Page 1

INVERTER

FR-D700

INSTRUCTION MANUAL (BASIC)

FR-D720-0.1K to 15K

FR-D740-0.4K to 15K

FR-D720S-0.1K to 2.2K

FR-D710W-0.1K to 0.75K

Thank you for choosing this Mitsubishi Inverter.

This Instruction Manual (B asic) provides handling info rmation and precautions for use of the equipment.

Please forward this Instru ction Manual (Basic) to the e nd user.

CONTENTS

OUTLINE ...................................................................................1

1

INSTALLATION AND WIRING ...................................................5

2

PRECAUTIONS FOR USE OF THE INVERTER.........................18

3

FAILSAFE OF THE SYSTEM WHICH USES THE INVERTER ...20

4

DRIVE THE MOTOR.................................................................21

5

ENERGY SAVING OPERATION FOR FANS AND PUMPS ........29

6

PARAMETERS .........................................................................30

7

TROUBLESHOOTING ..............................................................34

8

PRECAUTIONS FOR MAINTENANCE AND INSPECTION ........38

9

SPECIFICATIONS....................................................................40

10

To obtain the Instruction Manual (Applied) and the

Safety stop function instruction manual

Contact where you purchased the inverter, your Mitsubishi sales

representative, or the nearest Mitsubishi FA Center for the following

manuals:

y Instruction Manual (Applied) [IB(NA)-0600366ENG]

y Safety stop function instruction manual [BCN-A211508-000]

These manuals are required if you are going to utilize functions and

performance.

The PDF version of this manual is also available for download at

"MELFANS Web," the Mitsubishi Electric FA network service on the

world wide web (URL: http://www.MitsubishiElectric.co.jp/melfansweb)

700

1

2

3

4

5

6

7

8

9

10

Page 2

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment.

Please forward this Instruction Manual (Basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or ins pect the

inverter until you have read through the Instruction Manual

(Basic) and appended documents carefully and can use the

equipment correctly. Do not use this product until you have a

full knowledge of the equipment, safety information and

instructions.

In this Instruction Manual (Basic), the safety instruction levels

are classified into "WARNING" an d "CAUTION".

WARNIN G

CAUTION

CAUTION

The level may even lead to a serious

consequence according to conditions. Both instruction levels

must be followed because these are important to personal

safety.

Incorrect handling may cause

hazardous conditions, resulting in

death or severe injur y.

Incorrect handling may cause

hazardous conditions, resulting in

medium or slight injury, or may cause

only material damage.

1. Electric Shock Prevention

WARNING

z While power is ON or when the inverter is running, do not

open the front cover. Otherwise you may get an electric

shock.

z Do not run the invert er with the front cover o r wiring cover

removed. Otherwise you may access the exposed highvoltage terminals or the ch arging part of the circuitry and

get an electric shock.

z Even if power is OFF, do not remove the front cover except

for wiring or periodic inspection. You may accidentally

touch the charged inverter circuits and get an electric

shock.

z Before wiring or insp ection, power must be sw itched OFF.

To confirm that, LED indication of the operation panel must

be checked. (It must b e OFF.) Any person who is involved in

wiring or inspect ion shall wait for at least 10 minutes after

the power supply has been switched OFF and check that

there are no residual voltage using a test er or the like. The

capacitor is charged with high voltage for some time after

power OFF, and it is dangerous.

This inverter must be earthed (grounded). Earthing

z

(grounding) must conform to the requirements of national and

local safety regu lations and elect rical code (NEC secti on 250,

IEC 536 class 1 and other applicable standards).

A neutral-point ear thed (grounded) power su pply for 400V

class inverter in compliance with EN standard must be u sed.

z Any person who is involved in wiring or inspection of this

equipment shall be f ully competent to do the wor k.

z The inverter must be installed before wiring. Otherwise you

may get an electric shock or be injured.

z Setting dial and key operations must be performed with dry

hands to prevent an electr ic shock. Otherwise you may g et

an electric shock.

z Do not subject the ca bles to scratches, exc essive stress,

heavy loads or pinching. O therwise you may get an electric

shock.

z Do not change the cooling fan while power is ON. It is

dangerous to change the cooling fan while power is ON.

z Do not touch the printed circuit boa rd or handle the cab les

with wet hands. Otherwise you may get an electric shock.

z When measuring th e main circuit capacitor ca pacity, the DC

voltage is applied to the motor for 1s at powering OFF.

Never touch the motor terminal, etc. right after powering

OFF to prevent an e lectric shock.

2. Fire Prevention

z Inverter must be installed on a nonflammable wall without

holes (so that nobody touches the inverter heatsink on the

rear side, etc.). Mounting it to or near flammable material

can cause a fire.

z If the inverter has become faulty, the inverter pow er must

be switched OFF. A continuous flow of large current could

cause a fire.

z

When using a brake resistor, a sequence that will turn OFF

power when a fault signal is outp ut must be configured.

Otherwise the brake resistor may overheat due to damage of

the brake transistor and possibly cause a fire.

z Do not connect a resistor di rectly to the DC terminal s P/+

and N/-. Doing so could cause a fire.

CAUTION

3.Injury Prevention

z T he voltage applied to each termi nal must be the ones

specified in the Instru ction Manual. Otherwise bu rst,

damage, etc. may occu r.

z T he cables must be connected to t he correct terminals.

Otherwise burst, damage, etc. may occur.

z Po larity must be correct. Otherwise b urst, damage, etc.

may occur.

z W hile power is ON or for some time after power-OFF, do not

touch the inverter sin ce the inverter will be extremely hot.

Doing so can cause burns.

4. Additional Instructions

Also the following points must be noted to prevent an

accidental failure, injury, electric shock, etc.

CAUTION

(1) Transportation and Mounting

CAUTION

z The product must be transported in correct method that

corresponds to the weight. Failure to do so may lead to

injuries.

z Do not stack the boxes containing inverters higher than the

number recommended.

z The product must be installed to the position where

withstands the weight of the product according to the

information in the In struction Manual.

z Do not install or operate the inverter if it is d amaged or has

parts missing.

z W hen carrying the inverter, do not hold it by the front cover

or setting dial; it may fall off or fail.

z Do not stand or rest heavy objects on the product.

z The inverter mounting orientation must be correct.

z Foreign conductive objects must be prevented from

entering the inverter. That includes screws and metal

fragments or other flam mable substance such as oil.

z As the inverter is a precision instrument, do not drop or

subject it to impact.

z The inverter must be used under the following

environment: Other wise the inverter may be damaged.

Surrounding

air

temperature

Ambient

humidity

Storage

temperature

Atmosphere

Environment

Altitude/

vibration

∗1 Temperature applicable for a short t ime, e.g. in transit.

-10°C to +50°C (non -freezing)

90%RH or less (non-condensing)

-20°C to +65°C *1

Indoors (free from corrosive gas, flammable gas,

oil mist, dust and di rt)

Maximum 1,000m above sea level.

2

or less at 10 to 55Hz (directions of X, Y, Z

5.9m/s

axes)

A-1

Page 3

(2) Wiring

z Do not install a power factor correction capacitor or surge

suppressor/capacitor type filter on the inverter output side.

These devices on the inverter output side may be

overheated or burn out.

z The connection orientation of the output cables U, V, W to

the motor affects the rotation direction of the motor.

CAUTION

(3) Trial run

z Be fore starting operation, each parameter must be

confirmed and adjuste d. A failure to do so may cause som e

machines to make unexpected motions .

CAUTION

(4) Usage

z An y person must stay away from the equ ipment when the

retry function is set as it will restart suddenly after trip.

z

Since pressing key may not stop output depending on

the function setting status, separate circuit and switch that

make an eme rgency stop (po wer OFF, mechanical bra ke

operation for emergency stop, etc.) must be provided.

z OFF status of the start signal must be confirmed before

resetting the inver ter fault. Resetting in verter alarm with the

start signal ON restarts the motor suddenly.

z The inverter must be used for three-phase induction

motors.

Connection of any other electrical equipment to the inverter

output may damage the equipment.

z Do not modify the equipment.

Do not perform parts removal which is not instructed in this

z

manual. Doi ng so may lead to fault or damage of the pr oduct.

z The electronic thermal relay function does not guarantee

protection of the motor from overheating. It is

recommended to install bo th an external thermal a nd PTC

thermistor for overh eat protection.

z Do not use a magnetic contactor on the inverter input for

frequent starting/stopping of the inverter. Otherwise, the

life of the inverter decreases.

z The effect of electromagnetic interference must be reduced

by using an EMC filter or by other means. Otherwise

nearby electronic equipment may be affected.

z Appr opriate measures must be taken to suppress

harmonics. Otherwise power supply harmonics from the

inverter may heat/da mage the power factor correction

capacitor and generator.

z W hen driving a 400V class motor by the inverter, the motor

must be an insulation-enha nced motor or measures mus t

be taken to suppress surge voltage. Surge voltage

attributable to the wirin g constants may occur at the mot or

terminals, deteriorating the insulation of the motor.

When parameter clear or all parameter clear is performed, the

z

required parameters must be set again before starting

operations because all parameters return to the initial value.

z T he inverter can be easi ly set for high-speed op eration.

Before changing its setting, the performances of the motor

and machine must be f ully examined.

z Stop status cannot be hold by the inverter's brake function.

In addition to the inverter's brake function, a holding device

must be installed to ensu re safety.

z Be fore running an inverter which had been stored for a

long period, inspection and test operation must be

performed.

z Static electricity in your body must be discharged before

you touch the product. Otherwise the product may be

damaged.

z If you are installing the inverter t o drive a three-phase

device while you are contracted for lighting and power

service, consult your electric power supplier.

WARNING

CAUTION

(5) Emergency stop

CAUTION

z A sa fety backup such as an emer gency brake must be

provided to prevent hazardous condition to the machine

and equipment in case of inverter failure.

z When the breaker on the inverter input side trips, the wiring

must be checked for fault (sho rt circuit), and internal parts

of the inverter for a damage, etc. The cause of the trip must

be identified and removed before turning ON the power of

the breaker.

z When any protective function is activated, appropriate

corrective action must be taken, and the inverter must be

reset before resuming operation.

(6) Maintenance, inspection and parts replacement

CAUTION

z Do not c arry out a megger (insulation resistance) test on

the control circuit of the inverter. It will cause a failure .

(7) Disposal

CAUTION

z The inverter must be treated as industrial waste.

General instruction

Many of the diagrams and drawings in this Instruction Manual

(Basic) show the inverter without a cover or partially ope n for

explanation. Never operate the inverter in this manner. The

cover must be always rein stalled and the instruction in this

Instruction Manual (Basic) must be followed when operating

the inverter.

<Abbreviation>

y PU: Operation panel and parameter unit (FR-PU04/FR-

PU07)

y Inverter: Mitsubishi inver ter FR-D700 series

y FR-D700: Mitsubishi inverter FR-D700 series

y Pr.: Parameter number (Number assigned to function)

y PU operation: Operation using the PU (operation panel/FR-

PU04/FR-PU07)

y External operation: Operation using the control circuit

signals

y Combined operation: Operation using both the PU

(operation panel/FR-PU04/FR-PU07) and External operation

y Standard motor : SF-JR

y Constant torque motor: SF-HRCA

<Trademark>

y Company and product names herein are the trademarks

and registered tradem arks of their respect ive owners.

<Mark>

REMARKS:Additional helpful contents and relations

with other functions are stated.

Note

: Contents requiring caution or cases when

set functions are not activated are stated.

POINT

: Useful contents and points are stated.

<Related document>

Refer to the Instruction Manual (Applied) for further

information on the following points.

y Removal and reinstallation of th e cover

y Connection of stand-alone option unit

y EMC and leakage curr ents

y Detailed explanation on parameters

y Troubleshooting

y Check first when you have a trouble

y Inspection items (life diagnosis, cooling fan replacement)

y Measurement of main circu it voltages, currents and powers

y For customers who are re placing the conventional mod el

with this inverter

A-2

Page 4

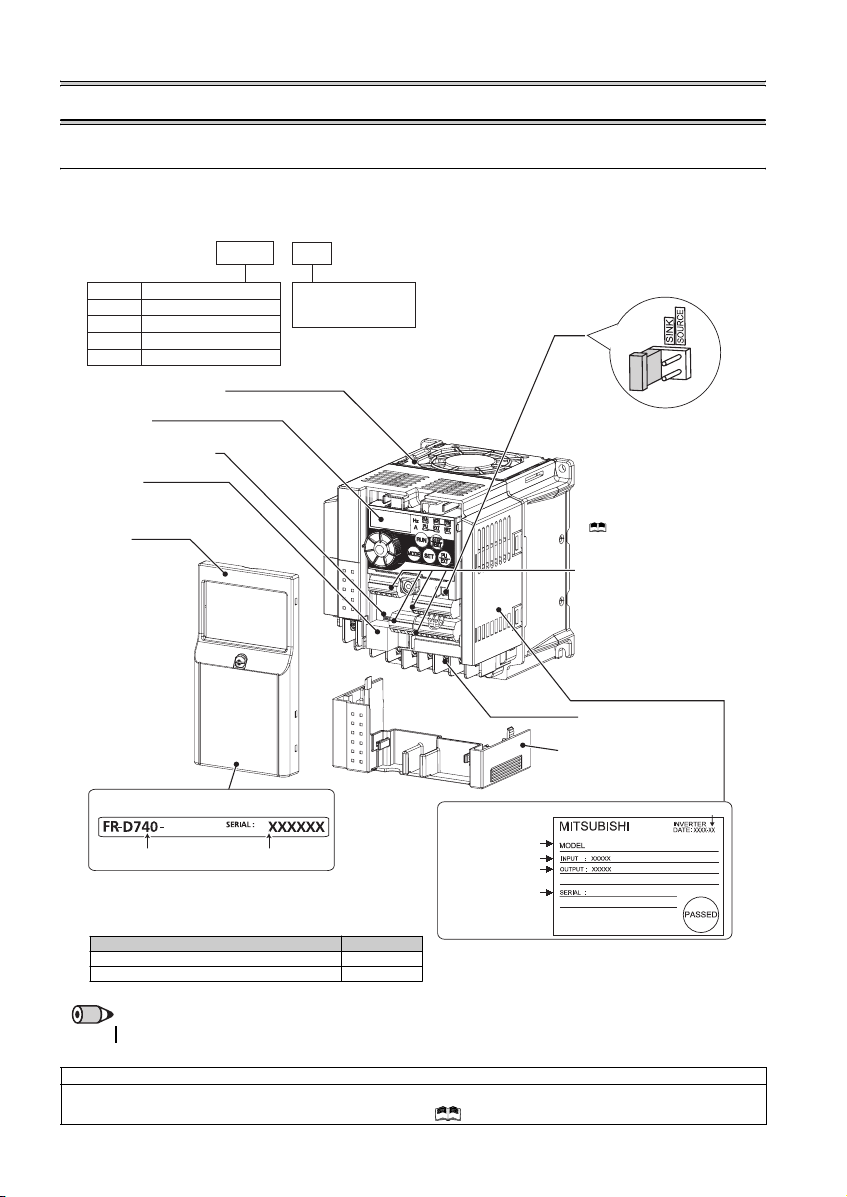

1 OUTLINE

1.1 Product checking and parts identification

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to ensure that

the product agrees with your order and the inverter is intact.

zInverter model

--

FR

D740 1.5

K

Symbol Voltage class

Three-phase 200V class

D720

Three-phase 400V class

D740

Single-phase 200V class

D720S

Single-phase 100V class

D710W

Cooling fan

Operation panel

(Refer to page 2)

Voltage/current input switch

(Refer to page 8)

PU connector

(Refer to page 8)

Front cover

Refer to the Instru ction

Manual (Applied) for

installation/removal.

