Page 1

LCD PROJECTOR

LC61 CHASSIS

MODEL

2008

FL7000U

This model is RoHS-compliant.

Provide servicing referring to “NOTES

FOR SERVICING RoHS-COMPLIANT

PRODUCTS” described in the service

manual.

Pb Solder, Pb Joints, Pb PCA

This product uses lead-free solder

on the circuit boards. For repairing

circuit boards, see "Precautions for

resoldering" in this Service Manual.

CAUTION

Before servicing this chassis, it is important that the service person reads the “SAFETY PRECAUTIONS” and “PRODUCT

SAFETY NOTICE” in this service manual.

Copyright © 2008 Mitsubishi Electric Corporation All Rights Reserved.

Page 2

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS

Follow the notes and instructions below when servicing RoHS-compliant

products.

1. For RoHS-compliant products, be sure to use RoHS-compliant service parts.

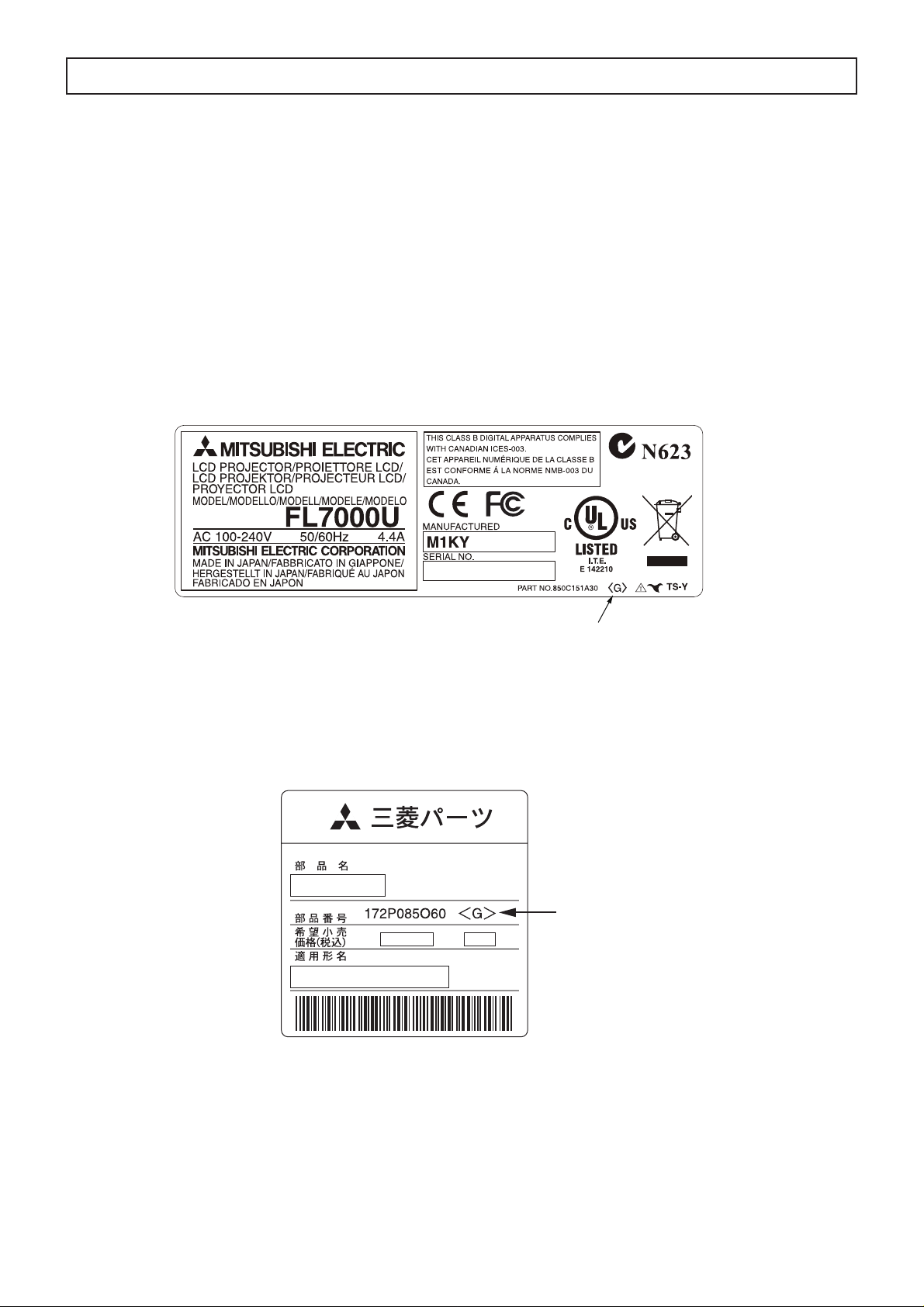

2. Check the presence of <G> marking on the rating plate to distinguish RoHScompliant product from non-RoHS-compliant product.

<G> marking

With <G> marking: RoHS-compliant product

Without <G> marking: Non-RoHS-compliant product

<Sample>

Mark position

3. Labels of RoHS-compliant service parts bear <G> marking for identifi cation purpose.

<Sample>

Parts Name

Parts No.

Model Name

E05R

Mark position

4. Don’t use non-RoHS-compliant parts with RoHS-compliant products.

5. Service parts for RoHS-compliant products are listed in the parts catalog contained

in the service manual.

- 2 -

Page 3

SPECIFICATIONS

• Rated Voltage

•

Power Consumption

•

Display Technology

• Projection Lens

•

Light Source Lamp

• Image Size

(projection distance)

•

Maximum Resolution

• S-Video Input

• Video Input

• Component Video Input

: AC 100 to 240V ; 50/60Hz,

• Analog Input

: 4.4A

:

1.1 inch LCD panel ; 3 pieces (for R,G,B)

:

Pixels ; 1,920 × 1,080 = 2,073,600 pixels

Total 6,220,800 pixels

:

Active pixel rate ; 99.9 % or more (each panel)

•

: F 1.8 - 2.1 f = 51 - 64 mm

: 275 W

:60 to 250 inch

(projection distance ; 2.6 to 11.2 m)

:

Computer signal

Maximum resolution ; 1,920 × 1,080 dots

(Compressed in the case of 1,600 × 1,200 dots)

Digital Input (DVI)

• Audio Input

• Speaker

• Control Terminal/

Others

• Dimensions

(not including protrusion)

Panel resolution ; 1,920 × 1,080 dots

:Video signal

NTSC/PAL/SECAM/4.43NTSC/PAL-M/PAL-N/PAL-60

• Weight

:Component signal

480i,480p,576i,576p,720p,1080i,1080p

•

Panel resolution ; 1,920 × 1,080 dots

:

Luminance signal ; 1.0 V(p-p) 75Ω (negative sync)

Chrominance signals ; 0.286 V(p-p) 75Ω (burst signal)

Operating temperatures

: 1.0 V(p-p) 75 Ω (negative sync)

: YC

BCR

;

Y ; 1.0 V(p-p) 75 Ω (negative sync)

C

0.7 V(p-p) 75 Ω

BCR ;

: RGB ;

0.7 V(p-p) 75 Ω (negative sync)

: YCBCR ;

Y ; 1.0 V(p-p) (negative sync)

C

: HD/CS ;

: VD ;

:

: 350 mVrms, 10 k

0.7 V(p-p)

BCR ;

TTL level (negative or positive polarity)

TTL level (negative or positive polarity)

DVI-D interface (TMDS single link) with HDCP

Ω or more

: 10 W mono Round type ø 4.5 cm × 1

: RS-232C (D-SUB 9 pin),USB,

LAN (RJ-45),REMOTE IN/OUT

: 371 (W) × 207 (H) × 434 (D) mm

(projector only)

443 (W) × 207 (H) × 434 (D) mm

(including the terminal cover)

: 9.8 kg (projector only)

: 10.5 kg (including the terminal cover)

: + 41 °F (+ 5°C) to 104 °F (+ 40 °C)

• Weight and dimensions shown are approximate.

• Design and specifi cations are subject to change without notice.

- 3 -

Page 4

CONTENTS

– FILE “COVERPGE” –

NOTES FOR SERVICING RoHS-COMPLIANT PRODUCTS ............................................................................... 2

SPECIFICATIONS ................................................................................................................................................. 3

CONTENTS ........................................................................................................................................................... 4

– FILE “EXPOSED” –

TRADE MARK, REGISTERED TRADEMARK ...................................................................................................... 1

PRODUCT SAFETY NOTICE ............................................................................................................................... 1

SAFETY PRECAUTIONS ...................................................................................................................................... 2

PRECAUTIONS FOR RESOLDERING ................................................................................................................. 3

PCB LOCATION .................................................................................................................................................... 4

EXPOSED VIEW ................................................................................................................................................... 6

L VP ASSY ........................................................................................................................................................ 6

Chassis 1 ASSY ............................................................................................................................................... 8

Chassis 2 ASSY ............................................................................................................................................... 10

Bottom case unit .............................................................................................................................................. 12

T erminal ASSY ................................................................................................................................................. 13

Optical unit 1 .................................................................................................................................................... 14

Optical unit 2 .................................................................................................................................................... 16

POSITION ADJUSTMENT OF MULTI LENS A ..................................................................................................... 17

DISASSEMBL Y ................................................................................................................... .................................. 18

1.Removal of the terminal cover ASSY ............................................................................................................ 18

2.Removal of the BOO PCB ASSY and BOO SUB PCB ASSY ....................................................................... 18

3.Removal of the lens unit and zoom focus motor ........................................................................................... 19

4.Removal of the top case unit and KEY PCB ASSY ...................................................................................... 20

5.Removal of the IRF PCB ASSY .................................................................................................................... 21

6.Removal of the MOTOR PCB ASSY ............................................................................................................. 21

7.Removal of the IRR PCB ASSY .................................................................................................................... 21

8.Removal of the speaker ................................................................................................................................ 22

9.Removal of the power fan ............................................................................................................................. 22

10.Removal of the MAIN PCB ASSY ............................................................................................................... 23

11.Removal of the TERMINAL PCB ASSY ...................................................................................................... 23

12.Removal of the DRIVE PCB ASSY and LCD block .................................................................................... 24

13.Removal of the drive fan ............................................................................................................................. 25

14.Removal of the PBS fan ............................................................................................................................. 25

15.Removal of the optical unit ......................................................................................................................... 26

16.Removal of the POWER PCB ASSY .......................................................................................................... 27

17.Removal of the lamp power unit ................................................................................................................. 28

18.Removal of the FILTER PCB ASSY and INLET PCB ASSY ....................................................................... 28

19.Removal of the POWER SUB PCB ASSY .................................................................................................. 29

20.Removal of the lamp fan ............................................................................................................................. 30

21.Removal of the LCD fan ............................................................................................................................. 30

22.Removal of the exhaust fan ........................................................................................................................ 31

23.Removal of the lens shift motor .................................................................................................................. 31

24.Removal of the lamp box ............................................................................................................................ 32

LAMP REPLACEMENT ......................................................................................................................................... 32

LEAD DRESS ........................................................................................................................................................ 33

PACKING ............................................................................................................................................................... 38

– FILE “MAINTENA” –

LAMP REPLACEMENT ......................................................................................................................................... 1

MAINTENANCE .................................................................................................................................................... 3

HOW TO USE THE LAMP JIG .............................................................................................................................. 4

DUST ON LCD PANEL .......................................................................................................................................... 5

RESET OF THE THERMAL PROTECTOR ........................................................................................................... 5

SERVICE COMMANDS ........................................................................................................................................ 6

Display the operation status screen ................................................................................................................. 6

Reset to the factory settings ............................................................................................................................ 6

Reset the lamp operating time ......................................................................................................................... 6

LIFE TIME OF THE CONSUMABLE PARTS ........................................................................................................ 7

FUNCTION MENU(SETTING MENU ONLY FOR SERVICE) ............................................................................... 8

REPLACEMENT OF THE MAIN PCB ASSY ......................................................................................................... 9

REPLACEMENT OF THE TERMINAL PCB ASSY ................................................................................................ 10

GAMMA ADJUSTMENT(WHITE BALANCE ADJUSTMENT) ............................................................................... 10

UNIFORMITY DATA TRANSFER .......................................................................................................................... 12

COLOR UNIFORMITY ADJUSTMENT ................................................................................................................. 13

DOWNLOAD OF THE FIRMWARE ....................................................................................................................... 15

CRITERIA OF THE DEFECT PIXEL ON THE LCD PANEL(FOR REFERENCE PURPOSE) .............................. 16

ABOUT LASER BEAM .......................................................................................................................................... 18

- 4 -

Page 5

– FILE “ELCTADJ” –

ELECTRICAL ADJUSTMENTS ............................................................................................................................. 1

Necessary Equipment and Connecting ........................................................................................................... 1

Test Signal ....................................................................................................................................................... 1

Adjustment with Microsoft

®

Windows® 95/98/Me/XP Operating System ......................................................... 2

Adjustment Procedures ................................................................................................................................... 3

– FILE “DIAGNO” –

DIAGNOSIS INFORMATION ................................................................................................................................. 1

DIAGNOSTIC SOFTWARE,TO READ WARNING HISTORY(PCGC8 Ver.2) ....................................................... 3

SPECIFICATION OF RGB SIGNALS IN EACH COMPUTER MODE OF THE PROJECTOR .............................. 5

– FILE “DIAGFLOW” –

DIAGNOSIS FLOW CHART .................................................................................................................................. 1

Image system .................................................................................................................................................. 1

Power source system 1 ................................................................................................................................... 2

Power source system 2 ................................................................................................................................... 3

Power source system 3 ................................................................................................................................... 4

– FILE “PCCONTRL” –

Controling the prijector using a personal computer ............................................................................................... 1

– FILE “PARTSLST” –

PARTS LIST .......................................................................................................................................................... 1

PCB LOCATION .............................................................................................................................................. 2

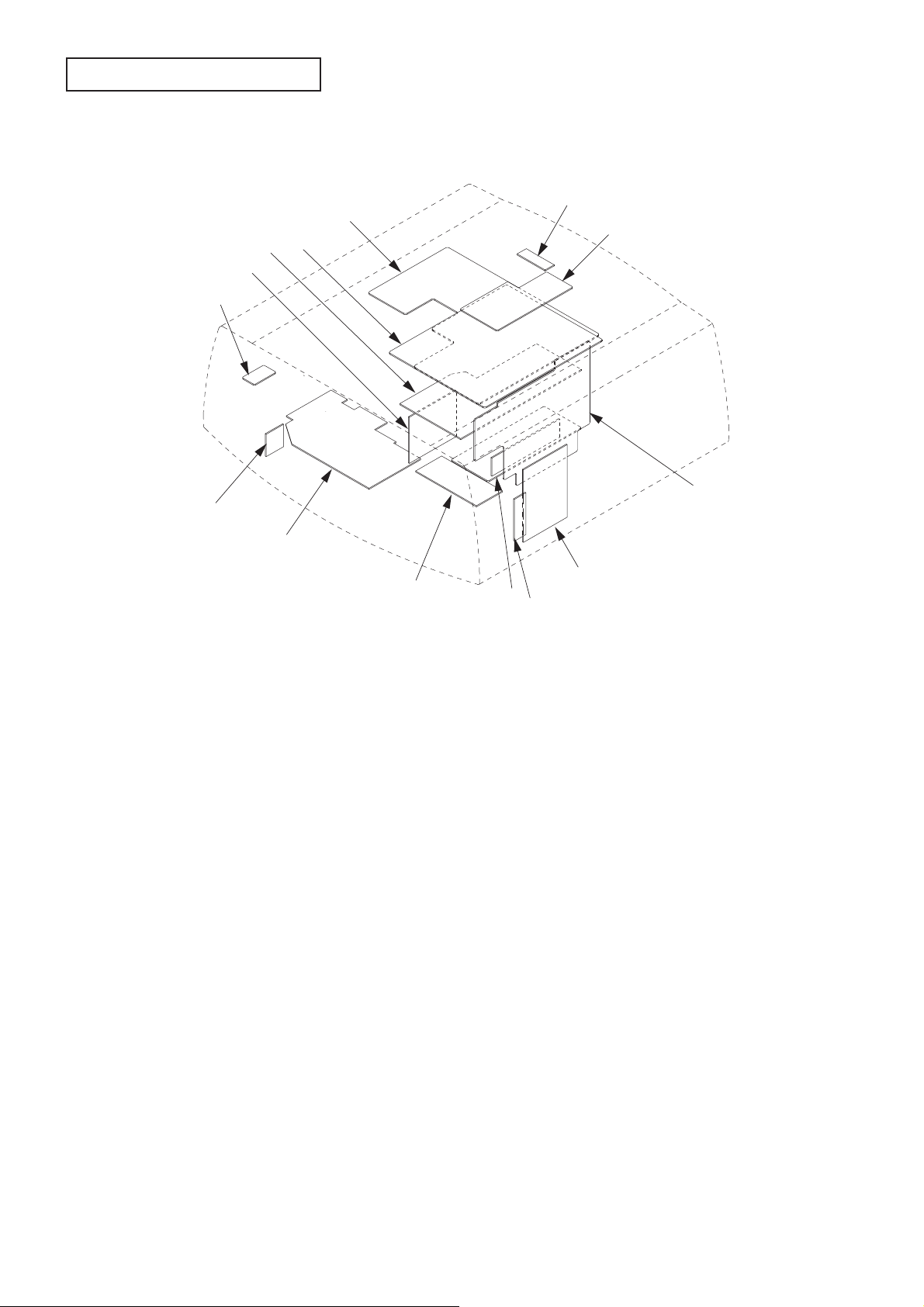

EXPOSED VIEW ............................................................................................................................................. 3

