REV

P.R U N

MON

PU

EXT

REV

SET

NET

FWD

FWD

STOP

RESET

FR-DU07

-

10

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

Long Service Life and Easy Maintenance

SYSTEM DESCRIPTION

New components for longer service

life

The components of this new generation of

frequency inverters are specified for a ser

vice life of 10 years (mean annual ambient

temperature 40°C, 80% load in an environ

ment free of aggressive gases, flammable

gases, oil mist, dust and dirt). Among other

things,thisismadepossiblebythe

newly-developed, long-life cooling fans

that are monitored by the inverter. The life

of the cooling fans can also be made signi

ficantly longer by using Parameter 244,

which controls the selective shutdown

feature.

Modern diagnostics functions furt

-

her extend service life

The ageing of the main circuit capacitors,

the control circuit power capacitor, the in

ternal cooling fans and the inrush current

limiter circuit can be checked with the mo

nitoring functions. If the inrush resistor

overheats an alarm is displayed.

The alarms for the main circuit capacitors,

control circuit capacitor, inrush current limiter and internal fans can all be output to

a network or via the optional FR-A7AY

module.

This makes it possible to prevent malfunctions by configuring diagnostics

alarms to be triggered when the end of the

service life is reached.

The inverter also has an internal program

that can evaluate the ageing of the main

circuit capacitors. This feature is only avai

lable when a motor is connected to the

inverter.

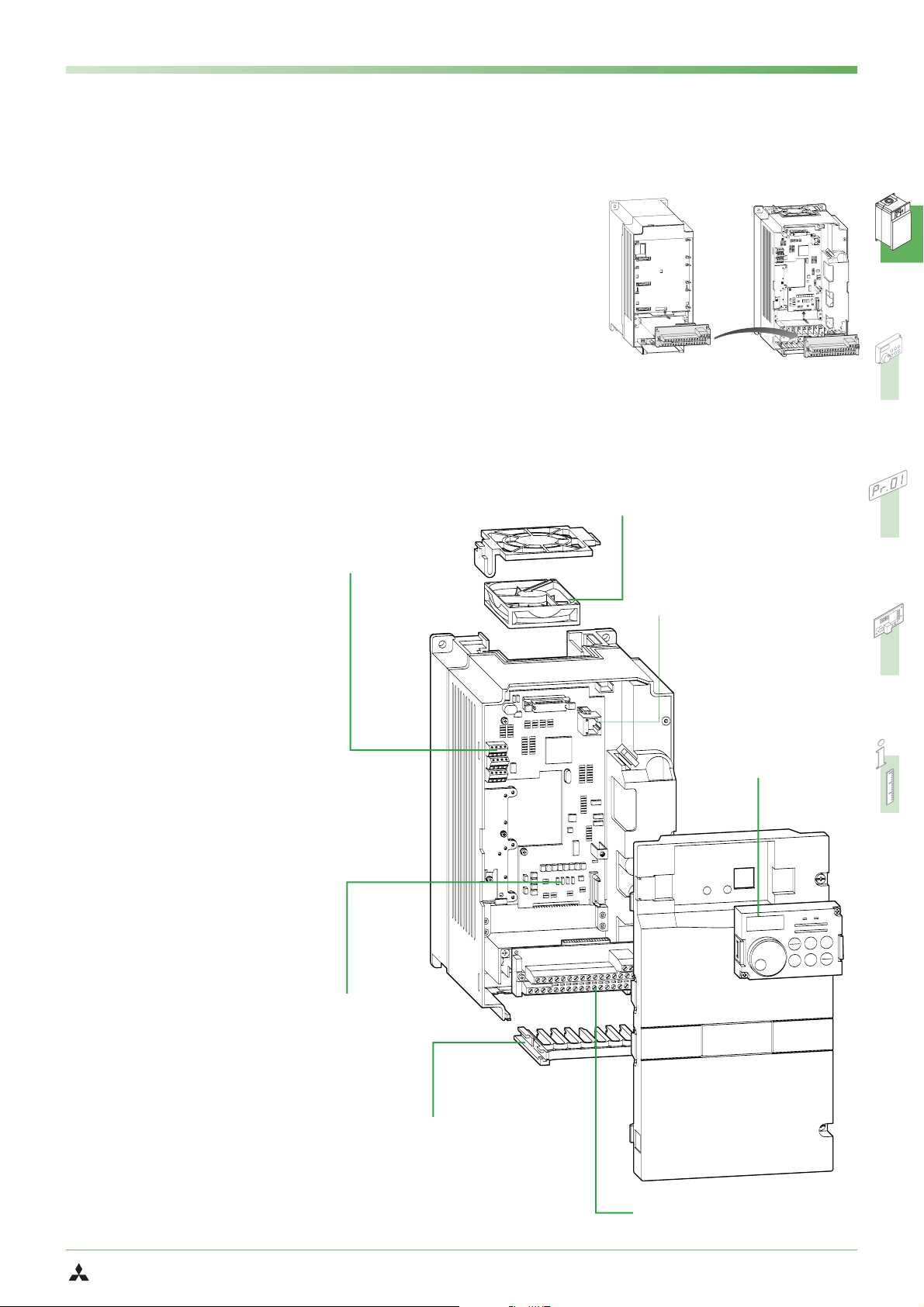

Easy replacement

The terminal block for the control circuit

connections is removable to enable easy

replacement of the inverter unit for servi

cing, which greatly facilitates both installa

tion and maintenance work. You can also

use the removable terminal block of the

FR-F500 series, which is compatible to the

FR-F700 series. However, please note that

some of the functions of the FR-F700 series

are not available when you use a terminal

block from the FR-F500 series.

-

-

-

RS-485

앬

interface

terminals

-

Replacement of the terminal block:

-

-

FR-F500

Easy replacement of the

앬

FR-F700

fan cassette

RJ45 connector for control

앬

panel and RS-485 communications port

앬

Removable

control panel

Service timer

The frequency inverters of this series all

have an integrated service timer that auto

matically triggers an alarm after a set num

ber of operating hours. This feature can be

used for monitoring the frequency inverter

itself or a peripheral component. The valu

es of the mean output current and the ser

vice timer can also be output as analog

signals.

Improved handling

The main cooling fan is easily accessible at

the top of the inverter unit, allowing quick

and easy replacement without removal of

the connection cables.

The cable guide comb (see illustration) is

removable and makes routing the cables

quick and trouble-free. After the cables

have been connected the cover can then

be replaced (for frequency inverters up to

type 00620).

