Mitsubishi FR-F740-00126-EC, FR-F740-00023-EC, FR-F740-00170-EC, FR-F740-00250-EC, FR-F740-00310-EC Instruction Manual

...

INVERTER

INSTRUCTION MANUAL (Applied)

FR-F740-00023 to 02160-EC

WIRING

PRECAUTIONS FOR USE

OF THE INVERTER

PARAMETERS

PROTECTIVE FUNCTIONS

SPECIFICATIONS

1

2

3

4

5

Thank you for choosing this Mitsubishi Inverter.

This Instruction Manual (applied) provides instructions for advanced use of the FR-F700 series inverters.

Incorrect handling might cause an unexpected fault. Before using the inverter, always read this instruction manual and the instruction

manual (basic) [IB-0600176ENG] packed with the product carefully to use the equipment to its optimum.

This section is specifically about safety matters

Do not attempt to instal l, op era te, maintain or inspect the inver ter unt il you

have read through instruction manual (basic) and a ppended documents

carefully and can use the equipment correctly. Do not use the inverter until

you have a full knowledge of the equipment, safety information and

instructions. In this instruction manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that even the level may lead to a serious consequence

according to conditions. Please follow the instructions of both levels

because they are important to personnel safety.

1. Electric Shock Prev en tion

• While power is on or when the inverter is running, do not open the front cover.

Otherwise you may get an electric shock.

• Do not run the inverter with the front cover or wiring cover removed.

Otherwise, you may access the exposed high-voltage terminals or the

charging part of the circuitry and get an electric shock.

•

Even if power is o ff, do not remove the front cover except for wirin g or periodic

inspection.You may access the charged inverter circuits and get an electric shock.

• Before starting wiring or inspection, check to make sure that the operation

panel indicator is off, wait for at least 10 minutes after the power supply has

been switched off, and check that there are no residual voltage using a tester

or the like. The capacitor is charged with high voltage for some time after

power off and it is dangerous.

• This inverter must be earthed. Earthing must conform to the requirements of

national and local safety regulations and electrical codes. (JIS, NEC section

250, IEC 536 class 1 and other applicable standards)

• Any person who is involved in the wiring or inspection of this equipment

should be fully competent to do the work.

• Always install t he inverter before wiring. Otherwise, you may get an elect ric

shock or be injured.

• Perform setting dial and key operations with dry hands to prevent an electric

shock. Otherwise you may get an electric shock.

• Do not subject the cables to scratches, excessive stress, heavy loads or

pinching. Otherwise you may get an electric shock.

• Do not replace the cooling fan while power is on. It is dangerous to replace

the cooling fan while power is on.

•

Do not touch the printed circuit board with wet hands. You may get an electric shock.

2. Fire Prevention

• Mount the inverter to incombustible material. Mounting it to or near

combustible material can cause a fire.

• If the inverter has become faulty, switch off the inverter power.

A continuous flow of large current could cause a fire.

•

Do not connect a resistor directly to the DC terminals P/+, N/−. This could cause a fire.

3. Injury Prevention

• Apply only the voltage specified in the instruction manual to each terminal.

Otherwise, burst, damage, etc. may occur.

• Ensure that the cables are connected to the correct terminals. Otherwise,

burst, damage, etc. may occur.

• Always make sure that polarity is correct to prevent damage, etc. Otherwise,

burst, damage, etc. may occur.

• While power is on or for some time after power-off, do not touch the inverter

as it is hot and you may get burnt.

4. Additional Instruc tions

Also note the following points to prevent an accidental failure, injury, electric

shock, etc.

(1) Transporta tion and inst allation

• When carrying products, use correct lifting gear to prevent injury.

• Do not stack the inverter boxes higher than the number recommended.

• Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the instruction manual.

• Do not install or operate the inverter if it is damaged or has parts missing.

• When carrying the inverter, do not hold it by the front cover or setting dial; it

may fall off or fail.

• Do not stand or rest heavy objects on the product.

• Check the inverter mounting orientation is correct.

• Prevent other conductive bodies such as screws and metal fragments or

other flammable substance such as oil from entering the inverter.

• As the inverter is a precision instrument, do not drop or subject it to impact.

• Use the inverter under the following environmental conditions. Otherwise, the

inverter may be damaged.

Ambient

temperature

Ambient humidity 90% RH or less (non-condensing)

Storage temperature -20°C to +65°C *

Atmosphere

Environment

Altitude, vibration

*Temperature applicable for a short time, e.g. in transit.

Assumes that incorrect handling may cause hazardous

conditions, resulting in death or sever e injury.

Assumes that incorrect handling may cause

hazardous conditions, resulting in medium or

slight injury, or may cause physical damage only.

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

LD -10°C to +50°C (non-freezing)

SLD

(initial setting)

-10°C to +40°C (non-freezing)

Indoors (free from corrosive gas,

flammable gas, oil mist, dust and dirt)

Maximum 1000m above sea level for

standard operati on. Aft er tha t de rate by 3%

for every extra 500m up to 2500m (92%)

2

5.9m/s

or less (conforming to J I S C 0040)

(2) Wiring

• Do not install a power factor correction capacitor or surge suppressor on the

inverter output side.

• The connection orientation of the output cables U, V, W to the motor will affect

the direction of rotation of the motor.

CAUTION

(3) Test operation and adjustment

• Before starting operation, confirm and adjust the parameters. A failure to do

so may cause some machines to make unexpected motions.

(4) Operation

• When you have chosen the retry function, stay away from the equipment as it

will restart suddenly after an alarm stop.

• The key is valid only when the appropriate function setting has been

made. Prepare an emergency stop switch separately.

• Make sure that the start signal is off before resetting the inverter alarm. A

failure to do so may restart the motor suddenly.

• The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this manual. Doing so

may lead to fault or damage of the inverter.

• The electronic thermal relay function does not guarantee protection of the

motor from overheating.

• Do not use a magnetic contactor on the inverter input for frequent starting/

stopping of the inverter.

• Use a noise filter to reduce the effect of electromagnetic interference.

Otherwise nearby electronic equipment may be affected.

• Take measures to suppress harmonics. Otherwise power supply harmonics

from the inverter may heat/damage the power factor correction capacitor and

generator.

• When a 400V class motor is inverter-driven, please use an insulationenhanced motor or measures taken to suppress surge voltages. Surge

voltages attributable to the wiring constants may occur at the motor terminals,

deteriorating the insulation of the motor.

• When parameter clear or all clear is performed, reset the required

parameters before starting operations. Each parameter returns to the initial

value.

• The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

• In addition to the inverter's holding function, install a holding device to ensure

safety.

• Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

• For prevention of damage due to static electricity, touch nearby metal before

touching this product to eliminate static electricity from your body.

(5) Emergency stop

• Provide a safety backup such as an emergency bra ke which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

• When the breaker on the inverter input side trips, check for the wiring fault

(short circuit), damage to internal parts of the inverter, etc. Identify the cause

of the trip, then remove the cause and power on the breaker.

• When the protective function is activated, take the corresponding corrective

action, then reset the inverter, and resume operation.

CAUTION

WARNING

CAUTION

CAUTION

(6) Maintenance, inspection and parts replacement

CAUTION

• Do not carry out a megger (insulation resistance) test on the control circuit of

the inverter.

(7) Disposing of the inverter

CAUTION

• Treat as industrial waste.

General instructions

Many of the diagrams and drawings in this instruction manual show the

inverter without a cover, or partially open. Never run the inverter in this

status. Always replace the co ver and follow this instruction manual when

operating the inverter.

A-1

CONTENTS

1 WIRING 1

1.1 Inverter and peripheral devices..........................................................................2

1.1.1 Peripheral devices..................................................................................................................... 3

1.2 Wiring....................................................................................................................4

1.2.1 Terminal connection diagram ........................ ....... ...... ...... ....... ...... ....... ...... ............................... 4

1.3 Main circuit terminal specifications...................................................................5

1.3.1 Specification of main circuit terminal ......................................................................................... 5

1.3.2 Terminal arrangement of the main circuit terminal, power supply and the motor wiring. .......... 5

1.3.3 Cables and wiring length ........................................................................................................... 7

1.4 Control circuit specifications ...........................................................................10

1.4.1 Control circuit terminals........................................................................................................... 10

1.4.2 Control circuit terminal layout .................................................................................................. 12

1.4.3 Wiring instructions ................................................................................................................... 13

1.4.4 When connecting the control circuit and the main circuit separately

to the power supply (separate power)..................................................................................... 14

1.4.5 Changing the control logic....................................................................................................... 16

1.5 Connection of stand-alone option units................... ..... ..................................18

1.5.1 Connection of the brake unit (FR-BU)..................................................................................... 18

1.5.2 Connection of the brake unit (BU type) ................................................................................... 19

1.5.3 Connection of the high power factor converter (FR-HC) ......................................................... 19

1.5.4 Connection of the power regeneration common converter (FR-CV) ....................................... 20

1.5.5 Connection of the power factor improving DC reactor (FR-HEL) ............................................ 20

1.5.6 When connecting the operation panel using a connection cable ............................................ 21

2 PRECAUTIONS FOR USE OF THE INVERTER 23

2.1 Panel design.......................................................................................................24

2.1.1 Inverter installation environment.............................................................................................. 24

2.1.2 Cooling system types for inverter panel .................................................................................. 26

2.1.3 Inverter placement................................................................................................................... 27

2.2 Precautions for use of the inverter ..................................................................28

2.3 Others .................................................................................................................29

2.3.1 Leakage currents and countermeasures................................................................................. 29

2.3.2 Power-off and magnetic contactor (MC).................................................................................. 31

2.3.3 Installation of a reactor ............................................................................................................ 31

2.3.4 Inverter-generated noises and their reduction techniques ...................................................... 32

2.3.5 EMC filter................................................................................................................................. 34

I

2.3.6 Power supply harmonics ......................................................................................................... 35

2.3.7 Inverter-driven 400V class motor............................................................................................. 36

3 PARAMETERS 37

3.1 Parameter List........................ ..... .... ..... ..................................... ..... ..... ...............38

3.1.1 Parameter list .......................................................................................................................... 38

3.2 Adjust the output torque of the motor (current) ............................................ 53

3.2.1 Manual torque boost (Pr.0, Pr.46) .......................................................................................... 53

3.2.2 Simple magnetic flux vector control (Pr.80, Pr.90) ................................................................. 54

3.2.3 Slip compensation (Pr. 245 to Pr. 247) .... ...... ....... ...... ...... ....... ...... ....... ...... ............................ 55

3.2.4 Stall prevention operation

(Pr.22, Pr.23, Pr.48, Pr.49, Pr.66, Pr.148, Pr.149, Pr.154, Pr.156, Pr.157)........................... 56

3.2.5 Load pattern selection (Pr.14) ................................................................................................ 60

3.2.6 Multiple rating (Pr.570) .................................. ....... ...... ...... ....... ...... ....... ...... ....... ...... ............... 61

3.3 Limit the output frequency............................................................................... 62

Content

3.3.1 Maximum/minimum frequency (Pr. 1, Pr. 2, Pr. 18) ............................................................... 62

3.3.2 Avoid mechanical resonance points (Frequency jump) (Pr. 31 to Pr. 36) .............................. 63

3.4 Set V/F pattern................................................................................................... 64

3.4.1 Base frequency, voltage (Pr.3, Pr.19, Pr.47).......................................................................... 64

3.4.2 Adjustable 5 points V/F (Pr. 71, Pr. 100 to 109)..................................................................... 66

3.5 Frequency setting by external terminals........................................................ 67

3.5.1 Multi-speed setting operation (Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239) ................. 67

3.5.2 Jog operation (Pr. 15, Pr. 16) ................................................................................................ 69

3.5.3 Input compensation of multi-speed and remote setting (Pr. 28)............................................. 71

3.5.4 Remote setting function (Pr. 59)............................................................................................. 72

3.6 Setting of acceleration/deceleration time and

acceleration/deceleration pat ter n.......................... .... ...................................... 74

3.6.1 Setting of the acceleration and deceleration time (Pr.7, Pr.8, Pr.20, Pr.21, Pr.44, Pr.45)...... 74

3.6.2 Starting frequency and start-time hold function (Pr.13, Pr.571) ............................................. 76

3.6.3 Acceleration/deceleration pattern (Pr.29, Pr.140 to Pr.143).............................. ...... ....... ...... .. 77

3.7 Selection and protection of a motor ............................................................... 78

3.7.1 Motor protection from overheat (Electronic thermal relay function) (Pr.9).............................. 78

3.7.2 Applied motor (Pr.71) ............................................................................................................. 80

3.8 Motor brake and stop operation...................................................................... 81

3.8.1 DC injection brake (Pr. 10 to Pr. 12)....................................................................................... 81

3.8.2 Selection of a regenerative brake (Pr. 30, Pr.70) ................................................................... 83

3.8.3 Stop selection (Pr.250)........................................................................................................... 84

II

3.9 Function assignment of external terminal and control................................. 85

3.9.1 Input terminal function selection (Pr.178 to Pr.189) ............................................................... 85

3.9.2 Inverter output shutoff signal (MRS signal, Pr. 17)................................................................. 87

3.9.3 Second function RT signal reflection time selection (Terminal RT, Pr. 155) .......................... 88

3.9.4 Start signal selection (Terminal STF, STR, STOP, Pr. 250)................................................... 89

3.9.5 Output terminal function selection (Pr. 190 to Pr. 196)........................................................... 91

3.9.6 Detection of output frequency (SU, FU, FU2 signal, Pr. 41 to Pr. 43, Pr. 50) ........................ 95

3.9.7 Output current detection function

(Y12 signal, Y13 signal, Pr. 150 to Pr. 153, Pr. 166, Pr. 167) ................................................ 96

3.9.8 Remote output function (REM signal, Pr. 495 to Pr. 497) ...................................................... 98

3.10 Monitor display and monitor output signal.................................................... 99

3.10.1 Speed display and speed setting (Pr.37, Pr.144)................................................................... 99

3.10.2 DU/PU monitor display selection (Pr.52, Pr.170, Pr.171, Pr.268, Pr.563, Pr.564, Pr.891) .. 100

3.10.3 CA, AM terminal function selection (Pr.54 to Pr.56, Pr.158, Pr.867, Pr.869) ....................... 104

3.10.4 Terminal CA, AM calibration (Calibration parameter C0 (Pr. 900), C1 (Pr. 901), C8 (pr.930) to

C11 (Pr. 931))....................................................................................................................... 106

3.11 Operation selection at power failure and instantaneous power failure..... 109

3.11.1 Automatic restart after instantaneous power failure

(Pr. 57, Pr. 58, Pr. 162 to Pr. 165, Pr. 611) .......................................................................... 109

3.11.2 Power failure-time deceleration-to-stop function (Pr. 261 to Pr. 266)................................... 112

3.12 Operation setting at alarm occurrence......................................................... 114

3.12.1 Retry function (Pr. 65, Pr. 67 to Pr.69)................................................................................. 114

3.12.2 Alarm code output selection (Pr.76) ..................................................................................... 116

3.12.3 Input/output phase failure protection selection (Pr.251, Pr.872) .......................................... 117

3.13 Energy saving operation and energy saving monitor................................. 118

3.13.1 Energy saving control and optimu m excita tio n contro l (Pr.6 0) ............. ...... ....... ...... ....... ...... 118

3.13.2 Energy saving monitor (Pr. 891 to Pr. 899) .......................................................................... 119

3.14 Motor noise, noise reduction......................................................................... 124

3.14.1 PWM carrier frequency and Soft-PWM control (Pr.72, Pr.240, Pr.260) ............................... 124

3.15 Frequency setting by analog input (terminal 1, 2, 4)................................... 125

3.15.1 Analog input selection (Pr.73, Pr.267).................................................................................. 125

3.15.2 Analog input compensation (Pr.73, Pr.242, Pr.243, Pr.252, Pr.253).................................... 127

3.15.3 Input filter time constant (Pr.74) ........................................................................................... 128

3.15.4 Bias and gain of frequency setting voltage (current)

(Pr. 125, Pr. 126, Pr. 241, C2(Pr. 902) to C7(Pr. 905)) ........................................................ 129

3.15.5 4mA input check of current input (Pr. 573)........................................................................... 134

3.16 Misoperation prevention and parameter setting restriction....................... 136

3.16.1 Reset selection/disconnected PU detection/PU stop selection (Pr.75) ................................ 136

III

3.16.2 Parameter write disable selection (Pr.77)............................................................................. 139

3.16.3 Reverse rotation prevention selection (Pr.78) ...................................................................... 140

