Page 1

LARGE CAPACITY INVERTER

FR-A500L

HIGH PERFORMANCE

HIGH-FUNCTIONS

FR-A560L-375K~900K-NA

- INSTRUCTION MANUAL -

Supplementary Manual

Refer to Operation/Instruction

Manual for FR-A500L.

MITSUBISHI

ELECTRIC

Page 2

Thank you for choosing this Mitsubishi Large Capacity Inverter.

This instruction manual gives handling information and precautions for use of this

equipment.

Incorrect handling might cause an unexpected f ault. Before using the inverter, please read

this manual carefully to use the equipment to its optimum.

This manual describes the parts which are different from the FR-A500L chassis driv e, up to

280kw. Please refer to the FR-A500L instruction manual for further details.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read through this instruction

manual and appended documents carefully and can use the equipment correctly.

Do not use the inverter until you have a full knowledge of the equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into “WARNING” and “CAUTION”.

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

Assumes that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

Assumes that incorrect handling may cause hazardous conditions, resulting in

medium or slight injury, or may cause physical damage only.

A‑1

Page 3

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

z

While power is on or when the inverter is running, do not open the front door. You may get an electric

shock.

z

Do not run the inverter with the front door opened. Contact with the exposed high-voltage term inals or

charging part of circuitry will cause an electric shock.

z

If power is off, do not open the front door except for wiring or periodic inspection. You may access the

charged inverter circuits and get an electric shock.

z

Before starting wiring or inspection, switch power off, wait for more at least 10 minutes and check for the

presence of any residual voltage with meter (see chapter 2 for-further details.) etc.

z

Any person who is involved in the wiring or inspection of this equipment should be fully com petent to do

the work.

z

Always install the inverter before wiring. Otherwise, you may get an electric shock or be injured.

z

Operate the switches with dry hands to prevent an electric shock.

z

Do not subject the cables to sc ratches, exc essive stres s, heavy loads or pinching. Other wise, you may

get an electric shock.

2. Fire Prevention

CAUTION

z

Install the inverter on an incombustible cubic le. Installing the inverter directly on or near a combus tible

surface could lead to a fire.

z

If the inverter has becom e faulty, switch off the inverter power. A continuous f low of lar ge curr ent could

cause a fire.

z

Do not connect the resistor directly to the DC terminals +(P), -(N). This could cause a fire.

3. Injury Prevention

CAUTION

z

Apply only the voltage specified in the instruction manual to each terminal to prevent damage, etc.

z

Ensure that the cables are connected to the correct terminals. Otherwise, damage, etc. may occur.

z

Always make sure that polarity is correct to prevent damage, etc.

z

After the inverter has been operating for a relatively long period of time, do not touch the inverter as it

may be hot and you may get burnt.

A‑2

Page 4

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.:

(1) Transportation and installation

CAUTION

z

When carrying products, use correct lifting gear to prevent injury.

z

Ensure that installation position and material can withstand the weight of the inverter. Install according

to the information in the Instruction Manual.

z

Do not operate if the inverter is damaged or has parts missing.

z

Do not stand or rest heavy objects on the inverter.

z

Check the inverter mounting orientation is correct.

z

Prevent screws, wire fragments, conduc tive bodies, oil or other flamm able substances f rom entering

the inverter.

z

Do not drop the inverter, or subject it to impact.

z

Use the inverter under the following environmental conditions:

Ambient

temperature

Ambient humidity

Storage

temperature

Ambience

Altitude, vibration

*For transportation

Temperature -20°C to 65°C (-4°F to 149°F)

Relative fumidity 90% or less

Air pressure 70kPa to 106kPa

-10°C to +40°C (14°F to 104°F) (non-freezing) for 530K-900K

-10°C to +40°C (14°F to 104°F) (non-freezing) at VT rating for 375K, 450K

-10°C to +50°C (14°F to 122°F) (non-freezing) at CT rating for 375K, 450K

90%RH or less (non-condensing)

-20°C to +65°C (-4°F to 149°F)

Indoors (free from corrosive gas, flammable gas, oil mist, dust and dirt)

Maximum 1000m (3280.80feet.) above sea level for standard operation.

After 1000 derate by 3% for every extra 500m up to 2500m (91%).

(2) Wiring

CAUTION

z

Do not fit capacitive equipment such as power factor correction capacitor, noise filter or surge

suppressor to the output of the inverter.

z

The connection orientation of the output cables U, V, W to the motor will affect the direction of rotation

of the motor.

(3) Trial run

CAUTION

z

Check all parameters, and ensure that the machine will not be damaged by sudden start-up.

A‑3

Page 5

(4) Operation

CAUTION

z

When you have chosen the retry function, stay away from the equipment as it will res tart suddenly

after an alarm stop.

z

The [STOP] key is valid only when the appropriate function setting has been made. Prepare an

emergency stop switch separately.

z

Make sure that the start s ignal is of f bef or e r esetting the inver ter alarm. A failure to do s o may restart

the motor suddenly.

z

The load used should be a three-phase induction motor only. Connection of any other electrical

equipment to the inverter output may damage the equipment.

z

The electronic overcurrent protection does not guarantee protection of the motor from overheat.

z

Do not use a magnetic contactor on the inverter input for frequent starting/stopping of the inverter.

z

Use a noise filter to reduce the effect of elec tromagnetic interference. Otherwise nearby electronic

equipment may be affected.

z

Take measures to suppress harmonics. Otherwise power harmonics from the inverter may

heat/damage the power capacitor and generator.

z

When an over 400V class motor is inverter-driven, it should be insulation-enhanced or surge voltages

suppressed. Surge voltages attributable to the wiring constants may occur at motor terminals,

deteriorating the insulation of the motor.

z

When param eter c lear or all clear is perf orm ed, each parameter returns to the factory setting. Re-set

the required parameters before starting operation.

z

The inverter can be easily set f or high- s peed operation. Before changing its setting, f ully exam ine the

performances of the motor and machine.

z

In addition to the inverter's holding function, install a holding device (e. g. mechanical brake) to ensure

safety.

z

Before running the inverter which had been stored f or a long period, always perform inspection and

test operation.

(5) Emergency stop

CAUTION

z

Provide a safety backup such as an emergency brake which will prevent the machine and equipm ent

from hazardous conditions if the inverter fails.

(6) Maintenance, inspection and parts replacement

CAUTION

z

Do not carry out a megger (insulation resistance) test on the control circuit of the inverter.

(7) Disposing of the inverter

CAUTION

z

Treat as industrial waste.

(8) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter without a cover, or par tially

open. NEVER run the inverter like this. Always replace the cover and follow this ins truction manual when

operating the inverter.

A‑4

Page 6

CONTENTS

1 OUTLINE .........................................................................................................................................1

1.1 Pre-Operation Information..............................................................................................................1

1.1.1 Precautions for operation.........................................................................................................1

1.2 Basic Configuration.........................................................................................................................2

1.2.1 Basic configuration...................................................................................................................2

2 INSTALLATION AND WIRING .......................................................................................................3

2.1 Installation.......................................................................................................................................3

2.1.1 Instructions for installation .......................................................................................................3

2.2 Wiring .............................................................................................................................................5

2.2.1 Terminal connection diagram .................................................................................................. 5

2.2.2 Wiring of the main circuit .........................................................................................................8

2.2.3 Wiring of the control circuit ....................................................................................................12

2.2.4 Connection to the PU connector............................................................................................ 16

2.2.5 Design information.................................................................................................................17

3 OPERATION..................................................................................................................................17

4 PARAMETER ................................................................................................................................18

4.1. Parameter list................................................................................................................................18

5 PROTECTIVE FUNCTIONS..........................................................................................................24

5.1 Errors (Alarms) .............................................................................................................................24

5.1.1 Error (alarm) definitions .........................................................................................................24

5.1.2 Correspondences between digital and actual characters......................................................28

5.1.3 Alarm code output..................................................................................................................29

5.1.4 Resetting the inverter.............................................................................................................29

5.2 Troubleshooting............................................................................................................................30

5.2.1 Checking the operation panel display at alarm stop ..............................................................30

5.2.2 Faults and check points.........................................................................................................32

5.3 Precautions for Maintenance and Inspection ............................................................................... 34

5.3.1 Precautions for maintenance and inspection.........................................................................34

5.3.2 Check items...........................................................................................................................34

5.3.3 Periodic inspection.................................................................................................................34

5.3.4 Insulation resistance test using megger ................................................................................ 35

5.3.5 Dielectric strength test ...........................................................................................................35

5.3.6 Replacement of parts.............................................................................................................38

5.3.7 Measurement of main circuit voltages, currents and power .................................................. 39

6 SPECIFICATIONS.........................................................................................................................41

6.1 Standard Specifications................................................................................................................41

6.1.1 Model specifications...............................................................................................................41

6.1.2 Common specifications..........................................................................................................42

6.1.3 Outline drawings....................................................................................................................44

APPENDICES...................................................................................................................................45

Appendix3............................................................................................................................................47

Appendix4............................................................................................................................................49

Appendix5............................................................................................................................................50

Page 7

CHAPTER 1

OUTLINE

This chapter gives information on the basic "outline" of this

product.

Always read the instructions in this chapter before using the

equipment.

1.1 Pre-Operation Information

1.2 Basic Configuration

<Abbreviations>

y

DU

Operation panel (FR-DU04)

y

PU

Operation panel (FR-DU04) and parameter unit (FR-PU04)

y

Inverter

Mitsubishi Large Capacity inverter FR-A500L series

y

FR-A500L

Mitsubishi Large Capacity inverter FR-A500L series

y

Pr.

Parameter number

y

PU operation

Operation using the PU (FR-DU04/FR-PU04)

y

External operation

Operation using the control circuit signals

y

Combined operation

Operation using both the PU (FR-DU04/FR-PU04) and

external operation

y

MT-A100E

Mitsubishi large capacity inverter MT-A100 series

<EXCELLENT> series

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

1

2

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

APPENDICES

1

Page 8

1.1 Pre-Operation Information

OUTLINE

1.1.1 Precautions for operation

Incorrect handling might cause the inverter to operate improperly, its life to be reduced considerably, or at the

worst, the inverter to be damaged. Handle the inverter properly in accordance with the information in each

section as well as the precautions and instructions of this manual to use it correctly.

This manual is written for the FR-A500L series large capacity inverters.

For handling information on the parameter unit (FR-PU04), inboard options, stand-alone options, etc., refer to

the corresponding manuals.

(1)

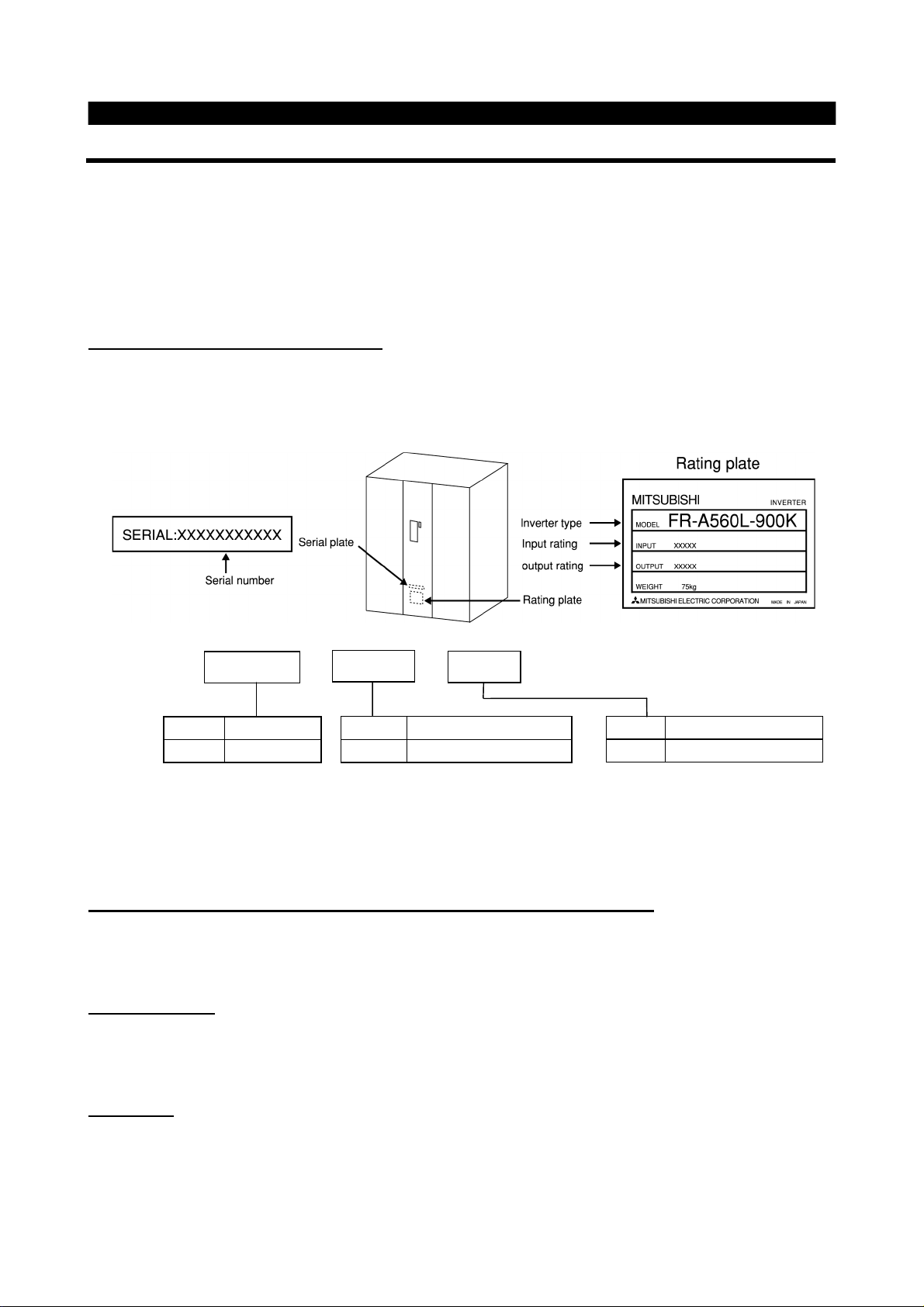

Unpacking and product check

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side

face to ensure that the product agrees with your order and the inverter is intact

1) Inverter type

FR - A560L - 900K -

2) Accessory

Instruction manual

If you have found any discrepancy, damage, etc., please contact your sales representative.

