Mitsubishi FR-A540-0.4K-55K, FR-A540-0.4K, FR-A520-0.4K-55K-NA, FR-A540-0.4K-55K-NA, FR-A500 Instruction Manual

...Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Page 2

HIGH FUNCTION

&

LOW ACOUSTIC NOISE

FR-A500

TRANSISTORIZED INVERTER

– INSTRUCTION MANUAL –

FR-A520-0.4K to 55K(-NA)

FR-A540-0.4K to 55K(-NA)(-EC)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

A - 1

Thank you for choosing this Mitsubishi transistorized Inverter.

This instruction manual gives handling information and precautions for use of this

equipment.

Incorrect handling might cause an unexpected fault. Before using the inverter, please read

this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read through this

instruction manual and appended documents carefully and can use the equipment correctly.

Do not use the inverter until you have a full knowledge of the equipment, safety information and

instructions.

In this instruction manual, the safety instruction levels are classified into “WARNING” and “CAUTION”.

Assumes that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

Assumes that incorrect handling may cause hazardous conditions, resulting in

medium or slight injury, or may cause physical damage only.

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow

the instructions of both levels because they are important to personnel safety.

CAUTION

WARNING

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

A - 2

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

z

While power is on or when the inverter is running, do not open the f ront c over. You m ay get an electric

shock.

z

Do not run the inverter with the front cover removed. O therwise, you may access the exposed highvoltage terminals or the charging part of the circuitry and get an electric shock.

z

If power is off, do not remove the f ront cover except f or wiring or periodic inspection. You may access

the charged inverter circuits and get an electric shock.

z

Before starting wiring or inspection, switch power off, wait for more at least 10 minutes and c heck for

the presence of any residual voltage with a meter (check chapter 2 for further details.) etc.

z

Use class 3 (200V) or special class 3 (400V) or higher earthing method to earth the inverter.

z

Any person who is involved in the wiring or inspection of this equipment should be fully competent to do

the work.

z

Always install the inverter before wiring. Otherwise, you may get an electric shock or be injured.

z

Operate the switches with dry hands to prevent an electric shock.

z

Do not subject the cables to scratches, exc ess ive stress , heavy loads or pinching. Otherwise, you may

get an electric shock.

z

Do not change the cooling fan while power is on. To do so will invite a hazardous condition.

2. Fire Prevention

CAUTION

z

Mount the inverter on an incombustible surf ace. Inst alling the inverter dir ectly on or near a combustible

surface could lead to a fire.

z

If the inverter has become faulty, switch off the inverter power. A continuous flow of large curr ent could

cause a fire.

z

Do not connect a resistor directly to the DC terminals P, N. This could cause a fire.

3. Injury Prevention

CAUTION

z

Apply only the voltage specified in the instruction manual to each terminal to prevent damage etc.

z

Ensure that the cables are connected to the correct terminals. Otherwise, damage etc. may occur.

z

Always make sure that polarity is correct to prevent damage etc.

z

After the inverter has been operating for a relativly long period of time, do not touc h the inverter as it

may be hot and you may get burnt.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

A - 3

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.:

(1) Transportation and installation

CAUTION

z

When carrying products, use correct lifting gear to prevent injury.

z

Do not stack the inverter boxes higher than the number recommended.

z

Ensure that installation position and material can withstand the weight of the inverter. Install

according to the information in the Instruction Manual.

z

Do not operate if the inverter is damaged or has parts missing.

z

Do not hold the inverter by the front cover; it may fall off.

z

Do not stand or rest heavy objects on the inverter.

z

Check the inverter mounting orientation is correct.

z

Prevent screws, wire fragments, conductive bodies, oil or other flamm able substances from entering

the inverter.

z

Do not drop the inverter, or subject it to impact.

z

Use the inverter under the following environmental conditions:

Ambient temperature

Constant torque: -10°C to +50°C (14°F to 122°F) (non-freezing)

(-10°C to +40°C with FR-A5CV attachment)

Variable torque: -10°C to +40°C (14°F to 104°F) (non-freezing)

(-10°C to +30°C with FR-A5CV attachment)

Ambient humidity 90%RH or less (non-condensing)

Storage temperature -20°C to +65°C* (-4°F to 149°F)

Ambience Indoors (free from corrosive gas, flammable gas, oil mist, dust and dirt)

Environment

Altitude, vibration

Maximum 1000m (3280.80 feet.) above sea level for standard operation.

After that derate by 3% for every extra 500m up to 2500m (91%).

••*Temperatures applicable for a short time, e.g. in transit.

(2) Wiring

CAUTION

z

Do not fit capacitive equipment such as a power factor correction capacitor, noise filter or surge

suppressor to the output of the inverter.

z

The connection orientation of the output cables U, V, W to the motor will affect the direction of

rotation of the motor.

(3) Trial run

CAUTION

z

Check all parameters, and ensure that the machine will not be damaged by a sudden start-up.

(4) Operation

CAUTION

z

When you have chosen the retry function, stay away from the equipm ent as it will restart s uddenly

after an alarm stop.

z

The [STOP] key is valid only when the appropriate function setting has been made. Prepare an

emergency stop switch separately.

z

Make sure that the start signal is off bef ore r es etting the inverter alarm. A failure to do so may restart

the motor suddenly.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

A - 4

CAUTION

z

The load used should be a three-phase induction motor only. Connection of any other electrical

equipment to the inverter output may damage the equipment.

z

The electronic overcurrent protection does not guarantee protection of the motor from overheating.

z

Do not use a magnetic contactor on the inverter input for frequent starting/stopping of the inverter.

z

Use a noise filter to reduce the effect of electromagnetic interference. Otherwise nearby electronic

equipment may be affected.

z

Take measures to suppress harmonics. Otherwise power harmonics from the inverter may

heat/damage the power capacitor and generator.

z

When a 400V class motor is inverter-driven, it should be insulation-enhanced or surge voltages

suppressed. Surge voltages attributable to the wiring constants may occur at the motor terminals,

deteriorating the insulation of the motor.

z

When parameter clear or all clear is per form ed, eac h param eter r eturns to the f actory setting. Re-set

the required parameters before starting operation.

z

The inverter can be easily set for high-speed operation. Before changing its setting, examine the

performance of the motor and machine.

z

In addition to the inverter's holding function, install a holding device to ensure safety.

z

Before running an inverter which had been stored for a long period, always perform inspection and

test operation.

(5) Emergency stop

CAUTION

z

Provide a safety backup such as an emergency brake which will prevent the machine and equipment

from hazardous conditions if the inverter fails.

(6) Maintenance, inspection and parts replacement

CAUTION

z

Do not carry out a megger (insulation resistance) test on the control circuit of the inverter.

(7) Disposing of the inverter

CAUTION

z

Treat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter without a cover, or partially

open. Never run the inverter like this. Always replace the cover and follow this instr uction manual when

operating the inverter.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

CONTENTS

I

287/,1(

1.1 Pre-Operation Information.........................................................................................................................................1

1.1.1 Precautions for operation....................................................................................................................................1

1.2 Basic Configuration....................................................................................................................................................2

1.2.1 Basic configuration .............................................................................................................................................2

1.3 Structure....................................................................................................................................................................3

1.3.1 Appearance and structure ..................................................................................................................................3

1.3.2 Removal and reinstallation of the front cover .....................................................................................................4

1.3.3 Removal and reinstallation of the operation panel..............................................................................................6

,167$//$7,21 $1' :,5,1*

2.1 Installation..................................................................................................................................................................7

2.1.1 Instructions for installation..................................................................................................................................7

2.2 Wiring ........................................................................................................................................................................9

2.2.1 Terminal connection diagram .............................................................................................................................9

2.2.2 Wiring of the main circuit ..................................................................................................................................12

2.2.3 Wiring of the control circuit ...............................................................................................................................18

2.2.4 Connection to the PU connector.......................................................................................................................22

2.2.5 Connection of stand-alone option units ............................................................................................................24

2.2.6 Design information............................................................................................................................................28

2.3 Other wiring .............................................................................................................................................................29

2.3.1 Power harmonics..............................................................................................................................................29

2.3.2 Japanese harmonic suppression guidelines.....................................................................................................30

2.3.3 Inverter-generated noises and reduction techniques........................................................................................33

2.3.4 Leakage currents and countermeasures..........................................................................................................37

2.3.5 Inverter-driven 400V class motor......................................................................................................................38

2.3.6 Peripheral devices............................................................................................................................................39

2.3.7 Instructions for compliance with the UL and CSA standards............................................................................41

2.3.8 Instructions for compliance with the European standards................................................................................42

2.3.9 Earthing (EC version)........................................................................................................................................43

23(5$7,21

3.1 Pre-Operation Information.......................................................................................................................................45

3.1.1 Devices and parts to be prepared for operation ...............................................................................................45

3.1.2 Power on...........................................................................................................................................................47

3.1.3 Parameter check...............................................................................................................................................47

3.2 Operation.................................................................................................................................................................53

3.2.1 Pre-operation checks........................................................................................................................................53

3.2.2 External operation mode (Operation using external input signals)...................................................................54

3.2.3 PU operation mode (Operation using the operation panel (FR-DU04))...........................................................55

3.2.4 Combined operation mode (Operation using the external input signals and PU)............................................56

3$5$0(7(5

4.1 Parameter List .........................................................................................................................................................57

4.2 Parameter Function Details.....................................................................................................................................63

z

Torque boost (Pr. 0, Pr. 46, Pr. 112).......................................................................................................................63

z

Output frequency range (Pr. 1, Pr. 2, Pr. 18) ..........................................................................................................64

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

II

z

Base frequency, base frequency voltage (Pr. 3, Pr. 19, Pr. 47, Pr. 113).................................................................65

z

Multi-speed operation (Pr. 4 to Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239)..............................................................66

z

Acceleration/deceleration time (Pr. 7, Pr. 8, Pr. 20, Pr. 21, Pr. 44, Pr. 45, Pr. 110, Pr. 111)..................................67

z

Electronic overcurrent protection (Pr. 9)..................................................................................................................68

z

DC dynamic brake (Pr. 10, Pr. 11, Pr. 12)...............................................................................................................69

z

Starting frequency (Pr. 13)......................................................................................................................................70

z

Load pattern selection (Pr. 14)................................................................................................................................70

z

Jog operation (Pr. 15, Pr. 16)..................................................................................................................................71

z

MRS input selection (Pr. 17) ...................................................................................................................................72

z

Stall prevention (Pr. 22, Pr. 23, Pr. 66, Pr. 148, Pr. 149, Pr. 154)...........................................................................73

z

Multi-speed input compensation (Pr. 28).................................................................................................................74

z

Acceleration/deceleration pattern (Pr. 29, Pr. 140 to Pr. 143).................................................................................75

z

Regenerative brake duty (Pr. 30, Pr. 70).................................................................................................................76

z

Frequency jump (Pr. 31 to Pr. 36)...........................................................................................................................77

z

Speed display (Pr. 37, Pr. 144)............................................................................................................................... 78

z

Up-to-frequency sensitivity (Pr. 41).........................................................................................................................79

z

Output frequency detection (Pr. 42, Pr. 43, Pr. 50, Pr. 116) ...................................................................................79

z

Second/third stall prevention (Pr. 48, Pr. 49, Pr. 114, Pr. 115)...............................................................................80

z

Monitor display/FM, AM terminal function selection (Pr. 52 to Pr. 54, Pr. 158).......................................................82

z

Monitoring reference (Pr. 55, Pr. 56).......................................................................................................................84

z

Automatic restart after instantaneous power failure (Pr. 57, Pr. 58, Pr. 162 to Pr. 165).........................................85

z

Remote setting function selection (Pr. 59) ..............................................................................................................87

z

Intelligent mode selection (Pr. 60)...........................................................................................................................88

z

Acceleration/deceleration reference current/lift mode starting frequency (Pr. 61 to Pr. 64)....................................90

z

Retry function (Pr. 65, Pr. 67 to Pr. 69)...................................................................................................................91

z

Applied motor (Pr. 71).............................................................................................................................................93

z

PWM carrier frequency (Pr. 72, Pr. 240).................................................................................................................94

z

Voltage input (Pr. 73) ..............................................................................................................................................95

z

Input filter time constant (Pr. 74).............................................................................................................................96

z

Reset selection/PU disconnection detection/PU stop selection (Pr. 75).................................................................96

z

Alarm code output selection (Pr. 76).......................................................................................................................98

z

Parameter write inhibit selection (Pr. 77) ................................................................................................................99

z

Reverse rotation prevention selection (Pr. 78)......................................................................................................100

z

Operation mode selection (Pr. 79) ........................................................................................................................101

z

Motor capacity/number of motor poles/speed control gain (Pr. 80, Pr. 81, Pr. 89) ...............................................104

z

Offline auto tuning function (Pr. 82 to Pr. 84, Pr. 90 to Pr. 94, Pr. 96)..................................................................105

z

Online auto tuning selection (Pr. 95).....................................................................................................................111

z

V/F control frequency (voltage) (Pr. 100 to Pr. 109)..............................................................................................113

z

Computer link operation (Pr. 117 to Pr. 124).........................................................................................................114

z

PID control (Pr. 128 to Pr. 134).............................................................................................................................124

z

Commercial power supply-inverter switch-over function (Pr. 135 to Pr. 139)........................................................131

z

Output current detection function (Pr. 150, Pr. 151)..............................................................................................135

z

Zero current detection (Pr. 152, Pr. 153)...............................................................................................................136

z

RT signal activated condition selection (Pr. 155)..................................................................................................137

z

Stall prevention function and current limit function (Pr. 156).................................................................................137

z

OL signal output timer (Pr. 157)............................................................................................................................ 139

z

User group selection (Pr. 160, Pr. 173 to Pr. 176)................................................................................................140

z

Watt-hour meter clear/actual operation hour meter clear (Pr. 170, Pr. 171).........................................................141

z

Input terminal function selection (Pr. 180 to Pr. 186)............................................................................................141

z

Output terminal function selection (Pr. 190 to Pr. 195) .........................................................................................144