MITSUBISHI ELECTRIC

-

-

-

8888

-

앬

Slot for optional

FWD

V

REV

PU

FWD

REV

EXT

STOP

SET

MODE

RESET

FR-DU07

P.RU N

MON

Hz

NET

EXT

A

PU

expansion cards

앬

Cable guide comb

앬

Removable terminal block

FR-F 740 EC/E1

11

SYSTEM DESCRIPTION

Specifications FR-F 740-00023 to -01160

Rated motor

capacity

[kW]

Rated

current

햷

[A]

Output capacity

[kVA]

Overload current

rating

Voltage

120% overlaod capacity

150% overlaod capacity

120%

overlaod

햶

capacity

150%

overlaod

capacity

120% overlaod capacity

150% overlaod capacity

120% overlaod capacity

150% overlaod capacity

햶

0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55

2.3

3.8

5.2

8.3

햷

I

rated

(2.0)

(3.2)

(4.4)

2.5 4.2 5.7 9.1 13.9 18.7 27.5 34.1 41.8 51.7 68.2 84.7 102.3 127.5

I

max. 60 s

I

max. 3 s

2.8 4.6 6.2 10 15.1 20.4 30 37.2 45.6 56.4 74.4 92.4 111.6 139.2

2.1

3.5

햷

I

rated

(1.8)

2.5 4.2 5.8 9.1 13.8 19.2 27.6 34.8 42 51.6 68.4 84 102 127.2

I

max. 60 s

3.1 5.2 7.2 11.4 17.2 24 34.5 43.5 52.5 64.5 85.5 105 127.5 159

I

max. 3 s

햶

1.8 2.9 4.0 6.3 9.6 13 19.1 23.6 29.0 35.8 47.3 58.7 70.9 88.4

(3.0)

4.8

(4.1)

12.6

(7.1)

(10.7)17(14.5)25(21.3)31(26.4)38(32.3)47(40.0)62(52.7)77(65.5)93(79.1)

7.6

11.5

(6.4)

(9.8)16(13)23(19)29(24)35(30)43(36)57(48)70(60)85(72)

1.6 2.7 3.7 5.8 8.8 12.2 17.5 22.1 26.7 32.8 43.4 53.3 64.8 80.8

120% of rated motor capacity for 3s;110% for 1 min. (max.ambient temperature 40°C) – typical for pumps and fans

150% of rated motor capacity for 3s;120% for 1 min. (max.ambient temperature 50°C) – typical for conveyor belts and centrifuges

3-phase AC,0 V to power supply voltage

116

(98.6)

106

(90)

Frequency range 0.5–400 Hz

Control method V/f control,optimum excitation control or simple magnetic flux vector control

Modulation control Sine evaluated PWM,Soft PWM

Carrier frequency 0.7 kHz–14.5 kHz (user adjustable)

Power supply voltage 3-phase,380–480 V AC, −15% / +10%

Voltage range 323–528 V AC at 50 / 60 Hz

Power supply frequency 50 / 60 Hz ±5%

Rated input

capacity

[kVA]

120% overlaod capacity

150% overlaod capacity

햶

2.8 5.0 6.1 10 13 19 22 31 37 45 57 73 88 110

2.54.55.59 121720283441526680100

Cooling Self cooling Fan cooling

Power loss

[kW]

120% overlaod capacity

150% overlaod capacity

햶

0.06 0.08 0.1 0.16 0.19 0.24 0.34 0.39 0.49 0.58 0.81 1.0 1.17 1.51

0.05 0.08 0.09 0.14 0.18 0.22 0.31 0.35 0.44 0.52 0.71 0.93 1.03 1.32

Frame size C D E F G H

Inverter weight [kg] 3.5 3.5 3.5 3.5 3.5 6.5 6.5 7.5 7.5 13 13 23 35 35

Reactor weight [kg] ––––––––––––––

햹

햲

The performance figures at the rated motor capacity are based on a motor voltage of 400 V.

햳

The overload capacity in % is the ratio of the overload current to the inverter’s rated current in the respective operating mode. For repeated duty cycles allow sufficient time for the inverter and the motor to

Order no.

156569 156570 156571 156572 156573 156594 156595 156596 156597 156598 156599 156600 156601 156602

cool below the temperature reached at 100% load. The waiting periods can be calculated using the r.m.s. current method (I² × t), for which knowledge of the duty.

햴

The maximum output voltage cannot exceed the power supply voltage. The output voltage can be varied over the entire power supply voltage range.

햵

The rated input capacity varies depending on the impedance values on the power supply side of the inverter (including the cables and input reactor).

햶

When the load curve with 120% overload capacity is selected the maximum permitted ambient temperature is 40°C.

햷

When operating with carrier frequencies ≥ 3 kHz this value is reduced automatically as soon as the frequency inverter exceeds the rated output current shown in parentheses (= 85% load).

햸

When the cable bushing for the optional expansion cards is broken out the unit has an IP 00 protection rating.

햹

The suffix EC or E1 in the model designation identifies the CE versions of the frequency inverter (for the European Union). The inverter types FR-F740-02160 and above are all delivered in the E1 version as

standard (PCBs with two coats of protective varnish). The EC version (varnished PCBs) is standard for types FR-F740 00023 through 01800. The other version as always available as an option.

