Mitsubishi FR-F720-75K, FR-F740-55K, FR-F720P-55K, FR-F720P-75K, FR-F740P-55K Instruction Manual

...

INVERTER

Plug-in option

PRE-OPERATION INSTRUCTIONS

1

FR-A7NF

INSTRUCTION MANUAL

FL remote

function

communication

INSTALLATION

WIRING

INVERTER SETTING

FL REMOTE COMMUNICATION

FUNCTION

CYCLIC TRANSMISSION

MESSAGE TRANSMISSON

DESCRIPTION AND CORRECTIVE

ACTION OF FAULT INDICATION

TROUBLESHOOTING

2

3

4

5

6

7

8

9

Thank you for choosing this Mitsubishi Inverter plug-in option.

This Instruction Manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this Instruction Manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this Instruction Manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Incorrect handling may cause

WARNING

CAUTION

The level may even lead to a serious

consequence according to conditions. Both instruction levels

must be followed because these are important to personal

safety.

CAUTION

hazardous conditions, resulting in

death or severe injury.

Incorrect handling may cause

hazardous conditions, resulting in

medium or slight injury, or may cause

only material damage.

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• While power is ON or when the inverter is running, do not

open the front cover. You may get an electric shock.

• Do not run the inverter with the front cover or wiring cover

removed. Otherwise, you may accidentally touch the exposed

high-voltage terminals and charging part and get an electric

shock.

• Even if power is OFF, do not remove the front cover except for

wiring or periodic inspection. You may accidentally touch the

charged inverter circuits and get an electric shock.

• Before wiring or inspection, power must be switched OFF. To

confirm that, LED indication of the operation panel must be

checked. (It must be OFF.) Any person who is involved in

wiring or inspection shall wait for at least 10 minutes after the

power supply has been switched OFF and check that there

are no residual voltage using a tester or the like. The

capacitor is charged with high voltage for some time after

power OFF, and it is dangerous.

• Any person who is involved in wiring or inspection of this

equipment shall be fully competent to do the work.

• The plug-in option must be installed before wiring. Otherwise,

you may get an electric shock or be injured.

• Do not touch the plug-in option or handle the cables with wet

hands. Otherwise you may get an electric shock.

• Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

A-1

2. Injury Prevention

3) Usage

CAUTION

• The voltage applied to each terminal must be the ones

specified in the Instruction Manual. Otherwise burst, damage,

etc. may occur.

• The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

• Polarity must be correct. Otherwise burst, damage, etc. may

occur.

• While power is ON or for some time after power-OFF, do not

touch the inverter as they will be extremely hot. Doing so can

cause burns.

3. Additional Instructions

Also the following points must be noted to prevent an accidental

failure, injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Do not install or operate the plug-in option if it is damaged or

has parts missing.

• Do not stand or rest heavy objects on the product.

• The mounting orientation must be correct.

• Foreign conductive objects must be prevented from entering

the inverter. That includes screws and metal fragments or

other flammable substances such as oil.

2) Trial run

CAUTION

• Before starting operation, each parameter must be confirmed

and adjusted. A failure to do so may cause some machines to

make unexpected motions.

WARNING

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• Static electricity in your body must be discharged before you

touch the product. Otherwise the product may be damaged.

4) Maintenance, inspection and parts replacement

CAUTION

• Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

• This inverter plug-in option must be treated as industrial

waste.

6) General instruction

Many of the diagrams and drawings in this Instruction Manual

show the inverter without a cover or partially open for

explanation. Never operate the inverter in this manner. The

cover must be reinstalled and the instructions in the inverter

manual must be followed when operating the inverter.

A-2

— CONTENTS —

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Inverter model ....................................................................................................................................1

1.2 Unpacking and product confirmation ..............................................................................................2

1.2.1 Product confirmation.......................................................................................................................................2

1.2.2 SERIAL number check ...................................................................................................................................3

1.3 Parts ....................................................................................................................................................7

1.4 LED status ..........................................................................................................................................8

1.4.1 Device status LED (DEV), remote status LED (RMT) ....................................................................................9

1.4.2 Transmitting (TX)/receiving (RX) LED ..........................................................................................................10

1.4.3 Communication set status LED (CHG).........................................................................................................10

1.5 Specifications...................................................................................................................................11

1.5.1 Inverter option specifications........................................................................................................................11

1.5.2 Communication specifications......................................................................................................................11

2 INSTALLATION 12

2.1 Pre-installation instructions ...........................................................................................................12

2.2 Installation of the communication option LED display cover .....................................................13

2.3 Installation procedure .....................................................................................................................14

2.4 Node address setting ......................................................................................................................16

3 WIRING 17

3.1 Connection to network ....................................................................................................................17

3.2 Cable specifications ........................................................................................................................18

3.3 Precautions for system configuration ...........................................................................................18

I

3.4 Wiring................................................................................................................................................19

4 INVERTER SETTING 21

4.1 Parameter list ...................................................................................................................................21

4.2 Operation mode setting...................................................................................................................24

4.2.1 Operation mode indication............................................................................................................................24

4.2.2 Operation mode switchover method.............................................................................................................25

4.3 Selection of control source for the Network operation mode .....................................................30

4.4 Operation at communication error occurrence ............................................................................32

4.4.1 Operation selection at communication error occurrence (Pr. 501, Pr. 502) .................................................32

4.4.2 Fault and measures......................................................................................................................................34

4.5 Inverter reset ....................................................................................................................................36

4.6 Frequency and speed conversion specifications.........................................................................37

5 FL REMOTE COMMUNICATION FUNCTION 38

5.1 Functions..........................................................................................................................................38

5.1.1 Output from the inverter to the network........................................................................................................38

5.1.2 Input to the inverter from the network...........................................................................................................39

5.2 Types of data communication ........................................................................................................40

6 CYCLIC TRANSMISSION 41

6.1 Common memory ............................................................................................................................42

6.1.1 Common memory area 1..............................................................................................................................44

6.1.2 Common memory area 2..............................................................................................................................45

6.2 Output data (master to inverter) .....................................................................................................48

6.2.1 Control input command ................................................................................................................................49

6.2.2 Set frequency ...............................................................................................................................................51

II

6.3 Input data (inverter to master) ........................................................................................................52

6.3.1 Inverter status monitor..................................................................................................................................53

6.3.2 Fault code.....................................................................................................................................................55

6.3.3 Life/warning ..................................................................................................................................................55

6.3.4 Output frequency monitor.............................................................................................................................57

6.3.5 Output current monitor..................................................................................................................................57

7 MESSAGE TRANSMISSON 58

7.1 Error response at word block read/write .......................................................................................61

7.2 Word block read/write .....................................................................................................................62

7.2.1 Virtual address space of word block read/write............................................................................................63

7.2.2 Product information ......................................................................................................................................64

7.2.3 Operation mode............................................................................................................................................66

7.2.4 Inverter status...............................................................................................................................................67

7.2.5 Set frequency ...............................................................................................................................................68

7.2.6 Inverter monitor ............................................................................................................................................69

7.2.7 Parameter.....................................................................................................................................................72

7.2.8 Calibration parameters .................................................................................................................................74

7.2.9 Fault record ..................................................................................................................................................76

7.3 Network parameter read ..................................................................................................................82

7.4 Log data read ...................................................................................................................................85

7.5 Log data clear...................................................................................................................................88

7.6 Profile read .......................................................................................................................................89

7.7 Message loopback ...........................................................................................................................93

8 DESCRIPTION AND CORRECTIVE ACTION OF FAULT INDICATION 94

9 TROUBLESHOOTING 95

III

1 PRE-OPERATION INSTRUCTIONS

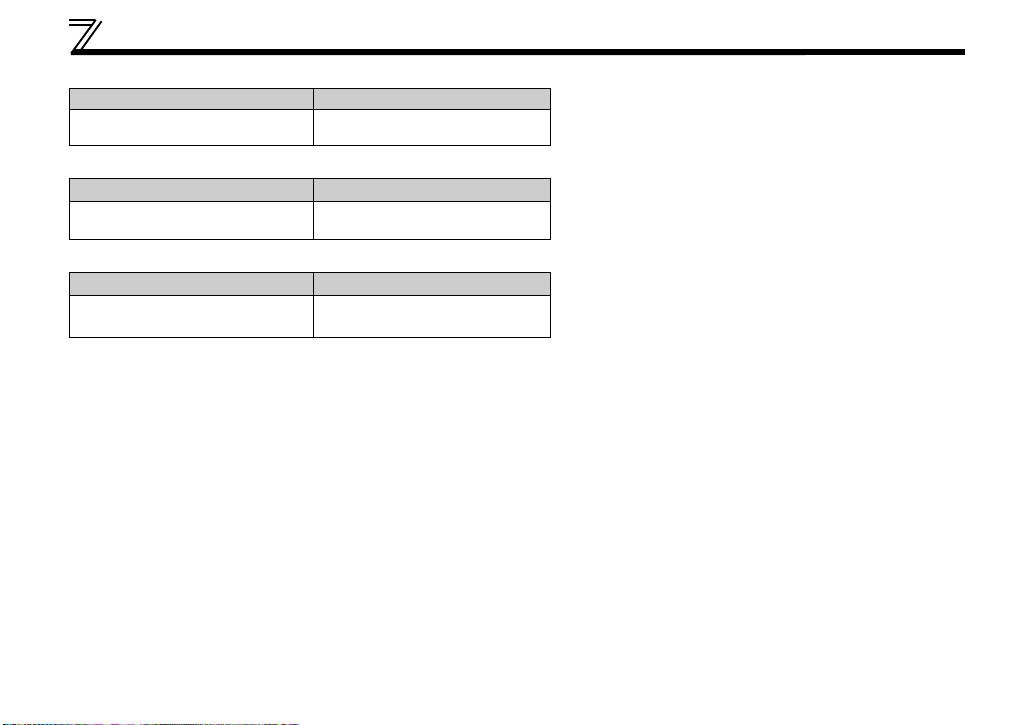

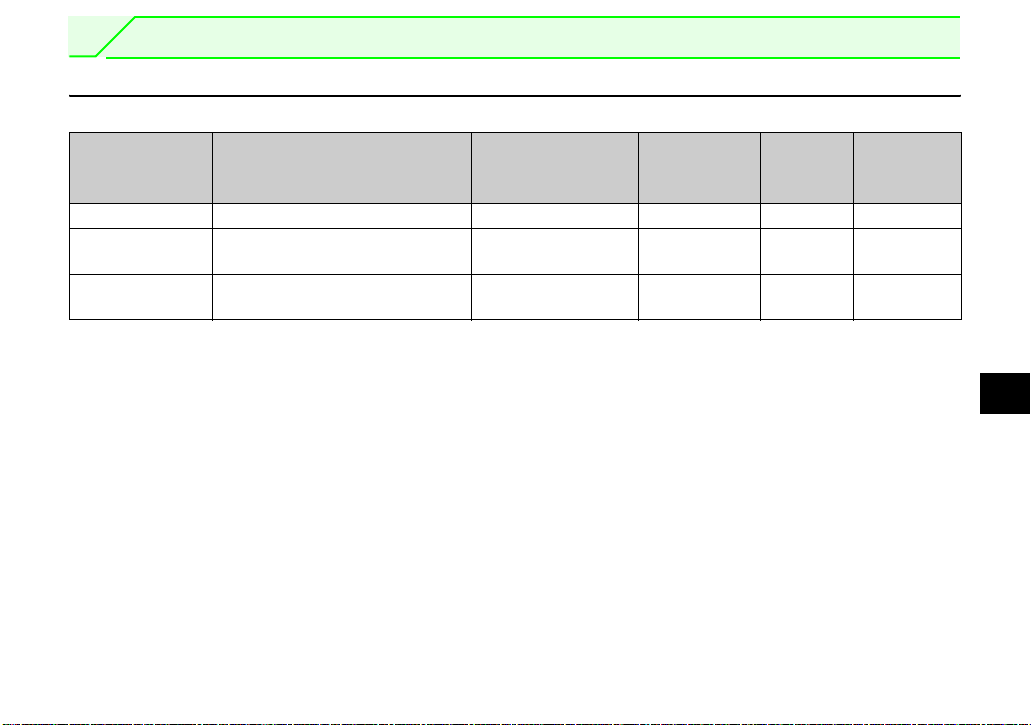

1.1 Inverter model

The inverter model, 55K and 75K stated in this Instruction Manual differs according to each -NA, -EC, CH(T) versions. Refer to the following correspondence table for each inverter model. (Refer to the Instruction

Manual of each inverter for the inverter model.)

For example, "for the 75K or higher" indicates "for the FR-A740-01440-NA or higher" in the case of FRA740 of NA version.