The cooling f an is removable .

Represents the

inverter capacity [kW]

Capacity plate

1.5K

Inverter model

• Accessory

· Fan cover fixing screws (M3 × 35mm)

These screws are necessary for compliance with the

EU Directive. (

Serial number

Refer to page 43

Capacity Quantity

1.5K to 3.7K 1

5.5K to 15K 2

)

Rating plate

Inverter model

Input rating

Output rating

Serial number

Control logic switchover jumper

connector

The jumper connector is in the sink

logic (SINK) when shipped from the

factory. Move the jumper connector

to change to the source logic

(SOURCE). Always fit the jumper

connector to the either position.

( Refer to the Inst ruction Manual

(Applied))

Control circuit terminal block

(Refer to page 9)

Main circuit terminal block

(Refer to p age 9)

Combed shaped wiring cover

Refer to the Instruction Manual

(Applied) for installation /removal.

Production year and month

FR-D740-1.5K

REMARKS

·

For how to find the SERIA L number, refer to page 46.

Harmonic suppression guideline (when inverters are used in Japan)

All models of general -purpose inverters used by specific consumers are covered by "Harmonic Su ppression Guidelines for Con sumers

Who Receive High Voltage or Special High Voltage". (For fur ther details, refer to Chapter 3 of the Instruction Manual (Applied).)

1

Page 5

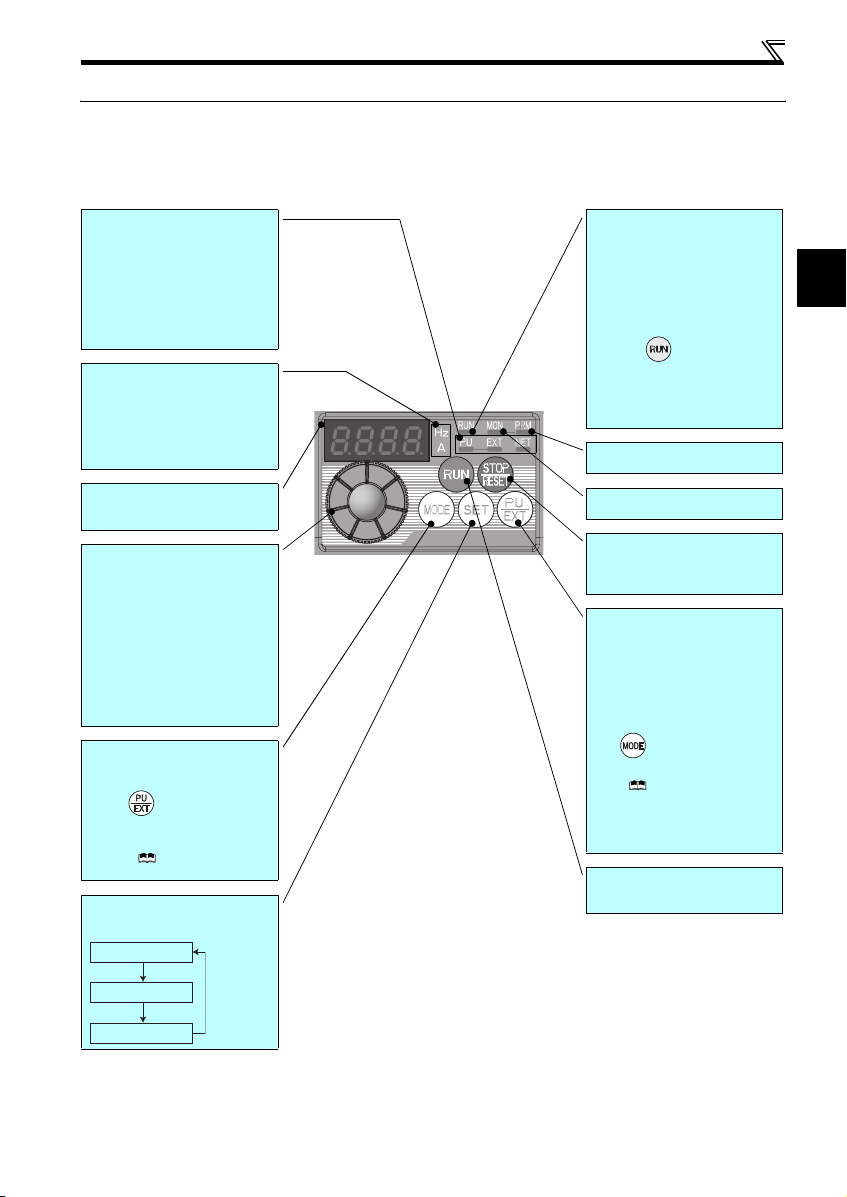

1.2 Operation panel

1.2.1 Names and functions of the operation panel

The operation panel cannot be removed from the inverter.

Operation panel

Operation mode indicator

PU: Lit to indicate P U operation mode.

EXT: Lit to indicate Extern al operation mode.

(Lit at power-ON at initial setting.)

NET: Lit to indicate Network operation mode.

PU, EXT: Lit to indicate External/PU

combined operation mode 1, 2.

These turn OFF whe n command source is

not on oper ation panel.

Unit indicator

Hz: Lit to indicate frequency.

(Flickers when the set frequency

monitor is displayed.)

A: Lit to indicate c urrent.

(Both "Hz" and "A" turn OFF when other

than the above is displayed.)

Monitor (4-digit LED)

Shows th e frequency, paramet er number,

etc.

Setting dial

(Setting dial: Mitsubishi inverter dial)

The setting dial is used to change the

frequency and parameter settings.

Press the setting dial to perform the

following operations:

y To display a set frequency in the

monitor mode

y To display the present setti ng during

calibration

y To display a fault history number in the

faults history mode

Mode switch over

Used to switch among different setting

modes.

Pressing simultaneously changes

the operation mode.

Pressing for a while (2s) can lock

operation. (

Manual (Applied))

Determination of each setting

If pressed during operation, monitor

changes as below:

Running frequency

Refer to the Instru ction

Operating status indicator

Lit or flicker during inverter operation.

* Lit: When the forward rotation operation

is being performed.

Slow flickering (1.4s cycle):

When the reverse rotation operation

is being performed.

Fast flickering (0.2s cycle):

yWhen was pressed or the start

command was given, but the

operation cannot be made.

yWhen the frequency command is less

than the starting frequency.

yWhen the MRS signal is input.

Parameter setting mode indicator

Lit to indicate paramete r setting mode.

Monitor indicator

Lit to indicate monitoring mode.

STOP operation

Used to stop operation commands.

Used to reset a fault when the protective

function (fault) is activated.

Operation mode switchover

Used to switch between the PU and

External operation modes.

To use the External operation mode

(operati on using a separat ely connecte d

frequency setting potentiometer and start

signal), press this key to lig ht up the EXT

indicator.

(Press simultaneously (0.5s), or

change

Pr. 79

mode .)

Manual (Applied))

PU: PU operation mode

EXT: External operation mode

Cancels PU stop also.

Start command

The rotation direction can be selected by

setting Pr. 40.

setting to change to c ombined

( Refer to the Instruction

∗

1

Output current

Output voltage

2

Page 6

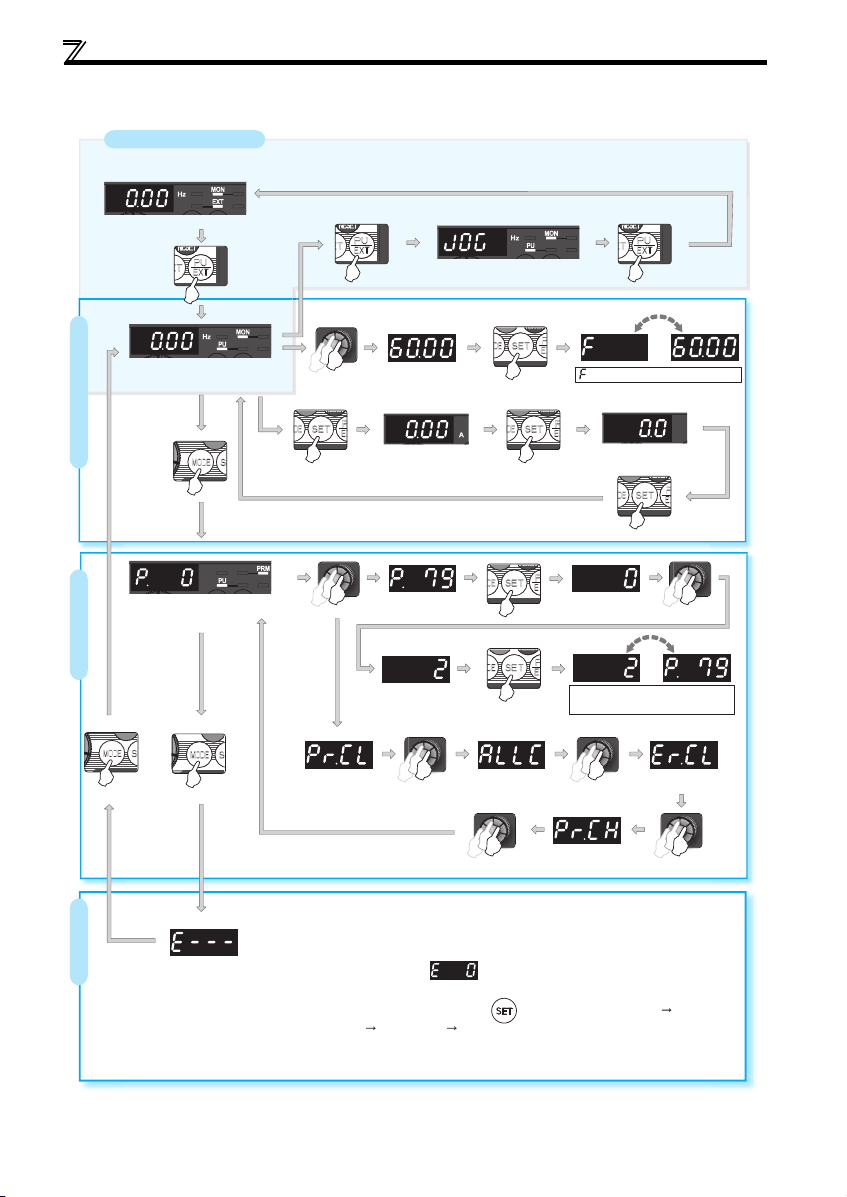

Operation panel

1.2.2 Basic operation (factory setting)

Operation mode switchover

At power-ON (External operation mode)

PU Jog operation mode

(Example)

PU operation mode

(output frequency monitor)

Parameter setting mode

Parameter settingFaults history Monitor/frequency setting

Value change

Output current monitor

Value change

Parameter clear All parameter

[Operation for displaying faults history]

The past eight faults can be displayed using the setting dial.

(The latest fault is ended by ".".)

When no fault history exists, is displayed.

While a fault is displayed:

The display shifts as follows by pressing : Output frequency at the fault

Output current Output voltage Energization time.

(After Energization time, it goes back to a fault display.)

Pressing the setting dial shows the fault history number.

STOP

clear

(Refer to page 35)

and frequency flicker alternately.

Frequency setting has been

written and completed!!

Output voltage monitor

Display the

present setting

(Example)

Parameter and a setting value

flicker alternately.

Parameter write is completed!!