12

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

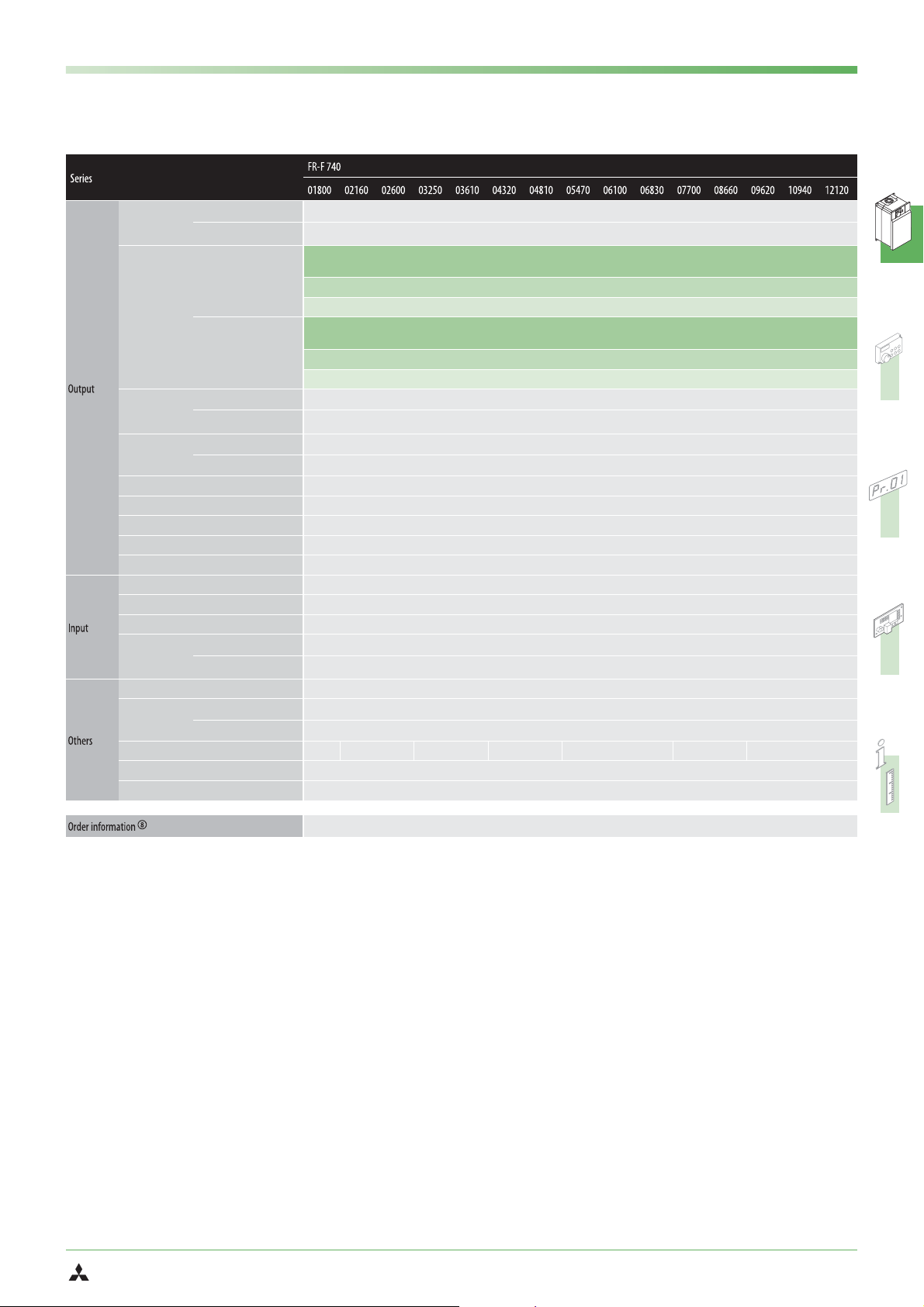

Specifications FR-F 740-01800 to -12120

SYSTEM DESCRIPTION

Rated motor

capacity

[kW]

Rated

current

햷

[A]

Output

capacity

[kVA]

Overload current

rating

Voltage

120% overlaod capacity

150% overlaod capacity

120%

overlaod

햶

capacity

150%

overlaod

capacity

120% overlaod capacity

150% overlaod capacity

120% overlaod capacity

150% overlaod capacity

햶

90 110 132 160 185 220 250 280 315 355 400 450 500 560 630

75 90 110 132 160 185 220 250 280 315 355 400 450 500 560

180

216

260

325

361

432

481

547

610

683

770

햷

I

rated

(153)

(184)

(221)

(276)

(307)

(367)

(409)

(465)

(518)

(581)

198 238 286 357 397 475 529 602 671 751 847 953 1058 1203 1333

I

max. 60 s

I

max. 3 s

216 259 312 390 433 518 577 656 732 820 924 1039 1154 1313 1454

144

180

216

260

325

361

432

481

547

햷

I

rated

(122)

(153)

(184)

(221)

(276)

(307)

(367)

(409)

173 216 259 312 390 433 518 577 656 732 820 924 1039 1154 1313

I

max. 60 s

216 270 324 390 487 541 648 721 820 915 1024 1155 1299 1443 1641

I

max. 3 s

햶

137 165 198 248 275 329 367 417 465 521 587 660 733 834 924

(465)

610

(518)

(654)

683

(581)

866

(736)

770

(654)

110 137 165 198 248 275 329 367 417 465 521 587 660 733 834

120% of rated motor capacity for 3s;110% for 1 min. (max.ambient temperature 40°C) – typical for pumps and fans

150% of rated motor capacity for 3s;120% for 1 min. (max.ambient temperature 50°C) – typical for conveyor belts and centrifuges

3-phase AC,0 V to power supply voltage

962

(818)

866

(736)

1094

(870)

962

(818)

1212

(1030)

1094

(870)

Frequency range 0.5–400 Hz

Control method V/f control,optimum excitation control or simple magnetic flux vector control

Modulation control Sine evaluated PWM,Soft PWM

Carrier frequency 0.7 kHz–6 kHz (user adjustable)

Power supply voltage 3-phase,380–500 V AC, −15% / +10%

Voltage range 323–550 V AC at 50 / 60 Hz

Power supply frequency 50 / 60 Hz ±5%

Rated input

capacity

[kVA]

120% overlaod capacity

150% overlaod capacity

햶

137 165 198 248 275 329 367 417 465 520 587 660 733 834 924

110 137 165 198 248 275 329 367 417 465 520 587 660 733 834

Cooling Fan cooling

Power loss

[kW]

120% overlaod capacity

150% overlaod capacity

햶

2.7 3.3 3.96 4.8 5.55 6.6 7.5 8.4 9.45 10.65 12.0 13.5 15.0 16.8 18.9

2.25 2.7 3.3 3.96 4.8 5.55 6.6 7.5 8.4 9.45 10.65 12.0 13.5 15.0 16.8

Frame size H J K L M N P

Inverter weight [kg] 37 50 57 72 72 110 110 220 220 220 235 235 285 285 285

Reactor weight [kg] 20 22 26 28 29 30 35 38 42 46 50 57 67 85 95

Order no.

158604 158605 158607 158608 158609 158610 158611 158612 158613 158614 158615 158616 158617 158619 158620

햲

The performance figures at the rated motor capacity are based on a motor voltage of 400 V.

햳

The overload capacity in % is the ratio of the overload current to the inverter’s rated current in the respective operating mode. For repeated duty cycles allow sufficient time for the inverter and the motor to

cool below the temperature reached at 100% load. The waiting periods can be calculated using the r.m.s. current method (I² × t), for which knowledge of the duty.

햴

The maximum output voltage cannot exceed the power supply voltage. The output voltage can be varied over the entire power supply voltage range.

햵

The rated input capacity varies depending on the impedance values on the power supply side of the inverter (including the cables and input reactor).

햶

When the load curve with 120% overload capacity is selected the maximum permitted ambient temperature is 40°C.

햷

When operating with carrier frequencies ≥ 2.5 kHz this value is reduced automatically as soon as the frequency inverter exceeds the rated output current shown in parentheses (= 85% load).

햸

When the cable bushing for the optional expansion cards is broken out the unit has an IP 00 protection rating.

햹

The suffix EC or E1 in the model designation identifies the CE versions of the frequency inverter (for the European Union). The inverter types FR-F740-02160 and above are all delivered in the E1 version as

standard (PCBs with two coats of protective varnish). The EC version (varnished PCBs) is standard for types FR-F740 00023 through 01800. The other version as always available as an option.

