Page 1

INVERTER

FR-F700P

INSTRUCTION MANUAL (BASIC)

FR-F720P-0.75K to 110K

FR-F740P-0.75K to 560K

Thank you for choosing this Mitsubishi Inverter.

This Instruction Manual (Basic) is intended for users who "just want to run the inverter".

1

2

3

4

5

6

7

8

OUTLINE ........................................................................................................1

INSTALLATION AND WIRING ......................................................................3

DRIVING THE IPM MOTOR <IPM> .............................................................41

DRIVING THE MOTOR ................................................................................46

ADJUSTMENT .............................................................................................71

TROUBLESHOOTING ...............................................................................116

PRECAUTIONS FOR MAINTENANCE AND INSPECTION......................141

SPECIFICATIONS......................................................................................150

700P

1

2

3

4

5

For the customers intending to use IPM motors ......... 41

This inverter is set for a general-purpose motor in the initial settings.

For use with an IPM motor, refer to page 41.

To obtain the Instruction Manual (Applied)

If you are going to utilize functions and performance, refer to the Instruction

Manual (Applied) [IB-0600412ENG].

The Instruction Manual (Applied) is separately available from where you

purchased the inverter or your Mitsubishi sales representative.

The PDF version of this manual is also available for download at "MELFANS

Web," the Mitsubishi Electric FA network service on the world wide web (URL:

http://www.MitsubishiElectric.co.jp/melfansweb)

6

7

8

Page 2

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment.

Please forward this Instruction Manual (Basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter

until you have read through this Instruction Manual (Basic) and

appended documents carefully and can use the equipment

correctly. Do not use the inverter until you have a full knowledge of

the equipment, safety information and instructions. In this

Instruction Manual (Basic), the safety instruction levels are

classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

Incorrect handling may cause hazardous

conditions, resulting in medium or slight

injury, or may cause only material damage.

CAUTION

The level may even lead to a serious consequence

according to conditions. Both instruction levels must be followed

because these are important to personal safety.

1.Electric Shock Prevention

WARNING

• While power is ON or when the inverter is running, do not open

the front cover. Otherwise you may get an electric shock.

• Do not run the inverter with the front cover or wiring cover removed.

Otherwise you may access the exposed high-voltage terminals or

the charging part of the circuitry and get an electric shock.

• Even if power is OFF, do not remove the front cover except for

wiring or periodic inspection. You may accidentally touch the

charged inverter circuits and get an electric shock.

• Before wiring, inspection or switching EMC filter ON/OFF

connector, power must be switched OFF. To confirm that, LED

indication of the operation panel must be checked. (It must be

OFF.) Any person who is involved in wiring, inspection or

switching EMC filter ON/OFF connector shall wait for at least 10

minutes after the power supply has been switched OFF and

check that there are no residual voltage using a tester or the like.

The capacitor is charged with high voltage for some time after

power OFF, and it is dangerous.

• This inverter must be earthed (grounded). Earthing (grounding)

must conform to the requirements of national and local safety

regulations and electrical code (NEC section 250, IEC 536 class

1 and other applicable standards). A neutral-point earthed

(grounded) power supply for 400V class inverter in compliance

with EN standard must be used.

• Any person who is involved in wiring or inspection of this

equipment shall be fully competent to do the work.

• The inverter must be installed before wiring. Otherwise you may

get an electric shock or be injured.

• Setting dial and key operations must be performed with dry

hands to prevent an electric shock. Otherwise you may get an

electric shock.

• Do not subject the cables to scratches, excessive stress, heavy

loads or pinching. Otherwise you may get an electric shock.

• Do not replace the cooling fan while power is ON. It is

dangerous to replace the cooling fan while power is ON.

• Do not touch the printed circuit board or handle the cables with

wet hands. Otherwise you may get an electric shock.

• When measuring the main circuit capacitor capacity (Pr. 259 Main

circuit capacitor life measuring = "1"), the DC voltage is applied to

the motor for 1s at powering OFF. Never touch the motor terminal,

etc. right after powering OFF to prevent an electric shock.

• IPM motor is a synchronous motor with high-performance

magnets embedded in the rotor. Motor terminals hold highvoltage while the motor is running even after the inverter power

is turned OFF. Before wiring or inspection, the motor must be

confirmed to be stopped. When the motor is driven by the load in

applications such as fan and blower, a low-voltage manual

contactor must be connected at the inverter's output side, and

wiring and inspection must be performed while the contactor is

open. Otherwise you may get an electric shock.

2. Fire Prevention

CAUTION

• Inverter must be installed on a nonflammable wall without holes

(so that nobody touches the inverter heatsink on the rear side,

etc.). Mounting it to or near flammable material can cause a fire.

• If the inverter has become faulty, the inverter power must be

switched OFF. A continuous flow of large current could cause a

fire.

• Do not connect a resistor directly to the DC terminals P/+ and N/

-. Doing so could cause a fire.

3. Injury Prevention

CAUTION

• The voltage applied to each terminal must be the ones specified

in the Instruction Manual. Otherwise burst, damage, etc. may

occur.

• The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

• Polarity must be correct. Otherwise burst, damage, etc. may

occur.

• While power is ON or for some time after power-OFF, do not

touch the inverter since the inverter will be extremely hot. Doing

so can cause burns.

4. Additional Instructions

Also the following points must be noted to prevent an accidental failure, injury,

electric shock, etc.

(1) Transportation and installation

CAUTION

• The product must be transported in correct method that

corresponds to the weight. Failure to do so may lead to injuries.

• Do not stack the boxes containing inverters higher than the

number recommended.

• The product must be installed to the position where withstands

the weight of the product according to the information in the

Instruction Manual.

• Do not install or operate the inverter if it is damaged or has parts

missing. This can result in breakdowns.

• When carrying the inverter, do not hold it by the front cover or

setting dial; it may fall off or fail.

• Do not stand or rest heavy objects on the product.

• The inverter mounting orientation must be correct.

• Foreign conductive objects must be prevented from entering the

inverter. That includes screws and metal fragments or other

flammable substance such as oil.

• As the inverter is a precision instrument, do not drop or subject it

to impact.

• The inverter must be used under the following environment:

Otherwise the inverter may be damaged.

Surrounding air

temperature

Ambient humidity 90% RH or less (non-condensing)

Storage temperature -20°C to +65°C

Atmosphere

Environment

Altitude, vibration

*1 Temperature applicable for a short time, e.g. in transit.

*2 2.9m/s

2

or less for the 185K or higher.

-10°C to +50°C (non-freezing)

Indoors (free from corrosive gas, flammable

gas, oil mist, dust and dirt)

Maximum 1000m above sea level for

standard operation. 5.9m/s

to 55Hz (directions of X, Y, Z axes)

*1

2

*2 or less at 10

A-1

Page 3

(2) Wiring

• Do not install a power factor correction capacitor, surge

suppressor or capacitor type filter on the inverter output side.

These devices on the inverter output side may be overheated or

burn out.

• The connection orientation of the output cables U, V, W to the

motor affects the rotation direction of the motor.

• IPM motor terminals (U, V, W) hold high-voltage while the IPM

motor is running even after the power is turned OFF. Before

wiring, the IPM motor must be confirmed to be stopped.

Otherwise you may get an electric shock.

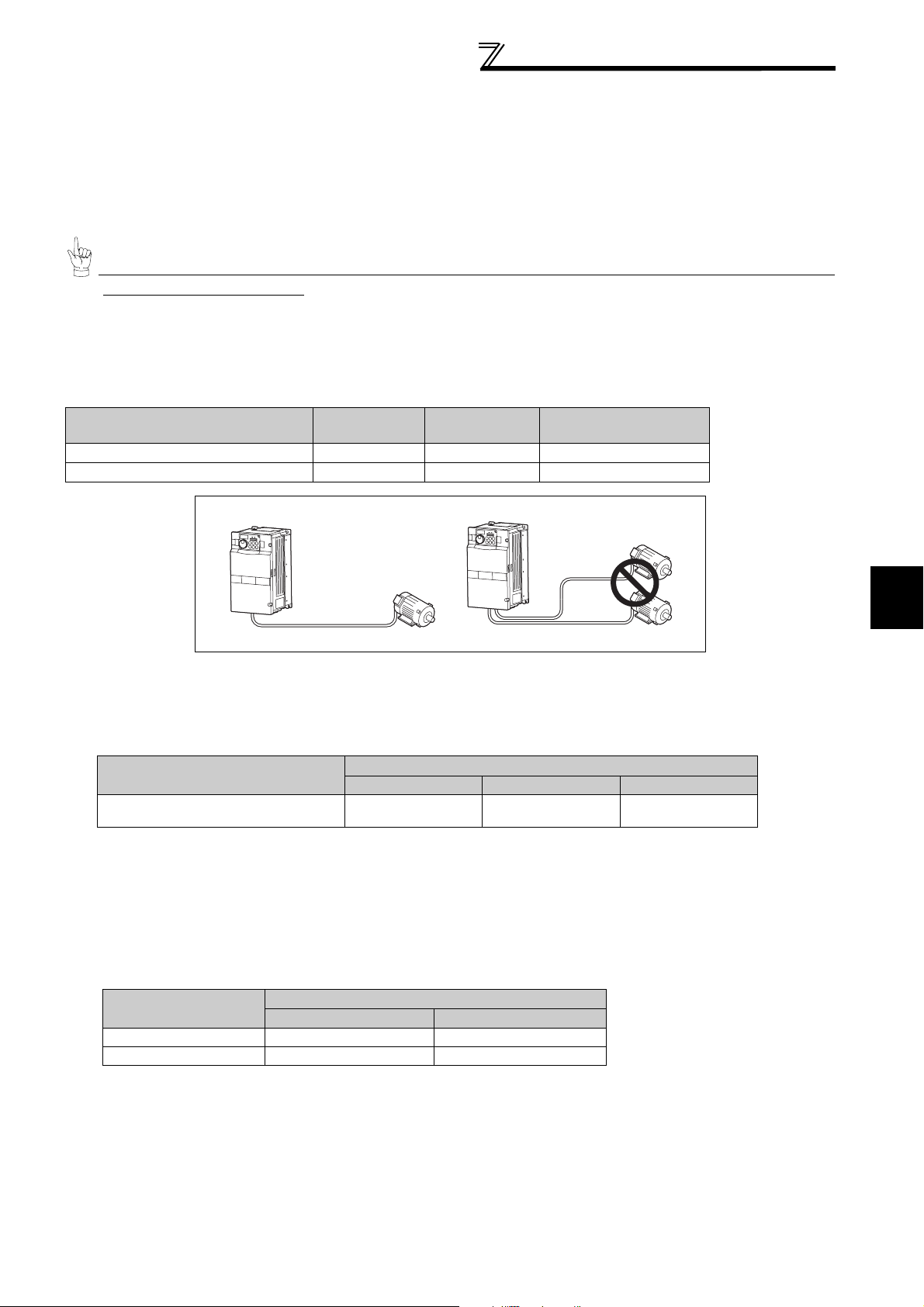

• Never connect an IPM motor to the commercial power supply.

Applying the commercial power supply to input terminals (U,V,

W) of an IPM motor will burn the IPM motor. The IPM motor must

be connected with the output terminals (U, V, W) of the inverter.

(3) Test operation and adjustment

• Before starting operation, each parameter must be confirmed

and adjusted. A failure to do so may cause some machines to

make unexpected motions.

(4) Operation

• The IPM motor capacity must be same with the inverter capacity.

(The 0.75K inverter can be used with a one-rank lower MM-EF

motor.)

• Do not use multiple IPM motors with one inverter.

• Any person must stay away from the equipment when the retry

function is set as it will restart suddenly after trip.

• Since pressing key may not stop output depending on the

function setting status, separate circuit and switch that make an

emergency stop (power OFF, mechanical brake operation for

emergency stop, etc.) must be provided.

• OFF status of the start signal must be confirmed before resetting

the inverter fault. Resetting inverter alarm with the start signal

ON restarts the motor suddenly.

• Do not use an IPM motor in an application where a motor is

driven by its load and runs at a speed higher than the maximum

motor speed.

• A dedicated IPM motor must be used under IPM motor control.

Do not use a synchronous motor, induction motor, or

synchronous induction motor under IPM motor control.

• The inverter must be used for three-phase induction motors or

the dedicated IPM motor.

Connection of any other electrical equipment to the inverter

output may damage the equipment.

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

CAUTION

WARNING

CAUTION

• The electronic thermal relay function does not guarantee

protection of the motor from overheating. It is recommended to

install both an external thermal and PTC thermistor for overheat

protection.

• Do not use a magnetic contactor on the inverter input for

frequent starting/stopping of the inverter. Otherwise the life of

the inverter decreases.

• The effect of electromagnetic interference must be reduced by

using a noise filter or by other means. Otherwise nearby

electronic equipment may be affected.

• Appropriate measures must be taken to suppress harmonics.

Otherwise power supply harmonics from the inverter may heat/

damage the power factor correction capacitor and generator.

• When driving a 400V class motor by the inverter, the motor must

be an insulation-enhanced motor or measures must be taken to

suppress surge voltage. Surge voltage attributable to the wiring

constants may occur at the motor terminals, deteriorating the

insulation of the motor.

• When parameter clear or all parameter clear is performed, the

required parameters must be set again before starting

operations because all parameters return to the initial value.

• The inverter can be easily set for high-speed operation. Before

changing its setting, the performances of the motor and machine

must be fully examined.

• Stop status cannot be hold by the inverter's brake function. In

addition to the inverter's brake function, a holding device must

be installed to ensure safety.

• Before running an inverter which had been stored for a long

period, inspection and test operation must be performed.

• For prevention of damage due to static electricity, nearby metal

must be touched before touching this product to eliminate static

electricity from your body.

• Do not connect an IPM motor under the general-purpose motor

control settings (initial settings). Do not use a general-purpose

motor under the IPM motor control settings. Doing so will cause

a failure.

• In the system with an IPM motor, the inverter power must be

turned ON before closing the contacts of the contactor at the

output side.

(5) Emergency stop

• A safety backup such as an emergency brake must be provided

to prevent hazardous condition to the machine and equipment in

case of inverter failure.

• When the breaker on the inverter input side trips, the wiring must

be checked for fault (short circuit), and internal parts of the

inverter for a damage, etc. The cause of the trip must be

identified and removed before turning ON the power of the

breaker.

• When any protective function is activated, appropriate corrective

action must be taken, and the inverter must be reset before

resuming operation.

CAUTION

A-2

(6) Maintenance, inspection and parts replacement

CAUTION

• Do not carry out a megger (insulation resistance) test on the

control circuit of the inverter. It will cause a failure.

(7) Disposing of the inverter

CAUTION

• The inverter must be treated as industrial waste.

General instructions

Many of the diagrams and drawings in this Instruction Manual

(Basic) show the inverter without a cover or partially open for

explanation. Never operate the inverter in this manner. The cover

must be always reinstalled and the instruction in this Instruction

Manual (Basic) must be followed when operating the inverter.

For more details on a dedicated IPM motor, refer to the Instruction

Manual of the dedicated IPM motor.

Page 4

— CONTENTS —

1 OUTLINE 1

1.1 Product checking and parts identification ..................................................................1

1.2 Step of operation ........................................................................................................2

2 INSTALLATION AND WIRING 3

2.1 Peripheral devices......................................................................................................4

2.2 Method of removal and reinstallation of the front cover.............................................6

2.3 Installation of the inverter and instructions.................................................................8

2.4 Wiring.......................................................................................................................... 9

2.4.1 Terminal connection diagram .................................................................................................... 9

2.4.2 EMC filter................................................................................................................................. 10

2.4.3 Specification of main circuit terminal ....................................................................................... 11

2.4.4 Terminal arrangement of the main circuit terminal, power supply and the motor wiring ......... 11

2.4.5 Control circuit terminals ........................................................................................................... 20

2.4.6 Changing the control logic ....................................................................................................... 23

2.4.7 Wiring of control circuit ............................................................................................................ 25

2.4.8 Mounting the operation panel (FR-DU07) on the enclosure surface ....................................... 26

2.4.9 RS-485 terminal block ............................................................................................................. 27

2.4.10 Communication operation........................................................................................................ 27

2.5 Connection of stand-alone option units.................................................................... 28

2.5.1 Connection of the brake unit (FR-BU2) ................................................................................... 28

2.5.2 Connection of the brake unit (FR-BU/MT-BU5) ....................................................................... 30

2.5.3 Connection of the brake unit (BU type) ................................................................................... 32

2.5.4 Connection of the high power factor converter (FR-HC/MT-HC)............................................. 32

2.5.5 Connection of the power regeneration common converter (FR-CV) (55K or lower)................ 34

2.5.6 Connection of the power regeneration converter (MT-RC) (75K or higher) ............................ 35

2.5.7 Connection of the power factor improving DC reactor (FR-HEL) ............................................ 36

CONTENTS

2.6 Power-OFF and magnetic contactor (MC)...............................................................37

2.7 Precautions for use of the inverter ........................................................................... 38

2.8 Failsafe of the system which uses the inverter ........................................................40

3 DRIVING THE IPM MOTOR <IPM> 41

3.1 Setting procedure of IPM motor control <IPM>.................................................... 41

3.2 Initializing the parameters required to drive an IPM motor (Pr.998) <IPM>......... 43

4 DRIVING THE MOTOR 46

4.1 Operation panel (FR-DU07) ..................................................................................... 46

4.1.1 Component of the operation panel (FR-DU07)........................................................................ 46

4.1.2 Basic operation (factory setting) .............................................................................................. 47

4.1.3 Easy operation mode setting (easy setting mode) .................................................................. 48

I

Page 5

4.1.4 Operation lock (Press [MODE] for an extended time (2s)) ...................................................... 49

4.1.5 Monitoring of output current and output voltage ...................................................................... 50

4.1.6 First priority monitor................................................................................................................. 50

4.1.7 Displaying the set frequency ................................................................................................... 50

4.1.8 Changing the parameter setting value..................................................................................... 51

4.2 Overheat protection of the motor by the inverter (Pr. 9) .......................................... 52

4.3 When the rated motor frequency is 50Hz (Pr. 3)<V/F><S MFVC> .........................53

4.4 Start/stop from the operation panel (PU operation mode).......................................54

4.4.1 Setting the set frequency to operate (example: performing operation at 30Hz) ...................... 54

4.4.2 Using the setting dial like a potentiometer at the operation ..................................................... 56

4.4.3 Setting the frequency by switches (three-speed setting) ......................................................... 57

4.4.4 Setting the frequency by analog input (voltage input) ............................................................. 59

4.4.5 Setting the frequency by analog input (current input) .............................................................. 60

4.5 Start/stop using terminals (External operation)........................................................61

4.5.1 Setting the frequency by the operation panel (Pr. 79 = 3) ....................................................... 61

