Page 1

INVERTER

1

2

3

4

5

6

7

8

9

10

11

FR-F700PJ INSTRUCTION MANUAL (BASIC)

FR-F720PJ-0.4K to 15K (F)

FR-F740PJ-0.4K to 15K (F)

1

2

Thank you for choosing this Mitsubishi Electric Inverter.

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment.

Please forward this Instruction Manual (Basic) to the end user.

CONTENTS

OUTLINE ...................................................................................1

INSTALLATION AND WIRING ...................................................6

PRECAUTIONS FOR USE OF THE INVERTER.........................20

FAILSAFE OF THE SYSTEM WHICH USES THE INVERTER ...22

DRIVING THE IPM MOTOR......................................................23

DRIVING THE MOTOR.............................................................25

ENERGY SAVING OPERATION FOR FANS AND PUMPS ........33

PARAMETERS .........................................................................34

TROUBLESHOOTING ..............................................................39

PRECAUTIONS FOR MAINTENANCE AND INSPECTION ........43

SPECIFICATIONS ....................................................................45

700PJ

For the customers intending to use IPM motors ......... 23

This inverter is set for a general-purpose motor in the initial settings.

For use with an IPM motor, refer to page 23.

To obtain the Instruction Manual (Applied)

Contact where you purchased the inverter, your Mitsubishi Electric sales

representative, or the nearest Mitsubishi Electric FA Center for the following

manual:

Instruction Manual (Applied) [IB(NA)-0600426ENG]

This manual is required if you are going to utilize functions and performance.

The PDF manuals are also available for download at the Mitsubishi

Electric FA Global Website (URL: http://www.MitsubishiElectric.co.jp/fa/).

3

4

5

6

7

8

9

10

11

Page 2

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment.

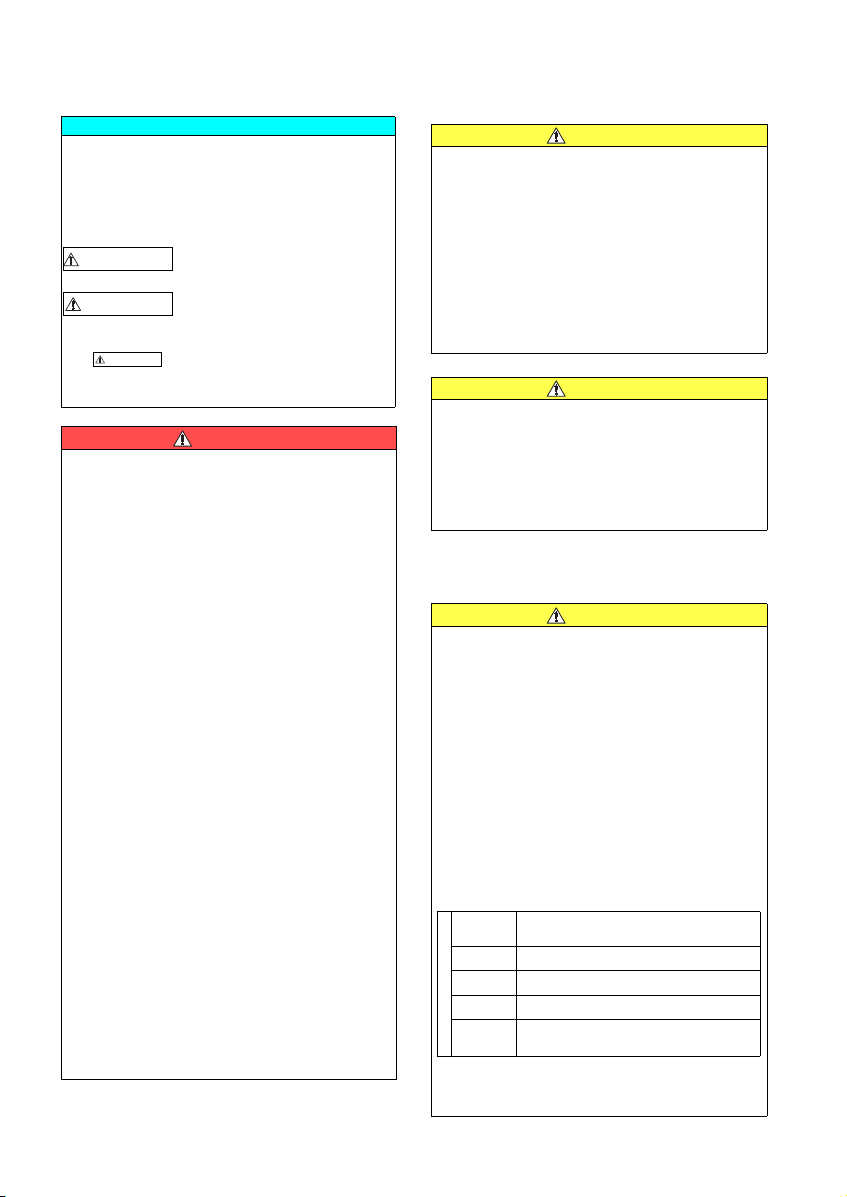

WARNING

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

Environment

Surrounding

air

temperature

-10°C to +50°C (non-freezing)

Ambient

humidity

90%RH or less (non-condensing)

Storage

temperature

-20°C to +65°C

Atmosphere

Indoors (free from corrosive gas, flammable gas,

oil mist, dust and dirt)

Altitude/

vibration

Maximum 1000m.

5.9m/s

2

or less at 10 to 55Hz

(directions of X, Y, Z axes)

Please forward this Instruction Manual (Basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, op erate, maintain or inspect the

inverter until you have read through the Instruction Manual

(Basic) and appended documents carefully and can use the

equipment correctly. Do not use this product until you have

a full knowledge of the equipment, safety information and

instructions.

In this Instruction Manual (Basic), the safety instruction

levels are classified into "WARNING" and "CAUTION".

The level may even lead to a serious

consequence according to conditions. Both instruction

levels must be followed because these are important to

personal safety.

Incorrect handling may cause

hazardous conditions, resulting in

death or severe injury.

Incorrect handling may cause

hazardous conditions, resulting in

medium or slight inju ry, or may cause

only material damage.

1. Electric Shock Prevention

While the inverter power is ON, do not remove t he front

cover or the wiring cover. Do not run the inverter with the

front cover or the wiring cover removed. Otherwise you

may access the exposed high voltage terminals or the

charging part of the circuitry and get an electric shock.

Even if power is OFF, do not remove the front cover

except for wiring or periodic inspection. You may

accidentally touch the charged inverter circuits and get an

electric shock.

Before wiring or inspection, power must be switched OFF.

To confirm that, LED indication of the operation panel

must be checked. (It must be OFF.) Any person who is

involved in wiring or insp ection shall wait for at le ast 10

minutes after the power supply has been switched OFF

and check that there are no residual voltage using a tester

or the like. The capacitor is charged with high voltage for

some time after power OFF, and it is dangerous.

This inverter must be earthed (grounded). Earthing

(grounding) must conform to the requirements of national

and local safety regulations and electrical code (NEC section

250, IEC 61140 class 1 and other appli cable standards). A

neutral-point earthed (grounded) power supply for 400V

class inverter in compliance with EN standard must be used.

Any person who is involved in wiring or inspection of this

equipment shall be fu lly competent to do the wo rk.

The inverter must be installed before wiring. Otherwise

you may get an electric shock or be injured.

Setting dial and key operations must be performed with

dry hands to prevent an electric shock. Otherwise you

may get an electric shock.

Do not subject the cables to scratches, excessive stress, heavy

loads or pinching. Otherwise you may get an electric shock.

Do not change the cooling fan while power i s ON. It is

dangerous to change the cooling fan while power is ON.

Do not touch the printed circuit board or handle the cables

with wet hands. Otherwise you may get an electric shock.

When measuring the main circuit capacitor capacity, the

DC voltage is applied to the motor for 1s at powering OFF.

Never touch the motor terminal, etc. right after powering

OFF to prevent an electric shock.

IPM motor is a synchronous motor with high-performance

magnets embedded in the rotor. Motor terminals hold high

voltage while the motor is running even after the inverter

power is turned OFF. Before wiring or inspection, the motor

must be confirmed to be stopped. When the motor is driven by

the load in applications such as fan and blower, a low-voltage

manual contactor must be connected at the inverter's output

side, and wiring and inspection must be performed while the

contactor is open. Otherwise you may get an electric shock.

A-1

2. Fire Prevention

Inverter (Filterpack) must be installed on a nonflammable

wall without holes (so that nobody touches the inverter

heatsink on the rear side, etc.). Mounting it to or near

flammable material can cause a fire.

If the inverter has become faulty, the inverter power must

be switched OFF. A continuous flow of large current could

cause a fire.

When using a brake resistor, a sequence that will turn OFF

power when a fault signal is output must be configured.

Otherwise the brake resistor may overheat due to damage

of the brake transistor and possibly cause a fire .

Do not connect a resistor directly to the DC terminals P/+

and N/-. Doing so could cause a fire.

Be sure to perform daily and periodic inspections as specified

in the Instruction Manual. If a produ ct is used without any

inspection, a burst, breakage, or a fire may occur.

3.Injury Prevention

The voltage applied to each terminal must be the ones

specified in the Instruction Manual. Otherwise burst,

damage, etc. may occur.

The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

Polarity must be correct. Otherwise burst, damage, etc.

may occur.

While power is ON or for some time after power-OFF, do not

touch the inverter (Filte rpack) since the inverte r (Filterpack)

will be extremely hot. Doi ng so can cause burns.

4. Additional Instructions

Also the following points must be noted to prevent an

accidental failure, injury, electric shock, etc.

(1) Transportation and Mounting

The product must be transported in correct method that

corresponds to the weight. Failure to do so may lead to

injuries.

Do not stack the boxes containing inverters higher than

the number recommended.

The product must be installed to the position where

withstands the weight of the product according to the

information in the Instruction Manual.

Do not install or operate the inverter (Filterpack) if i t is

damaged or has missing parts.

When carrying the inverter, do not hold it by the front

cover or setting dial; it may fall off or fail.

Do not stand or rest heavy objects on the product.

The inverter mounting orientation must be correct.

Foreign conductive objects must be prevented from

entering the inverter (Filterpack). That includes screws and

metal fragments or other flammable substance such as oil.

Because the inverter (Filterpack) is a precision

instrument, do not dr op or subject it to impact.

The inverter (Filterpack) must be used under the following

environment conditions: Otherwise the inverter

(Filterpack) may be damaged.

1 Temperature applicable for a short time, e.g. in transit.

2 When installing the Filterpack of 11K or 15K on the rear

panel of the inverter, do not install on moving objects or

places which vibrates (exceeding 1.96m/s

2

).

Page 3

If halogen-based materials (fluorine, chlorine, bromine,

CAUTION

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

iodine, etc.) infiltrate into a Mitsubishi Electric product,

the product will be damaged. Halogen-based materials are

often included in fumigant, w hich is used to steriliz e or

disinfest wooden packag es. When packaging, prev ent

residual fumigant components from being infiltrated into

Mitsubishi Electric products, or use an alternative

sterilization or disinfection method (heat disinfection,

etc.) for packaging. Sterilization of disinfection of wooden

package should also be performed before packaging the

product.

(2) Wiring

Do not install a power factor correction capacitor or surge

suppressor/capacitor type filter on the inverter output

side. These devices on the inverter output side may be

overheated or burn out.

The connection orientation of the output cables U, V, W to

the motor affects the rotation direction of the motor.

IPM motor terminals (U, V, W) hold high-voltage while the

IPM motor is running even after the power is turned OFF.

Before wiring, the IPM motor must be confirmed to be

stopped. Otherwise you may get an electric shock.

Never connect an IPM motor to the commercial power

supply. Applying the commercial power supply to input

terminals (U, V, W) of an IPM motor will burn the IPM

motor. The IPM motor must be connected with the output

terminals (U, V, W) of the inverter.

(3) Trial run

Before starting operation, each parameter must be

confirmed and adjusted. A failure to do so may cause

some machines to make unexpected motions.

(4) Usage

The IPM motor capacity must be same with the inverter

capacity. (The 0.75K inverter can be used with a one-rank

lower motor.)

Do not use multiple IPM motors with one inverter.

Any person must stay away from the equipment when the

retry function is set as it will restart suddenly after trip.

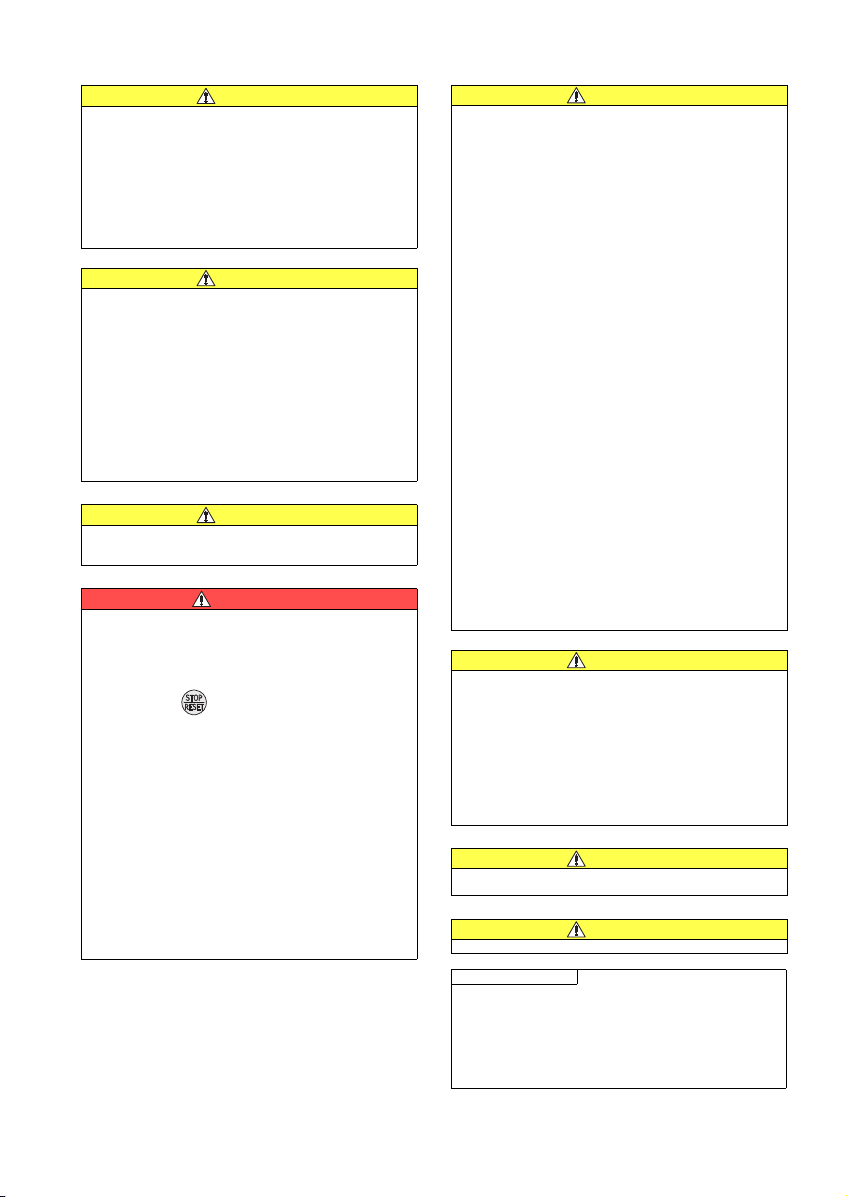

Since pressing key may not stop output depending

on the function setting status, separate circuit and switch

that make an emergency stop (power OFF, mechanical

brake operation for emergency stop, etc.) must be provided.