3.16.4 Display of applied parameters and user group function (Pr.160, Pr.172 to Pr.174) ............. 140

3.17 Selection of operation mode and operation location.................................. 142

3.17.1 Operation mode selection (Pr. 79)........................................................................................ 142

3.17.2 Operation mode at power on (Pr. 79, Pr. 340) ..................................................................... 150

3.17.3 Operation command source and speed command source during

communication operation (Pr. 338, Pr. 339, Pr. 550, Pr. 551).............................................. 151

3.18 Communication operation and setting......................................................... 156

3.18.1 Wiring and configuration of PU connector............................................................................ 156

3.18.2 Wiring and arrangement of RS-485 terminals ...................................................................... 158

3.18.3 Initial settings and specifications of RS-485 communication

(Pr. 117 to Pr. 124, Pr. 331 to Pr. 337, Pr. 341) ................................................................... 161

3.18.4 Communication EEPROM write selection (Pr. 342) ............................................................. 162

3.18.5 Mitsubishi inverter protocol (computer link communication)................................................. 163

3.18.6 Modbus-RTU communication specifications (Pr. 331, Pr. 332, Pr. 334, Pr. 343, Pr. 549) ... 173

3.19 Special operation and frequency setting...................................................... 184

3.19.1 PID control (Pr. 127 to Pr. 134, Pr. 575 to Pr. 577).............................................................. 184

3.19.2 Commercial power supply-inverter switchover function (Pr. 135 to Pr. 139, Pr. 159) .......... 192

3.19.3 Advanced PID function (pump function) (Pr. 575 to Pr. 591) ............................................... 197

3.19.4 Traverse function (Pr. 592 to Pr. 597) .................................................................................. 206

3.19.5 Regeneration avoidance function (Pr.882 to Pr.886) ........................................................... 208

Content

3.20 Useful functions.............................................................................................. 210

3.20.1 Cooling fan operation selection (Pr.244) .............................................................................. 210

3.20.2 Display of the life of the inverter parts (Pr. 255 to Pr .259)................................................... 211

3.20.3 Maintenance timer alarm (Pr.503, Pr.504) ........................................................................... 213

3.20.4 Current average value monitor signal (Pr.555 to Pr.557) ..................................................... 214

3.20.5 Free parameter (Pr.888, Pr.889) .......................................................................................... 216

3.21 Setting from the parameter unit, operation panel........................................ 217

3.21.1 PU display language selection (Pr.145) ............................................................................... 217

3.21.2 Operation panel frequency setting/key lock operation selection (Pr. 161) ........................... 217

3.21.3 Buzzer control (Pr. 990)........................................................................................................ 219

3.21.4 PU contrast adjustment (Pr.991) .......................................................................................... 219

3.22 Parameter clear........................... .... ...................................... .... ..... ................. 220

3.23 All parameter clear.................................... .... ...................................... .... ..... ... 221

3.24 Parameter copy............................... ..... ..... ..................................... ..... .... ..... ... 222

3.25 Parameter verification............................................ .... .................................... 223

IV

3.26 Check and clear of the alarm history.............................................................224

4 PROTECTIVE FUNCTIONS 227

4.1 List of alarm display............................................................. .... ..... ..................228

4.2 Causes and corrective actions.......................................................................229

4.3 Reset method of protective function .............................................................240

4.4 Correspondences between digital and actual characters ...........................240

4.5 Meters and measuring methods.....................................................................241

4.5.1 Measurement of powers........................................................................................................ 241

4.5.2 Measurement of voltages and use of PT............................................................................... 242

4.5.3 Measurement of currents....................................................................................................... 242

4.5.4 Use of CT and transducer ..................................................................................................... 243

4.5.5 Measurement of inverter input power factor .......................................................................... 243

4.5.6 Measurement of converter output voltage (across terminals P/+ - N/-)................................. 243

4.6 Check first when you have troubles. .............................................................244

4.6.1 Motor does not rotate as commanded................................................................................... 244

4.6.2 Motor generates abnormal noise........................................................................................... 244

4.6.3 Motor generates heat abnormally.......................................................................................... 244

4.6.4 Motor rotates in opposite direction ........................................................................................245

4.6.5 Speed greatly differs from the setting.................................................................................... 245

4.6.6 Acceleration/deceleration is not smooth................................................................................ 245

4.6.7 Motor current is large............................................................................................................. 245

4.6.8 Speed does not increase....................................................................................................... 245

4.6.9 Speed varies during operation............................................................................................... 245

4.6.10 Operation panel (FR-DU07) display is not operating............................................................. 245

4.6.11 Parameter write cannot be performed................................................................................... 245

5 SPECIFICATIONS 247

5.1 Rating................................................................................................................248

5.2 Common specifications ..................................................................................249

5.3 Outline dimension drawings...........................................................................251

5.3.1 Inverter outline dimension drawings...................................................................................... 251

5.3.2 Operation panel (FR-DU07) outline dimension drawings...................................................... 254

5.3.3 Parameter unit (FR-PU04) outline dimension drawings ........................................................ 254

V

1 WIRING

This chapter describes the basic "WIRING" for use of this

product.

Always read the instructions before using the equipment

1.1 Inverter and perip her a l dev ic es................ .. .............2

1.2 Wiring......................................................................4

1.3 Main circuit terminal specifications..........................5

1.4 Control circuit specifications....................................10

1.5 Connection of stand-alone option units...................18

<Abbreviations>

DU ..........................................Operation panel (FR-DU07)

PU..................... ..... ..... ...... ..... ..... .Operation panel (FR-DU07 ) a nd p aram eter unit (FR-PU04 )

Inverter ...................................Mitsubishi inverter FR-F700 series

FR-F700 .................................Mitsubishi inverter FR-F700 series

Pr............................................Parameter Number

PU operation...........................Operation using the PU (FR-DU07/FR-PU04).

External operation ..................Operation using the control circuit signals

Combined operation ............... Combined operation using the PU (FR-DU07/FR-PU04)

and external operation.

Mitsubishi standard motor ......SF-JR

Mitsubishi constant-torque motor

<Trademarks>

•L

ONWORKS is a registered trademark of Echelon Corporation in the U.S.A

• CC-Link is a registered trademark of CC-Link Partner Association.

• Other company and product names herein are the trademarks and registered

trademarks of their respective owners.

.SF-HRCA

1

2

3

4

5

1

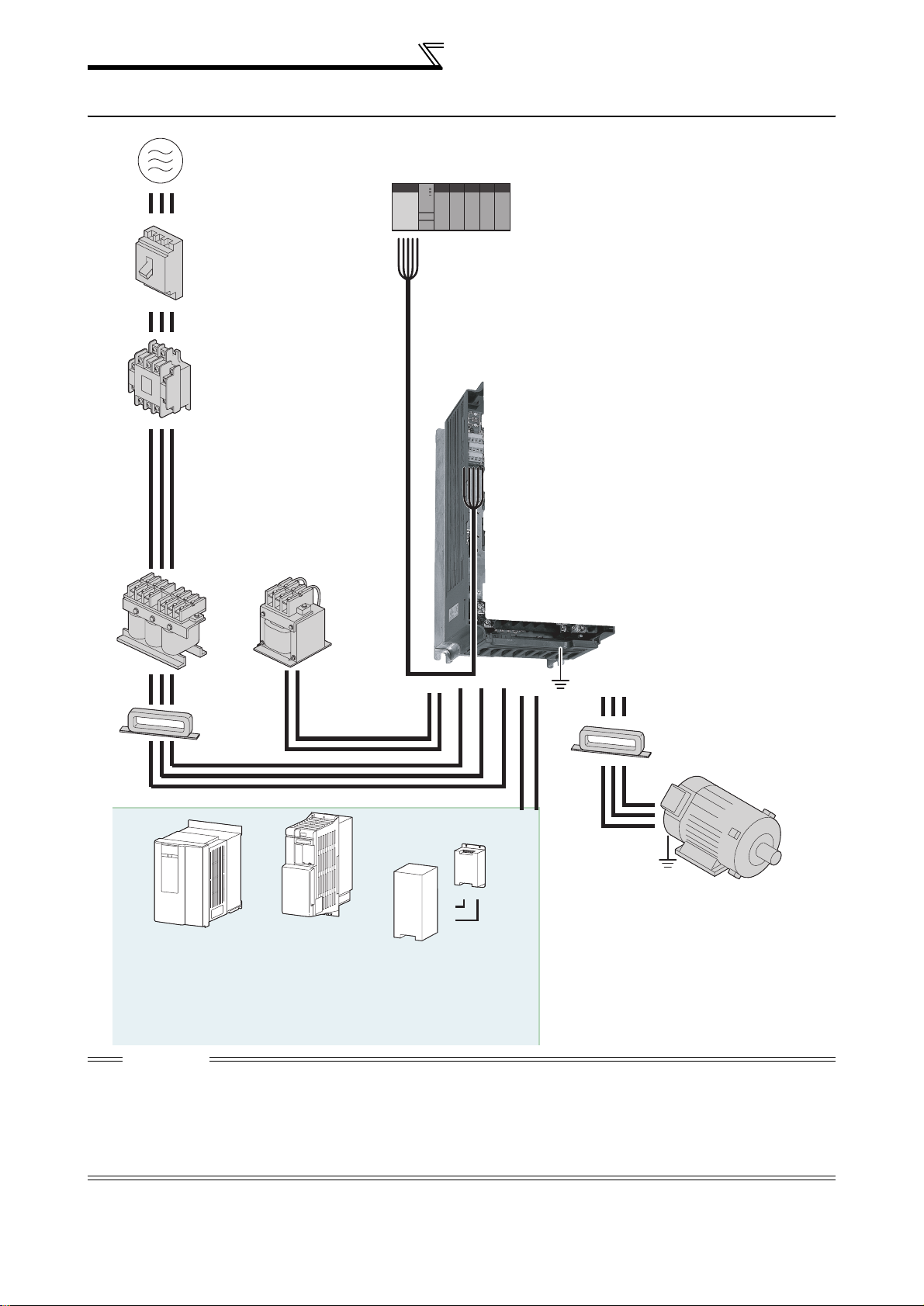

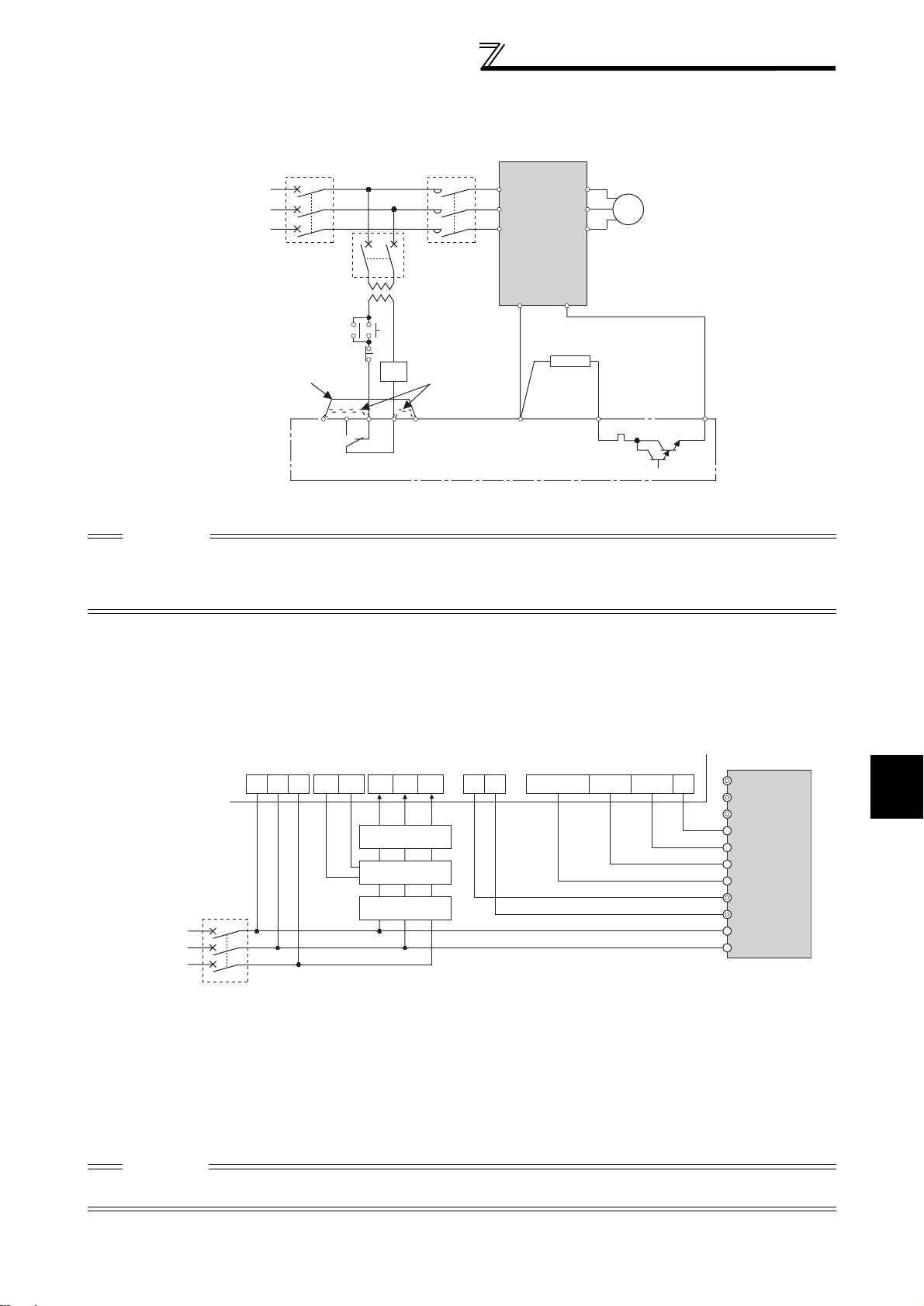

Inverter and peripheral devices

1.1 Inverter and peripheral devices

3-phase AC power supply

Use within the permissible power supply

specifications of the inverter.

(Refer to page 248)

Moulded case circuit

breaker (MCCB)

or earth leakage circuit

breaker (ELB), fuse

The breaker must be selected carefully since

an in-rush current flows in the inverter at

power on.

(Refer to page 3)

Magnetic contactor(MC)

Install the magnetic contactor to ensure safety.

Do not use this magnetic contactor to start and

stop the inverter.

Doing so will cause the inverter life to be shorten.

(Refer to page 3)

Reactor (FR-HAL, FR-HEL)

Reactors (option) should be used when power

harmonics measures are taken, the power factor

is to be improved or the inverter is installed near a

large power supply system (1000kVA or more).

The inverter may be damaged if you do not use

reactors.

Select the reactor according to the model.

Remove the jumpers across terminals P/+-P1 to

connect to the DC reactor.

(Refer to page 3.)

PLC

RS-485 terminal block

The inverter can be

connected with computers

such as PLC.

It supports Mitsubishi inverter

protocol and Modbus-RTU

(binary) protocol.

Inverter

(FR-F700)

The life of the inverter is influenced by ambient

temperature. The ambient temperature should be as low

as possible within the permiss ible range . Especi ally w hen

mounting the inverter inside an enclosure, take cautions

of the ambient temperature. (Refer to page 27)

Wrong wiring might lead to damage o f the inverter. The

control signal lines must be kept fully away from the main

circuit to protect them from noise.(Refer to page 4)

Refer to page 34 for the built-in EMC filter.

Noise filter

AC reactor

(FR-HAL)

Noise filter

(FR-BLF)

It is not necessary

for the 01160 or less.

DC reactor

(FR-HEL)

For the 01800 or more, a

DC reactor is supplied.

Always install the reactor.

P/+

P1

R/L1 S/L2 T/L3

N/-P/+

Earth

UVW

(FR-BSF01, FR-BLF)

Install a noise filter to reduce

the electromagnetic noise

generated from the inverter.

Effective in the range from

about 1MHz to 10MHz.

When more wires are passed

through, a more effective result

can be obtained.

Motor

Brake unit

*1

(FR-BU

, MT-BU5*2)

Earth

Devices connected to the output

Do not install a power factor correction capacitor,

varistor, arrester or radio noise filter on the output

side of the inverter.

When installing a moulded case circuit breaker on the

output side of the inverter, contact each manufacturer

for selection of the moulded case circuit breaker.

Earth

To prevent an electric shock, always earth the

motor and inverter.

High power factor

converter

*2

(FR-HC, MT-HC

Power supply harmonics

can be greatly suppressed.

Install this as required.

)

*1 Compatible with the 01160 or less.

*2 Compatible with the 01800 or more.

Power regeneration

common converter

*1

)

(FR-CV

Power regeneration

converter (MT-RC

Greater braking capability

is obtained.