Faults history clear

Initial value

change list

3

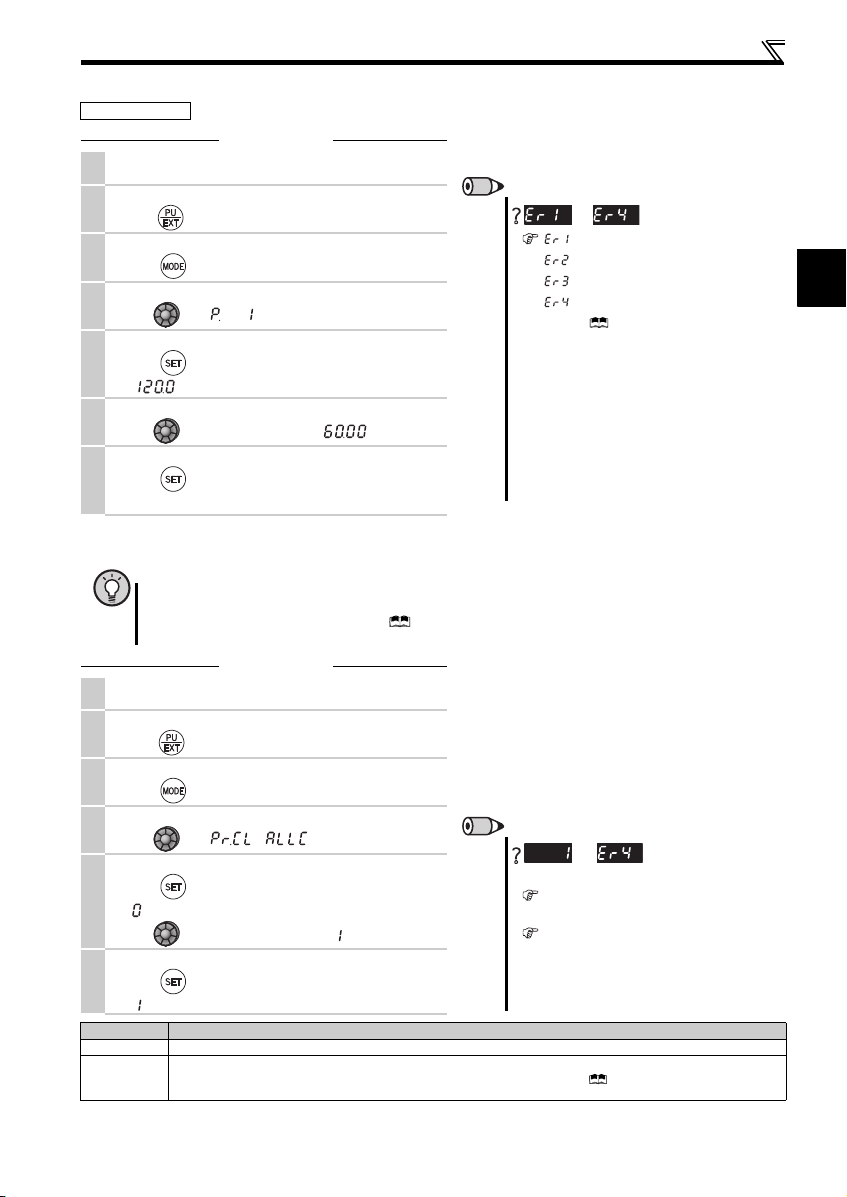

Page 7

1.2.3 Changing the parameter setting value

Operation example Change the Pr. 1 Maximum frequency setting.

Operation

Screen at power-ON

1.

The monitor display app ears.

Operation mode change

2.

Press to choos e the PU operation mode. PU i ndicator is li t.

Parameter setting mode

3.

Press to choose the parameter sett ing mode.

Selecting the parameter number

4.

Turn until (Pr. 1) appears.

Reading the setting value

Press to read the present set value .

5.

" "(120.0Hz (initial value) ) appears.

Changing the setting value

6.

Turn to c hange the set value to " " (60.00Hz).

Setting the parameter

Press to set.

7.

The parameter number an d the setting value flicker alte rnately.

1.2.4 Parameter clear/all parameter clear

POINT

y Set "1" in Pr.CL Parameter clear or ALLC all parameter clear to initialize parameters. (Parameters are not cleared

when "1" is set in Pr. 77 Parameter write selection.)

y Refer to the extended parameter list of the Instruction Manual (Applied) for parameters cleared with this

operation.

Operation

Screen at power-ON

1.

The monitor display app ears.

Operation mode change

2.

Press to choose the PU operation mode. PU indicator is lit.

Parameter setting mode

3.

Press to choose the parameter sett ing mode.

Selecting Parameter Clear (All Parameter Clear)

4.

Turn until ( ) appe ars.

Selecting the setting value

Press to read the present set value .

5.

" "(initial value) appears.

Turn to c hange it to the set value " ".

Executing Parameter Clear

6.

Press to set.

" " and Pr. CL (ALLC) indications flicker alterna tely.

Setting Description

0 Clear is not executed.

Sets parameters back to th e initial values. (Parame ter clear sets back all paramete rs except calibrati on parameters,

1

terminal function selection parameters to the initial values.) Refer to the parameter list of the Instructi on Manual (Applied) for

availability of parameter clear and all parameter cle ar.

Operation panel

REMARKS

to

appears .....Write disable error

appears

appears .....Calibration error

appears .....Mode designatio n error

(For details, refer to the Inst ruction Manual

(Applied).)

y The number of digits displayed on the ope ration

panel is four. Only the upper four digits of values can

be displayed and set. If the values to be displayed

have five digits or more including decimal places, the

fifth or later numerals cannot be displayed nor set.

(Example) For Pr. 1

When 60Hz is set, 60.00 is d isplayed.

When 120Hz is set, 120.0 is displayed and s econd

decimal place is not displayed nor set.

REMARKS

and

Why?

The inverter is not in the PU operation mode.

(Refer to the step 2. )

PU connector is us ed (when a parameter unit

(FR-PU04/FR-PU07) is us ed).

y Stop the inverter. Parameter clear is unavailable

when the inverter is running, and will cause the write

disable error.

is displayed...Why?

..... Write error during operation

are displayed al ternately ...

1

4

Page 8

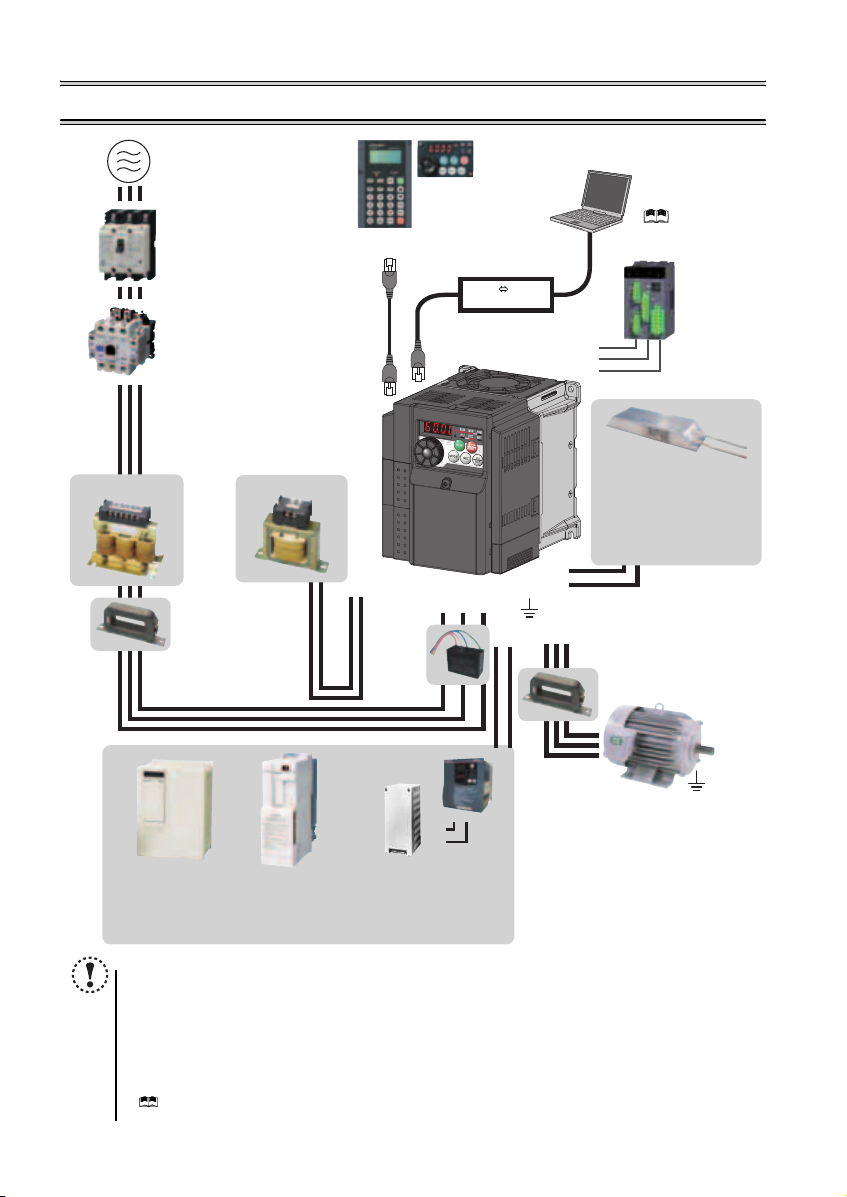

2 INSTALLATION AND WIRING

AC power supply

Use within the permissible power supply

specifications of the inverter. To ensure

safety, use a moulded case circuit breaker,

earth leakage circuit breaker or magnetic

contactor to switch power ON/OFF.

(Refer to page 40)

Moulded case circuit breaker

(MCCB) or earth leakage circuit

breaker (ELB), fuse

The breaker must be selected carefully

since an in-rush current flows in the

inverter at power on.

(Refer to page 6)

Magnetic contactor (MC)

Install the magnetic contactor to ensure

safety. Do not use this magnetic contactor

to start and stop the inverter. Doing so will

cause the inverter life to be shortened.

(Refer to page 6)

Reactor (FR-HAL, FR-HEL option)

Reactors (option) must be used when

power harmonics measures are taken,

the power factor is to be improved or the

inverter is installed near a large power

supply system (500kVA or more). The

inverter may be damaged if you do not

use reactors. Select the reactor according

to the model. Remove the jumpers across

AC reactor (FR-HAL)

* Filterpack (FR-BFP2), which contains DC reactor and noise filter in one package, is also available.

terminals P/+ and P1 to connect the DC reactor.

Install a noise filter (ferrite core)

to reduce the electromagnetic

noise generated from the

inverter. Effective in the range

from about 1MHz to 10MHz.

When more wires are passed

through, a more effective result

can be obtained. A wire should

be wound four turns or more.

High power factor

converter (FR-HC)

Power supply harmonics

can be greatly suppressed.

Install this as required.

DC reactor (FR-HEL) *

Noise filter (ferrite core) *

(FR-BSF01, FR-BLF)

Power regeneration

common converter

(FR-CV)

Great braking capability

is obtained.

Install this as required.

Parameter unit

(FR-PU07)

P/+

P1

Resistor unit (FR-BR)

Discharging resistor (GZG, GRZG)

The regenerative braking capability

of the inverter can be exhibited fully.

Install this as required.

NOTE

y

The life of the inverter is influenced by surrounding air temperature. The surrounding air temperature should be as low as

possible within the permissible range. This must be noted especially when the inverter is installed in an enclosure.

y Wrong wiring might lead to damage of the inverter. The control signal lines must be kept fully away from the main

circuit to protect them f rom noise. (Refer to page 8)

y Do not install a power factor correction capacitor, surge suppressor or noise filter (capacitor) on the inverter output

side. This will cause the inverter to trip or the capacitor and surge suppressor to be damaged. If any of the above

devices are connected, immediate ly remove them.

y Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the

communication device s (such as AM radios) used near the inverter. In this case, install the FR-BIF optiona l

(capacitor)

(for use in the input side only) or FR-BSF01 or FR-BLF

(

Refer to Chapter 3 of the Instructio n Manual (Applied)

y Refer to the Instruction Manual of each option and peripheral devices for details of peripheral devices.

Enclosure surface operation

panel (FR-PA07)

By connecting the connection cable

(FR-CB2) to the PU connector,

operation can be performed from

FR-PU07, FR-PA07.

Inverter (FR-D700)

Brake unit

(FR-BU2)

R/L1 S/L2T/L3

P/+

PR

Noise filter

(capacitor) *

(FR-BIF)

Reduces the

radio noise.

).

RS-485 RS-232C

PR

P/+

RS-232C - RS-485 converter is

required when connecting to PC

with RS-232C interface.

( Refer to the

Instruction Manual (Applied))

Converter

S1

S2

SC

P/+

PR

Noise filter (ferrite core)

Earth (Ground)

UW

N/-

P/+

Devices connected to the output

Do not install a power factor correction capacitor,

surge suppressor or noise filter (capacitor) on the output

side of the inverter. When installing a moulded case

circuit breaker on the output side of the inverter,

contact each manufacturer for selection of the

moulded case circuit breaker.

Earth (Ground)

To prevent an electric shock, always earth (ground)

the motor and inverter. For reduction of induction noise

from the power line of the inverter, it is recommended

to wire the earth (ground) cable by returning it to the

earth (ground) terminal of the inverter.

(FR-BSF01, FR-BLF)

Install a noise filter (ferrite core)

to reduce the electromagnetic

V

noise generated from the inverter.

Effective in the range from about

1MHz to 10MHz. A wire should be

wound four turns at a maximum.

noise filter (ferrite core)

Approved safety

relay module

Required for

compliance with

safety standard.

Brake resistor (FR-ABR,

MRS type, MYS type)

Braking capability can be

improved. (0.4K o r higher)

Always install a thermal relay

when using a brake resistor

whose capacity is 11K or higher.

(Refer to page 17)

to minimize interference.