LVP ASSY .................................................................................................................................................. 3

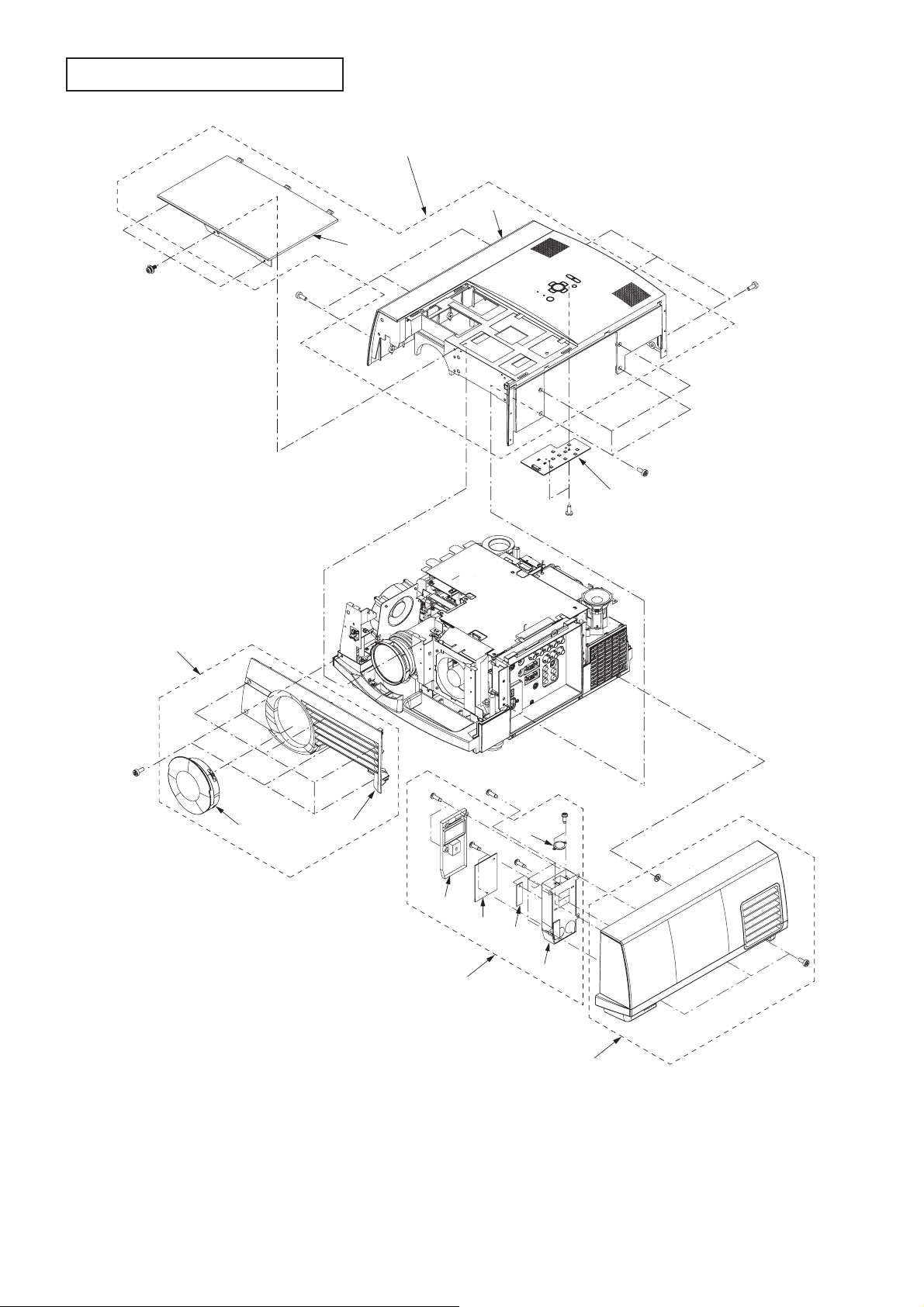

Chassis 1 ASSY ......................................................................................................................................... 4

Chassis 2 ASSY ......................................................................................................................................... 5

Bottom case unit ........................................................................................................................................ 6

Terminal ASSY ........................................................................................................................................... 6

Optical unit 1 .............................................................................................................................................. 7

Optical unit 2 .............................................................................................................................................. 8

PACKING ......................................................................................................................................................... 9

ELECTRICAL PARTS AND OTHERS .............................................................................................................. 10

– FILE “SCHEMATC” –

IC BLOCK DIAGRAMS

SCHEMATIC DIAGRAMS

PRINTED CIRCUIT BOARD PARTS LAYOUT

- 5 -

Page 6

TRADEMARK, REGISTERED TRADEMARK

Microsoft Windows 95/98/Me/XP are either registered trademarks or trademarks of Microsoft Corporation in the United States

and/or other countries.

Other brand or product names are trademarks or registered trademarks of their respective holders.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the projector have special safety related characteristics. These characteristics are often

not evident from visual inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, etc. Replacement parts which have these special safety characteristics are identifi ed in this ser-

vice manual. Electrical components having such features are identifi ed by shading on the schematic diagram and the parts list

of this service manual and by the supplementary sheet for this chassis to be issued subsequently.

- 1 -

Page 7

A

SAFETY PRECAUTIONS

North america

NOTICE: Observe all cautions and safety related notes located inside the cabinet and on the chassis.

Warning

1. Operation of this projector outside the cabinet or with the cover removed presents a shock hazard from the projector power

supplies.

2. When a short-circuit has occurred, replace those components that indicate evidence of overheating.

3. Grounding circuit continuity is vital for safe operation of equipment. Do not remove ground connection while the power cord

is still connected to the supply. Disconnect supply before servicing.

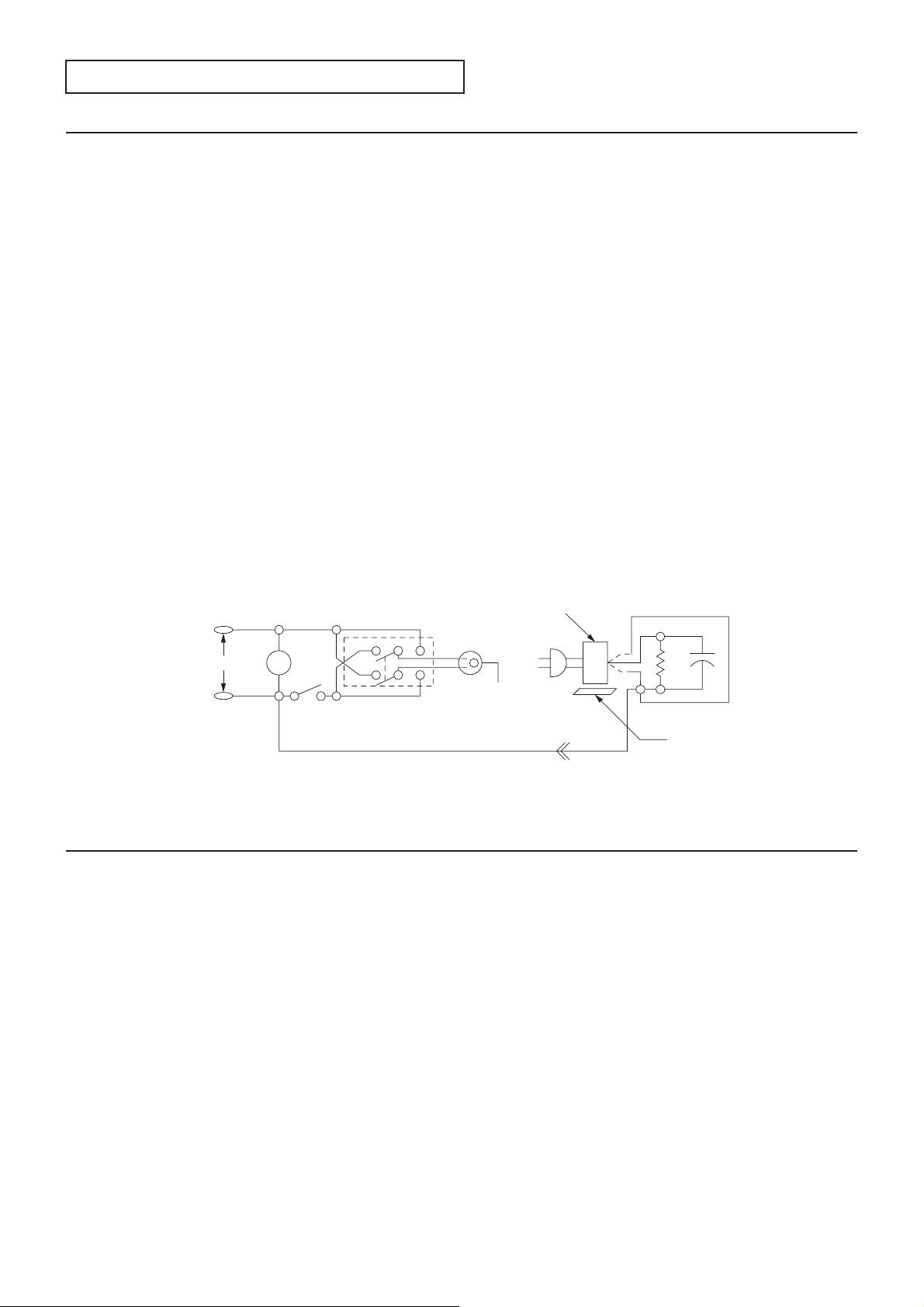

Leakage current check

Before returning the projector to the customer, it is recommended that leakage current be measured according to the follow-

ing methods.

1. Cold check

With the AC plug removed from the AC 100 to 240 V, place a jumper across the two AC plug prongs. Turn the projector AC

switch on. Using an ohm-meter, connect one lead to the AC plug and touch the other lead to each exposed metal part (metal

cabinet, screwheads, metal overlays, etc.), particularly any exposed metal part having a return path to the chassis. Exposed

metal parts having a return path to the chassis should have a minimum resistance reading of 1 megohm. Any resistance be-

low this value indicates an abnormality which requires corrective action. Exposed metal parts not having a return path to the

chassis will indicate an open circuit.

2. Hot check

Use the circuit in fi gure to perform this test.

(1) With switch S1 open, connect the projector to the measuring circuit. Immediately after connection, measure the leakage

current using both positions of switch S2, and with the switching devices in the projector in all of their operating positions.

(2) Switch S1 is then closed, energizing the projector. Immediately after closing the switch, measure the leakage current us-

ing both positions of switch S2, and with the switching devices in the projector in all of their operating positions. Current

measurements of items (1) and (2) are to be repeated after the projector has reached thermal stabilization. The leakage

current must not be more than 0.5 milliampere.

Projector

AC milliammeter

S2

C 100 to 240 V

V

S1

Grounding supply conductor

GH

(grounding)

open

B

Figure

A

Insulating table

Europe, other than USA

NOTICE: Observe all cautions and safety related notes located inside the cabinet and on the chassis.

Warning

1. An isolation transformer should be used between the projector and the AC supply point before any test/service is performed

on a LIVE chassis projector.

2. Operation of this projector outside the cabinet or with the cover removed, involves a shock hazard from the projector power

supplies. Work on the projector should not be attempted by anyone who is not thoroughly familiar with precautions neces-

sary when working on high voltage equipment.

3. When service is required, observe the original lead dressing. Extra precaution should be given to assure correct lead dress-

ing in the high voltage area. Where a short-circuit has occurred, replace those components that indicate evidence of over-

heating.

Leakage current cold check

Before returning the projector to the customer, it is recommended that leakage current be measured according to the following

methods.

With the AC plug removed from the AC source, place a jumper across the two AC plug prongs. Turn the projector AC switch on.

Using an 500 V D.C. Insulation Tester, connect one lead to the jumpered AC plug and touch the other lead to each exposed metal part (screwheads, etc.), particularly any exposed metal part having a return path to the chassis. Exposed metal parts having a

return path to the chassis should have a minimum resistance reading of 4 megohm. Any resistance below this value indicates an

abnormality which requires corrective action.

- 2 -

Page 8

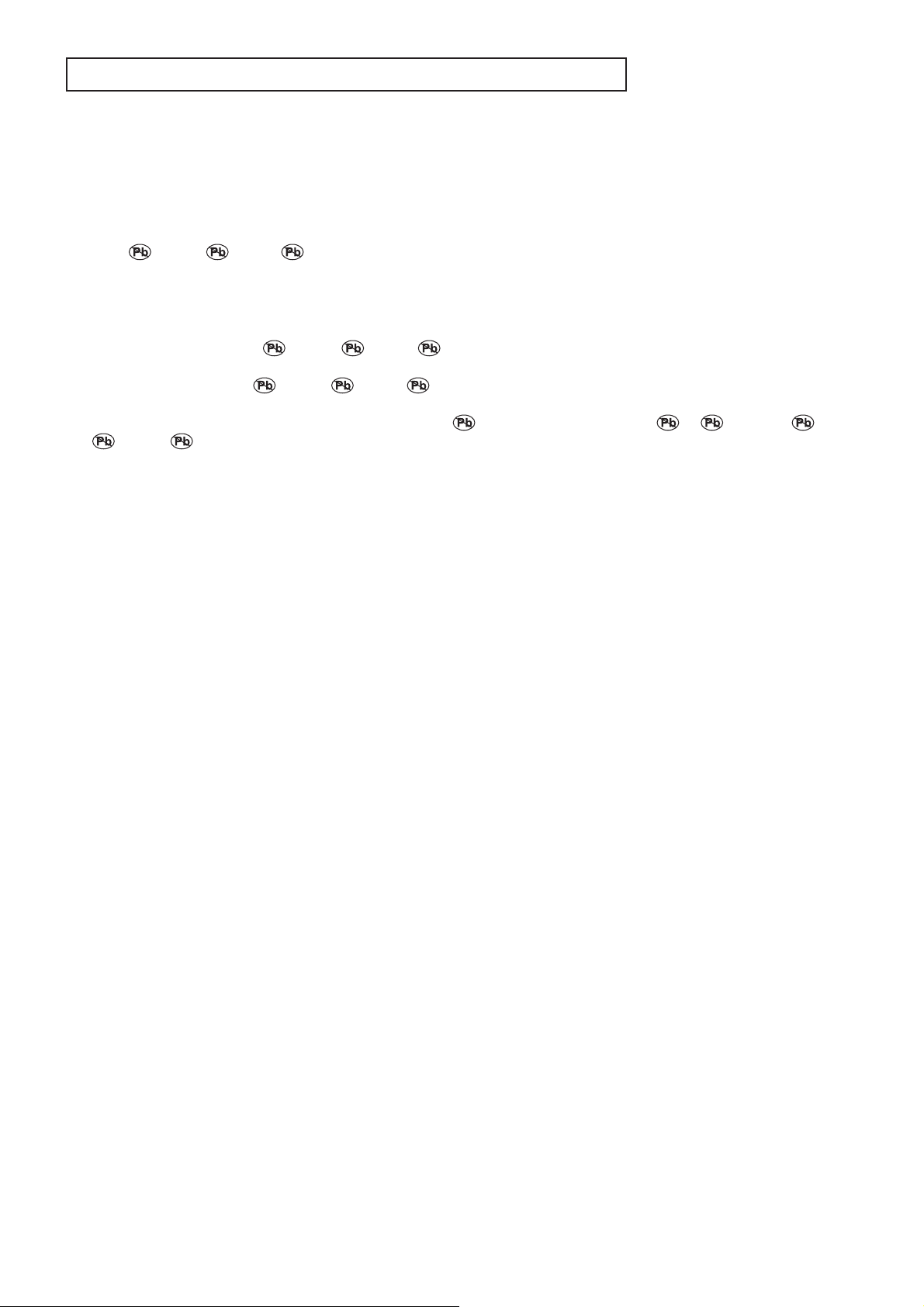

PRECAUTIONS FOR RESOLDERING

Lead-free solder is handled in a different way from eutectic solder. See below for details.