NA EC CH

FR-F720(P)-55K FR-F720-02330-NA ⎯⎯

F700

A700

FR-F720(P)-75K FR-F720-03160-NA ⎯⎯

FR-F740(P)-55K FR-F740-01160-NA FR-F740-01160-EC FR-F740-55K-CH(T)

FR-F740(P)-75K FR-F740-01800-NA FR-F740-01800-EC FR-F740-S75K-CH(T)

FR-A720-55K FR-A720-02150-NA ⎯⎯

FR-A720-75K FR-A720-02880-NA ⎯⎯

FR-A740-55K FR-A740-01100-NA FR-A740-01800-EC FR-A740-55K-CHT

FR-A740-75K FR-A740-01440-NA FR-A740-02160-EC FR-A740-75K-CHT

1

1

PRE-OPERATION INSTRUCTIONS

1.2 Unpacking and product confirmation

Take the plug-in option out of the package, check the product name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option for the FR-A700/F700(P) series inverter.

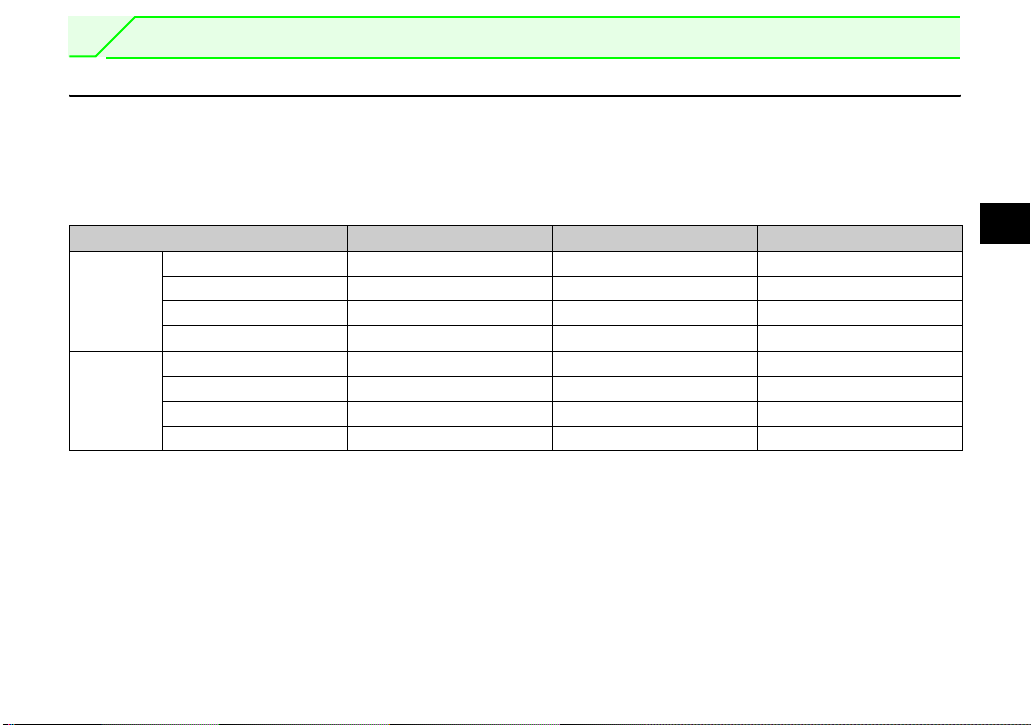

1.2.1 Product confirmation

Check the enclosed items.

Plug-in option

.........................................1

Mounting screw (M3 × 6mm)

............ 2 (Refer to page 14.)

Hex-head screw for option

mounting (5.5mm)

............. 1 (Refer to page 14.)

5.5mm

Communication option LED

display cover

............ 1 (Refer to page 13.)

2

PRE-OPERATION INSTRUCTIONS

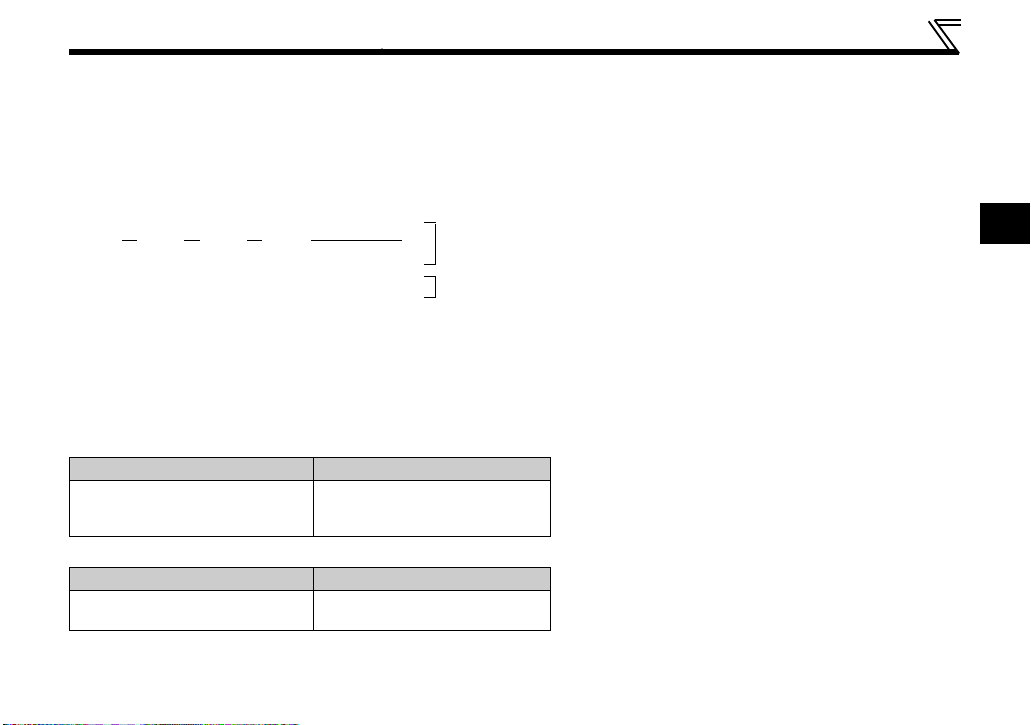

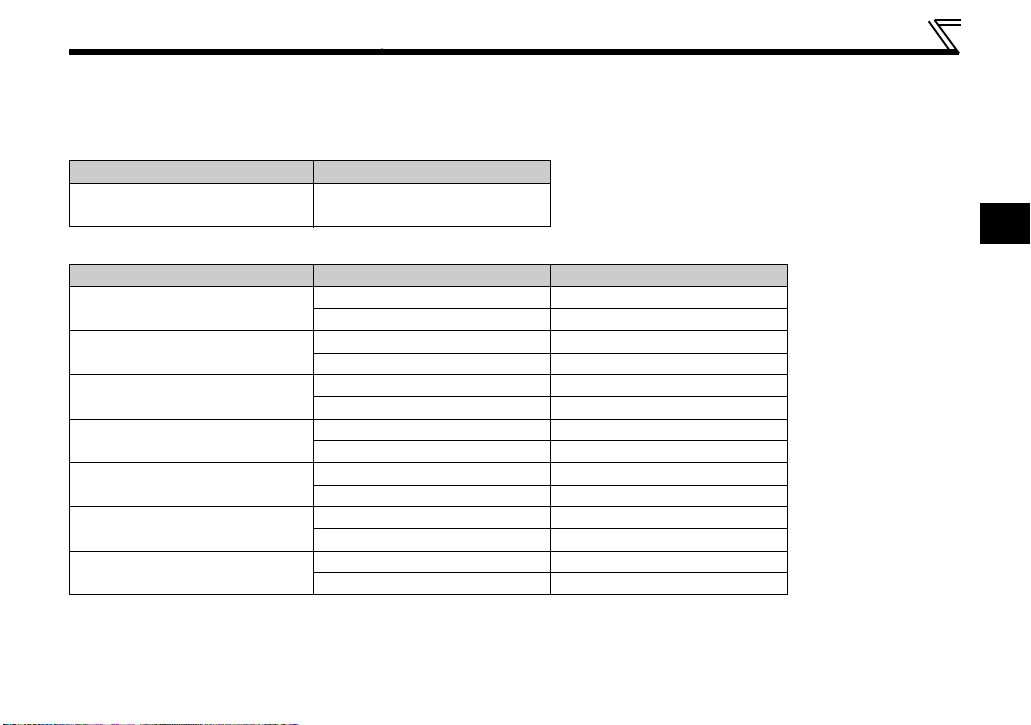

1.2.2 SERIAL number check

The plug-in option is compatible with the inverter having the following SERIAL number or later.

Check the SERIAL number indicated on the inverter rating plate or package.

z SERIAL number check

Refer to the inverter manual for the location of the rating plate.

Rating plate example

Symbol Year Month Control number

The SERIAL consists of one symbol, two characters indicating production year and month, and six characters indicating control number.

The last digit of the production year is indicated as the Year, and the Month is indicated by 1 to 9, X (October), Y (November), or Z (December.)

(1) PU/NET operation switchover (X65 signal) specification

The inverters with the following SERIAL are operated in the PU/NET operation switchover (X65 signal)

specification when connected with FR-A7NF.

z FR-A700 series

FR-A720-(-NA),

FR-A740FR-CA70-EC, FR-CA70-ECT

z FR-F700 series Japanese specification

FR-F720-0.75K to 110K,

FR-F740-0.75K to 560K

Regardless of their SERIAL numbers, all FR-F700P series inverters are operated with the PU operation interlock

(X12 signal) specification.

{ { {{{{{{

TC{{{A{{{G{{ TC number

Model SERIAL number

(-NA)(-EC)(-CHT),

Model SERIAL number

7X{{{{{{ to

03{{{{{{

91{{{{{{ or later

SERIAL

1

3

PRE-OPERATION INSTRUCTIONS

z FR-F700 series NA specification

Model SERIAL number

FR-F720-00046 to 04750-NA,

FR-F740-00023 to 12120-NA

z FR-F700 series EC specification

Model SERIAL number

FR-F740-00023 to 00620-EC,

FR-CF70-EC, FR-CF70-ECT

z FR-F700 series CHT specification

Model SERIAL number

FR-F740-0.75K to 55K-CHT,

FR-F740-S75K to S630K-CHT

91{{{{{{ or later

95{{{{{{ or later

93{{{{{{ or later

4

PRE-OPERATION INSTRUCTIONS

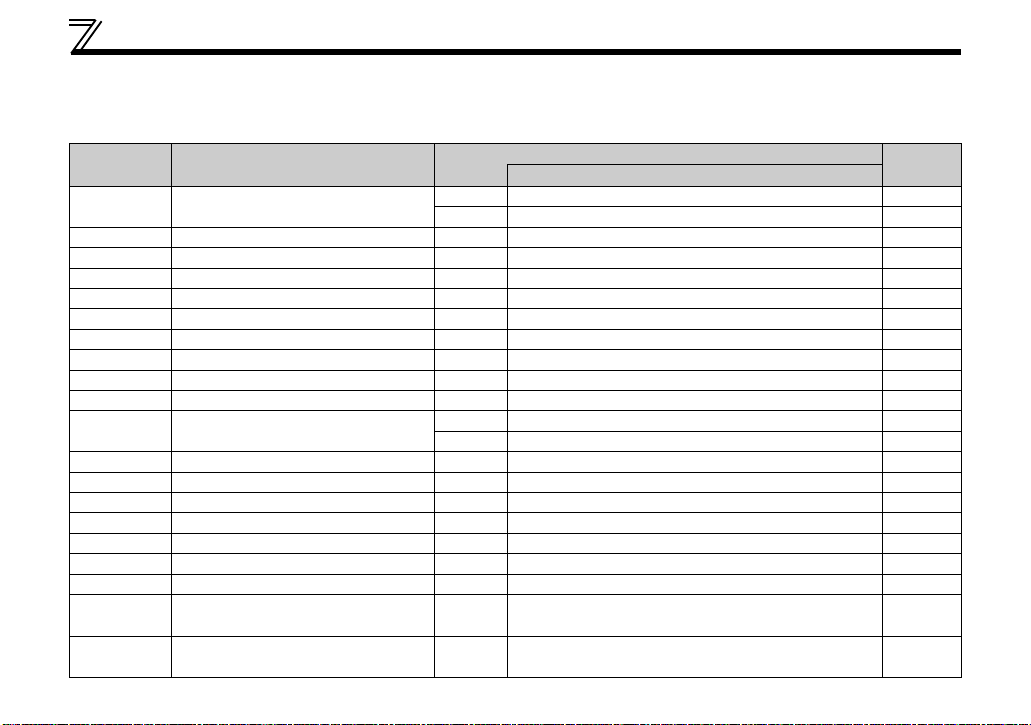

(2) PU operation interlock (X12 signal) specification

The FR-F700P series and the inverters with the following TC and SERIAL numbers are operated in the PU

operation interlock (X12 signal) specification when connected with FR-A7NF.

z FR-A700 series Japanese and NA specification

Model SERIAL number

FR-A720- (-NA)

FR-A740-

(-NA)

04{{{{{{

z FR-A700 series EC specification

Model TC number SERIAL number

FR-A740-00023 to 00052-EC

FR-A740-00083/00126-EC

FR-A740-00170/00250-EC

FR-A740-00310/00380-EC

FR-A740-00470/00620-EC

FR-CA70-EC

(Control unit)