(2)

Preparations of instruments and parts required for operation

Instruments and parts to be prepared depend on how the inverter is operated. Prepare equipment and parts

as necessary.

(3)

Installation

Symbol Voltage Class

A560L 600V class

Symbol Applicable Motor Capacity

900K Indicates capacity in “kW”

Symbol Specifications

NA U.S. specifications

To operate the inverter with high performance for a long time, install the inverter in a proper place, in a

correct direction, and with proper clearances.

(4)

Wiring

Connect the power supply, motor and operation signals (control signals) to the terminal block. Note that

incorrect connection may damage the inverter and peripheral devices. (See page 8.)

1

Page 9

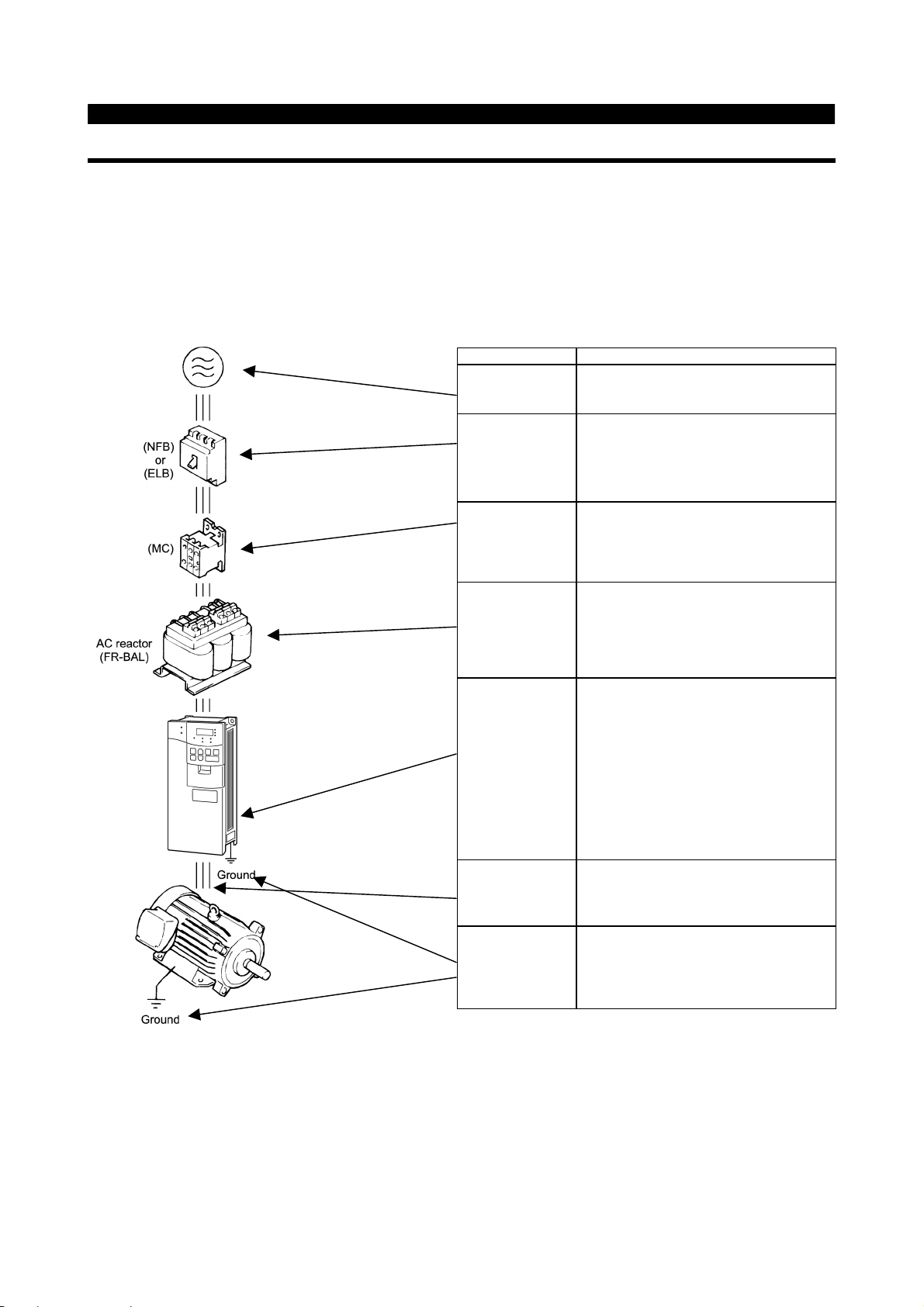

1.2 Basic Configuration

E

OUTLIN

1.2.1 Basic configuration

The following devices are required to operate the inverter. Proper peripheral devices must be selected and

correct connections made to ensure proper operation. Incorrect system configuration and connections can

cause the inverter to operate improperly, its life to be reduced considerably, and in the worst case, the

inverter to be damaged.

Please handle the inverter properly in accordance with the information in each section as well as the

precautions and instructions of this manual. (For connections of the peripheral devices, refer to the

corresponding manuals.)

Name

Power supply

Earth leakage

circuit breaker

(ELB) or no-fuse

breaker (NFB)

Magnetic

contactor

Reactors

Use the power supply within the permissible

power supply specifications of the inverter.

The breaker should be selected with care

since a large inrush current flows in the

inverter at power on.

The breaker must have overcurrent

protection and earth leakage protection.

The magnetic contactor need not be

provided. When installed, do not use

it to start or stop the inverter. It might reduce

the inverter life.

The reactors must be used when the power

factor is to be improved or the inverter is

installed near a large power supply system

(ten times or more of Inverter Output, and

wiring distance within 10m (32.81 feet) ).

Make selection carefully.

Description

z

The inverter life is influenced by ambient

temperature. The ambient temperature

should be as low as possible within the

permissible range.

Inverter

Devices

connected to the

output

Ground

This must be noted especially when the

inverter is installed in an enclosure.

z

Incorrect wiring might lead to inverter

damage. The control signal lines must be

kept fully away from the main circuit to

protect them from noise.

Do not connect a power capacitor, surge

suppressor or radio noise filter to the output

side.

To prevent an electric shock, always ground

the motor and inverter.

2

Page 10

CHAPTER 2

INSTALLATION AND WIRING

This chapter gives information on the basic "installation and

wiring" of this product.

Always read the instructions in this chapter before using the

equipment.

2.1 Installation

2.2 Wiring

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

3

5

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

APPENDICES

2

Page 11

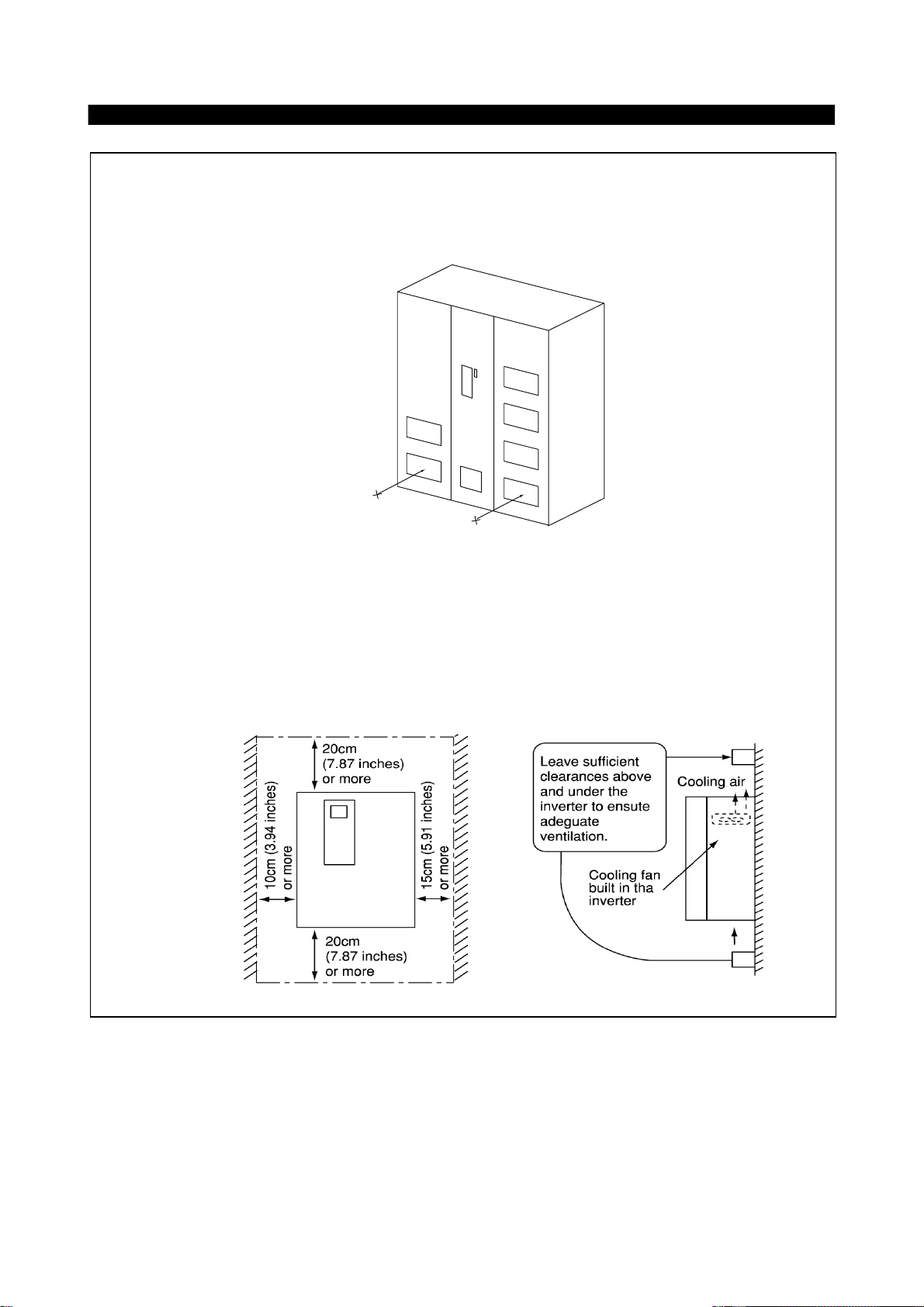

2.1 Installation

INSTALLATION AND WIRING

2.1.1 Instructions for installation

1) Handle the unit carefully.

The inverter uses plastic parts. Handle it gently to protect it from damage. Also, hold the unit with even strength

and do not apply too much strength to the front cover alone.

2) Install the inverter where it is not subjected to vibration.

Note the vibration of a cart, press, etc.

3) Note on ambient temperature

The inverter life is under great influence of ambient temperature. In the place of installation, ambient temperature

must be within the permissible range (-10°C to +40°C (14°F to 104°F) ). Check that the ambient temperature is

within that range in the positions shown in figure 3).

*For FR-A560L-375, 450K at constant torque (CT) rating maximum ambient temperature can be 50°C (122°F).