Motor

Earth (Ground)

(Refer to page 7)

noise filter

5

Page 9

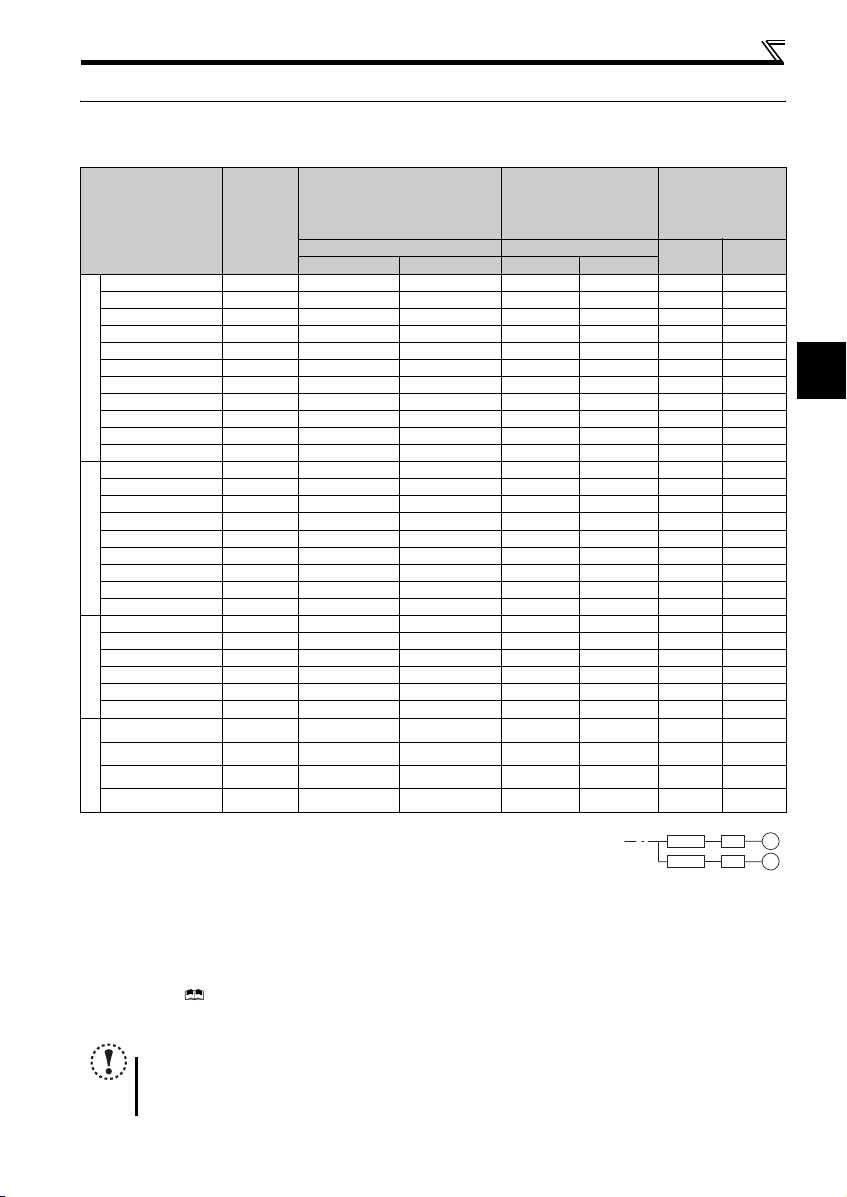

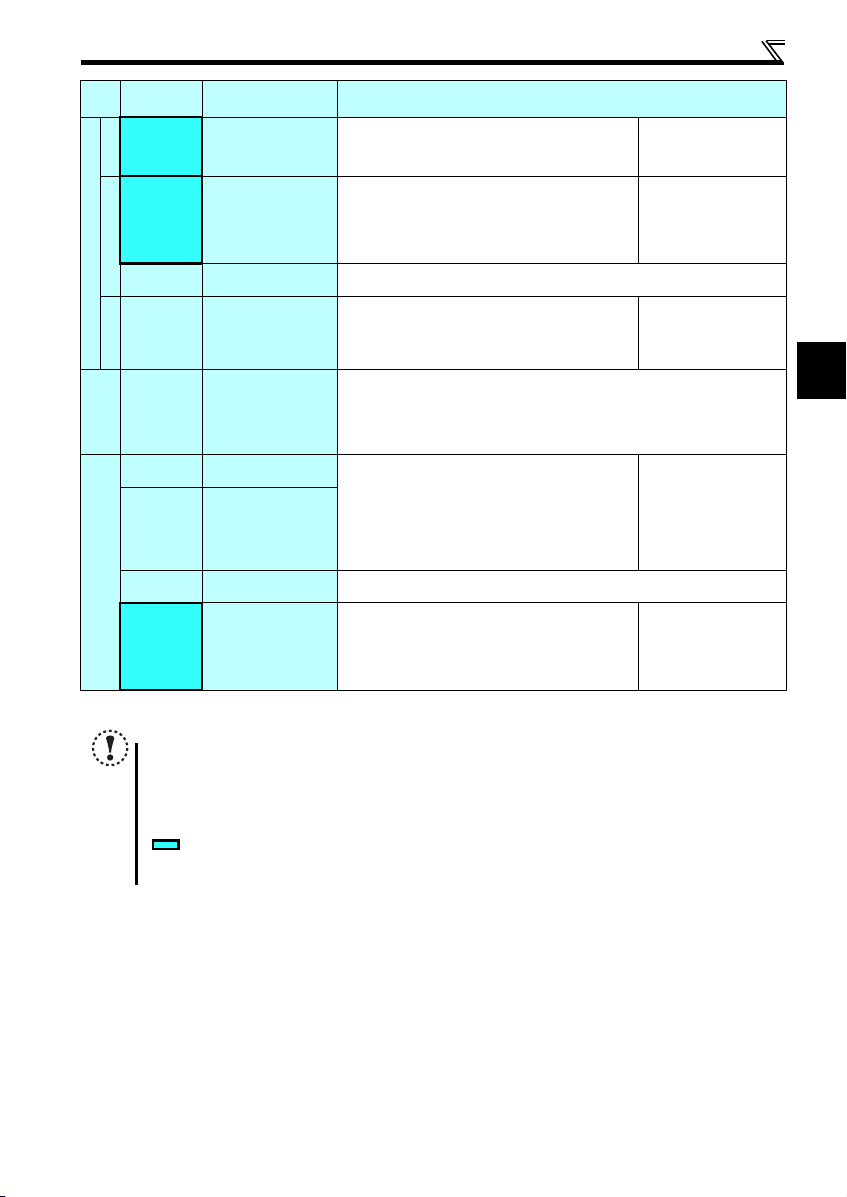

Peripheral devices

2.1 Peripheral devices

Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices.

Moulded Case Circuit Breaker

(MCCB) ∗1

(ELB) ∗2

(NF or NV type)

Reactor connection Reactor connection

Inverter Model

Motor

Output

(kW)

or Earth Leakage Circuit Breaker

without with without with

FR-D720-0.1K 0.1 5A 5A S-N10 S-N10 0.4K ∗5 0.4K ∗5

FR-D720-0.2K 0.2 5A 5A S-N10 S-N10 0.4K ∗5 0.4K ∗5

FR-D720-0.4K 0.4 5A 5A S-N10 S-N10 0.4K 0.4K

FR-D720-0.75K 0.75 10A 5A S-N10 S-N10 0.75K 0.75K

FR-D720-1.5K 1.5 15A 10A S-N10 S-N10 1.5K 1.5K

FR-D720-2.2K 2.2 20A 15A S-N10 S-N10 2.2K 2.2K

FR-D720-3.7K 3.7 30A 30A S-N20, S-N21 S-N10 3.7K 3.7K

FR-D720-5.5K 5.5 50A 40A S-N20, S-N21 S-N20, S-N21 5.5K 5.5K

Three-Phase 200V

FR-D720-7.5K 7.5 60A 50A S-N25 S-N20, S-N21 7.5K 7. 5K

FR-D720-11K 11 75A 75A S-N35 S-N35 11K 11K

FR-D720-15K 15 125A 100A S-N50 S-N50 15K 15K

FR-D740-0.4K 0.4 5A 5A S-N10 S-N10 H0.4K H0.4K

FR-D740-0.75K 0.75 5A 5A S-N10 S-N 10 H0.75K H0.75K

FR-D740-1.5K 1.5 10A 10A S-N10 S-N10 H1.5K H1.5K

FR-D740-2.2K 2.2 15A 10A S-N10 S-N10 H2.2K H2.2K

FR-D740-3.7K 3.7 20A 15A S-N10 S-N10 H3.7K H3.7K

FR-D740-5.5K 5.5 30A 20A S-N20, S-N21 S-N11, S-N12 H5.5K H5.5K

FR-D740-7.5K 7.5 30A 30A S-N20, S-N21 S-N20, S-N21 H7.5K H7.5K

Three-Phase 400V

FR-D740-11K 11 50A 40A S-N20, S-N21 S-N20, S-N21 H11K H 11K

FR-D740-15K 15 6 0A 50A S-N25 S-N20, S-N21 H15K H15K

FR-D720S-0.1K 0.1 5A 5A S-N10 S-N10 0 .4K ∗5 0.4K ∗5

FR-D720S-0.2K 0.2 5A 5A S-N10 S-N10 0 .4K ∗5 0.4K ∗5

FR-D720S-0.4K 0.4 10A 10A S-N10 S-N10 0.75K ∗5 0.75K ∗5

FR-D720S-0.75K 0.75 15A 10A S-N10 S-N 10 1.5K ∗5 1.5K ∗5

FR-D720S-1.5K 1.5 20A 20A S-N10 S-N10 2 .2K ∗5 2.2K ∗5

FR-D720S-2.2K 2.2 40A 30A S-N20, S-N21 S-N10 3.7K ∗5 3.7K ∗5

Single-Phase 200V

FR-D710W-0.1K 0.1 10A 5A S-N10 S-N10

FR-D710W-0.2K 0.2 10A 10A S-N10 S-N10 1 .5K ∗4, ∗5 — ∗6

FR-D710W-0.4K 0.4 15A 15A S-N10 S-N10 2 .2K ∗4, ∗5 — ∗6

FR-D710W-0.75K 0.75 30A 20A S-N10 S -N10 3.7K ∗4, ∗5 — ∗6

Single-Phase 100V

∗1 ySelect a MCCB according to the power supply capacity.

yInstall one MCCB per inverter.

∗2 For the use in the United States or Canada, select an UL and cUL certified fuse with Class T fuse equivalent cut-off

speed or faster with the appropriate rating for branch circuit protection. Alternatively, select a UL489 molded case circuit breaker (MCCB). (Refer to page 46)

∗3 Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic contactor is

used for emergency stop during motor driving, the electrical durability is 25 times.

If using an MC for emergency stop during motor driving, select an MC regarding the inverter input side current as JEM1038-AC-3 class rated current. When

using an MC on the inverter output side for commercial-power supply operation switching using a general purpose motor, select an MC regarding the motor

rated current as JEM1038-AC-3 class rated current.

∗4 When connecting a single-phase 100V power input model to a power transformer (50kVA or more), install an AC reactor (FR-HAL) so that the performance

is more reliable. ( Refer to Chapter 3 of the Instruction Manual (Applied))

∗5 The power factor may be slightly lower.

∗6 Single-phase 100V power input model is not compatible with DC reactor.

NOTE

y When the inverter capacity is larger than the motor capacity, select an MCCB and a magnetic contactor according to the inverter model,

and cable and reactor according to the motor output.

y When the breaker on the inverter input side trips, check for the wiring fault (short circuit), damage to internal parts of the inverter, etc.

Identify the cause of the trip, then remove the cause and power ON the breaker.

Magnetic Contactor (MC)

∗3

Reactor

FR-HAL FR-HEL

0.75K

∗4, ∗5

— ∗6

MCCB INV

MCCB INV

IM

IM

2

6

Page 10

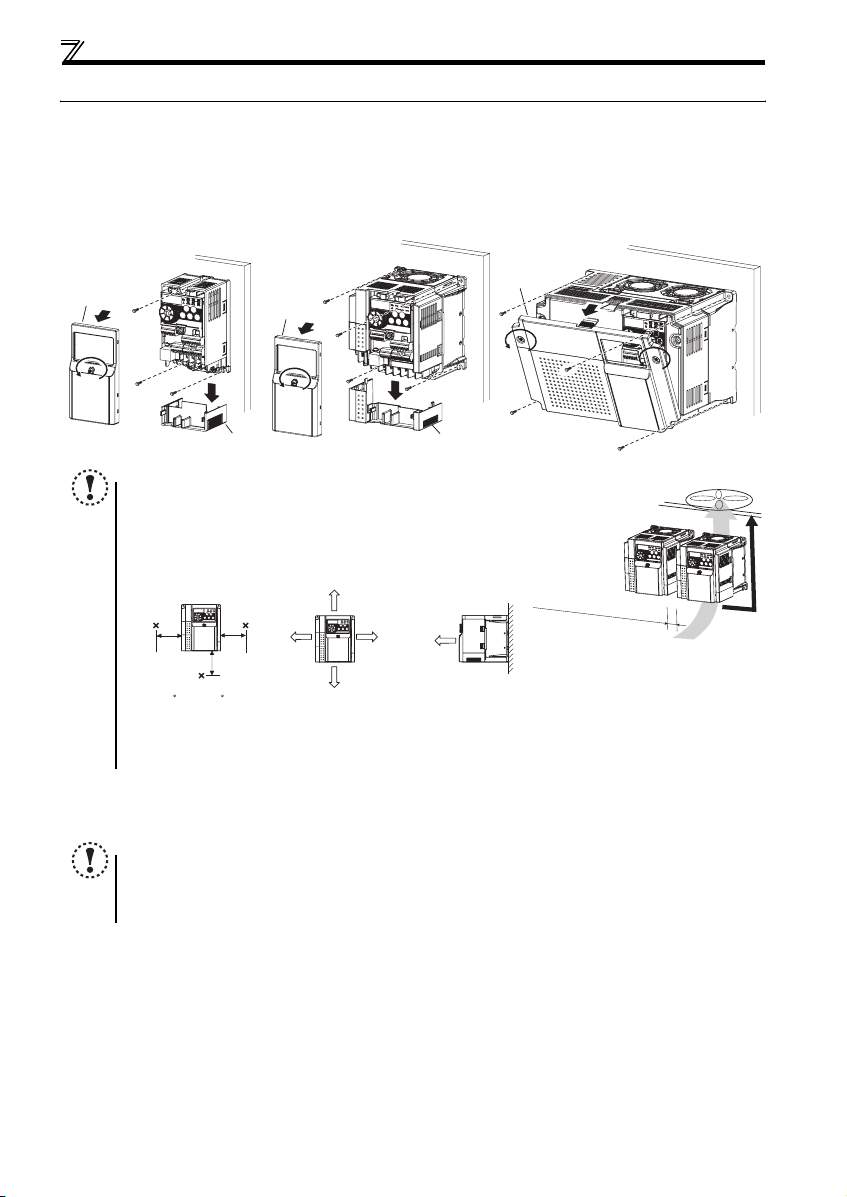

Installation of the inverters and precautions

2.2 Installation of the inverters and precautions

(1) Installation of the inverter

Enclosure surface mounting

Remove the front cover and wiring cover to mount the inverter to the surface. (Remove the covers in the directions of the

arrows.)