FR-CA70-ECT

(Control unit)

TC{{{A{{{G7{ C0{{{{{{{ or later

TC{{{A{{{G8{ A0{{{{{{{ or later

TC{{{A{{{G7{ C0{{{{{{{ or later

TC{{{A{{{G8{ B0{{{{{{{ or later

TC{{{A{{{G7{ Y0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ Z0{{{{{{{ or later

TC{{{A{{{G8{ B0{{{{{{{ or later

TC{{{A{{{G7{ Y0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ V0{{

TC{{{A{{{G8{ E0{{{{{{{ or later

TC{{{A{{{G7{ S0{{{{{{{ or later

TC{{{A{{{G8{ E0{{{{{{{ or later

{{{{{ or later

1

5

PRE-OPERATION INSTRUCTIONS

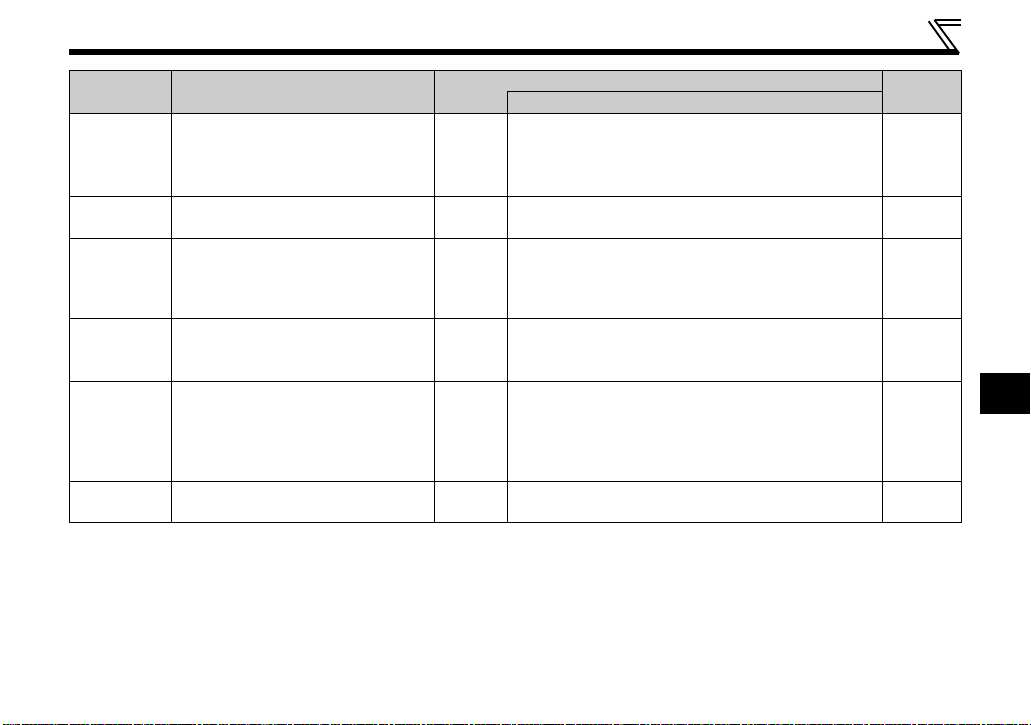

z FR-A700 series CHT specification

Model TC number SERIAL number

FR-A740-0.4K to 1.5K-CHT

FR-A740-2.2K/3.7K-CHT

FR-A740-5.5K/7.5K-CHT

FR-A740-11K/15K-CHT

FR-A740-18.5/22K-CHT

FR-A740-30K to 45K-CHT

FR-A740-55K-CHT

FR-A740-75K/90K-CHT

FR-A740-110K-CHT

FR-A740-132K-CHT

FR-A740-160K/185K-CHT TC{{{A{{{G7{ W0{{{{{{{ or later

FR-A740-220K to 280K-CHT TC{{{A{{{G7{ V0{{

FR-A740-315K/355K-CHT TC{{{A{{{G7{ U0{{{{{{{ or later

FR-A740-400K to 500K-CHT TC{{{A{{{G7{ R0{{{{{{{ or later

TC{{{A{{{G7{ A0{{{{{{{ or later

TC{{{A{{{G8{ Y0{{{{{{{ or later

TC{{{A{{{G7{ A0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ X0{{{{{{{ or later

TC{{{A{{{G7{ X0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ X0{{{{{{{ or later

TC{{{A{{{G7{ X0{{

TC{{{A{{{G8{ V0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ V0{{{{{{{ or later

TC{{{A{{{G7{ V0{{{{{{{ or later

TC{{{A{{{G8{ F0{{{{{{{ or later

TC{{{A{{{G7{ X0{{{{{{{ or later

TC{{{A{{{G8{ G0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ G0{{{{{{{ or later

{{{{{ or later

{{{{{ or later

6

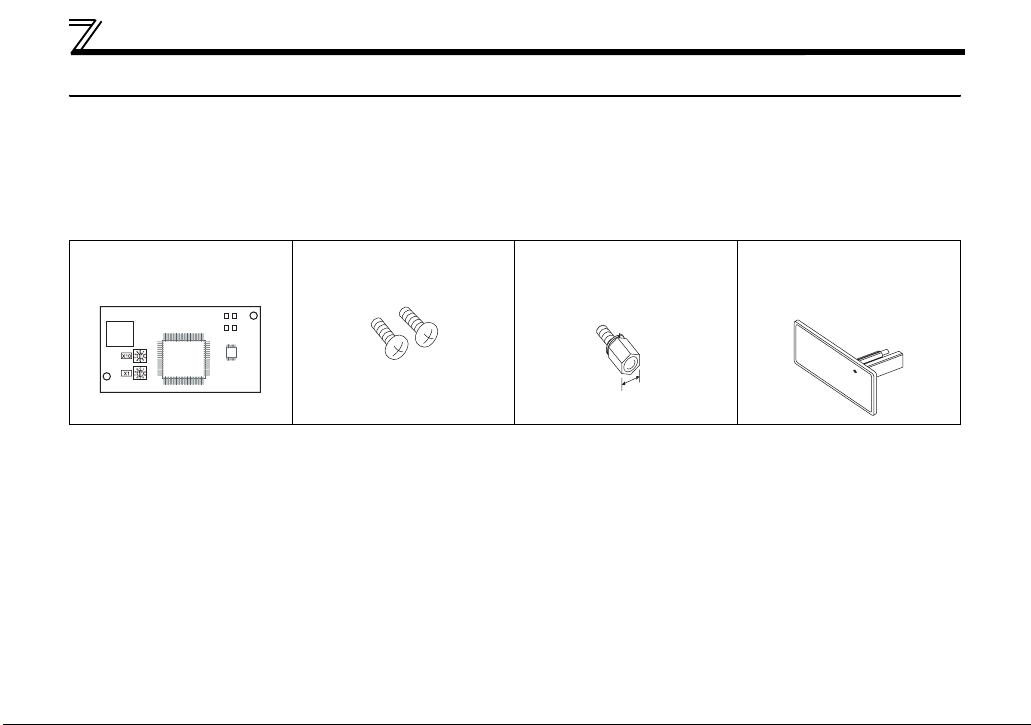

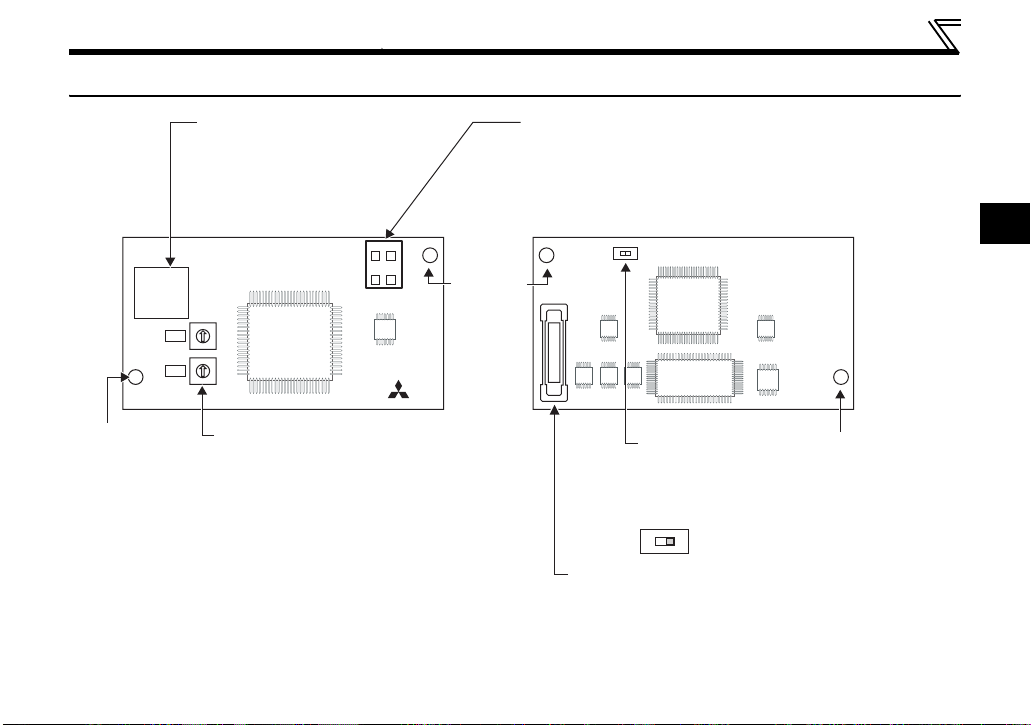

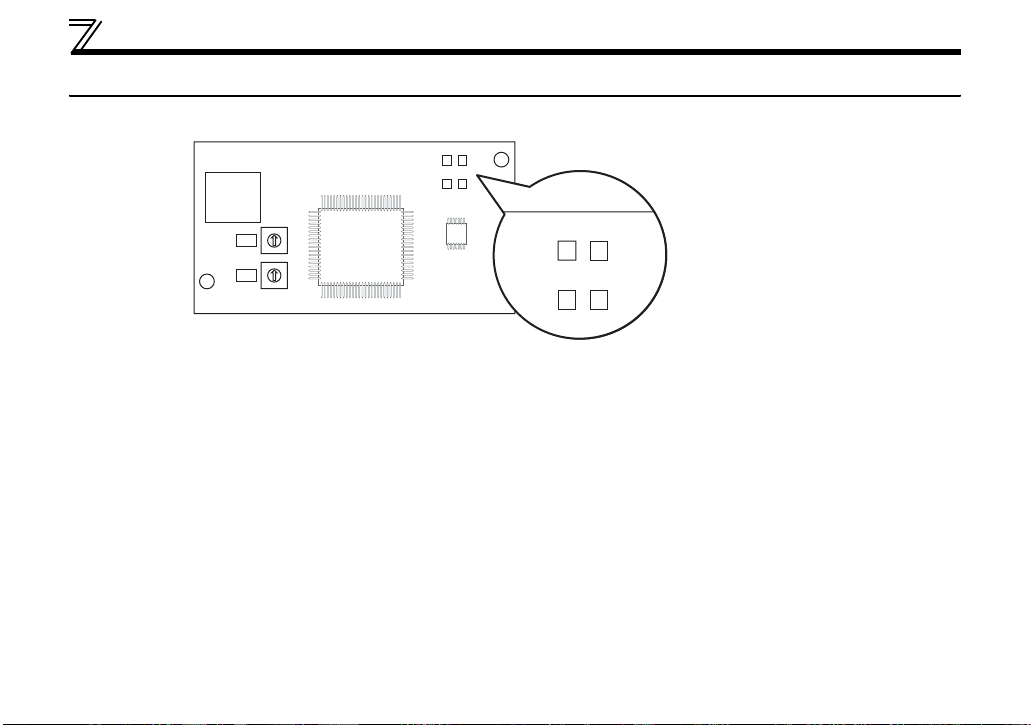

1.3 Parts

PRE-OPERATION INSTRUCTIONS

FR-A7NF

Mounting

hole

Connector for communication

Connect to the network by

connecting a FL-net dedicated

LED (operation status indication)

Lit/flicker/OFF of the LED indicate inverter

operation status.

cable.

Front view Rear view

D1 D2

SW2

0

1

9

2

8

3

X10

7

4

6

5

0

1

9

2

8

3

X1

7

4

6

5

SW1

Node address switch

Set the node address.

(Refer to page 16)

D3 D4

Mounting

hole

Connector

Connect to the inverter option connector.

(Refer to page 8)

SW3

Switch for manufacturer

setting

Do not change from

initially-set status (OFF).

SW3

N

2

L

O

1

Mounting

hole

7

PRE-OPERATION INSTRUCTIONS

D1 D2

S

D3 D4

1.4 LED status

Each LED indicates the operating status of the option unit and network according to the indication status.

D1 D2

D3 D4

SW2

0

1

9

2

8

3

X10

7

4

6

5

0

1

9

2

8

3

X1

7

4

6

5

SW1

FR-A7NF

D1: Communication set status LED (CHG)

D2: Device status LED (DEV)

D3: Reception/transmission LED (TX/RX)

D4: Remote status LED (RMT)

8

PRE-OPERATION INSTRUCTIONS

1.4.1 Device status LED (DEV), remote status LED (RMT)

LED Status

DEV RMT

Node Status Description

Power is OFF The inverter power is OFF.