4) Install the inverter on a non-combustible surface.

The inverter will be very hot (maximum. about 150°C (302°F) ). Install it on a non-combustible surface (e.g.

metal). Also leave sufficient clearances around the inverter.

5) Avoid high temperature and high humidity.

Avoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

Note: The cooling section outside the enclosure has the cooling fan. Do not use the inverter in any environment

where it is exposed to waterdrops, oil mist, dust, etc.

6) Avoid places where the inverter is exposed to oil mist, flammable gases, fluff, dust, dirt, etc.

Install the inverter in a clean place or inside a "totally enclosed" panel which does not accept any suspended

matter.

7) Note the cooling method when the inverter is installed in an enclosure.

When an inverter is mounted in an enclosure, the ventilation fans of the inverter and enclosure must be carefully

positioned to keep the ambient temperature of the inverter below the permissible value. If they are installed in

improper positions, the rise in ambient temperature will result in reduced performance of the inverter.

8) Secure the inverter vertically, with bolts.

Install the inverter on an installation surface securely and vertically with screws or bolts.

3

Page 12

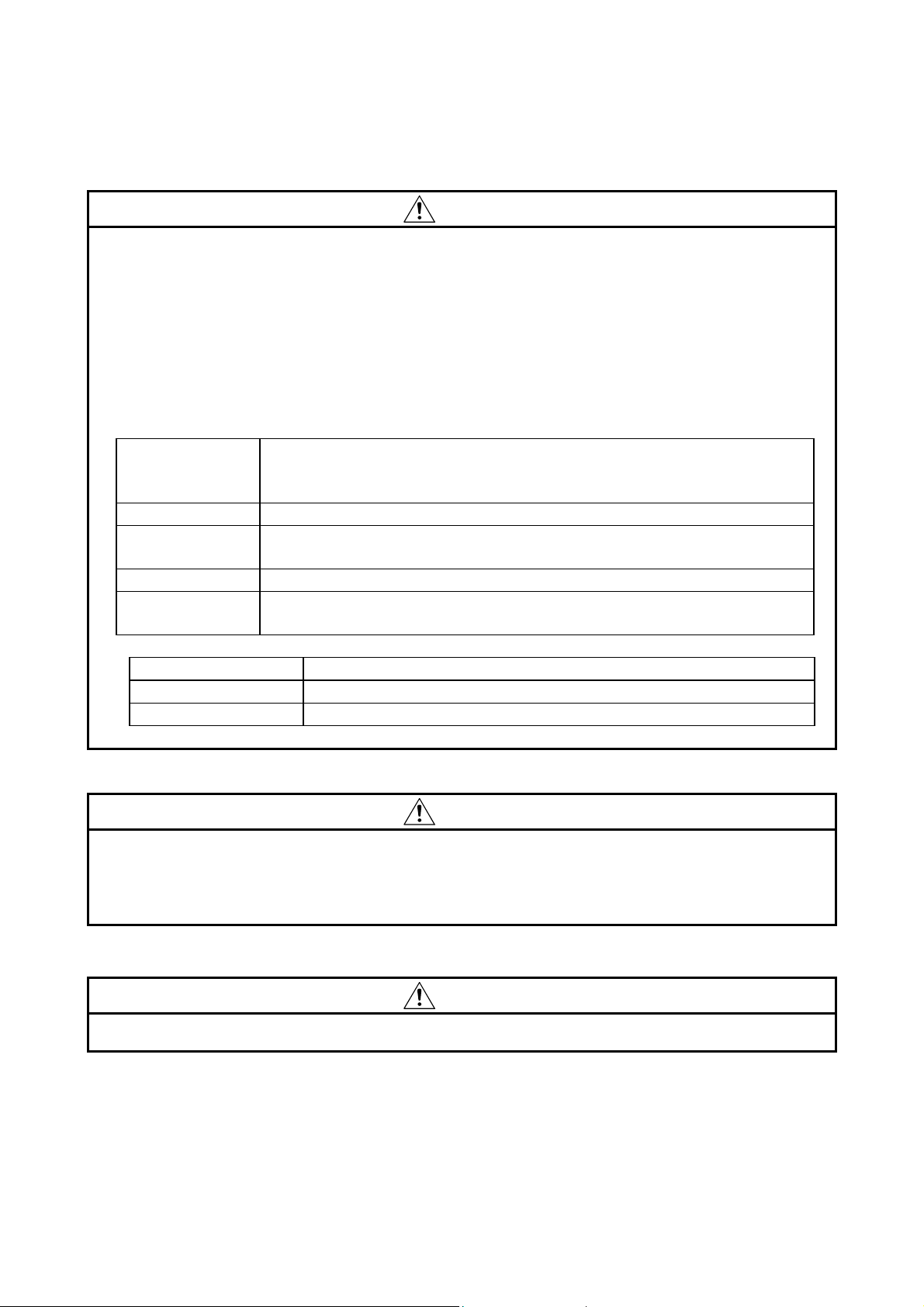

3) Note on ambient temperatures

FR-A560L-530〜900K

FR-A560L-375, 450K

40°C at 5cm (1.97 inch)

INSTALLATION AND WIRING

4

Page 13

2.2 Wiring

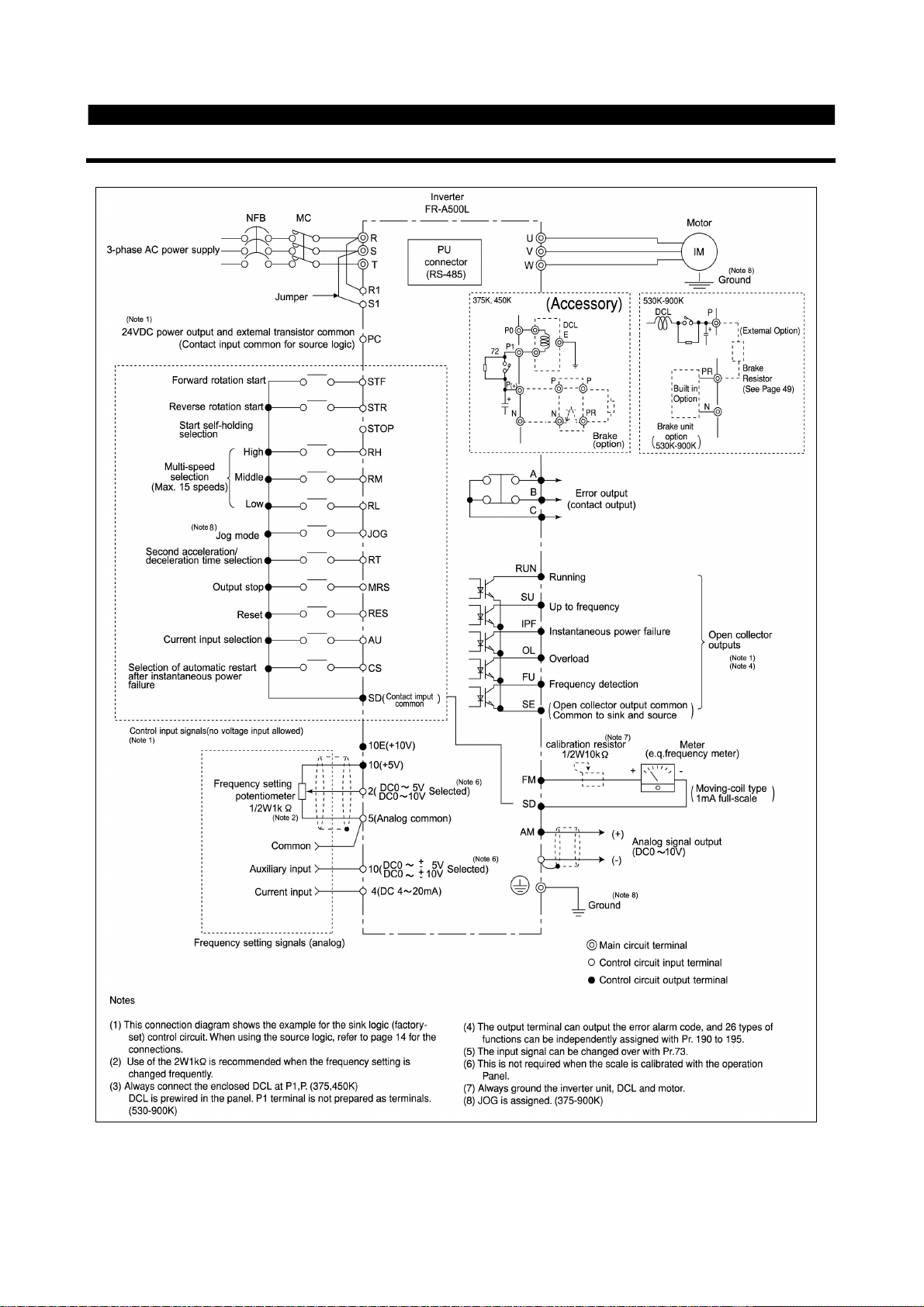

2.2.1 Terminal connection diagram

INSTALLATION AND WIRING

5

Page 14

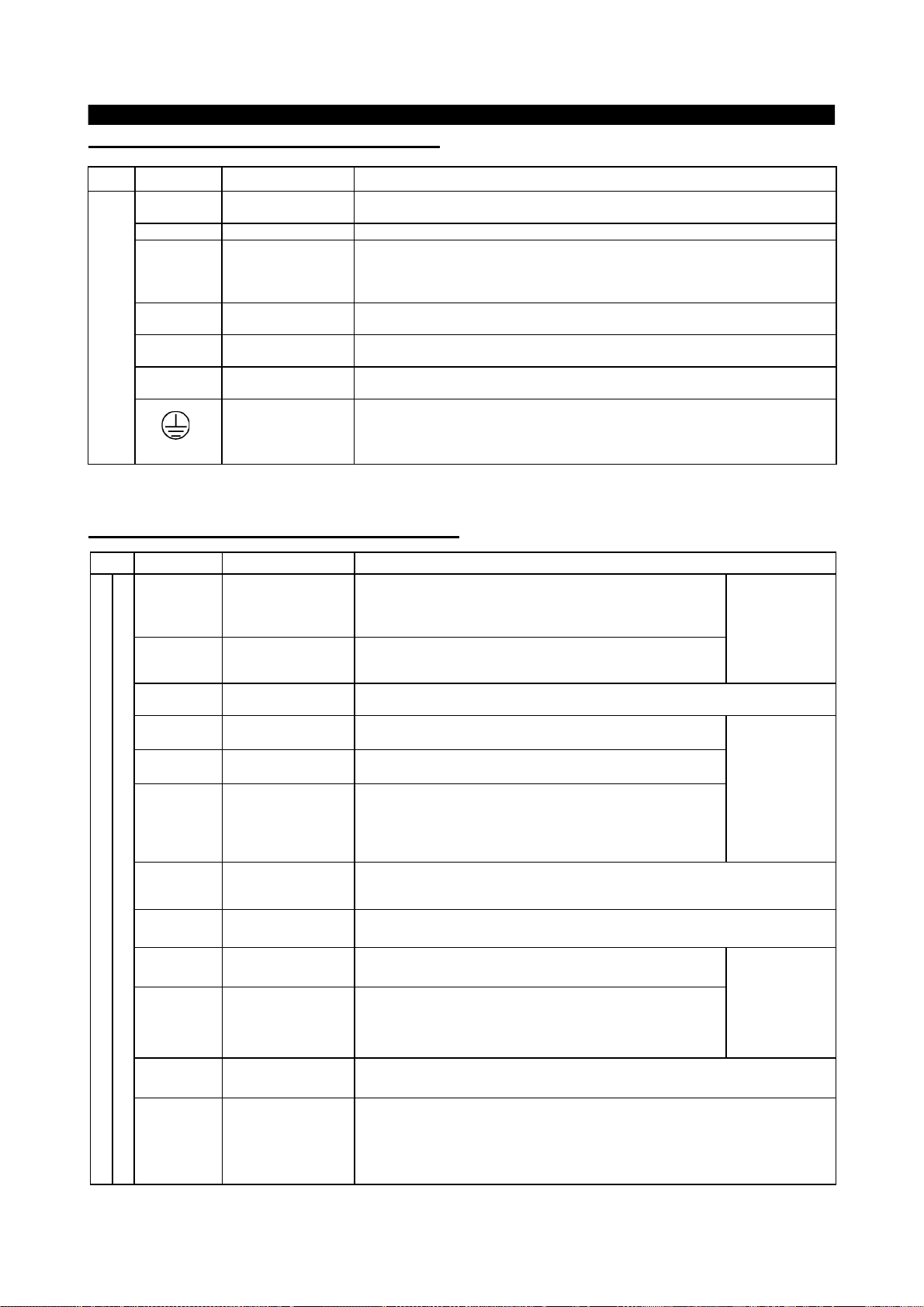

(1)

Description of main circuit terminals

INSTALLATION AND WIRING

Type

Main

circuit

Symbol

R, S, T

<L

, L2, L3>

1

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

R1, S1

<L

, L21>

11

P, N

<+,->

P, P1

P, PR

<+, PR>

Terminal Name

AC power input

Power supply for

control circuit

Optional converter

connection

DC reactor

connection

Brake resistor

connection

Ground For grounding the inverter chassis. Must be earthed.