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

13

SYSTEM DESCRIPTION

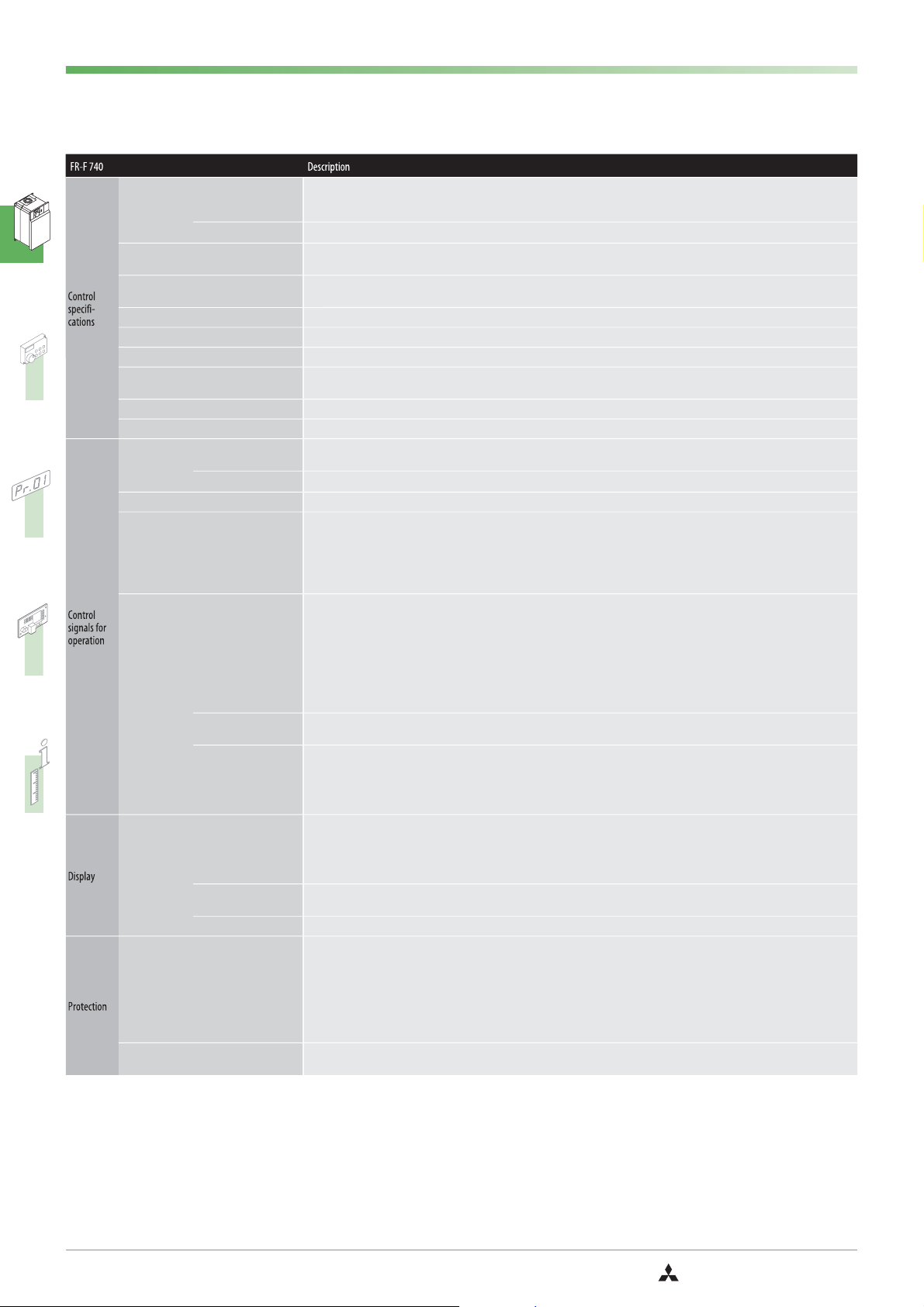

Specifications

Frequency

setting

resolution

Frequency accuracy

Voltage / frequency characteristics

Starting torque 120% (3 Hz) when set to simple magnetic flux vector control and slip compensation

Acceleration / deceleration time 0; 0.1 to 3600 s (can be set individually)

Acceleration / deceleration characteristics Linear or S-form course,user selectable

DC injection brake

Stall prevention Respones threshold 0–150%,user adjustable,also via analog input

Motor protection Electronic motor protection relay (rated current user adjustable)

Frequency

setting values

Start signal Available individually for forward rotation and reverse rotation. Start signal automatic self-holding input (3-wire input) can be selected.

Input signals

Output

signals

Control unit

display

(FR-PU04/

FR-DU07)

Protective

functions

Protection rating*

Analog input

Digital input

Analog input

Digital input

Operating state

When using the

FR-A7AY option

Pulse/analog output

Operating state

Alarm definition

Interactive guidance Operation guide/trouble shooting with a help function (FR-PU04 only)

0.015 Hz / 0–50 Hz (terminal 2, 4:0–10 V / 12 bit)

0.03 Hz / 0–50 Hz / (terminal 2, 4:0–5 V / 11 bit, 0–20 mA / 11 bit, terminal 1:−10–+10 V / 11 bit)

0.06 Hz / 0–50 Hz (terminal 1:0–±5 V / 10 bit)

0.01 Hz

±0.2% of the maximum output frequency (temperature range 25° ± 10°C) via analog input;

±0.01% of the set output frequency (via digital input)

Base frequency adjustable from 0 to 400 Hz;

selection between constant torque, variable torque or optional flexible 5-point V/f characteristics

Operating frequency (0–120 Hz),operating time ( 0–10 s) and operating voltage (0–30%) can be set individually.

The DC brake can also be activated via the digital input.

Terminal 2,4: 0–5 V DC,0–10 V DC, 0/4–20 mA

Terminal 1:0–±5 V DC, 0–±10 V DC

Operation panel or optional expansion board

Any of 12 signals can be selected using parameters 178 to 189 (input terminal function selection):

multi speed,second parameter function, terminal 4 input, JOG operation,automatic restart after instantaneous power failure, external thermal relay

input,FR-HC connection (inverter operation enable signal) and FR-HC connection (instantaneous power failure detection), control panel operation/ex

ternal interlock signal,PID control, control panel operation,control panel<->external operation,output stop, start self-holding,for ward/reverse rota

tion command,inverter reset,PTC thermistor input, PID forward/reverse operation switchover,control panel<->NET,NET<->external operation,

command source switchover

Any of 7 signals can be selected using parameter 190 to 196 (output terminal function selection):

Frequency control status,instantaneous power failure (under voltage),overload warning,output frequency detec tion,second output frequency

detection, regenerative brake with pre-alarm (01800 and above), electronic thermal relay function with pre-alarm,control panel operation

mode,inverter operation ready,output current detection, zero current detection,PID lower limit,PID upper limit, PID forward rotation/reverse rotation, commercial power supply-inverter switchover,direct mains operation motor 1-4,frequency inverter operation motor 1-4, inverter running

start command ON, deceleration at an instantaneous power failure,PID control activated, re-start, PID output suspension,life time alarm, alarm

output 3 (OFF signal), power savings average value update timing,current average monitor,alarm output2, maintenance timer alarm,remote

outputs,minor failure output, alarm output,traverse operation, open-collector outputs (5 outputs),relay outputs (2 outputs), alarm code outputs