Install this as required.

*2

P/+

PR

Resistor unit

*1

(FR-BR

The regenerative braking

)

capability of the inverter can be

exhibited fully.

Install this as required.

, MT-BR5*2)

PR

P/+

CAUTION

· Do not in st all a p ower fa ctor corr ecti on cap acitor o r surge supp ressor on the inve rter output s ide. This will c ause the in verter

to trip or power factor corr ec t io n capacitor, varistor and arrester to be damaged. If any of the above devices are conne ct ed,

immediately remove them.

· Electromagnetic wave interference

The input/out put (main ci rcuit) of t he invert er include s high freq uency compone nts, which may interfere w ith the co mmunicatio n

devices (such as AM radios) used near the inverter. An EMC filter can minimize noise interference.

(Refer to

· Refer to the instruction manual of each opti on a nd peripheral devices for details of pe ripheral devices.

page 34

.)

2

Inverter and peripheral devices

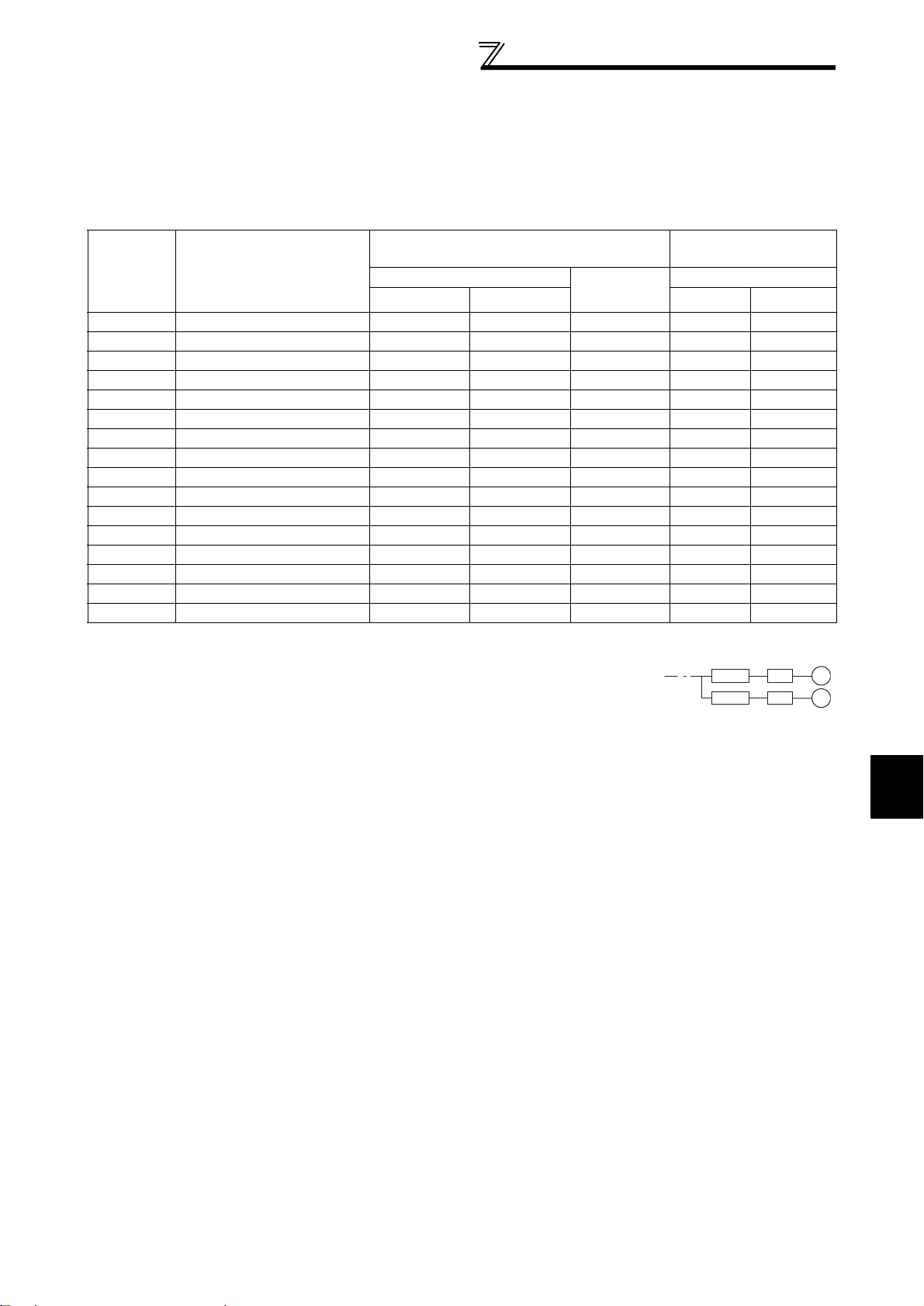

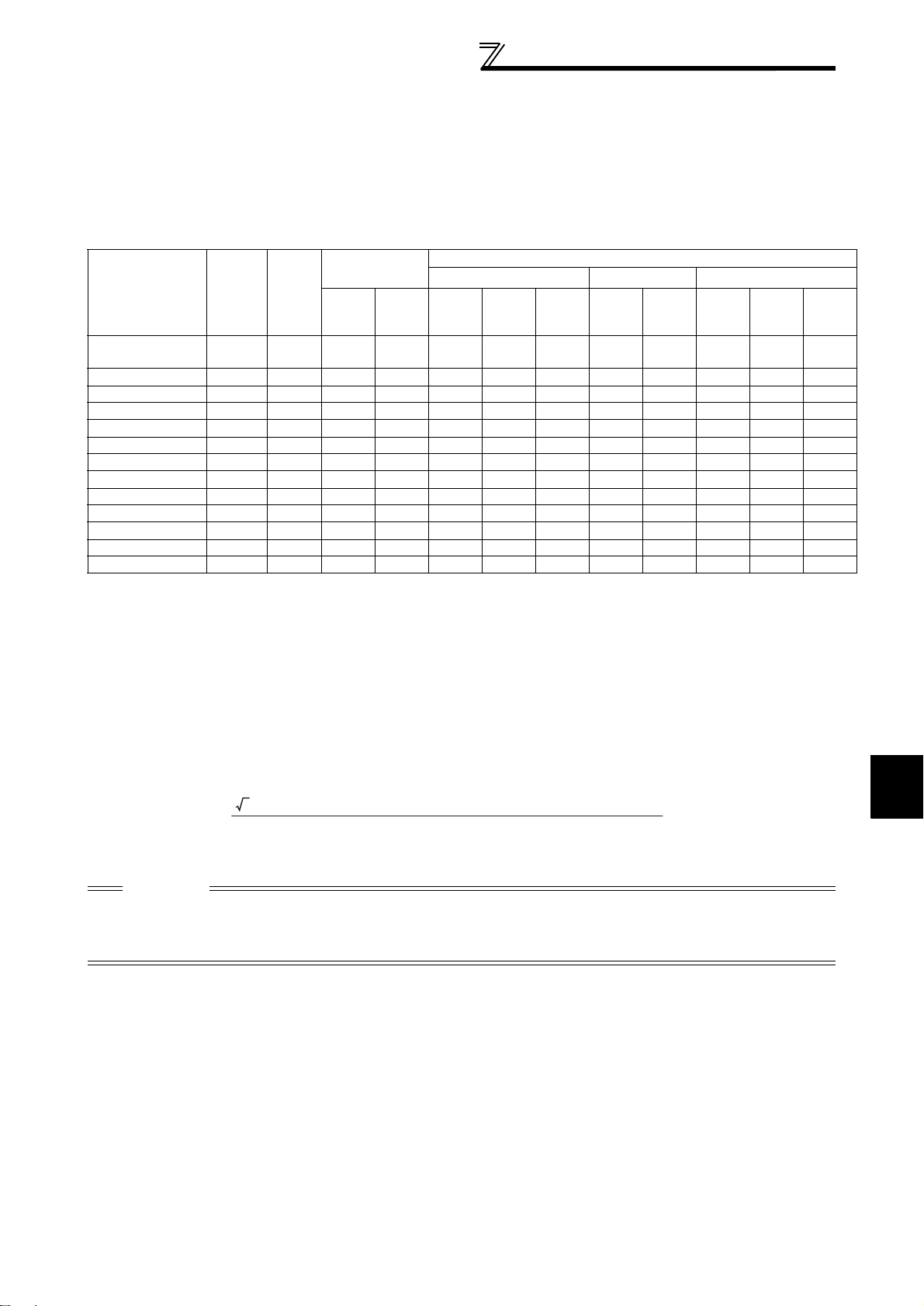

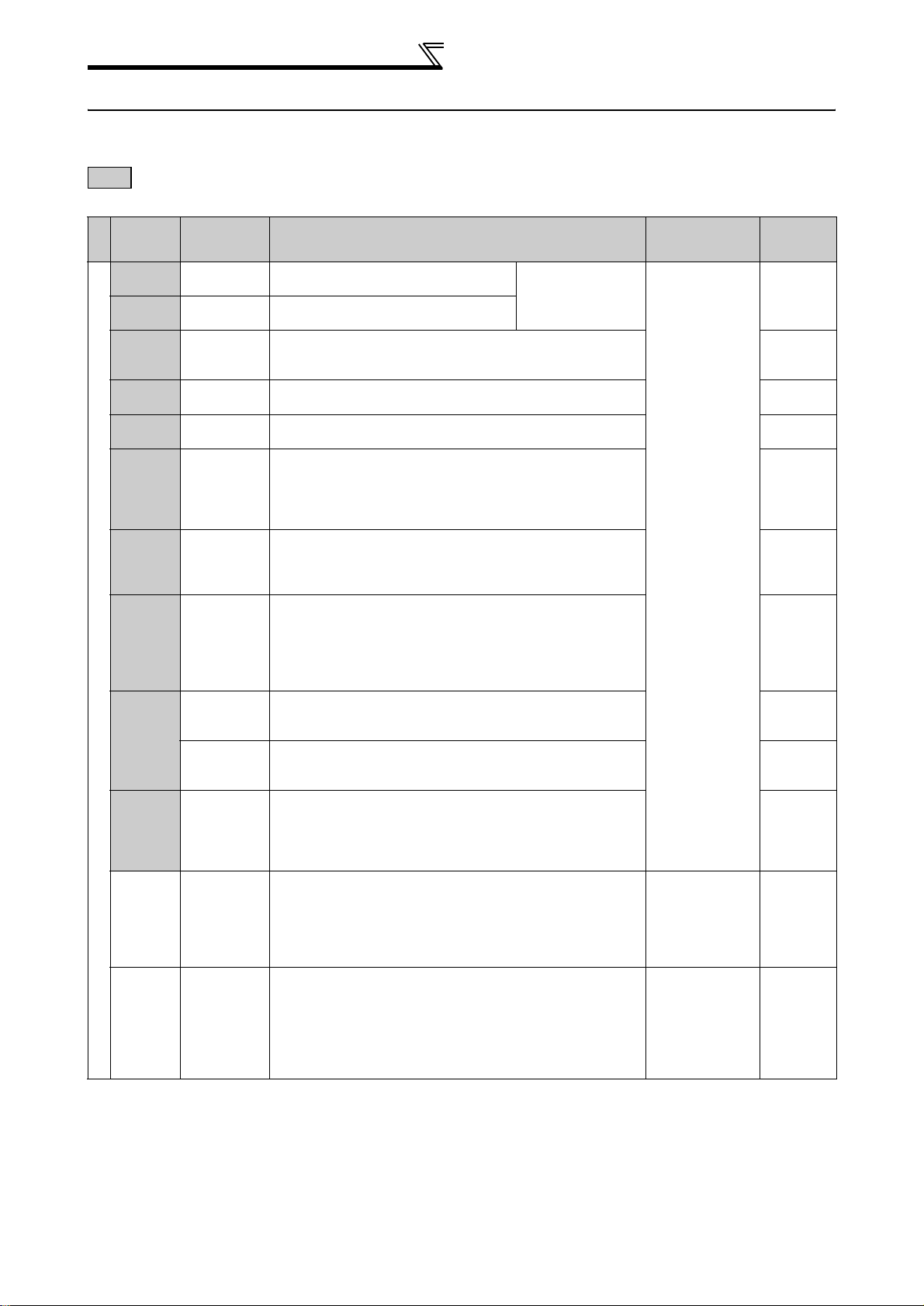

1.1.1 Peripheral devices

Check the motor capacity of the inverter you purchased. Appropriate peripheral devices must be selected according to the

capacity. Refer to the following list and prepare appropriate peripheral devices:

400V class

Input Side Magnetic

Contactor

*3

Reactor connection

without

with

Motor

Output (kW)

*1

Applicable Inverter Type

Breaker Selection

Reactor connection

without with

*2

with commercial

power-supply

operation

0.75 FR-F740-00023-EC 30AF 5A 30AF 5A 30AF 5A S-N10 S-N10

1.5 FR-F740-00038-EC 30AF 10A 30AF 10A 30 AF 10A S-N10 S-N10

2.2 FR-F740-00052-EC 30AF 10A 30AF 10A 30 AF 15A S-N10 S-N10

3.7 FR-F740-00083-EC 30AF 20A 30AF 15A 30 AF 20A S-N10 S-N10

5.5 FR-F740-00126-EC 30AF 30A 30AF 20A 30 AF 30A S-N20 S-N11, N12

7.5 FR-F740-00170-EC 30AF 30A 30AF 30A 30 AF 30A S-N20 S-N20

11 FR-F740-00250-EC 50AF 50A 50AF 40A 50A F 50 A S-N20 S-N20

15 FR-F740-00310-EC 100AF 60A 50AF 50A 100AF 60A S-N25 S-N20

18.5 FR-F740-00380-EC 100AF 75A 100AF 60A 100AF 75A S-N25 S-N25

22 FR-F740-00470-EC 100AF 100A 100AF 75A 100AF 100A S-N35 S-N25

30 FR-F740-00620-EC 225AF 125A 225AF 100A 225AF 125A S-N50 S-N50

37 FR-F740-00770-EC 225AF 150A 225AF 125A 225AF 150A S-N65 S-N50

45 FR-F740-00930-EC 225AF 175A 225AF 150A 225AF 175A S-N80 S-N65

55 FR-F740-01 160-EC 225AF 200A 225AF 175A 225AF 200A S-N80 S-N80

75 FR-F740-01800-EC 225AF 225A 400AF 300 A

90 FR-F740-02160-EC 225AF 225A 400AF 350 A

*1 Selections for use of the Mitsubishi 4-pole standar d motor with power supply voltage of 400VAC 50Hz.

*2 Select the MCCB according to the inverter power supply capacity.

Install one MCCB per inverter.

For installations in the United States or Canada, use the fuse certified by the UL and cUL.

(Refer to the Instruction Ma nual (bas ic s) .)

*3 The electrical durability of magnetic contactor is 500,000 times. When the magnetic contactor is used for emergency stop during motor

driving, the electrical durability is 25 times.

When using the MC for emerge ncy stop d urin g motor d riving or usin g on the motor si de dur ing c ommerc ial-power s upply op eration , select the

MC with class AC-3 rated current for the motor rated current.

*4 When the breaker on the inverter primary side trips, check for the wiring fault (short circuit), damage to internal parts of the inverter, etc.

Identify the cause of the trip, then remove the cause and power on the breaker.

