Page 1

HARDWARE MANUAL

F940GOT-SWD-E/LWD-E

Page 2

F940GOT-SWD-E/LWD-E

Foreword

• This manual contains text, diagrams and explanations which will guide the reader in the

correct installation and operation of the communication facilities of FX series.

• Before attempting to install or use the communication facilities of FX series this manual

should be read and understood.

• If in doubt at any stage of the installation of the communication facilities of FX series

always consult a professional electrical engineer who is qualified and trained to the local

and national standards which apply to the installation site .

Page 3

F940GOT-SWD-E/LWD-E

F940GOT-SWD-E/LWD-E

HARDWARE MANUAL

Manual number : JY992D77901

Manual revision : D

Date : February 2000

i

Page 4

F940GOT-SWD-E/LWD-E

Guidelines for the safety of the user and protection of the F940GOT-SWD-E/LWD-E

This manual provides infor mation for the installation and use of the Graphic Operation Terminal F940GOT.

The manual has been written to be used by trained and competent personnel. The definition of such a person

or persons is as follows;

a ) Any engineer who is responsible for the planning, design and construction of automatic equipment

using the product associated with this manual should be of a competent nature , (tr ai ned and qualified

to the local and national standards required to fulfill that role). These engineers should be fully aware

of safety with regards to automated equipment.

b ) Any commissioning or service engineer must be of a competent nature, trained and qualified to the

local and national standards required to fulfill that job. These engineers should also be trained in the

use and maintenance of the completed product. This includes being completely familiar with all associated documentation for the said product. All maintenance should be carried out in accordance with

established safety practices.

c ) All operators of the compliance product should be trained to use that product in a safe and coordi-

nated manner in compliance to established safety practices. The operators should also be familiar

with all documentation which is connected with the actual operation of the completed equipment.

Note:

The term ‘completed equipment’ refers to a third party constructed device which contains or uses the

product associated with this manual.

ii

Page 5

F940GOT-SWD-E/LWD-E

Note’s on the symbology used in this manual

At various times through out this manual certain symbols will be used to highlight points of information which

are intended to ensure the users personal safety and protect the integrity of the equipment. Whenever any of

the following symbols are encountered, its as sociated note must be read and unders tood. Each of the symbols used will now be listed with a brief description of its meaning.

Hardware warnings

1 ) Indicates that the identified danger

2 ) Indicates that the identified danger

3 ) Indicates a point of further interest or further explanation.

Software warnings

1 ) Indicates special care must be taken when using this element of software.

2 ) Indicates a special point of which the user of the as sociate softw are element should be a ware.

WILL

POSSIBLY

cause physical and property damage.

cause physical and property damage.

3 ) Indicates a point of interest or further explanation.

iii

Page 6

F940GOT-SWD-E/LWD-E

Memo

iv

Page 7

F940GOT-SWD-E/LWD-E

CONTENTS

1. INTRODUCTION...................................................................................1-1

1.1 Outline of product................................................................................................1-2

1.2 Product configuration...........................................................................................1-8

1.3 System configuration.........................................................................................1-14

2. Installation, Wiring and General Specifications.....................................2-1

2.1 Installation of main body......................................................................................2-1

2.2 Wiring of power supply........................................................................................2-4

2.3 Functions of operation keys and connectors.......................................................2-9

2.4 Outside dimensions...........................................................................................2-12

2.5 General specificationsl ......................................................................................2-13

2.6 Connection to personal computer......................................................................2-15

2.7 CPU port connection .........................................................................................2-18

2.8 Computer link port connection (MELSEC A Series)..........................................2-26

2.9 Connection to SYSMAC C Series .....................................................................2-29

2.10 Connection to FLEX-PC N Series .....................................................................2-32

2.11 Connection by general-purpose communication ...............................................2-35

3. Startup...................................................................................................3-1

3.1 Startup procedure................................................................................................3-2

3.2 Operation environment setting ............................................................................3-5

4. Extension Module...... ... .. ..................... ... ..................... .. ...................... ..4-1

4.1 Data transfer adaptor...........................................................................................4-1

v

Page 8

F940GOT-SWD-E/LWD-E

5. Maintenance..........................................................................................5-1

5.1 Outline of maintenance........................................................................................5-1

5.2 Replacement of battery .......................................................................................5-3

5.3 Replacement of backlight....................................................................................5-5

6. Troubleshooting.....................................................................................6-1

6.1 Power indication..................................................................................................6-1

7. Additional Functions (in Ver3.00 or later)..............................................7-1

7.1 Applicable Versions and Models .........................................................................7-1

7.2 Connection to MELSEC QnA Series PC.............................................................7-2

7.3 Connection to SLC 500 Series............................................................................7-3

7.4 Connection to Bar Code Reader .........................................................................7-5

7.5 Screen Hard Copy Function................................................................................7-7

7.6 Additional Function in Alarm History Display.......................................................7-8

7.7 Specification of Ten-Key Window Initial Display Position....................................7-8

8. Additional Functions (in V3.10 or later) .................................................8-1

8.1 Applicable Versions and Models .........................................................................8-1

9. Additional Functions (in V4.00 or later) .................................................9-1

9.1 Applicable Versions and Models .........................................................................9-1

Note to User

This manual describes installation, wiring and the specifications of the F940GOT.

For handling and operating procedures of the F940GOT main body, refer to the

F940GOT Operation Manual

offered separately.

vi

Page 9

F940GOT-SWD-E/LWD-E

1. INTRODUCTION

This section describes the product configuration and the system configuration of the graphic

operation terminal.

Confirm various functions of each unit.

INTRODUCTION 1.

1-1

Page 10

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

FX or

A Series PLC

Program

connector

GOT main body

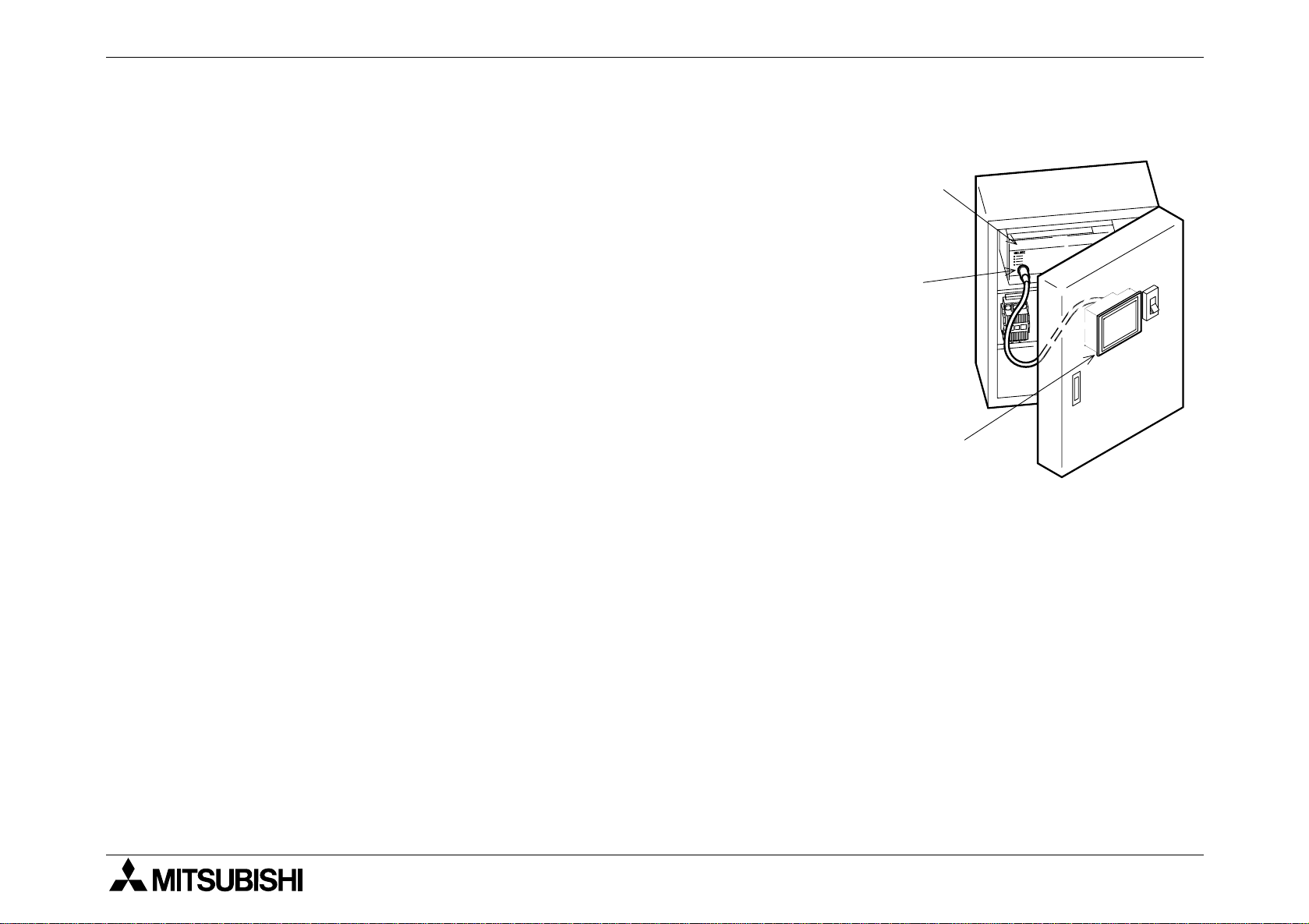

1.1 Outline of product

The graphic operation termin al (which may be hereafter

abbreviated as "GOT") is attached on the panel face of a

control panel or an operation pane l, and connected to a

program connector in an FX or A Series programmable

controller (which may be hereafter abbreviated as "PLC")

(except the A0J2) inside the control panel.

Not only the CPU port connection method but also the

computer link port connection method is available so that

the GOT can be connected to a PLC other than MELSEC

or a micro computer board.

You can monitor various devices and change the data of

the PLC while checking the screen of the GOT.

There are several display screens built in the GOT which

offer various functions. In addition, you can create display

screens.

The built-in screens (system screens) and the screens

made by the user (user screens) have the following functions respectively.

1-2

Page 11

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

User screens

1) Screen display function

The screens created by the user can be displ a y ed. The following functions can be assigned

to each screen. And the screens to be displayed can be limited using the security function.

a) Display function

-Up to 500 screens created by the user can be displayed. The screens can be created

using the FX-PCS-DU/WIN-E V2.00 for the DU or using the SWoD5C-GOTRE-PACK

("o" indicates a numeric not less than 1.) for the GOT. Two or more screens can be

overlaid or changed over.