How to distinguish circuit boards using lead-free solder from those using

eutectic solder

Circuit boards using lead-free solder

A mark of Solder, Joints, PCA or LFS (for limited marking space) is printed near the board assembly number on

the component side.

Circuit boards using eutectic solder

Circuit boards using eutectic solder are divided into two groups.

- Boards having no mark of

number.

- Boards having a mark of

pen near the board assembly number.

* Only when there is a limited marking space on the board,

PCA as P.

* Circuit boards using lead-free solder and those using eutectic solder may be used together in the same product.

Instructions for resoldering

- For circuit boards using lead-free solder, use lead-free solder.

- For circuit boards using eutectic solder, use eutectic solder.

- Separate the soldering iron for lead-free solder from that for eutectic solder completely for use.

(It is prohibited to use a same soldering iron for lead-free solder and eutectic solder.)

- For lead-free solder, it is advisable to use a soldering iron of at least 40 W because lead-free solder has a melting point approx. 35°C higher than that of eutectic solder as conventionally used. For wire solder, use M705ESC made by Senju Metal

Industry Co., Ltd.

- To remove solder, you can use desoldering wires for eutectic solder as conventionally used.

Solder, Joints, PCA or LFS (for limited marking space) near the board assembly

Solder, Joints, PCA or LFS (for limited marking space) that is painted out by a felt-