S-N150

S-N180

MCCB INV

MCCB INV

IM

IM

1

WIRING

3

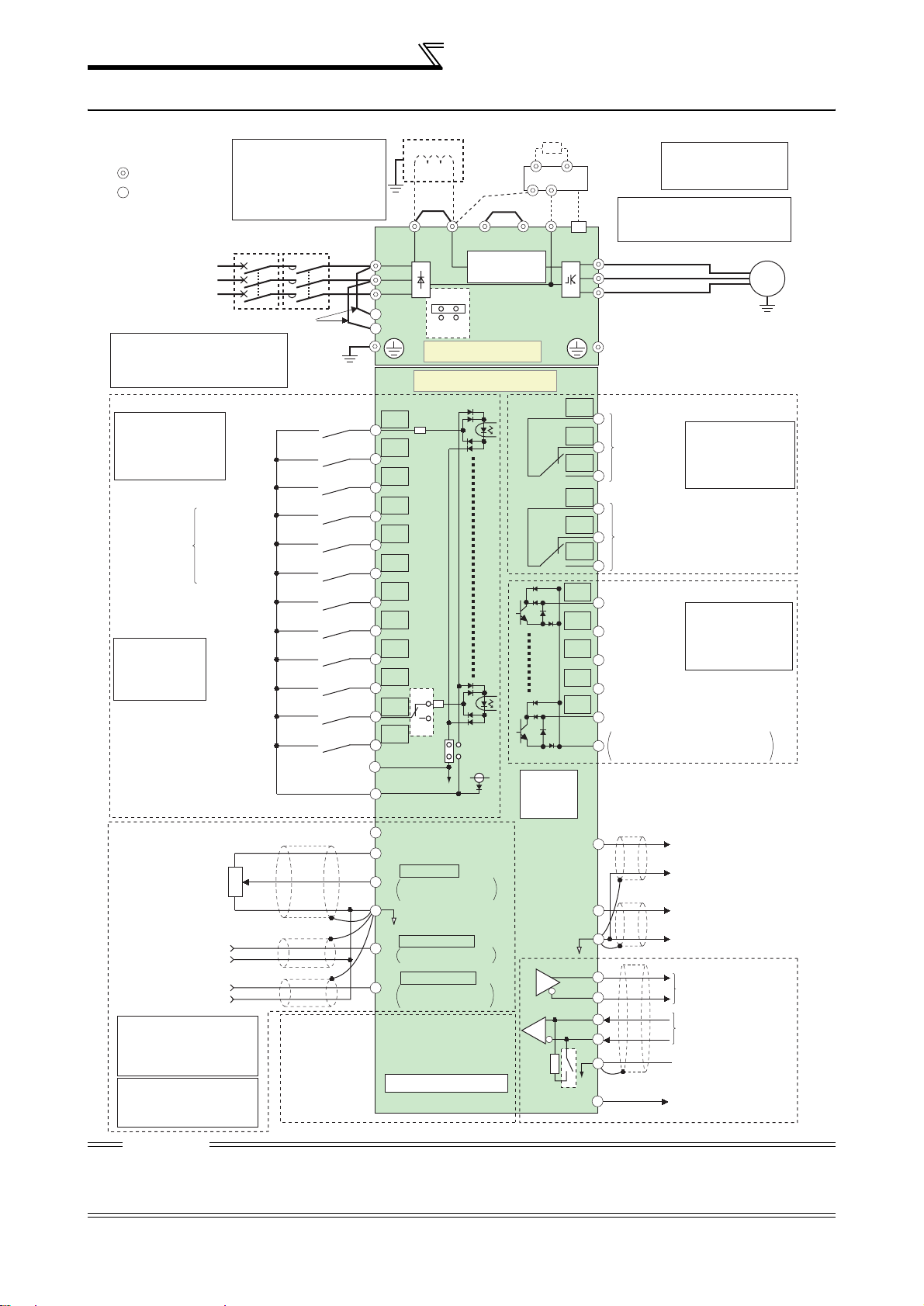

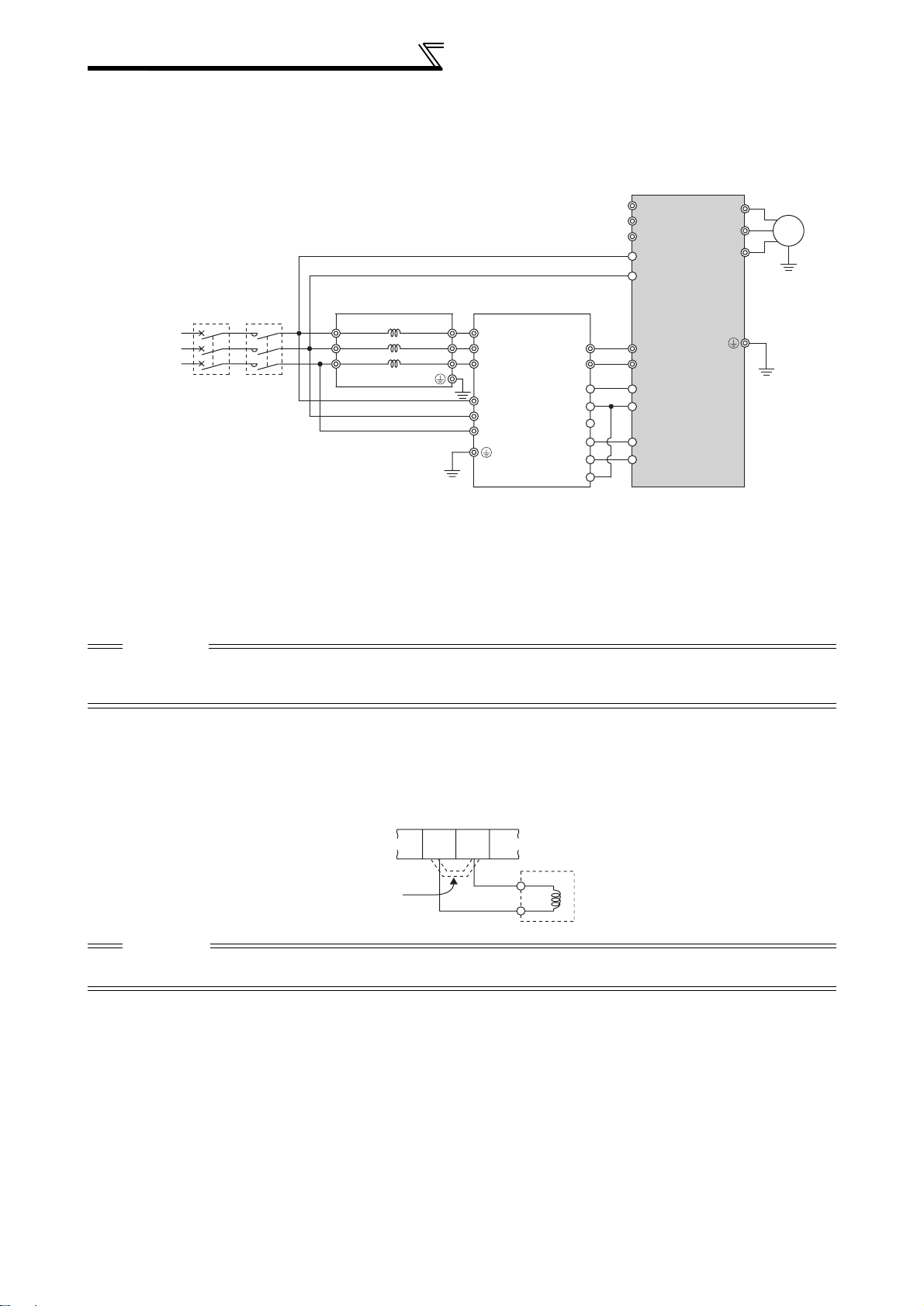

Wiring

1.2 Wiring

1.2.1 Terminal connection diagram

N/-

RUN

TXD+

TXD-

RXD+

RXD-

resistor

VCC

Brake resistor

(Option)

*6. The CN8 connector

Brake unit

(Option)

*7.

Please do not remove or use

terminals PR and PX or the

CN8

*6

jumper connected.

U

V

W

C1

B1

Relay output 1

(Alarm output)

A1

C2

B2

Relay output 2

A2

Running

SU

Up to frequency

IPF

Instantaneous

power failure

OL

Overload

FU

Frequency detection

SE

Open collector output common

Sink

/source common

CA

AM

5

SG

is provided with the

01800 or more.

Motor

IM

Relay output

Terminal functions

vary with the output

terminal assignment

(Pr. 195, Pr. 196)

Open collector output

Terminal functions

vary with the output

terminal assignment

(Pr. 190 to Pr. 194)

(+)

Analog current output

(0 to 20mADC)

(-)

(+)

Analog signal output

(0 to 10VDC)

(-)

RS-485 terminal

Data transmission

Data reception

GND

(Permissible load

5V

current 100mA)

Source logic

*1. DC reactor (FR-HEL)

Main circuit terminal

Control circuit terminal

3-phase AC

power supply

*2. To supply power to the

control circuit separately,

The DC reactor supplied with the

01800 or more should be

connected to these terminals.

When a DC reactor is connected,

remove the jumper across P1-P/+

for the 01160 or less.

Jumper

MC

*2

MCCB

Earth

Earth

R/L1

S/L2

T/L3

R1/L11

S1/L21

*1

Jumper

P1

P/+

Jumper

PR*7

Inrush current

limit circuit

ON

Connector for

with/without

OFF

EMC filter

Main circuit

PX*7

remove the jumper across

R1/L11 and S1/L21.

Control circuit

Control input signals (No voltage input allowed)

Terminal functions

vary with the input

terminal assignment

(Pr. 178 to Pr. 189)

Forward

rotation

start

Reverse

rotation

start

Start self-holding selection

High speed

Multi-speed

selection

Middle speed

Low speed

Jog mode

Second function selection

*3. AU terminal

can be used

Output stop

as PTC input

terminal.

Terminal 4 input selection

(Current input selection)

Selection of automatic restart

Contact input common (Sink)

(Common for external power supply transistor)

(Common for external power supply transistor)

after instantaneous

24VDC power supply

Contact input common

Reset

power failure

Frequency setting signal (Analog)

Ω

(+)

(-)

(+)

(-)

3

2

1

Connector

for plug-in option

connection

Frequency setting

potentiometer

1/2W1k

*5

Auxiliary input

Terminal 4 input

(Current input)

*

4. Terminal input

specifications can be

changed by analog input

specifications switchover

(Pr. 73, Pr. 267).

*

5. It is recommended to use

2W1kΩ when the

frequency setting signal is

changed frequently.

STF

STR

STOP

RH

RM

RL

JOG

RT

MRS

RES

*3

AU

AU

PTC

CS

SD

SOURCE

PC

10E(+10V)

10(+5V)

0 to 5VDC

2

0 to 10VDC

4 to 20mADC

5

(Analog common)

0 to ±10VDC

1

0 to ±5VDC

4 to 20mADC

4

0 to 5VDC

0 to 10VDC

Option connector 1

SINK

24V

selected

selected

selected

*

4

*

4

*

4

Terminating

PU

connector

CAUTION

· To prevent a malfunction due to noi se, keep the signal cables more th an 10cm away from the powe r ca bles.

· After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm , fai l ur e or ma lfunction. Always keep the inv er te r c le an.

When drilling mounting holes in a control box etc., take care not to allow chips and other foreign matter to enter the inverter.

Earth

4

1.3 Main circuit terminal specifications

r

1.3.1 Specification of main circuit terminal

Main circuit terminal specifications

Terminal

Symbol

R/L1,

S/L2,

T/L3

Terminal Name Description

Connect to the commercial power supply.

AC power input

Keep these termina ls open when u sing the high power factor converter

(FR-HC, MT - HC) or power rege nera tion commo n converte r (FR-C V).

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

Connected to the AC power supply terminals R/L1 and S/L2. To retain

the alarm display and alarm output or when using the high power factor

converter (FR-HC, MT-HC) or power regeneration common converter

(FR-CV), remove the jumpers from terminals R/L1-R1/L11 and S/L2-

R1/L11,

S1/L21

Power supply for

control circuit

S1/L21 and apply external power to these terminals.

Do not turn off the power supply for control circuit (R1/L1 1, S1/L21) with

the main circuit power (R/L1, S/L2, T/L3) on. Doing so may damage the

inverter. The circuit should be configured so that the main circuit power

(R/L1, S/L2, T/L3) is also turned off when the power supply for control

circuit (R1/L11, S1/L21) is off.

00380 or less : 60VA, 00470 to 02160 : 80VA

Connect the br ake un it (FR- B U, BU and MT-BU5), po we r

P/+, N/-

Brake unit

connection

regeneration common converter (FR-CV), high power factor

converter ( FR-H C and MT-HC) or pow er r e ge ne rat i on conv er ter (MTRC).

For the 01160 or less, remove the jumper across terminals P/+ - P1

and connect the DC reactor. (For the 01800 or more, a DC reactor

is standard-equipped.)

P/+, P1

DC reactor

connection

PR, PX Please do not remove or use terminals PR and PX or the jumper connected.

Earth For earthing the inverter chassis. Must be earthed.