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

III

z

User initial value setting (Pr. 199) .........................................................................................................................146

z

Programmed operation function (Pr. 200 to Pr. 231) ............................................................................................147

z

Cooling fan operation selection (Pr. 244)..............................................................................................................151

z

Stop selection (Pr. 250).........................................................................................................................................152

z

Power failure-time deceleration-to-stop function (Pr. 261 to Pr. 266) ...................................................................154

z

Stop-on-contact, load torque high-speed frequency selection (Pr. 270)...............................................................156

z

High-speed frequency control (Pr. 271 to Pr. 274)................................................................................................157

z

Stop on contact (Pr. 275, Pr. 276).........................................................................................................................161

z

Brake sequence function (Pr. 278 to Pr. 285).......................................................................................................164

z

Droop control (Pr. 286, Pr. 287)............................................................................................................................ 168

z

Meter (frequency meter) calibration (Pr. 900, Pr. 901)..........................................................................................169

z

Frequency setting voltage (current) bias and gain (Pr. 902 to Pr. 905).................................................................171

z

Buzzer control (Pr. 990) ........................................................................................................................................173

3527(&7,9( )81&7,216

5.1 Errors (alarms).......................................................................................................................................................174

5.1.1 Error (alarm) definitions..................................................................................................................................174

5.1.2 Correspondences between digital and actual characters...............................................................................177

5.1.3 Alarm code output...........................................................................................................................................178

5.1.4 Resetting the inverter......................................................................................................................................178

5.2 Troubleshooting.....................................................................................................................................................179

5.2.1 Checking the operation panel display at alarm stop.......................................................................................179

5.2.2 Faults and check points..................................................................................................................................180

5.3 Precautions for Maintenance and Inspection.........................................................................................................182

5.3.1 Precautions for maintenance and inspection..................................................................................................182

5.3.2 Check items....................................................................................................................................................182

5.3.3 Periodic inspection..........................................................................................................................................182

5.3.4 Insulation resistance test using megger .........................................................................................................183

5.3.5 Pressure test...................................................................................................................................................183

5.3.6 Replacement of parts......................................................................................................................................186

5.3.7 Inverter replacement.......................................................................................................................................187

5.3.8 Measurement of main circuit voltages, currents and power............................................................................188

63(&,),&$7,216

6.1 Standard Specifications.........................................................................................................................................190

6.1.1 Model specifications .......................................................................................................................................190

6.1.2 Common specifications...................................................................................................................................192

6.1.3 Outline drawings.............................................................................................................................................194

237,216

7.1 Option List..............................................................................................................................................................198

7.1.1 Stand-alone options........................................................................................................................................198

7.1.2 Inboard dedicated options ..............................................................................................................................200

$33(1',&(6

Appendix 1 Data Code List..........................................................................................................................................201

Appendix 2 List of Parameters Classified by Purposes of Use....................................................................................207

Appendix 3 Operating the Inverter Using a Single-Phase Power Supply....................................................................208

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

1

CHAPTER 1

OUTLINE

This chapter gives information on the basic "outline" of this

product.

Always read the instructions in this chapter before using the

equipment.

1.1 Pre-Operation Information........................................1

1.2 Basic Configuration..................................................2

1.3 Structure..................................................................3

<Abbreviations>

y

DU

Operation panel (FR-DU04)

y

PU

Operation panel (FR-DU04) and parameter unit (FR-PU04)

y

Inverter

Mitsubishi transistorized inverter FR-A500 series

y

Pr.

Parameter number

y

PU operation

Operation using the PU (FR-DU04/FR-PU04)

y

External operation

Operation using the control circuit signals

y

Combined operation

Operation using both the PU (FR-DU04/FR-PU04) and

external operation

y

FR-A200E

Mitsubishi transistorized inverter FR-A200 series

<EXCELLENT> series

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

CHAPTER 7 OPTIONS

APPENDICES

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

1.1 Pre-Operation Information

OUTLINE

1

1 OUTLINE

1.1 Pre-Operation Information

1.1.1 Precautions for operation

Incorrect handling might cause the inverter to operate improperly, its life to be reduced considerably, or at the

worst, the inverter to be damaged. Handle the inverter properly in accordance with the information in each

section as well as the precautions and instructions of this manual to use it correctly.

This manual is written for the FR-A500 series transistorized inverters.

For handling information on the parameter unit ( FR- PU04), inboar d options , stand- alone options , etc ., ref er to

the corresponding manuals.

(1)

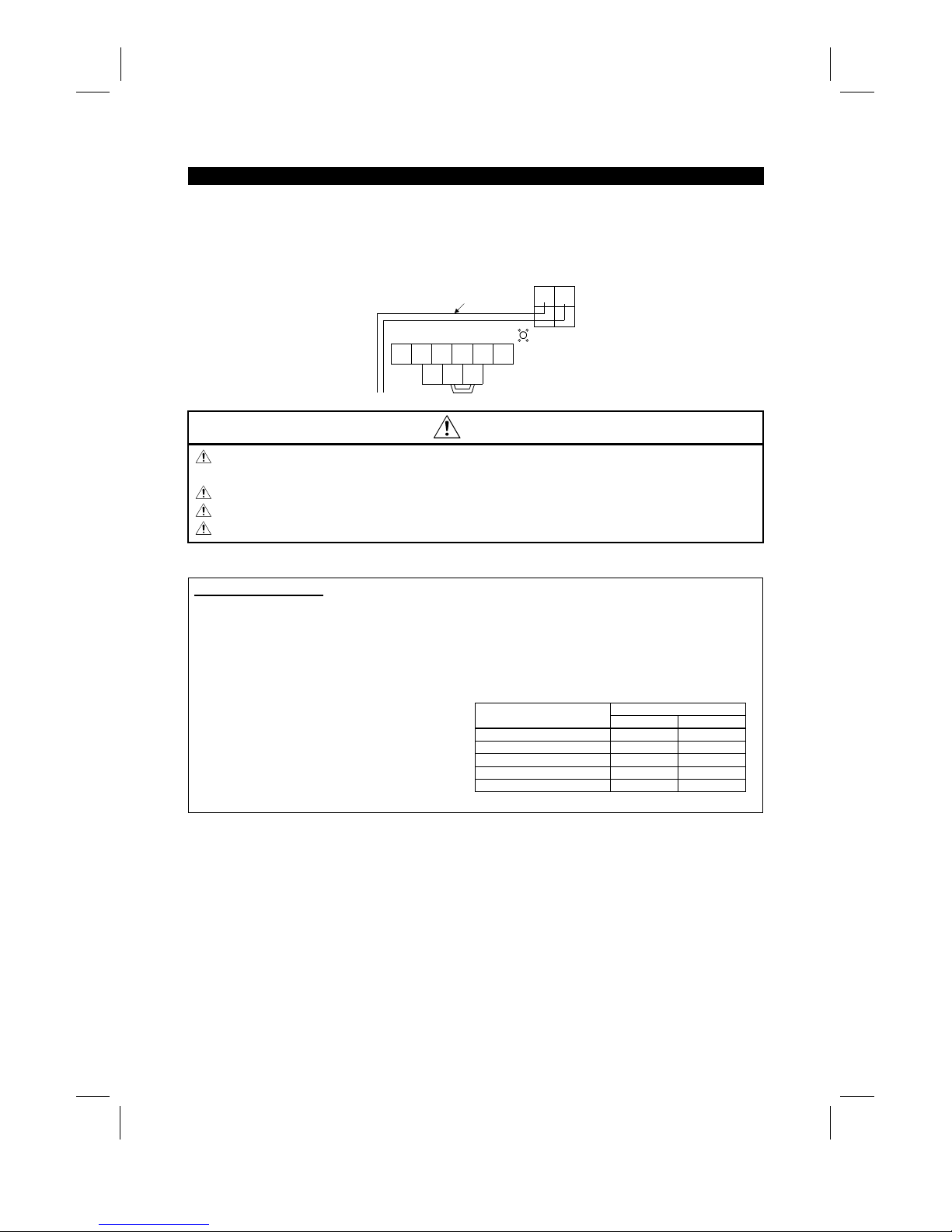

Unpacking and product check

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side

face to ensure that the product agrees with your order and the inverter is intact.

1) Inverter type

FR-A520-0.4K/

MITSUBISHI

MODEL

FR-A520-0.4K

INVERTER

POWER

INPUT

OUTPUT

SERIAL

MITSUBISHI ELECTRIC CORPORATION

0.4kW

XXXXX

MADE IN JAPAN

XXXXX

Capacity plate

Inverter type Serial number

Capacity plate

Rating plate

Rating plate

Input rating

Output rating

Serial number

Inverter type

FR- A520 - 0.4K -

Symbol Voltage Class

A520

A540

200V class

400V class

Symbol Applicable Motor Capacity

0.4K to 55K Indicates capacity in "kW".

Symbol Specifications

NoneNAJapanese specifications

U.S. specifications

EC European specifications

Applicable moto

r

capacity

2) Accessory

Instruction manual

If you have found any discrepancy, damage, etc., please contact your sales representative.

(2)

Preparations of instruments and parts required for operation

Instruments and parts to be prepared depend on how the inverter is operated. Prepare equipment and parts

as necessary. (Refer to page 45.)

(3)

Installation

To operate the inverter with high performance f or a long time, install the inverter in a proper place, in the

correct direction, and with proper clearances. (Refer to page 7.)

(4)

Wiring

Connect the power supply, motor and operation signals (control signals) to the terminal block. Note that

incorrect connection may damage the inverter and peripheral devices. (See page 12.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

1.2 Basic Configuration

OUTLINE

2

1.2 Basic Configuration

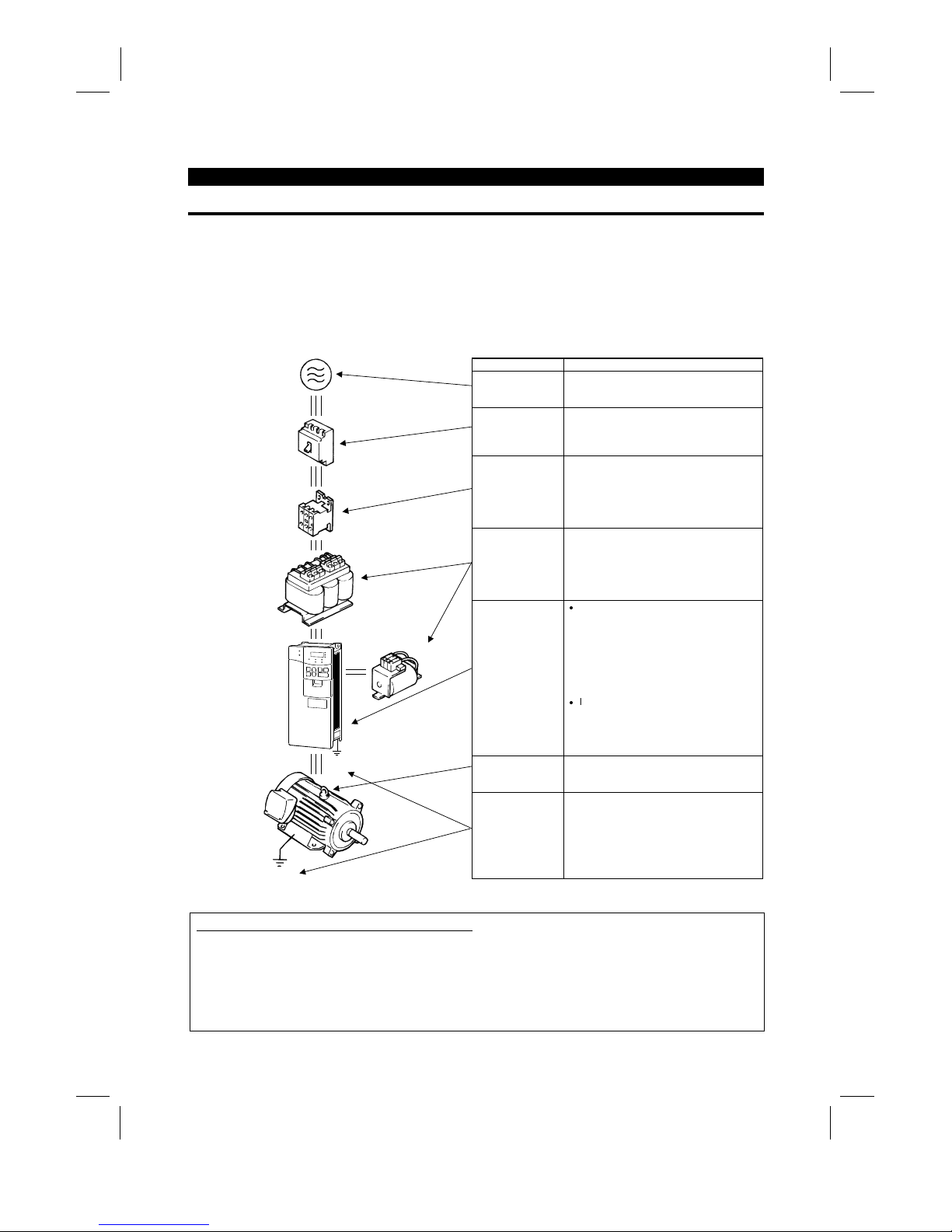

1.2.1 Basic configuration

The following devices are required to operate the inverter. Pr oper peripheral devices must be selected and

correct connections made to ensure proper operation. Inc orrect system configuration and connections can

cause the inverter to operate improperly, its life to be reduced considerably, and in the worst case, the

inverter to be damaged.

Please handle the inverter properly in accordance with the information in each section as well as the

precautions and instructions of this manual. (For connections of the peripheral devices, refer to the

corresponding manuals.)

Name Description

Power supply

Use the power supply within the perm is si ble

power supply specifications of the in verter.

(Refer to page 39.)

Earth leakage

circuit breaker

(ELB) or no-fuse

breaker (NFB)

The breaker should be selected with care

since a large inrush current flows in the

inverter at power on. (Refer to page 39.)

Magnetic

contactor

The magnetic contactor need not be

provided. When installed, do not us e it to

start or stop the inverter. It might reduce the

inverter life.

(Refer to page 39.)