4.5.2 Switching between the automatic operation and the manual operation (operation by the multi-

speed setting and the operation panel) (Pr.79=3) ................................................................... 63

4.5.3 Setting the frequency by switches (three-speed setting) (Pr. 4 to Pr. 6) ................................. 65

4.5.4 Setting the frequency by analog input (voltage input) ............................................................. 67

4.5.5 Changing the output frequency (60Hz, initial value) at the maximum voltage

input (5V, initial value) ............................................................................................................ 68

4.5.6 Setting the frequency by analog input (current input) .............................................................. 69

4.5.7 Changing the output frequency (60Hz, initial value) at the maximum current input

(at 20mA, initial value) ............................................................................................................. 70

5 ADJUSTMENT 71

5.1 Simple mode parameter list .....................................................................................71

5.2 Increasing the starting torque (Pr. 0) <V/F>............................................................. 73

5.3 Limiting the maximum and minimum output frequency (Pr. 1, Pr. 2) ......................74

5.4 Changing acceleration and deceleration time (Pr. 7, Pr. 8) ..................................... 75

5.5 Energy saving operation (Pr. 60) <V/F> .................................................................. 76

5.5.1 Energy saving operation (setting "4") ......................................................................................76

5.5.2 Optimum excitation control (setting "9")...................................................................................76

5.6 Selection of the start command and frequency command sources (Pr. 79) ...........78

5.7 Parameter clear, all parameter clear.................................................................... 79

5.8 Parameter copy and parameter verification ......................................................... 80

5.8.1 Parameter copy ....................................................................................................................... 80

5.8.2 Parameter verification.............................................................................................................. 81

5.9 Initial value change list......................................................................................... 82

5.10 Parameter list.......................................................................................................83

5.10.1 List of parameters classified by the purpose ........................................................................... 83

5.10.2 Display of the extended parameters........................................................................................86

5.10.3 Parameter list .......................................................................................................................... 87

6 TROUBLESHOOTING 116

II

Page 6

6.1 Reset method of protective function.......................................................................116

6.2 List of fault or alarm display.................................................................................... 117

6.3 Causes and corrective actions ............................................................................... 118

6.4 Correspondences between digital and actual characters......................................131

6.5 Check and clear of the faults history..................................................................132

6.6 Check first when you have a trouble......................................................................134

6.6.1 Motor does not start............................................................................................................... 134

6.6.2 Motor or machine is making abnormal acoustic noise........................................................... 136

6.6.3 Inverter generates abnormal noise........................................................................................ 136

6.6.4 Motor generates heat abnormally .......................................................................................... 136

6.6.5 Motor rotates in the opposite direction .................................................................................. 137

6.6.6 Speed greatly differs from the setting.................................................................................... 137

6.6.7 Acceleration/deceleration is not smooth ................................................................................ 137

6.6.8 Speed varies during operation............................................................................................... 138

6.6.9 Operation mode is not changed properly .............................................................................. 138

6.6.10 Operation panel (FR-DU07) display is not operating............................................................. 139

6.6.11 Motor current is too large....................................................................................................... 139

6.6.12 Speed does not accelerate.................................................................................................... 140

6.6.13 Unable to write parameter setting.......................................................................................... 140

6.6.14 Power lamp is not lit .............................................................................................................. 140

CONTENTS

7 PRECAUTIONS FOR MAINTENANCE AND INSPECTION 141

7.1 Inspection item .......................................................................................................141

7.1.1 Daily inspection ..................................................................................................................... 141

7.1.2 Periodic inspection ................................................................................................................ 141

7.1.3 Daily and periodic inspection................................................................................................. 142

7.1.4 Display of the life of the inverter parts ................................................................................... 143

7.1.5 Cleaning ................................................................................................................................ 145

7.1.6 Replacement of parts ............................................................................................................ 145

7.1.7 Inverter replacement.............................................................................................................. 149

8 SPECIFICATIONS 150

8.1 Rating .....................................................................................................................150

8.2 Common specifications ..........................................................................................152

8.3 Outline dimension drawings ................................................................................... 154

8.3.1 Inverter outline dimension drawings ...................................................................................... 154

8.4 Specification of premium high-efficiency IPM motor

[MM-EFS (1500r/min) series] ................................................................................. 163

8.5 Specification of high-efficiency IPM motor

[MM-EF (1800r/min) series].................................................................................... 164

8.6 Heatsink protrusion attachment procedure............................................................165

8.6.1 When using a heatsink protrusion attachment (FR-A7CN) ................................................... 165

8.6.2 Protrusion of heatsink of the FR-F740P-185K or higher ....................................................... 165

III

Page 7

APPENDICES 167

V/F

S

MFVC

IPM

Appendix 1 For customers who are replacing the conventional model

with this inverter ..................................................................................... 167

Appendix 1-1 Replacement of the FR-F500 series ......................................................................... 167

Appendix 1-2 Replacement of the FR-A100 <EXCELENT> series ................................................. 168

Appendix 2 SERIAL number check........................................................................... 168

Appendix 3 Instructions for UL and cUL compliance ............................................... 169

Appendix 4 Instructions for compliance with the EU Directives ............................... 171

Appendix 5 Compliance with the Radio Waves Act (South Korea).......................... 173

<Abbreviations>

DU: Operation panel (FR-DU07)

PU: Operation panel(FR-DU07) and parameter unit (FR-PU04/FR-PU07)

Inverter: Mitsubishi inverter FR-F700P series

FR-F700P: Mitsubishi inverter FR-F700P series

Pr.: Parameter Number (Number assigned to function)

PU operation: Operation using the PU (FR-DU07/FR-PU04/FR-PU07)

External operation: Operation using the control circuit signals

Combined operation: Combined operation using the PU (FR-DU07/FR-PU04/FR-PU07) and external operation

General-purpose motor: Three-phase induction motor

Standard motor: SF-JR

Constant-torque motor: SF-HRCA

Dedicated IPM motor:High-efficiency IPM motor MM-EF (1800r/min specification)

Premium high-efficiency IPM motor MM-EFS (1500r/min specification)

The following marks are used to indicate the controls as below.

(Parameters without any mark are valid for all controls.)

Mark Control method Applied motor (control)

V/F control

Simple magnetic flux

vector control

IPM motor control

Three-phase induction motor

(general-purpose motor control)

Dedicated IPM motor

(IPM motor control)

S

S

IPM

IPM

V/F

V/F

MFVC

MFVC

<Trademarks>

ONWORKS

L

®

is registered trademarks of Echelon Corporation in the U.S.A. and other countries.

Company and product names herein are the trademarks and registered trademarks of their respective owners.

IV

Page 8

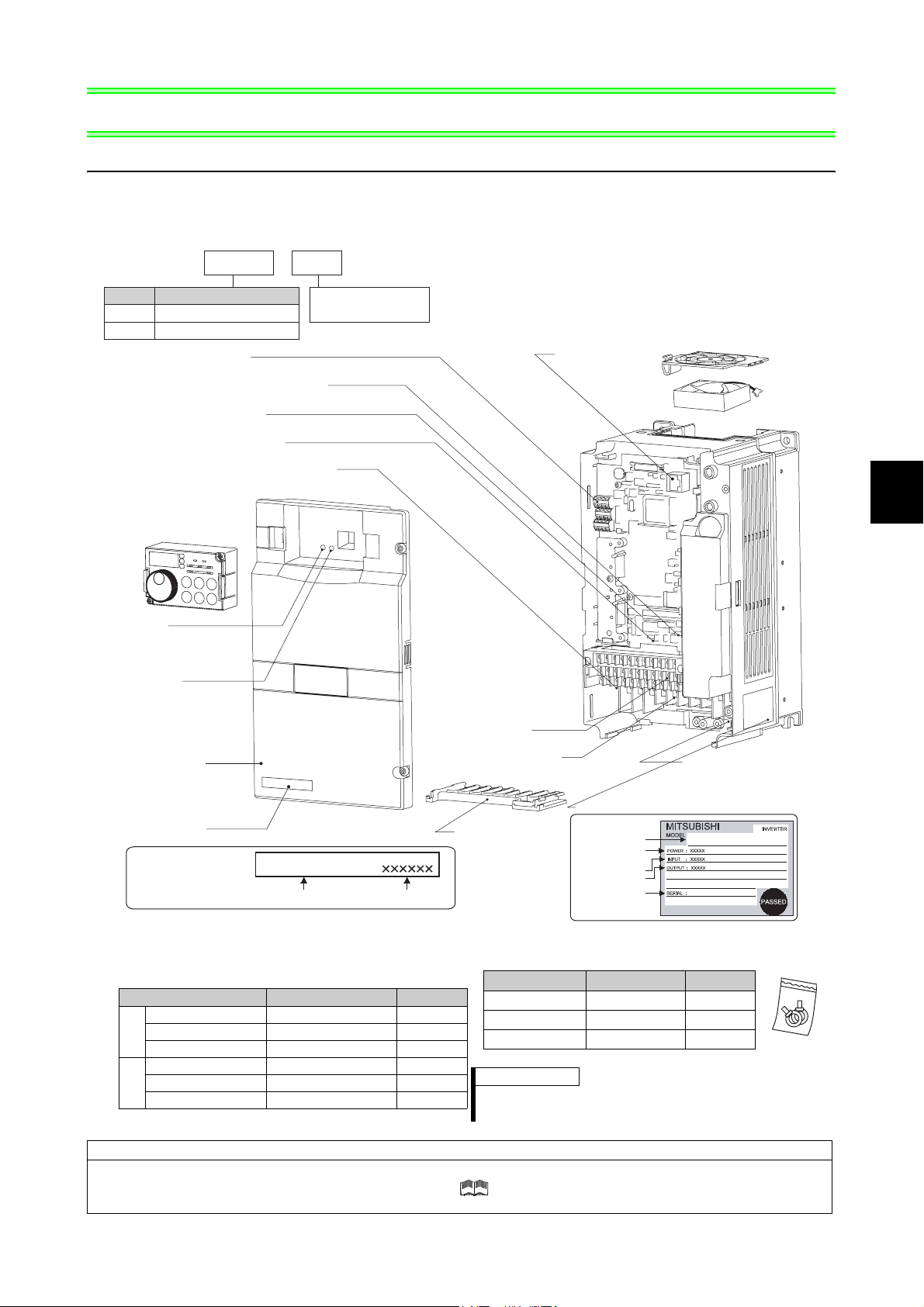

Product checking and parts identification

1 OUTLINE

1.1 Product checking and parts identification

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to

ensure that the product agrees with your order and the inverter is intact.

• Inverter Model

FR --F740P

Symbol

F720P

F740P

Connector for plug-in option connection

(Refer to the Instruction Manual of options.)

Voltage/current input switch

(Refer to page 9)

Operation panel (FR-DU07)

(Refer to page 6)

Power lamp

Lit when the control circuit

(R1/L11, S1/L21) is supplied

with power.

Alarm lamp

Lit when the inverter is

in the alarm status

(fault).

Voltage Class

Three-phase 200V class

Three-phase 400V class

RS-485 terminals

(Refer to page 27)

AU/PTC switchover switch

(Refer to Chapter 4 of the Instruction Manual (Applied).)

EMC filter ON/OFF connector

(Refer to page 10)

Front cover

(Refer to page 6)

Capacity plate

Capacity plate

5.5

Represents inverter

capacity (kW)

FR-F740P-5.5K

Inverter model

K

Main circuit terminal block

(Refer to page 20)

Serial number

Control circuit

terminal block

(Refer to page 11)

Combed shaped

wiring cover

(Refer to page 14)

PU connector

(Refer to page 26)

Rating plate

Rating plate

Inverter model

Applied motor

capacity

Input rating

Output rating

Serial number

Cooling fan

(Refer to page 146)

Charge lamp

Lit when power is

supplied to the main

circuit

(Refer to page 11)

FR-F740P-5.5K

1

OUTLINE

• Accessory

· Fan cover fixing screws (30K or lower)

(Refer to page 171)

Capacity Screw Size (mm) Quantity

2.2K to 5.5K M3 × 35 1

7.5K to 15K M4 × 40 2

200V

18.5K to 30K M4 × 50 1

3.7K, 5.5K M3 × 35 1

7.5K to 18.5K M4 × 40 2

400V

22K, 30K M4 × 50 1

· DC reactor supplied (75K or higher)

· Eyebolt for hanging the inverter (37K to 315K)

Capacity Eyebolt Size Quantity

37K M8 2

45K to 160K M10 2

185K to 315K M12 2

REMARKS

·

For removal and reinstallation of covers, refer to page 6.

· For how to find the SERIAL number, refer to page 168.

Harmonic suppression guideline

All models of General-purpose inverters used by specific consumers are covered by "Harmonic suppression guideline for

consumers who receive high voltage or special high voltage". ( For further details, refer to Chapter 3 of the Instruction

Manual (Applied) .)

1

Page 9

Step of operation

Step of operation

p

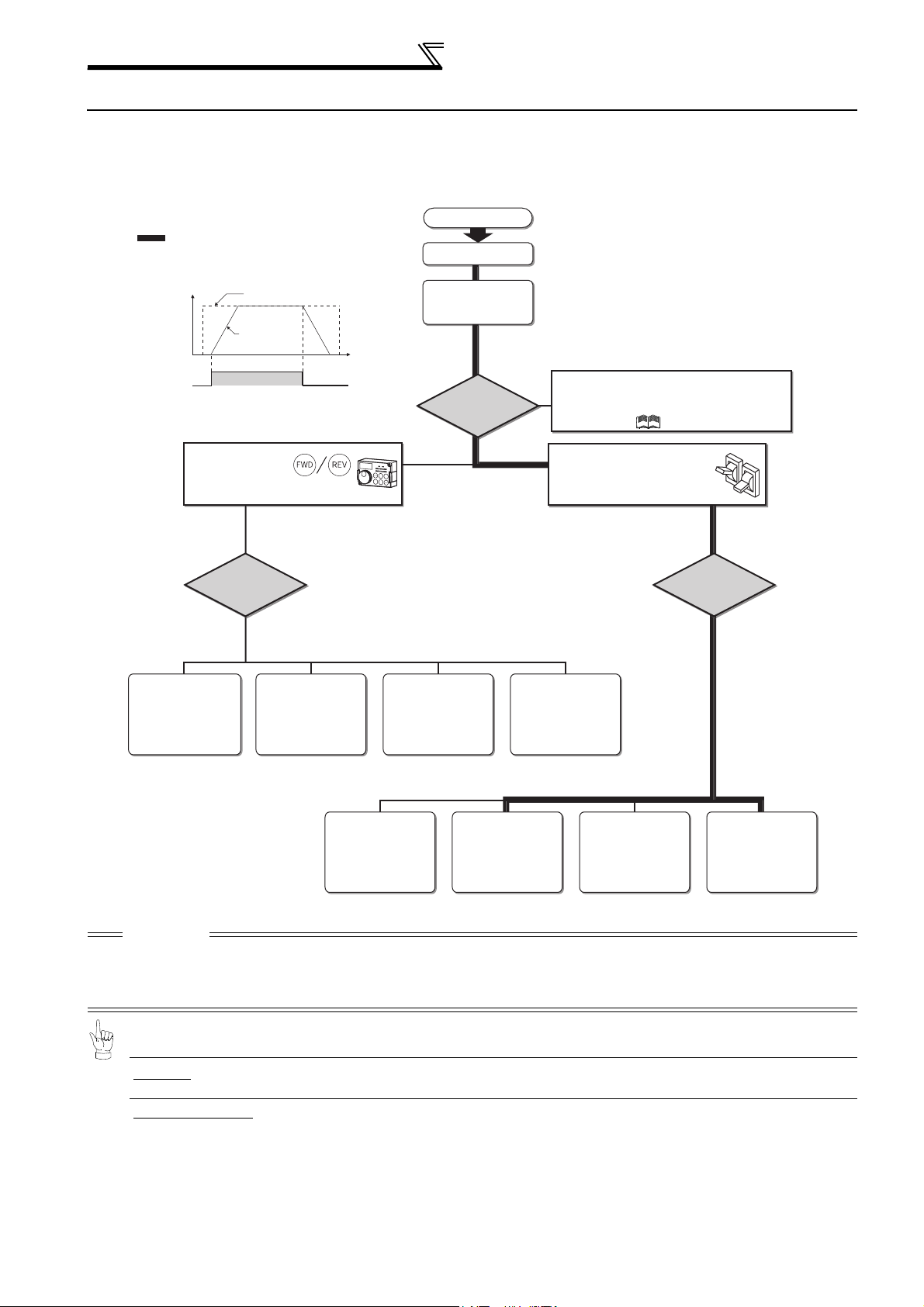

1.2 Step of operation

The inverter needs frequency command and start command. Frequency command (set frequency) determines the

rotation speed of the motor. Turning ON the start command starts the motor to rotate.

Refer to the flow chart below to perform setting.

Step of operation

o

: Initial setting

Installation/mounting

{Refer to page 8}

Frequency command

Inverter

output

Frequency

(Hz)

Frequency

command

Start command with

on the operation panel (PU)

Set from the

PU (FR-DU07/

FR-PU04/FR-PU07).

(PU)

{Refer to page 54} {Refer to page 57} {Refer to page 60} {Refer to page 59}

frequency

ON

How to

give a frequency

command?

Change frequency

with ON/OFF switches

connected to terminals

(multi-speed setting)

Time

(S)

(External) (External) (External)

Wiring of the power

supply and motor

How

to give a start

command?

Perform frequency

setting by a current

output device

(Connection across

terminals 4 and 5)

{Refer to page 11}

Start command using the PU connector and

RS-485 terminal of the inverter and plug-in

option (Communication)

Refer to Chapter 4 of the Instruction Manual (Applied) .

Connect a switch, relay, etc.

to the control circuit

terminal block of the inverter

to give a start command. (External)

Perform frequency

setting by a voltage

output device

(Connection across

terminals 2 and 5)

How to

give a frequency

command?

Set from the

PU (FR-DU07/

FR-PU04/FR-PU07).

(PU) (External) (External) (External)

{Refer to page 61} {Refer to page 65} {Refer to page 69} {Refer to page 67}

Change of frequency

with ON/OFF switches

connected to terminals

(multi-speed setting)

Perform frequency

setting by a current

output device

(Connection across

terminals 4 and 5)

Perform frequency

setting by a voltage

output device

(Connection across

terminals 2 and 5)

CAUTION

Check the following points before powering ON the inverter.

· Check that the inverter is installed correctly in a correct place. (Refer to page 8)

· Check that wiring is correct. (Refer to page 9)

· Check that no load is connected to the motor.