OFF status of the start signal must be confirmed before

resetting the inverter fault. Resetting inverter alarm with

the start signal ON restarts the motor suddenly.

Do not use an IPM motor in an application where a motor

is driven by its load and runs at a speed higher than the

maximum motor speed.

A dedicated IPM motor must be used under IPM motor

control. Do not use a synchronous motor, induction motor,

or synchronous induction motor under IPM motor control.

The inverter must be used for three-phase induction

motors or the dedicated IPM motor.

Connection of any other electrical equipment to the

inverter output may damage the equipment.

Do not modify the equipment.

Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the product.

The electronic thermal relay function does not guarantee

protection of the motor from overheating. It is

recommended to install both an external thermal and PTC

thermistor for overheat protection.

Do not use a magnetic contactor on the inverter input for

frequent starting/stopping of the inverter. Otherwise, the

life of the inverter decreases.

The effect of electromagnetic interference must be

reduced by using an EMC filter or by other means.

Otherwise nearby electronic equipment may be affected.

Appropriate measures must be taken to suppress

harmonics. Otherwise power supply harmonics from the

inverter may heat/damag e the power factor correction

capacitor and generator.

When driving a 400V class motor by the inverter, the

motor must be an insulation-enhanced motor or measures

must be taken to suppress surge voltage. Surge voltage

attributable to the wiring constants may occur at the

motor terminals, deteriorating the insulation of the motor.

When parameter clear or all parameter clear is performed,

the required parameters must be set again before starting

operations because all parameters return to the initial value.

The inverter can be easily set for high-speed operation.

Before changing its setting, the performances of the

motor and machine must be fully examined.

Stop status cannot be hold by the inverter's brake

function. In addition to the inverter's brake function, a

holding device must be installed to ensure safety.

Before running an inverter which had been stored for a

long period, inspection and test operation must be

performed.

Static electricity in your body must be discharged before

you touch the product. Otherwise the product may be

damaged.

Do not connect an IPM motor under the general-purpose

motor control settings (initial settings). Do not use a

general-purpose motor under the IPM motor control

setting. Doing so will cause a failure.

In the system with an IPM motor, the inverter power m ust

be turned ON before closing the contacts of the contactor

at the output side.

(5) Emergency stop

A safety backup such as an emergency brake must be

provided for devices or equipment in a system to prevent

hazardous conditions in case of failure of the inverter or

an external device controlling the inverter.

When the breaker on the inverter input side trips, the

wiring must be checked for fault (short circuit), and

internal parts of the inverter for a damage, etc. The cause

of the trip must be identified and removed before turning

ON the power of the breaker.

When any protective function is activated, appropriate

corrective action must be taken, and the inverter must be

reset before resuming operation.

(6) Maintenance, inspection and parts replacement

Do not carry out a megger (insulation resistance) test on

the control circuit of the inverter. It will cause a failure.

(7) Disposal

The inverter must be treated as industrial waste.

General instruction

Many of the diagrams and drawings in this Instruction

Manual (Basic) show the inverter without a cover or partially

open for explanation. Never operate the inverter in this

manner. The cover must be always reinstalled and the

instruction in this Instru ction Manual (Basic) m ust be

followed when operating the inverter.

For more details on a dedicated IPM motor, refer to the

Instruction Manual of the dedicated IPM motor.

A-2

Page 4

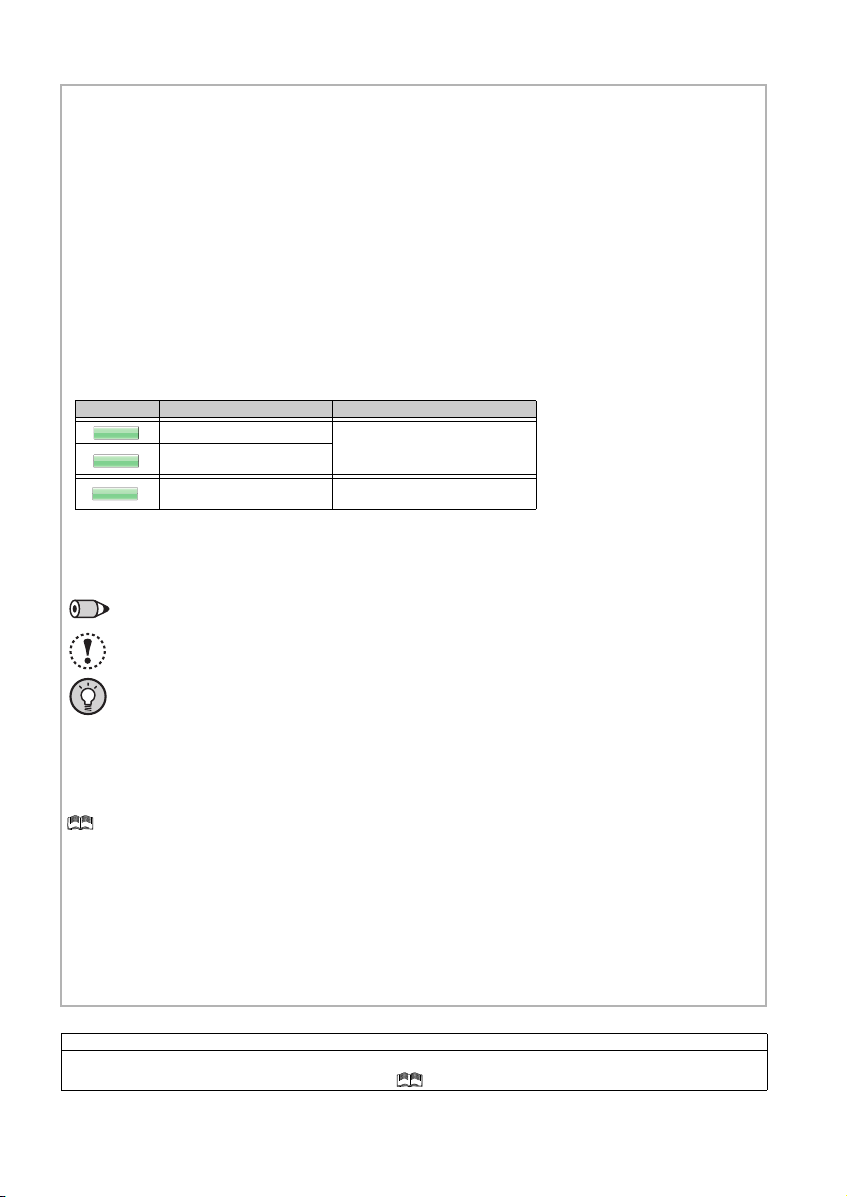

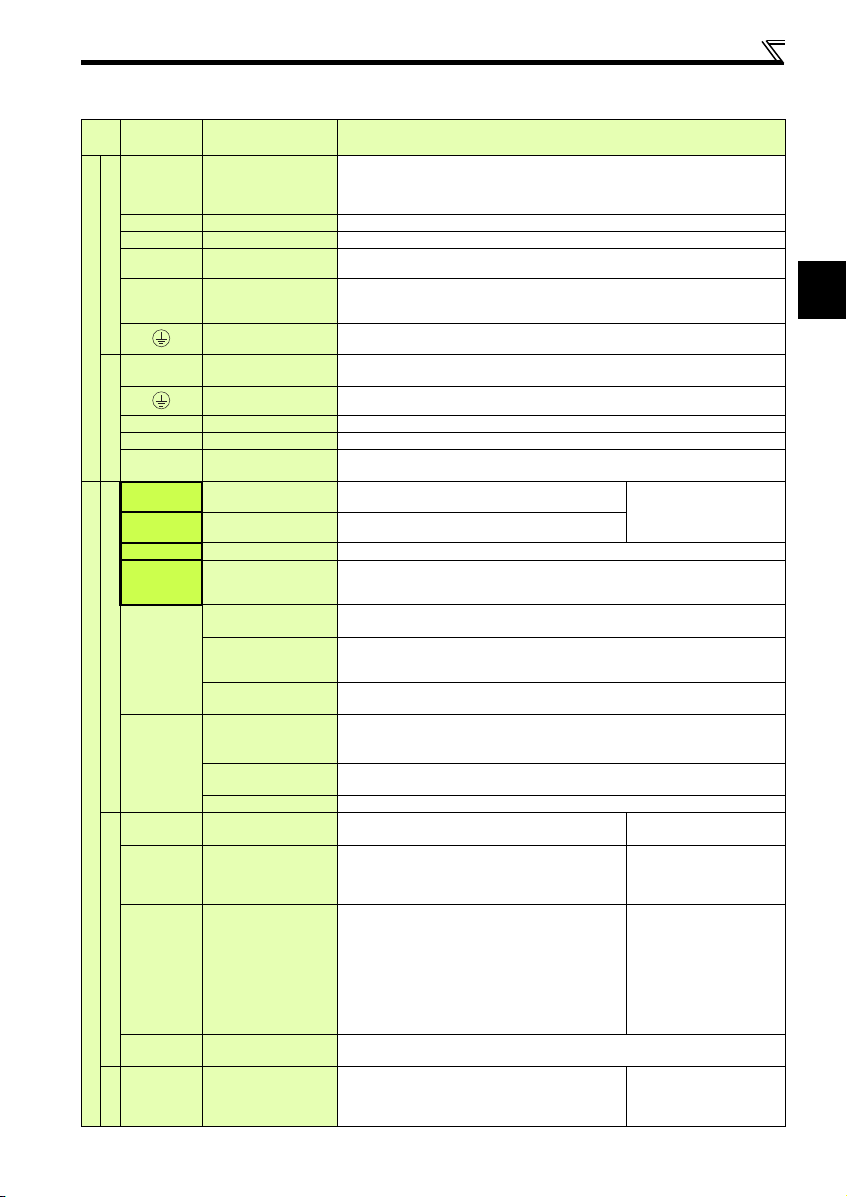

<Abbreviation>

Mark Control method Applied motor (control)

V/F control

Three-phase induction motor

(general-purpose motor control)

General-purpose magnetic

flux vector control

IPM motor control

Dedicated IPM motor

(IPM motor control)

V/FV/FV/F

GP

MFVCGP MFVCGP MFVC

IPMIPMIPM

• PU: Operation panel and parameter unit (FR-PU04

/FR-PU07)

• Inverter: Mitsubishi Electric inverter FR-F700PJ series

F700PJ: Mitsubishi Electric inverter FR-F700PJ series

•FR-

• Pr.: Parameter number (Number assigned to function)

• PU operation: Operation using the PU (operation panel/FR-PU04/FR-PU07)

• External operation: Operation using the control circuit signals

• Combined operation: Operation using both the PU (operation panel/FR-PU04/FR-PU07) and External operation

• General-purpose motor: Three-phase induction motor

• Standard motor: SF-JR

• Constant-torque motor: SF-HRCA

• Filterpack: FR-BFP2

• IPM motor: Dedicated IPM motor MM-EF(1800r/min specification)

The following marks are used to indicate the controls as below.

(Parameters without any mark are valid for all controls.)

<Trademark>

Company and product names herein are the trademarks and registered trademarks of their respective owners.

<Mark>

REMARKS:

Additional helpful contents and relations with other functions are stated.

NOTE: Contents requiring caution or cases when set functions are not activated are stated.

POINT: Useful contents and points are stated.

<Notes on descriptions in this Instruction Manual>

• Connection diagrams in this Instruction Manual appear with the control logic of the input terminals as sink logic, unless

otherwise specified. (For the control logic, refer to page 1.)

<Related document>

Refer to the Instruction Manual (Applied) for further information on the following points.

• Removal and reinstallation of the cover

• Connection of stand-alone option unit

• EMC and leakage currents

• Detailed explanation on parameters

• Troubleshooting

• Check first when you have a trouble

• Inspection items (life diagnosis, cooling fan replacement)

• Measurement of main circuit voltages, currents and powers

• For customers who are replacing the conventional model with this inverter

Harmonic suppression guideline (when inverters are used in Japan)

All models of general-purpose inverters used by specific consumers are covered by "Harmonic suppression guideline for consumers who

receive high voltage or special high voltage". (For further details, refer to Chapter 3 of the Instruction Manual (Applied).)