Reactors

The reactors must be used when t he power

factor is to be improved or the inverter is

installed near a large power supply system

(1000KVA or more and wiring distance

within 10m (32.81 feet)). Make selection

carefully.

Inverter

z

The inverter life is influenced by ambient

temperature. The ambient temperature

should be as low as possible within the

permissible range.

This must be noted especiall y when the

inverter is installed in an enclosure.

(Refer to page 7.)

z

Incorrect wiring might lead to inverter

damage. The control signal lines should

be kept away from the main circuit to

protect them from nois e. (Refer to page

9.)

Devices

connected to the

output

Do not connect a power capacitor, surge

suppressor or radio noise filter to the output

side.

(MC)

Ground

DC reactor

(FR-BEL)

Ground

(NFB)

or

(ELB)

AC reactor

(FR-BAL)

Ground

To prevent an electric shock, always ground

the motor and inverter.

Japanese Harmonic Suppression Guideline

The "harmonic suppression guideline for household appliances and general-purpose products" was issued

by the Ministry of International Trade and Industry in September, 1994. This

g

uideline applies to the

FR-A520-0.4K to 3.7K. By connection of the power factor im provin

g

reactor (FR-BEL or FR-BAL), this

product conforms to the "harm onic suppr ession technique f or transistor ized inverters (input c urrent 20A or

less)" set forth by the Japan Electrical Manufactures' Association.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

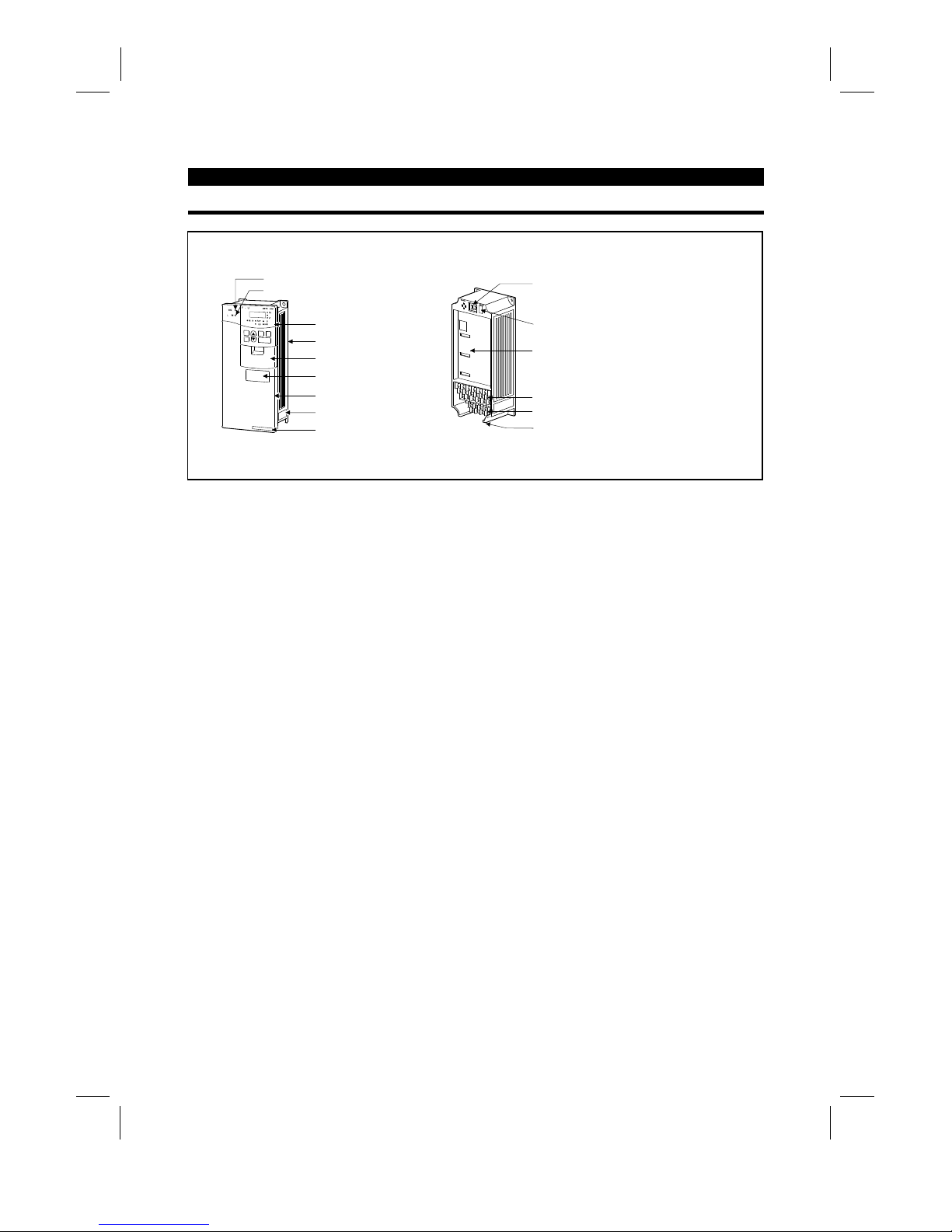

1.3 Structure

OUTLINE

3

1.3 Structure

1.3.1 Appearance and structure

(1) Front view (2) Without front cover

POWER lamp

ALARM lamp

Operation panel (FR-DU04)

Brake resistor* (Fitted to the back)

Accessory cover

Wiring port cover for option

Front cover

Rating plate

Capacity plate

Wiring cover

PU connector

(Provided with modular jack type relay connector)

(For use of RS-485 cable)

Modular jack type relay connector compartment

Inboard option mounting position

Control circuit terminal block

Main circuit terminal block

*7.5K or less inverters are equipped with an inboard brake resistor.

Note: The "EC" version of the FR-A500 uses pheonix type connectors f or the control circuit terminal

block.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

OUTLINE

4

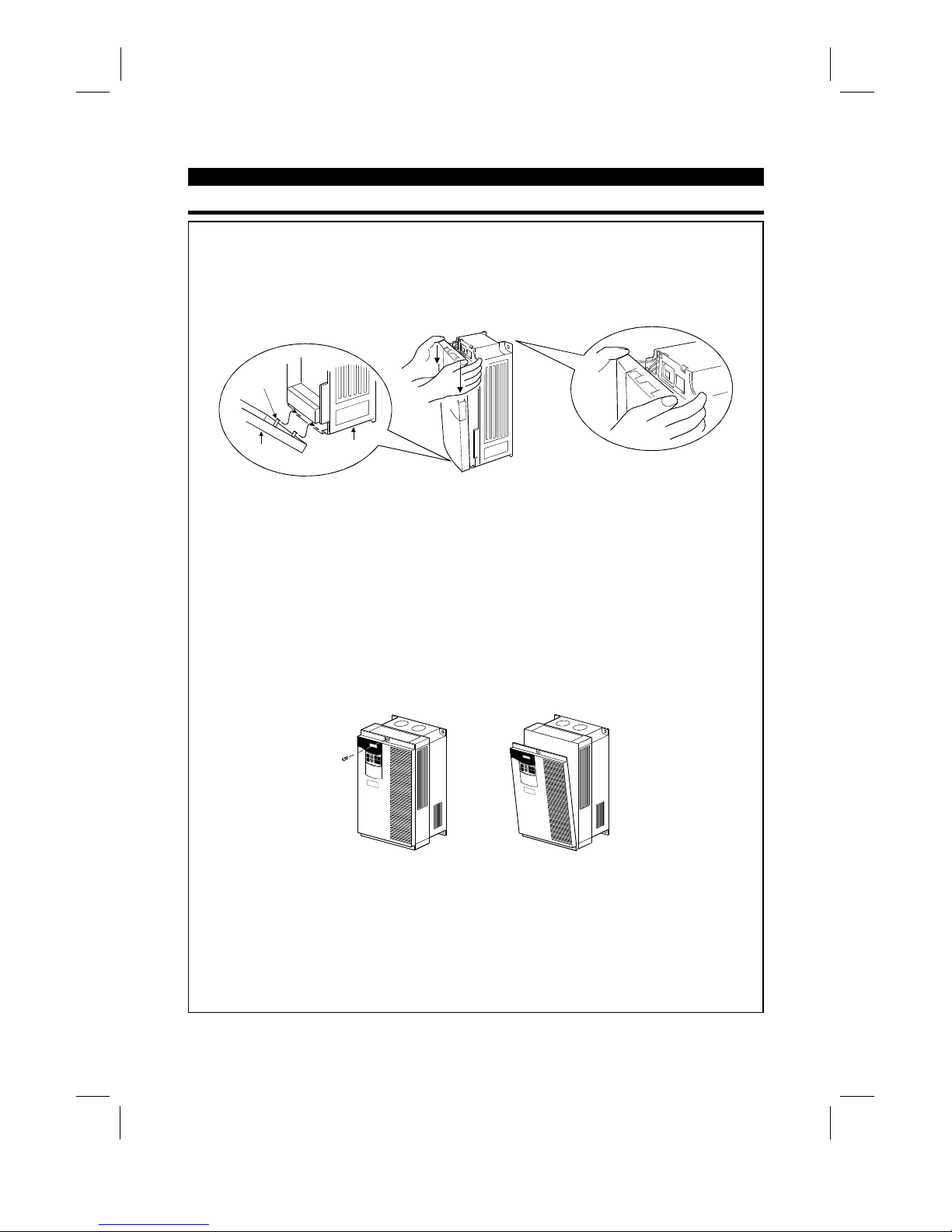

1.3.2 Removal and reinstallation of the front cover

FR-A520-0.4K to 11K, FR-A540-0.4K to 7.5K

•

Removal

1) Hold both sides of the front cover top and push the front cover down.

2) Hold down the front cover and pull it toward you to remove.

(The front cover may be removed with the PU (FR-DU04/FR-PU04) on.)

Front cover

Inverter

Catch

•

Reinstallation

1) Insert the catches at the bottom of the front cover into the sockets of the inverter.

2) Using the catches as supports, securely press the front cover against the inverter.

Note: When the operation panel is mounted and the front c over is removed, remove the operation

panel before reinstalling the front cover.

FR-A520-15K to 22K, FR-A540-11K to 22K

•

Removal

1) Remove the installation screw at top of the front cover.

2) Hold both ends of the front cover top.

3) Pull the front cover toward you to remove.

(The front cover may be removed with the PU (FR-DU04/FR-PU04) on.)

•

Reinstallation

1) Insert the catches at the front cover bottom into the sockets of the inverter.

2) Using the catches as supports, securely press the front cover against the inverter.

3) Fix the front cover with the top screw.

Note: When the operation panel is m ounted on the front cover removed, rem ove the operation panel

before reinstalling the front cover.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

OUTLINE

5

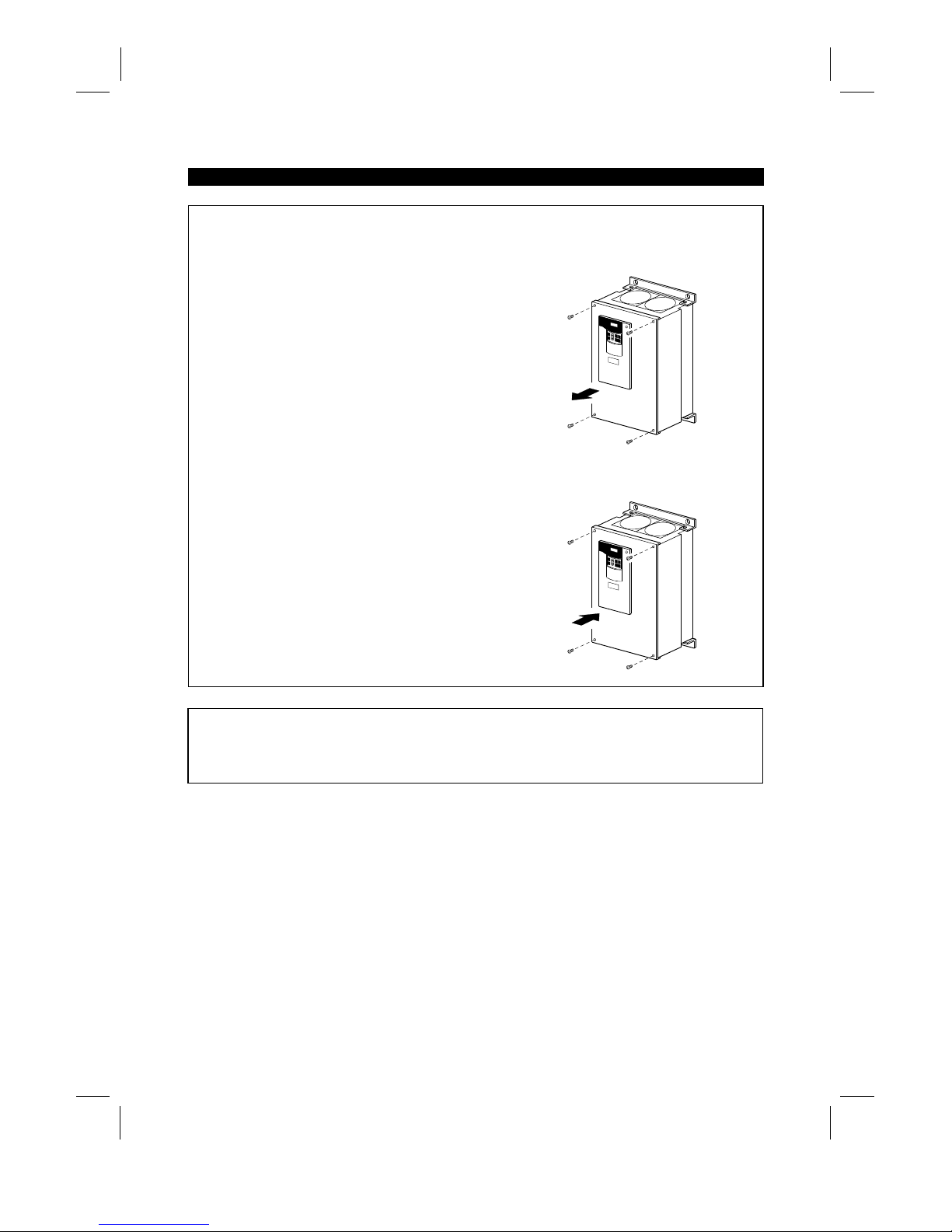

FR-A520-30K to 55K, FR-A540-30K to 55K

•

Removal

1) Remove the front cover mounting screws.