·When protecting the motor from overheat by the inverter, set Pr.9 Electronic thermal O/L relay (Refer to

page 52)

·To drive a general-purpose motor with the rated motor frequency of 50Hz, set Pr.3 Base frequency

(Refer to page 53)

2

Page 10

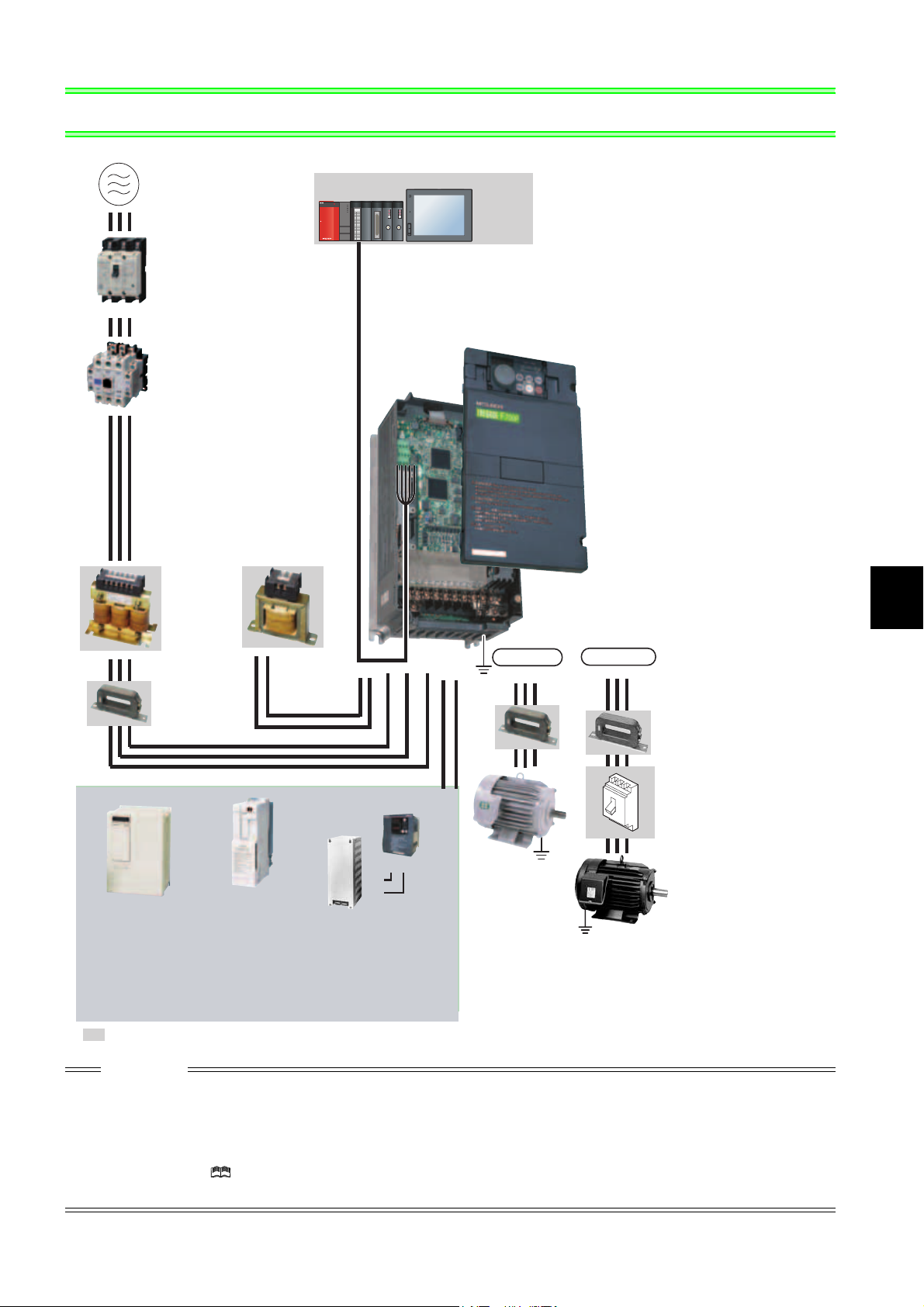

2 INSTALLATION AND WIRING

Three-phase AC power supply

Use within the permissible power supply

specifications of the inverter.

(Refer to page 150)

Moulded case circuit

breaker (MCCB)

or earth leakage circuit

breaker (ELB), fuse

The breaker must be selected carefully since

an in-rush current flows in the inverter at

power on.

(Refer to page 4)

Magnetic contactor(MC)

Install the magnetic contactor to ensure safety.

Do not use this magnetic contactor to start and stop

the inverter.

Doing so will cause the inverter life to be shortened.

(Refer to page 4)

Reactor (FR-HAL, FR-HEL)

Install reactors to suppress harmonics and to

improve the power factor. An AC reactor (FR-HAL)

(option) is required when installing the inverter near

a large power supply system (1000kVA or more).

The inverter may be damaged if you do not use

reactors.

Select the reactor according to the model.

For the 55K or lower, remove the jumpers across

terminals P/+ and P1 to connect to the DC reactor.

(Refer to Chapter 3 of

the Instruction Manual (Applied) .)

AC reactor

(FR-HAL)

DC reactor

(FR-HEL)

EMC filter

(ferrite core)

(FR-BLF)

The 55K or lower has a built-in

common mode choke.

(Refer to Chapter 3 of

the Instruction Manual (Applied) .)

For the 75K or higher, a

DC reactor is supplied.

Always install the reactor.

(Refer to page 36)

Power regeneration

High power factor

converter

*1

, MT-HC*2)

(FR-HC

Power supply harmonics

can be greatly suppressed.

Install this as required.

(Refer to page 32) (Refer to page 34 and 35)

*1 Compatible with the 55K or lower.

*2 Compatible with the 75K or higher.

: Install these options as required.

common converter

*1

)

(FR-CV

Power regeneration

converter (MT-RC

Greater braking capability

is obtained.

Install this as required.

*2

)

Programmable

controller

POWER

MODE

RUN

ERR

USER

BAT

BOOT

PULL

USB

PULL

Human machine interface

RUN

MNG

RUN

MNG

T.PASS

D.LINK

T.PASS

D.LINK

SD

RD

SD

RD

ERR

ERR

ERR

ERR

RS-485 terminal block

The inverter can be connected with a

computer such as a programmable

controller and with GOT (human

machine interface).

They support Mitsubishi inverter

protocol and Modbus-RTU (binary)

protocol.

R/L1 S/L2 T/L3

P/+

P1

Brake unit

*1

P/+

PR

, MT-BU5*2)

PR

P/+

(FR-BU2, FR-BU

Resistor unit

*1

, MT-BR5*2)

(FR-BR

The regeneration braking

capability of the inverter can be

exhibited fully.

Install this as required.

(Refer to page 28)

Inverter (FR-F700P)

The life of the inverter is influenced by surrounding

air temperature. The surrounding air temperature

should be as low as possible within the permissible

range. Especially when mounting the inverter

inside an enclosure, take cautions of the

surrounding air temperature. (Refer to page 8)

Wrong wiring might lead to damage of the inverter.

The control signal lines must be kept fully away

from the main circuit to protect them from noise.

(Refer to page 9)

Refer to page 10 for the built-in EMC filter.

IPM connection

U VW

N/-P/+

Earth

IM connection

UVW

(Ground)

Generalpurpose

motor

Earth

(Ground)

Devices connected

to the output

Do not install a power

factor correction capacitor,

surge suppressor or EMC filter (capacitor) on the

output side of the inverter.

When installing a moulded case circuit breaker on

the output side of the inverter, contact each

manufacturer for selection of the moulded case

circuit breaker.

Earth (Ground)

To prevent an electric shock, always earth

(ground) the motor and inverter.

Earth

(Ground)

EMC filter

(ferrite core)

(FR-BSF01, FR-BLF)

Install an EMC filter (ferrite

core) to reduce the

electromagnetic noise

generated from the inverter.

Effective in the range from

about 0.5MHz to 5MHz.

A wire should be wound four

turns at a maximum.

(Refer to Chapter 3 of the

Instruction Manual (Applied) .)

Contactor

Example) No-fuse

switch (DSN type)

Install a contactor in an

application where the IPM

motor is driven by the load

even at power-OFF of the

inverter. Do not open or

close the contactor while

the inverter is running

(outputting).

Dedicated IPM motor

(MM-EFS, MM-EF)

Use the specified motor.

IPM motors cannot be driven

by the commercial power

supply.

(Refer to page 163 and 164)

2

INSTALLATION AND WIRING

CAUTION

· Do not install a power factor correction capacitor, surge suppressor or capacitor type filter on the inverter output side. This will

cause the inverter to trip or the capacitor, and surge suppressor to be damaged. If any of the above devices are connected,

immediately remove them.

· Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the communication

devices (such as AM radios) used near the inverter. In this case, set the EMC filter valid to minimize interference.

(Refer to Chapter 2 of the Instruction Manual (Applied).)

· Refer to the instruction manual of each option and peripheral devices for details of peripheral devices.

· An IPM motor cannot be driven by the commercial power supply.

3

Page 11

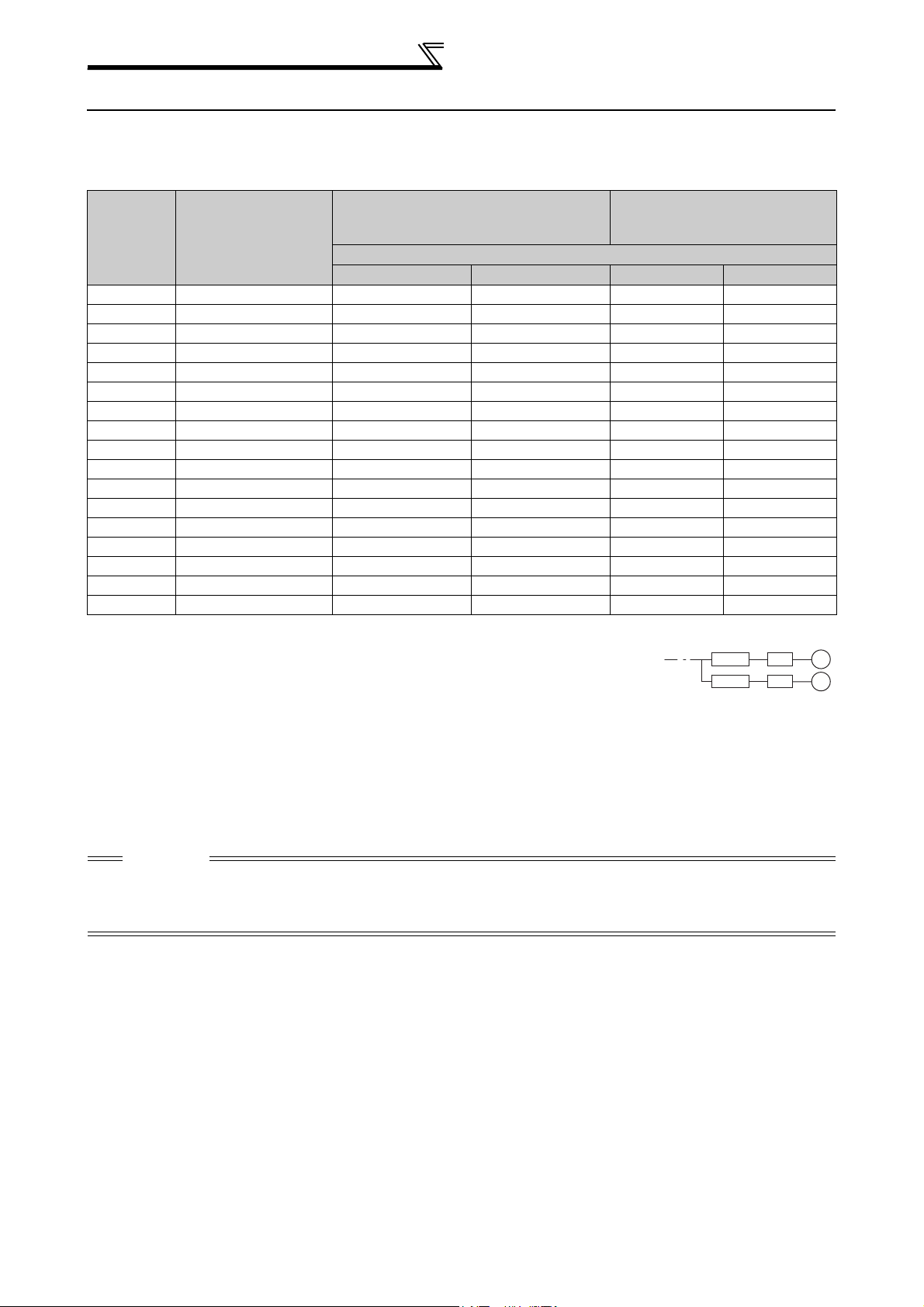

Peripheral devices

2.1 Peripheral devices

Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according

to the capacity. Refer to the following list and prepare appropriate peripheral devices:

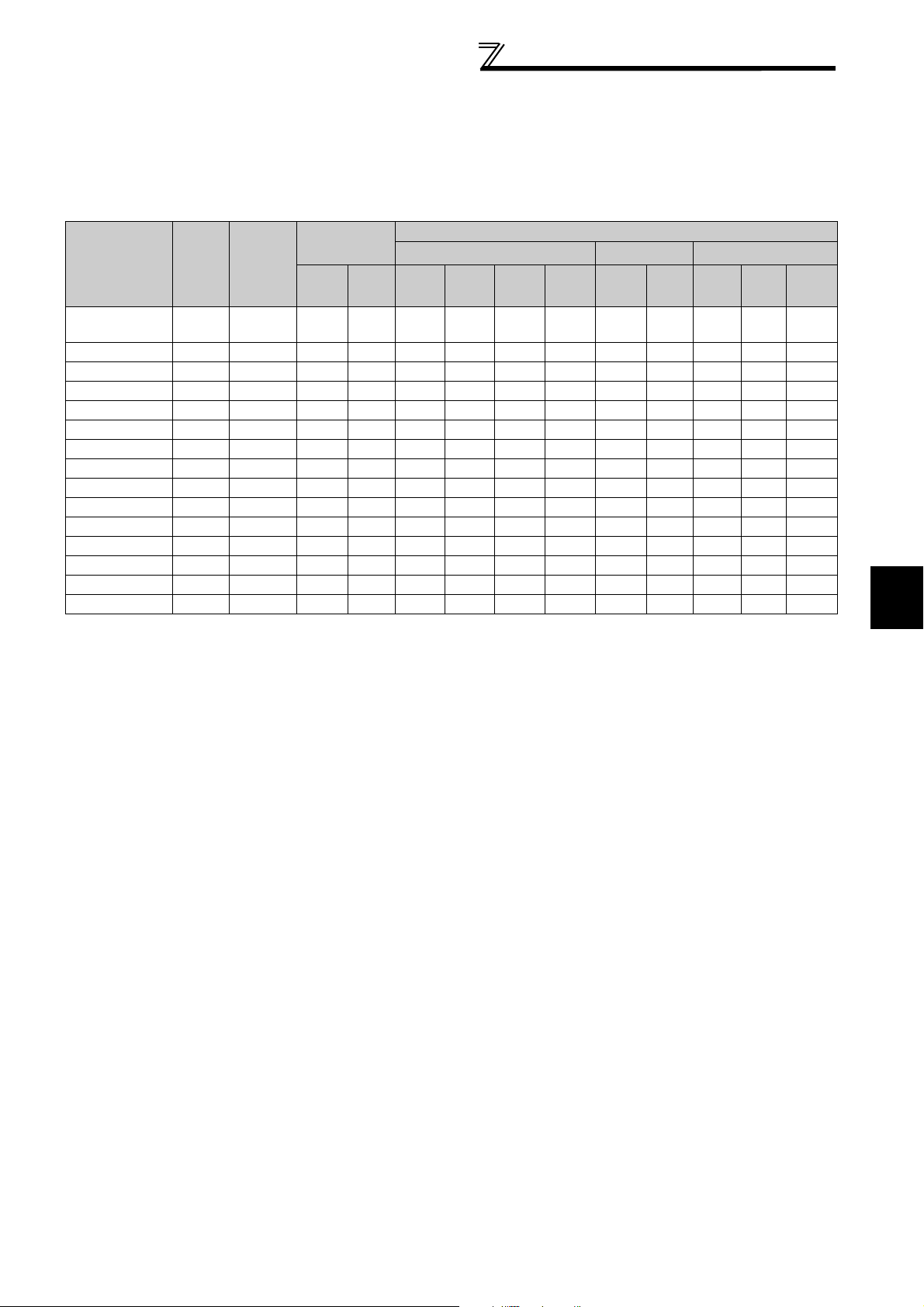

200V class

Moulded Case Circuit Breaker (MCCB) *2

Motor

Output (kW)

*1

Applicable Inverter

Model

or Earth Leakage Circuit Breaker (ELB)

(NF or NV type)

Power factor improving (AC or DC) reactor

Without With Without With

0.75 FR-F720P-0.75K 10A 10A S-N10 S-N10

1.5 FR-F720P-1.5K 15A 15A S-N10 S-N10

2.2 FR-F720P-2.2K 20A 15A S-N10 S-N10

3.7 FR-F720P-3.7K 30A 30A S-N20, S-N21 S-N10

5.5 FR-F720P-5.5K 50A 40A S-N25 S-N20, S-N21

7.5 FR-F720P-7.5K 60A 50A S-N25 S-N25

11 FR-F720P-11K 75A 75A S-N35 S-N35

15 FR-F720P-15K 125A 100A S-N50 S-N50

18.5 FR-F720P-18.5K 150A 125A S-N65 S-N50

22 FR-F720P-22K 175A 150A S-N80 S-N65

30 FR-F720P-30K 225A 175A S-N95 S-N80

37 FR-F720P-37K 250A 225A S-N150 S-N125

45 FR-F720P-45K 300A 300A S-N180 S-N150

55 FR-F720P-55K 400A 350A S-N220 S-N180

75 FR-F720P-75K ⎯ 400A ⎯

90 FR-F720P-90K ⎯ 400A ⎯

110 FR-F720P-110K ⎯ 500A ⎯

*1 Selections for use of the Mitsubishi 4-pole standard motor with power supply voltage of 200VAC 50Hz.

*2 Select the MCCB according to the power supply capacity.

Install one MCCB per inverter.

For using commercial-power supply operation, select a breaker with capacity which allows the motor to be

directly power supplied.

For installation in the United States, Class RK5, Class J, Class CC, Class L, Class T or any faster acting

fuses or UL 489 Molded Case Circuit Breaker (MCCB) must be provided, in accordance with the National

Electrical Code and any applicable local codes.

For installation in Canada, Class RK5, Class J, Class CC, Class L, Class T or any faster acting fuses or UL

489 Molded Case Circuit Breaker (MCCB) must be provided, in accordance with the Canada Electrical

Code and any applicable provincial codes. (Refer to page 169.)

*3 Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic

contactor is used for emergency stop during motor driving, the electrical durability is 25 times.