· Node address is out of range (other than 1 to 64).

· Optional board fault

· When mounted to the inverter which is not compatible with

Hardware fault

FL remote network is not connected

FL remote network at a remote stop

FL remote network

during remote connection

processing

Master is not present When the master is disconnected from FL remote network.

FL remote network

during remote operation

Own node is disconnected When the own node is disconnected from FL remote network.

the FR-A7NF (Refer to page 3 for the inverter which is

compatible with the FR-A7NF)

· When a contact fault occurs in an option connector between

the inverter and communication option.

Although hardware is normal, it is not connected to the FL

remote network.

It is correctly set to connect to the FL remote network and

waiting for remote I/O control.

Although remote I/O control started, initial processing is in

progress.

During remote I/O control

1

9

PRE-OPERATION INSTRUCTIONS

LED Status

DEV RMT

Node Status Description

Setting error

Duplicate node When node address is duplicate with other node address

Although it is connected to the FL remote, setting error is found.

(When the slave is not the one the master is expected.)

:OFF, : red is lit, : green is lit, :red is flickering, : green is flickering,

: red and green are alternately flickering

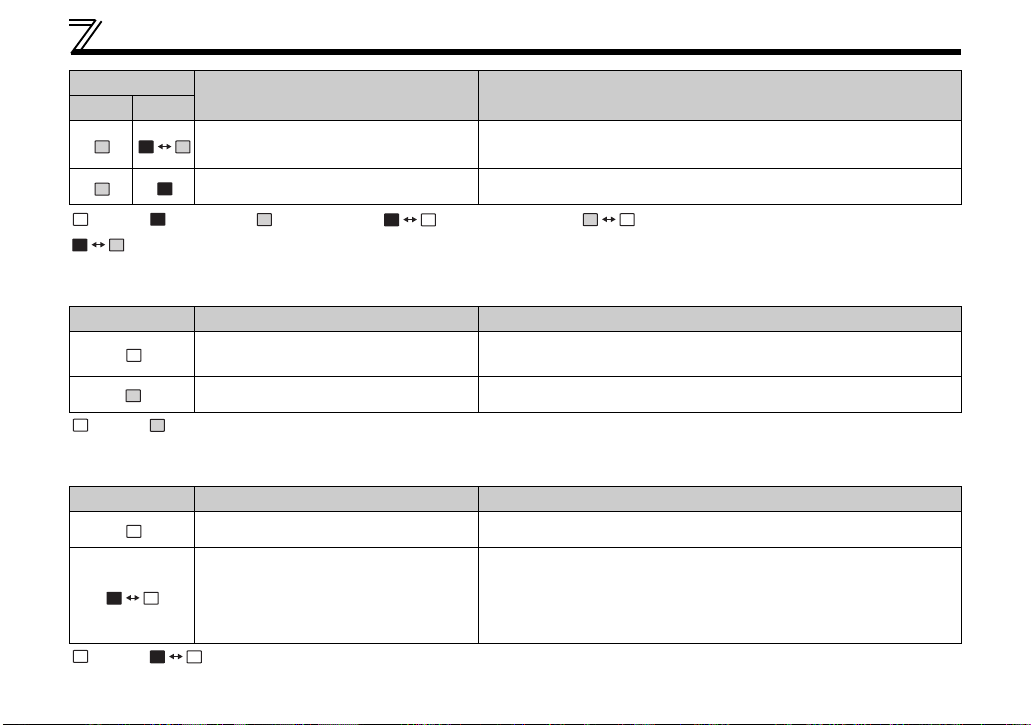

1.4.2 Transmitting (TX)/receiving (RX) LED

LED Status Node Status Description

Not transmitting (TX)/not receiving

(RX)

Transmitting (TX)/receiving (RX) Flickers at high speed during continuous transmitting/receiving

———

:OFF, : green is lit

1.4.3 Communication set status LED (CHG)

LED Status Node Status Description

Communication setting is not changed

Communication setting is changed

:OFF, : red is flickering

The red LED flickers when the applied setting and the node

address switch setting differ. The setting value of the node

address switch is applied by re-powering ON the inverter in this

status, then communication setting status LED turns OFF.

———

10

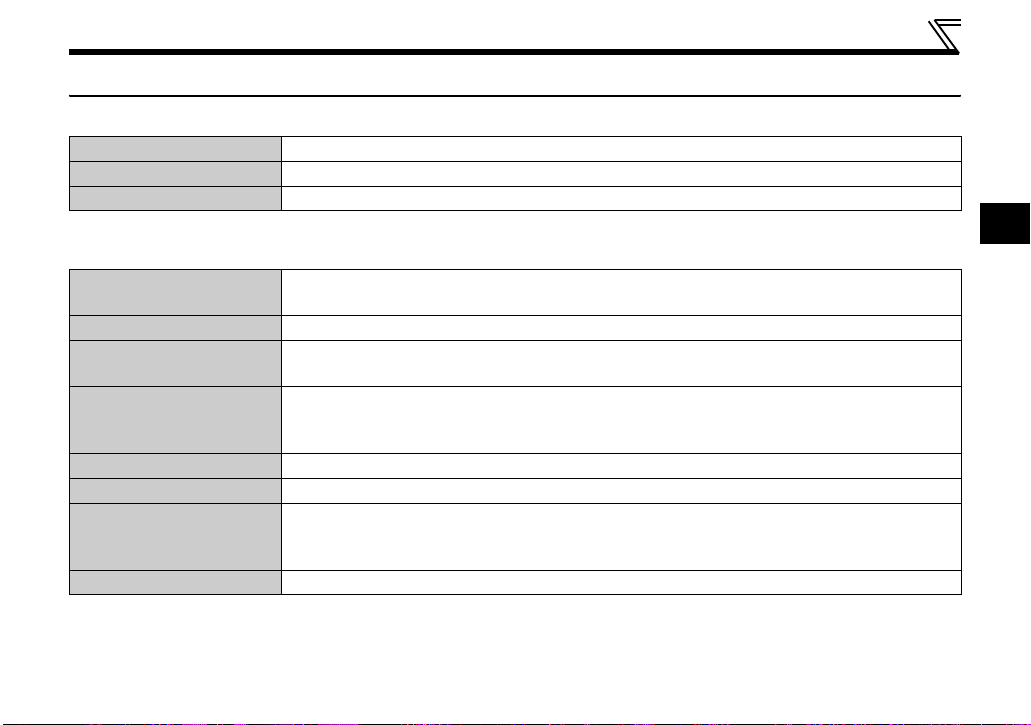

PRE-OPERATION INSTRUCTIONS

1.5 Specifications

1.5.1 Inverter option specifications

Power supply Supplied from the inverter

Typ e Inverter plug-in option (can be mounted/dismounted to/from the inverter front face)

FL-net dedicated cable Refer to page 18

1.5.2 Communication specifications

Maximum number of

connectable inverters

Communication speed Auto negotiation (auto detection) (10Mbps/100Mbps)

Topology

Communication

distance

Electrical interface Conforms to IEEE802.3u (conforms to CSMA/CD)

Transmission protocol FL remote

Node address setting

I/O points Input 64 points, output 64 points

64 units maximum

· Star (connection with a hub in the center)

· Star bus (connection with multiple hubs)

· Between node ⇔ hub: 100m maximum (Node indicate master and inverters.)

· Between hubs: 100m maximum

· Overall length: 2000m maximum

Can be set with node address switch (Refer to page 16).

The setting is applied to IP address as well.

(192.168.250.node address)

1

11

2 INSTALLATION

2.1 Pre-installation instructions

Make sure that the input power of the inverter is OFF.

CAUTION

With input power ON, do not install or remove the plug-in option. Otherwise, the inverter and

plug-in option may be damaged.

Static electricity in your body must be discharged before you touch the product. Otherwise the

product may be damaged.

12

INSTALLATION

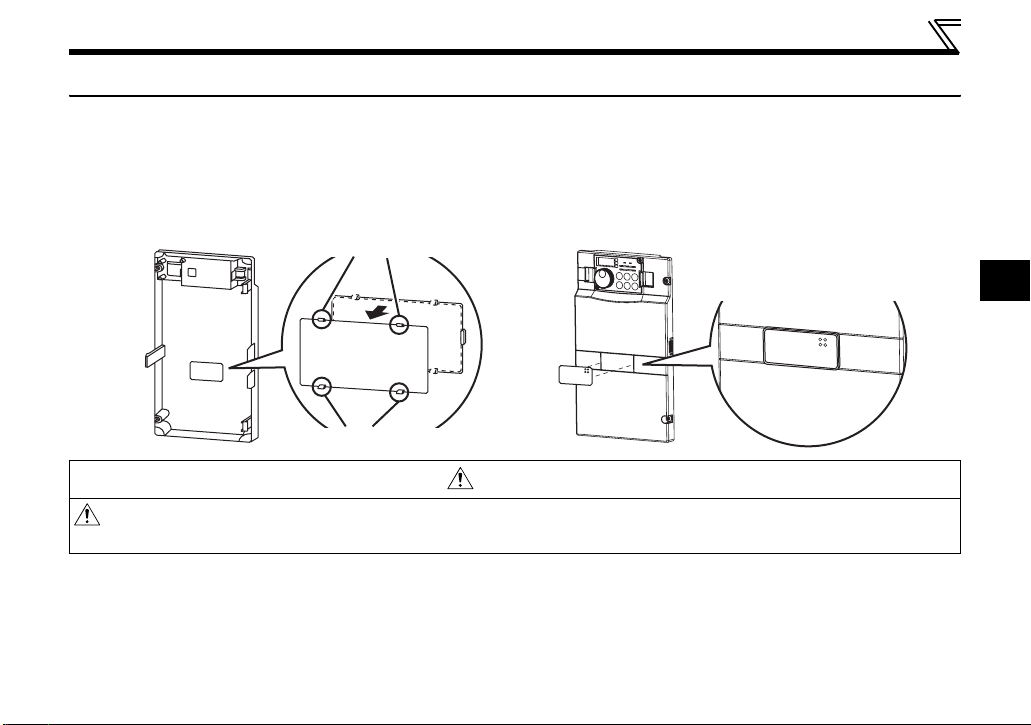

2.2 Installation of the communication option LED display cover

Mount the cover for displaying the operation status indication LED for the communication option on the

inverter front cover.

1)

Cut off hooks on the rear of the inverter front

cover with nipper, etc. and open a window for

fitting the LED display cover.

Cut off with a nipper, etc.

2)

Fit the communication option LED display

cover to the front of the inverter front cover

and push it into until fixed with hooks.

Fit it so that the position of

lenses is in the upper-right

of the LED display cover.

Fitting drawing

Cut off with a nipper, etc.

CAUTION

Take caution not to hurt your hand and such with portions left by cutting hooks of the rear of

the front cover.

2

13

INSTALLATION

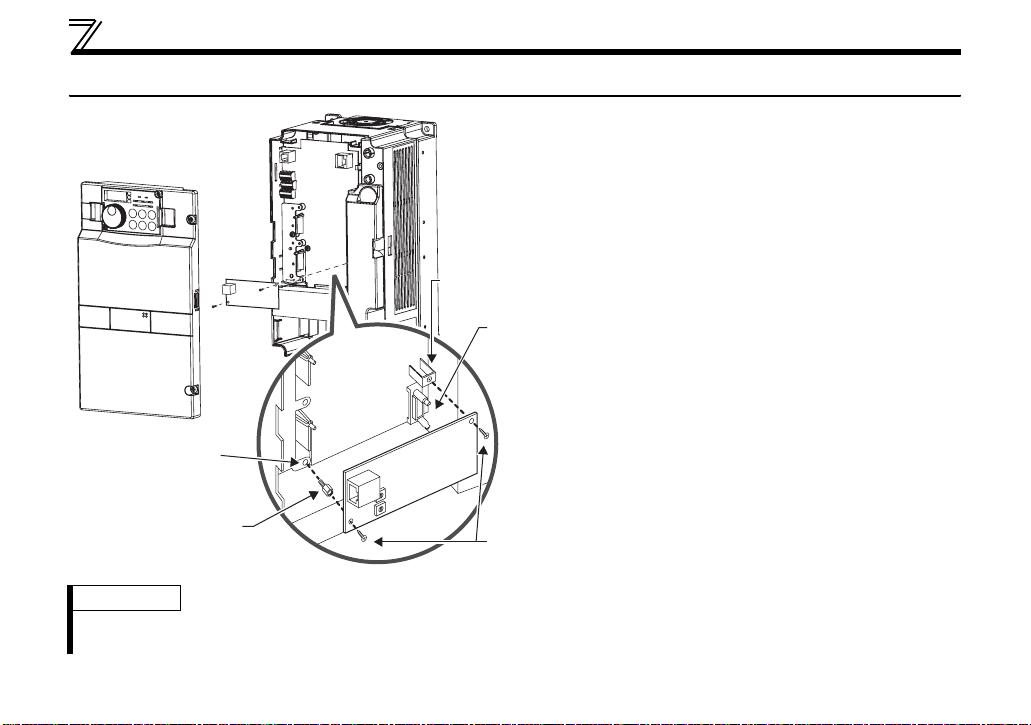

2.3 Installation procedure

1) Remove the inverter front cover.