Connect to the commercial power supply. Keep these terminals unconnected when

using the high power factor converter (MT-HC).

Connected to the AC power supply terminals R and S. To retain the alarm display

and alarm output or when using the high power factor converter (MT-HC), remove

the jumpers from terminals R-R1 and S-S1 and apply external power to these

terminals.

Connect the optional power return converter (MT-RC) or high power factor converter

(MT-HC).

Connect the enclosed DC reactor. (375, 450K)

DC reactor is prewired in 530-900K sizes.

Connect the optional FR-BR5 brake resistor.

Description

Note:<>Terminal names in parentheses are those of the EC version.

(2)

Description of control circuit terminals

Type

Input signals

Symbol

STF Forward rotation start

STR Reverse rotation start

STOP

RH,RM,RL Multi-speed selection

(JOG) JOG mode selection

RT

MRS Output stop

RES Reset

AU

Contacts, e.g. start, function setting

CS

SD

PC

Terminal Name

Start self-holding

selection

Second acceleration/

deceleration time

selection

Current input

selection

Automatic restart after

instantaneous power

failure selection

Contact input

common (sink)

24VDC power and

external transistor

common

Contact input

common (source)

Turn on the STF signal to start forward rotation and turn it off to

stop. Acts as a programmed operation start signal in the

programmed operation mode. (Turn on to start and turn off to

stop.)

Turn on the STR signal to start reverse rotation and turn it off to

stop.

Turn on the STOP signal to select the self-holding of the start signal.

Use the RH, RM and RL signals as appropriate to select multiple

speeds.

This terminal connected internally, can not be used by the

customer. (530-900KW :this signal is assigned in Factory.)

Turn on the RT signal to select the second acceleration/

deceleration time. W hen the second functions such as "second

torque boost" and "second V/F (base frequency)" functions have

been set, these functions can also be selected by turning on the

RT signal.

Turn on the MRS signal (20ms or longer) to stop the inverter output.

Used to shut off the inverter output to bring the motor to a stop by the magnetic

brake.

Used to reset the protective circuit activated. Turn on the RES signal for more than

0.1 sec, then turn it off.

Only when the AU signal is turned on, the inverter can be

operated with the 4-20mADC frequency setting signal.

With the CS signal on, restart can be made automatically when

the power is restored after an instantaneous power failure. Note

that this operation requires restart parameters to be set. When

the inverter is shipped from the factory, it is set to disallow restart.

Common terminal for the terminal FM.

Common output terminal for 24VDC 0.1A power (PC terminal).

When transistor output (open collector output), such as a programmable controller, is

connected, connect the external power supply common for transistor output to this

terminal to prevent a fault caused by leakage current. This terminal can be used as a

24VDC, 0.1A power output. When source logic has been selected, this terminal

serves as a contact input common.

Description

When the STF

and STR signals

are turned on

simultaneously,

the stop

command is

given.

Input terminal

function selection

(Pr. 180 to

Pr. 186) change

terminal

functions.

Input terminal

function selection

(Pr. 180 to Pr.

186) change

terminal

functions.

6

Page 15

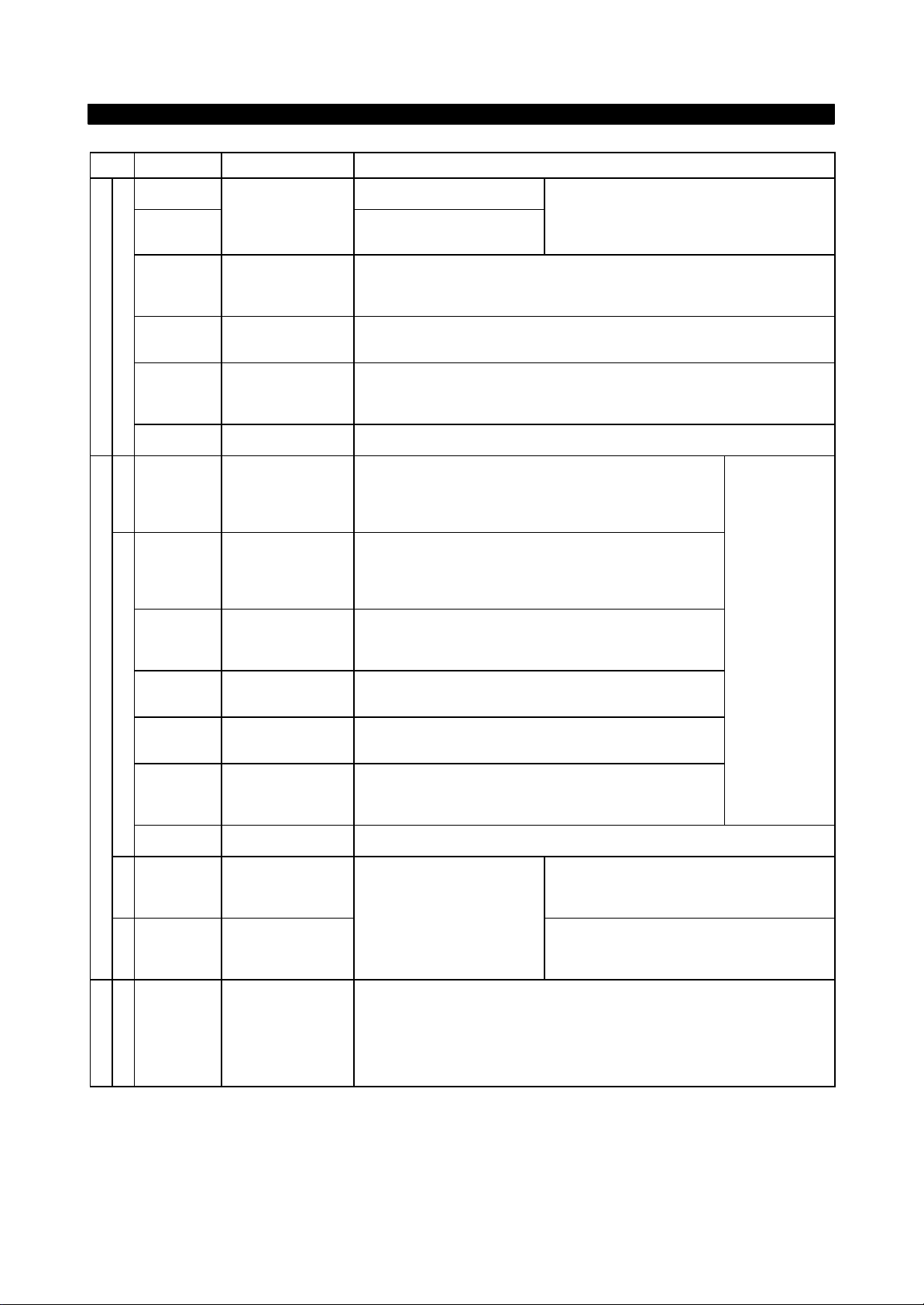

INSTALLATION AND WIRING

Type

Symbol

Terminal Name

Description

10E

10VDC, permissible load current

10mA10Frequency setting

power supply

5VDC, permissible load current

10mA

When the frequency setting potentiometer is

connected in the factory-set state, connect it to

terminal 10.

When it is connected to terminal 10E, change the

input specifications of terminal 2.

2

Frequency setting

(voltage)

By entering 0 to 5VDC (0 to 10VDC), the maximum output frequency is reached at

5V (or 10V) and I/O are proportional. Switch between input 0 to 5VDC (factory

setting) and 0 to 10VDC from operation terminal. Input resistance 10kΩ. Maximum

permissible voltage 20V.

4

Frequency setting

(current)

By entering 4 to 20mADC, the maximum output frequency is reached at 20mA and

I/O are proportional. This input signal is valid only when the AU signal is on. Input

resistance 250Ω. Maximum permissible current 30mA.

1

Auxiliary frequency

setting

By entering 0 to ±5VDC 0 to ±10VDC, this signal is added to the frequency setting

signal of terminal 2 or 4. Switch between input 0 to ±5VDC and 0 to ±10VDC

(factory setting) from operation terminal. Input resistance 10kΩ. Maximum

permissible voltage ±20V.

5

Frequency setting

input common

Common to the frequency setting signal (terminal 2, 1 or 4) and analog output

terminal AM. Do not earth.

A,B,C

Alarm output

Change-over contact output indicating that the output has been

stopped by the inverter protective function activated.

200VAC 0.3A, 30VDC 0.3A. Alarm: discontinuity across B-C

(continuity across A-C), normal: continuity across B-C

(discontinuity across A-C).

RUN

Inverter running

Switched low when the inverter output frequency is equal to or

higher than the starting frequency (factory set to 0.5Hz,

variable).

Switched high during stop or DC dynamic brake operation

Permissible load 24VDC 0.1A.

SU

Up to frequency

Switched low when the output frequency has reached within

±

10% of the set frequency (factory setting, variable). Switched

high during acceleration, deceleration or stop

. Permissible

load 24VDC 0.1A.

OL

Overload alarm

Switched low when the stall prevention function has caused

stall prevention to be activated. Switched high when stall

prevention is reset

. Permissible load 24VDC 0.1A.

IPF

Instantaneous power

failure

Switched low when instantaneous power failure or

undervoltage protection is activated

. Permissible load

24VDC 0.1A.

FU

Frequency detection

Switched low when the output frequency has reached or

exceeded the detection frequency set as appropriate. Switched

high when below the detection frequency

. Permissible load

24VDC 0.1A

Output terminal

function selection

(Pr. 190 to Pr.

195) change

terminal

functions.

SE

Open collector output

common

Common to the RUN, SU, OL, IPF and FU terminals.

FM

For meter

Factory setting of output item:

Frequency

Permissible load current 1mA

1440 pulses/second. at 60Hz

AM

Analog signal output

One selected from 16 monitoring

items, such as output

frequency, is output

.

The output signal is proportional

to the magnitude of each

monitoring item.

Factory setting of output item:

Frequency

Output signal 0 to 10VDC

Permissible load current 1mA

PU connector

With the operation panel connector, communication can be made through RS-485.

·

Conforming Standard : EIA Standard RS-485

·

Transmission format : Multi-drop link

·

Communication speed : Maximum 19200 baud rates

·

Overall length : 500m

Input signals

Analog frequency setting

Contact

Open collector

Output signals

Pulse

Analog

(note1)

(note 1)

(note 1)

(note 1)

(note 1)

(note 2)

RS485

Communication

Note1: Low indicates that the open collector outputting transistor is on (conducts). High indicates that the

transistor is off (does not conduct).

Note2: Not output while the inverter is reset.

7

Page 16

INSTALLATION AND WIRING

2.2.2 Wiring of the main circuit

(1)

Wiring instructions

1) Power must not be applied to the output terminals (U, V, W) of the inverter. Otherwise the inverter will be

damaged.

2) After wiring, wire off-cuts must not be left in the inverter.

Wire off-cuts can cause an alarm, failure or malfunction. Always keep the inverter clean.

3) Use thick cables to make a voltage drop of 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the

motor torque to decrease especially at the output of a low frequency.

4) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes harmonic components, which may interfere with the

communication devices (such as AM radios) used near the inverter. In this case, use shielded wire cables as

the power cable.

5) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF option) in the output side of the

inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be damaged. If any of the above

devices are installed, immediately remove them.

6) When rewiring after operation, make sure that the POWER lamp has gone off, and when more than 10minutes

have elapsed after power-off, check with a tester that the DC bus voltage is zero. After that, start rewiring work.

For some time after power-off, there is a dangerous voltage in the capacitor.

7) Top attachments should be removed before operating because of Air exhaust. Side attachments can be used

for fixing the unit. (See page 44)

Notes on Grounding

• Leakage currents flow in the inverter. To prevent an electric shock, the inverter and motor must be grounded

(grounding resistance: 10Ω or less.)

• Use the dedicated ground terminal to ground the inverter. (Do not use the screw in the case, chassis, etc.)

• The ground cable should have a thickness of 38mm2, or more, and be as short as possible. The grounding

point should be as close to the inverter as possible.