Solder may be indicated as S, Joints as J, and

- 3 -

Page 9

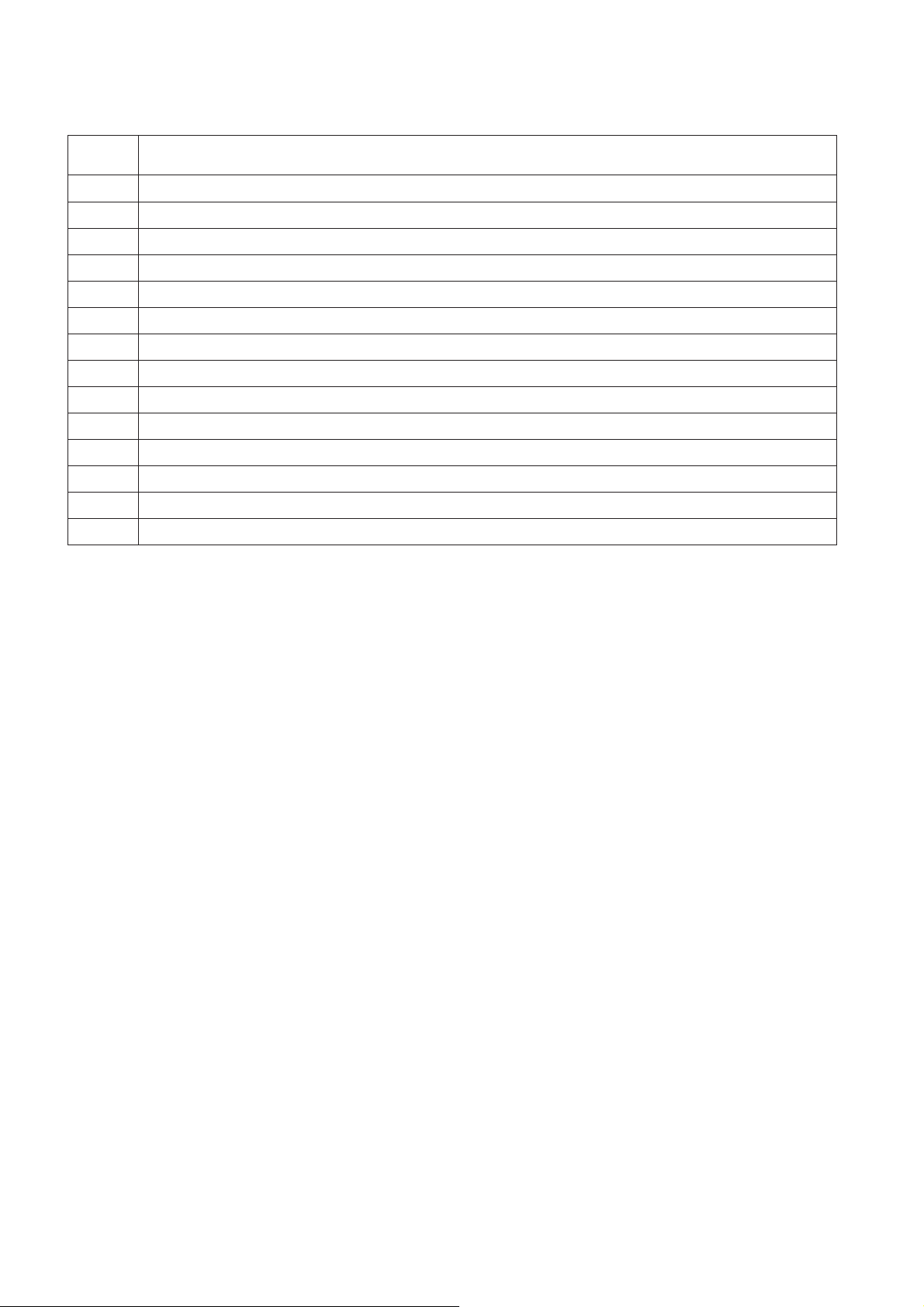

PCB LOCATION

14

5

4

3

2

1

13

12

11

6

7

8

9

10

Fig.1

- 4 -

Page 10

Parts list : See page 2 of PARTS LIST

Item No. Part name

1 IRF PCB ASSY

2 FILTER PCB ASSY

3 POWER PCB ASSY

4 MAIN PCB ASSY

5 DRIVE PCB ASSY

6 IRR PCB ASSY

7 KEY PCB ASSY

8 TERMINAL PCB ASSY

9 BOO PCB ASSY

10 BOO SUB PCB ASSY

11 Lamp power unit

12 INLET PCB ASSY

13 POWER SUB PCB ASSY

14 MOTOR PCB ASSY

Table 1

- 5 -

Page 11

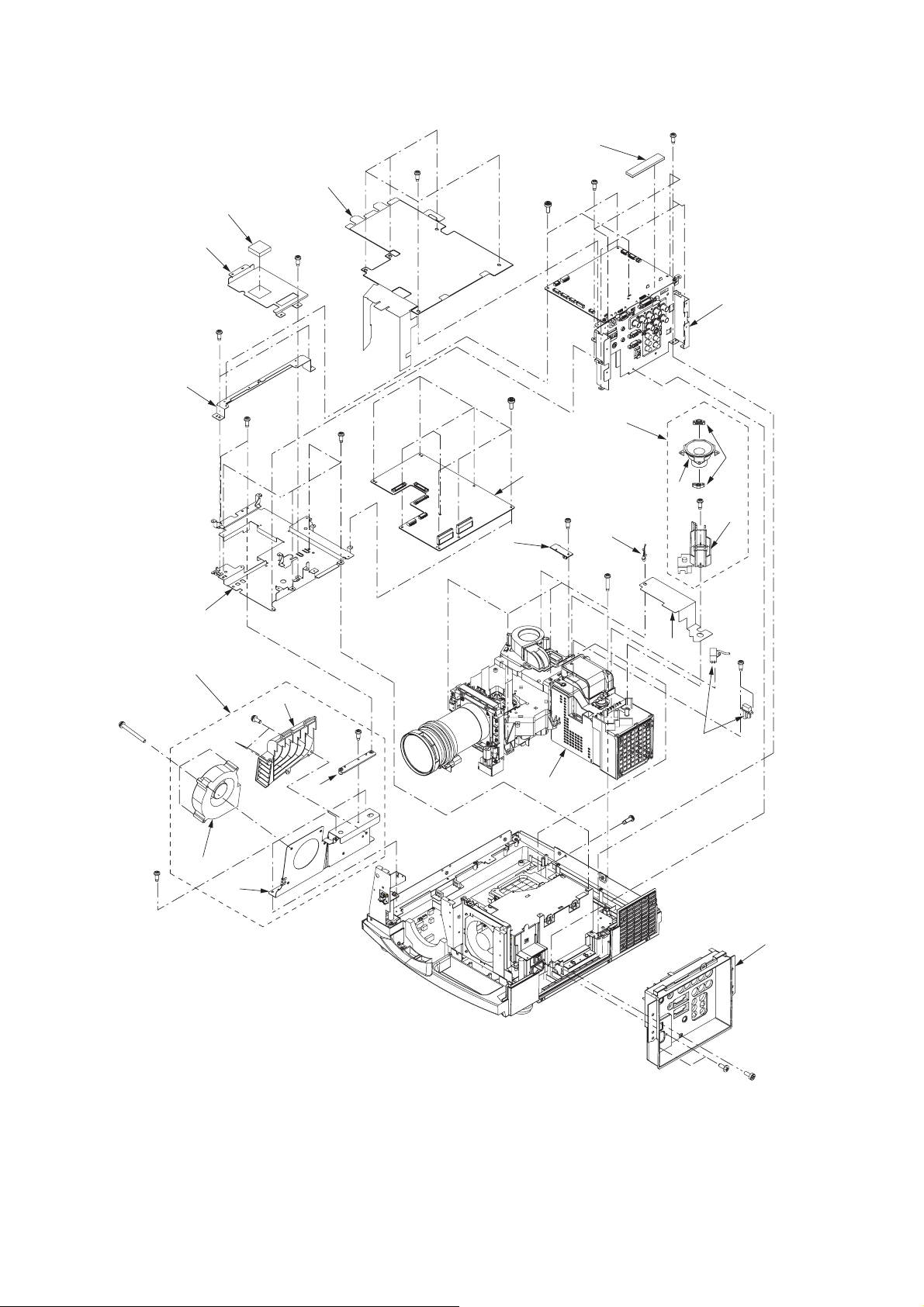

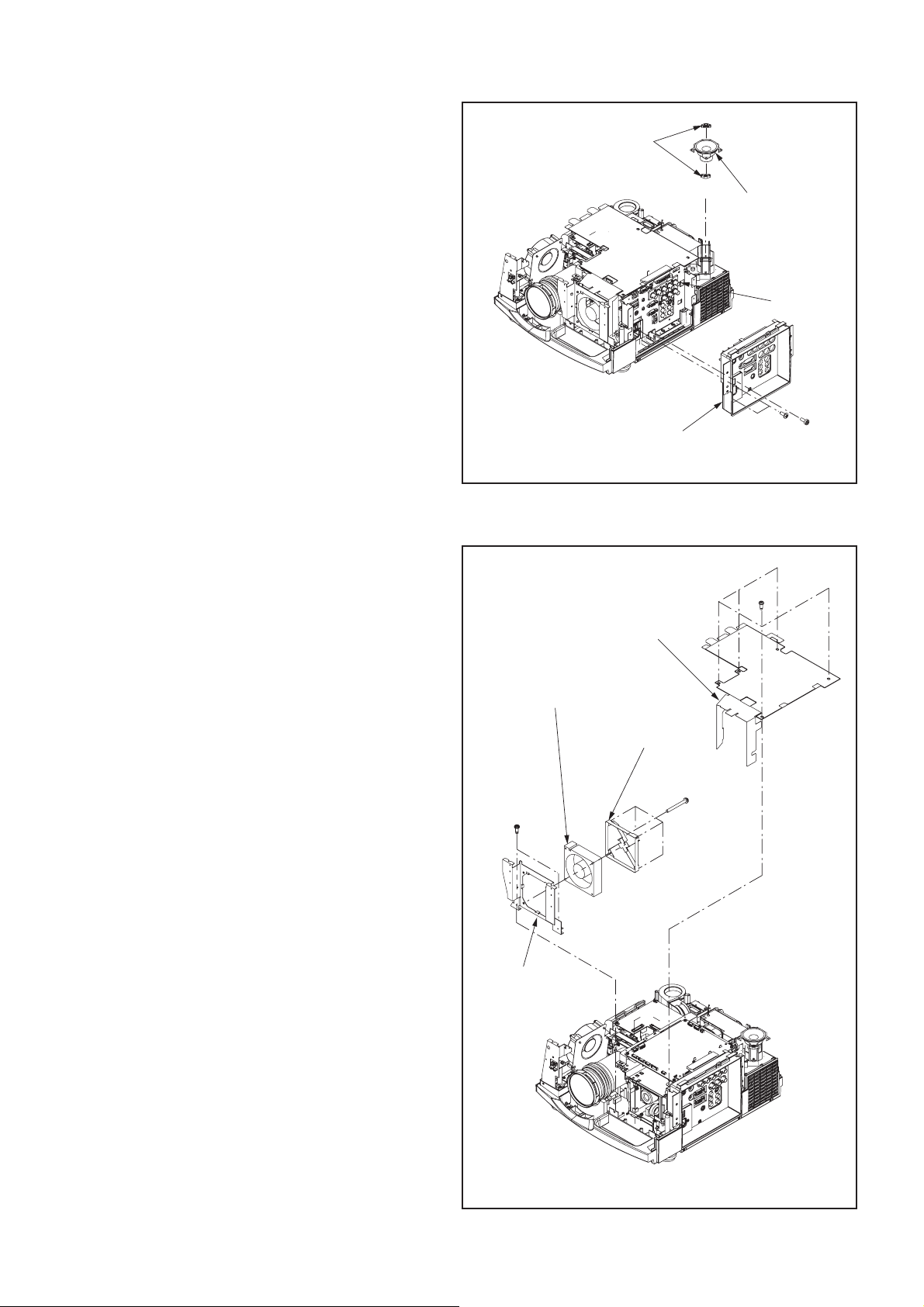

EXPOSED VIEW

A

L VP ASSY

Hx3

Jx3

11

13

12

Kx3

Lx4

14

Mx2

1

x6

Dx2

2

3

Cx4

Gx2

Ex2

6

5

10

Fx1

7

8

9

4

Bx3

Fig.2-1

- 6 -

Page 12

Parts list : See page 3 of PARTS LIST

Part name Number of screw

1.Front case ASSY None

2.Lens cap None

3.Front case unit Ax6

4.Terminal cover unit Bx3

5.Alarm unit ASSY Cx4

6.Alarm cover U Dx2

7.BOO PCB ASSY Ex2

8.BOO SUB PCB ASSY Fx1

9.Alarm cover L None

10.Sensor Gx2

11.Top case ASSY None

12.Top cover unit Hx3

13.Top case unit Jx3,Kx3,Lx4

14.KEY PCB ASSY Mx2

Table 2-1

- 7 -

Page 13

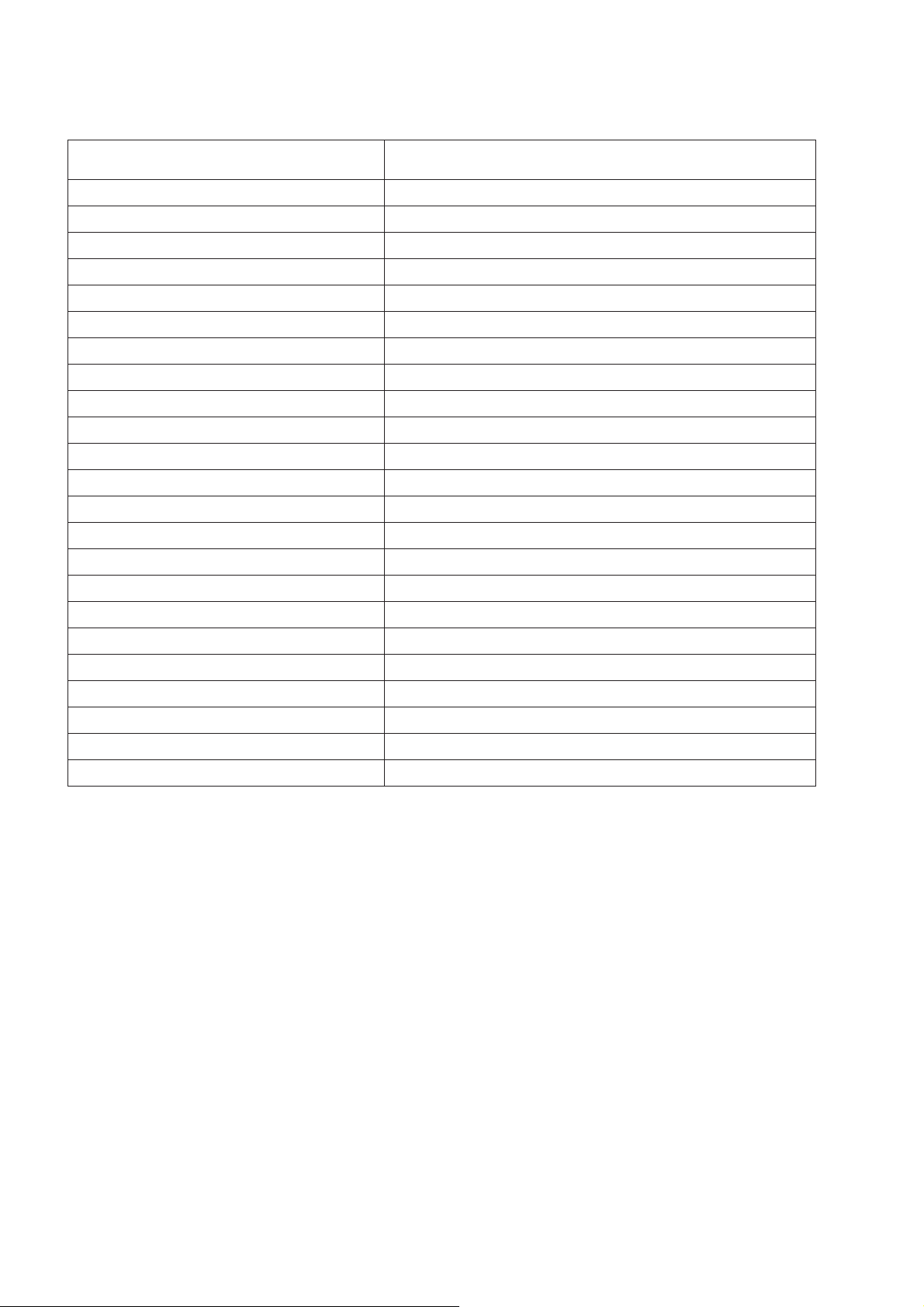

Chassis 1 ASSY

Cx5

2

5

Dx3

3

Fx3

Ex3

6

Hx2

7

9

10

Kx2

Gx1

Lx4

15

Jx8

8

Rx1

20

Ux5

16

21

17

4

18

Sx1

19

Tx2

Nx3

Mx2

12

Px3

11

13

14

Qx1

Fig.2-2

23

Vx1

22

Bx2

1

Ax1

- 8 -

Page 14

Parts list : See page 4 of PARTS LIST

Part name Number of screw

1.Terminal board unit Ax1,Bx2

2.Main barrier Cx5

3.Spacer cushion None

4.T erminal ASSY Dx3,Ex3,Fx3

5.Gum spacer None

6.Main radiator Gx1

7.Main PCB holder Hx2

8.DRIVE PCB ASSY Jx8

9.Drive PCB holder Kx2,Lx4

10.Drive fan ASSY None

11.Fan holder L Mx2

12.Drive fan Nx3

13.Fan PCB duct Px3

14.Shield holder Qx1

15.IRR PCB ASSY Rx1

16.Speaker ASSY None

17.Speaker None

18.Bush SP None

19.Holder SP Sx1

20.Lead clamper None

21.Thermo barrier None

22.Lamp power lead Tx2

23.Optical unit Ux5,Vx1

Table 2-2

- 9 -

Page 15

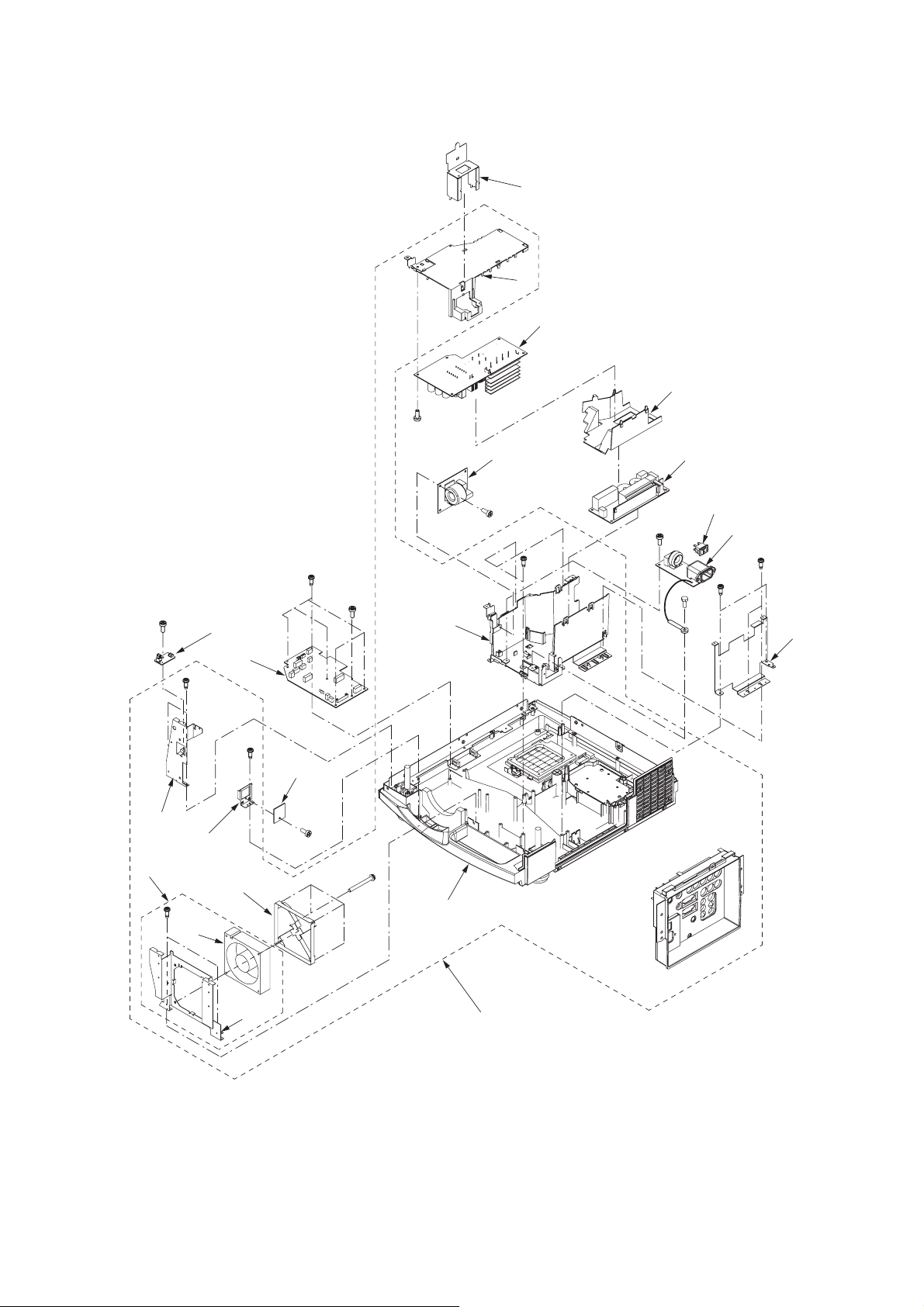

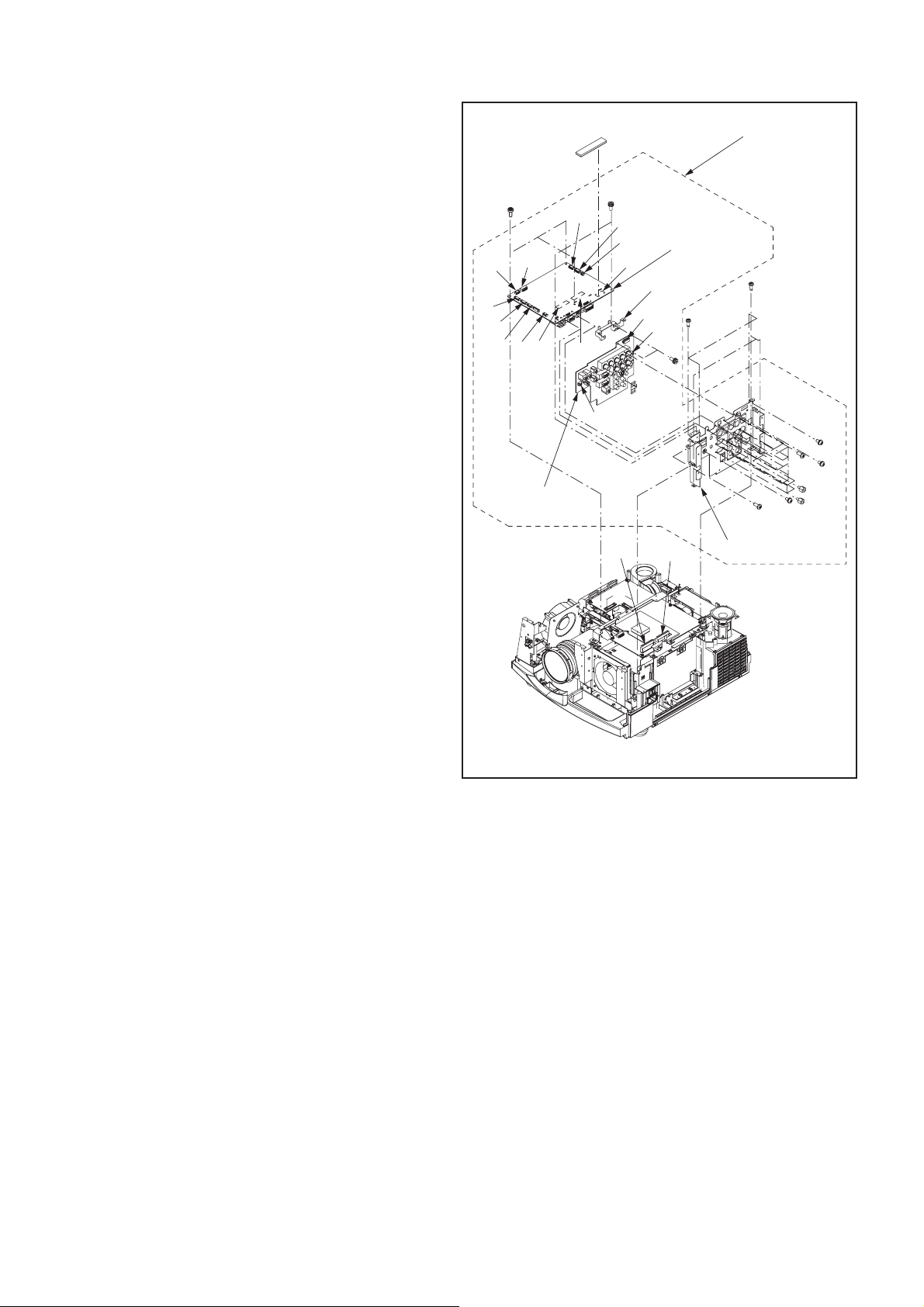

Chassis 2 ASSY

Lx1

17

12

13

14

15

16

Ax1

6

Mx1

Nx1

Gx5

Hx1

2

10

Bx2

Cx1

5

3

4

9

Ex2

8

Dx1

Fx4

20

21

Qx3

18

19

Kx2

Jx2

Px1

11

7

1

Fig.2-3

- 10 -

Page 16

Parts list : See page 5 of PARTS LIST

Part name Number of screw