FR-D720-0.1K to 0.75K

FR-D720S-0.1K to 0.75K

FR-D710W-0.1K to 0.4K

Front cover

NOTE

y When encasing multiple inverters, install them in paral lel as a cooling

measure.

y Install the inverter vertically.

y For heat dissipation and maintenance, allow minimum clearance shown

in the figures below fro m the inverter to the other devices and to the

inner surface of the enclosure.

5cm

Measurement

position

-10 C to +50 C

(non-freezing)

∗1 Allow 5cm or more clearance for 5.5K or higher.

∗2 When using the inverters at the surrounding air temperature of 40°C or less, the inverters can be installed without any clearance between

them (0cm clearance).

5cm

(2) Environment

Before installation, che ck that the environment meets the specifications on page 41.

Note

y Install the inverter on a strong surface securely and vertically with bolts.

y Leave enough clearances and take cooling measures.

y Avoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

y Install the inverter on a nonflammable wall surface.

FR-D720-1.5K to 3.7K

FR-D740-0.4K to 3.7K

FR-D720S-1.5K, 2.2K

FR-D710W-0.75K

Front cover

Wiring cover Wiring cover

Measurement

position

5cm

1cm or

more

∗1, ∗2

10cm or more

1cm or

∗1, ∗2

more

10cm or more

1cm or

more

∗1

FR-D720-5.5K to 15K

FR-D740-5.5K to 15K

Front cover

Refer to the clearances below.

7

Page 11

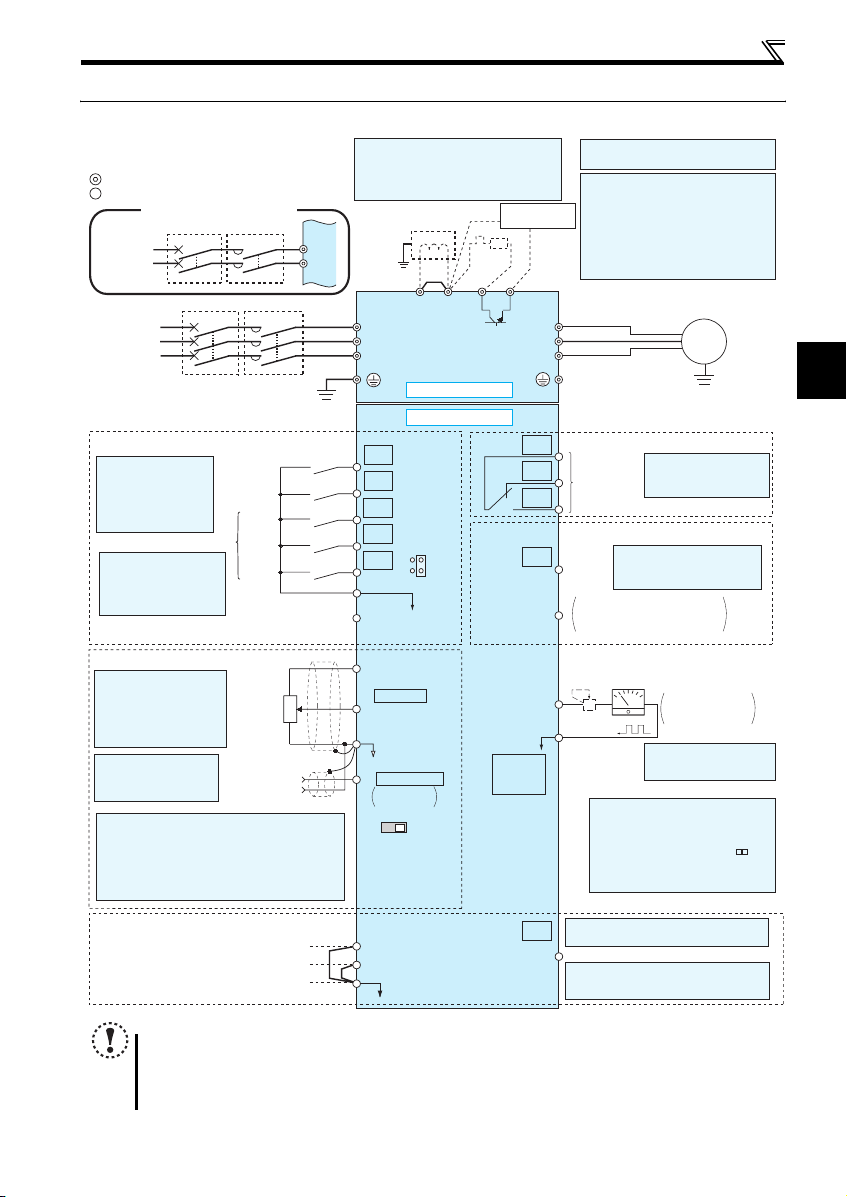

2.3 Wiring

2.3.1 Terminal connection diagram

Sink logic

Main circuit terminal

Control circuit terminal

Single-phase power input

Single-phase

AC power

supply

Three-phase

AC power

supply

Control input signals (No voltage input allowed)

The function of these

terminals can be

changed to the reset

signal, etc. with the input

terminal assignment

(Pr. 178 to Pr. 182)

*2 When using terminals PC-

SD as a 24VDC power

supply, take care not to

short across terminals

PC and SD.

Frequency setting signals (Analog)

*3 Terminal input specifications

can be changed by analog

input specifications

switchover (Pr. 73).

Terminal 10 and terminal 2

are used as PTC input

terminal (Pr. 561).

*4 It is recommended to

use 2W1kΩ when the

frequency setting signal

is changed frequently.

*5 Terminal input specifications can be changed by analog

input specifications switchover (Pr. 267). Set the

voltage/current input switch in the "V" position to select

voltage input (0 to 5V/0 to10V) and "I" (initial value) to

select current input (4 to 20mA).

To use terminal 4 (initial setting is current input), set "4"

in any of Pr.178 to Pr.182 (input terminal function

selection) to assign the function, and turn ON AU signal.

MCCB MC

MCCB MC

Earth

(Ground)

Forward

rotation start

Reverse

rotation start

High

.

Multi-speed selection

speed

Middle

speed

Low

speed

Contact input common

(Common for external power supply transistor)

24VDC power supply

3

Frequency

setting

potentiometer

1/2W1kΩ

*4

1

Terminal 4

(+)

input

(-)

(Current

input)

R/L1

S/L2

(Ground)

2

*

1. DC reactor (FR-HEL)

When connecting a DC reactor, remove the

jumper across P1 and P/+.

Single-phase 100V power input model is not

compatible with DC reactor.

Earth

R/L1

S/L2

T/L3

Jumper

*1

P1 P/+

*6

R

*7

PR

N/-

Main circuit

Control circuit

STF

STR

RH

RM

RL

SD

PC

10(+5V)

2 0 to 5VDC

(0 to 10VDC)

5(Analog common)

4 4 to 20mADC

0 to 5VDC

0 to 10VDC

VI

Voltage/current

input switch

*2

SOURCE

*5

*3

SINK

*5

connector

Brake unit

(Option)

RUN

PU

*9

*6 Terminal P1 is not available for single-

phase 100V power input model.

*7 Brake resistor (FR-ABR, MRS type, MYS

type)

Install a thermal relay to prevent an

overheat and burnout of the brake resistor.

Always install a thermal relay when using

a brake resistor whose capacity is 11K or

higher.

(The brake resistor can not be connected

to the 0.1K and 0.2K.)

U

V

W

C

B

A

Relay output

(Fault output)

Relay output

Open collector output

Terminal functions vary by

Pr. 190 RUN terminal function

Running

selection

Open collector output common

SE

Sink/source common

Calibration resistor

+

-

FM

*8

SD

*9 Operation and parameter setting can be

done from the parameter unit (FRPU07) and the enclosure surface

operation panel (FR-PA07).

(Use the option cable (FR-CB2 ).)

RS-485 communication can be utilized

from a personal computer and other

devices.

Wiring

Motor

IM

Earth (Ground)

Terminal functions vary

by Pr. 192 A,B,C terminal

function selection

Indicator

(Frequency meter, etc.)

Moving-coil type

1mA full-scale

*8 It is not necessary when

calibrating the indicator

from the operation panel.

2

Safety stop signal

Safe stop input (Channel 1)

Safe stop input (Channel 2)

Safe stop input common

NOTE

y To prevent a malfunction caus ed by noise, separate the signal c ables more than 10cm from the power cables. Also

separate the main circuit w ire of the input side and t he output side.

y After wiring, wire off cuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes

in an enclosure etc., take ca re not to allow chips and other foreign matter to enter the inverter.

y The output of the single-phase power input model is three-phase 200V.

Shorting

wire

Terminal functions vary by Pr. 197 SO

S1

S2

SC

SO

terminal function selection

Safety monitor output *10

*10 Common terminal of terminal SO is

terminal SC. (Connected to terminal SD

inside of the inverter.)

8

Page 12

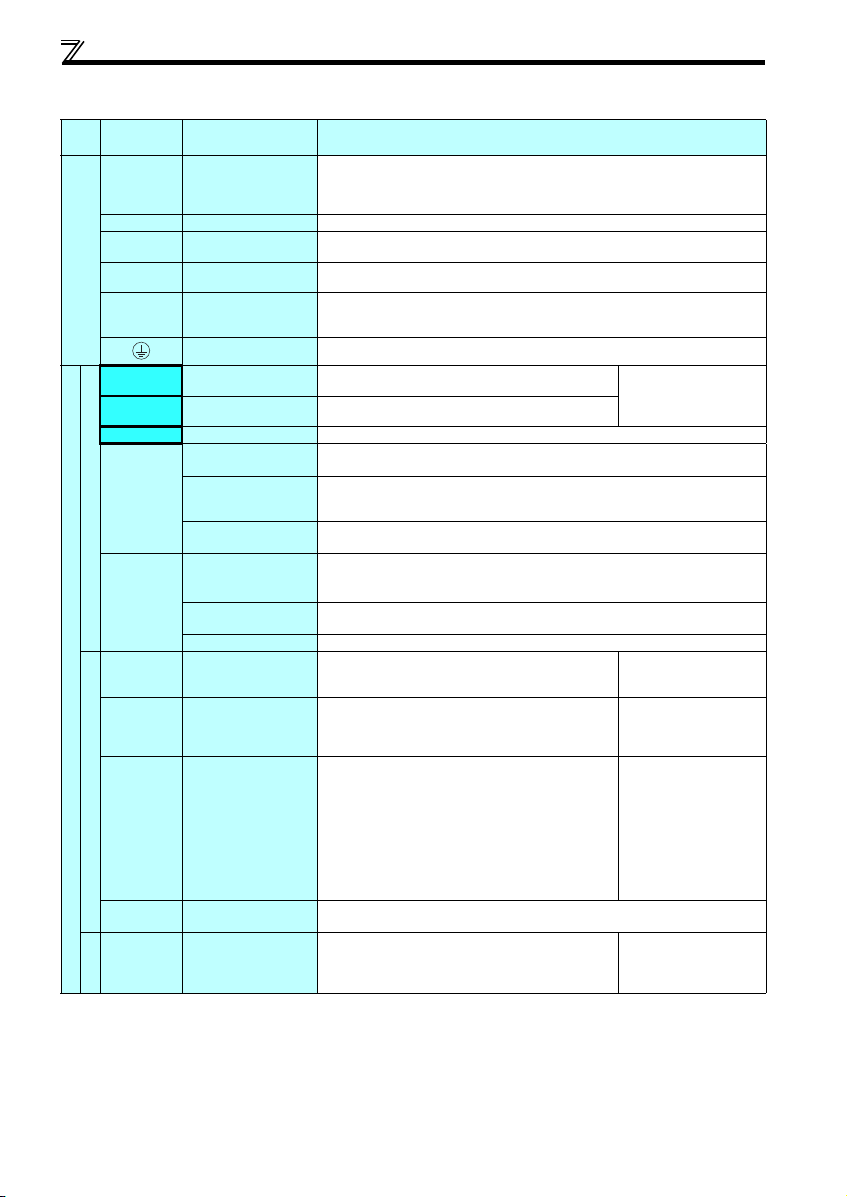

Wiring

2.3.2 Terminal specifications

Terminal

Typ e

Symbol

R/L1, S/L2,

T/L3

U, V, W Inverter output

P/+, PR Brake resistor connection

P/+, N/- Brake unit connection

Main circuit terminal

P/+, P1 ∗ DC reactor connection

STF Forward rotation start

STR Reverse rotation start

RH, RM, RL Multi-speed selection

SD

Contact input

PC

10

2

Control circuit terminal/Inpu t signal

4

Frequency setting

5

10

2

Thermistor

Terminal Name Terminal Specification

∗

AC power input

Earth (Ground)

Contact input common

(sink) (initial setting)

External transistor

common (source)

24VDC power supply

common

External transistor

common (sink)

(initial setting)

Contact input common

(source)

24VDC power supply

Frequency setting power

supply

Frequency setting

(voltage)

Frequency setting

(current)

Frequency setting

common

PTC thermistor input

Connect to the commercial power supply.