1)

2) Mount the hex-head screw for option

mounting into the inverter screw hole

(on earth plate) (size 5.5mm, tightening

torque 0.56Nxm to 0.75Nxm).

Screw hole for

option mounting

Inverter side

option

connector

3) Securely fit the connector of the plug-in

option to the inverter connector along

the guides.

4) Securely fix the both right and left sides

of the plug-in option to the inverter with

the accessory mounting screws.

(Tightening torque 0.33Nxm to

0.40Nxm)

If the screw holes do not line up, the

connector may not have been plugged

securely. Check for loose plugging.

Screw hole for

option mounting

(on earth plate)

Hex-head screw

for option mounting

2)

3)

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

4)

Mounting

screws

REMARKS

• Remove a plug-in option after removing two screws on both left and right sides.

(The plug-in option is easily removed if the control circuit terminal block is removed before.)

14

INSTALLATION

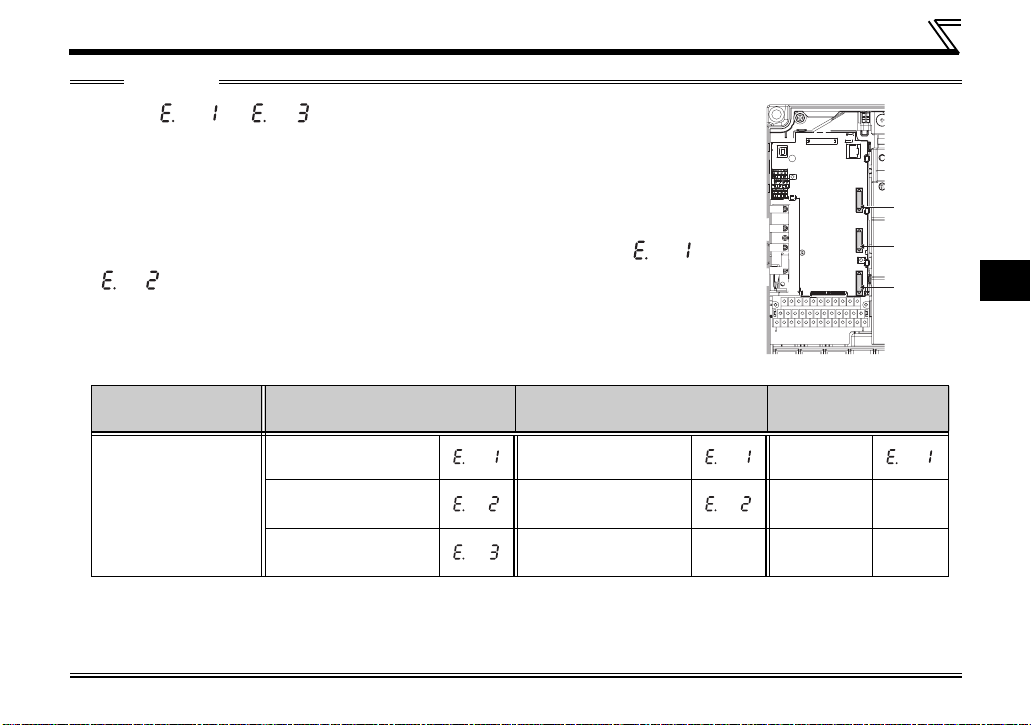

CAUTION

• One of " to " (option fault) appears when the inverter cannot rec-

ognize the option because it is improperly mounted, etc. One of the faults also

appears when an incompatible option is mounted to the inverter. Different indication will appear according to the mounted position (connector 1, 2, or 3).

• For an inverter having several option connectors, use the bottom connector to

mount the option.

If it is connected to a connector other than the bottom connector, " " or

" " (option fault) will appear and its operation will be disabled. Different

indication will appear according to the mounted position (connector 1 or 2).

• The number of option connectors differs by the model. The table below shows

how the fault indication differs according to the number of connectors and their

positions.

Number of option

connectors

Mounting position

and fault indication

3 2 1

Connector 1

(top connector)

Connector 2

(middle connector)

Connector 3

(bottom connector)

Connector 1

(top connector)

Connector 2

(bottom connector)

⎯⎯⎯⎯

Example of FR-A700

Connector 1

⎯⎯

(Refer to Chapter 1 of the inverter's Instruction Manual for the number of option connectors.

• Take caution not to drop a hex-head screw for option mounting or mounting screw during mounting and

removal.

• Pull out the option straight to remove. Otherwise, the connector may be damaged.

Connector 1

Connector 2

Connector 3

2

15

INSTALLATION

2.4 Node address setting

Set the node address between "1 to 64" using node address switches on the FR-A7NF (Refer to page 7).

The setting is applied when the power turns OFF once, then ON again.

Set the arrow (×) of the corresponding switches to the number to set a desired address.

z Setting example

Node address 1:

Set the "×" of X10(SW1) to "0" and the

X10

"×" of X1(SW2) to "1".

X1

CAUTION

• Set the node address switch to the switch number position correctly. If the switch

is set between numbers, normal data communication can not be established.

• If the node address switch is set to a value other than "1 to 64", it is invalid due to outside of setting

range. In this case, DEV LED of the option is lit red and E.OPT appears on the operation panel of the

inverter.

• You cannot set the same node address to other devices on the network. (Doing so disables proper

communication.)

• Set the inverter node address before switching ON the inverter and do not change the setting while

power is ON. Otherwise you may get an electric shock.

• Changes in the node address setting are applied only at the next power-ON. Therefore, if the node

address setting is changed, make sure to power OFF and ON the inverter power.

Node address 26:

0

1

9

2

8

3

7

4

Set the "×" of X10(SW1) to "2" and the

6

5

"×" of X1(SW2) to "6".

0

1

9

2

8

3

7

4

6

5

Good

example

0

1

9

2

8

3

7

4

6

5

X10

X1

Bad

example

9

8

7

6

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

0

1

2

3

4

5

16

3 WIRING

3.1 Connection to network

(1) Be sure to check the following before connecting the inverter to the network.

· Check that the FR-A7NF is correctly mounted to the inverter. (Refer to page 14)

· Check that the correct node address is set. (Refer to page 16)

· Check that the FL-net dedicated cable is correctly connected to the FR-A7NF. (Refer to page 18)

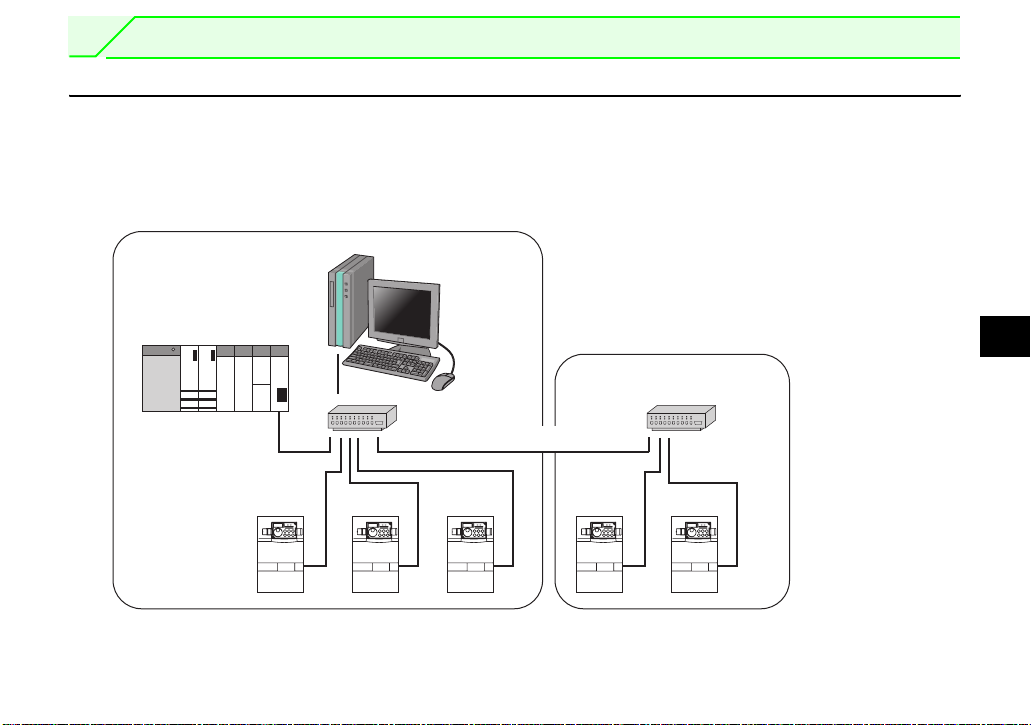

(2) System configuration

Segment 1

Master

100m maximum)

(

Personal computer

Segment 2

Hub

Cascade connection (100m maximum)

Inverter Inverter Inverter Inverter Inverter

Overall length: 2000m maximum

3

Hub

17

WIRING

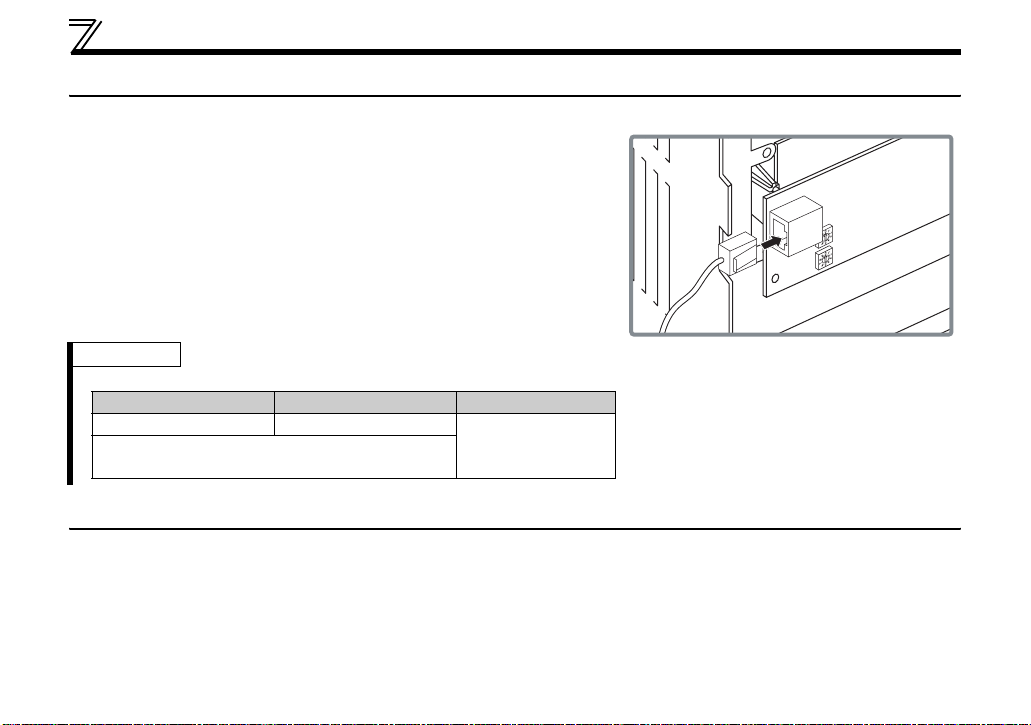

3.2 Cable specifications

Connect the FR-A7NF option unit to the FL remote network using the FL-net dedicated cable below.

Cables : TPCC5 or more (Twisted Pair Communication Cable

for LAN Category 5)

For the shape, use STP (Shielded Twisted Pair)

(according to the 100BASE-TX(IEEE802.3u)

standard)

Maximum wiring length:100m maximum between hub and inverter.

(according to the 100BASE-TX

(IEEE802.3u) standard)

REMARKS

y FL-net dedicated cable...recommended product (as of July 2011)

Typ e Cable Length (m) Maker

FLG-S-{{{ 1m to 100m

(Example: when the cable length is 1m)

FLG-S-010

Shinwa Co., Ltd.

3.3 Precautions for system configuration

Enough safety measures are necessary when installing the FL-net dedicated cable and connecting to the

FL remote network.

Consult the network provider and network administrator (person in charge of network planning and IP

address management) including terminal treatment of connection cable, construction of trunk cable, etc.

We are not responsible for system troubles from connecting to the FL remote network.