A-3

Page 5

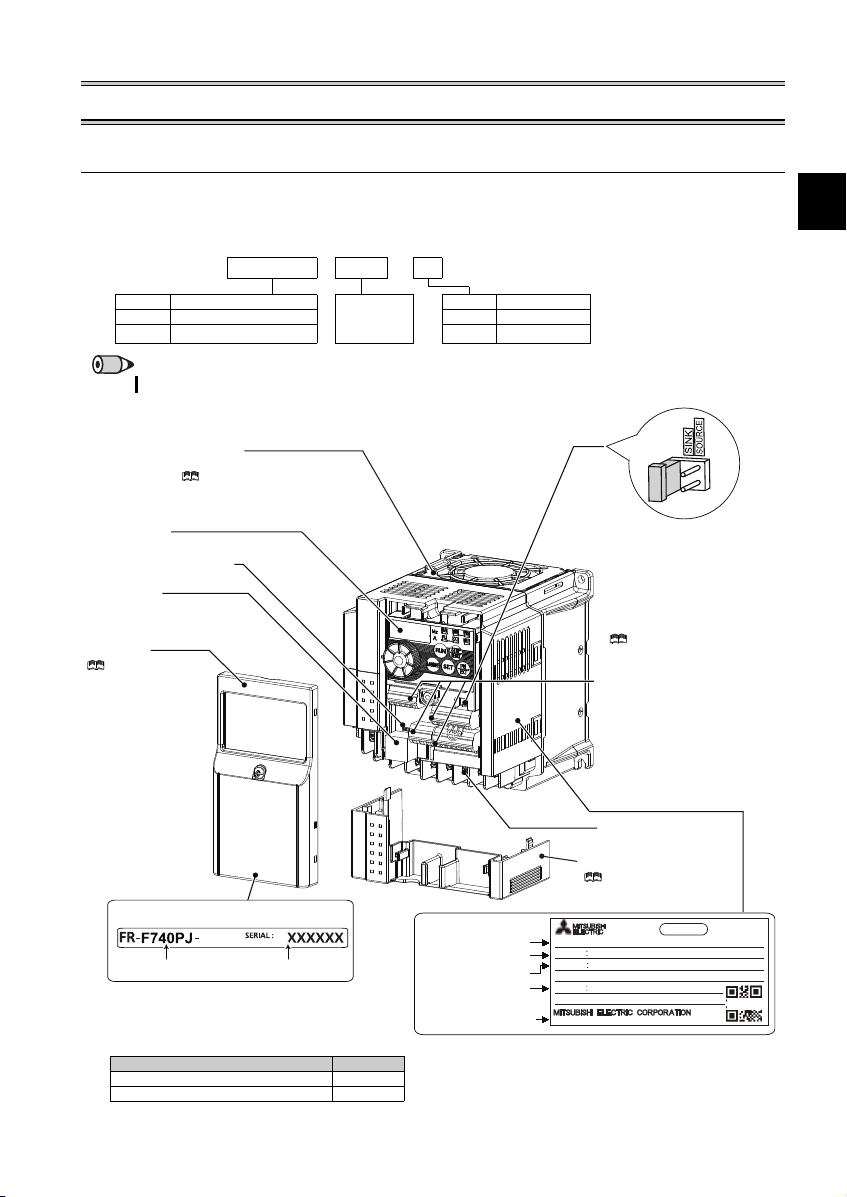

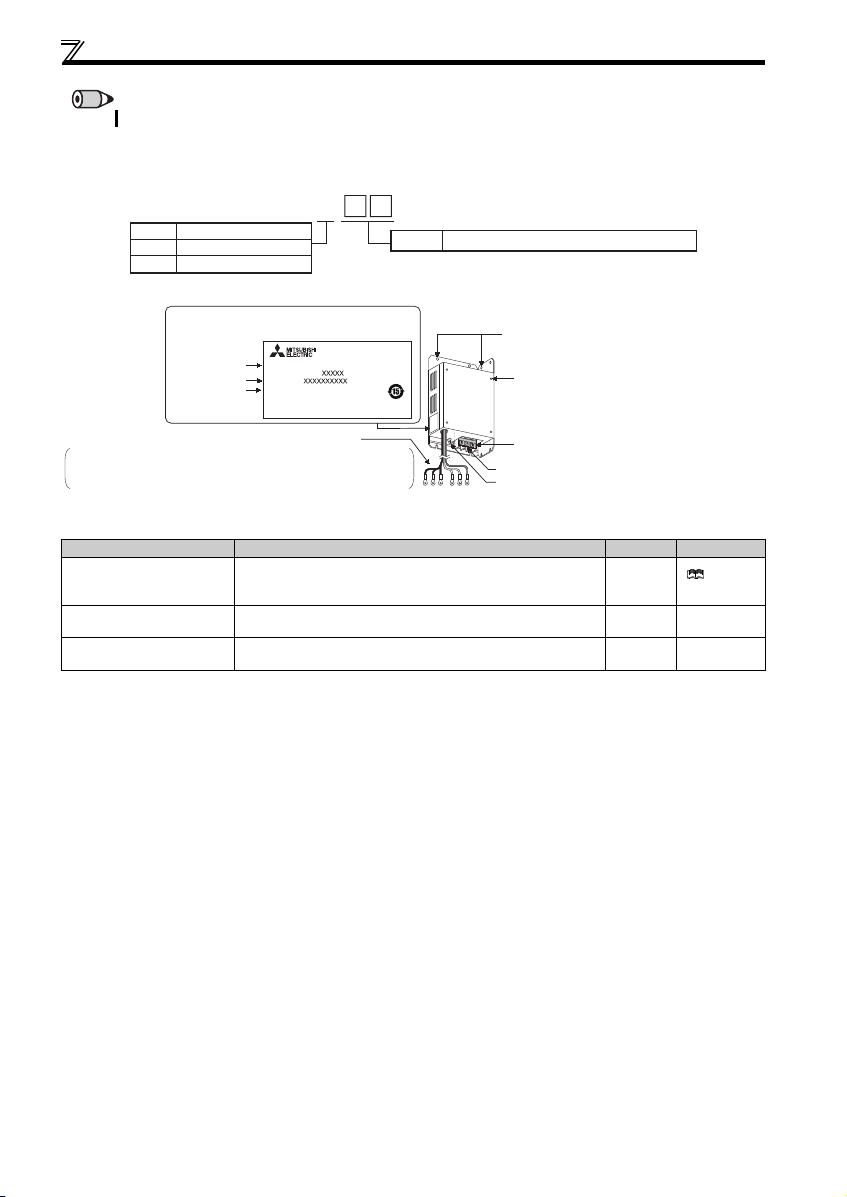

Product checking and parts identification

1

Capacity plate

Inverter model

Serial number

1.5K

Rating plate

Inverter model

Input rating

Output rating

Serial number

ᴾ

FR-F740PJ-1.5K

INPUT XXXXX

OUTPUT XXXXX

SERIAL

MADE IN JAPAN

PASS ED

INVERTER

MODEL

SAMPLE

Country of origin

Control circuit terminal block

(Refer to page 11.)

Control logic switchover jumper

connector

The jumper connector is in the sink

logic (SINK) when shipped from the

factory. Move the jumper connector

to change to the source logic

(SOURCE). Always fit the jumper

connector to the either position.

( Refer to the Instru ction Manual

(Applied).)

Combed shaped wiring cover

Refer to the Instructi on

Manual (Applied) for installation/

removal.

Main circuit terminal block

(Refer to page 11.)

Front cover

Refer to the

Instruction Manual

(Applied) for installation/

removal.

PU connector

(Refer to page 10.)

Voltage/current input switch

(Refer to page 10.)

Operation panel

(Refer to page 3.)

Cooling fan

The cooling fan is removable.

Refer to the Instruction Manual

(Applied) for installation/ removal.

Accessory

· Fan cover fixing screws (M3 35mm)

These screws are necessary for compliance

with the EU Directive.

(

Refer to page 51

.)

Capacity Quantity

1.5K to 3.7K 1

5.5K to 15K 2

1OUTLINE

1.1 Product checking and parts identification

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to ensure that

the product agrees with your order and the inverter is intact.

(1) Inverter

Inverter model

Symbol Voltage class Represents

F720PJ Three-phase 200V class None Without

F740PJ Three-phase 400V class F With

FR- F740PJ - 1.5 K

Symbol Filterpack

the inverter

capacity [kW]

REMARKS

Filterpack (FR-BFP2) is enclosed for the inverter with Filterpack ("F" at the end of its model names marked on the packaging box.)

1

Page 6

Product checking and parts identification

FR-BFP2- H K

0.4 to 15

Represents the applicable inverter capacity (kW)

Symbol

Applicable power voltage

None

200V class

400V class

H

Installation hole

Inverter rear panel

installation screw hole

Terminal block for commercial power supply connection

Black cable: connect to terminal R, S and T of the inverter

Red cable: connect to terminal P and P1 of the inverter

Green and yellow striped cable: connect to the earth (ground) terminal

Crimp terminals for the inverter connection

Rating plate

Terminal block cover

Filterpack model

Rating

SERIAL number

MODEL

FR-BFP2-H0.4K

BKORATED

SERIAL

MITSUBISHI ELECTRIC CORPORATION

Earth (Ground) terminal

MADE IN JAPAN

REMARKS

For how to find the SERIAL num ber, refer to page 55.

(2) Filterpack

Filterpack model

Parts name and plate

Enclosed items

Name Description Quantity Refer to page

Screw for leakage current

countermeasure and spacer

Rear panel installation

L-bracket

Screw for inverter rear panel

installation

The screw size differs according to capacities. ((H)7.5K or lower: M4×14, (H)11K and (H)15K: M5×20)

When the earth leakage breaker or earth leakage relay operates

unnecessarily due to leakage current, use this screw as a

countermeasure.

Enclosed for the 5.5K or higher 1 9

Use these screws for installation of Filterpack onto the inverter rear

panel.

1 for each

4 9

Instruction

Manual (Applied)

2

Page 7

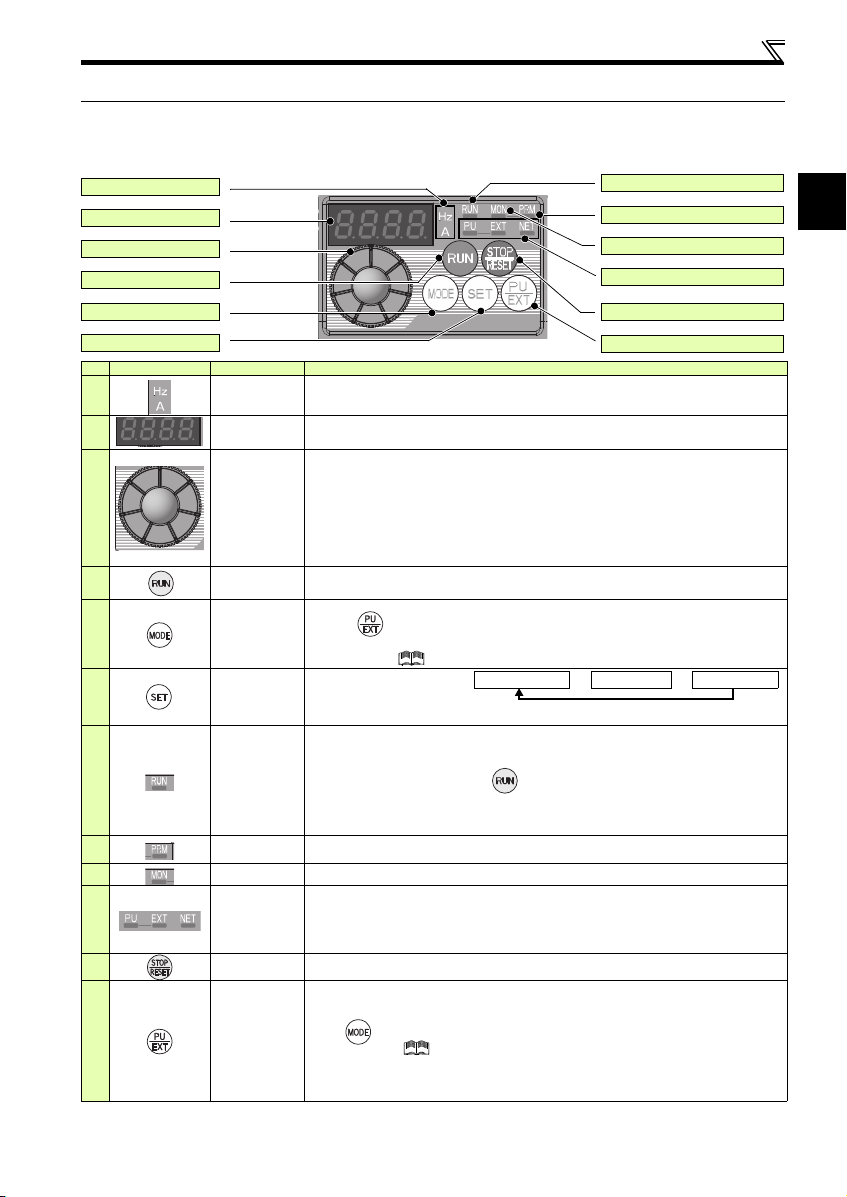

1

1.2 Operation panel

(a) Unit indicator

(b) Monitor (4-digit LED)

(c) Setting dial

(d) Start command

(e) MODE key

(f) SET key

(g) Operation status indicator

(h)

Parameter setting mode indicator

(i) Monitor indicator

(j) Operation mode indicat or

(k) STOP/RESET key

(l) PU/EXT key

Output frequencyOutput currentOutput voltage

*

Energy saving monitor is displayed when the

energy saving monitor is set with Pr. 52.

1.2.1 Names and functions of the operation panel

The operation panel cannot be removed from the inverter.

Operation panel

No. Component Name Description

(a)

(b)

(c)

(d)

(e)

(f)

(g)

Unit indicator

Monitor (4-digit

LED)

Setting dial

Start command Select the rotation direction in Pr. 40.

MODE key

SET key

Operation status

indicator

(h)

(i)

(j)

(k)

(l)

Parameter setting

mode indicator

Monitor indicator Lit to indicate the monitor mode .

Operation mode

indicator

STOP/RESET

key

PU/EXT key

Hz: Lit to indicate frequency. (Blinks when the set frequency monitor is displayed.)

A: Lit to indicate current.

(Both "Hz" and "A" turns OFF to indicate a value other than frequency or current.)

Shows the frequency, parameter number, etc.

(To monitor the output power, the set frequency and other items, set Pr. 52.)

The dial of the Mitsubishi Electric inverters. The setting dial is used to change the frequency

and parameter settings.

Press the setting dial to perform the following operations:

To display a control method (general-purpose motor control or IPM motor control) during th e

monitor mode

To display the set frequency when pressed for 1s or longer under PU operation mode or External/

PU combined operation mode (Pr. 79 = "3")

To display the present setting during calibration

To display a fault history number in the fault history mode

Used to switch among different setting modes.

Pressing simultaneously changes the operation mode.

Holding this key for 2 seconds locks the operation. The key lock is invalid when Pr. 161 = "0

(initial setting)." ( Refer to the Instruction Manual (Applied) .)

Used to enter a setting.

If pressed during the operation,

monitored item changes as the

following:

Lit or blinks during inverter operation.

* Lit: When the forward rotation o peration is being performed .

Slow blinking (1.4s cycle): When the reverse rotation operation is being performed.

Fast blinking (0.2s cycle): When has been pressed or the start command has been

When the frequency command is less than the starting fr equency.

When the MRS signal is being input.

Lit to indicate the parameter set ting mode.

PU: Lit to indicate the PU operation mode.

EXT: Lit to indicate the External operation mode. (EXT is lit at power-ON in the initial setting.)

NET: Lit to indicate the Network operation mode.

PU and EXT: Lit to indicate EXT/PU combined operation mode 1 and 2

All of these indicators are OFF when the command source is not a t the operation panel.

Used to stop operation commands.

Used to reset a fault when the protective function (fault) is activated.

Used to switch between the PU and External operation modes.

To use the External operation mode (operation using a separately connected frequency setting

potentiometer and start signal), press this key to light up the EXT indicator.

(Press simultaneously (0.5s), or change the Pr.79 setting to change to the combined

operation mode. ( Refer to the Instru ction Manual (Applied).)

PU: PU operation mode

EXT: External operation mode

Used to cancel the PU stop also.

*

given, but the operation cannot be made.

3

Page 8

Operation panel

Hz

A

While a fault is displayed:

The display shifts as follows by pressing : Output frequency at the fault

Output current Output voltage Energization time.

(After Energization time, it goes back to a fault display.)

Pressing the setting dial shows the fault history number.

STOP

Operation mode switchover

Parameter settingFault history Monitor/frequency setting

At power-ON (External operation mode)

PU operation mode

(output frequency monitor)

Parameter setting mode

PU Jog operation mode

Output current monitor

General-purpose

motor control

Set frequency

is displayed

Output voltage monitor

Display the

present setting

Value change

Keep pressing

the setting dial

Parameter write is completed.

Parameter and a setting value

appear alternately.

Parameter clear

Automatic

parameter setting

IPM parameter

initialization

All parameter

clear

Fault history clear

Initial value

change list

(Example)

(Example)

(After 1s)

Frequency setting has been

written and completed.

and frequency appear alternately.

[Operation for displaying fault history]

The past eight faults can be displayed using the setting dial.

(The latest fault is ended by ".".)

When no fault history exists, is displayed.

Value change

( Refer to Chapter 4 of the Instruct ion Manual (Applied).)

(Refer to page 5.)