8

Page 17

INSTALLATION AND WIRING

(2)

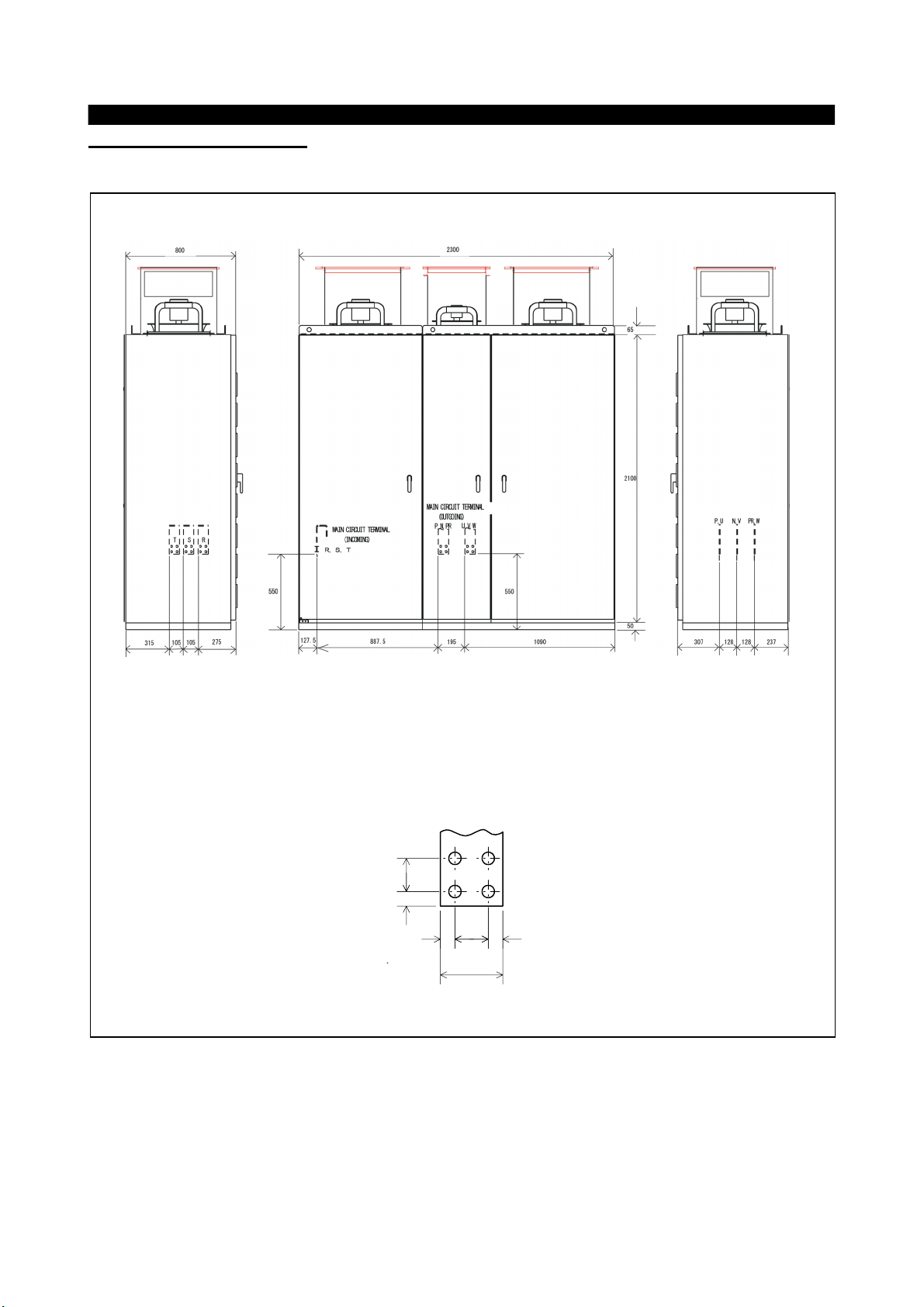

Terminal block layout

In the main circuit of the inverter, the terminals are arranged as shown below:

FR-A560L-530K〜900K

Left Side

MAIN CIRCUIT TERMINAL (Detail)

40

17.5

Front

4017.5 17.5

75

Right Side

Units

<mm>

9

Page 18

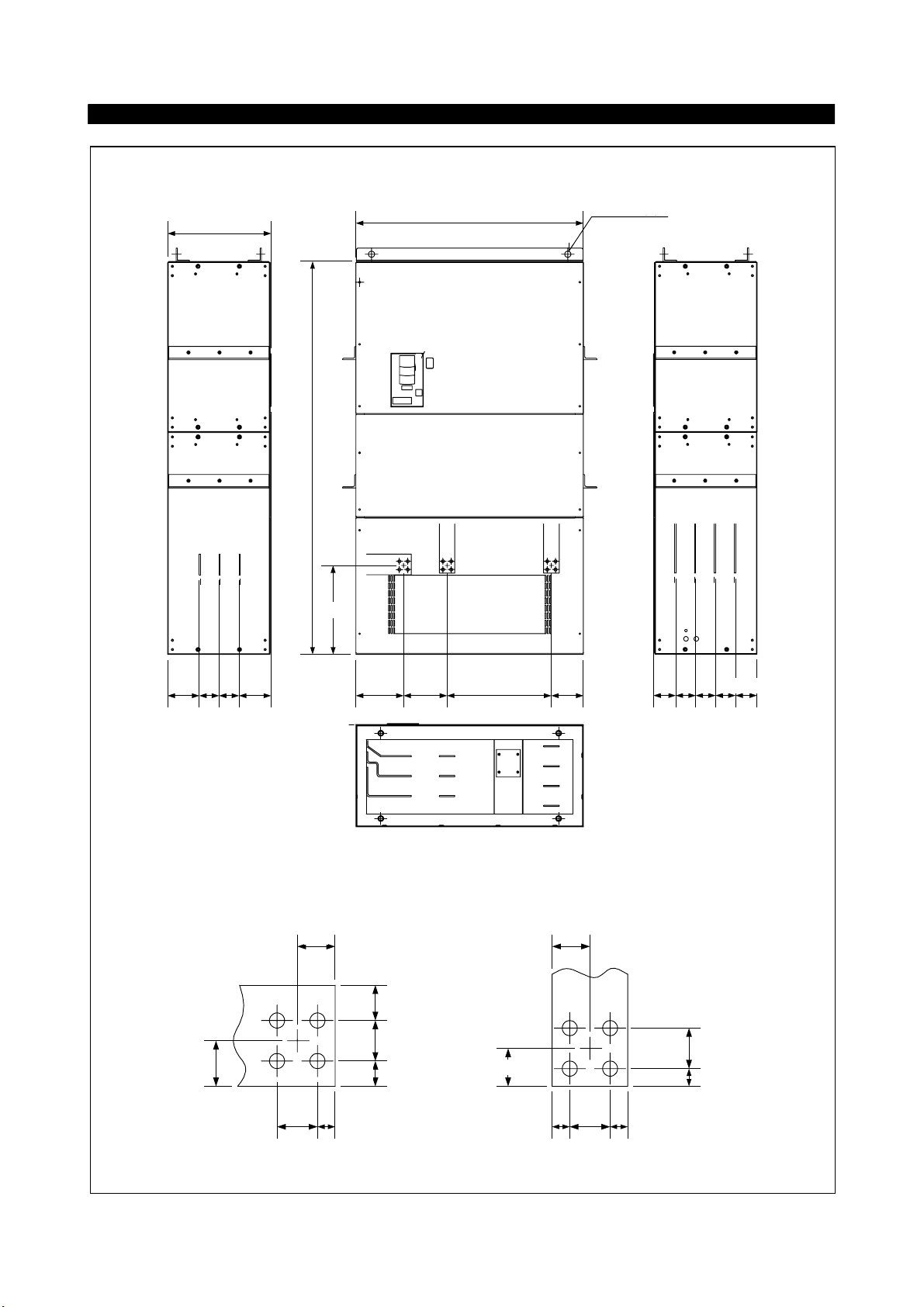

)

)

FR-A560L-375K, 450K

500

TSR

P1 N P

1900

INSTALLATION AND WIRING

1100

Rg[ pl

4‑φ 30

4 - 30

P0WVU

1569696152

R, S, T

TERMINAL (Detail

[q

45

430

37.5

35

40

35

230

505210

P

R

N

S

P1

T

P0

155

U

V

W

108 96 96 96 104

(Bottom View)

U, V, W, P0

P1, P, N

[q

TERMINAL (Detail

40

40

37.5

17.5

40

17.5

Units<mm

17.517.5 40

>

10

Page 19

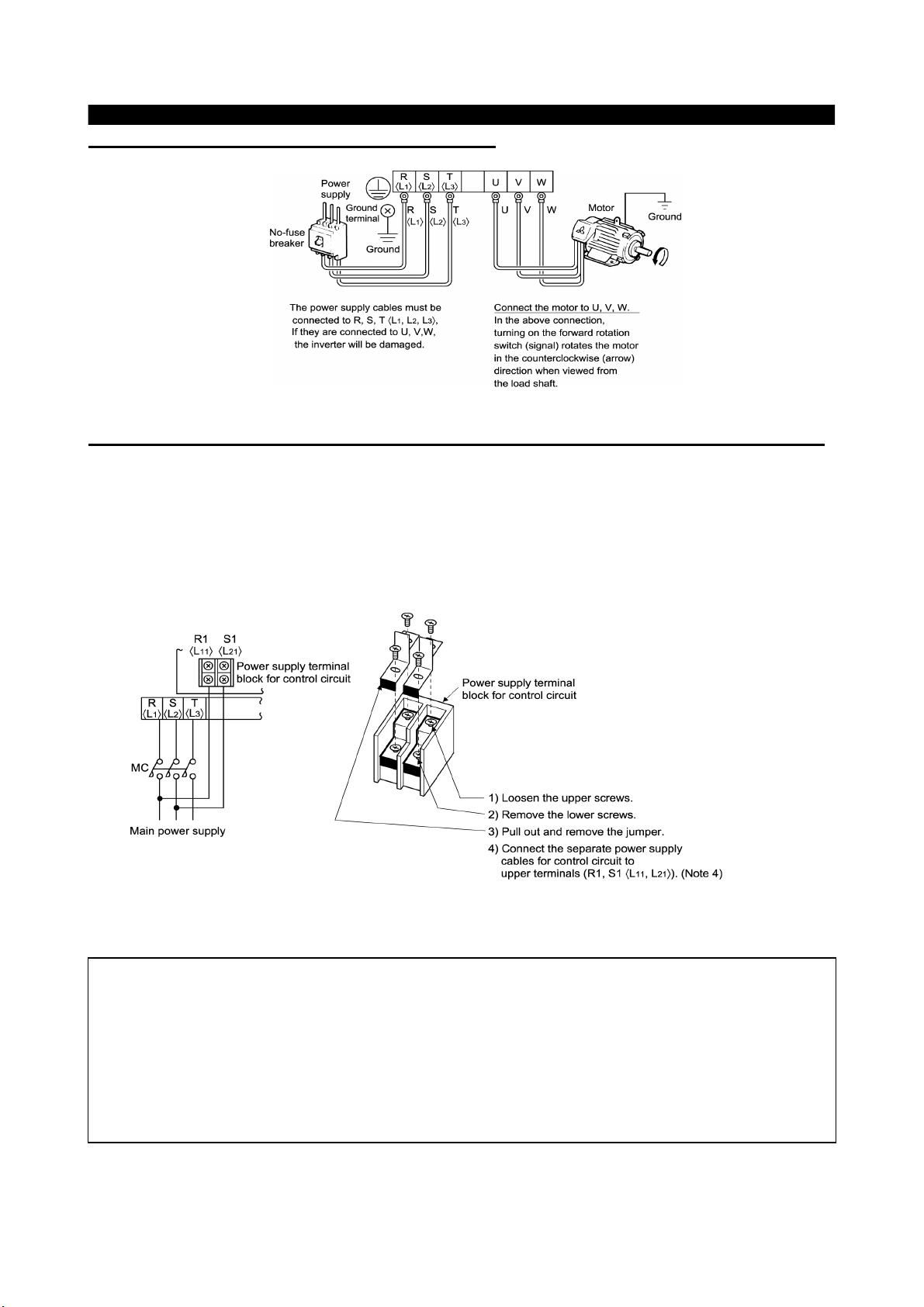

INSTALLATION AND WIRING

(3)

Connection of the power supply and motor

(4)

Connecting the control circuit to a power supply separately from the main circuit

If the magnetic contactor (MC) in the inverter power supply is opened when the protective circuit is operated,

the inverter control circuit power is lost and the alarm output signal cannot be kept on. To keep the alarm

signal on terminals R1 and S1 are available. In this case, connect the power supply terminals R1 and S1 <L

and L

> of the control circuit to the primary side of the MC.