18

WIRING

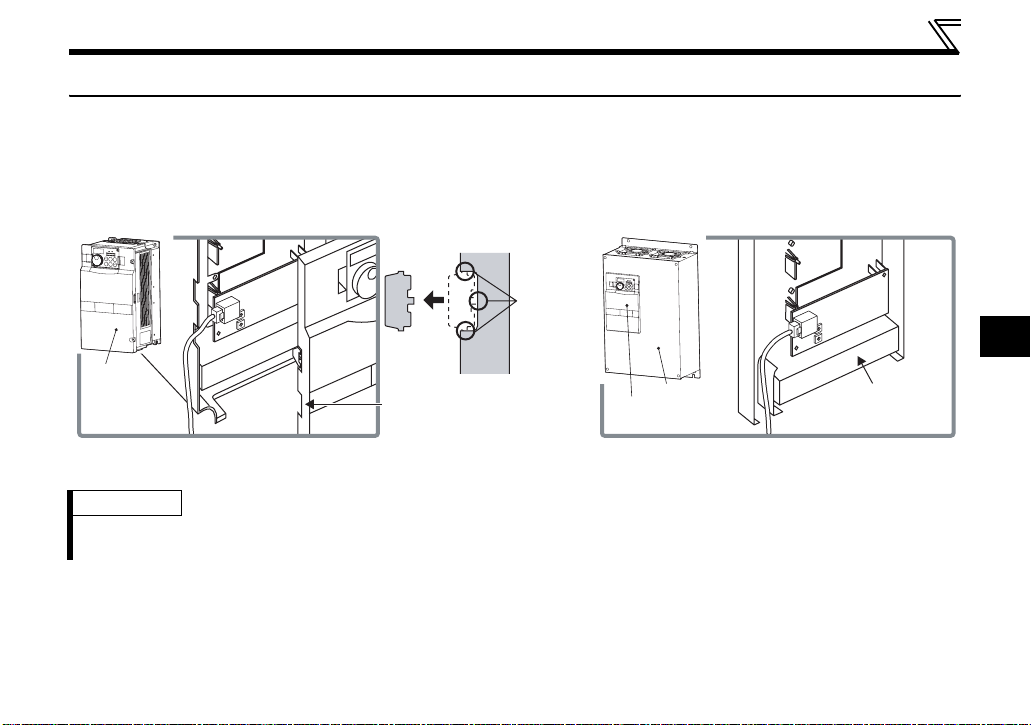

3.4 Wiring

For wiring of the inverter which has one front cover, route wires between the control circuit terminal block

and front cover. If cables can not be routed between the control circuit terminal block and front cover (about

7mm), remove a hook of the front cover and use a space become available.

For wiring of the inverter which has front cover 1 and 2, use the space on the left side of the control circuit

terminal block.

Cut off

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

Front cover

Cut off a hook on the inverter

front cover side surface.

(Cut off so that no portion is left.)

Inverter which has one front cover Inverter which has front cover 1 and 2

REMARKS

⋅ When the hook of the inverter front cover is cut off for wiring, the protective structure (JEM1030) changes to open

type (IP00).

with a

nipper,

etc.

Front cover 1

Front cover 2

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

Control circuit

terminal block

3

19

WIRING

C

AUTION

Do not connect the parameter unit (FR-PU07, etc.) to the FR-A7NF communication connector.

Doing so will damage the option.

When performing wiring using the space between the inverter front cover and control circuit

terminal block, take care not to subject the cable to stress.

After wiring, wire offcuts must not be left in the inverter. They may cause an error, failure or

malfunction.

20

4 INVERTER SETTING

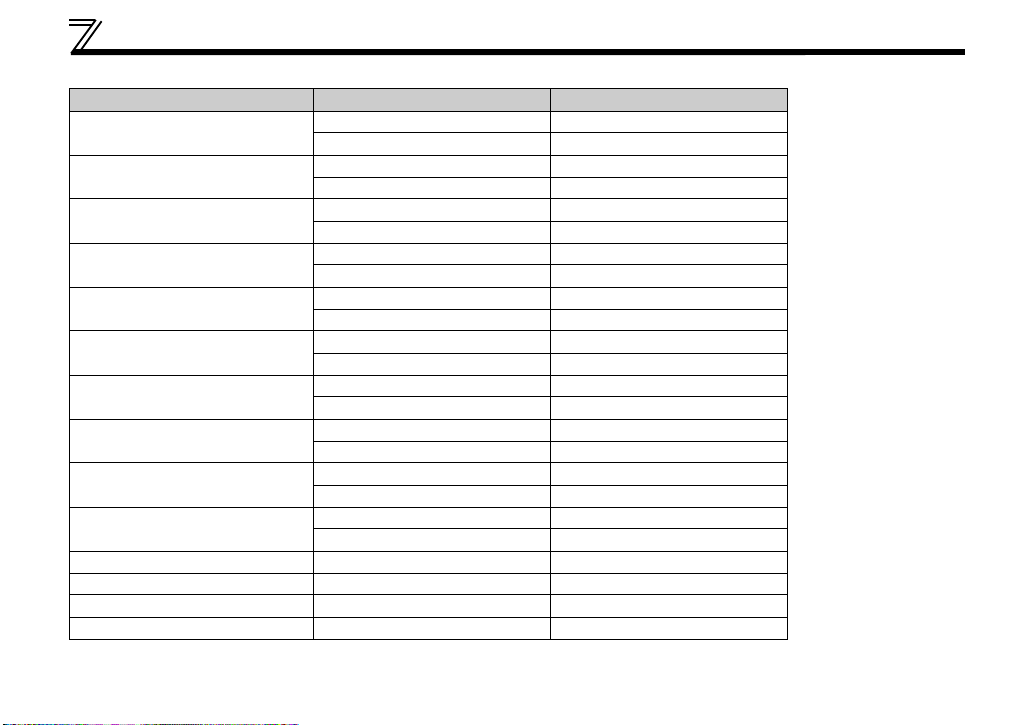

4.1 Parameter list

zThe following parameters are used for the communication option (FR-A7NF)

Parameter

Number

37 Speed display 0, 1 to 9998 1 0 37

144 Speed setting switchover

501

*

* Parameters which can be displayed when the plug-in option (FR-A7NF) is mounted.

Communication error occurrence

count display

Name Setting Range

0, 2, 4, 6, 8, 10, 102,

104, 106, 108, 110

01032

Minimum

Setting

Increments

1437

Initial

Value

Refer to

Page

4

21

INVERTER SETTING

zParameters whose functions are always the same

When the FR-A7NF is mounted to the inverter, following parameter functions are always the same.

(Changed setting is invalid even if the setting value is changed.)

Parameter

Number

79 Operation mode selection

180 RL terminal function selection 0 Low-speed operation command

181 RM terminal function selection 1 Middle-speed operation command

182 RH terminal function selection 2 High-speed operation command

183 RT terminal function selection 3 Second function selection

184 AU terminal function selection 9999 — (no function)

185 JOG terminal function selection 9999 — (no function)

186 CS terminal function selection 9999 — (no function)

187 MRS terminal function selection 24 Output stop

188 STOP terminal function selection 9999 — (no function)

189 RES terminal function selection

190 RUN terminal function selection 0 Inverter running

191 SU terminal function selection 1 Up to frequency

192 IPF terminal function selection 2 Instantaneous power failure/undervoltage

193 OL terminal function selection 3 Overload alarm

194 FU terminal function selection 4 Output frequency detection

195 ABC1 terminal function selection 99 Fault output

196 ABC2 terminal function selection 9999 — (no function)

338

339

Communication operation

command source

Communication speed command

source

Name Setting

*3 Network operation mode 25

0

7

*4 PU operation interlock 25

*3 PU/NET operation switchover

65

12 *4 PU operation interlock

0 Operation command source communication 30

0 Speed command source communication 30

Function

Refer

to Page

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

22

INVERTER SETTING

Parameter

Number

340

342

500 *1

502 *1

550

551

*1 Parameters which can be displayed when the plug-in option (FR-A7NF) is mounted.

*2 Refer to the inverter manual for details.

*3 This setting is for the inverters with the PU/NET operation switchover (X65 signal) specification.

*4 This setting is for the inverters with the PU operation interlock (X12 signal) specification. (Refer to page 5)

The X12 signal is valid only when it is input via FL remote communication. (Refer to page 50) (It is invalid when input

from a control circuit terminal of the inverter.)

Communication startup mode

selection

Communication EEPROM write

selection

Communication error execution

waiting time

Stop mode selection at

communication error

NET mode operation command

source selection

PU mode operation command

source selection

Name Setting

10

0

0

1

9999

2

Function

Started in Network operation mode. Operation

mode can be changed between the PU

operation mode and Network operation mode

from the operation panel.

Parameter values written by communication are

written to the EEPROM and RAM.

There is no waiting time since the communication

line fault occurrence until communication error

(0s). Note that actual time depends on the

detection time on FL remote network.

The inverter decelerates to stop at

communication fault occurrence, when provide

a fault output.

Automatic communication option recognition

Normally, control source of the RS-485 terminal

is valid. When a communication option is

mounted, the control source of the

communication option is valid.

Selects the PU connector as the PU operation

mode operation source.

(Refer to page 3)

Refer

to Page

25

— *2

— *2

33

4

— *2

— *2

23

INVERTER SETTING

4.2 Operation mode setting

Powering ON the inverter with the communication option (FR-A7NF) mounted starts the inverter in Network

operation mode.

(1) Network operation [NET] ... Controls the inverter with instructions from the network via the

communication option.

Functions of Pr.79 and Pr.340 are always the same when the FR-A7NF is

mounted.

(2) PU operation [PU].............. Controls the inverter from the key of the operation panel (FR-DU07)

mounted on the inverter or parameter unit (FR-PU07/FR-PU04).

(3) External operation [EXT] ...Controls the inverter by switching ON/OFF external signals connected to

the control circuit terminals of the inverter.

(The operation mode can not be changed to External operation mode when

the FR-A7NF is mounted.)

4.2.1 Operation mode indication

FR-DU07

Operation mode indication

(The inverter operates according to the LED lit mode.)

PU: PU operation mode

EXT: External operation mode

NET: Network operation mode *2

*1 The operation mode can not be changed to External operation mode when the FR-A7NF is mounted.

*2 "NET" is displayed when the FR-A7NF is mounted.

*1

24

4.2.2 Operation mode switchover method

Power-on

*

Network operation

C

External operation

INVERTER SETTING

A

PU operation

D

E

F

* When powering ON the inverter with the FR-A7NF mounted, the inverter starts in Network operation mode.

B

4

25

INVERTER SETTING

zOperation mode switchover

Symbol Switchover Type Switchover Method

The operation mode can not be switched in power-ON status. After powering OFF

External operation →

A

PU operation

the inverter, remove the FR-A7NF, then power ON the inverter again. Then, press

the of the PU (FR-DU07/FR-PU07/FR-PU04).

B

C

D

E

F

PU operation →

External operation

Network operation →

External operation

External operation →

Network operation

Network operation →

PU operation

PU operation →

Network operation

The operation mode can not be switched in power-ON status. After powering OFF

the inverter, remove the FR-A7NF, then power ON the inverter again.

The operation mode can not be switched in power-ON status. After powering OFF

the inverter, mount the FR-A7NF to the option connector (option connector 3 for

FR-A700 series), then power ON the inverter again.

Turn ON the PU/NET operation switchover signal. (Refer to page 27)

*1

Turn ON the X12 signal (Bit11), which gives operation commands through FL

remote communication, and press on the PU (FR-DU07/FR-PU07/FR-

PU04). (Refer to page 28)

Turn OFF the PU/NET operation switchover signal. (Refer to page 27)

*2

*1

Turn OFF the X12 signal (Bit11), which gives operation commands through FL

remote communication. (Refer to page 28)

*2

*1 This setting is for the inverters with the PU/NET operation switchover (X65 signal) specification. (Refer to page 3)

*2 This setting is for the inverters with the PU operation interlock (X12 signal) specification. (Refer to page 5)

26

INVERTER SETTING

(1) Operation mode switching by the PU/NET operation switchover signal (X65)

Combination of the FL remote communication control input command (PU/NET signal) (refer to page 49)

and the external terminal RES (X65 signal) determines ON/OFF of the PU/NET operation switchover

signal and the operation mode as shown in the below table.

Note that operation mode can be changed only during a stop (during a motor stop, start command (STF,

STR) is OFF).

FL remote communication control input command

(PU/NET signal)

RES terminal of external terminal (X65 signal) OFF OFF ON ON

PU/NET operation switchover signal (Operation mode) OFF (NET) ON (PU) ON (PU) ON (PU)

OFF ON OFF ON

PU: PU operation mode

NET: Net work operation mode

REMARKS

• This function is available for the inverters with the SERIAL numbers on page 3.

4

27

INVERTER SETTING

(2) Operation mode switching by the PU operation interlock signal (X12)

PU operation interlock is a function that forcefully changes the operation mode to the Network operation

mode at turn-OFF of the X12 signal (Bit 11), which gives operation commands through FL remote

communication.

This function prevents the operation mode from being accidentally unswitched from the PU operation

mode. If the operation mode left unswithced from the PU operation mode, the inverter does not reply to the

commands sent through FL remote communication.