1.Bottom case ASSY None

2.IRF PCB ASSY Ax1

3.Front holder L Bx2

4.Motor PCB holder Cx1

5.MOTOR PCB ASSY Dx1

6.Power fan ASSY None

7.Fan holder F Ex2

8.Power fan Fx4

9.Fan guard None

10.POWER SUB PCB ASSY Gx5,Hx1

11.Power shield L Jx2,Kx2

12.SW shield None

13.Power box T unit None

14.POWER PCB ASSY Lx1

15.Power fi n None

16.Lamp power unit None

17.FILTER PCB ASSY Mx1

18.Seesaw switch None

19.INLET PCB ASSY Nx1,Px1

20.Power box B unit Qx3

21.Bottom case unit None

Table 2-3

- 11 -

Page 17

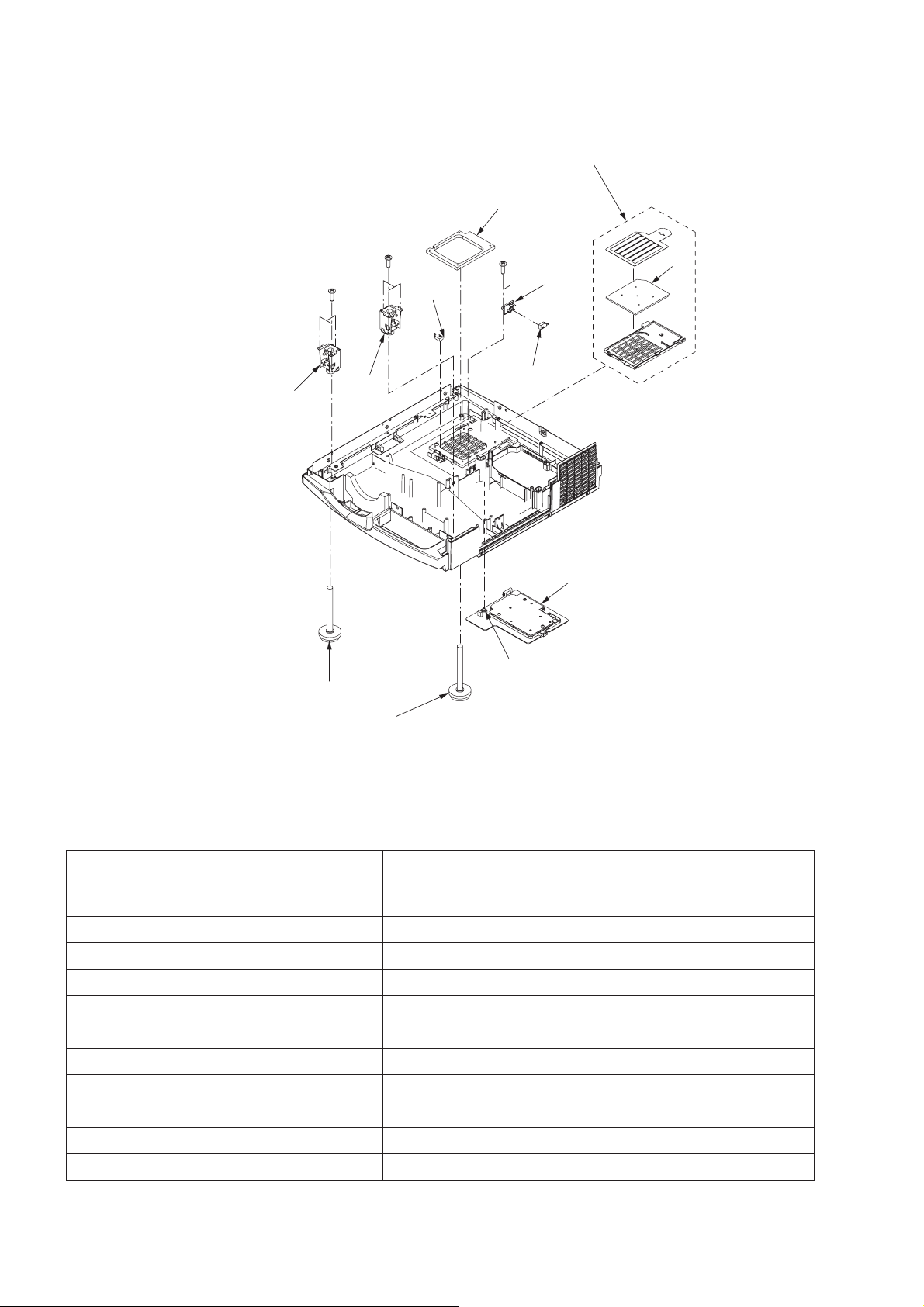

Bottom case unit

Cx3

Dx3

1

4

Bx2

7

5

2

8

9

10

11

Fig.2-4

6

3

Ax1

Parts list : See page 6 of PARTS LIST

Part name Number of screw

1.Filter unit None

2.Fan fi lter None

3.Lamp cover unit Ax1

4.Fan cushion None

5.SW holder Bx2

6.Micro SW None

7.Micro SW None

8.Adjustment foot ASSY Cx3

9.Adjustment foot ASSY Dx3

10.Adiuster unit None

11.Adiuster unit None

Table 2-4

- 12 -

Page 18

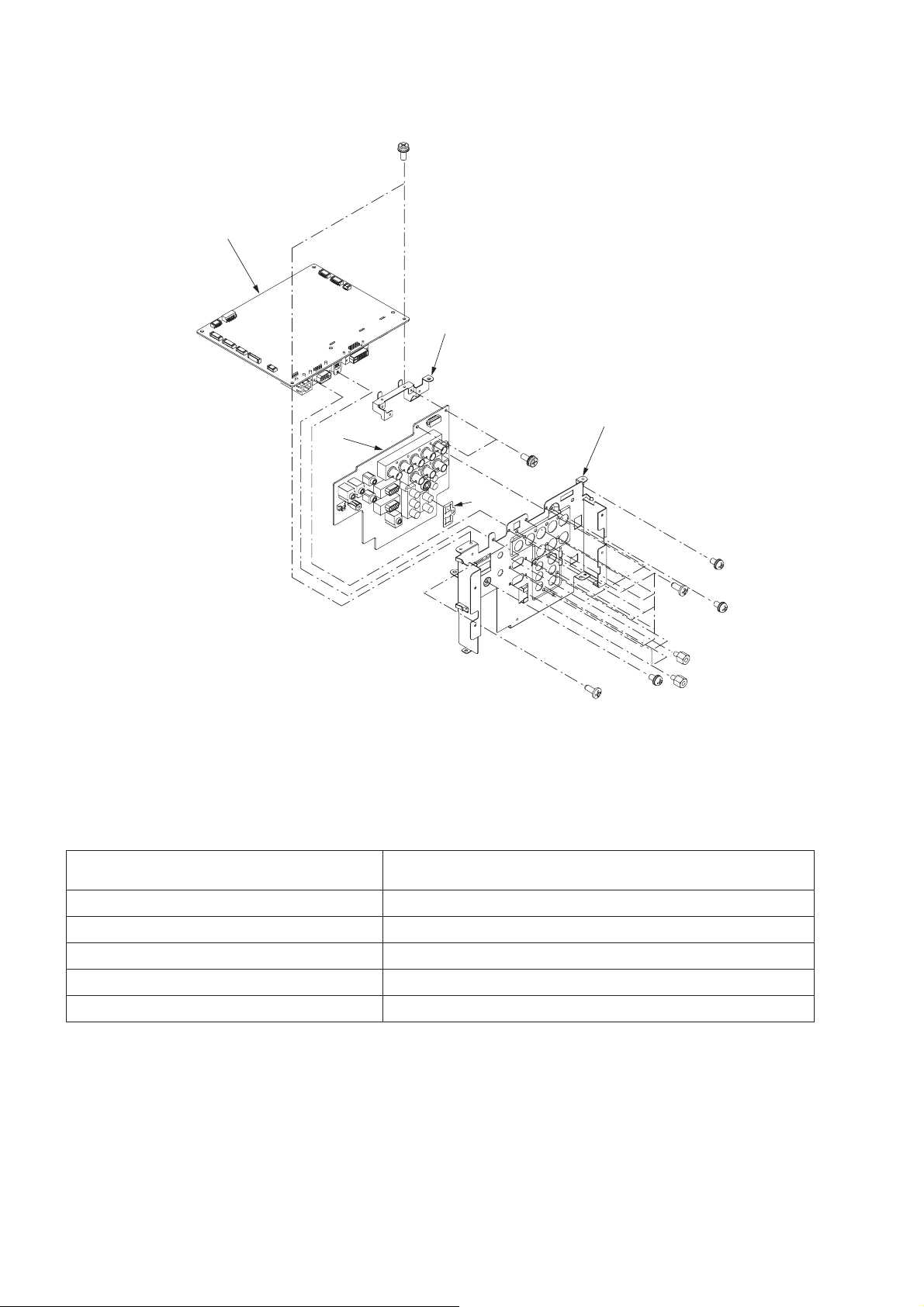

T erminal ASSY

Ax2

1

5

2

4

3

Jx2

Fx1

Fig.2-5

Parts list : See page 6 of PARTS LIST

Part name Number of screw

1.MAIN PCB ASSY Ax2,Bx4,Cx1

2.Terminal holder Dx8,Ex4,Fx1,Gx1,Hx1

3.Pin jack shield None

4.TERMINAL PCB ASSY Jx2

5.PCB holder None

Cx1

Hx1

Gx1

Dx8

Bx4

Ex4

Table 2-5

- 13 -

Page 19

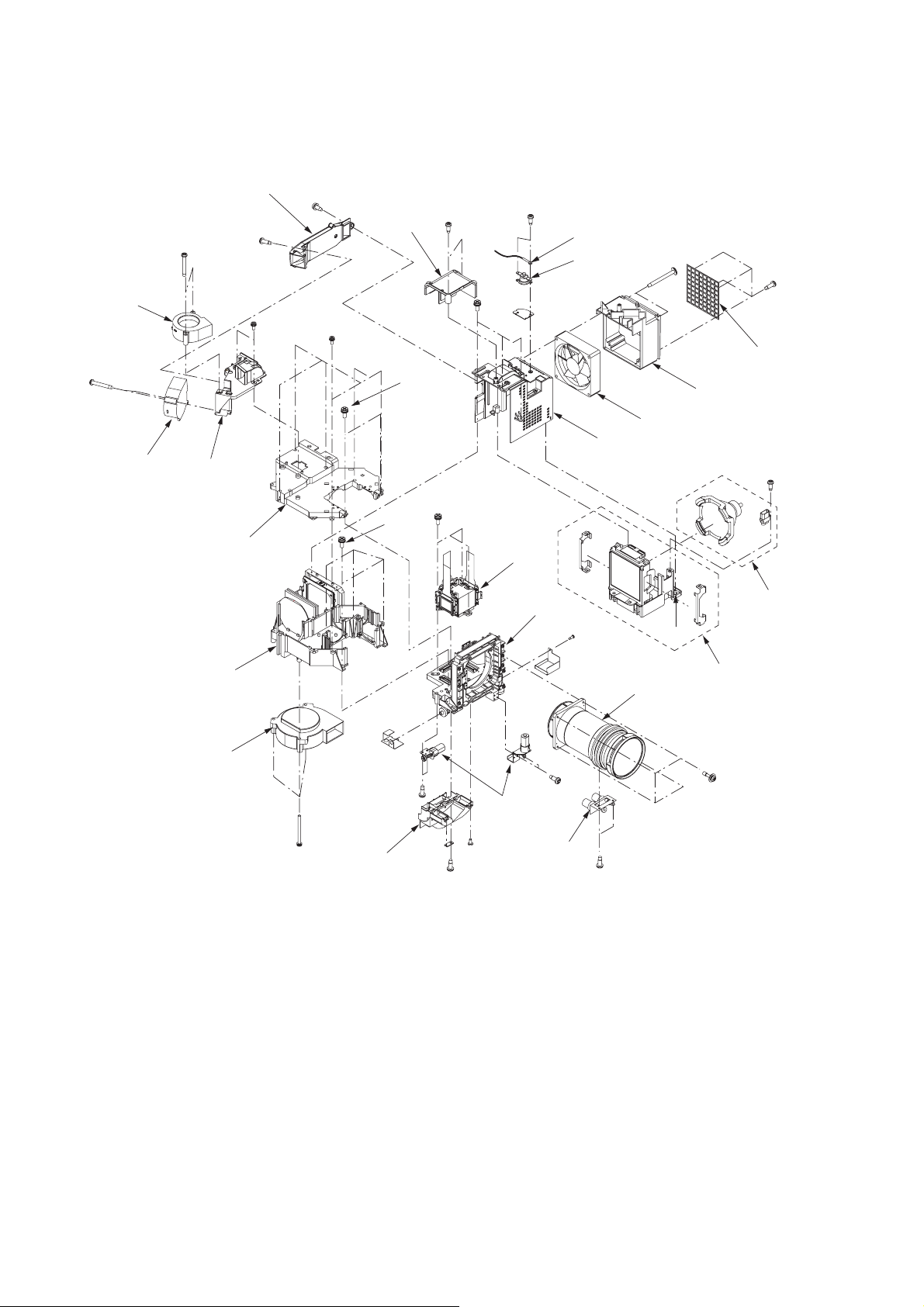

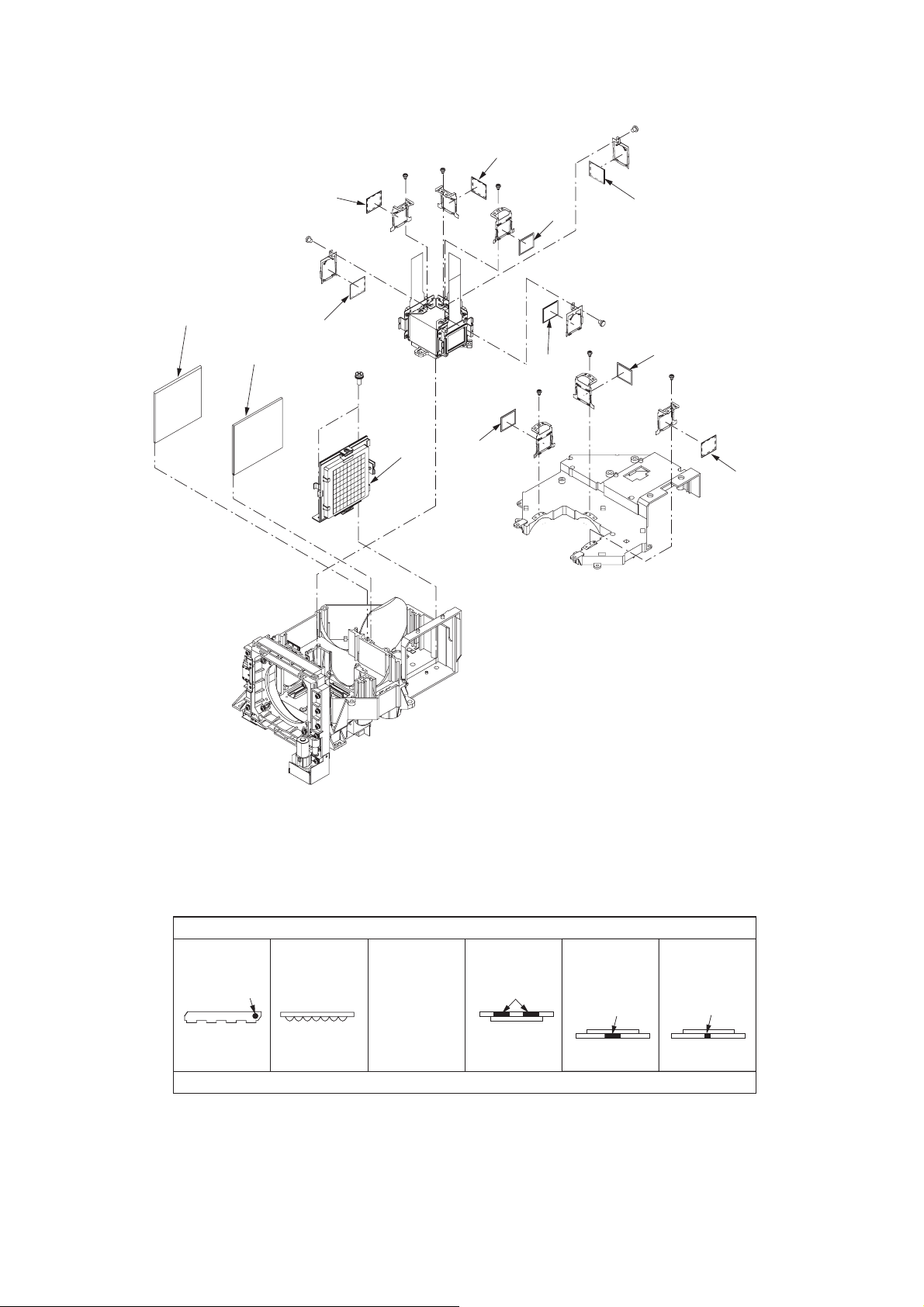

Optical unit 1

Fx2

1

Ex2

5

6

Bx1

7

12

Gx2

Ax1

Lx6

Nx4

Cx2 Dx2

2

Mx2

Qx3

Kx3

15

22

3

4

11

Jx2

10

Hx4

8

9

Sx1

17

Rx2

14

13

Px3

21

Wx2

Zx1

Yx1

Fig.2-6

20

Vx2

16

18

Tx4

19

Ux2

- 14 -

Page 20

Parts list : See page 7 of PARTS LIST

Part name Number of screw

1.Lamp duct Ax1,Bx1

2.Lamp cover T duct Cx2

3.Thermistor Dx1

4.Thermostat Dx2

5.PBS fan Ex2

6.Lamp fan Fx2

7.PBS duct Gx2

8.Grille Hx4

9.Exhaust duct Jx2

10.Exhaust fan None

11.Lamp cover T Kx3

12.Sub frame cover Lx6,Mx2

13.Sub frame Nx4

14.LCD fan Px3

15.LCD block Qx3

16.Lamp case ASSY Rx2

17.Lamp Sx1

18.Lens unit Tx4

19.Zoom focus motor Ux2

20.Lens shift motor Vx2,Wx2

21.LCD duct Yx1,Zx1

22.Main F shift base None

Table 2-6

- 15 -

Page 21

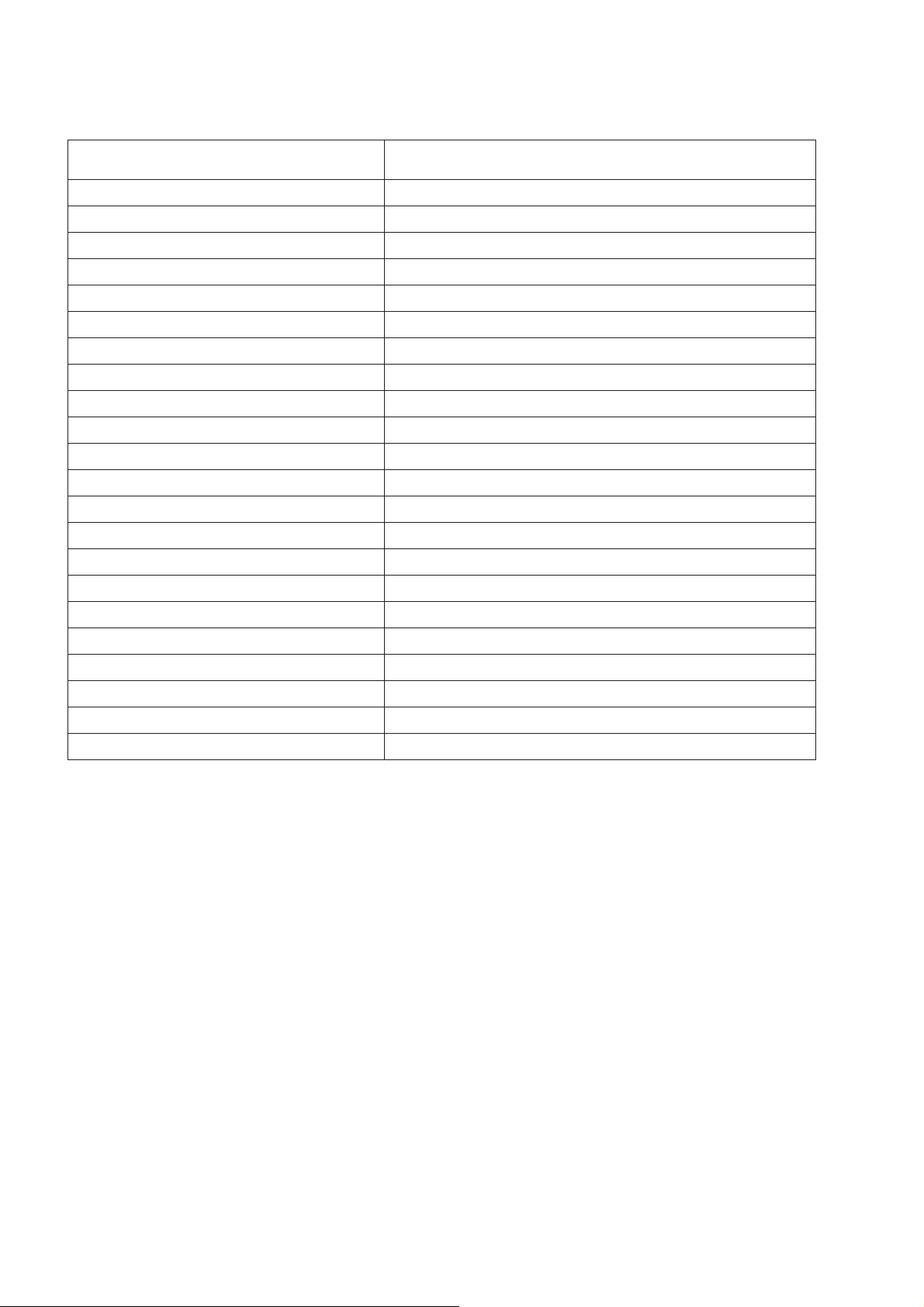

Optical unit 2

Fx1

Jx1

Kx1

12

Gx1

1

2

9

Ax2

3

11

Hx1

8

10

Ex1

7

Cx1

Dx1

6

5

1

Bx

4

Fig.2-7

Dlrections which the setting parts face in

Light source side(Lamp side)