•

Reinstallation

1) Fix the front cover with the mounting screws.

Note: 1. Make sure that the front cover has been reinstalled securely.

2. The sam e ser ial number is printed on the capacity plate of the front c over and the r ating plate of

the inverter. Before reinstalling the front cover, c heck the serial number to ensure that the cover

removed is reinstalled to the inverter from where it was removed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

OUTLINE

6

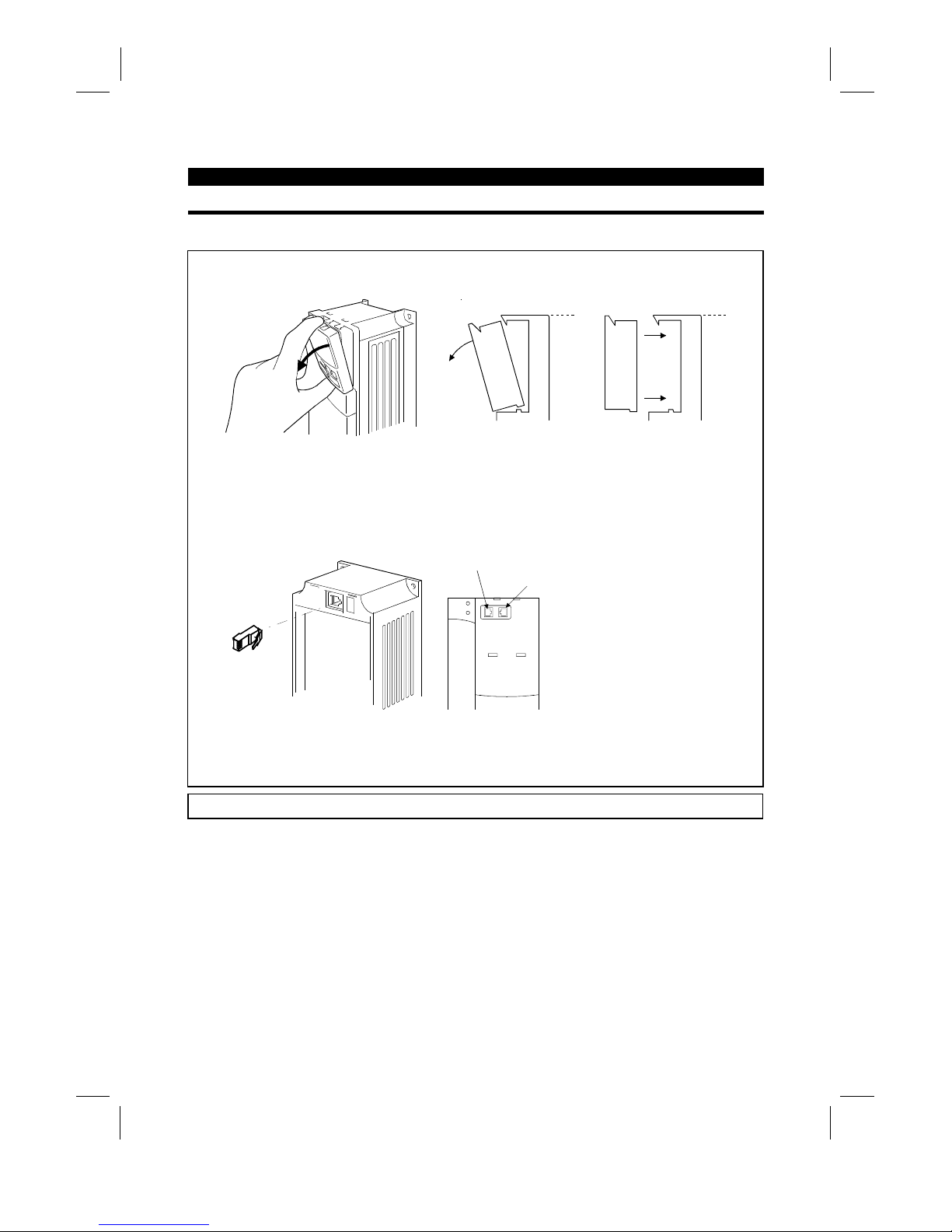

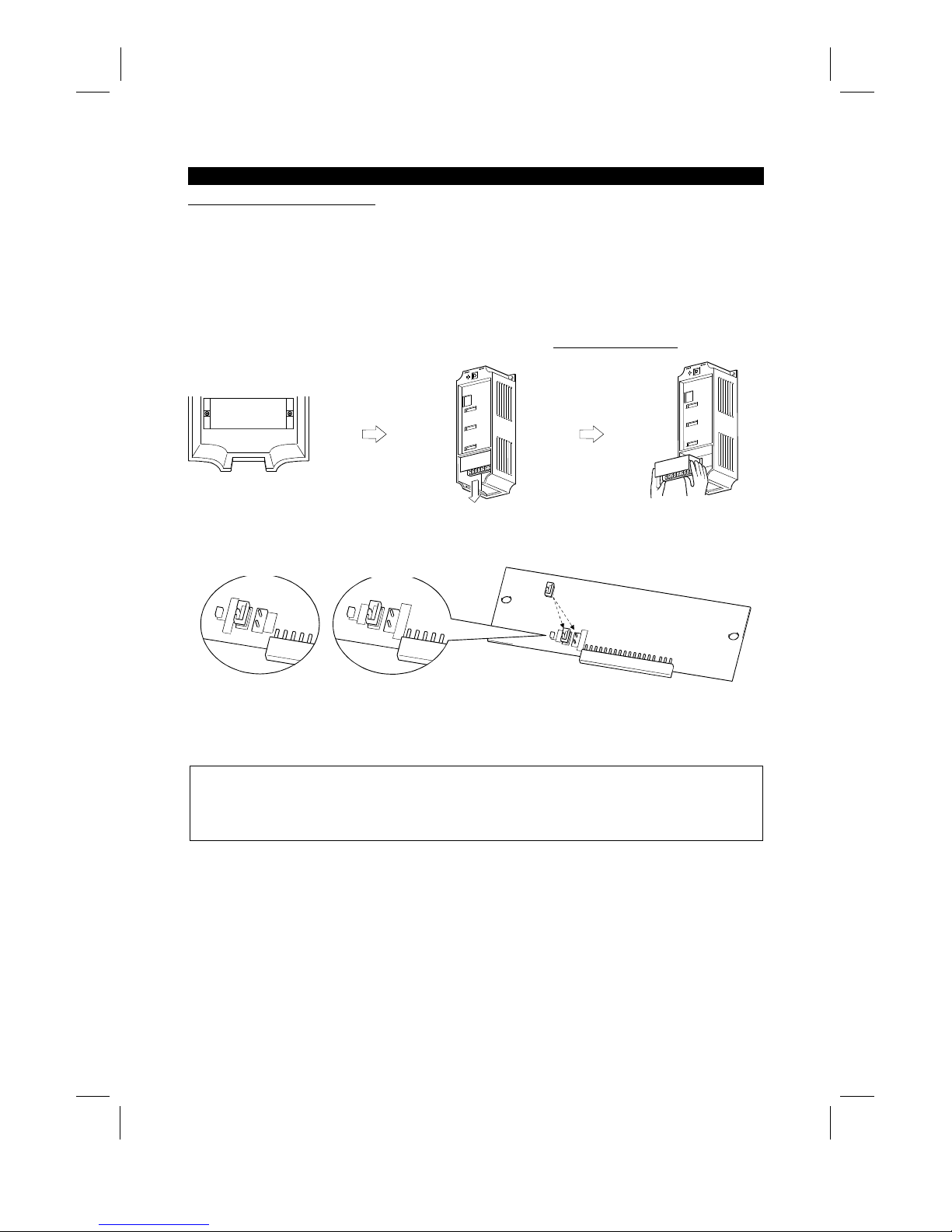

1.3.3 Removal and reinstallation of the operation panel

To ensure safety, remove and reinstall the operation panel after switching power off.

•

Removal

Hold down the top button of the operation panel and pull the operation panel toward you to remove.

Removal

Reinstallation

To reinstall, insert straight and mount securely.

•

Reinstallation using the connection cable

1) Remove the operation panel.

2) Disconnect the modular jack type relay connector. (Place the disconnec ted m odular j ack type relay

connector in the modular jack type relay connector compartment.)

Modular jack type relay connector compartment

Modular jack type relay connector

3) Securely plug one end of the connection cable into the PU connector (m odular jack type relay

connector) of the inverter and the other end into the operation panel.

Note: Install the operation panel only when the front cover is on the inverter.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 17

2

CHAPTER 2

INSTALLATION AND WIRING

This chapter gives information on the basic "installation and

wiring" of this product.

Always read the instructions in this chapter before using the

equipment.

2.1 Installation................................................................ 7

2.2 Wiring ...................................................................... 9

2.3 Other wiring .............................................................29

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

CHAPTER 7 OPTIONS

APPENDICES

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

2.1 Installation

INSTALLATION AND WIRING

7

2 INSTALLATION AND WIRING

2.1 Installation

2.1.1 Instructions for installation

1) Handle the unit carefully.

The inverter uses plastic parts. Handle it gently to protect it from damage. Also, hold the unit with even

strength and do not apply too much strength to the front cover alone.

2) Install the inverter in a place where it is immune to vibration. (5.9 m/s

2

{0.6G} or less)

Also note the cart, press, etc.

3) Note on ambient temperature

The inverter life is under great influence of ambient temperature. In the place of installation, ambient

temperature must be within the permissible range (depending upon the operation mode and conditions

(see ambient temperature specifications on page 190). Check that the ambient temperature is within that

range in the positions shown in figure 3).

4) Install the inverter on a non-combustible surface.

The inverter will be very hot (maximum about 150°C). Install it on a non-combustible surface (e.g. metal).

Also leave sufficient clearances around the inverter.

5) Avoid high temperature and high humidity.

Avoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

6) The amount of heat generated in an enclosure can be reduced c onsiderably by placing the heat sink

outside the enclosure.

Note: 1. Use the option (FR-A5CN

) for installation. The mounting area should be cut to the panel

cutting dimensions.

2. The cooling section outside the enclosure has the cooling fan. Do not use the inverter in any

environment where it is exposed to waterdrops, oil mist, dust, etc.

7) Avoid places where the inverter is exposed to oil mist, flammable gases, fluff, dust, dirt etc.

Install the inverter in a clean place or inside a "totally enclosed" panel which does not accept any

suspended matter.

8) Note the cooling method when the inverter is installed in an enclosure.

When two or more inverters are installed or a ventilation fan is mounted in an enclosure, the inverters and

ventilation fan must be installed in proper positions with extreme care taken to keep the ambient

temperatures of the inverters below the permissible value. If they are installed in improper positions, the

ambient temperatures of the inverters will rise and ventilation effect will be reduced.

9) Install the inverter securely with screws or bolts in the vertical direction.

3) Note on ambient temperature

Measurement

position

Measurement

position

5cm

(1.97 inches)

5cm

(1.97 inches)

5cm

(1.97 inches)

4) Clearances around the inverter

10cm (3.94 inches)

5cm (1.97 inches)

or more *

*: 1cm (0.39 inches) or more for model 3.7K or less

Leave sufficient

clearances above

and under the

inverter to ensure

adequate ventilation.

Cooling fan built

in the inverter

Cooling air

5cm (1.97 inches)

or more *

or more

10cm (3.94 inches)

or more

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

INSTALLATION AND WIRING

8

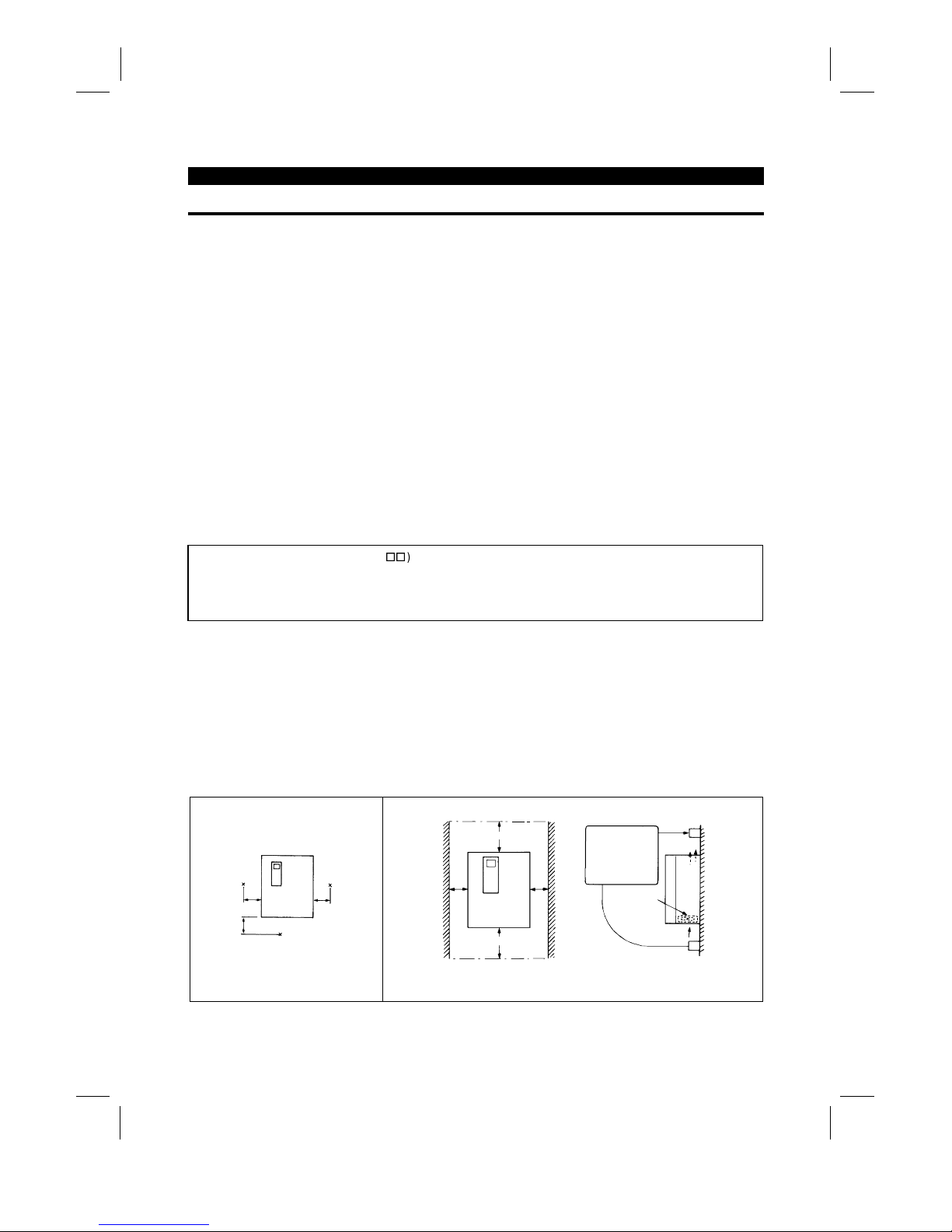

8) For installation in an enclosure

Ventilation fan

(Correct example)

Position of Ventilat ion Fan

Inveter Inveter

Inveter

(Correct example) (Incorrect example)

Built-in cooling fan

Inveter

Inveter

Inveter

Accommodation of two or more inv erters

(Incorrect example)

9) Vertical mounting

(1)

Wiring cover and handling (22K or less

)

1) When cable conduits are not connected

Cut the protective bushes of the wiring cover with nippers or a cutter before running the cables.