-Not only characters such as alphabets, numerics, Hiragana, Katakana and Kanji but

also simple graphics such as straight lines, circles and rectangles can be displayed. In

the F940GOT-SWD-E, screens can be displayed in 8 colors.

b) Monitor function

-Set values and current values of word devices in the PLC can be displayed in numerics

or bar graphs for monitoring.

-The specified range of the screen can be displayed reversely in accordance with the

ON/OFF status of bit devices in the PLC.

1-3

Page 12

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

c) Data change function

-The numeric data being monitored can be changed.

d) Switch function

-By manipulating the operation keys in the GOT, bit devices in the PLC can be set to ON

and OFF. The displa y panel face can be assigned as touch keys to offer the switch fu nction.

Make sure to press a touch key by fingers.

If a touch key is pressed by a hard or sharp object, it may become failed.

1-4

Page 13

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

System screens

1) Monitor function

a) List program (only in the FX Series)

- Programs can be read, written and monitored in the form of instruction list program.

b) Buffer memory (only in the FX

2N

and FX

2NC

Series)

-The contents of buffer memories (BFMs) of special blocks can be read, written and

monitored.

c) Device monitor

-The ON/OFF status of each device and the set value and the current value of each

timer, counter and data register in the PLC can be monitored and changed.

-Specified bit devices can be forcedly set to ON and OFF.

Different from the monitor function in the screen display function described in the previous page, the s cre en c an be displayed only inp uttin g a des ired device No. from the keyboard.

1-5

Page 14

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

d) Data sampling function

The current v alue of specified data regi sters are acquired in a const ant cycle or when the

trigger condition is satisfied.

-The sampling data can be displayed in the form of list or graph.

-The sampling data can be output to a printer in the form of list.

e) Alarm function

Alarm messages can be assigned to up to 256 consecutive bit devices in the PLC.

When a bit de vice becomes ON, the assi gned message is displa y ed (ov erlapped) on the

user screen.

In addition, a specified user screen can be displayed by setting a corresponding bit

device to ON.

-When a bit device becomes ON, a corresponding message is displayed on the user

screen. The message list can be also displayed.

-Up to 1,000 alarms (turning ON of bit devices) can be stored as the alarm history.

-The number of alarms occurred in each device can be stored.

*As to 2], the alarm history can be output to a printer using the screen creation soft-

ware.

1-6

Page 15

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

f) Other functions

Many other functions are built in.

-The real-time clock is built in, and the current time can be set and displayed.

-The GOT can function as an interface to enable data communication between the PLC

and a personal computer in which the relay ladder creation software is started up. At

this time, the GOT screen can be displayed also.

-The screen contrast and the buzzer sound volume can be adjusted.

1-7

Page 16

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

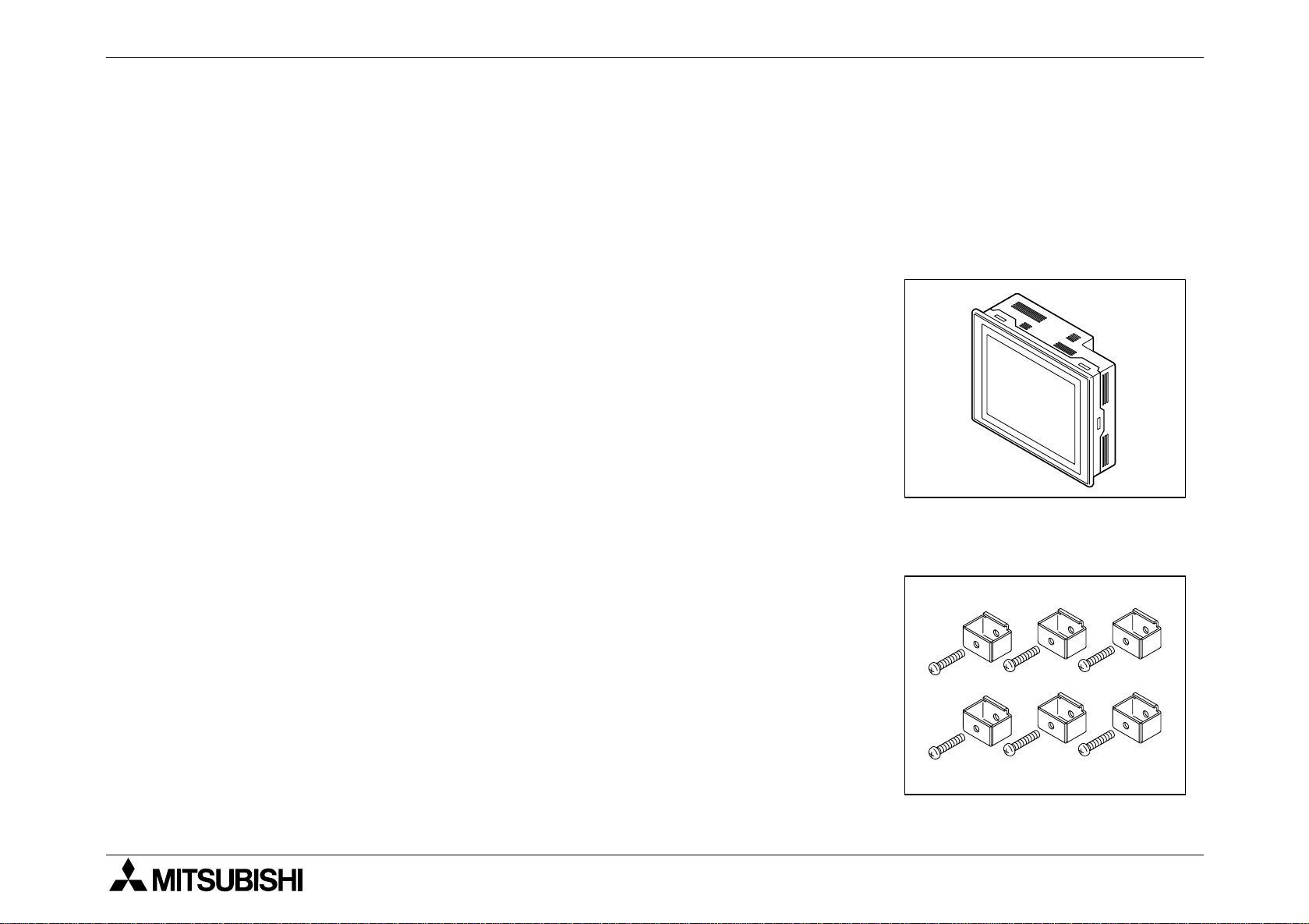

1.2 Product configuration

The GOT is equipped with accessories (1) to (3) below.

Parts (4) to (8) are offered as options.

1) F940GOT (main body)

F940GOT-SWD-E: 5.7" STN type LCD (with eight colors)

F940GOT-LWD-E: 5.7" STN type LCD (with black and white)

2) Metal fixtures

Metal fixtures used to attach the GOT to a control panel

- Metal fixture 6 pieces

- Tightening bolt 6 pieces (M3 x 20)

1-8

Page 17

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

3) Packing

Packing to prevent dusts and water

Used to attach the GOT to a control panel

1-9

Page 18

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

Optional parts

4) Software to create user screens (3.5" FD)

FX-PCS-DU/WIN-E V2.10 or later

(in accordance with the Windows95)

SWoD5C-GOTRE-PACK

("o" indicates a numeric not less than 1.)

(in accordance with the Windows95 and the WindowsNT)

5) Connection cable FX-40DU-CAB (3 m, 9.84 ft)

Connection cable FX-40DU-CAB-10M (10 m, 32.81 ft)

Connection cable FX-50DU-CABL

(3m, 9.84 ft, with L-shape connector on the GOT side)

Each of them is an optional cab le to connect the GOT and the

FX/FX

2C

/A Series PLC.

1-10

Page 19

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

6) Connection cable FX-50DU-CAB0 (3 m, 9.84 ft)

Connection cable FX-50DU-CAB0-1M (1 m, 3.28 ft)

Connection cable FX-50DU-CAB0-10M (10 m, 32.81 ft)

Connection cable FX-50DU-CAB0-20M (20 m, 65.62 ft)

Connection cable FX-50DU-CAB0-30M (30 m, 98.43 ft)

Connection cable FX-50DU-CAB0L

(3 m, 9.84 ft, with L-shape connector on the GOT side)

Each of them is an optional cable to connect the GOT and

the FX

0

/FX0S/FX0N/FX2N/FX

2NC

Series PLC.

By using either one, the GOT can be directly connected to

the PLC.

7) Two-port interface FX-2PIF

This is an optional interface to use the GOT and a periph-

eral unit to create sequence programs at the same time.

This is not required when the GOT is connected to a gener-

alpurpose personal computer or connected to a peripheral

unit via a computer link unit.

1-11

Page 20

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

8) Battery PM-20BL (spare part)

This is used to bac k up the alarm history data, the real-time

clock, etc.

This is attached when the GOT is delivered.

9) EPROM memory to store the user screen data FX-EPROM4M

This is an optional EPR OM memory (M27C4002-**F (4 MB)

manuf actured b y SGS-THOMSON) to save the user screen

data.

The user screen data can be written using a general-purpose ROM writer connected to the screen creation software.

1-12

Page 21

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

10) Data transfer adaptor F9GT-40UMB

This is an optional adaptor to connect the FX-EPROM-4M

9) and transfer the user scre en data to the flush memor y

inside the GOT.

When a same screen is to be transferred to two or more

GOT u nits, transfer can be performed quickly and easily

using this adaptor compared with the s creen creation s oftware.

11) Protection sheet F9GT-40PSC (5 sheets)

This optional sheet protects the display screen against

dirt.

Adhere it on the screen.

12) Replacement backlight F9GT-40LTS

This is a spare part of the display screen backlight.

The backlight is built in when the GOT is delivered.