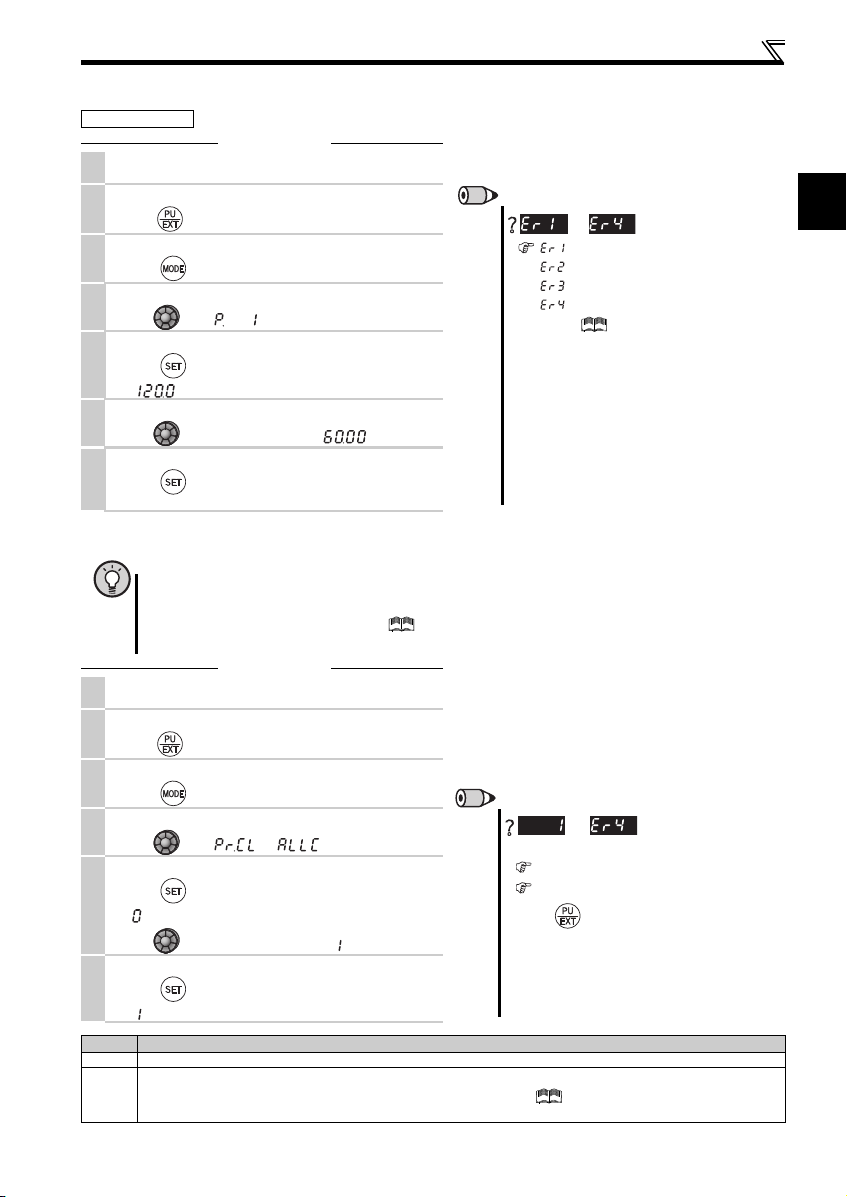

1.2.2 Basic operation (factory setting)

4

Page 9

1

1.2.3 Changing the parameter setting value

REMARKS

is displayed...Why?

appears .... Write disable error

appears .... Write error during operation

appears .... Calibration error

appears ....Mode designation error

For details, refer to the Instruction Manual

(Applied).

The number of digits displayed on the operation

panel is four. Only the upper four digits of values can

be displayed and set. If the values to be displayed

have five digits or more including decimal places, the

fifth or later numerals cannot be displayed nor set.

(Example) For Pr. 1

When 60Hz is set, 60.00 is displayed.

When 120Hz is set, 120.0 is displayed and second

decimal place is not displayed nor set.

REMARKS

are displayed alternately ...

Why?

The inverter is not in the PU operation mode.

PU connector or USB connector is used.

1. Press . [PU] is lit and the monitor (4-digit LED)

displays "1". (When Pr. 79 = "0" (initial value))

2. Carry out operation from step 5 again.

Stop the inverter. Parameter clear is unavailable

when the inverter is running, and w ill cause the write

disable error.

Operation example C hange the Pr. 1 Maximum frequency setting.

Screen at power-ON

1.

The monitor display appears.

Operation mode change

2.

Press to choose the PU operation mode. PU indicator is lit.

Parameter setting mode

3.

Press to choose the parameter setting m ode.

Selecting the parameter number

4.

Turn until " " (Pr. 1) appears.

Reading the setting value

5.

Press to read the present set value.

" "(120.0Hz (initial value)) appears.

Changing the setting value

6.

Turn to change the set value to " " (60.00Hz).

Setting the parameter

7.

Press to set.

The parameter number and the setting value blink alternately.

1.2.4 Parameter clear/all parameter clear

POINT

Set "1" in Pr.CL Parameter clear or ALLC all parameter clear to initialize parameters. (Parameters are not cleared

when "1" is set in Pr. 77 Parameter write selection.)

Refer to the extended parameter list of the Instruction Manual (Applied) for parameters cleared with this

operation.

Screen at power-ON

1.

The monitor display appears.

Operation mode change

2.

Press to choose the PU operation mode. PU indicator is lit.

Parameter setting mode

3.

Press to choose the parameter setting m ode.

Selecting Parameter Clear (All Parameter Clear)

4.

Turn until " " (" ") appears

Selecting the setting value

Press to read the present set value.

5.

" "(initial value) appears.

Turn to change it to the set value " ".

Press to set.

6.

Press to set.

" " and Pr. CL (ALLC) indications blink alte rnately.

Setting Description

0 Clear is not executed.

1

Sets parameters back to the initial values. (Parameter clear sets back all parameters except calibration parameters, terminal

function selection parameters to the initial values.) Refer to the parameter list of the Instruction Manual (Applied) for

availability of parameter clear and all para meter clear.

Operation panel

Operation

to

Operation

and

5

Page 10

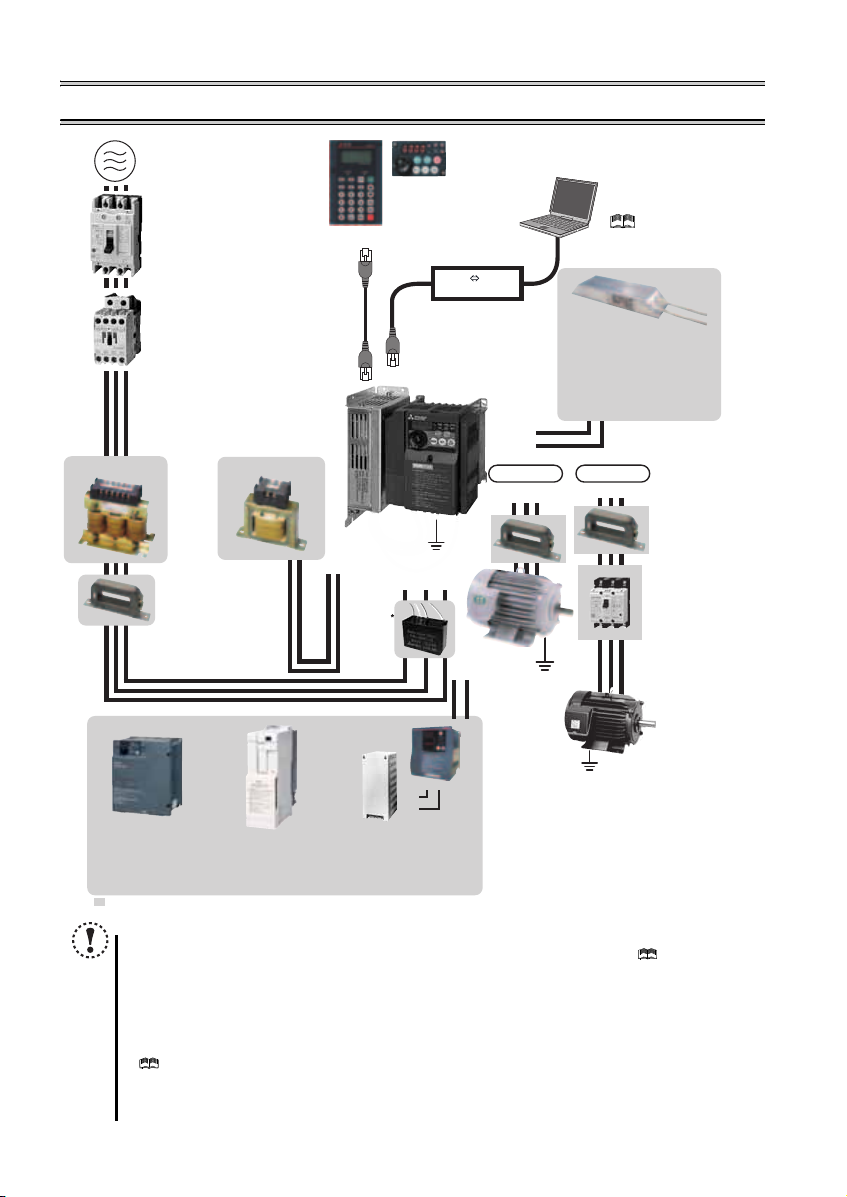

2 INSTALLATION AND WIRING

AC power supply

Use within the permissible power supply

specifications of the inverter. To ensure

safety, use a molded case circuit breaker,

earth leakage circuit breaker or magnetic

contactor to switch power ON/OFF.

Magnetic contactor (MC)

Install the magnetic contactor to ensure

safety. Do not use this magnetic contactor

to start and stop the inverter. Doing so will

cause the inverter life to be shortened.

Noise filter

(ferrite core)

(FR-BSF01,

FR-BLF)

Install a noise filter

(ferrite core) to reduce

the electromagnetic

noise generated from

the inverter.Effective

in the range from

about 0.5MHz to 5MHz.

A wire should be

wound four turns at a

maximum.

Devices connected

to the output

Do not install a power

factor correction capacitor,

surge suppressor or capacitor type filter on the output

side of the inverter. When installing a molded case

circuit breaker on the output side of the inverter,

contact each manufacturer for selection of the

molded case circuit breaker.

The regenerative braking capability

of the inverter can be exhibited fully.

Power supply harmonics

can be greatly suppressed.

High power factor

converter (FR-HC2)

Power regeneration

common converter

(FR-CV)

R/L1 S/L2T/L3

P1

P/+

P/+

N/-

P/+

PR

Great braking capability

is obtained.

Reactor (FR-HAL, FR-HEL option)

Reactors (option) must be used when

power harmonics measures are taken,

the power factor is to be improved or the

inverter is installed near a large power

supply system (500kVA or more). The

inverter may be damaged if you do not

use reactors. Select the reactor according

to the model. Remove the jumpers across

terminals P/+ and P1 to connect the DC reactor.

Noise filter (ferrite core) *

(FR-BSF01, FR-BLF)

Molded case circuit breaker (MCCB),

earth leakage circuit breaker (ELB),

or fuse

The breaker must be selected carefully

since an in-rush current flows in the

inverter at power on.

Install a noise filter (ferrite core)

to reduce the electromagnetic

noise generated from the

inverter. Effective in the range

from about 1MHz to 10MHz.

When more wires are passed

through, a more effective result

can be obtained. A wire should

be wound four turns or more.

* Not necessary if Filterpack (FR-BFP2) is used.

Earth (Ground)

To prevent an electric shock, always earth (ground)

the motor and inverter. For reduction of induction noise

from the power line of the inverter, it is recommended

to wire the earth (ground) cable by returning it to the

earth (ground) terminal of the inverter.

AC reactor (FR-HAL)

DC reactor (FR-HEL) *

Parameter unit

(FR-PU07)

Enclosure surface operation

panel (FR-PA07)

By connecting the connection cable

(FR-CB2) to the PU connector,

operation can be performed from

FR-PU07, FR-PA07.

Noise filter

(capacitor)

(FR-BIF)

P/+

P/+

PR

PR

Brake unit

(FR-BU2)

Reduces the

radio noise.

Resistor unit (FR-BR)

Discharging resistor (GZG, GRZG)

UVW

VUW

IM connection

IPM connection

Contactor

Example) No-fuse

switch (DSN type)

Install a contactor in

an application where

the IPM motor is

driven by the load

even at power-OFF

of the inverter. Do

not open or close

the contactor while

the inverter is

running (outputting).

Dedicated IPM

motor (MM-EFS,

MM-EF)

Use the

specified motor.

An IPM motor

cannot be driven

by the

commercial

power supply.

Earth

(Ground)

Generalpurpose

motor

Earth (Ground)

Inverter

FR-F700PJ

: Install this as required.

Earth

(Ground)

RS-232C - RS-485 converter is

required when connecting to PC

with RS-232C interface.

RS-485 RS-232C

Converter

(Refer to page 45.)

(Refer to page 7.)

(Refer to page 7.)

( Refer to the

Instruction Manual

(Applied).)

Brake resistor (FR-ABR,

MRS type, MYS type)

Braking capability can be improve d.

Always install a thermal relay when

using a brake resistor whose

capacity is 11K or higher.

(Refer to the Instruction Manual

(Applied).)

6

NOTE

The life of the inverter is influenced by surrounding ai r temperature. Use the product within the permissible surro unding

air temperature. This mu st be noted especiall y when the inverter is in stalled in an enclosure.

the Instruction Manual (Applied) .)

Wrong wiring might lead to damage of the inverter. The control signal lines must be kept fully away from the main

circuit to protect them from noise. (Refer to page 10.)

Do not install a power factor correction capacitor, surge suppressor or capacitor type filter on the inverter output

side. This will cause the inver ter to trip or the capacitor and surge s uppressor to be damaged. If an y of the above

devices are connected, immediately remove them.

Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the

communication devices (such as AM radios) used near the inverter. In this case, install the FR-BIF optional EMC filter

(capacitor) (for use in the input side only) or FR-BSF01 or FR-BLF EMC filter (ferrite core) to minimize interference.

( Refer to Chapter 3 of the Instruction Manual (Applied).)

Refer to the Instruction Manual of each option and peripheral devices for details of peripheral devices.

An IPM motor cannot be driven by the commercial power supply.

An IPM motor is a motor with permanent magnets embedded inside. High voltage is generated at the motor terminals

while the motor is running. Before closing the contactor at the output side, make sure that the inverter power is ON

and the motor is stopped.