123 7,8,9 10,11,12

Flat surface

Marking Color marking

Shaved edge

Uneven surface

Flat surface Flat surface

In possible

directions

Convex

Projection side(Lamp side)

4,5,6

Surface to stick

the polarizer on

Color marking

4,7,10 :

5,8,11 :

6,9,12 :

- 16 -

Surface to stick

the polarizer on

Color marking Color marking

Flat surface Flat surface

Surface to stick

the polarizer on

Blue

Green

Red

Page 22

Parts list : See page 8 of PARTS LIST

A

Part name Number of screw

1.PBS ASSY None

2.Multi lens B None

3.Multi lens A Ax2

4.Polarizer (B) IN Bx1

5.Polarizer (G) IN Cx1

6.Polarizer (R) IN Dx1

7.Polarizer (B) OUT Ex1

8.Polarizer (G) OUT Fx1

9.Polarizer (R) OUT Gx1

10.Polarizer (B) PURI Hx1

11.Polarizer (G) PURI Jx1

12.Polarizer (R) PURI Kx1

Table 2-7

POSITION ADJUSTMENT OF MULTI LENS A

Follow the steps below for the adjustment after replacing the

multi lens A.

Number of jig screw : 859C746O10

1. Fasten two screws (a) to secure the Multi lens A

temporarily.

2. Project a full white raster on the screen.

3. Adjust the position of the multi lens A to correct color

unevenness near the screen edges.

To adjust the vertical position, turn the screw (b).

To adjust the horizontal position, use the jig screw (c).

4. Fasten two screws (a) and two screws (d) tightly to

secure the Multi Lens A fi rmly.

ax2

b

d

x2

Multi lens

c

- 17 -

Page 23

DISASSEMBLY

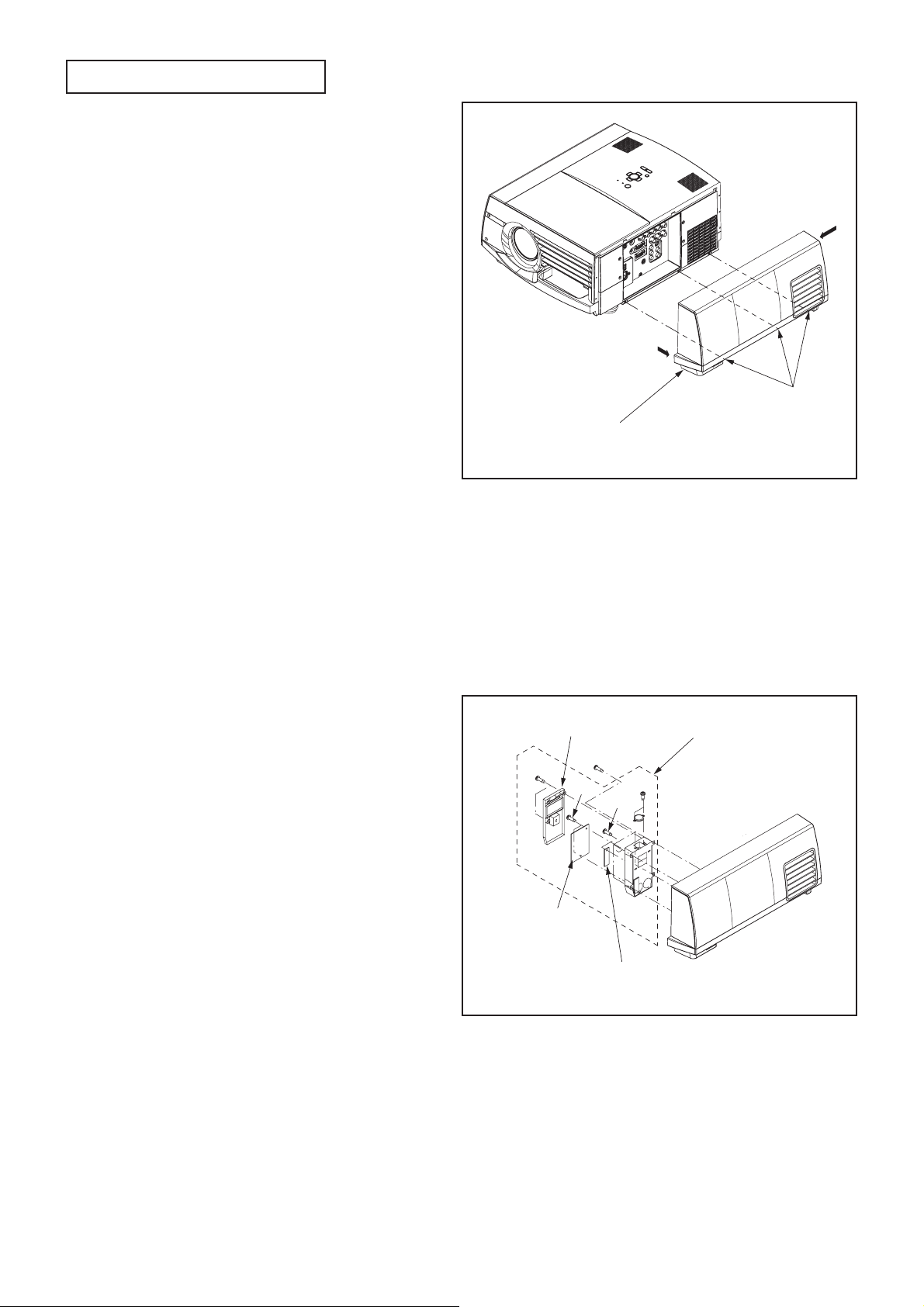

1. Removal of the terminal cover ASSY

1. Loosen the three screws (a) as shown in Fig. 3-1.

2. Open the bottom of the terminal cover ASSY outward

(as shown by the arrow (A)) as shown in Fig. 3-1.

3. Slide the top of the terminal cover ASSY to the front

for removal (as shown by the arrow (B)) as shown in

Fig. 3-1.

B

A

ax3

Terminal cover ASSY

Fig. 3-1

2. Removal of the BOO PCB ASSY and BOO SUB PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Remove of the terminal cover ASSY”.

2. Remove the four screws (a) as shown in Fig. 3-2.

3. Remove the alarm unit ASSY as shown in Fig. 3-2.

4. Remove the two screws (b) as shown in Fig. 3-2.

5. Remove the alarm cover U as shown in Fig. 3-2.

6. Remove the two screws (c) as shown in Fig. 3-2.

7. Remove the BOO PCB ASSY as shown in Fig. 3-2.

8. Remove the screw (d) as shown in Fig. 3-2.

9. Remove the BOO SUB PCB ASSY as shown in Fig.

3-2.

Alarm cover U

bx2

BOO PCB ASSY

ax4

cx2

BOO SUB PCB ASSY

Alarm unit ASSY

dx1

Fig. 3-2

- 18 -

Page 24

3. Removal of the lens unit and zoom focus motor

1. Remove the six screws (a) as shown in Fig. 3-3.

2. Pull the top and left side of the front case unit (as

shown by the arrow (A)) as shown in Fig. 3-3.

3. Raise the left side of the front case unit (as shown by

the arrow (B)) as shown in Fig. 3-3.

4. Pull the left side of the front case unit to front for re-

moval (as shown by the arrow (c)) as shown in Fig.

3-3.

5. Remove the three screws (b) as shown in Fig. 3-3.

6. Slide the top cover unit to the front (as shown by ar-

row (D)) as shown in Fig. 3-3.

7. Remove the top cover unit to upward (as shown by

the arrow (E)) as shown Fig. 3-3.

8. Disconnect the connector (MA) as shown in Fig. 3-3.

9. Loosen the four screws (c) as shown in Fig. 3-3.

10. Remove the lens unit as shown Fig. 3-3.

11. Remove the two screws (d) as shown in Fig. 3-3.

12. Remove the zoom focus motor as shown in Fig. 3-3.

Top cover unit

D

E

bx3

Lens unit

cx4

Zoom focus motor

dx2

ax6

A B

C

Fig. 3-3

MA

Front case unit

- 19 -

Page 25

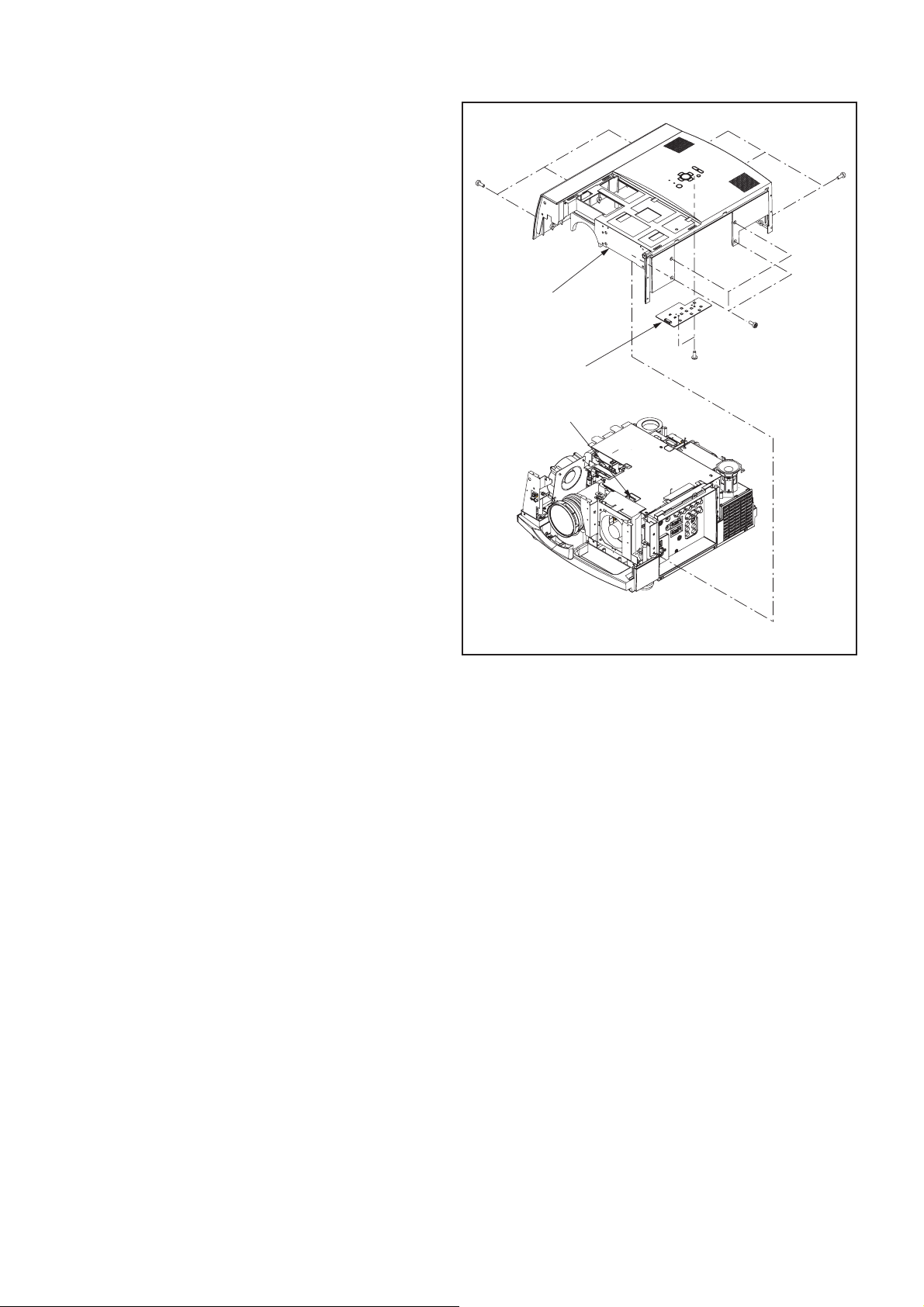

4. Removal of the top case unit and KEY PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the three screws (a), three screws (b) and

four screws (c) as shown in Fig. 3-4.

4. Disconnect the connector (ST) as shown in Fig. 3-4.

5. Remove the top case unit as shown in Fig. 3-4.

6. Remove the two screws (d) as shown in Fig. 3-4.

7. Remove the KEY PCB ASSY as shown in Fig. 3-4.

ax3

Top case unit

KEY PCB ASSY

ST

bx3

cx4

dx2

Fig. 3-4

- 20 -

Page 26

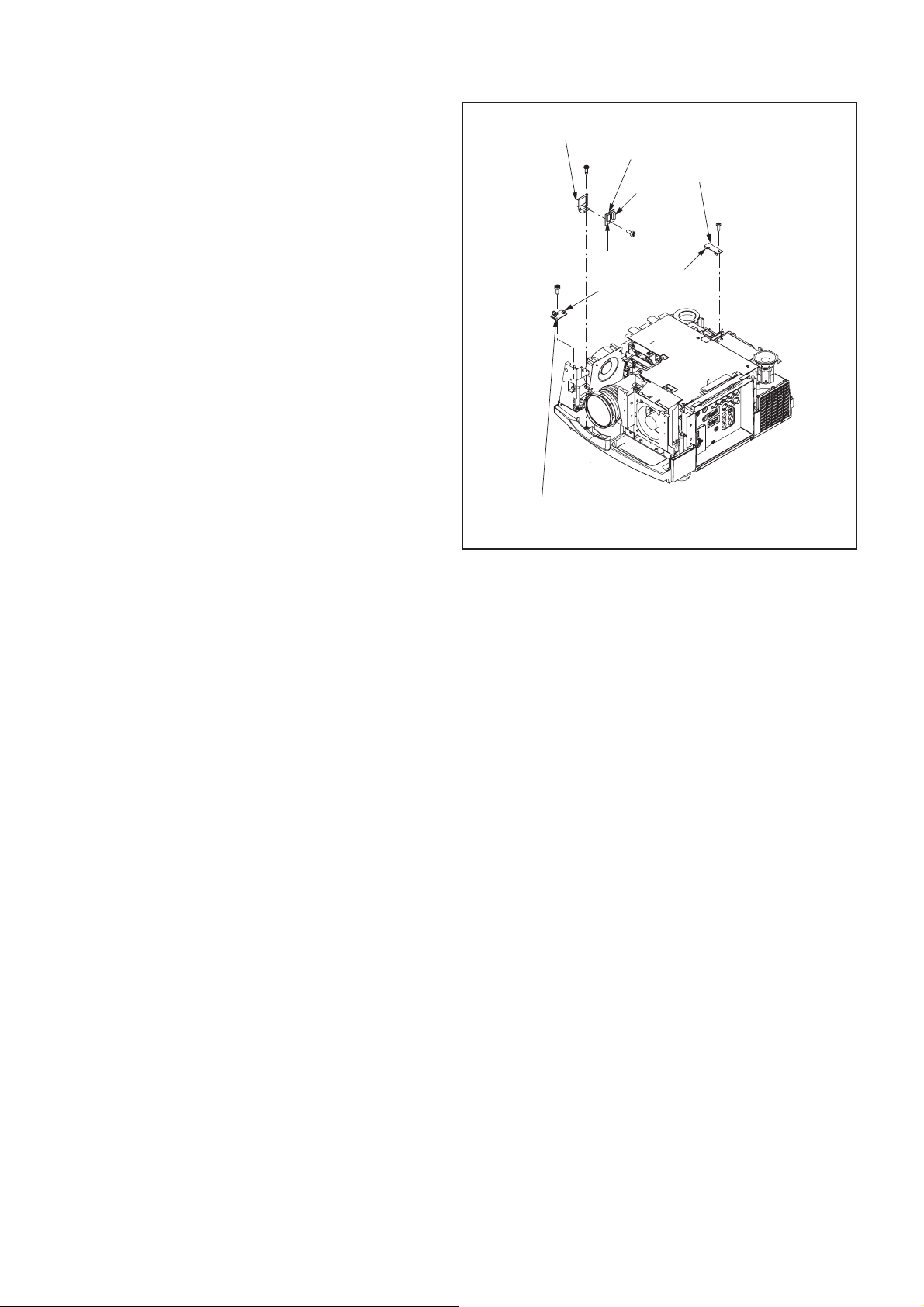

5. Removal of the IRF PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the screw (a) as shown in Fig. 3-5

5. Disconnect the connector (AM) as shown in Fig. 3-5

6. Remove the IRF PCB ASSY as shown in Fig. 3-5.

6. Removal of the MOTOR PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the screw (b) as shown in Fig. 3-5.

5. Remove the motor PCB holder as shown in Fig. 3-5.

6. Remove the screw (c) as shown in Fig. 3-5.

7. Disconnect the two connectors (MA and MV) as

shown in Fig. 3-5.