1-13

Page 22

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

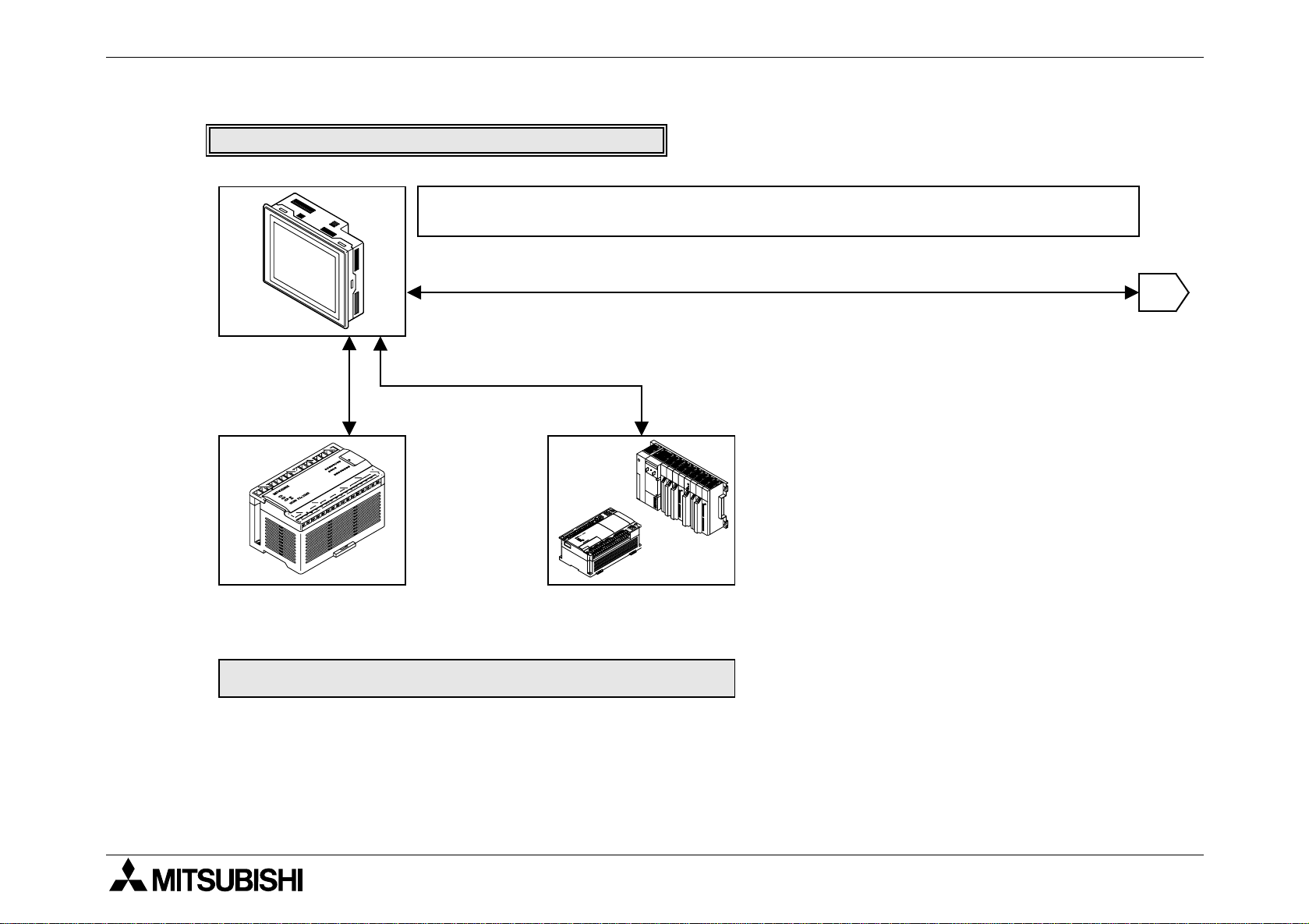

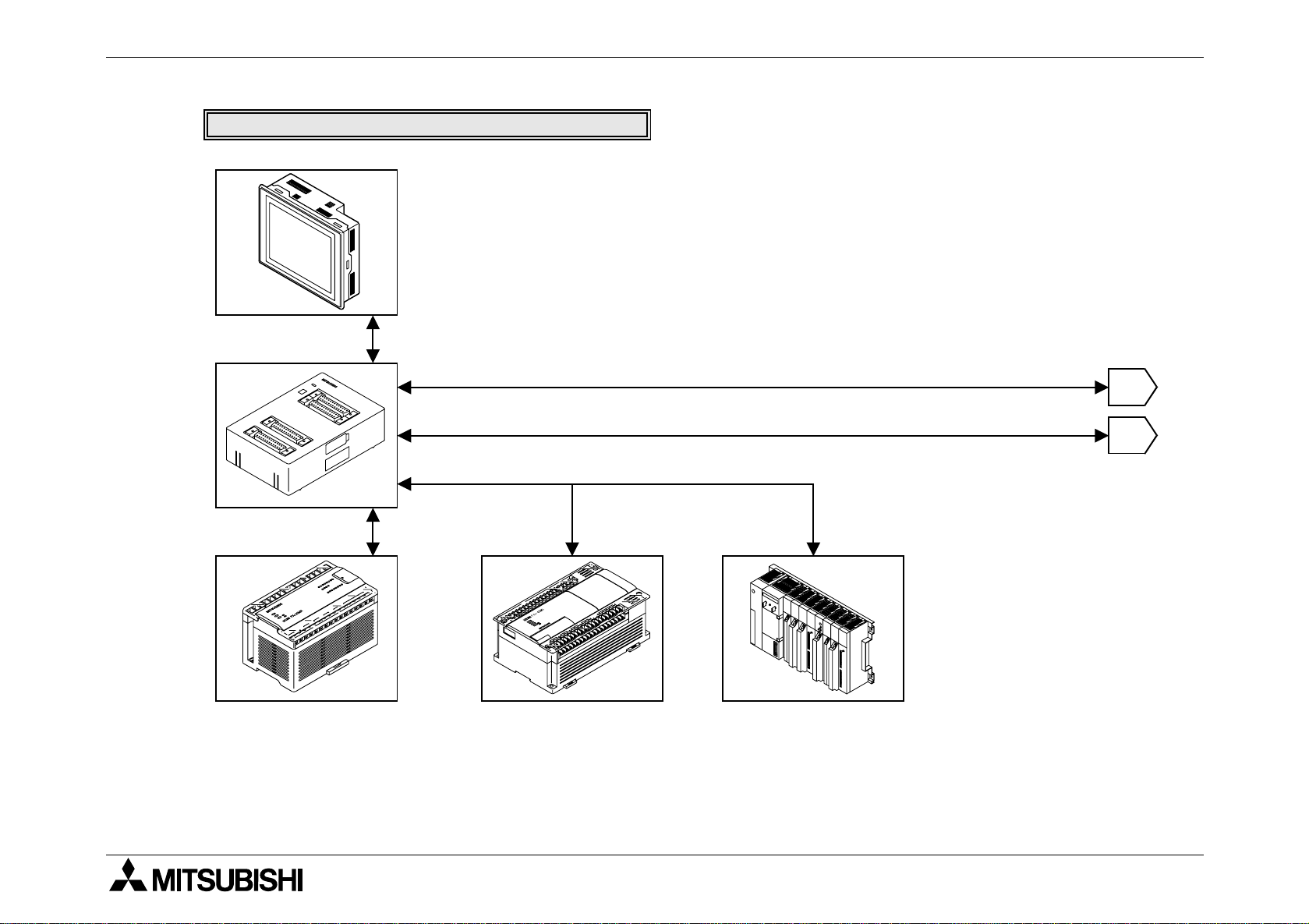

1.3 System configuration

The system configuration to use the GOT is described below.

When the GOT is directly connected to the PLC

F940GOT-SWD-E/LWD-E

Connection cable FX50DU-CAB0 for CPU

port connection*1

:When the GOT is connec ted via a computer link unit, refer to

Section 2.

Data transfer cable FX -232CAB-1 (when the RS -232C c onnector in the personal

computer is 9-pin t ype) or Dat a transfer cable FX-232CAB-2 (when the RS-232C

connector in the pers onal computer is half-pitch,14-pi n type)

Attach a ROM to the F9GT-40UMB, then connect it to a connec tor provided on the rear

face of the GOT.

Data transfer cable F2-232CA B-1

It cannot be used when a computer link (RS-232C communication) is used.

Connection cable FX-40DU-CAB *1

*1 Connection cables of different lengt h are av ai l abl e.

(Refer to the options in "1. 2 P roduct configuration".)

1

2

3

FX0/FX0S/FX0N/FX2N/

2NC

FX

Series

PC

FX/FX

A Series (except QnA)

Motion controller

Series

2C

1-14

Page 23

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

Peripheral units for GOT

General-purpose personal computer

(screen creation software)

1

Data transfer cable F2-232CA B -1

(when the RS-232C connector in the

personal computer is 25-pin type)

Connected to RS-232C connec tor in GOT

2

EPROM memory

FX-EPROM-4M

(User screen data can be written

using a general-purpose ROM writ er.)

3

Screen creation sof tware for DU FXPCS-DU/WIN-E (V2.10 or later)

Screen creation sof tware for A900GOT

SW D5C-GOTRE-PACK

(" " is a numeric not less than 1.)

ROM writer

General-purpose ROM writer

Printer

< Dedicated printers >

GT-10A

K6PR(-K), A7(N)PR

< General-purpose printers >

ESC/P

Printer equipped with RS-232C interface

(Prints out sampling data, alarm history and alarm mes sages.)