Do not connect anything to these terminals when using the high power factor converter (FRHC) or power regeneration common converter (FR-CV).

* When using single-phase power inpu t, terminal s are R/L1 and S/L2.

Connect a three-phase squirrel-cage motor.

Connect a brake resistor (FR-ABR, MRS type, MYS type) across terminals P/+ and PR.

(The brake resistor can not be connected to the 0.1K and 0.2K.)

Connect the brake unit (FR-BU2), power regeneration common converter (FR-CV) or high

power factor converter (FR-HC).

Remove the jumper across terminals P/+ and P1 and connect a DC reactor. (Single-phase

100V power input model is not compatible with the DC reactor.)

* Terminal P1 is not available for single-phase 100V power input model.

For earthing (grounding) the inverter chassis. Must be earthed (grounded).

Turn ON the STF signal to start forward rotati on and turn it OFF

to stop.

Turn ON the STR signal to start reverse rotation and turn it

OFF to stop.

Multi-speed can be selected according to the combination of RH, RM and RL signals.

Common terminal for contact input terminal (sink logic) and terminal FM.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the source logic to avoid

malfunction by undesirable current.

Common output terminal for 24VDC 0.1A power supply (PC terminal).

Isolated from terminals 5 and SE.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the sink logic to avoid

malfunction by undesirable current.

Common terminal for contact input terminal (source logic).

Can be used as 24VDC 0.1A power supply.

Used as power supply when connecting potentiometer for

frequency setting (speed setting) from outside of the inverter.

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output

frequency at 5V (10V) and makes input and output

proportional. Use Pr. 73 to switch between input 0 to 5VDC

input (initial setting) and 0 to 10VDC.

Inputting 4 to 20mADC (or 0 to 5V, 0 to 10V) provides the

maximum output frequency at 20mA and makes input and

output proportional. This input signal is valid only when the AU

signal is ON (terminal 2 input is invalid). To use terminal 4

(initial setting is current input), set "4" in any of Pr.178 to Pr.182

(input terminal function selecti on) to assign the function, and turn

ON AU signal.

Use Pr. 267 to switch among input 4 to 20mA (initial setting), 0

to 5VDC and 0 to 10VDC. Set the voltage/current input switch

in the "V" posit ion to select volta ge input (0 to 5V/0 to 10V).

Frequency setting signal (terminal 2, 4) common terminal. Do not earth (ground).

For connecting PTC thermistor output.

When PTC thermistor protection is valid (Pr. 561 ≠ "9999"),

terminal 2 is not available for frequency setting.

When the STF and STR

signals are turned ON

simultaneously, the stop

command is given.

5VDC

permissible load current

10mA

Input resistance10kΩ ± 1kΩ

Permissible maximum voltage

20VDC

Current input:

Input resistance 249Ω ± 5Ω

Maximum permissible current

30mA

Voltage input:

Input resistance10kΩ ± 1kΩ

Permissible maximum voltage

20VDC

Adaptive PTC th ermistor

specification

Heat detection resistance :

500Ω to 30kΩ (Set by Pr. 561)

9

Page 13

Wiring

Ter min al

Typ e

Symbol

A, B, C

Relay

RUN Inverter running

Open collector

SE

Control circuit terminal/Outp ut signal

FM For meter

Pulse

— PU co nnector

Communication

S1

S2

SC

Safety stop function *

SO

* For more details, refer to the Safety stop function instruction manual (BCN-A211508-000). (Please contact your sales representative for the manual.)

NOTE

y To change the input specification for terminal 4, set Pr. 267 and the voltage/current input switch correctly, then input

the analog signal relevant to the setting. Applying a voltage with voltage/current input switch in "I" position (current

input is selected) or a current with switch in "V" position (voltage input is selected) could cause component damage

to the inverter or analog circuit of output devices.

y Connecting the power supply to the inverter output terminals (U, V, W) will damage the inverter. Do not per form such

wiring.

y indicates that terminal functions can be selected using Pr. 178 to Pr. 182, Pr. 190, Pr. 192, Pr. 197 (I/O terminal

function selection).

y The terminal names and functions shown here are the initial settings.

Terminal Name Terminal Specification

Relay output

(fault output)

Open collector output

common

Safety stop input

(Channel 1)

Safety stop input

(Channel 2)

Safety stop input terminal

common

Safety monitor output

(open collector output)

1 changeover contact output indicates that the inverter

protective function has activated and the output stopped.

Fault: discontin uity across B-C ( continuity across A -C),

Normal: continuity across B-C (discontinuity across A-C)

Switched Low when the inverter output frequency is equal to or

higher than the starting frequency (initial value 0.5Hz).

Switched High during stop or DC injection brake operation.

(Low is when the open collector output transistor is ON

(conducts). High is when the transistor is OFF (does not

conduct).)

Common terminal of terminal RUN.

Used to output a selected monitored item (such as Output

frequency) among several monitored items.

(Not output during inverter reset.)

The output signal is proportional to the magnitude of the

corresponding monitored item.

With the PU connector, communication can be established through RS-485.

yConforming standard: EIA-485 (RS-485)

yTransmission format: Multidrop link

yCommunication speed: 4800 to 38400bps

yOverall length: 500m

Terminals S1 and S2 are for safety stop in put signals used with

the safety relay module. Terminals S1 and S2 are used

simultaneously (dual channel). Inverter output is shut off by

shortening/opening across terminals S1 and SC and across S2

and SC. In the initial status, term inals S1 and S2 are shorted

with terminal SC by shortening wire.

Remove the shortening wire and connect the safety relay

module when using the safety stop function.

Common terminal for terminals S1, S2 and SO. Connected to terminal SD inside of the

inverter.

The signal ind icates the stat us of safety stop i nput.

Low indicates safe state, and High indicates drive enabled or

fault detected.

(Low is when the open collector output transistor is ON

(conducts). High is when the transistor is OFF (does not

conduct).)

Contact capacity:230VAC

0.3A (power factor =0.4)

30VDC 0.3A

Permissible load 24VDC

(maximum 27VDC) 0.1A

(a voltage drop is 3.4V

maximum when the signal is

ON)

Permissible load current 1mA

1440 pulses/s at 60Hz

Input resistance 4.7kΩ

Voltage when contacts are

open

21 to 26VDC

When contacts are shortcircuited

4 to 6mADC

Permissible load 24VDC

(maximum 27VDC) 0.1A

(a voltage drop is 3.4V

maximum when the signal is

ON)

2

10

Page 14

Wiring

r

r

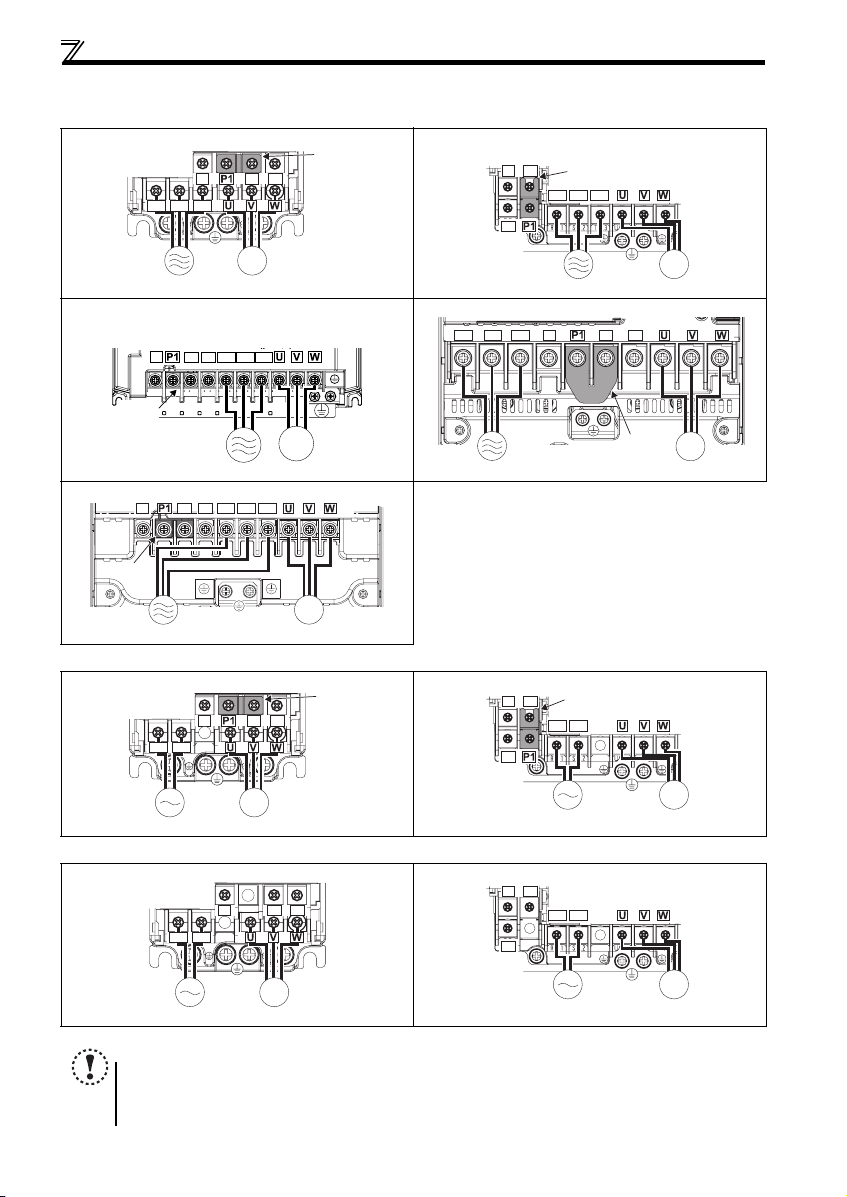

2.3.3 Terminal arrangement of the main circuit terminal, power supply and the motor wiring

zThree-phase 200V/400V class

FR-D720-0.1K to 0.75K FR-D720-1.5K to 3.7K

N/-

P/+ PR

R/L1 S/L2 T/L3

Jumpe

FR-D740-0.4K to 3.7K

N/-

PR

P/+

R/L1 S/L2 T/L3

Jumper

IM

MotorPower supply

FR-D720-5.5K, 7.5K

FR-D740-5.5K, 7.5K

N/-

Jumper

P/+ PR

R/L1 S/L2 T/L3

FR-D720-11K, 15K

R/L1 S/L2 T/L3

IM

FR-D740-11K, 15K

N/-

Jumper

Power supply

zSingle-phase 200V class

FR-D720S-0.1K to 0 .75K FR-D720S-1.5K, 2.2K

R/L1 S/L2

zSingle-phase 100V class

FR-D710W-0.1K to 0.4K FR-D710W-0.75K

P/+

N/-

R/L1 S/L2

PR

Power supply Motor

R/L1 S/L2 T/L3

P/+ PR

IM

MotorPower supply

N/-

P/+ PR

IM

Motor

Jumpe

N/-

PR

N/-

PR

Power supply

N/-

P/+

R/L1 S/L2

P/+

R/L1 S/L2

Jumper

P/+

PR

Jumper

IM

Motor

IM

MotorPower supply

IM

MotorPower supply

IM

MotorPower supply

NOTE

y Make sure the power cables are connected to the R/L1, S/L2, T/L3. (Phase need not be matched.) Never connect the

power cable to the U, V, W of the inverter. Doing so w ill damage the inverter.

y Connect the moto r to U, V, W. Turning ON the forward ro tation switch (signal) at t his time rotates the motor

counterclockwise when viewed from the load shaft.