21

<Connection procedure>

11

Note: 1. W hen the main circuit power (R, S, T) <L

(terminals R1, S1<L

2. W hen using a separate power supply, the jumpers across R-R1 and S-S1 <L

L

>must be removed. Otherwise the inverter may be damaged.

2-L21

3. For a different power supply system which takes the power of the control circuit from other than

the primary side of the MC, the voltage should be equal to the main circuit voltage.

4. The power supply cables must not be connected to the lower terminals. If connected, the inverter

may be damaged.

, L21>). Otherwise the inverter may be damaged.

11

, L2, L3,> is on, do not switch off the control power

1

and

1-L11

11

Page 20

INSTALLATION AND WIRING

2.2.3 Wiring of the control circuit

(1)

Wiring instructions

1) Terminals SD, SE and 5 are common to the I/O signals and isolated from each other. These common terminals

must not be connected to each other or earthed.

2) Use shielded or twisted cables for connection to the control circuit terminals and run them away from the main

and power circuits (including the 200V relay sequence circuit).

3) The frequency input signals to the control circuit are micro currents. When contacts are required, use two or

more parallel micro signal contacts or a twin contact to prevent a contact fault.

4) It is recommended to use the cables of 0.75mm2 gauge for connection to the control circuit terminals.

If the cable gauge used is 1.25mm2 or more, the front cover may be lifted when there are many cables running

or the cables are run improperly, resulting in an operation panel or parameter unit contact fault.

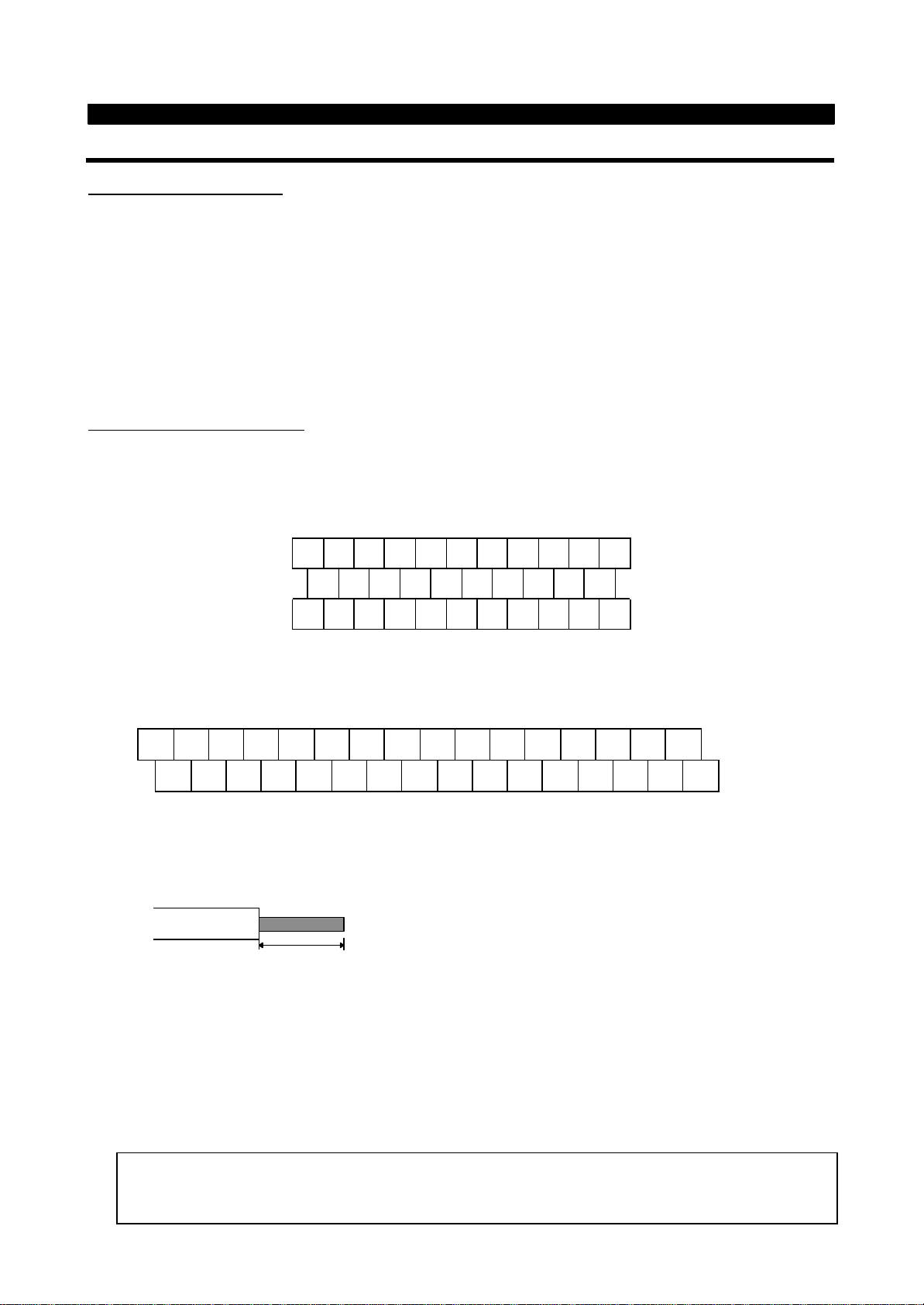

(2)

Terminal block layout

l

NA version(OR Version

In the control circuit of the inverter, the terminals are arranged as shown below:

Terminal screw size: M3.5

)

A

B C PC AM 10 E 1 0 2 5 4 1

RL

RM RH RT AU STOP MRS RES SD FM

SE RUN SU IPF OL FU SD STF STR JOG CS

l

EC version

Terminal screw size : M3

A B C SD AM 10E 10 2 5 4 1 RL RM RH RT AU

SE RUN SU LPF OL FU STOP MRS RES PC STF STR JOG CS FM SD

<Wiring procedure>

1) For the wiring of the control circuit, strip the sheaths of the cables and use them as they are.

Strip the sheath to the following dimension. If too much is stripped this may cause a short circuit with

the neighboring cable. If too little stripped this may cause cable disconnection.

6mm ± 1mm

2) Loosen the terminal screw and insert the cable into the terminal.

3) Tighten the screw to the specified torque.

Undertigthening can cause cable disconnection or malfunction. Overtightening can cause a short circuit or

malfunction due to the screw or unit damaged.

Tightening torque : 5 to 6 kgf・cm

Note : Wire the stripped cable by twisting it to prevent it from becoming loose. (Do not plate the cable with

solder.)

Note : 1. Use a NFB (No fuse breakers) or fuse on the inverter input (primary) side.

2. Make sure that the control circuit terminal wiring does not touch power circuit terminals (or

screws) or conducting power circuit.

12

Page 21

INSTALLATION AND WIRING

(3)

Changing the control logic

The input signals are set to sink logic for the NA version, and to source logic for the EC version.

To change the control logic, the connector on the back of the control circuit terminal block must be moved to

the other position.

(The output signals may be used in either the sink or source logic independently of the connector position.)

1) Loosen the two mounting screws in both ends of the control circuit terminal block. (The screws cannot be

removed.)

With both hands, pull down the terminal block from the back of the control circuit terminals.

2) Remove the connector in the sink logic position on the back surface of the control circuit terminal block

and fit it to the source logic position.

3) Using care not to bend the pins of the control circuit connector, reinstall the control circuit terminal block

and fix it with the mounting screws.

Note: 1. Make sure that the control circuit connector is fitted correctly.

2. While power is on, never disconnect the control circuit terminal block.

3. The sink-source logic change-over connector must be fitted in only one of those positions. If it is

fitted in both positions at the same time, the inverter may be damaged.

13

Page 22

INSTALLATION AND WIRING

4) Sink logic type

• In this logic, a signal switches on when a current flows out of the corresponding signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE is common to the open collector

output signals.

AX40

RUN

SU

SE

DC24V

Current

R

STF

R

STR

SD

• When using an external power supply for transistor output, use terminal PC as a common to prevent

misoperation caused by leakage current. (Do not connect terminal SD of the inverter with terminal 0V of

the external power supply.)

STF

STR

RH

RM

RL

RES

PC

SD

Inverter

DC24V

(SD)

AY40 type

transistor ou tput

module

1

2

3

4

5

6

9

10

DC24V

1

2

9

R

R

R

R

8

14

Page 23

INSTALLATION AND WIRING

5) Source logic type

• In this logic, a signal switches on when a current flows into the corresponding signal input terminal.

Terminal PC is common to the contact input signals. Terminal SE is common to the open collector

output signals.

PC

Current

STF

STR

R

R

• When using an external power supply for transistor output, use terminal SD as a common to prevent

misoperation caused by leakage current.

SE

RUN

SU

DC24V

AX80

1

2

8

9

R

R

R

R

DC24V

PC

STF

STR

SD

Inverter

DC24V

(SD)

AY-80

9

1

2

10

(4)

How to use terminals “STOP”, “CS” and “PC”

1) Using the “STOP” terminal

A connection example (for sink logic) for self-holding the start signal (forward

rotation, reverse rotation) is shown on the right.

2) Using the “CS” terminal

This terminal is used to perform automatic restart after instantaneous power failure

and commercial power supply-inverter switch-over operation.

<Example: Automatic restart after instantaneous power failure in sink logic>

Connect terminals CS-SD and set a value other than “9999” in Pr. 57 “coasting time

for automatic restart after instantaneous power failure”.

3) Using the “PC” terminal

This terminal can be used as 24VDC power output using SD as a common terminal.

Specifications: 18V to 26VDC, 0.1A permissible current

Note that the wiring length should be within 30m.

Do not short terminals PC-SD.

When terminal PC is used as a 24V power supply, leakage current from transistor

output cannot be prevented.

STOP

Stop

Forward

rotation

Reverse

rotation

CS SD

(Short)

MRS

RES

SD

STF

STR

15

Page 24

A

B

INSTALLATION AND WIRING

2.2.4 Connection to the PU connector

(1)

When connecting the operation panel or parameter unit using a connection

cable

<Recommended cable connector>

• Parameter unit connection cable (FR-CB2) (option) or the following connector and cable.

• Connector: RJ45 connector

Example: 5-554720-3, Nippon AMP

• Cable: Cable conforming to EIA568 (e.g. 10BASE-T cable)

Example: SGLPEV 0.5mm×4P, MITSUBISHI CABLE INDUSTRIES, LTD.

Note: The maximum wiring length is 20m (65.62 feet).

(2)

For RS-485 communication

With the operation panel disconnected, the PU connector can be used for communication operation from a

personal computer etc.

<PU connector pin-outs>

Viewed from the inverter (receptacle side) front

①

⑧

①

②

③

④

SG

P5S

RDA

SDB

⑤

⑥

⑦

⑧

SD

RD

SG

P5S

Note: 1. Do not connect the PU connector to the computer’s LAN board, FAX modem socket or

telephone modular connector. Otherwise, the product may be damaged due to electrical

specification differences.

2. Pins 2 and 8 (P5S) provide power to the operation unit or parameter unit. Do not use these pins

for RS-485 communication.

Use the connector and cable as detailed below.

• Connector: RJ45 connector

Example: 5-554720-3, Nippon AMP

• Cable: Cable conforming to EIA568 (e.g. 10BASE-T cable)

Example: SGLPEV 0.5mm×4P, MITSUBISHI CABLE INDUSTRIES, LTD.

When the communication board of the personal computer has the RS-232C specifications, prepare an

RS-485, RS-232C converter.

Example of converter.

1) Model: FA-T-RS40

Converter

Industrial Systems Division Mitsubishi Electric Engineering Co., Ltd.

2) Model: DINV-485CAB

Interface built-in cable

Dia Trend Co., Ltd.

16

Page 25

L

INSTALLATION AND WIRING

2.2.5 Design information

1) For commercial power supply-inverter switch-over operation, provide electrical and mechanical interlocks

for MC1 and MC2 designed for commercial power supply-inverter switch-over.

When there is a commercial power supply-inverter switch-over circuit as shown below, the inverter will be

damaged by leakage current from the power supply due to arcs generated at the time of switch-over or

chattering caused by a sequence error.

2) If the machine must not be restarted when power is restored after a power failure, provide a magnetic

contactor in the inverter’s primary circuit and also make up a sequence which will not switch on the start

signal.

If the start signal (start switch) remains on after a power failure, the inverter will automatically restart as

soon as the power is restored.

3) When the power supply used with the control circuit is different from the one used with the main circuit,

make up a circuit which will switch off the main circuit power supply terminals R, S, T<L

power supply terminals , R1, S1<L

, L21> for the control circuit are switched off.