(4 bits via open-collector)

In addition to the above operating modes parameters 313-319 (function selection for the additional 7 output terminals) can also be used to assign the following four signals: control circuit capacitor life,main circuit capacitor life,cooling fan life, inrush current limit circuit life

You can also use parameter 54 (assign analog current output) and 158 (assign analog voltage output) to assign the following displays to one or

both outputs:

output frequnecy,motor current (steady or peak), output voltage, frequency setting value,motor running speed, converter output voltage (steady

or peak), electronic thermal relay function load factor, input voltage, output voltage, load meter, reference voltage output,motor load factor,en

ergy saving effect,regenerative brake circuit duty (01800 and above),PID set point, PID process value

Output frequency,motor current (steady or peak value),output voltage, alarm indication,frequency setting, motor running speed, converter out

put voltage (steady or peak value),electronic thermal load factor,input power,output power,road meter,cumulative energization time,actual

operation time,motor load factor, watt-hours meter,power saving effect, cumulative saving power, regenerative brake circuit duty (01800 and

above),PID set point, PID process value, PID deviation monitor,I/O terminal monitor,optional input terminal monitor (FR-DU07 only),optional

output terminal monitor (FR-DU07 only),option fitting state monitor (FR-PU04 only), terminal assignment state (FR-PU04 only)

Alarm definition is displayed when the protective function is activated,the output voltage/current/frequency/cumulative energization time right

before the protection function was activated and the past 8 alarm definitions are stored.

Overcurrent cutoff (during acceleration, deceleration or at constant speed),overvoltage cutoff (during acceleration, deceleration or at constant

speed), inverter protection thermal operation,motor protection thermal operation, heatsink overheat, instantaneous power failure occurence,

under voltage,input phase failure, motor overload,output shor t circuit, ground fault overcurrent,output phase failure,external thermal relay

operation,PTC thermistor operation, option alarm,parameter error,control unit disconnection, retry count excess,CPU alarm, power supply short

for control panel,24 V DC power output short, output current detection value over,inrush resitance overheat,communication error (frequency

inverter), analog input alarm,internal circuit alarm (15 V DC power supply),fan fault, overcurrent stall prevention,overvoltage stall prevention,

electronic thermal pre-alarm,control unit stop,maintenance timer alarm (FR-DU07 only), MT-BU5 external brake module overload (01800 and

above),parameter write error,copy error,operation panel lock, parameter copy error

IP20 (FR-F 740-00023 to -00620);

IP00 (FR-F 740-00770 to -12120)

-

-

-

-

쐓

FR-DU07: IP40 (does not apply for the PU connection)

14

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

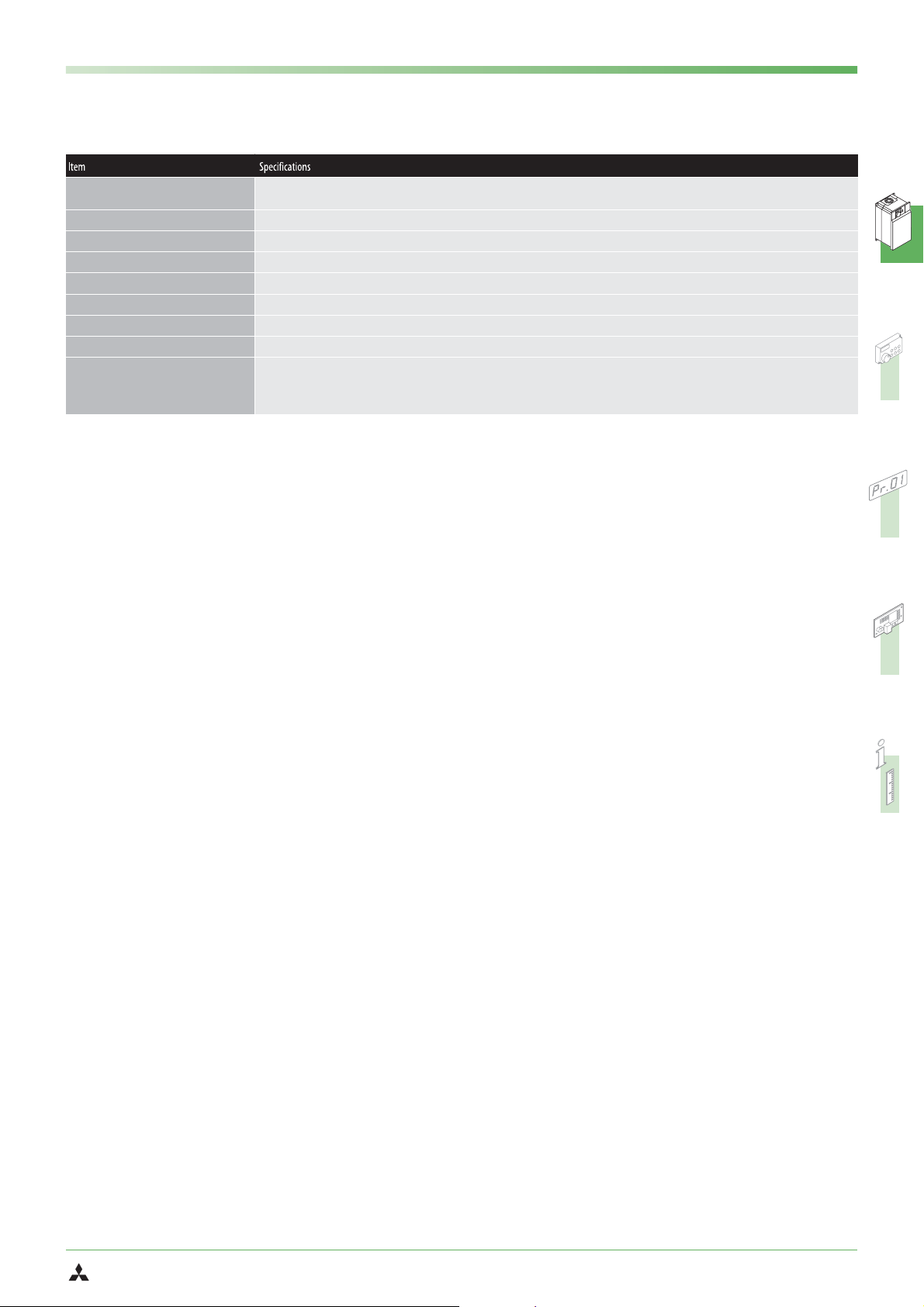

General Operating Conditions

SYSTEM DESCRIPTION

Ambient temperature in operation

Storage temperature*

Ambient humidity

Altitude

Shock resistance

Vibration resistance

Ambience conditions

Certifications

Max. cable length

*

Theproductmayonlybeexposedtothefullextremesofthistemperature range for short periods (e.g. during transportation).