11

IM

MotorPower supply

Page 15

Wiring

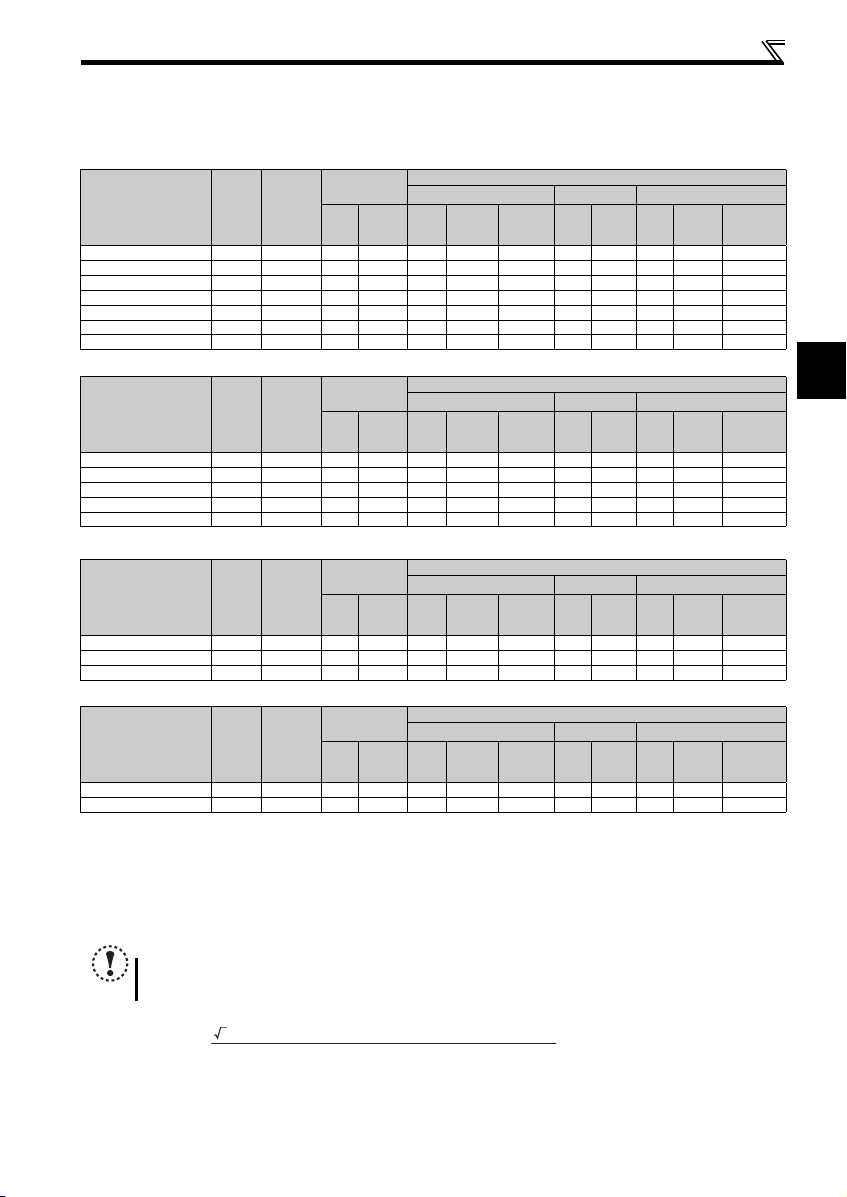

(1) Cable sizes etc., of the main control circuit terminals and earth (ground) terminals

Select the recommended cable size to ensure that a voltage drop will be 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque to

decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

Three-phase 200V class (when input power supply is 220V)

N·m

Crimping

Terminal

R/L1

S/L2

T/L3

HIV Cables, etc. (mm2) ∗1

R/L1

U, V, W

S/L2

T/L3

U, V, W

Earthing

(grounding)

Ter mi nal

Applicable Inverter

Model

FR-D720-0.1K to 0.75K M3.5 1.2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

FR-D720-1.5K, 2.2K M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-D720-3.7K M4 1.5 5.5-4 5.5 -4 3.5 3.5 3.5 12 12 4 4 4

FR-D720-5.5K M5 2.5 5.5-5 5.5 -5 5.5 5.5 5.5 10 10 6 6 6

FR-D720-7.5K M5 2.5 14-5 8- 5 14 8 5.5 6 8 16 1 0 6

FR-D720-11K M5 2.5 14-5 14-5 14 14 14 6 6 1 6 16 16

FR-D720-15K M6 (M5) 4.4 22-6 22-6 22 22 14 4 4 25 25 16

Screw

Size ∗4

Tightening

Tor que

Three-phase 400V class (when input power supply is 440V)

N·m

Crimping

Terminal

R/L1

S/L2

T/L3

HIV Cables, etc. (mm2) ∗1

R/L1

U, V, W

S/L2

T/L3

U, V, W

Earthing

(grounding)

Ter mi nal

Applicable Inverter

Model

FR-D740-0.4K to 3.7K M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-D740-5.5K M4 1.5 5.5-4 2-4 3.5 2 3.5 12 14 4 2.5 4

FR-D740-7.5K M4 1.5 5.5-4 5.5 -4 3.5 3.5 3.5 12 12 4 4 4

FR-D740-11K M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-D740-15K M5 2.5 8-5 8-5 8 8 8 8 8 10 10 10

Screw

Size ∗4

Tightening

Tor que

Single-phase 200V class (when input power supply is 220V)

N·m

Crimping

Terminal

R/L1

S/L2

HIV Cables, etc. (mm2) ∗1

R/L1

U, V, W

S/L2

U, V, W

Earthing

(grounding)

Ter mi nal

Applicable Inverter

Model

FR-D720S-0.1K to 0.75K M3.5 1.2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

FR-D720S-1.5K M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-D720S-2.2K M4 1.5 5 .5-4 2-4 3 .5 2 3.5 12 14 4 2.5 4

Screw

Size ∗4

Tightening

Tor que

Single-phase 100V class (when input power supply is 100V)

N·m

Crimping

Terminal

R/L1

S/L2

HIV Cables, etc. (mm2) ∗1

R/L1

U, V, W

S/L2

U, V, W

Earthing

(grounding)

Ter mi nal

Applicable Inverter

Model

FR-D710W-0.1K to 0.4K M3.5 1.2 2- 3.5 2-3.5 2 2 2 14 14 2.5 2.5 2 .5

FR-D710W-0.75K M4 1.5 5.5-4 2-4 3.5 2 2 12 14 4 2.5 2 .5

∗1 The cable size is that of the cable (HIV cable (600V class 2 vinyl-insulated cable) etc.) with continuous maximum permissible temperature of 75°C. Assumes

that the surrounding air temperature is 50°C or less and the wiring distance is 20m or less.

∗2 The recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C. Assumes that the surrounding

air temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in the United States.)

∗3 The recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in Europe.)

∗4 The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, PR, P/+, N/-, P1 and a screw for earthing (grounding).

Screw size for earthing (grounding) the FR-D720-15K is indicated in parentheses.

For single-phase power input, the terminal screw size indicates the size of terminal screw for R/L1, S/L2, U, V, W, PR, P/+, N/-, P1 and a screw for earthing

(grounding).

Screw

Size ∗4

Tightening

Tor que

NOTE

y

Tighten the terminal screw to the specified torque. A screw that has been tightened too loosely can cause a short circuit or

malfunction. A screw that has been tightened too tightly can cause a short circuit or malfunction due to the unit breakage.

y Use crimping terminals with insulation sleeve to wire the power supply and motor.

The line voltage drop can be calculated by the following formula:

Line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop (torque

reduction) in the low speed range.

3 × wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000

cable

cable

cable

cable

Cable Size

AWG ∗2

R/L1

S/L2

U, V, W

T/L3

Cable Size

AWG ∗2

R/L1

S/L2

U, V, W

T/L3

Cable Size

AWG ∗2

R/L1

U, V, W

S/L2

Cable Size

AWG ∗2

R/L1

U, V, W

S/L2

PVC Cables, etc. (mm2) ∗3

R/L1

S/L2

T/L3

PVC Cables, etc. (mm2) ∗3

R/L1

S/L2

T/L3

PVC Cables, etc. (mm2) ∗3

R/L1

S/L2

PVC Cables, etc. (mm2) ∗3

R/L1

S/L2

U, V, W

U, V, W

U, V, W

U, V, W

Earthing

(grounding)

cable

Earthing

(grounding)

cable

Earthing

(grounding)

cable

Earthing

(grounding)

cable

2

12

Page 16

Wiring

(2) Total wiring length

The overall wiring length for connection of a single motor or multiple motors should be within the value in the table below.

100V, 200V class

Pr. 72 PWM frequency selection Setting

(carrier frequency)

1 (1kHz) or less 200m 200m 300 m 500m 500m

2 to15

(2kHz to 14.5kHz)

0.1K 0.2K 0.4K 0.75K

30m 100m 200m 300m 500m

400V class

Pr. 72 PWM frequency selection Setting

(carrier frequency)

1 (1kHz) or less 200m 200m 300m 50 0m 500m

2 to15

(2kHz to 14.5kHz)

0.4K 0.75K 1.5K 2.2K

30m 100 m 200m 300m 500m

When driving a 400V class motor by the inverter, surge voltages attributable to the wiring constants may occur at the motor

terminals, deteriorating the insulation of the motor. Take the following measures 1) or 2) in this case.

1) Use a "400V class inverter-driven insulation-enhanced motor" and set frequency in Pr. 72 PWM frequency selection

according to wiring length

Wiring Length

50m or less 50m to 100m Exceeding 100m

Carrier frequency

14.5kHz or less 8kHz or less 2kHz or less

2) Connec t the surge voltage suppression filter (FR-A SF-H/FR-BMF -H) on the inverter output side.

NOTE

y Especially for long-distance wiring, the inverter may be affected by a charging current caused by the stray

capacitances of the wiring, leading to a malfunction of the overcurrent protective function, fast response current limit

function, or stall prevention function or a malfunction or fault of the equipment connected on the inverter output side.

If malfunction of fast-response current limit function occurs, disable this function. If malfunction of stall prevention

function occurs, increa se the stall level. ( Refer to Pr. 22 Stall prevention operation level and Pr. 156 Stall prevention

operation selection in the chapter 4 of the Instruction Manual (applied))

y When using the automatic restart after instantaneous power failure function with wiring length exceeding below,

select without frequen cy search (Pr. 162 = "1, 11"). (

Motor capacity 0.1kW 0.2kW 0.4kW or higher

Wiring length 20m 50m 100m

Refer to Chapter 4 of the Instruction M anual (Applied))

1.5K or

higher

3.7K or

higher

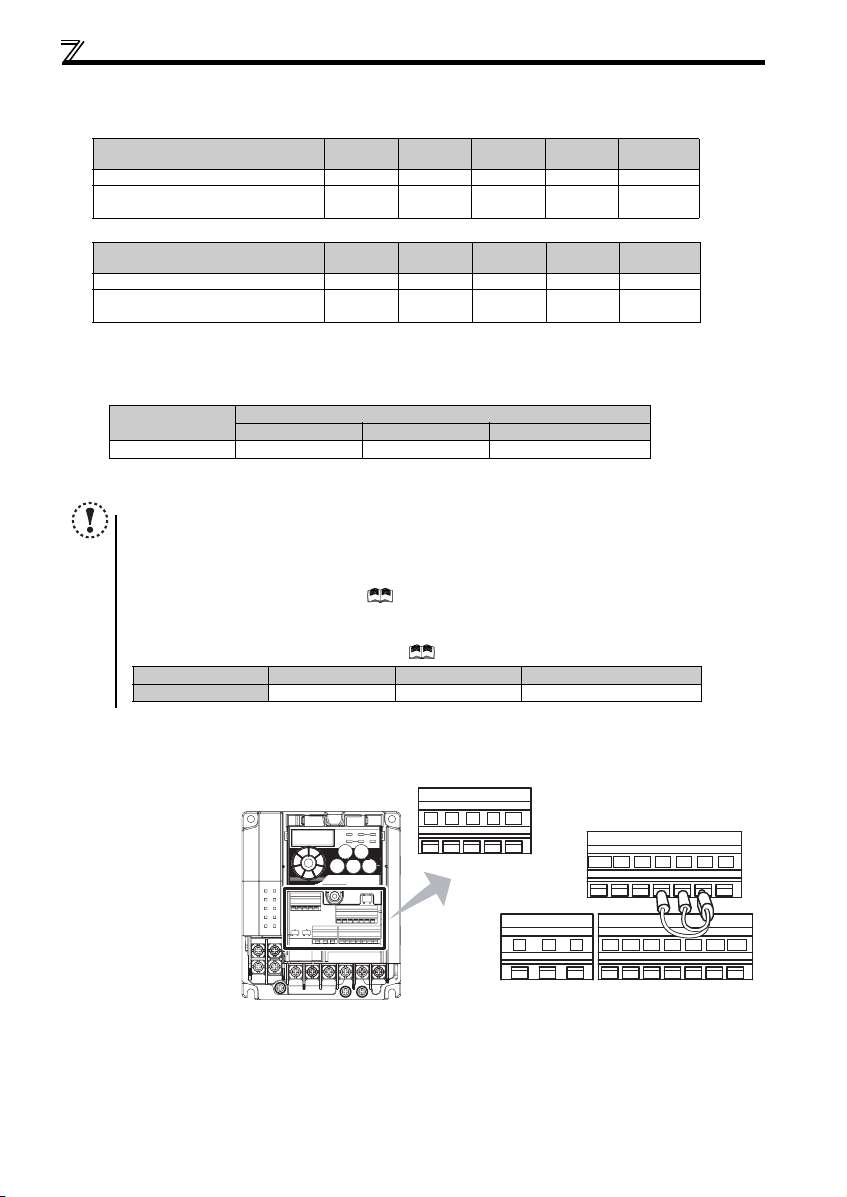

2.3.4 Wiring of control circuit

(1) Control circuit terminal layout

Recommend wire size:

0.3mm

2

to 0.75mm

2

13

10 2 5 4

FM

RUN SE S1 S2 SCSO

CBA

SD

STF

PCSDRHRMRL

STR

Page 17

Wiring

r

(2) Wiring method

zWiring

Use a blade terminal and a wire with a sheath stripped off for the control circuit wiring. For a single wire, strip off the sheath of

the wire and apply directly.

Insert the blade terminal or the single wire into a socket of the terminal.

1) Strip off the sheath about the length below. If the length of the sheath peeled is too long, a short circuit may occur

among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it.

Wire stripping length

2) Crimp the blade terminal.

Insert wires to a blade terminal, and check that the wires come out for about 0 to 0.5 mm from a sleeve.

Check the condition of the blade ter minal after crimping. Do not use a blade terminal of which the crimping is

inappropriate, or the face is damaged.

Wire

Shell

Sleeve

0 to 0.5mm

10mm

Damaged

Crumpled tip

Unstranded

wires

Wires are not inserted

into the shell

Blade terminals available on the market: (as of February 2012)

zPhoenix Contact Co.,Ltd.