Wiring cover

Protective bush

WARNING

Do not remove the protective bushes. Otherwise, the cable sheathes may be scratched by the wiring cover

edges, resulting in a short circuit or ground fault.

2) When cable conduits are connected

Remove the corresponding protective bushes and connect the cable conduits.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

2.2 Wiring

INSTALLATION AND WIRING

9

2.2 Wiring

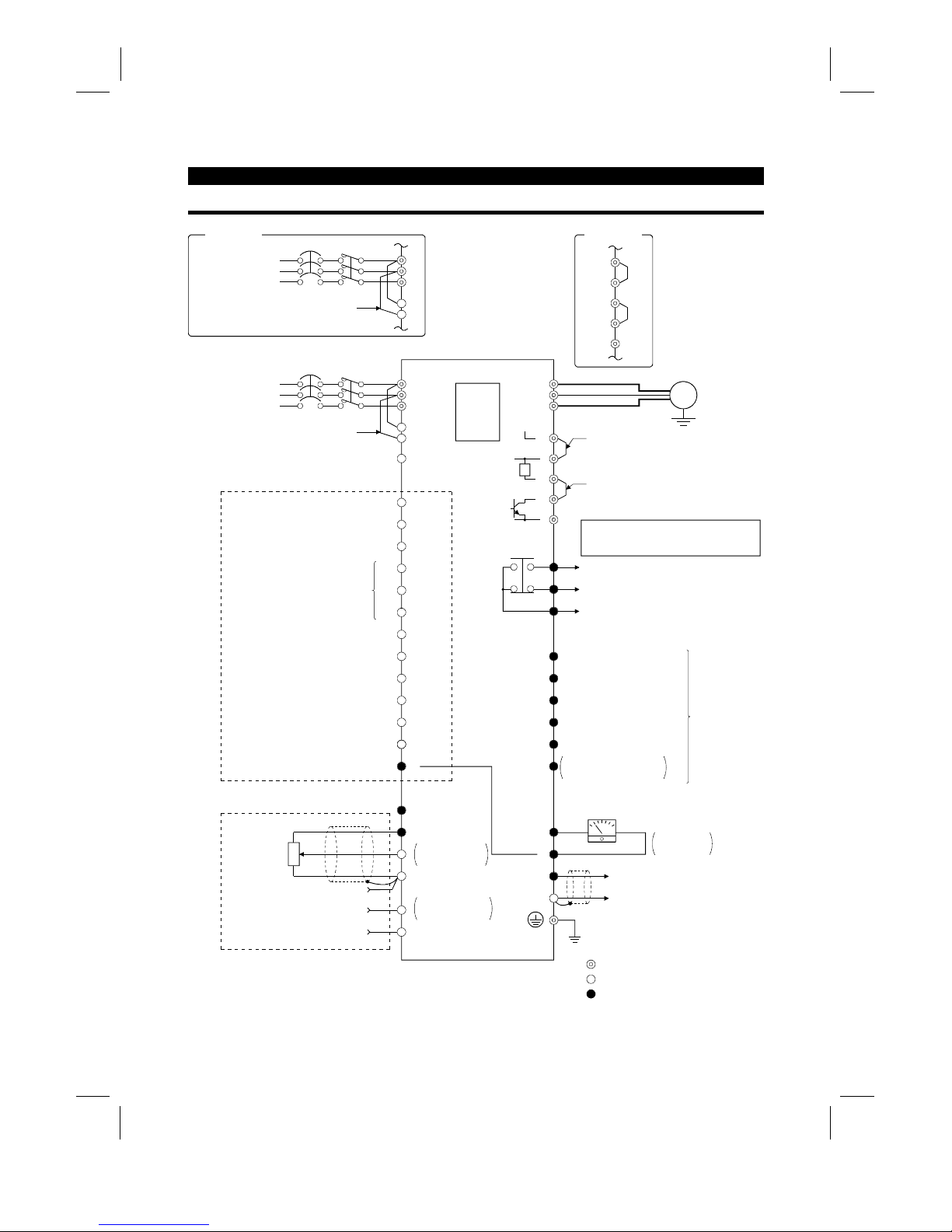

2.2.1 Terminal connection diagram

NFB

R

S

T

R1

S1

PC

STF

STR

STOP

RH

RM

RL

JOG

RT

MRS

RES

AU

CS

SD

10E(+10V)

10(+5V)

2

5

2

3

1

1

4 (4 to 20mADC)

Frequency setting

potentiometer

1/2W1k

Ω

RUN

SU

IPF

OL

FU

SE

FM

SD

IM

A

B

C

U

V

W

P1

P

PX

PR

N

+−

(

−

)

(

+

)

AM

5

R

Ground

Main circuit terminal

Control circuit input terminal

Control circuit output terminal

3-phase AC power supply

Jumper

24VDC power output and external transistor common

(Contact input common for source logic)

Forward rotation start

Reverse rotation start

Start self-holding selection

High

Middle

Low

Jog mode

Second acceleration/deceleration time selection

Output stop

Reset

Current input selection

Selection of automatic restart

after instantaneous power failure

(Contact input common for sink logic)

Control input signals (no voltage input allowed)

Frequency setting signals (analog)

Common

Auxiliary input

Current input

0 to 5VDC

0 to 10VDC

Selected

(Analog common)

0 to ± 5VDC

0 to ±10VDC

Selected

PU

connector

(Note)

(Note)

Motor

Ground

Jumper

Remove this jumper when using FR-BEL.

Jumper

Remove this jumper when using FR-ABR.

Note: Terminals PR, PX are provided for

FR-A520-0.4K to 7.5K.

FR-A540-0.4K to 7.5K

Alarm detection

Running

Up to frequency

Instantaneous power failure

Overload

Frequency detection

Open collector output common

Common to sink and source

Open collector

outputs

Meter

(e.g. frequency meter)

Moving-coil type

1mA full-scale

Analog signal output

(0 to 10VDC)

Multi-speed selection

(RS-485)

NFB

L

1

L

2

L

3

L

11

L

21

3-phase AC power supply

Jumper

EC version

P1

+

PX

PR

–

EC version

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

INSTALLATION AND WIRING

10

(1)

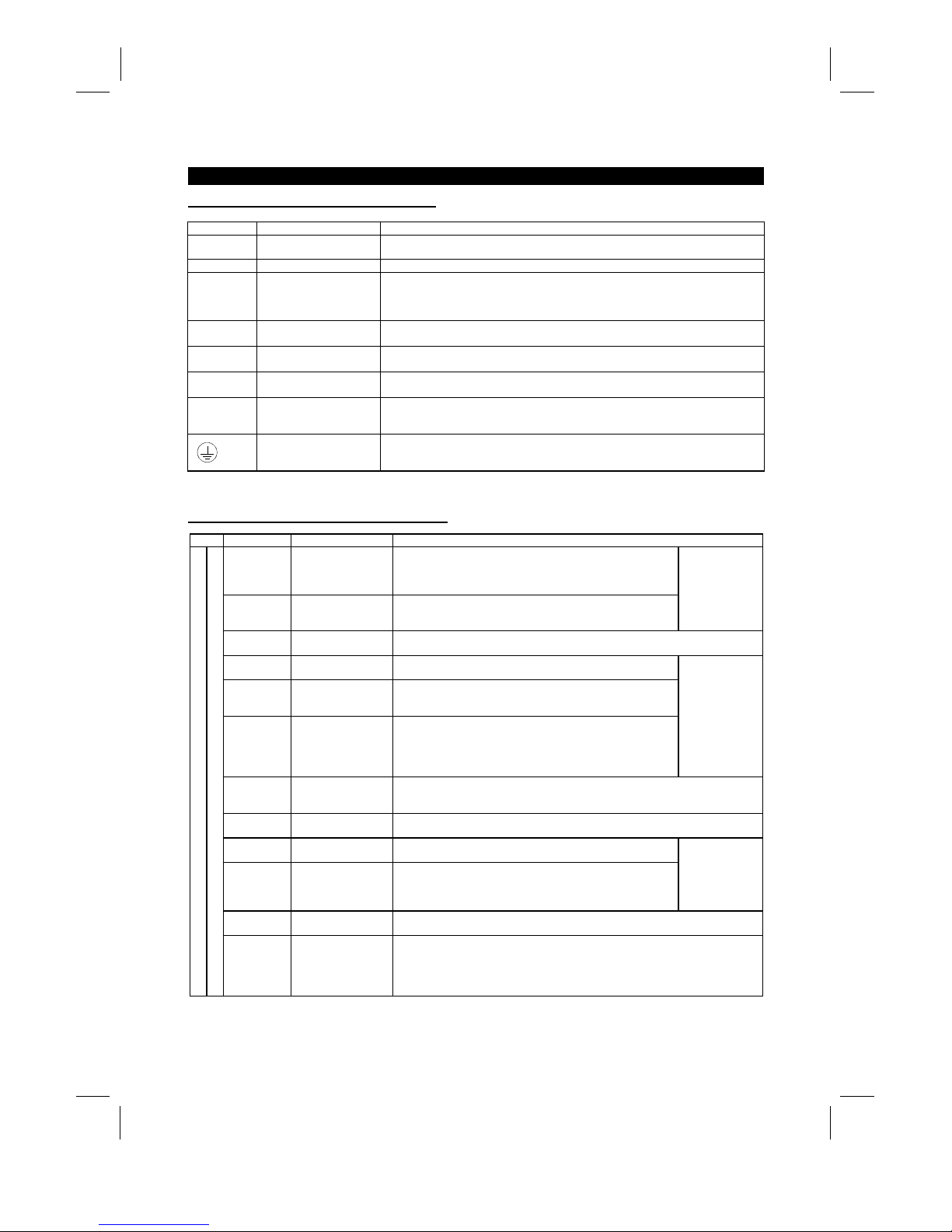

Description of main circuit terminals

Symbol Terminal Name Description

R, S, T

〈

L

1

, L2, L

3

〉

AC power input

Connect to the commerci al power supply. Keep these t erminals unconnected when

using the high power factor converter (FR-HC).

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

R1, S1

〈

L

11

, L

21

〉

Power supply for control

circuit

Connected to the AC power supply terminals R and S 〈L

1

and L

2

〉

. To retain the alarm

display and alarm output or when using the high power factor converter (FR-HC),

remove the jumpers from terminals R-R1 and S-S1 〈L

1

-

L11 and L

2

-

L

21

〉

and apply

external power to these terminals.

P, PR

〈+

, PR

〉

Brake resistor connection

Disconnect the jumper from terminals PR-PX and connect the optional brak e resistor

(FR-ABR) across terminal s P-PR.

P, N

〈+, −〉

Brake unit connection

Connect the optional FR-BU brake unit, power return convert er (FR-RC) or high power

factor converter (FR-HC).

P, P1

〈+

, P1

〉

Power factor improving

DC reactor connection

Disconnect the jumper from terminals P-P1

〈+

-P1〉 and connect the optional power

factor improving reactor (FR-BEL).

PR, PX

Built-in brake circuit

connection

When the jumper is c onnected across terminals PX-PR (factory setting),

the built-in brake circuit is val i d.

(Provided for 7.5K or less.)

Ground For grounding the inverter chassis. Must be earthed.

Note: 〈 〉 Terminal names in parentheses are those of the EC version.

(2)

Description of control circuit terminals

Type Symbol Terminal Name Description

STF Forward rotation start

Turn on the STF signal to start forward rotation and t urn i t off to

stop. Acts as a programmed operation start signal in the

programmed operation mode. (Turn on to s tart and turn off to

stop.)

STR Reverse rotation start

Turn on the STR signal to start reverse rot at i on and turn it off to

stop.

When the STF

and STR signals

are turned on

simultaneously,

the stop

command is

given.

STOP

Start self-holding

selection

Turn on the STOP signal to select t he self-holding of the start signal.

RH•RM•RL Multi-speed selection

Use the RH, RM and RL signals as appropriate to select multiple

speeds.

JOG JOG mode selecti on

Turn on the JOG signal to select jog operati on (factory setting).

Jog operation can be performed with the start signal (STF or

STR).

RT

Second acceleration/

deceleration time

selection

Turn on the RT signal to select the sec ond acceleration/

deceleration time. When the second functions such as "second

torque boost" and "second V/F (base frequency)" functions have

been set, these functions c an al so be selected by turning on the

RT signal.

Input terminal

function selection

(Pr. 180 to

Pr. 186) change

terminal

functions.

MRS Output stop

Turn on the MRS signal (20ms or longer) to stop t he i nverter output.