−10°C to +50°C (non-freezing)

For selection of the load characteristics with a 120% overload rating the max.temperature is 40°C.

−20 to +65°C

Max.90% RH (non-condensing)

Max.1000 m above NN

10 G (3 times each in 3 directions)

Max.0.6 G

For indoor use only,avoid environments containing corrosive gases,install in a dust-free location.

UL / CSA / CE / EN / Gost / CCC

2 kHz: up to 300 m for 0023,other types up to 500 m

< 5 kHz: up to 200 m for 0023,up to 300 m for 0038, other types up to 500 m

5–9 kHz: up to 100 m

≥10 kHz: up to 50 m

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

15

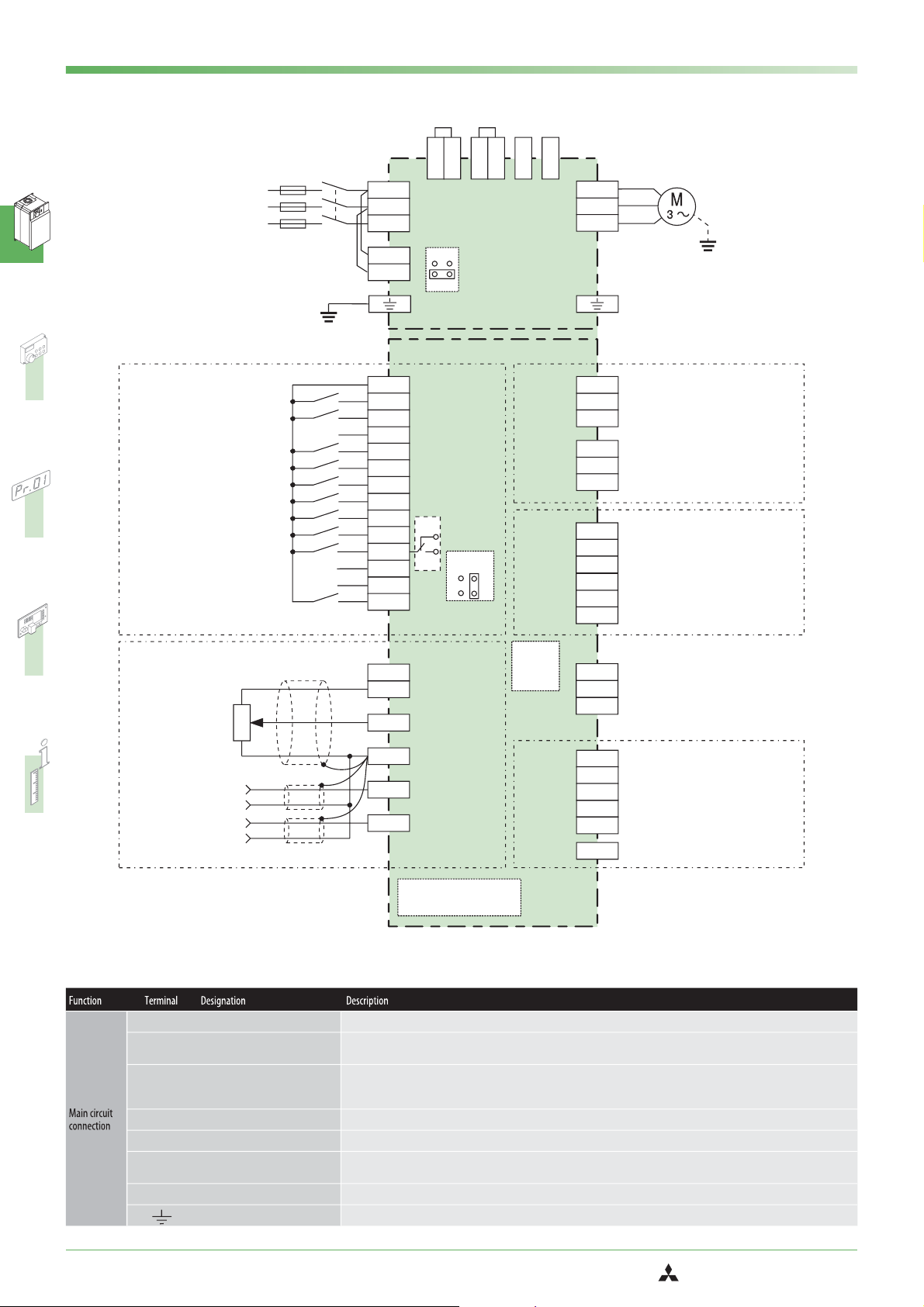

SYSTEM DESCRIPTION

Block Diagram

24 V DC Output (max. 100 mA)

Start self-retaining selection

Multi-speed

selection

Control input signals

Current input selection / PTC

Selection of automatic restart

3phase AC

power supply

Control circuit mains

supply connection

Protective earth

Forward rotation start

Reverse rotation start

High speed

Middle speed

Low speed

Second function selection

Jog mode

Output stop

Common

Reset

L1

L2

L3

L11

L21

PC

STF

STR

STOP

RH

RM

RL

RT

JOG

MRS

AU

CS

SD

RES

P1

P/+

ON

Jumper for activating the

integrated interference

suppression filter

OFF

Main circuit

Control circuit

AU

PTC

PCT

SOURCE

PX

PR

SINK

Intermediate circuit connections

N/-

CN8*

Motor

U

V

W

A1

Relay output 1

B1

(Alarm output)

C1

A2

Relay output 2

B2

C2

Running (Motor operation)

RUN

frequency setting value/current

SU

value comparison

IPF

Instantaneous power failure

OL

Overload

FU

Frequency detection

SE

Power supply for OC outputs

*The CN8 connector is provi

ded with the inverter 01800 or

more.

Relay outputs

Open collector

-

outputs

10E

10

2

5

1

4

inputs

Frequency setting

Frequency setting

potentiometer

0,5W1kΩ

Auxiliary input

Current input

(+)

(-)

(+)

(-)

*

Input area can be set

via parameters.

Terminal Assignment of Main Circuit Terminals

L1, L2, L3

P/+, N/−

P1, P/+

PR, PX

U, V, W

L11, L21

CN8

Mains supply connection Mains power supply of the inverters (380–480 V AC,50/60 Hz); (380-500 V – 01800 and above)

External brake unit connection

Converter choke coil connection

Motor connection Voltage output of the inverter (3-phase,0 V up to power supply voltage,0,5–400 Hz)

Control circuit mains supply

connection

Ext. brake transistor control Control connection for the MT-BU5 external brake module

PE Protective earth connection of inverter

An optional external brake resistor can be connected to the terminals P and N or you can connect a optional high power factor con

verter.