8. Remove the MOTOR PCB ASSY as shown in Fig.

3-5.

Motor PCB holder

MOTOR PCB ASSY

bx1

ax1

IRF PCB ASSY

MV

AM

MA

cx1

Fig. 3-5

IRR PCB ASSY

dx1

AL

7. Removal of the IRR PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Removal the screw (d) as shown in Fig. 3-5.

5. Disconnect the connector (AL) as shown in Fig. 3-5.

6. Remove the IRR PCB ASSY as shown in Fig. 3-5.

- 21 -

Page 27

8. Removal of the speaker

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the two screws (a) and screw (b) as shown

in Fig. 3-6.

5. Remove the terminal board unit as shown in Fig. 3-6.

6. Disconnect the connector (TL) as shown in Fig. 3-6.

7. Remove the bush SP as shown in Fig. 3-6.

8. Remove the speaker as shown in Fig. 3-6.

9. Removal of the power fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the fi ve screws (a) as shown in Fig. 3-7.

5. Remove the main barrier as shown in Fig. 3-7

6. Remove the two screws (b) as shown in Fig. 3.-7.

7. Remove the fan holder F as shown in Fig. 3-7.

8. Remove the four screws (c) as shown in Fig. 3-7.

9. Remove the fan guard and power fan as shown in

Fig. 3-7.

Power fan

bx2

Bush SP

Terminal board unit

Fig. 3-6

Main barrier

Fan guard

Speaker

TL

bx1

ax2

ax5

cx4

- 22 -

Fan holder F

Fig. 3-7

Page 28

10. Removal of the MAIN PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the three screws (a), two screws (b), four

screws (c) and screw (d) as shown in Fig. 3-8.

7. Disconnect the connectors (SA, SC,SD, SE, SF, SL,

SQ, SX and SZ) as shown in Fig. 3-8.

8. Remove the MAIN PCB ASSY as shown in Fig. 3-8.

Note: The DV-SV connector, DW-SW connector and SK-TK

connector are connected directly each other.

Disconnect these connectors before removing the

MAIN PCB ASSY.

ax3

SQ

SF

SC

SE

TERMINAL

PCB ASSY

SD

SV SW

SA

SL

TW

bx2

SZ

MAIN PCB ASSY

SX

SK

PCB holder

TK

TL

nx2

T erminal ASSY

ex3

dx1

fx3

mx1

gx8

hx4

jx1

kx1

cx4

11. Removal of the TERMINAL PCB

ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the three screws (a), three screws (e) and

three screws (f) as shown in Fig.3-8.

7. Disconnect the connectors (SA, SC, SD, SE,SF, SL,

SQ, SX, SZ, TL and TW) as shown in Fig. 3-8.

8. Remove the terminal ASSY as shown in Fig. 3-8.

Note: The DV-SV connector and DW-SW connector are

connected directly each other.

Disconnect these connectors before removing the

terminal ASSY .

9. Remove the two screws (b), four screws (c), screw (d),

eight screws (g), four screws (h), screw (j), screw (k)

and screw (m) as shown in Fig. 3-8.

10. Remove the MAIN PCB ASSY and terminal holder as

shown in Fig. 3-8.

Note: The SK-TK connector are connected directly each

other.

Disconnect these connectors before removing the

MAIN PCB ASSY.

11. Remove the two screws (n) as shown Fig. 3-8.

12. Remove the TERMINAL PCB ASSY as shown Fig.

3-8.

DWDV

Fig. 3-8

Terminal holder

- 23 -

Page 29

Y

12. Removal of the DRIVE PCB

ASSY and LCD block

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the screw (a) as shown in Fig. 3-9.

8. Remove the main radiator as shown in Fig. 3-9.

9. Remove the two screws (b) as shown in Fig. 3-9.

10. Remove the main PCB holder as shown in Fig. 3-9.

11. Remove the eight screws (c) as shown in Fig. 3-9.

12. Disconnect the connectors (DB, DG, DP and DR) as

shown in Fig. 3-9.

13. Remove the DRIVE PCB ASSY as shown in Fig. 3-9.

14. Remove the three screws (d) as shown in Fig. 3-9.

15. Remove the LCD block as shown in Fig. 3-9.

Main PCB holder

bx2

DR

DP

LCD block

Main radiator

ax1

DG

cx8

DB

dx3

DRIVE PCB ASS

Fig. 3-9

- 24 -

Page 30

13. Removal of the drive fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block ”.

8. Remove the two screws (a) and four screws (b) as

shown in Fig. 3-10.

9. Remove the drive PCB holder as shown in Fig. 3-10.

10. Remove the two screws (C) as shown in Fig. 3-10.

11. Disconnect the connector (ND) as shown in Fig. 3-10.

12. Remove the fan holder L as shown in Fig. 3-10.

13. Remove the three screws (d) as shown in Fig. 3-10.

14. Remove the drive fan as shown in Fig. 3-10.

PBS fan

cx2

Drive PCB holder

ax2

ex2

ND

bx4

NB

14. Removal of the PBS fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block ”.

8. Remove the fan holder L according to “13. Removal

of the drive fan”.

9. Remove the two screws (e) as shown in Fig. 3-10.

10. Disconnect the connector (NB) as shown in Fig. 3-10.

11. Remove the PBS fan as shown in Fig. 3-10.

dx3

Fan holder L

Drive fan

Fig. 3-10

- 25 -

Page 31

15. Removal of the optical unit

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the screw (a) as shown in Fig. 3-11.

11. Remove the holder SP, lead clamper and thermo bar-

rier as shown in Fig. 3-11.

12. Remove the two screws (b) as shown in Fig. 3-11.

13. Disconnect the lamp power lead and thermostat con-

nector as shown in Fig. 3-11.

14. Remove the fi ve screws (c) and screws (d) shown in

Fig. 3-11.

15. Disconnect the connectors (MA, NB, NK, NR, and

NS) as shown in Fig. 3-11.

16. Remove the optical unit as shown in Fig. 3-11.

Thermo barrier

Optical unit

NB

NR

MA

Holder SP

Lead clamper

NK

NS

cx5

ax1

dx1

bx2

Lamp power

lead

Thermostat

connector

Fig. 3-11

- 26 -

Page 32

16. Removal of the POWER PCB

ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the terminal board unit according to “8. Re-

moval of the speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block ”.

8. Remove the drive PCB holder according to “13. Re-

moval of the drive fan”.

9. Disconnect the thermostat connector according to “15.

Removal of the optical unit”.

10. Remove the two screws (a) and two screws (b) as

shown in Fig. 3-12.

11. Remove the power shield L and SW shield as shown

in Fig. 3-12.

12. Release the three hook (c) as shown in Fig. 3-12.

13. Lift the power box T unit and disconnect the connec-

tor (RD, RF and RH) as shown in Fig. 3-12.

14. Remove the power box T unit as shown in Fig. 3-12.

15. Remove the screw (d) as shown in Fig.3-12.

16. Release the three hook (e) as shown in Fig. 3-12.

17. Remove the POWER PCB ASSY as shown in Fig.

3-12.

POWER PCB ASSY

RH

dx1

Fig. 3-12

SW shield

Power box T unit

bx2

ex3

RF

RD

Power shield L

cx3

ax2

- 27 -

Page 33

17. Removal of the lamp power unit

Y

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the tspeaker according to “8. Removal of the

speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block ”.

8. Remove the drive PCB holder according to “13. Re-

moval of the drive fan”.

9. Disconnect the lamp power lead and thermostat con-

nector according to “15. Removal of the optical unit”.

10. Remove the power box T unit according to “16. Re-

moval of the POWER PCB ASSY”.

11. Remove the power fi n as shown in Fig. 3-13.

12. Release the two hook (a) as shown in Fig. 3-13.

13. Remove the lamp power unit as shown in Fig. 3-13.

Power fin

Lamp power unit

ax2

Fig. 3-13

18. Removal of the FILTER PCB

ASSY and INLET PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the speaker according to “8. Removal of the

speaker”.

5. Remove the main barrier according to “9. Removal of

the power fan”.

6. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

7. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block ”.

8. Remove the drive PCB holder according to “13. Re-

moval of the drive fan”.

9. Disconnect the lamp power lead and thermostat con-

nector according to “15. Removal of the optical unit”.

10. Remove the power box T unit according to “16. Re-

moval of the POWER PCB ASSY”.

11. Remove the screw (a) as shown in Fig. 3-14.

12. Lift the FILTER PCB ASSY and disconnect the con-

nector (PP) as shown in Fig. 3-14.

13. Remove the FILTER PCB ASSY as shown in Fig.

3-14.

14. Remove the screw (b) and screw (c) as shown in

Fig.-3-14.

15. Remove the INLET PCB ASSY as shown in Fig.

3-14.

INLET PCB ASSY

bx1

FILTER PCB ASS

cx1

ax1

PP

Fig. 3-14

- 28 -

Page 34

Y

19. Removal of the POWER SUB

PCB ASSY

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

1 1. Remove the fi ve screws (a) and screw (b) as shown

in Fig. 3-15.

12. Disconnect the connectors (NA, NH, NM, NV) as

shown in Fig. 3-15.

13. Remove the POWER SUB ASSY as shown Fig. 3-15.

NM

NV

ax5

bx1

POWER SUB PCB ASS

NH

NA

Fig. 3-15

- 29 -

Page 35

20. Removal of the lamp fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

11. Remove the two screws (a) as shown in Fig. 3-16.

12. Remove the lamp fan as shown in Fig. 3-16.

Lamp fan

ax2

LCD fan

bx3

Fig. 3-16

21. Removal of the LCD fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

11. Remove the three screws (b) as shown in Fig. 3-16.

12. Remove the LCD fan as shown in Fig. 3-16.

- 30 -

Page 36

22. Removal of the exhaust fan

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

11. Remove the four screws (a) as shown in Fig.3-17.

12. Remove the grille as shown in Fig. 3-17.

13. Remove of the two screws (b) as show in Fig.3-17.

14. Remove of the exhaust dust and exhaust fan.

Grille

Exhaust fan

bx2

ax4

Exhaust duct

Fig. 3-17

23. Removal of the lens shift motor

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

11. Remove the two screws (a) and two screws (b) as

shown in Fig. 3-18.

12. Remove the lens shift motor as shown in Fig. 3-18.

Lens shift motor

ax2

bx2

Fig. 3-18

- 31 -

Page 37

24. Removal of the lamp box

1. Remove the terminal cover ASSY according to “1.

Removal of the terminal cover ASSY”.

2. Remove the front case unit and top cover unit ac-

cording to “3. Removal of the lens unit and zoom focus motor”.

3. Remove the top case unit according to “4. Removal

of the top case unit and KEY PCB ASSY”.

4. Remove the IRR PCB ASSY according to “7. Remov-

al of the IRR PCB ASSY”.

5. Remove the speaker according to “8. Removal of the

speaker”.

6. Remove the main barrier according to “9. Removal of

the power fan”.

7. Remove the terminal ASSY according to “11. Remov-

al of the TERMINAL PCB ASSY”.

8. Remove the DRIVE PCB ASSY according to “12. Re-

moval of the DRIVE PCB ASSY and LCD block”.

9. Remove the fan holder L according to “13. Removal

of the drive fan”.

10. Remove the optical unit according to “15. Removal of

the optical unit”.

11. Loosen the two screws (a) as shown in Fig. 3-19.

12. Remove the lamp box as shown in Fig. 3-19.

ax2

Lamp box

Fig. 3-19

LAMP REPLACEMENT

Note: Only service persons ore allowed to replace the lamp.

When replacing the lamp, be sure to wear gloves to

prevent the lamp from scratches and fi ngerprints that

can cause breakage of the lamp.

Removal

1. Remove the screw (a) and the power socket as

shown in Fig. 4-1.

2. Remove the side spring as shown in Fig. 4-1.

3. Remove the lamp as shown in Fig. 4-1.

Installation

1. Install the lamp in the reverse order of removal.

Note: Mount the lamp with the fl at area of the refl ect base

facing up.

Run the lead wire of the lamp so that it doesn't touch

the refl ector and the refl ect base.

Lamp

Side spring

Reflector

Power socket

Reflector base

ax1

Fig. 4-1

- 32 -

Page 38

LEAD DRESS

Note: The inner wires are clamped so that they do not come close to heat generating or high voltage parts. After servicin-

groute all wires in their original position.

Lead wire routing in the bottom case unit

Run the SL lead wire

outside this rib.

Clampe the SL lead

wire with the tape.

Run the SL lead wire

along the mark line.

±5

35

AL

SL

Connect the shorter SL lead wire here.

Connect the longer SL lead wire here.

Fig. 5-1

Lead wire routing after the POWER SUB PCB ASSY,

MOTOR PCB ASSY and power box B unit are attached

Power box B unit

POWER SUB PCB ASSY

MOTOR PCB ASSY

Run the NC,NE and NF lead wires

through the clamper.

NE

NV

NM

MV

NF

NC

Fig. 5-2

NP

NH

NW

Run the NC,NE,NF,NH and NP lead wires

through the clamper.

- 33 -

Page 39

Lead wire routing after the INLET PCB ASSY,

FILTER PCB ASSY, lamp power unit and power fan are attached

Lamp power unit

CN3

FILTER PCB ASSY

CN2

CN1

FL

PP

NA

Retain the NA and NW lead wires using the clamper.

FN

FG

Power fan

Clamp the FR,FS,FT and FU

lead wires after connecting them

to seesaw switch.

INLET PCB ASSY

Fig. 5-3

Lead wire routing after the POWER PCB ASSY and

IRF PCB ASSY are attached

FT

FR

FU

FS

Seesaw switch

AM

IRF PCB ASSY

RT2

RT1

RF

RD

RH

Run the AM lead wire

through the notch of the front holder L.

RE

Fig. 5-4

- 34 -

POWER PCB ASSY

Run the RE lead wire

through the hole of the power fin.

Page 40

Lead wire routing after the optical unit and

IRR PCB ASSY are attached

Run the SL lead wire

through the hook of

the optical unit.

Run the NB,NK,NR

and NS lead wires

through the two

clampers.

NB

IRR PCB ASSY

NK

NS

NR

AL

optical unit

Clamp the brown and red

lead wires with the band.

Run the thermostat

lead wires over the lamp

power lead wire.

MA

Fig. 5-5

- 35 -

Page 41

Lead wire routing after the drive fan and

DRIVE PCB ASSY are attached

Retain the SL,SX and SZ lead wires

using the clamper.