Used to shut off the inverter output to bring the motor to a stop by the magnetic

brake.

RES Reset

Used to reset the protective circuit activated. Turn on the RES signal for more than

0.1 second, then turn it off.

AU

Current input

selection

Only when the AU signal is turned on, the inverter can be

operated with the 4-20mADC frequency setting signal.

CS

Automatic restart after

instantaneous power

failure selection

With the CS signal on, restart can be made automatically when

the power is restored after an instantaneous power failure. Note

that this operation requires restart parameters to be set. When

the inverter is shipped from t he factory, it is set to disallow restart.

In

put terminal

function selection

(Pr. 180 to

Pr. 186) change

terminal

functions.

SD

Contact input

common (sink)

Common to the contact i nput terminals and terminal FM. Common output term i nal f or

24VDC 0.1A power (PC terminal).

Input signals

Contacts, e.g. start (S TF), stop (STOP) etc.

PC

24VDC power and

external transistor

common

Contact input

common (source)

When transistor output (open collector output), such as a programmable controller, is

connected, connect the external power supply common for transistor output to this

terminal to prevent a fault caus ed by l eakage current. This terminal can be used as a

24VDC, 0.1A power output. When source logic has been selected, this terminal

serves as a contact input common.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

INSTALLATION AND WIRING

11

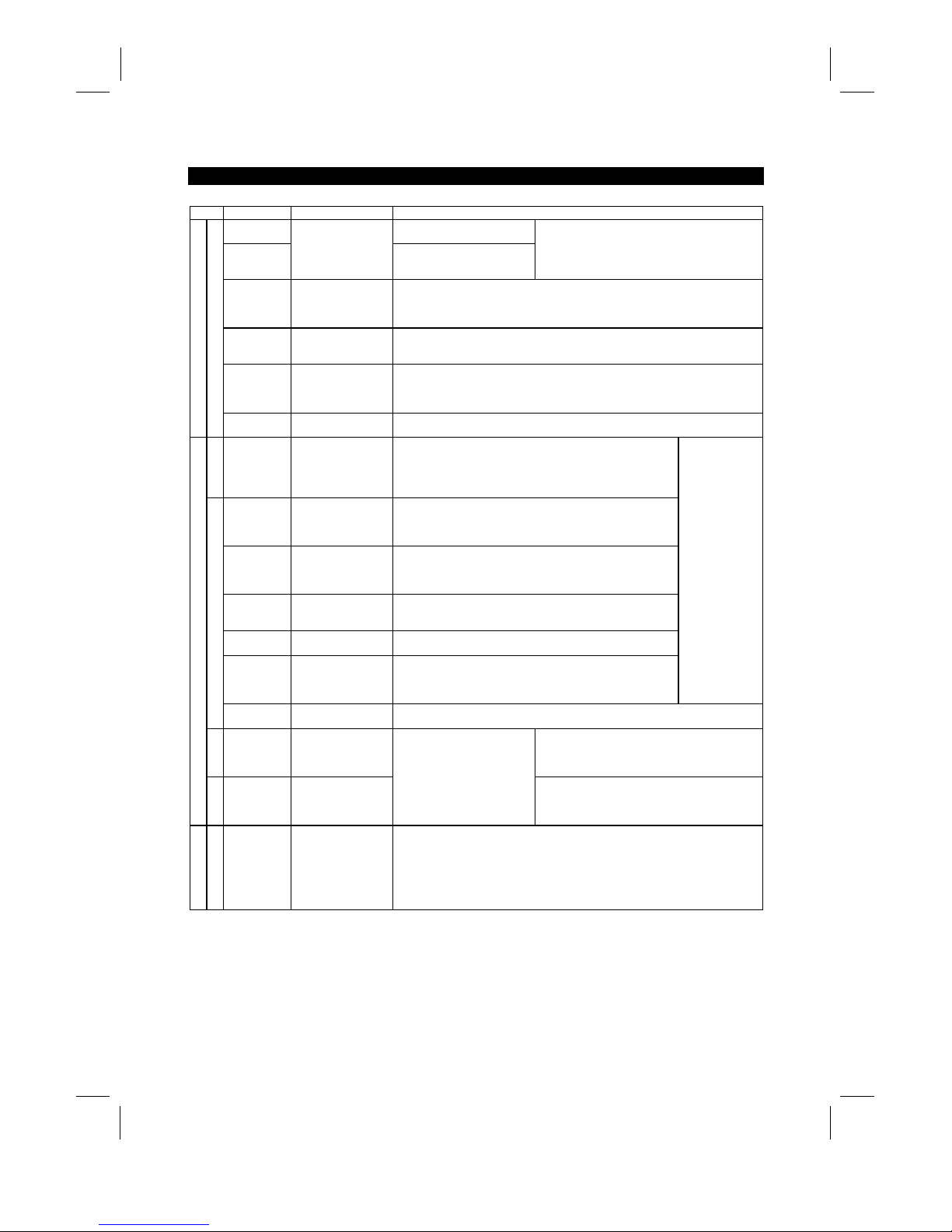

Type Symbol Terminal Name Description

10E

10VDC, permissible load

current 10mA

10

Frequency setting

power supply

5VDC, permissible load current

10mA

When the frequency setti ng potentiometer is

connected in the factory-set s tate, connect it to

terminal 10.

When it is connect ed t o terminal 10E, change the

input specifications of terminal 2.

2

Frequency setting

(voltage)

By entering 0 to 5VDC (0 to 10VDC), the maxim um output frequency is reached at 5V

(or 10V) and I/O are proportional. Switch between input 0 to 5V DC (f actory setting)

and 0 to 10VDC from the operation panel. Input resistance 10kΩ. Maximum

permissible voltage 20V.

4

Frequency setting

(current)

By entering 4 to 20mADC, the maxim um output frequency is reached at 20mA and

I/O are proportional. This input signal i s valid only when the AU signal is on. Input

resistance 250Ω. Maximum permissible current 30mA.

1

Auxiliary frequency

setting

By entering 0 to ±5VDC 0 to ±10VDC, this signal is added to the frequency setting

signal of terminal 2 or 4. Switch between input 0 to ±5VDC and 0 to ±10VDC (factory

setting) from the operation panel. I nput resistance 10kΩ. Maximum permissible

voltage ±20V.

Input signals

Analog frequency setting

5

Frequency setting

input common

Common to the frequency setting signal (terminal 2, 1 or 4) and analog output

terminal AM. Do not earth.

Contact

A, B, C Alarm output

Change-over contact output indicating t hat the output has been

stopped by the inverter protective function activated.

200VAC 0.3A, 30VDC 0.3A. Alarm: discontinuity across B-C

(continuity across A-C), norm al : continuity across B-C

(discontinuity across A-C).

RUN Inverter running

Switched low when the inverter output frequency is equal to or

higher than the starting frequency (factory set to 0.5Hz, variable).

Switched high during stop or DC dynamic brake operat i on (*2).

Permissible load 24VDC 0.1A.

SU Up to frequency

Switched low when the output frequency has reached within

±

10% of the set frequency (fact o ry setting, variable). Switched

high during acceleration, deceleration or s t op (*2). Permissible

load 24VDC 0.1A.

OL Overload alarm

Switched low when the stall prevention function has c aus ed stall

prevention to be activated. Switched high when stall prevention is

reset (*2). Permissible load 24VDC 0.1A.

IPF

Instantaneous power

failure

Switched low when instantaneous power failure or undervoltage

protection is activated (*2). P ermissible load 24VDC 0.1A.

FU Frequency detection

Switched low when the output frequency has reached or

exceeded the detection frequency set as appropriate. Switched

high when below the detection frequency (*2). Permiss i bl e l oad

24VDC 0.1A

Output terminal

function selection

(Pr. 190 to

Pr. 195) change

terminal

functions.

Open collector

SE

Open collector output

common

Common to the RUN, SU, OL, I P F and F U t erminals.

Pulse

FM For meter

Factory setting of output item:

Frequency

Permissible load current 1mA

1440 pulses/second at 60Hz

Output signals

Analog

AM Analog signal output

One selected from 16

monitoring items, s uch as

output frequency, is output. (*3)

The output signal is

proportional to the magnitude

of each monitoring item.

Factory setting of output item:

Frequency

Output signal 0 to 10VDC

Permissible load current 1mA

Communication

RS-485

PU connector

With the operation panel connector, communication can be made through RS-485.

·

Conforming Standard : EIA Standard RS -485

·

Transmission format : Multi-drop link

·

Communication speed : Maximum 19200 baud rat es

·

Overall length : 500m

*1: Terminals PR and PX are provided for the FR-A520-0.4K to 7.5K, FR-A540-0.4K to 7.5K.

*2: Low indicates that the open collector outputting transistor is on (conducts). High indicates that the

transistor is off (does not conduct).

*3: Not output while the inverter is reset.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

INSTALLATION AND WIRING

12

2.2.2 Wiring of the main circuit

(1)

Wiring instructions

1) Crimping terminals with insulation sleeves are recommended for use with the power and motor cables.

2) Cut the protective bushes of the wiring cover when running the cables. (22K or less)

3) Power must not be applied to the output terminals (U, V, W) of the inverter . Otherwise the inverter will be

damaged.

4) After wiring, wire off-cuts must not be left in the inverter.

Wire off-cuts can cause an alarm, failure or malfunction. Always keep the inverter clean.

When drilling mounting holes in a control box etc., exercise care to prevent chips and other foreign matter

from entering the inverter.

5) Use cables of the recommended size for wiring to make the voltage drop 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause

the motor torque to decrease especially at the output of a low frequency.

6) The overall wiring length should be 500m (1640.40feet) maximum.

Especially for long distance wiring, the overcurrent protection may be misactivated or the devices connected to the

output side may misoperate or become faulty under the influence of a charging current due to the stray capacitance

of the wiring. Therefore, the maximum overall wiring length should be as indicated in the following table. (When two

or more motors are connected to the inverter, the total wiring length should be within the indicated value.)

Inverter Capacity 0.4K 0.75K 1.5K or more

Non-low acoustic noise mode 300m (984.24 feet) 500m (1640.40 feet) 500m (1640.40 feet)

Low acoustic noise mode 200m (656.16 feet) 300m (984.24 feet) 500m (1640.40 feet)

Overall wiring length (1.5K or more)

300m (984.24 feet) + 300m (984.24 feet) = 600m (1968.48 feet)

500m

(1640.40 feet) maximum

300m

(984.24 feet)

300m

(984.24 feet)

7) Connect only the recommended optional brake resistor between the terminals P and PR 〈+ and PR〉.

These terminals must not be shorted.

8) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes harmonic components, which may interfere with the

communication devices (such as AM radios) used near the inverter. In this case, install the FR-BIF optional radio

noise filter (for use in the input side only) or FR-BSF01 or FR-BLF line noise filter to minimize interference.

9) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF option) in the output side of the

inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be damaged. If any of the above devices

are installed, immediately remove them. (If the FR-BIF radio nois e filter is connected, switching power off during

motor operation may result in E.UVT. In this case, connect the radio noise filter in the primary side of the

electromagnetic contactor.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

INSTALLATION AND WIRING

13

10) When rewiring after operation, m ake sure that the POW ER lam p has gone off, and when more than 10

minutes have elapsed after power-off, chec k with a tester that the voltage is zero. After that, s tart rewiring

work. For some time after power-off, there is a dangerous voltage in the capacitor.

11) Use the space on the left-hand side of the m ain circuit terminal block to run the cable for c onnection of

the control circuit power terminals R1, S1 〈L

11

, L

21

〉

of the FR-A520-11K.

N

UVW

P1

R1 S1

P

Screw size (M5)

Connection cable

Charge lamp

T

〈L3〉

R

〈L1〉S〈L2〉

〈−〉 〈+〉

〈L11〉〈L21〉

CAUTION

Do not use residual current protective device as the only protection against indirect contact.

Protective earth connection essential.

Do not connect more than 2 wires on the protective earth terminal.

Use contactor and no fuse breaker EN/IEC standard compliant.

Use transformer or surge absorber EN/IEC standard compliant.

Notes on Grounding

•

Leakage currents flow in the inverter. To prevent an electric shock, the inverter and motor must be

grounded (200V class...class 3 grounding, grounding resis tance 100Ω maximum), (400V clas s... special

class 3 grounding, grounding resistance 10Ω or less.).

•

Use the dedicated ground terminal to ground the inverter. (Do not us e the screw in the case, chass is,

etc.)

(Unit: mm2)

Ground Cable Gauge

Motor Capacity

200V class 400V class

3.7kW (5HP) or less 3.5 2

5.5k, 7.5Kw (7.5HP, 10HP) 5.5 3.5

11 to 15Kw (15 to 20HP) 14 8

18.5 to 37kW (25 to 50HP) 22 14

45, 55Kw (60, 75HP) 38 22

•

The ground cable should be as thick as possible.

Its gauge should be equal to or larger than those

indicated in the following table. The grounding

point should be as near as possible to the inverter

to minimize the ground cable length.