An optional choke coil can be connected to the terminals P1 and P/+. The jumper on terminals P1 and P/+ must be removed when

this optional choke coil is used on frequency inverter models 01160 and below.The DC reactor supplied with the unit must be installed

on frequency inverter models 01800 and above.

Please do not remove or use terminals PR and PX or the jumper connected.

To use external power for the control circuit connect the mains power to L11/L21 (and remove jumpers L1 and L2).

+10 V

+5 V

0–5 V DC

(0–10 V DC

4–20 mA DC)*

0– 10 V DC±

(0– 5 V DC)*±

4–20 mA DC

(0–5 V DC

0–10 V DC)*

Connector/Slot for plug-in

option connection

PU Connector

AM

CA

5

TXD+

TXD-

RXD+

RXD-

SG

VCC

Analog signal output (0 – 10 V DC / 1 mA)

Analog signal output (0/4 – 20 mA)

Analog output common

Data transmission

Data reception

GND (Ground)

5 V (max. 100 mA)

RS-485

terminal

-

16

FR-F 740 EC/E1

MITSUBISHI ELECTRIC

Terminal Assignment of Signal Terminals

SYSTEM DESCRIPTION

STF Forward rotation start

STR Reverse rotation start

STOP Start self-retaining selection

RH, RM, RL Multi-speed selection

JOG Jog mode selection

RT Second parameter settings

MRS Output stop

RES RESET input

Current input selection

AU

PTC input

Automatic restart after instanta

CS

neous power failure

Reference potential (0V) for the

SD

PC terminal (24V)

PC 24 V DC output

10 E

Voltage output for

potentiometer

10

Input for frequency setting

2

value signal

Reference point for frequency

5

setting value signal

Auxiliary input for frequency set-

1

ting value signal

0–±5 (10) V DC

4 Input for setting value signal

A1, B1, C1

A2, B2, C2

Potential free

Relay output 1 (Alarm)

Potential free

Relay output 2

Signal output for motor

RUN

operation

Signal output for frequency set

ting value/current value

SU

comparison

Signal output for instantaneous

IPF

power failure

OL Signal output for overload alarm

Signal output for monitoring

FU

output frequency

Reference potential for signal

SE

outputs

CA Current output 0–20 mA

Analog output 0–10 V

AM

(1 mA)

Connection of control panel

—

(via RS485 terminal)

RS484 terminal

—

(via RS485 terminal)

The motor rotates forward, if a signal is applied to terminal STF.

The motor rotates reverse,if a signal is applied to terminal STR.

The start signals are self-retaining, if a signal is applied to terminal STOP.

Preset of 15 different output frequencies

The JOG mode is selected,if a signal is applied to terminal JOG (factory setting).The inverters FR-A 540L-G 375 k and 450 k are not

equipped with a JOG terminal.The start signals STF and STR determine the rotation direction.

A second set of parameter settings is selected, if a signal is applied to terminal RT.

The inverter lock stops the output frequency without regard to the delay time.You can select a make or break signal for the controller

inhibit function by changing parameter 17.

An activated protective circuit is reset,if a signal is applied to the terminal RES (t > 0,1 s).

The 0/4–20mA signal on terminal 4 is enabled by a signal on the AU terminal.

If you connect a PTC temperature sensor you must assign the PTC signal to the AU terminal and set the slide switch on the control cir

cuit board to the PTC position.

The inverter restarts automatically after a power failure,if a signal is applied to the terminal CS.

When “sink”control logic is selected by setting the control signal jumper a specific control function is triggered when the correspond

ing control terminal is connected to the SD terminal.

When “source”control logic is selected and you are using external 24V power you must connect the 0V of the external power supply to

terminal SD.The SD terminal is isolated from the digital electronics with optocouplers.

Internal power supply 24 V DC/0,1 A output

Output voltage 10 V DC.

Max.output current 10 mA.

Recommended potentiometer:1 kΩ, 2 W linear

Output voltage 5 V DC.

Max.output current 10 mA.

Recommended potentiometer:1 kΩ, 2 W linear

The setting value 0–10 V or 0/4–20 mA is applied to this terminal. You can switch between voltage and current setpoint values with

parameter 73.The input resistance is 10 kΩ.

Terminal 5 is the reference point for all analog setting values and for the analog output signal AM and CA.The terminal is not isolated

from the reference potential of the control circuit and must not be earthed.

An additional voltage setting value signal of 0–±5 (10) V DC can be applied to terminal 1.

The voltage range is preset to 0–±10 V DC.The input resistance is 10 kΩ.

The setting value 0/4–20 mA or 0–10 V is applied to this terminal.You can switch between voltage and current setpoint values with

parameter 73.The input resistance is 250 Ω.

The current setting value is enabled via terminal function AU.

The alarm is output via relay contacts. The block diagram shows the normal operation and voltage free status.If the protective

function is activated,the relay picks up.The maximum contact load is 200 V AC / 0.3 A or 30 V DC / 0.3 A.

Any of the available 42 output signals can be used as the output driver.

The maximum contact load is 230 V AC / 0.3 A oder 30 V DC / 0.3 A.

The output is switched low, if the inverter output frequency is equal to or higher than the starting frequency.

The output is switched high,if no frequency is output or the DC brake is in operation.

-

The SU output supports a monitoring of frequency setting value and frequency current value.The output is switched low,once the fre

quency current value (output frequency of the inverter) approaches the frequency setting value (determined by the setting value sig

nal) within a preset range of tolerance.

The output is switched low for a temporary power failure within a range of 15 ms ≤t

The OL is switched low, if the output current of the inverter exceeds the current limit preset in parameter 22 and the stall prevention is

activated.If the output current of the inverter falls below the current limit preset in parameter 22,the signal at the OL output is

switched high.

The output is switched low once the output frequency exceeds a value preset in parameter 42 (or 43).Otherwise the FU output is

switched high.

The potential that is switched via open collector outputs RUN, SU,OL, IPF and FU is connected to this terminal.

One of 18 monitoring functions can be selected,e.g. external frequency output. CA and AM output can be used simultaneously.

The functions are determined by parameters.

An amperemeter can be connected (measuring range:0–20 mA).

One of 18 monitoring functions can be selected,e.g. external frequency output. CA and AM output can be used simultaneously.

The functions are determined by parameters.

A DC voltmeter can be connected.The max. output voltage is 10 V.

Communications via RS485

I/O standard:RS485, Multi-Drop operation,4,800 – 38,400 Baud (overall length: 500 m)

Communications via RS485

I/O standard:RS485, Multi-Drop operation,300 – 38,400 Baud (overall length: 500 m)

≤ 100 ms or for under voltage.