(

Refer to Chapter 3 of

Page 11

Peripheral devices

2

Front cover

Front cover

Front cover

Wiring cover Wiring cover

FR-F720PJ-0.4K, 0.75K FR-F720PJ-1.5K to 3.7K

FR-F740PJ-0.4K to 3.7K

FR-F720PJ-5.5K or higher

FR-F740PJ-5.5K or higher

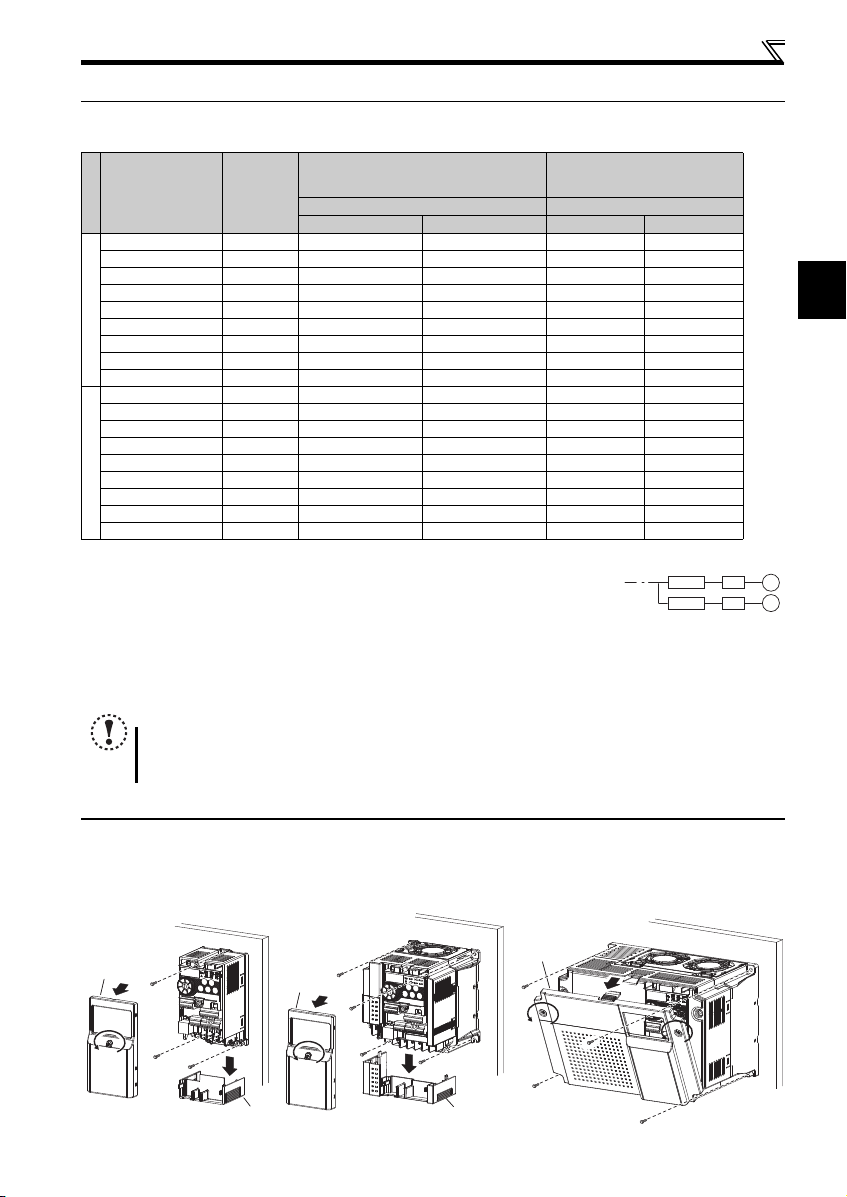

2.1 Peripheral devices

Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices.

Motor

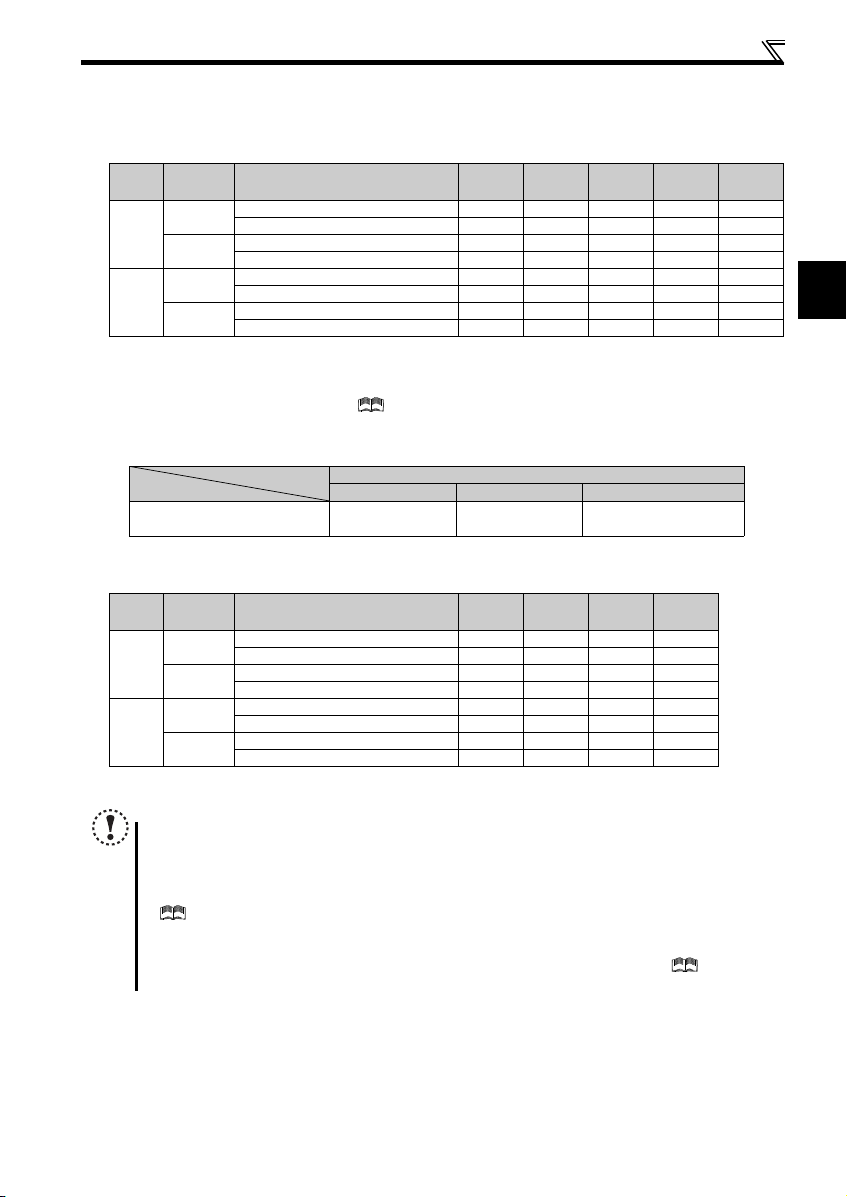

Inverter Model

Vol tag e

FR-F720PJ-0.4K 0.4 5A 5A S-T10 S-T10

FR-F720PJ-0.75K 0.75 10A 5A S-T10 S-T10

FR-F720PJ-1.5K 1.5 15A 10A S-T10 S-T10

FR-F720PJ-2.2K 2.2 20A 15A S-T10 S-T10

FR-F720PJ-3.7K 3.7 30A 30A S-T21 S-T10

FR-F720PJ-5.5K 5.5 50A 40A S-T35 S-T21

200V class

FR-F720PJ-7.5K 7.5 60A 50A S-T35 S-T35

FR-F720PJ-11K 11 75A 75A S-T35 S-T35

FR-F720PJ-15K 15 125A 100A S-T50 S-T50

FR-F740PJ-0.4K 0.4 5A 5A S-T10 S-T10

FR-F740PJ-0.75K 0.75 5A 5A S-T10 S-T10

FR-F740PJ-1.5K 1.5 10A 10A S-T10 S-T10

FR-F740PJ-2.2K 2.2 15A 10A S-T10 S-T10

FR-F740PJ-3.7K 3.7 20A 15A S-T10 S-T10

FR-F740PJ-5.5K 5.5 30A 20A S-T21 S-T12

400V class

FR-F740PJ-7.5K 7.5 30A 30A S-T21 S-T21

FR-F740PJ-11K 11 50A 40A S-T21 S-T21

FR-F740PJ-15K 15 60A 50A S-T35 S-T21

Assumes the power supply voltage is for a dedicated IPM motor or of a Mitsubishi Electric 50Hz 4-pole standard motor.

Select an MCCB according to the power supply capacity.

Install one MCCB per inverter.

For the use in the United States or Canada, refer to page 54, and select an appropriate fuse or molded case circuit

breaker (MCCB).

Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic contactor is

used for emergency stop during motor driving, the electrical durability is 25 times.

If using an MC for emergency stop during motor driving, select an MC regarding the inverter input side current as JEM1038-AC-3 class rated current. When

using an MC on the inverter output side for commercial-power supply operation switching using a general-purpose motor, select an MC regarding the motor

rated current as JEM1038-AC-3 class rated current.

Output

(kW)

NOTE

When the inverter capacity is larger than the motor capacity, select an MCCB and a magnetic contactor according to the inverter model,

and cable and reactor according to the motor output.

When the breaker on the inverter input side trips, check for the wiring fault (short circuit), damage to internal parts of the inverter, etc.

Identify the cause of the trip, then remove the cause and power ON the breaker.

2.2 Installation of the inverters and precautions

Molded Case Circuit Breaker (MCCB)

or Earth Leakage Circuit Breaker (ELB)

(NF or NV type)

Reactor or Filterpack Connection Reactor or Filterpack Connection

Without With Without With

Magnetic Contactor (MC)

MCCB INV

MCCB INV

M

M

2.2.1 Installation of the inverter (without Filterpack)

Enclosure surface mounting

Remove the front cover and wiring cover to mount the inverter to the surface. (Remove the covers in the directions of the arrows.)

7

Page 12

Installation of the inverters and precautions

10cm or more

10cm or more

Measurement

position

Measurement

position

5cm

5cm

5cm

-10 C to +50 C

(non-freezing)

1cm or

more

∗1, ∗2

1cm or

more

∗1, ∗2

1cm or

more

∗1

FR-F720PJ-1.5K to 3.7KFR-F720PJ-0.4K to 0.75K

FR-F740PJ-0.4K to 3.7K

Screw for inverter rear

panel installation

Screw for inverter rear

panel installation

Front cover

Front cover

Wiring cover

Wiring cover

Screw for inverter rear

panel installation

Screw for inverter rear

panel installation

L-bracket installation screw

Screw for inverter

rear panel installation

Rear panel installation L-bracket

Screw for inverter rear panel installation

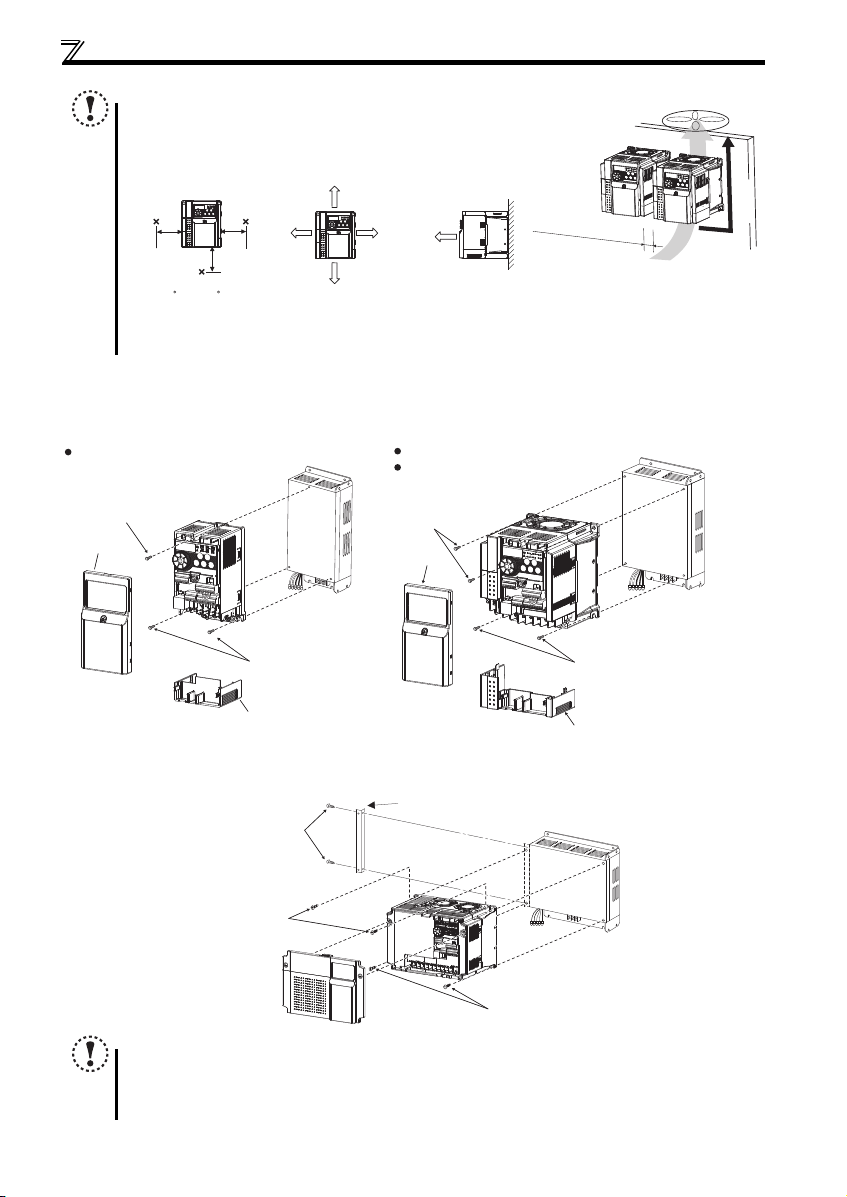

NOTE

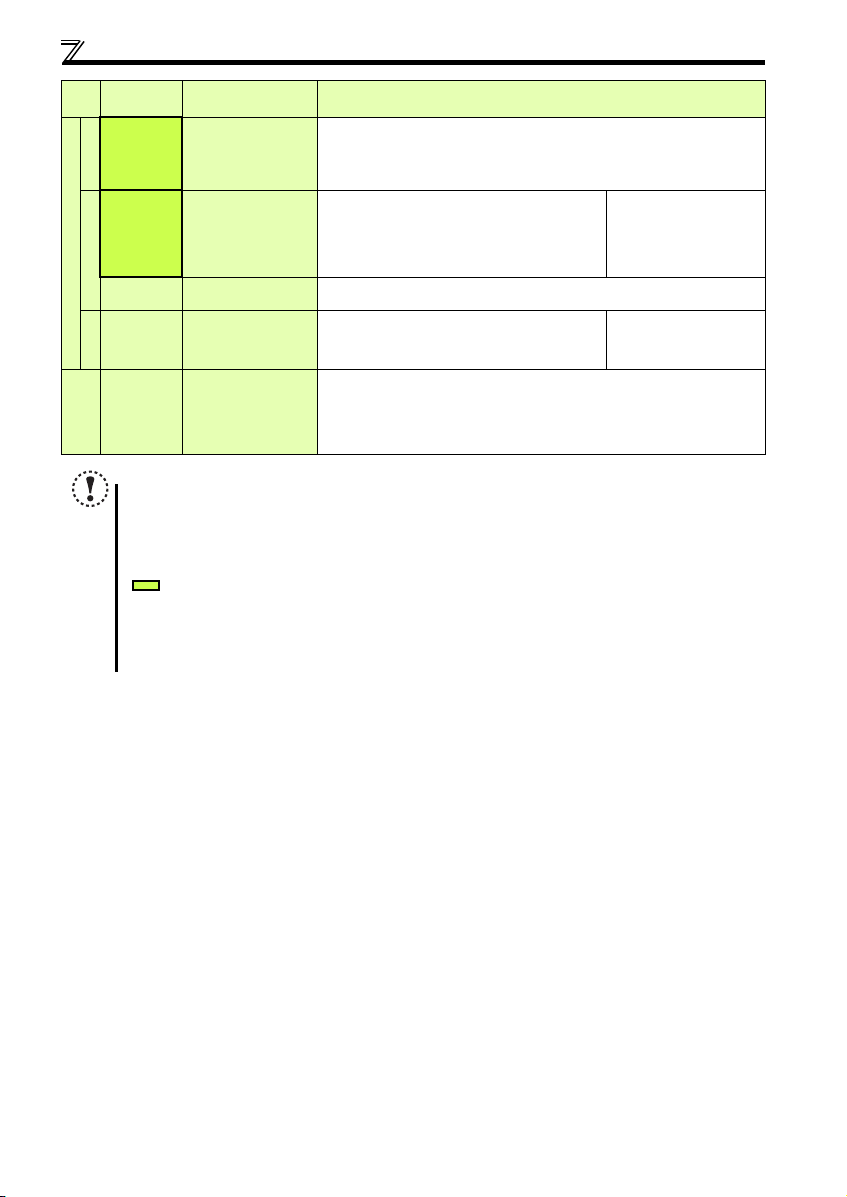

When encasing multiple inverters, install them in parallel as a cool ing

measure.