11

4) Since the input signals to the control circuit are on a low level, use two parallel micro signal contacts or a

twin contact for contact inputs to prevent a contact fault.

5) Do not apply a large voltage to the contact input terminals (e.g. STF) of the control circuit.

6) Do not apply a voltage directly to the alarm output signal terminals (A, B, C).

Always apply a voltage to these terminals via a relay coil, lamp, etc.

7) Make sure that the specifications and rating match the system requirements.

1) Commercial power supply-inverter switch-over

MC1

Interlock

2) Low-level signal contacts

, L2, L3 > when the

1

Inverter

U

V

W

MC2

Sneak current

IM

ow-level signal contacts

Twin contact

Power

supply

R, <L1>

S, <L2>

T, <L3>

17

Page 26

CHAPTER 3

OPERATION

This chapter provides the basic "operation" information for

use of this product.

Always read this chapter before using the equipment.

3.1 Pre-Operation Information

3.2 Operation

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・

Refer to FR-A540L/A560L

Refer to FR-A540L/A560L

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

APPENDICES

3

Page 27

CHAPTER 4

PARAMETERS

This chapter explains the "parameters" of this product.

Always read the instructions before using the equipment.

4.1 Parameter List

4.2 Parameter Function Details

Note: By making parameter settings, you can change the functions of contact input

terminals RL, RM, RH, RT, AU, CS and open collector output terminals RUN, SU,

IPF, OL, FU. Therefore, signal nam es cor responding to the functions are used in

the description of this chapter (except in the wiring exam ples). Note that they are

not terminal names.

The setting in brackets refer to the “EC” versions default settings.

・・・・・・・・・・・・・・・・・・

・・・・・・・

18

Refer to FR-A540L/A560L

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

APPENDICES

4

Page 28

4.1 Parameter List

PARAMETERS

Minimum

Setting

Increments

0

Torque boost (Note 1)

0 to 30%

0.1%

1%

481Maximum frequency

0 to 60Hz

0.01Hz

60Hz

492Minimum frequency

0 to 120Hz

0.01Hz

0Hz

493Base frequency

0 to 400Hz

0.01Hz

60Hz<50Hz>

504Multi-speed setting (high speed)

0 to 400Hz

0.01Hz

60Hz

515Multi-speed setting (middle speed)

0 to 400Hz

0.01Hz

30Hz

516Multi-speed setting (low speed)

0 to 400Hz

0.01Hz

10Hz

517Acceleration time

0 to 3600 sec/

0 to 360 sec

0.1 sec/

0.01 sec

15 sec

528Deceleration time

0 to 3600 sec/

0 to 360 sec

0.1 sec/

0.01 sec

15 sec

52

9

Electronic thermal O/L relay

0 to 3600A

0.1A

Rated output cur-

rent

5210DC injection brake operation frequency

0 to 120Hz, 9999

0.01Hz

3Hz

5411DC injection brake operation time

0 to 10 sec, 8888

0.1 sec

0.5 sec

5412DC injection brake voltage

0 to 30%

0.1%

1%

5413Starting frequency

0 to 60Hz

0.01Hz

0.5Hz

5514Load pattern selection (Note 1)

0 to 510

5515Jog frequency

0 to 400Hz

0.01Hz

5Hz

5616Jog acceleration/deceleration time

0 to 3600 sec/

0 to 360 sec

0.1 sec/

0.01 sec

0.5 sec

5617MRS input selection

0,210

5718High-speed maximum frequency

0 to 400Hz

0.01Hz

60Hz

5719Base frequency voltage (Note 1)

0 to 1000V, 8888, 9999

0.1V

9999<8888>

5720Acceleration/deceleration reference

frequency

1 to 400Hz

0.01Hz

60Hz<50Hz>

5721Acceleration/deceleration time

increments

0,110

57

*22

Stall prevention operation level

0 to 150%, 9999

0.1%

150%

58

*23

Stall prevention operation level at

double speed

0 to 150%, 9999

0.1%

9999

5824Multi-speed setting (speed 4)

0 to 400Hz, 9999

0.01Hz

9999

5925Multi-speed setting (speed 5)

0 to 400Hz, 9999

0.01Hz

9999

5926Multi-speed setting (speed 6)

0 to 400Hz, 9999

0.01Hz

9999

5927Multi-speed setting (speed 7)

0 to 400Hz, 9999

0.01Hz

9999

5928Multi-speed input compensation

0, 110

5929Acceleration/deceleration pattern

0, 1, 2, 3

1

0

6030Regenerative function selection

0, 1, 2

1

0

6131Frequency jump 1A

0 to 400Hz, 9999

0.01Hz

9999

6232Frequency jump 1B

0 to 400Hz, 9999

0.01Hz

9999

6233Frequency jump 2A

0 to 400Hz, 9999

0.01Hz

9999

6234Frequency jump 2B

0 to 400Hz, 9999

0.01Hz

9999

6235Frequency jump 3A

0 to 400Hz, 9999

0.01Hz

9999

6236Frequency jump 3B

0 to 400Hz, 9999

0.01Hz

9999

62

37

Speed display

0,1 to 9998

1

0

6341Up-to-frequency sensitivity

0 to 100%

0.1%

10%

6442Output frequency detection

0 to 400Hz

0.01Hz

6Hz

64

43

Output frequency detection for reverse

rotation

0 to 400Hz, 9999

0.01Hz

9999

6444Second acceleration/deceleration time

0 to 3600 sec/

0 to 360 sec

0.1 sec/

0.01 sec

5 sec

6545Second deceleration time

0 to 3600 sec/

0 to 360 sec, 9999

0.1 sec/

0.01 sec

9999

6546Second torque boost (Note 1)

0 to 30%, 9999

0.1%

9999

6547Second V/F (base frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

65

*48

Second stall prevention operation

current

0 to 150%

0.1%

150%

6549Second stall prevention operation

frequency

0 to 400Hz, 9999

0.01Hz

0

65

50

Second output frequency detection

0 to 400Hz

0.01Hz

30Hz

64

PARAMETER

Func-

tion

Parameter

Number

Basic functions

Name Setting Range

Factory Setting

Refer To

Page:

<Note9>

Standard operation functions

Output

terminal

functions

Second functions

18

Page 29

PARAMETERS

Minimum

Setting

Increments

52

DU/PU main display data selection

0, 5 to 14, 17, 18, 20,

23, 24, 25, 100

1

0

6753PU level display data selection

0 to 3, 5 to 14, 17, 18

1

1

6754FM terminal function selection

1 to 3, 5 to 14,

17, 18, 21

1

1

6755Frequency monitoring reference

0 to 400Hz

0.01Hz

60Hz<50Hz>

69

56

Current monitoring reference

0 to 3600A

0.1A

Rated output

current

6957Restart coasting time

0 to 30 sec, 9999

0.1 sec

9999

70

58

Restart cushion time

0 to 60 sec

0.1 sec

1.0 sec

70

59

Remote setting function selection

0, 1, 2

1

0

7260Intelligent mode selection

0 to 810

7361Reference I for intelligent mode

0 to 3600A, 9999

0.1A

9999

75

*62

Ref. I for intelligent mode accel.

0 to 150%, 9999

0.1%

9999

75

*63

Ref. I for intelligent mode decel.

0 to 150%, 9999

0.1%

9999

7564Starting frequency for elevator mode

0 to 10Hz, 9999

0.01Hz

9999

7565Retry selection

0 to 510

7666Stall prevention operation level

reduction starting frequency

0 to 400Hz

0.01Hz

60Hz<50Hz>

7767Number of retries at alarm occurrence

0 to 10,101 to 110

1

0

7668Retry waiting time

0 to 10 sec

0.1 sec

1 sec

7669Retry count display erasure

00

7670Special regenerative brake duty

0 to 100%

0.1%

0%

7771Applied motor

0 to 8, 13 to 18

1

0

7872PWM frequency selection

0, 1, 2

1

1

79730-5V/0-10V selection

0 to 5, 10 to 15

1

1

8074Filter time constant

0 to 811

8175Reset selection/disconnected PU

detection/PU stop selection

0 to 3, 14 to 17

1

14

8176Alarm code output selection

0, 1, 2, 3

1

0

8377Parameter write disable selection

0, 1, 2

1

0

8478Reverse rotation prevention selection

0, 1, 2

1

0

85

79

Operation mode selection

0 to 810

8680Motor capacity

0 to 3600kW, 9999

0.1kW

9999

8981Number of motor poles

2, 4, 6, 12, 14, 16, 9999

1

9999

8982Motor exciting current (Note 6)

0 to , 9999

1

9999

90

*83

Rated motor voltage

0 to 1000V

0.1V

575V

9084Rated motor frequency

50 to 120Hz

0.01Hz

60Hz<50Hz>

9089Speed control gain

0 to 200%

0.1%

100%

8990Motor constant (R1) (Note 6)

(Note 6)

(Note 6)

9999

9091Motor constant (R2) (Note 6)

(Note 6)

(Note 6)

9999

9092Motor constant (L1) (Note 6)

(Note 6)

(Note 6)

9999

9093Motor constant (L2) (Note 6)

(Note 6)

(Note 6)

9999

9094Motor constant (X) (Note 6)

(Note 6)

(Note 6)

9999

9095Online auto tuning selection

0, 110

96

96

Auto tuning setting/status

0, 1, 101

1

0

90

100

V/F1 (first frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

98

101

V/F1 (first frequency voltage)

(Note 1)

0 to 1000V

0.1V

0

98

102

V/F2 (second frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

98

103

V/F2 (second frequency voltage)

(Note 1)

0 to 1000V

0.1V

0

98

104

V/F3 (third frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

98

105

V/F3 (third frequency voltage) (Note 1)

0 to 1000V

0.1V

0

98

106

V/F4 (fourth frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

98

Func-

Parameter

tion

Automatic

Number

Display functions

restart

functions

function

Additional

Name Setting Range

Factory Setting

Refer To

Page:

<Note9>

Operation selection functions

Motor constants

characteristics

5-point flexible V/F

19

Page 30

Minimum

Setting

Increments

107

V/F4 (fourth frequency voltage)

(Note 1)

0 to 1000V

0.1V

0

98

108

V/F5 (fifth frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

98

109

V/F5 (fifth frequency voltage)

(Note 1)

0 to 1000V

0.1V

0

98

110

Third acceleration/deceleration time

0 to 3600 sec/

0 to 360 sec, 9999

0.1 sec/

0.01 sec

9999

99

111

Third deceleration time

0 to 3600 sec/

0 to 360 sec, 9999

0.1 sec/

0.01 sec

9999

99

112

Third torque boost (Note 1)

0 to 30.0%, 9999

0.1%

9999

99

113

Third V/F (base frequency) (Note 1)

0 to 400Hz, 9999

0.01Hz

9999

99

*114

Third stall prevention operation current

0 to 150%

0.1%

150%

99

115

Third stall prevention operation

frequency

0 to 400Hz

0.01Hz

0

99

116

Third output frequency detection

0 to 400Hz, 9999

0.01Hz

9999

99

117

Station number

0 to 31

1

0

99

118

Communication speed

48, 96, 192

1

192

99

119

Stop bit length/data length

0, 1 (data length 8)

10, 11 (data length 7)

1

1

99

120

Parity check presence/absence

0, 1, 2

1

2

99

121

Number of communication retries

0 to 10, 9999

1

1

99

122

Communication check time interval

0, 0.1 to 999.8 sec,

9999

0.1

0<9999>

99

123

Waiting time setting

0 to 150ms, 9999

10ms

9999

99

124

CR, LF presence/absence selection

0,1,211

99

128

PID action selection

10, 11, 20, 21

1

10

109

129

PID proportional band

0.1 to 1000%, 9999

0.1%

100%

109

130

PID integral time

0.1 to 3600 sec, 9999

0.1 sec

1 sec

109

131

Upper limit

0 to 100%, 9999

0.1%

9999

109

132

Lower limit

0 to 100%, 9999

0.1%

9999

109

133

PID action set point for PU operation

0 to 100%

0.01%

0%

109

134

PID differential time

0.01 to 10.00 sec, 9999

0.01 sec

9999

109

135

Commercial power supply-inverter

switch-over sequence output terminal

selection

0, 1, 2

1

0

116

136

MC switch-over interlock time

0 to 100.0 sec

0.1 sec

1.0 sec

116

137

Start waiting time

0 to 100.0 sec

0.1 sec

0.5 sec

116

138

Commercial power supply-inverter

switch-over selection at alarm

occurrence

0, 110

116

139

Automatic inverter-commercial power

supply switch-over frequency

0 to 60.00Hz, 9999

0.01Hz

9999

116

140

Backlash acceleration stopping

frequency (Note 7)

0 to 400Hz

0.01Hz

1.00Hz

119

141

Backlash acceleration stopping time

(Note 7)