When using the MC for emergency stop during motor driving or using on the motor side during commercial-power supply operation, select the

MC with class AC-3 rated current for the motor rated current.

Input Side Magnetic Contactor*3

S-N300

S-N300

S-N400

MCCB INV

MCCB INV

M

M

CAUTION

⋅ When the inverter capacity is larger than the motor capacity, select an MCCB and a magnetic contactor according to the

inverter model, and select cable and reactor according to the motor output.

⋅ When the breaker on the inverter primary side trips, check for the wiring fault (short circuit), damage to internal parts of the

inverter, etc. Identify the cause of the trip, then remove the cause and power ON the breaker.

4

Page 12

Peripheral devices

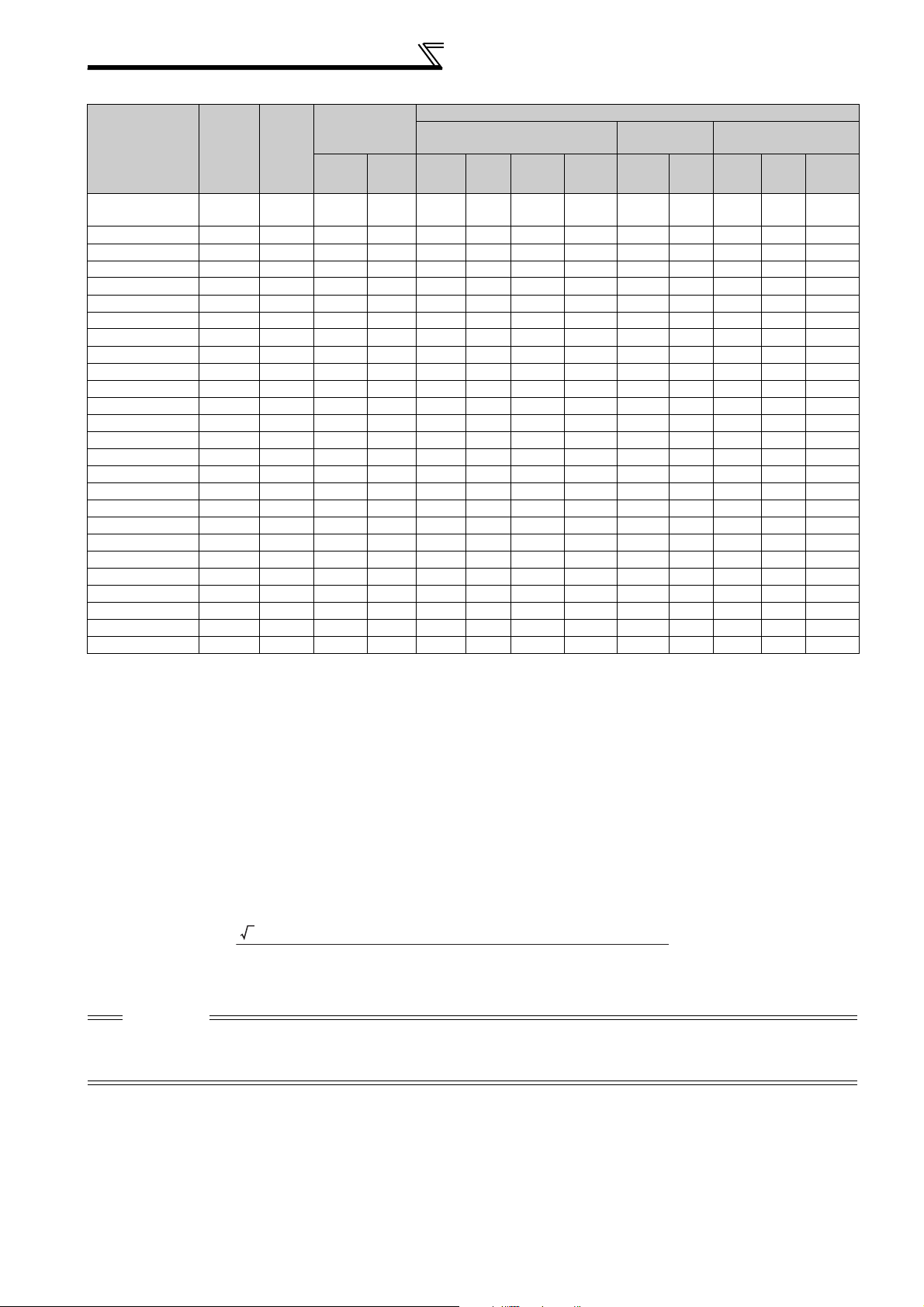

400V class

Motor

Output

(kW)

*1

Applicable Inverter

Model

0.75 FR-F740P-0.75K 5A 5A S-N10 S-N10

1.5 FR-F740P-1.5K 10A 10A S-N10 S-N10

2.2 FR-F740P-2.2K 10A 10A S-N10 S-N10

3.7 FR-F740P-3.7K 20A 15A S-N10 S-N10

5.5 FR-F740P-5.5K 30A 20A S-N20, S-N21 S-N11, S-N12

7.5 FR-F740P-7.5K 30A 30A S-N20, S-N21 S-N20, S-N21

11 FR-F740P-11K 50A 40A S-N20, S-N21 S-N20, S-N21

15 FR-F740P-15K 60A 50A S-N25 S-N20, S-N21

18.5 FR-F740P-18.5K 75A 60A S-N25 S-N25

22 FR-F740P-22K 100A 75A S-N35 S-N25

30 FR-F740P-30K 125A 100A S-N50 S-N50

37 FR-F740P-37K 150A 125A S-N65 S-N50

45 FR-F740P-45K 175A 150A S-N80 S-N65

55 FR-F740P-55K 200A 175A S-N80 S-N80

75 FR-F740P-75K ⎯ 225A ⎯ S-N95

90 FR-F740P-90K ⎯ 225A ⎯ S-N150

110 FR-F740P-110K ⎯ 225A ⎯ S-N180

132 FR-F740P-132K ⎯ 400A ⎯ S-N220

150 FR-F740P-160K ⎯ 400A ⎯ S-N300

160 FR-F740P-160K ⎯ 400A ⎯ S-N300

185 FR-F740P-185K ⎯ 400A ⎯ S-N300

220 FR-F740P-220K ⎯ 500A ⎯ S-N400

250 FR-F740P-250K ⎯ 600A ⎯ S-N600

280 FR-F740P-280K ⎯ 600A ⎯ S-N600

315 FR-F740P-315K ⎯ 700A ⎯ S-N600

355 FR-F740P-355K ⎯ 800A ⎯ S-N600

400 FR-F740P-400K ⎯ 900A ⎯ S-N800

450 FR-F740P-450K ⎯ 1000A ⎯

500 FR-F740P-500K ⎯ 1200A ⎯

560 FR-F740P-560K ⎯ 1500A ⎯

*1 Selections for use of the Mitsubishi 4-pole standard motor with power supply voltage of 400VAC 50Hz.

*2 Select the MCCB according to the power supply capacity.

Install one MCCB per inverter.

For using commercial-power supply operation, select a breaker with capacity which allows the motor to be

directly power supplied.

For installation in the United States, Class RK5, Class J, Class CC, Class L, Class T or any faster acting

fuses or UL 489 Molded Case Circuit Breaker (MCCB) must be provided, in accordance with the National

Electrical Code and any applicable local codes.

For installation in Canada, Class RK5, Class J, Class CC, Class L, Class T or any faster acting fuses or UL

489 Molded Case Circuit Breaker (MCCB) must be provided, in accordance with the Canada Electrical

Code and any applicable provincial codes. (Refer to page 169.)

*3 Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic

contactor is used for emergency stop during motor driving, the electrical durability is 25 times.

When using the MC for emergency stop during motor driving or using on the motor side during commercial-power supply operation, select the

MC with class AC-3 rated current for the motor rated current.

CAUTION

⋅ When the inverter capacity is larger than the motor capacity, select an MCCB and a magnetic contactor according to the

inverter model, and select cable and reactor according to the motor output.

⋅ When the breaker on the inverter primary side trips, check for the wiring fault (short circuit), damage to internal parts of the

inverter, etc. Identify the cause of the trip, then remove the cause and power ON the breaker.

Moulded Case Circuit Breaker (MCCB) *2

or Earth Leakage Circuit Breaker (ELB)

Input Side Magnetic Contactor*3

(NF or NV type)