Install the inverter vertically.

For heat dissipation and maintenance, allow minimum clearance shown

in the figures below from the inverter to the other devices and to the

inner surface of the enclosure.

Allow 5cm or more clearance for 5.5K or higher.

When using the inverters at the surrounding air temperature of 40C or less, the inverters can be installed without any clearance between

them (0cm clearance).

2.2.2 Installation of the inverter and Filterpack (for rear panel installation)

<0.4K to 3.7K>

Remove the front cover and wiring cover to attach the inverter.

Vertical

<5.5K to 15K>

Remove the L-bracket installation screws from Filterpack (two for the 7.5K or lower, three for the 11K or higher), and attach

the included L-bracket to Filterpack with these screws. Remove the front cover to attach the inverter.

8

NOTE

When encasing multiple inverters, install them in parallel as a cooling measure.

Install the inverter (Filterpack) vertically.

When installing the Filterpack to the inverter, use the included installation screws for the inverter rear panel.

Using a longer screw may damage the Filterpack.

Side-by-side installation is not available for Filter packs.

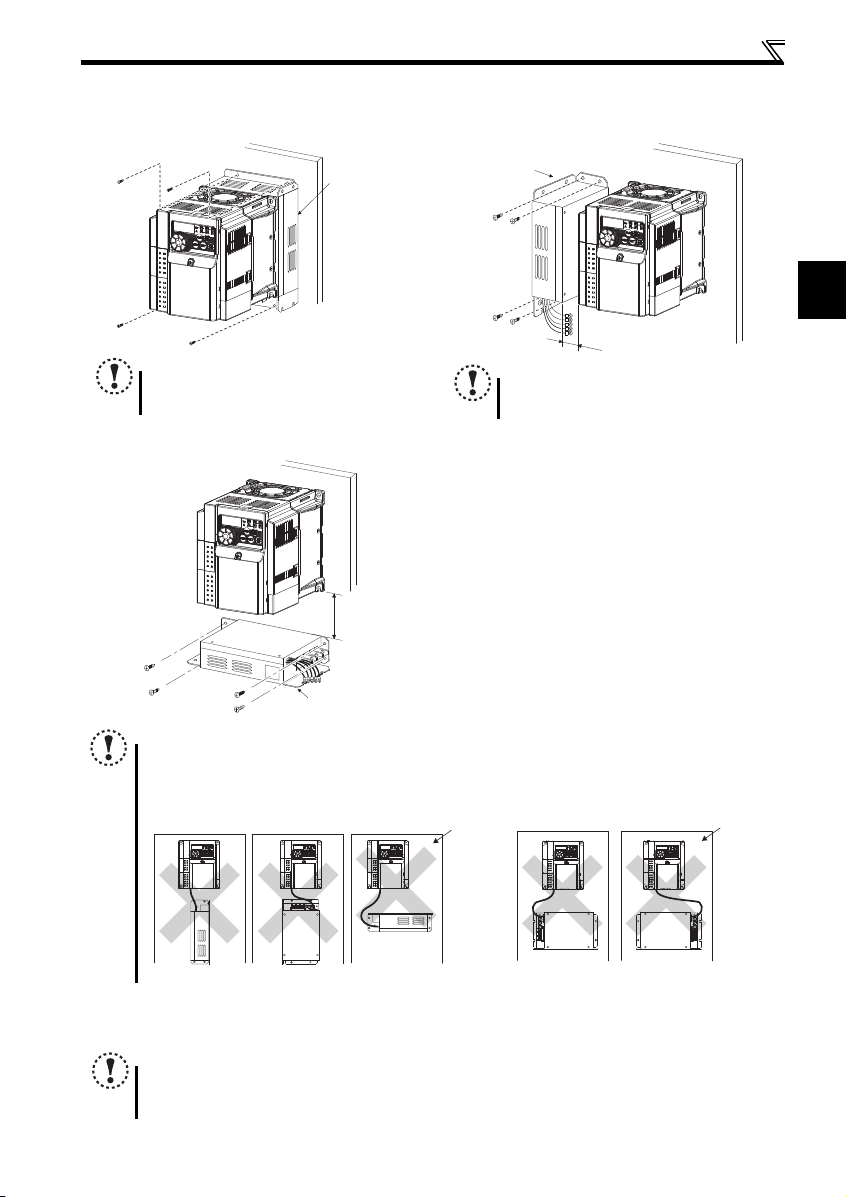

Page 13

Installation of the inverters and precautions

2

Filterpack

NOTE

When installing Filterpack of 11K or 15K on the rea r

panel of the inverter, do not install on mo ving objects

or places which vibrates (exceeding 1.96m/s

2

).

Filterpack

1cm or more

NOTE

To release heat of the inverter and Filterpack,

leave clearance of 1 cm or more when installing

the inverter and Filterpack.

Filterpack

10cm or more

<Invert installation of Filterpack><Sideway installation of Filterpack>

Enclosure

2.2.3 Installation of Filterpack

The following installations are recommended for Filterpack and the inverter. For wiring of Filterpack and the inverter, refer to

Rear panel installation Side panel installation

Underneath installation

page 13

.

NOTE

Install Filterpack with the wiring portion facing right.

Underneath installation is not available for 11K and 15K.

To release heat, leave clearance of 10cm or more between the inverter and Filterpack.

To prevent malfunctions and damages, never perform installations in the following manners. Only install according to

the recommended mounting methods.

2.2.4 Environment

Before installation, check that the environment meets the specifications on page 46.

NOTE

Install the inverter on a strong surface securely and vertically with bolts.

Leave enough clearances and take cooling measures.

Avoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

Install the inverter on a nonflammable wall su rface.

Enclosure

9

Page 14

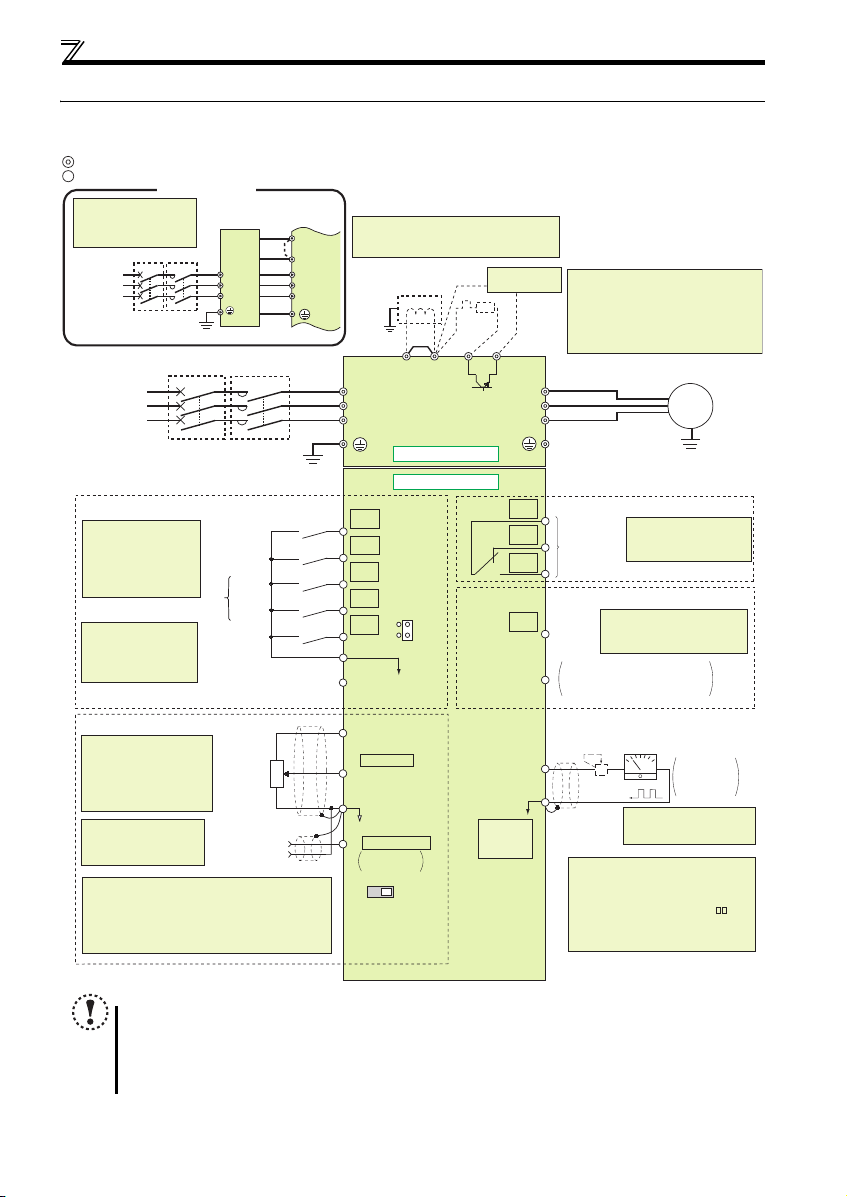

2.3 Wiring

Earth

(Ground)

Motor

M

Earth (Ground)

Three-phase

AC power

supply

MCCB MC

R/L1

P1 P/+

PR

N/-

S/L2

T/L3

U

V

W

Earth

(Ground)

*7 Brake resistor (FR-ABR, MRS type, MYS

type)

Install a thermal relay to prevent an

overheat and burnout of the brake resistor.

Always install a thermal relay when using

a brake resistor whose capacity is 11K or

higher.

*8 It is not necessary when

calibrating the indicator

from the operation panel.

Forward

rotation start

Reverse

rotation start

Middle

speed

High

speed

Terminal 4

input selection

Control input signals (No voltage input allowed)

24VDC power supply

(Common for external power supply transistor)

Contact input common

STR

STF

RH

RM

AU

SD

PC

Relay output

Running

Open collector output

Open collector output common

Sink/source common

RUN

SE

A

B

C

Frequency setting signals (Analog)

2 0 to 5VDC

10(+5V)

2

3

1

4 4 to 20mADC

Frequency

setting

potentiometer

1/2W1kΩ

Terminal 4

input

(Current

input)

(+)

(-)

5(Analog common)

*5 It is recommended to

use 2W1kΩ when the

frequency setting signal

is changed frequently.

*5

*3 When using terminals

PC-SD as a 24VDC

power supply, take

care not to short across

terminals PC and SD.

PU

connector

*2. DC reactor (FR-HEL)

When connecting a DC reactor, remove the

jumper across P1 and P/+.

Control circuit terminal

Main circuit terminal

Sink logic

Jumper

*2

*7

*3

*4

*6

The function of these

terminals can be

changed to the reset

signal, etc. with the input

terminal assignment

(Pr. 178 to Pr. 182)

.

Multi-speed selection

Terminal functions vary by

Pr. 190 RUN terminal function

selection

Terminal functions vary

by Pr. 192 A,B,C terminal

function selection

SINK

SOURCE

VI

*6

0 to 5VDC

(0 to 10VDC)

0 to 10VDC

*6 Terminal input specifications can be changed by analog

input specifications switchover (Pr. 267). Set the

voltage/current input switch in the "V" position to select

voltage input (0 to 5V/0 to10V) and "I" (initial value) to

select current input (4 to 20mA).

To use terminal 4 (initial setting is current input), turn

ON AU signal.

Voltage/current

input switch

Main circuit

Control circuit

R

Relay output

(Fault output)

Brake unit

(Option)

FM

SD

Indicator

(Frequency meter,

etc.)

+

-

Moving-coil

type 1mA

full-scale

Calibration resistor

*8

*9

*4 Terminal input specifications

can be changed by analog

input specifications

switchover (Pr. 73).

Terminal 10 and terminal 2

are used as PTC input

terminal (Pr. 561).

With Filterpack

Three-phase

AC power

supply

MCCB MC

R/L1

P1

P/+

S/L2

T/L3

Earth (ground)

*1 Remove the jumper

across the terminals P1

and P/+ to install

Filterpack.

Jumper

*1

R0

S0

T0

P1

P

Filterpack

FR-BFP2

GND

R

S

T

*9 Operation and parameter setting can be

done from the parameter unit

(FR-PU07) and the enclosure surface

operation panel (FR-PA07).

(Use the option cable (FR-CB2 ).)

RS-485 communication can be utilized

from a personal computer and other

devices.

2.3.1 Terminal connection diagram

Wiring

10

NOTE

To prevent a malfunction caused by noise, separate the signal cables more than 10cm from the power cables. Also

separate the main circuit wire of the input side and the output side.

After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes

in an enclosure etc., take ca re not to allow chips and othe r foreign matter to ent er the inverter.

Terminals S1, S2, SC, and SO are for manufacturer setting. Do not remove the shortening wires across terminals S1

and SC and terminals S2 and SC.

Page 15

Wiring

2

2.3.2 Terminal specifications

Terminal

Typ e

Symbol

R/L1, S/L2,

T/L3

U, V, W Inverter output

P/+, PR Brake resistor connection

P/+, N/- Bra ke unit connection

Inverter

P/+, P1

Main circuit

R0, S0, T0

R, S, T Inverter power supply

Filterpack

P, P 1 DC reactor terminal

GND

STF Forward rotation start

STR Reverse rotation start

RH, RM Multi-speed s election

AU Terminal 4 input selection

SD

Contact input

PC

10

Control circuit/Input signal

2

4

Frequency setting

5

10

2

Thermistor

Terminal Name Terminal Specification

Connect to the commercial power supply.

AC power input

DC reactor (Filterpack)

connection

Earth (Ground)

Commercial power

supply input

Earth (Ground)

Inverter earth (ground)

connection

Contact input common

(sink) (initial setting)

External transistor

common (source)

24VDC power supply

common

External transistor

common (sink)

(initial setting)

Contact input common

24VDC power supply

Frequency setting power

Frequency setting

(voltage)

Frequency setting

(current)

Frequency setting

common

PTC thermistor input

(source)

supply

Do not connect anything to these terminals when using the high power factor converter (F RHC2) or power regeneration common converter (FR-CV).

To use Filterpack, connect the R, S, and T cables of Filterpack.

Connect a three-phase squirrel-cage moto r or a dedicated IPM motor.

Connect a brake resistor (FR-ABR, MRS type, MYS type) across terminals P/+ and PR.

Connect the brake unit (FR-BU2), power regeneration common conve rter (FR-CV) or high

power factor converter (FR-HC2).

Remove the jumper across terminals P/+ and P1 and connect a DC reactor.

To use Filterpack, remove the jumper across the terminals P/+ and P1, then connect the P and

P1 cables of Filterpack.

For earthing (grounding) the inverter chassis. Must be earthed (g rounded).