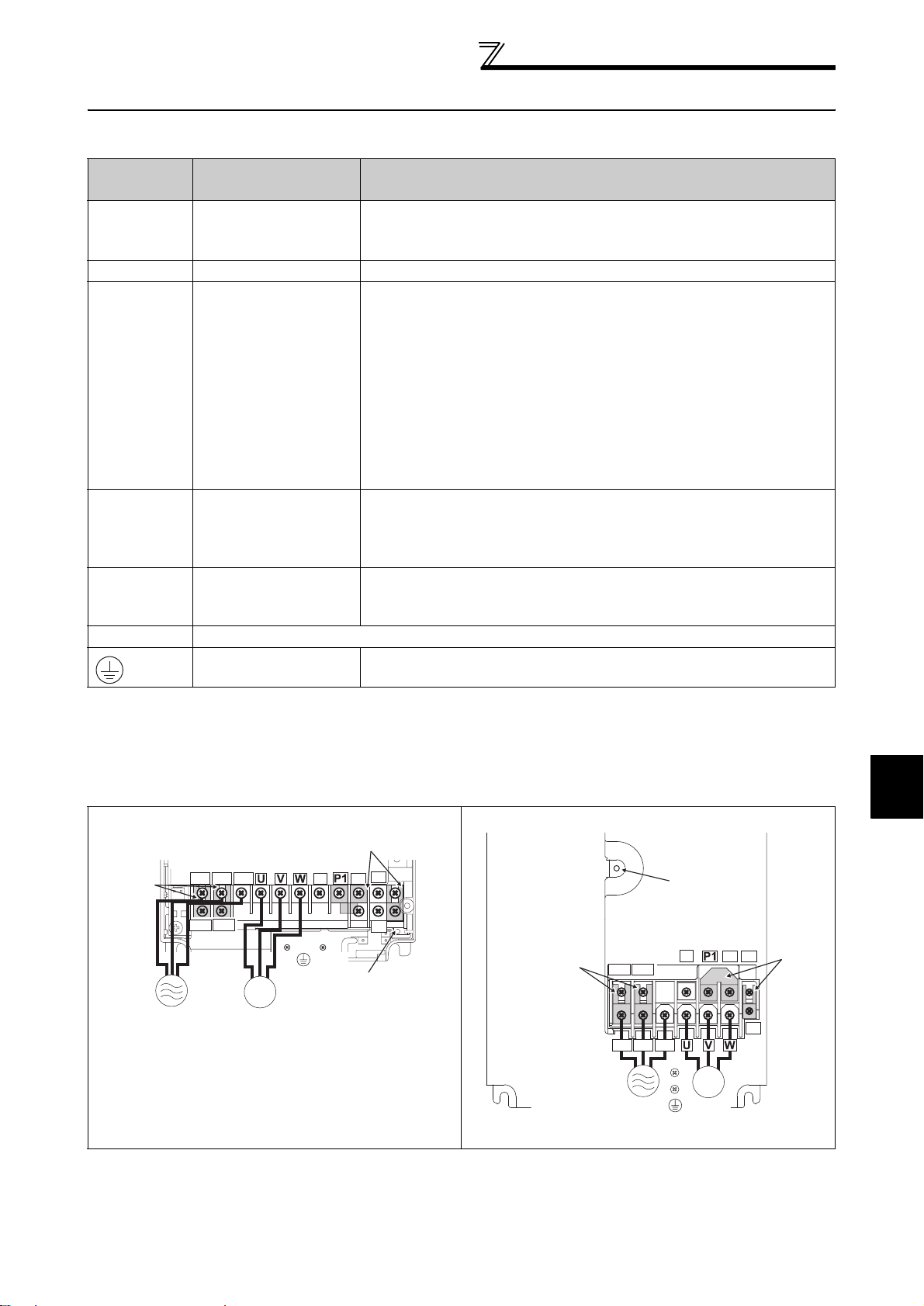

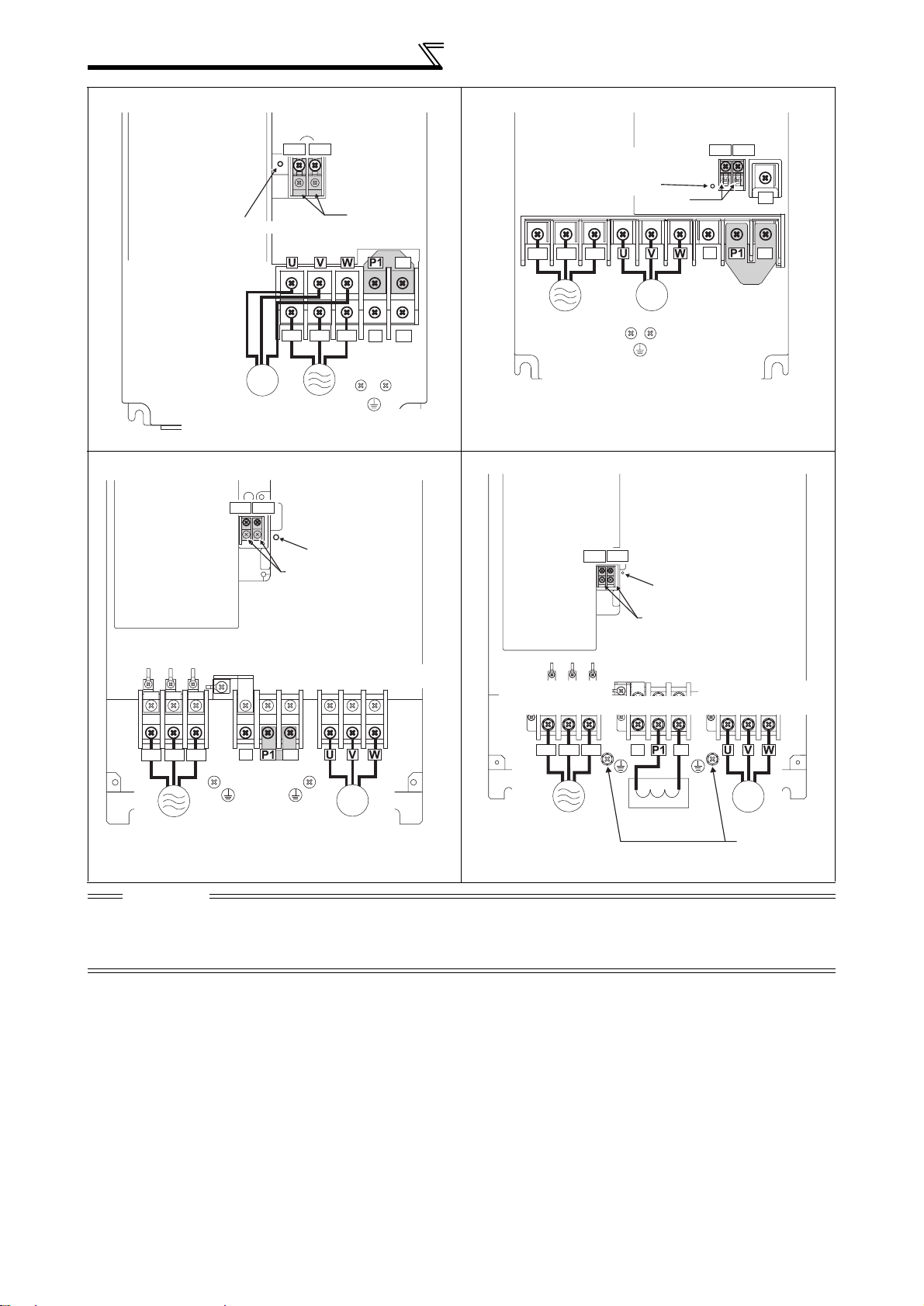

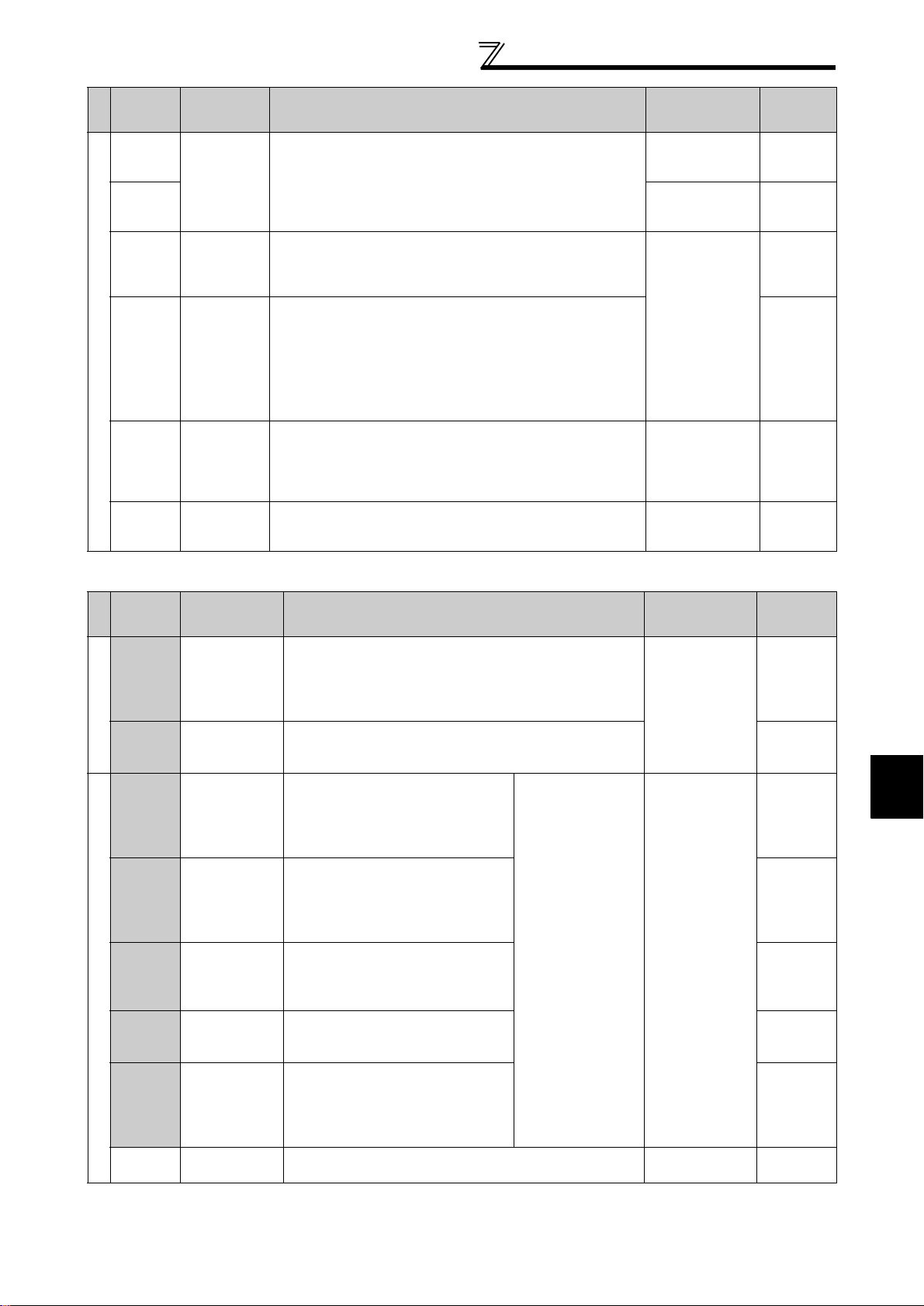

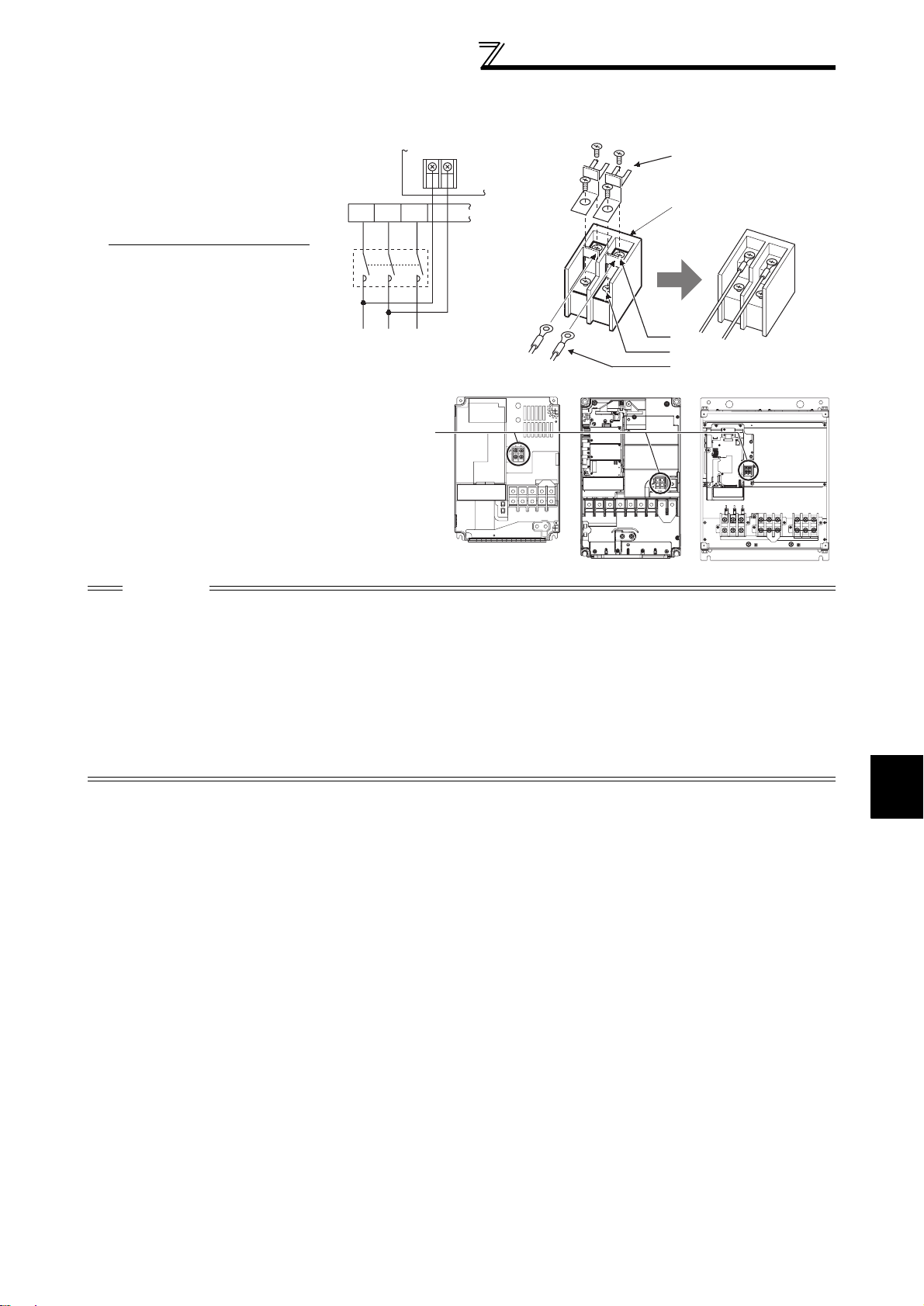

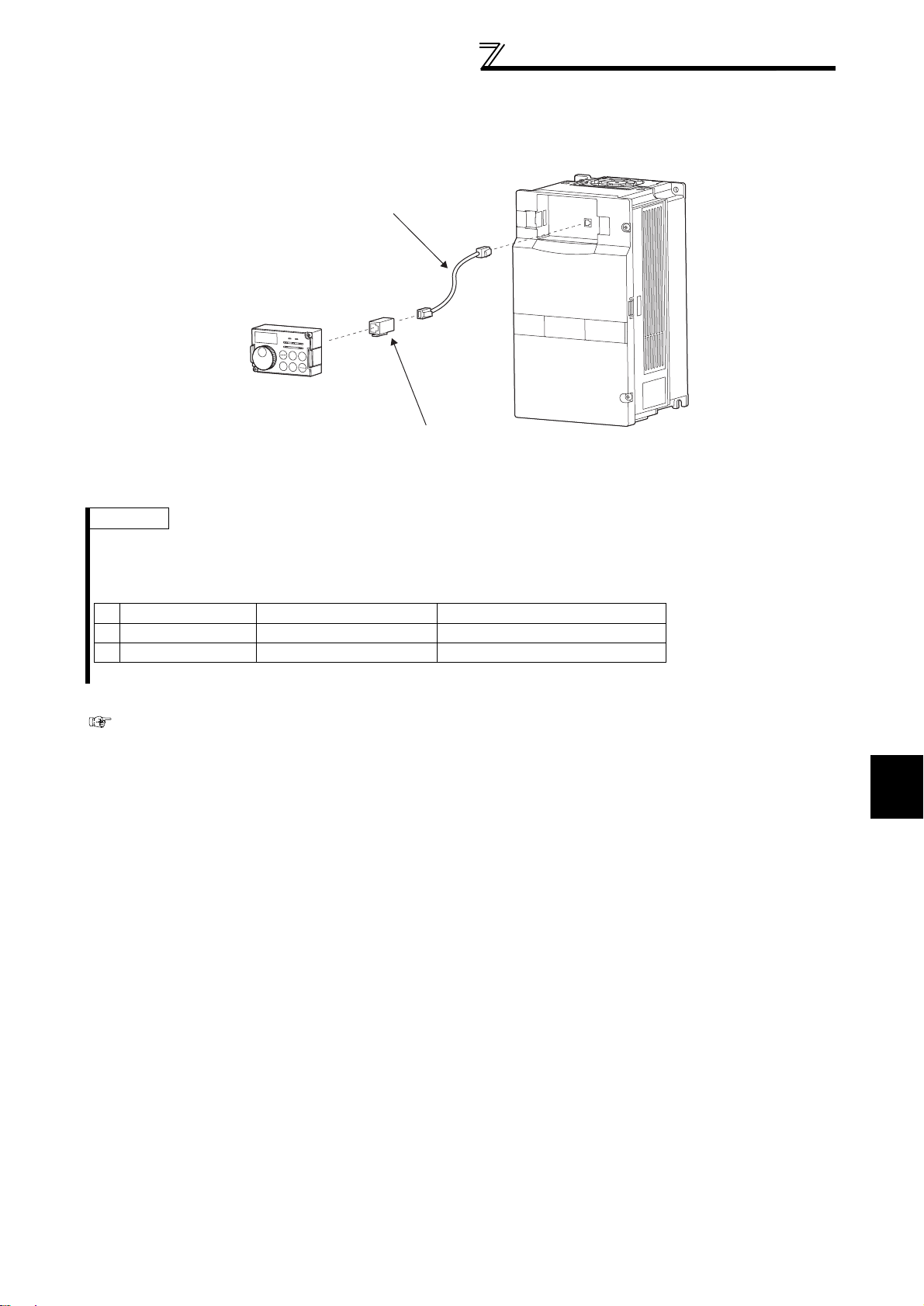

1.3.2 Terminal arrangement of the main circuit terminal, power supply and the motor wiring.

400V class

FR-F740-00023 to 00126-EC FR-F740-00170, 00250-EC

Jumper

Power supply

Screw size (M4)

R/L1 S/L2 T/L3

R1/L11 S1/L21

IM

Motor

Screw size

(M4)

N/-

Jumper

PR

P/+

PX

Charge lamp

Jumper

Screw size

(M4)

R1/L11 S1/L21

R/L1 S/L2 T/L3

Charge lamp

N/-

P/+

PR

Jumpe

PX

IM

Power supply

Motor

Screw size

(M4)

1

WIRING

5

Main circuit terminal specifications

IM

R/L1 S/L2 T/L3

N/-

P/+

R1/L11 S1/L21

DC reactor

Screw size (M10)

FR-F740-00310, 00380-EC FR-F740-00470, 00620-EC

R1/L11 S1/L21

Charge lamp

Screw size (M5)

Screw size

(M4)

R/L1 S/L2 T/L3

Jumper

Jumper

N/-

P/+

PR

Screw size (M6)

R/L1 S/L2 T/L3

Power supply

Charge lamp

Screw size (M6)

IM

Motor

Power supply

Screw size (M5)

FR-F740-00770 to 01160-EC FR-F740-01800 to 02160 - EC

R1/L11 S1/L21

Screw size(M4)

Charge lamp

Jumper

Screw size (M4)

Screw size (M4)

Jumper

IM

Motor

Charge lamp

R1/L11 S1/L21

N/-

Jumper

PR

P/+

Jumper

Screw size

(00770A: M6

R/L1 S/L2 T/L3

Power

supply

00930A, 01160A: M8)

N/-

P/+

Jumper

Screw size

(00770A: M6

00930A, 01160A: M8)

IM

Motor

Screw size

(01800: M8, 02160: M10)

Power

supply

Screw size

(01800: M8, 02160: M10)

Motor

Screw size

(01800: M8,

02160: M10)

CAUTION

· The power supply cables must be connec ted to R/L1, S/L2, T/L3. Never conn ect the power cable to the U, V, W of the

inverter. Doing so will damage the inverter. (Phase sequence needs not to be matched.)

· Connect the motor to U, V, W. At this time, turning on the forward rotation switch (signal) rotates the motor in the

counterclockwise direction when viewed from the motor shaft.