Power factor improving (AC or DC) reactor

Without With Without With

1000A

Rated product

1000A

Rated product

1200A

Rated product

MCCB INV

MCCB INV

M

M

2

INSTALLATION AND WIRING

5

Page 13

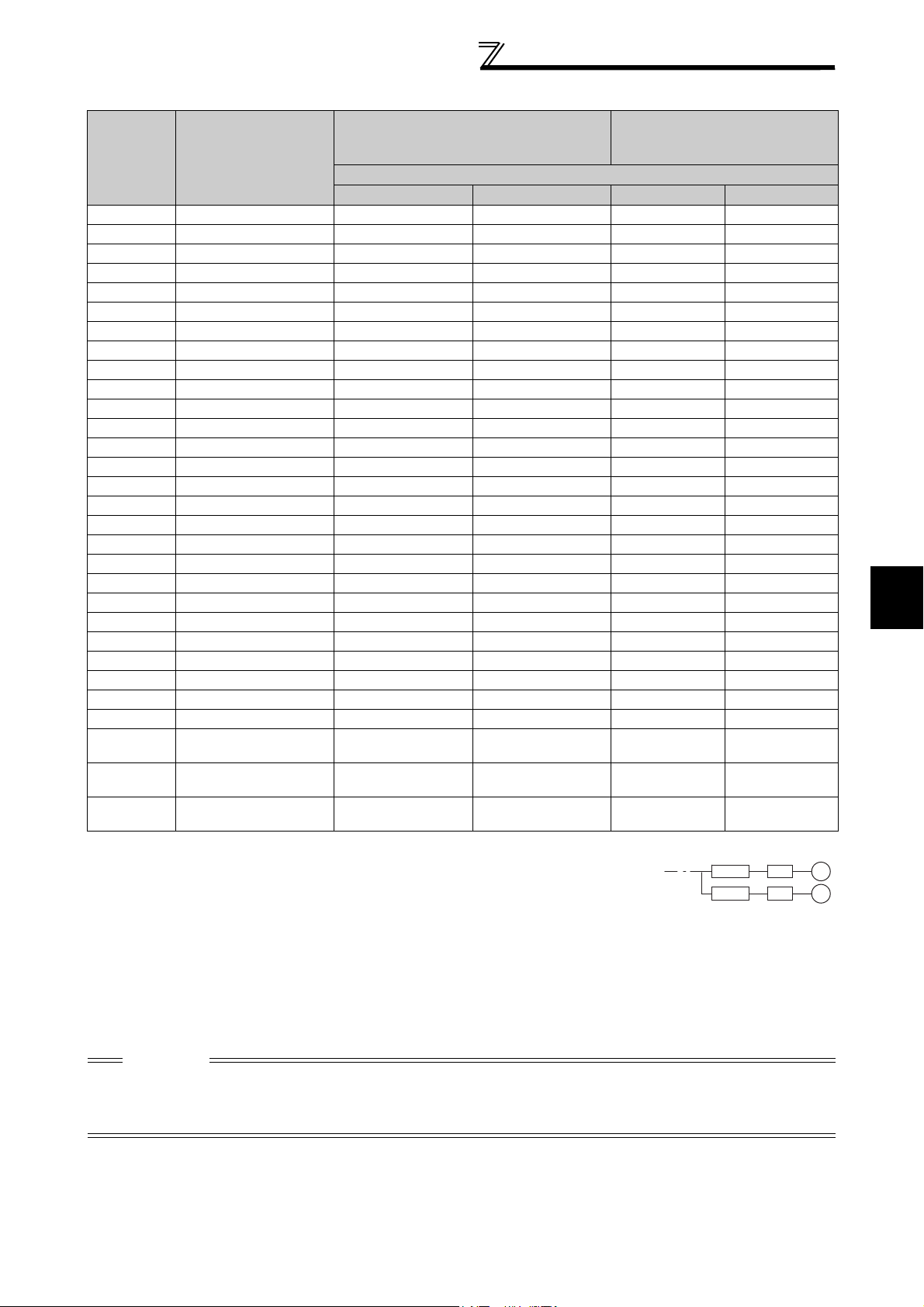

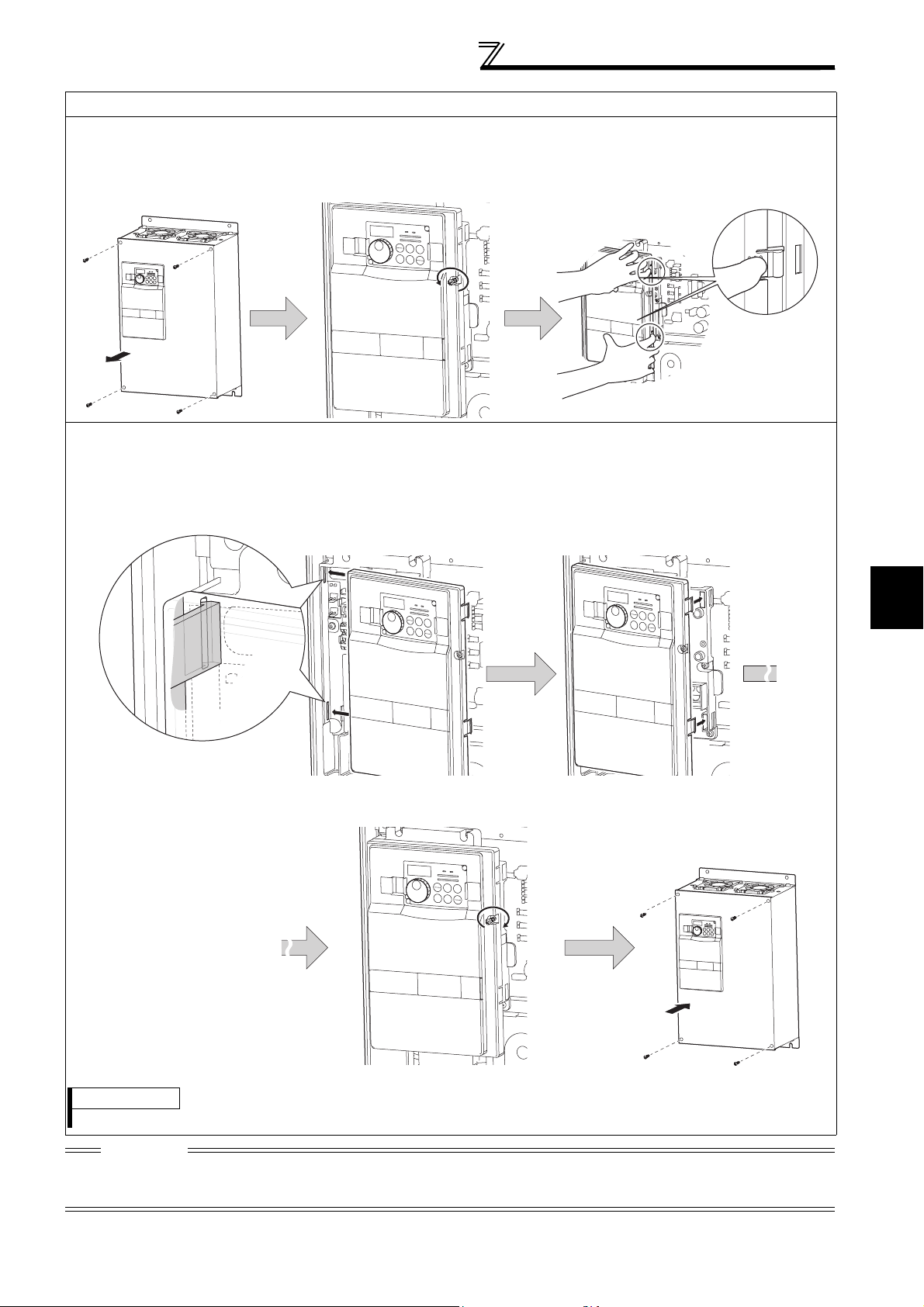

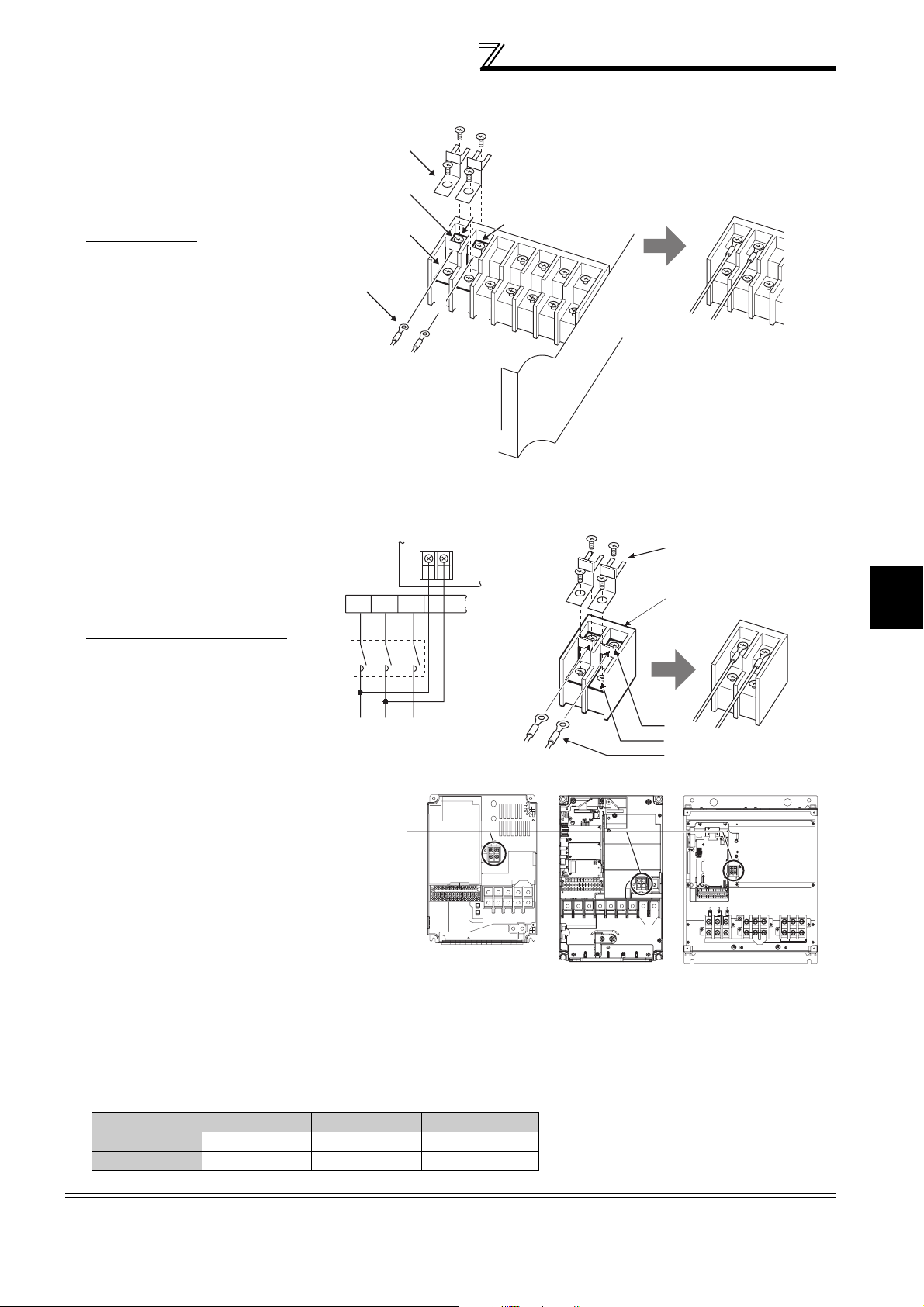

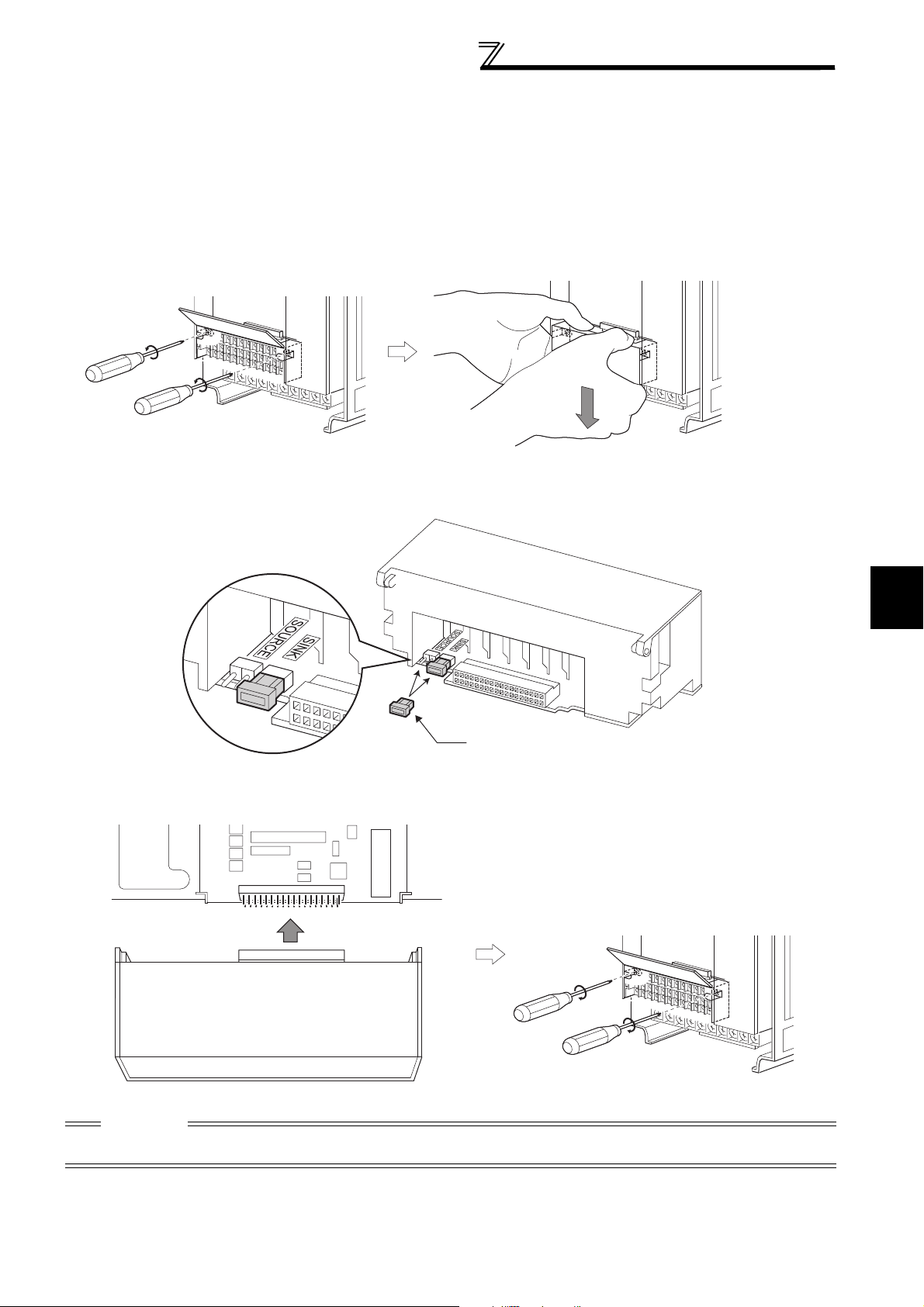

Method of removal and reinstallation of the

front cover

2.2 Method of removal and reinstallation of the front cover

•Removal of the operation panel

1) Loosen the two screws on the operation panel.

(These screws cannot be removed.)

When reinstalling the operation panel, insert it straight to reinstall securely and tighten the fixed screws of the

operation panel.

2) Push the left and right hooks of the operation panel

and pull the operation panel toward you to remove.

FR-F720P-30K or lower, FR-F740P-30K or lower

•

Removal

1) Loosen the installation screws of the

front cover.

Front cover

2) Pull the front cover toward you to remove by pushing an

installation hook using left fixed hooks as supports.

Front cover

•Reinstallation

1) Insert the two fixed hooks on the left side of

the front cover into the sockets of the

inverter.

2) Using the fixed hooks as supports,

securely press the front cover

against the inverter.

(Although installation can be done

with the operation panel mounted,

make sure that a connector is

securely fixed.)

Installation hook

3) Tighten the installation

screws and fix the front

cover.

Front cover

Front cover

Front cover

6

Page 14

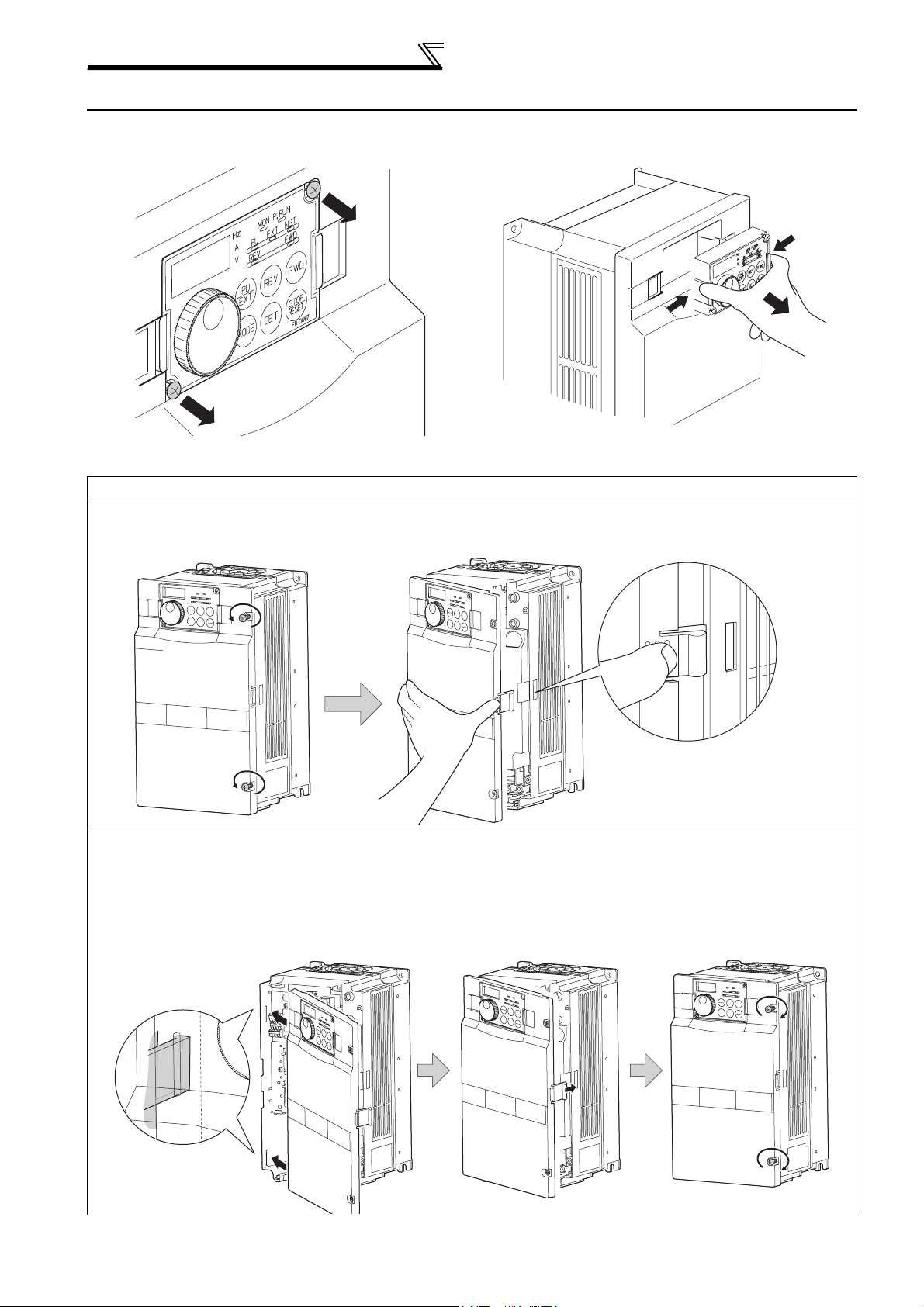

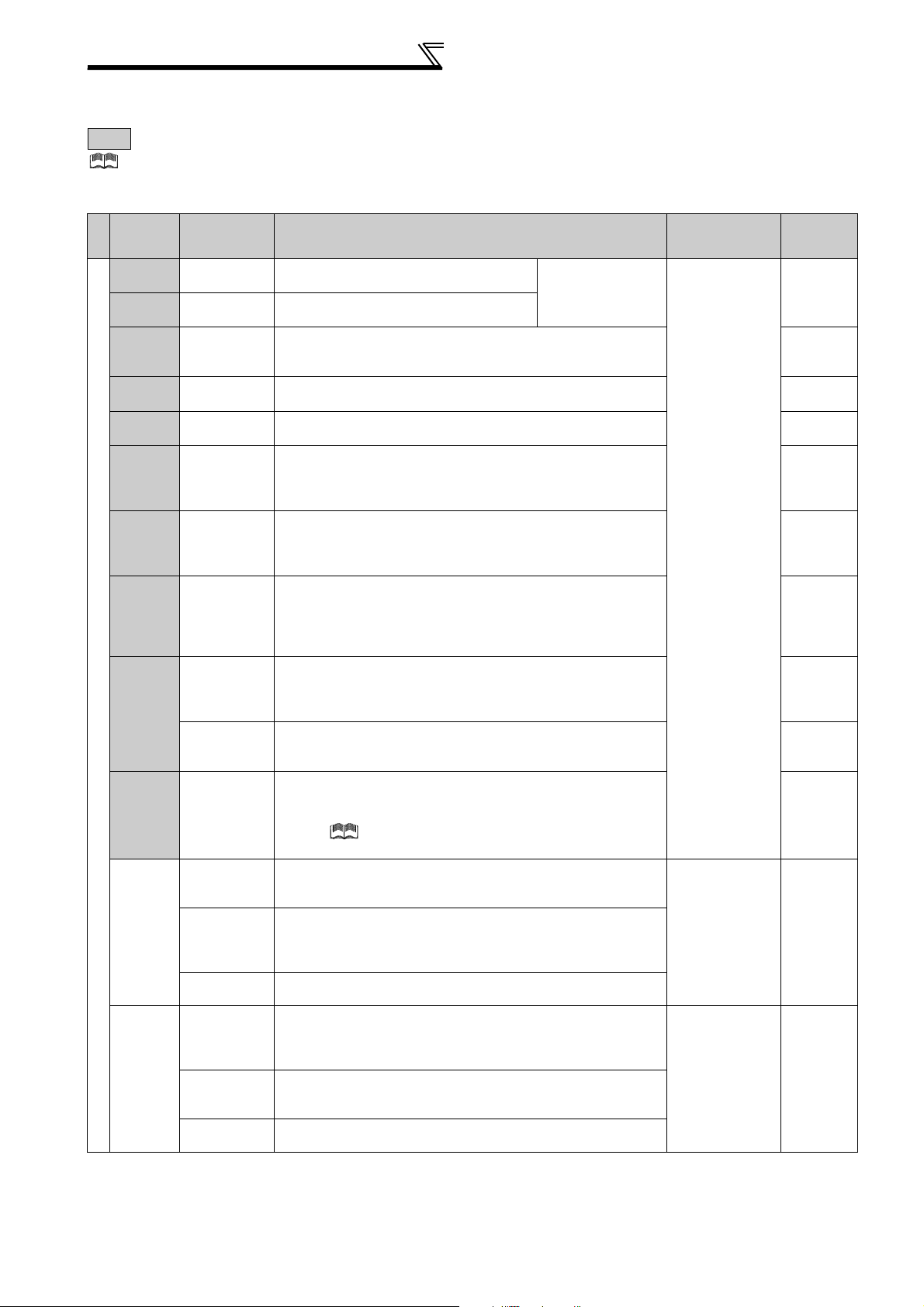

FR-F720P-37K or higher, FR-F740P-37K or higher

•

Removal

1) Remove installation screws on

the front cover 1 to remove the

2) Loosen the installation

screws of the front cover 2.

front cover 1.

Front cover 1

Front cover 2

•Reinstallation

1) Insert the two fixed hooks on the left side of the

front cover 2 into the sockets of the inverter.

Method of removal and reinstallation of the

front cover

3) Pull the front cover 2 toward you to

remove by pushing an installation

hook on the right side using left

fixed hooks as supports.

Installation hook

2) Using the fixed hooks as supports, securely

press the front cover 2 against the inverter.

(Although installation can be done with the

operation panel mounted, make sure that a

connector is securely fixed.)

Front cover 2 Front cover 2

3) Fix the front cover 2 with the

installation screws.

Front cover 2

2

4) Fix the front cover 1 with the

installation screws.

INSTALLATION AND WIRING

Front cover 1

REMARKS

⋅ For the FR-F740P-185K or higher, the front cover 1 is separated into two parts.

CAUTION

Fully make sure that the front cover has been reinstalled securely. Always tighten the installation screws of the front cover.

The same serial number is printed on the capacity plate of the front cover and the rating plate of the inverter. Before reinstalling the

front cover, check the serial numbers to ensure that the cover removed is reinstalled to the inverter from where it was removed.

7

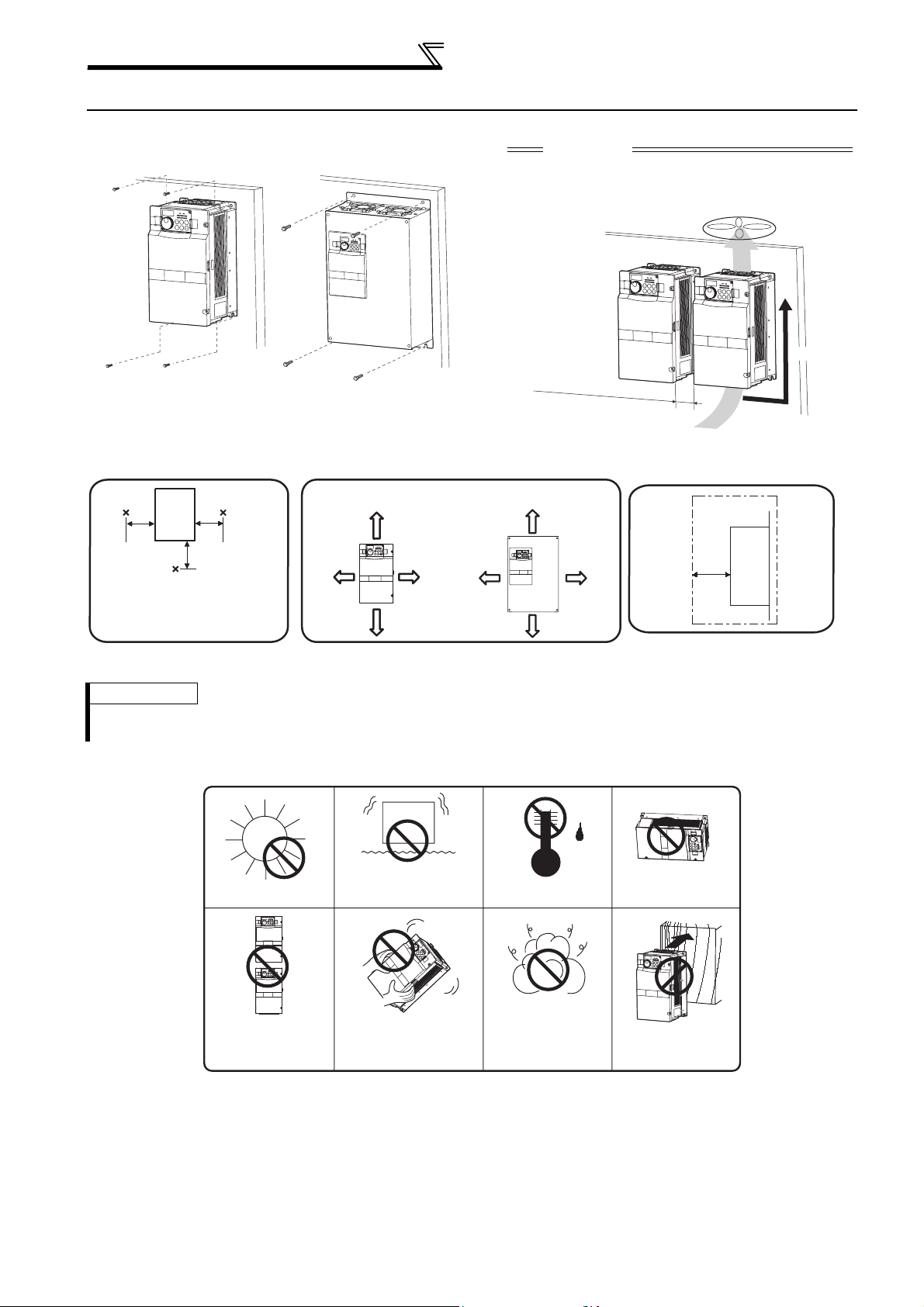

Page 15

Installation of the inverter and instructions

2.3 Installation of the inverter and instructions

• Installation of the Inverter

Installation on the enclosure

30K or lower 37K or higher

CAUTION

⋅ When encasing multiple inverters, install them in

parallel as a cooling measure.