•

Ground the motor on the inverter side using one

wire of the 4-core cable.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

INSTALLATION AND WIRING

14

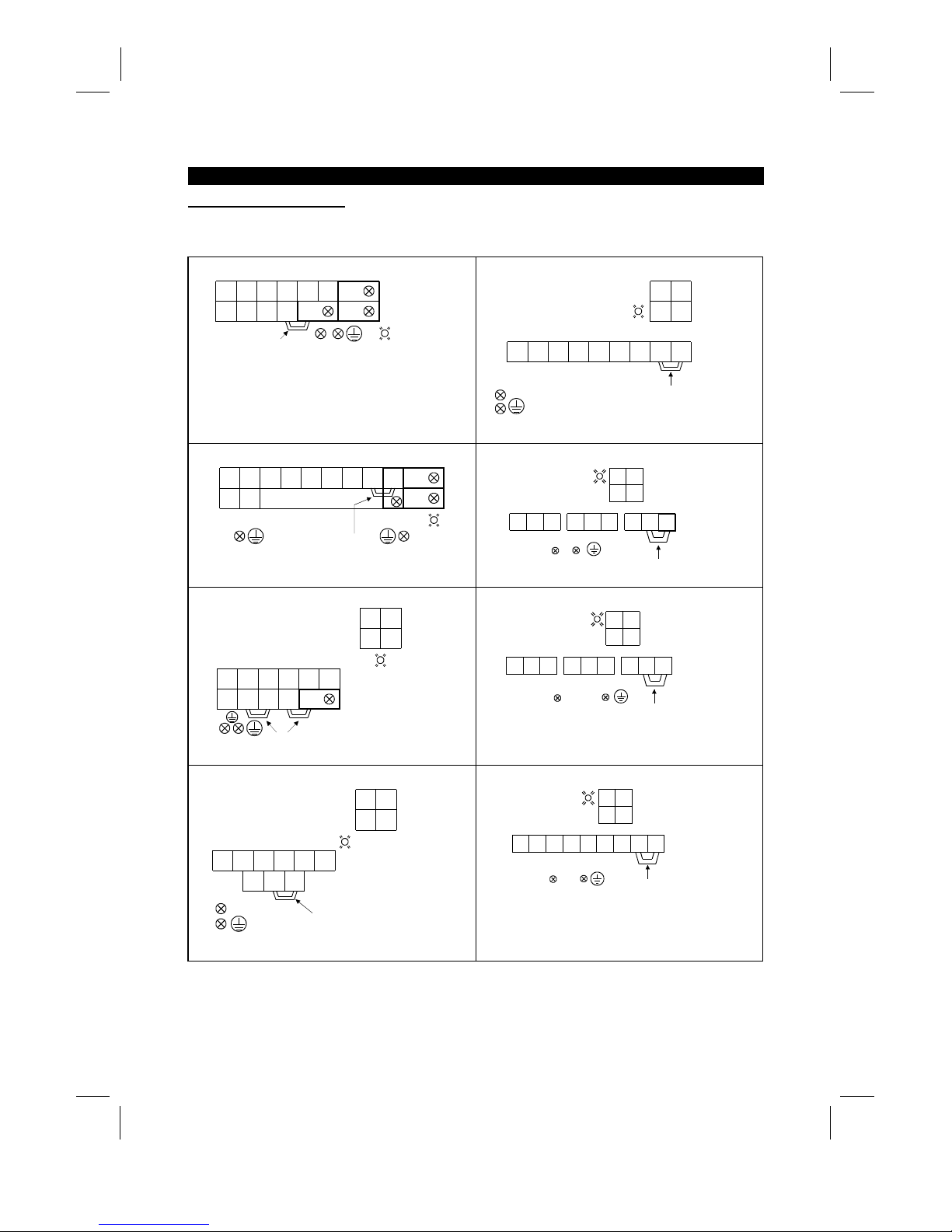

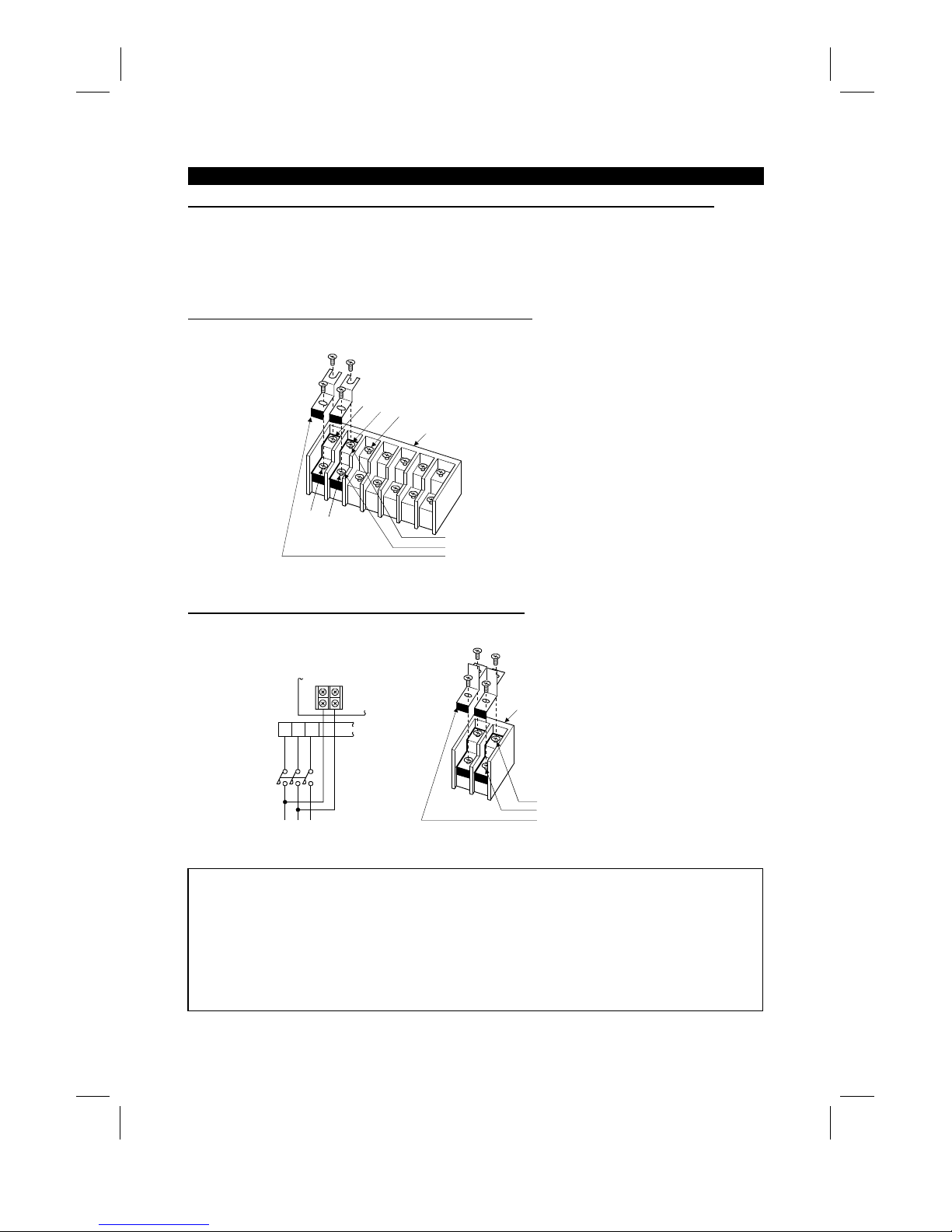

(2)

Terminal block layout

In the main circuit of the inverter, the terminals are arranged as shown below:

1) 200V class

FR-A520-0.4K, 0.75K

RR1STUVWPR

S1 N P1 P

(M4)

PX

Jumper

Screw size(M4)

Charge lamp

FR-A520-15K, 18.5K, 22K

RSTUVWNP1P

RS

R1 S1

Screw size

15K(M6)

18.5K,22K(M8)

Jumper

Charge lamp

Screw size (M4)

Screw size (M6)

FR-A520-1.5K, 2.2K, 3.7K

RR1STUVW PR

S1

NP1P

PX

(M4)

Jumper

Screw size (M4)

Charge lamp

FR-A520-30K

RST UVW

R1 S1

N P1 P

RS

Charge lamp

Screw size (M4)

Screw size (M8)

Screw size (M6) Jumper

FR-A520-5.5K, 7.5K

RNSTUVW

P1 P PR PX

R1RS1

S

(M5)

Jumpers

Charge lamp

Screw size

(M4)

Screw size(M5)

FR-A520-37K, 45K

RST UVW

R1 S1

N P1 P

RS

Charge lamp Screw size (M4)

Screw size (M10)

Screw size (M8)

Jumper

FR-A520-11K

RNSTUVW

P1 P

R1RS1

S

Jumper

Screw size (M4)

Charge lamp

Screw size (M5)

S

crew size (M5)

FR-A520-55K

RSTUVW

R1 S1

N P1 P

RS

Charge lamp

Screw size (M4)

Screw size (M12)

Screw size (M8)

Jumper

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

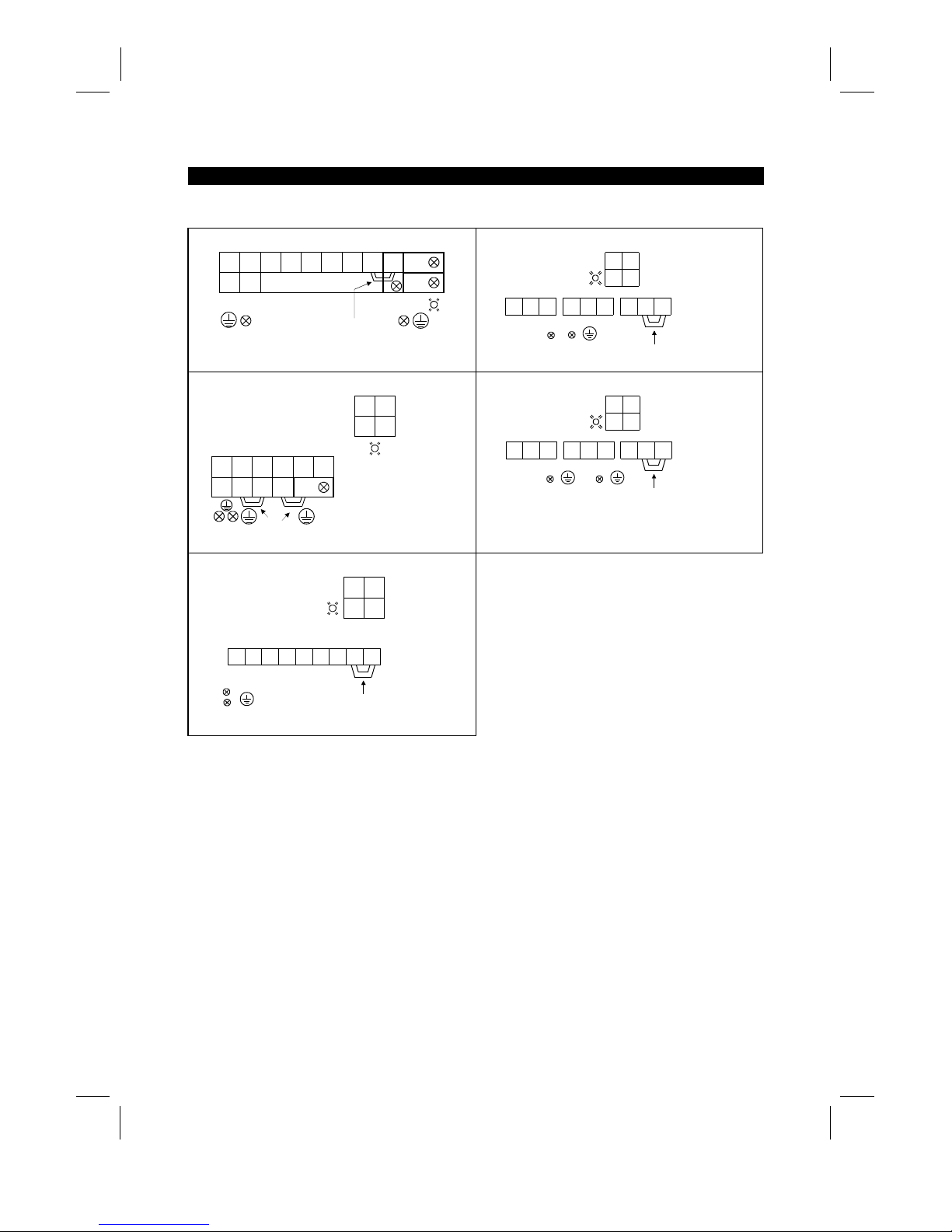

INSTALLATION AND WIRING

15

2) 400V class

FR-A540-0.4K, 0.75K, 2.2K, 3.7K

UVW PRP1

PX

(M4)

Screw size (M4)

Jumper

Charge lamp

R

〈L1〉S〈L2〉T〈L3〉

N

〈–〉P〈+〉

R1

〈

L

11

〉S1〈

L

21

〉

FR-A540-30K

UVW P1

Jumper

Screw size (M4)

Screw size (M6)

Screw size (M6)

Charge lamp

S

〈L2〉R〈L1〉T〈L3〉

R

〈L1〉S〈L2〉

R1

〈L11〉S1〈L12〉

N

〈–〉P〈+〉

FR-A540-5.5K, 7.5K

UVW

P1 PR PX

(M5)

Screw size (M4)

Charge lamp

Screw size (M4)

Jumpers

R

〈

L

1

〉S〈

L

2

〉T〈

L

3

〉

N

〈–〉

P

〈+〉

R

〈L1〉S〈L2〉

R1

〈L11〉S1〈L12〉

FR-A540-37K, 45K, 55K

S

〈

L

2

〉R〈

L

1

〉

UVW P1

Jumper

Screw size (M4)

Screw size (M8)

Screw size (M8)

Charge lamp

T

〈

L

3

〉

R

〈L1〉S〈L2〉

R1

〈L11〉S1〈L12〉

N

〈–〉P〈+〉

FR-A540-11K, 15K, 18.5K, 22K

S

〈

L

2

〉

UVW P1

Jumper

Screw size (M4)

Charge lamp

Screw size (M6)

Screw size (M6)

R

〈

L

1

〉T〈

L

3

〉

R

〈L1〉S〈L2〉

R1

〈L11〉S1〈L12〉

N

〈–〉P〈+〉

Note: 〈 〉 Terminal names in parentheses are those of the EC version.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