6

Main circuit terminal specifications

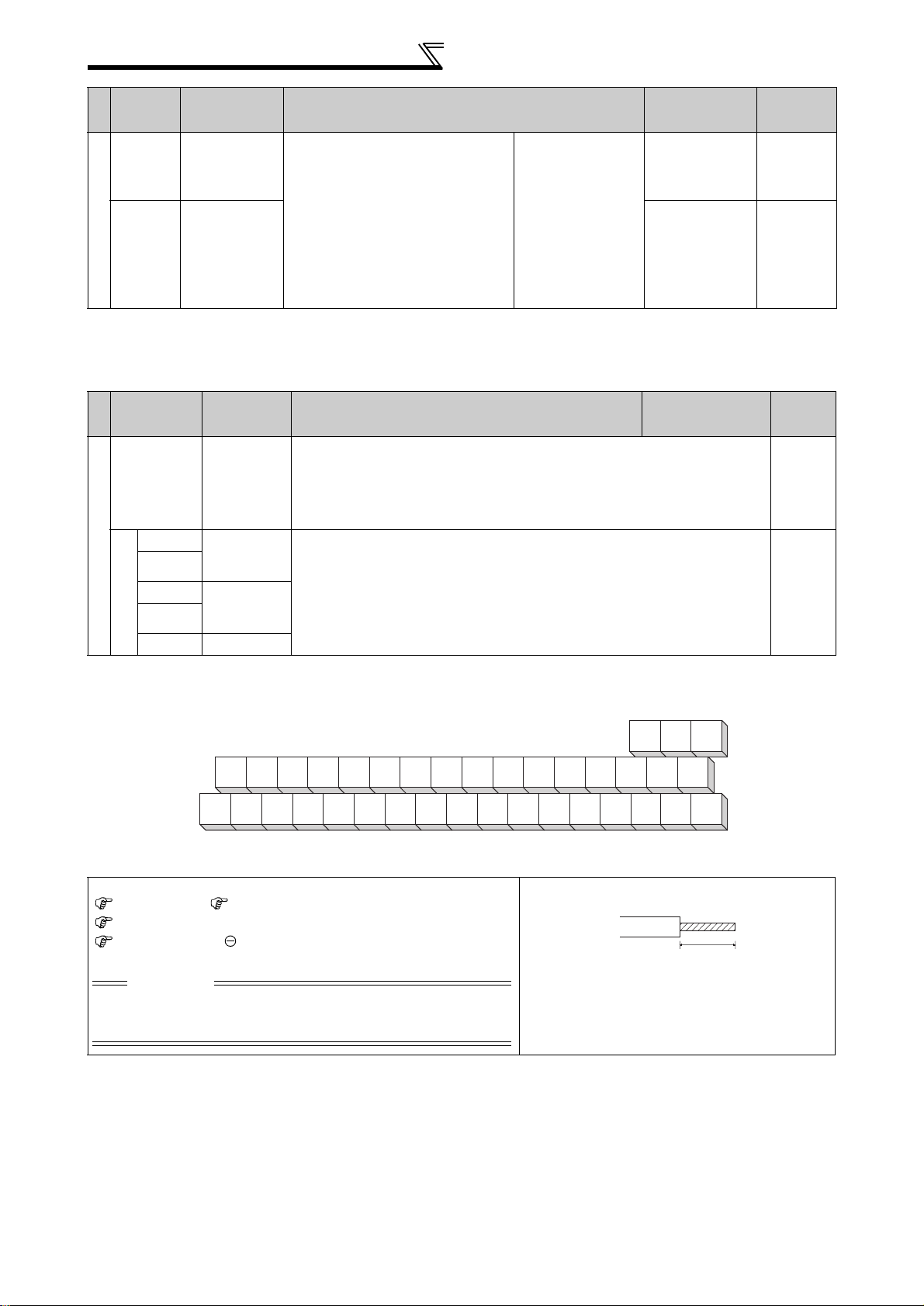

1.3.3 Cables and wiring length

(1) Applied cable size

Select the recommended cable size to ensure that a voltage drop will be 2% max.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor

torque to decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

400V class (when input power supply is 440V based on the rated current for 110% overload for 1 minute)

Applicable

Inverter Type

FR-F740-00023 to

00083-EC

FR-F740-00126-EC M4 1.5 2-4 2-4 2 2 3.5 12 14 2.5 2.5 4

FR-F740-00170-EC M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-F740-00250-EC M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-F740-00310-EC M5 2.5 8-5 8-5 8 8 8 8 8 10 10 10

FR-F740-00380-EC M5 2.5 14-5 8-5 14 8 14 6 8 16 10 16

FR-F740-00470-EC M6 4.4 22-6 14-6 22 14 14 4 6 25 16 16

FR-F740-00620-EC M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-00770-EC M6 4.4 22-6 22-6 22 22 14 4 4 25 25 16

FR-F740-00930-EC M8 7.8 38-8 38-8 38 38 22 1 2 50 50 25

FR-F740-01160-EC M8 7.8 60-8 60-8 60 60 22 1/0 1/0 50 50 25

FR-F740-01800-EC M8 7.8 60-10 60-10 60 60 38 1/0 1/0 50 50 25

FR-F740-02160-EC M10 14.7 100-10 100-10 100 100 38 3/0 3/0 70 70 35

*1 For the 01160 or less, the recommended cable size is that of the HIV cable (600V class 2 vinyl-insulated cable) with continuous maximum permissible

temperature of 75°C. Assumes that the ambient temperature is 50°C or less and the wiring distance is 20m or less.

For the 01800 or more, the recommended cable size is that of LMFC (heat resistant flexible cross-linked polyethylene insulated cable) with continuous

maximum permissible temperature of 105°C. Assumes that the ambient temperature is 50°C or less and wiring is performed in an enclosure.

*2 For the 00930 or less, the recommended cable size is that of the THHW cable with continuous maximum permissible temperature of 75°C. Assumes that

the ambient temperature is 40°C or less and the wiring distance is 20m or less.

For the 01160 or more, the recommended cable size is that of THHN cable with continuous maximum permissible temperature of 90°C. Assumes that

the ambient temperature is 40°C or less and wiring is performed in an enclosure.

*3 For the 00930 or less, the recommended cable size is that of the PVC cable with continuous maximum permissible temperature of 70°C. Assumes that

the ambient temperature is 40°C or less and the wiring distance is 20m or less.

For the 01160 or more, the recommended cable size is that of XLPE cable with continuous maximum permi ssible temperature of 90°C. Assumes t ha t th e

ambient temperature is 40°C or less and wiring is performed in an enclosure.

*4 The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W , and a screw for earthing.

Terminal

Screw

Size

Tightening

Torque

*4

N·m

M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

Crimping

Terminal

R/L1, S/L2,

T/L3

U, V, W

HIV, etc. (mm2) *1

R/L1, S/L2,

T/L3

U, V, W

Earth

Cable

Gauge

The line voltage drop can be calculated by the following expression:

line voltage drop [V]=

3 × wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop

(torque reduction) in the low speed range.

CAUTION

· Tighten the termin al scr ew to the specified torque.

A screw that has been t igh ten t oo loosely can cause a short c ircu it or ma l fu nct i on.

A screw that has been t igh ten t oo tightly can cause a short circ ui t or mal f unction due to the unit breakage .

· Use crimping terminals with insulation sleeve to wire the power supply and motor.

Cable Sizes

AWG *2

R/L1, S/L2,

T/L3

U, V, W

PVC, etc. (mm2) *3

R/L1, S/L2,

T/L3

U, V, W

Earth

Cable

Gauge

1

WIRING

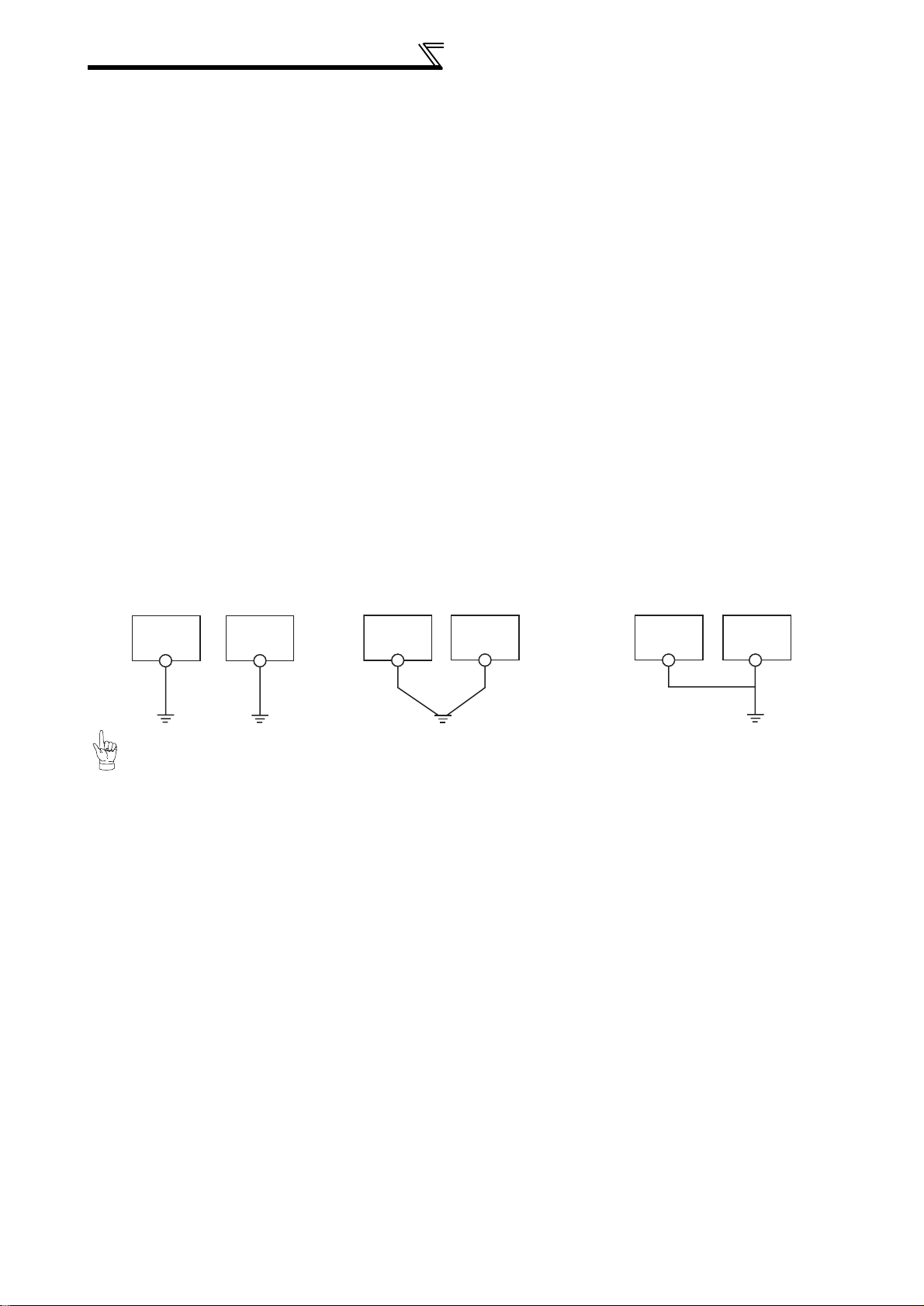

(2) Notes on earthing

Leakage currents flow in the inverter. To prevent an electric shock, the inverter and motor must be earthed. ((This

inverter must be earthed. Earthing must conform to the requirements of national and local safe ty regulati ons an d el ectric al

codes. (JIS, NEC section 250, IEC 536 c lass 1 and other appl icable st andards)

Use the dedicated earth terminal to earth the inverter. (Do not use the screw in the casing, chassis, etc.)

Use the thickest possible earth cable.Use the cable whose size is equal to or greater than that indicated in the

above table, and minimize the cable length. The earthing point should be as near as possible to the inverter.

7

Main circuit terminal specifications

Always earth the motor and inverter.

1)Purpose of earthingGenerally, an electrical apparatus has an earth terminal, which must be connected to the

ground before use.

An electrical circuit is usually insulated by an insulating material and encased. However, it is impossible to

manufacture an insulating material that can shut off a leakage current completely, and actually, a slight current

flow into the case. The purpose of earthing the case of an electrical apparatus is to prevent operator from

getting an electric shock from this leakage current when touching it.

To avoid the influence of external noises, this earthing is important to audio equipment, sensors, computers and

other apparatuses that handle low-level signals or operate very fast.

2)Earthing methods and earthing work

As described previously, earthing is roughly classified into an electrical shock prevention type and a noiseaffected malfunction prevention type. Therefore, these two types should be discriminated clearly, and the

following work must be done to prevent the leakage current having the inverter's high frequency components

from entering the malfunction prevention type earthing:

(a) Where possible, use independent earthing for the inverter. If independent earthing (I) is impossible, use

joint earthing (II) where the inverter is connected with the other equipment at an earthing point. Joint

earthing as in (III) must be avoided as the inverter is connected with the other equipment by a common

earth cable.

Also a leakage current including many high frequency components flows in the earth cables of the inverter

and inverter-driven motor. Therefore, they must use the independent earthing method and be separated

from the earthing of equipment sensitive to the aforementioned noises.

In a tall building, it will be a good policy to use the noise malfunction prevention type earthing with steel

frames and carry out electric shock prevention type earthing in the independent earthing method.

(b) This inverter must be earthed. Earthing must conform to the requirements of national and local safety

regulations and electrical codes. (JIS, NEC section 250, IEC 536 class 1 and other applicable standards).

(c) Use the thickest possible earth cable. The earth cable should be of not less than the size indicated in the

above table.

(d) The grounding point should be as near as possible to the inverter, and the ground wire length should be as

short as possible.

(e) Run the earth cable as far away as possible from the I/O wiring of equipment sensitive to noises and run

them in parallel in the minimum distance.

Inverter

Class C grounding

400V class

Other

equipment

Inverter

Other

equipment

400V class

Class C grounding

Inverter

400V class Class C grounding

equipment

Other

For use in compliance with the European Directive (Low Voltage Directive), refer to the Instru ction Manual (bas ics).

8

Main circuit terminal specifications

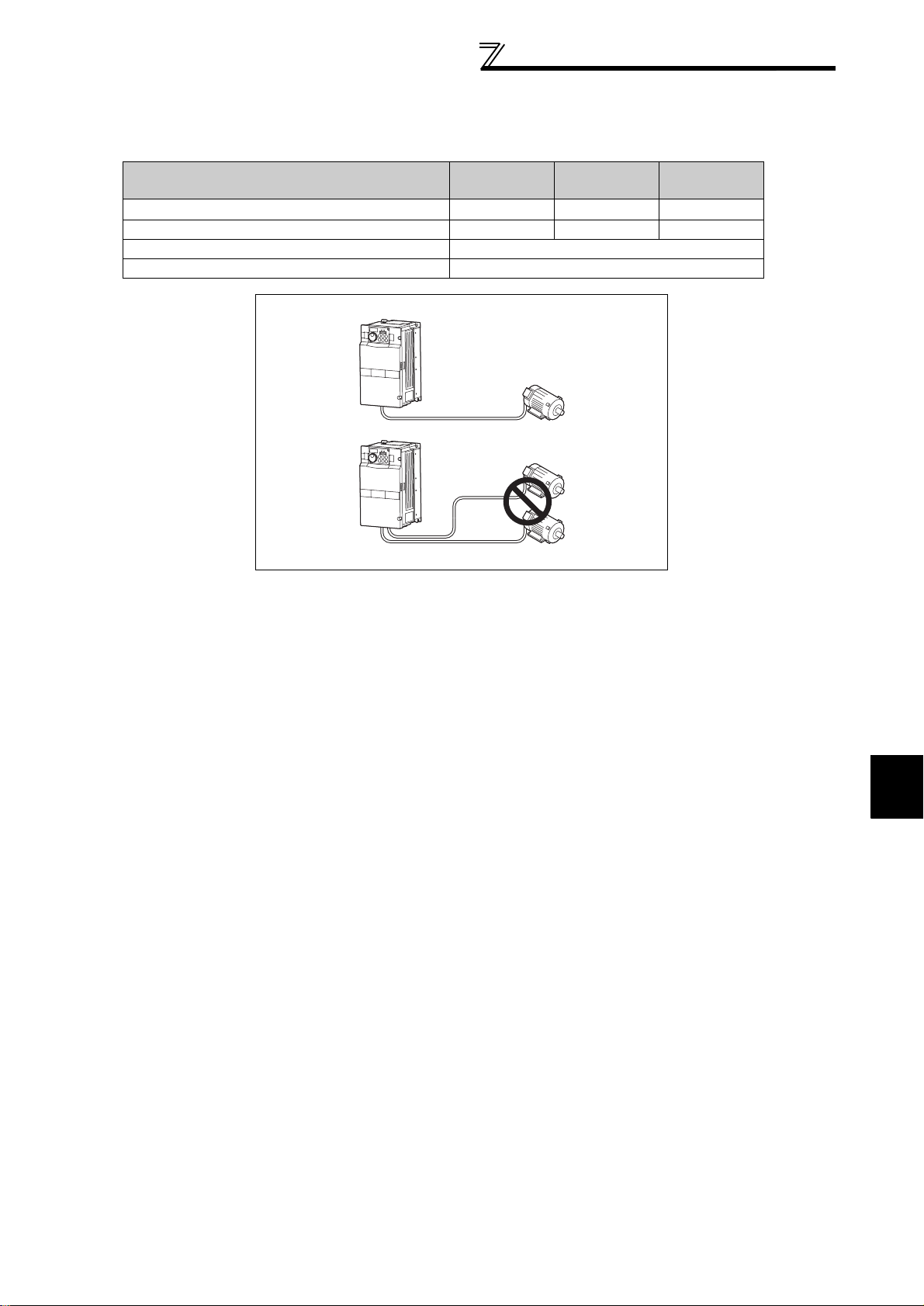

(3) Total wiring length

The wiring length should be 500m maximum.