⋅ Install the inverter vertically.

Vertical

Fix six points for the FR-F740P-185K

to 400K and fix eight points for the

FR-F740P-450K to 560K.

Refer to the clearances below.

• Install the inverter under the following conditions.

Surrounding air temperature and humidity

Measurement

position

Inverter

5cm

Measurement

position

5cm

5cm

Temperature: -10°C to 50°C

Humidity: 90% RH maximum

Leave enough clearances as a

cooling measure.

Clearances

55K or lower 75K or higher

10cm or more

5cm

or more *

5cm

or more *

10cm or more

*1cm or more for 3.7K or lower

(front)

10cm

or more

20cm or more

10cm

or more

20cm or more

Clearances (side)

Inverter

5cm

or more

*

*1cm or more for 3.7K or lower

REMARKS

•

For replacing the cooling fan of the FR-F740P-185K or higher, 30cm of space is necessary in front of the inverter.

Refer to page 146 for fan replacement.

• The inverter consists of precision mechanical and electronic parts. Never install or handle it in any of the following

conditions as doing so could cause an operation fault or failure.

Direct sunlight

Vertical mounting

(When installing two or

more inverters, install

them in parallel.)

Vibration(5.9m/s2 * or mor e at 1 0 to

55Hz (directions of X, Y, Z axes))

*2.9m/s2 or more for the 185K or

higher

Transportation by

holding the front cover

High temperature,

high humidity

Oil mist, flammable

gas, corrosive gas,

fluff, dust, etc.

Horizontal placement

Mounting to

combustible material

8

Page 16

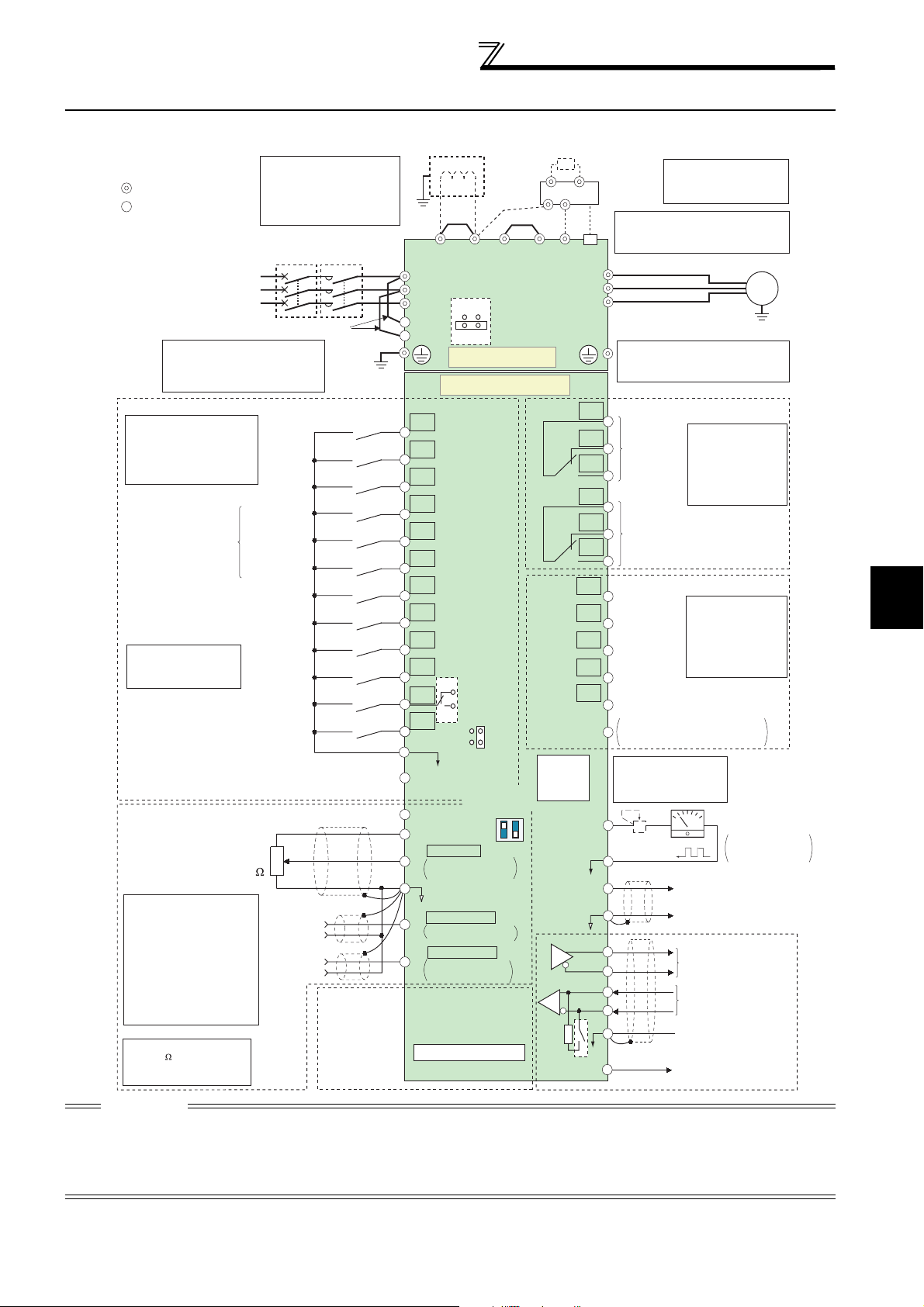

2.4 Wiring

2.4.1 Terminal connection diagram

Wiring

*7

N/-

*8

RUN

PU

connector

TXD+

TXD-

RXD+

RXD-

resistor

VCC

Resistor unit

(Option)

Brake unit

(Option)

*7.

CN8

*6

U

V

W

C1

B1

A1

C2

B2

A2

Running

SU

Up to frequency

IPF

Instantaneous

power failure

OL

Overload

FU

Frequency detection

SE

*

9. It is not necessary

FM

SD

AM

5

SG

*6. A CN8 (for MT-BU5)

connector is provided

with the 75K or higher.

Do not use PR and PX terminals.

Please do not remove the jumper

connected to terminal PR and PX.

*8.

The 200V class 0.75K and 1.5K

are not provided with the ON/OFF

connector EMC filter.

Relay output 1

(Fault output)

Relay output 2

Open collector output common

Sink

/

source common

when calibrating the

indicator from the

operation panel.

+-

Calibration

resistor *9

(+)

(-)

5V

Motor

M

Earth

(ground)

cable

Relay output

Terminal functions

vary with the output

terminal assignment

(Pr. 195, Pr. 196)

(Refer to Chapter 4 of

the Instruction Manual

(Applied))

Open collector output

Terminal functions

vary with the output

terminal assignment

(Pr. 190 to Pr. 194)

(Refer to Chapter 4 of

the Instruction Manual

(Applied))

Indicator

(Frequency meter, etc.)

Moving-coil type

1mA full-scale

Analog signal output

(0 to 10VDC)

RS-485 terminals

Data transmission

Data reception

GND

(Permissible load

current 100mA)

Sink logic

Main circuit terminal

Control circuit terminal

Three-phase AC

power supply

*2. To supply power to the

control circuit separately,

remove the jumper across

R1/L11 and S1/L21.

Control input signals (No voltage input allowed)

Terminal functions vary

with the input terminal

assignment

(Pr. 178 to Pr. 189)

(Refer to Chapter 4 of the

Instruction Manual (Applied))

Start self-holding selection

Multi-speed

selection

Second function selection

*3. AU terminal can be

used as PTC input

terminal.

Terminal 4 input selection

(Current input selection)

Selection of automatic restart

Contact input common

(Common for external power supply transistor)

Frequency setting signal (Analog)

Frequency setting

potentiometer

*

4. Terminal input specifications

can be changed by analog

input specifications switchover

(Pr. 73, Pr. 267). Set the

voltage/current input switch in

the OFF position to select

voltage input (0 to 5V/0 to

10V) and ON to select current

input (0 to 20mA).

(Refer to Chapter 4 of the

Instruction Manual (Applied))

*

5. It is recommended to use

2W1k when the

frequency setting signal is

changed frequently.

*1. DC reactor (FR-HEL)

Be sure to connect the DC reactor

supplied with the 75K or higher.

When a DC reactor is connected

to the 55K or lower, remove the

jumper across P1 and P/+.

MCCB

Forward

rotation

start

Reverse

rotation

start

High speed

Middle speed

Low speed

Jog operation

Output stop

Reset

after instantaneous

power failure

24VDC power supply

3

2

1/2W1k

*5

1

Auxiliary

input

Terminal

4 input

(Current

input)

MC

Jumper

Earth

(Ground)

(+)

(-)

(+)

(-)

Connector

for plug-in option

connection

*1

Earth

Jumper

(ground)

P1

R/L1

S/L2

T/L3

*2

R1/L11

S1/L21

P/+

ON

OFF

Jumper

PR

*7

EMC filter

ON/OFF

connector

PX

Main circuit

Control circuit

STF

STR

STOP

RH

RM

RL

JOG

RT

MRS

RES

*3

AU

AU

PTC

CS

SD

PC

10E(+10V)

10(+5V)

0 to 5VDC

2

0 to 10VDC

0 to 20mADC

5

(Analog common)

0 to ±10VDC

1

0 to ±5VDC

4 to 20mADC

4

0 to 5VDC

0 to 10VDC

Option connector 1

SINK

SOURCE

*4

Voltage/current

input switch

4

ON

OFF

Initial value

selectable

Initial

value

selectable

Initial

value

selectable

2

*

4

*

4

*

4

Terminating

CAUTION

· To prevent a malfunction due to noise, keep the signal cables more than 10cm away from the power cables. Also separate the

main circuit wire of the input side and the output side.

· After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean.

When drilling mounting holes in an enclosure etc. take care not to allow chips and other foreign matter to enter the inverter.

· Set the voltage/current input switch correctly. Operation with a wrong setting may cause a fault, failure or malfunction.

2

INSTALLATION AND WIRING

9

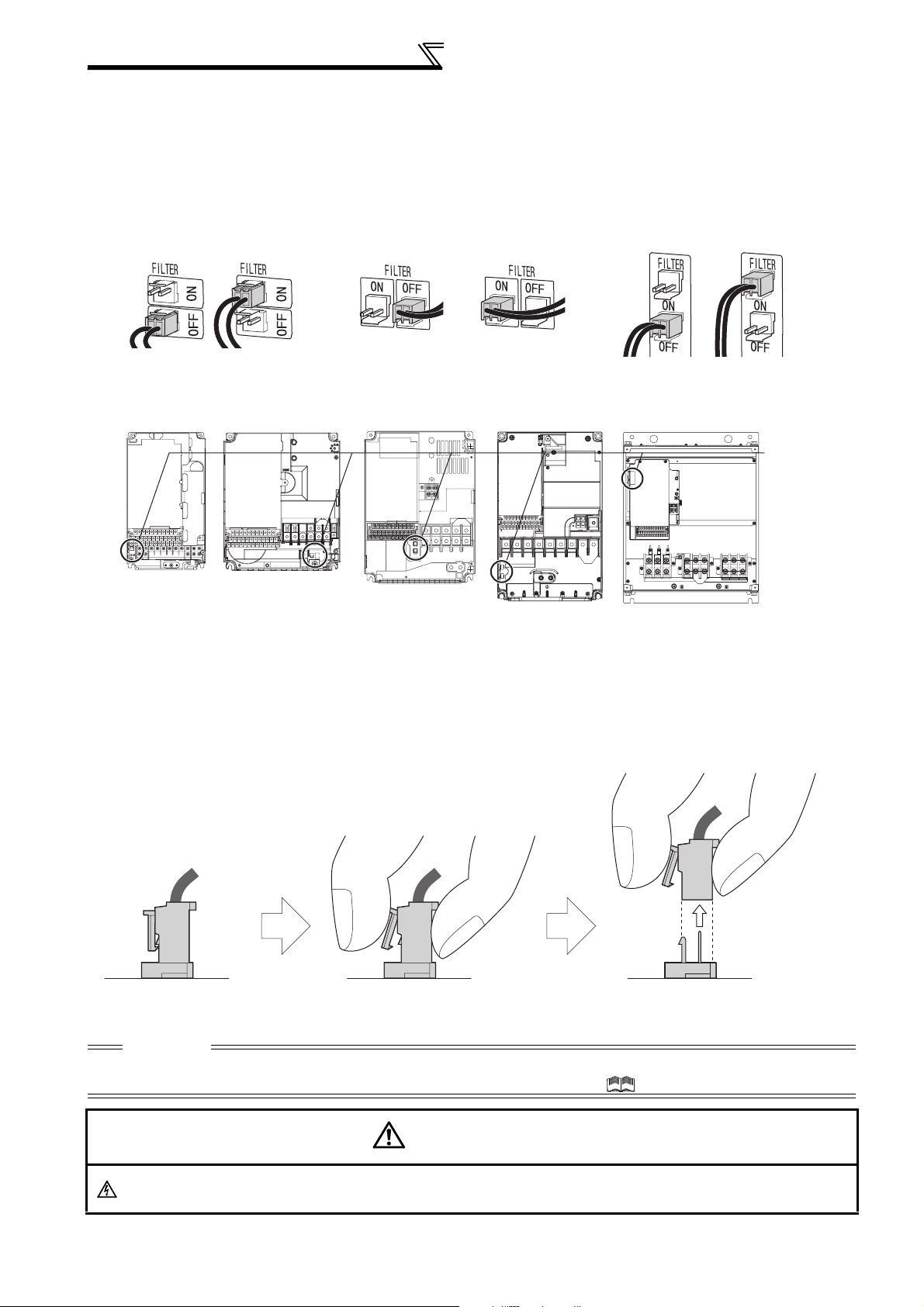

Page 17

Wiring

r

r

2.4.2 EMC filter

This inverter is equipped with a built-in EMC filter (capacitive filter) and common mode choke.

The EMC filter is effective for reduction of air-propagated noise on the input side of the inverter.

The EMC filter is factory-set to disable (OFF). To enable it, fit the EMC filter ON/OFF connector to the ON position.

The input side common mode choke, built-in the 55K or lower inverter, is always valid regardless of ON/OFF of the

EMC filter ON/OFF connector.

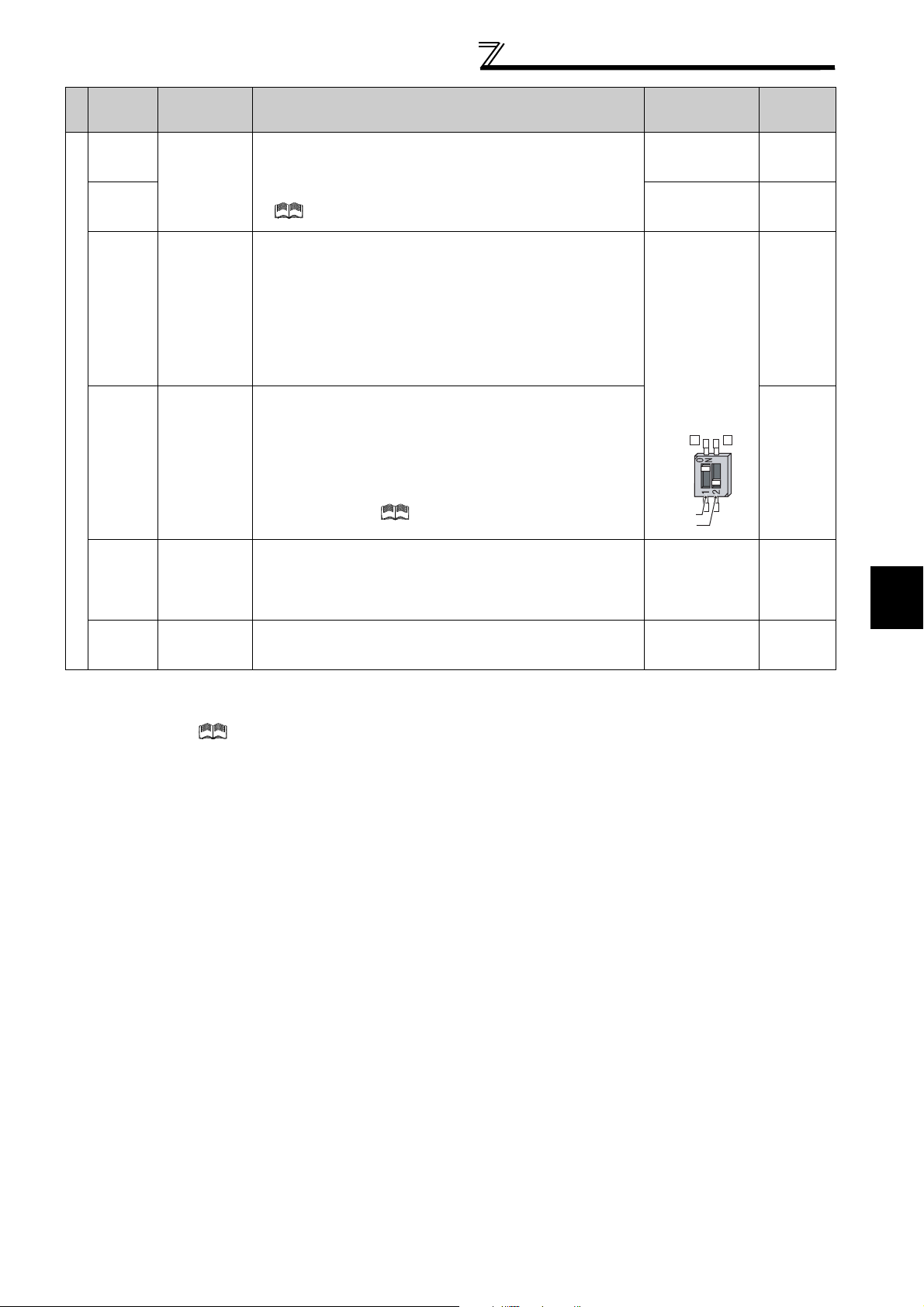

5.5K or lower

EMC filter OFF EMC filter OFF EMC filter OFFEMC filter ON EMC filter ON EMC filter ON

(initial setting) (initial setting) (initial setting)

FR-F720P-2.2K to 5.5K

FR-F740P-0.75K to 5.5K

FR-F720P-7.5K, 11K

FR-F740P-7.5K, 11K

FR-F740P-15K, 18.5K

7.5K, 11K

FR-F720P-15K

FR-F720P-18.5K to 30K

FR-F740P-22K, 30K

15K or higher

FR-F720P-37K or higher

FR-F740P-37K or higher

EMC filte

ON/OFF

connecto

VUW

The FR-F720P-0.75K and 1.5K are not provided with the EMC filter ON/OFF connector. (Always ON)

<How to disconnect the connector>

(1) Before removing a front cover, check to make sure that the indication of the inverter operation panel is OFF, wait

for at least 10 minutes after the power supply has been switched OFF, and check that there are no residual voltage

using a tester or the like. (For the front cover removal method, refer to page 6.)