1-15

Page 24

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

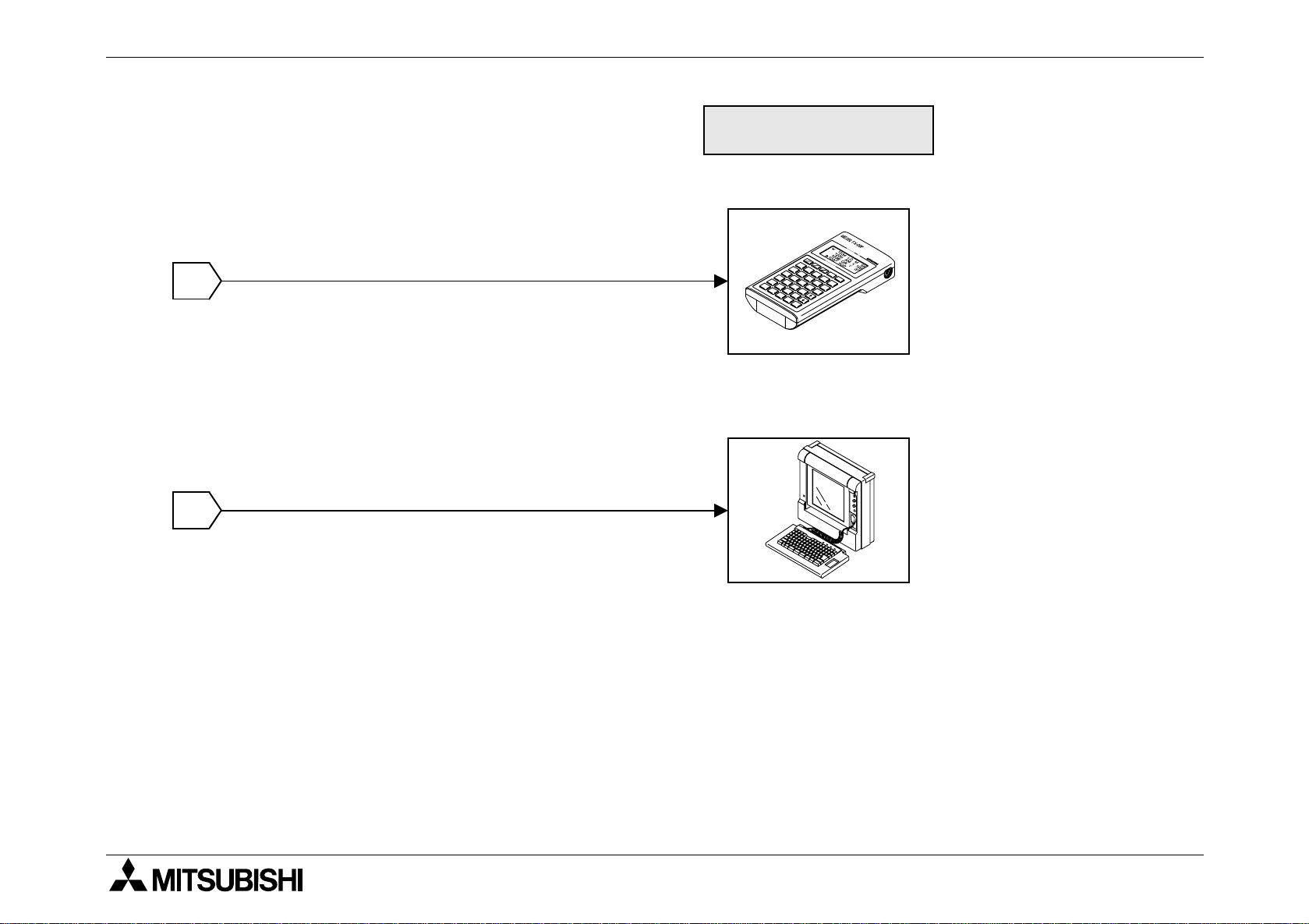

The figure below shows connection to peripheral units used to create sequence programs.

When built-in two-port interfa ce function is used

F940GOT-SWD-E/LWD-E

When the two-port interface f unction is used, the operation environment should be set.

(Refer to the description on "SERIAL PORT" on the SET-UP MODE screen.)

Data transfer cable FX -232CAB-1

Connection cable FX50DU-CAB0 for CPU

port connection*1

(when the RS-232C connector in the pers onal computer is 9-pin type)

Data transfer cable F2-232CA B-2

(when the RS-232C connector in the pers onal computer is half-pitch, 14-pin type)

Connected to RS-232C connector in GOT

Connection cable FX-40DU-CAB *1

*1 Connection cables of different lengt h are av ai l abl e.

(Refer to the options in "1. 2 P roduct configuration".)

1

FX0/FX0S/FX0N/FX2N/

2NC

Series

FX

FX/FX2C Series

A Series (except QnA)

Motion controller

PC

1-16

Page 25

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

Peripheral unit to create

sequence programs

General-purpose

personal computer

* A general-purpose computer can be directly connected, and

both the GOT and the personal computer can be used at

the same time (without using the FX-2PIF).

1

When the two-port interface f unction is used using the sof tware

package SW D5C(F)-GPPW-E, make sure to use the

connection cabl e having the model name shown on the left to

connect a personal computer.

Note:

This two-port inte rface function is effective in CPU port connection ( via the RS-422). This

function is not a v ailab le in computer link connec tion (via the RS-422 or the RS-232C) and CPU

port connection (via the RS-232C).

And even in CPU po r t connect ion (via the RS-422 ), this funct ion is not available when two or

more GOT units are connected (Refer to Paragraph 2.7.).

1-17

Page 26

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

When the two-port interface FX-2PIF is used

F940GOT-SWD-E/LWD-E

Two-port interface

FX-2PIF

Data transfer cable

FX-422CAB0

2NC

FX

Series

Connection cable FX-40DU-CAB/EN

Program cable FX-20P-CAB

Data transfer cable AC30R4

Data transfer cable FX-422CAB or

Data transfer cable FX-422CAB-150

FX/FX

2C

/ SeriesFX0/FX0S/FX0N/FX2N/

1

2

A Series (except QnA)

1-18

Page 27

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

Peripheral unit to create

sequence programs

Handy programming

panel FX-10P -E/20P-E

1

(A Series cannot be used.)

A7PHP/A7HGP

A6GPP/A6PHP

The FX2N/FX

can be used in the

instruction/device

2

range of the F X Series.

2NC

Series

Note:

The two-port interface FX-2PIF is available in CPU por t connection (via the RS-422). This

interface is not available in computer link connection (via the RS-422 or the RS-232C) and

CPU port connection (via the RS-232C).

And even in CPU port connection (via the RS-422), this interface is not available when two or

more GOT units are connected (Refer to Paragraph 2.7.).

1-19

Page 28

F940GOT-SWD-E/LWD-E INTRODUCTION 1.

1-20

Page 29

F940GOT-SWD-E/LWD-E

Installation, Wiring and General Specifications 2.

2. Installation, Wiring and General Specifications

This section describes installation of the GOT and wiring of the power supply.

2.1 Installation of main body

Caution on installation

• Use the unit in the environment for the general specifications described in the manual.

Never use the unit in a place with dusts, soot, conductive dusts, corrosiv e gas or flam mable gas, place exposed to high temperature, condensation or wind and rain or a place

subject to vibrations or impacts.

If the unit is used in an unfa v or ab le place described above, electrical shoc k, fire, malfunction, damages of the unit or deterioration of the unit may be caused.

• Never drop cutting chips and wiring chips into the vent ila tion wind ow of the graphic oper-

ation terminal when you drill screw holes or perform the wiring work.

Fire, failure or malfunction may be caused.

• Connect a connection cable and mount an extension module securely to the specified

connectors respectively while the power is turned off.

Imperfect connection may cause malfunction.

2-1

Page 30

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

153 (6.02 )

+1

- 0

mm

(inches)

121 (4.76 )

+1

-0

+0.04

- 0.00

+0.04

- 0.00

a)

b)

c)

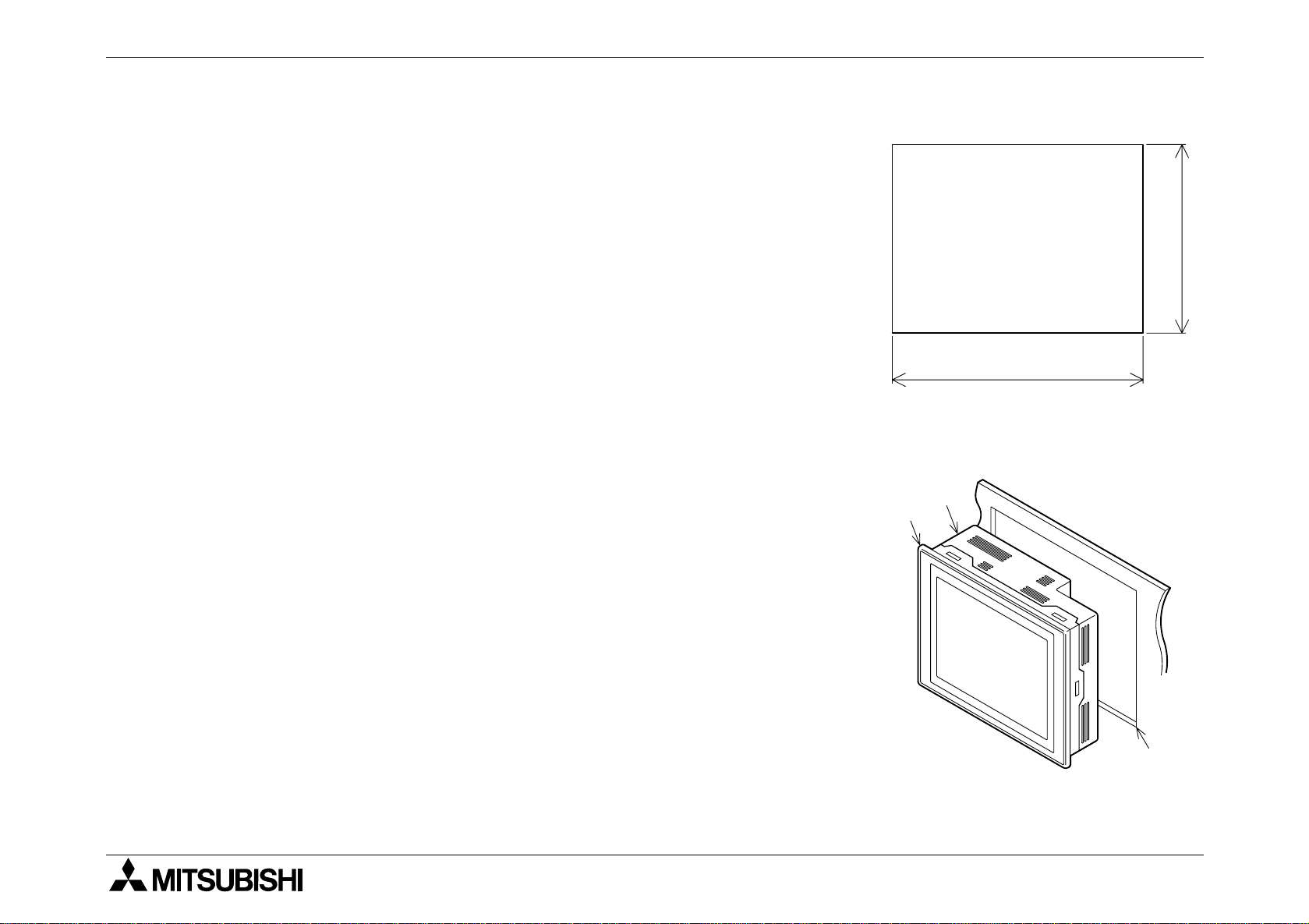

The GOT is to be embedded in a panel. Perform the installation procedure described below.

1) Machining the mounting panel face

On the panel face, drill a mounting hole of the dimensions

shown on the right.

* Make sure that the plate thic kness of the mounting pa nel

is 5 mm (0.2 inches) or less.