0 to 360 sec

0.1 sec

0.5 sec

119

142

Backlash deceleration stopping

frequency (Note 7)

0 to 400Hz

0.01Hz

1.00Hz

119

143

Backlash deceleration stopping time

(Note 7)

0 to 360 sec

0.1 sec

0.5 sec

119

144

Speed setting switch-over

0, 2, 4, 6, 8, 10, 102,

104, 106, 108, 110

1

4

119

*148

Stall prevention level at 0V input

0 to 150%

0.1%

120%

58

*149

Stall prevention level at 10V input

0 to 150%

0.1%

150%

58

PARAMETERS

Func-

Parameter

tion

Number

characteristics

5-point flexible V/F

Third functions

Name Setting Range

Factory Setting

Refer To

Page:

<Note9>

Communication functions

PID control

inverter switch-over

Commercial power supply-

Backlash

Display

functions

Additional

20

Page 31

PARAMETERS

Minimum

Setting

Increments

150

Output current detection level

0 to 200%

0.1%

150%

120

151

Output current detection period

0 to 10 sec

0.1 sec

0

120

152

Zero current detection level

0 to 200%

0.1%

5.0%

121

153

Zero current detection period

0 to 1 sec

0.01 sec

0.5 sec

121

154

Voltage reduction selection during stall

prevention operation

0, 111

121

155

RT activated condition

0, 1010

122

*156

Stall prevention operation selection

0 to 31 (Odd), 100

1

0

122

157

OL signal waiting time

0 to 25 sec, 9999

0.1 sec

0

124

158

AM terminal function selection

1 to 3, 5 to 14,

17, 18, 21

1

1

124

160

User group read selection

0, 1, 10, 11

1

0

125

162

Automatic restart after instantaneous

power failure selection

0, 1, 2

1

0

125

163

First cushion time for restart

0 to 20 sec

0.1 sec

0 sec

125

164

First cushion voltage for restart

0 to 100%

0.1%

0%

125

*165

Restart stall prevention operation level

0 to 150%

0.1%

150%

125

170

Watt-hour meter clear

00

126

171

Actual operation hour meter clear

00

126

173

User group 1 registration

0 to 999

1

0

125

174

User group 1 deletion

0 to 999, 9999

1

0

125

175

User group 2 registration

0 to 999

1

0

125

176

User group 2 deletion

0 to 999, 9999

1

0

125

180

RL terminal function selection

0 to 99, 9999

1

0

126

181

RM terminal function selection

0 to 99, 9999

1

1

126

182

RH terminal function selection

0 to 99, 9999

1

2

126

183

RT terminal function selection

0 to 99, 9999

1

3

126

184

AU terminal function selection

0 to 99, 9999

1

4

126

*185

JOG terminal function selection

Already Assigned

126

186

CS terminal function selection

0 to 99, 9999

1

6

126

190

RUN terminal function selection

0 to 199, 9999

1

0

128

191

SU terminal function selection

0 to 199, 9999

1

1

128

192

IPF terminal function selection

0 to 199, 9999

1

2

128

193

OL terminal function selection

0 to 199, 9999

1

3

128

194

FU terminal function selection

0 to 199, 9999

1

4

128

195

A, B, C terminal function selection

0 to 199, 9999

1

99

128

199

User's initial value setting

0 to 999, 9999

1

0

130

Func-

Parameter

tion

Automatic restart after

Number

Current

detection

Sub functions

function

Additional

failure

instantaneous power

Name Setting Range

Factory Setting

Refer To

Page:

<Note9>

Initial

monitor

User functions

Terminal assignment functions

function

Additional

* Pr.185 : This terminal is already assigned in Factory. User can not use.

21

Page 32

PARAMETERS

Minimum

Setting

Increments

200

Programmed operation minute/second

selection

0 to 310

131

201

Program set 1

1 to 10

0 to 2: Rotation direction

0 to 400,

9999:Frequency

0 to 99.59: Time

1

0.1Hz

0

9999

0

131

211

Program set 2

11 to 20

0 to 2: Rotation direction

0 to 400,

9999:Frequency

0 to 99.59: Time

1

0.1Hz

0

9999

0

131

221

Program set 3

21 to 30

0 to 2: Rotation direction

0 to 400,

9999:Frequency

0 to 99.59: Time

1

0.1Hz

0

9999

0

131

231

Timer setting

0 to 99.590

131

232

Multi-speed setting (speed 8)

0 to 400Hz, 9999

0.01Hz

9999

135

233

Multi-speed setting (speed 9)

0 to 400Hz, 9999

0.01Hz

9999

135

234

Multi-speed setting (speed 10)

0 to 400Hz, 9999

0.01Hz

9999

135

235

Multi-speed setting (speed 11)

0 to 400Hz, 9999

0.01Hz

9999

135

236

Multi-speed setting (speed 12)

0 to 400Hz, 9999

0.01Hz

9999

135

237

Multi-speed setting (speed 13)

0 to 400Hz, 9999

0.01Hz

9999

135

238

Multi-speed setting (speed 14)

0 to 400Hz, 9999

0.01Hz

9999

135

239

Multi-speed setting (speed 15)

0 to 400Hz, 9999

0.01Hz

9999

135

240

Soft-PWM setting

1

1

135

244

Cooling fan operation selection

1

0

135

250

Stop selection

0 to 100 sec, 9999

0.1 sec

9999

135

251

Start holding time

0 to 10 sec, 9999

0.1 sec

9999

136

261

Power failure stop selection

0, 1

1

0

137

262

Subtracted frequency at deceleration

start

0 to 20Hz

0.01Hz

3Hz

137

263

Subtraction starting frequency

0 to 120Hz, 9999

0.01Hz

60Hz<50Hz>

137

264

Power-failure deceleration time 1

0 to 3600/

0 to 360 sec

0.1 sec/

0.01 sec

5 sec

137

265

Power-failure deceleration time 2

0 to 3600/

0 to 360 sec, 9999

0.1 sec/

0.01 sec

9999

137

266

Power-failure deceleration time switch-

over frequency

0 to 400Hz

0.01Hz

60Hz

137

270

Stop-on-contact/load torque high-speed

frequency control selection

0, 1, 2, 3

1

0

139

271

High-speed setting maximum current

0 to 200%

0.1%

50%

140

272

Mid-speed setting minimum current

0 to 200%

0.1%

100%

140

273

Current averaging range

0 to 400Hz, 9999

0.01Hz

9999

140

274

Current averaging filter constant

1 to 4000

1

16

140

275

Stop-on-contact exciting current low-

speed multiplying factor (Note 5)

0 to 1000%, 9999

1%

9999

143

276

Stop-on-contact PWM carrier frequency

(Note 5)

0, 1, 2, 9999

1

9999

143

Func-

Parameter

tion

Number

Programmed operation

Multi-speed operation

Name Setting Range

0, 1

Minute or second

Minute or second

Minute or second

Factory Setting

Refer To

Page:

<Note9>

Sub functions

function

Stop selection

Sub

functions

Power failure stop function

function

Selection

control

frequency

High-speed

0, 1

contact

Stop on

22

Page 33

PARAMETERS

Minimum

Setting

Increments

278

Brake opening frequency (Note 3)

0 to 30Hz

0.01Hz

3Hz

142

279

Brake opening current (Note 3)

0 to 200%

0.1%

130%

142

280

Brake opening current detection time

(Note 3)

0 to 2 sec

0.1 sec

0.3 sec

142

281

Brake operation time at start (Note 3)

0 to 5 sec

0.1 sec

0.3 sec

142

282

Brake operation frequency (Note 3)

0 to 30Hz

0.01Hz

6Hz

142

283

Brake operation time at stop (Note 3)

0 to 5 sec

0.1 sec

0.3 sec

142

284

Deceleration detection function

selection (Note 3)

0, 110

142

285

Overspeed detection frequency

0 to 30Hz, 9999

0.01Hz

9999

142

*570

CT/VT Selection

0, 110

151

900

FM terminal calibration

152

901

AM terminal calibration

152

902

Frequency setting voltage bias

0 to 10V

0 to 60Hz

0.01Hz

0V

0Hz

154

903

Frequency setting voltage gain

0 to 10V

1 to

400Hz

0.01Hz

5V

60Hz

<50Hz>

154

904

Frequency setting current bias

0 to 20mA

0 to 60Hz

0.01Hz

4mA

0Hz

154

905

Frequency setting current gain

0 to 20mA

1 to

400Hz

0.01Hz

20mA

60Hz

<50Hz>

154

990

Buzzer control

0, 111

156

991

Parameter unit parameters

Refer to the parameter unit instruction manual for details.

Func-

Parameter

tion

Number

Brake sequence functions

Calibration functions

l function

Additiona

Name Setting Range

Factory Setting

Refer To

Page:

<Note9>

Note: 1. Indicates the parameter settings which are ignored when the advanced magnetic flux vector control

mode is selected.

2. The half-tone screened parameters allow their settings to be changed during operation if 0 (factory

setting) has been set in Pr. 77. (Note that the Pr. 72 and Pr. 240 settings cannot be changed during

external operation.)

3. Can be set when Pr. 80, 81 ≠ 9999, Pr. 60 = 7 or 8.

4. Can be accessed when Pr. 80, 81 ≠ 9999, Pr. 77 = 801.

5. Can be accessed when Pr. 270 = 1 or 3, Pr. 80, 81 ≠ 9999.

6. The setting range and min. setting unit will differ according to the Pr. 71 "applied motor" setting value.

7. Can be accessed when Pr. 29 = 3.

8. Parameters marked asterisk (*) on top are different setting range, factory setting or function from

FR-A540L.

9. Page numbers correspond to A540/A560L instruction manual, IB07401-0x.

23

Page 34

CHAPTER 5

PROTECTIVE FUNCTIONS

This chapter explains the "protective functions" of this

product.

Always read the instructions before using the equipment.

5.1 Errors (Alarms)

5.2 Troubleshooting

5.3 Precautions for Maintenance and Inspection

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・

24

30

・・・

34

CHAPTER 1 OUTLINE

CHAPTER 2 INSTALLATION AND WIRING

CHAPTER 3 OPERATION

CHAPTER 4 PARAMETERS

CHAPTER 5 PROTECTIVE FUNCTIONS

CHAPTER 6 SPECIFICATIONS

APPENDICES

5

Page 35

5.1 Errors (Alarms)

PROTECTIVE FUNCTIONS

Operatio

n Panel

Display

(FR-DU04)

Paramete

r Unit

(FR-PU04)

Name

Description

E.OC1

OC During

During

E.OC2

Stedy Spd

During

constant

E.OC3

OC During

During

Overcurrent

shut-off

When the inverter output current reaches or exceeds approx. 200% of

the rated current, the protective circuit is activated to stop the inverter

output.

E.OV1

OV During

During

E.OV2

Stedy Spd

During

constant

E.OV3

OV During

During

Regenerative

overvoltage

shut-off

If regenerative energy from the running motor causes the inverter's

internal main circuit DC voltage to reach or exceed the specified value,

the protective circuit is activated to stop the inverter output.

This may also be activated by a surge voltage generated in the power

supply system.

E.THM

Motor

Ovrload

Motor

The electronic overcurrent protection in the inverter detects motor

overheat due to overload or cooling capability reduced during constant-

speed operation. When 85% of the preset value is reached, pre-alarm

(TH indication) occurs. When the specified value is reached, the

protective circuit is activated to stop the inverter output. When a special

motor such as a multi-pole motor or more than one motor is run, the

motor cannot be protected by the electronic overcurrent protection.

Provide a thermal relay in the inverter output circuit.

E.THT

Inv.

Overload

Overload

shut-off

(electronic

overcurrent

protection)

Inverter

If a current not less than 150% of the rated output current flows and

overcurrent shut-off (OC) does not occur (200% or less), inverse-time

characteristics cause the electronic overcurrent protection to be

activated to stop the inverter output. (Overload immunity: 150%, 60 sec)

At low-speed regions, the operation time may be short.

E.IPF

Inst.Pwr.

Loss

Instantaneous power failure

protection

If a power failure has occurred in excess of 15msec (this applies also

to inverter input shut-off), this function is activated to stop the inverter

output to prevent the control circuit from misoperation. At this time, the

alarm output contacts are opened (across B-C) and closed (across A-

C).

(Note 1) If a power failure persists for more than 100ms, the alarm

output is not provided, and if the start signal is on at the time of power

restoration, the inverter will restart. (If a power failure is instantaneous

within 15msec, the control circuit operates properly.)

E.UVT

Under

Voltage

Undervoltage protection

If the inverter power supply voltage drops, the control circuit will not

operate properly. Furthermore, the motor torque could drop and the heat