X12

signal

ON

OFF

Operation mode Parameter write

Operation mode (PU, NET) switching is enabled

Output stop during Network operation

Forcibly switched to Network operation mode

Network operation is enabled

Switching to the PU operation mode is disabled

Function/Operation

Parameter write is enabled (depending on Pr. 77

Parameter write selection and each parameter write

conditions. Refer to the Inverter Manual for details.)

Parameter write is disabled

(Note that the Pr.297 setting is available

when Pr.296 ≠ "9999.")

REMARKS

• This function is available for the inverters with the SERIAL numbers on page 5.

28

INVERTER SETTING

<Function/operation changed by switching ON-OFF the X12 signal>

Operating Condition

Operation

mode

PU

Network

*1 The operation mode switches to the Network operation mode independently of whether the start signal (STF,

STR) is ON or OFF. Therefore, the motor is run in the Network operation mode when the X12 signal is turned OFF

with either of STF and STR ON.

*2 At fault occurrence, pressing of the operation panel resets the inverter.

Status

During stop ON → OFF

Running ON → OFF

During stop

Running

X12 Signal

OFF → ON

ON → OFF Disallowed

OFF → ON During operation → output stop Disallowed

ON → OFF Output stop

Operation

Mode

*1

*1 Disallowed

Network *2

Operating Status

If Network operation frequency

setting and start signal are

entered, operation is performed

in that status.

During stop

→ operation Disallowed

Switching to PU

Operation Mode

Disallowed

Allowed

CAUTION

⋅ If the X12 signal is ON, the operation mode cannot be switched to the PU operation mode when the start

signal (STF, STR) is ON.

⋅ The X12 signal is valid only when it is input via FL remote communication. (The X12 signal is invalid when it

is input from a control circuit terminal of the inverter.)

⋅ When the FR-A7NF is mounted, Pr.79 Operation mode selection and Pr.340 Communication startup mode selection

settings are invalid.

4

29

INVERTER SETTING

4.3 Selection of control source for the Network operation mode

⋅ As control sources, there are operation command source that controls signals related to the start

command and function selection of the inverter and speed command source that controls signals related

to frequency setting.

⋅ Commands from external terminal and communication are as listed below when the FR-A7NF is mounted.

Operation command

Running frequency from communication NET —

Terminal 2 — —

Terminal 4 — —

Terminal 1 Compensation —

Low-speed operation command/ remote setting

clear

Middle-speed operation command/ remote

setting deceleration

High-speed operation command/ remote setting

acceleration

PU operation interlock NET —

*2

PU/NET operation switchover *3 Combined —

*1

Fixed functions

(Functions

equivalent to

terminals)

Terminal RL

Terminal RM

Terminal RH

Terminal RT Second function selection NET —

Terminal RES

(X12)

Terminal RES

(X65)

Terminal MRS Output stop Combined —

Operation valid

location

NET

NET

NET

Remarks

Pr. 59 = "0"

(multi-speed)

Pr. 59 = "1, 2" (remote)

30

INVERTER SETTING

Operation valid

location

Remarks

Pr. 59 = "0"

(multi-speed)

Pr. 59 = "1, 2" (remote)

Operation

command

through FL

remote

communication

Operation command

STF signal Forward rotation command NET —

STR signal Reverse rotation command NET —

RL signal Low-speed operation command NET

RM signal Middle-speed operation command NET

RH signal High-speed operation command NET

RT signal Second function selection NET —

X12 signal

MRS signal Output stop NET —

PU/NET signal

Error reset Error reset NET —

*2 PU operation interlock NET —

*1

PU/NET operation switchover *3 NET —

*1 This setting and signal are for the inverters with the PU/NET operation switchover (X65 signal) specification.

(Refer to page 3)

*2 This setting and signal are for the inverters with the PU operation interlock (X12 signal) specification.

(Refer to page 5)

*3 Functions of "RES terminal (X65 signal) of external terminal" and "FL remote communication control input

command (PU/NET signal)" are the same.

[Explanation of table]

NET :Control from network is only valid

Combined :Operation from either external terminal or communication is valid.

⎯ :Operation from either external terminal or computer is invalid.

Compensation :Control by signal from external terminal is only valid if Pr. 28 Multi-speed input compensation setting is "1".

CAUTION

• The settings of Pr. 338 Communication operation command source and Pr. 339 Communication speed command source

are invalid when used with the FR-A7NF.

4

31

INVERTER SETTING

4.4 Operation at communication error occurrence

4.4.1 Operation selection at communication error occurrence (Pr. 501, Pr. 502)

You can select operations at communication error occurrences by setting Pr. 501 and Pr. 502 under network

operation.

(1) Display and erasure of communication error occurrence count

The cumulative number of communication error occurrences can be indicated.

Writing "0" to Pr.501 Communication error occurrence count display erases this cumulative count.

Parameter

Number

501

Name Setting Range

Communication error

occurrence count display

010

Minimum Setting

Increments

Initial Value

Count timing depending on

communication line status

Normal Error

Incremented by 1

Normal Error

Incremented by 1

At the point of communication line error occurrence, Pr. 501 Communication error occurrence count

display is incremented by 1.

CAUTION

• The communication error count occurrence is stored into RAM temporarily. Since this data is stored in

EEPROM at one-hour intervals, performing power-ON reset or inverter may cause the Pr. 501 data to be the

value stored in EEPROM the last time depending on the reset timing.

32

INVERTER SETTING

(2) Inverter operation at communication error occurrence

If a communication line error or an error of the option unit itself occurs when the FR-A7NF is mounted,

the inverter operates in the same manner as when Pr. 502 Stop mode selection at communication error =

"1" regardless of setting value of Pr. 502.

zOperation at error occurrence

Error Definition Operation Indication Fault Output

Communication line Decelerated to stop

Communication option itself Decelerated to stop E.1, E.2 or E.3 lit after stop Provided after stop

E.OP1, E.OP2 or E.OP3 lit after

stop

Provided after stop

zOperation at error removal

Error Definition Operation Indication Fault Output

Communication line Kept stopped E.OP1, E.OP2 or E.OP3 kept lit Kept provided

Communication option itself Kept stopped E.1, E.2 or E.3 kept lit Kept provided

CAUTION

• A communication line error [E.OP1 (fault data: HA1), E.OP2 (fault data:HA2), E.OP3 (fault data: HA3)] is an

error that occurs on the communication line, and an error of the communication option unit itself [E. 1 (fault

data: HF1), E. 2 (fault data:HF2), E. 3 (fault data: HF3)] is a communication circuit error in the option.

• The fault output indicates fault output signal (terminal ABC1) or fault bit output.

• When the setting was made to provide a fault output, the fault record is stored into the faults history. (The

fault record is written to the faults history when a fault output is provided.)

When no fault output is provided, the error record overwrites the fault indication of the faults history

temporarily, but is not stored.

After the error is removed, the fault record is reset and returns to the ordinary monitor, and the faults

history returns to the preceding fault indication.

• The deceleration time is the ordinary deceleration time setting (e.g. Pr. 8, Pr. 44, Pr. 45).

4

33

INVERTER SETTING

4.4.2 Fault and measures

(1) The inverter operates as follows at fault occurrences.

Fault

Location

Inverter

Communication

line

Communication

option

* Depends on the Pr. 502 setting

Inverter operation Inverter trip Inverter trip Inverter trip

Data communication Continued Continued Continued

Inverter operation

Data communication Stop Stop Stop

Communication

option

connection

error

Error of

communication

option itself

Status

Inverter

operation

Data

communication

Inverter

operation

Data

communication

Network

Operation

Decelerated to

stop

Decelerated to

stop

Continued Continued Continued

Decelerated to

stop

Stop Stop Stop

Operation Mode

External

Operation

Continued Continued

Inverter trip * Inverter trip *

Continued Continued

PU Operation

34

INVERTER SETTING

(2) Measures at fault occurrences

Fault Indication Fault Definition Measures

· Check that a cable is not disconnected from the communication

E.OP1, E.OP2, E.OP3

E.OPT

E.1, E.2, E.3

* When faults other than the above are displayed, refer to the inverter manual and remove the cause of the fault.

Communication

option fault

Option fault

connector.

· Check that a cable between own node and other nodes (including

switching hub) is not disconnected.

Check the node address setting. (Refer to page 16)

If an option board becomes faulty, contact your sales representative.

· Mount the communication option to the lowest option connector.

(Refer to page 14)

· Mount a communication option to the inverter compatible with the

FR-A7NF. (Refer to page 3)

· Check the connection between the inverter and option unit for poor

contact, etc. and remove the cause of the error. (Refer to page 14)

4

35

INVERTER SETTING

4.5 Inverter reset

zOperation conditions of inverter reset

Which resetting method is allowed or not in each operation mode is described below.

Operation Mode

Resetting Method

Inverter reset Not allowed

Reset from the network

Input the RES signal via a control circuit terminal of the inverter.

Switch OFF inverter power Enabled Enabled Enabled

Reset from the PU/DU

*1 Inverter reset via Network is invalid.

*2 Reset can be made only when the protective function of the inverter is activated.

*3 As the FR-A7NF is not mounted, reset from network can not be performed.

*4 Set "62 (RES signal)" in Pr. 178 STF terminal function selection or Pr. 179 STR terminal function selection to assign the

function to a terminal.

Error reset at inverter fault

(Refer to page 49)

Inverter reset Enabled Enabled Enabled

Reset at inverter fault Enabled Enabled Enabled

*2

CAUTION

• When E.OP1, E.OP2 or E.OP3 (communication line error) has occurred, reset cannot be made from the

network. Reset the inverter by making a power-ON reset, resetting with RES signal, etc.

• The inverter can not be controlled for about 1s after release of a reset command .

• At reset execution, the inverter resets, but the FR-A7NF continues communication.

• At occurrence of E.1, E.2 or E.3 (Option fault), reset can not be performed from the network. Reset the

inverter by making a power-ON reset, resetting with RES signal, etc.

Network

Operation

Allowed Not allowed *3 Not allowed

*4 Enabled Enabled Enabled

External

Operation

*1 Not allowed *3 Not allowed

PU

Operation

36

INVERTER SETTING

4.6 Frequency and speed conversion specifications

When setting or monitoring a frequency through the FR-A7NF, the frequency is set or monitored in 0.01Hz

increments regardless of the Pr. 37 Speed display setting. When setting or monitoring a speed through the

FR-A7NF, the speed is calculated with Pr.144 Speed setting switchover as shown below.

Speed setting, monitoring (1r/min increments) = frequency × 120 / number of motor poles (Pr. 144*)

* When Pr. 144 = "102 to 110," the formula is calculated with the value of (Pr. 144 - 100). When Pr. 144 ="0," the

formula is calculated with 4 poles.

REMARKS

• Refer to the Instruction Manual of the inverter for details of Pr. 37 and Pr. 144.

4

37

5 FL REMOTE COMMUNICATION FUNCTION

5.1 Functions

5.1.1 Output from the inverter to the network

Main items to be output from the inverter (FR-A7NF) to the network and their descriptions are explained

below. (

{: with function, ×: without function)

Item Description

Inverter monitor

Inverter status Monitors the output signal of the inverter.

Operation mode read Reads the operation mode of the inverter.

Output frequency

read

Parameter read Reads parameter settings of the inverter.

Fault description Monitors the fault history of the inverter.

Monitor various items such as inverter output

current and output voltage.

Monitors the output frequency of the inverter.

Cyclic

Transmission

× {

{{

× {

{{

× {

× {

Message

Transmission

REMARKS

• Refer to the inverter manual for functions controllable from the network in each operation mode.

Refer to

Page

69

53, 67

66

57, 69

72

76

38

FL REMOTE COMMUNICATION FUNCTION

5.1.2 Input to the inverter from the network

Main items which can be commanded from the network to the inverter and their descriptions are explained

below. (

* Parameter writing is available only for the inverters with the SERIAL on page 5. Parameters can be written while

{: with function, ×: without function)

Item Description

Sets the control input command such as

Run command

Frequency setting Sets the running frequency of the inverter.

Parameter write * Sets parameters of the inverter.

Faults history batch

clear

the X12 signal (Bit11), which gives operation commands through FL remote communication, is ON.

forward rotation signal (STF) and reverse

rotation signal (STR).

Clears the fault of the inverter.

Cyclic

Transmission

{ × 49

{ ×

× {

× {

Message

Transmission

REMARKS

• Refer to the inverter manual for functions controllable from the network in each operation mode.

Refer to

Page

51

72

76

5

39

FL REMOTE COMMUNICATION FUNCTION

5.2 Types of data communication

FL remote data communication supports "cyclic transmission" which transmits data periodically (refer to

page 41) and "message transmission" which transmits data non-periodically (refer to page 58).

40

Cyclic transmission

Cyclic data

with token

Message data

Cyclic transmission + message transmission

6 CYCLIC TRANSMISSION

Cyclic transmission transmits data periodically. Each node shares data through common memory. (Refer to

page 42 for common memory. )

Data of I/O area is updated periodically by cyclic transmission.

The master controls the inverter by setting run command (control input command, set frequency, etc.) in

the output data area.

The inverter sets the inverter status (output frequency, output current, various signals, etc.) in the input

data area and sends it to the master.