To use Filterpack, connect the GND cable of Filterpack.

Connect to the commercial power supply.

For earthing (grounding) the Filterpack. Must be earthed (grounded) .

Connect to R/L1, S/L2, and T/L3 of the inverter.

Remove the jumper across terminals

Connect to the earth (ground) terminal of the inverter.

Turn ON the STF signal to start forward rotation and turn it

OFF to stop.

Turn ON the STR signal to start reverse rotation and turn it

OFF to stop.

Multi-speed can be selected according to the combination of RH and RM signals.

The terminal 4 function is available only when the AU signal is ON. (the operation with the

frequency setting signal of 4 to 20mA DC is available)

Turning ON the AU signal disables the terminal 2 (voltage input) function.

Common terminal for contact input terminal (sink logic) and t erminal FM.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the source logic to avoid

malfunction by undesirable current.

Common output terminal for 24VDC 0.1A power supply (PC terminal).

Isolated from terminals 5 and SE.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the sink logic to avoid

malfunction by undesirable current.

Common terminal for contact input terminal (source logic).

Can be used as 24VDC 0.1A power supply.

Used as power supply when connecting potentiometer for

frequency setting (speed setting) from outside of the inverter.

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum

output frequency at 5V (10V) and makes input and output

proportional. Use Pr. 73 to switch between input 0 to 5VDC

input (initial setting) and 0 to 10VDC.

Inputting 4 to 20mADC (or 0 to 5V, 0 to 10V) provides the

maximum output frequency at 20mA and makes input and

output proportional. The input signal to terminal 4 is valid

only when the AU signal is ON (terminal 2 input is invalid).

Use Pr. 267 to switch from among input 4 to 20mA (initial

setting), 0 to 5VDC and 0 to 10VDC. Set the voltage/current

input switch in the "V" position to select voltage input (0 to

5V/0 to 10V).

Frequency setting signal (terminal 2 or 4) common terminal. Do not earth (ground).

For connecting PTC thermistor output.

When PTC thermistor protection is valid (Pr. 561 "9999"),

terminal 2 is not available for frequency setting.

P/+

and P1, and connect to th e terminals

When the STF and STR signals

are turned ON simultaneously,

the stop command is given.

5VDC

permissible load current 10mA

Input resistance10k1k

Permissible maximum voltage

20VDC

Current input:

Input resistance 2495

Maximum permissible current

30mA

Voltage input:

Input resistance10k 1k

Permissible maximum voltage

20VDC

Adaptive PTC thermistor

specification

Heat detection resistance :

500 to 30k (Set by Pr. 561)

P/+

and P1 of the inverter.

11

Page 16

Wiring

Terminal

Typ e

Symbol

A, B, C

Relay

RUN Inverter running

Open collector

SE

Control circuit terminal/Output signal

FM For meter

Pulse

— PU connector

Communication

NOTE

To change the input specification for terminal 4, set Pr. 267 and the voltage/current input switch correctly, then input

the analog signal relevant to the setting. Applying a voltage with voltage/current input switch in "I" position (current

input is selected) or a current with switch in "V" position (voltage input is selected) could cause component damage

of the inverter or analog circuit of output devices.

Connecting the power supply to the inverter output terminals (U, V, W) will damage the inverter. Do not perform such

wiring.

indicates that terminal functions can be selected using Pr. 178 to Pr. 182, Pr. 190 and Pr. 192 (I/O terminal function

selection).

The terminal names and functions shown here are the initial settings.

Terminals S1, S2, SC, and SO are for manufacturer setting. Do not connect anything to these.

Doing so may cause an inverter failure. Do not remove the shortening wires across terminals S1 and SC and

terminals S2 and SC. Removing either shortening wire disables the inverter operation.

Terminal Name Terminal Specification

1 changeover contact output indicates that the inverter protectiv e function has activated and

Relay output

(fault output)

Open collector output

common

the output stopped.

Fault: discontinuity across B-C (continuity across A-C),

Normal: continuity across B-C (discontinuity across A-C)

Contact capacity:230VAC 0.3A (power factor =0.4) 30VDC 0.3A

Switched Low when the inverter output frequency is equal to

or higher than the starting frequency (initial value 0.5Hz).

Switched High during stop or DC injection brake operation.

(Low is when the open collector output transistor is ON

(conducts). High is when the transistor is OFF (does not

conduct).)

Common terminal of terminal RUN.

Selected one e.g. output frequency from monitored items.

(Not output during inverter reset.)

The output signal is proportional to the magnitude of the

corresponding monitored item.

With the PU connector, communication can be established through RS-485.

Conforming standard: EIA-485 (RS-485)

Transmission format: Multidrop link

Communication speed: 4800 to 38400bps

Overall length: 500m

Permissible load 24VDC

(maximum 27VDC) 0.1A

(a voltage drop is 3.4V maximum

when the signal is ON)

Permissible load current 1mA

1440 pulses/s at full scale

12

Page 17

Wiring

2

MotorPower supply

N/-

P/+ PR

M

R/L1 S/L2 T/L3

Jumper

Motor

Power supply

N/-

P/+

PR

M

R/L1 S/L2 T/L3

Jumper

N/-

P/+

PR

R/L1 S/L2 T/L3

Jumper

MotorPower supply

M

Motor

M

N/-

P/+

PR

R/L1 S/L2 T/L3

Earth

(Ground)

R0 S0 T0

Power supply

Filterpack

(FR-BFP2)

Inverter

Jumper

Connection example with FR-F740PJ-11K

TSRP1 P

GND

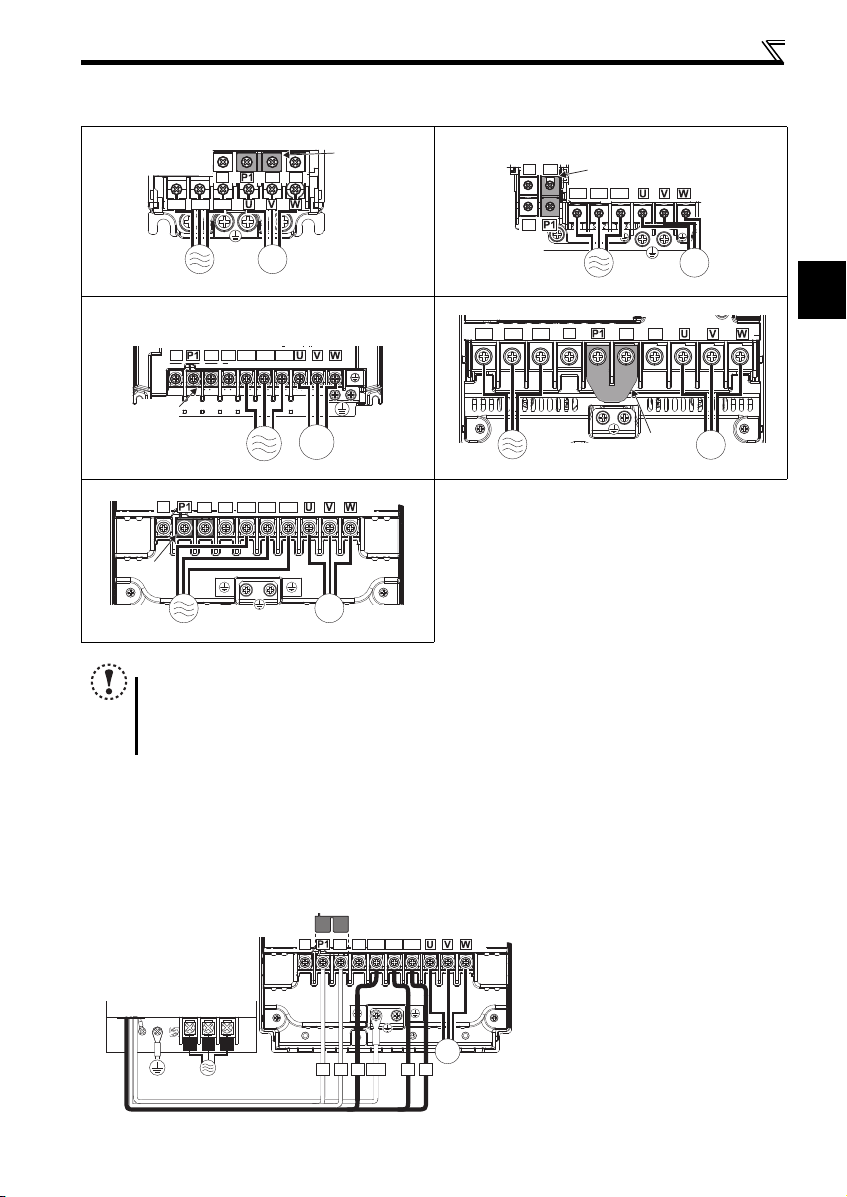

2.3.3 Terminal arrangement of the main circuit terminal, power supply and the motor wiring

Three-phase 200V/400V class

FR-F720PJ-0.4K to 0.75K FR-F720PJ-1.5K to 3.7K

FR-F740PJ-0.4K to 3.7K

FR-F720PJ-5.5K, 7.5K

FR-F740PJ-5.5K, 7.5K

N/-

Jumper

P/+ PR

R/L1 S/L2 T/L3

FR-F720PJ-11K, 15K

M

FR-F740PJ-11K, 15K

N/-

Jumper

Power supply

NOTE

For the inverters without Filterpacks, make sure the power cables are connected to R/L1, S/L2, and T/L3. (Phase does

not need to be matched.) Never connect the power cable to the U, V, and W of the inverter. Doing so will damage the

inverter.

Connect the motor to U, V, and W. Turning ON the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

2.3.4 Wiring of the inverter and Filterpack

Perform wiring of the inverter and Filterpack in the following procedure.

(1) Connect the commercial power supply to terminals R0, S0 and T0 of the Filterpack.

(2) Connect the earthing cable (green and yellow striped cable) of the Filterpack to the inverter earth (ground) terminal.

(3)

Connect the power supply cable (black cable) of the Filterpack to terminals R, S and T. (Phase sequence need not be matched.

Remove the jumper across terminals P and P1 of the inverter, and connect the P and P1 cables (red cable) of the Filterpack

(4)

(5) Connect the motor cable to the inverter output terminals (U, V, W). (Match the phase sequence)

Power supply Motor

R/L1 S/L2 T/L3

P/+

PR

M

Motor

)

.

13

Page 18

Wiring

3 × wire resistance [mΩ/m] × wiring distance [m] × current [A]

1000

NOTE

For the inverters with Filterpacks, make sure the power cables are connected to terminals R0, S0, and T0 of the

Filterpack (FR-BFP2). (Phase sequence does not need to be matched)

Never connect the power cable to the U, V, W of the inverter. Doing so will damage the inverter.

When connecting Filterpack, make sure that the jumper across terminals P and P1 of the inverter is removed.

Connect the GND cable of Filterpack to the earth (ground) terminal of the inverter.

Use the earth (ground) terminal of Filterpack for earthing (grounding). The inverter is earthed (grounded) through

Filterpack.

Connect the Filterpack terminals P and P1 to the inverter terminals of P/+ and P1, respectively. Improper connections

may damage the inverter.

2.3.5 Cables and wiring length

(1) Applicable cable size

Select the recommended cable size to ensure that a voltage drop will be 2% at maximum.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque to

decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

Three-phase 200V class (when input power supply is 220V)

Ter min al

Applicable Inverter

Model

FR-F720PJ-0.4K to

0.75K

FR-F720PJ-1.5K, 2.2K M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-F720PJ-3.7K M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-F720PJ-5.5K M5 2.5 5.5-5 5.5-5 5.5 5.5 5.5 10 10 6 6 6

FR-F720PJ-7.5K M5 2.5 14-5 8-5 14 8 5.5 6 8 16 10 6

FR-F720PJ-11K M5 2.5 14-5 14-5 14 14 8 6 6 16 16 1 6

FR-F720PJ-15K

Tightening

Screw

Tor que

Size

N·m

M3.5 1.2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

M6

4.4

(M5)

(2.5)

Terminal

R/L1

S/L2

T/L3

22-6

(14-5)

Crimp

U, V, W

(14-5)

HIV Cables, etc. (mm2)

R/L1

S/L2

T/L3

22-6

22 22 14 4 4 25 25 16

U, V, W

Earthing

Three-phase 400V class (when input power supply is 440V)

Ter min al

Applicable Inverter

Model

FR-F740PJ-0.4K to 3.7K M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-F740PJ-5.5K M4 1.5 5.5-4 2-4 3.5 2 3.5 12 14 4 2.5 4

FR-F740PJ-7.5K M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 12 12 4 4 4

FR-F740PJ-11K M4 1.5 5.5-4 5.5-4 5.5 5.5 5.5 10 10 6 6 10

FR-F740PJ-15K

The cable size is that of the cable (HIV cable (600V class 2 vinyl-insulated cable) etc.) with continuous maximum permissible temperature of 75°C. Assumes

that the surrounding air temperature is 50°C or less and the wiring distance is 20m or less.

The recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C. Assumes that the surrounding

air temperature is 40°C or less and the wiring distance is 20m or less.

(For the use in the United States or Canada, refer to page 54.)

The recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less.

(Selection example for use mainly in Europe.)

The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, PR, P/+, N/-, P1 and a screw for earthing (grounding). Terminal screw size

for Filterpack (FR-BFP2) is same as the terminal screw size for the inverter.

Screw size for earthing (grounding) the FR-F720PJ-15K is indicated in parenthesis.

Screw sizes of the terminals R0, S0, and T0 and the earthing terminal of FR-BFP2-H15K are indicated in parenthesis.

For the earthing cable size for Filterpack, use the same size as for the inverter.

Screw

Size

M5

(M6)

Tightening

Tor que

N·m

2.5

(4.4)

Terminal

R/L1

S/L2

T/L3

8-5

(14-6)

Crimp

U, V, W

(14-6)

HIV Cables, etc. (mm2)

R/L1

S/L2

T/L3

8-5

88 5.5881010 10

U, V, W

Earthing

NOTE

Tighten the terminal screw to the specified torque. A screw that has been tightened too loosely can cause a short circuit or

malfunction. A screw that has been tightened too tightly can cause a short circuit or malfunction due to the unit breakage.

Use crimp terminals with insulation sleeve to wire the power supply and motor.