2) Inserting the GOT into the panel face

Attach a packing to the GOT. Insert the GOT from the fro nt

of the panel face.

a) GOT

b) Packing

c) Mounting hole

2-2

Page 31

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Enlarged view

a)

b)

a)

b)

-

+

24VDC

5 (0.20)

or less

57 (2.24)

152 (5.98)

120 (4.72)

mm

(inches)

3) Fixing the GOT

Hang the hook of each metal fixture (offered as accessory)

to a mounting hook hole in the GOT. Tighten a mounting

bolt (offered as accessory) securely in each position.

The GOT can be fixed in four positions at corners.

However, to prevent dusts and water, fix the GOT in six

positions.

a) Metal fixture

b) Tightening bolt

* Make sure that the tightening torque for each tightening

bolt is 0.3 to 0.5 N m.

4) Inside dimensions of the panel required for installation

When installing the GOT, make sure that the inside dimen-

sions shown on the right are assured in the panel.

a) PLC connection cable

b) Packing

2-3

Page 32

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.2 Wiring of power supply

Cautions on Wiring

• Make sure to shut down the power supply outside the unit before starting installation or

wiring.If the power supply is not shut down outside, electrical shock or damages of the

unit may be caused.

CAUTION

• Connect the DC power cable to a dedicated terminal as described in this manual.

If the AC power supply is connected to a DC power terminal or an I/O terminal, the

graphic operation terminal may be burnt.

• Attach a fuse of 2A to the 24V DC po wer supply. Connect the + side and the - side of the

DC power supply correctly as described in this manual.

If the power supply is connected reversely, failures may be caused.

• Use wires of 1.25 mm

2

or more for a ground terminal in the graphic operation terminal.

When supplying the po wer from a prog ramm abl e controller, connect a ground terminal in

the graphic operation terminal to a ground terminal in the programmable controller and

perform Class 3 grounding. When supplying the power from the outside, connect a

ground terminal in the graphic operation terminal to a ground terminal in the connected

external power supply unit and perform Class 3 grounding.

Never perform common grounding with strong electrical systems.

2-4

Page 33

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

The power is supplied to the GOT from a PLC or an external power supply unit.

• Connection examples

1) When the power is supplied from an FX Series PLC (Refer to "Cautions on connection" in

the next page.)

Connect the power terminal in the GOT to the 24V DC service power supply in the PLC

basic unit or PLC extension unit.

2A

Class 3

Class 3

grounding

grounding

24V 0V S/S RUN X0 X1 X2

PLC GOT

- +

DC

24V

2-5

Page 34

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2) When the power is supplied from an external power supply unit

Connect the power terminal provide d on the rear face of the GO T to the 24V DC terminal in

the external power supply unit.

Class 3

grounding

24V 0V S/S RUN X0 X1 X2

PLC GOT

Class 3

grounding

2A

- +

DC

24V

2-6

Page 35

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Specifications of power supply unit

Specifications

Item

F940GOT-LWD F940GOT-SWD

Supply voltage 24V DC

+10%

-15%

Power ripple 200mV or less

Current consumption 390mA / 24V DC 410mA / 24V DC

Allowable instantaneous

power interruption duration

Operation shall be continued against instantaneous

power interruption for less than 5 ms.

2-7

Page 36

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Cautions on connection

• The current consumption of the GOT is as shown in the table above. When supplying the

power to the GOT from the 24V DC service po wer in the FX Series PLC basic unit or extension unit, take into account the total current supplied to proximity switches and extension

blocks. If the total current exceeds the capacity of the ser vice power, the GOT should

obtain the power from an exter nal power supply unit. In the case of the FX

0

/FX0S/FX

0N

Series PLC, an external power supply unit is required.

• Even if instantaneous power interruption for less than 5 ms occurs in the power supply unit,

the GOT continues its operation.

When power interruption for 5 ms or more or the voltage drop occurs, the GOT stops its

operation. However, when the power is recovered, the GOT automatically restarts operation. (The screen displayed after recover y is deter mined by the operation environment setting.)

• For wir ing of the power supply, use electric wires of 0.75 mm

2

or more so that voltage drop

does not occur. Use crimp-style terminals of M3 size, and tighten them securely with the

torque of 0.5 to 0.8 N m so that troubles will not occur.

2-8

Page 37

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

POWER

162 (6.38)

130 (5.12)

a)

mm (inches)

2.3 Functions of operation keys and connectors

1) Front panel

a) Display unit

Allows graphic display of 320 × 240 dots.

Character string: 20 full-width characters × 15 lines

40 half-width characters × 15 lines

Alphabets, numerics, Katakana characters and Kanji

characters (JIS Level 1) can be displayed in the size of

1 to ×4 in each of the vertical and horizontal directions.

×

Alphabets, numerics and Katakana characters can be

displayed also in the size of ×1/4.

2-9

Page 38

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

-

+

24VDC

152 (5.98)

b)c)

a)

mm (inches)

2) Rear panel

a) Power terminal

Supplies the power to the GOT, and allows grounding.

b) Battery PM-20BL

Backs up the sampling data, the alarm history and the

current time.

The screen data is stored in the built-in flush memory,

and does not require the battery.

c) Extension interface

Connects an optional e x tension equipment.

Connects the data transfer adopter F9GT-40UMB to

transfer the screen data stored in the EPROM.

2-10

Page 39

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

RS232C

RS422

a)

b)

3) Connectors provided on the side

Used when a printer is connected or when a PLC is con-

nected via a computer link unit.

a) Connector for personal computer (RS-232C connector):

D-sub 9-pin, male

b) Connects a personal computer to transfer to the PLC

the screen data created by the screen creation software

and sequence programs using the two-port interface

function.

2-11

Page 40

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.4 Outside dimensions

57 (2.24)

5

(0.20)

RS232C RS422

120 (4.72)

152 (5.98)

162 (6.38)

POWER

130 (5.12)

Outside painting color: Munsell 0.08GY 7.64/0.81

Mass: Approximately 1.0 kg including metal fixtures (0.1 kg)

Panel cut dimensions: 153 × 121 (6.02 × 4.76 )

-0

+1

+1

-0

+0.04

-0.00

+0.04

-0.00

Unit: mm (inches)

2-12

Page 41

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.5 General specificationsl

Ambient temperature

Ambient humidity

Vibration resistance

Impact resistance

Noise resistance

During operation: 0 to +50°C (0 to +40°C when extension interface is used)

During storage: -20 to +60°C

During operation: 35 to 85%RH (Condensation shall not be allowed.)

Frequency Acceleration Amplitude

When inter-

In accor-

mittent

10-57Hz - 0.075mm

10 times in

each of X,

dance with

JIS B3501

vibrations

are applied

57-150Hz

9.8m/s

2

-

Y and Z

directions

and IEC

1131-2

When continuous

vibrations

10-57Hz - 0.035mm

57-150Hz 4.9m/s

2

-

(for 80

minutes)

are applied

In accordance with JIS B3501 and IEC 1131-2 (147 m/s

2

, three times in

each of X, Y and Z directions)

By noise simulator whose noise voltage is 1,000 Vp-p, noise width is 1µs and

cycle is 30 to 100 Hz

Withstand voltage

Insulation resistance

Grounding

Operating atmosphere

Protection structure

500V AC for 1 minute

500V DC, 5MΩ or more by megger

Class 3 grounding

Corrosive gas and much dusts shall not be detected.

IP65F

Between all power terminals as a whole

and ground terminal

2-13

Page 42

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

24V DC +10%, -15%

Supply voltage

Current consumption: 390 mA/24V DC (F940GOT-LWD-E)

410 mA/24V DC (F940GOT-SWD-E)

Display element

Screen

Service life

Backlight

Key

Interface

STN type full-dot matrix LCD, m onochrome (F940GOT-LWD-E) or color

(F940GOT-SWD-E)

LCD of 320 x 240 dots, 20 full-width characters × 15 lines,

Effective display size: 115 × 86 mm (5.7 inches)

LC: Approximately 50,000 hours

Cold cathode tube (Service life: 25,000 times or more)

50 touch keys maximum/screen, 20 × 12 matrix

One channel in conformance to RS-422 for communication with PLC

One channel in conformance to RS-232C for transfer of screen data

Extension interface for connection of optional extension unit

2-14

Page 43

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.6 Connection to personal computer

Use the following cable to connect a personal computer.

b)

a)

c)

a) F940GOT

b) Personal computer

c) FX-232CAB-1, FX-232CAB-2 or F2-232CAB-1

2-15

Page 44

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Pin assignment and connection diagram of transfer cables

- Transfer cable FX-232CAB-1

D-sub

(female)

9-pin

5

4

3

2

1

9

8

7

6

Personal

computer

side

- Transfer cable FX-232CAB-2

7

Half

pitch

9-pin

1

14

Personal

computer

side

8

2

3

6

8

5

4

1

2

4

9

11

14

12

13

2

3

6

8

5

4

3

4

2

6

8

5

GOT side

GOT side

5

4

3

2

1

5

4

3

2

1

9

8

7

6

9

8

7

6

D-sub

(female)

9-pin

D-sub

(female)

9-pin

2-16

Page 45

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

- Transfer cable F2-232CAB-1

D-sub

(male)

25-pin

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

20

19

18

17

16

15

14

Personal

computer

side

1

2

3

5

6

7

20

2

3

GOT

8

side

4

5

6

5

4

3

2

1

9

8

7

6

D-sub

(female)

9-pin

2-17

Page 46

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

OUT

I N

OUT

CPU¥E

PROG¥E

5

4

3

2

1

0

7

6

5

4

3

2

1

0

X7

X6

X5

X4

X3

X2

X1

X0

COM

N

L

Y5

Y4

Y3

Y2

COM2

Y1

COM1

Y0

COM0

COM

24+

RUN

POWER

c)

f)

a)

2.7 CPU port connection

Use either of the following cables to connect the PLC directly.

2C

1) When connecting the FX/FX

/A Series

2) When connecting the FX

0

/FX0S/FX0N/FX2N/FX

2NC

Series

1) 2)

a)

b)

d)

e), g)

* When the screen mode is selected while a cable is not connected, a communication

error occurs.

2-18

Page 47

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

a) F940GOT

b) FX-40DU-CAB, FX-40DU-CAB-10M or FX-50DU-CABL

c) FX-50DU-CAB0, FX-50DU-CAB0-1M, FX-50DU-CAB0-10M,

FX-50DU-CAB0-20M, FX-50DU-CAB0-30M or FX-50DU-CAB0L

2C

d) FX/FX

Series PLC

e) A Series PLC

AnN, AnA, AnS, AnSJ, AnSH, A1SJH, A2C, A2CJ, A0J2H, AnU, AnUS, A2USH or A1FX

CPU

f) FX

0

/FX0S/FX0N/FX2N/FX

2NC

Series PLC

g) Motion controller

A171SCPU-S3, A171SHCPU, A172SHCPU or A272UHCPU

2-19

Page 48

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Pin assignment and connection diagram of connection cables (The connection cables are

offered as options.)