(2) When disconnecting the connector, push the fixing tab and pull the connector straight without pulling the cable or

forcibly pulling the connector with the tab fixed. When installing the connector, also engage the fixing tab securely.

If it is difficult to disconnect the connector, use a pair of long-nose pliers, etc.

EMC filter

ON/OFF connector

(Side view)

Disengage connector fixing tab. With tab disengaged,

pull up connector straight.

CAUTION

⋅ Fit the connector to either ON or OFF.

⋅ Enabling (turning ON) the EMC filter increases leakage current. (Refer to Chapter 3 of the Instruction Manual (Applied))

WARNING

While power is ON or when the inverter is running, do not open the front cover. Otherwise you may get an electric shock.

10

Page 18

2.4.3 Specification of main circuit terminal

Wiring

Term inal

Symbol

R/L1,

S/L2,

T/L3

U, V, W Inverter output

Term inal Name Description

Connect to the commercial power supply.

AC power input

Keep these terminals open when using the high power

factor converter (FR-HC, MT-HC) or power regeneration

common converter (FR-CV).

Connect a three-phase squirrel-cage motor or dedicated

IPM motor.

Connected to the AC power supply terminals R/L1 and S/

L2. To retain the fault display and fault output or when

using the high power factor converter (FR-HC, MT-HC) or

power regeneration common converter (FR-CV), remove

the jumpers from terminals R/L1 and R1/L11, and S/L2

R1/L11,

S1/L21

Power supply for

control circuit

and S1/L21, and apply external power to these terminals.

The power capacity necessary when separate power is

supplied from R1/L11 and S1/L21 differs according to the

inverter capacity.

15K or lower 18.5K 22K or higher

200V class 60VA 80VA 80VA

400V class 60VA 60VA 80VA

Connect the brake unit (FR-BU2, FR-BU, BU and MT-

P/+, N/-

Brake unit

connection

BU5), power regeneration common converter (FR-CV),

high power factor converter (FR-HC and MT-HC) or power

regeneration converter (MT-RC).

For the 55K or lower, remove the jumper across terminals

P/+ and P1, and connect the DC reactor. (Be sure to

connect the DC reactor supplied with the 75K or higher.)

When a DC reactor is not connected, the jumper across

P/+, P1

DC reactor

connection

terminals P/+ and P1 should not be removed.

PR, PX Please do not remove or use terminals PR and PX or the jumper connected.

Earth (ground)

For earthing (grounding) the inverter chassis. Must be

earthed (grounded).

Refer to

Page

11

11

18

28

2

36

—

17

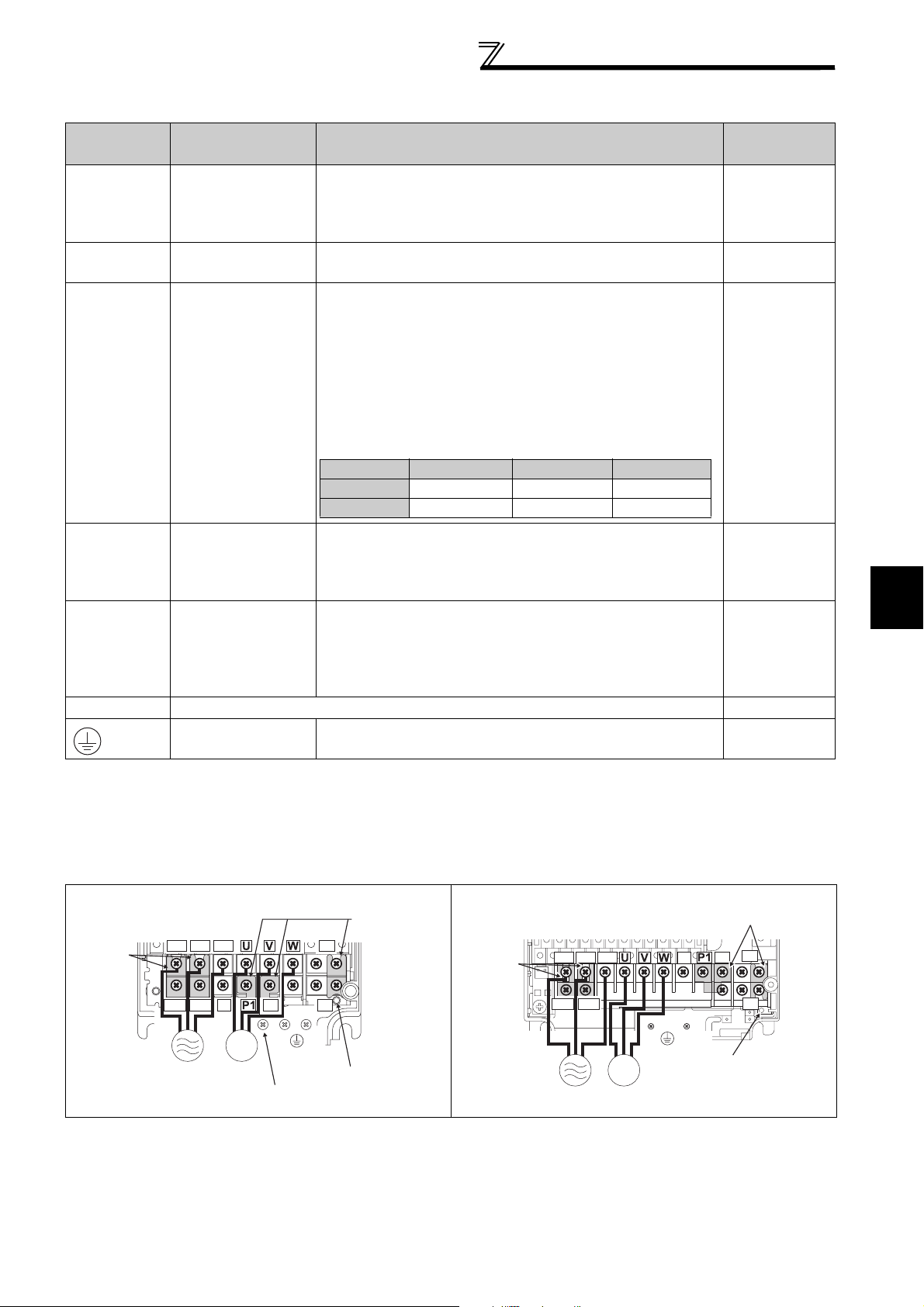

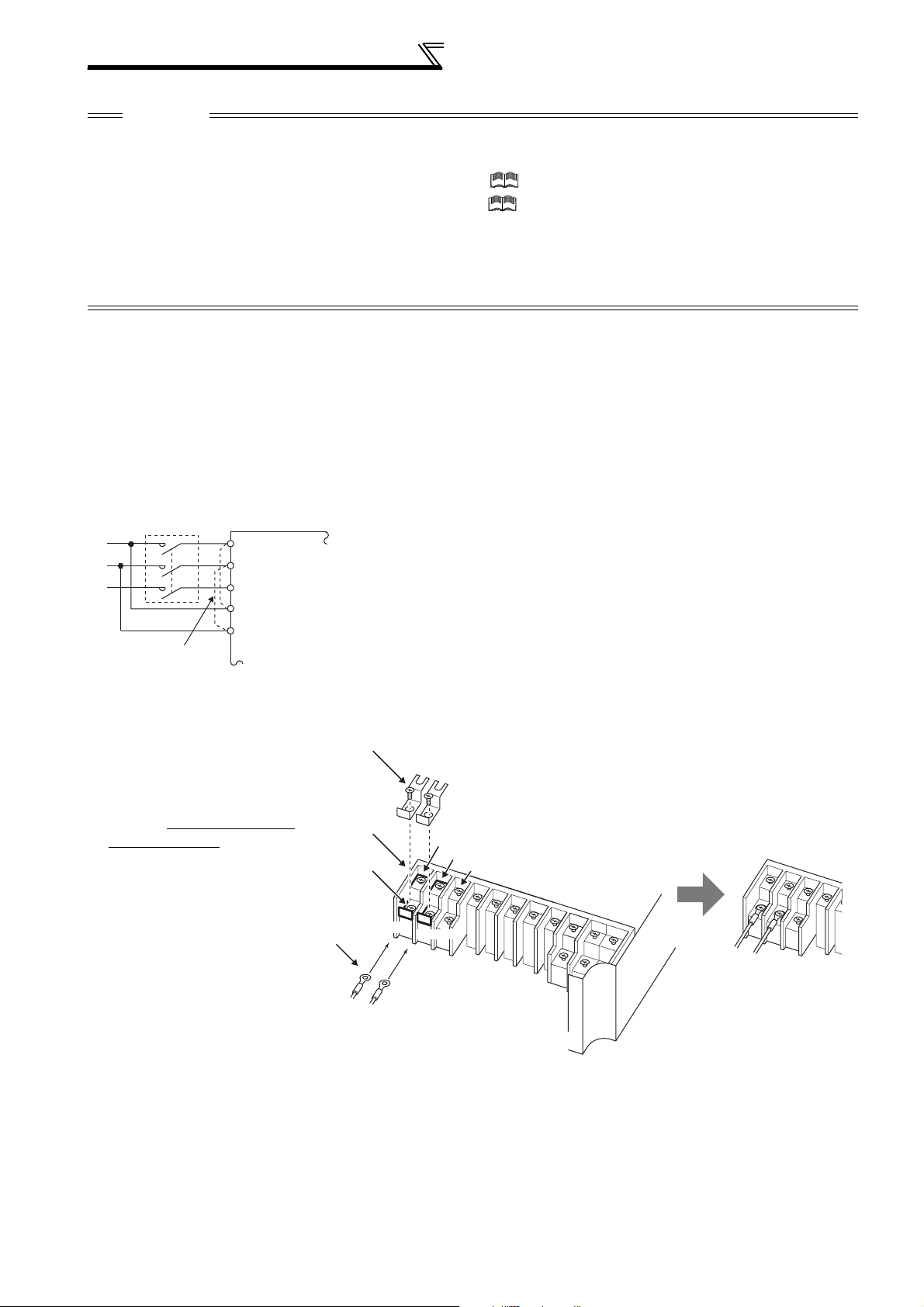

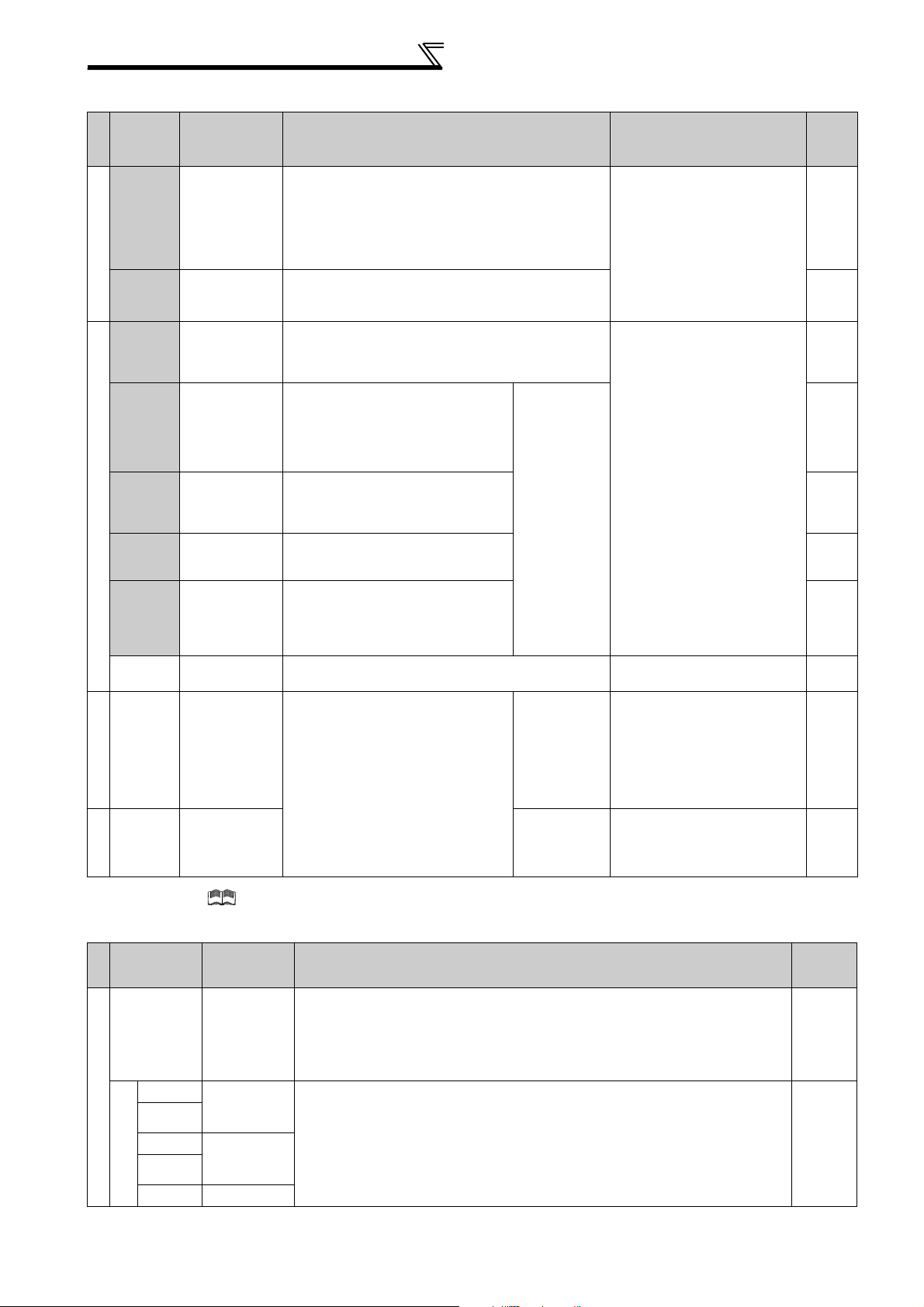

2.4.4 Terminal arrangement of the main circuit terminal, power supply and the motor wiring

200V class

FR-F720P-0.75K, 1.5K FR-F720P-2.2K to 5.5K

Jumper

PR

P/+

PX

Charge lamp

Jumper

Screw size (M4)

R/L1

S/L2

R1/L11

S1/L21

Power supply

Jumper

T/L3

N/-

P/+

M

Motor

As this is an inside cover fixing screw,

do not remove it.

PX

Screw size

(M4)

PR

Charge lamp

Jumper

Screw size (M4)

R/L1 S/L2 T/L3

R1/L11 S1/L21

Power

supply

M

Motor

N/-

Screw size

(M4)

INSTALLATION AND WIRING

11

Page 19

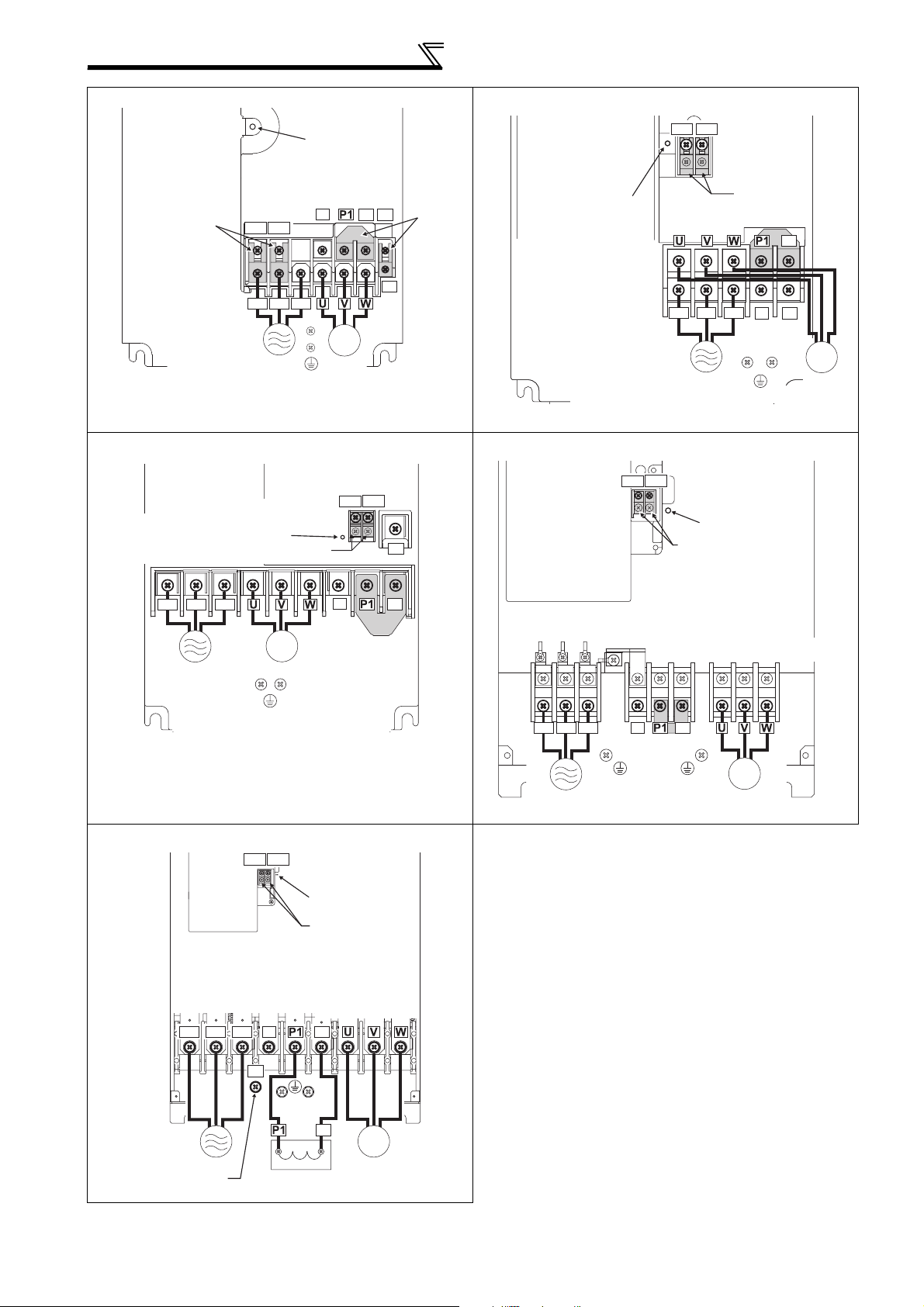

Wiring

r

FR-F720P-7.5K, 11K FR-F720P-15K

Charge lamp

Jumper

Screw size

(M5)

**

R1/L11 S1/L21

R/L1 S/L2 T/L3

N/-

P/+

*

PR

PX

*

Jumpe

Charge lamp

Screw size (M5)

M

Power supply

* Screw size of terminal

R1/L11, S1/L21, PR

and PX is M4.