The line voltage drop can be calculated by the following formula:

Line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop (torque

reduction) in the low speed range.

cable

cable

Cable Size

AWG

R/L1

S/L2

U, V, W

T/L3

Cable Size

AWG

R/L1

S/L2

U, V, W

T/L3

PVC Cables, etc. (mm2)

R/L1

S/L2

T/L3

PVC Cables, etc. (mm2)

R/L1

S/L2

T/L3

U, V, W

U, V, W

Earthing

cable

Earthing

cable

14

Page 19

Wiring

2

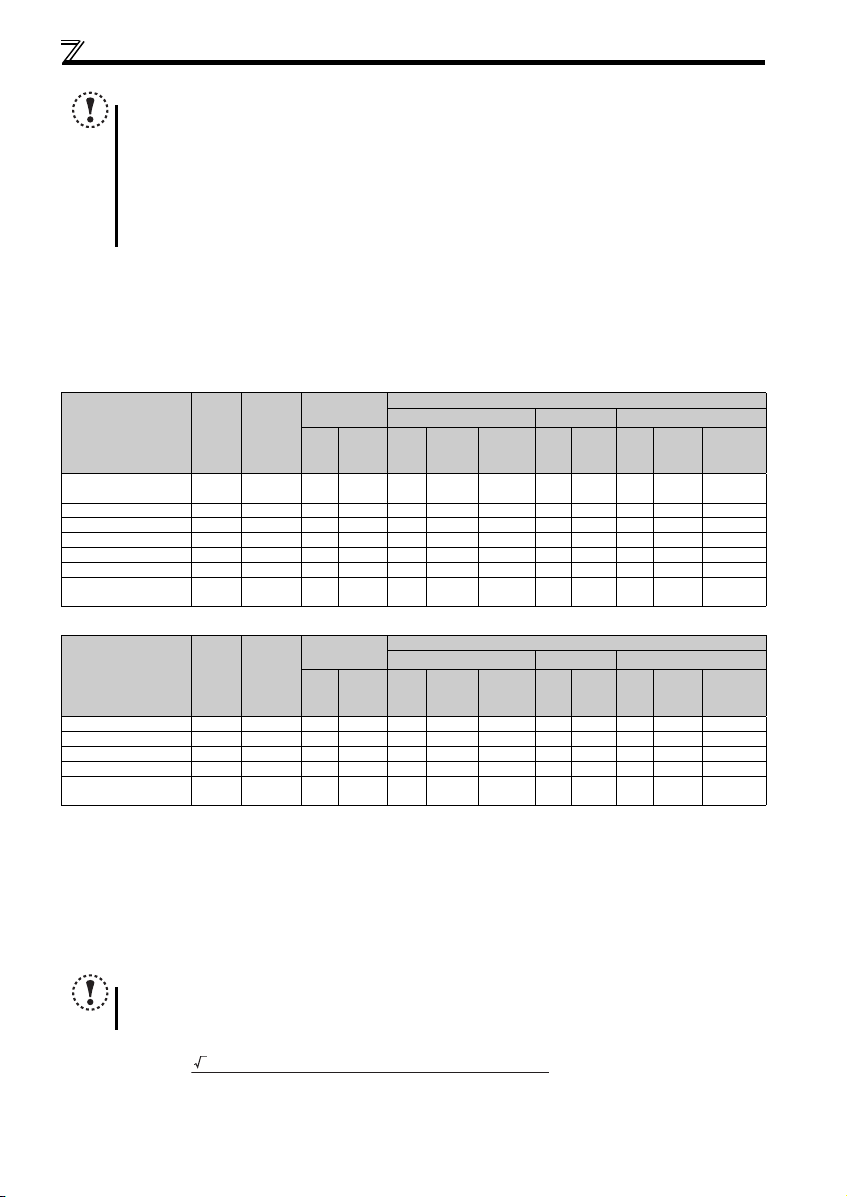

(2) Total wiring length

Under general-purpose motor control

Connect one or more general-purpose motors within the total wiring length shown in the following table.

Vol tag e

Cable Type

Class

Unshielded

200V

Shielded

Unshielded

400V

Shielded

When driving a 400V class motor by the inverter, surge voltages attributable to the wiring constants may occur at the

motor terminals, deteriorating the insulation of the motor.

If that is the case, use a "400V class inverter-driven insulation-enhanced motor" and set frequency in Pr. 72 PWM

frequency selection according to wiring length. (

class motor with an inverter.)

Pr. 72 PWM frequency selection Setting

(carrier frequency)

cable

cable

cable

cable

1 (1kHz) or lower 300m 500m 500m 500m 500m

2 (2kHz) or higher 200m 300m 500m 500m 500m

1 (1kHz) or lower 75m 100m 100m 100m 100m

2 (2kHz) or higher 50m 75m 100m 100m 100m

1 (1kHz) or lower 200m 200m 300m 500m 500m

2 (2kHz) or higher 30m 100m 200m 300m 500m

1 (1kHz) or lower 50m 50m 75m 100m 100m

2 (2kHz) or higher 10m 25m 50m 75m 100m

0.4K 0.75K 1.5K 2.2K

Refer to Chapter 3 in the Instruction Manual (Applied) to drive a 400V

3.7K

or Higher

50m or less 50m to 100m Exceeding 100m

Wiring Length

Pr. 72 PWM frequency selection Setting

(carrier frequency)

15 (14.5kHz) or less 8 (8kHz) or less 2 (2kHz) or less

Under IPM motor control

Use the following length of wiring or shorter when connecting an IPM motor.

Vol tag e

Class

200V

400V

Cable Type

Unshielded

Shielded

Unshielded

Shielded

Pr. 72 PWM frequency selection Setting

(carrier frequency)

cable

cable

cable

cable

4 (2.5kHz) or lower 100m 100m 100m 100m

5 (5kHz) or higher 30m 30m 30m 30m

4 (2.5kHz) or lower 75m 100m 100m 100m

5 (5kHz) or higher 30m 30m 30m 30m

4 (2.5kHz) or lower 50m 100m 100m 100m

5 (5kHz) or higher 30m 30m 30m 30m

4 (2.5kHz) or lower 50m 50m 75m 100m

5 (5kHz) or higher 10m 25m 30m 30m

0.4K 0.75K 1.5K

2.2K

or Higher

Use one dedicated IPM motor for one inverter. Multiple IPM motors cannot be connected to an inverter.

NOTE

Especially for long-distance wiring, the inverter may be affected by a charging current caused by the stray

capacitances of the wiring, leading to a malfunction of the overcurrent protective function, fast-response current limit

function, or stall prevention function or a malfunction or fault of the equipment connected on the inverter output side.

If malfunction of fast-response current limit function occurs, disable this function.

If malfunction of stall prevention function occurs, increase the stall level.

( Refer to Pr. 22 Stall prevention operation level and Pr. 156 Stall prevention operation selection in Chapter 4 of the Instruction

Manual (Applied).)

When using the automatic restart after instantaneous power failure function for a general-purpose motor with the

wiring length longer than 100m, select "without frequency search" by setting Pr.162 = "1 or 11." (

4 of the Instruction Manual (Applied).)

Refer to Chapter

15

Page 20

Wiring

STF

STR

PCSDRHRMAU

FM

CBA

10 2 5 4

RUN SE S1 S2 SCSO

SD

Crumpled tip

Wires are not inserted

into the sleeve

Unstranded

wires

Damaged

WireWire

SleeveSlee

ve

0 to 0.5mm0 to 0.5mm

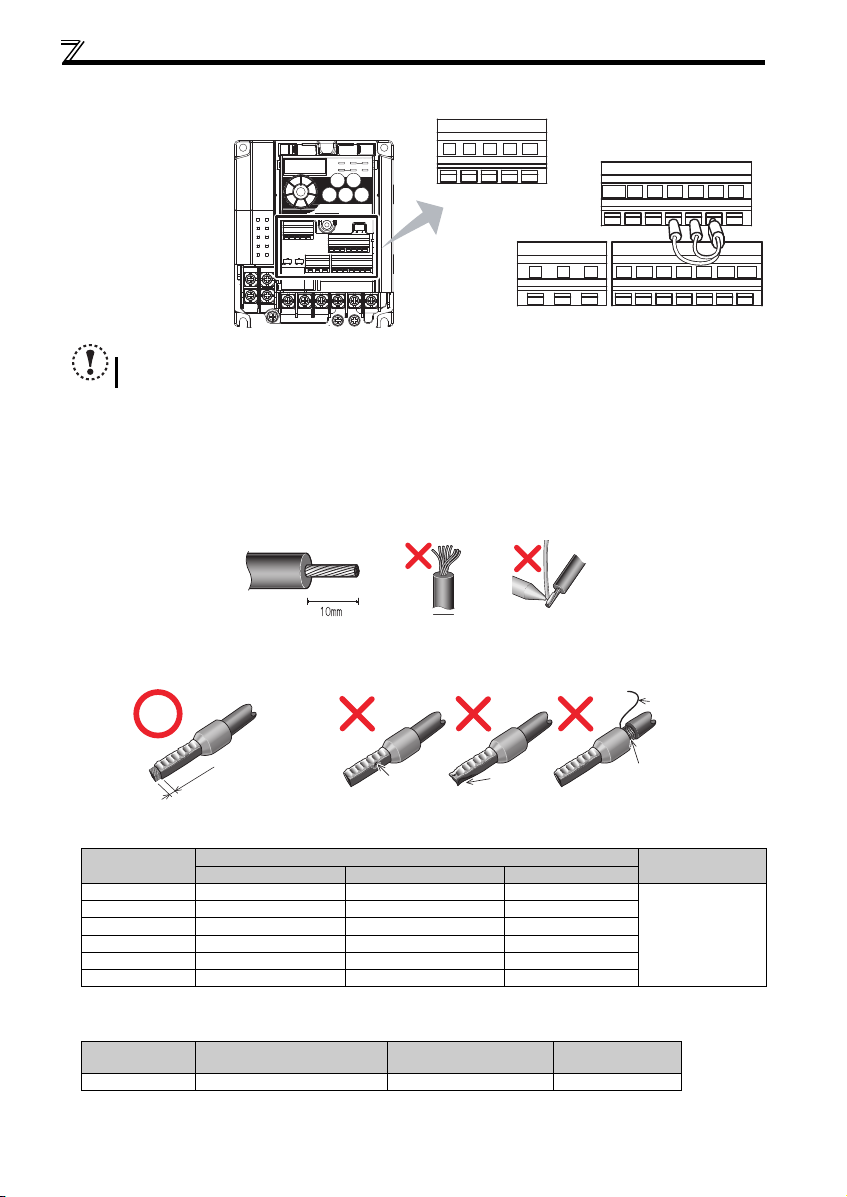

2.3.6 Wiring of control circuit

(1) Control circuit terminal layout

Recommend wire size:

2

0.3mm

to 0.75mm

NOTE

Do not remove the shortening wires across the terminals S1 and SC and the terminals S2 and SC.

Removing either shortening wire disables the inverter operation.

(2) Wiring method

Wiring

Use a blade terminal and a wire with a sheath stripped off for the control circuit wiring. For a single wire, strip off the sheath of

the wire and apply directly. Insert the blade terminal or the single wire into a socket of the terminal.

1) Strip off the sheath about the length below. If the length of the sheath peeled is too long, a short circuit may occur

among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it.

2

Wire stripping length

2) Crimp the blade terminal.

Insert wires to a blade terminal, and check that the wires come out for about 0 to 0.5 mm from a sleeve.

Check the condition of the blade terminal after crimping. Do not use a blade terminal of which the crimping is

inappropriate, or the face is damaged.

Blade terminals available on the market: (as of January 2017)

Phoenix Contact Co., Ltd.

Wire Size (mm2)

0.3 AI 0,34-10TQ — —

0.5 AI 0,5-10WH — AI 0,5-10WH-GB

0.75 AI 0,75-10GY A 0,75-10 AI 0,75-10GY-GB

1 AI 1-10RD A1-10 AI 1-10RD /1000GB

1.25, 1.5 AI 1,5-10BK A1,5-10 AI 1,5-10BK/1000GB

0.75 (for two wires) AI-TWIN 2 x 0,75-10GY — —

A ferrule terminal with an insulation sleeve compatible with MTW wire which has a thick wire insulation

Applicable for terminal ABC.

NICHIFU Co., Ltd.

Wire Size (mm2)

0.3 to 0.75 BT 0.75-11 VC 0.75 NH 69

With Insulation Sleeve Without In sulation Sleeve For UL Wire

Blade Terminal Product

Number

16

Ferrule Terminal Model

Insulation Cap Product

Number

Crimping Tool

Product Number

Crimping Tool

Name

CRIMPFOX 6

Page 21

Wiring

2

r

r

NOTE

Pulling out the terminal block forcefully without pushing

the open/close button all the way down may damage the

terminal block.

Use a small flathead screwdriver (Tip thickness: 0.4mm/

tip width: 2.5mm).

If a flathead screwdriver with a narrow tip is used,

terminal block may be damaged.

Products available on the market: (as of February 2016)

Place the flathead screwdriver vertical to the open/close

button. In case the blade tip slips, it may cause to damage of inverter or injury.

Product Typ e Manufacturer

Flathead

screwdriver

SZF 0- 0,4 x 2,5 Phoenix Contact Co., Ltd.

3) Insert the wire into a socket.

When using a single wire or a stranded wire without a blade terminal, push an

open/close button all the way down with a flathead screw driver, and insert the wire.

Open/close button

Flathead screwdrive

NOTE

When using a stranded wire without a blade terminal, twist enough to avoid short circuit with a nearby terminals or

wires.

Place the flathead screwdriver vertical to the open/close button. In case the blade tip slips, it may cause to damage of

inverter or injury.

Wire removal

Pull the wire with pushing the open/close button all the

way down firmly with a flathead screwdriver.

Open/close button

Flathead screwdrive

(3) Control circuit common terminals (SD, 5, SE)

• Terminals SD, SE and 5 are common terminals for I/O signals. (All common terminals are isolated from each other.) Do not

earth them. Avoid connecting the terminals SD and 5 and the terminals SE and 5.

• Terminal SD is a common terminal for the contact input terminals (STF, STR, RH, RM, AU) and the pulse train output

terminal (FM). The open collector circuit is isolated from the internal control circuit by photocoupler.

• Terminal 5 is a common terminal for the frequency setting signals (terminals 2 or 4). It should be protected from external

noise using a shielded or twisted cable.

• Terminal SE is a common terminal for the open collector output terminal (RUN). The contact input circuit is isolated from the

internal control circuit by photocoupler.

17

Page 22

Wiring

(4) Wiring instructions

• It is recommended to use the cables of 0.3mm2 to 0.75mm2 gauge for connection to the control circuit terminals.

• The maximum wiring length should be 30m (200m for terminal FM).

• Do not short across terminals PC and SD. Inverter may be damaged.

• When using contact inputs, use two or more parallel micro-signal contacts or

twin contacts to prevent contact faults since the control circuit input signals are

micro-currents.

• To suppress EMI, use shielded or twisted cables for the control circuit

terminals and run them away from the main and power circuits (including the

200V relay sequence circuit). For the cables connected to the control circuit terminals, connect their shields to the common

terminal of the connected control circuit terminal. When connecting an external power supply to the terminal PC, however,

connect the shield of the power supply cable to the negative side of the external power supply. Do not directly earth

(ground) the shield to the enclosure, etc.

• Always apply a voltage to the fault output terminals (A, B, C) via a relay coil, lamp, etc.

• When using an external power supply for transistor output, note the following points to prevent a malfunction caused by

undesirable current.

Do not connect any terminal SD on the inverter and the 0V terminal of the external power supply (when the sink logic is

selected).

Do not connect terminal PC on the inverter and the +24V terminal of the external power supply (when the source logic is

selected).

Do not install an external power source in parallel with the internal 24VDC power source (connected to terminals PC and

SD) to use them together.

Refer to Chapter 2 of the Instruction Manual (Applied) for the detail.

Micro signal contacts Twin contacts

2.3.7 Assigning signals (output stop signal (MRS), reset signal (RES), etc.) to contact input terminals

POINT

Use Pr.178 to Pr.182 (input terminal function selection) to select and change the functions assigned to input

terminals.

To assign the output stop signal (MRS) to the terminal RH, for example, assign "24" to Pr.182 RH terminal

function selection. (Refer to page 5 to change a parameter setting value.)

Pr. Name

178

STF terminal function selection

179