- Connection cable FX-40DU-CAB (L, -10M) or FX-50DU-CABL

D-sub

(male)

25-pin

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

20

19

18

17

16

15

14

PLC

side

2

3

4

5

7

15

16

17

18

8

21

1

2

3

4

5

6

7

8

9

GOT

side

5

4

3

2

1

- Connection cable FX-50DU-CAB0 (L, -1M, -10M, -20M, -30M)

MINI-DIN

(male)

8-pin

3

4

6

1

7

2

8

5

PLC

side

2

7

6

3

1

4

5

1

2

4

5

6

7

9

GOT

side

5

4

3

2

1

9

8

7

6

9

8

7

6

D-sub

(male)

25-pin

D-sub

(male)

9-pin

2-20

Page 49

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• When the CPU in the FX/A Series PLC is directly connected, up to four GOT units can be

connected to one PLC (1-to-N connection).

As the connection type, select "CPU PORT (RS232C)" or "CPU PORT (RS422)" in "CONNECTION" on the PLC TYPE screen.

System configuration

Side of GOTFX/A Series

1st unit 2nd unit 3rd unit 4th unit

RS-422 communication

Maximum extension

distance: 30 m (98.4 ft)

RS-232C

communication

15 m (49.2 ft)

RS-422C

communication

30 m (98.4 ft)

RS-232C

communication

15 m (49.2ft)

Note:

While the GO T display is used, peripheral units of the GOT and peripheral units used to cre-

ate sequence programs cannot be used except when the following system configuration is

realized using the FX

2N

-422-BD in the FX2N Series. Cables to connect such peripheral

units should be disconnected while the GOT display is used.

2-21

Page 50

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Connection diagram

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Connection cable examples:

1st GOT: FX-50DU-CAB0

(equivalent to connection cable for PLC)

2nd GOT: FX-232CAB-1

3rd GOT: Cable created by user

(Refer to the connection diagram.)

4th GOT: FX-232CAB-1

Communication speed: The communication speed with the PLC becomes slower as the

number of connected GOT units becomes larger.

When the speed in the case one GOT unit is connected is regarded as "1",

Speed in 1st unit x 2 = Speed in 2nd unit (1/2 of speed in 1st unit)

Speed in 2nd unit x 2 = Speed in 3rd unit (1/4 of speed in 1st unit)

Speed in 3rd unit x 2 = Speed in 4th unit (1/8 of speed in 1st unit)

• In this case, peripheral units used to create sequence programs can be connected using

programming connectors in the FX

2N

unit.

2-22

Page 51

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• In the case of the FX2N Series, communication can be performed by CPU port connection

2N

(RS-232C communication) using the FX

-232-BD.

In this case also, In the case of the FX

port connection (RS-232C communication) using the FX

2N

Series, communication can be performed by CPU

2N

-232-BD.

In this case also, up to four GOT units can be connected to one PLC (1-to-N connection).

Up to four GOT units can be connected to one PLC (1-to-N connection).

To connect peripheral units used to create sequence programs, use programming connectors in the FX

2N

main unit.

System configuration

Series

FX

2N

RS-232C communication

Maximum extension

distance: 15 m (49.2 ft)

FX

-232-BD

2N

RS-422

communication

30m (98.4ft)

RS-232

communication

15m (49.2 ft)

RS-422

communication

30m (98.4 ft)

2-23

Page 52

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Connection cable examples:

1st GOT: FX-232CAB-1

2nd GOT: Cable created by user

(Refer to the connection diagram.)

3rd GOT: FX-232CAB-1

4th GOT: Cable created by user

(Refer to the connection diagram.)

Connection diagram

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Communication speed: The communication speed with the PLC becomes slower as the

number of connected GOT units becomes larger.

When the speed in the case one GOT unit is connected is regarded as "1",

Speed in 1st unit x 2 = Speed in 2nd unit (1/2 of speed in 1st unit)

Speed in 2nd unit x 2 = Speed in 3rd unit (1/4 of speed in 1st unit)

Speed in 3rd unit x 2 = Speed in 4th unit (1/8 of speed in 1st unit)

2-24

Page 53

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

<Cautions on connection of two or more GOT units>

When two or more GOT units are connect ed to the FX/ A/QnA Ser ies PLC, communication is

performed in the location sequence from the GOT unit nearest to the CPU (th at is, in the

sequence of the 1st, 2nd, 3rd and 4th GOT units). Accordingly, when turning on the power of

the GOT units for the first time, turn on the power from the one nearest to the CPU.

If the power cannot be turned on in the GOT units from the one nearest to the CPU, set the

GOT units (in "SET-UP MODE") or the screen creation software so that communication is performed while the title screen display time is different by 2 to 3 seconds in each GOT unit.

Setting example: The title screen display time is different by 2 seconds in each GOT unit, and

communication is started from the GOT unit nearest to the CPU.

FX/A/QnA Title screen display time (initial value: 4 sec)

1st GOT: 4 sec 2nd COT: 6 sec 3rd COT: 8 sec 4th COT: 10 sec

* Perform the same setting without regard to the conn ecti on type (RS-232C or RS-4 22) of two

or more GOT units.

2-25

Page 54

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.8 Computer link port connection (MELSEC A Series)

The GOT can be connected to the MELSEC A Series via a computer link unit as shown below.

• Applicable PLC units and computer link units

< A Series >

AJ71UC24 A1SJ71UC24-R2/R4/PRF A1SJ71C24-R2/R4/PRF

A1SCPU24-R2 A2CCPUC24 (PRF)

For the communication setting f or the computer link unit, re f er to the F940GOT Operation Manual offered separately.

• System configuration

Programming

connector

is not used.

RS232C

RS232C

RS422

RS422

For the connection diagram, refer to the next page.

To computer link unit

2-26

Page 55

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Connect the GOT to the computer link unit (PLC) as shown below.

< For RS-422 communication >

1

6

GOT

2

side

7

5

5

4

3

2

1

9

D-sub

8

(male)

7

9-pin

6

Terminal

block

Computer link

unit side

(PLC side)

RDA

RDB

SDA

SDB

SG

< For RS-232C communication > The connection cable F2-232CAB is also available.

D-sub

25-pin

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

Computer link

20

19

18

17

16

15

14

unit side

(PLC side)

FG

SD

RD

RS

CS

DSR

SG

CD

DTR

1

2

3

4

5

6

7

8

20

1

2

3

7

GOT

8

side

6

5

4

5

4

3

2

1

9

8

7

6

D-sub

(female)

9-pin

2-27

Page 56

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

< For RS-232C communication >

D-sub

9-pin

CD

1

RD

2

5

4

3

2

1

9

Computer link

8

7

6

unit side

(PLC side)

SD

DTR

SG

DSR

RS

CS

3

4

5

6

7

8

1

2

3

GOT

4

5

6

7

8

side

5

4

3

2

1

9

8

7

6

D-sub

(female)

9-pin

2-28

Page 57

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.9 Connection to SYSMAC C Series

The GO T can be connecte d to the SYSMAC C Series manufactured b y OMR O N via a host link

unit as shown below.

• Applicable PLC units and host link units

< SYSMAC C Series >

A host link unit or a CPU equipped with an interface for host link is required.

For the setting of the host link unit, refer to the F940GOT Operation Manual offered

separately.

• System configuration

To host link unit

RS232C

RS232C RS422

RS422

2-29

Page 58

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Connect the GOT to the host link unit (SYSMAC C Series) as shown below.

For connection of a model not shown in the examples below, refer to the manual of the C

Series link unit.

< For RS-422 communication > Example of connection to C200H-LK202-V1

1

6

GOT

2

7

5

side

5

4

3

2

1

9

8

7

6

D-sub

9-pin

1

5

4

3

2

1

9

8

7

6

Host link

unit side

(C200H side)

RDB

RDA

SDB

SDA

SG

6

5

9

3

< For RS-232C communication > Example of connection to C200H-LK201-V1

D-sub

25-pin

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

20

19

18

17

16

15

14

Host link

unit side

(C200H side)

FG

SD

RD

RS

CS

SG

1

2

3

4

5

7

1

2

GOT

3

7

side

8

5

5

4

3

2

1

9

8

7

6

D-sub

(male)

9-pin

D-sub

(female)

9-pin

2-30

Page 59

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

< For RS-232C communication >

Example of connection to CQM1 (in which RS-232C port is built in)

D-sub

9-pin

FG

1

5

4

3

2

1

9

8

7

6

COM1

side

SD

RD

RS

CS

SG

2

3

4

5

9

1

2

GOT

3

7

side

8

5

5

4

3

2

1

9

8

7

6

D-sub

(female)

9-pin

2-31

Page 60

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.10 Connection to FLEX-PC N Series

The GOT can be connected to the FLEX-PC N Series manufactured by FUJI Electric via a link

unit shown below.

• Connection type

Link port connection (RS-422)

Link port connection (RS-232C)

CPU port connect ion (RS-232C)

Select the connection type using

the operation envir onment setting

described in the nex t section or

the screen creation software.

• Applicable PLC units and link units

< FLEX-PC N Series >

A link unit (general-purpose RS-232C/RS485 interface module) is required to be connected. Or a CPU in which an RS-232C interface is built in is required.

• System configuration

RS232C

RS232C

RS422

RS422

To link unit or built-in RS-232C interface

2-32

Page 61

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Link unit

- NB Series

NB-RS1-AC, NB-RS1-DC

-NJ Series

NJ-RS2, NJ-RS4

- NS Series

NS-RS1

- CPU in which RS-232C interface is built in NJ-CPU-B16

• Connection diagram

Connect the GOT and the link unit (PLC) as shown below.

< For link port connection (RS-422) >

RDA

Terminal

block

Link unit side

(PLC side)

RDB

SDA

SDB

SG

1

6

GOT

2

side

7

5

5

4

3

2

1

9

D-sub

8

(male)

7

9-pin

6

2-33

Page 62

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

< For link port connection (RS-232C) >

D-sub

25-pin

13

12

11

10

9

8

7

6

5

4

3

2

1

25

24

23

22

21

Link unit side

20

19

18

17

16

15

14

(PLC side)

FG

SD

RD

RS

CS

DSR

SG

DTR

1

2

3

4

5

6

7

20

< For connection of built-in RS-232C interface >

D-sub

15-pin

8

7

6

5

4

3

2

1

15

14

13

12

11

10

9

PLC side

RD

SD

RS

CS

SG

2

3

4

5

7

1

2

3

7

8

6

5

4

2

3

7

8

5

GOT

side

GOT

side

5

4

3

2

1

5

4

3

2

1

9

8

7

6

9

8

7

6

D-sub

(female)

9-pin

D-sub

(female)

9-pin

2-34

Page 63

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

2.11 Connection by general-purpose communication

The GOT can be connected to a general controller such as micro computer board.