Data

Node 1 Node 2

Node 1

Node 2

Node 3

Node 4

Node n

Node 1

Node 2

Node 3

Node 4

Node n

Token

FL remote

Node 3

Node 1

Node 2

Node 3

Node 4

Node n

Node

Node 1

Node 2

Node 3

Node 4

Node n

Node n

Node 1

Node 2

Node 3

Node 4

Node n

6

Common

memory

41

CYCLIC TRANSMISSION

6.1 Common memory

Concept of common memory is stated below.

(1) The common memory is used as a shared memory between nodes which perform cyclic transmission.

(2) The common memory has two areas which are "common memory area 1" and "common memory area

2".

Common memory area 1 is I/O data area. Common memory area 2 is the control information area.

Two different areas can be assigned to each node.

(3) When the area each node sends exceed the transmission size (1024 byte) by one frame, data is

transmitted by multiple frames.

(4) When receiving data which are divided into multiple frames as (3), common memory is not updated until

all frames sent from one node are received. Synchronism per node unit is guaranteed.

(5) Entire network has an area of 8k bit (0.5k word) + 8k word = 8.5k word.

The maximum send data capacity per one node is 8.5k word. (Note that one word is 2 byte.)

15

2

0

2

42

Common memory area 1

=Input/output data area

Common memory area 2

=Control information area

0.5k Word

8k Word

Common memory

8.5k Word

area

CYCLIC TRANSMISSION

(6) Among common memory, both common memory area 1 and common memory 2 can be set as a

transmission area of one node as desired within the maximum area.

(7) Each node on FL remote network can share the same data in the whole system by broadcasting data

at a constant period. In addition, each node has own transmission area which does not overlap each

other to exchange data. (For common memory function, the transmission area assigned to one node

is a receive area for other nodes.)

Common memory

of node = 01

(Send)

(Receive)

(Receive)

(Receive)

Common memory

of node = 02

(Receive)

(Send)

(Receive)

(Receive)

Common memory

of node = 03

(Receive)

(Receive)

(Receive)

(Send)

Common memory

of node = 04

(Receive)

(Receive)

(Send)

6

(Receive)

43

CYCLIC TRANSMISSION

6.1.1 Common memory area 1

Size Description Refer to Page

Input data

(Inverter→master)

Output data

→inverter)

(Master

Input data

(Inverter

(Master

* When accessing a message, the access size should be the size stated in the table above.

→master)

Output data

→inverter)

REMARKS

x

When node status is other than "during FL remote network remote operation", all output data is changed to "0".

(Refer to

x When transmitting a message, common memory area 1 and 2 are read only. (Refer to page 63)

page 9

256 words

(512 byte)

256 words

(512 byte)

Virtual address

(byte

boundary)

H00000000 0 4 Input data (#1)

H00000008 4 4 Input data (#2)

H00000010 8 4 Input data (#3)

H000001F0 248 4 Input data (#63)

H000001F8 252 4 Input data (#64)

H00000200 256 4 Output data (#1)

H00000208 260 4 Output data (#2)

H00000210 264 4 Output data (#3)

H000003F0 504 4 Output data (#63)

H000003F8 508 4 Output data (#64)

for change of the setting.)

Data to be sent from inverter to master (4 words).

The data includes inverter status, output frequency, etc.

Data to be sent from master to inverter (4 words).

The data includes start command, frequency command, etc.

Applications

Address

(word boundary)

Size

(word boundary)

:

:

(Number in parentheses indicates

Description

node address)

52

48

44

6.1.2 Common memory area 2

Size

Control information (inverter→master) 1024 word (2048 byte)

Control information (master→inverter) 1024 word (2048 byte)

CYCLIC TRANSMISSION

Virtual address

(byte

boundary)

H00000400 0 1 Slave status (#)

H00000402 1 1 Actual status slave type (#1)

(1) Control information

(inverter

(2) Control information

(master

* When accessing a message, the access size should be the size stated in the table above.

→master)

→inverter)

H00000404 2 14 Simple setting check area (#1)

H00000BE0 1008 1 Slave status (#64)

H00000BE2 1009 1 Actual status slave type (#64)

H00000BE4 1010 14 Simple setting check area (#64)

H00000C00 1024 1 Remote control area (#1)

H00000C02 1025 1 Expected slave type (#1)

H00000C04 1026 14 Simple setting area (#1)

H000013E0 2032 1 Remote control area (#64)

H000013E2 2033 1 Expected slave type (#64)

H000013E4 2034 14 Simple setting area (#64)

Address

(word

boundary)

(word

boundary)

Size

Applications

Description

(Number in parentheses indicates node

:

:

REMARKS

x When sending a message, common memory area 1 and 2 are read only. (Refer to page 63)

address.)

6

45

CYCLIC TRANSMISSION

(1) Control information (inverter→master)

<Slave status>

Value Slave status

0 FL remote network is not connected

1 FL remote network remote at a stop

FL remote network remote connection

2

processing

3 FL remote network remote operating

4 Master is not present

5 Own node is disconnected

6 Setting error

<Actual slave type>

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

H00 to H3F (One point to 64 point)

Output points

H00 to H3F (One point to 64 point)

Input points

Subsequent area

0: Not used, 1:Used

0: Output not used (0 point)

1: Output used

Subsequent area

0: Not used, 1: Used

0: Input not used (0 point)

1: Input used

<Simple setting check area>

Not used. (Displays data imported in the simple setting area set from the master.)

46

(2) Control information (master→inverter)

<Remote control area>

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Not used

<Expected slave type>

Refer to page 46 for <Actual slave type>

<Simple setting check area>

Not used

CYCLIC TRANSMISSION

Remote control flag

0: Remote control stop

1: Remote control start

6

47

CYCLIC TRANSMISSION

6.2 Output data (master to inverter)

[Master output area (from master → inverter)]

Address

Word

0 4(n-1)+256 Control input command (Refer to page 49)

1 4(n-1)+257 — (not used)

2 4(n-1)+258 Set frequency (0.01 Hz increments) (Refer to page51)

3 4(n-1)+259 — (not used)

(word boundary)

(n: node address)

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Applications

48

CYCLIC TRANSMISSION

6.2.1 Control input command

Set control input command such as forward and reverse rotation commands.

Bit Signal Description

0 STF signal

1 STR signal

2 RL signal

3 RM signal

4 RH signal

5 RT signal*1

6 to 8

— (not used)

Forward

rotation

command

Reverse

rotation

command

Pr. 59 = 0 (initial value) Low-speed operation command

*1

Pr. 59 = 1, 2

Pr. 270 = 1

Pr. 59 = 0 (initial value) Middle-speed operation command

*1

Pr. 59 = 1, 2

Pr. 59 = 0 (initial value) High-speed operation command

*1

Pr. 59 = 1, 2

*4 Remote setting (setting clear) Pr. 59

*5 Stop-on contact selection 0

*4 Remote setting (deceleration) Pr. 59

*4 Remote setting (acceleration) Pr. 59

0: second function selection invalid,

1: second function selection valid

Pr. 270 = 1

*5 Stop-on contact selection 1

(Always 0) —

Bit0 Bit1 Command

Forward rotation: 0 Reverse rotation: 0 Stop command

Forward rotation: 1 Reverse rotation: 0

Forward rotation: 0 Reverse rotation: 1

Forward rotation: 1 Reverse rotation: 1 Stop command

Forward rotation

command

Reverse rotation

command

Related

Parameter

—

Pr. 4 to Pr. 6,

Pr. 24 to Pr. 27

Pr. 270, Pr. 275,

Pr. 276

Pr. 4 to Pr. 6,

Pr. 24 to Pr. 27

Pr. 4 to Pr. 6,

Pr. 24 to Pr. 27

Pr. 44 to Pr. 51

Pr. 270, Pr. 275,

Pr. 276

6

49

CYCLIC TRANSMISSION

Bit Signal Description

9

10

MRS signal

*1

— (not used)

PU/NET

*1, *2

signal

Output stop

(Always 0) —

PU/NET

operation

switchover

0: output shut off cancel,

1: output shut off

0: Network operation mode,

1: PU operation mode

(Refer to page 27 for details)

Related

Parameter

Pr.17

—

PU operation interlock (Refer to page 28)

Function/Operation

Parameter write is disabled

(Note that the Pr.297 setting is available

when Pr.296 ≠ "9999.")

Parameter write is enabled (depending

on Pr. 77 Parameter write selection and

each parameter write conditions. Refer to

the Inverter Manual for details.)

—

11

12 to 14

X12 signal

*1, *3

— (not used)

Bit11

Forcibly switched to Network operation

mode

0

Network operation is enabled

Switching to the PU operation mode is

disabled

Operation mode (PU, NET) switching is

1

enabled

Output stop during Network operation

Operation mode Parameter write

(Always 0) —

Resets the inverter when the setting of Bit15 is changed from 0 to 1 at

15 Error reset

occurrence of inverter error. Resetting the inverter resets the fault and

initializes the inverter status.

—

(FL remote communication continues.)

*1 Signals of the Bit2 to Bit5, Bit9, and Bit11 can not be changed. Even when changed using Pr.178 to Pr.183, Pr.187

and Pr.189, the settings are invalid. Refer to the inverter manual for details of Pr. 178 to Pr.183, Pr.187 and Pr.189.

*2 This setting is for the inverters with the PU/NET operation switchover (X65 signal) specification. (Refer to page 3)

*3 This setting is for the inverters with the PU operation interlock (X12 signal) specification. (Refer to page 5)

50

CYCLIC TRANSMISSION

*4 When Pr. 59 Remote function selection = "1" or "2", the functions of the RL, RM and RH signals are changed as given

in the table.

*5 When Pr. 270 Stop-on contact/load torque high-speed frequency control selection = "1", functions of RL and RT signals

are changed as in the table. (The setting is available for the FR-A700 series.)

REMARKS

x The values of each bit, "0" and "1," indicate "OFF" and "ON."

6.2.2 Set frequency

The set frequency can be set in 0.01Hz increments.

Bit Range Unit

0 to 15 0.00Hz to 400.00Hz 0.01Hz

Example:

If you want to set 120.00Hz, set 12000, which is the value multiplied by 100.

REMARKS

x Regardless of the Pr. 37 Speed display setting, the value is always set in frequency (Hz).

6

51

CYCLIC TRANSMISSION

6.3 Input data (inverter to master)

[Master input area (inverter → master)]

Address

Word

0 4(n-1)+0 Inverter status monitor (Refer to page 53)

1 4(n-1)+1 Life/warning (Refer to page55) Fault code (Refer to page 55)

2 4(n-1)+2 Output frequency monitor (Refer to page 57)

3 4(n-1)+3 Output current monitor (Refer to page 57)

(word boundary)

(n: node address)

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Applications

52

CYCLIC TRANSMISSION

6.3.1 Inverter status monitor

Monitors the output signal of the inverter from the network.

Bit Signal Description Related parameter

During forward

0

rotation

During reverse

1

running

2 RUN signal

3 SU signal

4 IPF signal

5 OL signal

6 FU signal

7 ALM signal

8, 9

— (not used) (Always 0) —

Inverter

*1

running

Reached the

*1

frequency

Instantaneous

*1

power failure/

undervoltage

*1 Overload alarm

Output

frequency

*1

detection

*1 Fault

Bit0 Bit1 Operation

Forward rotation: 0 Reverse rotation: 0 During stop

Forward rotation: 1 Reverse rotation: 0 During forward rotation

Forward rotation: 0 Reverse rotation: 1 During reverse running

Forward rotation: 1 Reverse rotation: 1 Not used

When the inverter output frequency reaches or exceeds

Pr.13 Starting frequency, the value changes to "1".

When the output frequency reaches the set frequency,

the value changes to "1".

When an instantaneous power failure or undervoltage

protection activates, the value changes to "1".

While stall prevention function is activated, the value

changes to "1".

When the output frequency reaches the frequency set

in Pr. 42 (Pr. 43 for reverse rotation), the value changes

to "1".

When the inverter protective function is activated to

stop the output (fault), the value changes to "1".

—

—

—

Pr. 41

Pr. 57

Pr. 22, Pr. 23,

Pr. 66

Pr. 42, Pr. 43

—

6

53

CYCLIC TRANSMISSION

Bit Signal Description Related parameter

— (not used)*2 (Always 0) —

10

Edit signal

11 NET signal

12 Y12 signal

13 Y13 signal

14 READY signal Reset cancel

15 — (not used) (Always 0) —

*1 Signals of the Bit2 to Bit7 can not be changed. Even if signals are changed using Pr.190 to Pr.195, settings are

invalid.

Refer to the inverter manual for details of Pr. 190 to Pr. 195.

*2 This setting is for the inverters with the PU/NET operation switchover (X65 signal) specification. (Refer to page 3)

*3 This setting is for the inverters with the PU operation interlock (X12 signal) specification. (Refer to page 5)

*3 Edit enabled

0: Command (run command/speed command) can not be given through

network

1: Command (run command/speed command) can be given through

network

Output current