IPF

-

-

-

-

MITSUBISHI ELECTRIC

FR-F 740 EC/E1

17

CONTROL PANELS

Built-in Operation Panel FR-DU07 (Standard)

Selected operating mode

Four-digit 7-segment display for operating pa

rameters,error codes and other functions

Operating mode selector

PU: Operation via panel keys

앫

EXT:Operation via external signals

앫

Jog shuttle for quick adjustment of the in

verter frequency and parameter settings

-

-

Setting monitoring and frequency

PU operation mod

(output frequency monitor)

8.8.8.8.

8.8.8.8.

MON

Hz

A

PU

V

REV

PU

EXT

MODE

Value change

EXT

REV

SET

P. RU N

NET

FWD

FWD

RESET

STOP

FR-DU07

Shows that the frequency inverter is in

operation

Keys for starting the inverter

FWD: Start motor forwards

앫

REV:Start motor in reverse

앫

Functions:

MODE: Switches the mode for selecting

앫

the dislay functions

SET: Key for confirming and applying

앫

parameter and frequency settings

STOP/RESET:Stop and reset functions

앫

Example

and frequency flicker

Frequency setting has been

written and completed

Setting parameters

Parameter setting mode

Output current monitor Output voltage monitor

Select parameter

Parameter clear Parameter all clear Alarm clear

Display the current setting

Parameter and a setting value

flicker alternately

18

FR-F 740 EC/E1

Parameter copy

MITSUBISHI ELECTRIC

Control Panel FR-PU04 (Option)

The control panel FR-PU04 with extended

functions is available as optional accessory.

This control panel provides a 10-key key

pad for a direct entering of numerical

values. A 4-row LC display returns opera

tional data, parameter names or status

and error messages in uncoded text.

The control panel displays text in the

following selectable languages:

English, German, French, Spanish,

Swedish, Italian, Finnish, and Japanese.

In addition to the functions* of the

standard control panel the FR-PU04 dis

plays and monitors 21 different values

and states in total.

The control unit FR-PU04 is used instead of

the standard control unit FR-DU04 and can

be replaced by this after use.

*

The parameter copy function and the parameter and alarm dis

play functions are restricted when the panel is connected to the

FR-F 740.

-

-

-

CONTROL PANELS

50

50

SET

SHIFT

READ

PARAMETER UNIT

EXT

ESC

8

5

2

WRITE

Hz

00

Hz

00

PU

9

FWD

6

REV

3

STOP

RESET

4-row LCD display (backlit)

앫 Interactive parameter setting

앫 Help function

앫 Error indication

앫 21 different displays (frequency,current,

voltage,etc.)

The desired operating mode is selected by press

ing the buttons MONITOR,SET,EXT OP or PU OP.

Keys for the selection of specific functions via

the display and the entering of numerical

values.

-

0

-

U

4

P

-

R

F

- - - STOP EXT

- - - STOP EXT

MON

HELP

7

4

1

0

-

Menu Guide to the Control Panel FR-PU04

Displaying the parameter list

Press the SET key to enter the parameter

setting menu. Then press the HELP key to

display the parameter lists. After pressing

the READ key, the according parameter va

lue will be read in.

Copying parameters

Press the SET key and then the ▲ key to

enter the copy mode. Now you find three

choices:

앬

Press the READ key to read out all

parameters from the inverter.

앬

Press the WRITE key to write

parameters to the inverter.

앬

Press the ▼ key to verify the values

stored in the control panel and the

inverter.

Display of

output

frequency

-

Display of

output

current

Display of

output

voltage

Display of

alarm history

MONI-

TOR

0 00

- - - STOP EXT

SHIFT

00000

- - -

STOP

EXT

SHIFT

0

- - -

STOP

EXT

SHIFT

Hz

A

SHIFT

0.00Hz

0.00A

- - -

V

SHIFT

0. 0V

STOP EXT

SHIFT

Others

<HELP>

SHIFT

Display of

alarms

(up to 8)

HELP

Monitor

selection

MITSUBISHI ELECTRIC

Alar m Histor y

<READ>

READ

15UVT

26UVT

3

4

7

8

FR-F 740 EC/E1

19

CONTROL PANELS

MON

PU

EXT

NET

FWD

P. R U N

Operating Modes

The inverter can alternatively be operated

via external signals or directly via the ope

ration panel FR-DU07 or the control panels

FR-PU04.

On the FR-DU07 control panel the opera

ting mode is selected by pressing the

PU/EXT key. On the FR-PU04 the EXT key

selects operation by external signals and

the PU key selects operation via the control

panel.

Operation from the control panel

The direction of rotation and frequency

setting of the inverter are controlled from

the built-in operation panel.

The setting of the output frequency is

increased or decreased via the Digital Dial.

Sample connection

-

These connections

are required for

Mains

L1

L2

L3

Start

combined

operation or

operation by

external signals.

The example below shows the operational

steps for a frequency setting with following

motor start and motor stop.

Frequency

setting

Q1

FR-F 740 EC

I

I

I

S1

S2

R1

L1

L2

L3

PC

STR

STF

10

2

5

U

V

W

Motor

Operation by external signals

The direction of rotation and frequency

setting of the inverter are controlled by

external signals. The following figure

shows the display on the built-in

operation panel FR-DU07 for forward rota

tion of the motor and a frequency of 50 Hz.

-

햲

Press the PU/EXT key

PU

EXT

햳

Set frequency with

Digital Dial

+-

햴

Press SET key to confirm

SET

햵

Press FWD to start the motor

FWD

PU

PU

PU

PU

PU

PU

PU

FWD

Hz

A

V

PU

EXT

MODE

REV

P.R U N

MON

PU

EXT

NET

FWD

FWD

REV

STOP

SET

RESET

FR-DU07

Combined operation

In addition to the operation by external

signals and the operation from the control

panel (built-in or external) the inverter can

be operated in combined operation mode.

앬

Setting value preset from the control

panel and external starting signal.

앬

External setting value signal and star

ting signal from the control panel.

-

햶

Stop motor

20

STOP

RESET

FR-F 740 EC/E1

PU

PU

FWD

MITSUBISHI ELECTRIC

VFD Setup Software

CONTROL PANELS

The VFD Setup Software is a powerful

tool for the operation of your frequency in

verter. The software (version 2.4) is MS

Windows 95/98/ME/XP and NT/2000 com

patible, and therefore allows the inverter

operation via any conventional personal

computer. Several frequency inverters can

be set up, operated, and monitored simul

taneously across a network or via a perso

nal computer or notebook. The software is

designed for all frequency inverters of the

MITSUBISHI FR-S 500, FR-E 500, FR-A 500,

FR-F 500 and FR-F 700* series.

The connection between personal compu

ter and inverter is established either

via an RS485 network or directly via an

SC-FR PC adapter cable available separately.

MITSUBISHI

700

FREQROL-F

ock

h

rics

t