(The connected controller is hereafter referred to as "host (unit)".)

• Outline

In genera-purpose communication, the host unit is connected to the GOT via the RS-232C

and functions as the parent station in communication. Inside the GOT, there is a data area

to hold word data and bit data. The host unit can read and write the data area using communication commands.

The contents of display and control in the GOT are determined by the screen data created

using the screen creatio n softw are in the pers onal compu ter. The screen data specifies the

lay out of objects dis pla yed on the screen, and sp ecifies actions to be perf ormed by pressin g

of touch keys.

The GOT is equipped with the function to display the word data in the form of numbers and

bar graphs, the function to access the data for changing the status of the bit data using

switches, etc.

The target of access is the data area inside the GOT. The data location to be accessed is

specified by the screen data.

2-35

Page 64

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

Accordingly, to display the data stored in the host unit on the screen, the host unit should

transfer the data to the data area inside the GOT using write commands. The transfer destination is a location specified by the screen data. The data change result by manipulation

of ke ys can be tr a nsferred from the data area inside the GOT to the host unit if the host unit

gives read commands. In general-purpose communication, interrupt codes can be sent as

change triggers.

GOT

Screen data

Display/Input Internal data

Host unit

(micro computer board, etc.)

RS232C

2-36

Page 65

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Connection diagram

Connect the GOT and the host unit as shown below.

FG

SD

RD

Host side

SG

1

2

3

GOT

7

8

side

6

4

5

5

4

3

2

1

9

D-sub

8

(male)

7

9-pin

6

* The control lines RTS, CTS, DTR and DSR are not used.

2-37

Page 66

F940GOT-SWD-E/LWD-E Installation, Wiring and General Specifications 2.

• Communication setting

The setting related to communication can be performed using the screen creation software

or the GOT main body.

To use general-purpose communication,

- Screen creation software: Set the connected personal computer to "General-Purpose

Communication".

- GOT main body: Select "SET-UP MODE", "PLC SYSTEM" and "GENERAL-PURPOSE

COMMUNICATION" in this order.

To set the baud rate, the data length, the stop bit length and the parity,

- Screen creation software: Sel ect "Others ", " S yst em Settin gs" an d "DU Serial Printer Set-

tings"

- GOT main body: Select "SET-UP MODE" and "SERIAL PORT (RS-232C)" in this order.

Set each parameter to an either value shown below.

Baud rate

Data length

Stop bit length

Parity

19,200 / 9,600 / 4,800 / 2,400 / 1,200 / 600 or 300 bps

8 or 7 bits

1 or 2 bits

Even, odd or none

2-38

Page 67

F940GOT-SWD-E/LWD-E

3. Startup

This section describes the startup procedure from turning on of the power of the GOT to selection of the mode.

This section describes also the environment setting important to use of the GO T. Make sure to

read this section carefully.

Startup 3.

3-1

Page 68

F940GOT-SWD-E/LWD-E Startup 3.

3.1 Startup procedure

This paragraph describes the star tup procedure from tur ning on of the power of the GOT to

selection of the mode.

Perform wiring of the

power supply unit of t he GOT .

Connect the PLC.

Turn on the

power without

pressing the

touch key.

The OPENING SCREEN is displayed.

The SET-UP MODE screen

is displayed.

Turn on the

power while

pressing the

touch key.

•Perform wiring of the power supply unit of the GOT.

(Refer to Section 2.)

•Connect the GOT and the PLC with an optional connection

cable.

•Turn on the power of the GOT. When the power is turned on

while the upper l eft cor ner (which fun ctions as a touch key)

of the screen of th e GOT is pressed and he ld for 1 second or

more, the SET-UP MODE screen is displayed.

(Refer to "3.2 Operation environment setting".)

•The OPENING SCREEN screen indicating the model name,

etc. is displayed for the period set in "OPENING SCREEN"

on the SET-UP MODE screen.

•On the SET-UP MODE screen, set the used mode, the connected PLC name, etc.

The operation environment can be set on the OTHER

1

MODE screen.

3-2

Page 69

F940GOT-SWD-E/LWD-E Startup 3.

1

A user screen is displayed.

When there is no screen data

The SELECT MODE

screen is displayed.

The selected mode

screen is displayed.

•A user screen is displayed. If any user screen has not been

created, the SELECT MODE screen is displayed as follows.

•The SELECT MODE screen is displ ayed. Each menu item on

2

the screen functions as a touch key. When a desired one is

pressed, the corresponding mode is selected.

* This SELECT MODE screen can be called also by press-

ing a corner of the screen set in "MAIN MENU CALL

KEY" on the SET-UP MODE screen.

•The selected mode screen is displayed.

2

The screen mode is

selected.

•If the menu call key is not set in "MAIN M ENU CAL L KEY " on

the SET-UP MODE screen, the user screen mode is

selected.

3-3

Page 70

F940GOT-SWD-E/LWD-E Startup 3.

[ SELECT MODE screen ]

[ SELECT MODE ]

USER SCREEN MODE

HPP MODE

SAMPLING MODE

ALARM MODE

TEST MODE

OTHER M O DE

END

3-4

Page 71

F940GOT-SWD-E/LWD-E Startup 3.

3.2 Operation environment setting

The operation environment setting function performs initial setting important to operation of the

GO T. The SET-UP MODE screen can be displa yed by turning on the power while pres sing and

holding the upper left corner of the screen in accordance with "3.1 Startup procedure" or by

selecting "SET-UP MODE" on the OTHER MODE screen.

If an entry code has been registered using the secur ity function (described in the F940GOT

Operation Manual offered separately), however, the operation environment can be set only

when an entry code input by the user is equivalent to the registered entry code.

Turn on the power while pressing and

holding the upper left c orner of the screen.

Set the system language (Refer to p. 44.).

Press the END key.

The SET-UP MODE screen is displayed.

a)

b)

c)

d)

e)

f)

g)

h)

i )

j )

[ SET-UP MODE screen ]

[ SET-UP MODE ]

LANGUAGE

PLC TYPE

SERIAL PORT

OPENING SCREEN

MAIN MENU CALL KEY

SET CLOCK

SET BACKLIGHT

BUZZER

LCD CONTRAST

CLEAR USER DATA

END

k)

l )

l )

3-5

Page 72

F940GOT-SWD-E/LWD-E Startup 3.

The areas enclosed with broken lines function as touch keys.

(Broken lines are not actually displayed on the screen.)

a) LANGUAGE

Allows to set the language displayed on the system screens such as Japanese and

English.

b) PLC TYPE

Allows to set the connected PLC type.

c) SERIAL PORT

To be selected when a pr inter is connected to the GOT or when communication is performed between the GOT and a micro computer board.

d) OPENING SCREEN

Allows to set the duration in which the OPENING SCREEN screen is displayed immediately after the power is turned on.

e) MAIN MENU CALL KEY

Allows to set the position of the touch key which calls the SELECT MODE screen from

the screen mode (in which a user screen is displayed).

f) SET CLOCK

Allows to set the time used in the time switch and the time display.

g) SET BACKLIGHT

Allows to set the time at which the backlight becomes extinguished.

3-6

Page 73

F940GOT-SWD-E/LWD-E Startup 3.

h) BUZZER

Allows to set the buzzer sound issued when a key is pressed.

i) LCD CONTRAST

Allows to set the LCD brightness.

j) CLEAR USER DATA

Deletes the user screen data.

k) END

Exits the SET-UP MODE screen.

l) Cursors

Change over the menu item on the SET-UP MODE screen.

3-7

Page 74

F940GOT-SWD-E/LWD-E Startup 3.

Each setting screen is displayed as shown below. On each screen, when the END key at the

upper righ t corne r is pressed after se tting is completed, the SET-UP MODE s creen is displayed.

[ PLC TYPE screen ]

[ PLC TYPE ]

SYSTEM LANGUAGE:

ENGLISH

CHARACTER

SET:

ENGLISH

END

a)

b)

• Set the language used on the system screens and the

user screens.

a) SYSTEM LANGUAGE

Allows to set the language displayed on the system

screens and in error messages.

JAPANESE and ENGLISH are available.

b) CHARACTER SET

Allows to set the language displayed on the user

screens. JAPANESE, CHINESE and KOREAN are

available. Only one language can be selected at a

time.

(CHINESE and KOREAN will be available in a few

days.)

3-8

Page 75

F940GOT-SWD-E/LWD-E Startup 3.

[ PLC TYPE screen ]

[ PLC TYPE ]

PLC TYPE:

CONNECTION:

STATION #:

FX SERIES

CPU PORT

* *

END

a)

b)

c)

• Select the connected PLC ty pe .

• The areas on the screen

enclosed with solid li nes function as touch keys. Every time

a touch key is pressed, the displayed contents a re changed

over.

a) PLC TYPE

Allows to select either one among FX SERIES, A

SERIES, C SERIES (manufactured by OMRON), N

SERIES (manufactured by FUJI Electric) and UNIVERSAL (general-purpose communication).

b) CONNECTION

Allows to set the connection method of the PLC

selected in 1] above.

- CPU PORT: The GOT is connected directly to the

program connector in the PLC.

The FX Series and the A Series are available.

- LINK PORT (RS422): The GOT performs communication in accordance with the RS-422 v ia a link unit.

The A Series, the C Series and the N Series are

available.

- LINK PORT (RS232C): The GOT perf orms communication with the DU in accordance with the RS232C via a link unit.

The A Series, the C Series and the N Series are

available.

3-9

Page 76

F940GOT-SWD-E/LWD-E Startup 3.

c) STATION #

Allows to set the station No. of the link unit connected

to the GO T when "LINK PORT" is selected in 2] abov e .

3-10

Page 77

F940GOT-SWD-E/LWD-E Startup 3.

[ SERIAL PORT]

[ SERIAL PORT]

SPEED

DATA BIT

STOP BIT

PARITY

HANDSHAKING

PRINTAER

9600 bps

:

7 bit

:

1 bit

:

Even

:

XON/XOFF

:

NOT USED

:

END

•Set the serial communication parameters for the printer

used to print out alarm messages and sampling data.

•Make sure to set "PRINTER" to "USE" when a printer is

connected.

When it is set to "USE", the two-port interface

function is not available.