Wire Size (mm2)

0.3 AI 0,5-10WH — —

0.5 AI 0,5-10WH — AI 0,5-10WH-GB

0.75 AI 0,75-10GY A 0,75-10 AI 0, 75-10GY-GB

1 AI 1-10RD A1-10 AI 1- 10RD/1000GB

1.25, 1.5 AI 1,5-10BK A1,5-10 AI 1,5 -10BK/1000GB

0.75 (for two wires) AI-TWIN 2 x 0, 75-10GY — —

∗1 A blade terminal with an insulation sleeve compatible with MTW wire which has a thick wire insulation

∗2 Applicable for terminal ABC.

with insulation sleeve without insulation sleeve for UL wire ∗1

Blade Terminal Model

∗2

zNICHIFU Co.,Ltd.

Wire Size (mm2)

0.3 to 0.75 BT 0.75-11 VC 0.75 NH 69

Blade terminal product

number

Insulation product number

Crimping tool

product number

3) Insert the wire into a socket.

When using a single wire or a stranded wire without a blade terminal, push an

open/close button all the way down with a flathead screw driver, and insert the wire.

Open/close button

Crimping Tool

Name

CRIMPFOX 6

2

Flathead screwdrive

NOTE

y When using a stranded wire without a blade terminal, twist enough to avoid short circuit with a nearby terminals or

wires.

y Place the f lathead screwdriver ve rtical to the open/clo se button. In case t he blade tip slips, it ma y cause damage to

inverter or injury.

14

Page 18

Wiring

r

zWire removal

Pull the wire with pushing the open/close button all the

way down firmly with a flat head screwdr iver.

Open/close button

Flathead screwdrive

(3) Control circuit common terminals (SD, 5, SE)

Terminals SD, SE and 5 are common terminals for I/O sign als.(All common terminals are isolated from each other.) Do not

earth them. Avoid connecting the terminals SD and 5 and the terminals SE and 5.

Terminal SD is a common terminal for the contact input terminals (STF, STR, RH, RM, RL) and frequency output signal (FM).

The open collector circuit is isolated from the internal control circuit by photocoupler.

Terminal 5 is a common terminal for the frequency setting signals (terminals 2 or 4). It should be protected from external noise

using a shielded or twisted cable.

Terminal SE is a common terminal for the open collector output terminal (RUN). The contact input circuit is isolated from the

internal control circuit by photocoupler.

(4) Wiring instructions

1) It is recommended to use the cables of 0.3mm2 to 0.75mm2 gauge for connection to the control circuit terminals.

2) The maximum wiring length should be 30m (200m for terminal FM).

3) Do not short across terminals PC and SD. Inverter may be damaged.

4) When using contact inputs, use two or more parallel micro-signal contacts or

twin contacts to prevent contact faults since the control circuit input signals are

micro-currents.

NOTE

y Pulling out the terminal block forcefully without pushing

the open/close button all the way down may damage the

terminal block.

y Use a small flathead scr ewdriver (Tip thickness: 0.4mm/

tip widt h: 2.5mm) .

If a flathead screwdriver with a narrow tip is used,

terminal block may be damaged.

Products available on the market :(as of Oct. 2008)

Product Ty pe Manufacturer

Flathead

screwdriver

y Place the flath ead screwdriver vertical t o the open/close

button. In case the blade tip slips, it may cause damage

to inverter or injury.

SZF 0- 0,4 x 2,5 Phoenix Contact Co.,Ltd.

5) Use shielded or twisted cables for connection to the control circuit terminals

and run them awa y from the main and power circu its (including the 200V relay

sequence circuit).

6) Do not apply a voltage to the contact input terminals (e.g. STF) of the control circuit.

7) Always apply a voltage to the fault output terminals (A, B, C) via a relay coil, lamp, etc.

Micro signal contacts Twin contacts

2.3.5 Assigning signals (output stop signal (MRS), reset signal (RES), etc.) to contact

input terminals

POINT

y Use Pr.178 to Pr.182 (input terminal function selection) to select and change the functions assigned to input

terminals.

To assign the output stop signal (MRS) to the terminal RH, for example, assign "24" to Pr.182 RH terminal

function selection. (Refer to page 4 to change a parameter setting value.)

Pr. Name

178

STF terminal function selection

179

STR terminal function selection

RL terminal function selection

180

RM terminal function selection

181

RH terminal function selection

182

NOTE

y Changing the terminal assignment using Pr.178 to Pr.182 (input terminal function selection) may affect the other functions.

Set parameters after confirming the function of each terminal.

Initial

Val ue

0: Low-speed operation com mand (RL)

60

1: Middle-speed operat ion command (RM)

2: High-speed operation command (RH)

3: Second function sele ction (RT)

61

4: Terminal 4 input selection (AU)

5: JOG operation selectio n (JOG)

0

7: External thermal relay input (OH)

8: Fifteen speed selection ( REX)

10: Inverter operation enable signal ( X10)

1

(FR-HC/FR-CV connection)

12: PU operation externa l interlock (X12)

14: PID control valid terminal (X14)

2

16: PU-External operatio n switchover (X16)

Range

18: V/F switchover (X1 8)

24: Output stop (MRS)

25: Start self-holding selection (STOP )

60: Forward rotation (STF )

61: Reverse rotation (STR) ∗2

62: Inverter reset (RES )

65: PU-NET operation s witchover (X65)

66: External-NET operation switc hover

(X66)

67: Command source swi tchover (X67)

9999: No function

∗1 Assigned to STF terminal (Pr. 178) only

∗2 Assigned to STR terminal (Pr. 179) only

∗1

15

Page 19

Wiring

2.3.6 Safety stop function

(1) Description of the function

The terminals related to the safety stop function are shown below.

Ter min al

Symbol

S1 ∗1 For input of safety stop c hannel 1. Between S1 and SC / S 2 and SC

S2

∗1 For input of safety stop channel 2.

For output of safety stop c ondition.

SAFE

SO

∗2

RUN

∗3

∗1 In the initial status, terminal S1 and S2 are shorted with terminal SC by shortening wire. Remove the shortening wire and connect the safety relay module

when using the safety stop function.

∗2

In the initial setting, safety monitor output signal (SAFE signal) is assigned to terminal SO. The function can be assigned to other terminals by setting "80 (positive

logic) or 180 (negative logic)" to any of

∗3 In the initial setting, inverter running (RUN signal) is assigned to terminal RUN. Set "81" to Pr. 190 RUN terminal function selection to assign SAFE2 signal. The

function can be assigned to other terminals by setting "81 (positive logic) or 181 (negative logic)" to any of Pr. 190, Pr. 192 or Pr. 197 (Output terminal function

selection). ( Refer to Chapter 4 of the Instruction Manual (Applied))

∗4 At an internal safety circuit fault, E.SAF or E.CPU is displayed on the operation panel.

The signal is output when i nverter output is shut off due to the safety stop

signal

function.

SC Common terminal for S1,S2,SO signals. (SC is co nnected terminal SD internally.) —

SAFE2

Outputs when an alarm or failure is detected

signal

Outputs when there is no inte rnal safety circuit fault

SE Com mon terminal for open collec tor outputs (terminal RUN) —

Pr. 190, Pr. 192 or Pr. 197 (Output terminal function selection)

NOTE

y Use SAFE signal for the purpose to monitor safety stop status. SAFE signal cannot be used as safety stop input

signal to other devices (other than the safety relay module.)

y SAFE2 signal can only be used to output an alarm or to prevent restart of an inverter. The signal cannot be used as

safety stop input sig nal to other devices.

(2) Wiring connection diagram

To prevent restart at fault occurrence,

connect terminals RUN (SAFE2 signal) and

SE to terminals XS0 and XS1, which are the

feedback input terminals of the safety relay

module.

By setting Pr.190 RUN terminal function

selection = "81 (SAFE2 signal)", terminal

RUN is turned OFF at fault occurrence.

∗1 Output signals differ by the setting of Pr. 190, Pr.

192 and Pr. 197 (Output terminal function selection).

∗2 Input signals differ by the setting of Pr. 178 to Pr.

182 (Input terminal function s election).

NOTE

y Changing the terminal assignment using Pr. 190, Pr. 192, and Pr. 197 (output terminal function selection) may affect the

other functions. Set parameters after confirming the function of each terminal.

(3) Safety stop function operation

Input power

O F F ----- ----- ----- O F F O F F O u tp u t sh u t of f ( Sa f e st a t e )

Input signal

S1-SC S2- SC SAFE∗3 SAFE2∗3

Short Short

ON

∗1 At an internal safety circuit fault, E.SAF or E.CPU is displayed on the operation panel.

∗2 SA is displayed on the operation panel when both the S1 and S2 signals are in the open state without any internal safety circuit fault (E.SAF, E.CPU).

∗3 ON: Transistor used for an open collector output is conducted.

OFF: Transistor used for an open collector output is not conducted.

For more details, refer to the Safety stop function instruction manual (BCN-A211508-000). (Please contact your sales representa tive

for the manual.)

Open Open

Short Open N/A OFF OFF Output s hutoff (Safe state)

Open

Internal safety

Short N/A OFF OFF Output shutoff (Safe state)

y

Pr. 178

y

Pr. 179

y

Pr. 190

y

Pr. 197

DC24V

MITSUBISHI MELSEC Safety relay module

" N/A " denotes a condi tion where circuit fault does not apply.

circuit∗1

No failure OFF ON Drive enabled

Detected O FF OFF Outp ut shutoff (Safe state)

No failure∗2 ON ON Output shutoff (Safe state)

Detected O FF OFF Outp ut shutoff (Safe state)

Description

∗4

= "60 (initial value)"

= "25"

= "81"

= "80 (initial value)"

START/RESET

Emergency

stop button

COM0

+24V

X0 X1

Internal

Safety

Circuit

24G

QS90SR2SN-Q

Output signal

Open: In safety stop mode.

Short: Other than safety stop mode.

OFF: Drive enabled, or drive stop (at

an internal safety circui t fault

ON: Drive stop (no internal safety

OFF: Internal safety cir cuit fault ∗4

ON: No internal safety circuit fault ∗4

. (

Refer to Chapter 4 of the Instruction Manual (Applied)

∗1

SO (SAFE)

monitor

∗1

RUN (SAFE2)

SE

STF

∗2

STF

STR(STOP)

STOP

COM1

XS0

XS1

Z10

Z00

K1

K2

Z11 Z01 Z21

S1

S2

SC

Z20

SD

circuit fault

I/O control

∗2

∗4)

Inverter

Output

shutoff

circuit

R/L1

S/L2 T/L3

U V W

∗4)

)

IM

Operation state

2

16

Page 20

Connection of a dedicated external brake resistor (MRS type, MYS type, FR-ABR)

r

2.4 Connection of a dedicated external brake resistor (MRS type, MYS type, FR-ABR)

Install a dedicated brake resistor (MRS type, MYS type, FR-ABR) outside when the motor driven by the inverter is made to run

by the load, quick deceleration is required, etc. Connect a dedicated brake resistor (MRS type, MYS type, FR-ABR) to

terminal P/+ and PR. (For the locations of terminal P/+ and PR, refer to the terminal block layout (page 11).)

Set parameters below. (

Connected Brake Resistor Pr. 30 Regenerative function selection Setting Pr. 70 Special regenerative brake duty Setting

MRS type, MYS type 0 (initial value) —

MYS type

(used at 100% torque/6%ED)

FR-ABR 1

z It is recommended to configure a sequence, which shuts off power in the input side of the inverter by the external thermal

relay as shown below, to prevent overheat and burnout of the brake resistor (MRS type, MYS type) and high duty brake

resistor (FR-ABR) in case the regenerative brake transistor is damaged. (The brake resistor cannot be connected to the

0.1K and 0.2K.)

<Example 1>

Power supply

ON

∗1 Refer to the table below for the type number of each capacity of thermal relay and the diagram below for the connection.

(Always install a thermal relay when using a brake resistor whose capacity is 11K or higher.)

∗2 When the power supply is 400V class, install a step-down transformer.

Power

Supply

Vol tag e

100V,

200V

Power

Supply

Vol tag e

100V,

200V

400V

MC

Brake Resistor

MRS120W200 TH-N 20CXHZ-0.7A

MRS120W100 TH-N 20CXHZ-1.3A

MRS120W60 TH-N20 CXHZ-2.1A

MRS120W40 TH-N20 CXHZ-3.6A

MYS220W50

(two units in para llel)

High-duty

Brake Resistor

FR-ABR-0.4K TH-N20CXHZ-0.7A

FR-ABR-0.75K TH-N20CXHZ-1.3A

FR-ABR-2.2K TH-N20CXHZ-2.1A

FR-ABR-3.7K TH-N20CXHZ-3.6A

FR-ABR-5.5K TH-N20CXHZ-5A

FR-ABR-7.5K TH-N20CXHZ-6.6A

FR-ABR-11K TH-N20CXHZ-11A

FR-ABR-15K TH-N20CXHZ-11A

FR-ABR-H0.4K T H-N20CXHZ-0.24A

FR-ABR-H0.75K TH-N20CXHZ-0.35A

FR-ABR-H1.5K T H-N20CXHZ-0.9A

FR-ABR-H2.2K T H-N20CXHZ-1.3A

FR-ABR-H3.7K T H-N20CXHZ-2.1A

FR-ABR-H5.5K T H-N20CXHZ-2.5A

FR-ABR-H7.5K T H-N20CXHZ-3.6A

FR-ABR-H11K TH-N20CXHZ-6.6A

FR-ABR-H15K TH-N20CXHZ-6.6A

NOTE

y The brake resistor connected should only be the dedicated brake resistor.

y Perform wiring and operation according to the Instruction Manual of each option unit.

Brake resistor cannot be used with the brake unit, high power factor converter, power supply regeneration converter, etc.

y

y Do not use the brake resistor with a lead wir e extended.

y Do not connect a resistor directly to termin als P/+ and N/-. This cou ld cause a fire.