(The overall wiring length for connection of multiple motors should be within the value in the table below.)

Pr. 72 PWM frequency selection setting

(carrier frequency)

2 (2kH) or less

3 (3kHz), 4 (4kHz) 200m 300m 500m

5 (5kHz) to 9 (9kHz) 100m

10 (10kHz) or more 50m

00023 00038

300m 500m 500m

00052 or

more

Total wiring length (00038 or more)

500m or less

300m

300m

300m + 300m = 600m

When driving a 400V class motor by the inverter, surge voltages attributable to the wiring constants may occur at

the motor terminals, deteriorating the insulation of the motor.

Refer to page 36 for measures against deteriorated insulation.

·

1

WIRING

9

Control circuit specifications

1.4 Control circuit specifications

1.4.1 Control circuit terminals

indicates Pr. 178 to Pr. 196 (I/O terminal function selection) (Refer to page 85.)

(1) Input signals

Terminal

Symbol

Type

STF

STR

STOP

RH,

RM, RL

JOG

RT

MRS Output stop

RES Reset

Contact i nput

AU

CS

SD

PC

Terminal

Name

Forward

rotation start

Reverse

rotation start

Start selfholding

selection

Multi-speed

selection

Jog mode

selection

Second

acceleration/

deceleration

time

selection

Terminal 4

input selection

PTC input

Selection of

automatic

restart after

instantaneous

power failure

External

transistor

common,

contact input

common

(sink)

24VDC

power supply,

contact input

common

(source)

Description

Turn on the STF signal to start forward

rotation and turn it off to stop.

Turn on the STR signal to start reverse

rotation and turn it off to stop.

Turn on the STOP signal to self-hold the start signal . 85

Multi-speed can be sele ct ed according to the combinat ion of

RH, RM and RL signals.

Turn on the JOG signal to select Jog operation (initial setting)

and turn on the start signal to start Jog op er at io n.

Turn on the RT signal to select secon d acceleration/

deceleration time.

When the second functi on such as "second torque boo st " and

"second V/F (base frequen cy) " ar e set, turning on the RT

signal sel ects these func t ions.

Turn on the MRS signal (20ms or more) to s top th e i nverter

output.

Use to shut off the inverter output when stopping the motor by

electromagnetic bra ke.

Used to reset alarm output pr ovided when protective func tion

is activated.

Turn on the RES signal for more than 0.1s, then turn it off.

Initial setting is for reset always. By setting Pr.75, reset can be

set to enabled only at an inverter alarm occurrence. Recover

about 1s after reset is cancelled.

T erminal 4 is made valid only when the AU signal is turned on. (The

frequency setting signal can be set between 4 and 20mADC.)

Turning the AU signal on makes terminal 2 (voltage input) invalid.

AU terminal is used as PTC input term inal (thermal protection

of the motor). When using it as PTC input terminal, set the AU/

PTC switch to PTC.

When the CS signal is left on, the inverter restarts automatically at

power restora tion. Note that restart settin g is necessary for this

operation. In the init ial se ttin g, a res t ar t is disa b led .

(Refer to Pr.57 Restart coasting time, page

Common terminal for contact input terminal and terminal CA

for sink logic.

Common output terminal fo r 24 VDC 0. 1A power supply (PC

terminal).

Isolated from terminals 5 and SE.

When connecting the transistor output (open collector output),

such as a programmable controller (PLC), connect the external

power supply common for transistor output to this terminal to

prevent a malfunction caused by undesirable currents.

Can be used as 24VDC 0.1A power supply.

When source logic ha s bee n selected, this terminal ser ves as

NO contact input common.

When the STF and

STR signals are turned

on simultaneously, the

stop command is given.

109

)

Rated

Specifications

Input resistance

4.7kΩ

Voltage at

opening: 21 to

27VDC

Contacts at

short-circuited: 4

to 6mADC

-------------------- —

Power supply

voltage range 22

to 26VDC

Current

consumption

100mA

Refer to

85

85

85

85

85

85

125

79

85

17

10

Control circuit specifications

Terminal

Symbol

Type

10E

10

2

4

Frequency setting

1

5

Terminal

Name

Frequency

setting

power

supply

Frequency

setting

(voltage)

Frequency

setting

(current)

Frequency

setting

auxiliary

Frequency

setting

common

Description

When connecting the frequency setting potentiometer at an

initial status, connect it to termi nal 10.

Change the input specifications when connecting it to terminal

10E. (Refer to Pr.73 Analog input selection in page 127.)

Inputting 0 to 5VDC (or 0 to 10V, 0 to 20mA) provides the

maximum output frequency at 5V (10V, 20mA) and makes

input and output proportional. Use Pr.73 to switch from among

input 0 to 5VDC (initial setting ), 0 to 10VDC, and 0 to 20mA.

Inputting 0 to 20mADC (or 0 to 5V, 0 to 10V) provides the

maximum output frequency at 20mA (5V, 10V) makes input

and output proportional. This input signal is valid only when the

AU signal is on (terminal 2 input is invalid). Use Pr.267 to

switch between the input 0 t o 20m A (initial value) and 0 to

5VDC, 0 to 10VDC.

Inputti ng 0 t o 5 VDC or 0 to 1 0VD C ad ds t hi s si gn al t o t er m in al

2 or 4 frequency setting signal. Use Pr.73 to switch bet w een

the input 0 to ±5VDC and 0 to ±10 VD C (ini t ial sett in g) .

Common terminal for frequency setting signal (terminal 2, 1 or

4) and analog output terminal AM . Do not earth.

Rated

Specifications

10VDC±0.4V

Permissible load

current 10mA

5.2VDC±0.2V

Permissible load

current 10mA

Voltage input:

Input resistance

10kΩ ± 1kΩ

Maximum

permissible

voltage 20VDC

Current input:

Input resistance

250Ω ± 2%

Maximum

permissible

current 30mA

Input resistance

10kΩ ± 1kΩ

Maximum

permissible voltage

± 20VDC

-------------------- 12 5

Refer to

125

125

125

125

125

(2) Output signals

Terminal

Symbol

Type

A1,

B1,

C1

Relay

A2,

B2,

C2

RUN

SU

OL Overload alarm

Open collector

IPF

FU

SE

Terminal

Name

Relay output 1

(alarm ou tput)

Relay output 2 1c Contact output 91

Inverter

running

Up to

frequency

Instantaneous

power failure

Frequency

detection

Open collector

output common

Description

Changeover contact output indicates that the inverter

protective function has activated and the output stopped.

Abnormal: No conduction across B-C (Across A-C

Continuity), Normal: Across B-C Continuity (No conduction

across A-C)

Switched low when the inverter outpu t

frequency is equal to or higher than th e

starting frequency (initial value 0.5 Hz).

Switched high during stop or DC

injection brake operation.

Switched low when the output fr equency

reaches within the range of ±10% (initial

value) of the set frequency. Switched

high during acceleration/decelera tion

and at a stop.

Switched low when stall prevention is

activated by the stall preven tion

function. Switched high when stall

prevention is cancelled.

Switched low when an instantaneous

power failure and under voltage

protections are activat ed.

Switched low when the inverter

output frequency is equal to or higher

than the preset detected frequency

and high when less than the pre set

detected frequency.

Common terminal for terminals RUN, SU, OL, IPF, FU -------------------- -----

*1

*1

Alarm code (4bit)

output (Refer to page

116.)

*1

*1

*1

Rated

Specifications

Contact

capacity:

230VAC 0.3A

(Power

factor=0.4)

30VDC 0.3A

Permissible load

24VDC 0.1A

Refer to

91

91

91

91

91

91

1

WIRING

11

Control circuit specifications

Terminal

Symbol

Type

CA

Analog

AM

*1 Low indicates that the open collector output transistor is on (conducts).

High indicates that the trans istor is off (does not conduct).

*2 Not output during inverter reset.

Terminal

Name

Analog current

output

Analog voltage

output

Description

Select one e.g. output freq uency

from mon i tor items.

The output signal is propo rti ona l to

the magnitude of the corresponding

monitoring item.

*2

(3) Communication

Terminal

Symbol

Type

PU

connector

TXD+

RS-485

TXDRXD+

RXD-

RS-485 terminal

SG Earth

Terminal

Name

PU

connector

Inverter

transmission

terminal

Inverter

reception

terminal

Description

With the PU connector, communicatio n can be made through RS-485.

(for connection on a 1:1 basi s only)

. Conforming standard : RS-485

. Transmission format : Multidrop

. Communication speed : 4800 to 38400bps

. Overall length : 500m

With the RS-485 termin al , c om m unication can be made throu gh R S- 485.

Conforming standard : RS-485

Transmission format : Multidrop link

Communication spee d : 300 to 38400bps

Overall length : 500m

Output item:

Output frequency

(initial setting)

Rated

Specifications

Load impedance

200Ω to 450Ω

Output signal 0 to

20mADC

Output signal 0

to 10VDC

Permissible load

current 1mA

(load impedance

10kΩ or more)

Resolution 8 bit

Rated

Specifications

Refer to

104

104

Refer to

156

158

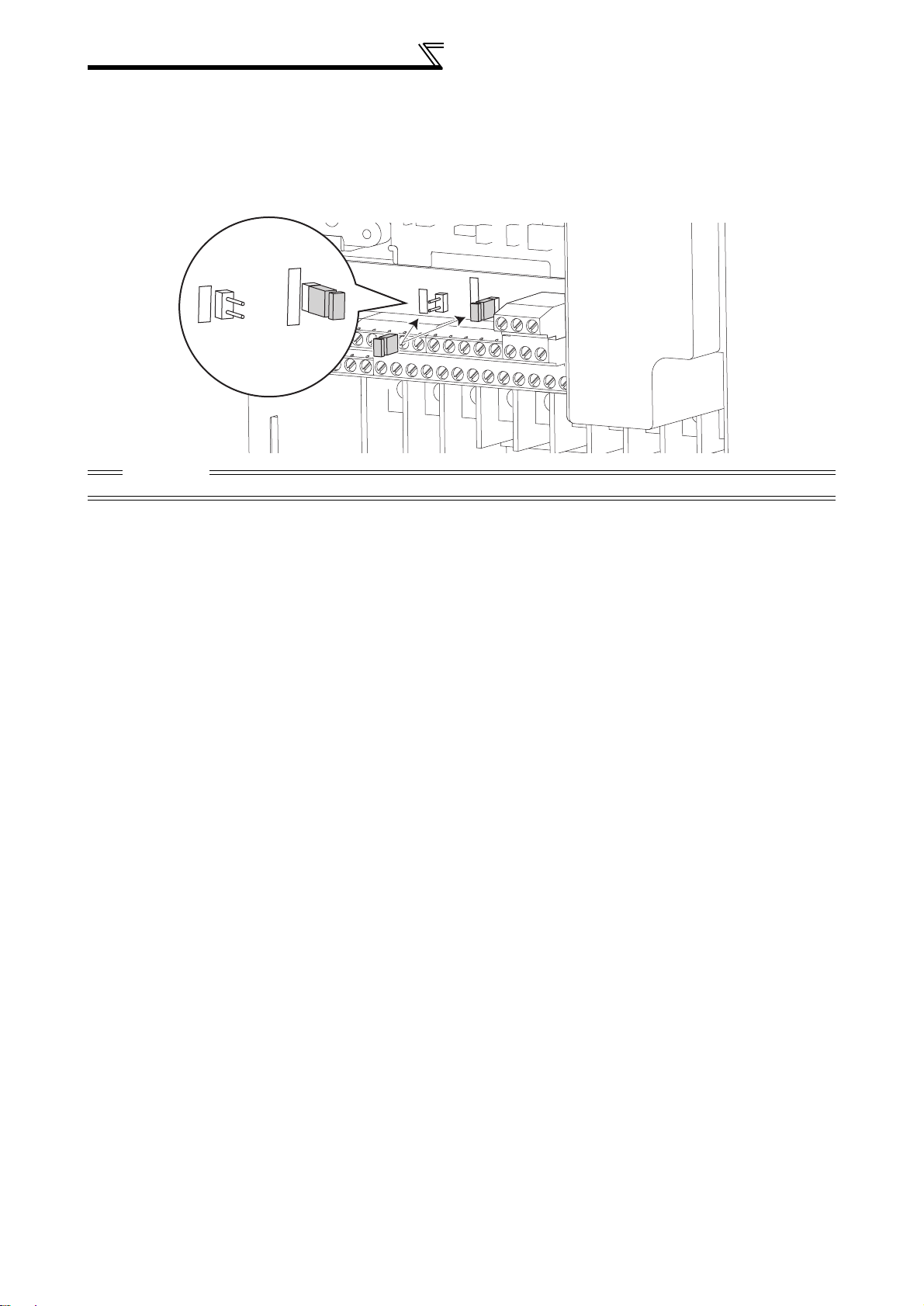

1.4.2 Control circuit terminal layout

RL

C2B2A2C1B1A1

(1) Wiring method

Loosen the terminal screw and insert the cable into the terminal.

Screw Size: M3 Tightening Torque: 0.5N·m to 0.6N·m

Cable size: 0.3mm

Screwdriver:Small flat-blade screwdriver (Edge thickness: 0.4mm/

Edge width: 2.5mm)

CAUTION

Undertightening can cause cable disconnection or ma l fu nct i on .

Overtightening can cause a short circuit or malfunction due to

damage to the screw or unit.

2

to 0.75mm

2

CA SD PC

STOP

RT

AURHRM

RES STF STR PC

OLIPFSURUNSE14521010EAMPC

FU

MRS

JOG CS

Cable stripping size

6mm

Wire the stripped cable after twisting it to

prevent it from becoming loose. In addition, do

not solder it. *

12

Control circuit specifications

(2) Common terminals of the control circuit (PC, 5, SE)

Terminals PC, 5, and SE are all common terminals (0V) for I/O signals and are isolated from each other.

Terminal PC is a common terminal for the contact input terminals (STF, STR, STOP, RH, RM, RL, JOG, RT, MRS,

RES, AU, CS).

The open collector circuit is isolated from the internal control circuit by photocoupler.

Terminal 5 is a common terminal for frequency setting signal (terminal 2, 1 or 4), analog current output terminal (CA)

and analog output terminal AM.

It should be protected from external noise using a shielded or twisted cable.

Terminal SE is a common terminal for the open collector output terminal (RUN, SU, OL, IPF, FU).

The contact input circuit is isolated from the internal control circuit by photocoupler.

(3) Signal inputs by contactless switches

The contacted input terminals of the inverter (STF, STR, STOP,

RH, RM, RL, JOG, RT, MRS, RES, AU, CS) can be controlled

using a transistor instead of a contacted switch as shown on the

right.

PC

Inverter

+24V

STF, etc.

External signal input using transistor

R

1.4.3 Wiring instructions

1) Use shielded or twisted cables for connection to the control circuit terminals and run them away from the main

and power circuits (including the 200V relay sequence circuit).

2) Use two or more parallel micro-signal contacts or twin

contacts to prevent a contact faults when using contact inputs

since the control circuit input signals are micro-currents.

Micro signal contacts Twin contacts

3) Do not apply a voltage to the contact input terminals (e.g. STF) of the control circuit.