Remove slack in the SL lead wires

by pulling them in the arrow’ s direction.

DR

Drive fan

ND

Run the ND lead wire

through the clamper of fan holder L.

Retain the DP and SD lead wires

using the clamper.

DG

DRIVE PCB ASSY

DB

DP

Run the SC,SE and SF lead wires

through the clamper.

Fig. 5-6

- 36 -

Page 42

Lead wire routing after the speaker and

terminal ASSY are attached

Speaker

SX

SZ

SL

TL

Terminal ASSY

SD

SQ

SE

SC

SF

Run the TW lead wire

over the main barrier.

Fig. 5-7

Run the TL lead wire

through the hook of

the terminal holder.

SA

TW

Run the TW lead wire

through the upper hook of

the terminal holder.

Run the SA lead wire

through the two hooks of

the terminal holder.

- 37 -

Page 43

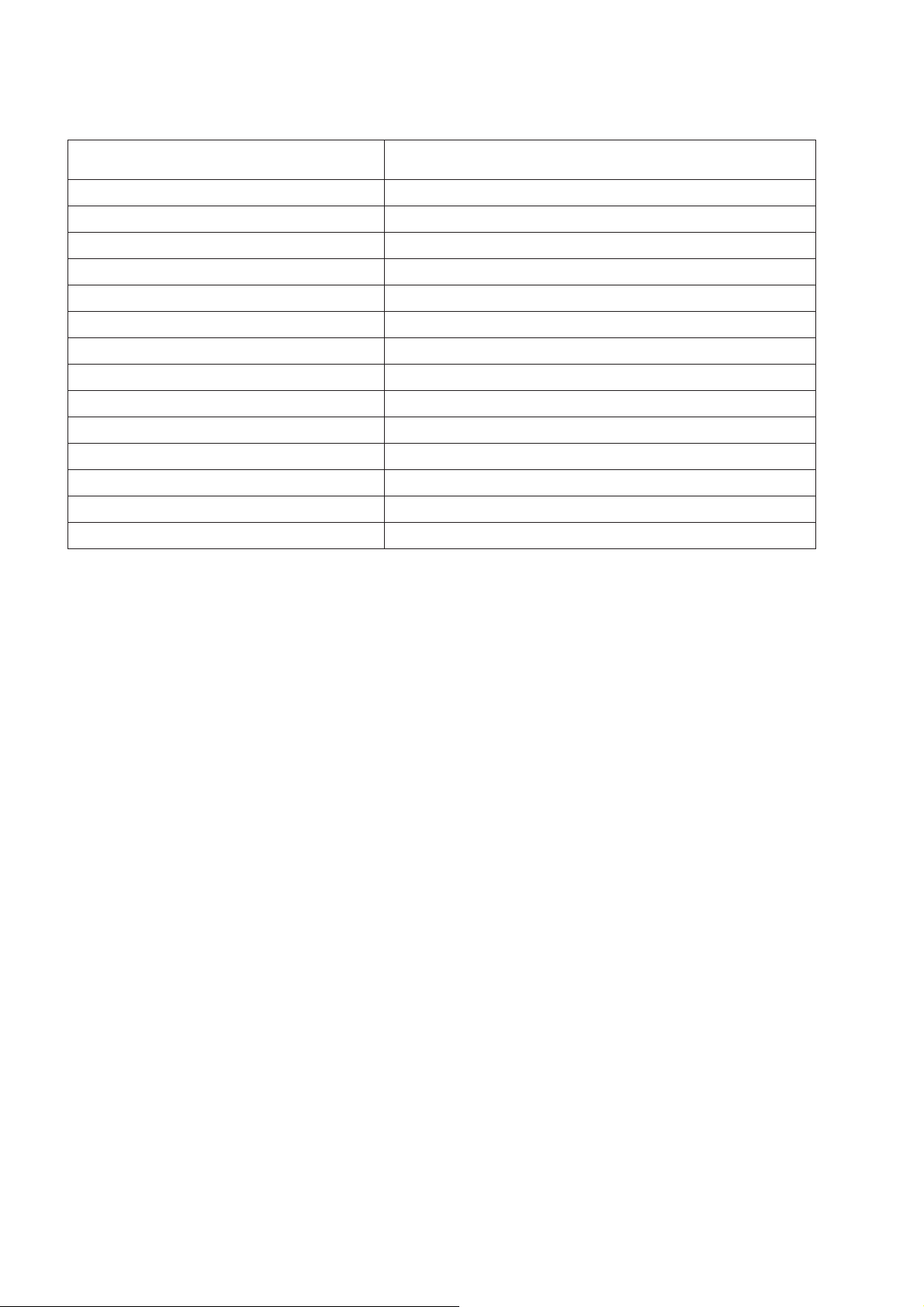

PACKING

10,11,12

13,14,15

16,17

10,18,19

20,21,22

9

6,7,8

Parts list : See page 9 of PARTS LIST

4,5

Item No. Part name

1 Packing case

2 Cushion T/B

3 Packing sheet

4 Fan fi lter

2

3

1

5 Packing bag

6 Terminal cover unit

7 Alarm unit ASSY

8 Packing sheet

9 Paking case

10 Packing bag

11 Quick reference

12 IB CD-ROM

13 Remote hand unit

14 Battery

15 Short pin plug

16 Ring

- 38 -

17 Ring B

18 Control cable

19 VGA cable

20 AC power cord (EU)

21 AC power cord (US)

22 AV cable

Page 44

LAMP REPLACEMENT

This projector is equipped with a lamp to project images. This lamp is a consumable. It may burn out or its brightness

may decrease during use. In such cases, replace the lamp with a new one as soon as possible. Be sure to replace the

lamp with a new lamp separately sold that is exclusive to this projector. Contact your dealer for purchase of the lamp.

Spare lamp VLT-XL6600LP

Warning:

• Be careful not to drop the lamp fi xing screws into the inside of the projector. Don’t put a metal piece or fl ammable

object into the projector. Using the projector with any foreign object present inside may result in electric shock or

fi re. When you can’t remove the foreign object from the inside, contact your dealer for removal.

• Be sure to install the lamp securely. When the lamp isn’t installed properly, it won’t illuminate. Improper installation

may also result in fi re.

• Don’t shake the removed lamp or don’t lift it above your face. You may be injured in your eye by fl ying or falling

glass fragments.

• Don’t replace the lamp immediately after use because the lamp cover is very hot. You may get burned. Turn off the

power using the POWER button. After the lamp goes out, wait about 2 minutes until the intake and exhaust fans

for cooling the lamp stop rotating. Then turn off the main power switch, unplug the power cord, and wait at least 1

hour to allow the lamp to cool down enough to the touch.

• Do not touch the lamp directly. It may break and cause injury or burn.

Interval of lamp replacement

The recommended interval of lamp replacement is about 4000 hours

depending on the operating environment and may be shorter than 4000 hours

*1*2

of consecutive use. Such interval differs

*1*2

. Decrease in luminescence and/or

color brightness indicates that the lamp needs to be replaced. When the lamp operation time exceeds 3000 hours*1,

the indicator will blink alternately between green and red (while the lamp is lit; when the lamp is not lit, the indicator

will be lit red only) and the lamp replacement message will appear on the screen for 1 minute everytime the lamp

is turned on. When the lamp has been used for about 3800 hours

will appear on the screen for 1 minute every 20 hours

*1*2

hours

, the projector automatically shuts off and can’t be used until the lamp is replaced and the lamp

*1

thereafter. When the lamp operation time exceeds 4000

*1

, the replacement message (LAMP EXCHANGE)

operation time is reset.

*1: Duration when LAMP MODE of the INSTALLATION menu is set to LOW. When it is set to STANDARD, this duration will be

shorted.

*2: When LAMP MODE is set to STANDARD, this duration will be shorted to 2000 hours.

Caution:

• Don’t remove the lamp for any purpose other than replacement. Unnecessary removal of the lamp may result in a

breakdown.

• This projector uses a high-pressure mercury lamp as the light source. The high-pressure mercury lamp may

explode or fail to illuminate permanently because of an impact, scratch, or deterioration through use. The period

of time until explosion or permanent failure to illuminate varies considerably from lamp to lamp, depending on

operation conditions. Therefore, the lamp may explode soon after the start of use.

• The possibility of explosion of the lamp increases if you use it beyond its replacement period. When the instruction

of lamp replacement appears, replace it with a new one immediately even if the lamp is still lighting normally.

• When the high-pressure mercury lamp explodes, glass fragments will scatter inside or outside the lamp box and

the gas charged inside the lamp will diffuse inside or outside the projector. The gas inside the lamp contains

mercury. Be careful not to breathe it or avoid it from entering your eye or mouth. If you should breathe it or if it

should enter your eye or mouth, see a doctor immediately.

• In the event that the high-pressure mercury lamp exploded, glass fragments may have been scattered inside the

projector. Ask your dealer to replace the lamp and to inspect the inside of the projector. When you clean or replace

the lamp by yourself, be sure to hold the handle of the lamp. You may get injured by glass fragments.

• Don’t replace the lamp while the projector is installed on the ceiling. Glass fragments may fall from the projector,

entering your eye or mouth causing injury.

• When placing the projector upside down to replace the lamp or conduct maintenance, ensure that the projector is

securely placed before working with it.

• Be sure to use the lamp exclusive to this projector, VLT-XL6600LP. Use of other lamps may cause a failure of the

projector.

- 1 -

Page 45

To replace the lamp:

(c)

(a)

(a)

Handle

(c)

1. Turn off the main power switch and unplug the power cord.

2. Reverse the projector gently.

3. Loosen the screw (a) using a Phillips screwdriver (+), and

remove the lamp cover (b).

4. Loosen the screws (c) using a Phillips screwdriver (+).

5. Pull up the handle.

6. Pull out the lamp box by the handle while holding the

(b)

projector.

• Pull the lamp box out of the projector slowly. If it is

pulled out quickly, the lamp may break scattering glass

fragments.

• Do not spill liquid on the removed lamp box or do not

place it near any fl ammable object or where children

can reach to prevent injury or fi re.

7. Load a new lamp box securely into the projector in the right

orientation.

8. Put the handle back to the original position.

• Make sure that the handle is locked.

9. Tighten up the screws (c) using a Phillips screwdriver (+).

10. Tighten up the screw (a) using a Phillips screwdriver (+) to

secure the lamp cover.

Reset of the lamp operation time

11. Plug the power cord into the wall outlet and turn on the

main power switch.

12. Hold down the W, X, and POWER buttons on the control

panel at the same time about 3 seconds.

Important:

• Unless these 3 buttons are held down at the same time, the lamp operation time isn’t reset.

• Make sure that the STATUS indicator is lit twice and the lamp operation time is reset successfully.

• The projector doesn’t turn on if the lamp cover isn’t attached securely.

• Be sure to reset the lamp operation time whenever you replace the lamp.

• Do not reset the lamp operation time unless you replace the lamp.

• The lamp is fragile. If it is broken, be careful not to cut yourself with glass fragments.

• Contact your dealer for a new lamp.

• This projector uses a lamp that contains mercury. Disposal of the lamp or the projector with the lamp may be

regulated due to environmental considerations. For disposal or recycling information, please contact your local

authorities or the Electronic Industries Alliance: www.eiae.org. (For the U.S. only.)

- 2 -

Page 46

MAINTENANCE

Warning:

• Never use fl ammable air duster or other materials when cleaning the air-fi lter. Flammable substances may ignite

causing fi re or backdown when the lamp is illuminated.

• Do not use fl ammable solvents (benzene, thinner, etc.) and fl ammable aerosols when cleaning the projector body

and lens. Flammable substances may ignite causing fi re or breakdown while the lamp is illuminating.

Caution:

Be sure to turn off the lamp and unplug the power cord from the wall outlet before you perform any maintenance on

the projector.

Cleaning of the air-fi lter

Clean the air-fi lter frequently (about once a month). If the fi lter or

ventilation grilles become clogged with dirt or dust, the temperature inside the projector may rise and cause troubles, such as

damage to the inside parts and shortening the life of the panels.

• When the temperature inside the projector rises, the STATUS

indicator will blink orange and the lamp will be turned off.

1. To remove the fi lter cover, slide the cover in the direction of the

arrow.

2. Remove the air-fi lter from the fi lter cover.

3. Wash the air-fi lter or change it with a new fi lter.

• Use water or diluted mild detergent to clean the fi lter. Rinse

the fi lter thoroughly and let it dry completely.

4. Attach the air-fi lter to the fi lter cover.

5. Attach the fi lter cover to the projector.

• Make sure that the air-fi lter is attached correctly without

displacement.

Important:

• If the fi lter is damaged or becomes extremely dirty, change it

with a new fi lter. Contact your dealer for a new fi lter.

• Use the dedicated fi lter only.

• The power will not turn on if the fi lter cover is improperly

installed.

Caution:

Be sure to use the projector with an air-fi lter. If not, dust may get inside the projector causing fi re and failure.

Filter cover

Filter cover

Air-fi lter

Cleaning of the projector and the ventilation slots

Use a soft cloth to clean the projector and the ventilation grilles. When the grilles become dirty, wipe them with a soft

cloth dampened with diluted mild detergent, and then wipe them with a dry cloth.

• Clean the inside of the terminal cover frequently as dust is apt to be collected.

To protect the surface of the projector from fading or deteriorating:

• Do not spray insecticide on or inside the projector.

• Do not use benzine or thinner to clean it.

• Do not let rubber or plastic materials contact with projector.

Cleaning of the lens

Use a standard lens-cleaning brush or a piece of lens tissue dampened with lens cleaning fl uid. The lens surface is

fragile. Use only recommended, nonabrasive lens-cleaning materials. Do not touch the lens with your fi ngers.

- 3 -

Page 47

HOW TO USE THE LAMP JIG

Lamp jig is used, with the MAIN PCB ASSY removed. To

check the performance and operation of the OPTICAL UNIT.

The jig is mainly used to remove dust on the LCD panel.

No. : 859C670O80

How to Use

1. Remove the PCB-MAIN according to "10. Removal of

PCB-MAIN" of Disassembly.

2. Connect the connectors (SA, SC, SD, SE, and SX) removed from the MAIN PCB ASSY to the connectors on the

lamp jig.

3. Turn off the FAN-ON and LAMP-ON switches on the lamp

jig.

4. Set four fan voltage adjustment controls to the center position.

5. Connect the power cord to the projector.

6. Turn on the FAN-ON and LAMP-ON switches in hat order.

7. Check the Optical Unit after the lamp is turned on.

8. After running the test, turn off the LAMP-ON switch on the

lamp jig to put out the lamp.

9. Wait about 2 minutes after the lamp is turned off then

turn off the FAN-ON switch on the lamp jig.

10. Pull out the power cord.

11. Remove the PCB-JIG and assemble the product by reversing the disassembly procedure.

Note: Insulate the back side of the lamp jig to prevent it from

touching the metal plate.

Controls for adjusting

the FAN voltage

SE

SC

SD

SX

FAN_ON

LAMP_ON

SA

Lamp jig

WARNING

This symbol means that you should use UV radiation eye and skin

protection during serving if it takes 30 minutes or longer.

- 4 -

Page 48

DUST ON LCD PANEL

Small amount of dust might lie on the LCD panel or polarizer

plate in the course of operating time of the LCD projector and

cause poor image. Residual dust inside the product might

collect on the LCD panel or polarizer plate. and cause poor

image. Clean the inside of the product, as follows.

Symptom

When Projecting R, G, B Monochrome

Pictures and White Raster

• Dust appears to be a black spot such as a missing pixel on

R, G, B monochrome pictures. The black spot appears to

be blurry when the picture is in focus.

Note: If the black part appears sharp in the shape of LCD

pixels when the picture is in focus, the defect lies in

LCD panel.

• Cyan, magenta, or yellow blurry spot appears, when the

picture is in focus on the white raster.

Note: If the spot appears sharp in the shape LCD pixels

when the picture is in focus, the defect lies in LCD

panel.

When Projecting Black Picture

• R, G, or B blurry light appears on the black picture when

the picture is in focus.

Note: If R, G, or B point appears sharp in the shape LCD

pixels on the black picture when the picture is in focus, the defect lies in LCD luminescent points.

Before Cleaning

Before cleaning the inside of the product, be sure to check the

fitter of the intake fan and replace if too dusty.

When reinstalling the filter, confirm carefully that there is