Screw size (M5)

FR-F720P-18.5K to 30K FR-F720P-37K to 55K

Screw size

(M6 for 18.5K,

M8 for 22K and 30K)

Screw size (M4)

Charge lamp

Jumper

Motor

R1/L11 S1/L21

Screw size

(M4)

PR

R/L1 S/L2 T/L3

R1/L11 S1/L21

R1/L11 S1/L21

Screw size

Power supply

Screw size (M5)

Charge lamp

Jumper

(M4)

Jumper

Jumper

N/-

P/+

PR

M

Motor

R/L1 S/L2 T/L3

Power supply

FR-F720P-75K to 110K

R/L1 S/L2 T/L3

M

Motor

Screw size (M6)

R1/L11 S1/L21

Screw size (M4)

N/-

N/-

Jumper

Charge lamp

Jumper

Screw size (M12)

P/+

P/+

R/L1 S/L2 T/L3

Power

supply

Screw size

(M8 for 37K, M10 for 45K and 55K)

N/-

P/+

Jumper

Screw size

(M6 for 37K,

M8 for 45K and 55K)

M

Motor

12

Power supply

Screw size (M12)

(for option)

P/+

Screw size

(M10)

P/+

DC reactor

M

Motor

Page 20

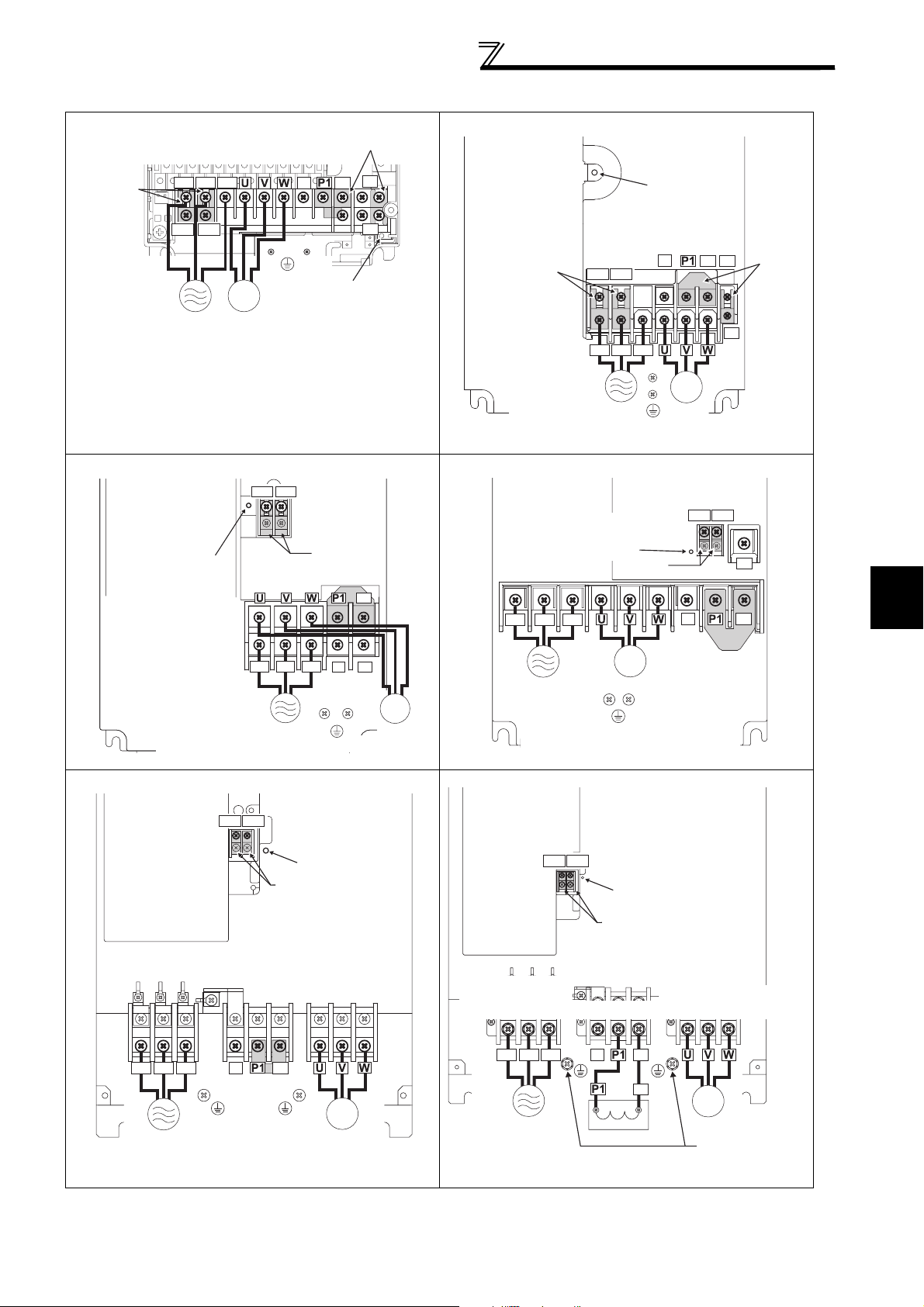

400V class

r

FR-F740P-0.75K to 5.5K FR-F740P-7.5K, 11K

Jumper

Screw size (M4)

R/L1 S/L2 T/L3

N/-

P/+

Jumper

PR

Wiring

Charge lamp

R1/L11 S1/L21

Power

supply

M

Motor

Screw size

(M4)

PX

Jumper

Charge lamp

Screw size

FR-F740P-15K, 18.5K FR-F740P-22K, 30K

R1/L11 S1/L21

Screw size

(M4)

Charge lamp

Screw size (M5)

R/L1 S/L2 T/L3

Jumper

Jumper

N/-

Screw size (M6)

P/+

R/L1 S/L2 T/L3

PR

Power supply

M

Power supply

Screw size (M5)

Motor

R1/L11 S1/L21

(M4)

R/L1 S/L2 T/L3

Power supply

Charge lamp

Screw size (M6)

N/-

M

Motor

Screw size

(M4)

Screw size (M4)

Jumper

M

Motor

P/+

PR

R1/L11 S1/L21

N/-

Jumper

Jumpe

PX

PR

2

P/+

FR-F740P-37K to 55K FR-F740P-75K to 110K

R1/L11 S1/L21

Screw size(M4)

Power

supply

R1/L11 S1/L21

R/L1 S/L2 T/L3

Power

supply

Jumper

Screw size (M6 for 37K,

M8 for 45K and 55K)

N/-

P/+

Jumper

Screw size

(M6 for 37K,

M8 for 45K and 55K)

Charge lamp

M

Motor

Screw size (M4)

Screw size

(M8 for 75K,

M10 for 90K and 110K)

R/L1 S/L2 T/L3

Charge lamp

Jumper

Screw size (M10)

N/-

P/+

P/+

DC reactor

INSTALLATION AND WIRING

Screw size

(M8 for 75K,

M10 for 90K and 110K)

M

Motor

Screw size

(M8 for 75K,

M10 for 90K and 110K)

13

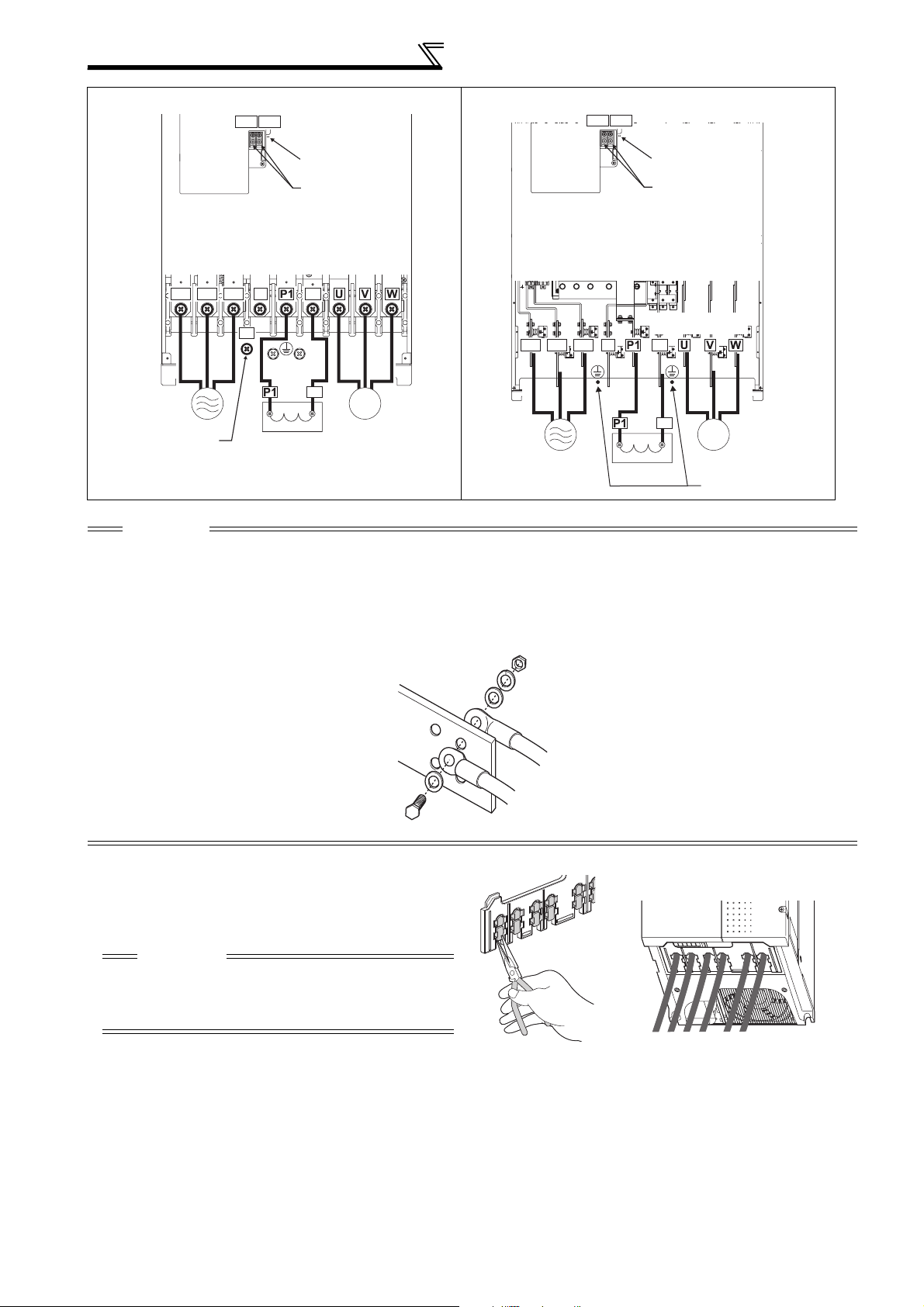

Page 21

Wiring

FR-F740P-132K to 220K FR-F740P-250K to 560K

R1/L11 S1/L21

Screw size (M4)

R1/L11 S1/L21

Screw size (M4)

Charge lamp

Jumper

Screw size (M12)

P/+

R/L1 S/L2 T/L3

Charge lamp

Jumper

Screw size

(M10 for 132K and 160K,

M12 for 185K and 220K)

N/-

P/+

P/+

Screw size

(M10)

P/+

R/L1 S/L2 T/L3

N/-

M

Power supply

Screw size (M12)

(for option)

DC reactor

Motor

Power supply

CAUTION

· The power supply cables must be connected to R/L1, S/L2, T/L3. (Phase sequence needs not to be matched.) Never connect

the power cable to the U, V, W of the inverter. Doing so will damage the inverter.

· Connect the motor to U, V, W. At this time, turning ON the forward rotation switch (signal) rotates the motor in the

counterclockwise direction when viewed from the motor shaft.

· When wiring the inverter main circuit conductor of the 250K or higher, tighten a nut from the right side of the conductor. When

wiring two wires, place wires on both sides of the conductor. (Refer to the drawing below.) For wiring, use bolts (nuts) provided

with the inverter.

P/+

M

Motor

DC reactor

Screw size (M10)

• Handling of the wiring cover

(FR-F720P-18.5K, 22K, FR-F740P-22K, 30K)

For the hook of the wiring cover, cut off the necessary

parts using a pair of long-nose pliers etc.

CAUTION

Cut off the same number of lugs as wires. If parts where

no wire is put through has been cut off (10mm or more),

protective structure (JEM1030) becomes an open type

(IP00).

14

Page 22

Wiring

(1) Cable size and other specifications of the main circuit terminals and the earthing terminal

Select the recommended cable size to ensure that a voltage drop will be 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor

torque to decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

200V class (when input power supply is 220V)

Cable Sizes

Earthing

cable

AWG/MCM *2

R/L1,

S/L2,

U, V, W

T/L3

PVC, etc. (mm2) *3

R/L1,

S/L2,

T/L3

U, V, W

Earthing

cable

Applicable

Inverter Model

FR-F720P-0.75K

to 2.2K

Ter min al

Screw

Size

Tightening

*4

Torq ue

N·m

Ter mina l

R/L1,

S/L2,

T/L3

U, V, W

HIV, etc. (mm2) *1

R/L1,

S/L2,

U, V, W P/+, P1

T/L3

M4 1.5 2-4 2-4 2 2 2 2 14 14 2.5 2.5 2.5

Crimping

FR-F720P-3.7K M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 3.5 12 12 4 4 4

FR-F720P-5.5K M4 1.5 5.5-4 5.5-4 5.5 5.5 5.5 5.5 10 10 6 6 6

FR-F720P-7.5K M5 2.5 14-5 8-5 14 8 14 5.5 6 8 16 10 16

FR-F720P-11K M5 2.5 14-5 14-5 14 14 14 14 6 6 16 16 16

FR-F720P-15K M5 2.5 22-5 22-5 22 22 22 14 4 6 (

*5)25 25 16

FR-F720P-18.5K M6 4.4 38-6 38-6 38 38 38 22 2 2 35 35 25

FR-F720P-22K M8 (M6) 7.8 38-8 38-8 38 38 38 22 2 2 35 35 25

FR-F720P-30K M8 (M6) 7.8 60-8 60-8 60 60 60 22 1/0 1/0 50 50 25

FR-F720P-37K M8 (M6) 7.8 80-8 80-8 80 80 80 22 3/0 3/0 70 70 35

FR-F720P-45K

FR-F720P-55K

FR-F720P-75K

FR-F720P-90K

FR-F720P-110K

*1 The cable size is that of the cable (HIV cable (600V class 2 vinyl-insulated cable) etc.) with continuous maximum permissible temperature of

75°C. Assumes that the surrounding air temperature is 50°C or less and the wiring distance is 20m or less.

*2 The recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C. Assumes that the

surrounding air temperature is 40°C or less and the wiring distance is 20m or less.

(Selection example for use mainly in the United States.)

*3 For the 15K or lower, the recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C.

Assumes that the surrounding air temperature is 40°C or less and the wiring distance is 20m or less.

For the 18.5K or higher, the recommended cable size is that of the cable (XLPE cable) with continuous maximum permissible temperature of

90°C. Assumes that the surrounding air temperature is 40°C or less and wiring is performed in an enclosure.

(Selection example for use mainly in Europe.)

*4 The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, and a screw for earthing (grounding).

A screw for earthing (grounding) of the 22K or higher is indicated in ( ).

*5 When connecting the option unit to P/+, P1, N/-, use THHN cables for the option and terminals R/L1, S/L2, T/L3, U, V, W.

M10 (M8)

M10 (M8)

M12 (M10)

M12 (M10)

M12 (M10)

14.7 100-10 100-10 100 100 100 38 4/0 4/0 95 95 50

14.7 100-10 100-10 100 100 100 38 4/0 4/0 95 95 50

24.5 150-12 150-12 125 125 150 38 250 250 ⎯⎯ ⎯

24.5 150-12 150-12 150 150 2×100 38 2×4/0 2×4/0 ⎯⎯ ⎯

24.5 100-12 100-12 2×100 2×100 2×100 38 2×4/0 2×4/0 ⎯⎯ ⎯

2

15

INSTALLATION AND WIRING

Page 23

Wiring

400V class (when input power supply is 440V)

Crimping

Applicable

Inverter Model

FR-F740P-0.75K

to 3.7K

Ter mi nal

Screw

Size

Tightening

Torque

*4

M4 1.5 2-4 2-4 2 2 2 2 14 14 2.5 2.5 2.5

(Compression)

N·m

Ter mina l

R/L1,

S/L2,

T/L3

U, V, W

HIV, etc. (mm2) *1

R/L1,

S/L2,

U, V, W P/+, P1

T/L3

FR-F740P-5.5K M4 1.5 2-4 2-4 2 2 3.5 3.5 12 14 2.5 2.5 4

FR-F740P-7.5K M4 1.5 5.5-4 5.5-4 3.5 3.5 3.5 3.5 12 12 4 4 4

FR-F740P-11K M4 1.5 5.5-4 5.5-4 5.5 5.5 5.5 8 10 10 6 6 10

FR-F740P-15K M5 2.5 8-5 8-5 8 8 8 8 8 8 10 10 10

FR-F740P-18.5K M5 2.5 14-5 8-5 14 8 14 14 6 8 16 10 16

FR-F740P-22K M6 4.4 14-6 14-6 14 14 22 14 6 6 16 16 16

FR-F740P-30K M6 4.4 22-6 22-6 22 22 22 14 4 4 25 25 16

FR-F740P-37K M6 4.4 22-6 22-6 22 22 22 14 4 4 25 25 16

FR-F740P-45K M8 7.8 38-8 38-8 38 38 38 22 1 2 50 50 25

FR-F740P-55K M8 7.8 60-8 60-8 60 60 60 22 1/0 1/0 50 50 25

FR-F740P-75K M8 7.8 60-8 60-8 60 60 60 38 1/0 1/0 50 50 25

FR-F740P-90K M10 14.7 60-10 60-10 60 60 80 38 3/0 3/0 50 50 25

FR-F740P-110K M10 14.7 80-10 80-10 80 80 100 38 3/0 3/0 70 70 35

FR-F740P-132K M10 14.7 100-10 100-10 100 100 100 38 4/0 4/0 95 95 50

FR-F740P-160K M10 14.7 150-10 150-10 125 125 150 38 250 250 120 120 70

FR-F740P-185K

FR-F740P-220K

FR-F740P-250K

FR-F740P-280K

FR-F740P-315K

FR-F740P-355K

FR-F740P-400K

FR-F740P-450K

FR-F740P-500K

FR-F740P-560K

*1 For the FR-F740P-55K or lower, the recommended cable size is that of the cable (e.g. HIV cable (600V class 2 vinyl-insulated cable)) with continuous