INSTALLATION AND WIRING

16

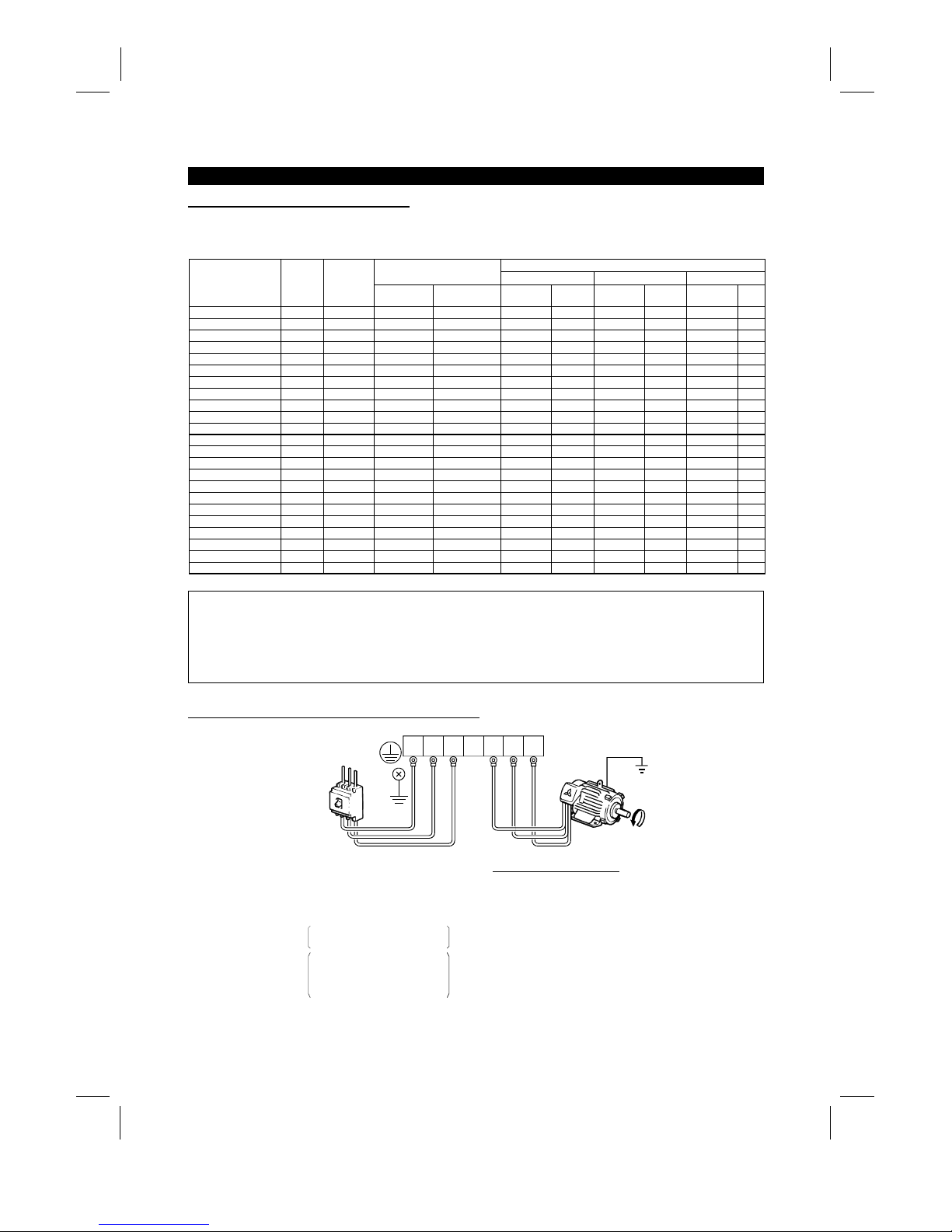

(3)

Cables, crimping terminals, etc.

The following table lists the cables and crim ping terminals used with the inputs (R, S, T) 〈L1, L2, L

3

〉

and

outputs (U, V, W) of the inverter and the torques for tightening the screws:

Cables (Note 1)

Crimping Terminals

mm

2

AWG PVC

Applicable Inverter Type

Terminal

Screw

Size

Tightening

Torque

Kgf⋅cm

(N⋅m)

R, S, T

〈

L1, L2, L3

〉

U, V, W

R, S, T

〈

L1, L2, L3

〉

U, V, W

R, S, T

〈

L1, L2, L3

〉

U, V, W

R, S, T

〈

L1, L2, L3

〉

U, V,

W

FR-A520-0.4K to 2.2K M4 15 (1) 2-4 〈2.5-4〉2-4 〈2.5-4

〉

2 2 14 14 2.5 2.5

FR-A520-3.7K M4 15 (1) 5.5-4 〈4-4〉5.5-4 〈2.5-4

〉

3.5 3.5 12 12 4 2.5

FR-A520-5.5K M5 26 (2) 5.5-5 〈6-5〉5.5-5 〈4-5

〉

5.5 5.5 10 10 6 4

FR-A520-7.5K M5 26 (2) 14-5 〈16-5〉8-5 〈6-5

〉

14 8 6 8 16 6

FR-A520-11K M5 26 (2) 14-5 〈16-5〉14-5 〈16-5

〉

14 14 6 6 16 10

FR-A520-15K M6 45 (4) 22-6 〈35-6〉22-6 〈16-6

〉

22 22 4 4 35 16

FR-A520-18.5K M8 80 (7) 38-8 〈35-8〉38-8 〈25-8

〉

38 38 2 2 35 25

FR-A520-22K M8 80 (7) 38-8 〈70-8〉38-8 〈35-8

〉

38 38 2 2 70 35

FR-A520-30K M8 80 (7) 60-8 〈95-8〉60-8 〈30-8

〉

60 60 1/0 1/0 95 50

FR-A520-37K M10 150 (14) 100-10 〈95-8〉100-10 〈70-8〉100 100 4/0 4/0 75 70

FR-A520-45K M10 150 (14) 100-10 100-10 〈95-40〉100 100 4/0 4/0

−−

FR-A520-55K M12 250 (24) 150-12 150-12 〈110-12〉150 150 MCM300 MCM300

−−

FR-A540-0.4K to 3.7K M4 15 (1) 2-4 〈2.5-4〉2-4 〈2.5-4

〉

2 2 14 14 2.5 2.5

FR-540-5.5K M4 15 (1) 5.5-4 〈4-4〉2-4 〈2.5-4

〉

3.5 2 12 14 4 2.5

FR-540-7.5K M4 15 (1) 5.5-4 〈4-4〉5.5-4 〈4-4

〉

3.5 3.5 12 12 4 4

FR-540-11K M6 45 (4) 5.5-6 〈6-6〉5.5-6 〈6-6

〉

5.5 5.5 10 10 6 6

FR-540-15K M6 45 (4) 14-6 〈16-6〉8-6 〈10-6

〉

14 8 6 8 16 10

FR-540-18.5K M6 45 (4) 14-6 〈16-6〉8-6 〈10-6

〉

14 8 6 8 16 10

FR-540-22K M6 45 (4) 22-6 〈25-6〉14-6 〈16-6

〉

22 14 4 6 25 16

FR-540-30K M6 45 (4) 22-6 〈25-6〉22-6 〈25-6

〉

22 22 4 4 25 25

FR-540-37K M8 80 (7) 38-8 〈37-8〉22-8 〈25-8

〉

38 22 2 4 35 25

FR-540-45K M8 80 (7) 38-8 〈50-8〉38-8 〈35-8

〉

38 38 2 2 50 35

FR-540-55K M8 80 (7) 60-8 〈70-8〉60-8 〈50-8

〉

60 60 1/0 1/0 70 50

Note: 1. The cables used should be 75°C (167°F) copper cables.

2. Tighten the terminal screws to the specified torques.

Undertightening can cause a short or misoperation.

Overtightening can cause the screws and unit to be damaged, resulting in a short or

misoperation.

(4)

Connection of the power supply and motor

Ground

Ground

Ground

terminal

Power

supply

UVW

UVW

Motor

No-fuse

breaker

The power supply cables

must be connected to R, S, T

〈

L

1

, L2, L

3

〉

.

If they are connected to U, V,

W, the inverter will be damaged.

Phase sequence need not be

matched.

For use with a single-phase

power supply,the power supply

cables must be connected to

R and S 〈L

1

and L

2

〉

.

Connect the motor to U, V, W.

In the above connection,

turning on the forward rotation

switch (signal) rotates the motor

in the counterclockwise (arrow)

direction when viewed from

the load shaft.

R

〈

L

1

〉S〈

L

2

〉T〈

L

3

〉

R

〈

L

1

〉S〈

L

2

〉T〈

L

3

〉

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

INSTALLATION AND WIRING

17

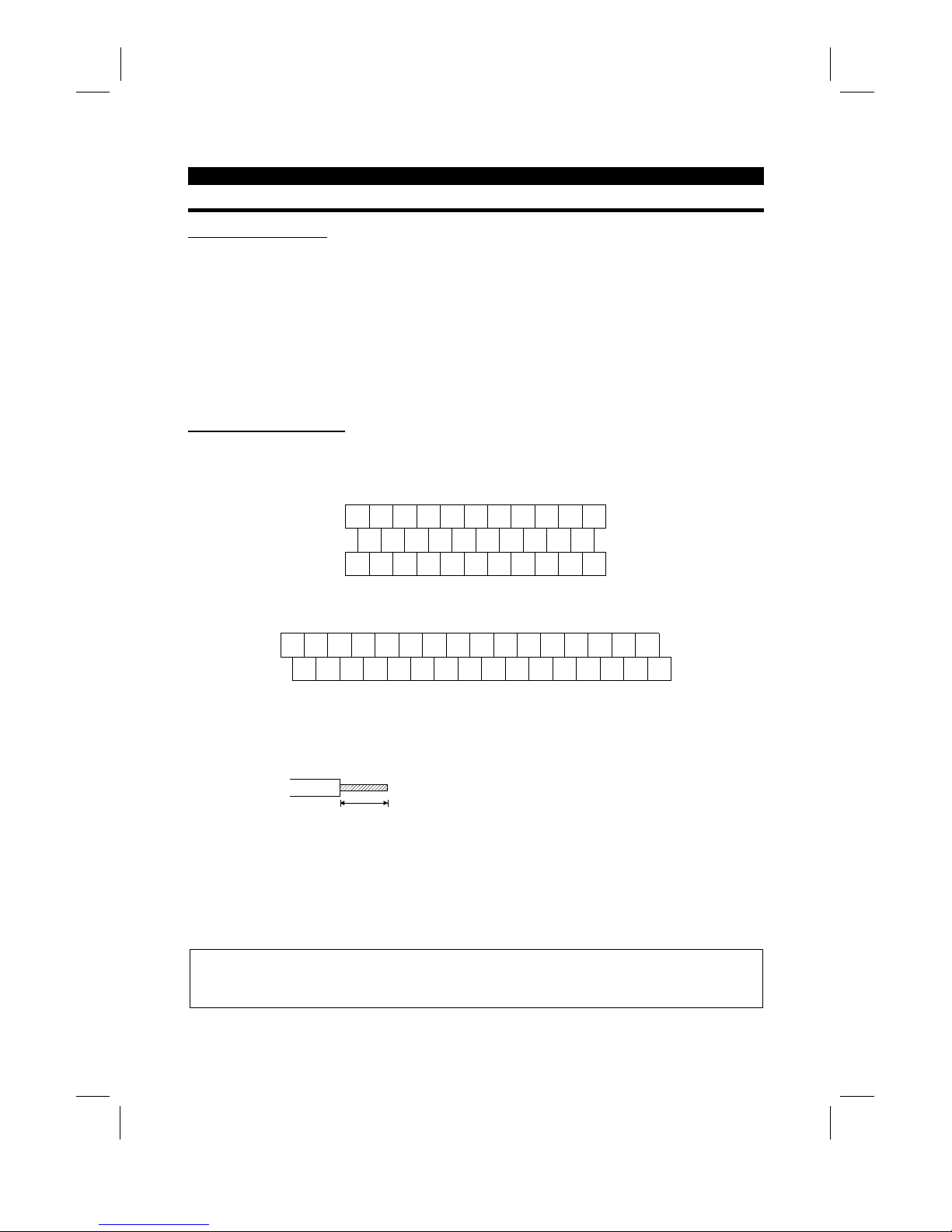

(5)

Connecting the control circuit to a power supply separately from the main circuit

If the magnetic contactor (MC) in the inverter power supply is opened when the protective circuit is oper ated,

the inverter control circuit power is lost and the alarm output signal cannot be k ept on. To keep the alarm

signal on terminals R1 and S1 are available. In this case, c onnec t the power supply terminals R1 and S1 〈L

11

and L

21

〉

of the control circuit to the primary side of the MC.

• Model FR-A520-0.4K to 3.7K, FR-A540-0.4K to 3.7K

<Connection procedure>

R

〈L1〉

S

〈L2〉

T

〈L3〉

R1 〈L11〉

S1 〈L21〉

4) Connect the separate power supply cables for control circuit to the

lower terminals (R1, S1 〈L11, L21〉). (Note 4)

Terminal block for main circuit

1) Loosen the upper screws

2) Remove the lower screws.

3) Remove the jumpers.

• Model FR-A520-5.5K to 55K, FR-A540-5.5K to 55K

<Connection procedure>

M

C

1) Loosen the upper screws.

2) Remove the lower screws.

3) Pull out and remove the jumper.

4) Connect the separate power supply

cables for control circuit to the

upper terminals (R1, S1 〈L11, L21〉). (Note 4)

Power supply terminal

block for control circuit

Main power supply

Power supply terminal

block for control circuit

R

〈

L

1

〉S〈

L

2

〉T〈

L

3

〉

R1

〈

L

11

〉S1〈

L

21

〉

Note: 1. When the main circuit power (R, S, T ) 〈L1 L2, L

3

〉

is on, do not switch off the control power

(terminals R1, S1 〈L

11

, L

21

〉

). Otherwise the inverter may be damaged.

2. W hen using a separate power supply, the jumpers acros s R-R1 and S-S1 〈L

1

-

L

11

and L

2

-

L

21

〉

must be removed. Otherwise the inverter may be damaged.

3. For a diff erent power supply system which takes the power of the control c ircuit from other than

the primary side of the MC, the voltage should be equal to the main circuit voltage.

4. For the FR-A520-5.5K to 55K, FR-A540-5.5K to 55K, the power supply cables must not be

connected to the lower terminals. If connected, the inverter may be damaged.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

INSTALLATION AND WIRING

18

2.2.3 Wiring of the control circuit

(1)

Wiring instructions

1) Terminals SD, SE and 5 are com mon to the I/O signals and isolated from each other . These common

terminals must not be connected to each other or earthed.

2) Use shielded or twisted cables for connection to the control circuit terminals and run them away from the

main and power circuits (including the 200V relay sequence circuit).