4) Always apply a voltage to the alarm output terminals (A, B, C) via a relay coil, lamp, etc.

5) It is recommended to use the cables of 0.75mm

If the cable gauge used is 1.25mm

2

or more, the front cover may be lifted when there are many cables running

or the cables are run improperly, resulting in an operation panel contact fault.

6) The wiring length should be 30m maximum.

Wiring of the control circuit of the 01800 or more

For wiring of the control circuit of the 01800 or more, separate away from wiring of the main circuit.

Make cuts in rubber bush of the inverter side and lead wires.

2

gauge for connection to the control circuit terminals.

1

WIRING

Rubber bush

(view from the inside)

Make cuts along the lines inside with

a cutter knife and such.

<Wiring>

13

Control circuit specifications

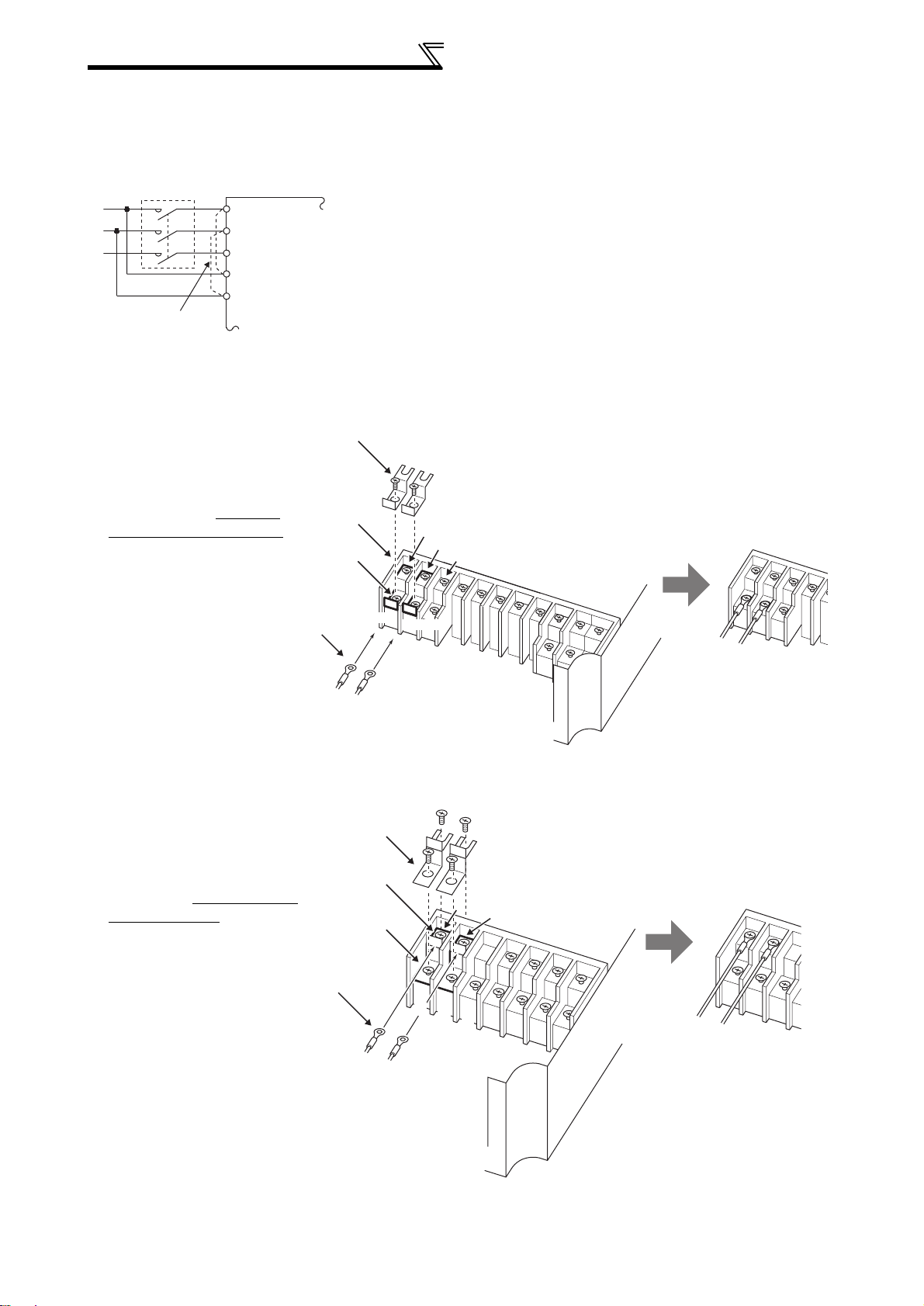

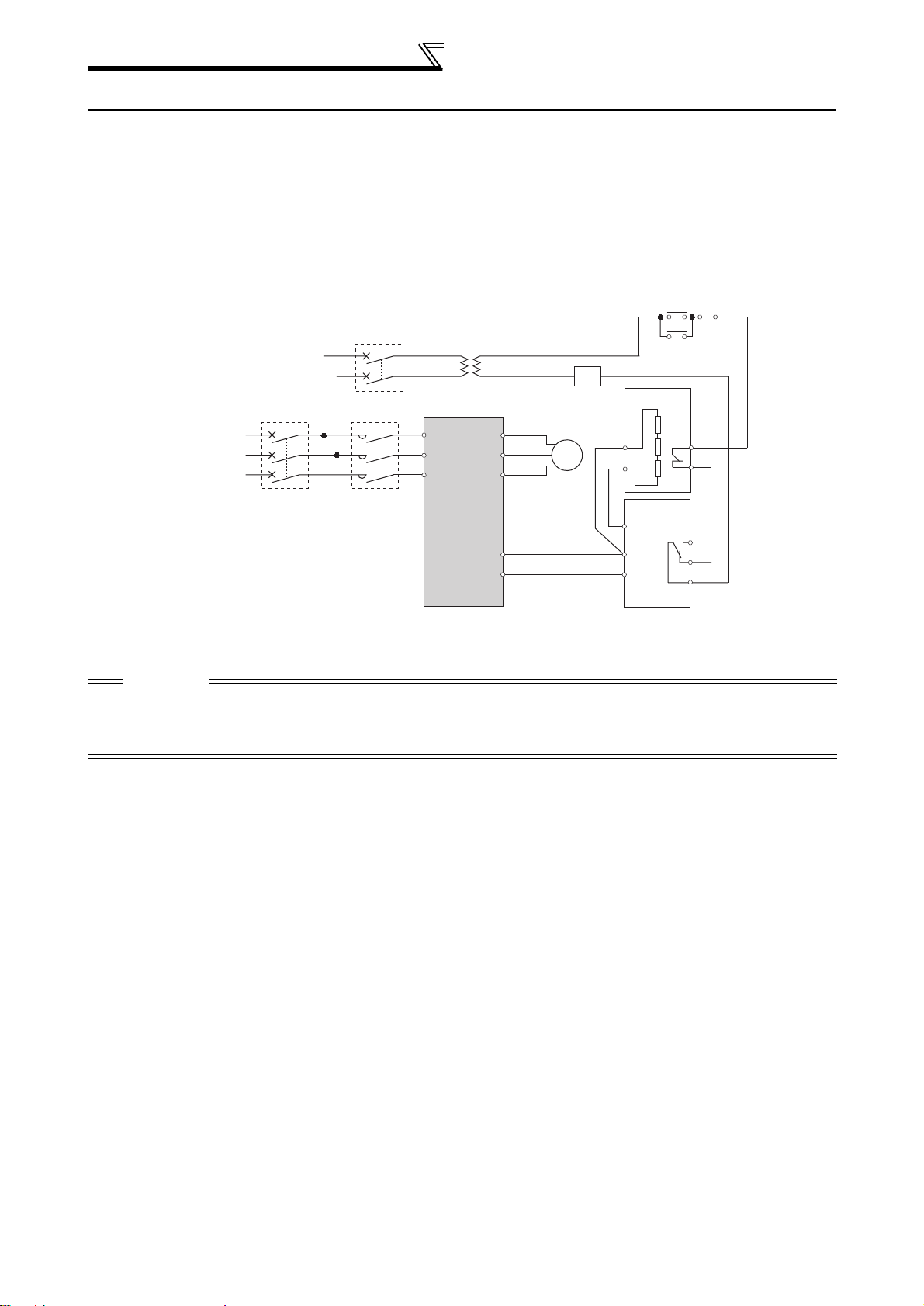

1.4.4 When connecting the control circuit and the main circuit separately

to the power supply (separate power)

<Connection diagram> When the protected circuit is activated, opening of the electromagnetic

MC

Inverter

R/L1

S/L2

T/L3

R1/L11

S1/L21

Remove the jumper

• FR-F740-00023 to 00126-EC

contactor (MC) on the inverter power supply side results in power loss in

the control circuit, disabling the alarm output signal retention. Terminals

R1/L11 and S1/L21 are provided to hold an alarm signal. In this case,

connect the power supply terminals R1/L11 and S1/L21 of the control

circuit to the primary side of the MC.

1)Loosen the upper screws.

2)Remove the lower screws.

3)Remove the jumper

4)Connect the separate

power supply cable for the

control circuit to the lower

terminals (R1/L11, S1/L21).

•FR-F740-00170, 00250-EC

1)Remove the upper screws.

2)Remove the lower screws.

3)Remove the jumper.

4)Connect the separate power

supply cable for the control

circuit to the upper terminals

(R1/L11, S1/L21).

3)

1)

2)

4)

R1/L11

R/L1

S/L2

T/L3

S1/L21

Main circuit terminal block

3)

1)

R1/L11

2)

S1/L21

R1/L11

S1/L21

R1/L11

S1/L21

14

4)

R/

S/

L1

T/

L2

L3

Main circuit

terminal block

• FR-F740-00310 to 02160-EC

1)Remove the upper screws.

2)Remove the lower screws.

3)Pull the jumper toward you to

remove.

4)

Connect the separate power supply

cable for the control circuit to the

upper terminals (R1/L11, S1/L21)

Never connect the power cable to

the terminals in the lower stand.

Doing so will damage the inverter.

.

MC

R/L1

S/L2

T/L3

R1/

L11

S1/

L21

Power supply

terminal block

for the control circuit

Control circuit specifications

3)

Power supply terminal block

for the control circuit

R1/L11

S1/L21

Main power supply

1)

2)

4)

00310, 00380 000470, 00620 00770 to 02160

Power supply

terminal block for

the control circuit

VUW

CAUTION

1. Do not turn off the co ntrol pow er (t ermin als R1/L11 and S1/L21) with the m ain circu it pow er (R/L 1, S /L2, T /L3) on. Do ing

so may damage the inverter.

2. Be sure to use the inverter with the jumpers across terminals R/L1-R1/L11 and S/L2-S1/L21 removed when supplying

power from other sources. The inverter may be dam aged if you do not remove the jum per.

3. The vo ltage sho uld be th e sam e as th at of th e main c ontrol c ircuit w hen th e control circuit p ower is suppl ied from o ther tha n the

primary side of the MC.

4. The power capacity is 60VA or more for 00380 or 80VA or more for 00470 to 02160 when separate power is supplied from R1/L11,

S1/L21.

5. When the power supp ly used w ith the control ci rcuit is differen t from the one us ed with th e main ci rcuit, m ake up a circuit

which will switch off the main circuit power supply terminals R/L1, S/L2, T/L3 when the control circuit power supply

terminals R1/L11, S1/L21 are switched off.

1

15

WIRING

Control circuit specifications

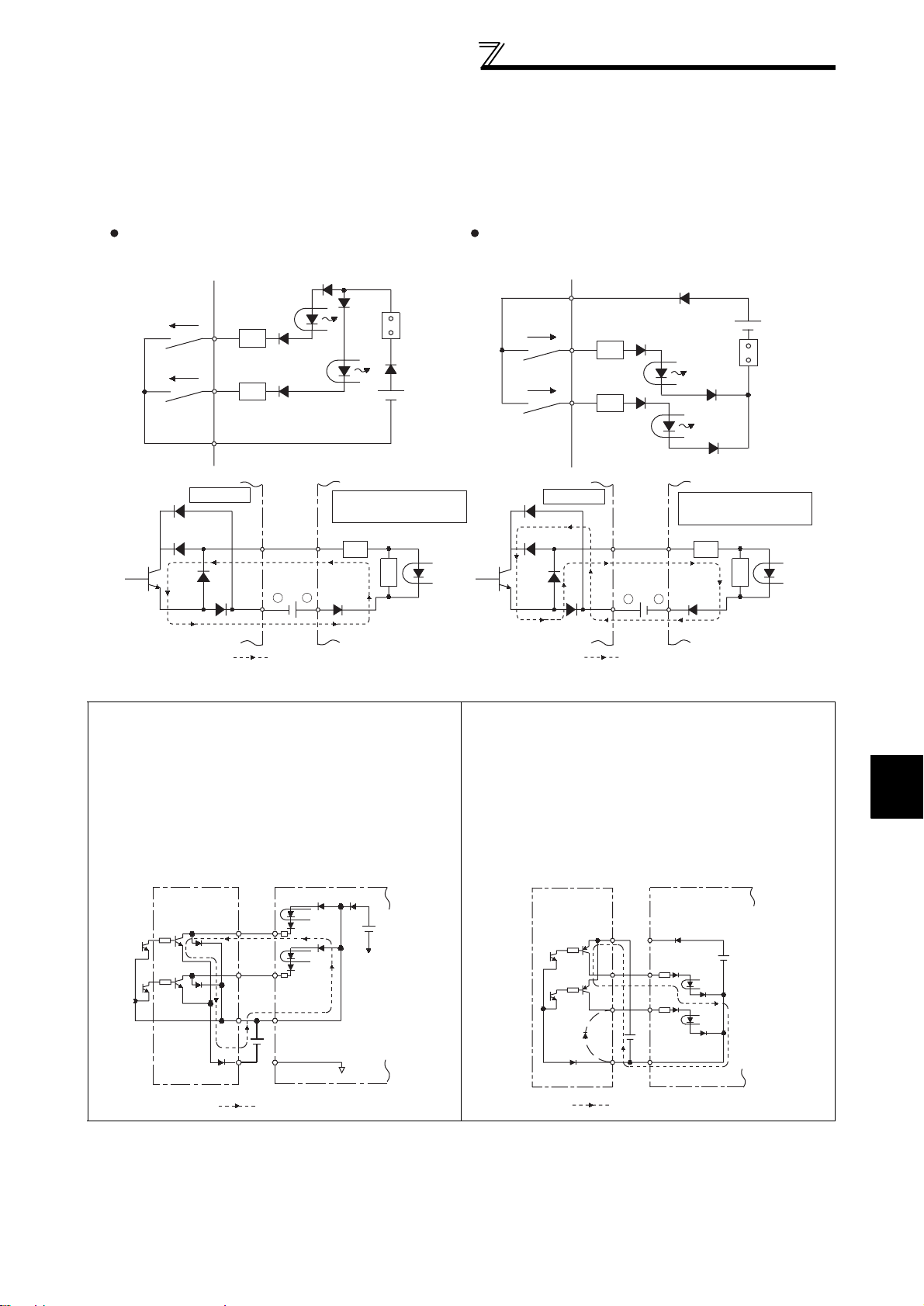

1.4.5 Changing the control logic

The input signals are set to source logic (SOURCE) when shipped from the factory.

To change the control logic, the jumper connector on the control circuit terminal block must be moved to the other

position.

(The output signals may be used in either the sink or source logic independently of the jumper connector position.)

E

C

K

IN

SINK

SOURCE

S

CAUTION

Turn off the inverter power before switch i ng a jum per connector.

R

U

O

S

16

Control circuit specifications

r

Sink logic and source logic

⋅ In sink logic, a signal switches on when a current flows from the corresponding signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the open collector output

signals.

⋅ In source logic, a signal switches on when a current flows into the corresponding signal input terminal.

Terminal PC is common to the contact input signals. Terminal SE is common to the open collector output

signals.

Current flow concerning the input/output signal

when sink logic is selected

Sink logic

current

STF

STR

SD

Inverter

RUN

SE

R

R

1

-

+

9

24VDC

Current flow

DC input (sink type)

<Example: AX40>

R

R

Sink

connector

Current flow concerning the input/output signal

when source logic is selected

Source logic

PC

current

STF

R

STR

R

Inverter

RUN

SE

+

24VDC

Current flow

DC input (source type)

<Example: AX80>

1

R

-

9

Source

connecto

R

• When using an external power supply for transistor output

⋅ Sink logic type

Use terminal PC as a common terminal to prevent a

malfunction caused by undesirable current. (Do not

connect terminal SD of the inverter with terminal 0V