•The areas enclosed with broken lines function as touch

keys.

Every time a touch key is pressed, the displayed contents are changed over.

•When "LINK PORT (RS232C)" is selected on the PLC

TYPE screen, any printer cannot be connected.

3-11

Page 78

F940GOT-SWD-E/LWD-E Startup 3.

[ OPENNING SCREEN ]

[ OPENNING SCREEN ]

DISPRAY TIME 20 SEC.

5 6 7 8 9 CLR

0 1 2 3 4 ENT

END

•Set the duration in the unit of second in which the

OPENING SCREEN screen indicating the model

name, the version, etc. is displayed when the power is

turned on.

•When the touch key "DISPLAY TIME" is pressed, the

time can be set using the ten-key pad displayed at the

bottom of the screen.

•Enter the desired display time using the ten-key pad displa y ed at the botto m of the scre en, then p ress the ENT

key to register the input time.

* When "DISPLAY TIME" is set to "0", the OPENING

SCREEN screen indicating only the version is displayed for 4 seconds.

It is recommended to set 1 second or more for the

FX Series and 4 seconds or more for the A Series.

3-12

Page 79

F940GOT-SWD-E/LWD-E Startup 3.

[ MENU CALL ]

[ MENU CALL KEY screen ]

SELECT CALL KEY LOCATION

END

•Set the menu call key which changes over the screen

mode (in which a user screen is displayed) to the

SELECT MODE screen.

The menu call key is mesh type, and 2 x 2 in size.

• One or two corners can be selected among the

four corners of the screen.

• When the menu call key is not set, only the screen

mode is available. Any other mode is not available.

• If another touch key is assigned to the corners to

which the menu call key has been assigned, the menu

call function is disabled.

3-13

Page 80

F940GOT-SWD-E/LWD-E Startup 3.

[ SET CLOCK ]

[ SET CLOCK ]

DATE 1 / 3 / 1999

TIME 10: 10: 10

5 6 7 8 9 CLR

0 1 2 3 4 ENT

END

• Set the time used in the time switch, the sampling

mode and the alarm mode.

•When "DATE" or "TIME" is selected, date or time can be

entered using the ten-key pad displayed at the bottom

of the screen. Enter the desired da te or time, and

press the ENT key to register it.

3-14

Page 81

F940GOT-SWD-E/LWD-E Startup 3.

[ SET BACKLIGHT ]

[ SET BACKLIGHT ]

OFF TIME 10 MIN.

5 6 7 8 9 CLR

0 1 2 3 4 ENT

END

•Set the time at which the backlight of the display screen

becomes extinguished. When a touch key is not

pressed or the user screen is not changed over within

the specified OFF time, the backlight becomes extinguished.

•When "OFF TIME" is pressed, the OFF time can be set

within the range of 0 to 99 minutes usi ng the ten-key

pad displayed at the bottom of the screen. Enter the

desired time, and press the ENT key to register it.

•The service life is 25,000 hours in the backlight.

•The control device b2 should be set to ON so that the

backlight OFF function is enabled. (Refer to the

F940GOT Operation Manual.)

3-15

Page 82

F940GOT-SWD-E/LWD-E Startup 3.

[ BUZZER ]

[ BUZZER ]

BUZZER ON

BUZZER OFF

[ LCD CONTRAST ]

[ LCD CONTRAST ]

END

END

•Set whether or not the buzzer sound is to be issued

when a key is pressed or an error occurs.

•Select "BUZZER ON" or "BUZZER OFF".

•The LCD brightness can be set in 15 steps.

When the key is pressed, the LCD becomes darker.

When the key is pressed, the LCD becomes

brighter.

3-16

Page 83

F940GOT-SWD-E/LWD-E Startup 3.

[ CLEAR USER DATA]

[ CLEAR USER DATA]

OK TO CLEAR USER DATA?

YES

NO

•The screen data stored in the GOT can be cleared.

END

•When "YES" is selected, the message "NOW CLEARING USER DATA" is displayed and no key is accepted.

When the message "COMPLETED!" is displayed, the

data is cleared completely.

3-17

Page 84

F940GOT-SWD-E/LWD-E Startup 3.

3-18

Page 85

F940GOT-SWD-E/LWD-E

4. Extension Module

This section descr ibes handling of the extension module interface provided on the rear face of

the GOT.

4.1 Data transfer adaptor

The data transfer adaptor F9GT-40UMB is used to store the user screen data stored in the

EPROM for user screen data FX-EPROM-4M to the flush memor y in the GOT. (The user

screen data can be written to the EPROM using the screen creation software.)

This adaptor is useful when a same screen is transferred to two or more GOT units.

Extension Module 4.

4-1

Page 86

F940GOT-SWD-E/LWD-E Extension Module 4.

b)

a)

d)

c)

Operating procedure

a)FX-EPROM-4M

b)F9GT-40UMB

c)User screen/system screen selector switch

d)Extension module interface

1)Attach the FX-EPROM-4M a) in which user screens are saved to

the F9GT-40UMB b).

Pay rigid attention not to bend leads of the FX-EPROM-4M a) nor

touch them with bare fingers.

2)Put upward the user screen/system screen selector switch c).

If this switch is put downward by mistake and data is transferred,

user screens will not be displayed normally.

In this case, put the selector switch c) upward and transfer the

data again.

3)Attach the F9GT-40UMB to the extension module interface d).

Make sure that the power of the GOT has been turned off preliminarily.

4)Turn on the power of the GOT. Then, the screen data will be automatically transferred to the GOT in 2 to 3 minutes.

4-2

Page 87

F940GOT-SWD-E/LWD-E Extension Module 4.

5)When transfer is finished, make sure to turn off the power of

the GOT and remove the adaptor b).

4-3

Page 88

F940GOT-SWD-E/LWD-E Extension Module 4.

4-4

Page 89

F940GOT-SWD-E/LWD-E

5. Maintenance

This section describes maintenance such as replacement of the battery and the backlight.

5.1 Outline of maintenance

Cautions on startup and maintenance

• Connect correctly the battery for m emory back up. Never charge, disassemb le , h eat, put

into fire nor short-circuit the battery for memory backup.

If the battery for memory backup is handled in such a way, it may be burst or take fire.

• Before replacing the backlight, turn off the power and remove the graphic operation terminal main body from the panel.

If the backli ght is replaced while the graphic operation te rminal is attached on the pa nel,

Maintenance 5.

it may drop and injure you.

If the backlight is replaced while the power is supplied, you may get electrical shock.

5-1

Page 90

F940GOT-SWD-E/LWD-E Maintenance 5.

CAUTION

• Make sure to turn off the power before attaching or removing an extension module.

If an extension module is attached/removed while the power is supplied, the contents

stored in the memory or the EPROM memory itself may be damaged.

• Never disassemble nor modify the unit.

If the unit is disassembled or modified, failure, malfunction or fire may be caused.

* For repair, contact MITSUBISHI ELECTRIC SYSTEM SERVICE.

• Turn off the power before connecting or disconnecting a connection cable.

If a connection cable is connected/disconnected while the power is supplied, failure or

malfunction may be caused.

Cautions on disposal

• When disposing of the unit, handle it as industrial waste.

Consumable parts which may shorten the service life are not built in the GOT.

However, the service life is 5 years in the battery, approximately 50,000 hours in the LCD

and 25,000 hours or more in the backlight.

It is recommended to replace these parts periodically using the procedure described

below.

In addition, inspect other equipment and pay rigid attention to the following points.

5-2

Page 91

F940GOT-SWD-E/LWD-E Maintenance 5.

5.2 Replacement of battery

When the battery voltage drops, the control de vices f or system information set by the screen creation software becomes ON. The control devices are interloc king with auxiliary relays in the PLC.

It is recommended to attac h a lamp us ing the o utput of the PLC so that th e ON/OFF st atus of th e

7th bit can be monitored from the outside.

For the details of control devices, refer to the Operation Manual.

Example :When the FX-PCS-DU/WIN are used.

When the head No. of the control devices is set to M0.

M6: Battery voltage drop Becomes ON when the battery voltage drops.

This control device is used in a sequence program as follows.

Battery voltage drop

M6

Y

Indication outside PLC

Example :When the SW1D5C-GOTR-PACK are used.

When the system information of the write device is set D20.

D24 b3: Battery voltage drop Becomes ON when the battery voltage drops.

This control device is used in a sequence program as follows.

M8000

M0V D24 K1M20

Battery voltage drop

M23

Y

Indication outside PLC

5-3

Page 92

F940GOT-SWD-E/LWD-E Maintenance 5.

The alarm history and the sampling data are held for approximately 1 month after the control dev ic e for battery voltage drop becomes ON. After 1 mon th, the se da ta can not be held.

It is recommended to replace the battery soon.

a)

a) Battery PM-20BL

1) Turn off the power of the GOT.

2) Open the small window provided on the rear panel.

3) Remove the current b attery from the holder. Disconnect

the connector.

4) Within 30 seconds, connect the connector of a new battery.

5) Inser t the new battery into the holder. Close the small

window.

* The battery backs up the alarm history, the sampling data and the current tim e. Because

the screen data is stored in the flush memory, it is held even if the battery becomes disabled.

5-4

Page 93

F940GOT-SWD-E/LWD-E Maintenance 5.

5.3 Replacement of backlight

Replace the backlight F9GT-40LTS using the following procedure.

b)

a)

c)

d)

Replacement procedure

a)Mounting screw

b)Backlight connector

c)Backlight F9GT-40LTS

d)Backlight fixing holder

1) Make sure that the power of the GOT is turned off.

Remove the mounting screws a) located at four corners, and slowly remove the rear panel.

Note:If the rear panel is pulled with an excessive

force, the cable connecting the rear panel and

the front panel may be disconnected or the PCB

may be damaged. Be careful.

2) Disconnect the backlight connector b).

3) Remove the backlight F9GT-40LTS c) from the backlight fixing holder d).

It is recommended to insert a screwdriver into the

holder. Then, the backlight can be taken out easily.

4) Attach a new backlight F9GT-40LTS c). Put it into the

GO T b y perf orming the steps a) to c) in the re v erse order

5-5

Page 94

F940GOT-SWD-E/LWD-E Maintenance 5.

5-6

Page 95

F940GOT-SWD-E/LWD-E

6. Troubleshooting

This section describes troubleshooting during operation.

6.1 Power indication

When an abnormality has occurred, check the following points.

The PO WER LED in the GOT is lit by the 5 V pow er supply inside the GOT. When the PO WER

LED is extinguished, nothing is displayed on the screen or no key is accepted, the power supply may be insufficient.